Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Protect fingers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

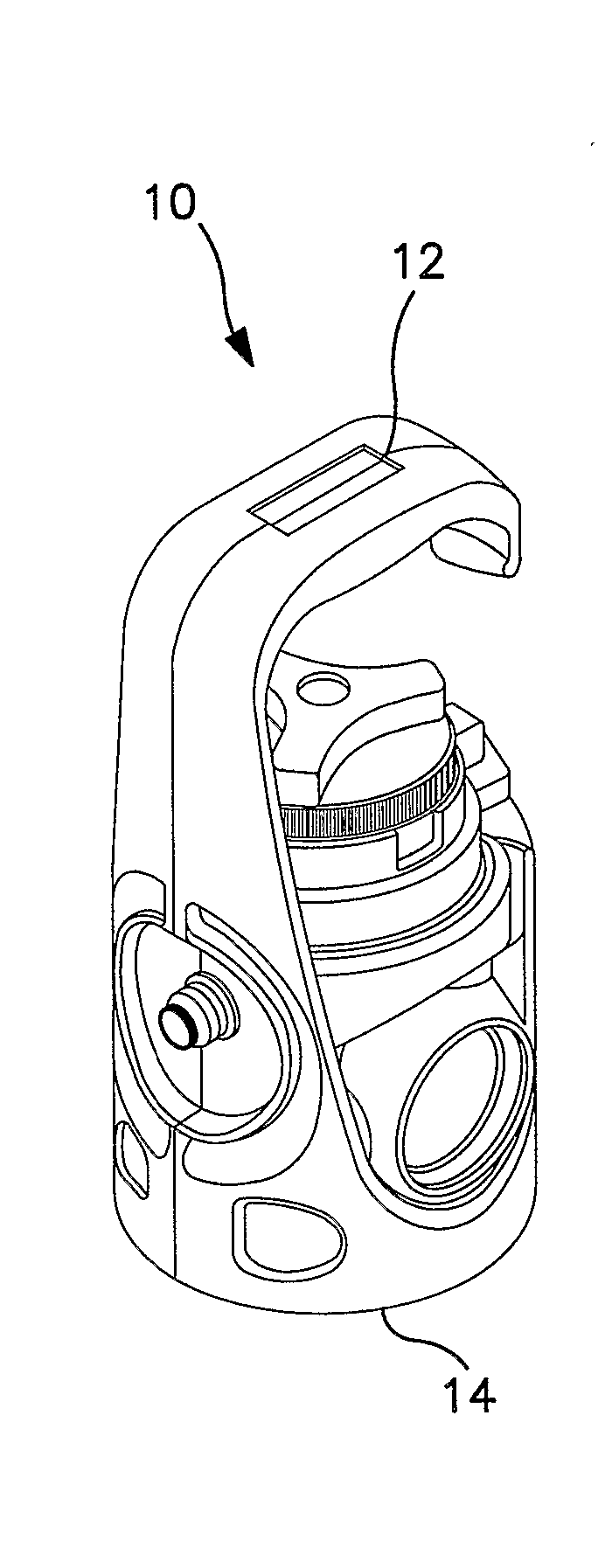

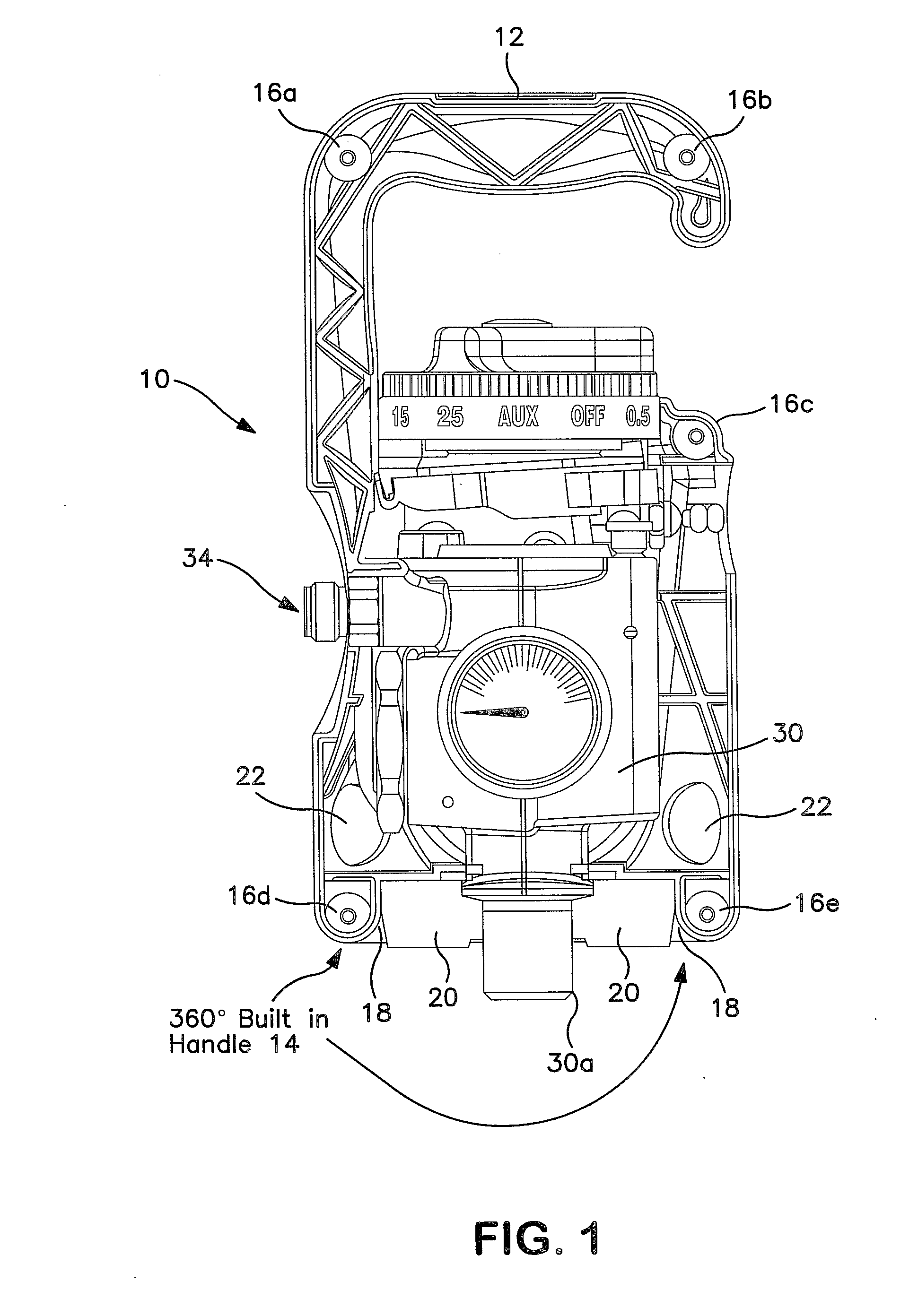

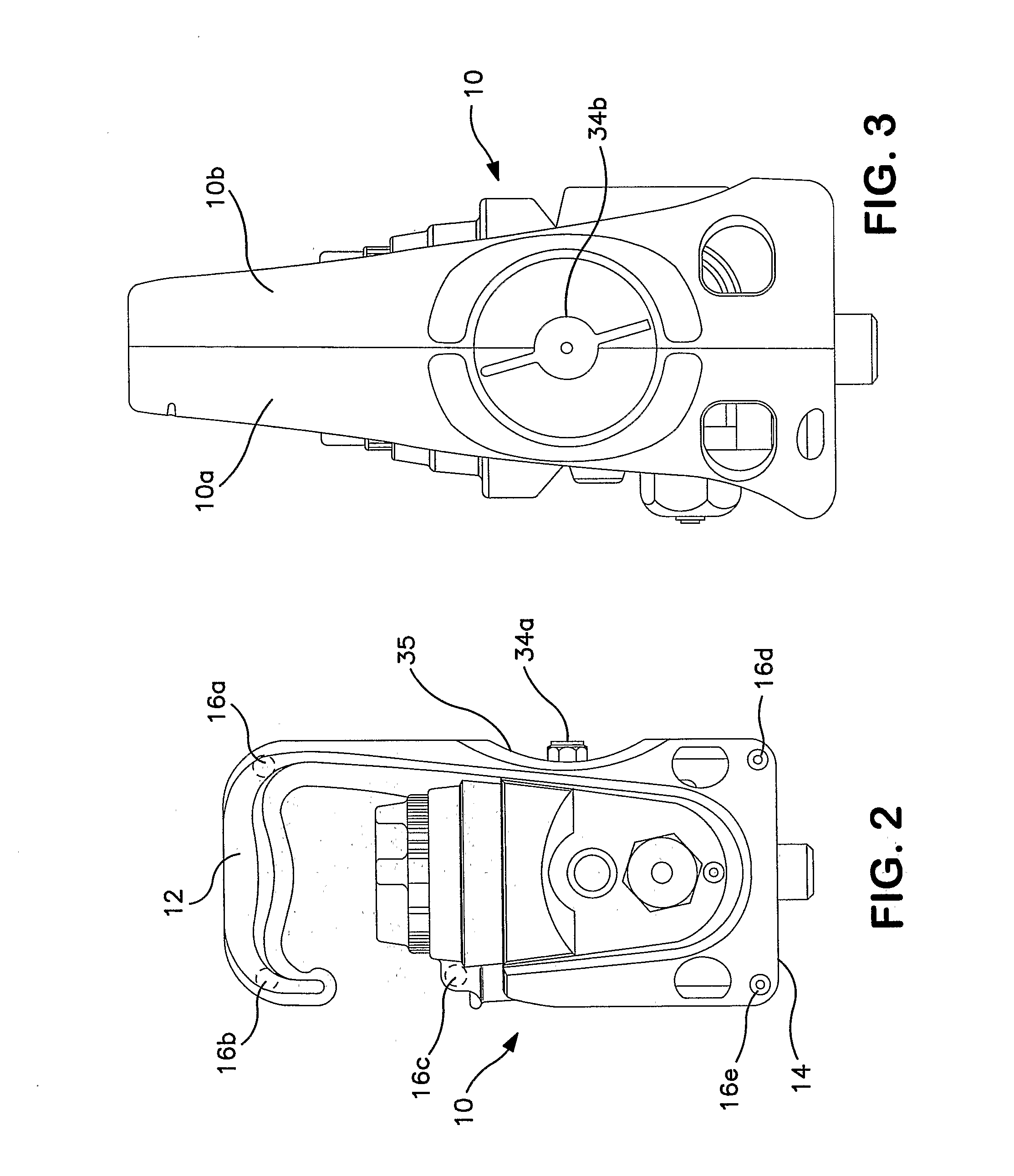

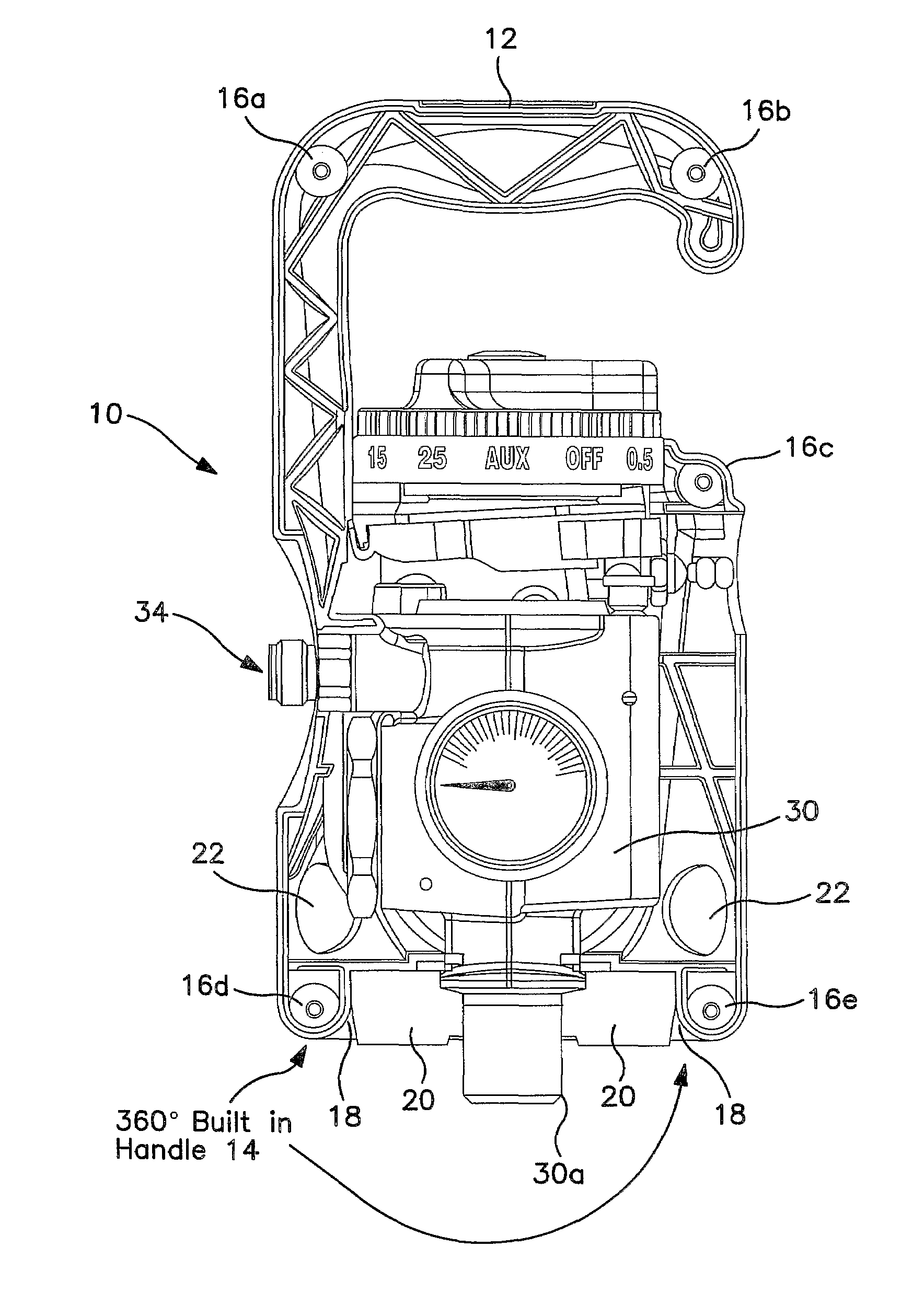

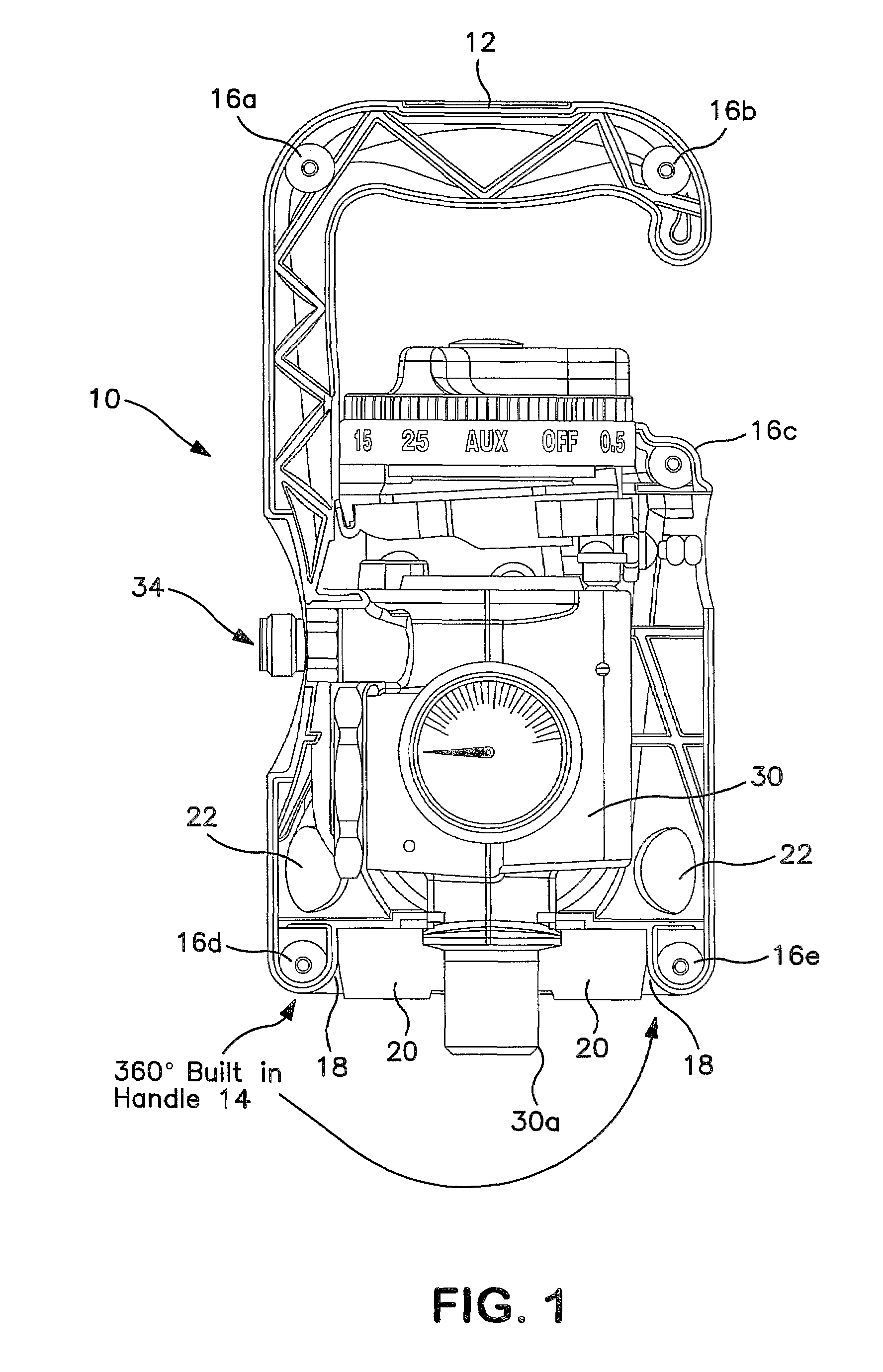

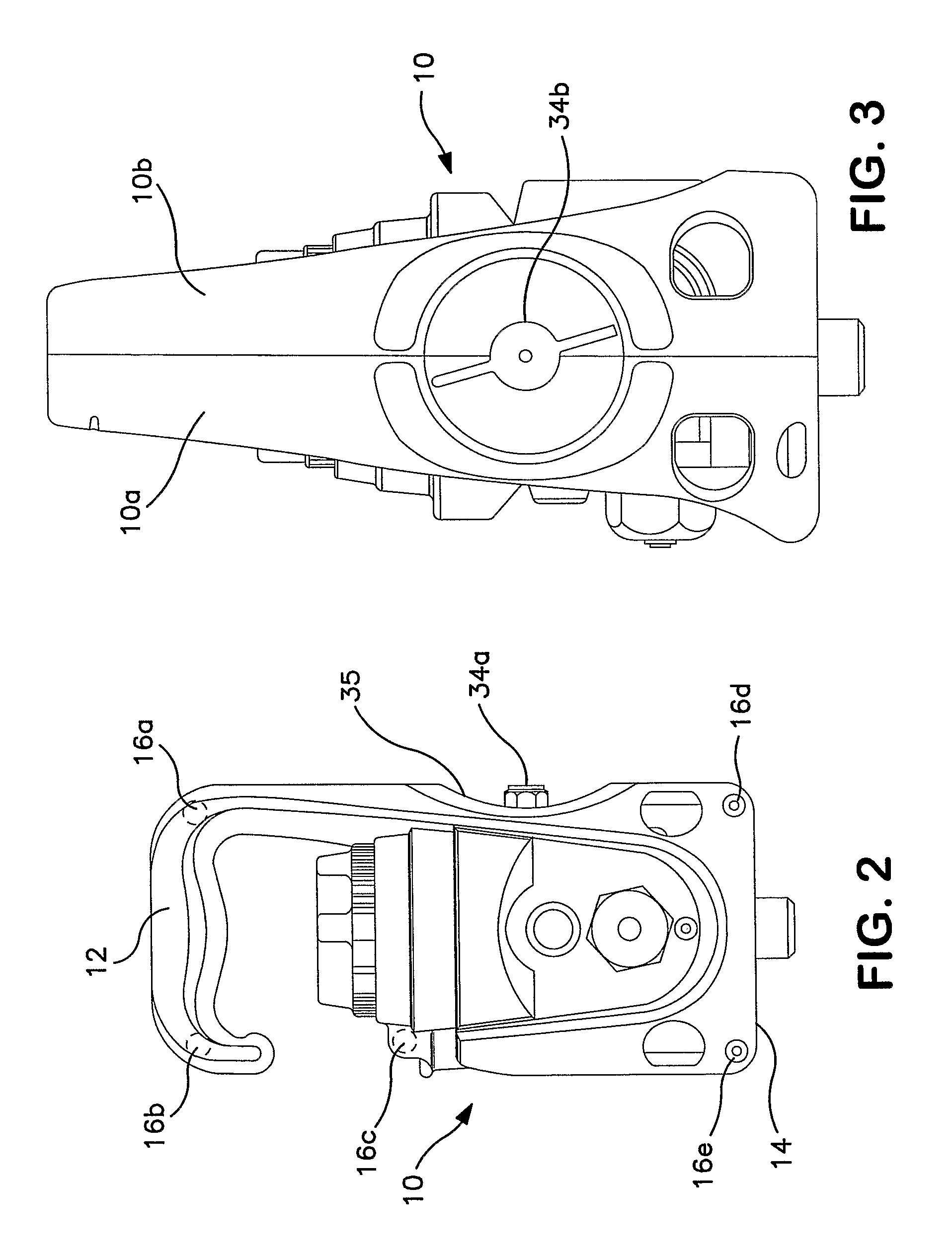

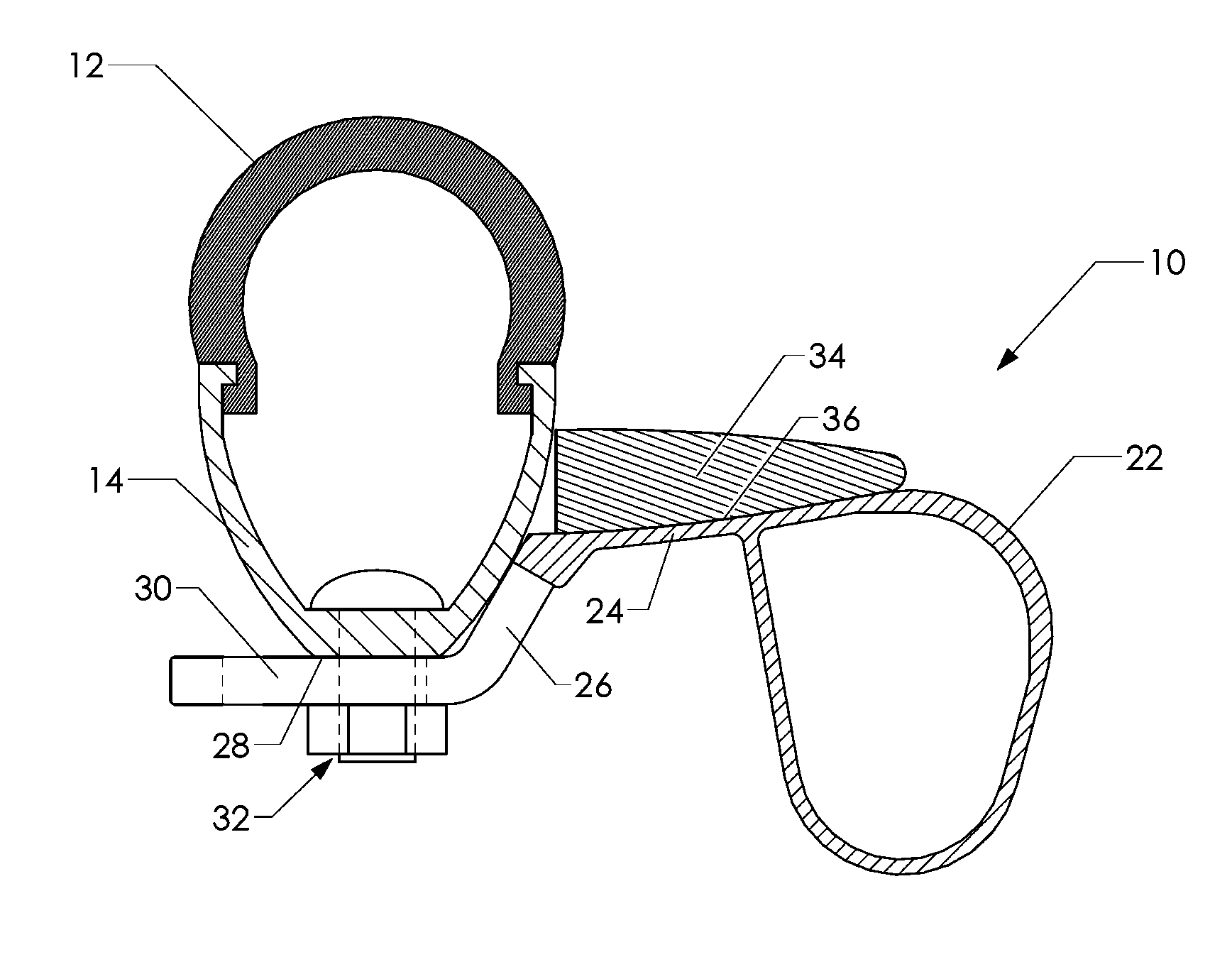

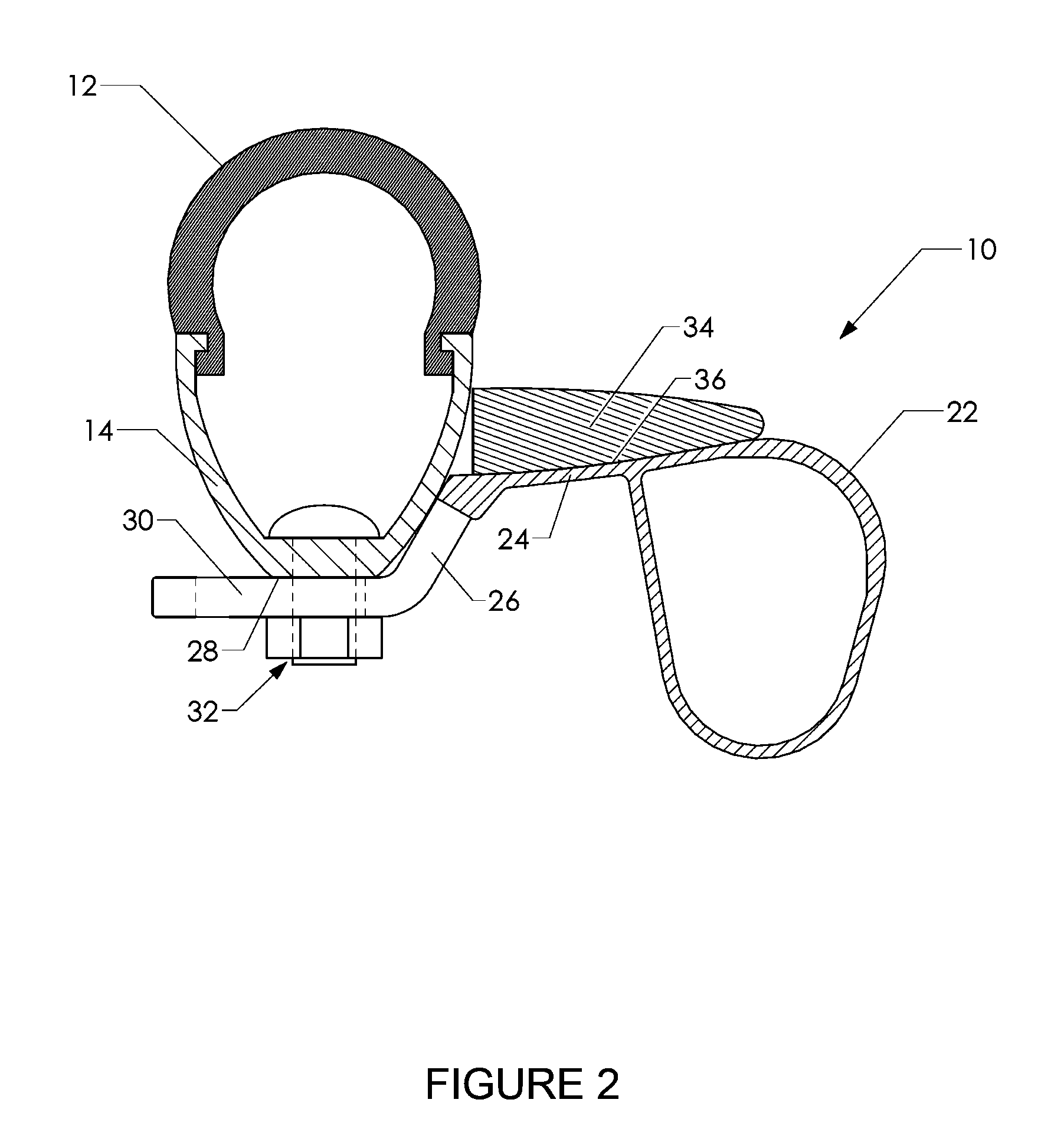

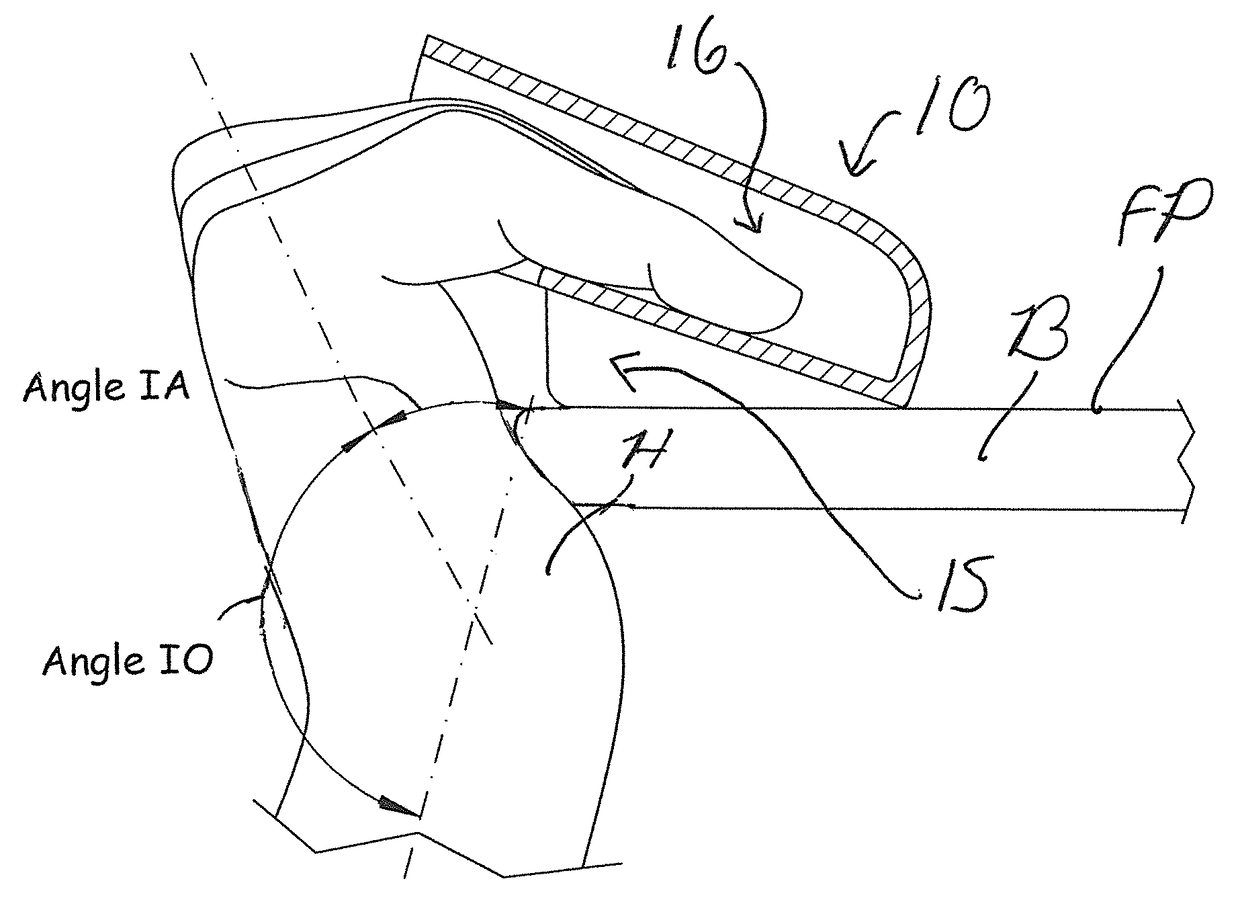

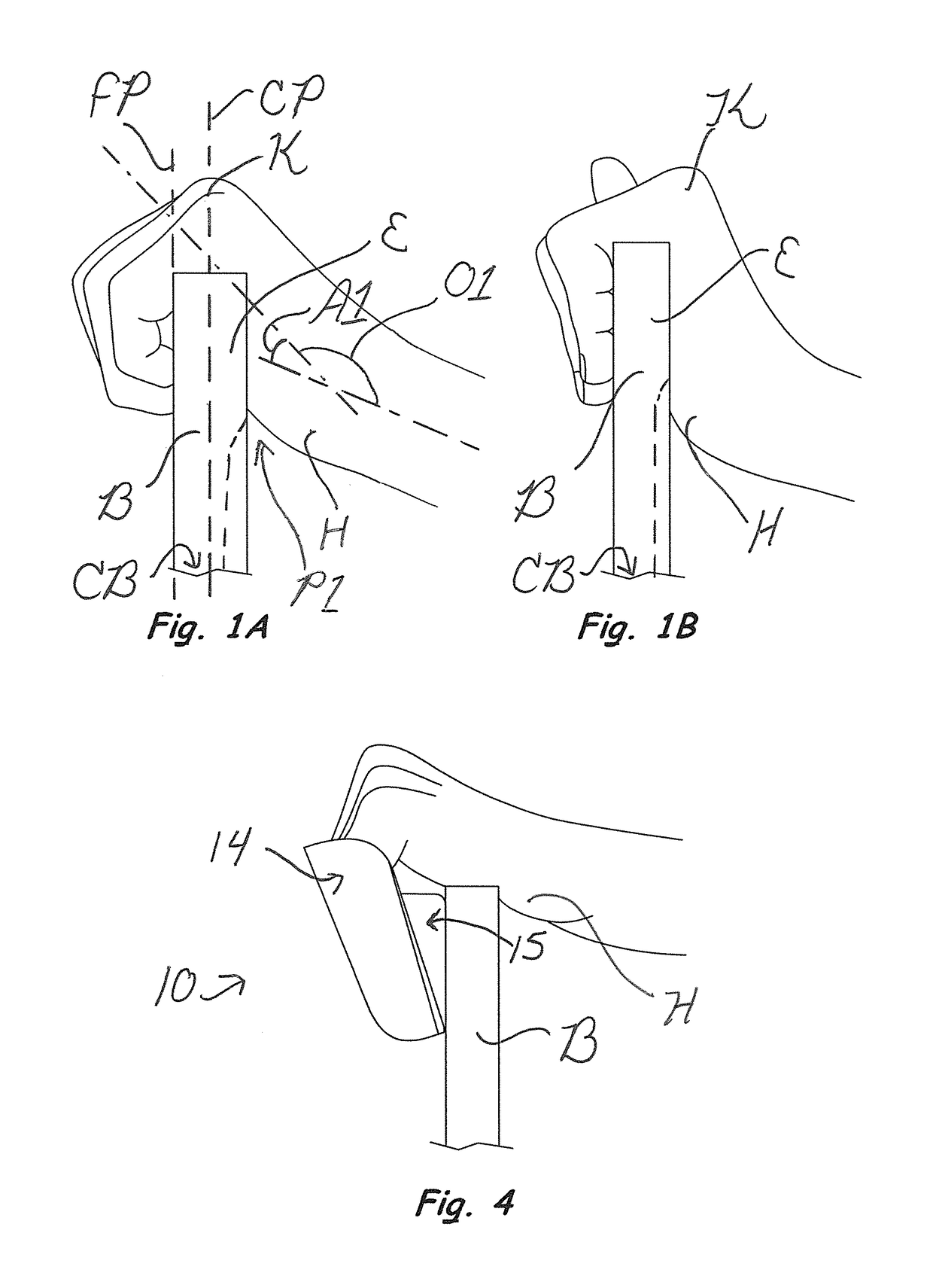

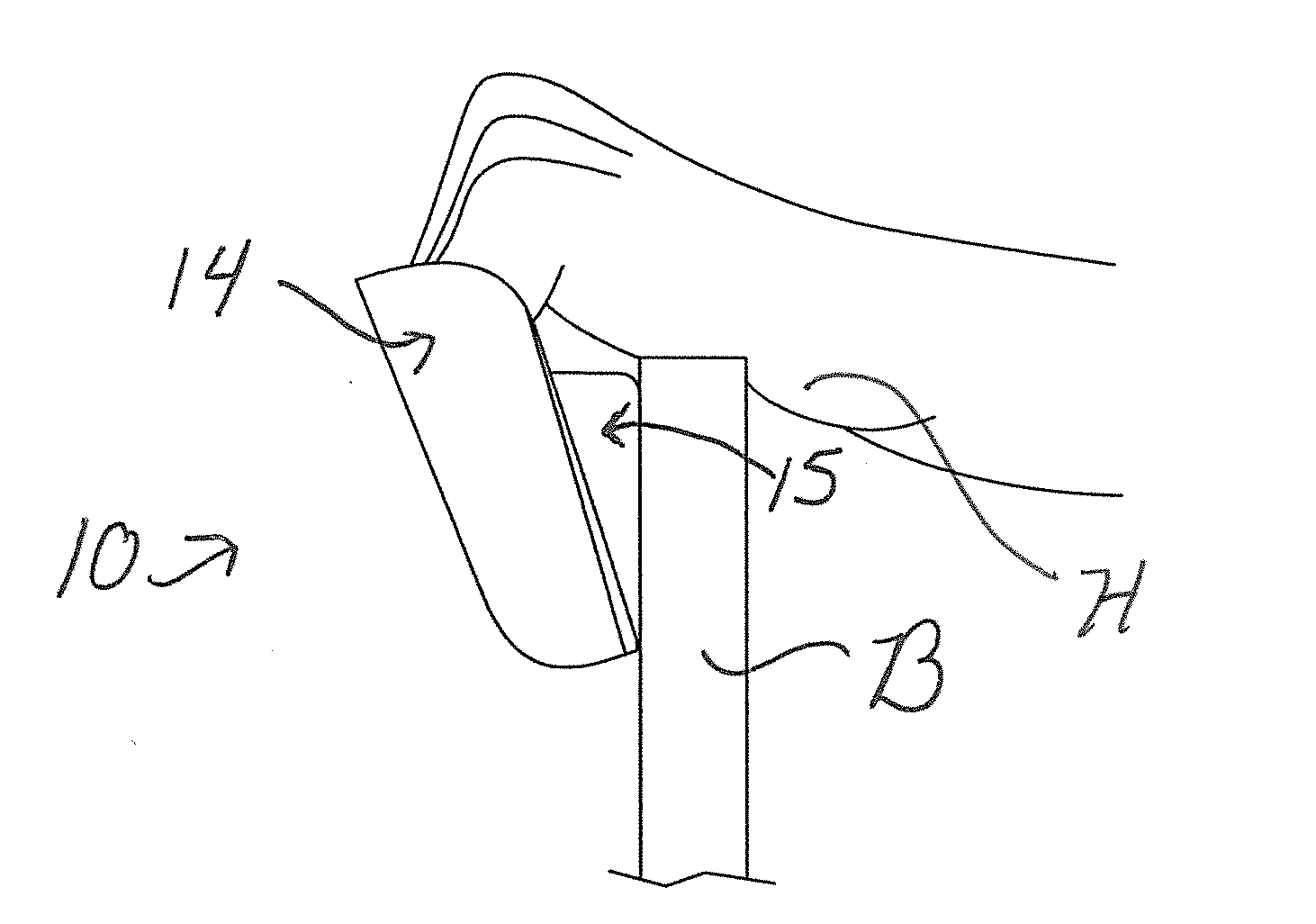

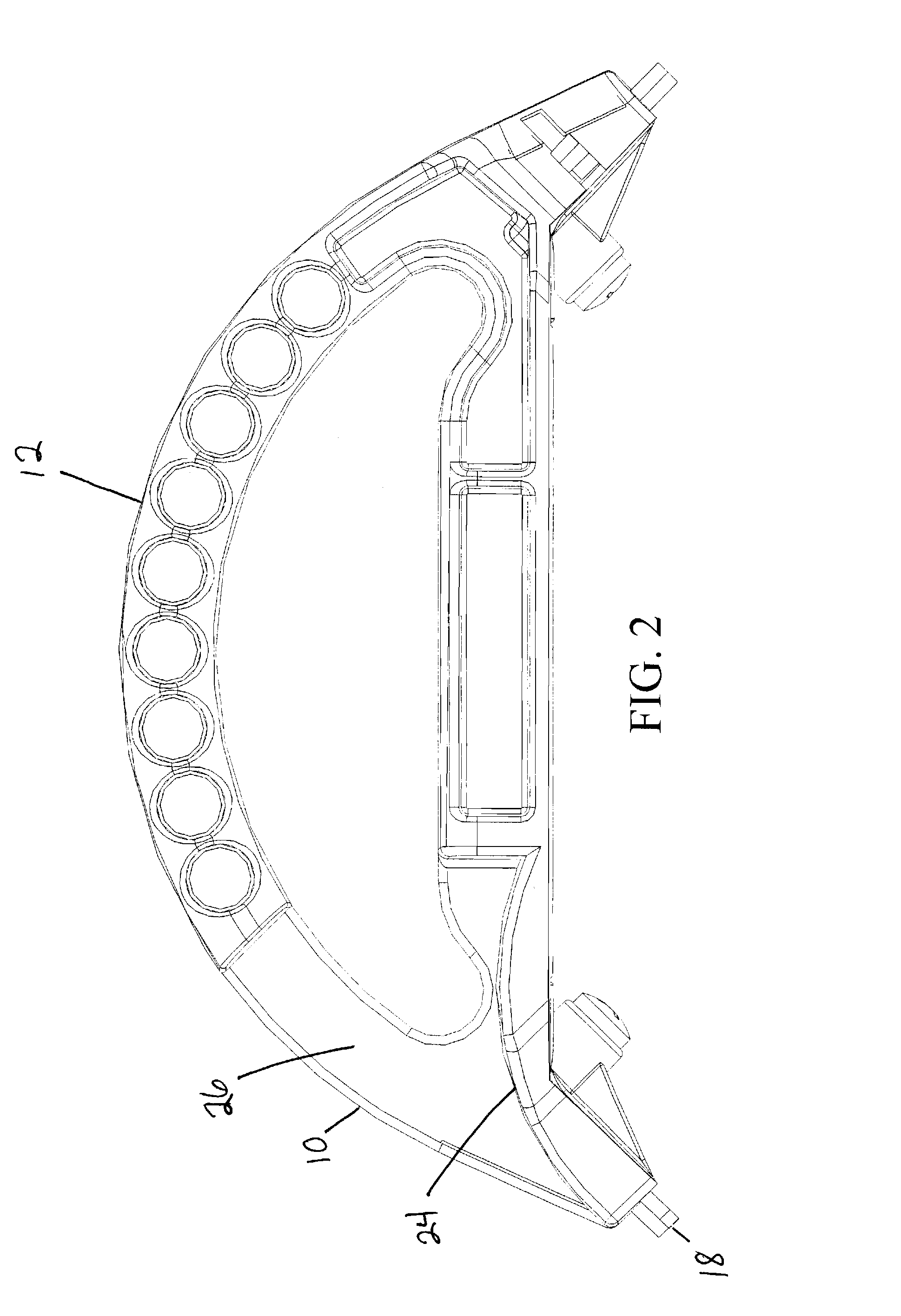

Ergonomic Shroud For Medical Gas Cylinders

ActiveUS20070257498A1Increased Versatility and SecurityEasy to liftCapsTravelling carriersGas cylinderEngineering

The present invention provides a handle or shroud for carrying or manipulating portable gas cylinders and gas cylinder valves for the administration of medical gases, such as oxygen. The shroud of the present invention provides improved safety and versatility to the handling process of such cylinders and valves. In one embodiment, the handle or shroud allows an individual to lift the cylinder, valve and shroud from about 26″ off the ground or floor with the wrist turned up.

Owner:PRAXAIR TECH INC

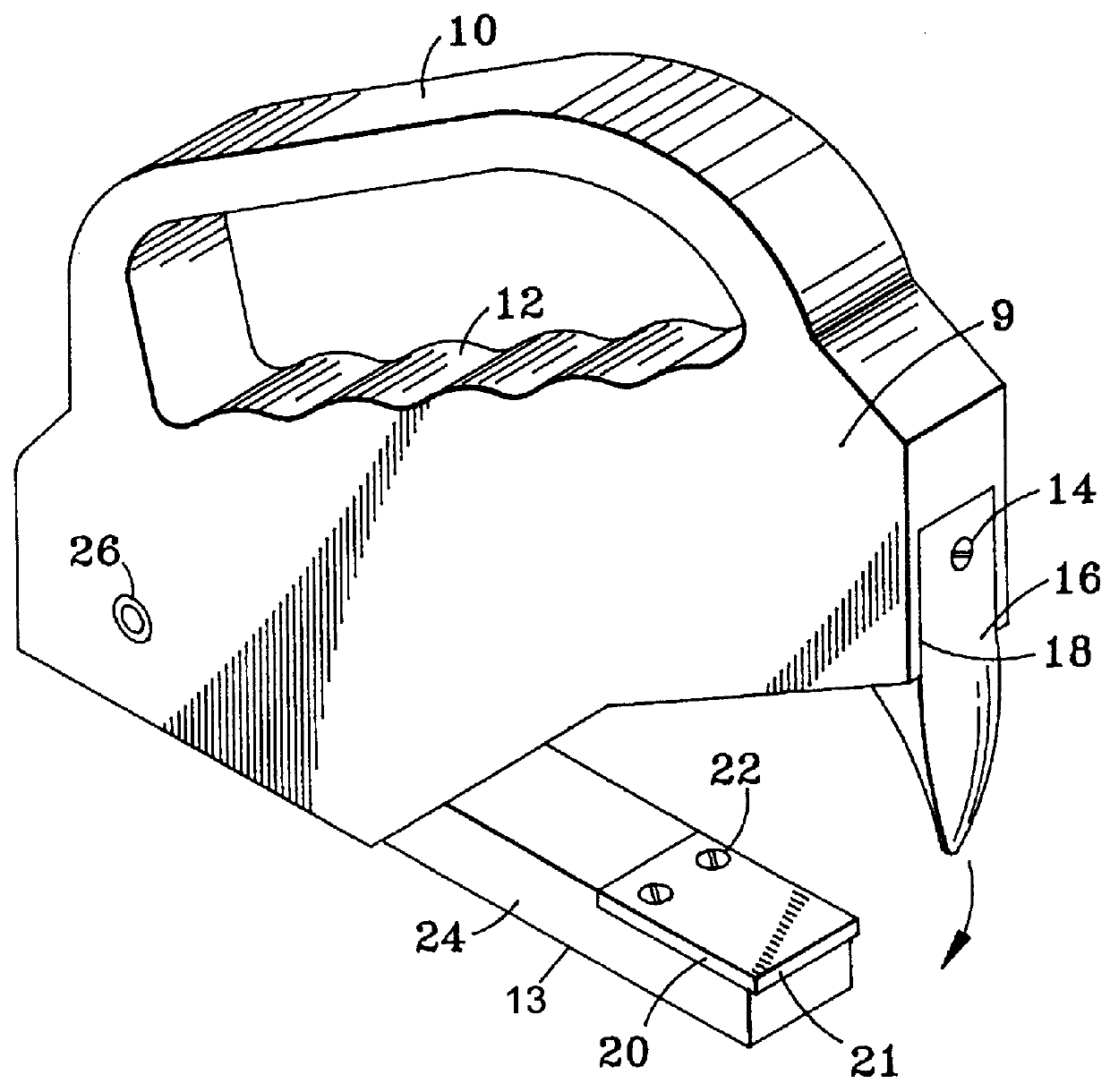

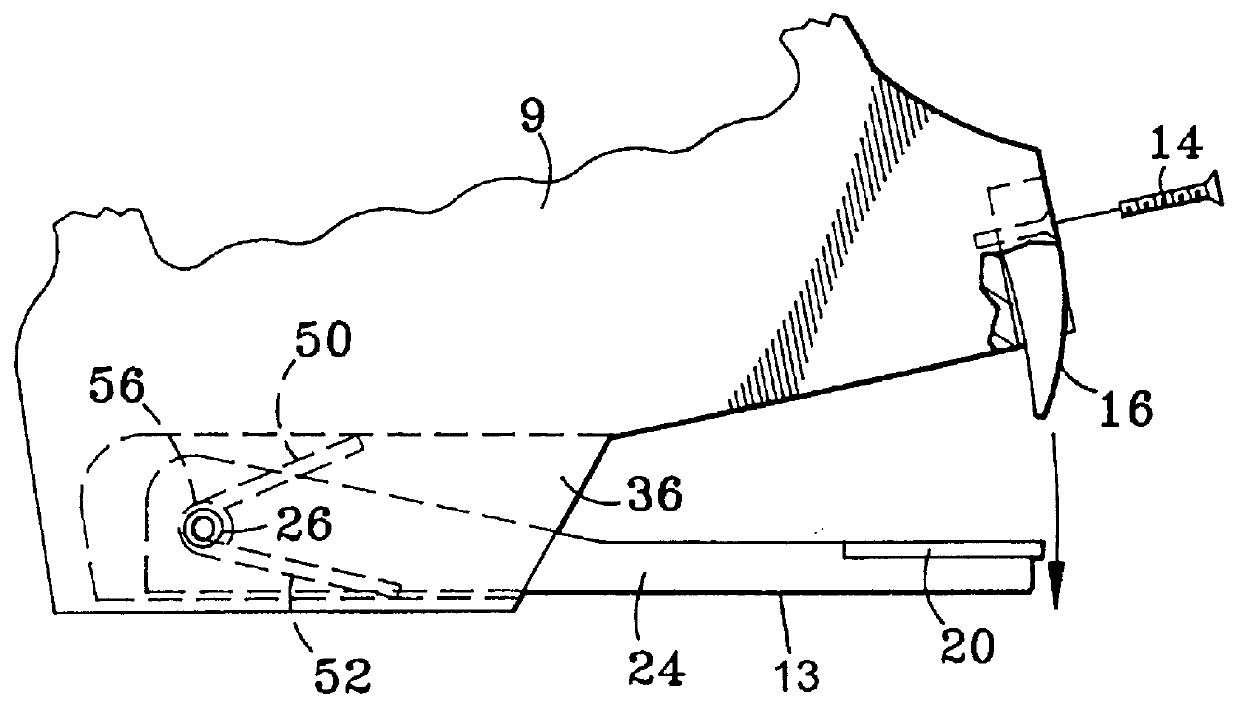

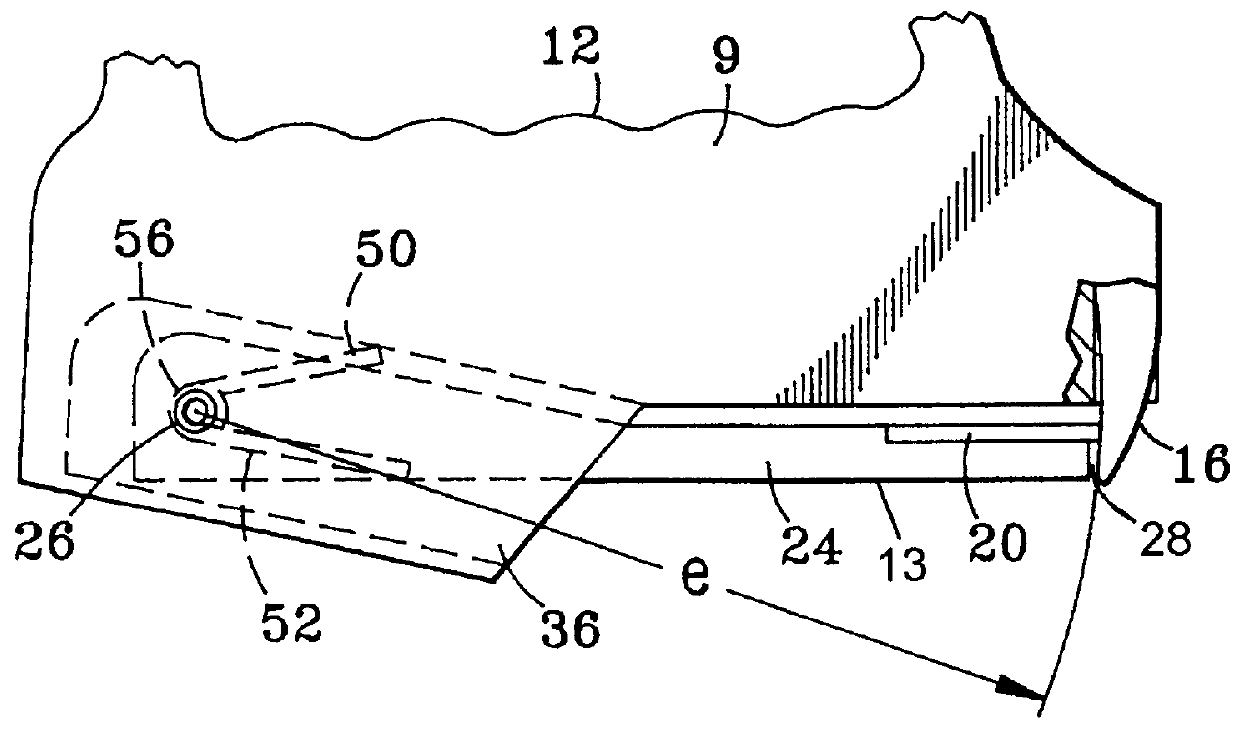

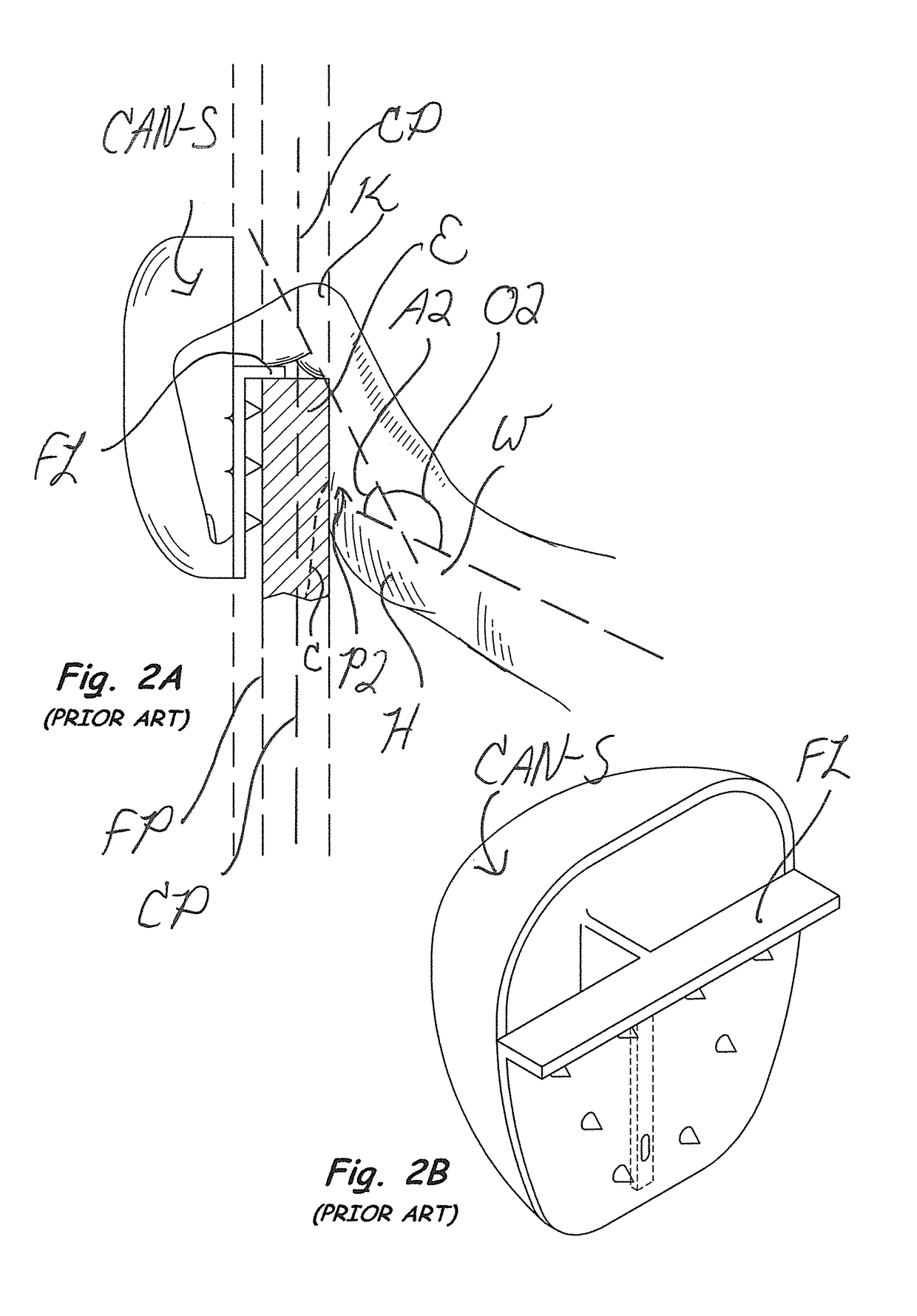

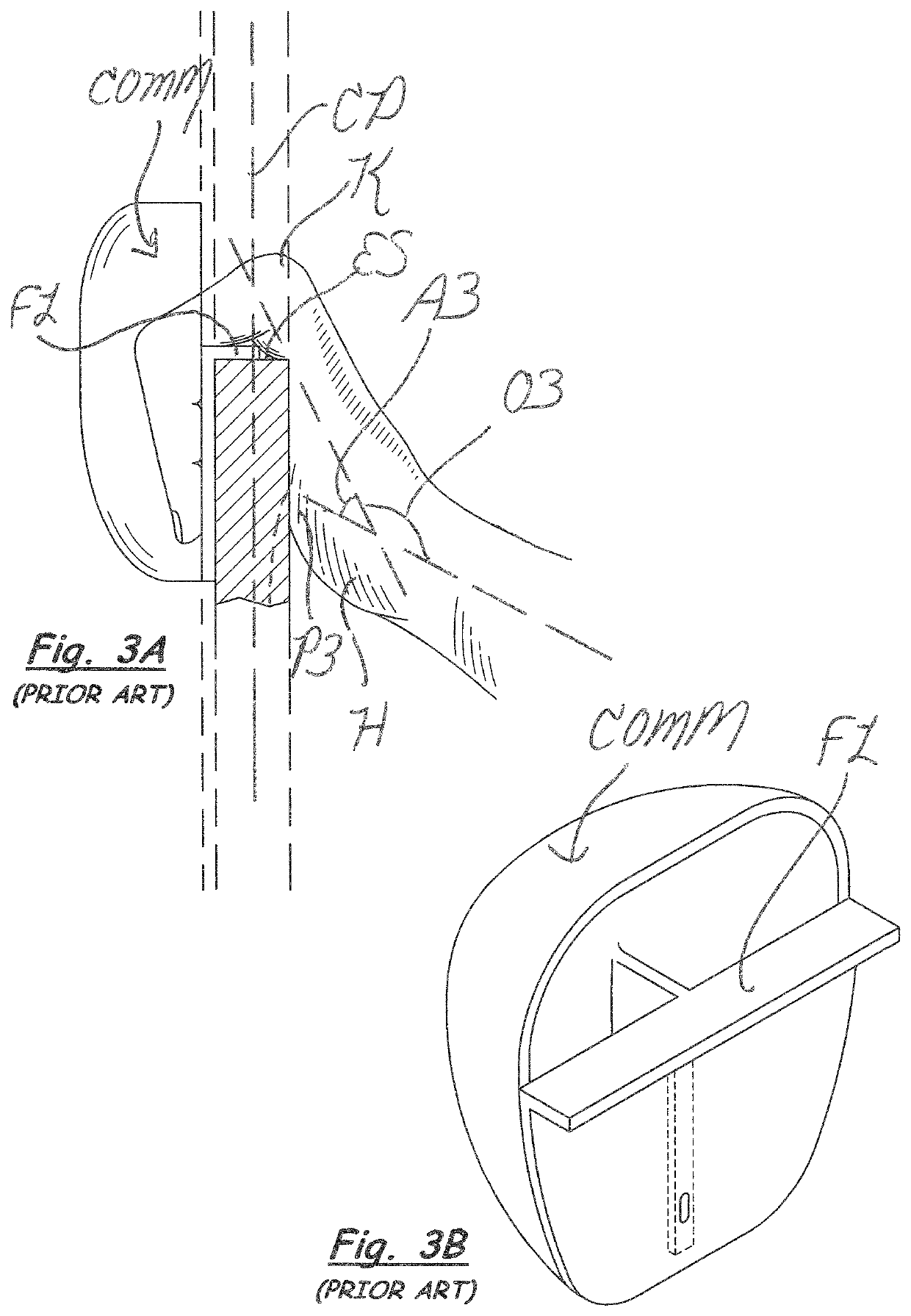

Combination stapler and staple remover

InactiveUS6089435AProtect fingersMinimize pullingStapling toolsNail extractorsEngineeringPerpendicular direction

A device for removing staples from papers, cloth, or other material without tearing or mutilating the material. The device utilizes a heel of palm to finger gripping action to facilitate a more natural action for removing staples. Staples are extracted by way of a jaw which opposes a wedge-shaped piece to an abutting plate piece, which straightens the staple while simultaneously pulling it out of the paper in a perpendicular direction. The wedge-shaped piece includes a portion