Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduce design costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

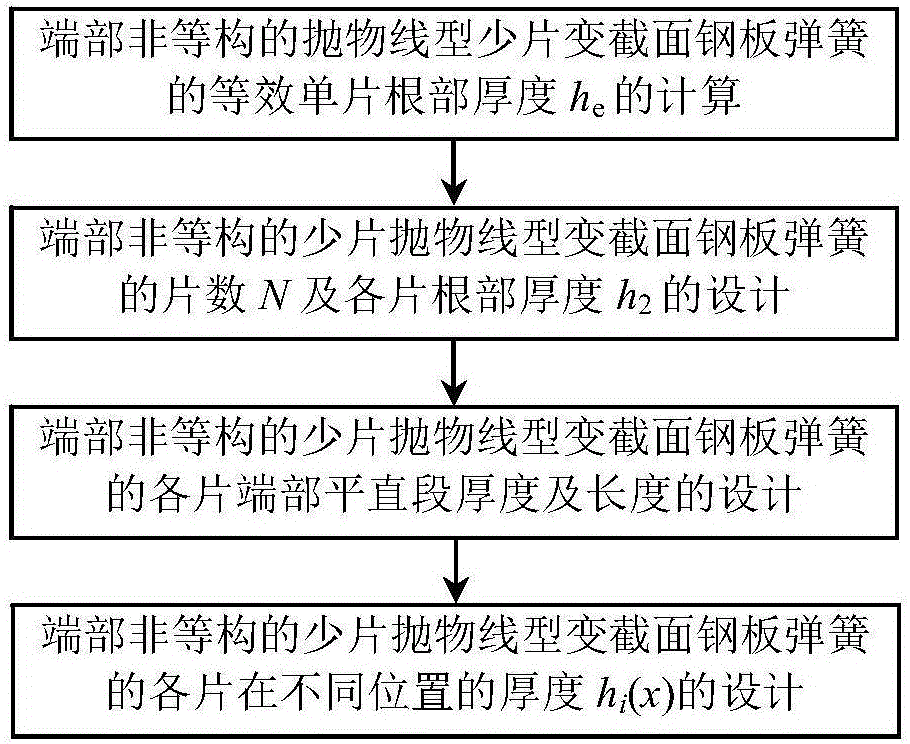

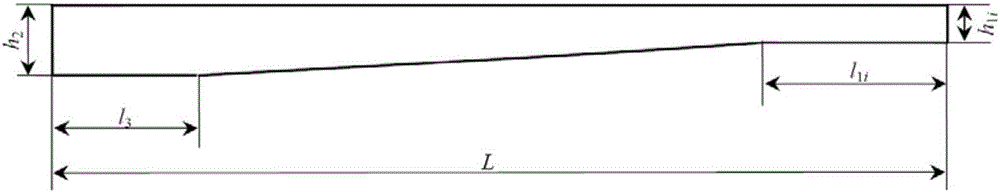

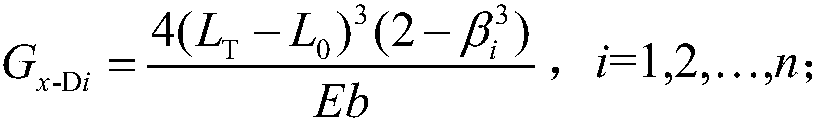

Design method of few-leaf parabolic isostress steel plate spring provided with ends of different structures

ActiveCN105697625AImprove transportation efficiencyImprove driving safetyGeometric CADLeaf springsEngineeringLine segment

The invention relates to a design method of a few-leaf parabolic isostress steel plate spring provided with ends of different structures and belongs to the technical field of suspension steel plate springs. The design method comprises the steps that firstly, the root thickness he of equivalent single leaves is determined according to the installation structure, required rigidity design value and the parabolic segment thickness ratio primary value of the steel plate spring, and the maximum permissible thickness [h2] of the few-leaf variable-cross-section steel plate spring is determined according to the permissible stress; and secondly, the number N of the leaves of the few-leaf variable-cross-section steel plate spring, the root thickness of the few-leaf variable-cross-section steel plate spring, and the thickness h1i and length l1i of end straight sections and the few-leaf variable-cross-section steel plate spring are designed according to he and [h2]. It is known through an ANSYS simulation verification, by the adoption of the design method, the parameter design values of the few-leaf parabolic variable-cross-section steel plate spring provided with the end of different structures can be obtained accurately and reliably, the design level and performance of a product can be improved, the quality of the spring is improved, the cost of the spring is reduced, and the vehicle traveling smoothness is improved; and meanwhile, design and testing expenses are reduced, and the development speed of the product is increased.

Owner:山东恒日悬架弹簧股份有限公司

Gearbox of small tractor

InactiveCN103291857AFlexible matchingEasy to useControlled membersToothed gearingsGear wheelControl theory

The invention relates to the field of manufacturing and modification of agricultural machinery, in particular to a gearbox of a small tractor. A supplementary gearbox is additionally arranged on an existing gearbox, and a main variable shaft (IX shaft) is arranged in the supplementary gearbox. After a poking fork controls variable speed, on one hand, motive power is transmitted back to transmission gears of an original front drive through a carrier gear and a front drive clutch gear, and on the other hand, the motive power is transmitted to gears and shafts of a rear drive through a rear drive clutch gear. Due to the control by the poking fork, separation and reunion between the front drive clutch gear and the rear drive clutch gear are achieved, the front drive and the rear drive of the small tractor can carry out outputting in a completely synchronous mode, and at the same time, the front drive and the rear drive can be freely controlled to carry out the outputting independently according to needs. The gearbox of the small tractor can be flexibly matched with agricultural implements with different purposes, and is convenient to use. Most parts are universal with those of the existing gearbox, design and manufacturing expenses are reduced to the maximum extent, and the gearbox is convenient to use and maintain. The gearbox is suitable for transforming industry-agriculture-12 type small tractors.

Owner:GUANGXI YIZHOU YUCHAI AGRI EQUIP

Design method of energy-regenerative suspension power generator power based on shock absorber speed features

InactiveCN104317983AImprove the design levelRobust Design MethodSpecial data processing applicationsArray data structureDynamo

The invention relates to a design method of energy-regenerative suspension power generator power based on shock absorber speed features, and belongs to the technical field of an energy-regenerative suspension. The design method is characterized in that for vehicles with good running smoothness, the automobile energy-regenerative suspension power generator power is designed through the analysis and the processing on test data according to the installing angle of an original vehicle-mounted shock absorber, a suspension lever ratio and a damping force array and a displacement array measured by damping feature tests of the original vehicle-mounted shock absorber at the shock speed. When the method provided by the invention is used, the energy-regenerative suspension power generator power can be accurately and reliably designed; the optimum power design value of an energy-regenerative suspension power generator can be obtained, so that the energy-regenerative suspension achieves the best damping matching; the vehicle running smoothness is improved; the design and test cost of the energy-regenerative suspension power generator can be reduced; the product development speed is accelerated; and a reliable design method is provided for the vehicle energy-regenerative suspension power generator power design.

Owner:SHANDONG UNIV OF TECH

Handrail end circular arc punching and forming device

The invention relates to a handrail end circular arc punching and forming device. The handrail end circular arc punching and forming device comprises an upper die seat, a lower die seat and a circular arc punching mechanism installed between the upper die seat and the lower die seat, wherein the circular arc punching mechanism consists of a male die, a supporting female die, a male die fixing plate and a supporting die core, the male die fixing plate provided with the male die is arranged on the upper die seat, the supporting die core is installed on the lower die seat, the male die is vertically arranged above the supporting die core, the supporting female die is fixedly arranged under the supporting die core, and the supporting female die and the male die are located on the same vertical line. A die is convenient to manufacture and maintain and compact in structure, the design work can be greatly simplified, a design period is shortened, and the cutter design and manufacture cost is reduced.

Owner:JIANGSU YONGGANG GROUP CO LTD

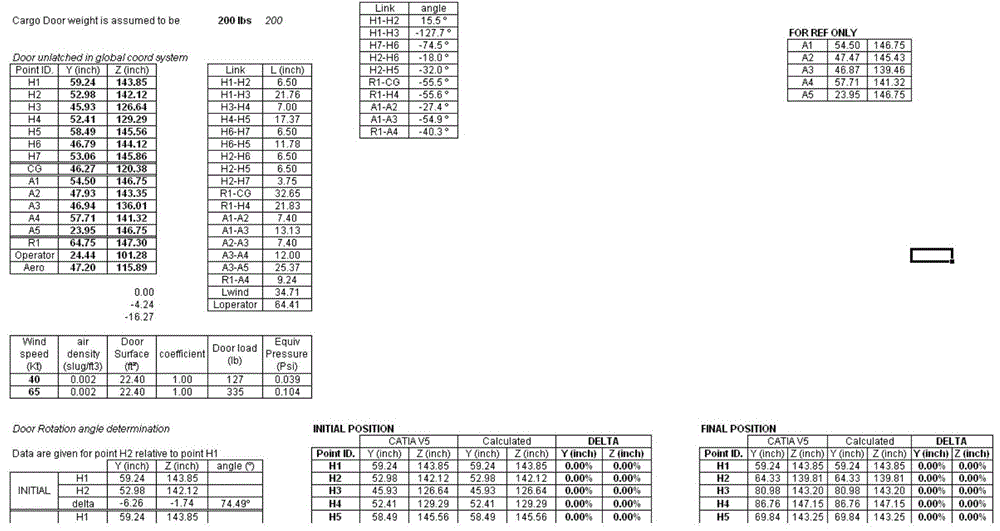

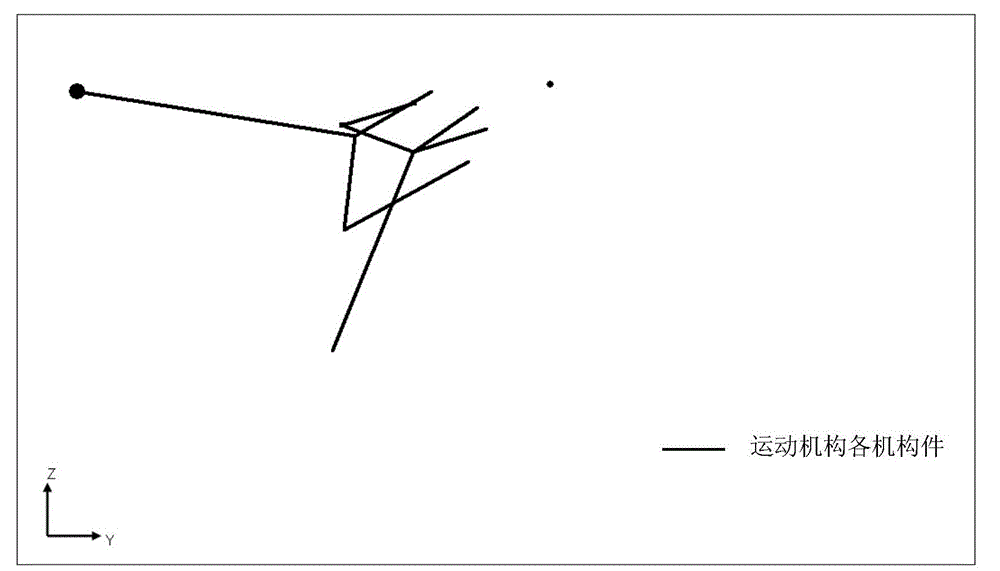

Method for fast extracting loads in movement mechanism and optimizing design scheme

