Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Reduce shaft voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

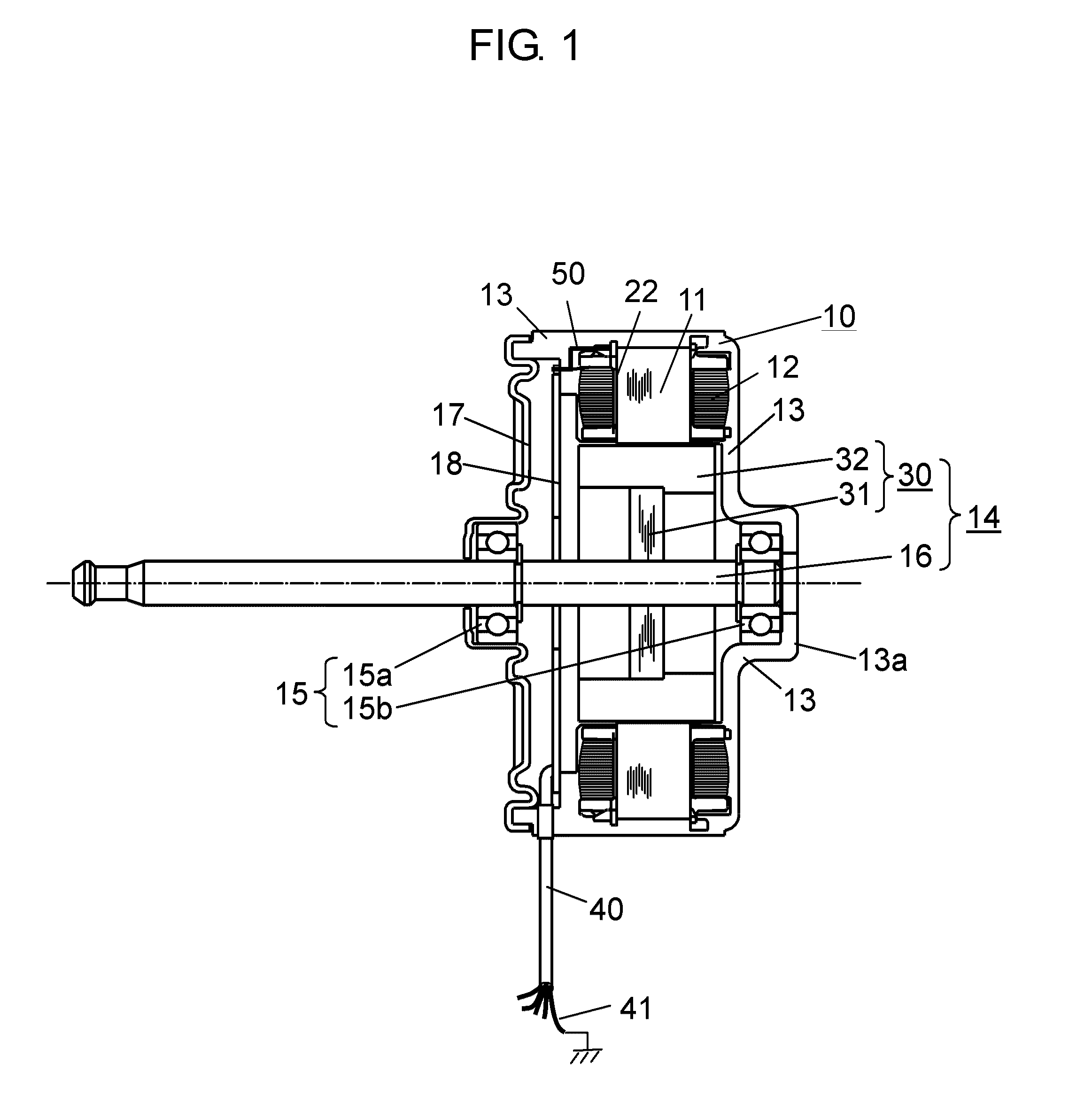

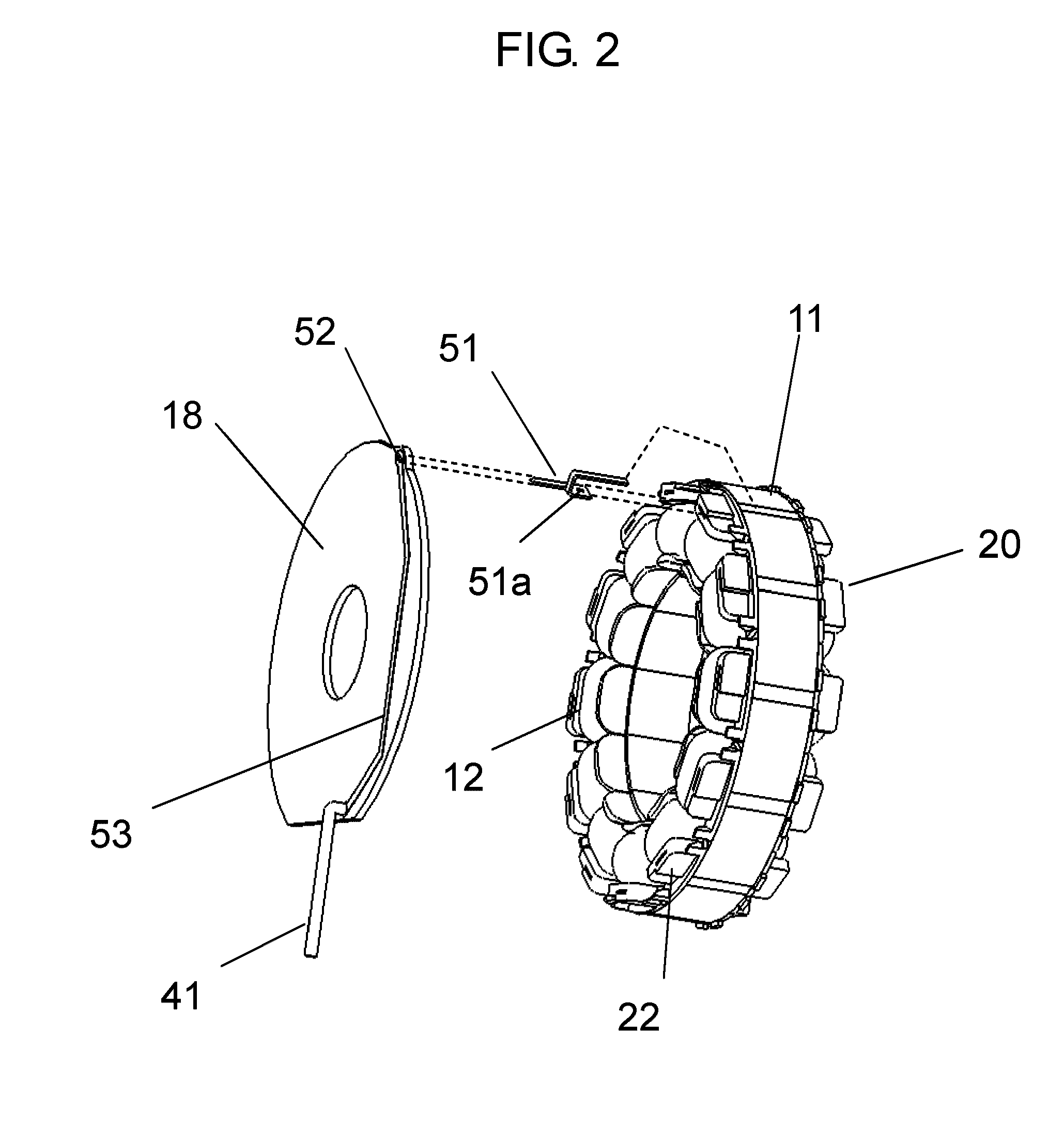

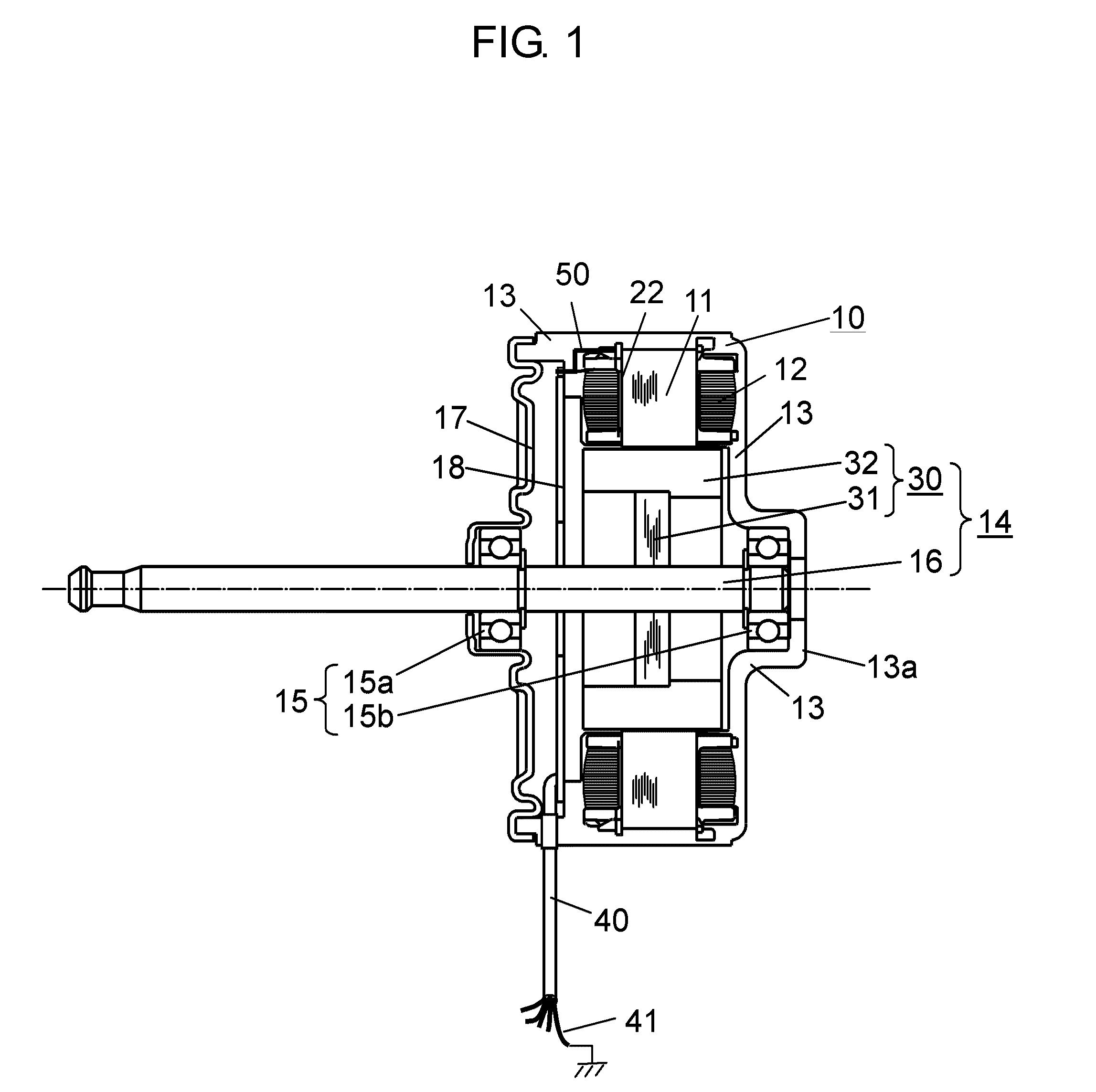

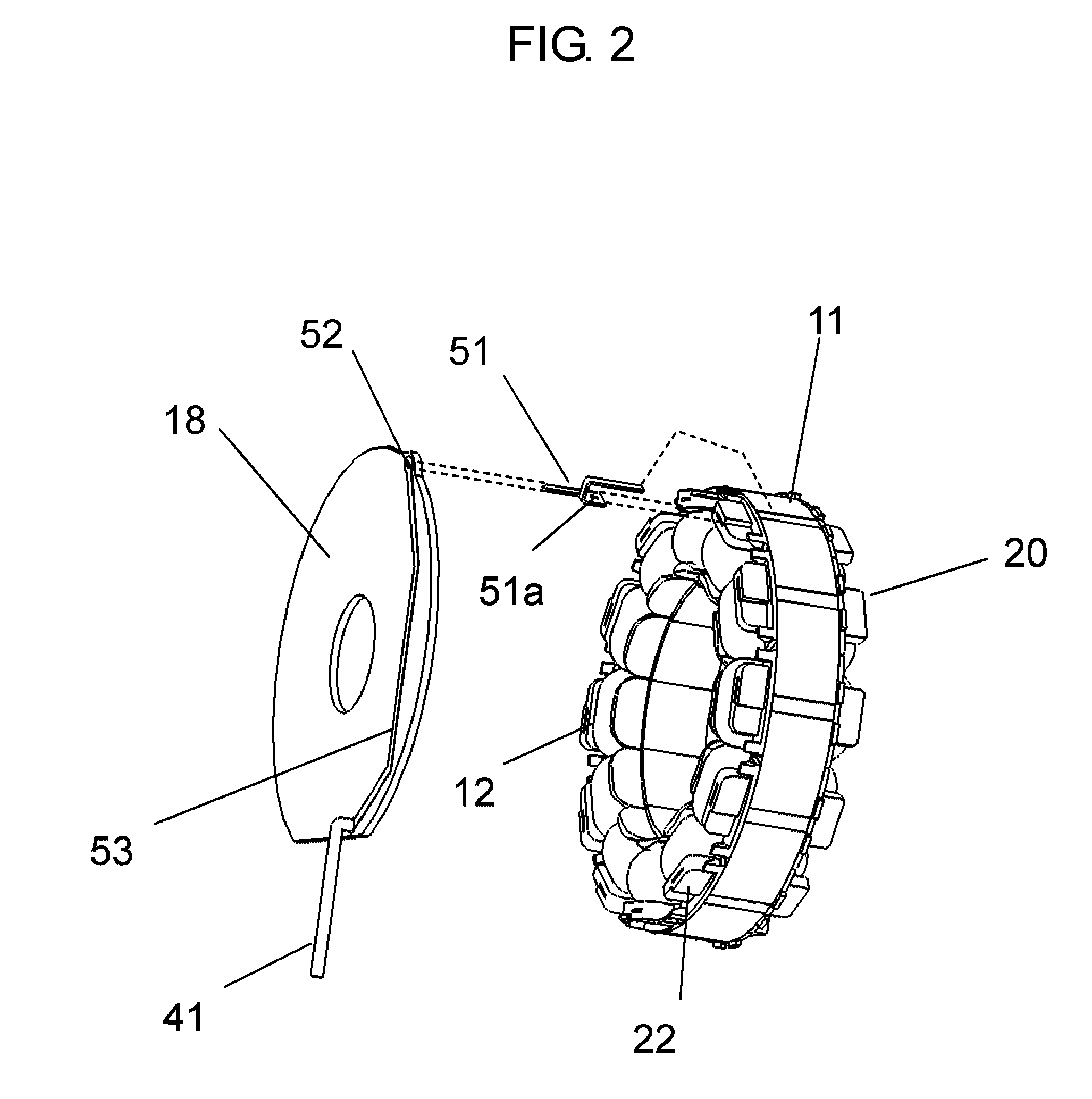

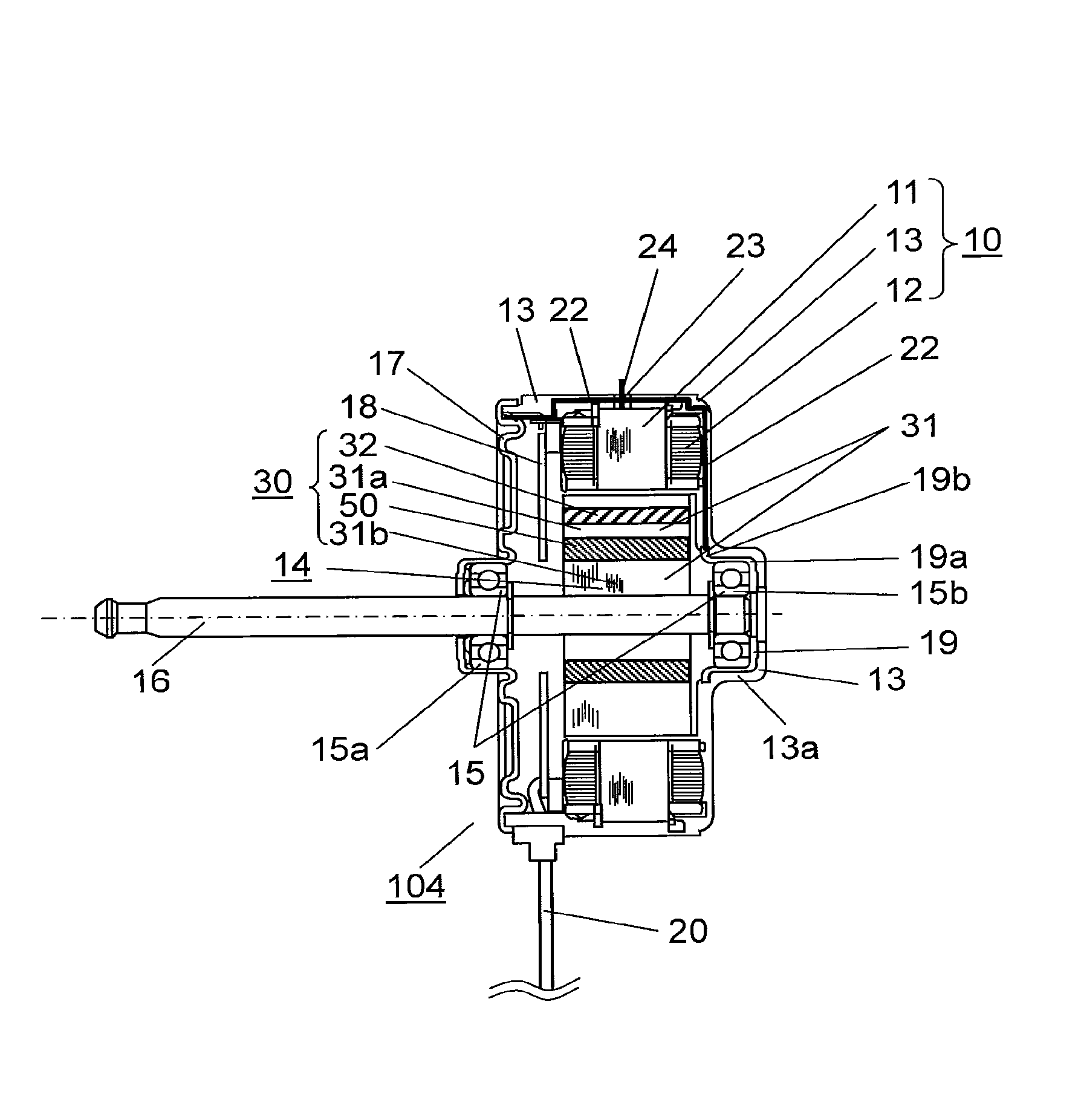

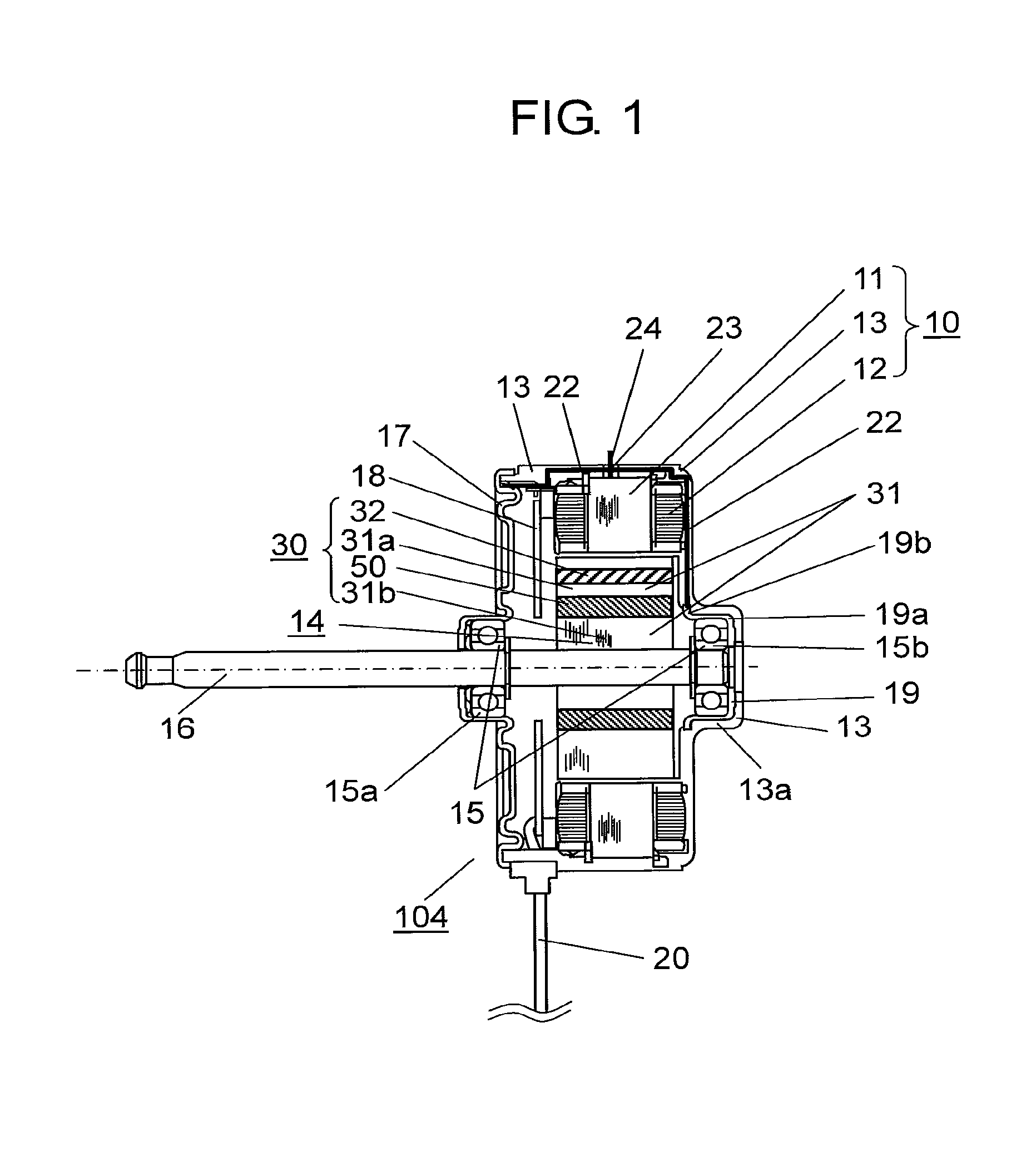

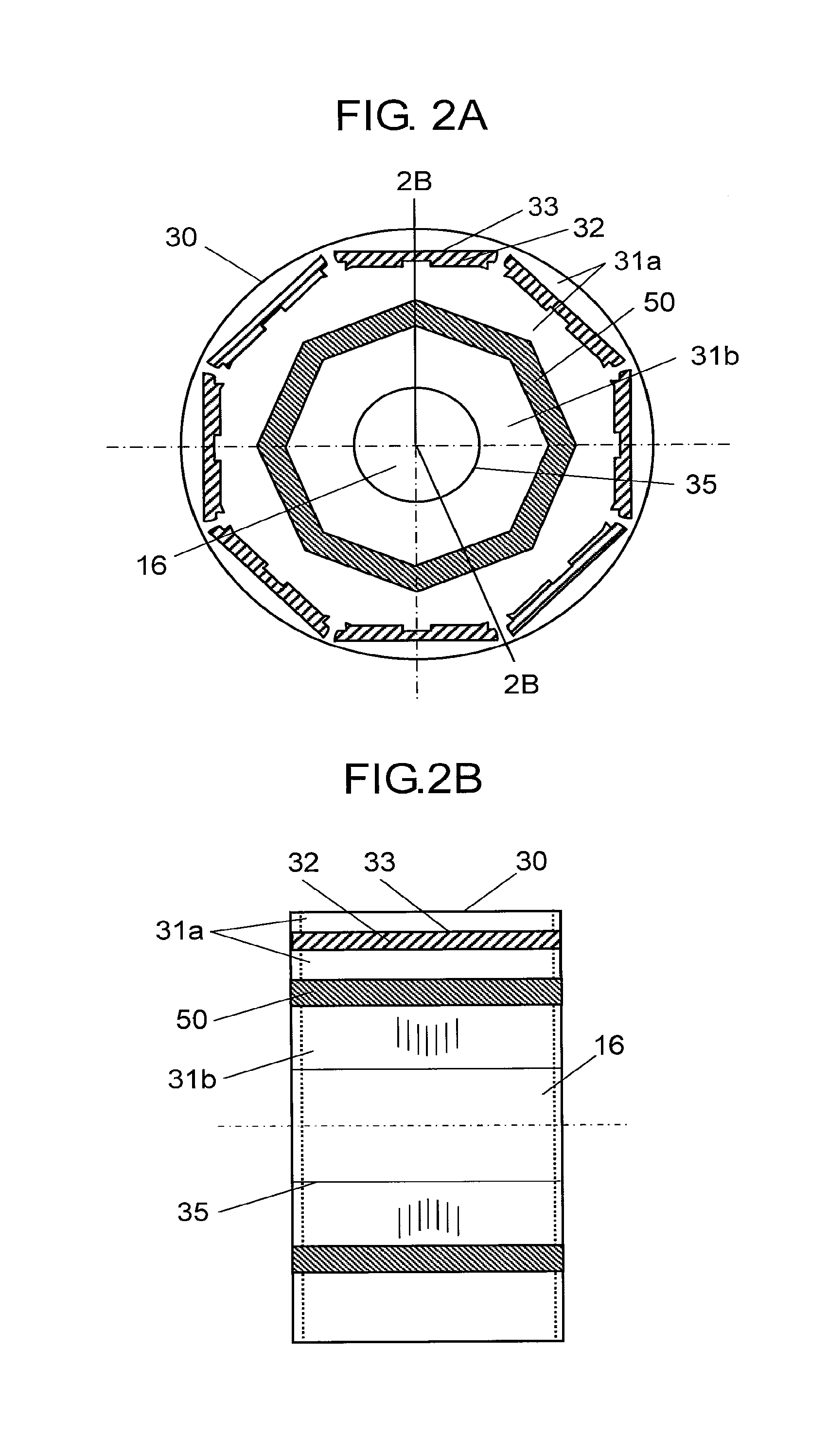

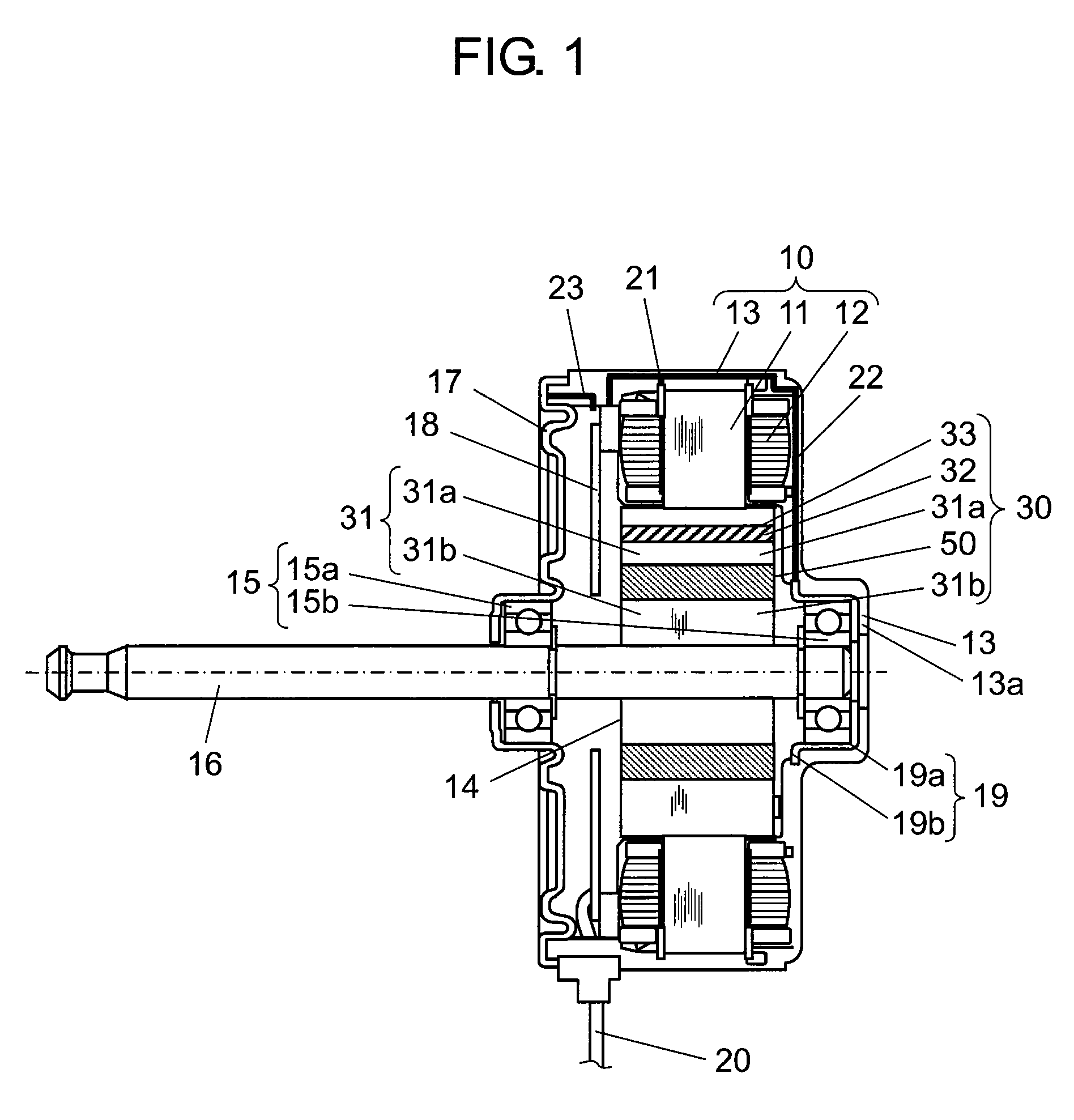

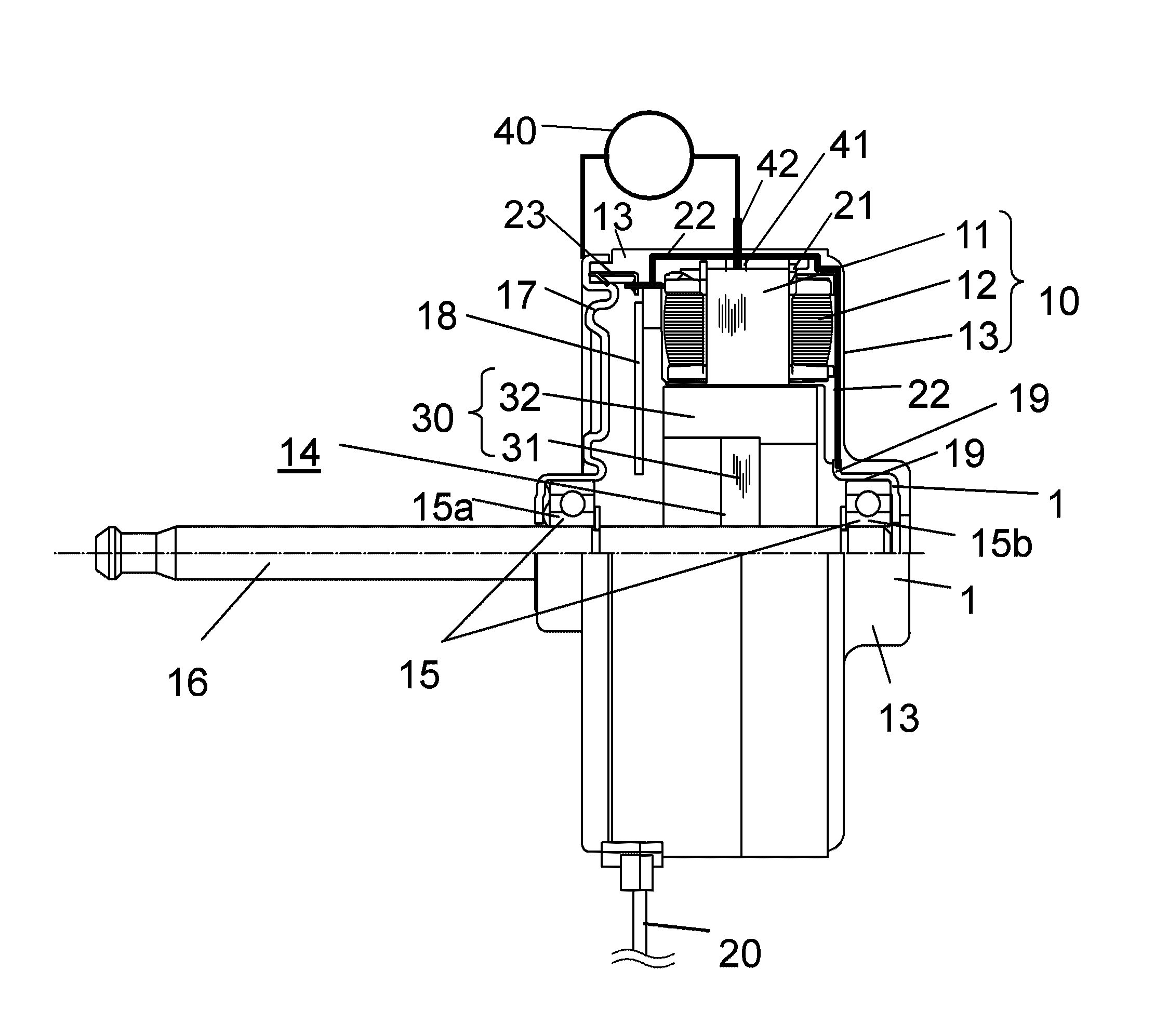

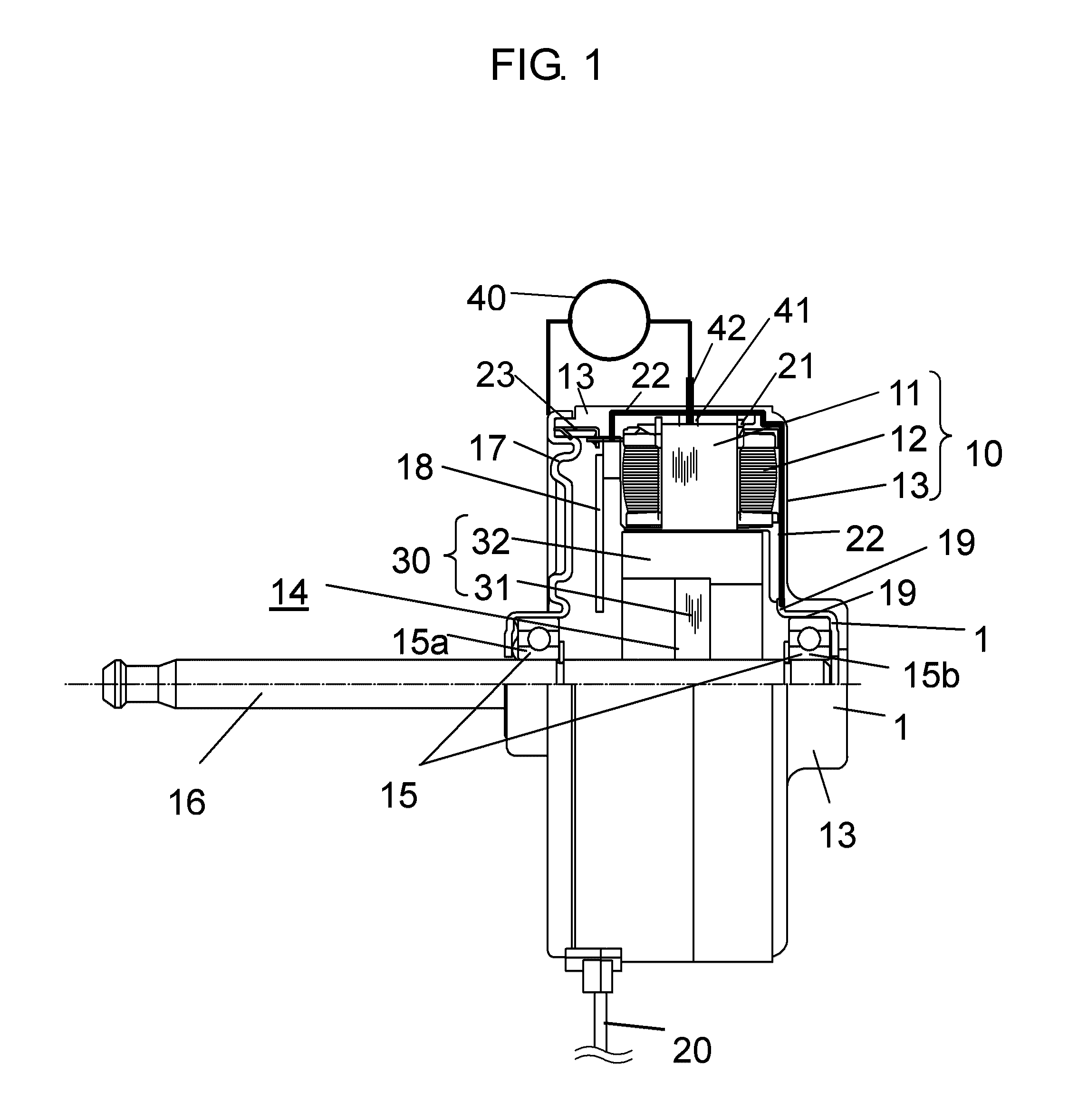

Axial-Gap Dynamo-Electric Machine

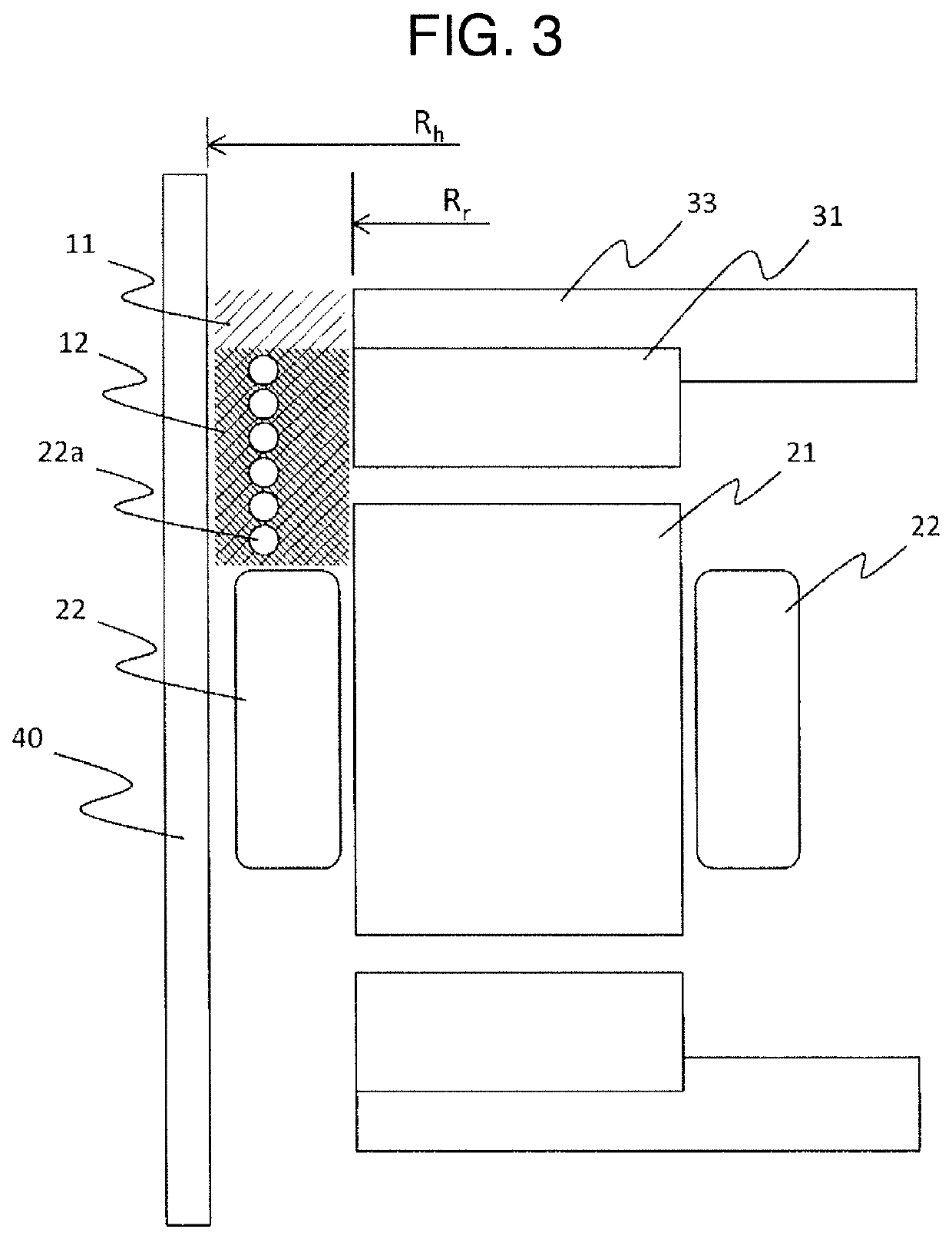

ActiveUS20170194823A1Reduce shaft voltageImprove reliabilityWindingsAssociation with grounding devicesShaft voltageDynamo

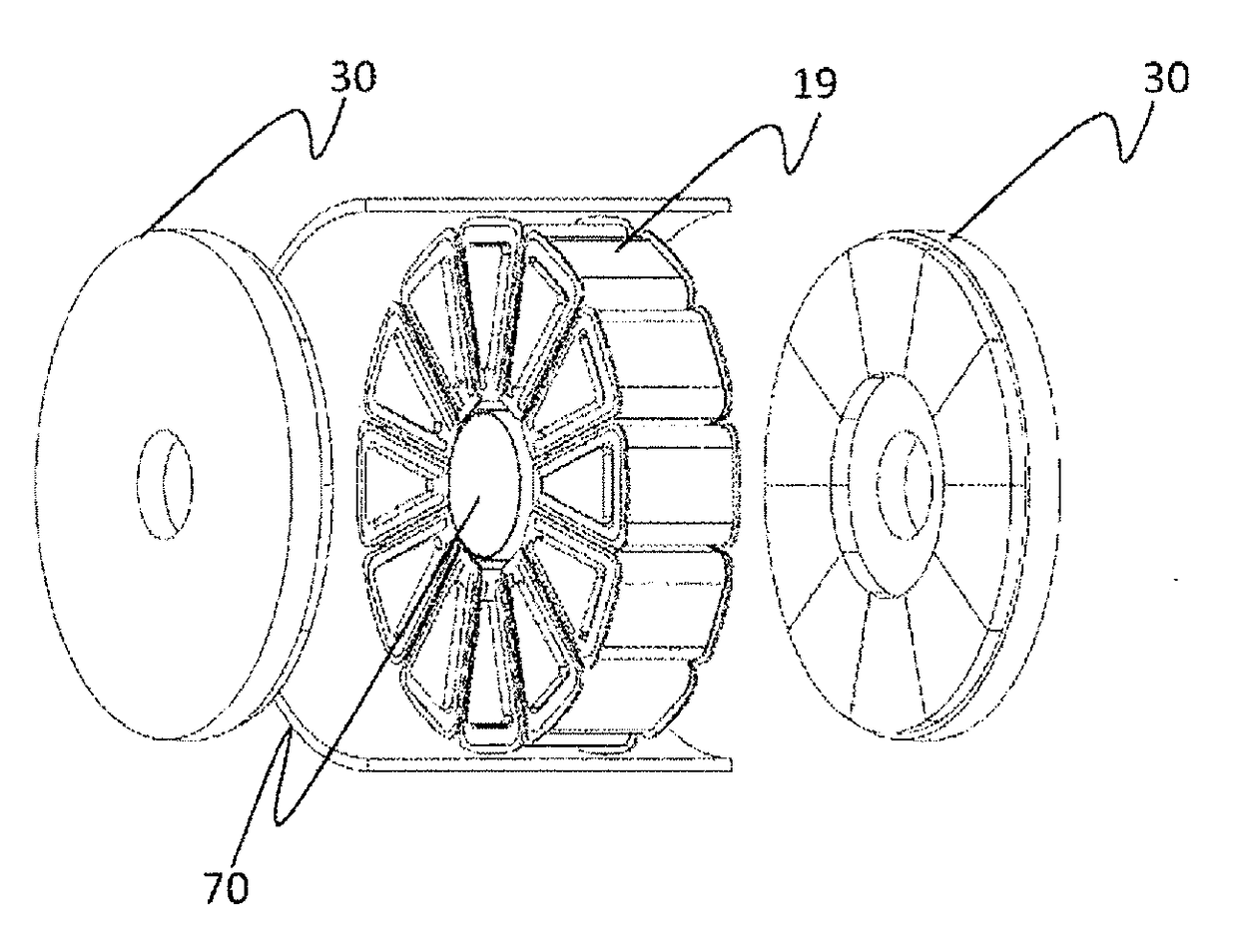

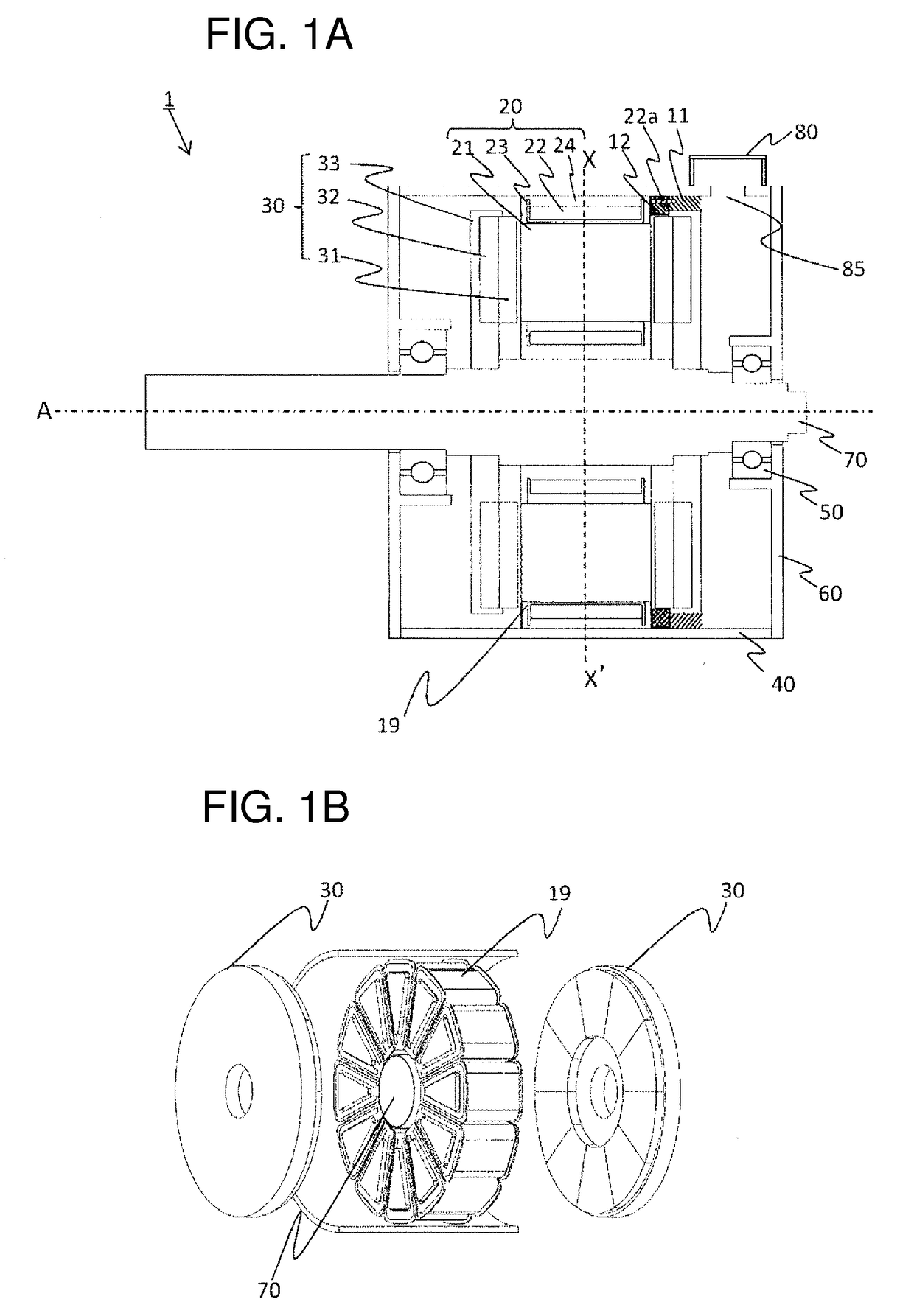

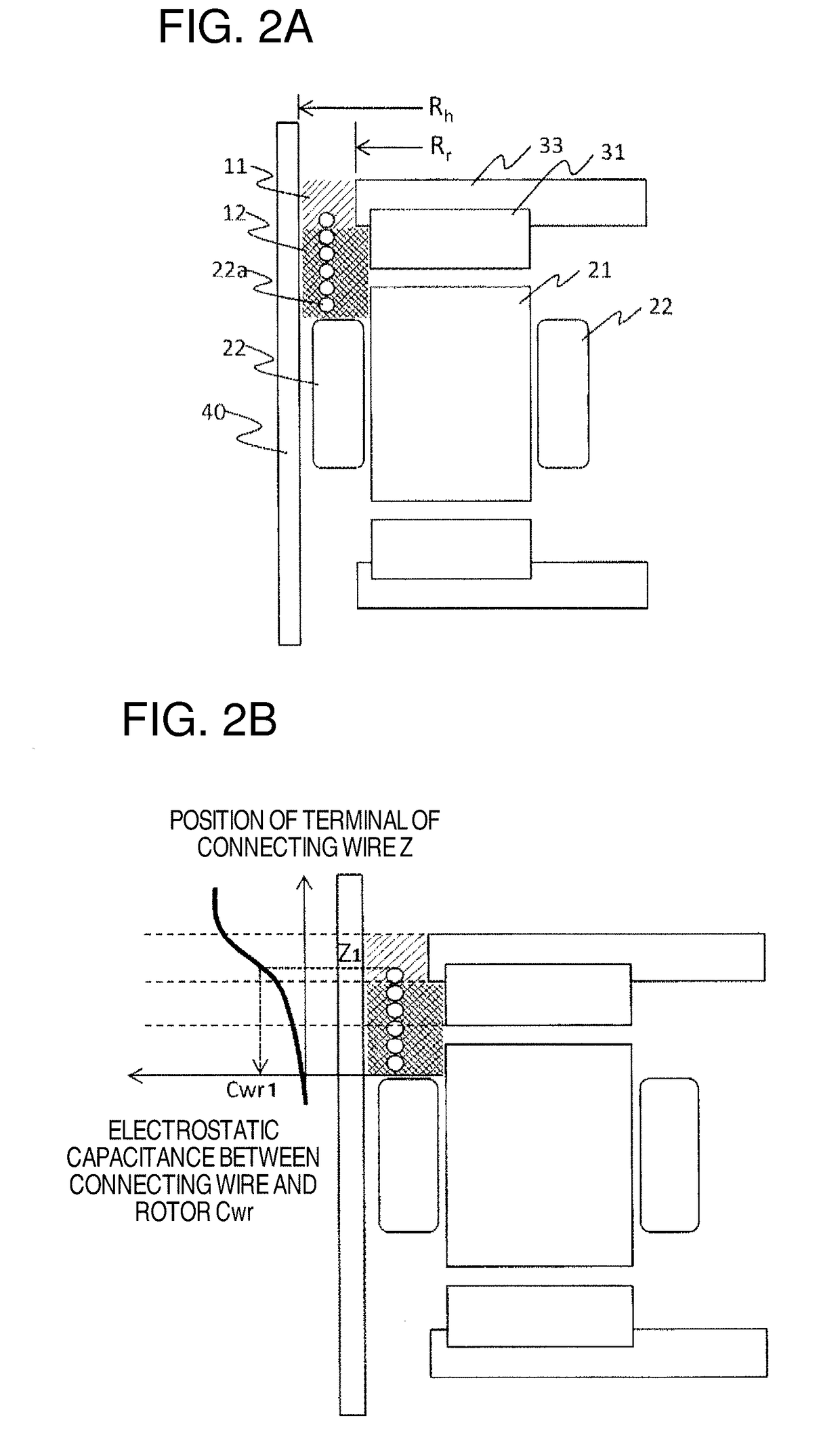

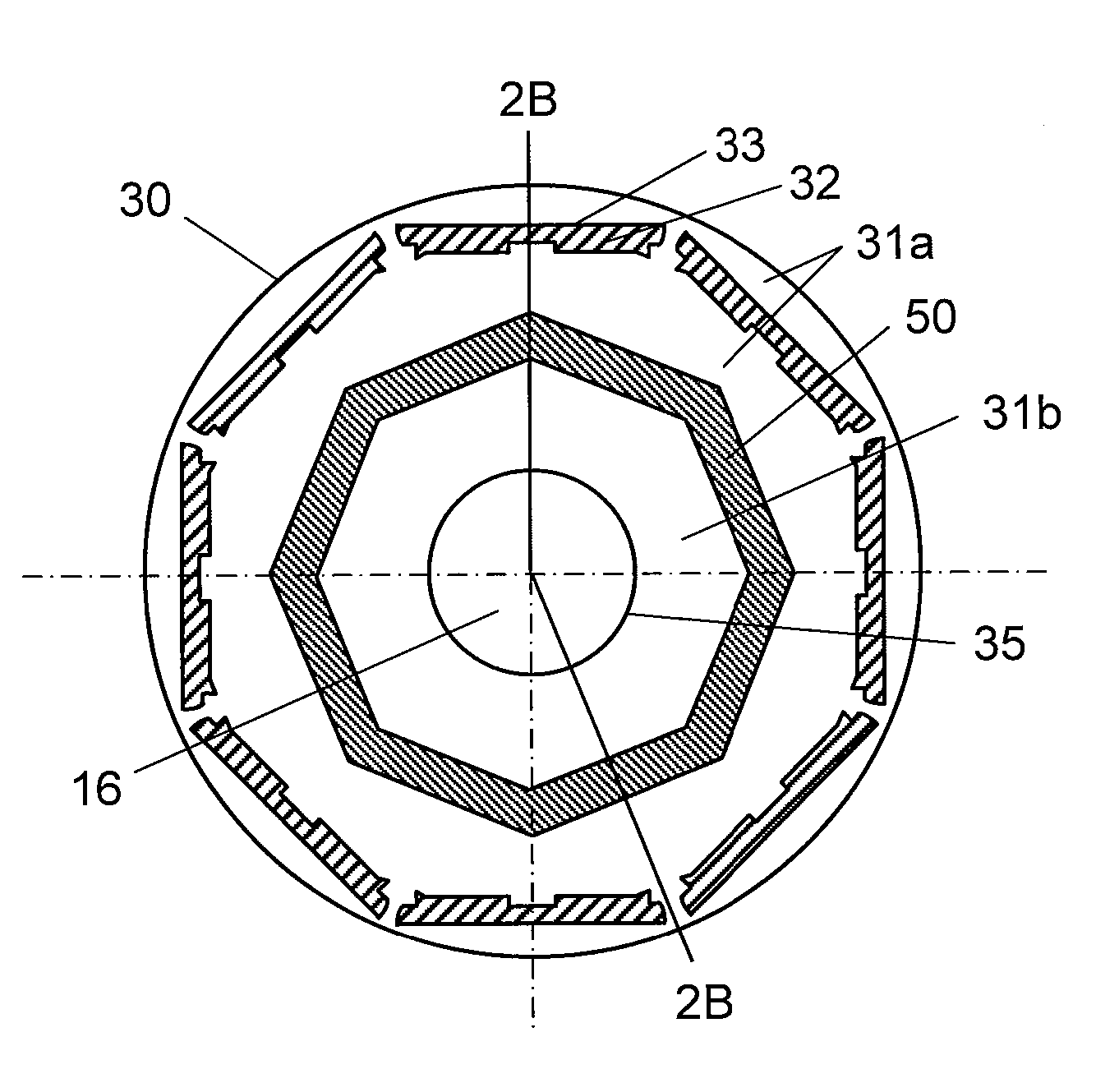

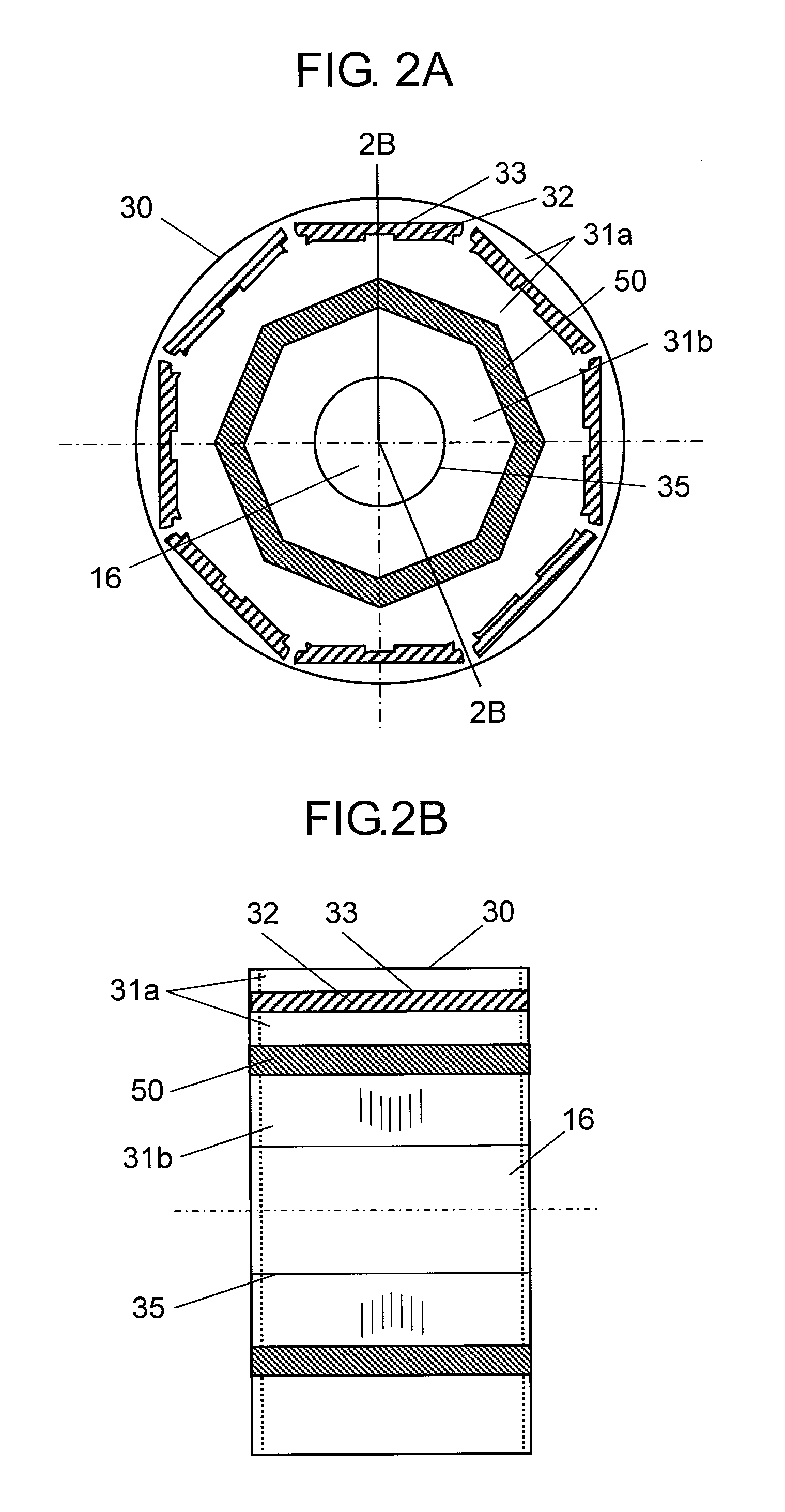

This invention reduces the shaft voltage of an axial-air-gap dynamo-electric machine while ensuring high output and high efficiency. Said axial-air-gap dynamo-electric machine comprises the following: a stator comprising a plurality of stator cores, each of which comprises a core and a coil, arranged in a circle around a shaft; a housing, the inside surface of which faces the stator radially; and at least one rotor, the surface of which faces the surface of the stator with a prescribed air gap interposed therebetween in the radial direction of the shaft. The rotor has, on the outside thereof, a conductive section comprising a conductive member. This axial-air-gap dynamo-electric machine has a first region where the inside surface of the housing faces the aforementioned conductive section radially and a second region, closer to the stator than the first region is, that extends to the coil side surfaces that face the rotor. The proportion of connecting wires in the second region is higher than in the first region.