where its width and thickness increase to dimensions wherein the sum of the width plus twice the thickness exceeds the slightly less than the total length of the three sides of the staples being removed, thus facilitating complete extraction. The device is readily incorporated into a standard stapler, so that both staple insertion and staple removing functionality are readily incorporated within a single device.

Owner:MALEK SHAHIN S

Ergonomic shroud for medical gas cylinders

ActiveUS7703821B2Increased Versatility and SecurityEasy to liftCapsTravelling carriersGas cylinderEngineering

The present invention provides a handle or shroud for carrying or manipulating portable gas cylinders and gas cylinder valves for the administration of medical gases, such as oxygen. The shroud of the present invention provides improved safety and versatility to the handling process of such cylinders and valves. In one embodiment, the handle or shroud allows an individual to lift the cylinder, valve and shroud from about 26″ off the ground or floor with the wrist turned up.

Owner:PRAXAIR TECH INC

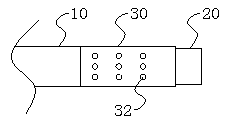

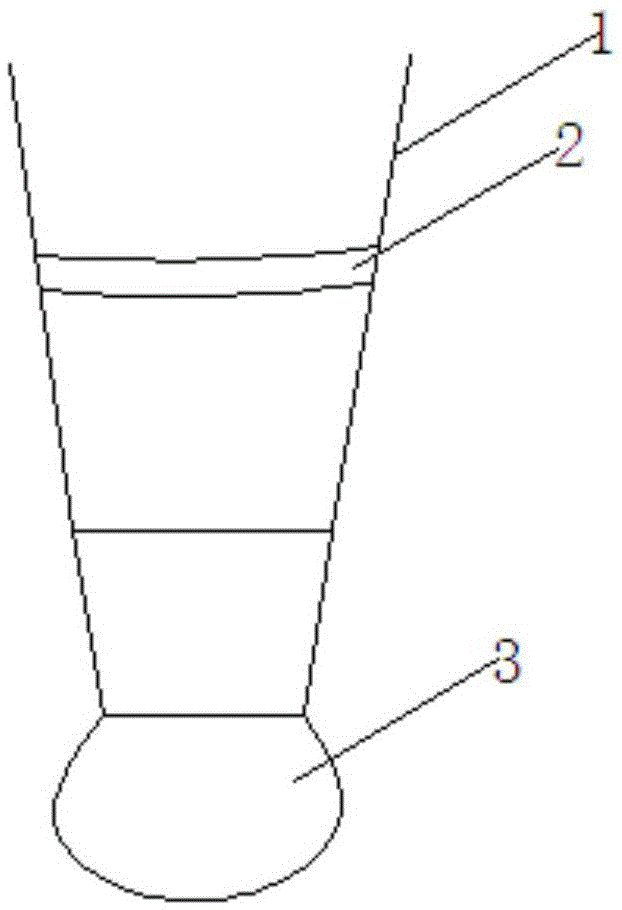

Method for independently regulating smoke concentration of cigarette and telescopic cigarette

The invention discloses a method for independently regulating smoke concentration of a cigarette and the telescopic cigarette. According to the method, the aim of independently regulating the smoke concentration of the cigarette is achieved by initiatively regulating the length of a filter tip by a smoker. Adjustable dilution of the smoke is further achieved by adopting one-way ventilating materials or setting a hole structure on the basis of the adjustable filter tip, based on the same cigarette, dilution of main stream smoke is achieved by initiatively adjusting the length of the filter tip and the number of ventilation holes, and the smokers can adjust the smell of the cigarette according to the favorite smell of the smoke, and select the concentration of the smoke by himself so as to obtain strong sensory stimulation or the light smoke.