ActiveCN104200013AShorten the design cycleReduce R&D costsSpecial data processing applicationsEngineeringEntity model

The invention relates to a method for fast extracting loads in a movement mechanism and an optimizing design scheme. The method includes the following steps that firstly, a movement mechanism principle diagram is built up, load conditions of the movement mechanism are determined, and a movement tract diagram is generated; secondly, load information of the movement mechanism is extracted, a movement mechanism driving load curve is automatically drawn, multiple load conditions of the movement mechanism are overlapped, and the maximum load which the movement mechanism can bear is extracted; thirdly, an initial scheme of the movement mechanism is optimally designed, and the design of the movement mechanism can be optimal finally. By means of the scheme, in the initial design period, the inner loads of parts in different conditions and moments can be fast extracted according to coordinate positions of a mechanism part so that strength persons can conduct primary strength check and optimal design on a mechanism system before obtaining a specific Catia entity model of the mechanism part, it is ensured that the design of the mechanism system is the optimal scheme from the beginning, and therefore a design period can be fully shortened and development cost is saved.

Owner:AVIC SAC COMML AIRCRAFT

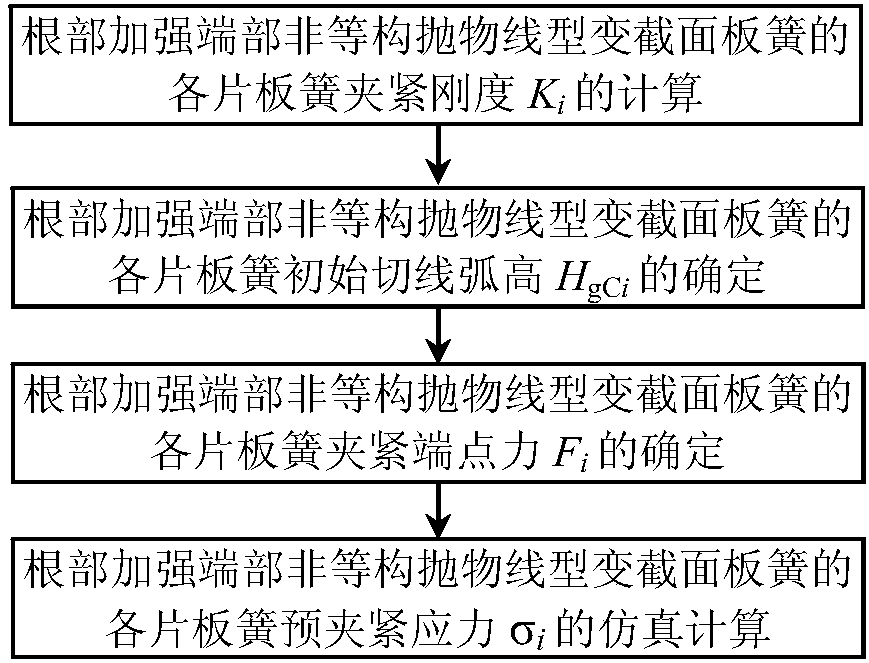

Matching design method for pre-clamping stress of double-reinforced-root non-equal-thickness variable-cross-section leaf springs

InactiveCN108412929AAccurate and reliable pre-clamping stressAccurate and reliable match to design valuesGeometric CADLeaf springsDesign methodsDesign values

The invention relates to a matching design method for the pre-clamping stress of double-reinforced-root non-equal-thickness variable-cross-section leaf springs, and belongs to the technical field of suspension taper leaf springs. According to the matching design method, matching design can be carried out on the pre-clamping stress of each of the double-reinforced-root non-equal-thickness parabolicvariable-cross-section leaf springs according to the number of the leaf springs, the structure parameters of each leaf spring, the elasticity modulus, the rated load and the allowable stress of a first leaf spring under the rated load; through a prototype test, the matching design method for the pre-clamping stress of the double-reinforced-root non-equal-thickness variable-cross-section leaf springs is accurate, accurate and reliable matching design values of the pre-clamping stress of each leaf spring can be obtained, and a reliable technical foundation can be laid for the design of the camber height of a free tangent line; by means of the method, the pre-clamping stress of each leaf spring can be ensured to meet the design requirements, the design level and the reliability of products can be improved, the service life of the products can be prolonged, the driving safety of vehicles can be improved; and meanwhile, the design and test cost of the products can be lowered, and the product development speed can be increased.

Owner:SHANDONG UNIV OF TECH

Matching design method for pre-clamping stress of equal-thickness main springs of first-stage gradually changed rigidity plate springs

InactiveCN108253059AImprove the design levelImprove reliabilityGeometric CADLeaf springsEngineeringDesign methods

Owner:SHANDONG UNIV OF TECH

Design method of lasers

InactiveCN105022854AEasy to modifyQuickly compare pros and consSpecial data processing applicationsDesign cycleGeometric modeling

The invention relates to the technical field of lasers, and particularly discloses a design method of lasers. The design method comprises the following steps: analyzing a gas path system of a laser, and simplifying the parts with different flow velocity characteristics into independent geometric models, and establishing a control equation according to different physical model characteristics; building a calculation model according to the established control equation and the tested boundary condition, calculating repeatedly to obtain a reasonable flow field; testing a boundary condition of a dispersed phase, selecting a suitable dispersed phase calculation module and performing dispersed phase calculation; predicting the motion curves of particles according to the calculated dispersed phase calculation result and optimizing a design scheme of the gas path system of the laser. According to the design method of the lasers provided by the invention, a computational fluid dynamics technology is applied to the design field of gas lasers gradually; besides, the design scheme is optimized, which is beneficial to accelerating the design cycle and reducing the design cost.

Owner:东莞市鼎先激光科技股份有限公司

Modular container type distributing station

InactiveCN107520969AHigh reuse rateReduce design costsSold ingredients supply apparatusContainerizationBelt conveyor

The invention relates to a distributing station in cement production equipment, in particular to a modular container type distributing station. The modular container type distributing station comprises a distributing bin, a quantitative feeder and 40 GP containers, wherein a distributing bin body is integrated in a 40 GP container; a straight section part on the upper part of the distributing bin is a detachable baffle structure and can be used for assembling in field; the quantitative feeder and a supporting platform thereof on the lower part of the distributing bin body are integrated in another 40 GP container; a mixture belt conveyor 8 is partially positioned in a 40 GP container 3; a cable, a crane span structure and a lamp are pre-assembled in the 40 GP container 3; and two of the 40 GP containers can be directly mounted in an overlapped manner in field through corner fittings, twist locks and bolts. The structure is designed in a containerization, equipment arranged in the containers is pre-assembled, and therefore, the modular container type distributing station has great convenience and economy in the aspects of transportation, mounting, production running and the like, and meanwhile has functions of rapid disassembling, assembling in other places, production and the like.

Owner:CBMI CONSTR

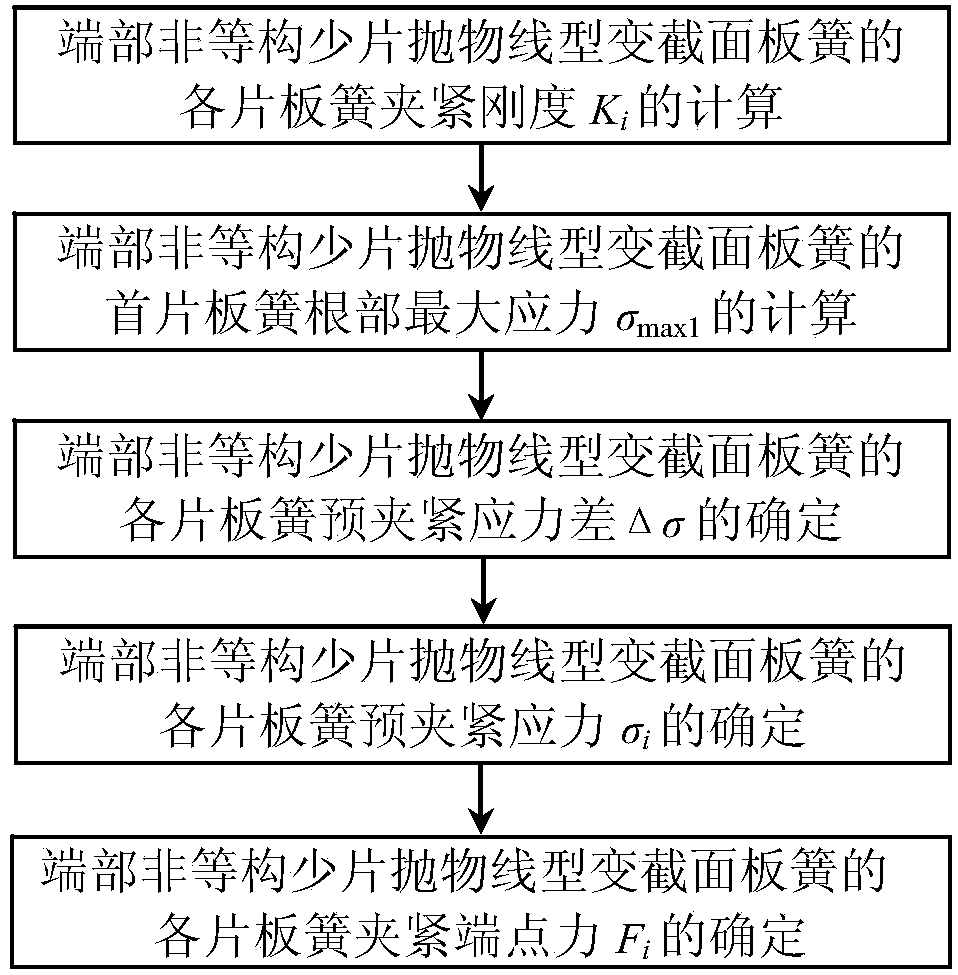

Matching design method for pre-clamping stress of end-reinforced root non-equal-thickness variable cross-section leaf spring

InactiveCN108223648AAccurate and reliable match to design valuesAccurate and reliable development speedGeometric CADLeaf springsEngineeringDesign methods

The invention relates to a matching design method for the pre-clamping stress of an end-reinforced root non-equal-thickness variable cross-section leaf spring and belongs to the technical field of taper leaf springs. The method can be used for matching design of the pre-clamping stress of all leaf spring bodies of the end-reinforced root non-equal-thickness taper parabolic type variable cross-section leaf spring according to the number, elasticity modulus and structure parameters of leaf spring bodies as well as the allowable stress of the first leaf spring body at a rated load. Prototype testing shows that the matching design method for the pre-clamping stress of the end-reinforced root non-equal-thickness variable cross-section leaf spring is correct, accurate and reliable matching design values of the pre-clamping stress of the leaf spring bodies can be obtained, and a reliable technological foundation is laid for design of free tangent line arc heights of the leaf spring bodies. The method can ensure that the pre-clamping stress of the leaf spring bodies meets design requirements, the design level and reliability of products are improved, the service life of products is prolonged, and vehicle running safety is improved; and meanwhile, the design and testing cost of products is reduced, and the development speed is increased.

