Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduce cogging force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

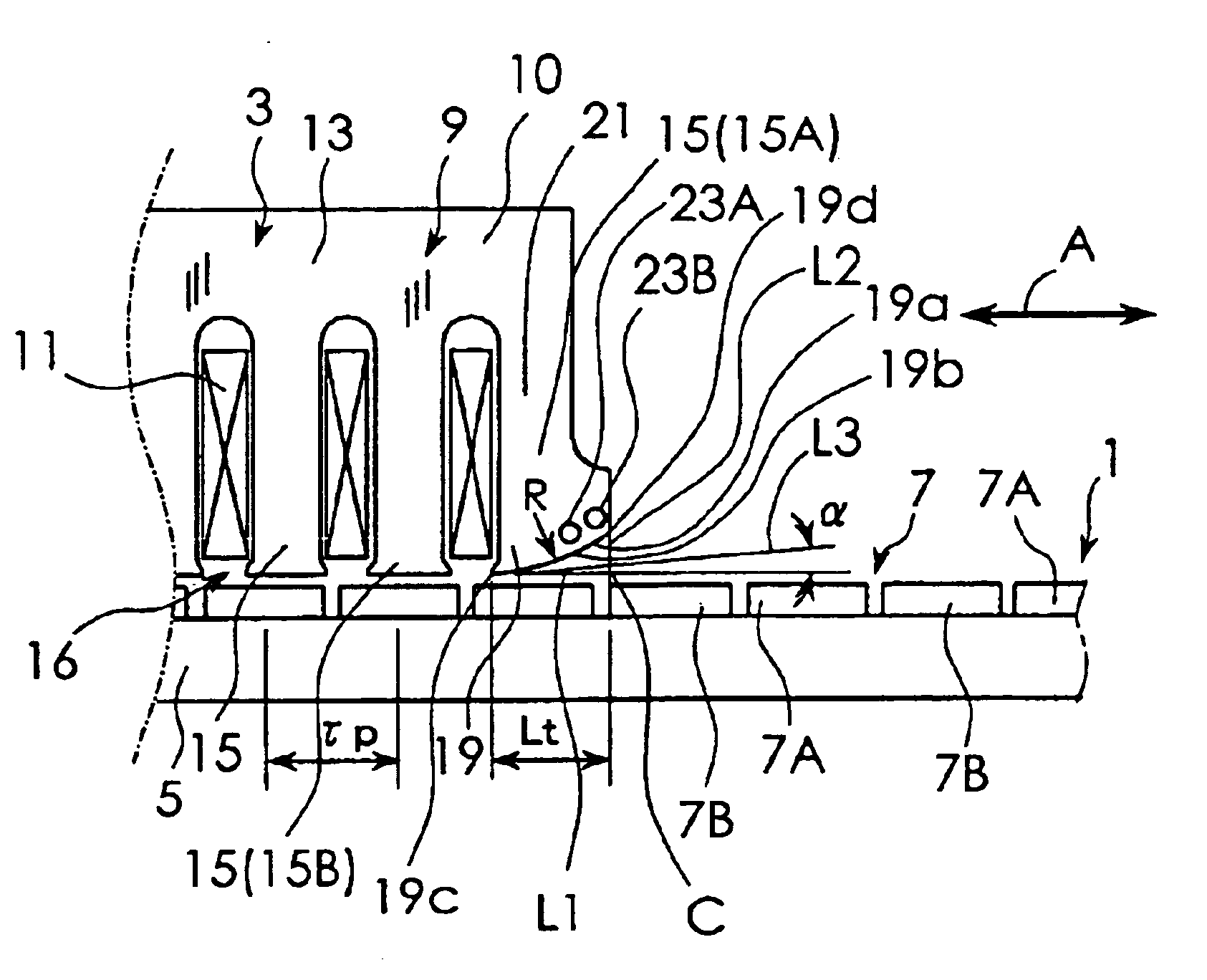

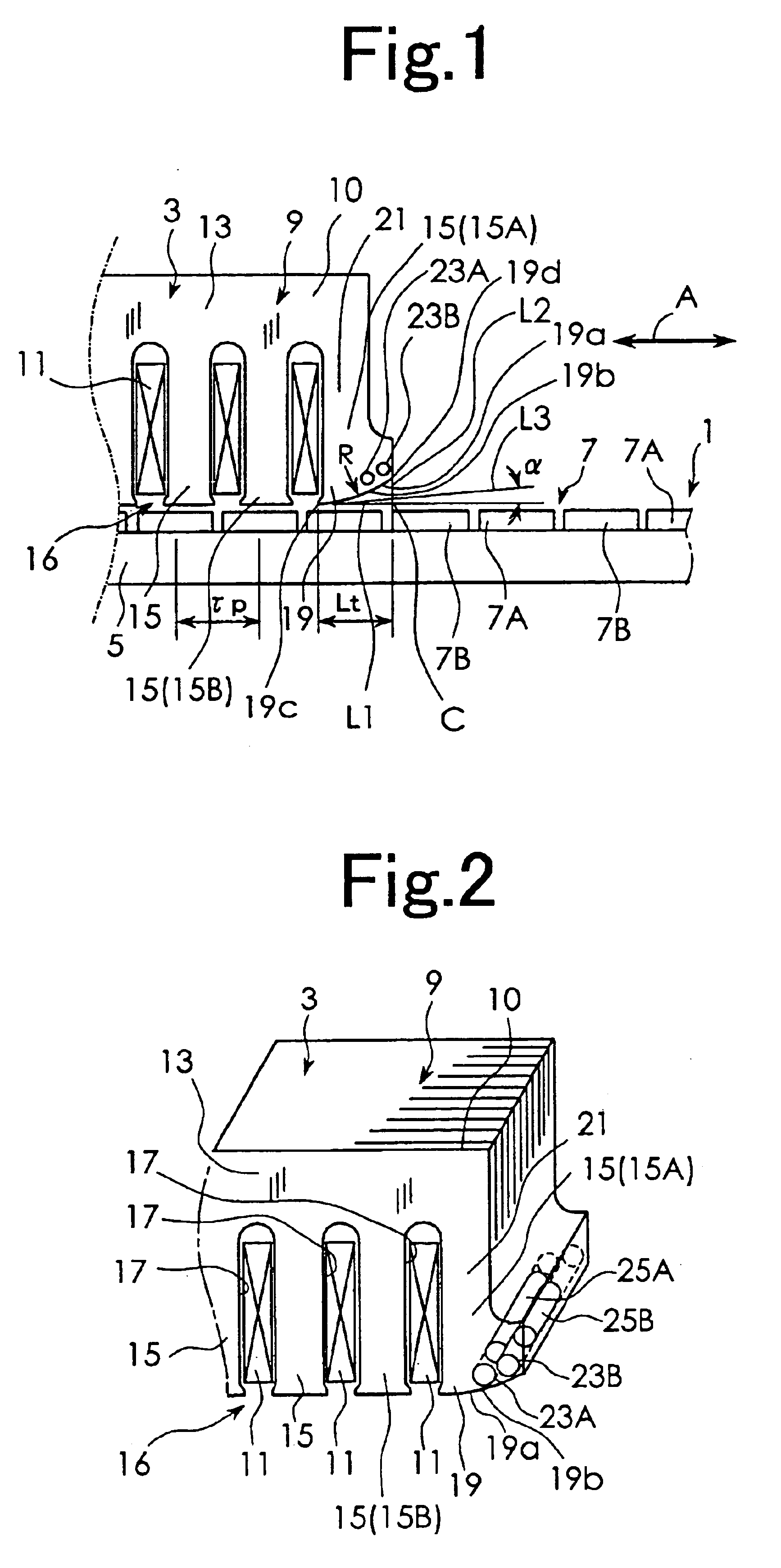

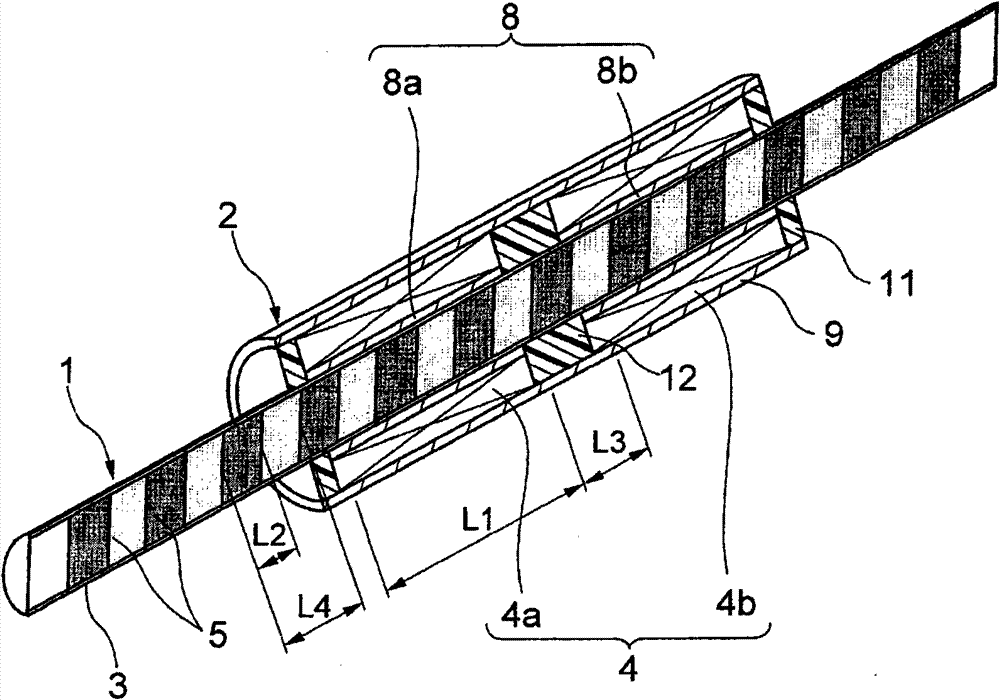

Linear motor for use in machine tool

InactiveUS20060012252A1High precision machiningReduce cogging forceMagnetic circuitMechanical energy handlingLaser processingElectric machine

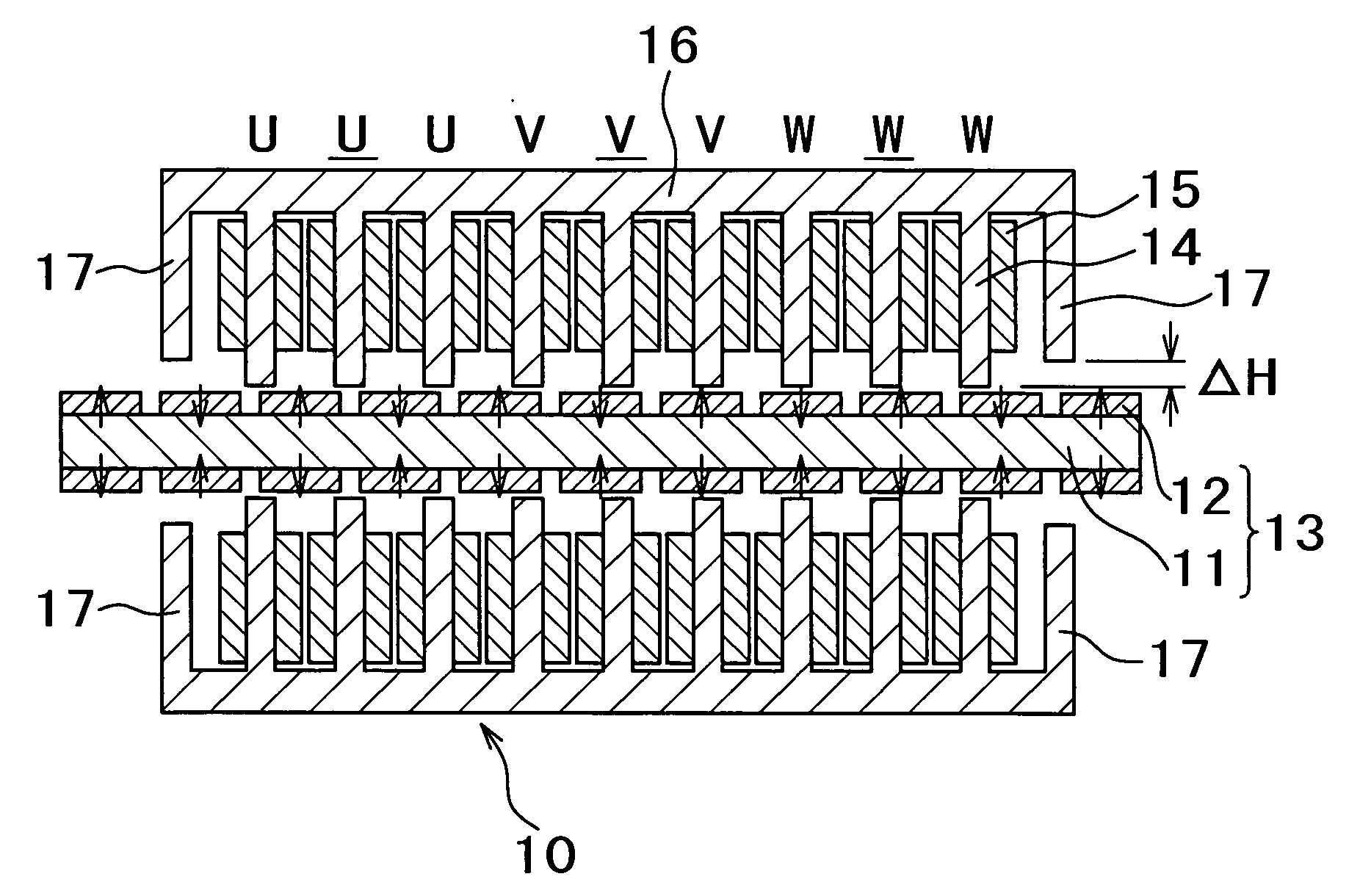

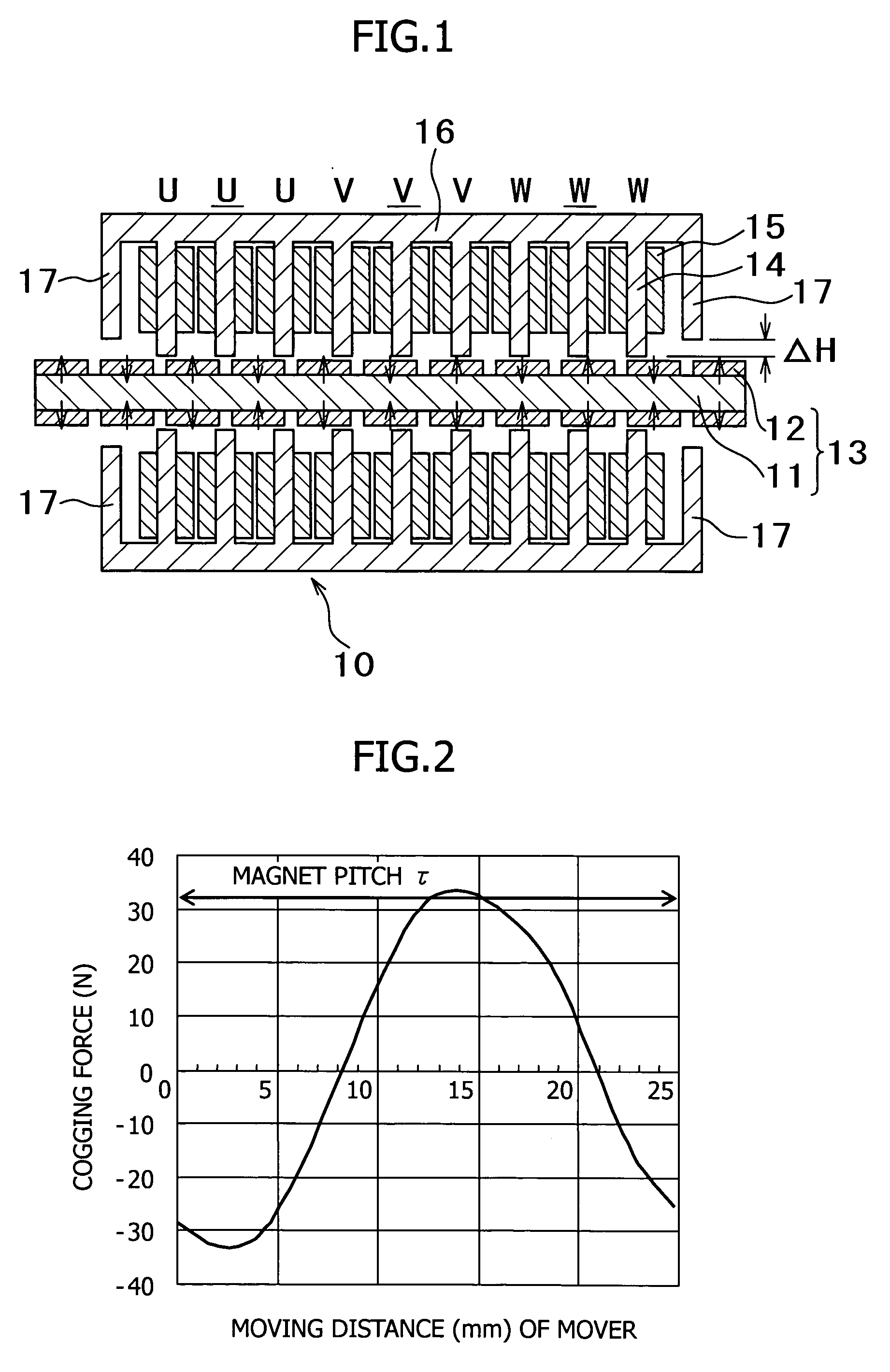

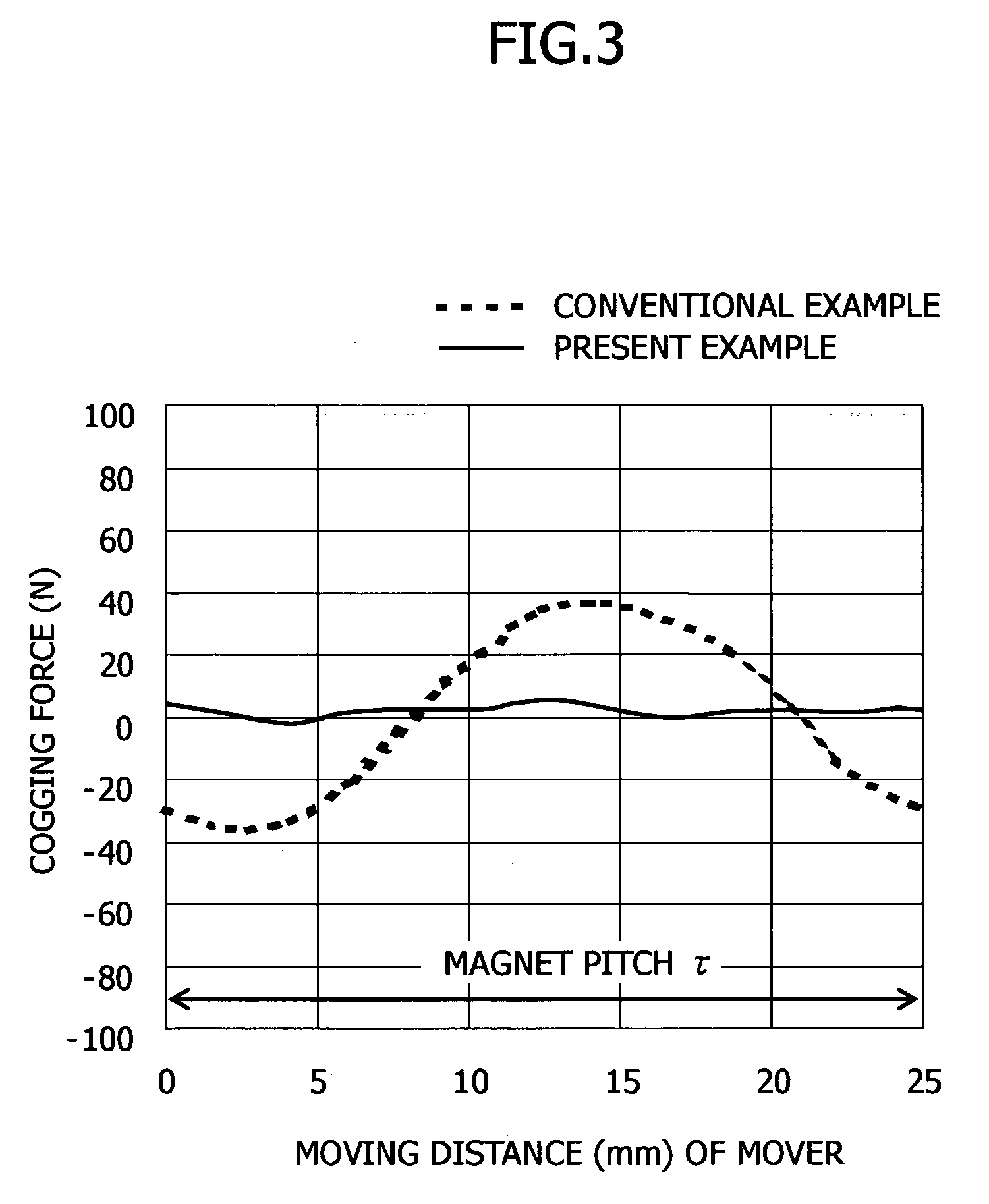

The invention is a linear motor that improves the processing speed of machine tools is also a linear motor with significantly reduced cogging force, with which high-speed and high-accuracy processing can be realized. More specifically, the invention is a linear motor for use in a machine tool comprising a stator in which a plurality of permanent magnets having the same shape are mounted on both faces of a plate-like yoke at even intervals such that the permanent magnets have polarities being perpendicular to a direction in which a pair of movers move and alternating in the moving direction; the movers in which armature cores wound with armature coils are disposed such that the armature cores are opposed to the rows of the permanent magnets on the both faces of the stator; and magnetic cores that are disposed on both ends of the movers such that the distance between the magnetic cores and the rows of the permanent magnets is longer than that between the armature cores and the rows of the permanent magnets. Moreover, provided is a laser processing machine in which the above-mentioned permanent magnet type linear motor is used for a three-dimensional moving mechanism.