Owner:CHINA TOBACCO GUANGDONG IND

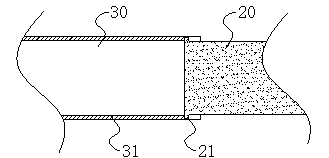

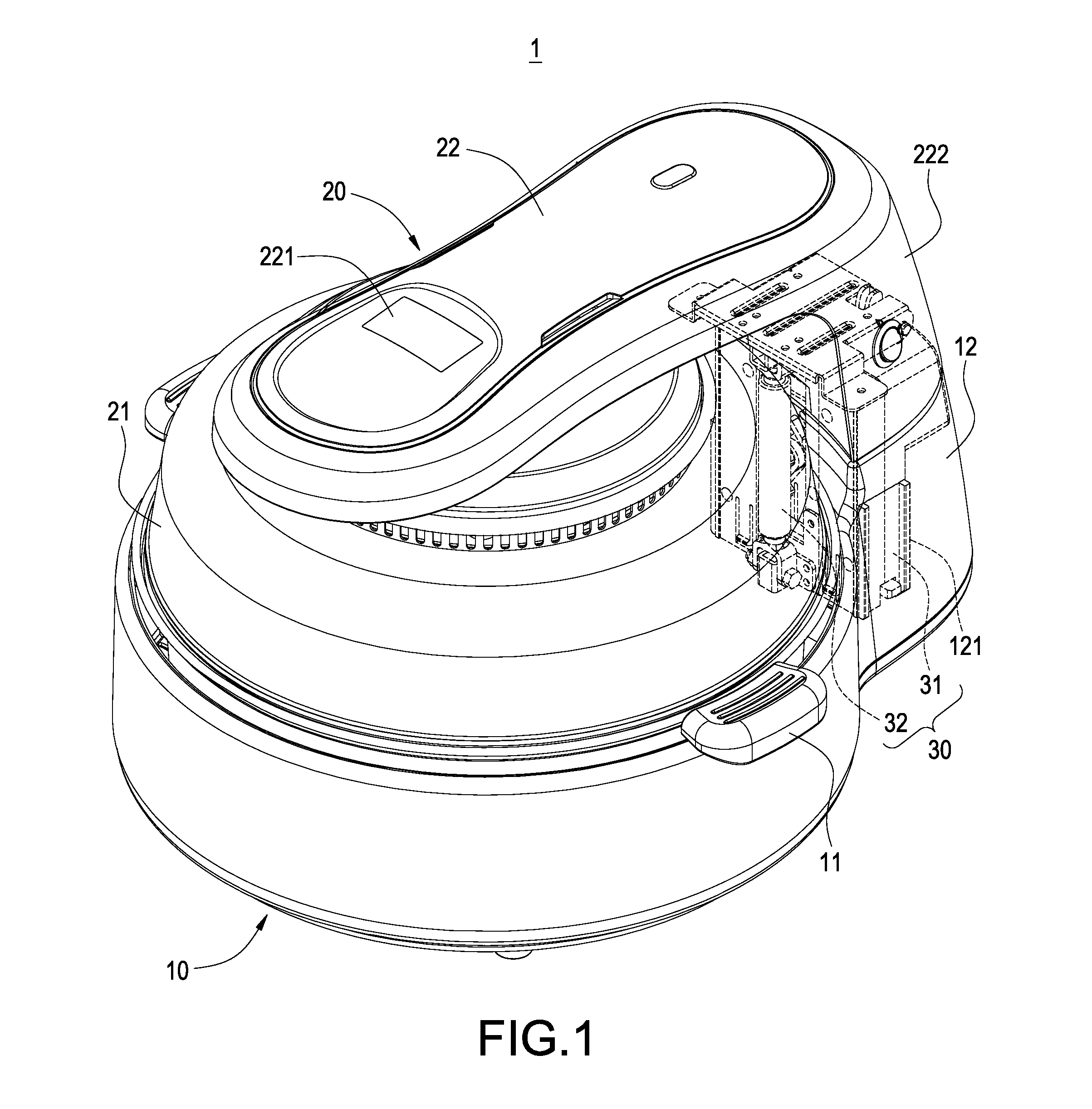

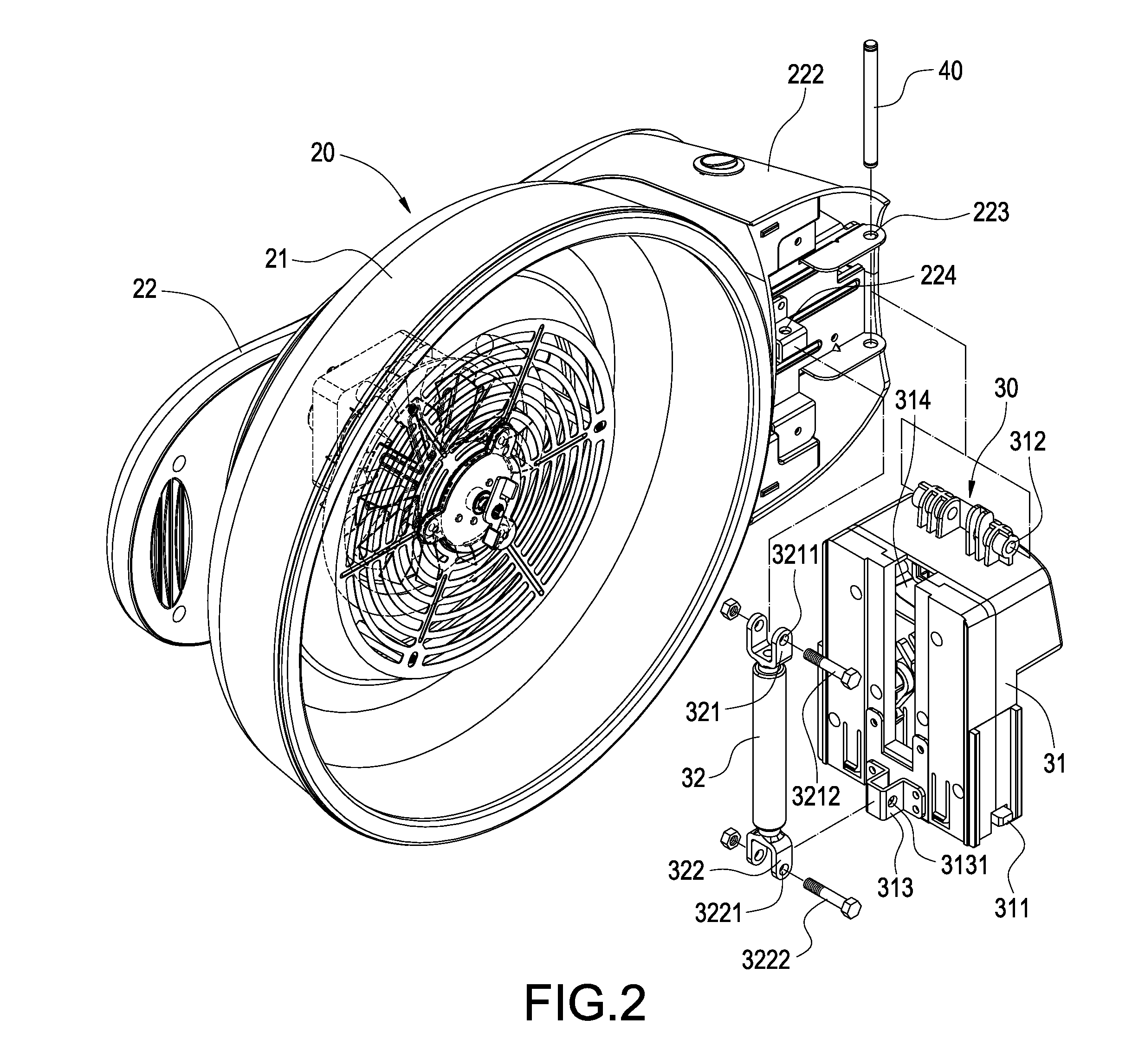

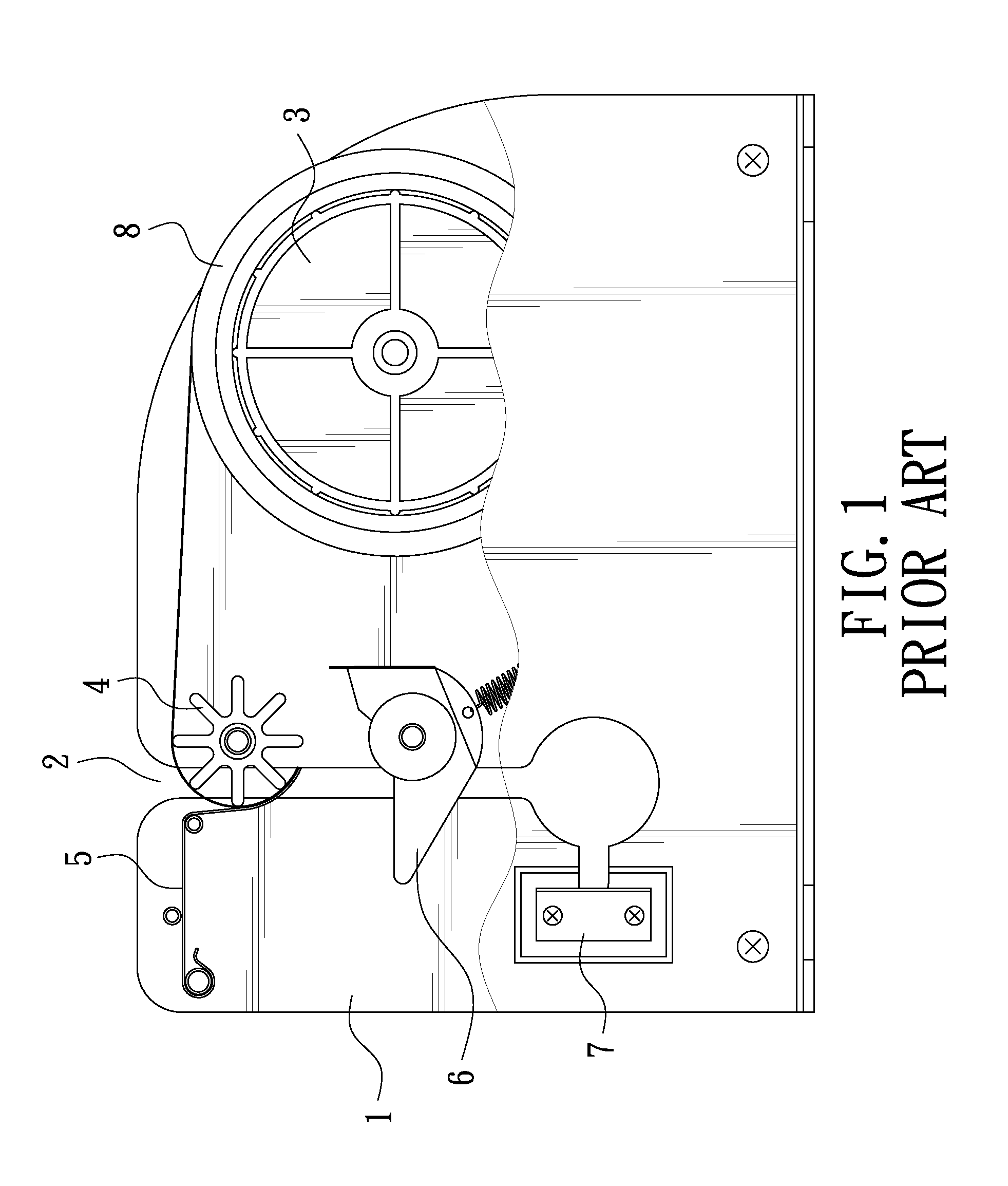

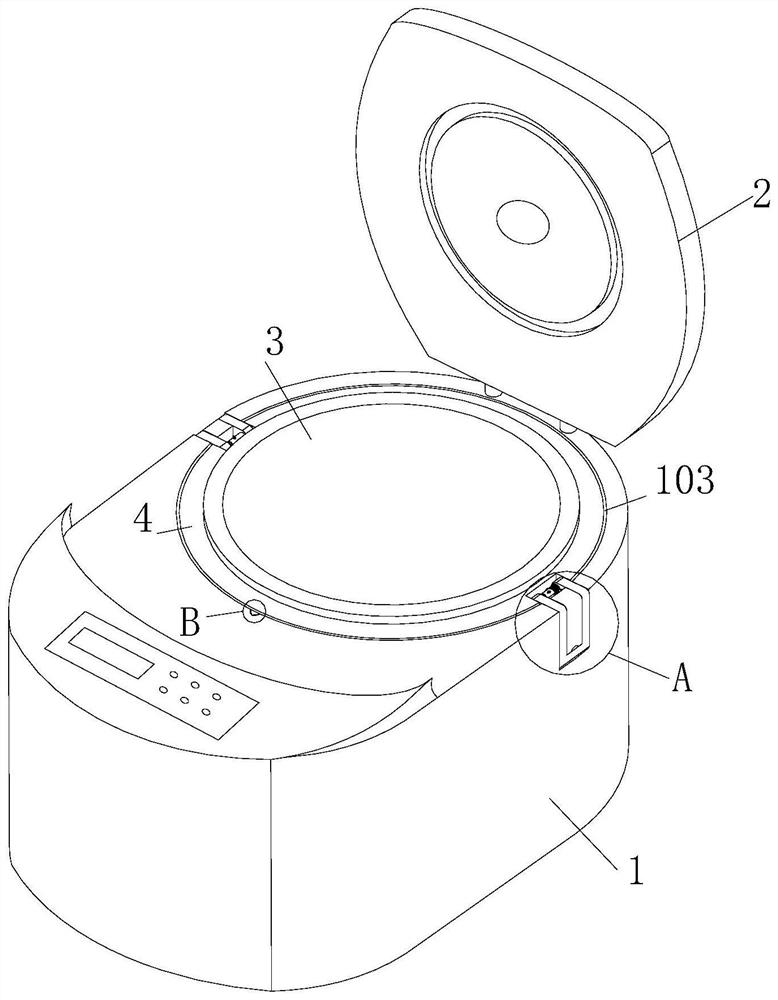

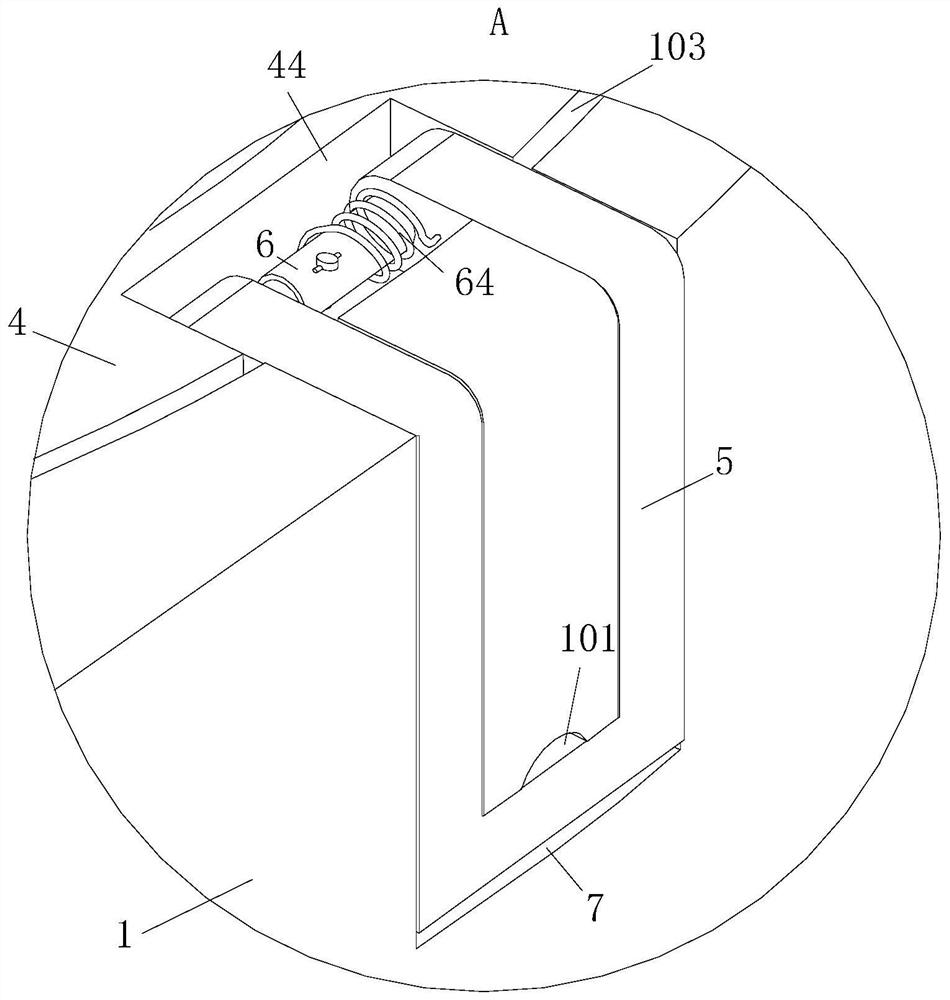

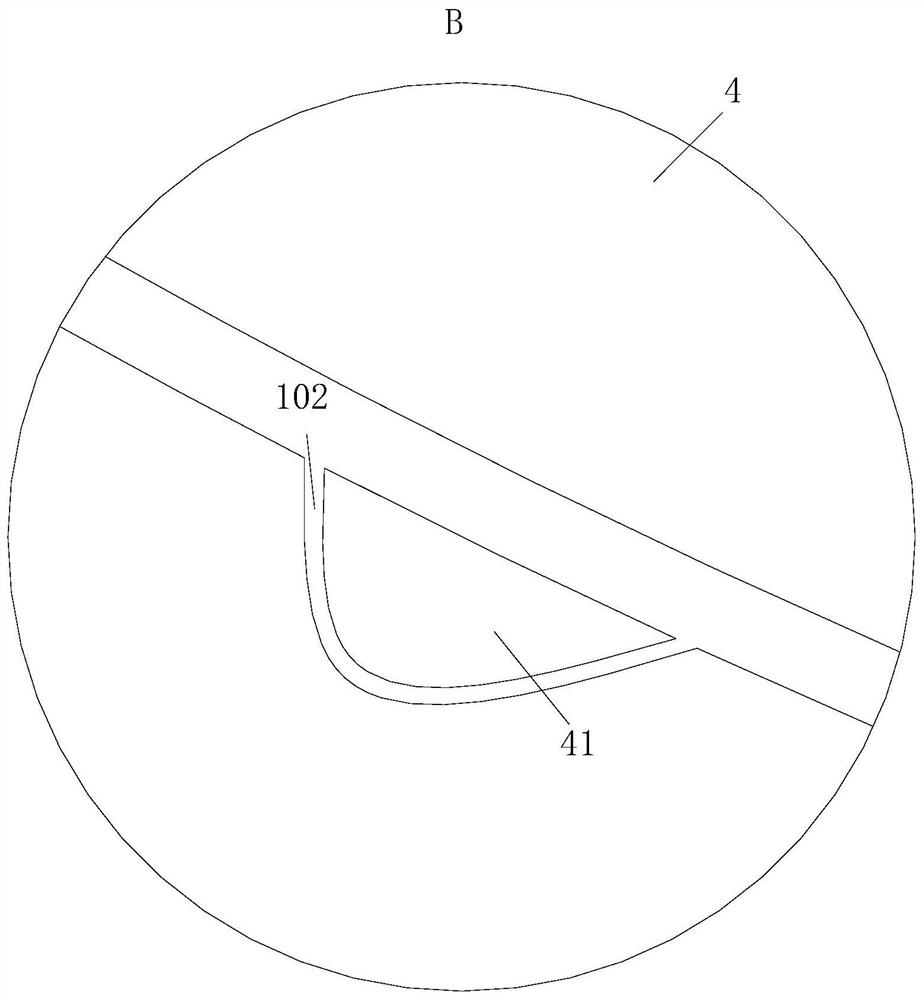

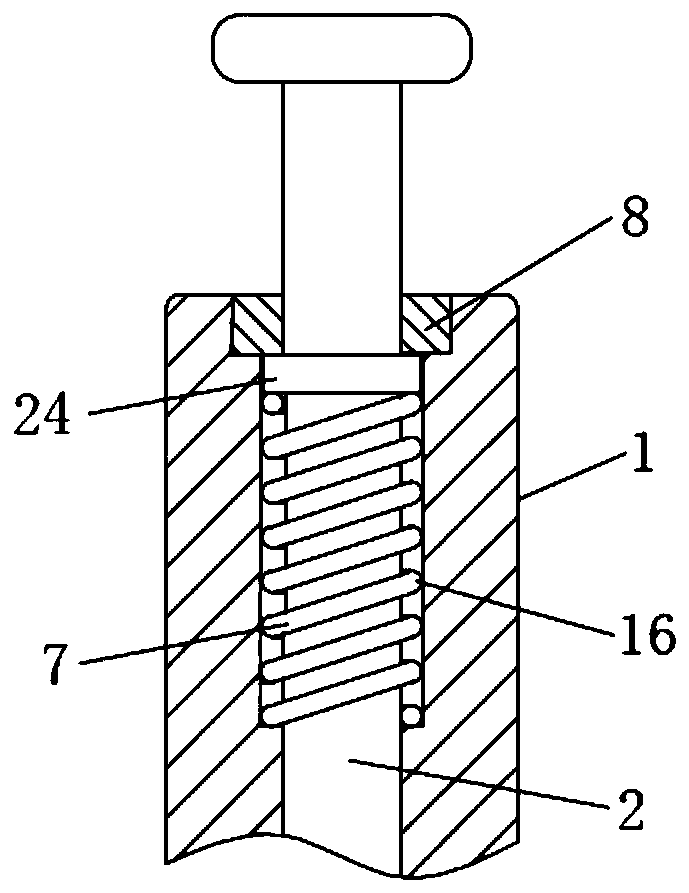

Pot with a cover-lifting mechanism

InactiveUS20120067903A1Less forceImproves practicabilityCapsCooking-vessel lids/coversEngineeringPiston rod

A pot includes a pot body, an upper cover pivotally covering the pot body, and a cover-lifting mechanism connected between the pot body and the upper cover. The cover-lifting mechanism includes a piston rod. Both ends of the piston rod are pivotally connected to the pot body and the upper cover respectively. The piston rod extends corresponding to an angle between the upper cover and the pot body when the upper cover is lifted. With this arrangement, the user can lift the upper cover with a less force. Further, the upper cover can be prevented from covering the pot body suddenly to damage the components and electric circuits therein and to protect the user's finger from getting hurt if the user puts his / her finger on the upper edge of the pot body. Therefore, the present invention really improves the practicability and safety of a pot.

Owner:TALL & STOUT INDAL CORP

Packaging scissors

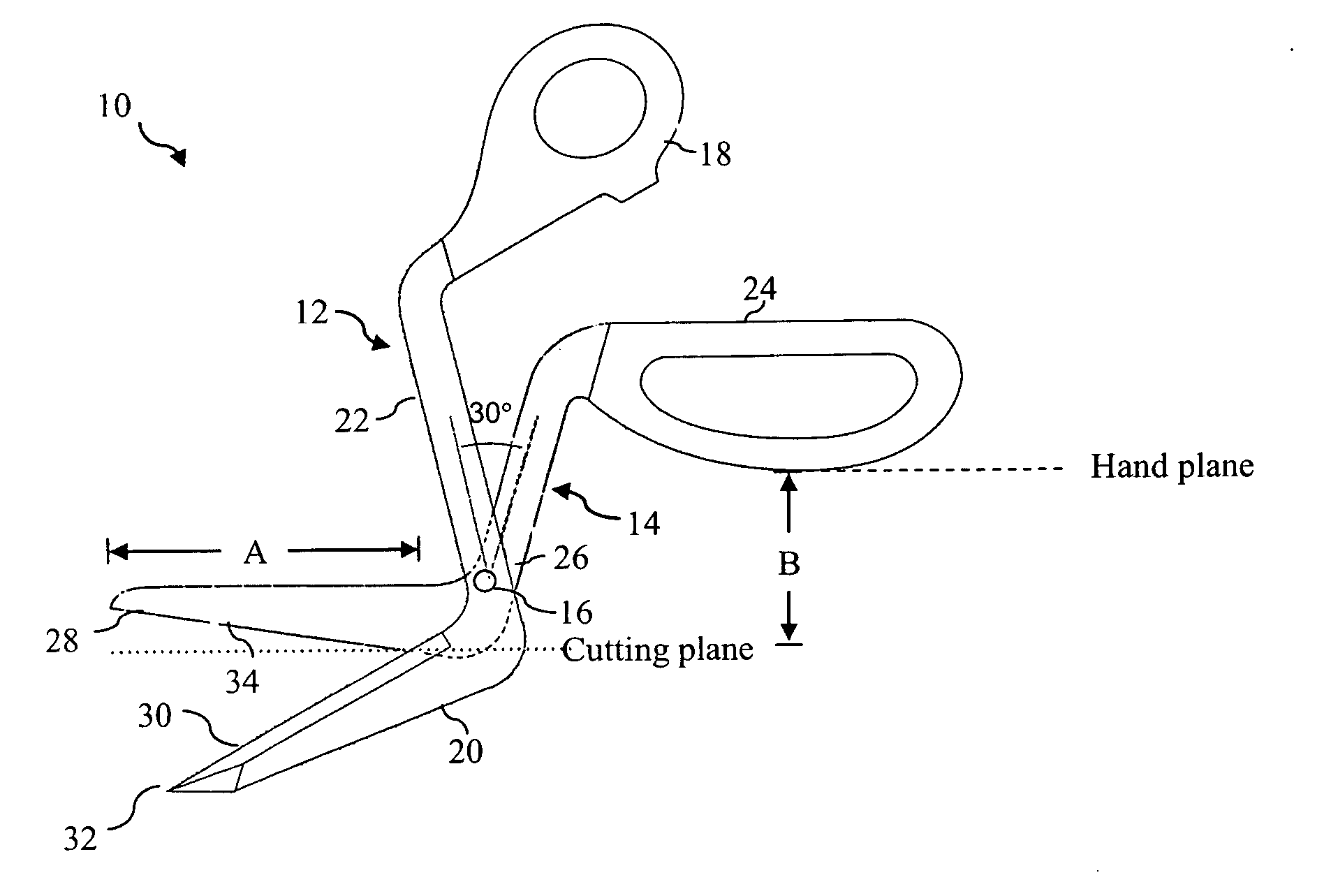

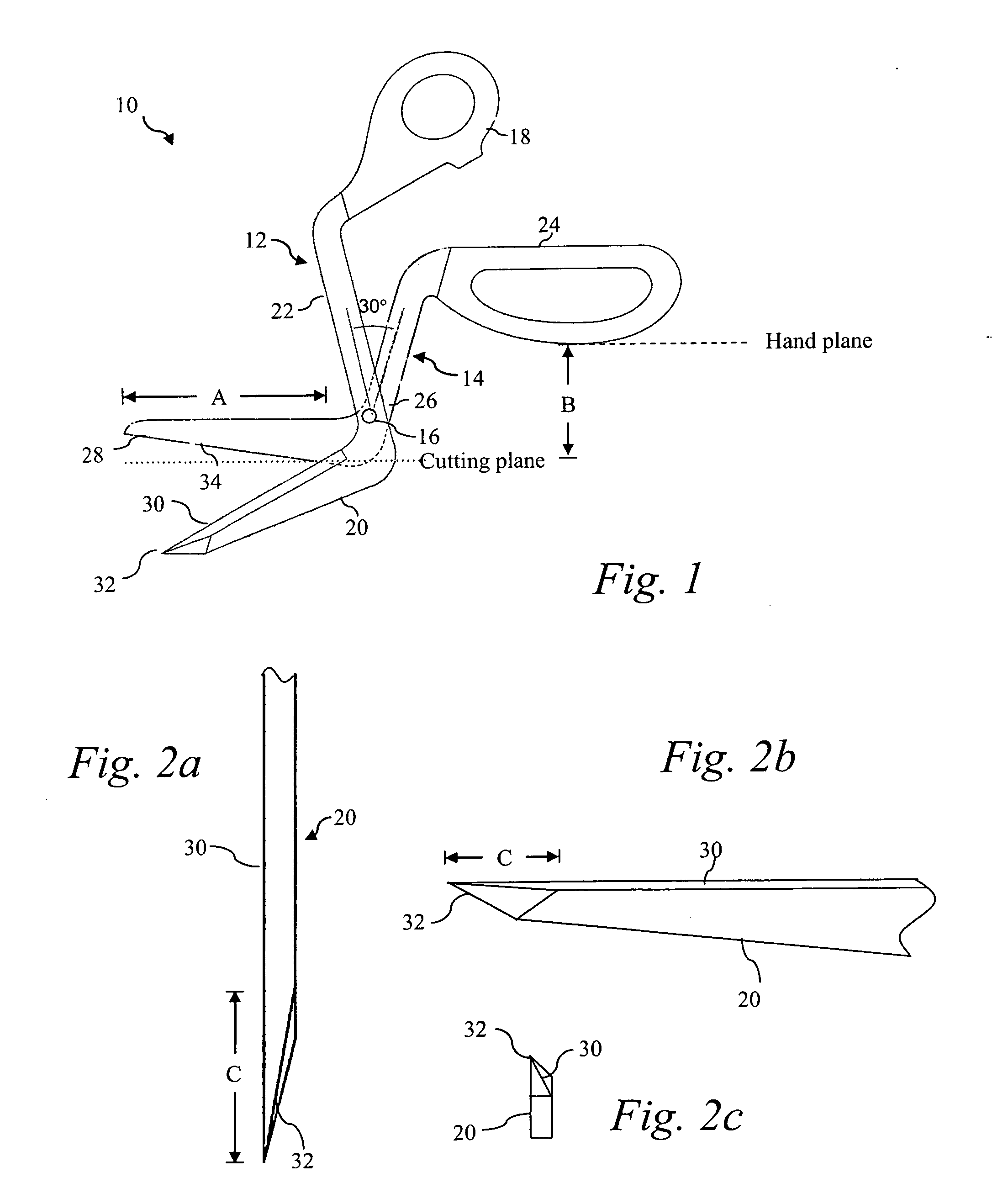

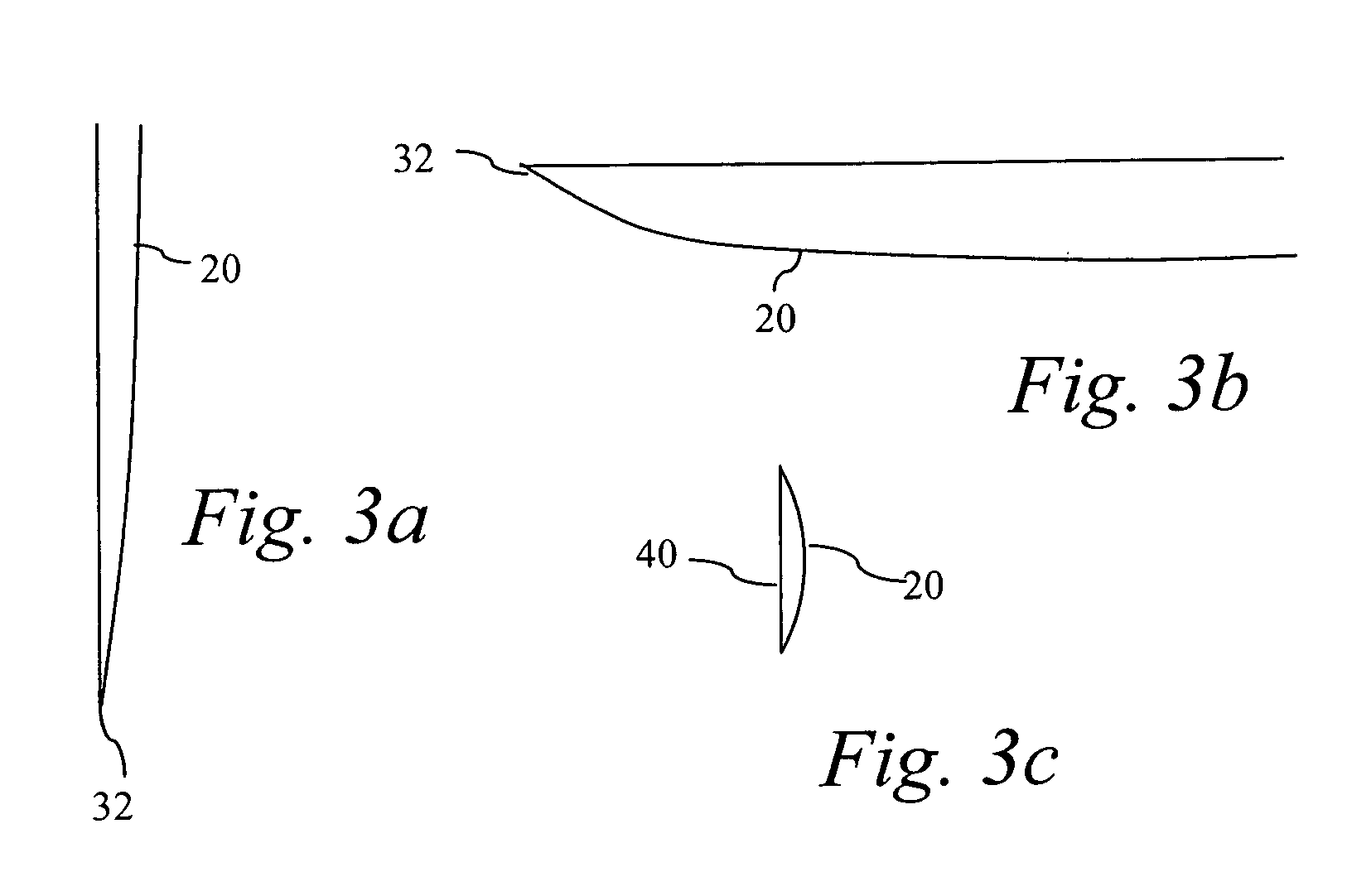

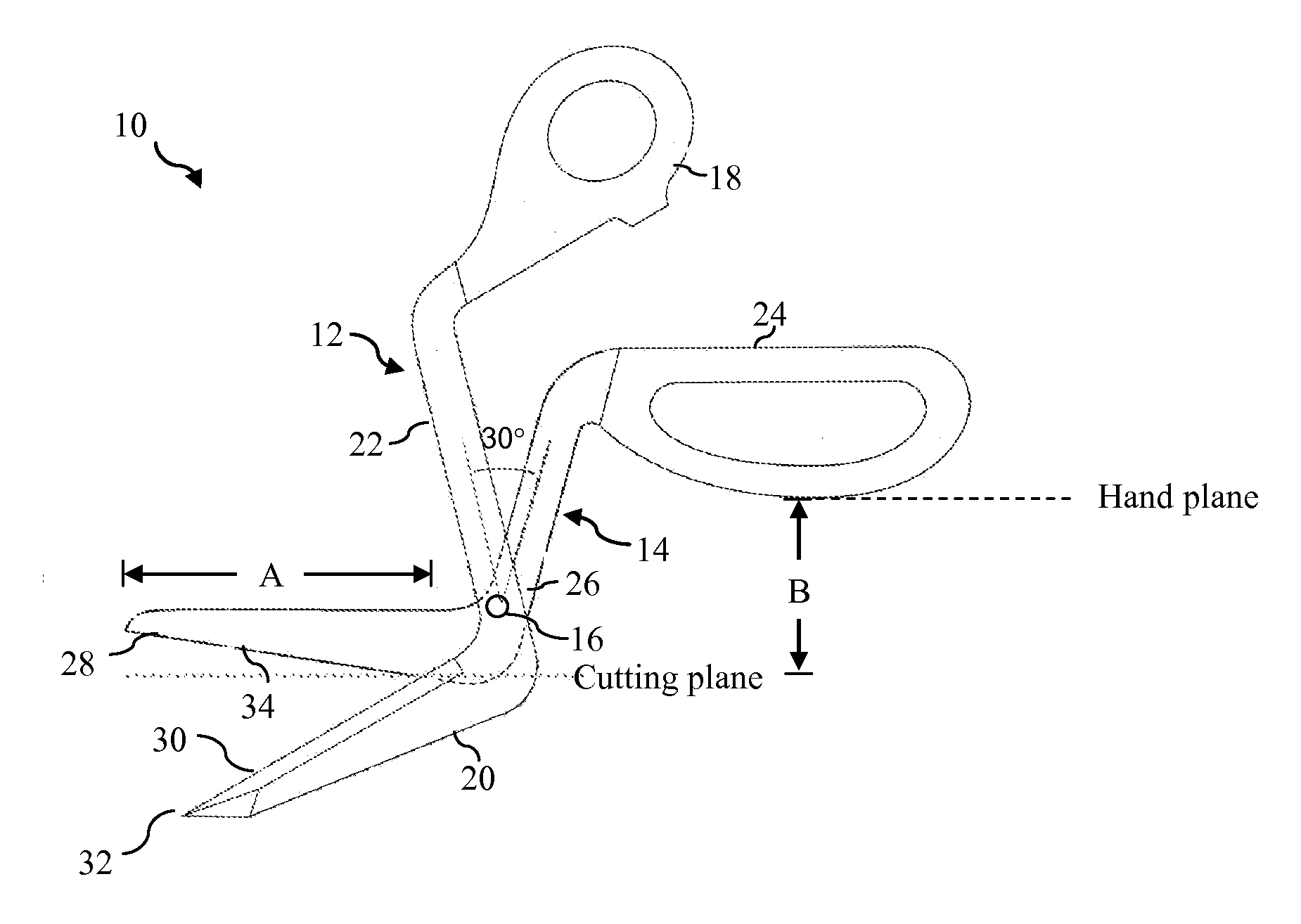

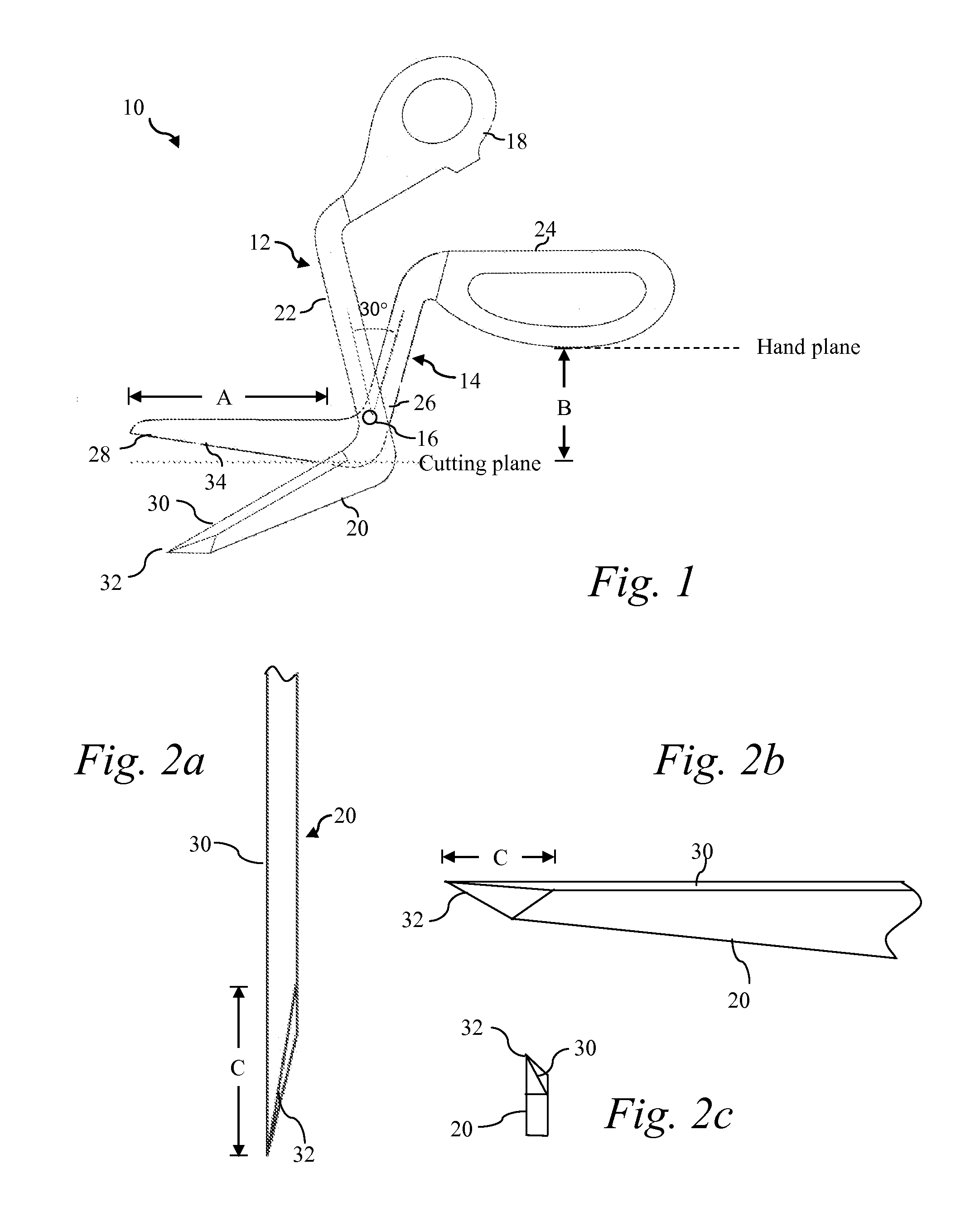

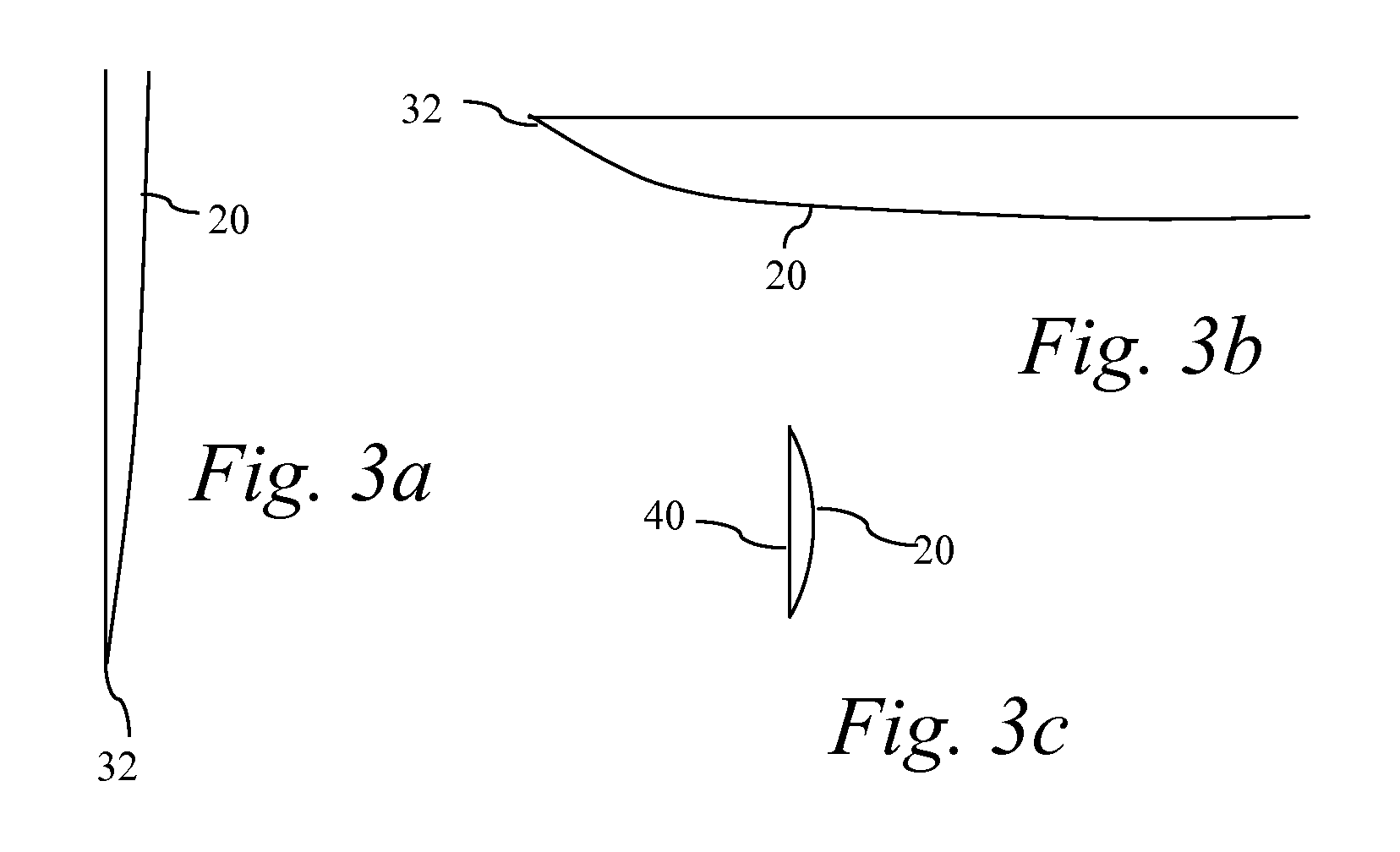

Scissors for cutting thermoformed plastic packages, or similar packages, have lever members including a handle portion, a offset portion and a cutting portion. The cutting potion includes cooperating blades of approximately 2.5 inches, with one of the blades having a pointed tip for piercing the packaging material. The offset portion keeps the user's hand at least 1.5 to 2 inches above a cutting plane, such that the cut material, which has sharp edges, does not scratch or cut the user's hand.