Owner:SHANDONG UNIV OF TECH

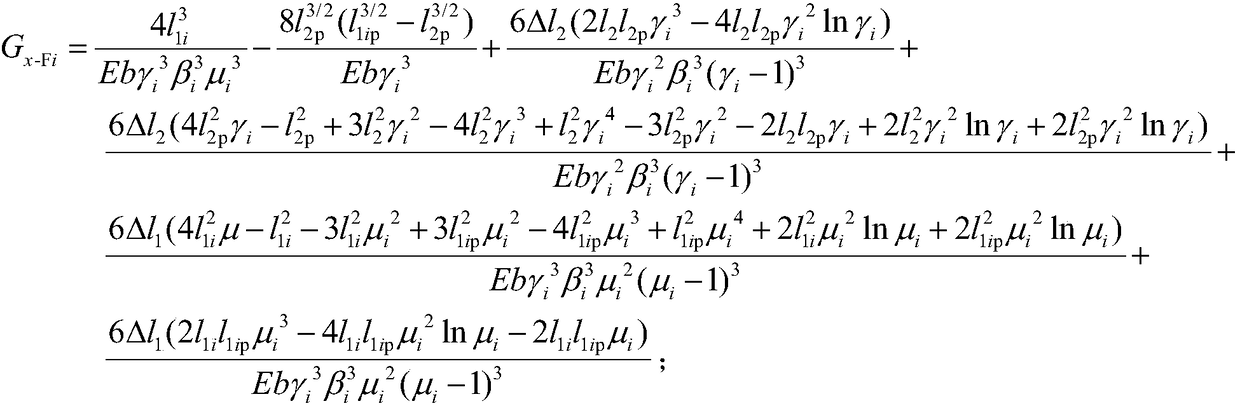

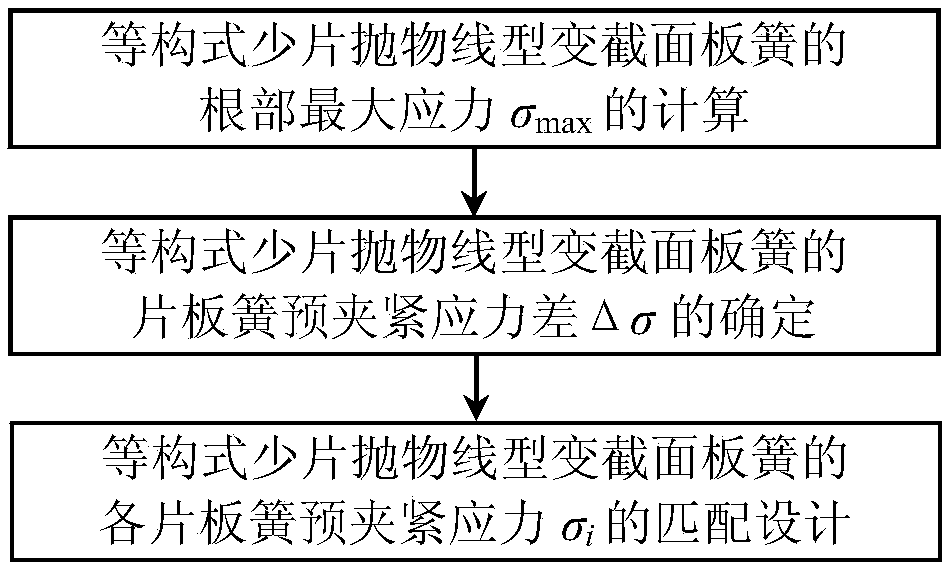

Matching design method for isomorphic parabolic type taper-leaf spring pre-clamping stress

InactiveCN108591330AAccurate and reliable match to design valuesMeet the requirements of modern CAD designGeometric CADVibration dampersEngineeringDesign methods

The invention relates to a matching design method for isomorphic parabolic type taper-leaf spring pre-clamping stress, and belongs to the technical field of suspension taper-leaf springs. According tothe matching design method, according to the number of leaf springs, the structure parameters, the rated load and the allowable stress of the first leaf spring under the rated load, matching design is carried out on the pre-clamping stress of each leaf spring of the isomorphic parabolic type taper-leaf spring. Through a prototype test, the matching design method for the isomorphic parabola type taper-leaf spring pre-clamping stress can be proved to be accurate, a reliable technical method is provided for the matching design of the pre-clamping stress of each leaf spring, and a reliable technical foundation is laid for the design of the free tangent arc height of each leaf spring. By using the method, the pre-clamping stress of each leaf spring can be ensured to meet the design requirements, the design level and the reliability of a product are improved, the service life of the product is prolonged, and the driving safety of a vehicle is improved; and meanwhile, the design cost and test cost of the product are reduced, and the product development speed is increased.

Owner:SHANDONG UNIV OF TECH

A Method of Quickly Extracting the Internal Load of the Kinematic Mechanism and Optimizing the Design Scheme

ActiveCN104200013BShorten the design cycleReduce R&D costsSpecial data processing applicationsEntity modelUltimate tensile strength

The invention relates to a method for fast extracting loads in a movement mechanism and an optimizing design scheme. The method includes the following steps that firstly, a movement mechanism principle diagram is built up, load conditions of the movement mechanism are determined, and a movement tract diagram is generated; secondly, load information of the movement mechanism is extracted, a movement mechanism driving load curve is automatically drawn, multiple load conditions of the movement mechanism are overlapped, and the maximum load which the movement mechanism can bear is extracted; thirdly, an initial scheme of the movement mechanism is optimally designed, and the design of the movement mechanism can be optimal finally. By means of the scheme, in the initial design period, the inner loads of parts in different conditions and moments can be fast extracted according to coordinate positions of a mechanism part so that strength persons can conduct primary strength check and optimal design on a mechanism system before obtaining a specific Catia entity model of the mechanism part, it is ensured that the design of the mechanism system is the optimal scheme from the beginning, and therefore a design period can be fully shortened and development cost is saved.

Owner:AVIC SAC COMML AIRCRAFT

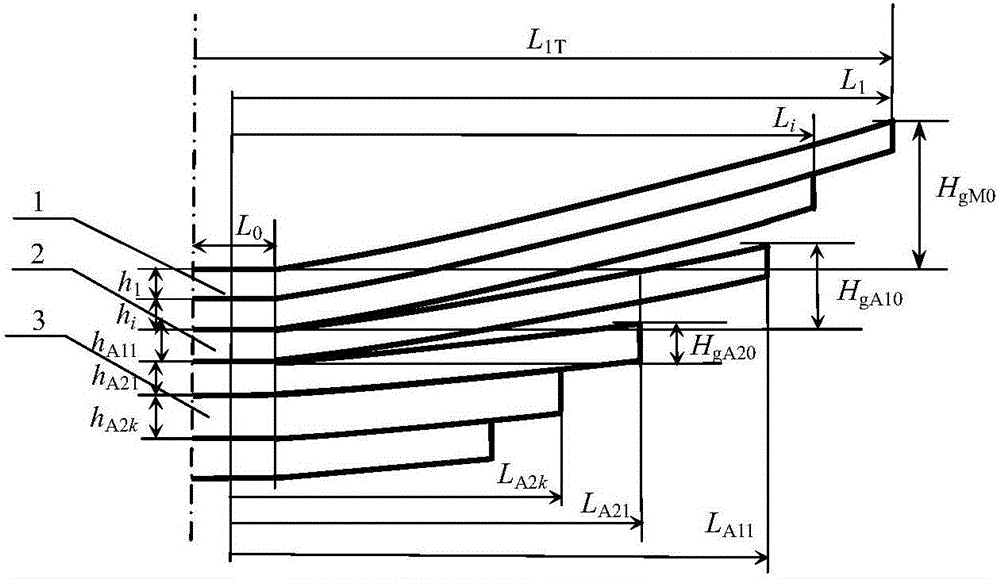

Two-stage main spring type non-equal offset frequency type gradually-changed severity leaf spring stress intensity checking method

ActiveCN106895101AMeet the stress intensity design requirementsImprove driving safetyGeometric CADLeaf springsStress strengthStrength design

The invention relates to a two-stage main spring type non-equal offset frequency type gradually-changed severity leaf spring stress intensity checking method, and belongs to the technical field of suspension steel plate springs. According to structure parameters of a first-stage main spring, a second-stage main spring and an auxiliary spring, the u-bolt clamping distance, starting contact loads of all times, the maximum load and the allowable stress, on the basis of maximum stress calculation of root parts of all leaf springs, and the stress strength of the two-stage main spring type non-equal offset frequency type gradually-changed severity leaf springs is checked. Through a model machine loading stress test, it is known that the two-stage main spring type non-equal offset frequency type gradually-changed severity leaf spring stress intensity checking method is right, and reliable technological method is provided for leaf spring strength checking and CAD software developing. By means of the method, the leaf spring stress strength design requirement can be guaranteed, and the product design level, quality and reliability and the vehicle travelling safety are improved; and meanwhile, the design and test cost can be reduced, and the product developing speed is increased.

