Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Quick release connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric air supply filtering type protective hood

PendingCN111729217AImprove efficiencyAvoid pollutionBreathing filtersBreathing masksInflatableElectrical and Electronics engineering

The invention discloses an electric air supply filtering type protective hood comprising a transparent hood body and an inflatable sealing base detachably arranged at the bottom of the hood body, wherein a cavity with an open bottom is formed in the hood body, and the hood body can sleeve the head in a direction from the top of the head of a user to the neck; an annular transverse zipper is formedat the bottom of the hood body, the sealing base is connected to the hood body through the transverse zipper, and the sealing base can tightly sleeve the neck of the user after being inflated so as to seal the cavity; at least two ventholes are formed in the hood body, a connector capable of being connected with an electric air feeder is detachably arranged on the ventholes, and a filter is embedded into the connector; internal threads in pipe connection with the electric air feeder are formed on the inner wall of the connector; and external threads in threaded connection with a closing cap are formed on the outer wall of the connector. The electric air supply filtering type protective hood is simple in structure, good in sealing performance and convenient to take off and wear; and the comfort is optimized.

Owner:ANHUI ZHONGNAN AIR DEFENCE WORKS PROTECTIVE EQUIP

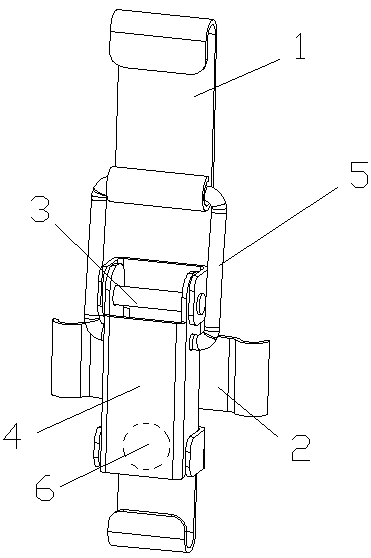

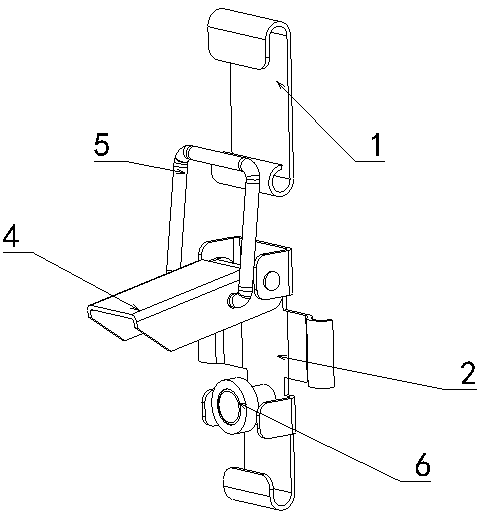

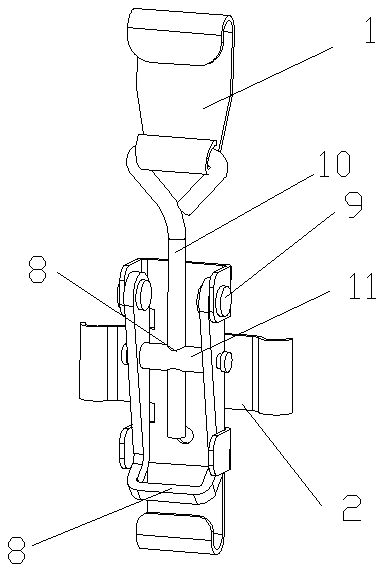

Novel bag cage connection assembly and use method thereof

PendingCN110280077AQuick release connectionPracticalDispersed particle filtrationTransportation and packagingEngineeringRivet

The invention provides a novel bag cage connection assembly and a use method thereof. The connection assembly comprises a locking device for connecting adjacent bag cages, wherein the locking device comprises an upper hook; the upper side of the upper hook is hooked on the bag cages; a lower buckle hook of which the lower side is hooked on the bag cages is arranged below the upper hook; a buckle lock cover is hinged to the upper side of the lower buckle hook through a rivet shaft; a square connecting rod is arranged between the upper side of the buckle lock cover and the lower side of the upper hook; the upper side of the square connecting rod is hooked and fixed on the lower side of the upper hook; the lower side of the square connecting rod penetrates through the buckle lock cover and is rotatably matched with the buckle lock cover. According to the assembly provided by the invention, the structure is simple, the design is reasonable, quick connection between two sections of the bag cages is realized by applying an eccentric clamping principle, the structure is stable, the use is convenient, the versatility is excellent, and the innovativeness is realized.

