Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

257results about How to "Prevent wrong discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

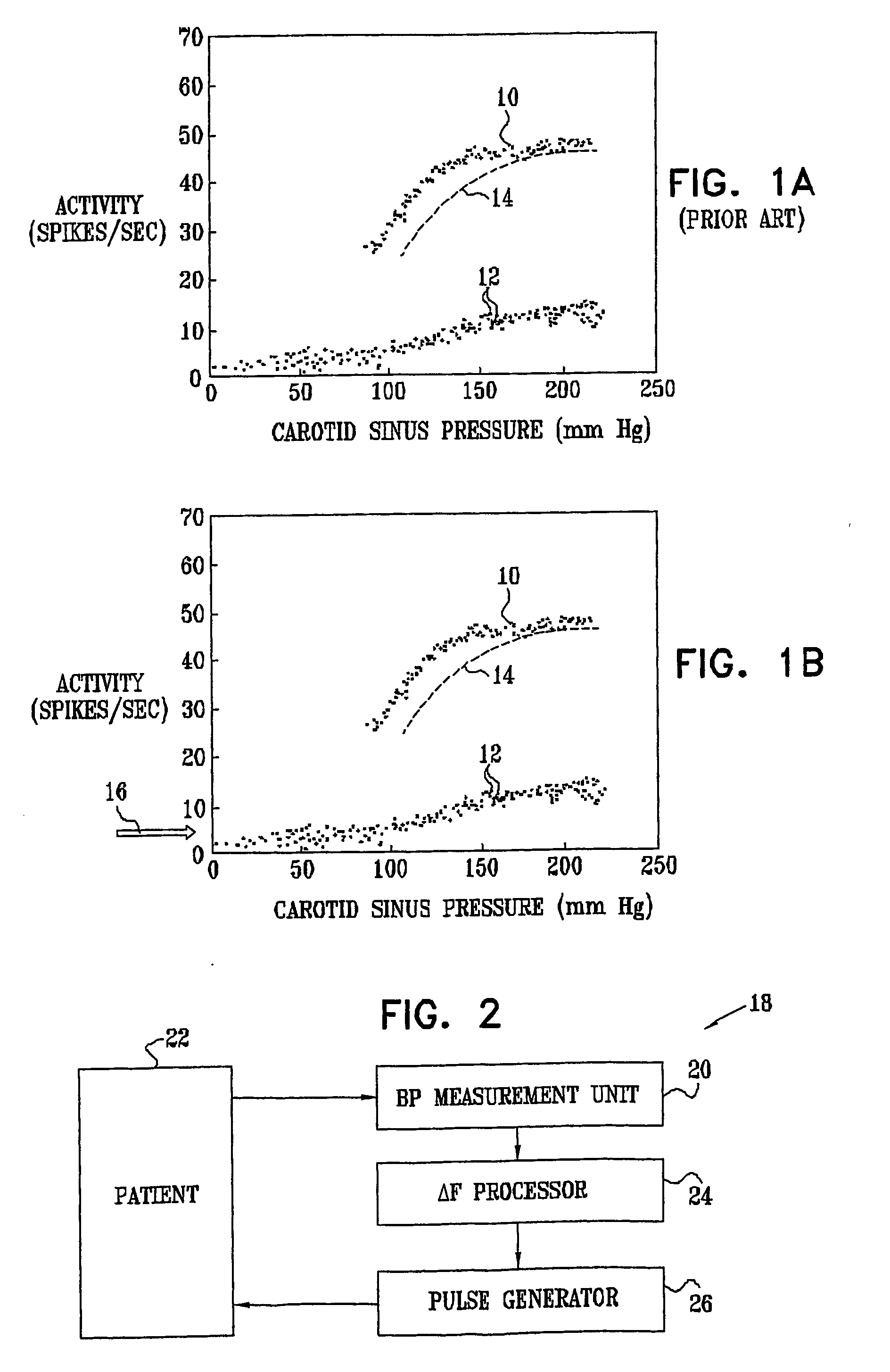

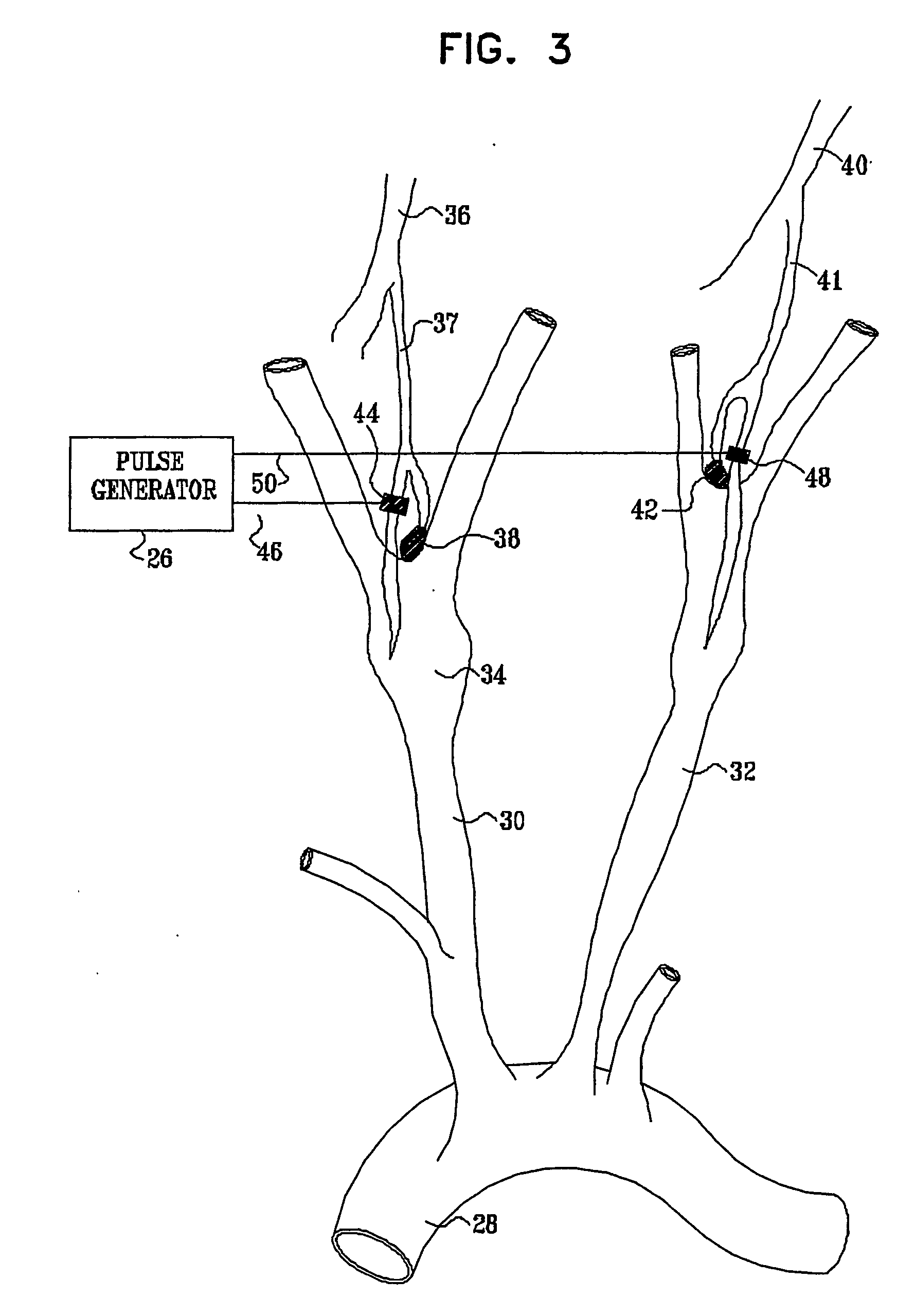

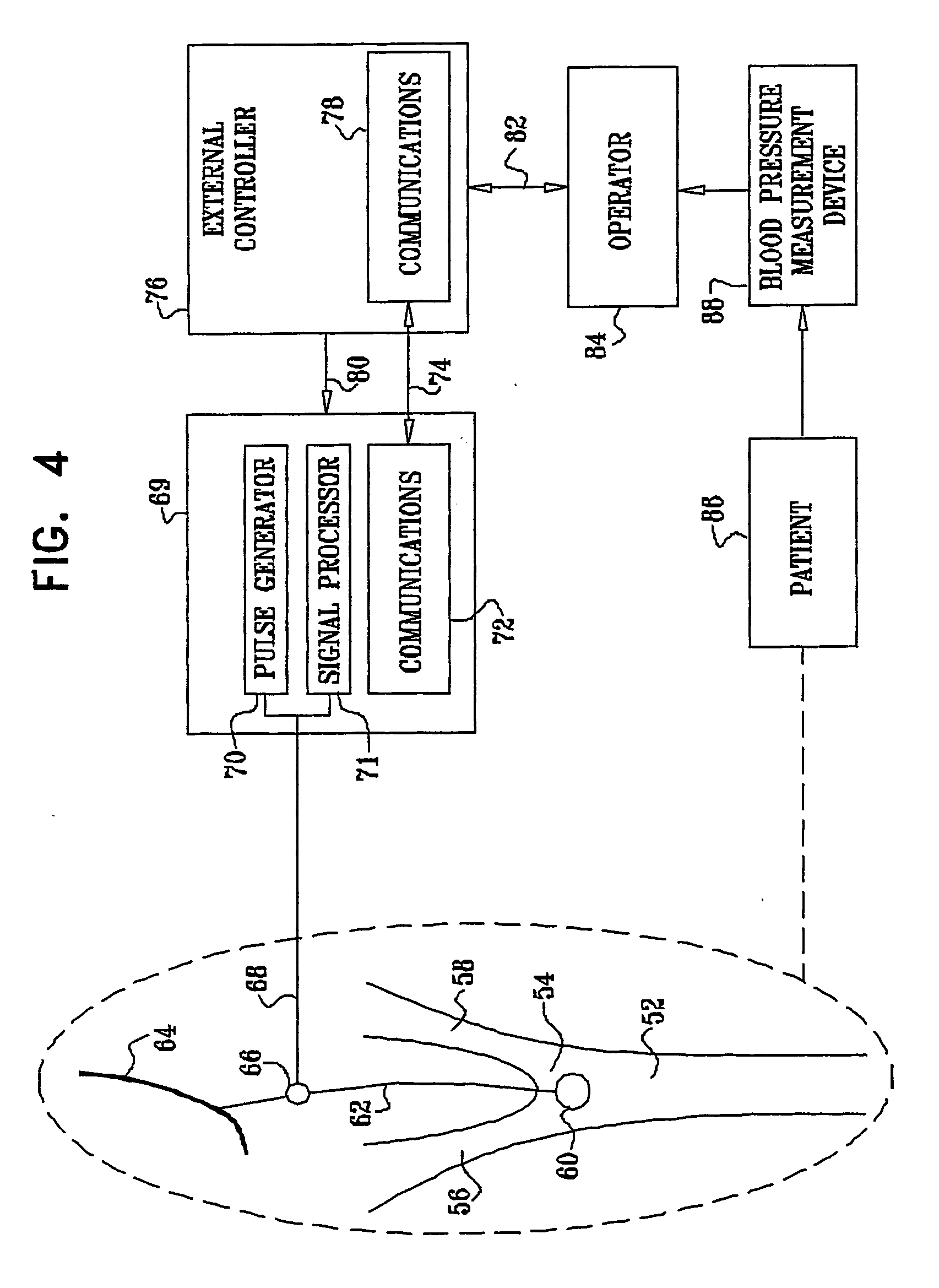

Technique for blood pressure regulation

InactiveUS20060089678A1High baroreceptor discharge rateHigh activityInternal electrodesEvaluation of blood vesselsWhole bodyBaroreceptor function

An implantable device (20) uses the carotid baroreflex in order to control systemic blood pressure. The implant includes sampling and pulse stimulation electrodes (44) preferably located on the carotid sinus nerve branch of the glossopharyngeal nerve, adjacent and distal to the carotid sinus baroreceptors. The stimulators have an external control unit, which communicates with the implant for determining appropriate operational parameters, and for retrieving telemetry information from the device's data bank. Typically two internal devices are implanted, one at each side of the patient's neck.

