Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Smooth cutting action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

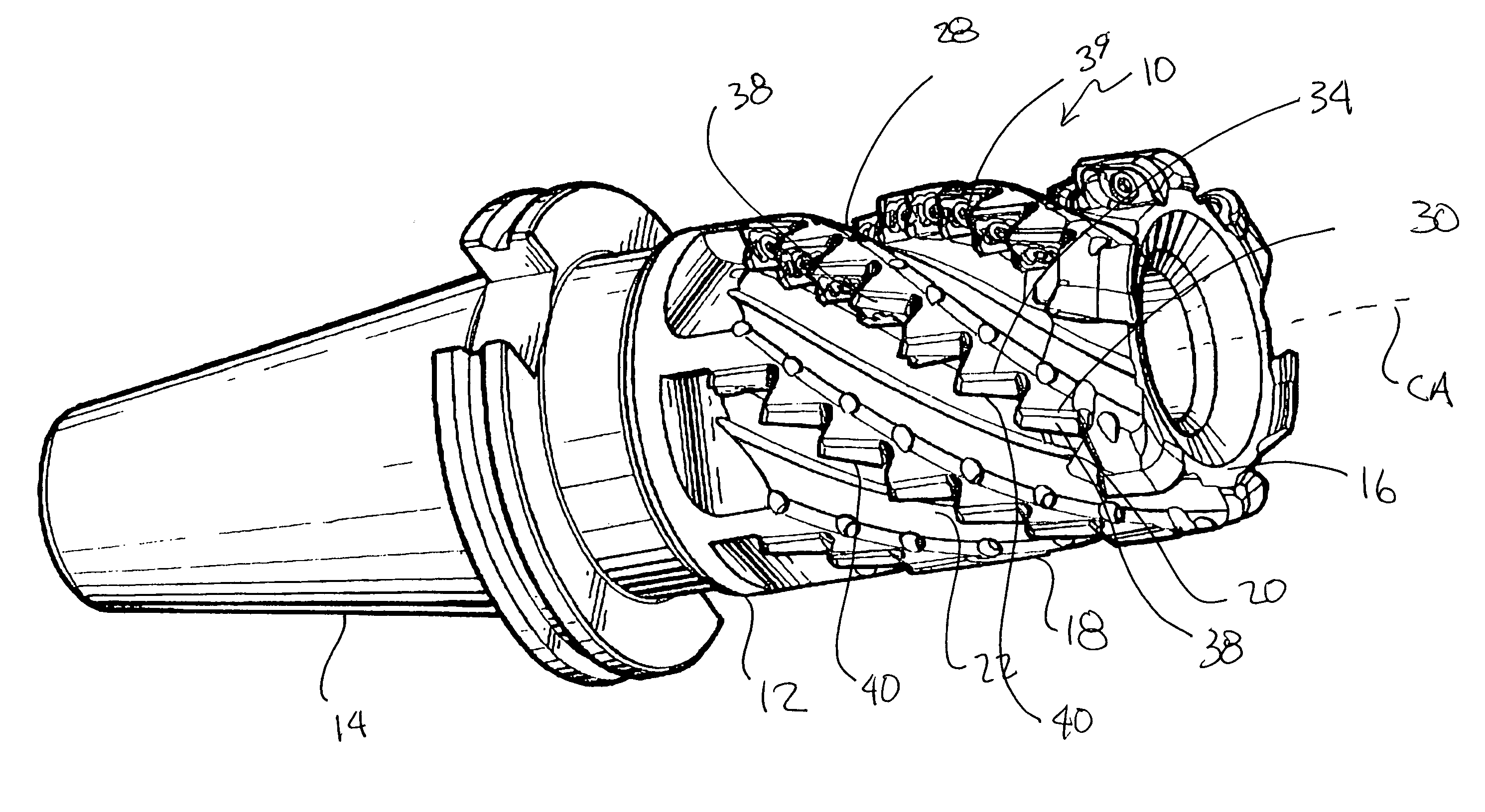

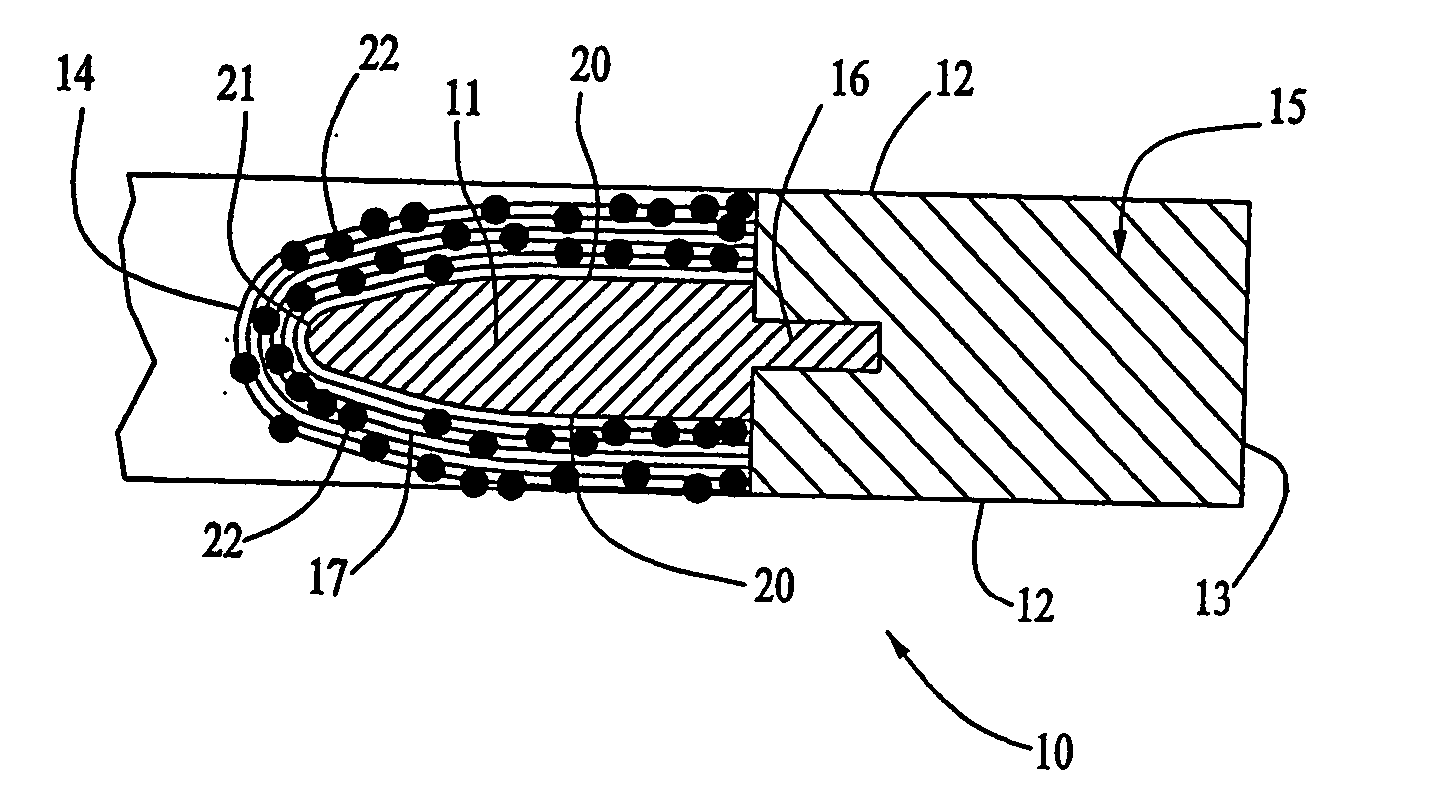

Milling cutter

InactiveUS6976811B1High surface finishSmooth cutting actionMilling cuttersShaping cuttersFluteMilling cutter

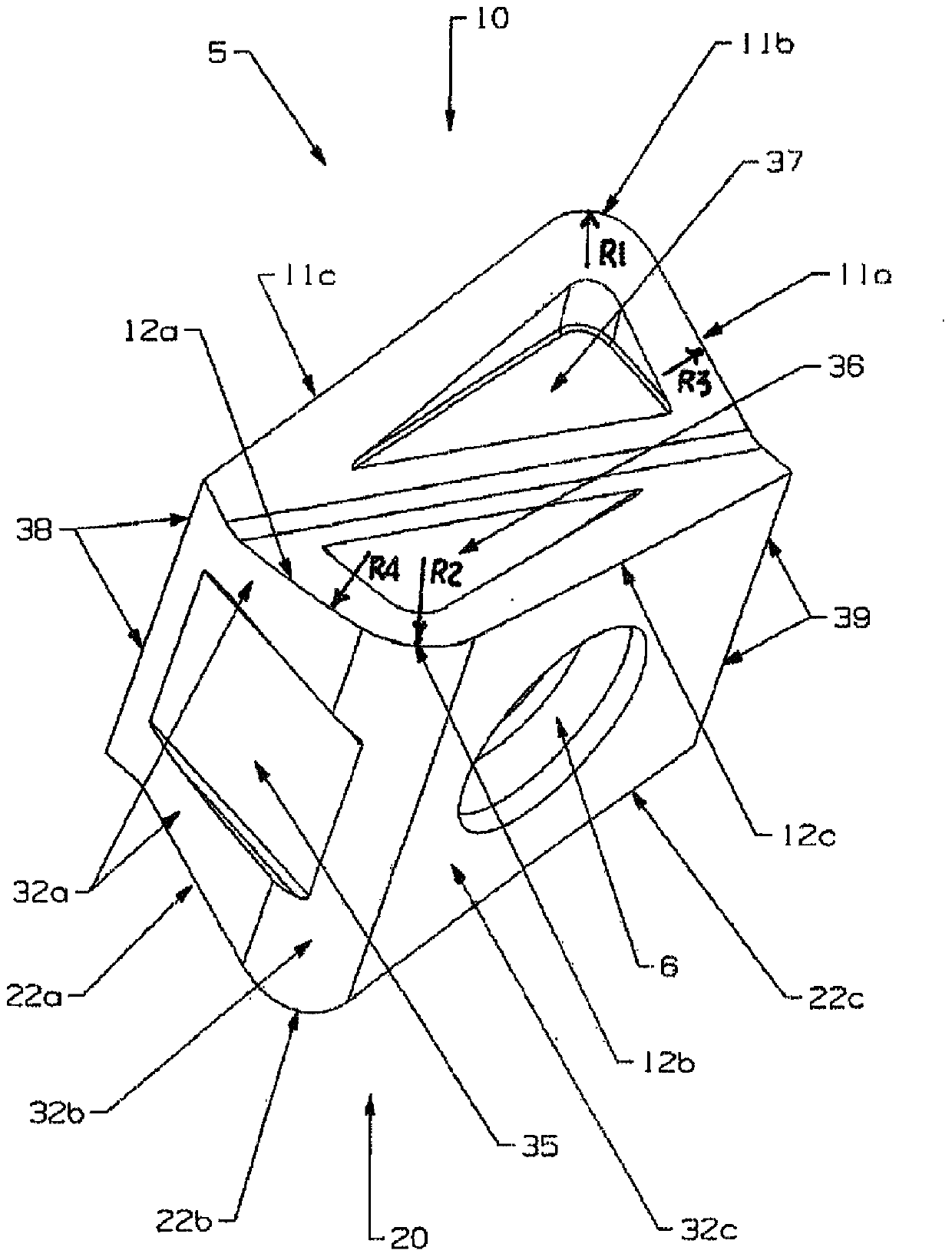

A cutting tool for cutting a workpiece comprising a tool body having an outer surface thereon and a central axis therein and including at least a first and second spiraling flute in the outer surface, each flute including a plurality of inserts secured therein to define an axial rake angle, wherein the axial rake angle of the inserts varies between flutes and within each flute.

Owner:KENNAMETAL INC

Wrap film cutting apparatus

InactiveUS20050166738A1Quickly and effectively smoothFacilitate smooth cutting actionFlat article dispensingMetal working apparatusEngineeringKnife blades

A wrap film cutting apparatus includes a guide rail and a sliding cutter slidably mounted on the guide rail. The sliding cutter is provided with a blade mounted therein covertly. The guide rail is covered with an attractive layer made of a polymeric material at a top surface thereof for attracting a wrap film to be cut. Accordingly, the wrap film cutting apparatus can facilitate smooth cutting action to further enhance convenience for the user.

