Lifting trolley

A trolley and lifting platform technology, which can be used in trolleys, motor vehicles, multi-axle trolleys, etc., can solve the problems of labor-intensive, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

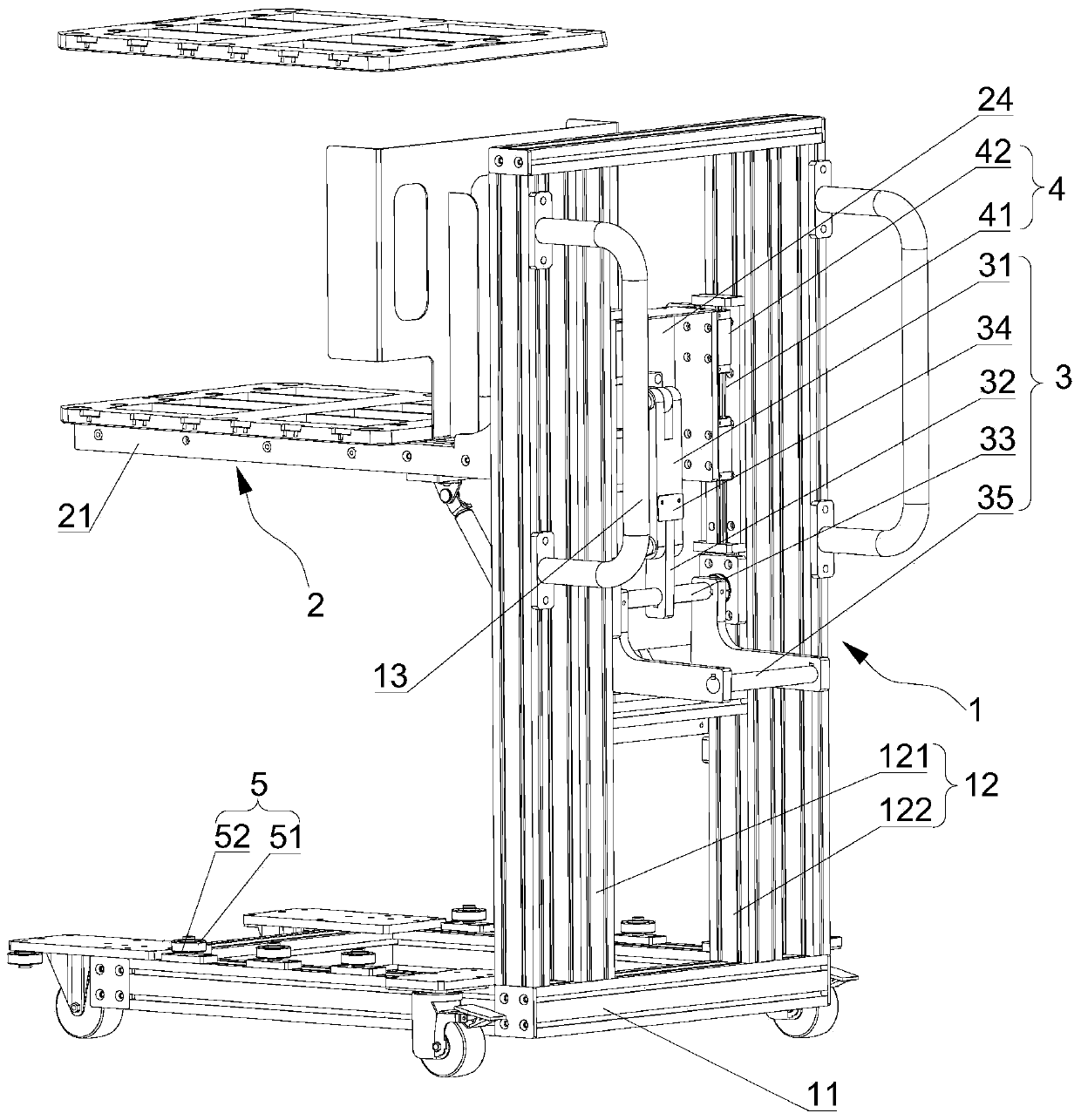

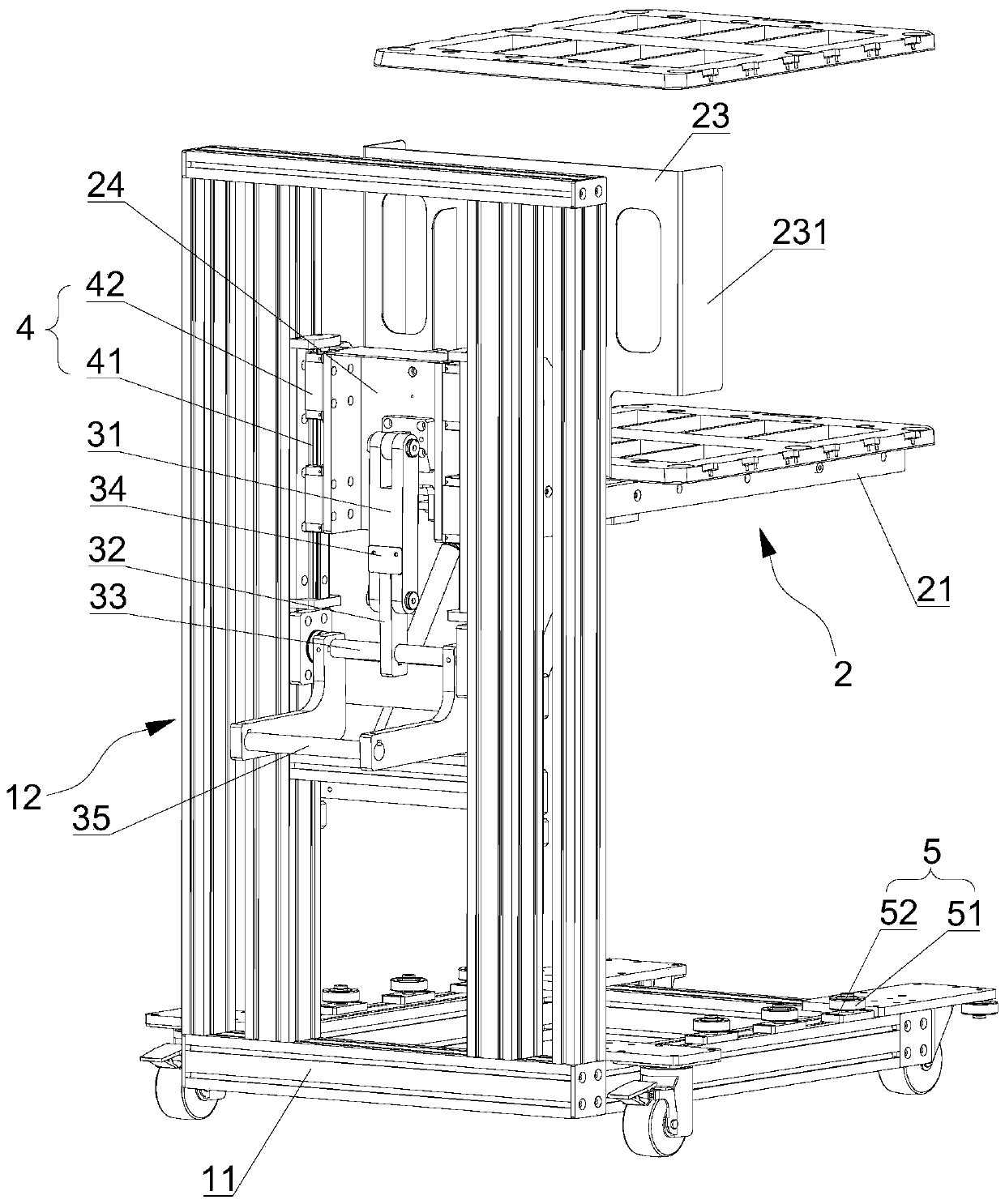

[0047] Such as Figure 1-Figure 4 As shown, this embodiment provides a lifting trolley for docking with the machine platform, transporting to the machine platform and picking and placing products or materials at the machine platform. The lifting trolley includes a bracket 1, a lifting platform assembly 2 and a connecting rod assembly 3, wherein the bracket 1 can move, the lifting platform assembly 2 is slidably arranged on the bracket 1, and the lifting platform assembly 2 can be vertically aligned with the bracket 1. direction to slide back and forth. The connecting rod assembly 3 is respectively connected to the lifting platform assembly 2 and the support 1. When the lifting platform assembly 2 is at the highest point, the connecting rod assembly 3 moves to the limit position and can be kept at the limit position.

[0048] The support 1 is "L" type, and the support 1 includes a mobile support 11 and a support frame 12, and the bottom of the mobile support 11 is rotatably pr...