Owner:XIAMEN UNIV TAN KAH KEE COLLEGE

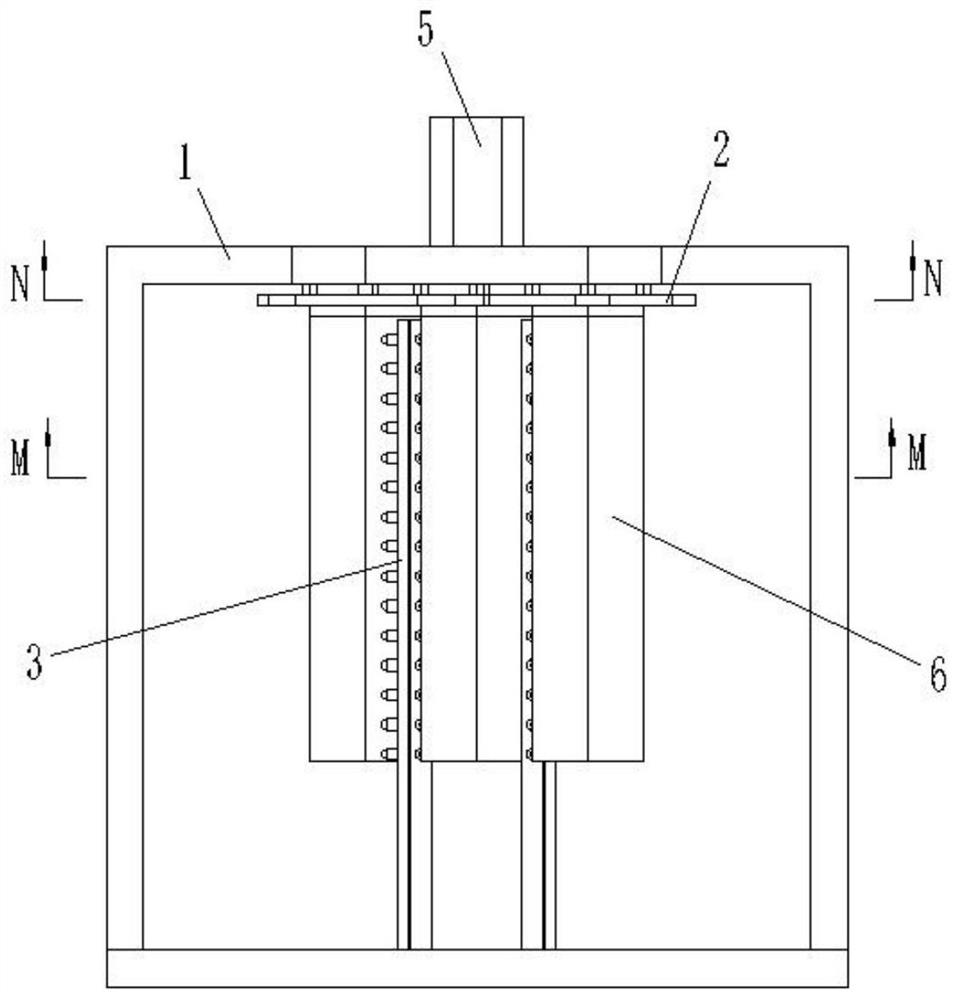

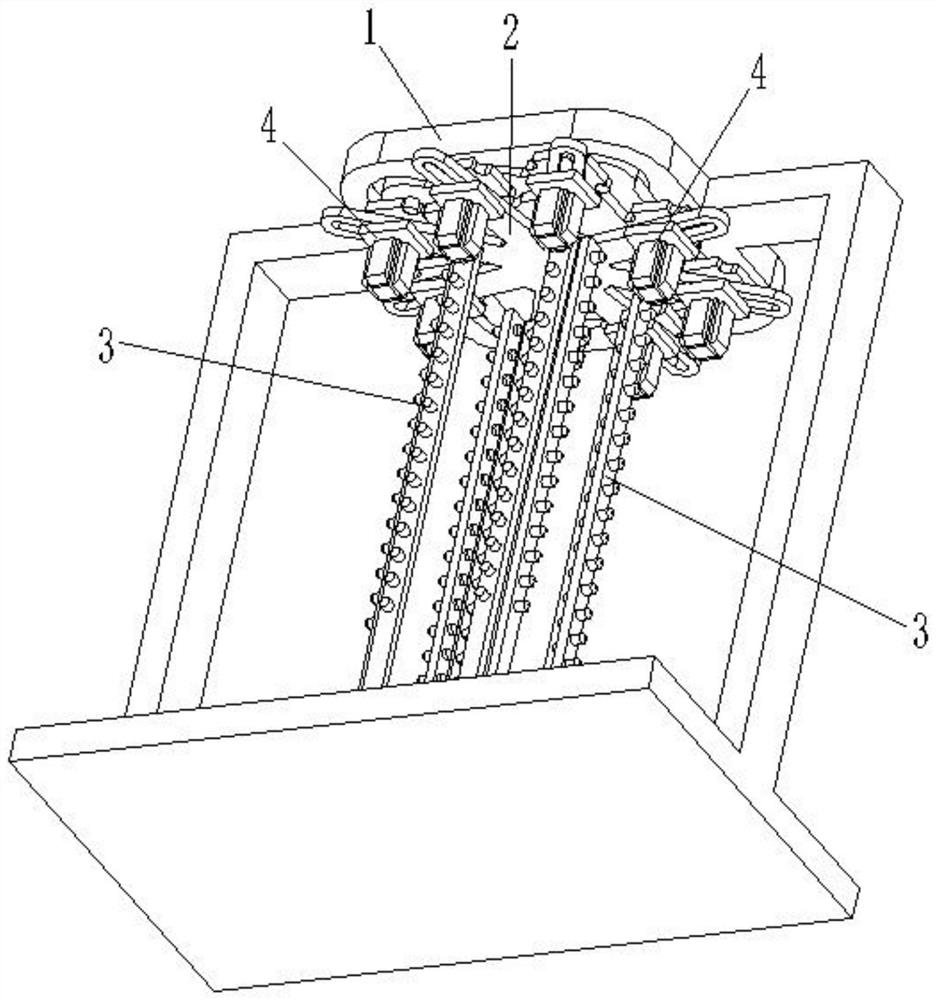

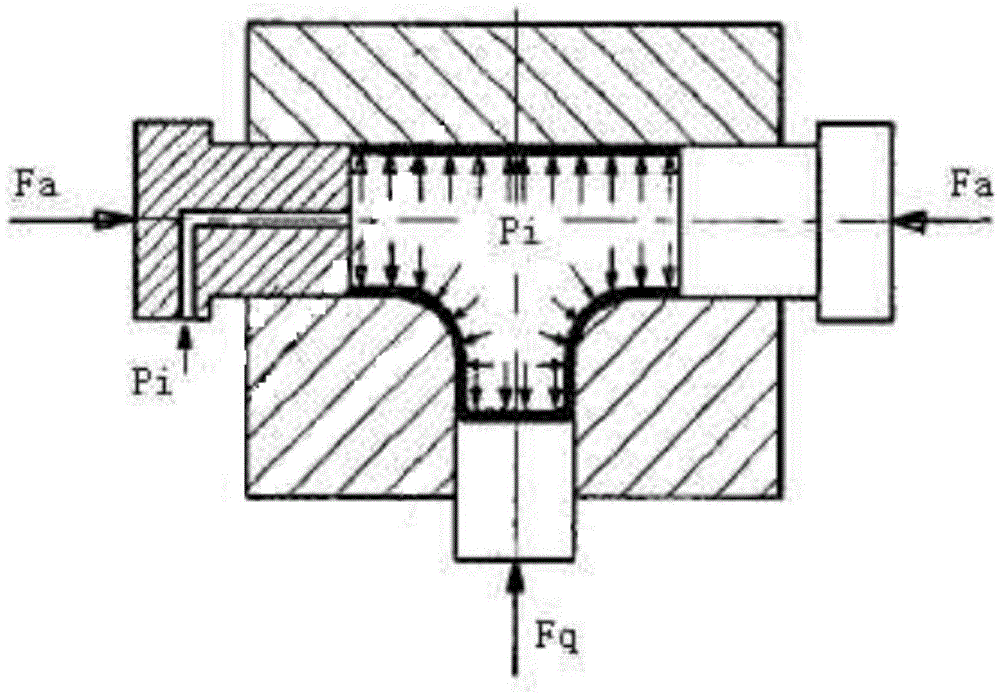

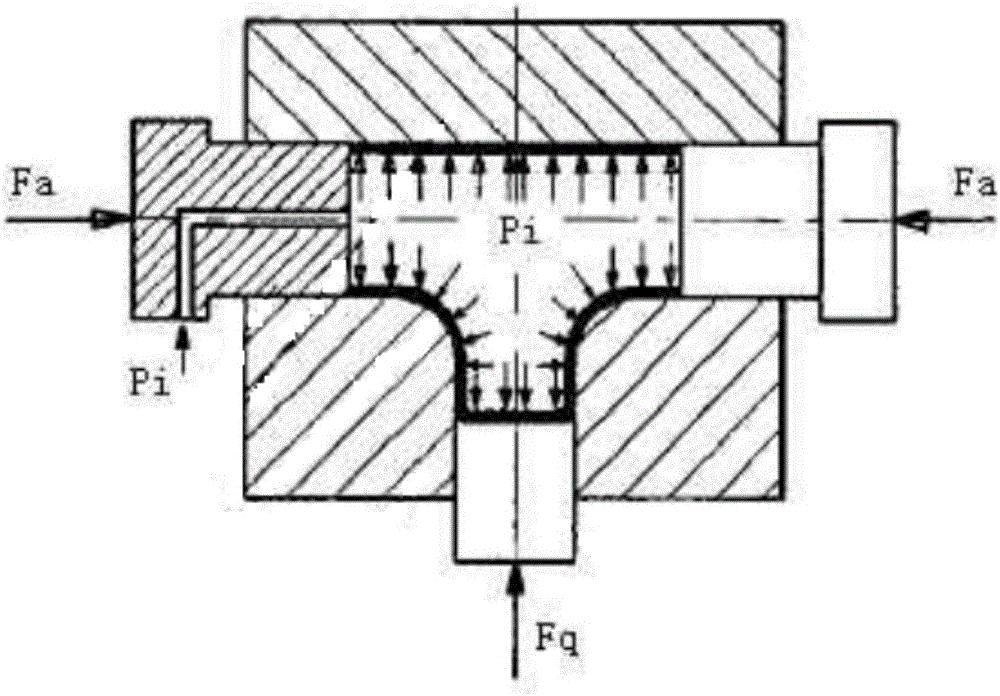

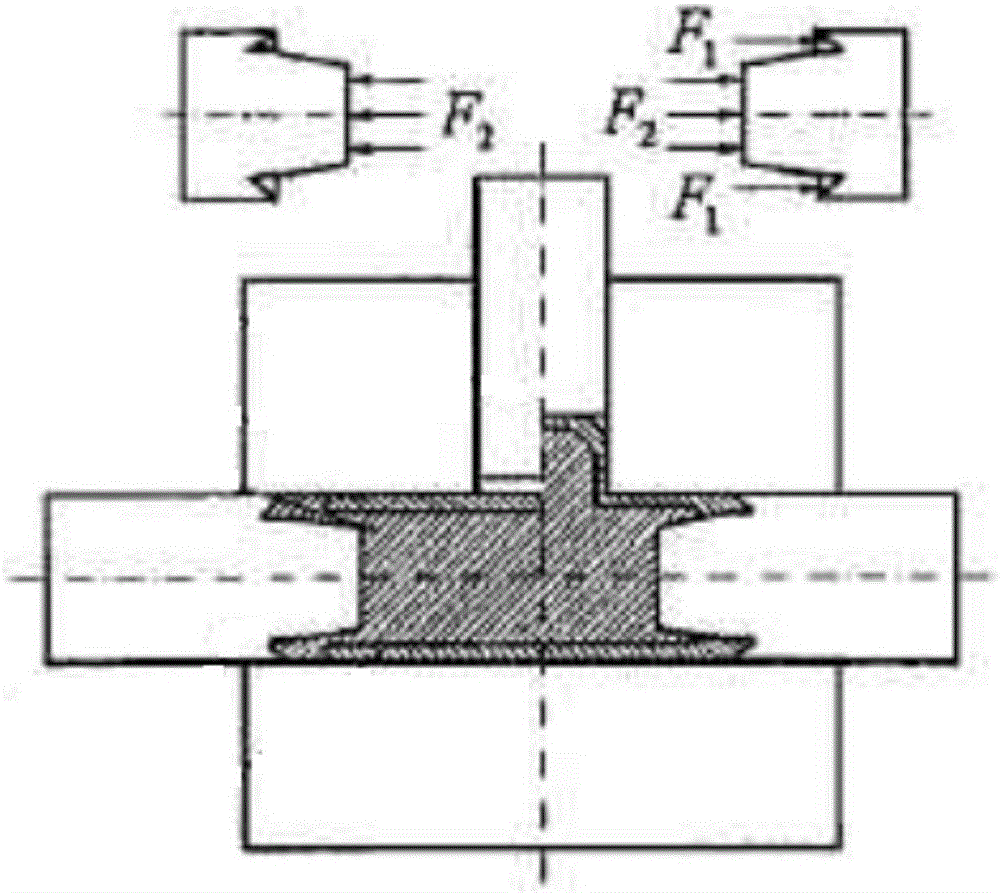

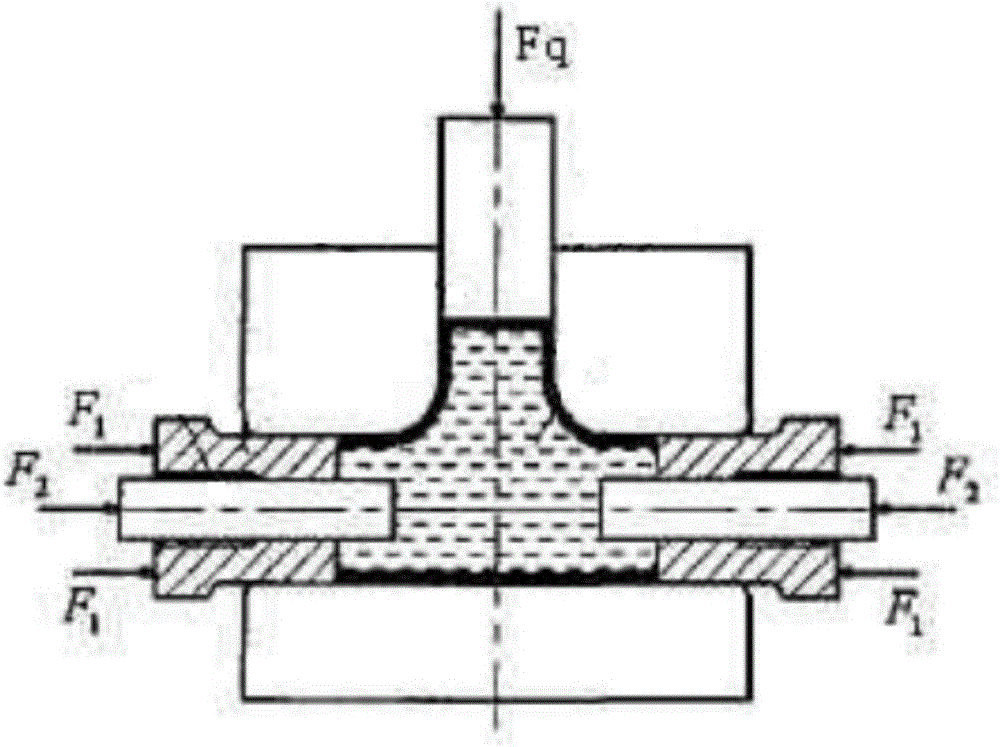

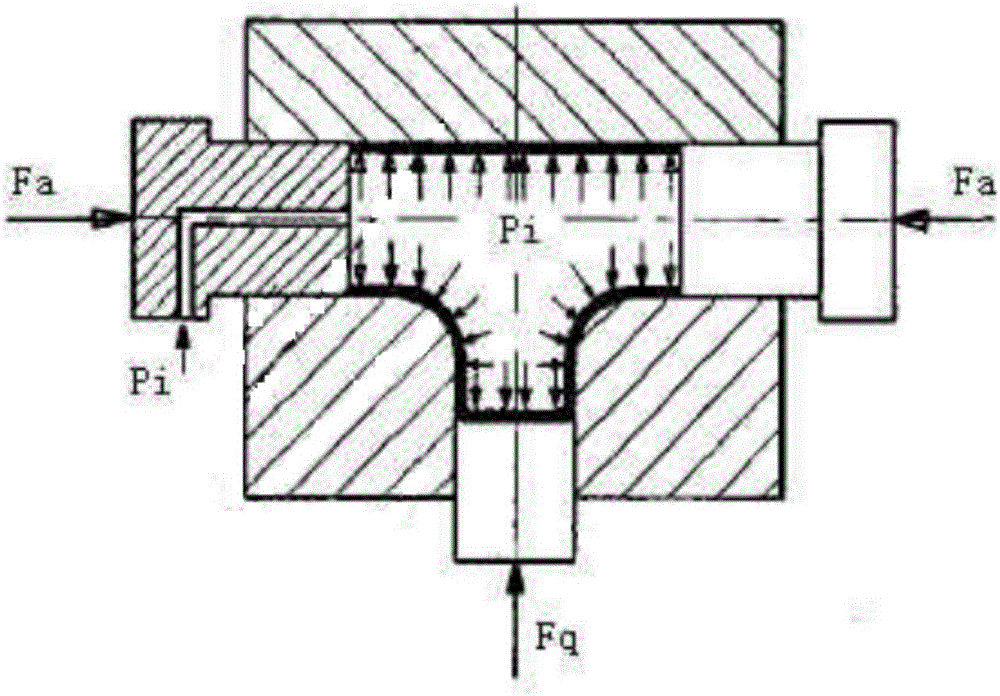

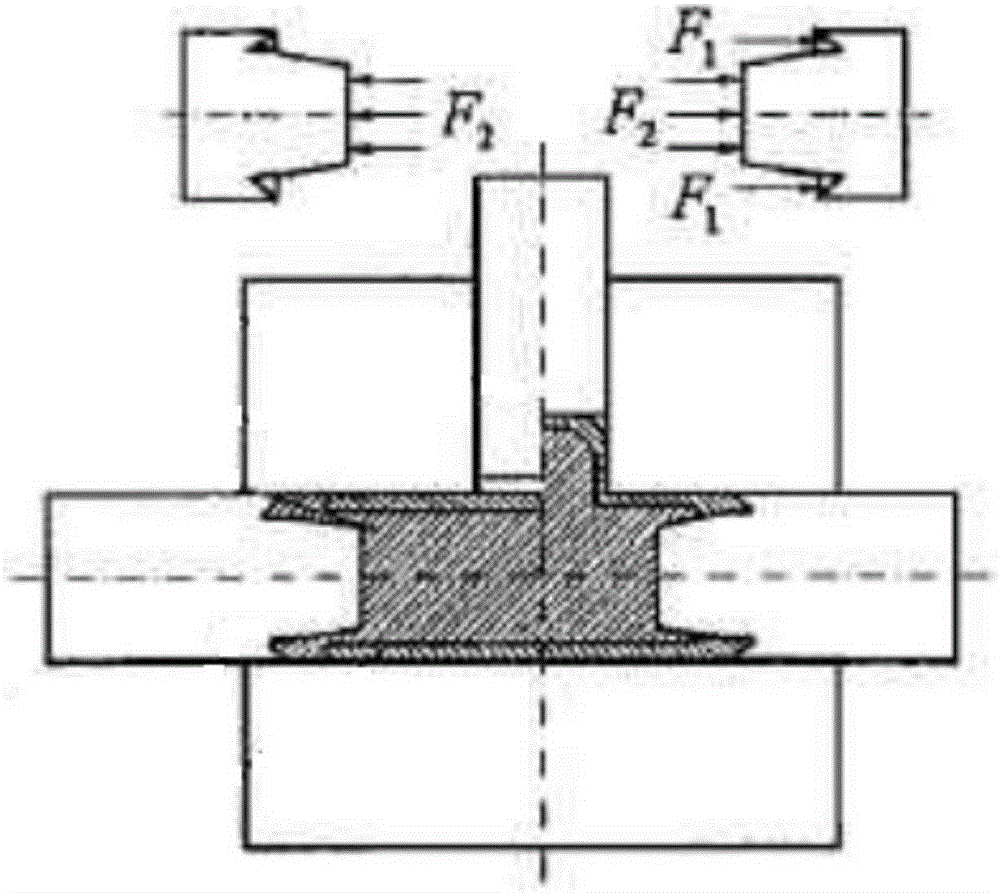

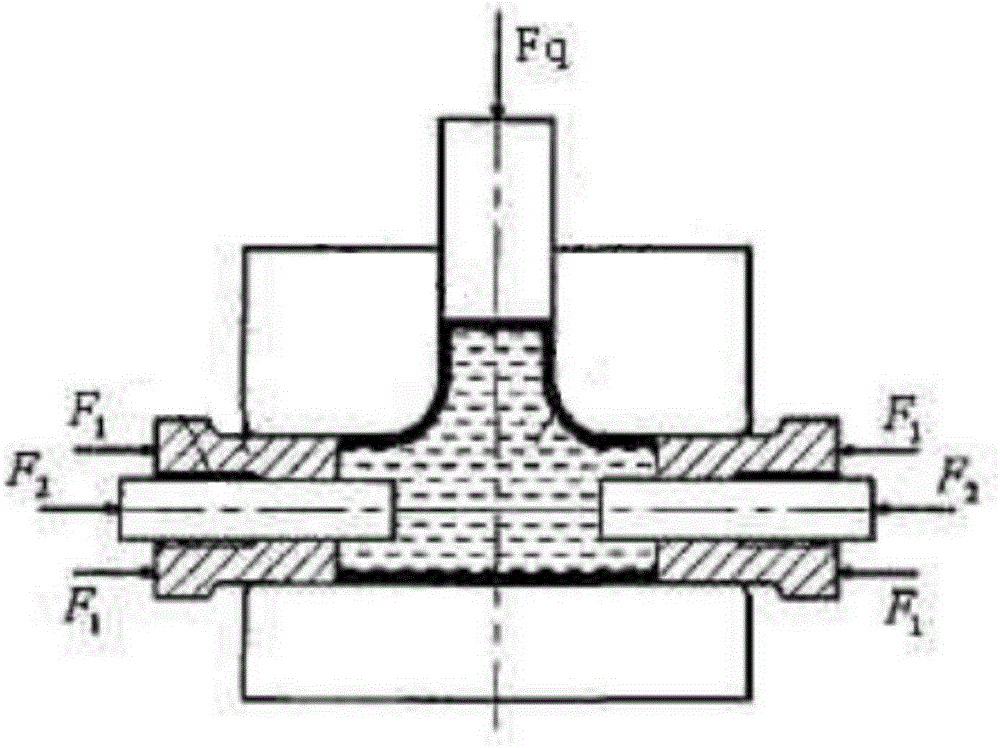

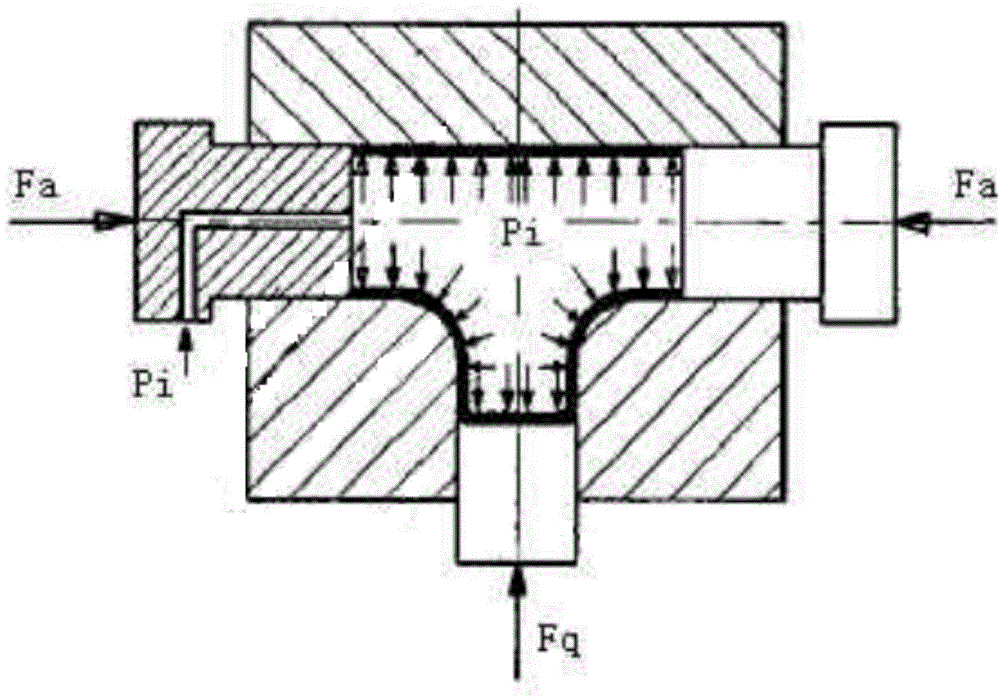

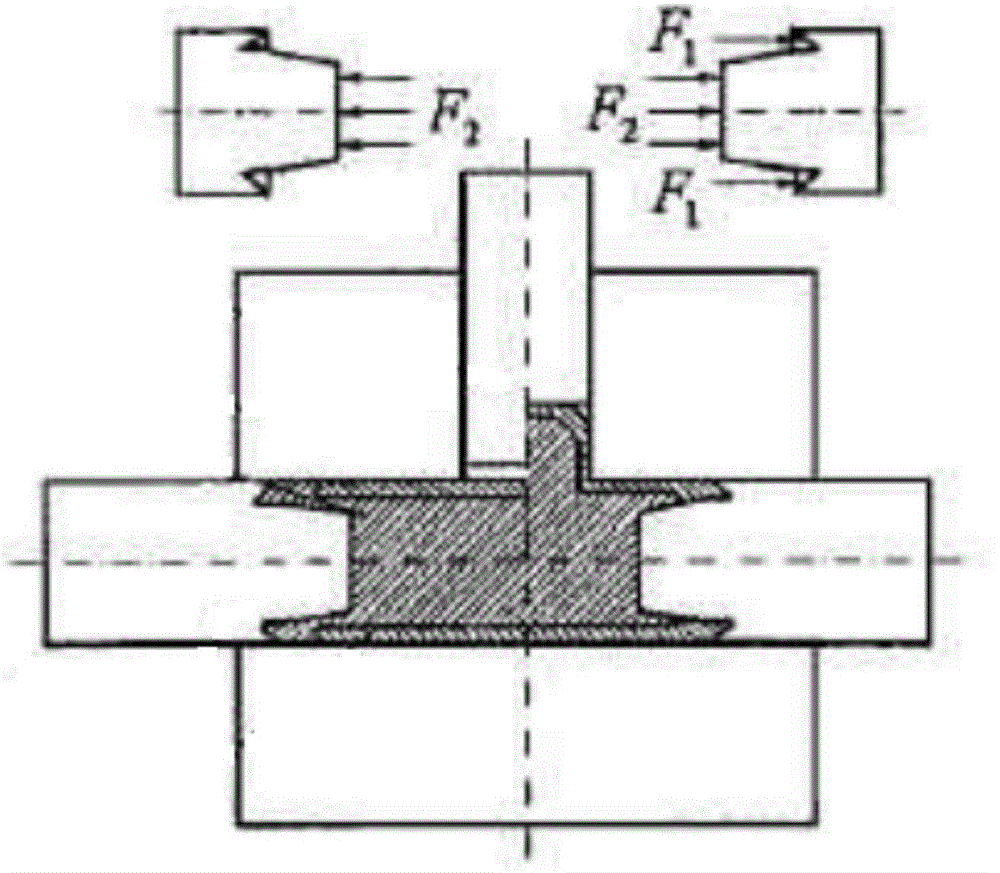

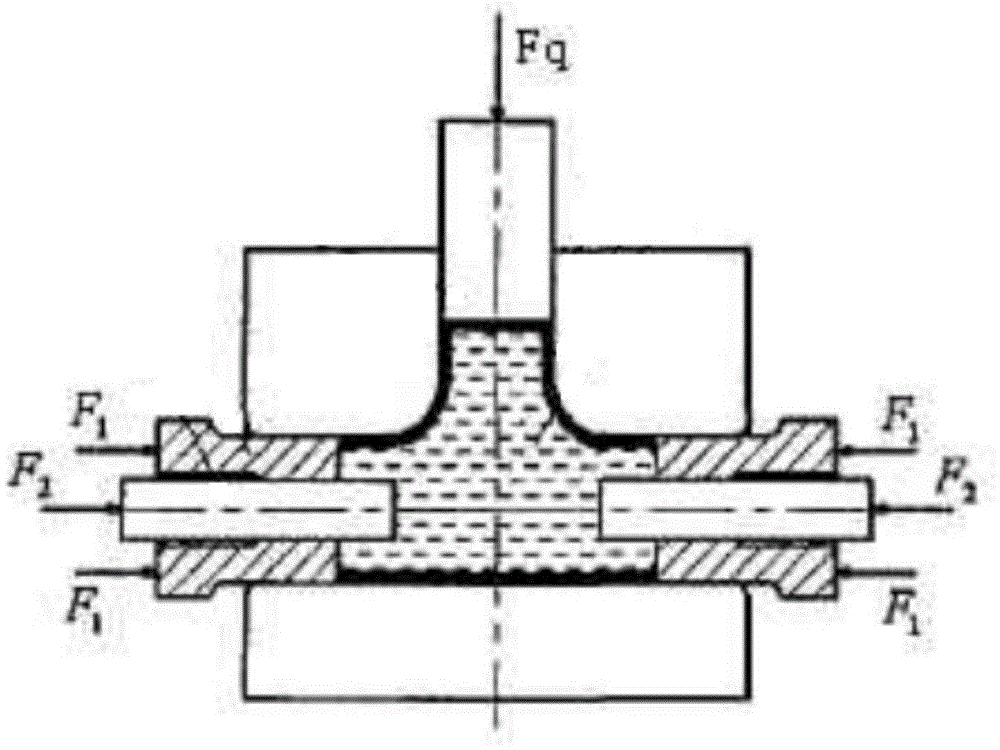

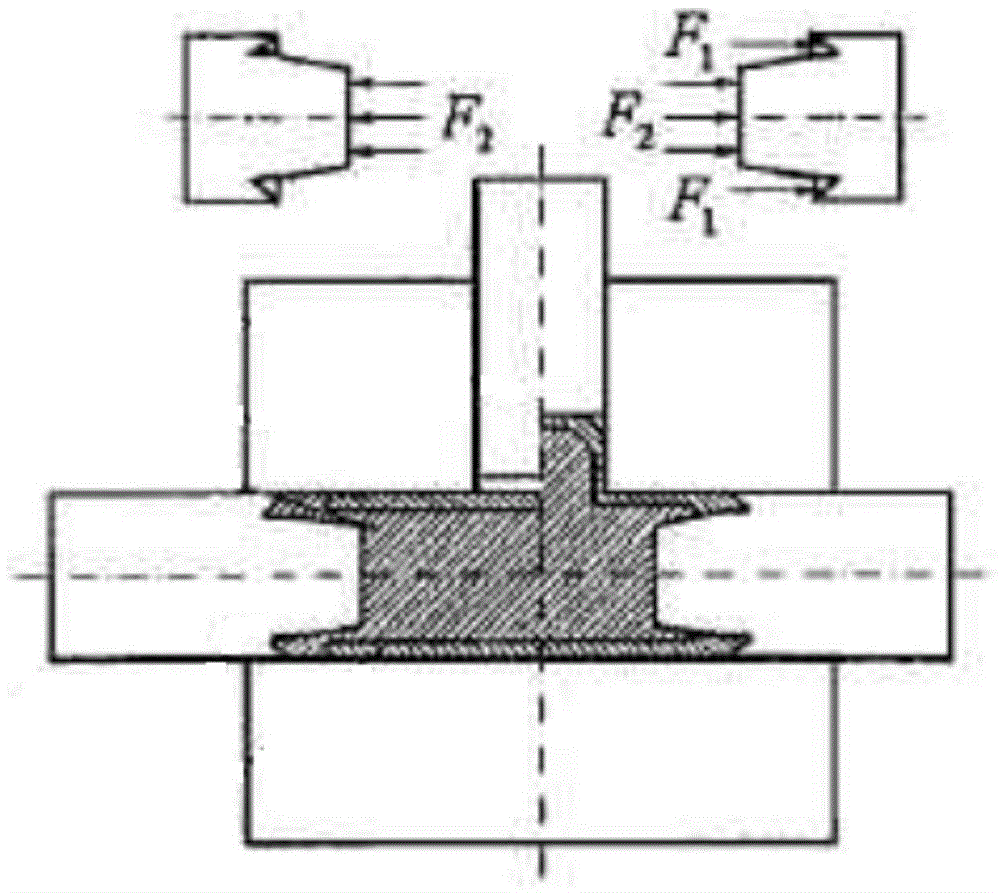

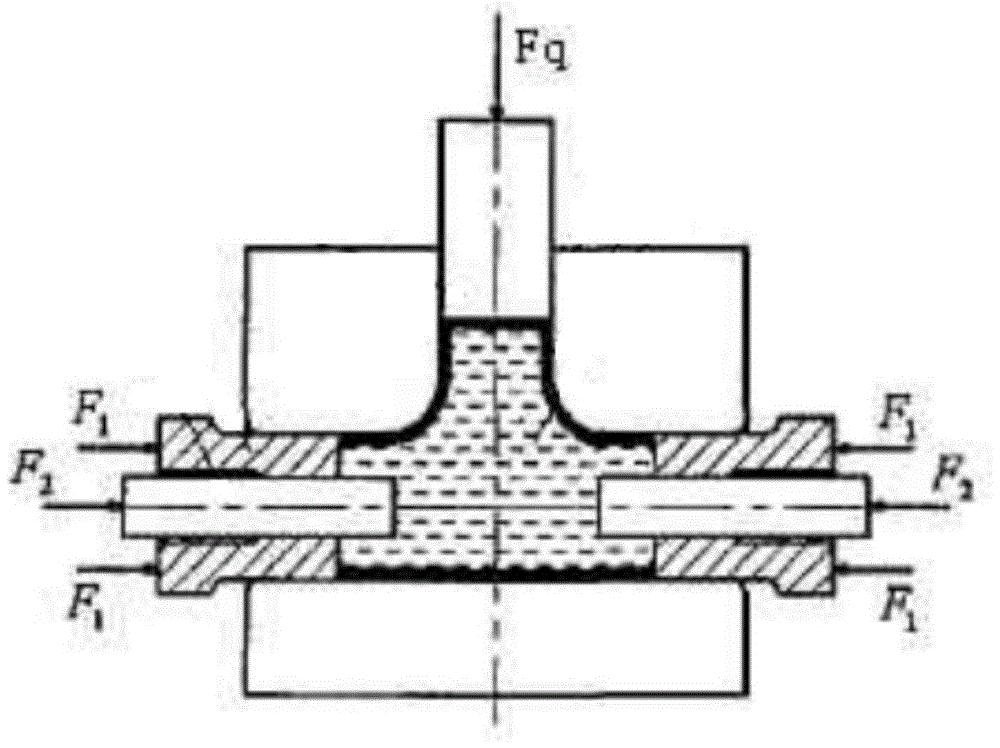

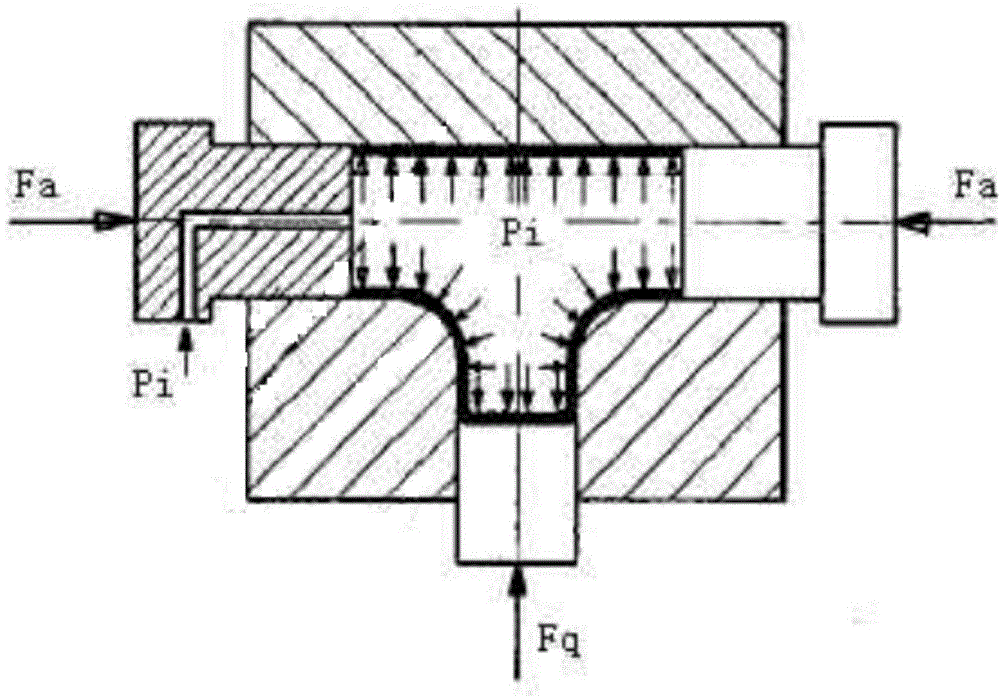

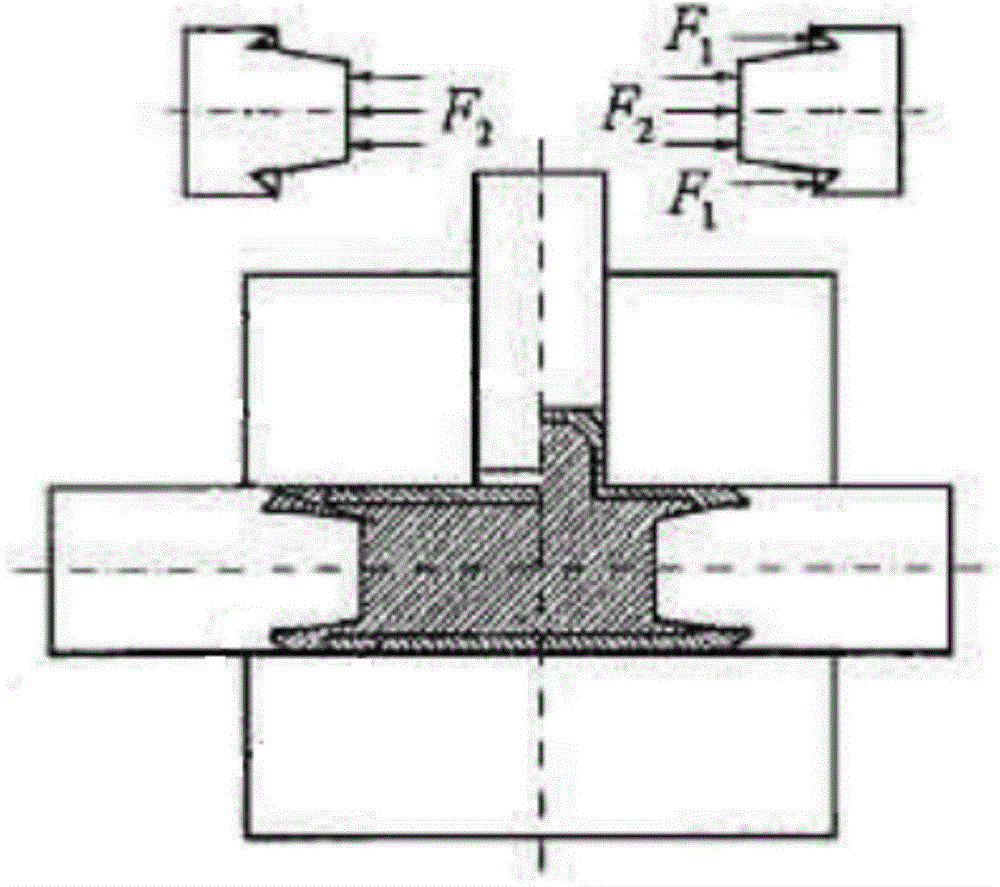

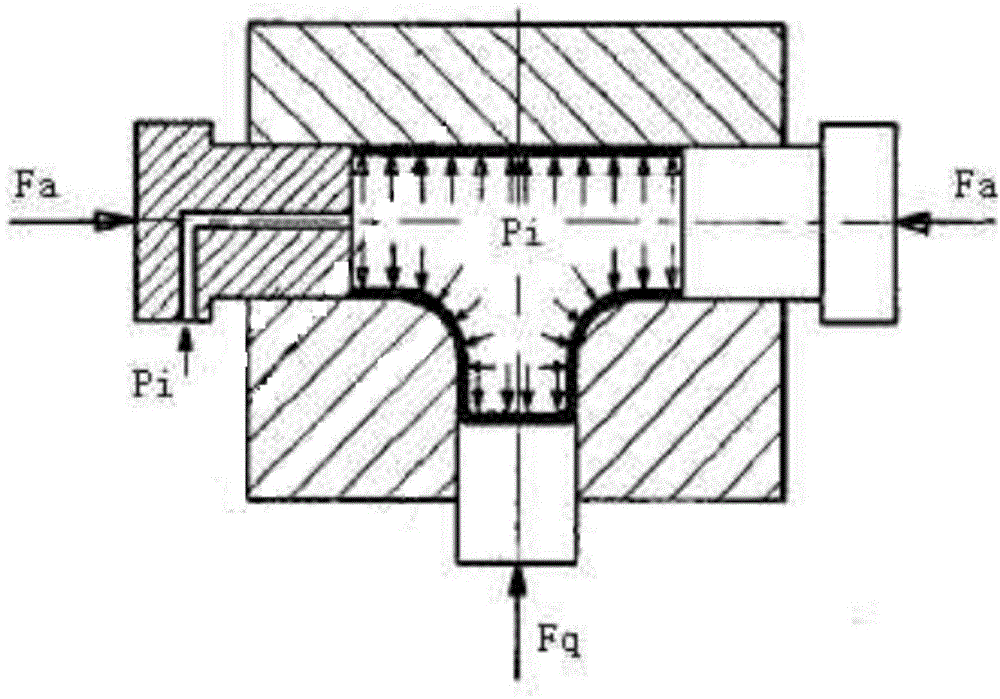

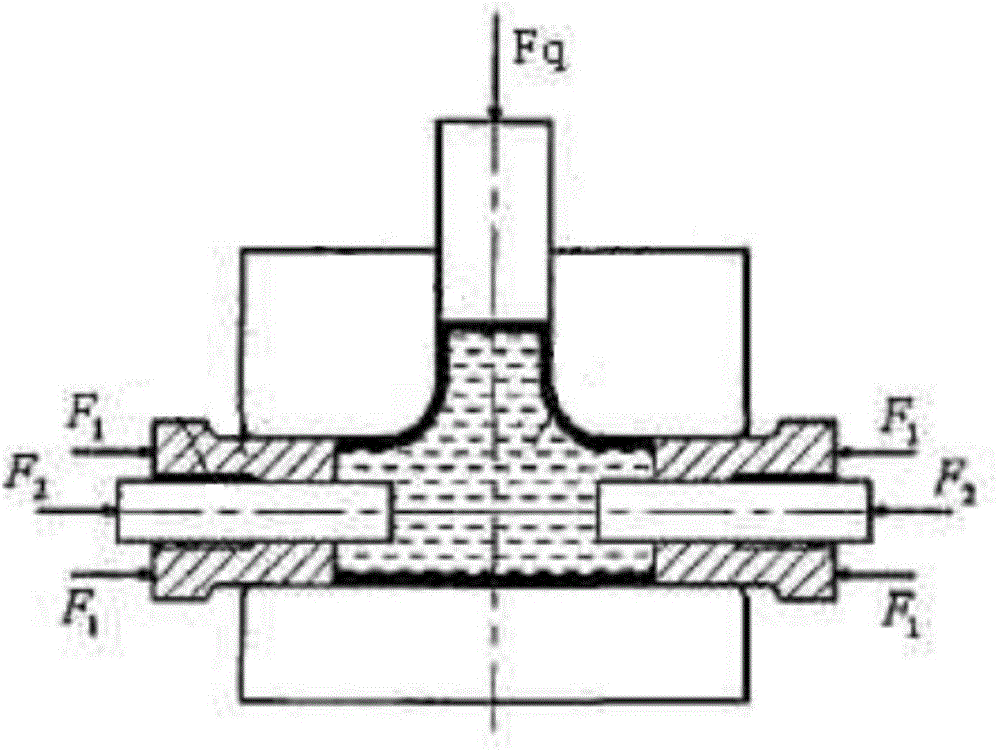

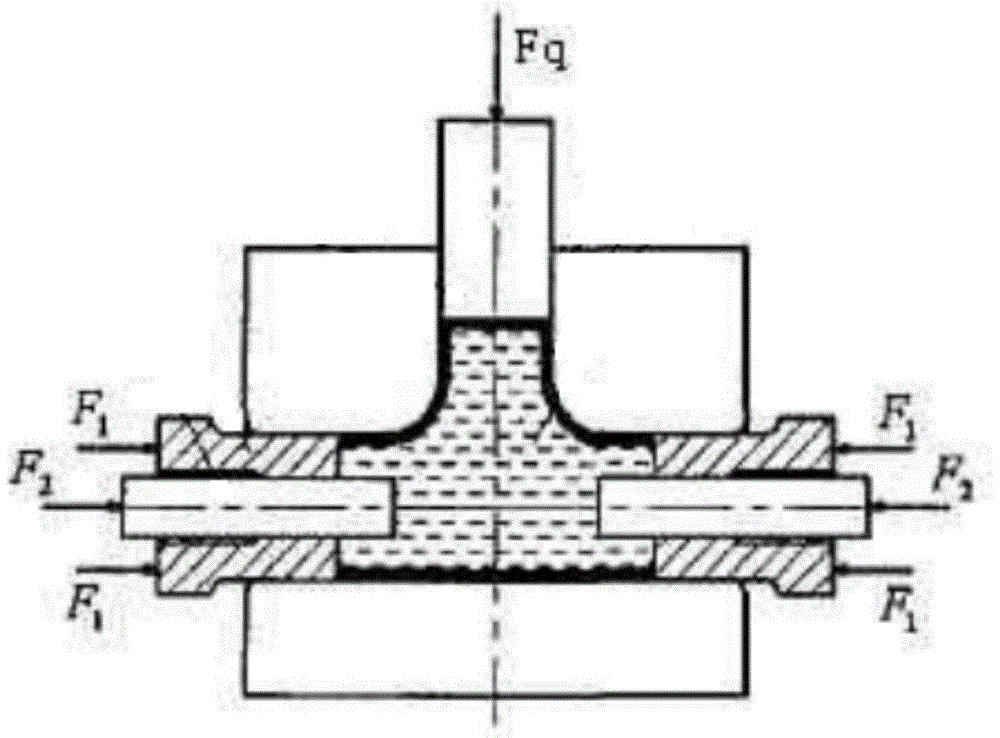

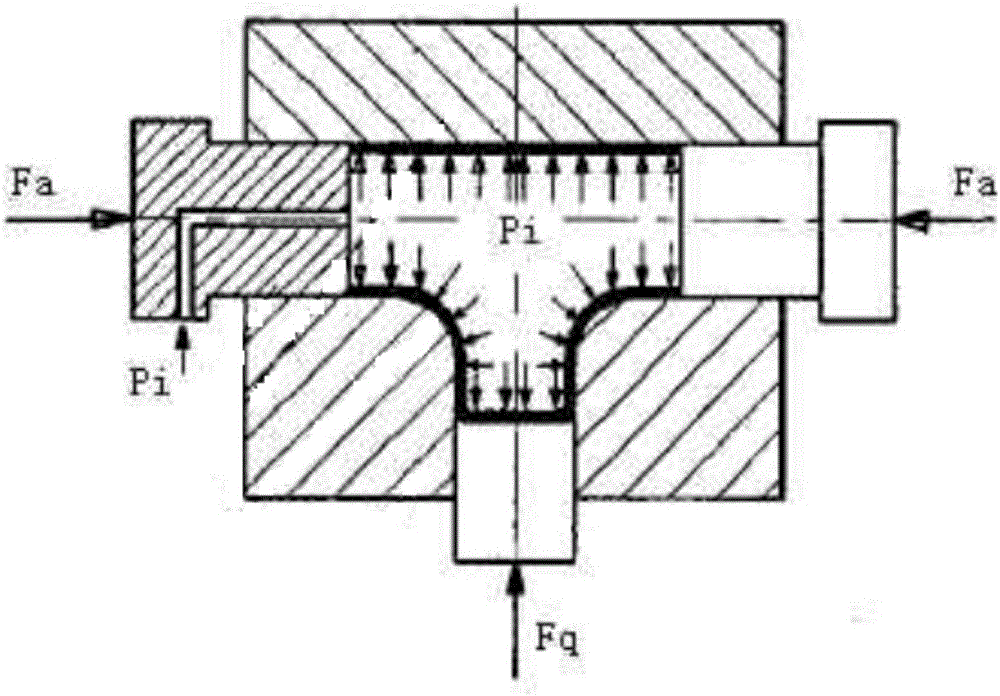

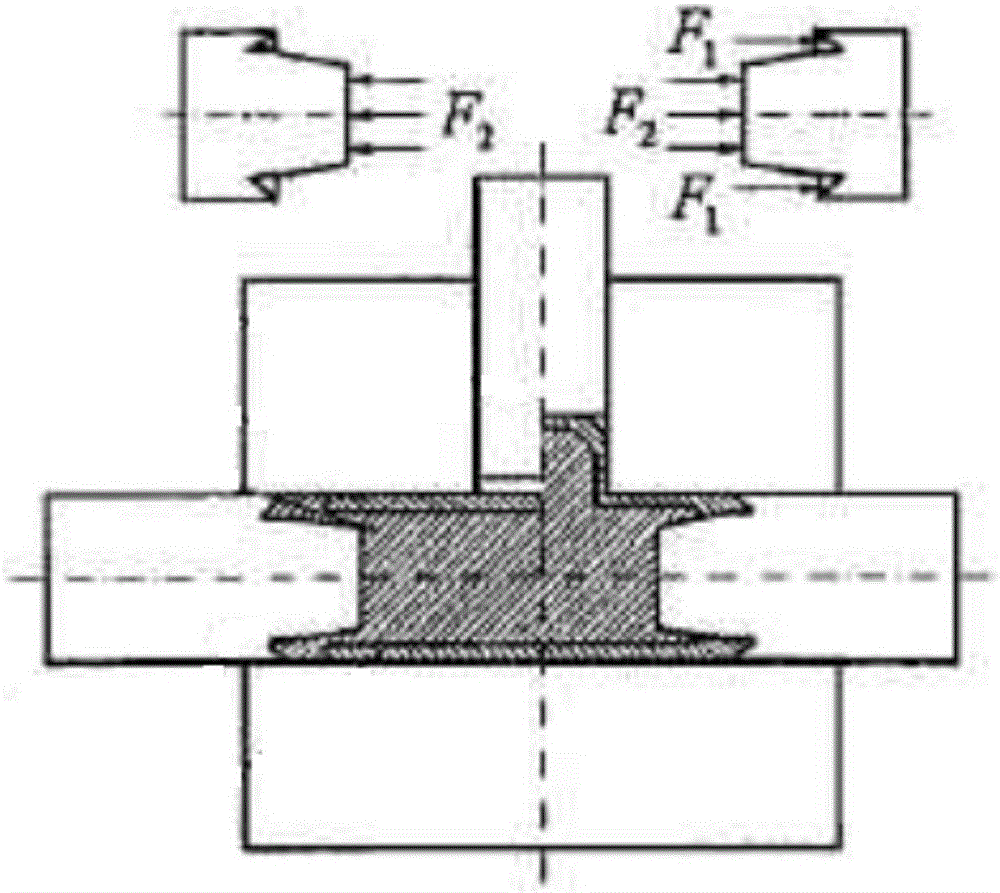

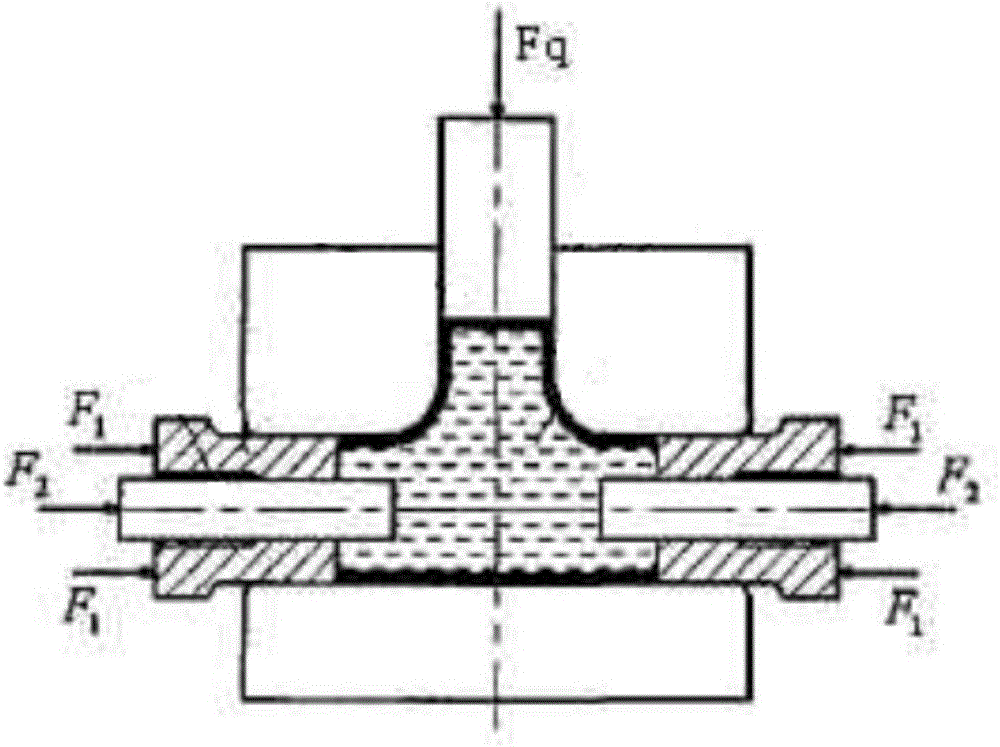

Rigid-plastic compound multi-cylinder latch-type bulging device for three-way pipe

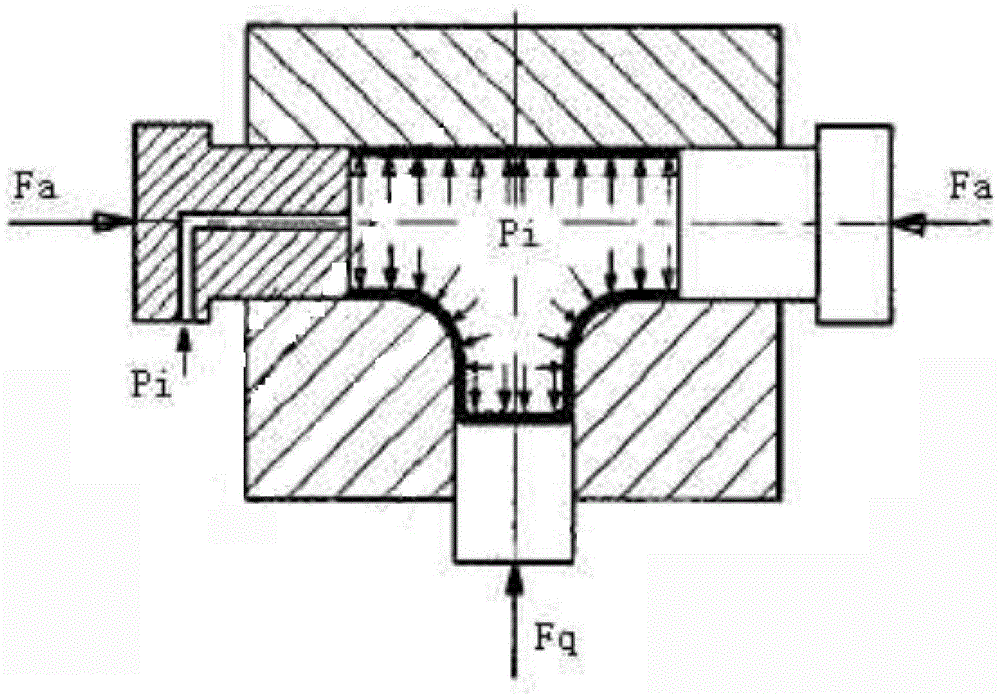

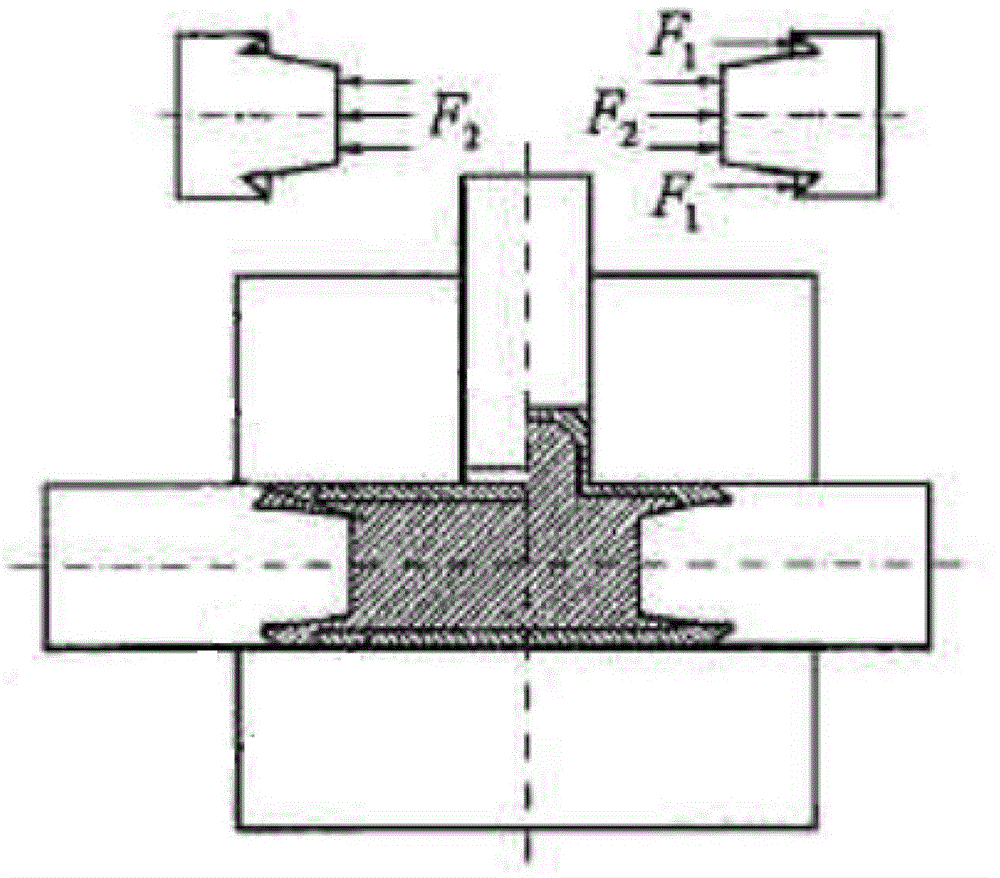

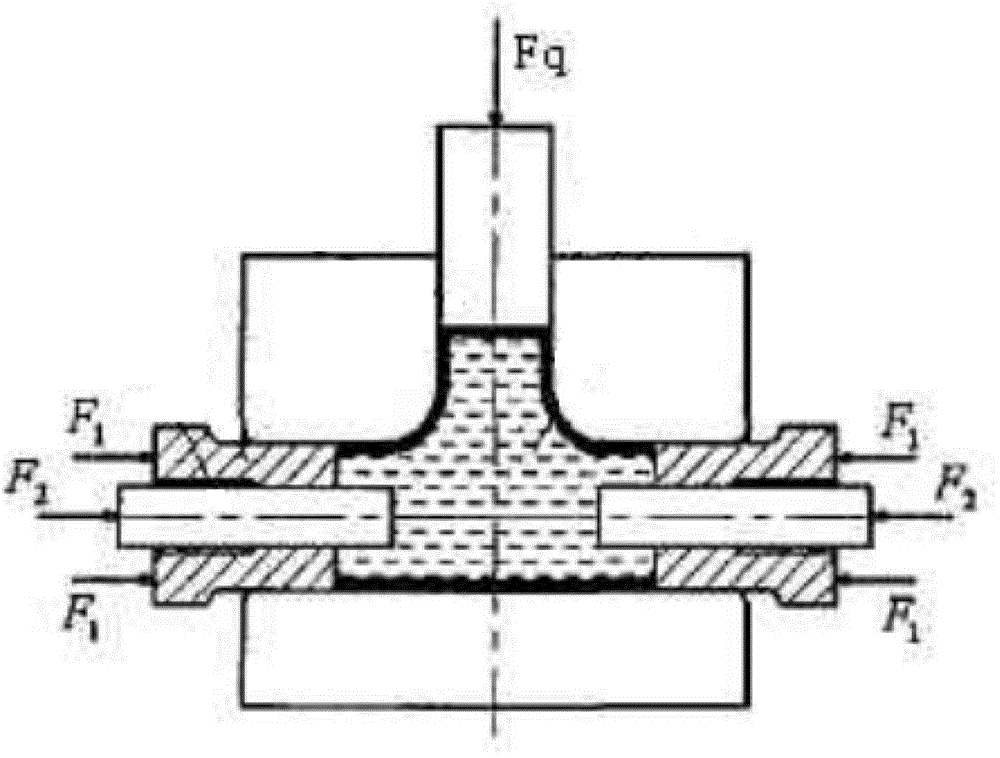

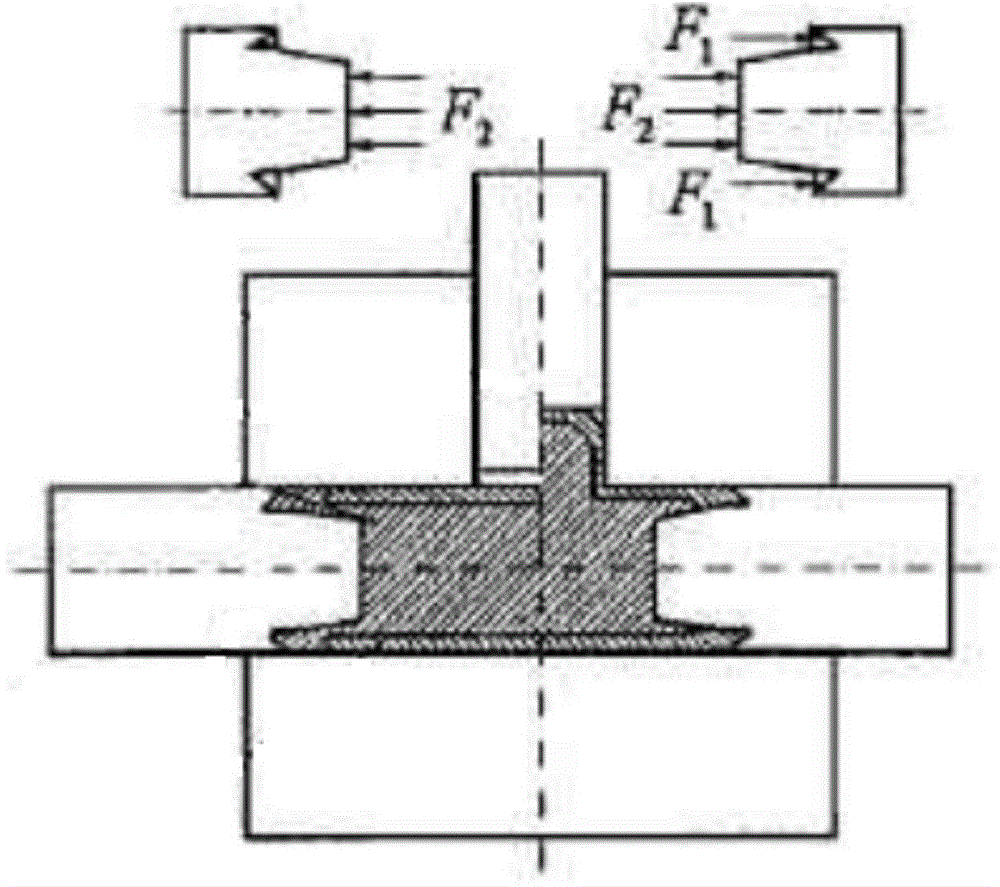

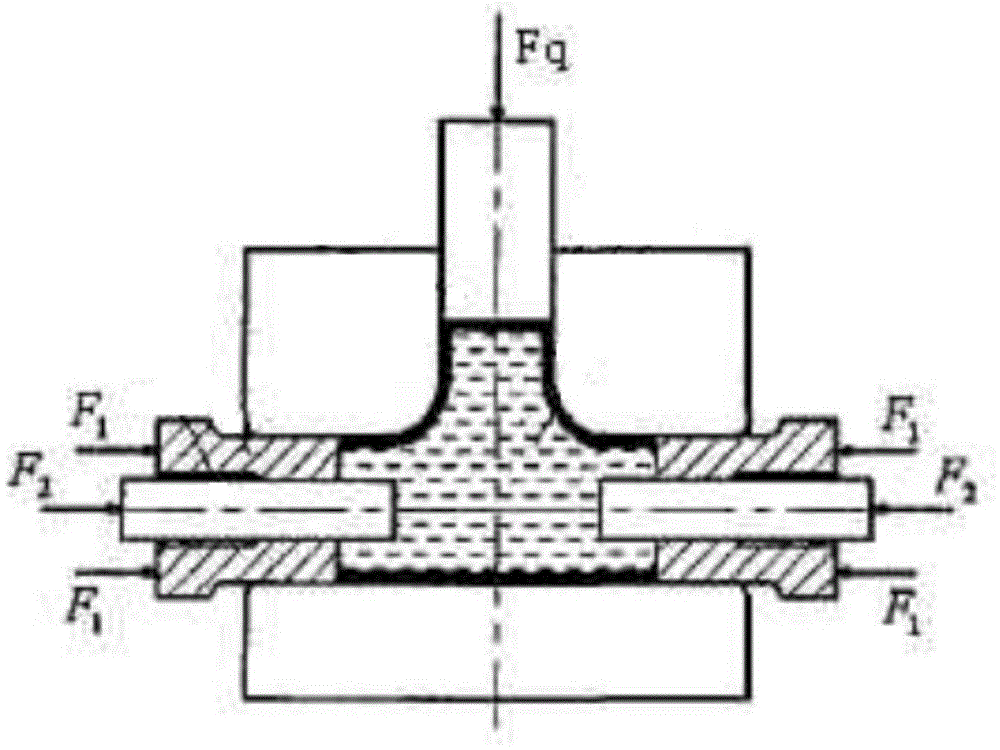

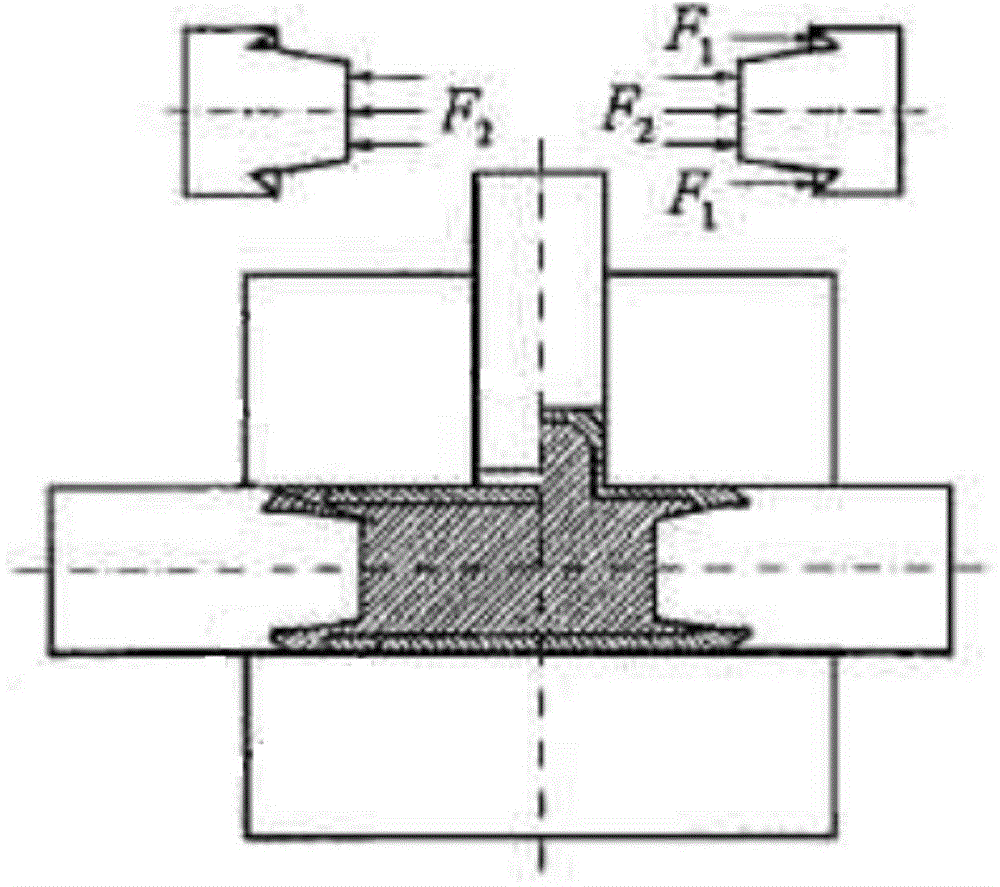

The invention discloses a rigid-plastic compound multi-cylinder latch-type bulging device for a three-way pipe. The device comprises an upper semi mold and a lower semi mold, wherein a forming cavity is formed between the upper semi mold and the lower semi mold; bulging extrusion punches are installed at two ends of the forming cavity respectively; a branch pipe forming cavity is formed in the lower semi cavity; a balancing punch is installed inside the branch pipe forming cavity; a rigid bulging inner mold is arranged between two bulging extrusion punches and comprises pushing rods located at two ends respectively; a forming inner mold block is arranged between two pushing rods; the forming inner mold block is connected with two pushing rods through double-hinge connecting rods; two connecting grooves facing towards the opening of the branch pipe forming cavity are formed in opposite ends of two pushing rods respectively; limiting structures are arrange in the connecting grooves; each pushing rod is installed inside corresponding bulging extrusion punch in a sliding fit mode, and a latch-type quick disassembly connection structure is arranged on one of the pushing rods; thrust devices are arranged at two ends of the forming cavity respectively; each thrust device comprises extrusion hydraulic cylinders and a central hydraulic cylinder; and at least three extrusion hydraulic cylinders distributed annularly and uniformly are arranged.

