Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Shorten the lifting stroke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

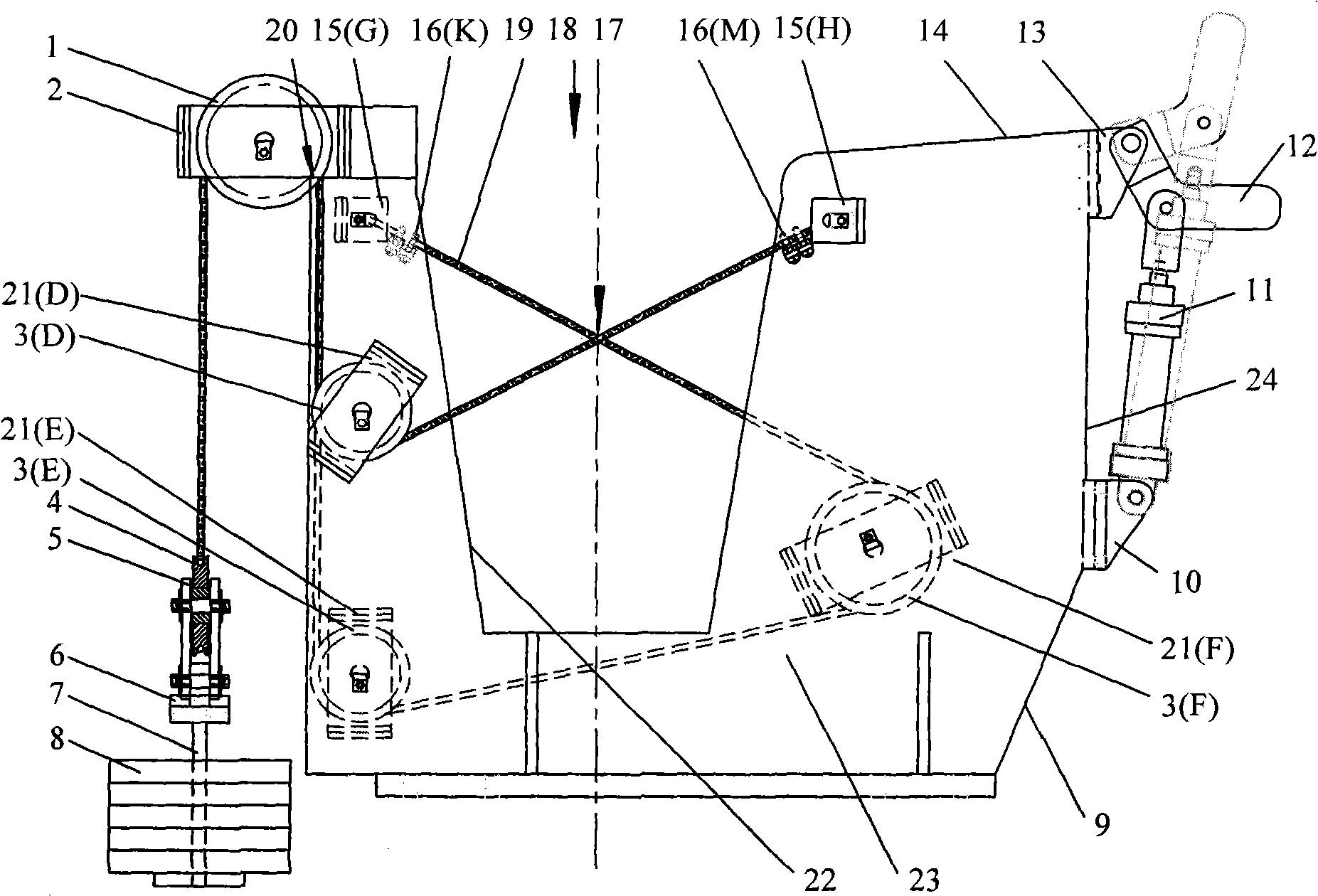

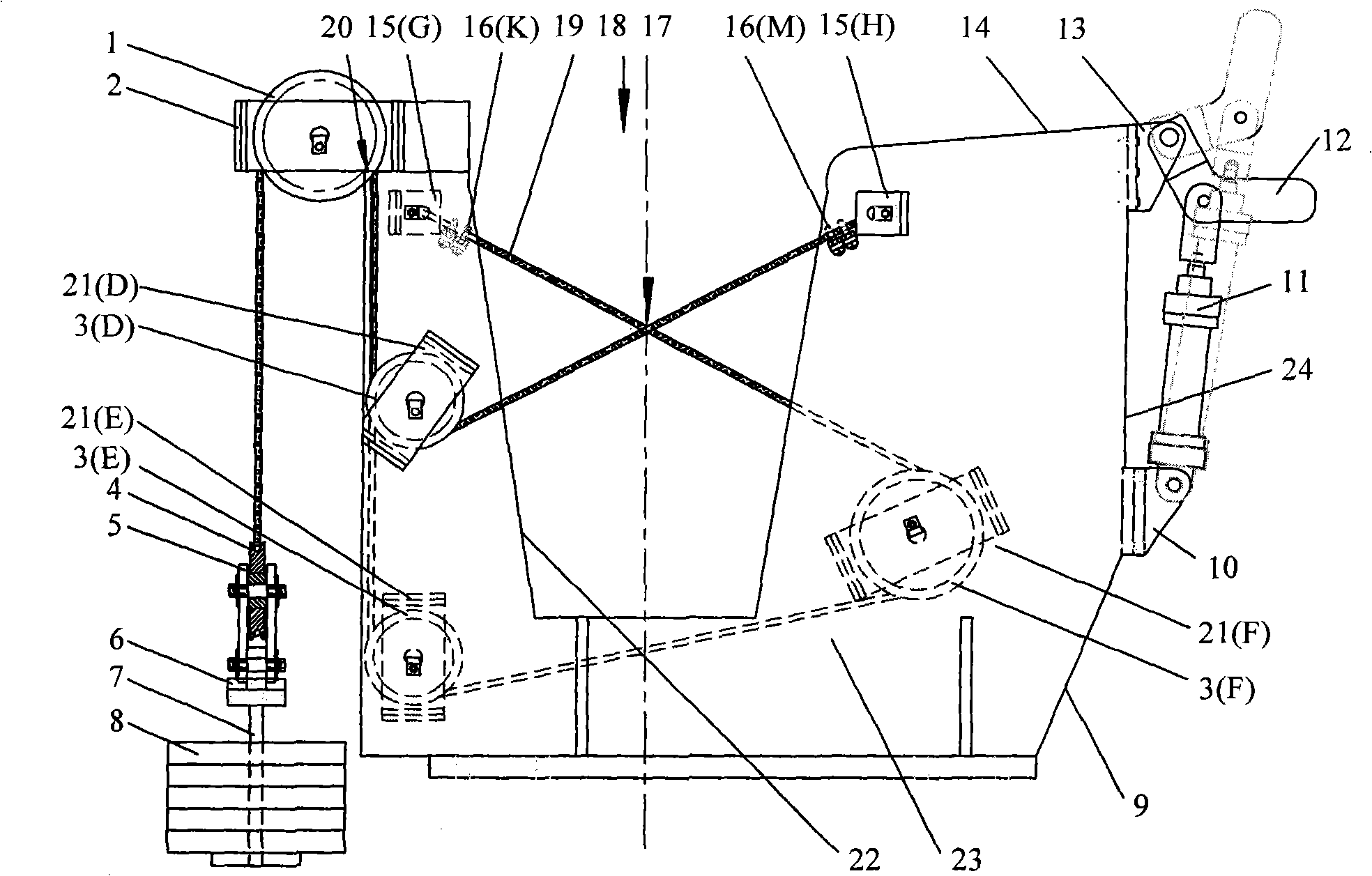

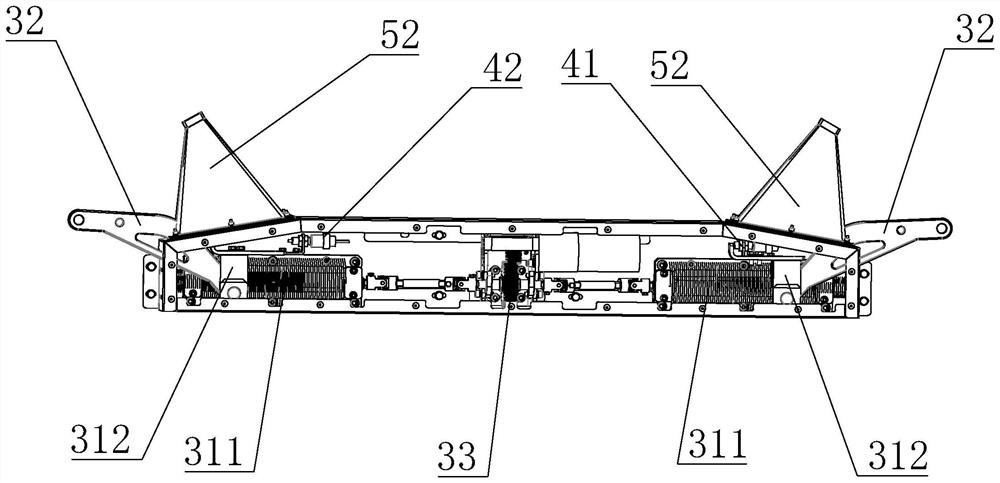

Window glass lifter, window glass lifting mechanism and vehicle

ActiveCN103015827ALarge lifting strokeShorten the lifting strokePower-operated mechanismMechanical engineeringRisk stroke

