Mixed fabric with uniform textile thickness

A technology of uniform thickness and fabric, applied in the direction of layered products, etc., can solve the problems of pure cotton fabrics such as easy to shrink, not crisp, easy to wrinkle, etc., and achieve the effect of uniform thickness of the fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

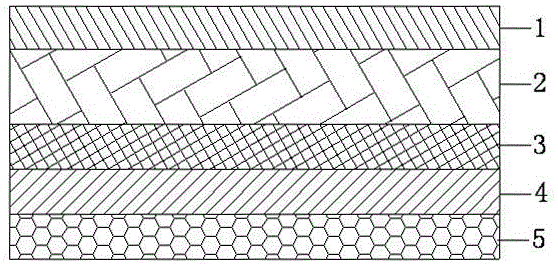

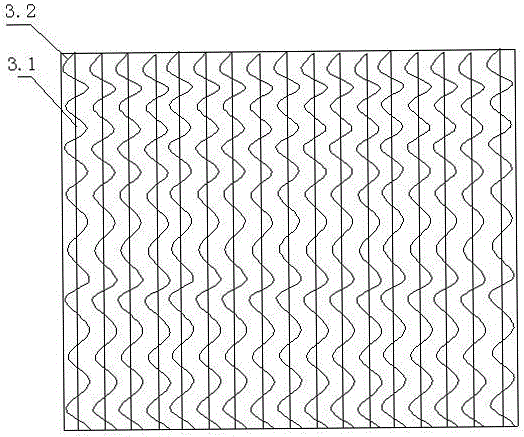

[0013] see figure 1 and figure 2 , the present invention relates to a fabric with a uniform thickness and thickness, which includes a pure cotton fabric 1, a layer of bamboo charcoal fiber layer 2 is provided under the pure cotton fabric 1, and an antistatic layer 3 is also provided under the bamboo charcoal fiber layer 2 , the antistatic layer 3 is made of core-spun silk fiber, the fiber includes a yarn 3.1 and a metal wire 3.2, the metal wire 3.2 is wound on the yarn 3.1, and the bottom of the antistatic layer 3 is covered with a layer of blended cloth 4. The blended fabric 4 is formed by blending soybean fiber and pure cotton fiber. A layer of base layer 5 is compounded under the blended fabric 4. The pure cotton fabric 1, the bamboo charcoal fiber layer 2, the antistatic layer 3 and the blended fabric 4 Adjacent layers are bonded by glue.

[0014] The thickness of this kind of fabric is evenly mixed with the yarn and metal wire in the fabric to form an anti-static layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com