Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Reduce the amount of excavation work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for second mining mining-stopping line coal column in super thick coal layer

ActiveCN107313778ARecovery is safe and reliableAvoid safety accidentsUnderground miningSurface miningEconomic benefitsEngineering

The invention discloses a method for second mining a mining-stopping line coal column in a super thick coal layer. The method comprises the following steps that (1), positions of a coal column second mining working surface transporting gate trough and a rail gate trough are stimulated; (2) comprehensive probing is conducted on an original working surface goaf area where the super thick coal layer mining-stopping line coal column is located, and potential safety hazard is removed; (3) a roadway in the propelling direction of the coal column second mining working surface is dug at the upper part of the super thick coal layer, and the roadway is filled; (4) a coal column second mining working surface mining returning roadway and a affiliated oblique roadway are dug, so that the coal column second mining working surface mining returning roadway and the affiliated oblique roadway form a completed producing system, and the coal column second mining working surface is arranged; (5) a bottom plate of the roadway is drilled from top to bottom for using as a filled pipeline; (6) filling paste is prepared, the filling paste is evenly injected into one side, close to the original working surface goaf area, of the transporting gate trough along the filled pipeline; and (7) comprehensive mining is conducted on the coal column second mining working surface. According to the method for second mining the mining-stopping line coal column in the super thick coal layer, the compressed coal amount is reduced, waste of coal resources is avoided, the economic benefits of enterprises are improved, and the service life of mines and mining areas is prolonged.

Owner:TAIYUAN UNIV OF TECH

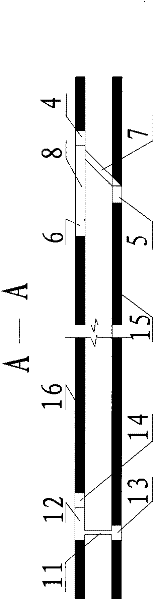

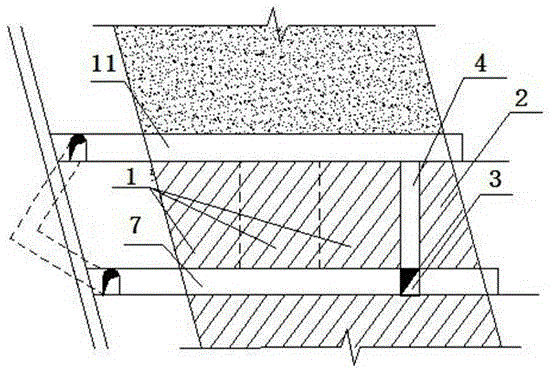

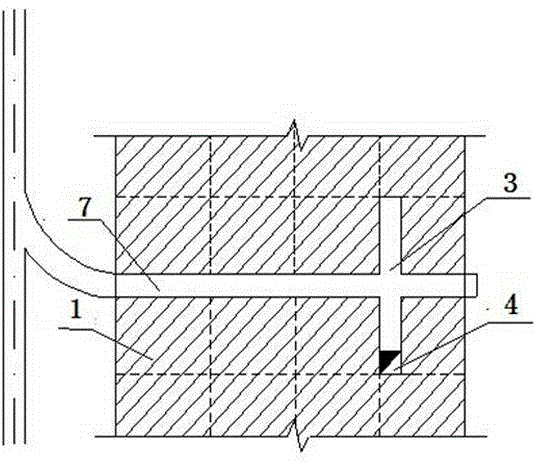

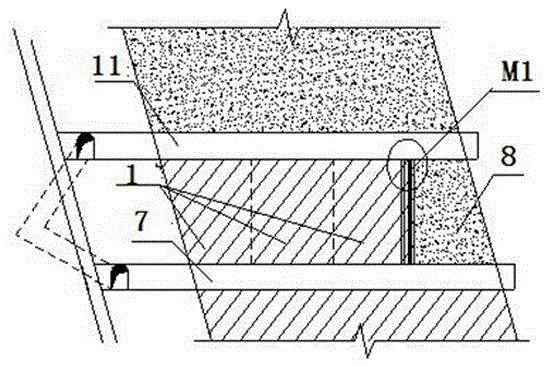

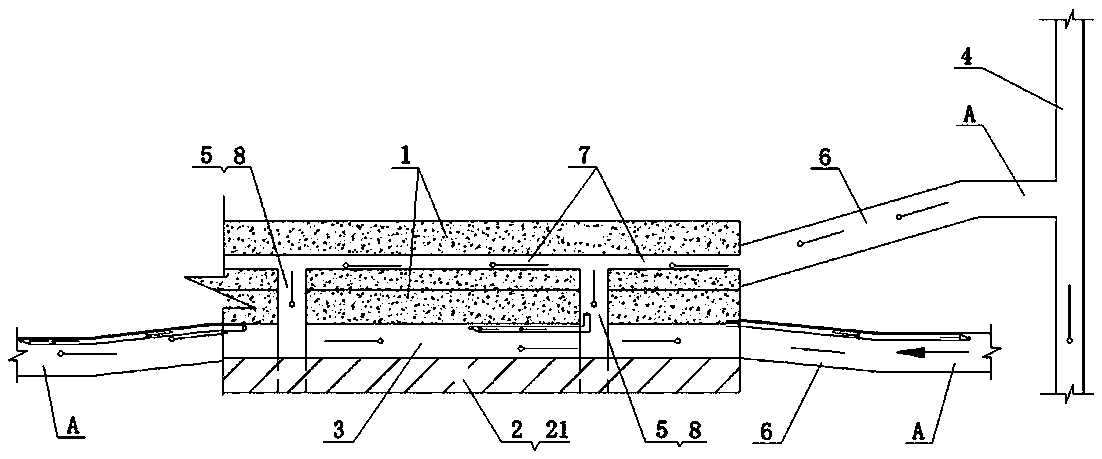

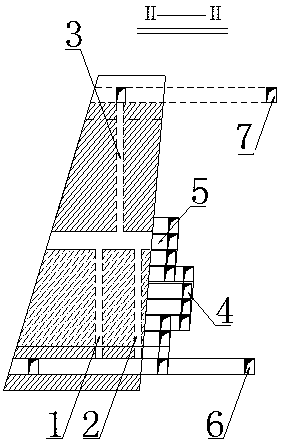

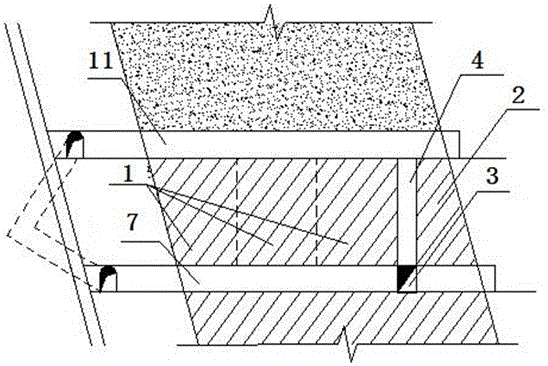

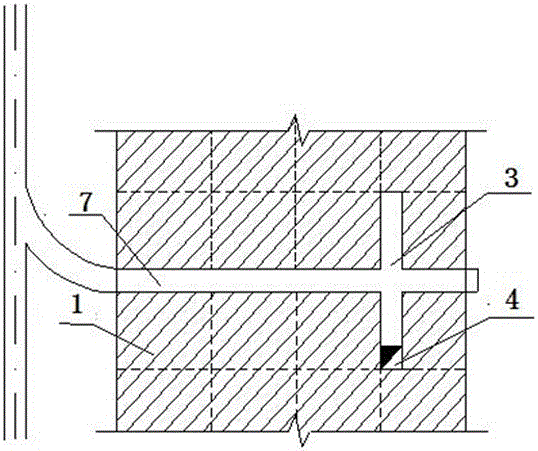

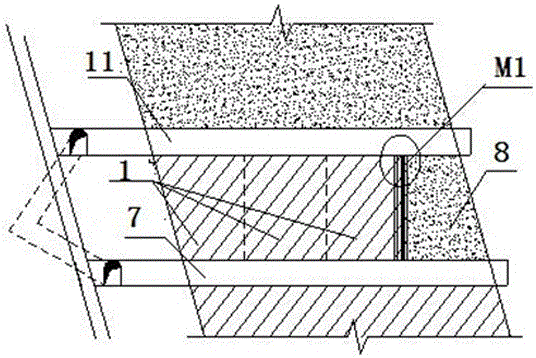

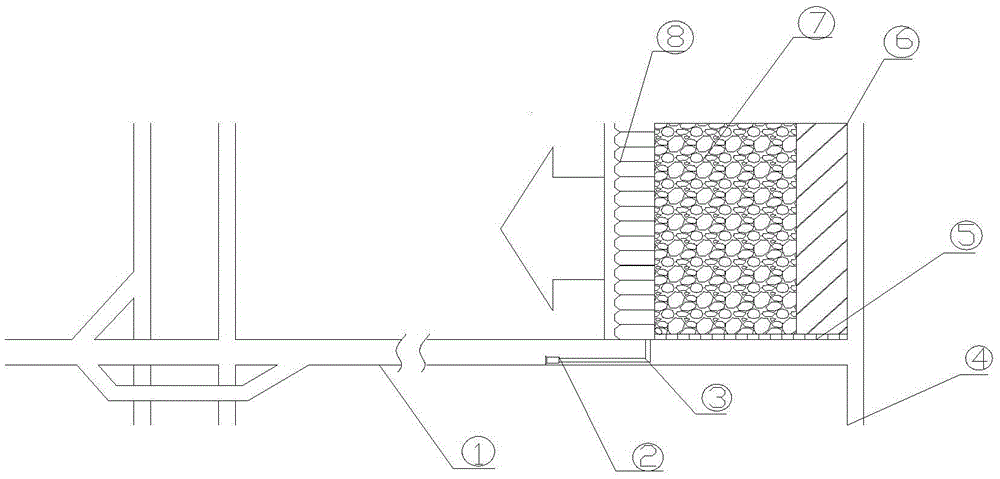

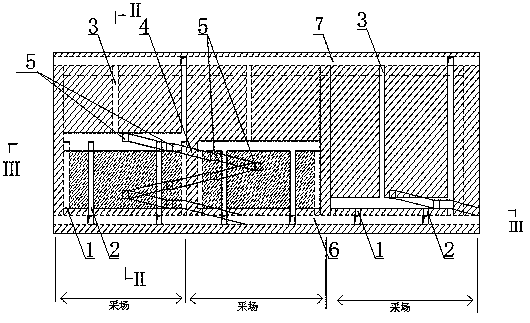

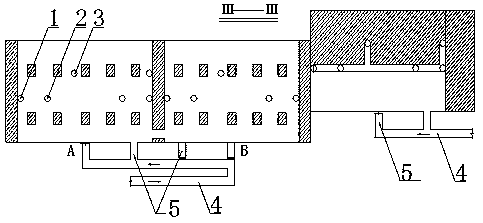

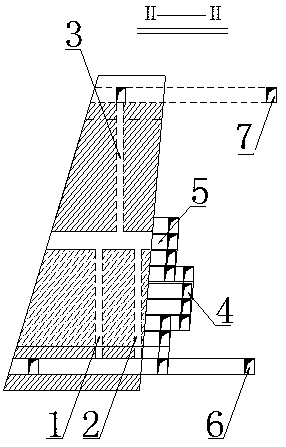

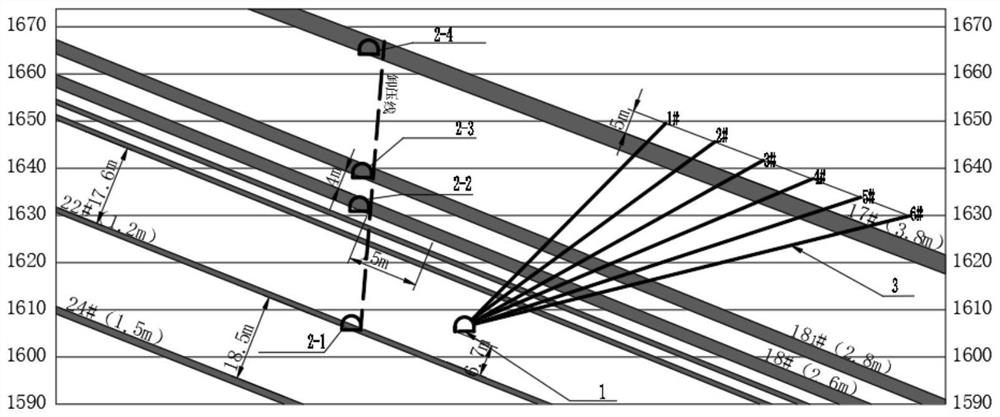

Close-range thin coal layer simultaneous mining and parallel transporting method

InactiveCN102392640AReduce the amount of excavation workIncrease productionUnderground miningSlitting machinesCentralized managementCoal

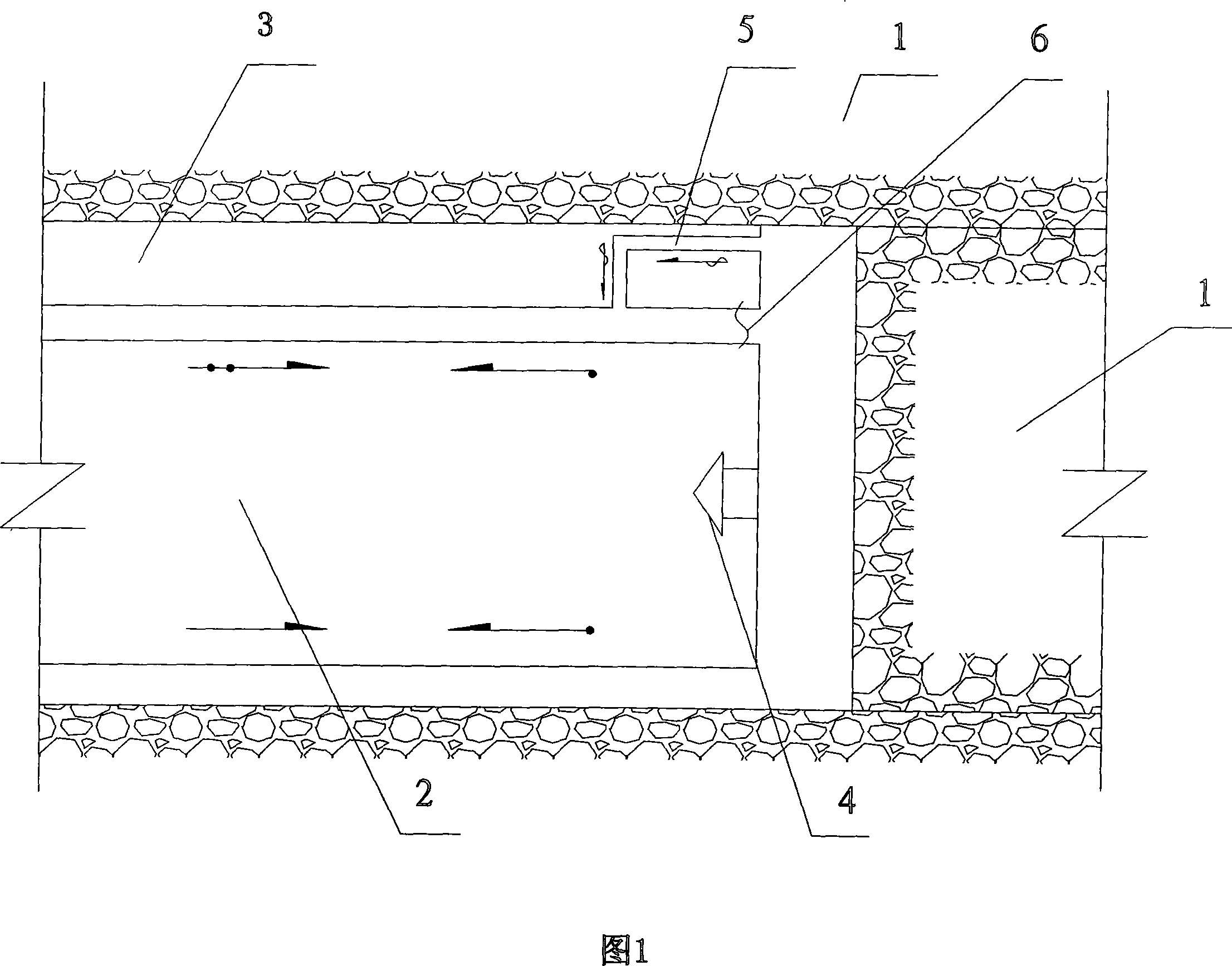

The invention discloses a close-range thin coal layer simultaneous mining and parallel transporting method, aiming to solve the problems caused by layer mining of the existing close-range thin coal layers, such as resource waste, serious flood, difficult mining distribution of lower layer coal, long mining period, low yield, high tunneling and supporting difficulties, high cost and the like. The method is characterized by arranging a centralized transport roadway, a centralized track roadway and a centralized air return roadway along the coal layers or top and bottom plates of the coal layers, simultaneously arranging two coal faces on the close-range thin coal layers and simultaneously mining and transporting coal. The method has the following beneficial effects: simultaneous mining and centralized transporting of the upper and lower coal layers are realized; relative to layer mining, by adopting the method, the tunneling quantities of the roadways are reduced, a belt conveyer can be simultaneously omitted, and the convenience is provided for centralized management of production; and especially for the close-range thin coal layers, the production system is simplified, the convenience is provided for centralized management, the production cost is lowered, and the mine output and the production efficiency are improved.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