Owner:HITACHI IND EQUIP SYST CO LTD

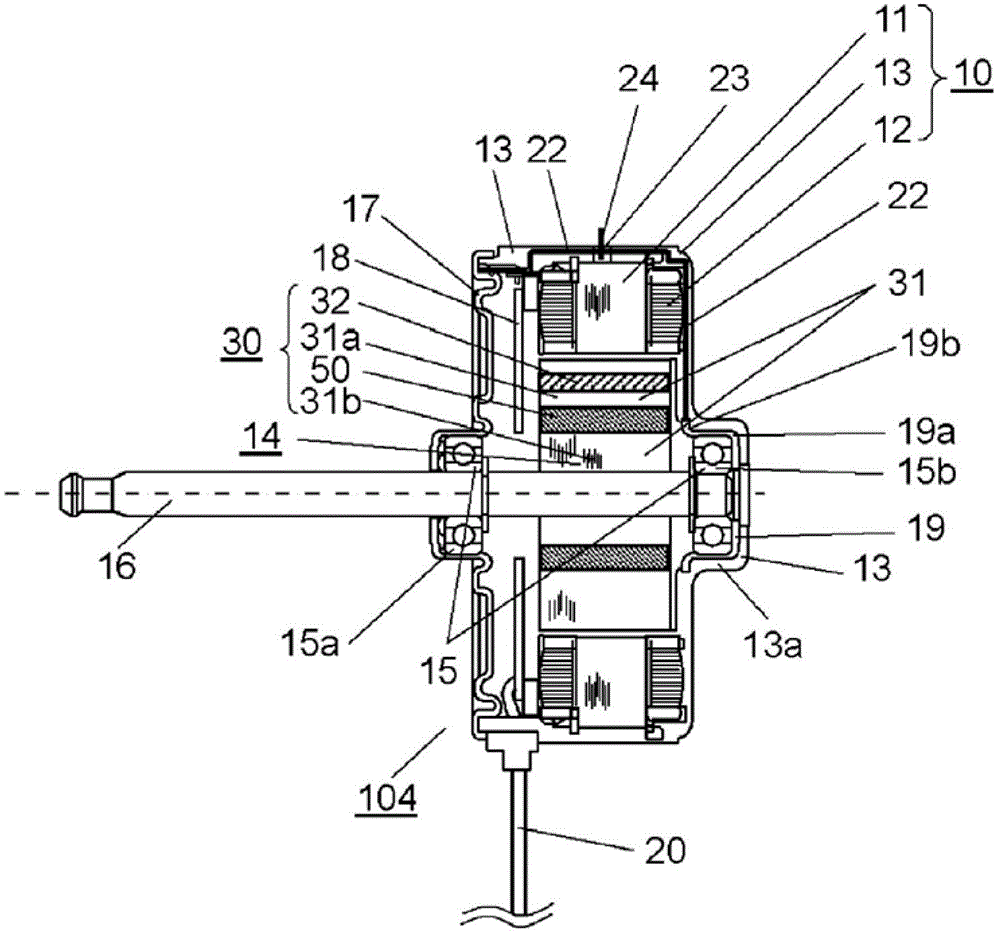

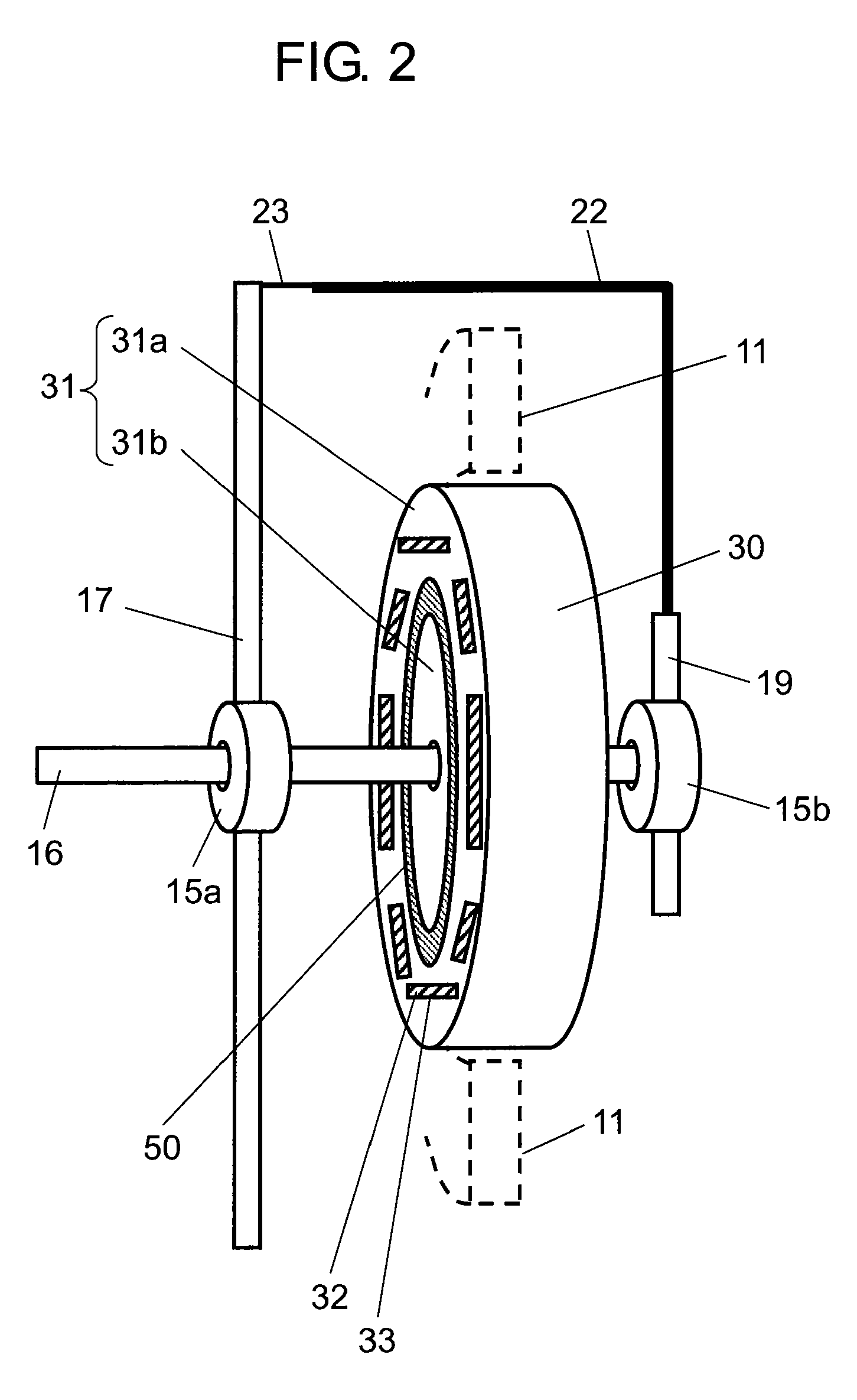

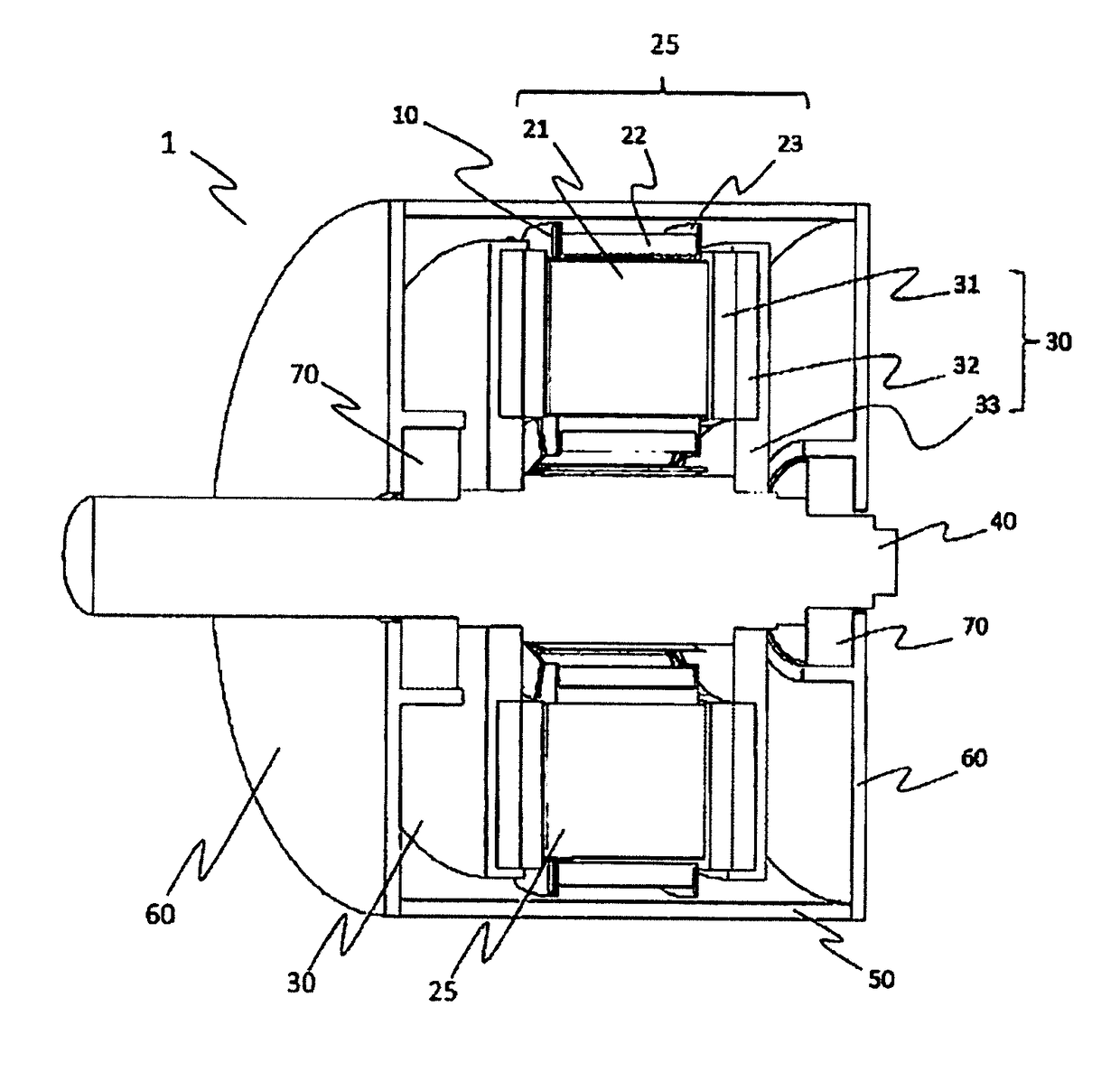

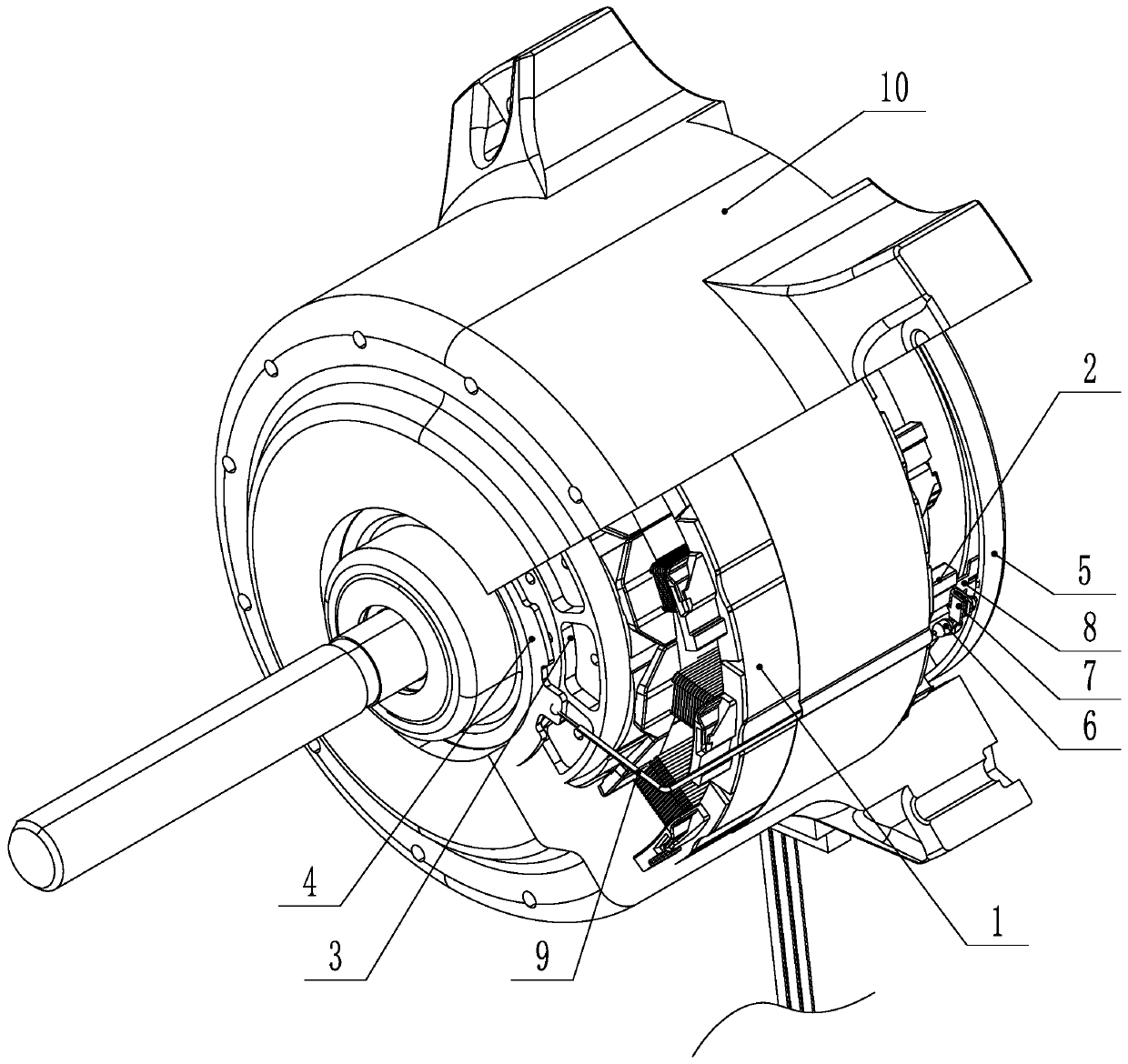

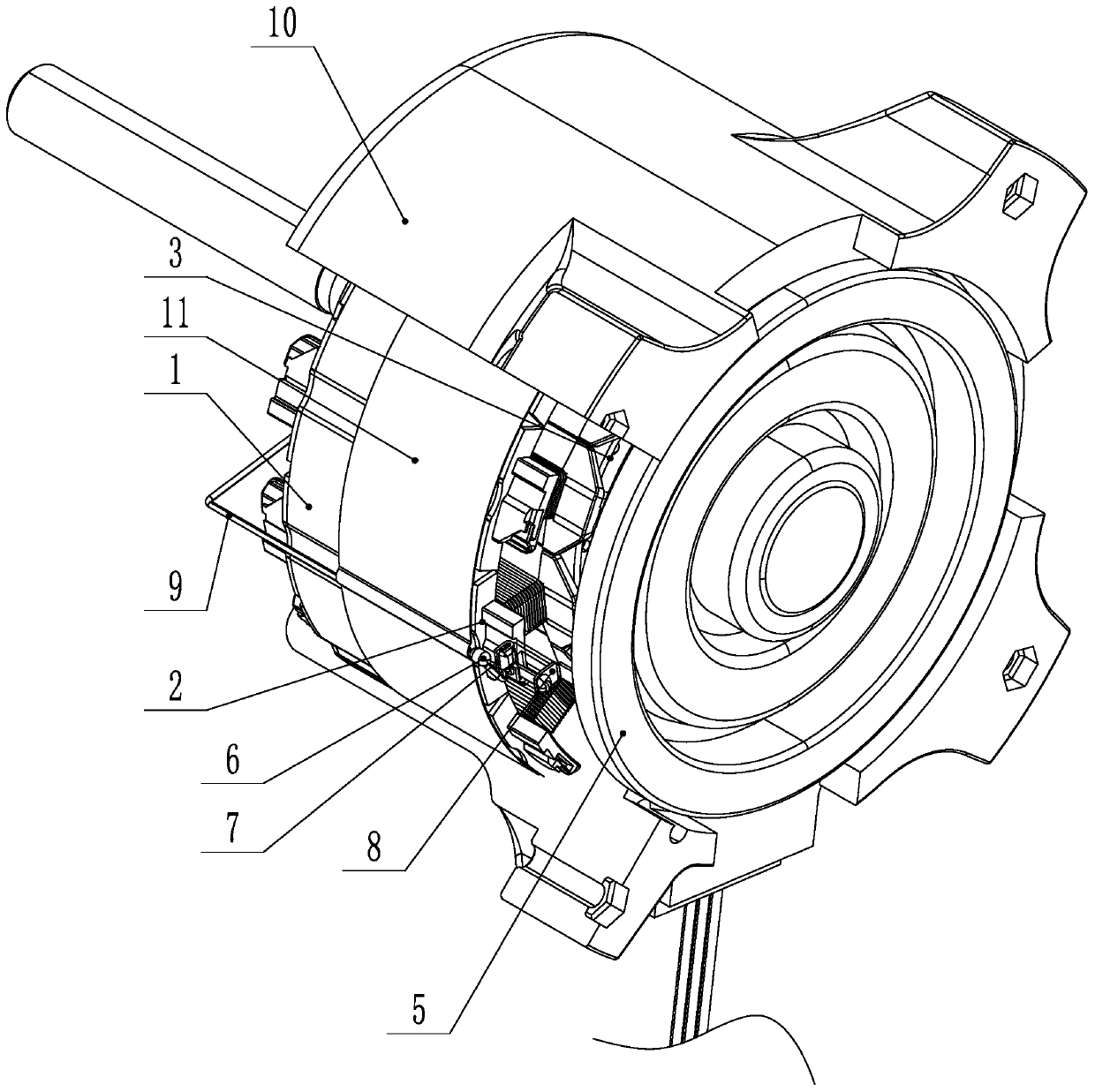

Motor and electric device using same

ActiveUS20110234025A1Shaft voltage be reduceReduce shaft voltageTorque ripple controlAssociation with control/drive circuitsElectric driveElectricity

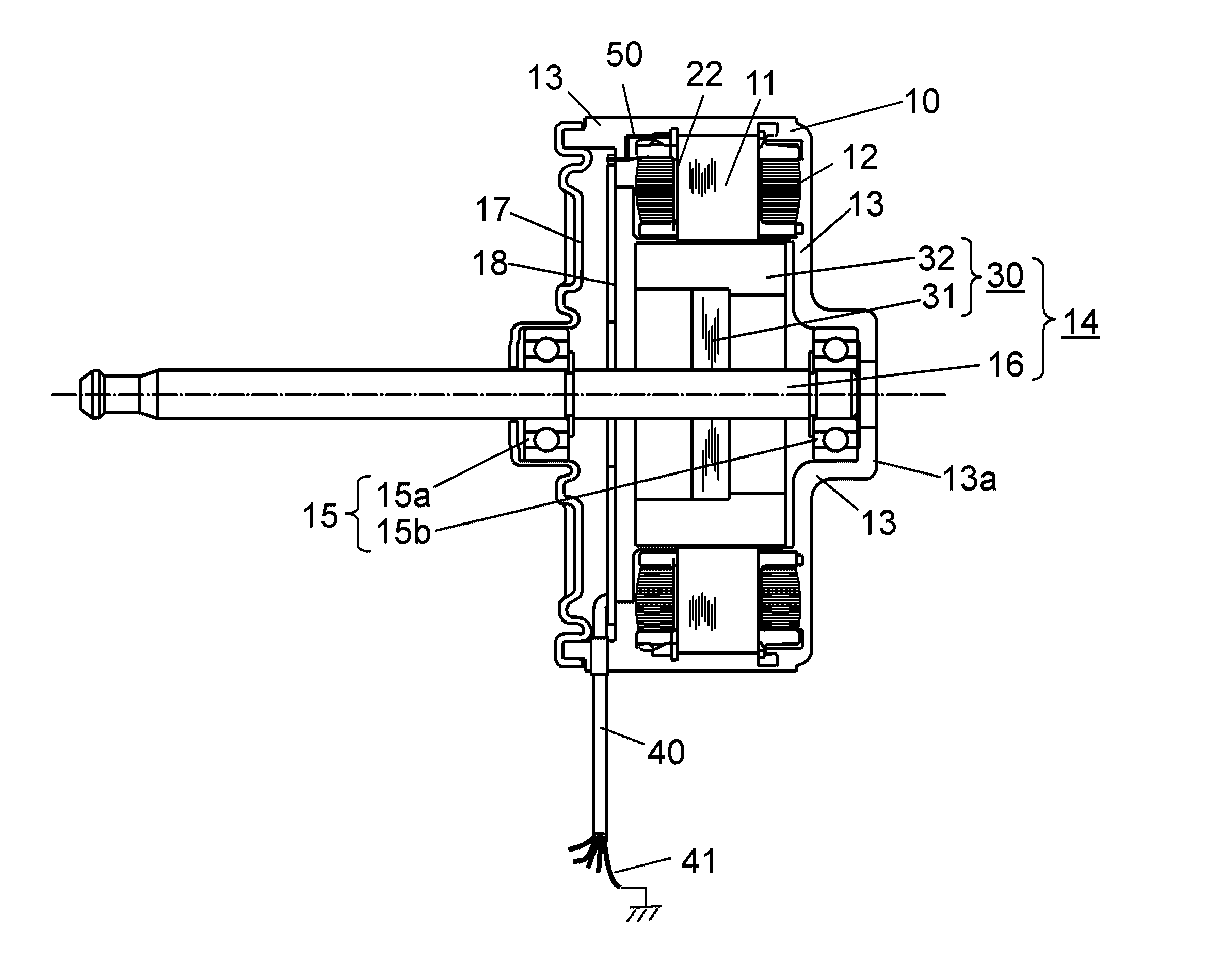

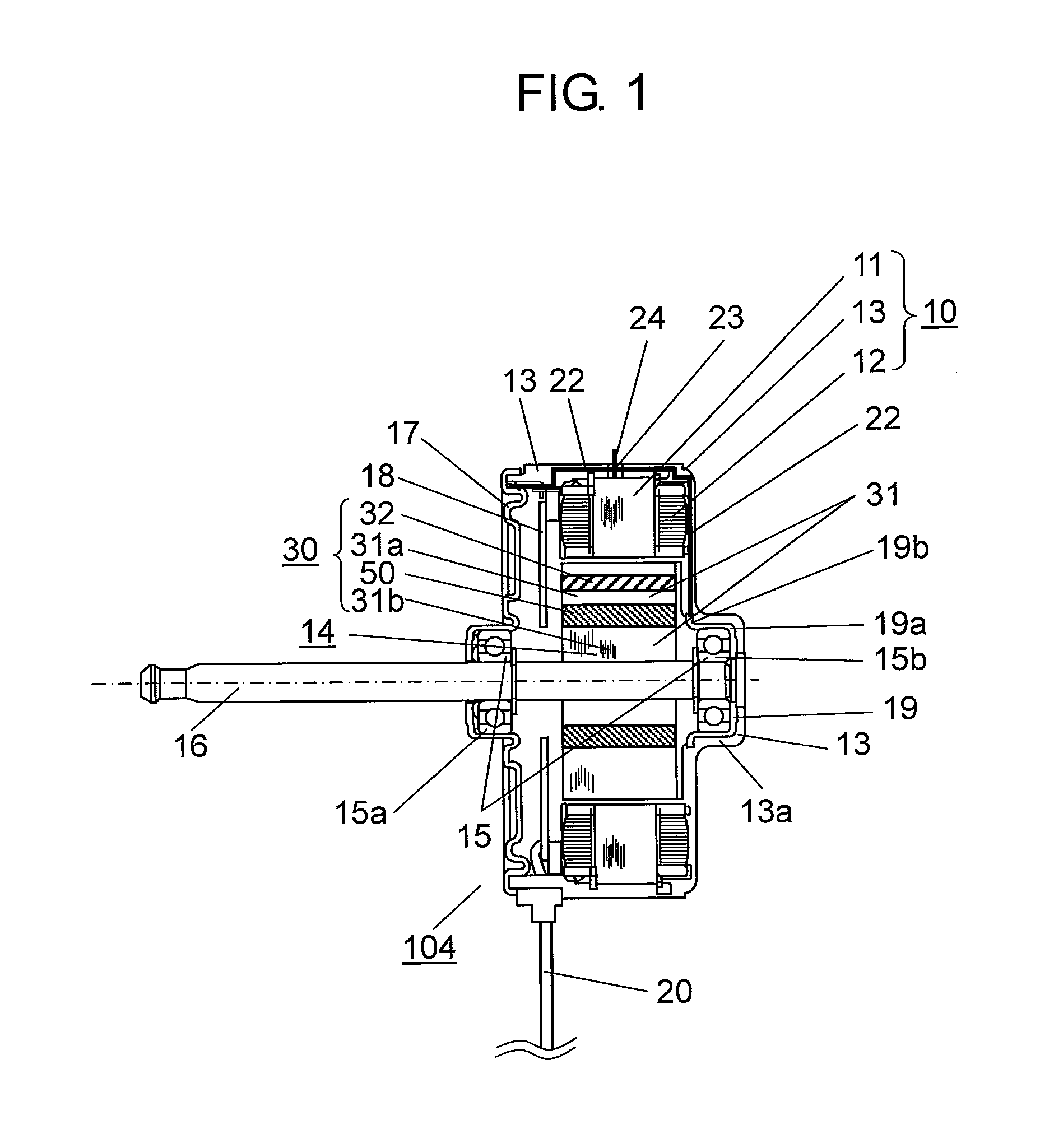

A motor includes: a stator molded integrally with an insulating resin having a fixing member including a stator iron core and a winding wound thereon; a rotor arranged to face the stator about a shaft; a bearing rotatably supporting the shaft; a bracket fixing the bearing; and a drive circuit substrate having a drive circuit mounted thereon for driving the winding. The stator iron core is electrically connected to a ground serving as a reference point of a zero potential on the drive circuit substrate through a conductive member.

Owner:PANASONIC CORP

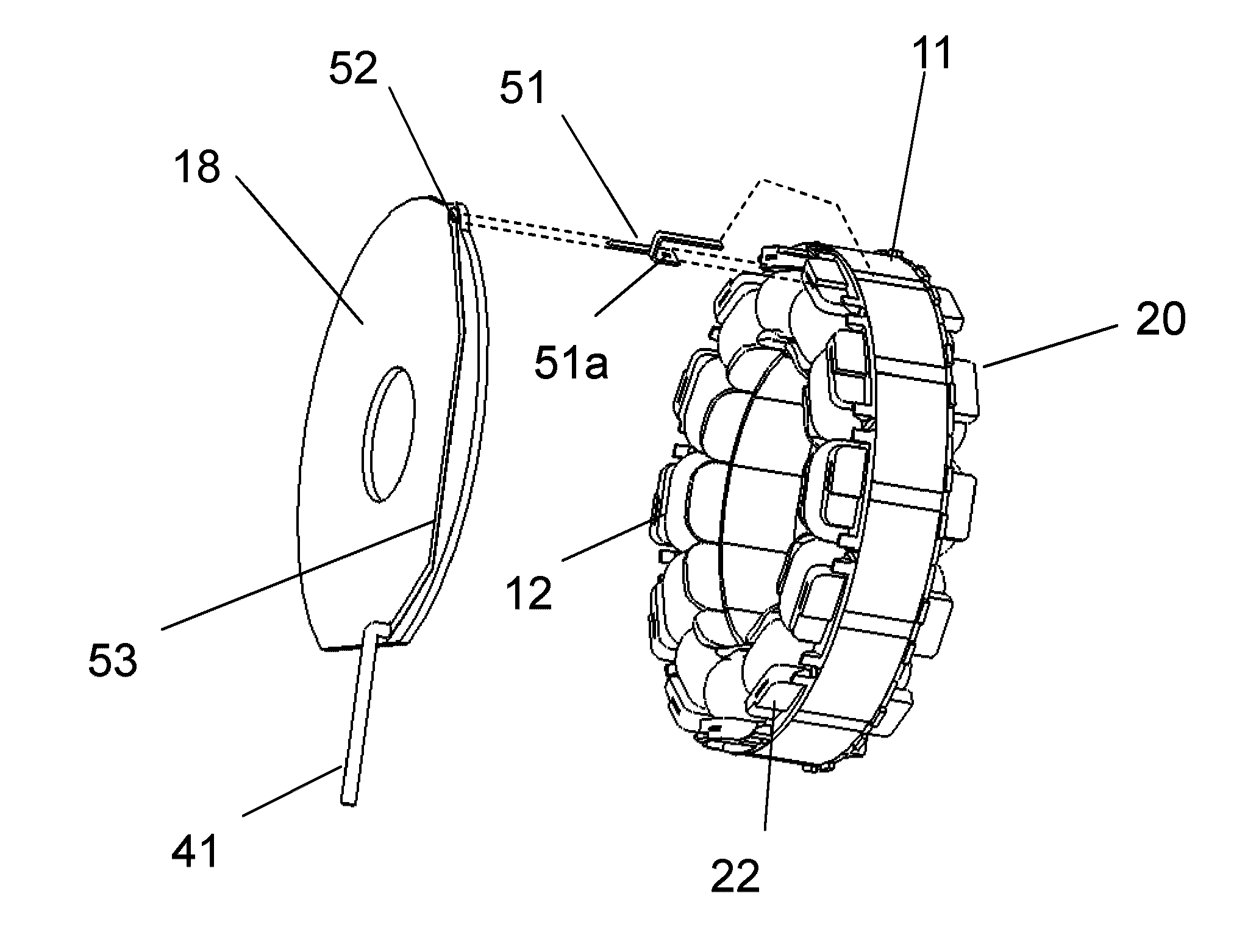

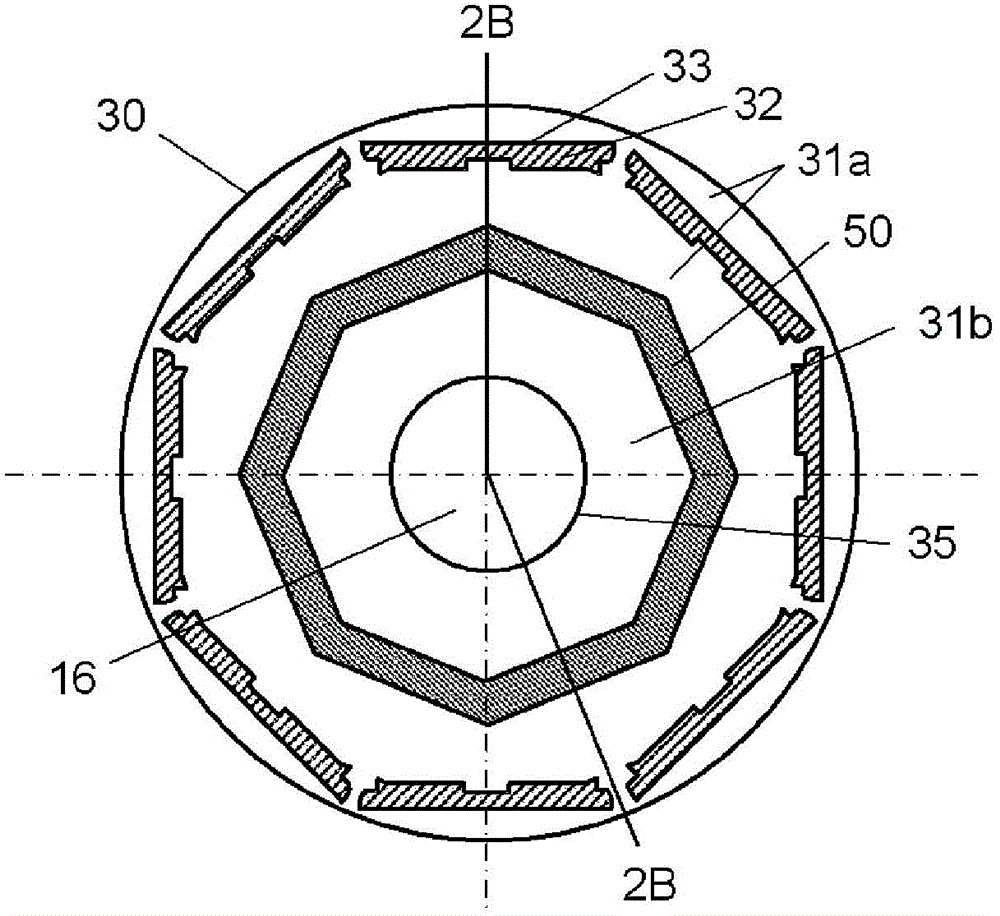

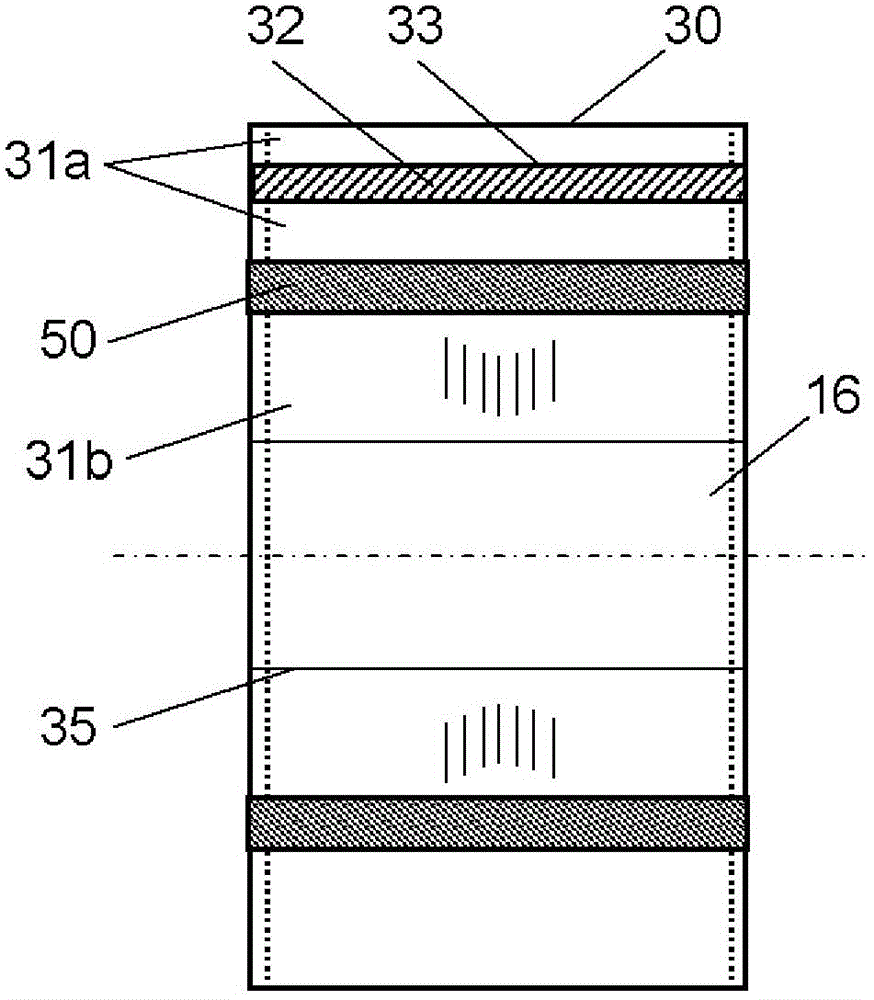

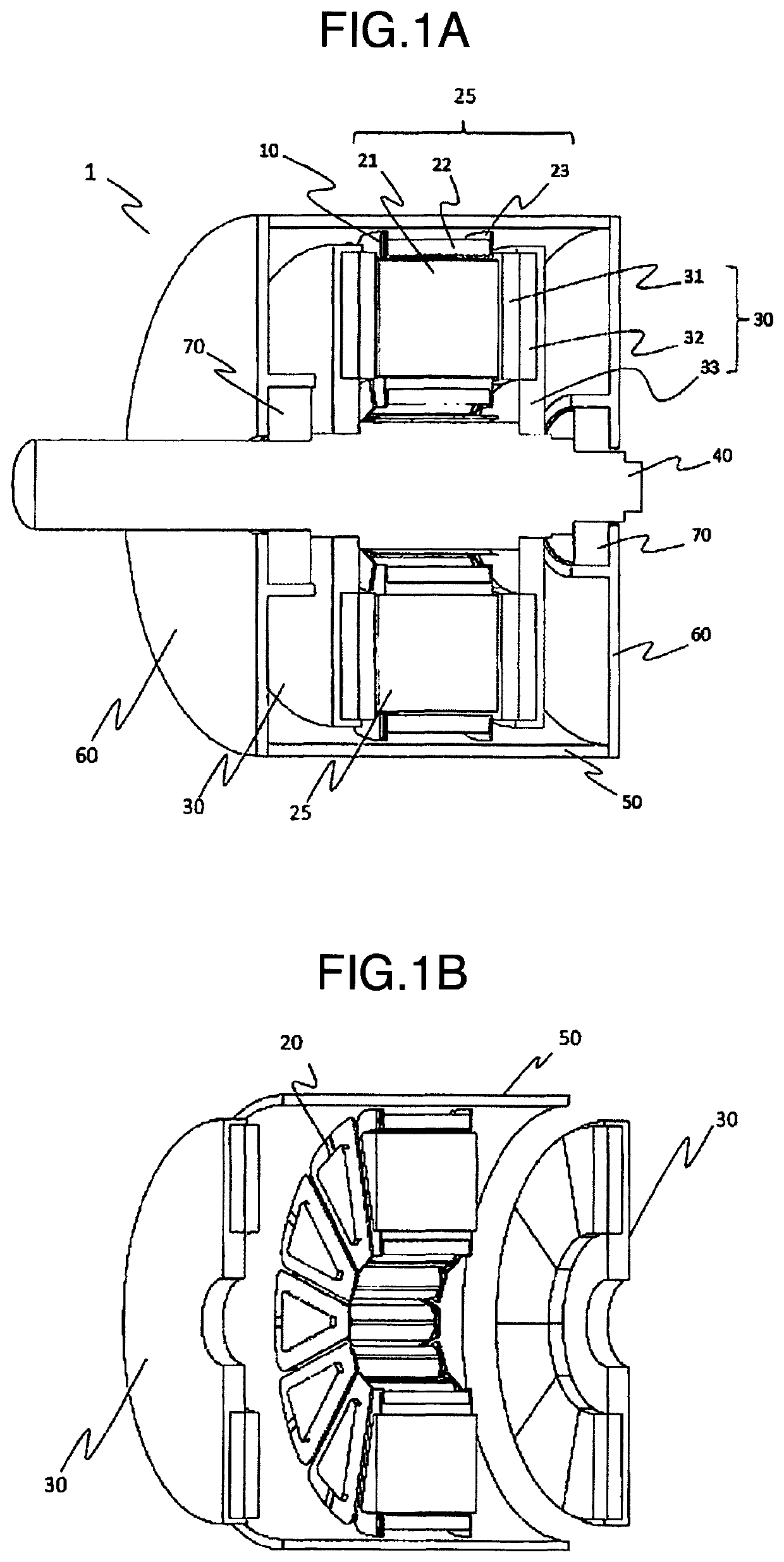

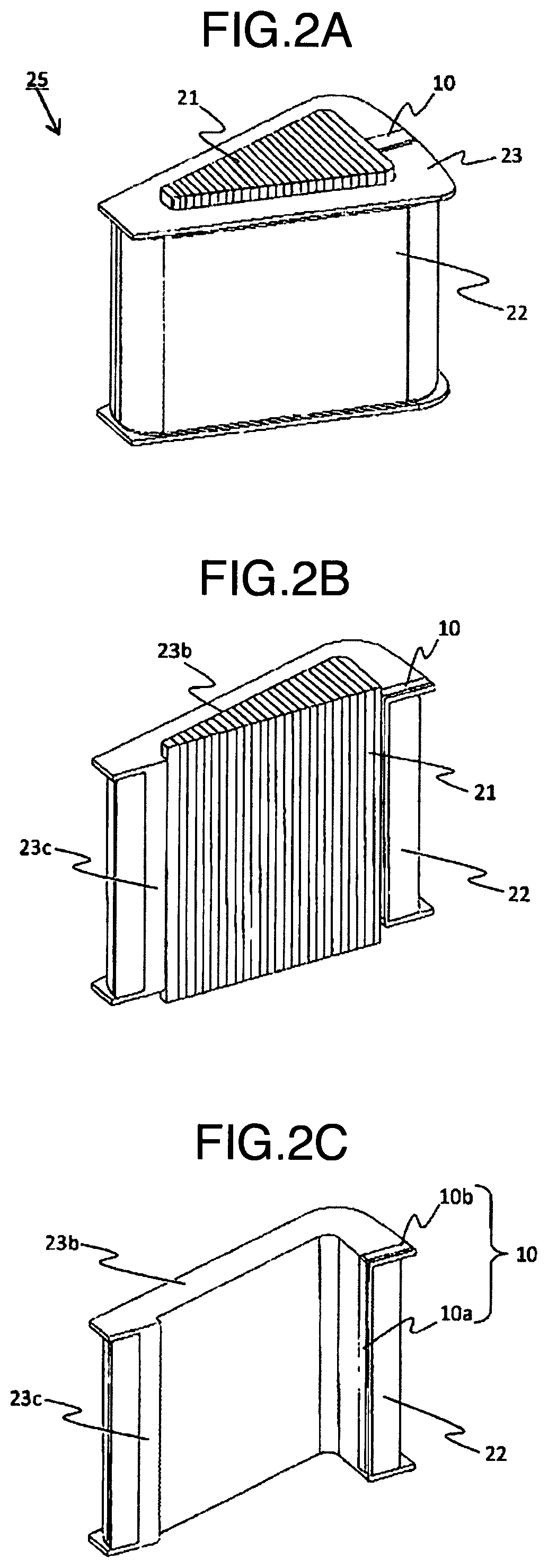

Electric motor and electric device provided therewith

ActiveUS20120112588A1High retention strengthInhibitionAssociation with grounding devicesMagnetic circuitDielectric layerMagnet

Provided is an electric motor driven by an inverter of PWM method, and devised to retard electrolytic corrosion in a bearing. A rotating body of a rotor comprises an outer iron core configuring an outer peripheral portion of the rotating body, an inner iron core configuring an inner peripheral portion connected to a shaft, a dielectric layer disposed between the outer iron core and the inner iron core, a plurality of insertion holes penetrating the outer iron core in the axial direction, and permanent magnets inserted individually in the plurality of insertion holes. It thus becomes possible to increase impedance of the rotor side (inner ring side of bearing) to approximate it to impedance of the stator side (outer ring side of the bearing) to thereby bring high frequency potentials balanced between the inner ring side and the outer ring side of the bearing, so as to provide the electric motor that retards electrolytic corrosion liable to occur in the bearing, and an electric device equipped with the same.

