Gearbox of small tractor

A technology for tractors and gearboxes, which is applied to mechanical equipment, mechanical control devices, and controlled components. It can solve the problems of high modification costs, complex structure of transmission devices, and poor versatility of parts, so as to reduce design and manufacturing costs and facilitate Use and maintenance, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

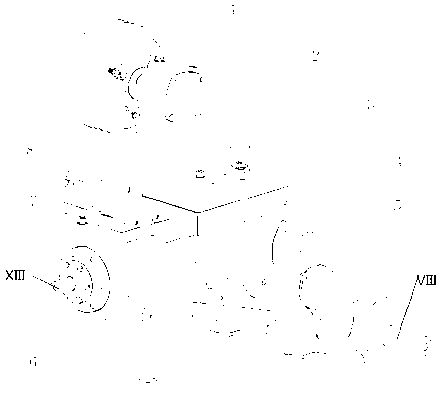

[0024] Such as figure 1 , 2 As shown, the small-sized tractor gearbox includes the main gearbox 5, and the main gearbox includes I~Ⅷ shafts, the I shaft is provided with a high-speed driving gear 11 and a low-speed driving gear 12, and the II shaft is provided with a reverse intermediate gear 21 , Shaft III is equipped with reverse gear 31, driving gear I gear 32, bridge gear 33, driving gear III gear 34 and driving gear II gear 35, front drive clutch gear 41 is set on axis IV, and front drive intermediate gear is set on shaft V 51. Differential gear sets (61, 62, 63) are arranged on the VI shaft, reduction gears 71 (72) are respectively arranged on the two VII shafts, and driving gears 81 are respectively arranged on the two VIII shafts.

[0025] An auxiliary gearbox 6 is also connected to the main gearbox 5, and the auxiliary gearbox is provided with shafts Ⅸ~XⅢ, and the shaft Ⅸ is provided with I-reverse gear 91, central transmission gear 92 and II-III gear passive gear. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com