Owner:XINCHANG HANGDA MACHINERY MFG

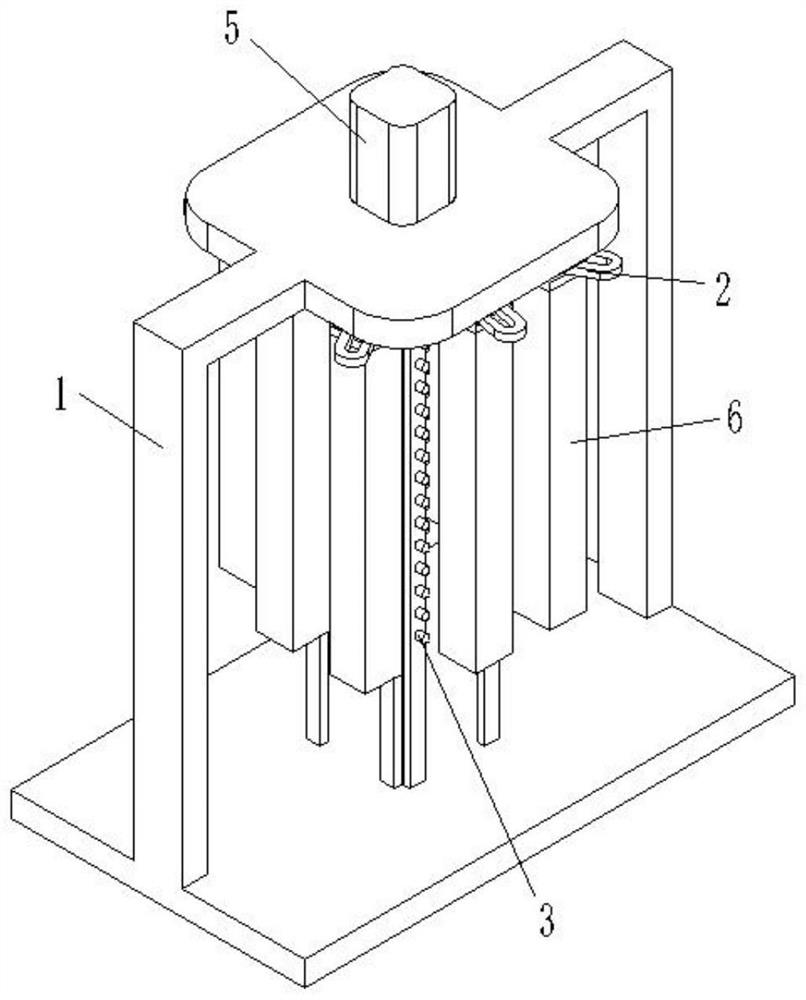

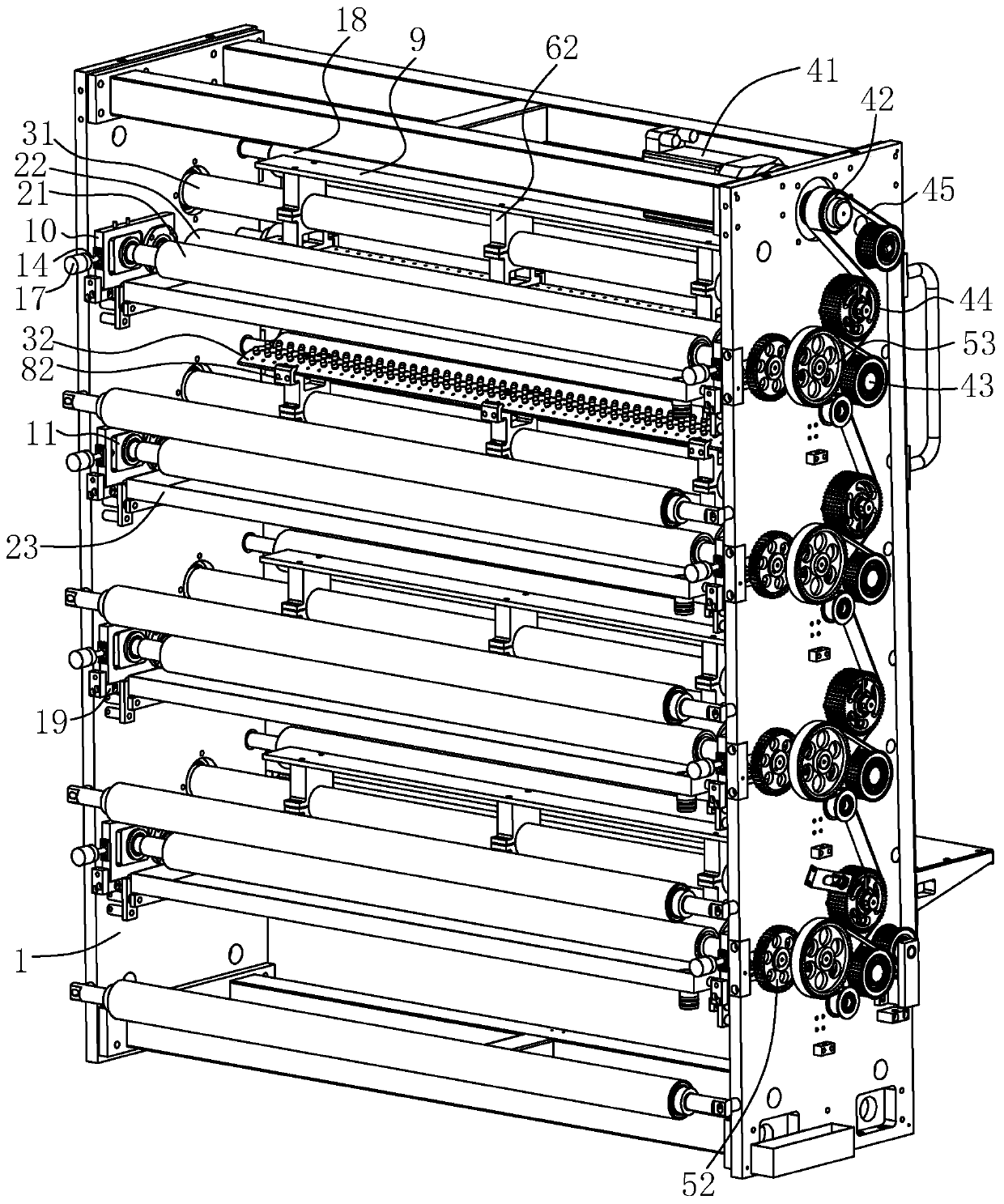

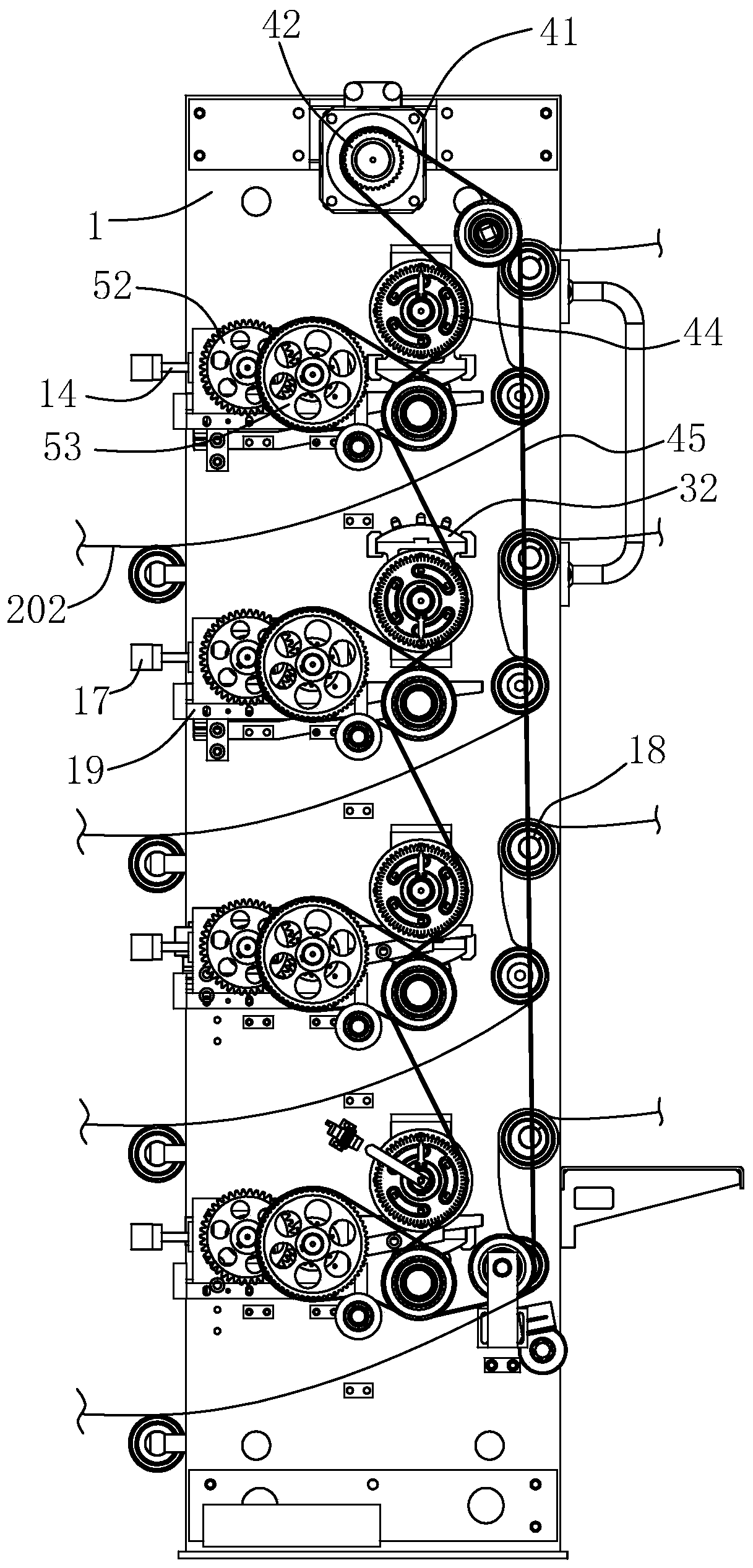

Aluminum profile spraying system and aluminum profile spraying method

ActiveCN113171903AImprove spray qualityImprove spraying effectLiquid surface applicatorsSpraying apparatusEngineeringMaterials science

The invention belongs to the technical field of aluminum profile preparation, and discloses an aluminum profile spraying system and a spraying method. The aluminum profile spraying system comprises a supporting frame, a rotating disc, spraying head assemblies and connecting assemblies; the rotating disc is rotationally connected with the supporting frame; the connecting assemblies are connected with the rotating disc and can rotate relative to the supporting frame along with the rotating disc; the spraying head assemblies are fixedly connected with the supporting frame and rotate relative to the rotating disc in the circumferential direction; and to-be-sprayed profiles are detachably and fixedly connected with the connecting assemblies, and the surfaces, connected with the connecting assemblies, of the to-be-sprayed profiles are parallel to spraying faces formed by spraying heads in the spraying head assemblies. When aluminum profile spraying treatment is conducted by adopting the aluminum profile spraying system, the positions of the aluminum profiles in the spraying process can be adjusted, so that coatings with uniform thickness on the surfaces of the aluminum profiles are achieved, and the spraying quality and effect are improved.

Owner:广西西铝铝业有限公司

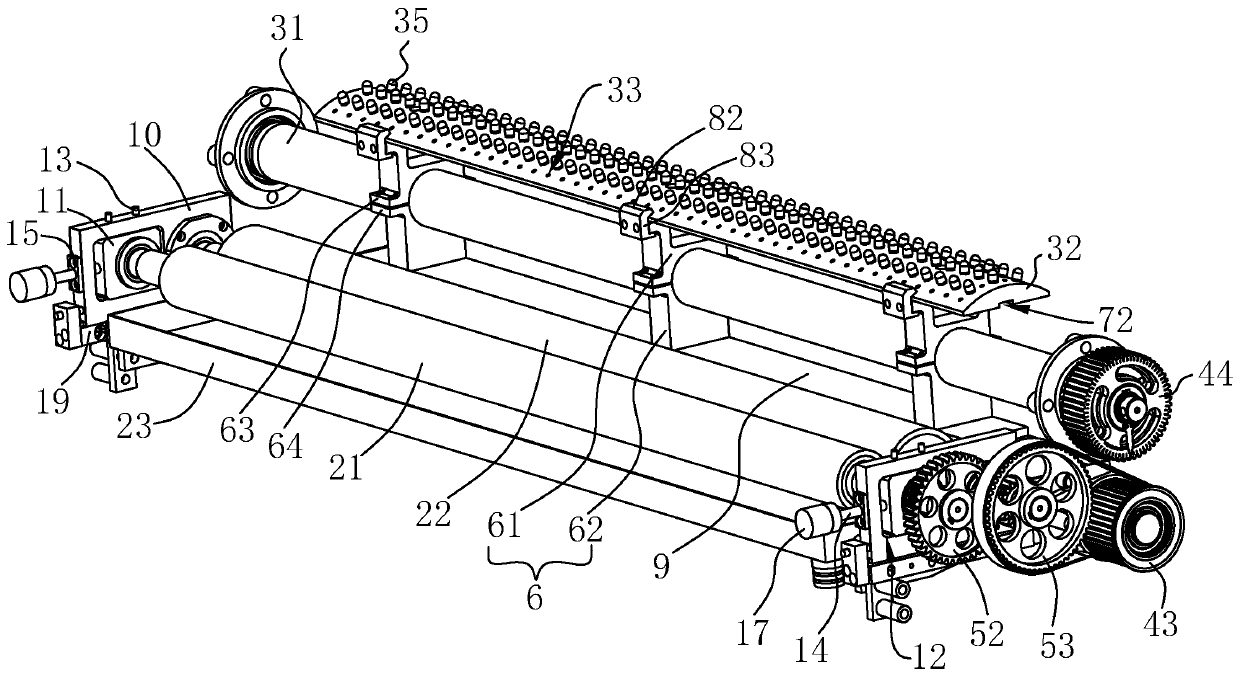

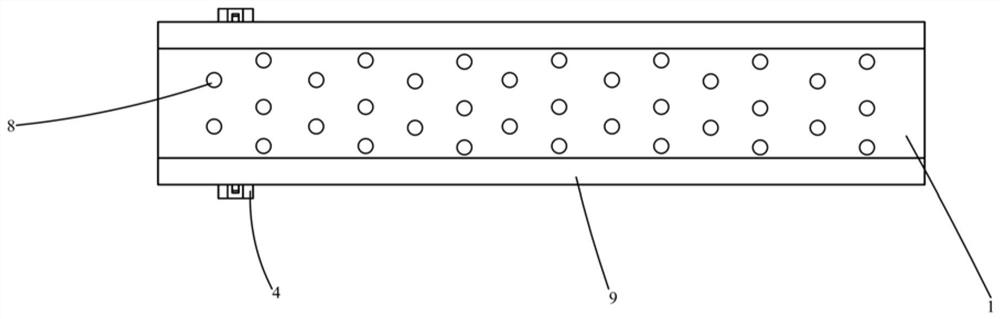

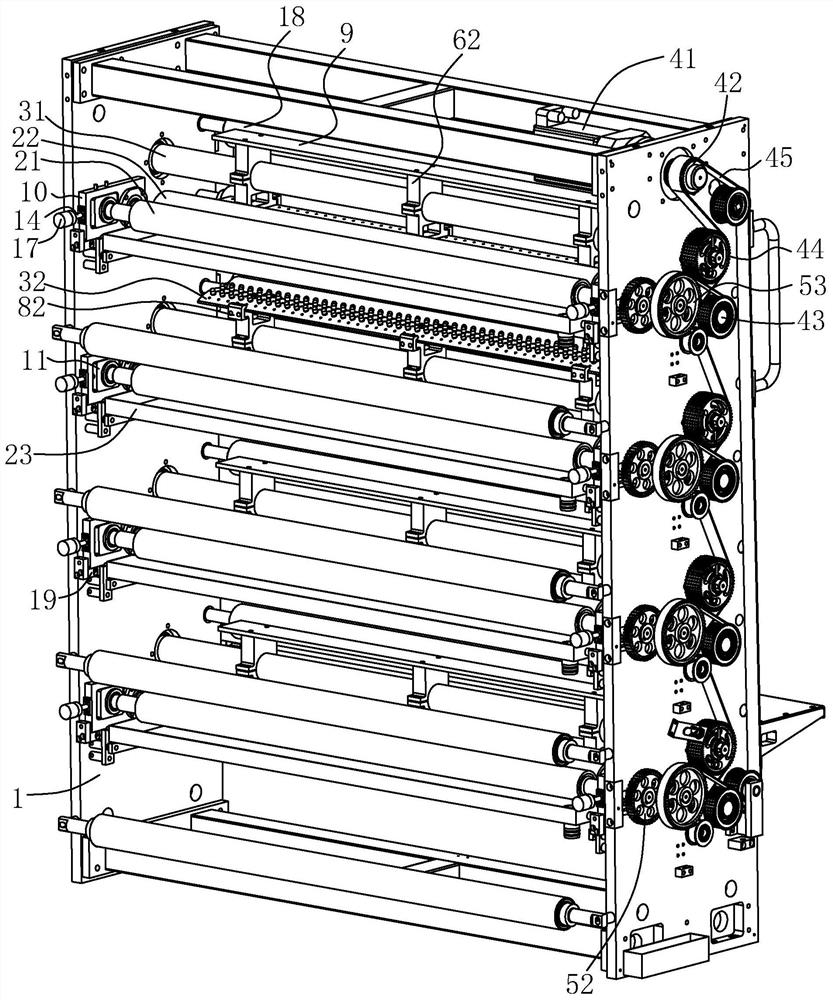

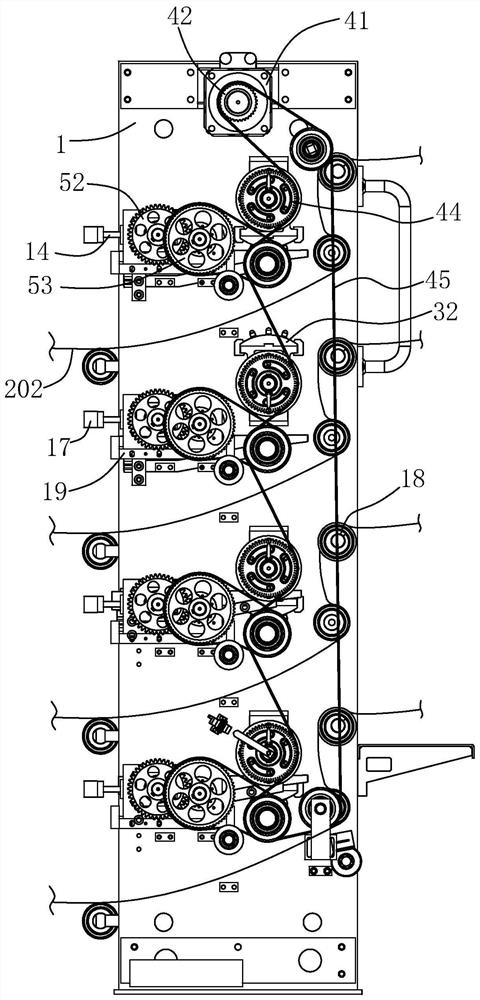

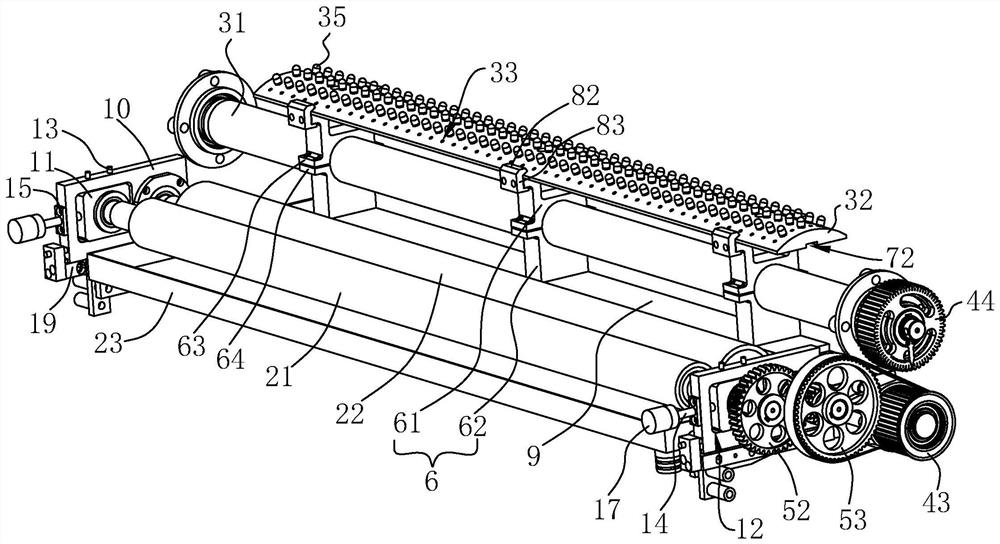

Transverse adhesive dispensing device

ActiveCN111516299AEasy to adjustRealize detachable connectionLiquid surface applicatorsBag making operationsPhysicsPaper sheet

The invention relates to the technical field of paper bag cylinders, in particular to a transverse adhesive dispensing device. The transverse adhesive dispensing device comprises a machine frame; an adhesive feeding component and an adhesive dispensing roller component are arranged on the machine frame; the adhesive dispensing roller component comprises an adhesive dispensing rotating roller, an adhesive dispensing aluminum bed and a plurality of adhesive dispensing heads; the two ends of the adhesive dispensing rotating roller are rotatably connected to the machine frame; the adhesive dispensing aluminum bed is detachably mounted on the adhesive dispensing rotating roller; a plurality of mounting holes are formed in the side, far away from the adhesive dispensing rotating roller, of the adhesive dispensing aluminum bed; the adhesive dispensing heads are detachably connected to the mounting holes; and the adhesive dispensing heads dip an adhesive liquid from the adhesive feeding component. The transverse adhesive dispensing device has the beneficial effects that when the position needing to be subjected to adhesive dispensing of strip-shaped paper is changed, the positions of the adhesive dispensing heads can be adjusted by working personnel according to the position needing to be subjected to the adhesive dispensing of the strip-shaped paper.