Owner:UNDERHILL RODNEY

Packaging Scissors

InactiveUS20100037464A1Hand protectionProtect fingersPortable power-driven toolsMetal working apparatusEngineeringKnife blades

Scissors for cutting thermoformed plastic packages, or similar packages, have lever members including a handle portion, a offset portion and a cutting portion. The cutting portion includes cooperating blades of approximately 2.5 inches, with one of the blades having a pointed tip for piercing the packaging material. The offset portion keeps the user's hand at least 1.5 to 2 inches above a cutting plane, such that the cut material, which has sharp edges, does not scratch or cut the user's hand.

Owner:UNDERHILL RODNEY

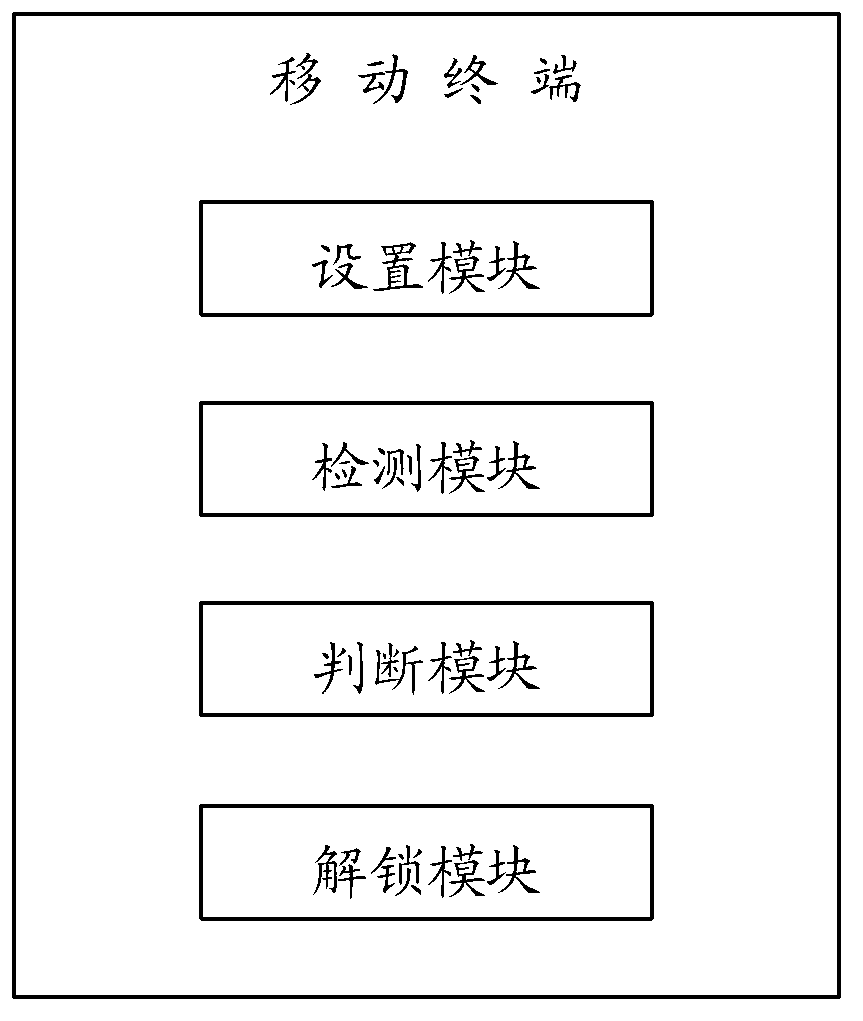

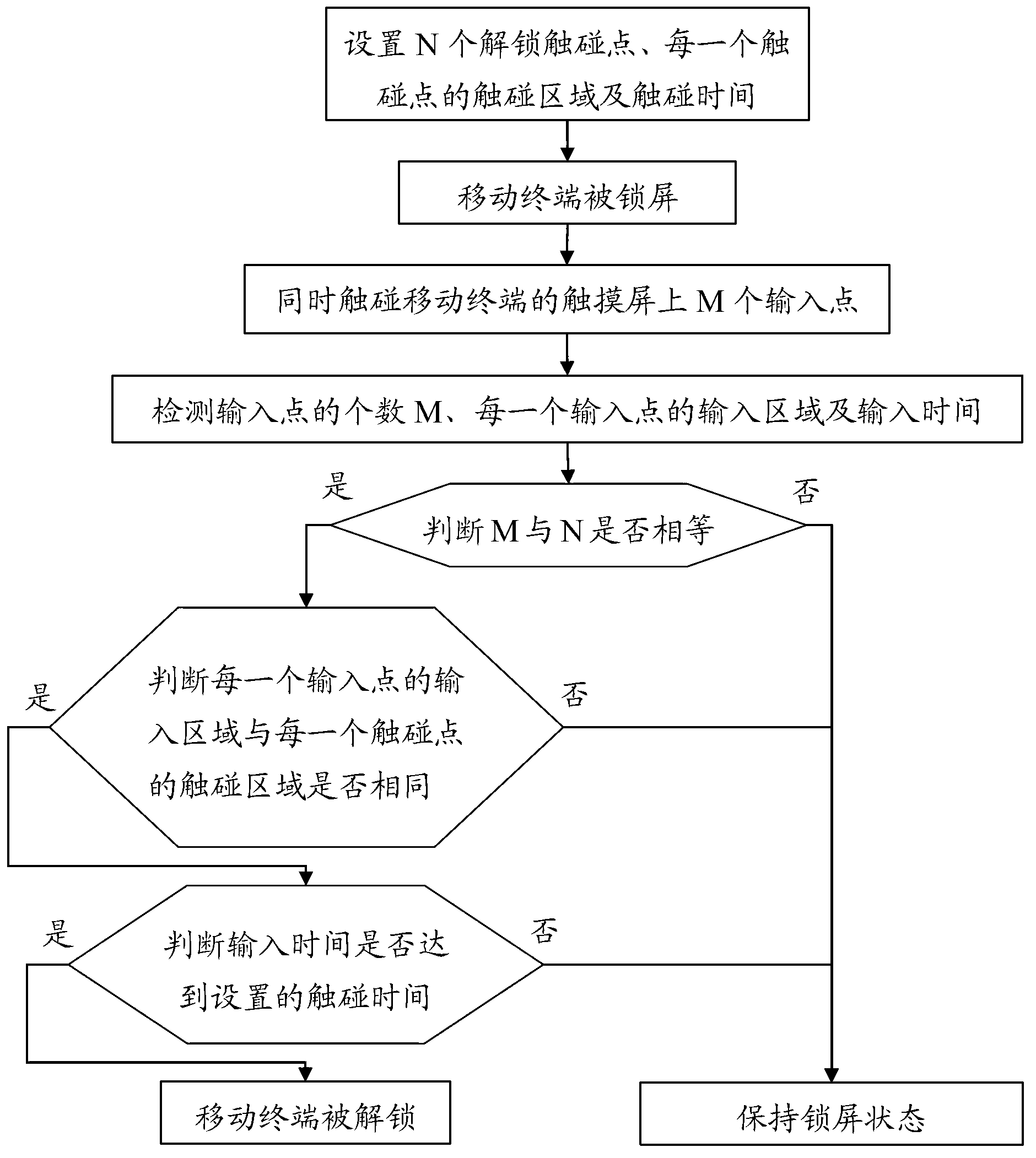

Mobile terminal with touch unlocking function and method for touch unlocking of mobile terminal

InactiveCN102799387AExtended service lifeProtect fingersInput/output processes for data processingReal-time computing

A mobile terminal with a touch unlocking function comprises a setting module, a detection module, a judgment module and an unlocking module, wherein the setting module is provided with N unlocking touch points, a touch area of each touch point and touch time for simultaneously touching; N is greater than or equal to 2; the detection module is used for detecting M input points, an input area of each input point and an input time for simultaneously touching; M is greater than or equal to 1; the judgment module is used for judging whether M is equal to N or not; if so, judging whether the input area of each input point is identical with the touch area of each touch point or not; if so, judging whether the input time which is obtained by simultaneously touch of M input points reaches the touch time set in the setting module or not, if so, an unlocking signal is transmitted to the unlocking module; and the unlocking module executes an unlocking action and the mobile terminal is unlocked. The invention further provides a method for touch unlocking of the mobile terminal. The mobile terminal provided by the invention is convenient to operate and is higher in practicability.

Owner:PHICOMM (SHANGHAI) CO LTD

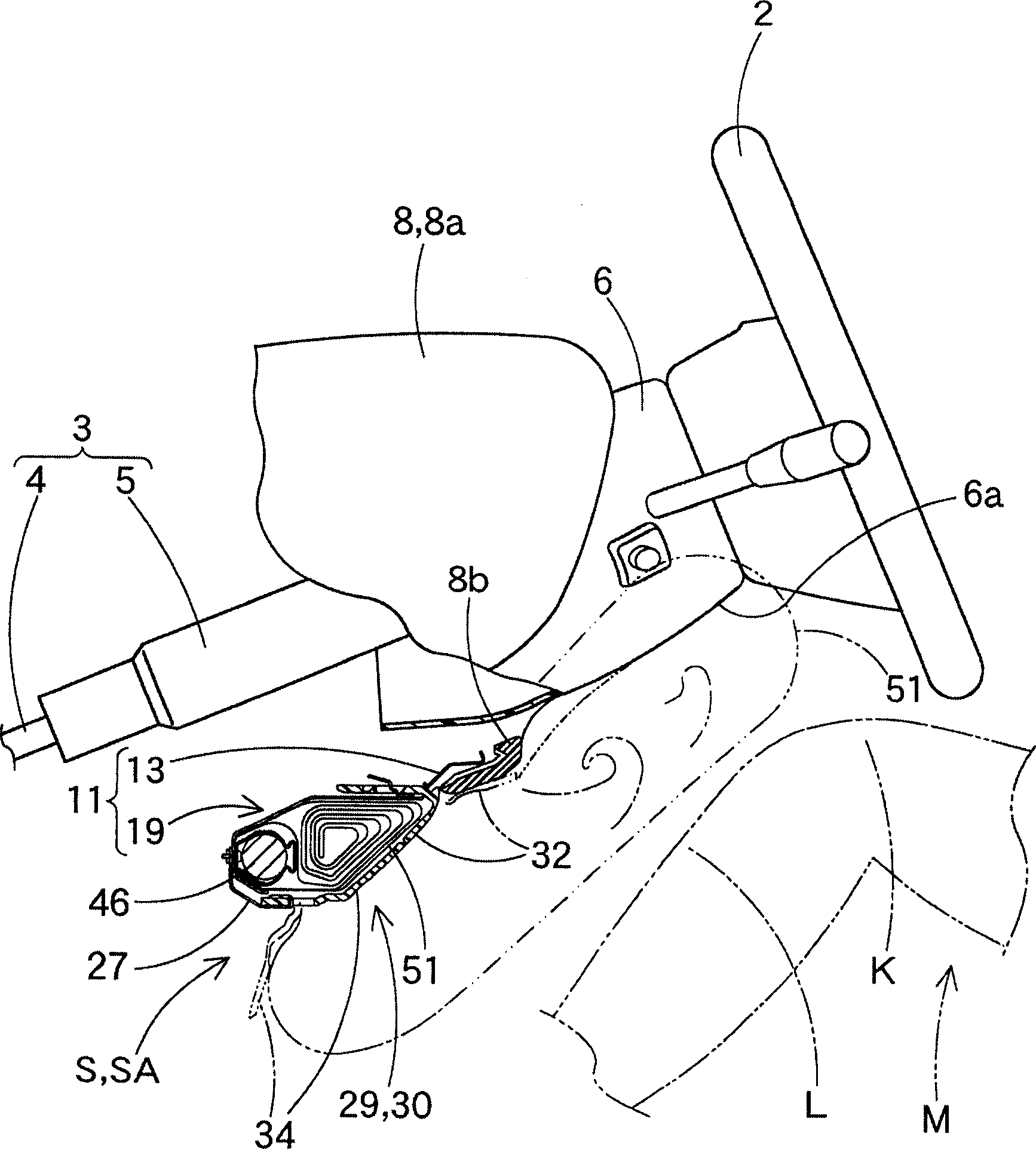

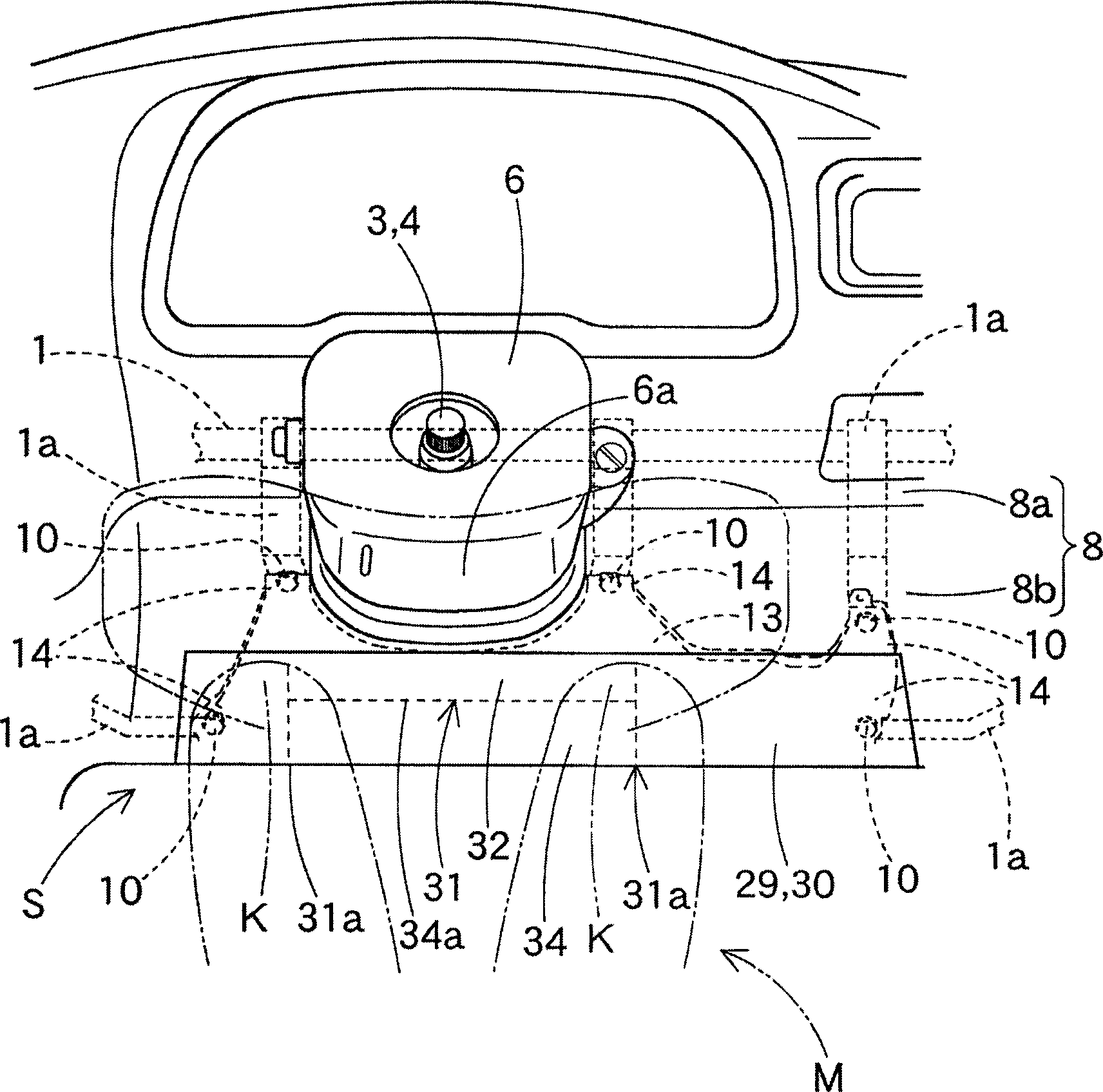

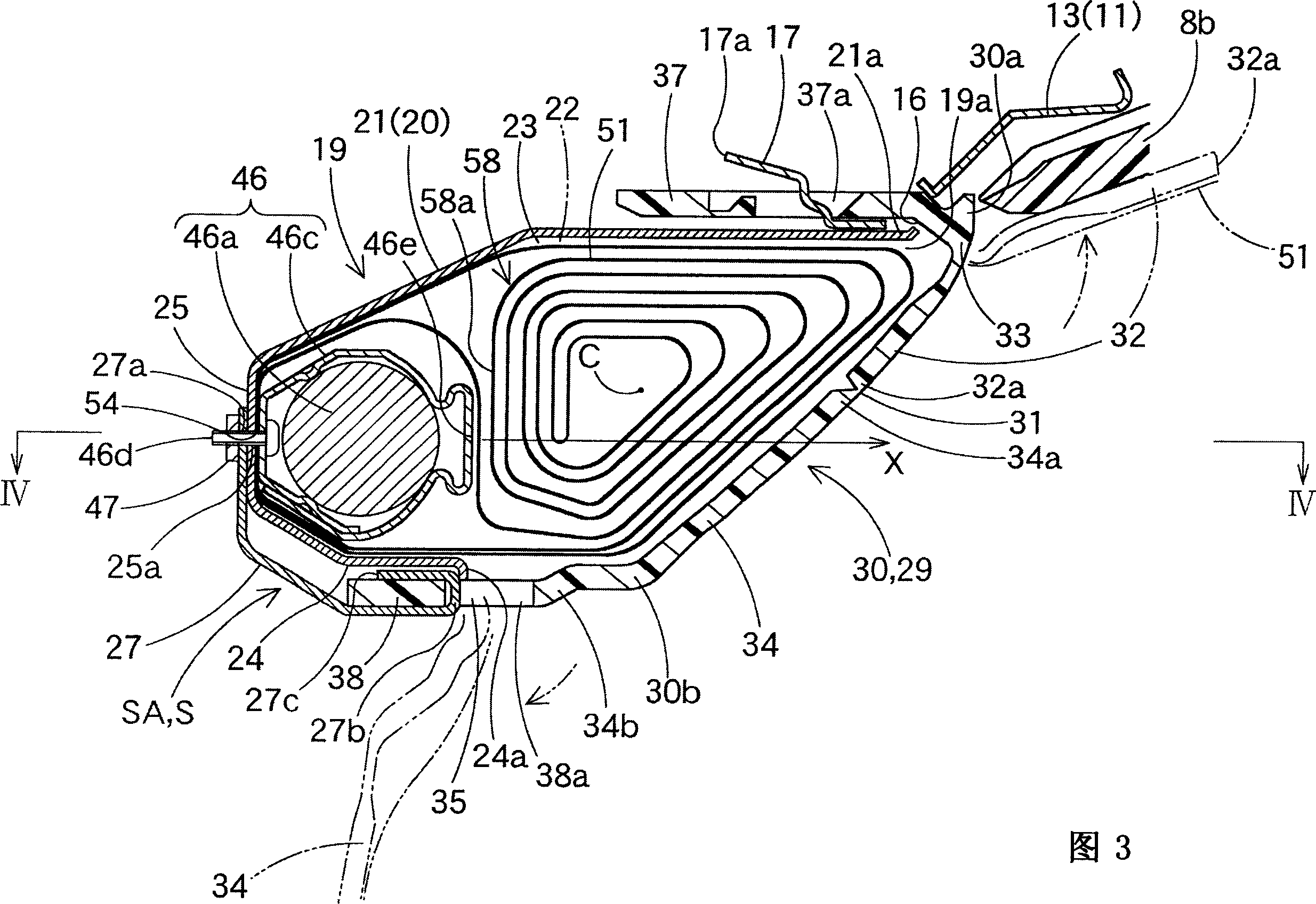

Airbag device for protecting knee

InactiveCN1836937AAchieve lightweightReduce extrusion pressurePedestrian/occupant safety arrangementEngineeringAirbag

Owner:TOYODA GOSEI CO LTD

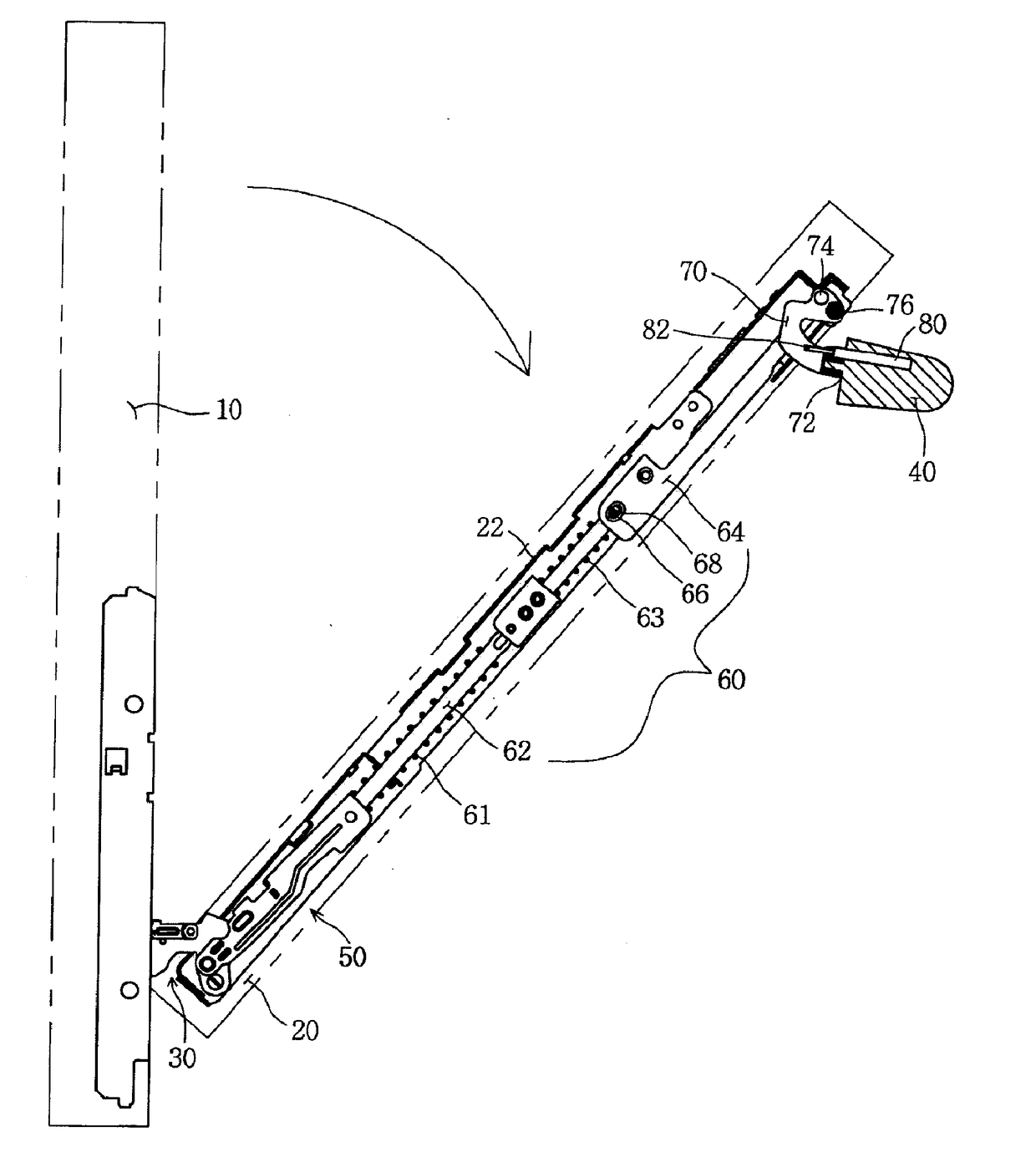

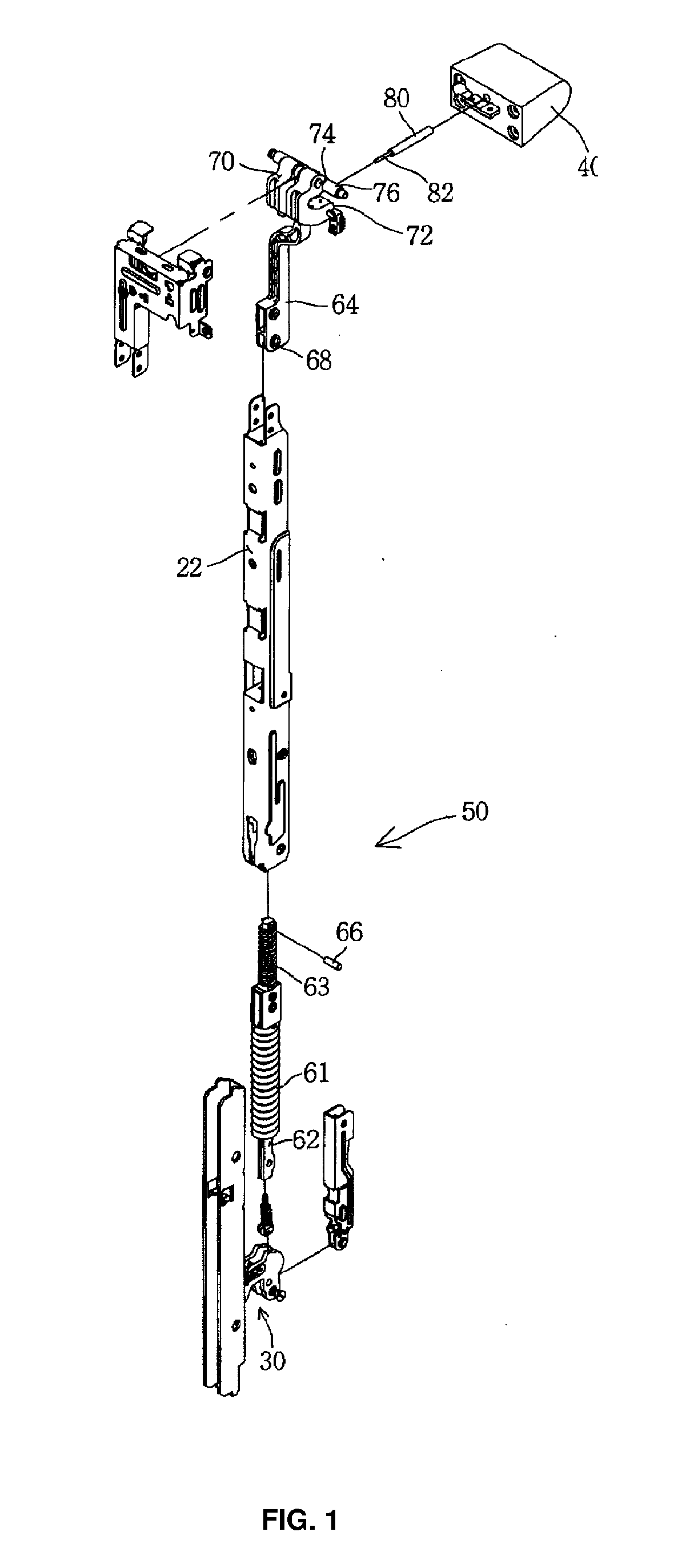

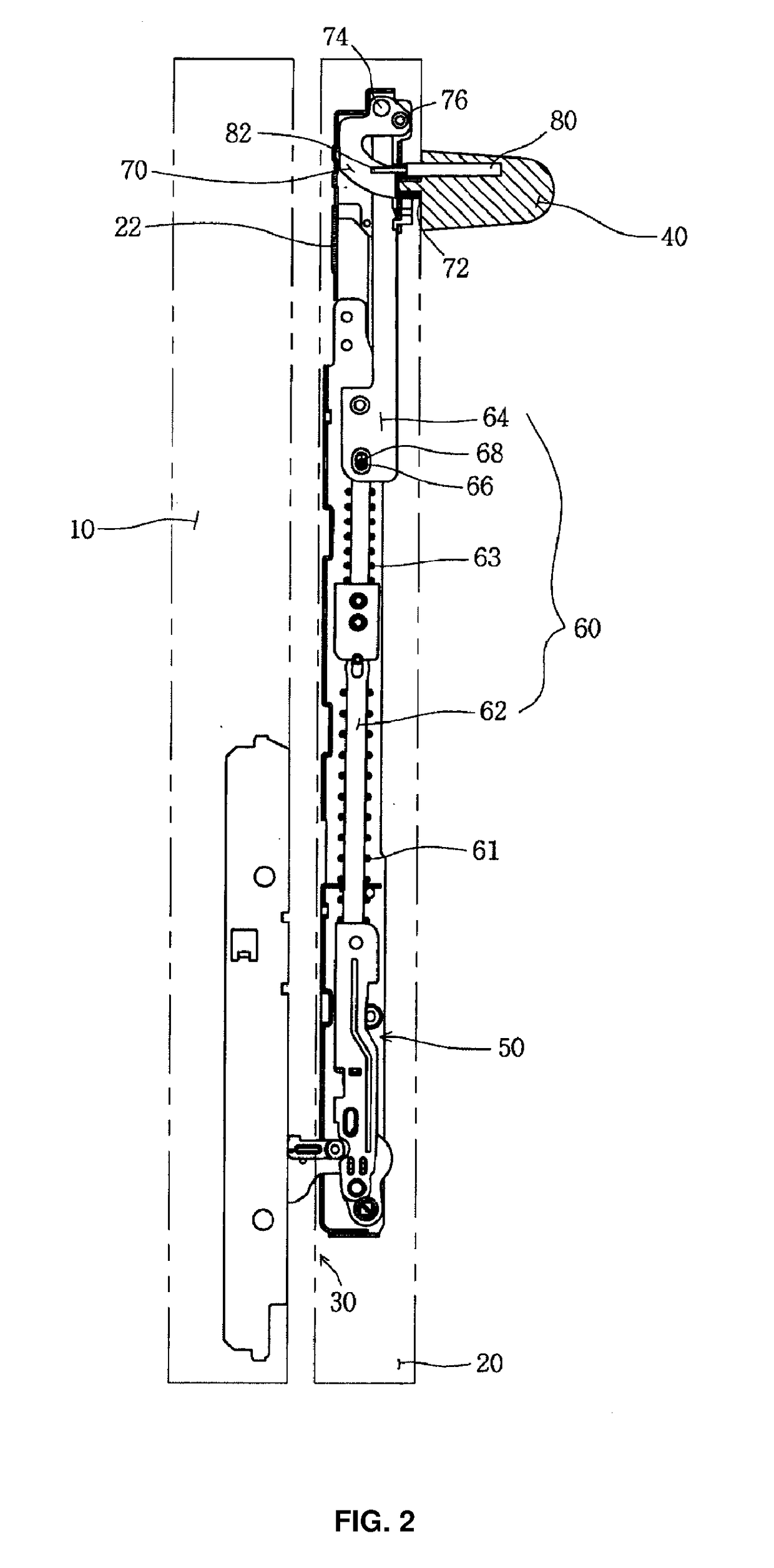

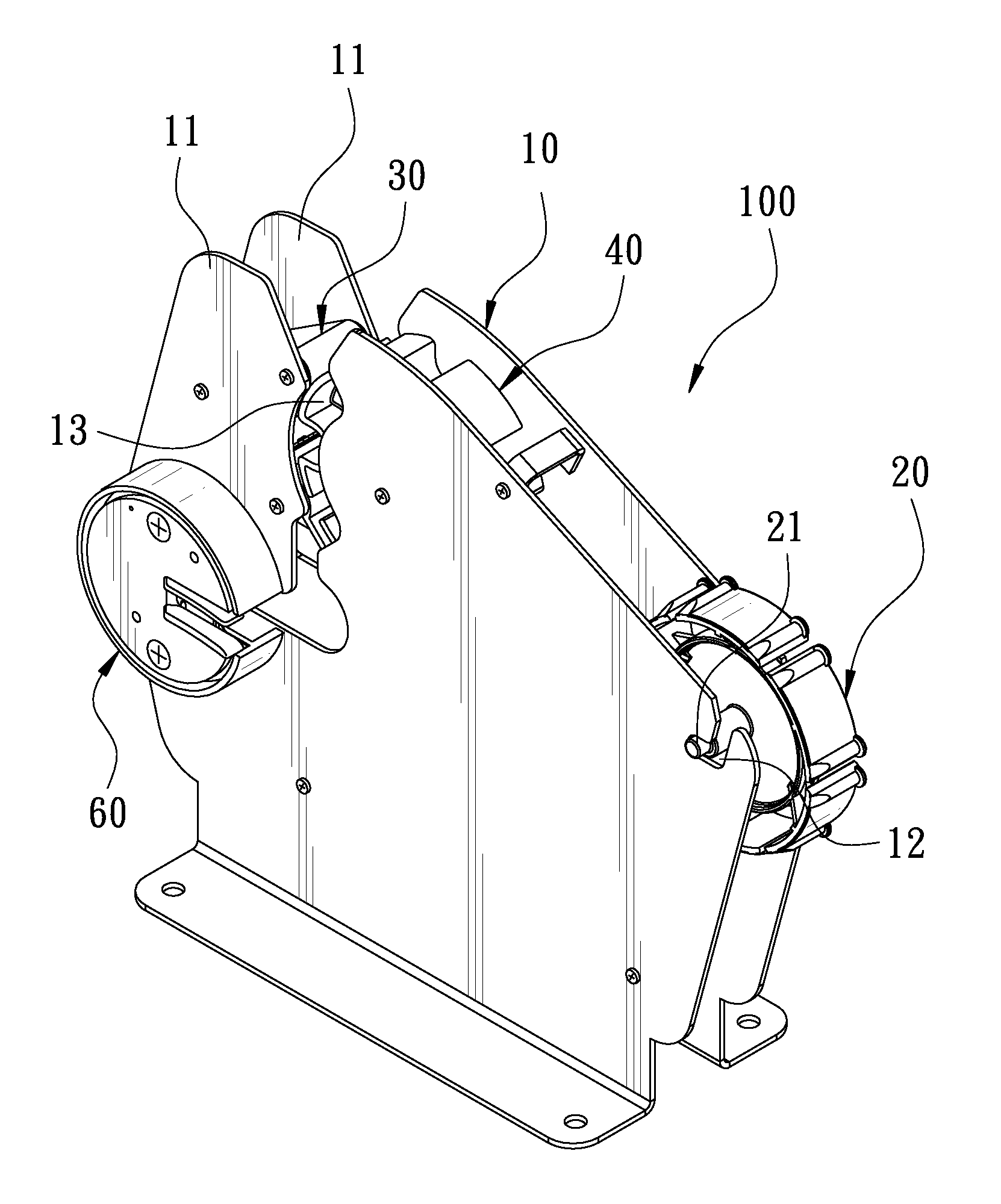

Door handle

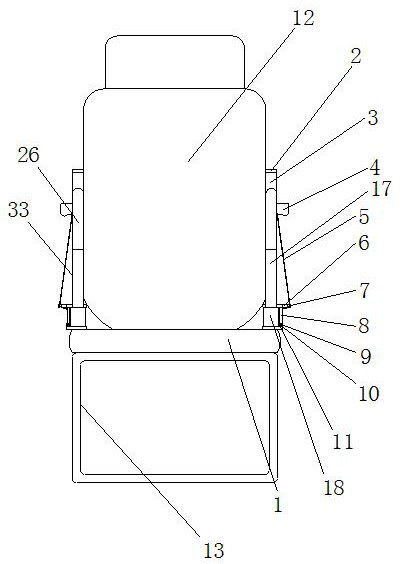

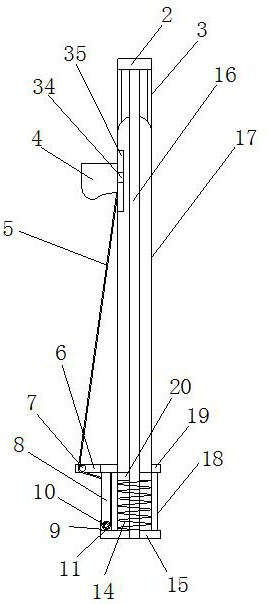

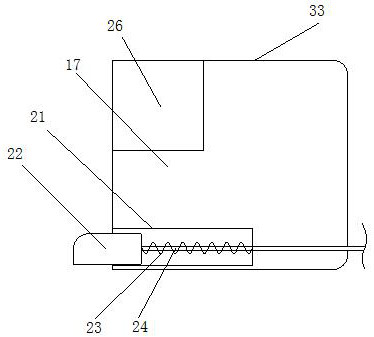

ActiveUS20180283698A1Protect fingersDoors for stoves/rangesDomestic stoves or rangesShock absorberDoor handle

The present invention relates to a door handle that tilts upward when a door is open initially, and after the tilting has been completed, is slowly returned to an initial state thereof through the resistance of a damper, so that even if a user's fingers are caught in a space between the door handle and the door, the door handle can protect the user's fingers from safety accidents. According to the present invention, the door handle is located on an upper end of a front surface of a door for opening and closing a body so as to open and close a cooking compartment formed inside the body at the time when the door pulls and rotates around door hinges, and the door handle includes a first actuating rod disposed in a vertically erected state on each of both sides of the door and having an end connected to the corresponding door hinge in such a manner as to be movable upward and downward, a second actuating rod disposed above the first actuating rod and coupled to a front end of the first actuating rod by means of a pin, a rotating member having an end coupled to the door handle and a front end coupled to the second actuating rod by means of a pin, and a hinge pin having both ends coupled to a door bracket fixed to the door after passing through the front end of the rotating member, wherein the second actuating rod has an elongated hole formed on a lower end thereof so as to allow the pin for connecting the first actuating rod and the second actuating rod to be fitted thereto in such a manner as to be movable upward and downward.