Owner:BRAINSGATE LTD

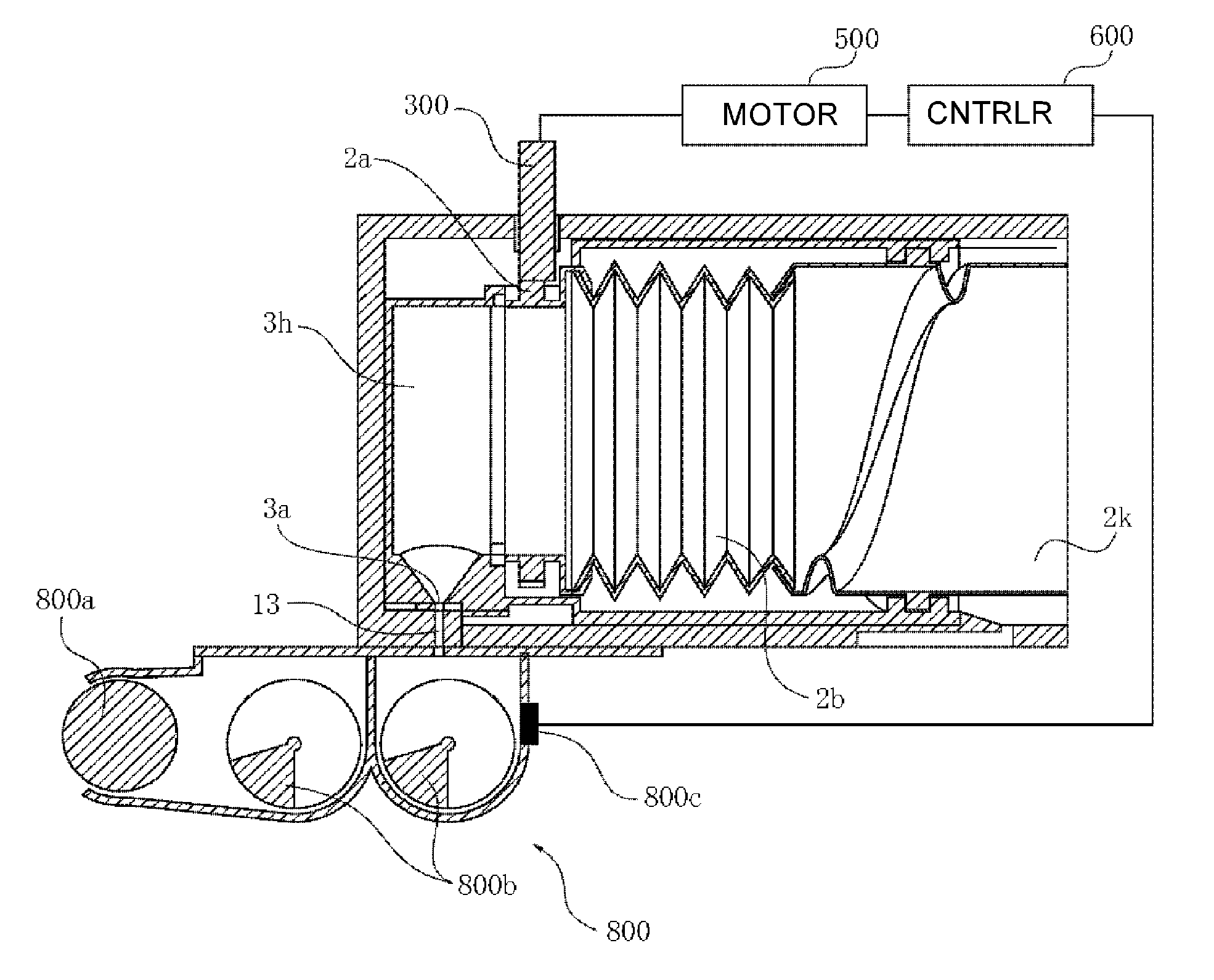

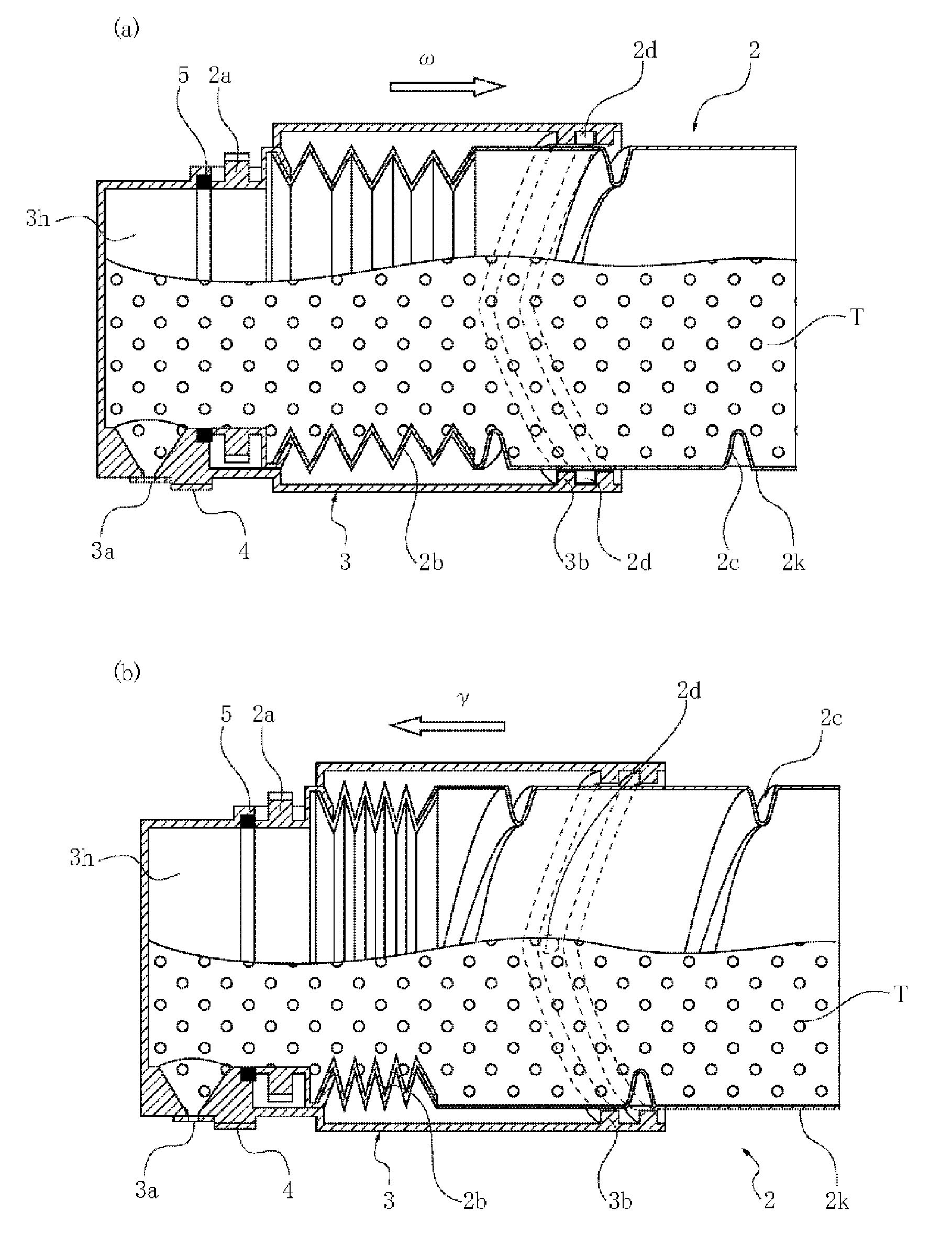

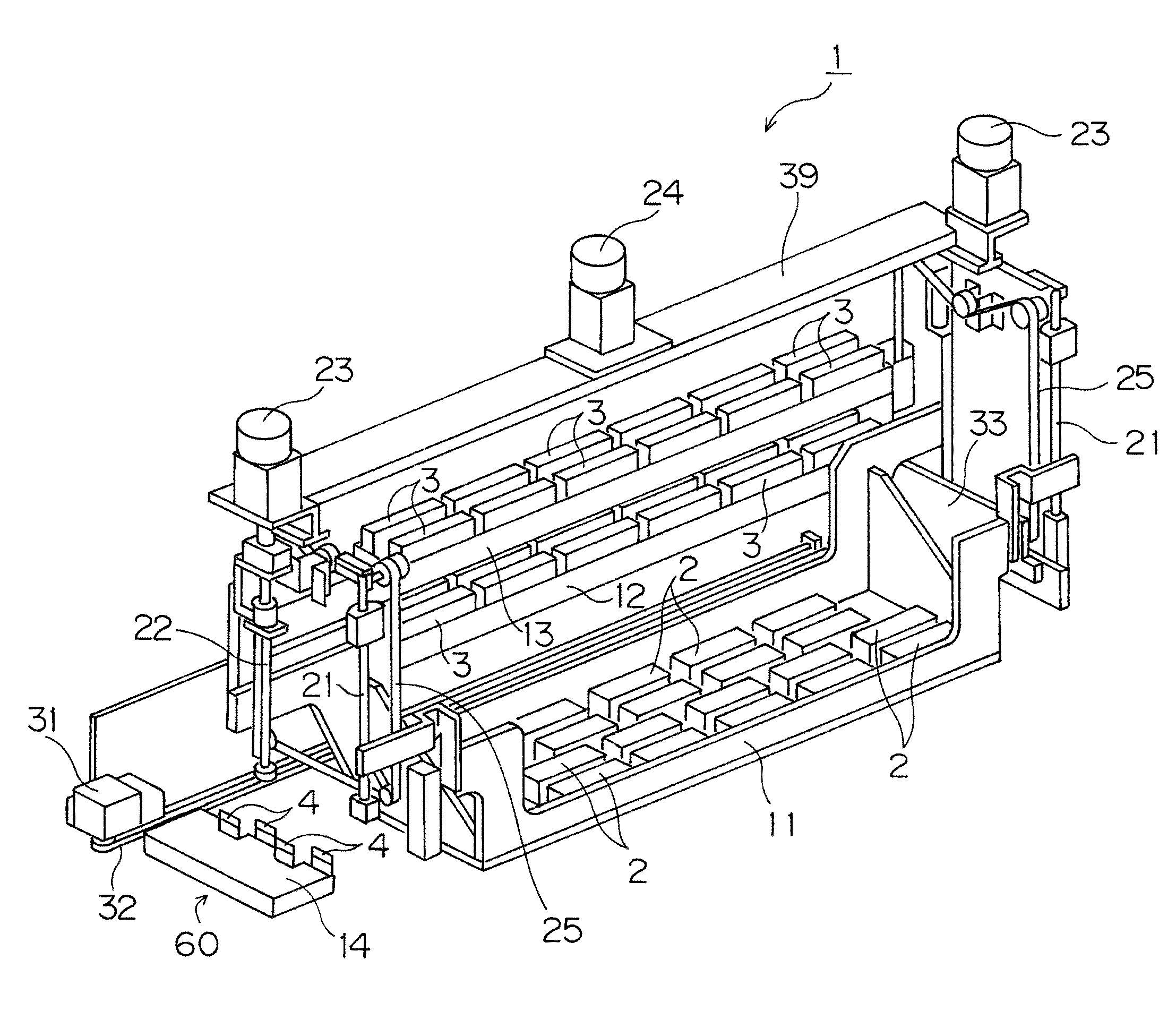

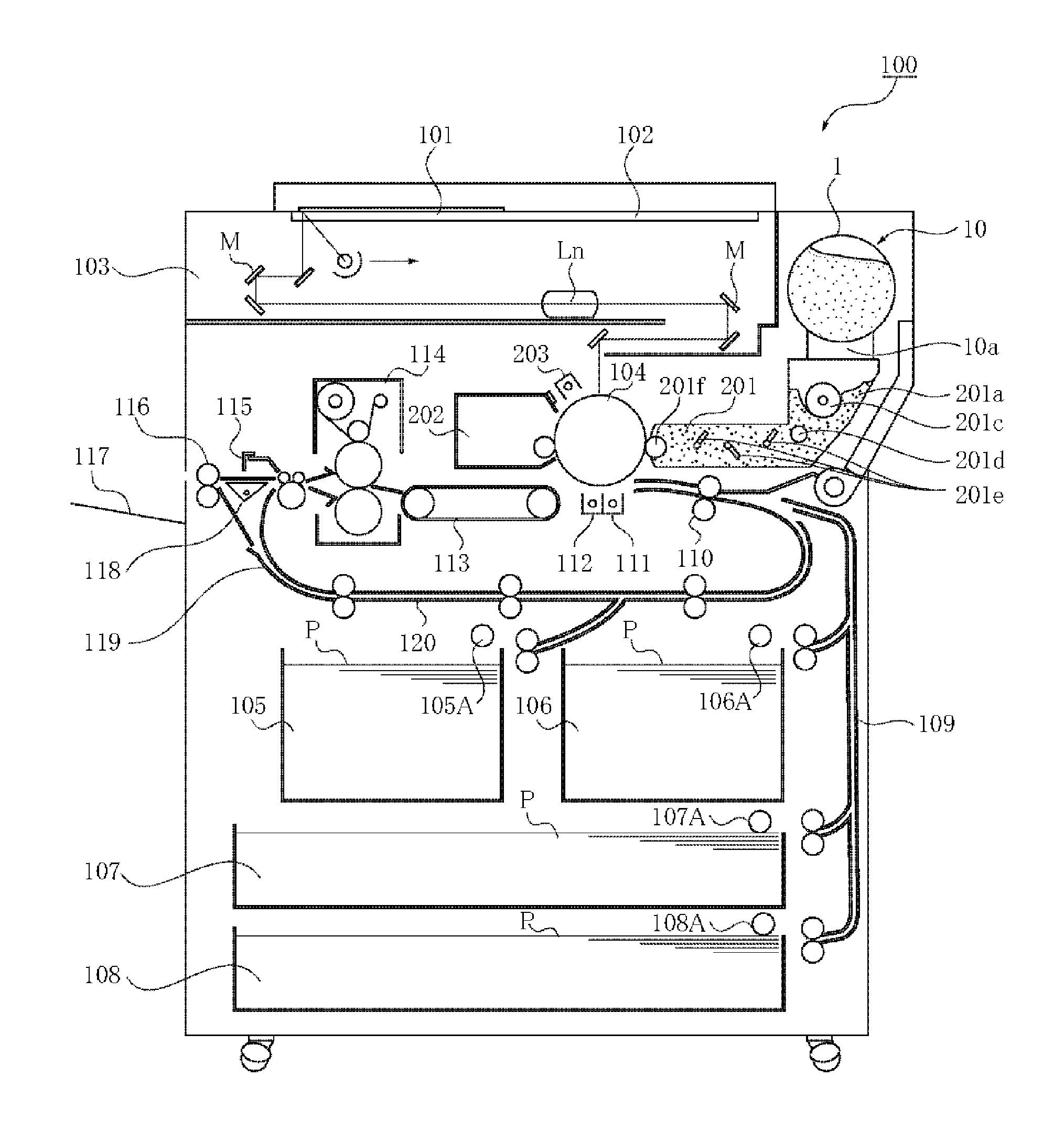

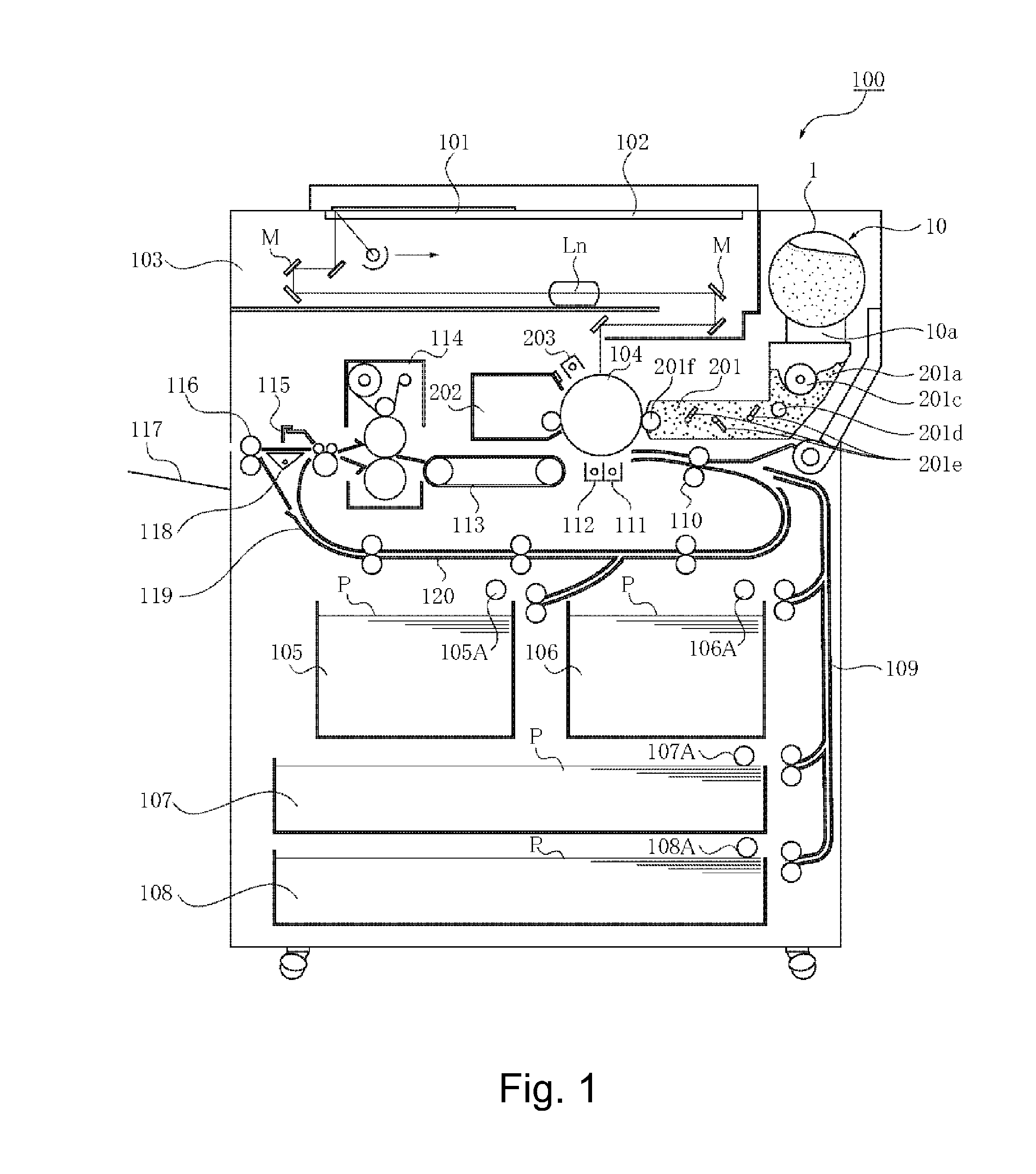

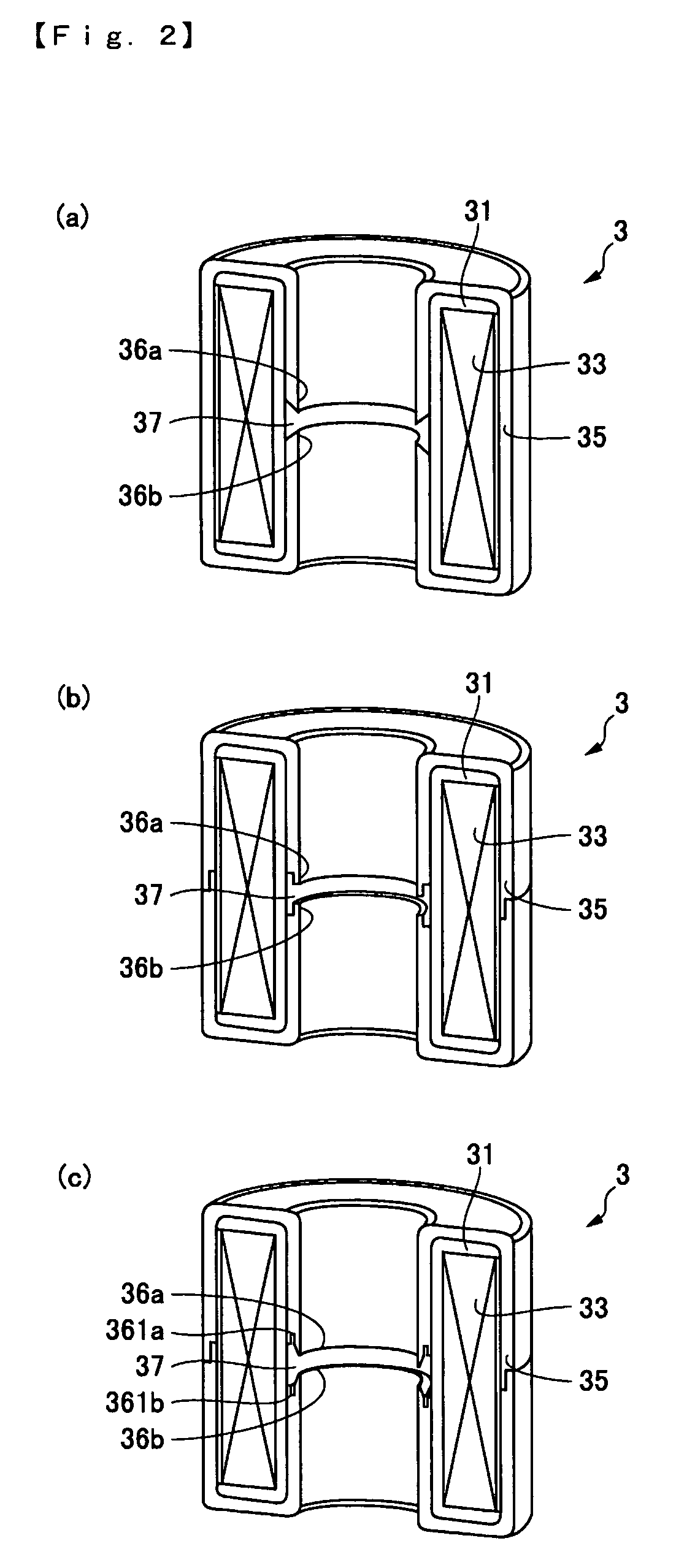

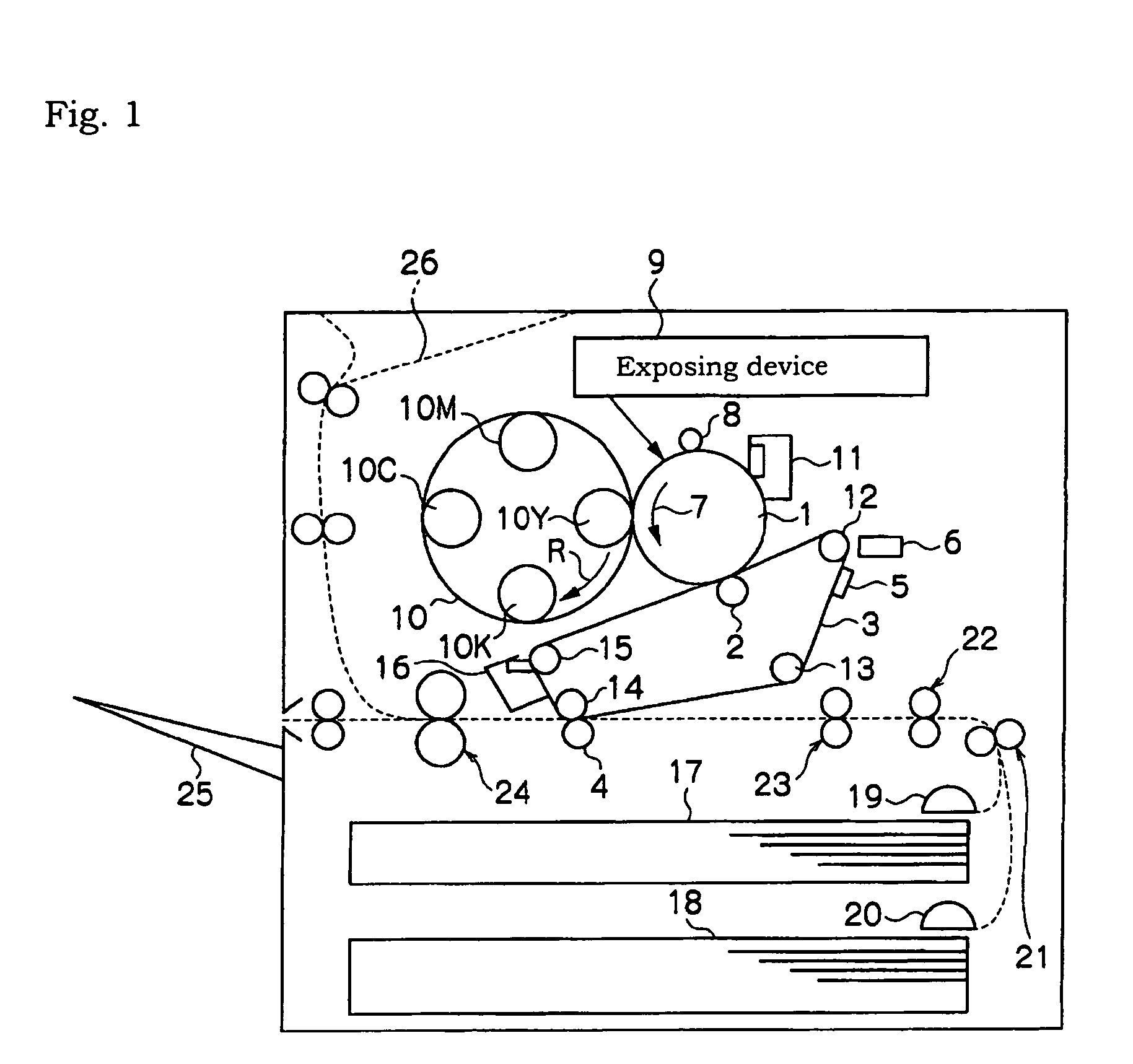

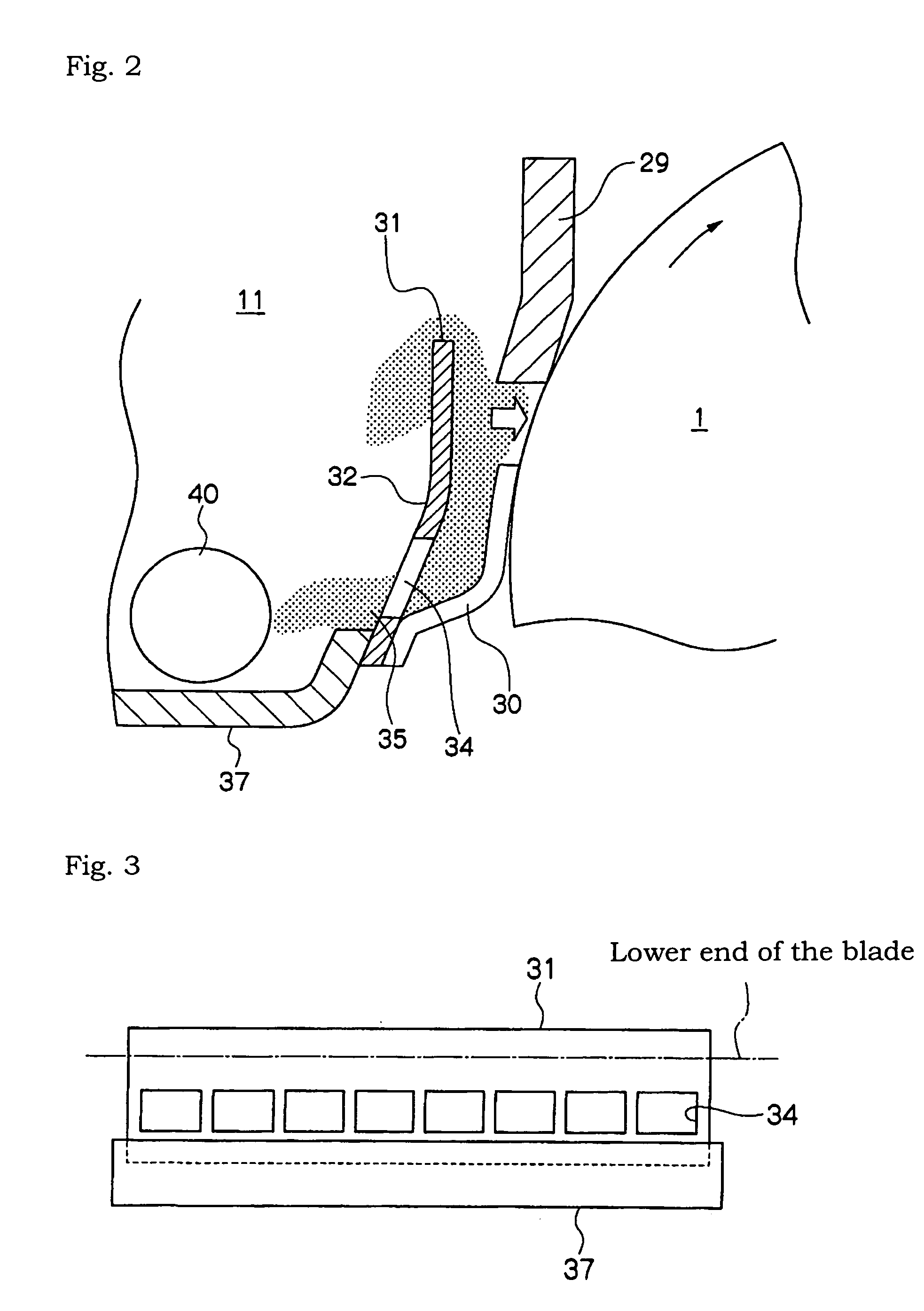

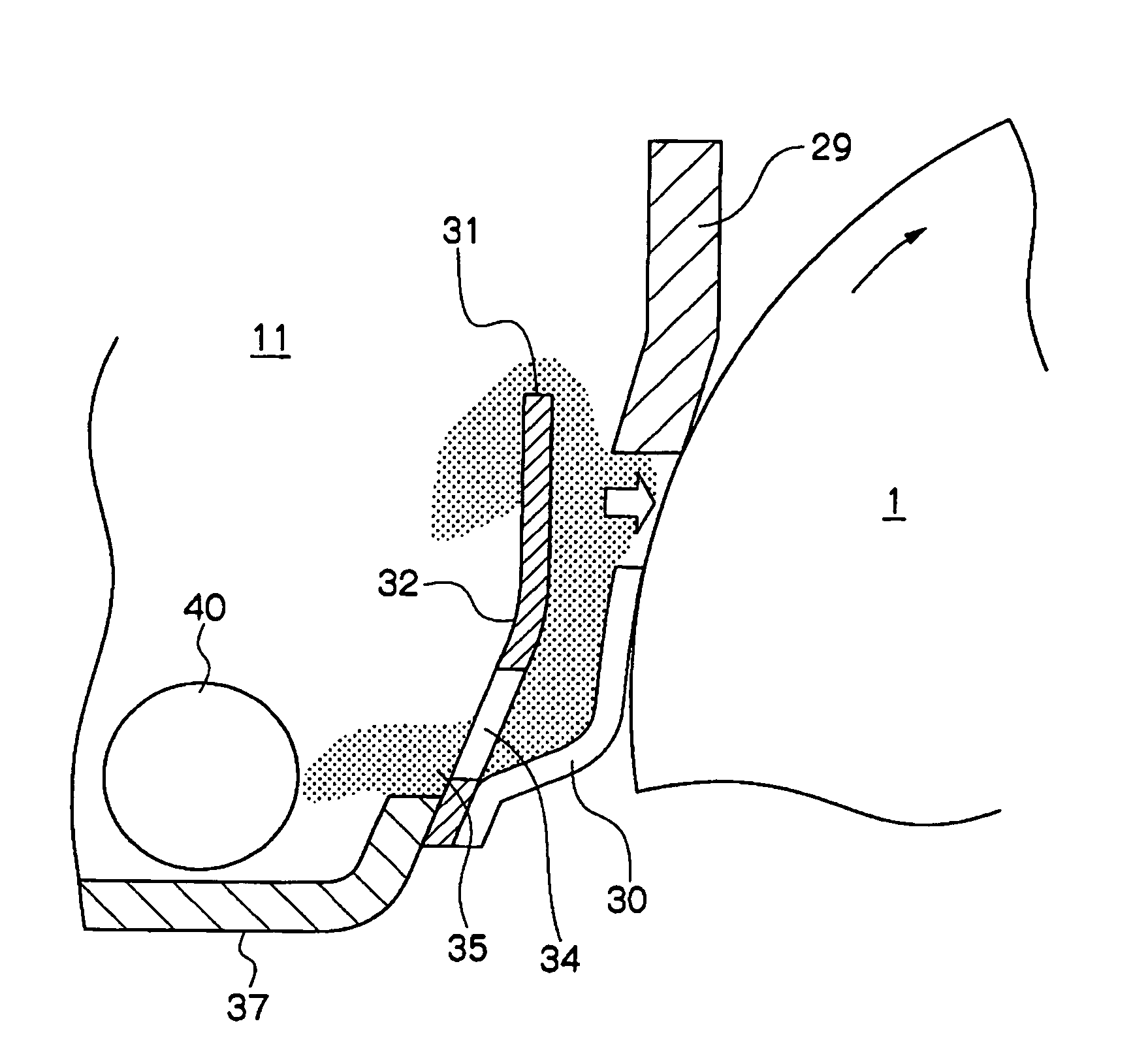

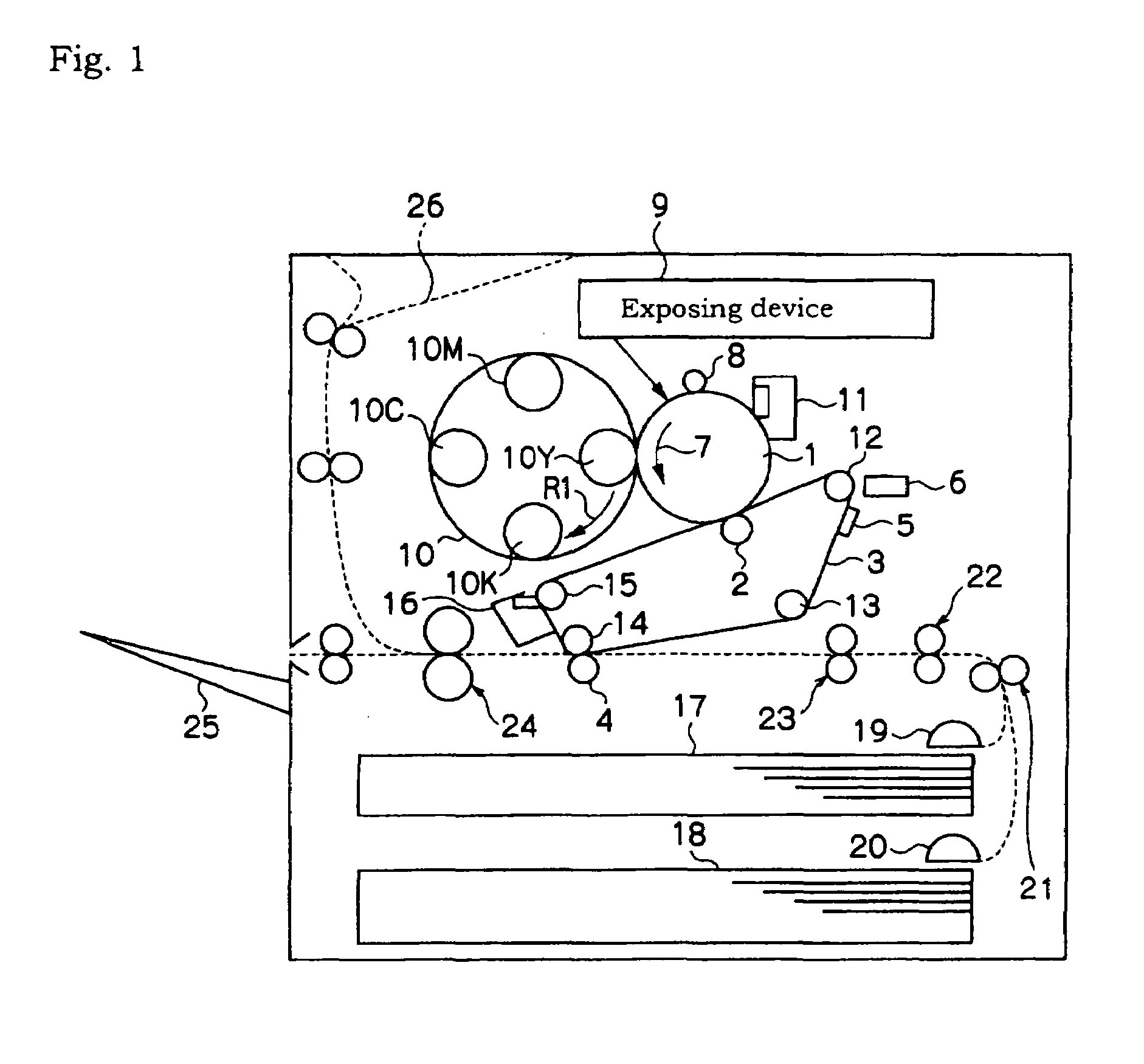

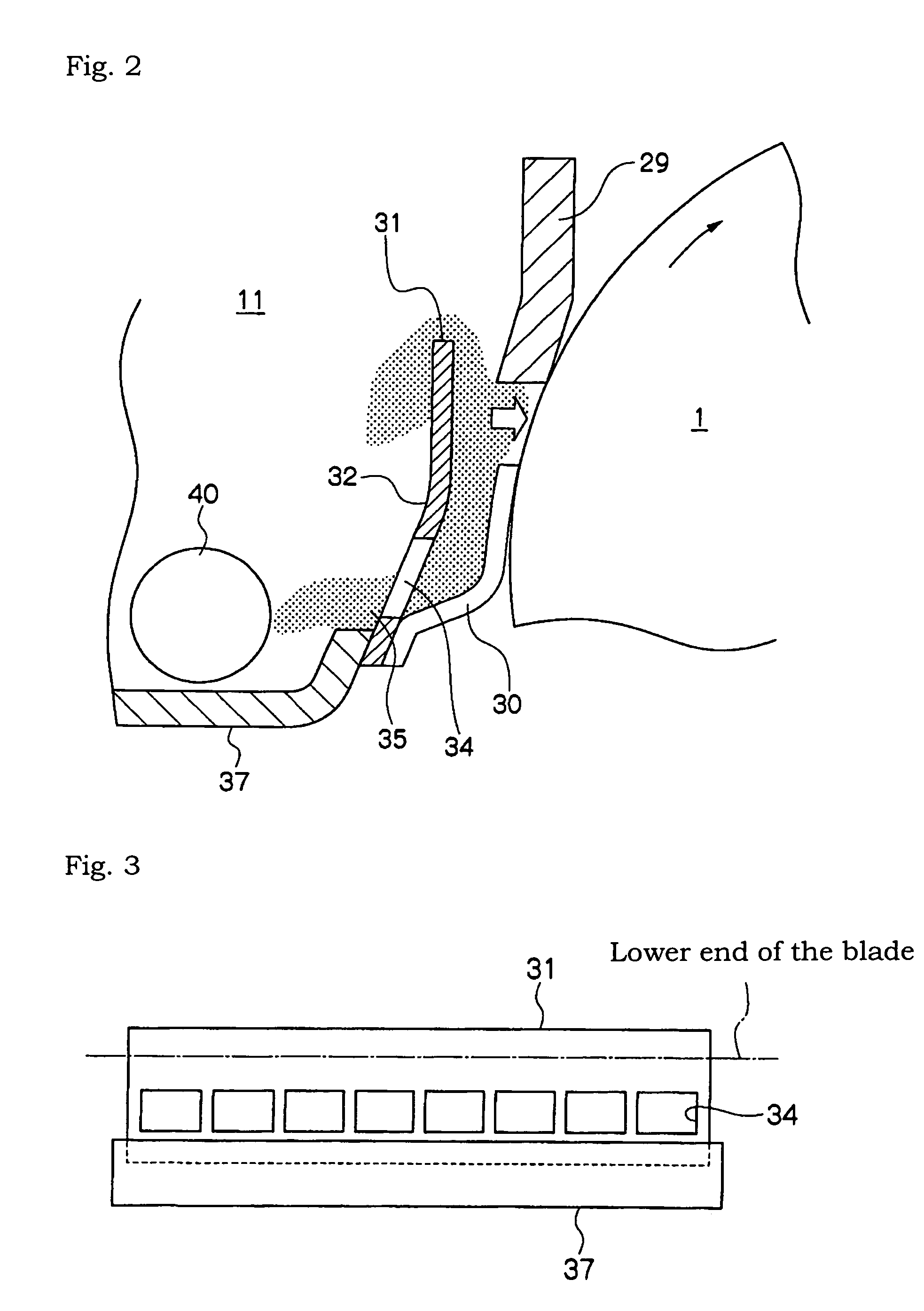

Developer supply container and developer supplying system

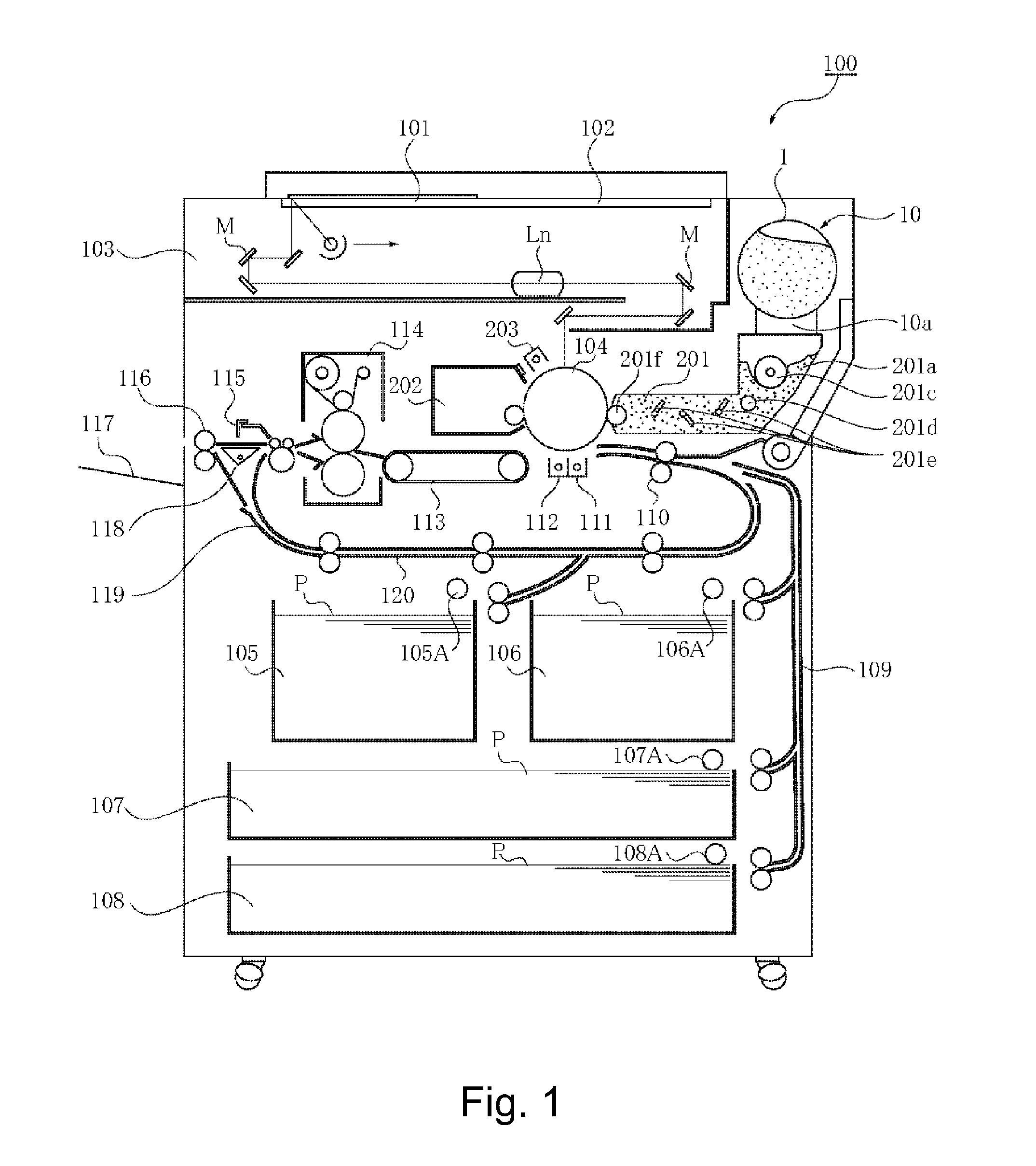

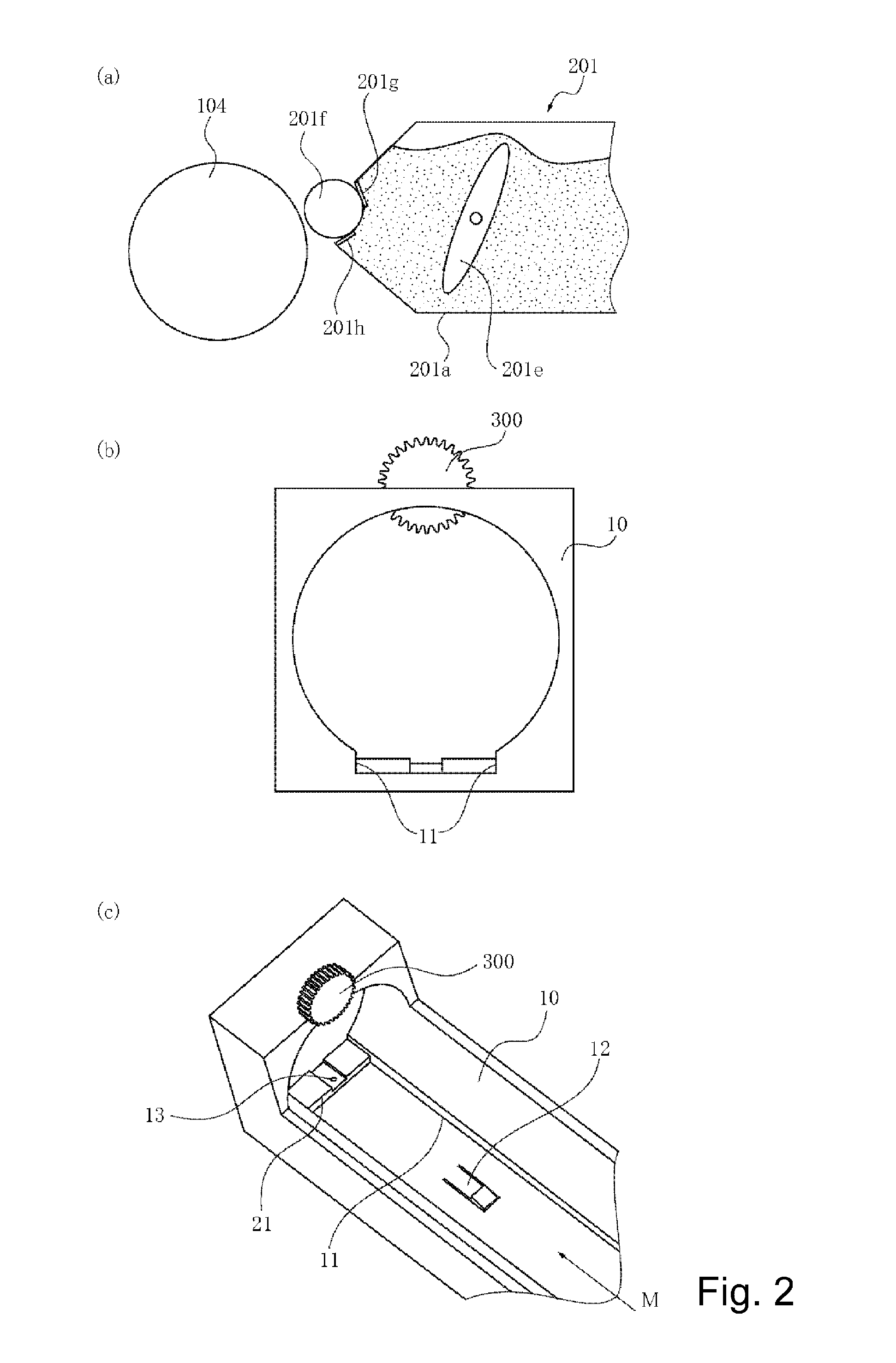

ActiveUS20120014713A1Prevent wrong dischargeElectrographic process apparatusReciprocating motionImaging equipment

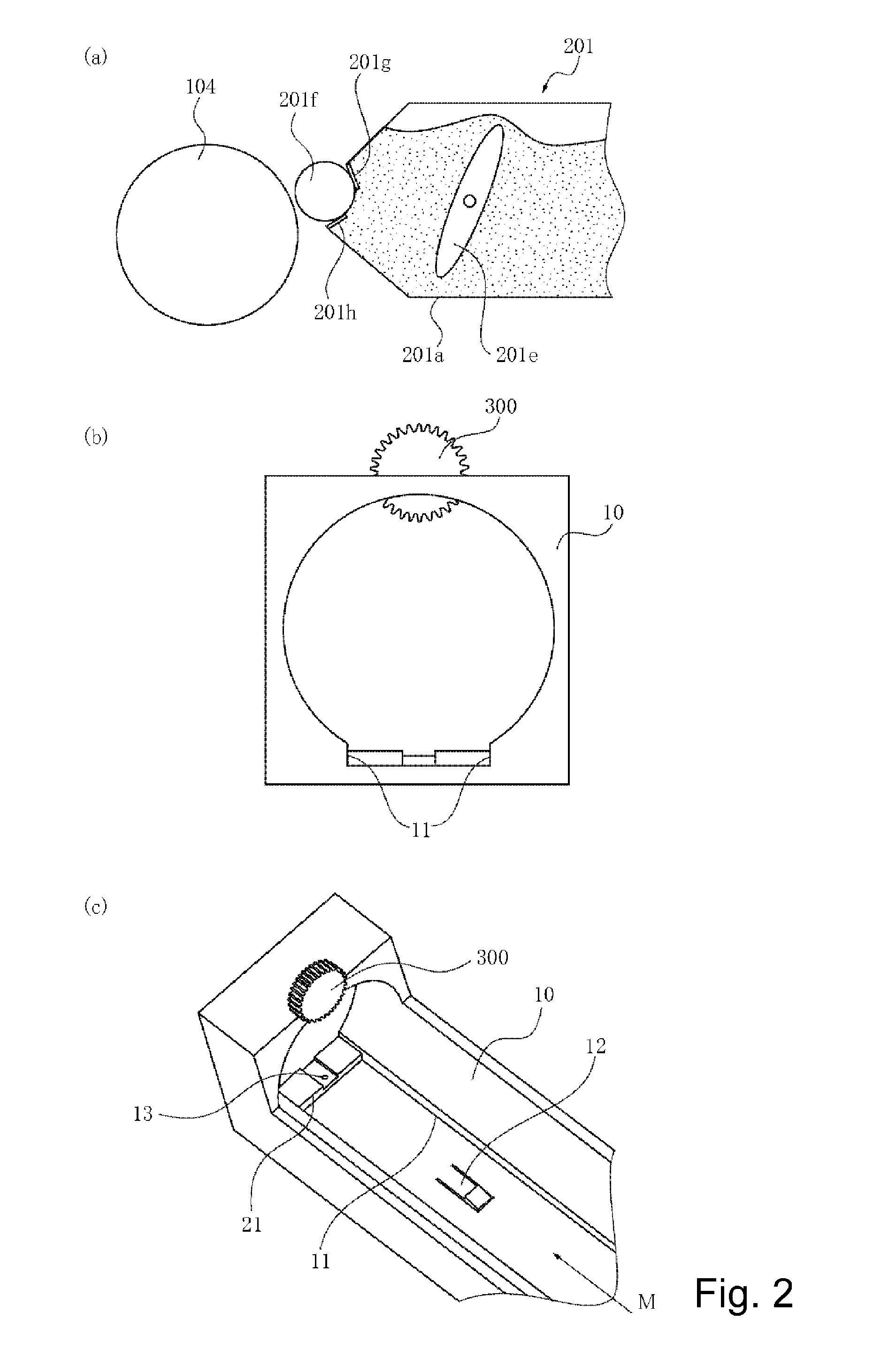

In the case that a developer supply container is provided with a feeding portion for feeding a developer by receiving a rotational force and a pump portion for discharging the developer by reciprocation, and the rotational force and a reciprocating force are received from a main assembly side of an image forming apparatus, there is a liability that a driving connection is not properly established between a portion of the developer supply container for receiving the reciprocating force and a portion of the main assembly side for applying the reciprocating force.The developer supply container is provided with a drive converting mechanism for converting the rotational force received from the main assembly side to a force for operating a volume changing type pump.

Owner:CANON KK

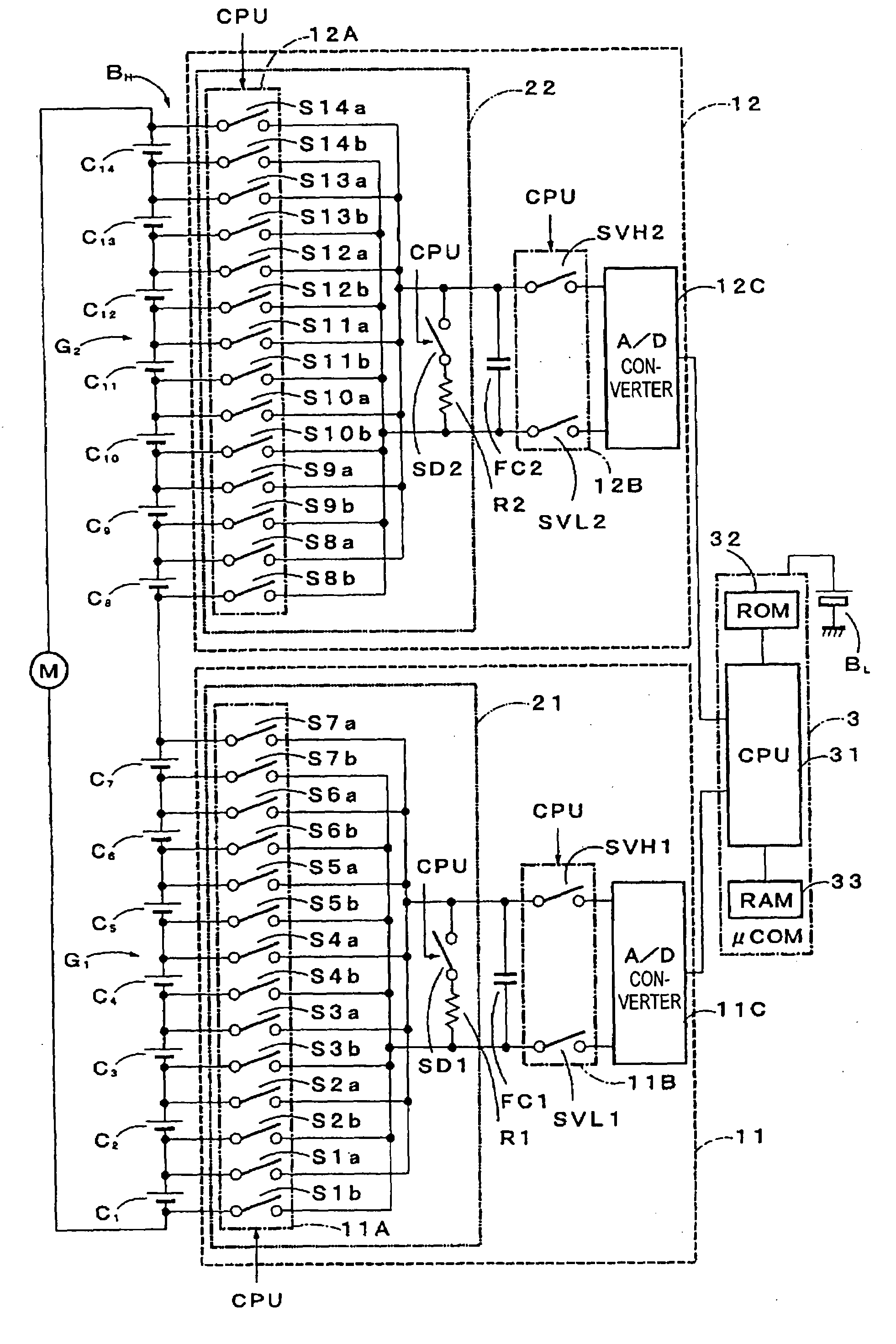

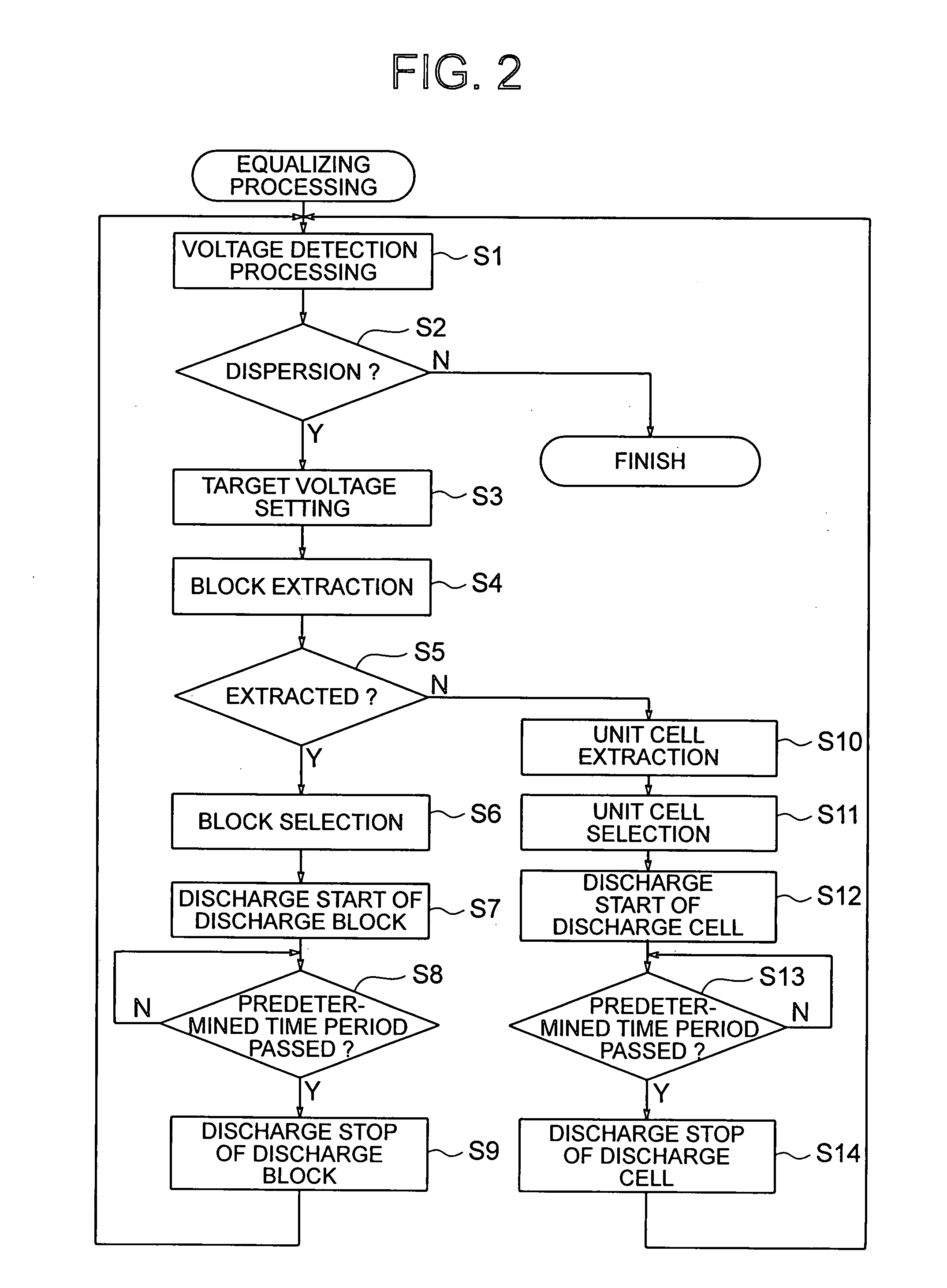

State-of-charge adjusting apparatus

InactiveUS20080036424A1Shorten a time to reach the capacity equalizationShorten the timeCharge equalisation circuitCircuit monitoring/indicationElectrical batteryState of charge

The state-of-charge adjusting apparatus which enables to shorten a time to reach a capacity equalization is provided. A CPU extracts a block consisting of a plurality of unit cells connected continuously to each other, the plurality of the unit cells each having a voltage higher than a target voltage, and connects both ends of each block to a discharge resistance to make each block discharge. Thereafter, the CPU extracts a unit cell having a voltage higher than the target voltage and connects both ends of the extracted unit cell to the discharge resistance to make the extracted unit cell discharge until the voltage of the extracted unit cell reaches the target voltage.

