Fixed beam type tyres forming vulcanizer

A technology for shaping and vulcanizing tires, which is applied in the field of fixed-beam tire shaping and vulcanizing machines. It can solve the problems of large space occupied by beam translation, difficult processing and manufacturing, and inconvenient loading and unloading of tires. It achieves flexible disassembly, easy processing, and convenient loading and unloading of tires. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Take the application in 5000 tire shaping vulcanizing machine as an example to illustrate the technical solution of the present invention.

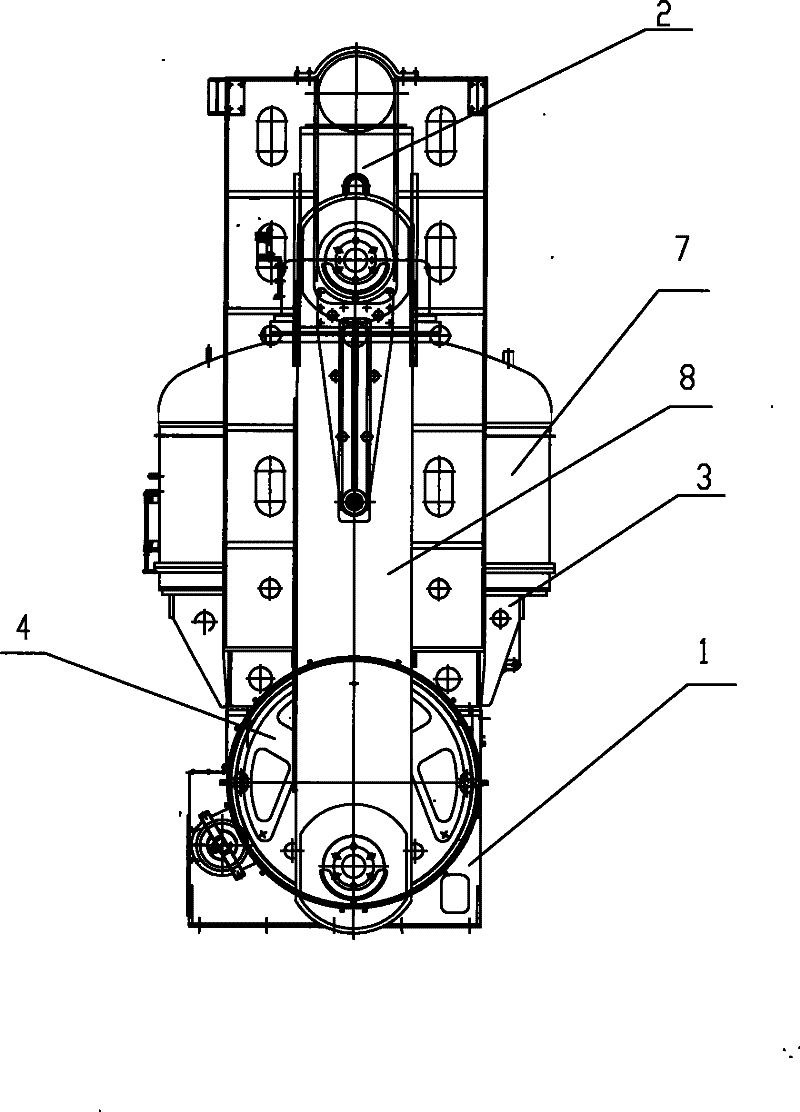

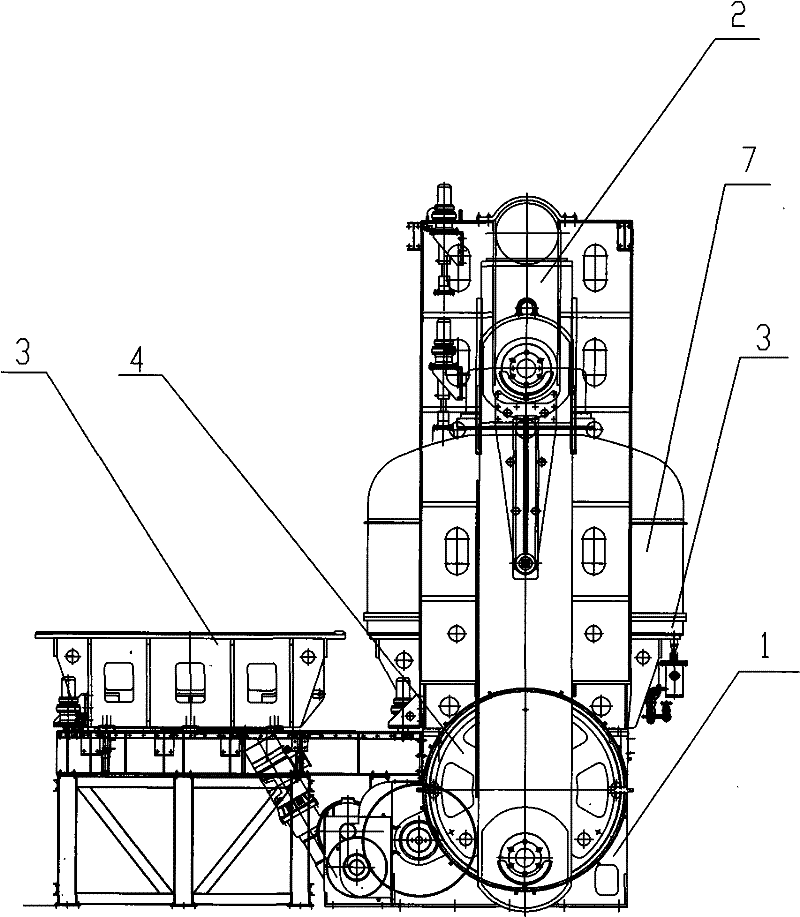

[0022] The main components of the 5000 tire shaping vulcanizer include base 1, beam 2, upper vulcanization chamber 7, lower vulcanization chamber 3, central mechanism and transmission gear 4.