Owner:SEO WON KOREA

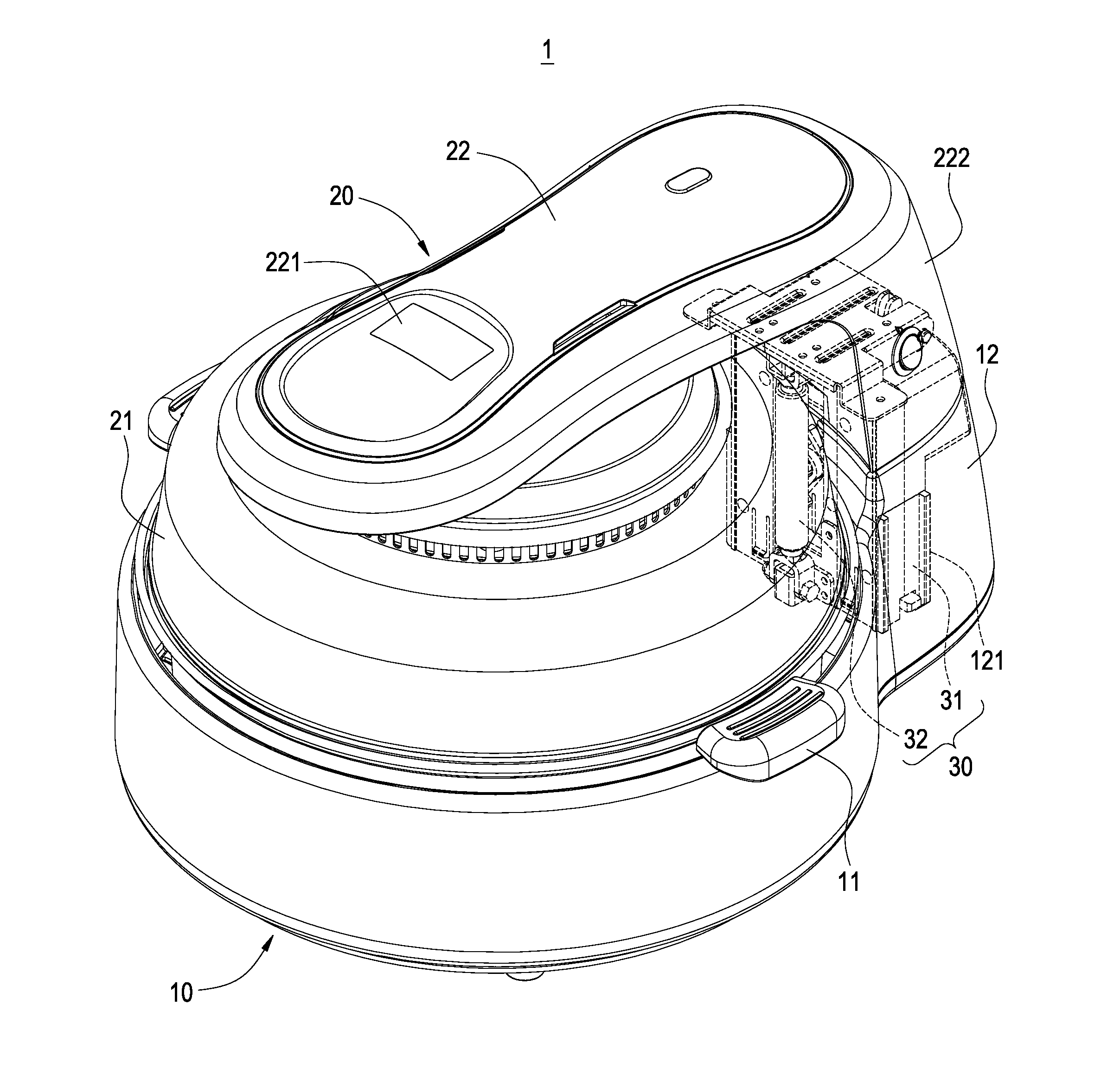

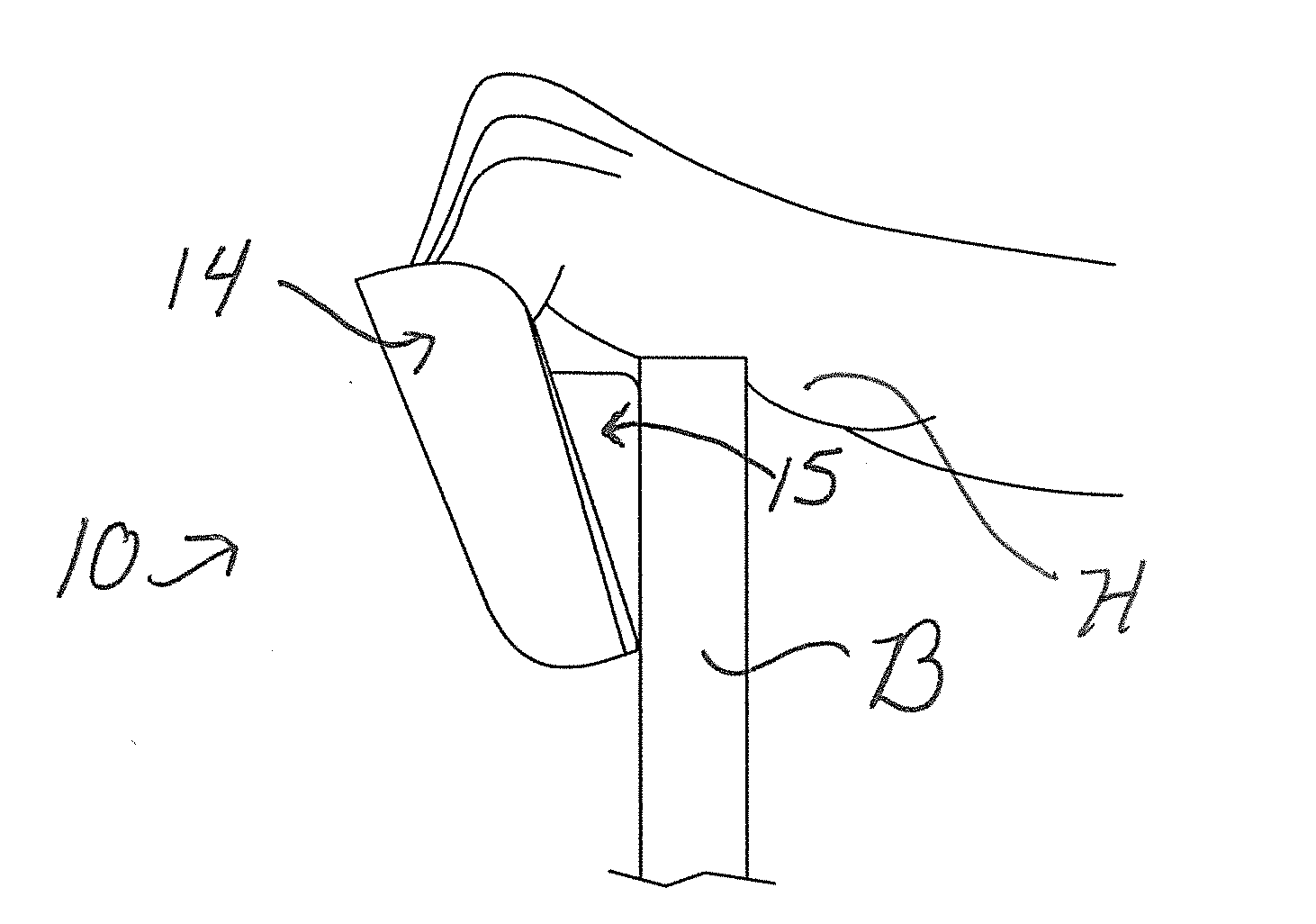

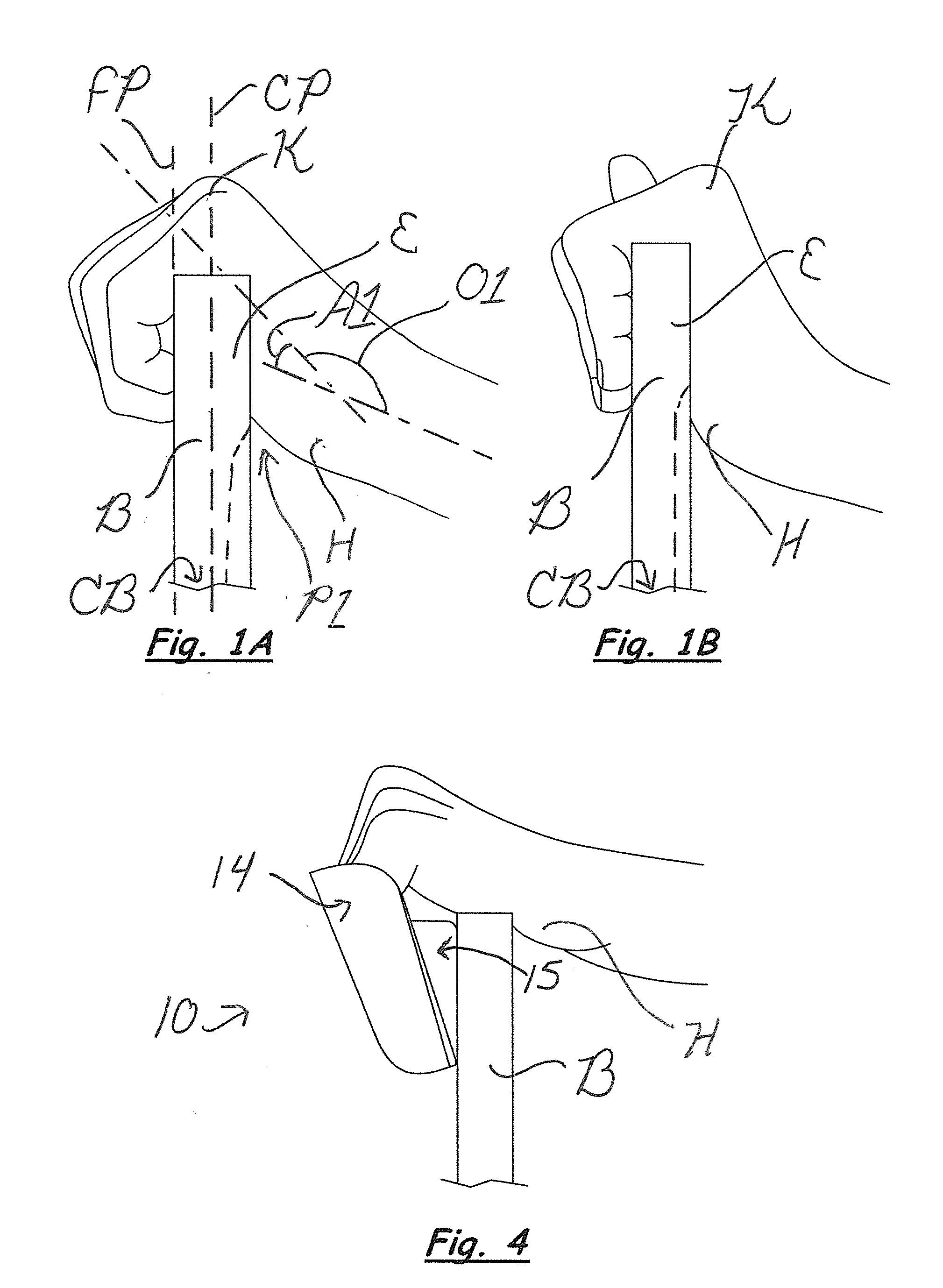

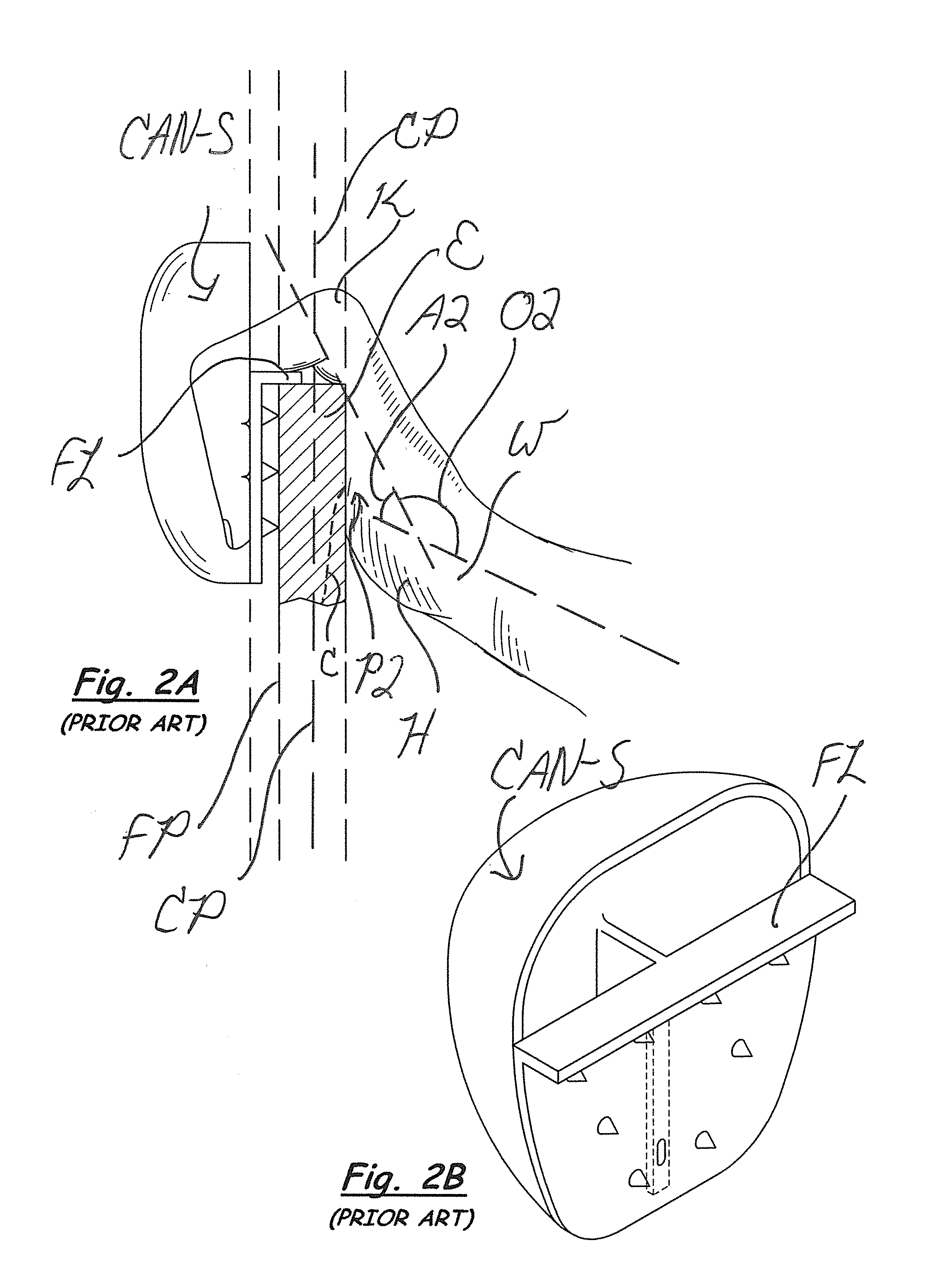

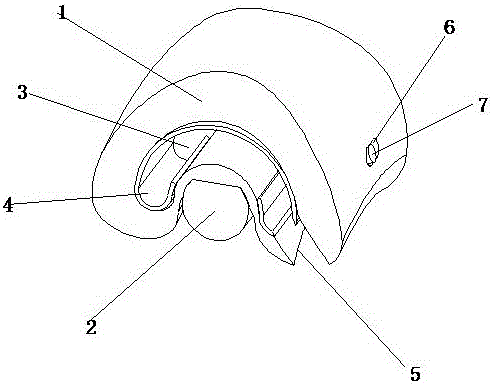

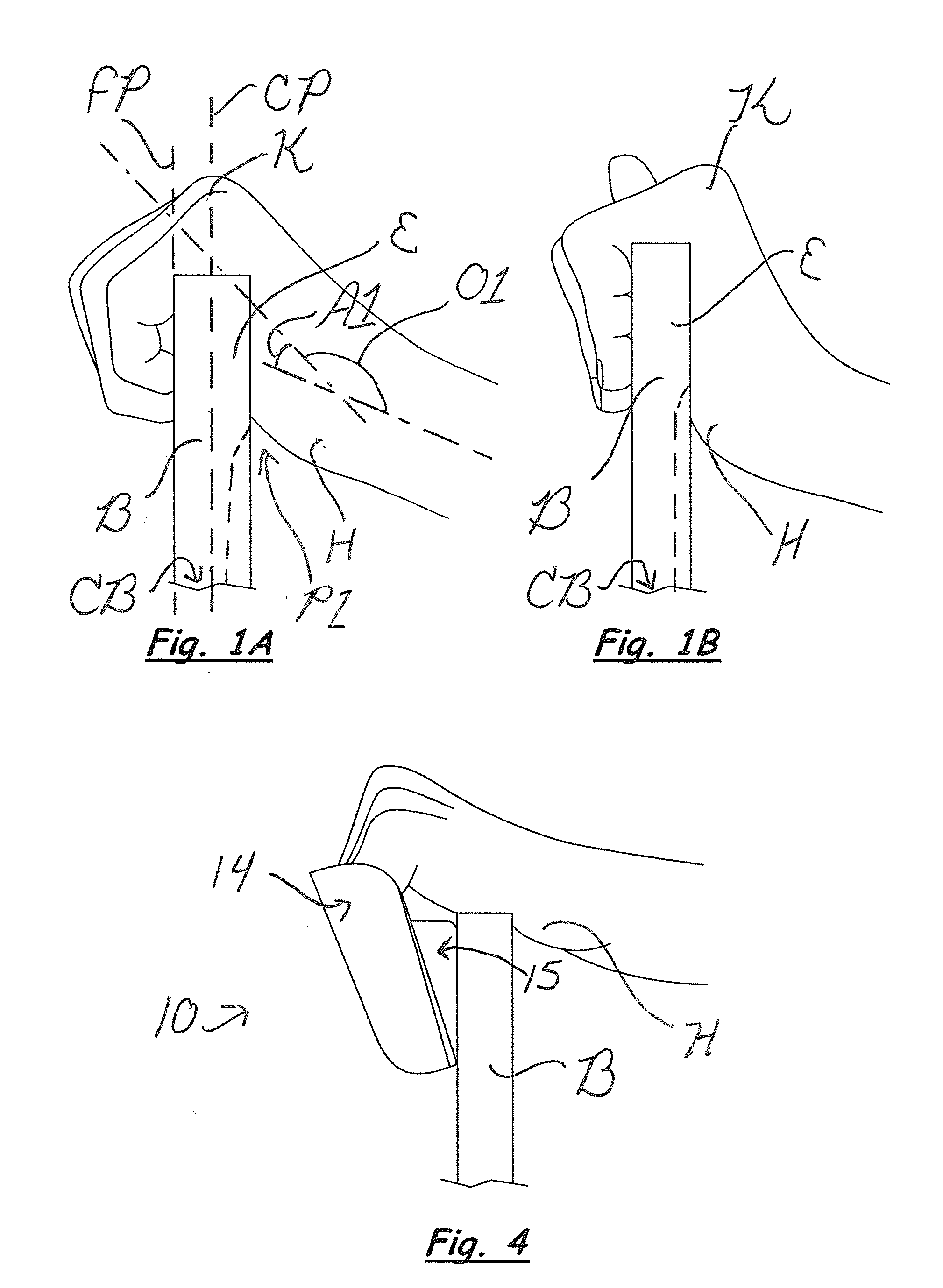

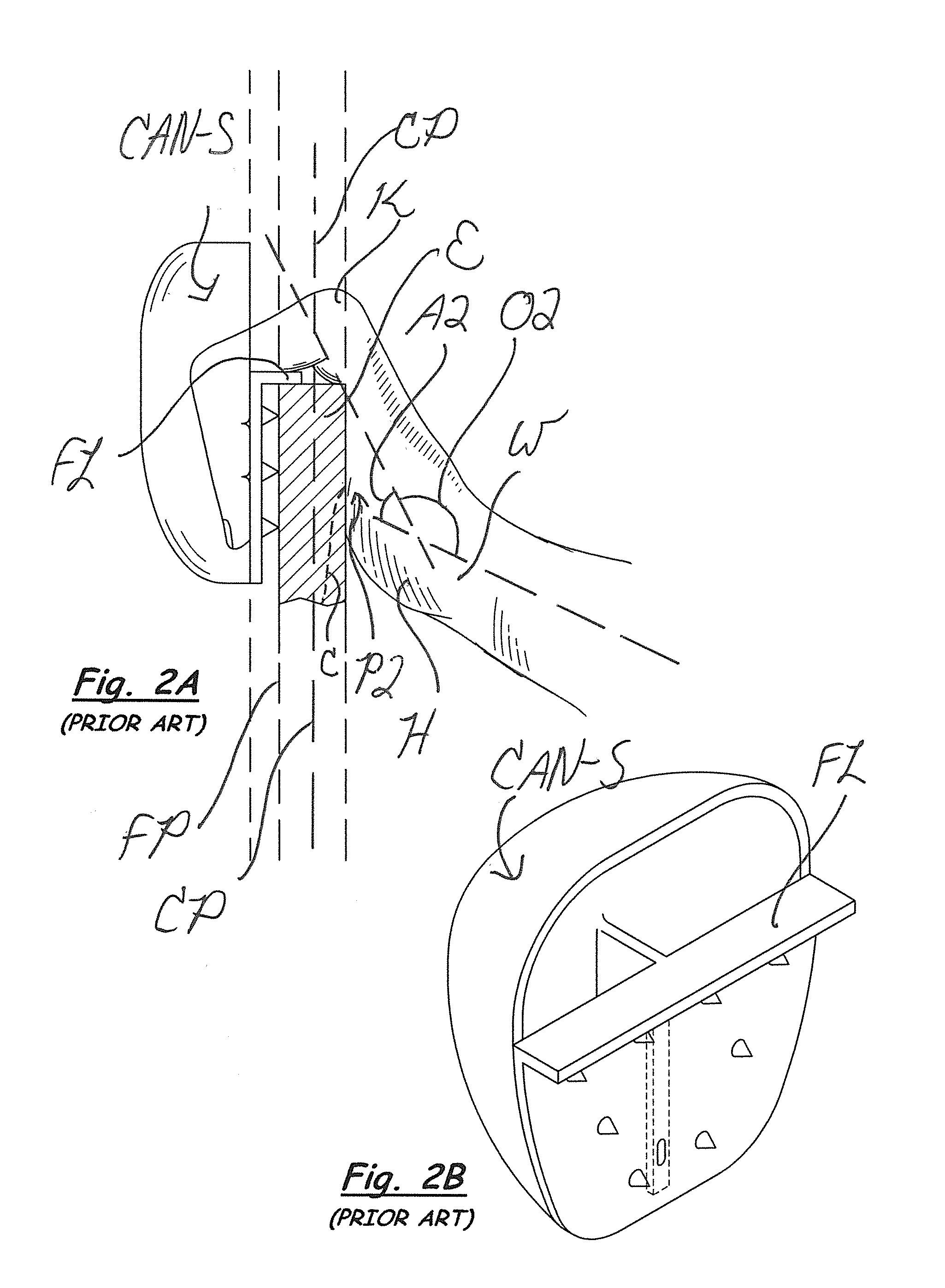

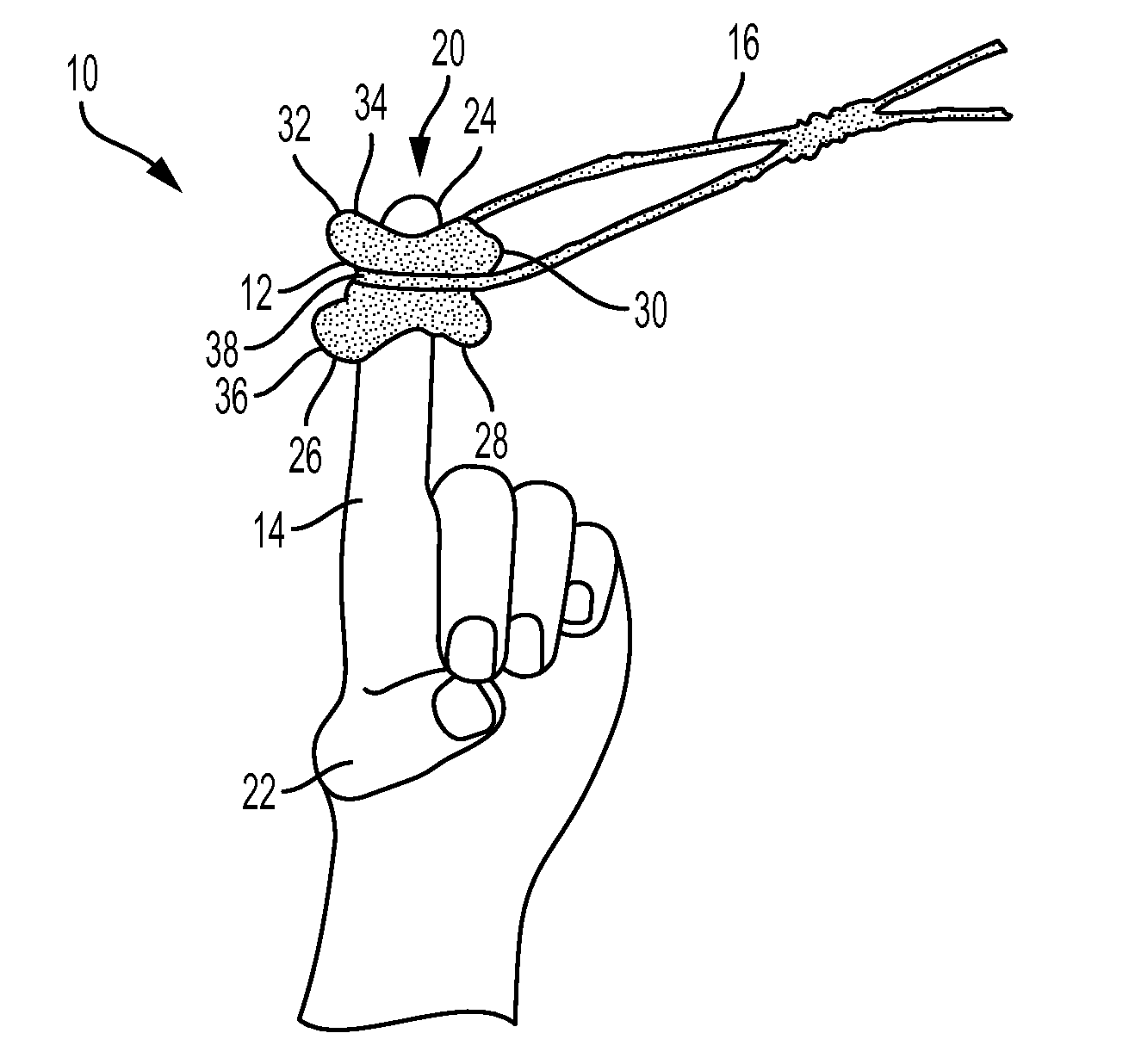

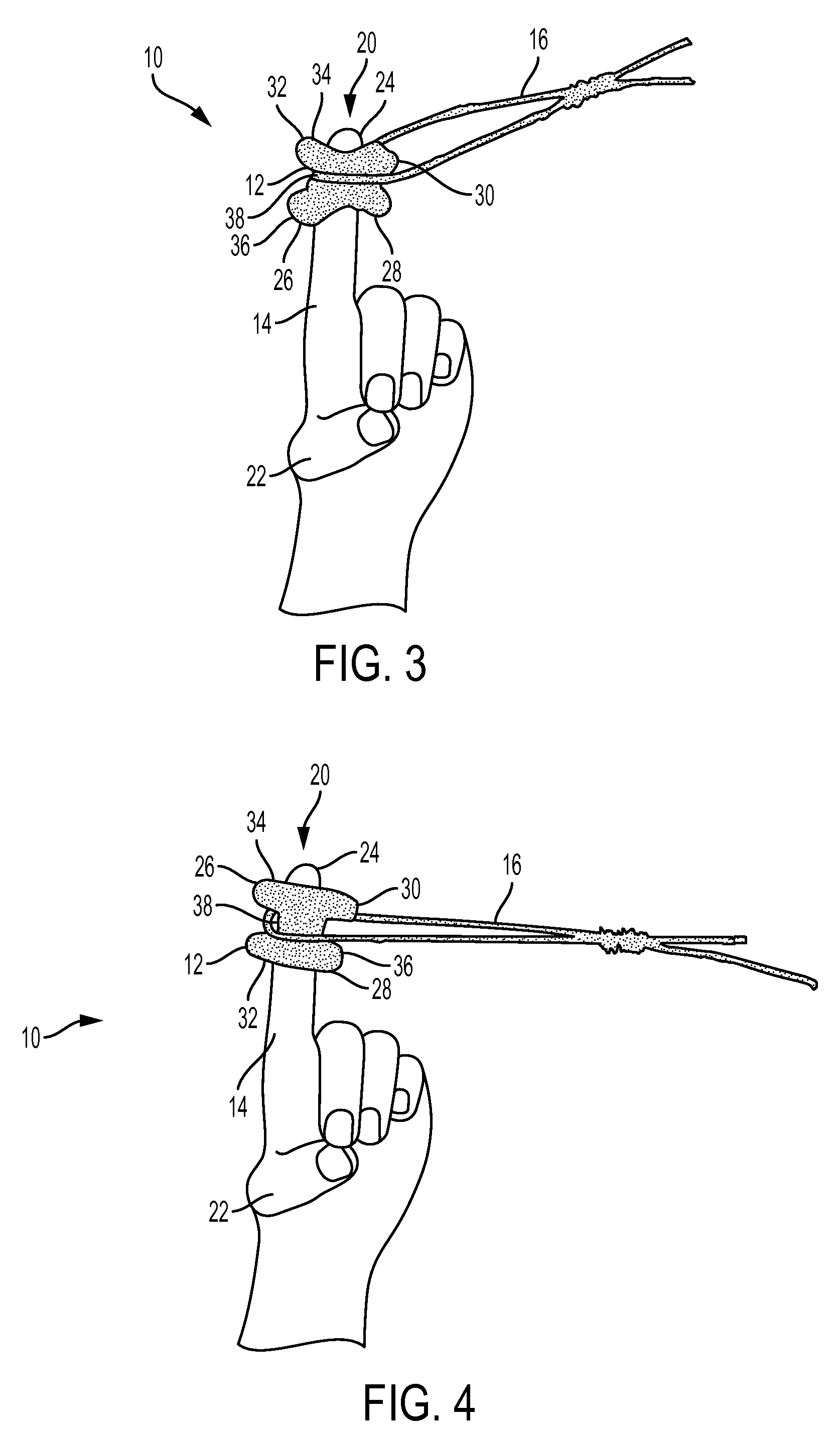

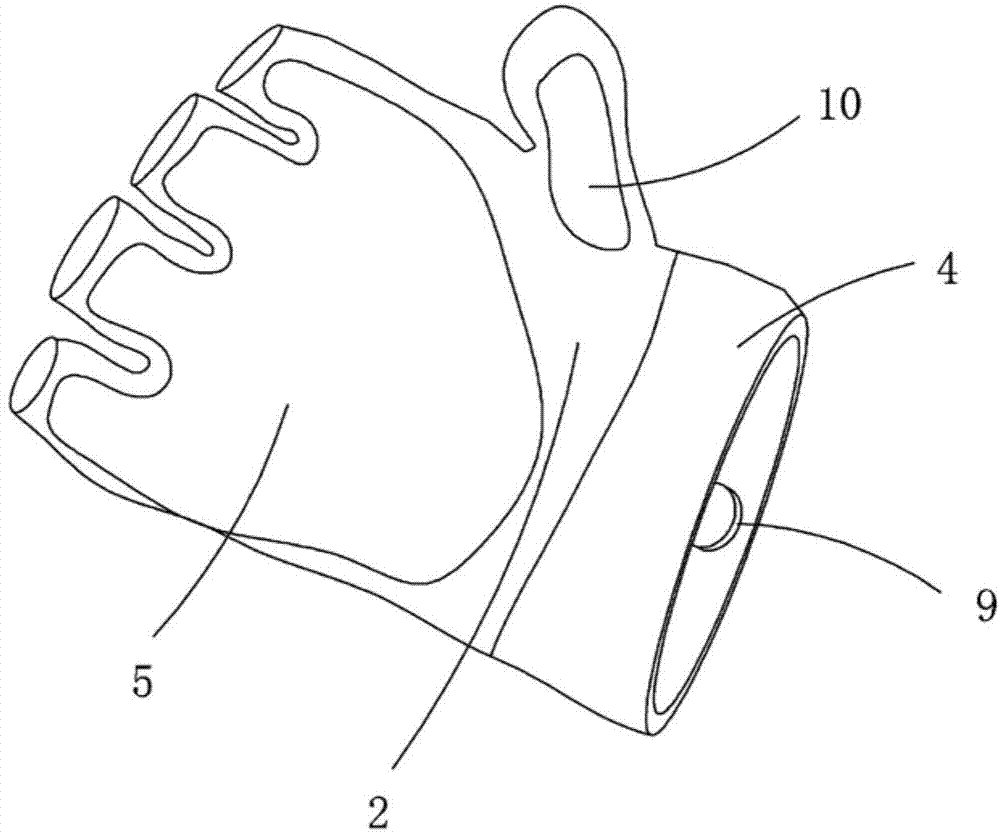

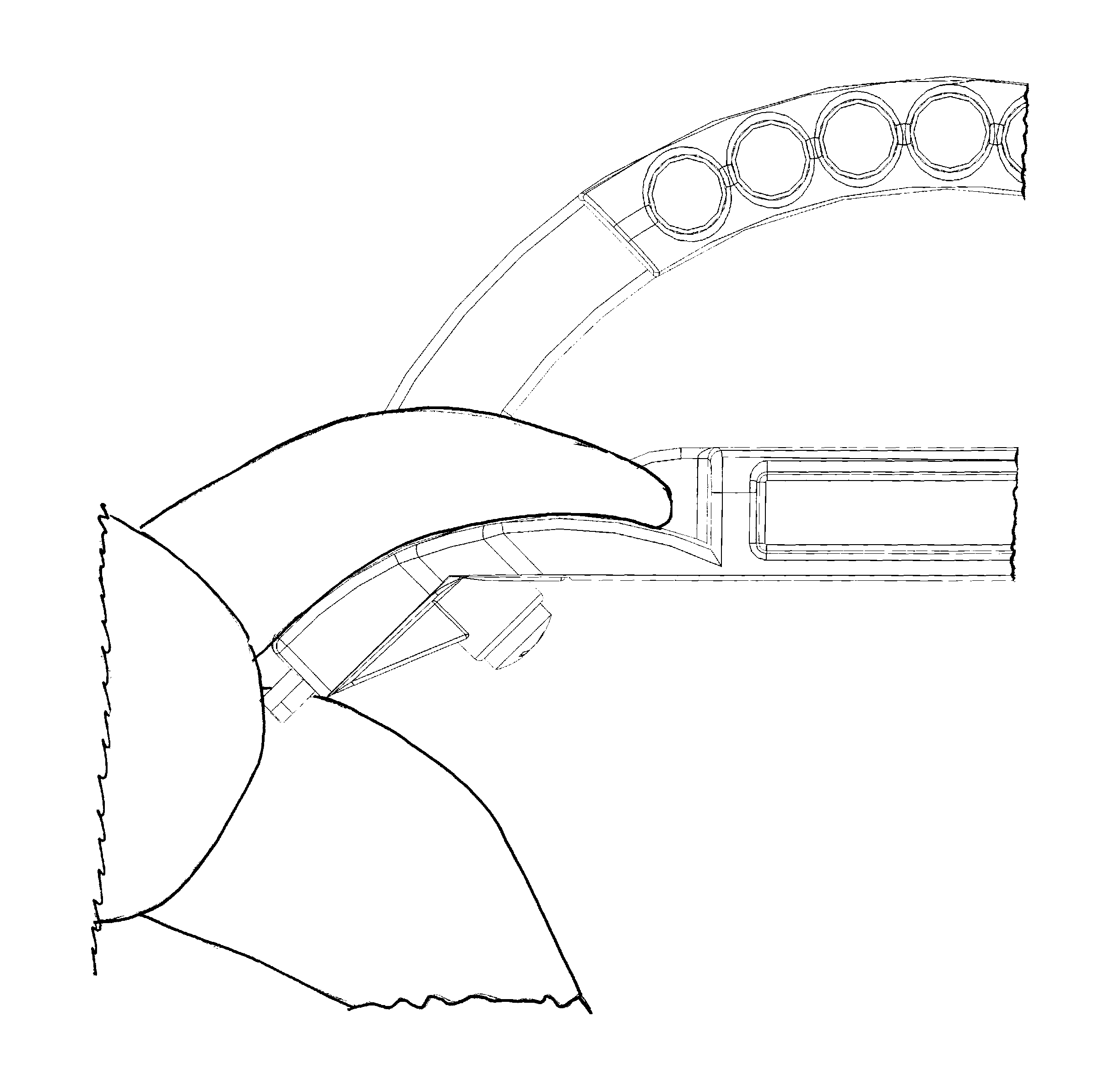

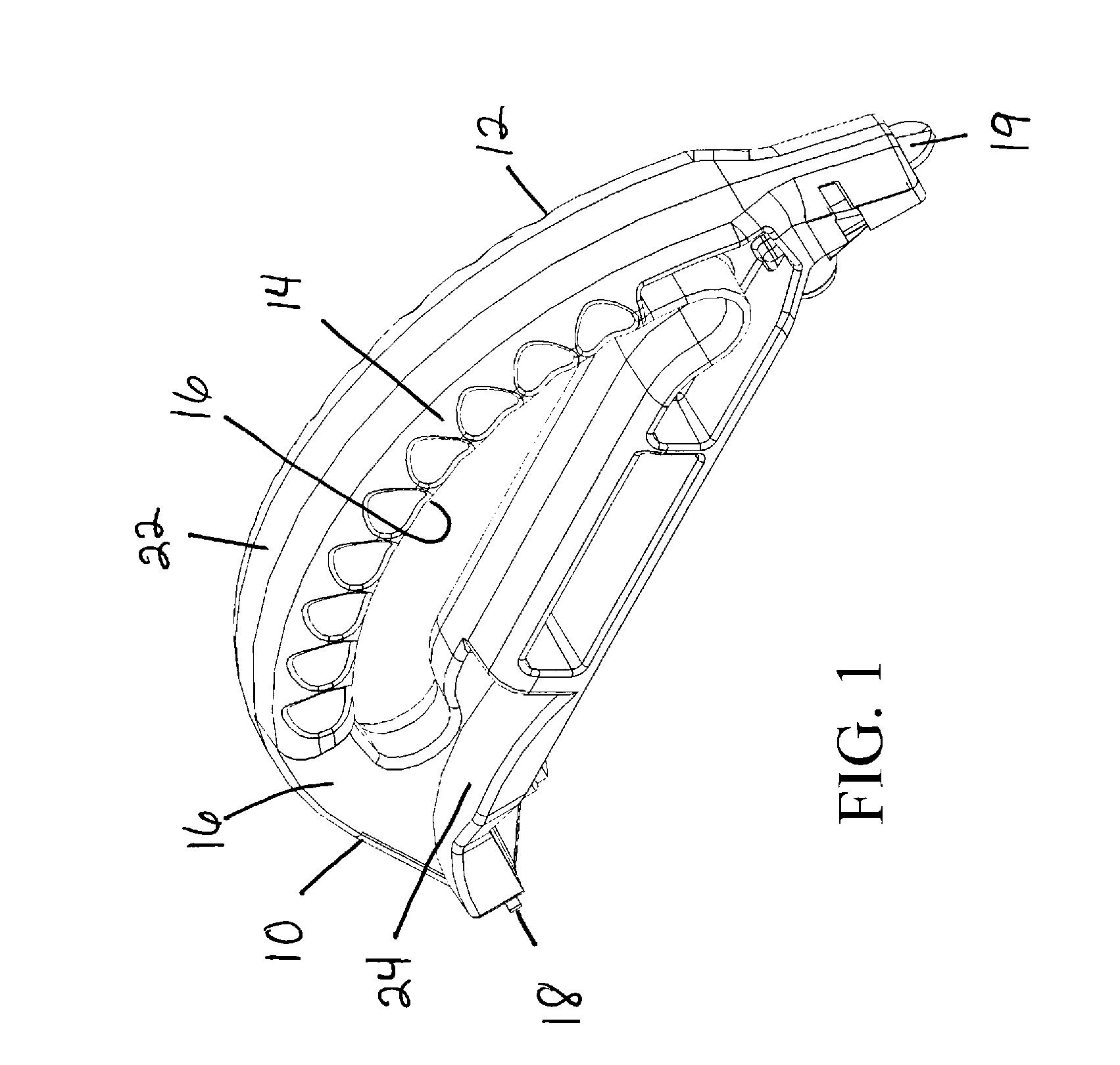

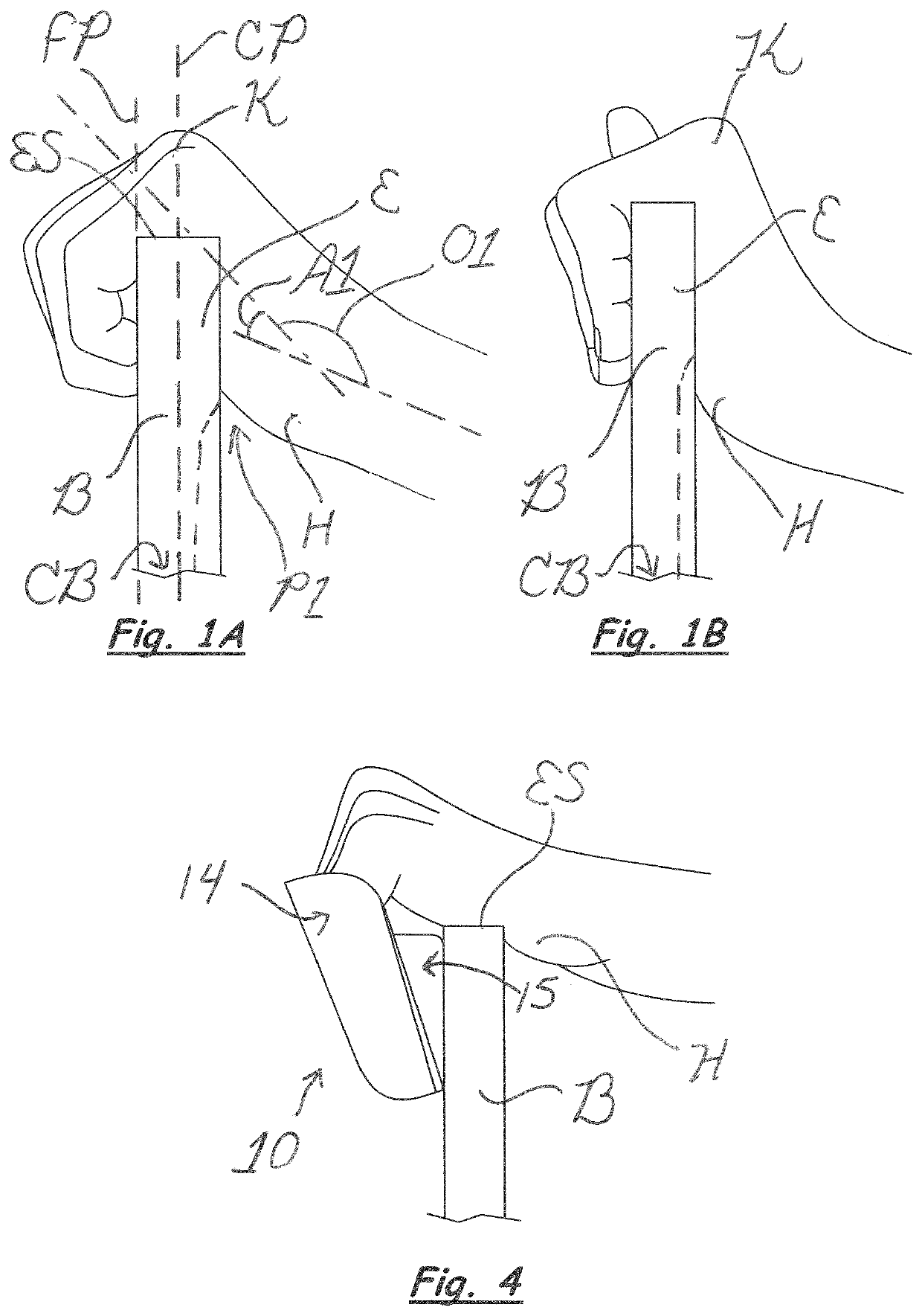

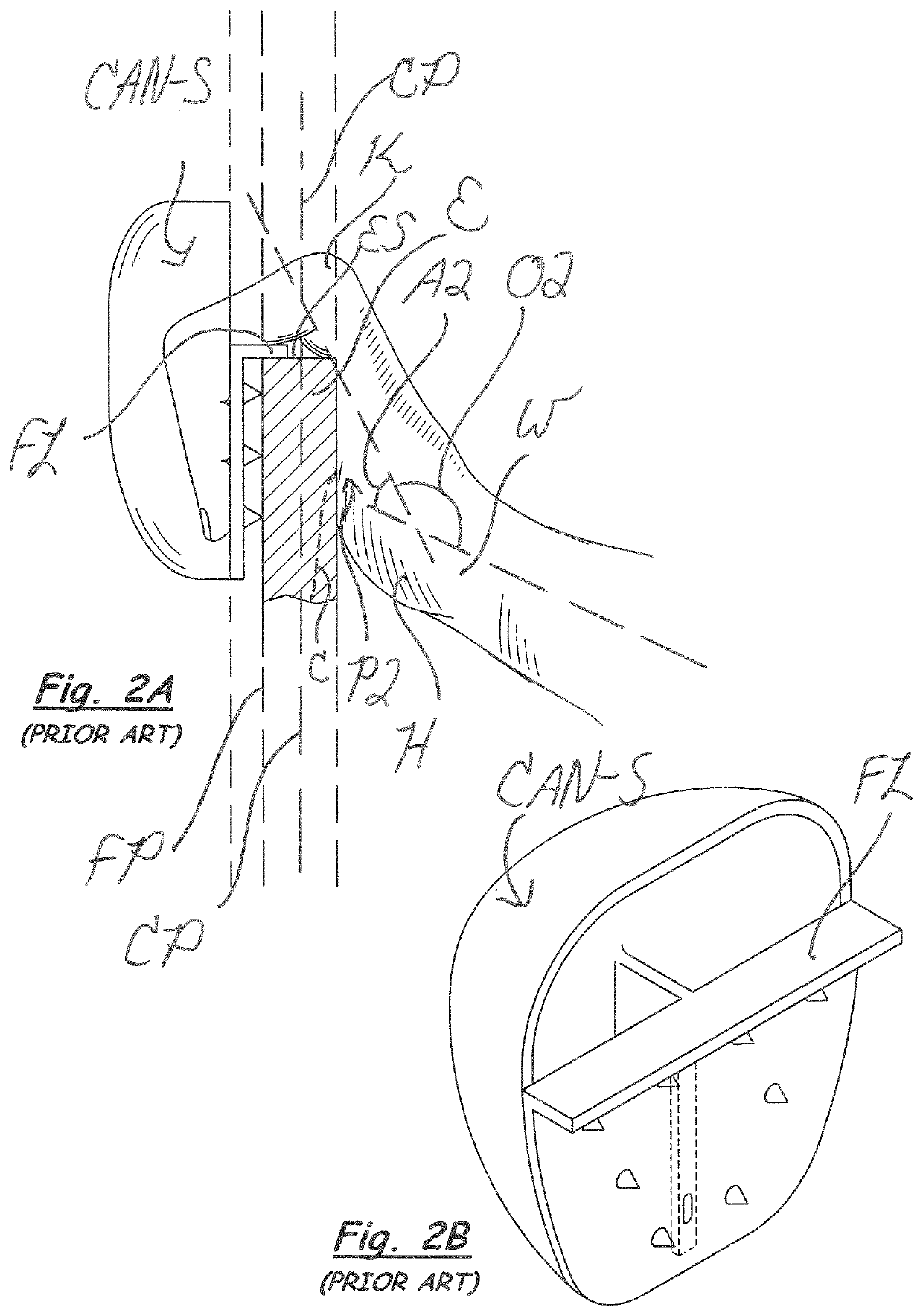

Device for finger protection in martial arts

ActiveUS20150080193A1Difficult to hangReduce the gripWing handlesWing knobsEngineeringPreventing injury

A protection device for a holder of a martial arts board / target provides protection from direct impact and / or from the force / shock that is transmitted rearward to the hand and wrists of the holder of the board / target. The device receives the board / target holder's fingers, and a slanted floor inside the device urges the fingers into a generally curled or other inwardly-slanted position, and urges the rest of the hand, the wrist, and forearm into ergonomic and safer positions. The device is preferably made of material(s) in a particular hardness range that protects the user's fingers but that also prevents injury to the striker who is hitting / kicking the board / target. There are preferably no flanges or stops that limit placement of the device to particular places on the board, but rather the holder determines and controls the placement.

