Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Large load torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

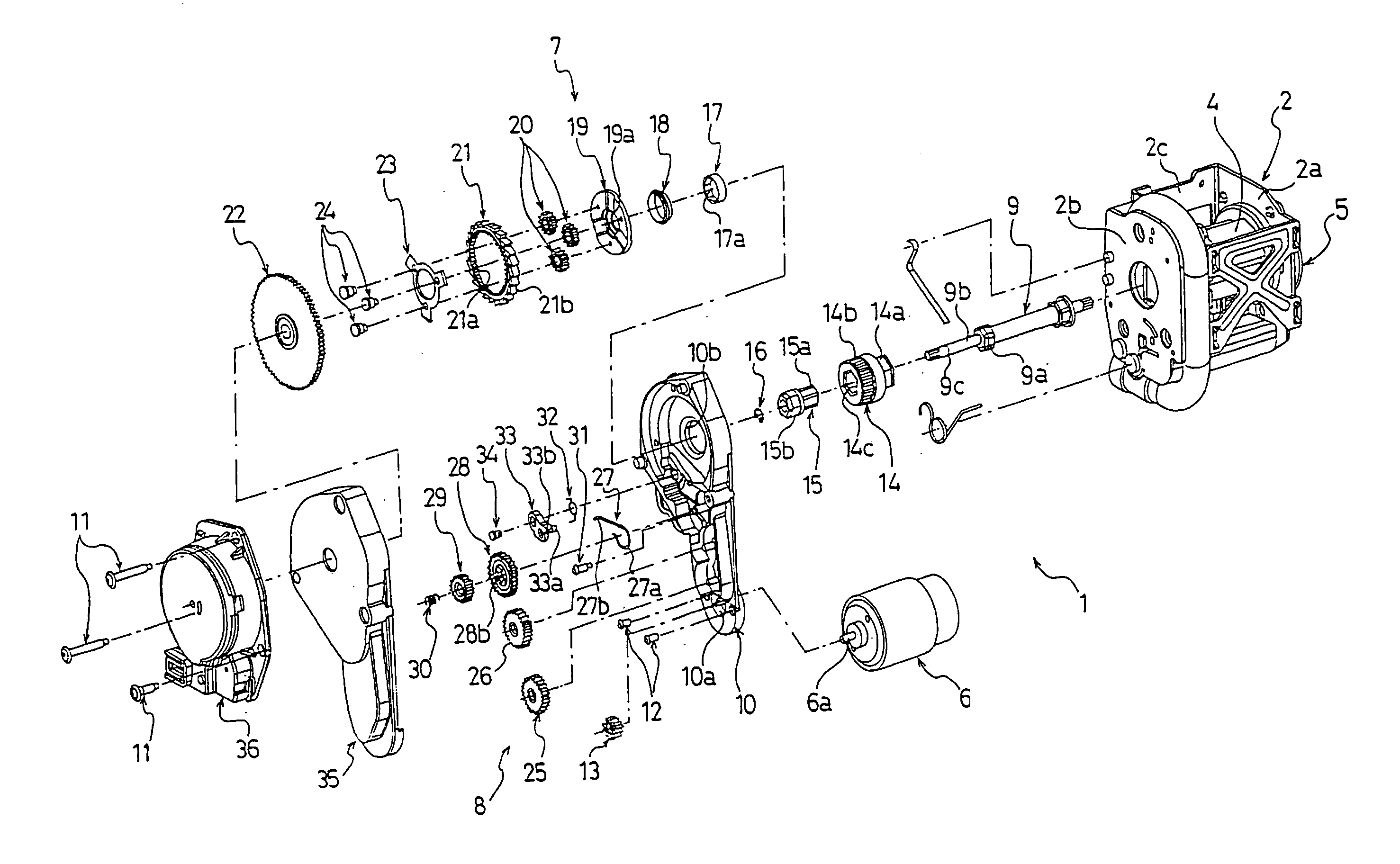

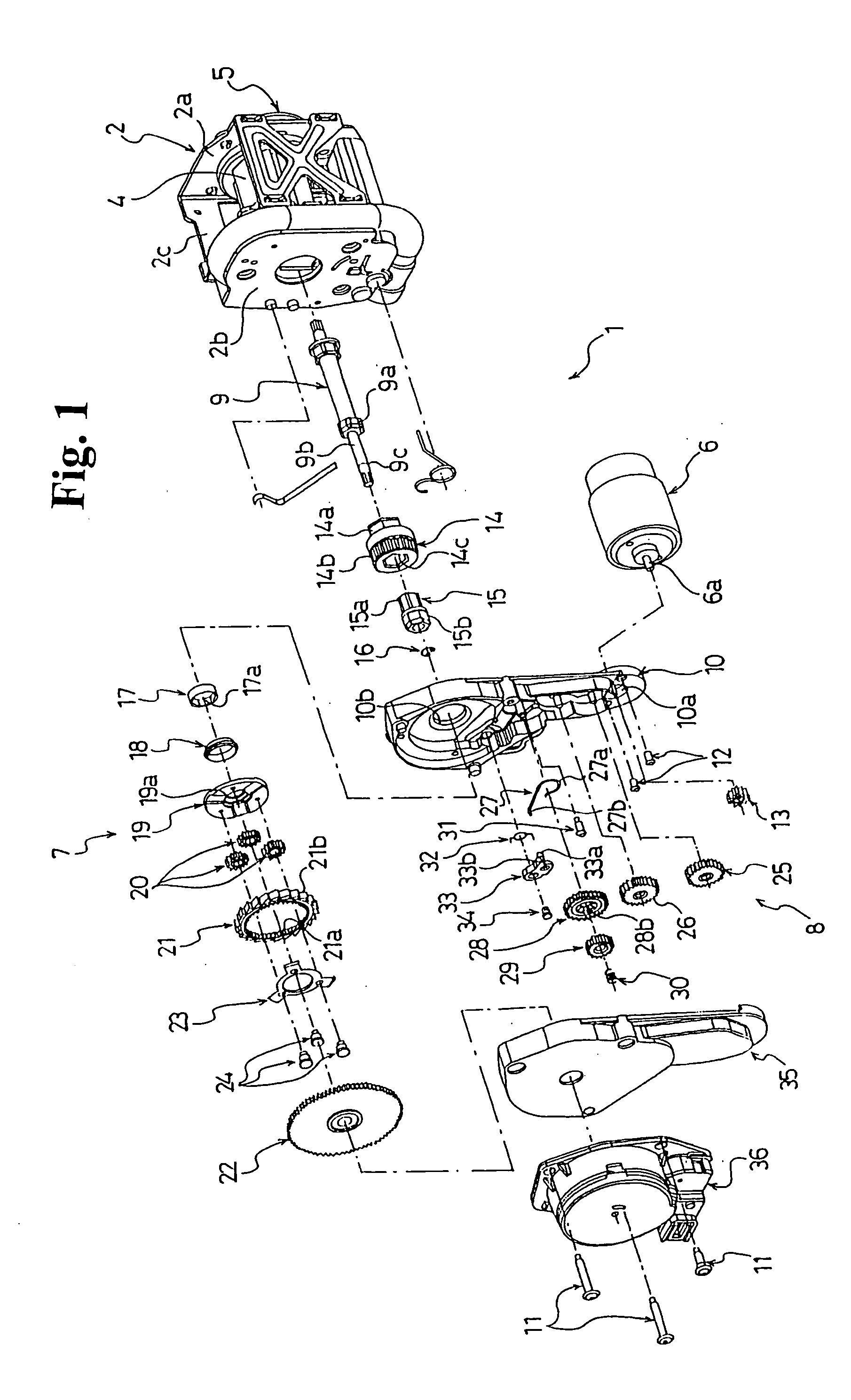

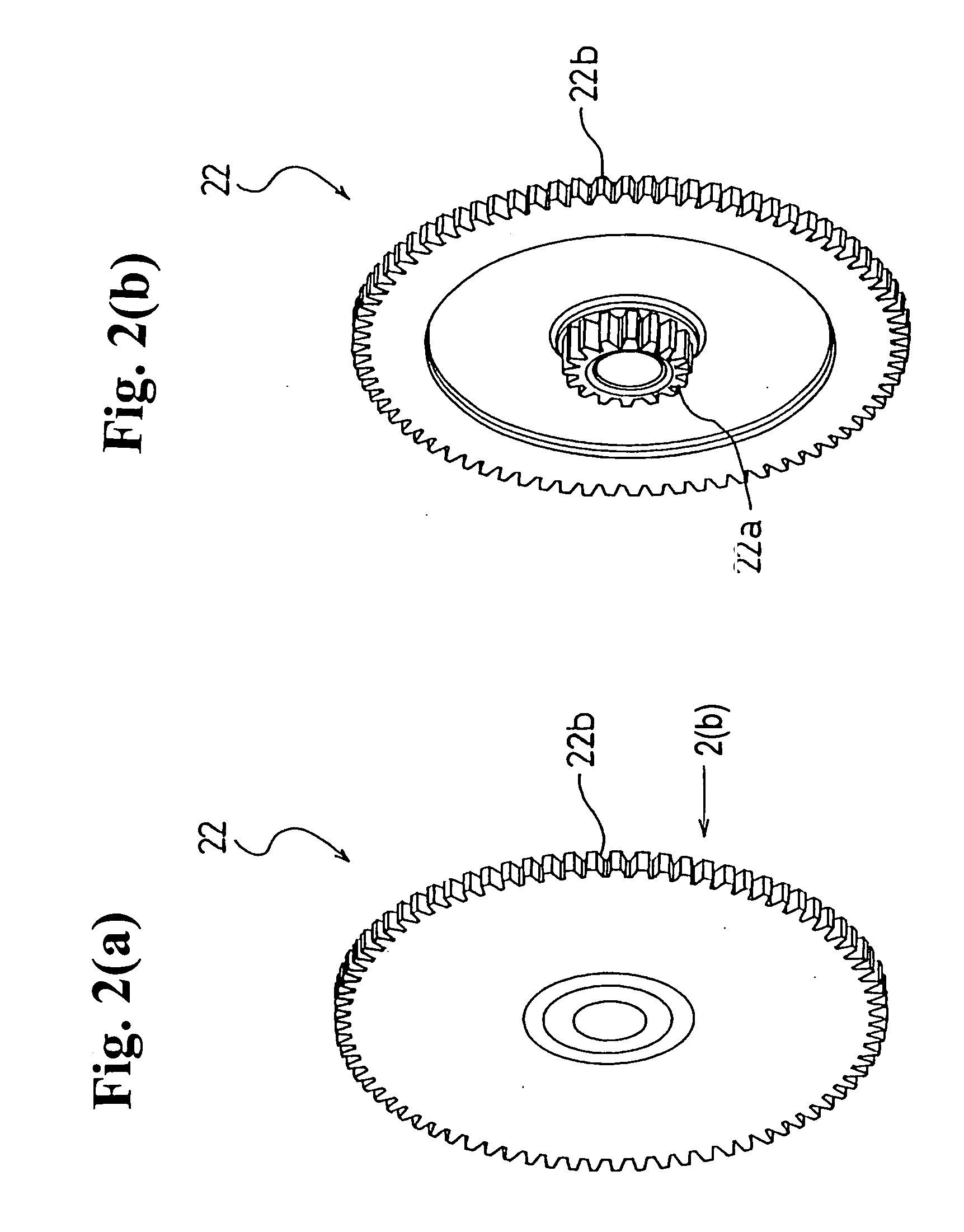

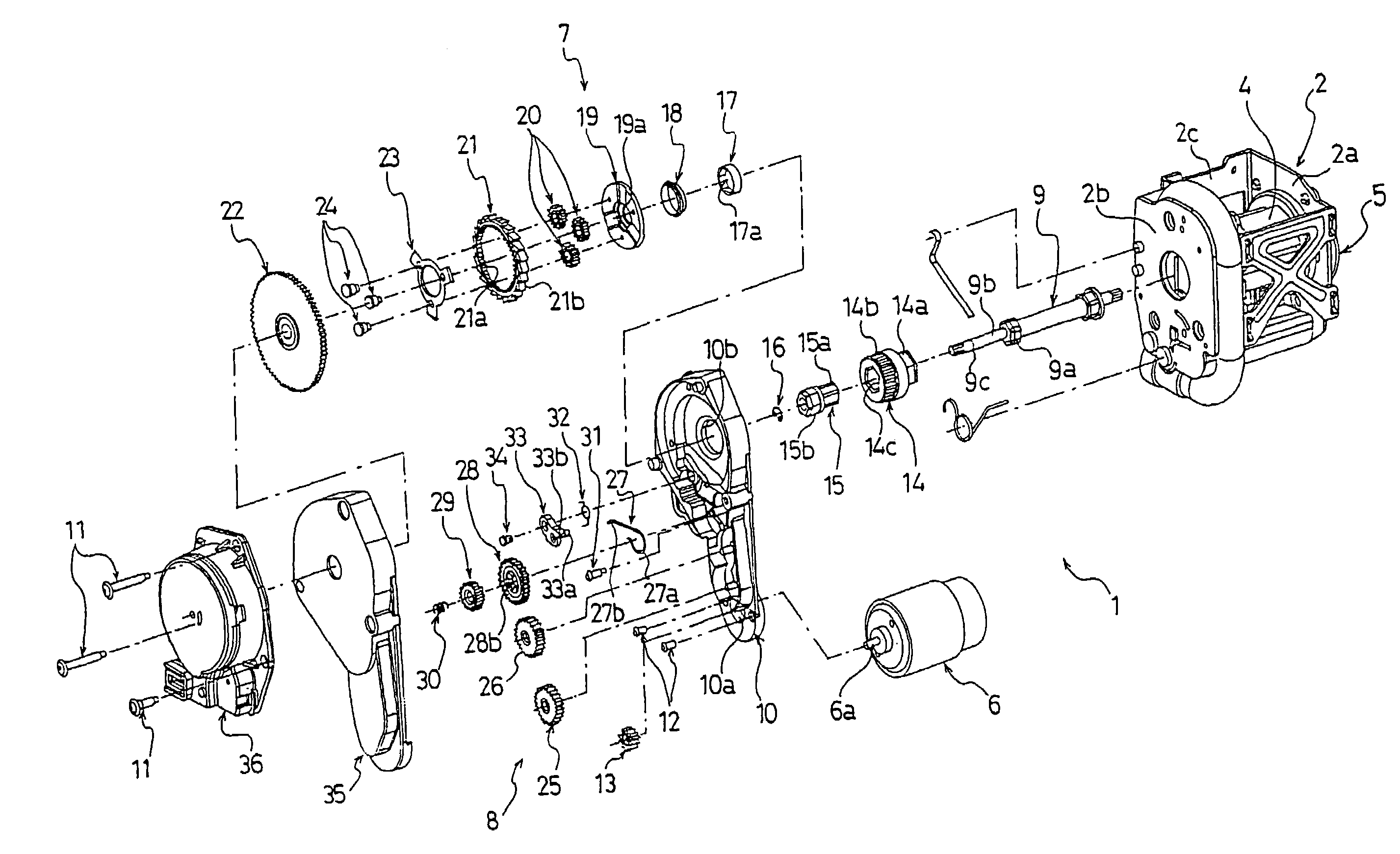

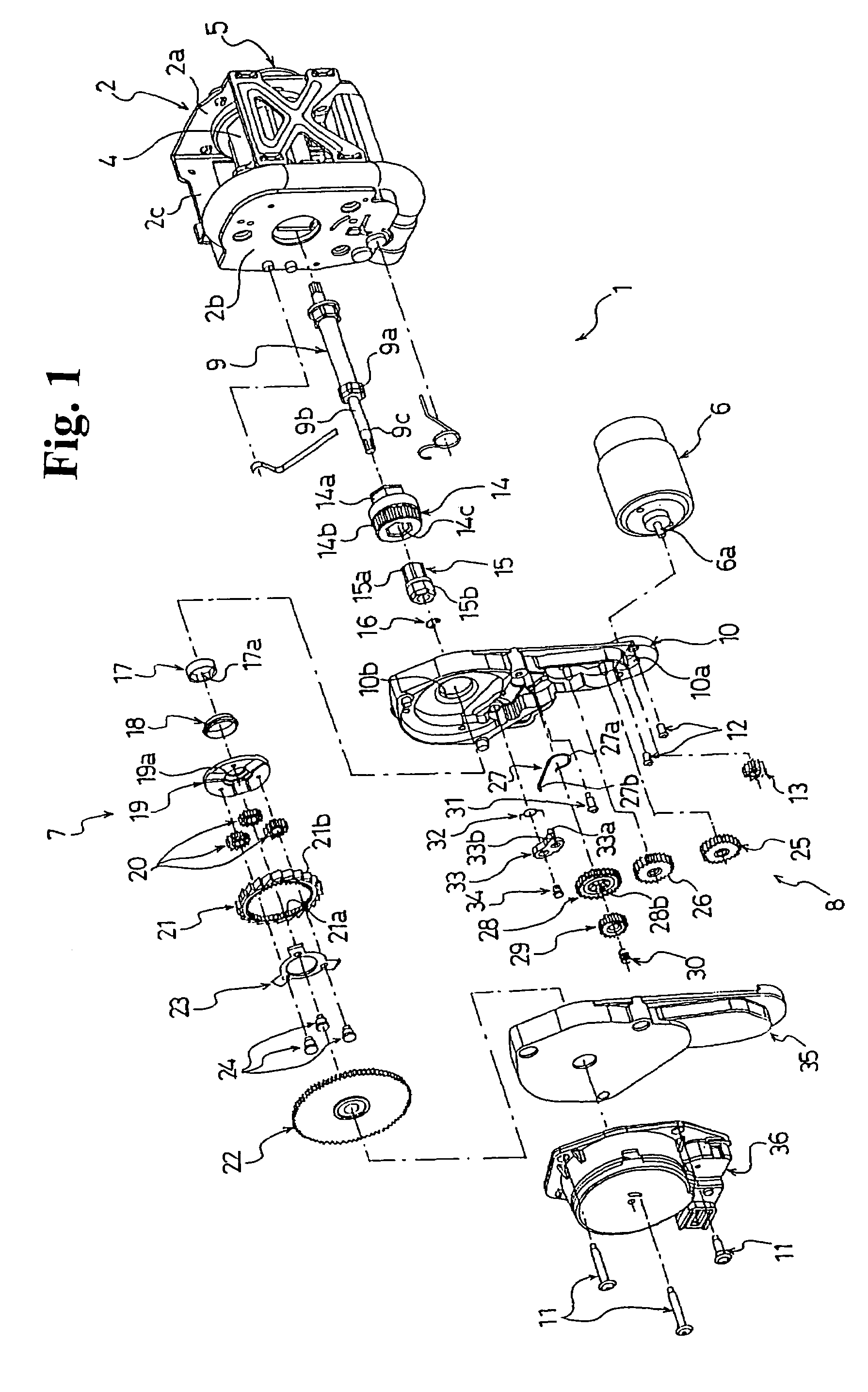

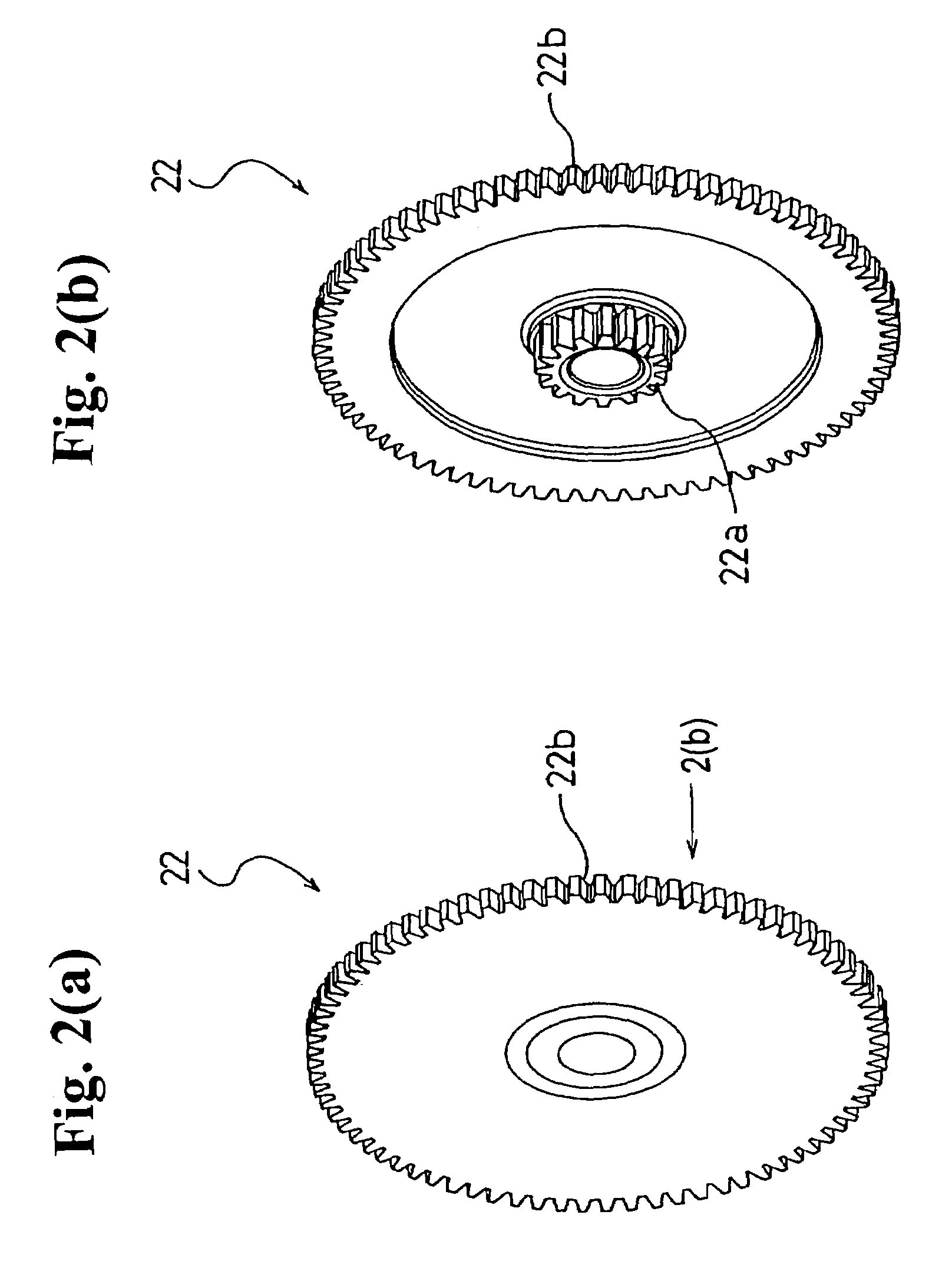

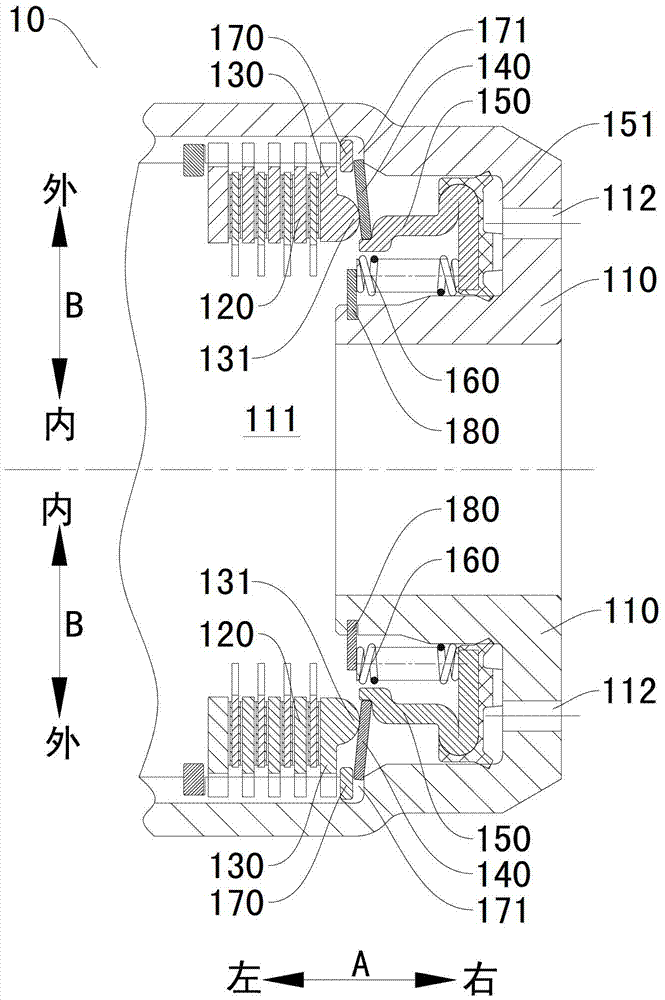

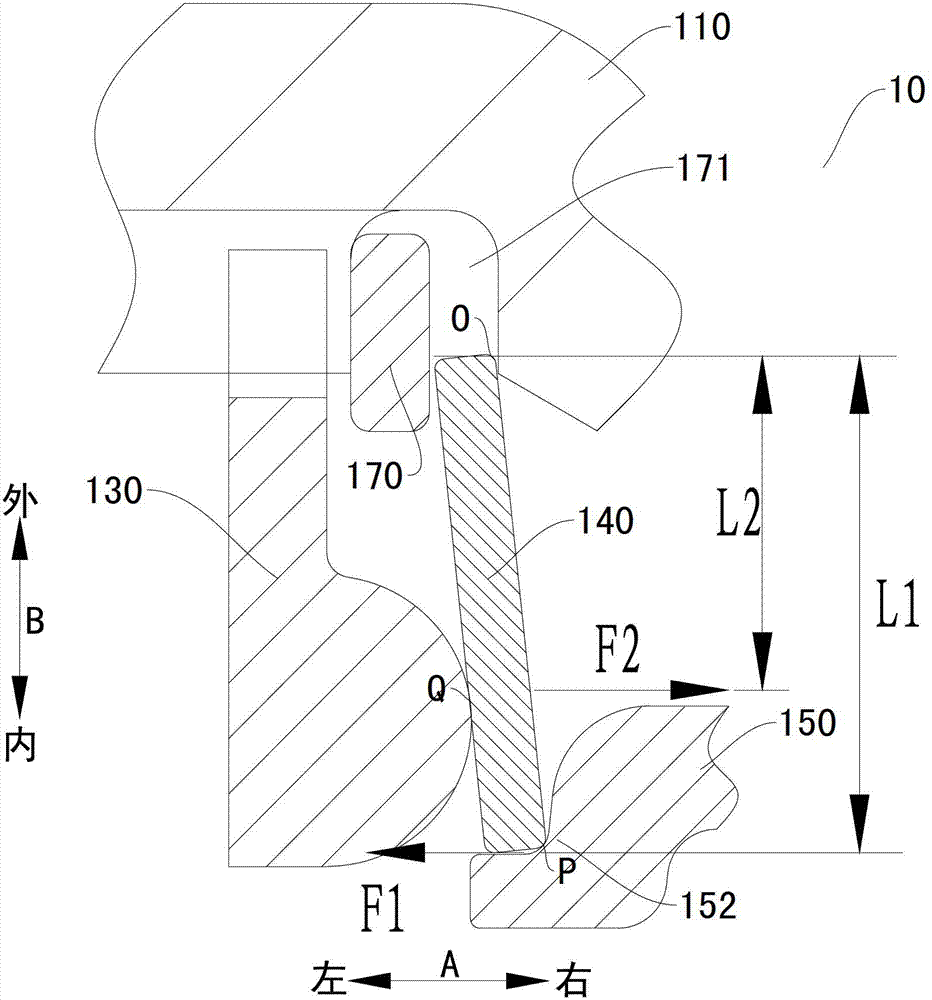

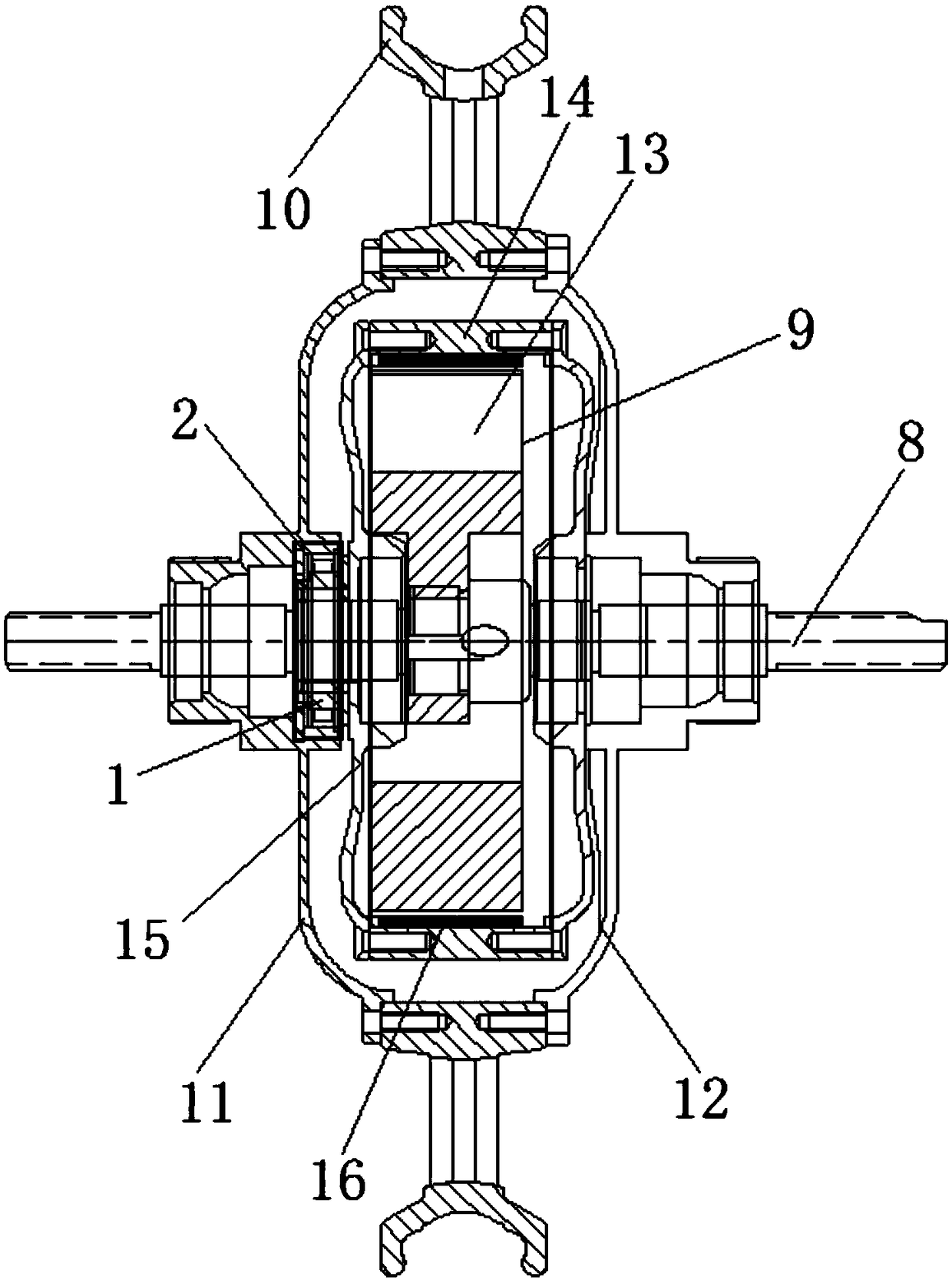

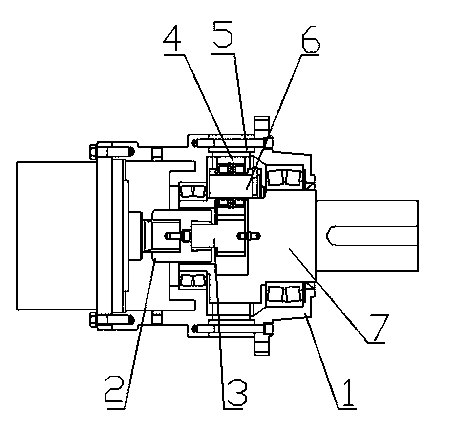

Seat belt retractor and seat belt device

InactiveUS20050029382A1Reduce load torqueHigh strengthBelt retractorsBelt control systemsSeat beltTorque transmission

A seat belt retractor for winding a seat belt includes a spool for winding the seat belt, a motor connected to the spool for generating driving torque to rotate the spool, a driving torque transmission mechanism disposed between the motor and the spool and formed of a gear for transmitting the driving torque of the motor to the spool, and a torque limiter mechanism disposed in the driving torque transmission mechanism for preventing a load greater than a predetermined level from being. transmitted to the driving torque transmission mechanism.

Owner:JOYSON SAFETY SYST JAPAN KK

Seat belt retractor and seat belt device

InactiveUS7392959B2Reduce load torqueLarge load torqueBelt retractorsBelt control systemsSeat beltTorque transmission

A seat belt retractor for winding a seat belt includes a spool for winding the seat belt, a motor connected to the spool for generating driving torque to rotate the spool, a driving torque transmission mechanism disposed between the motor and the spool and formed of a gear for transmitting the driving torque of the motor to the spool, and a torque limiter mechanism disposed in the driving torque transmission mechanism for preventing a load greater than a predetermined level from being transmitted to the driving torque transmission mechanism.

Owner:JOYSON SAFETY SYST JAPAN KK

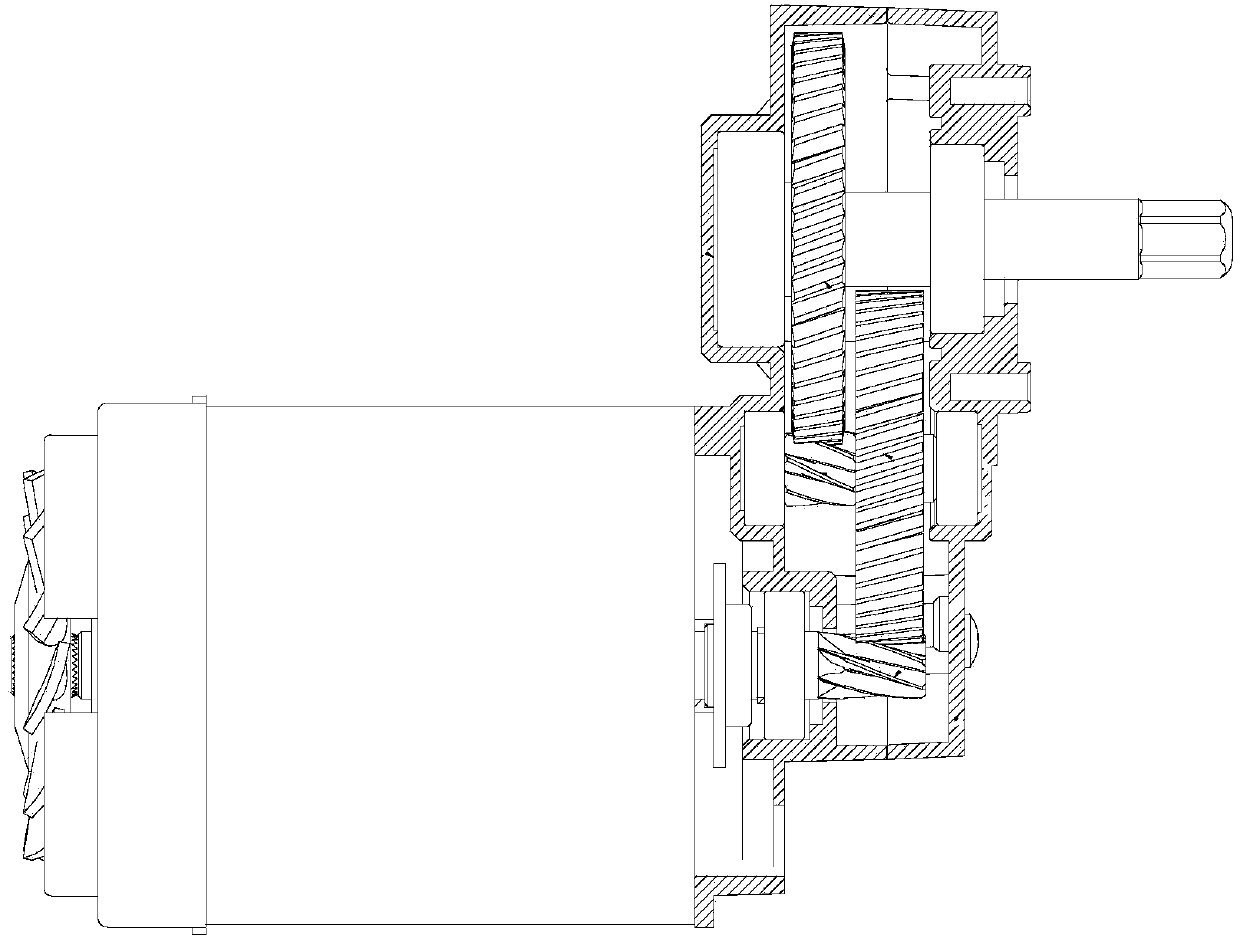

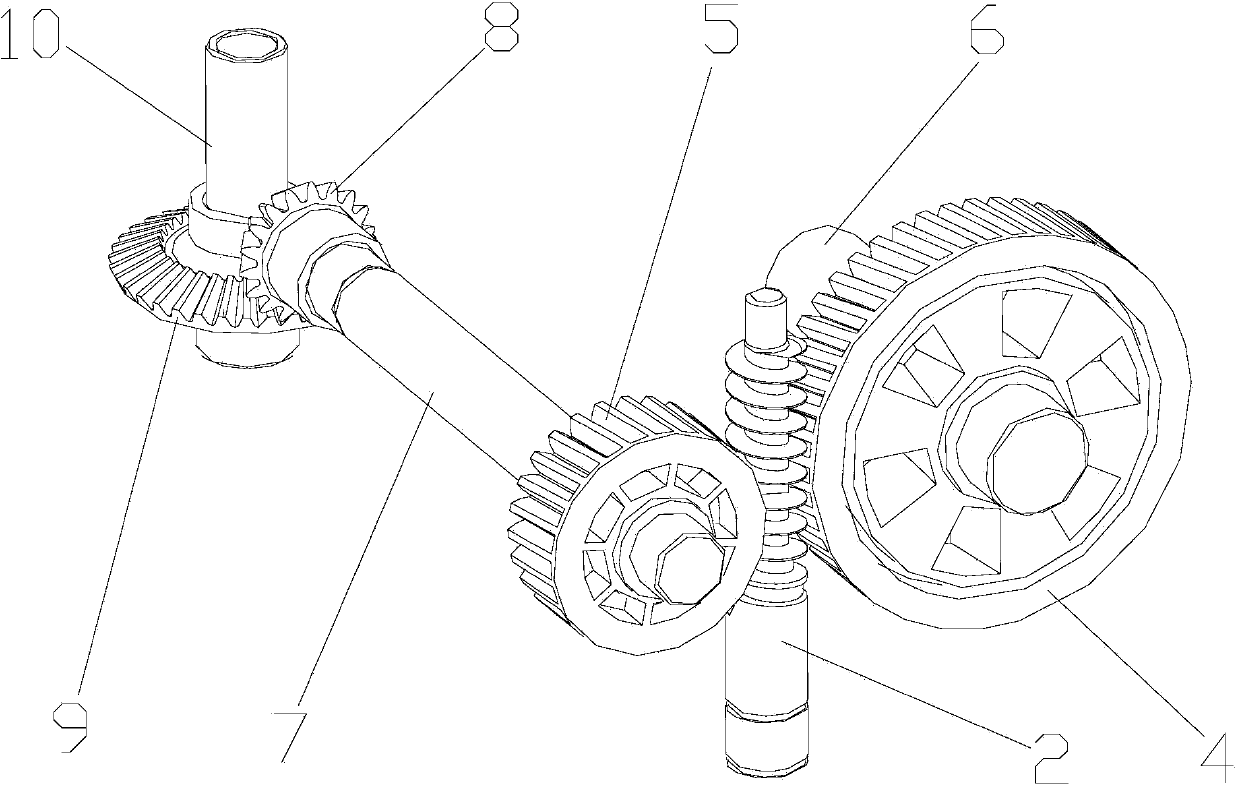

Food processing multifunctional DC (direct current) motor

InactiveCN104218730ALarge load torqueReduce running noiseToothed gearingsMechanical energy handlingDrive shaftControl engineering