Owner:SHIN ETSU CHEM IND CO LTD

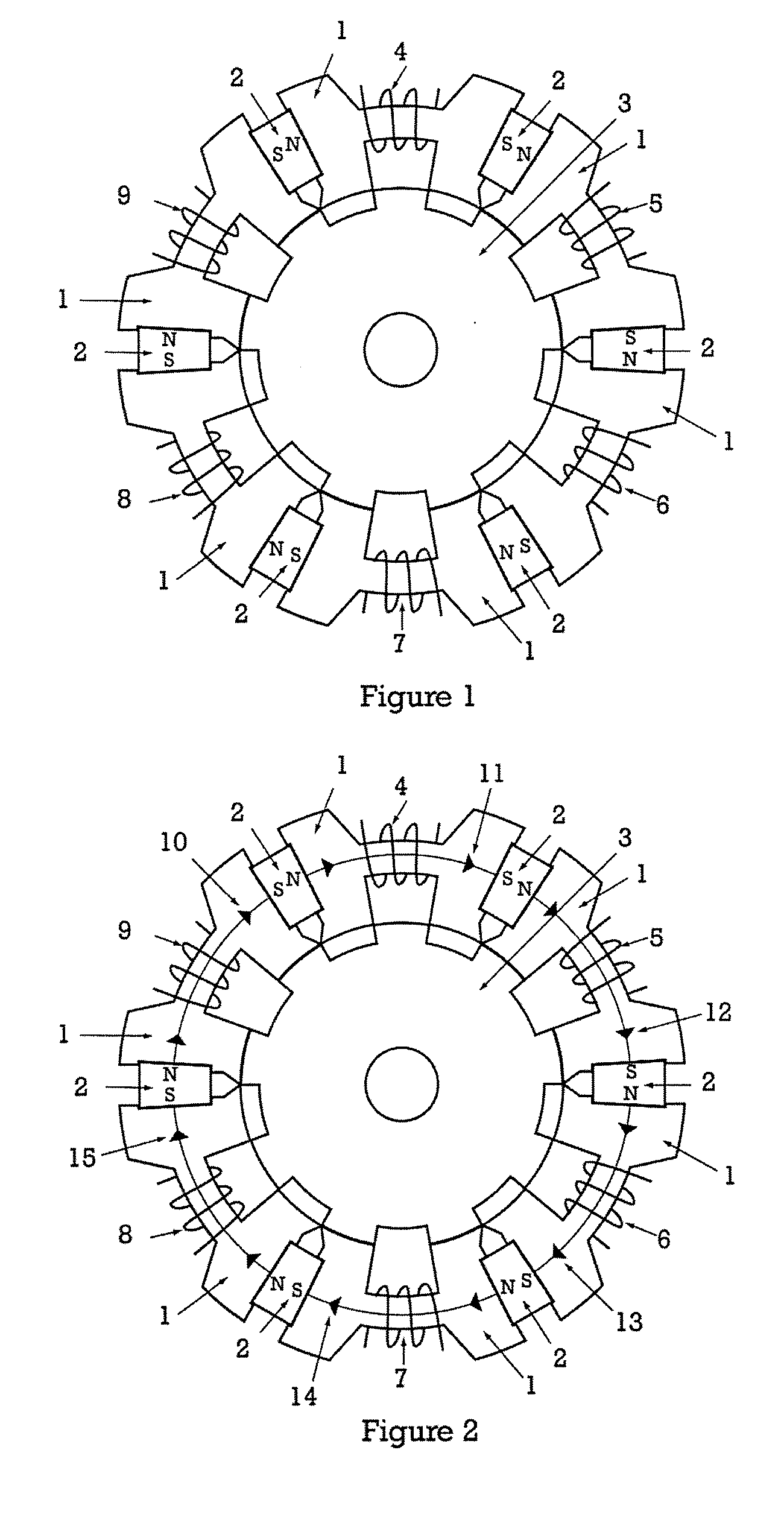

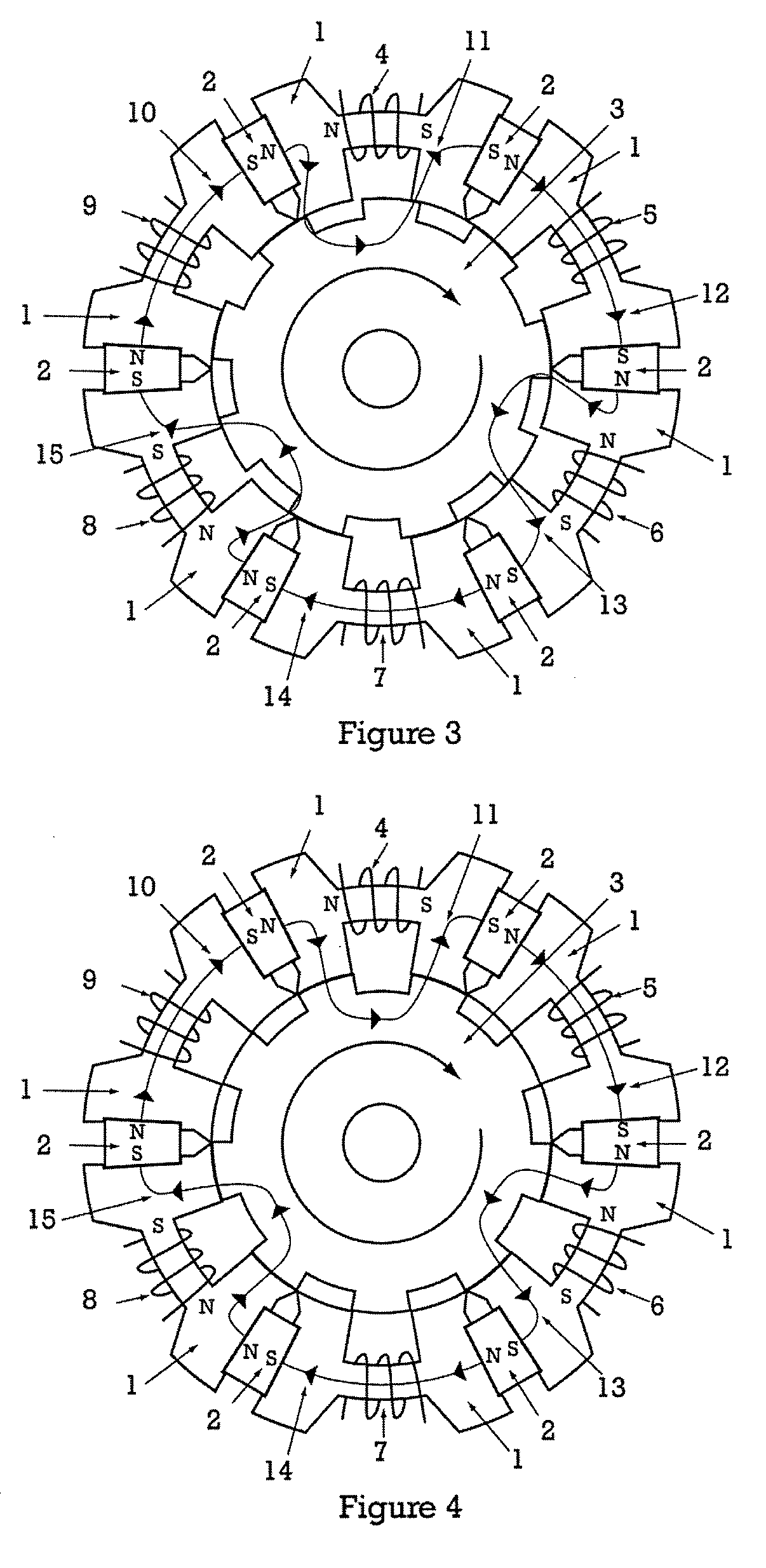

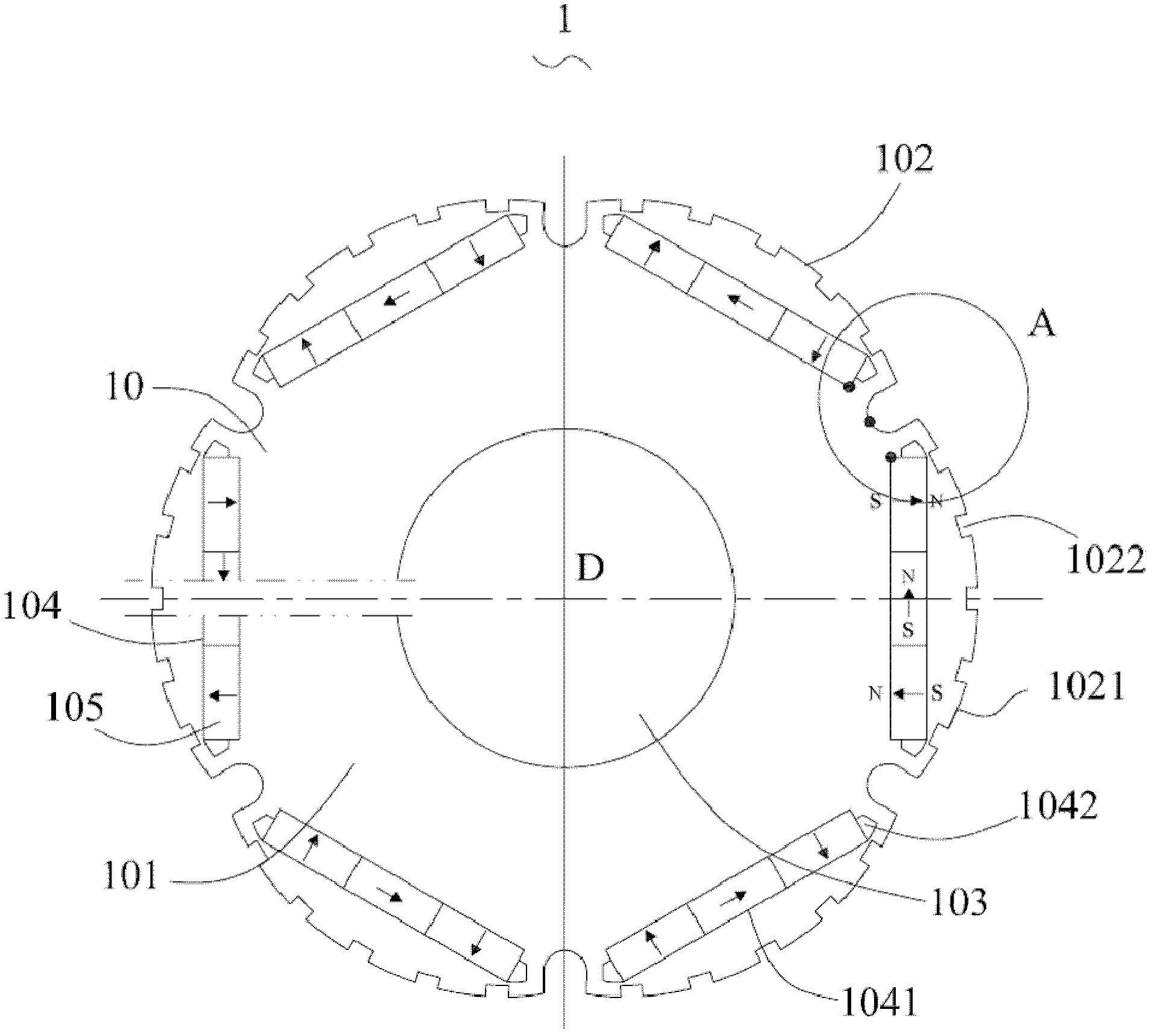

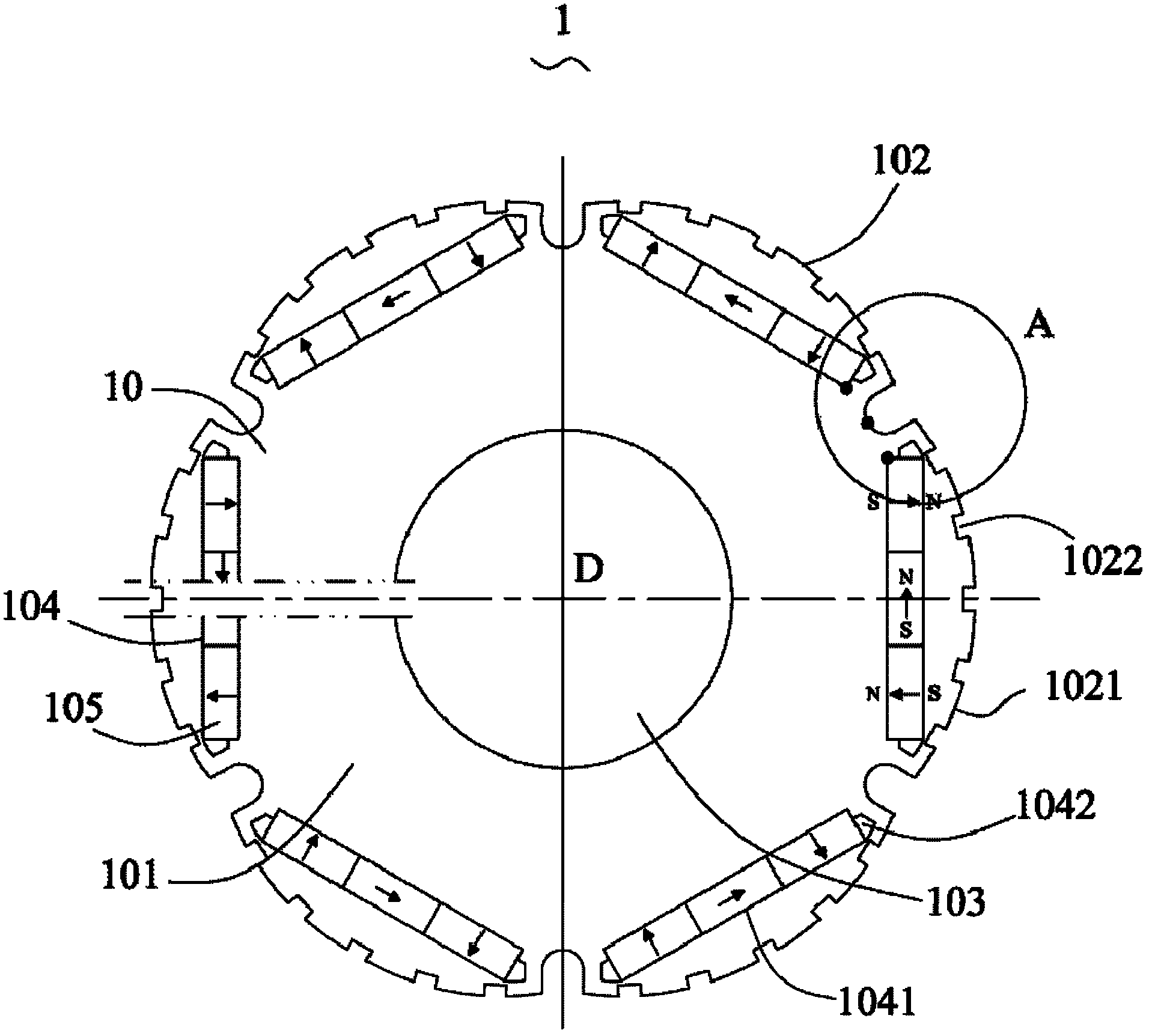

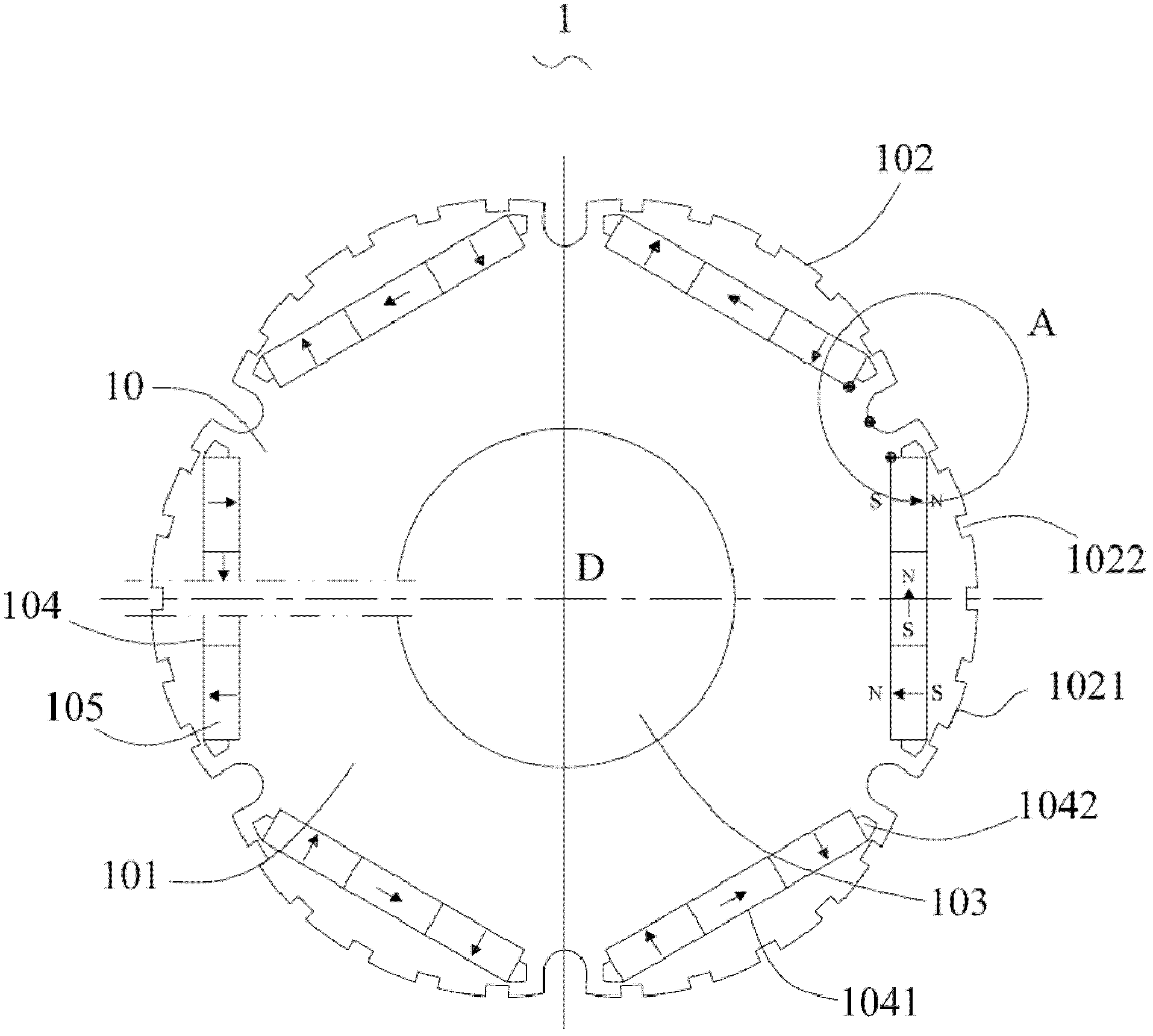

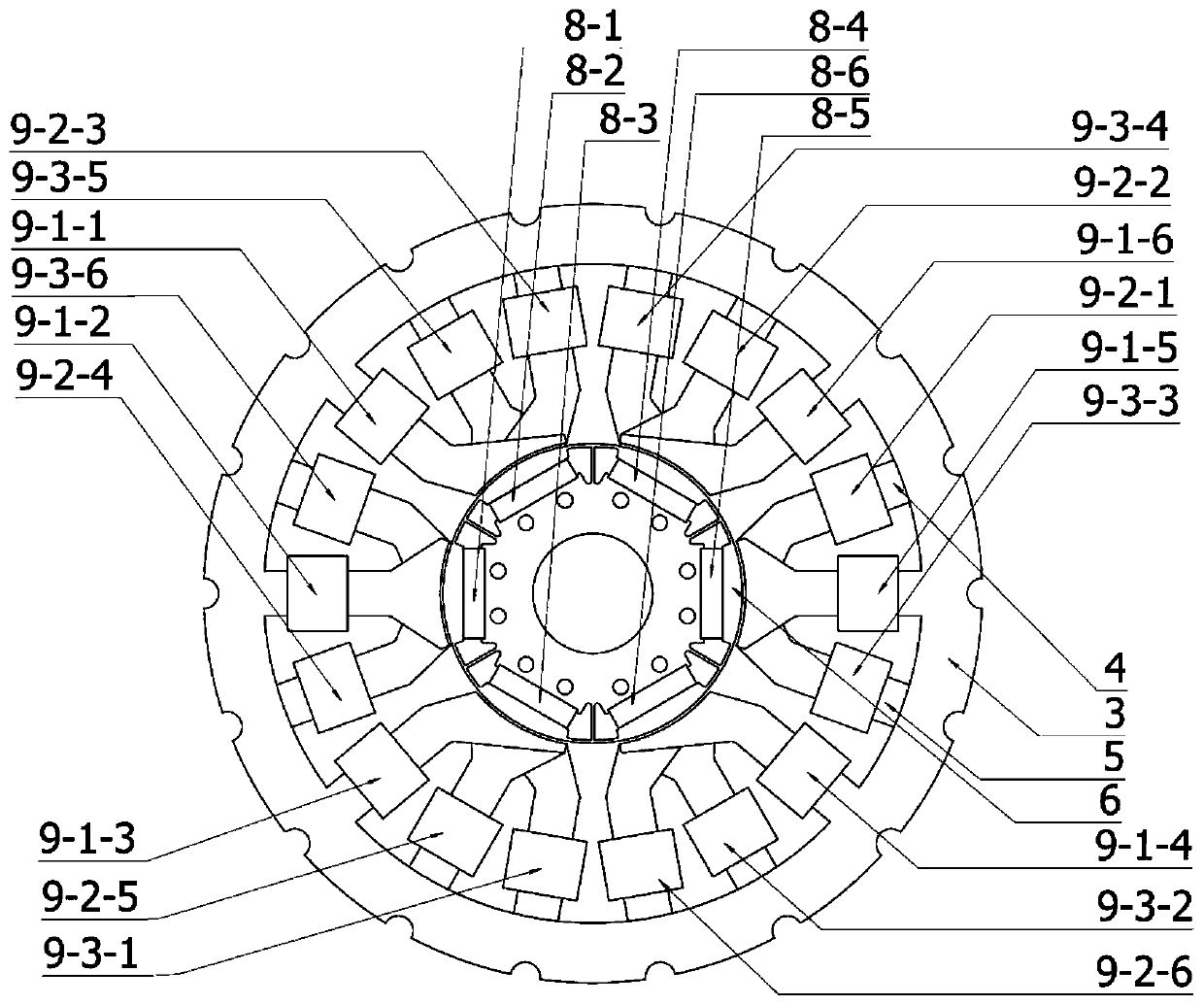

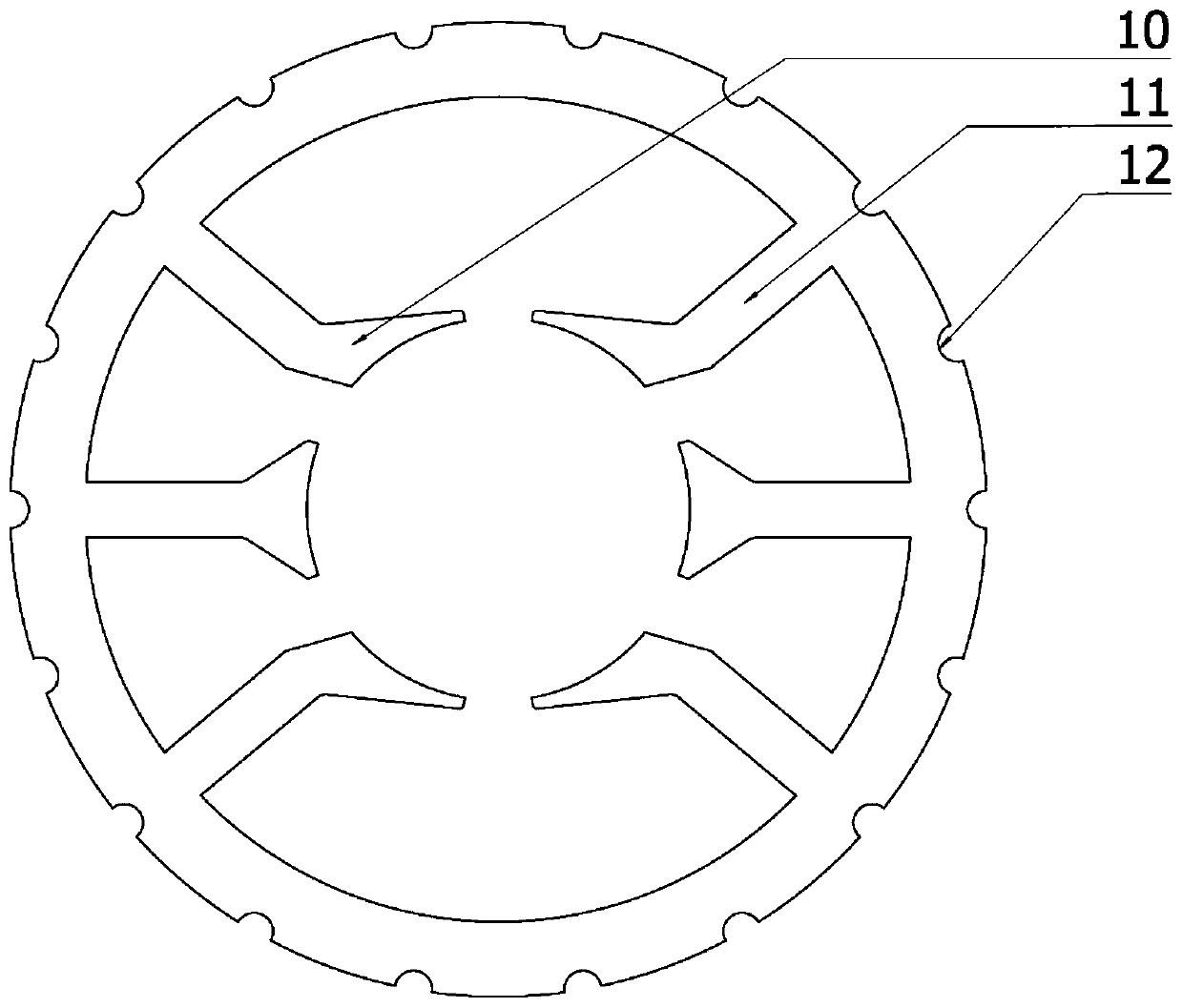

Hybrid permanent magnet motor

ActiveUS20090160391A1Reduce cogging forceImprove efficiencySynchronous generatorsElectronic commutation motor controlStable statePermanent magnet motor

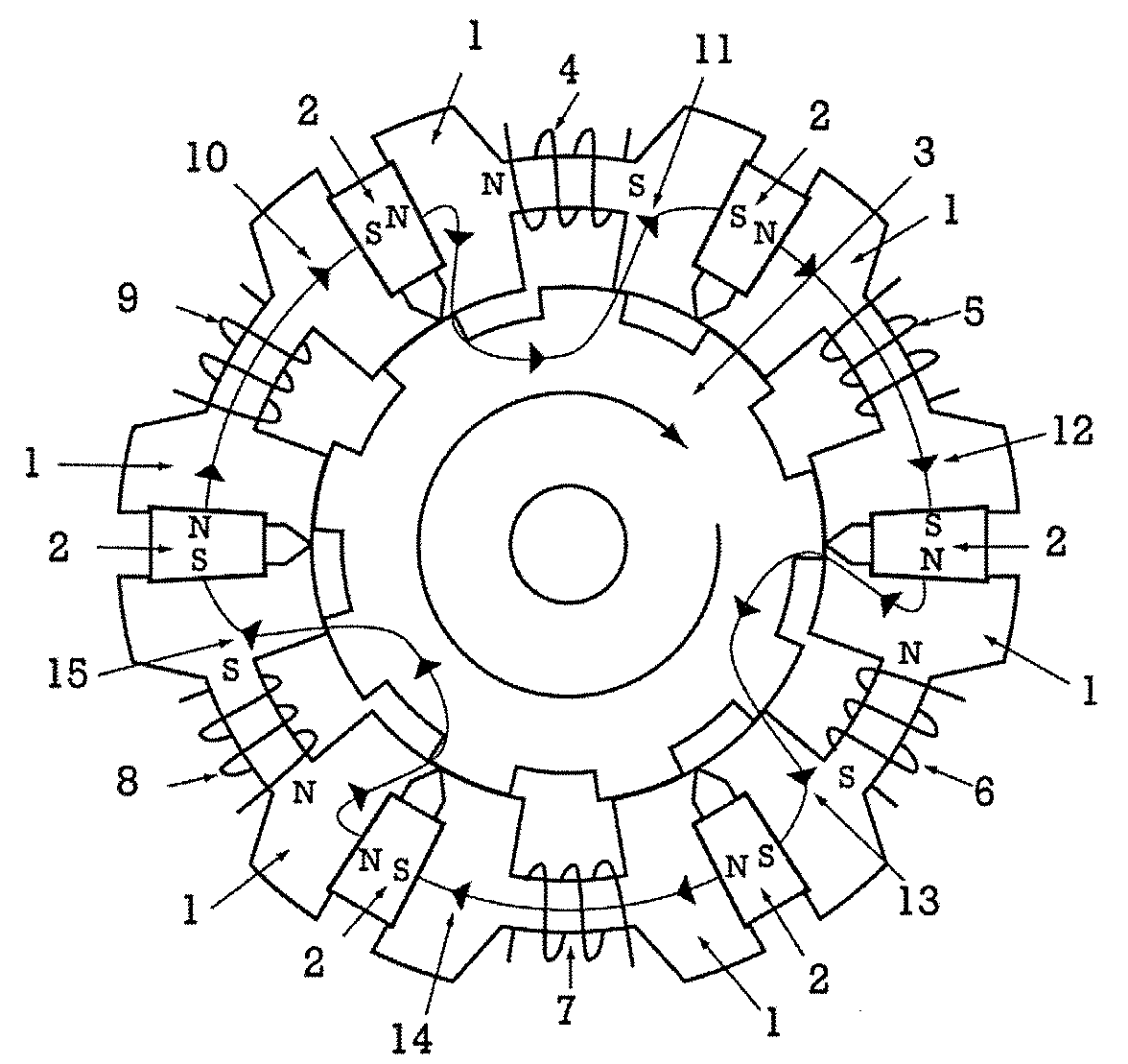

An electro-mechanical device that functions as a motor or a generator and methods for constructing and using such electro-mechanical device are provided. The electro-mechanical device features permanent magnets placed in a magnetically attracting manner and inter-dispersed between control coils. The control coils are energized to create a flux opposing the flux of the permanent magnets and to create a rotational torque on the poles of a salient pole rotor before those poles align with the poles of the energized control coil stator segment. Power can be generated by placing the flux of the control coils in a steady state and mechanically rotating the salient pole rotor. The electro-mechanical device provides little or no cogging forces, high-efficiency operation, and a high power density.

Owner:QM POWER

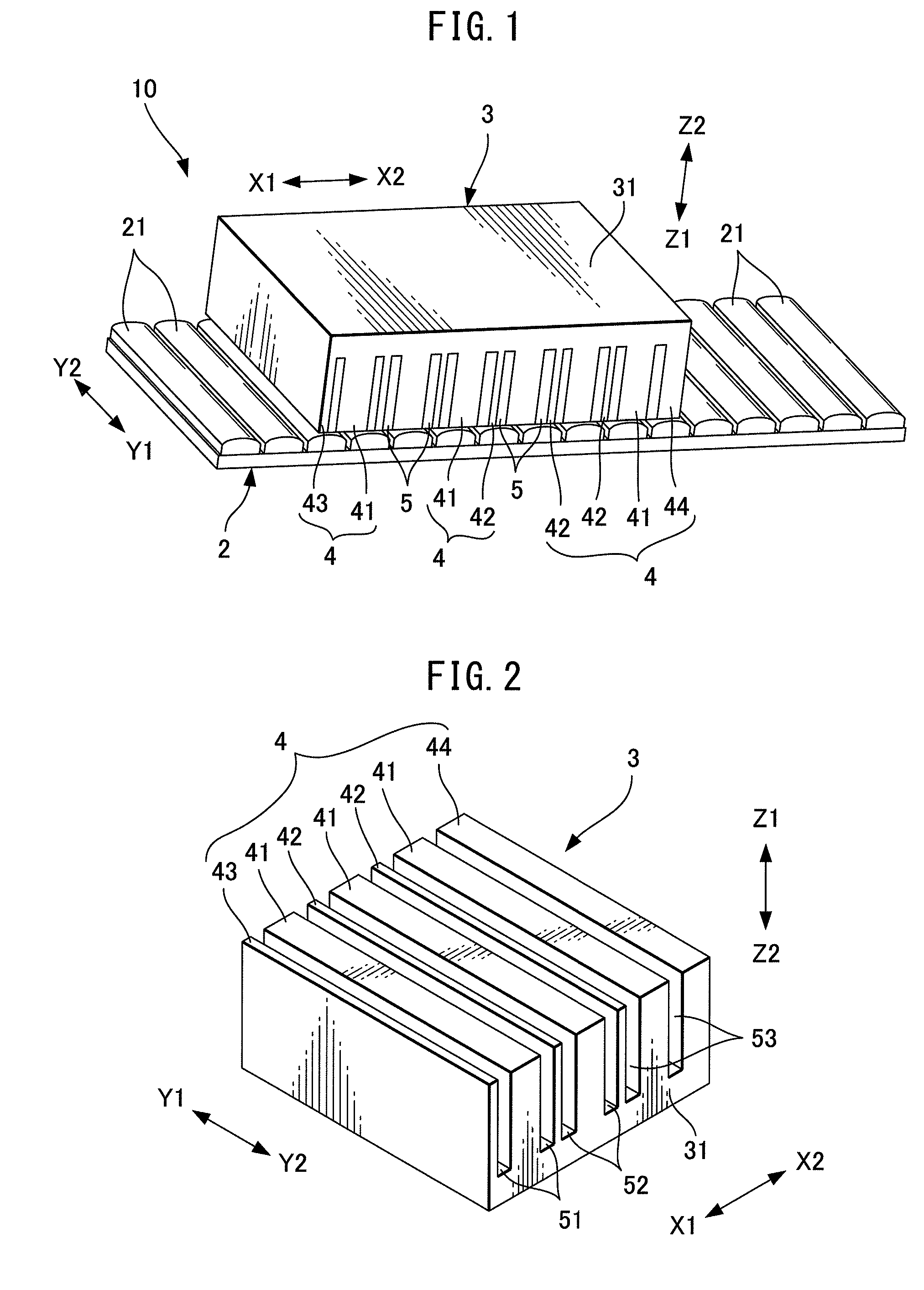

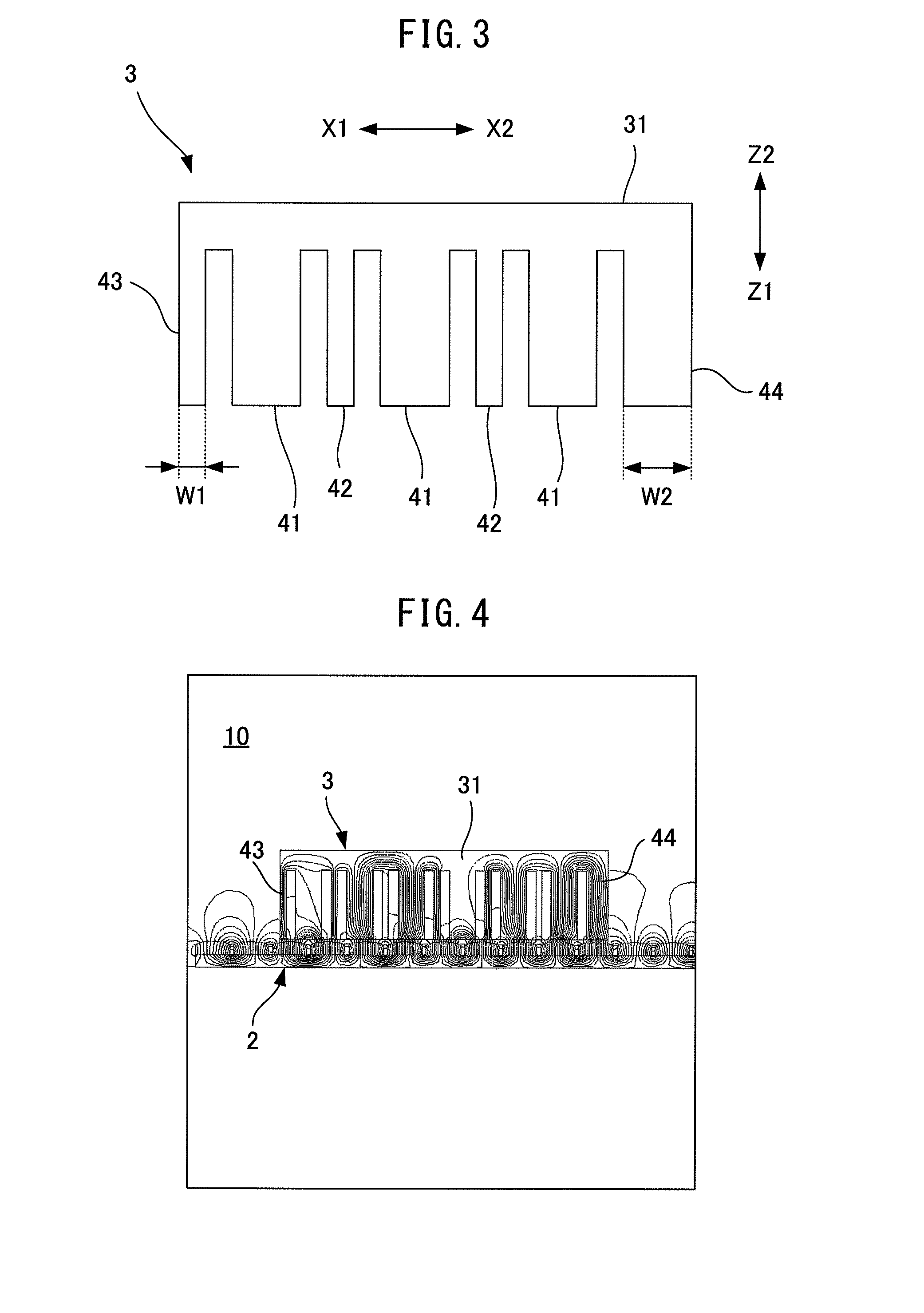

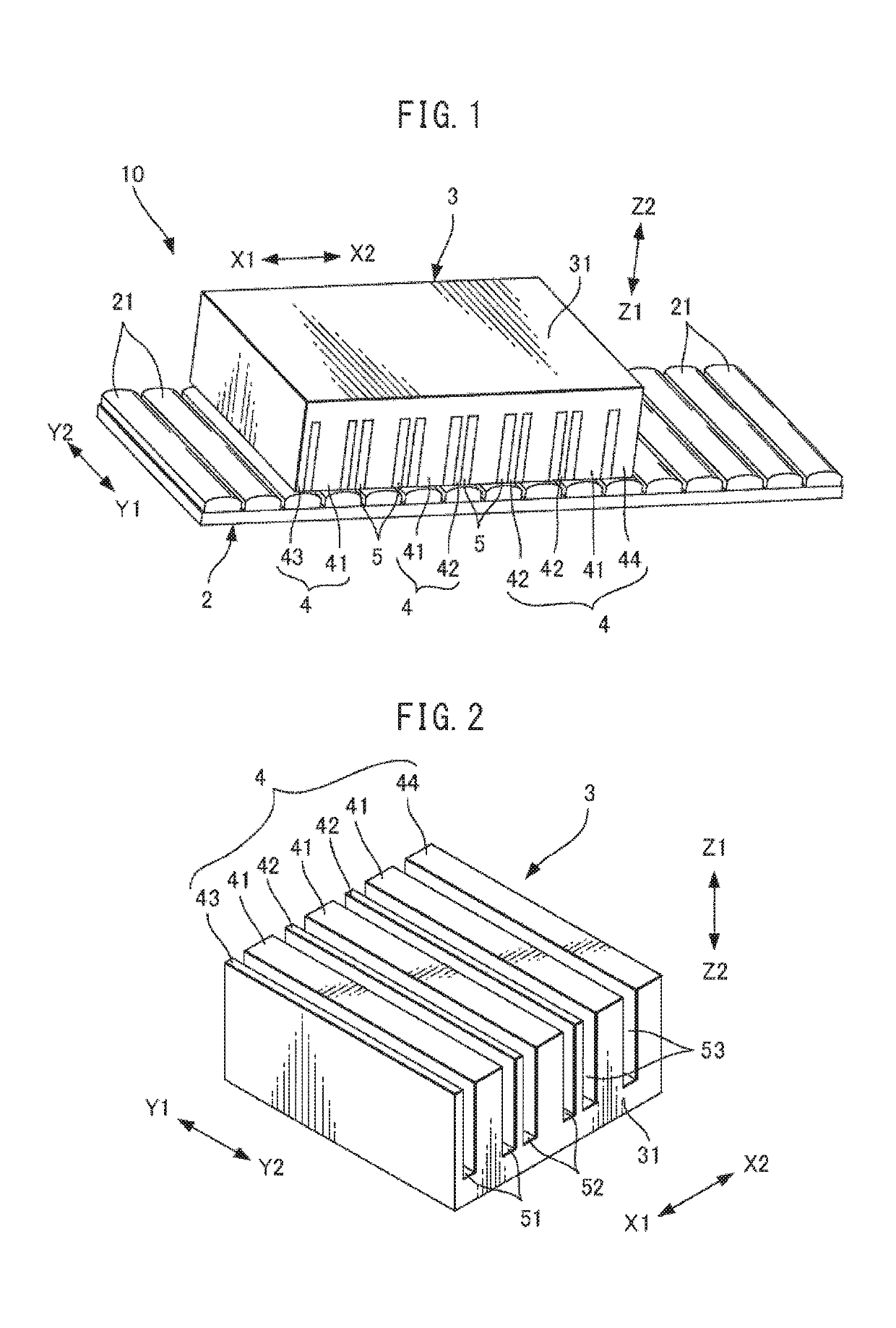

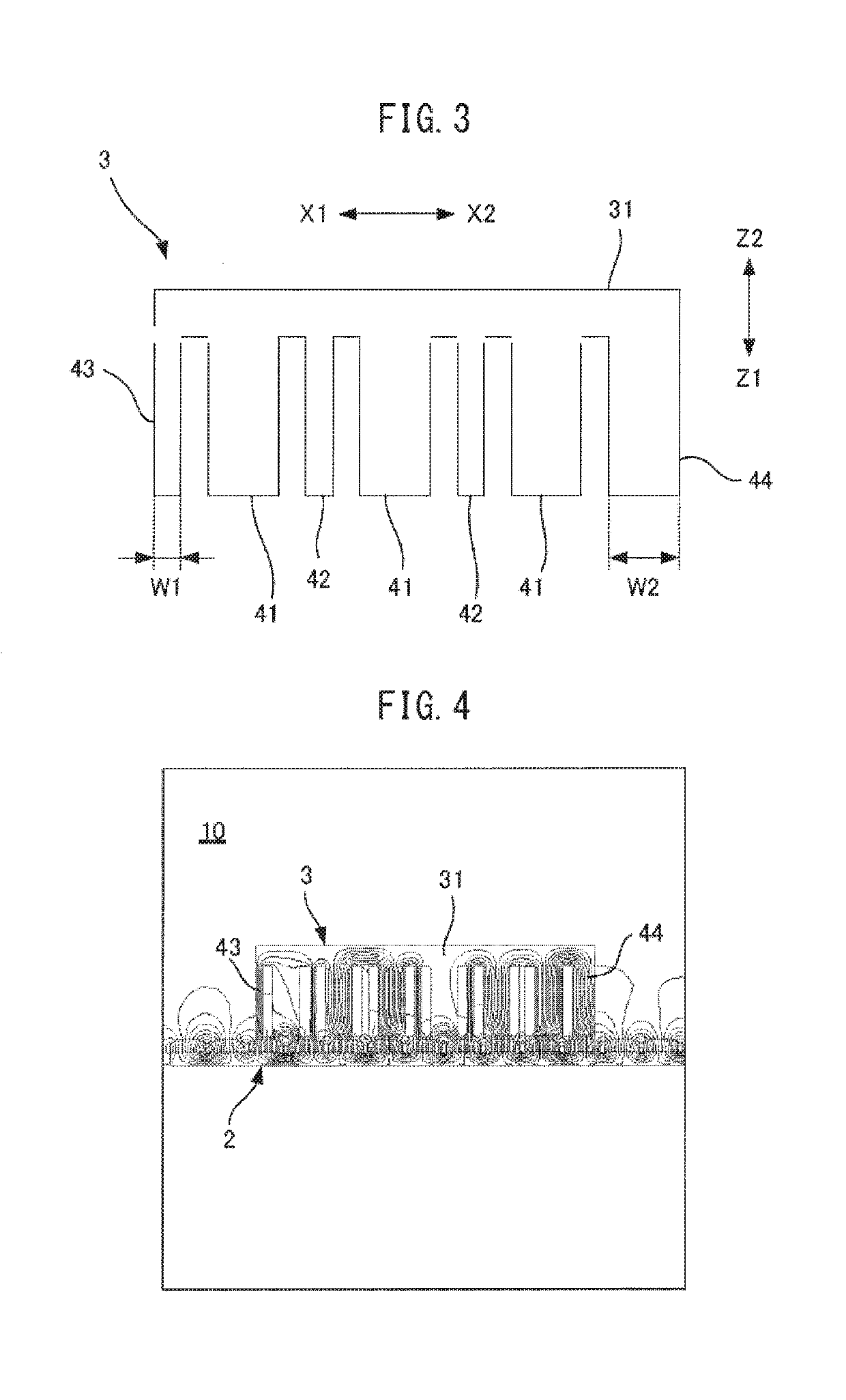

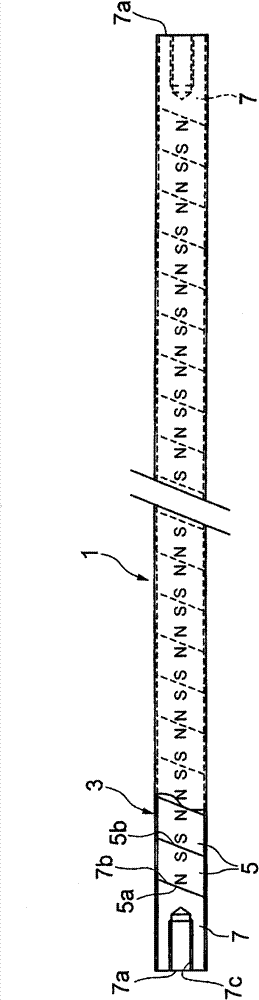

Linear motor with reduced cogging force

ActiveUS6949846B2Reduce cogging forceEasy to shapeManufacturing dynamo-electric machinesPropulsion systemsMagnetic polesEngineering

