Matching design method for isomorphic parabolic type taper-leaf spring pre-clamping stress

A parabola and variable cross-section technology, which is applied in the design characteristics of spring/shock absorber, leaf spring, computer-aided design, etc., can solve the problems that cannot meet the requirements of the suspension with few leaf springs of variable cross-section, and the lack of accurate and reliable constructions. Parabolic variable-section leaf springs and other problems, to achieve the effect of reducing design and test costs, improving the design level, and speeding up the development speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

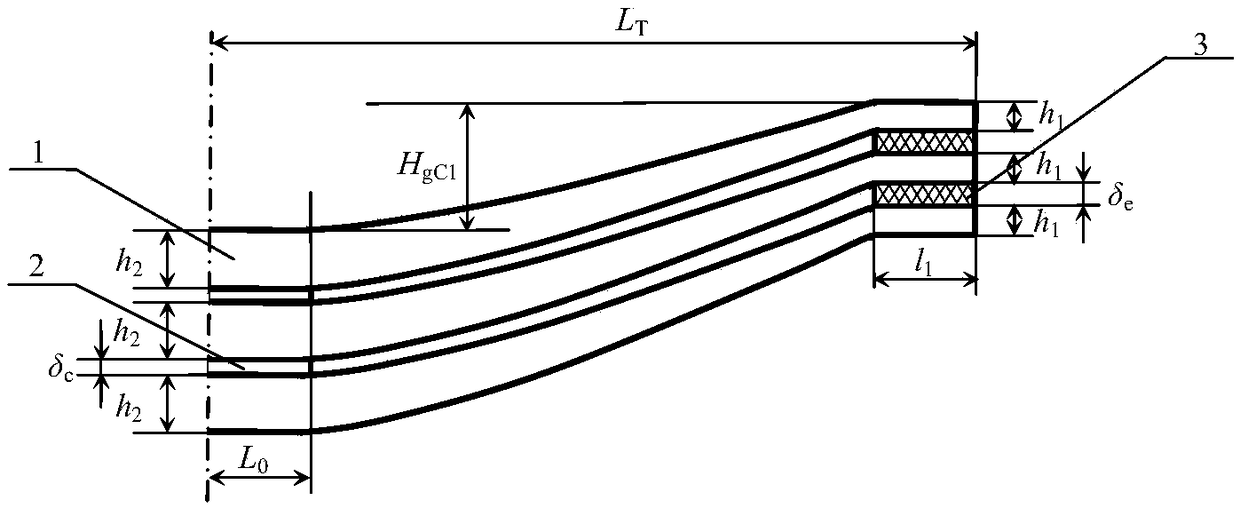

[0021] Embodiment one: the width b=60mm of a certain constructional formula few parabolic variable-section leaf springs, half of the span L T =570mm, half the length L of the straight section of the root clamped by the saddle bolt 0 = 50mm. The number of leaf springs n=3, the thickness h of the straight section at the root of each leaf spring 2 =18mm. Rated load P N = 16000N, the allowable stress of the first leaf spring under rated load [σ 1 ]=400MPa. According to the number of leaf springs, structural parameters, rated load and the allowable stress of the first leaf spring under the rated load, the pre-clamping stress of each leaf spring of the less-parabolic variable-section leaf spring of the same structure is matched. design.

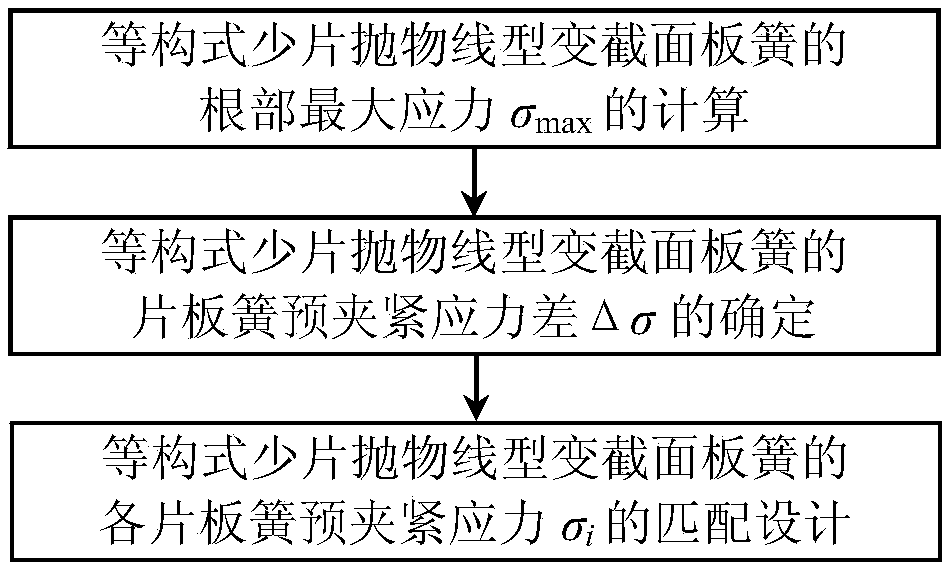

[0022] The matching design method of the pre-clamping stress of the equal-structure few-piece parabolic variable-section leaf spring provided by the example of the present invention, its matching design process is as follows figure 1 As show...

Embodiment 2

[0035] Embodiment two: the width b=60mm of a few pieces of parabolic variable-section leaf spring of a certain construction formula, half span L T =570mm, half the length L of the straight section at the root 0 = 50mm. The number of leaf springs n=4, the thickness h of the straight section at the root of each leaf spring 2 = 16 mm. Rated load P N =16800N, the allowable stress of the first leaf spring under rated load [σ 1 ]=400MPa. According to the number of leaf springs, structural parameters, rated load and the allowable stress of the first leaf spring under the rated load, pre-clamp each leaf spring of the structure with a small number of parabolic variable-section leaf springs Stress matching design.

[0036] Using the same design method and steps as in Embodiment 1, the free tangent arc heights of each leaf spring of the few-sheet parabolic variable-section leaf springs of such structures are designed, and the specific design steps are as follows:

[0037] (1) The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com