Switching type loading adjustment device and method

A technology of adjusting device and loading rod, applied in measuring device, using stable tension/pressure test material strength, instrument and other directions, can solve the problems of low efficiency, can not meet the adjustment of loading uniformity, etc., to reduce the volume, The effect of improving loading efficiency and shortening lifting stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

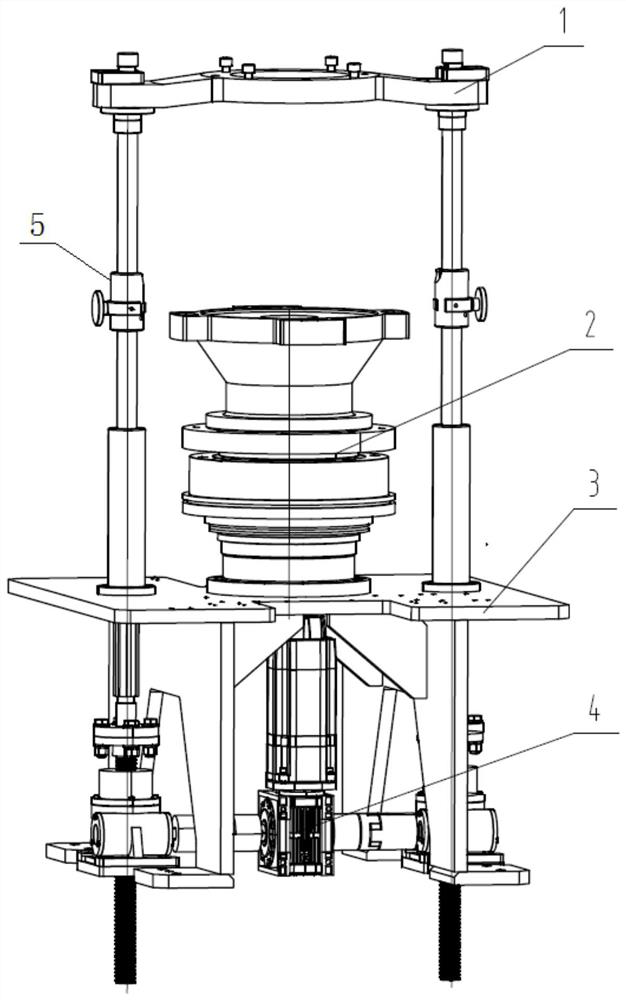

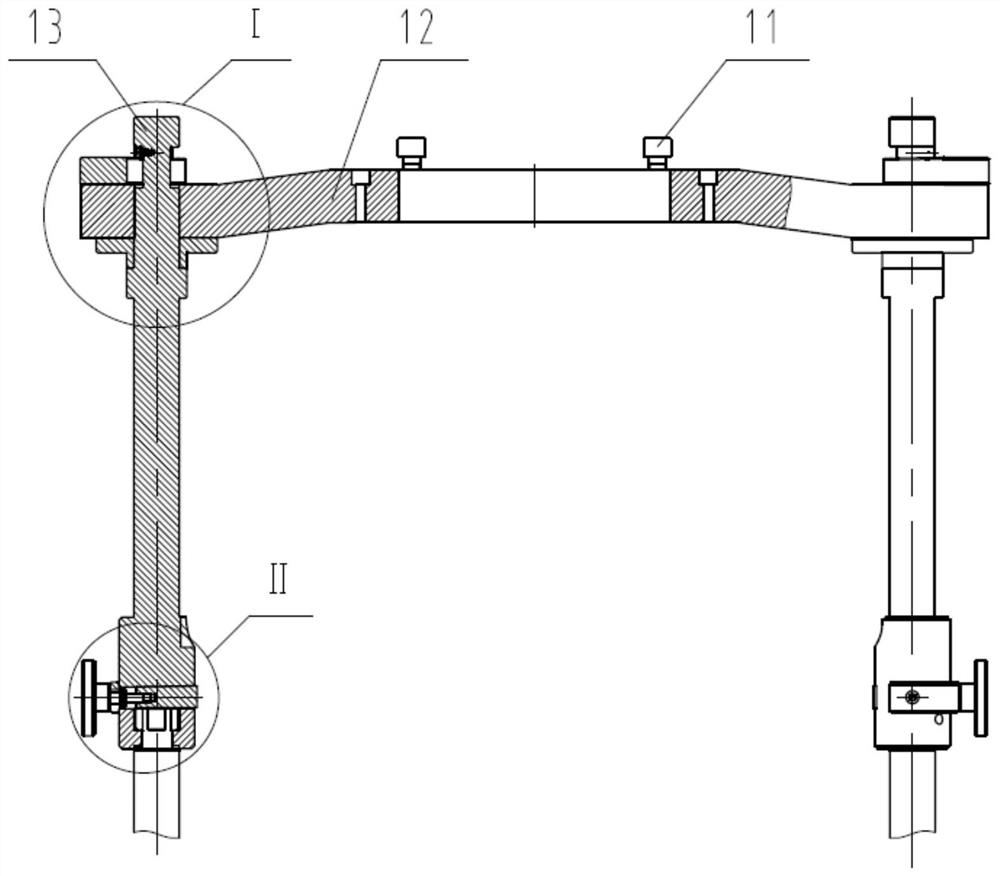

[0041] Such as Figure 1 to Figure 7 As shown, a transfer-type loading adjustment device of the present invention includes a mounting base 3, which provides an installation support interface; also includes a bearing platform 2, a synchronous lifting mechanism 4, and a loading mechanism 1, and the mounting base 3 is provided with Carrying platform 2, described carrying platform 2 is used for placing the product to be loaded and tested; The synchronous elevating mechanism 4 is provided under the described mounting base 3, and the screw rods on both sides of the synchronous lifting mechanism 4 pass upwardly through the mounting base 3 and the The loading mechanism 1 is connected; the loading mechanism 1 includes two loading rods 13 and a loading beam 12 , and the loading beam 12 is sheathed on the two loading rods 13 .