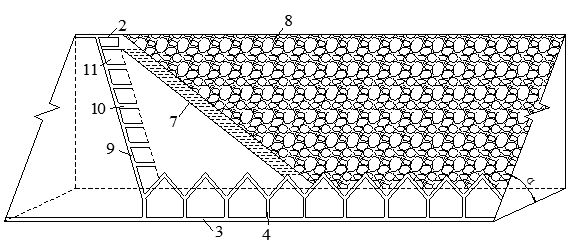

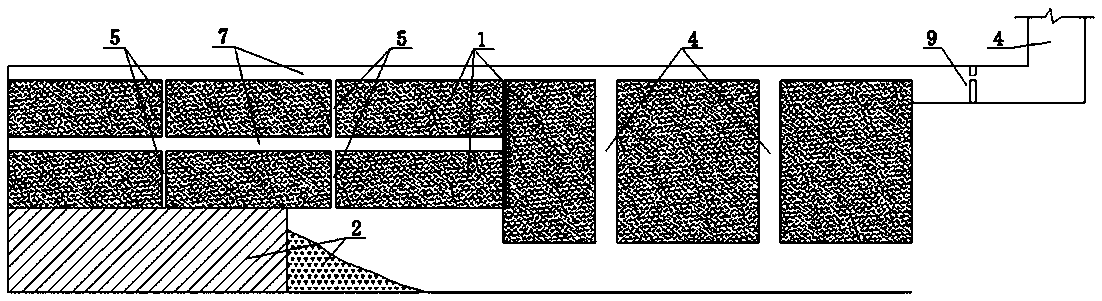

Kerve-free sublevel filling mining method

ActiveCN104453904ASqueeze fullyFlexible control of exposure areaUnderground miningSurface miningEngineeringOperating time

The invention provides a kerve-free sublevel filling mining method. The kerve-free sublevel filling mining method specifically comprises the following steps: dividing sublevel chambers and splitting ore blocks, carrying out mining preparation and cutting engineering arrangement, carrying out kerve explosion, firstly carrying out extraction and filling operation of splitting ore blocks, carrying out extrusion groove explosion to form a cutting groove during extraction of adjacent ore blocks, utilizing a compensation space formed by extrusion explosion to carry out normal explosion extraction operation, after the extraction of a second splitting ore block, entering the next adjacent splitting ore block, forming the cutting groove through extrusion groove explosion, carrying out extraction, and cycling the extraction process of the adjacent ore blocks. Kerve-free explosion is adopted from the second splitting ore to form a stope cutting groove; compared with a normal cutting kerve method, the engineering of cutting a level and cutting a dooryard is eliminated, the operating time is reduced, the stope extraction period is reduced, the mining operation cost is reduced, the stope labor efficiency is improved, the method is suitable for mining ore deposits with poor stability of surrounding rock, and stope top base plate and hanging side surrounding rock collapse can be effectively controlled.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

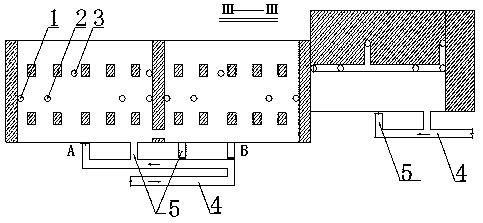

Underground no pillar recovery method of coal mine

InactiveCN101033689AImprove the recovery rate of coal resourcesReduce roadway excavation work and maintenanceUnderground miningTunnel/mines ventillationDrill holeCoal pillar

The invention provides a pack recovery method without coal wedge. It contains the following technologies: set up coal wedge, drilling along and vertical space, stoping coal wedge, ventilation system, engaging measure, safe and transport measure. Construct and drill round hole along the gob brim of picked working face on afterbody of working face and drill holes along the roof by drilling along space. 1-3 round holes are taken as circulating holes of stoping working face. Drilling vertical space drills holes connecting with drilling along space in track tunnel. The number of holes is same as that of drilling along space. The invention arranges ventilating holes along the gob brim, which can avoid and weaken the influence of fixed stay pressure, replace remaining and digging tunnels along space and improve the recovery rate of coal resource. It reduces quantities and maintenance of tunnel driving. The drilling along space is safe, highly active and has low-loss.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

Mining method for large-inclined angle laminar non-coal solid mineral deposit

InactiveCN102536238AImprove effective utilizationGrow fastUnderground miningSurface miningSlant angleEngineering

The invention provides a mining method for large-inclined angle laminar non-coal solid mineral deposit, which comprises the following steps of: tunneling open-off cut, section tailgate, section haulage way, finishing cut and cut-off, remaining and setting a protective jamb at one side of the finishing cut adjacent to a working face, and setting a fake slant angle beta along with a working face boosting direction from a through place between the finishing cut and the section tailgate; and recovering from the tailgate to the haulage way according to the set direction of the fake slant angle beta, and along with the boosting of the working face, additionally increasing a horizontal dense support isolated gob, so that the working face mine pressure control can be obviously improved by a horizontal sectionalized dense support cutting supporting, waste rock baffling and isolating gob. The steps are sequentially circulated till that the large-inclined angle laminar non-coal mining of the whole mining area is completed. The method is particularly suitable for the laminar thin mineral deposit with the ore bed inclined angle of 30-60 degrees, and can be suitable for the thickness change of the ore bed; and the method is safe and convenient for workers to work on the working face, and the working face is quick in boosting speed, and the method is high in efficiency.

Owner:CHINA UNIV OF MINING & TECH

Mining method of layering and non-segmented roadway filling in downward approach of broken surrounding rock ore body

InactiveCN103628878BReduce construction difficultyOperational aspectsUnderground miningSurface miningLoss rateMineralogy

Owner:SHANDONG UNIV OF SCI & TECH

Coal and gas coordination mining method

InactiveCN106468177ASave drainingReduce the amount of excavation workUnderground miningSurface miningCoalEnvironmental geology

A coal and gas coordination mining method relates to the coal mine mining and gas extraction field; a plurality of parallel bedding pores are arranged in the present section and the lower adjacent section along the coal seam direction in a haulage way, and are connected with extraction pipelines so as to extract gas from the coal seam area in the upper and lower sections; the method also comprises the following steps: tunneling back to a tailgate of the present section when the gas extraction is over, and tunneling to the haulage way of the lower section in the same time; finishing the present working face extraction when the tunneling is completed; repeating said steps until extractions of all section coal seams are finished. The advantages are that the coal and gas coordination mining method can save gas total extraction time, can accelerate coal road tunneling speed, thus realizing extraction, tunneling and drawing balance, and improving production efficiency.

Owner:LIUPANSHUI NORMAL UNIV

Super-short-wall coal mining method

InactiveCN104088642AHigh recovery rateImprove coal cutting efficiencyUnderground miningSurface miningMining engineeringTransit system

The invention discloses a super-short-wall coal mining method. According to the super-short-wall coal mining method, a special air returning roadway for mining small coal pillars at a mining area boundary being about 4m wide is connected with an air returning main roadway and a transportation main roadway; a mining machine at the lower part of the coal pillar is in orbital connection with one roadway so as to be simultaneously used for transporting and introducing air; the roadway is internally provided with a scraper plate conveyor, a reversed loader, a rail and a partial ventilator; a fully mechanized coal mining surface adopts a super-short machine body single-roller coal mining machine with a rocker arm in the middle of a machine body and a fully mechanized coal mining hydraulic bracket is improved; a flexible blower dryer is suspended below a top beam; an independent-head roadway is used for ventilating and the partial ventilator is matched to ventilate in a pressing-in manner. A goaf is treated by adopting a full caving method in a manner of arranging a remained gateway along goaf at the lower side of the goaf. On the basis of reasonably solving the basic problems of a transportation system, a ventilation system and a material transporting and recrement discharging system, the problem that the coal mining machine repeatedly passes through a fault when being used for cutting coal is avoided; the work amount of the roadway is reduced, the boundary coal can be flexibly recycled and the recovery rate is increased.

Owner:SHANDONG UNIV OF SCI & TECH

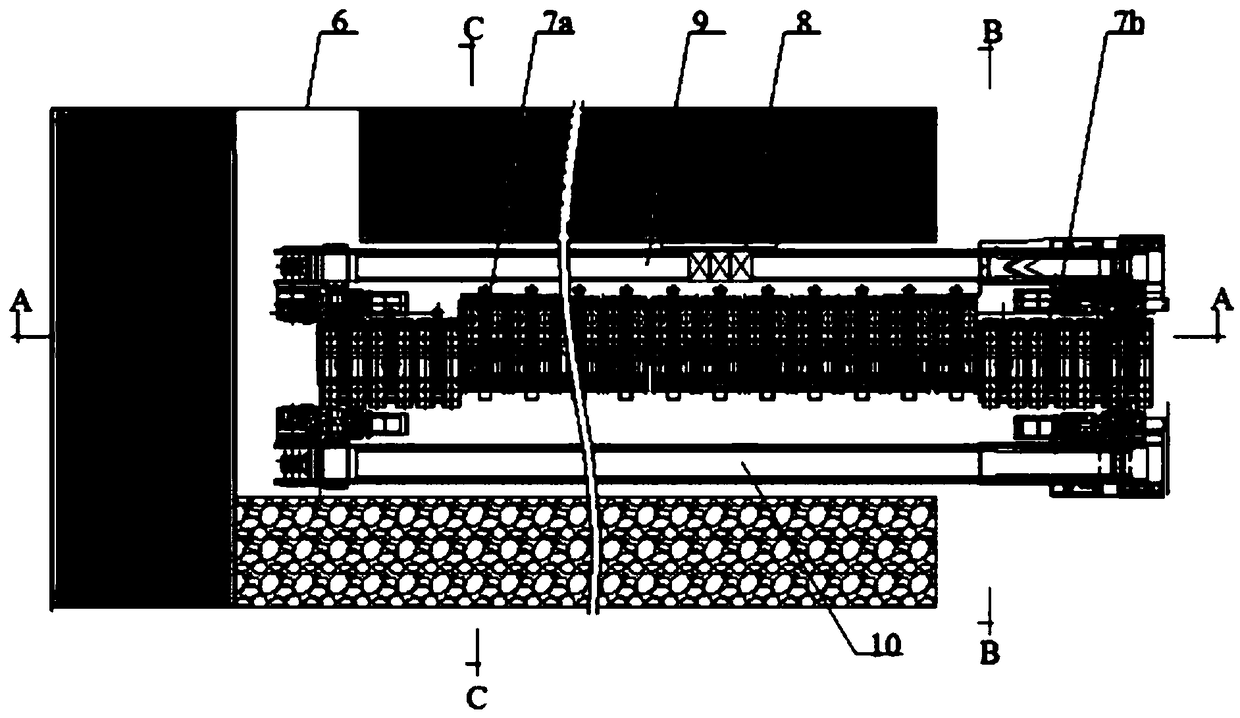

L-shaped fully-mechanized caving mining method and early-warning monitoring method for extremely-thick coal seam under slope of open-pit mine

InactiveCN108756887AAdaptableRealize one-time full-layer miningMining devicesOpen-pit miningGeomorphologySynthetic aperture radar

The invention discloses an L-shaped fully-mechanized caving mining method and early-warning monitoring method for an extremely-thick coal seam under a slope of an open-pit mine. The L-shaped fully-mechanized caving mining method and early-warning monitoring method comprises the following steps that a non-internal-discharging area is reserved in an open-pit mine pit, and the open-pit slope of the non-internal-discharging area is subjected to slope surrounding rock reinforcement; a working face cut hole and a transportation crossheading are sequentially tunneled along a bottom plate of the coalseam until reaching the boundary of the open-pit slope, and L-shaped longwall working face arrangement is formed; one end of the transportation crossheading communicates with a stoping working face, the other end of the transportation crossheading communicates with a mine ventilation system, and an internal top coal caving hydraulic support is arranged in the stoping working face; fully-mechanizedequipment is mounted in the stoping working face for stoping; an underground sound monitoring probe is mounted on slope surrounding rock; and a fixing platform is arranged in the non-internal-discharging area in an erected mode, and a three-dimensional laser scanner and a foundation synthetic aperture radar are mounted on the fixing platform. The coal mining method is high in adaptability, less in investment, quick in effect, large in output of working face, high in production efficiency, safe and reliable.