The invention discloses a food processing multifunctional DC motor. The food processing multifunctional DC motor comprises a DC permanent magnet motor body, a worm shaft and a reducer box. The DC permanent magnet body is fixed to the reducer box; the tail end of the worm shaft is fixed inside the reducer box through a bearing; both sides of the worm shaft are engaged with a worm I and a worm II respectively; an output shaft I is embedded inside the worm I, a transmission shaft is embedded inside the worm II, the other end of the transmission shaft is matched with a bevel gear I through pressing, the bevel gear I is engaged with a bevel gear II, and the inside of the bevel gear II is matched with an output shaft Ii through pressing; the output shaft I and the transmission shaft are spatially crossed with the worm shaft at 90 degrees, and the output shaft II is spatially crossed with the transmission shaft at 90 degrees. The food processing multifunctional DC motor has the advantages of being simple and reasonable in structure and low in manufacturing and using cost and can drive multiple branches simultaneously, reduce noise and meet the requirements of household appliances on low noise during operation.

Owner:JIANGSU MEIJIA MOTOR

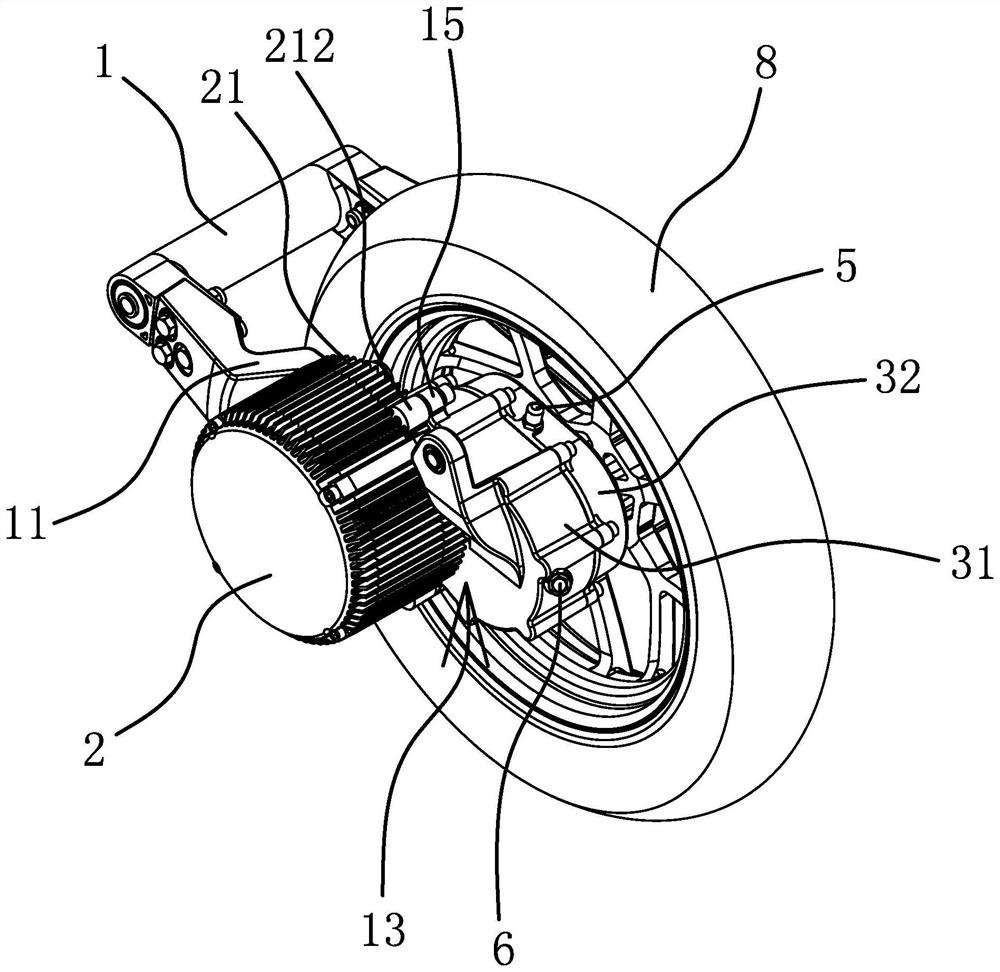

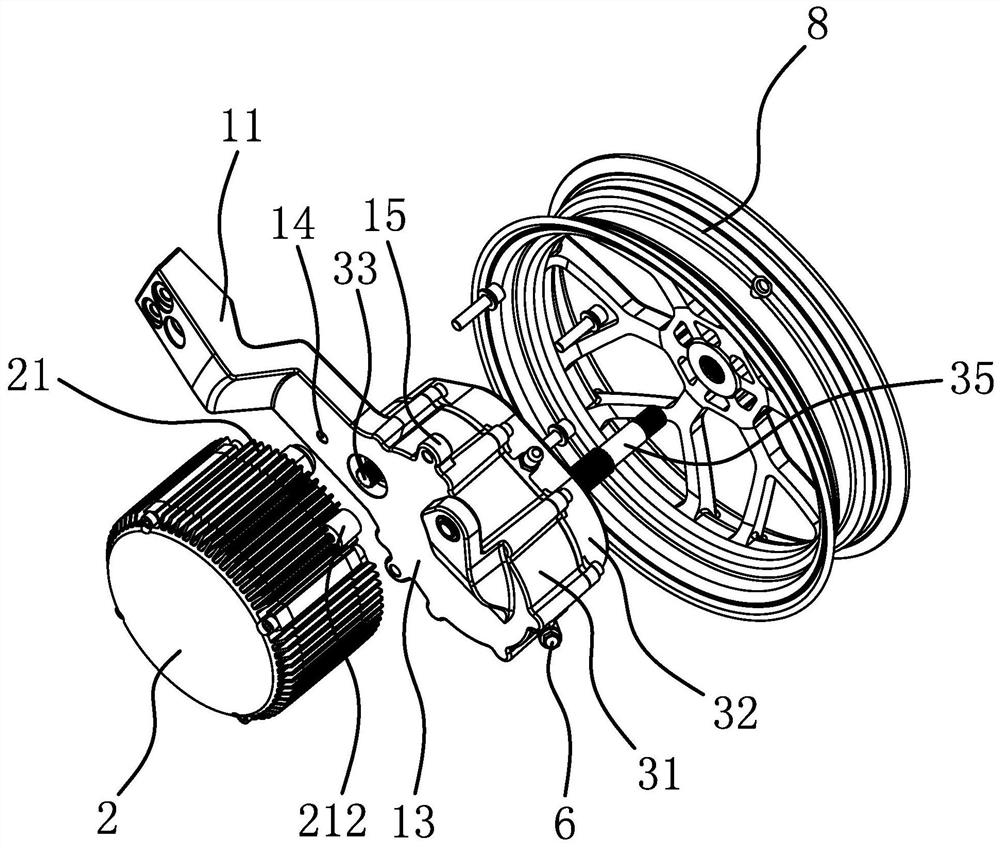

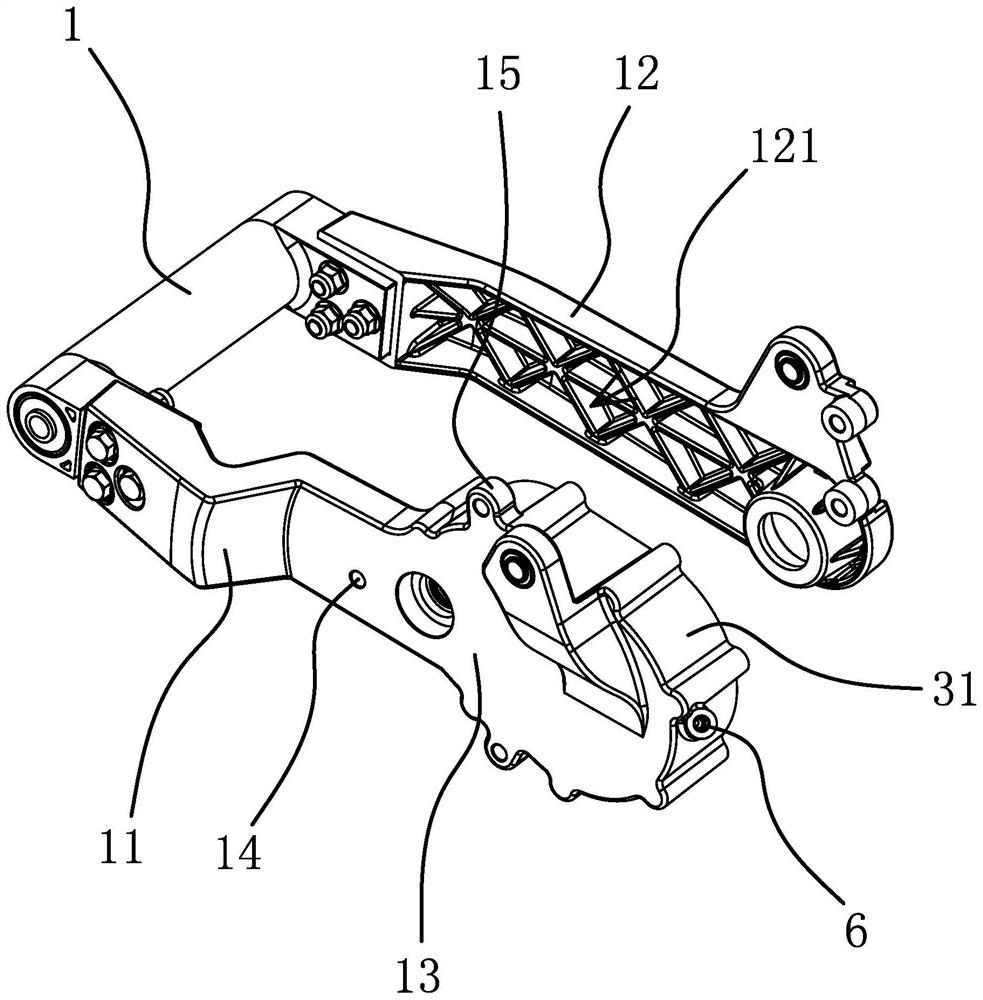

Side-hung driving motor assembly of electric vehicle

InactiveCN111907637AReasonable useImprove balanceWheel based transmissionMotorcyclesElectric machineryElectric cars

The invention provides a side-hung driving motor assembly of an electric vehicle, and belongs to the technical field of electric vehicles. The problem that an existing electric vehicle with a side-hung driving motor is poor in balance is solved. The electric vehicle comprises wheels, the side-hung driving motor assembly comprises a bottom fork and a motor, the bottom fork comprises a left fork armand a right fork arm, the wheels are arranged between the left fork arm and the right fork arm, the side-hung driving motor assembly further comprises a speed reducing and changing mechanism, the left fork arm is bent towards the wheels, and a concave installation space is formed in the outer side of the left fork arm. The motor is located in the installation space and fixedly connected with theleft fork arm, an installation cavity is formed in the inner side of the rear end of the left fork arm, the speed reducing and changing mechanism is arranged in the installation cavity, the inner sidewall of the right fork arm is concavely arranged in the direction away from the wheel to form a receding space, and the motor is connected with the wheel through the speed reducing and changing mechanism. The electric vehicle with the side-hung driving motor has the advantage of being good in balance.