Owner:SINOPACKER INT

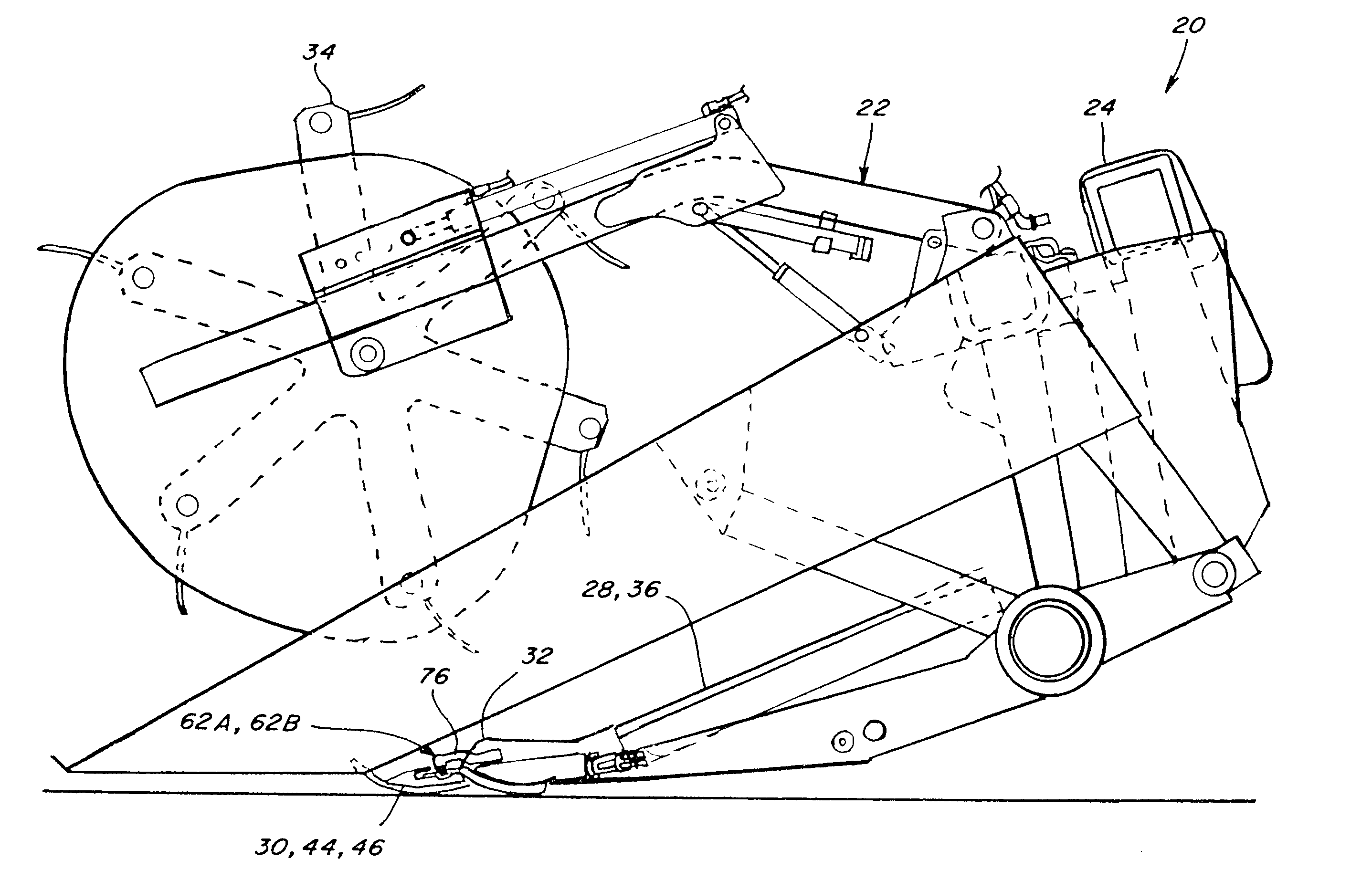

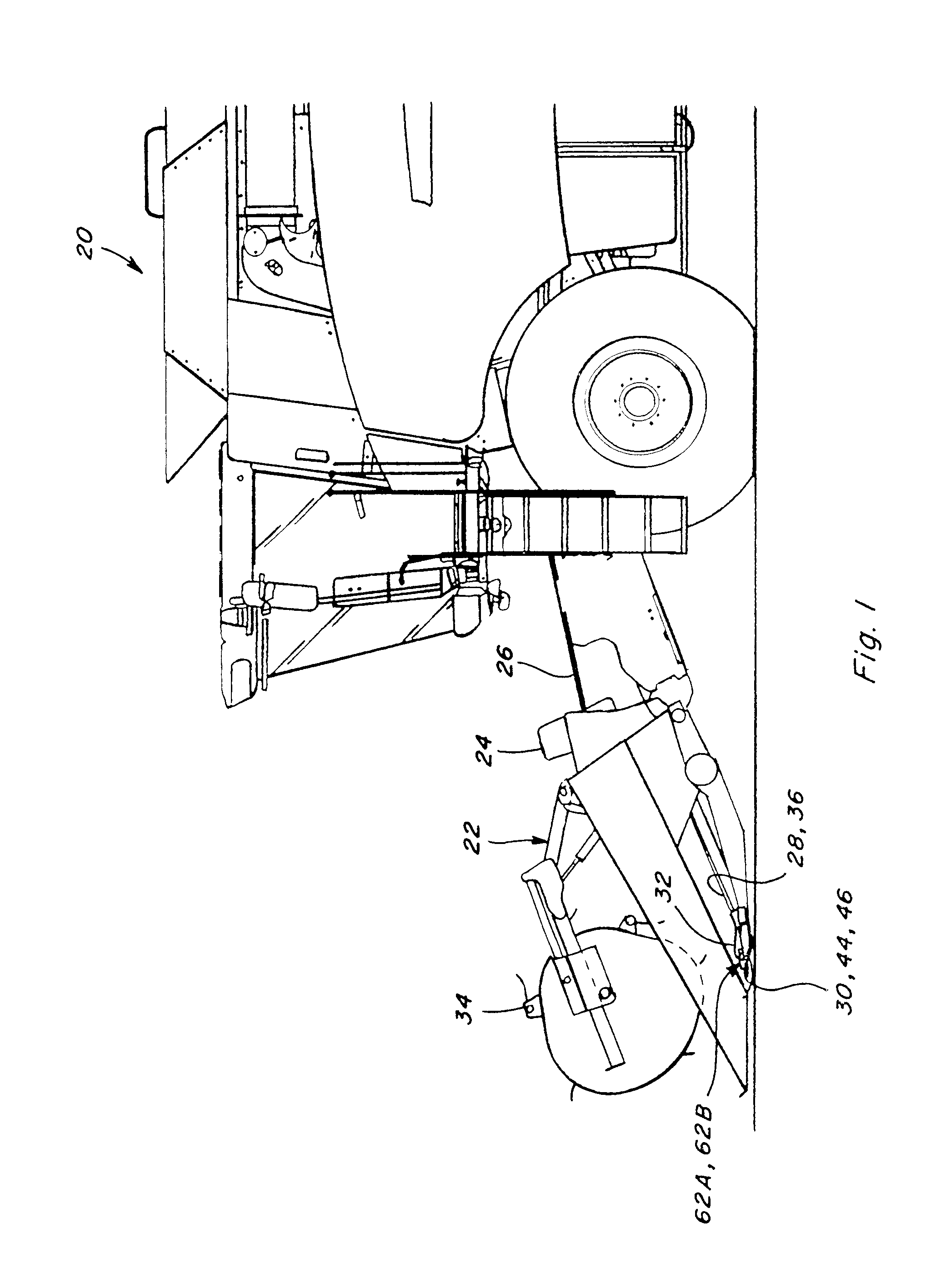

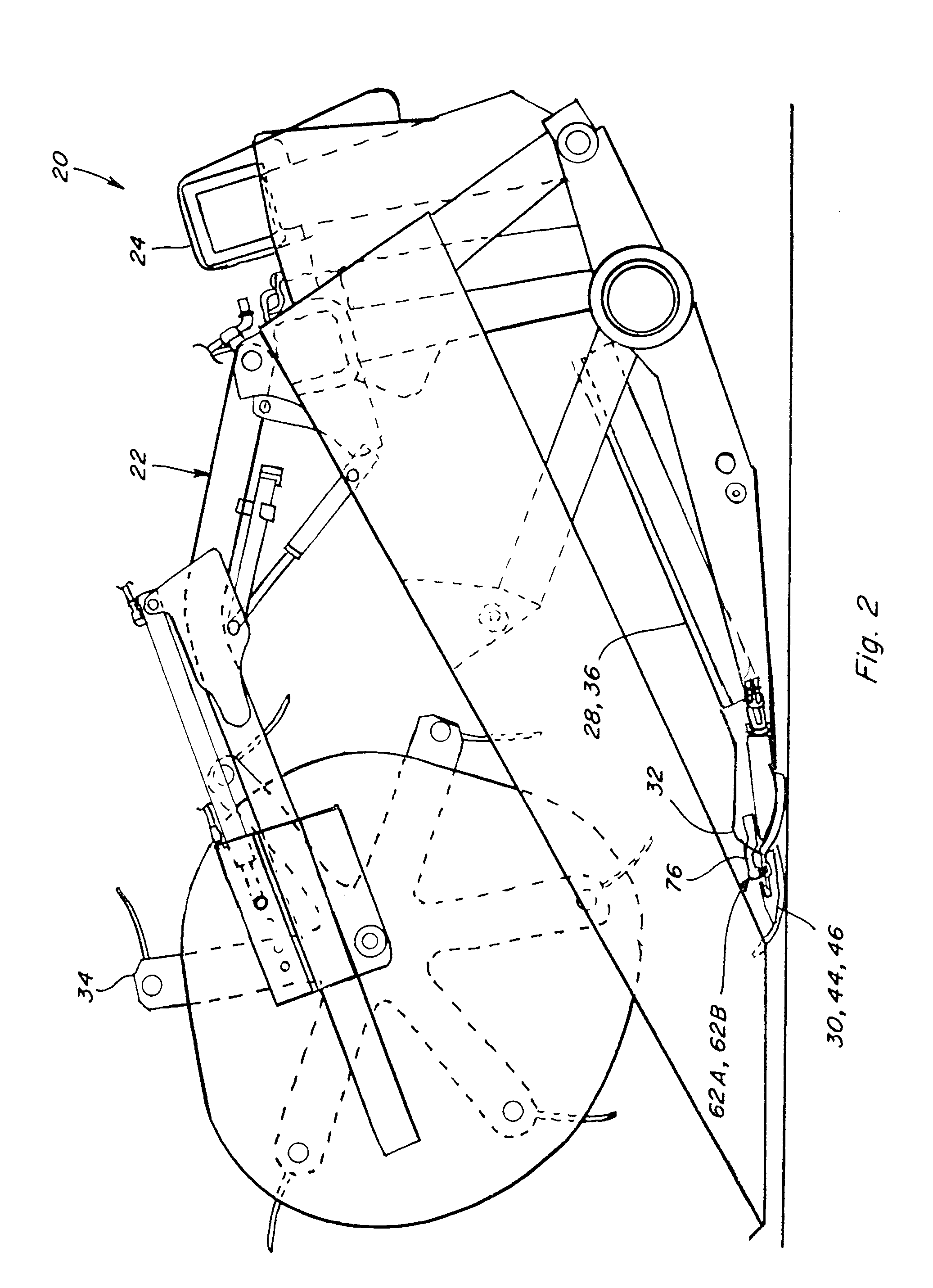

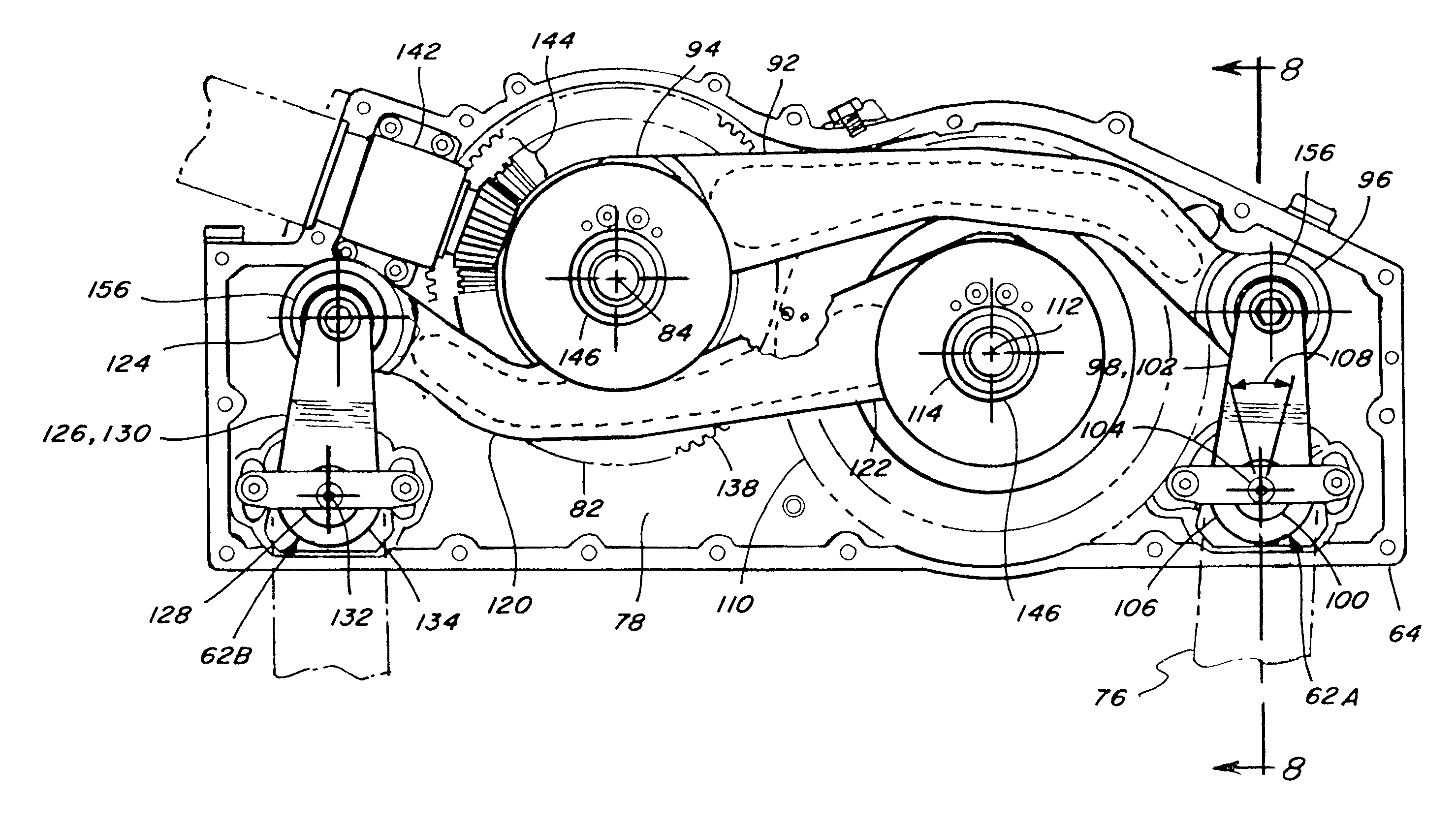

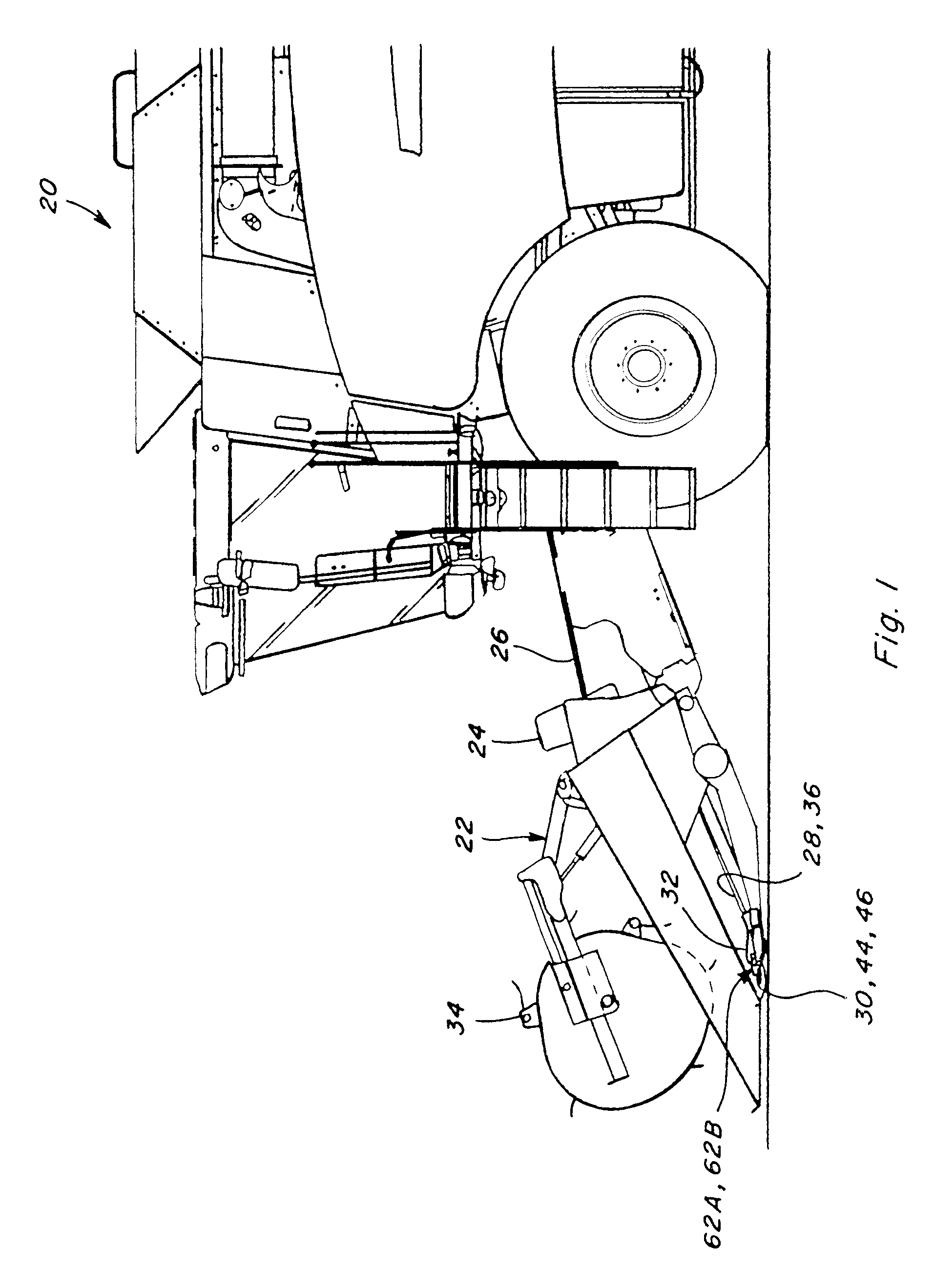

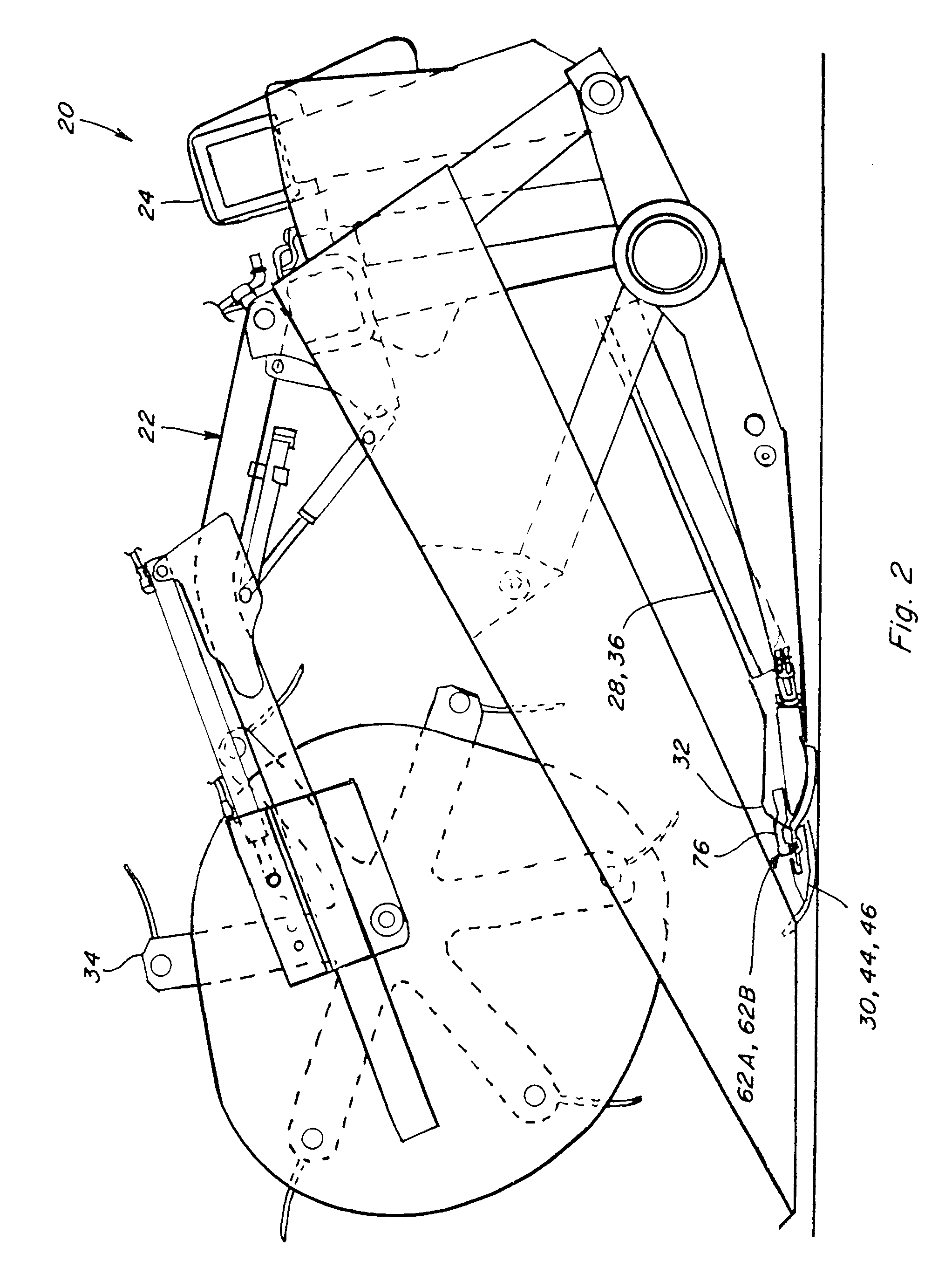

Low Profile Sickle Drive

A sickle drive incorporated into a generally flat package or enclosure or floor. The drive includes an epicyclic mechanism, including a rotatable input element in an upper region of a cavity of the enclosure, and an eccentric element below the input element rotatable eccentrically thereby. A drive arm is connected to the eccentric element for rotation about, and eccentric rotation with, the eccentric element, and extends to a pivot element which can be the only component extending upwardly from the enclosure or floor, such that the shaft will be pivoted by the eccentric movement of the drive arm. A knife arm connects to the pivot element and a sickle knife assembly which will be reciprocated by the pivoting action. A second epicyclic arrangement can be employed such that opposite forces generated by operation of the drive will be largely canceled.

Owner:BLUE LEAF I P INC

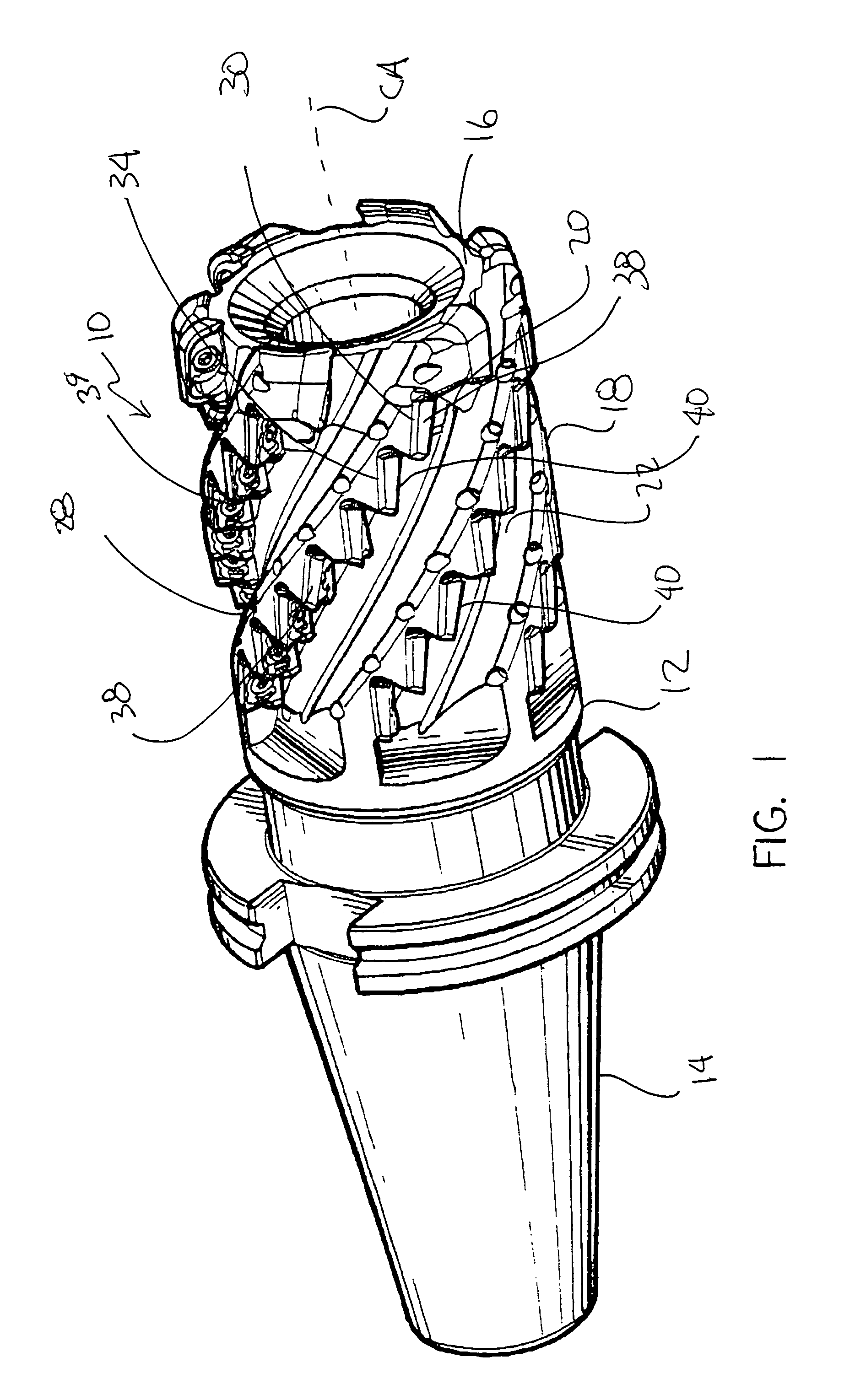

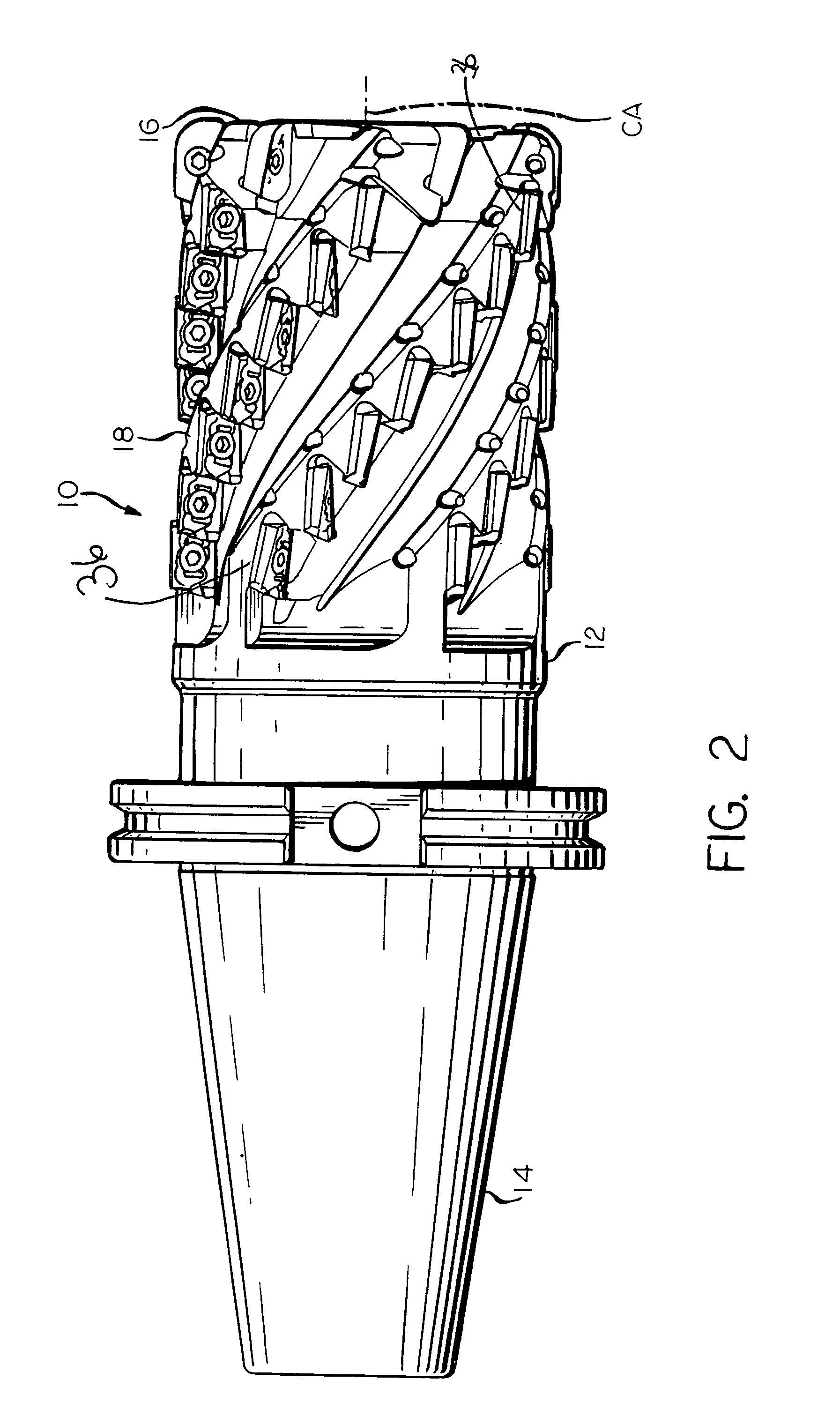

Helical cutting insert with progressive cutting edge

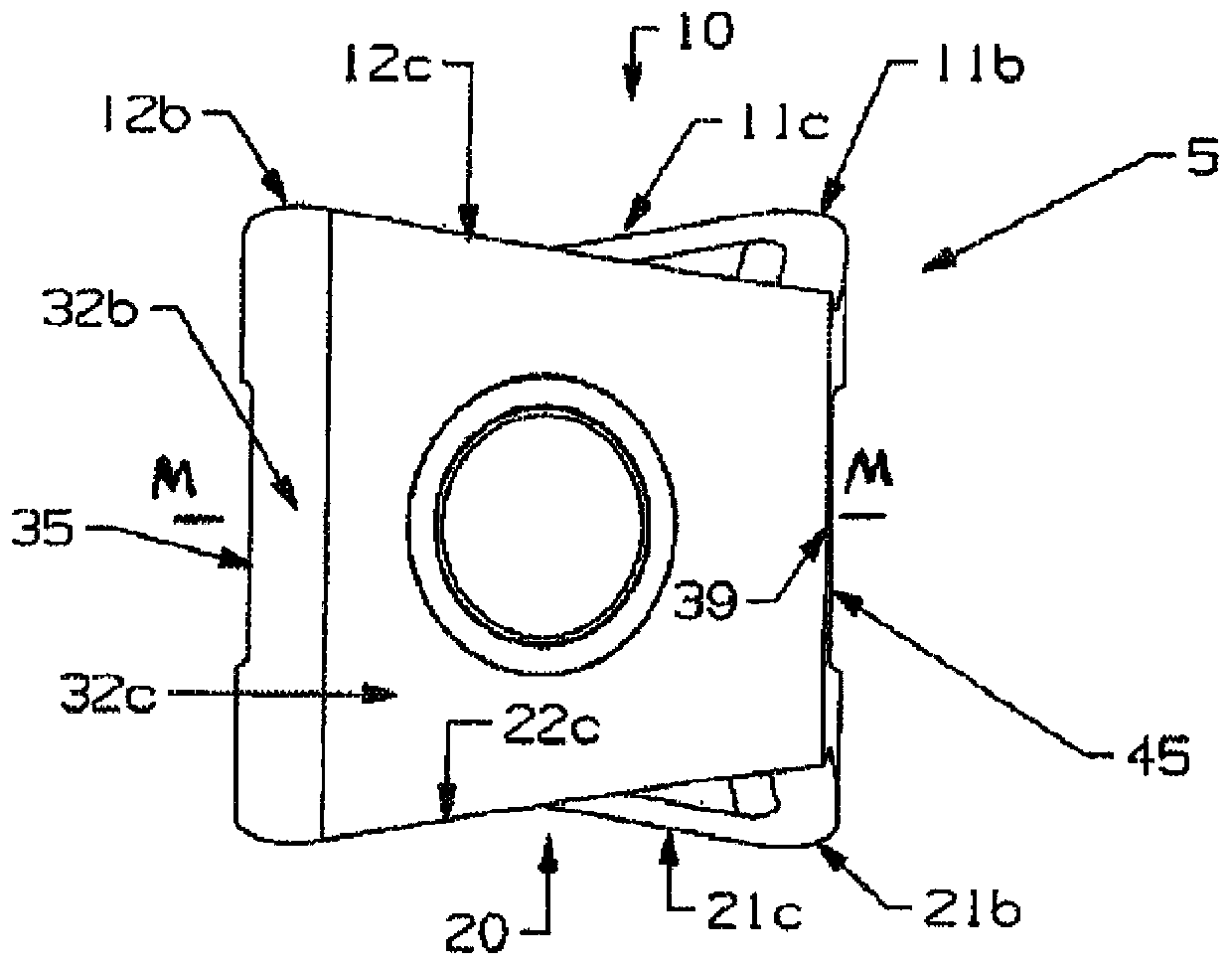

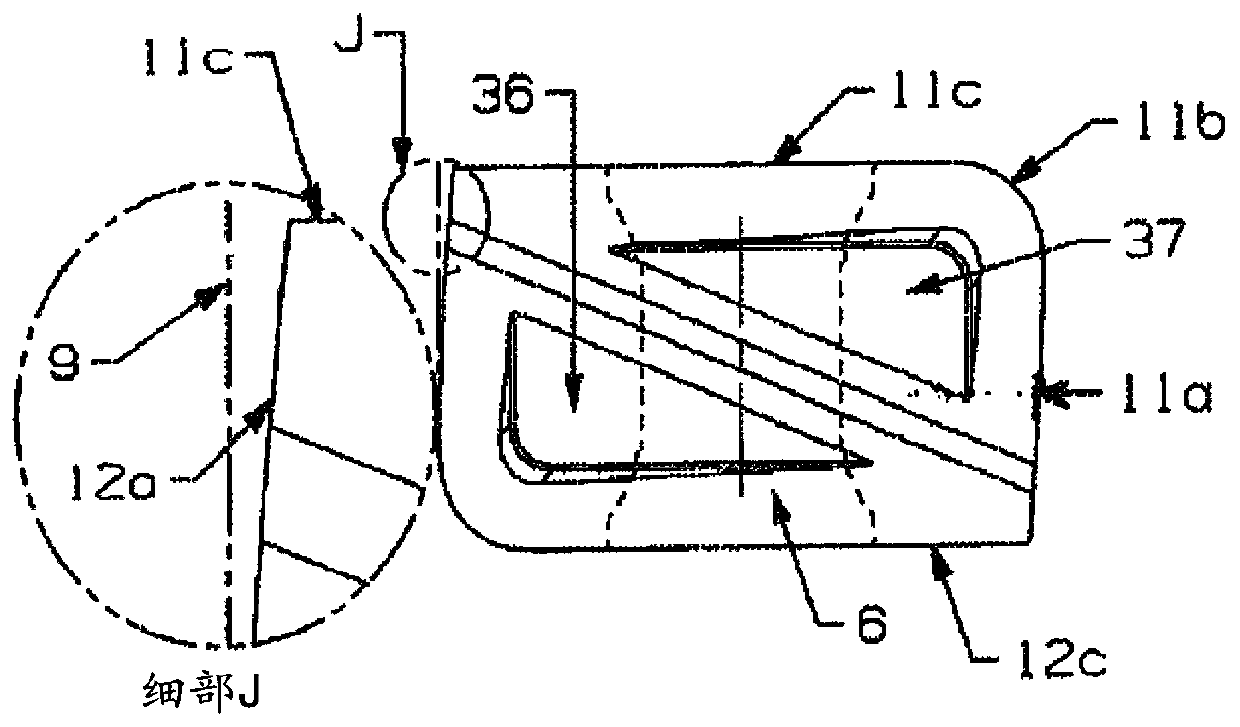

InactiveUS20060280567A1Less powerLess torqueMilling cuttersShaping cuttersEngineeringMechanical engineering

An indexable, helical cutting insert includes at least one axial clearance slash extending from a bottom surface to one of said side walls forming a wiper on an edge of the axial clearance slash. In another embodiment, the cutting insert includes at least one inside cutting edge that extends outwardly a distance from the side wall. In another embodiment, the helical cutting insert includes at least one progressive cutting edge. In another embodiment, the cutting insert includes at least one helical cutting edge that is curved inwardly to enable the cutting insert to perform machining operations on cutters having different diameters.

