Clutch disc, friction clutch device and drive train

A technology for friction clutches and clutch discs, which is applied to the fields of friction clutch devices themselves, dry clutches, friction clutch devices, and drive trains of motor vehicles, and can solve the problems of increased wear of clutch discs 30 and increased component loads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

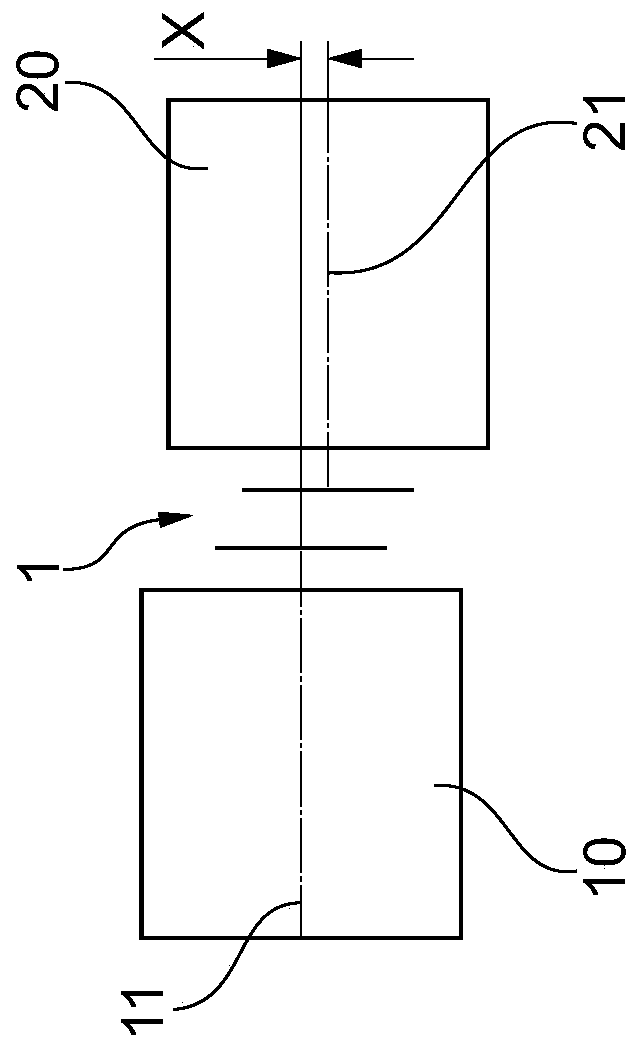

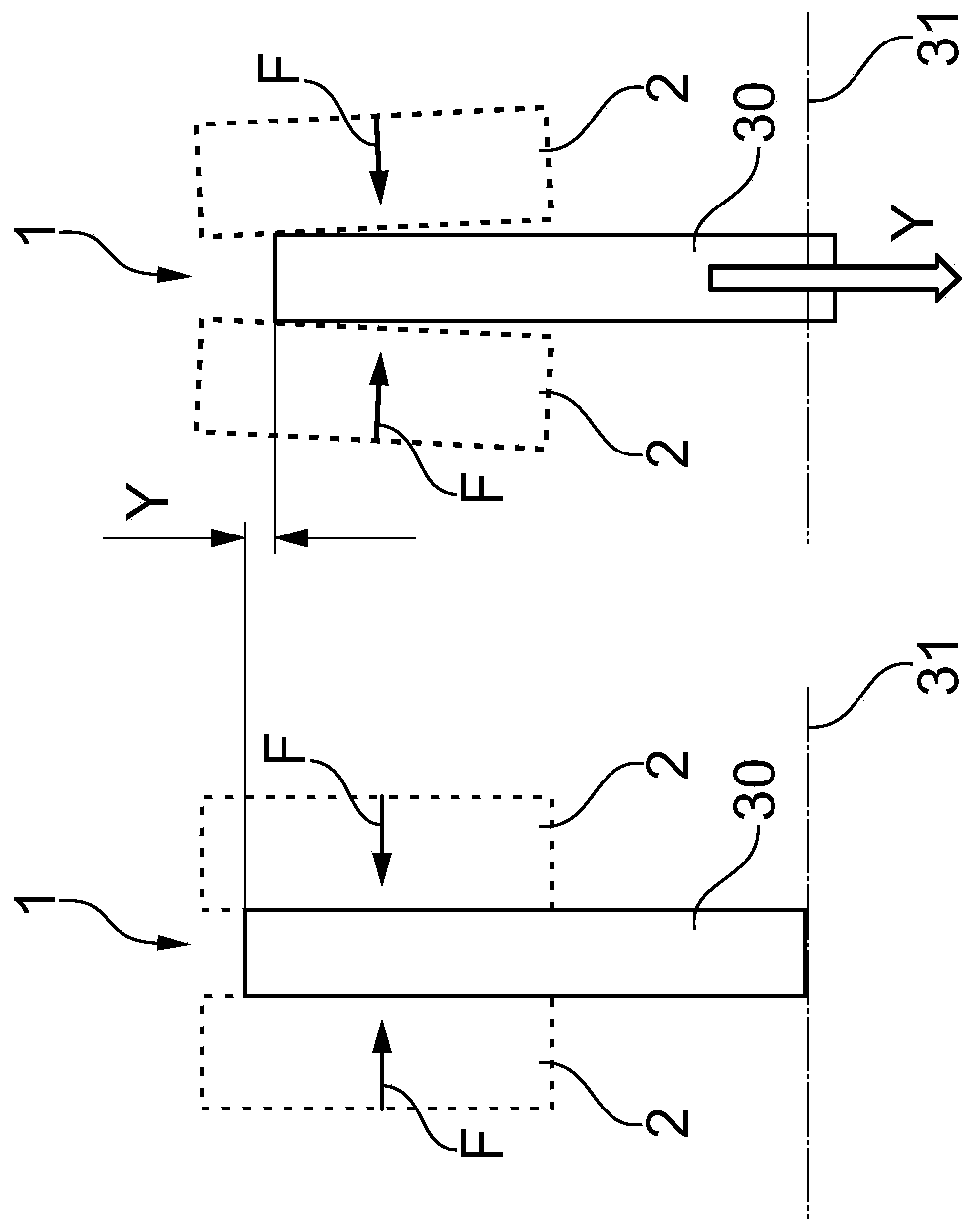

[0056] discussed Figure 1 to Figure 4 , used to illustrate the prior art.

[0057] Figure 5 and 6 A clutch disc 30 according to the invention is shown in , wherein, Figure 6 shown in enlarged view Figure 5 Part of the area shown in D.

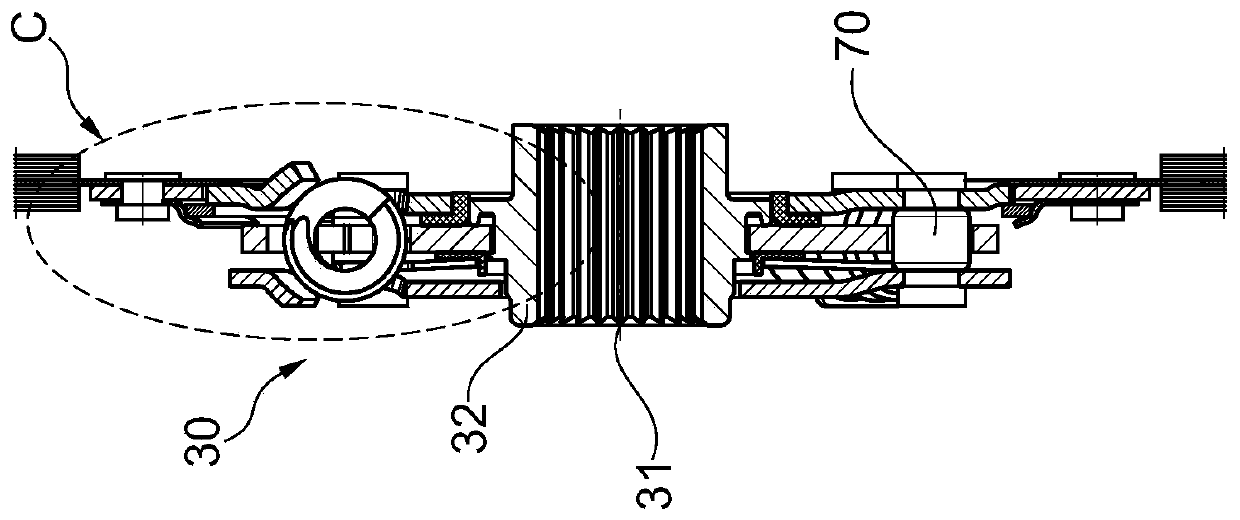

[0058] The structure of the clutch disc 30 according to the present invention is basically similar to image 3 and Figure 4 The structure of a conventional clutch disc is illustrated.

[0059] The clutch disc according to the invention differs from conventional clutch discs essentially in that, in addition to the first hub flange 40, the clutch disc according to the invention also has a second hub flange 41 which is opposite to the It is arranged parallel to and rotationally symmetrical to the first hub flange 40 .

[0060] Depending on the direction of load (pull or push), at least one hub flange 40 , 41 engages on the hub 32 so that torque can be transmitted from the hub flange 40 , 41 to the hub 32 . A spring element 50 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com