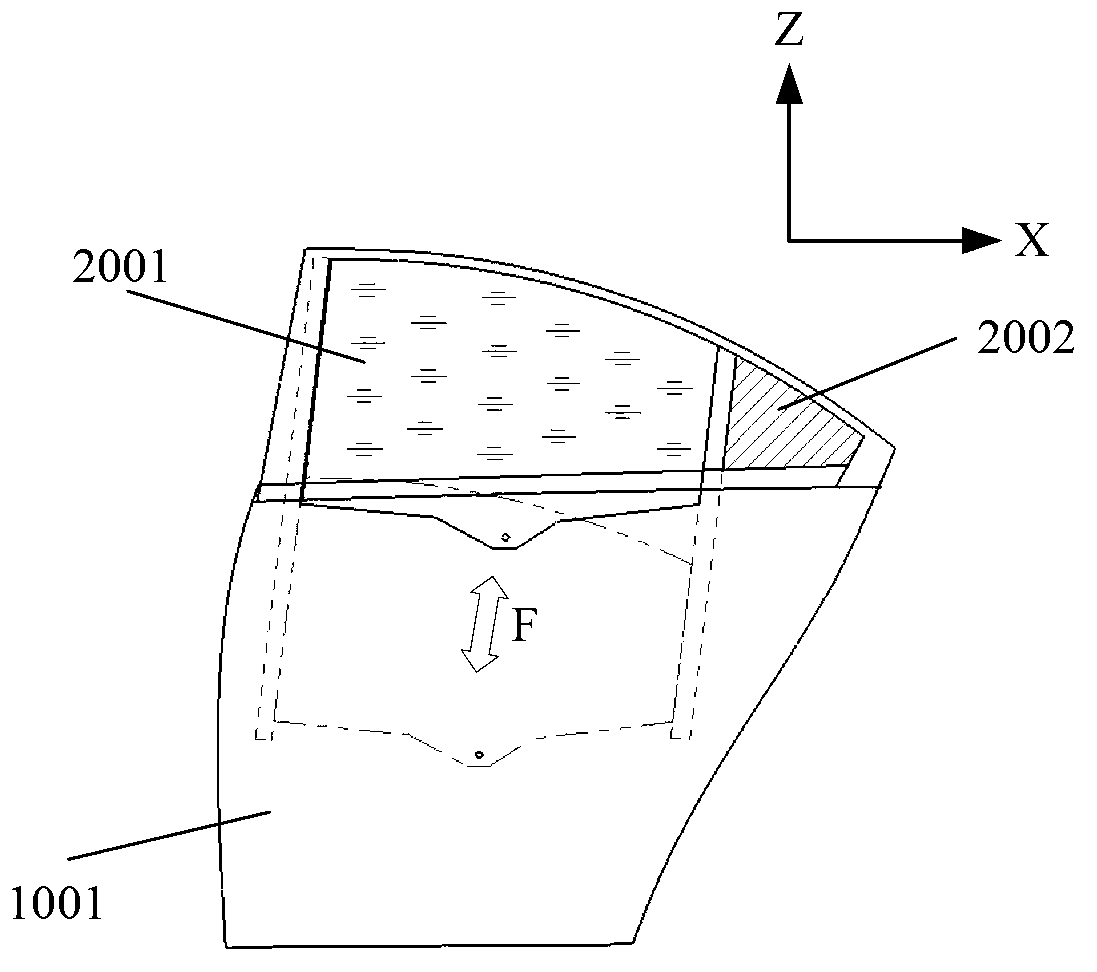

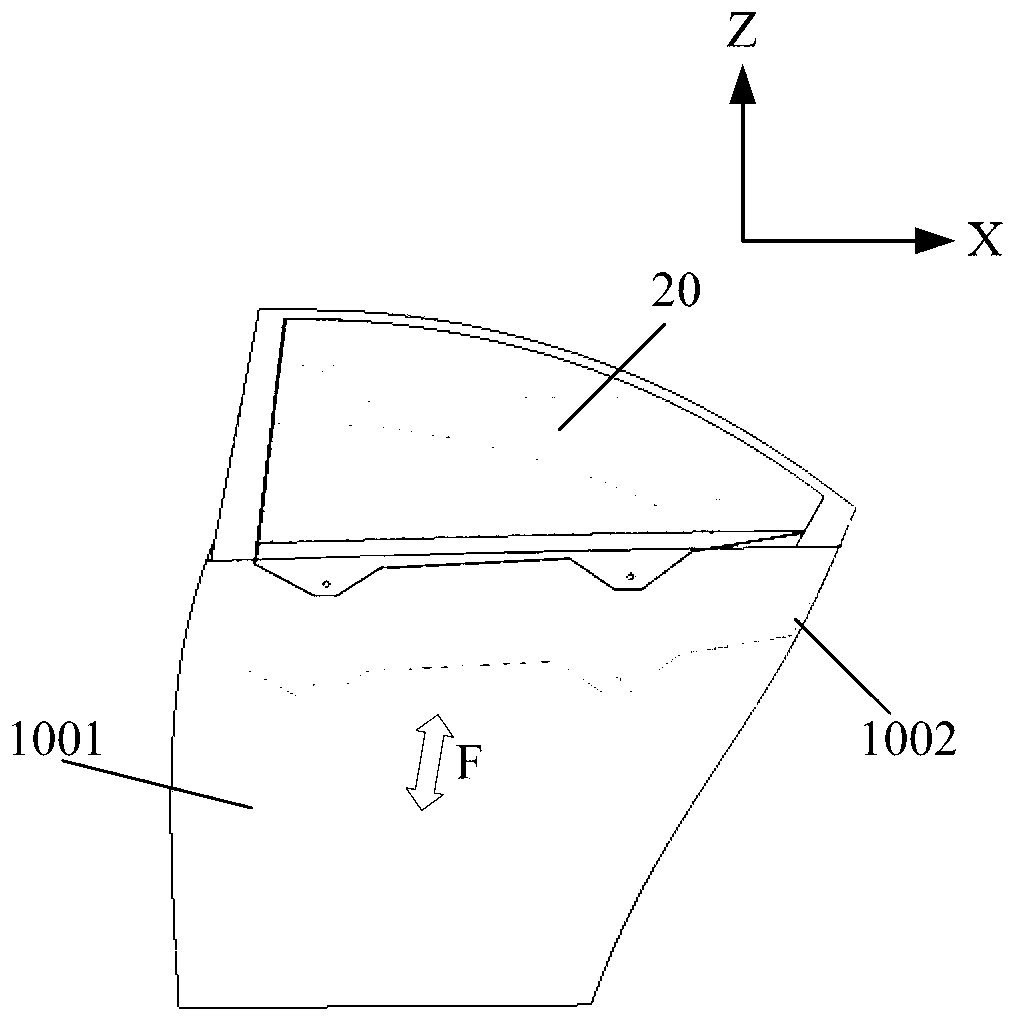

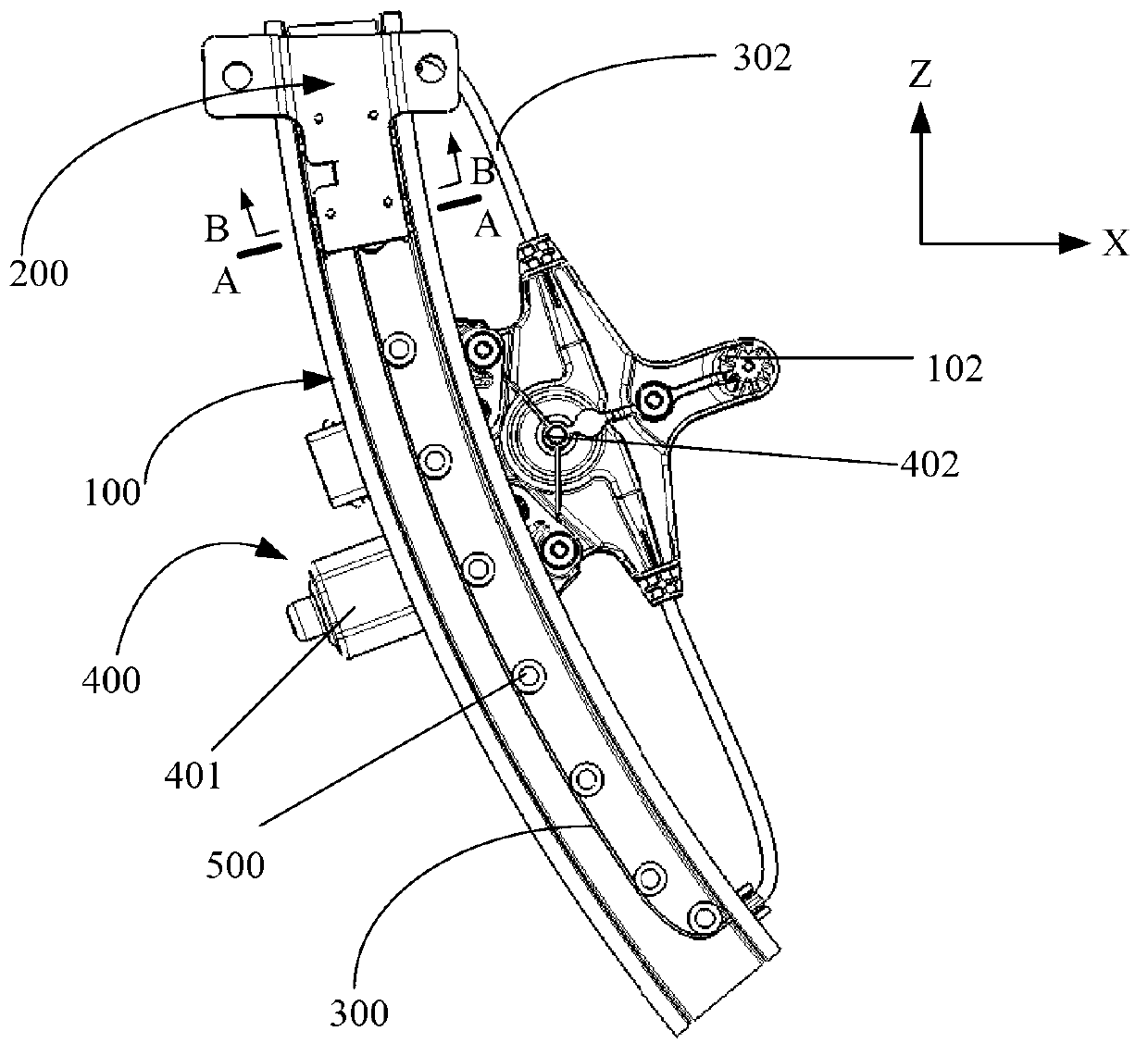

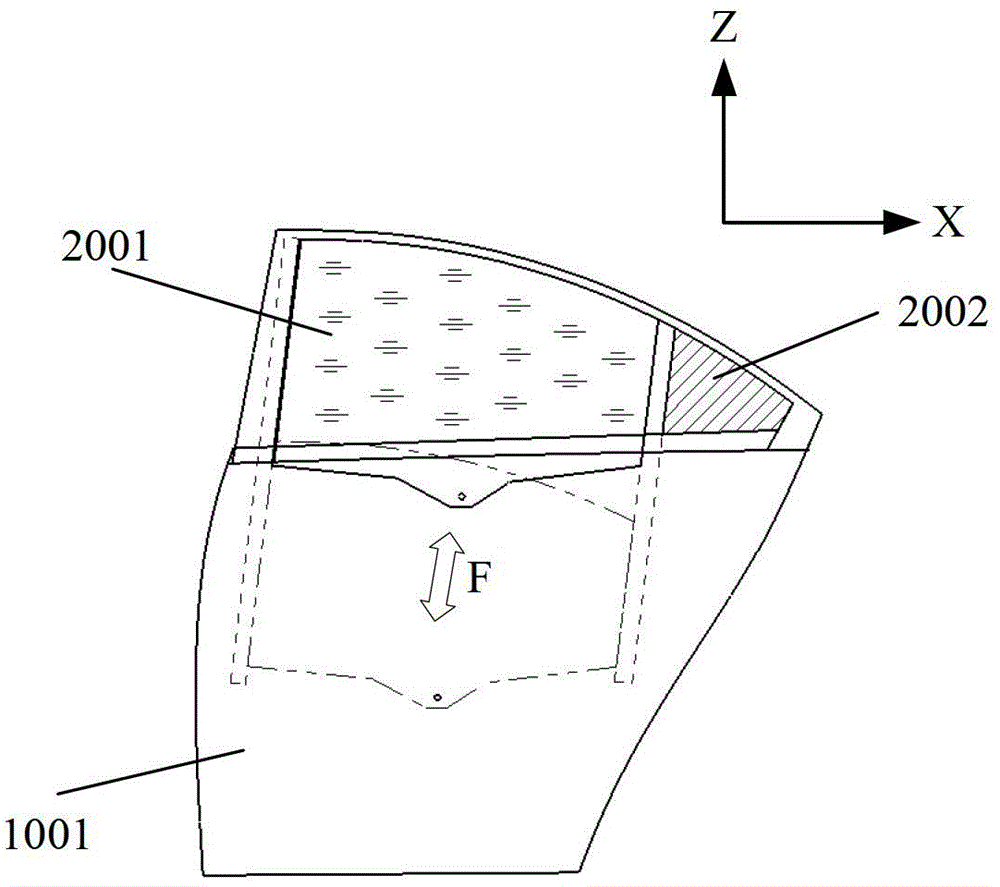

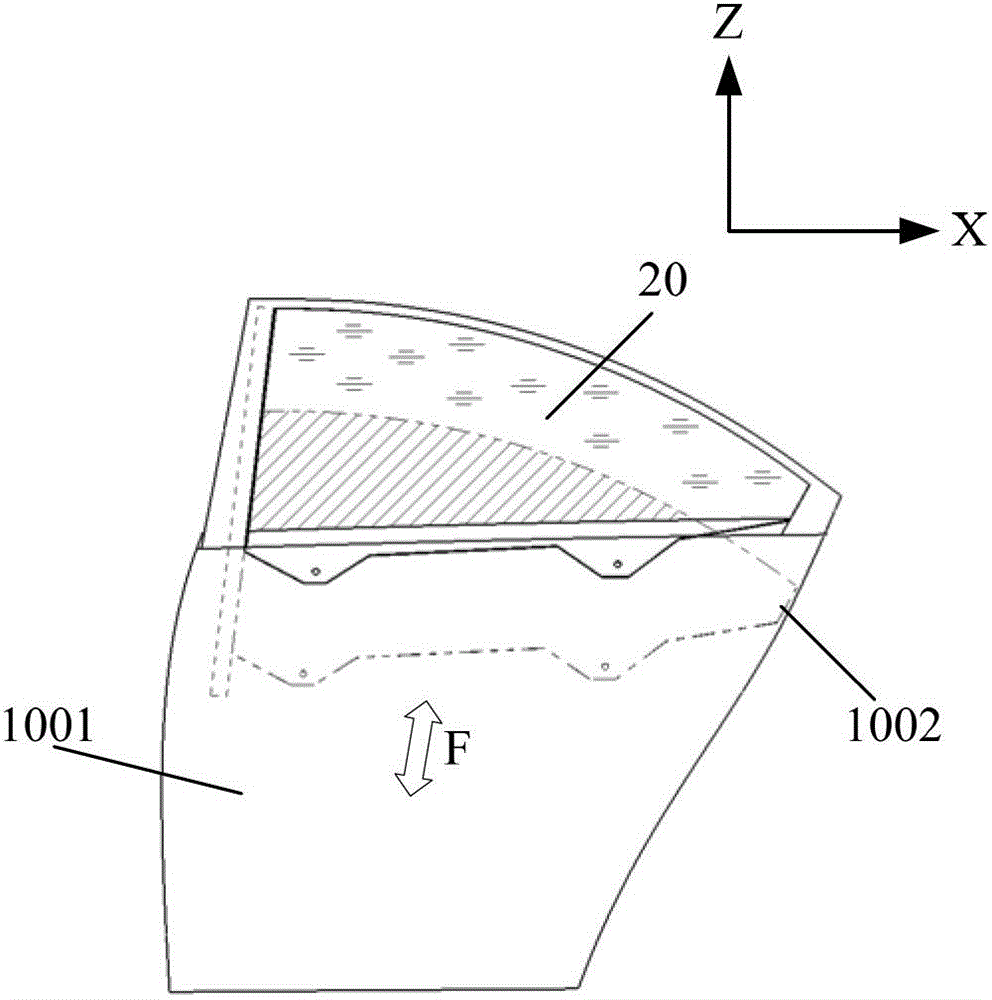

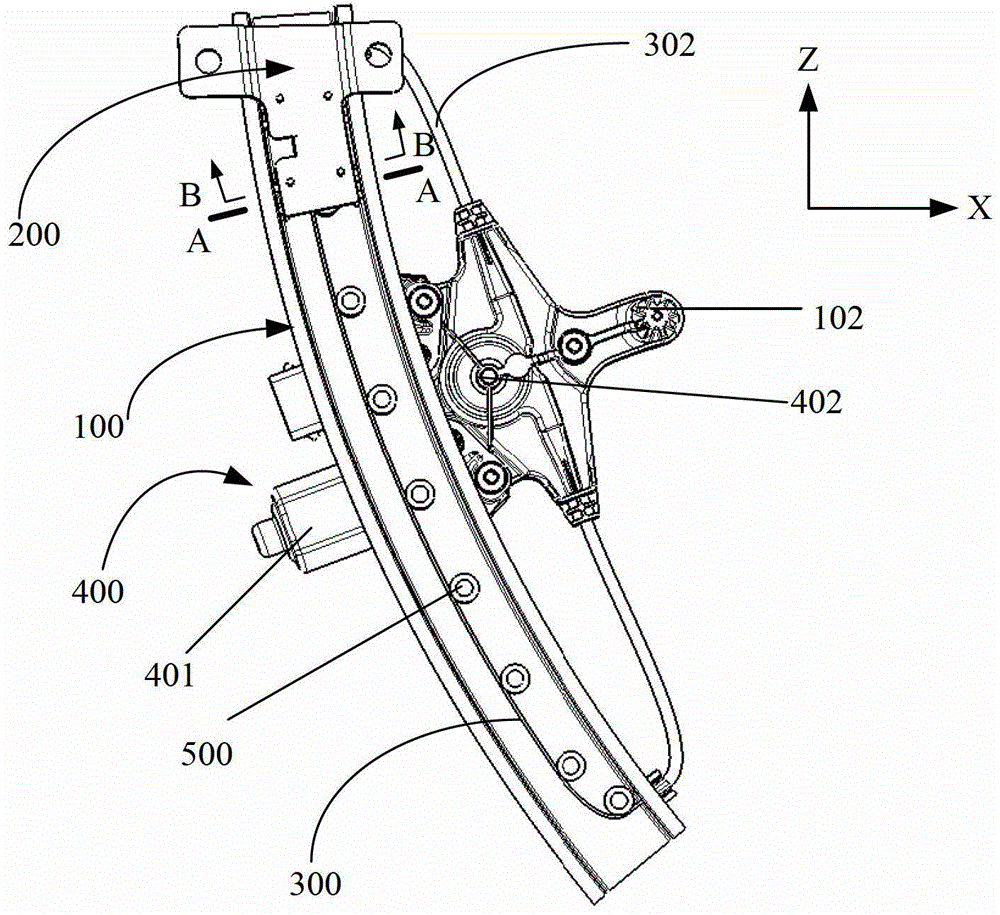

The invention provides a window glass lifter, a window glass lifting mechanism and a vehicle. The window glass lifting mechanism comprises a guide slide rail, a window glass bracket slider, a pull wire and a driving mechanism, the window glass bracket slider is used for driving widow glass to ascend and descend along the guide slide rail, is arranged on the slide rail and is capable of moving along the guide slide rail, the pull wire is used for pulling the window glass bracket slider to reciprocate along the guide slide rail and is fixedly connected with the window glass bracket slider, the driving mechanism is used for providing power for movement of the pull wire and is connected with the pull wire, and the guide slide rail is an arc-shaped guide slide rail which is capable of guiding the window glass bracket slider to reciprocate along an arc-shaped track so as to drive the window glass to ascend and descend along the arc-shaped track. The guide slide rail is arranged as the arc-shaped guide slide rail to guide the window glass bracket slider to move along the arc-shaped track and further drive the window glass to move along the arc-shaped track, so that the window glass is large in lifting stroke on one side and small in lifting stroke on the other side, and further the descending stroke of the window glass and particularly corner-less window glass can meet requirements.

Owner:BAIC MOTOR CORP LTD

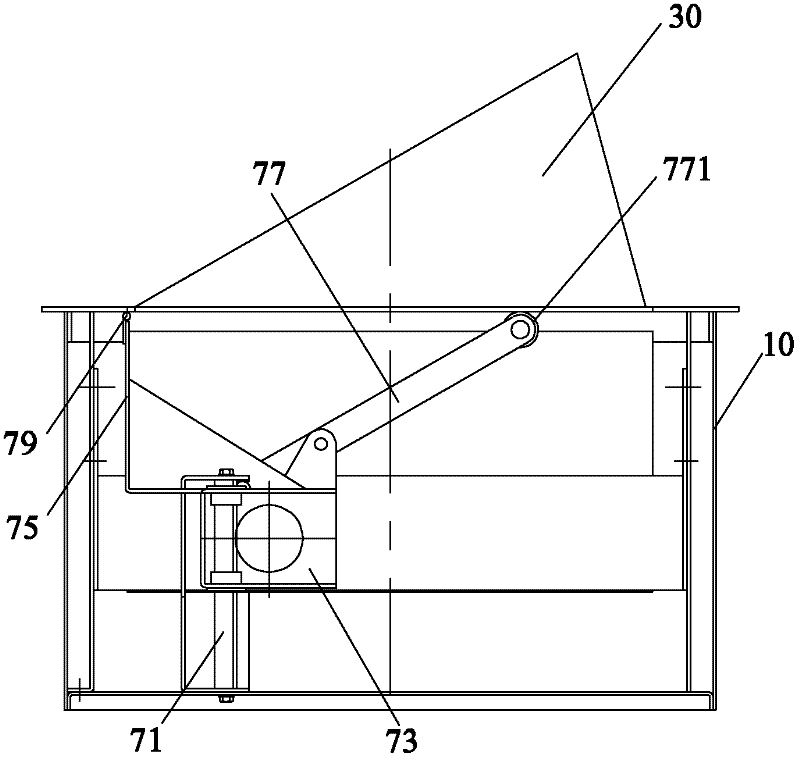

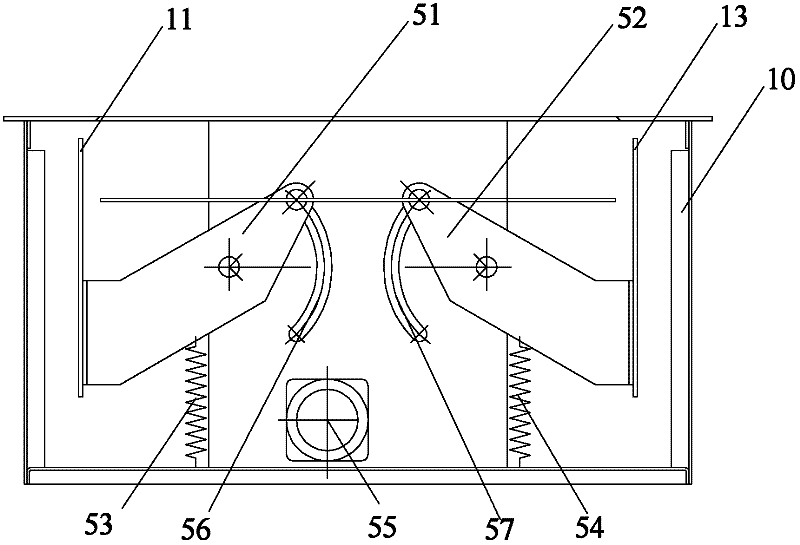

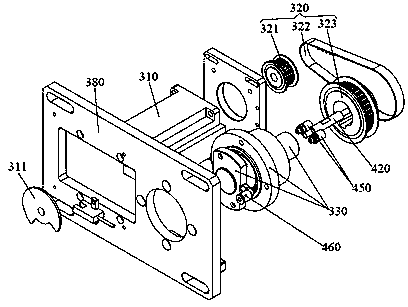

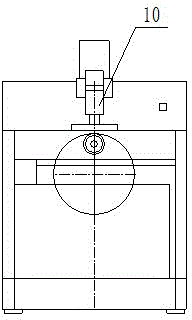

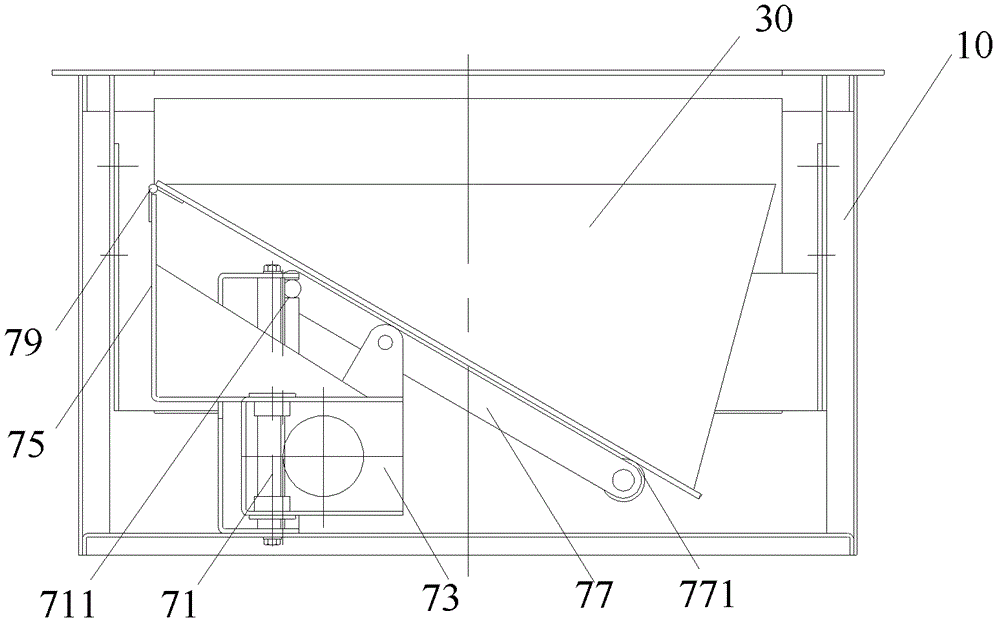

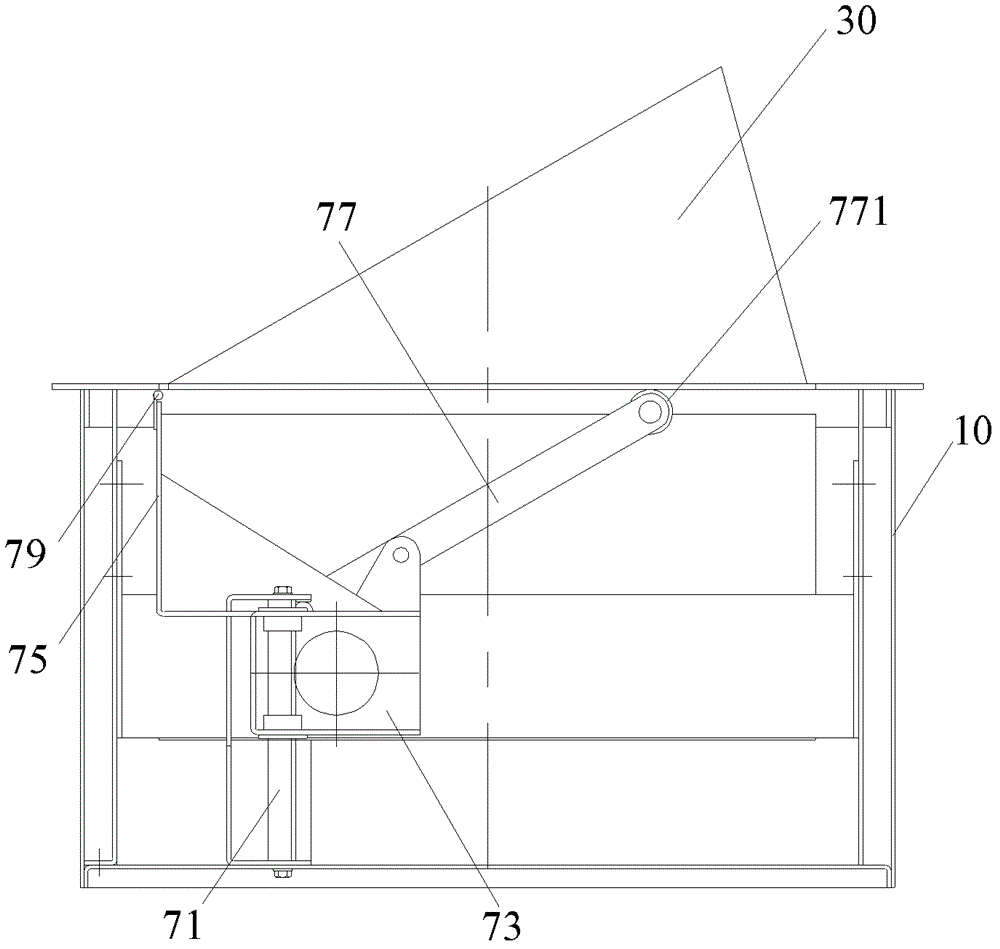

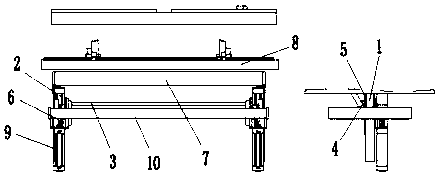

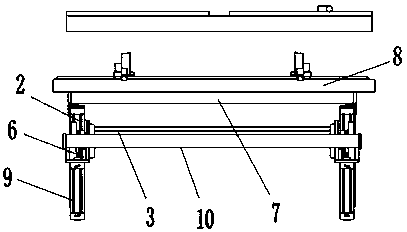

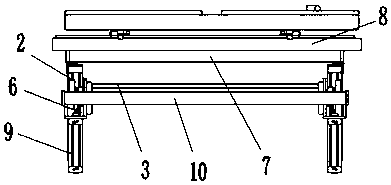

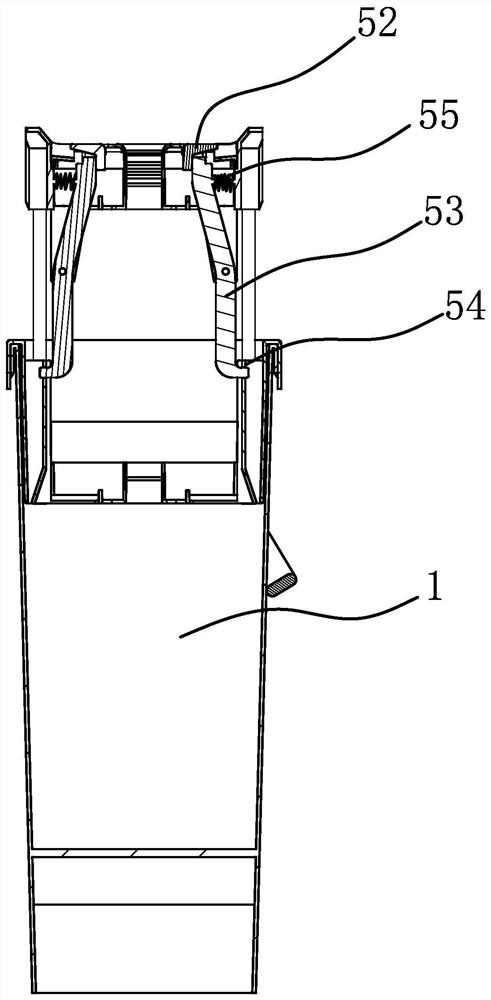

Liftable display system

ActiveCN102226936ALower the altitudeSolve space problemsStands/trestlesIdentification meansDisplay deviceEngineering

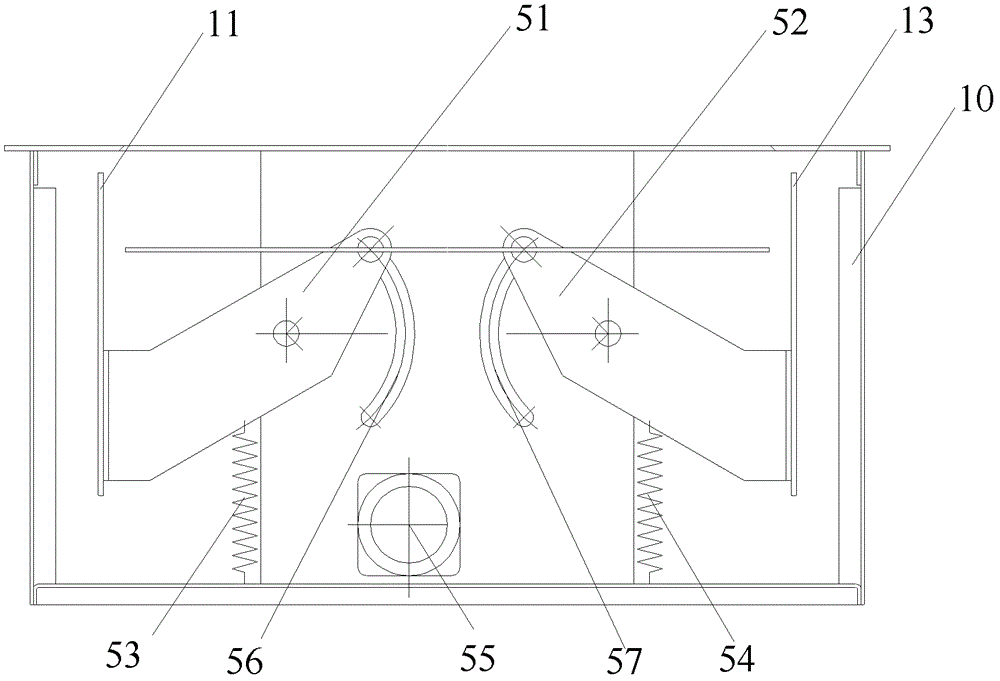

The invention provides a liftable display system which comprises a shell (10), a display device (30), a first turnover mechanism and a second turnover mechanism, wherein the shell is provided with two turnover doors (11, 13) opposite to each other; the display device (30) comprises a displayer, a controller and a memory; the first turnover mechanism is in drive connection with the two turnover doors (11, 13), so that the two turnover doors (11, 13) can be in an opening state and a closing state; and the second turnover mechanism is in drive connection with the display device (30), so that thedisplay device (30) can be in a lifting state outside the shell (10) and in a recovery state in the shell (10). The liftable display system provided by the invention has the advantages of small occupied space, and short opening or closing time.

Owner:SHANXI BETTER TECH DEV

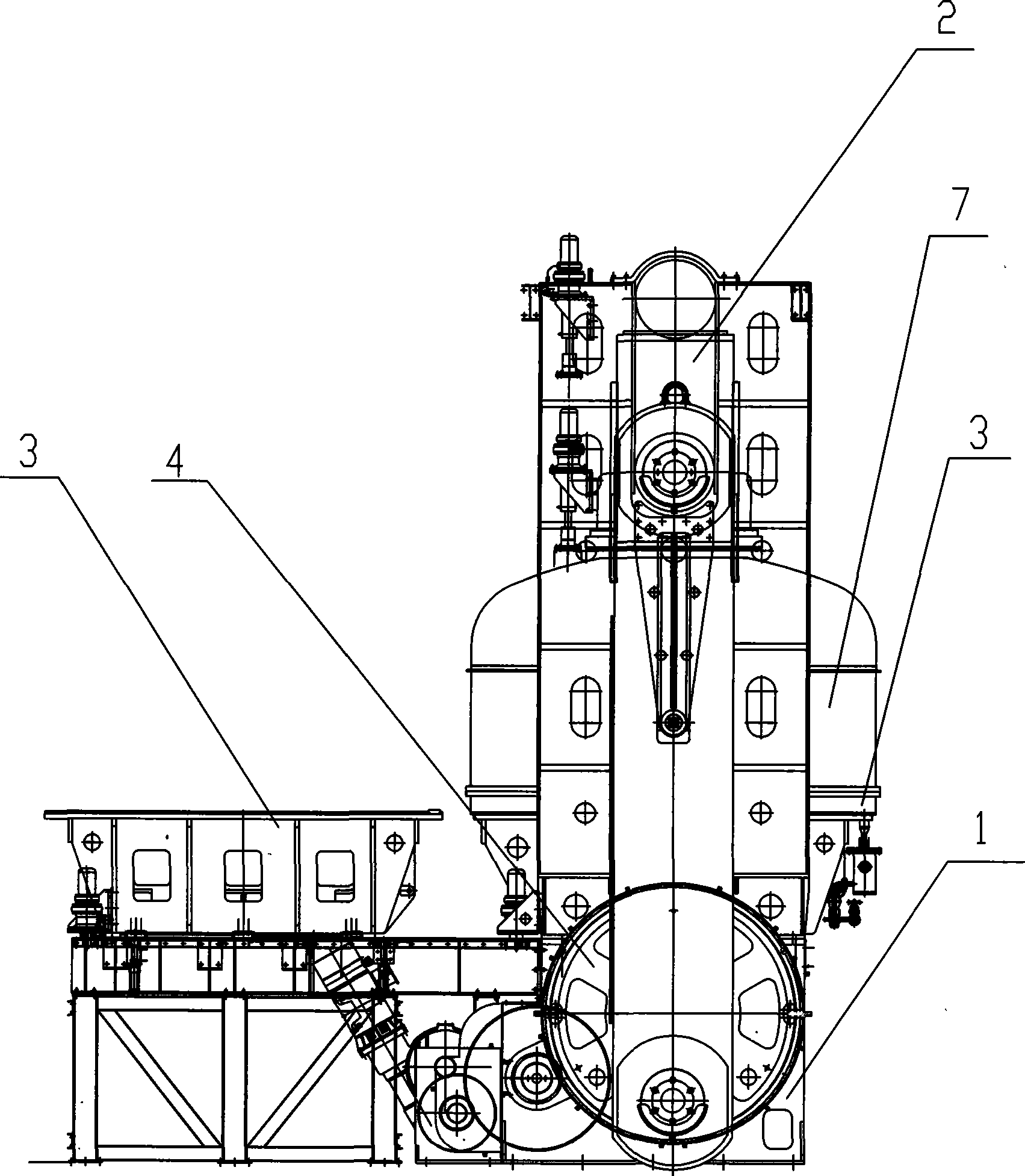

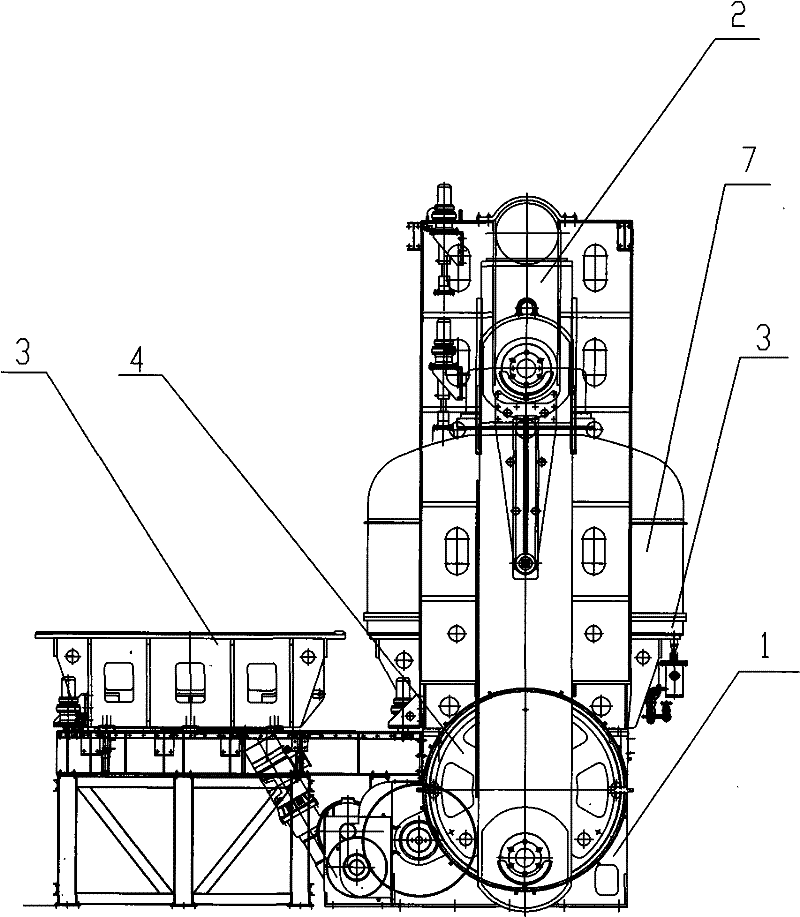

Fixed beam type tyres forming vulcanizer

The invention discloses a fixed beam type tire forming vulcanizer. In the invention, a beam is fixed in motionless; only the short-offset vertical lift is carried out; a lower vulcanizing chamber and a central mechanism are removed out of a base by a translation mechanism; the internal pipeline and the external pipeline of the central mechanism are movably connected; the base adopts a segregated structure; and a transmission gear adopts the simple assembly-and-disassembly structure. The novel structure of the invention can also realize all the functions of the traditional vulcanizer, in addition, the overall structure is simpler and more reliable, and the processing, installation and maintenance are convenient.

