Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Improve the accuracy of folding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

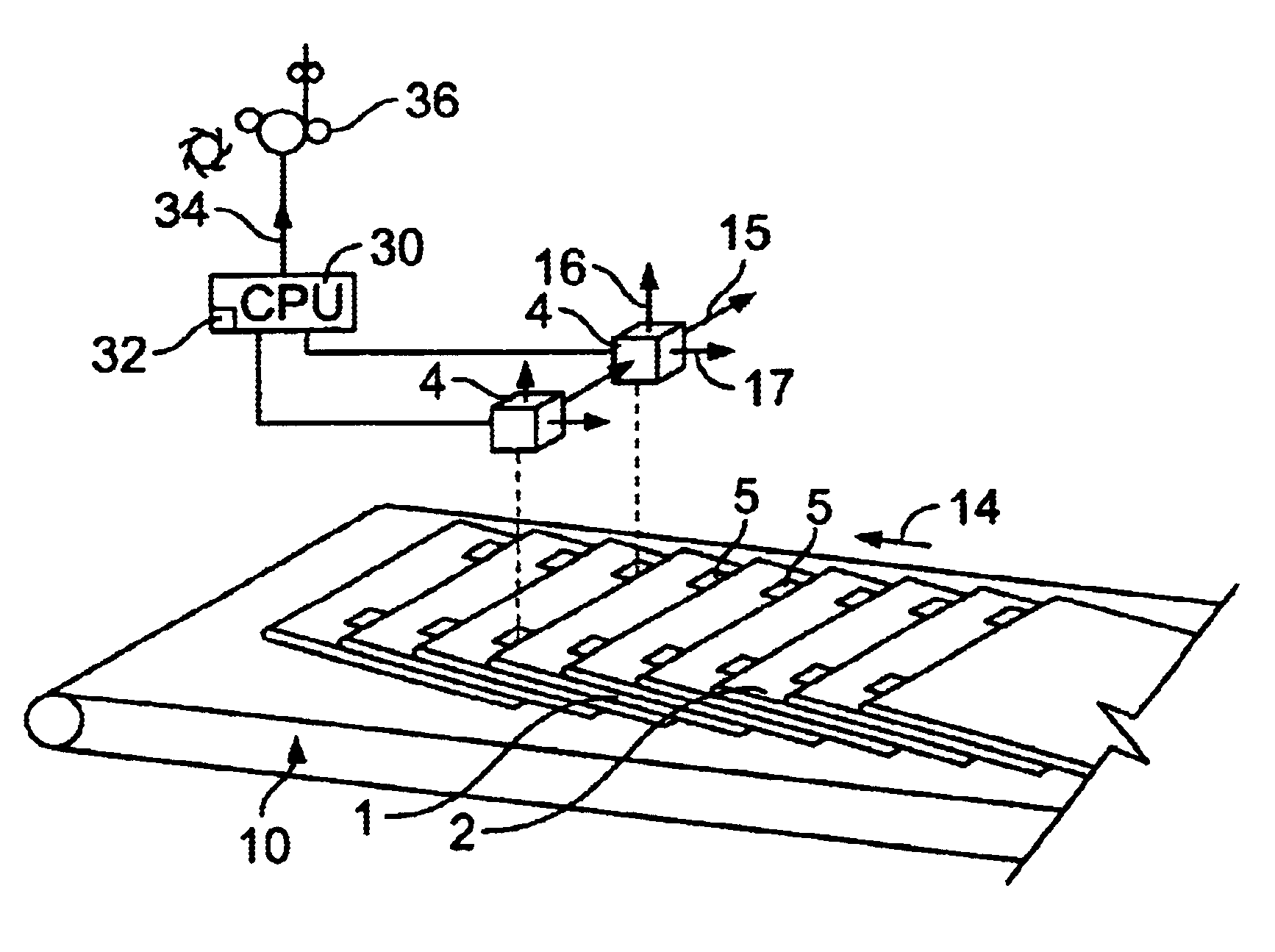