Owner:KENNAMETAL INC

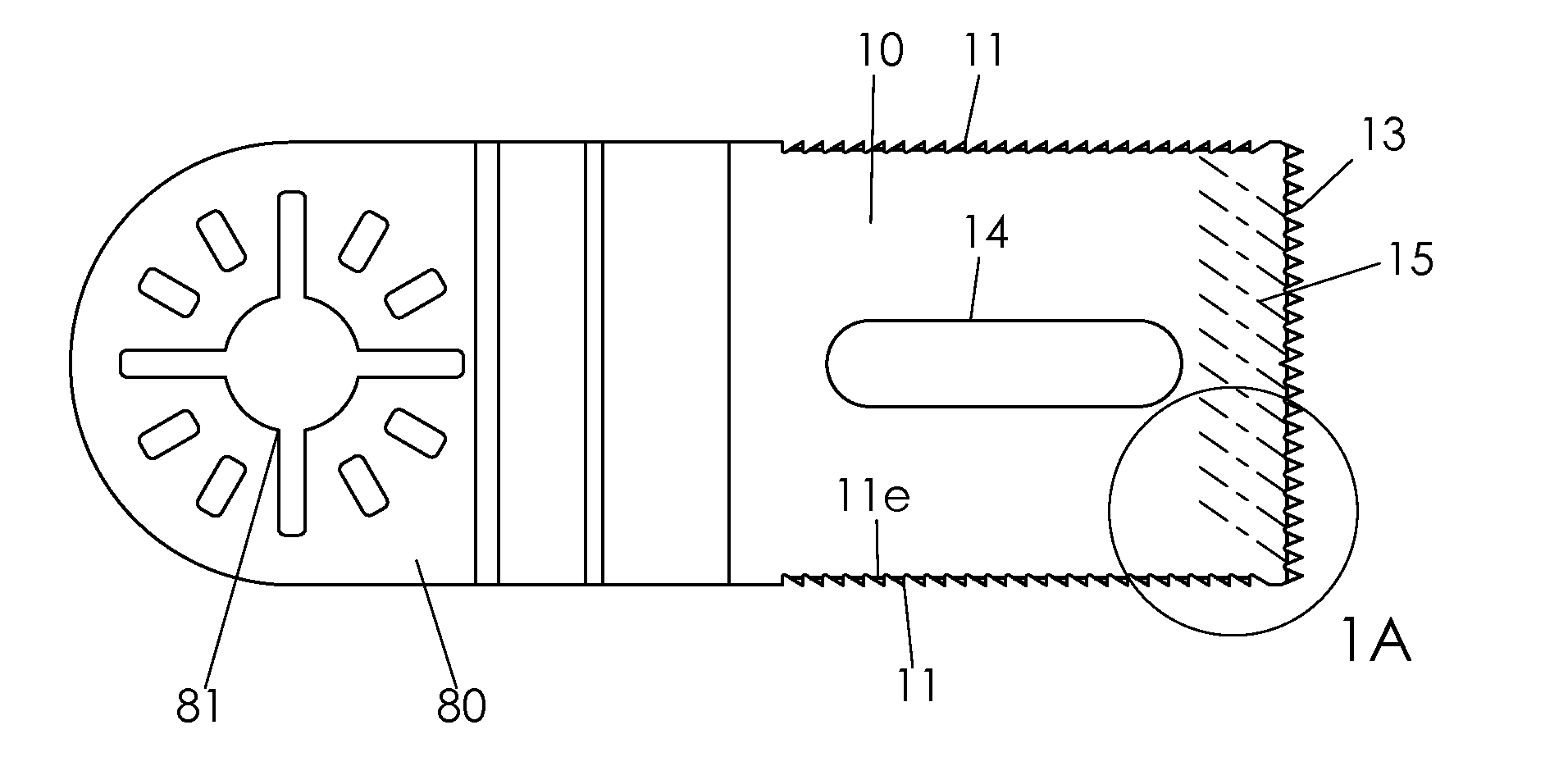

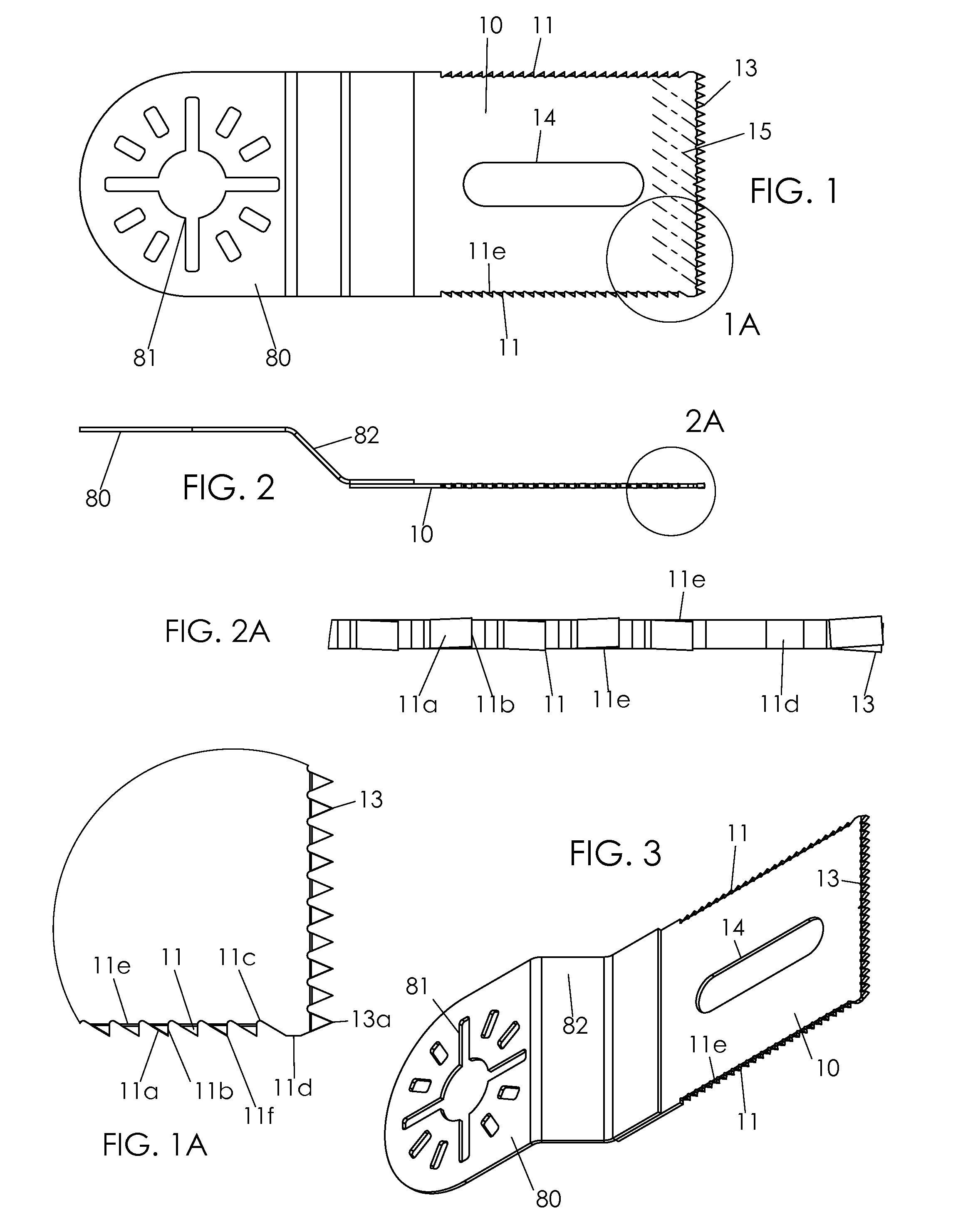

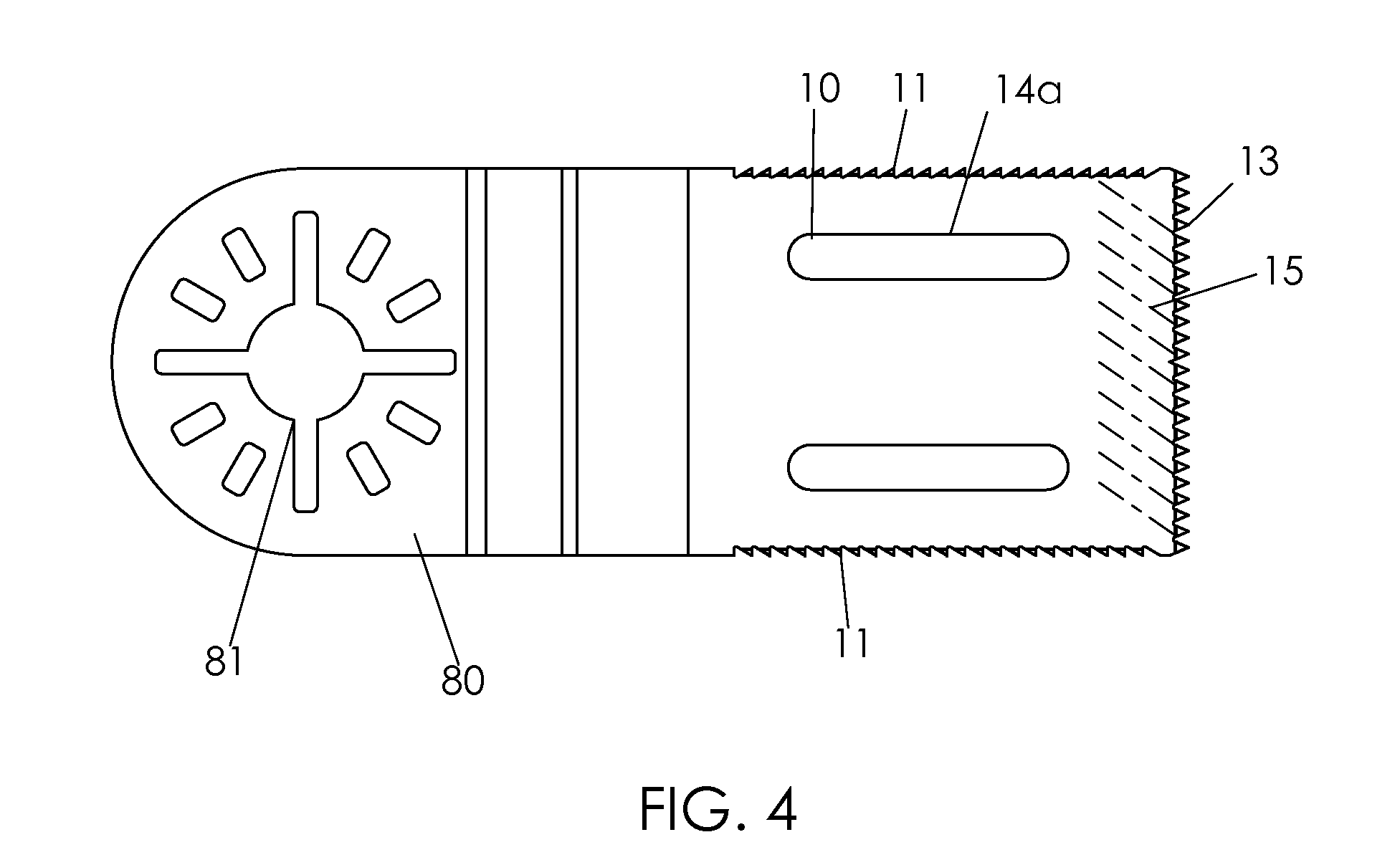

Cutting blade for oscillating tool

ActiveUS20160082605A1Smooth cutting actionFast and efficient cuttingPower driven reciprocating sawsMetal working apparatusEngineeringPower tool

An improved blade for use with an oscillating power tool is disclosed. A rectangular style blade includes side teeth to eject debris and allow rapid but well controlled blind plunge cuts. The side teeth are preferably asymmetric with a forward orientation to bias debris out and the blade inward. Preferably one or more openings or slots allow for additional debris removal. The side teeth also allow for controlled side cutting.

Owner:WORKTOOLS

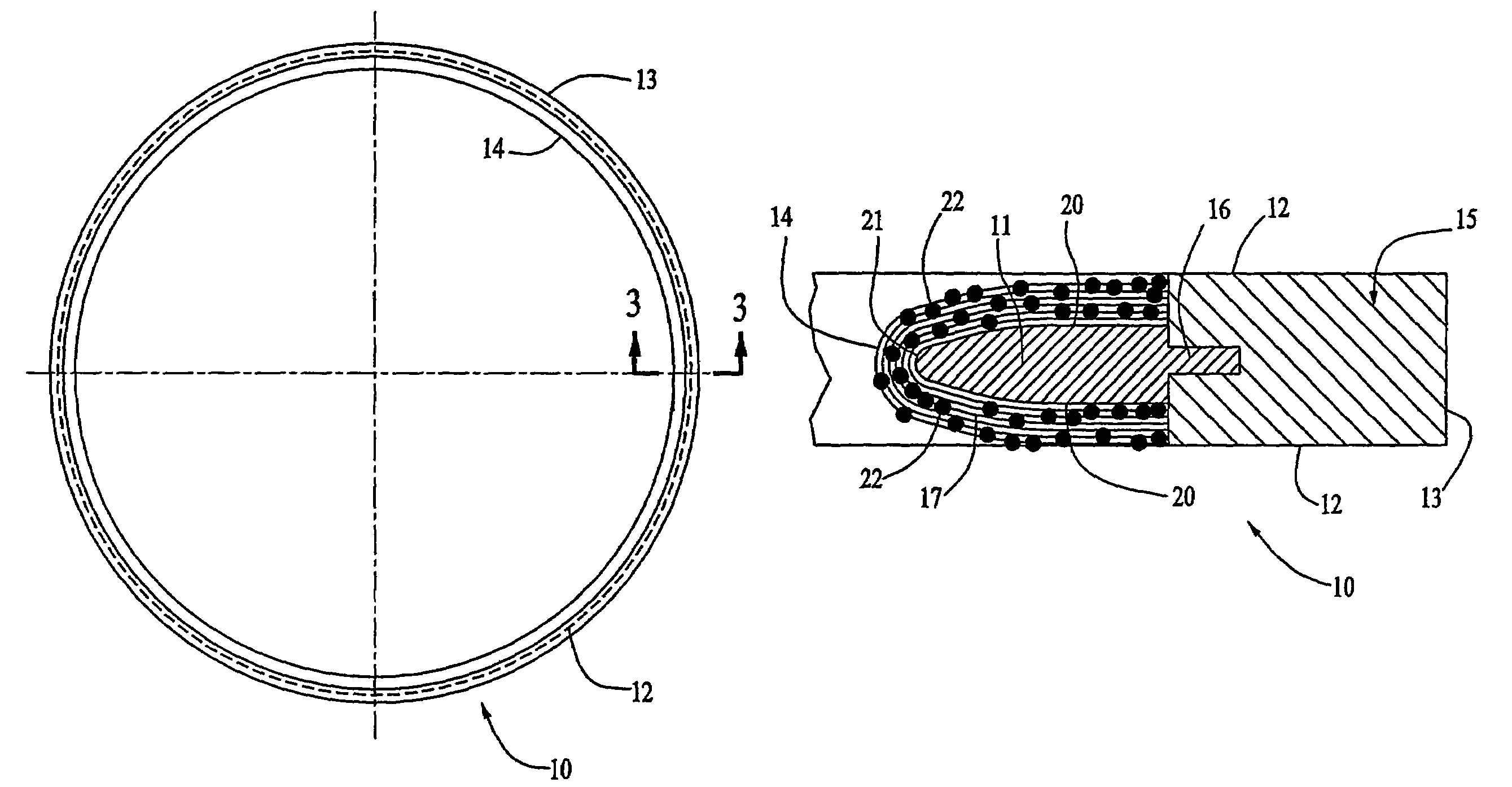

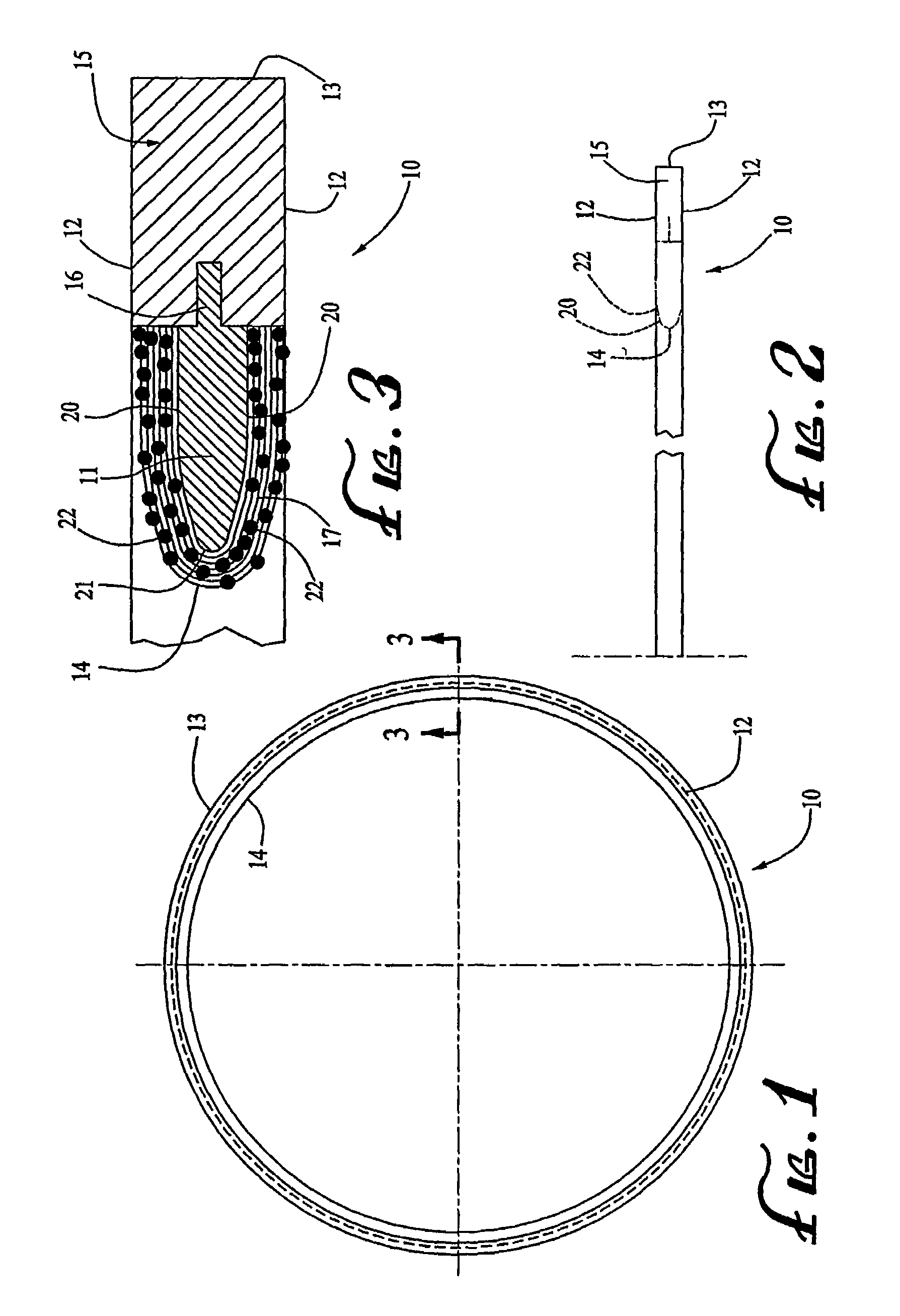

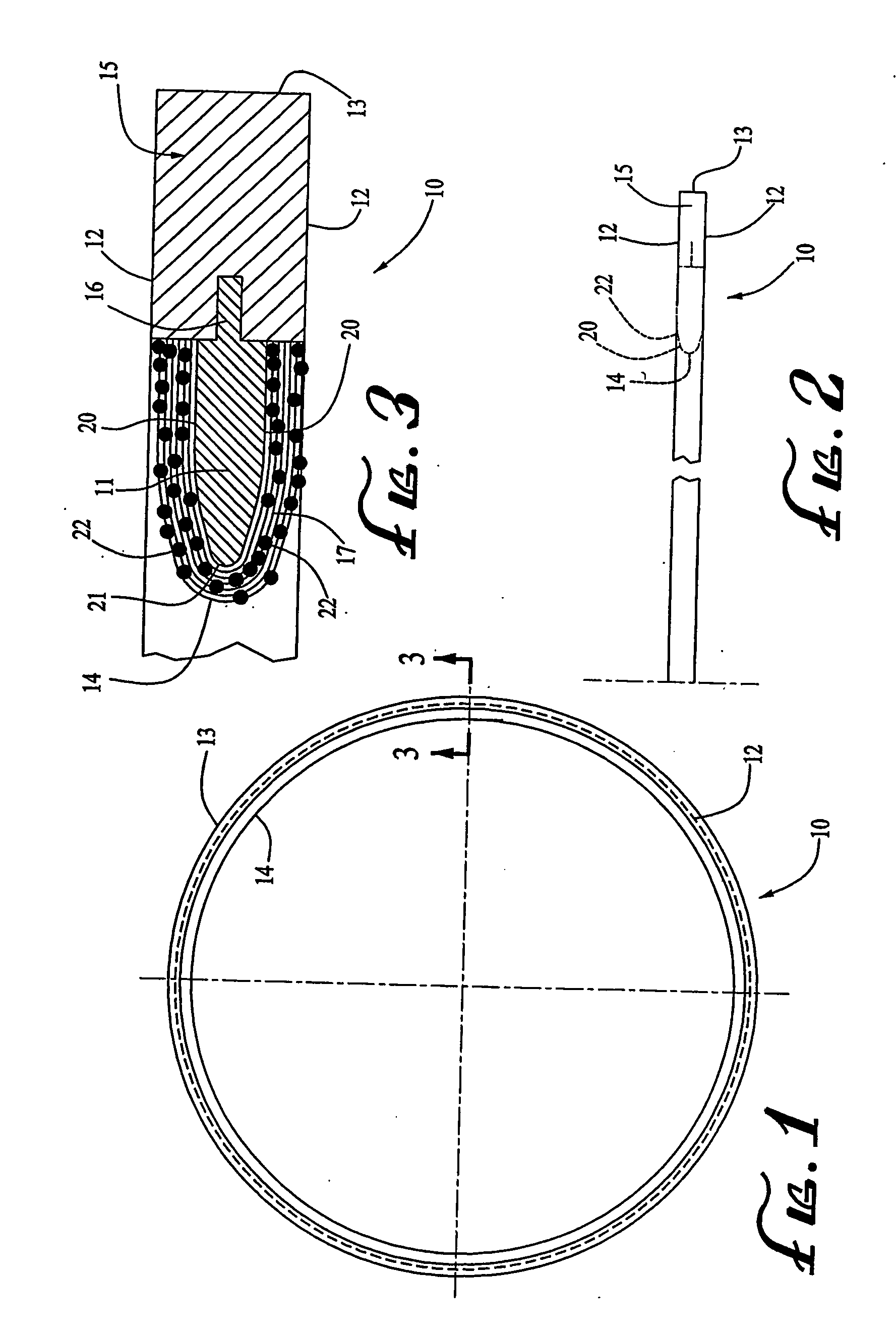

Blade ring saw blade

InactiveUS7350518B2Raise the gradeSmooth cutting actionRevolution surface grinding machinesMetal sawing toolsStraight pathKnife blades

Owner:GEMINI SAW

Low profile sickle drive

A sickle drive incorporated into a generally flat package or enclosure or floor. The drive includes an epicyclic mechanism, including a rotatable input element in an upper region of a cavity of the enclosure, and an eccentric element below the input element rotatable eccentrically thereby. A drive arm is connected to the eccentric element for rotation about, and eccentric rotation with, the eccentric element, and extends to a pivot element which can be the only component extending upwardly from the enclosure or floor, such that the shaft will be pivoted by the eccentric movement of the drive arm. A knife arm connects to the pivot element and a sickle knife assembly which will be reciprocated by the pivoting action. A second epicyclic arrangement can be employed such that opposite forces generated by operation of the drive will be largely canceled.

Owner:BLUE LEAF I P INC

Helical cutting insert with multiple cutting edges

ActiveUS7753625B2Less powerSmooth cutting actionMilling cuttersShaping cuttersEngineeringKnife blades

Owner:KENNAMETAL INC

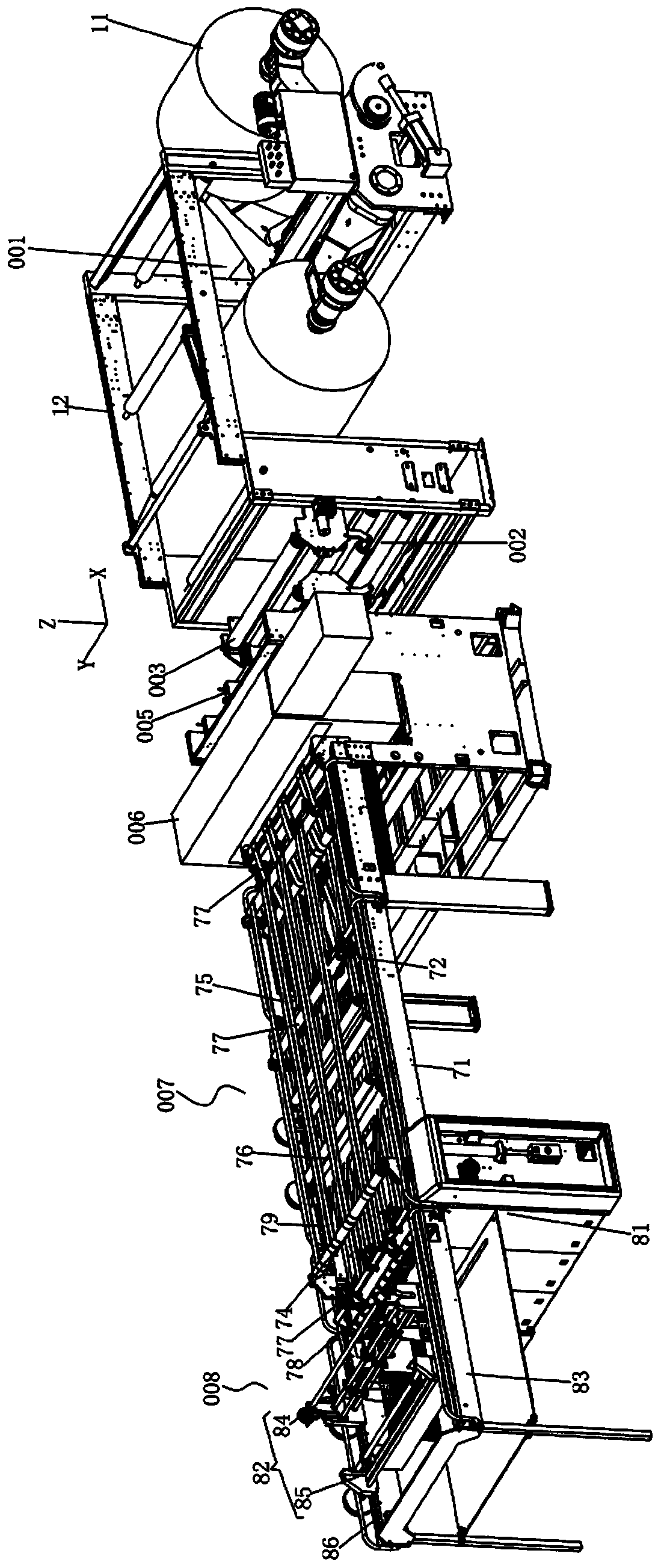

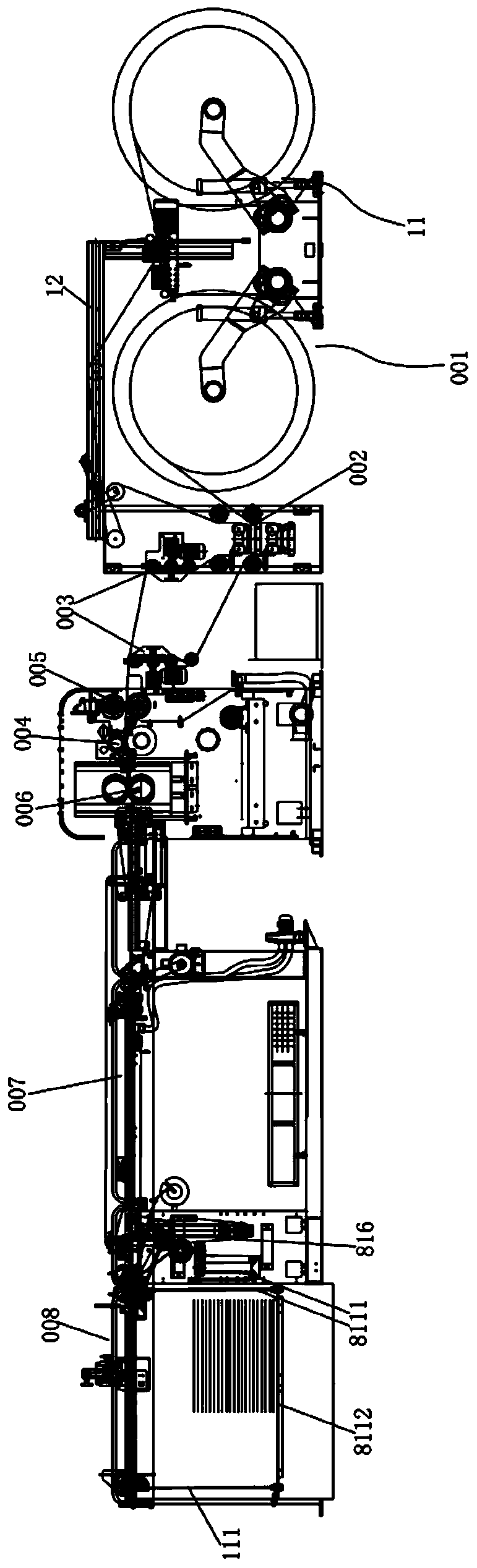

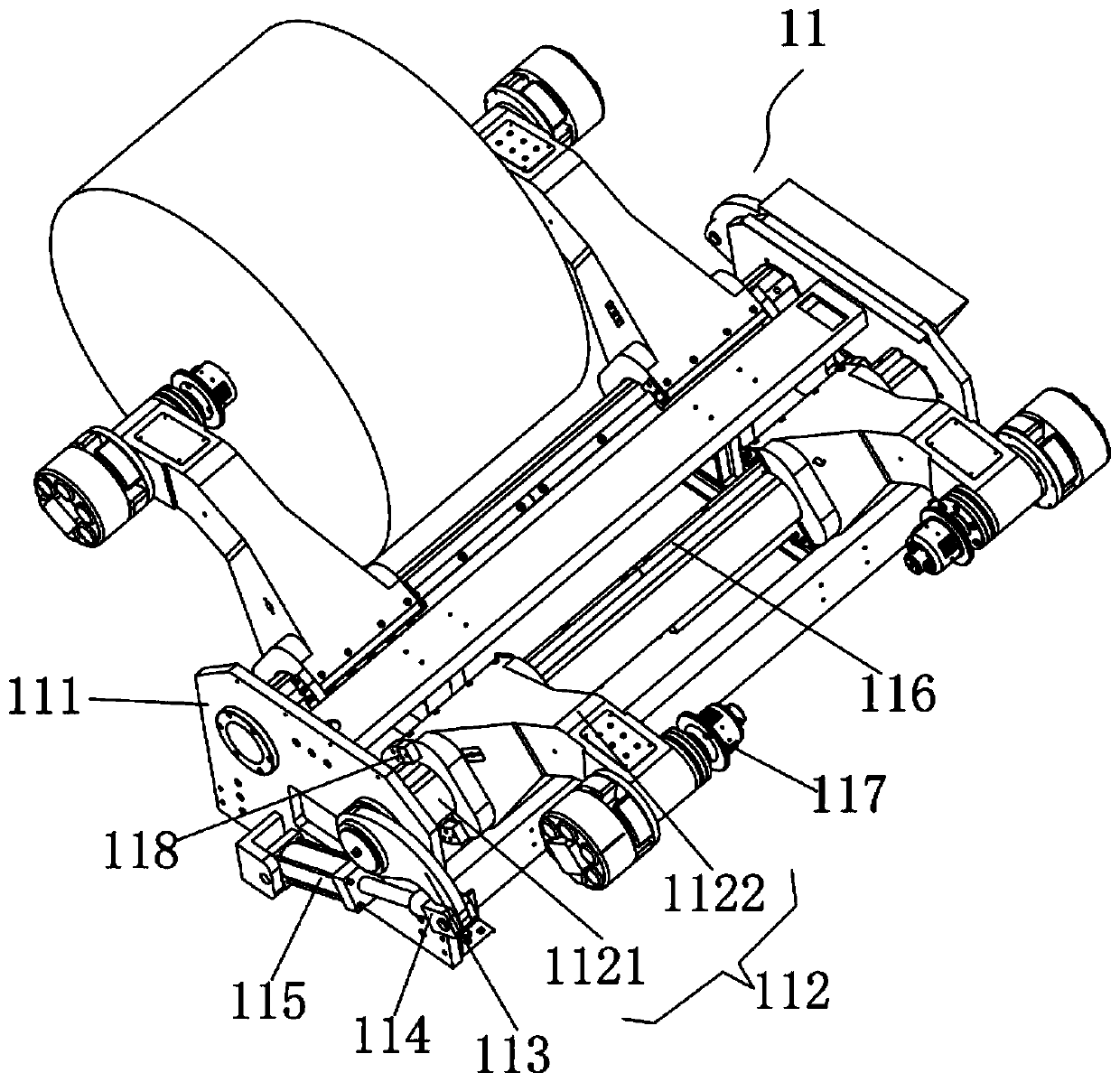

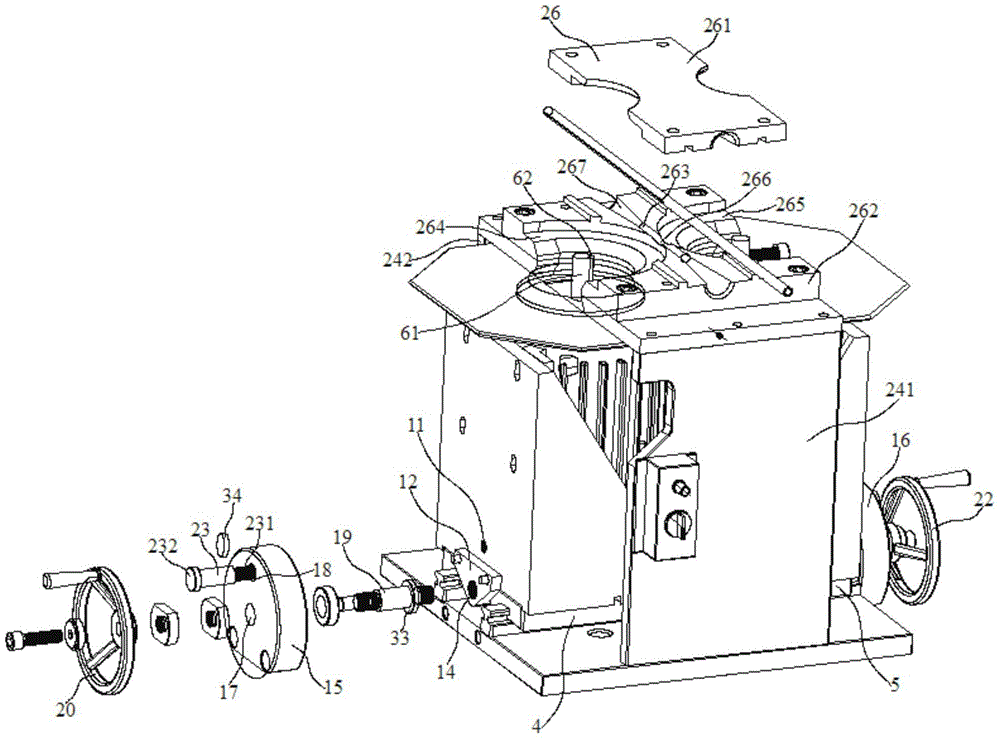

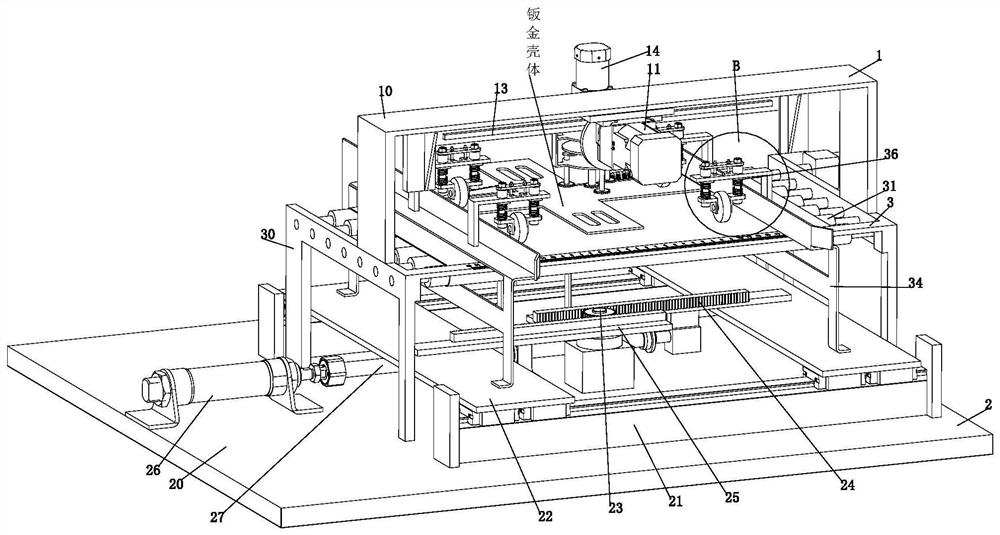

Double rotary knife roll paper splitting machine

PendingCN110271895AHigh dimensional consistencyLarge size errorPile receiversMetal working apparatusRolling paperTraction system

The invention discloses a double rotary knife roll paper splitting machine which comprises a paper supply system, a traction system, a conveying system and a paper collecting system. The paper supply system is used for being matched with a correcting system and a retroflection system to transfer a plurality of roller paper layers along a transverse direction; the traction system is used for sending laminated roll paper to a traction system of double rotary roller trimmer knife after pulling the roll paper to a stripping system; the conveying system comprises a high speed lower conveying assembly and a laminated paper conveying assembly in butt joint connection through a paper pass assembly and also comprises a high speed upper conveying assembly, a reducing assembly and a paper pressing assembly; the high speed lower conveying assembly and the laminated paper conveying assembly are matched with the high speed upper conveying assembly, and a pile of paper can be overlapped to the previous pile of paper successively and is transferred to the paper collecting system by matching with a conveying speed difference generated by the high speed upper conveying assembly and the laminated paper conveying assembly with reduction of the reducing assembly; and the paper collecting system is used for carrying each pile of paper and stacking the paper.