Owner:WENLING JIUZHOU ELECTROMECHANICAL

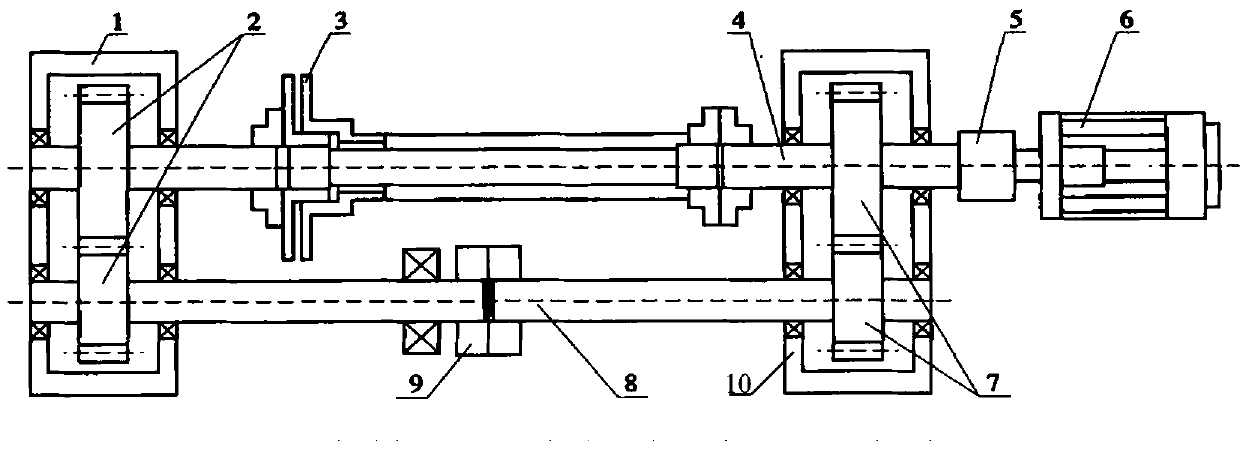

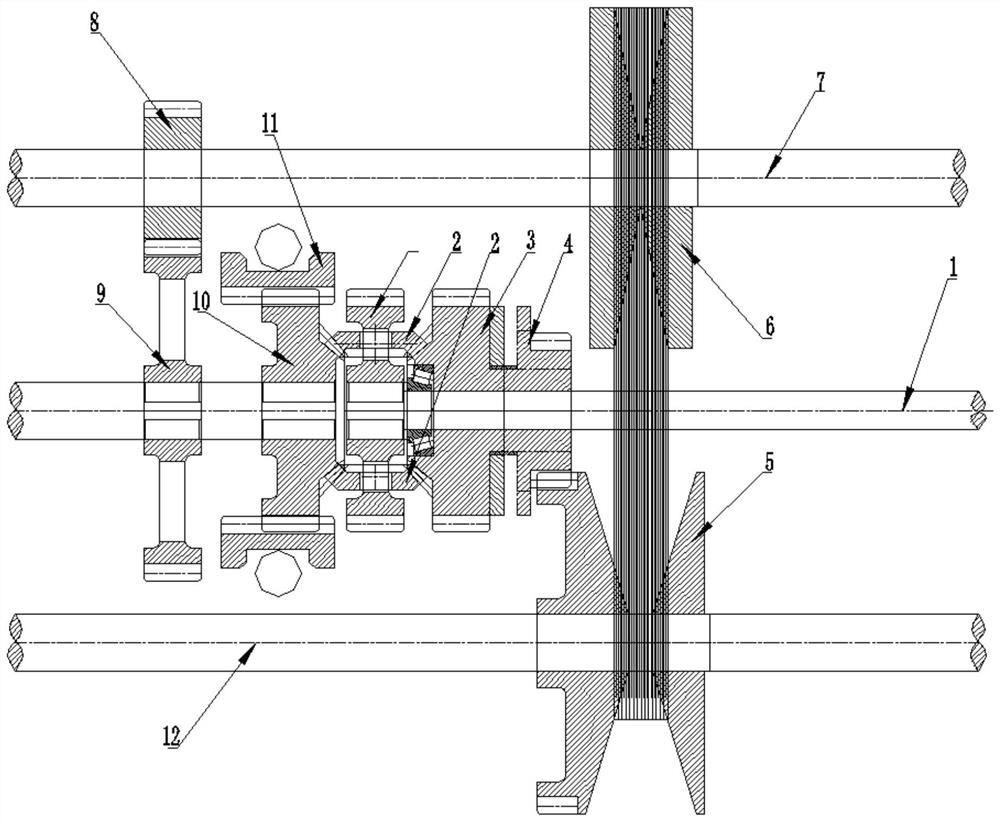

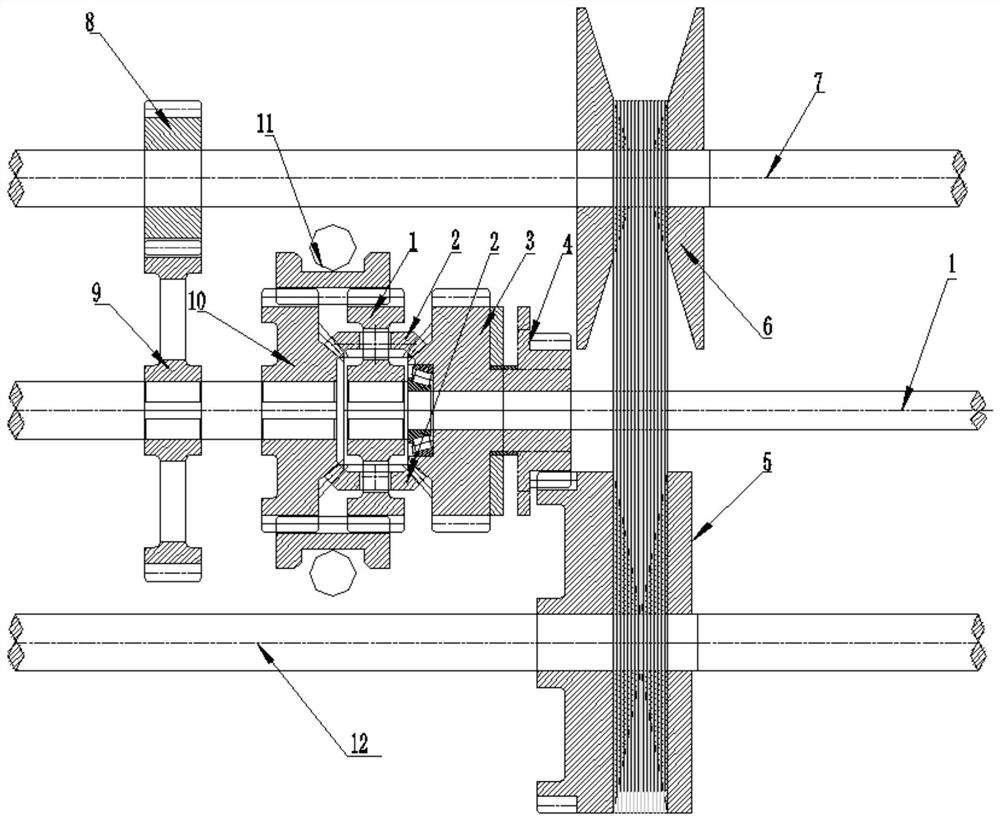

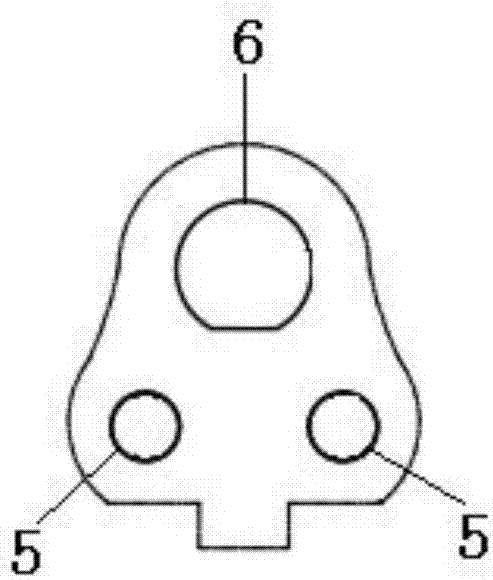

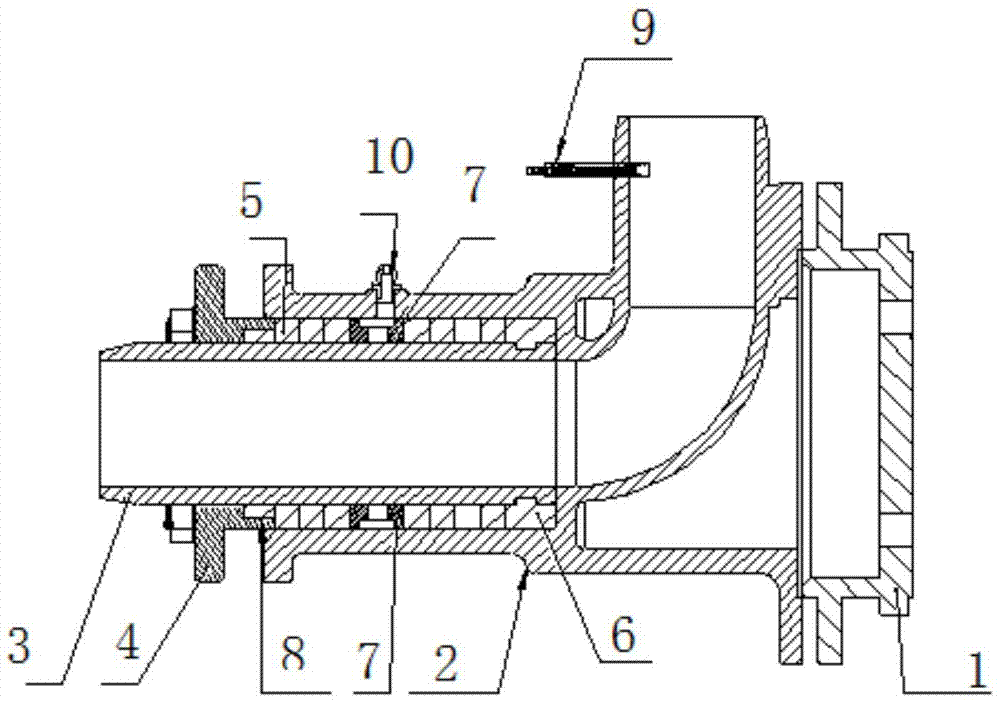

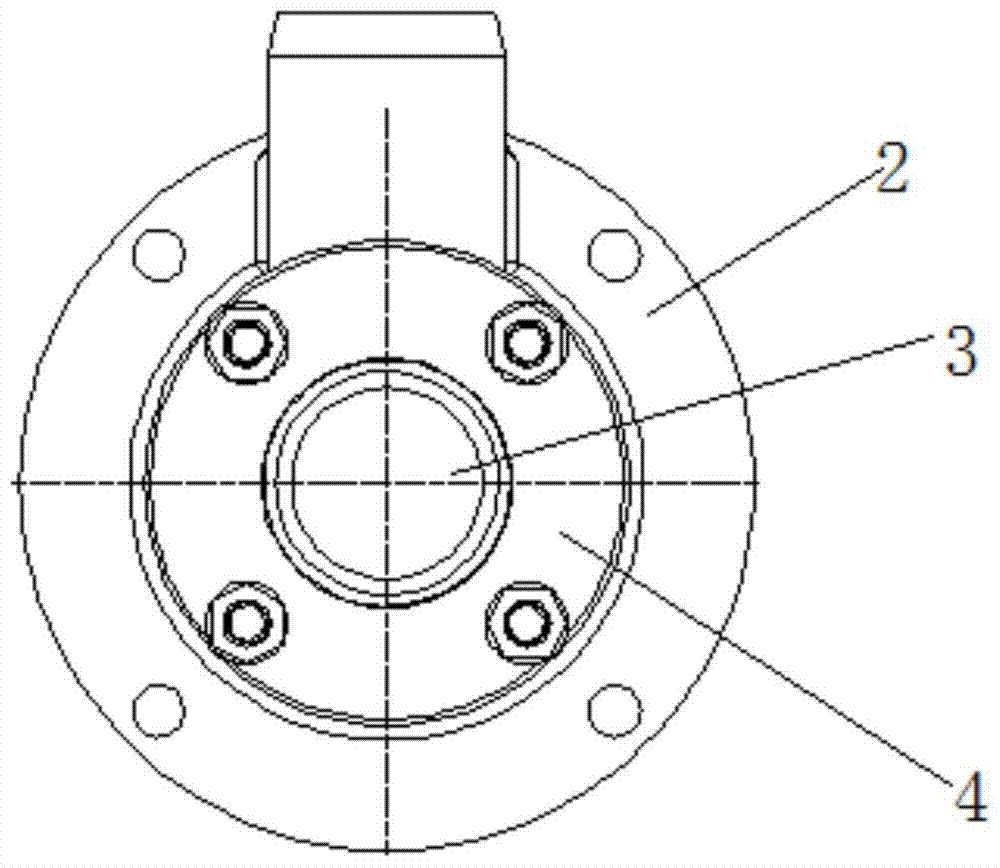

Gear fatigue testing machine considering gear misalignment and gear surface unbalanced loading

The invention discloses a gear fatigue testing machine considering gear misalignment and gear surface unbalanced loading. The gear fatigue testing machine is composed of a testing gear case (1), a torque clutch (3), an input shaft (4), a coupler (5), a motor (6), an accompanying gear case (10), and output shaft (8) and a loading clutch (9) through assembling; the gear fatigue testing machine controls misalignment and unbalanced loading of a gear pair in the gear case through a simple and easy mechanical apparatus so as to monitor a vibration signal of the gear case, is simple in structure, hasa wide range of application and can effectively complete experimental simulation of misalignment and unbalanced loading faults of different gear parameters.

Owner:JIANGSU JINXIANG TRANSMISSION EQUIP

Clutch disc, friction clutch device and drive train

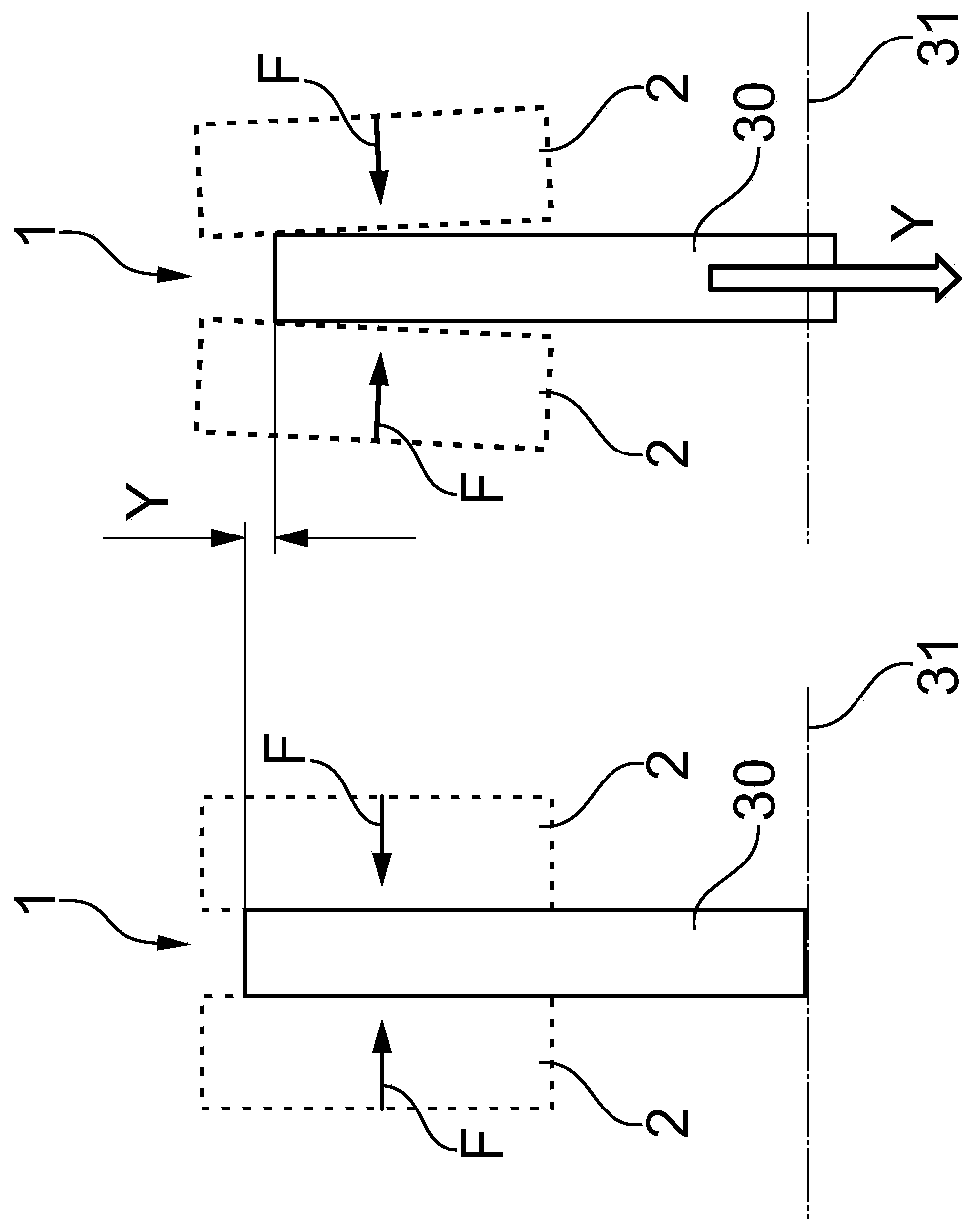

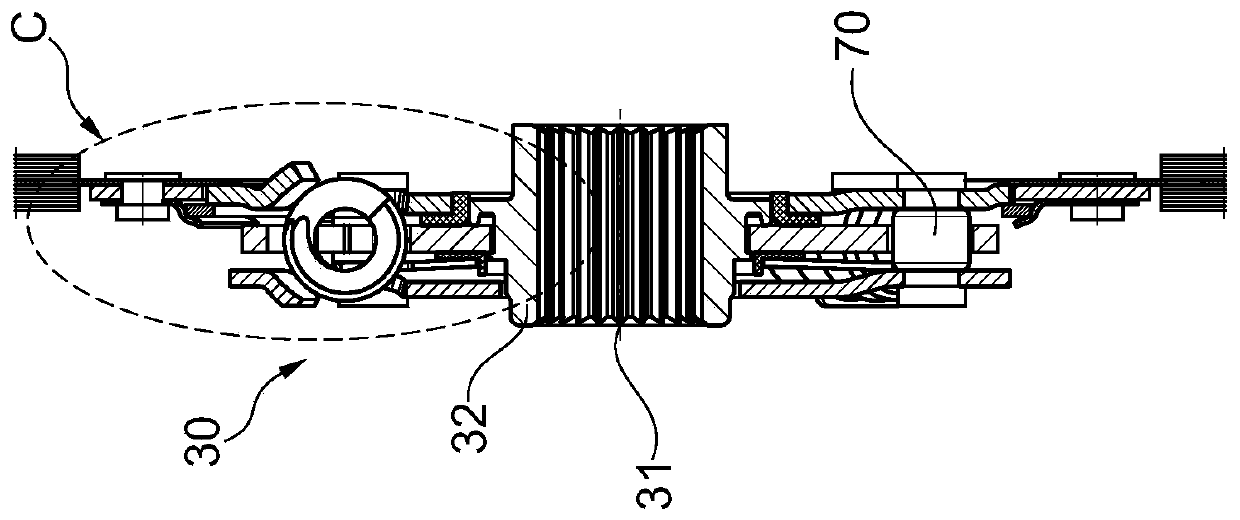

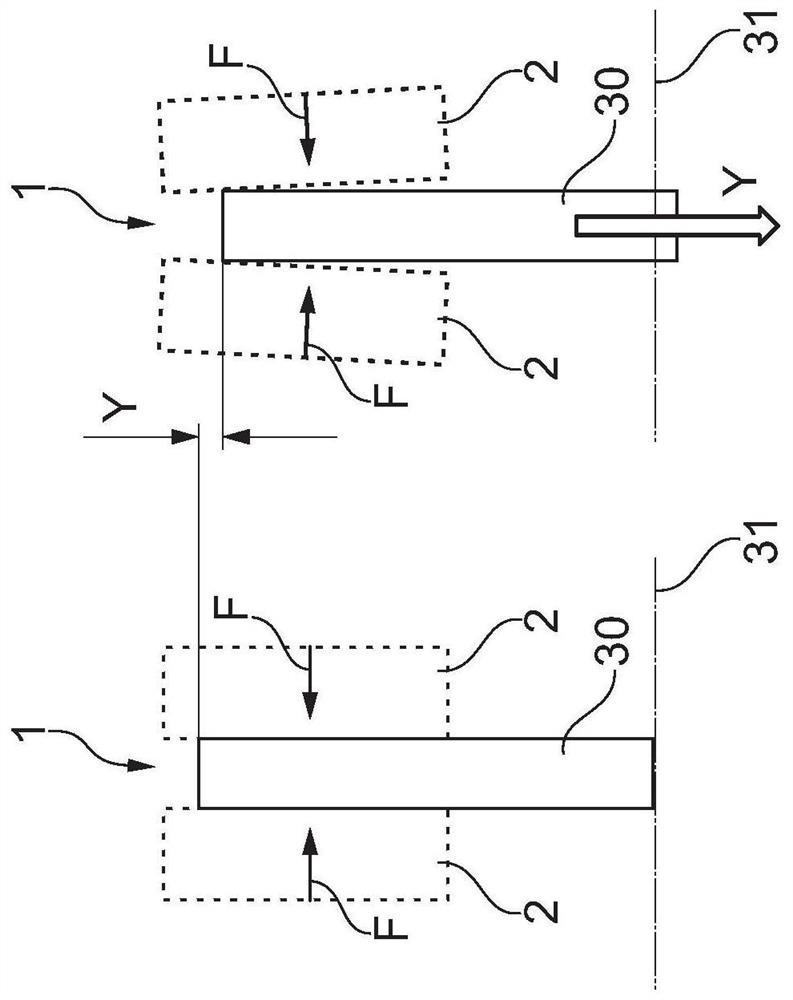

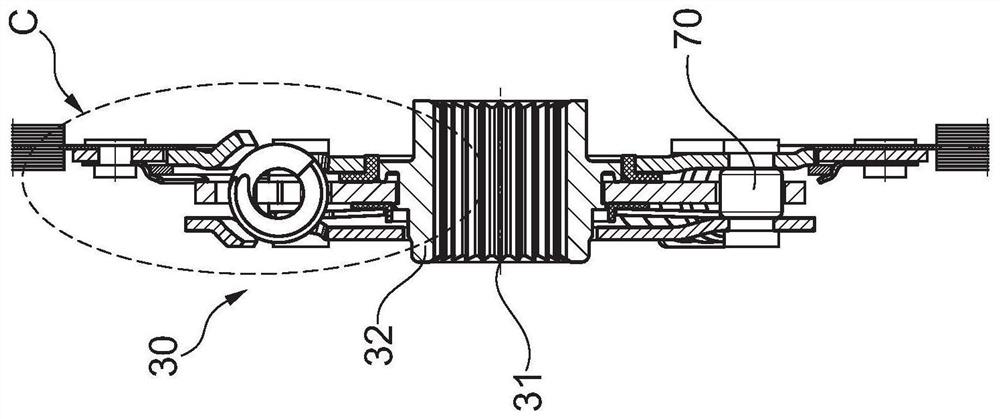

ActiveCN109790877AReduce frictionAchieve lateral offsetRotating vibration suppressionFriction clutchesEngineeringRadial displacement

The invention relates to a clutch disc for a friction clutch device and to the friction clutch device itself, and to a drive train. The clutch disc (30) comprises a hub (32) for torque-resistant connection to a shaft; a friction element (33) for frictionally applying a torque to the clutch disc (30); and a first hub flange (40) and a second hub flange (41), wherein at least the first hub flange (40) is connected in a torque-resistant manner to the hub (32). The clutch disc (30) has spring elements (50) which couple the two hub flanges mechanically to each other between same so that the hub flanges can rotate relative to each other. The clutch disc (30) is designed such that the two hub flanges (40, 41) can be offset laterally to each other. By means of the proposed clutch disc, it is possible to compensate a lateral and / or radial offset and / or a radial displacement while ensuring a long service life on account of reduced friction conditions on the damping springs of the clutch disc.

