Lever Type Accident Vehicle Lift

A lifting device and lever-type technology, applied in the field of transportation, can solve the problems of long movement of the jack, time-consuming and laborious lifting, hidden safety hazards, etc., to achieve the effect of convenient lifting, shortening the lifting stroke, and protecting the operator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

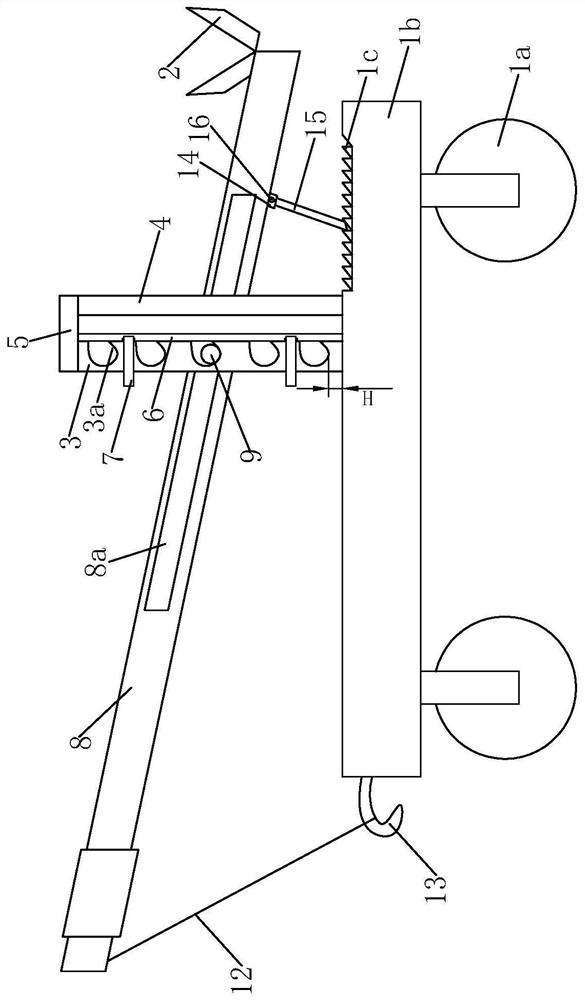

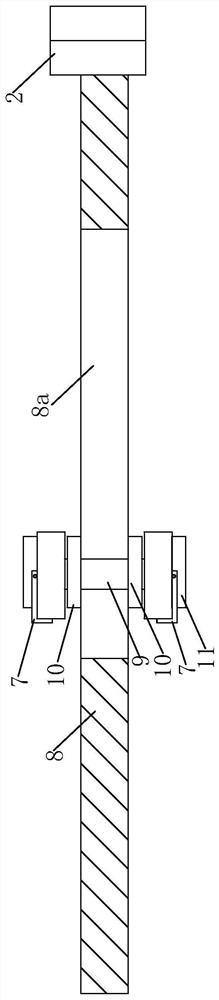

[0019] Such as figure 1 , 2 As shown, a lever-type accident vehicle lifting device is mainly composed of a supporting trolley 1, a lifting block 2, a supporting assembly, a lifting rod 8, a supporting shaft 9 and a locking nut 10, etc. Wherein, the bottom of the supporting platform 1b supporting the trolley 1 has two rotating shafts arranged side by side, the rotating shafts are in rotation with the supporting platform 1b, and a supporting wheel 1a is coaxially fixed at both ends of each rotating shaft. In addition, the support trolley 1 is a follower trolley without power itself. The height of the top surface of the support platform 1b from the ground is 20cm, and the right part of the top surface of the support platform 1b has two support assemblies arranged side by side.

[0020] Each support assembly includes a vertical plate 3 and a movable positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com