Owner:DONGGUAN JUNXING MACHINERY TECH

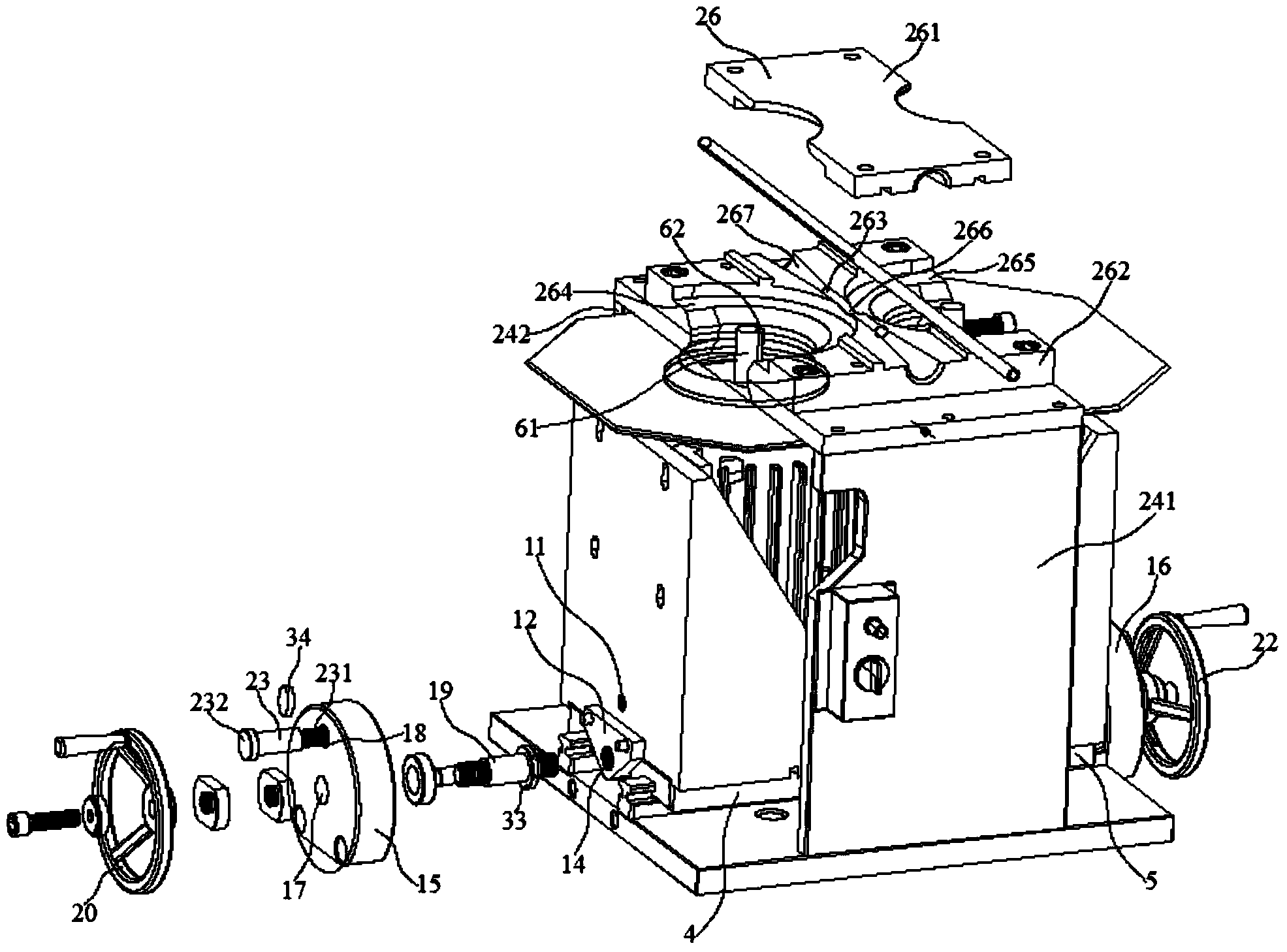

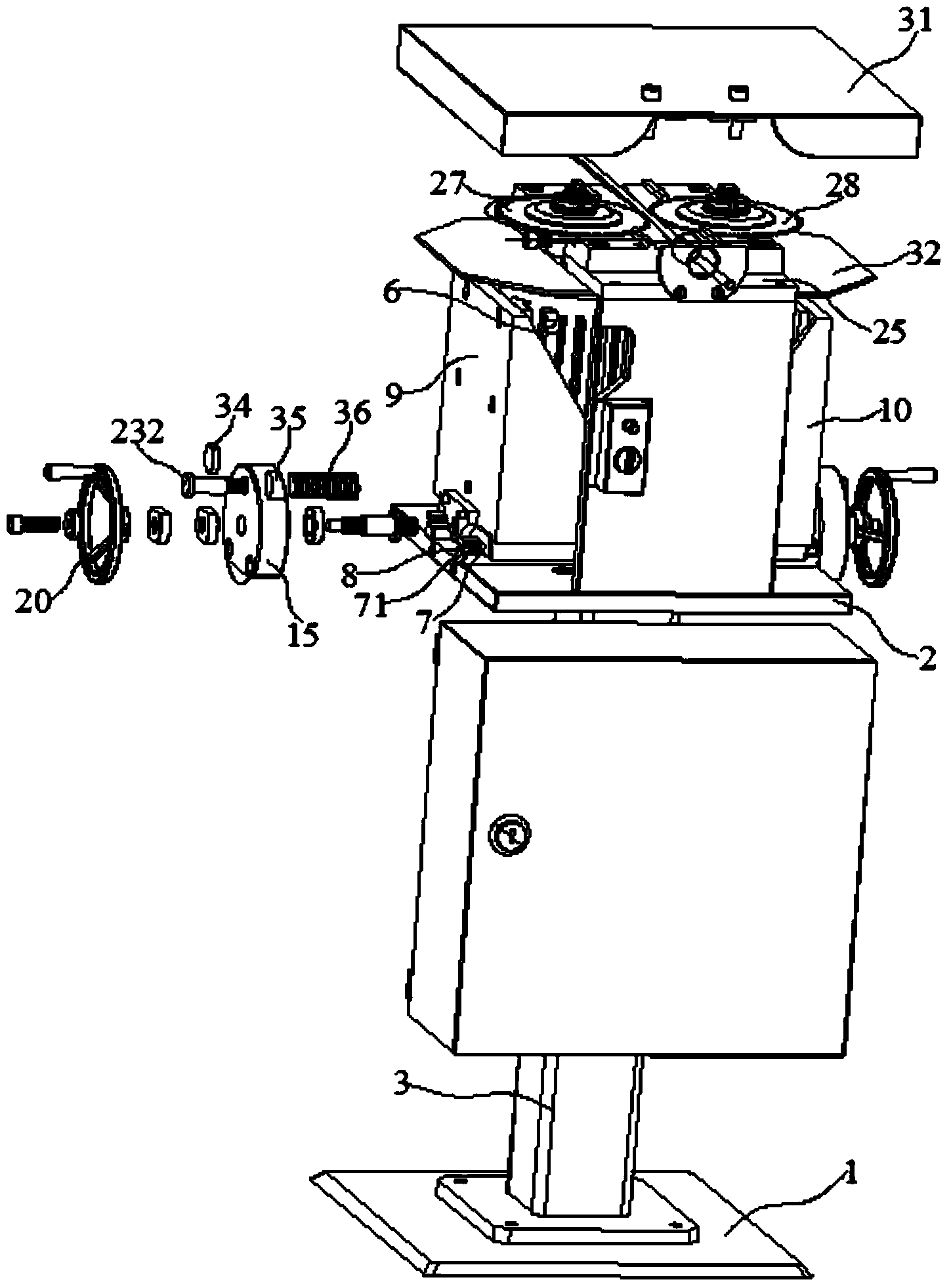

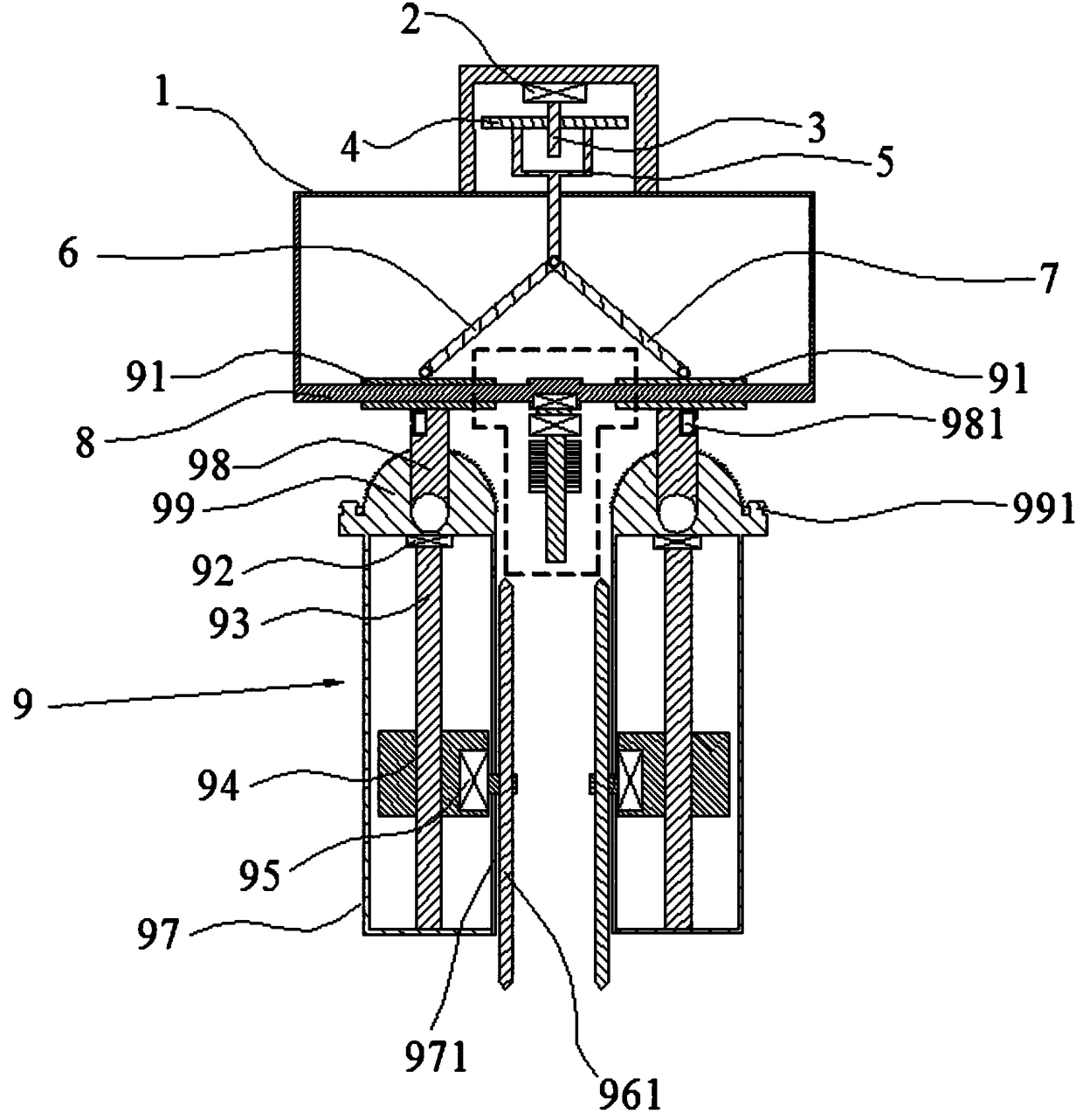

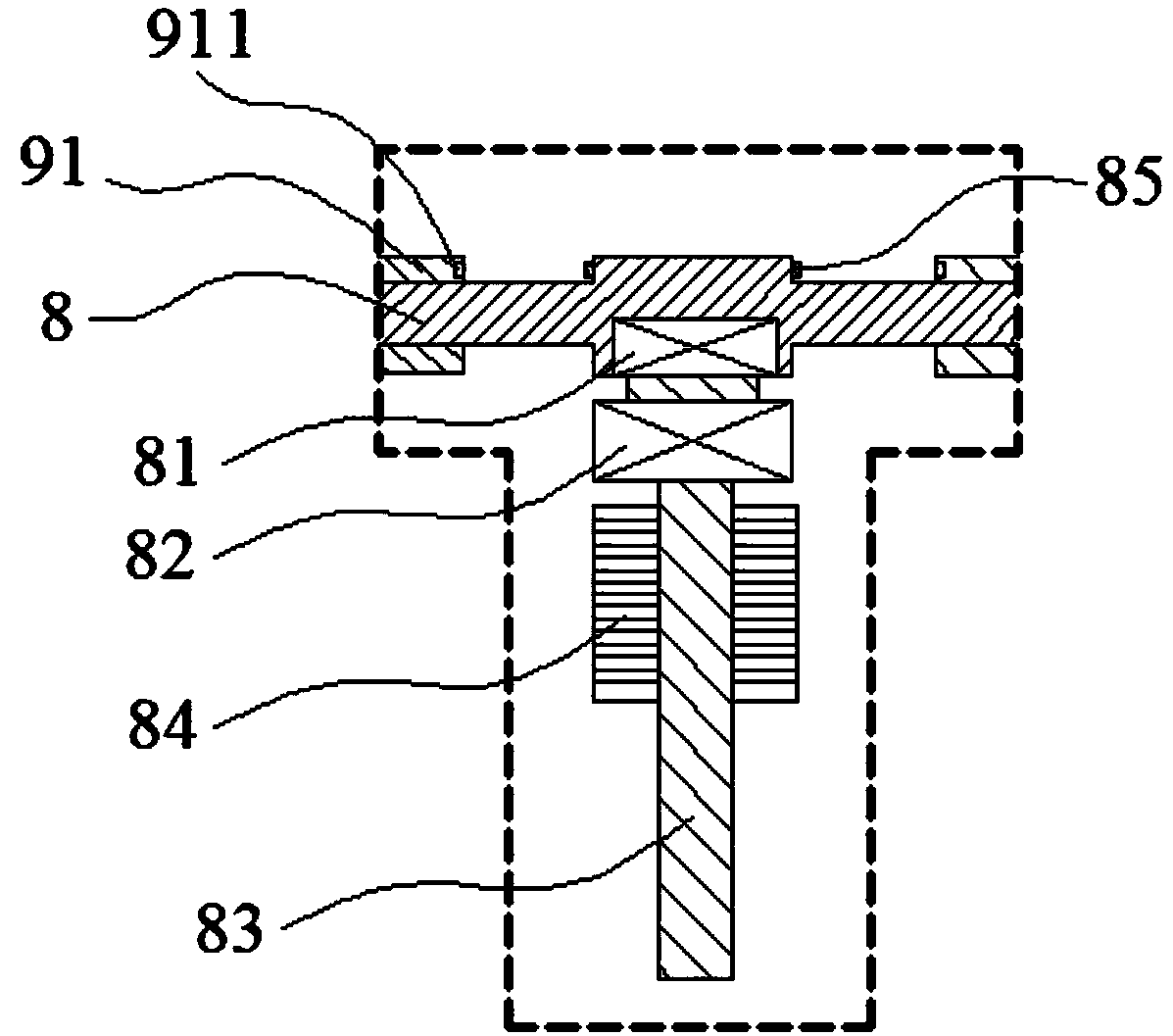

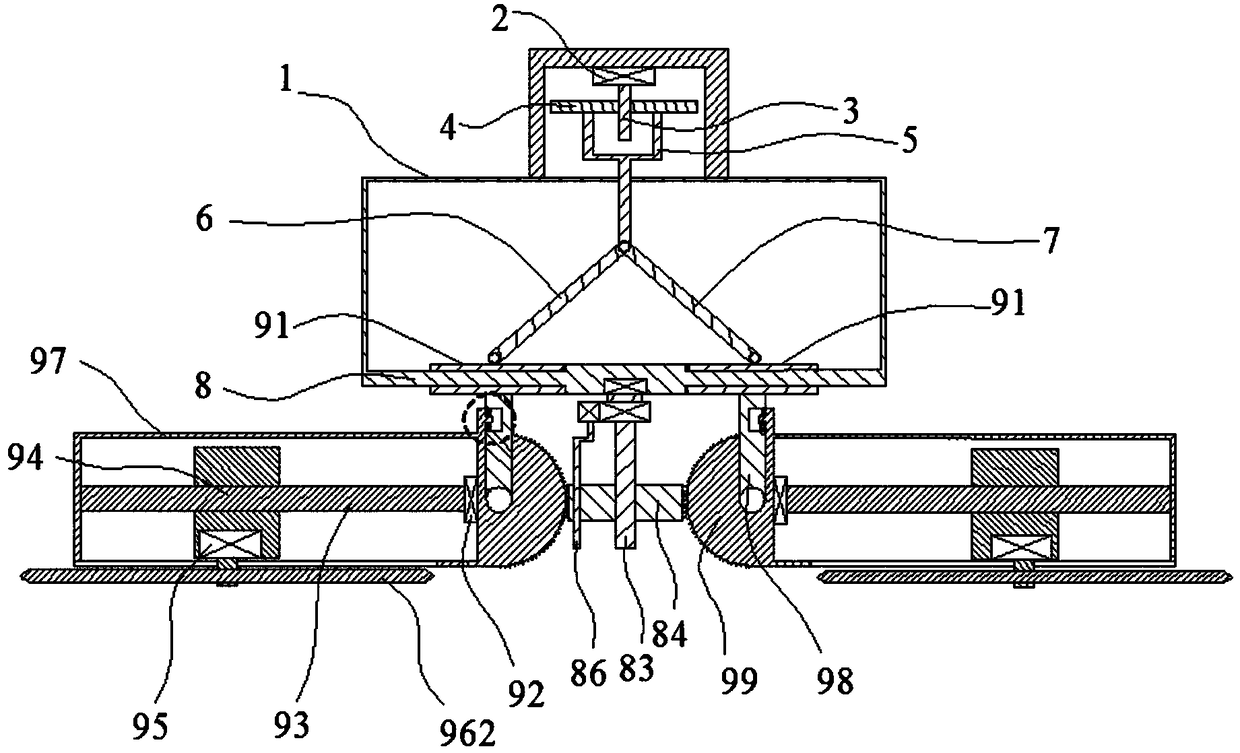

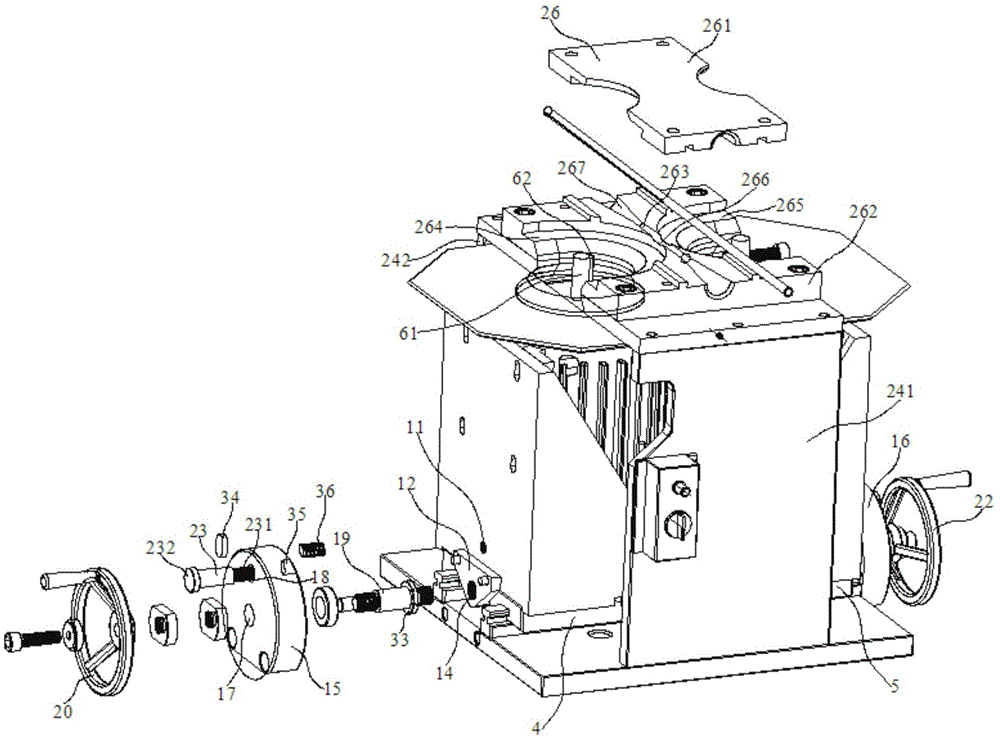

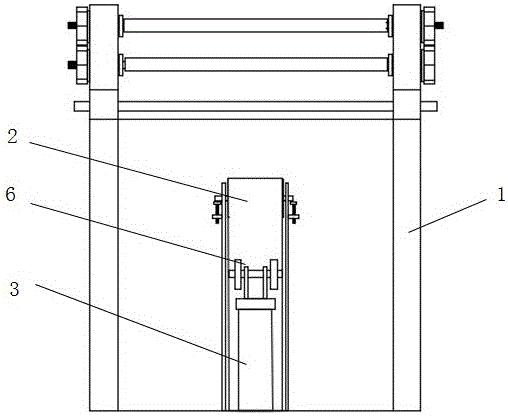

Cable protective metal sleeve peeling machine

ActiveCN103683128AImprove stripping efficiencyReduce labor intensityApparatus for removing/armouring cablesEngineering

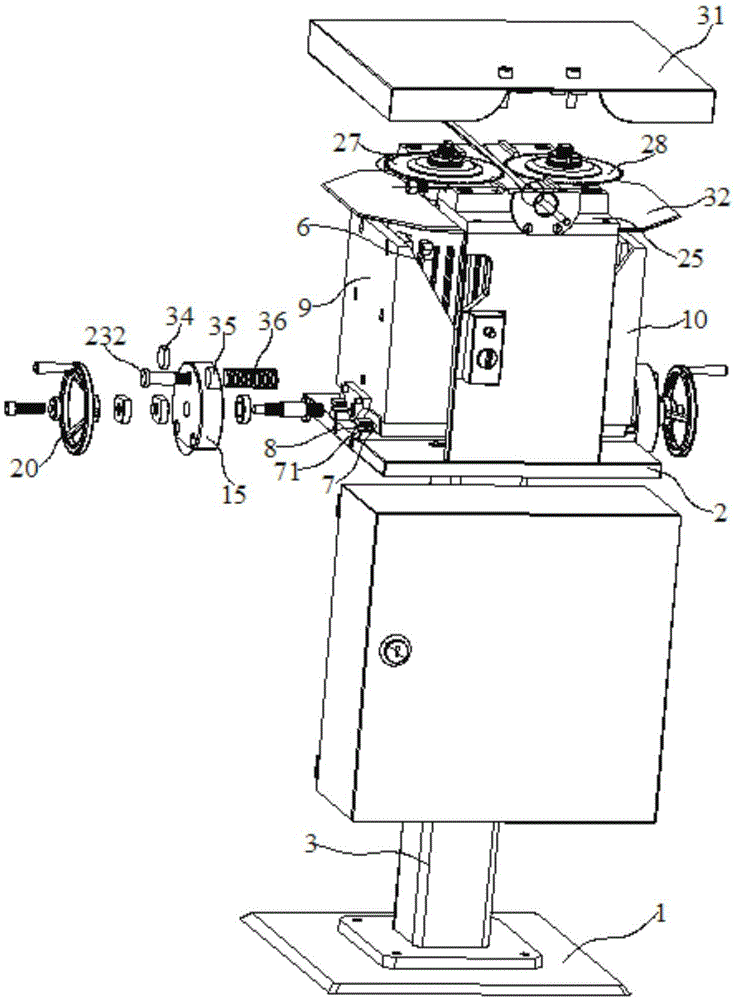

The invention discloses a cable protective metal sleeve peeling machine. The cable protective metal sleeve peeling machine comprises a base, a fixed bottom plate, a stand column fixed between the base and the fixed bottom plate, a left motor support, a right motor support and two motors. One of the two motors is installed on the left motor support, and the other motor is installed on the right motor support. Two sliding blocks are fixed to the lower surface of the left motor support in parallel, and two sliding blocks are fixed to the lower surface of the right motor support in parallel. Two linear rails are arranged on the fixed bottom plate in parallel. The linear rails are sequentially embedded into grooves of the sliding blocks of the left motor support and grooves of the sliding blocks of the right motor support respectively. A left baffle with an adjusting screw hole and a right baffle with an adjusting screw hole are fixed to the outer side of the left motor support and the outer side of the right motor support respectively. A left connecting plate with a driving screw hole and a right connecting plate with a driving screw hole are fixed to the outer side of the left baffle and the outer side of the right baffle respectively. The left connecting plate and the right connecting plate are located between the two linear rails, and the driving screw holes are located below the left motor support and the right motor support respectively. According to the cable protective metal sleeve peeling machine, the problem that protective metal layers are difficult to cut and peel in the metal sleeve cable detection, connection and installation processes is solved, the peeling efficiency is improved, and the long protective metal layers are peeled.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