Owner:山东恒日悬架弹簧股份有限公司

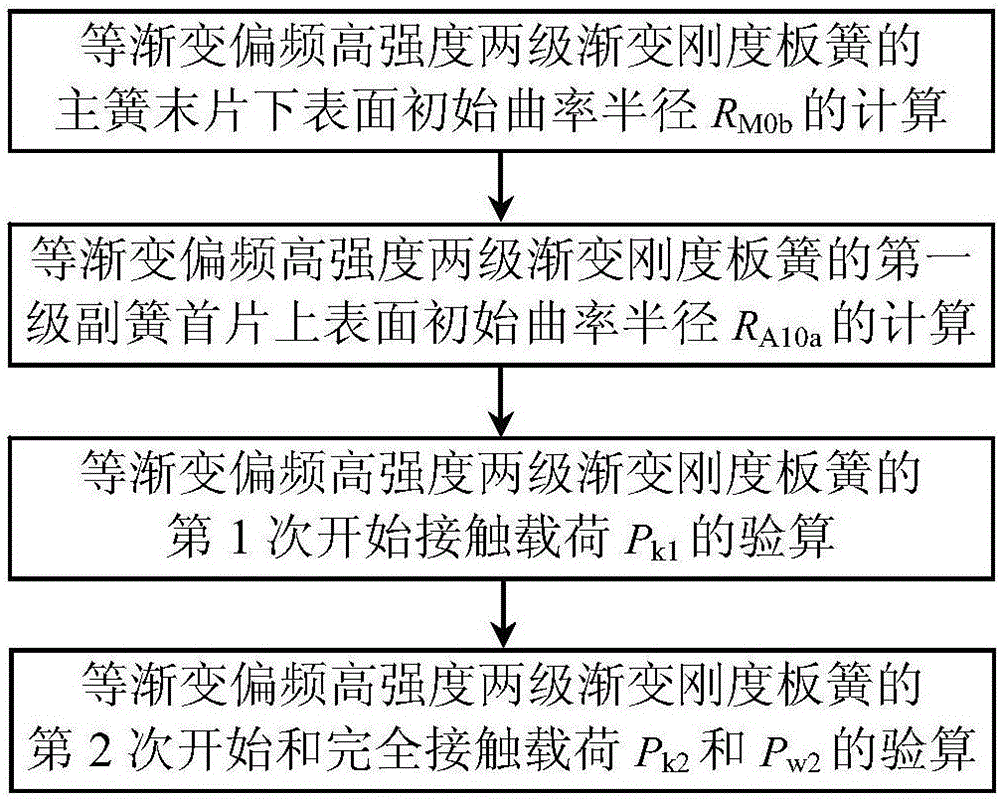

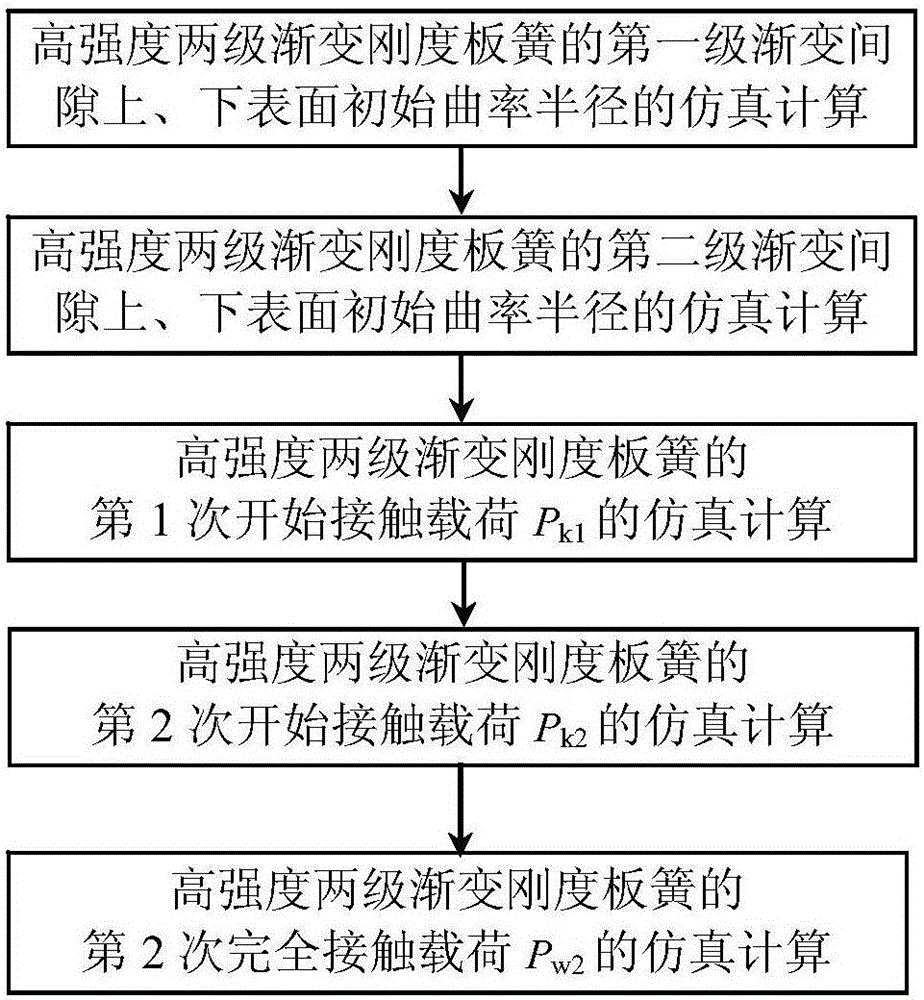

Equi-gradual offset frequency high-strength two-stage gradual rigidity plate spring contact load calculating method

InactiveCN106802995AImprove ride comfortImprove securityGeometric CADDesign optimisation/simulationEngineeringHigh intensity

The invention relates to an equi-gradual offset frequency high-strength two-stage gradual rigidity plate spring contact load calculating method and belongs to the technical field of vehicle suspension plate springs. The method can achieve calculation of the contact load of equi-gradual offset frequency high-strength two-stage gradual rigidity plate springs according to the structural parameters, the elasticity modulus and the initial designed tangent arc heights of every main spring and every auxiliary spring. Through comparison of calculated value with design required value and sample machine test value, the equi-gradual offset frequency high-strength two-stage gradual rigidity plate spring contact load calculating method is correct and provides reliable technological base for characteristic simulation and verification of equi-gradual offset frequency high-strength two-stage gradual rigidity plate springs. The equi-gradual offset frequency high-strength two-stage gradual rigidity plate spring contact load calculating method can obtain accurate and reliable contact load calculation value, ensure that the characteristics of plate springs can meet design requirements, improves the design level, quality and performance of products, reduces design and test costs and accelerates the development process of products.

Owner:SHANDONG UNIV OF TECH

Simulation calculating method for pre-clamping stress of straight-root type equal-thickness overlaid plate springs

InactiveCN108591326AImprove driving safetyMeet the design requirementsGeometric CADVibration dampersDesign valuesElastic modulus

The invention relates to a simulation calculating method for pre-clamping stress of straight-root type equal-thickness overlaid plate springs, and belongs to the technical field of suspension steel plate springs. Simulation calculation can be carried out on pre-clamping stress of all plate springs of assembled and clamped straight-root type equal-thickness overlaid plate springs according to the number of plate springs, structure parameters of all plate springs, design values of free tangent arc heights and elastic modulus. It can be known through a prototype test that the simulation calculating method for pre-clamping stress of the straight-root type equal-thickness overlaid plate springs is correct, accurate and reliable simulation calculating values of pre-clamping stress of all equal-thickness plate springs can be obtained, and the reliable technical method is provided for simulation calculation of pre-clamping stress of the straight-root type equal-thickness overlaid plate springs. By means of the method, it can be ensured that pre-clamping stress of all plate springs meets the design requirement, the design level and reliability of products are improved, the service life of the products is prolonged, and vehicle running safety is improved; and meanwhile, design and test costs of the products are lowered, and the product development speed is increased.

Owner:SHANDONG UNIV OF TECH

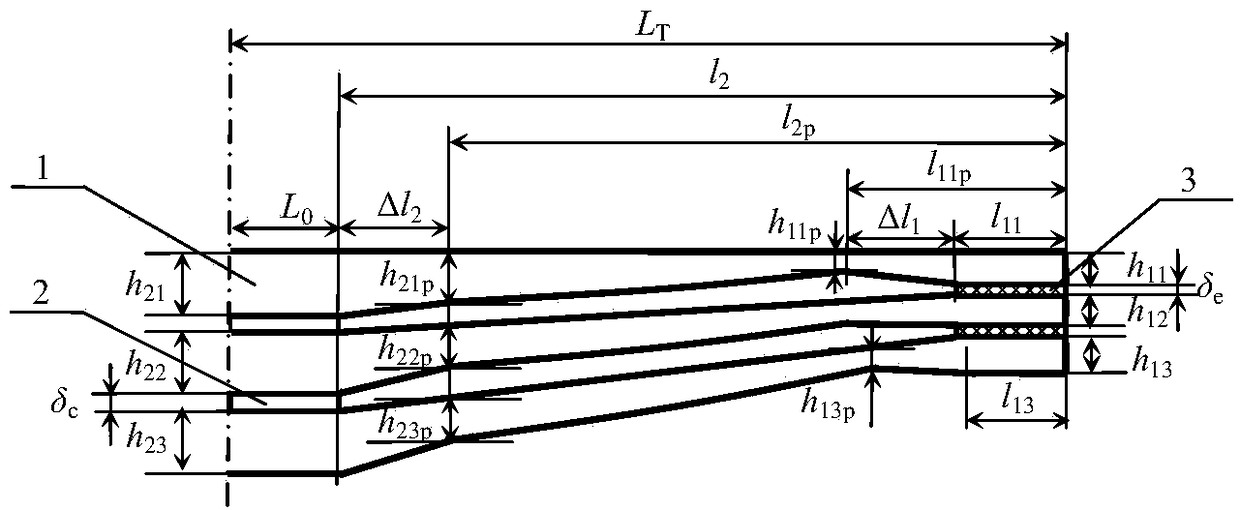

Simulating calculation method of preclamping stress of enhanced-root non-isostructural-end variable-section leaf spring

InactiveCN108153993AAccurate and reliable pre-clamping stressMeet the requirements of modern CAD designDesign optimisation/simulationSpecial data processing applicationsEngineeringVehicle driving

The invention relates to a simulating calculation method of preclamping stress of an enhanced-root non-isostructural-end variable-section leaf spring and belongs to the technical field of less-laminated leaf springs for suspensions. According to the number of leaf spring laminations, elastic modulus, root and end pad thicknesses, structural parameters of the leaf spring laminations and design value of free tangent arc height, it is possible to perform simulating calculation on preclamping stress for each leaf spring lamination after the assembly and clamping of an enhanced-root non-isostructural-end parabolic variable-section leaf spring. Prototype testing may show that the simulating calculation method of preclamping stress of the enhanced-root non-isostructural-end variable-section leafspring is accurate, accurate and reliable simulating calculated value of preclamping stress can be acquired, and a reliable technical process is provided for the simulating calculation of preclampingstress. By using the method, it is possible to ensure that preclamping stress of each leaf spring lamination meets the simulating calculated value, increase product design level, improve reliability,extend the service life and improve vehicle driving safety; in addition, design and test expenditures are cut down, and product development speed is increased.