Owner:YAZAKI CORP

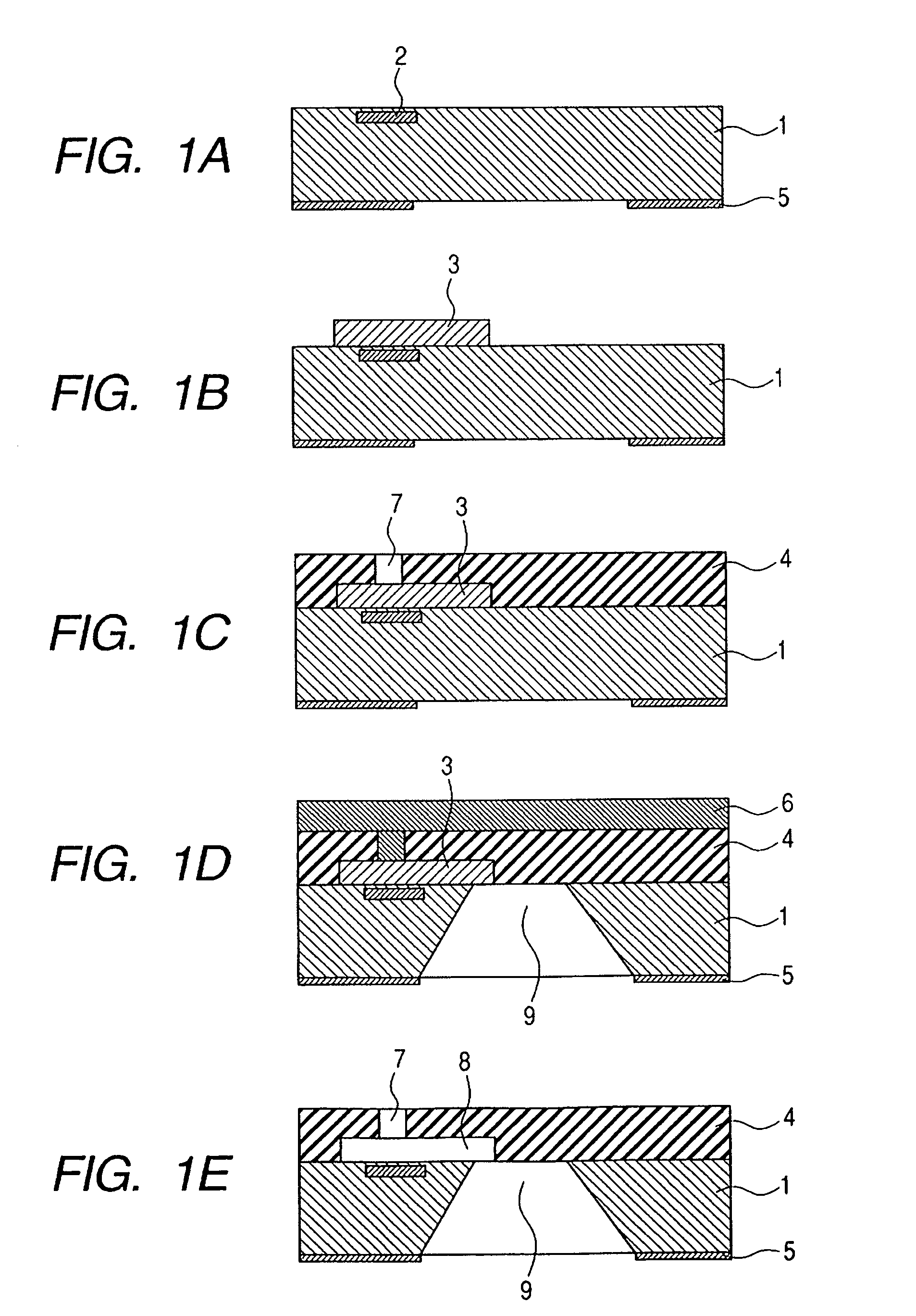

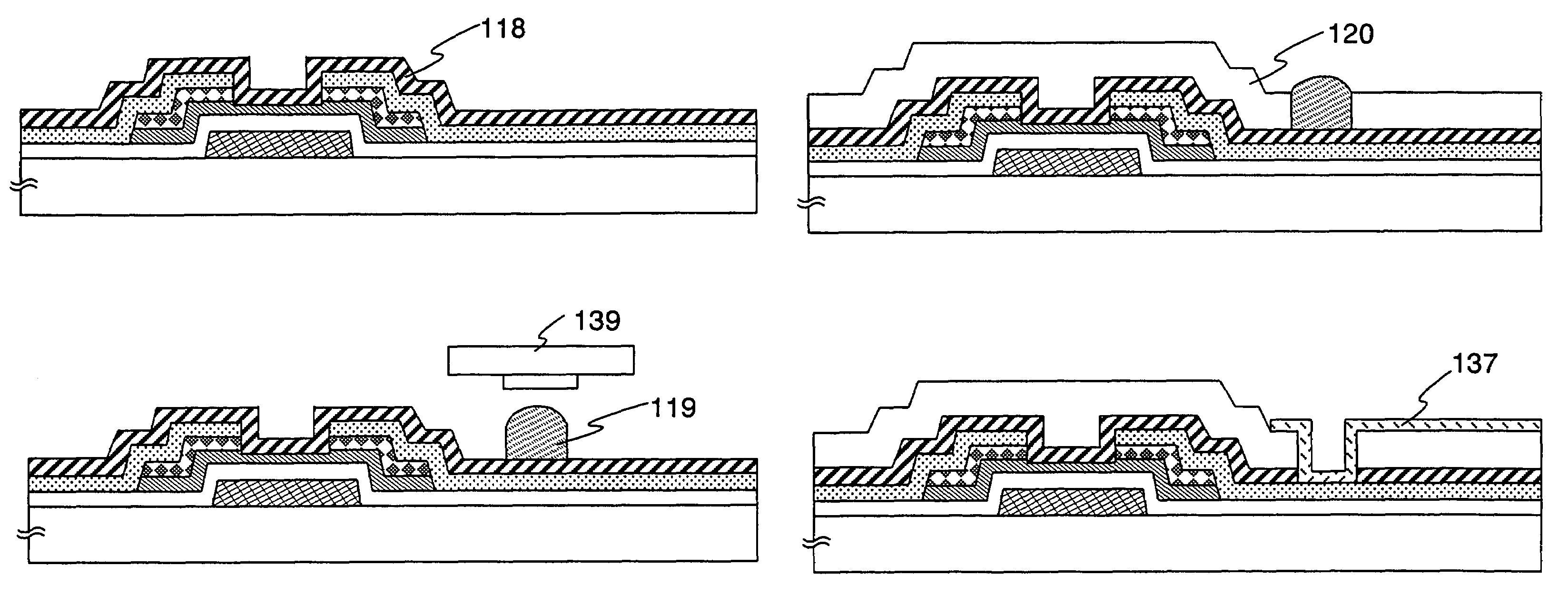

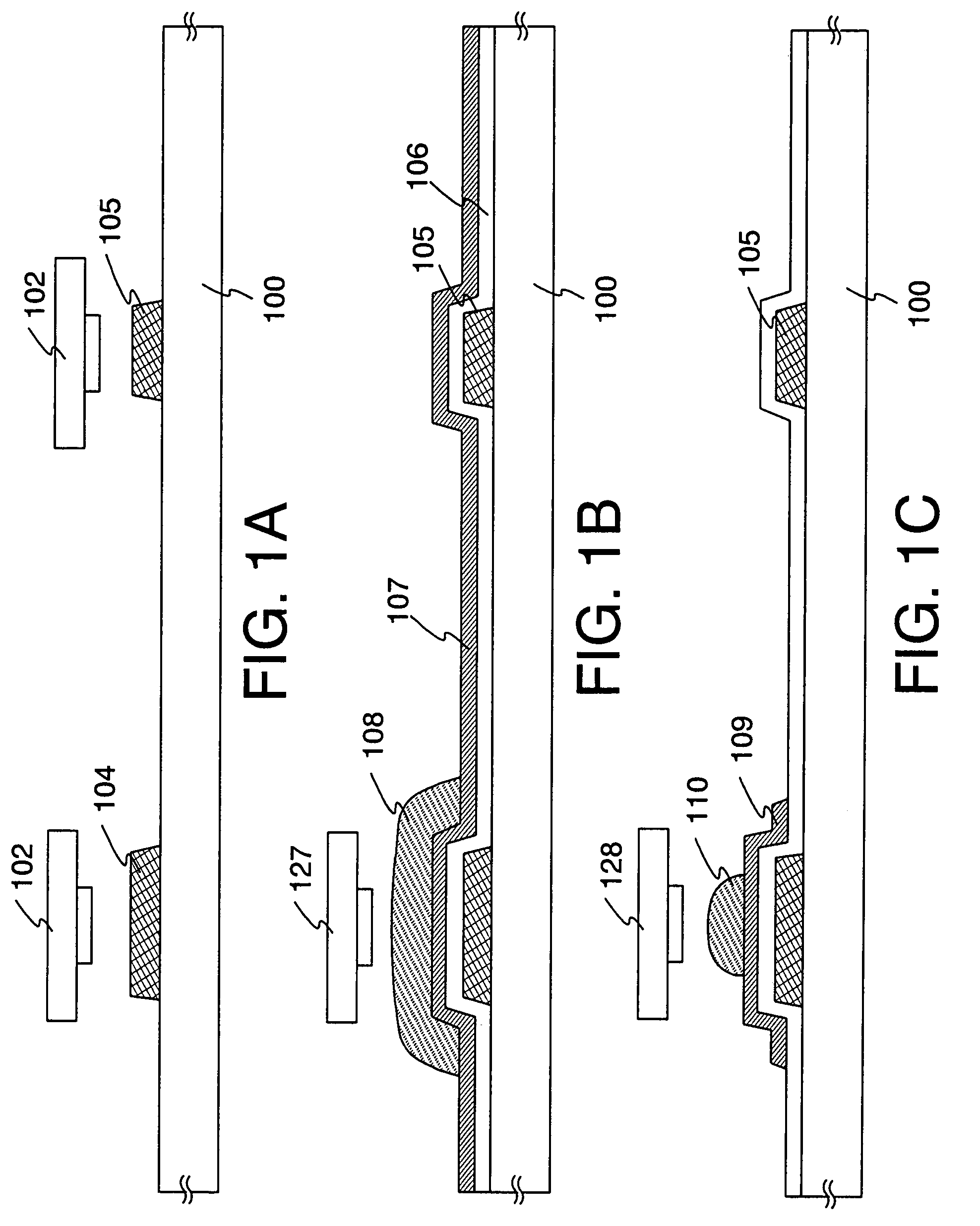

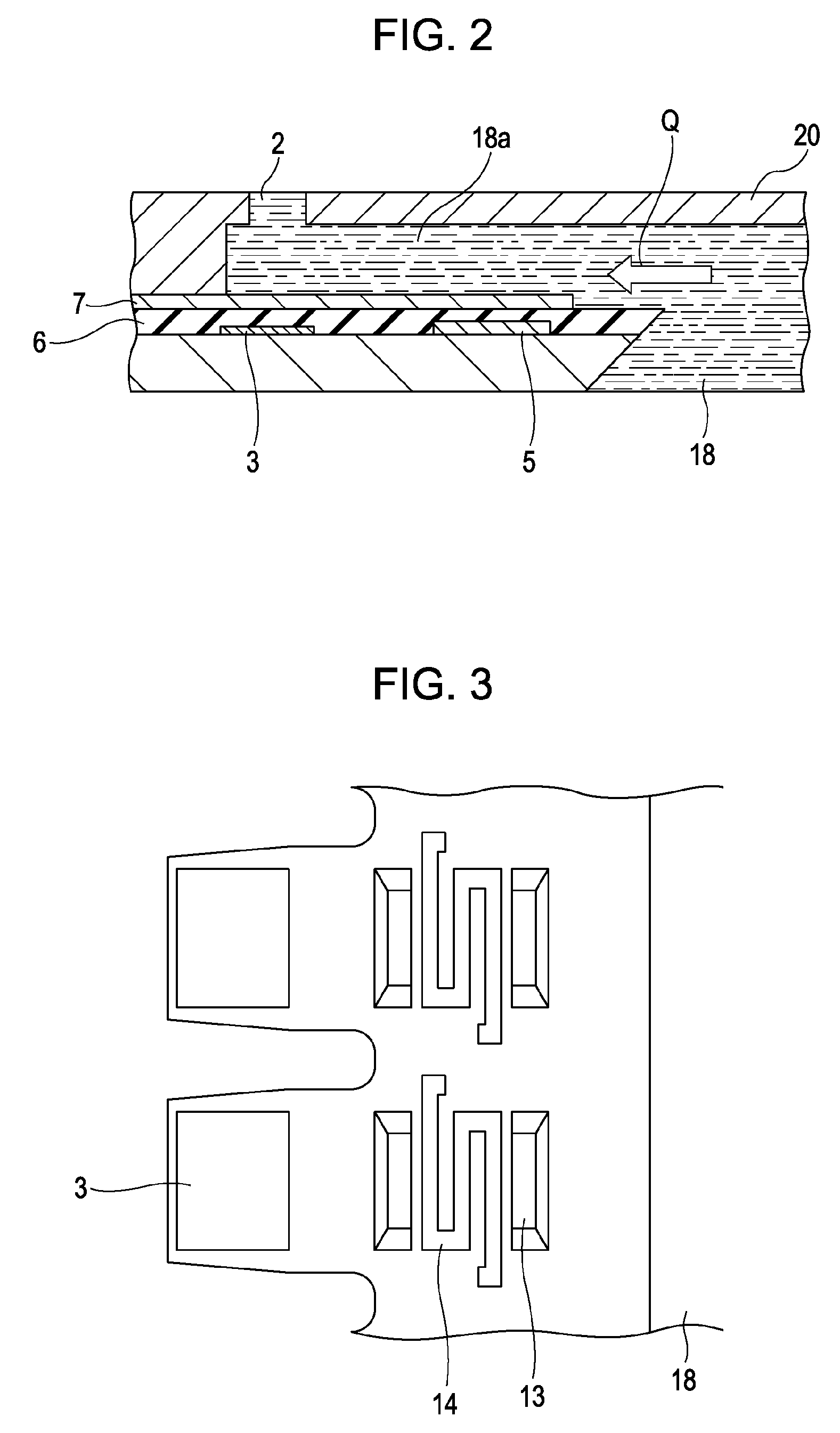

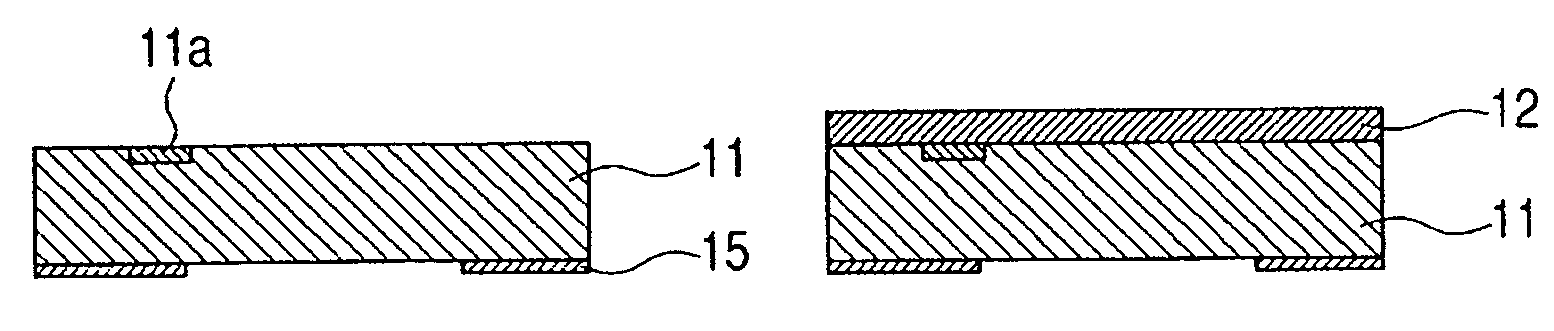

Forming method of contact hole, and manufacturing method of semicondutor device, liquid crystal display device and EL display device

When forming a contact hole by a conventional manufacturing step of a semiconductor device, a resist is required to be formed on almost entire surface of a substrate so as to be applied on a film other than an area in which a contact hole is to be formed, leading to drastically reduced throughput. According to a forming method of a contact hole and a manufacturing method of a semiconductor device, an EL display device and a liquid crystal display device of the invention, an island shape organic film is selectively formed over a semiconductor layer, a conductive layer or an insulating layer, and an insulating film is formed around the island shape organic film to form a contact hole. Therefore, a conventional patterning using a resist is not required, and high throughput and low cost can be achieved.

Owner:SEMICON ENERGY LAB CO LTD

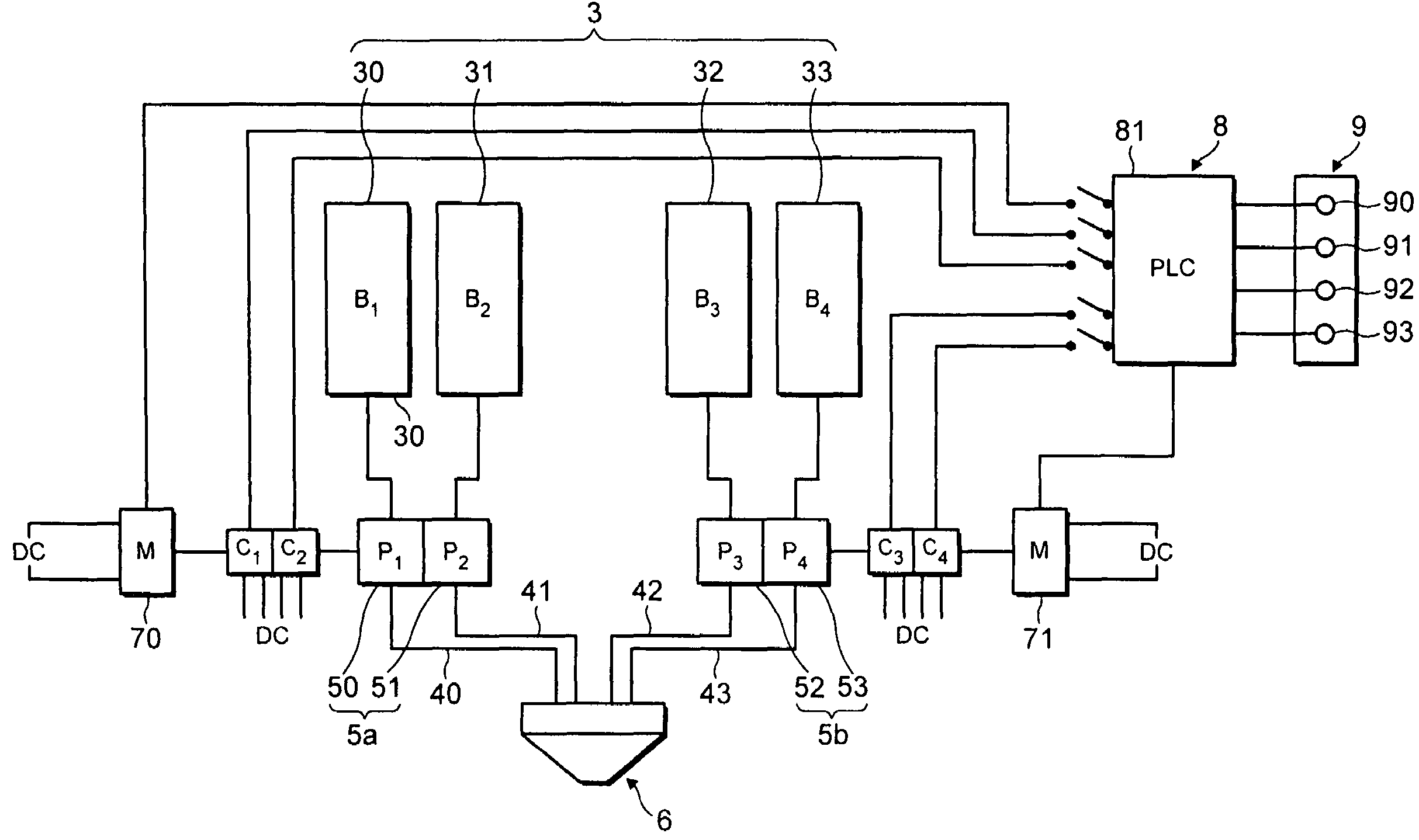

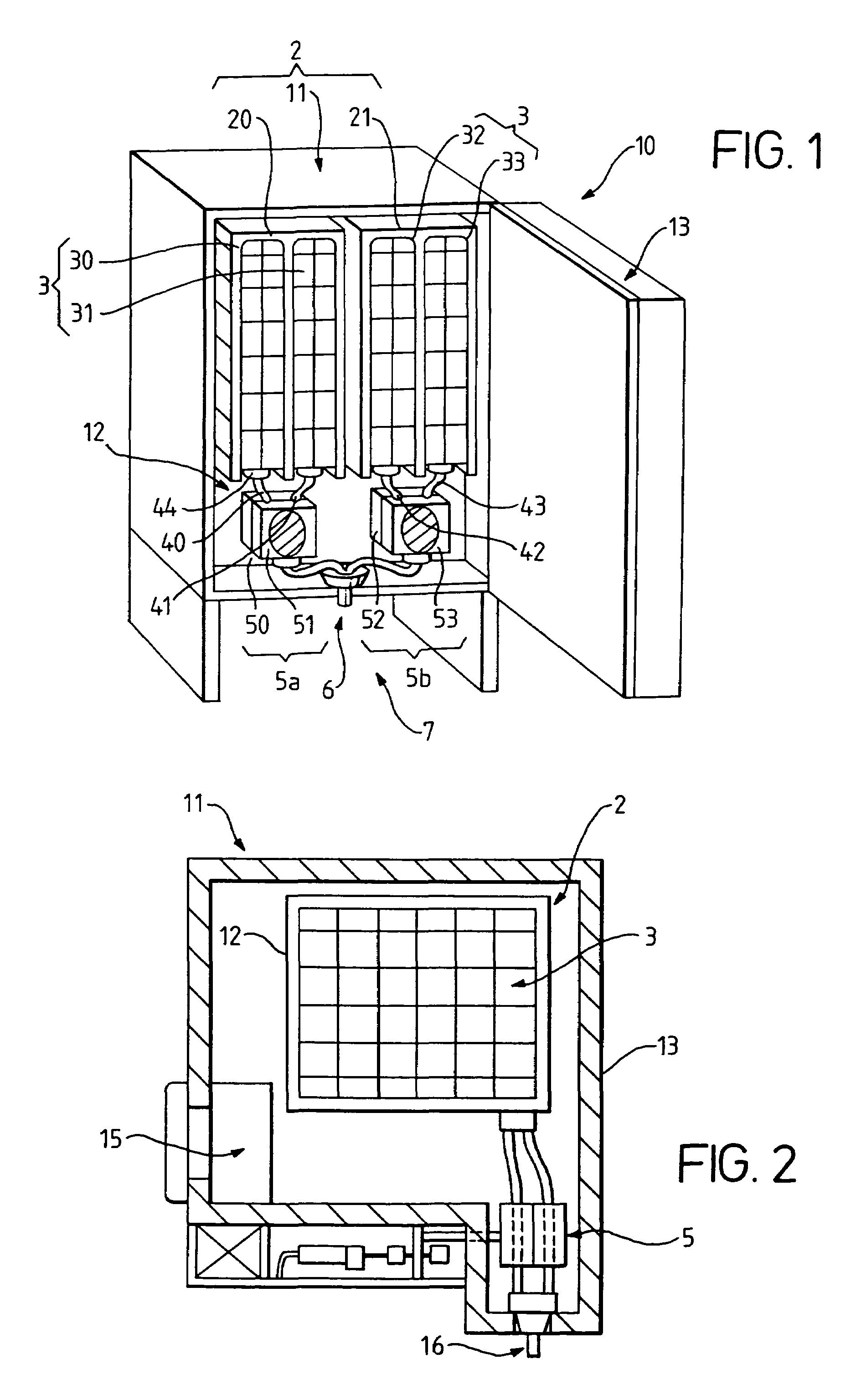

Device and method for on-demand dispensing of spoonable or drinkable food products having visual appearance of multi-components

InactiveUS7559346B2Minimize cross contaminationLittle maintenanceMilk preparationLiquid fillingPortion sizeEngineering

The invention relates to a dispensing system and method for on-demand dispensing of spoonable or drinkable food products in a container. Single servings or larger portions of these products can be dispensed. The system and method achieve dispensing of the product with a visual differentiation of the components in the container. The container may be translucent or transparent so that the consumer can view the visually differentiated product therein. The products form yet another embodiment of the invention.

Owner:NESTEC SA

Developer supply container and developer supplying system

ActiveUS8565649B2Prevent wrong dischargeElectrographic process apparatusMechanical engineeringVolume change

In the case that a developer supply container is provided with a feeding portion for feeding a developer by receiving a rotational force and a pump portion for discharging the developer by reciprocation, and the rotational force and a reciprocating force are received from a main assembly side of an image forming apparatus, there is a liability that a driving connection is not properly established between a portion of the developer supply container for receiving the reciprocating force and a portion of the main assembly side for applying the reciprocating force. The developer supply container is provided with a drive converting mechanism for converting the rotational force received from the main assembly side to a force for operating a volume changing type pump.