Owner:FOSHAN TECON PACKAGE MACHINERY

T-branch pipe locking type rigid-plasticity combined type bulging equipment

The invention discloses T-branch pipe locking type rigid-plasticity combined type bulging equipment. The T-branch pipe locking type rigid-plasticity combined type bulging equipment comprises an upper half die and a lower half die. A forming cavity is arranged between the upper half die and the lower half die, and the two ends of the forming cavity are provided with bulging squeezing punches respectively. The lower half die is provided with an axis branch pipe forming cavity and a balance punch is installed in the branch pipe forming cavity. A rigid bulging inner die is arranged between the two bulging squeezing punches and comprises push rods located at the two ends respectively, and a forming inner die block which is matched with the branch pipe forming cavity and used for driving a pipe blank to bulge and deform is arranged between the two push rods; the forming inner die block is connected with the two push rods through double-hinge connecting rods; the opposite ends of the two push rods are provided with connecting grooves opened towards the branch pipe forming cavity; a limiting structure is arranged in each connecting groove; the push rods are installed in the corresponding bulging squeezing punches respectively in a sliding matching mode, and one of the push rods is provided with a locking type rapid detaching and connecting structure. Thrust devices are arranged at the two ends of the forming cavity and comprise compound hydraulic cylinders.

Owner:XINCHANG HANGDA MACHINERY MFG

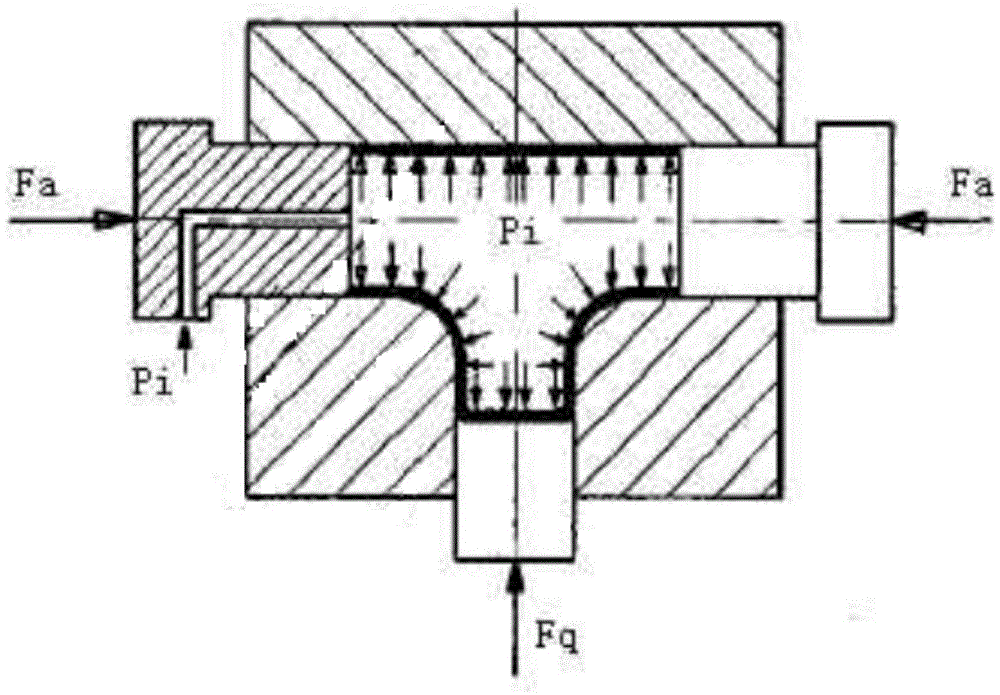

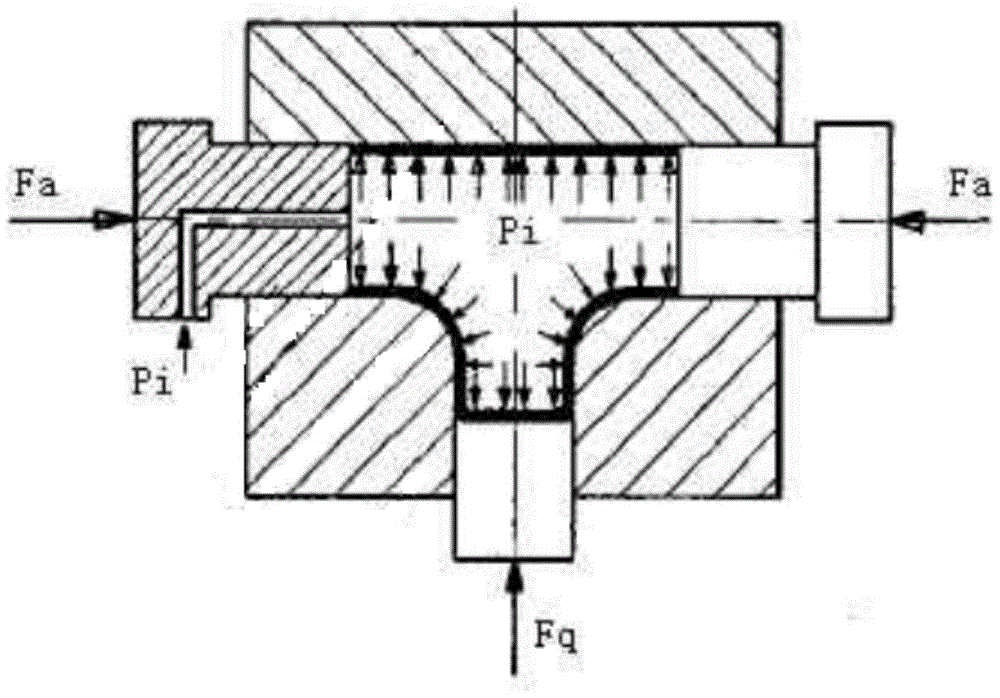

Hydraulic control type large-diameter T-branch pipe locking type rigid-plasticity combined bulging forming equipment

InactiveCN105268810AMeet the requirements of bulge formingPrecise control of liquid bulging pressureShaping toolsHydraulic cylinderEngineering

The invention discloses hydraulic control type large-diameter T-branch pipe locking type rigid-plasticity combined bulging forming equipment. The hydraulic control type large-diameter T-branch pipe locking type rigid-plasticity combined bulging forming equipment comprises an upper half die and a lower half die. A forming cavity is arranged between the upper half die and the lower half die, and the two ends of the forming cavity are provided with bulging squeezing punches respectively. The lower half die is provided with a branch pipe forming cavity and a balance punch is installed in the branch pipe forming cavity. A rigid bulging inner die is arranged between the two bulging squeezing punches and comprises push rods located at the two ends respectively, and a forming inner die block matched with the branch pipe forming cavity and used for driving a pipe blank to bulge and deform is arranged between the two push rods; the forming inner die block is connected with the two push rods through double-hinge connecting rods; the axes of the push rods are parallel to the axis of the forming cavity, and the push rods are installed in the corresponding bulging squeezing punches respectively in a sliding matching mode; a bulging liquid inlet and a bulging liquid outlet are formed in each bulging squeezing punch; one of the push rods is provided with a locking type rapid detachment and connecting structure; compound hydraulic cylinders are arranged at the two ends of the forming cavity respectively; an auxiliary pressure mechanism is arranged between the two push rods.

Owner:XINCHANG HANGDA MACHINERY MFG

Steel wire rope cleaning equipment

ActiveCN107350187ARealize automatic scrubbingPrevent splashLiquid surface applicatorsGeneral water supply conservationElectricityBristle

The invention discloses steel wire rope cleaning equipment. The steel wire rope cleaning equipment comprises a control unit, a first frequency converter, a second frequency converter, a wireless emitting device, a lifting motor, a rotary motor, a supporting base, a liquid storage box, a dirt collecting box and a barrel brush used for brushing a steel wire rope, wherein the barrel brush is positioned in an inner cavity of the dirt collecting box; the barrel brush, the dirt collecting box, the liquid storage box and the rotary motor are arranged on the supporting base; a lifting beam is arranged on the top of the supporting base; the lifting motor is arranged on lifting equipment; a mooring rope is arranged between the rotary shaft of the lifting motor and the lifting beam; a transmission system is arranged between the rotary motor and the barrel brush; a water faucet is arranged on the liquid storage box; a liquid outlet of the water faucet is positioned above bristles of the barrel brush; the control unit, the first frequency converter, the second frequency converter and the wireless emitting device are arranged in the control box; the first frequency converter and the second frequency converter are electrically connected between the control unit and the wireless emitting device; and wireless receiving devices are correspondingly arranged on the lifting motor and the rotary motor. The steel wire rope cleaning equipment is efficient and environmentally friendly, saves time and labor, and solves the potential safety hazard problem in a steel wire rope cleaning process.

Owner:窑河闸管理处

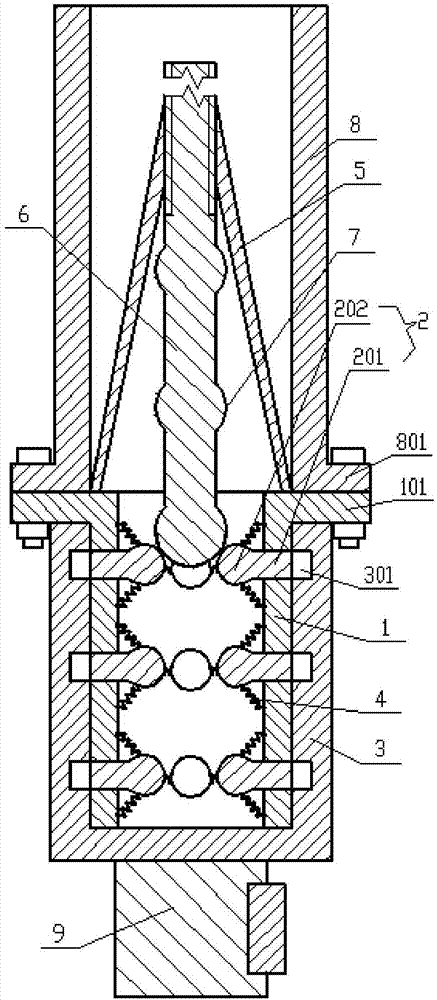

Rapid connection type coupling

The invention discloses a quick-connect coupling, which includes a multi-position trigger mechanism and a socket; the body of the multi-position trigger mechanism is provided with a multi-layer handle, the handle includes a sliding column and a touch ball, and the touch ball is located on the body In the through hole, the sliding column extends horizontally from the outer wall of the body; the handles are arranged in a circular array at the center of the through hole, and the two sides of each touch ball are connected with two cylindrical springs; the top of the body is provided with a cone , the conical cylinder is located in the connecting cylinder and is fixedly connected with the main body; the valve stem is screwed in the conical cylinder, and the number of steel balls on the valve stem is the same as the number of layers of the handle; there are multi-layer horizontal settings on the inner wall of the socket. The blind holes are in a circular array centered on the center of the socket; the body is embedded in the socket, and matching ribs and grooves are respectively provided on the outer wall of the body and the inner wall of the socket to When the valve stem is screwed down, the steel ball can squeeze the sliding column of the handle into the corresponding blind hole on the inner wall of the socket. The invention can realize fast connection and disassembly.

Owner:王华银

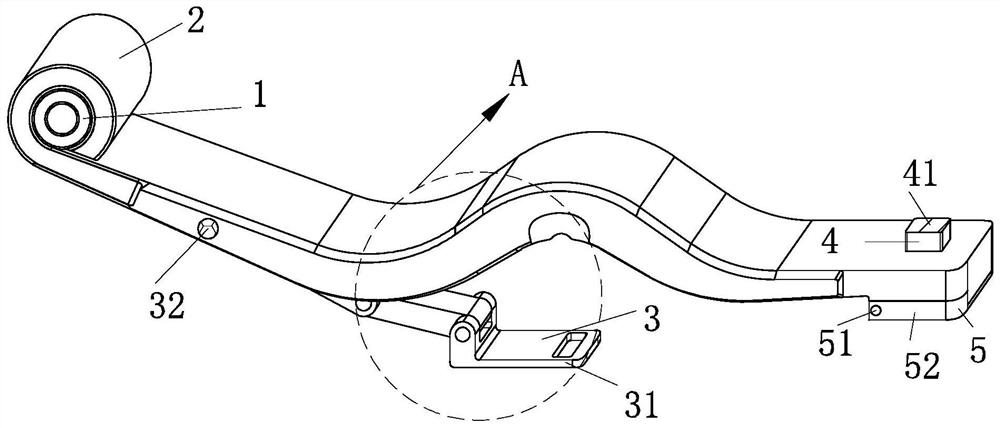

Air suspension arc-shaped guide arm

InactiveCN112572078ASmall amount of deformationExtended service lifeResilient suspensionsPivoted suspension armsPhysicsAir suspension

The invention relates to the technical field of automobile parts and particularly relates to an air suspension arc-shaped guide arm. The guide arm comprises a lining, a guide arm body, a heat dissipation structure, a connecting structure, a limiting structure, a positioning structure and a driving structure, wherein the guide arm body of the arc-shaped structure is changed into an original Z-shaped structure and is in an arc shape, so that deformation and residual stress are smaller and the service life is longer when the guide arm body is machined, meanwhile, the arc-shaped structure of the guide arm body is matched with a circular-section axle for use, and due to the fact that the shape of the arc-shaped structure is closer to the circle, machining precision is improved; the axle and theguide arm can be mounted through smaller parts, meanwhile, the guide arm body and the axle are more convenient and faster to mount and dismount through mounting of the positioning structure, ventilation in the guide arm body is facilitated through the heat dissipation structure when the axle and the guide arm body shake, and the service life of the guide arm is prolonge; the guide arm body is rapidly cooled through air cooling, and therefore the situation that in the deformation process, the use performance is affected by the volume heat of the guide arm body is effectively prevented.

Owner:厦门鸾创科技有限公司

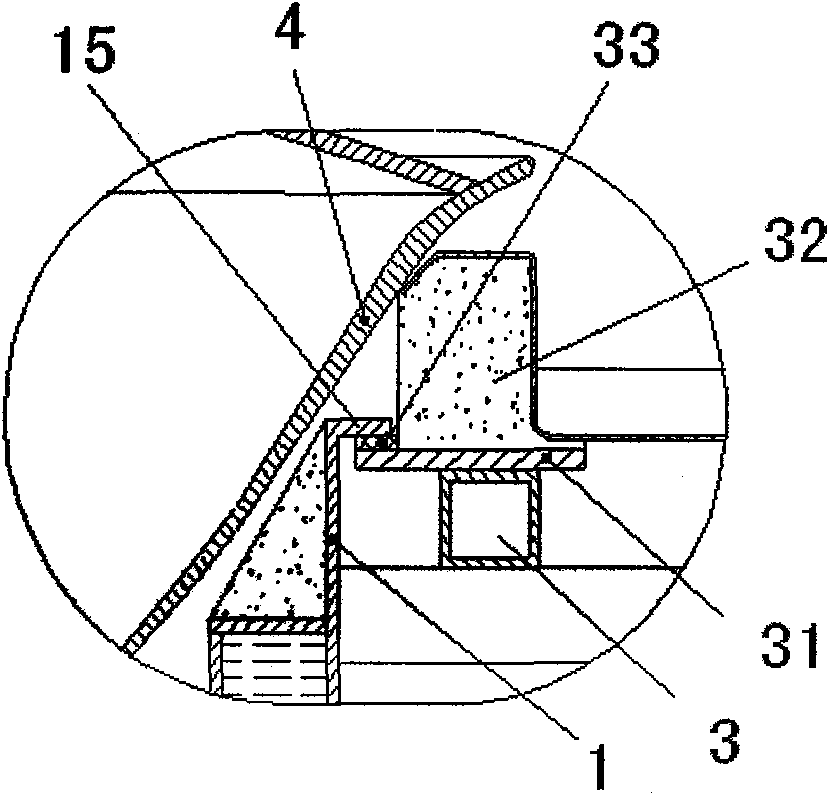

A kind of oblique angle tongue-and-groove building formwork

ActiveCN105442831BImprove connection strengthUniform force strengthAuxillary members of forms/shuttering/falseworksForming/stuttering elementsEngineeringTongue and groove

Owner:NENGCHENG GRP

Automatic steel wire rope cleaning machine

ActiveCN107413700ARealize automatic scrubbingSolve potential safety hazardsLiquid surface applicatorsCleaning using toolsLeft halfBristle

An automatic steel wire rope cleaning machine comprises a supporting seat, a motor, a liquid storage box, a stain collecting box and a cylindrical brush used for brushing steel wire ropes. The cylindrical brush is located in an inner cavity of the stain collecting box and comprises a left half cylinder body and a right half cylinder body. One side of the left half cylinder body is hinged to one side of the right half cylinder body, and the other side of the left half cylinder body is connected with the other side of the right half cylinder body in a fast opening-closing mode. The cylindrical brush, the stain collecting box, the liquid storage box and the motor are all installed on the supporting seat. A lifting cross beam used for hoisting lifting equipment is arranged at the top of the supporting seat. A transmission system for driving the cylindrical brush to rotate is installed between a rotary shaft of the motor and the cylindrical brush. Faucets are installed on the liquid storage box. Liquid outlets of the faucets are located above bristles of the cylindrical brush. After the faucets are opened, liquid in the liquid storage box can drop onto the bristles. An inner cavity of the liquid storage box is divided into an oil storage cavity body and a cleaning solution storage cavity body through a partition plate. The two faucets communicate with the oil storage cavity body and the cleaning solution storage cavity body correspondingly. The automatic steel wire rope cleaning machine is efficient, environmentally friendly and capable of saving time and effort, and potential safety hazards in the steel wire rope cleaning process are avoided.