Owner:TIANDI SCI & TECH CO LTD

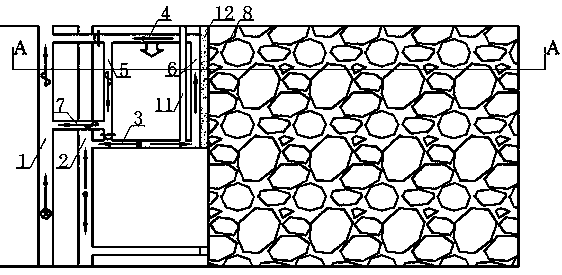

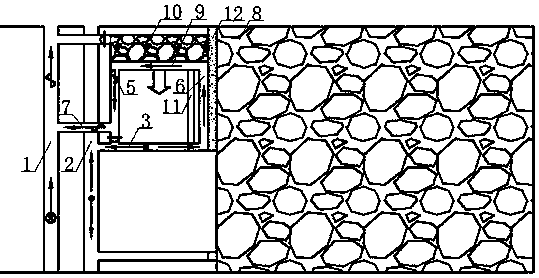

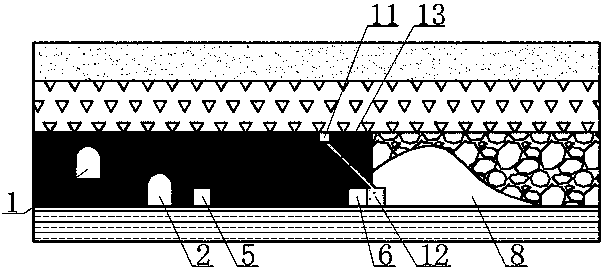

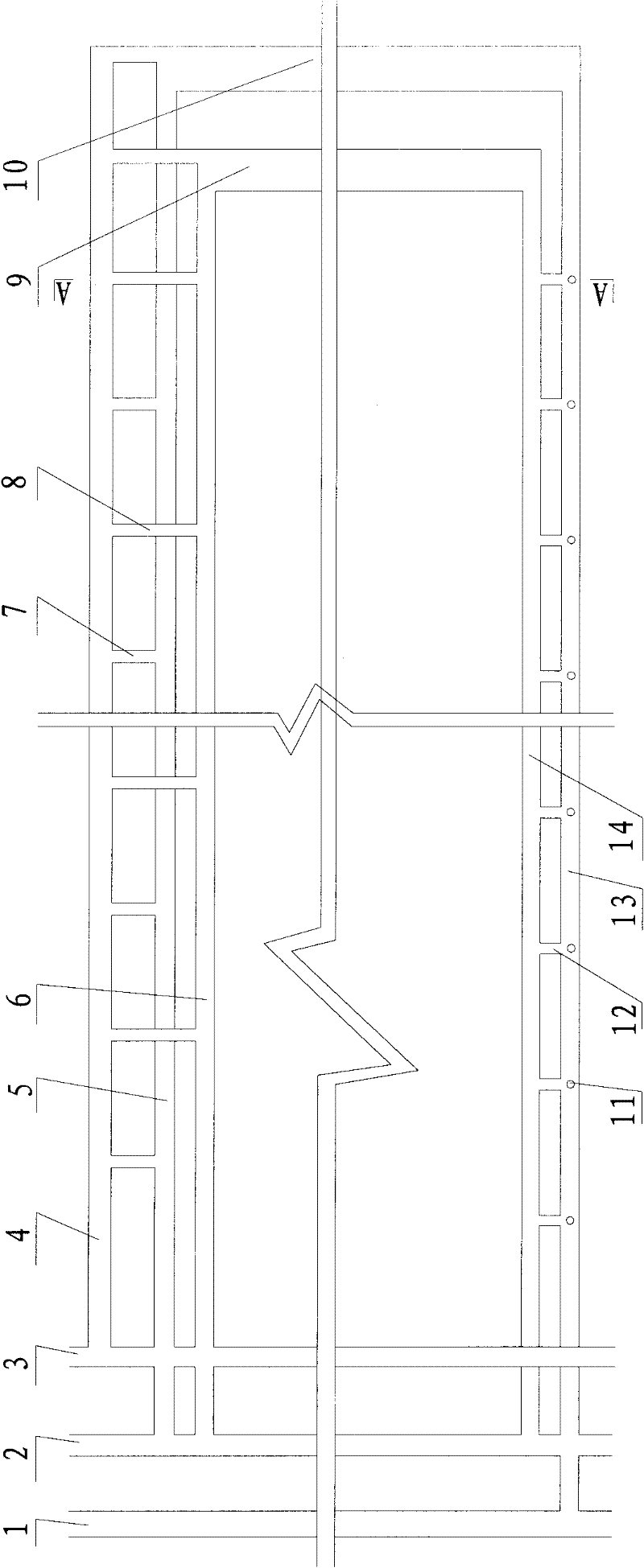

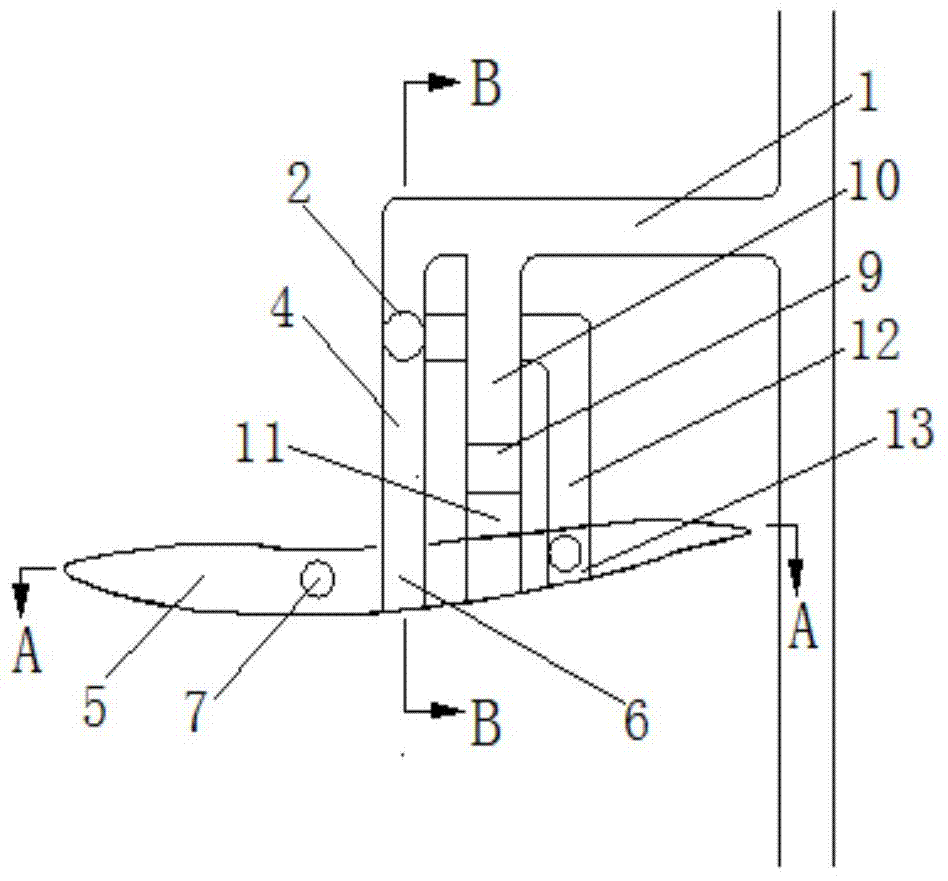

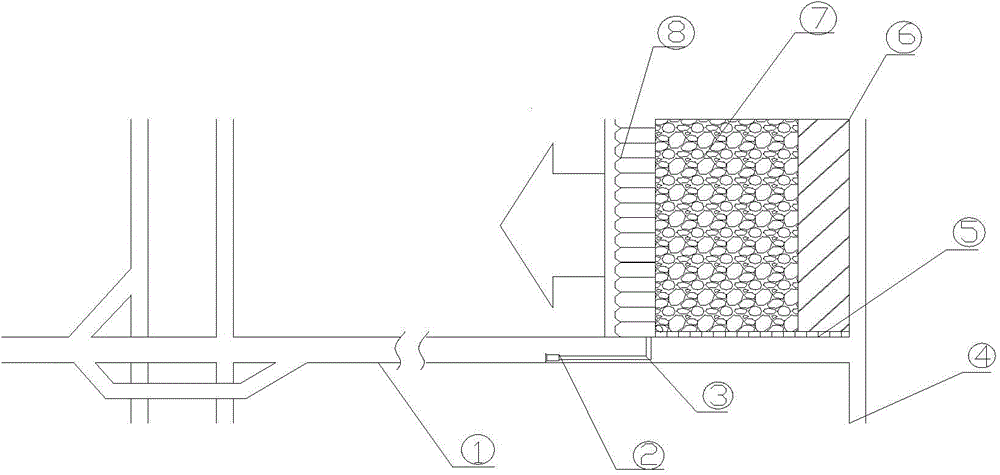

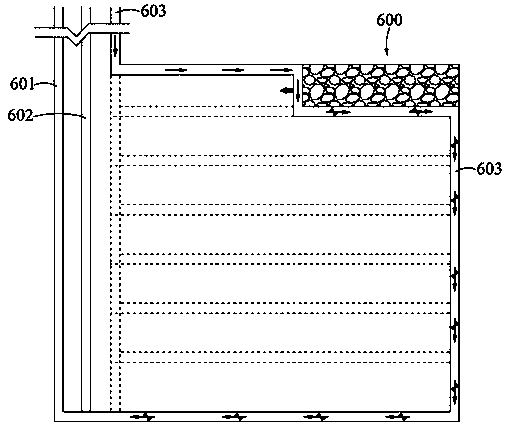

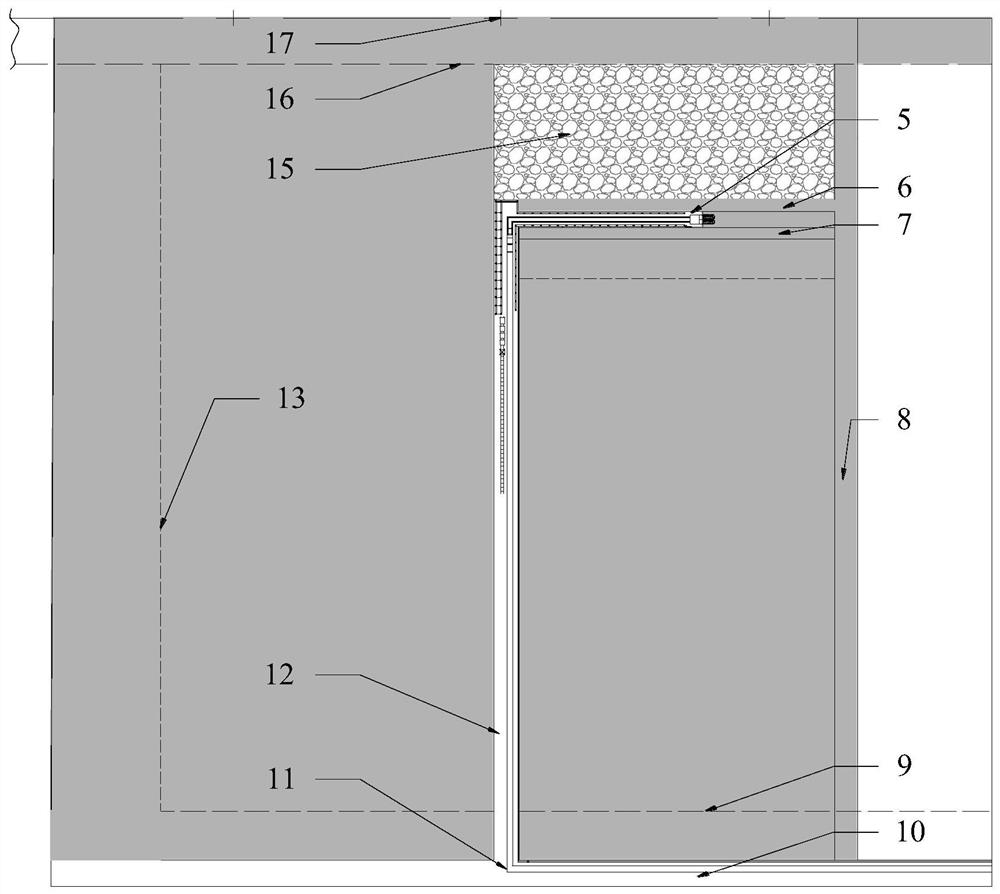

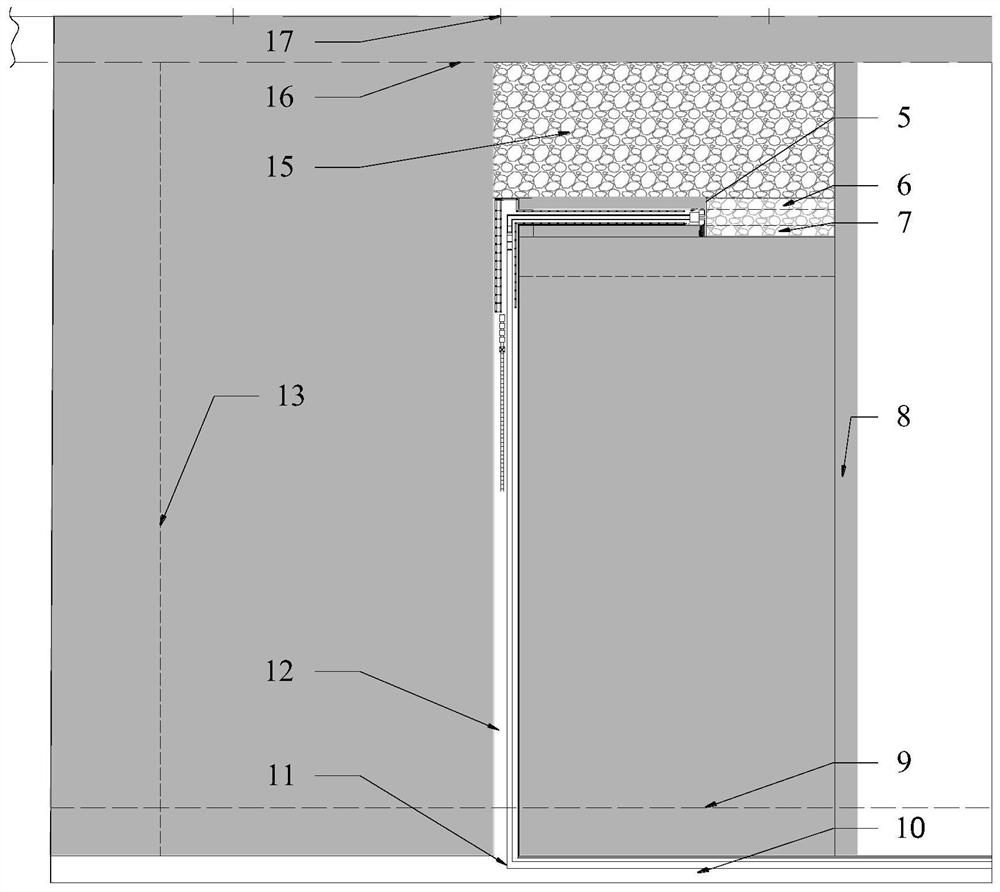

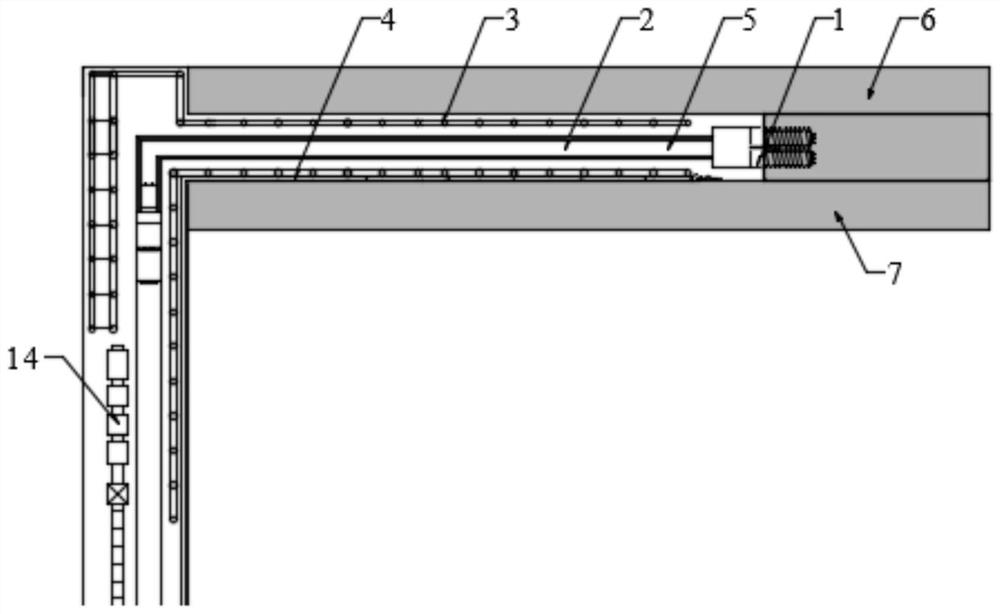

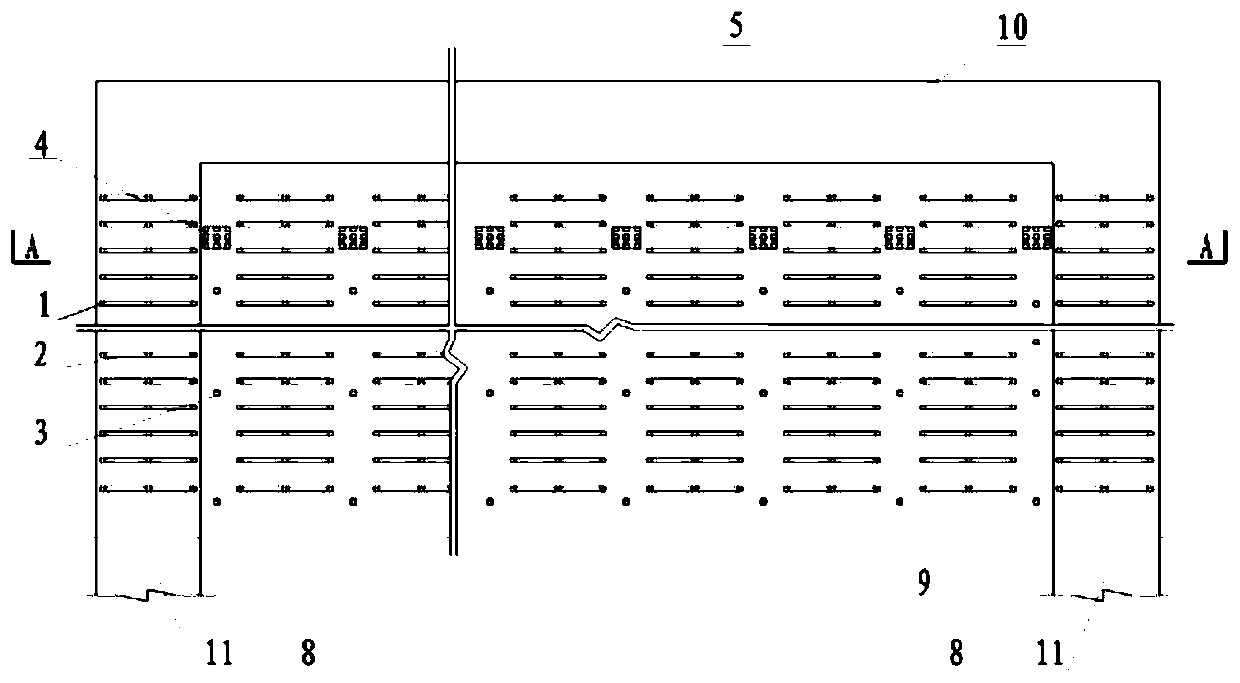

Local air return system capable of being quickly constructed

PendingCN107725093AImprove recovery rateReduce the amount of excavation workTunnel/mines ventillationWorking environmentShaft mining

The invention discloses a local air return system that can be quickly constructed, comprising a goaf filling layer, an ore body, a roadway along a vein, a return air shaft, and an air return duct. The roadway along a vein is arranged along the direction of the ore body, and the The goaf filling layer is arranged on the top of the vein roadway and its extension direction, and the return air duct is buried vertically or obliquely in the goaf filling layer, and the lower end of the return air duct is connected to the roadway along the vein or extends to the extension of the roadway along the vein direction and the upper end is connected to the return air shaft. The present invention buries the air return duct by using the goaf filling area on the upper part of the pre-mined ore body, and connects the air return duct and the air return shaft to the return air system in the mining area to form a local return air system, thereby shortening the ventilation line and effectively reducing the return airway The amount of excavation works is increased, the wind flow on the working surface is increased, the ventilation efficiency is improved, the air quality of the working environment is improved, and the production is effectively served. The invention has the characteristics of simple and reliable structure, low cost, convenient construction and high ventilation efficiency.