Owner:GUILIN RUBBER MACHINERY CO LTD

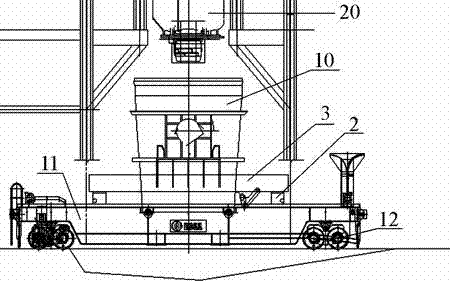

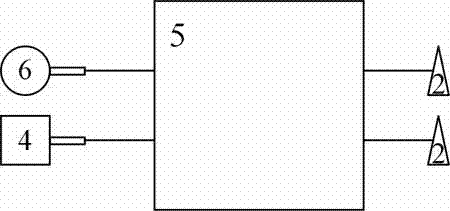

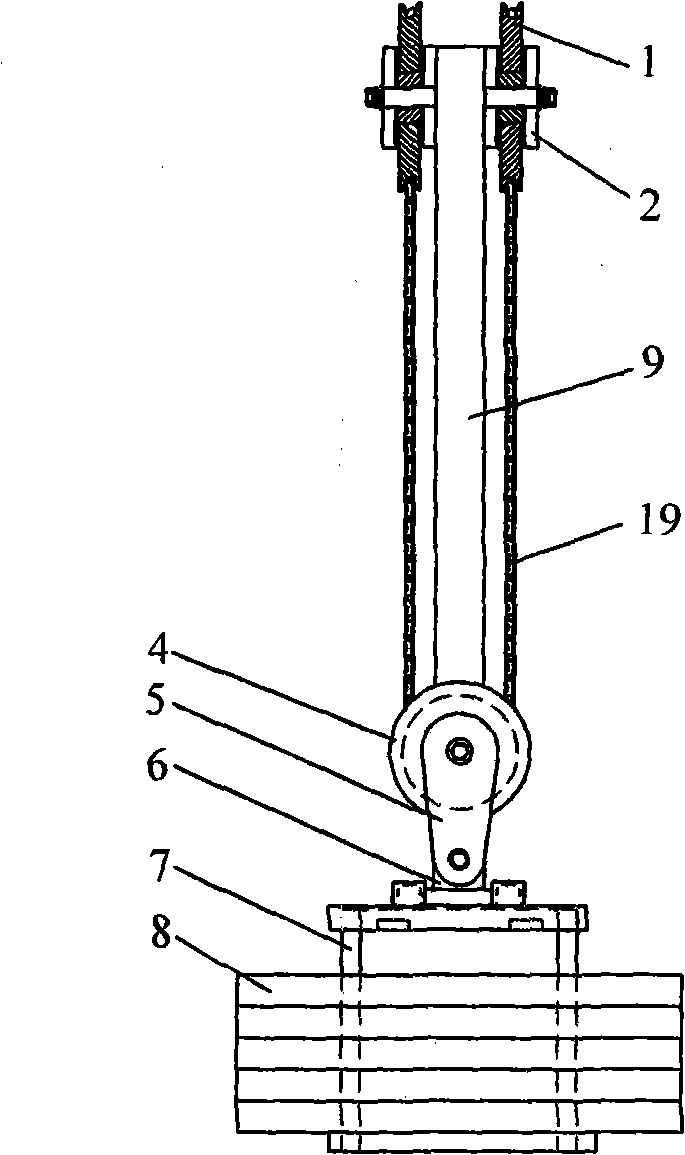

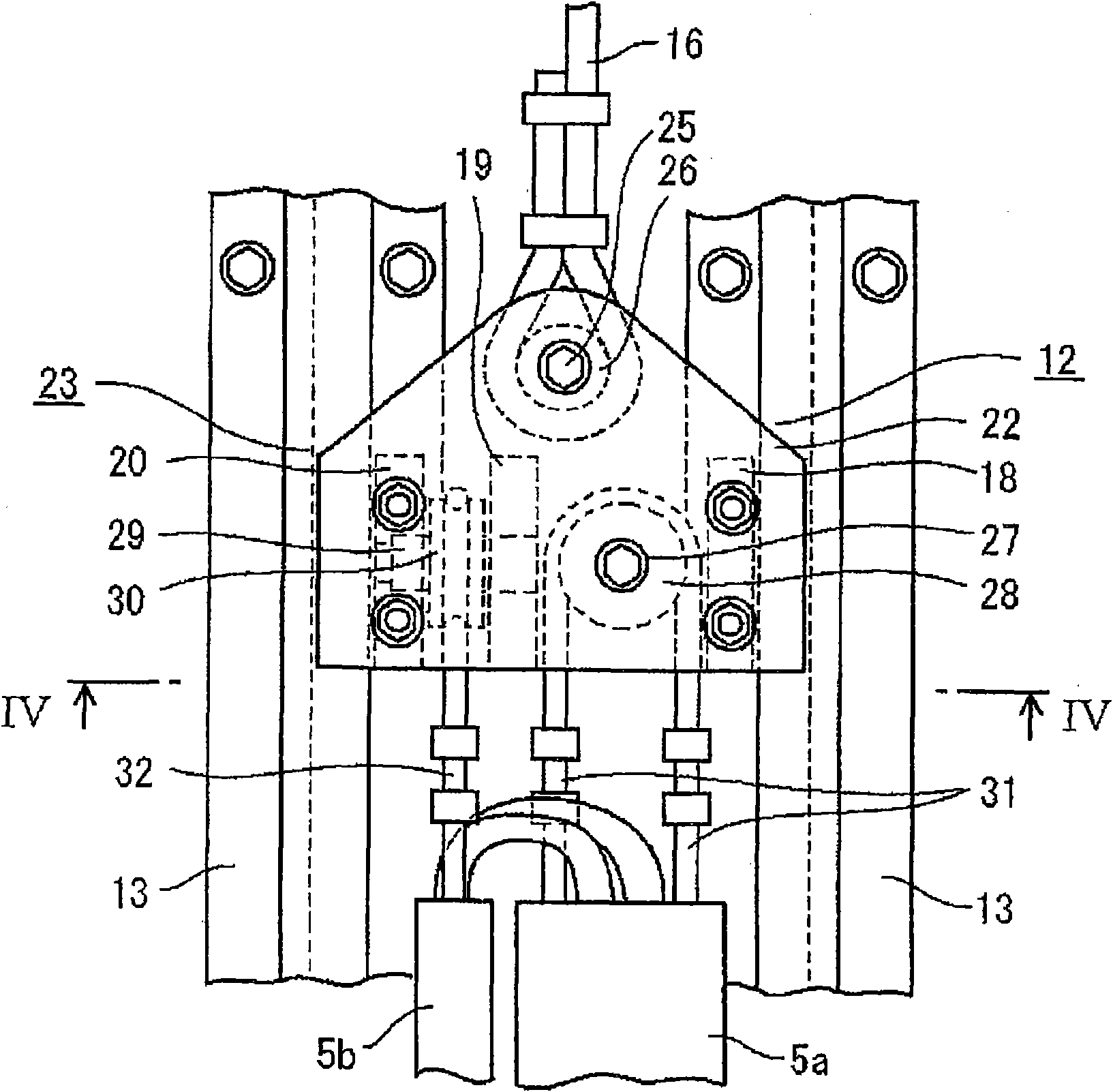

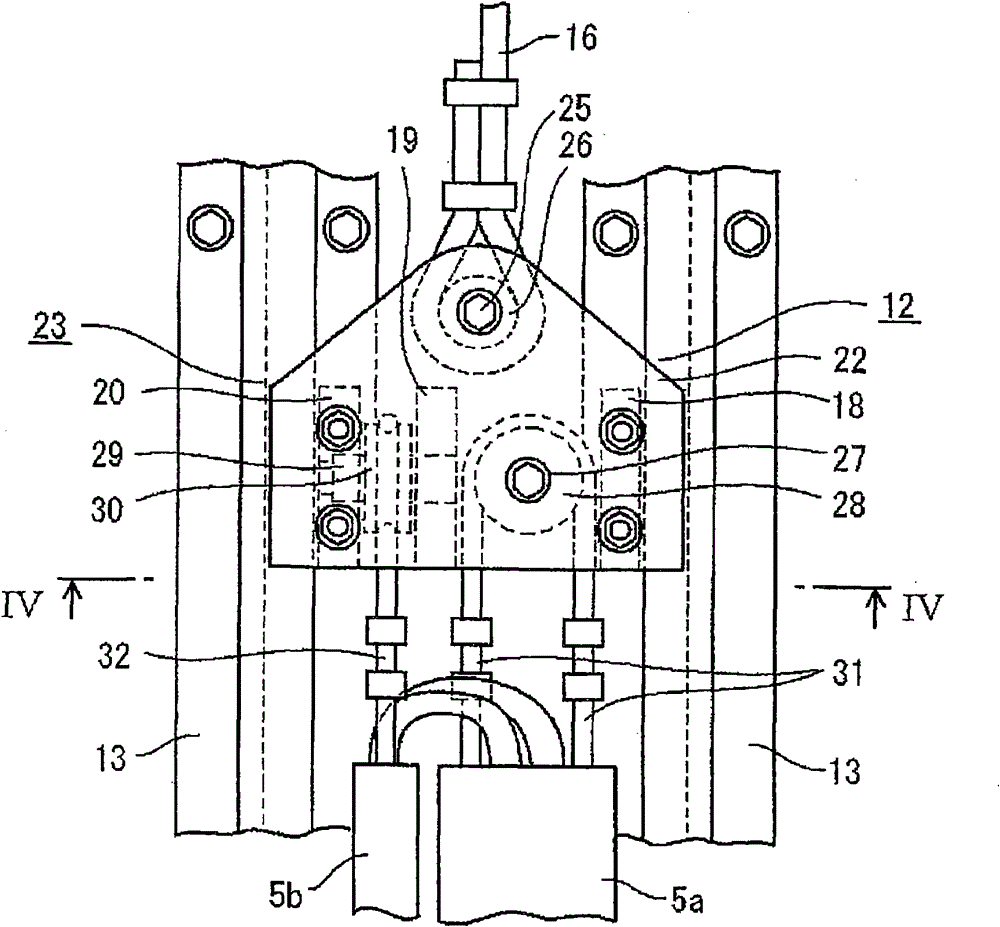

Jacking ladle car and applications thereof in vacuum circulating degasification refining method

InactiveCN102826490ASolve layout difficultiesShorten the lifting strokeLifting devicesReducerPneumatic motor

The invention relates to the field of steel refining by vacuum treatment, and particularly relates to a jacking ladle car and applications of the jacking ladle car in a vacuum circulating degasification refining method. The jacking ladle car comprises a car body (11) and a wheel group (12). The jacking ladle car is characterized by also comprising electric jacks (2), a support frame (3), motors (4), a double-input double-output speed reducer (5) and a pneumatic motor (6); bases of the electric jacks (2) are respectively fixed at the four corners at the upper part of the car body (11); movable rods of each electric jack (2) are respectively fixed into pits at the lower parts of the four corners of the support frame (3); and a rotating shaft of each motor (4) is connected with an input shaft of the double-input double-output speed reducer (5), and two output shafts of each double-input double-output speed reducer (5) are connected with one electric jack (2). The jacking ladle car is simple in structure, convenient to manufacture, safe and reliable.

Owner:BAOSTEEL ENG & TECH GRP

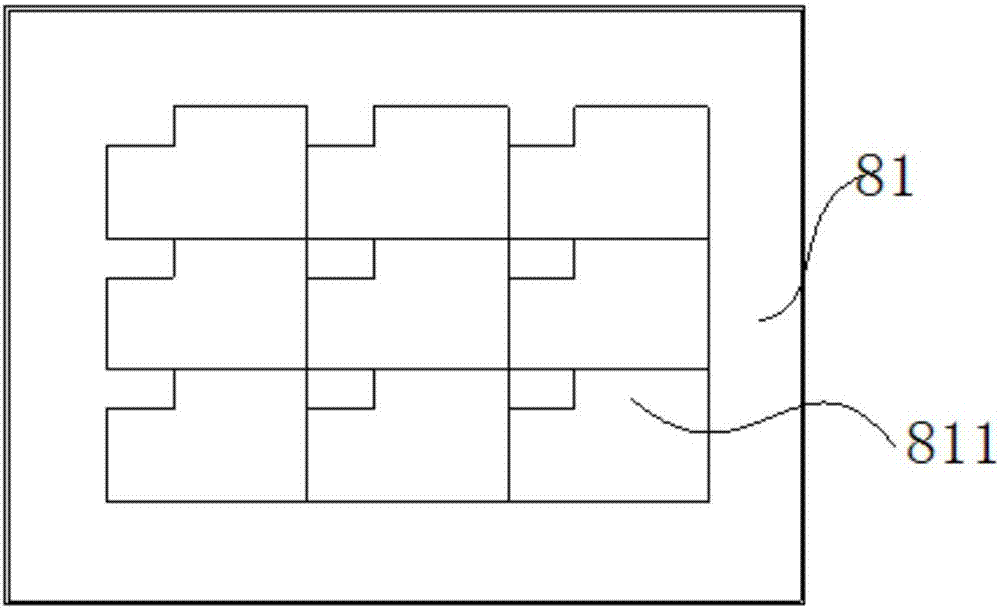

Material gathering unit

InactiveCN101525058APlay a buffer roleMove up and down flexiblyBundling machine detailsFixed bearingHydraulic cylinder

The invention relates to a material gathering unit, which comprises a charging basket (9) and a briar dressing device; wherein, the charging basket (9) has one or more, each charging basket is provided with a cone-shaped collection port (18) which runs through two lateral surfaces of the whole charging basket, one end table-board of one of two wings of the collection port is a material receiving sloping bench (14) which inclines toward the centre of the collection port; the briar dressing device comprises a bracket arm seat (13) on a lateral wall (24) and a fixed bearing (10), an L-shaped bracket arm (12) and a hydraulic cylinder (11) which are rotatably connected together; wherein, the bracket arm seat on the lateral wall is arranged on one wing with the material receiving sloping bench (14) and corresponding to the internal inclined plane (22) of the collection port (18), the L-shaped bracket arm (12) and the hydraulic cylinder (11) are respectively rotatably connected with the bracket arm seat (13) and the fixed bearing (10), the charging basket (9) is also provided with a blanking cushioning device and an elevator mechanism. The material gathering unit is simple and flexible to be operated, has small shaking and low noise, thus improving workshop environment.

Owner:CERI TECH

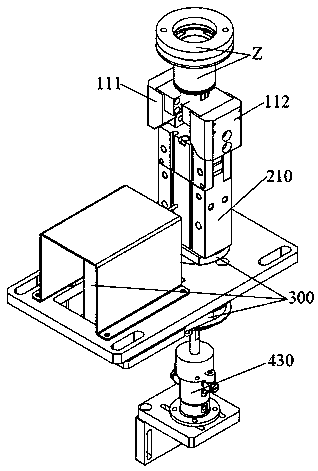

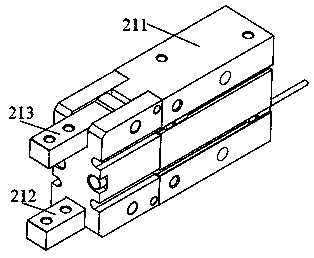

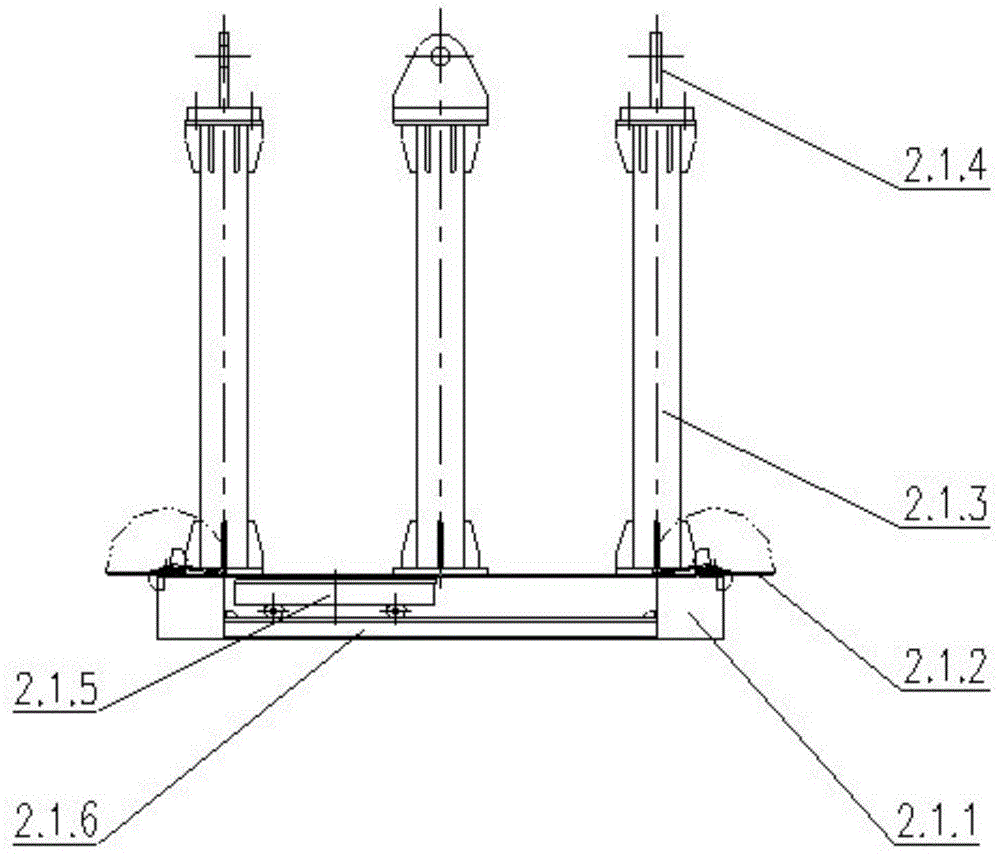

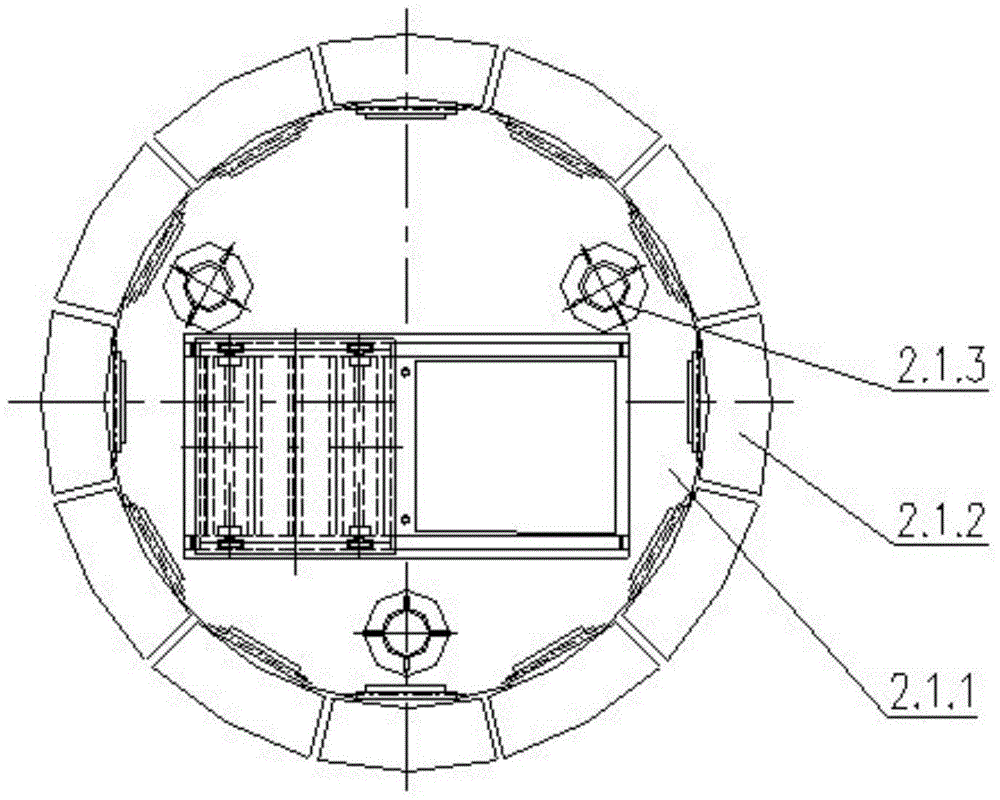

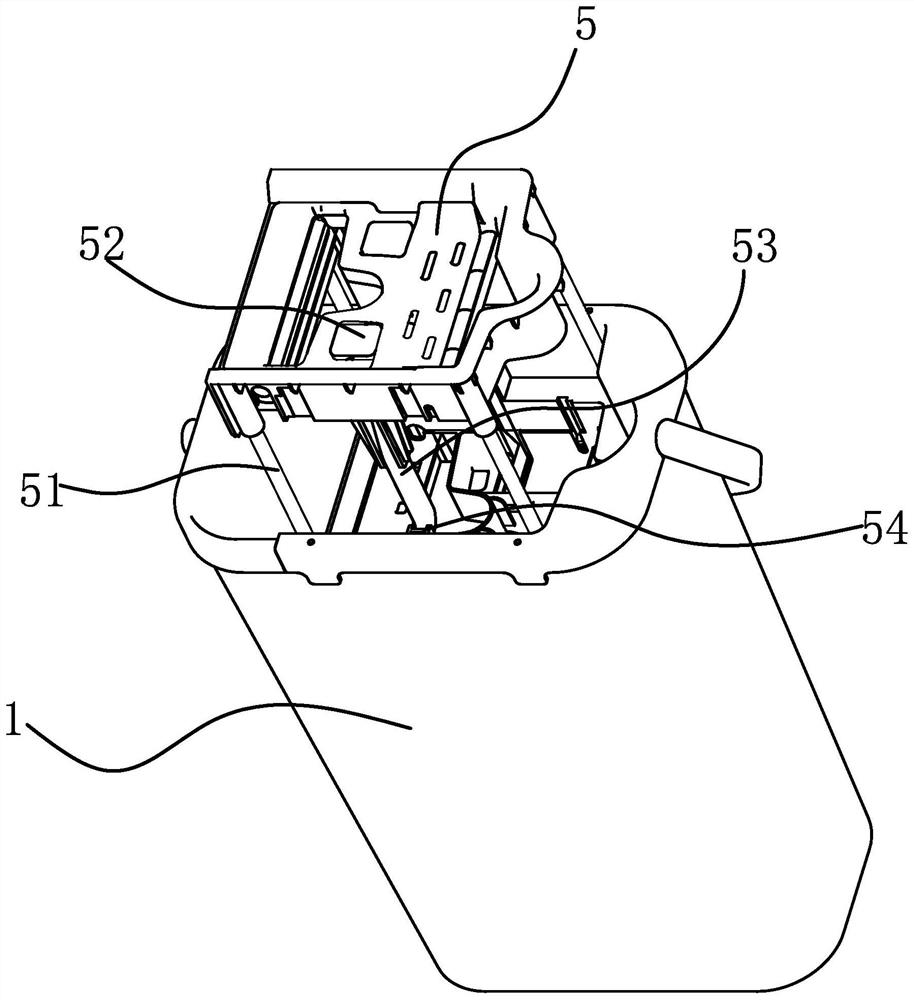

Jig clamping and rotating mechanism and ball bulb assembling system

PendingCN108927648AAvoid collisionShorten the lifting strokeMetal working apparatusEngineeringMechanical engineering

The invention discloses a jig clamping and rotating mechanism and a ball bulb assembling system. The jig clamping and rotating mechanism comprises a finger air cylinder, a left clamp is arranged on aleft gas claw of the finger air cylinder, and a right clamp is arranged on a right gas claw of the finger air cylinder. The finger air cylinder is connected with a rotation assembly used for driving the finger air cylinder to rotate. According to the provided jig clamping and rotating mechanism, when a jig is clamped, the finger air cylinder can be directly used for driving the left clamp and theright clamp to rotate by 90 degrees, then the included angle between the left clamp and the right clamp can be freely adjusted within 0-180 degrees, wherein the included angle can be smaller than 180degrees, provided that collisions between the clamps and a workbench are avoided; and the left clamp and the right clamp are prevented from colliding with the rotating workbench, the lifting stroke ofthe air cylinder and the clamps is omitted, and the ball bulb work efficiency is improved.