Embodiment 2

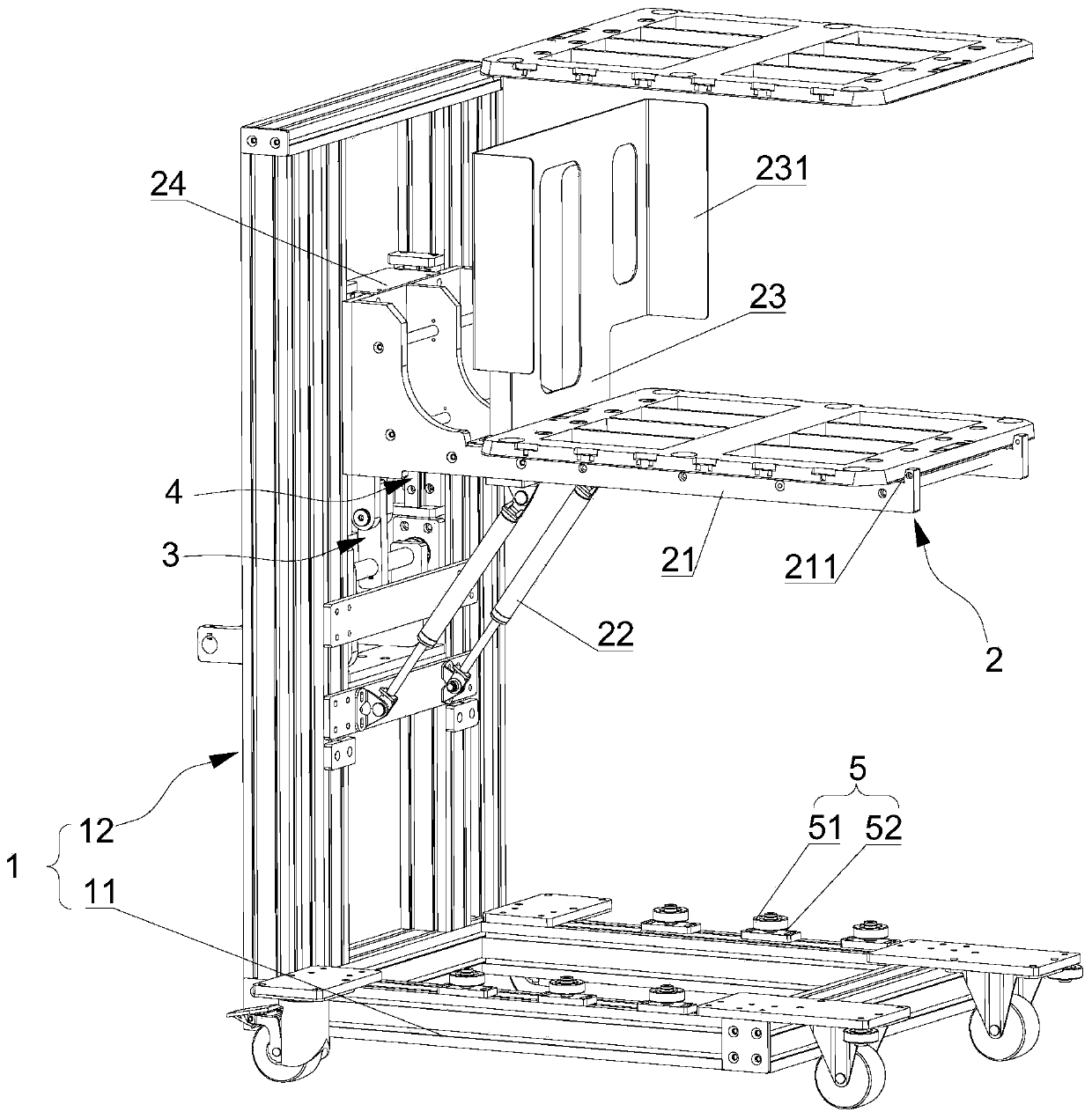

[0060] On the basis of the first embodiment above, the difference from the first embodiment is that the structural form of the connecting rod assembly 3 and the connection relationship with other structural parts are different, as follows, as Figure 5 as shown, Figure 5 Schematic diagram of the lift trolley structure.

[0061] The connecting rod assembly 3 includes a first connecting rod 31, one end of the first connecting rod 31 is hinged with a second connecting rod 32, and the other end is hinged at the lifting stage assembly 2, and the second connecting rod 32 is located above the first connecting rod 31 . The connecting rod assembly 3 also includes a rotating shaft 33, the rotating shaft 33 is horizontally installed on the second connecting rod 32, and its two ends are rotatably connected to the bracket 1, the rotating shaft 33 can drive the second connecting rod 32 to move, and the rotating shaft 33 is arranged on Above the first connecting rod 31.

[0062] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com