Owner:PANASONIC CORP

Motor and electrical appliance provided with same

ActiveUS20130119806A1Reduce shaft voltagePotential differenceAssociation with grounding devicesMagnetic circuit rotating partsFixed bearingEngineering

An electric motor includes a stator that has a stator winding wound on a stator iron core; a rotor having a rotating body with a rotating shaft in the center; a bearing for journaling the rotating shaft; and two conductive brackets for fixing the bearing. The rotating body holds a magnet such that the magnet faces the stator, and is fastened to the rotating shaft penetrating through the center of the rotating body. In the rotating body, a dielectric layer is formed between the rotating shaft and the outer circumference of the rotating body. The dielectric layer has a polygonal shape with the rotating shaft in the center. An electric device includes the thus configured electric motor.

Owner:PANASONIC CORP

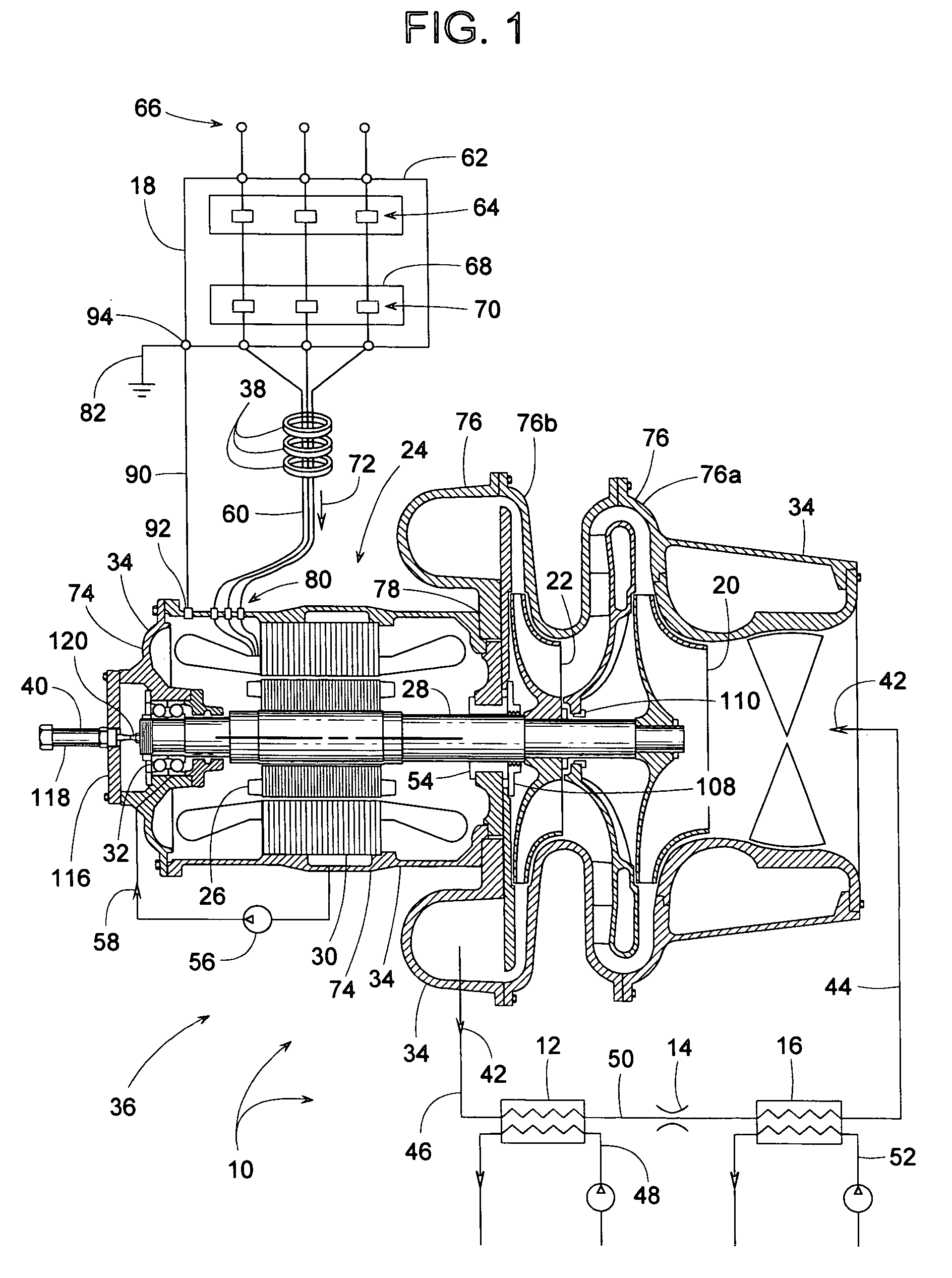

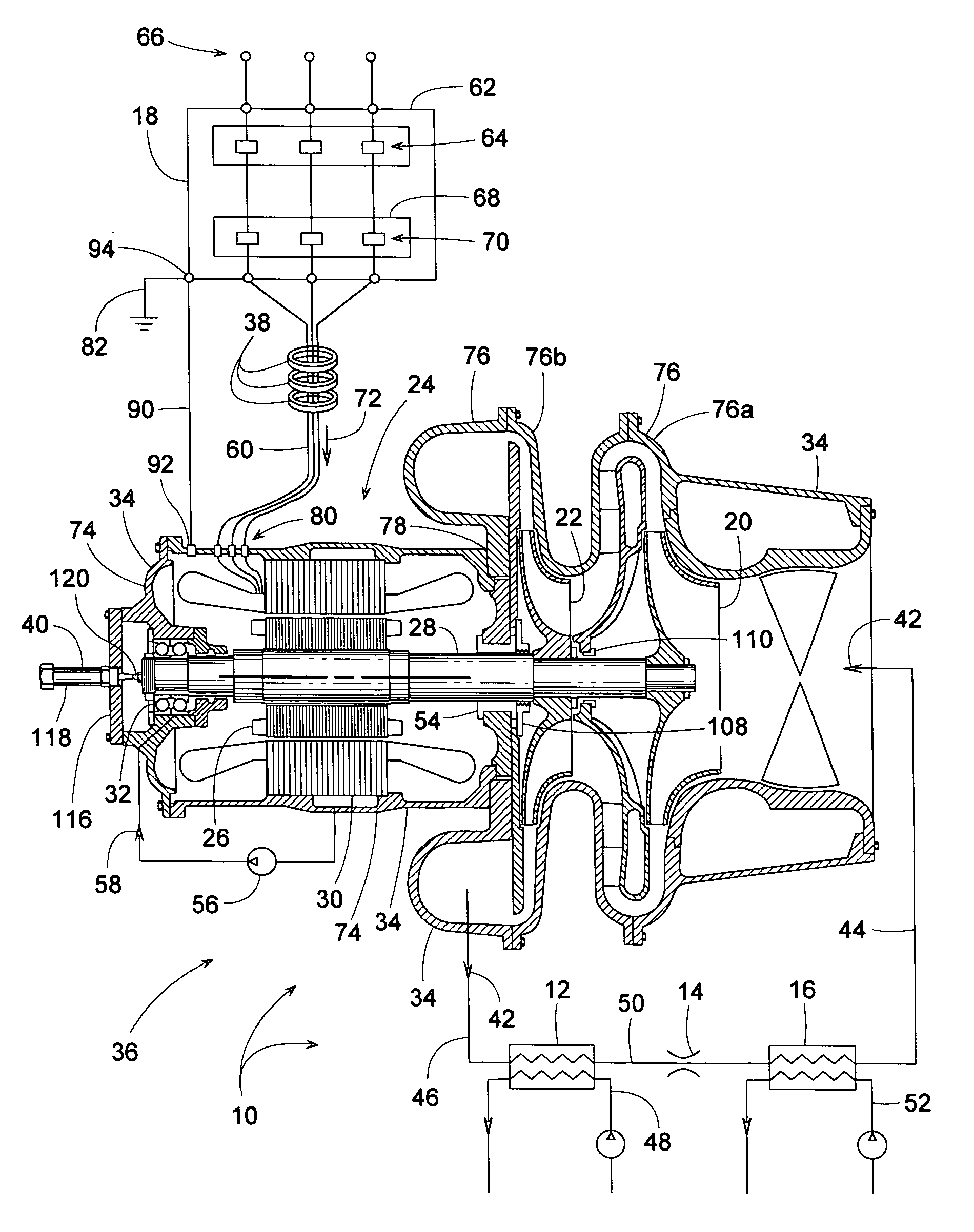

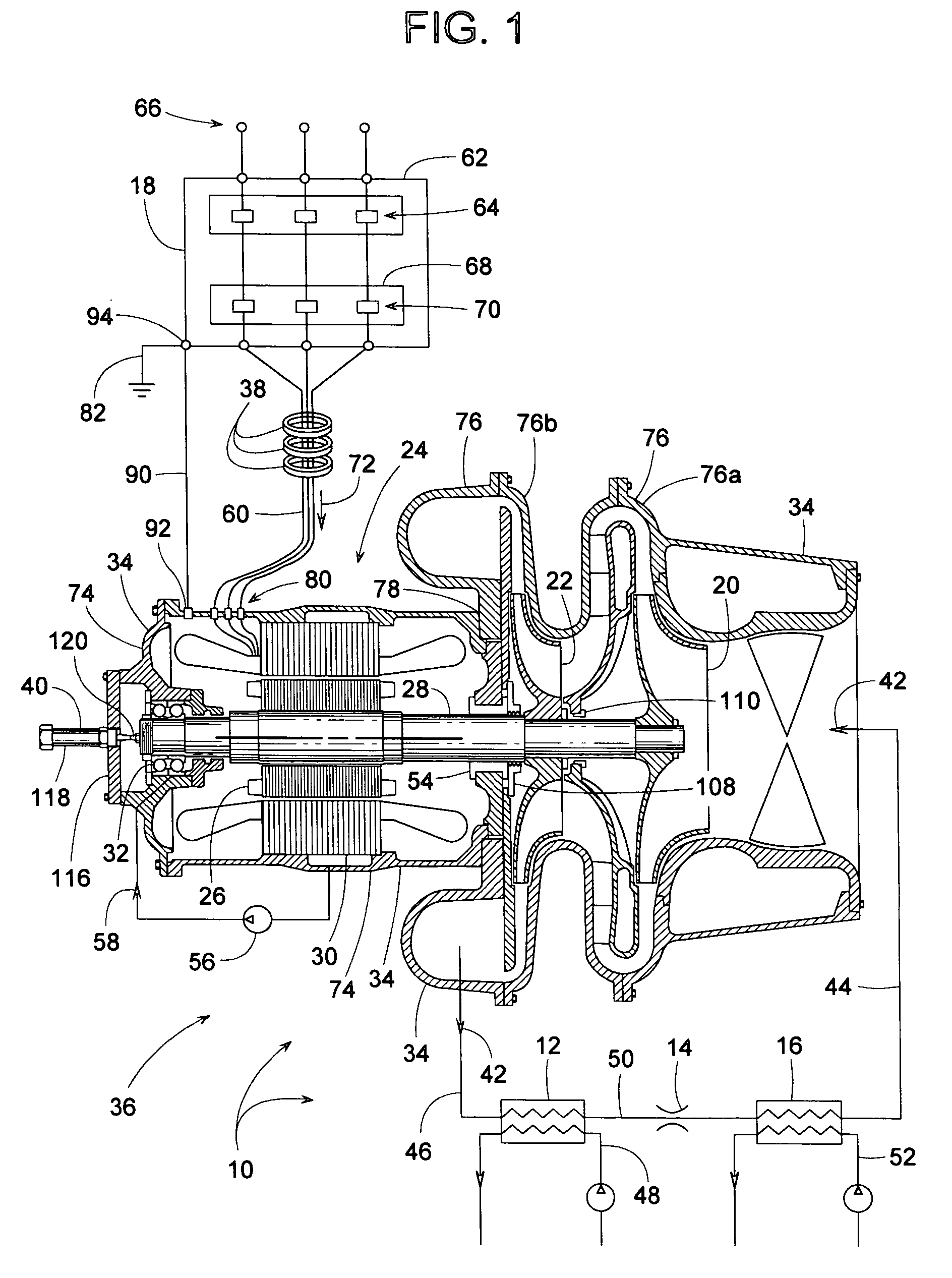

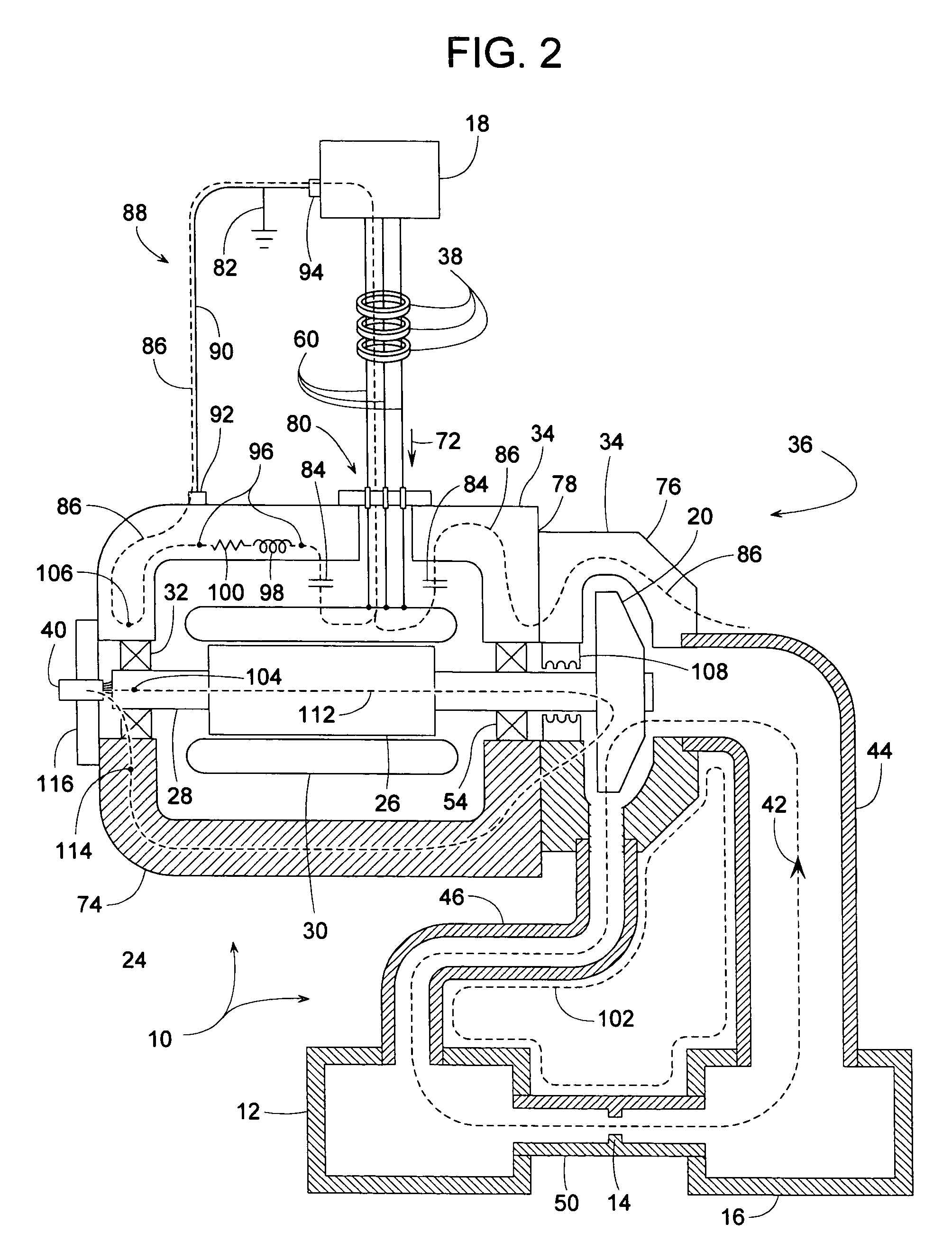

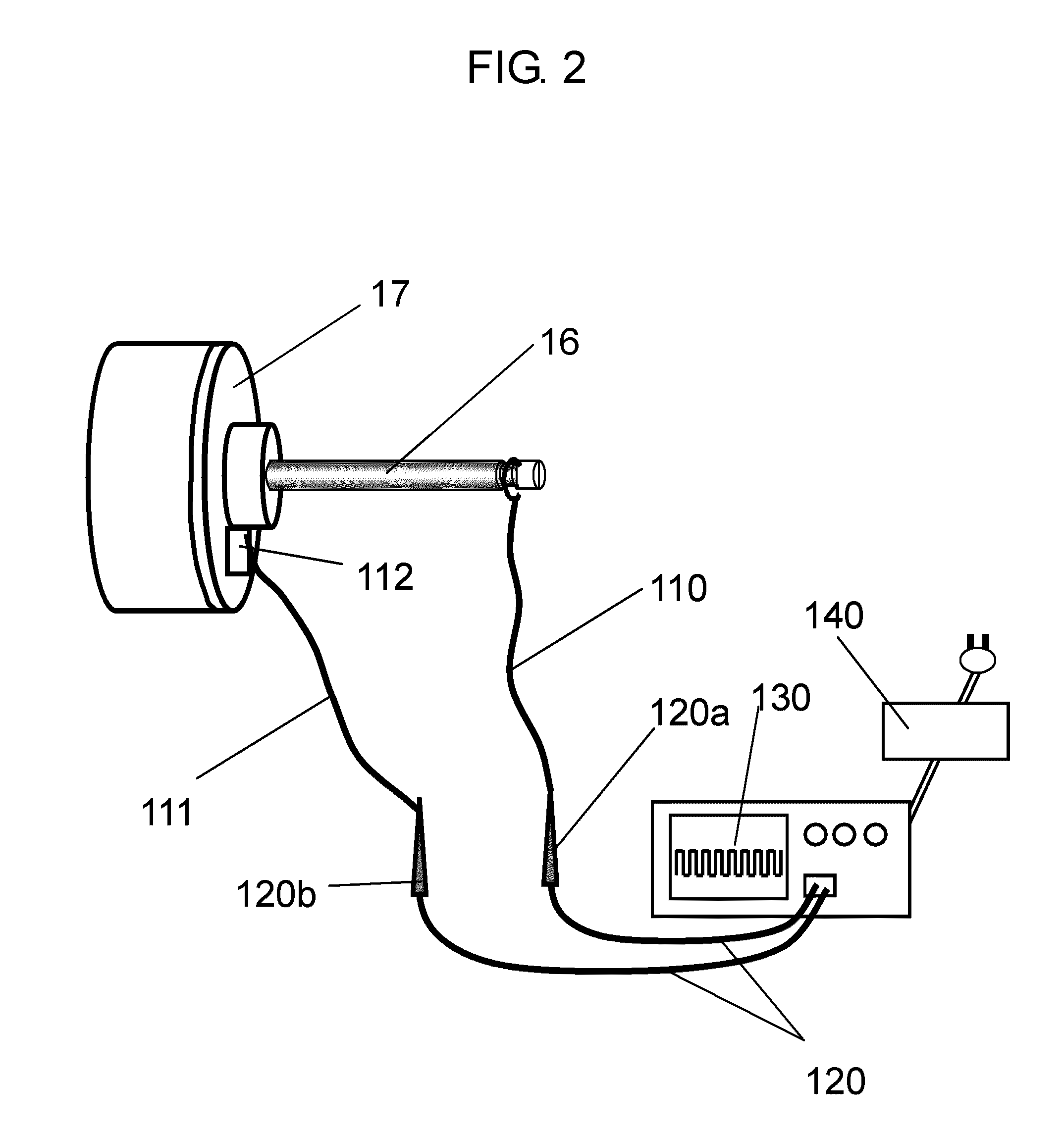

System for protecting bearings and seals of a refrigerant compressor

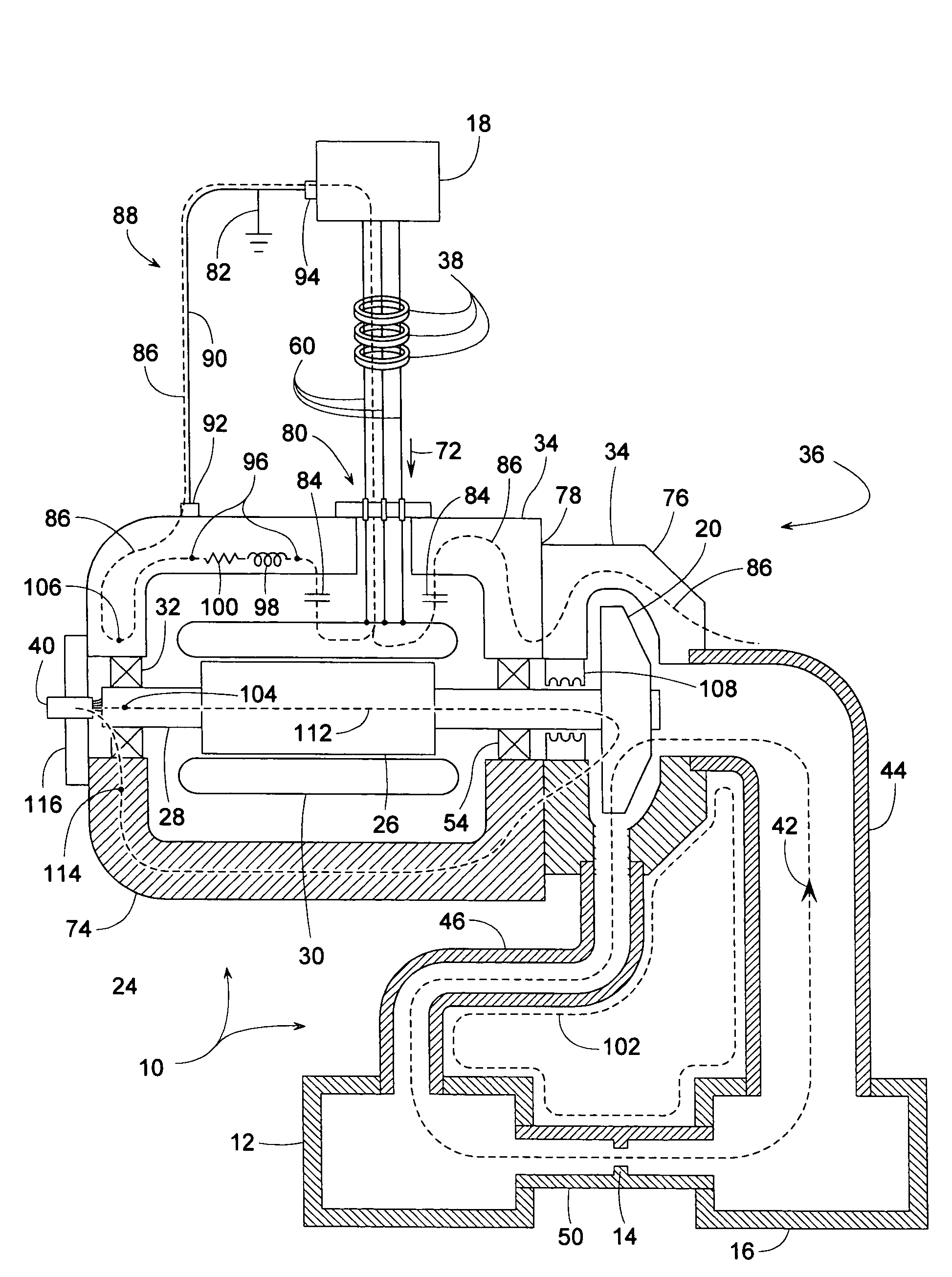

ActiveUS20080166246A1Reduce shaft voltageReduce frequencyCompressorAC motor controlFrequency changerGround contact

To protect the bearings, lubricant and seals of a refrigerant compressor, the compressor includes one or more inductors for mitigating a high frequency common mode current that produces a high frequency shaft voltage. Each inductor is a ring of magnetic material encircling three insulated cables that convey three-phase power from an adjustable frequency drive to the compressor's motor. Without the inductors, the high frequency shaft voltage can become damagingly high due to the length of a cast iron housing that can be particularly long if the housing contains both a motor and several centrifugal impellers. The high frequency shaft voltage is just one component of a composite adverse shaft voltage. Another component, known as an operationally induced shaft voltage, can be reduced by a grounding contact, so instead of using just an inductor or just a contact, both can be used to provide a total solution to the problem.

Owner:TRANE INT INC

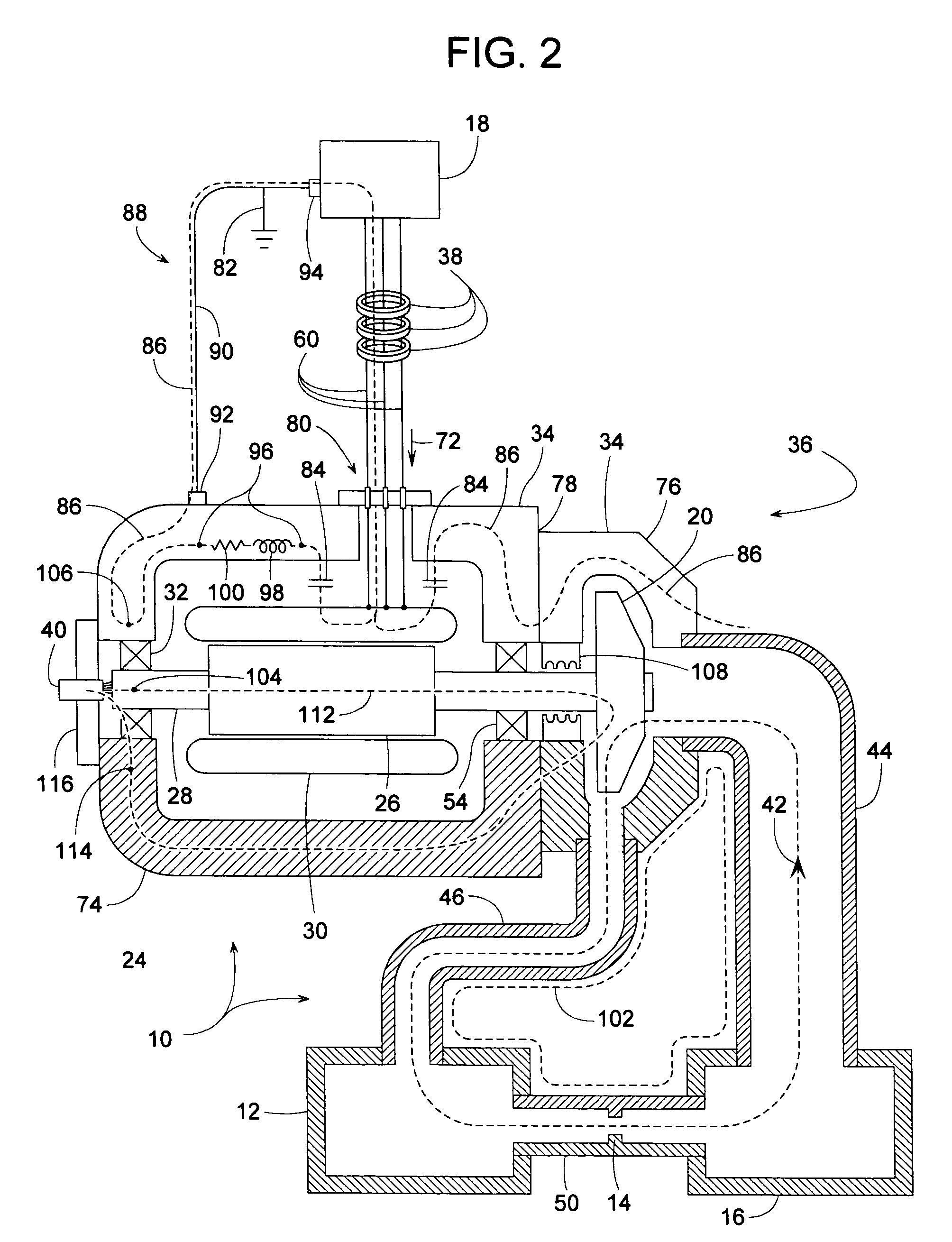

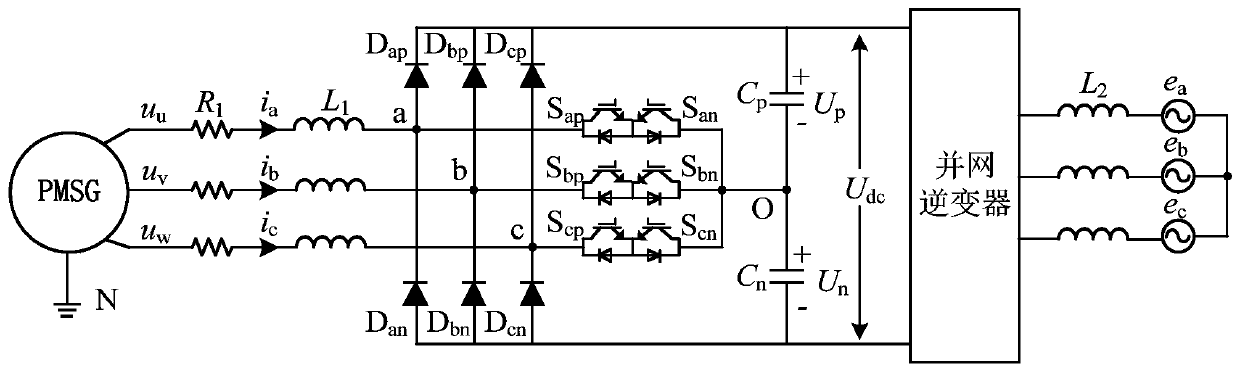

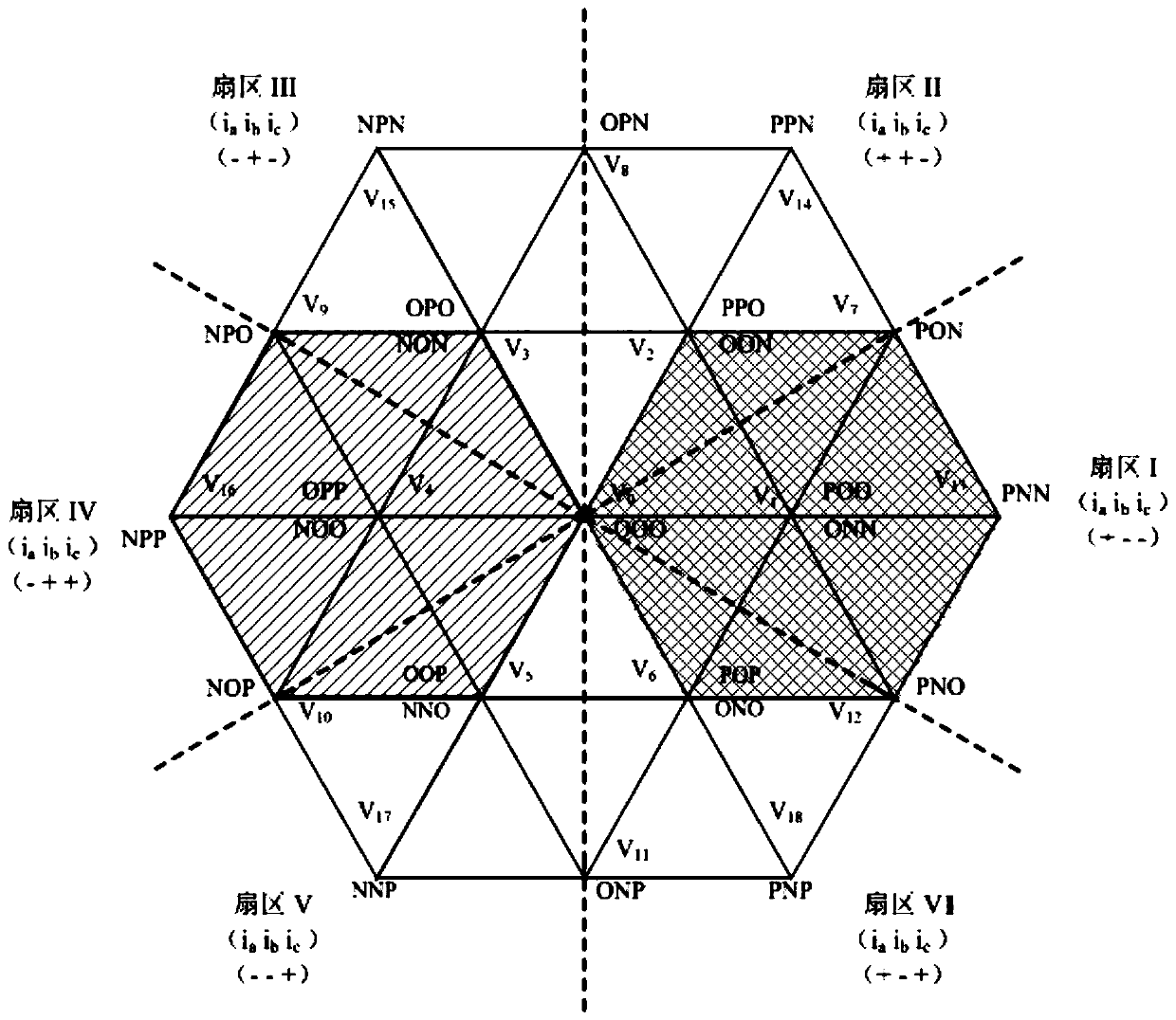

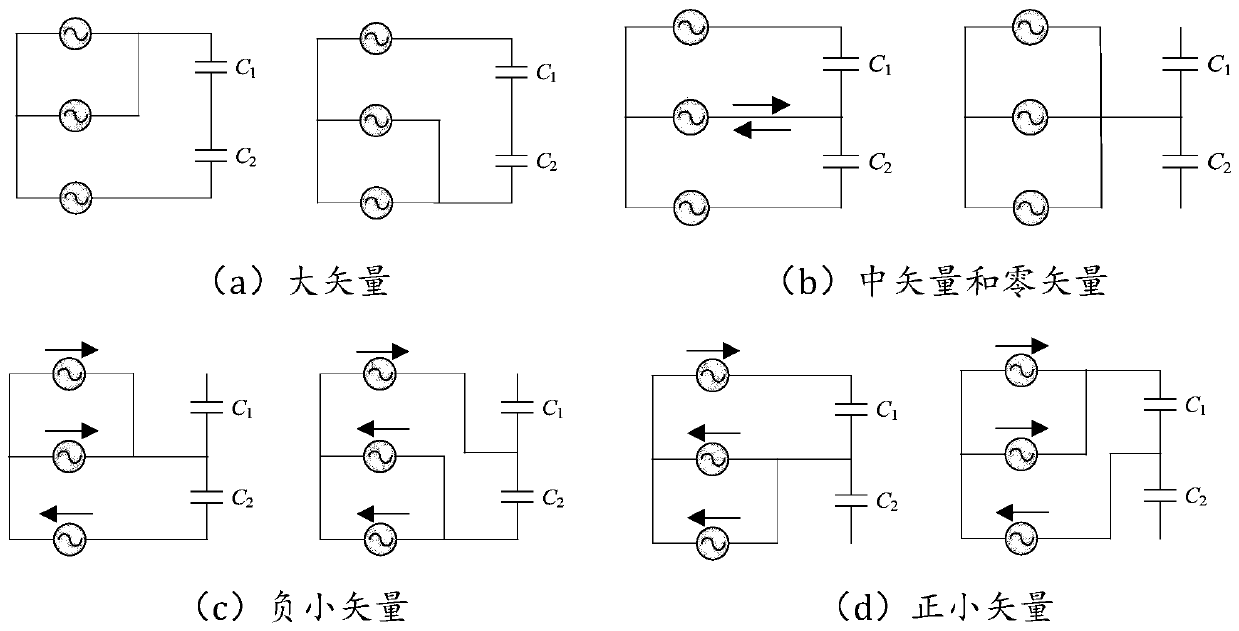

Predictive control system and method for reducing common-mode voltage of three-level VIENNA rectifier system

ActiveCN108988667AHigh output levelImprove output waveform qualityAc-dc conversionSingle network parallel feeding arrangementsThree levelVoltage vector

The invention discloses a predictive control system and a method for reducing the common-mode voltage of a three-level VIENNA rectifier system, which are used for solving the problems of high common-mode voltage of the three-level VIENNA rectifier system in a wind power generation system, zero-crossing point distortion of an AC side current and unbalance of a DC side neutral point voltage. The algorithm limits the common-mode voltage of the system to a very low range. The coupling problem of current zero-crossing distortion and DC neutral-point voltage imbalance control is solved. By classifying the space voltage vectors, the computational complexity is greatly reduced. The algorithm does not need current inner loop controller and PWM modulation module, and avoids the design of complex controller and the selection of complex parameters. The system and method have characteristics of simpleness, directness and effectiveness, which makes the algorithm has high application value.