Owner:SHENZHEN XUANSHUO INTELLIGENT MANUFACTURING TECHNOLOGY CO LTD

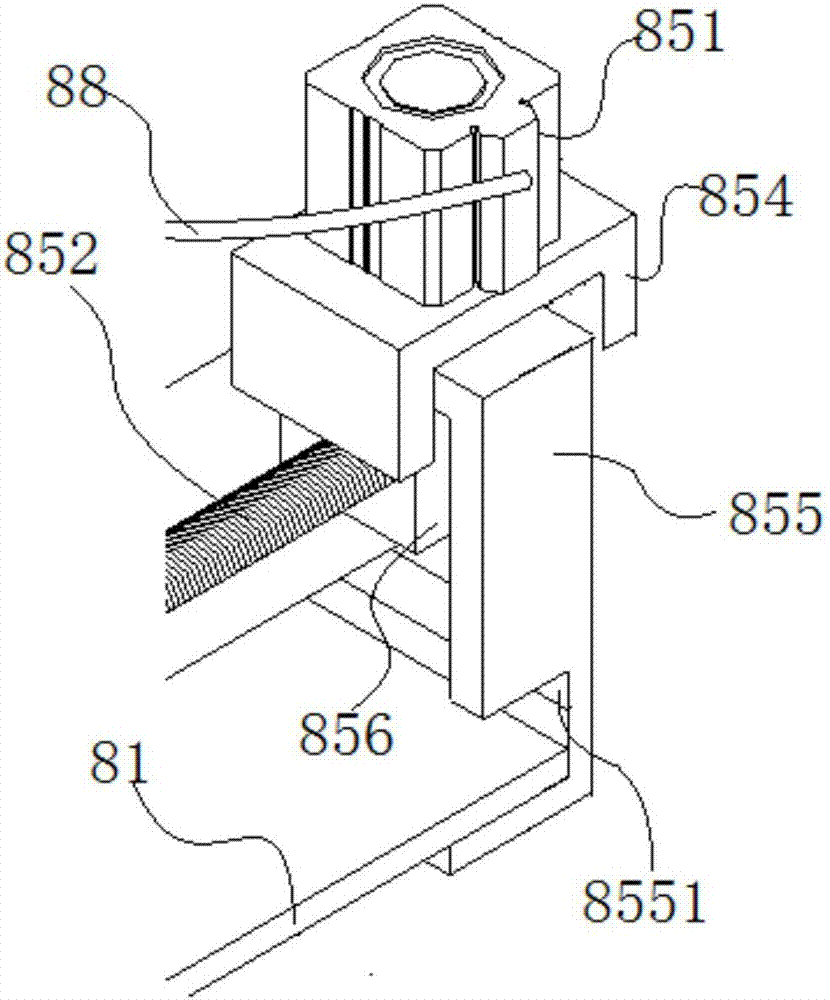

Hot melting damping fin punching and cutting device and punching method thereof

ActiveCN107363901AHigh viscoelasticityReduce the risk of useMetal working apparatusPunchingStructural engineering

The invention discloses a hot melting damping fin punching and cutting device and a punching method thereof, and belongs to the technical field of vehicle damping. The hot melting damping fin punching and cutting device comprises a punching and cutting device body, and a special conveying belt penetrating through the punching and cutting device body for conveying hot melting damping fins, wherein the punching and cutting device body comprises two support tables on two sides of the special conveying belt, punching tables flatly placed and fixed on the side surfaces of the two support tables, and lifting height adjusting mechanisms; and the punching tables are connected with cutter molds detachably mounted at the bottoms of the punching tables through the lifting height adjusting mechanisms. The punching heights and thicknesses of the cutter molds are adaptively adjusted through the lifting height adjusting mechanisms; and after the hot melting damping fins are effected, the lifting travels can be shortened, and the damage of the conveying belt due to excessive punching is prevented. The device solves the problems of bad burrs in cutting of the damping fins and short service life of the conveying belt.

Owner:MAANSHAN LIANHONG SYNTHETIC MATERIALS

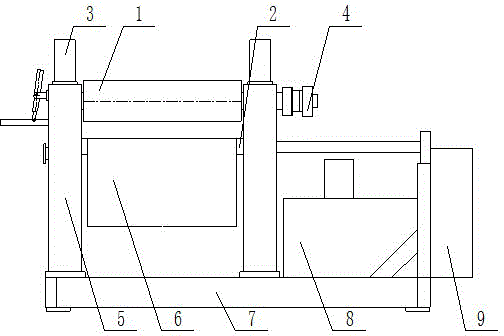

Two-roller plate rolling machine with reversely-arranged flexible roller

The invention provides a two-roller plate rolling machine with a reversely-arranged flexible roller and relates to the technical field of plate rolling machines. The two-roller plate rolling machine comprises the flexible roller, a rigid roller, a lifting oil cylinder, a hydraulic motor, a support wallboard, a chassis base, a hydraulic system, an electrical apparatus control system and an overturning oil cylinder. The support wallboard is arranged on one side of the upper portion of the chassis base. The lifting oil cylinder is reversely arranged at the upper end of the support wallboard. The flexible roller is horizontally arranged on the upper portion of the support wallboard. The power output end of the lifting oil cylinder is connected with the two ends of the flexible roller. One end of a roller shaft of the flexible roller is connected with the hydraulic motor. The other end of the flexible roller is provided with the overturning oil cylinder. The rigid roller is horizontally arranged below the flexible roller. The hydraulic system is arranged on the other side of the upper portion of the chassis base. The electrical apparatus control system is arranged on one side of the hydraulic system. Both the hydraulic system and the electrical apparatus control system are connected with the hydraulic motor. By means of the two-roller plate rolling machine, the purpose that cylinder bodies of workpieces of the large diameter can be roll-bent is achieved effectively, and meanwhile the stability and safety of the formed cylinder bodies are guaranteed.

Owner:NANTONG CHAOLI ROLLING MACHINE PRODUCING

Hot-melt damping fin cooling and punching device and production method thereof

ActiveCN107351184AReduce adhesionAvoid it happening againDomestic cooling apparatusLighting and heating apparatusEngineeringAir blower

The invention discloses a hot-melt damping fin cooling and punching device and a production method thereof and belongs to the technical field of car damping. The hot-melt damping fin cooling and punching device comprises an air cooling mechanism, a punching shearing device body and a dedicated conveying belt which penetrates the punching shearing device body to convey hot-melt damping fins. The air cooling mechanism comprises an air cooling box, an air blower and an air cooling conveying belt. The air blower is fixed into the air cooling box and covers over the air cooling conveying belt. The tail end of the air cooling conveying belt is connected with the dedicated conveying belt through the hot-melt damping fins in the conveying process, and the hot-melt damping fins are conveyed to the dedicated conveying belt. The punching shearing device body comprises supports on the two sides of the dedicated conveying belt, punching tables which are horizontally arranged and fixed to the side faces of the two supports, and lifting type height adjusting mechanisms. The punching tables are connected with cutting dies detachably installed at the bottoms of the punching tables through the lifting type height adjusting mechanisms. Through the hot-melt damping fin cooling and punching device and the production method thereof, the problems that too much burrs are generated on the hot-melt damping fins during shearing, and the service life of the conveying belts is short are solved.

Owner:MAANSHAN LIANHONG SYNTHETIC MATERIALS

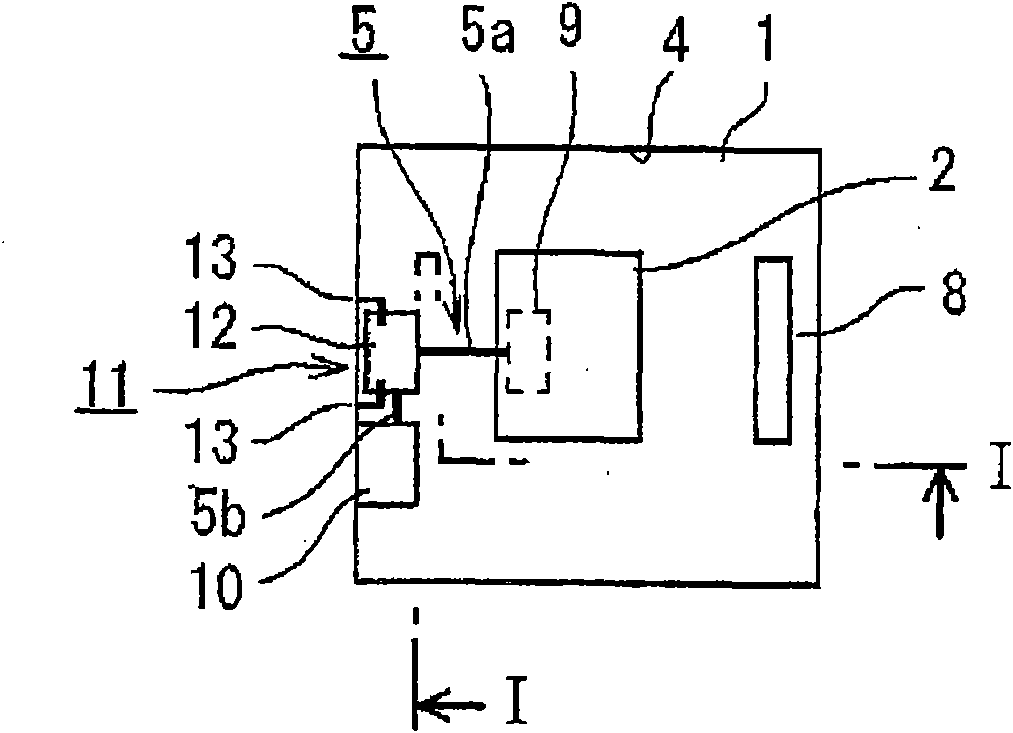

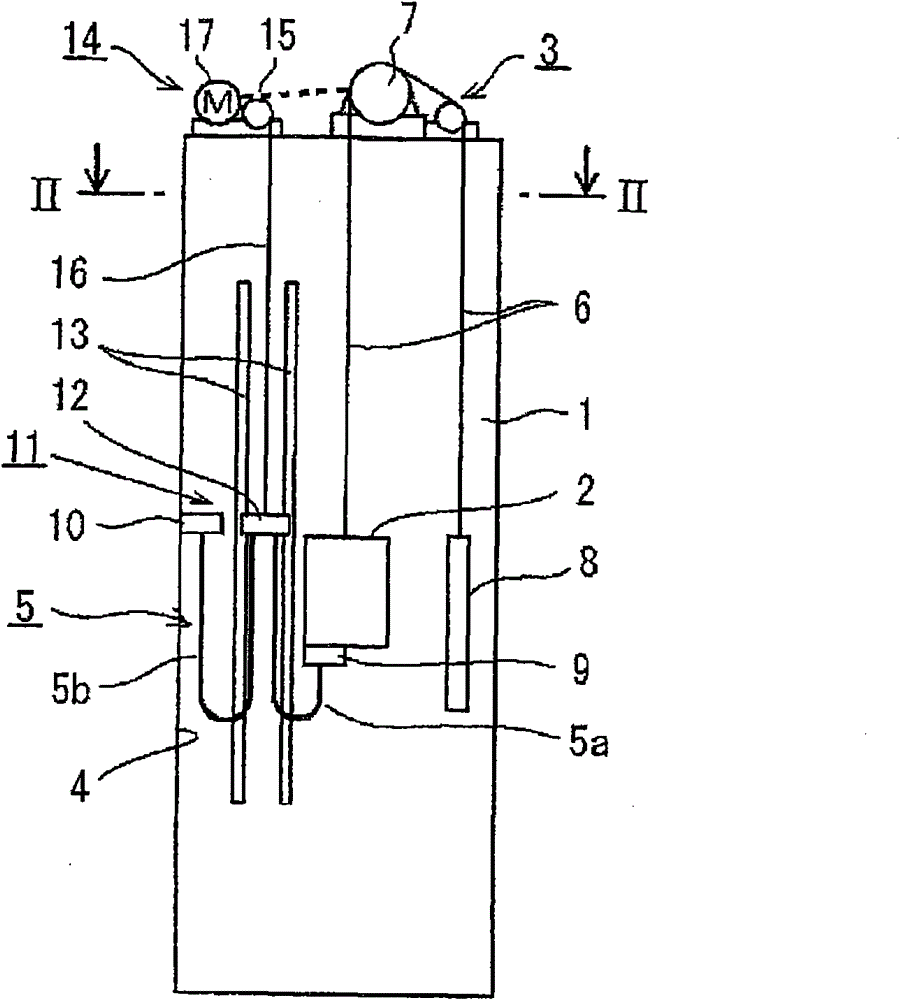

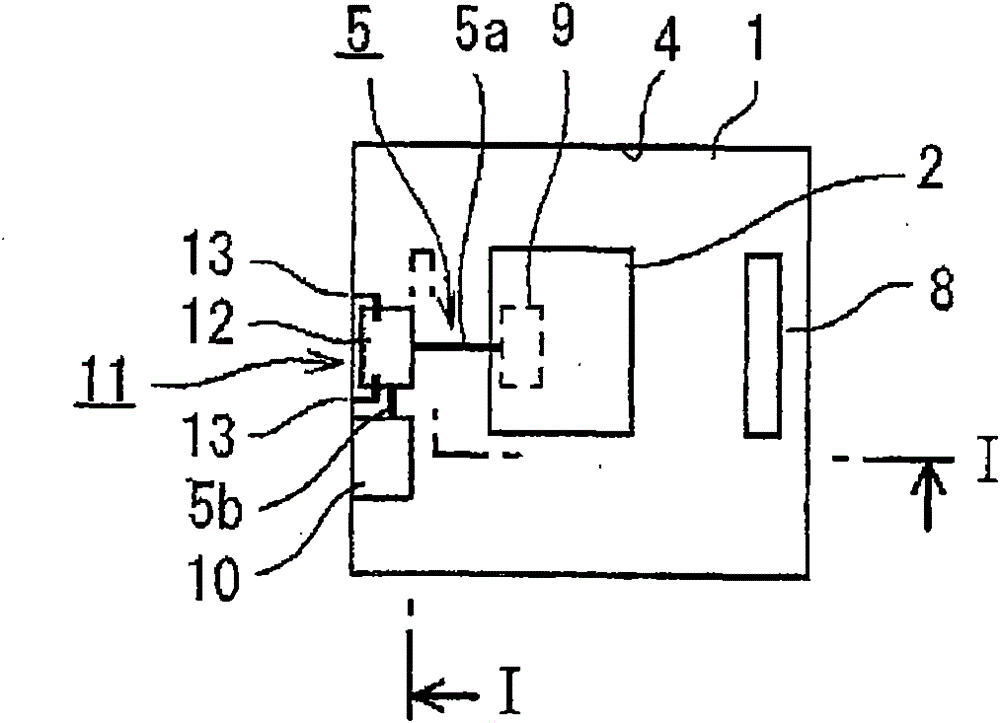

Elevator

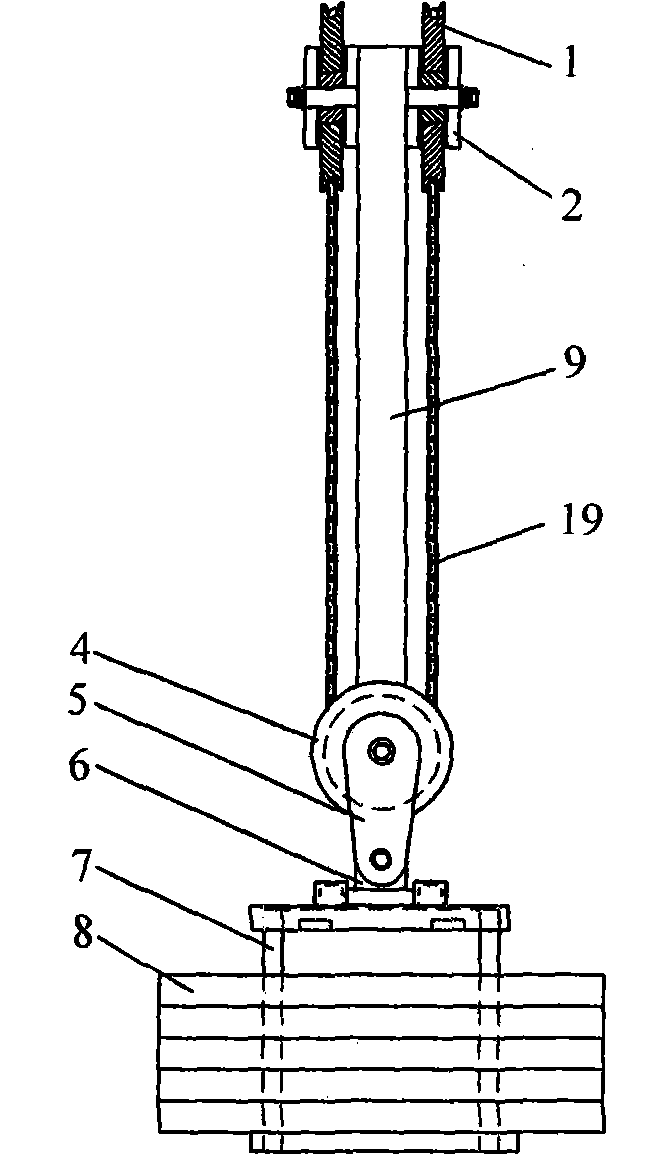

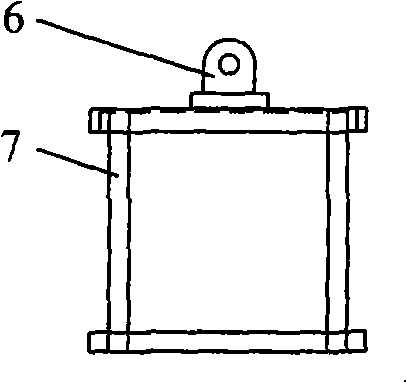

InactiveCN101962146ASuspension length reducedShorten the lifting strokeElevatorsBuilding liftsEngineering

The invention provides an elevator. A suspension length of a control cable is relative small relative to a lifting stroke. The elevator comprises a control cable, wherein one end of the control cable is connected with a lift well and another end is connected with an elevator car. In the elevator, the middle part of the control cable is supported by a movable lifting device and the movable liftingdevice lifts respective with the lifting of the elevator car in the lift well and the lifting distance of the movable lifting device is shorter than the moving distance of the elevator car. The movable lifting device comprises: a movable lifting rack connected with the control cable; a guide rail supporting the movable lifting rack to life in the lift well; and a driving device for making the movable lifting rack move along the guide rail. The lifting length of the control cable is reduced relative to the stroke of the elevator car.

