An automatic cutting machine

A tape cutting machine, automatic technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of slow cutting action, large space occupation, low cutting efficiency, etc., to achieve fast cutting action, Small space occupation and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

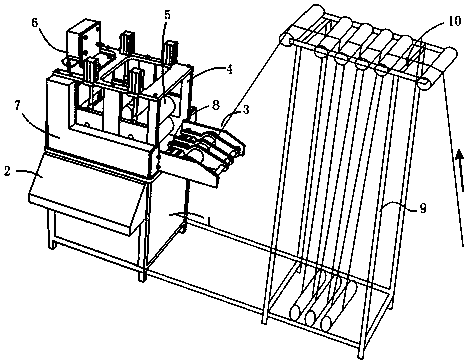

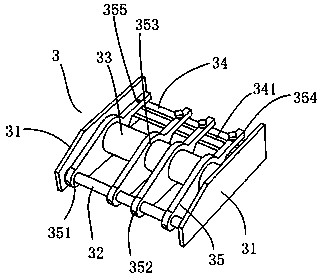

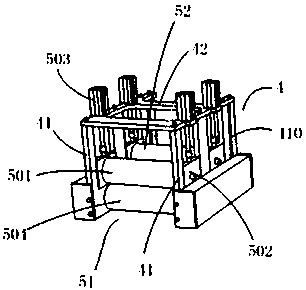

[0023] Such as Figure 1-4 An automatic tape cutting machine of the present invention is shown, comprising a distribution box 1, a console 2, a positioning anti-channeling frame 3, a feed roller frame 4, a feed roller device 5, a cutter device 6 and a transmission box 7, and the console 2 is set On the side of the distribution box 1, the feeding roller frame 4 is installed on the upper end of the distribution box 1, the positioning anti-channeling frame 3 is installed and fixed on the feeding end of the feeding roller frame 4, and the feeding roller device 5 is installed on the feeding roller frame 4 Above, the cutter device 6 is installed on the discharge end of the feed roller frame 4, and the transmission box 7 is installed on the outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com