Owner:CANON KK

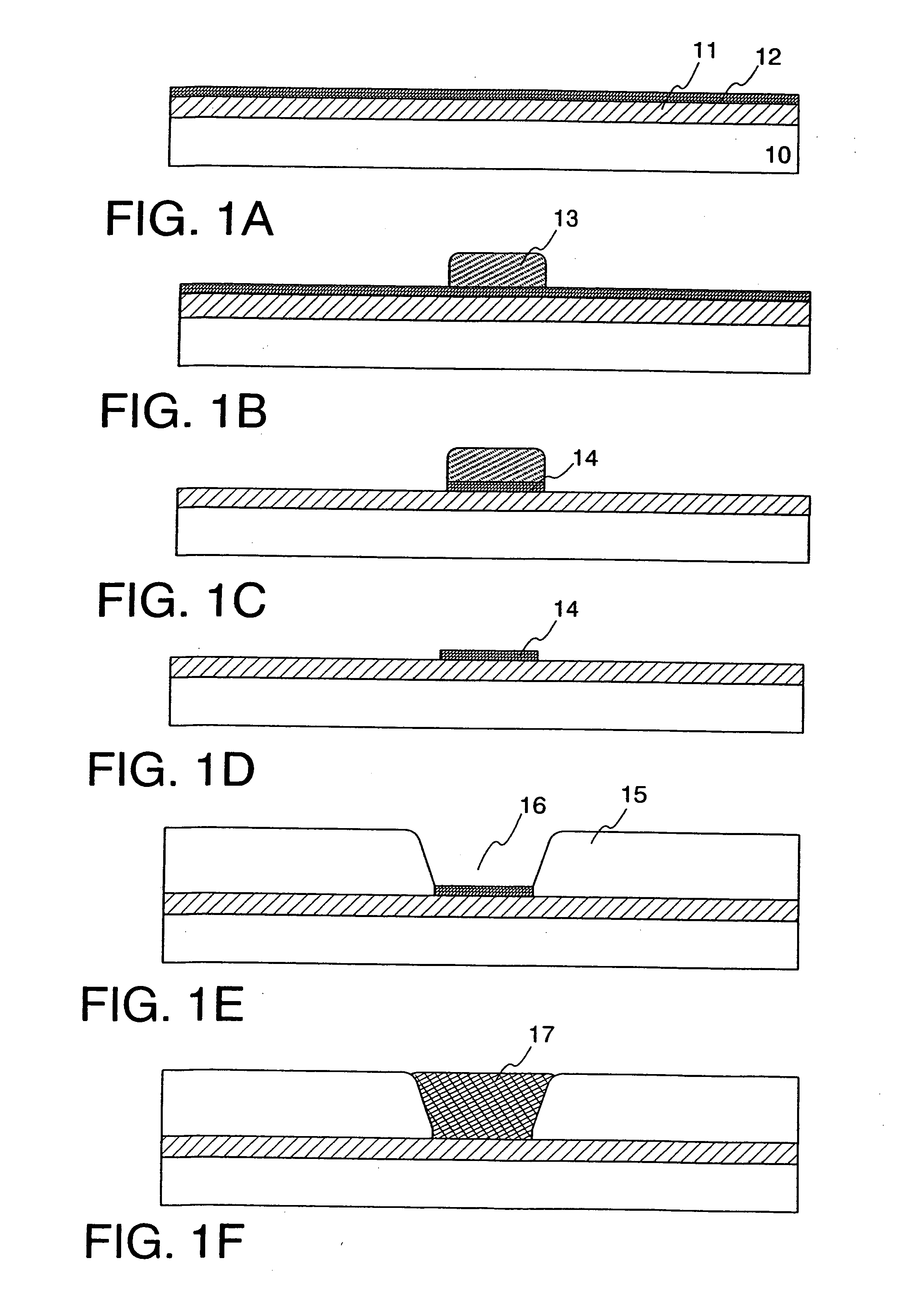

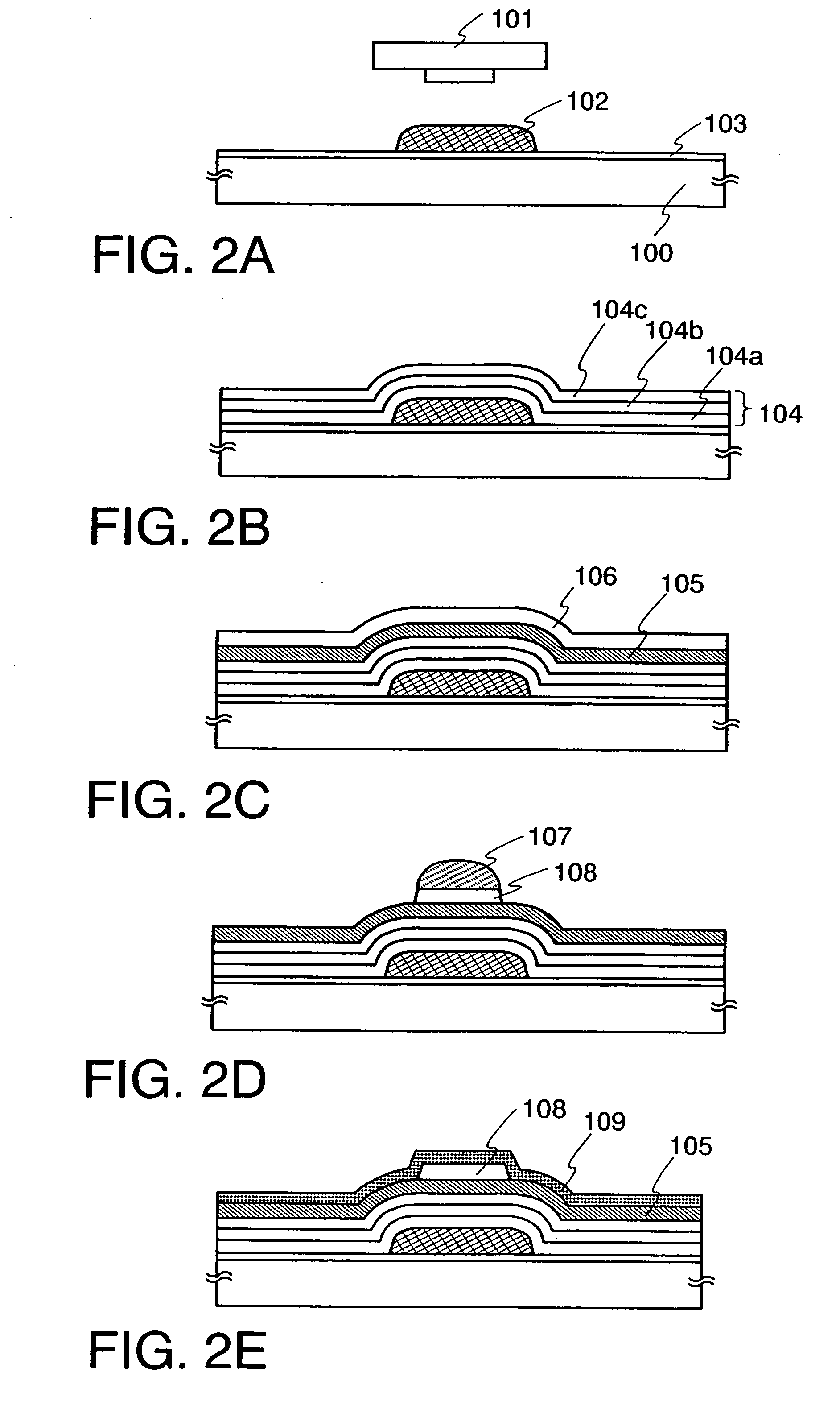

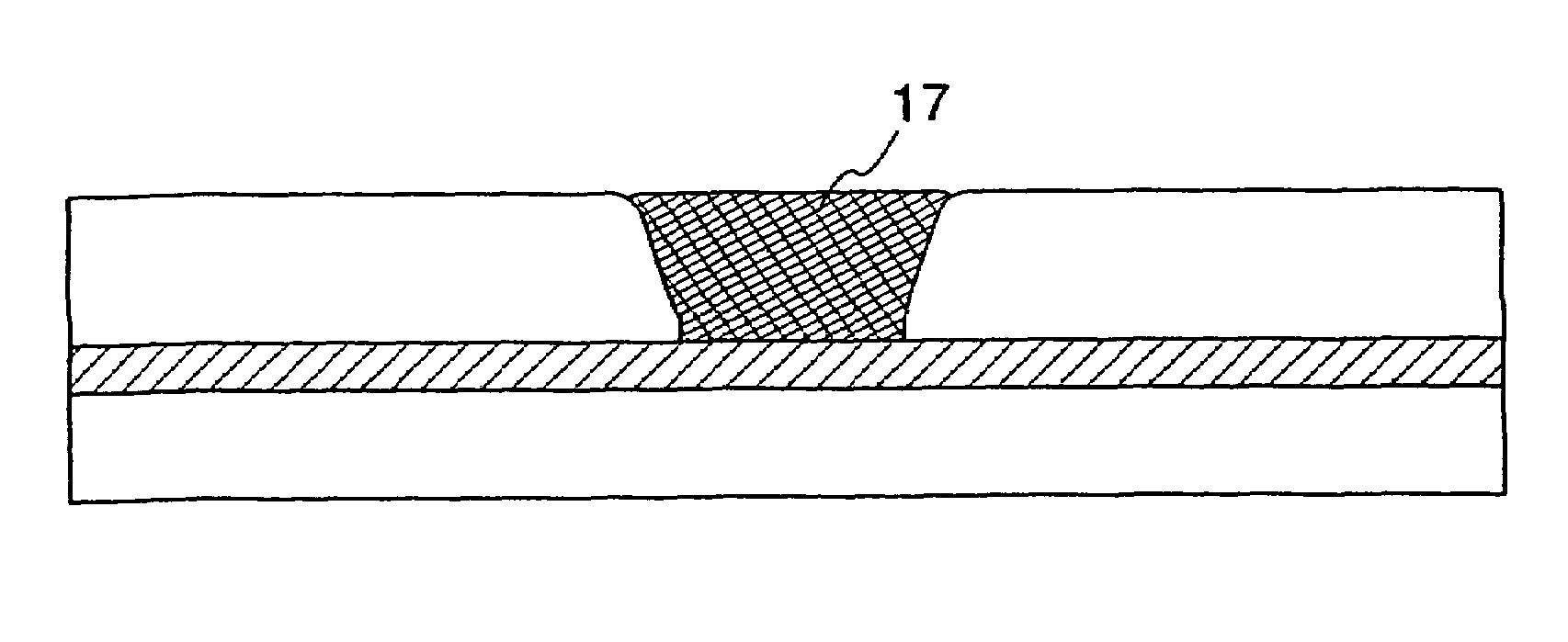

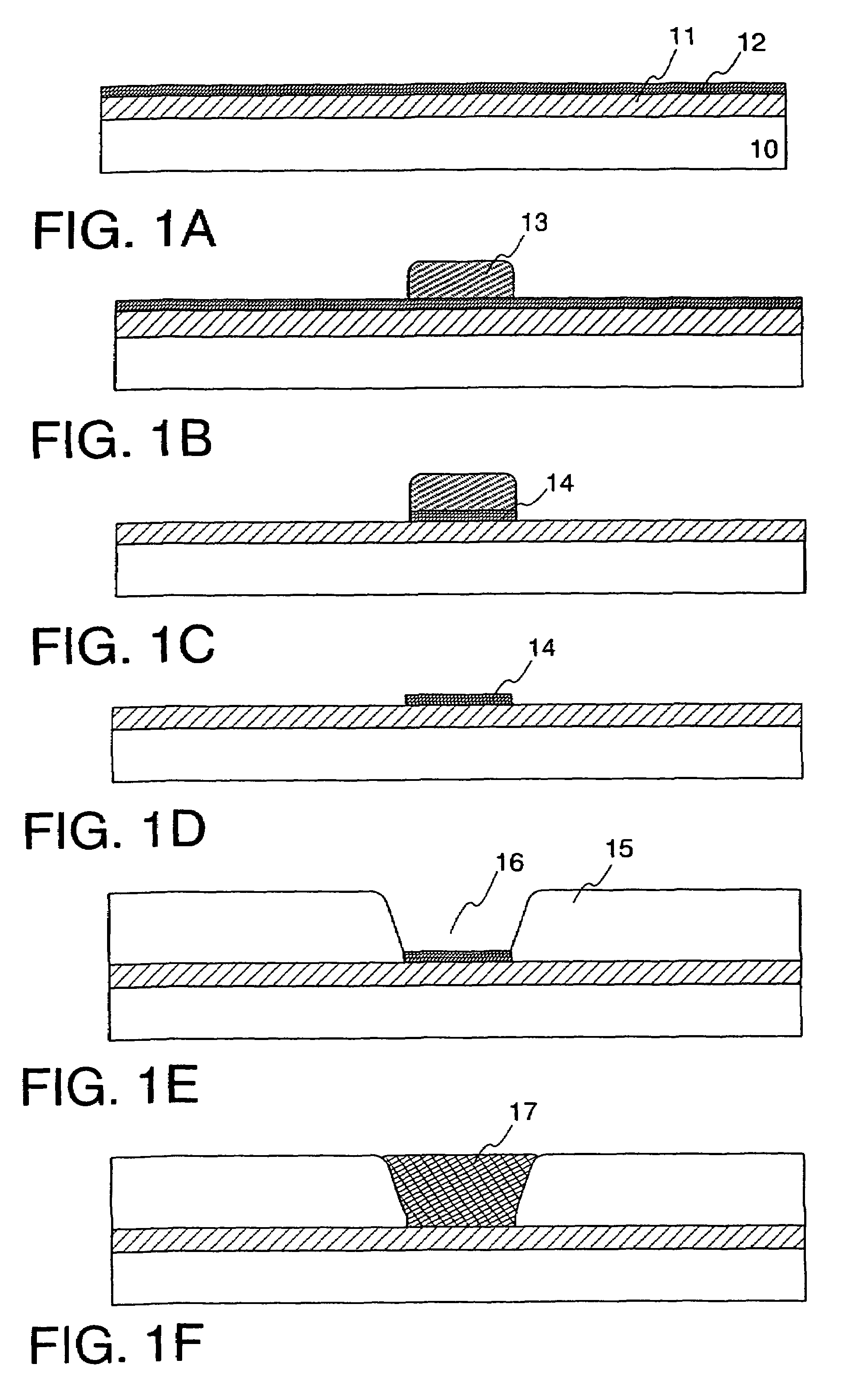

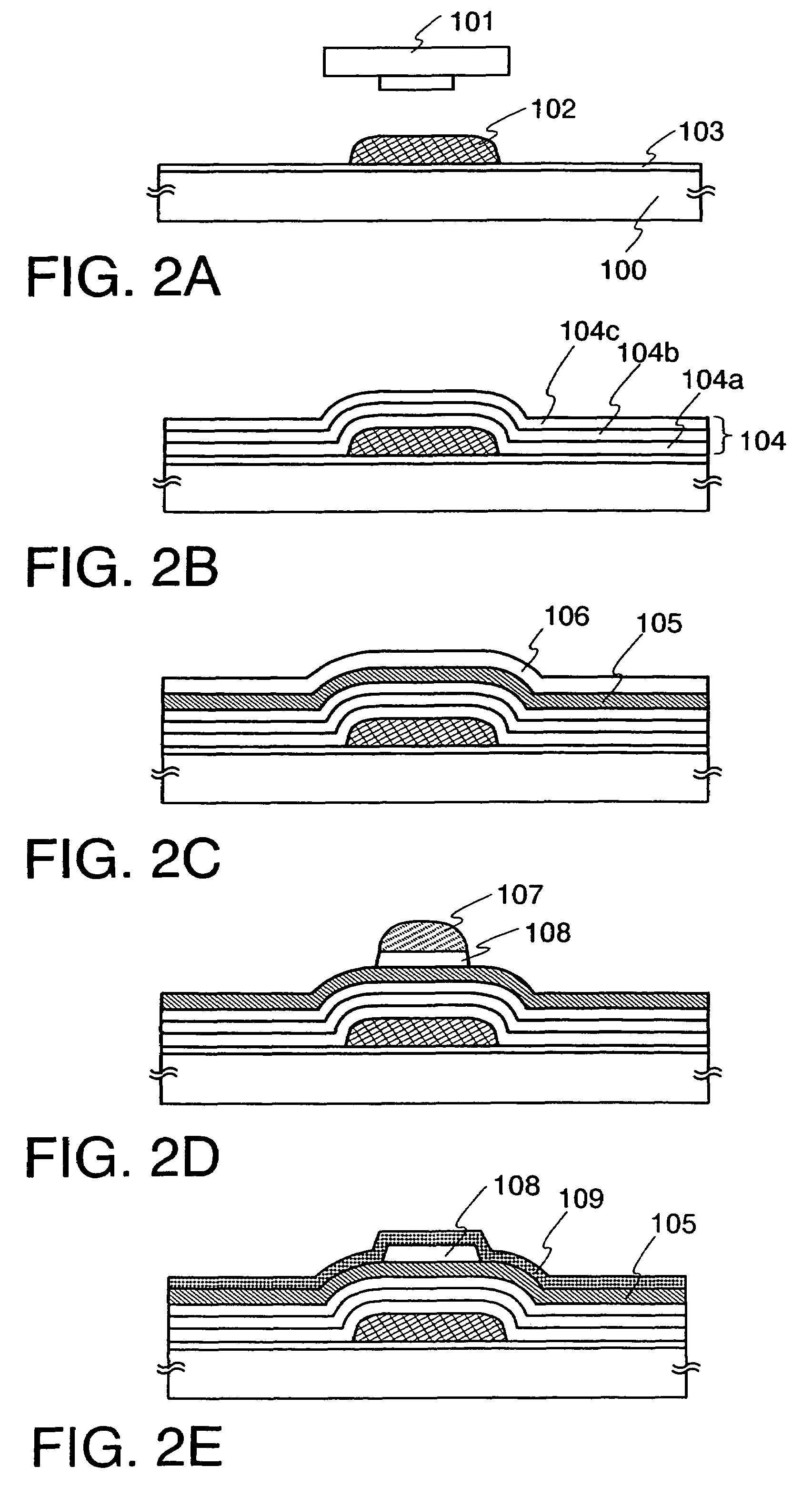

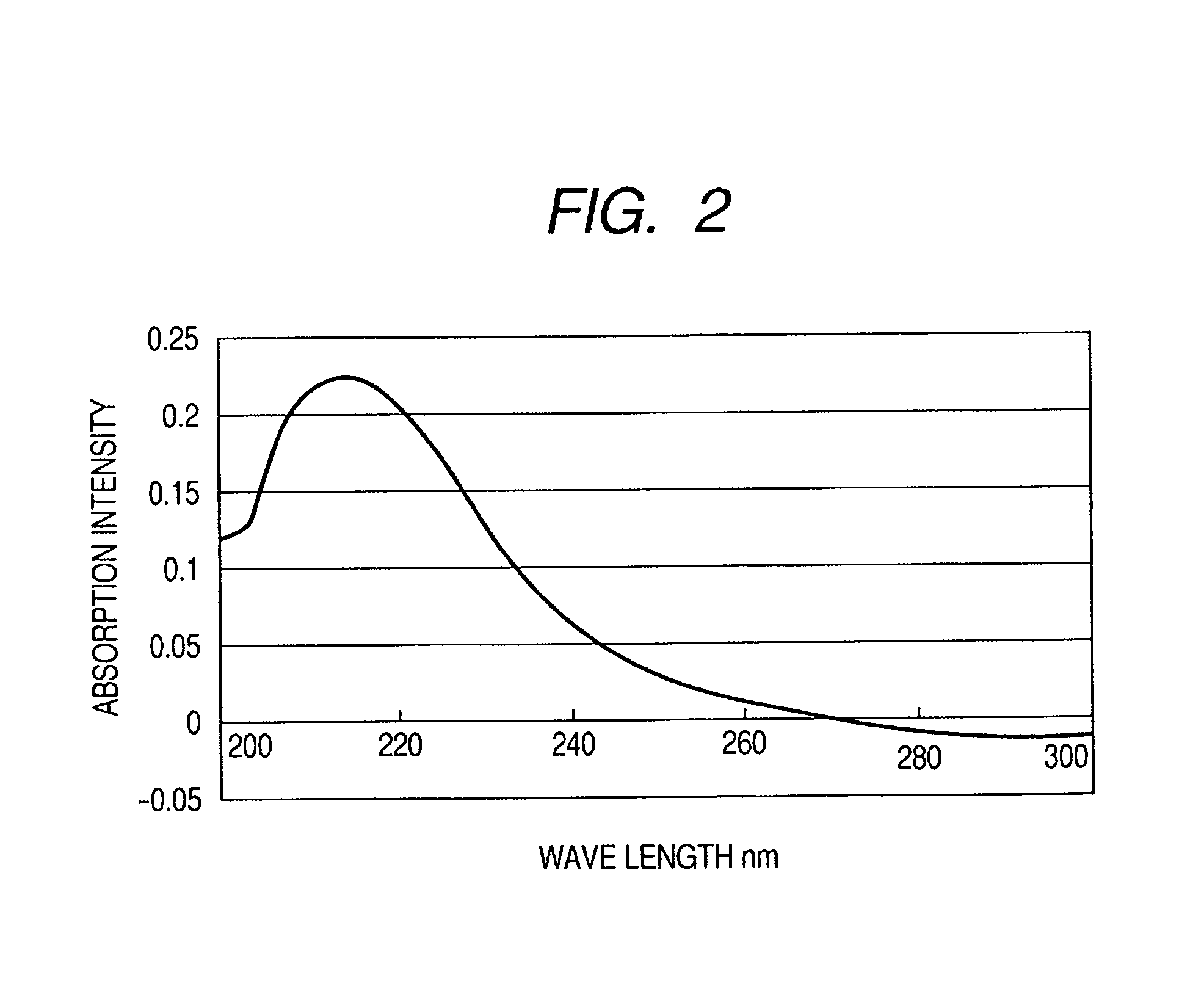

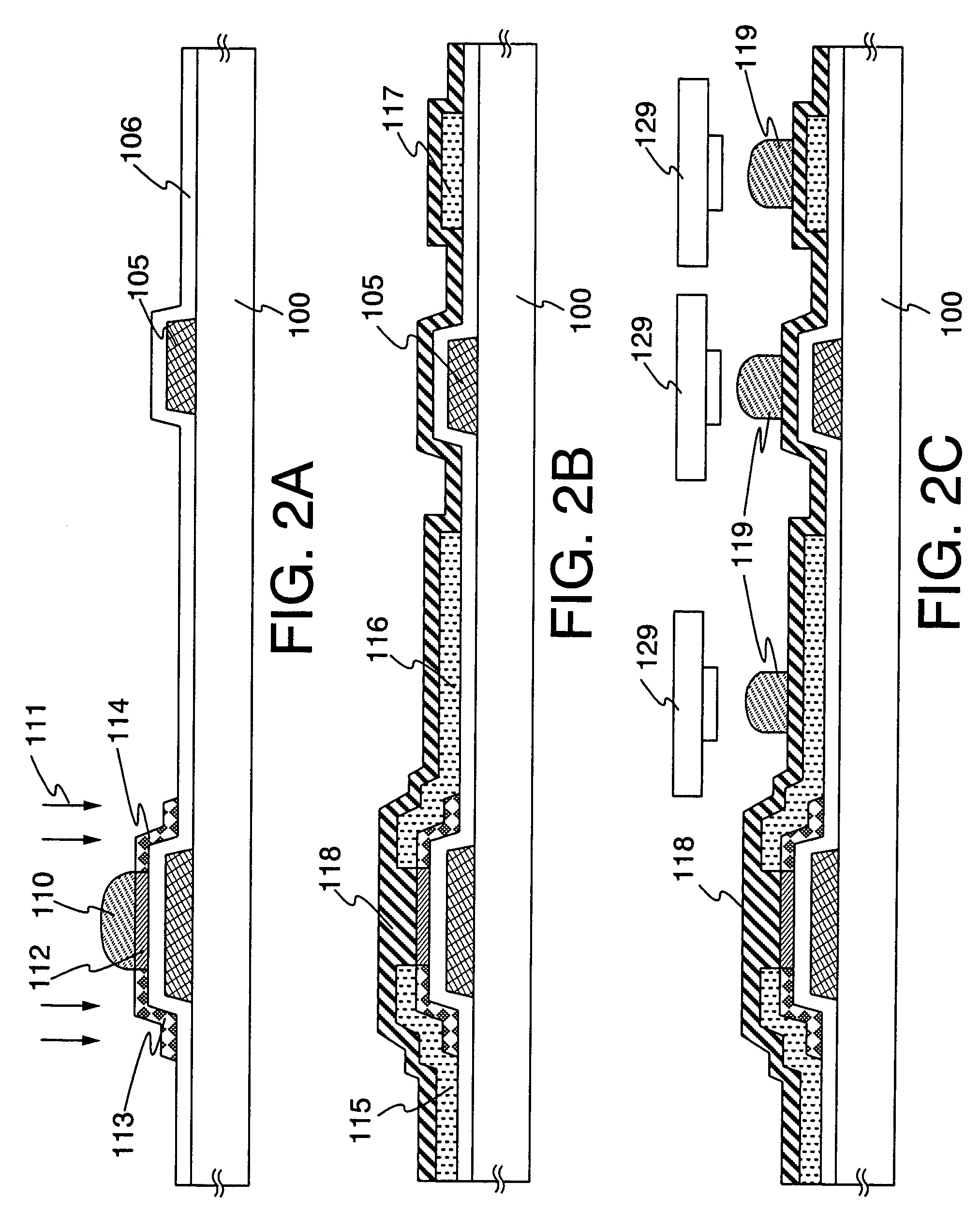

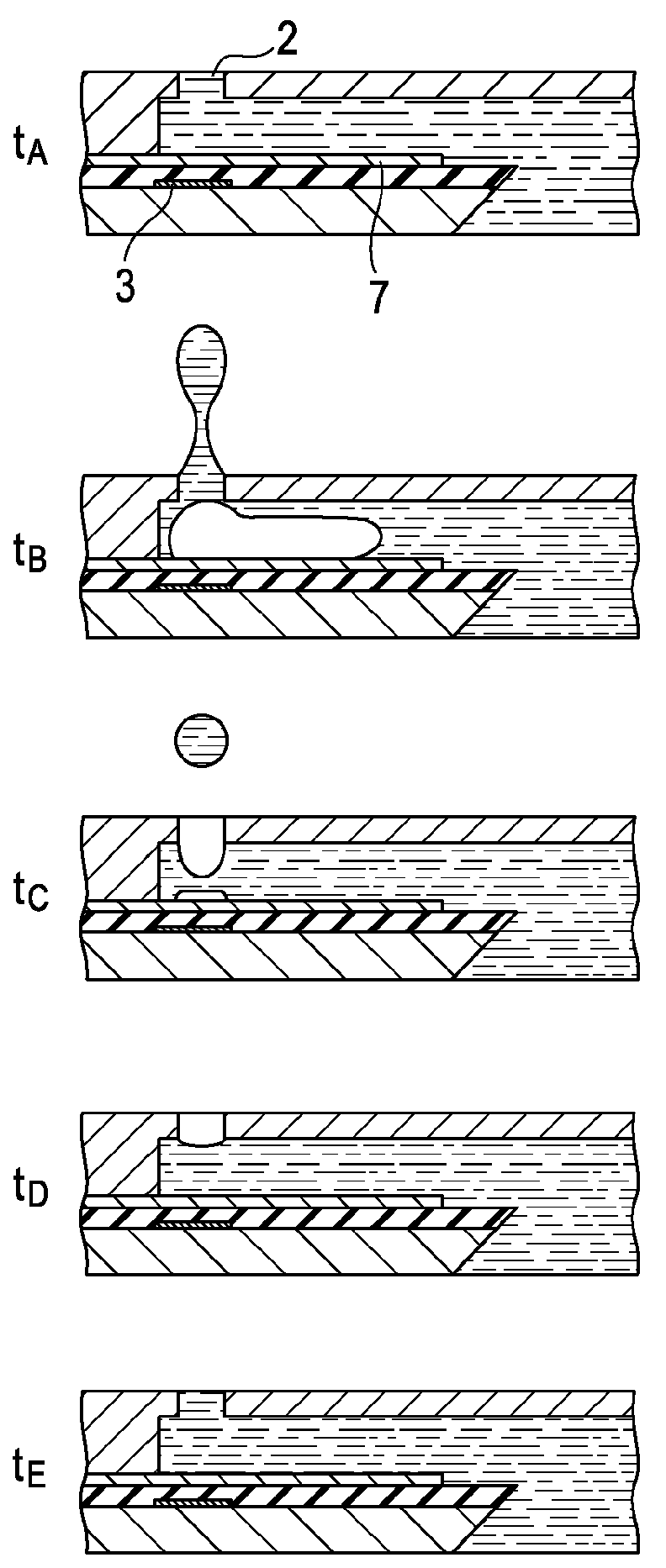

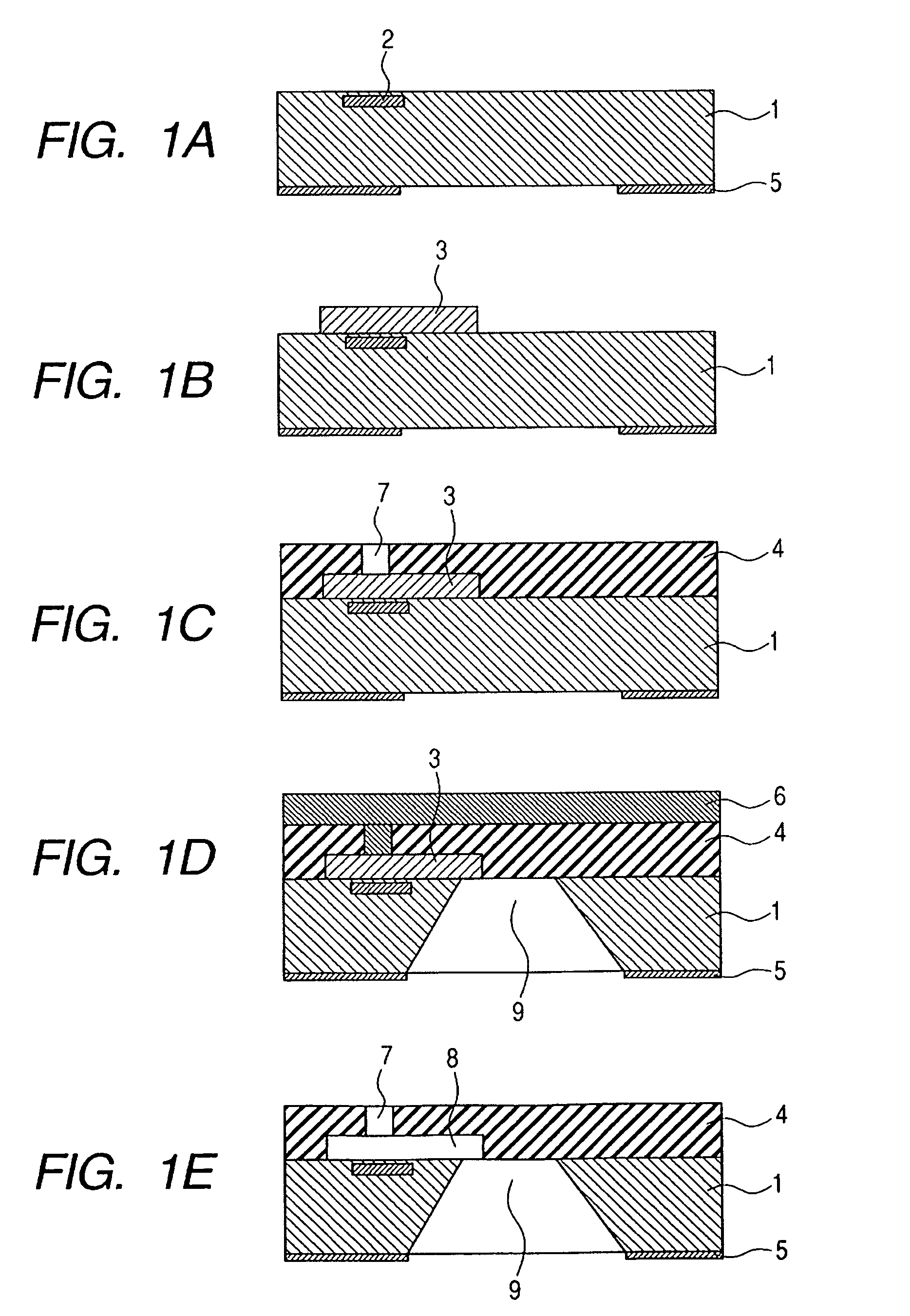

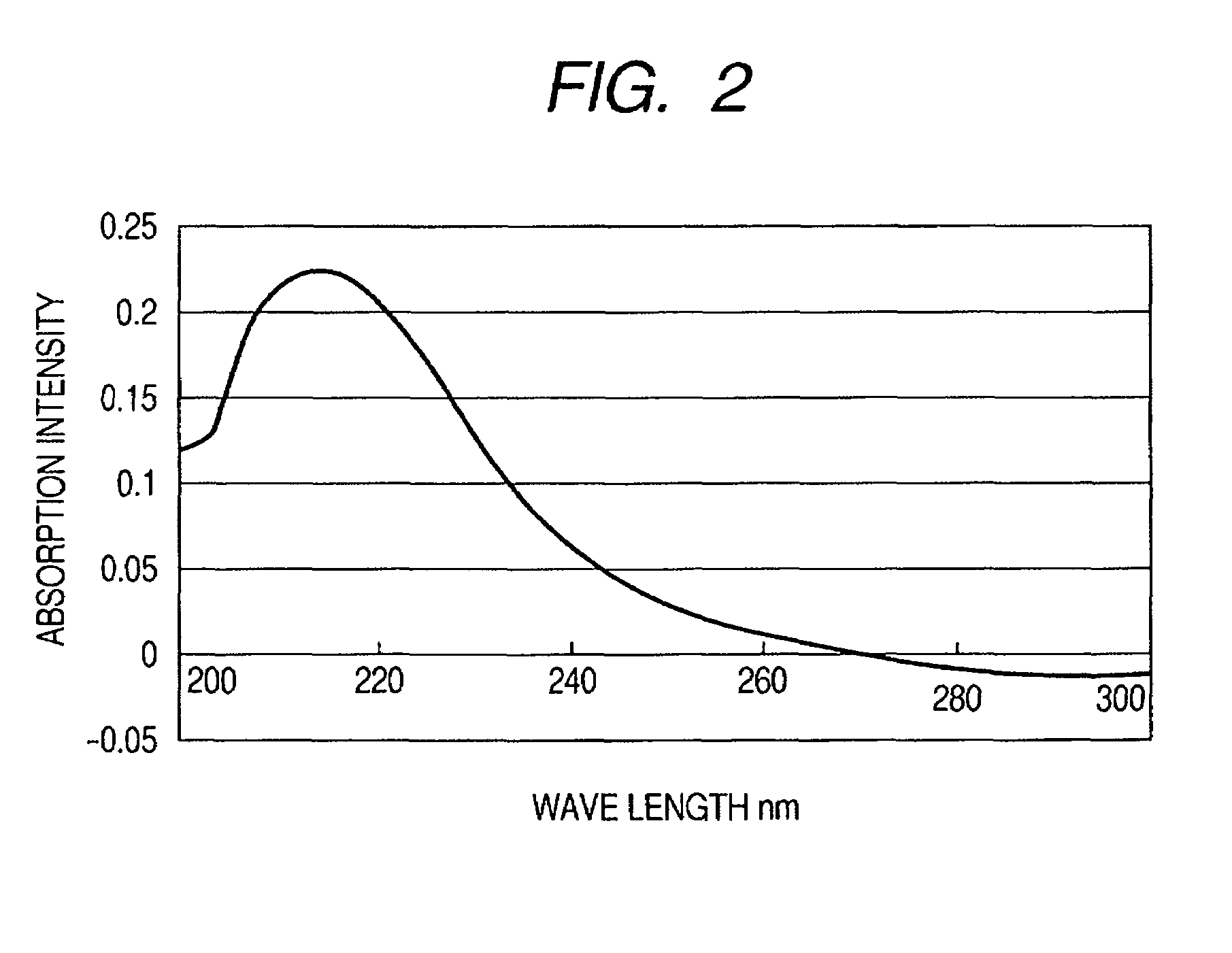

Liquid discharge head manufacturing method, and liquid discharge head obtained using this method

InactiveUS20060277755A1Prevent wrong dischargeWriting implementsMetal-working apparatusMethacrylateChemical compound

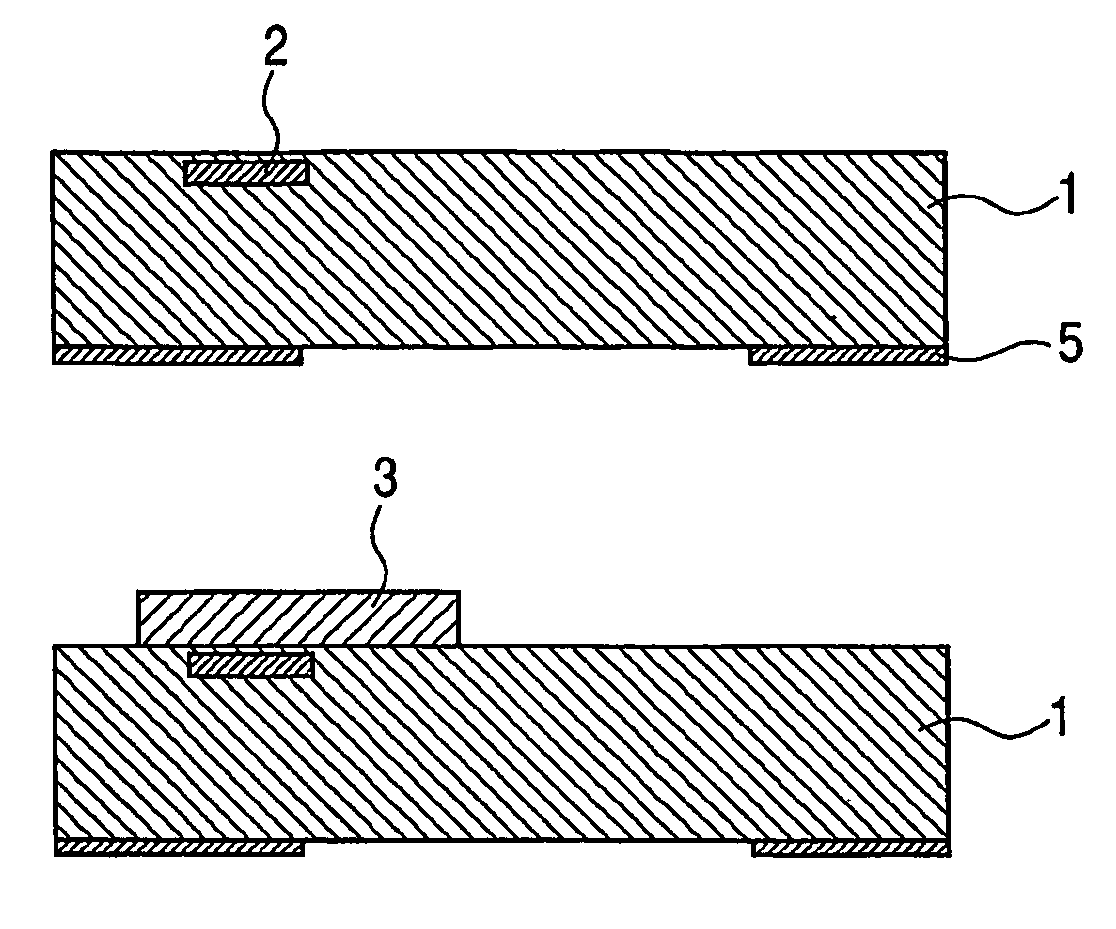

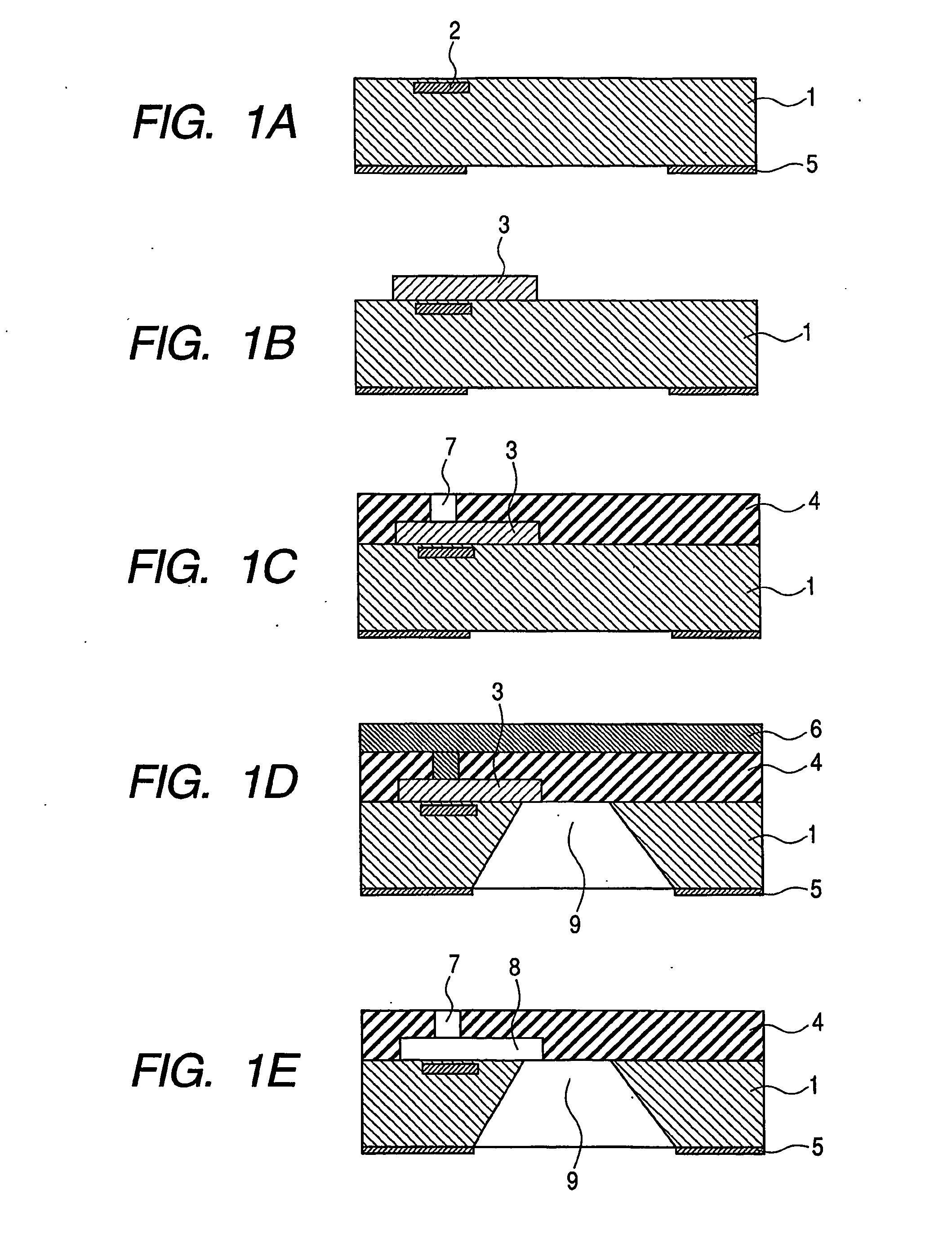

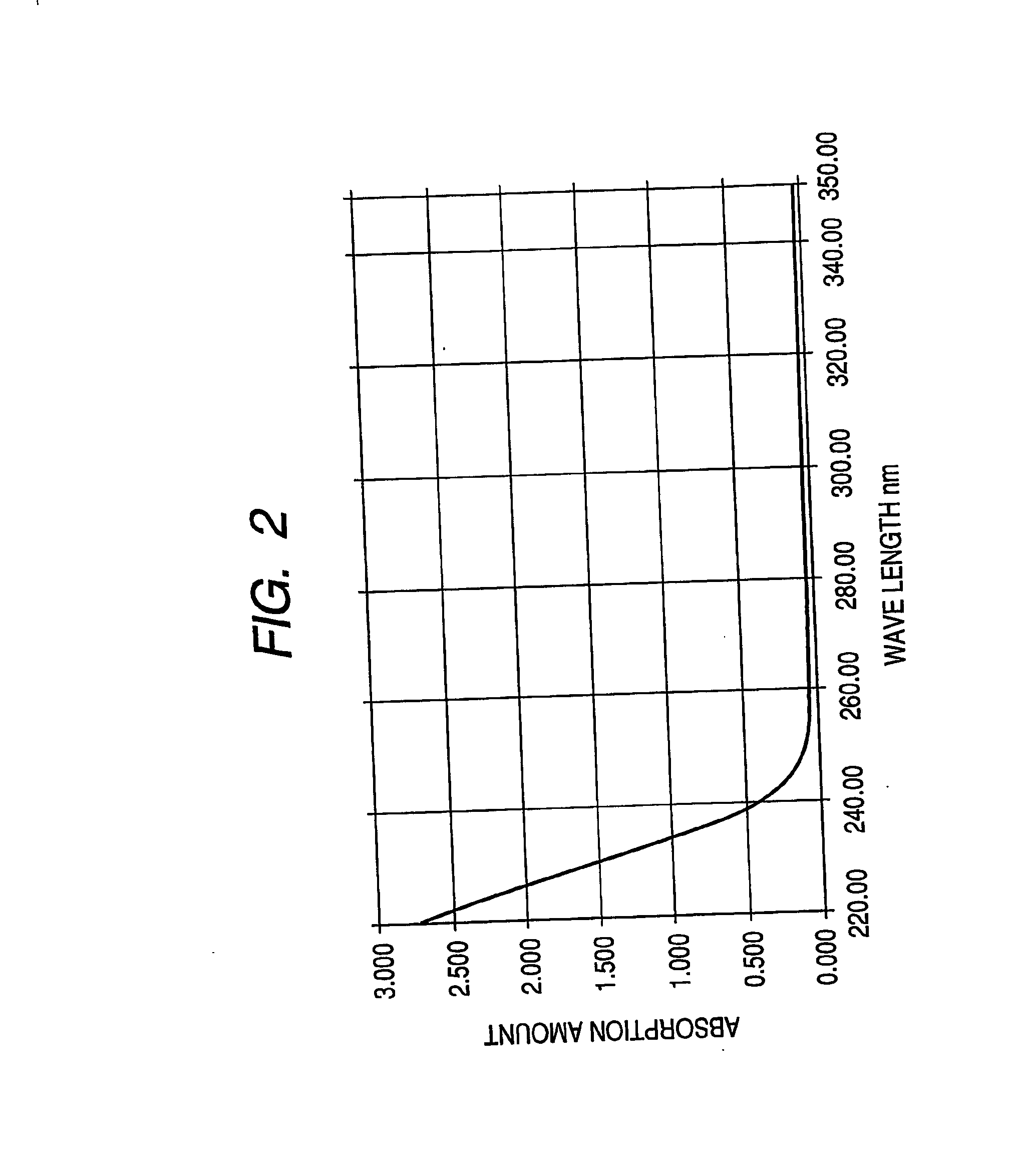

According to the present invention, a method for manufacturing a liquid discharge head includes the steps of: forming a solid layer for forming a flow path on a substrate on which an energy generating element is arranged to generate energy that is used to discharge liquid; forming, on the substrate where the solid layer is mounted, a coating layer for coating the solid layer; forming a discharge port used to discharge a liquid, through a photolithographic process, in the coating layer deposited on the solid layer; and removing the solid layer to form a flow path that communicates with the energy element and the discharge port, whereby a material used for the coating layer contains a cationically polymerizable chemical compound, cationic photopolymerization initiator and an inhibitor of cationic photopolymerization, and whereby a material of the solid layer that forms a boundary with a portion where the discharge port of the coating layer are formed contains a copolymer of methacrylic acid and methacrylate ester.