Owner:MITSUBISHI ELECTRIC CORP

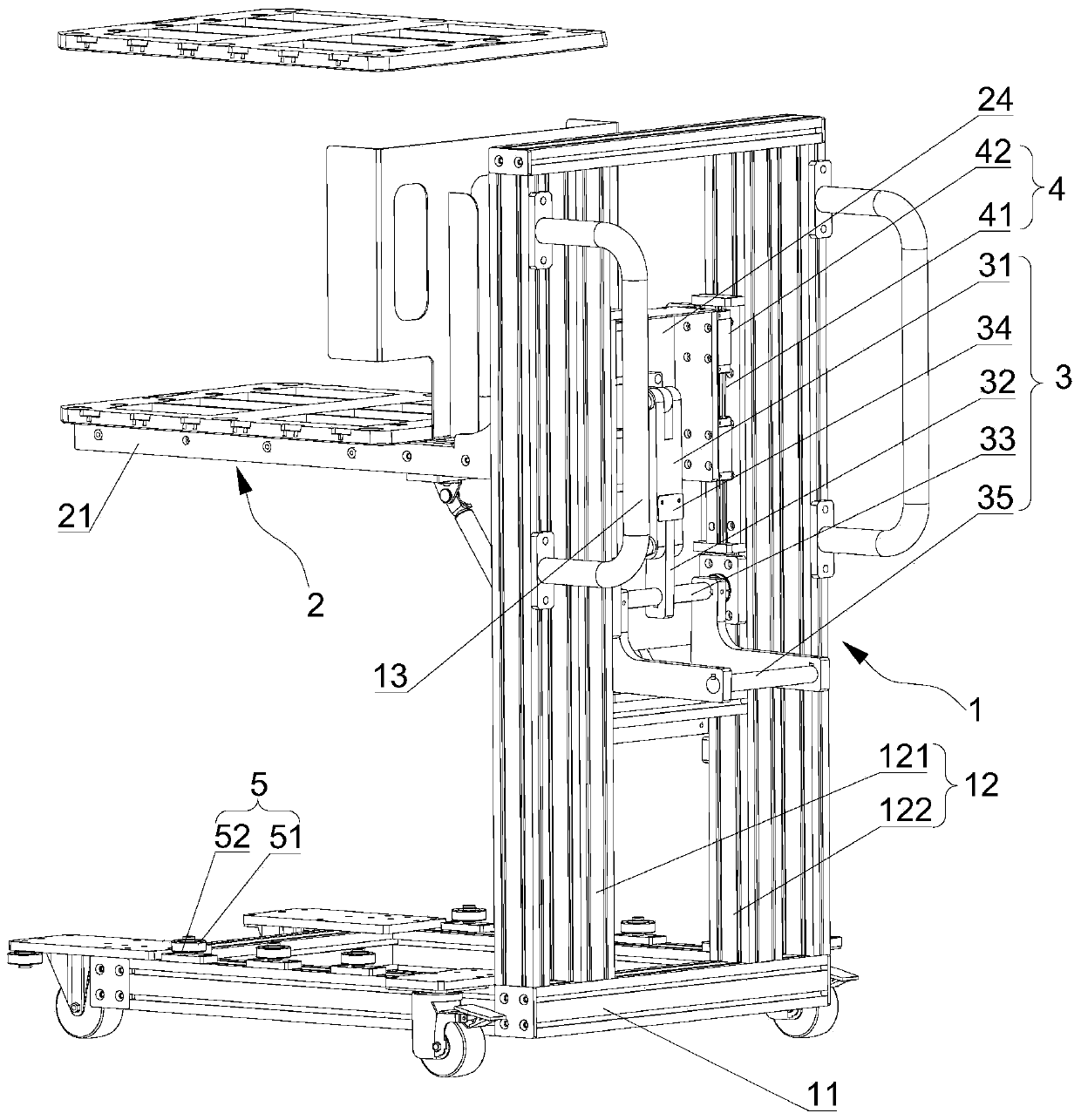

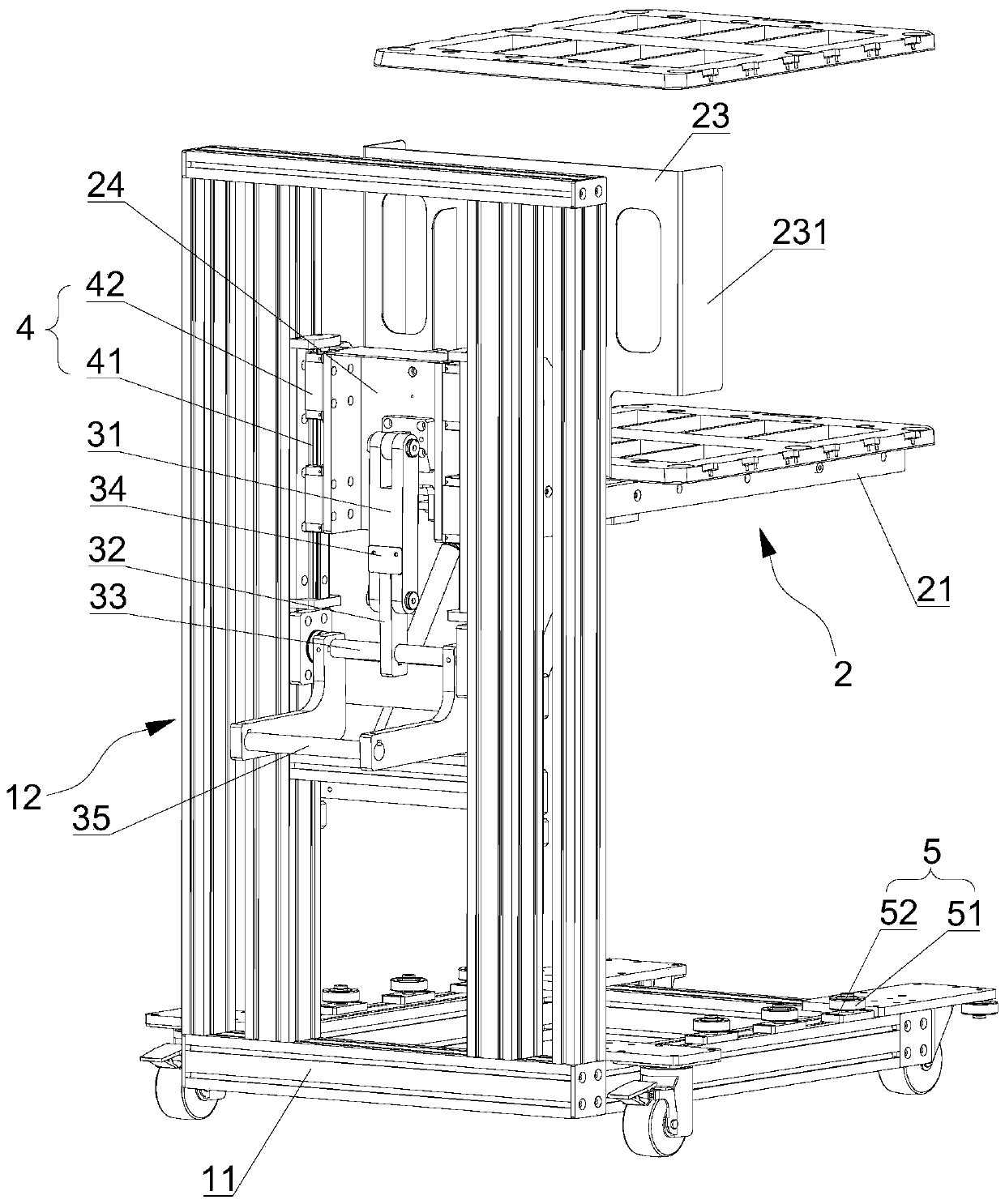

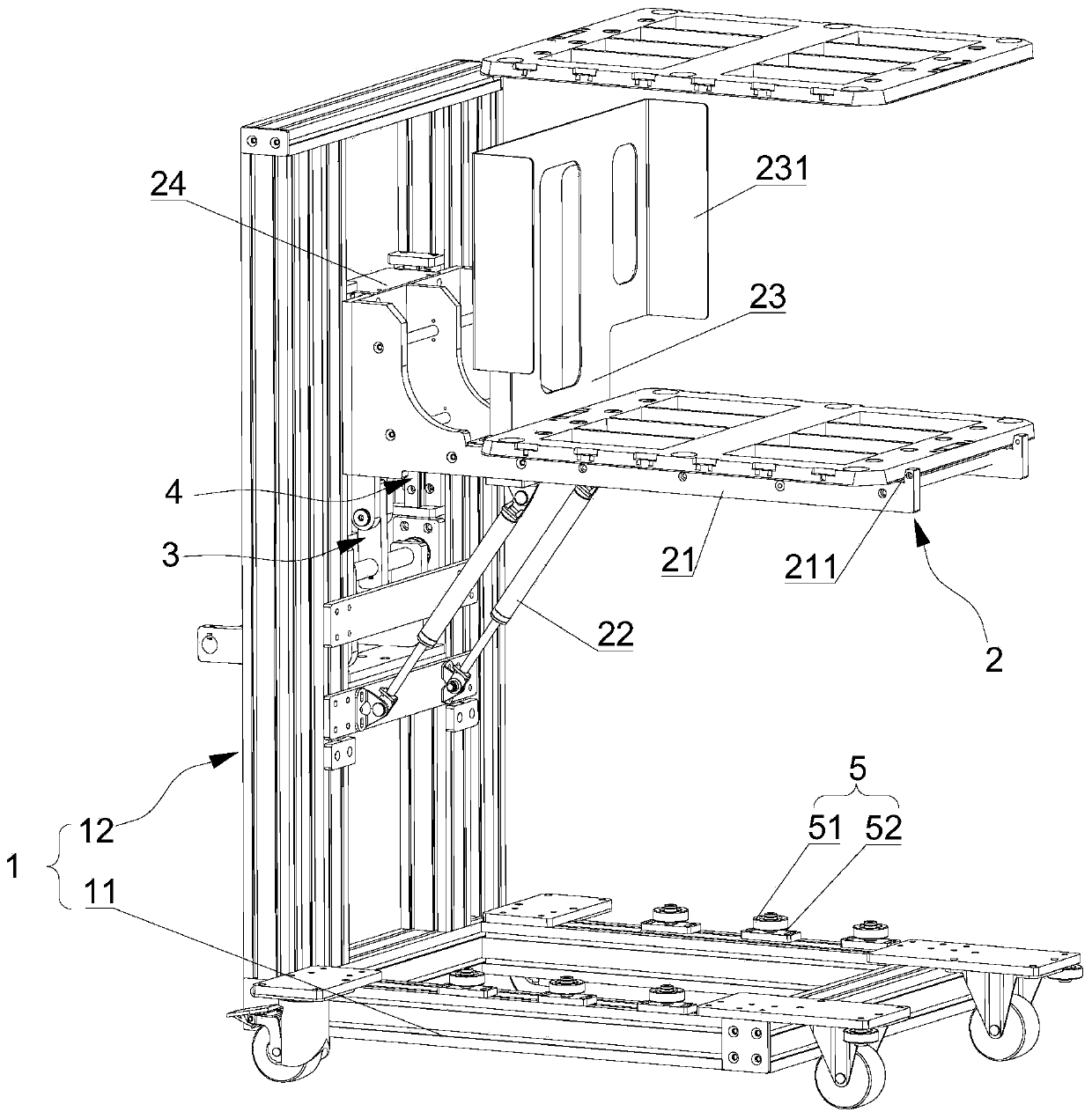

Lifting trolley

InactiveCN110843888ASimple structureShorten the lifting strokeHand carts with multiple axesButt jointEngineering

The invention relates to the technical field of material handling, and discloses a lifting trolley. The lifting trolley comprises a bracket and a connecting rod assembly, wherein the bracket can move,a lifting platform assembly is slidably arranged on the bracket, and the lifting platform assembly can slide back and forth in the vertical direction relative to the bracket; and the connecting rod assembly is correspondingly connected with the lifting platform assembly and the bracket, when the lifting platform assembly is located at the highest point, the connecting rod assembly moves to the limit position, and can be kept at the limit position. The lifting trolley can accurately butt joint a machine platform, place materials on the machine platform, and can take the materials from the machine platform.

Owner:SUZHOU JINGLAI OPTO CO LTD

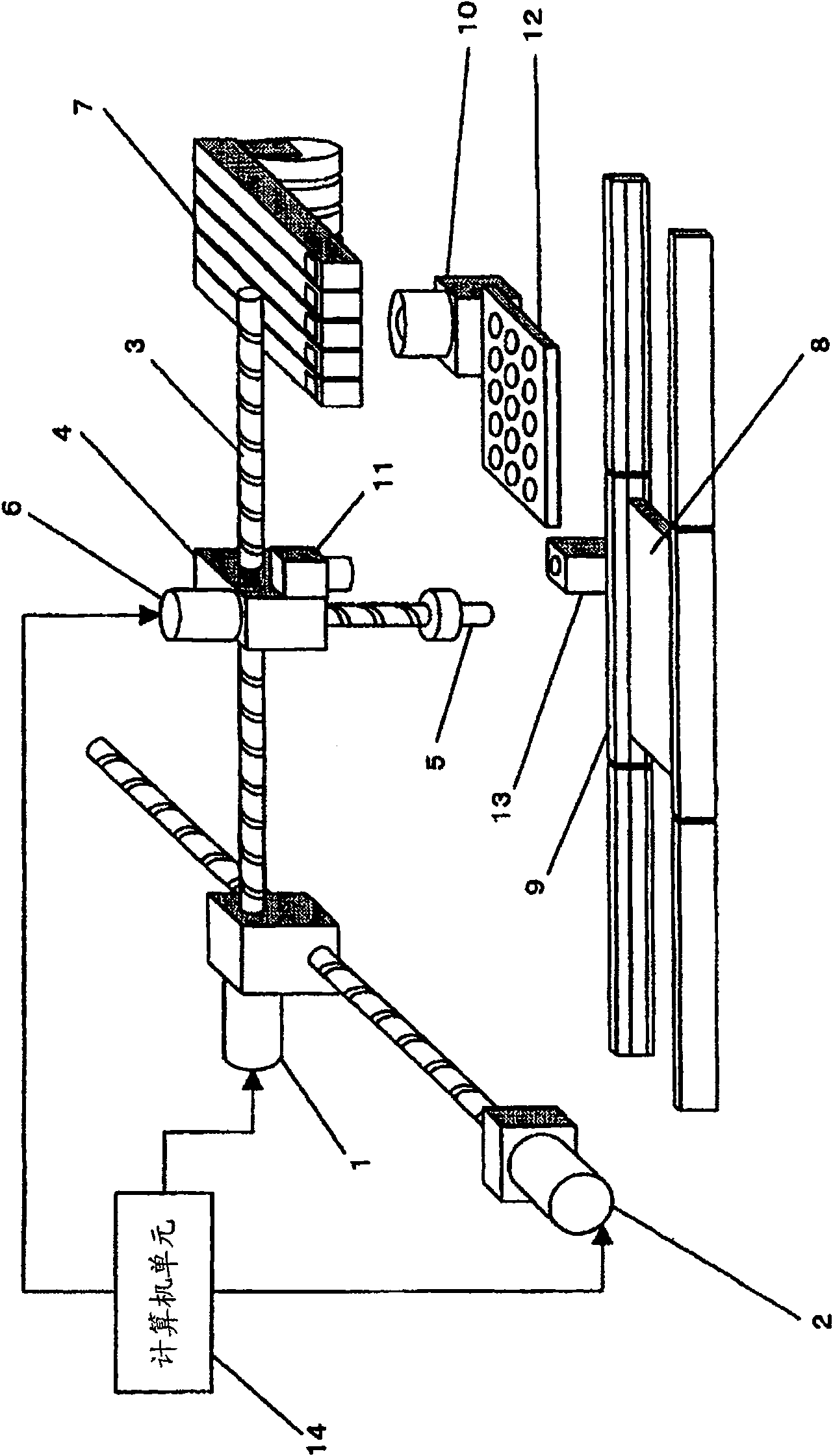

Device for mounting part

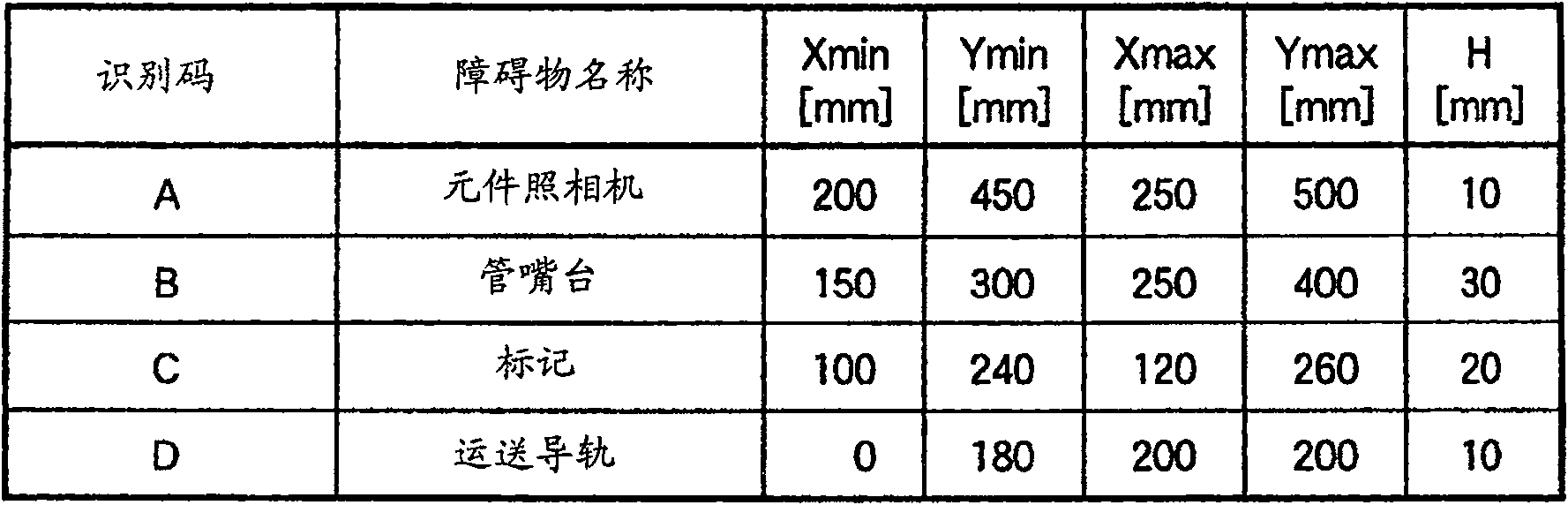

InactiveCN100551221CShorten exercise timeIncrease productivityElectrical componentsEngineeringNozzle

A device for installing parts, which can improve production efficiency by reducing the movement time of nozzles, the device includes a nozzle lifting device and a control device for controlling the movement position and movement timing of the nozzle movement device, wherein the control The device stores the position and height of the obstacle between the component feeder and the circuit board, and after the electronic component is photographed by the component camera, lowers the nozzle while it has passed the obstacle, or enables the nozzle to avoid the obstacle The route movement of the object. In the component mounting area, the nozzle is moved at the movement height in the component mounting area, and when the component is mounted, the nozzle is lowered from the movement height in the component mounting area. Therefore, the lifting stroke of the nozzle (5) can be reduced. Furthermore, the lifting of the nozzle is performed in an arcuate course.

Owner:PANASONIC CORP

Window glass lifting mechanism and vehicle

ActiveCN103015827BLarge lifting strokeShorten the lifting strokePower-operated mechanismEngineeringMechanical engineering

The invention provides a window glass lifter, a window glass lifting mechanism and a vehicle. The window glass lifting mechanism comprises a guide slide rail, a window glass bracket slider, a pull wire and a driving mechanism, the window glass bracket slider is used for driving widow glass to ascend and descend along the guide slide rail, is arranged on the slide rail and is capable of moving along the guide slide rail, the pull wire is used for pulling the window glass bracket slider to reciprocate along the guide slide rail and is fixedly connected with the window glass bracket slider, the driving mechanism is used for providing power for movement of the pull wire and is connected with the pull wire, and the guide slide rail is an arc-shaped guide slide rail which is capable of guiding the window glass bracket slider to reciprocate along an arc-shaped track so as to drive the window glass to ascend and descend along the arc-shaped track. The guide slide rail is arranged as the arc-shaped guide slide rail to guide the window glass bracket slider to move along the arc-shaped track and further drive the window glass to move along the arc-shaped track, so that the window glass is large in lifting stroke on one side and small in lifting stroke on the other side, and further the descending stroke of the window glass and particularly corner-less window glass can meet requirements.

Owner:BAIC MOTOR CORP LTD

Switching type loading adjustment device and method

PendingCN112730040AShorten the lifting strokeReduce volumeMaterial strength using tensile/compressive forcesStructural engineeringElectrical and Electronics engineering

The invention discloses a switching type loading adjustment device and method, and the device comprises a mounting base which provides a mounting support interface; the device further comprises a bearing table, a synchronous lifting mechanism and a loading mechanism, wherein the bearing table is arranged on the mounting base, and the bearing table is used for placing a to-be-detected product. The synchronous lifting mechanism is arranged below the mounting base, and screw rods on the two sides of the synchronous lifting mechanism upwards penetrate through the mounting seat and are connected with a loading mechanism; the loading mechanism comprises two loading rods and a loading beam, and the loading beam is arranged on the two loading rods in a sleeving manner. The device further comprises an adapter, and the connecting and locking of the screw rods on the two sides of the synchronous lifting mechanism and the loading rod are realized. The device is simple and reasonable in structure, rapid installation of the loading rod and the loading beam is achieved, and repeated positioning is reliable; the size of the loading device is reduced, the lifting stroke is shortened, and the loading efficiency is improved; and a loading gap uniformity adjusting function is also realized.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