Owner:SHANDONG UNIV

Brushless motor and electric device using same

ActiveUS8587167B2Reduce shaft voltageTorque ripple controlAssociation with control/drive circuitsBrushless motorsElectricity

A motor includes: a stator molded integrally with an insulating resin having a fixing member including a stator iron core and a winding wound thereon; a rotor arranged to face the stator about a shaft; a bearing rotatably supporting the shaft; a bracket fixing the bearing; and a drive circuit substrate having a drive circuit mounted thereon for driving the winding. The stator iron core is electrically connected to a ground serving as a reference point of a zero potential on the drive circuit substrate through a conductive member.

Owner:PANASONIC CORP

System for protecting bearings and seals of a refrigerant compressor

ActiveUS7922467B2Reduce shaft voltageReduce frequencyAC motor controlPump componentsFrequency changerEngineering

Owner:TRANE INT INC

Motor and electrical appliance provided with same

ActiveCN103155368AInhibit galvanic corrosionReduce shaft voltageAssociation with grounding devicesMagnetic circuit rotating partsFixed bearingEngineering

A motor of the present invention is provided with: a stator that has a stator winding wound around a stator core; a rotor that has a rotation axle as the center thereof, and comprises a rotating body; bearings that support the rotation axle; and two conductive brackets onto which the bearings are anchored. The rotating body holds a magnet in a state opposed to the stator, and is connected to the rotation axle such that the rotation axle penetrates the center thereof. In the rotating body, a dielectric layer is formed between the rotation axle and the outer circumference of the rotating body. The dielectric layer is made to be a polygon with the rotation axle as the center thereof. An electrical appliance of the present invention has such a motor mounted thereon.

Owner:PANASONIC INTPROP MANAGEMENT CO LTD

Motor and electrical appliance provided with same

ActiveUS8546989B2Reduce shaft voltagePotential differenceAssociation with grounding devicesMagnetic circuit rotating partsDielectric layerMagnet

An electric motor includes a stator that has a stator winding wound on a stator iron core; a rotor having a rotating body with a rotating shaft in the center; a bearing for journaling the rotating shaft; and two conductive brackets for fixing the bearing. The rotating body holds a magnet such that the magnet faces the stator, and is fastened to the rotating shaft penetrating through the center of the rotating body. In the rotating body, a dielectric layer is formed between the rotating shaft and the outer circumference of the rotating body. The dielectric layer has a polygonal shape with the rotating shaft in the center. An electric device includes the thus configured electric motor.

Owner:PANASONIC CORP

Electric motor with rotating body and electric device provided therewith

ActiveUS8901788B2Improving impedanceReduce shaft voltageAssociation with grounding devicesMagnetic circuit rotating partsEngineeringDielectric layer

Owner:PANASONIC CORP

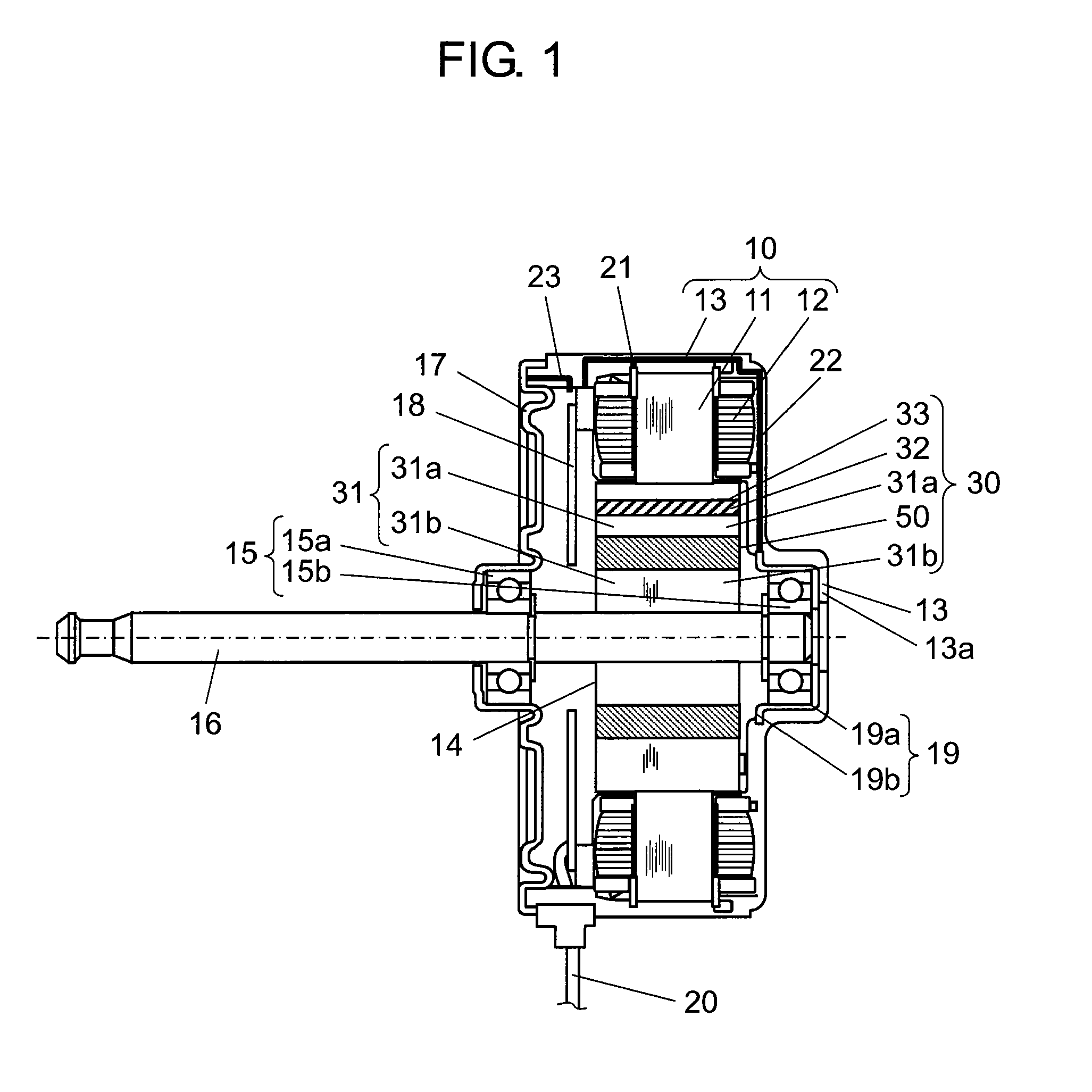

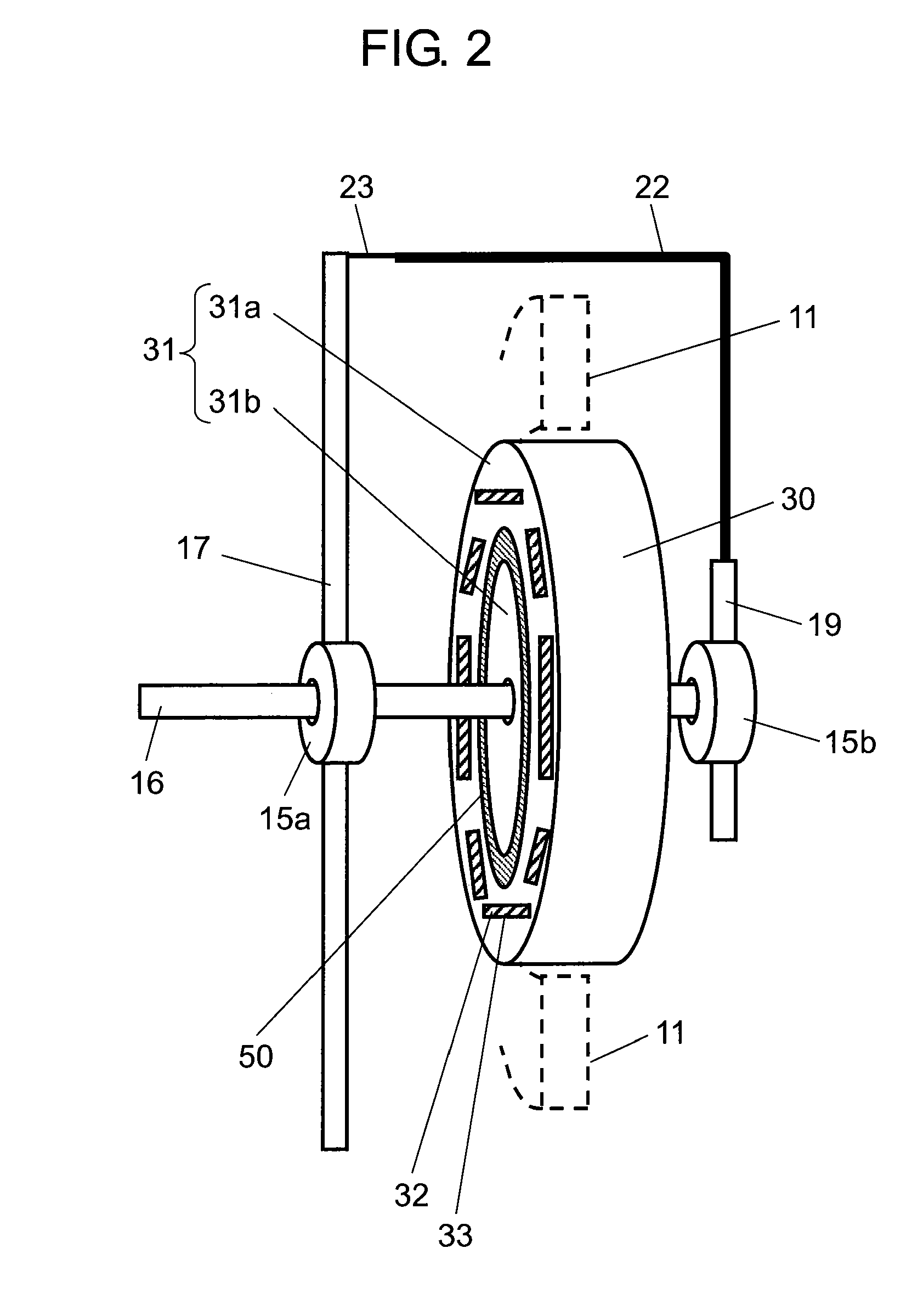

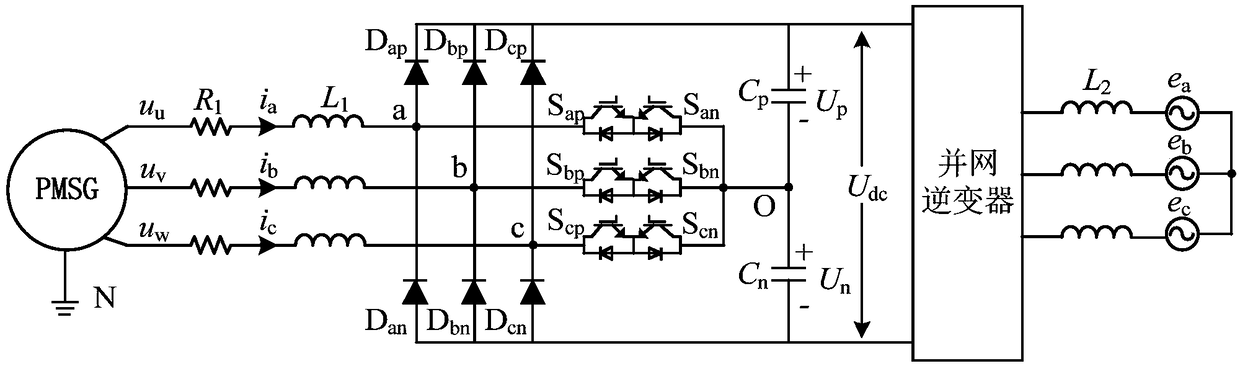

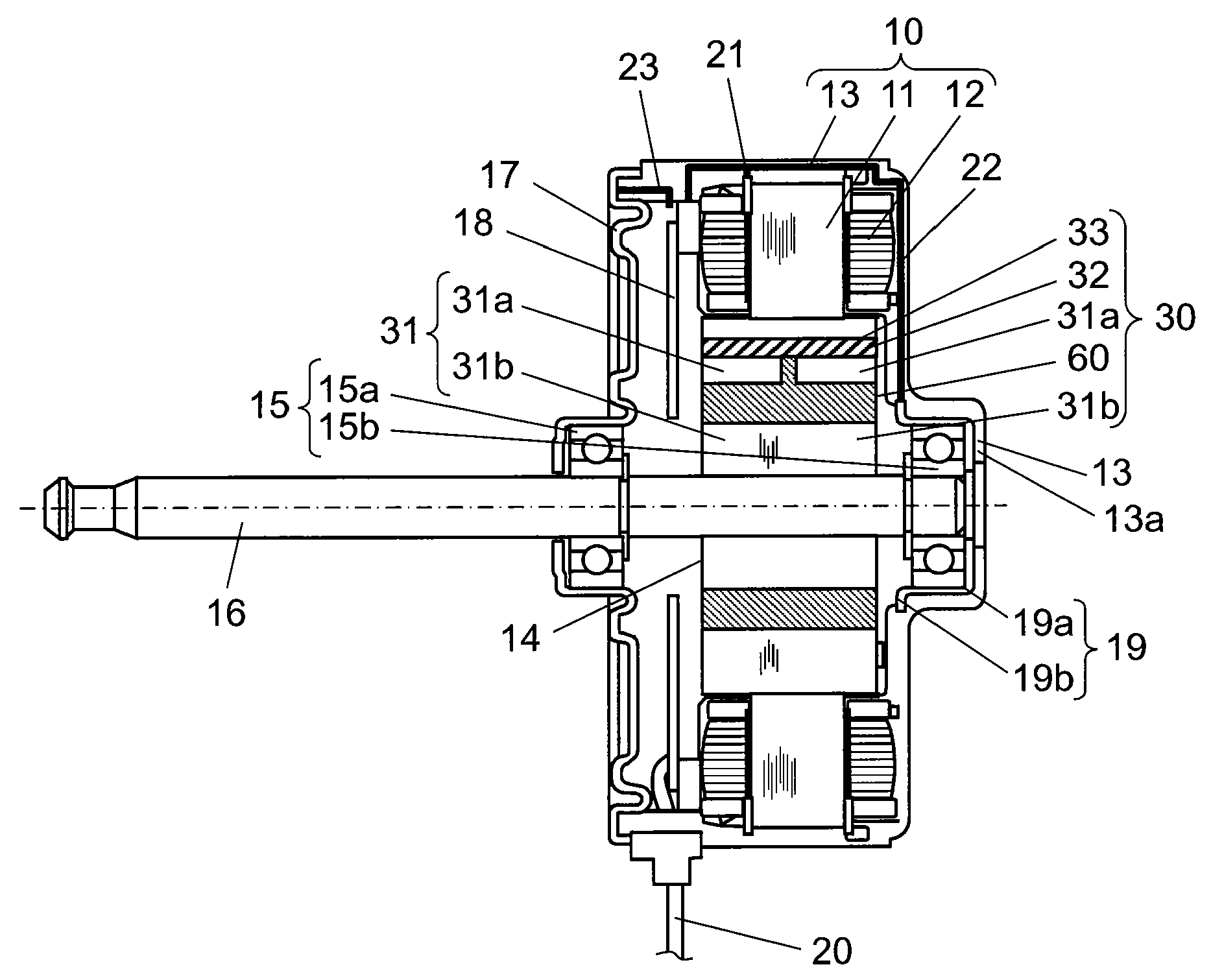

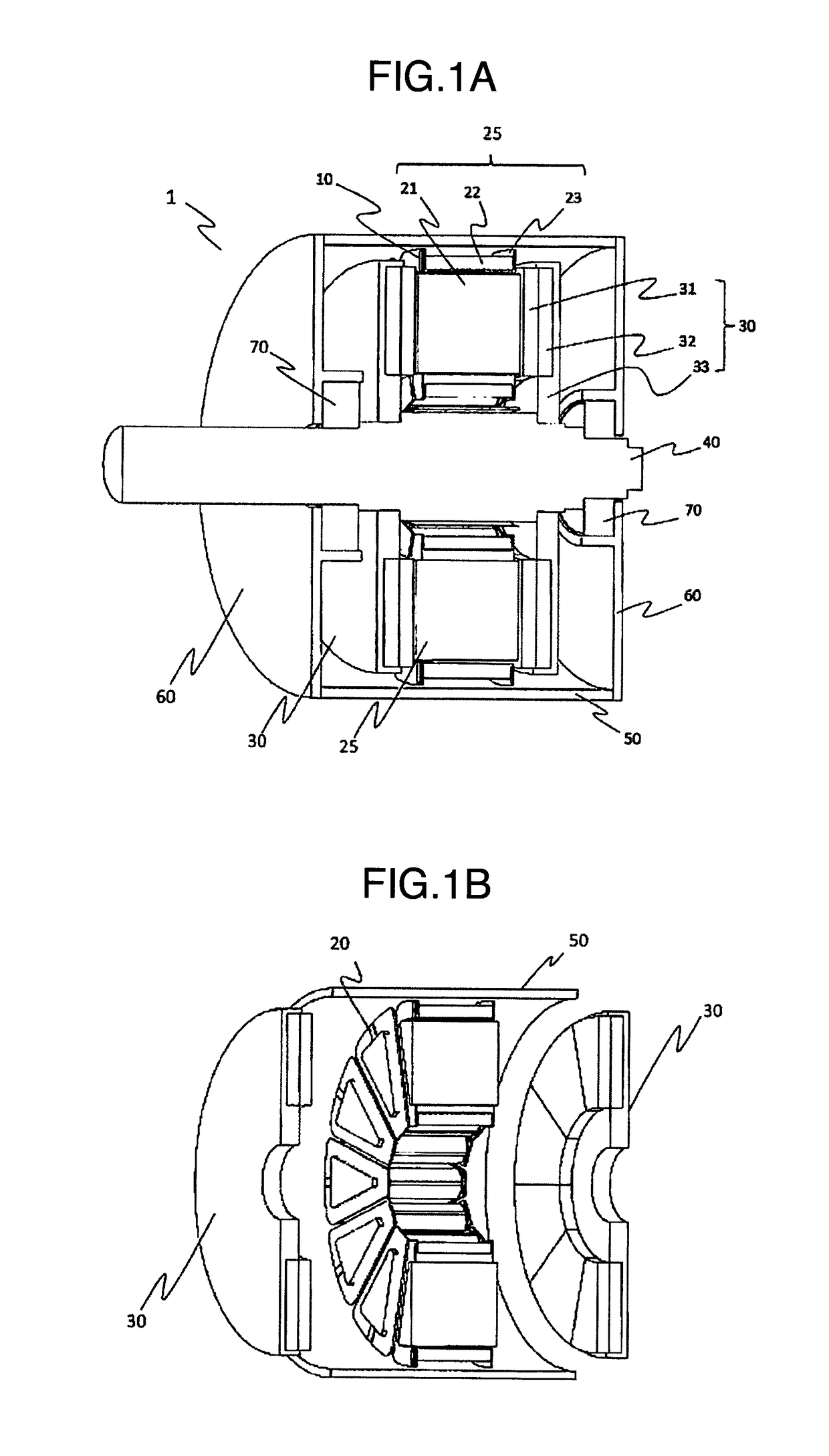

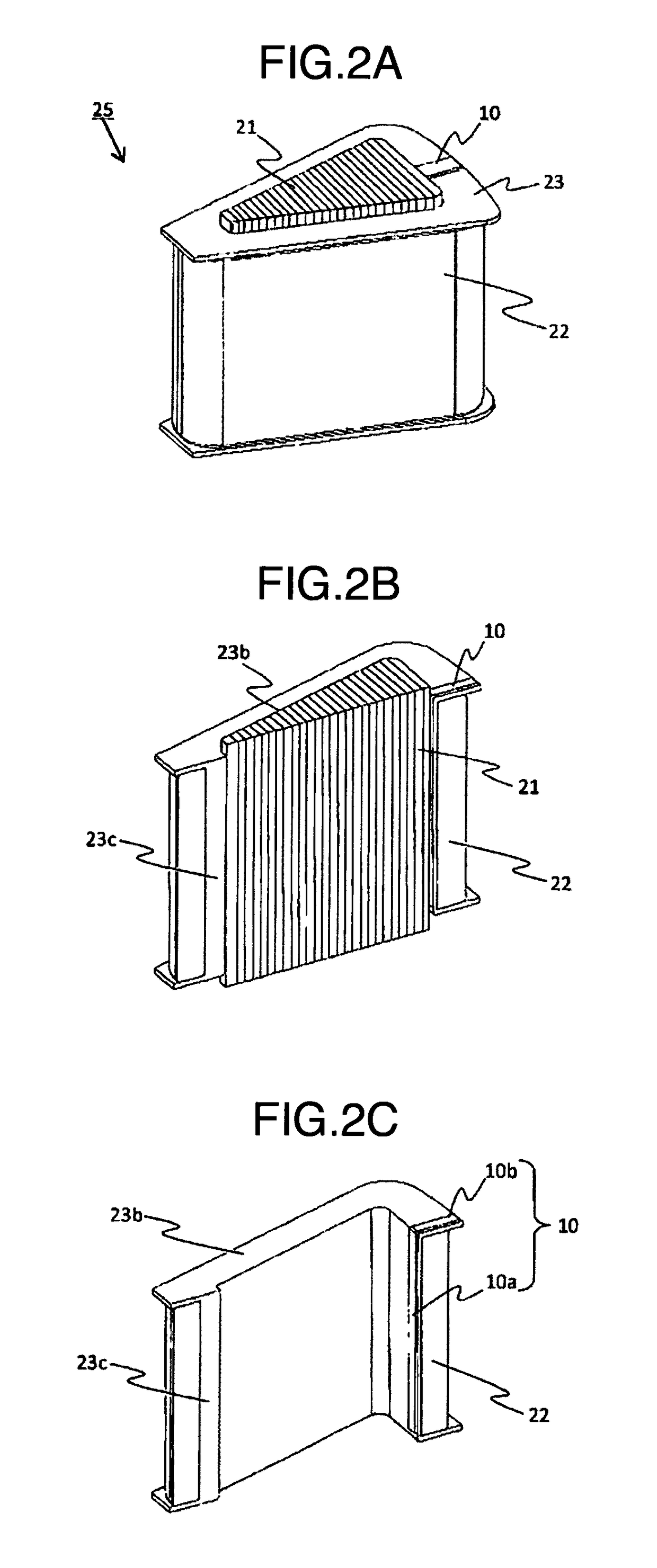

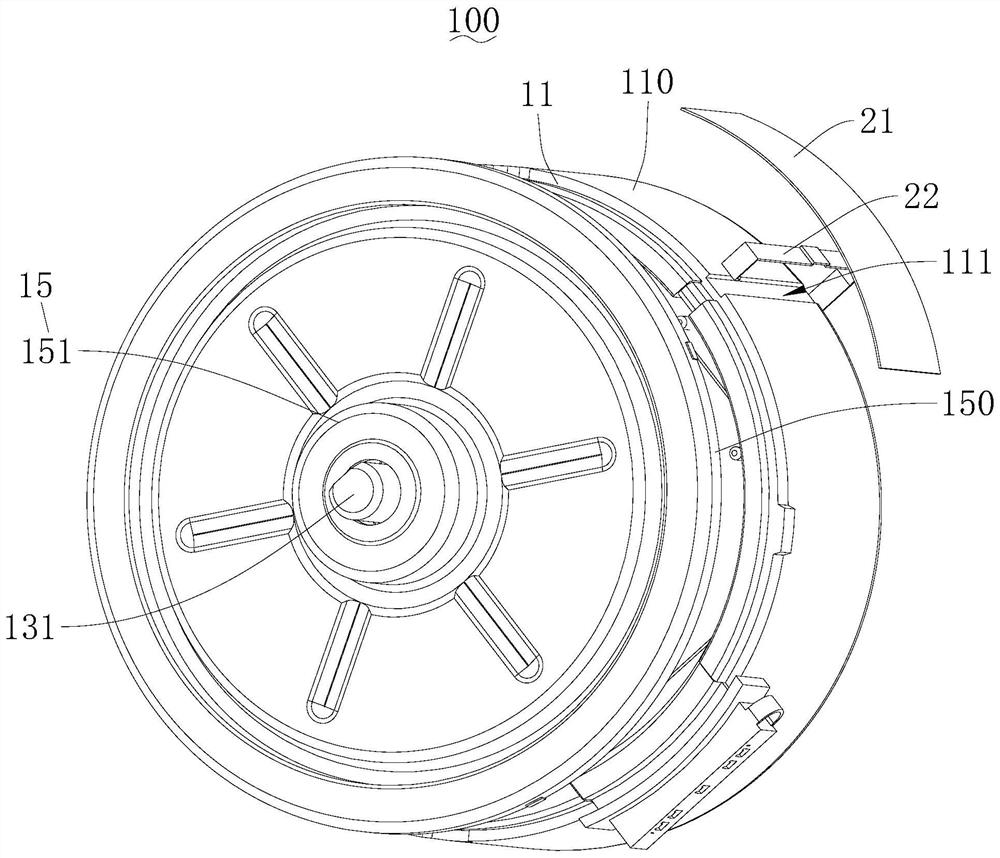

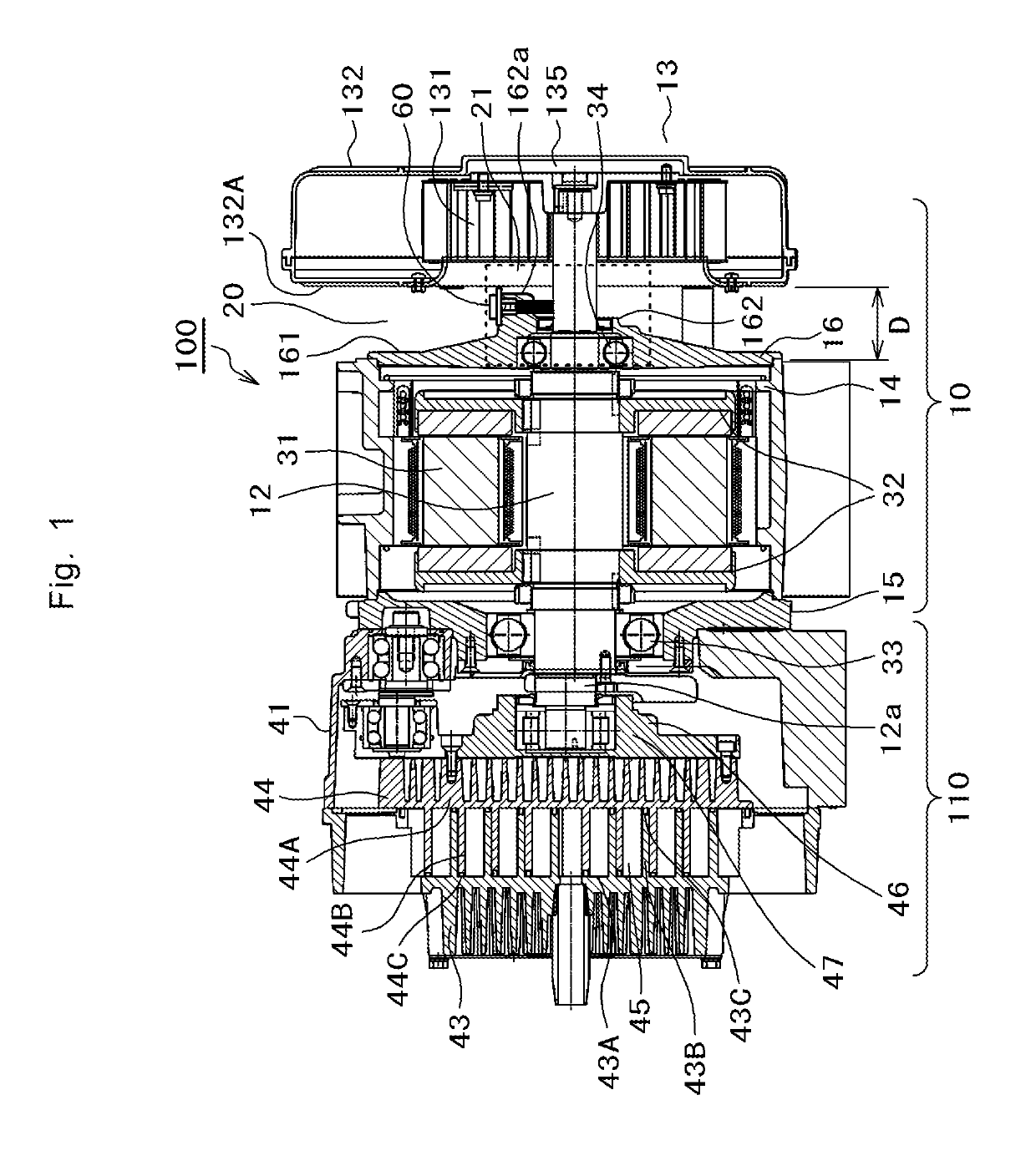

Axial Air Gap Rotating Electric Machine

ActiveUS20170155297A1Assemblability is ensuredReduce shaft voltageAssociation with control/drive circuitsAssociation with grounding devicesRotational axisBobbin

To ensure ready assembly of a stator and reliably reduce the shaft voltage in an axial air gap rotating electric machine, an axial air gap rotating electric machine has a circular ring-shaped stator formed by a plurality of stator cores arranged about a rotational axis direction in a ring shape. Each stator core comprises a tubular bobbin and a coil, with the tubular bobbin having an iron core inserted into a bobbin inner tubular portion substantially matching the peripheral shape of the iron core. The axial air gap rotating electric machine has a first conductive member having a horizontal portion and a vertical portion contacting the end surface of the bobbin opening portion. The horizontal portion contacts parts of the iron core outer peripheral surface and the inner peripheral surface of the bobbin inner tubular portion, and the vertical portion is conductively connected to the inner circumferential housing surface.

Owner:HITACHI IND EQUIP SYST CO LTD

Motor and electric device using same

ActiveUS8502427B2Lower impedanceReduce shaft voltageWindings insulation materialAssociation with grounding devicesFixed bearingConductor Coil

A motor includes: a stator including a stator iron core on which a winding is wound; a rotor including a rotating body that holds a magnet in a circumferential direction to face the stator and a shaft that fastens the rotating body to penetrate a center of the rotating body; a bearing that supports the shaft; and two conductive brackets that fix the bearing. The two brackets are electrically connected to each other, and a capacitor serving as an impedance adjusting member that adjusts impedances between the stator iron core and the electrically connected two brackets is arranged.

Owner:PANASONIC CORP

Axial-gap dynamo-electric machine

ActiveUS11165312B2Reduce shaft voltageImprove reliabilityWindingsAssociation with grounding devicesElectric machineEngineering

This invention reduces the shaft voltage of an axial-air-gap dynamo-electric machine while ensuring high output and high efficiency. Said axial-air-gap dynamo-electric machine comprises the following: a stator comprising a plurality of stator cores, each of which comprises a core and a coil, arranged in a circle around a shaft; a housing, the inside surface of which faces the stator radially; and at least one rotor, the surface of which faces the surface of the stator with a prescribed air gap interposed therebetween in the radial direction of the shaft. The rotor has, on the outside thereof, a conductive section comprising a conductive member. This axial-air-gap dynamo-electric machine has a first region where the inside surface of the housing faces the aforementioned conductive section radially and a second region, closer to the stator than the first region is, that extends to the coil side surfaces that face the rotor. The proportion of connecting wires in the second region is higher than in the first region.