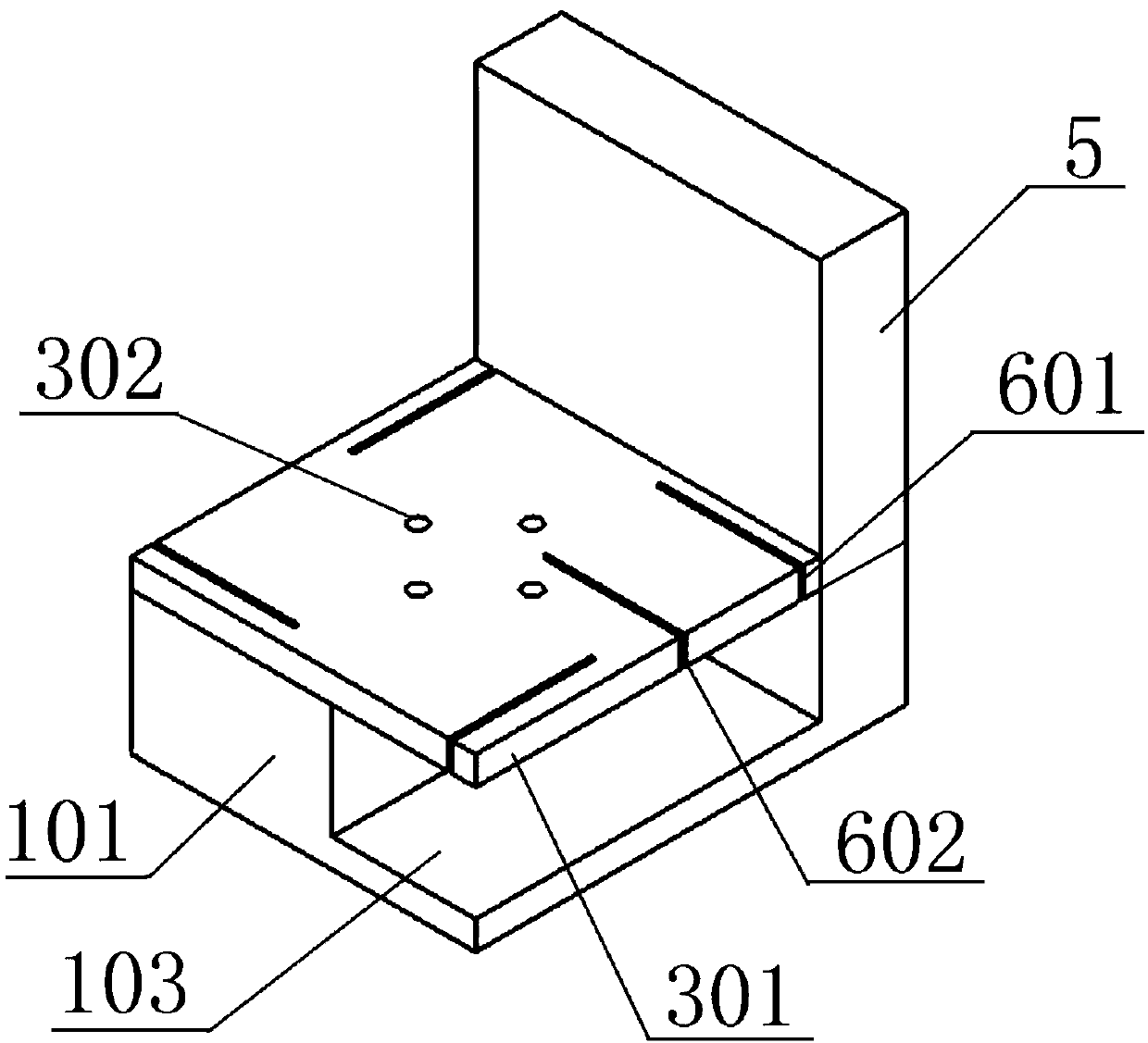

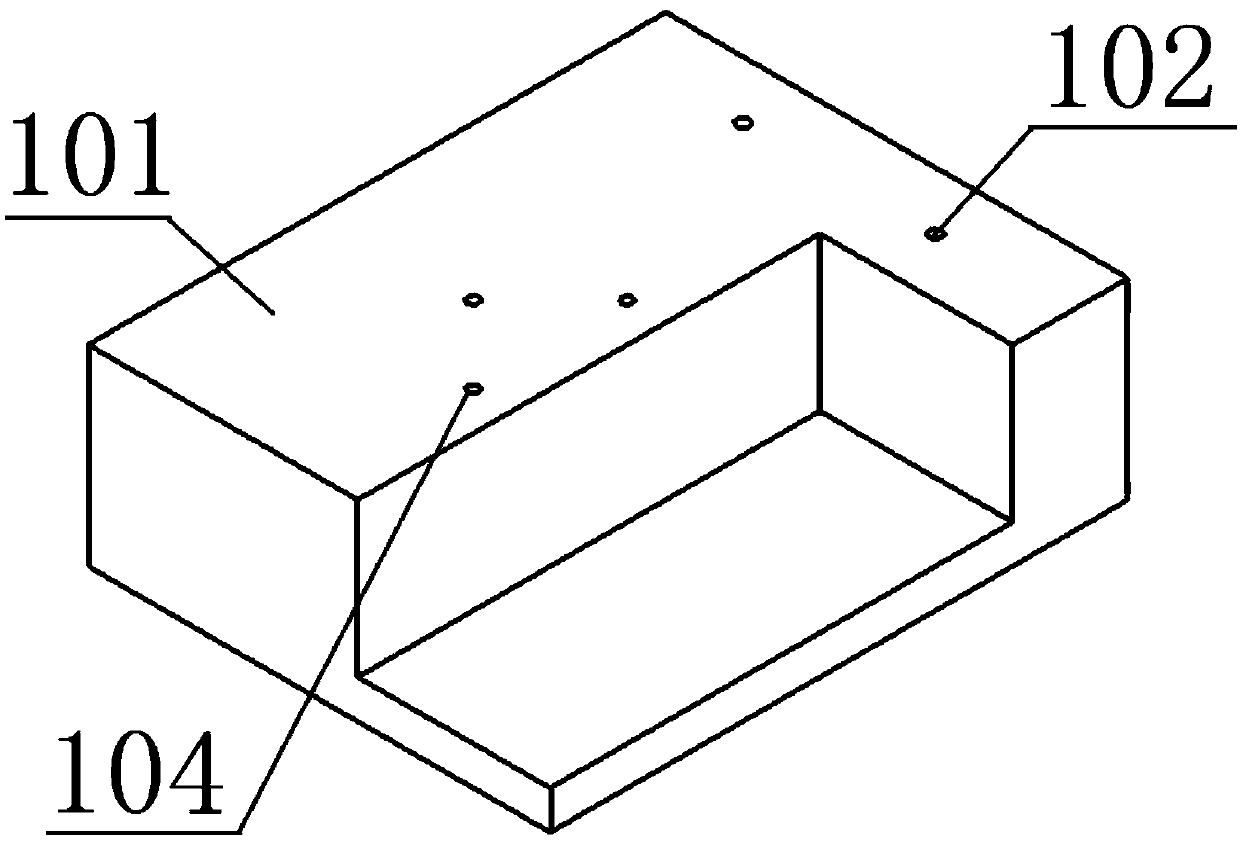

Positive and negative pressure moulding die

InactiveCN106217486AControl relative motionEasy to operateMetal working apparatusRelative motionMechanical engineering

The invention discloses a positive and negative pressure moulding die. The positive and negative pressure moulding die is characterized by comprising an upper die and a lower die, wherein the lower die comprises a carrying table, slide modules arranged just below the carrying table, and a rolling shaft, wherein a rotary shaft carrying out fixed autorotation is arranged at a centre below the carrying table; a drive module and a guide block are connected to the two ends of each slide module respectively; slide guide rails are arranged at the bottoms of the two slide modules; the two guide blocks are located above and below the rotary shaft respectively, and roll on the rotary shaft; the top of each slide module is configured to be a slope surface which sequentially comprises a first slope surface and a second slope surface; and each first slope surface is close to the corresponding guide block, and each second slope surface is close to the corresponding drive module. According to the positive and negative pressure moulding die disclosed by the invention, a cutting action is more stable during a running process of the whole device, and cutting efficiency is higher through configuring the top surface of each slide module to be the slope surface; and meanwhile, the device is capable of further improving stability by virtue of the guide blocks, and effectively controlling the relative movement of the slide modules at the two sides, thus increasing the production efficiency.