Owner:SHANDONG UNIV OF TECH

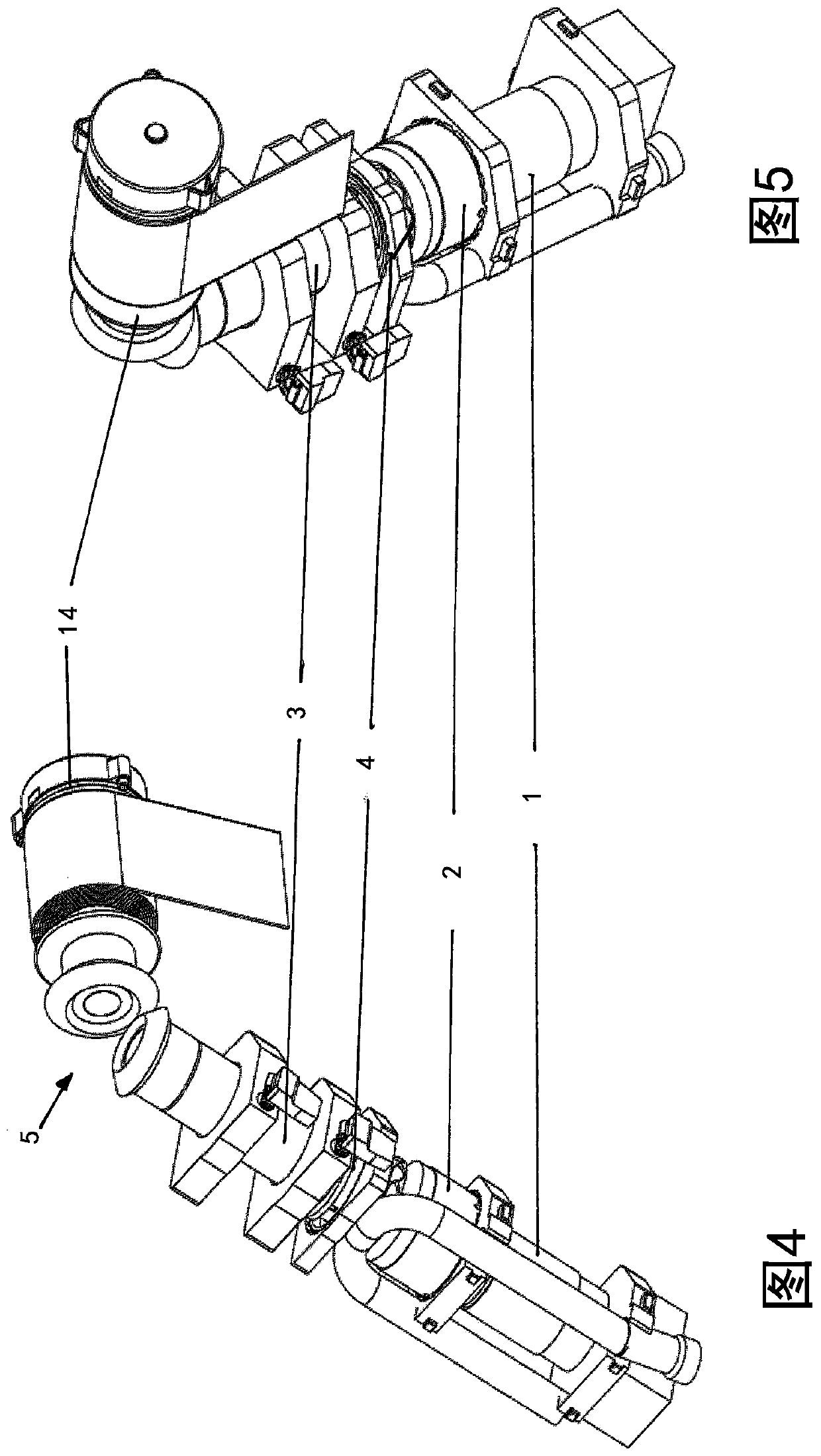

Seat belt retractor

InactiveCN111098820AReduce design costsLow costBelt retractorsBelt anchoring devicesRotational axisSeat belt

The invention relates to a seat belt retractor (40). The seat belt retractor (40) has a belt spool (14), a seat belt (12) that can be wound thereon to a belt spool, and at least a first and a second assembly (1, 2), wherein the first and the second assembly (1, 2) are arranged coaxially to each other and at a first angle (A) to the rotational axis (B) of the belt spool (14) and are connected together by a flex coupling or an angular gear.

Owner:AUTOLIV DEV AB

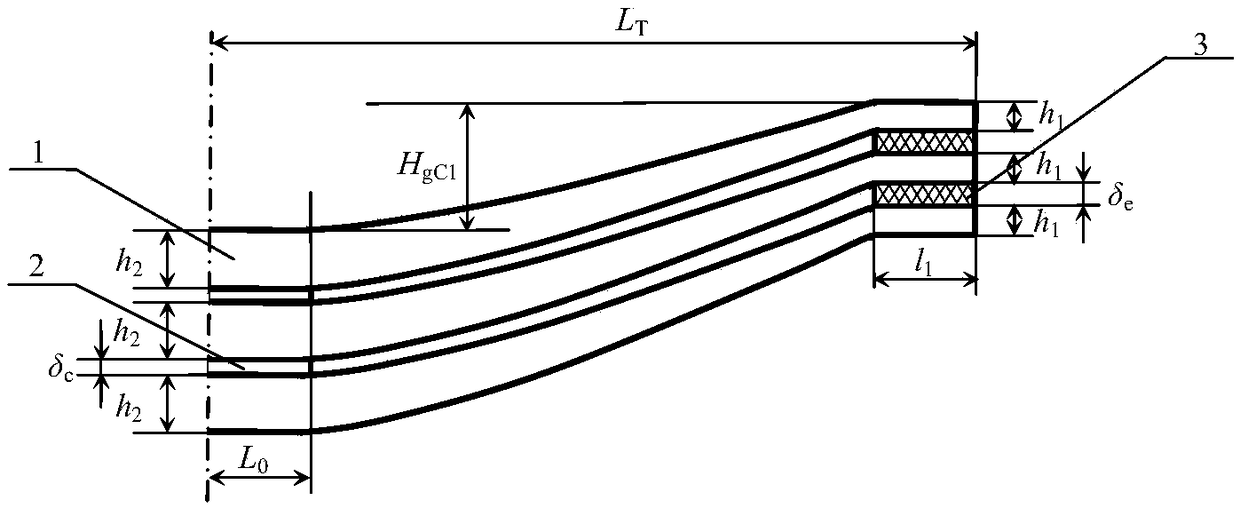

End-reinforced iso-structured small variable-section plate spring preclamping stress matching design method

InactiveCN108278307AImprove driving safetyImprove the design levelGeometric CADLeaf springsVehicle drivingDesign methods

The invention relates to an end-reinforced iso-structured small variable-section plate spring preclamping stress matching design method, and relates to the technical field of suspension small variable-section plate springs. According to the number of plate springs, structural parameters of the plate springs, rated load and allowed stress of a first plate spring under the rated load, matching design is performed on preclamping stress of each plate spring of end-reinforced iso-structured small variable-section plate springs. Known from prototype testing, the end-reinforced iso-structured small variable-section plate spring preclamping stress matching design method is correct; and reliable technological base is laid for design of free tangent line arc height of each plate spring. The method can guarantee the preclamping stress of each plate spring to meet the design requirements so as to improve the product design level, the product reliability, the product service life and the vehicle driving safety, meanwhile, reduces the product design and test costs, and accelerates the product development speed.