Owner:YILIANG CHIHONG MINING IND

Pre-pumping outburst prevention technology utilizing drill hole instead of stone drift

InactiveCN103670498ASave roadway engineering and underground drilling engineeringSimplify production and auxiliary systemsFluid removalGas removalCoal miningVertical segment

A pre-pumping outburst prevention technology utilizing a drill hole instead of stone drift comprises the following steps that firstly, , a pumping and exploiting drill hole and an engineering drill hole are formed in the ground through a drilling machine used on the ground, the pumping and exploiting drill hole is a vertical full hole casing pipe, the engineering drill hole comprises a vertical section, a deflecting section, a horizontal section and a horizontal fracturing section, and the casing pipe is placed into the vertical section and the deflecting section to fix a well; secondly, the horizontal fracturing section is then built after the horizontal section of the engineering drill hole and the pumping and exploiting drill hole are communicated; thirdly, high-pressure fracturing fluid is injected into a horizontal fracturing hole through a ground high-pressure pump, and a horizontal hole in the horizontal fracturing section is fractured; fourthly, a pumping and exploiting device is installed to pump and exploit coal mining lane stripe gas. The underground coal layer bottom board rock stone drift is replaced by the ground deflecting drill hole, puncturing layer hole pumping and exploiting is replaced by coal layer bottom board fracturing releasing, the ground of coal road stripe gas pre-pumping outburst prevention work of coal mine gas area comprehensive treatment is achieved, and the purpose of safe, efficient, low-consumption, energy-saving, emission-reducing and environment-friendly coal mine production is achieved.

Owner:ANHUI HAOHUI ENERGY TECH

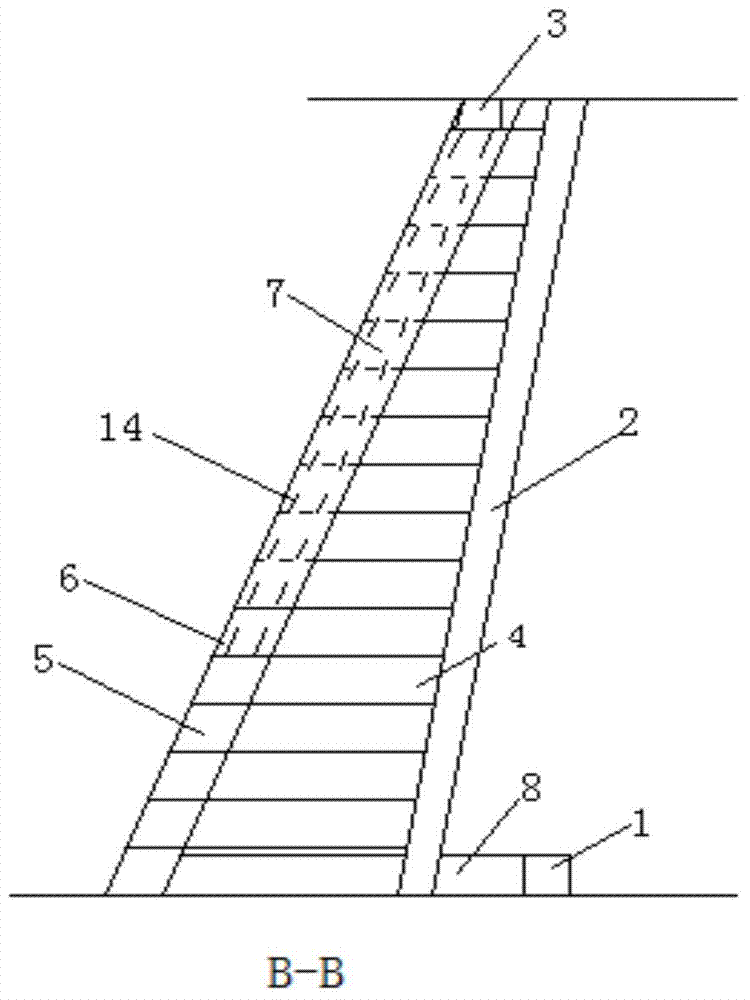

Slope ramp arrangement method applied to overhand cut-and-fill mining method stope

ActiveCN109505604AReduce the amount of excavation workSolve the nearby filling problemUnderground miningSurface miningEngineeringCut and fill

The invention discloses a slope ramp arrangement method applied to an overhand cut-and-fill mining method stope. The method comprises the following steps that when an ore body is stoped by an overhandcut-and-fill mining method, at one side of the stope, a returning type slope ramp is reversely and upwards dug from a lower horizontal middle section roadway; the slope ramp and each layer of the stope are communicated through short communication passages; the slope ramp is constructed section by section along with the rising of layered stoping of the stope until being communicated with the upperhorizontal middle section roadway; the slope ramp is used as the safe passage of the stope and a shovel conveyor transfer layer passage during the stope layered stoping; after the stope layered stoping is completed, the slope ramp is used as a main slope ramp between the upper horizontal middle section roadway and the lower horizontal middle section roadway. The digging and mining ratio is reduced; the nearest filling of the filling waste stone can be realized; important significance is realized for reducing the production cost and realizing the energy-saving environmental-friendly treatmentof the waste stone.

Owner:南京银茂铅锌矿业有限公司

Sectional filling mining method without pull slot

ActiveCN104453904BFlexible control of exposure areaEffective collapseUnderground miningSurface miningEngineeringOperating time

The invention provides a kerve-free sublevel filling mining method. The kerve-free sublevel filling mining method specifically comprises the following steps: dividing sublevel chambers and splitting ore blocks, carrying out mining preparation and cutting engineering arrangement, carrying out kerve explosion, firstly carrying out extraction and filling operation of splitting ore blocks, carrying out extrusion groove explosion to form a cutting groove during extraction of adjacent ore blocks, utilizing a compensation space formed by extrusion explosion to carry out normal explosion extraction operation, after the extraction of a second splitting ore block, entering the next adjacent splitting ore block, forming the cutting groove through extrusion groove explosion, carrying out extraction, and cycling the extraction process of the adjacent ore blocks. Kerve-free explosion is adopted from the second splitting ore to form a stope cutting groove; compared with a normal cutting kerve method, the engineering of cutting a level and cutting a dooryard is eliminated, the operating time is reduced, the stope extraction period is reduced, the mining operation cost is reduced, the stope labor efficiency is improved, the method is suitable for mining ore deposits with poor stability of surrounding rock, and stope top base plate and hanging side surrounding rock collapse can be effectively controlled.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