Owner:SANYO DENKI CO LTD

Linear motor for use in machine tool

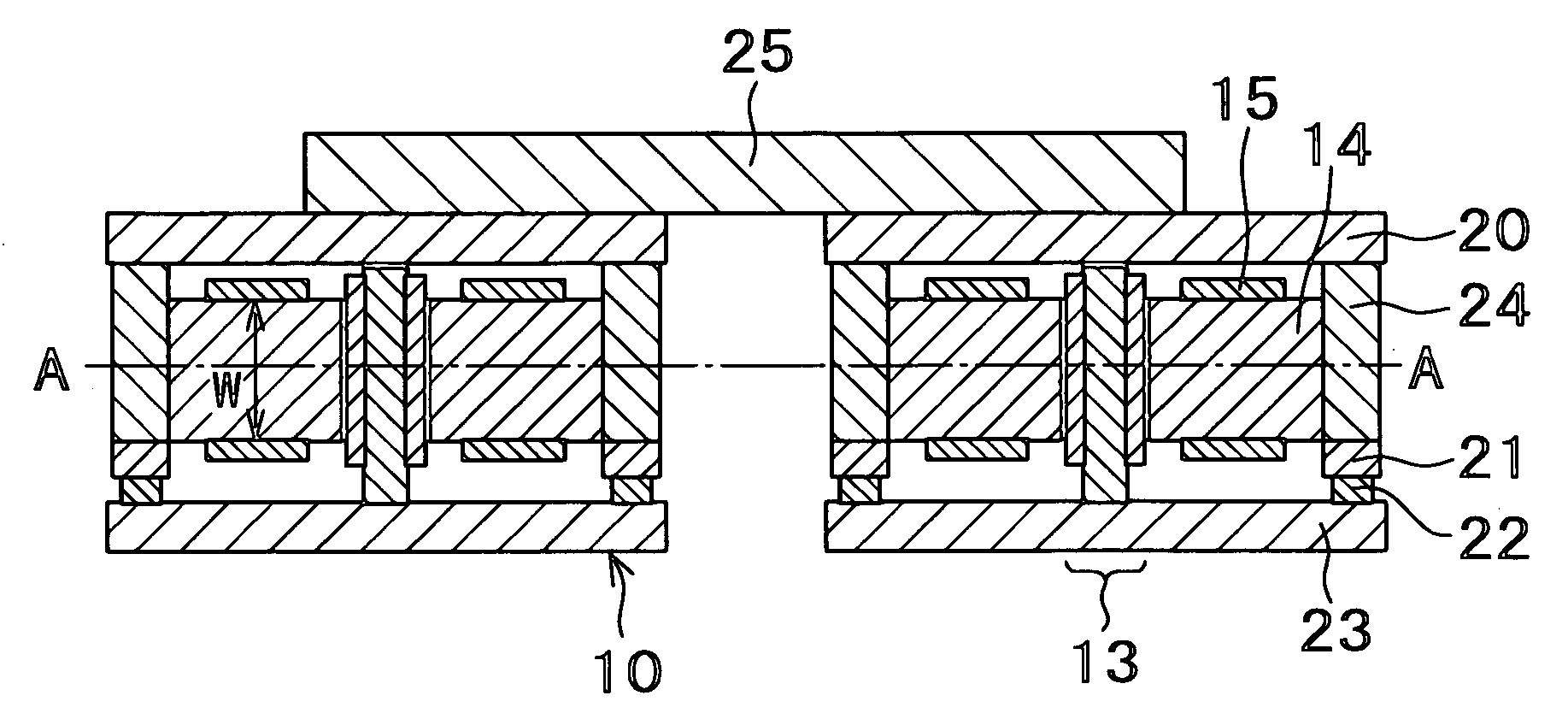

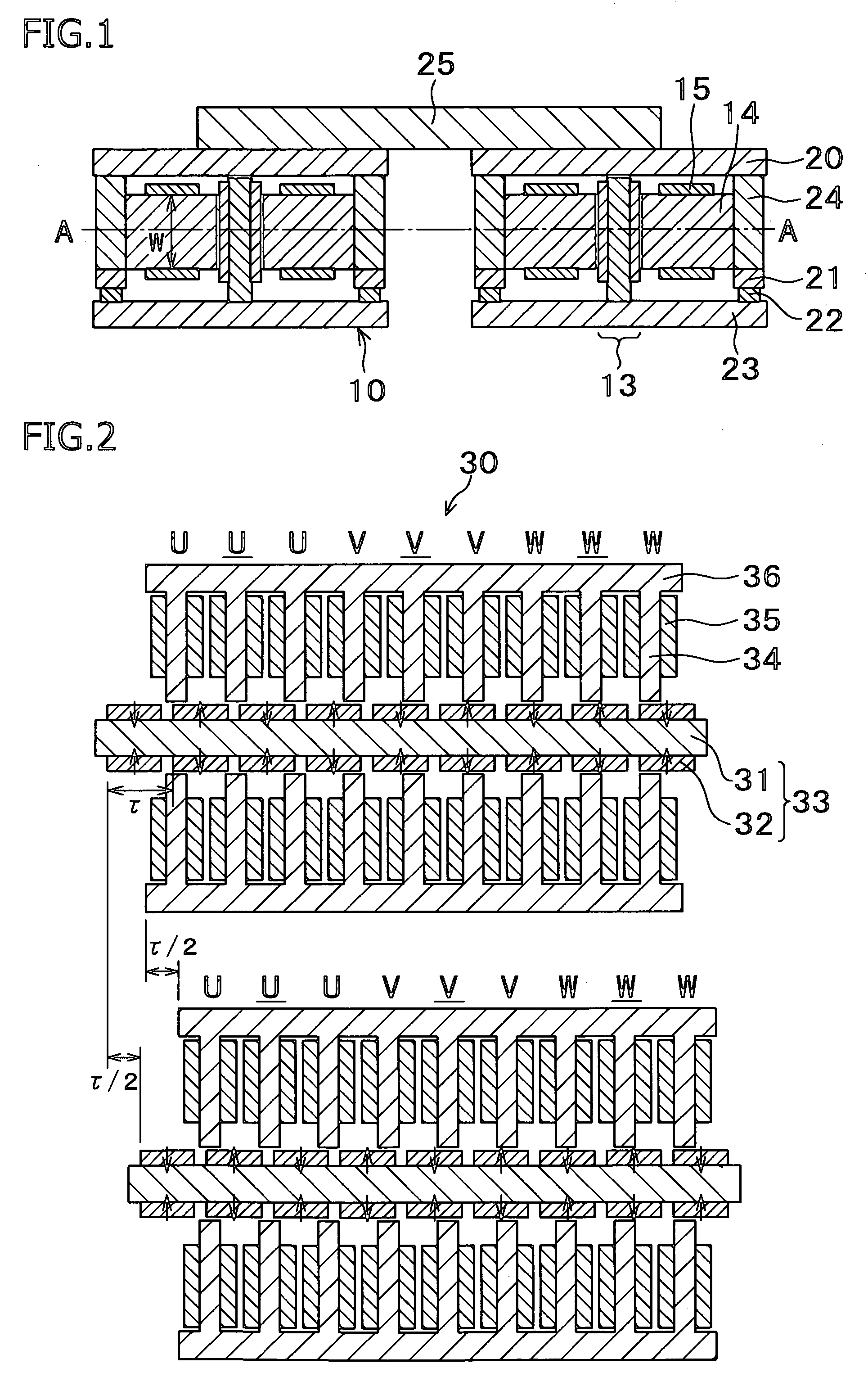

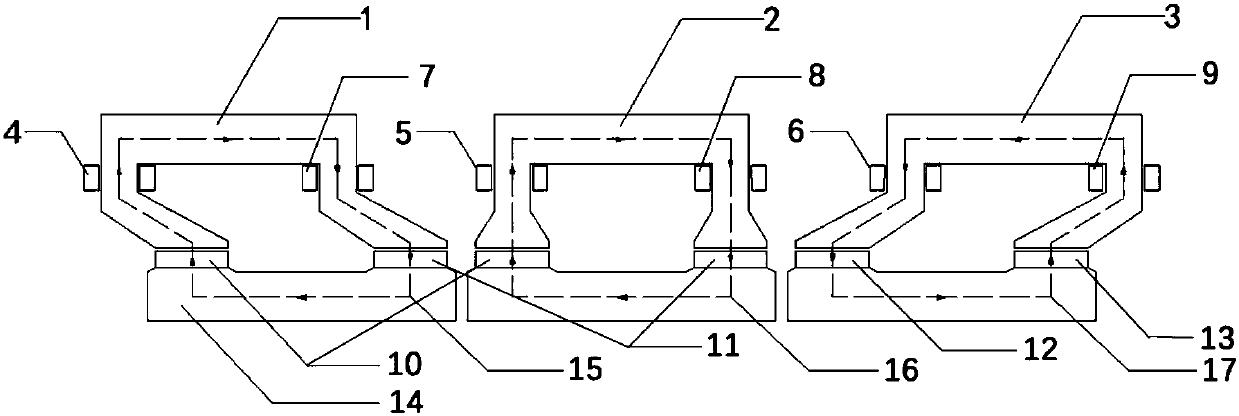

InactiveUS20060012251A1High speed machiningHigh precision machiningMagnetic circuitPropulsion systemsElectric machineElectrical polarity

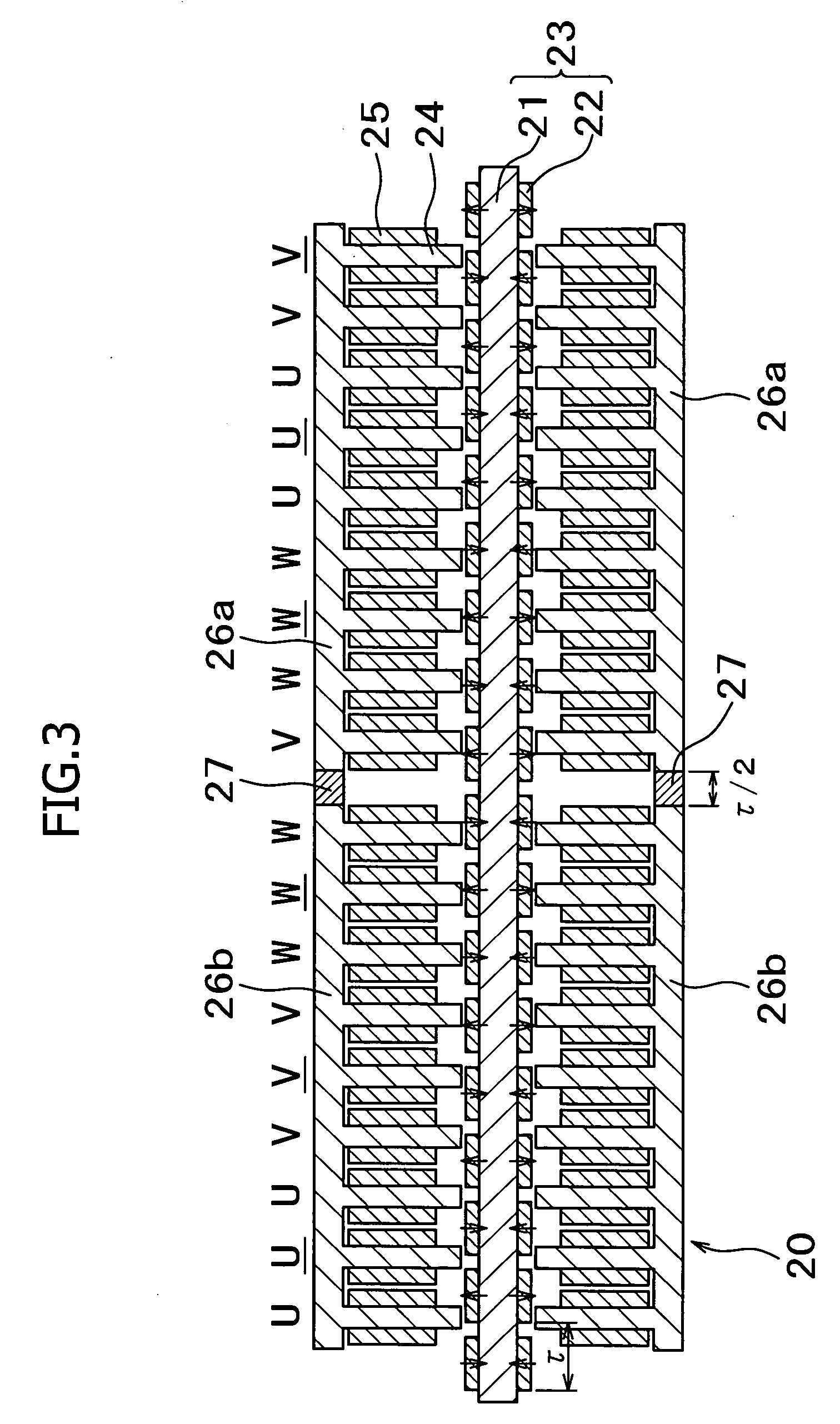

The invention is a linear motor that improves the processing speed of machine tools and is also a linear motor that can improve the thrust in order to achieve high acceleration. More specifically, the invention is a linear motor for use in a machine tool comprising linear motor units, each unit comprising a stator in which a plurality of permanent magnets having the same shape are mounted on both faces of a plate-like yoke at even intervals such that the permanent magnets have polarities being perpendicular to a direction in which a pair of movers move and alternating in the moving direction; and the movers in which armature cores wound with armature coils are disposed such that the armature cores are opposed to the rows of the permanent magnets on the both faces of the stator, wherein the linear motor units are disposed in parallel. When the number of the linear motor units is N and a magnet pitch, which is the sum of the width of each of the permanent magnets and the distance between adjacent permanent magnets, is τ, the linear motor units are preferably disposed such that the linear motor units are displaced in the moving direction of the movers by a natural number multiple of τ / N.

Owner:SHIN ETSU CHEM IND CO LTD

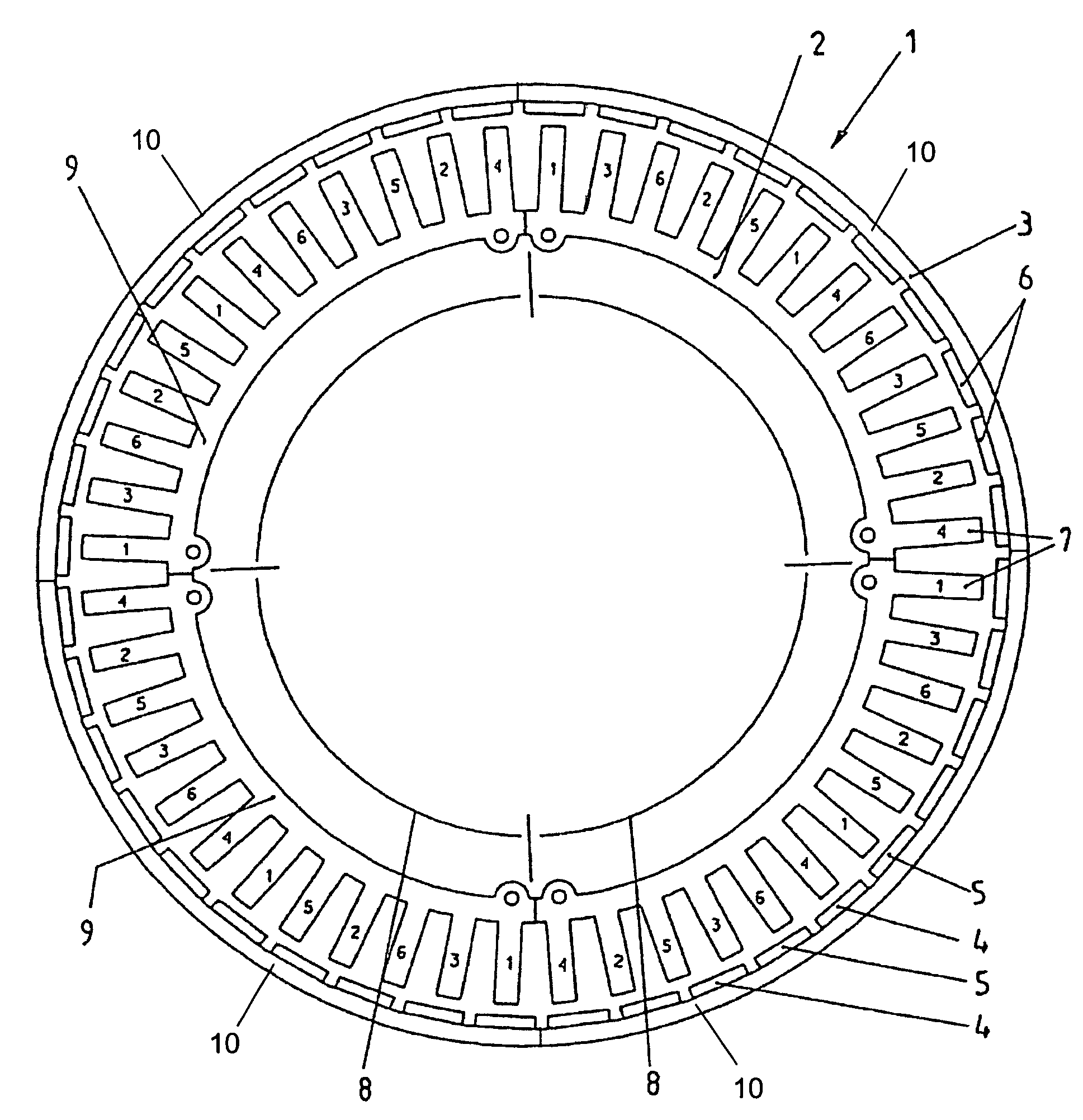

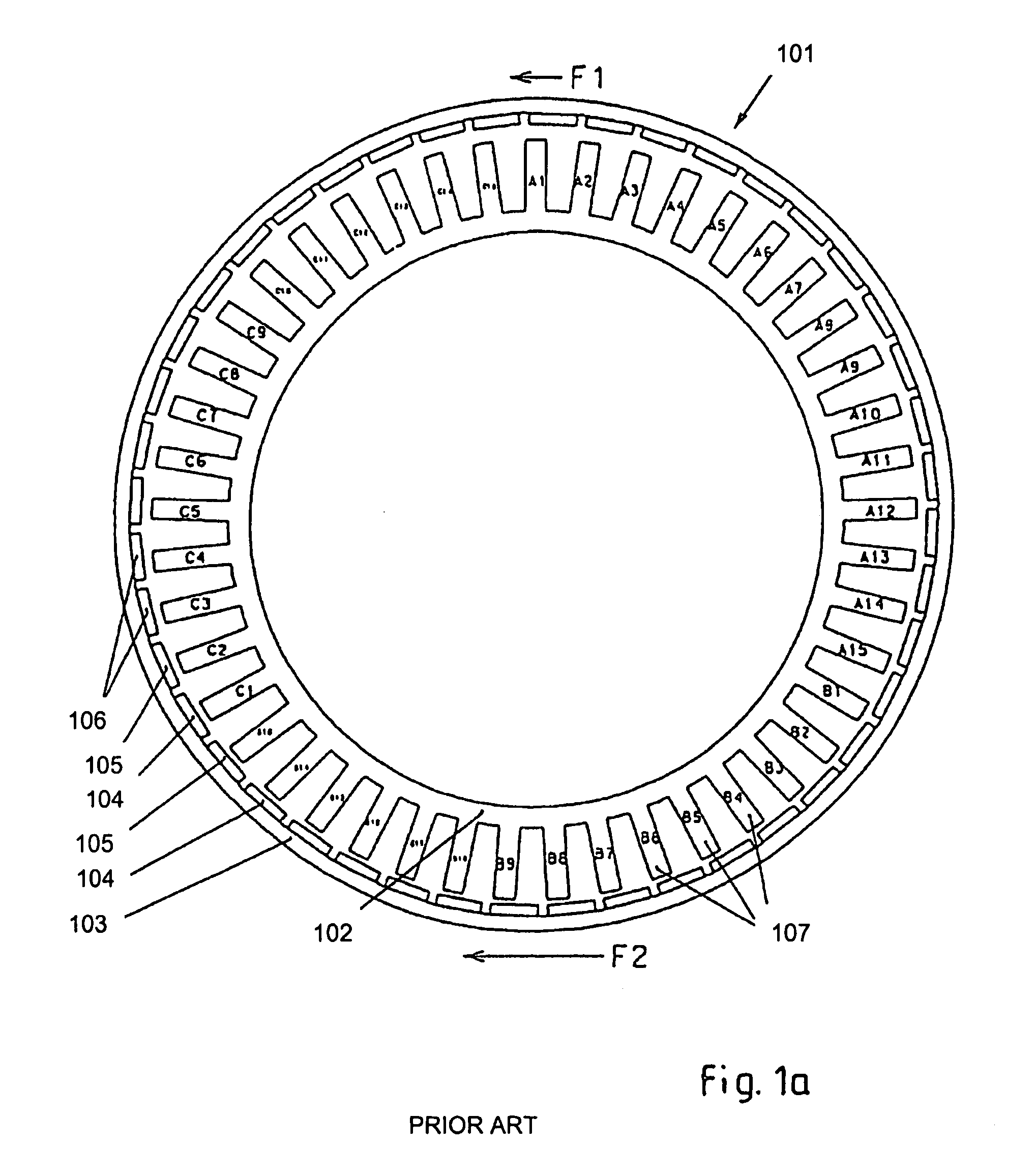

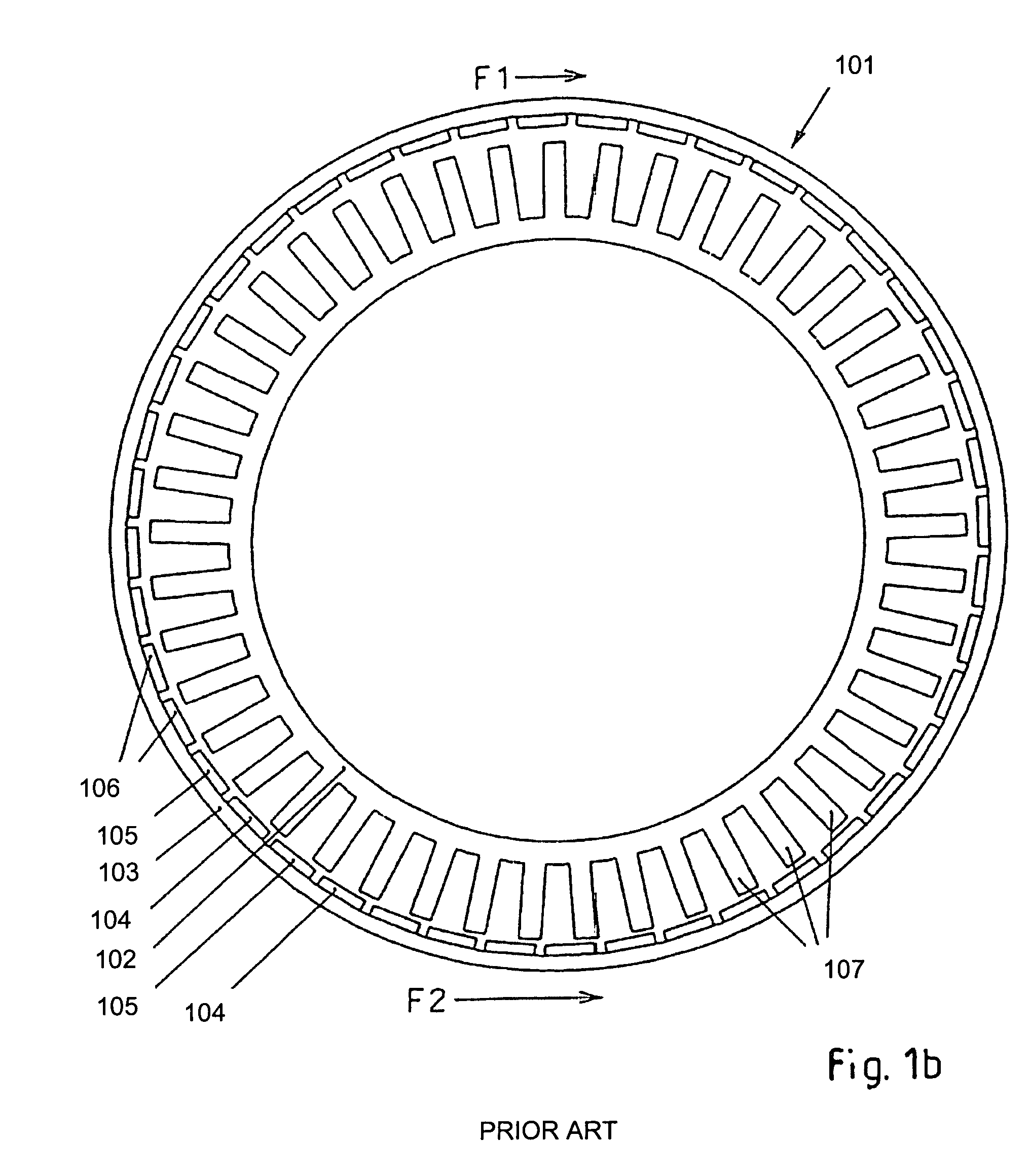

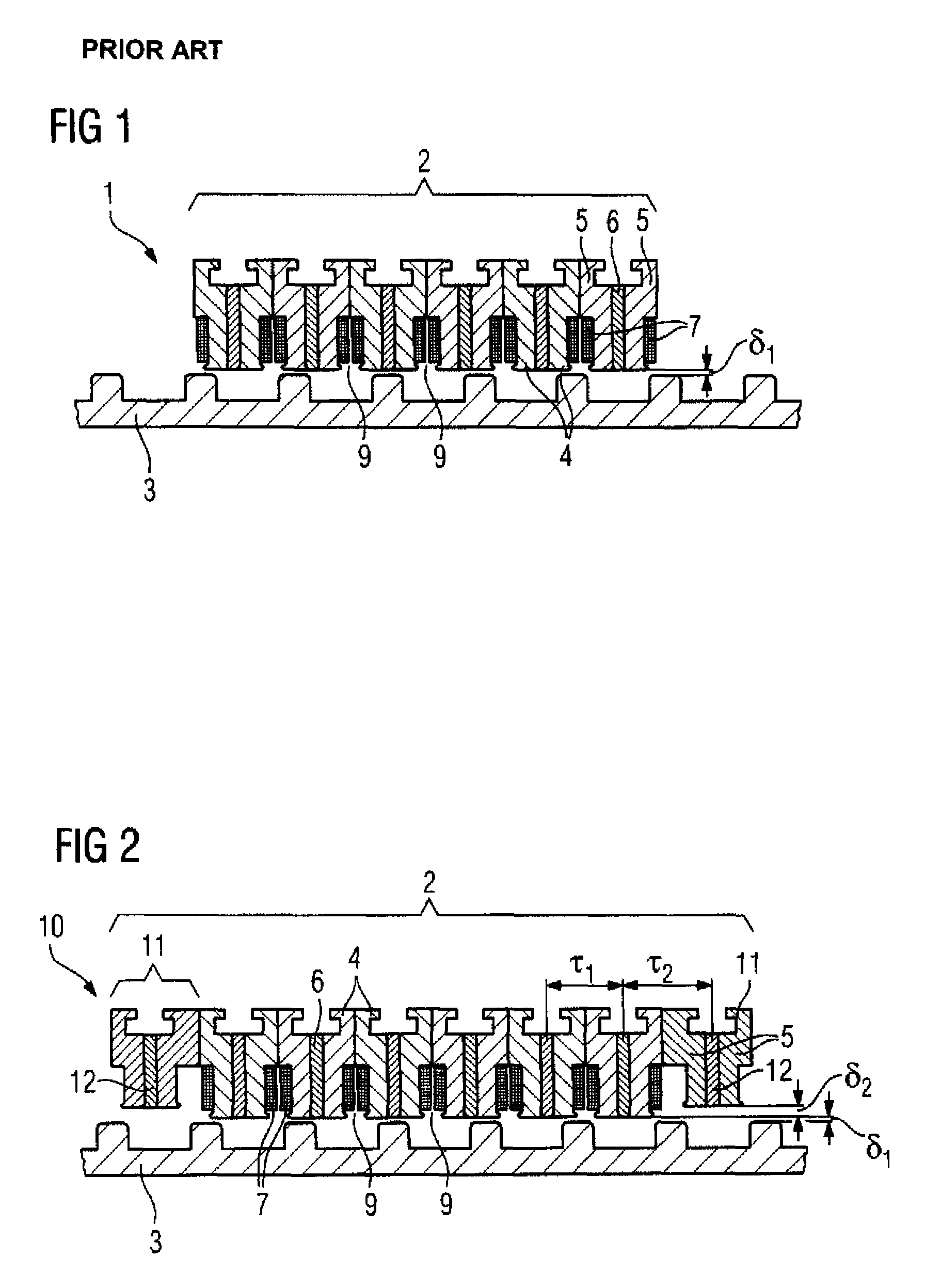

Multi pole electrical machine with reduced cogging force

InactiveUS7321176B2Improve efficiencyReduce cogging forceSynchronous generatorsWindingsStator polesPhysics

A multi pole electrical machine includes an armature and a stator. The armature is movable in a direction of armature motion with regard to said stator and includes armature pole pairs. These armature pole pairs follow each other in the direction of armature motion. Each armature pole pair corresponds to one magnetic period. The stator includes a differing fixed number of stator poles per armature pole pair to reduce a cogging force of the electrical machine. An arrangement of the stator poles, with regard to both electrical and magnetic aspects, includes at least two identical sub-arrangements of stator poles. These sub-arrangements of stator poles follow each other in the direction of armature motion. Each of the sub-arrangements of stator poles is associated with one or more armature pole pairs and includes more than three of stator poles.

Owner:INVACARE CORP +1

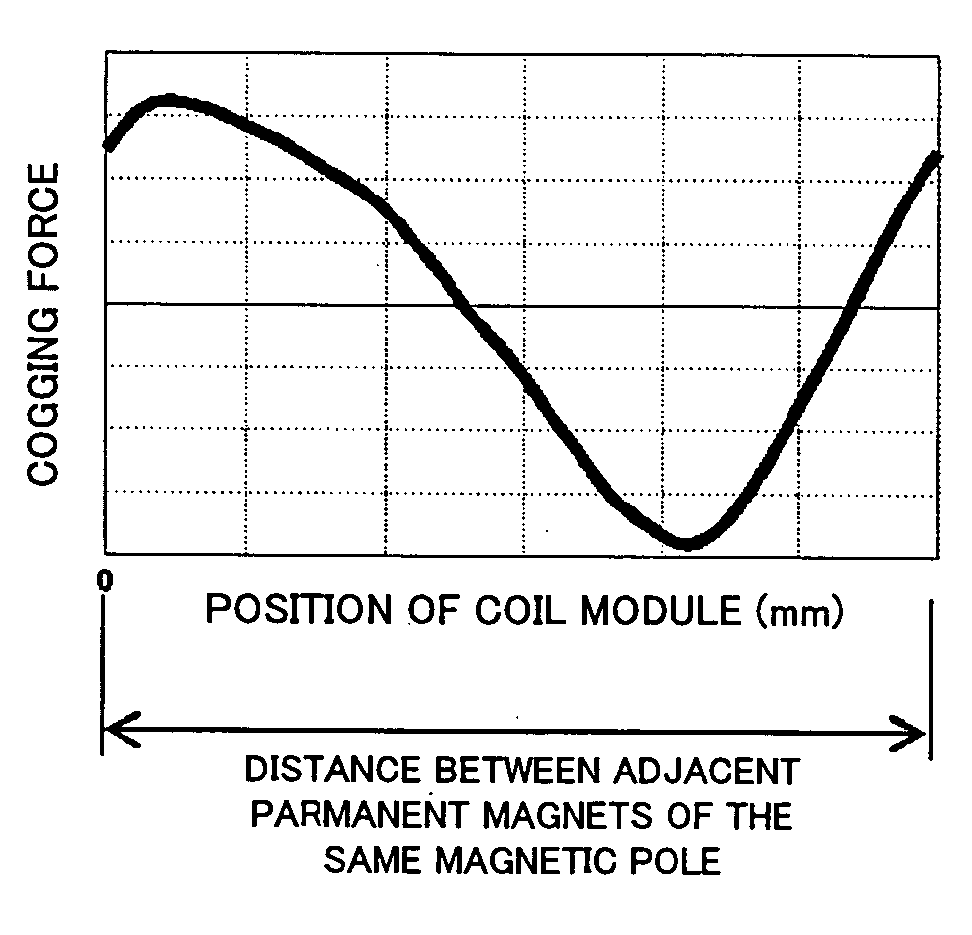

Linear driving device

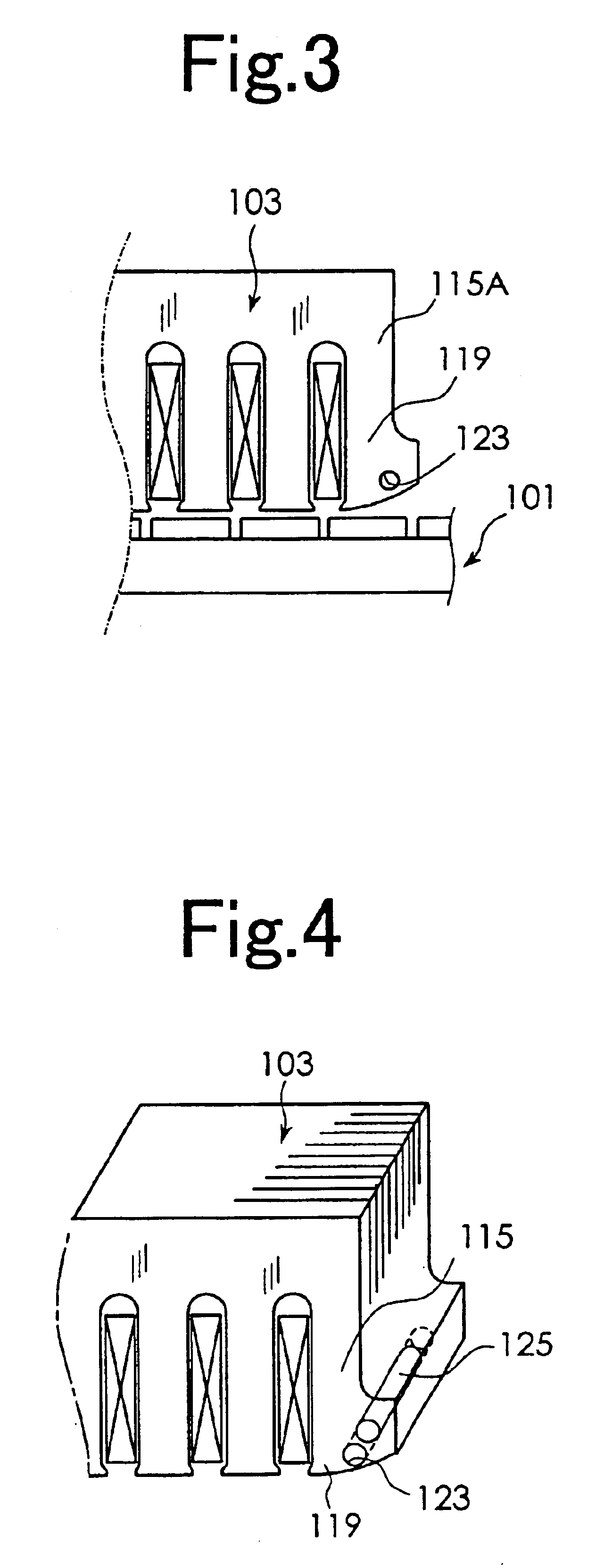

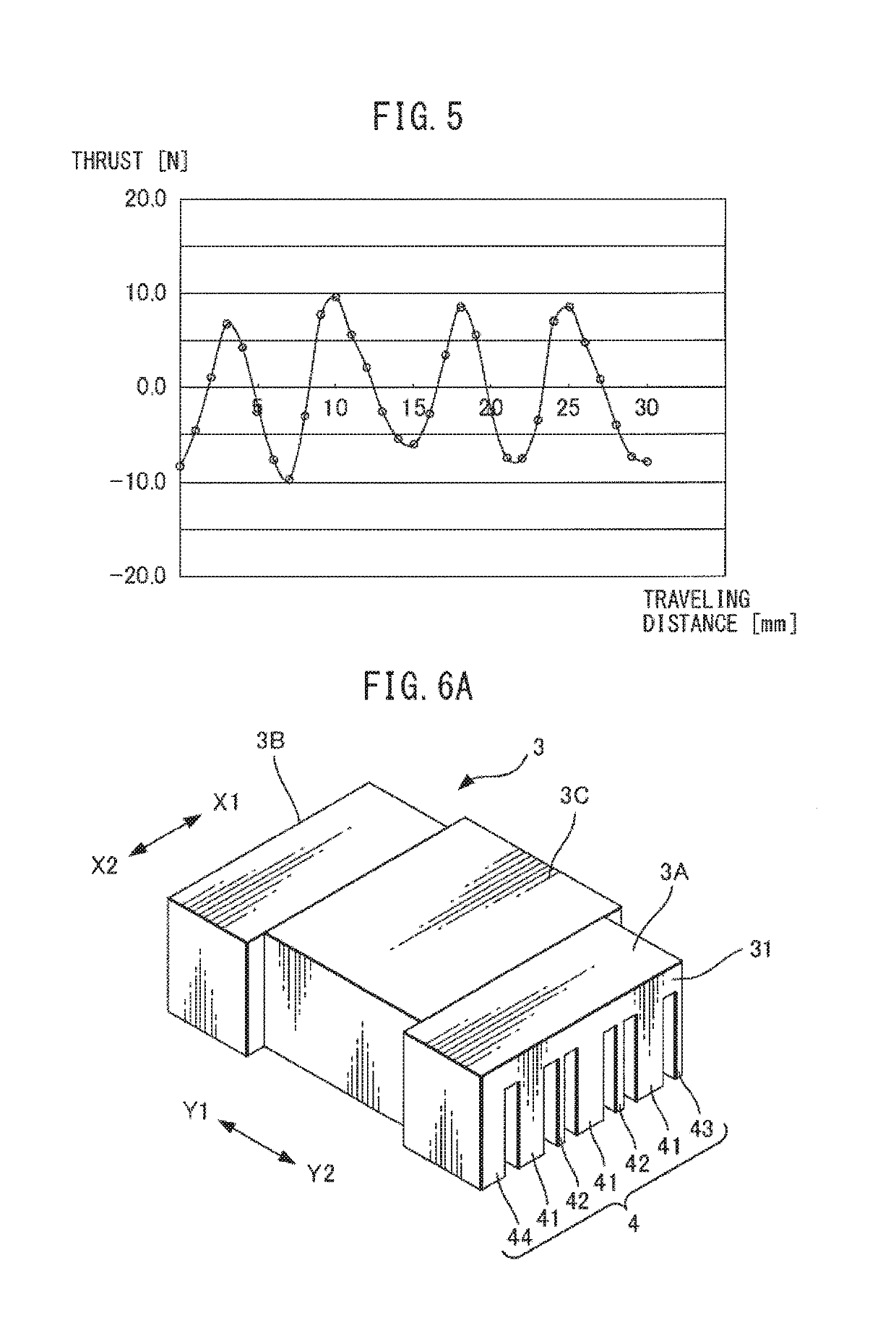

InactiveUS20060006743A1Reduce cogging forceSimple structureMagnetic circuitMechanical energy handlingWave shapeElectrical polarity

A linear driving device that reduces a cogging force with a simple structure as opposed to a drive mechanism having an existing structure, deals with a plurality of cogging waveforms having different periods, and suppresses not only the cogging force but also pitching that is vertical oscillation. The device has a structure provided with a plurality of magnet arrays in which permanent magnets having different polarities are alternately and rectilinearly arranged in the same direction, and a plurality of coil modules having a plurality of teeth and slots fitted with armature coils. The arrangement distance between the coil modules disposed along the displacing direction of each of the magnet arrays equals the sum or remainder of the length corresponding to a half of any one of periods possessed by the cogging force generated when the coil modules move by one magnetic pole and an integer multiple of the length of a magnetic pole pair. The coil modules are connected to each other by a connecting member, and the connecting member makes relative motion along the magnet arrays.