Owner:SCHAEFFLER TECH AG & CO KG

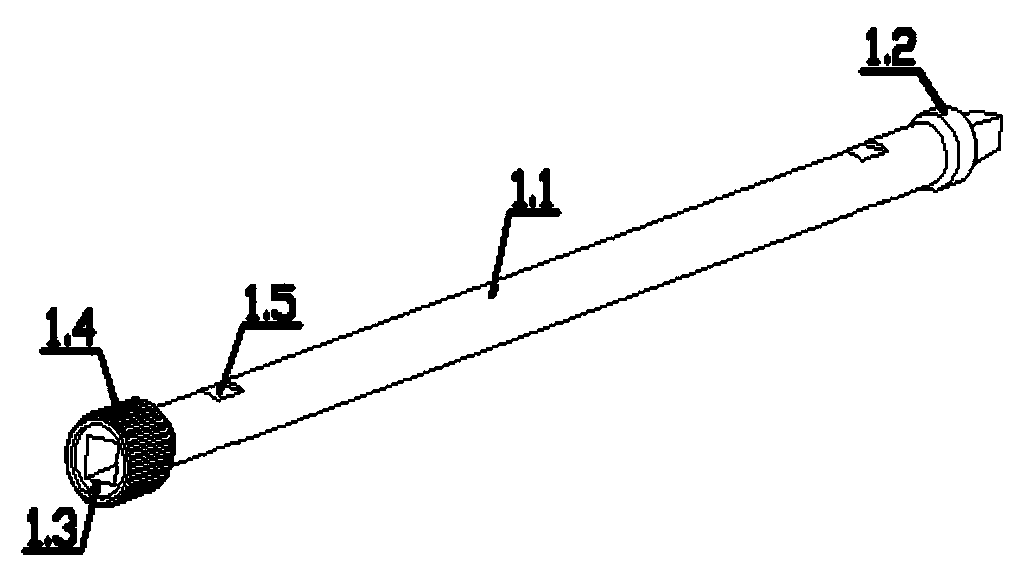

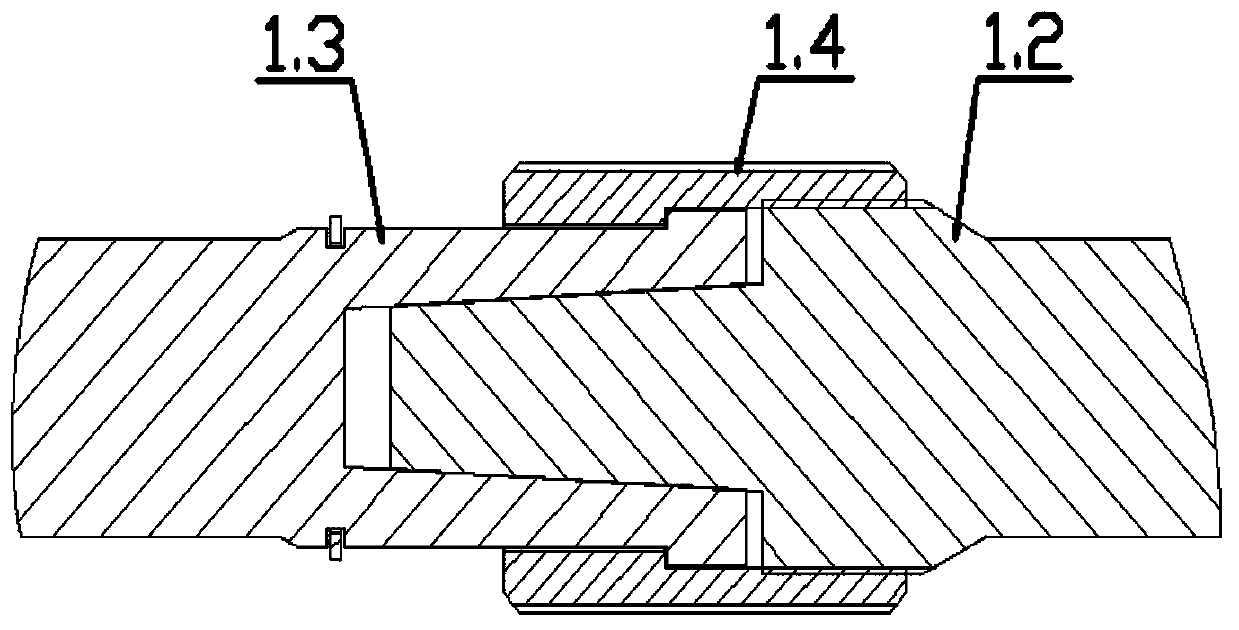

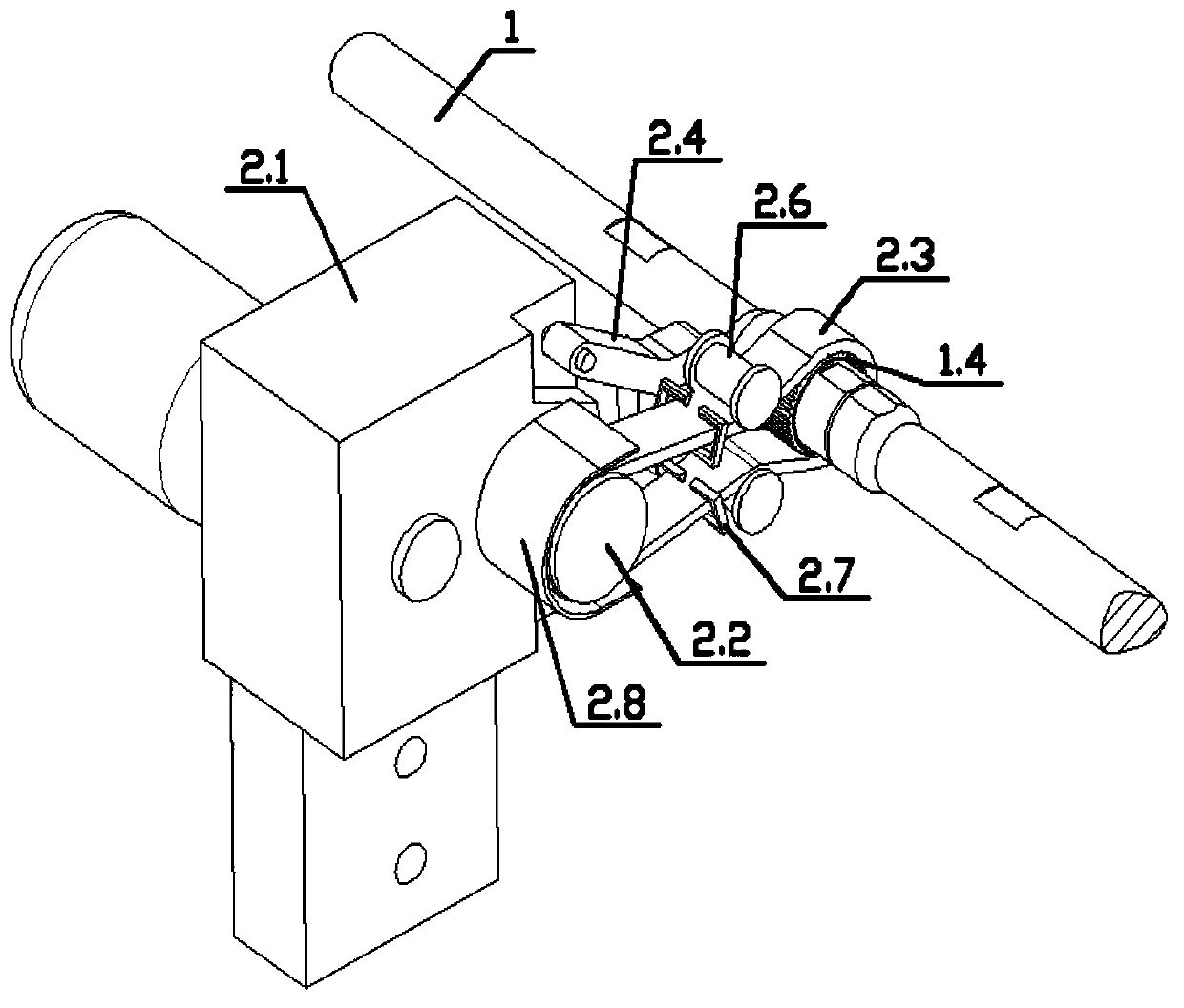

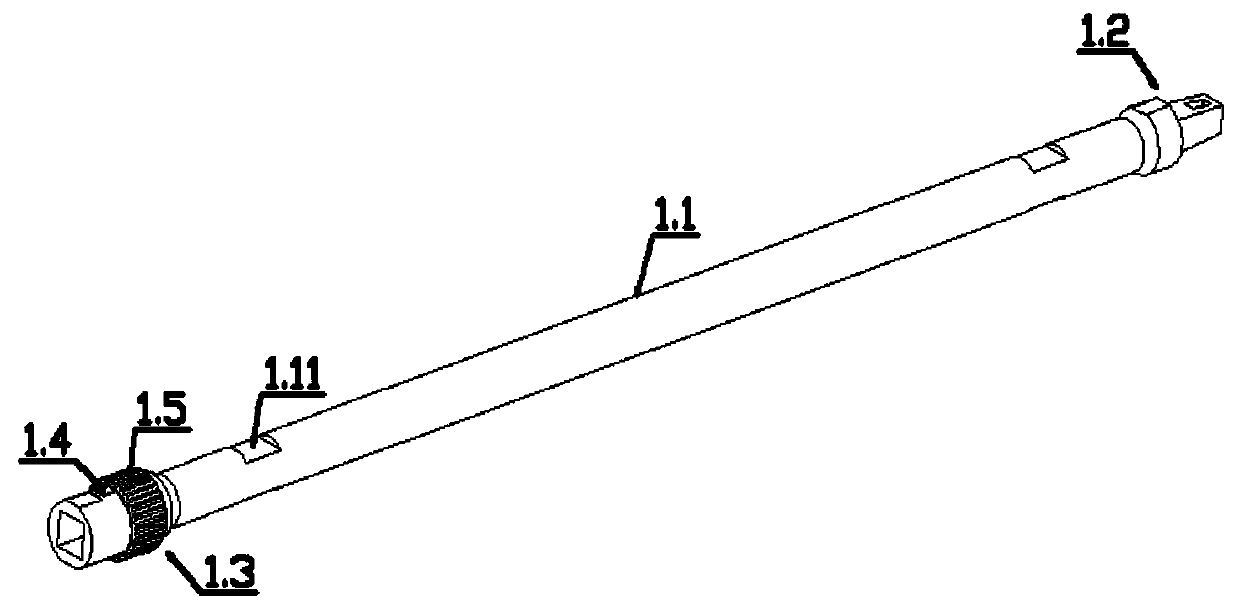

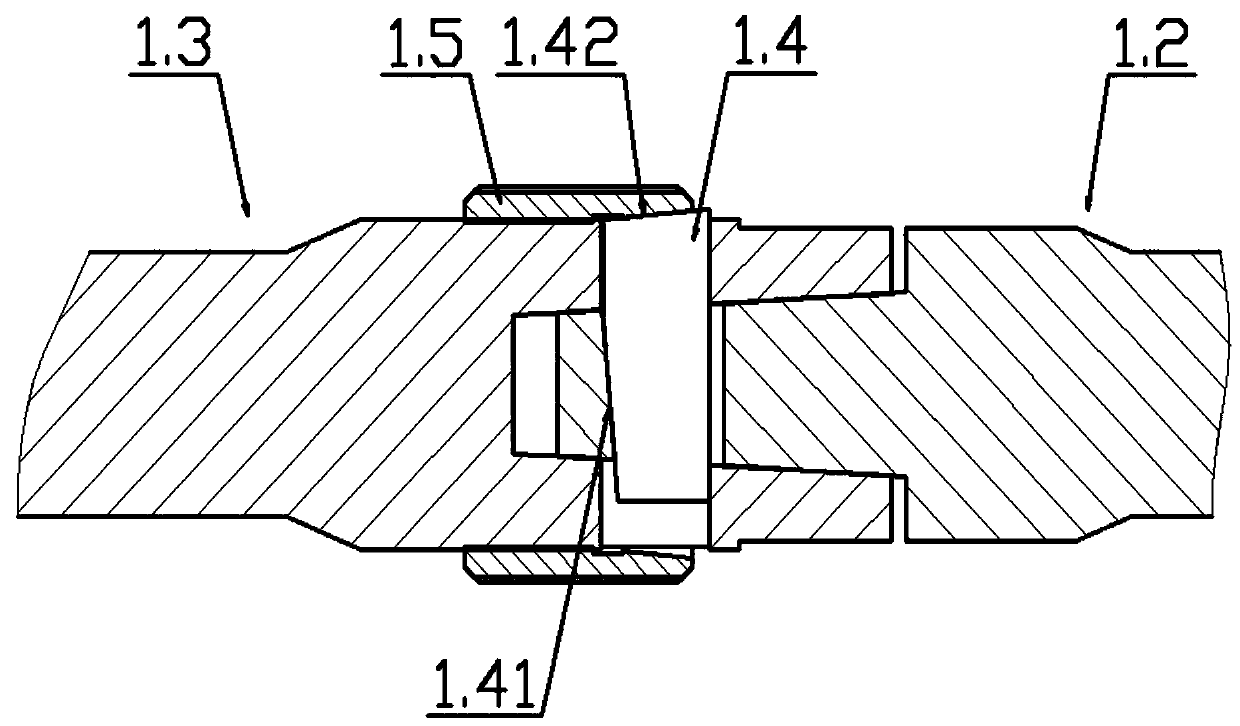

Easy-to-disassemble drill rod and drill rod automatic assembling and disassembling equipment applied to same

PendingCN110552640AQuick installationQuick releaseDrilling rodsDrilling casingsControl systemUltimate tensile strength

The invention discloses an easy-to-disassemble drill rod. The easy-to-disassemble drill rod comprises a rod body, a connecting head, a connecting tail and a connecting nut, wherein the connecting headand the connecting tail are connected to the two ends of the rod body, the connecting head is provided with an axial rectangular pyramid table, the connecting tail is provided with a rectangular pyramid hollow, and a synchronous pulley is arranged on the outer circle surface of the connecting nut. Through coaxial matching of the rectangular pyramid table and the rectangular pyramid hollow, the drill rod can be rapidly assembled and disassembled, and the advantages of being large in bearing torque, long in service life, easy to disassemble, low in cost and the like are achieved. Drilling rod automatic assembling and disassembling equipment applied to the easy-to-disassemble drill rod is arranged on one side of a drilling machine, and comprises a connecting nut assembling and disassemblingmechanism, a drill rod assembling and disassembling mechanism and a control system. The connecting nut assembling and disassembling mechanism can quickly assemble and disassemble the connecting nut, so that manual operation is replaced by mechanical action; the drill rod assembling and disassembling mechanism is high in automation degree, automatic assembling and disassembling of the drill rod arerealized, the labor intensity of operators is greatly reduced, and the working efficiency is improved; and a drill rod circulation box of the drilling rod automatic assembling and disassembling equipment is large in capacity, and the problems of placing, carrying and transporting of the drill rod are solved at the same time.

Owner:洛阳风动工具有限公司

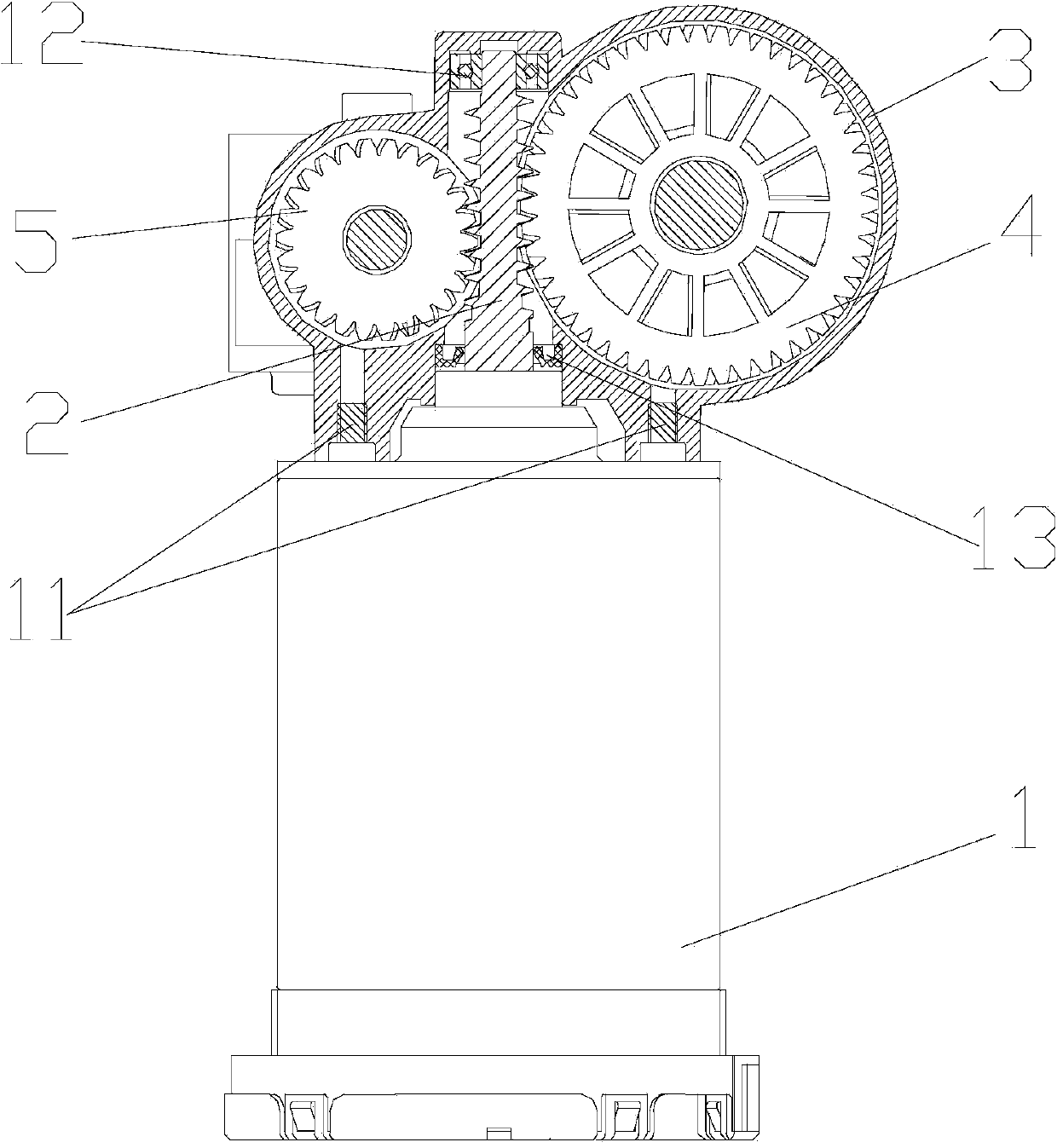

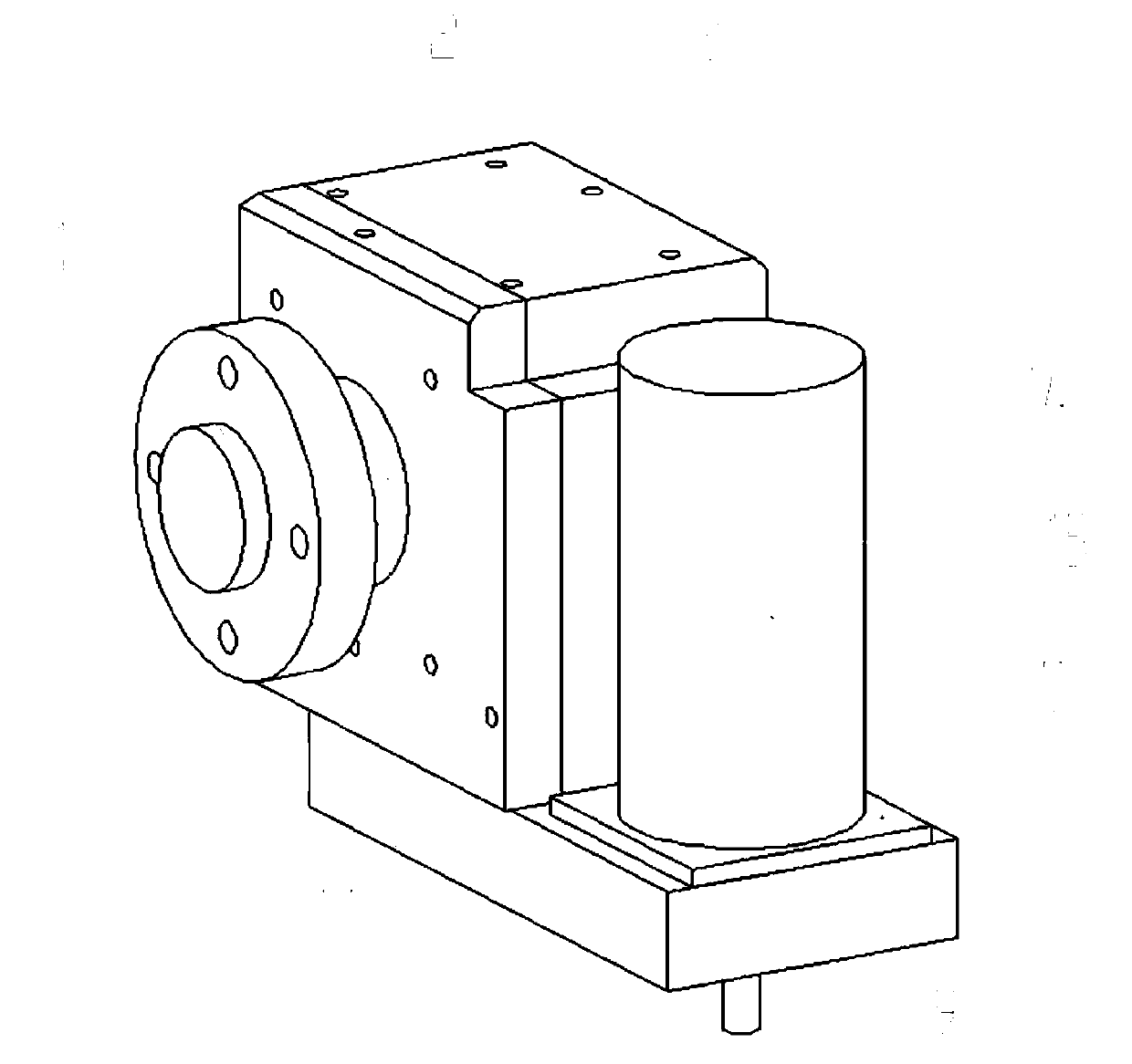

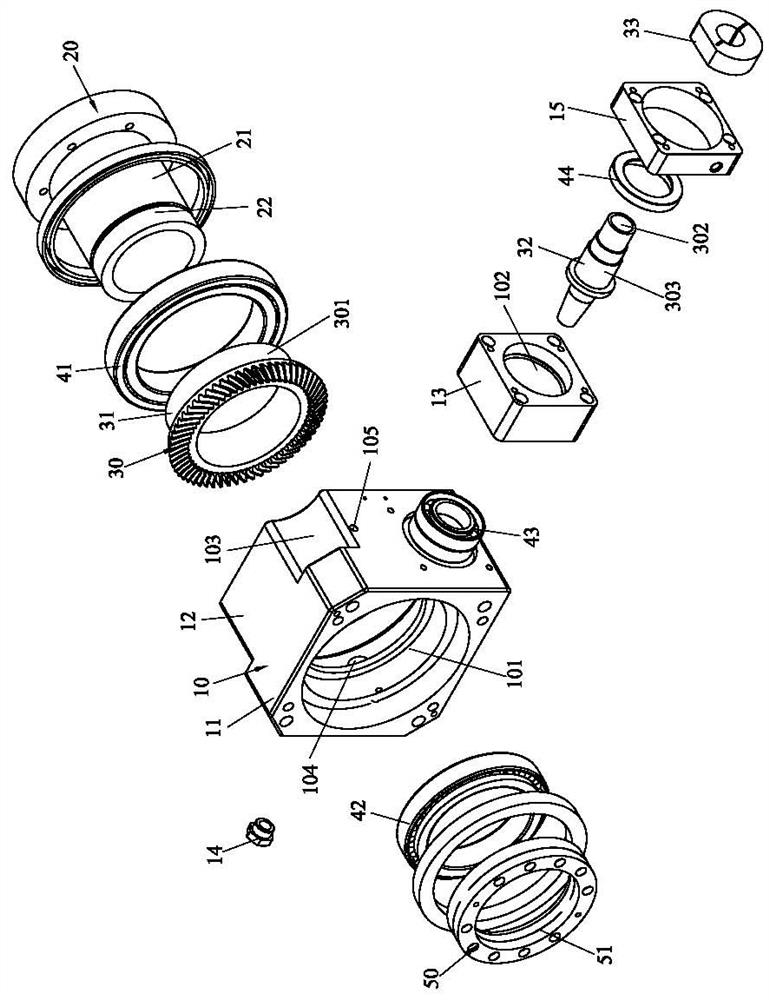

Hypoid reducer with parallel shaft gear transmission

PendingCN111594580ATo overcome the lack of precisionEnsure highest positioning accuracyToothed gearingsGearing detailsGear driveGear wheel

The invention discloses a hypoid reducer with parallel shaft gear transmission. A motor flange is assembled on a motor and assembled with an upper case cover, the upper case cover and a lower case cover are connected to form a first cavity, the first cavity is provided with an input gear, an intermediate gear and an output gear which are engaged, the input gear is assembled on a motor shaft, the input gear is driven to rotate through the motor shaft, the upper case cover is connected with a case body, the case body is assembled with a bearing cover to form a second cavity, and a pair of engaged hypoid gears are contained in the second cavity to transmit power. The hypoid reducer with the parallel shaft gear transmission, a large transmission ratio in a very small space can be realized, theaccuracy is high, and the noise is low; and a shortcoming of a traditional reversing reducer in accuracy is overcame, even if in the case of high dynamic operation, the highest positioning accuracy of a transmission device and the maximum accuracy of a machinery and equipment can be ensured, at the same time, the noise of a reducer is reduced, and the transmission is more stable.

Owner:ZHEJIANG UNIV KUNSHAN INNOVATION INST

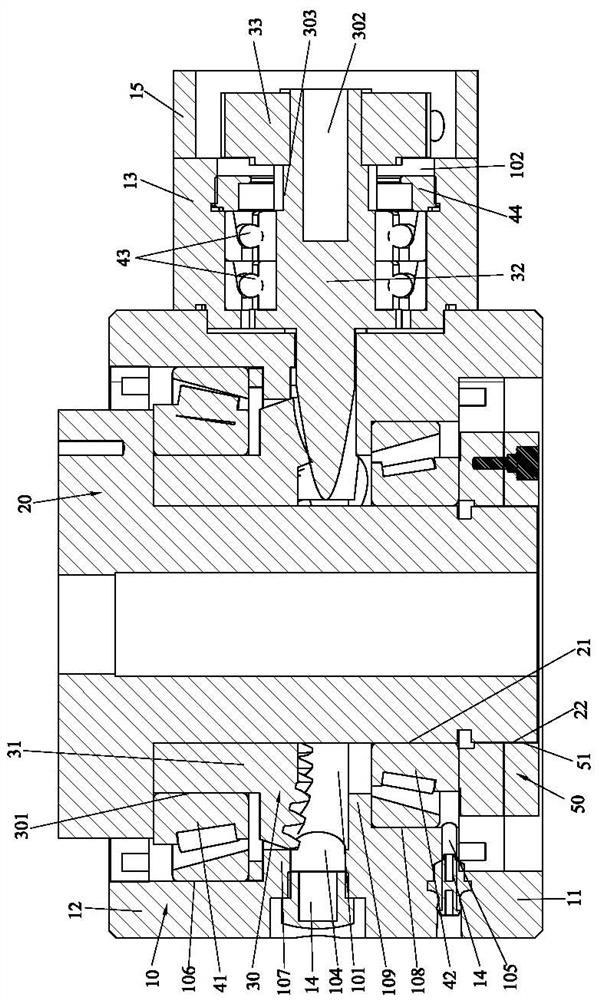

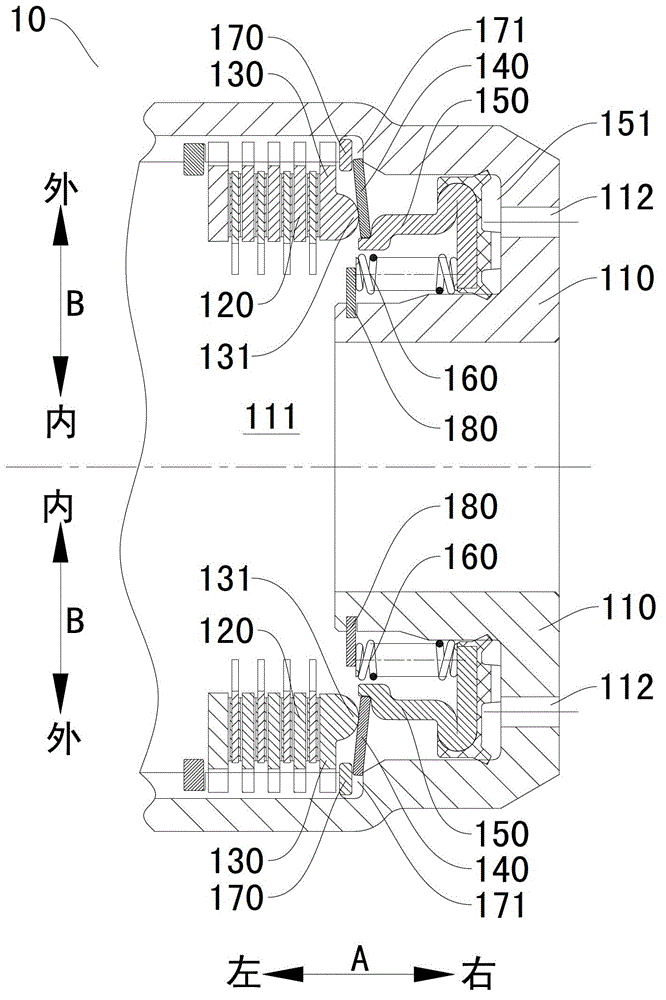

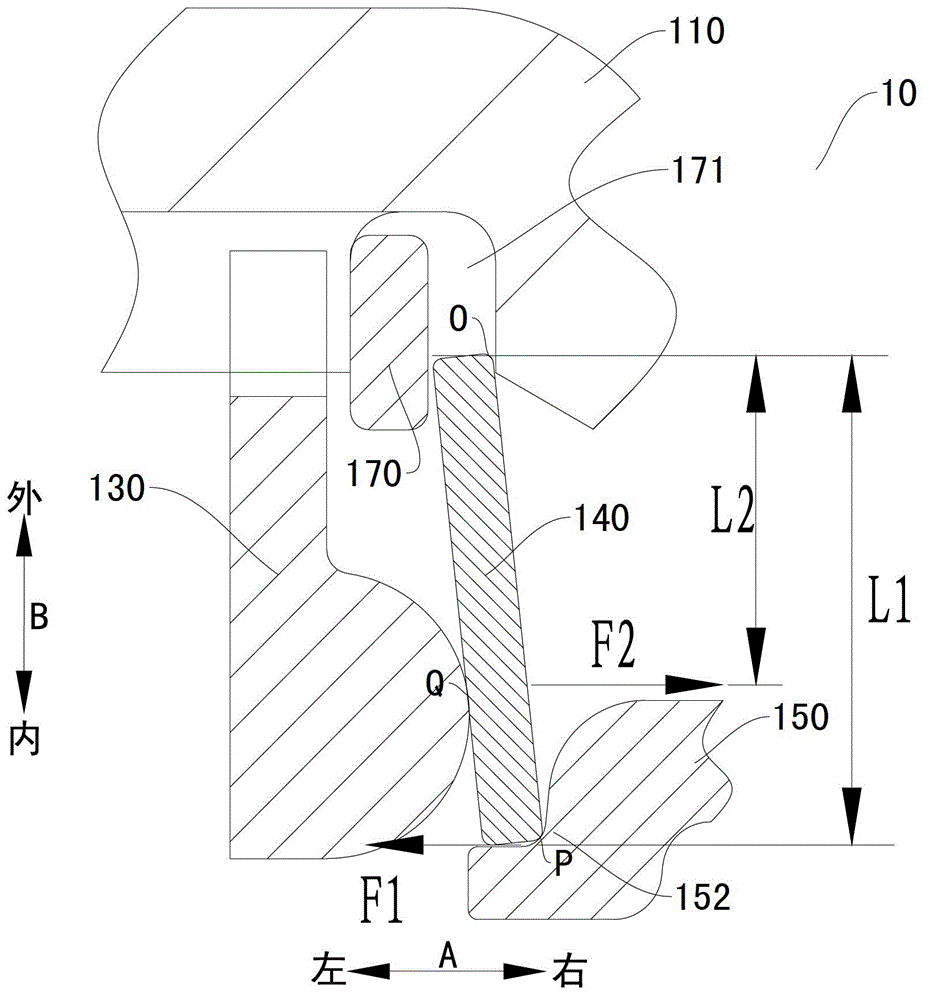

Clutch and vehicle with same

InactiveCN103307134ALarge load torqueStable force transmissionFluid actuated clutchesEngineeringPiston

The invention discloses a clutch and also discloses a vehicle with the clutch. The clutch comprises a body, a friction piece, a combination piece, a force transmission piece, a piston and an elastic piece, wherein the body is internally provided with an accommodating cavity; the force transmission piece can be pivotably arranged in the accommodating cavity; the piston is movably arranged in the accommodating cavity and between a separation position and a combination position; on the combination position, the piston is contacted with the force transmission piece and applies a first driving force to the force transmission piece; the force transmission piece is contacted with the combination piece and applies a second driving force to the combination piece so as to ensure that the combination piece and the fraction piece can be conveniently combined; the distance between the contact part of the piston and the force transmission piece and the pivoting point of the force transmission piece is greater than that between the contact part of the force transmission piece and the combination piece and the pivoting point of the force transmission piece. The clutch disclosed by the embodiment of the invention has the advantages of large torque capacity, more smooth driving force transmission, no need of increasing the pressure of hydraulic oil, small size and the like.