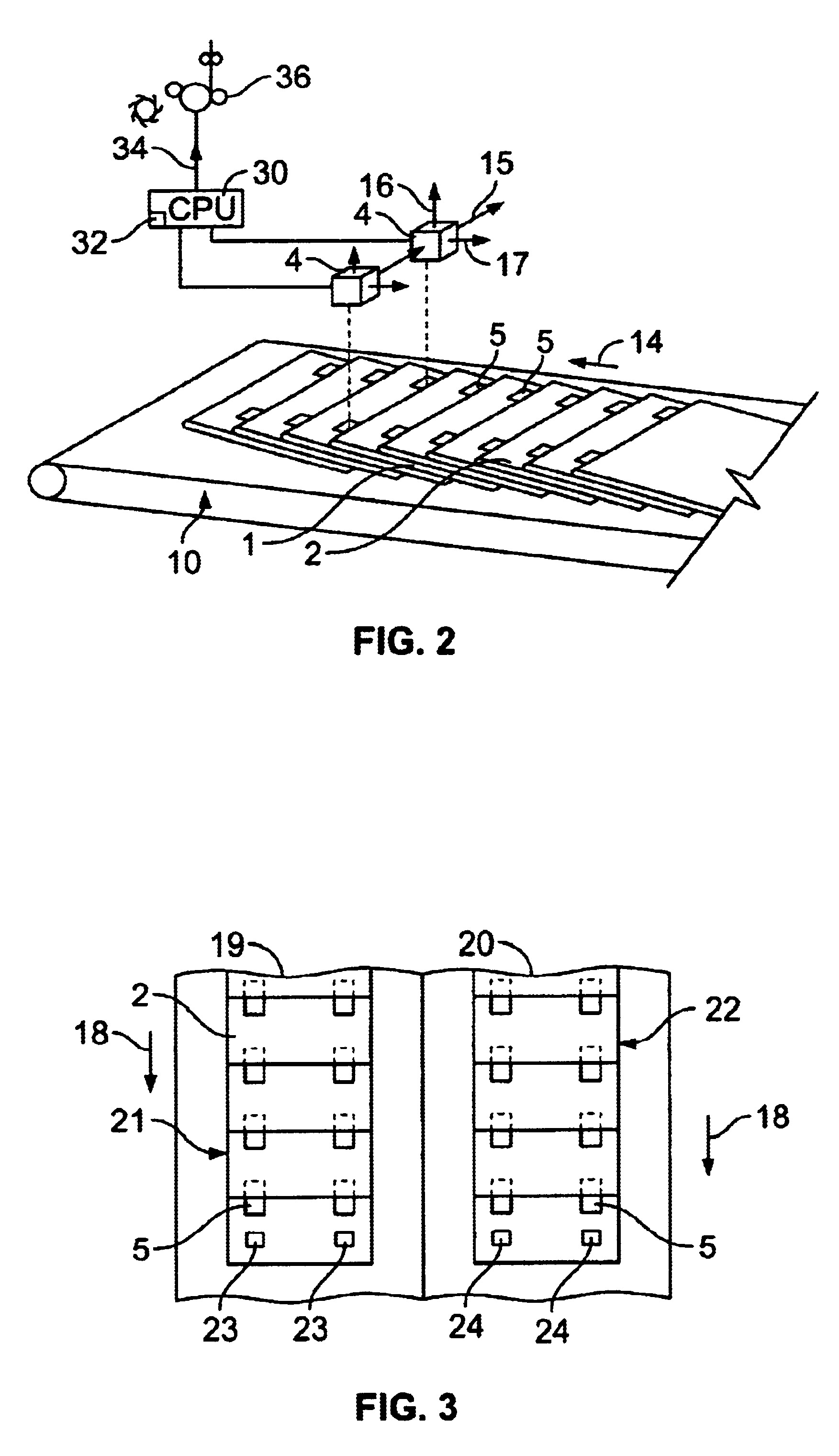

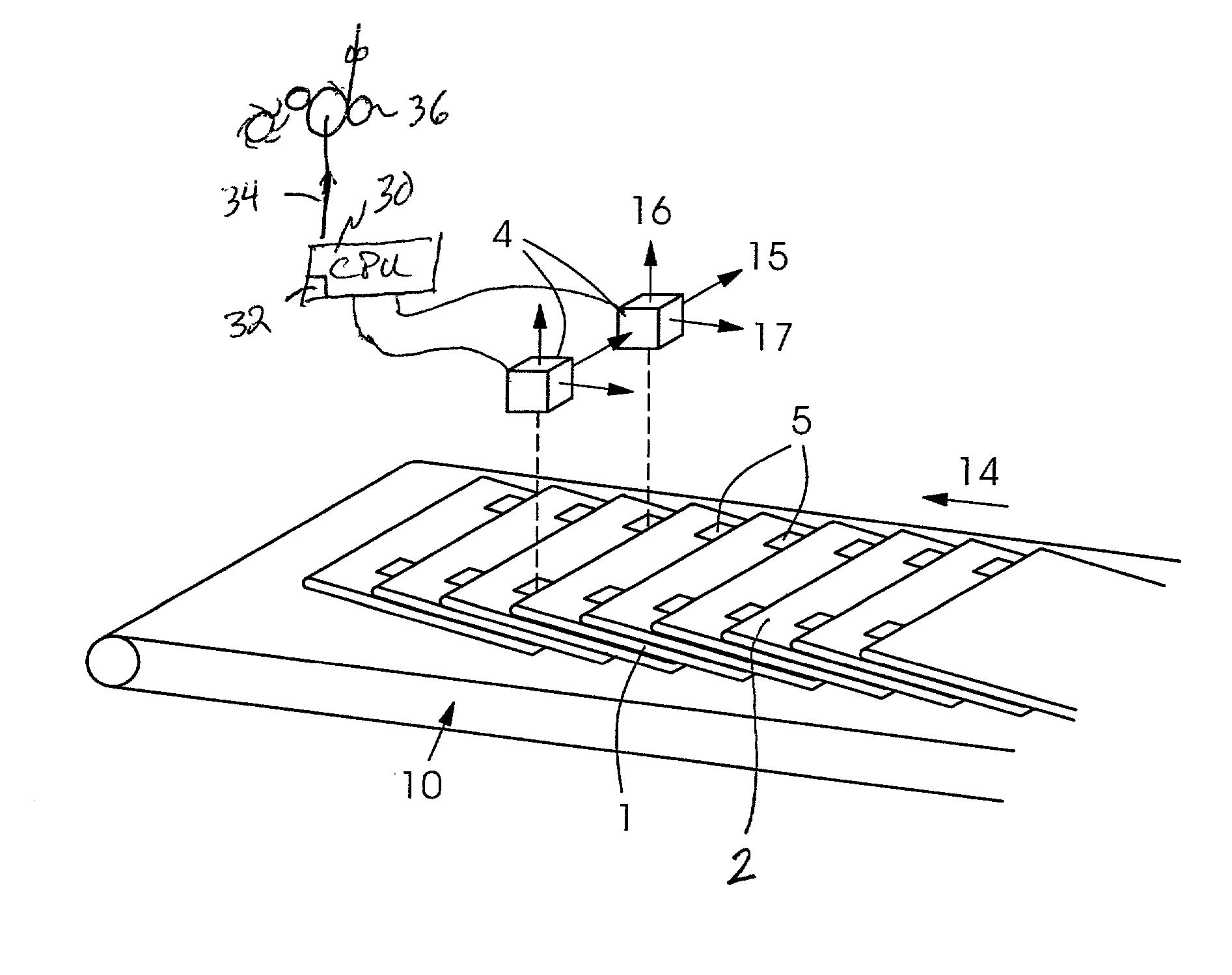

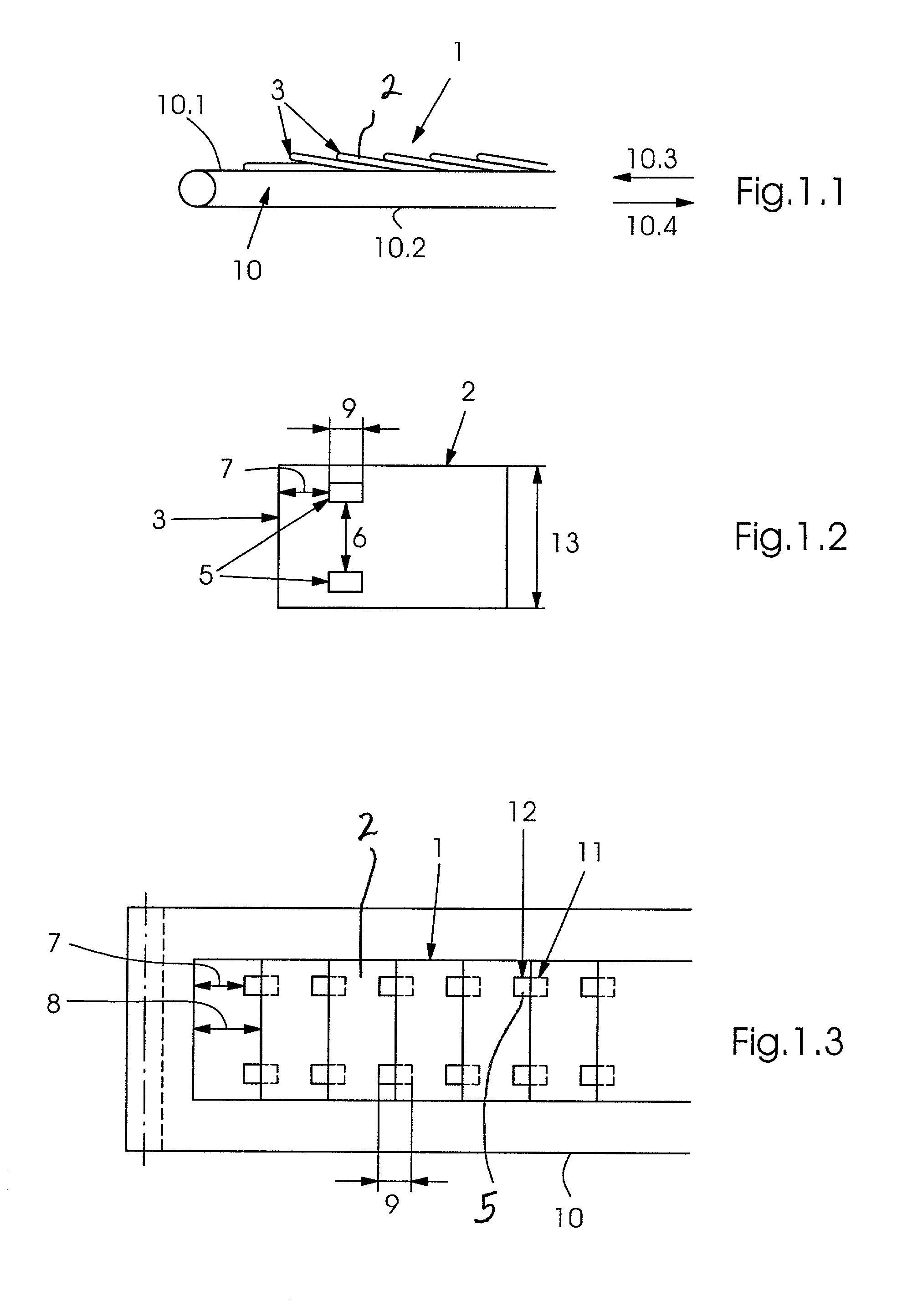