Owner:SHANDONG UNIV OF TECH

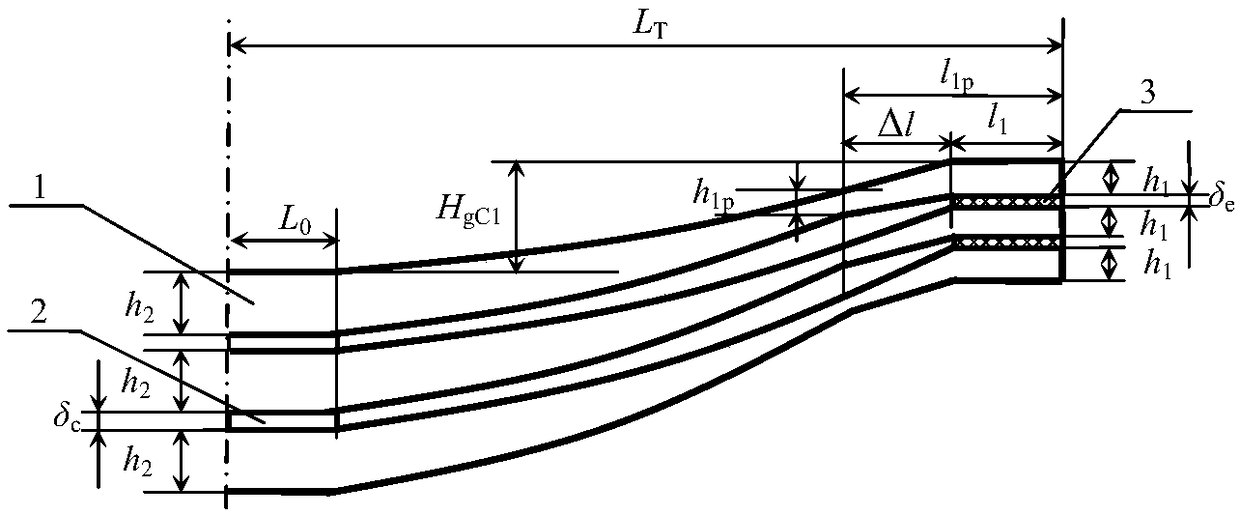

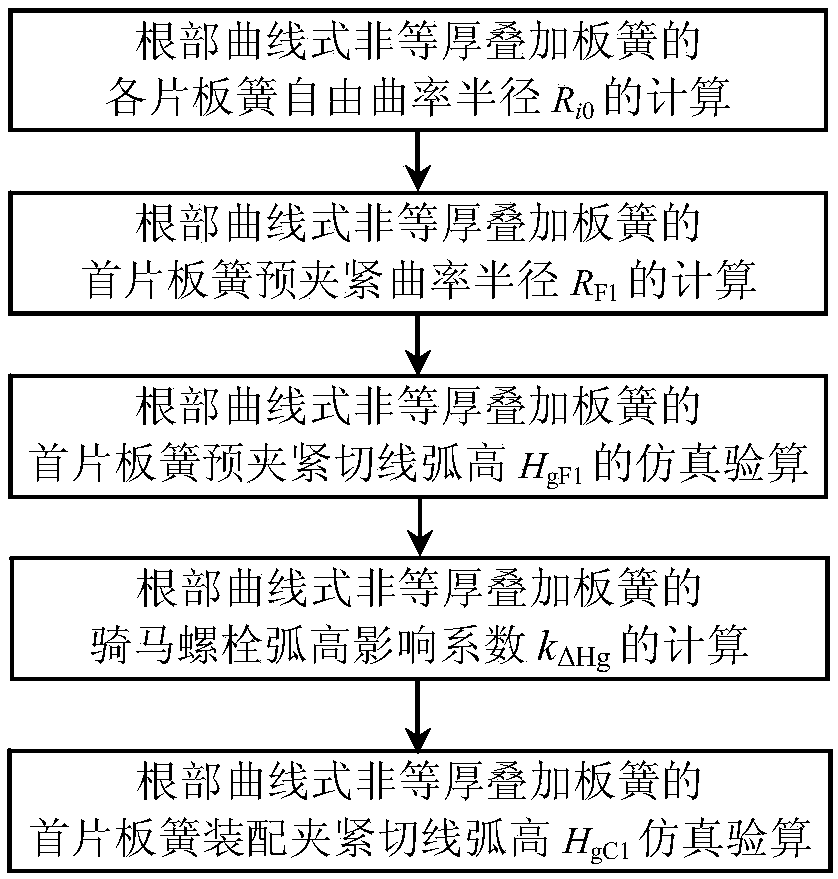

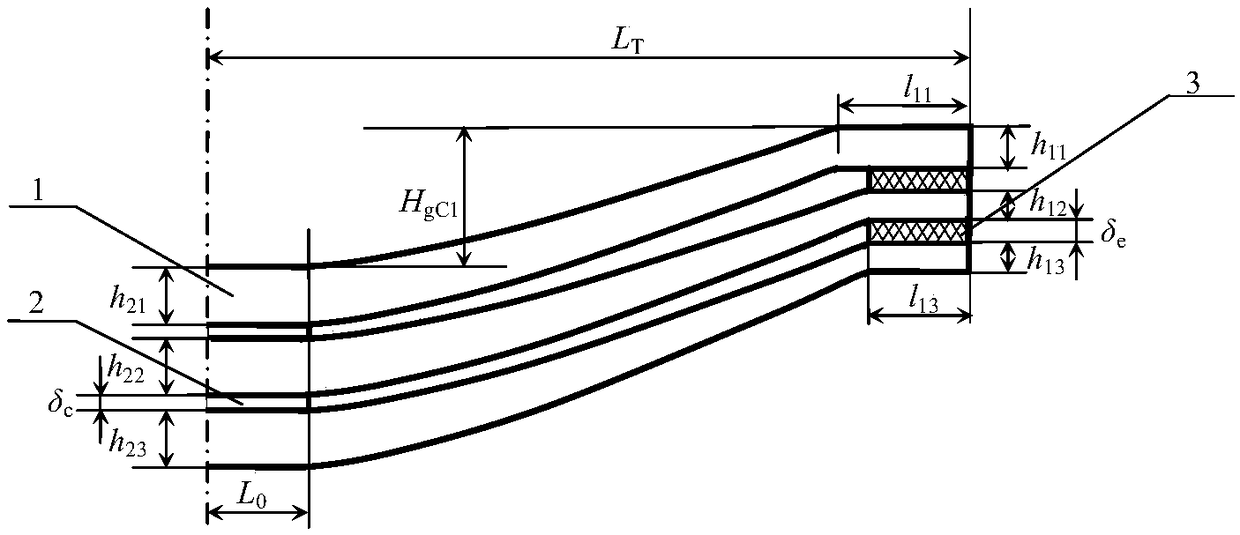

Simulation calculation method for tangent arc height of root curve type unequal-thickness stacked plate springs

InactiveCN108266477AReliable designMeet the requirements of modern CAD designGeometric CADLeaf springsRate of developmentEngineering

The invention relates to a simulation calculation method for the tangent arc height of root curve type unequal-thickness stacked plate springs, belonging to the technical field of a suspension steel plate spring. According to the number of the plate springs, the structure parameters of each plate spring and the design value of a free tangent arc height, the simulation calculation method conducts simulation calculation for the preclamped tangent arc height of the first plate spring of the root curve type unequal-thickness stacked plate springs after a bolt penetrates through the center and is clamped and the assembly clamping tangent arc height of the first plate spring of the root curve type unequal-thickness stacked plate springs after a U-bolt is assembled and clamped. By prototype testing, the simulation calculation method is correct and can obtain accurate and reliable simulation calculation values of the preclamped tangent arc height and the assembly clamping tangent arc height. By using the method, the design level and reliability of a product can be improved, the service life of the product can be prolonged, and the vehicle driving safety can be improved. Meanwhile, the design and testing expenses of the product are reduced, and the rate of development of the product is increased.

Owner:SHANDONG UNIV OF TECH

Simulation calculation algorithm for pre-clamping stress of root non-equal-thickness small-piece variable-section leaf springs

InactiveCN108150573AImprove driving safetyAccurate and reliable pre-clamping stressGeometric CADLeaf springsEngineeringType variable

The invention relates to a simulation calculation algorithm for pre-clamping stress of root non-equal-thickness small-piece variable-section leaf springs, and belongs to the technical field of suspension small-piece variable-section leaf springs. According to the simulation calculation algorithm, simulation calculation can be carried out on the pre-clamping stress of each leaf spring after the root non-equal-thickness small-piece parabola type variable-section springs are assembled and clamped based on the leaf spring number, structural parameters of each leaf spring, the design value of freetangent arc height, elasticity modulus, the thicknesses of a root gasket and an end gasket; through a prototype test, the simulation calculation algorithm for the pre-clamping stress of the root non-equal-thickness small-piece variable-section leaf springs is correct, and a reliable technical method is provided for the simulation calculation of pre-clamping stress of the root non-equal-thickness small-piece parabola type variable-section leaf springs; by means of the simulation calculation algorithm, the pre-clamping stress of each leaf spring can be ensured to meet the design requirement, andthe design level, reliability and the service life of products and driving safety of a vehicle are improved; and meanwhile, the design and experimental expense of the products are reduced, and the product development speed is increased.

Owner:SHANDONG UNIV OF TECH

Determination method for clamping end point force of end non-iso-structured small-blade variable-section plate springs

InactiveCN108223640AImprove the design levelImprove reliabilityGeometric CADLeaf springsEngineeringVehicle driving

The invention discloses a determination method for clamping end point force of end non-iso-structured small-blade variable-section plate springs, and belongs to the technical field of suspension small-blade variable-section plate springs. The method can determine the clamping end point force of each plate spring of the end non-iso-structured small-blade variable-section plate springs according tothe number of the plate springs, structural parameters of each plate spring, elastic modules, rated load and allowable stress of the first plate spring under the rated load. Through prototype testing,the determination method for the clamping end point force of the end non-iso-structured small-blade variable-section plate springs is correct; accurate and reliable clamping end point force values ofeach plate spring can be obtained; and reliable technological base is laid for free tangent line arc height design of each plate spring. The method can improve the product design level, reliability and service life and the vehicle driving safety, meanwhile, reduces the product design and testing costs, and accelerates the product development speed.

Owner:SHANDONG UNIV OF TECH

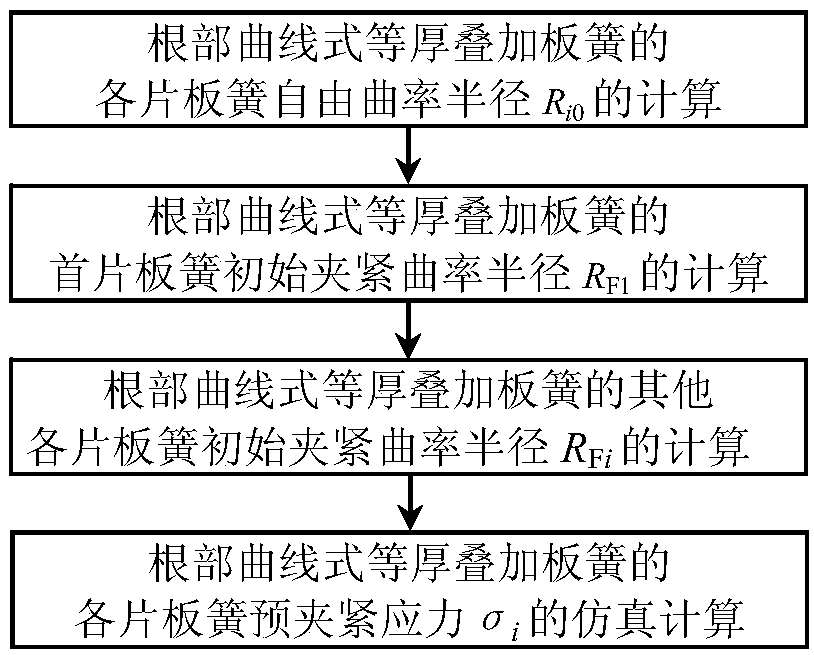

Simulating calculation algorithm for root curvilinear type equal thickness stacked leaf spring pre-clamping stress

InactiveCN108256221AAccurate and reliable technical methodMeet the design requirementsDesign optimisation/simulationSpecial data processing applicationsVehicle drivingDesign values

The invention relates to a simulating calculation algorithm for root curvilinear type equal thickness stacked leaf spring pre-clamping stress, and belongs to the technical field of suspension steel plate springs. On the basis of the number of spring leaves, structural parameters of each spring leaf, a design value of the free tangent arc height and elasticity modulus, simulating calculation is performed on pre-clamping stress of each spring leaf of a root curvilinear type equal thickness stacked leaf spring obtained after a central penetrating bolt is pre-clamped. A development test shows thatthe simulating calculation algorithm for the root curvilinear type equal thickness stacked leaf spring pre-clamping stress is accurate, and the reliable technical method is provided for simulating calculation for pre-clamping stress of each spring leaf of the root curvilinear type equal thickness stacked leaf spring. By means of the method, it is ensured that the pre-clamping stress of each spring leaf meets the design requirement, the design level and reliability of the product are improved, the service life is prolonged, and the vehicle driving safety can be improved; meanwhile, the productdesign and testing cost is lowered, and the product development speed is increased.