Owner:JIANGSU BAOXINRUI MACHINERY CO LTD

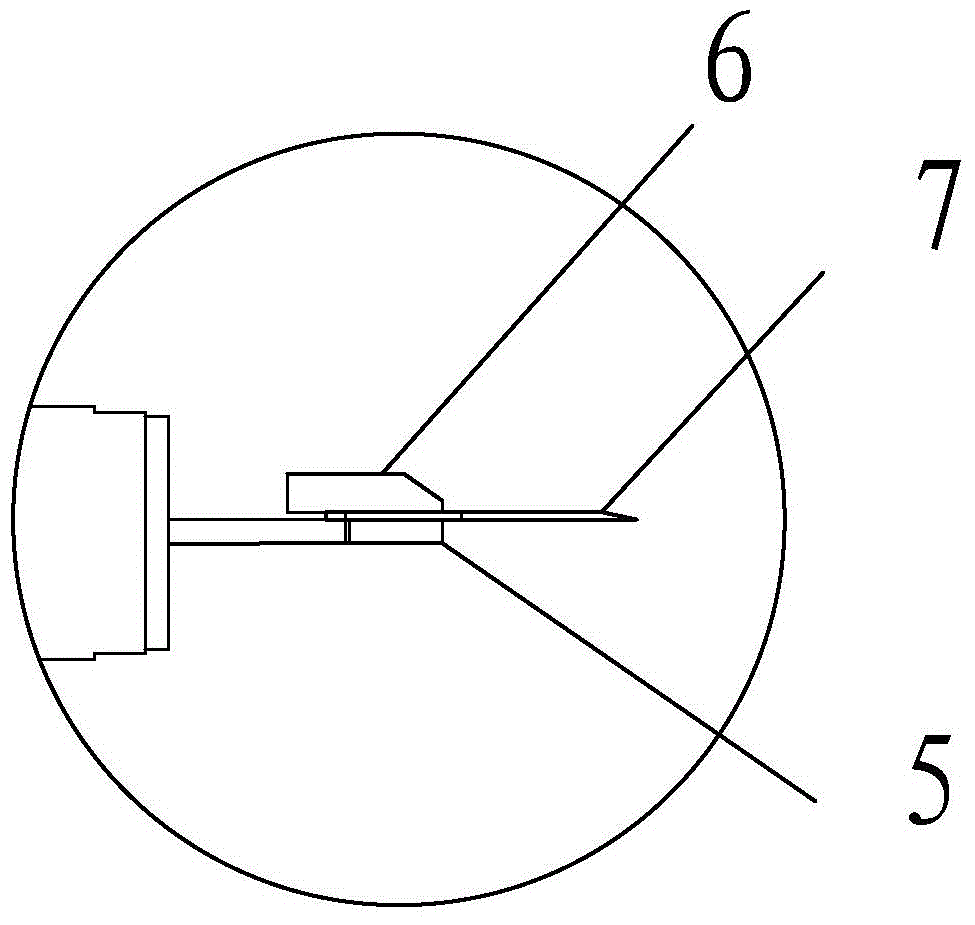

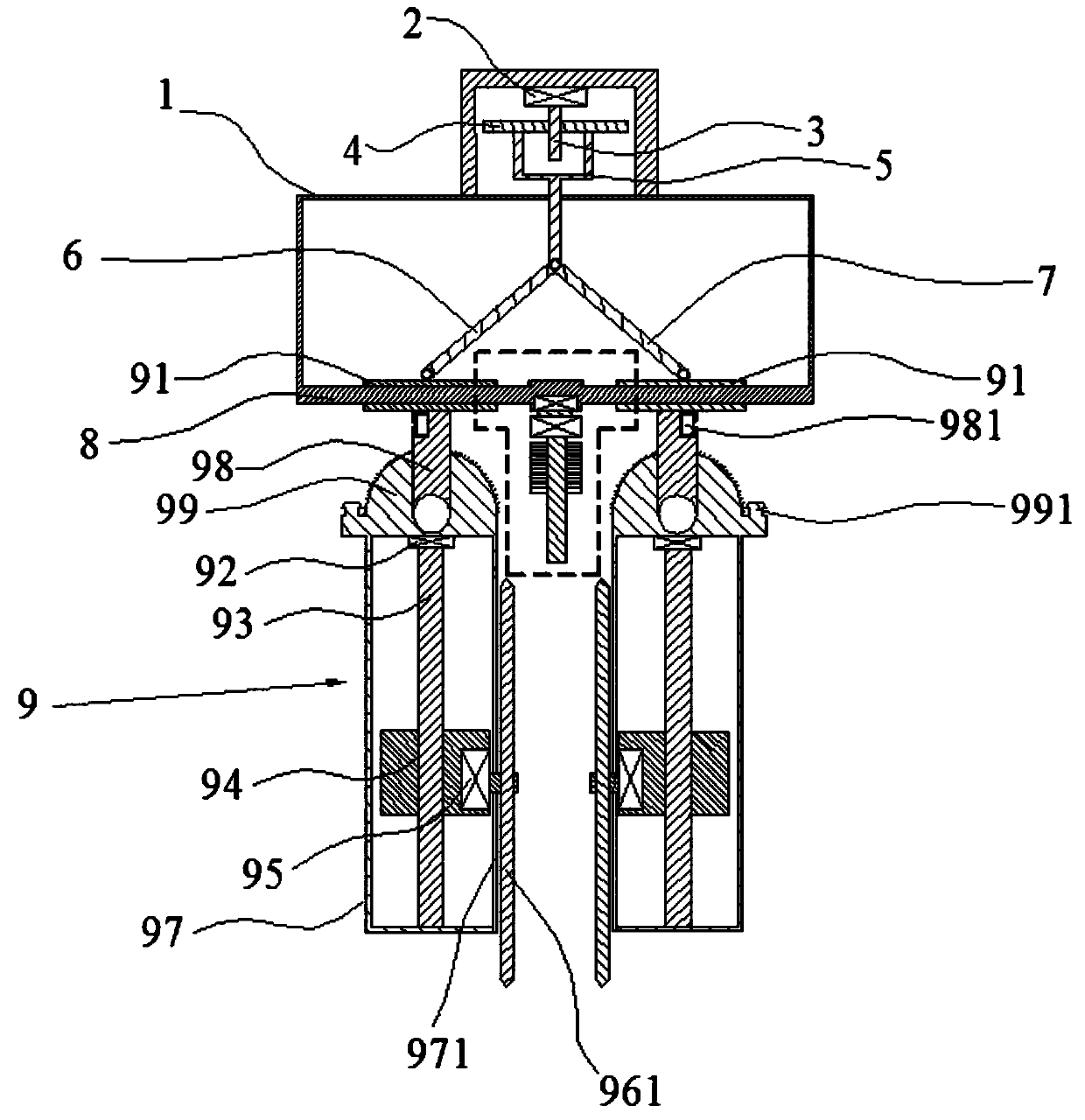

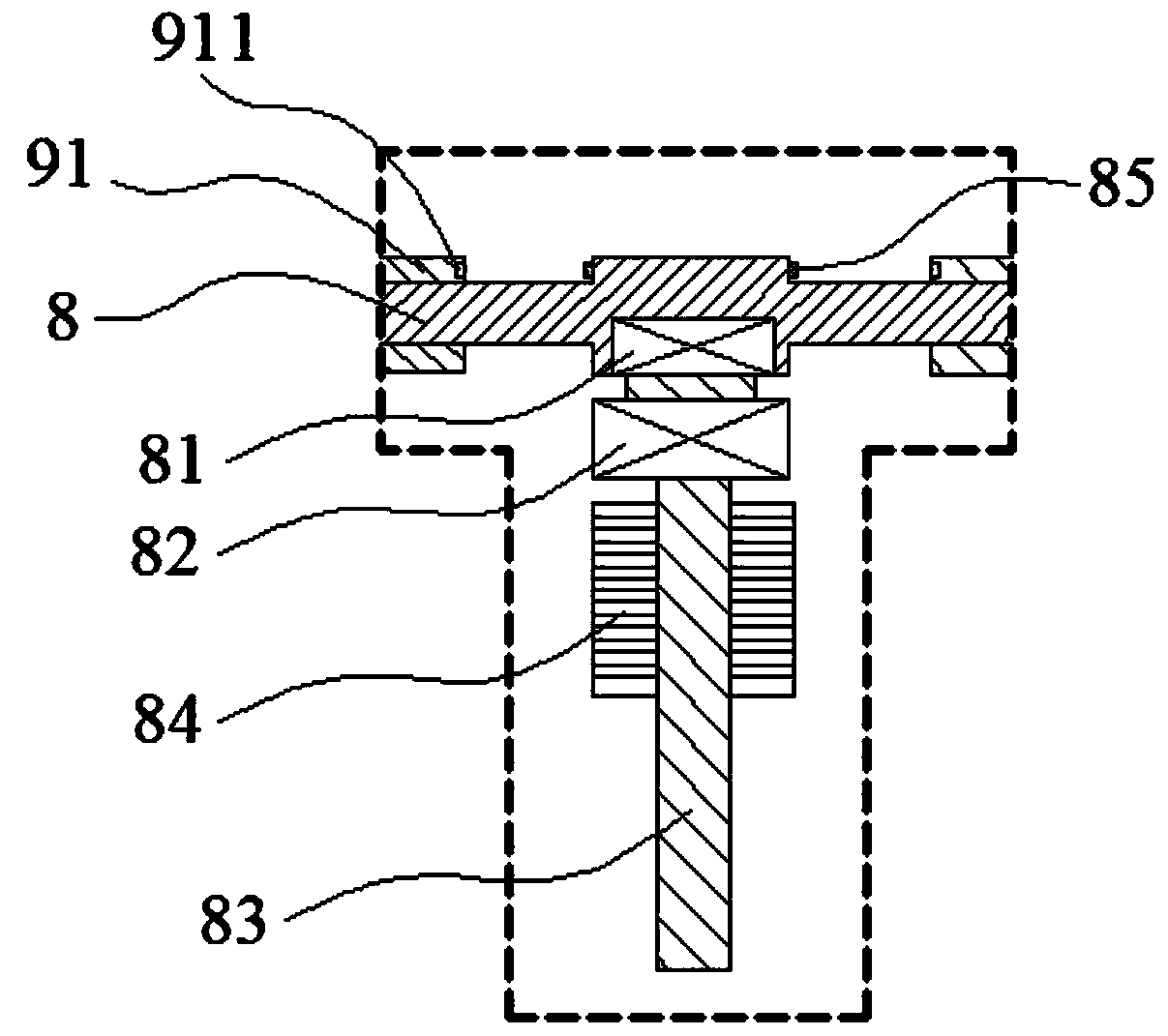

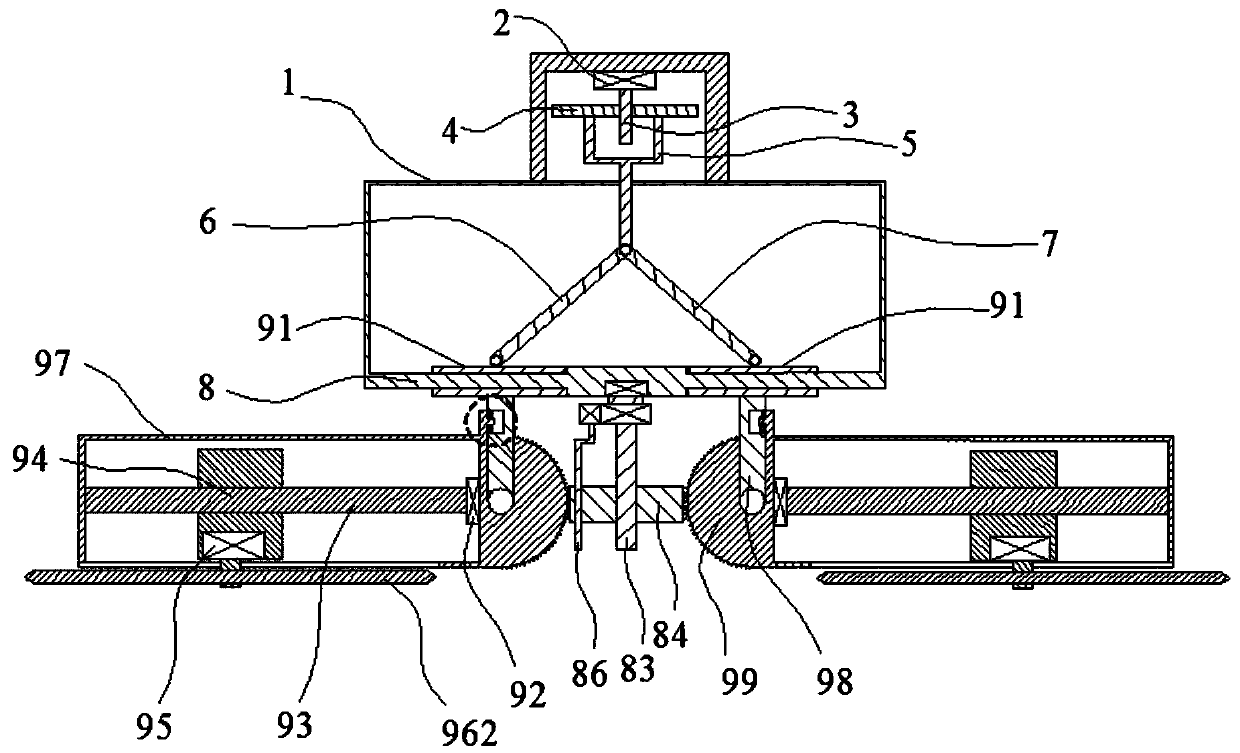

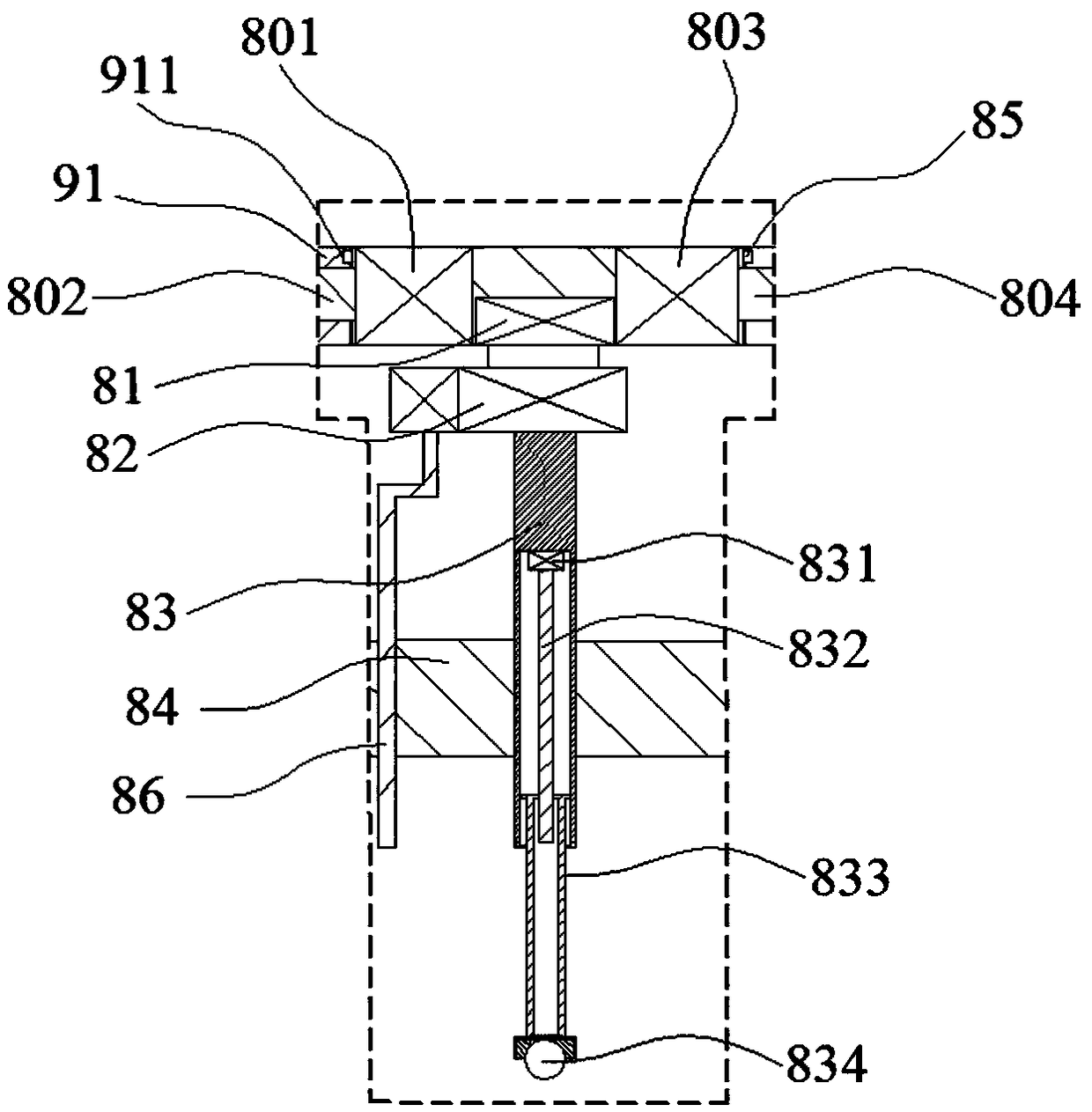

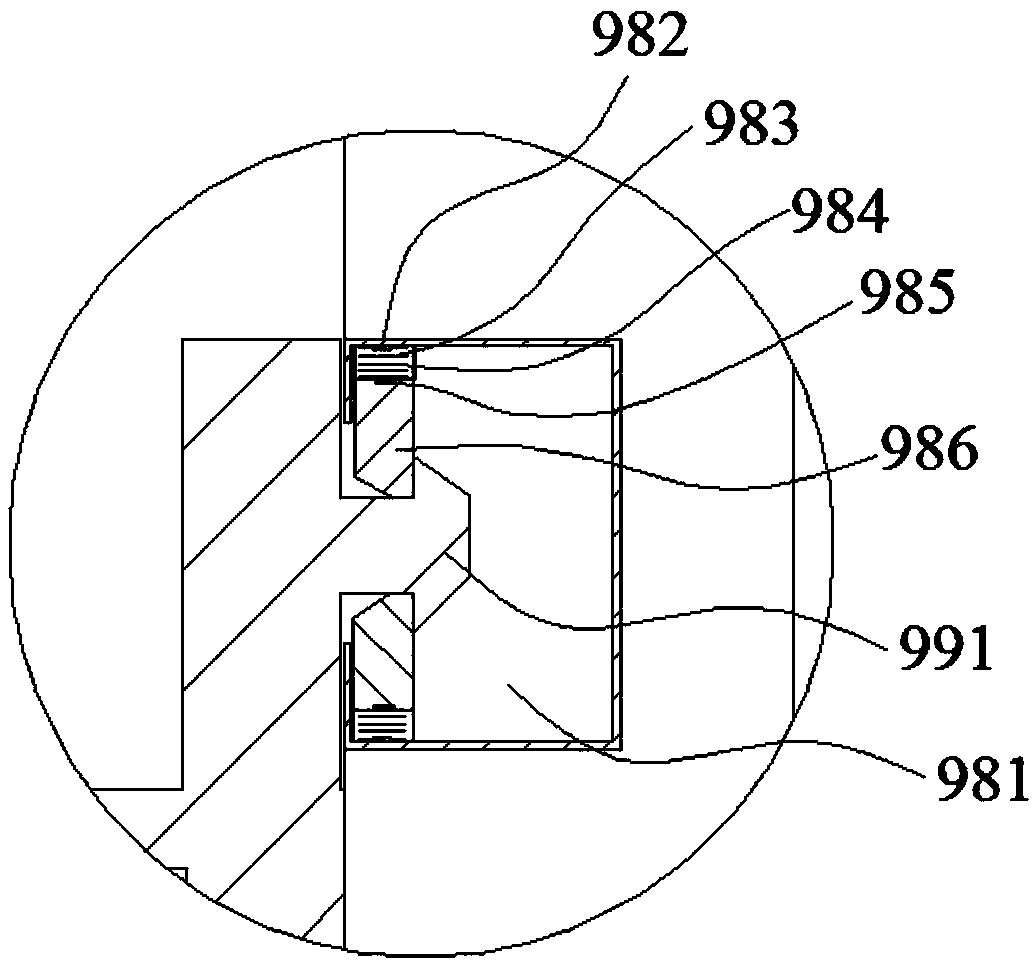

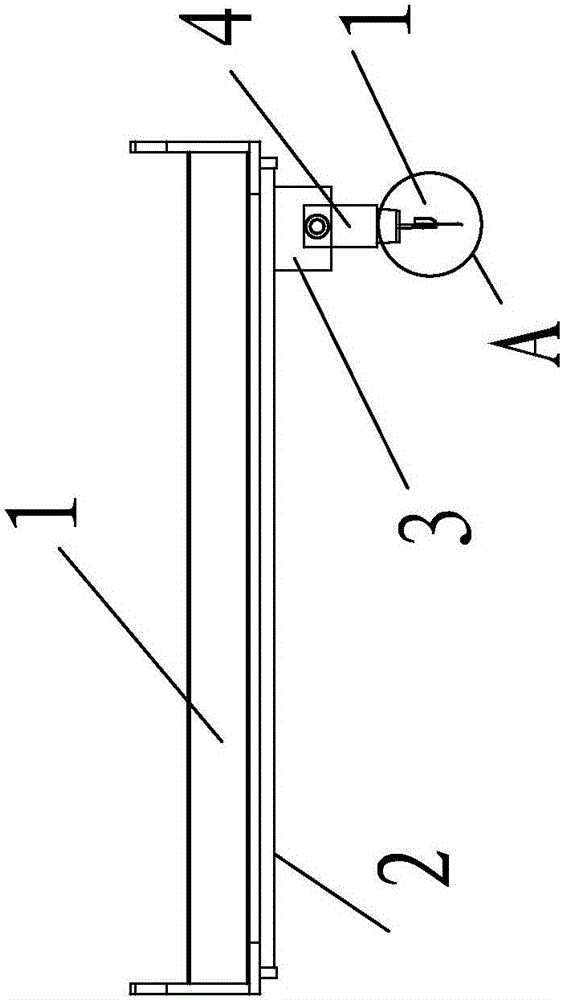

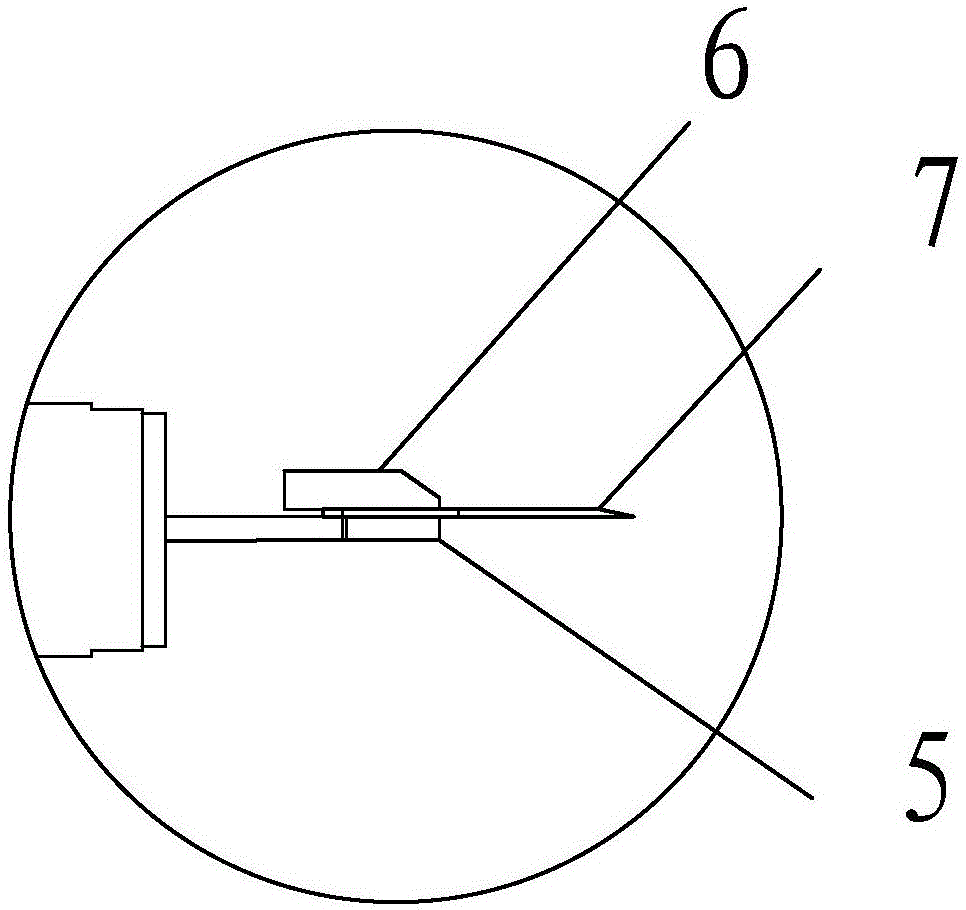

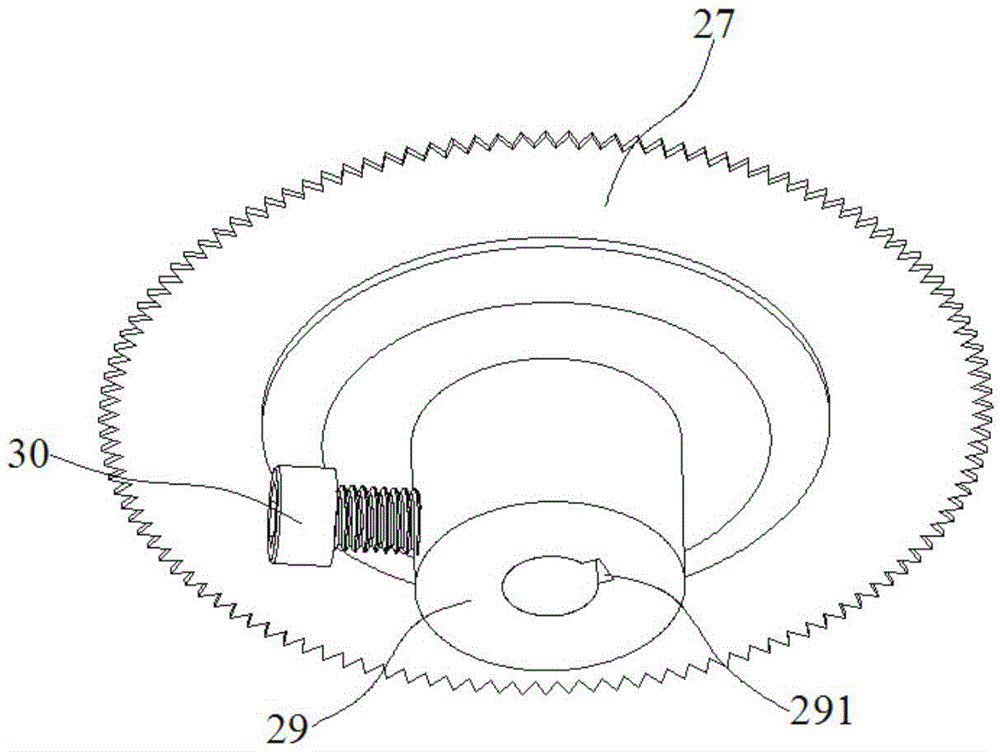

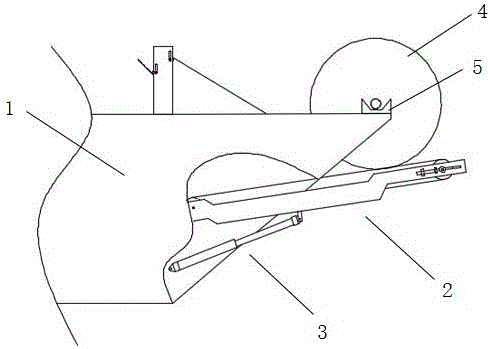

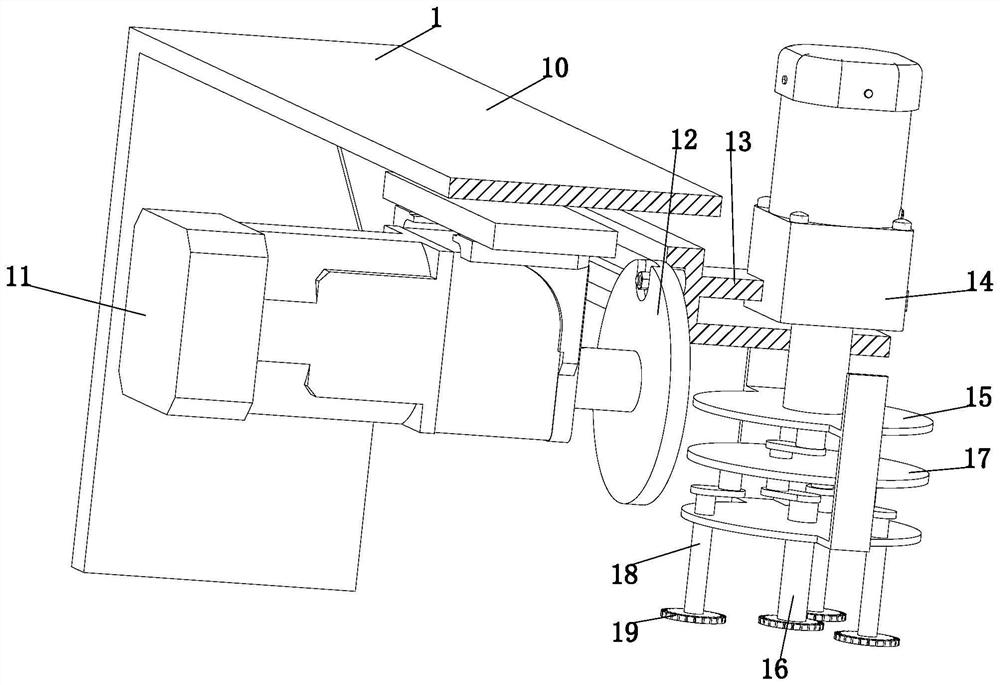

Fly cutter mechanism

InactiveCN105729549AFast cutting actionSmooth cutting actionMetal working apparatusEngineeringFilm material

The invention provides a fly cutter mechanism. The fly cutter mechanism comprises a rodless air cylinder. The air cylinder comprises an air chamber and a sliding rod located below the air chamber. A sliding block penetrates the sliding rod. A fly cutter block is movably arranged on the sliding block. A fly cutter is clamped below the fly cutter block through an upper clamping plate and a lower clamping plate. The fly cutter mechanism is used for cutting film materials and has the beneficial effects that the cutting action is rapid and stable, and a notch is straight.

Owner:李新春

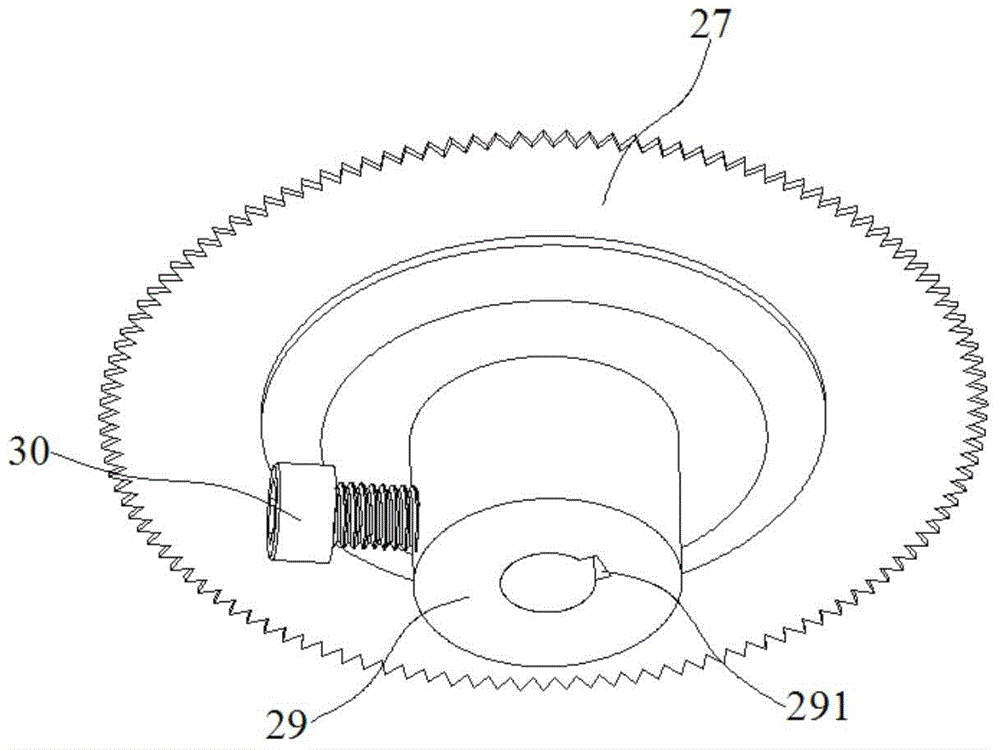

A cutting and grinding machine

InactiveCN108161467BFlexible adjustmentChainsaw cutting action is smoothOther manufacturing equipments/toolsEngineeringGear tooth

The invention provides a cutting and grinding integrated machine which comprises a shell, two mounting frame assemblies and a direction adjusting mechanism. A sliding rod is arranged on the lower endface of the shell, and sleeved with two third sliding blocks. The lower ends of the two third sliding blocks are provided with supporting rods correspondingly, and the lower ends of the supporting rods are movably connected with the mounting frame assemblies correspondingly. The two mounting frame assemblies are symmetrically arranged, and the end face of the limiting end of the upper end of eachmounting frame assembly is in a circular arc shape and is provided with gear teeth. The direction adjusting mechanism is arranged in the middle of the sliding rod, and comprises fifth sliding blocks which vertically slide and are located between the two mounting frame assemblies. The two ends of the fifth sliding blocks are provided with gear teeth engaged with the end faces of the limiting ends.By using the cutting and grinding integrated machine, the function of cutting or grinding can be switched according to the need, the effect that one machine has multiple purposes is achieved, and theflexibility, convenience and rapidness are achieved.

Owner:CHIFENG TUOJIA PHOTOELECTRIC CO LTD

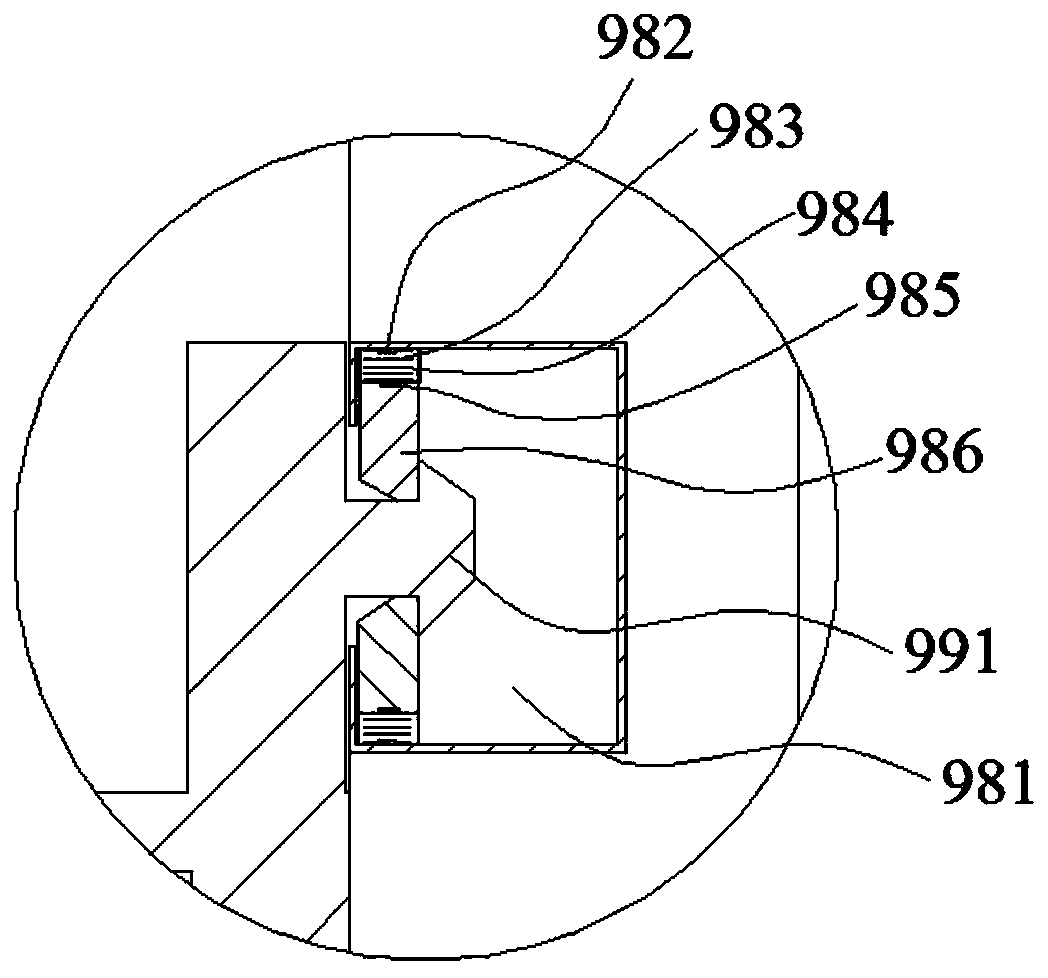

Battery disassembling clamp

PendingCN108213568ASmooth axial movementSmooth cutting actionMetal sawing devicesEngineeringElectrical and Electronics engineering

The invention provides a battery disassembling clamp. Rails are arranged at the bottom of a saw table. A to-be-cut battery is placed on a sliding table, and the sliding table can drive the battery toslide along the rails. The sliding table has a first state of moving to the position below an electric saw to enable the electric saw to cut the battery and a second state of getting away from the electric saw to enable the electric saw to stop cutting the battery. In the battery disassembling clamp, the electric saw is arranged above the to-be-cut battery, the battery moves in the extending direction of the rails, through limiting of the saw table and the rails, it can be ensured that the battery carries out stable axial movement and cutting action, and therefore errors generated during manual operation are effectively avoided.

Owner:HEBEI YINLONG NEW ENERGY +1

Metal sheath stripping device for rail transit cable

ActiveCN103683129ASolve the difficulty of cutting and peelingImprove stripping efficiencyApparatus for removing/armouring cablesEngineeringRail transit

The invention discloses a metal sheath stripping device for a rail transit cable. The device comprises a base, a fixed base plate, a stand column fixed between the base and the fixed base plate, a left motor support, a right motor support and two motors, wherein one of the two motors is mounted on the left motor support, the other motor is mounted on the right motor support, two sliding blocks are fixed on the lower surface of the left motor support in parallel, two sliding blocks are fixed on the lower surface of the right motor support in parallel, two linear guide rails are arranged on the fixed base plate in parallel and are embedded into grooves of the sliding blocks of the left motor support and grooves of the sliding blocks of the right motor support in sequence, a left baffle provided with an adjusting threaded hole is fixed on the outer side of the left motor support, a right baffle provided with an adjusting threaded hole is fixed on the outer side of the right motor support, a left connecting plate provided with a driving threaded hole is fixed on the outer side of the left baffle, a right connecting plate provided with a driving threaded hole is fixed on the outer side of the right baffle, the left connecting plate and the right connecting plate are located between the two linear guide rails, and the driving threaded holes are located below the left motor support and the right motor support. The metal sheath stripping device for the rail transit cable overcomes the difficulty in cutting and stripping of a metal sheath during detection, connection and installation of metal sheath cables, stripping efficiency is improved, and stripping of long metal sheaths is achieved.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Cable metal sheath stripping machine

ActiveCN103683128BProtective coreSolve the difficulty of cutting and peelingApparatus for removing/armouring cablesEngineering

The invention discloses a cable protective metal sleeve peeling machine. The cable protective metal sleeve peeling machine comprises a base, a fixed bottom plate, a stand column fixed between the base and the fixed bottom plate, a left motor support, a right motor support and two motors. One of the two motors is installed on the left motor support, and the other motor is installed on the right motor support. Two sliding blocks are fixed to the lower surface of the left motor support in parallel, and two sliding blocks are fixed to the lower surface of the right motor support in parallel. Two linear rails are arranged on the fixed bottom plate in parallel. The linear rails are sequentially embedded into grooves of the sliding blocks of the left motor support and grooves of the sliding blocks of the right motor support respectively. A left baffle with an adjusting screw hole and a right baffle with an adjusting screw hole are fixed to the outer side of the left motor support and the outer side of the right motor support respectively. A left connecting plate with a driving screw hole and a right connecting plate with a driving screw hole are fixed to the outer side of the left baffle and the outer side of the right baffle respectively. The left connecting plate and the right connecting plate are located between the two linear rails, and the driving screw holes are located below the left motor support and the right motor support respectively. According to the cable protective metal sleeve peeling machine, the problem that protective metal layers are difficult to cut and peel in the metal sleeve cable detection, connection and installation processes is solved, the peeling efficiency is improved, and the long protective metal layers are peeled.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Blade ring saw blade

InactiveUS20060243114A1Prolong lifeProtection from damageRevolution surface grinding machinesMetal sawing toolsStraight pathKnife blades

Owner:GEMINI SAW

Helical cutting insert with progressive cutting edge

InactiveUS20070086865A1Less powerSmooth cutting actionMilling cuttersShaping cuttersEngineeringMechanical engineering

An indexable, helical cutting insert includes at least one axial clearance slash extending from a bottom surface to one of said side walls forming a wiper on an edge of the axial clearance slash. In another embodiment, the cutting insert includes at least one inside cutting edge that extends outwardly a distance from the side wall. In another embodiment, the helical cutting insert includes at least one progressive cutting edge. In another embodiment, the cutting insert includes at least one helical cutting edge that is curved inwardly to enable the cutting insert to perform machining operations on cutters having different diameters.