Owner:CANON KK

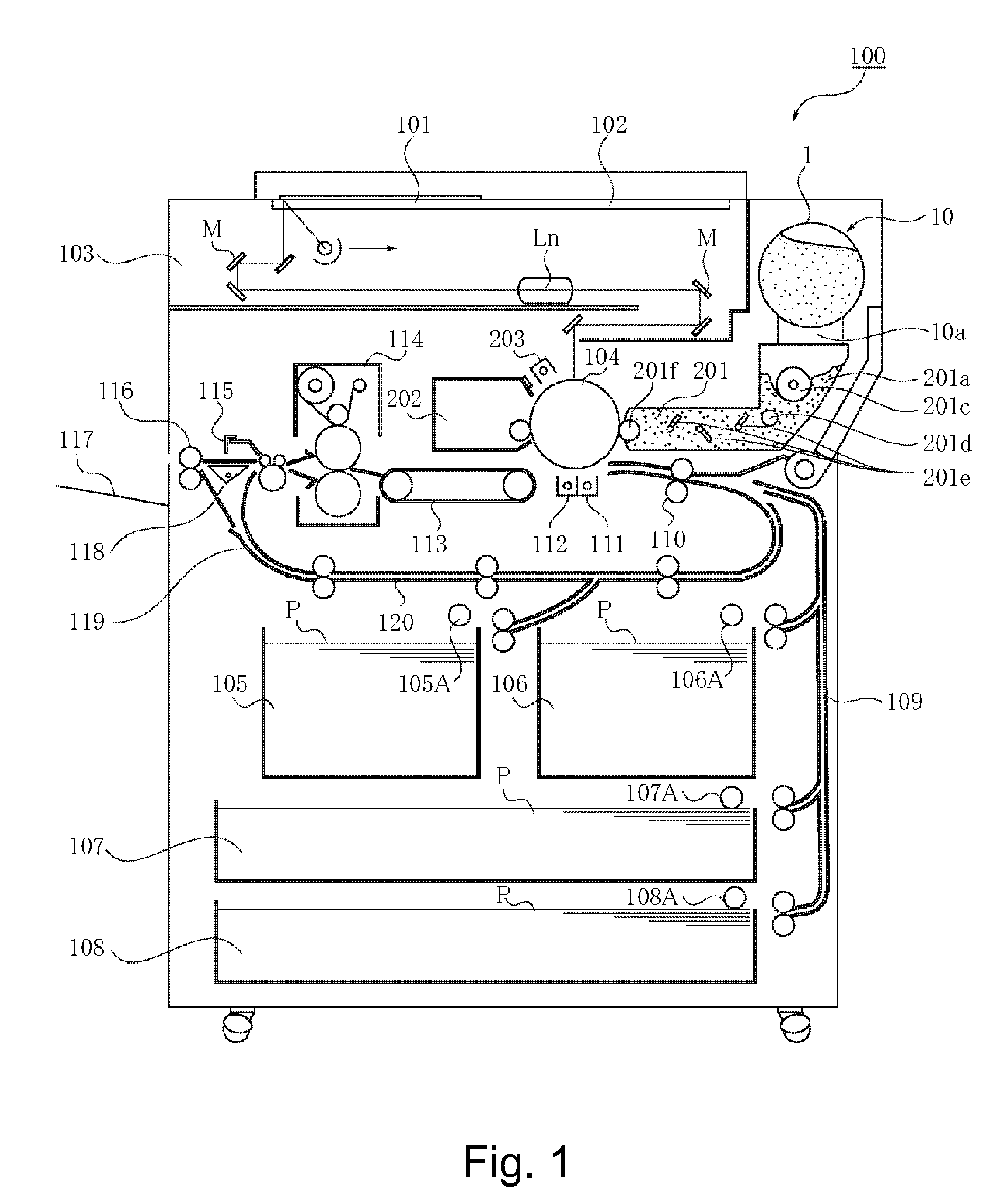

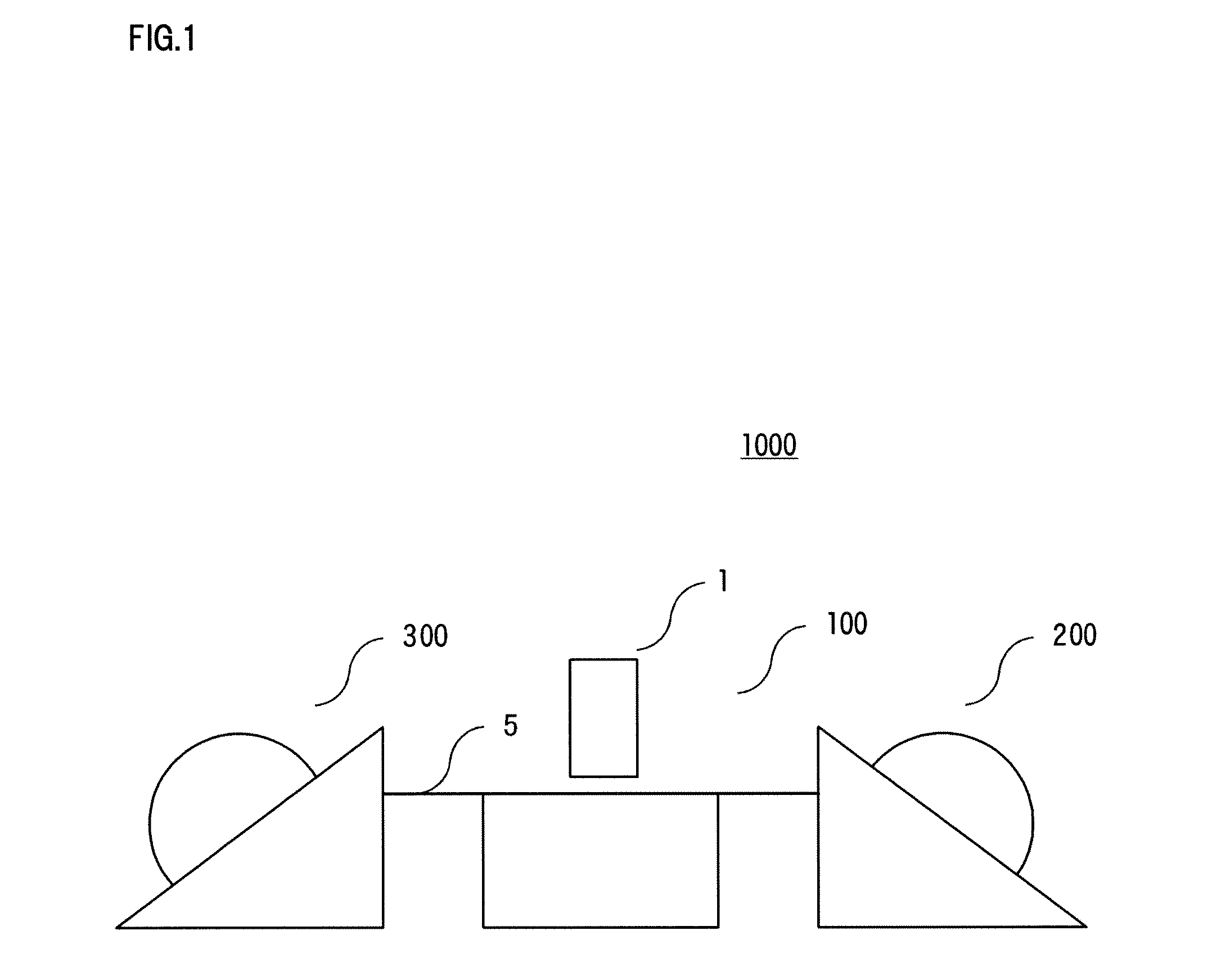

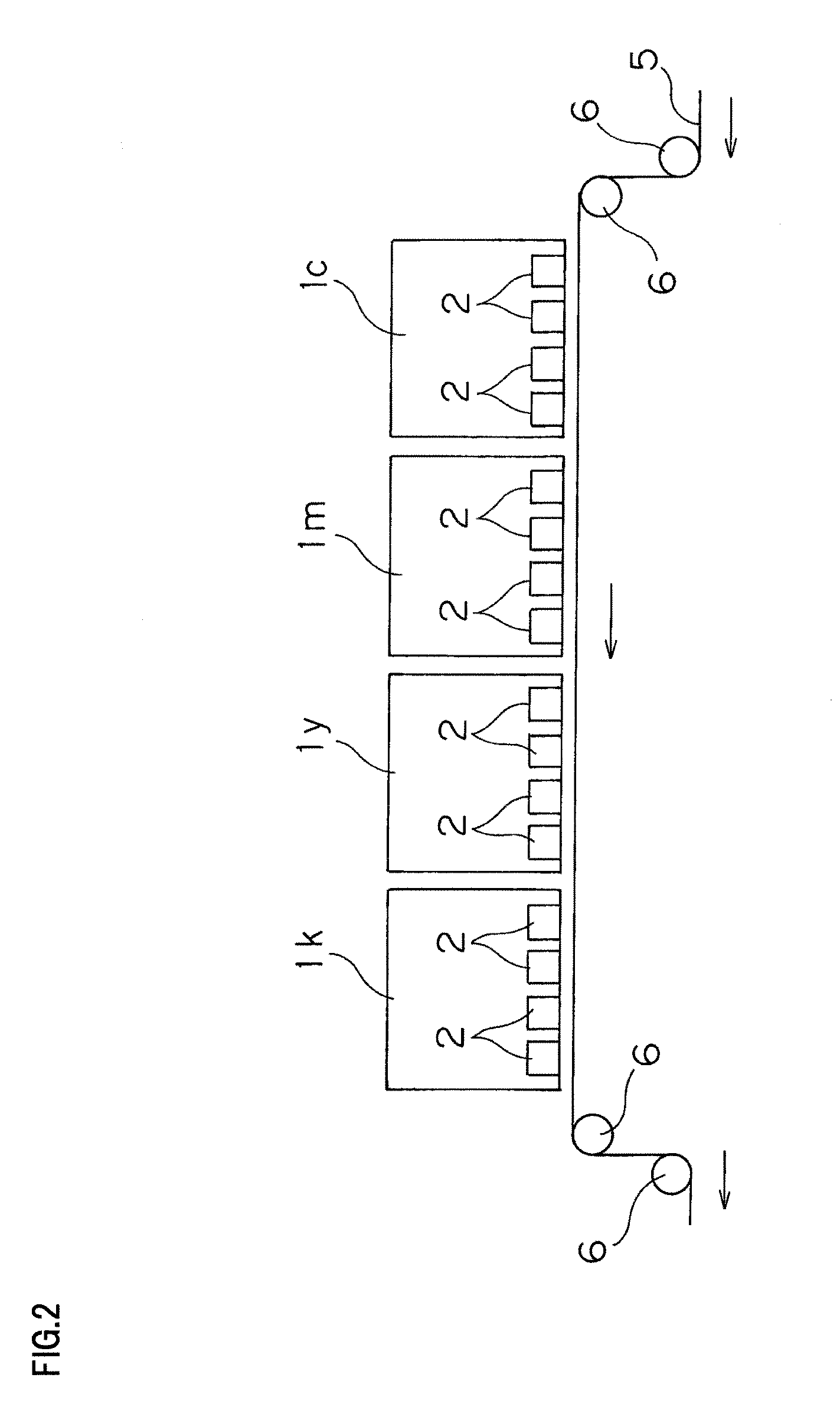

Inkjet printing apparatus

An inkjet printing apparatus 100 includes an inkjet head holder 11 holding inkjet heads 2, and a pair of head cap holders 12 and 13 holding head caps 3. When the inkjet head holder 11 is in a raised position, the head cap holders 12 and 13 are arranged as horizontally juxtaposed in a capping position, where the respective inkjet heads 2 and the respective head caps 3 are opposed to each other, below the inkjet head holder 11. When the inkjet head holder 11 is in a lowered position, the head cap holders 12 and 13 are arranged as vertically superposed in a withdrawn position laterally of a vertical movement area of the inkjet head holder 11.

Owner:DAINIPPON SCREEN MTG CO LTD

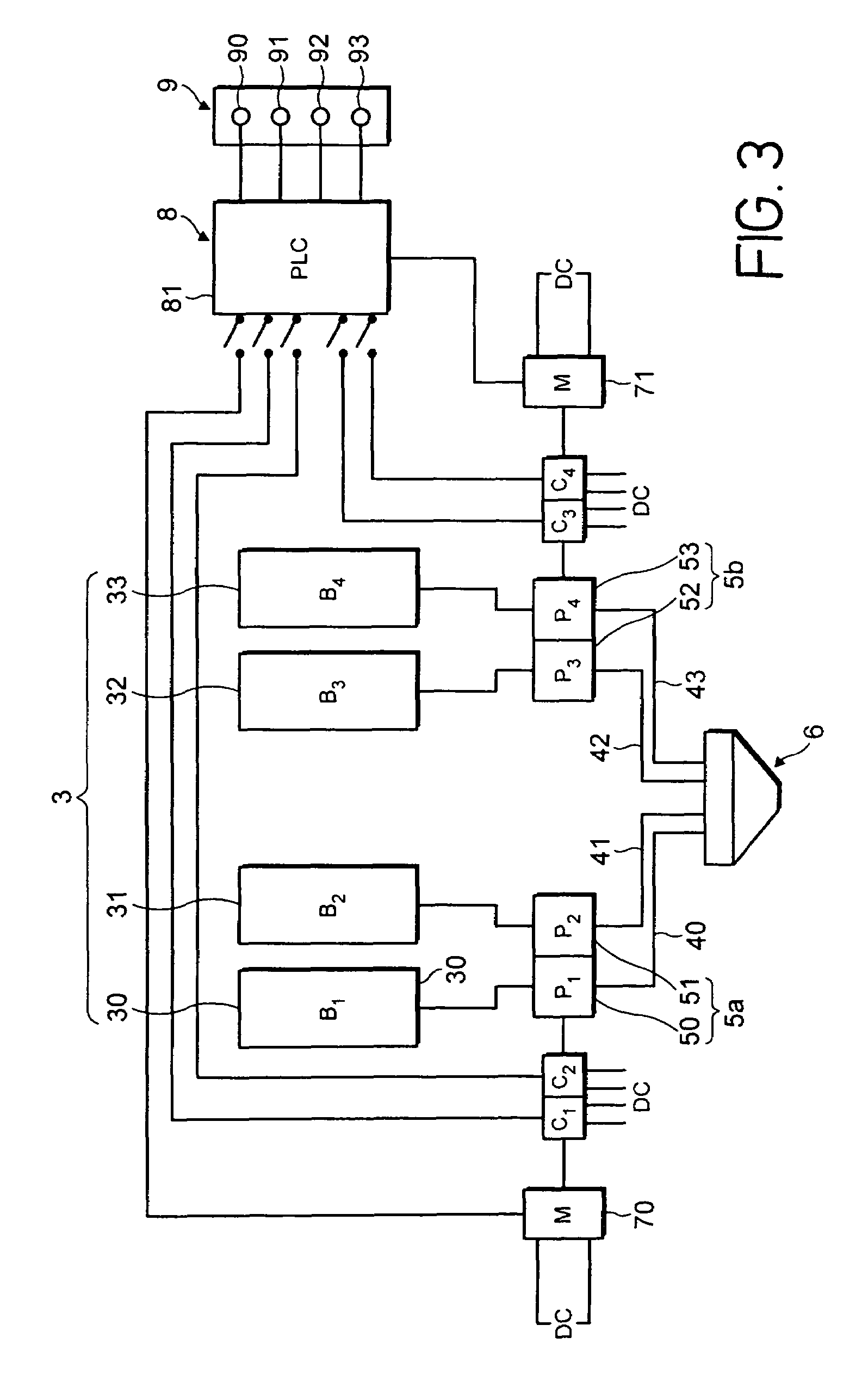

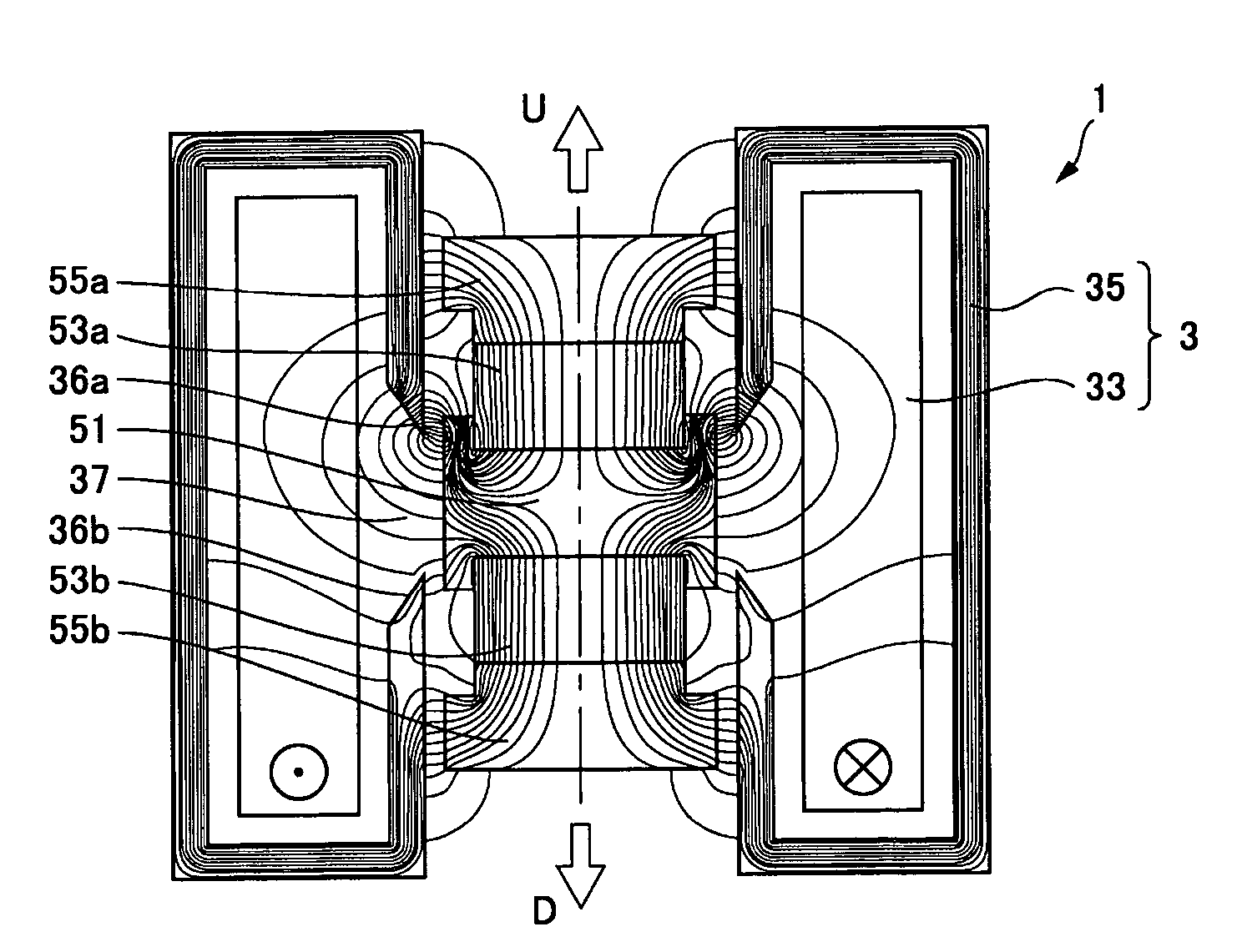

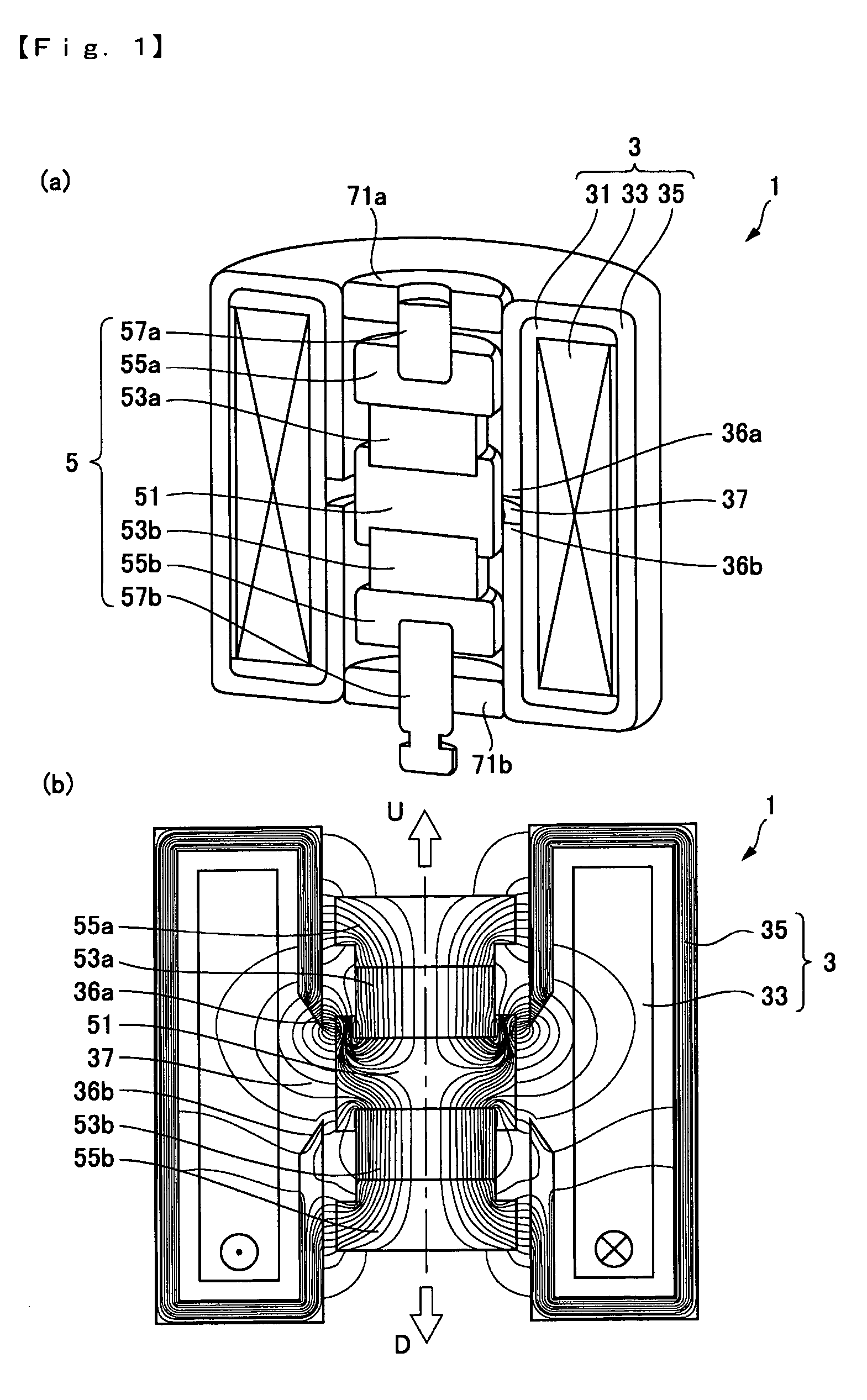

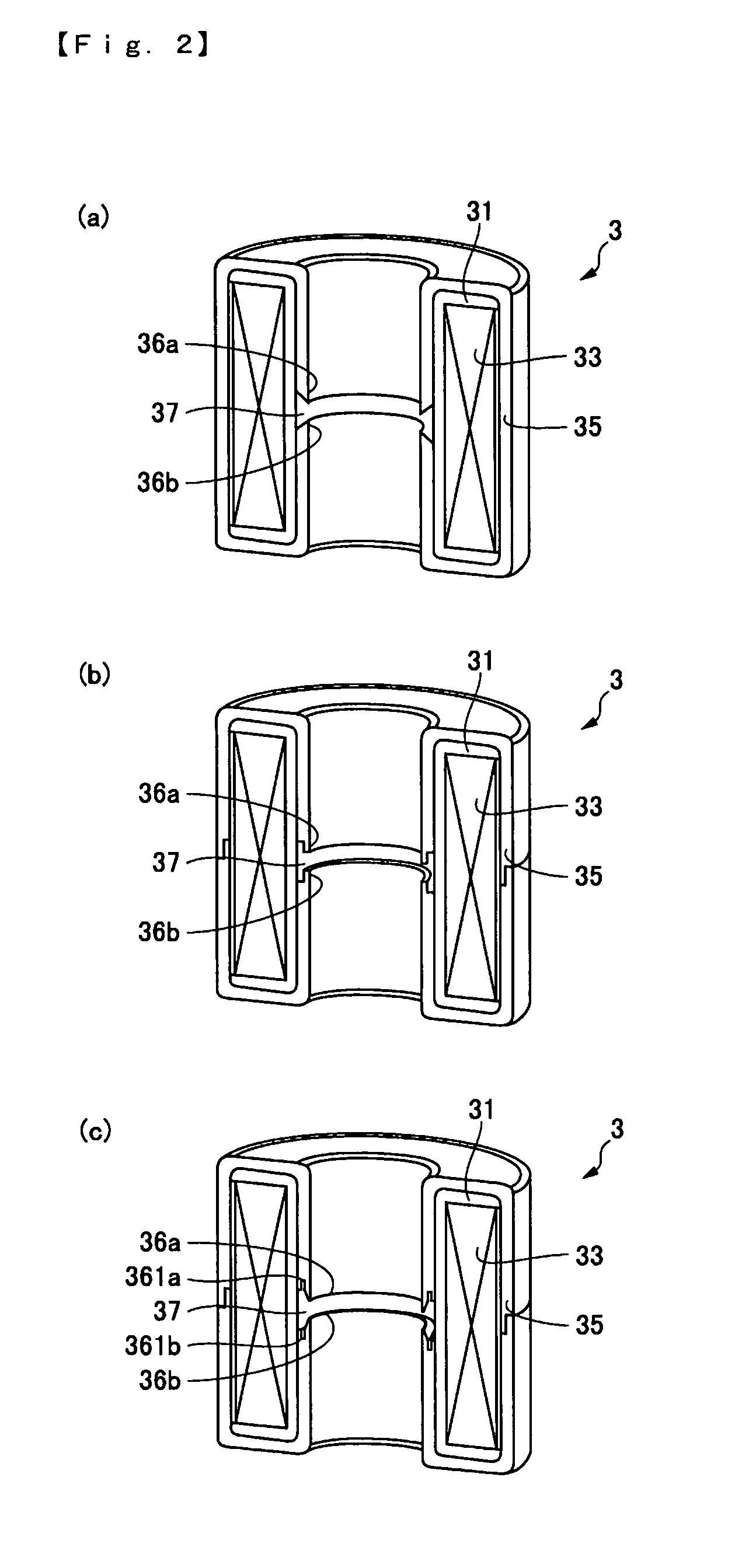

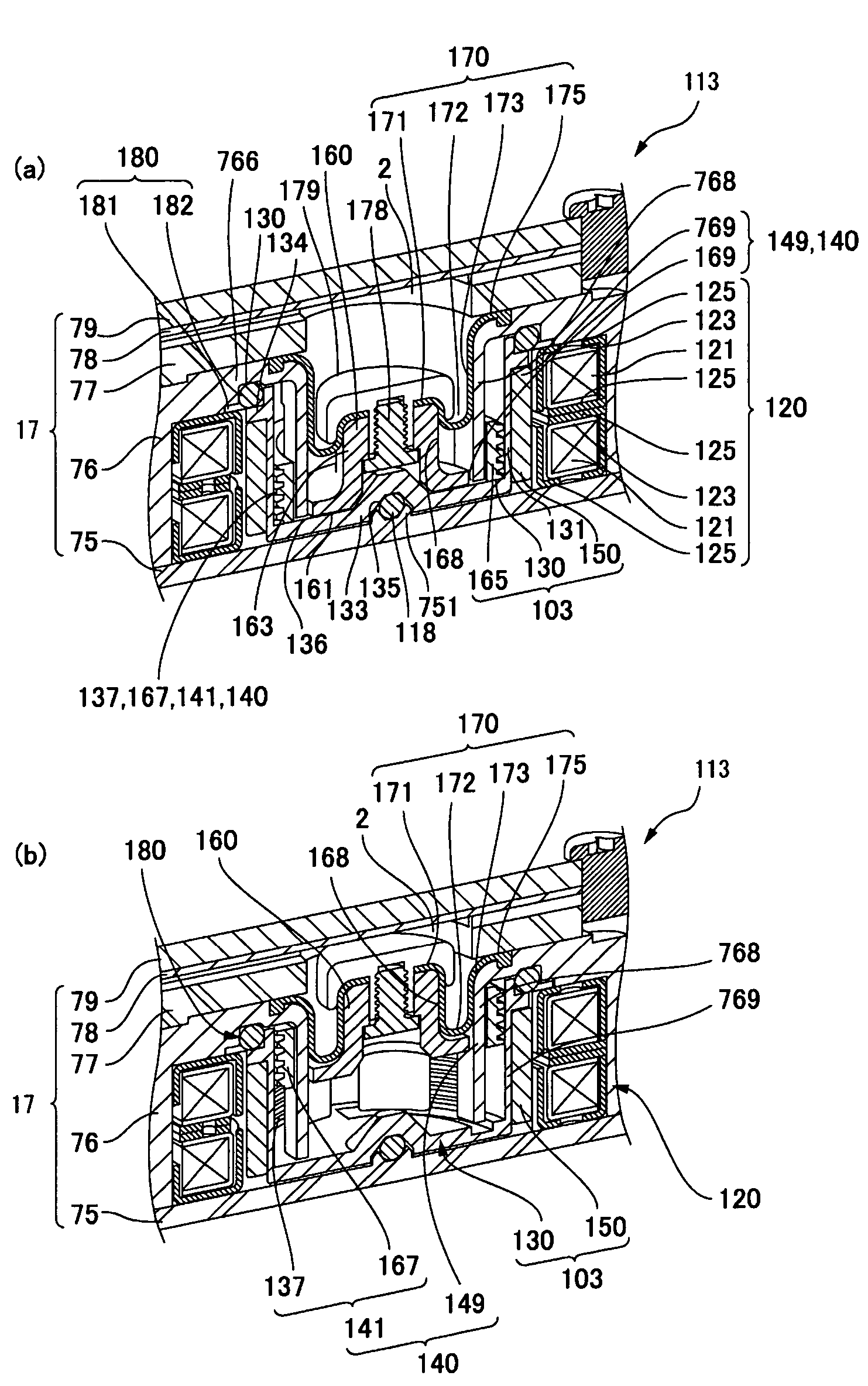

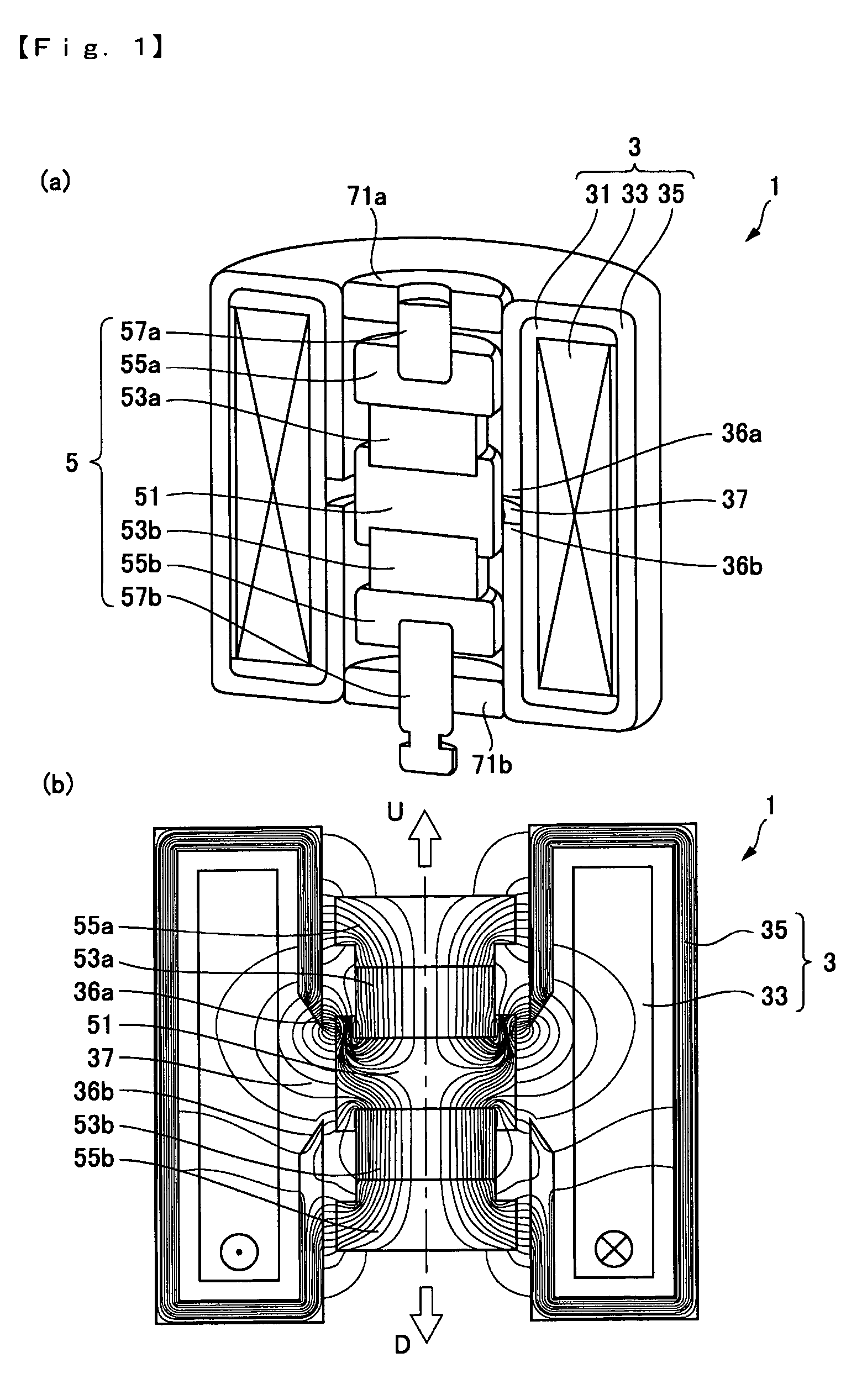

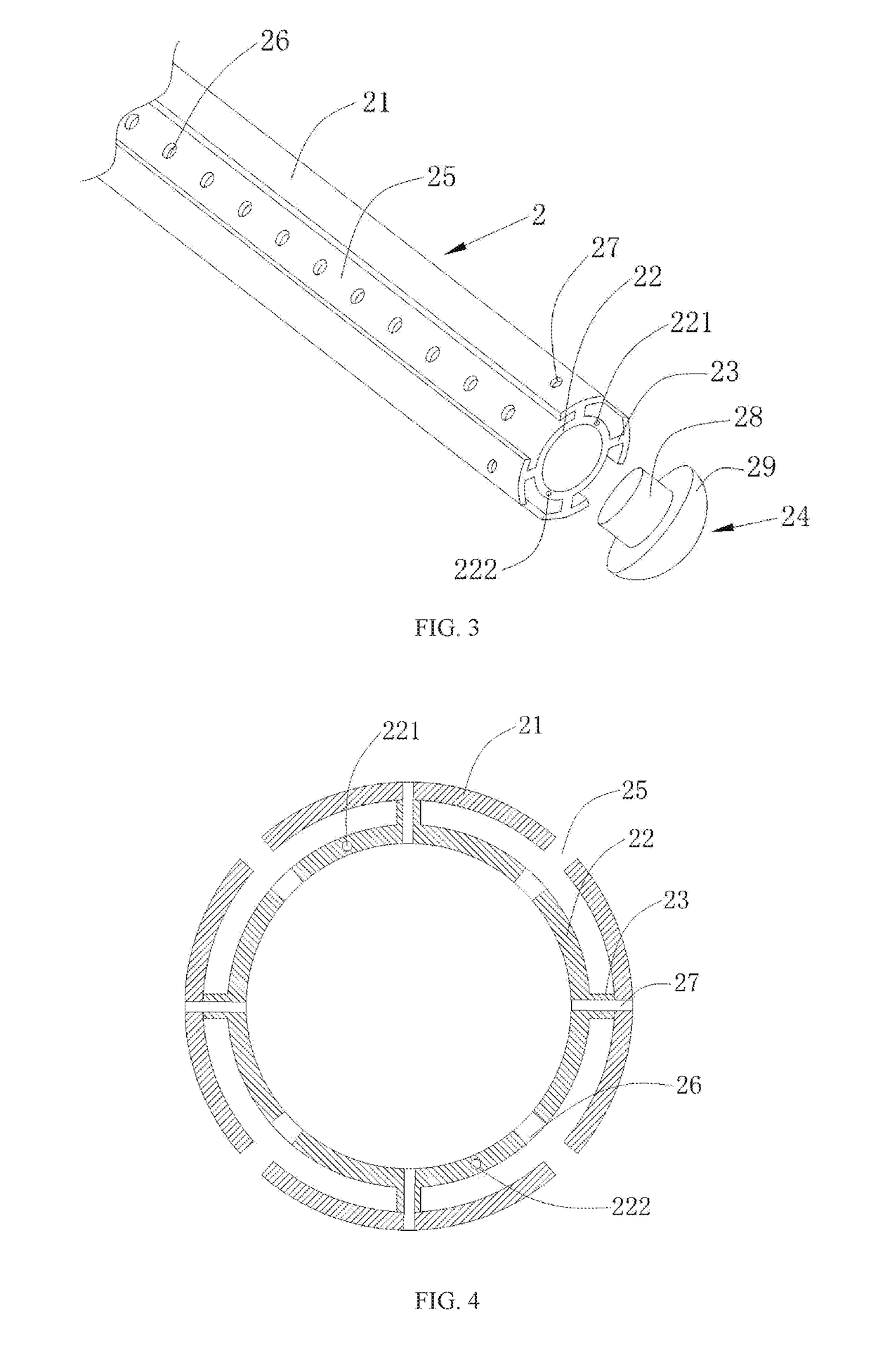

Linear actuator, and valve device and pump device using the same

InactiveUS20060145797A1Large thrustSuitable for mass productionPositive displacement pump componentsFlexible member pumpsElectrical polarityEngineering

A linear actuator may include a fixed body having a coil wound around in a ring-shaped manner and a movable body. The movable body may include a first movable body side yoke which is disposed on the inner side of the coil and a pair of magnets which is laminated on both sides in an axial direction of the first movable body side yoke such that the same polarities of the magnets face the first movable body side yoke. The movable body may be driven in the axial direction. The linear actuator may be applied to a valve device and a pump device.