Owner:REDMOND STEVEN DOUGLAS +1

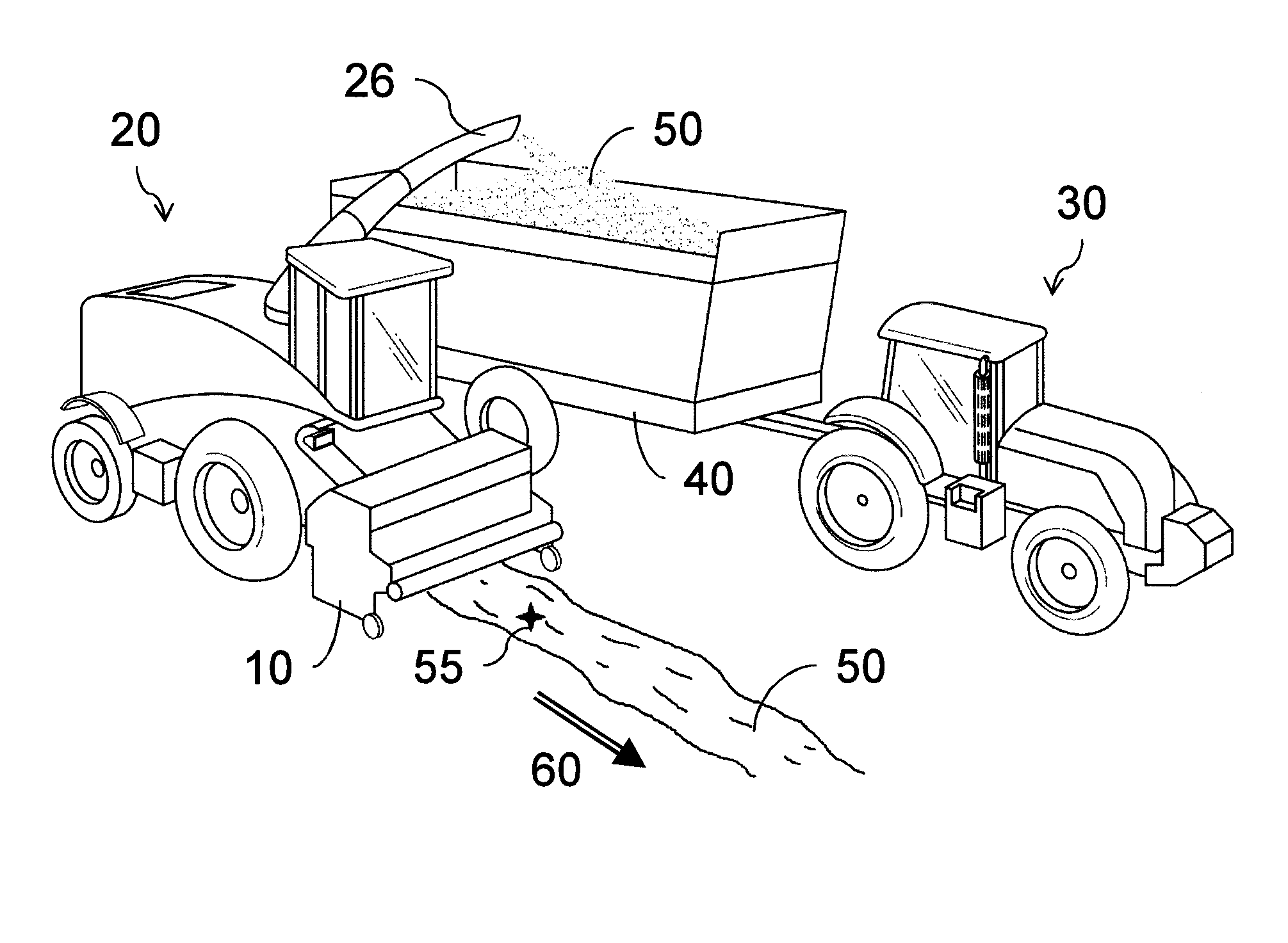

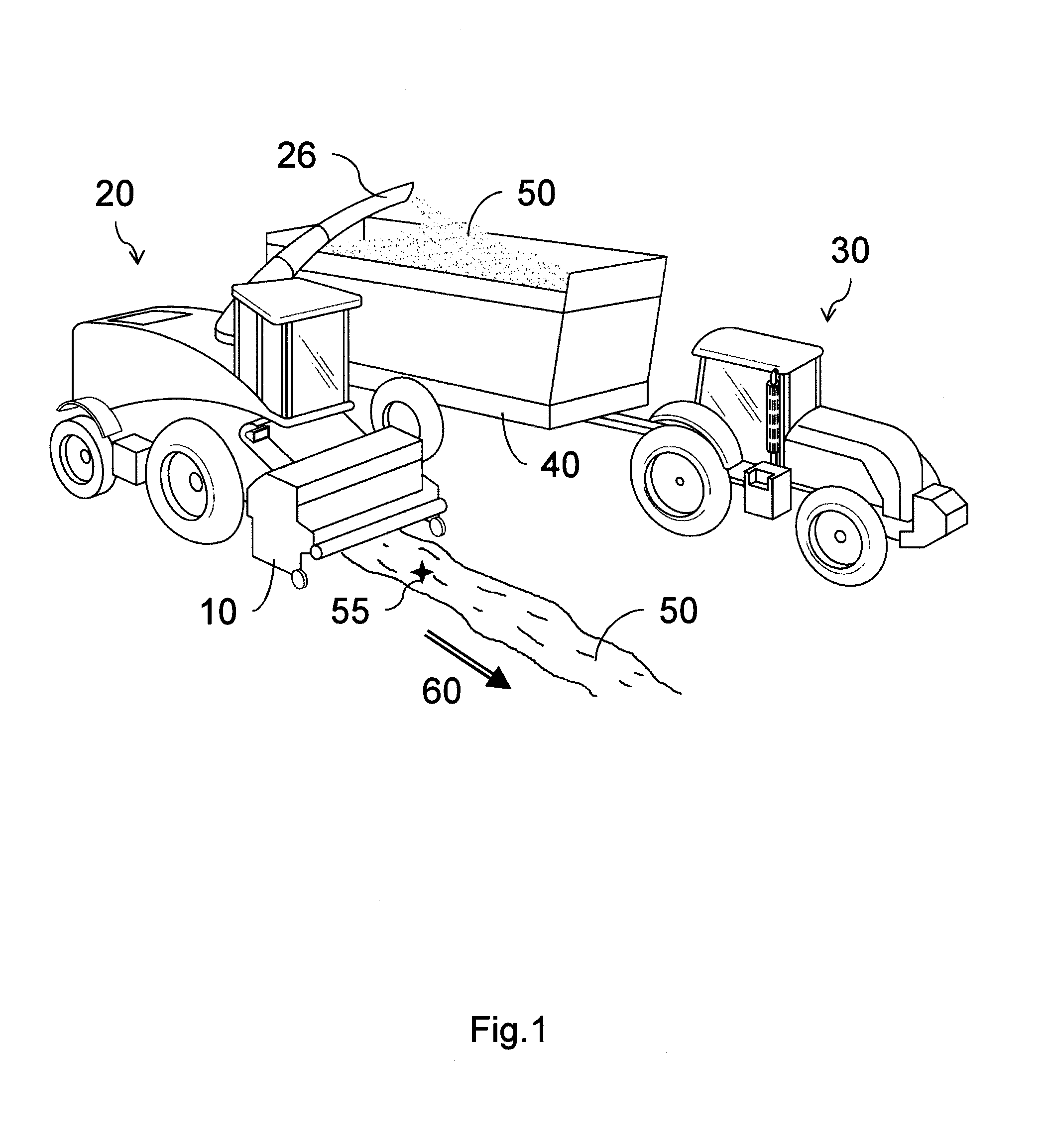

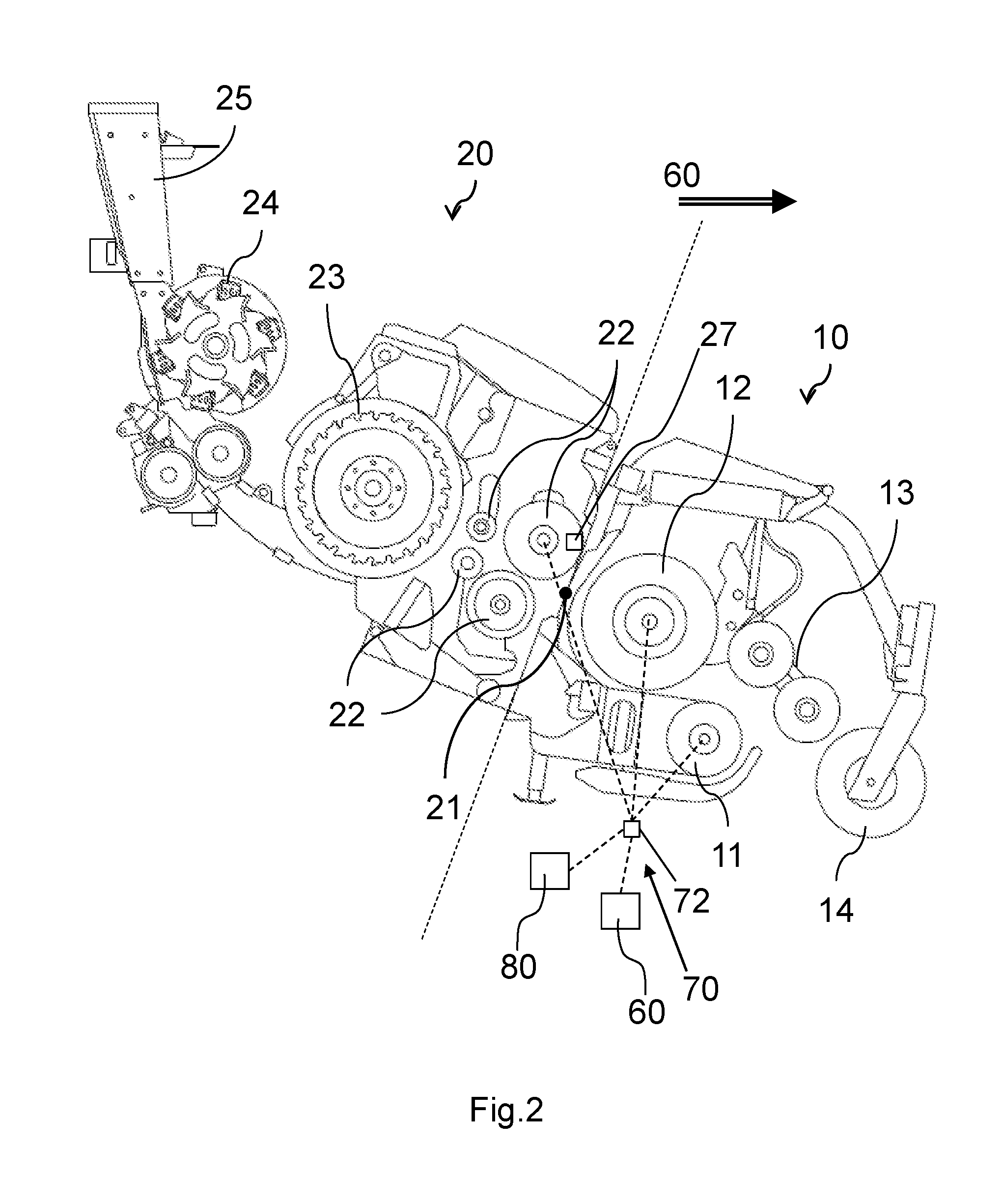

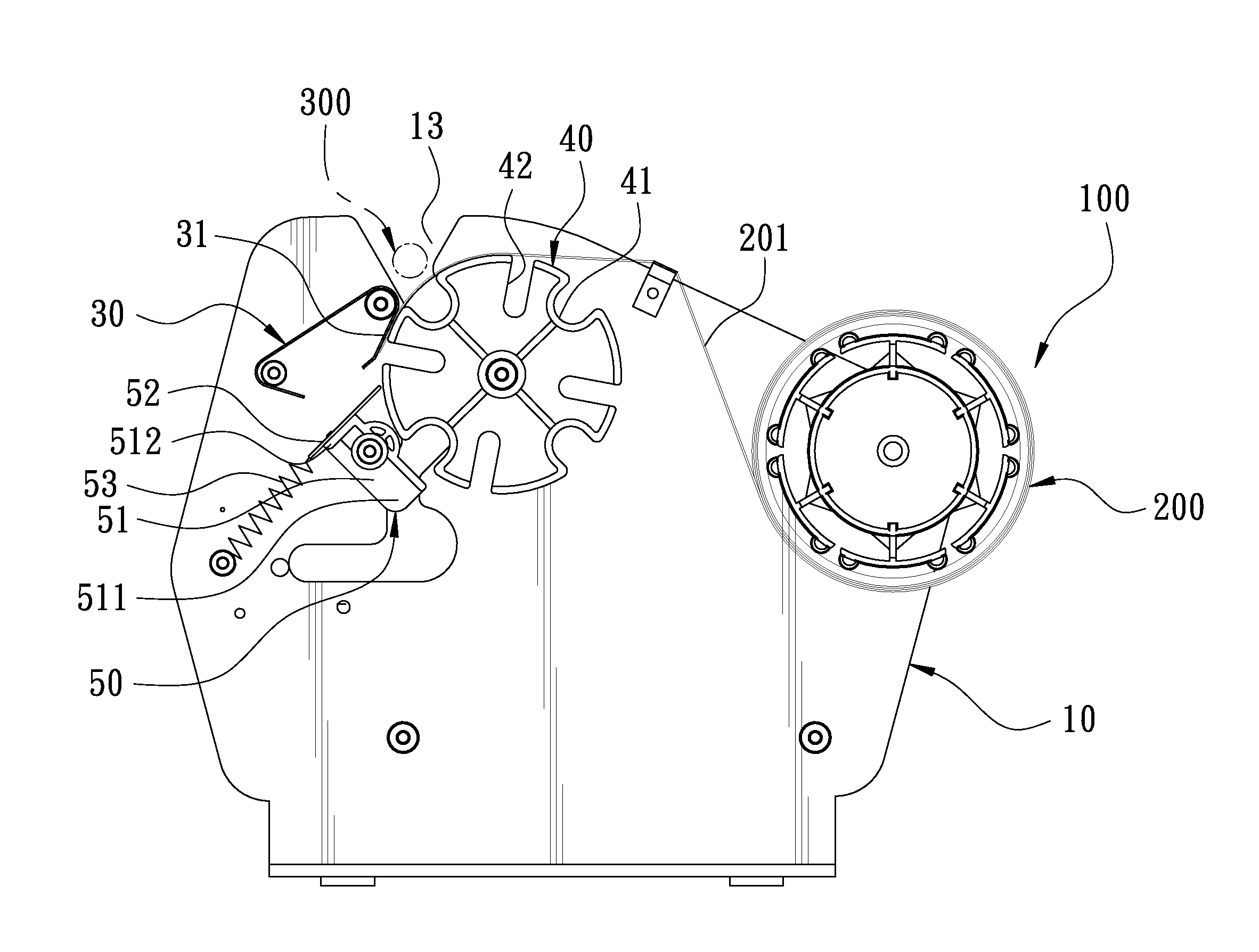

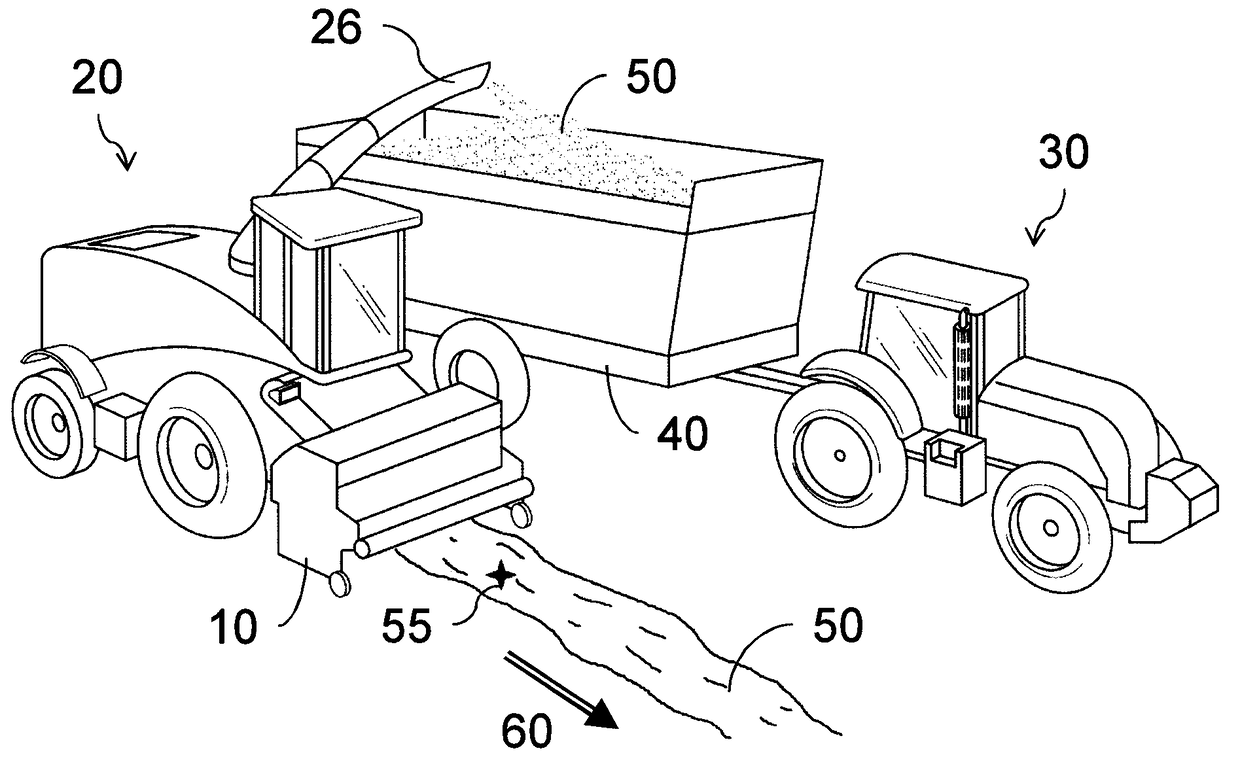

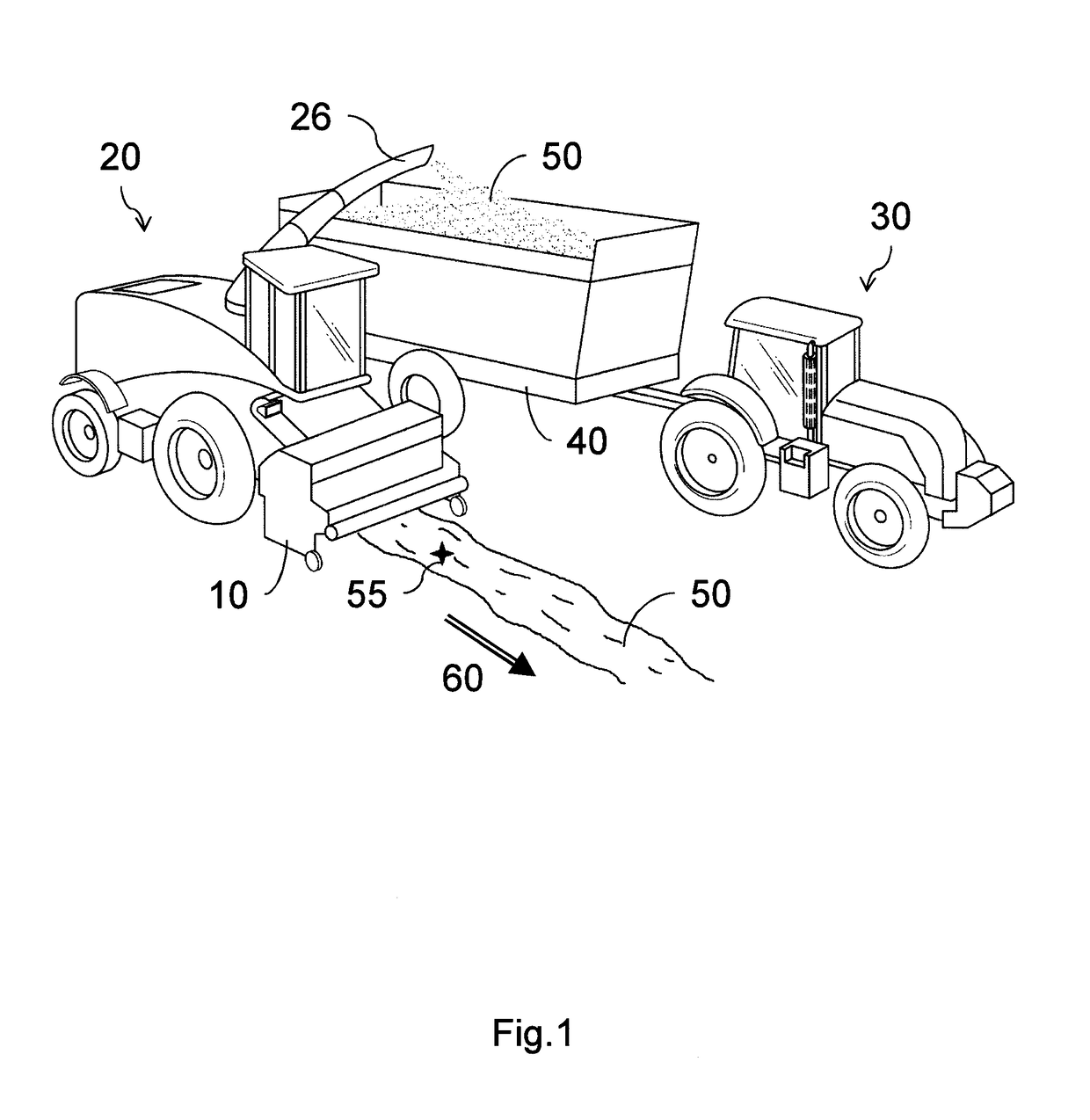

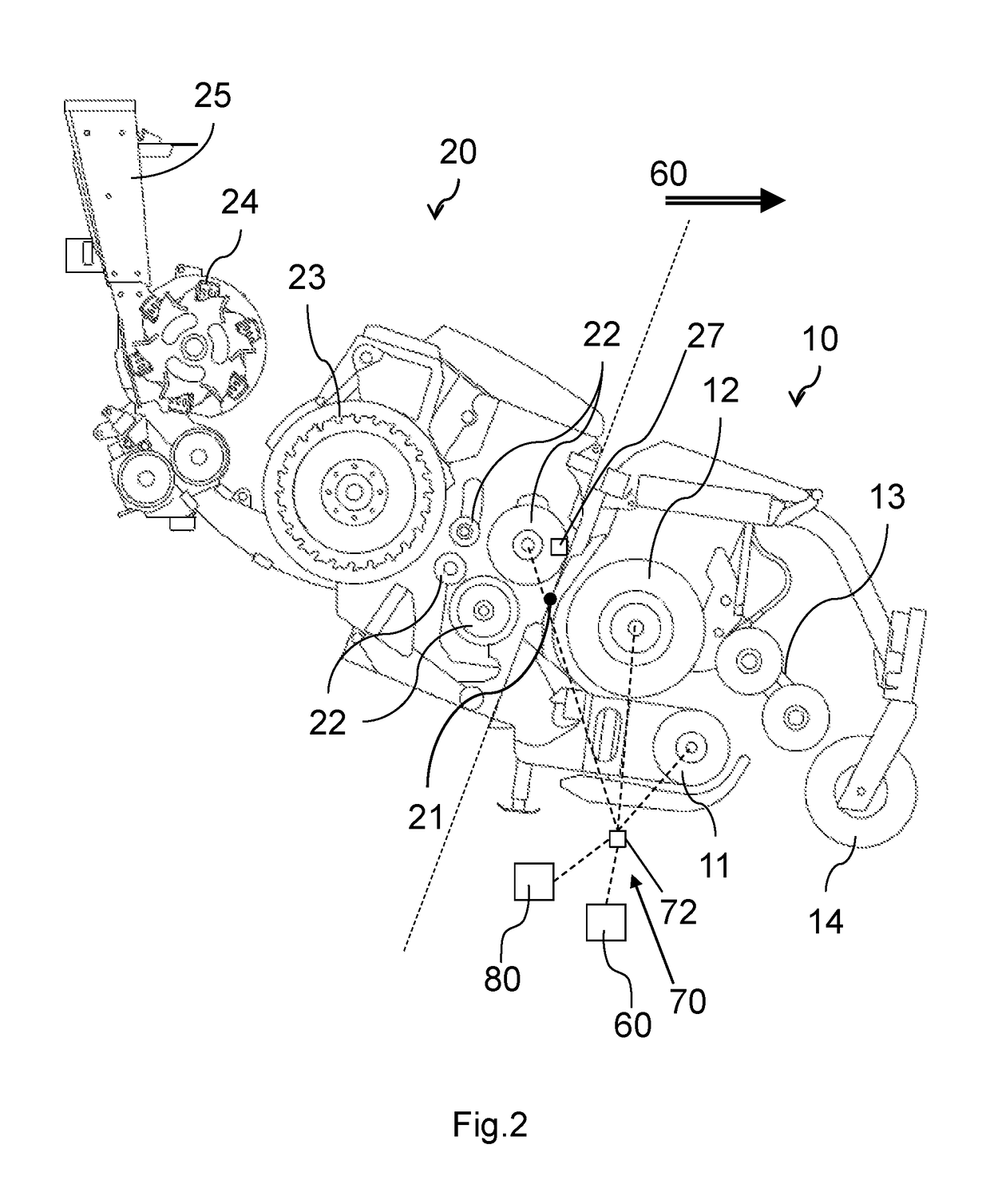

Crop Pick-Up, Agricultural Equipment and Method of Ejecting a Foreign Object

ActiveUS20160302360A1Protect fingersEasily be detected and ejectedLoadersHarvestersEngineeringAgriculture

A pick-up, an agricultural implement, and a method for ejecting a foreign object by the crop pick-up and the agricultural implement are provided. The agricultural implement comprises a crop inlet to collect picked-up crop. The crop pick-up comprises a reel with pick-up fingers to pick up the crop from the field, an auger to transport the picked-up crop to the crop inlet of the agricultural implement, and drive means. The drive means rotate the reel and the auger in a pick-up direction and a collection direction for picking up and transporting the crop, and a retrieval direction for retrieving already collected crop when a foreign object is detected in the collected crop. The crop pick-up further comprises ejection means to actively rotate the reel in an ejection direction for ejecting the retrieved crop.