Owner:窑河闸管理处

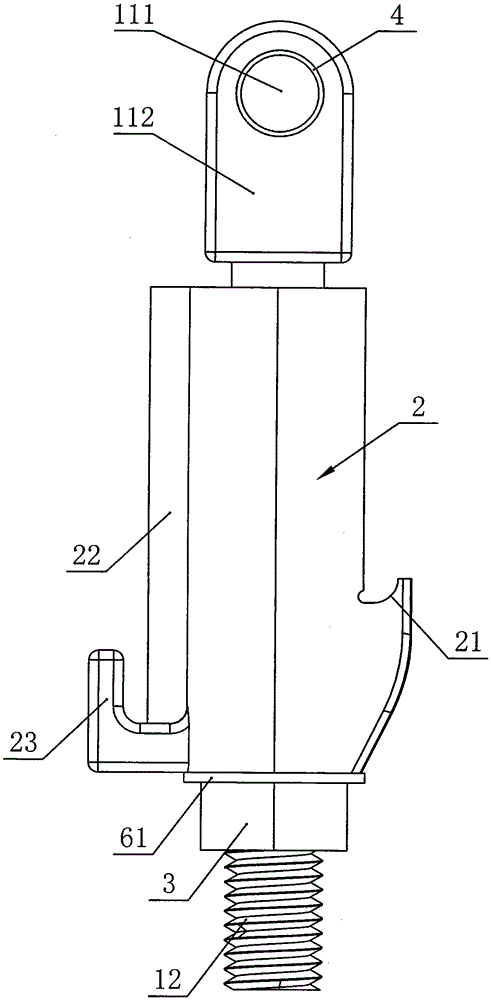

A quick connection device with an open container body and a sealing cap

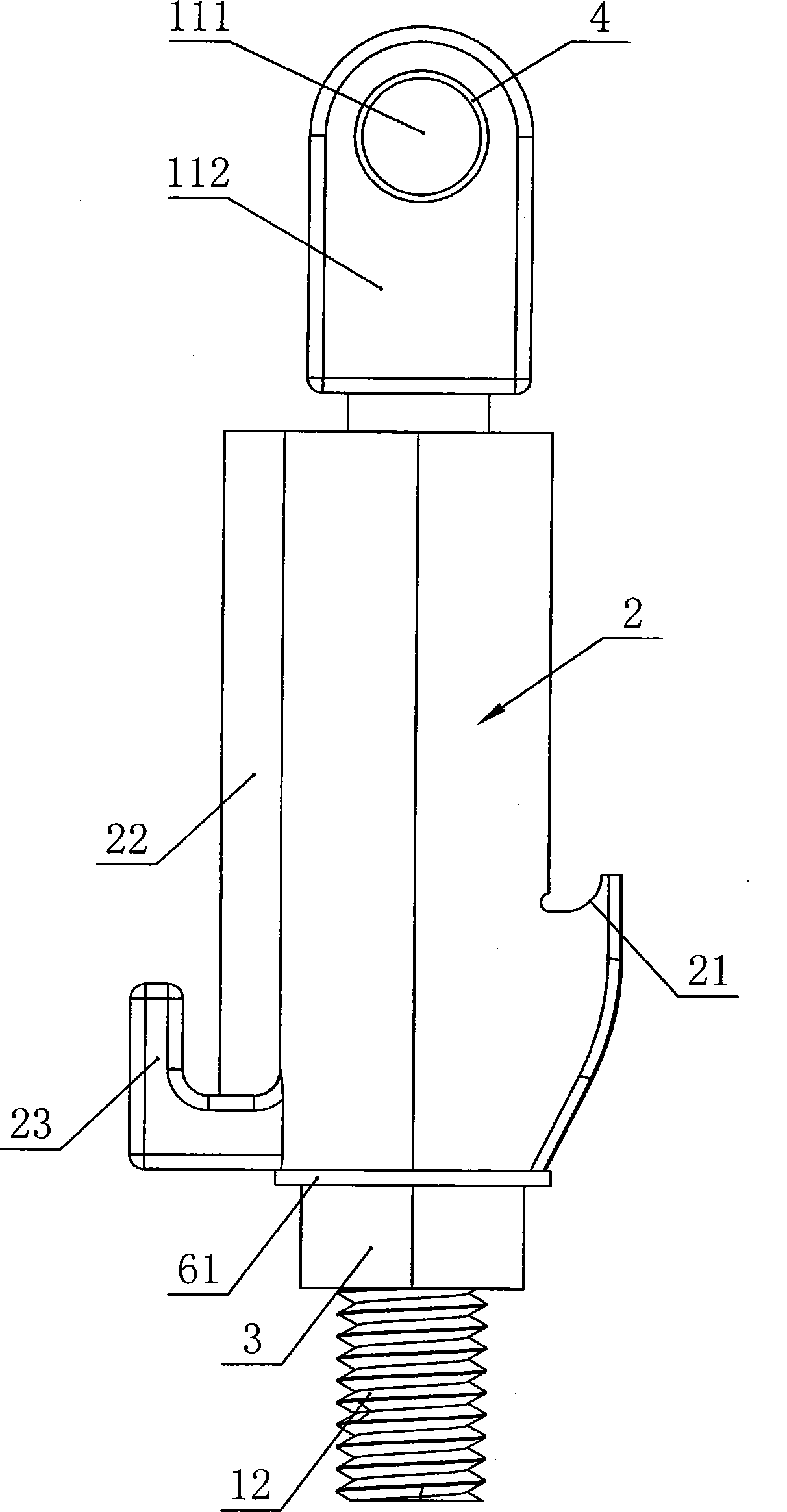

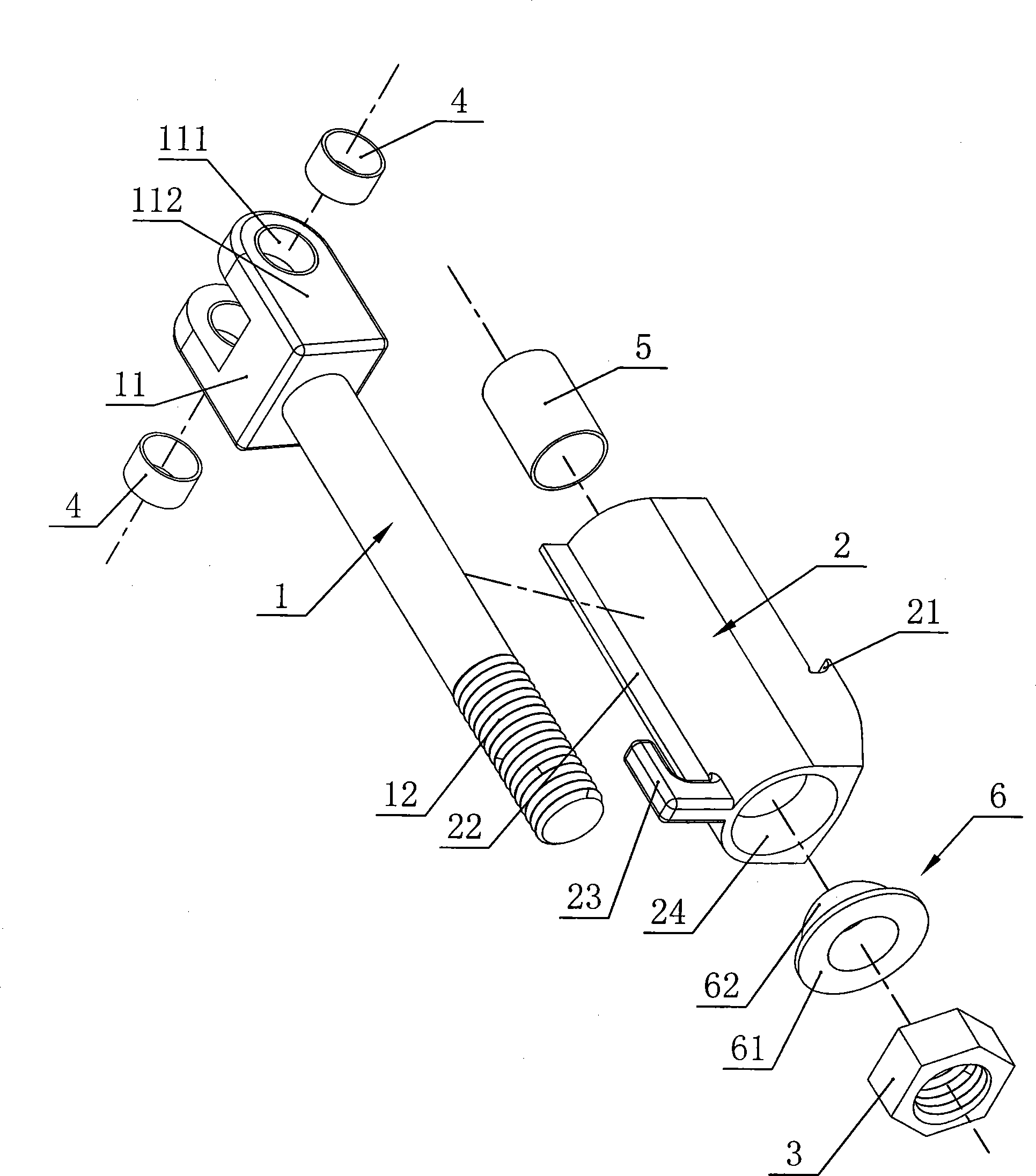

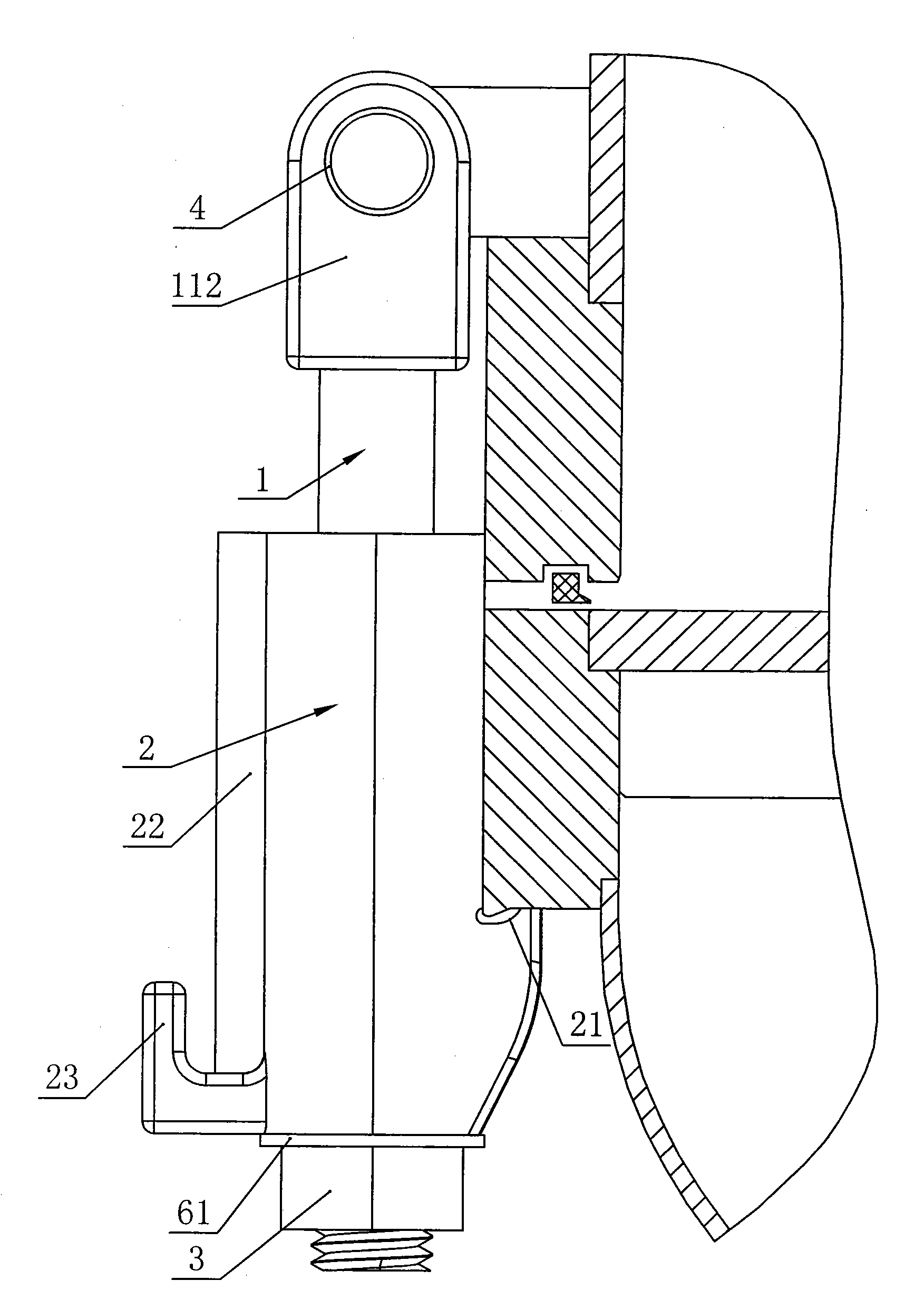

ActiveCN104235362BNo need to increase thicknessQuick release connectionPressure vesselsCouplingEngineering

The invention discloses a quick connection device for a container body with an opening and a sealing cover, which comprises a joint bolt, a locking hook and a nut. One end of the joint bolt is integrally formed with a The hinged and fixed lifting ring, the other end of the swing bolt is provided with an external thread that can be screwed and fixed with the nut, the locking hook is slidably fitted on the swing bolt, and the locking The hook is correspondingly provided with a locking hook head that can be hooked and fixed with the flange on the container body or the sealing cover, and the nut is screwed on the swing bolt, and forms the shaft of the locking hook correspondingly. Fixed to the limit. Adopting the above-mentioned structure, not only can realize the fast loading and unloading connection between the sealing cap and the opening end of the container body, but also relatively reduce the processing steps, and will not affect the rigidity of the flange that cooperates with the locking hook, so that people do not need to increase the The thickness of the flange can achieve the purpose of saving materials.

Owner:温州同庆车业股份有限公司

Hydraulic control tee joint buckling rigid-plastic compounded bulging equipment

InactiveCN105234246APrecise control of liquid bulging pressureControl pressureHydraulic cylinderEngineering

The invention discloses hydraulic control tee joint buckling rigid-plastic compounded bulging equipment. The hydraulic control tee joint buckling rigid-plastic compounded bulging equipment comprises an upper half die and a lower half die, wherein a forming cavity is arranged between the upper half die and the lower half die. The two ends of the forming cavity are each provided with a bulging squeezing punch head. The lower half die is provided with an axis branch pipe forming cavity, and a balance punch head is installed in the branch pipe forming cavity. A rigid bulging inner die is arranged between the two bulging squeezing punch heads and comprises push rods located at the two ends respectively, and a forming inner die block is arranged between the two push rods. The forming inner die block is connected with the two push rods through a double-hinge connecting rod. The opposite ends of the two push rods are provided with connecting grooves facing an opening of the branch pipe forming cavity, and a limiting structure is arranged in each connecting groove. The push rods are installed in the corresponding bulging squeezing punch heads respectively in a sliding fit mode. A bulging liquid inlet and a bulging liquid outlet are formed in each bulging squeezing punch head. One push rod is provided with a buckling rapid detachment and connection structure. Thrust devices are arranged at the two ends of the forming cavity respectively, and each thrust device comprises a hydraulic cylinder meeting the requirement.

Owner:XINCHANG HANGDA MACHINERY MFG

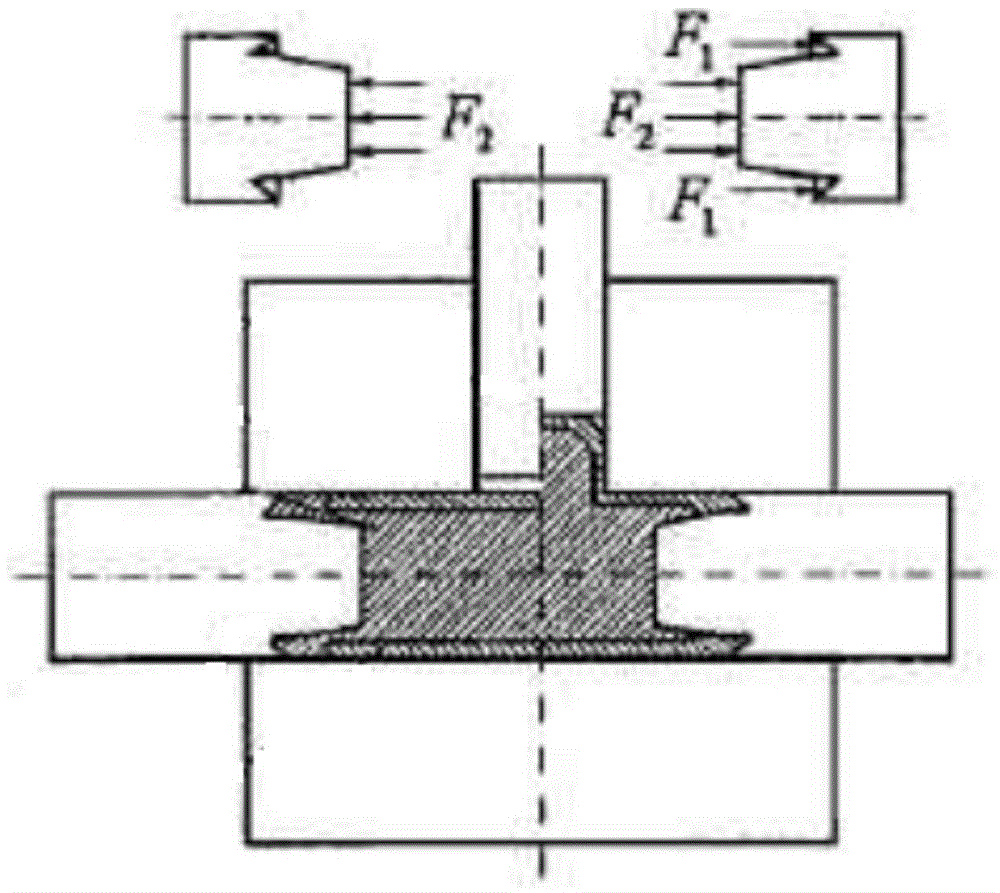

Rigid-plastic compound multi-cylinder locking bulging forming apparatus for large-caliber hydraulic controlled type three-way pipes

InactiveCN105290190AMeet the requirements of bulge formingPrecise control of liquid bulging pressureShaping toolsHydraulic cylinderEngineering

The invention discloses a rigid-plastic compound multi-cylinder locking bulging forming apparatus for large-caliber hydraulic controlled type three-way pipes. The rigid-plastic compound multi-cylinder locking bulging forming apparatus comprises an upper half die and a lower half die; a forming cavity is formed between the upper half die and the lower half die; bulging extrusion punches are mounted at the two ends of the forming cavity, respectively; a branch pipe forming cavity is formed in the lower half die and a balance punch is mounted in the branch pipe forming cavity; a rigid bulging inner die is arranged between the two bulging extrusion punches; the rigid bulging inner die comprises push rods located at both ends, respectively, and a forming inner module is arranged between the two push rods; the forming inner module is connected with the two push rods through double hinged connecting rods; the push rods are mounted in the corresponding bulging extrusion punches in a sliding fit manner; a bulging liquid inlet and a bulging liquid outlet are formed in the bulging extrusion punches, and a quick demounting connecting structure is arranged on one push rod; thrusters are arranged at the two ends of the forming cavity, respectively; each thruster comprises an extruding hydraulic cylinder and a central hydraulic cylinder; an auxiliary pressure mechanism is arranged between the two push rods.

Owner:XINCHANG HANGDA MACHINERY MFG

Goods delivery plate of sorting device for medicine logistics storage

PendingCN113458018AHigh degree of automationQuick release connectionSortingStructural engineeringMechanical engineering

The invention discloses a goods delivery plate of a sorting device for medicine logistics storage. The goods delivery plate comprises a goods delivery plate body and is characterized in that a turnover plate is arranged at the bottom of the goods delivery plate body, the right end of the goods delivery plate body is hinged to the right end of the turnover plate through a connecting shaft, a pair of lifting devices is arranged on the front side and the rear side of the goods delivery plate body, the two ends of each lifting device are hinged to the side wall of the goods delivery plate body and the side wall of the turnover plate respectively, an arc-shaped clamping groove communicating with the front end face and the rear end face of the turnover plate is formed in the bottom of the turnover plate in a concave mode, a threaded hole communicating with the arc-shaped clamping groove is formed in the right end of the turnover plate in a concave mode, and a locking bolt is connected into the threaded hole in a threaded mode. According to the goods delivery plate, turn over is achieved through cooperation of the rotating shaft and the lifting devices, goods on the goods delivery plate can be automatically turned to the designated position, and the automation degree is high.

Owner:江苏澳洋医药物流有限公司

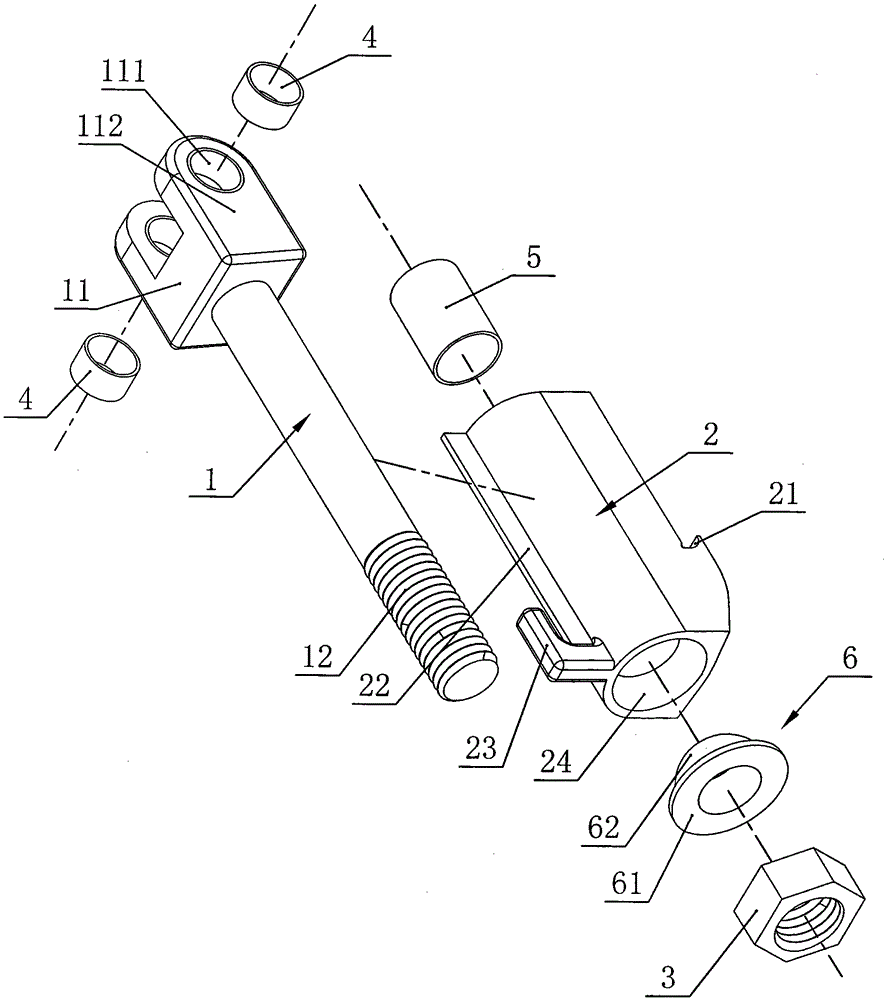

Quick connecting device with open container body and sealing cover

ActiveCN104235362ANo need to increase thicknessQuick release connectionPressure vesselsEngineeringScrew thread

The invention discloses a quick connecting device with an open container body and a sealing cover. The quick connecting device comprises a swing bolt, a locking hook and a nut; a ring which can be fixedly hinged to the container body or the sealing cover is integrally formed on the end part of one end of the swing bolt; the end part of the other end of the swing bolt is provided with external threads which can be fixedly spirally connected with the nut; the locking hook sleeves the swing bolts in a sliding manner, and is correspondingly provided with a locking hook head which can be fixedly matched with a flange on the container body or the sealing cover; the nut is spirally connected to the swing bolt, and the axial limiting fixation to the locking hook is correspondingly formed. By adopting the structure, the sealing cover and the open end of the container body are quickly detached and connected, processing procedures are relatively reduced, and the rigidity of the flange matched with the locking hook head cannot be influenced, so that the thickness of the flange is not required to be increased, and the aim of saving materials is fulfilled.

Owner:温州同庆车业股份有限公司

Lock catch type rigid and plastic compound bulging die for hydraulically-controlled T-branch pipe

InactiveCN105251852AReduce thrustPrecise control of liquid bulging pressureEjection devicesHinge angleEngineering

The invention discloses a lock catch type rigid and plastic compound bulging die for a hydraulically-controlled T-branch pipe. The lock catch type rigid and plastic compound bulging die comprises an upper half die and a lower half die. A forming cavity is formed between the upper half die and the lower half die. Bulging squeezing punches are mounted at the two ends of the forming cavity respectively. The lower half die is provided with a branch pipe forming cavity, and a balance punch is mounted in the branch pipe forming cavity. A rigid bulging inner die is arranged between the two bulging squeezing punches and comprises pushing rods located at two ends respectively. A forming inner die block is arranged between the two pushing rods. The forming inner die block is connected with the two pushing rods through double-hinge connection rods. The opposite ends of the pushing rods are provided with connection grooves facing the opening of the branch pipe forming cavity. Limiting structures used for preventing the axes of the two double-hinge connection rods from coinciding are arranged in the connection grooves. The axes of the pushing rods are parallel to the axis of the forming cavity. The pushing rods are mounted in the corresponding bulging squeezing punches in a sliding fit mode respectively. Bulging liquid inlets and bulging liquid outlets are formed in the bulging squeezing punches. One pushing rod is provided with a lock catch type quick detaching connection structure.

Owner:XINCHANG HANGDA MACHINERY MFG

Rigid-plastic compound multi-cylinder locking bulging forming apparatus for hydraulic controlled type three-way pipes

InactiveCN105290192AReduce thrustControl liquid bulging pressureShaping toolsEngineeringPlastic compound

The invention discloses a rigid-plastic compound multi-cylinder locking bulging forming apparatus for hydraulic controlled type three-way pipes. The rigid-plastic compound multi-cylinder locking bulging forming apparatus comprises an upper half die and a lower half die; a forming cavity is formed between the upper half die and the lower half die; bulging extrusion punches are mounted at the two ends of the forming cavity, respectively; a branch pipe forming cavity is formed in the lower half die and a balance punch is mounted in the branch pipe forming cavity; a rigid bulging inner die is arranged between the two bulging extrusion punches; the rigid bulging inner die comprises push rods located at both ends, respectively, and a forming inner module is arranged between the two push rods; the forming inner module is connected with the two push rods through a connecting rod; the push rods are mounted in the corresponding bulging extrusion punches in a sliding fit manner; a bulging liquid inlet and a bulging liquid outlet are formed in the bulging extrusion punches, and a quick demounting connecting structure is arranged on one push rod; thrusters are arranged at the two ends of the forming cavity, respectively; each thruster comprises extruding hydraulic cylinders and a central hydraulic cylinder, and at least three extruding hydraulic cylinder comprises are arranged evenly about an axis of the central hydraulic cylinder.

Owner:XINCHANG HANGDA MACHINERY MFG

Hydraulic controlled type latched rigid-plastic compound bulging and forming device for three-way pipe

InactiveCN105290189AReduce sizeControl liquid bulging pressureShaping toolsEngineeringPlastic compound

A hydraulic controlled type latched rigid-plastic compound bulging and forming device for a three-way pipe. The device comprises an upper semi mold and a lower semi mold, wherein a forming cavity is formed between the upper semi mold and the lower semi mold; bulging extrusion punches are installed at two ends of the forming cavity respectively; a branch pipe forming cavity is formed in the lower semi cavity; a balancing punch is installed inside the branch pipe forming cavity; a rigid bulging inner mold is arranged between two bulging extrusion punches and comprises pushing rods located at two ends respectively; a forming inner mold block is arranged between two pushing rods; the forming inner mold block is connected with two pushing rods through a connecting rod mechanism; the axes of the pushing rods are parallel to the axis of the forming cavity and are installed inside corresponding bulging extrusion punches in a sliding fit mode respectively; a bulging liquid inlet and a bulging liquid outlet are formed in each bulging extrusion punch; a latch-type quick disassembly connection structure is arranged on one of the pushing rods; and thrust devices which are used for driving the bulging extrusion punches to slide in the forming cavity and driving the pushing rods to slide in the bulging extrusion punches are arranged at two ends of the forming cavity respectively.

Owner:XINCHANG HANGDA MACHINERY MFG

Hydraulically controlled type t-branch pipe lock catch type rigidity and plasticity composite bulging device

A hydraulically controlled type t-branch pipe lock catch type rigidity and plasticity composite bulging device comprises an upper half die and a lower half die. A forming cavity is formed between the upper half die and the lower half die, and the two ends of the forming cavity are each provided with a bulging extrusion punch. The lower half die is provided with an axis branch pipe forming cavity, and a balancing punch is installed in a branch forming cavity. A rigidity bulging inner die is arranged between the two bulging extrusion punches, the rigidity bulging inner die comprise push rods located at two ends respectively, a forming inner die block is arranged between the two push rods, and the forming inner die block is connected with the two push rods through two hinged connecting rods. The opposite ends of the two push rods are provided with connecting grooves with openings facing the branch pipe forming cavity. Limiting structures used for preventing the axes of the two hinged connecting rods from coinciding are arranged in the connecting grooves. The push rods are installed in the corresponding bulging extrusion punches in a sliding fit mode respectively. A bulging liquid inlet and a bulging liquid outlet are formed in the bulging extrusion punches. One of the push rods is provided with a lock catch type connecting structure capable of being dismounted quickly. The two ends of the forming cavity are each provided with a thrust device.