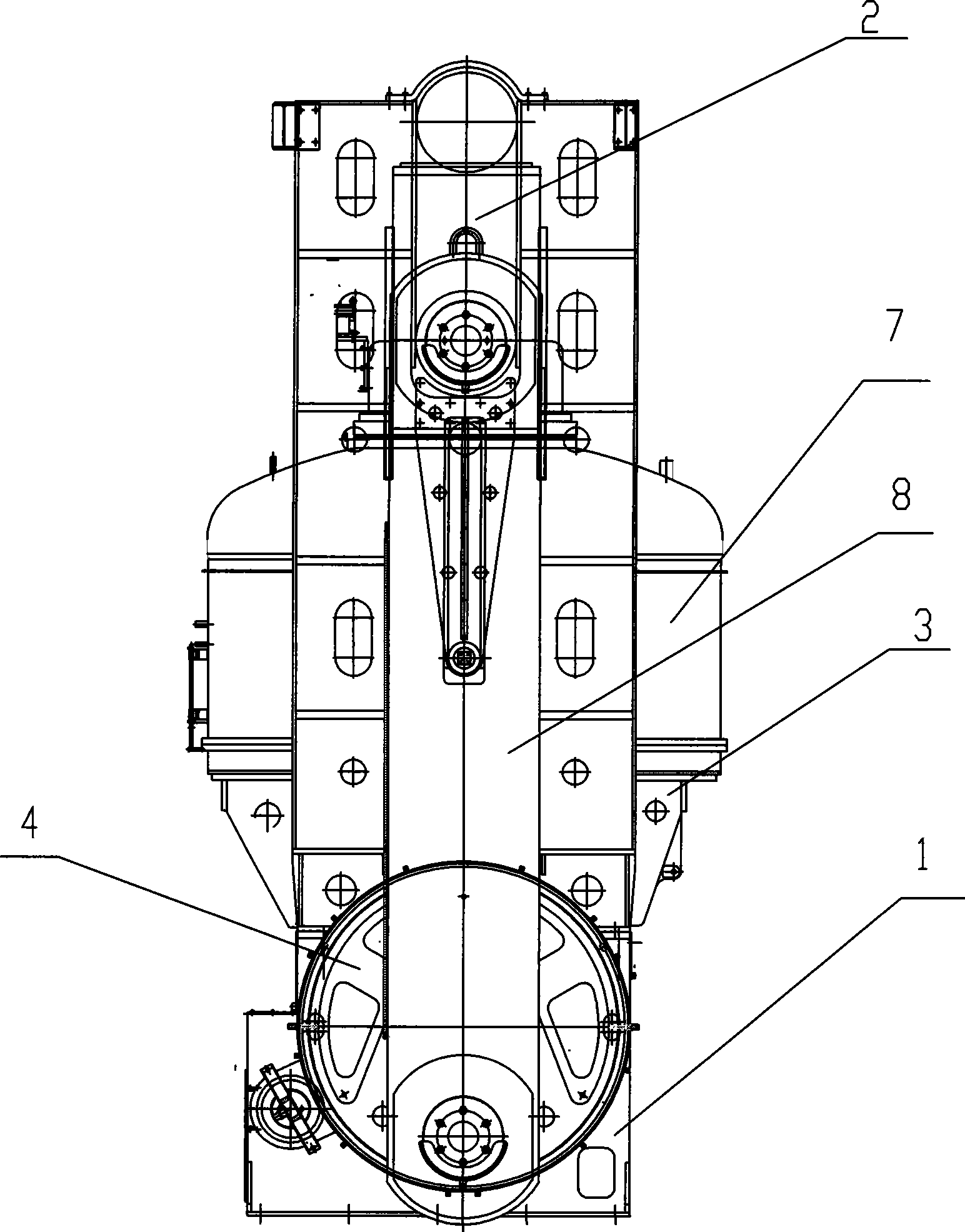

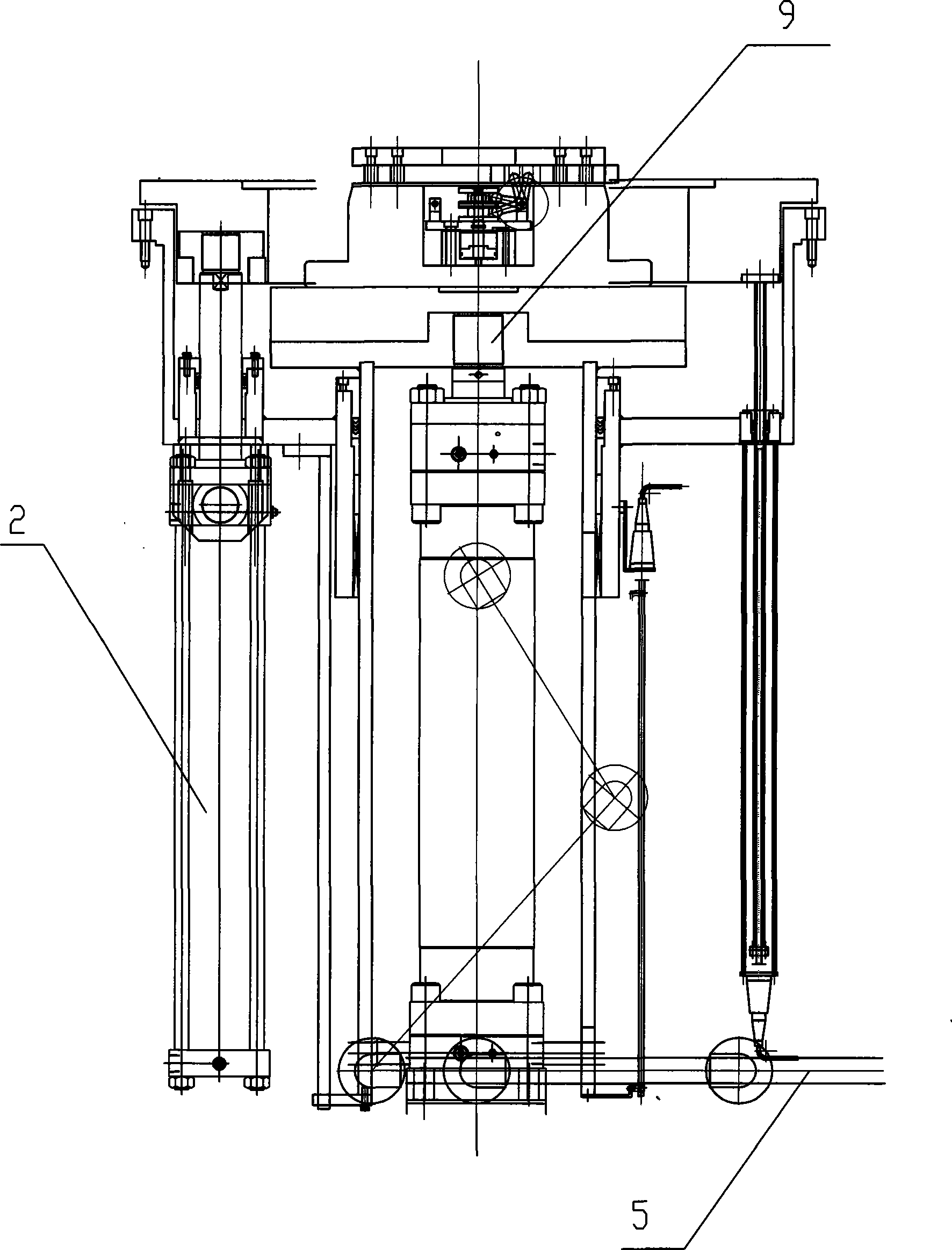

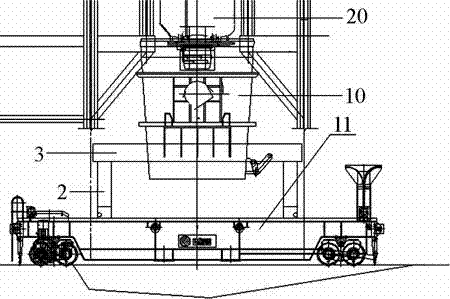

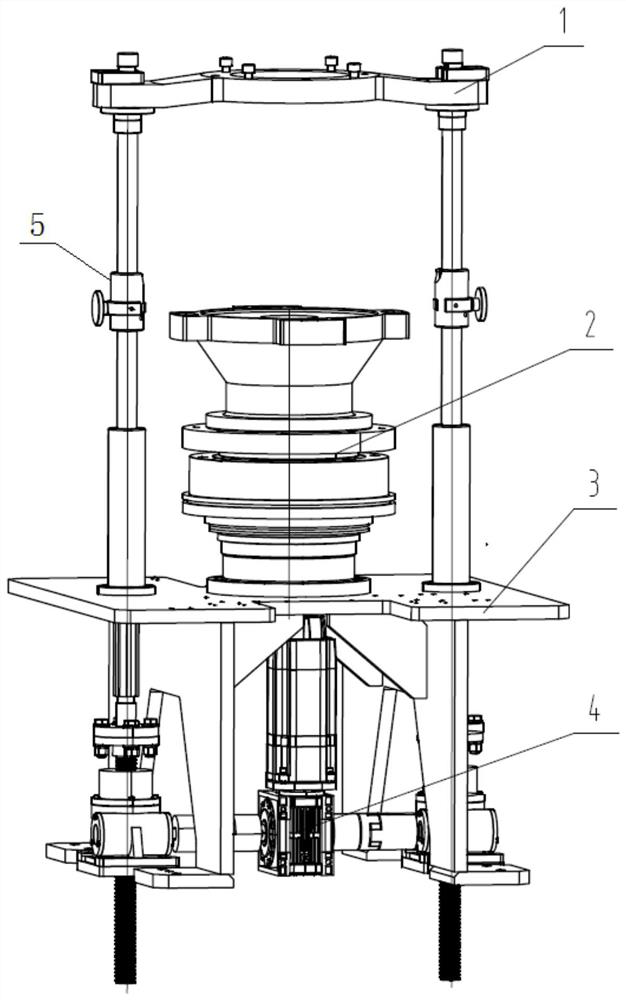

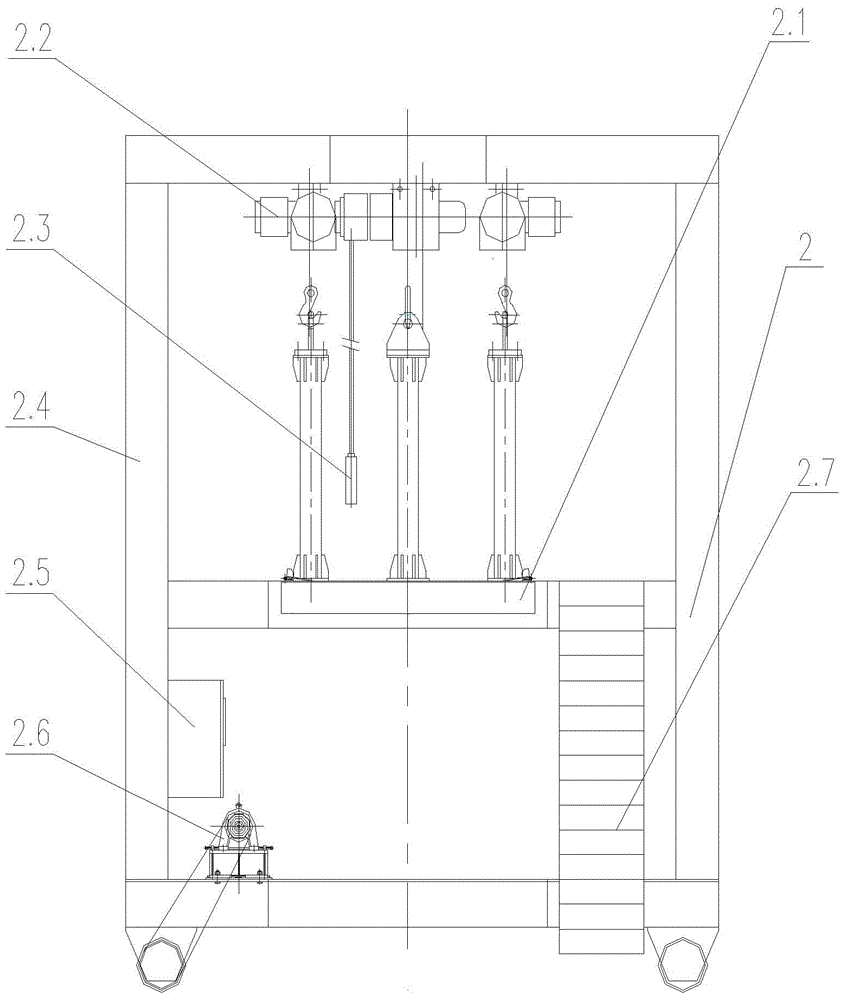

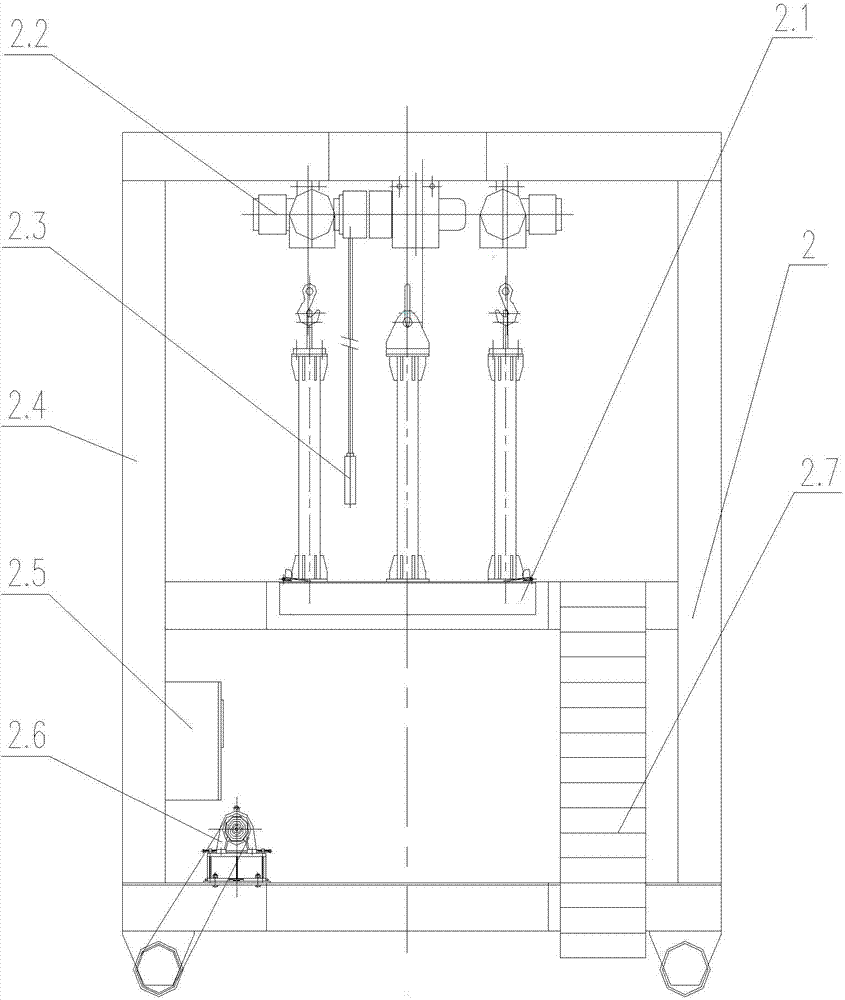

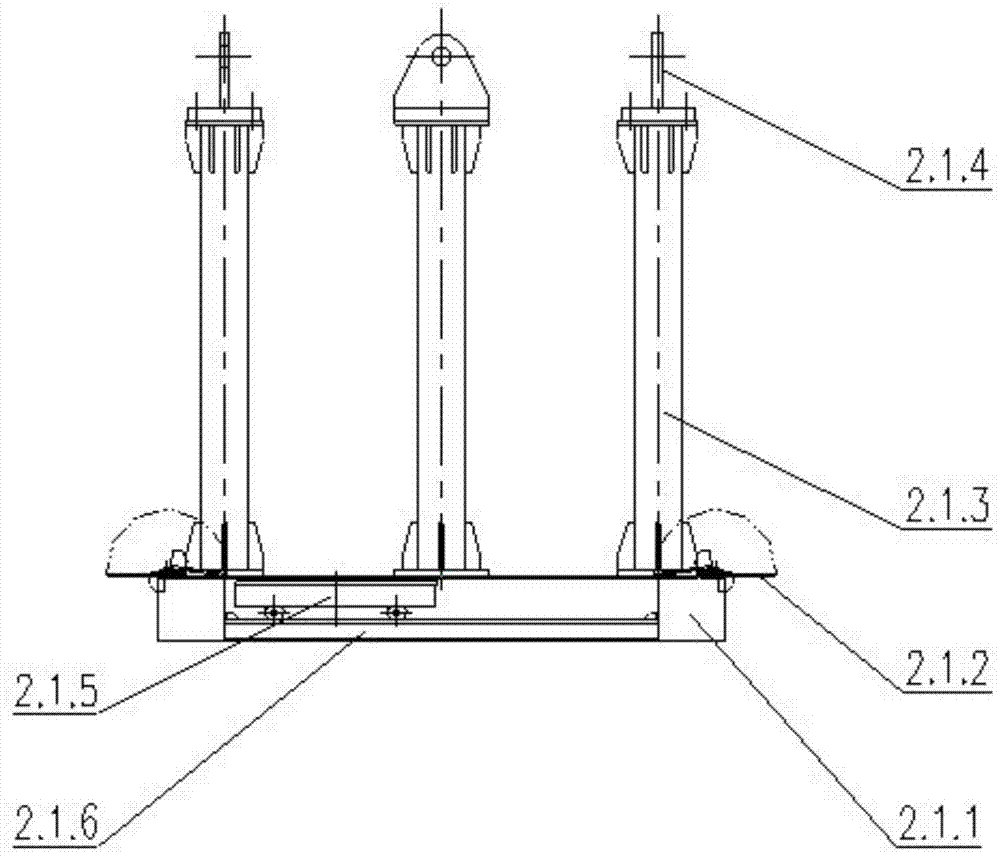

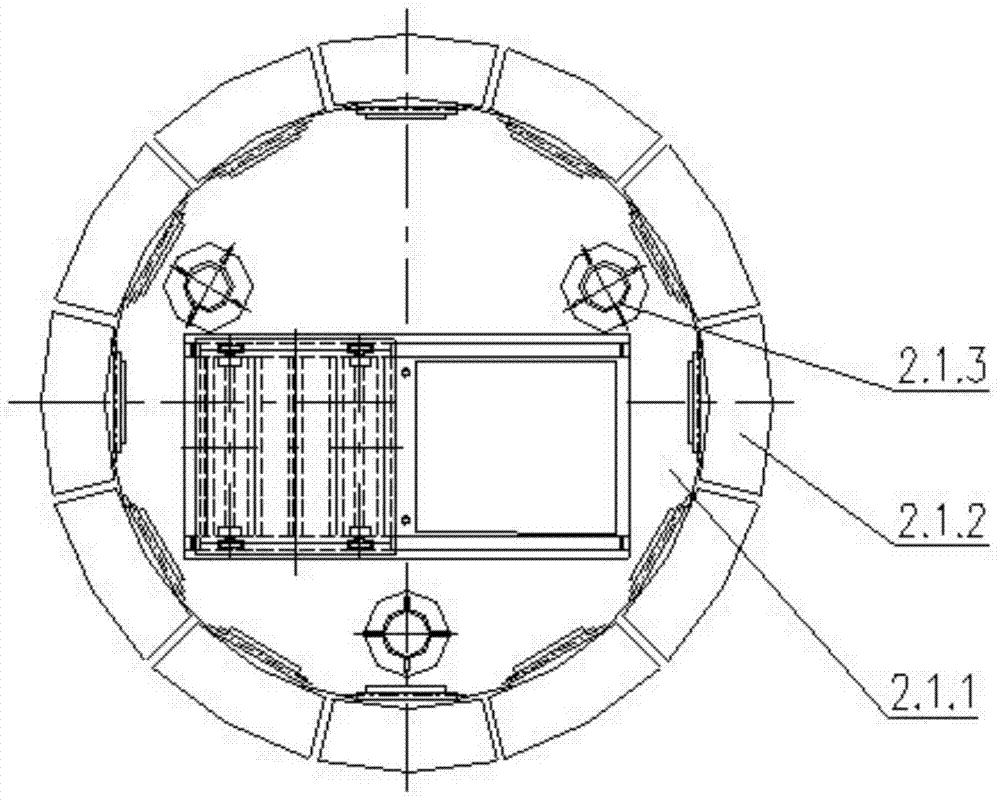

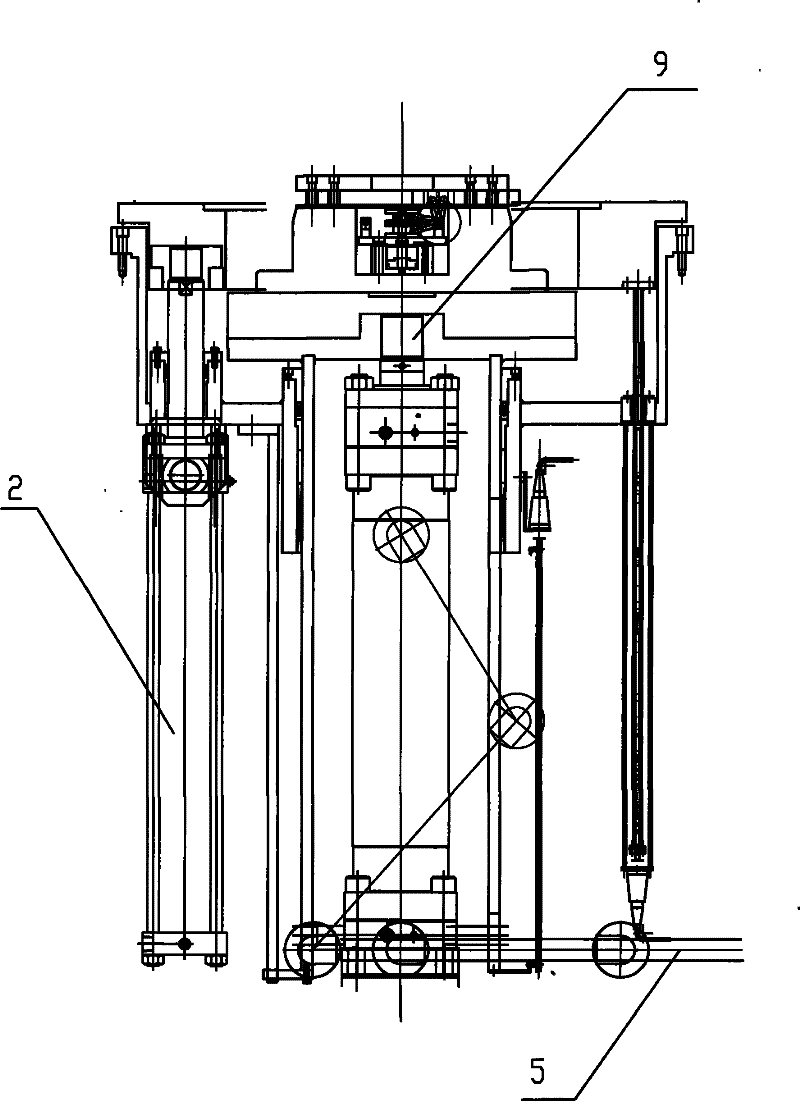

A rh vacuum tank repairing device

ActiveCN104726647BShorten the lifting strokeReduce the overall heightVehicle frameArchitectural engineering

The invention discloses an RH vacuum tank building device. The RH vacuum tank building device comprises a building trolley, wherein the building trolley comprises a frame; the frame is a three-layer steel structure frame; a lifting mechanism is fixed on the top layer, and a lifting platform is hung on the lifting mechanism; the lifting mechanism is electrically connected with a lifting controller and is controlled by the lifting controller; a mobile controller and a driving mechanism are installed on the bottom layer of the frame; the driving mechanism is electrically connected with the mobile controller and is controlled by the mobile controller; a straight ladder is arranged between the middle layer and the bottom layer of the frame. The driving mechanism is controlled by the mobile controller, so that the building trolley is horizontally moved to the building position; the lifting mechanism is controlled by the lifting controller for providing power to the lifting platform, and then the lifting mechanism is declined from the upper tank to the tank body and the worker can enter the tank; when the lifting platform reaches the position near the bottom part of the lower tank, a cover plate trolley is moved away, and the worker descends to the bottom part of the lower tank to build through an opened manhole. The tank body placing position and the work plane height are reduced and the lifting route of the building platform is shortened. The RH vacuum tank building device has the characteristics of reliable lifting and convenient and safe operation.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Liftable display system

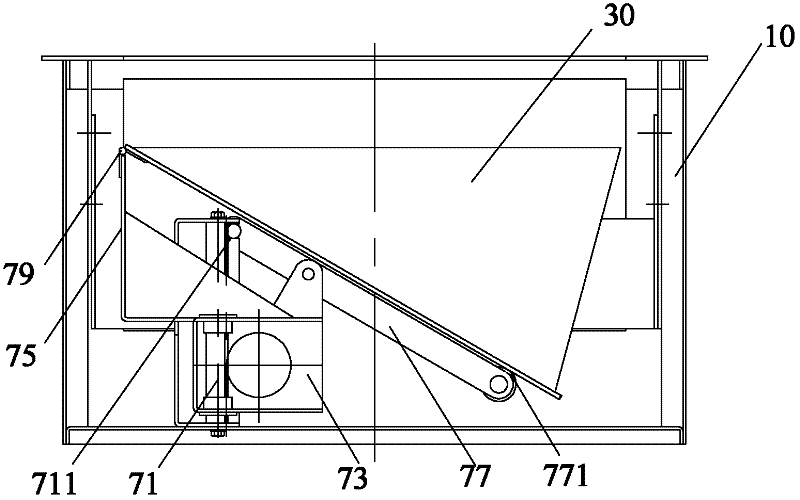

ActiveCN102226936BLower the altitudeShorten the lifting strokeStands/trestlesIdentification meansDisplay deviceEngineering

The invention provides a liftable display system which comprises a shell (10), a display device (30), a first turnover mechanism and a second turnover mechanism, wherein the shell is provided with two turnover doors (11, 13) opposite to each other; the display device (30) comprises a displayer, a controller and a memory; the first turnover mechanism is in drive connection with the two turnover doors (11, 13), so that the two turnover doors (11, 13) can be in an opening state and a closing state; and the second turnover mechanism is in drive connection with the display device (30), so that thedisplay device (30) can be in a lifting state outside the shell (10) and in a recovery state in the shell (10). The liftable display system provided by the invention has the advantages of small occupied space, and short opening or closing time.

Owner:SHANXI BETTER TECH DEV

Lever Type Accident Vehicle Lift

The invention discloses a lever type accident vehicle lifting device. A movable positioning plate is arranged between a vertical plate and a fixed limit plate. The lower end of the movable positioningplate is slidingly matched with the top surface of a support platform, and the upper end of the movable positioning plate end is slidably matched with a connecting plate. Two L-shaped locking blocksare arranged side by side up and down on the side of the movable positioning plate, and the hanging end of one side of each locking block is hinged to the movable positioning plate through a verticalpin shaft; the bottom surface of the right end of a lifting rod is fixedly provided with support lugs side by side front and back, the upper end of a protective plate is located between the two support lugs, the upper end of the protective plate is hinged to the two support lugs by a horizontal pin, and the lower end of the protective plate can be snapped into a single tooth of a protective sawtooth. The remaining part of the invention except a lifting block is not under the chassis of the vehicle, and the operator is not required to extend the body under the vehicle when positioning the device, the safety is high, and the height of the top surface of the support platform of the device is 20 cm from the ground, which can effectively shorten the lifting travel, saving time and effort.

Owner:安徽省华腾农业科技有限公司经开区分公司

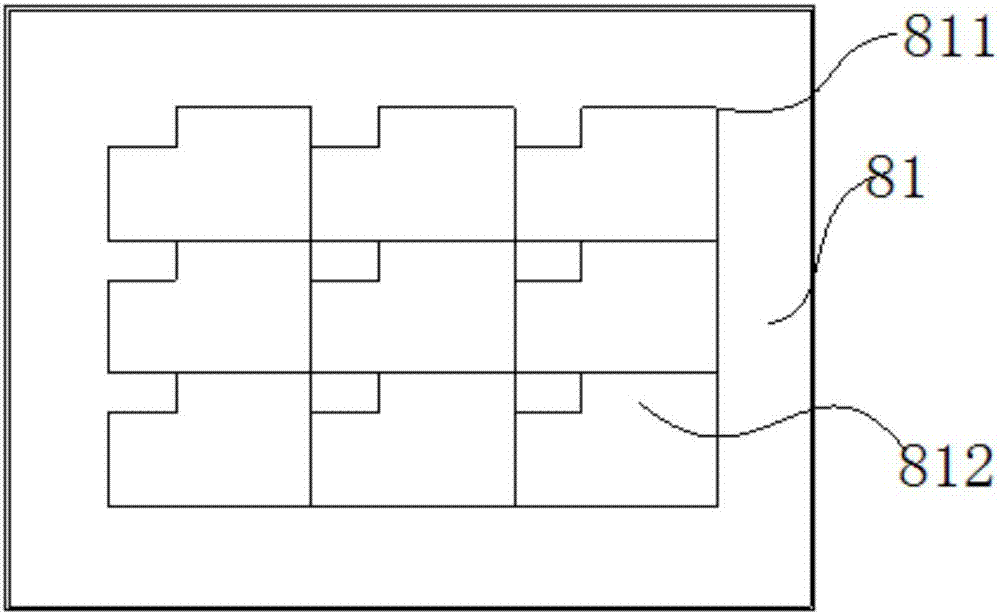

Design method of mold casting pit for vehicle-mounted mold casting steel pouring system

ActiveCN104827016BEasy accessAvoid lower operating costsCasting plantsMolten metal conveying equipmentsProduction lineBrick

The invention relates to the field of metallurgy and specifically relates to a die casting pit design of a vehicle-mounted die casting steel pouring system. The die casting pit design comprises the following steps: arranging A and B two die casting steel pouring pit production lines, wherein the two die casting steel pouring pit production lines are arranged in two different spans respectively, the bottom portion and the inner walls of each die casting pit are respectively paved with a layer of refractory bricks, and a refractory drying room for casting is arranged between the two die casting lines; according to the height of different ingot types of steel ingot dies and use ratio in production, designing the A span to be a two-stage die casting pit, and designing the B span to be a three-stage die casting pit; and putting one-position, two-position, six-position and eight-position four kinds of chassis in the die casting pits according to the corresponding ingot types. According to the design, die casting steel pouring vehicle lift stroke, height change of different ingot types of ingot dies, production power demand information and chassis change characteristics are taken into full consideration, a step-type die casting pit design is adopted, and thus demand for different ingot types and different product die casting production is met by adopting die casting pits with different depths, adjusting the number of central casting pipe bases and improving steel ladle height.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