Owner:HITACHI IND EQUIP SYST CO LTD

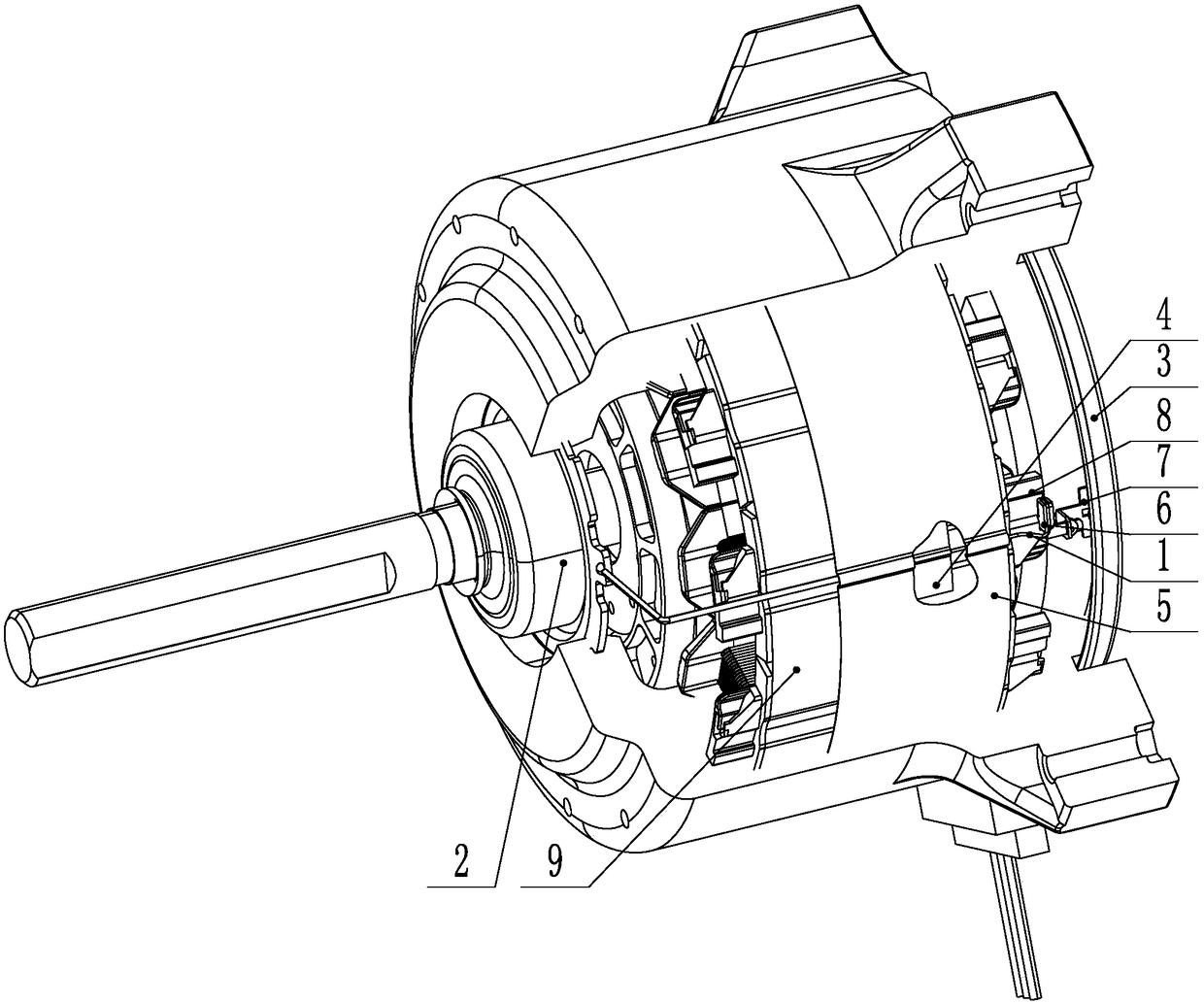

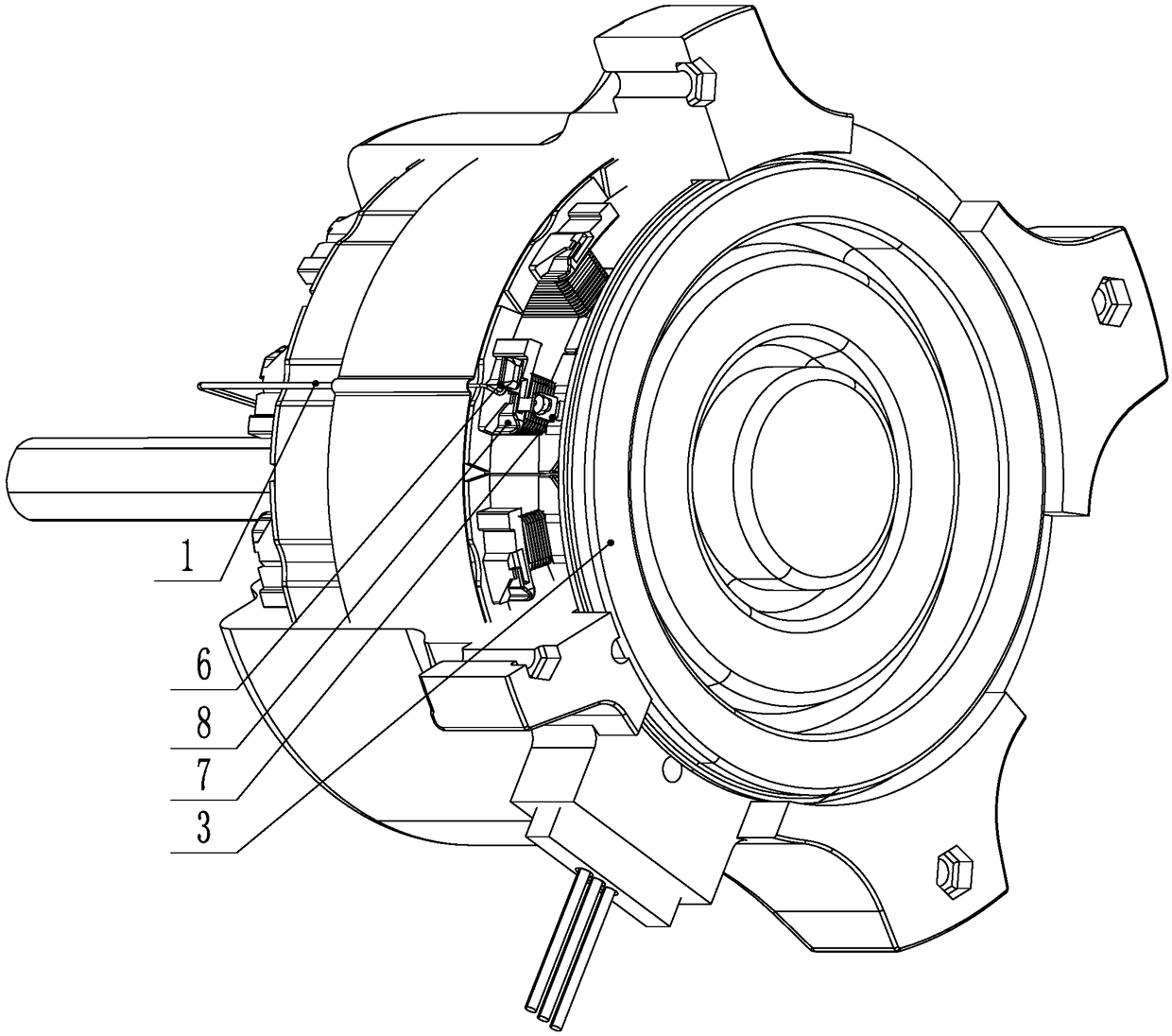

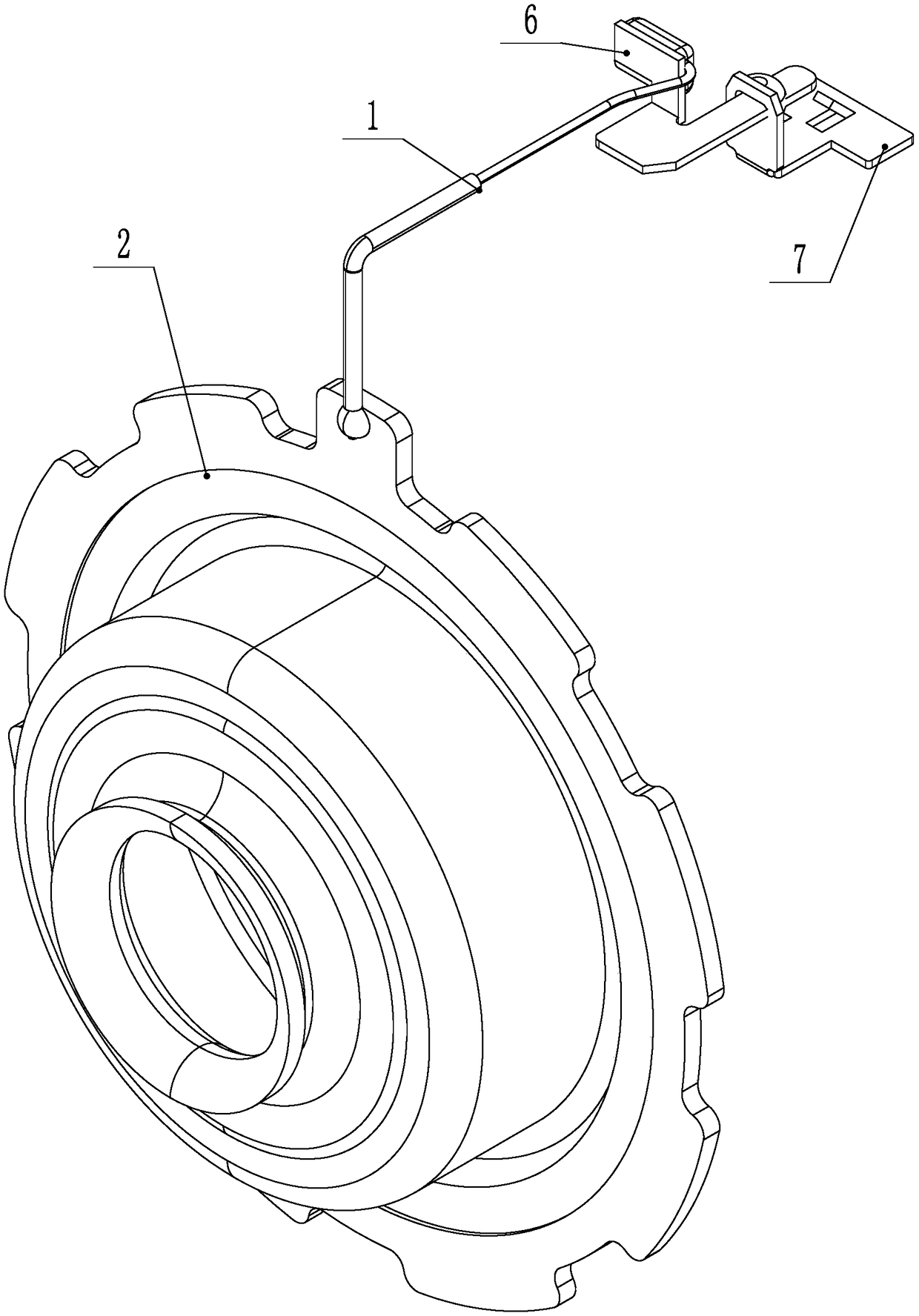

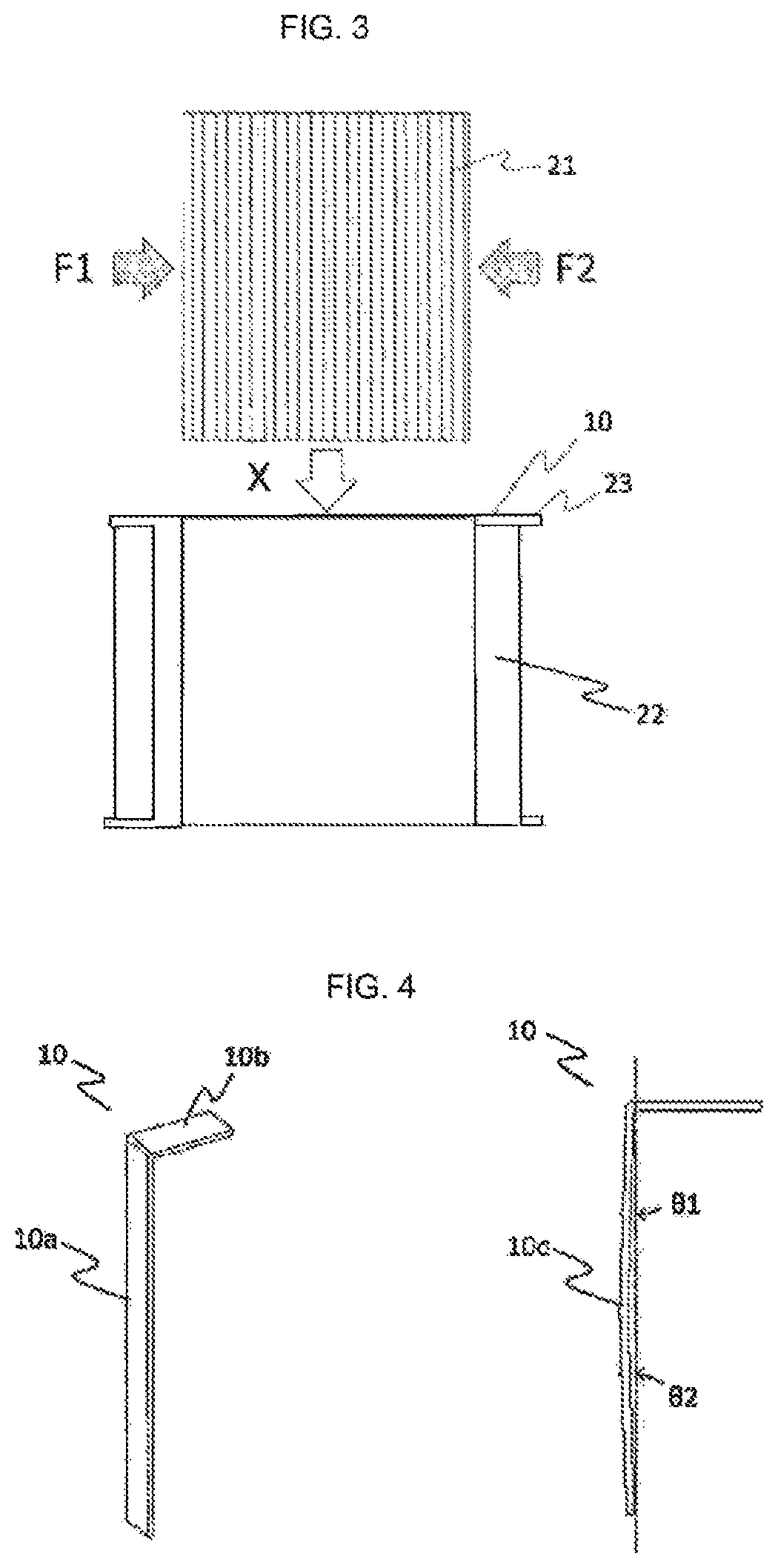

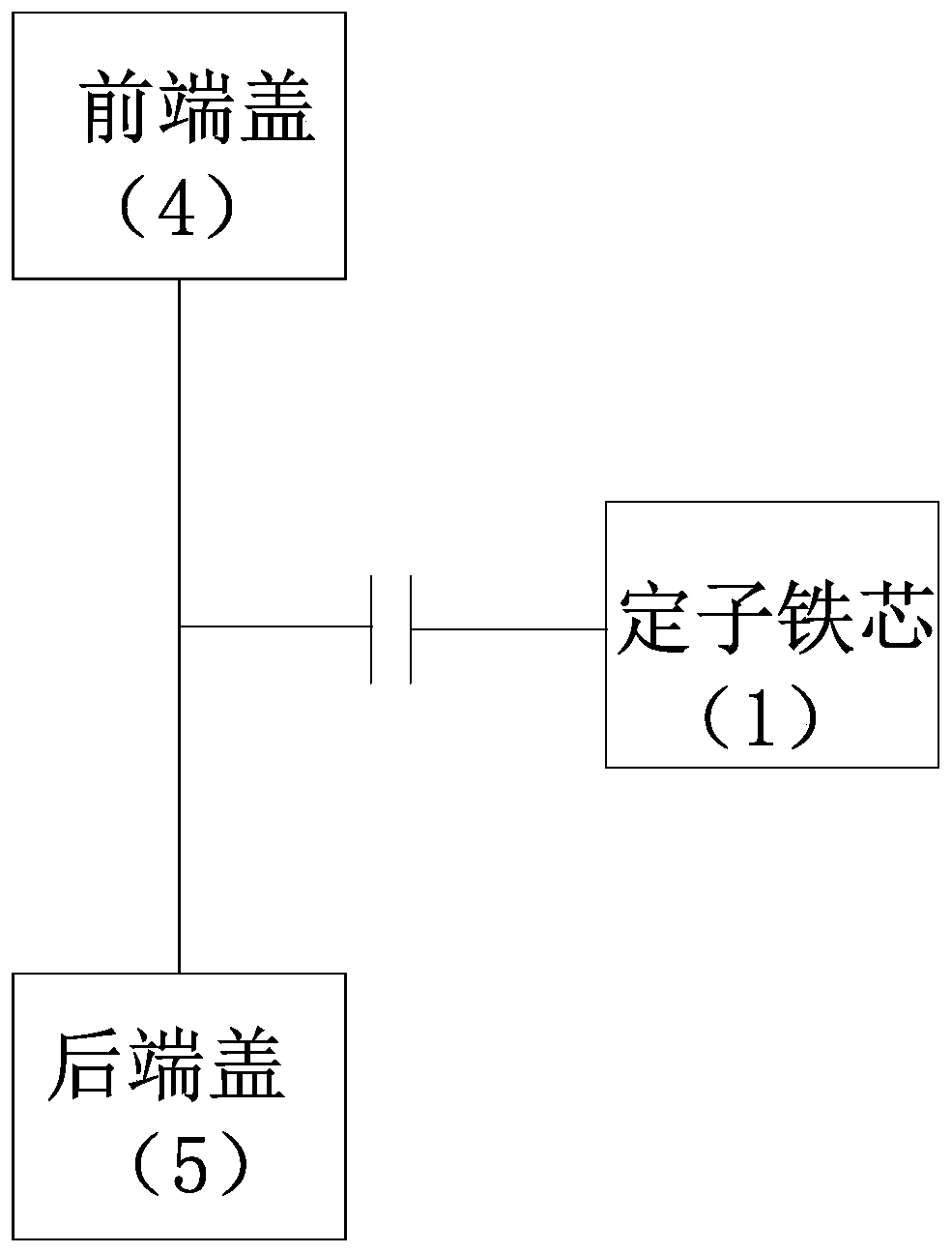

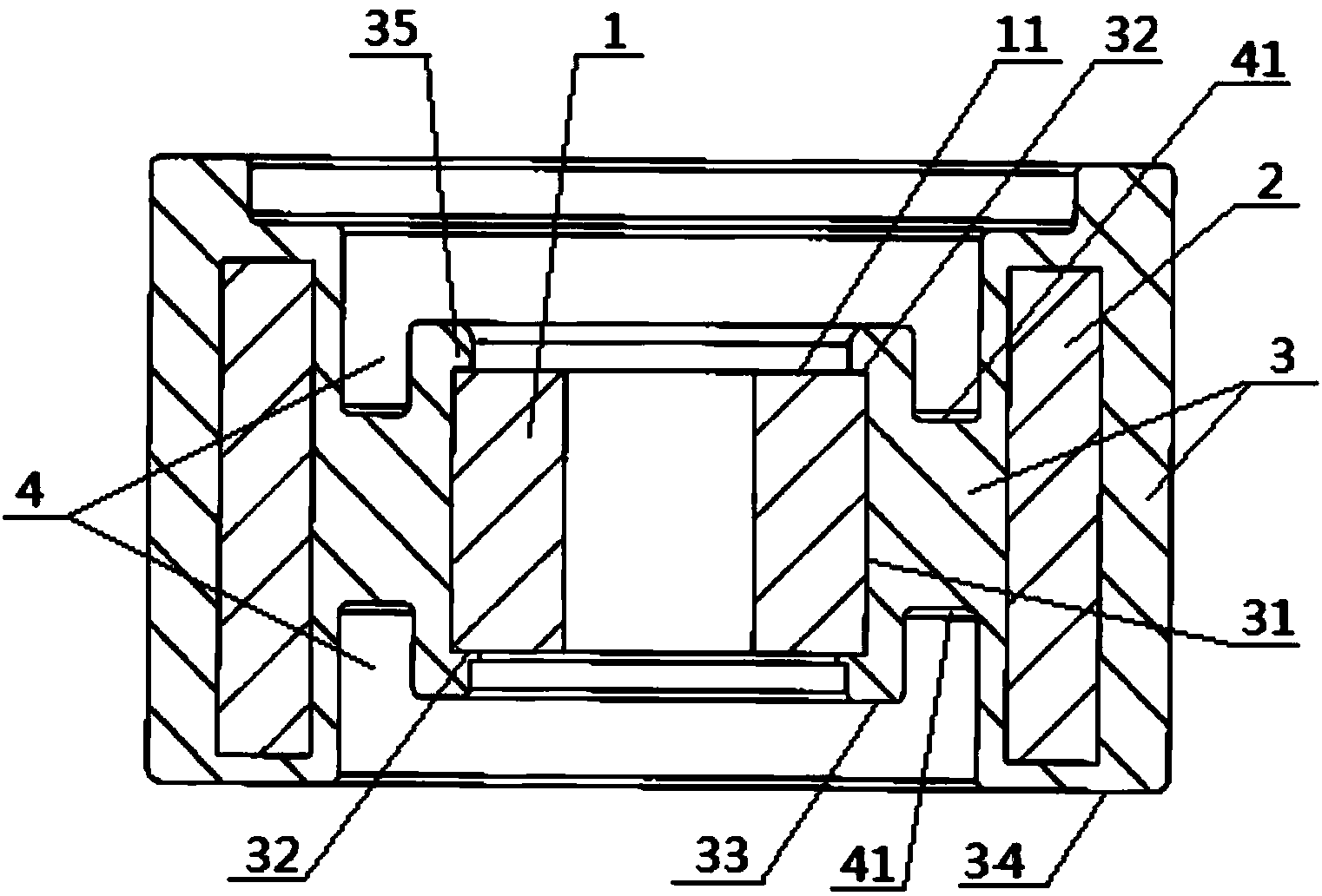

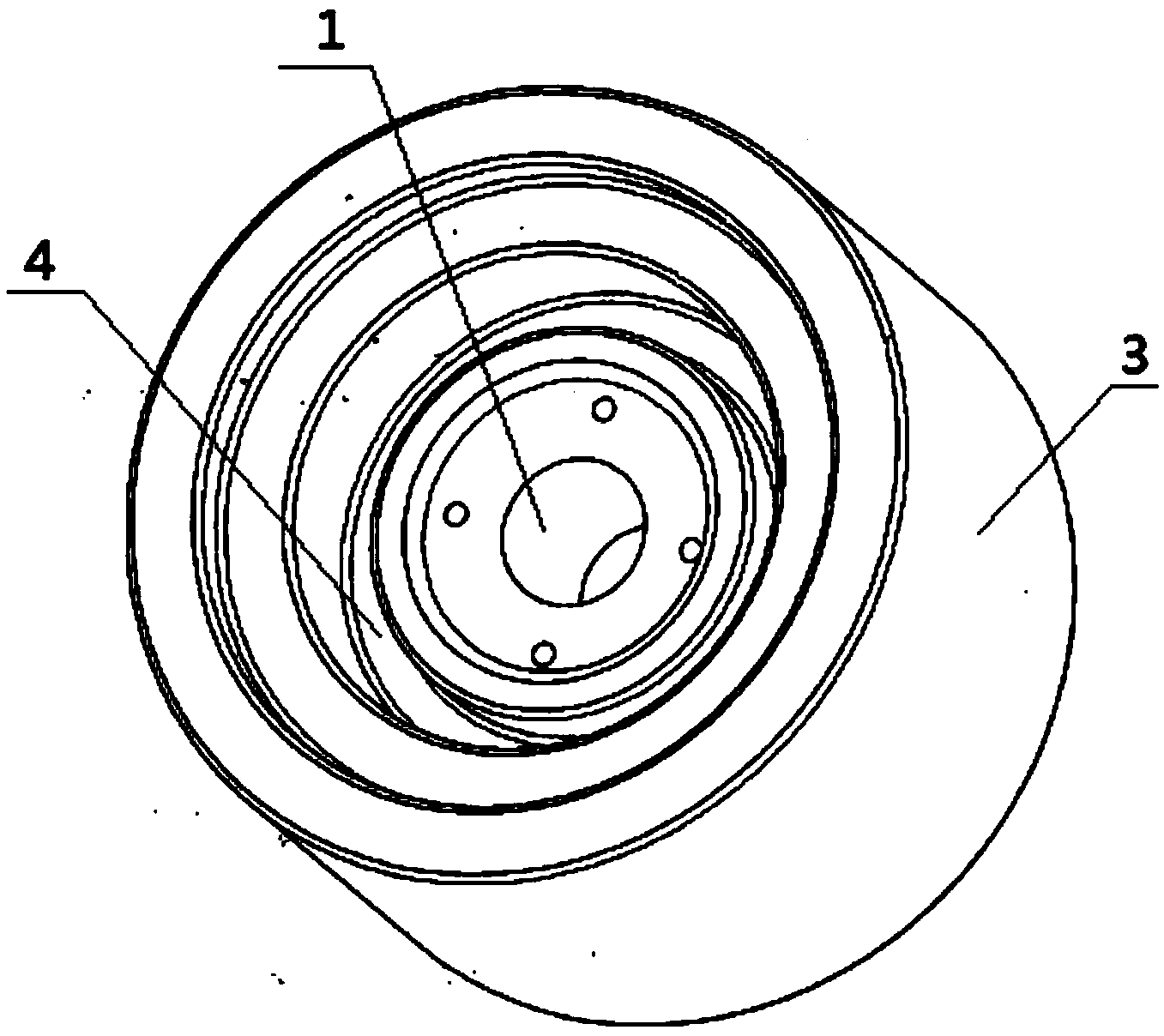

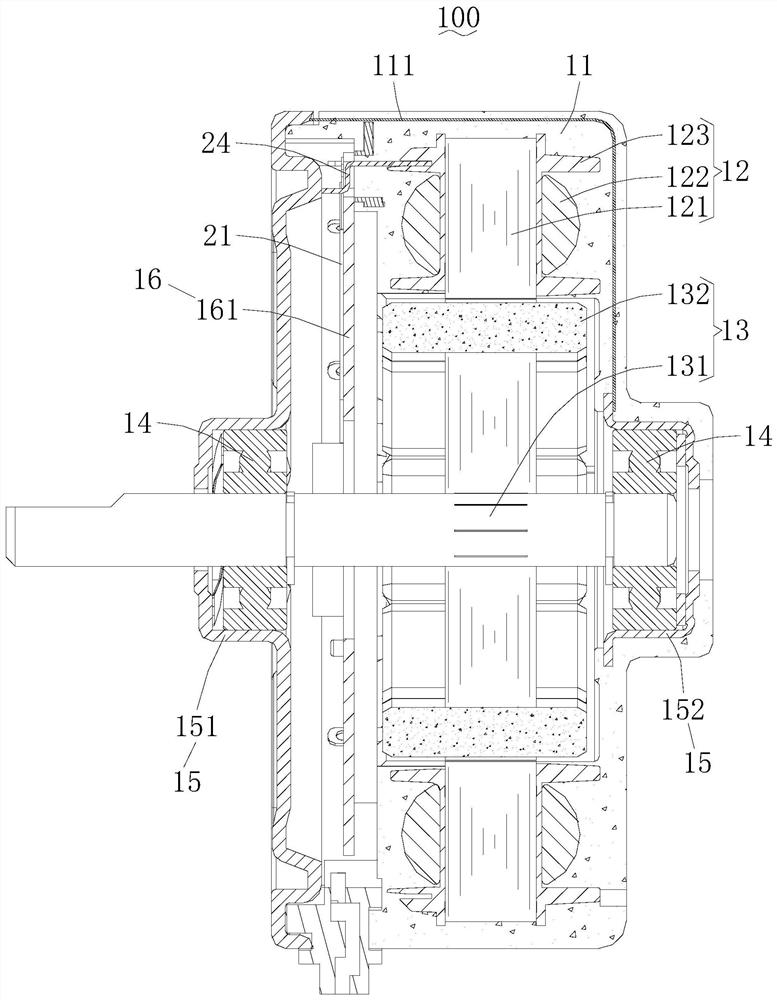

Shaft voltage reduction structure and plastic packaging motor equipped with shaft voltage reduction structure

PendingCN108964335AReduced risk of corrosionGuaranteed lifeStructural associationSupports/enclosures/casingsElectricityPlastic packaging

The invention discloses a shaft voltage reduction structure and a plastic packaging motor equipped with the shaft voltage reduction structure and relates to the field of a motor. For a plastic packaging EC (BLDC) motor in the prior art, after plastic packaging of a stator, a stator core and front and rear end covers achieve insulation, induction voltage difference between the stator and the end covers occurs, so an electrical corrosion problem of a bearing rolling channel and balls occurs. The shaft voltage reduction structure comprises a wire, a stator core electrical connection member and anend cover electrical connection member, wherein a first end of the wire is electrically connected with the first end cover, the wire is electrically connected with the stator core through the statorcore electrical connection member, a second end of the wire is electrically connected with the second end cover through the end cover electrical connection member arranged on an insulation framework,and the first end cover, the stator core and the second end cover are in an equipotential state. The shaft voltage reduction structure is advantaged in that the end covers at two sides and the statorcore are made to achieve effective conduction to form the equipotential state, the shaft voltage is greatly reduced, the electrical corrosion risk of a bearing is reduced, service life and reliabilityof the motor are guaranteed, and product applicability is wider.

