Two-roller plate rolling machine with reversely-arranged flexible roller

A flexible roll and inverted technology, which is applied in the field of flexible roll inverted two-roll plate bending machine, can solve the problems of poor stability, potential safety hazards, unfavorable bending of large-diameter workpiece cylinders, etc., and achieve improved stability and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

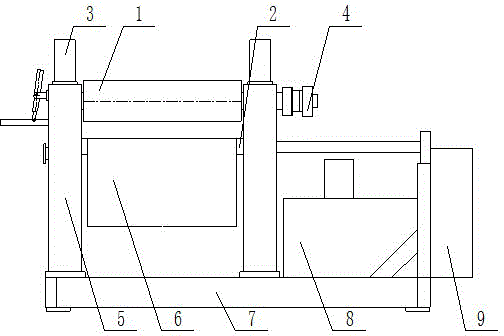

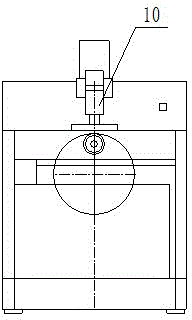

[0010] refer to figure 1 , this embodiment adopts the following technical solutions: it includes flexible rollers (rubber rollers), rigid rollers (molds) 2, lifting cylinders 3, hydraulic motors 4, bracket wall panels 5, chassis bases 7, hydraulic systems 8, electrical control systems 9. Turn over the oil cylinder 10, the upper side of the chassis seat 7 is provided with a bracket wall plate 5, the upper end of the bracket wall plate 5 is inverted and provided with a lifting cylinder 3, and the upper part of the bracket wall plate 5 is horizontally provided with a flexible roller (rubber roller) 1, The power output end of the lifting cylinder 3 is connected to both ends of the flexible roller (rubber roller) 1, one end of the roller shaft of the flexible roller (rubber roller) 1 is connected to a hydraulic motor 4, and the other end of the flexible roller (rubber roller) is provided with a tipping The oil cylinder 10 and the rigid roller (mold) 2 are horizontally arranged und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com