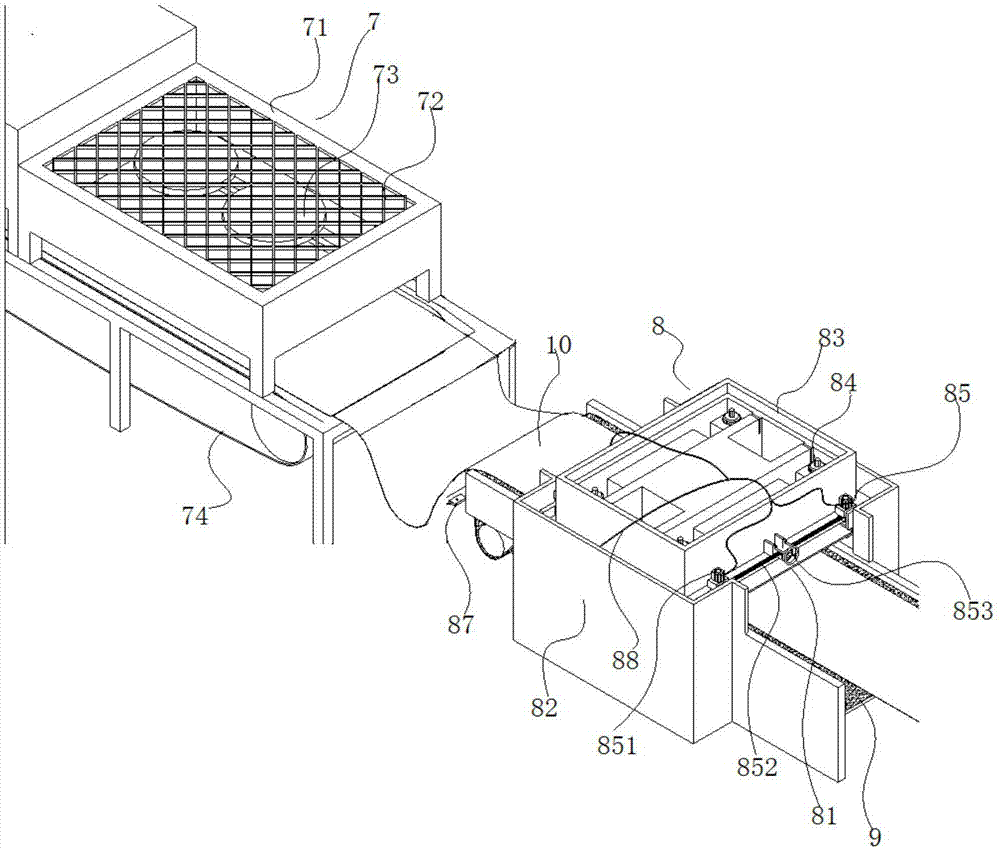

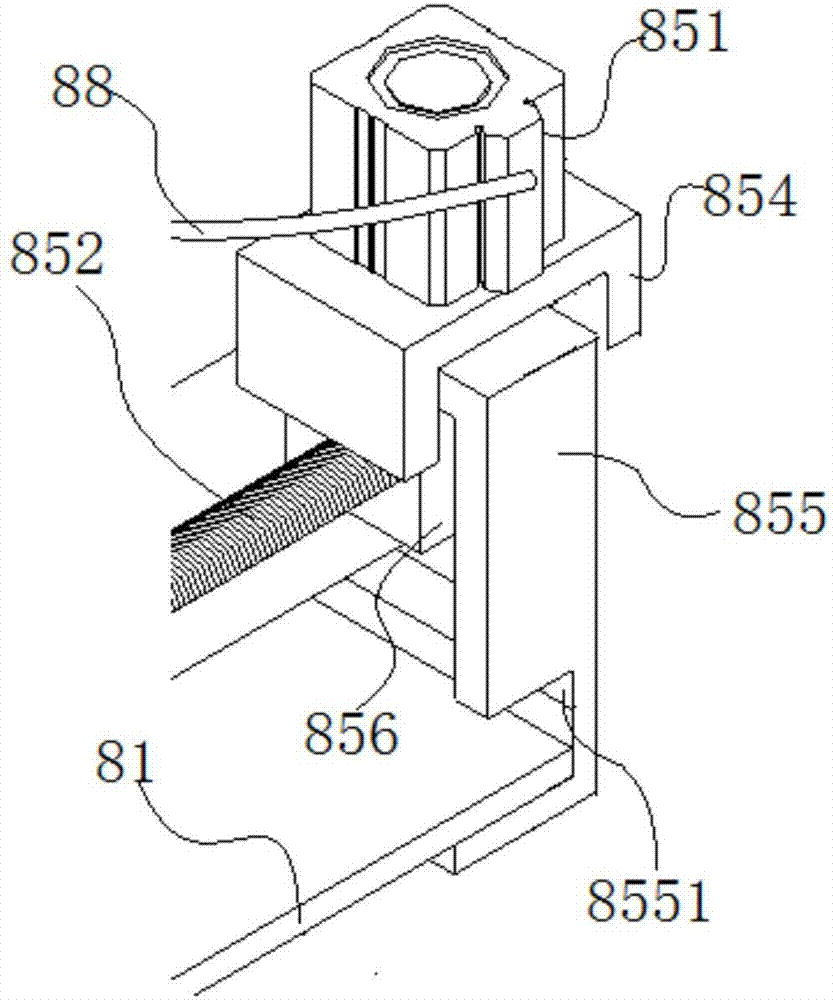

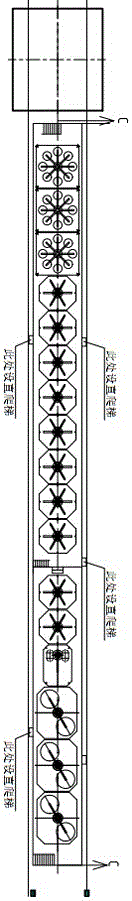

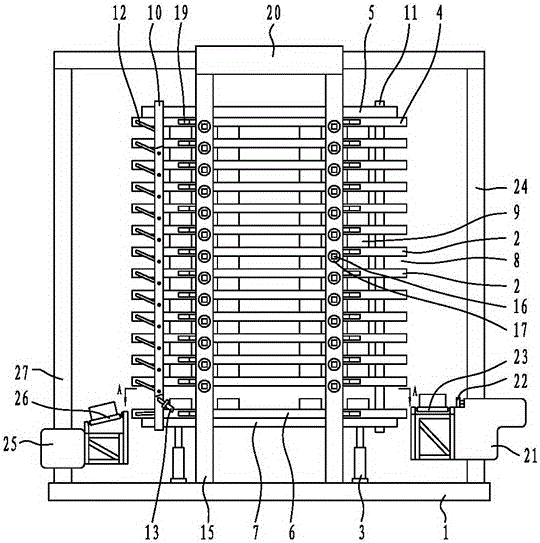

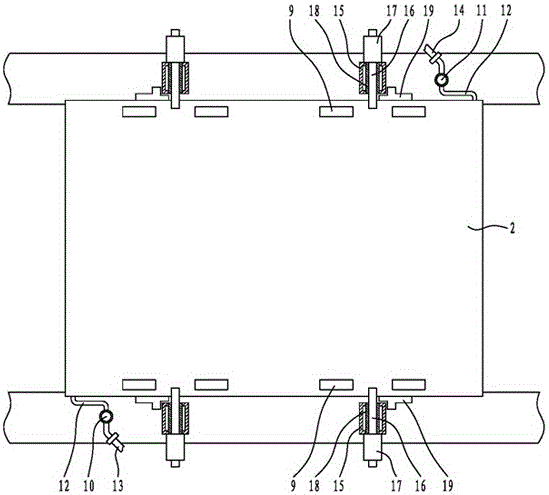

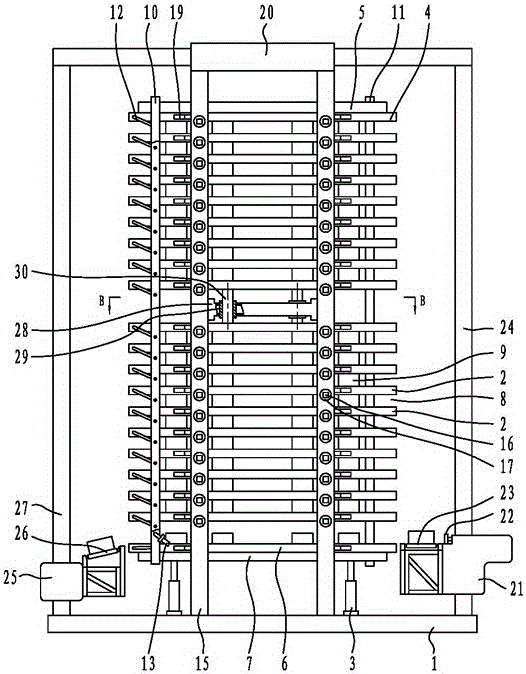

A horizontal plate freezer

ActiveCN104764272BShorten the lifting strokeImprove efficiencyLighting and heating apparatusRefrigeration devicesEngineeringMechanical engineering

The invention relates to a horizontal type plate freezer. The horizontal type plate freezer comprises a basic part, freezing plates, a lifting device, a top plate, a bottom plate, freezing layers and contour blocks and refrigerant hoses, wherein the freezing plates are arranged in a laminated mode, the freezing plates and the lifting device of the freezing plates are located above the basic part, the top plate is located above the freezing plate at the top layer, the bottom plate is located below the freezing plate at the bottom layer, the freezing layers are arranged between the adjacent freezing plates, the contour blocks are arranged at the two edges of the freezing layers, and the refrigerant hoses are arranged on the freezing plates respectively and are connected with a refrigerant inlet collection pipe and a refrigerant outlet collection pipe; latch pillars are arranged at the two sides of the laminated freezing plates and are fixedly connected with the basic part, the positions, corresponding to all the freezing layers, of each latch pillar are provided with movable latches which are movably connected with the corresponding latch pillar, and the movable latches are driven by movable latch driving devices. Each movable latch bears the weight of the corresponding freezing plate and frozen articles above the movable latch, so the space between every two adjacent freezing plates is increased to facilitate material feeding and discharging operations, the frozen articles on the freezing layers of the rest freezing plates are still in a normal frozen state, and therefore the horizontal type plate freezer is high in efficiency.

Owner:SIFANG TECH GRP CO LTD

RH vacuum tank building device

ActiveCN104726647AShorten the lifting strokeLifting is stable and reliableVehicle frameArchitectural engineering

The invention discloses an RH vacuum tank building device. The RH vacuum tank building device comprises a building trolley, wherein the building trolley comprises a frame; the frame is a three-layer steel structure frame; a lifting mechanism is fixed on the top layer, and a lifting platform is hung on the lifting mechanism; the lifting mechanism is electrically connected with a lifting controller and is controlled by the lifting controller; a mobile controller and a driving mechanism are installed on the bottom layer of the frame; the driving mechanism is electrically connected with the mobile controller and is controlled by the mobile controller; a straight ladder is arranged between the middle layer and the bottom layer of the frame. The driving mechanism is controlled by the mobile controller, so that the building trolley is horizontally moved to the building position; the lifting mechanism is controlled by the lifting controller for providing power to the lifting platform, and then the lifting mechanism is declined from the upper tank to the tank body and the worker can enter the tank; when the lifting platform reaches the position near the bottom part of the lower tank, a cover plate trolley is moved away, and the worker descends to the bottom part of the lower tank to build through an opened manhole. The tank body placing position and the work plane height are reduced and the lifting route of the building platform is shortened. The RH vacuum tank building device has the characteristics of reliable lifting and convenient and safe operation.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Material gathering unit

InactiveCN101525058BPlay a buffer roleMove up and down flexiblyBundling machine detailsFixed bearingLow noise

The invention relates to a material gathering unit, which comprises a charging basket (9) and a briar dressing device; wherein, the charging basket (9) has one or more, each charging basket is provided with a cone-shaped collection port (18) which runs through two lateral surfaces of the whole charging basket, one end table-board of one of two wings of the collection port is a material receiving sloping bench (14) which inclines toward the centre of the collection port; the briar dressing device comprises a bracket arm seat (13) on a lateral wall (24) and a fixed bearing (10), an L-shaped bracket arm (12) and a hydraulic cylinder (11) which are rotatably connected together; wherein, the bracket arm seat on the lateral wall is arranged on one wing with the material receiving sloping bench (14) and corresponding to the internal inclined plane (22) of the collection port (18), the L-shaped bracket arm (12) and the hydraulic cylinder (11) are respectively rotatably connected with the bracket arm seat (13) and the fixed bearing (10), the charging basket (9) is also provided with a blanking cushioning device and an elevator mechanism. The material gathering unit is simple and flexible to be operated, has small shaking and low noise, thus improving workshop environment.

Owner:CERI TECH

Electric vehicle battery compartment lifting device

PendingCN114379350AGuaranteed lifting accuracyImprove grasping accuracyCharging stationsElectric propulsion mountingVehicle frameElectric-vehicle battery

The invention discloses an electric vehicle battery compartment lifting device which comprises a first lifting mechanism and a second lifting mechanism, and the two lifting mechanisms each comprise a sliding assembly and a swing arm; the sliding assembly is in driving connection with the driving mechanism, the swing arm is arranged between the frame and the battery bin, and the battery bin is hung below the frame through the swing arm. The two swing arms are provided with opposite translation ends and rotating ends, the translation ends and the rotating ends have height difference, the translation ends of the two swing arms are fixedly connected with the sliding parts of the same sliding assembly, the rotating ends of the two swing arms are hinged to the frame at intervals, and the two swing arms are symmetrically arranged along the center line of the battery bin and can synchronously swing between the initial positions and the unfolding positions in a reciprocating mode. The lifting stability and accuracy of the battery compartment can be improved, the lower space of the vehicle body can be fully utilized, and the effective lifting stroke of the battery compartment can be obtained in the limited vertical space.

Owner:ZHEJIANG KANDI SMART BATTERY SWAP TECH CO LTD

Lower heating lifting assembly of forming machine

The invention discloses a lower heating lifting assembly of a forming machine. The lower heating lifting assembly of the forming machine comprises two groups of heating frame lifting frames, upper lifting cylinders and lifting synchronous shafts, wherein the tops of the two groups of heating frame lifting frames are separately and fixedly connected with the two sides of the bottom of a lower heating frame; the upper lifting cylinders are arranged on the two sides of the bottom of the lower heating frame; the bottom parts of the upper lifting cylinders are connected with lower lifting cylindersthrough fixing blocks; heating frame transverse-moving frames sleeve the outer walls of the two groups of lower lifting cylinders; the inner walls of the heating frame transverse-moving frames are welded to the fixing blocks; and the lifting synchronous shafts are installed between the two groups of upper lifting cylinders. According to the lower heating lifting assembly of the forming machine, the lower heating lifting assembly of the forming machine is driven to operate through the upper and lower double-layer lifting cylinders, and the upper and lower double-layer lifting cylinders on bothsides are synchronously transported by adopting the lifting synchronous shafts and a gear rack in combination with a linear guide rail, so that the lifting is stable, and the lower heating lifting assembly of the forming machine is suitable for wide popularization and use.

Owner:ANHUI XINMENG EQUIP CO LTD

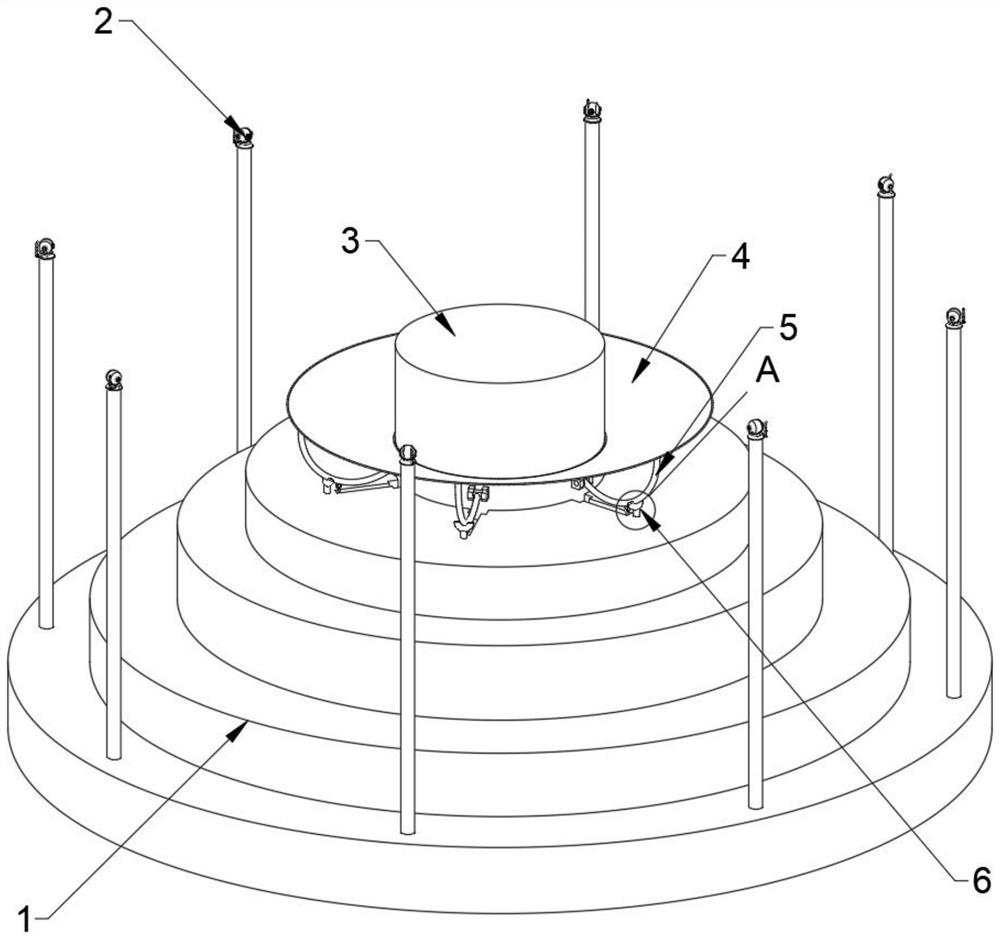

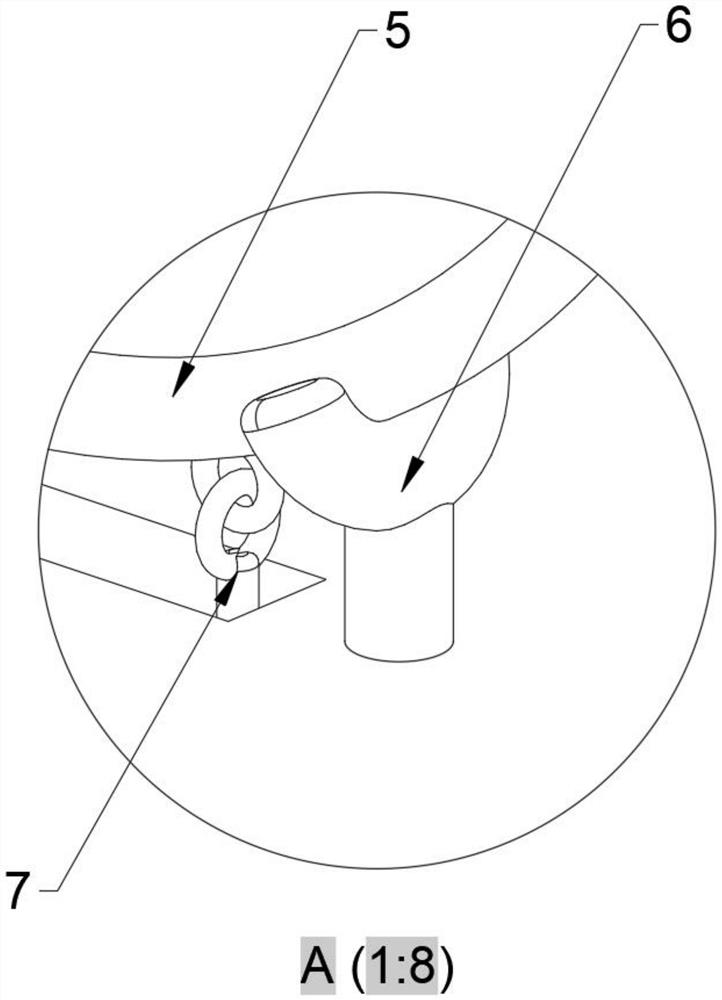

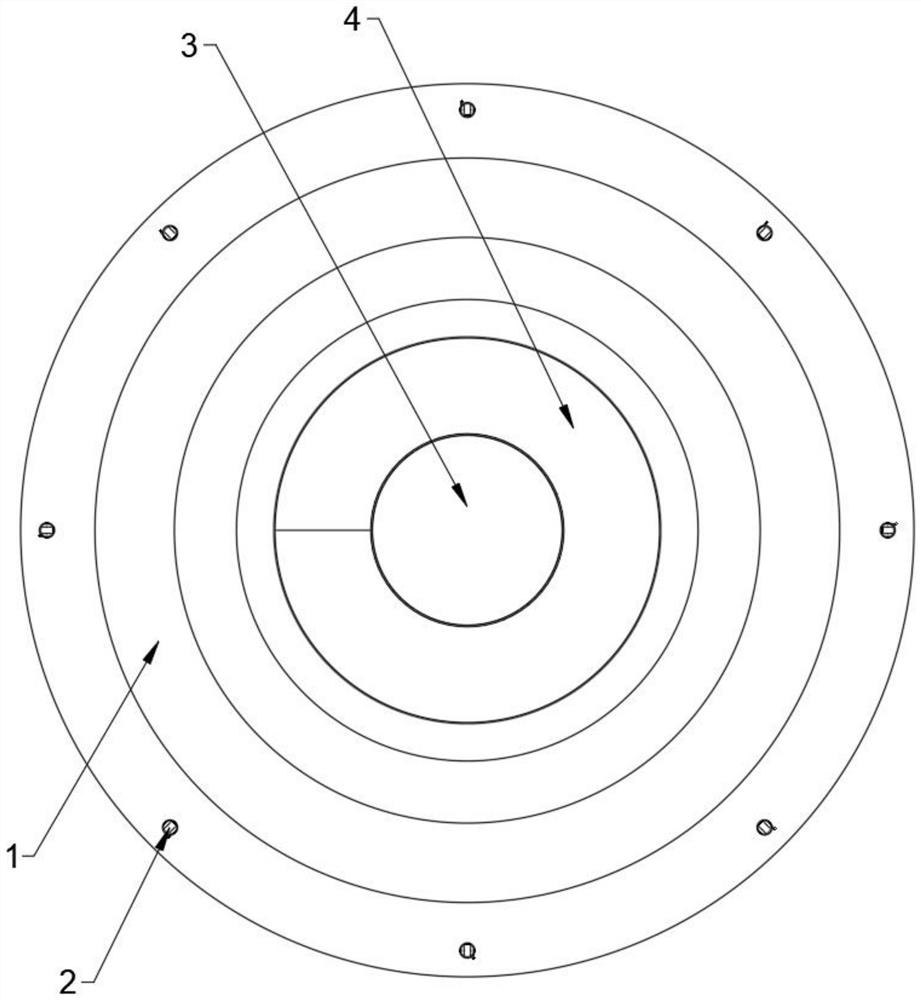

An anti-drop training device for stage performance lifting high platform dance practice

ActiveCN109745675BTraining RealizationImprove training effectStage arrangementsStiltsSimulationEngineering

Owner:曹嘉睿

A lower heating and lifting component of a molding machine

The invention discloses a lower heating and lifting assembly of a molding machine, which includes a heating frame lifting frame, an upper lifting cylinder and a lifting synchronous shaft. Both sides of the bottom of the heating frame are fixedly connected, and both sides of the bottom of the lower heating frame are equipped with upper lifting cylinders. The bottom of the upper lifting cylinders is connected with a lower lifting cylinder through a fixed block. The translation frame of the heating frame, the inner wall of the translation frame of the heating frame is welded to the fixed block, and the lifting synchronous shaft is installed between the two groups of upper and lower cylinders. The invention is driven and operated by the upper and lower double-layer lifting cylinders, and the upper and lower double-layer lifting cylinders on both sides adopt the lifting synchronous shaft and the rack and pinion to cooperate with the linear guide rail for synchronous transportation, so as to ensure its stable lifting and is suitable for wide promotion and use.

Owner:ANHUI XINMENG EQUIP CO LTD

Die casting pit design of vehicle-mounted die casting steel pouring system

ActiveCN104827016AEasy accessAvoid lower operating costsCasting plantsMolten metal conveying equipmentsProduction lineBrick

The invention relates to the field of metallurgy and specifically relates to a die casting pit design of a vehicle-mounted die casting steel pouring system. The die casting pit design comprises the following steps: arranging A and B two die casting steel pouring pit production lines, wherein the two die casting steel pouring pit production lines are arranged in two different spans respectively, the bottom portion and the inner walls of each die casting pit are respectively paved with a layer of refractory bricks, and a refractory drying room for casting is arranged between the two die casting lines; according to the height of different ingot types of steel ingot dies and use ratio in production, designing the A span to be a two-stage die casting pit, and designing the B span to be a three-stage die casting pit; and putting one-position, two-position, six-position and eight-position four kinds of chassis in the die casting pits according to the corresponding ingot types. According to the design, die casting steel pouring vehicle lift stroke, height change of different ingot types of ingot dies, production power demand information and chassis change characteristics are taken into full consideration, a step-type die casting pit design is adopted, and thus demand for different ingot types and different product die casting production is met by adopting die casting pits with different depths, adjusting the number of central casting pipe bases and improving steel ladle height.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Elevator

InactiveCN101962146BSuspension length reducedShorten the lifting strokeElevatorsBuilding liftsEngineering

The invention provides an elevator. A suspension length of a control cable is relative small relative to a lifting stroke. The elevator comprises a control cable, wherein one end of the control cable is connected with a lift well and another end is connected with an elevator car. In the elevator, the middle part of the control cable is supported by a movable lifting device and the movable lifting device lifts respective with the lifting of the elevator car in the lift well and the lifting distance of the movable lifting device is shorter than the moving distance of the elevator car. The movable lifting device comprises: a movable lifting rack connected with the control cable; a guide rail supporting the movable lifting rack to life in the lift well; and a driving device for making the movable lifting rack move along the guide rail. The lifting length of the control cable is reduced relative to the stroke of the elevator car.

Owner:MITSUBISHI ELECTRIC CORP

Cleaning barrel of cleaning device

ActiveCN112956978ALower the altitudeLower height requirementCarpet cleanersFloor cleanersEngineeringTransfer mechanism

The invention relates to a cleaning barrel of a cleaning device and belongs to the technical field of cleaning. A problem that in the prior art, a cleaning barrel needs to be higher than a cleaning device is solved. The cleaning barrel of the cleaning device comprises a barrel body, wherein an opening is formed in the barrel body, the cleaning device can enter the barrel body along the opening of the barrel body, and a water feeding structure capable of wetting at least one part of the cleaning device stretching into the barrel body is arranged in the barrel body; the barrel body is provided with a transferring mechanism which lifts and transfers liquid of a wetting part of the cleaning device to the non-wetting part of the cleaning device through movement of the cleaning device. The cleaning barrel is advantaged in that the transfer mechanism is arranged, power is provided through vertical movement of the cleaning device, liquid of the wetted part of the cleaning device is transferred to the non-wetted part, the requirement for the height of the water level is lowered, and therefore the height of the barrel can be lowered.

Owner:JIAXING JACKSON TRAVEL PROD CO LTD

Fixed beam type tyres forming vulcanizer

The invention discloses a fixed beam type tire forming vulcanizer. In the invention, a beam is fixed in motionless; only the short-offset vertical lift is carried out; a lower vulcanizing chamber and a central mechanism are removed out of a base by a translation mechanism; the internal pipeline and the external pipeline of the central mechanism are movably connected; the base adopts a segregated structure; and a transmission gear adopts the simple assembly-and-disassembly structure. The novel structure of the invention can also realize all the functions of the traditional vulcanizer, in addition, the overall structure is simpler and more reliable, and the processing, installation and maintenance are convenient.

