Ground connection structure for reducing shaft voltage of double-fed wind generator

A technology for wind turbines and grounding structures, applied in the direction of structural connection, connection with grounding devices, electrical components, etc., can solve the problems of insufficient shaft voltage reduction structure, damage to insulation layer, high cost, etc., and achieve reasonable structure, The effect of reducing shaft voltage and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

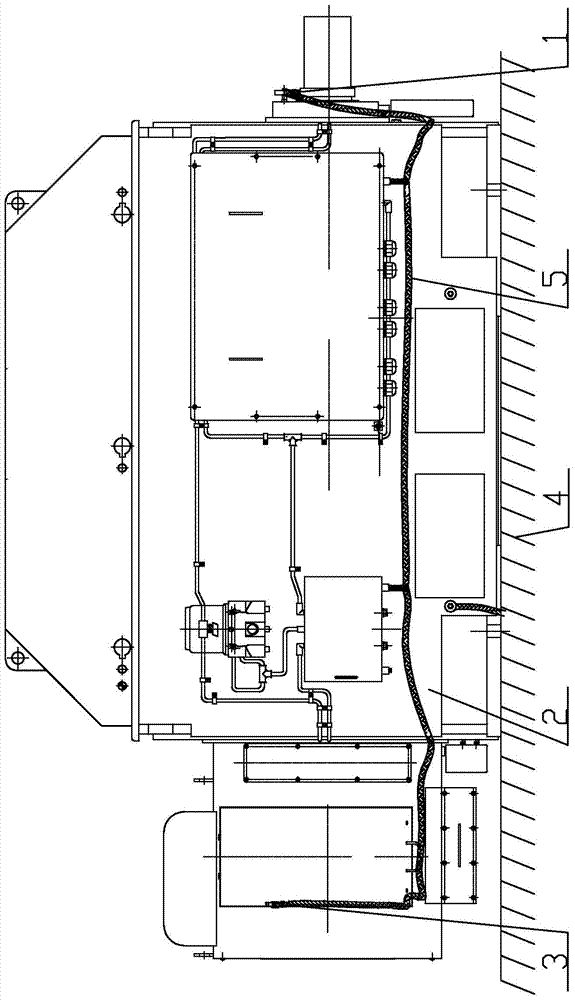

[0016] Such as figure 1 As shown, the present invention mainly includes a shaft extension end connection shaft carbon brush 3, a machine base shell 2 and a non-shaft extension end connection shaft carbon brush 1, the shaft extension end connection shaft carbon brush 3 is installed on the shaft extension end of the generator, and the non-shaft end connection shaft carbon brush 1 The shaft carbon brush 1 at the extension end is installed on the non-shaft extension end of the generator. The frame shell 2 is fixed on the motor foundation 4 .

[0017] The shaft carbon brush 3 at the extension end, the frame housing 2 and the carbon brush 1 at the non-extension end shaft are connected sequentially through the electrical connection wire 5, so that they maintain zero potential at the same time, and do not form a current loop, thus avoiding the loss of shaft c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com