A kind of high imitation cashmere core-spun yarn and its preparation process

A preparation process and a cashmere-like technology, applied in the field of spinning, can solve the problems of poor fabric elasticity and shape retention, affecting the aesthetics of cashmere sweaters, and expensive cashmere products, etc., and achieve excellent moisture absorption and perspiration, excellent comprehensive performance, and beneficial effects. for antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

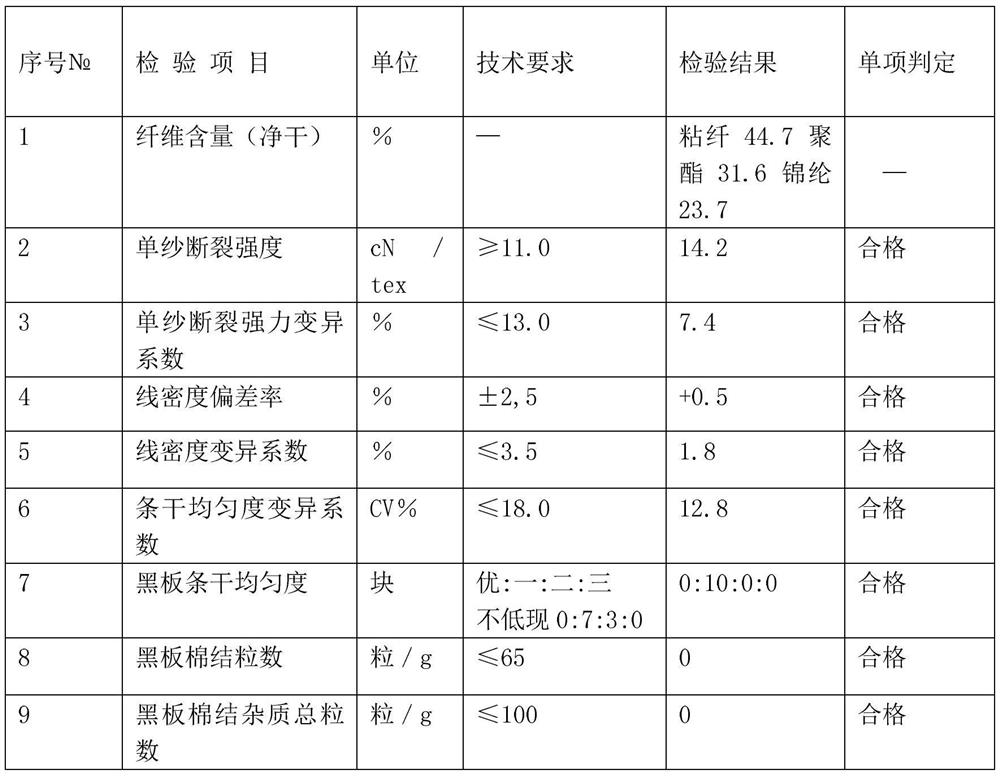

[0028] The high-imitation cashmere core-spun yarn of the present invention adopts polyester filament as the core yarn, adopts high-imitation cashmere blended fiber as the outsourcing yarn of the core-spun yarn, and the high-imitation cashmere blended fiber is hollow viscose fiber, nylon, graphene composite nylon The blended fibers of polyester filaments and high-imitation cashmere blended fibers are proportioned by weight percentage: 29-33% polyester filaments, 60-64% hollow viscose fibers and nylon, 5-9% The graphene composite nylon, the yarn number of the core-spun yarn is 19-57tex; wherein, the weight ratio of the hollow viscose fiber to the nylon is 22-23:8-9.

[0029] The polyester filament of the present invention adopts 55.6dtex Z twist and S twist PBT polyester fila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com