Owner:FANUC LTD

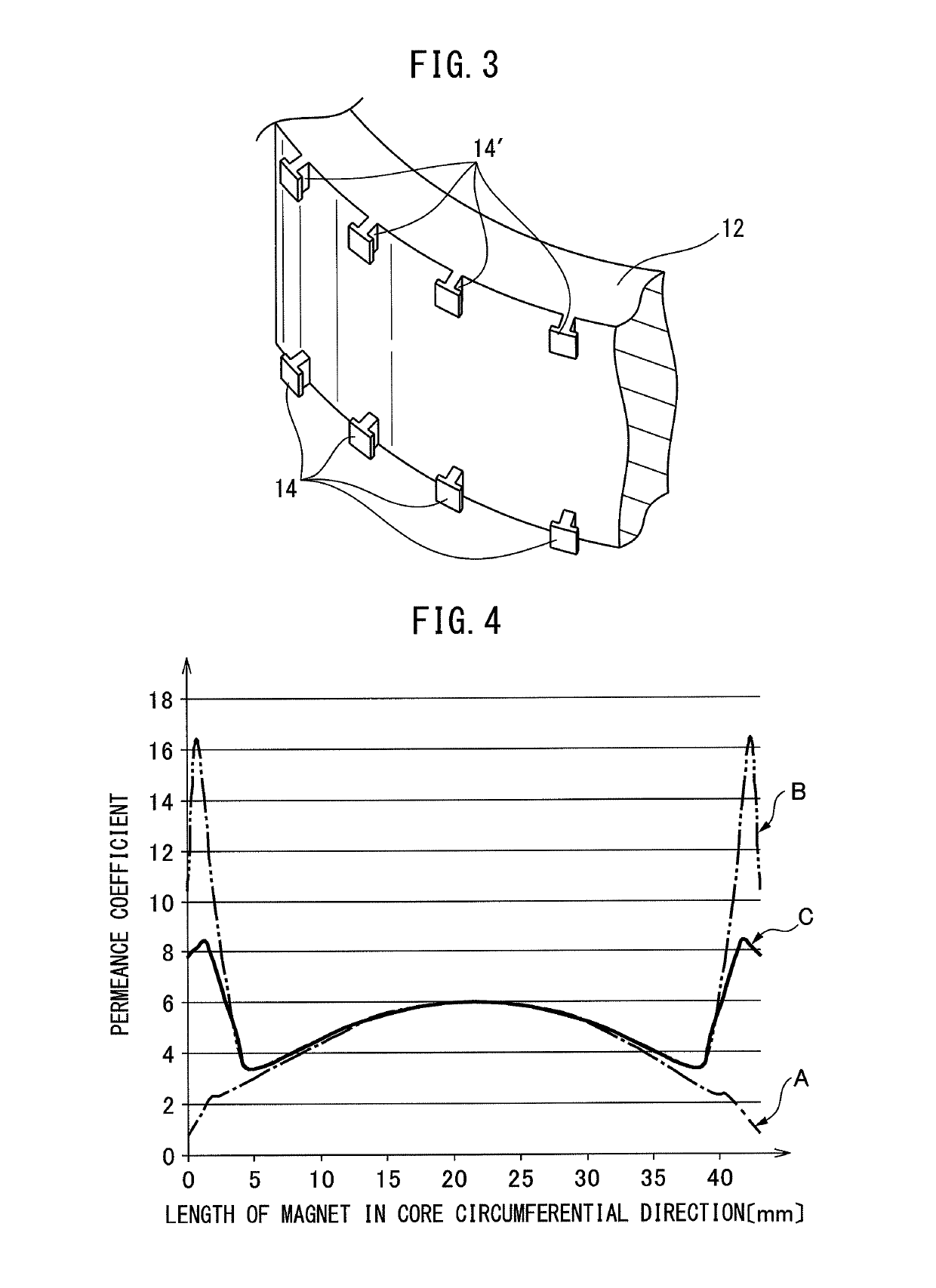

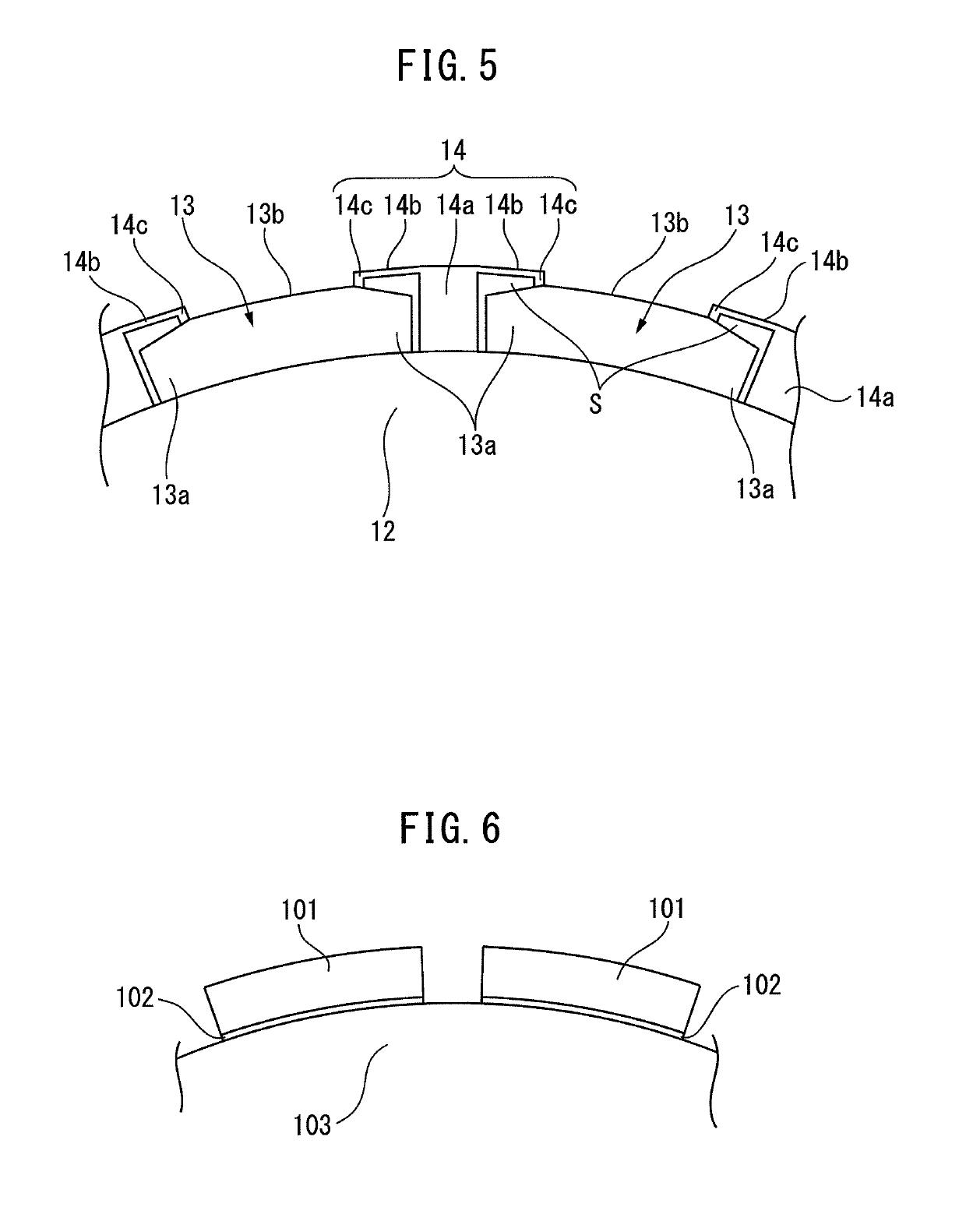

Motor rotor

ActiveCN102510149AReduce cogging forceExcellent magnetic propertiesMagnetic circuit rotating partsControl theoryMagnet

Owner:SUZHOU DRANE ELECTRIC MOTORS

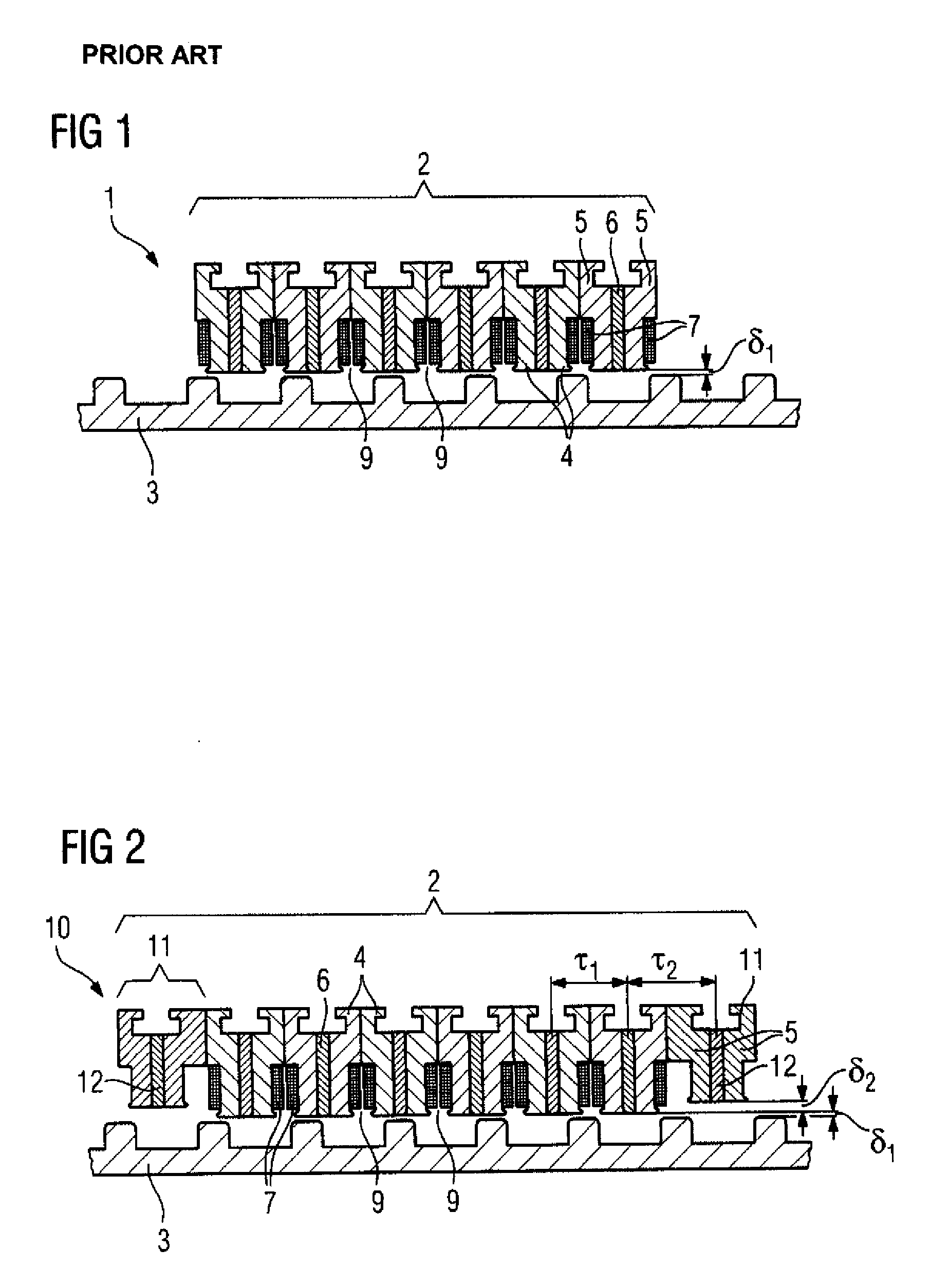

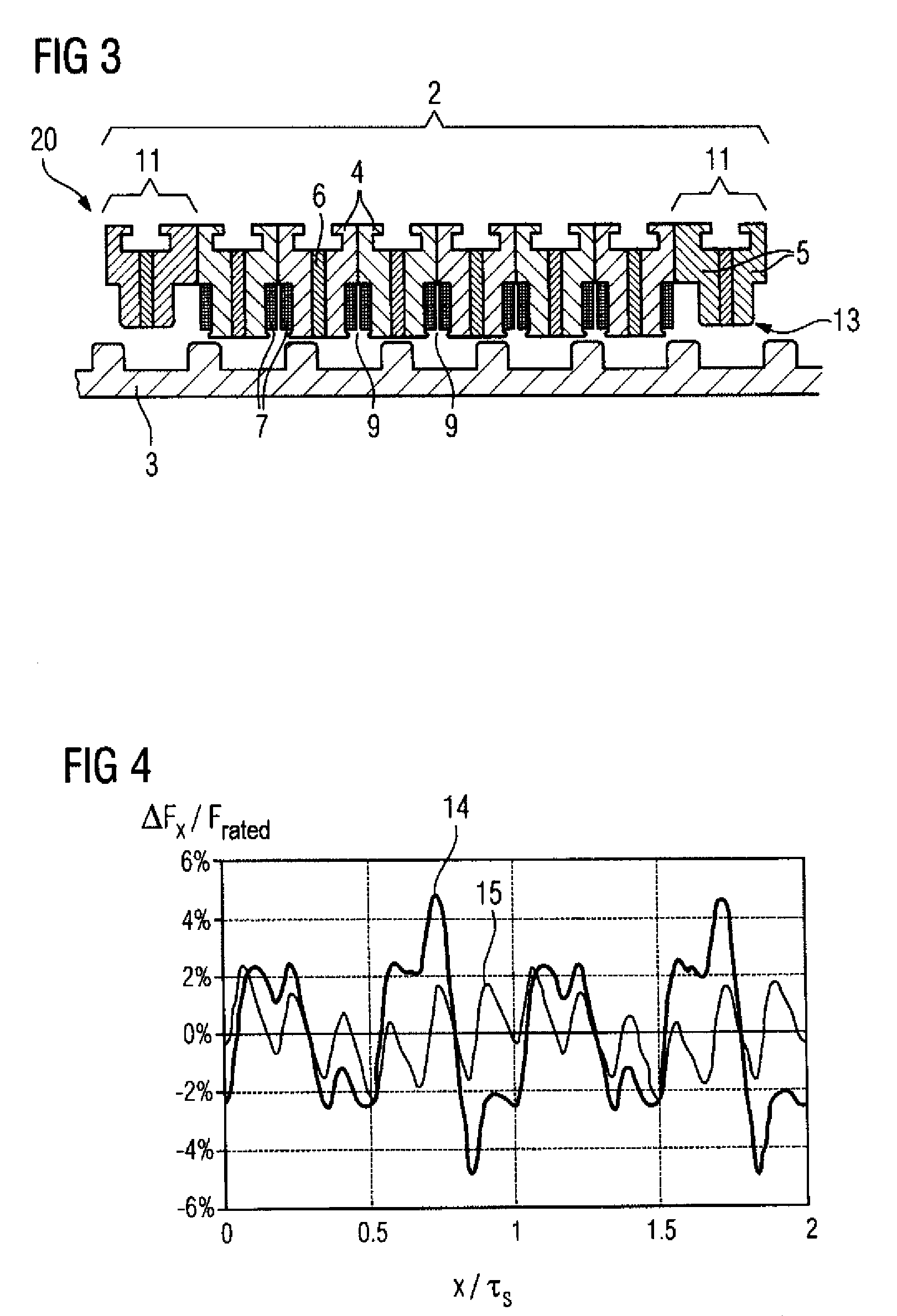

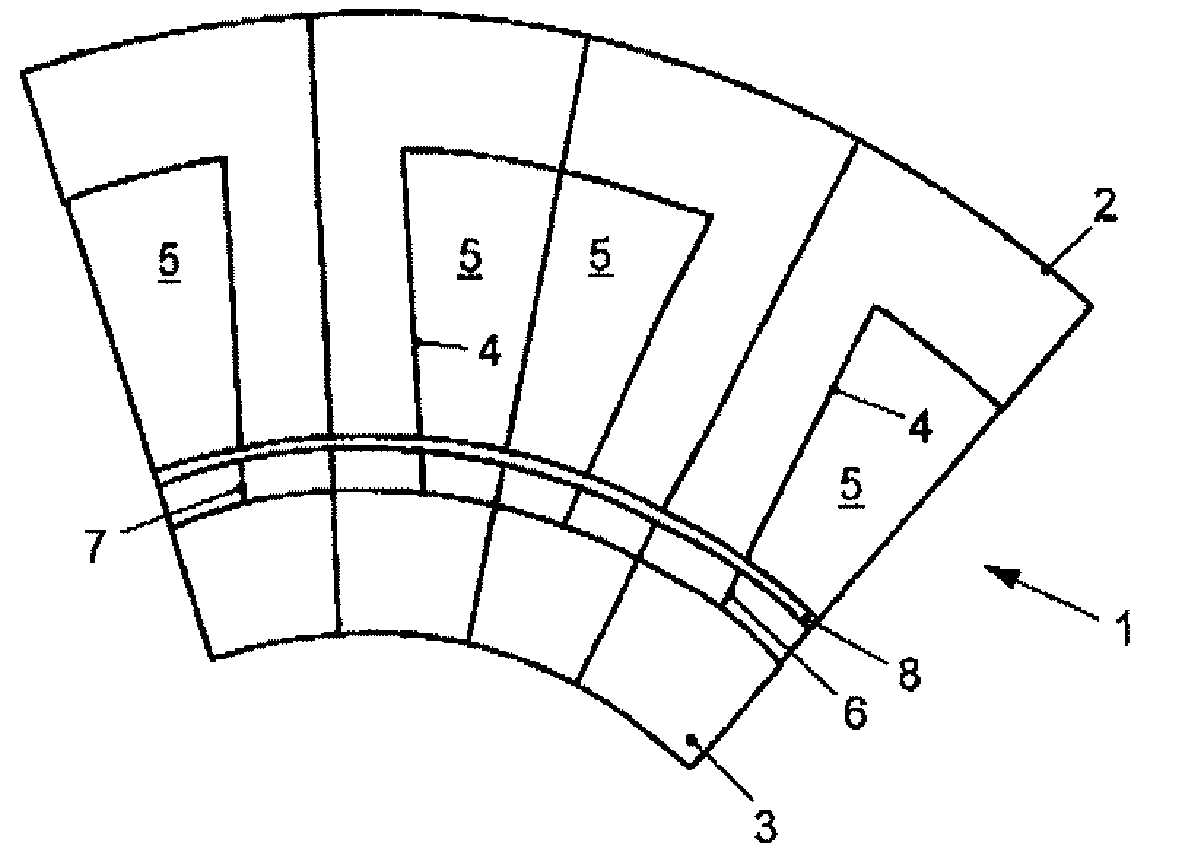

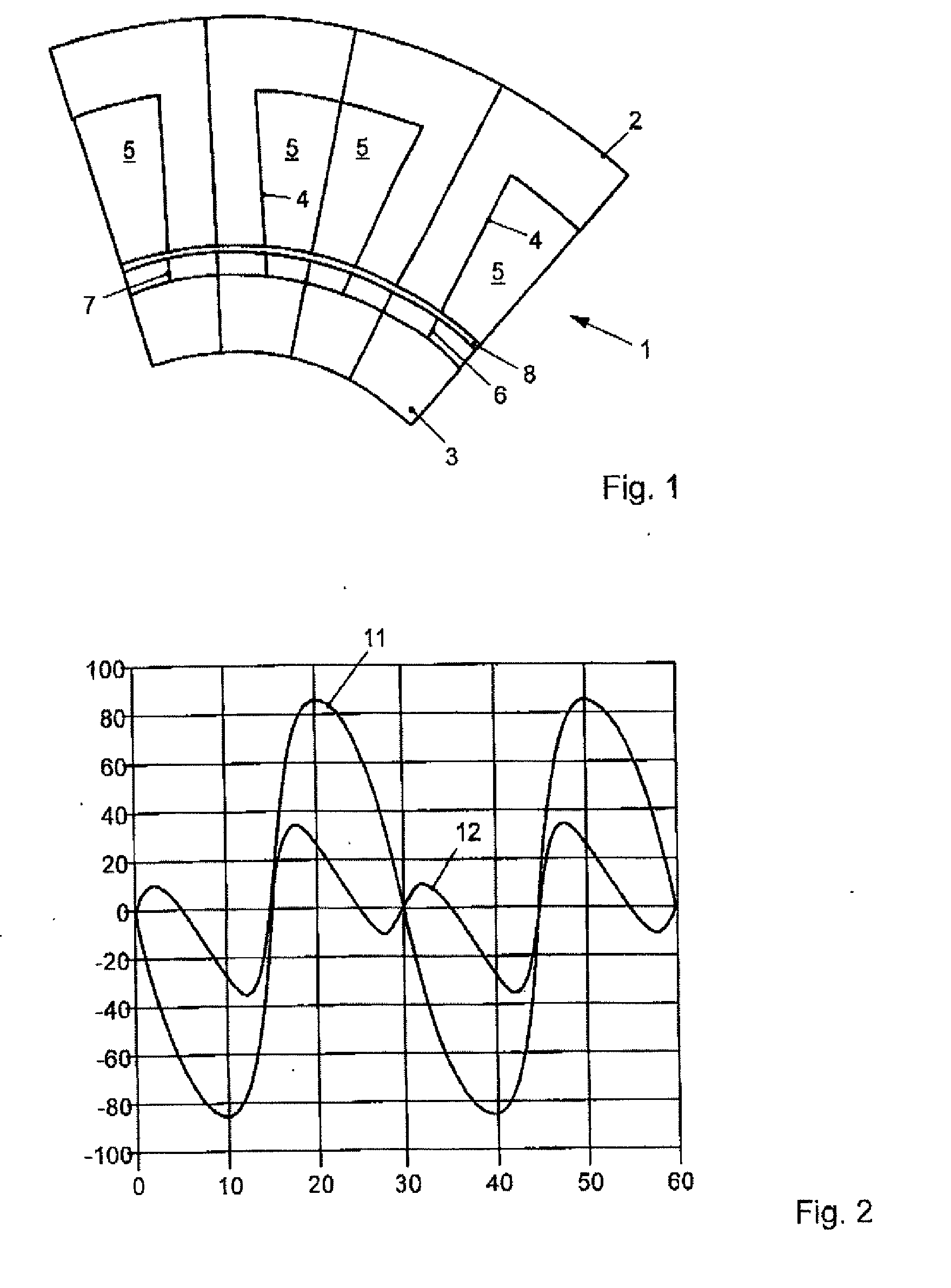

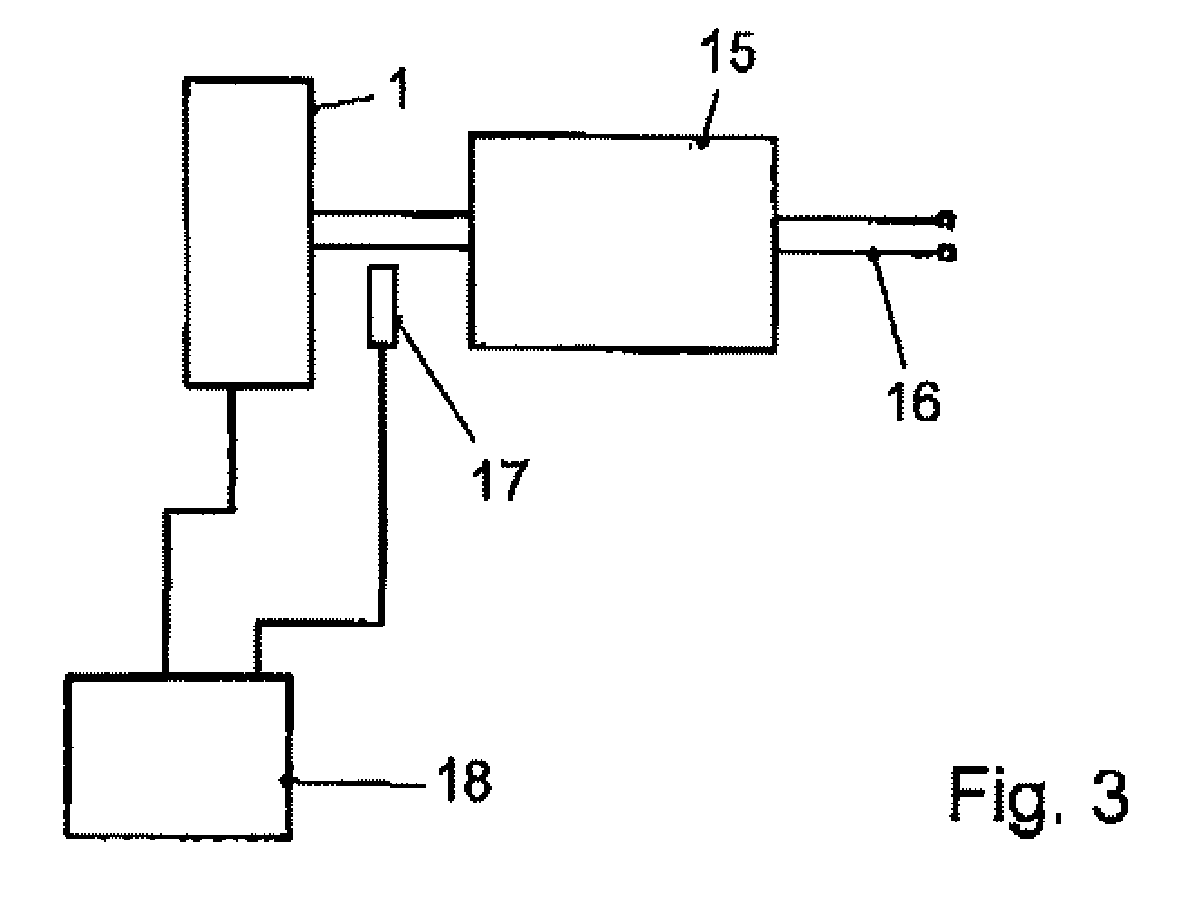

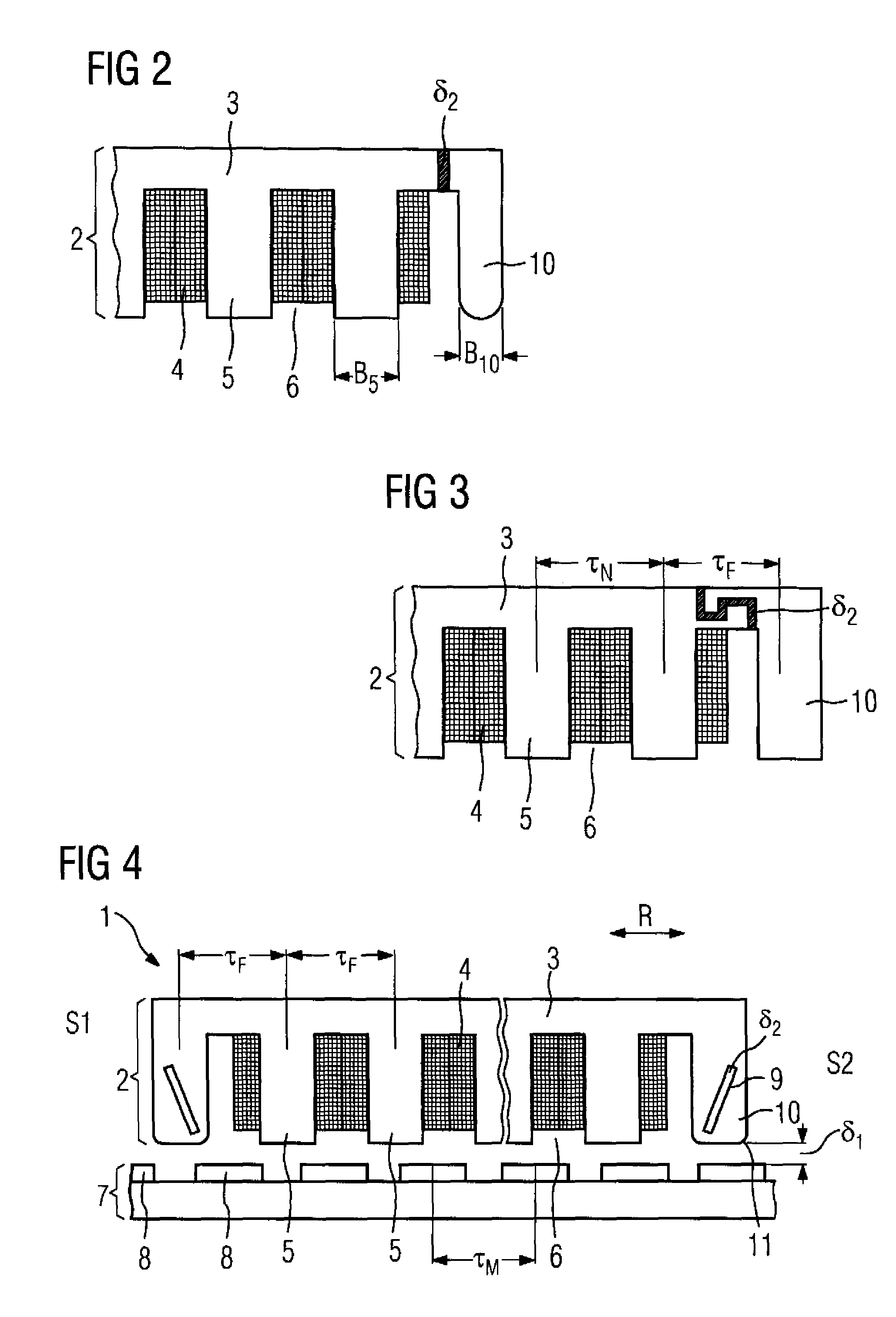

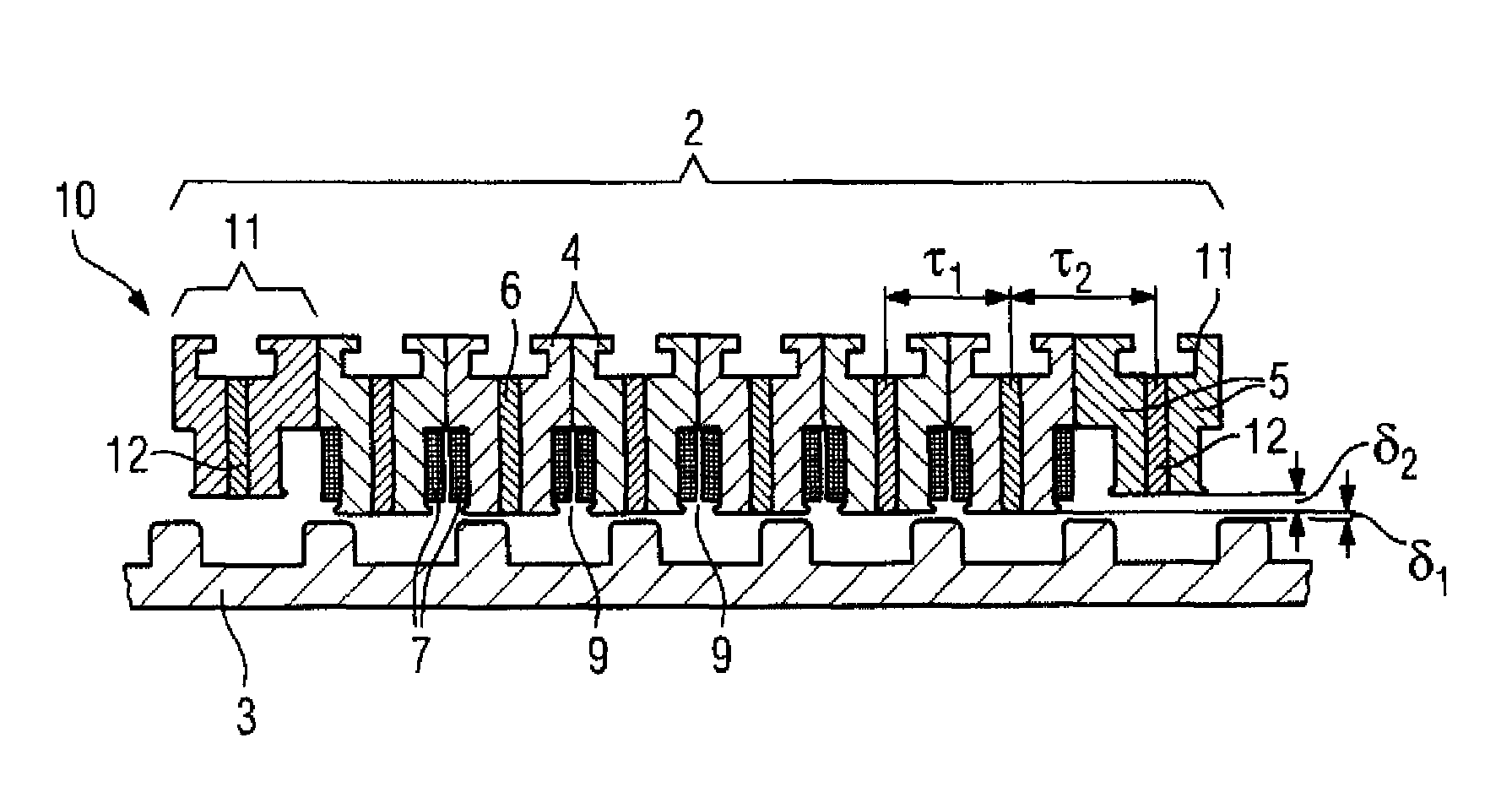

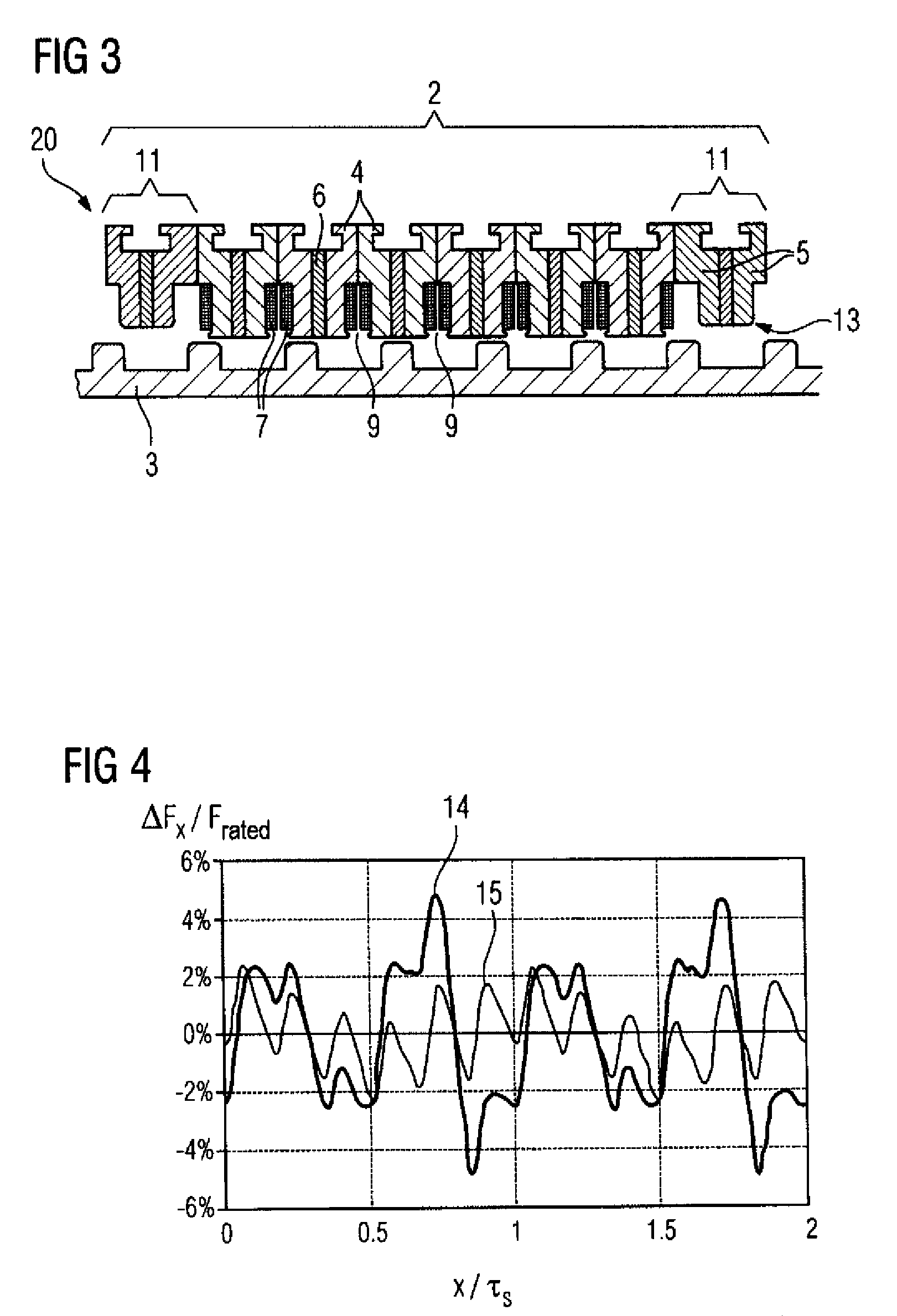

Primary part and linear electrical machine with force ripple compensation

InactiveUS20090206681A1Reduce cogging forceReduced active and passive force rippleSynchronous machine detailsPropulsion systemsEngineeringConductor Coil

A linear electric motor including a primary part having a flux guiding element on the end faces of the primary part, a three-phase winding on the primary part that produces a first magnetic field and a permanent magnet on each end face that produces a second magnetic field that is superimposed on the first field to reduce force ripple is disclosed. The primary part has tooth modules and also end-tooth modules. The end-tooth modules have no winding, are located on the end face, and are smaller in volume than and shaped differently from the tooth modules. The primary part is separated from a secondary part by an air gap, and the end-tooth modules are separated from the secondary part by an additional air gap.