Owner:XINCHANG HANGDA MACHINERY MFG

T-branch lock catch type rigidity and plasticity compound bulging forming equipment

The invention discloses T-branch lock catch type rigidity and plasticity compound bulging forming equipment which comprises an upper half die and a lower half die. A forming cavity is arranged between the upper half die and the lower half die, and the two ends of the forming cavity are each provided with a bulging extrusion punch. A branch pipe forming cavity is arranged on the lower half die, and a balance punch is mounted in the branch pipe forming cavity. A rigid bulging inner die is arranged between the two bulging extrusion punches, and comprises push rods located at the two ends of the rigid bulging inner die respectively. A forming inner die block which is matched with the branch pipe forming cavity and used for driving a pipe blank to achieve bulging forming is arranged between the push rods. The forming inner die block and the two push rods are connected through a connecting rod mechanism, the axes of the push rods are in slide fit with the forming cavity, and the push rods are mounted in the corresponding bulging extrusion punches. One push rod is provided with a lock catch type quick-disassembling connection structure, and compound hydraulic cylinders which are used for driving the bulging extrusion punches to slide in the forming cavity and used for driving the push rods to slide in the bulging extrusion punches are arranged at the two ends of the forming cavity.

Owner:XINCHANG HANGDA MACHINERY MFG

Locking rigid-plastic compound bulging forming apparatus for large-caliber three-way pipes

InactiveCN105290195AMeet the requirements of bulge formingEasy to driveEngineeringMechanical engineering

The invention discloses a locking rigid-plastic compound bulging forming apparatus for large-caliber three-way pipes. The locking rigid-plastic compound bulging forming apparatus comprises an upper half die and a lower half die; a forming cavity is formed between the upper half die and the lower half die; bulging extrusion punches are mounted at the two ends of the forming cavity, respectively; a branch pipe forming cavity is formed in the lower half die and a balance punch is mounted in the branch pipe forming cavity; a rigid bulging inner die is arranged between the two bulging extrusion punches; the rigid bulging inner die comprises push rods located at both ends, respectively, and a forming inner module is arranged between the two push rods; the forming inner module is connected with the two push rods through double hinged connecting rods; axes of the push rods are in sliding fit with the forming cavity, respectively, and push rods are mounted in the corresponding bulging extrusion punches; and a quick demounting connecting structure is arranged on one push rod; compound hydraulic cylinders for driving the bulging extrusion punches to slide in the forming cavity and driving the push rods to slide in the bulging extrusion punches are arranged at the two ends of the forming cavity, respectively; an auxiliary pressure mechanism is arranged between the two push rods.

Owner:XINCHANG HANGDA MACHINERY MFG

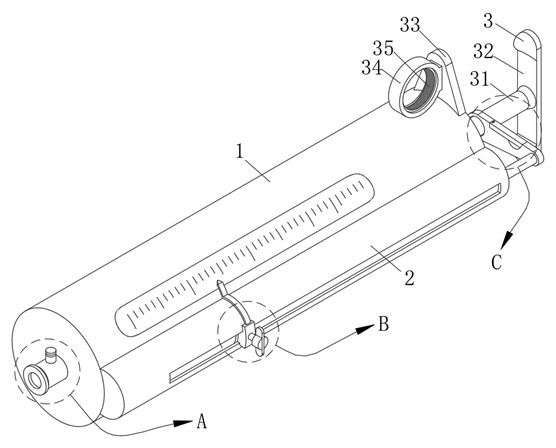

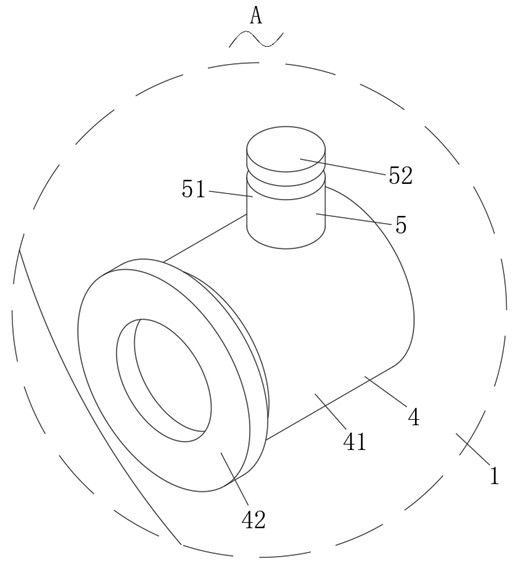

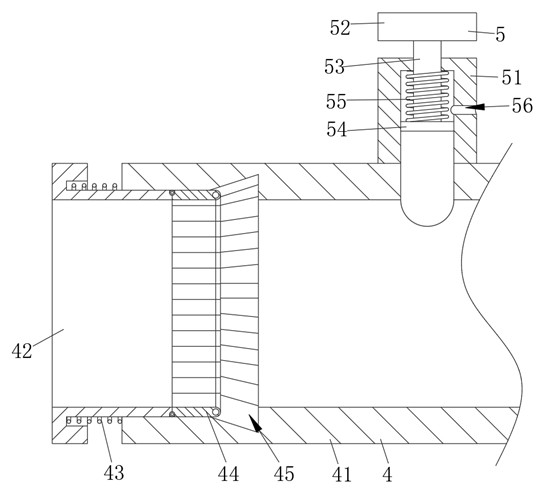

Catheter flushing system for implantable intravenous infusion port

The invention relates to the technical field of medical equipment, in particular to a catheter flushing system for an implantable venous port, which comprises a main body, an auxiliary body is arranged on one side of the main body, an operating mechanism is mounted on the main body, a butt joint mechanism and a pressure relief mechanism are arranged at one end of the main body, and a pulse mechanism and a quantification mechanism are arranged in the auxiliary body. The quantifying mechanism limits the pulse mechanism, and a synchronizing mechanism is connected between the pulse mechanism and the operating mechanism; through the butt joint mechanism, the main body and the guide pipe can be quickly disassembled and connected, and the operation efficiency is improved; through the arrangement of the pressure relief mechanism, the effect of pressure overload protection can be achieved, and the situation that the pressure for injection is too large is avoided; by means of the pulse mechanism, the effect similar to pulse is achieved when injection is executed, and the catheter is effectively flushed; quantitative injection can be conveniently achieved through the quantitative mechanism, accurate medication is achieved, and the use safety of the device is improved; pulse and normal injection modes can be conveniently switched according to actual use requirements through the synchronizing mechanism, and operation is more flexible and efficient.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Rigid and plastic composite multiple-cylinder buckle type bulging forming equipment for large-caliber three-way pipe

InactiveCN105312392AMeet the requirements of bulge formingEasy to driveHydraulic cylinderComputer module

Rigid and plastic composite multiple-cylinder buckle type bulging forming equipment for a large-caliber three-way pipe comprises an upper half die and a lower half die. A forming cavity is formed between the upper half die and the lower half die. Bulging squeezing punches are mounted at the two ends of the forming cavity respectively. A branch pipe forming cavity is formed in the lower half die. A balance punch is mounted in the branch pipe forming cavity. A rigid bulging inner die is arranged between the two bulging squeezing punches and comprises push rods located at the two ends respectively. A forming inner die block is arranged between the two push rods and connected to the two push rods through double-hinge connecting rods. The push rods are mounted in the corresponding bulging squeezing punches in a sliding fit mode. One push rod is provided with a buckle type quick dismounting connecting structure. Thrust devices are arranged at the two ends of the forming cavity respectively. Each thrust device comprises at least three squeezing hydraulic cylinders and a central hydraulic cylinder, wherein the squeezing hydraulic cylinders are uniformly and annularly distributed around the axis of the central hydraulic cylinder. An auxiliary pressure mechanism is arranged between the two push rods.

Owner:XINCHANG HANGDA MACHINERY MFG

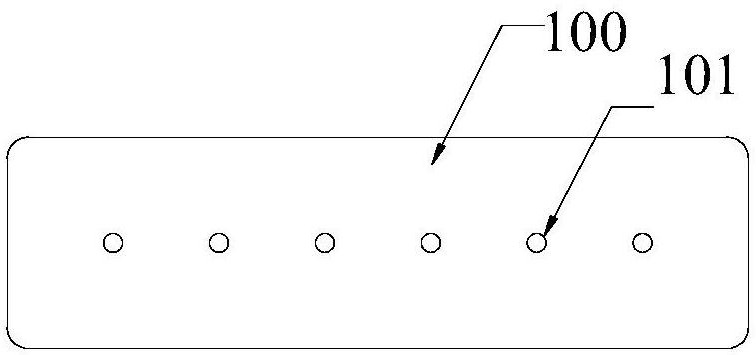

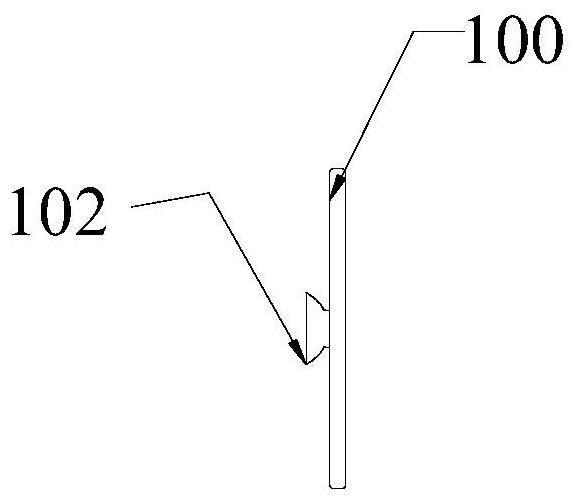

Ventricular wall injection assist device

ActiveCN107638615BHigh positioning accuracyAffects precise positioningIntravenous devicesRat heartReoperative surgery

The invention discloses a ventricular wall injection assisting device, which comprises a flexible belt-shaped main body made of biocompatible materials, a plurality of positioning holes are distributed on the belt-shaped main body, and the belt-shaped main body is made of biocompatible materials. A plurality of vacuum suction cups are arranged on the back of the main body, and the positions of the vacuum suction cups and the positioning holes do not coincide. In the ventricular wall injection assisting device of the present invention, a detachable connection is formed between the vacuum suction cup and the outer surface of the heart to fix the belt-shaped main body on the outer surface of the heart. Injecting non-contracting substances such as hydrogels separately can effectively improve the positioning accuracy of the injection point, shorten the operation time, and avoid residual pigment pollution in the patient's body.