Owner:GREAT WALL MOTOR CO LTD

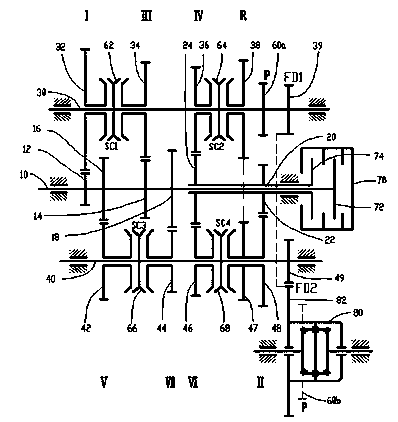

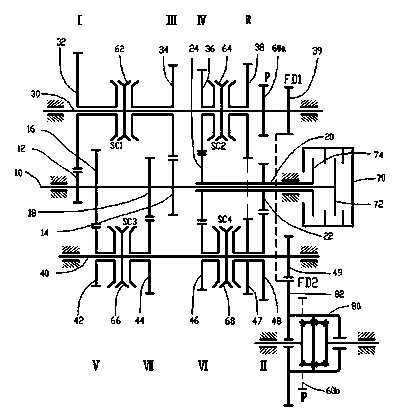

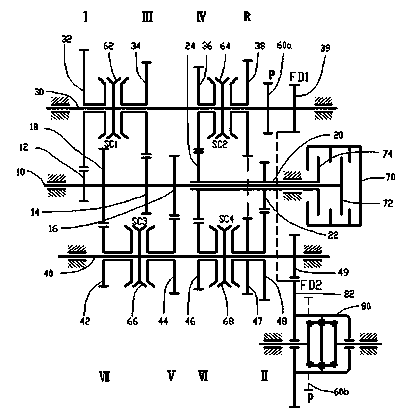

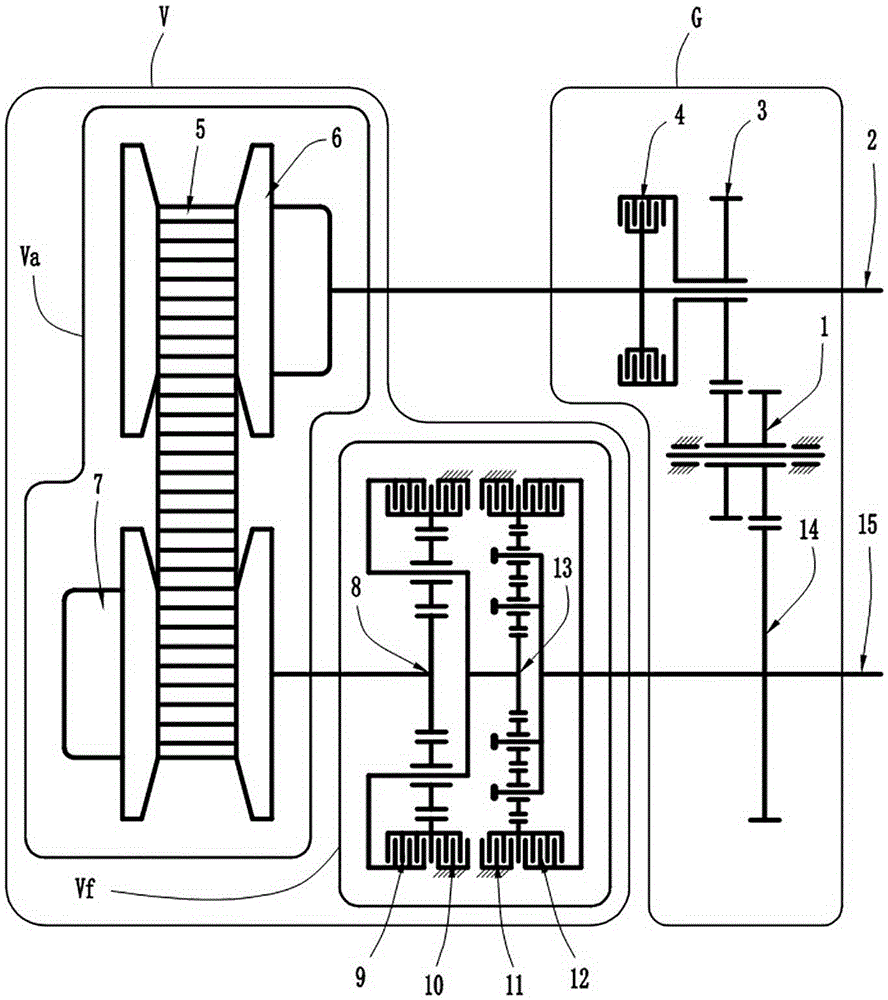

Dual-clutch automatic transmission device

InactiveCN103671754AIncrease stiffnessReduce the overall heightToothed gearingsTransmission elementsLow speedAutomatic transmission

Disclosed is a dual-clutch automatic transmission device. The dual-clutch automatic transmission device comprises an inner input shaft, an outer input shaft, two countershafts, a dual clutch, a differential assembly, a plurality of normally-engaged gear sets and a plurality of synchronizer devices, wherein the inner input shaft and the outer input shaft are coaxially arranged, and the normally-engaged gear sets are arranged on the shafts respectively. The dual-clutch automatic transmission device is characterized in that a first-speed gear and a second-speed gear serve as low-speed gears and are arranged at the shaft ends of a shaft system of a gearbox respectively; a first-speed driven gear and a reverse driven gear are arranged on the same countershaft; the center distance between the countershaft where the first-speed driven gear is located and the inner input shaft is larger than that between the other countershaft and the inner input shaft, and the center distance between the countershaft where the first-speed driven gear is located and the outer input shaft is larger than that between the other countershaft and the outer input shaft. The dual-clutch automatic transmission device can provide seven or six forward gears and one reverse gear and has the advantages that the structure is simple, reverse motion safety is high, the number of gears is large and the gear transmission ratio degree and the freedom are high, and therefore the dual-clutch automatic transmission device is excellent in comfort performance and lower in oil consumption.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Multi-wedge-surface drill rod and drill rod automatic assembling and disassembling equipment applied to same

PendingCN110552632AQuick installationQuick releaseDrilling rodsDrilling casingsControl systemUltimate tensile strength

The invention discloses a multi-wedge-surface drill rod. The multi-wedge-surface drill rod comprises a rod body, a connecting head, a connecting tail, a locking wedge block and a locking nut, whereinthe connecting head and the connecting tail are connected to the two ends of the rod body, the connecting head is provided with an axial rectangular pyramid table, the connecting tail is provided witha rectangular pyramid hollow, and a synchronous pulley is arranged on the outer circle surface of the locking nut. Through coaxial matching of the rectangular pyramid table and the rectangular pyramid hollow, the drill rod can be rapidly assembled and disassembled, and the advantages of being large in bearing torque, long in service life, easy to disassemble, low in cost and the like are achieved. Drill rod automatic assembling and disassembling equipment applied to the multi-wedge-surface drill rod is arranged on one side of a drilling machine and comprises a locking nut assembling and disassembling mechanism, a locking wedge block assembling and disassembling mechanism, a drill rod assembling and disassembling mechanism and a control system. According to the drill rod automatic assembling and disassembling equipment, the automation degree is high, automatic assembling and disassembling of the drill rod are realized, the labor intensity of operators is greatly reduced, and the working efficiency is improved; and a drill rod circulation box of the drill rod automatic assembling and disassembling equipment is large in capacity, and the problems of placing, carrying and transportingof the drill rod are solved at the same time.

Owner:洛阳风动工具有限公司

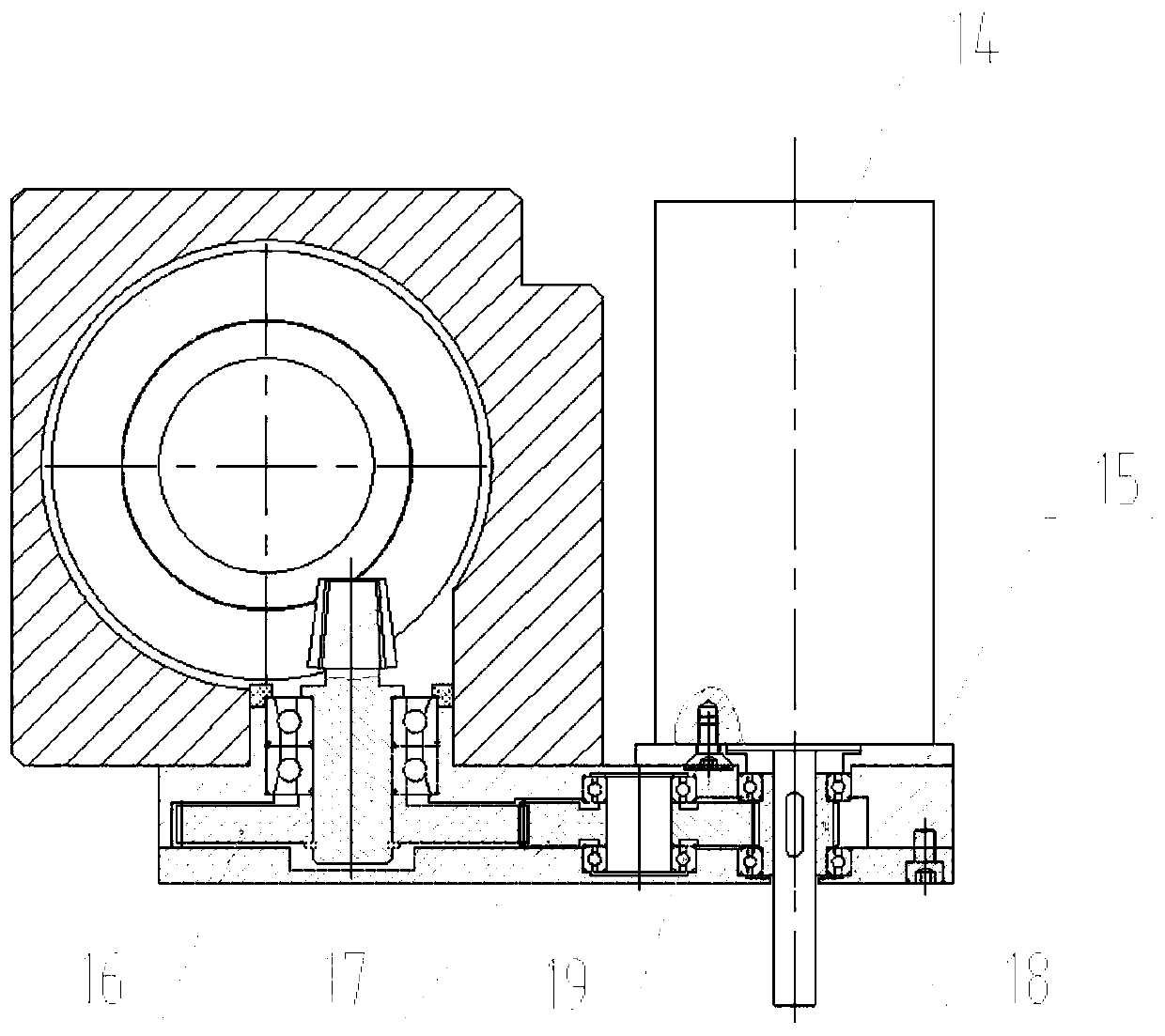

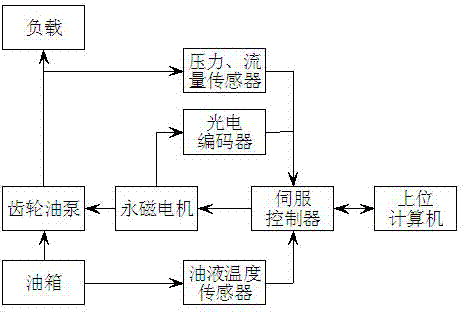

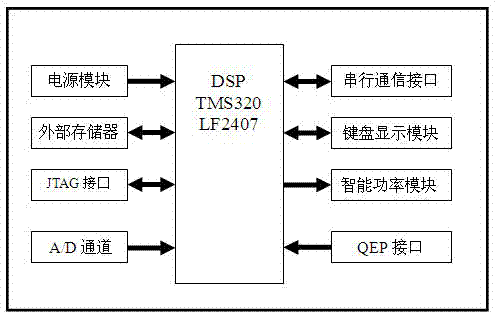

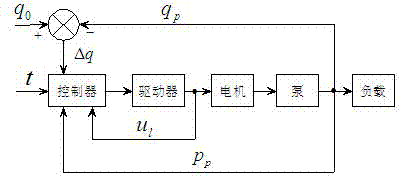

Energy-efficient hydraulic power supply driven by permanent magnet servo motor

InactiveCN101900153BLarge overload multipleQuick responseFluid-pressure actuator testingFluid-pressure actuator componentsLow speedClosed loop

The invention discloses an energy-efficient hydraulic power supply driven by a permanent magnet servo motor, which comprises the permanent magnet servo motor, a servo controller, a hydraulic oil pump (comprising a gear oil pump, a vane pump, and a plunger pump), a sensor and the like. An oil pump is driven by the high-efficiency permanent magnet servo motor which has good mechanical characteristic, large overload magnification, and high speed regulation performance; a system for redundancy monitoring of system flow and pressure by pressure-flow double closed loop control and the voltage and current of the motor is adopted; and an oil temperature compensation function is realized. According to different hydraulic pressure load working conditions, three working modes of pressure self-adaption, flow self-adaption, and power self-adaption are provided, and each working mode is optimized by adopting different control strategies. Therefore, the energy-efficient hydraulic power supply has the advantages of wide application range, high system efficiency, high low-speed stability, quick response, accurate speed regulation and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

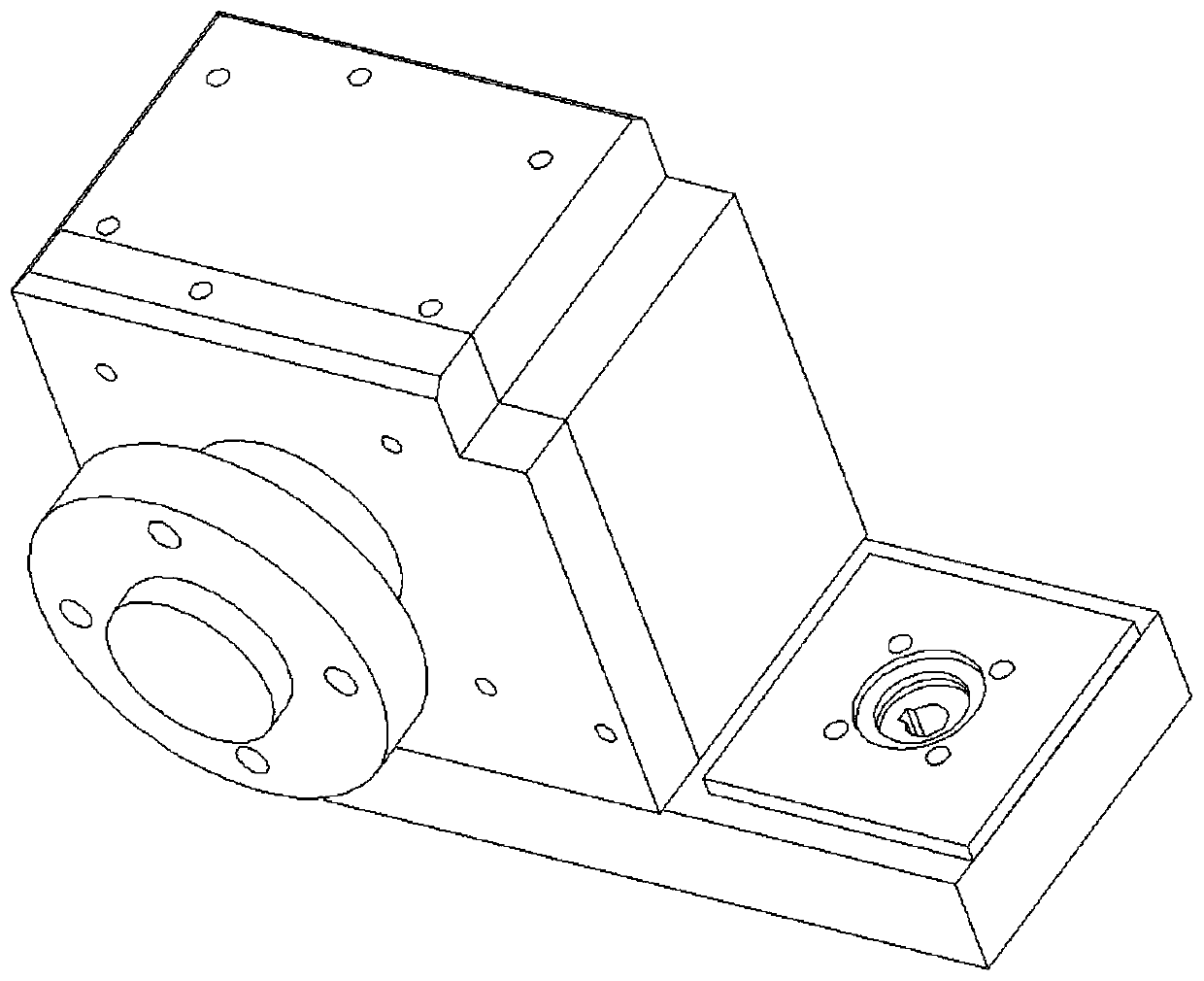

Wave gear type hollow rotating platform

PendingCN112747081ARealize self-locking functionHigh precisionToothed gearingsGearing detailsRotary stageGear drive

The invention discloses a wave gear type hollow rotating platform. The wave gear type hollow rotating platform comprises a shell, an output rotating table and a wave gear set; a first installation cavity is formed in the upper end face of the shell in a penetrating mode, and a second installation cavity communicates with the first installation cavity is formed in the side face of the shell; the output rotating table is of a hollow structure and is rotatably mounted in the first installation cavity; the wave gear set comprises a driven gear and a driving gear. The arc-shaped driven gear and the conical driving gear are adopted in a matched mode to form a wave gear set, transmission of 4-5 conical tooth surfaces meshed with the driven gear can be achieved at the same time, the characteristics of high precision and large bearing torque are achieved due to the fact that the number of the tooth surfaces of the gears meshed at the same time is large, and a hollow device is achieved due to the fact that the diameter of the driven gear is large and a large through hole can be formed in the middle of the driven gear, and due to the fact that the transmission mode is offset 40-degree meshing transmission, a certain self-locking function can be achieved.

Owner:深圳卓创传动科技有限公司

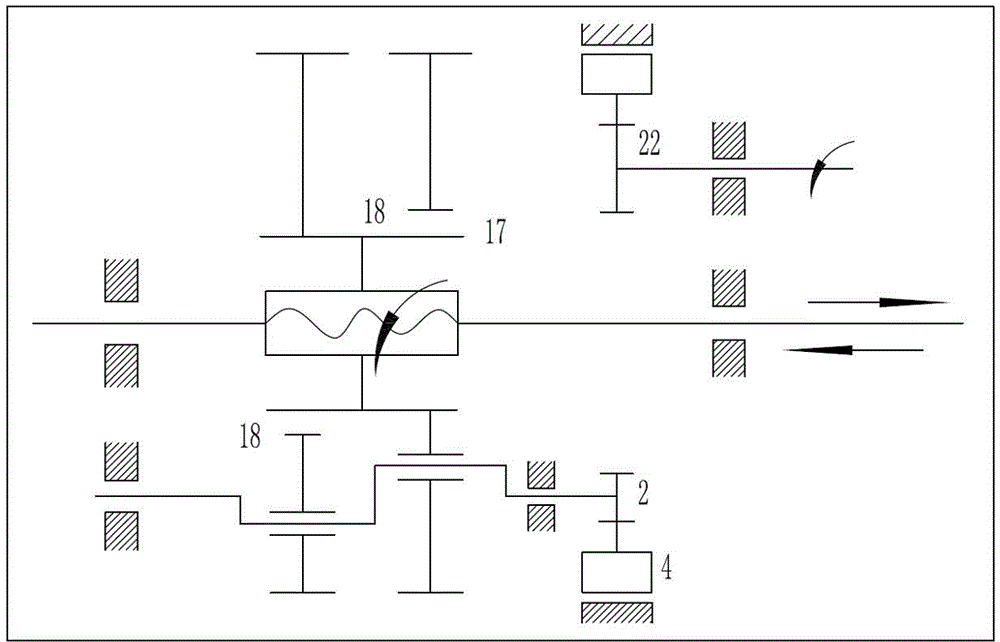

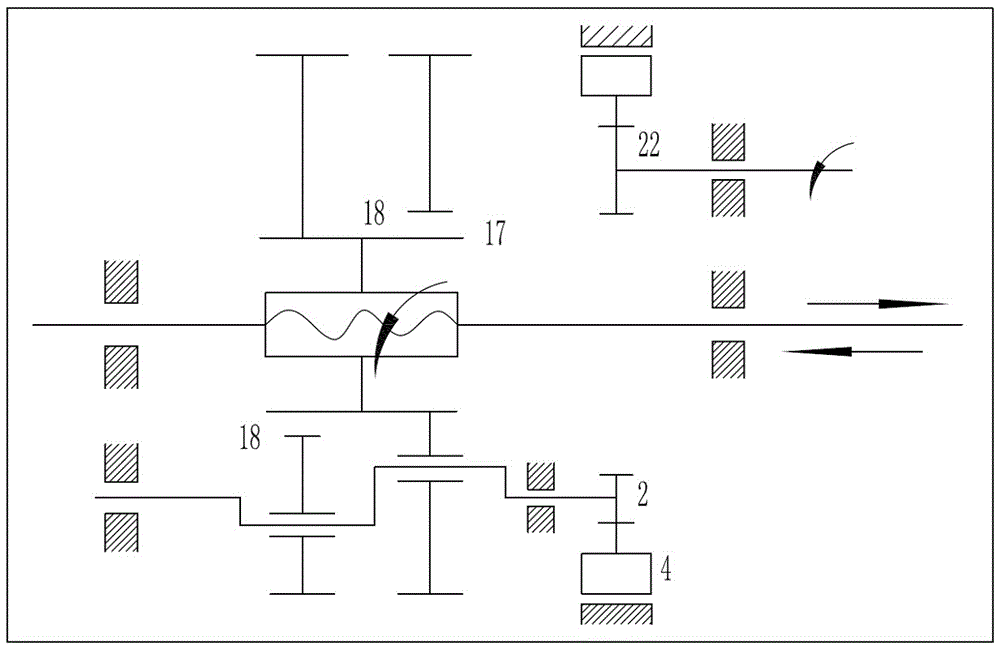

Step transition continuously variable transmission scheme

The invention discloses a stepless speed changing transmission scheme. According to the scheme, a metal belt type stepless speed changing unit, a forward gear and reverse gear planetary gear mechanism, a range shift planetary gear mechanism and a transition gear mechanism between an input shaft and an output shaft of a speed changer are mainly included. Two transmission routes are placed between the input shaft and the output shaft of the speed changer, one route is a serial-connecting route of the stepless speed changing unit and the range shift mechanism, and the other route a transition gear transmission route. The second route only has a transient effect. Before range shift mechanism gear shifting, the transmission ratios of the two routes are the same, and transition from the stepless speed changing unit route to the transition gear route is carried out. After the transition is completed, the transmission ratio of the stepless speed changer is changed, the transmission ratios of the two routes are the same again, transition from the transition gear route to the stepless speed changing unit route is carried out, and after the transition is completed, the stepless speed changing unit transmission ratio can be changed. So far, gear shifting is completed. During the gear shifting process, the two routes have simultaneous transmission moment, power interrupting does not exist, clutch and brake driving and driven friction pieces have no relative rotating, impact does not exist, and the overall gear ratio of the speed changer is expanded.