Owner:KENNAMETAL INC

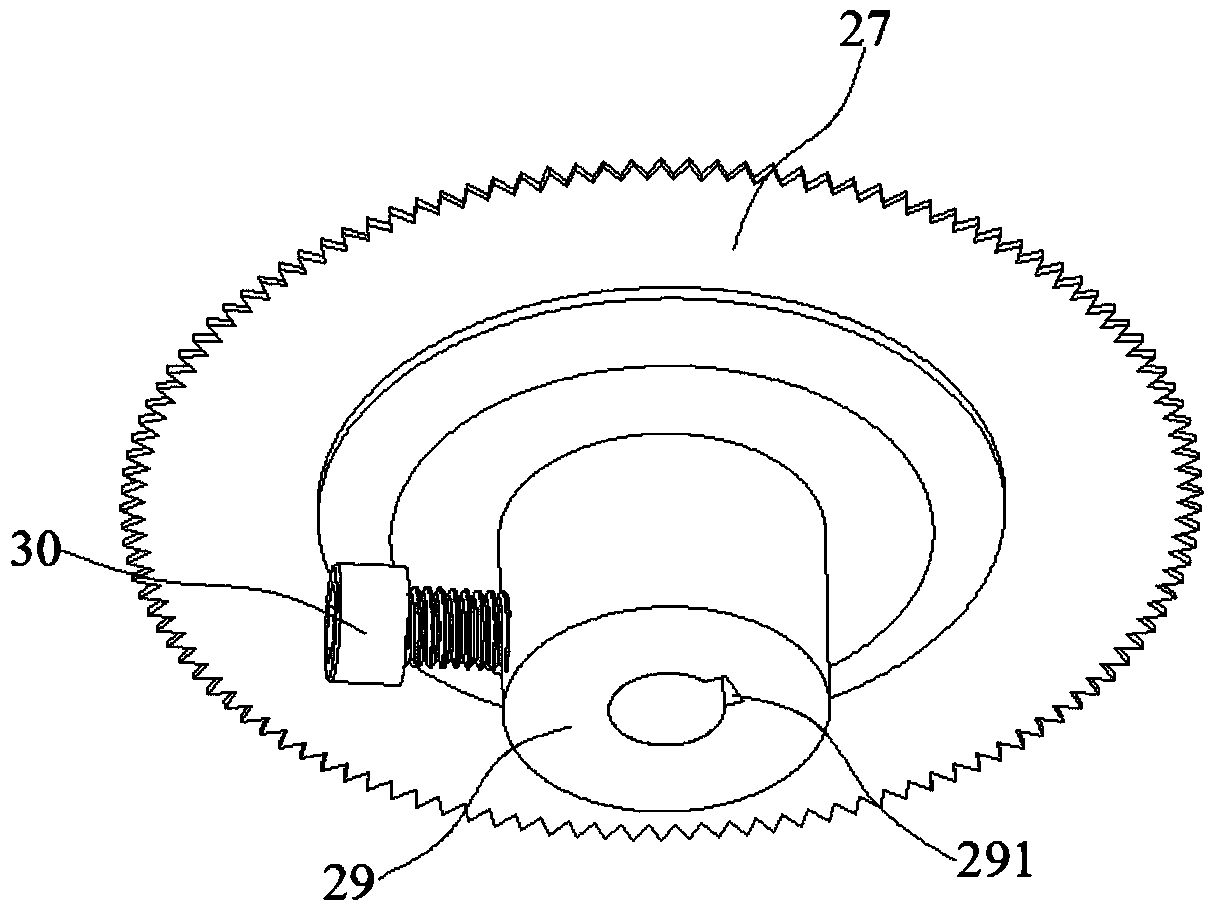

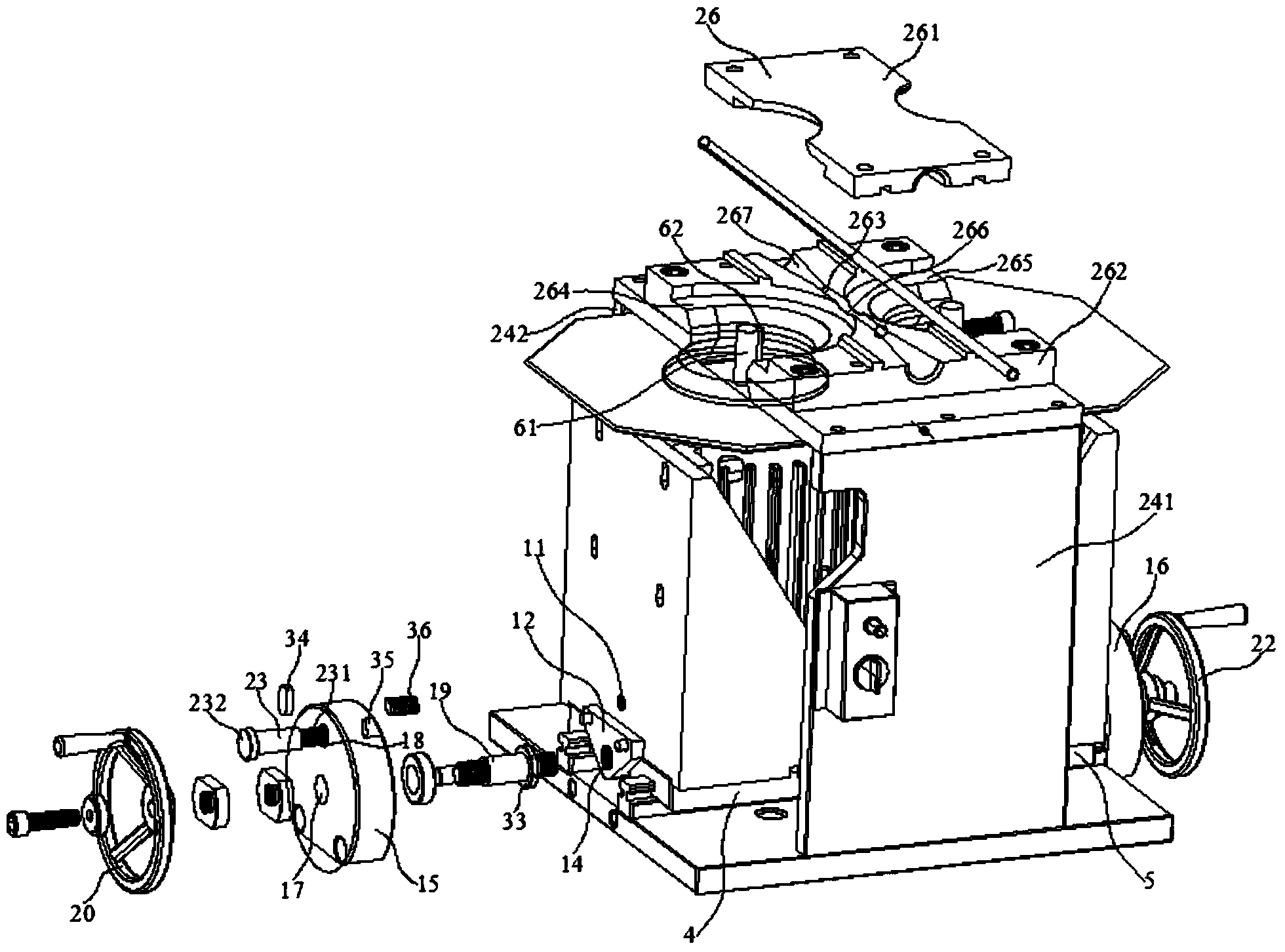

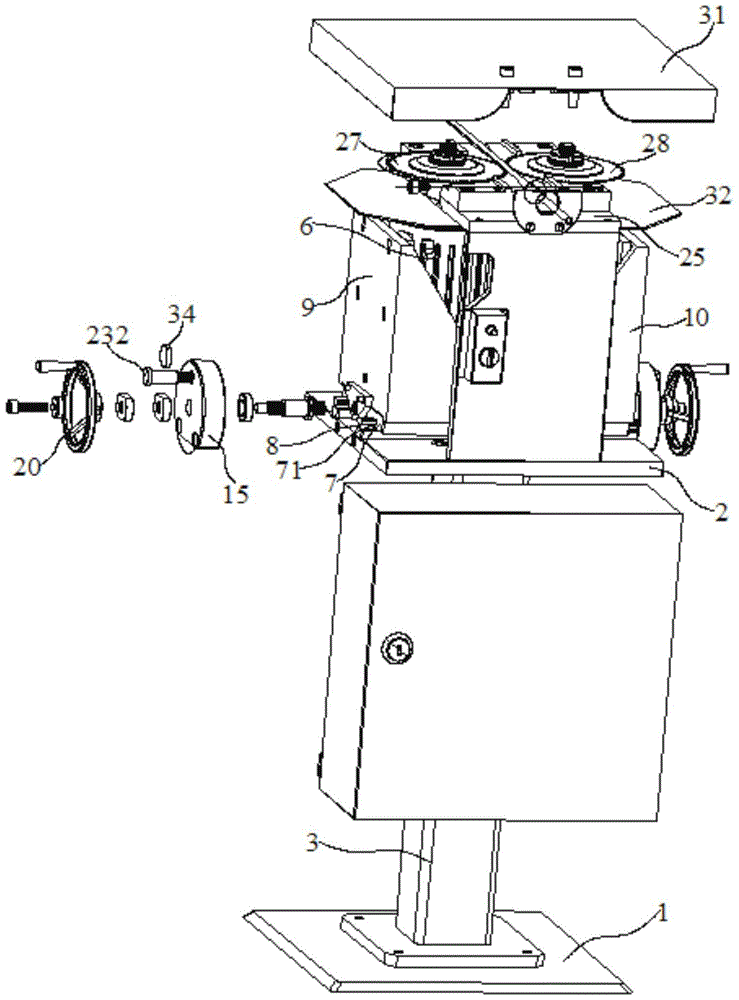

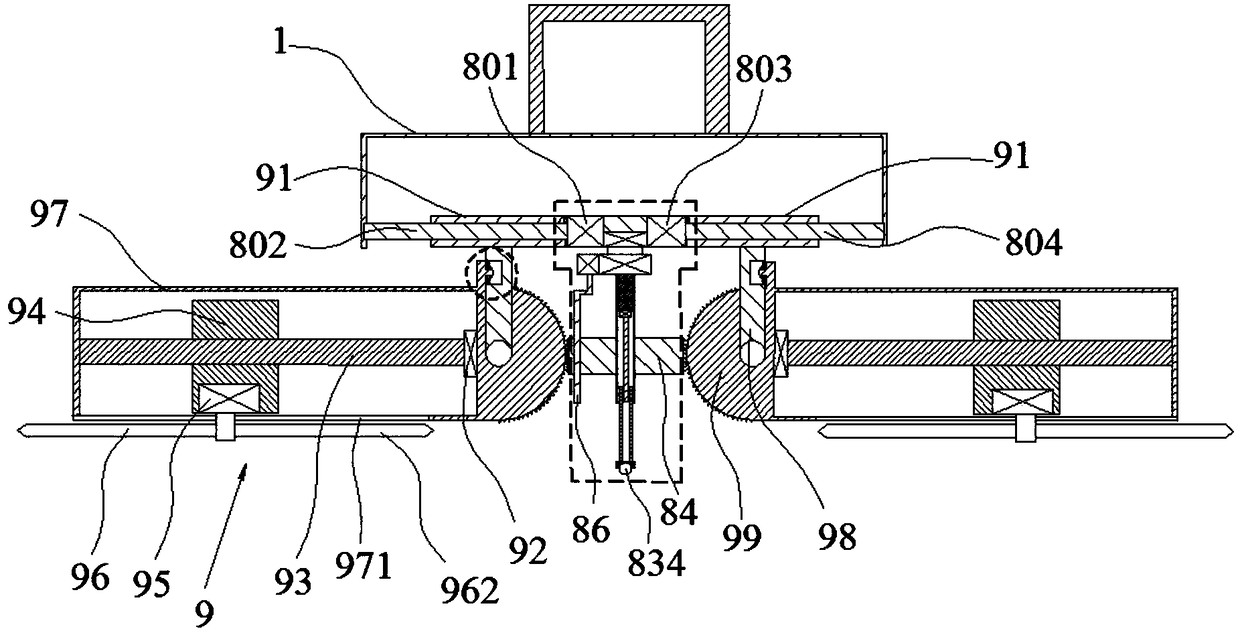

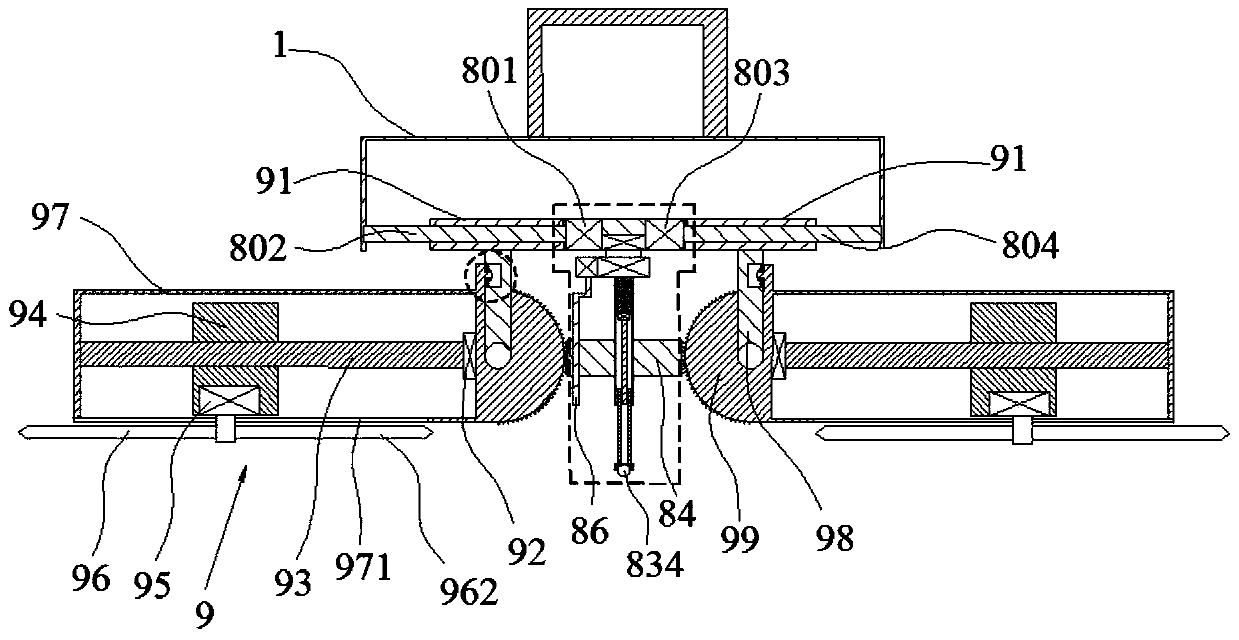

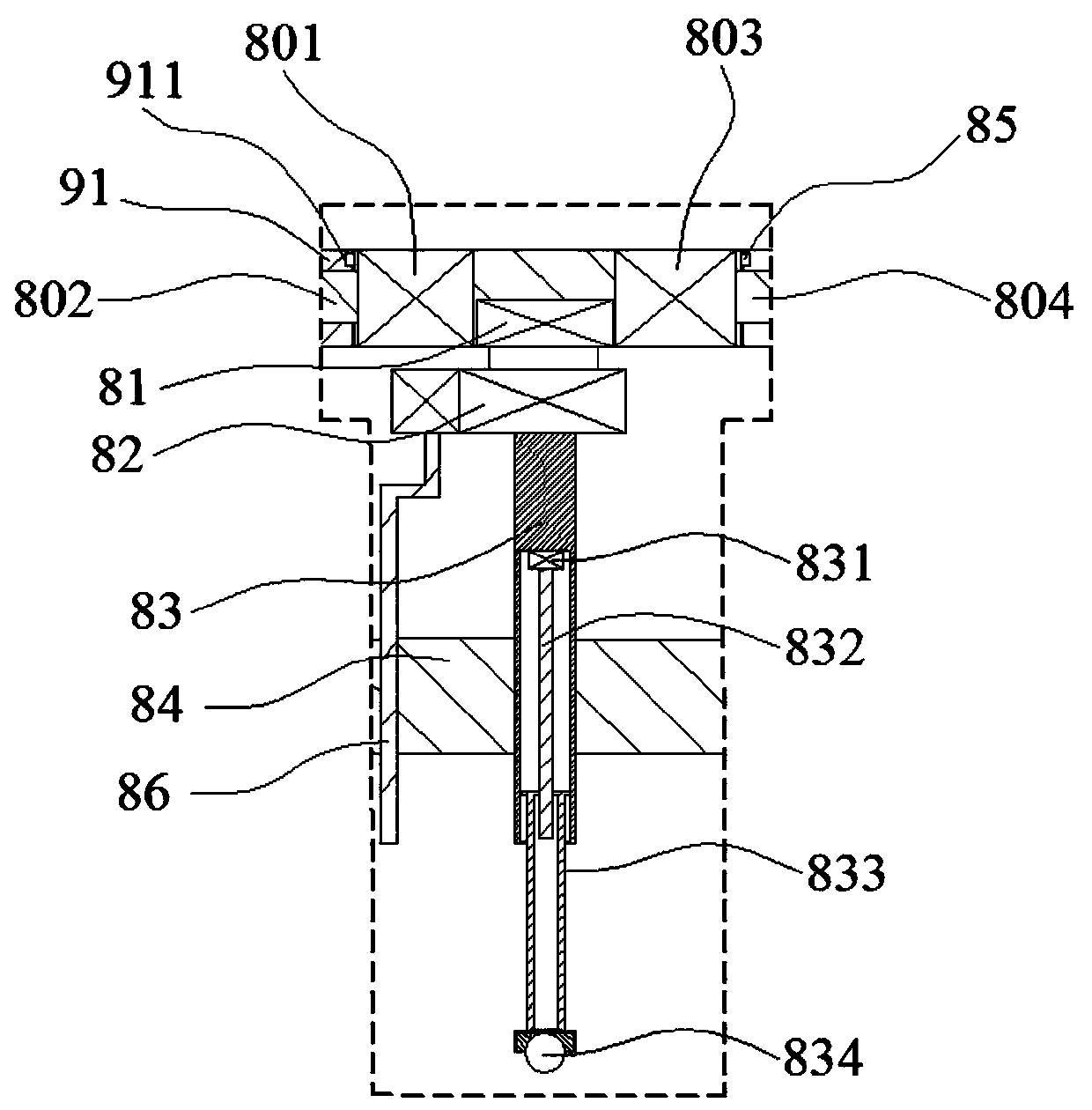

Cutting and grinding integrated machine

InactiveCN108161467AStable structureChainsaw cutting action is smoothOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention provides a cutting and grinding integrated machine which comprises a shell, two mounting frame assemblies and a direction adjusting mechanism. A sliding rod is arranged on the lower endface of the shell, and sleeved with two third sliding blocks. The lower ends of the two third sliding blocks are provided with supporting rods correspondingly, and the lower ends of the supporting rods are movably connected with the mounting frame assemblies correspondingly. The two mounting frame assemblies are symmetrically arranged, and the end face of the limiting end of the upper end of eachmounting frame assembly is in a circular arc shape and is provided with gear teeth. The direction adjusting mechanism is arranged in the middle of the sliding rod, and comprises fifth sliding blocks which vertically slide and are located between the two mounting frame assemblies. The two ends of the fifth sliding blocks are provided with gear teeth engaged with the end faces of the limiting ends.By using the cutting and grinding integrated machine, the function of cutting or grinding can be switched according to the need, the effect that one machine has multiple purposes is achieved, and theflexibility, convenience and rapidness are achieved.

Owner:CHIFENG TUOJIA PHOTOELECTRIC CO LTD

Grinding-height-adjustable cutting and grinding integrated machine

ActiveCN108145664AChainsaw cutting action is smoothSmooth cutting actionPortable power-driven toolsMechanical engineeringEngineering

The invention provides a grinding-height-adjustable cutting and grinding integrated machine comprising a shell, a direction adjusting mechanism, a height adjusting mechanism and two symmetrical mounting frame assemblies. A first screw and a second screw are arranged on the lower end surface of the shell, and two first sliding blocks are movably connected with the two mounting frame assemblies through supporting rods correspondingly and sleeve the first screw and the second screw correspondingly; a fourth motor at the upper end of the direction adjusting mechanism is connected between a first motor and a second motor, a fourth screw is arranged at the lower end of the direction adjusting mechanism, and the fourth screw is provided with a cavity with an opening at the lower end; the height adjusting mechanism is located in the cavity of the fourth screw, the top of the cavity is provided with a sixth motor which is in driving connection with a fifth screw, the upper end of a fourth sliding block is in threaded connection with the fifth screw and slides up and down along with the rotation of the fifth screw, and the lower end of the fourth sliding block is connected with a supportingwheel. By using an electric saw with the adjustable grinding height, the functions of cutting and grinding can be switched according to requirements, and one machine achieves multiple purposes, and isflexible and convenient to use.

Owner:JINHUA ZHONGXIN HARDWARE TOOLS

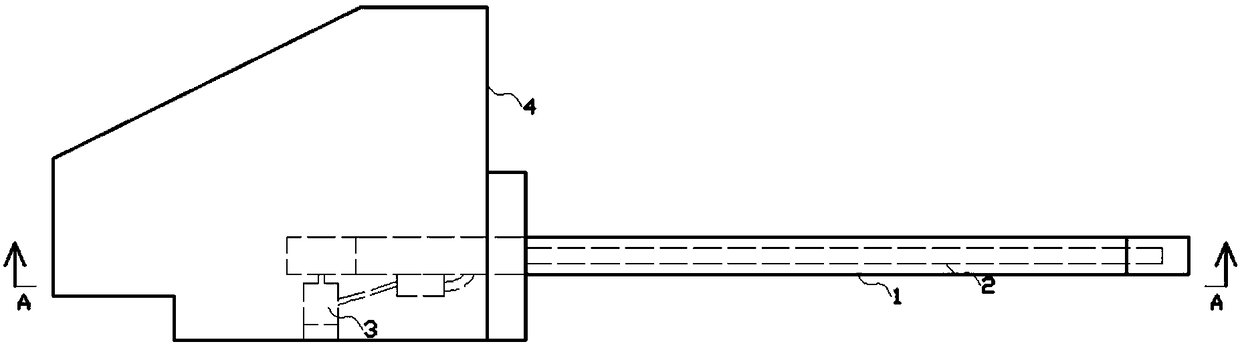

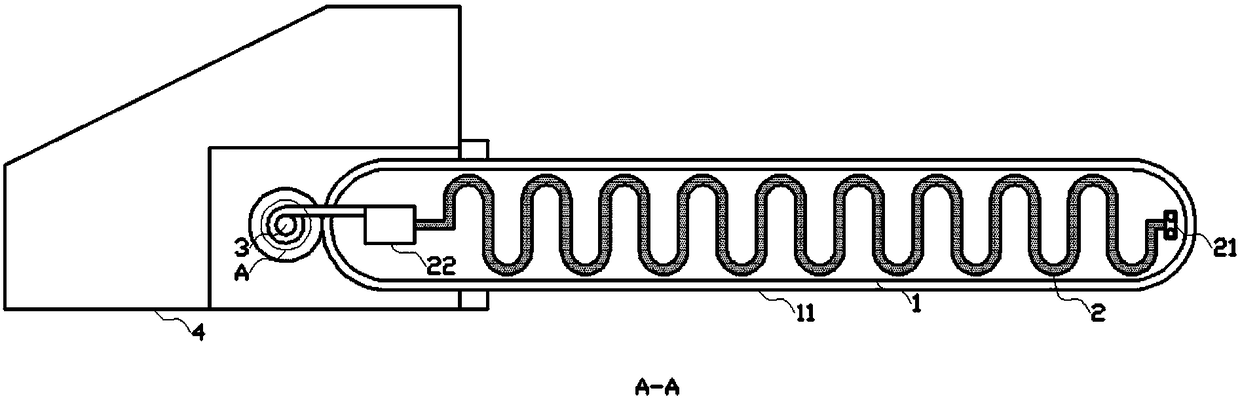

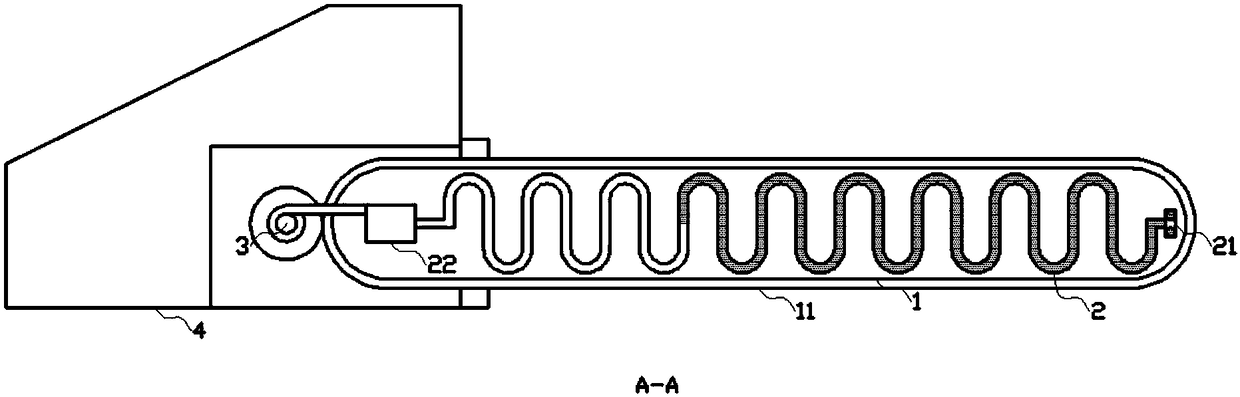

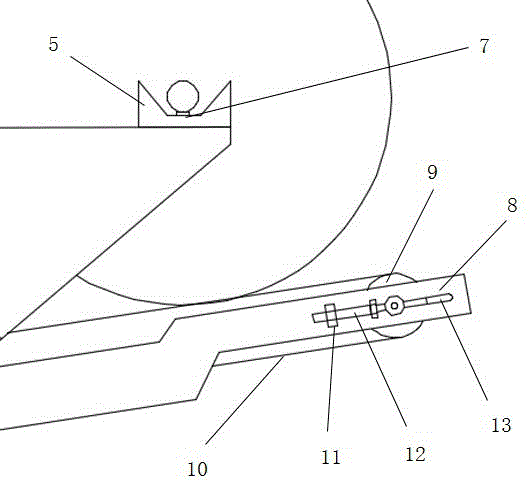

Fly cutter mechanism

InactiveCN105946030AFast cutting actionSmooth cutting actionMetal working apparatusFilm materialAir chamber

The invention provides a fly cutter mechanism. The mechanism comprises a rodless air cylinder. The air cylinder comprises an air chamber and a sliding rod located below the air chamber; a sliding block penetrates the sliding rod, a fly cutter block is movably arranged on the sliding block, and a fly cutter is clamped on the lower portion of the fly cutter block through an upper clamping plate and a lower clamping plate; and the fly cutter mechanism is used for cutting a film material and has the beneficial effects of being rapid in cutting action, stable, straight in cutting opening and the like.

Owner:JIANGSU SHANGKUN BIOLOGICAL EQUIP

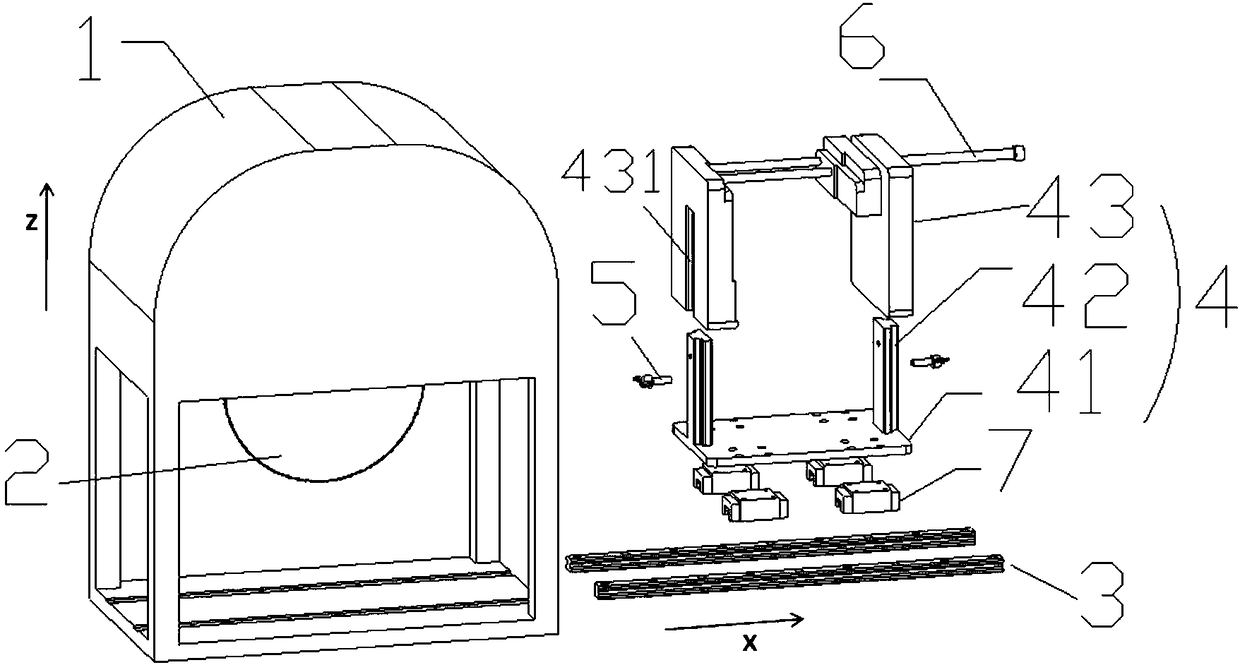

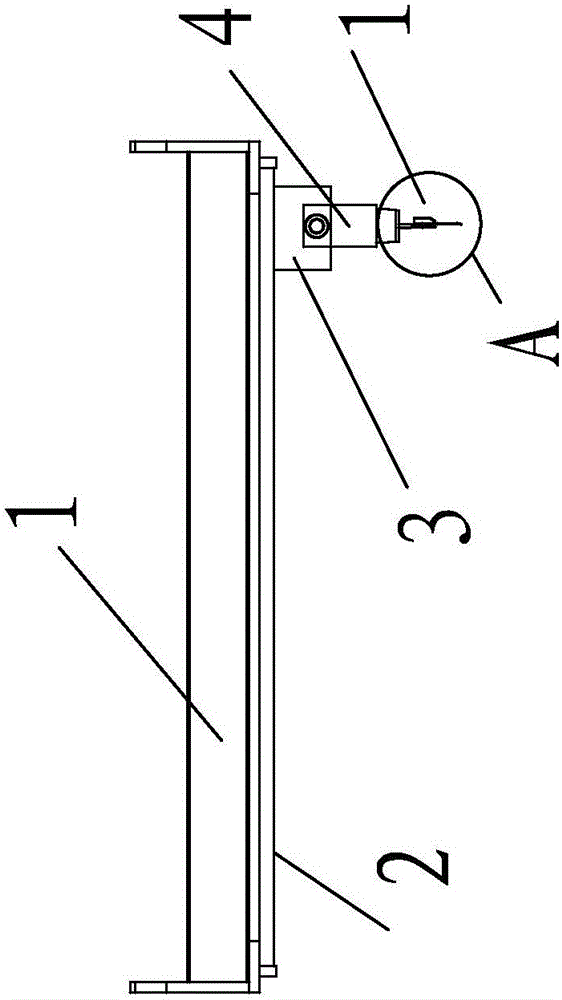

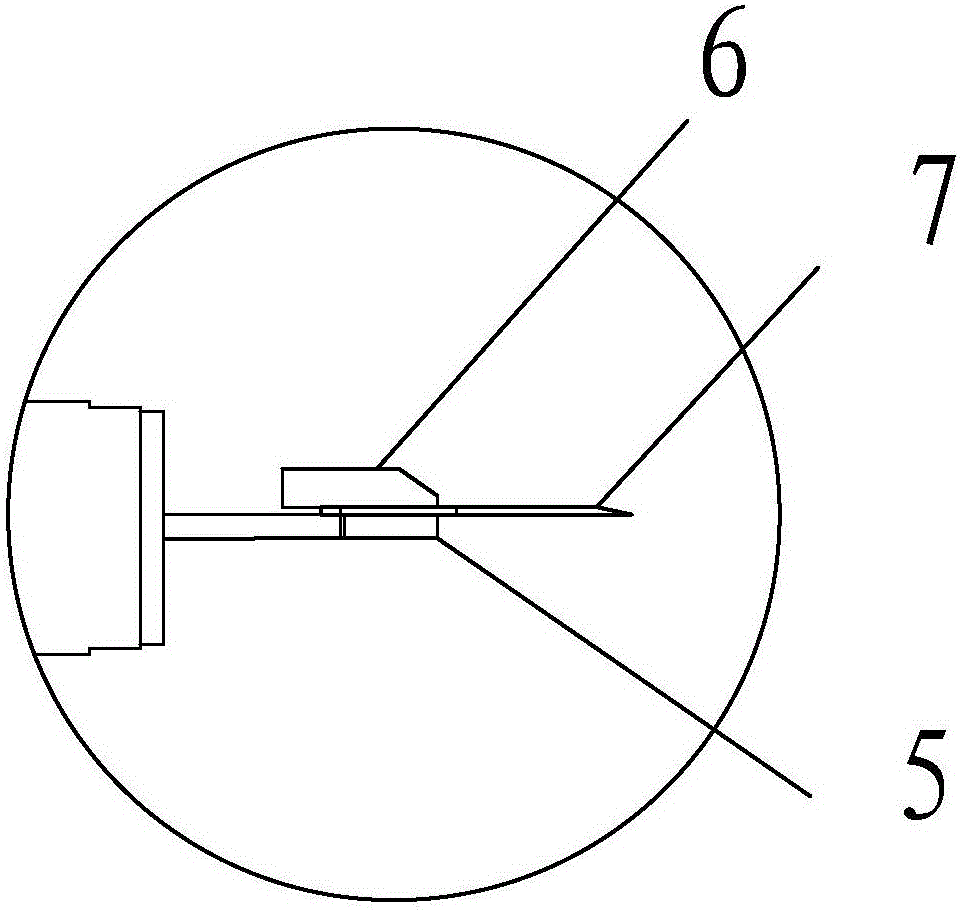

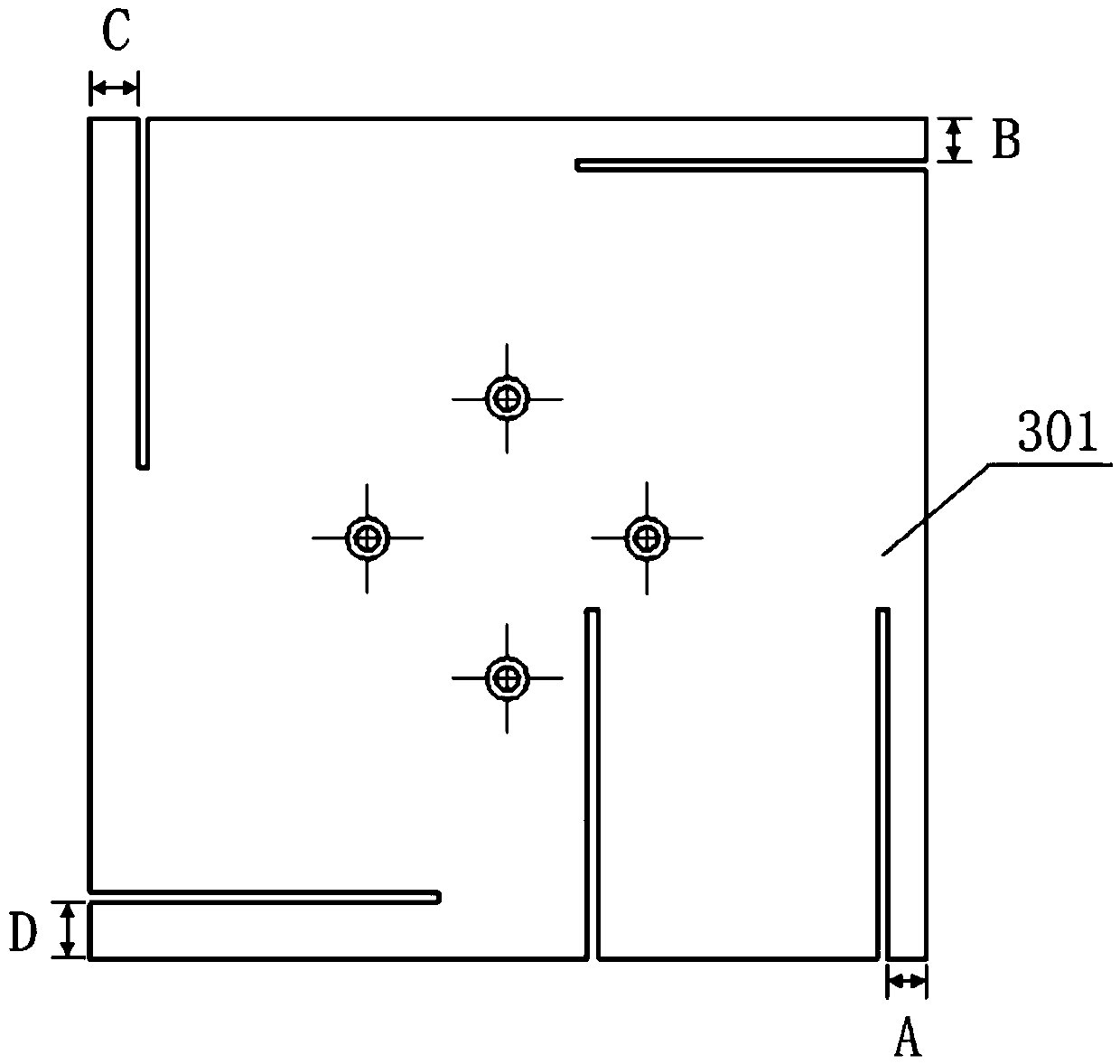

A device and method for making large-section and large-thickness brain tissue slices

