Fly cutter mechanism

A flying knife and one air chamber technology, applied in metal processing and other directions, can solve problems such as insufficient stability, slow manual cutting speed, uneven incision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0011] The invention provides a flying knife mechanism, which has the advantages of fast and stable cutting action, straight incision, etc., and is widely used for automatic film cutting of film materials.

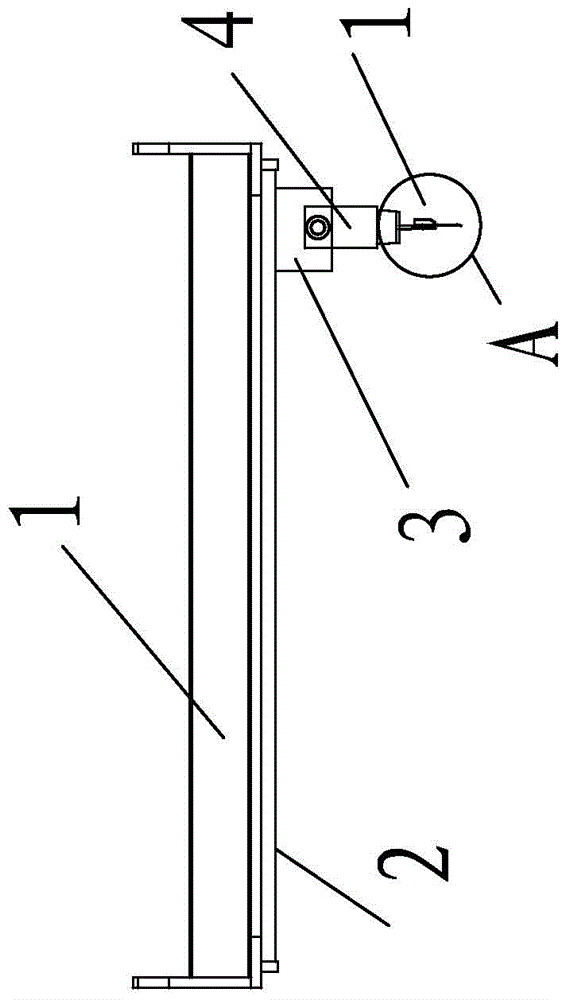

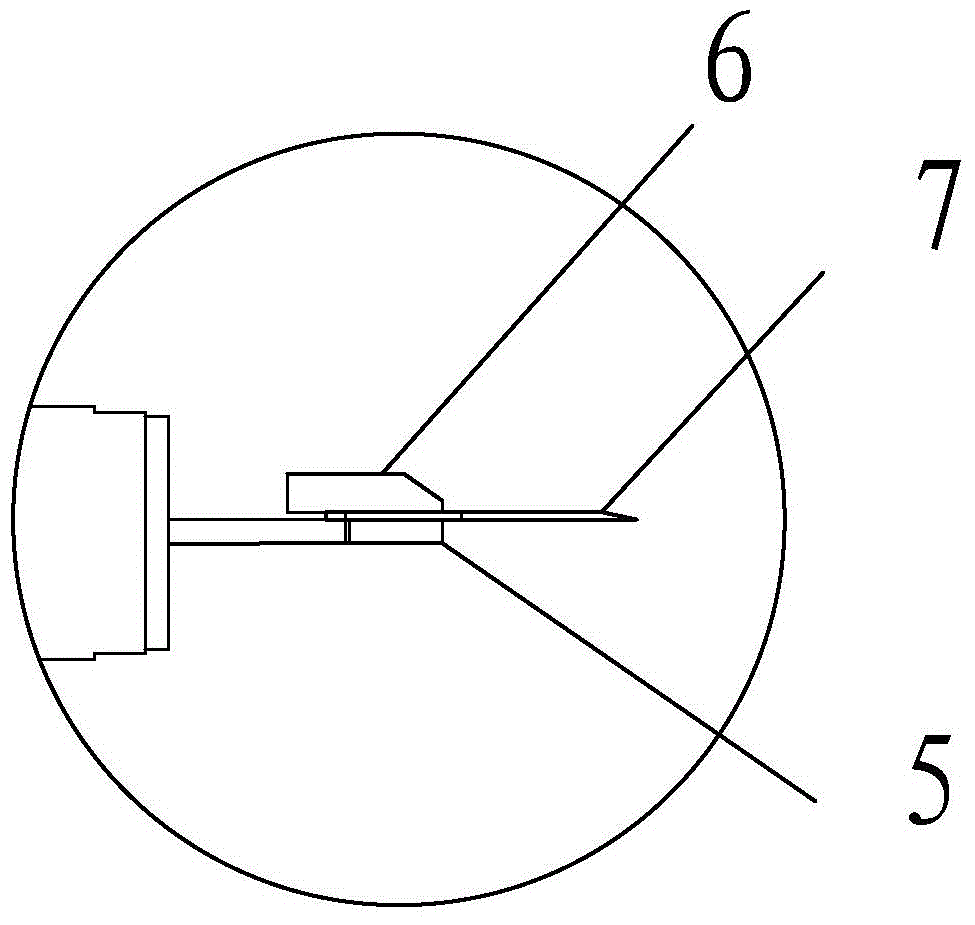

[0012] Such as figure 1 and 2 As shown, a flying knife mechanism is characterized in that it includes a rodless cylinder, the cylinder includes an air chamber 1 and a slide rod 2 positioned below the air chamber 1, the slide rod 2 passes through a slide block 3, the slide A flying knife block 4 is movable on the block 3, and a flying knife 7 is clamped by an upper clamping plate 5 and a lower clamping plate 6 under the flying knife block 4 .

[0013] Implementation: When working, the flying knife 7 on the flying knife block 4 is kept vertical to the slider 2, the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com