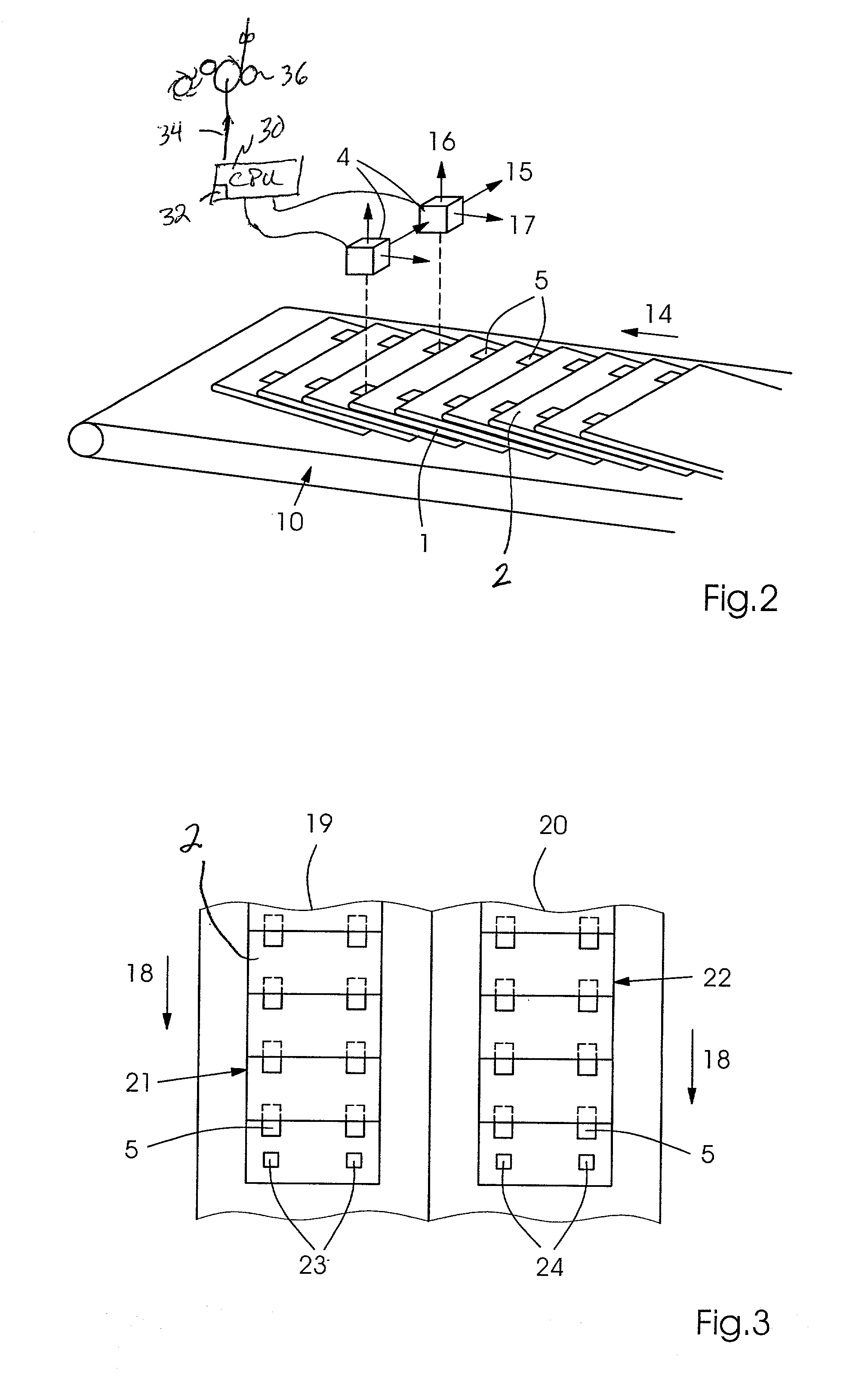

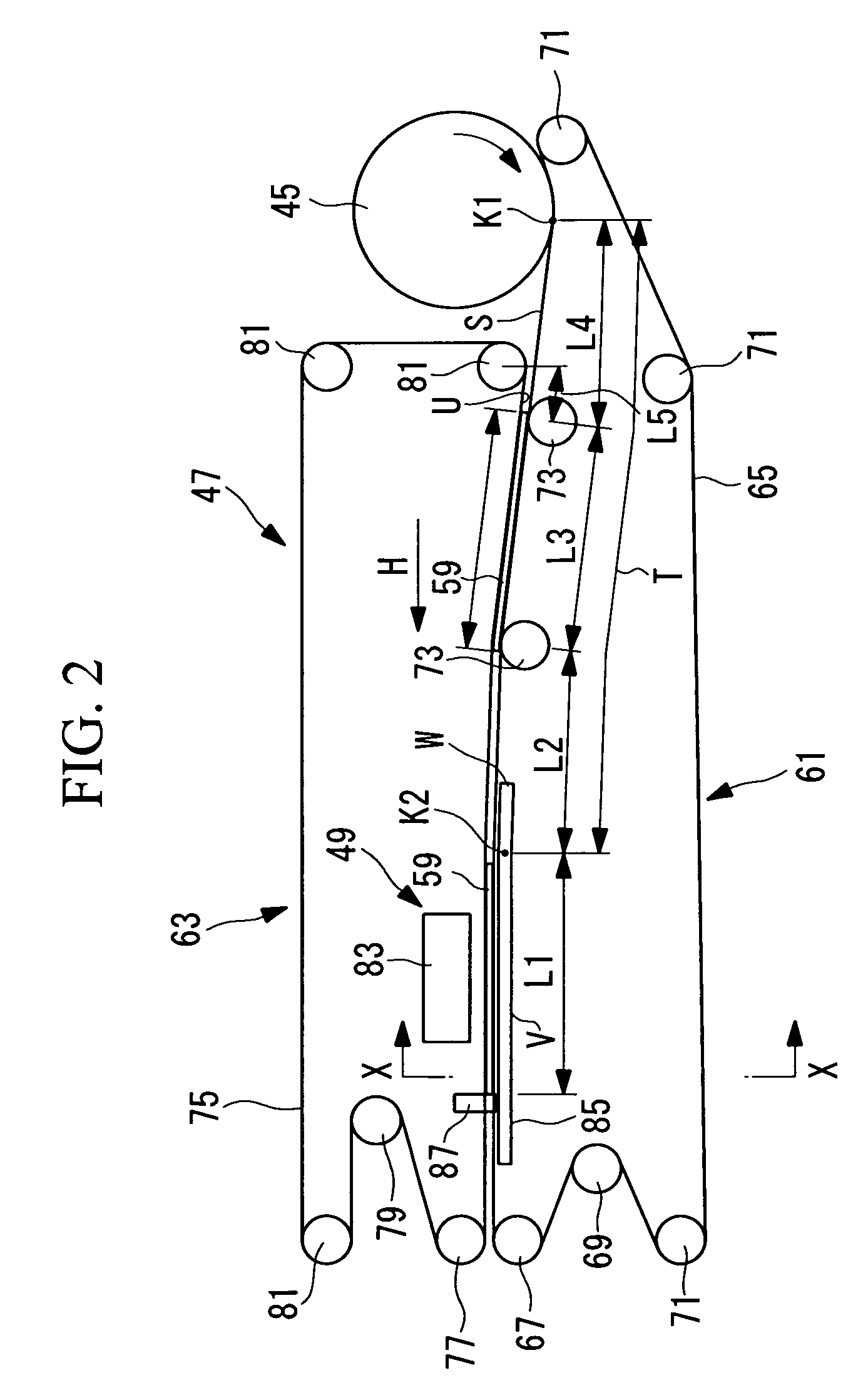