Owner:WOLONG ELECTRIC GRP CO LTD

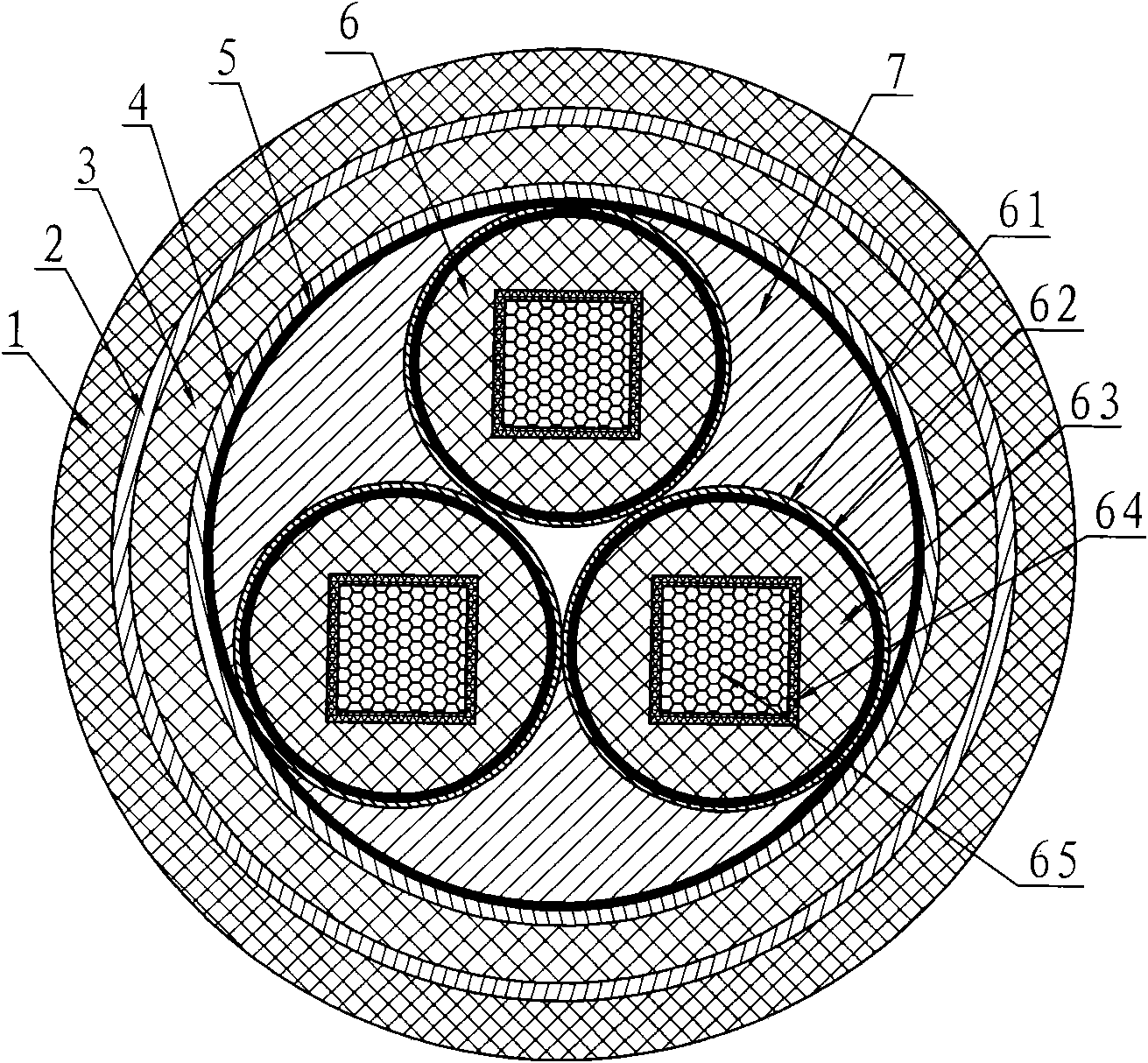

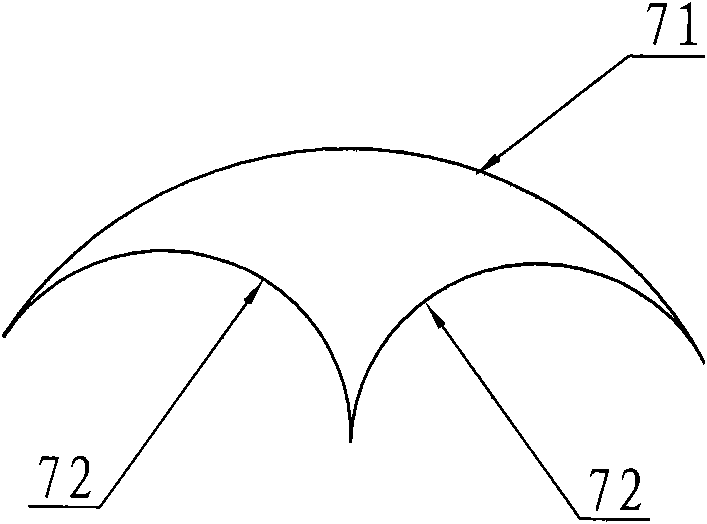

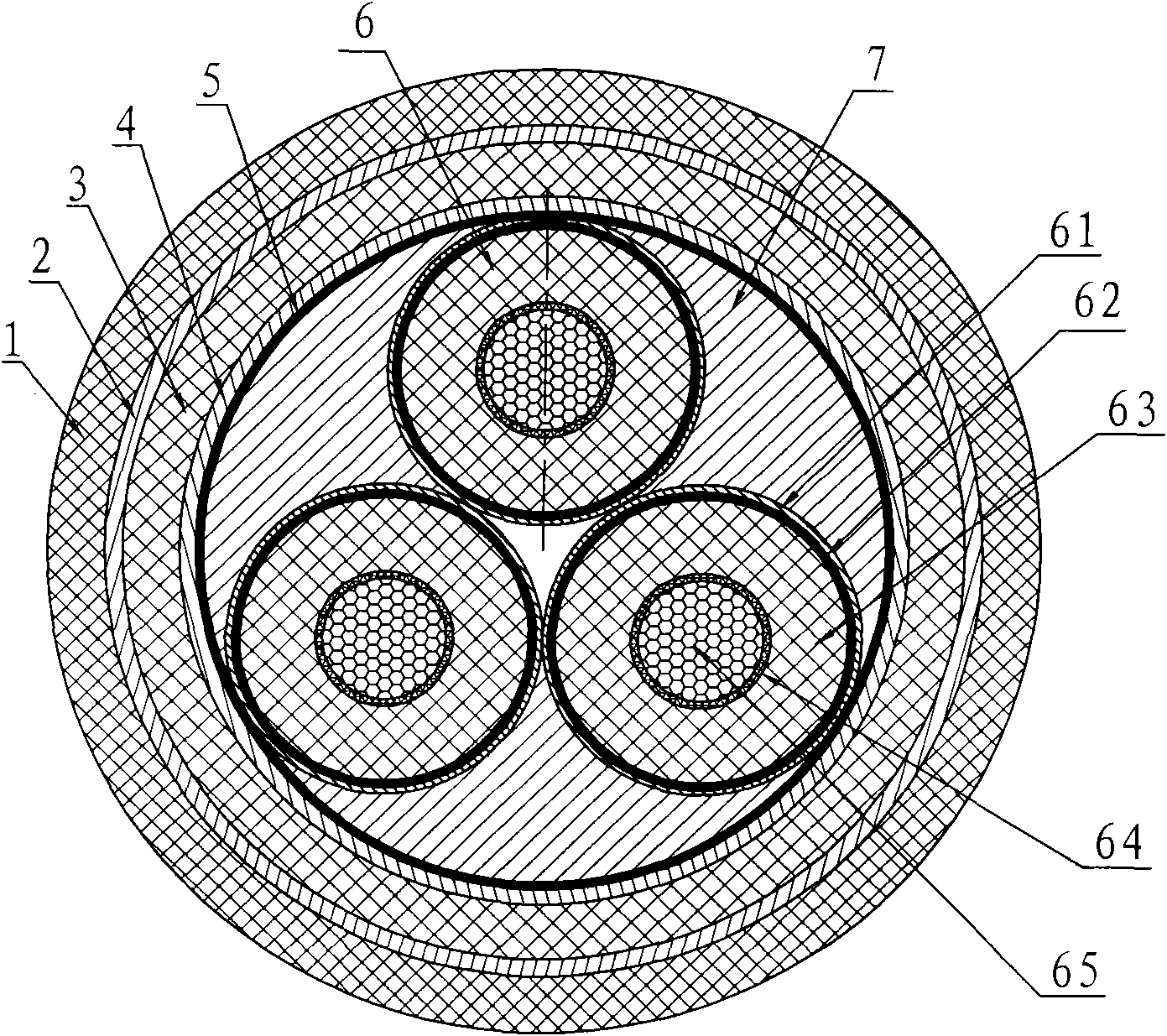

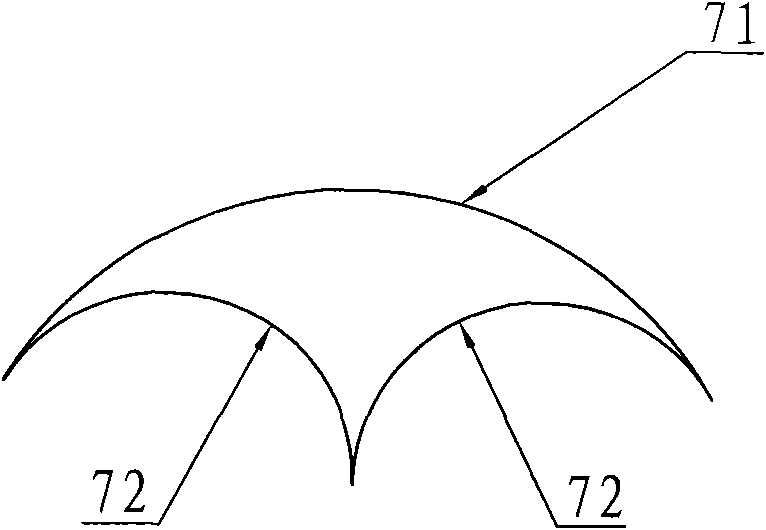

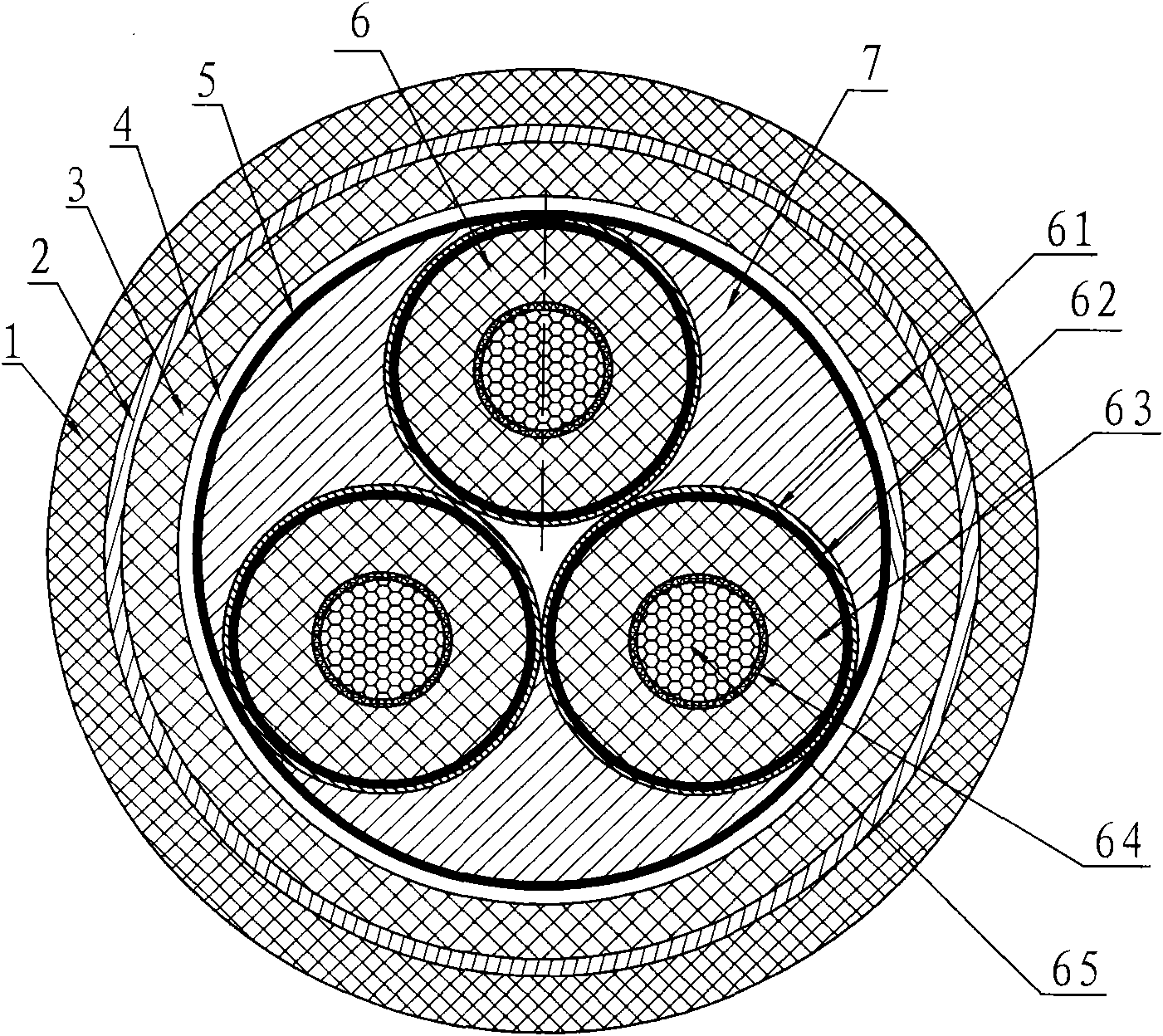

Triple shielding flame retardant type single core nuclear power cable

InactiveCN102074296AWon't interfereEliminate distractionsPower cables with screens/conductive layersNuclear powerEngineering

The invention discloses a triple shielding flame retardant type single core nuclear power cable which comprises an outer insulating sleeve, a first shielding layer, an inner insulating sleeve, a second shielding layer, a bus insulating net belt, a sub-line and a sub-line filling-pressing strip, wherein the sub-line comprises a sub-line shielding layer, a sub-line insulating net belt, a sub-line sheath, a heat insulating film and a lead core, and the exterior of the lead core is sequentially provided with the heat insulating film, the sub-line sheath, the sub-line insulating net-belt and the sub-line shielding layer. Because three lead cores are respectively wrapped by the sub-line sheath, the sub-line insulating net belt and the sub-line shielding layer, three sub-lines are filled and pressed by the filling-pressing strip and are glued firmly into a cable, each lead core is subjected to three passes of metallic shielding, the power cable can not be interfered by an external electric field and an external magnetic field in the power transmission process, an electromagnetic field generated by the power cable is also shielded, and the electricity and control system of an adjacent distribution circuit can not be interfered. By means of the special arrangement structure of the triple shielding flame retardant type single core nuclear power cable, a shaft voltage generated by an electric appliance in service in a frequency conversion loop is reduced, and the practice safety of the electric appliance is protected.

Owner:JINTAN JINLU CABLE MATERIAL

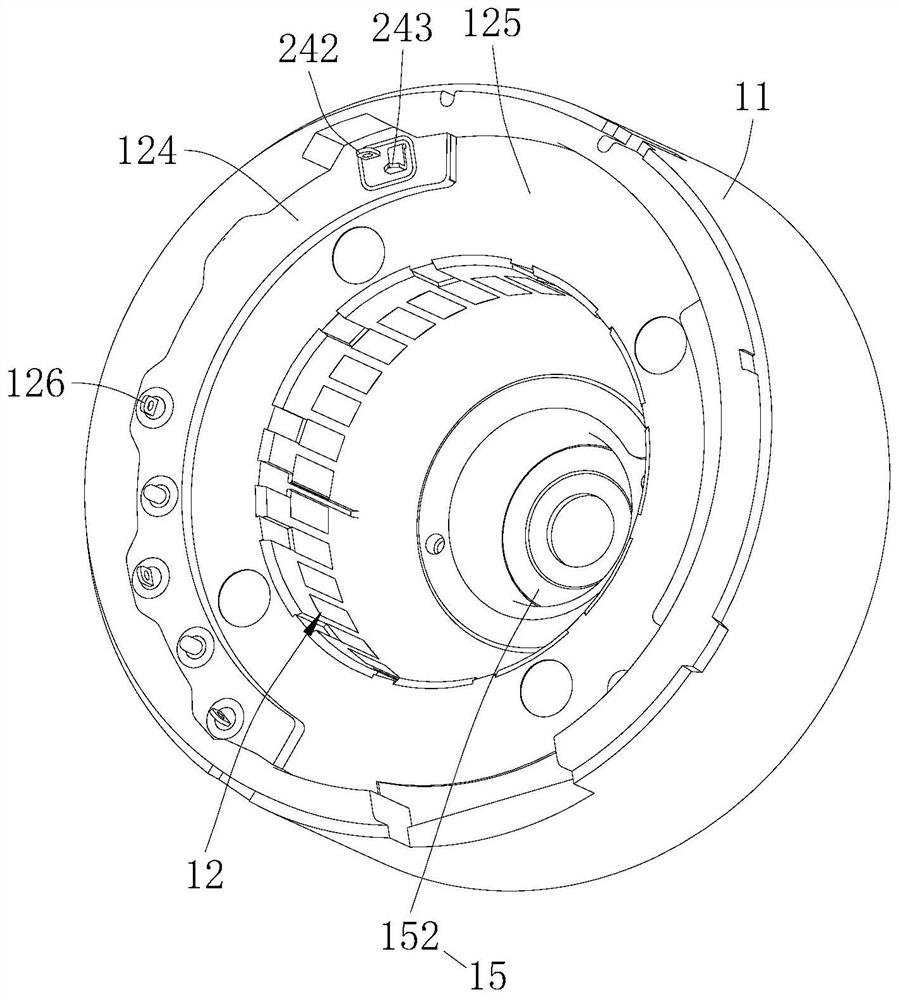

Brushless motor and electrical equipment

ActiveCN112366878APrevent Galvanic CorrosionReduce shaft voltageMagnetic circuit rotating partsBearing assemblyBalance shaftShaft voltage

The invention provides a brushless motor and electrical equipment. The brushless motor comprises a casing, a stator and a rotor, the stator comprises a stator core and a winding, the rotor comprises arotor core and a rotating shaft, corresponding positions of two ends of the rotating shaft are respectively sleeved with a bearing, and two ends of the casing are respectively provided with a bearingbracket. The brushless motor further comprises a conducting strip used for adjusting capacitive reactance between the stator iron core and the bearing bracket, the conducting strip is attached to theouter circumferential face of the casing, and in the radial direction of the casing, the conducting strip and the stator iron core have at least part of the opposite area. The conducting strip is attached to the outer peripheral surface of the casing, so that the conducting strip and the stator core have opposite areas, coupling capacitance is formed between the stator core and the conducting strip, the bearing bracket is located at the end of the casing, equivalent capacitance between the stator core and the bearing bracket is adjusted, potential between the bearing outer ring and the bearing inner ring is balanced, and the service life of the motor is prolonged. The potential between the bearing outer ring and the bearing inner ring is close, so that the shaft voltage is reduced, and the bearing is prevented from generating electric corrosion.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Ground connection structure for reducing shaft voltage of double-fed wind generator

InactiveCN103580390ALow costReasonable structureAssociation with grounding devicesElectricityWind power system

The invention relates to a motor ground connection structure, in particular to a ground connection structure for reducing the shaft voltage of a double-fed wind generator, and belongs to the technical field of wind generators. The ground connection structure comprises a shaft extension terminating shaft carbon brush, a machine base outer shell and a non-shaft extension terminating shaft carbon brush all of which are sequentially connected through an electric connecting line. The ground connection structure is low in cost, reasonable in structure and obvious in effect, a method for reducing the shaft voltage is added, the ground connection structure is suitable for being applied in a wind power system with requirements for zero maintenance and high reliability, and the reliability of wind electricity operation is improved.

Owner:SEC ELECTRIC MACHINERY

Axial air gap rotating electric machine

ActiveUS10530210B2Assemblability is ensuredReduce shaft voltageAssociation with control/drive circuitsAssociation with grounding devicesRotational axisBobbin

Owner:HITACHI IND EQUIP SYST CO LTD

Structure for reducing shaft voltage of PWM inverter driving type plastic package motor

PendingCN110601454AEffective conductionAvoid the risk of galvanic corrosionSoldered/welded conductive connectionsDynamoelectric machine connectorsEquipotentialEngineering

The invention discloses a structure for reducing shaft voltage of a PWM inverter driving type plastic package motor, which relates to the field of motors. In the existing PWM inverter driving type plastic package motor, a high-frequency switch of a power element can cause change of common-mode voltage and parasitic capacitance at each position in the motor, so that a potential difference is generated between an inner ring and an outer ring of a bearing, an oil film of bearing lubricating grease is easily damaged, the bearing is damaged by electrocorrosion, and electrocorrosion generated by theinner ring, the outer ring and a ball is always a key factor influencing the service life of the motor. According to the structure disclosed in the invention, a front end cover and a rear end cover are connected through a conductive piece to realize equipotential, and a capacitor is connected between the conductive piece and a stator core. Effective conduction among the front end cover, the rearend cover and the stator iron core is conveniently realized, the equipotential is formed, the capacitor is arranged between the end cover and the stator core, a proper amount of capacitance is added,and finally, the external induction capacitance of the inner ring and the outer ring of the bearing is balanced, so that the shaft voltage is effectively reduced, the electrocorrosion risk of the bearing is avoided, the service life of the motor is prolonged, and the reliability is improved.

Owner:WOLONG ELECTRIC GRP CO LTD

Brushless motor and electrical equipment

ActiveCN112311128APrevent Galvanic CorrosionReduce potential differenceStructural associationSupports/enclosures/casingsBrushless motorsElectrical connection

The invention provides a brushless motor and electrical equipment, the brushless motor comprises a casing, a stator and a rotor, the stator comprises a stator iron core and a winding, the rotor comprises a rotor core and a rotating shaft, the rotating shaft is sleeved with bearings, two ends of the casing are each provided with a bearing bracket for fixing the two bearings, a first conducting strip and a second conducting strip are arranged between at least one bearing bracket and the stator iron core, the first conducting strip and the second conducting strip are oppositely arranged side by side at intervals, the first conducting strip is electrically connected with the stator iron core, and the second conducting strip is electrically connected with the adjacent bearing brackets. The brushless motor is internally provided with the first conducting strip and the second conducting strip which are electrically connected with the stator core and the bearing brackets respectively, and thefirst conducting strip and the second conducting strip are arranged side by side at an interval, so that the first conducting strip and the second conducting strip can be matched to adjust the capacitive reactance between the stator core and the bearing brackets, the potential of the bearing outer ring is close to that of the bearing inner ring, shaft voltage is reduced, and electric corrosion ofthe bearing is avoided.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Triple shielding flame-retardant type power cable special for nuclear power

ActiveCN102074298AEliminate distractions from the outside worldReduce shaft voltagePower cables with screens/conductive layersShaft voltageFrequency conversion

The invention relates to a triple shielding flame-retardant type power cable special for nuclear power, which comprises an outer insulating sleeve, a first shielding layer, an inner insulating sleeve, a second shielding layer, bus insulating grid belts, sub-wires and sub-wire filling press strips, wherein the sub-wires comprise a sub-wire shielding layer, a sub-wire insulating grid belt, a sub-wire protective sleeve, a heat insulating membrane and wire cores; and the heat insulating membrane, the sub-wire protective sleeve, the sub-wire insulating grid belt and the sub-wire shielding layer are sequentially arranged outside the wire cores. The three wire cores are wrapped by the heat insulating membrane, the sub-wire protecting sleeve, the sub-wire insulating grid belt and the sub-wire shielding layer respectively, the three sub-wires are filled and pressed through the sub-wire filling press strips and firmly glued into a cable and each wire core is shielded through three paths of metal, thus, outside electric fields and magnetic fields cannot interfere with the power cable in the transmission course of electric power; the electric and magnetic fields generated by the electric power are shielded to prevent the interference on an electric and control system of the adjacent distribution circuits; and the special ranking structure of the power cable reduces the shaft voltage generated by electric equipment in a frequency conversion circuit in the operation course and protects the practical safety of the electric equipment.

Owner:JIANGSU CGN JINWO ELECTRONIC TECHNOLOGY CO LTD

Motor and electrical equipment with same

PendingCN112366880AReduce motor shaft voltageReduced risk of galvanic corrosion damageAssociation with grounding devicesMagnetic circuit rotating partsElectric machineryShaft voltage

The invention belongs to the technical field of motors, and relates to a motor and electrical equipment with the motor. A traditional integrated bearing bracket is separated into a stator bracket partand a bearing supporting part, a bracket insulating layer is arranged between the stator bracket part and the bearing supporting part, and equivalently, an insulating layer capacitor is added betweenthe stator bracket part and the bearing supporting part. Due to the arrangement of the bracket insulating layer, the equivalent capacitance of the stator side can be greatly reduced. In the loop of the high-frequency circuit, the shaft voltage is the voltage division of the two ends of the bearing capacitor, and the equivalent capacitor of the stator side is equivalently connected to the bearingouter ring side of the bearing capacitor in series. Therefore, the equivalent capacitance of the stator side is reduced through the arrangement of the bracket insulating layer, so that the two ends ofthe bearing capacitor obtain smaller voltage division, i.e., the shaft voltage is reduced. An electrode structure is arranged to reduce shaft voltage and shaft current. The risk of bearing electrocorrosion is reduced. For a motor which is large in power and adopts a large metal shell to improve the installation strength and guarantee heat dissipation, the risk of electrocorrosion damage to a motor bearing can be reduced.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Predictive control system and method for reducing common mode voltage of three-level vienna rectifier system

ActiveCN108988667BHigh output levelImprove output waveform qualityAc-dc conversionSingle network parallel feeding arrangementsThree levelVoltage vector

The invention discloses a predictive control system and method for reducing the common-mode voltage of a three-level VIENNA rectifier system, which are used to solve the high common-mode voltage of the three-level VIENNA rectifier system in a wind power generation system, the distortion of the zero-crossing point of the current on the AC side, and the distortion of the current on the DC side. The problem of unbalanced midpoint voltage. This algorithm limits the common mode voltage of the system to a very low range; solves the problem of current zero-crossing distortion and DC midpoint voltage unbalanced control coupling; and greatly reduces the amount of calculation by classifying space voltage vectors. The algorithm does not need the current inner loop controller and PWM modulation module, which avoids the design of complex controller and the selection of complex parameters. It is simple, intuitive and effective, which makes the algorithm have high use value.

Owner:SHANDONG UNIV

Brushless motor and electrical equipment

ActiveCN112311127APrevent Galvanic CorrosionRealize adjustable capacitive reactanceStructural associationSupports/enclosures/casingsBalance shaftShaft voltage

The invention provides a brushless motor and electrical equipment, the brushless motor comprises a casing, a stator and a rotor, the stator comprises a stator iron core and a winding, the rotor comprises a rotor core and a rotating shaft, a bearing is sleeved on the rotating shaft, two ends of the casing are provided with bearing brackets respectively, each bearing bracket is insulated from the stator iron core, a conducting strip used for balancing the potentials of the bearing inner ring and the bearing outer ring in a matched mode is arranged between at least one bearing bracket and the stator iron core, and the conducting strip is electrically connected with the stator iron core and one adjacent bearing bracket. According to the brushless motor, the conducting strip is arranged betweenthe stator iron core and the bearing brackets, and the conducting strip is electrically connected with one of the stator iron core and the adjacent bearing bracket, so that the conducting strip is incapacitance connection with the stator iron core or the adjacent bearing bracket, the capacitive reactance between the stator iron core and the bearing bracket is adjusted, the potentials of the bearing outer ring and the bearing inner ring are balanced, the potentials of the bearing outer ring and the bearing inner ring are close, the shaft voltage is reduced, and the bearing is prevented from electric corrosion.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Brushless motor and electrical equipment

PendingCN112311129AReduce potential differenceReduce shaft voltageStructural associationSupports/enclosures/casingsBrushless motorsCapacitance

The invention provides a brushless motor and electrical equipment, the brushless motor comprises a casing, a stator and a rotor, the stator comprises a stator iron core and a winding, the rotor comprises a rotor core and a rotating shaft, the rotating shaft is sleeved with a bearing, two ends of the casing are each provided with a bearing bracket, conducting strips are arranged on the peripheral side of the stator iron core at intervals, the conducting strips and the stator iron core have at least a part of opposite area, the conducting strips and at least one bearing bracket are arranged in an insulating mode, an electric strip is attached to the outer surface of each bearing bracket, a dielectric layer is arranged between the electric strip and the corresponding bearing bracket, and theelectric strips are electrically connected with the conducting strips. The conducting strips are arranged on the peripheral side of a stator iron core at intervals, so that coupling capacitance is formed between the stator iron core and the conducting strips; the electric strips are arranged on the bearing brackets, so that the capacitor is formed between the electric strips and the bearing brackets, and the electric strips are electrically connected with the conducting strips, thereby adjusting the capacitive reactance between the bearing brackets and the stator iron core, reducing the potential difference between an inner ring and an outer ring of a bearing, reducing the shaft voltage and avoiding electric corrosion.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

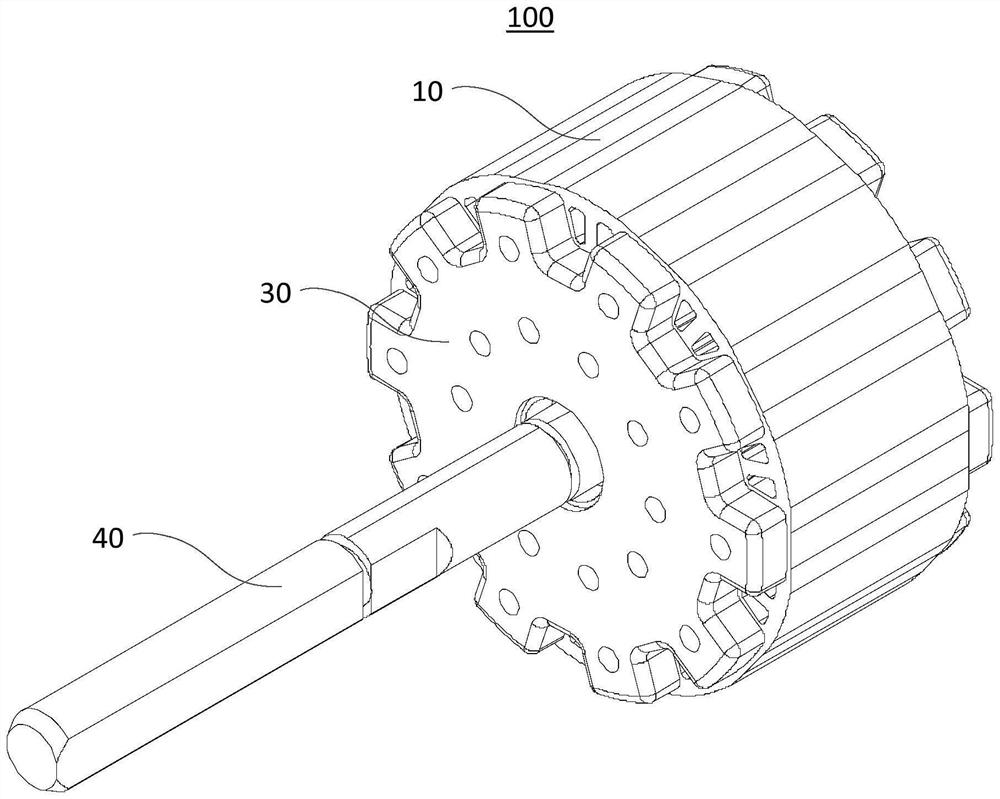

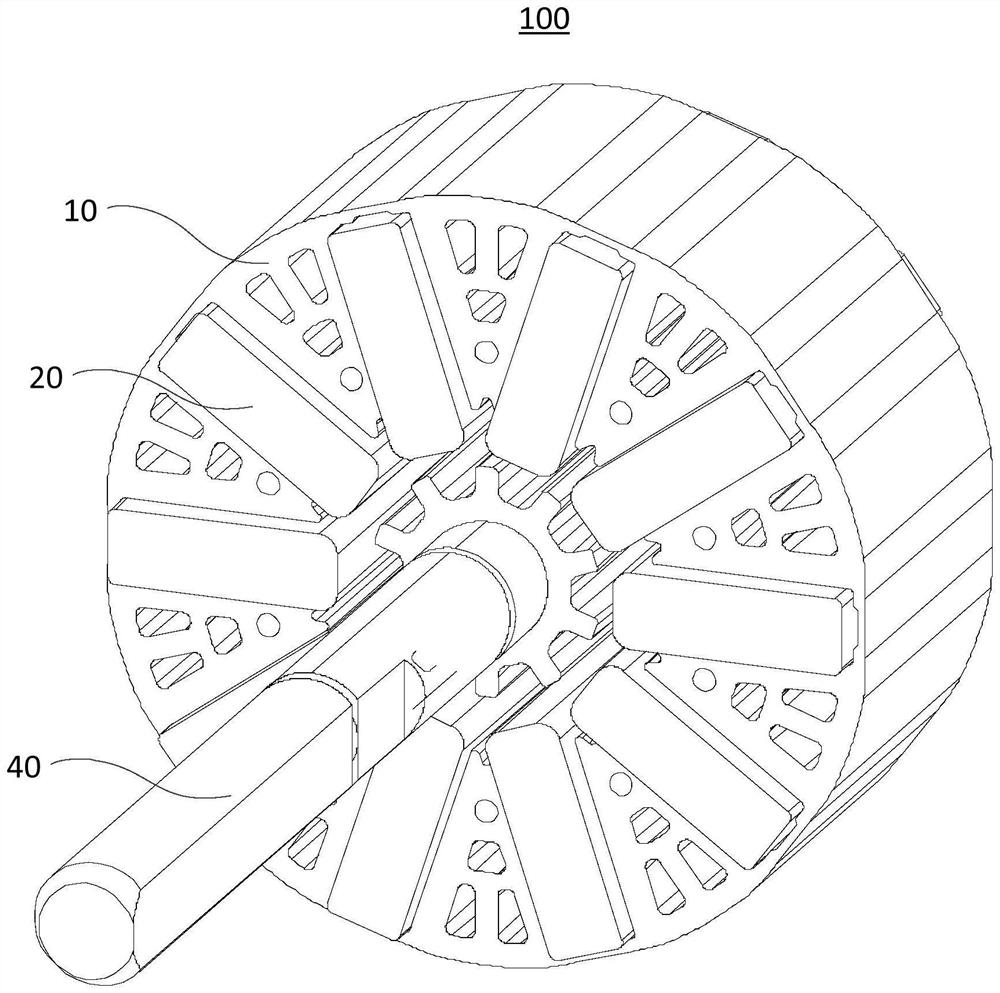

Motor rotor and motor

ActiveCN103944294APrevent Galvanic CorrosionReduce shaft voltageMagnetic circuit rotating partsEngineeringShaft voltage

The invention discloses a motor rotor which comprises an inner iron core and an outer iron core. The inner iron core and the outer iron core are arranged concentrically and are fixed through an insulation frame. The motor rotor is characterized in that the thickness h of the inner iron core and the thickness H of the outer iron core satisfy the relation that h : H is larger than or equal to 0.5 and smaller than 1, and the distance between a plane where either end face of the inner iron core is placed and a plane where an end face on the same side of the outer iron core is placed is 0.5 H-0.5 h. According to the designing scheme that the thickness of the inner iron core is smaller than the thickness of the outer iron core, shaft voltage can be lowered, and poor motor electric corrosion is reduced.