Owner:SIEMENS AG

Machine for fixing

InactiveUS20110025156A1High cogging forceIncrease forceTransformersSynchonous clutches/brakesEngineeringDegrees of freedom

Owner:WITTENSTEIN GROUP

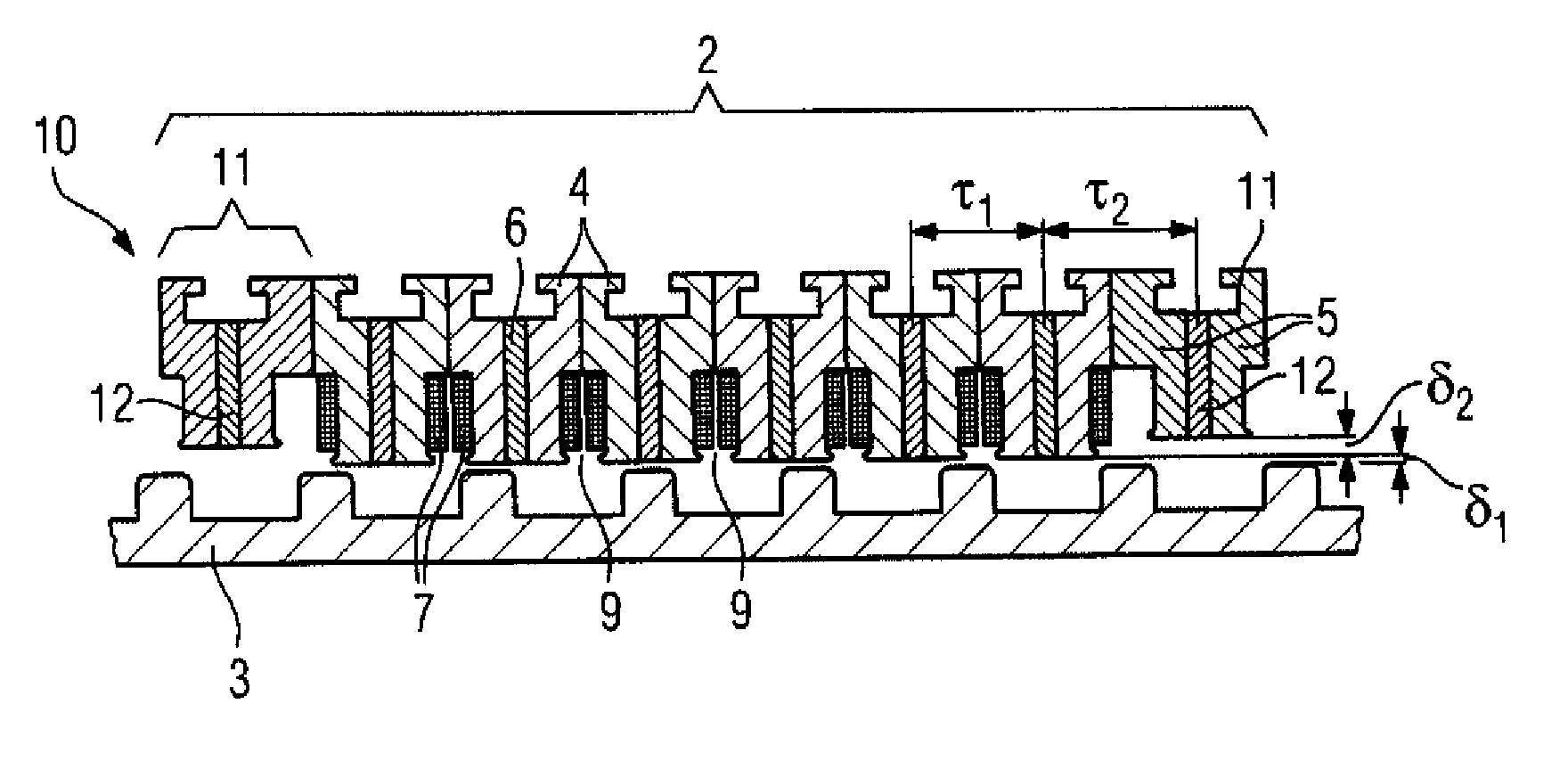

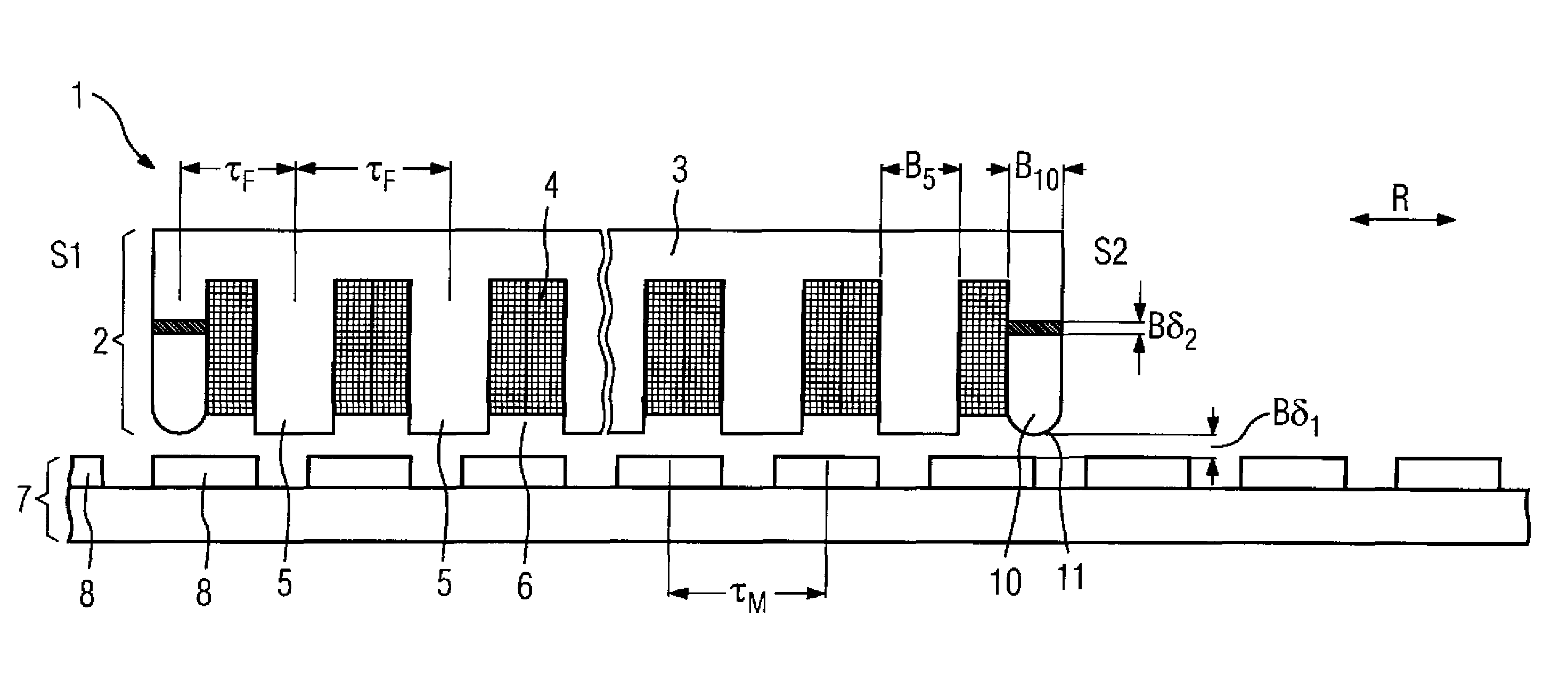

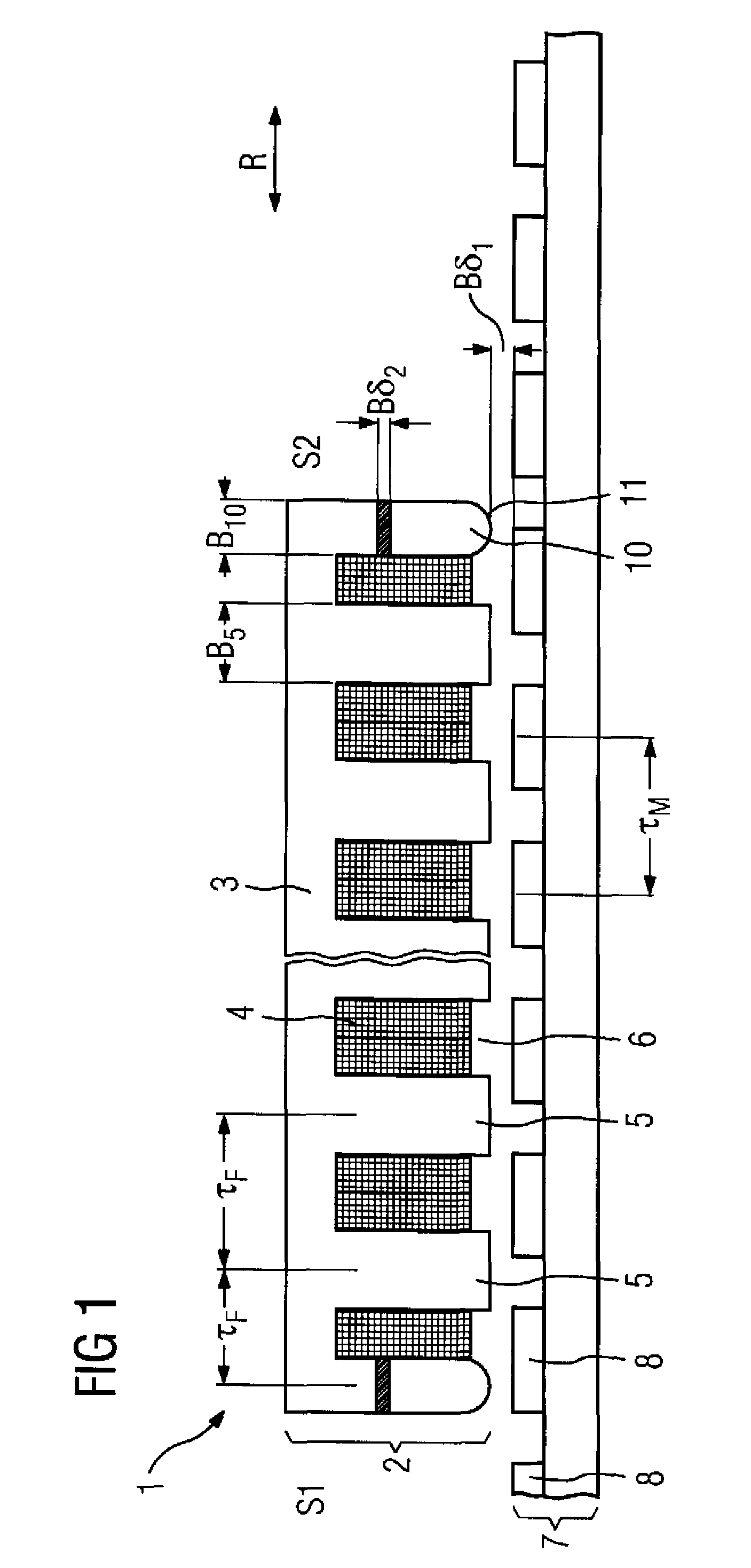

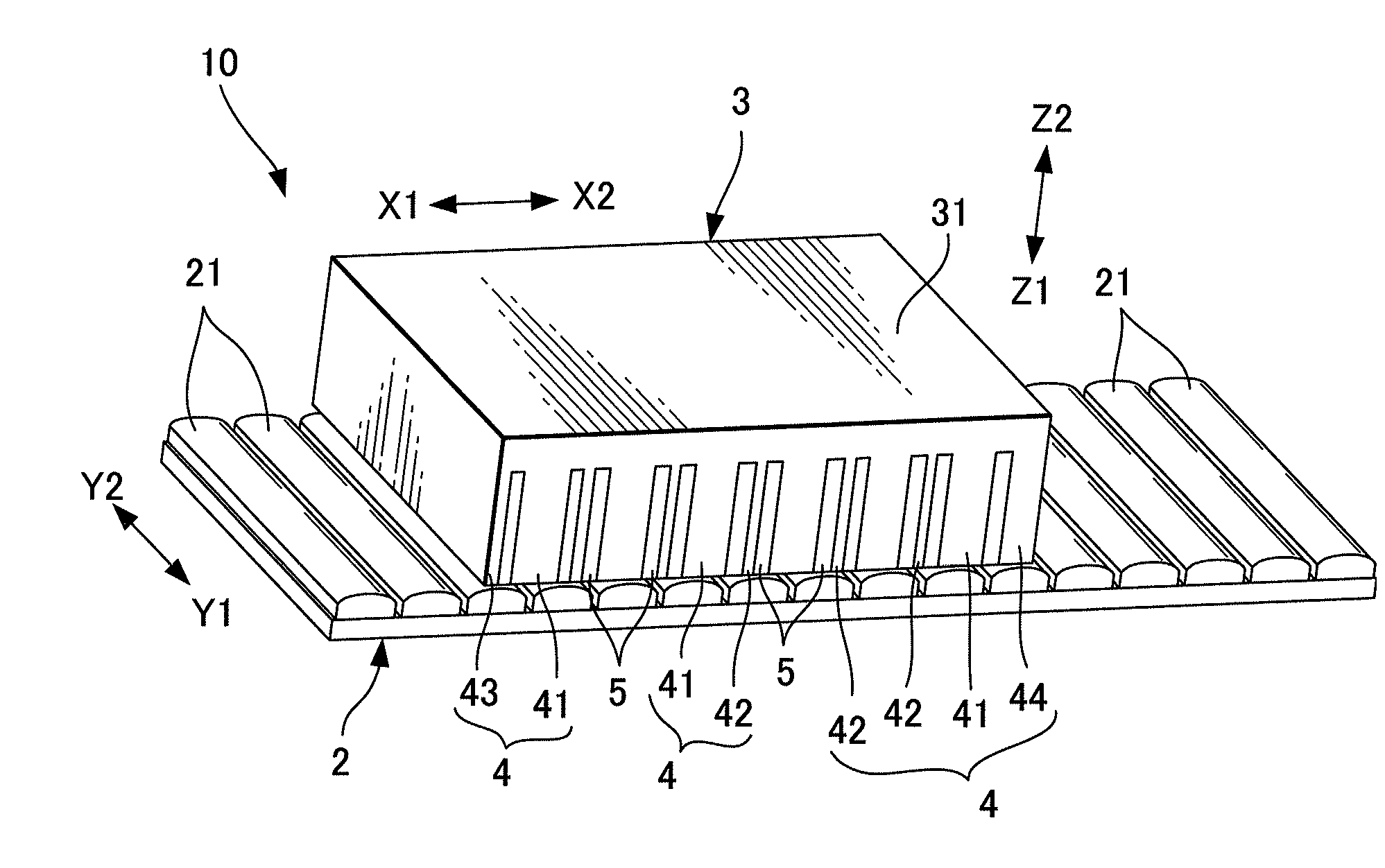

Linear motor with force ripple compensation

ActiveUS8076804B2Electromotive force is reducedStrengthen the magnetic fieldMagnetic circuitPropulsion systemsSecondary componentEngineering

The invention relates to a primary component (2) for an electric motor (1), said primary component (2) being formed from at least one bundle of laminations (3) and comprises at least one flux guiding element (10) on one or both front faces (S1, S2) to reduce the ripple effect, said primary component (2) being separated from a secondary component (7) by a first air gap (δ1). The primary component (2) has at least one section (δ2) in the region of the flux guiding element (10), said section (δ2) being electrically non-conducting (Kel=0) and having a negligibly low magnetic permeability (μr≅1).

Owner:SIEMENS AG

Primary part and linear electrical machine with force ripple compensation

InactiveUS7893569B2Reduce cogging forceReduced active and passive force rippleSynchronous machine detailsPropulsion systemsEngineeringConductor Coil

A linear electric motor including a primary part having a flux guiding element on the end faces of the primary part, a three-phase winding on the primary part that produces a first magnetic field and a permanent magnet on each end face that produces a second magnetic field that is superimposed on the first field to reduce force ripple is disclosed. The primary part has tooth modules and also end-tooth modules. The end-tooth modules have no winding, are located on the end face, and are smaller in volume than and shaped differently from the tooth modules. The primary part is separated from a secondary part by an air gap, and the end-tooth modules are separated from the secondary part by an additional air gap.