Method and device for determining the accuracy of a fold position

InactiveUS6935998B2Fast and reliableQuick analysisMechanical working/deformationFunction indicatorsBiomedical engineering

Owner:HEIDELBERGER DRUCKMASCHINEN AG

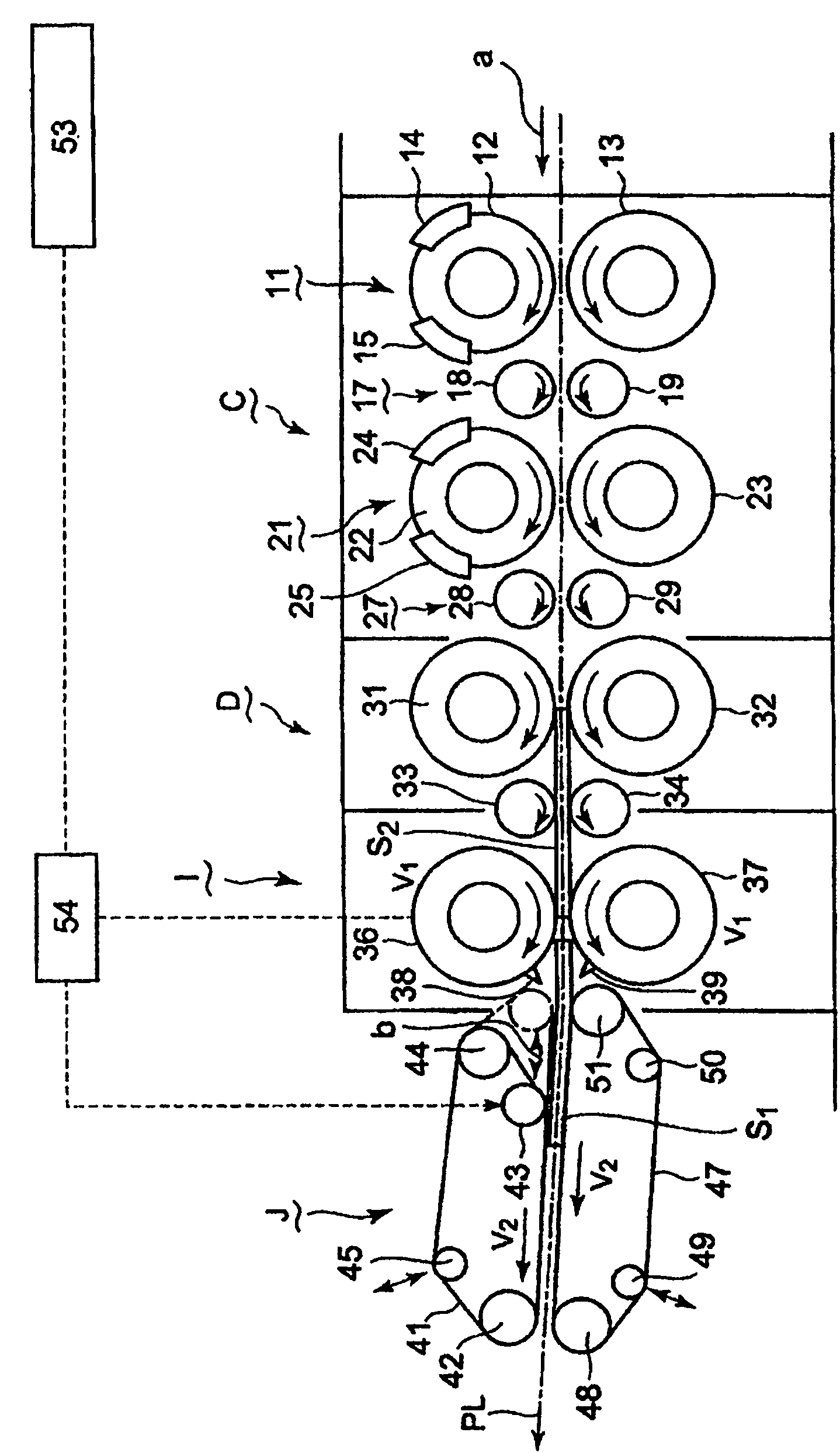

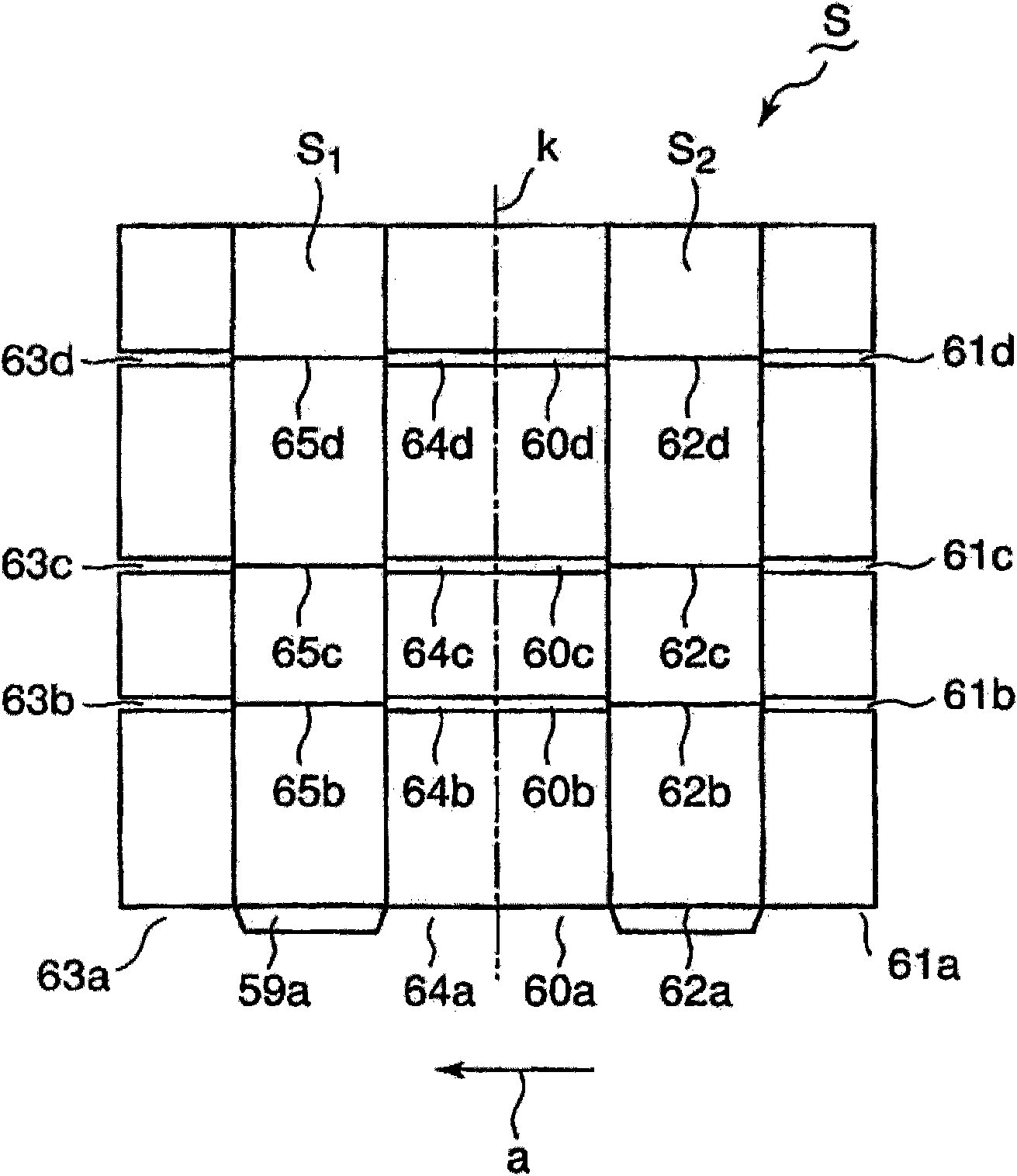

