Mining method for large-inclined angle laminar non-coal solid mineral deposit

A mining method and technology with a large inclination angle, which are applied in surface mining, underground mining, special mining, etc., can solve the problem of reducing the production speed and output of the longwall caving method, increasing the amount of rock excavation outside the vein, and the labor intensity of support work. and other problems, to achieve the effect of improving the effective utilization rate, making full use of time, and reducing the amount of tunneling works.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

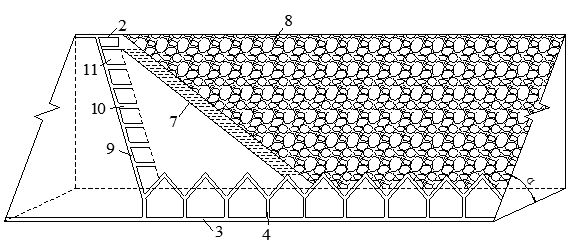

[0017] The mining method of the large-inclination layered non-coal solid ore deposit of the present invention first divides the large-inclination-angle layered non-coal solid ore deposit in the entire mining area into sections, and cuts the section ore deposits according to the conventional existing technology. 1. Section return air Headway 2, section transportation headway 3, closing eye 9, contacting headway 10, and a protective ore pillar 11 is left on the side of the closing eye 9 against the working face. Then, starting from the intersection of the cutout 1 and the section return air level roadway 2, set the pseudo-inclination angle β to 20°~30° along the advancing direction of the working face, and set the pseudo-inclination angle β from the return air level Lane 2 carries out mining in the direction of transport level lane 3, such as figure 1 Shown;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com