Owner:王亚

Reduction gear with group drive of involute gear and cycloid gear

The invention discloses a reduction gear with group drive of an involute gear and a cycloid gear. A double reduction mechanism with group drive of the planetary involute gear and the cycloid gear is arranged in a closed cavity; a planetary involute gear drive reduction mechanism is formed in the mode that a motor rotates to drive a sun gear to rotate and then drive an annular gear and a planetary gear to rotate; a cycloid gear group drive reduction mechanism comprises an eccentric shaft, a cycloid gear ring and a cycloid gear, the gear tooth difference of the cycloid gear ring and the cycloid gear is one gear tooth, an internal gear tooth and an external gear tooth are meshed to form an internal gearing reduction mechanism, wherein the gear tooth difference is one gear tooth.

Owner:合肥耀辉太阳能热力工程科技有限公司

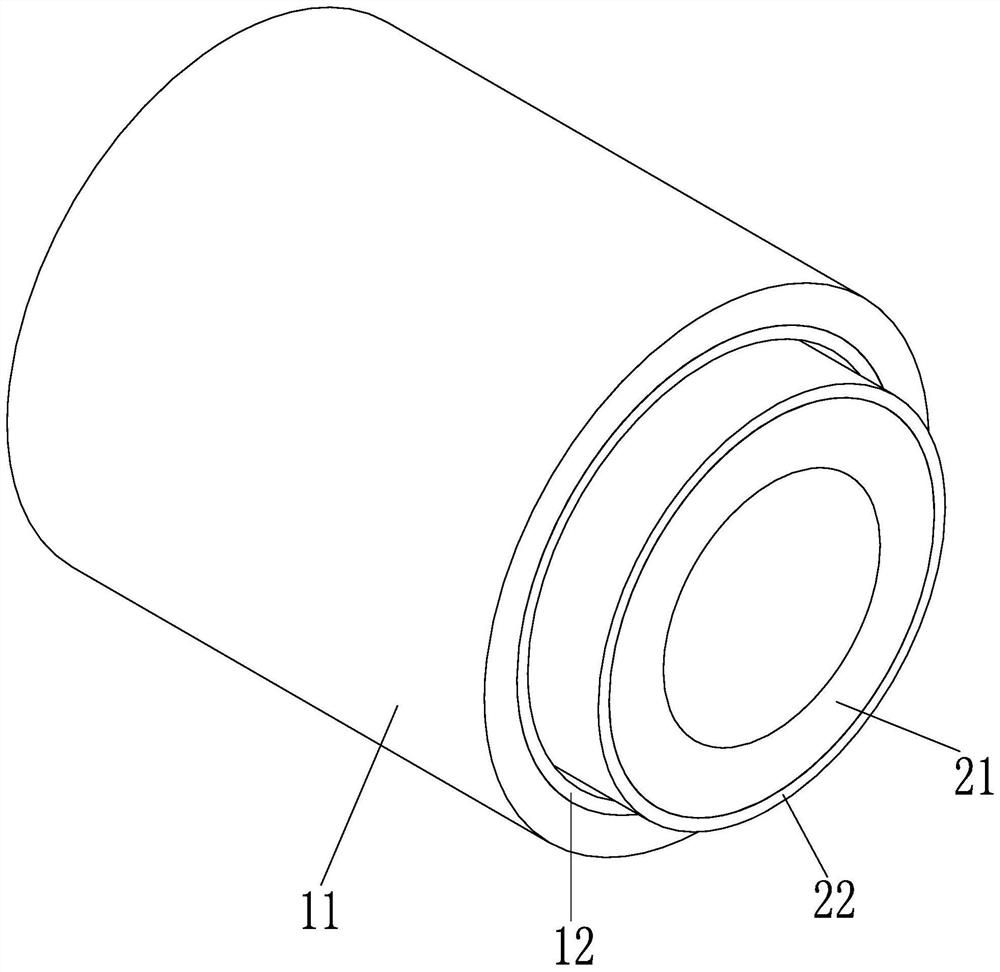

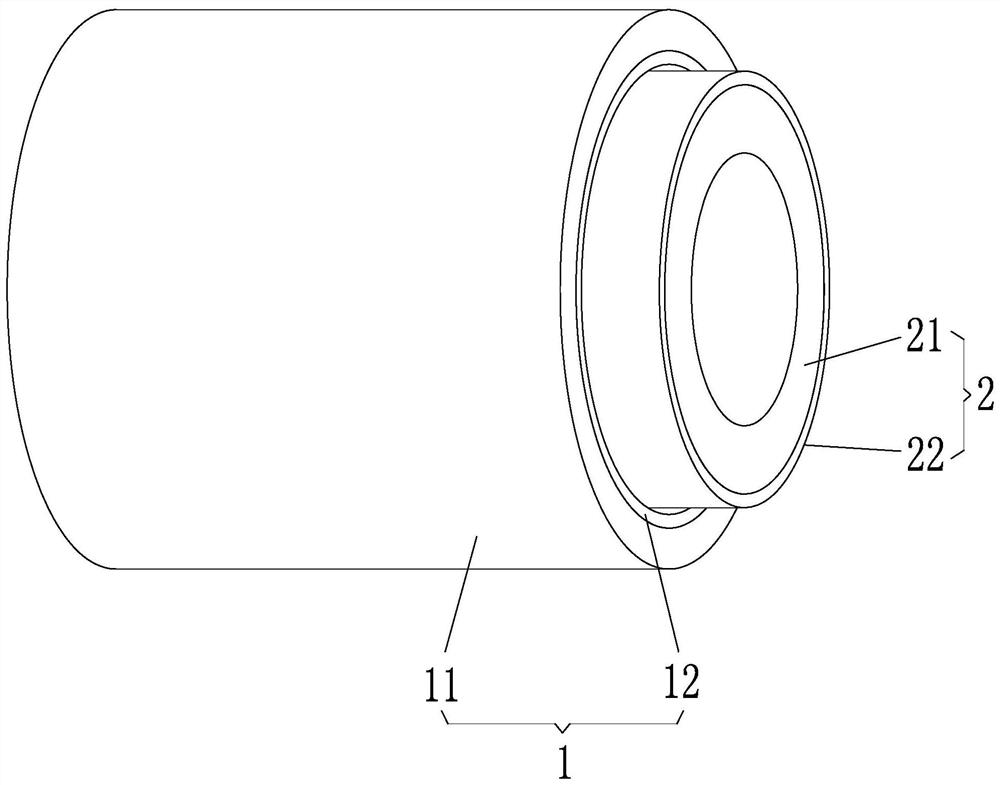

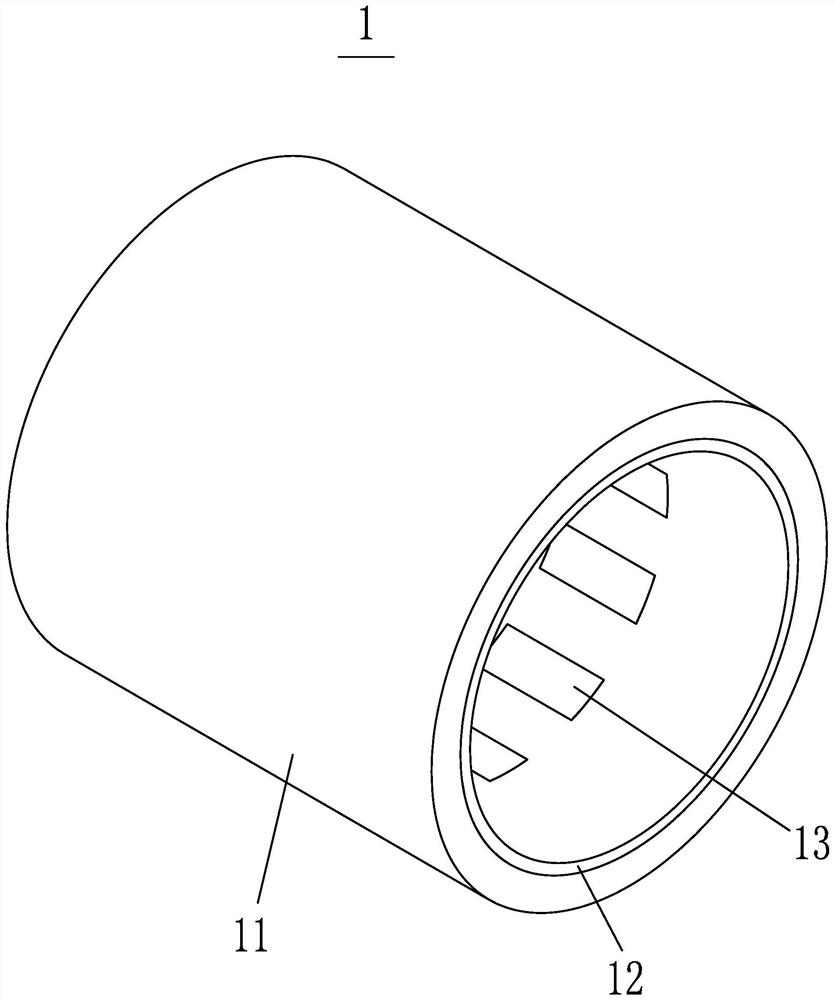

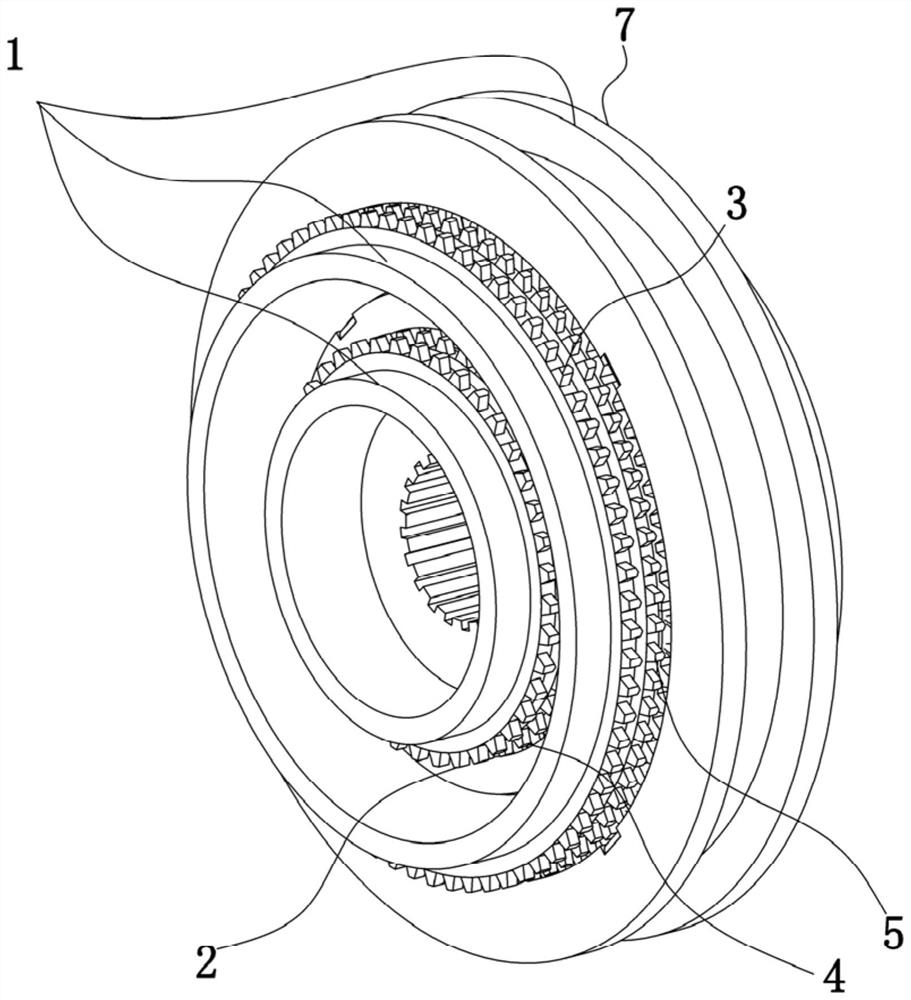

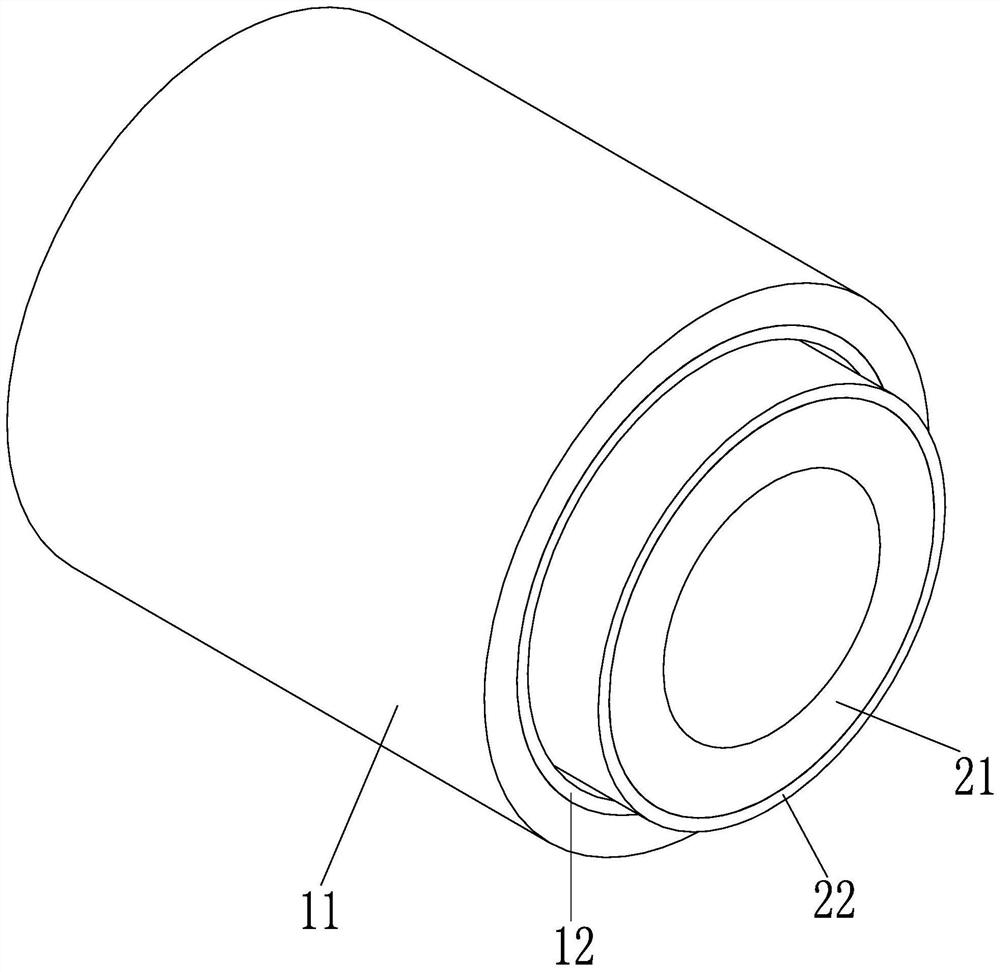

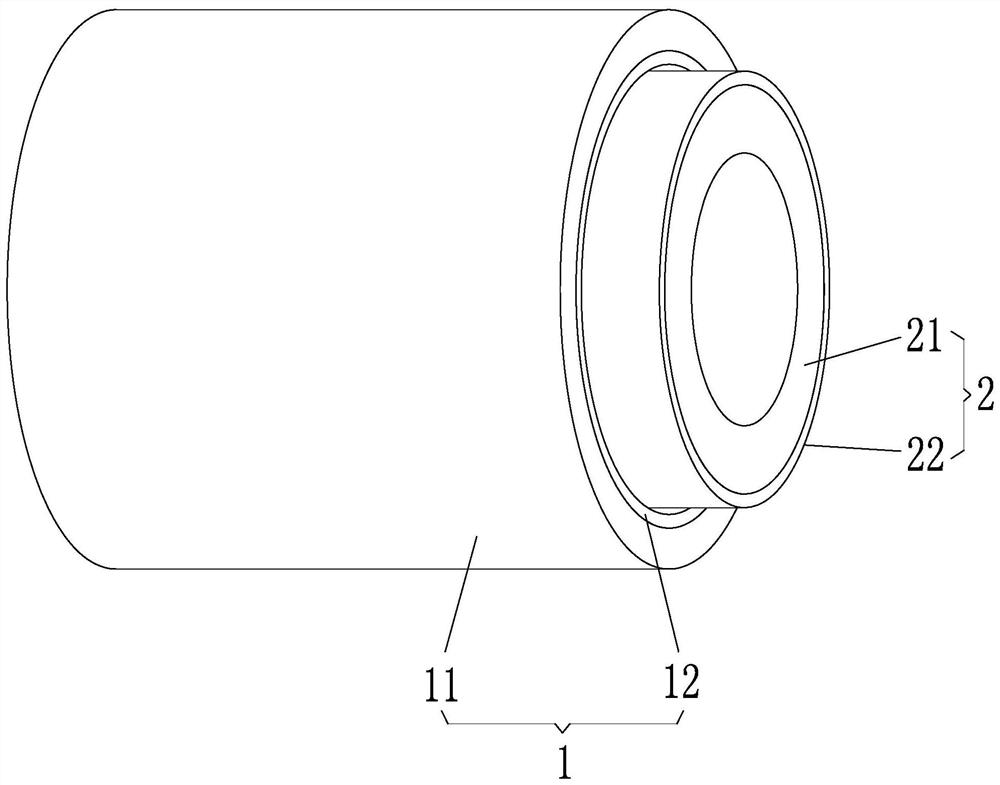

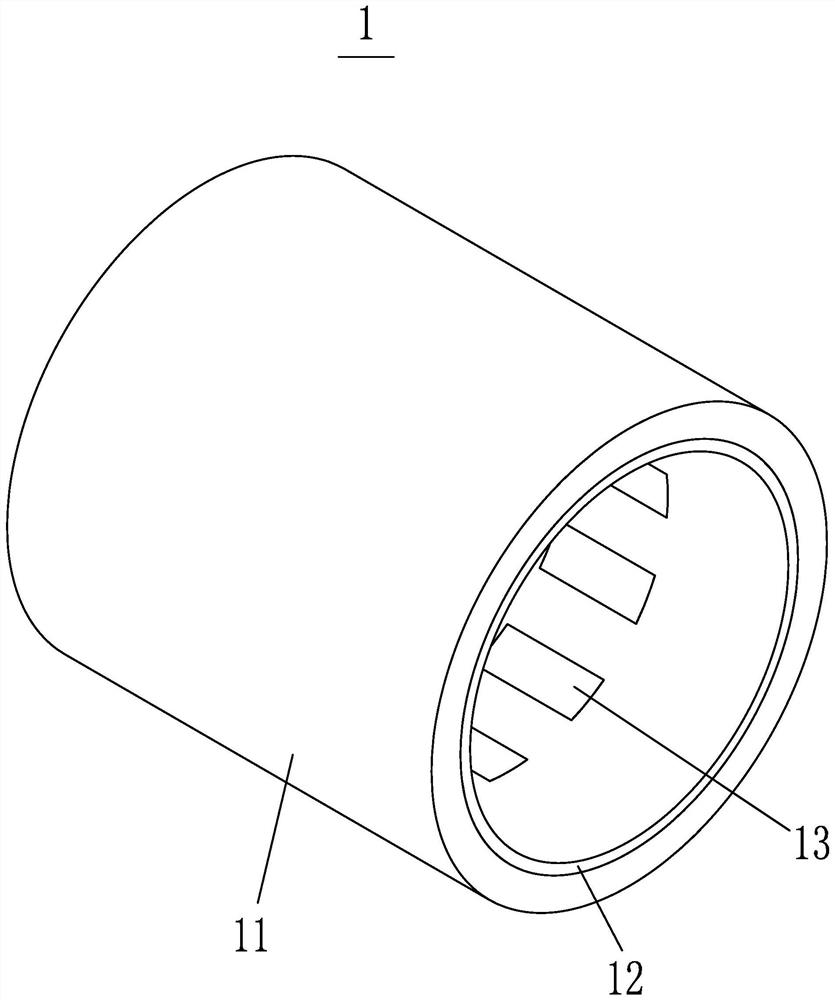

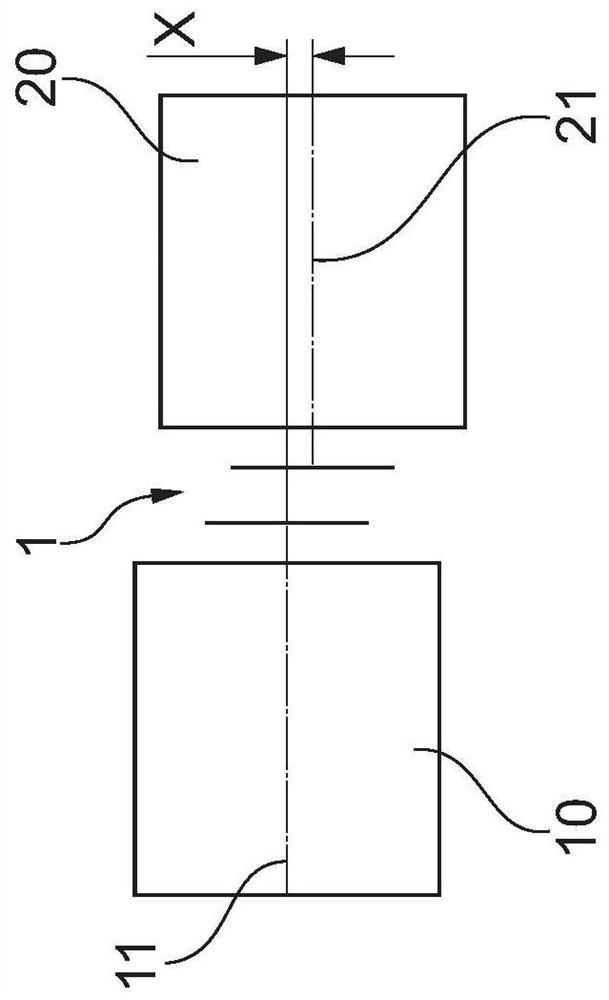

A cylindrical hybrid magnetic coupling

ActiveCN112821716BRealize asynchronous to synchronous effectChange magnetic momentAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesCouplingMagnet

The invention discloses a cylindrical hybrid magnetic coupling. The shaft coupling includes a cylindrical structure 1 and a cylindrical structure 2. The cylindrical structure 1 includes an outer cylinder, a mounting cylinder 1 and a plurality of magnets 1, and the cylindrical structure 2 includes an inner cylinder, a mounting cylinder 2 and a plurality of magnets 2. The installation cylinder one is located in the outer cylinder and is connected with the outer cylinder. A plurality of magnets are arranged around the central axis of the installation cylinder one and installed on the installation cylinder one. The second installation cylinder is located outside the inner cylinder and connected with the inner cylinder. A plurality of second magnets are arranged around the central axis of the second installation cylinder and installed on the second installation cylinder. There are two working conditions in the present invention. When the first magnet and the second magnet partially overlap in the radial space, the first working condition of the present invention is similar to the permanent magnet synchronous coupling; when the first magnet and the second magnet do not overlap in the radial space, this The second working condition of the invention is similar to the permanent magnet eddy current coupling; the present invention can change the magnetic moment by changing the axial relative position of the outer cylinder and the inner cylinder, so as to realize the stable conversion of the working condition during operation.