Owner:SIEMENS AG

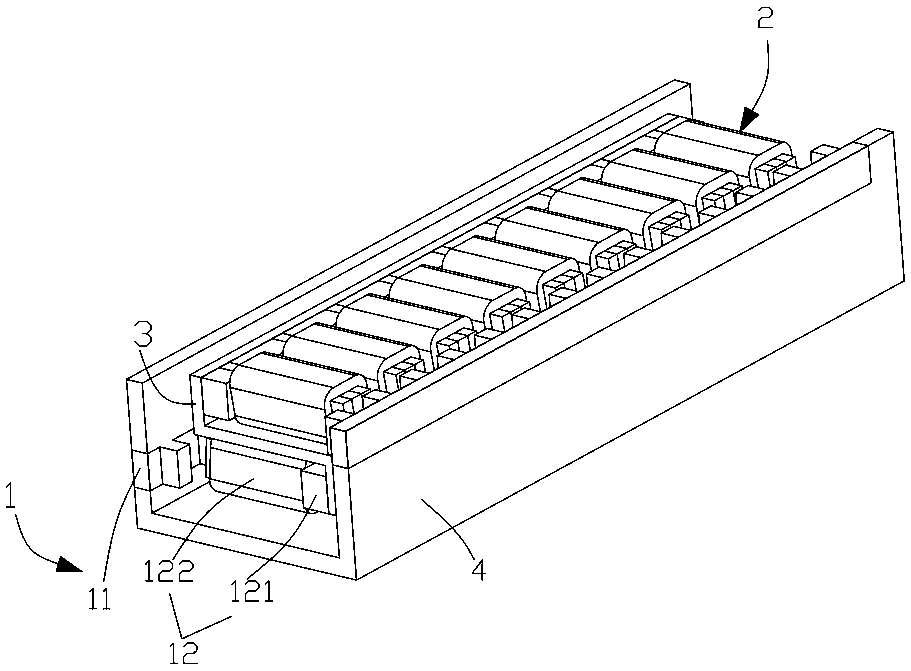

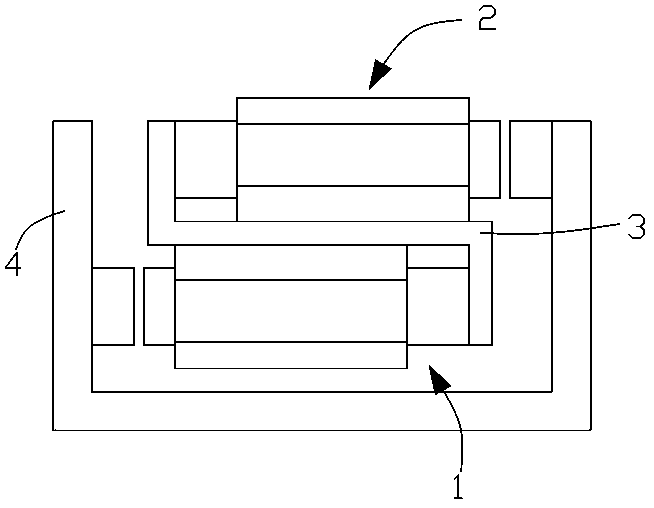

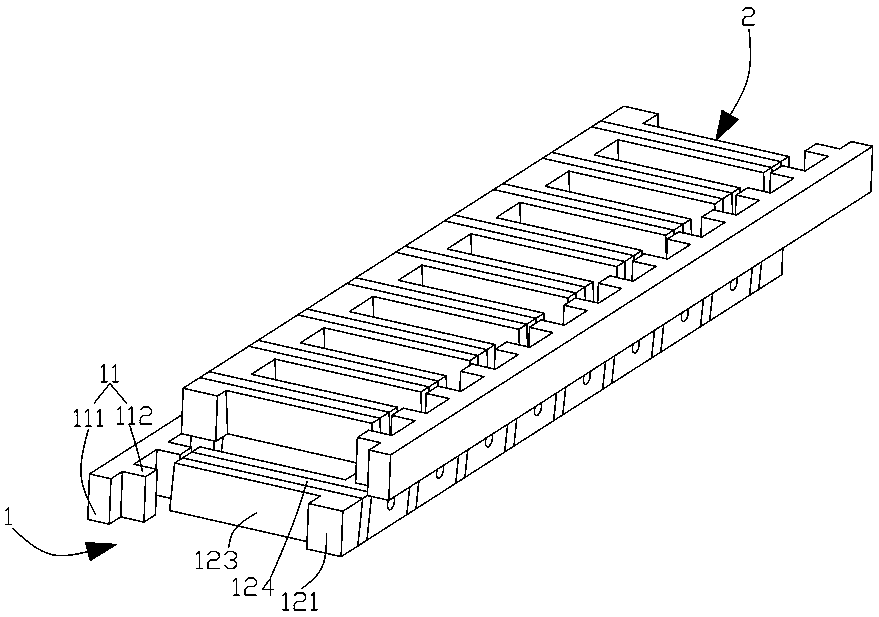

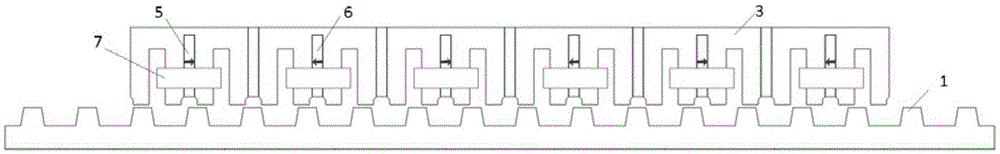

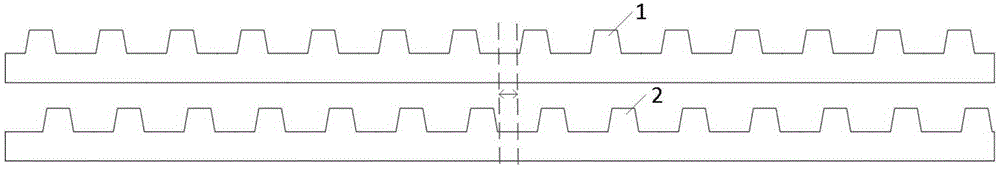

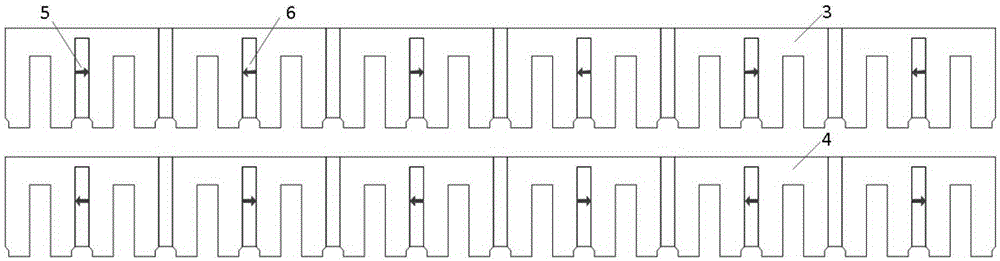

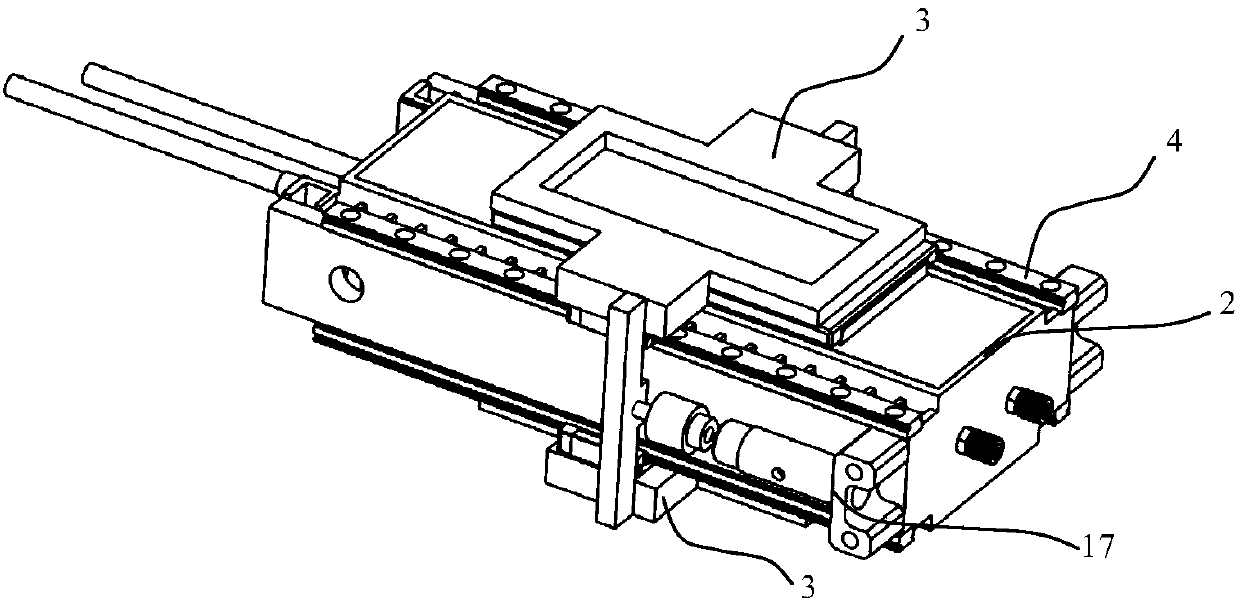

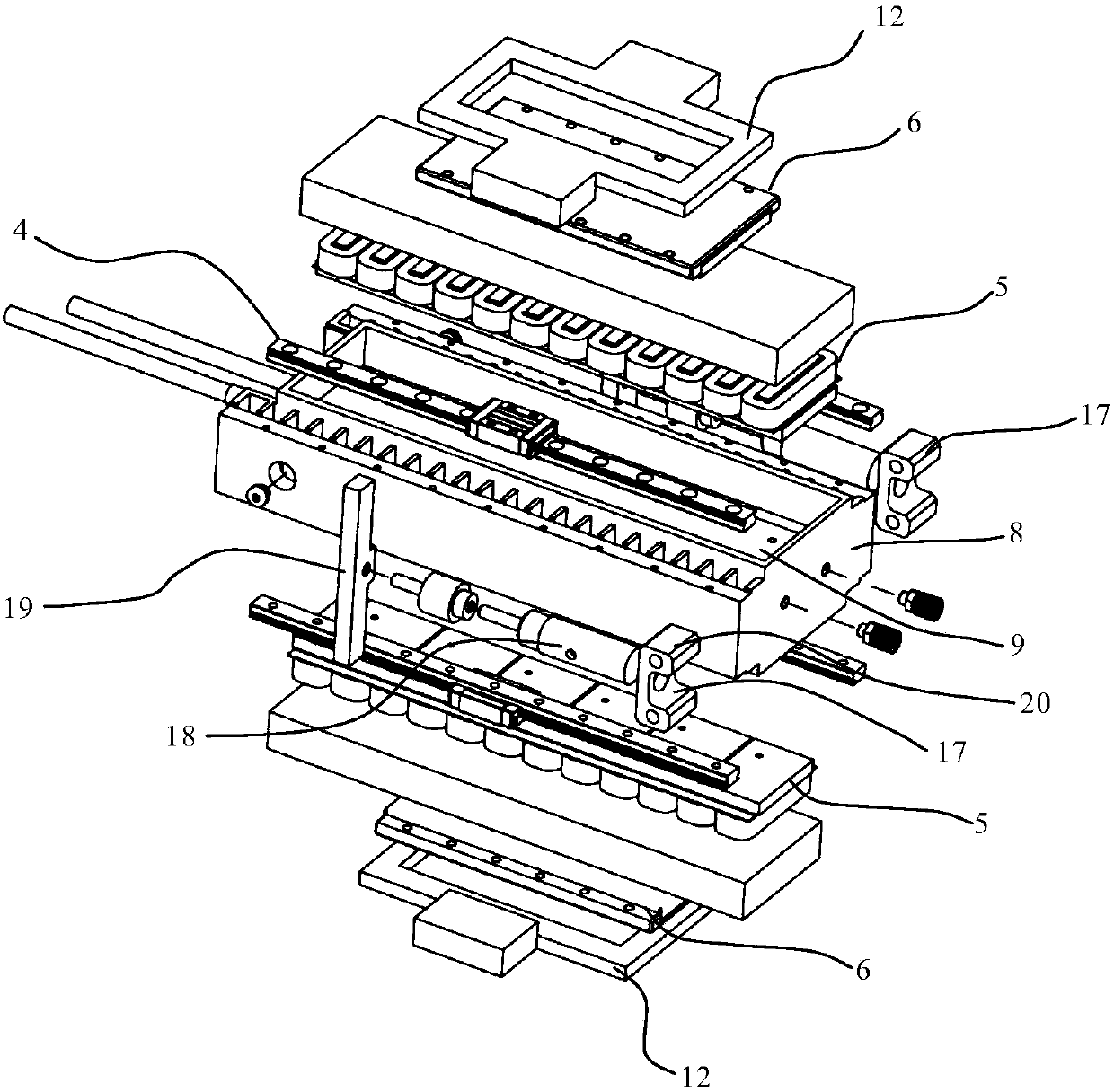

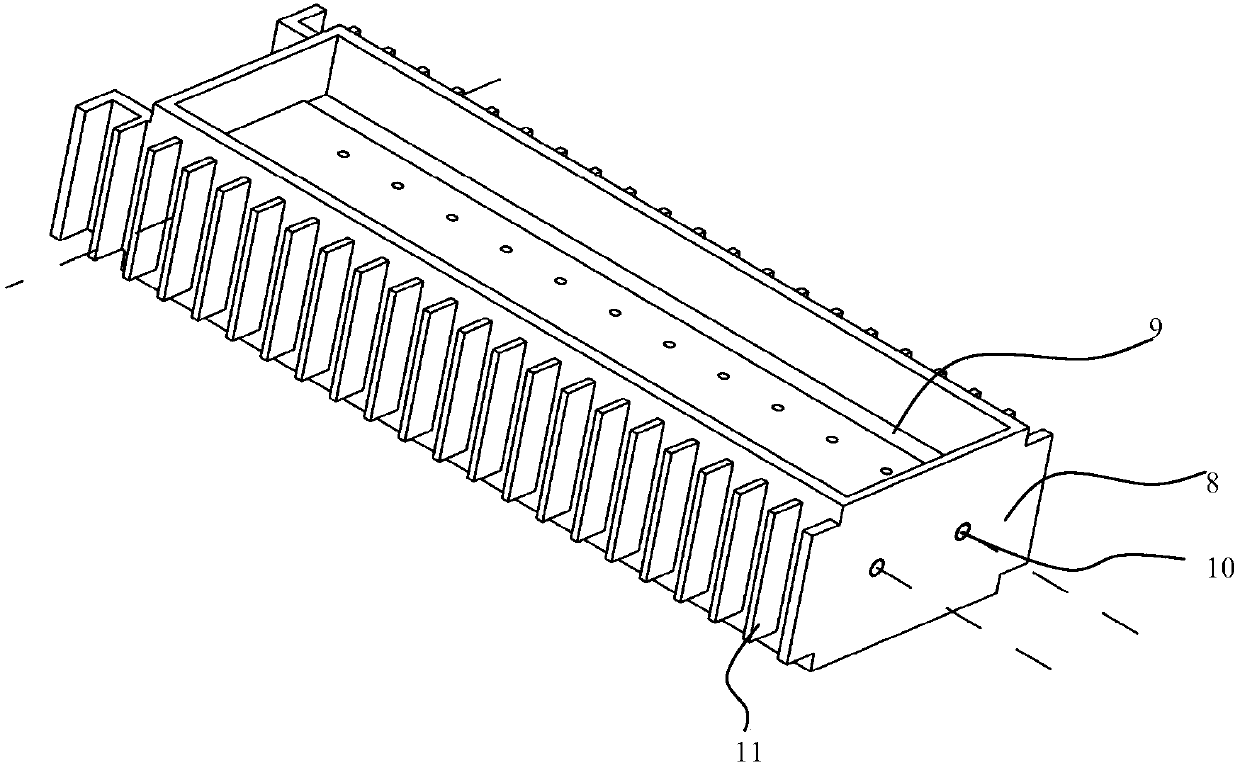

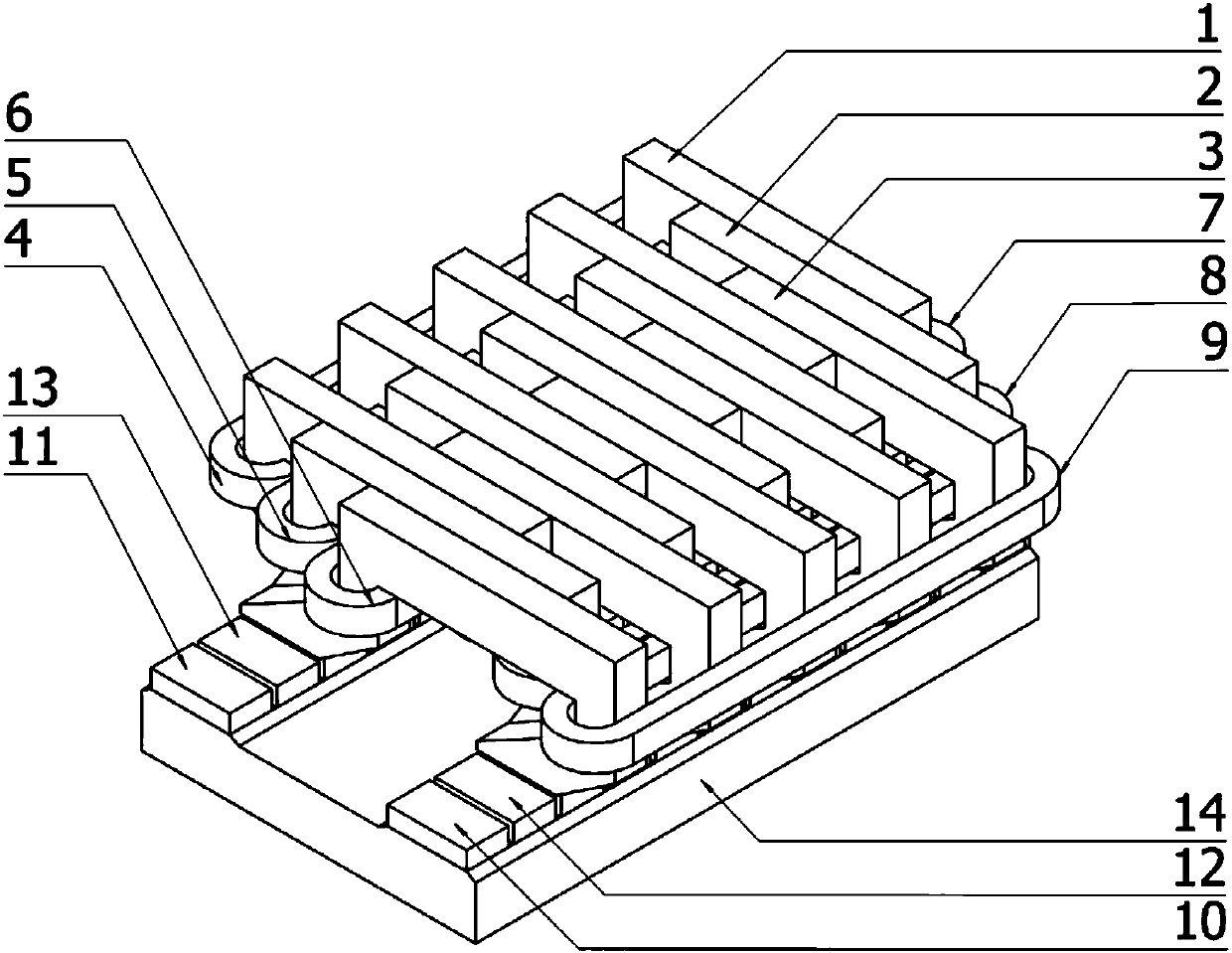

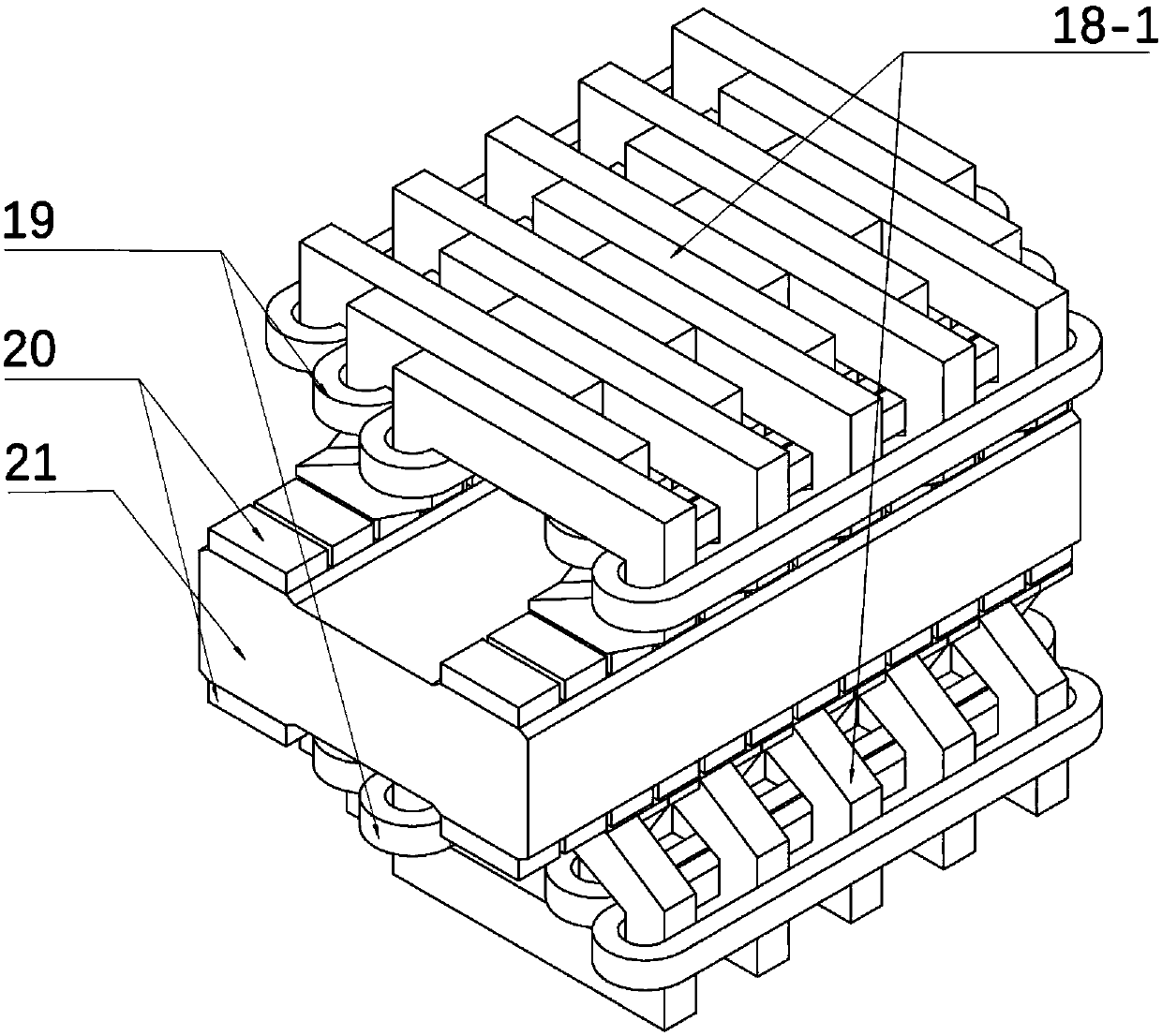

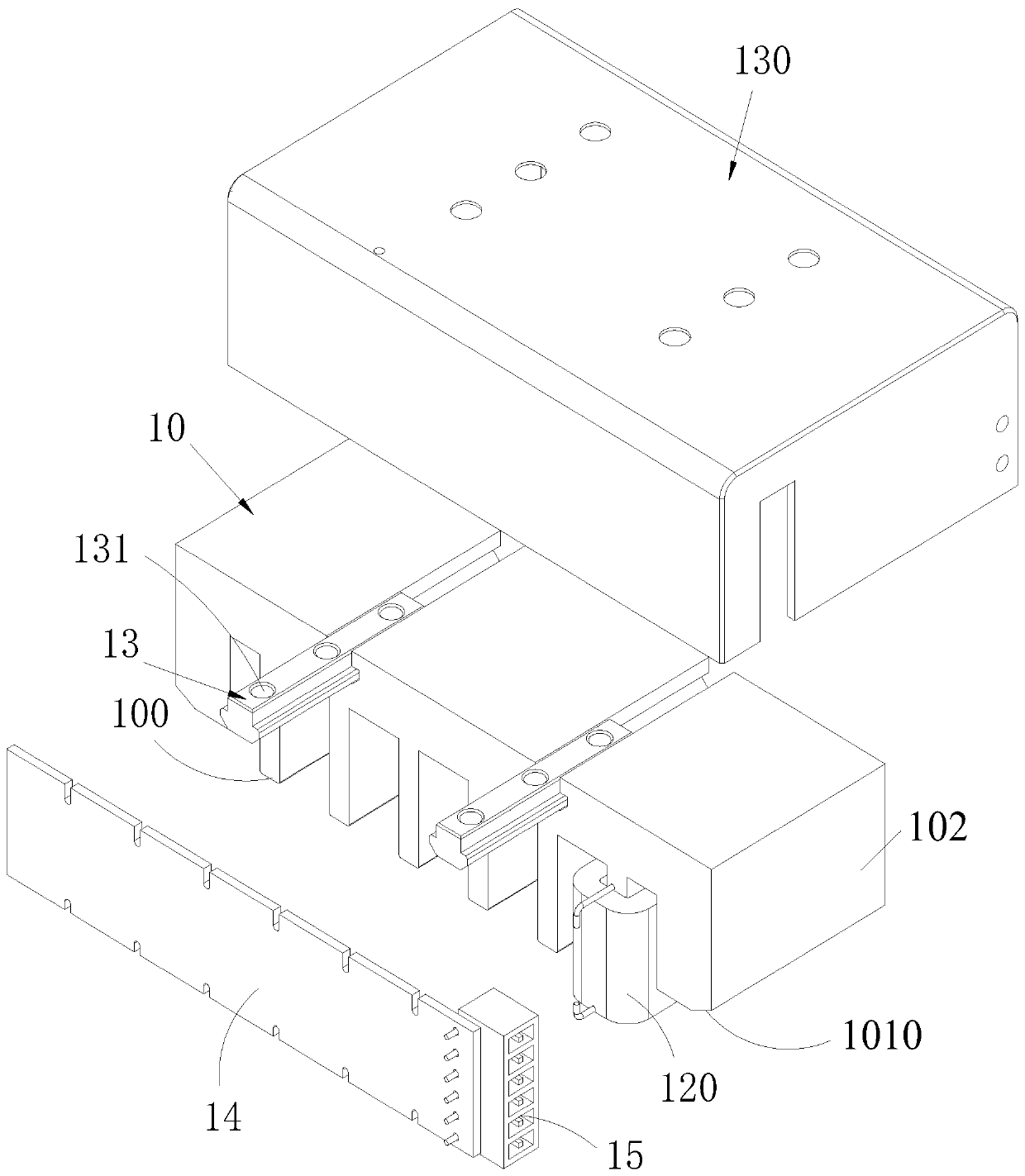

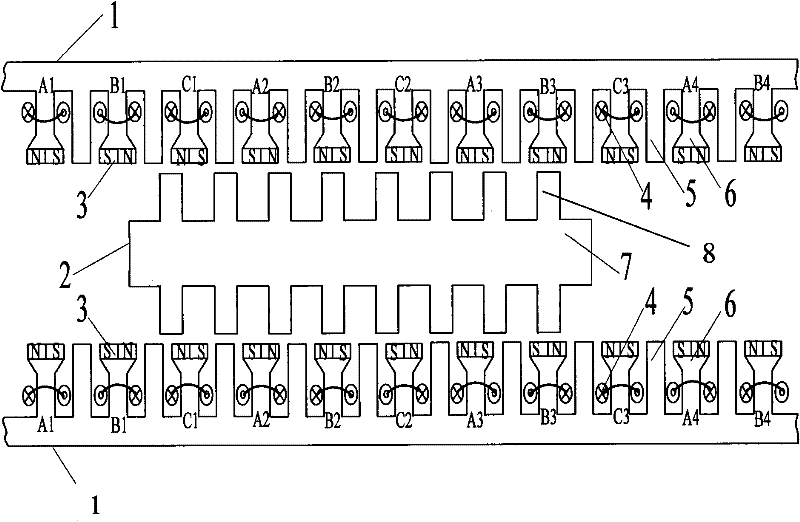

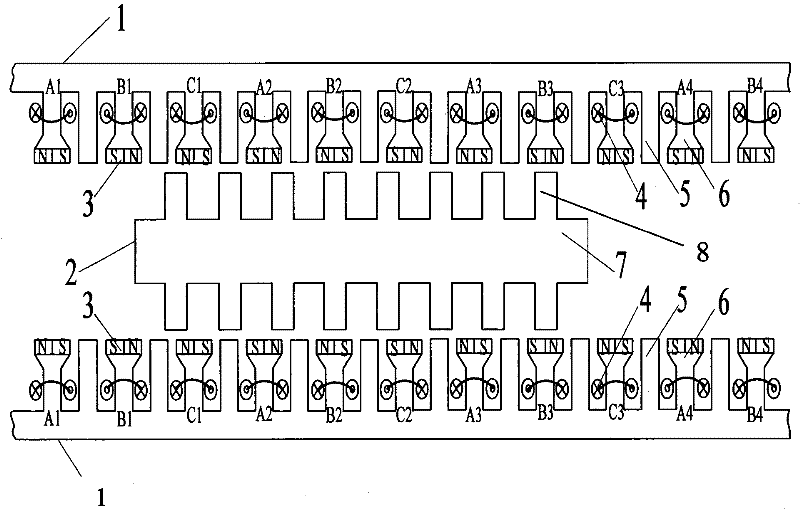

Primary iron core staggered driving structure, a linear motor and numerical control equipment

The invention relates to a primary iron core staggered driving structure, a linear motor and numerical control equipment. The primary iron core staggered driving structure comprises first driving assemblies and second driving assemblies superposed in turn, and connecting pieces used for connecting the first driving assemblies and the second driving assemblies. The first driving assemblies and thesecond driving assemblies form at least one linear driving mechanism. According to the invention, the first driving assemblies and the second driving assemblies are sequentially staggered and superposed, which can multiply the number of iron cores. The two driving assemblies are arranged in opposite directions in the direction perpendicular to the moving direction of the rotor, so that the primaryiron cores are staggered in the vertical direction, the size of the motor can be reduced, the thrust density can be improved, the cogging force of the linear motor is reduced, and the operation stability is improved. On the other hand, the first driving assemblies and the second driving assemblies which are superposed in a staggered mode can counteract normal magnetic attraction force.

Owner:GREE ELECTRIC APPLIANCES INC

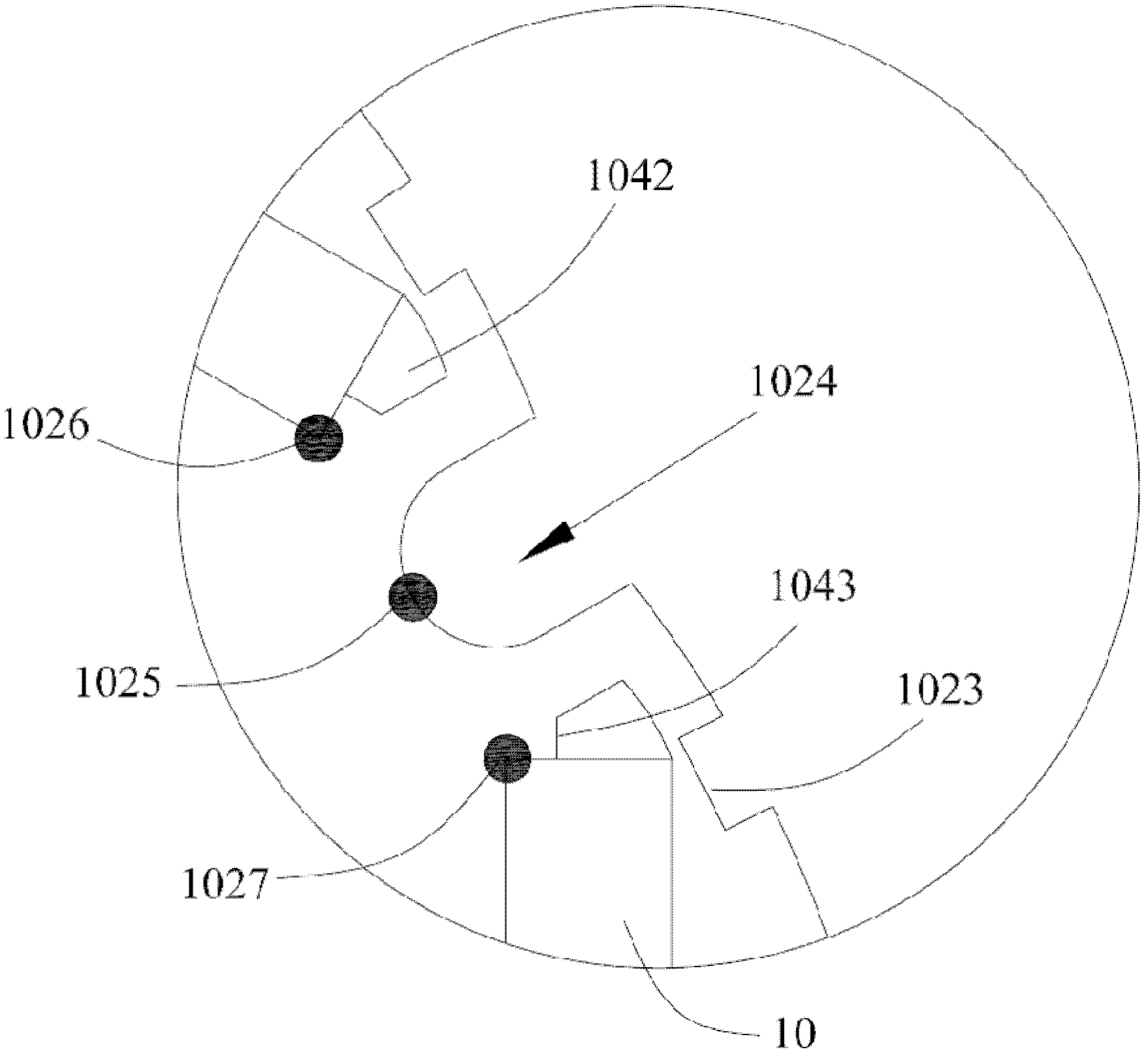

Flat plate type linear switch flux linkage motor and staggered tooth displacement selection method thereof

The invention provides a flat plate type linear switch flux linkage motor and a tooth teeth displacement selection method thereof. The motor is divided into two sections of the same structure in the left part and the right part; the excitation directions of excitation sources in the same mover position in the two sections are opposite; the stator convex teeth of the two sections are spaced at a staggered tooth displacement from front to back; the staggered tooth displacement enabling the maximum counter potential fundamental current amplitude and the minimum ratio between second harmonics and fundamental current amplitude is taken as the staggered tooth displacement I; a staggered tooth displacement that is most close to the staggered tooth displacement I and enables the cogging force peak value to the minimum is taken as the staggered tooth displacement I; and the staggered tooth displacement of the motor is selected according to the comparison of the two staggered tooth displacements. According to the flat plate type linear switch flux linkage motor structure and the staggered tooth displacement selection method therefor, the staggered tooth displacement selection method is applicable to multiple kinds of flat plate type structural linear motors; and due to the staggered tooth displacement selection, high counter potential sine degree, large amplitude, low cogging force, and low thrust pulse can be realized for the motors of any excitation modes, any number of stator poles, and any number of mover poles.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

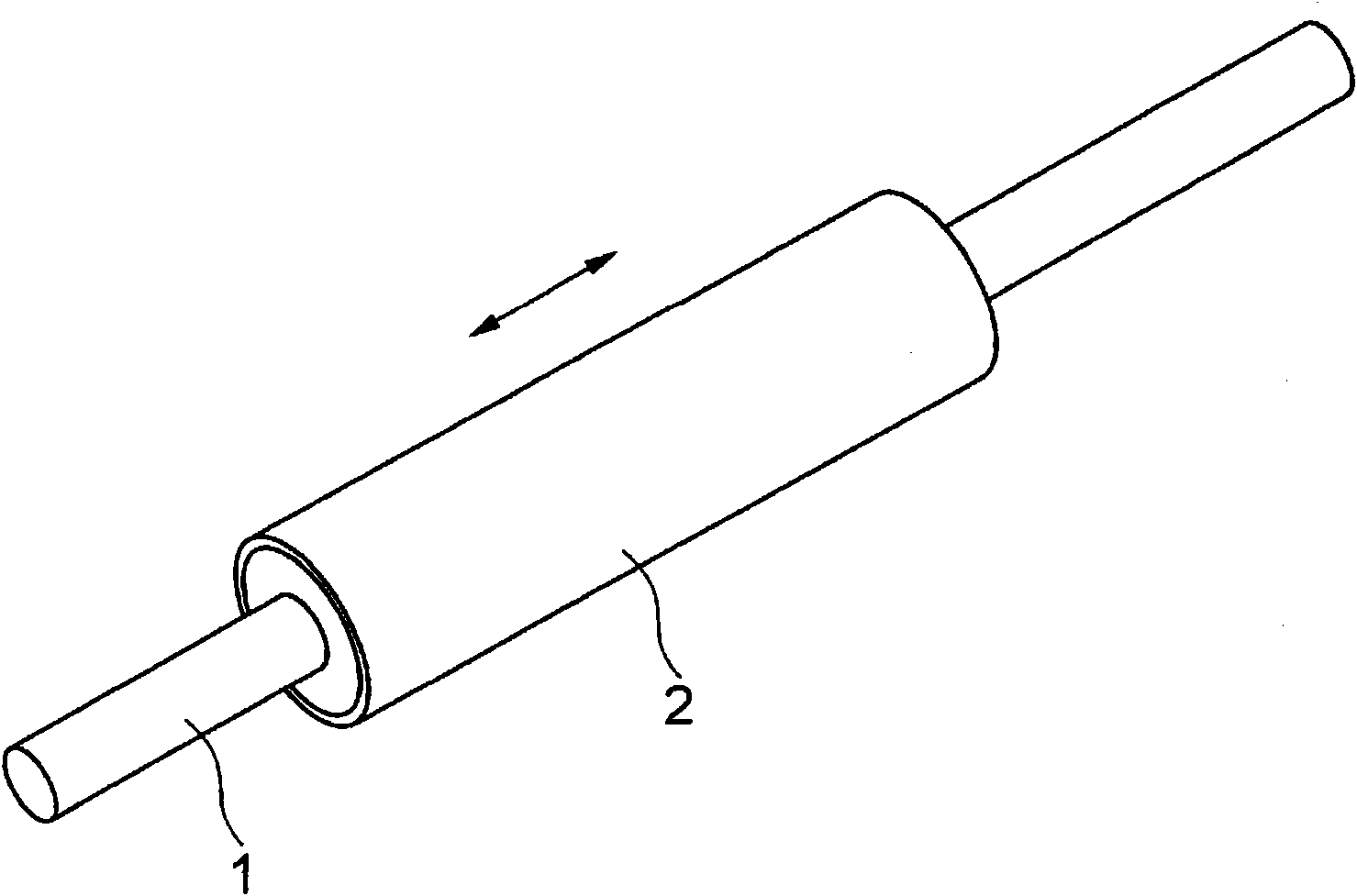

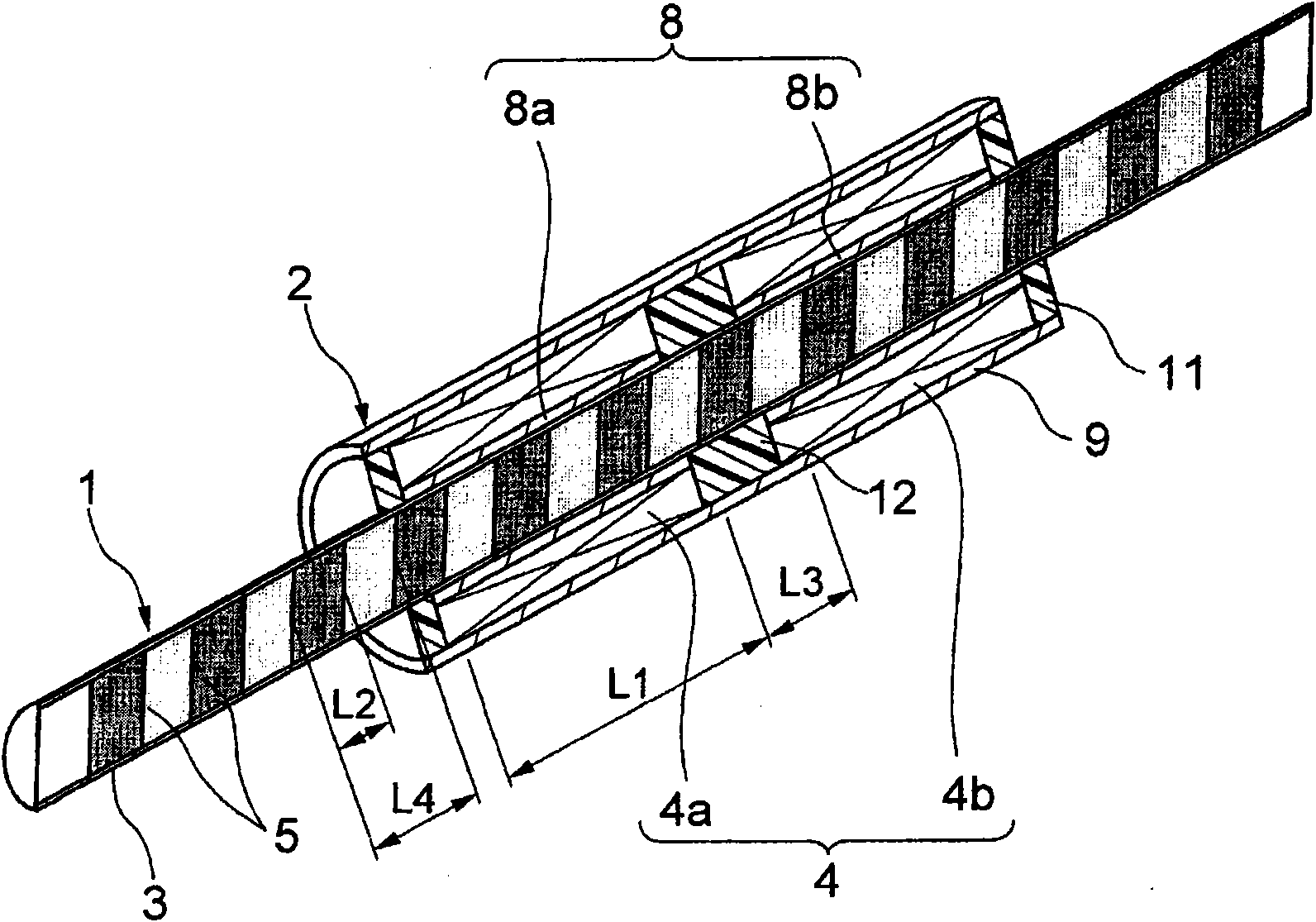

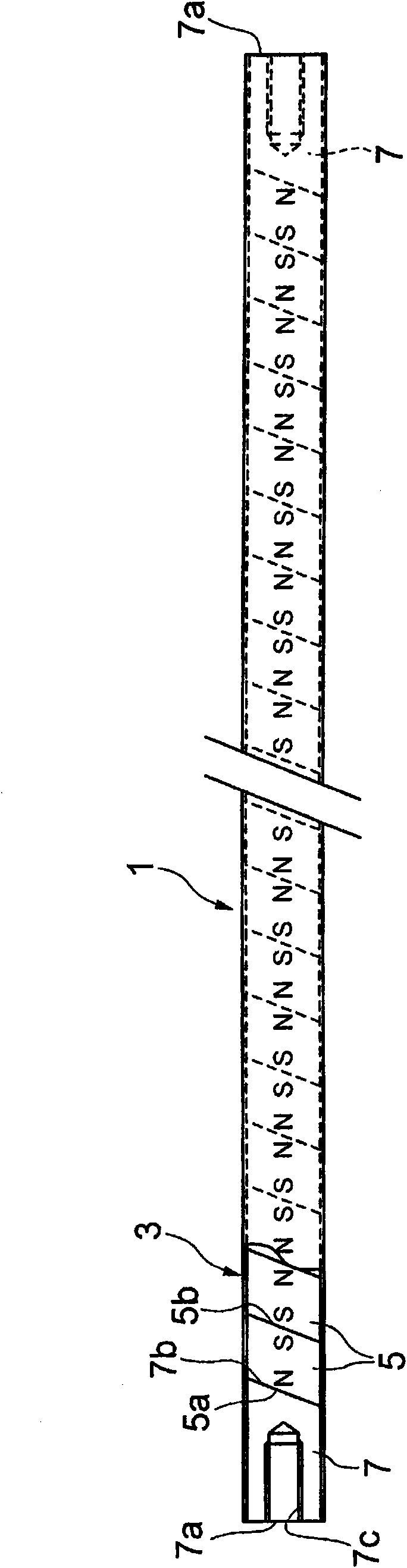

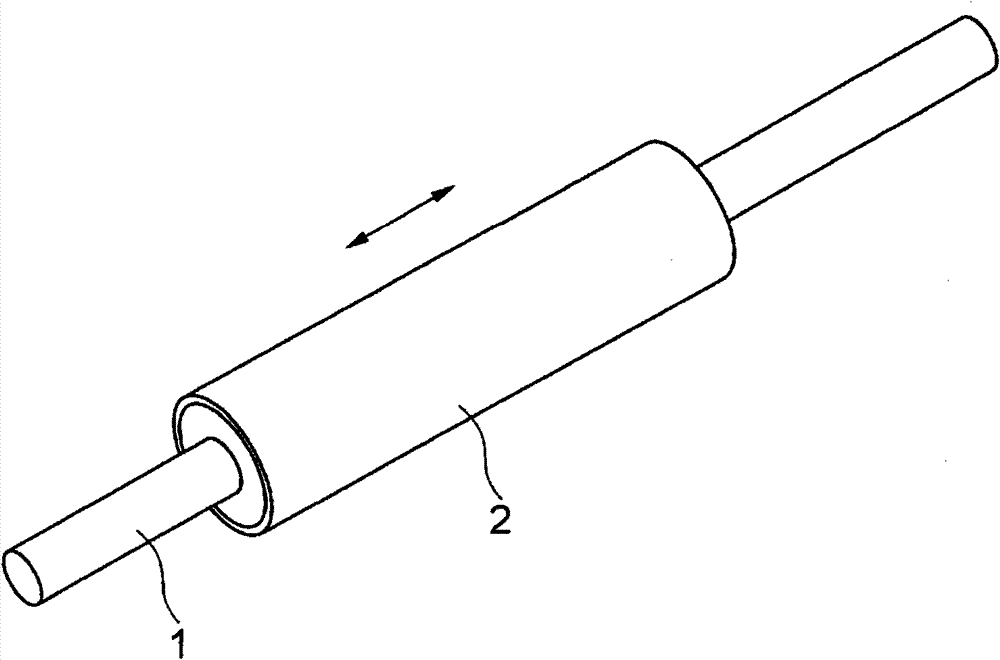

Linear stepping motor

ActiveCN101911451ASmall magnetic resistancePrecise positioningPropulsion systemsPhysicsStepper motor

Provided is a linear stepping motor capable of simplifying the structure and achieving a high thrust. The linear stepping motor comprises a field magnet (1) having N- and S- magnetic poles magnetized alternately in an axial direction, an armature (2) having at least two-phase coils (4), and a control device for magnetizing the two-phase coils (4) and switching the coils (4) to be magnetized. At least the two-phase coils (4) enclose the field magnet (1). On the inner side of at least the two-phase coils (4), inner cores (8) of a magnetic material are arranged through a clearance from the fieldmagnet (1). The attractions and / or repulsions between the magnetic poles generated at the two axial end portions of the exciting coils (4) and the magnetic poles of the field magnet (1) are utilized to move the field magnet (1) linearly by each predetermined step stroke relative to the armature (2).

Owner:THK CO LTD

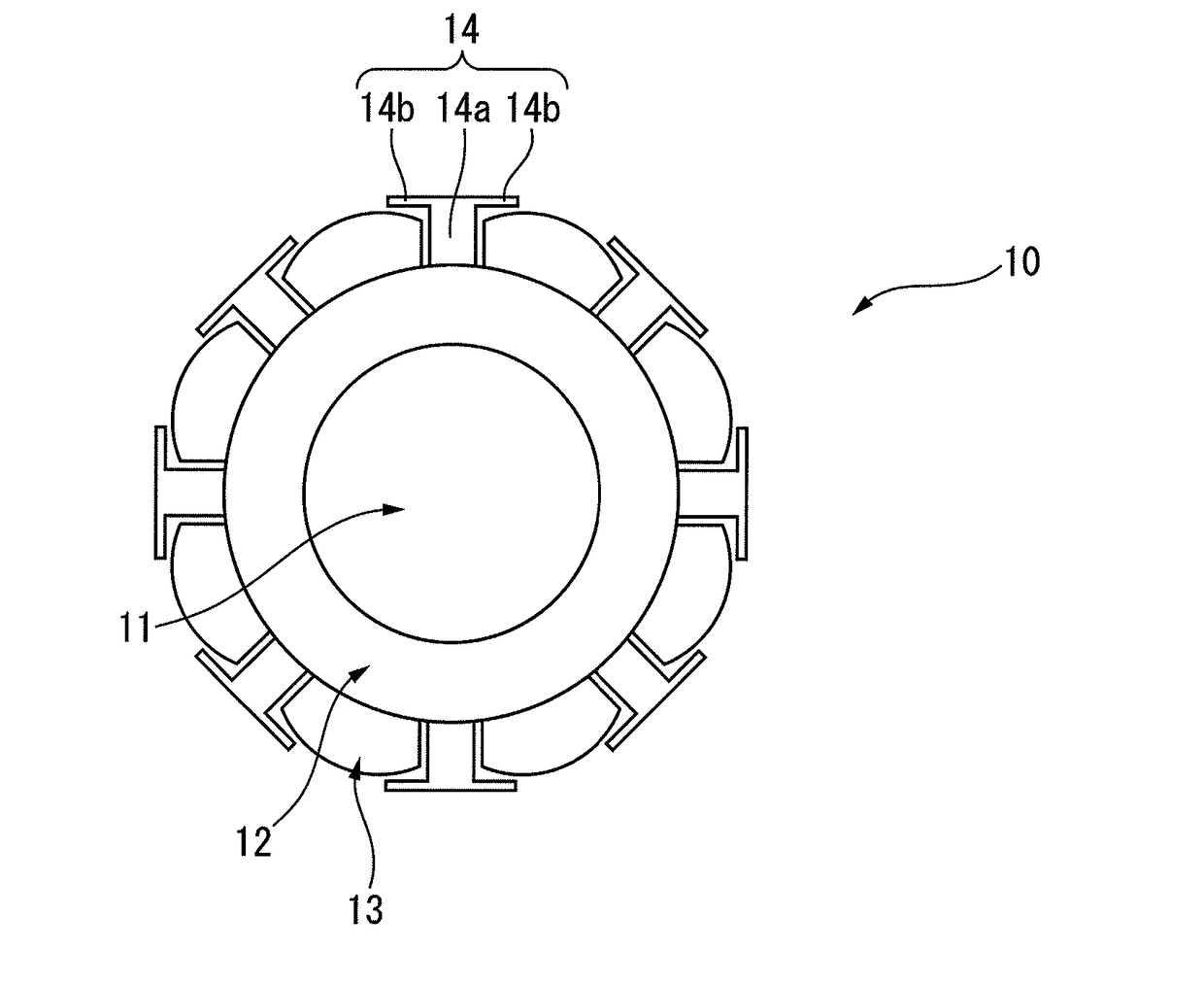

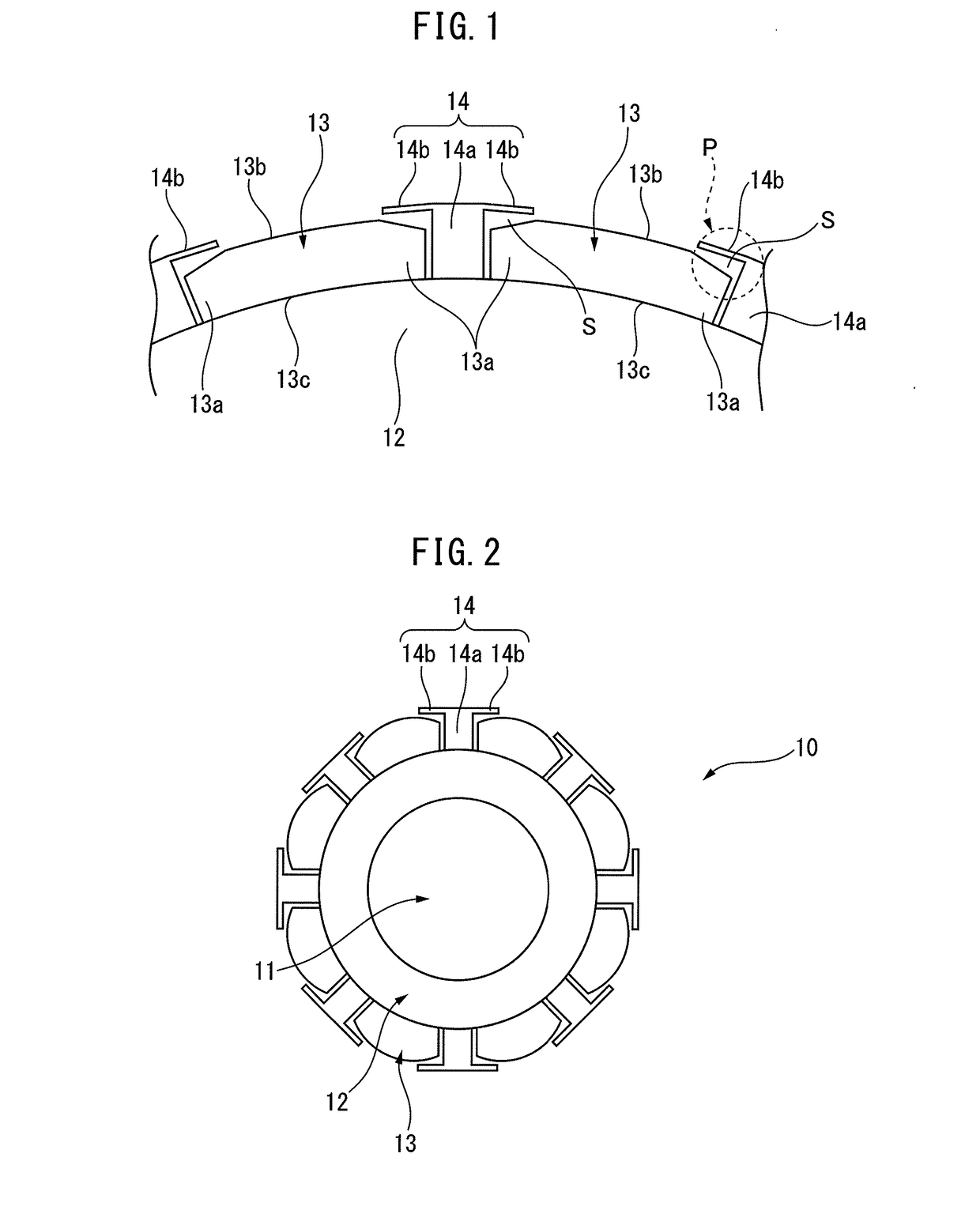

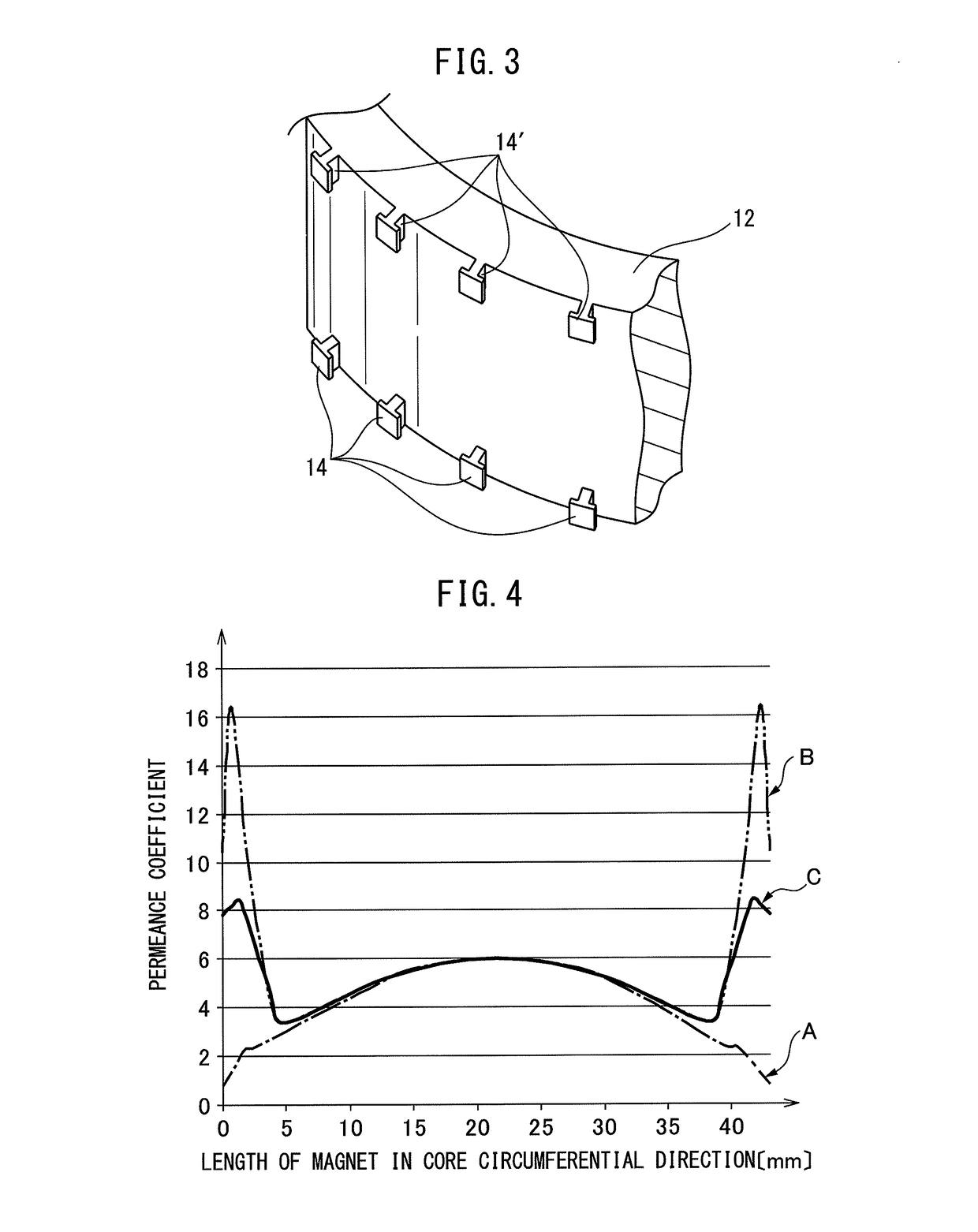

Permanent magnet rotor for synchronous electric motor

ActiveUS10312757B2Reduce cogging forceReduce demagnetizationMagnetic circuit rotating partsPermanent magnet rotorSynchronous motor