Owner:SANKYO SEIKI MFG CO LTD

Developer supply container and developer supplying system

ActiveUS20140016967A1Prevent wrong dischargeElectrographic process apparatusReciprocating motionEngineering

In the case that a developer supply container is provided with a feeding portion for feeding a developer by receiving a rotational force and a pump portion for discharging the developer by reciprocation, and the rotational force and a reciprocating force are received from a main assembly side of an image forming apparatus, there is a liability that a driving connection is not properly established between a portion of the developer supply container for receiving the reciprocating force and a portion of the main assembly side for applying the reciprocating force.The developer supply container is provided with a drive converting mechanism for converting the rotational force received from the main assembly side to a force for operating a volume changing type pump.

Owner:CANON KK

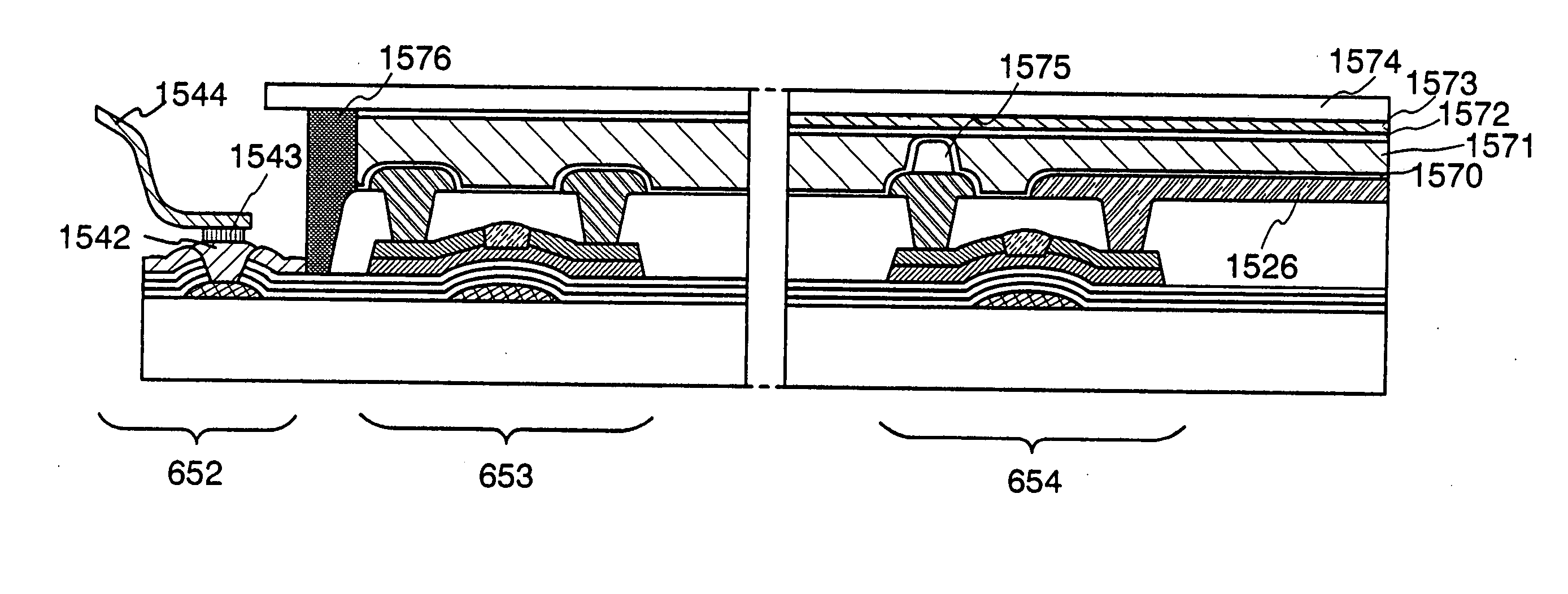

Forming method of contact hole, and manufacturing method of semiconductor device, liquid crystal display device and EL display device

When forming a contact hole by a conventional manufacturing step of a semiconductor device, a resist is required to be formed on almost entire surface of a substrate so as to be applied on a film other than an area in which a contact hole is to be formed, leading to drastically reduced throughput. According to a forming method of a contact hole and a manufacturing method of a semiconductor device, an EL display device and a liquid crystal display device of the invention, an island shape organic film is selectively formed over a semiconductor layer, a conductive layer or an insulating layer, and an insulating film is formed around the island shape organic film to form a contact hole. Therefore, a conventional patterning using a resist is not required, and high throughput and low cost can be achieved.

Owner:SEMICON ENERGY LAB CO LTD

Liquid discharge head manufacturing method, and liquid discharge head obtained using this method

InactiveUS20070099121A1Prevent wrong dischargePhotomechanical apparatusSemiconductor/solid-state device manufacturingChemical compoundEngineering

According to the present invention, a method for manufacturing a liquid discharge head includes the steps of depositing a solid layer for forming a flow path on a substrate on which an energy generating element is arranged to generate energy that is used to discharge liquid, forming, on the substrate where the solid layer is mounted, a coating layer for coating the solid layer, forming a discharge port used to discharge a liquid, through a photolithographic process, in the coating layer formed on the solid layer, and removing the solid layer to form a flow path that communicates with the energy element and the discharge port, whereby a material used for the coating layer contains a cationically polymerizable chemical compound, cationic photopolymerization initiator and a inhibitor of cationic photopolymerization, and whereby a material of the solid layer that forms a boundary with a portion where the discharge port of the coating layer is formed contains a copolymer of methacrylic anhydride and methacrylate ester.

Owner:CANON KK

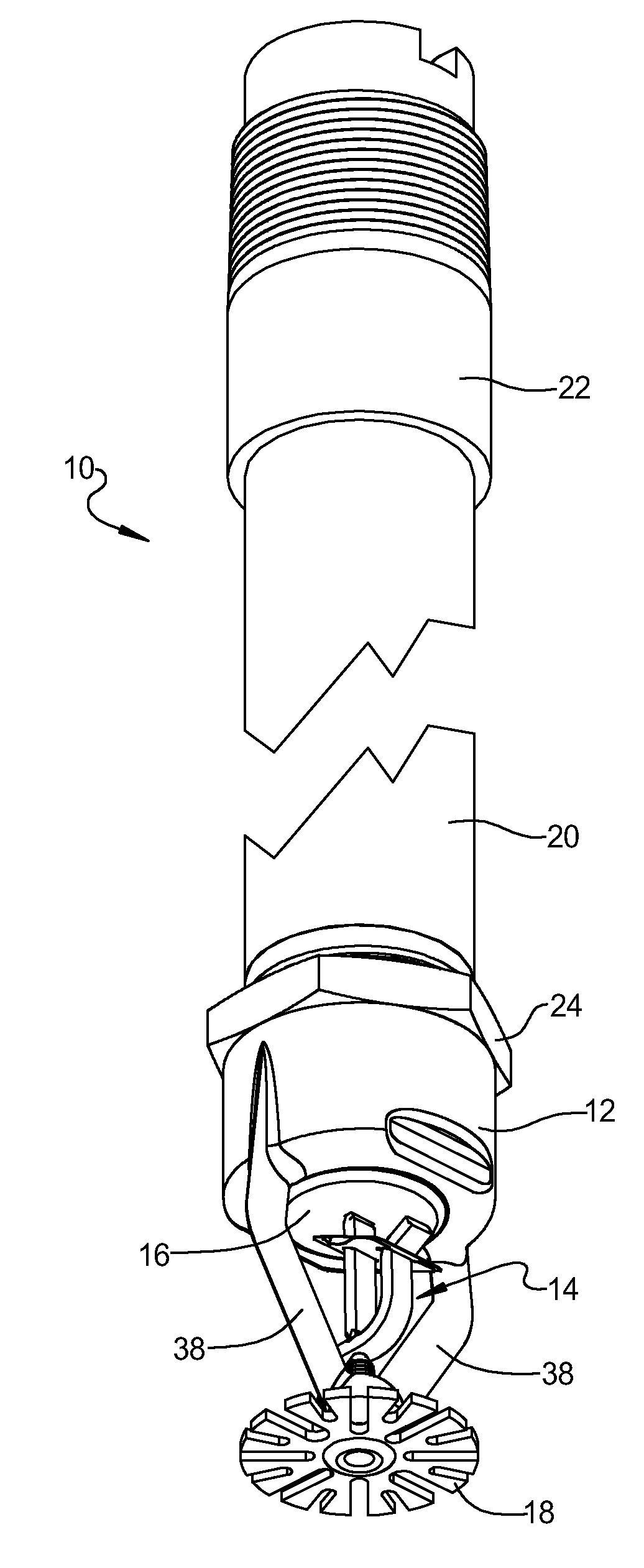

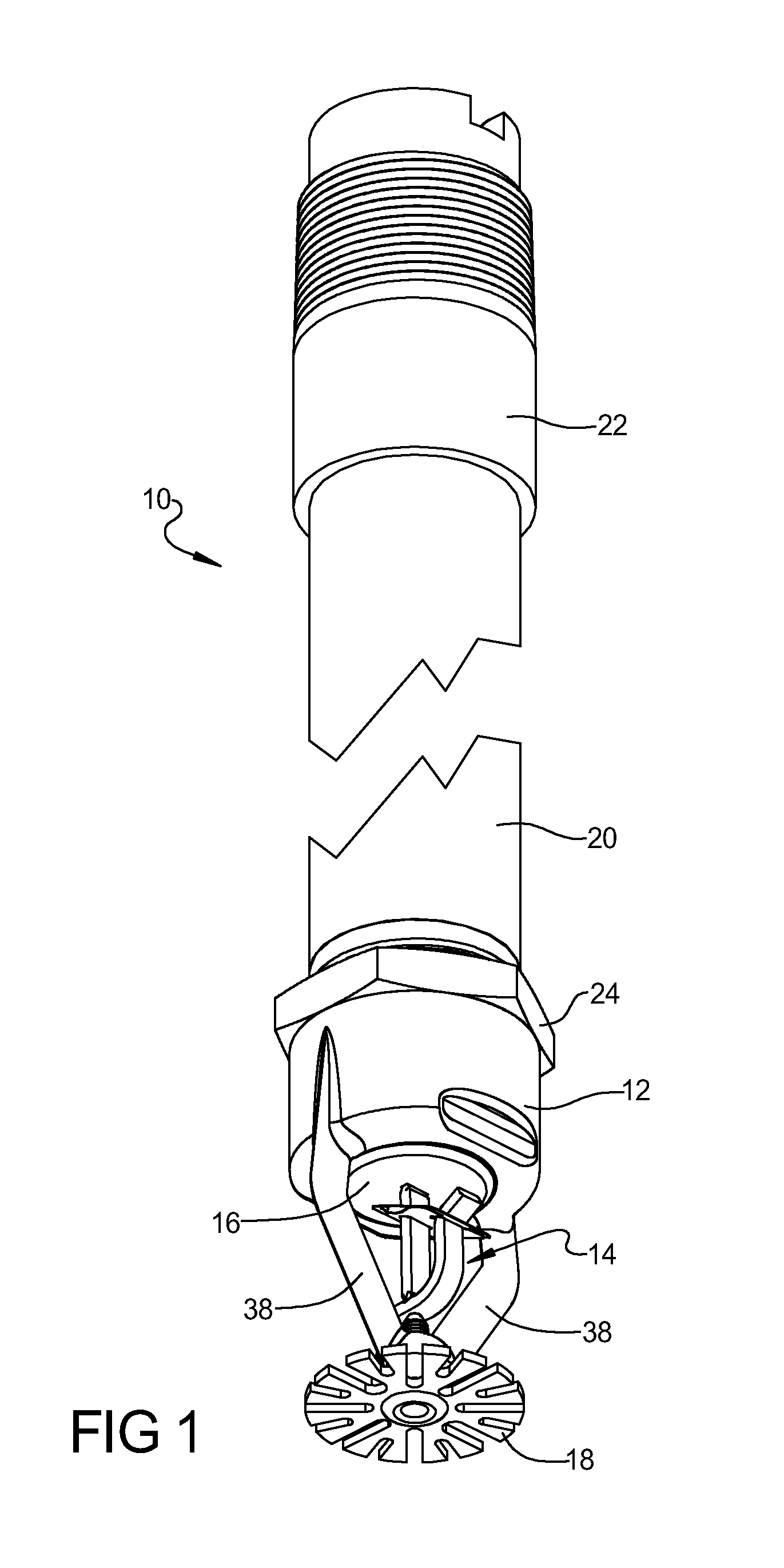

Dry Sprinkler Assembly

InactiveUS20090294138A1Improve toleranceCost effectiveFire rescueThin material handlingEngineeringBiological activation

A dry pipe sprinkler assembly is provided including a sprinkler body having a thermally responsive trigger mounted thereto. A housing, including an inlet end and an outlet end is provided with the outlet end being connected to the sprinkler body. A seal member is disposed at the inlet end of the housing, and a load mechanism extends between the thermally responsive element and the seal member. The load mechanism may include a support portion, a passage tube portion, and an outlet orifice portion slidably received within the housing and movable within the housing upon activation of the thermally responsive trigger to allow the seal member to be dislodged from the inlet end of the housing to allow suppressant fluid to flow therethrough. The dry pipe sprinkler assembly allows the use of different outlet orifice members to provide dry pipe sprinkler assemblies having different K factors while utilizing common components for the remaining dry pipe sprinkler assembly.

Owner:VIKING

Pump apparatus

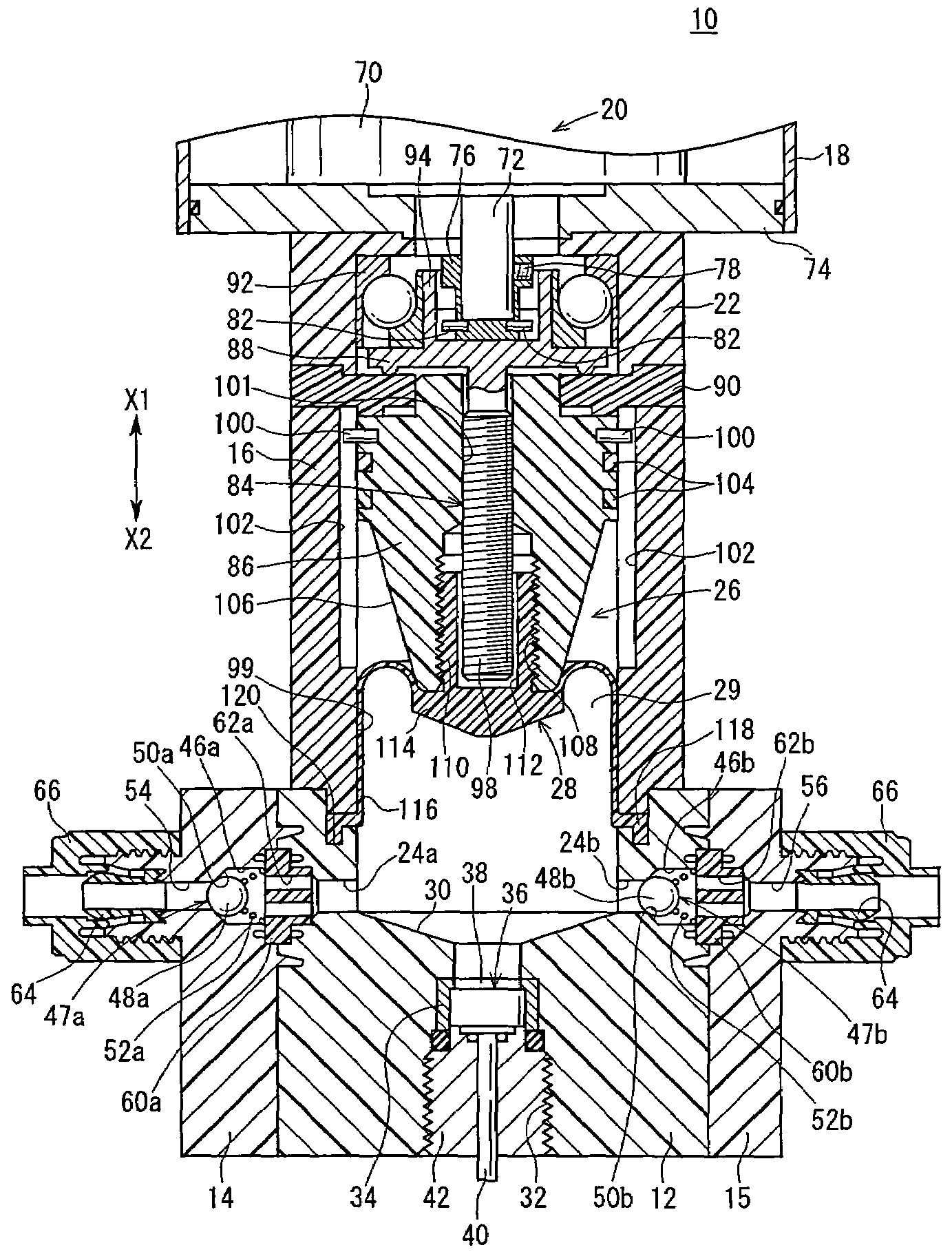

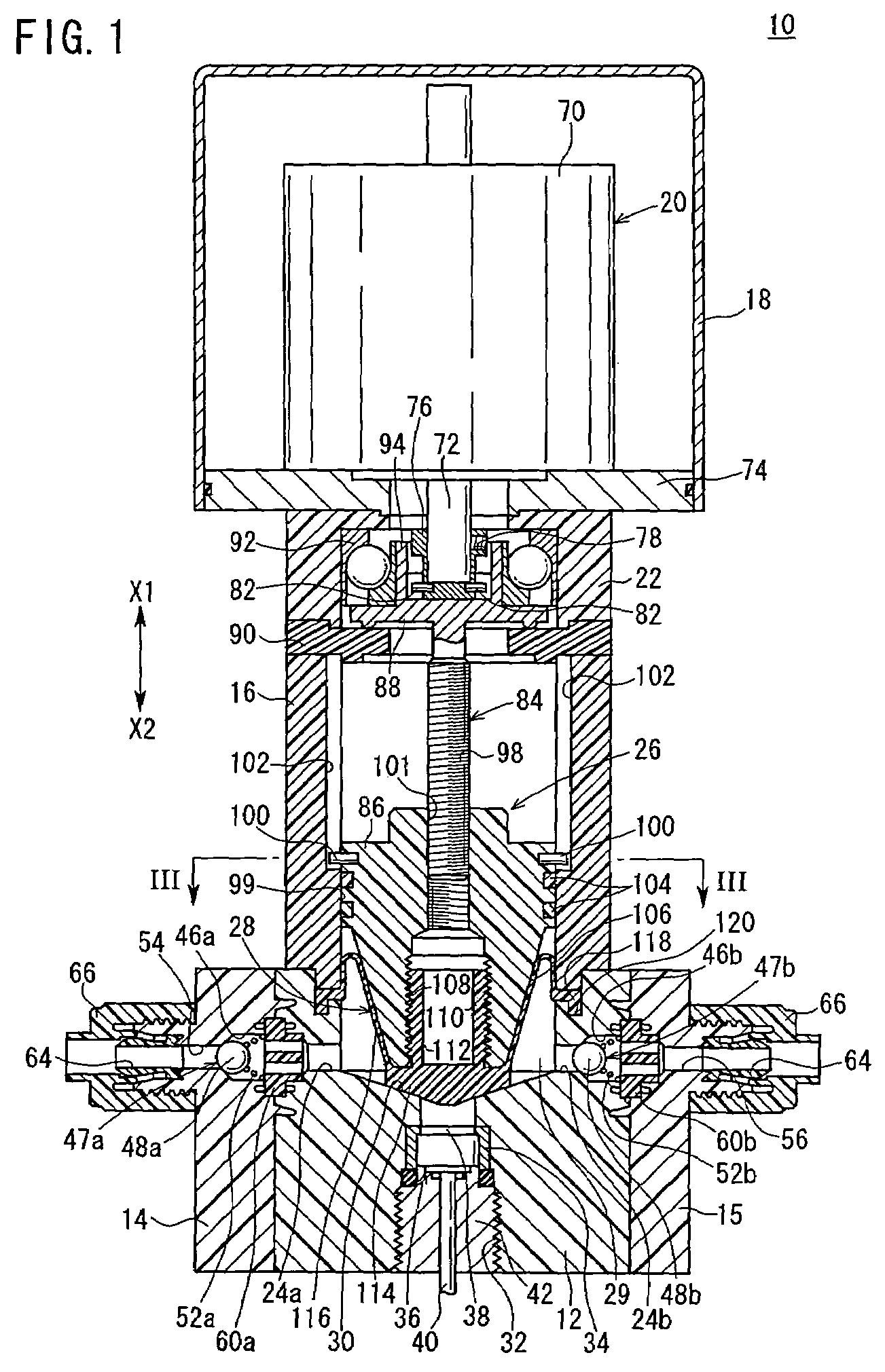

ActiveUS7293967B2Low costPrevent wrong dischargeFluid parameterFlexible member pumpsPump chamberEngineering

A constant rate discharge pump comprises a rotary shaft which is rotatable together with a rotary driving source, a piston which is displaceable in an axial direction in a pump chamber of a body by the rotation of the rotary shaft and which has a tapered surface having diameters reduced downwardly on an outer circumference thereof, and a skirt section which is disposed on the piston and which extends radially outwardly. The constant rate discharge pump further includes a valve plug membrane of a resin material which is displaceable together with the piston, and a pressure sensor installed in the body which detects a pressure of a fluid flowing through the pump chamber.

Owner:SMC CORP

Linear actuator, and valve device and pump device using the same

InactiveUS7537437B2Large thrustSuitable for mass productionPositive displacement pump componentsFlexible member pumpsElectrical polarityEngineering

A linear actuator may include a fixed body having a coil wound around in a ring-shaped manner and a movable body. The movable body may include a first movable body side yoke which is disposed on the inner side of the coil and a pair of magnets which is laminated on both sides in an axial direction of the first movable body side yoke such that the same polarities of the magnets face the first movable body side yoke. The movable body may be driven in the axial direction. The linear actuator may be applied to a valve device and a pump device.

Owner:SANKYO SEIKI MFG CO LTD

Image forming apparatus and process cartridge

ActiveUS20060024100A1Avoid damageAvoid less flexibilityElectrographic process apparatusElectrography/magnetographyImage formationEngineering

Owner:FUJIFILM BUSINESS INNOVATION CORP

Image forming apparatus using electrophotography and process cartridge

ActiveUS7177582B2Avoid damageAvoid deformationElectrographic process apparatusImage formationEngineering

Owner:FUJIFILM BUSINESS INNOVATION CORP

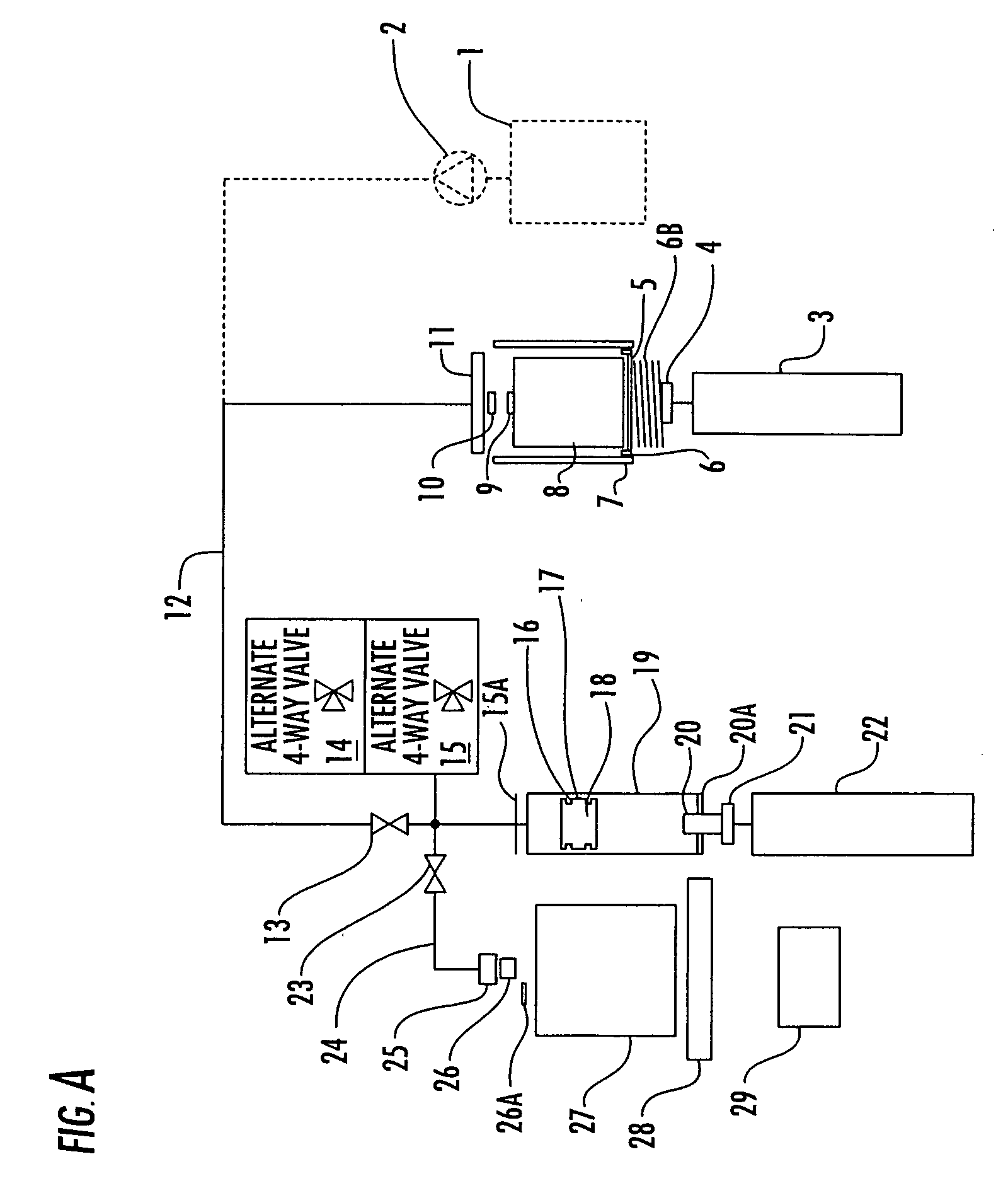

Methodology and apparatus for storing and dispensing liquid components to create custom formulations

InactiveUS20060048841A1Opportunities decreasePrevent wrong dischargeMixer accessoriesLiquid transferring devicesEngineeringVALVE PORT

The invention is directed to methodologies and apparatuses in which materials are dispensed in order to create a desired finished product. The present invention improves upon the container in which the material is stored, shipped and used and does so by incorporating a pressure responsive silicone dispense valve configured to allow the dispensing of a specific amount of material through it in a controllable, metered fashion.

Owner:GFI INNOVATIONS

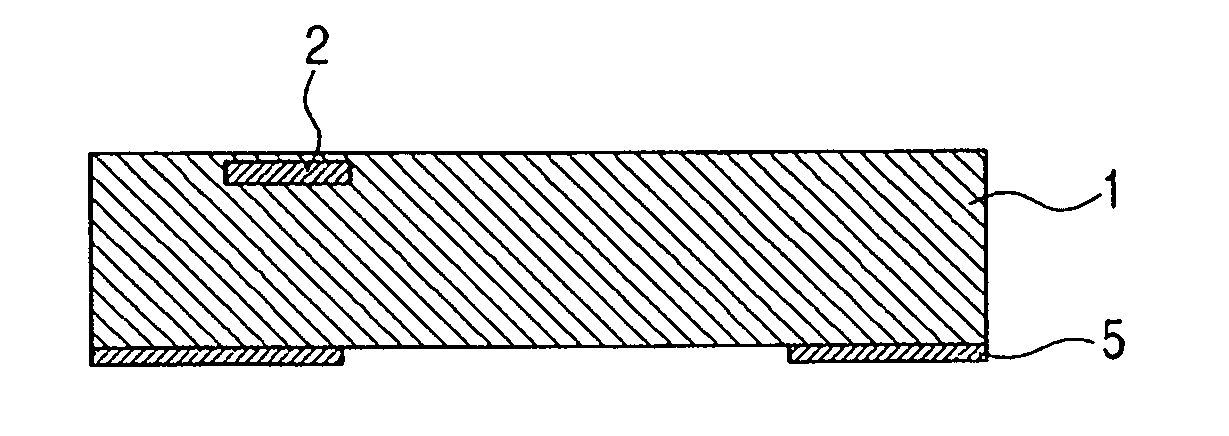

Fabrication method of a semiconductor device using liquid repellent film

In the case where a contact hole is formed by a conventional process of the semiconductor device fabrication, a resist is required to be formed almost entirely over a substrate in order to form the resist over the film where the contact hole is not formed. Accordingly, the throughput is considerably low. Further, when the resist spreads to the area of the contact hole when the amount of the resist to be applied and the surface state of the base are not fully controlled, contact defect would occur. Thus, improvements are required. According to the invention, in forming a semiconductor device, a part to be a contact hole of the semiconductor device may be covered with a first organic film that is liquid repellent. Subsequently, a second organic film serving as an insulating film is formed on the area where the first organic film is not formed, and the first organic film is removed thereafter to form a contact hole.

Owner:SEMICON ENERGY LAB CO LTD

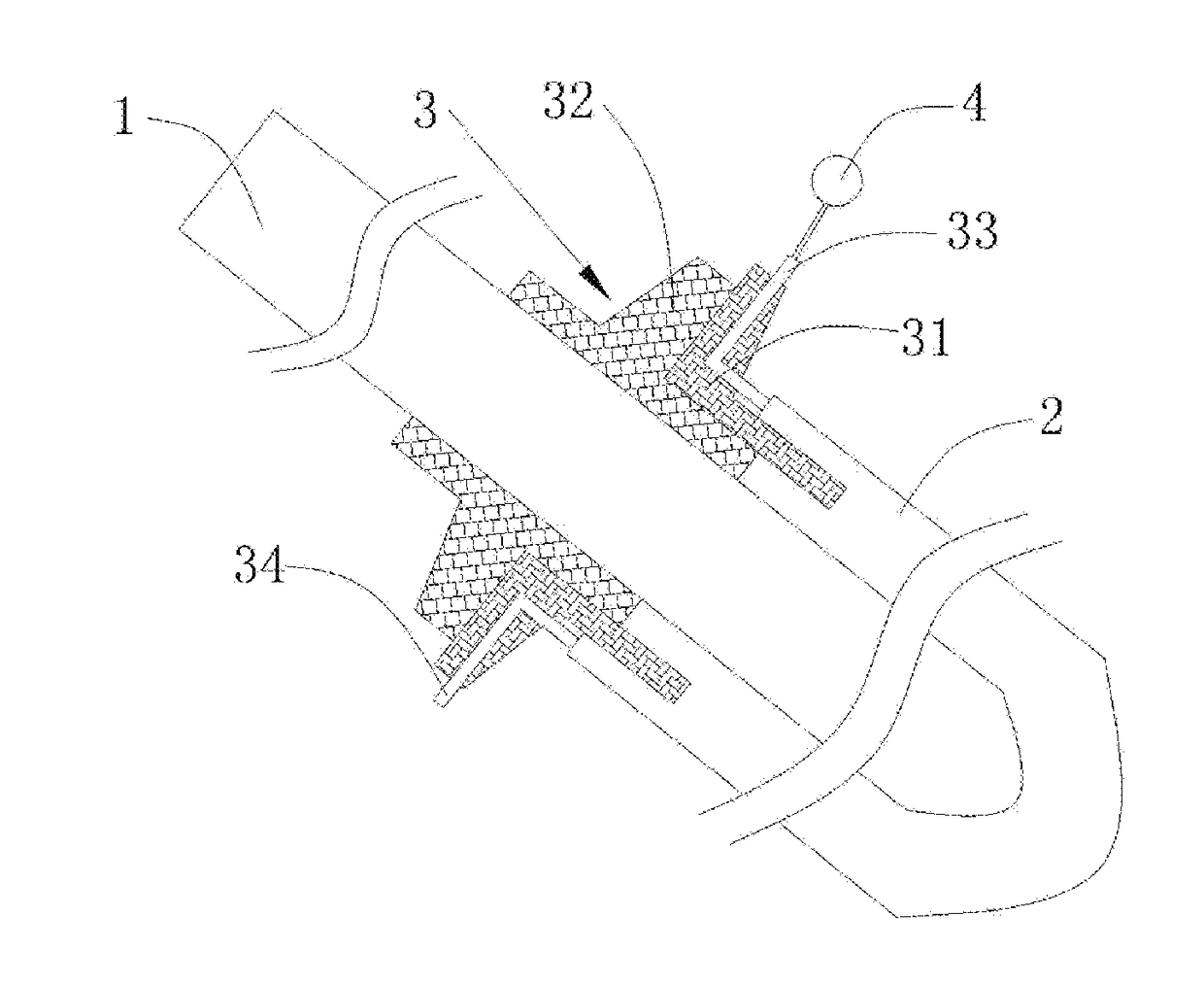

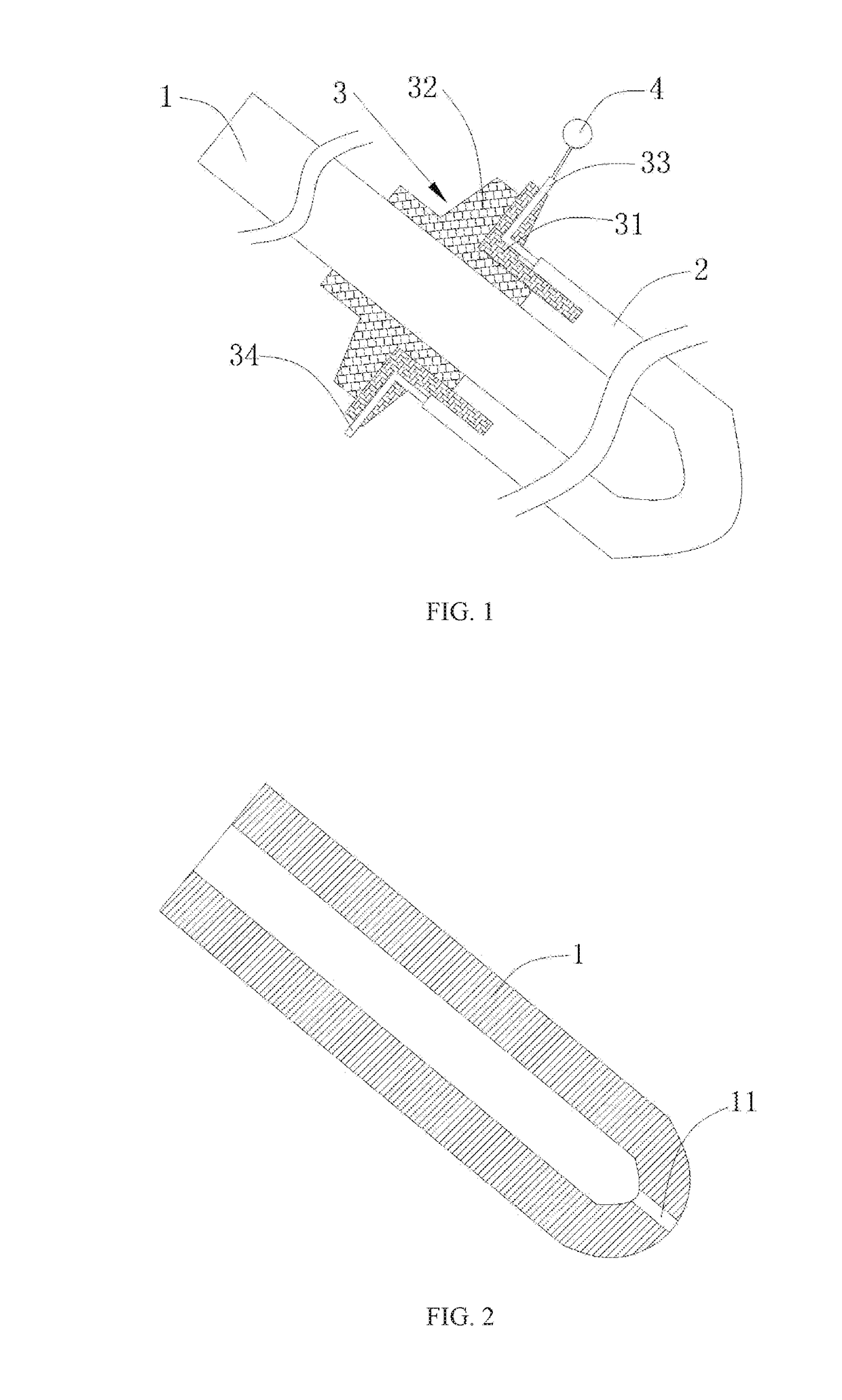

Cross-shaped double sleeve drainage tube

InactiveUS20180078684A1Monitor instantaneous negative pressure strengthPrevent tissue and organWound drainsMedical devicesDraining tubeCatheter

The present invention discloses a cross-shaped double sleeve drainage tube, including an inner draining tube, a connecting member, an external sleeve tube, an inner guiding tube, a support rack, a block member, and a pressure sensor. A left end of the inner draining tube is formed in an opening, and a right end of the inner draining tube is sealed. A tube wall at the right end of the inner draining tube is provided with an inner draining hole. The connecting member combines the inner draining tube in the tunnel of the inner guiding tube. The left and right ends of the external guiding tube are formed in an opening, respectively. The tube wall at the right end of the external guiding tube is provided with a plurality of draining grooves. The inner guiding tube is installed in the tunnel of the external guiding tube through the support rack. The left and right ends of the inner guiding tube are formed in an opening, respectively, with the left end thereof connected with the tube wall of the external guiding tube. The tube wall of the inner guiding tube is provided with a pressure monitoring tunnel, an infusing tunnel, and an external draining hole. The block member includes a block head disposed in the right end opening of the inner guiding tube to block the opening and a block body to block the right end of the external guiding tube. A gap is formed between the left face of the block body and the right face of the external guiding tube. The pressure sensor is connected to the pressure monitoring tunnel.

