Adjustable wheelchair handrim with movable friction band

a technology of handrims and friction bands, which is applied in the direction of mechanical control devices, instruments, process and machine control, etc., can solve the problems of increased deceleration, increased friction between hands and handrims, and high occurrence of upper extremity injuries, so as to reduce slippage and the needed gripping force, improve the effect of user pushes, and reduce the required gripping force during propulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

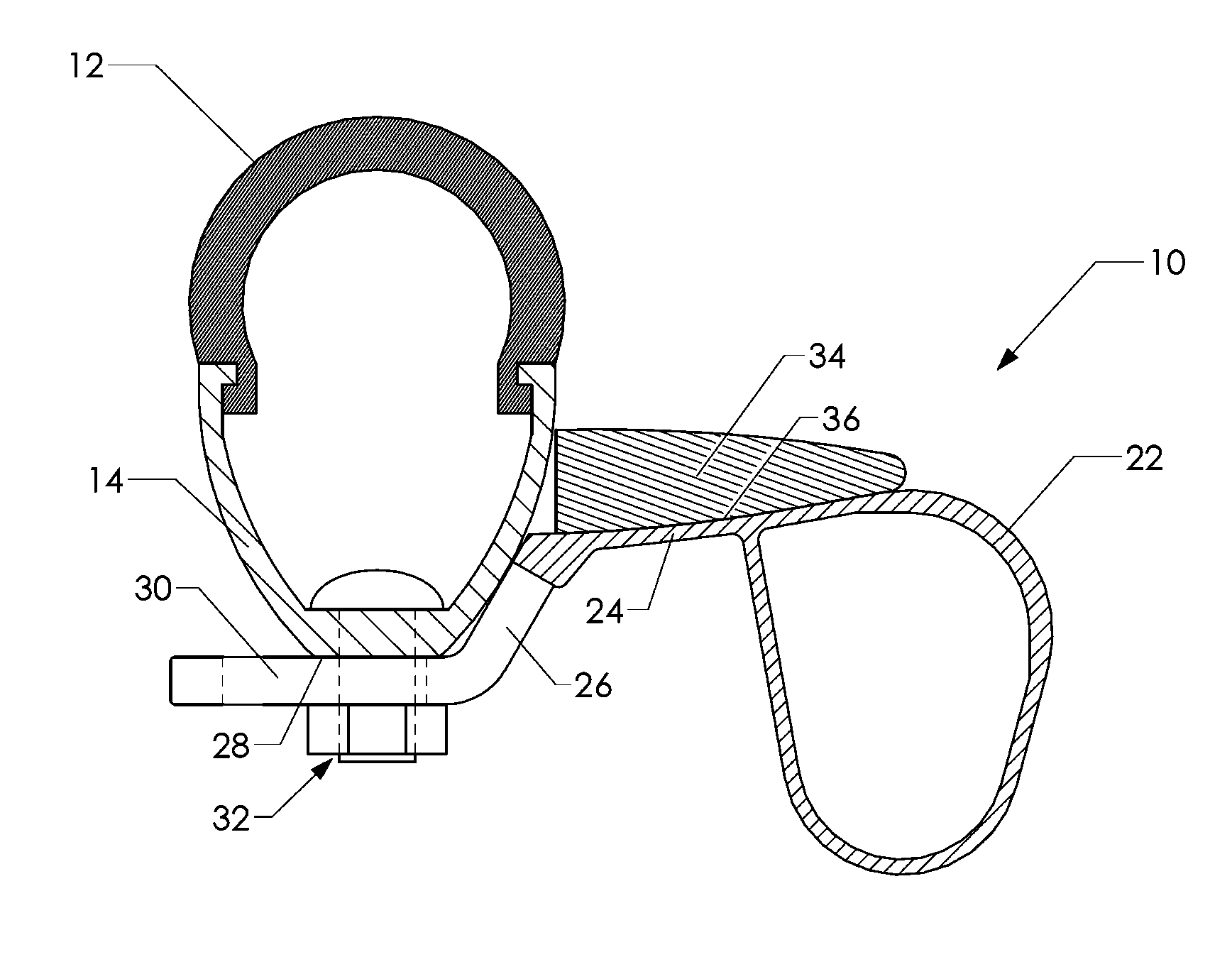

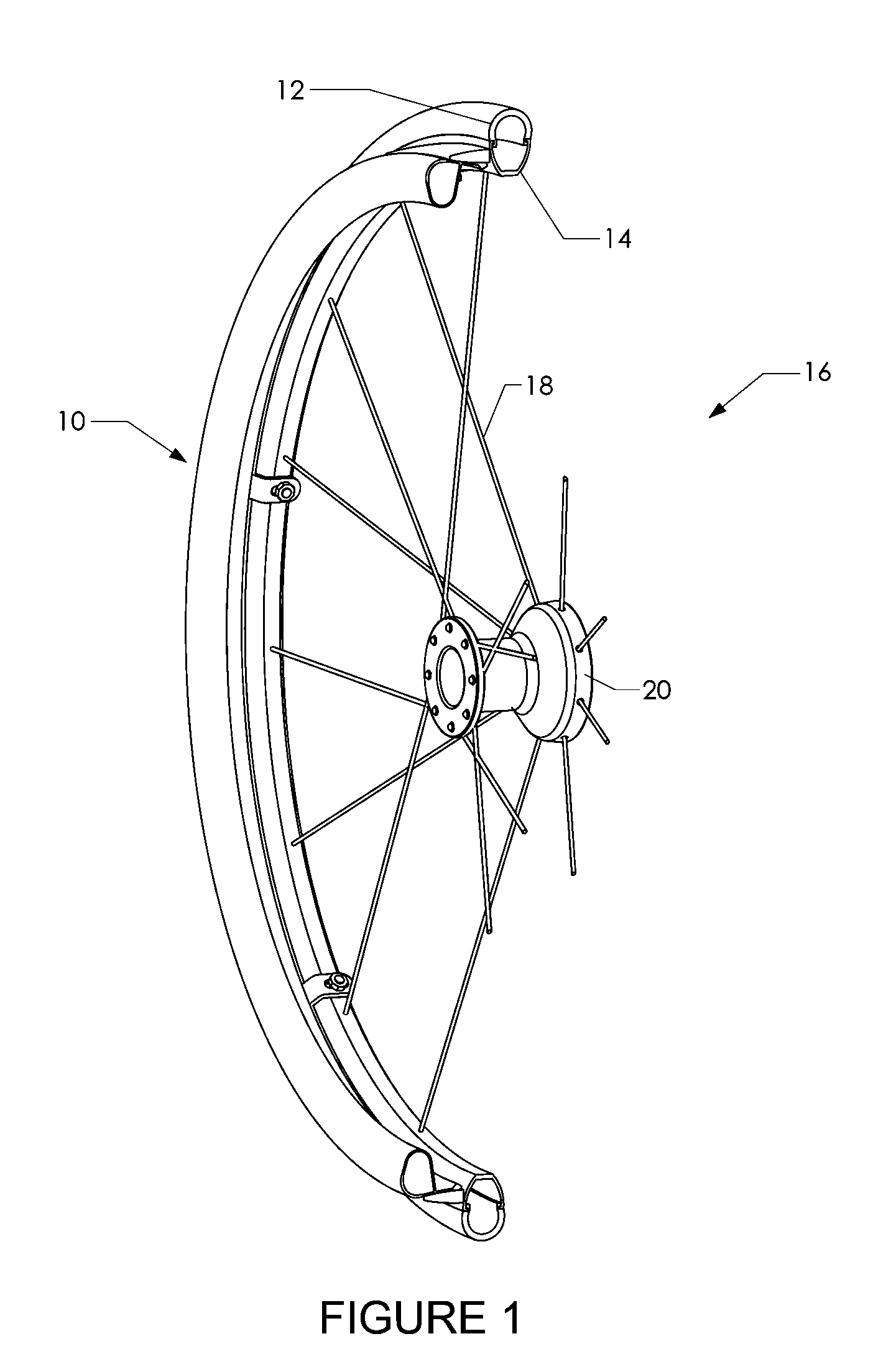

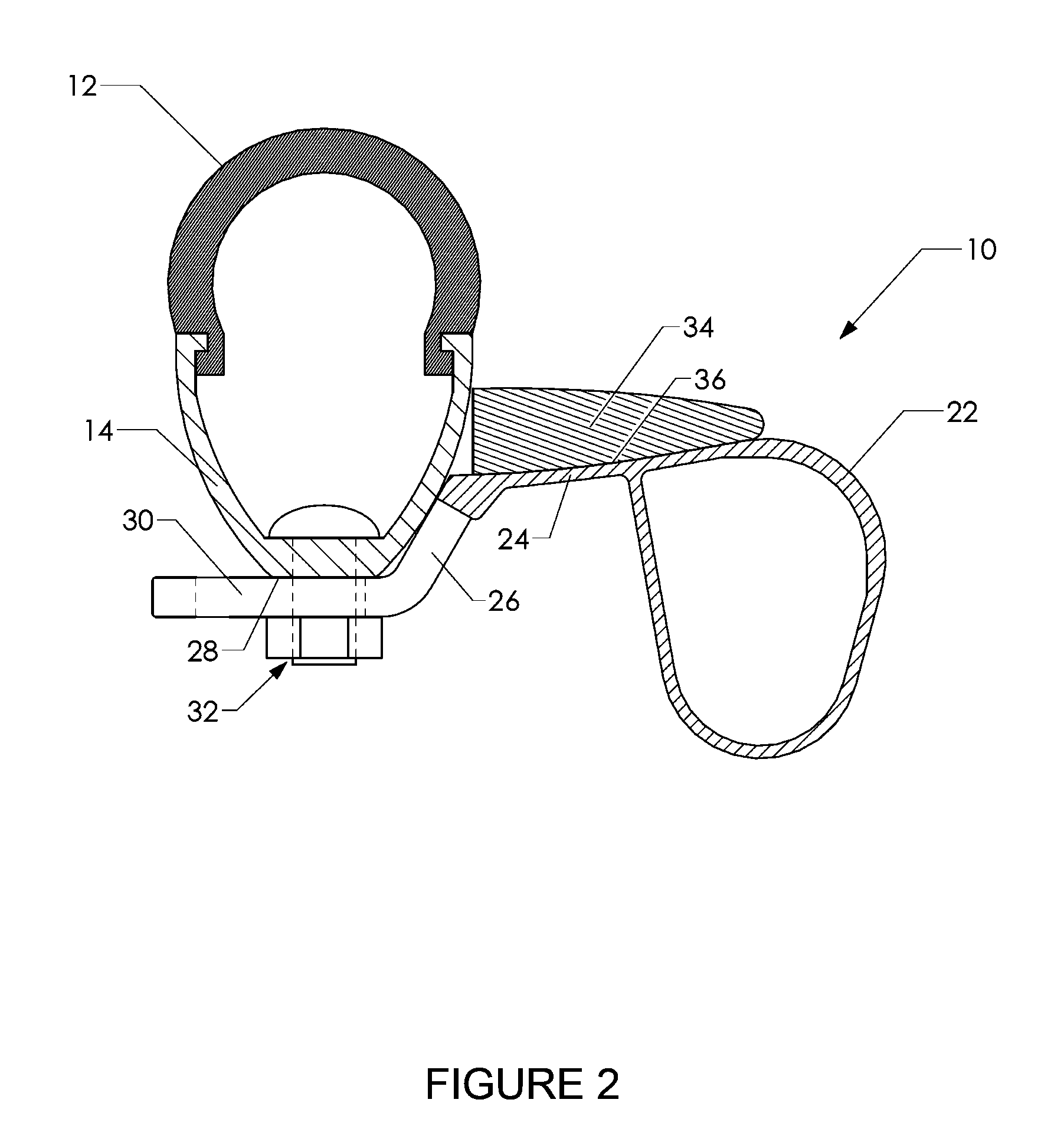

[0023]In one exemplary embodiment, as shown in FIG. 1, the present invention comprises an adjustable wheelchair handrim with movable friction band 10 that a wheelchair user can use to propel their manual wheelchair. The adjustable wheelchair handrim with movable friction band 10 mounts to a standard wheelchair wheel rim 14 that is subsequently connected to the tire 12. The assembly of the aforementioned parts, with additional spokes 18 and a wheel hub 20, comprise a typical manual wheelchair wheel 16, where the user can grip and apply a torque to the handrim causing rotation of the wheel assembly.

[0024]The adjustable wheelchair handrim with movable friction band 10 is comprised of an ergonomic tubular handrim 22 which transforms directly into a drive surface 24, as can be seen in FIG. 2. The ergonomic tubular handrim 22 contains a profile that matches the shape of the hand and is sized to this manner. The drive surface 24 continuously extends from the top surface of the ergonomic tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com