Cutting and grinding integrated machine

A technology of cutting, grinding and all-in-one machine, which is applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of inability to adjust the cutting width and depth, consume a lot of physical strength, occupy space, etc., and achieve stable structure, stable cutting action, and application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

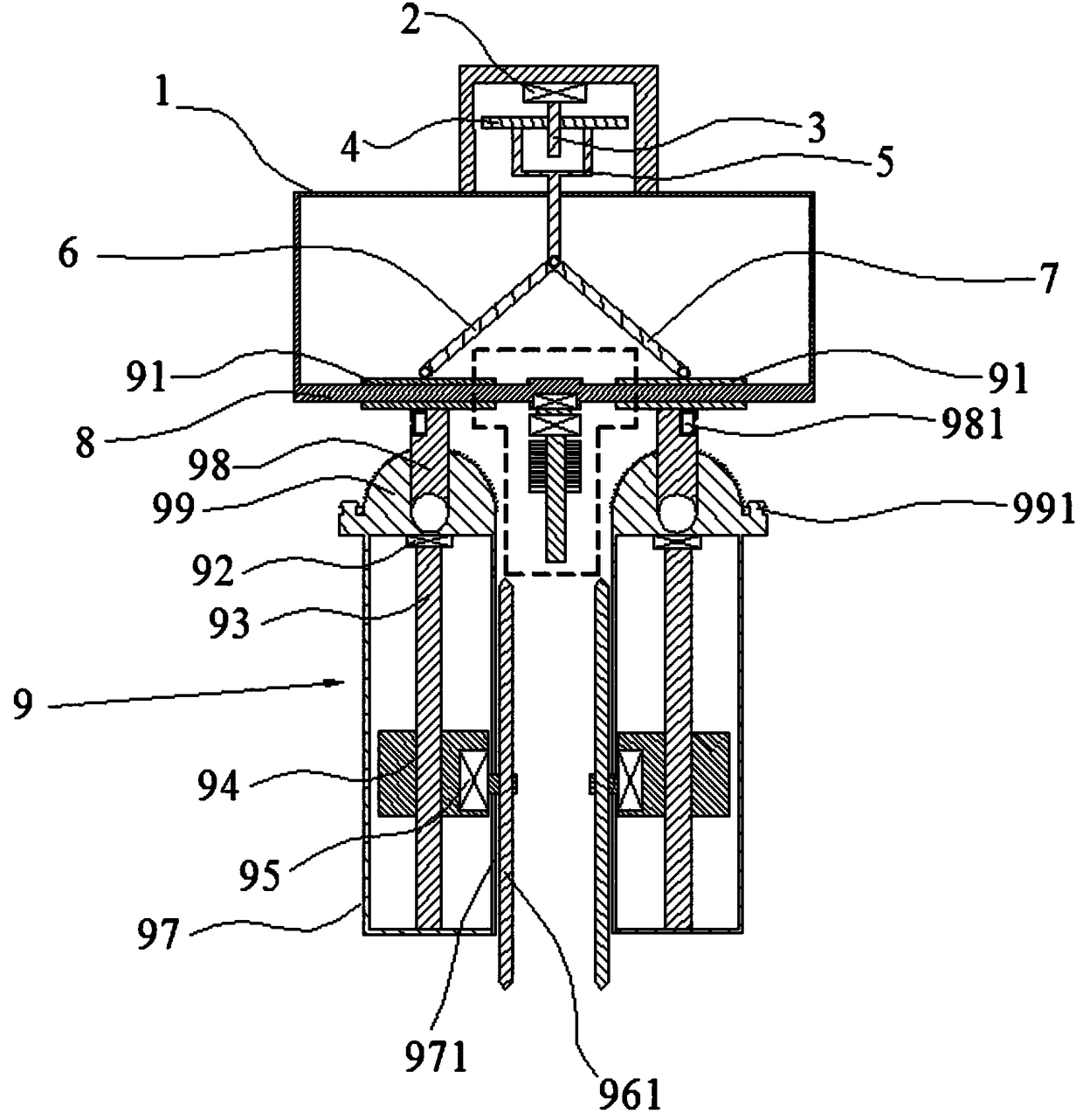

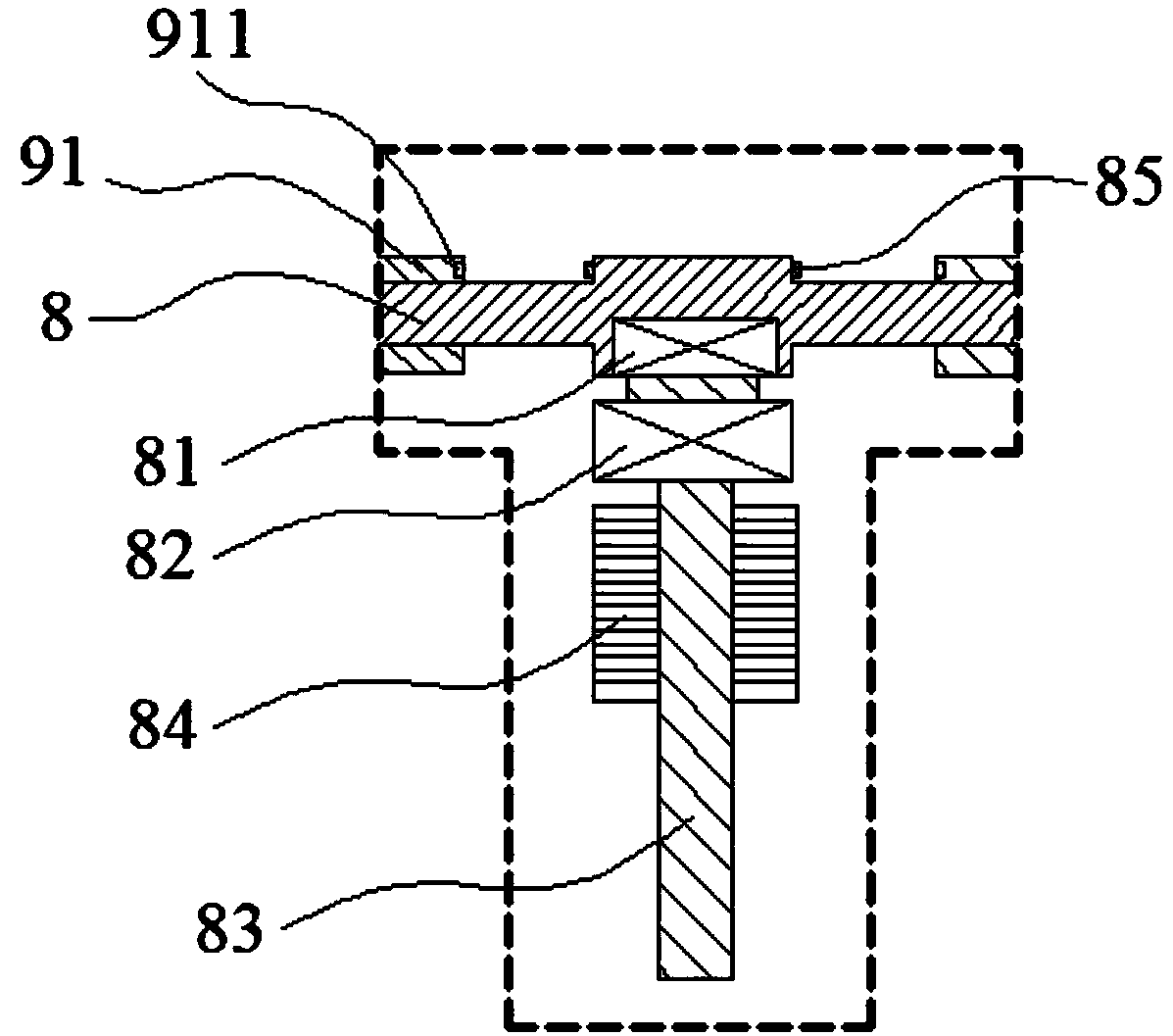

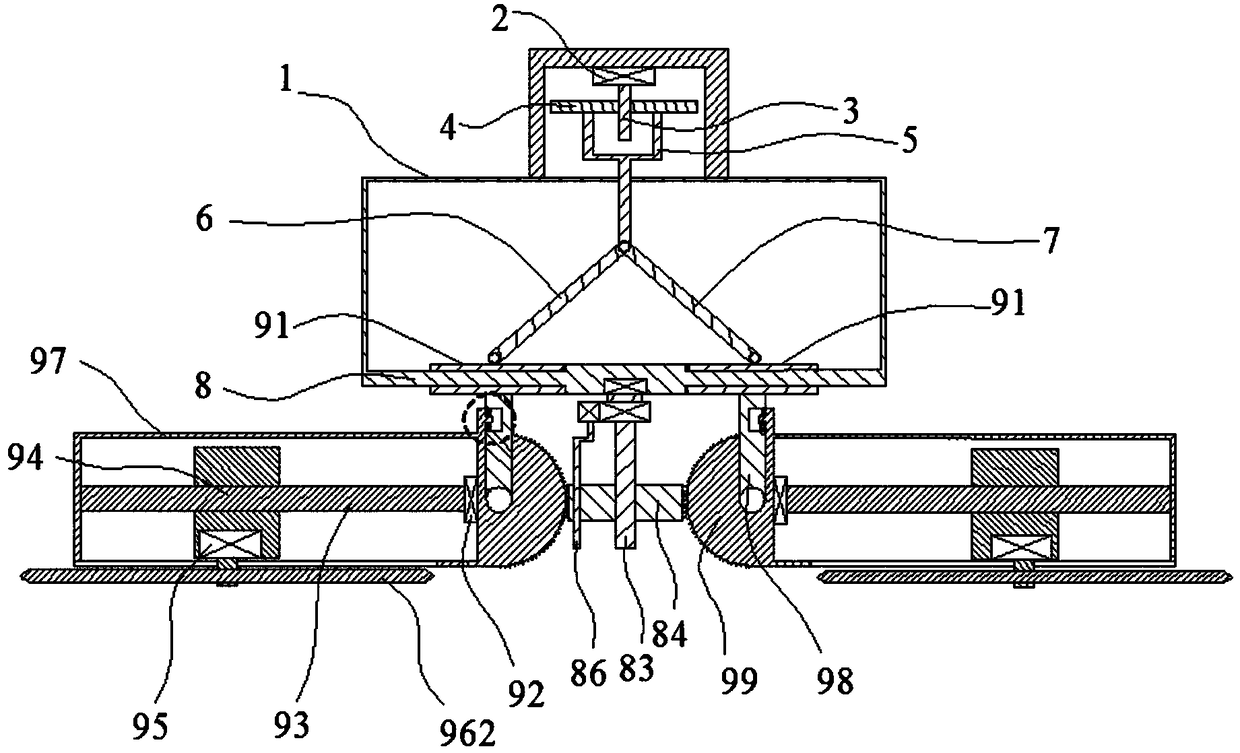

[0037] This embodiment provides an integrated cutting and grinding machine, which includes a housing 1, two sets of mounting bracket assemblies 9 and a direction adjustment mechanism; the lower end of the housing 1 is provided with a sliding rod 8, and two The third slide block 91, the lower ends of the two third slide blocks 91 are provided with support rods 98, and the lower ends of the support rods 98 are all movably connected to the mounting frame assembly 9, and two groups of mounting frame assemblies 9 are symmetrically arranged, and the upper ends of each group of mounting frame assemblies 9 The end face of the limiting end 99 is arc-shaped and provided with