Owner:FANUC LTD

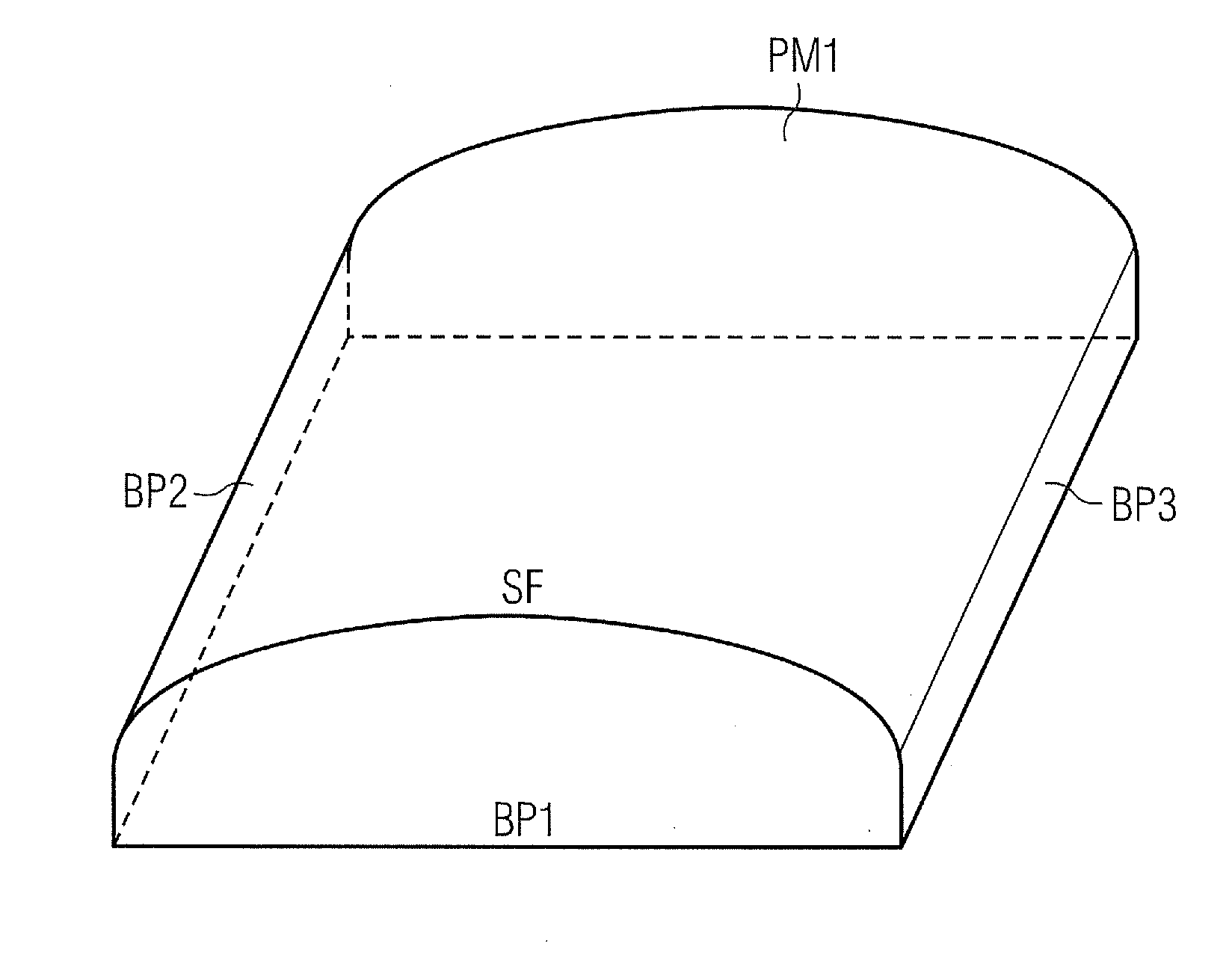

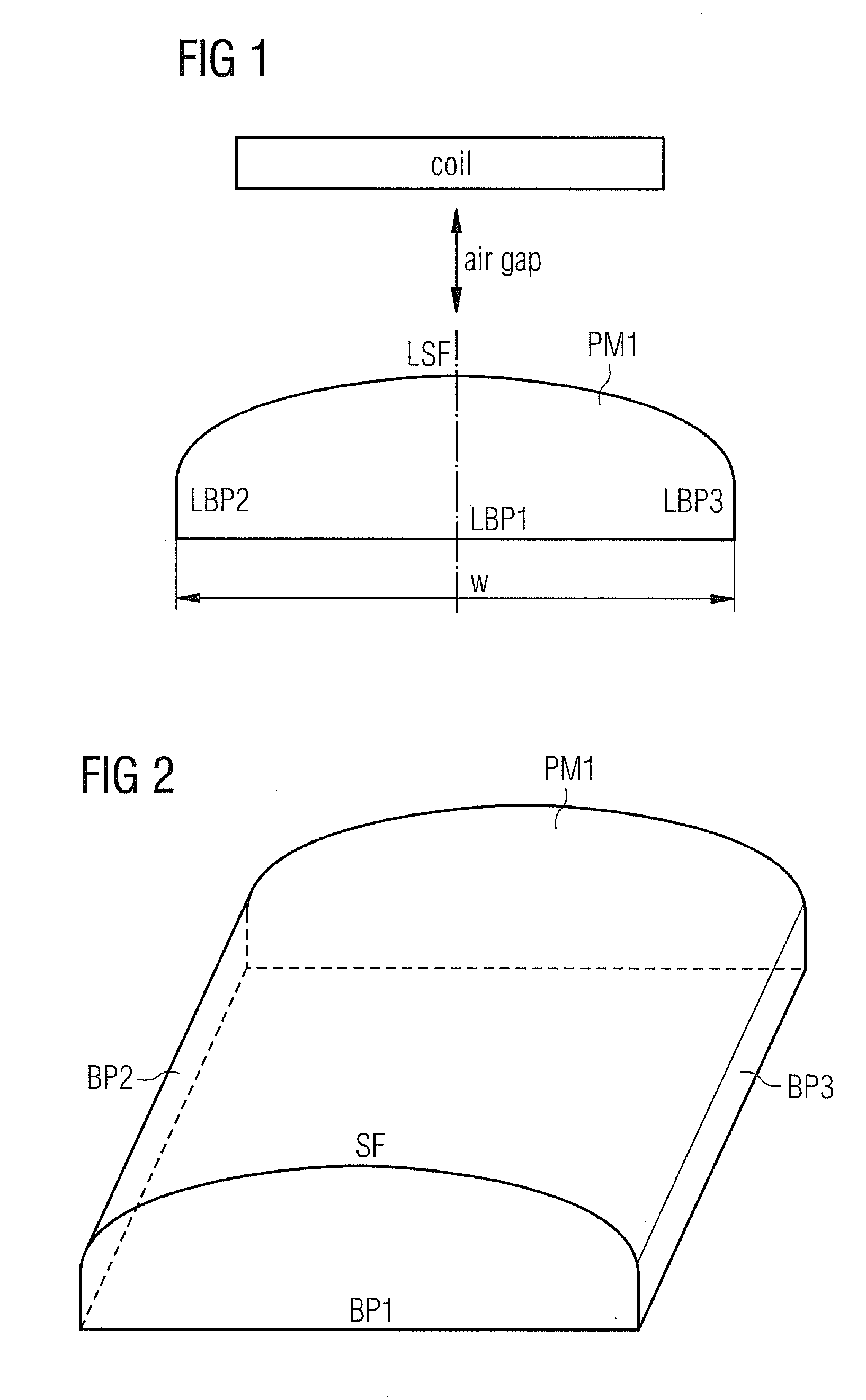

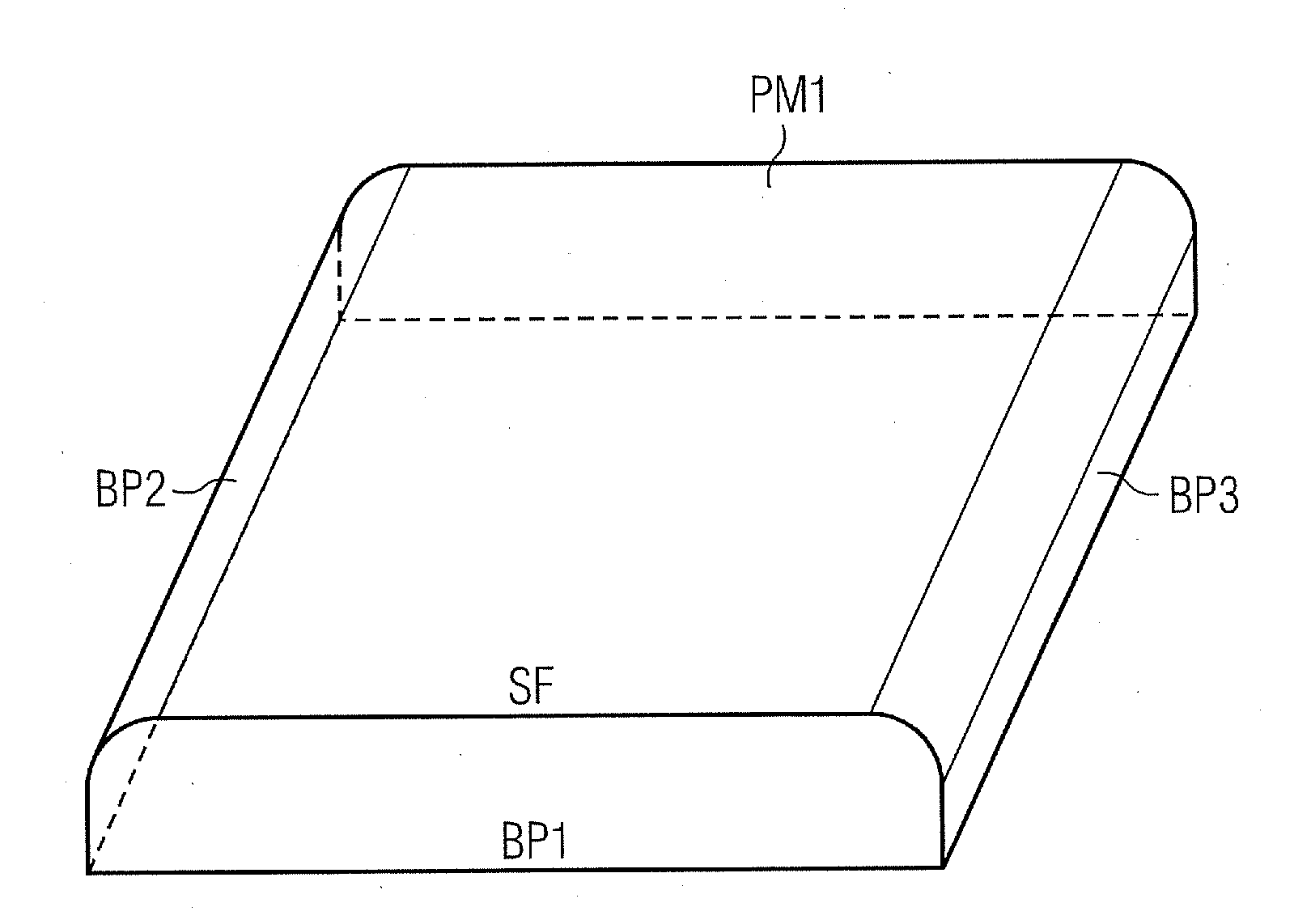

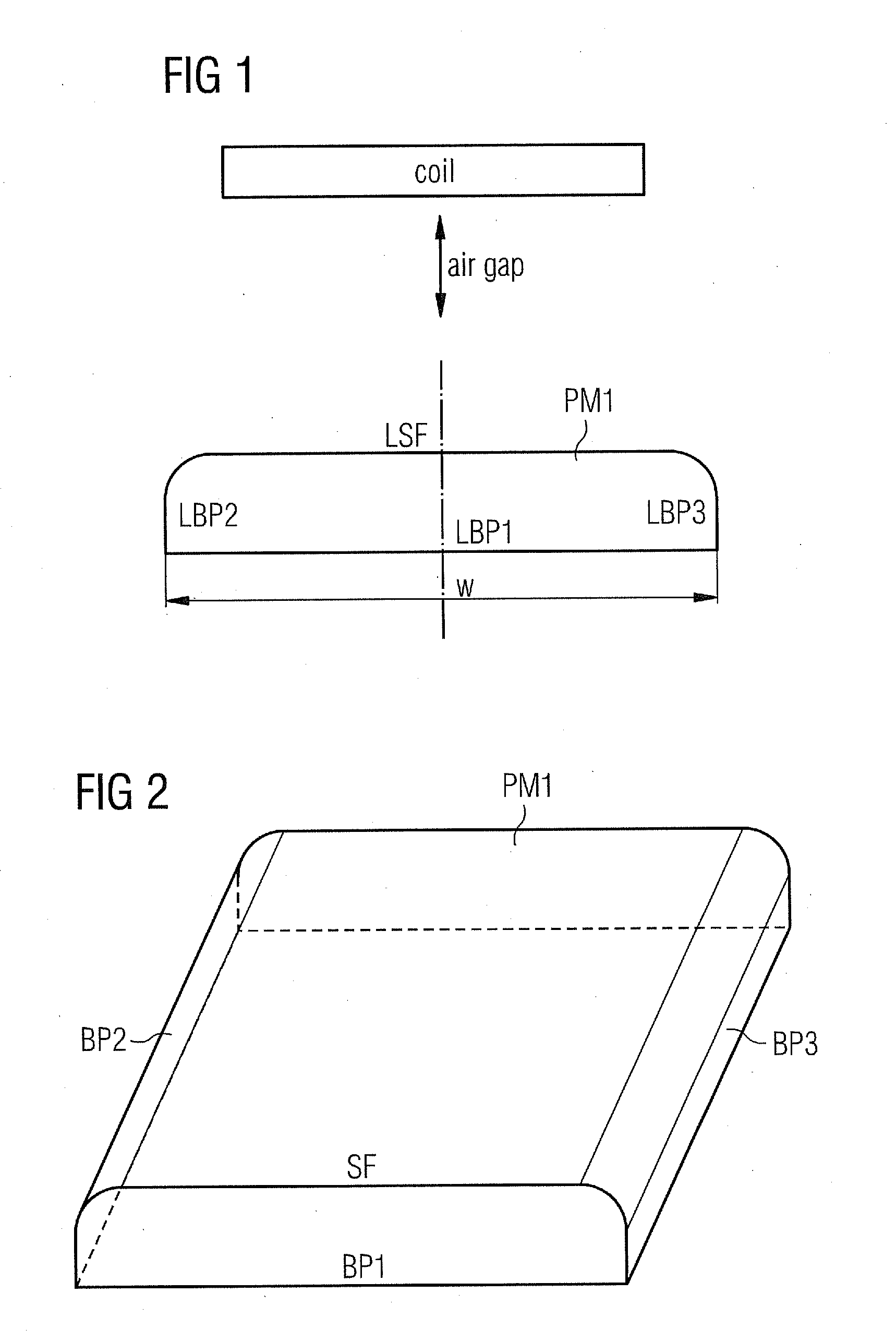

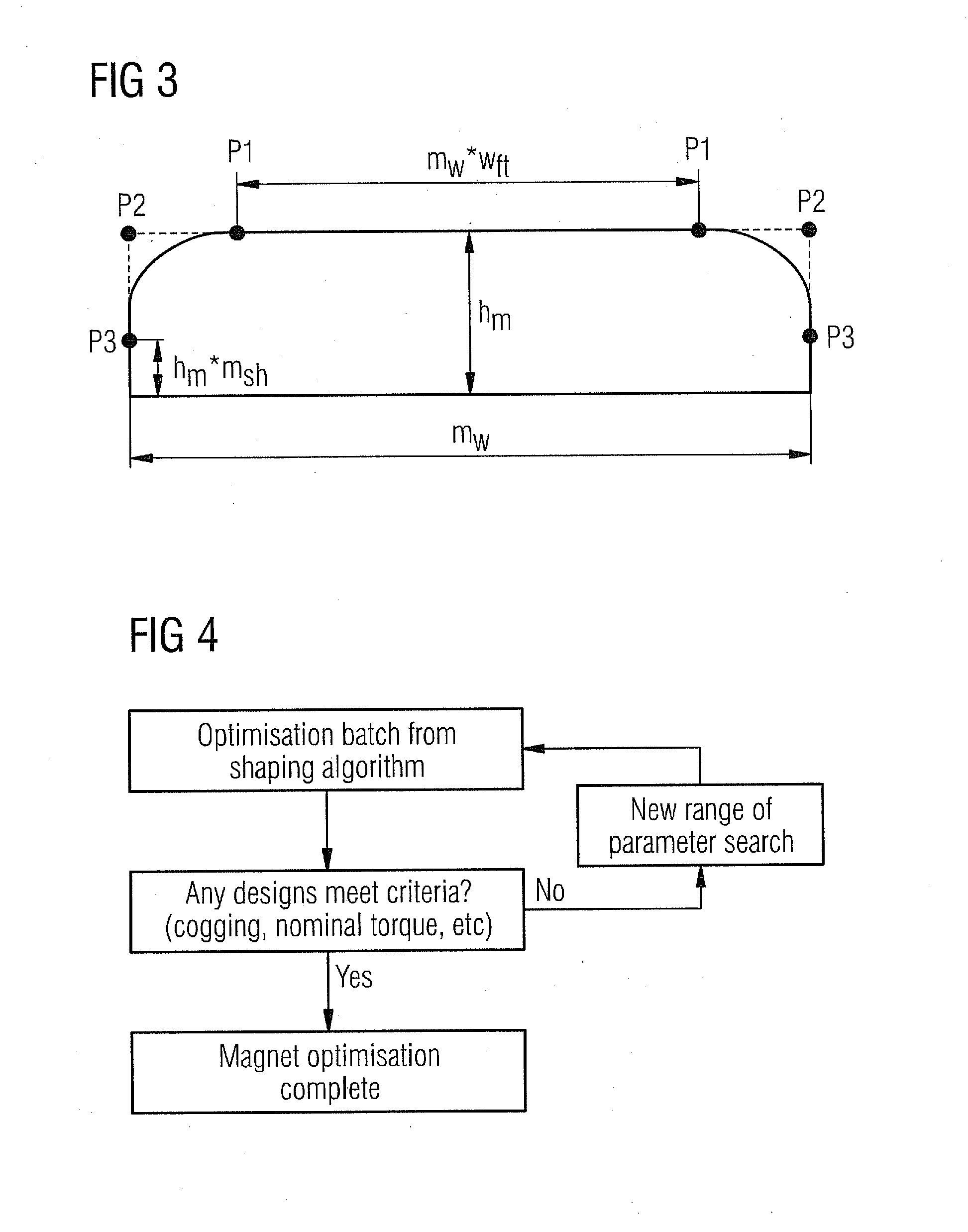

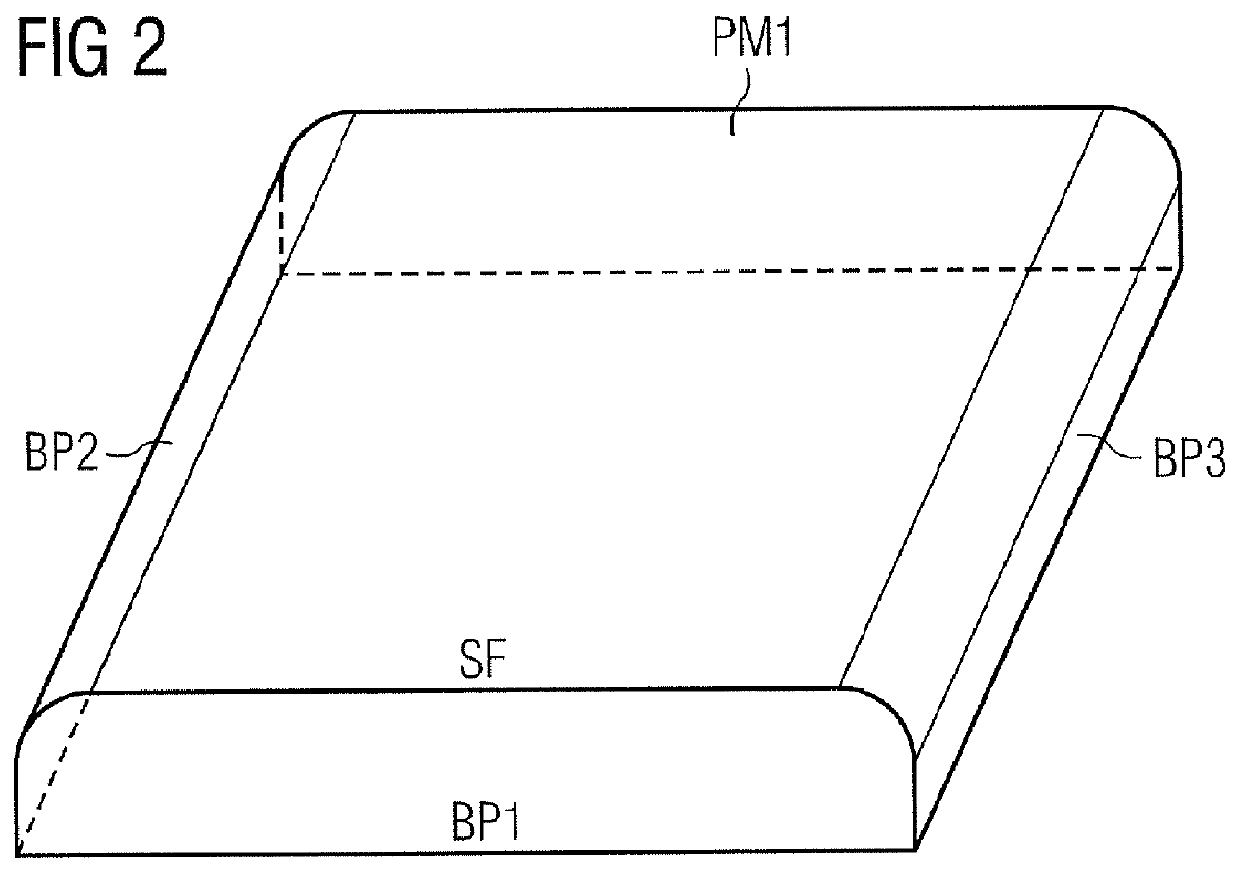

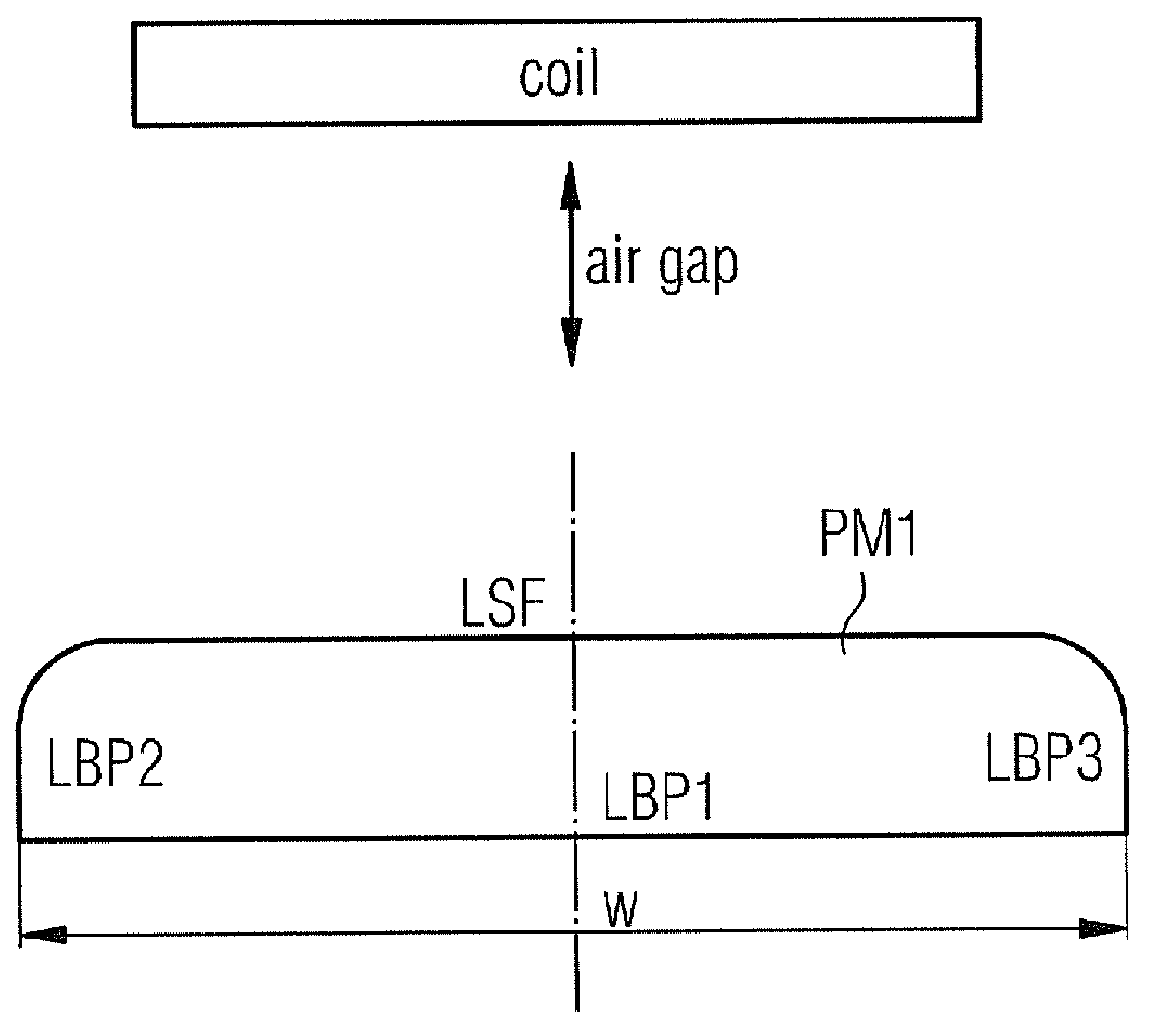

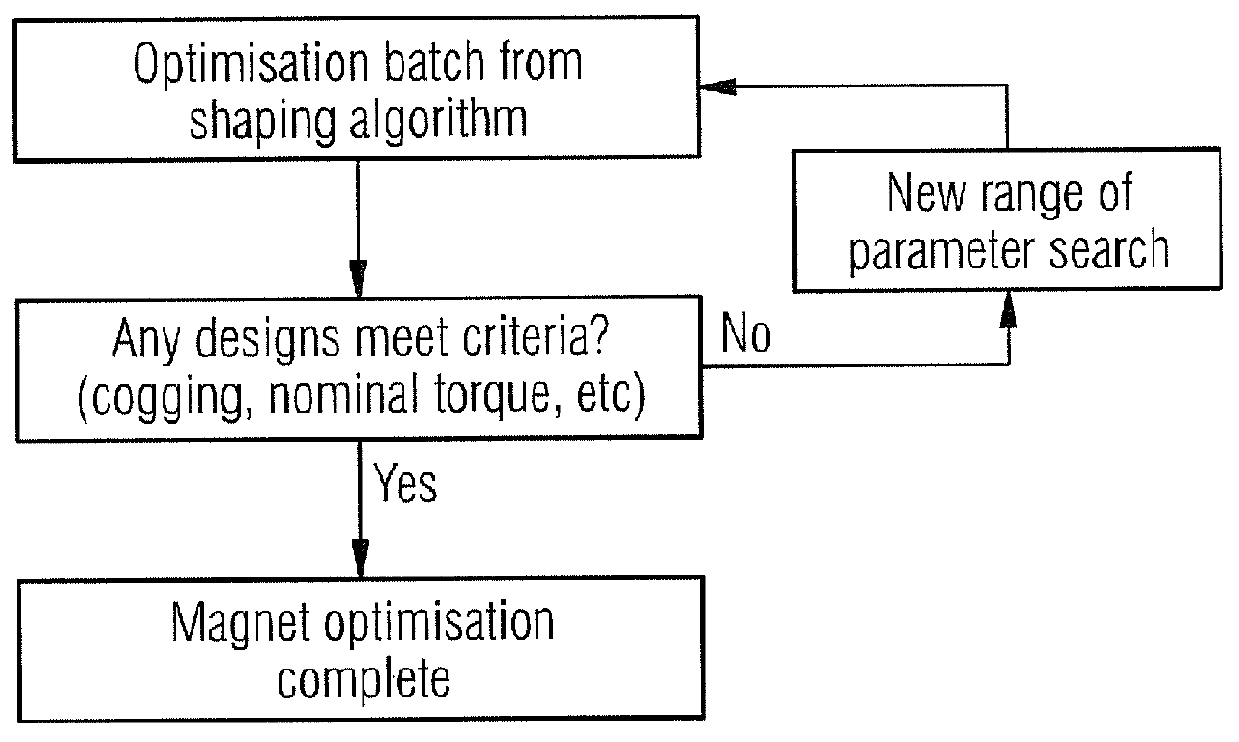

Electrical Machine and Permanent-Magnet

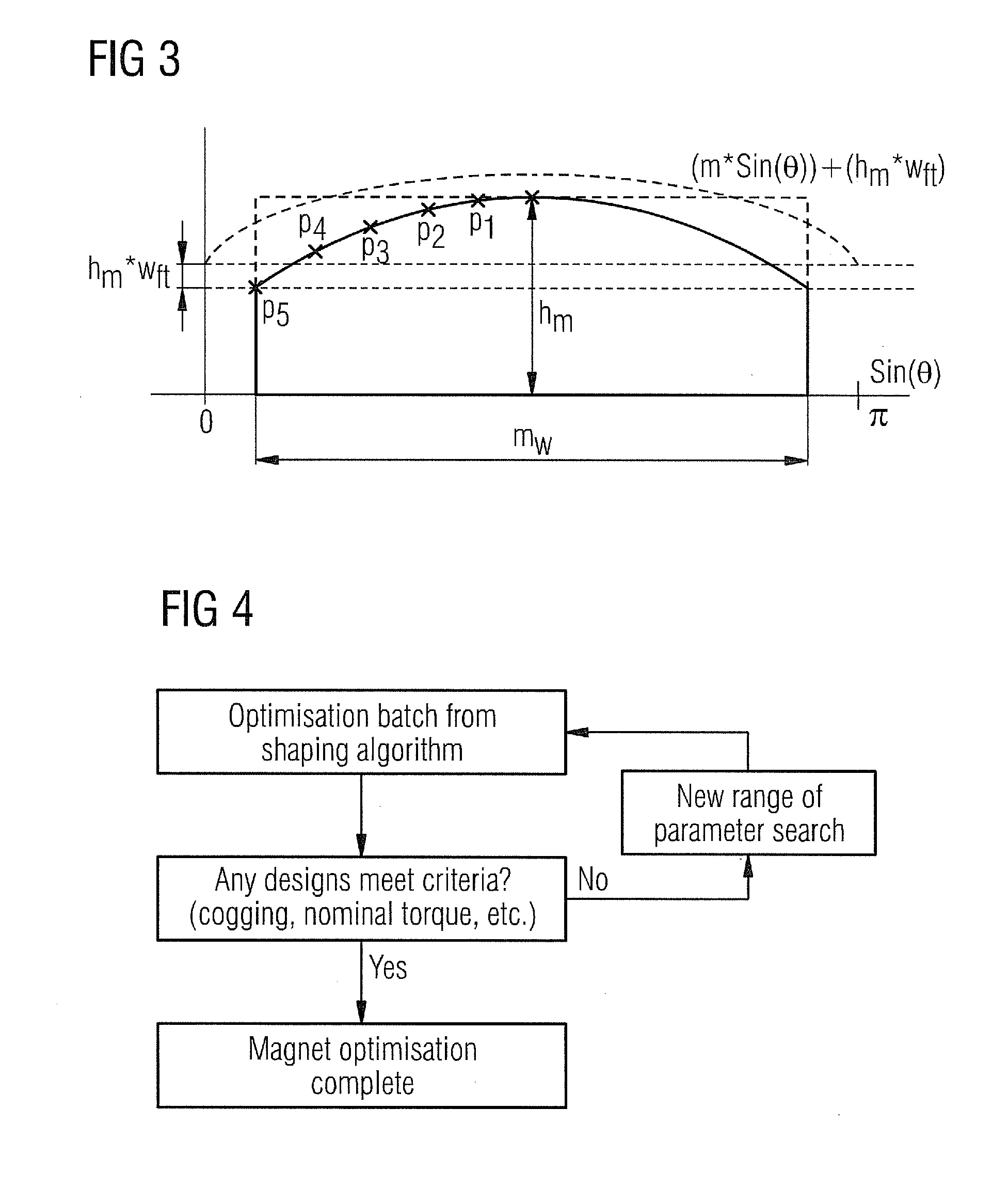

InactiveUS20110248594A1Improve machine efficiencyThe process is fast and efficientMagnetic circuitWind energy generationPhysicsMagnet

An electrical machine including a permanent magnet and a coil is provided. The coil is arranged to interact with the permanent magnet via an air gap, which located between the two. The permanent magnet includes a surface, which is aligned to the coil and to the air gap so that that magnetic forces of the permanent magnet interact via the surface and the air gap with the coil by a magnetic flux density distribution. The surface has a cross-section having a shape that approximates at least partly to a sinusoidal function, causing the magnetic flux distribution in the air gap to be substantially sinusoidal.