Owner:SHANDONG UNIV OF TECH

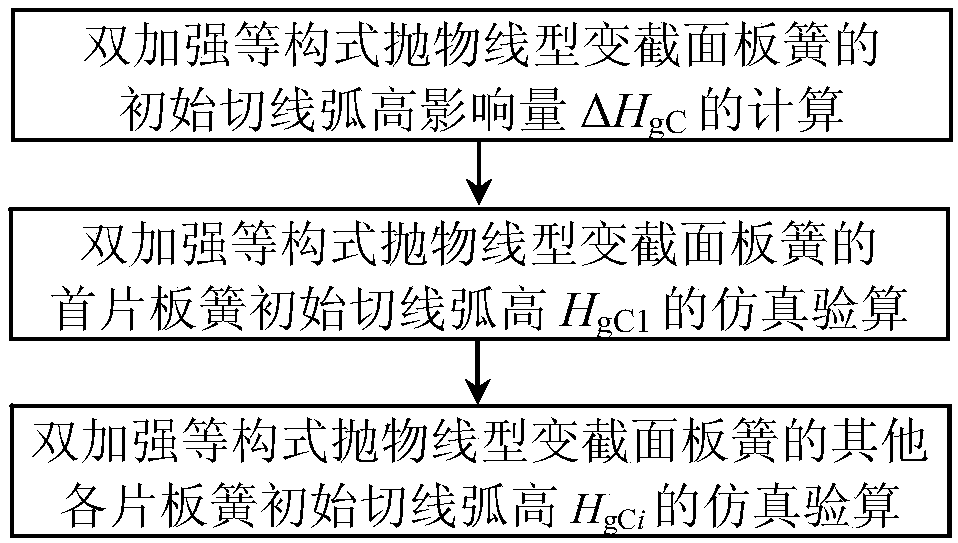

Simulation checking calculation method for initial tangent arc height of double-reinforced isomorphic few-leaf variable-section leaf spring

InactiveCN108256231AAccurate and reliable initial tangent arcMeet the requirements of modern CAD designGeometric CADDesign optimisation/simulationReal variableEngineering

The invention relates to a simulation checking calculation method for the initial tangent arc height of a double-reinforced isomorphic few-leaf variable-section leaf spring, and belongs to the technical field of suspension few-leaf variable-section leaf springs. According to the method, based on the number of leaves of the leaf spring, the structural parameter and free tangent arc height design value of each leaf of the leaf spring and the thicknesses of gaskets at the root and the end, simulation checking calculation is conducted on the initial tangent arc height of each leaf of the leaf spring after the double-reinforced isomorphic parabola-shaped variable-section leaf spring is assembled and clamped. Through a prototype test, it can be known that the simulation checking calculation method for the initial tangent arc height of the double-reinforced isomorphic few-leaf variable-section leaf spring is accurate, and an accurate and reliable simulation checking calculation value of the initial tangent arc height of each leaf of the leaf spring is obtained. By means of the method, it can be ensured that the initial tangent arc height of the first leaf of the leaf spring after being assembled and clamped meets design requirements, and the design level, reliability and service life of a product and the running-safety performance of a vehicle are improved; meanwhile, the design and test costs of the product are reduced, and the development rate of the product is increased.

Owner:SHANDONG UNIV OF TECH

Method for designing blanking lengths of auxiliary springs of high-strength first-grade plate spring having gradually changing stiffness

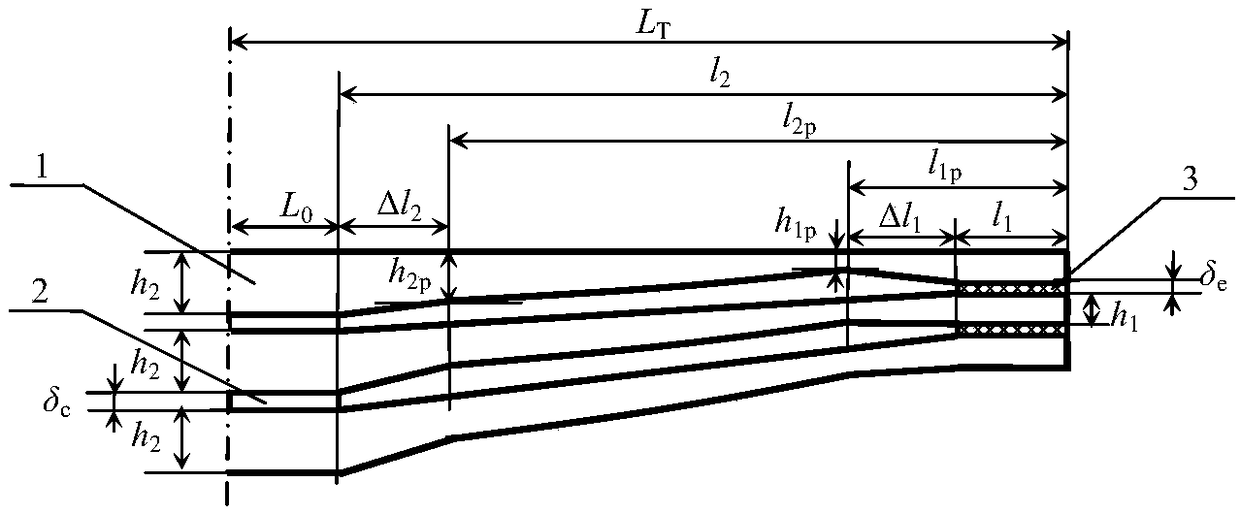

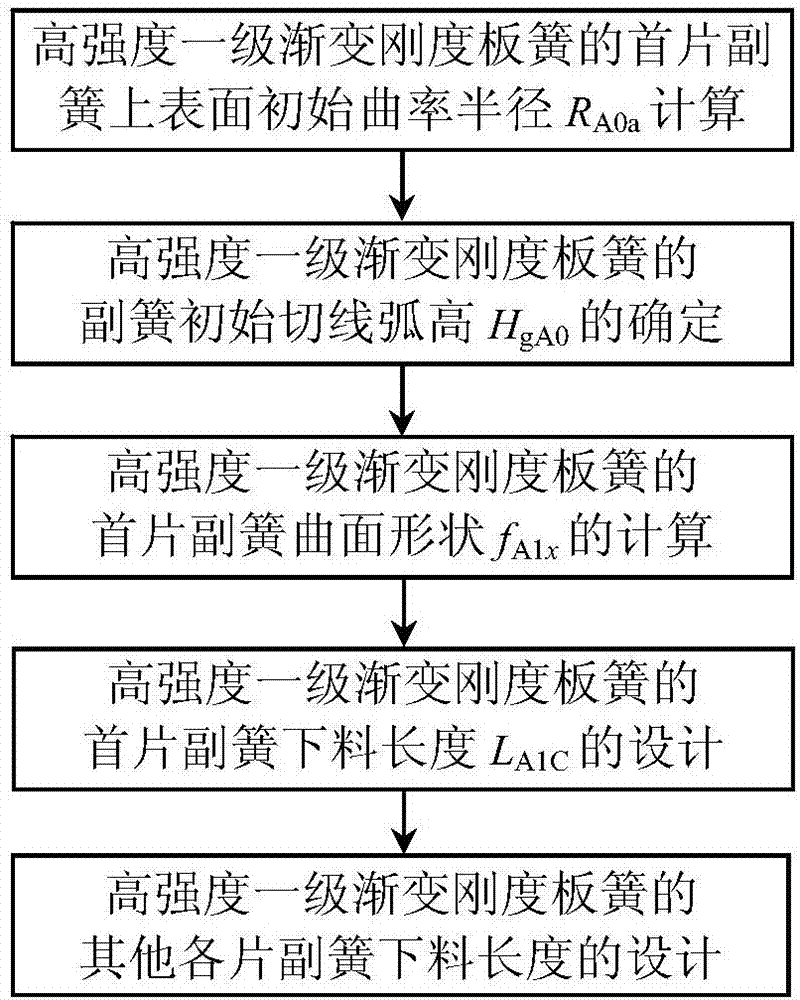

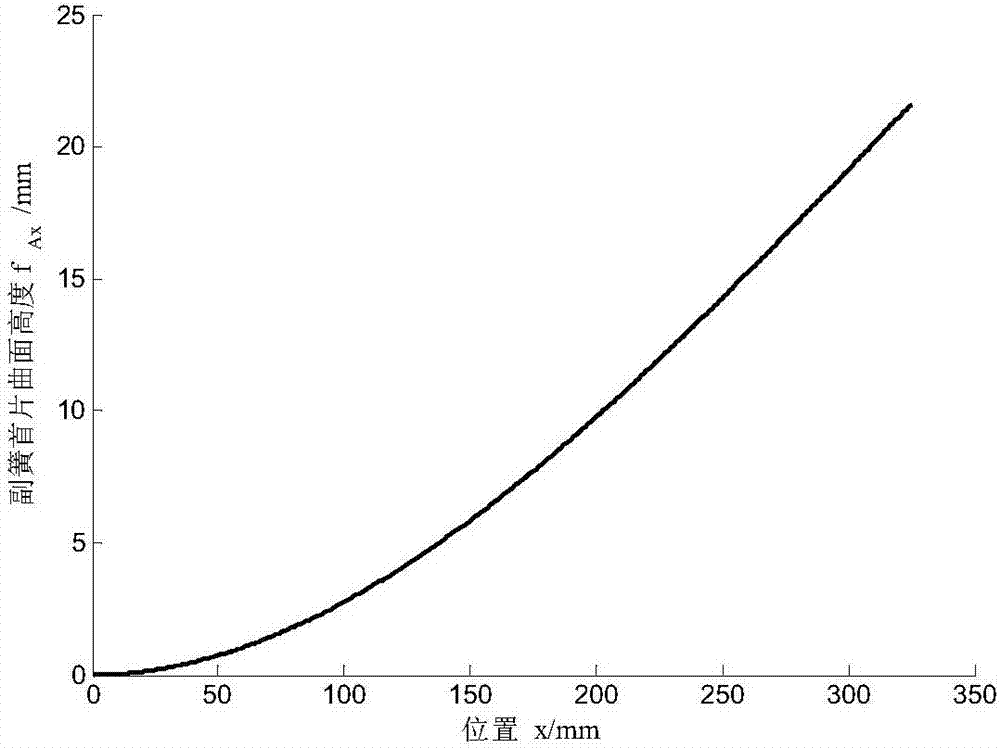

InactiveCN106855903AAccurate and reliable design requirementsSave materialGeometric CADDesign optimisation/simulationHigh intensityEngineering

The invention relates to a method for designing blanking lengths of auxiliary springs of a high-strength first-grade plate spring having gradually changing stiffness and belongs to the technical field of suspension steel plate springs. The blanking lengths of auxiliary springs can be accurately designed through curved-surface microelements and superposing calculation on the basis of auxiliary spring initial tangent arc height design and first-auxiliary-spring initial curved-surface shape calculation according to structure parameters and elasticity modulus of main springs and the auxiliary springs, initial tangent arc heights of the main springs and beginning contact loads. It can be known through a prototype blanking processing test that the established method for designing the blanking lengths of the auxiliary springs of the high-strength first-grade plate spring having gradually changing stiffness is correct and lays an important technical base. By utilizing the method, blanking length design values of the auxiliary springs can be accurately obtained, the material saving rate can be improved, a processing technology can be improved, and the production efficiency can be improved. In addition, the design and testing expenses can be reduced, and the product development speed can be improved.