[0042] An adapter 5 is also included to realize the connection and locking of the screw rods on both sides of the synchronous lifting mechanism 4 and the loading...

Embodiment 2

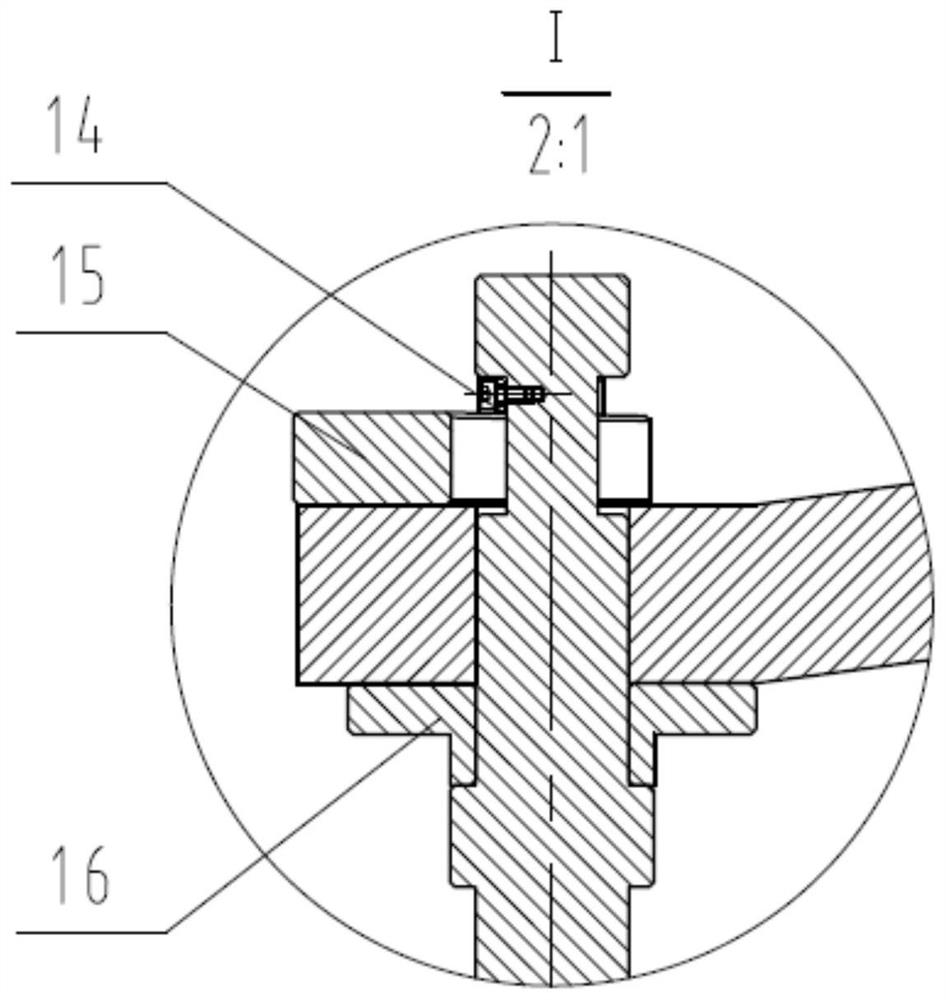

[0045] Such as Figure 1 to Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the adapter 5 includes a limit ring 17, a locking screw 18, and a wedge post 19, and the wedge post 19 is installed in the end of the loading rod 13. The locking screw 18 is inserted into the wedge column 19 from the side of the loading rod 12; the limit ring 17 is installed on the side of the loading rod 13 and embedded in the locking screw 18 slot to limit the lateral movement of the locking screw 18 , thereby tightening the wedge column 19 to eliminate backlash.

[0046]In this embodiment, the loading mechanism 1 further includes a slanted ring 14, a wedge 15, and a sleeve 16, and the loading beam 12 is sleeved on the two loading rods 13 through the sleeve 16; The block 15 and the slant ring 14 are locked; the slant ring 14 is mounted on the journal of the loading rod 13 by screws.

[0047] In this embodiment, the loading mechanism 1 further includes adjustment p...

Embodiment 3

[0056] Such as Figure 1 to Figure 7 As shown, the difference between this embodiment and Embodiment 2 is that the adjusting member can also be realized by adjusting bolts or adjusting studs, and the number and arrangement form are not limited.

[0057] In this embodiment, the synchronous lifting mechanism 4 is realized by using a synchronous motor, a synchronous electric cylinder, a hydraulic cylinder or an air cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com