Owner:GUILIN RUBBER MACHINERY CO LTD

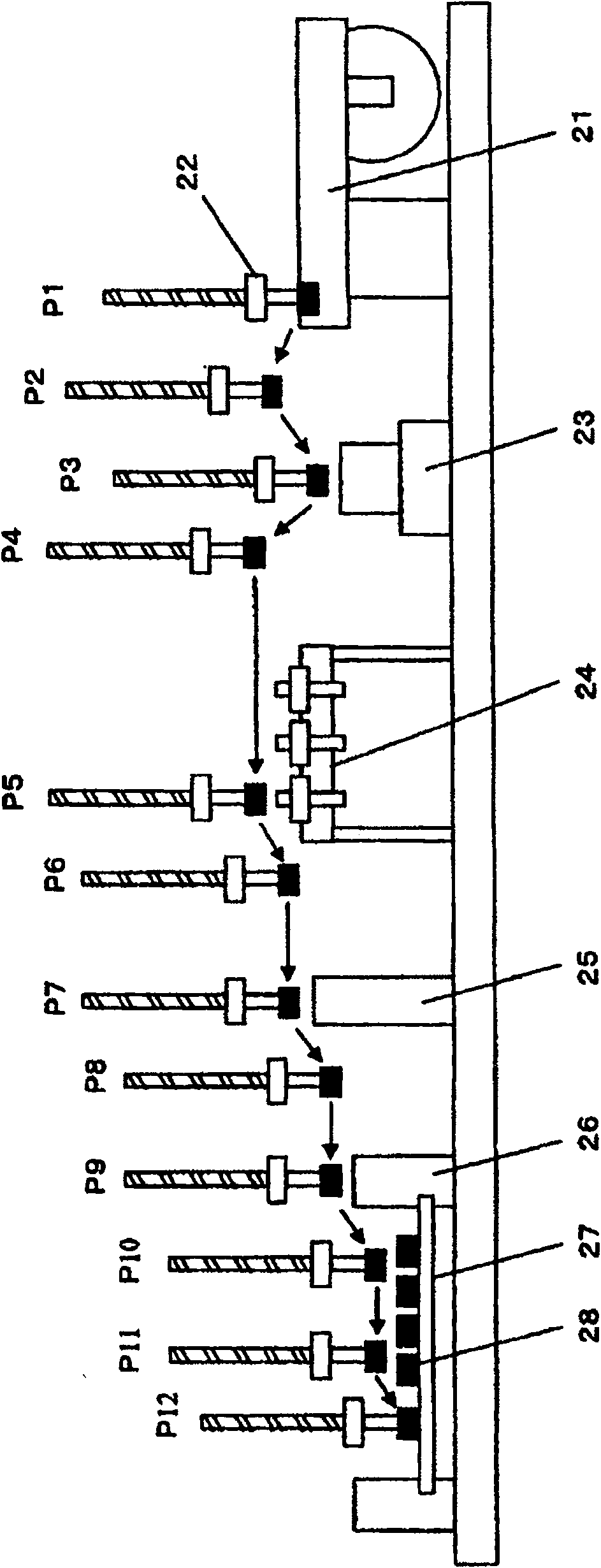

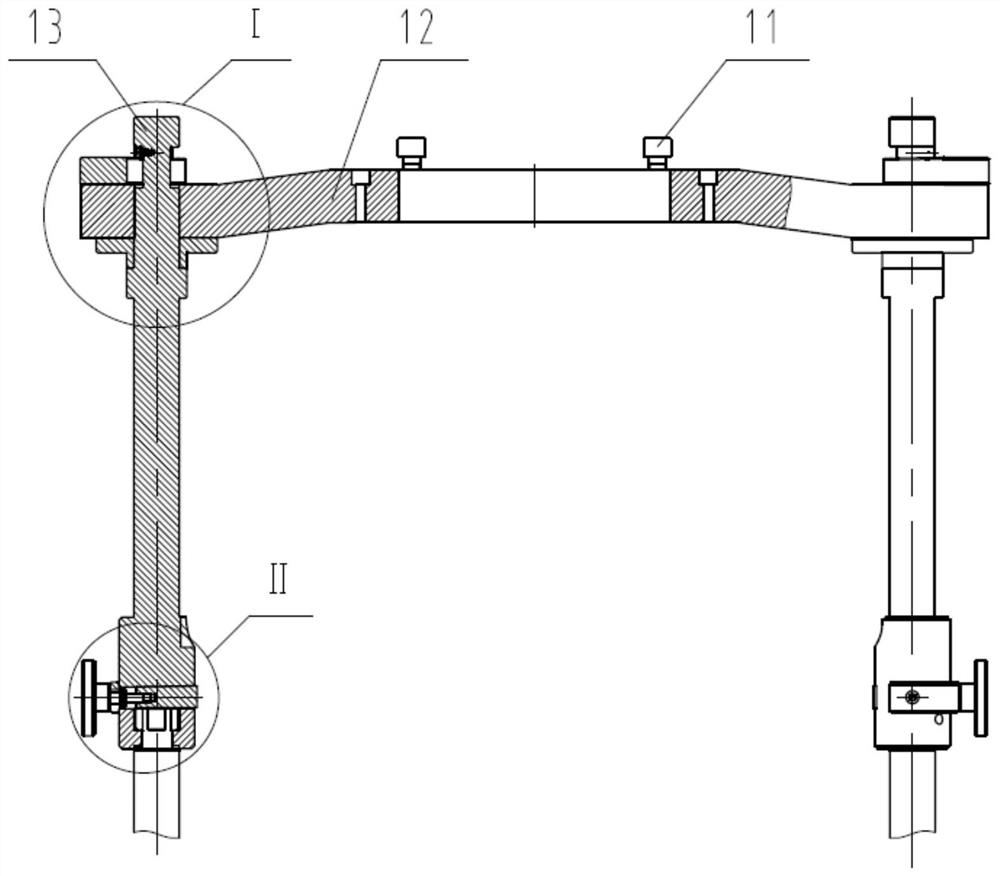

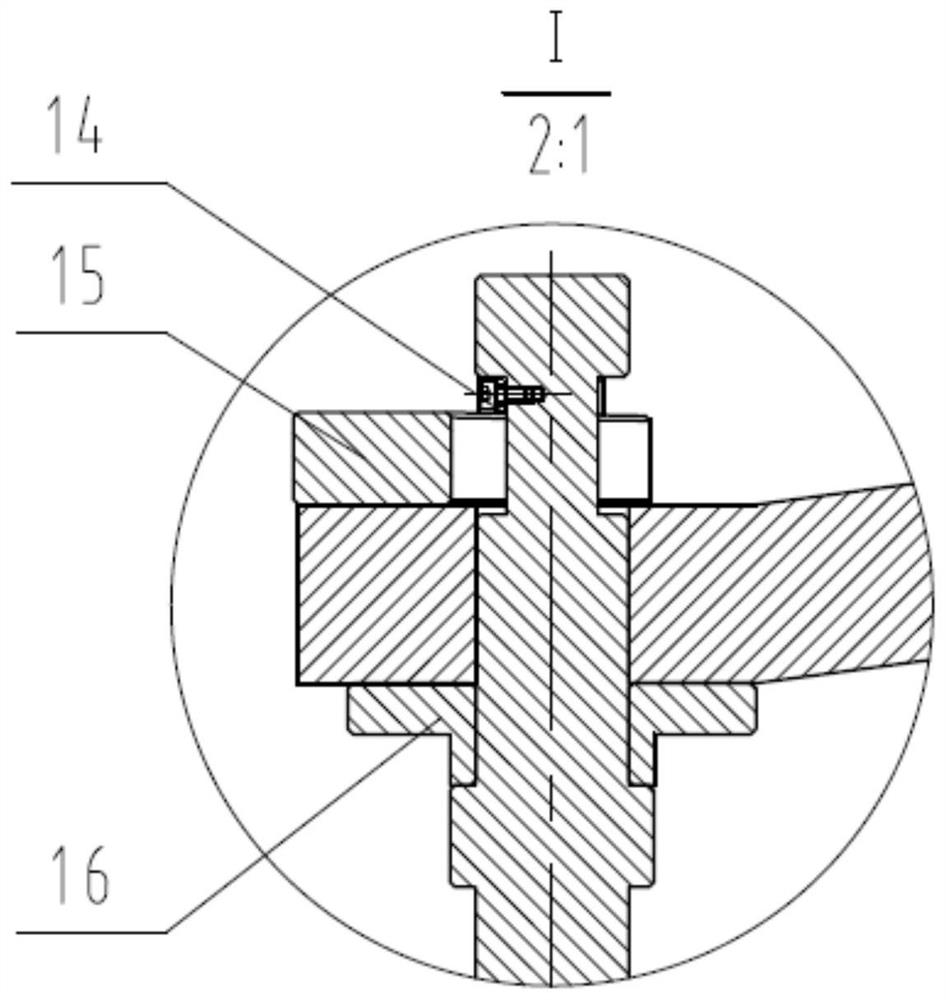

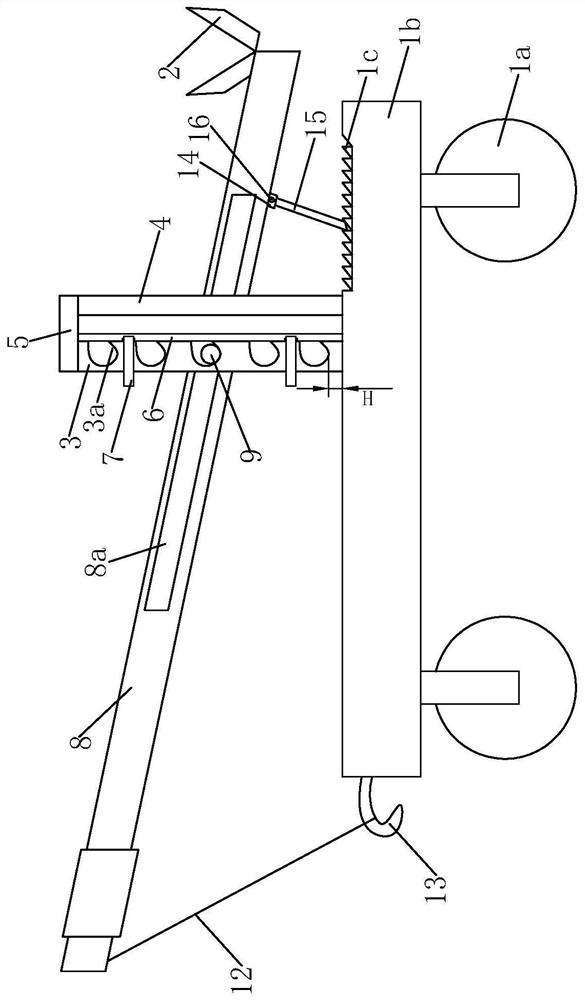

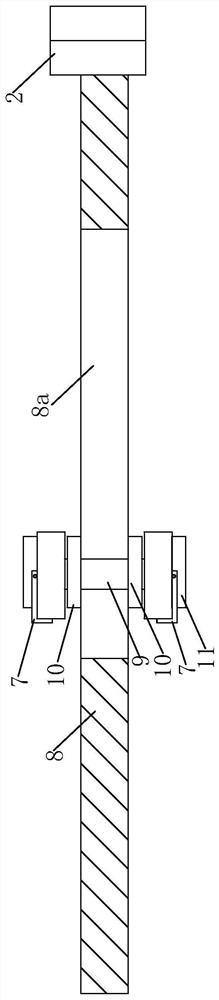

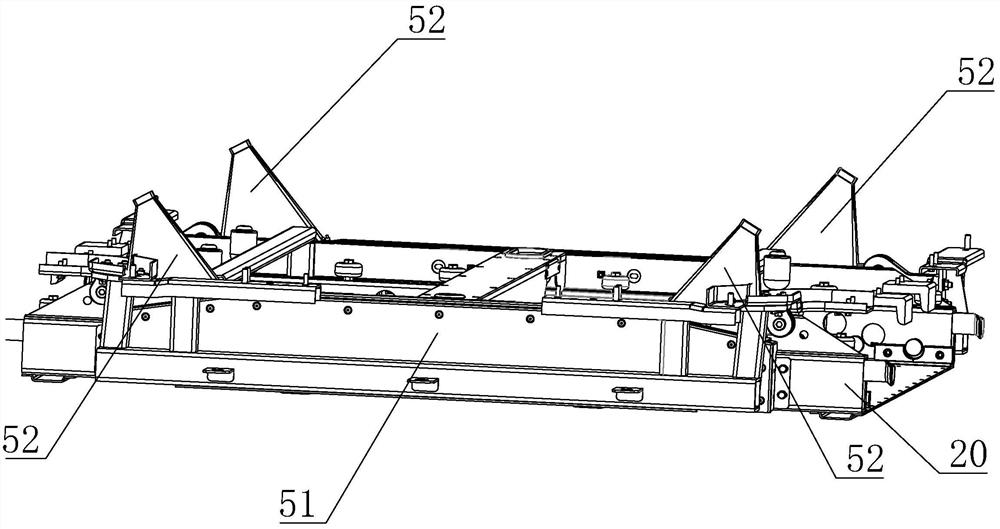

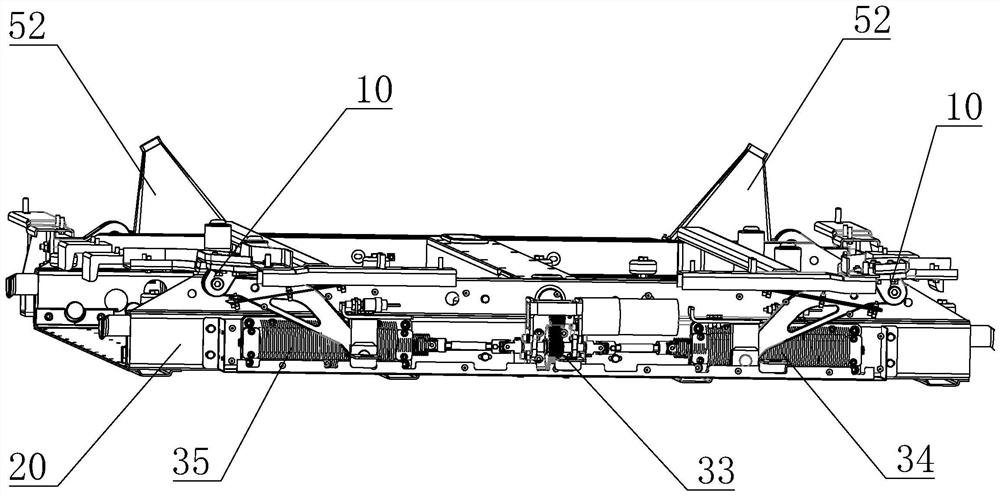

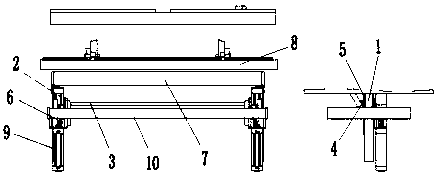

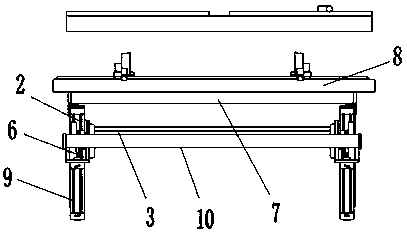

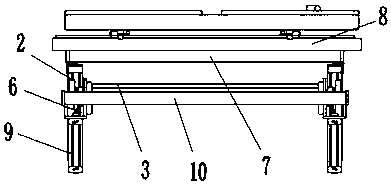

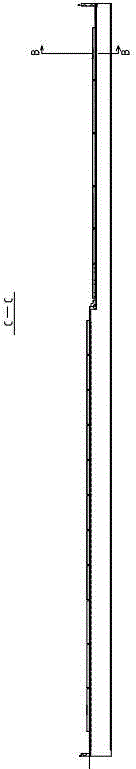

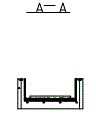

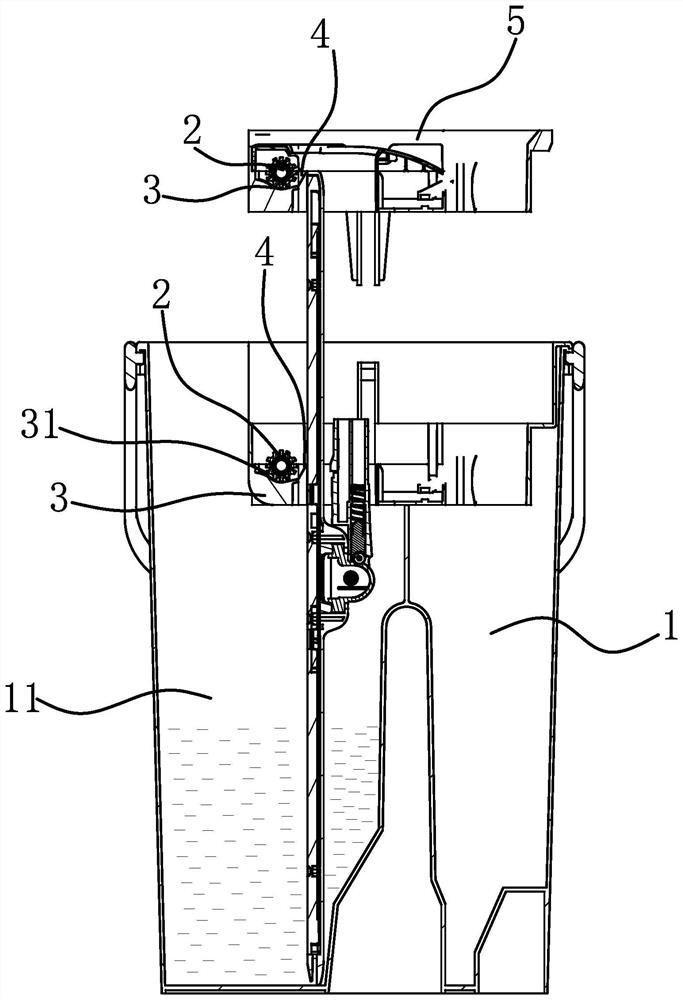

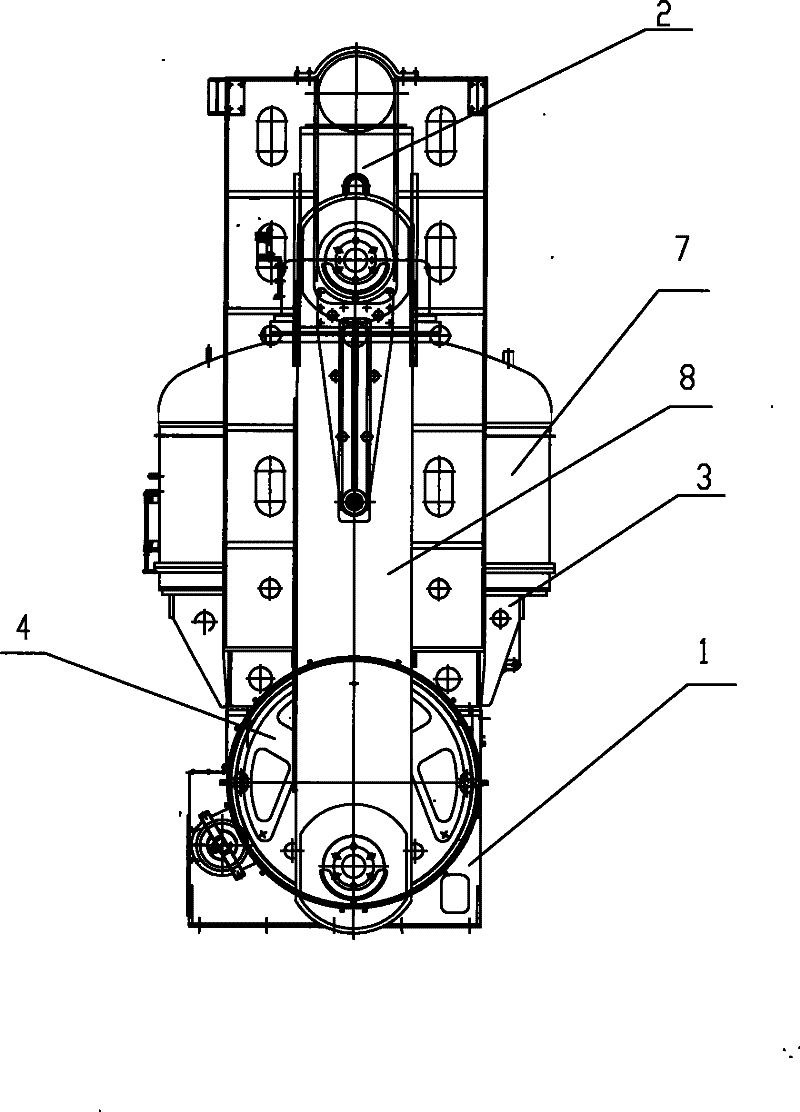

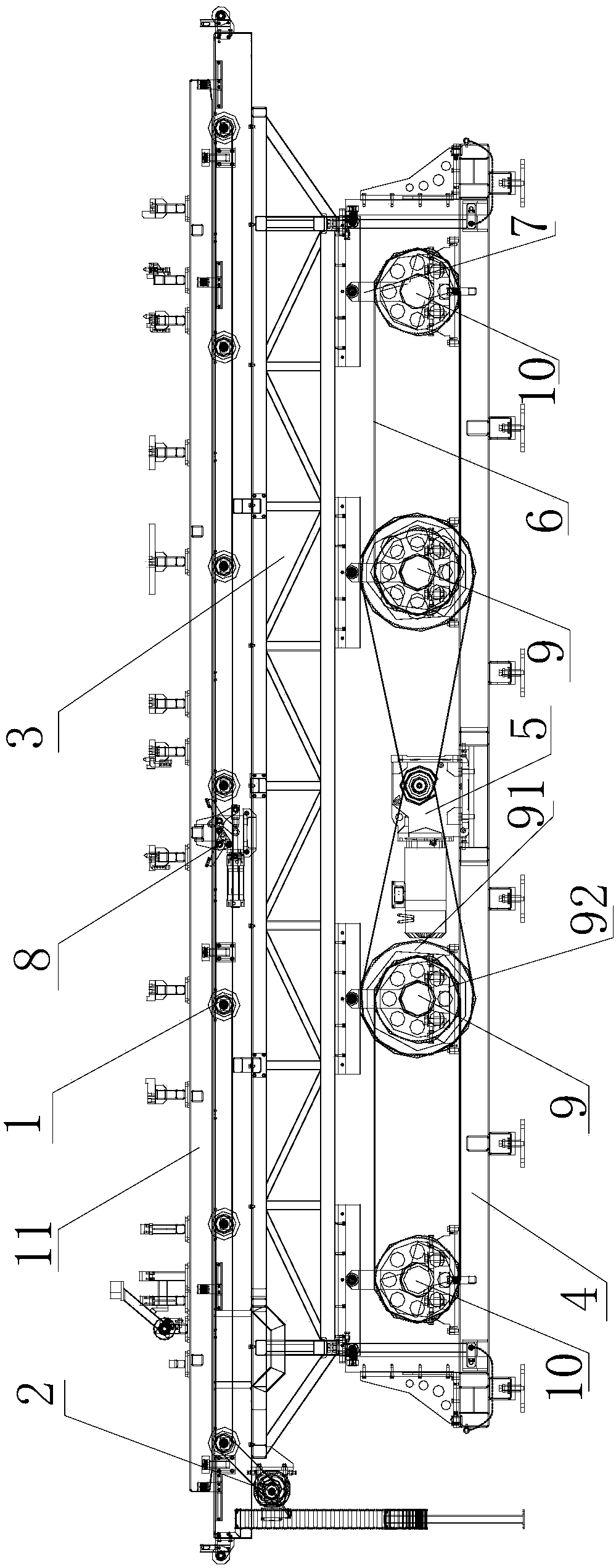

An Automatic Lifting Roller Bed for Body Welding

ActiveCN106041404BLarge lifting strokeShorten the lifting strokeWelding/cutting auxillary devicesAuxillary welding devicesRocker armClutch

The invention relates to an automatic lifting roller bed for welding vehicle bodies. The automatic lifting roller bed comprises a roller way (1), a roller way driving mechanism (2), a welding framework (3), a bottom support (4) and a lifting mechanism, wherein the roller way (1) is driven by the roller way driving mechanism (2) and is fixed on the welding framework (3); the welding framework (3) and the bottom support (4) are in sliding connection with each other in a vertical direction; the lifting mechanism is arranged between the welding framework (3) and the bottom support (4) and comprises a motor assembly (5) and at least one synchronous belt wheel and a synchronous belt (6); a rocker arm (7) is arranged on each synchronous belt wheel; one end of the rocker arm (7) is coaxial with the synchronous belt wheel, and a rolling wheel is arranged at the tail of the other end of the rocker arm (7); rolling wheel sliding grooves matched with the rolling wheels are formed in the bottom of the welding framework (3). Compared with the prior art, the automatic lifting roller bed for welding vehicle bodies is especially applicable to places with small lifting ranges; a clutch mechanism is arranged, so that the roller bed also has two lifting strokes and is applicable to more operating conditions.

Owner:SHANGHAI FULANGDE MACHINERY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com