Bamboo charcoal fiber fabric with strong breathability and strong sweat-releasing property

A bamboo charcoal fiber and fabric technology, applied in textile, clothing, protective clothing, etc., can solve the problems of poor fabric rigidity and flexibility, weak fabric, poor three-dimensional sense, etc., and achieve strong three-dimensional sense, delicate hand feel, and strong breathability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

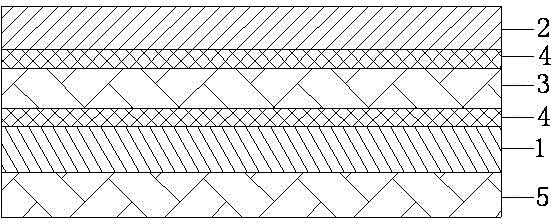

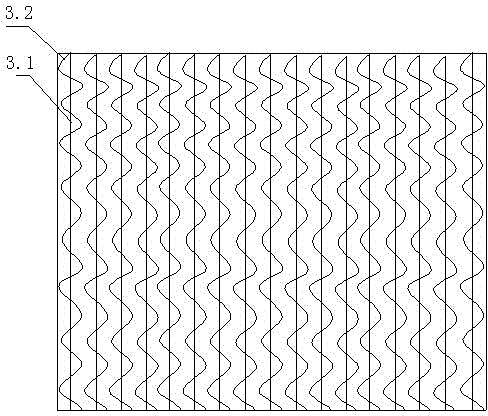

[0013] see figure 1 and figure 2 , the present invention relates to a breathable perspiration strong bamboo charcoal fiber fabric, it comprises bamboo charcoal fiber 1, the above described bamboo charcoal fiber 1 is covered with a layer of non-woven fabric 2, the bottom is covered with a layer of base layer 5, described non-woven fabric 2 and bamboo charcoal An antistatic layer 3 is also provided between the fibers 1, and the antistatic layer 3 is made of cored silk fibers, which include yarns 3.1 and metal wires 3.2, and the metal wires 3.2 are wound on the yarns 3.1 , between the bamboo charcoal fiber 1 and the antistatic layer 3 and between the antistatic layer 3 and the non-woven fabric 2 are bonded by a glue layer 4 .

[0014] Both the bamboo charcoal fiber and the non-woven fabric in this breathable and sweat-wicking strong bamboo charcoal fiber fabric have good air permeability. Variable, poor three-dimensional effect, can form various wrinkle effects, shiny metallic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com