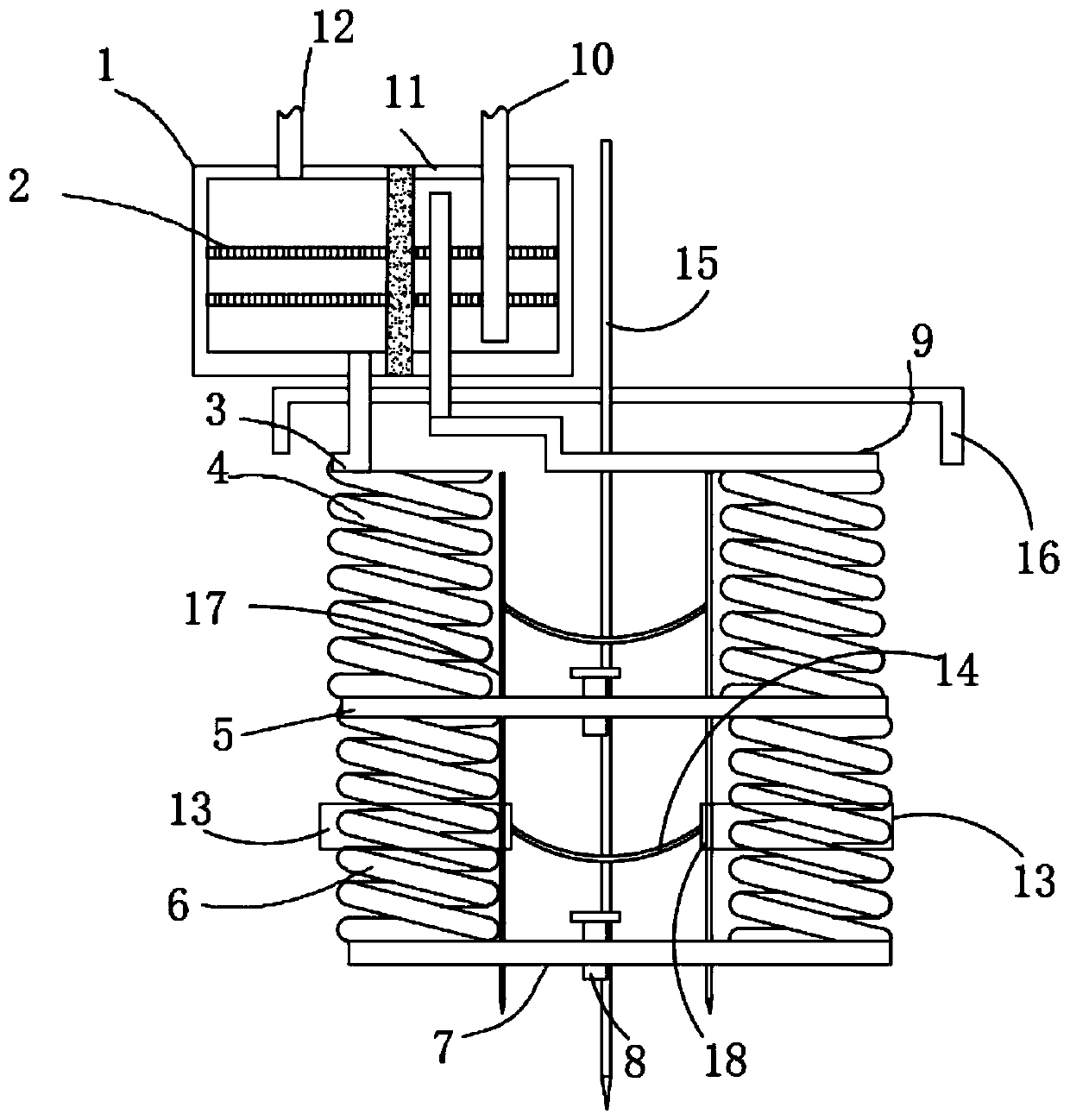

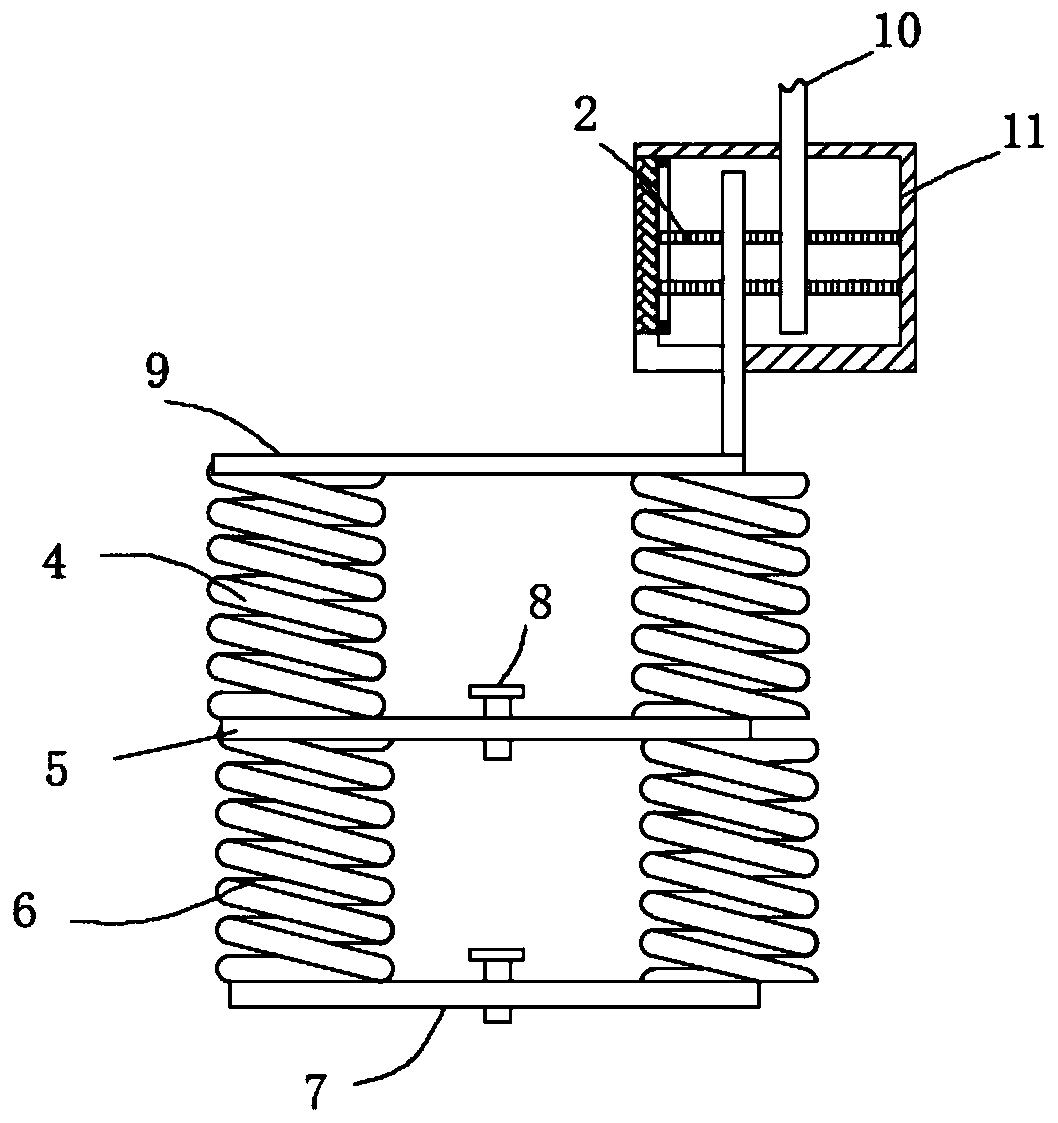

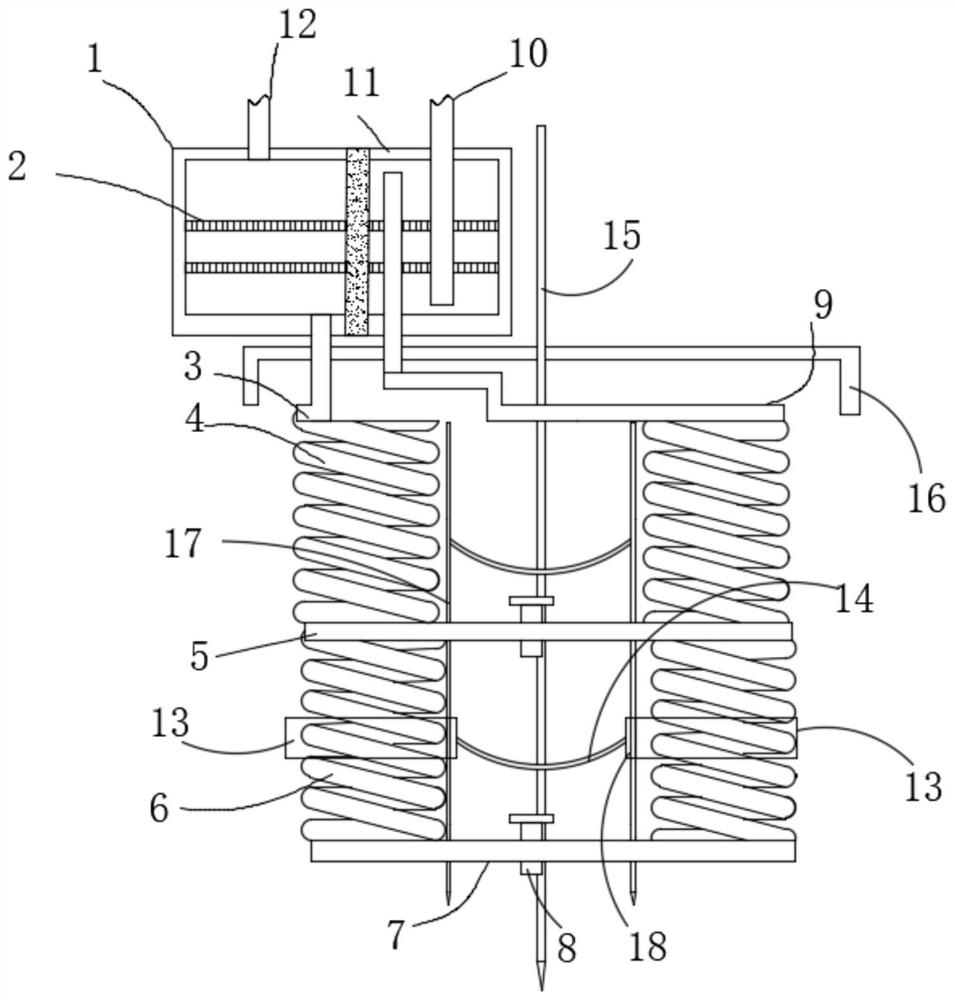

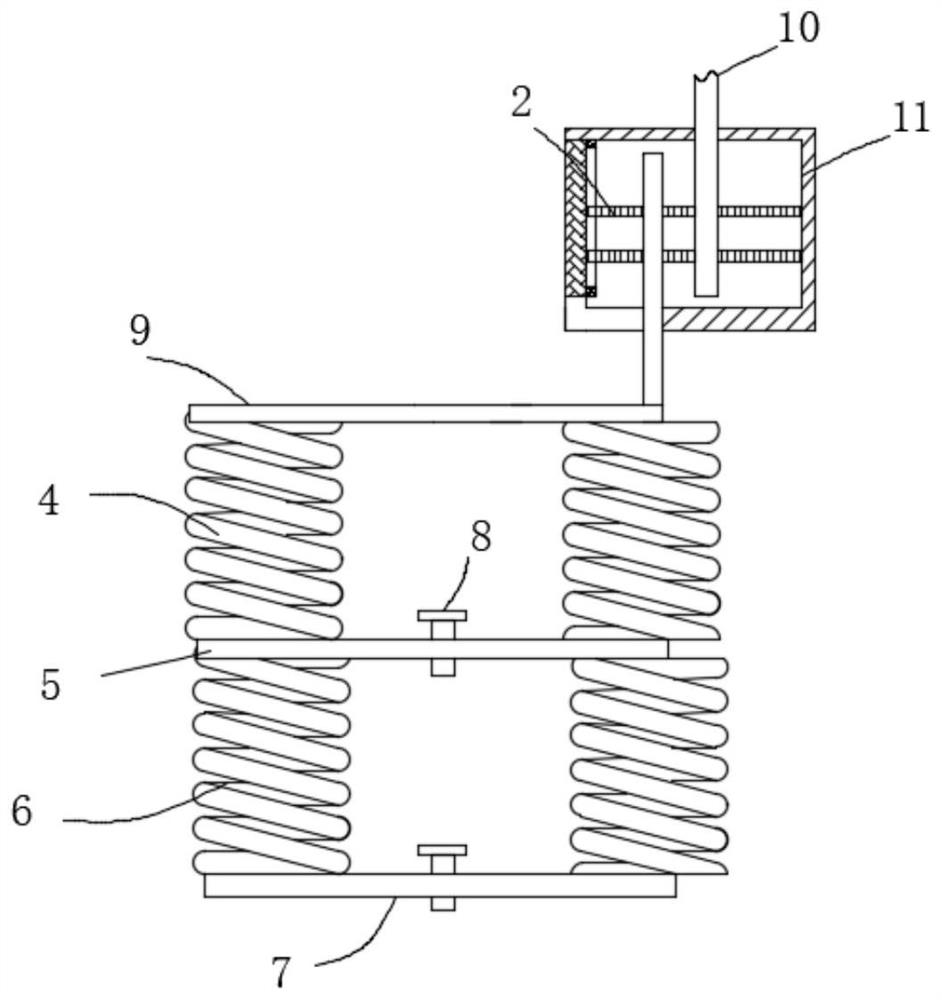

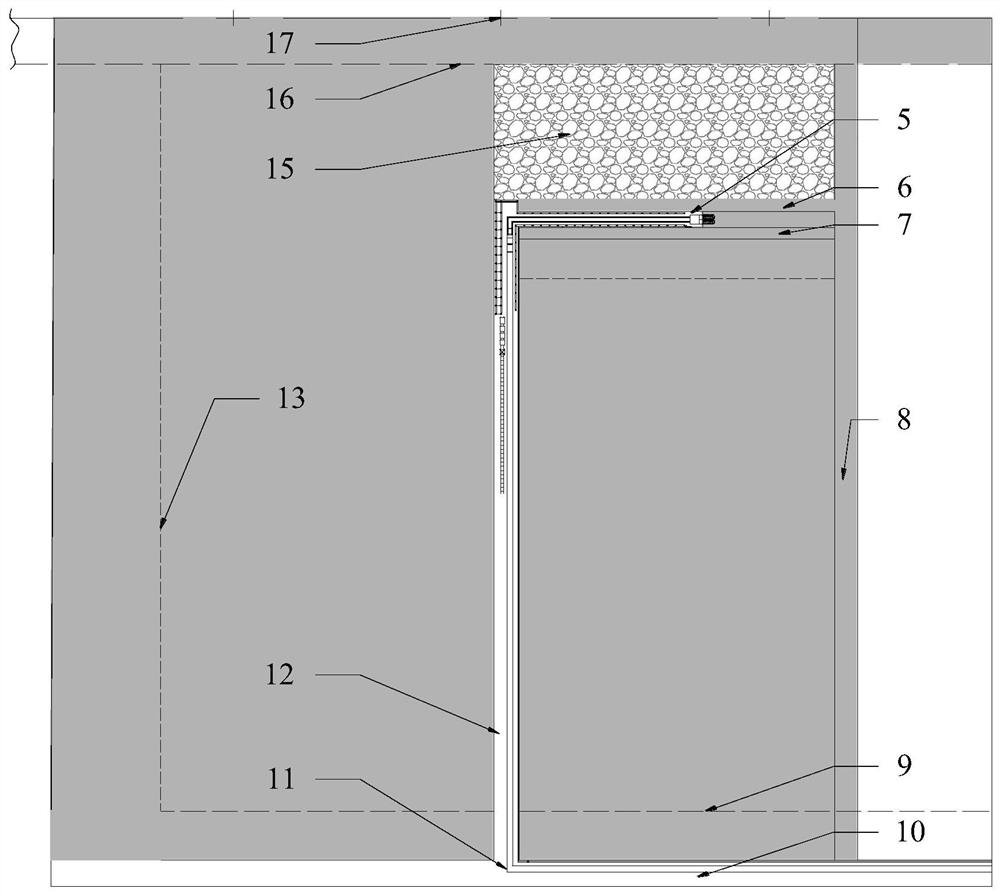

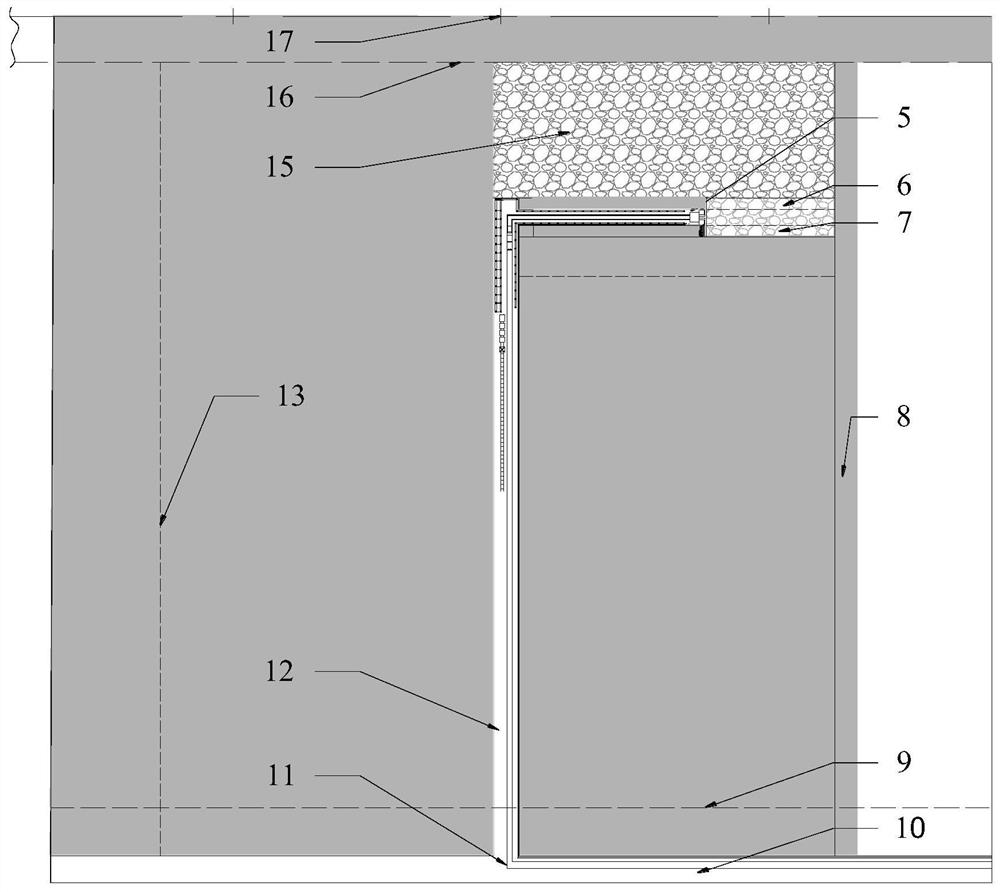

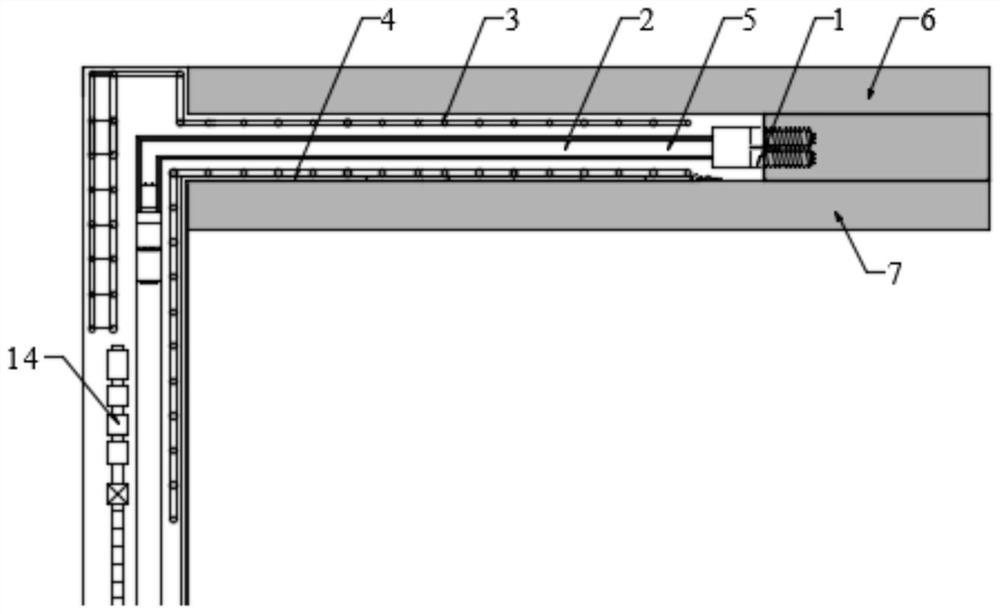

Buried pipe heat exchanger of small ground source heat pump and buried hole entering method thereof

ActiveCN111536810ASolve the large amount of engineeringSolve efficiency problemsCollector components/accessoriesGeothermal energy generationEngineeringThermal water

The invention discloses a buried pipe heat exchanger of a small ground source heat pump, and relates to the technical field of heat pump devices. The buried pipe heat exchanger of the small ground source heat pump provides the following scheme for solving the problem that the existing engineering quantity is large, the buried pipe heat exchanger comprises a hot water tank and a cold water tank which are fixedly connected, filter plates are fixedly connected to the inner walls of the hot water tank and the cold water tank correspondingly, the upper side of the hot water tank is fixedly connected with a water inlet pipe, the bottom of the hot water tank is fixedly connected with a discharge pipe, the other end of the discharge pipe is fixedly connected with a plurality of first condensationpipes arranged in parallel, and the ends, away from the discharge pipe, of the first condensation pipes are connected with second condensation pipes and connecting pipes through tee joints, and the lower ends of the second condensation pipe are fixedly connected with communicating pipes. The buried pipe heat exchanger of the small ground source heat pump is simple in structure and convenient to use, the heat exchange function can be well achieved, the size is reduced, the excavation work amount is reduced, the cost is saved, meanwhile, the flow is controlled, and energy is saved.