Owner:GUANGZHOU SUN SHING BIOTECH CO LTD

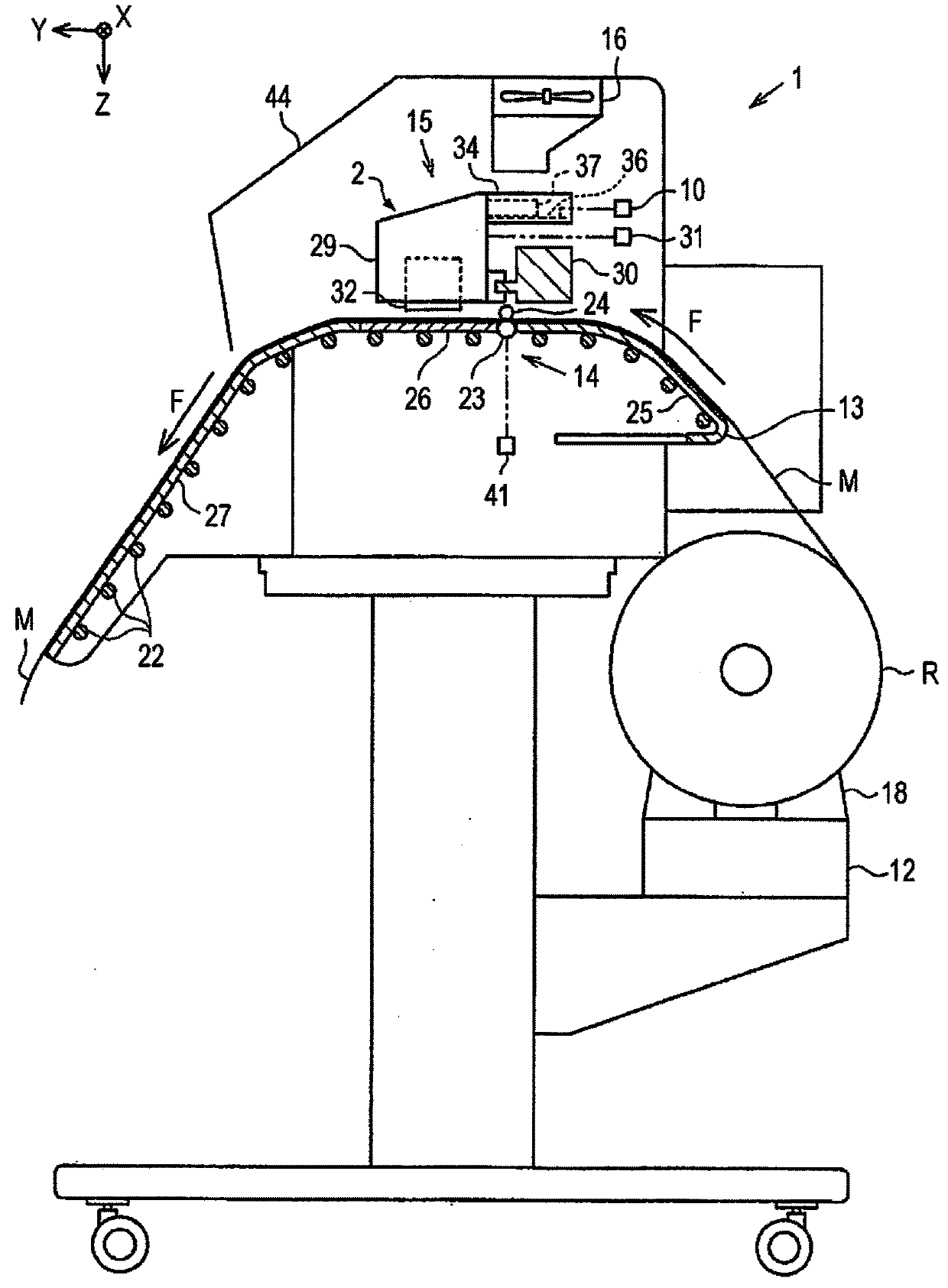

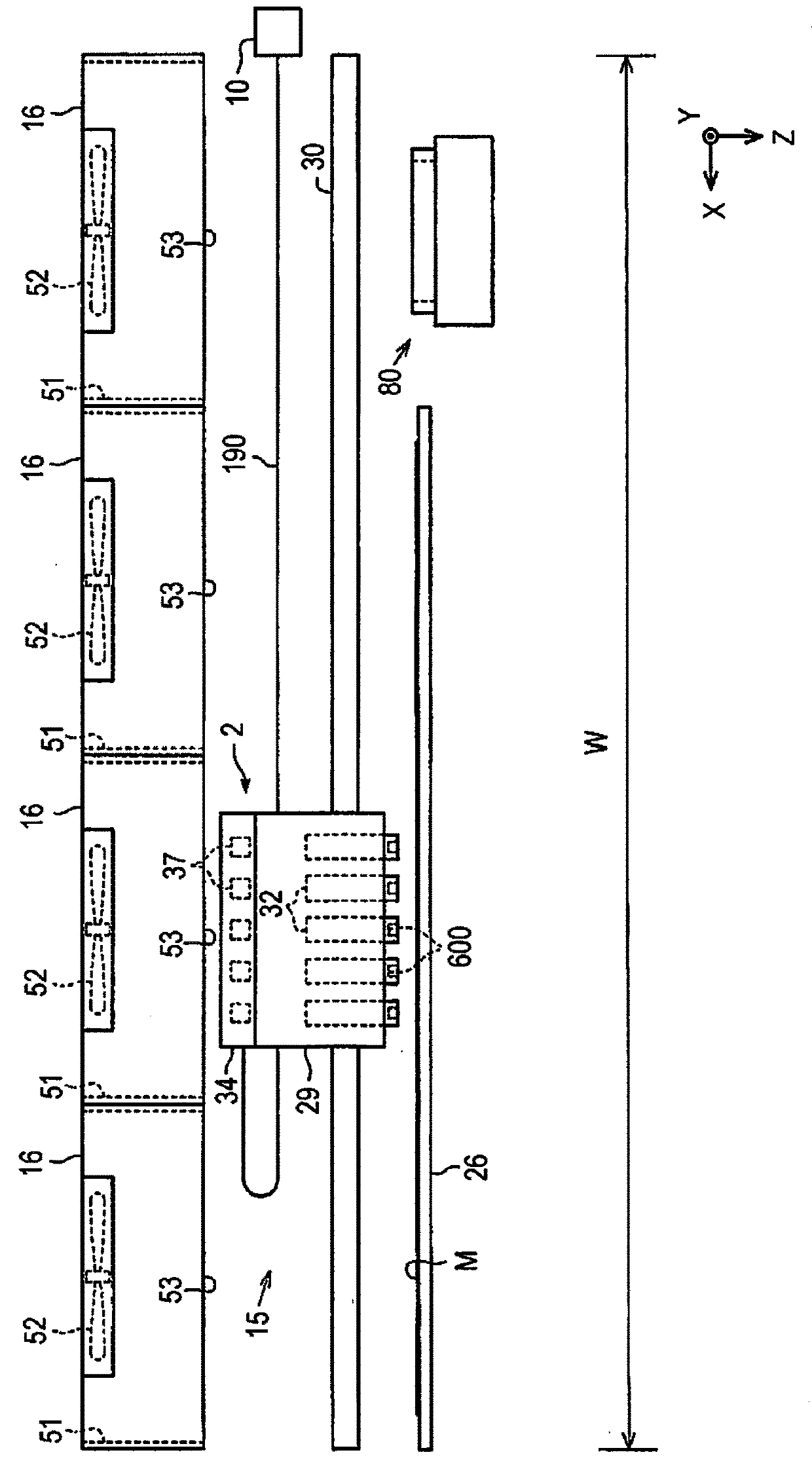

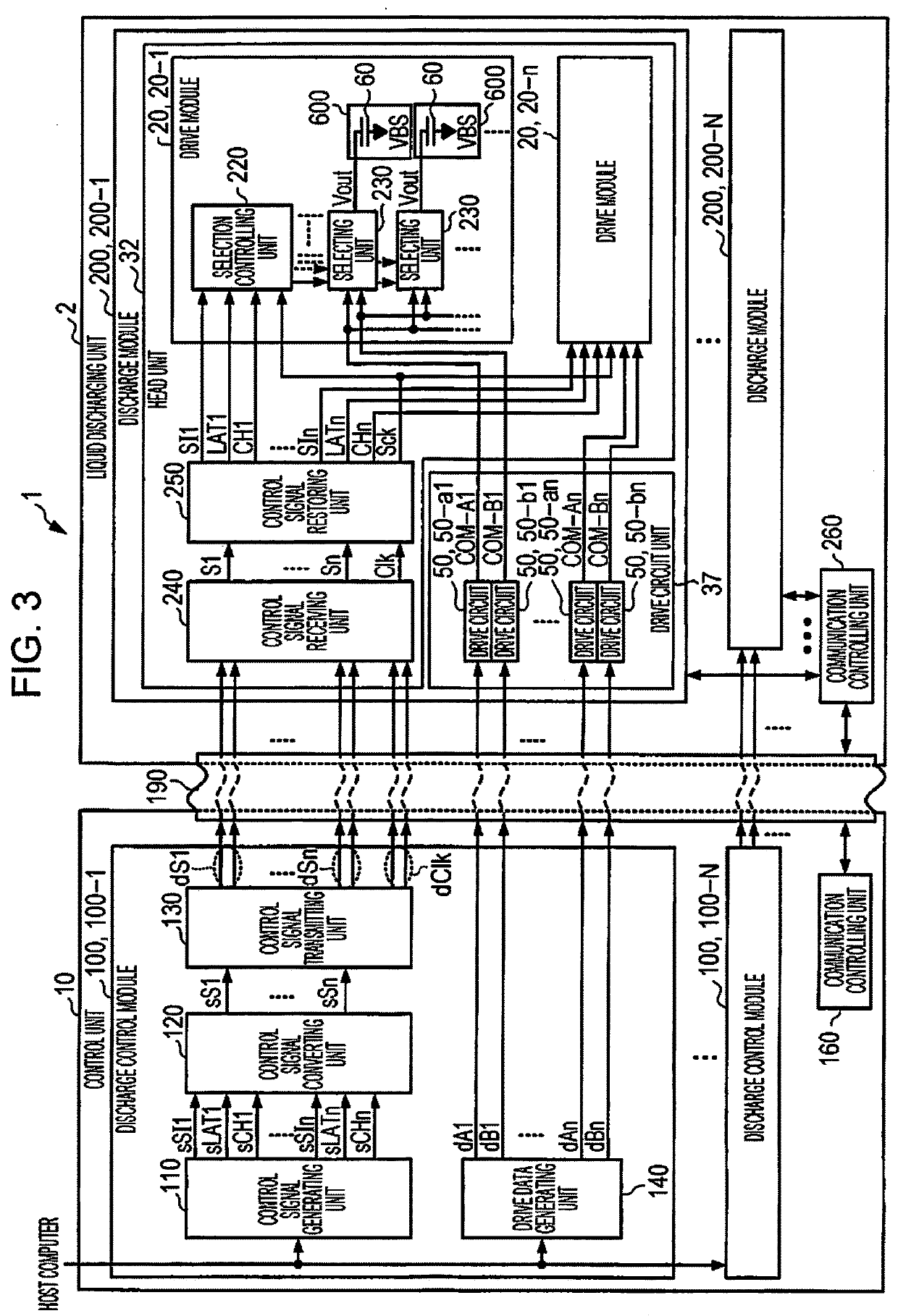

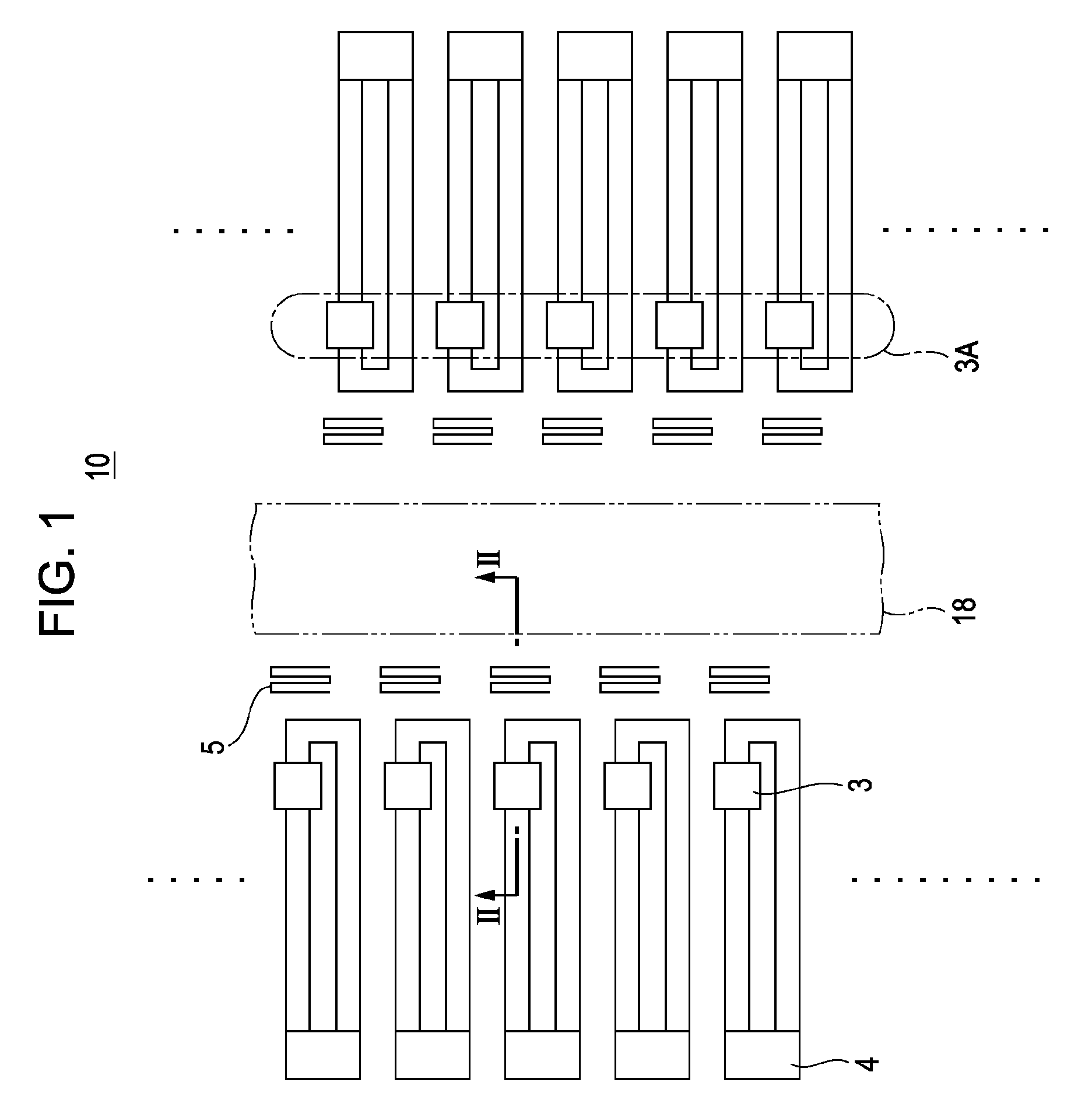

Liquid discharging apparatus and circuit substrate

ActiveUS20180178510A1Prevent wrong dischargeReduce the possibilityPiezoelectric/electrostrictive/magnetostrictive devicesOther printing apparatusControl signalShortest distance

There is provided a liquid discharging apparatus including a head unit that has a first driving element and discharges a first liquid based on a first drive signal for driving the first driving element and a first control signal for controlling application of the first drive signal to the first driving element and a circuit substrate. First drive signal transmitting wiring through which the first drive signal is transmitted. The shortest distance between a first side of the circuit substrate and the first drive signal transmitting wiring is shorter than the shortest distance between the first drive signal transmitting wiring and the first control signal transmitting wiring. The shortest distance between a second side opposing the first side of the circuit substrate and the first control signal transmitting wiring is shorter than the shortest distance between the first drive signal transmitting wiring and the first control signal transmitting wiring.

Owner:SEIKO EPSON CORP

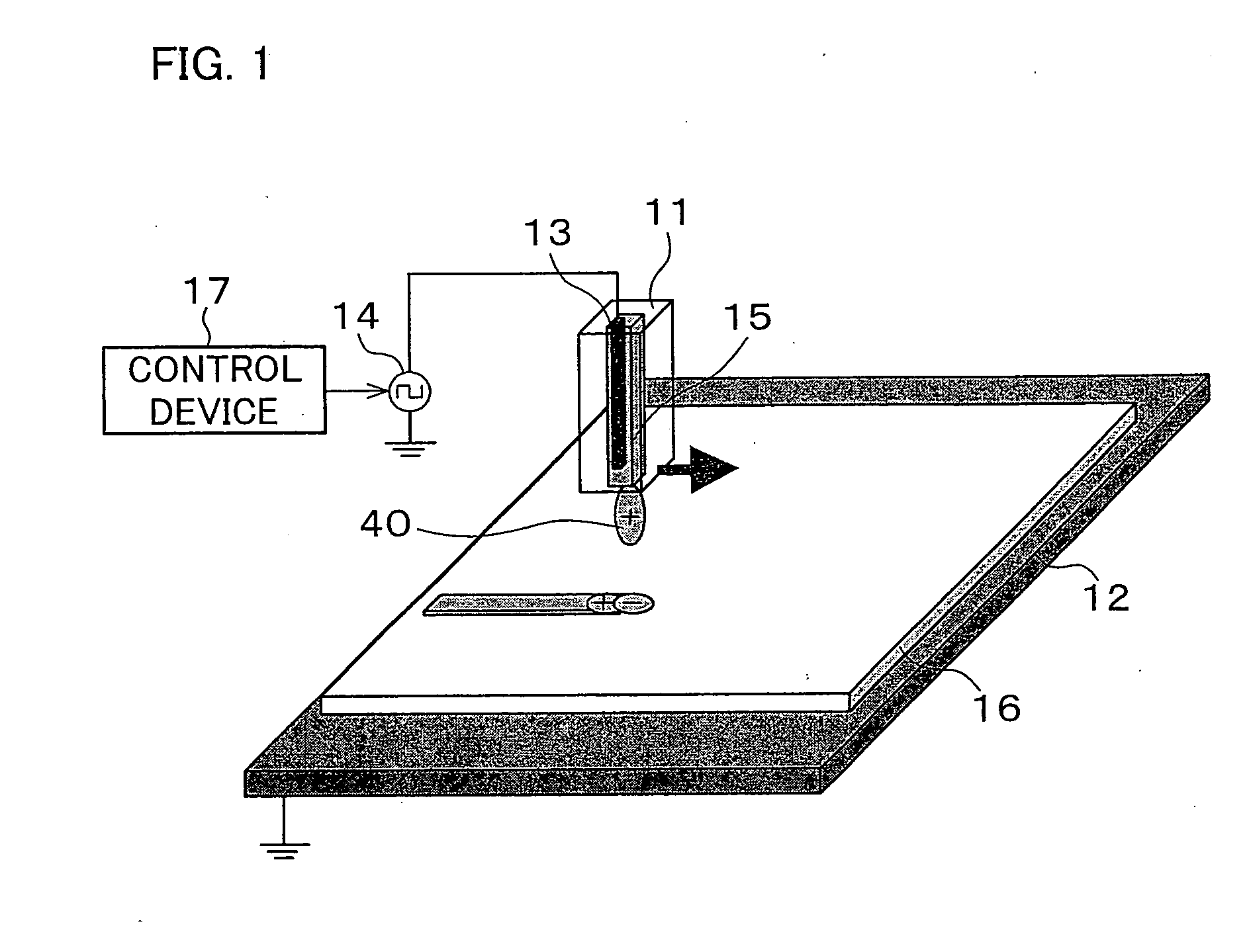

Electrostatic suction type fluid discharge device, electrostatic suction type fluid discharge method, and plot patern formation method using the same

ActiveUS20060262163A1Accurate landing positionReduce the driving voltageConductive pattern formationPrintingElectrical polarityEngineering

An electrostatic suction type fluid discharge device supplies a drive voltage from a power source between a nozzle and an insulating substrate, so as to supply an electric charge to a discharge material supplied into the nozzle. As a result, the discharge material is discharged from the nozzle hole onto the insulating substrate. The diameter of the hole of the nozzle falls within the range between φ0.01 μm and φ25 μm, the power source outputs, as the drive voltage, a bipolar pulse voltage that alternates between positive and negative and has a frequency of not less than 1 Hz.

Owner:SHARP KK +2

Inkjet recording head and inkjet recording apparatus having the same

InactiveUS20090085946A1Accurately detect ink discharging failureImprove throughputOther printing apparatusRecording headEngineering

An inkjet recording head includes a passage communicating with a discharge port for discharging ink, a discharging heater provided in the passage for generating energy to discharge ink from the discharge port, and a detecting unit provided in the passage for detecting a temperature of ink that changes in accordance with heat energy generated by the detecting unit and a flow of ink in the passage.

Owner:CANON KK

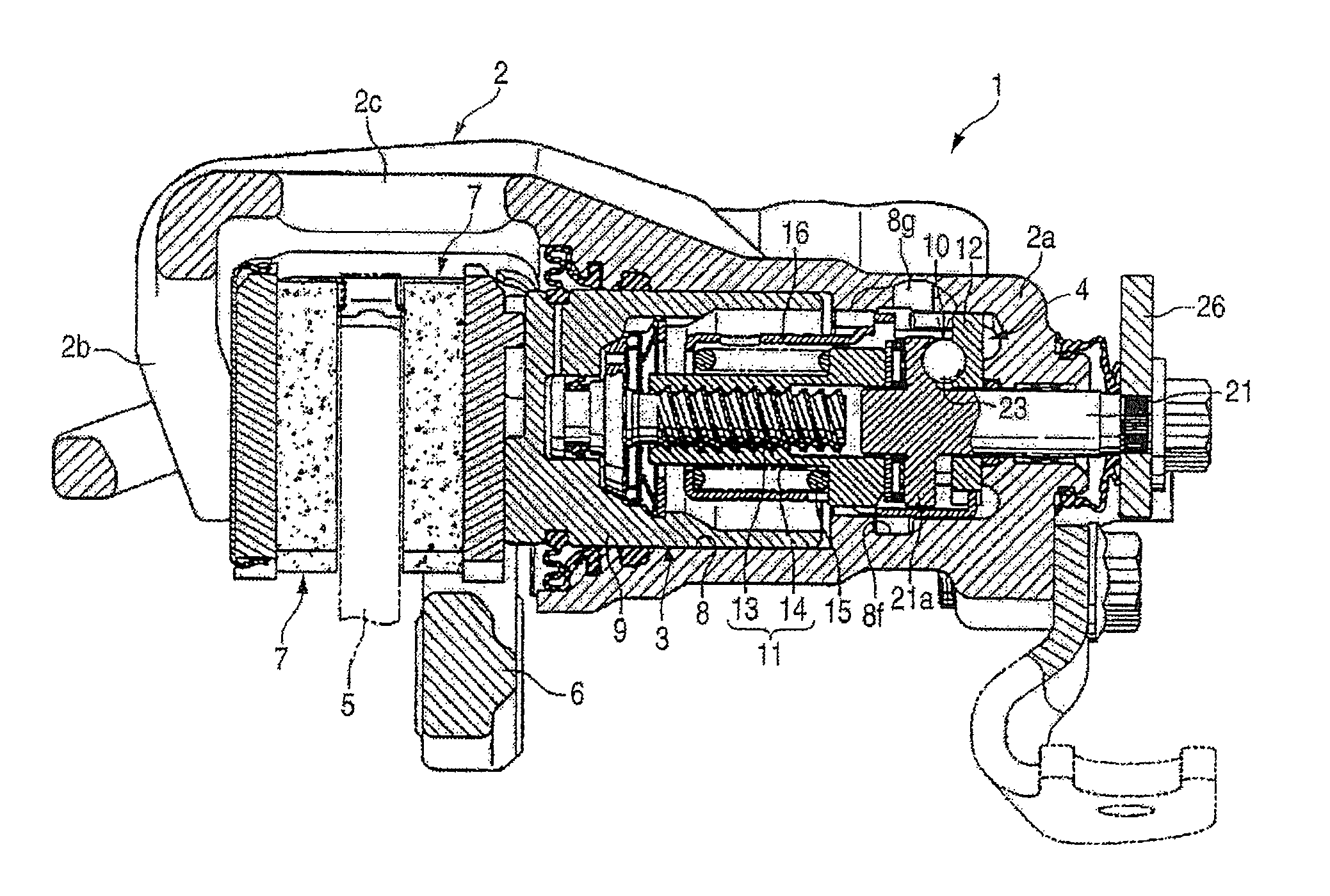

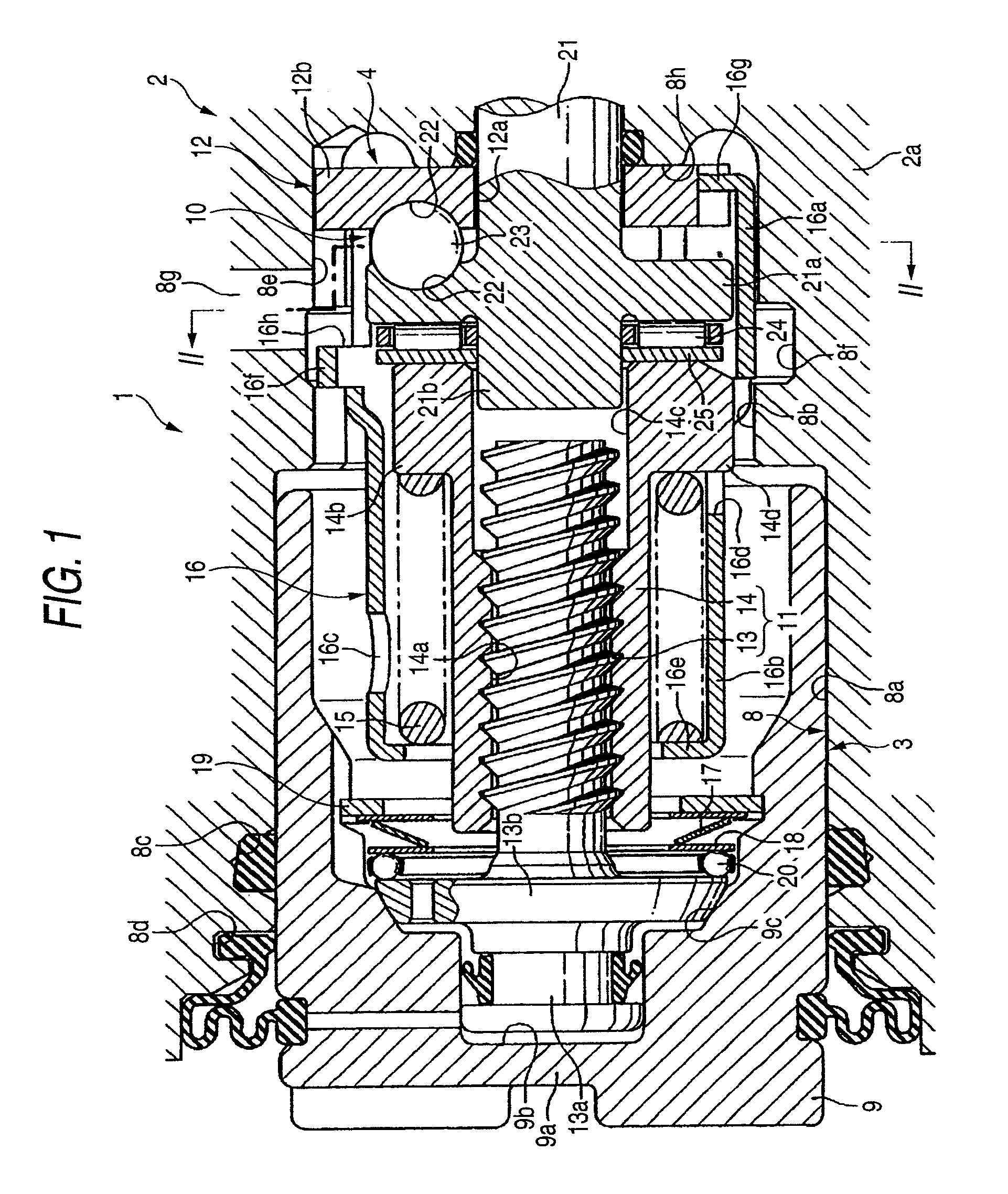

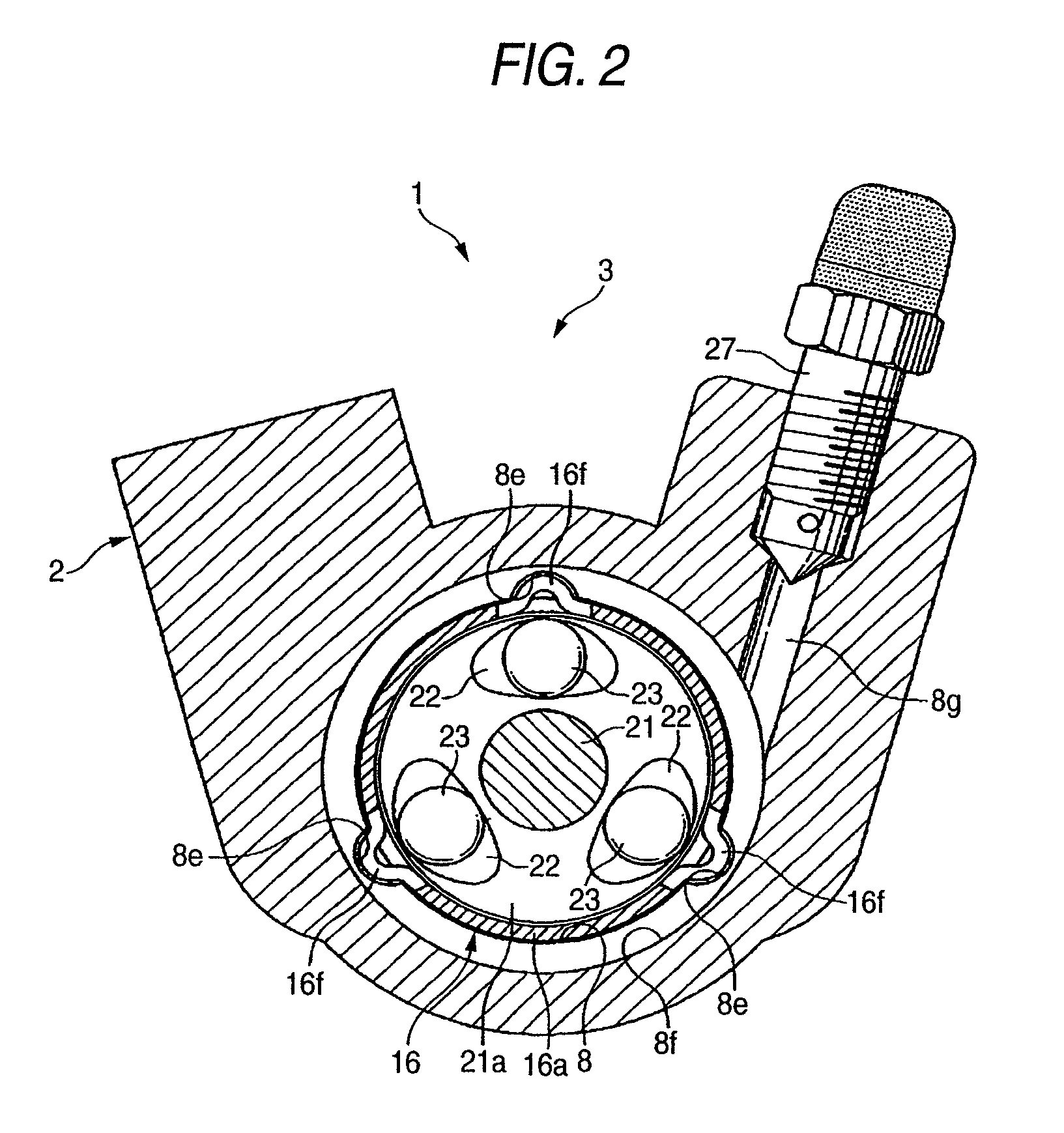

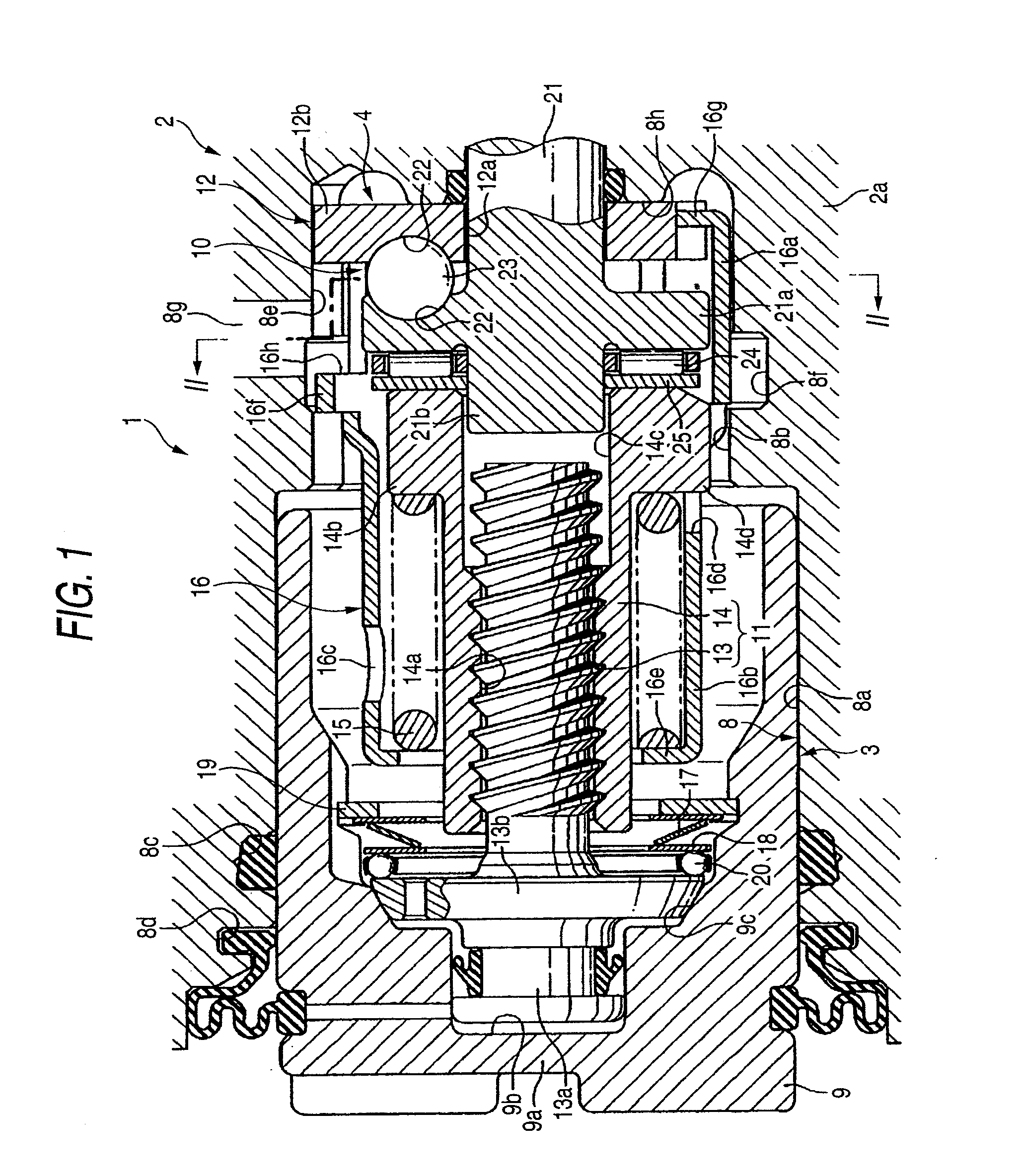

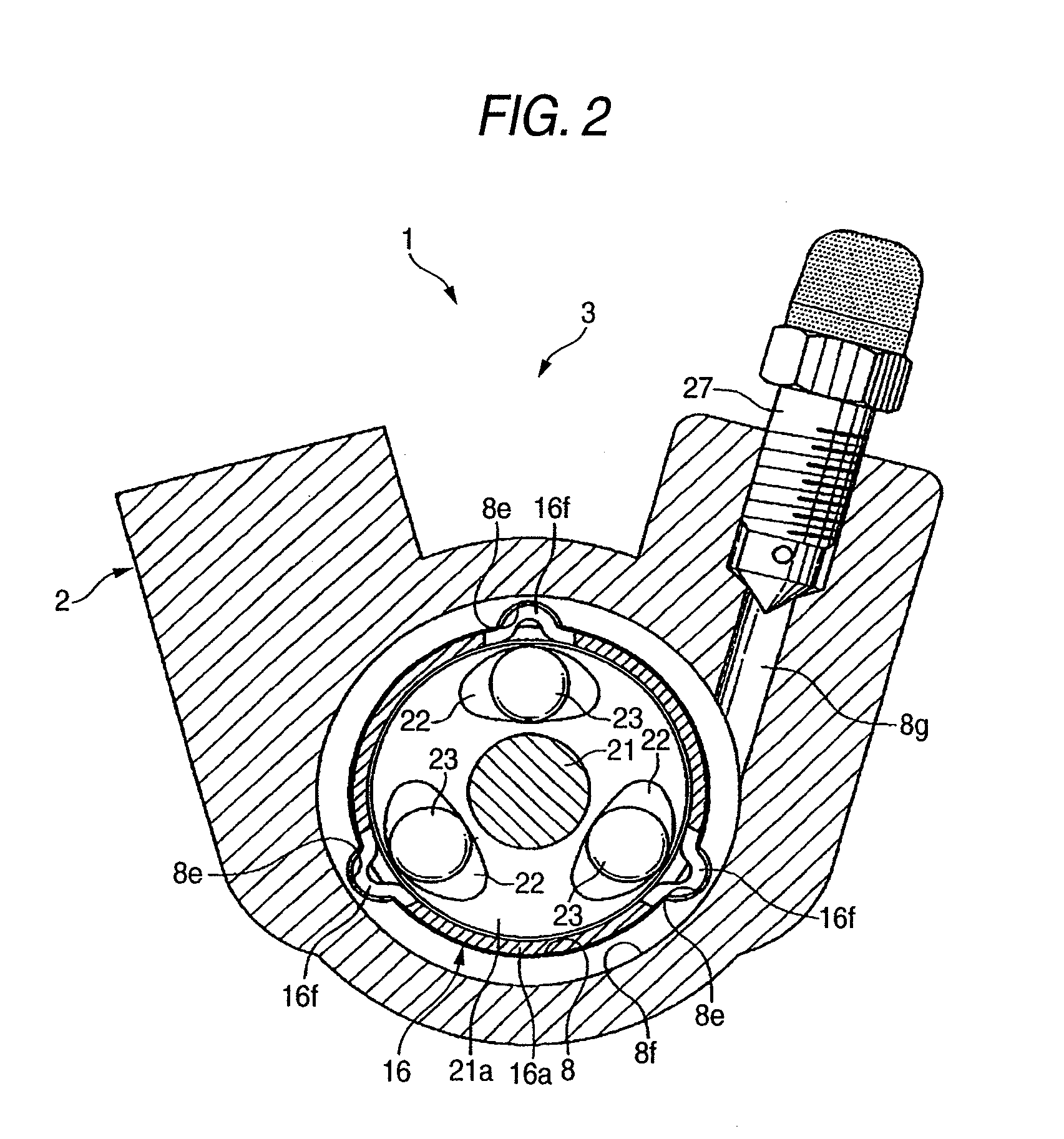

Disk brake apparatus

ActiveUS8069961B2Improve efficiencySimple structureBraking element arrangementsMechanically actuated brakesCalipersCam

Engaging grooves 8e extending in the cylinder axial direction and circumferential grooves 8f formed in a cylinder axial direction middle portion of the engaging grooves 8 are formed on a bottom side of a cylinder hole 8. Engaging rib 12b engaging with the engaging groove 8e and engaging rib 16d which engages with the engaging groove 8e and fits to the circumferential groove 8f are formed on a fixed side cam plate 12 and a housing, respectively. A bleeder hole 8g which penetrates communicates with the engaging grooves 8e and circumferential grooves 8f of the cylinder hole 8 is drilled in a caliper body 2. Communication holes 16h which allow communication between the inside and outside of the housing 16 is formed at a bottom side of the cylinder hole 8 rather than the engaging rib 16f of the housing.