InactiveCN106289856BSolve problems that are difficult to produce with high qualitySmooth cutting actionWithdrawing sample devicesEngineeringPig brain

The invention relates to a making device and method for large-section and large-thickness brain tissue slices, and belongs to the related technical field of biological histology and pathology experiments. The device mainly comprises a base with a groove, and the groove is used for preventing interference between a knife and the base when the knife is used for cutting brain tissue; the top of the base is detachably connected with a locating plate and a stop block separately, and the height of the stop block is higher than that of the locating plate; the stop block is a cuboid, and the left side face serves as the datum plane of brain tissue to be cut, wherein the locating plate is provided with guide grooves used for guiding the knife. According to the making device, the locating plate and the stop block are detachably connected, and therefore replacing is convenient; the guide grooves comprise one chopping guide groove and four slicing guide grooves, the distances between the slicing guide grooves and the side wall of the locating plate are different, and therefore the brain tissue slices with different thicknesses can be cut. According to the making device and method for the large-section and large-thickness brain tissue slices, the problem that large-section and large-thickness brain tissue slices of pig brains, cattle brains and the like are difficult to manufacture at high quality is effectively solved.

Owner:SHANDONG UNIV QILU HOSPITAL

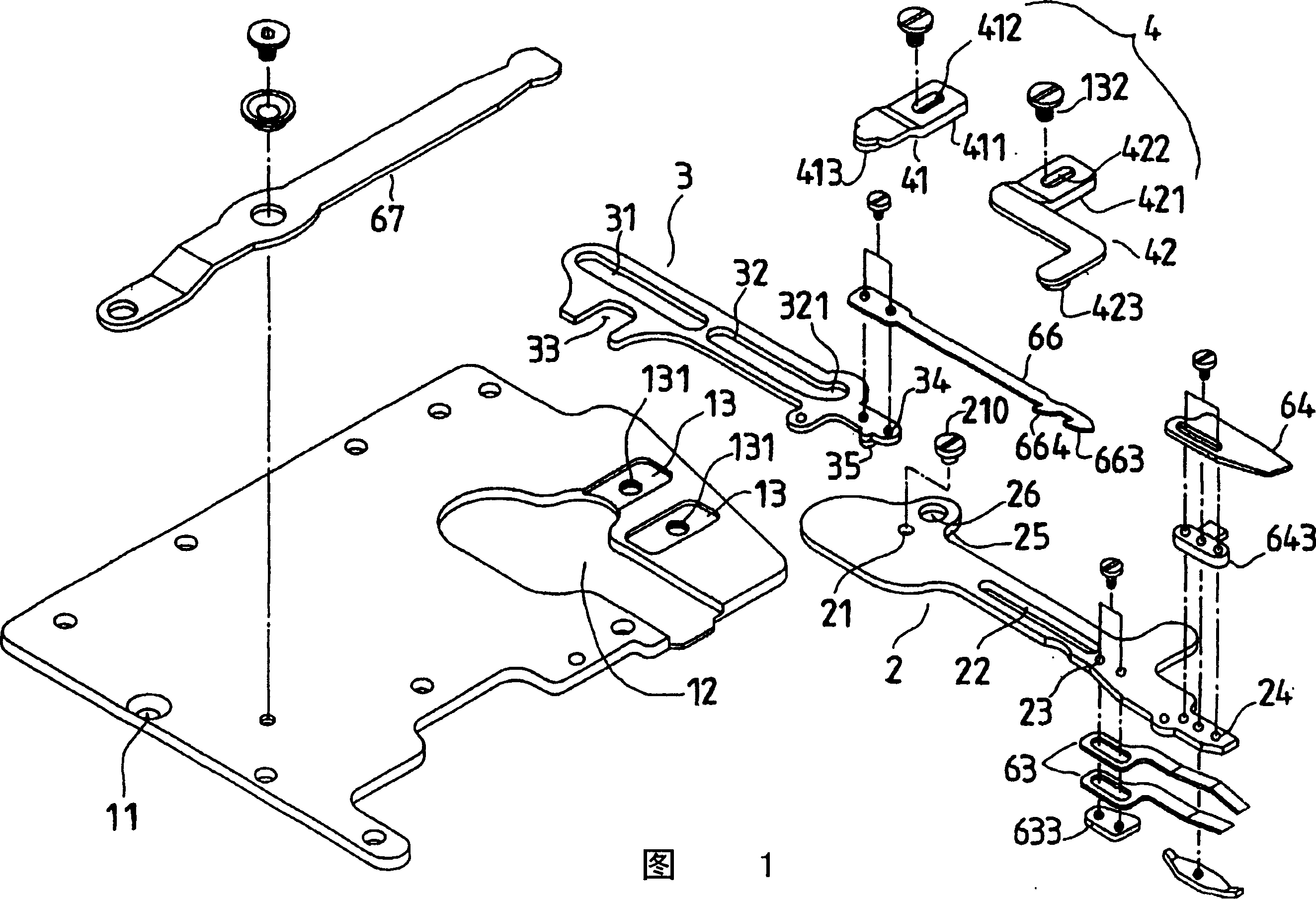

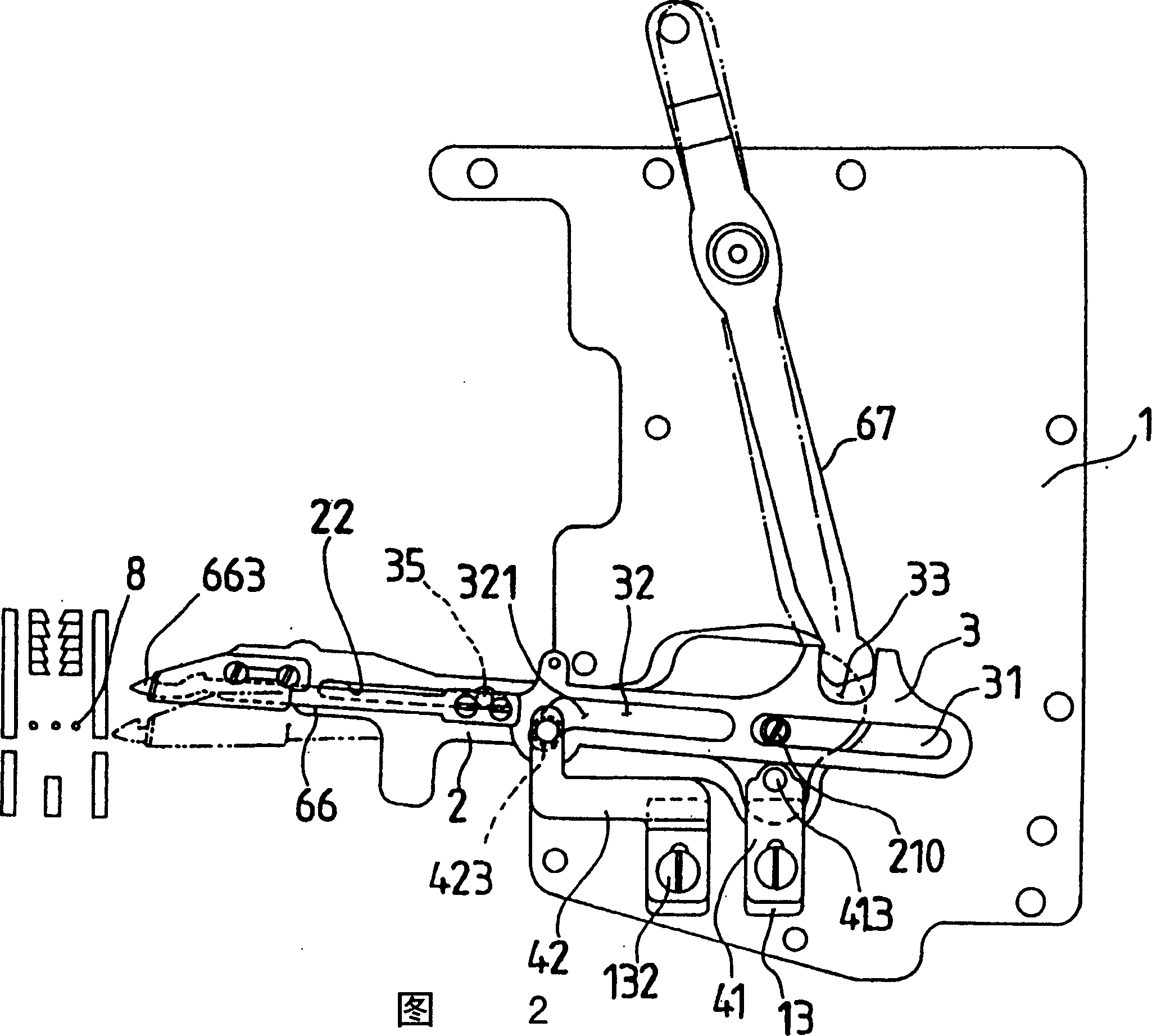

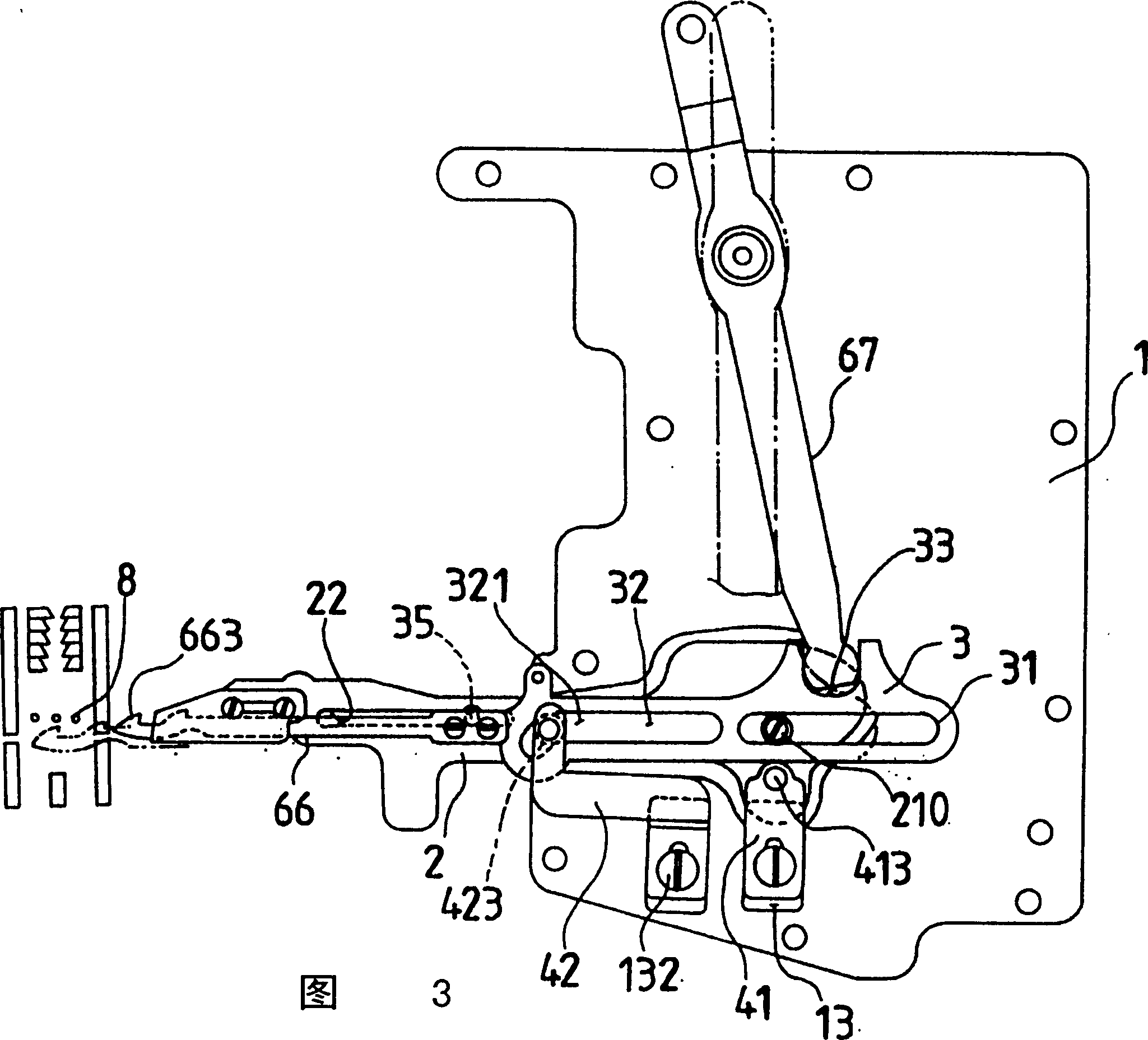

Improved string cutter for sewing machine

InactiveCN1173089CReduce frustrationExtended service lifeNeedle severing devicesEngineeringCantilever

The improved string cutter for sewing machine has one cantilever combination for precise displacement regulation. The stub below the left cantilever is set inside the long hole in the hooked rod arm, and the stub below the right cantilever is set lug hole of the cutting arm, so that the cutting arm has small oscillating torque around the stub and small oscillating load and driving force while change the path. The oscillation is smooth and moderate and has raised string cutting effect. The improved string cutter is precise and practical.

Owner:顾飞龙

Fly-cutter mechanism

InactiveCN106064397AFast cutting actionSmooth cutting actionMetal working apparatusFilm materialEngineering

The invention provides a fly-cutter mechanism. The mechanism comprises a rodless cylinder, wherein the cylinder comprises an air chamber and a sliding rod located below the air chamber; the sliding rod penetrates through a sliding block; a fly-cutter block is movably arranged on the sliding block; and a fly-cutter is clamped by an upper clamping plate and a lower clamping plate below the fly-cutter block. The fly-cutter mechanism is used for cutting film materials and has the advantages of rapid and steady cutting actions, straight cuts and the like.

Owner:镇江奥立特机械制造有限公司

Double-sided tangential cutting insert

ActiveCN110325308AGuaranteed surface finishGuaranteed verticalityMilling cuttersMilling cutting insertsStructural engineeringMechanical engineering

The invention discloses a double-sided tangential cutting insert comprising a pair of cutting rake faces, a pair of major side surfaces and a pair of opposing minor side faces each having a twisted convex shape. Each of the cutting rake faces is defined between a pair of main cutting edges, a pair of full nose cutting edges, and a pair of opposing convex minor cutting edges. Each of the minor sidefaces is defined between one of the convex minor cutting edges at one of the rake faces and one of the convex minor cutting edges at the other one of the rake faces wherein, at each minor side face,a ridge line interconnects an apex of the convex minor edge at the one of the rake faces and an apex of the convex minor cutting edge at the other one of the rake faces. Other variants and embodimentsare broadly contemplated herein.

Owner:KENNAMETAL INC

Metal sheath stripping device for rail transit cables

ActiveCN103683129BSolve the difficulty of cutting and peelingAchieve strippingApparatus for removing/armouring cablesEngineeringRail transit

The invention discloses a metal sheath stripping device for a rail transit cable. The device comprises a base, a fixed base plate, a stand column fixed between the base and the fixed base plate, a left motor support, a right motor support and two motors, wherein one of the two motors is mounted on the left motor support, the other motor is mounted on the right motor support, two sliding blocks are fixed on the lower surface of the left motor support in parallel, two sliding blocks are fixed on the lower surface of the right motor support in parallel, two linear guide rails are arranged on the fixed base plate in parallel and are embedded into grooves of the sliding blocks of the left motor support and grooves of the sliding blocks of the right motor support in sequence, a left baffle provided with an adjusting threaded hole is fixed on the outer side of the left motor support, a right baffle provided with an adjusting threaded hole is fixed on the outer side of the right motor support, a left connecting plate provided with a driving threaded hole is fixed on the outer side of the left baffle, a right connecting plate provided with a driving threaded hole is fixed on the outer side of the right baffle, the left connecting plate and the right connecting plate are located between the two linear guide rails, and the driving threaded holes are located below the left motor support and the right motor support. The metal sheath stripping device for the rail transit cable overcomes the difficulty in cutting and stripping of a metal sheath during detection, connection and installation of metal sheath cables, stripping efficiency is improved, and stripping of long metal sheaths is achieved.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

An all-in-one cutting and grinding machine with adjustable grinding height

ActiveCN108145664BChainsaw cutting action is smoothSmooth cutting actionPortable power-driven toolsElectric machineryMachine

The invention provides a grinding-height-adjustable cutting and grinding integrated machine comprising a shell, a direction adjusting mechanism, a height adjusting mechanism and two symmetrical mounting frame assemblies. A first screw and a second screw are arranged on the lower end surface of the shell, and two first sliding blocks are movably connected with the two mounting frame assemblies through supporting rods correspondingly and sleeve the first screw and the second screw correspondingly; a fourth motor at the upper end of the direction adjusting mechanism is connected between a first motor and a second motor, a fourth screw is arranged at the lower end of the direction adjusting mechanism, and the fourth screw is provided with a cavity with an opening at the lower end; the height adjusting mechanism is located in the cavity of the fourth screw, the top of the cavity is provided with a sixth motor which is in driving connection with a fifth screw, the upper end of a fourth sliding block is in threaded connection with the fifth screw and slides up and down along with the rotation of the fifth screw, and the lower end of the fourth sliding block is connected with a supportingwheel. By using an electric saw with the adjustable grinding height, the functions of cutting and grinding can be switched according to requirements, and one machine achieves multiple purposes, and isflexible and convenient to use.

Owner:JINHUA ZHONGXIN HARDWARE TOOLS

Anti-overheating efficient chain saw felling device for forest trees

The invention provides an anti-overheating efficient chain saw felling device for forest trees. The anti-overheating efficient chain saw felling device comprises a chain saw module, a cooling module and a pressurization module; the chain saw module comprises a chain and a saw plate; a groove is formed in the saw plate; the cooling module comprises a water pipe, a sprayer and a transmission piece;openings are formed in the two ends of the water pipe, and a pressure valve is designed on the sprayer; an air inlet hole and an air outlet hole are formed in the transmission part, and cooling wateris designed in the water pipe; the pressurization module comprises a turbine shell and an impeller; an air inlet and an air outlet are formed in the turbine shell, a rotating hole is formed in a turbine, and a rotating shaft is arranged in the rotating hole. The anti-overheating efficient chain saw felling device for the forest trees can conduct jetting on cutting faces during felling so as to discharge sawdust; meanwhile, the water in the pressurization module can absorb heat generated by the chain saw during felling, so that the use efficiency of the chain saw is improved.

Owner:姚松年

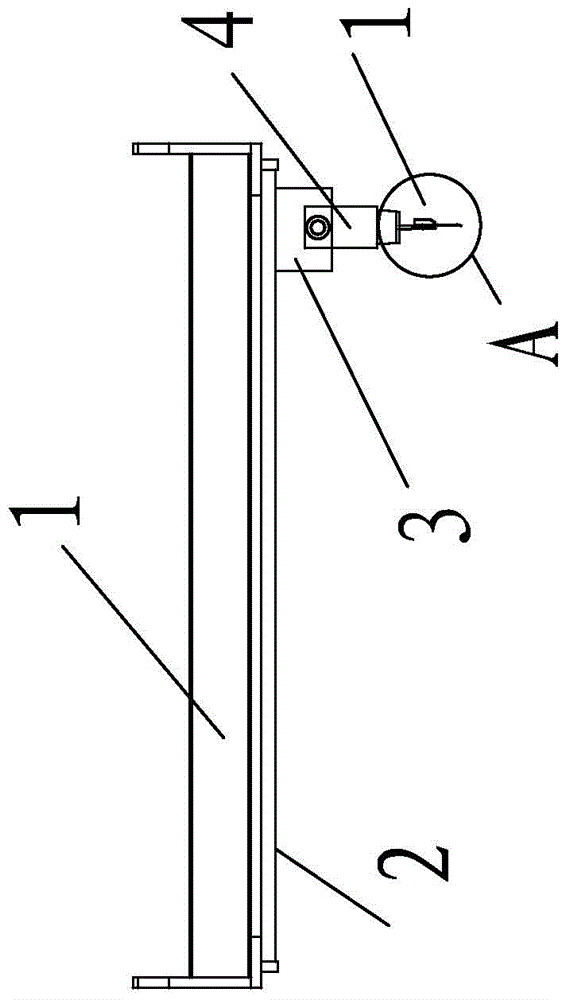

Automatic paper feeding device of tissue paper machine

InactiveCN105731144AGuaranteed release rate of tapeGuarantee quality and efficiencyWebs handlingTissue paperPaper sheet

The invention discloses an automatic paper feeding device for a paper towel machine, which is arranged at the front end of the paper towel machine and used to provide paper towels for the paper towel machine, including a frame, a conveying device and a supporting device. The groove of the roll; the conveying device can provide power for the paper roll to convey the paper towel to the paper towel machine; the supporting device is used to support the conveying device; the bottom of the groove is provided with a weight sensor for monitoring the paper roll weight, and generate electrical signals; the supporting device includes a controller; the controller is connected with the weight sensor, receives the electrical signal from the weight sensor, and controls the supporting device to provide appropriate supporting force, and adjusts the conveying device and the paper roll pressure between. The present invention uses a controller to control the supporting device to provide proper supporting force for the conveying device, and changes are made at any time as the weight of the paper roll changes.

Owner:JURONG DONGFA GENERAL MERCHANDISE CO LTD

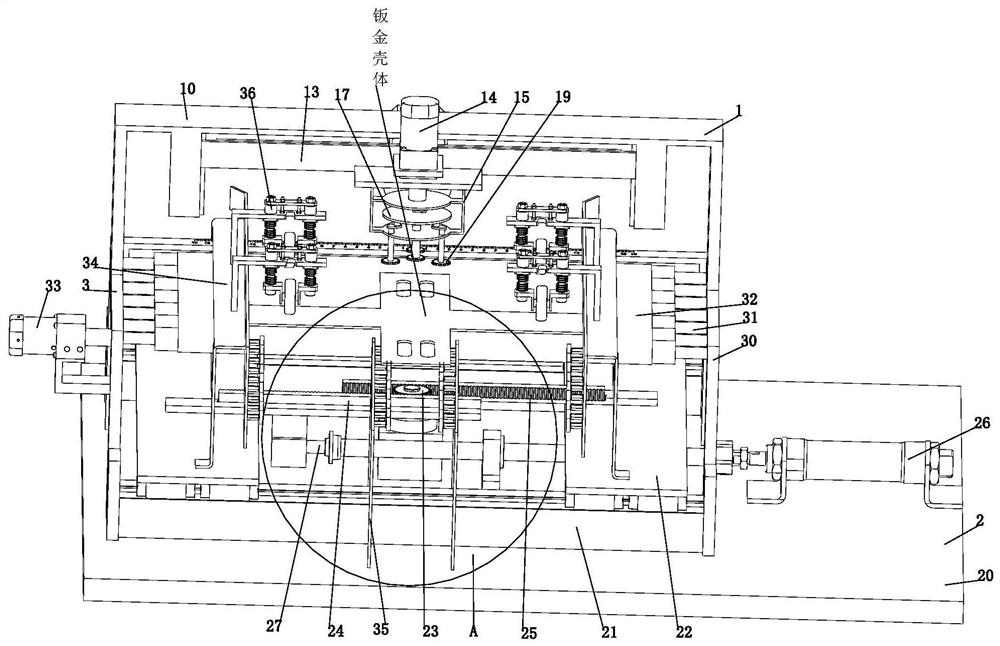

A kind of electrical high and low voltage complete set of sheet metal shell automatic finishing equipment and processing method

ActiveCN111604747BAvoid shakingReduce frictional resistanceEdge grinding machinesGrinding drivesPunchingLow voltage

The invention provides a complete set of electric high and low voltage sheet metal shell automatic finishing equipment and processing method, including an actuator, a spacing guide mechanism and a delivery mechanism, the delivery mechanism is installed on the spacing guide mechanism, and the delivery mechanism An executive mechanism is installed on it, and the executive mechanism and delivery mechanism are located directly above the spacing guide mechanism; the present invention can solve the problem that the back of the electrical cabinet sheet metal will be damaged after punching the cooling holes by a stamping machine. There are punched metal burrs. Nowadays, the punched metal burrs are mostly polished by manual hand-held grinding machines. This operation process is cumbersome, and this method is inefficient and cannot meet the needs of modern industrial production.

Owner:杭州一科奕华机电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com