Owner:潘碧琼

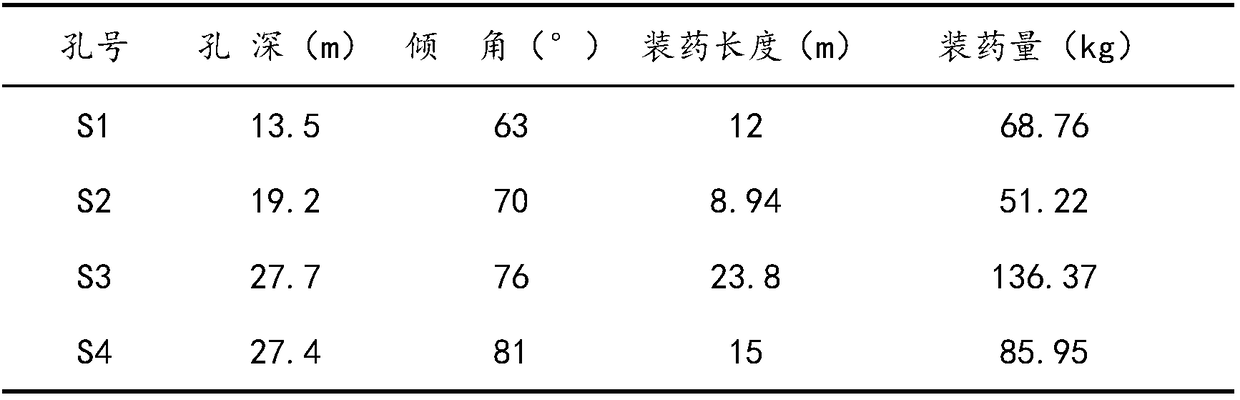

Method for achieving fine blasting by replacing vertical deep hole with downward fan-shaped deep hole

The invention provides a method for achieving fine blasting by replacing a vertical deep hole with a downward fan-shaped deep hole, and relates to the technical field of exploration. The method is characterized by comprising the following steps of stoping and rock drilling, optimization of stoping design, design of a stoping process for the downward fan-shaped deep hole, determination of blastingparameters, priming circuit connection, perforating deviation correction, determination of explosive charging requirements, and explosive charging and blasting. The method is reasonable, the workloadcan be reduced, the equipment utilization rate can be increased, and the working pace is quickened.

Owner:安徽马钢张庄矿业有限责任公司

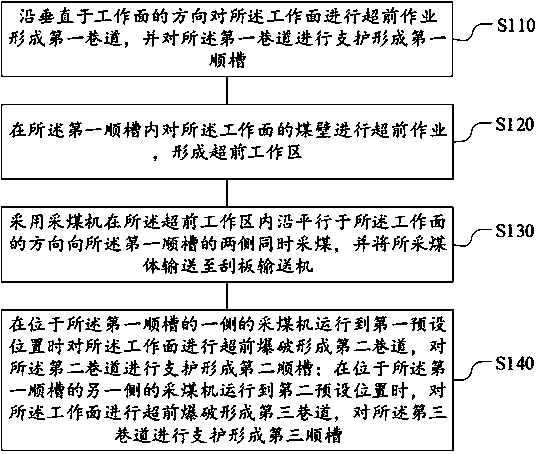

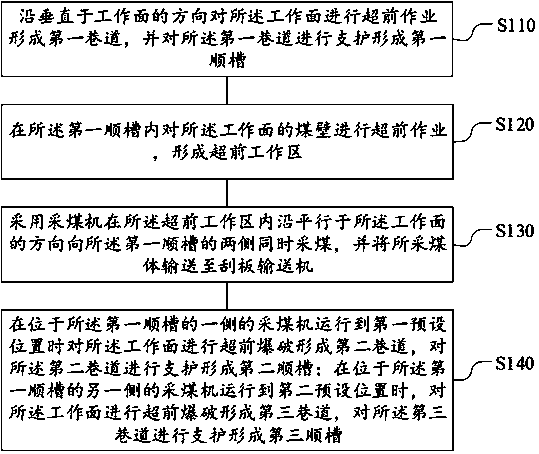

Ultra-thin coal seam longwall mining method based on N00 construction method

ActiveCN111219191AAvoid early excavationAvoid wastingUnderground miningTunnel/mines ventillationLongwall miningMining engineering

The invention provides an ultra-thin coal seam longwall mining method based on an N000 construction method, and relates to the technical field of mining. The ultra-thin coal seam longwall mining method includes the steps that advancing operation is performed on a working face in the direction perpendicular to the working face to form a first roadway, and the first roadway is supported to form a first gate road; an advance working area is formed in the first gate road; coal mining machines are adopted to simultaneously mine coal in the advance working area in the direction parallel to the working surface towards both sides of the first gate road, and a mined coal body is transported to a scraper conveyor; when the coal mining machine located on one side of the first gate road runs to a first preset position, the working face is blasted to form a second roadway, and the second roadway is supported to form a second gate road; and when the coal mining machine located on the other side of the first gate road runs to a second preset position, the working face is blasted to form a third roadway, and the third roadway is supported to form a third gate road. According to the ultra-thin coalseam longwall mining method based on the N000 construction method, roadway tunneling in advance can be avoided, the coal mining cost is reduced, the coal mining efficiency is improved, and the wasteof resources is avoided.

Owner:BEIJING ZHONGKUANG INNOVATION ALLIANCE ENERGY & ENVIRONMENTAL SCI RES INST

A buried tube heat exchanger of a small ground source heat pump and a method for inserting buried holes into the ground

ActiveCN111536810BReduce volumeReduce the amount of excavation workCollector components/accessoriesGeothermal energy generationThermodynamicsEngineering

The invention discloses a buried tube heat exchanger for a small ground source heat pump, which relates to the technical field of heat pump devices. Aiming at the existing problem of large engineering volume, the following scheme is proposed, which includes fixedly connected hot water tanks and cold water tanks , the inner walls of the hot water tank and the cold water tank are fixedly connected with filter plates, the upper side of the hot water tank is fixedly connected with a water inlet pipe, the bottom of the hot water tank is fixedly connected with a discharge pipe, and the other side of the discharge pipe One end is fixedly connected with a plurality of first condensation pipes arranged in parallel, and the end of the first condensation pipe away from the discharge pipe is connected with a second condensation pipe and a connecting pipe through a tee, and the lower end of the second condensation pipe is fixedly connected with a communication pipe. Tube, the present invention is simple in structure, easy to use, can carry out heat exchanging function very well, reduces volume, reduces excavation engineering quantity, saves cost, controls flow at the same time, saves energy.

Owner:潘碧琼

A kind of ultra-short-wall coal mining method

InactiveCN104088642BHigh recovery rateImprove coal cutting efficiencyUnderground miningSurface miningMining engineeringCoal pillar

The invention discloses a super-short-wall coal mining method. According to the super-short-wall coal mining method, a special air returning roadway for mining small coal pillars at a mining area boundary being about 4m wide is connected with an air returning main roadway and a transportation main roadway; a mining machine at the lower part of the coal pillar is in orbital connection with one roadway so as to be simultaneously used for transporting and introducing air; the roadway is internally provided with a scraper plate conveyor, a reversed loader, a rail and a partial ventilator; a fully mechanized coal mining surface adopts a super-short machine body single-roller coal mining machine with a rocker arm in the middle of a machine body and a fully mechanized coal mining hydraulic bracket is improved; a flexible blower dryer is suspended below a top beam; an independent-head roadway is used for ventilating and the partial ventilator is matched to ventilate in a pressing-in manner. A goaf is treated by adopting a full caving method in a manner of arranging a remained gateway along goaf at the lower side of the goaf. On the basis of reasonably solving the basic problems of a transportation system, a ventilation system and a material transporting and recrement discharging system, the problem that the coal mining machine repeatedly passes through a fault when being used for cutting coal is avoided; the work amount of the roadway is reduced, the boundary coal can be flexibly recycled and the recovery rate is increased.

Owner:SHANDONG UNIV OF SCI & TECH

Longwall Mining Method of Ultra-thin Coal Seam Based on n00 Construction Method

ActiveCN111219191BAvoid early excavationAvoid wastingUnderground miningTunnel/mines ventillationLongwall miningMining engineering

The present disclosure provides an extremely thin coal seam longwall mining method based on the N00 method, and relates to the technical field of mining. The mining method comprises the following steps: performing an advanced operation on a working face along a direction perpendicular to the working face to form a first roadway, supporting the first roadway to form a first trough; forming an advanced working area in the first trough; and using a shearer In the advanced working area, the coal is mined simultaneously on both sides of the first trough along the direction parallel to the working face, and the mined coal is transported to the scraper conveyor; the shearer on one side of the first trough runs When reaching the first preset position, the working face is blasted to form a second roadway, and the second roadway is supported to form a second trough; the shearer on the other side of the first trough runs to the second preset position. When in position, blast the working face to form the third roadway, and support the third roadway to form the third trough. The mining method of the present disclosure can avoid excavating the roadway in advance, reduce the cost of coal mining, improve the efficiency of coal mining, and avoid waste of resources.

Owner:BEIJING ZHONGKUANG INNOVATION ALLIANCE ENERGY & ENVIRONMENTAL SCI RES INST

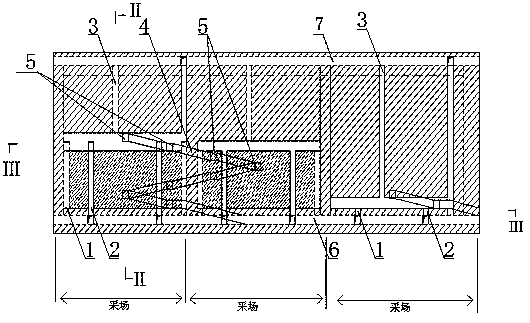

Mining, digging, transporting, supporting and ventilation integrated intelligent mining technology

ActiveCN111706329AReduce the amount of excavation workSimple work surface layoutUnderground miningSurface miningRock tunnelProcess engineering

The invention discloses a mining, digging, transporting, supporting and ventilation integrated intelligent mining technology. The working surface arrangement manner is simplified, so that the tunneling work amount of a half-coal-rock tunnel is reduced effectively; and unmanned working surface mining with mining, digging, transporting, supporting and ventilation coordinated control is realized through automatic devices such as a double-drum coal cutter, a scraper conveyer capable of realizing right-angle turning, an automatic loading and unloading type support, a telescopic air duct and the like. Compared with traditional mining, the technology has the characteristics of simple working surface arrangement, low roadway tunneling rate, high coal production rate, high device automation degree,safe, capability of realizing efficient and intelligent mining and the like and has the broad popularization and application prospects.

Owner:CHINA UNIV OF MINING & TECH

Close-range thin coal layer simultaneous mining and parallel transporting method

InactiveCN102392640BReduce the amount of excavation workIncrease productionUnderground miningSlitting machinesCentralized managementCoal

The invention discloses a close-range thin coal layer simultaneous mining and parallel transporting method, aiming to solve the problems caused by layer mining of the existing close-range thin coal layers, such as resource waste, serious flood, difficult mining distribution of lower layer coal, long mining period, low yield, high tunneling and supporting difficulties, high cost and the like. The method is characterized by arranging a centralized transport roadway, a centralized track roadway and a centralized air return roadway along the coal layers or top and bottom plates of the coal layers, simultaneously arranging two coal faces on the close-range thin coal layers and simultaneously mining and transporting coal. The method has the following beneficial effects: simultaneous mining and centralized transporting of the upper and lower coal layers are realized; relative to layer mining, by adopting the method, the tunneling quantities of the roadways are reduced, a belt conveyer can be simultaneously omitted, and the convenience is provided for centralized management of production; and especially for the close-range thin coal layers, the production system is simplified, the convenience is provided for centralized management, the production cost is lowered, and the mine output and the production efficiency are improved.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

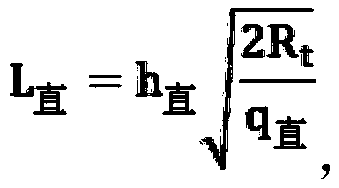

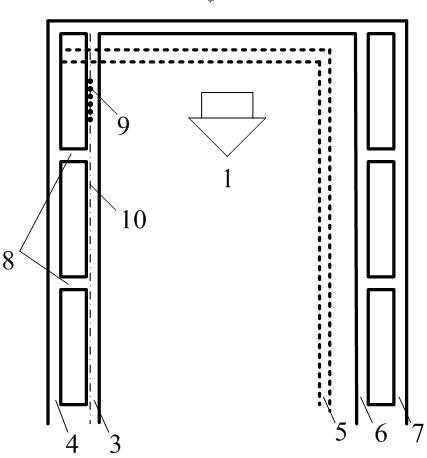

A kind of advancing coal mining method adopting goaf roof support in underground coal mine

ActiveCN108979687BAvoid cycleCaving controlUnderground chambersTunnel liningMining engineeringCoal pillar

The invention relates to a support method for a top board in an underground coal mine, belonging to the technical field of mining technology and environment protection. The method comprises the following steps: acquiring an initial caving step pitch of an immediate roof of a working surface, an initial fracture step pitch of an upper roof, lithological characters and thicknesses of the immediate roof and the upper roof in the underground coal mine; according to the initial caving step pitch of the immediate roof, synchronously supporting the immediate roof of a goaf through anchor rods, anchorbeams and anchor cables during formation of the goaf; adopting an anchor cable group to support the upper roof through the immediate roof of the goaf when the unsupported roof distance of the goaf isless than the initial fracture step pitch range of the upper roof; and determining the model, the length and the inter-row space of the anchor cable group till finishing advancing of a working surface; as the working surface is advanced, keeping a crossheading in the working surface in the goaf in order to form passages for production, ventilation, transport, drainage and safety and till advancing of the working surface is finished. A forward-type coal mining method adopting the top board to support in the goaf of the underground coal mine has features such as no coal column and tunnel; a simple method; and easy operation. Additionally, the top board is controlled not to collapse.

Owner:BEIJING YZH COAL ENG DESIGN

An integrated intelligent mining process for mining, transportation, branch and communication

ActiveCN111706329BOptimize layoutReduce the rate of penetrationUnderground miningSurface miningProcess engineeringMachine

The invention discloses an intelligent mining technology integrating mining, transportation, support and communication, which effectively reduces the excavation engineering volume of semi-coal and rock roadways by simplifying the layout of the working face, adopts double-drum coal cutters, scraper conveyors that can turn at right angles, and automatic loading and unloading Automatic equipment such as vertical support and telescopic air duct realizes unmanned working face mining with coordinated control of mining, transportation and support; compared with traditional mining, this method has the advantages of simple working face layout, low roadway excavation rate, high coal recovery rate, and equipment automation. High, safe and efficient intelligent mining and other characteristics, has broad prospects for promotion and application.