Owner:HITACHI ASTEMO LTD

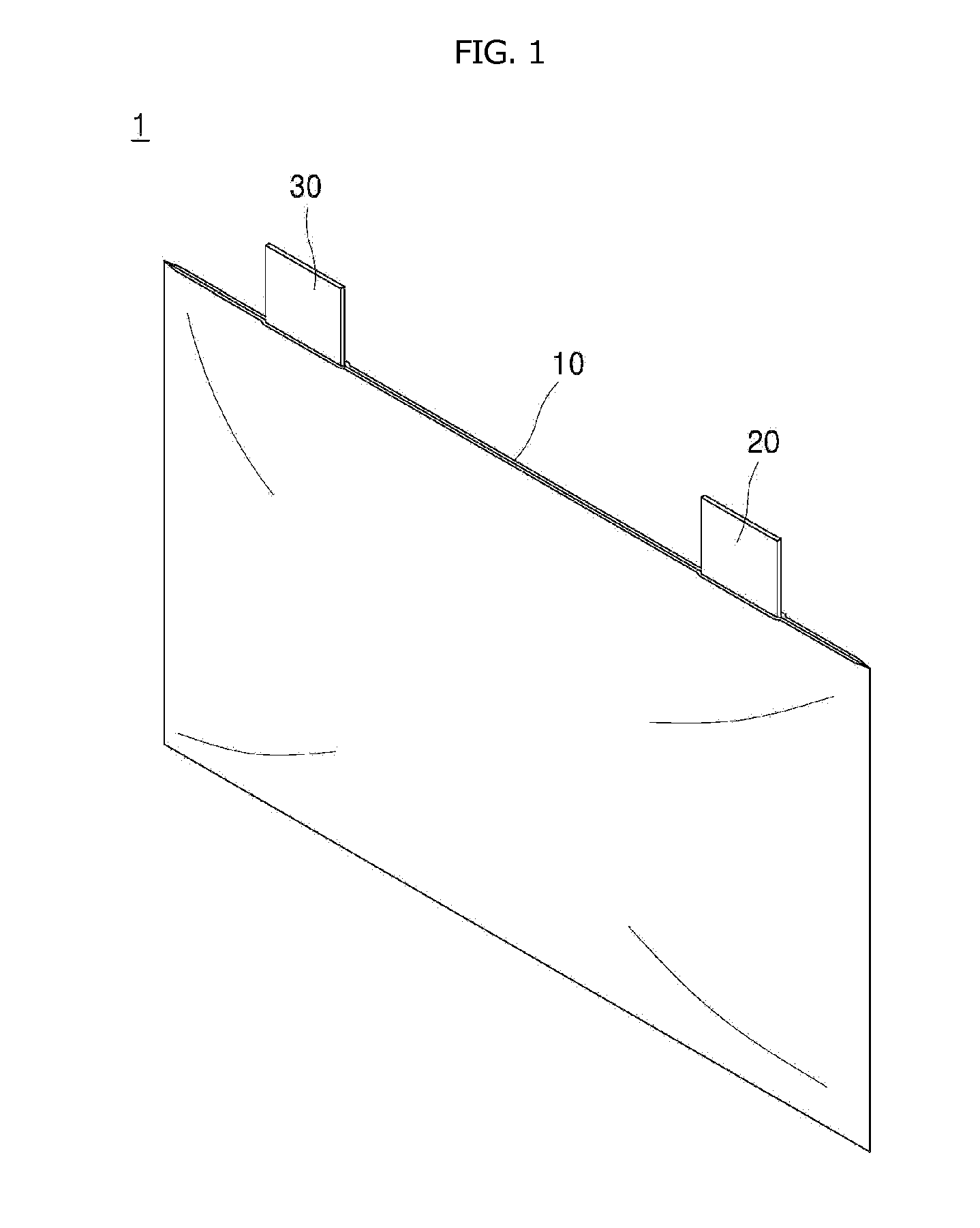

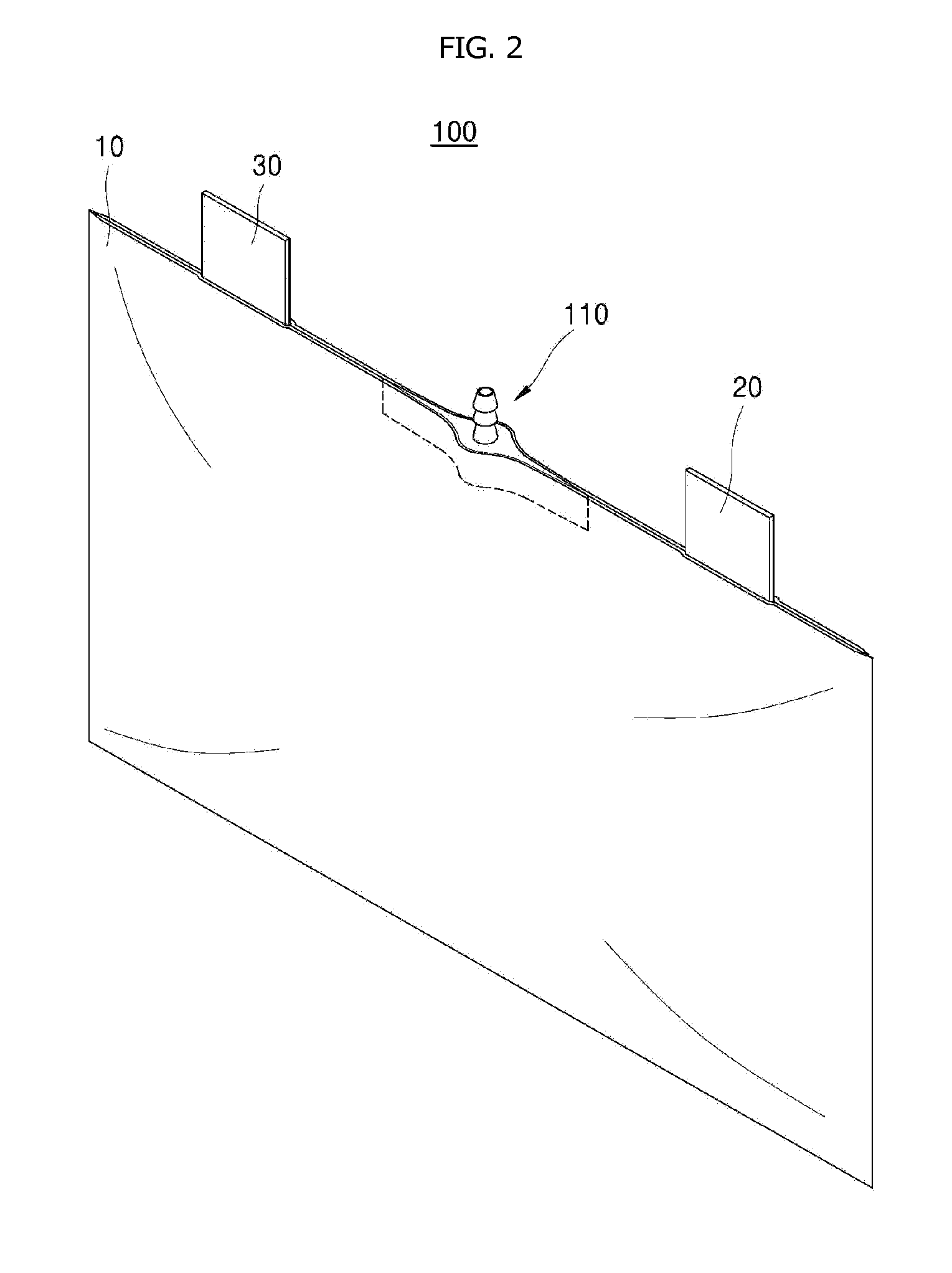

Pouch type lithium secondary battery having tubular passage structure

ActiveUS20160020452A1Simplify manufacturing processImprove performanceFinal product manufactureVent arrangementsUrologyElectrolyte

Provided is a pouch type lithium secondary battery having a tubular passage structure. The pouch type lithium secondary battery having a tubular passage structure includes: a tubular passage structure having a passage of injecting an electrolyte from an outer portion of a pouch and discharging gas from an inner portion of the pouch by communicating the inner portion of the pouch with the outer portion of the pouch.

Owner:SK ON CO LTD

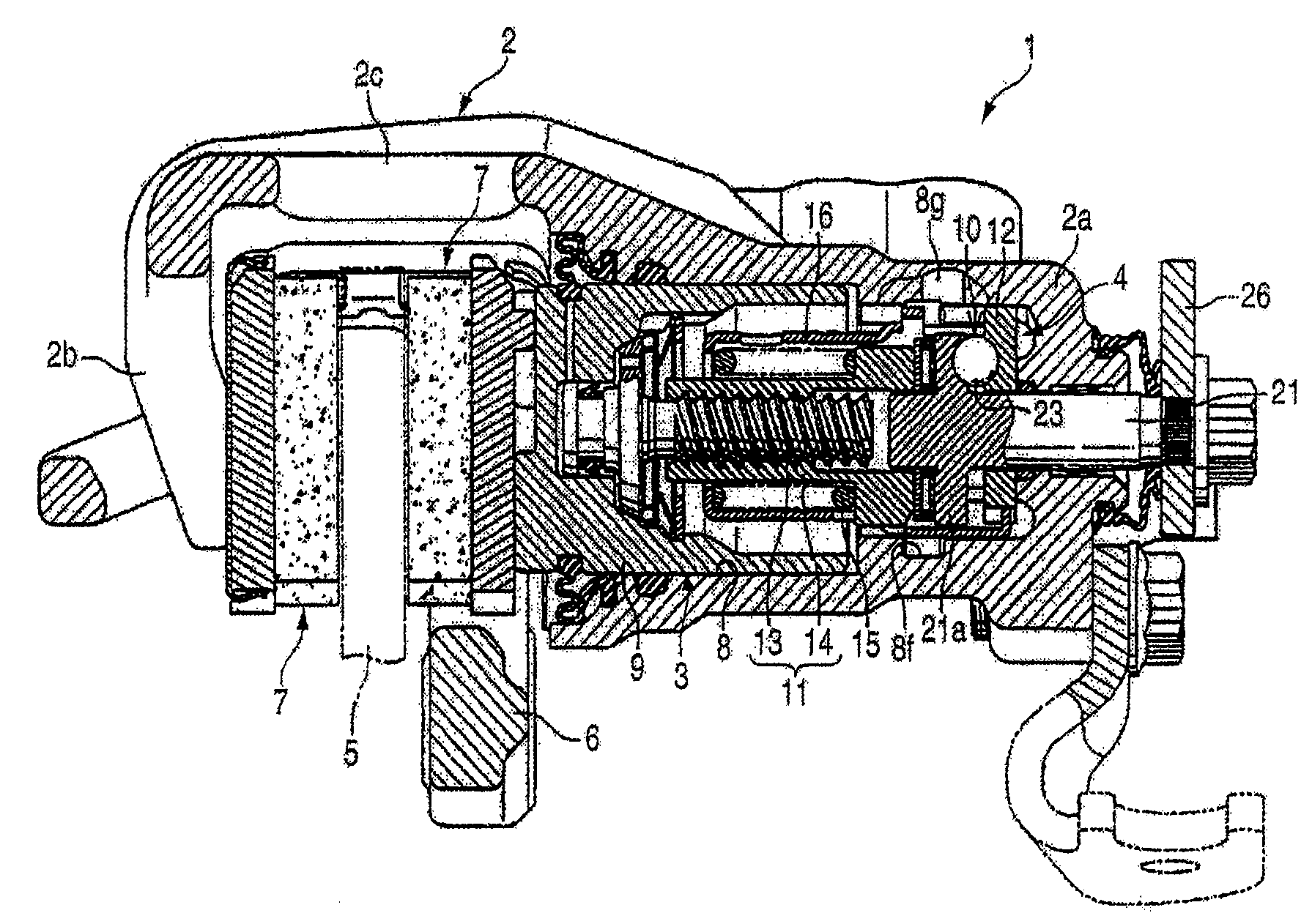

Disk brake apparatus

ActiveUS20090014257A1Enhanced efficiencySimple structureBraking element arrangementsMechanically actuated brakesDisc brakeCam

Engaging grooves 8e extending in the cylinder axial direction and circumferential grooves 8f formed in a cylinder axial direction middle portion of the engaging grooves 8 are formed on a bottom side of a cylinder hole 8. Engaging rib 12b engaging with the engaging groove 8e and engaging rib 16d which engages with the engaging groove 8e and fits to the circumferential groove 8f are formed on a fixed side cam plate 12 and a housing, respectively. A bleeder hole 8g which penetrates communicates with the engaging grooves 8e and circumferential grooves 8f of the cylinder hole 8 is drilled in a caliper body 2. Communication holes 16h which allow communication between the inside and outside of the housing 16 is formed at a bottom side of the cylinder hole 8 rather than the engaging rib 16f of the housing.

Owner:HITACHI ASTEMO LTD

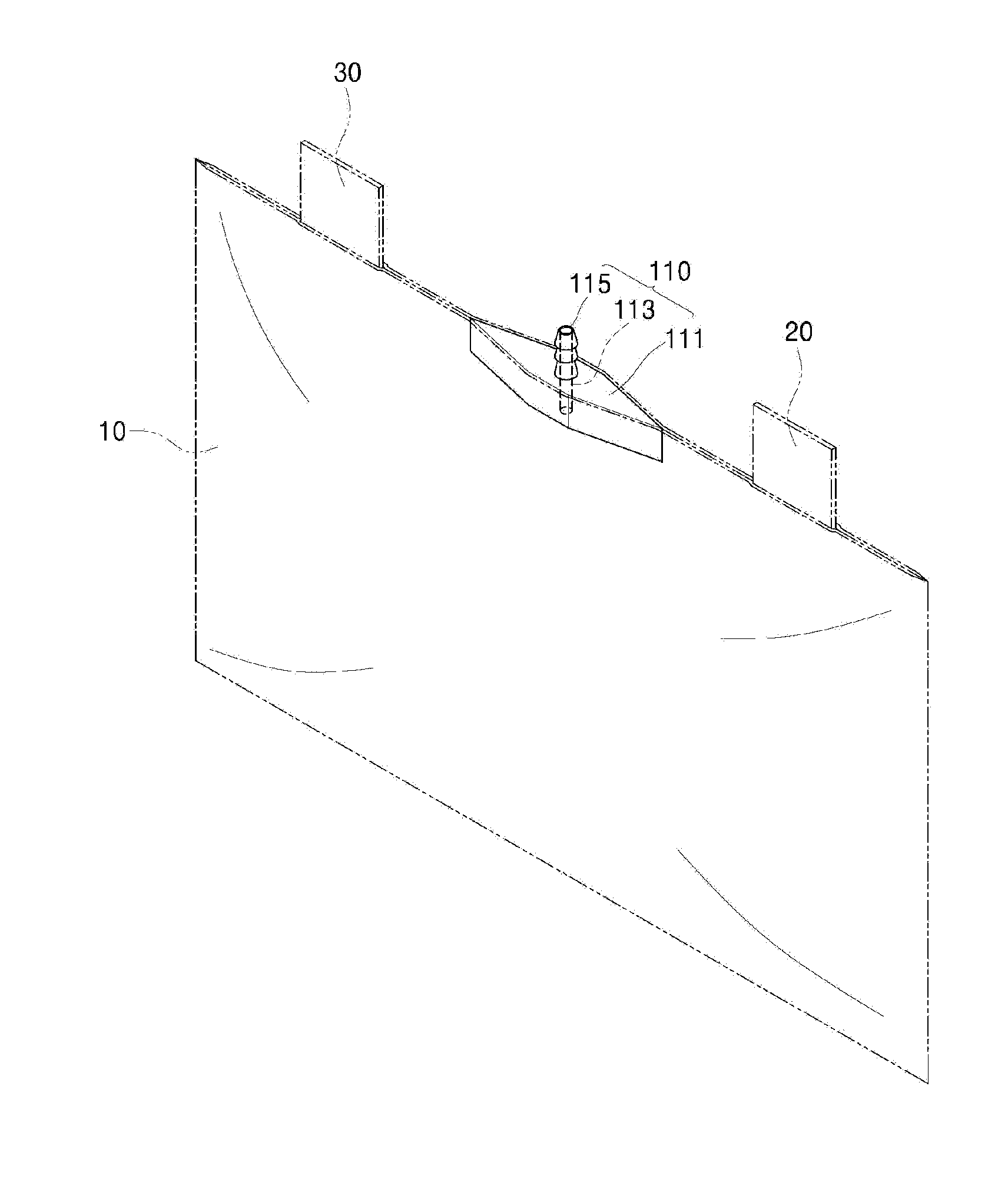

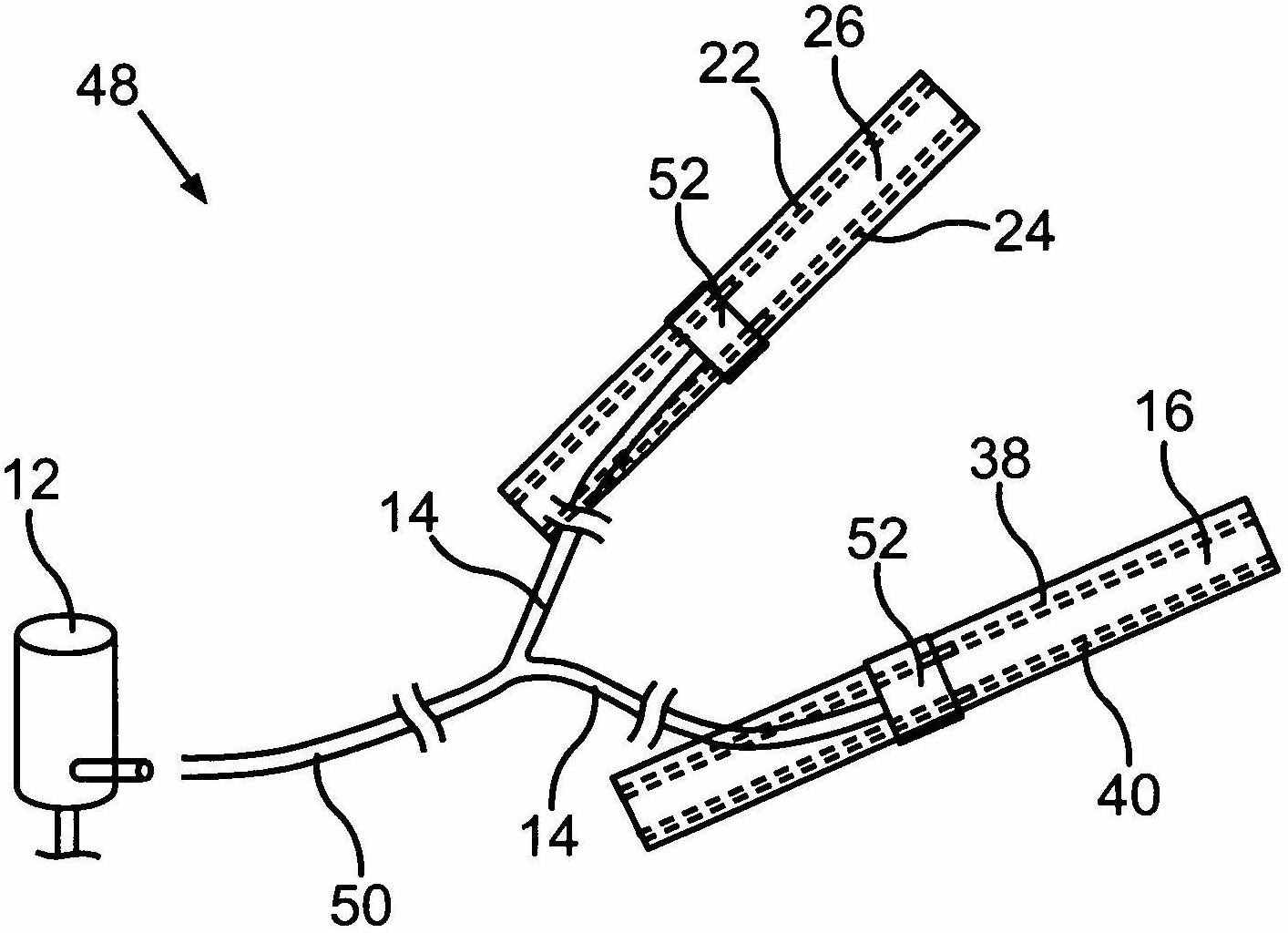

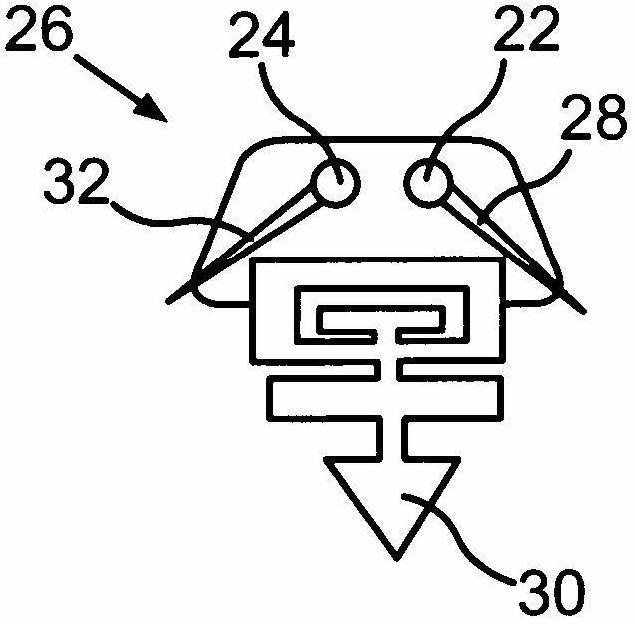

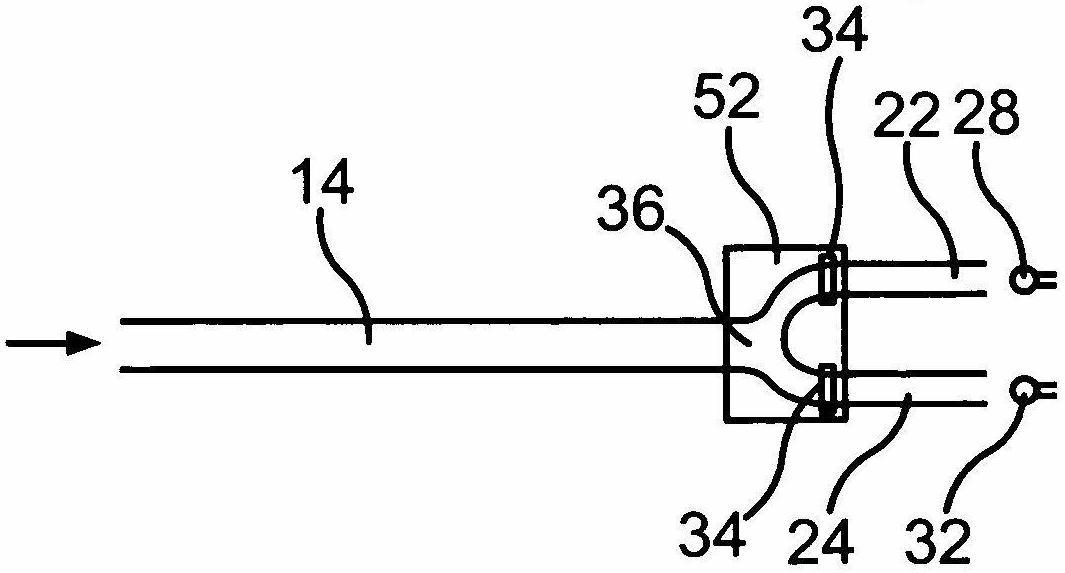

Wiper arrangement and method for operating a wiper arrangement for a motor vehicle

InactiveCN102652083APrevent wrong dischargeShort reaction timeVehicle cleaningEngineeringMechanical engineering

The invention relates to a wiper arrangement (48) with an associated windscreen washing system for a motor vehicle. The windscreen washing system comprises a washing liquid supply pipe (14) leading to outlets. The outlets are preferably arranged on the wiper blade (16, 26) and can consequently be moved together with a corresponding wiper arm of the wiper arrangement (48). A coupling part (52), by means of which the wiper blade (16, 26) is connected to the respective wiper arm, and which moves with the wiper arm as the latter moves, has switching valves. The discharge of washing liquid from the outlets can be controlled by means of the switching valves. Furthermore, the invention relates to a method for operating such wiper arrangement (48).

Owner:DAIMLER AG

Liquid discharge head manufacturing method, and liquid discharge head obtained using this method

InactiveUS7629111B2Prevent wrong dischargePhotomechanical apparatusSemiconductor/solid-state device manufacturingChemical compoundEngineering

Owner:CANON KK

Methodology and apparatus for storing and dispensing liquid components to create custom formulations

InactiveUS7789111B2Opportunities decreasePrevent wrong dischargeLiquid fillingMixer accessoriesEngineeringMechanical engineering

Owner:GFI INNOVATIONS

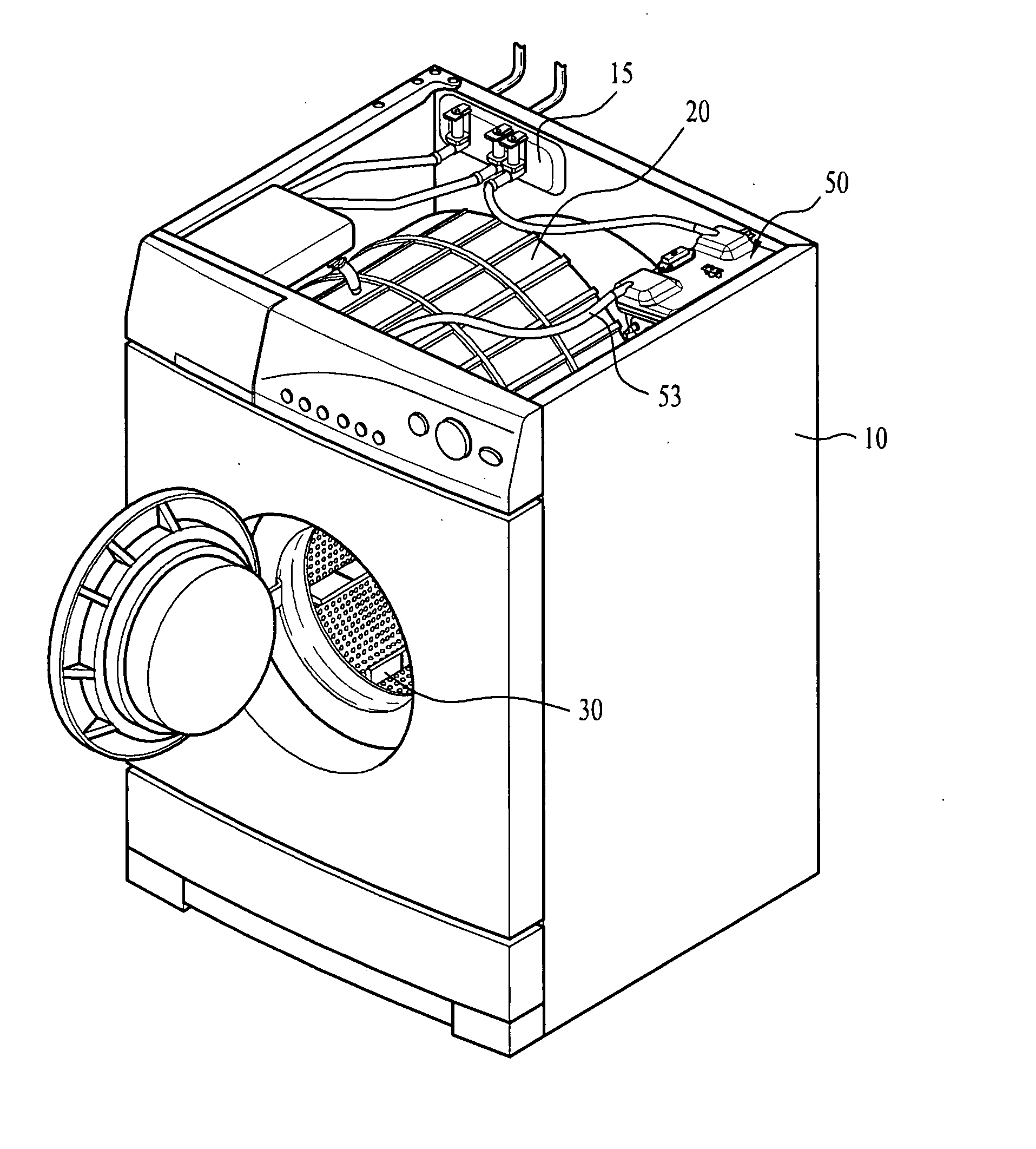

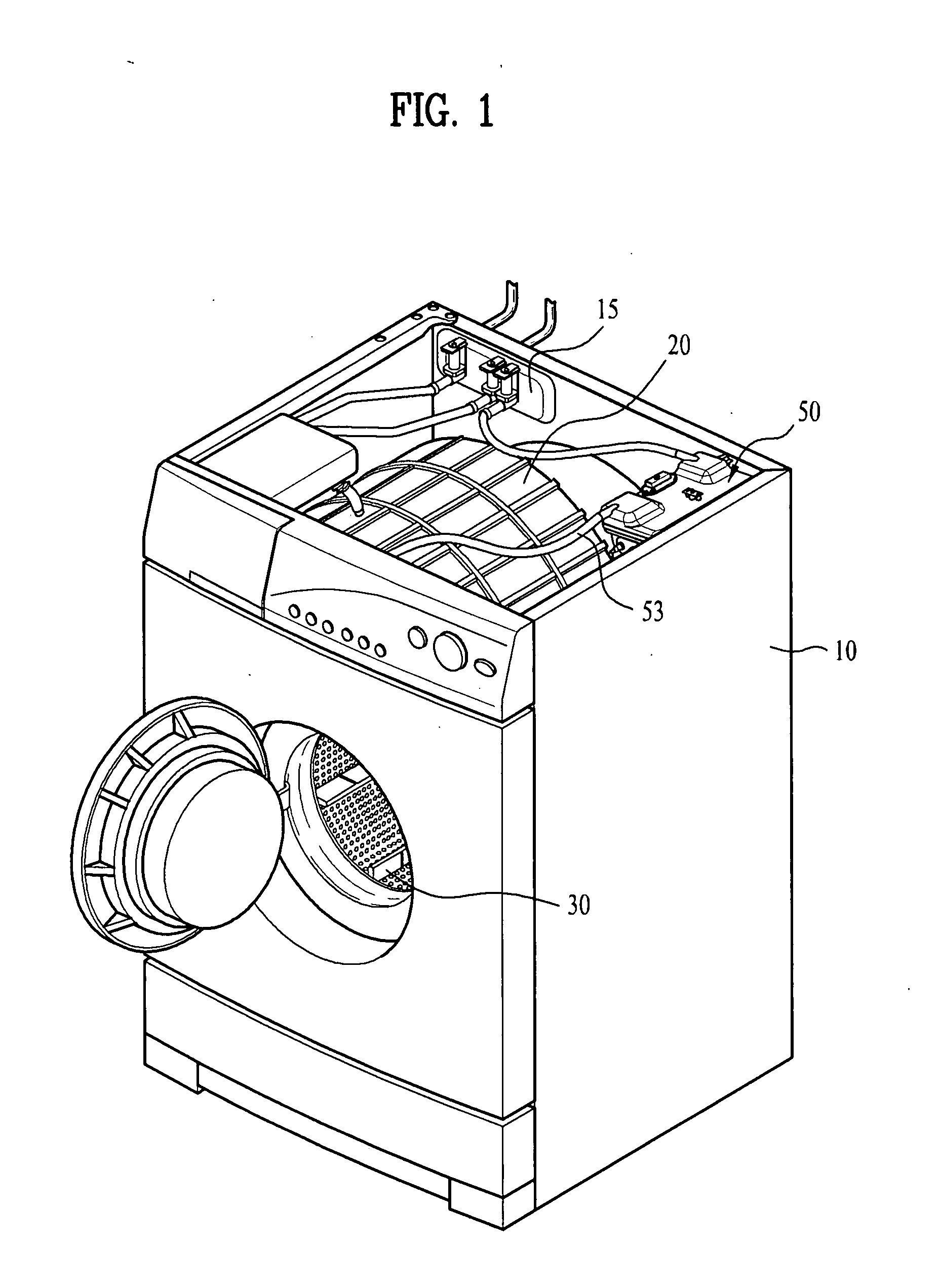

Laundry machine and method of controlling steam generator thereof

InactiveUS20080006300A1Accurate operation limit timeReduce unnecessary power consumptionOther washing machinesControl devices for washing apparatusLaundryControl theory

A laundry machine and controlling method thereof are disclosed, by which malfunctions of a steam generator and laundry machine and fire due to the overheating of a heater can be prevented. The present invention includes a steam generator having a heater and a controller turning of the heater if an operation time of the heater exceeds a operation limit time set in the course of driving the heater.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com