Step transition continuously variable transmission scheme

A technology of continuously variable speed and continuously variable speed unit, which is applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

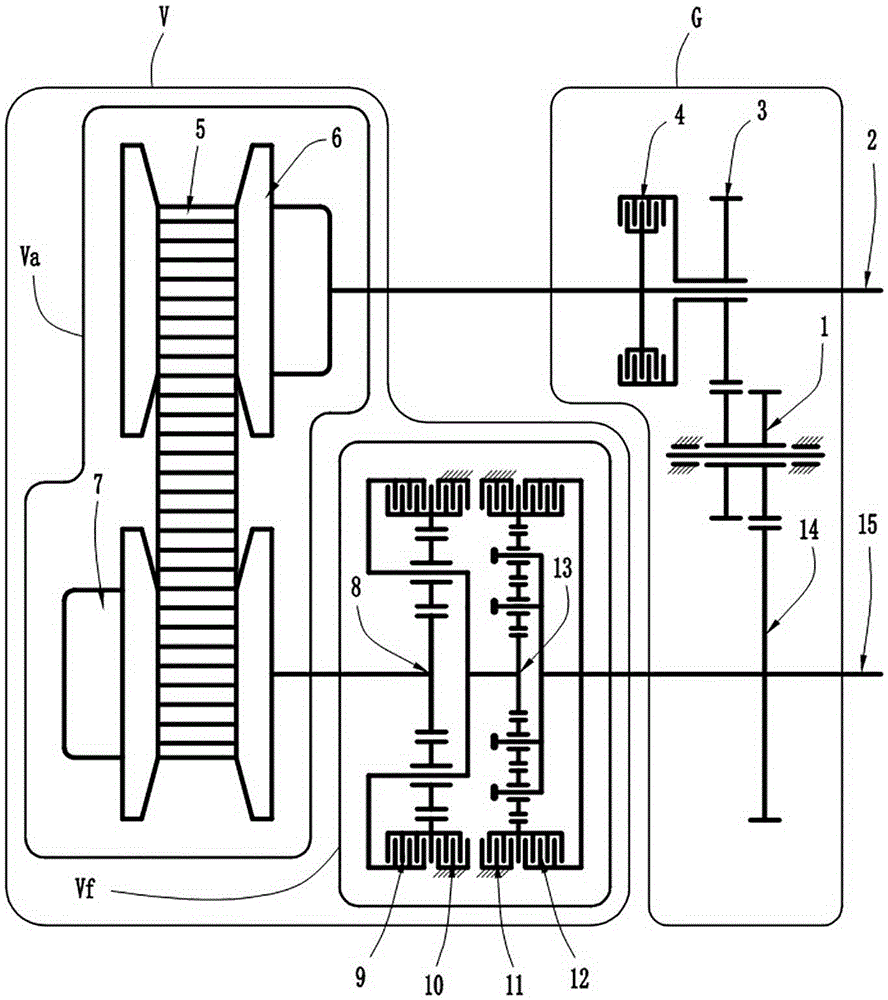

[0005] This set of continuously variable transmission device is applicable to any form of continuously variable transmission unit, and there is no limitation on the structure of auxiliary transmission, which can be either fixed shaft type or planetary gear type. In this example, a metal belt type continuously variable transmission unit and a planetary gear type auxiliary transmission are used for illustration. Therefore, the continuously variable transmission device in this example is composed of metal belt continuously variable transmission unit Va, auxiliary transmission Vf, transition gear transmission path G between transmission input shaft 1 and transmission output shaft 15 . There are two transmission paths: one is the continuously variable transmission path V composed of the continuously variable transmission unit Va and the auxiliary transmission Vf in series; the other is the transition gear transmission path G between the transmission input shaft 1 and the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com