Owner:CHINA UNIV OF MINING & TECH

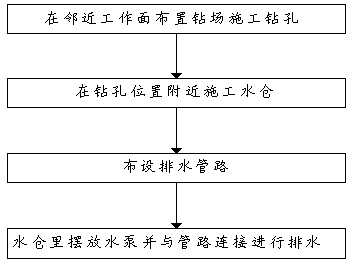

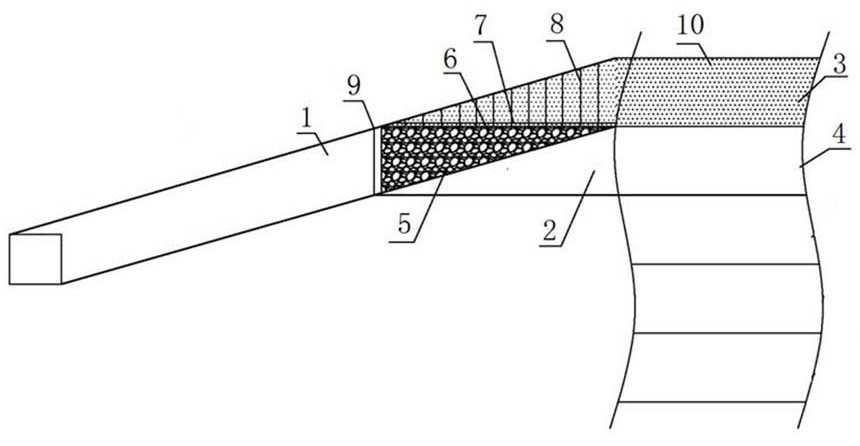

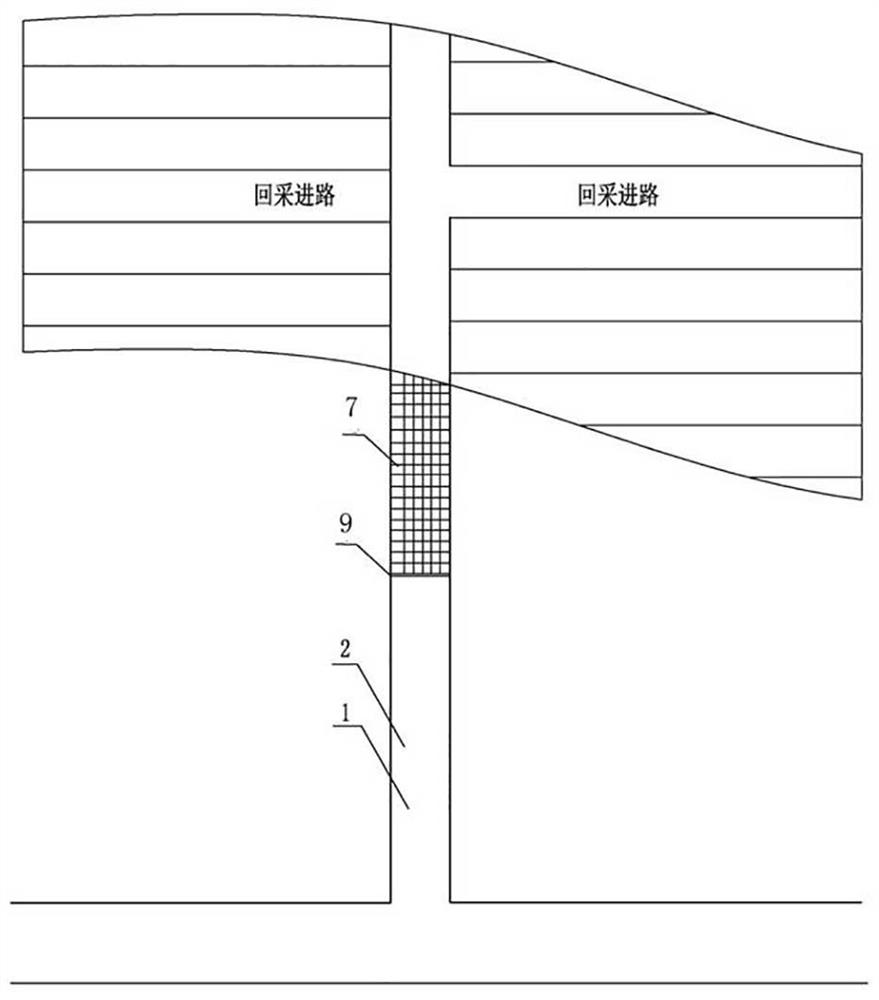

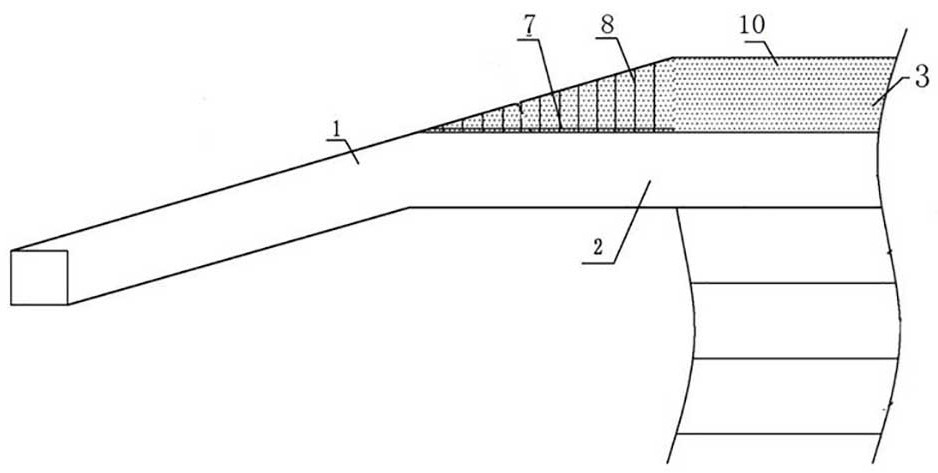

Method for underground coal mine sequential mining working face hysteresis drilling drainage

InactiveCN110886620AShorten production timeReduce the amount of excavation workDrainageMining engineeringSequential mining

The invention relates to a method for underground coal mine sequential mining working face hysteresis drilling drainage. The method comprises the following specific steps of (1) arranging a drill field for constructing drilled holes near the working face; (2) constructing a water bin near the positions of the drilled holes; (3) laying a drainage pipeline; and (4) placing a water pump in the waterbin, and connecting the water pump with the pipeline for drainage. According to the method, a drainage tunnel is eliminated, the tunneling work amount and investment are reduced, and the production time of a stoping working face is shortened.

Owner:SHAANXI BINCHANG WENJIAPO MINING IND CO LTD

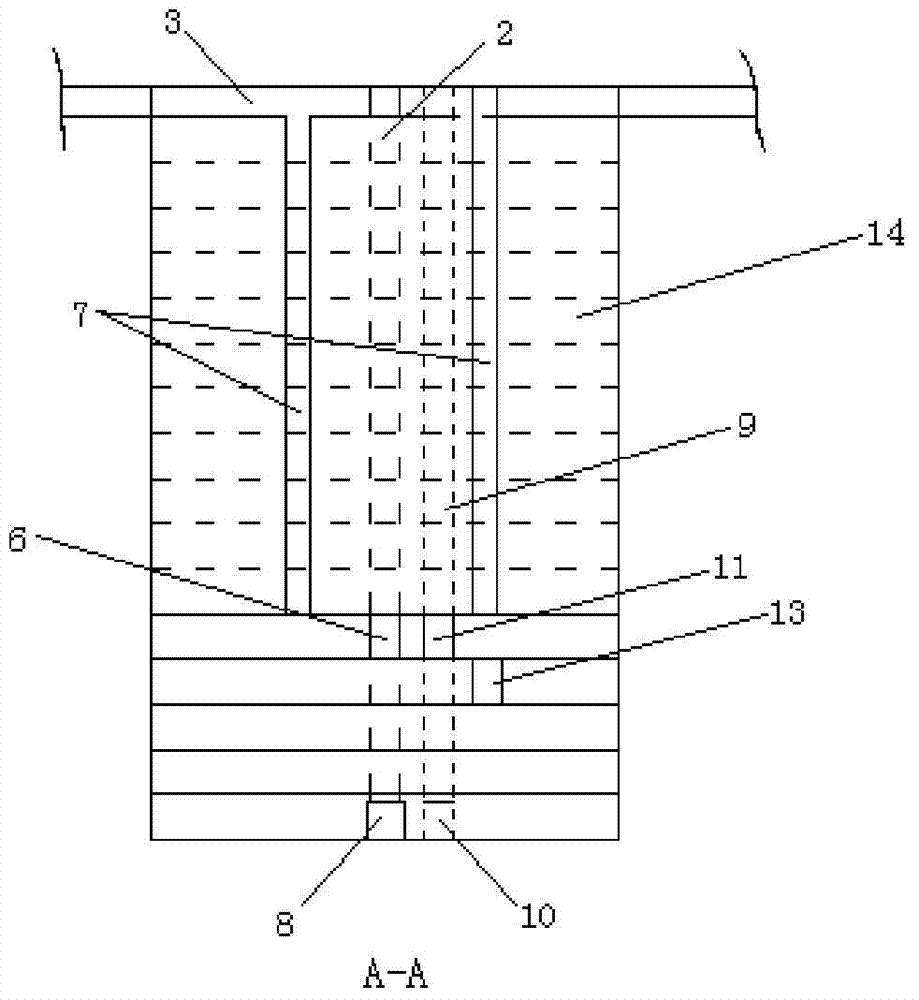

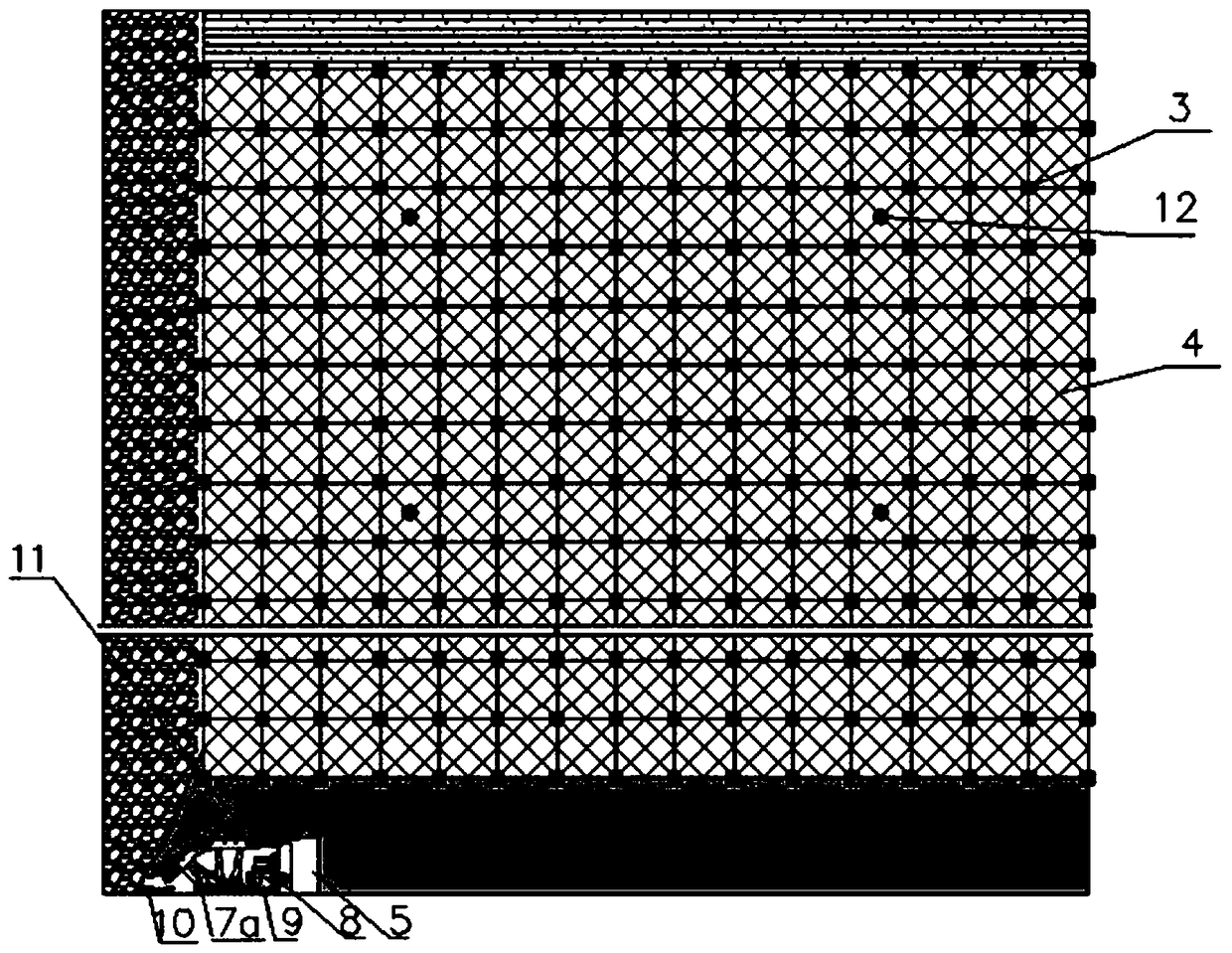

Method for constructing layer connection roadways by top slicing and cemented filling mining process

ActiveCN113107588AReduce the amount of excavation workImprove securityMining devicesMaterial fill-upMesh reinforcementProcess engineering

The invention discloses a method for constructing layer connection roadways by a top slicing and cemented filling mining process. The operations from the step a to the step e are carried out on the layer connection roadway of a previous layer and an ore body of the previous layer, so that the layer connection roadway of the previous layer can be fully utilized by the layer connection roadway of a next layer; new layer connection roadways do not need to be tunneled again, so that the number of the newly tunneled layer connection roadways can be greatly reduced, the tunneling work amount is greatly reduced, and the problems that the layer connection roadways are difficult and complex to arrange and the opening positions of the layer connection roadways are difficult to select are solved; through the operations from the step a to the step e, a roof of the formed layer connection roadway of the next layer is a filling body formed by a reinforcing mesh, filling slurry and hanging reinforcing steel bars, the safety and the stability are good, and supporting is not needed any more; and the layer connection roadway of the previous layer is fully utilized by the layer connection roadway of the next layer, so that the tunneling work amount can be reduced, and the tunneling support cost can be reduced.

Owner:金川镍钴研究设计院有限责任公司 +1

The ramp layout method applied to the stope of upward layered filling mining method

ActiveCN109505604BReduce the amount of excavation workSolve the nearby filling problemUnderground miningSurface miningMining engineeringStructural engineering

The invention discloses a slope ramp arrangement method applied to an overhand cut-and-fill mining method stope. The method comprises the following steps that when an ore body is stoped by an overhandcut-and-fill mining method, at one side of the stope, a returning type slope ramp is reversely and upwards dug from a lower horizontal middle section roadway; the slope ramp and each layer of the stope are communicated through short communication passages; the slope ramp is constructed section by section along with the rising of layered stoping of the stope until being communicated with the upperhorizontal middle section roadway; the slope ramp is used as the safe passage of the stope and a shovel conveyor transfer layer passage during the stope layered stoping; after the stope layered stoping is completed, the slope ramp is used as a main slope ramp between the upper horizontal middle section roadway and the lower horizontal middle section roadway. The digging and mining ratio is reduced; the nearest filling of the filling waste stone can be realized; important significance is realized for reducing the production cost and realizing the energy-saving environmental-friendly treatmentof the waste stone.

Owner:南京银茂铅锌矿业有限公司

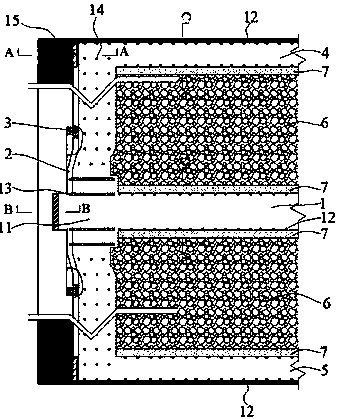

Method for reusing upper-layer working face roadway for lower-layer working face

ActiveCN113605919AReduce the amount of excavation workSolve wasteMaterial fill-upTunnelsMining engineeringMechanical engineering

The invention belongs to the technical field of coal mining, and particularly relates to a method for reusing an upper-layer working face roadway for a lower-layer working face. The method comprises the following steps of (S100) dividing a working face into an upper-layer working face and a lower-layer working face, mining the upper-layer working face first, and then mining the lower-layer working face; (S200) tunneling an upper-layer working face roadway; (S300) stoping the upper-layer working face; (S400) before the lower-layer working face is mined, filling a connection roadway so as to solve the roof contact problem and the goaf conduction problem when the lower-layer working face is stoped to the area; (S500) tunneling the lower-layer working face; and (S600) stoping the lower-layer working face. According to the method, the upper-layer working face roadway is reserved to be reused for the lower-layer working face, so that the problem of waste of roadway resources in a boundary area or a special area is solved, the roadway tunneling work amount is reduced, and the tension situation of mine excavation connection is relieved.

Owner:SHANXI JINMEI GRP TECH RESEACH INST

Outburst prevention method for close-distance coal seam group area of middling coal group

PendingCN114278363AReduce governance costsReduce the amount of excavation workGas removalMining engineeringMechanical engineering

The invention discloses an outburst prevention method for a close-distance coal seam group area of a middling coal group. The method comprises the steps that a gas drainage roadway is constructed, and drill holes are formed to conduct area pre-drainage on one or more coal seams at the same time. The problems that in the prior art, when gas treatment is carried out on areas with complex coal seam occurrence geological conditions, soft coal seams and high gas pressure, construction conditions are limited, cost is high, the treatment period is long, comprehensive tunneling single-entry is low, drilling cannot be accurately positioned, and common drilling cannot be accurately positioned are solved.