[0023] like figure 1 As shown, the crossbeam 2 is fixedly installed above the base 1 through the wall panels on both sides, and the crossbeam 2 is operated by the connecting rod 8 to only move up and down. The upper vulcanization chamber 7 vertically lifts with the crossbeam 2, and the lifting distance is 2200mm.

[0024] like image 3 As shown, the lower vulcanization chamber 3 is located on the base 1 during vulcanization, and the base 1 is moved out of the base 1 through the translation mechanism connected with the base 1 when loading and unloading tires.

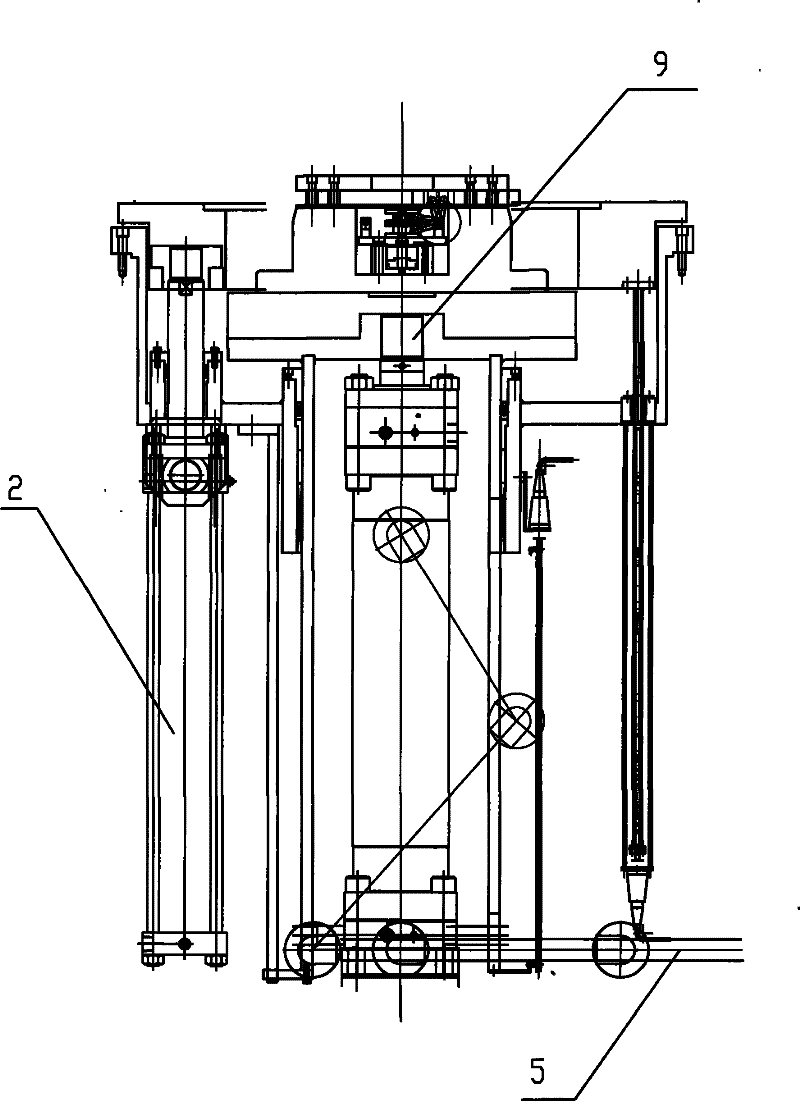

[0025] like figure 2 As shown, the supporting central mechanism moves together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com