A method for producing diamond-shaped fancy threads by using waste textiles

A technology for waste textiles and production methods, applied in textiles and papermaking, application, knotting, etc., can solve the problems of fiber strength and length loss, fiber spinnability decline, product use performance and added value. , the effect of increasing spinnability and increasing the added value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Disinfect the recycled waste red textiles, then cut the textiles into cloth pieces of 50mm×50mm, and then open the cloth pieces into a single fiber state to obtain recycled fibers;

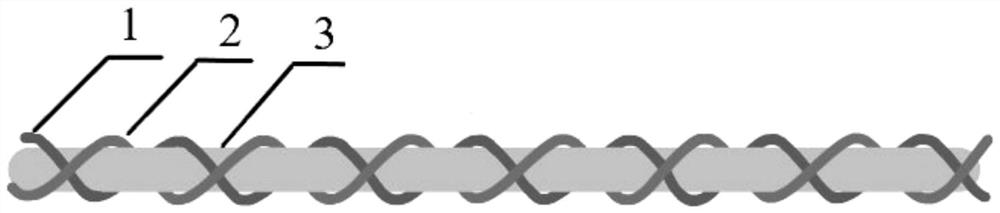

[0035] (2) blending recycled fiber with cotton-type white PLA fiber to obtain light pink roving 3 with a linear density of 700Tex; the mass ratio of recycled fiber to PLA fiber is 2.5:7.5;

[0036] The blended spinning includes the opening and cleaning process, the carding process, the drawing process and the roving process performed in sequence;

[0037]In the opening and cleaning process, a double-drum axial flow opener (the speed of the first beater is 414r / min, the speed of the second beater is 424r / min) and the cleaning machine equipped with a three-roller beater (the roller speed is from in to out) are used. 1191r / min, 2104r / min and 3428r / min respectively);

[0038] In the carding process, the rotation speed of the licker-in is 1000r / min, the rotation speed of the cylinder is 400...

Embodiment 2

[0044] (1) Disinfect the recycled waste white textiles, then cut the textiles into cloth pieces of 50mm×50mm, and then open the cloth pieces into a single fiber state to obtain recycled fibers;

[0045] (2) Blending recycled fiber, cotton-type white PLA fiber and cotton-type red viscose fiber to obtain pink roving 3 with a linear density of 680Tex; the mass ratio of recycled fiber, PLA fiber and viscose fiber is 2 :3:5;

[0046] The blended spinning includes the opening and cleaning process, the carding process, the drawing process and the roving process performed in sequence;

[0047] In the opening and cleaning process, a double-drum axial flow opener (the speed of the first beater is 420r / min, the speed of the second beater is 440r / min) and the cleaning machine equipped with a three-roller beater (the speed of the rollers are from in to out) are used. 1191r / min, 2104r / min and 3428r / min respectively);

[0048] In the carding process, the rotation speed of the licker-in is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com