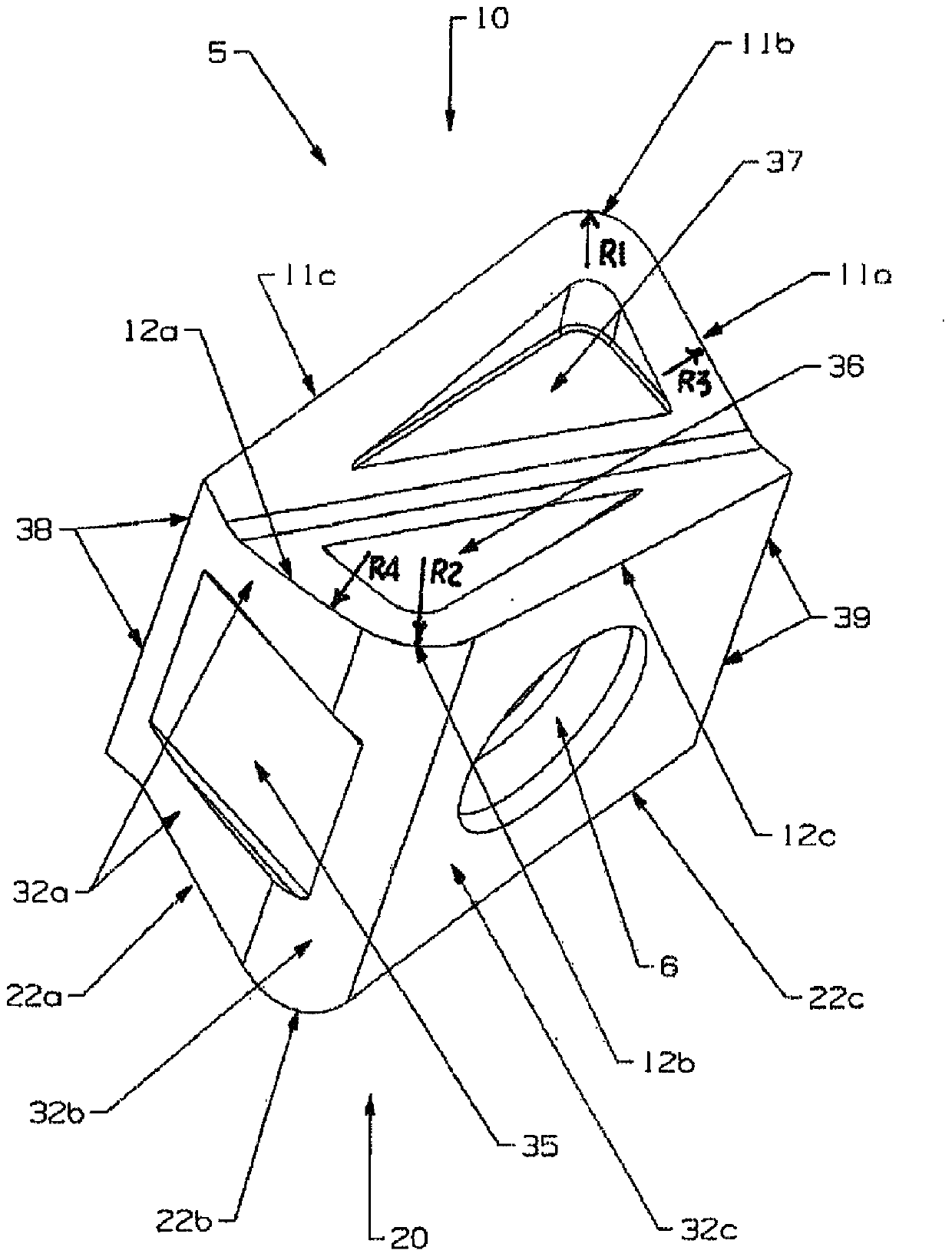

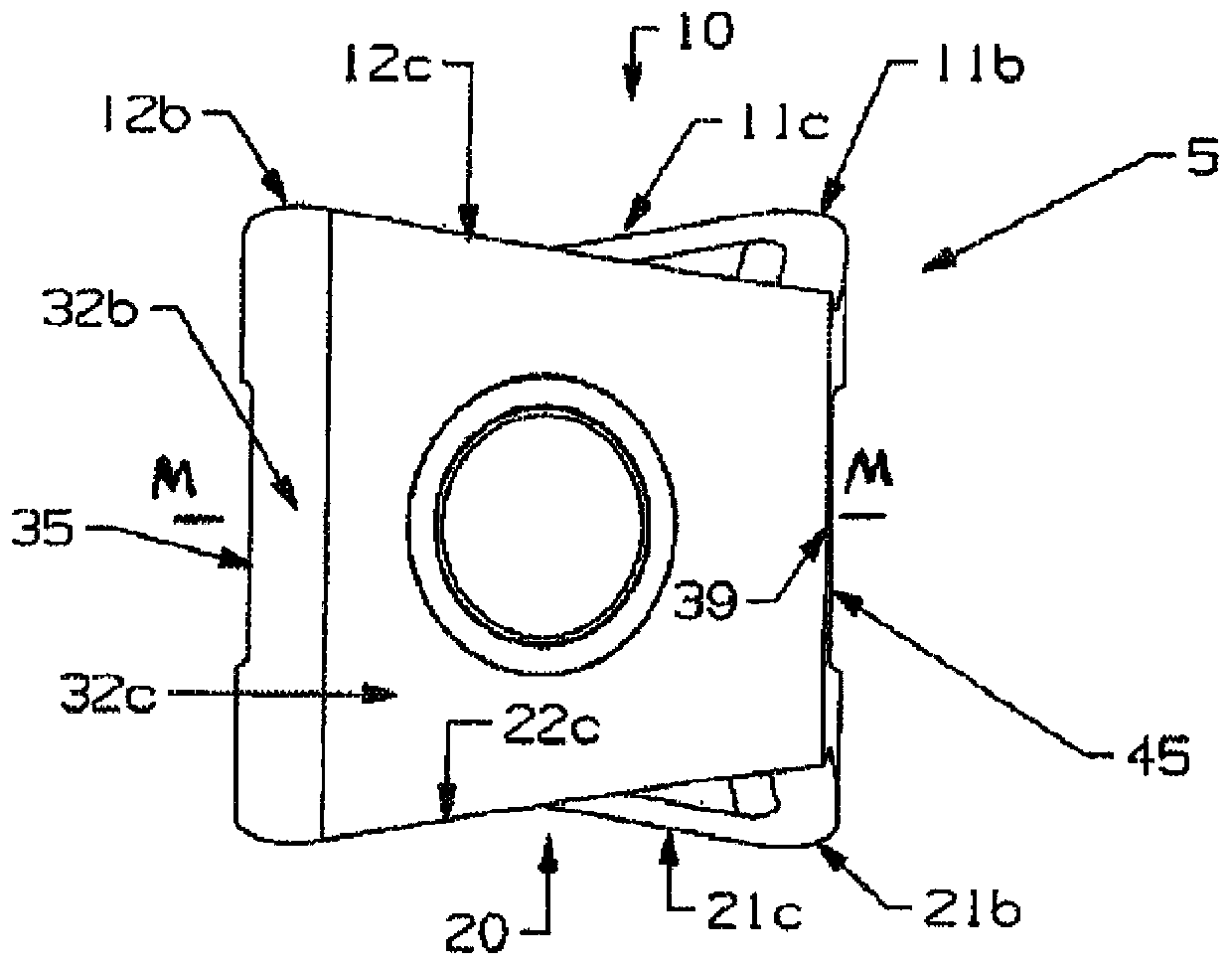

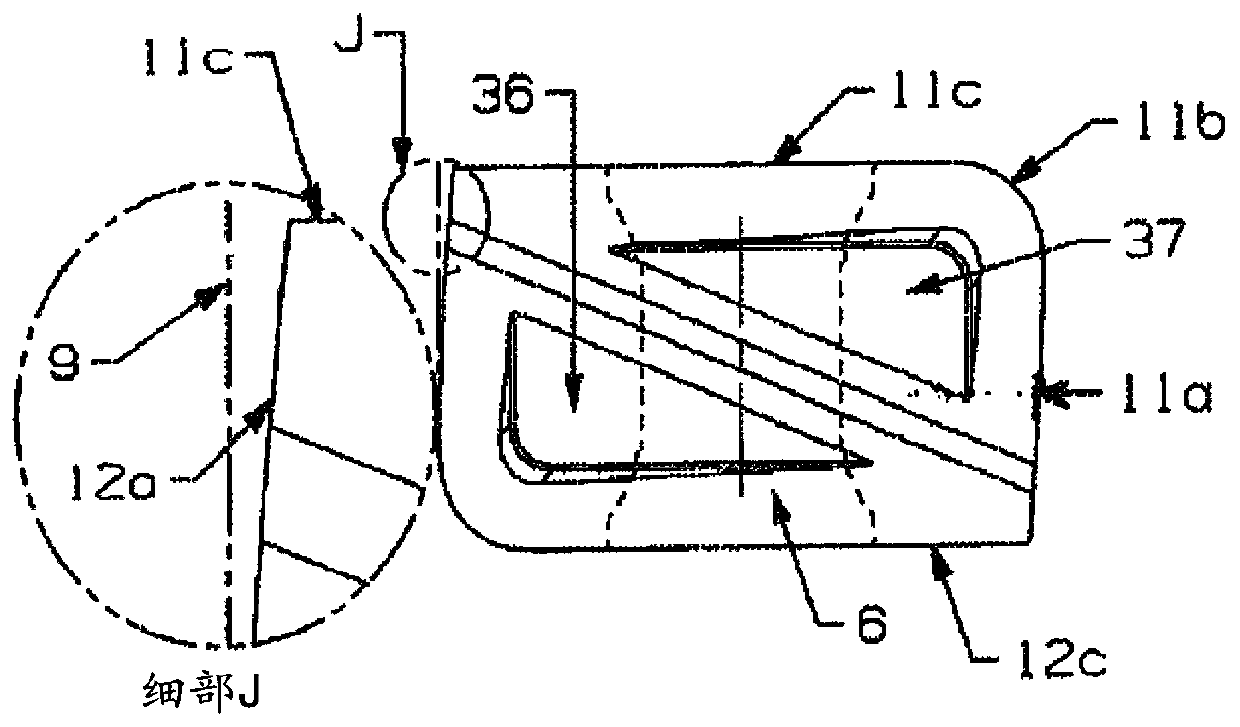

Double-sided tangential cutting insert

An insert, double-sided technology, applied in the [0006] field, can solve problems such as difficult to effectively balance, complex cutting edge geometry, etc., to achieve the effect of ensuring surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] It should be readily understood that the components of the embodiments of the invention as generally described and illustrated in the drawings herein may be arranged and designed in a wide variety of different configurations in addition to the exemplary embodiments described. Accordingly, the following more detailed description of embodiments of the invention as shown in the accompanying drawings is not intended to limit the scope of embodiments of the invention as claimed, but is merely an illustration of exemplary embodiments of the invention. represent.

[0044] In the description of the non-limiting specific embodiments of the invention and in the claims, all numbers expressing amounts or characteristics of ingredients and products, processing conditions, etc., except in operating examples or unless otherwise indicated, are to be understood as Modified in all cases by the term "about". Accordingly, unless indicated to the contrary, any numerical parameters set fort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com