Operating device for shut-off needles in injection-moulding devices with needle valve nozzles

An action and nozzle technology, applied in the field of closing needle action devices, can solve the problems of high cost, high construction height, increased installation time and manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

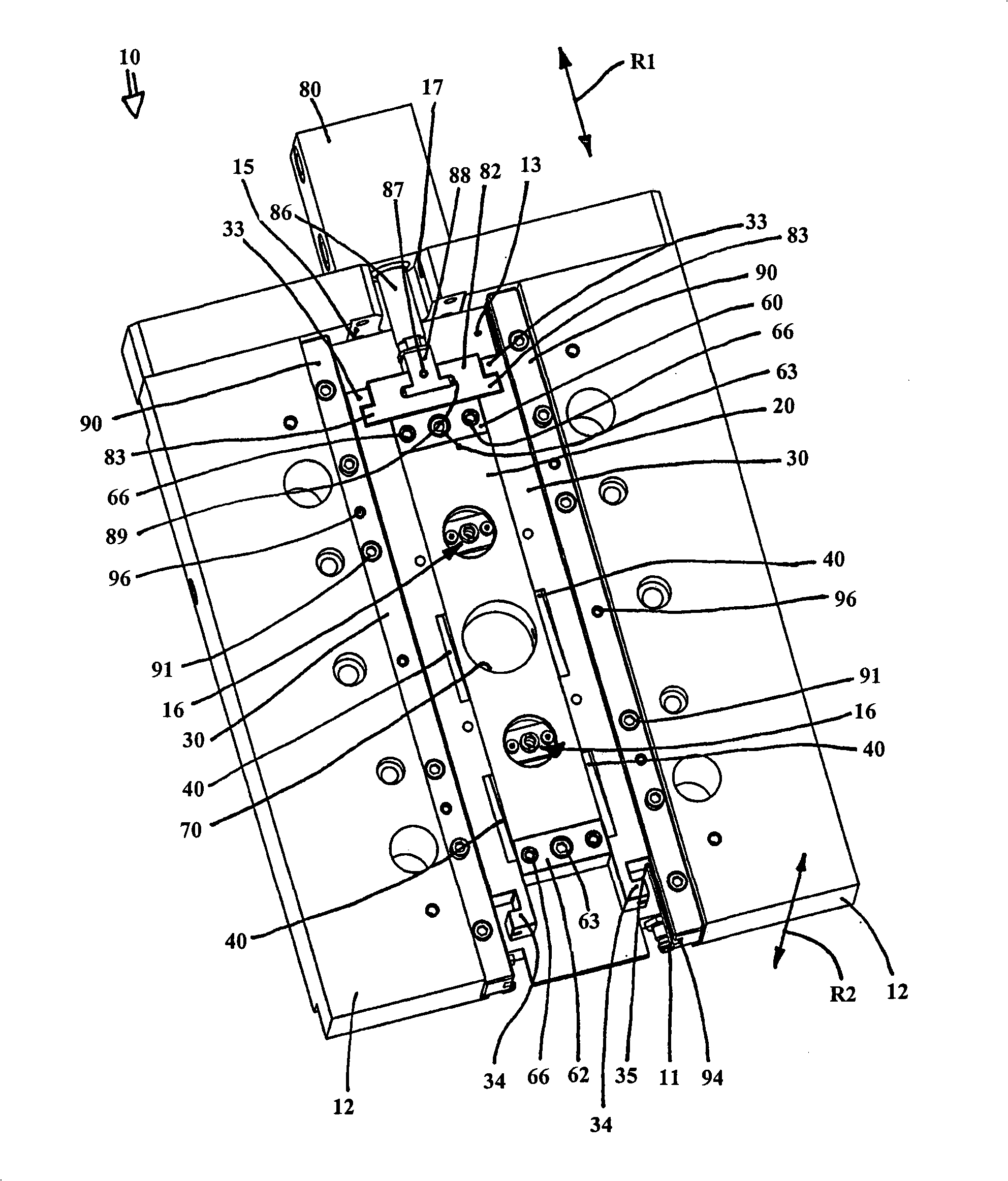

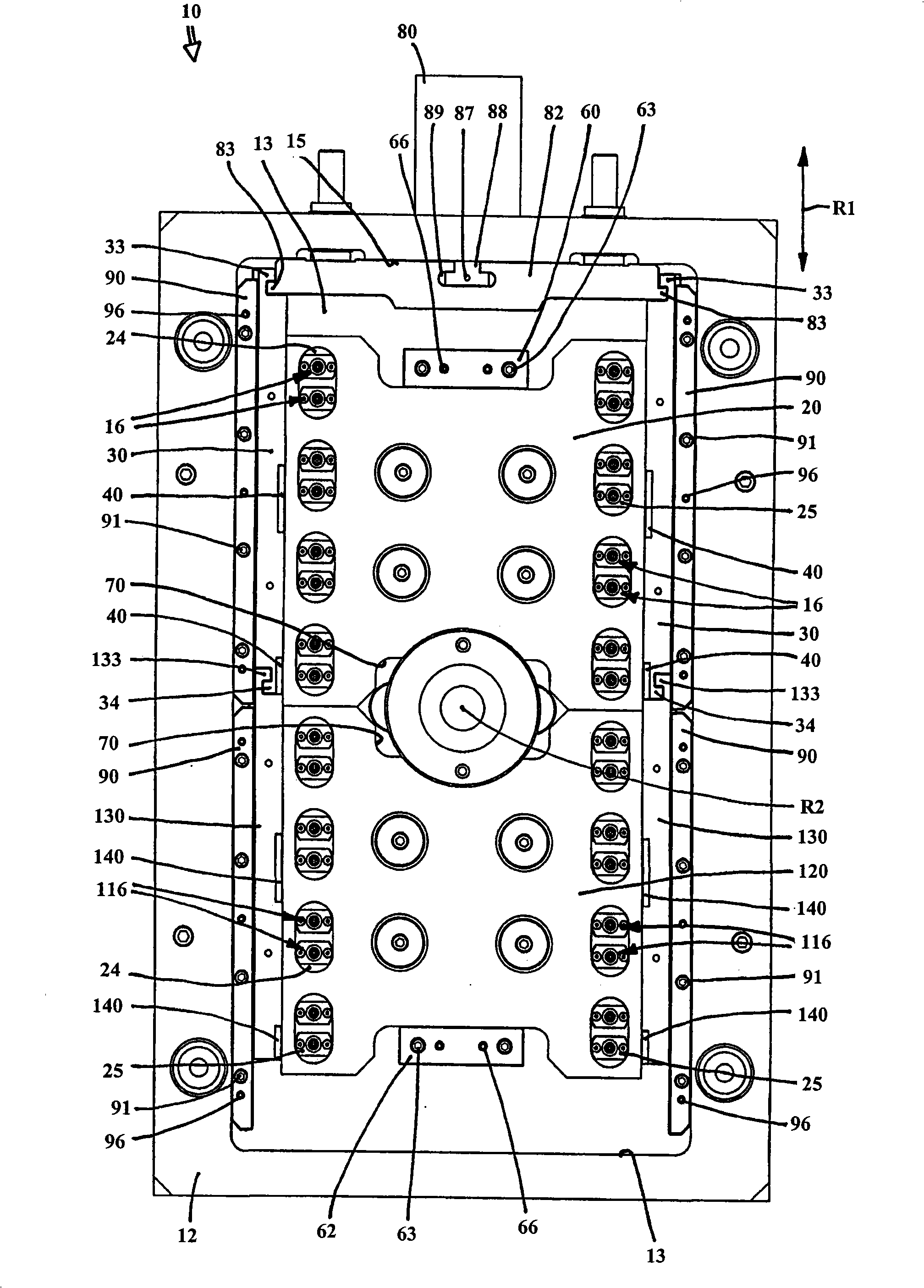

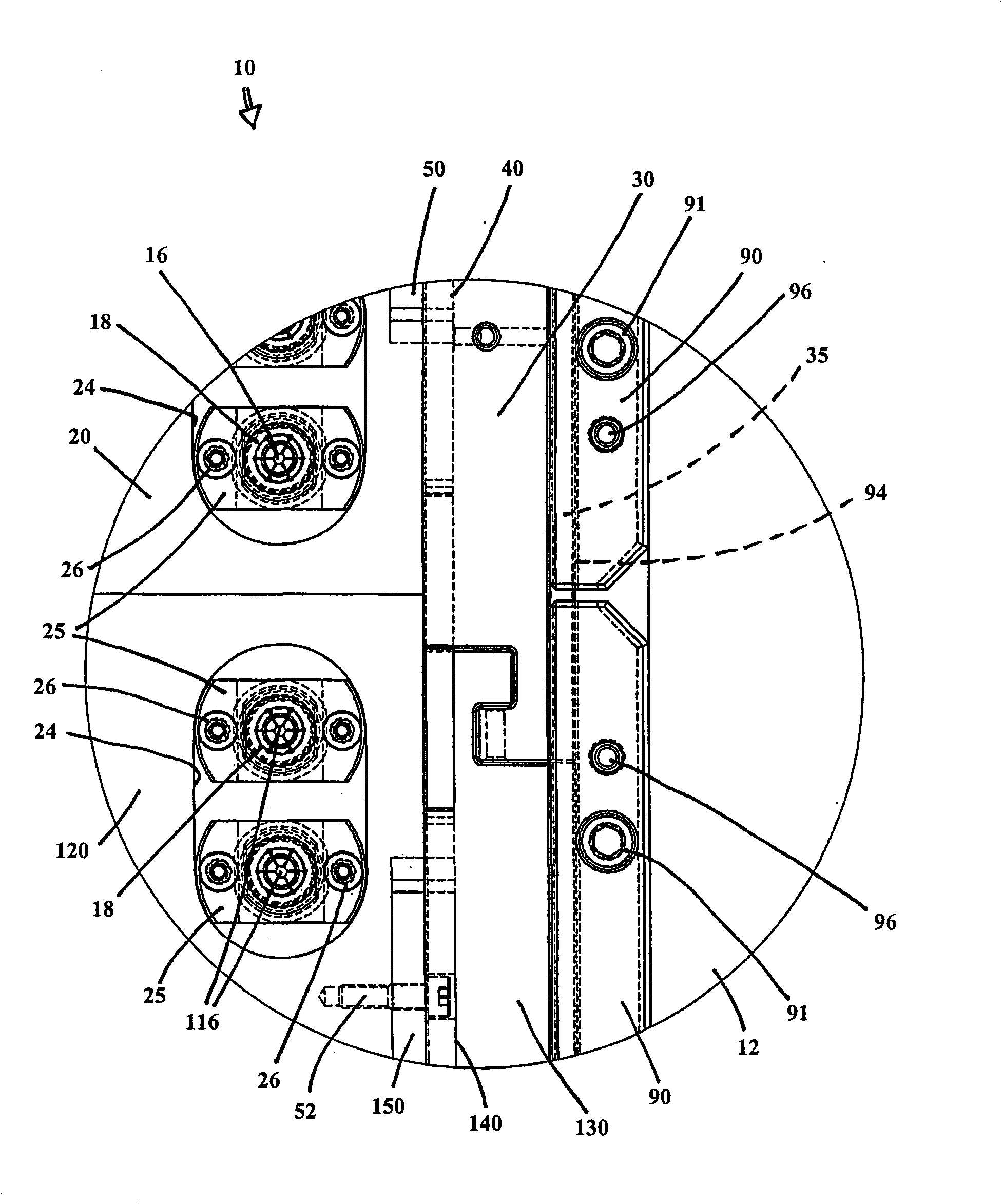

[0029] figure 1 The actuating device, indicated overall at 10, is used for actuating a plurality of shut-off needles 16 in an injection molding unit (not further shown). The injection molding unit is used to produce molded parts from flowable materials such as molten plastic. For this purpose, several needle shut-off nozzles (also not shown in detail) are provided below the distribution plate (not shown). They feed the molten plastic to be processed to a separable mold insert (likewise not shown), the casting opening of which is periodically opened and closed by the closing pin 16 .

[0030] Above the distribution plate there is a tension plate 12 which is provided with a generally rectangular depression or recess 13 for accommodating the action device 10 . Hoses or lines for a flow medium which flows through the spreader plate 12 in bores (not shown) can be connected via the connections 11 . The tensioning plate and the operating device 10 are thus always optimally tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com