Owner:PANASONIC APPLIANCES MOTOR HANGZHOU

Rotor and motor

PendingCN114567097AReduce vibration noiseChange capacitanceMagnetic circuit rotating partsSupports/enclosures/casingsDynamic balanceElectric machinery

The invention discloses a rotor and a motor. The rotor is characterized in that a rotor iron core comprises a shaft ring part and a plurality of fan-shaped parts arranged around the shaft ring part at intervals, a containing groove is formed between every two adjacent fan-shaped parts, and the shaft ring part is provided with a shaft hole; the rotor shaft is arranged in the shaft hole in a penetrating mode, and the hole diameter of the shaft hole is larger than the shaft diameter of the rotor shaft; a plurality of magnets, wherein each magnet is embedded in one accommodating groove; the damping parts are filled between the fan-shaped parts and the shaft ring part and between the rotor shaft and the inner side face of the shaft hole, the damping parts are further filled in the filling holes of the fan-shaped parts, the bonding strength of the fan-shaped parts and the damping parts is further enhanced, electromagnetic harmonics on the rotor can be reduced through the damping parts, and the service life of the rotor is prolonged. The purpose of weakening vibration and vibration noise of the rotor is achieved; and the balance holes of the fan-shaped parts can be used for correcting the dynamic balance of the rotor, so that the running stability of the rotor can be improved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

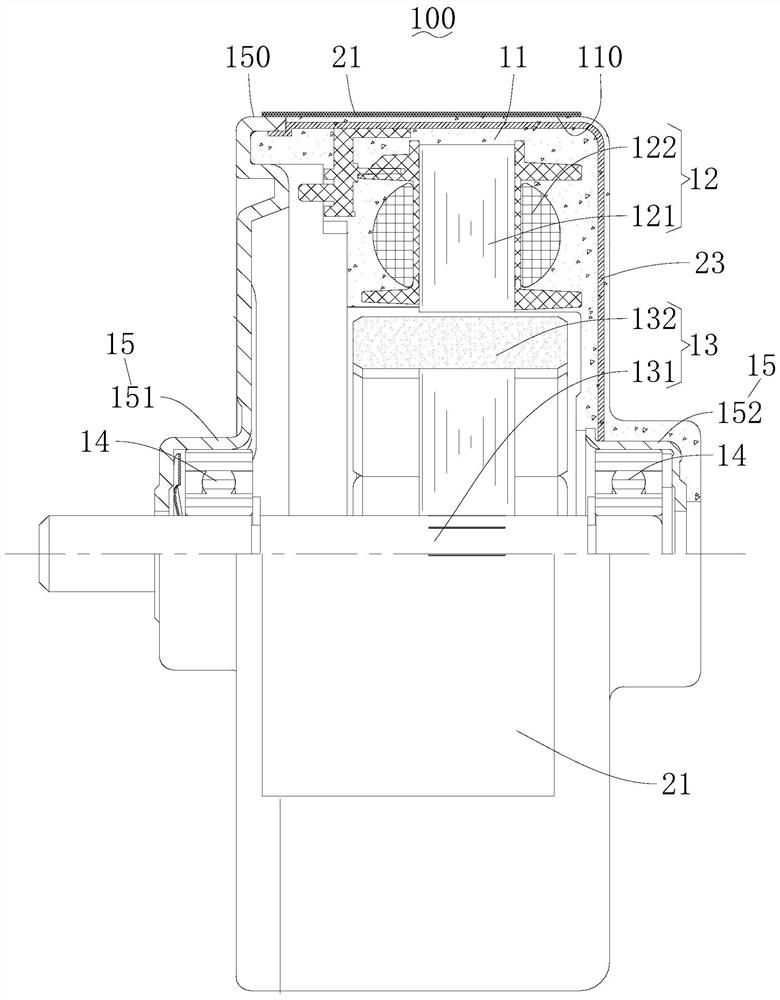

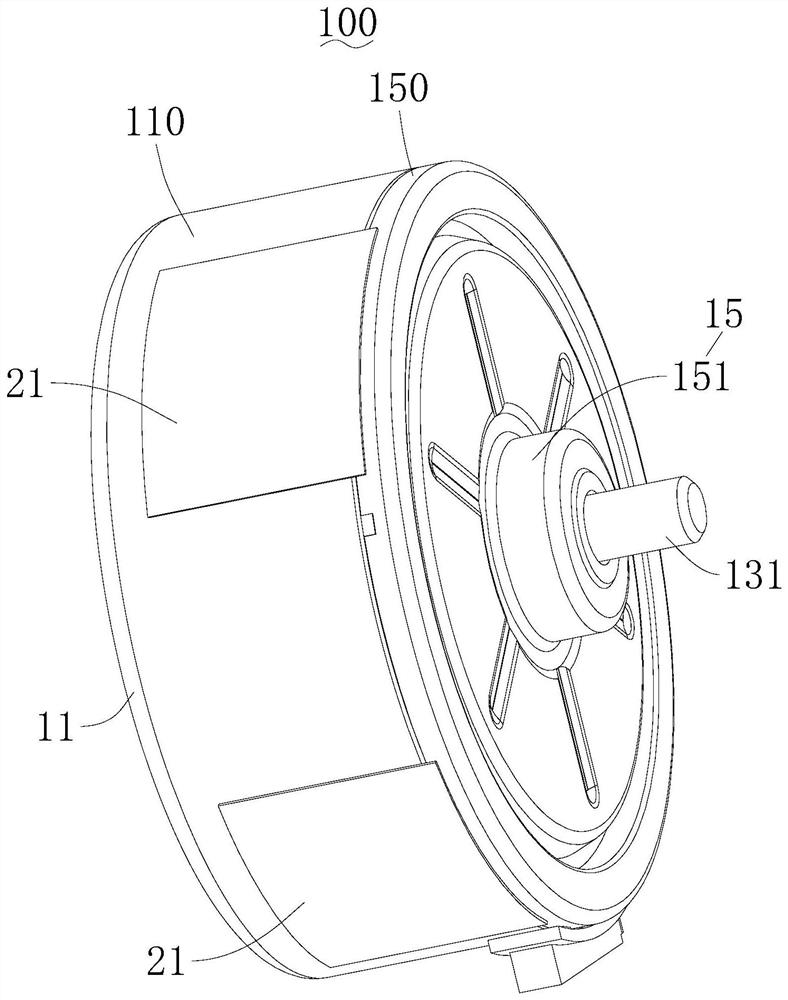

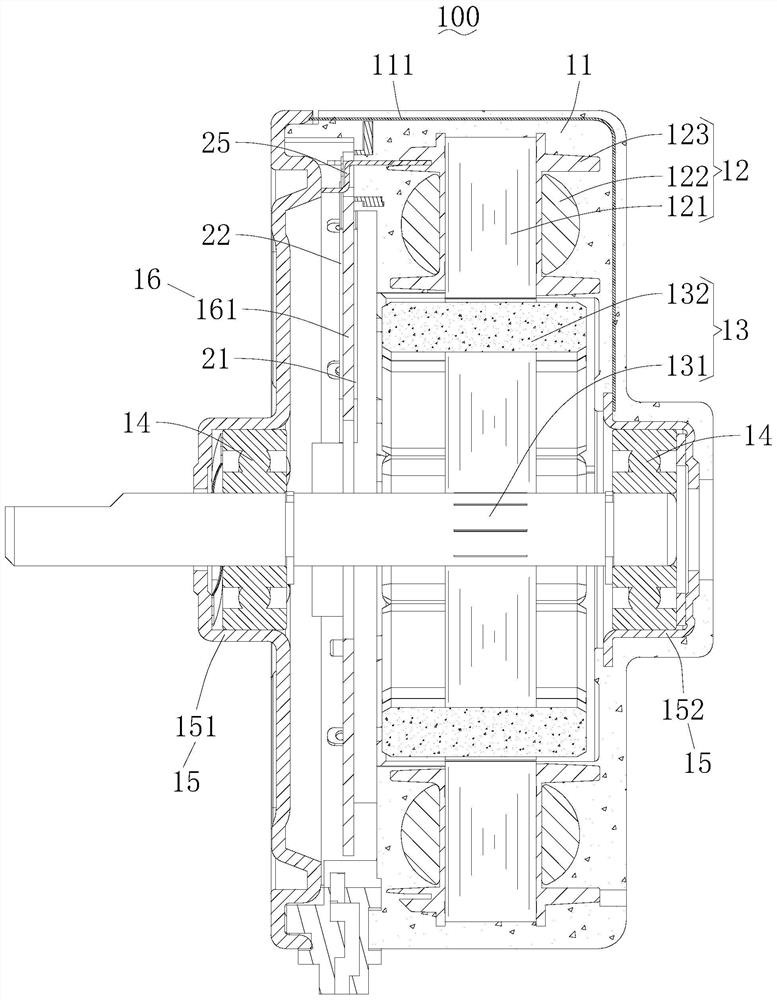

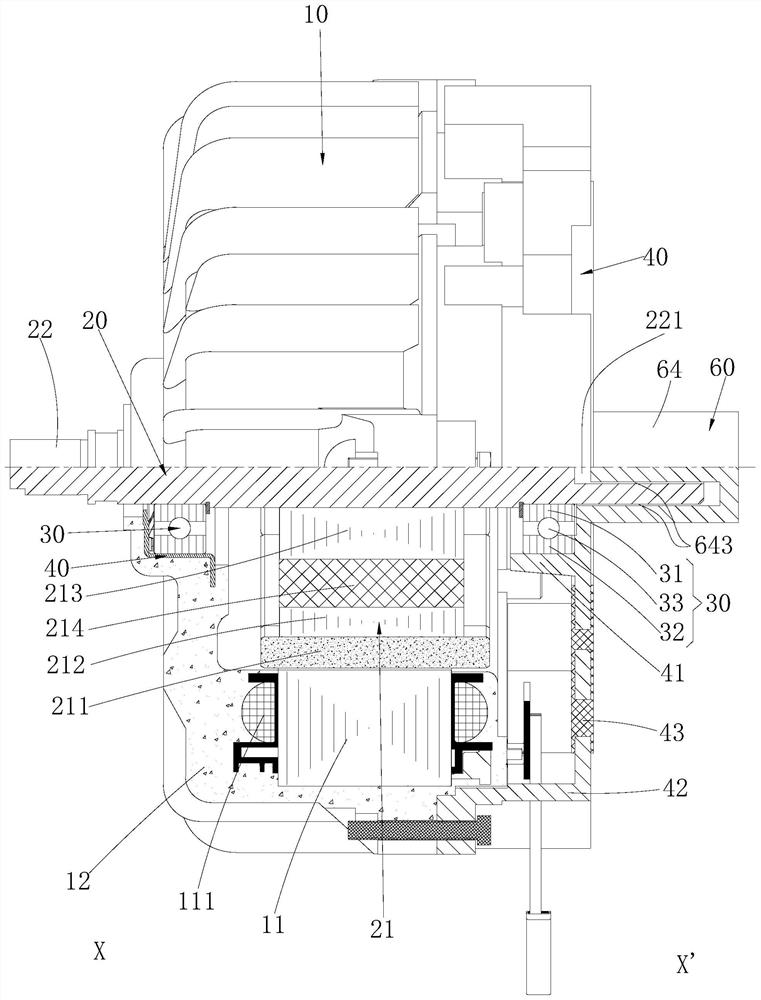

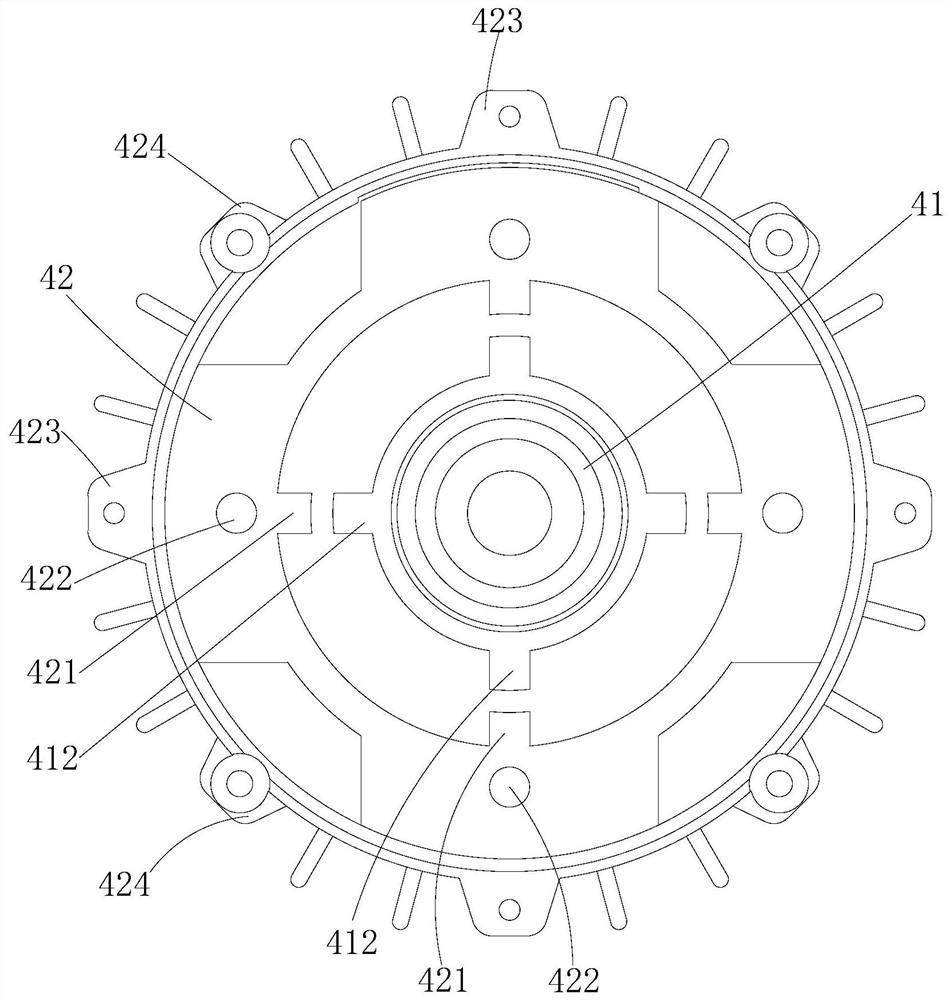

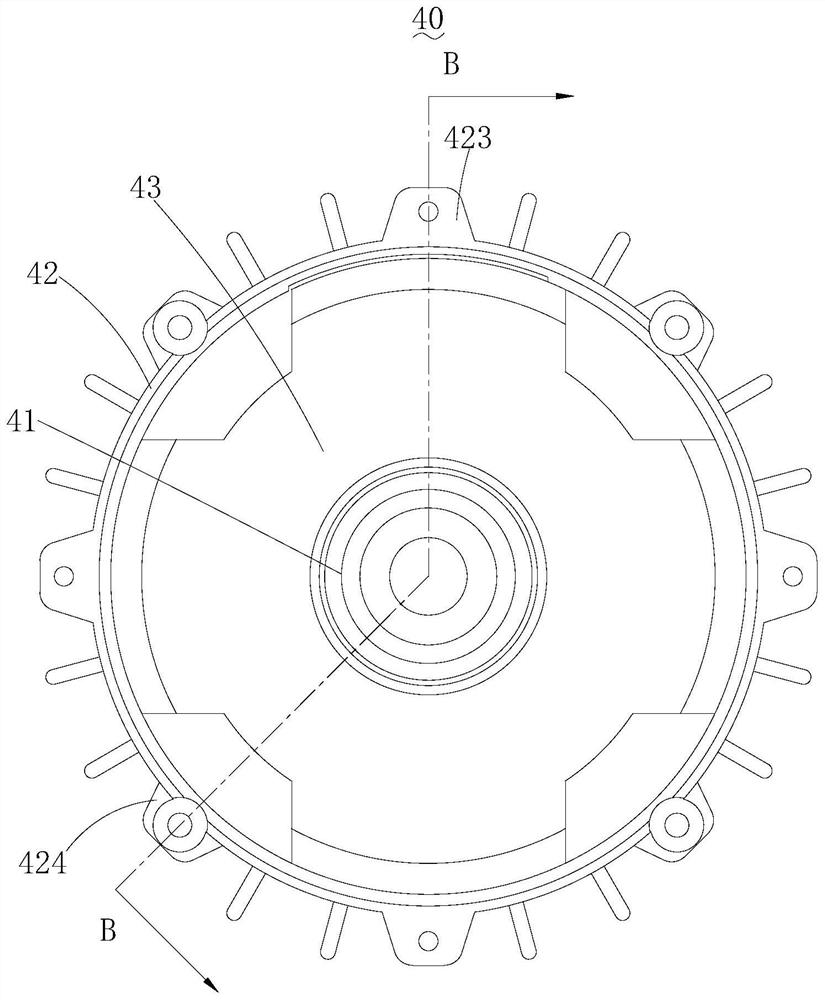

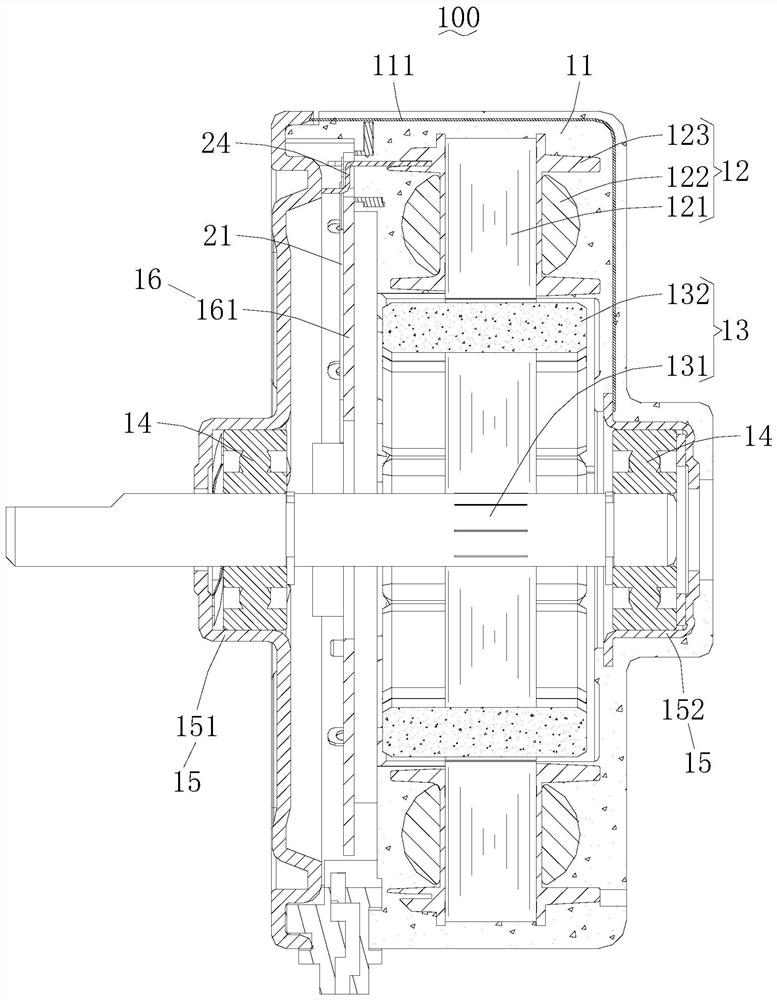

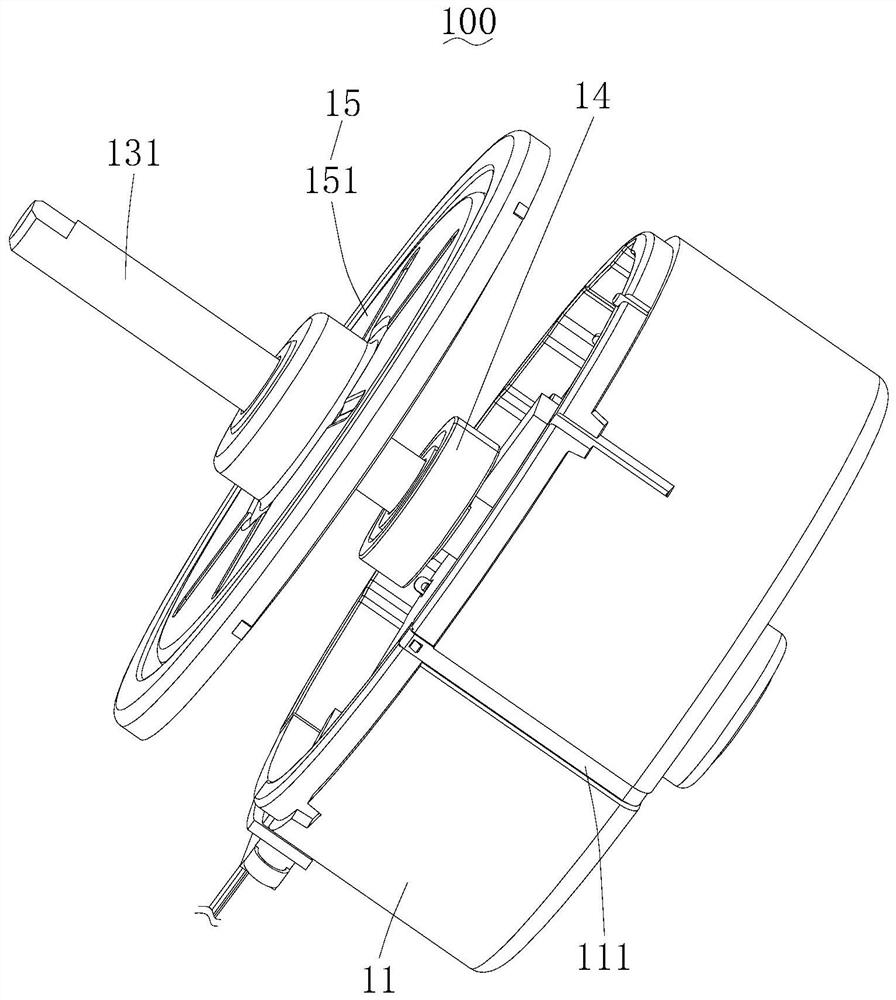

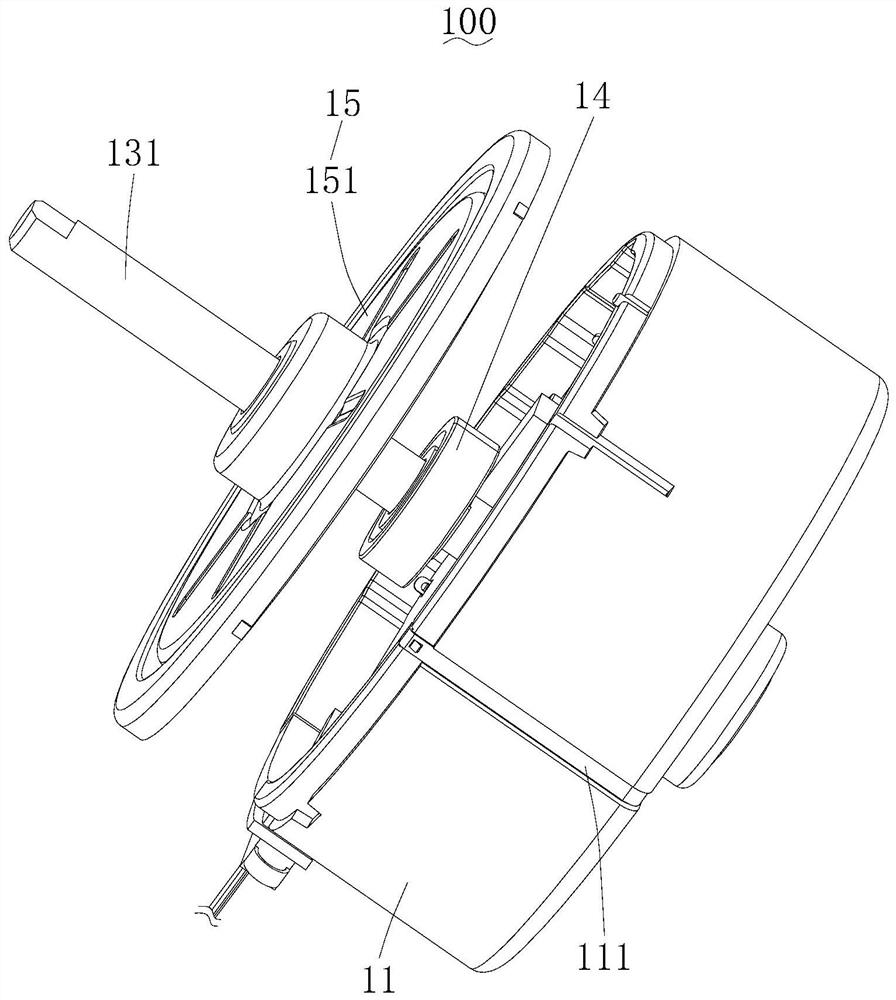

Scroll Compressor

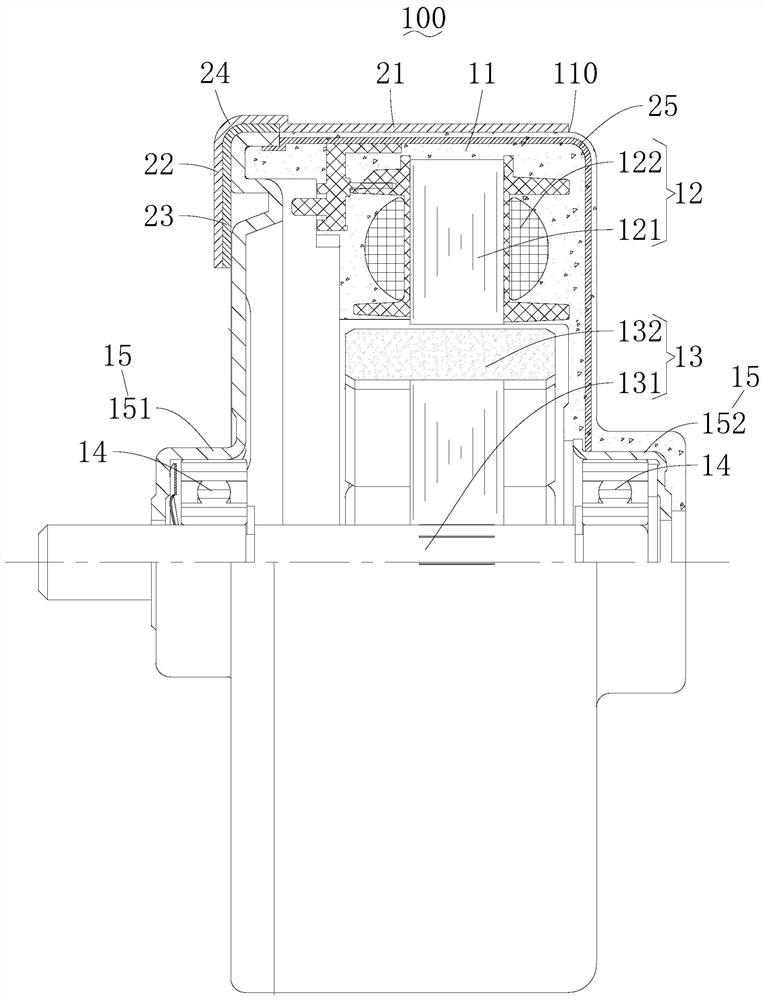

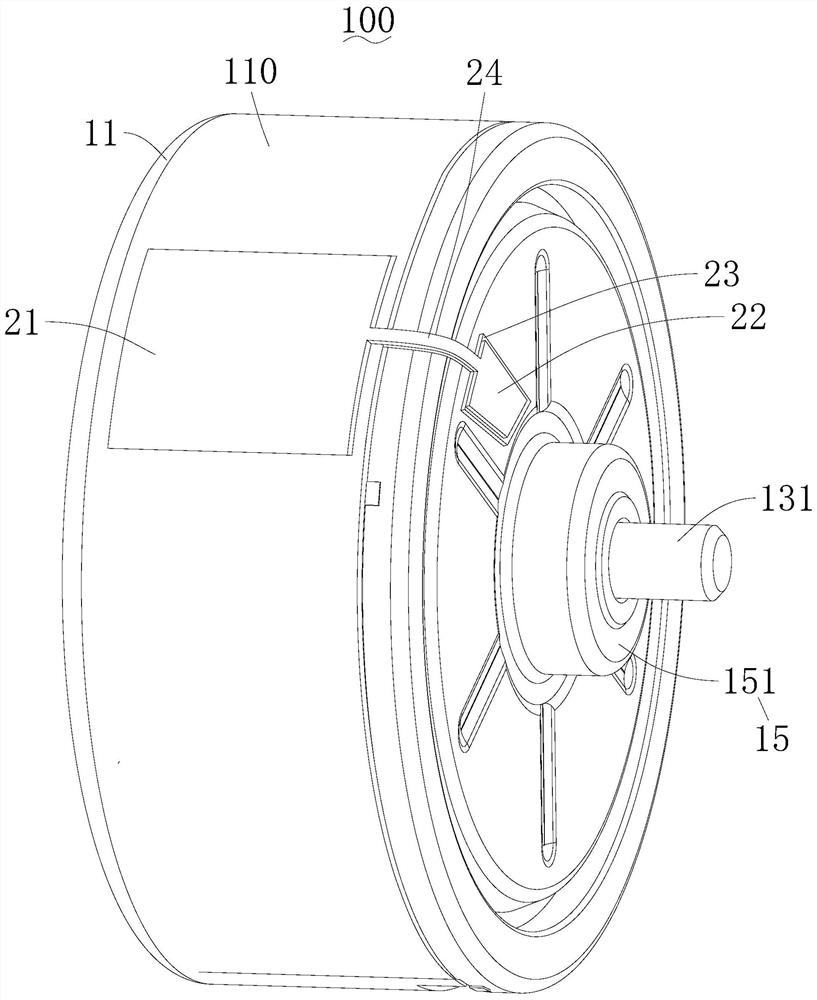

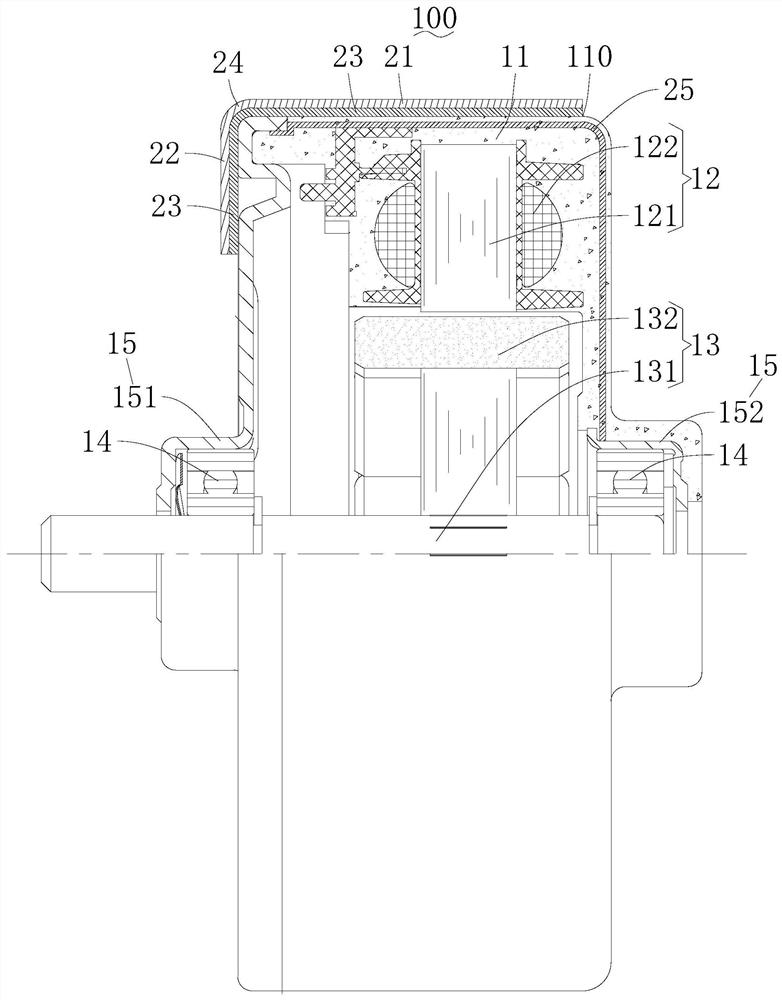

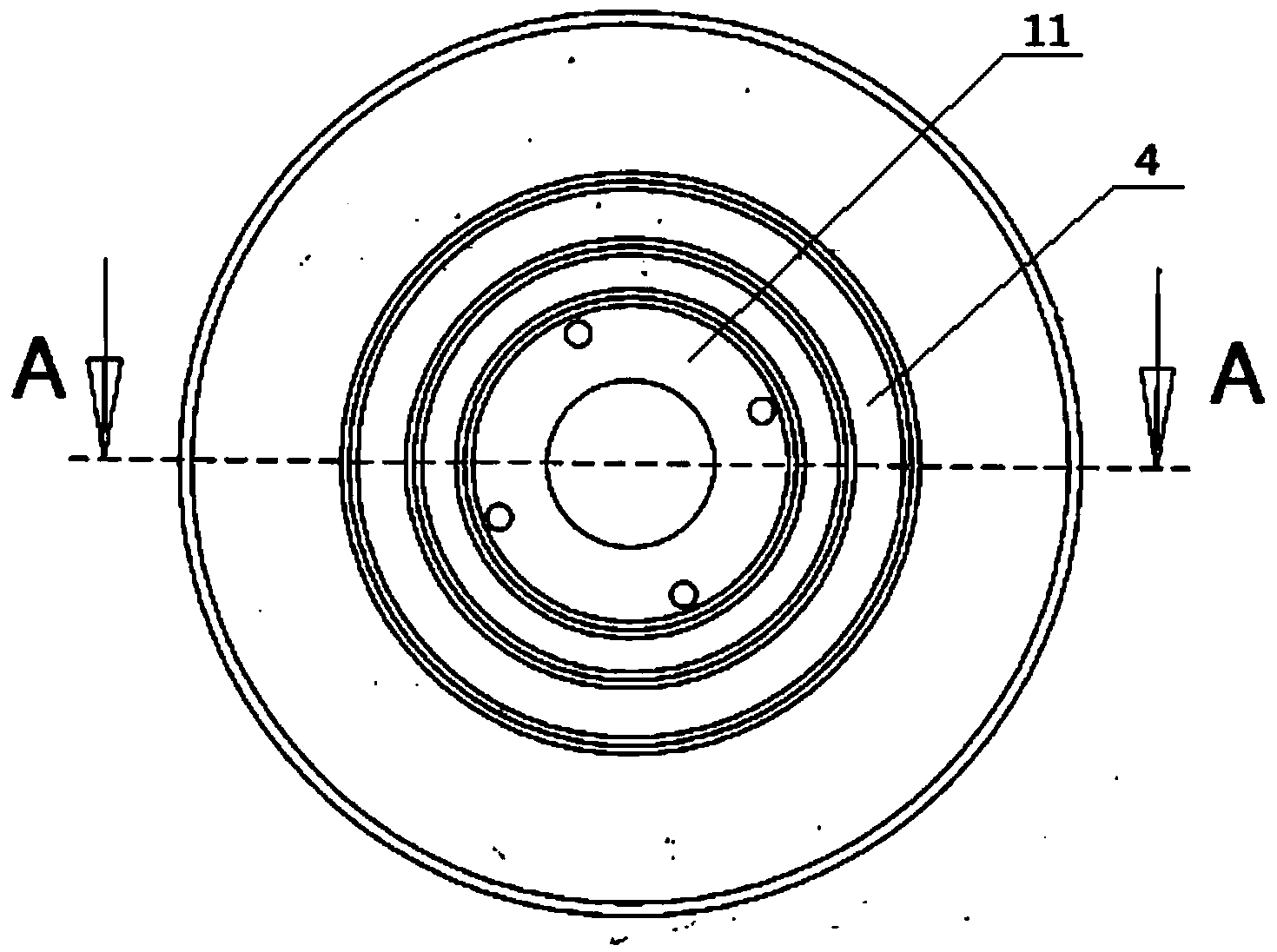

ActiveUS20190334407A1Reduce shaft voltageSave spaceBearing assemblyMagnetic circuitMechanical engineeringShaft voltage

Provided is a scroll compressor capable of reducing a shaft voltage and achieving space savings for the entire apparatus. A scroll compressor 100 includes a rotor 32 that is stored in a motor casing 14; a stator 31 that is stored in the motor casing 14, and drives the rotor 32 to rotate; a rotary shaft 12 that is held by bearings 33 and 34, and rotates integrally with the rotor 32; an end bracket 16 through which one end portion of the rotary shaft 12 passes, and which seals the motor casing 14; an orbiting scroll 44 that supports the other end portion of the rotary shaft 12, and orbits as the rotary shaft 12 rotates; a fixed scroll 43 that is disposed facing the orbiting scroll 44; a suction type cooling fan 13 which is fixed to one end portion of the rotary shaft 12 while being apart by a clearance from the end bracket 16, and which suctions outside air through a suction port provided in an end surface 132A of a fan cover 132, and generates cooling wind for cooling the fixed scroll 43 or the orbiting scroll 44 in the fan cover 132, as a rotary vane 131 accommodated in the fan cover 132 rotates; and a discharge brush 60 which is fixed to the end bracket 16 facing the cooling fan 13, and one end of which is in contact with the rotary shaft 12.

Owner:HITACHI IND EQUIP SYST CO LTD

Brushless motors and electrical equipment

ActiveCN112311127BPrevent Galvanic CorrosionRealize adjustable capacitive reactanceStructural associationSupports/enclosures/casingsBrushless motorsCapacitance

The invention provides a brushless motor and electrical equipment. The brushless motor includes a casing, a stator and a rotor. The stator includes a stator core and windings. The rotor includes a rotor core and a rotating shaft. A bearing is set on the rotating shaft. Bearing brackets are respectively installed at each end, and each bearing bracket is insulated from the stator core. At least one of the bearing brackets and the stator core is provided with a conductive sheet for balancing the potential of the inner ring of the bearing and the outer ring of the bearing. The conductive sheet Electrically connected to the stator core and one of the adjacent bearing brackets. In the brushless motor, a conductive sheet is arranged between the stator core and the bearing bracket, and the conductive sheet is electrically connected to the stator core and one of the adjacent bearing brackets, so that the conductive sheet forms a capacitor with the stator core or the adjacent bearing bracket. connection, and then adjust the capacitive reactance between the stator core and the bearing bracket to balance the potential of the bearing outer ring and the bearing inner ring, so that the potential of the bearing outer ring and the bearing inner ring is similar to reduce the shaft voltage and avoid the bearing. Electric corrosion.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com