Owner:GUIZHOU PANJIANG REFINED COAL

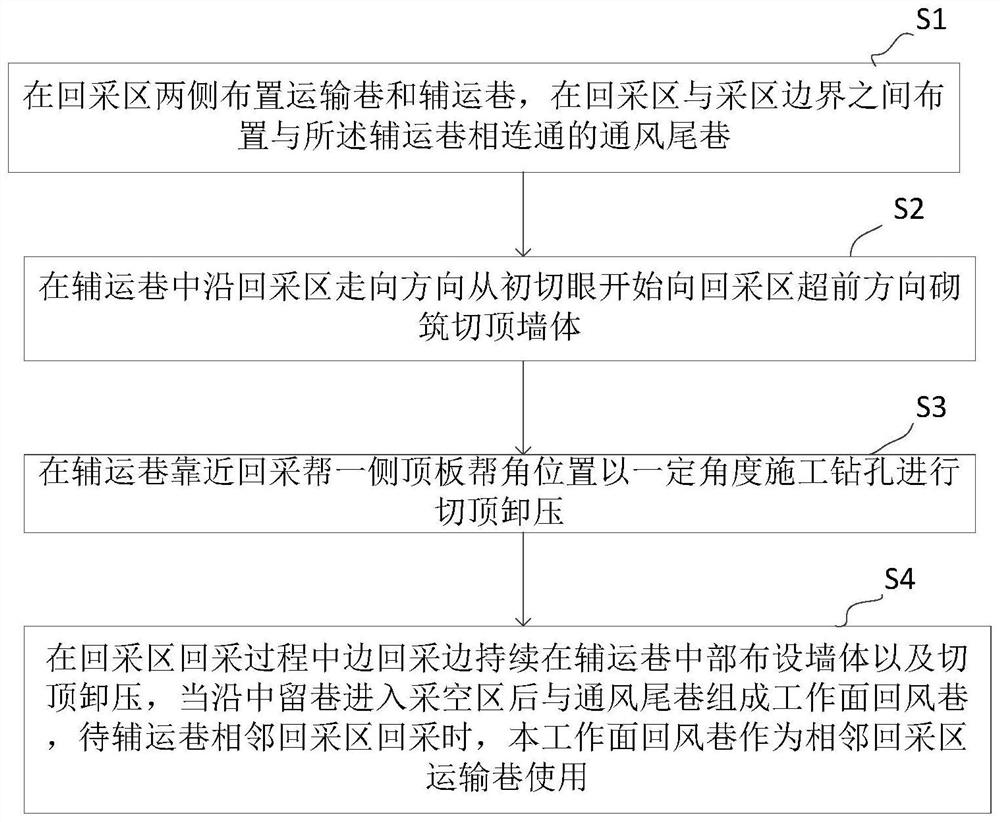

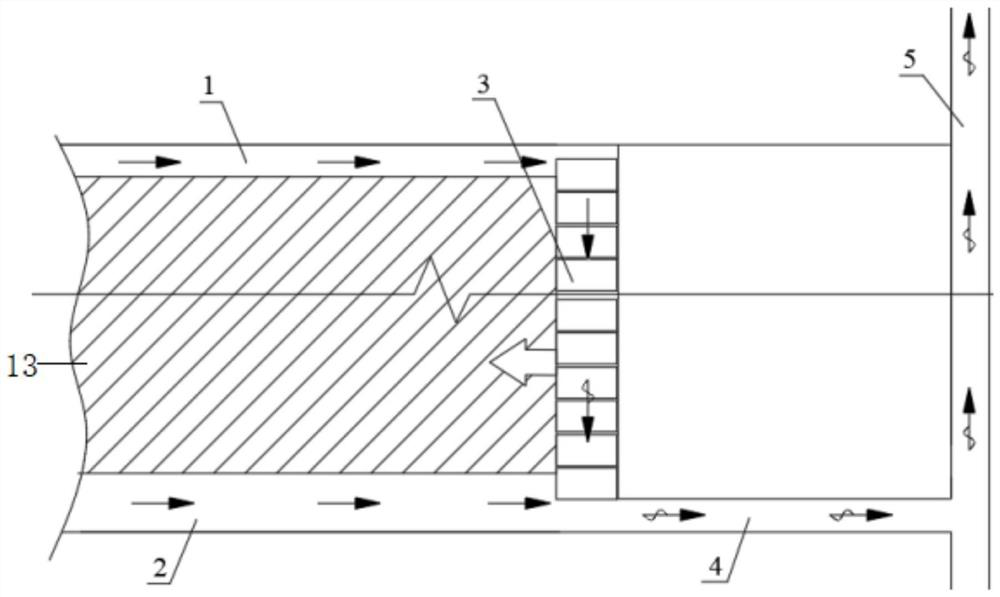

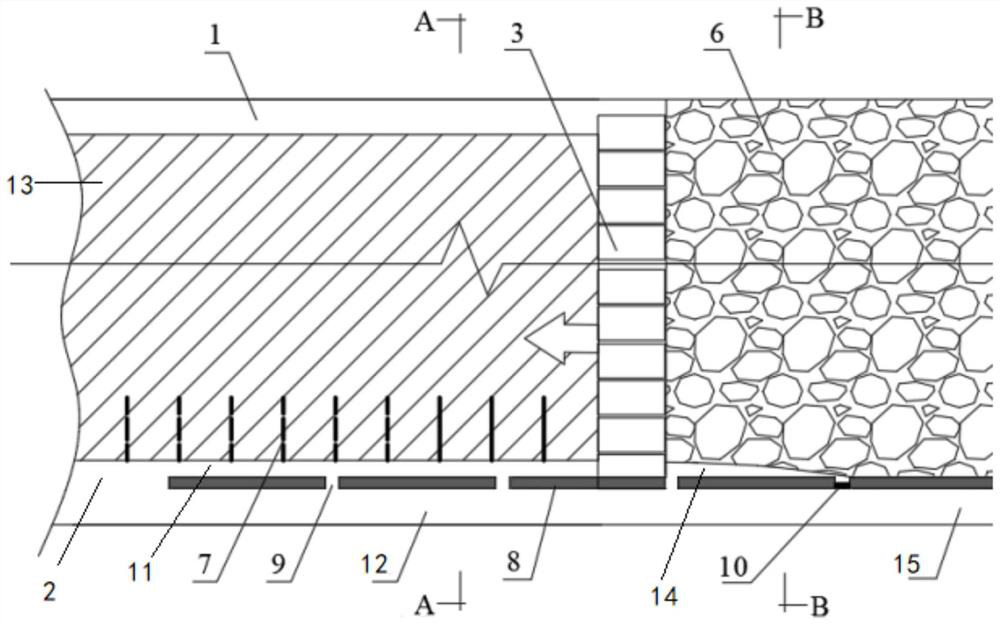

Arrangement method of strong dynamic pressure coal seam roadway along middle reserved wall body

PendingCN114165233ASolve technical problemsImprove one-shot molding rateUnderground miningTunnel/mines ventillationMining engineeringStructural engineering

The invention provides a method for arranging a strong dynamic pressure coal seam roadway along a middle reserved wall. The method comprises the steps that a transportation roadway and an auxiliary transportation roadway are arranged on the two sides of a stoping area, and a ventilation tail roadway communicating with the auxiliary transportation roadway is arranged between the stoping area and the boundary of the stoping area; a wall body with a cut top is built in the auxiliary transportation roadway in the length direction from the initial cut hole by a certain distance, so that the wall body divides the auxiliary transportation roadway into a reserved roadway and another middle retaining roadway; roof cutting and pressure relief are conducted at a certain angle at the top plate slope angle position, close to one side of the stoping slope, of the auxiliary transportation roadway; in the stoping process of the stoping area, wall laying and roof cutting pressure relief are continuously conducted in the middle of the auxiliary transportation roadway while stoping is conducted, a working face air return roadway is formed by a gob behind the working face along the middle retained roadway and the ventilation tail roadway, and when the adjacent working face is stoped, the working face air return roadway is used as a transportation roadway. A roadway arrangement process combining middle wall reserving and advanced pressure relief is adopted, so that the one-time forming rate of a roadway is high, the deformation of the roadway is small, and the ends are easy to maintain.

Owner:CCTEG COAL MINING RES INST +1

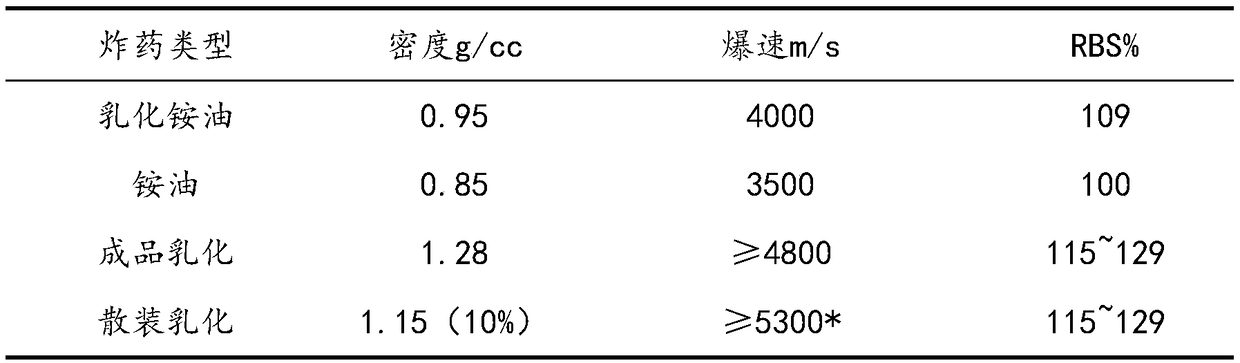

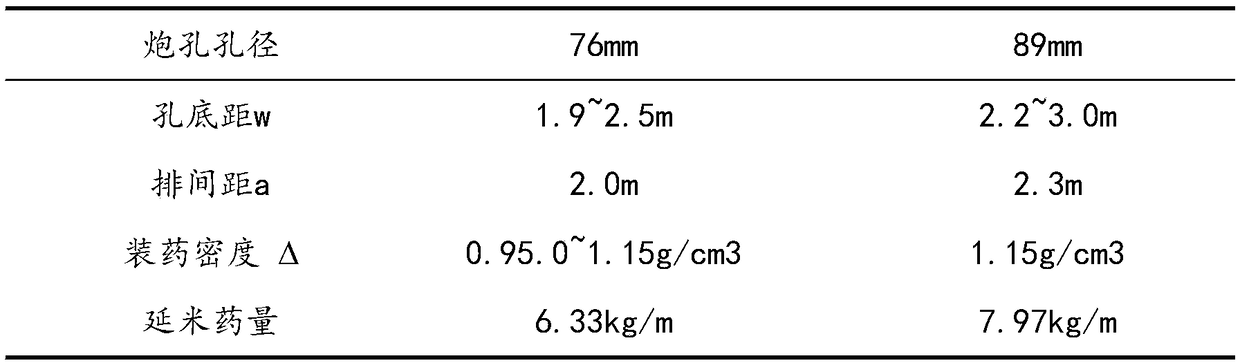

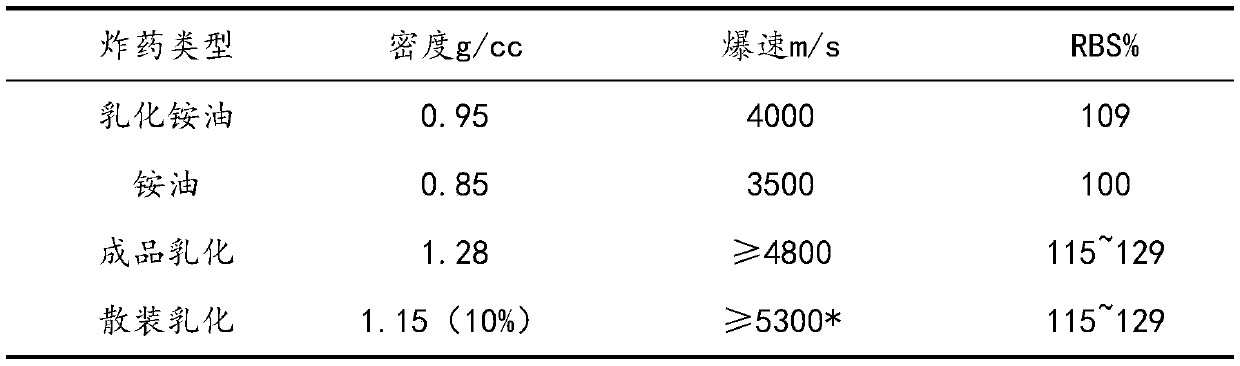

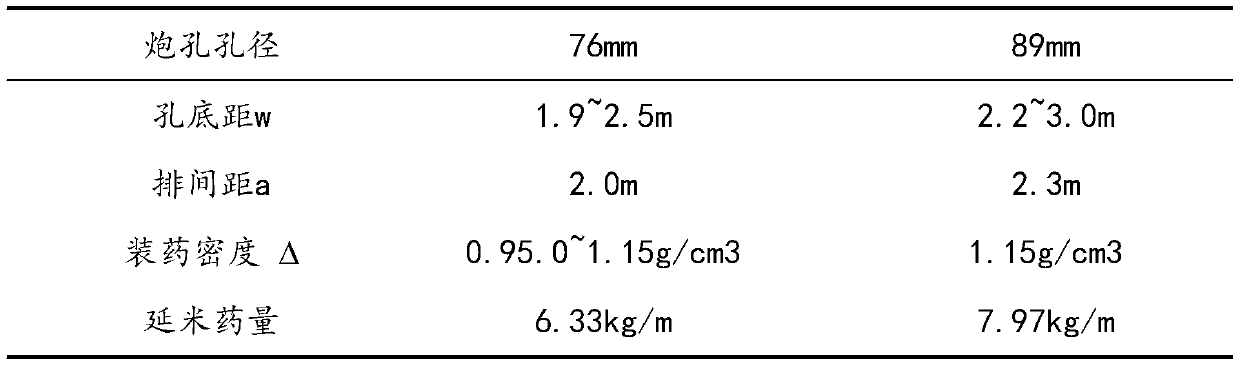

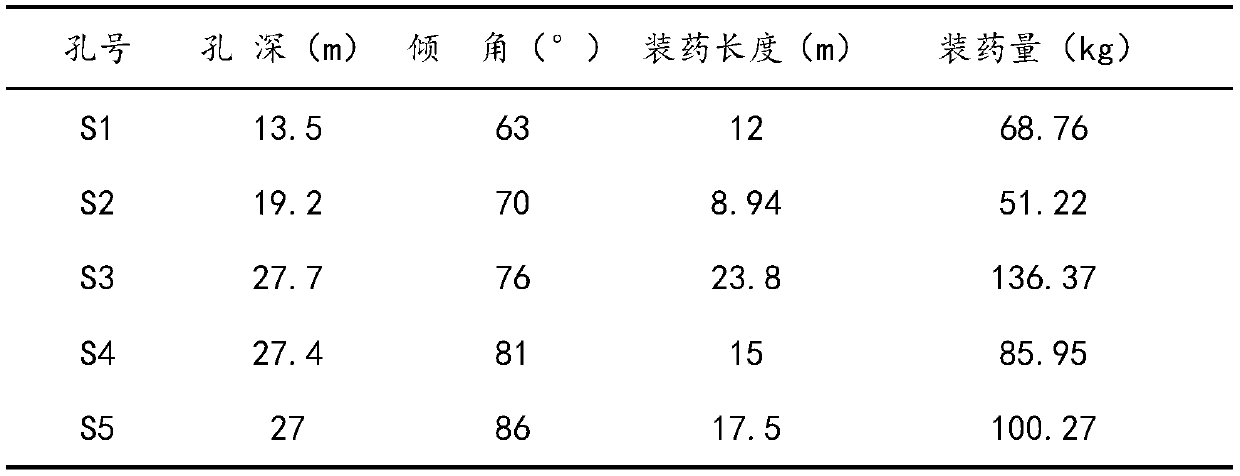

The fine blasting method of downward fan-shaped deep holes instead of vertical deep holes

ActiveCN108709467BReduce the amount of excavation workIncrease usageBlastingTEX-explosiveMining engineering

The invention provides a method for achieving fine blasting by replacing a vertical deep hole with a downward fan-shaped deep hole, and relates to the technical field of exploration. The method is characterized by comprising the following steps of stoping and rock drilling, optimization of stoping design, design of a stoping process for the downward fan-shaped deep hole, determination of blastingparameters, priming circuit connection, perforating deviation correction, determination of explosive charging requirements, and explosive charging and blasting. The method is reasonable, the workloadcan be reduced, the equipment utilization rate can be increased, and the working pace is quickened.

Owner:安徽马钢张庄矿业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com