Feeding device of automatic patch pocket machine

A bag sticking machine and material cutting technology, which is applied in the direction of cloth feeding mechanism, sewing machine components, textiles and paper making, etc., can solve the problems of rising manufacturing cost, large space occupation, and inability to get rid of it, so as to achieve agile cutting action and manufacturing. Low cost and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

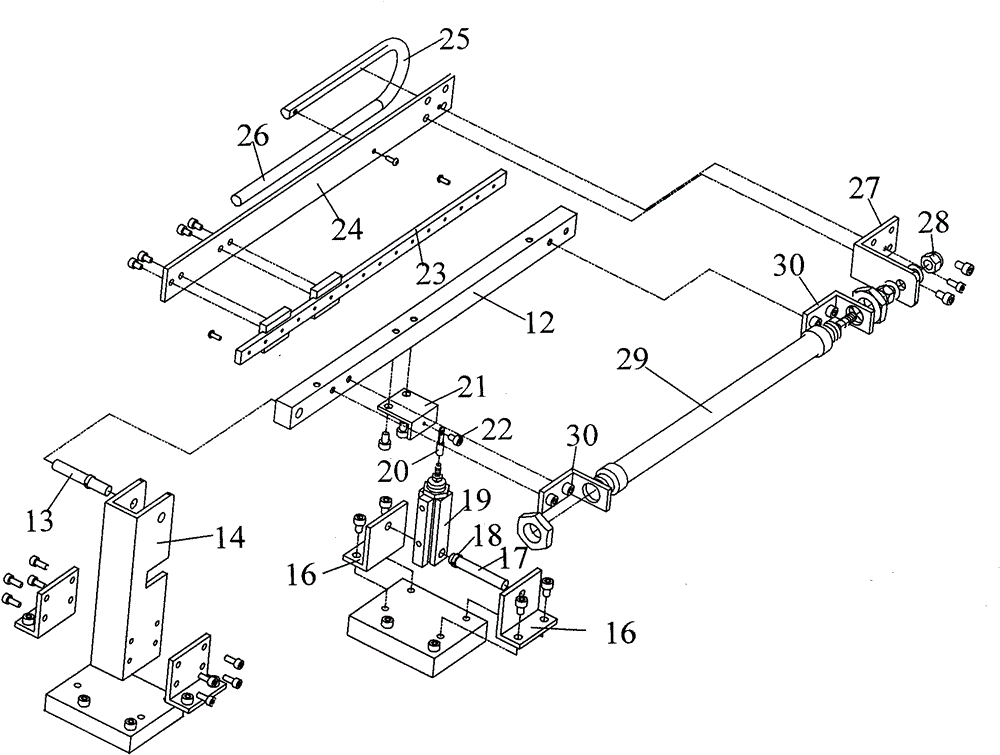

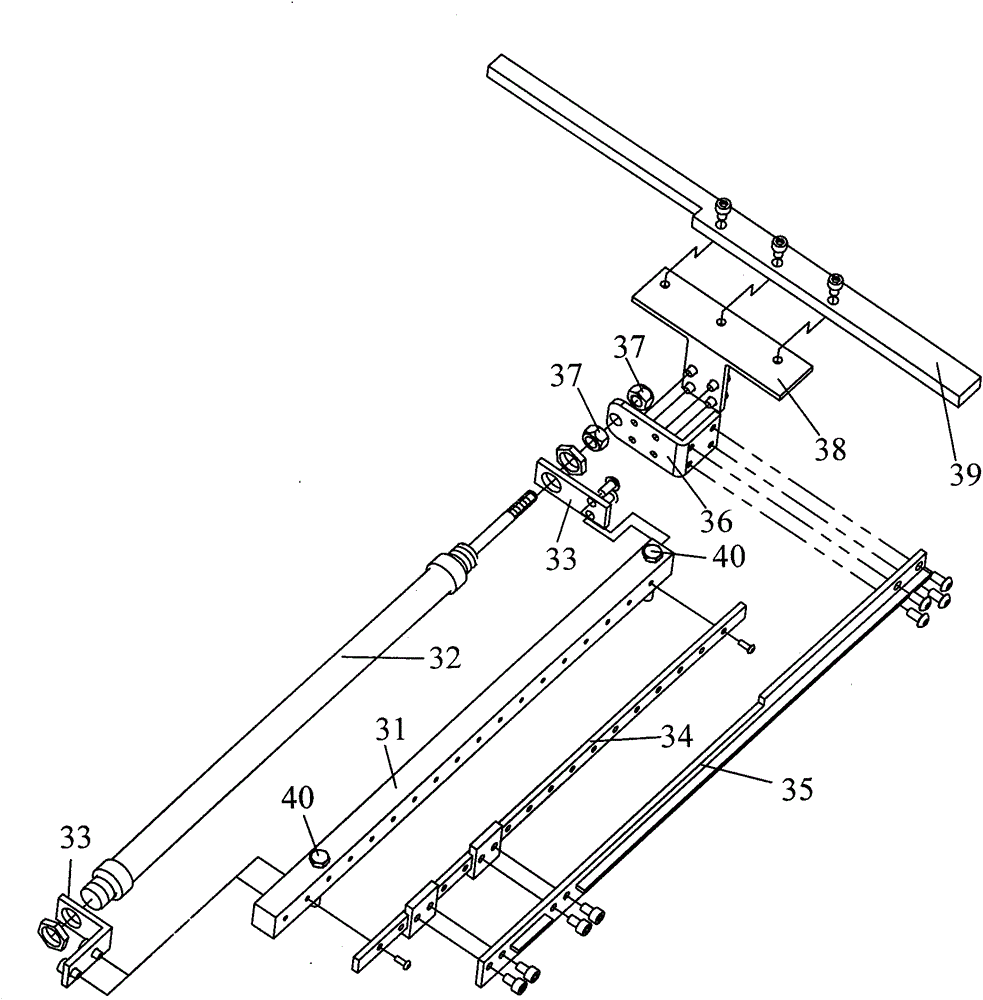

[0013] The unloading device of the automatic bag pasting machine of the present invention comprises a material pressing and receiving mechanism located under the right side of the bag