gear teeth. The middle part of the slide bar 8 is provided with a direction adjustment mechanism, which includes a fifth slide block 84 that slides up and down and is located in two sets of mounting bracket assemblies. 9, both ends of the fifth sliding block 84 have gear teeth meshing with the end surface of the limi...

Embodiment 2

[0039] Such as Figure 1-4As shown, this embodiment provides an integrated cutting and grinding machine, which includes a housing 1, two sets of mounting bracket assemblies 9 and a direction adjustment mechanism; Two third slide blocks 91 are established, and the lower ends of the two third slide blocks 91 are provided with support rods 98, and the lower ends of the support rods 98 are movably connected to the mounting frame assemblies 9, and two groups of mounting frame assemblies 9 are arranged symmetrically, each group of mounting frame assemblies The end face of the limiting end 99 at the upper end of 9 is arc-shaped and is provided with gear teeth. The middle part of the slide bar 8 is provided with a direction adjustment mechanism. The direction adjustment mechanism includes a fifth slider 84 that slides up and down and is located in two Between the mounting frame assembly 9 , both ends of the fifth sliding block 84 have gear teeth engaged with the end faces of the limit...

Embodiment 3

[0041] Such as Figure 1-4 As shown, this embodiment provides an integrated cutting and grinding machine, which includes a housing 1, two sets of mounting bracket assemblies 9 and a direction adjustment mechanism; Two third slide blocks 91 are established, and the lower ends of the two third slide blocks 91 are provided with support rods 98, and the lower ends of the support rods 98 are movably connected to the mounting frame assemblies 9, and two groups of mounting frame assemblies 9 are arranged symmetrically, each group of mounting frame assemblies The end face of the limiting end 99 at the upper end of 9 is arc-shaped and is provided with gear teeth. The middle part of the slide bar 8 is provided with a direction adjustment mechanism. The direction adjustment mechanism includes a fifth slider 84 that slides up and down and is located in two Between the mounting frame assembly 9 , both ends of the fifth sliding block 84 have gear teeth engaged with the end faces of the limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com