Owner:SIEMENS AG

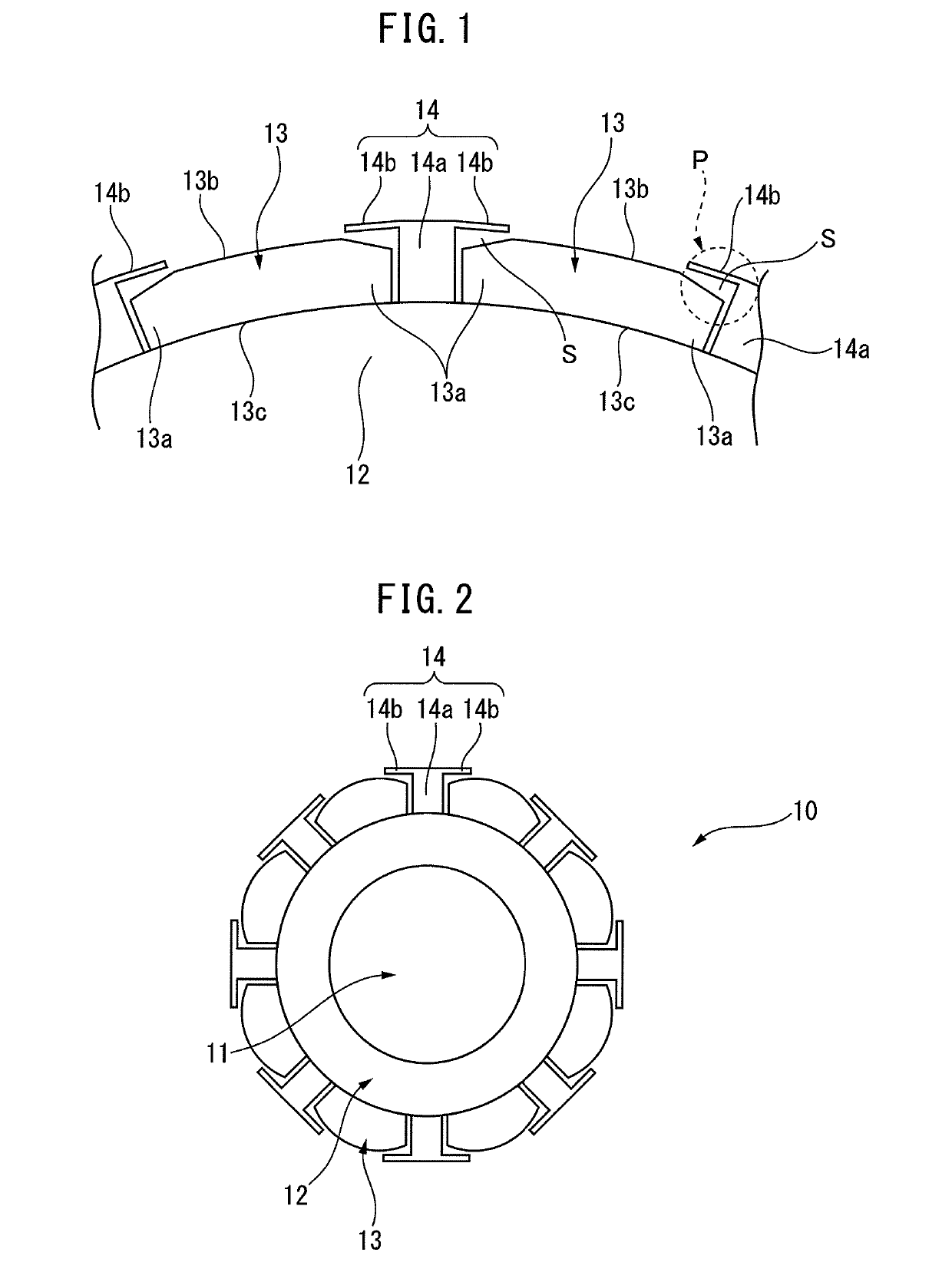

Permanent magnet rotor for synchronous electric motor

ActiveUS20170117765A1Reduce cogging forceReduction of demagnetization resistantMagnetic circuit rotating partsSynchronous motorMagnet

Provided is a permanent magnet rotor that includes a plurality of magnets sequentially disposed on an outer circumferential surface of a core having a cylindrical shape along a circumferential direction of the core and a plurality of projection portions each disposed between the magnets adjacent to each other. Then a cover portion is formed such that a height of a space in a radial direction of the core is more reduced as from a base portion of the projection portions toward a tip end of the cover portion.

Owner:FANUC LTD

Linear motor

PendingCN108023460AReduce thrust fluctuationReduce cogging forcePropulsion systemsStator coilLinear motor

The application discloses a linear motor. The linear motor is provided with a stator, a rotor and a guide rail, wherein the guide rail is arranged on the stator; the rotor is arranged to move relativeto the stator along the guide rail; the stator is provided with a stator coil unit; the rotor is provided with a permanent magnet unit; the permanent magnet unit comprises back iron and a permanent magnet array arranged on the back iron; the permanent magnet array is provided with a primary magnet and an auxiliary magnet arranged on at least one end of the permanent magnet unit; the auxiliary magnet is located on the outer side of the primary magnet on the outermost side of the permanent magnet array; and the auxiliary magnet is narrower than the primary magnet. The linear motor disclosed bythe invention is small in thrust ripple and cogging force.

Owner:苏州盛拓半导体科技有限公司

Flat-plate-type transverse flux permanent magnet synchronous linear generator

ActiveCN107742969AReduce lossImprove space utilizationPropulsion systemsTransverse fluxPrimary Tooth

Provided is a flat-plate-type transverse flux permanent magnet synchronous linear generator. The generator comprises flat-plate-type transverse flux primary pole iron cores, a flat-plate-type transverse flux secondary pole iron core, secondary pole magnetic steel and a racetrack winding; the secondary magnetic steel is flatly laid and arrayed on the surface of the flat-plate-type transverse flux secondary pole iron core in the z axis direction that a motor moves by adopting a surface-mount mode. A flat-plate-type transverse flux primary pole is mounted parallel to and opposite to the secondarymagnetic steel, and air gaps are formed between flat-plate-type transverse flux primary tooth pole shoes and the secondary magnetic steel; the racetrack winding winds around pole bodies of flat-plate-type transverse flux primary pole iron core tooth poles. The flat-plate-type transverse flux permanent magnet synchronous linear generator can be applied to direct-driving-type wave energy generationsystems.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Electrical machine and permanent-magnet

ActiveUS20110248508A1Improve machine efficiencyThe process is fast and efficientMagnetic circuitMachines/enginesMagnetic flux density distributionBessel function

An electrical machine including a permanent magnet and a coil is provided. The coil is arranged to interact with the permanent magnet via an air gap, which located between the two. Electrical power is generated in the coil when the permanent magnet or the coil is moved in their relative position to each other. The permanent magnet includes a surface, which is aligned to the coil and to the air gap so that that magnetic forces of the permanent magnet interact via the surface and the air gap with the coil by a magnetic flux density distribution. The permanent magnet also includes a base plane and a transition area. A first side of the surface is connected with the adjacent base plane via the transition area. The cross-section of the transition between the surface and the adjacent base plane is determined by a Bezier function.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Electrical machine and permanent-magnet

ActiveUS8217546B2Improve machine efficiencyThe process is fast and efficientMagnetic circuitDC commutatorElectric machineMagnetic flux density distribution

An electrical machine including a permanent magnet and a coil is provided. The coil is arranged to interact with the permanent magnet via an air gap, which located between the two. Electrical power is generated in the coil when the permanent magnet or the coil is moved in their relative position to each other. The permanent magnet includes a surface, which is aligned to the coil and to the air gap so that that magnetic forces of the permanent magnet interact via the surface and the air gap with the coil by a magnetic flux density distribution. The permanent magnet also includes a base plane and a transition area. A first side of the surface is connected with the adjacent base plane via the transition area. The cross-section of the transition between the surface and the adjacent base plane is determined by a Bezier function.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

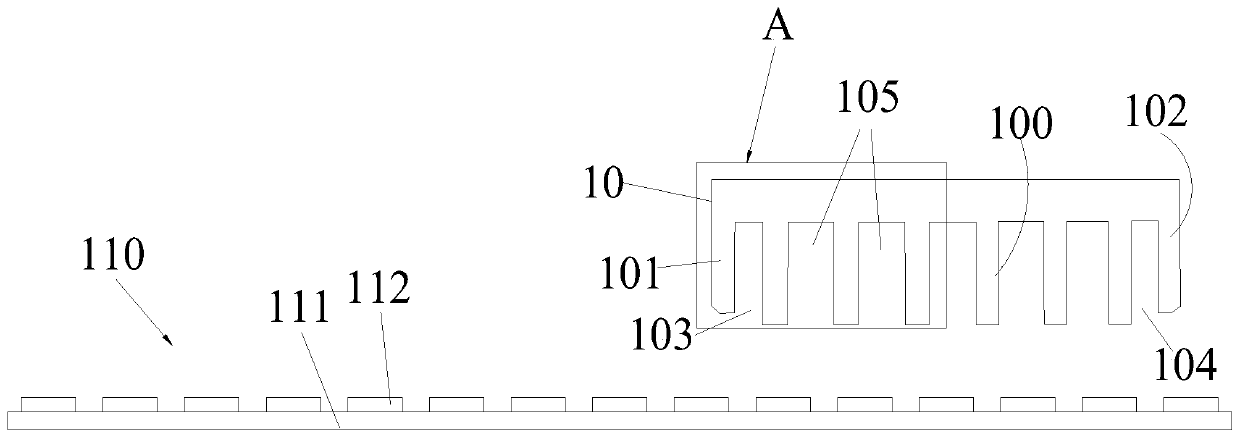

Permanent magnet synchronous linear motor with low thrust pulsation

PendingCN110768506ASolve the problem of high cogging forceReduce cogging forcePropulsion systemsElectric machineClassical mechanics

The invention relates to the technical field of a linear motor and discloses a permanent magnet synchronous linear motor with low thrust pulsation. The motor comprises a mover and a stator, wherein the mover and the stator are oppositely arranged, the mover comprises an iron core, a plurality of windings and a circuit board, a lower end of the iron core extends towards the stator to form a plurality of iron core columns arranged at intervals, the windings are arranged on the iron core columns in a sleeving mode, the windings are electrically connected with the circuit board, the stator is arranged on a base and comprises a magnetic conductive substrate and a plurality of permanent magnets of which N-S poles are arranged in parallel in a staggered manner, the front-end iron core column arranged towards the stator is formed at a front end of the mover, the rear-end iron core column arranged towards the stator is formed at a rear end of the mover, and end teeth are arranged on the front-end iron core column and the rear-end iron core column. The motor is advantaged in that in the moving process of the mover, under the action of the end teeth at the front end and the rear end of the mover, the cogging force and thrust pulsation can be effectively reduced, and the application of the linear motor in high-precision occasions is facilitated.

Owner:深圳线马科技有限公司

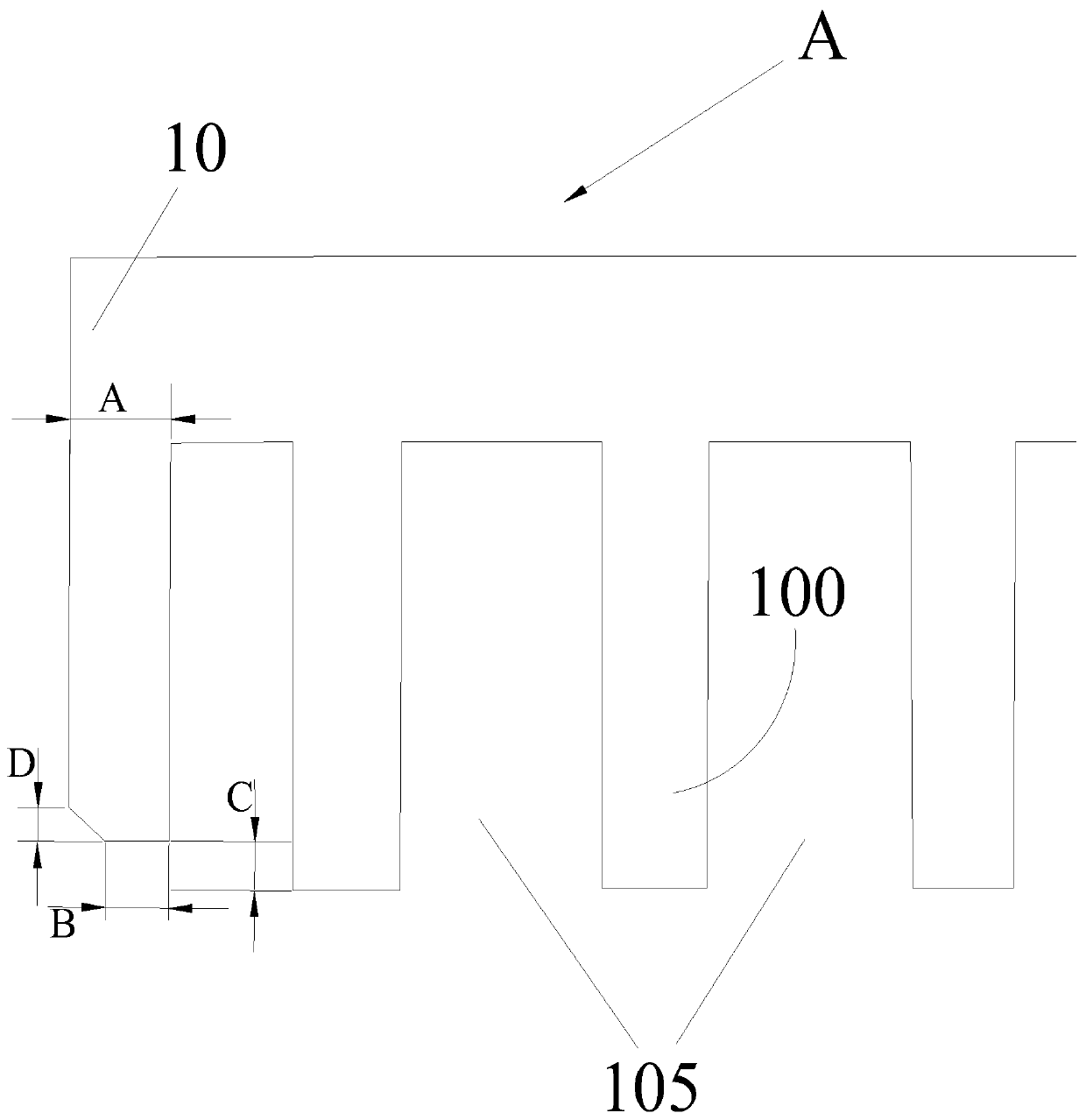

Linear motor with reduced cogging force

A linear motor includes a plurality of magnets arranged at equal intervals, and an armature arranged opposite to the magnets and including an armature core having a plurality of teeth extending toward the magnets. The teeth include a first tooth located at one end in the thrust direction and a second tooth located at the other end on the opposite side. The first tooth and the second tooth have different dimensions or shapes so as to reduce cogging force generated due to the structure of the armature core at the ends in the thrust direction.

Owner:FANUC LTD

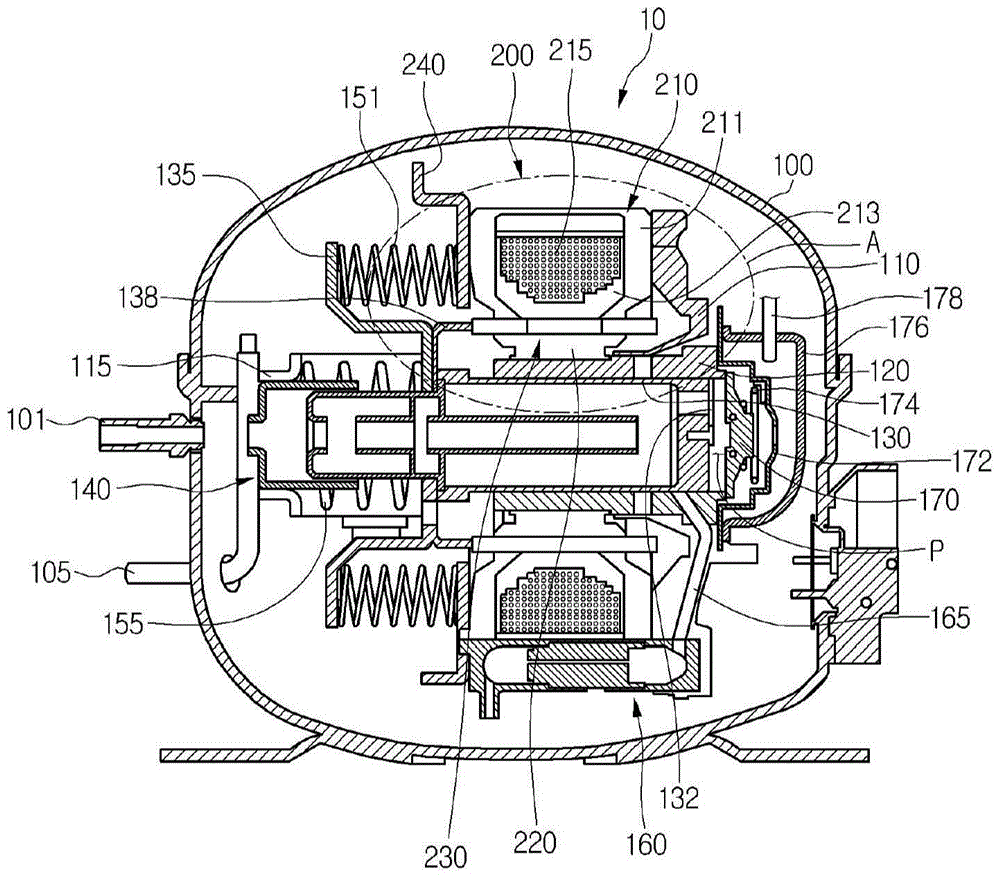

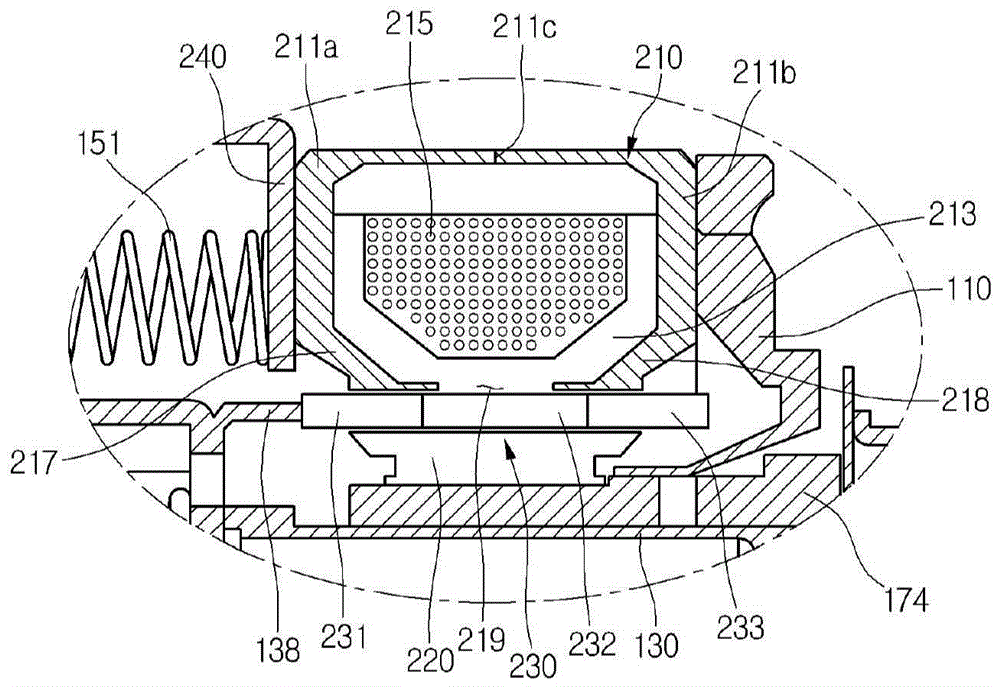

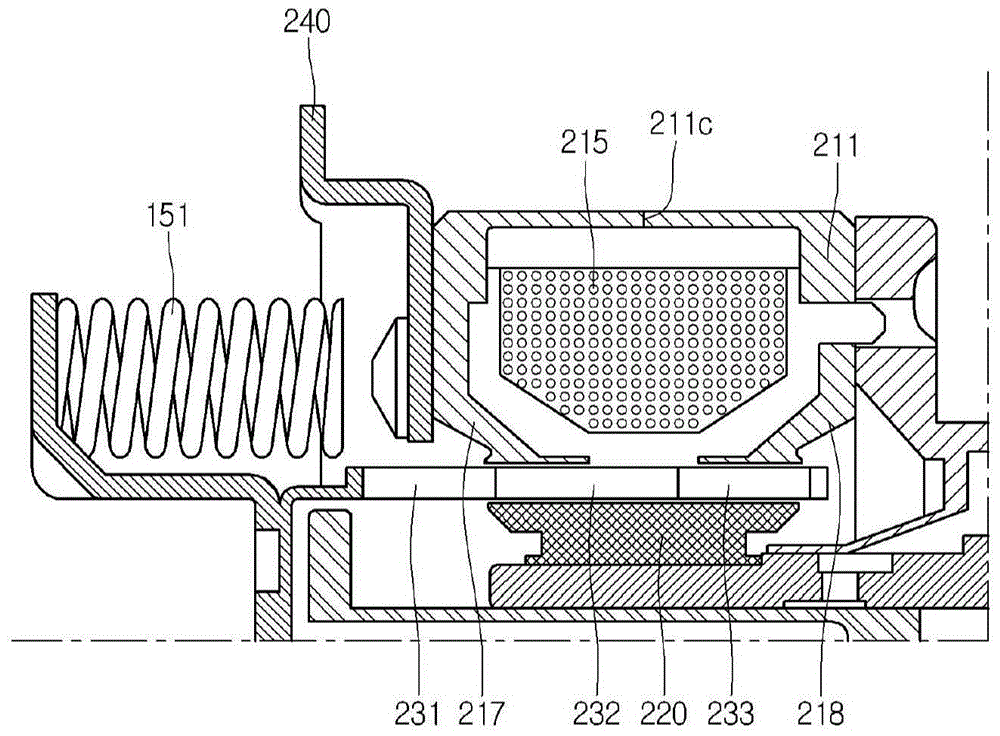

linear compressor

ActiveCN104251194BIncrease thrustLarge thrustReciprocating/oscillating/vibrating magnetic circuit partsPositive displacement pump componentsReciprocating motionLinear compressor

The present invention relates to linear compressors. A linear compressor according to an embodiment of the present invention includes: a cylinder forming a refrigerant compression space, a piston capable of reciprocating axially inside the cylinder, and a linear motor that supplies thrust to the piston; the linear motor includes : The outer stator includes a first stator magnetic pole, a second stator magnetic pole and an opening, the opening is formed between the first stator magnetic pole and the second stator magnetic pole, and the inner stator is separated from the outer stator The configuration, and the permanent magnets, are arranged in a manner capable of moving in the gap between the outer stator and the inner stator, and include three magnetic poles; Between two magnetic poles at both ends, it is formed in such a way that it is longer than the magnetic poles at both ends.

Owner:LG ELECTRONICS INC

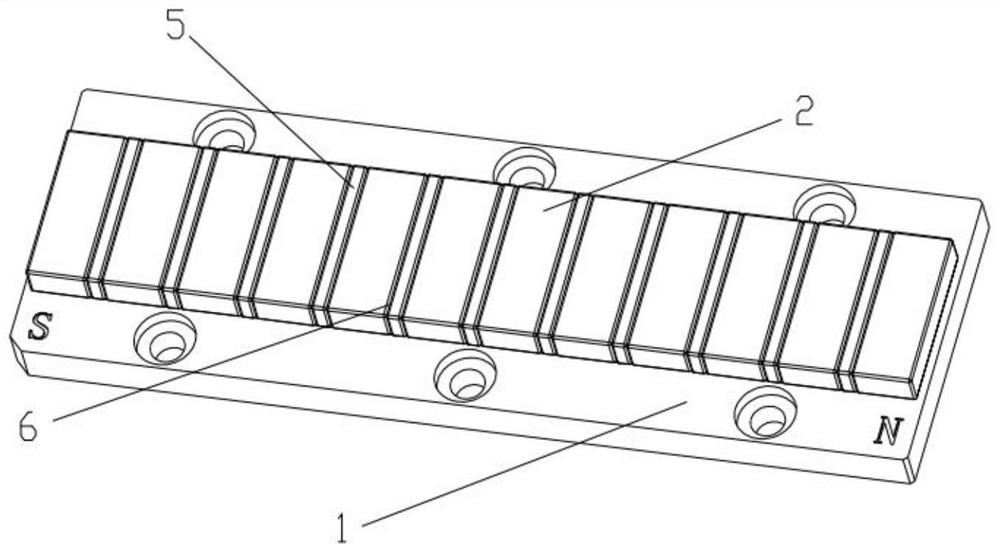

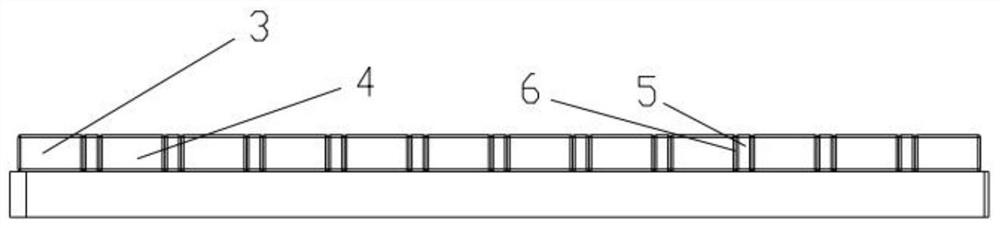

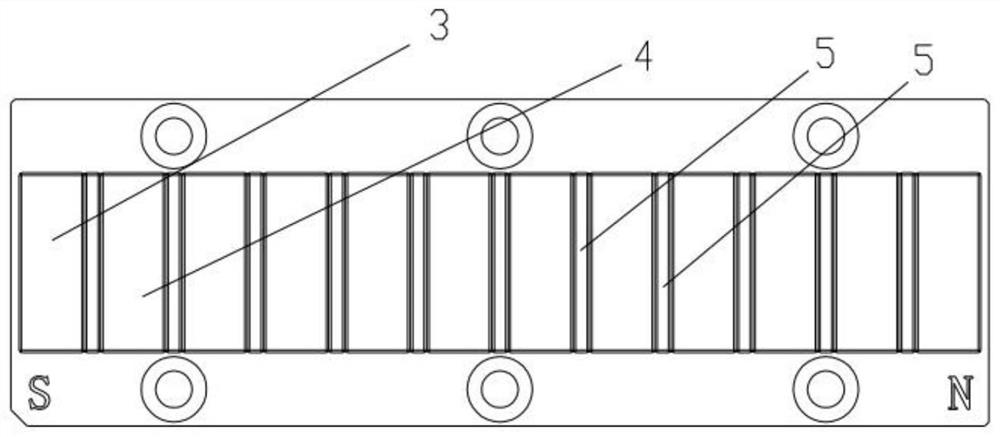

Large and small magnetic unit pole interval type stator for linear motor

PendingCN113629908AReduce CatonHigh precisionMagnetic circuit stationary partsPropulsion systemsMagnetic tension forceElectric machine

The invention relates to a large and small magnetic unit pole interval type stator for a linear motor, which comprises a placing plate and a large magnetic unit. The large magnetic unit comprises S poles and N poles, the S poles and the N poles are distributed in a linear array shape in the length direction of the placing plate, the S poles and the N poles are distributed in a staggered manner, the S poles and the N poles are separated, the S poles and the N poles are uniformly distributed on the placing plate, and gaps are formed between the S poles and the N poles. The stator is characterized in that small magnetic units are arranged between the S poles and the N poles, the gaps are specifically rectangular, the small magnetic units are specifically located in the gaps, and the small magnetic units are distributed on the placing plate in a linear array mode. According to the large and small magnetic unit pole interval type stator for a linear motor, the cogging force generated in the motion process of the linear motor is reduced, the jamming in the motion process of the linear motor is reduced, the precision of the linear motor is improved, the overall magnetic force of the rotor is increased, and the thrust of the linear motor is improved.

Owner:江苏群科智能科技股份有限公司

Linear motor with reduced cogging force

A linear motor includes a plurality of magnets arranged at equal intervals, and an armature arranged opposite to the magnets and including an armature core having a plurality of teeth extending toward the magnets. The teeth include a first tooth located at one end in the thrust direction and a second tooth located at the other end on the opposite side. The first tooth and the second tooth have different dimensions or shapes so as to reduce cogging force generated due to the structure of the armature core at the ends in the thrust direction.

Owner:FANUC LTD

Motor rotor

ActiveCN102510149BReduce cogging forceExcellent magnetic propertiesMagnetic circuit rotating partsControl theoryMagnet

Owner:SUZHOU DRANE ELECTRIC MOTORS

Fault-tolerance permanent magnet linear motor

ActiveCN101789676BReduce cogging forceReduce thrust fluctuationPropulsion systemsFault tolerancePermanent magnet linear motor

The invention discloses a fault-tolerance permanent magnet linear motor, which is applied to the field of linear driving with high reliability and high efficiency. The fault-tolerance permanent magnet linear motor comprises a stator, a mover and armature windings, wherein the length of the mover is smaller than that of the stator, a plurality of armature teeth are uniformly distributed on the stator at intervals, the armature windings are wound on the armature teeth, a set of armature windings is arranged in a tooth groove of each armature tooth, an insulation tooth is arranged between every two adjacent armature teeth, permanent magnets are pasted and arranged on the end parts of the armature teeth, the height of the insulation teeth is larger than that of the armature teeth pasted and provided with the permanent magnets, and the mover is in a projected electrode shape formed by a mover iron core and a plurality of mover teeth. The invention has the advantages of simple structure, high power density and high reliability, and is favorable for reducing the tooth groove force of the motor. Physical isolation, heat isolation and magnetic circuit decoupling exist between phases of themotor, the permanent magnets are favorable for heat dissipation, and the motor has strong fault operation and fault-tolerance performance.

Owner:JIANGSU UNIV

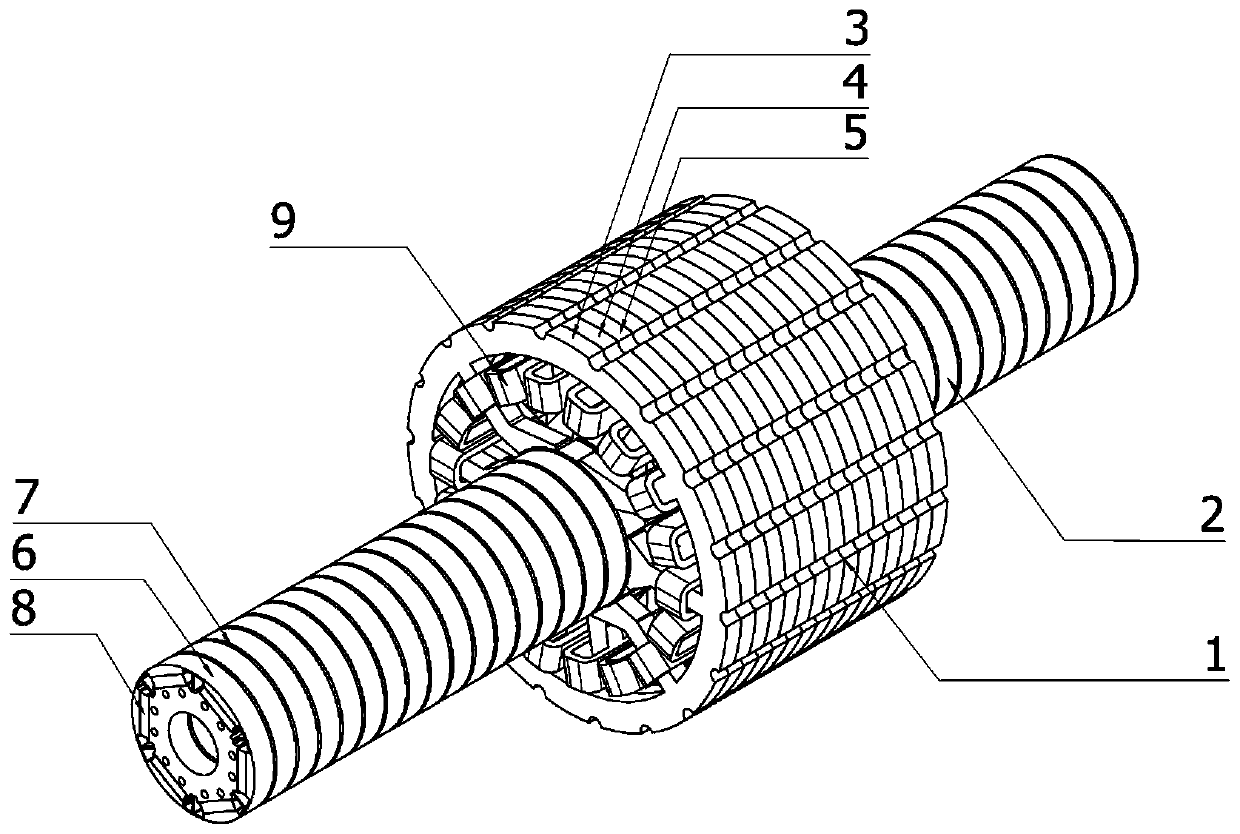

A Cylindrical Transverse Flux Permanent Magnet Synchronous Linear Generator

ActiveCN107800265BImprove reliabilityIncrease profitMagnetic circuitPropulsion systemsEngineeringPole piece

Provided is a cylindrical traverse flux permanent magnet synchronous linear generator. The cylindrical traverse flux permanent magnet synchronous linear generator comprises a primary side (1) and a secondary side (2) which are both cylindrical and in traverse flux. The primary side (1) comprises an A-phase primary iron core (3), a B-phase primary iron core (4), a C-phase primary iron core (5) andtrack-type windings (9), and the track-type windings (9) wind around tooth pole bodies of the primary iron cores. The secondary side (2) comprises secondary iron core units (6), magnetic-insulated sheets (7) and secondary magnetic steel (8), the secondary magnetic steel (8) is nested in the secondary iron core units (6), the secondary iron core units (6) and the magnetic-insulated sheets (7) are arranged at intervals, secondary permanent magnets are nested in the secondary iron core units (6), the cylindrical primary side (1) and the secondary side (2) in the traverse flux are arranged in a concentric manner, the outer side of the secondary side (2) is sleeved by the primary side (1), and an air gap is arranged between tooth pole shoes of the primary side and the surface of the secondary side. The cylindrical traverse flux permanent magnet synchronous linear generator is used for a direct-driven wave energy generation system.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Linear stepping motor

ActiveCN101911451BSmall magnetic resistanceLarge thrustPropulsion systemsMagnetic polesAtomic physics

Owner:THK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com