Owner:BLUE LEAF I P INC

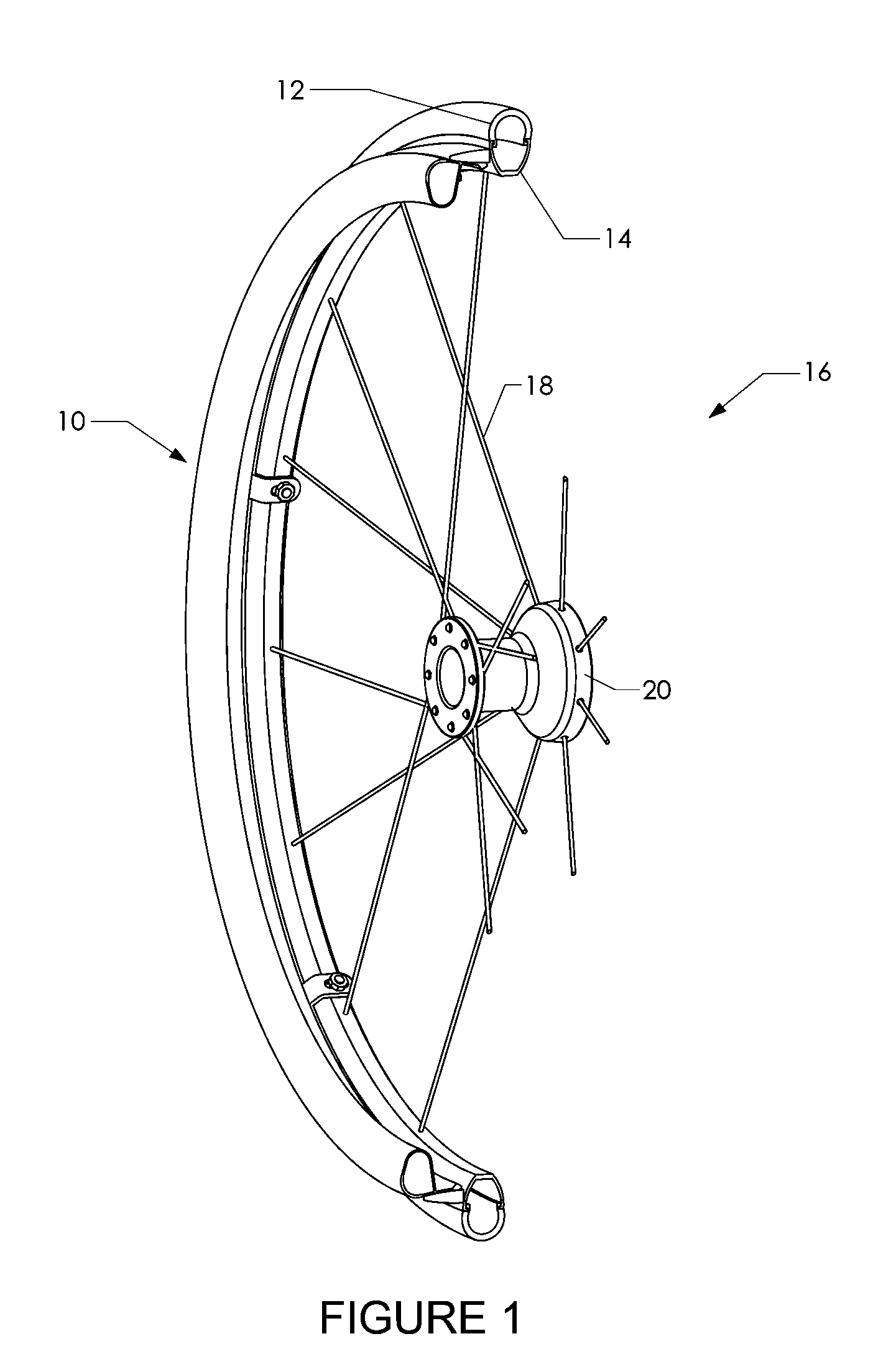

Adjustable wheelchair handrim with movable friction band

InactiveUS8770611B2Improve effectivenessImprove efficiencyControlling membersMechanical apparatusWheelchair handrimEngineering

An adjustable manual wheelchair handrim with a moveable elastomeric friction band. The position of the tubular handrim can be moved to a desired location relative to the wheel rim depending on the needs and limits of the user. The movable friction band is stretched around the drive surface of the handrim at a desired location preventing it from moving and providing increased frictional properties when gripped by the user during pushes. The friction band can be permanently affixed at a location to further prevent movement and slippage between the handrim and the friction band.

Owner:MAX MOBILITY

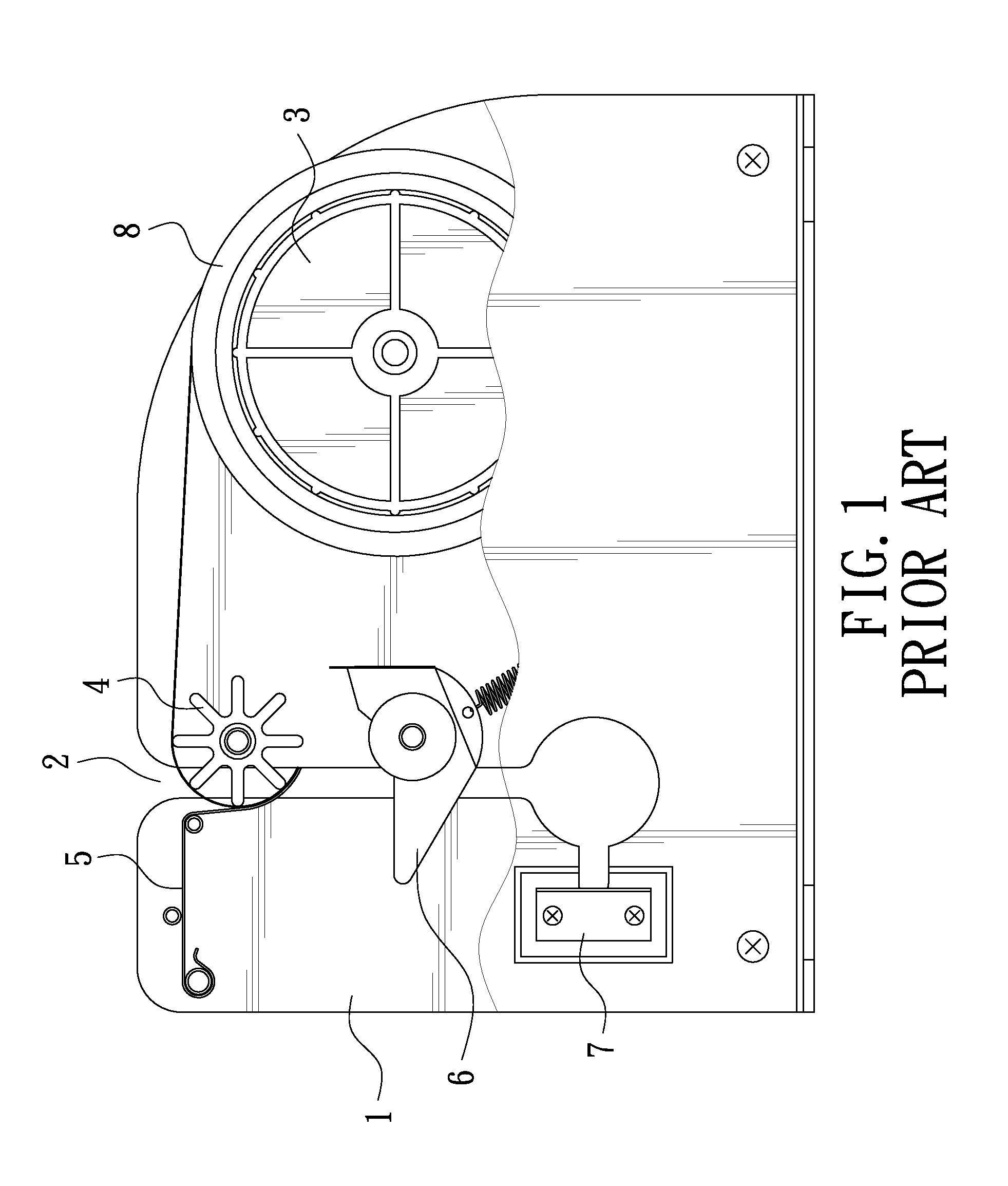

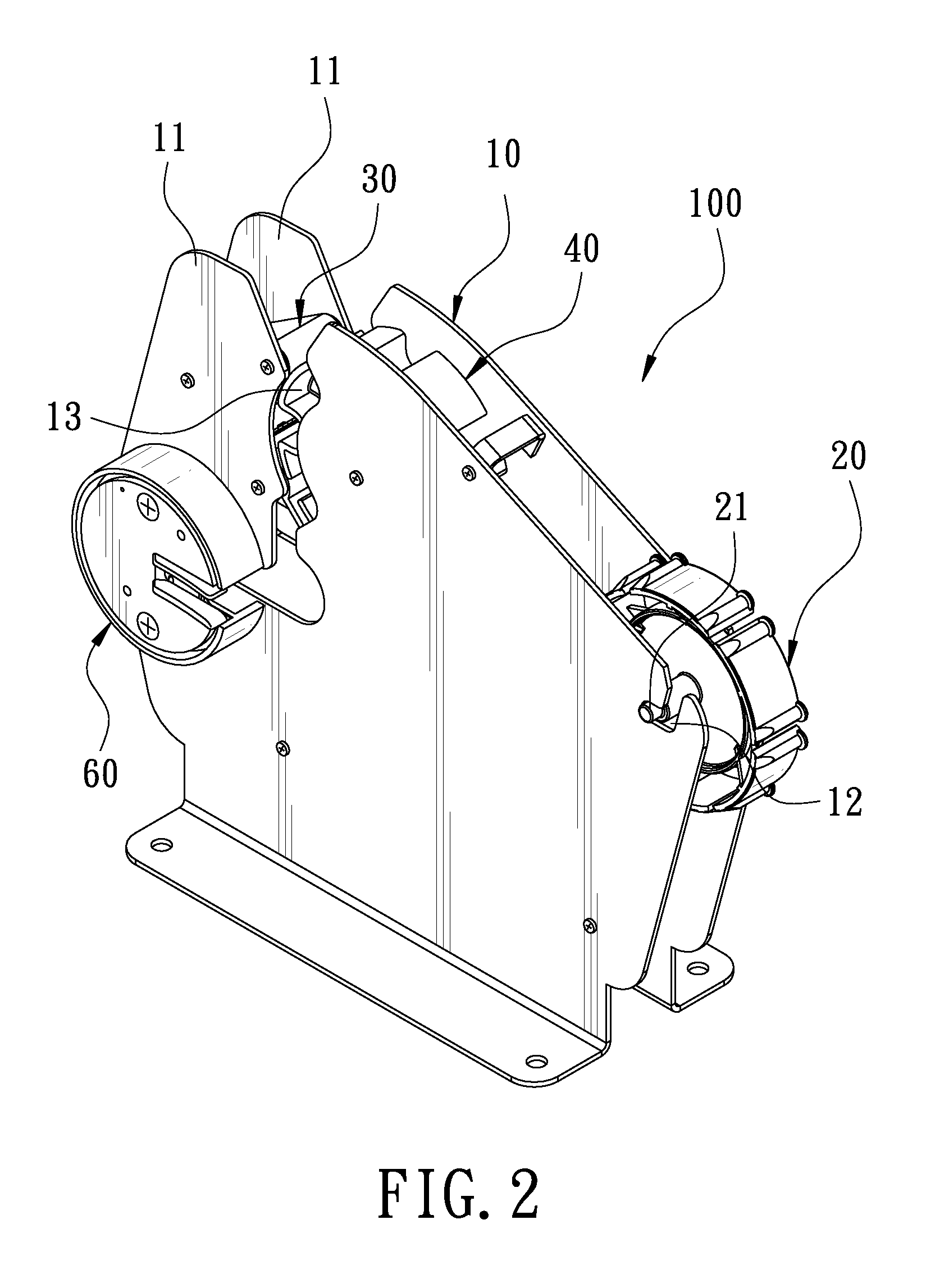

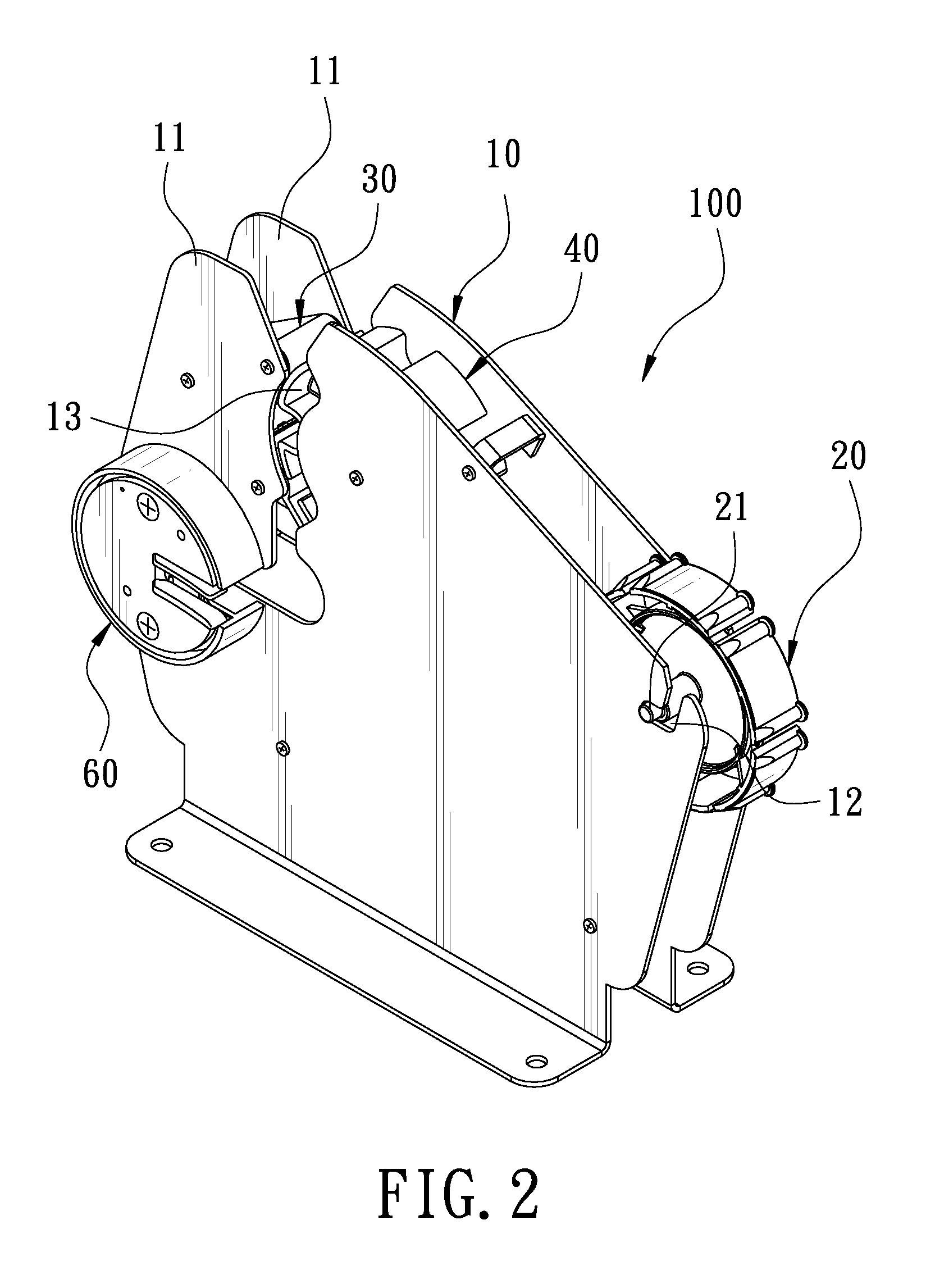

Bag neck sealer

ActiveUS20130160401A1Protect fingersAvoid finger injuryWrapper twisting/gatheringPackaging automatic controlEngineeringKnife blades

Owner:YU CHEN HSIU MAN

Protective boxing glove

The invention provides a protective boxing glove, comprising a glove body; an inner cavity capable of receiving a hand of a user is arranged in the glove body, the rear of the glove body is provided with an opening communicated with the inner cavity, the bottom of the glove body corresponding to the palm of the user is provided with a cylindrical grip body, a balloon layer is arranged in the inner cavity, the outer wall of the balloon layer is bonded to the inner wall of the inner cavity, the glove body has a through hole, an intake tube is arranged in the through hole and is communicated with the inside of the balloon layer, an end of the intake tube is provided with an air nozzle, and the air nozzle is arranged at the inner part of the through hole close to the surface of the glove body. The protective boxing glove has the advantages a fist of an athlete can be wrapped tightly, bruise in fingers caused in training is avoided, and fingers of the athlete are protected effectively.

Owner:天津市新泰丰泽科技有限公司

Device for finger protection in martial arts

A protection device for a holder of a martial arts board / target provides protection from direct impact and / or from the force / shock that is transmitted rearward to the hand and wrists of the holder of the board / target. The device receives the board / target holder's fingers, and a slanted floor inside the device urges the fingers into a generally curled or other inwardly-slanted position, and urges the rest of the hand, the wrist, and forearm into ergonomic and safer positions. The device is preferably made of material(s) in a particular hardness range that protects the user's fingers but that also prevents injury to the striker who is hitting / kicking the board / target. There are preferably no flanges or stops that limit placement of the device to particular places on the board, but rather the holder determines and controls the placement.

Owner:REDMOND STEVEN DOUGLAS +1

Device for finger protection in martial arts

A protection device for a holder of a martial arts board / target provides protection from direct impact and / or from the force / shock that is transmitted rearward to the hand and wrists of the holder of the board / target. The device receives the board / target holder's fingers, and a slanted floor inside the device urges the fingers into a generally curled or other inwardly-slanted position, and urges the rest of the hand, the wrist, and forearm into ergonomic and safer positions. The device is preferably made of material(s) in a particular hardness range that protects the user's fingers but that also prevents injury to the striker who is hitting / kicking the board / target. There are preferably no flanges or stops that limit placement of the device to particular places on the board, but rather the holder determines and controls the placement.

Owner:REDMOND STEVEN DOUGLAS +1

Bag neck sealer

ActiveUS8739500B2Protect fingersAvoid finger injuryWrapper twisting/gatheringPackaging automatic controlEngineeringKnife blades

Owner:YU CHEN HSIU MAN

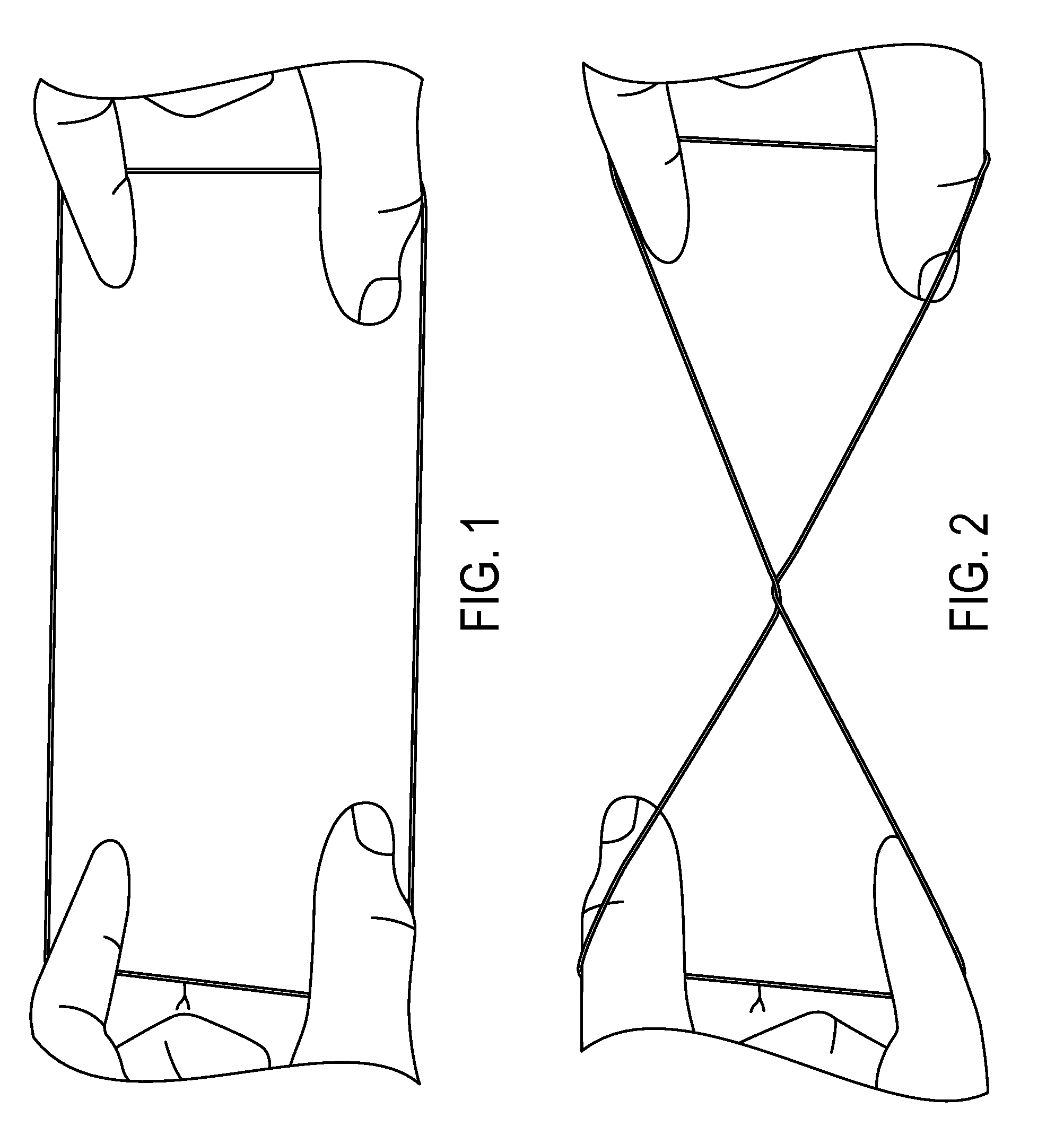

Hair threading apparatus and method

InactiveUS20160270459A1Barrier to frictionProtect fingersGarment special featuresFinger bandagesSkin exposureBiomedical engineering

A protective device for protecting the fingers of a user from cuts while hair threading is presented. The protective device has a guard configured to overlie at least a portion of a finger of a user. The thread for hair threading is wrapped around a portion of the guard so that the thread does not directly come into contact with the skin. The guard has an attachment member configured to maintain the thread in the desired position relative to the finger of the user.

Owner:MUELLER III MICHAEL

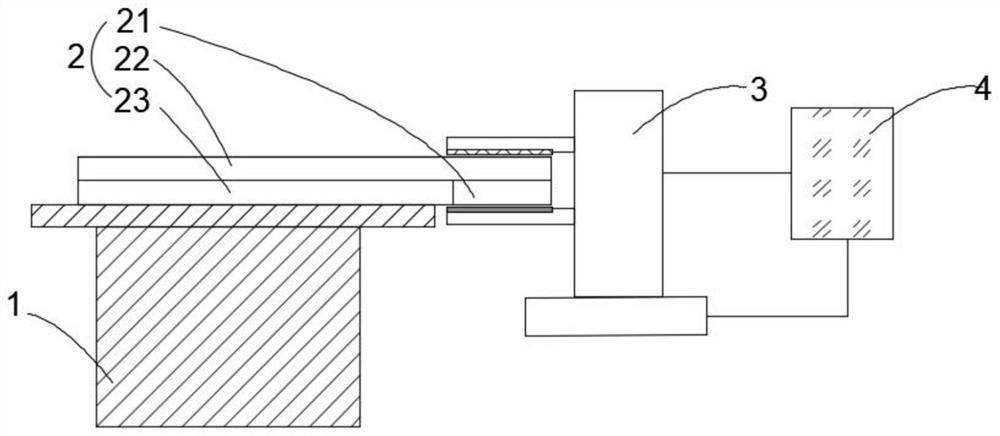

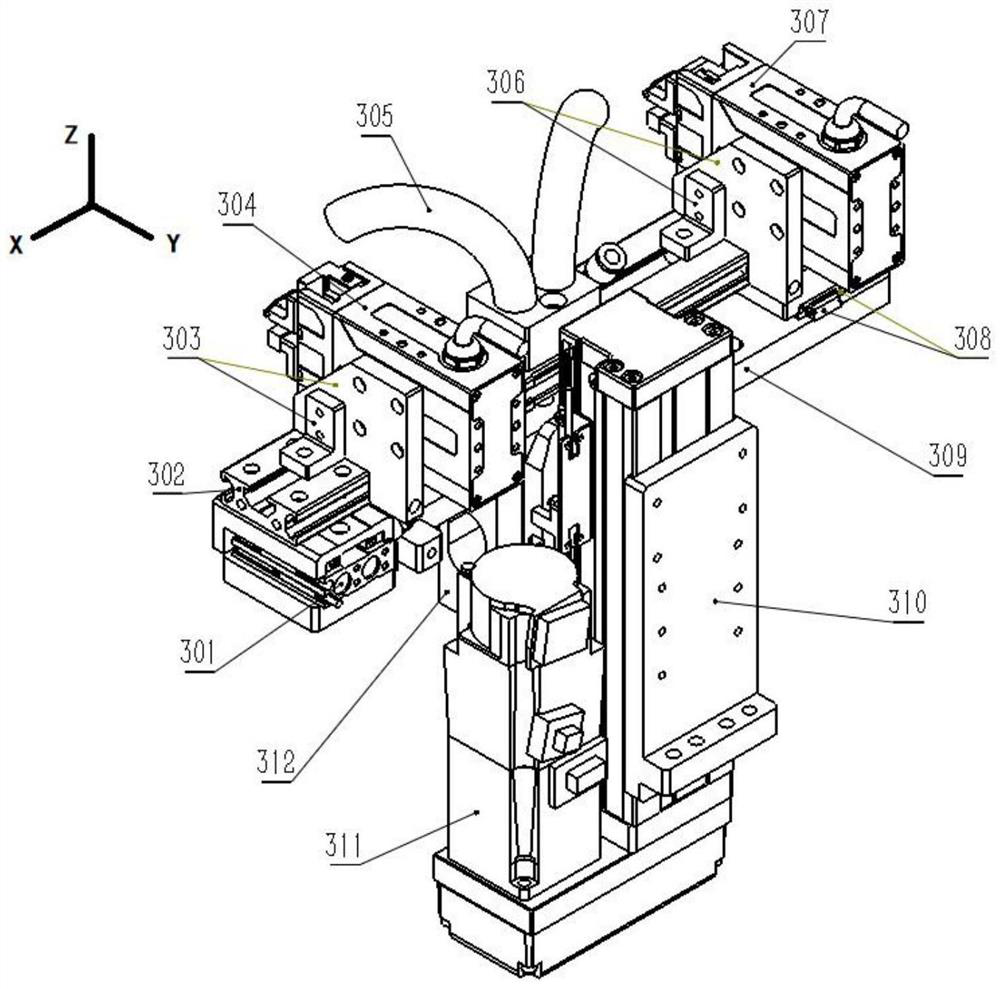

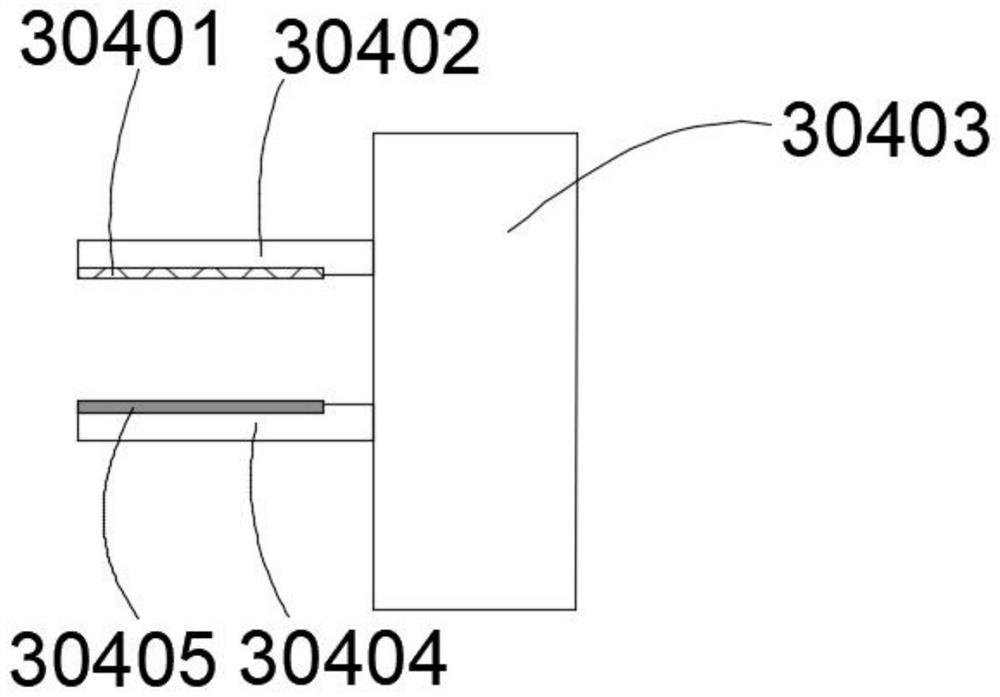

Residual material removing mechanism for liquid crystal panel

PendingCN114265222AIncrease productivityReduce fragmentationNon-linear opticsLiquid-crystal displayControl system

According to the technical scheme, the residual material removing mechanism is characterized in that the residual material removing mechanism comprises an objective table and a residual material removing assembly, the objective table is used for fixing the liquid crystal panel, and the objective table can be of a turnover platform or a robot arm or other structures; the residual material removing assembly removes residual materials on one side of a circuit layer of the liquid crystal panel through a clamping jaw assembly A. The clamping jaw assembly A moves in the Z-axis direction under dragging of the first module and moves in the Y-axis direction under dragging of the Y-axis controller. The upper clamping jaw and the lower clamping jaw drag the upper friction part and the lower friction part to clamp the residual material area of the liquid crystal display panel when relatively translating under the control of the servo control system, and can be suitable for the liquid crystal display panels with different thickness specifications; and under dragging of the Y-axis controller, different friction forces are generated on the upper surface and the lower surface of the liquid crystal panel residual material area, meanwhile, airflow with certain pressure is applied to the separation area through the air pipe, and therefore the cut liquid crystal panel residual materials are separated.