Owner:DEKE MEDTECH HANGZHOU INC

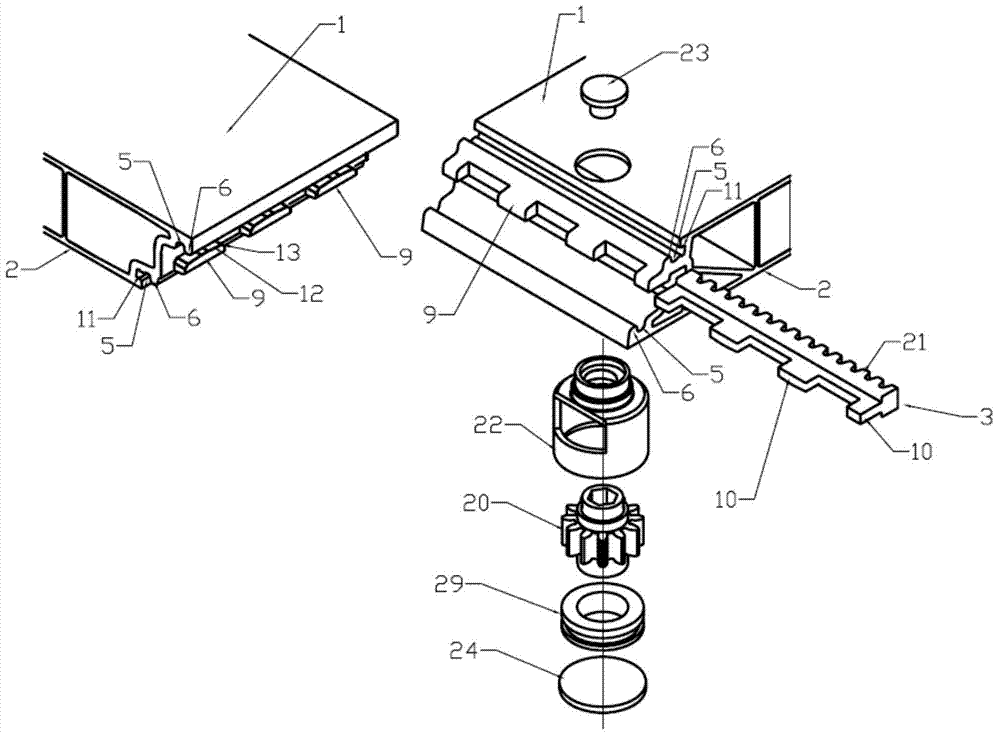

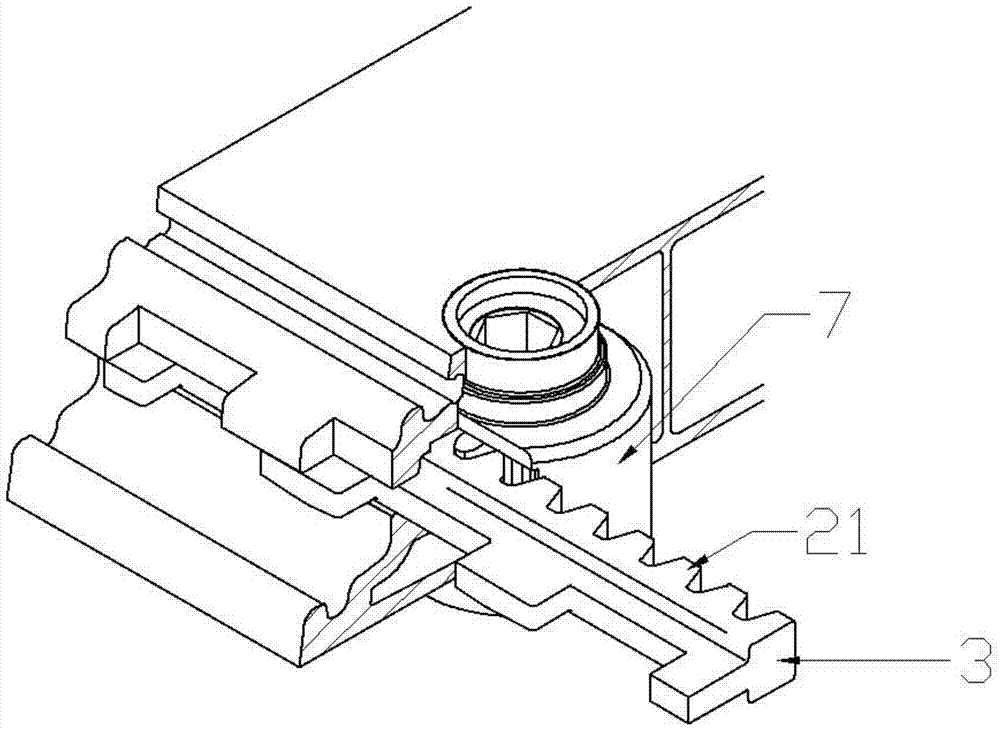

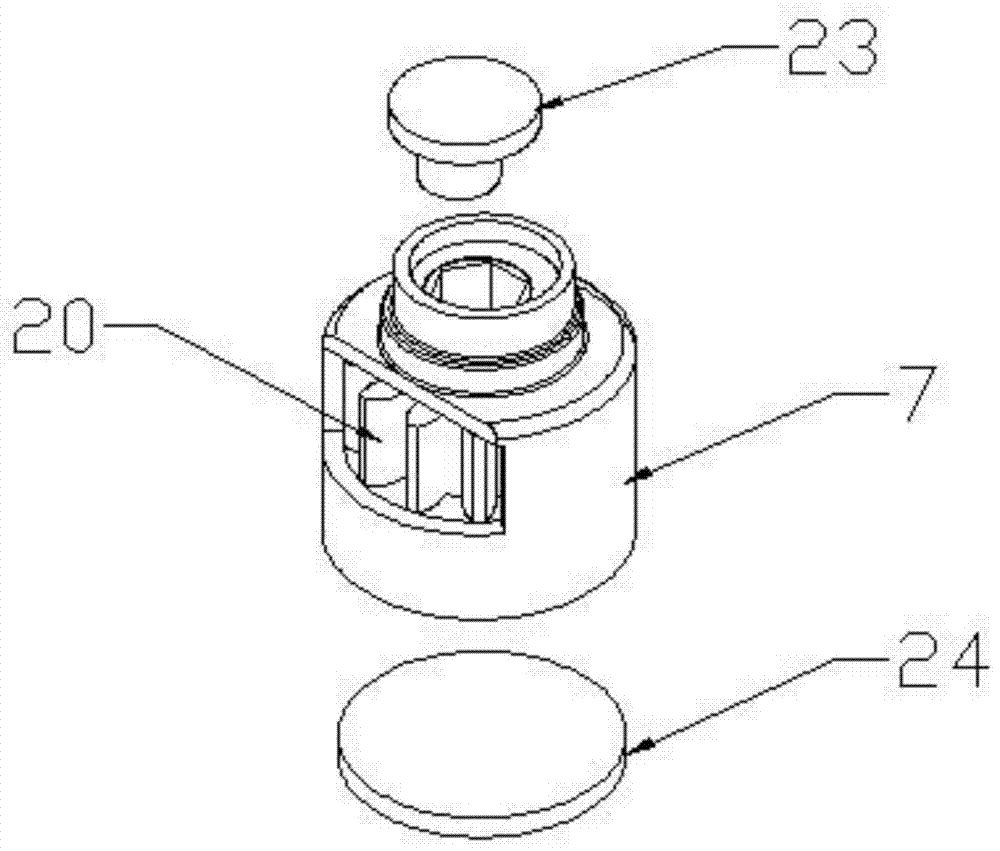

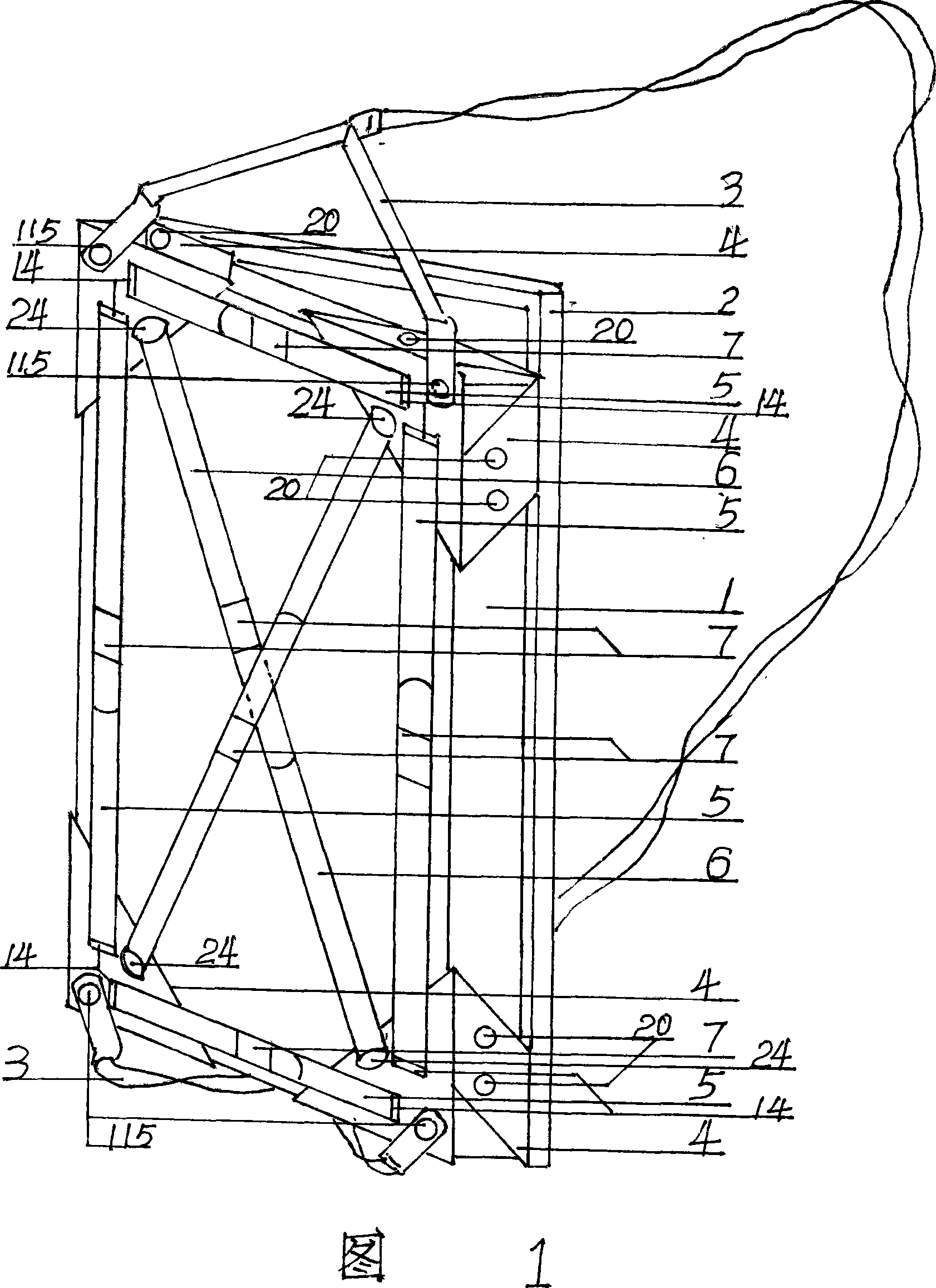

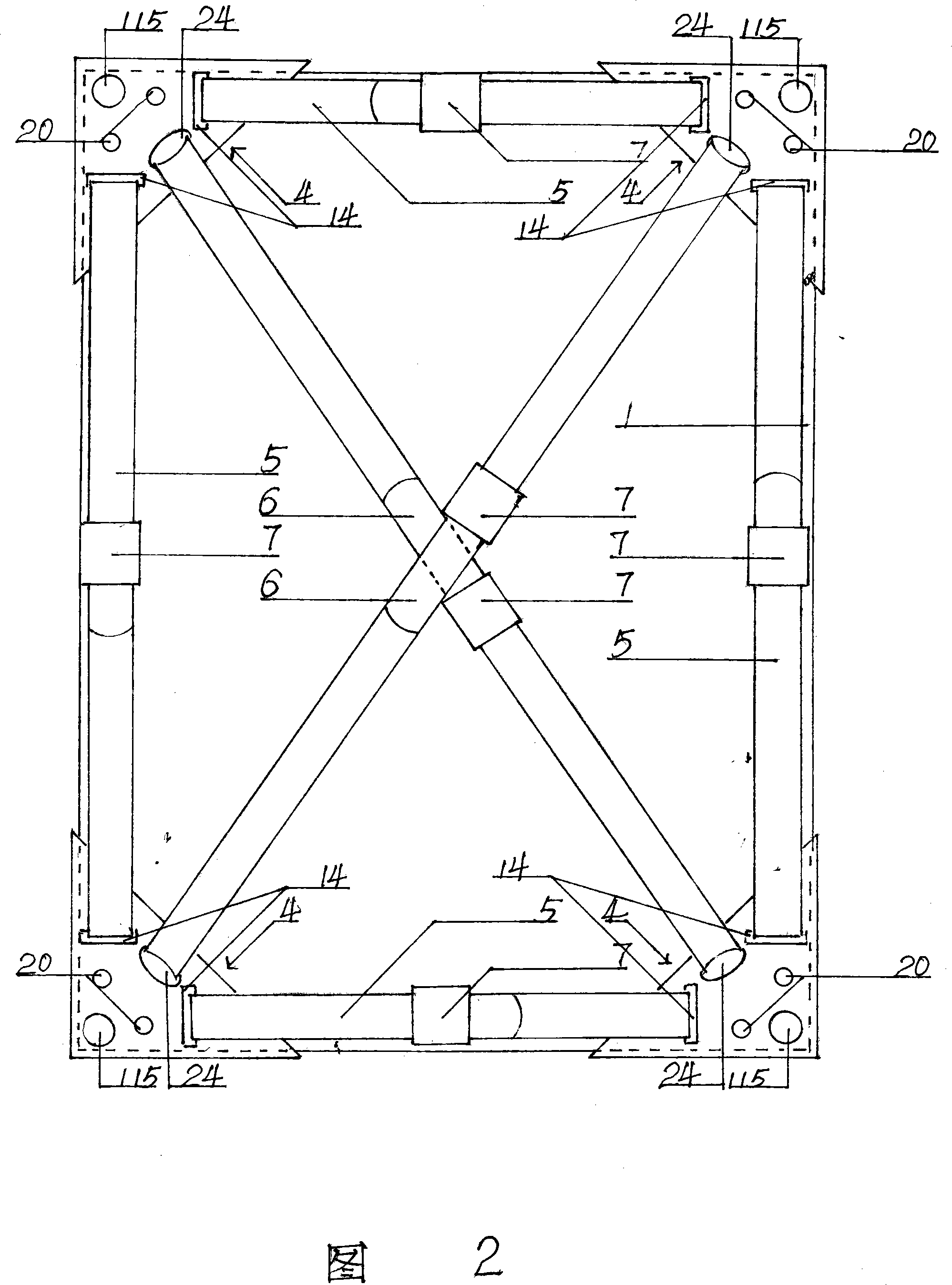

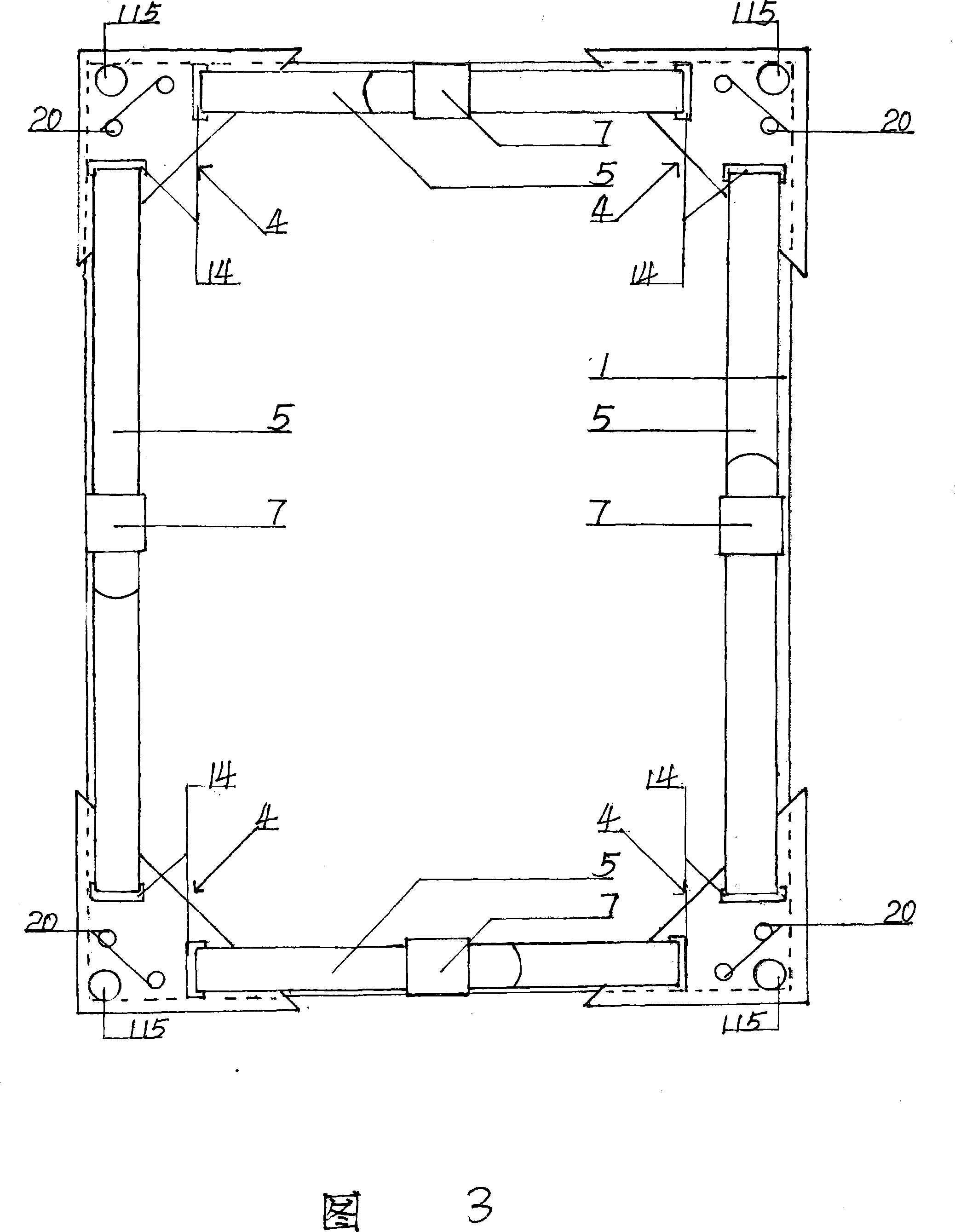

Device for binding gallus of portable notebook type computer

InactiveCN101176589AAvoid wear and tearQuick release connectionTravelling sacksDigital data processing detailsKey pressingDiagonal

The invention discloses a binding device for the carrying straps of a portable laptop, relating to the technical field of laptop and laptop bag, which adopts the technical proposal that: each angle sleeve is connected with the binding strips at the edges of the rectangular to form a rectangular; or each angle sleeve is crossed with the binding strips at the diagonals of the rectangular to form the shape of an X; the four angle sleeves are firmly sleeved on the four angles at the keyboard chassis of the laptop through tightening the binding strips at the four edges of the rectangular or the binding strips at the two diagonals of the rectangular; then the four angle sleeves are connected with the carrying straps of the laptop; thus, the invention is realized without changing the original design of the laptop. The invention has the advantages that: the laptop can be hung on the neck and operated when standing or walking without putting on a desk; the laptop can be carried without other backpacks; the keystrokes and the interfaces around the keyboard chassis of the laptop are not affected,, and the invention can be assembled and disassembled conveniently and quickly.

Owner:倪云飞

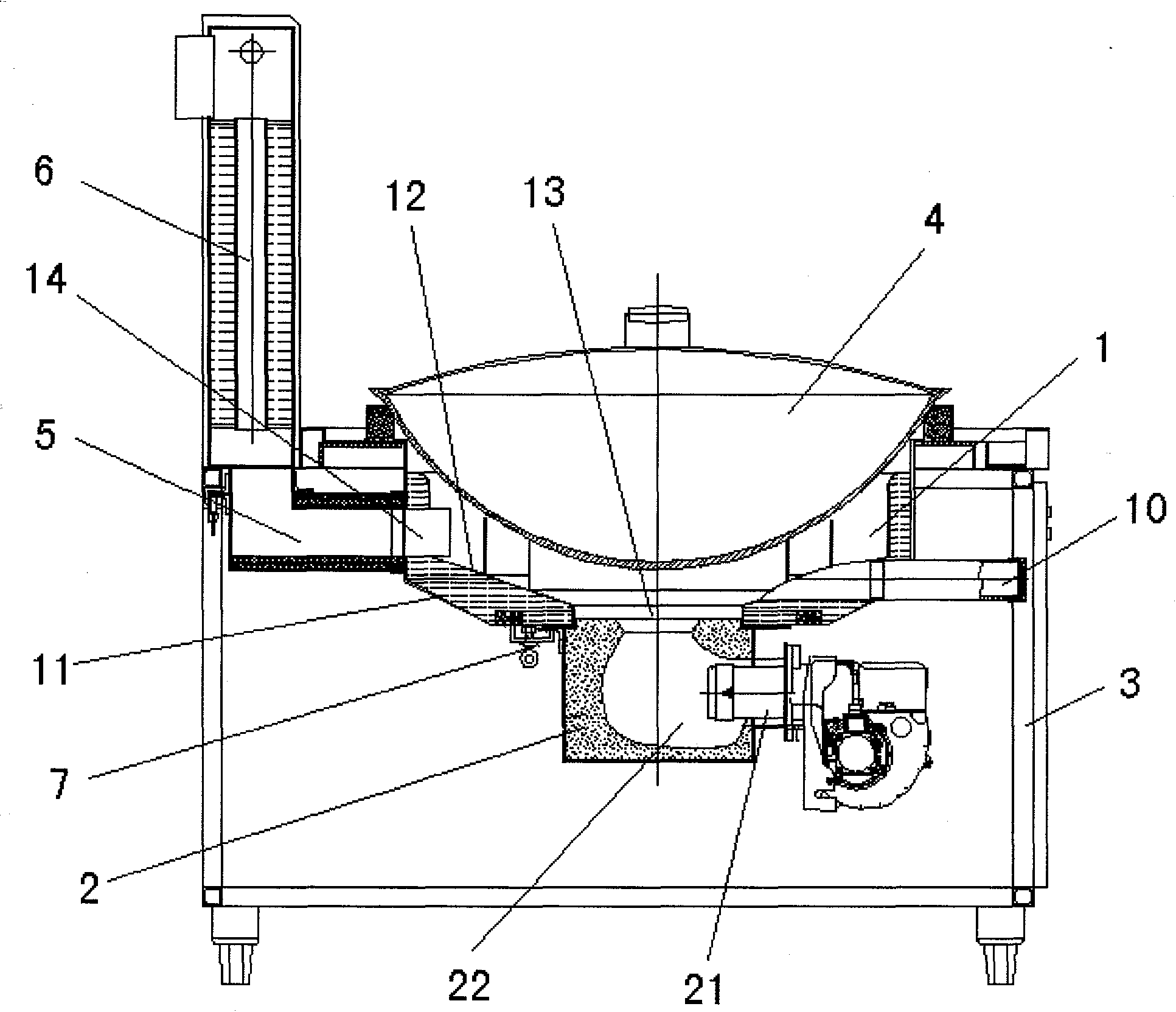

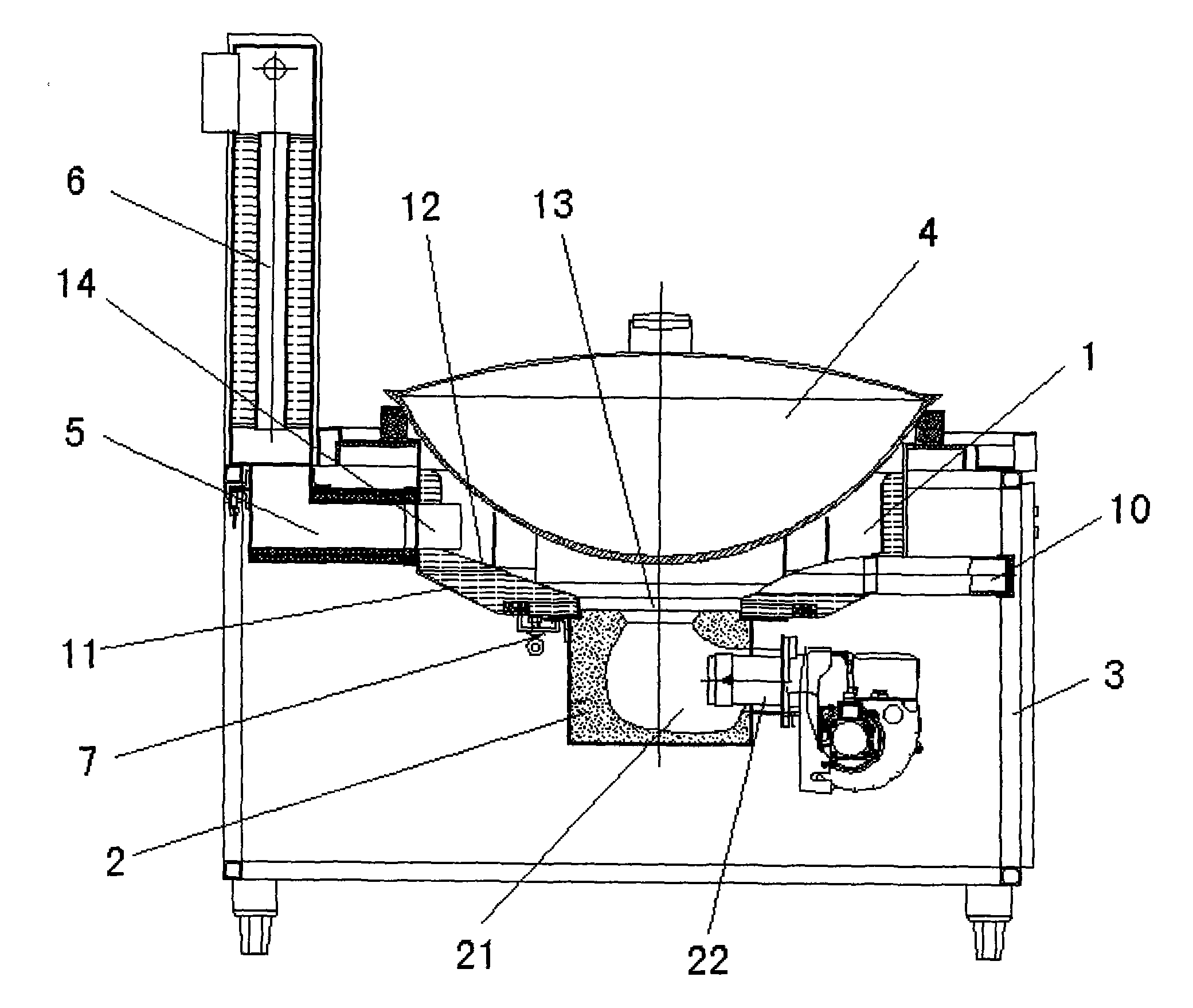

Fast combining and interchanging multi-fuel cooking stove

ActiveCN101482275BReduced Product SpecificationsLarge choiceDomestic stoves or rangesLighting and heating apparatusFiberSludge

The invention relates to a fast-assembly interchangeable multi-fuel cooking furnace, characterized in that the furnace comprises a grate, an upper furnace body and a lower furnace body, a circle of annular grate plate arranged on the grate, a circle of furnace edge arranged on the top of the grate plate and fitted and supported with a supplementary food pot of which periphery is steel, a pair of handles for interchange welded on the inner wall of the steel symmetrically, pond sludge arranged on the inner wall of the steel, an annular high-temperature ceramic fibre pad arranged on the grate plate inside of the furnace edge, and a circle of convex edge circumferentially arranged on the top of the upper furnace body, wherein the dead weights of the upper and lower furnace bodies are pressed on the high-temperature ceramic fibre pad through the convex edge, a bottom inlet of the upper furnace body and a top outlet of the lower furnace body are faced and connected into an integrated body through a fixing piece, a flue is slidingly arranged on the grate on one side of the upper furnace body, and two ends of the flue are connected to a flue outlet of the upper furnace body and a chimney through connecting pieces. The invention can be used in the fixed kitchens and other places needing furnaces widely.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

A horizontal dispensing device

ActiveCN111516299BRealize detachable connectionQuick release connectionLiquid surface applicatorsBag making operationsIndustrial engineeringPaper sheet

The present invention relates to the technical field of paper bag tube production equipment, more specifically, it relates to a transverse dispensing device, comprising a frame, the frame is provided with a gluing assembly and a dispensing roller assembly, and the dispensing roller assembly includes a dispensing roller, The dispensing aluminum bed and several dispensing heads, the two ends of the dispensing roller are rotatably connected to the frame, the dispensing aluminum bed is detachable and installed on the dispensing roller, and the side of the dispensing aluminum bed away from the dispensing roller is provided with a Multiple mounting holes, the dispensing head is detachably connected to the mounting holes, and the dispensing head dips the glue from the gluing component. The beneficial effect of the present invention is that when the position where glue needs to be dispensed on the strip-shaped paper changes, the staff can adjust the position of the glue-dispensing head according to the position where glue needs to be dispensed on the strip-shaped paper.

Owner:江西新明峰包装科技有限公司

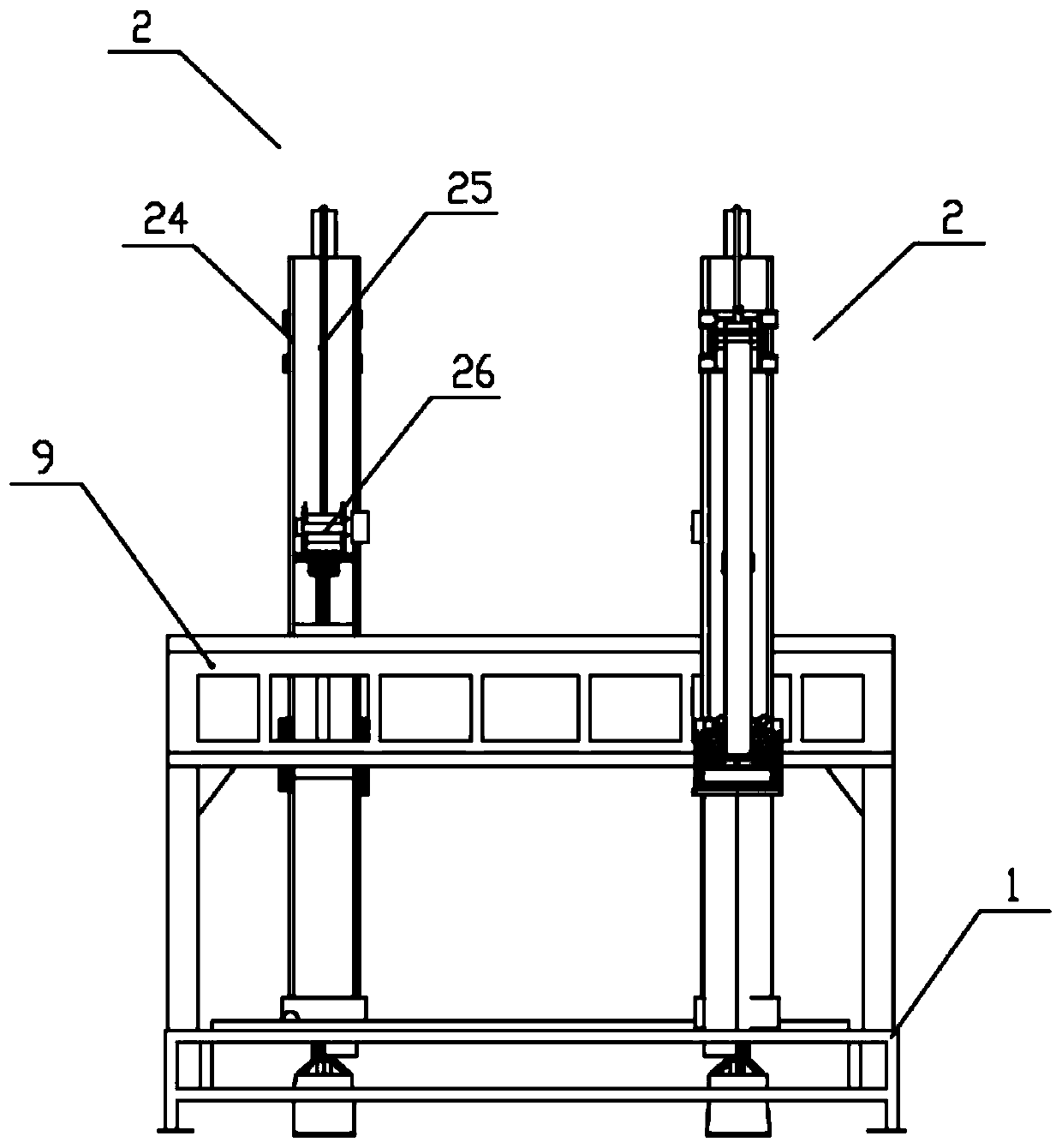

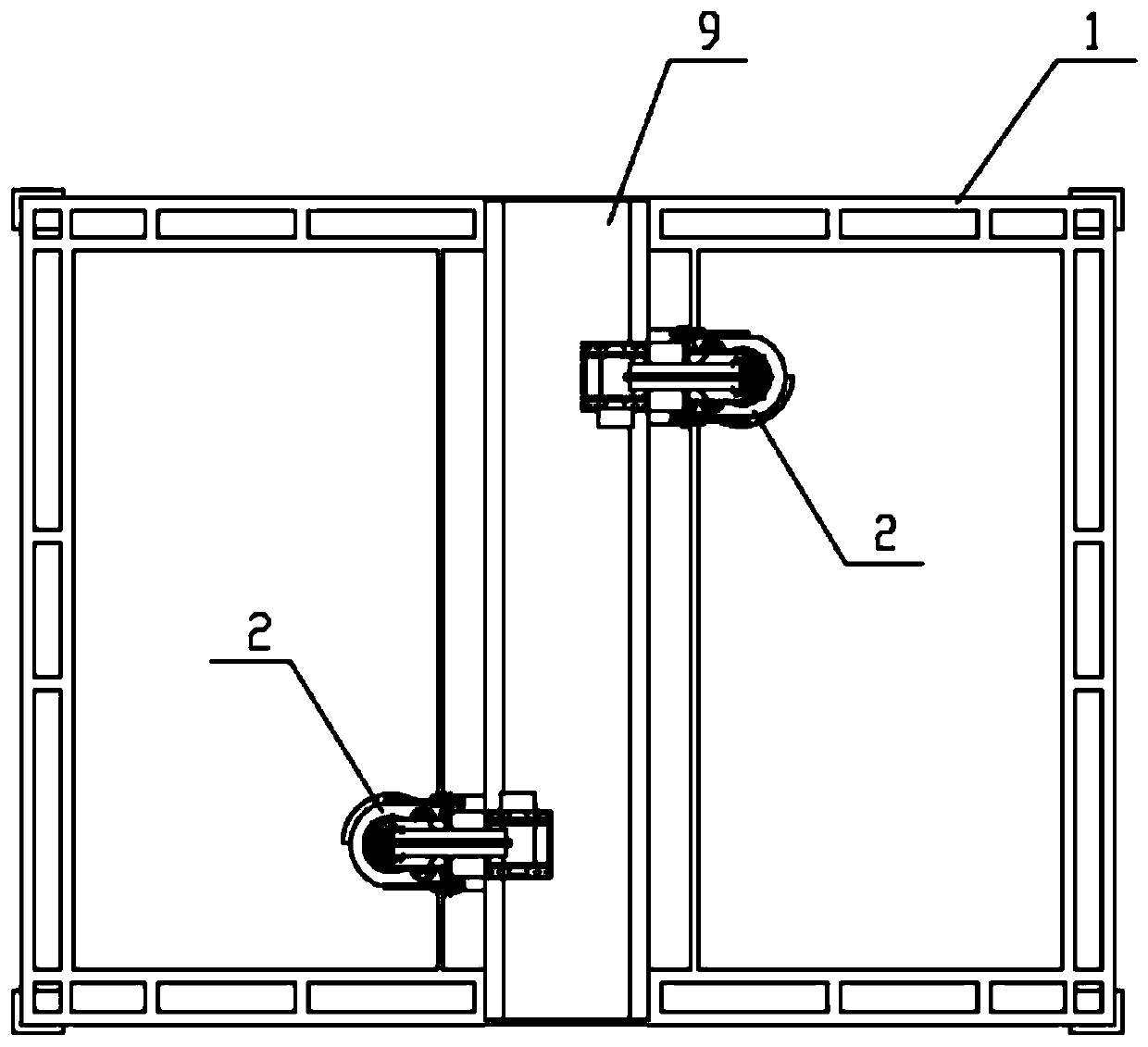

Rotary drilling rig for angling method construction and using method thereof

PendingCN111236856AImprove construction efficiencyStable hole formationDerricks/mastsBulkheads/pilesArchitectural engineeringPortal frame

The invention relates to a rotary drilling rig for angling method construction and a using method thereof, and belongs to the technical field of foundation construction equipment. The rotary drillingrig comprises two rotary drilling rig bodies, a support frame and a transverse movement driving mechanism for driving the rotary drilling rig bodies to move horizontally, wherein the rotary drilling rig bodies are in sliding connection with horizontal sliding rails on the support frame, the support frame comprises a base and a portal frame, water-permeable pile casings are movably arranged on thelower portion of power heads of the rotary drilling rig bodies, and when drilling rods descend, the water-permeable pile casings are driven to descend. According to the rotary drilling rig, the rotaryexcavating drill bodies can be transversely moved and displaced, the hole forming position can be changed without moving the support frame, and the construction efficiency can be improved; during construction, the two rotary drilling rig bodies work simultaneously, so that the construction efficiency can be improved by more than two times; permeable pile casings are adopted for protecting walls,and clear water construction method is adopted, and the underground water quality of the surrounding environment is not influenced; and the rotary drilling rig is particularly suitable for a bridge crane angling method and a trestle lateral angling method without constructing a ground construction sidewalk, the construction environment can be protected, and damage to the environment can be reducedto the maximum extent.

Owner:成都天府轨谷科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com