Owner:HEFEI UNIV OF TECH

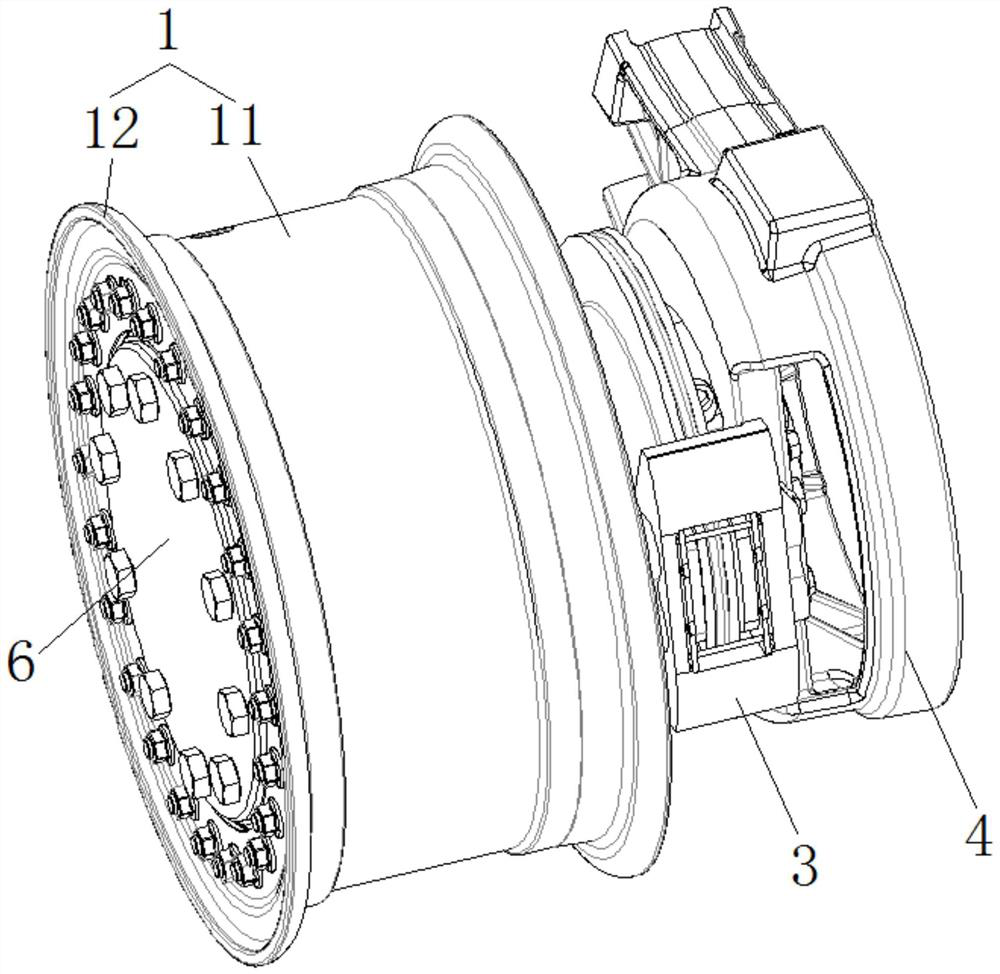

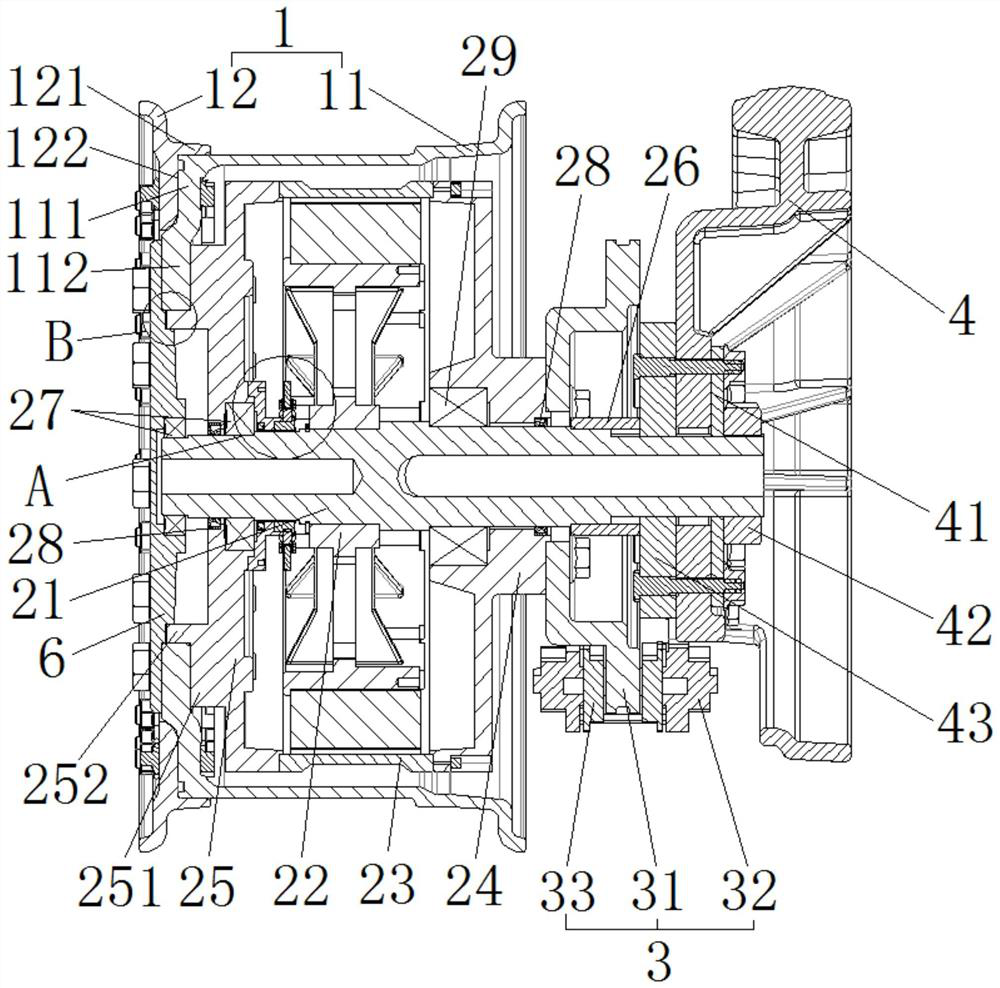

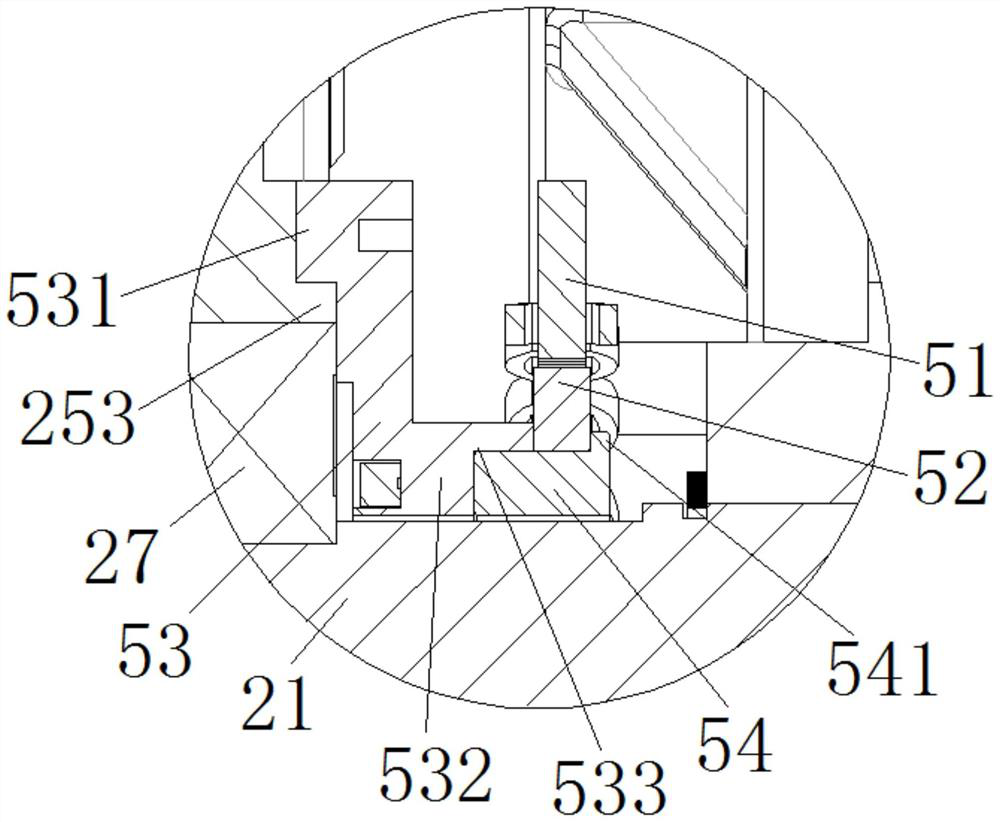

Hub Motors for Unmanned Vehicles

ActiveCN112389189BWeight increaseImprove the situation of uneven forceMotor depositionStructural associationResolverClassical mechanics

The invention discloses a hub motor for an unmanned vehicle, which includes a motor body, the motor body includes a central shaft, a stator, a rotor and a resolver, hub fixed end covers and disc brake fixed end covers are installed on both sides of the rotor, and the rotor is arranged on the stator An air gap is formed between the rotor and the stator, the resolver includes a resolver stator and a resolver rotor, an air gap is formed between the resolver stator and the resolver rotor, the resolver stator is fixedly connected to the stator, and the resolver rotor is fixed to the hub The end cover is fixedly connected, and the resolver rotor is fixedly connected with the fixed end cover of the hub through the fixed base of the resolver rotor and the fixed aluminum block of the resolver rotor. The outer edge of the rotor fixing base extends axially to form a fifth protruding ring, and the inner surface of the fifth protruding ring is attached to the outer surface of the fourth protruding ring. The invention adopts double bearing support by increasing the wheel hub support plate, which is firm in installation, high in reliability, and can bear relatively large bearing torsion force.

Owner:ZHEJIANG WANGDEFU MOTOR

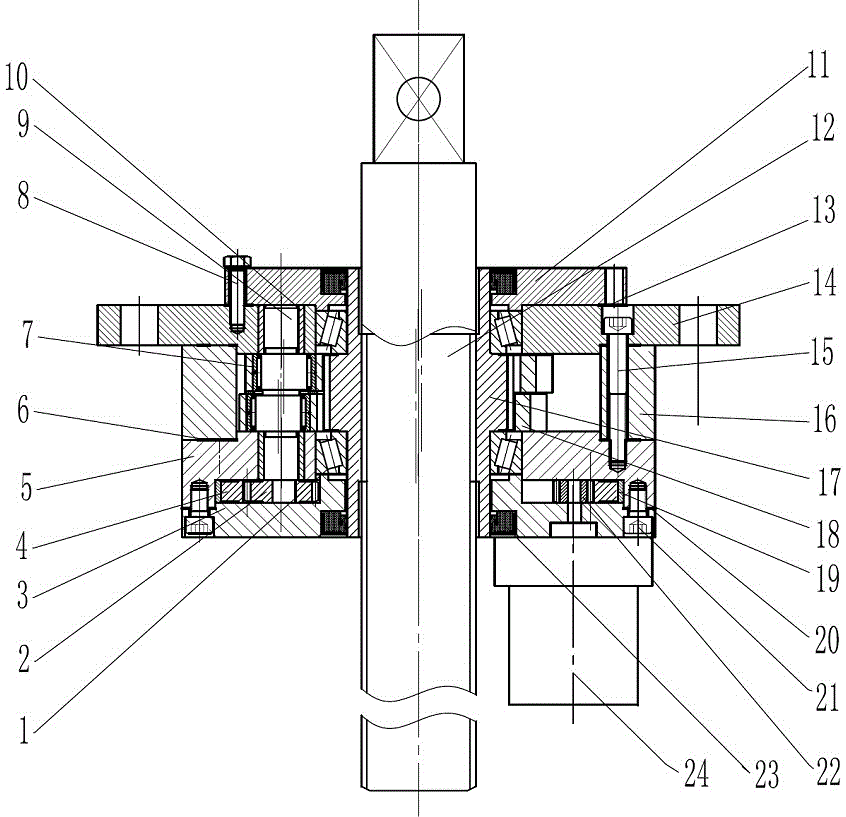

Stepless speed change servo planetary gear transmission capable of being broken and twisted

PendingCN113775720ALarge load torqueVariable speedGearboxesGearingGear transmissionAutomotive engineering

The invention relates to the technical field of transmissions, and particularly discloses a stepless speed change servo planetary gear transmission capable of being broken and twisted. The stepless speed change servo planetary gear transmission comprises a cross planetary input shaft, a transmission unit, a CVT (continuously variable transmission) main belt wheel, a CVT auxiliary belt wheel, an auxiliary belt wheel connecting shaft, an auxiliary belt wheel connecting shaft small gear and an output shaft connecting large gear, wherein the transmission unit is in transmission connection with the cross planetary input shaft, and the CVT main belt wheel is in transmission connection with the transmission unit, the CVT auxiliary belt wheel is in transmission connection with the CVT main belt wheel, the auxiliary belt wheel connecting shaft, the auxiliary belt wheel connecting shaft small gear and the output shaft connecting large gear are in transmission connection, and the output shaft connecting large gear is in transmission connection with the cross planetary input shaft. Compared with an AT transmission, a DCT transmission and a CVT transmission, the transmission is large in bearing torque, fast in speed change, smooth in process, long in service life, simple in structure and low in manufacturing cost; and meanwhile, the barriers of manufacturing technologies of various types of transmissions are avoided, and the effects of energy conservation and emission reduction are achieved.

Owner:柯春庆

Anti-backlash type steering transmission shaft steel ball retainer

PendingCN112065872AImprove wear resistanceImprove volume stabilityYielding couplingEngineeringBall (bearing)

Owner:NORTHERN HEAVY IND GRP CO LTD

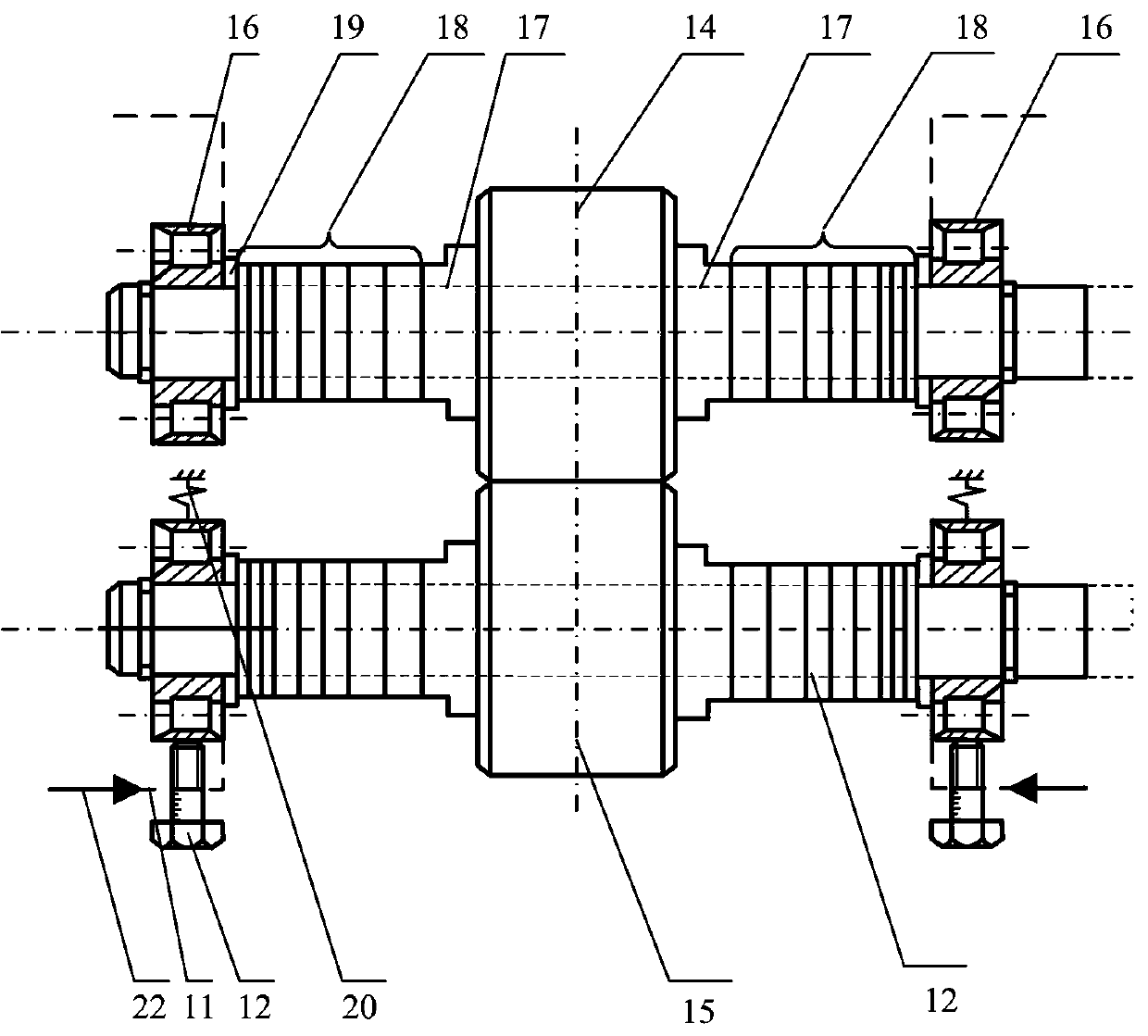

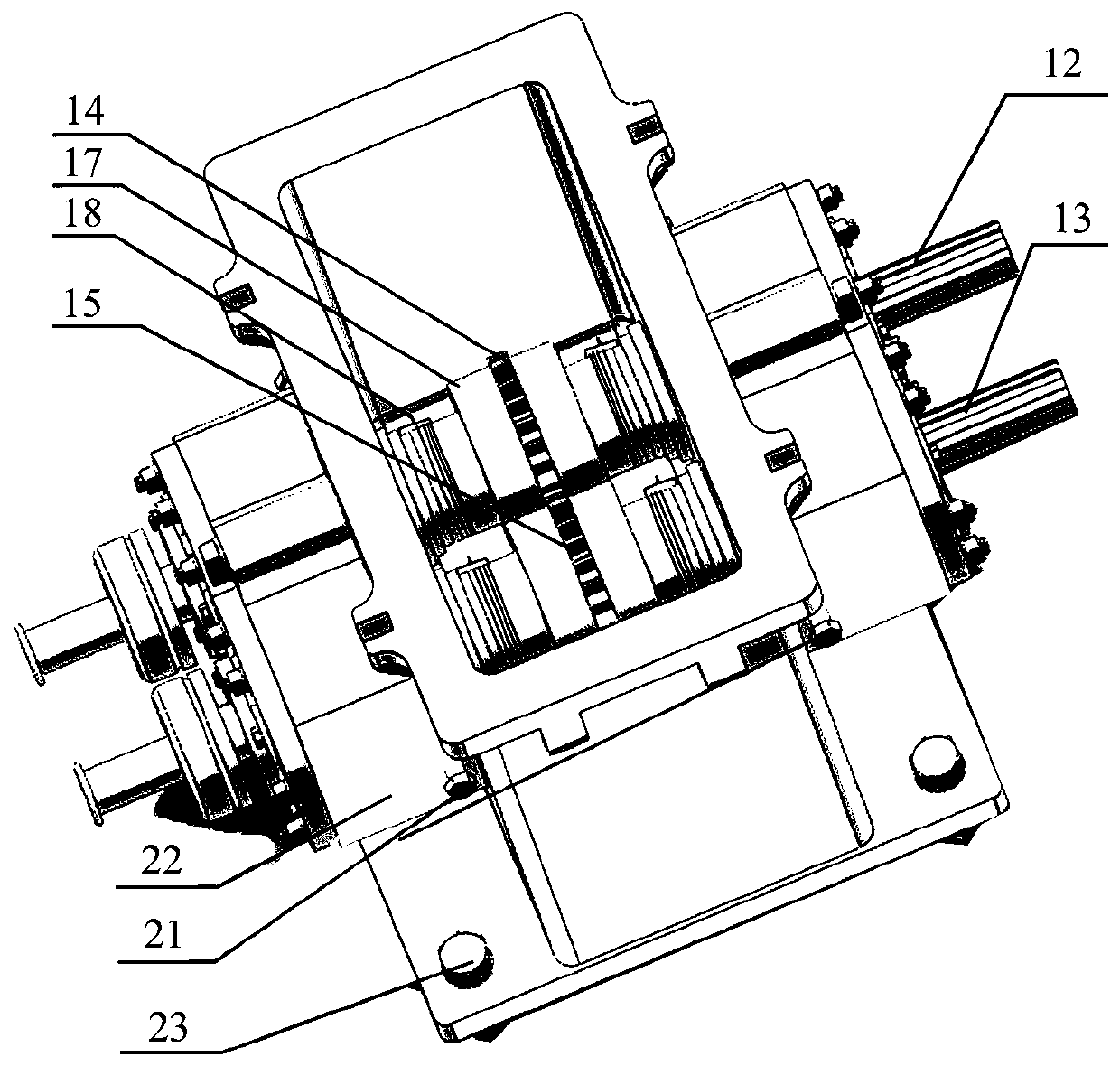

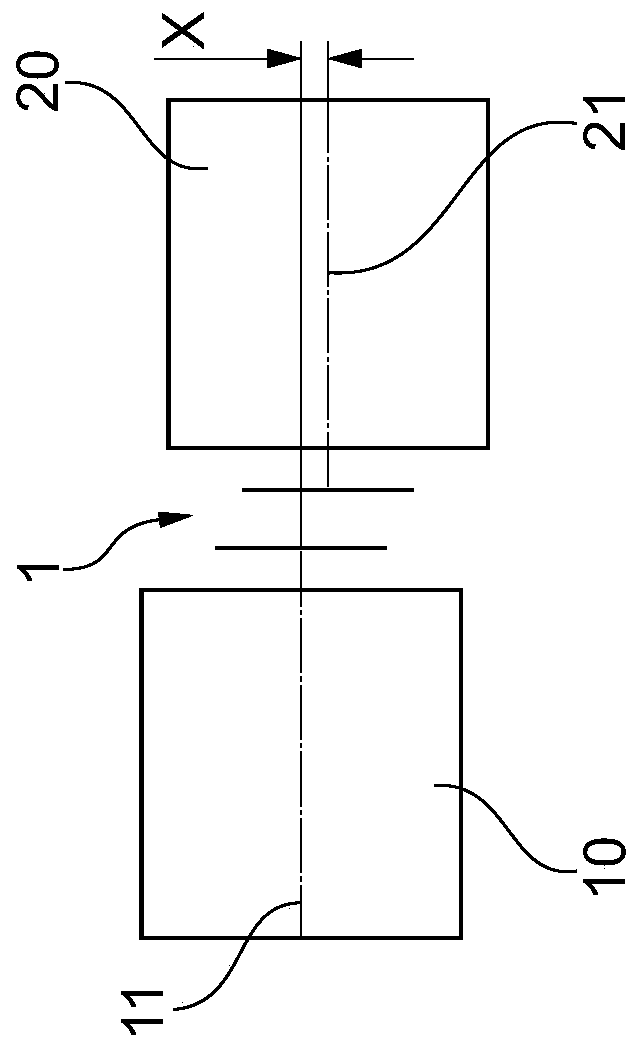

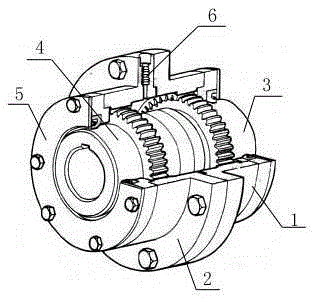

Coupler

InactiveCN106704393ALarge load torqueSimple structureYielding couplingCouplings for rigid shaftsGear transmissionEngineering

The invention discloses a coupler, and belongs to the field of mechanical components. The coupler comprises an upper coupler body and a lower coupler body which are connected through a flange. Inner gear teeth of the upper coupler body are engaged with an upper coupler sleeve, and inner gear teeth of the lower coupler body are engaged with the lower coupler sleeve. The end face of the upper coupler body seals the upper coupler sleeve through a sealing ring, and the end face of the lower coupler body seals the lower coupler sleeve through a sealing ring. The problem about large torque transmission in the coupler using process is mainly solved, torque transmission between a shaft and the coupler can be achieved through gear transmission in the coupler, and the coupler is large in bearing torque, simple in structure, convenient and fast to use and wide in application range.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