pasting machine body, a material dragging mechanism located above the right side of the bag pasting machine table top, and a material dragging mechanism located on the right side of the bag pasting machine table top. The push mechanism below.

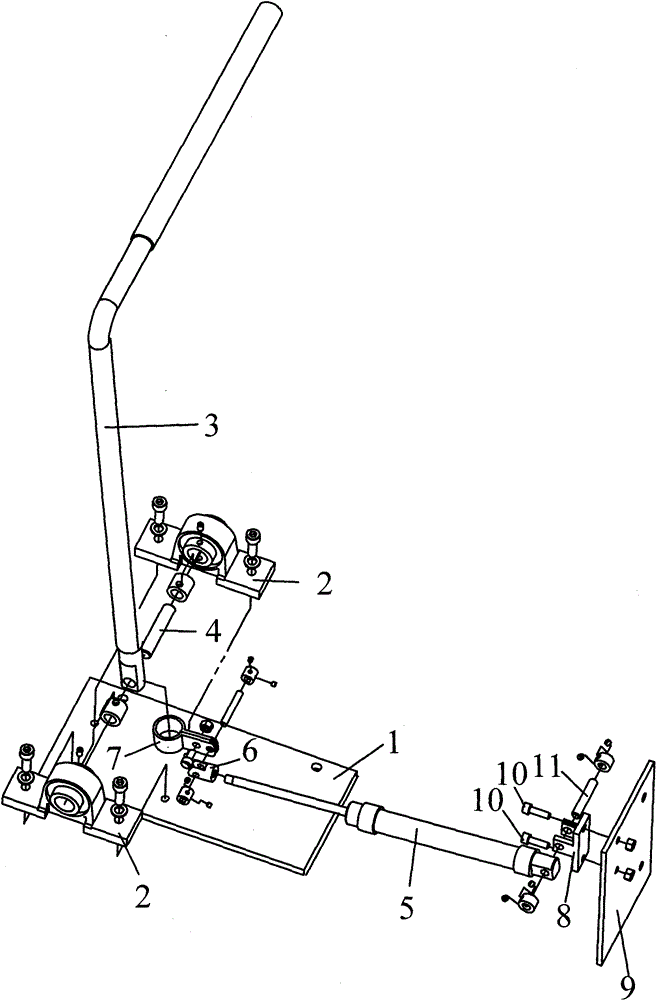

[0014] Such as figure 1 As shown, the pressing and receiving mechanism of the present invention is provided with a horizontal mounting plate 1 on the frame of the bag pasting machine, and two bearing blocks 2 are arranged on the horizontal mounting plate 1, and the bearing blocks 2 are fixed with the horizontal mounting plate 1 by screws. A right-angled elbow 3 is sandwiched between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com