Owner:SHANDONG UNIV OF TECH

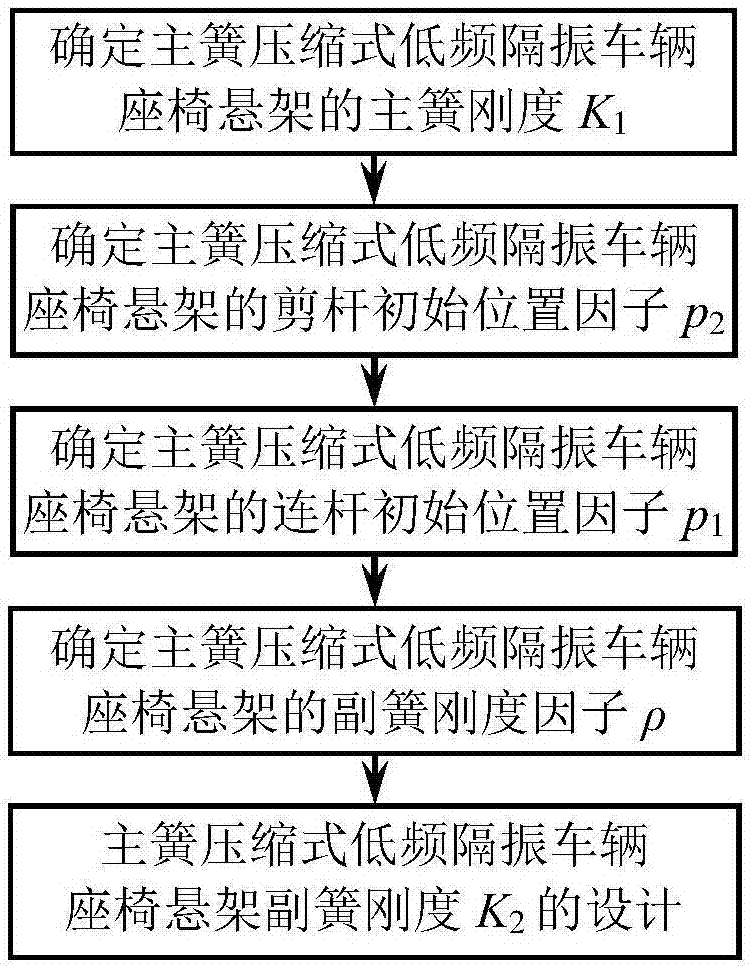

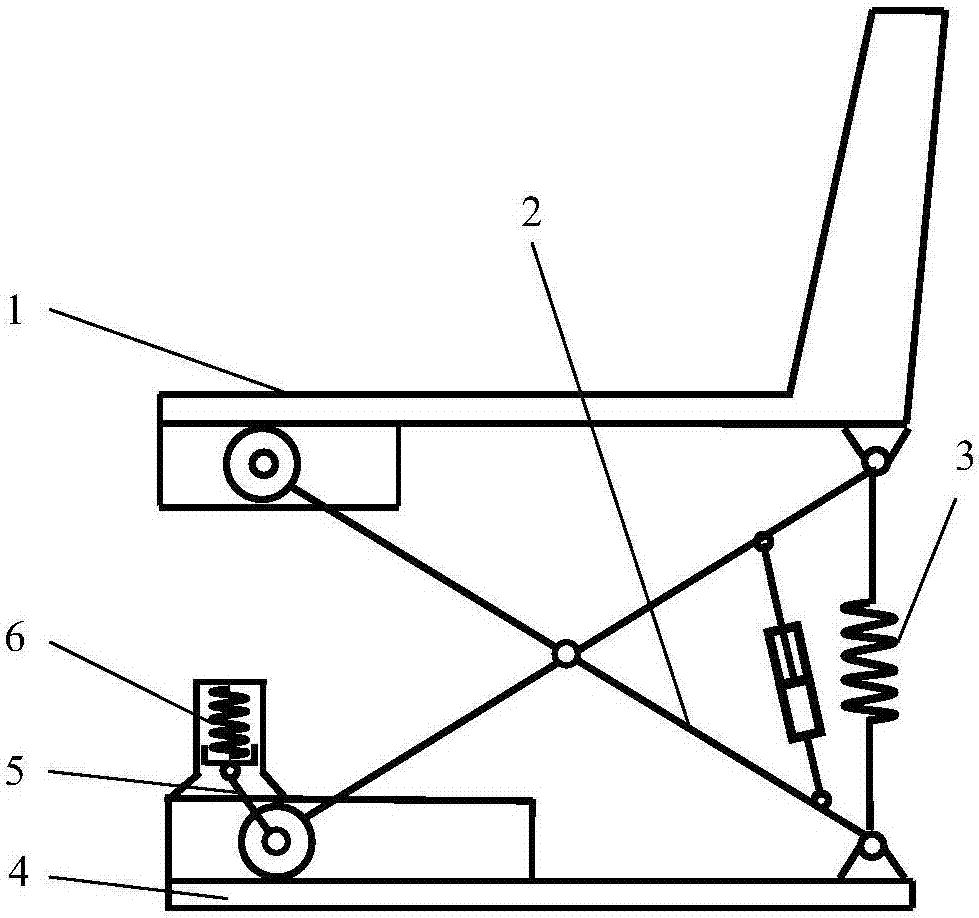

Design method of main-spring compression type low-frequency vibration-isolation vehicle seat suspension vice-spring stiffness

ActiveCN107391874AReduce design costsReduce test costsGeometric CADSpecial data processing applicationsComputer Aided DesignDesign cycle

The invention relates to a design method of main-spring compression type low-frequency vibration-isolation vehicle seat suspension vice-spring stiffness and belongs to the technical field of vehicle seats with an aim to solve problems that previous design methods of the main-spring compression type low-frequency vibration-isolation vehicle seat suspension vice-spring stiffness are not reliable and a design method adopting 'experience with repeated trials' cannot meet requirements of modern CAD (computer-aided design) design and rapid development of the vehicle seats. With the method provided, the suspension vice-spring stiffness can be designed rapidly, accurately and reliably according to structure parameters of the main-spring compression type low-frequency vibration-isolation seat suspension vice-spring stiffness and crew quality of the seats, and the shortcoming of repeated trials in the traditional design methods is avoided; with the method, design level and quality and vibration-isolation performance of the main-spring compression type low-frequency vibration-isolation vehicle seats can be improved, design and trial costs of the seats are reduced, design cycle is shortened, and seat development is sped up.

Owner:梁山润华挂车配件制造有限公司

Memory positioning device

PendingCN110906963AReduce design costsImprove versatilityMeasurement apparatus componentsComputer hardwareMechanical engineering

Owner:CHANGXIN MEMORY TECH INC

Matching design method for pre-clamping stress of non-equal-thickness main spring of two-stage progressive stiffness leaf spring

InactiveCN108278300AImprove driving safetyImprove the design levelGeometric CADLeaf springsVehicle drivingDesign methods

The invention relates to a matching design method for pre-clamping stress of a two-stage gradual stiffness plate spring with a non-equal-thickness main spring, belonging to the technical field of suspension gradual stiffness plate springs. The invention can carry out matching design on the pre-clamping stress of each non-equal-thickness main spring of the two-stage gradual change rigidity leaf spring according to the number of the main leaf spring, the number of the secondary leaf springs at each stage, the structural parameters of each leaf spring, the first and second contact loads, the rated load and the allowable stress of the first leaf main spring under the rated load. Through the prototype test, it can be seen that the matching design method for the pre-clamping stress of the non-equal-thickness main spring of the two-stage graded stiffness leaf spring provided by the invention is correct, which lays a reliable technical foundation for the design of the free tangent arc height of the non-equal-thickness main spring of the two-stage graded stiffness leaf spring. The method can ensure that the pre-clamping stress of each non-equal-thickness main spring meets the design requirements and improve the design level, reliability, service life and vehicle driving safety of products. At the same time, reduce the cost of product design and testing and speed up product development.

Owner:SHANDONG UNIV OF TECH

Simulating calculation method for pre-clamping stress of equal-thickness main springs of first-level gradual rigidity leaf spring

InactiveCN108223646AAccurate and reliable pre-clamping stressImprove driving safetyGeometric CADLeaf springsEngineeringCalculation methods

The invention relates to a simulating calculation method for the pre-clamping stress of equal-thickness main springs of a first-level gradual rigidity leaf spring and belongs to the technical field ofsuspension gradual rigidity leaf springs. The method can be used for simulating calculation of the pre-clamping stress of the assembled and clamped equal-thickness main springs of the first-level gradual rigidity leaf spring according to the number, structure parameters, design values of free tangent line camber heights and elasticity modulus of the main springs. Prototype testing shows that thesimulating calculation method for the pre-clamping stress of the equal-thickness main springs of the first-level gradual rigidity leaf spring is correct, accurate and reliable simulating calculation values of the pre-clamping stress of the equal-thickness main springs can be obtained, and the reliable technological method is provided for simulation calculation of the pre-clamping stress of the equal-thickness main springs of the first-level gradual rigidity leaf spring. The method can ensure that the pre-clamping stress of the equal-thickness main springs meets design requirements, the designlevel and reliability of products are improved, the service life of products is prolonged, and vehicle running safety is improved; and meanwhile, the design and testing cost of products is reduced, and the development speed is increased.

Owner:SHANDONG UNIV OF TECH

Contact load simulating calculation method for high-strength two-level gradually changing stiffness plate spring

InactiveCN106777803AImprove ride comfortImprove securityGeometric CADLeaf springsEngineeringCalculation methods

The invention relates to a contact load simulating calculation method for a high-strength two-level gradually changing stiffness plate spring, and belongs to the technical field of vehicle suspension steel plate springs. The contact load of the equal offset frequency high-strength two-level gradually changing stiffness plate spring can be calculated in a simulating manner according to structural parameters of main springs and auxiliary springs, elastic modulus, initial tangent arc height design values of the main springs and initial arc height design values of the first-level auxiliary spring and the second-level auxiliary spring by the aid of the relation between the contact load and the deflection of the main springs and the auxiliary springs and the relation between the curvature radius and the initial tangent arc height. According to comparison of verification values with design requirement values and model machine experiment test values, the contact load simulating calculation method for the high-strength two-level gradually changing stiffness plate spring is correct. By the method, accurate and reliable contact load simulating calculation values can be acquired, so that product design level, quality and performances are improved. Besides, design and experiment expenses are reduced, and product development is accelerated.

Owner:SHANDONG UNIV OF TECH

Method for checking and analyzing numerical value of moving blade of steam turbine

ActiveCN113204841AShorten the Design Checkout ProcessShorten the overall cycleGeometric CADSpecial data processing applicationsEngineeringNumerical models

The invention discloses a method for checking and analyzing numerical value of a moving blade of a steam turbine, which comprises the following steps of: performing static vibration characteristic measurement and data analysis on a steam turbine moving blade, surveying and mapping a three-dimensional molded line of the steam turbine moving blade, and establishing a three-dimensional model of the steam turbine moving blade, a cyclic symmetric three-dimensional model of a gear train and a corresponding finite element numerical model; carrying out numerical calculation and judgment analysis on the centrifugal stress of the steam turbine moving blade under different working conditions according to the material attributes of the steam turbine moving blade; carrying out numerical calculation, analysis and evaluation on static and dynamic vibration characteristics of a single steam turbine moving blade and a wheel train; and finally, carrying out comprehensive evaluation on a steam turbine moving blade numerical check analysis result. The method has wider applicability and feasibility, the analysis result is more accurate, the application is simple and easy to understand, the method can be suitable for checking and analyzing various steam turbine moving blades, the safety and stability of the steam turbine moving blades are remarkably improved, and the method has important engineering application value for improving the safety and economy of the whole machine.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com