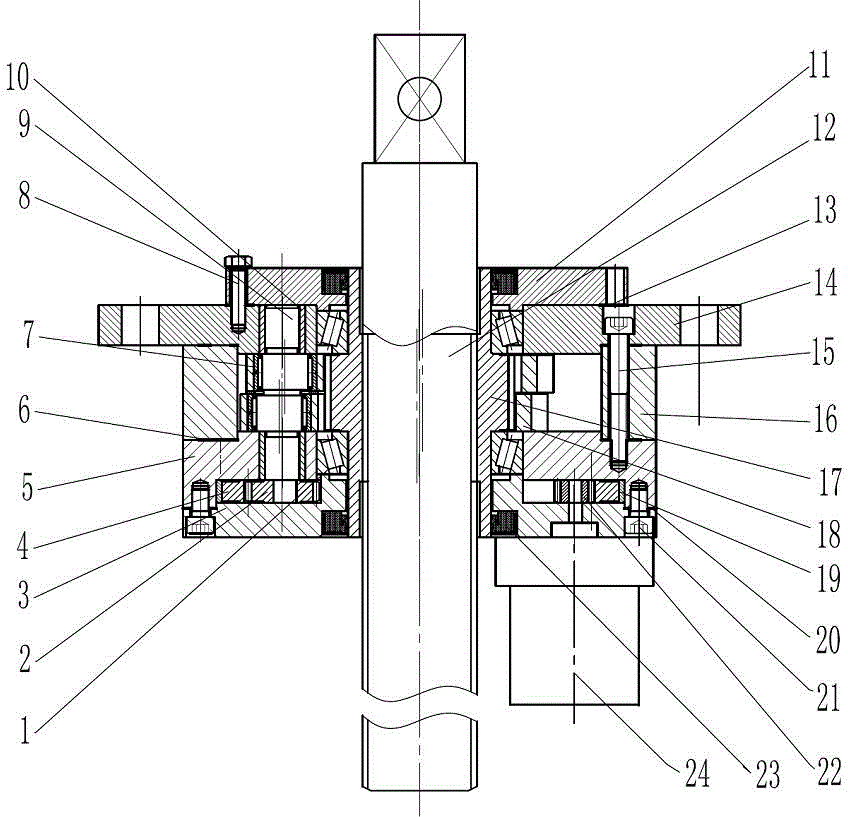

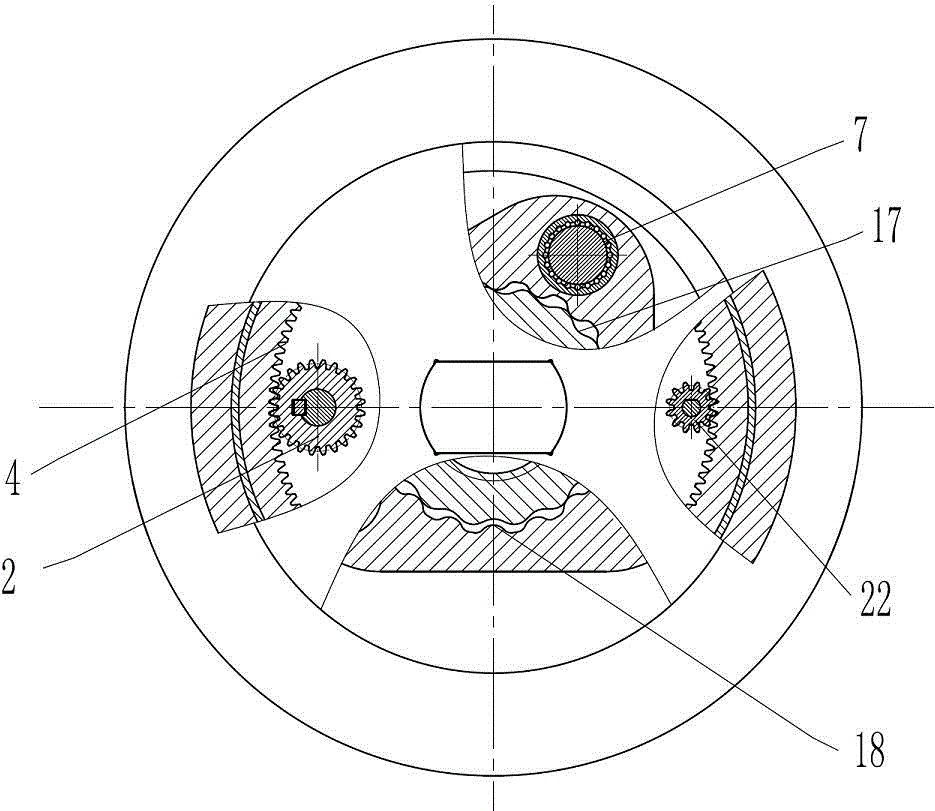

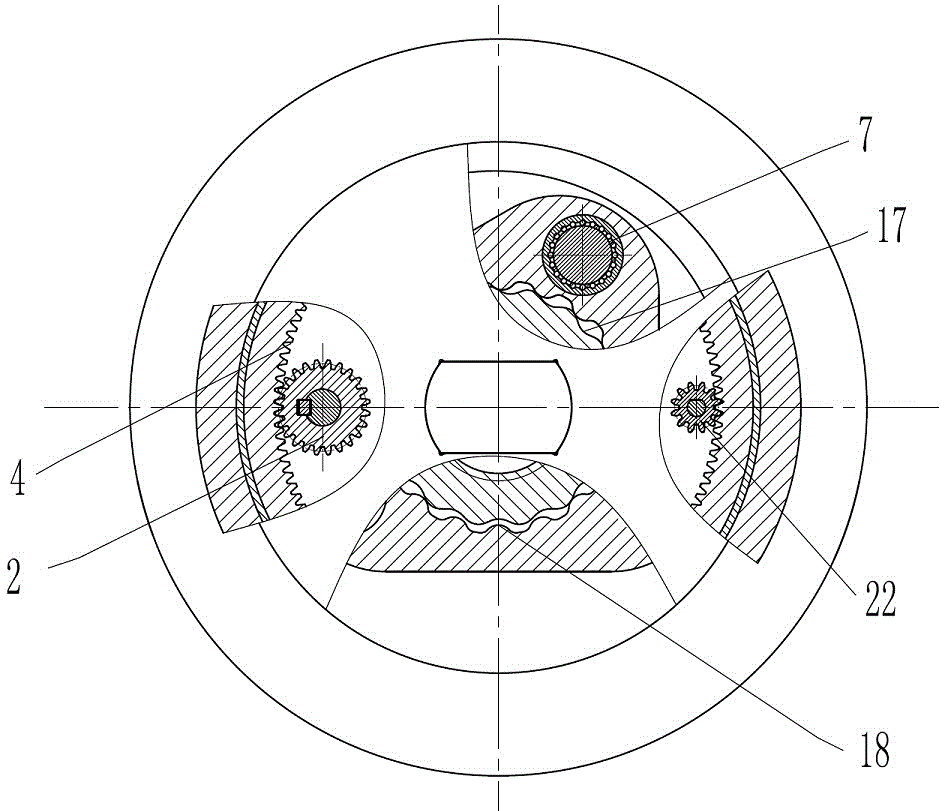

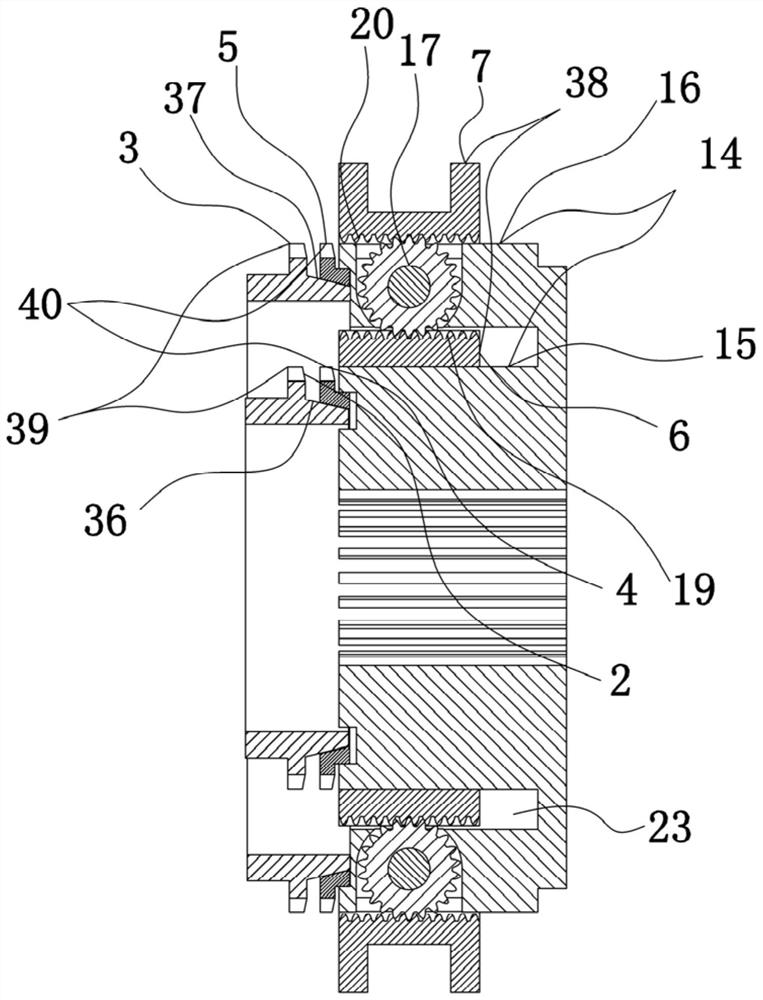

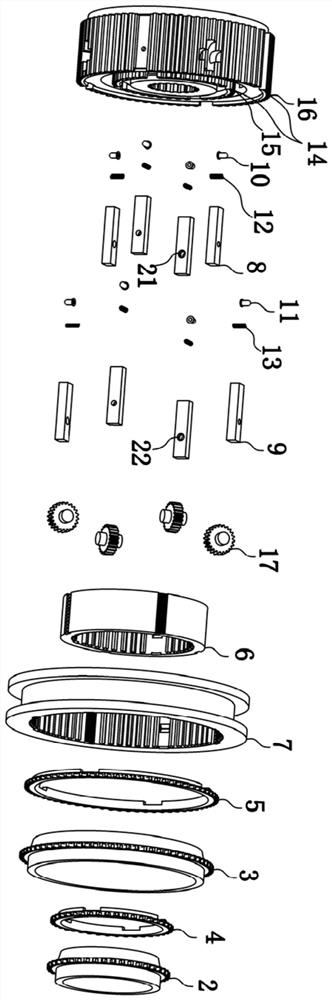

Clutch and demagnetizing slide motor using same

PendingCN109281955AAddressing Torque DropsSolve problems such as stuckMagnetically actuated clutchesMechanical energy handlingEngineeringClutch

The invention belongs to the technical field of drive equipment, and relates to a clutch. The clutch comprises an inner ring and an outer ring, wherein the inner ring is arranged in the outer ring; anannular cavity is formed between the inner ring and the outer ring; a wedge block mechanism is arranged in the annular cavity; the wedge block mechanism comprises a wedge block support seat and wedgeblock assemblies; a plurality of installation grooves are uniformly distributed in the wedge block support seat; the wedge block assemblies are arranged in the plurality of installation grooves whichare uniformly distributed at intervals separately; an elastic pressure ring is arranged at the outer side of each wedge block assembly; and the wedge block assemblies are tightly clamped onto the inner ring under the action of the elastic pressure rings. According to the clutch, through the design of an inclined arc surface at one end making contact with the inner ring, of each wedge block assembly, and the design of the elastic pressure ring at one end away from the corresponding inclined arc surface, of each wedge block assembly, the problems of torque decline, clamping stagnation and the like caused due to the eccentricity of an existing clutch on an inner ring and an outer ring, are solved; and the clutch has the advantages of being simple in manufacturing process, reliable in working, large in bearing torque, high in eccentric adaptability, long in service life and the like.

Owner:常州市武进金顺机电有限公司

A deceleration device for combined transmission of involute gear and cycloid gear

The invention discloses a deceleration device for combined transmission of involute gear and cycloid gear. In a closed cavity, a two-stage deceleration mechanism for combined transmission of planetary involute gear and cycloid gear is provided; the planetary The involute gear transmission deceleration mechanism is formed by the rotation of the motor to drive the sun gear to rotate, and then drives the inner ring gear and the planetary gear to rotate; the cycloid gear transmission deceleration mechanism is composed of an eccentric shaft, a cycloid ring gear and a cycloid wheel Composition, the cycloid ring gear and the cycloid wheel have a tooth difference, and when the internal and external teeth are meshed, an internal meshing reduction mechanism with a tooth difference of one tooth is formed.

Owner:合肥耀辉太阳能热力工程科技有限公司

Optional clutch

Owner:陈学琴

Single-stage planetary gear speed reducer

The invention discloses a single-stage planetary gear speed reducer which comprises a shell, a gear coupler, a sun gear, a planetary gear, an internal gear, a pin roll and an output shaft. The gear coupler is fixedly connected with the sun gear, the sun gear is meshed with the planetary gear, the planetary gear is connected with the output shaft through the pin roll, and the internal gear is meshed with the planetary gear. The single-stage planetary gear speed reducer is different from a traditional speed reducer, is a planetary speed reducer, and has the advantages of being large in load torque, high in speed ratio, large in starting-allowed impact load, small in size and the like.

Owner:安徽费洛卡重工传动有限公司

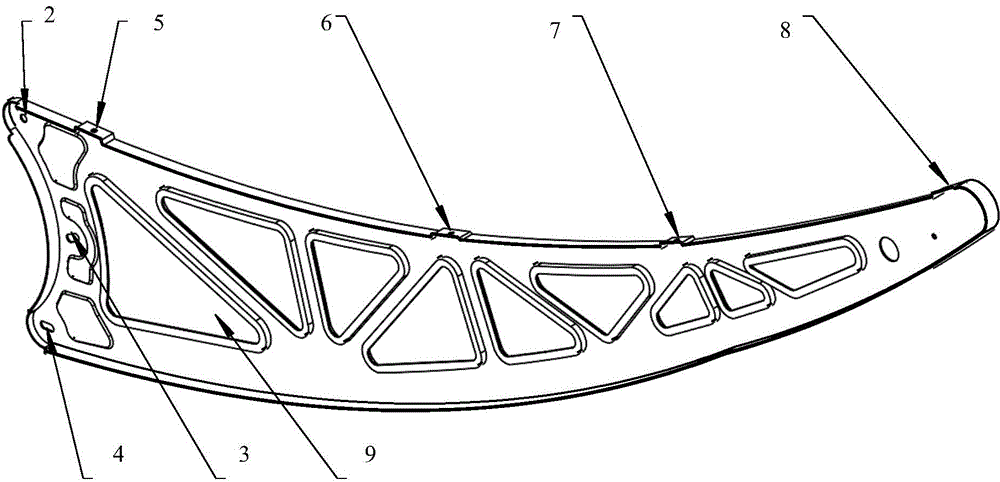

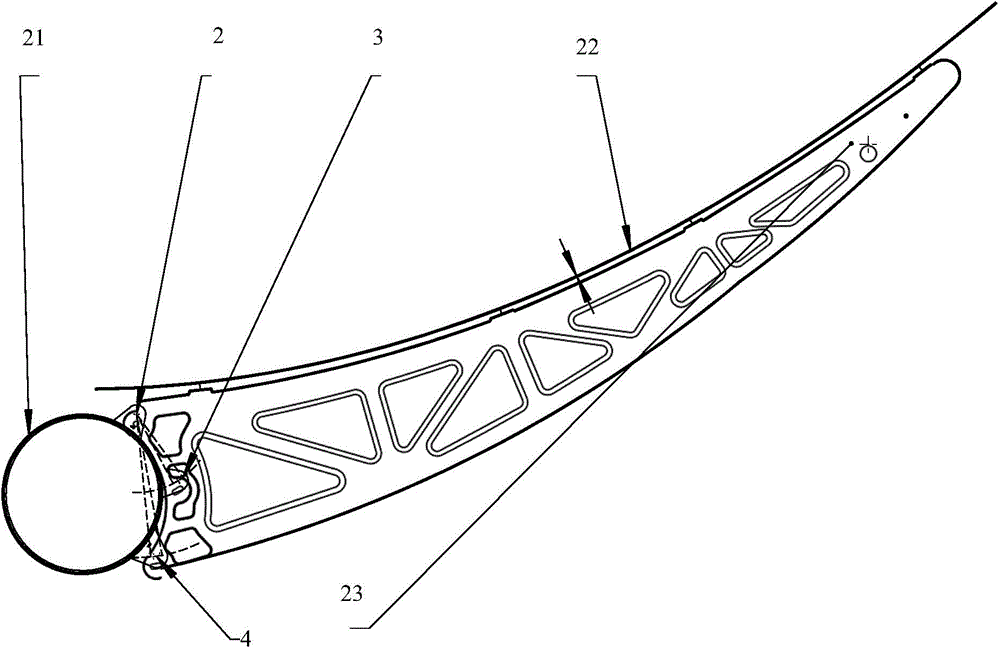

Adjustable support arm for mounting solar channel type reflector glass

InactiveCN104697217ASimple structureEasy to installSolar heat devicesSolar thermal energy generationEngineeringSolar energy

The invention relates to an adjustable support arm for mounting solar channel type reflector glass. The adjustable support arm integrally adopts an ivory planer structure, and the wide end of the planer structure is arc-shaped. A first fixing hole is formed in the upper end at the wide end of the adjustable support arm, the first fixing hole is a round hole and used for fixedly connecting with a corresponding fixing part on a rotating pipe, and a first rotating mounting hole and a second rotating mounting hole are respectively formed in the middle and the lower end of the wide end. Both the first rotating mounting hole and the second rotating mounting hole are arc holes, and the positions of both the two arc holes are on an arc with the first fixing hole as a center. A plurality of fixing holes for fixing the solar channel type reflector glass are formed in the top of the support arm.

Owner:SHOUHANG ENERGY SAVING SOLAR THERMAL TECH CO LTD

Clutch and vehicle with the clutch

InactiveCN103307134BLarge load torqueStable force transmissionFluid actuated clutchesEngineeringPiston

The invention discloses a clutch and also discloses a vehicle with the clutch. The clutch comprises a body, a friction piece, a combination piece, a force transmission piece, a piston and an elastic piece, wherein the body is internally provided with an accommodating cavity; the force transmission piece can be pivotably arranged in the accommodating cavity; the piston is movably arranged in the accommodating cavity and between a separation position and a combination position; on the combination position, the piston is contacted with the force transmission piece and applies a first driving force to the force transmission piece; the force transmission piece is contacted with the combination piece and applies a second driving force to the combination piece so as to ensure that the combination piece and the fraction piece can be conveniently combined; the distance between the contact part of the piston and the force transmission piece and the pivoting point of the force transmission piece is greater than that between the contact part of the force transmission piece and the combination piece and the pivoting point of the force transmission piece. The clutch disclosed by the embodiment of the invention has the advantages of large torque capacity, more smooth driving force transmission, no need of increasing the pressure of hydraulic oil, small size and the like.

Owner:GREAT WALL MOTOR CO LTD

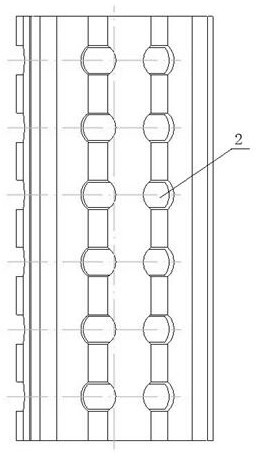

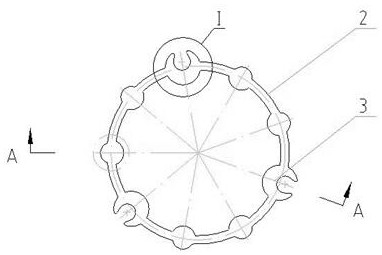

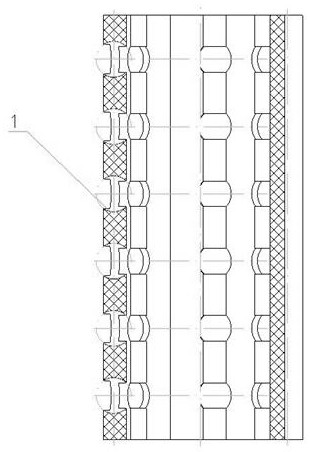

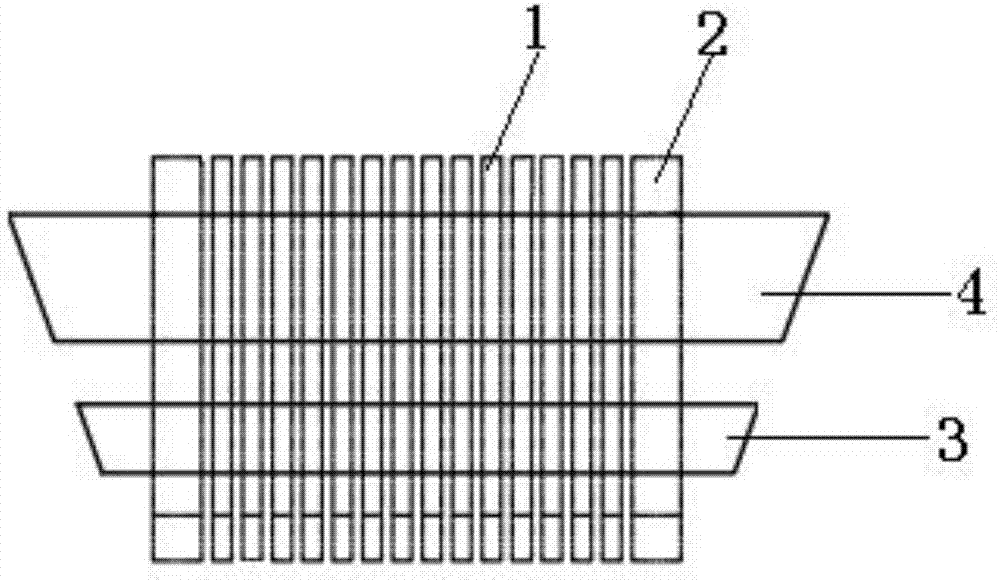

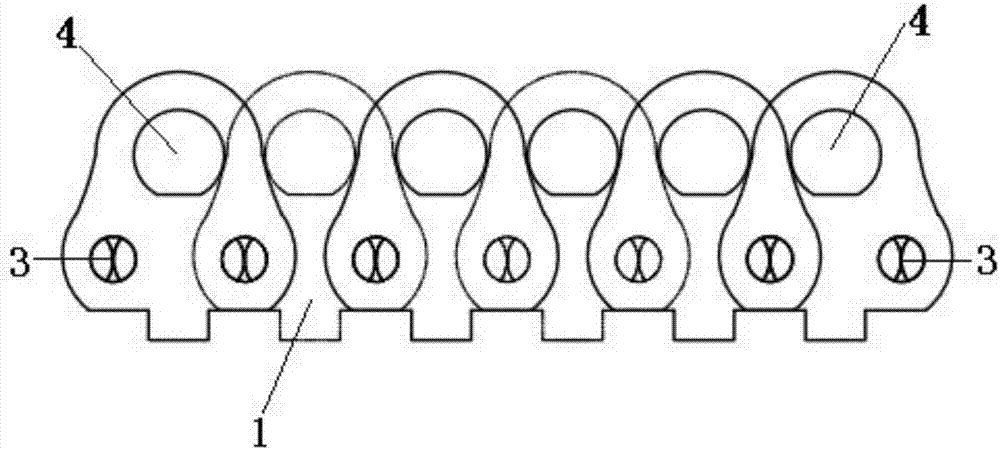

Chain for improving transmission performance

The invention discloses a chain for improving transmission performance. The chain comprises transmission chain pieces, chain pin shafts and supporting pin shafts, wherein chain pin shaft holes and a supporting pin shaft hole are formed in each transmission chain piece; chain pin shaft holes are symmetrically arranged at two ends of one side of the corresponding transmission chain piece; the supporting pin shaft hole is located on the other side of the corresponding transmission chain piece; the chain pin shafts penetrate through the chain pin shaft holes and the supporting pin shafts penetrate through the supporting pin shaft holes, so that the transmission chain pieces form a transmission chain array. According to the chain for improving transmission performance, the structural design is reasonable, the process can be simplified, meanwhile, the bending strength of the chain joints is increased, so that the chain bears larger torque, and therefore the purpose of improving the transmission performance of the chain is achieved.

Owner:王国斌

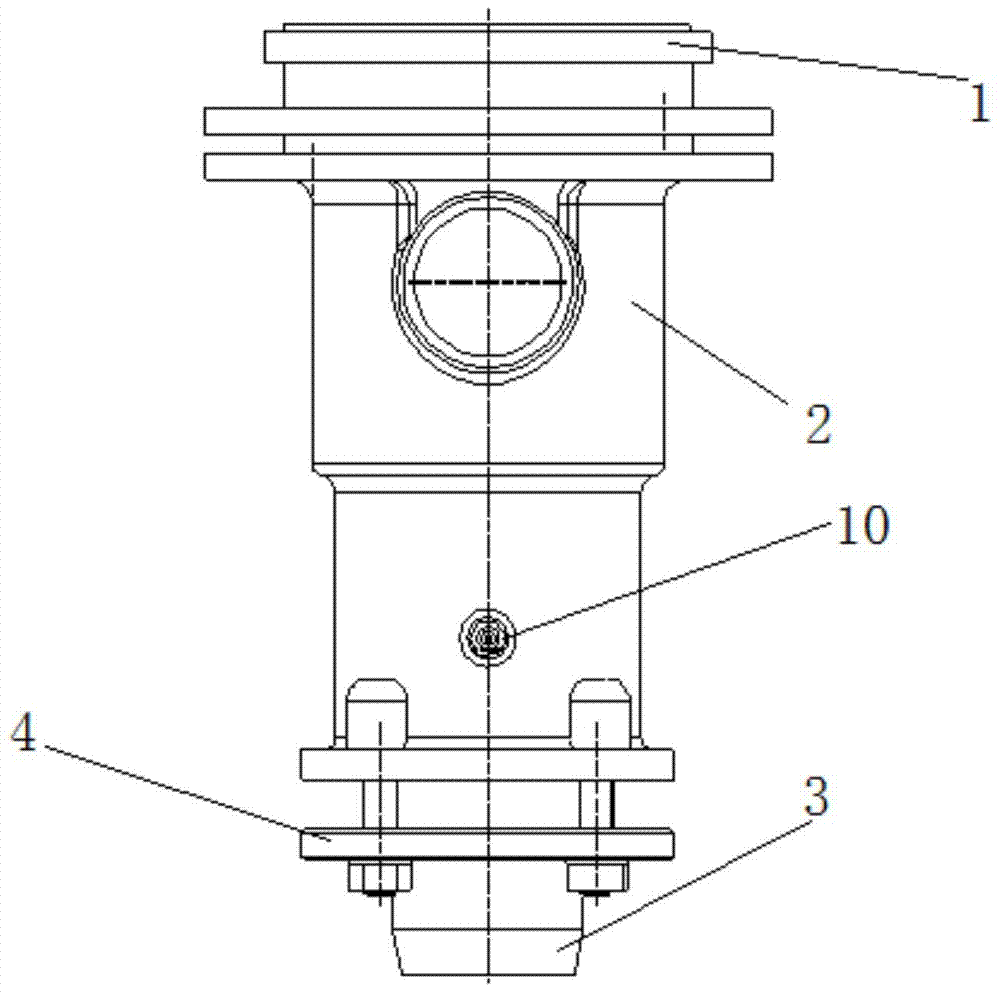

A flange connection center centering rotary sealer

The invention relates to a flanged connection centring rotation sealer which comprises a sealer baffle, a sealer housing, center sleeve, a gland, filling, locating sleeves, a hole ring and an oil cup, wherein the sealer baffle is in a flanged shape and is fixedly connected with the sealer housing; the sealer housing comprises a hollow pipe part and an elbow part; the locating sleeves are placed in the hollow pipe part of the sealer housing; the center sleeve is located by the locating sleeve and mounted in the hollow pipe part of the sealer housing and can rotate relative to the hollow pipe part of the sealer housing; the filling is mounted between the center sleeve and the hollow pipe part of the sealer housing; the gland is connected with an opening of the hollow pipe part of the sealer housing; the hole ring is located in the hollow pipe part of the sealer housing and mounted outside the center sleeve; the oil cup is mounted on the housing at the hollow pipe part of the sealer housing; and the hole ring is communicated with the oil cup.

Owner:SHOUHANG ENERGY SAVING SOLAR THERMAL TECH CO LTD

Cylinder type mixed magnetic coupling

ActiveCN112821716ARealize asynchronous to synchronous effectChange magnetic momentAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesCouplingSoftware engineering

The invention discloses a cylinder type mixed magnetic coupling. The coupling comprises a first cylindrical structure and a second cylindrical structure, the first cylindrical structure comprises an outer cylinder, a first mounting cylinder and a plurality of first magnets, and the second cylindrical structure comprises an inner cylinder, a second mounting cylinder and a plurality of second magnets. The first mounting cylinder is arranged in the outer cylinder and connected with the outer cylinder, and the multiple first magnets are arranged around the center axis of the first mounting cylinder and installed on the first mounting cylinder. The second mounting cylinder is located outside the inner cylinder and connected with the inner cylinder, and the multiple second magnets are arranged around the center axis of the second mounting cylinder and installed on the second mounting cylinder. Two working conditions exist, and when the first magnets and the second magnets are partially overlapped in the radial space, the first working condition is similar to a permanent magnet synchronous coupler; when the the first magnets and the second magnets are not overlapped in the radial space, the second working condition is similar to that of a permanent magnet eddy current coupling; the magnetic moment can be changed by changing the axial relative position of the outer cylinder and the inner cylinder, and stable conversion of working conditions in operation is achieved.

Owner:HEFEI UNIV OF TECH

Clutch discs, friction clutch units and drive trains

ActiveCN109790877BAvoid noiseCompensate or dampen torsional vibrationsRotating vibration suppressionFriction clutchesClassical mechanicsControl theory

A clutch disc for a friction clutch device as well as the friction clutch device itself and a drive train. The clutch disc (30) comprises a hub (32) for torque-proof connection to a shaft, a friction element (33) for frictionally inputting torque into the clutch disc (30) and a first hub flange (40 ) and the second hub flange (41), wherein at least the first hub flange (40) is connected to the hub (32) in a torque-proof manner, wherein the clutch disc (30) has a spring element (50) which is The two hub flanges are mechanically coupled to each other between the two hub flanges so that the hub flanges can rotate relative to each other, wherein the clutch disc (30) is configured such that the two hub flanges (40, 41) Can be laterally offset from each other. With the clutch disk proposed here, lateral or radial offsets or radial displacements can be compensated, while at the same time ensuring a long service life due to the reduced friction ratio at the damping spring of the clutch disk.

Owner:SCHAEFFLER TECH AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com