Owner:WUXI SHANGSHI ELECTRONICS TECH

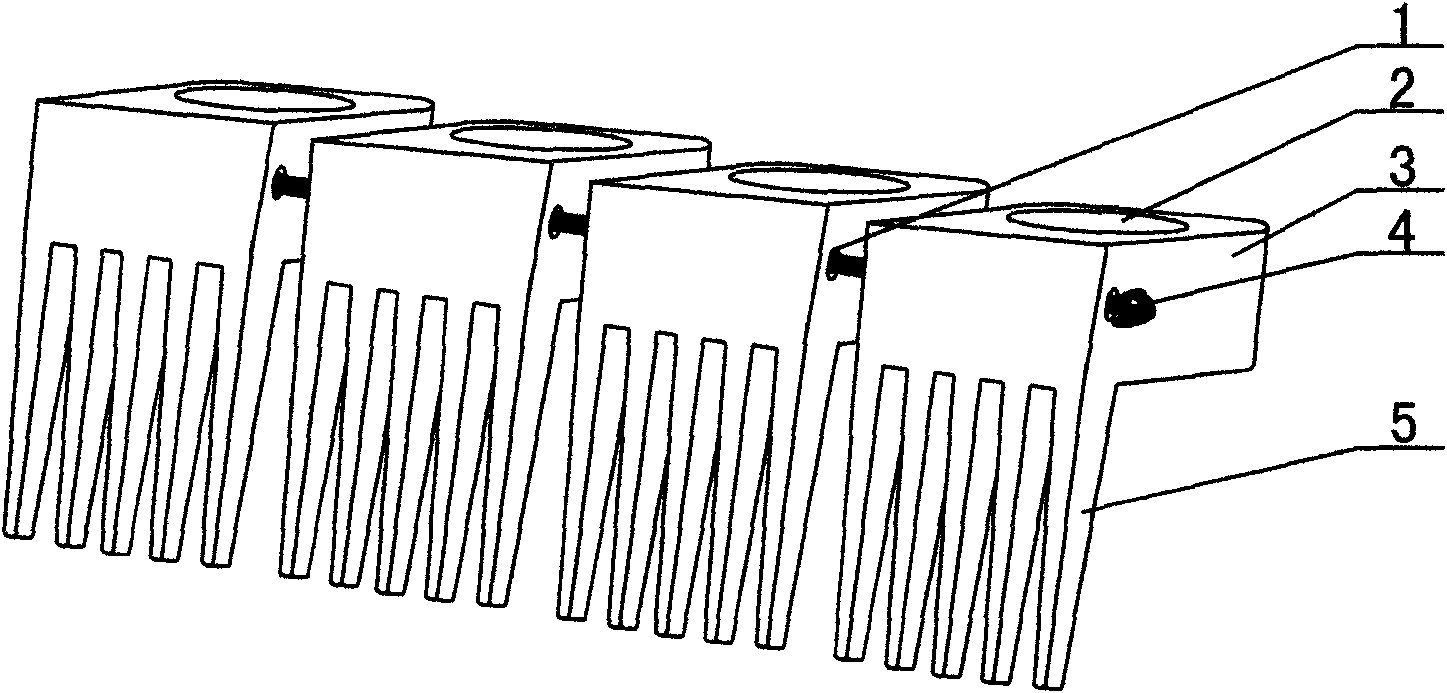

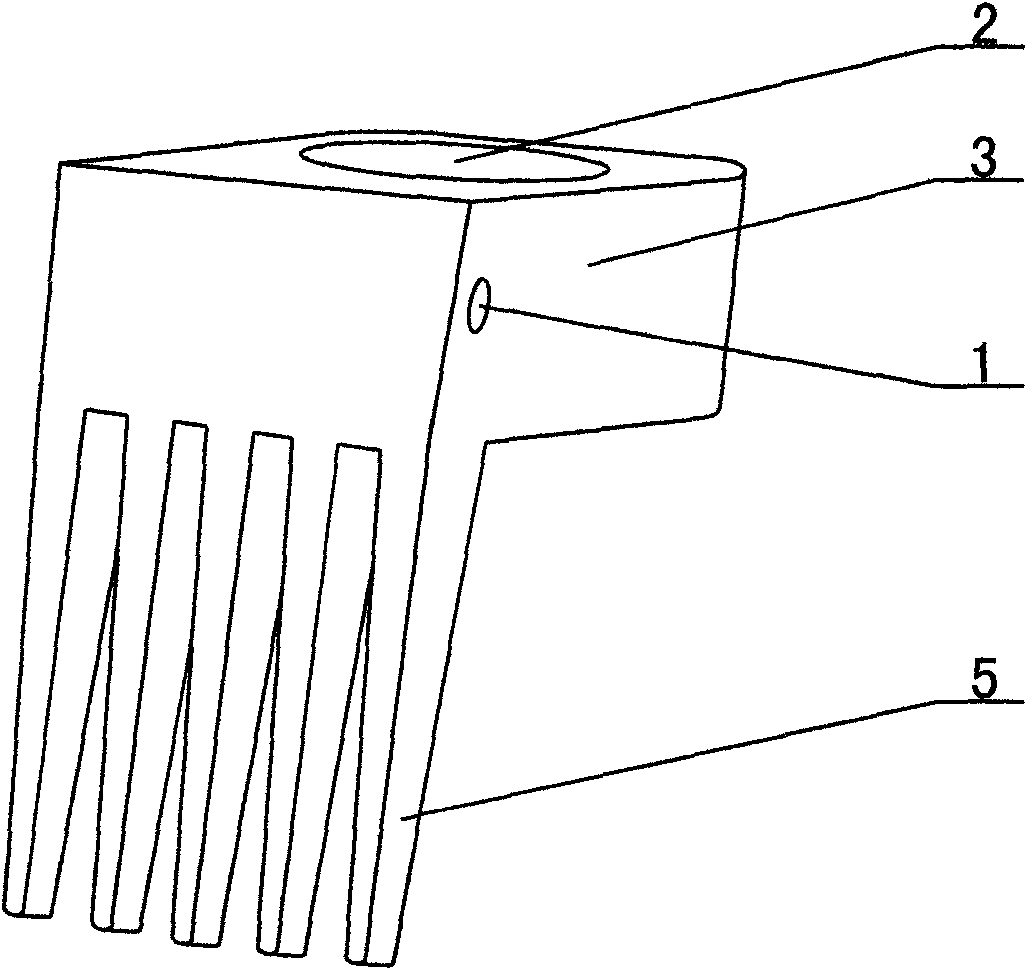

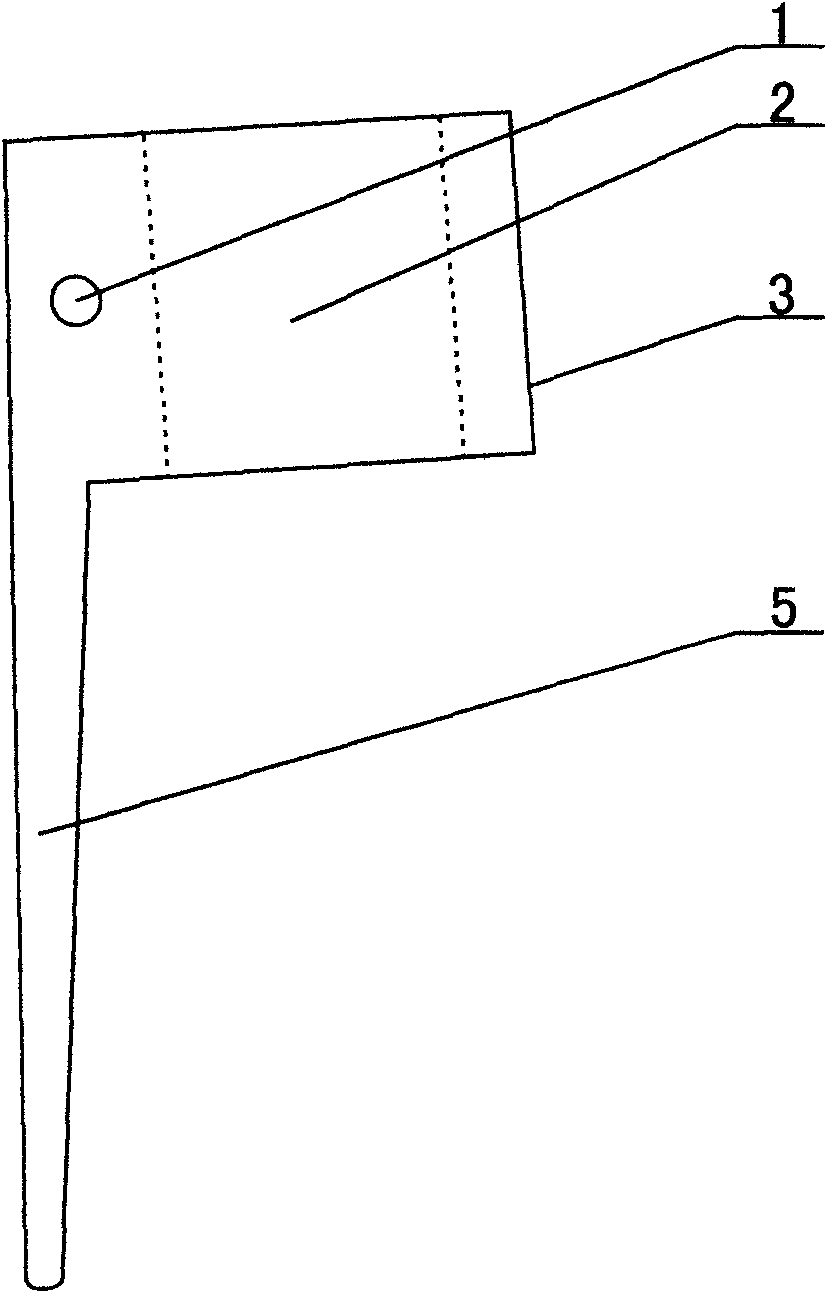

Finger comb

The invention relates to a comb, in particular to a finger comb. The front part of a finger sleeve (3) is a plane, the lower part of the front plane of the finger sleeve (3) is provided with a plurality of comb teeth (5) extended downwards, gaps are arranged between the comb teeth (5), the middle of the finger sleeve (3) is provided with a finger hole (2) which penetrates to the lower part of thefinger sleeve (3), and thereby the finger comb is formed; and through holes (1) of at least two finger combs are connected in series by a rubber band elastic (4) to form a rowed comb. A finger can beinserted into the finger hole of the finger sleeve of the finger comb, the number of the finger combs in use can be determined according to need, the head can be cleaned by the finger comb when beingwashed, or the finger comb also can be used as an itch scratcher after the comb teeth are lengthened, and in particular, the finger comb also can be utilized to scratch the itching back which the hands cannot reach.

Owner:HAIMEN HAIZHEN VACUUM EQUIP

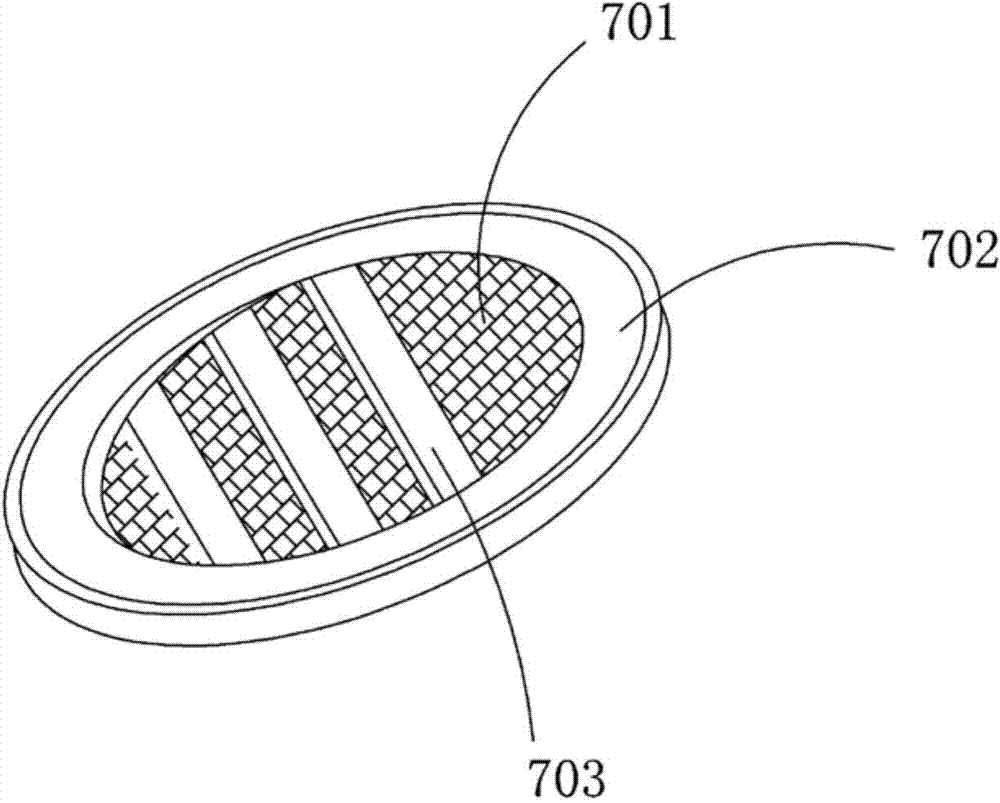

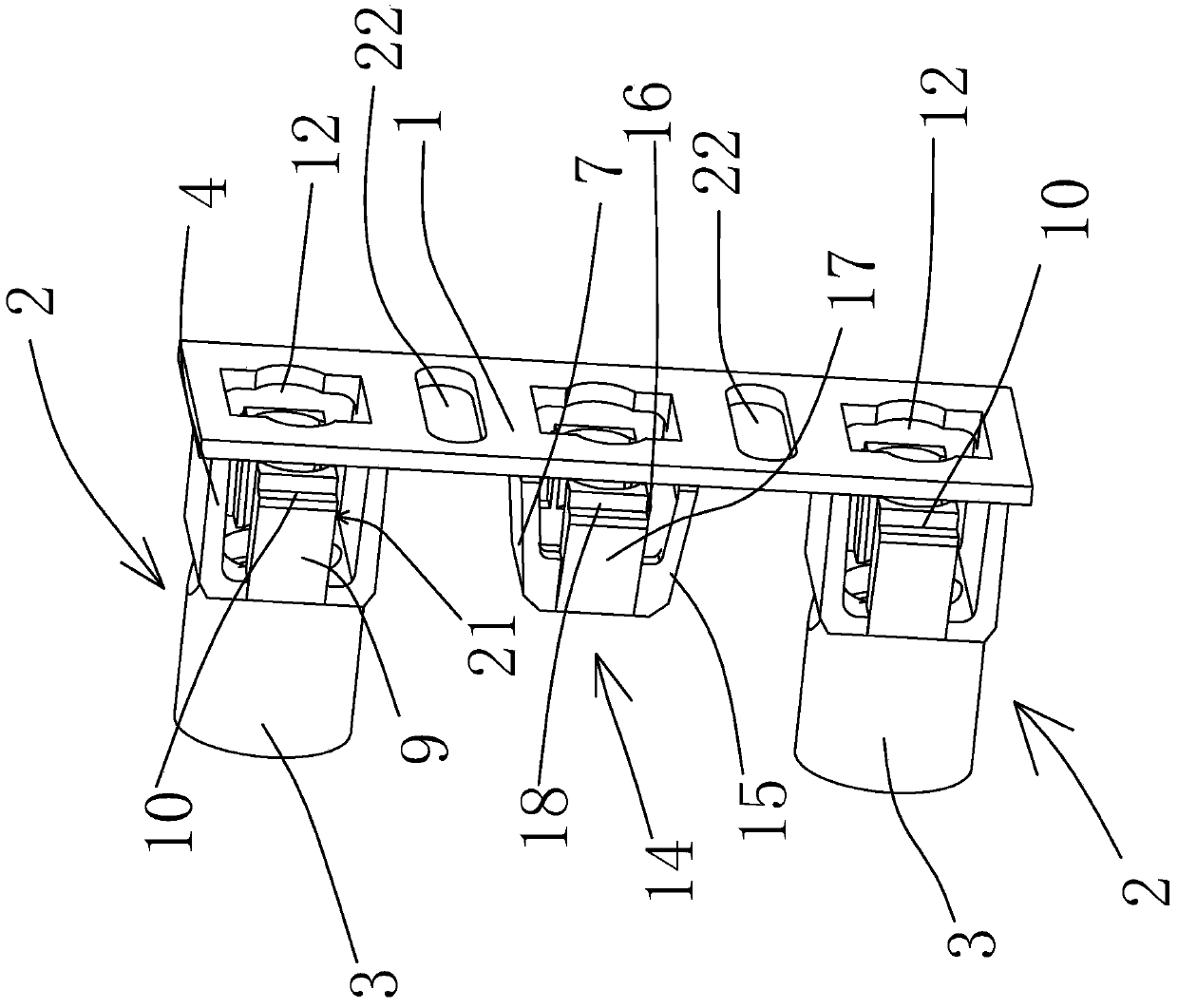

Half-finger tactical glove

InactiveCN103785161AIn line with the principles of ergonomic designComfortable to wearSport apparatusRubber ringEngineering

The invention relates to a half-finger tactical glove. The half-finger tactical glove comprises a glove body which comprises a finger portion, a palm portion, a hand back portion and a wrist portion, and the palm portion is covered with a leather layer; four protruding portions are arranged at the positions, corresponding to joints of the human body, of the hand back portion; the four-finger back portions of the finger portions are respectively connected with a breathable and waterproof device; each breathable and waterproof device comprises breathable cotton cloth and a hollow oval rubber ring, and partition strips are arranged inside each hollow oval rubber ring; a hook and loop fastener is arranged on the wrist portion; the wrist portion is provided with a nylon buckle making the glove be worn conveniently and rapidly; the leather layer is arranged on the palm portion in a sewn mode by adopting double threads; a leather layer a is further arranged on the front surface of the thumb portion of the finger portion in a sewn mode. The half-finger tactical glove is light, convenient to wear, flexible, and resistant to abrasion and cold, service life of the half-finger tactical glove is prolonged, and the half-finger tactical glove is more comfortable to wear, achieves comprehensive protection, can be used for multiple industries of military training, fitness, riding and the like, and is applicable to different people and wide in application range.

Owner:HUZHOU LINGHU ZHONGZHAO JINHUI SILK WEAVING FACTORY

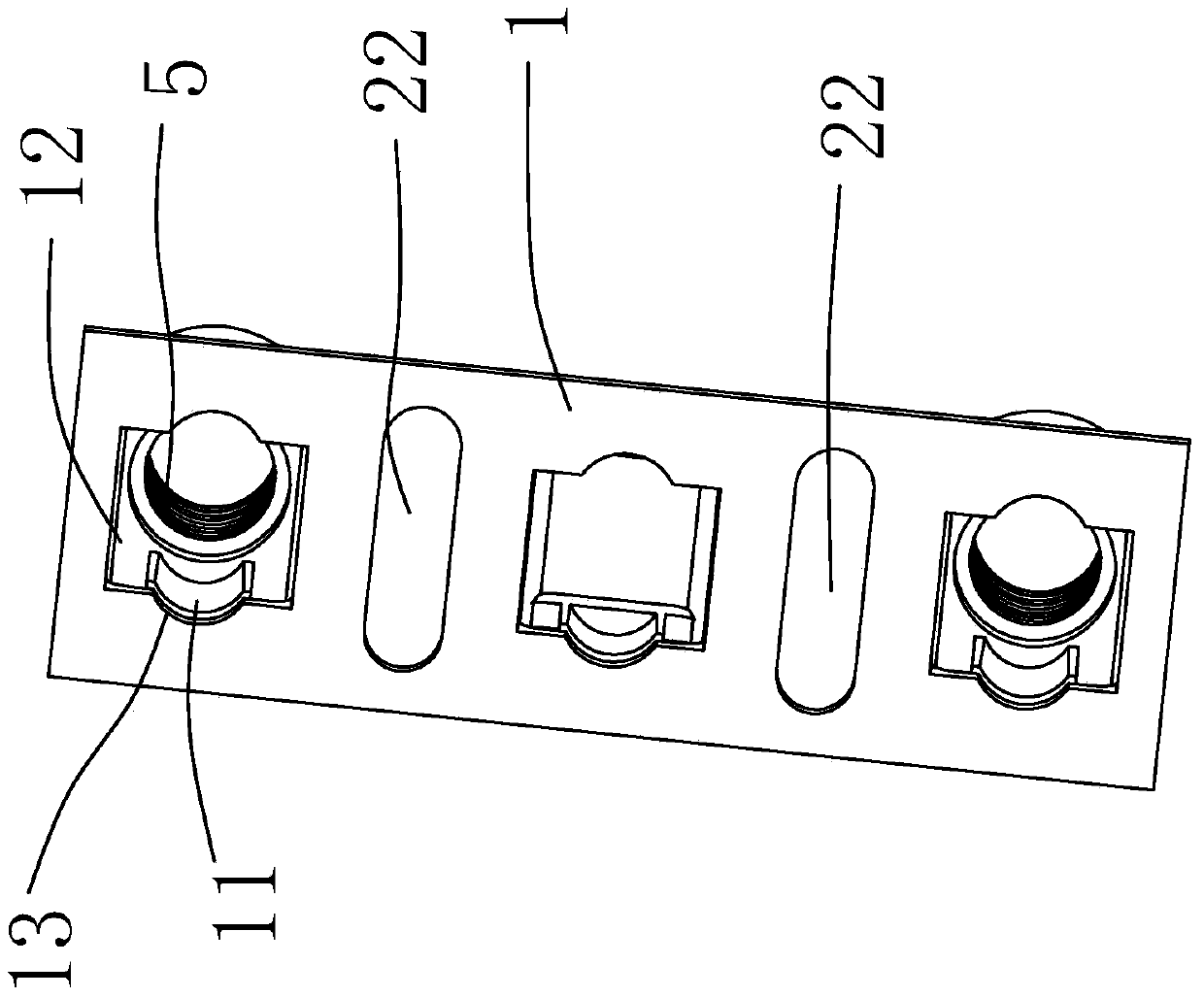

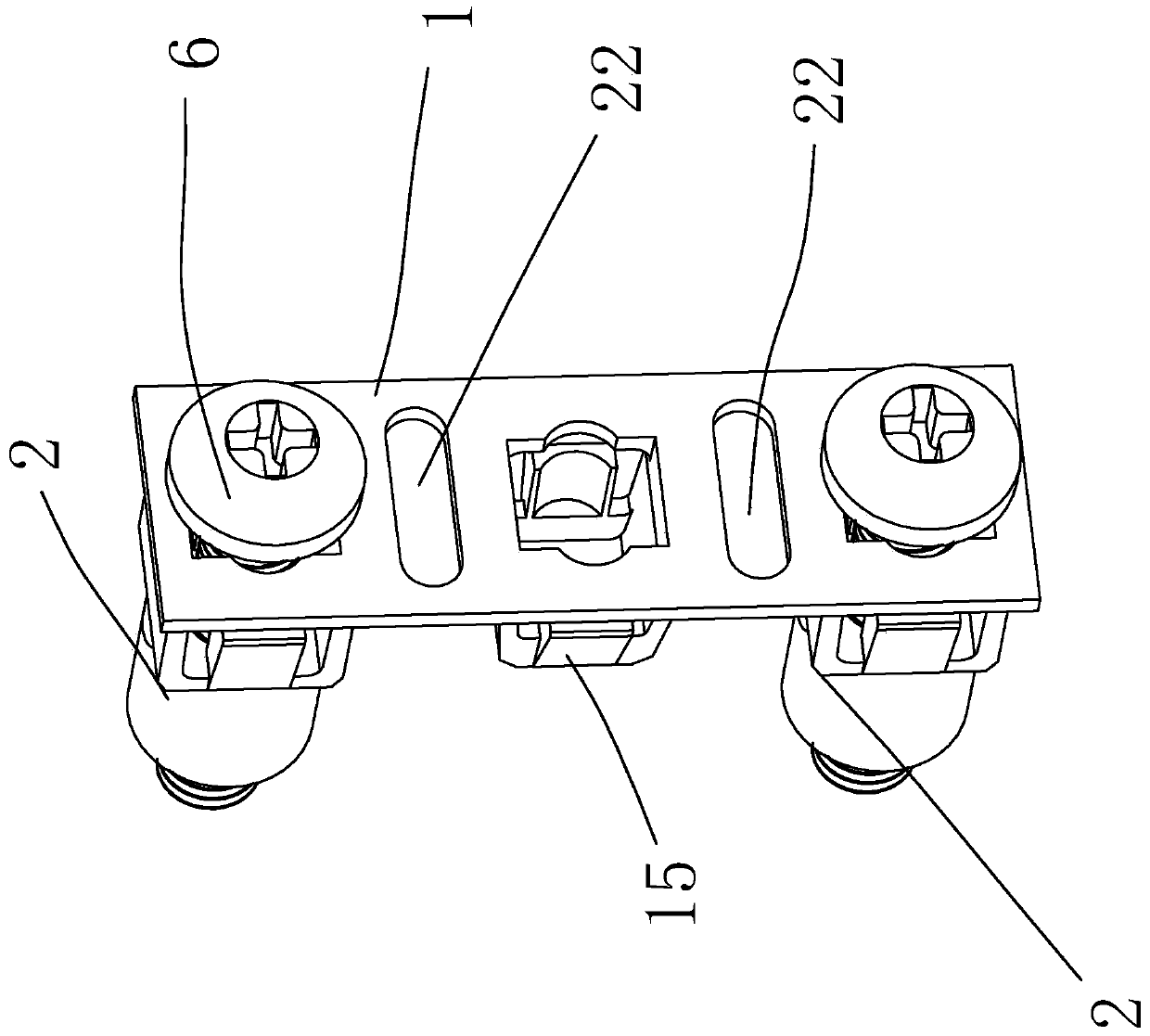

A rack connection accessory and its distribution frame

ActiveCN106028178BImprove convenienceNo damageSelection arrangementsDistribution frameMechanical engineering

Owner:ZHEJIANG SHIP ELECTRONICS TECH

High-comfort computer chair

InactiveCN112890487AImprove comfortAvoid discomfortStoolsAdjustable chairsEngineeringMechanical engineering

The invention relates to the technical field of computer chairs, and discloses a high-comfort computer chair, the upper side of a chair cushion is fixedly provided with two screws, the two screws are both sleeved with supporting plates in a threaded mode, some people like to curl legs on the chair to use a computer, and when a user needs to curl the legs, the user can curl the legs by supporting the supporting plates on the left side and the right side with two hands. When the supporting plates are supported by hands, the two triggering strips are moved upwards by fingers, so that the two triggering ropes are driven to move upwards, the two rotating plates can be driven to rotate in the directions away from each other through supporting of the two rotating columns, and the two supporting plates can be driven to move downwards when the two supporting plates are supported; meanwhile, through the two screw rods, the two supporting plates can rotate in the direction away from each other while moving downwards, so that enough space can be provided for the two legs of the user, the situation that the two supporting plates can prevent the two legs of the user from being curled is avoided, and the discomfort of the user is avoided.

Owner:山东鲁南大数据产业发展有限公司

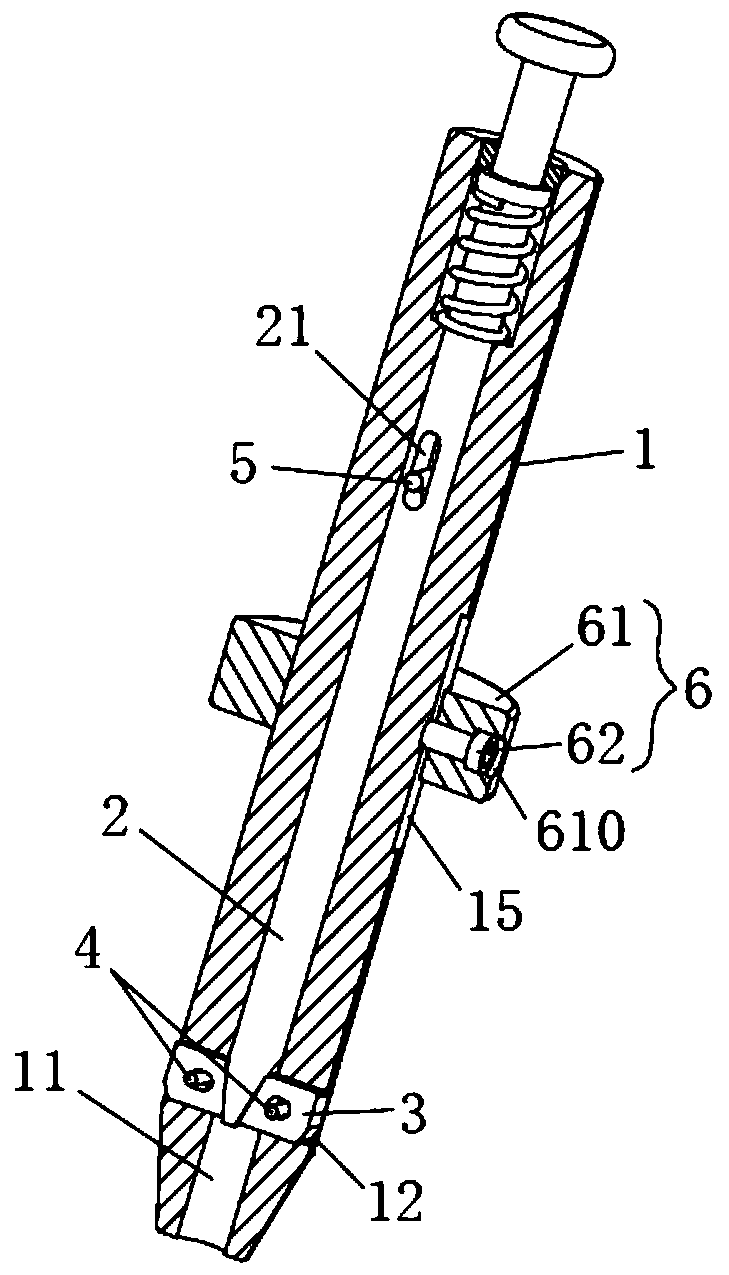

An energy-saving rice cooker

ActiveCN113261842BAvoid direct contactProtect fingersCooking insertsAgricultural engineeringStructural engineering

The invention relates to the technical field of electric cookers, in particular to an energy-saving electric cooker, comprising a pot body, a pot cover and an inner pot; an inner pot cover and a handle; the inner wall of the pot is provided with an annular groove; The upper end surfaces of the pot body are connected, and the inner part of the annular groove is slidably connected to the inner pot sleeve; the inner pot is nested inside the inner pot sleeve, and two rectangular grooves are symmetrically arranged on the outer wall of the inner pot sleeve; A connecting hole is symmetrically arranged on the wall of each groove, and a rotating shaft is connected between the two connecting holes; a handle is rotatably connected to the rotating shaft; in the present invention, the temperature of the inner liner is relatively high and the temperature of the inner liner needs to be reduced by setting the inner tank cover and the handle. When the pot is taken out, the handle is manually lifted and the inner pot is taken out under the drive of the inner pot cover, which avoids the direct contact between the operator's fingers and the inner pot, protects the operator's fingers, and reduces the risk of the operation. Simplified operation, convenient and fast.

Owner:江门市南光电器实业有限公司

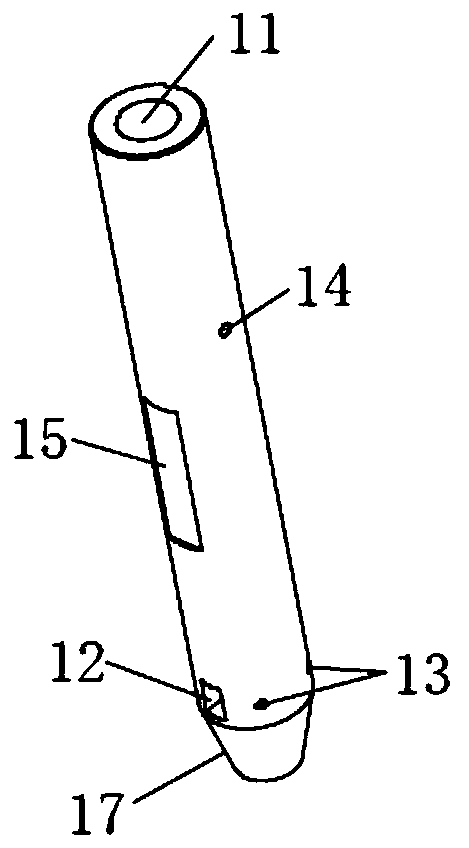

Honing material taking device and material taking method thereof

ActiveCN110524405ACause some damagesExtended service lifeHoning machinesGrinding feedersHoning oilEngineering

The invention discloses a honing material taking device and a material taking method thereof, and belongs to the technical field of honing machining. The honing material taking device comprises a cylindrical shell; a center hole penetrating through the shell in the axis direction of the shell is formed in the shell, and at least one sliding block mounting hole penetrating through the center hole in the radial direction is formed in the lower portion of the shell; sliding blocks with the number same as that of the sliding block mounting holes are movably mounted in the sliding block mounting holes; a movable push rod is inserted into the center hole and is movably connected with the shell; the movable push rod is pushed to the lower end of the shell along the center hole, and the movable push rod extrudes the sliding blocks to enable the sliding blocks to slide outwards along the sliding block mounting holes and protrude out of the shell. During material taking, the honing material taking device is inserted into a workpiece, the upper end of the movable push rod is pressed, the sliding blocks are extruded out through the movable push rod and abut against the inner wall of the workpiece, and therefore the workpiece is taken out of a honing clamp. According to the honing material taking device, the honing material taking device is used for replacing finger material taking of workers, the operation is easy, safe and labor-saving, efficiency is high, and honing oil cannot be polluted.

Owner:安徽多邦珩磨技术有限公司

Sharpening tool

ActiveUS9004986B2Easy to useProtect fingersRevolution surface grinding machinesCutting toolsEngineeringMechanical engineering

A portion of the sharpener handle is recessed to receive the curved blade of a lopper. The cutaway allows the sharpening element to sharpen the lopper blade along its entire length. Additional sharpening elements can be positioned along the handle to provide a multipurpose sharpening tool.

Owner:LOCAN PROPERTIES

Chalk clamp

InactiveCN105620097AIncrease profitProtect fingersBoard cleaning devicesWriting connectorsBiomedical engineering

The invention relates to a chalk clamp. The chalk clamp comprises a chalk clamp, a sleeve and an eraser; the sleeve is connected with the chalk clamp through a sleeving mode; and the eraser is connected with the chalk clamp through a clamping mode. The chalk clamp can improve the chalk utilization rate, protects fingers and skin, and is convenient and simple in use.

Owner:青岛讯达捷电子科技有限公司

Crop pick-up, agricultural equipment and method of ejecting a foreign object

ActiveUS9936642B2Easily be detected and ejectedShorten the timeLoadersHarvestersEngineeringAgriculture

A pick-up, an agricultural implement, and a method for ejecting a foreign object by the crop pick-up and the agricultural implement are provided. The agricultural implement comprises a crop inlet to collect picked-up crop. The crop pick-up comprises a reel with pick-up fingers to pick up the crop from the field, an auger to transport the picked-up crop to the crop inlet of the agricultural implement, and a driver. The driver rotates the reel and the auger in a pick-up direction and a collection direction for picking up and transporting the crop, and a retrieval direction for retrieving already collected crop when a foreign object is detected in the collected crop. The crop pick-up further comprises an ejector to actively rotate the reel in an ejection direction for ejecting the retrieved crop.

Owner:BLUE LEAF I P INC

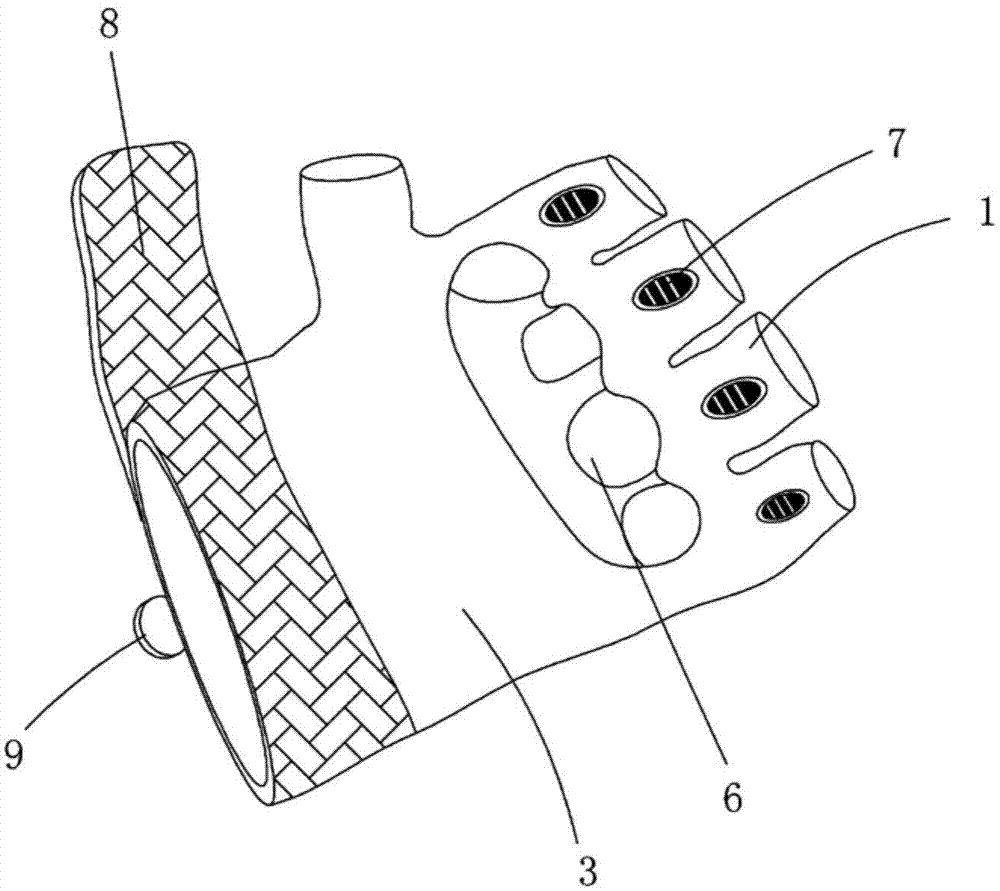

Device for finger and hand protection in martial arts

ActiveUS10632361B2Avoid injuryProtect fingersCombat sportsMulti-purpose toolsPhysical medicine and rehabilitationHand parts

A protection device for a holder of a martial arts board / target provides protection from direct impact and / or from the force / shock that is transmitted rearward to the hand and wrists of the holder of the board / target. The device receives the board / target holder's fingers, and a slanted floor inside the device urges the fingers into a generally curled or other inwardly-slanted position, and urges the rest of the hand, the wrist, and forearm into ergonomic and safer positions. The device is preferably made of material(s) in a particular hardness range that protects the user's fingers but that also prevents injury to the striker who is hitting / kicking the board / target. There are preferably no flanges or stops that limit placement of the device to particular places on the board, but rather the holder determines and controls the placement.

Owner:REDMOND STEVEN DOUGLAS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com