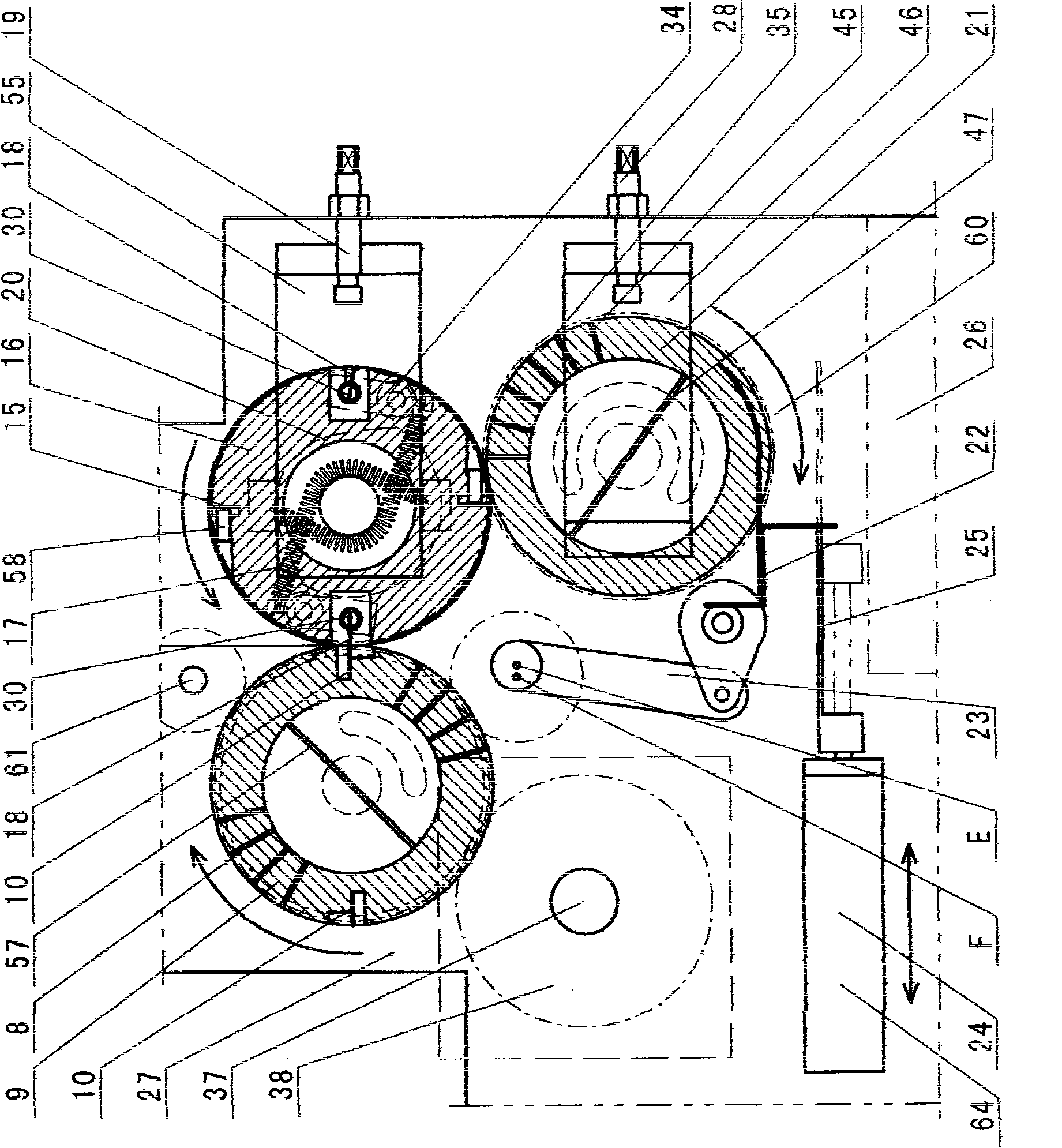

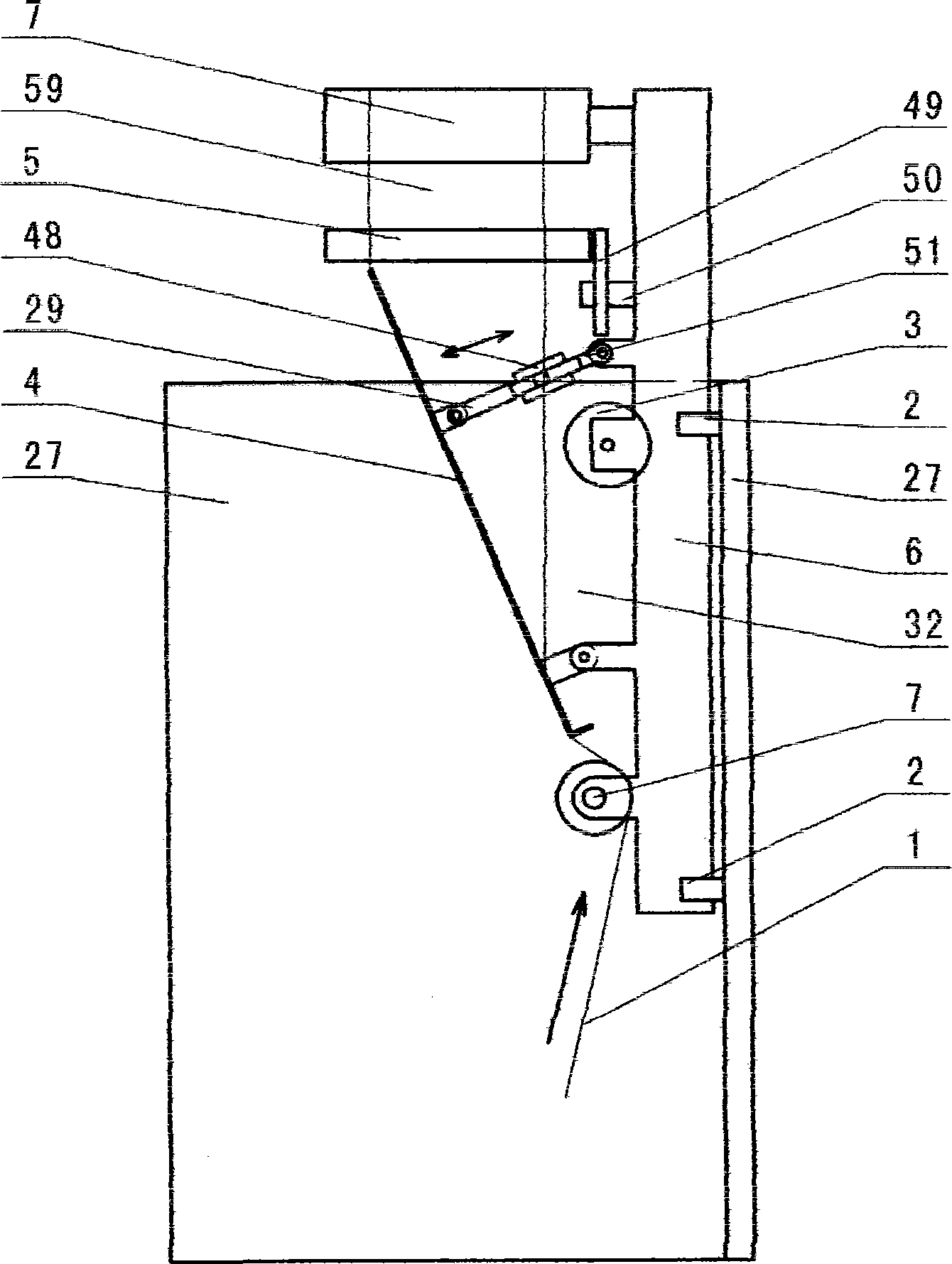

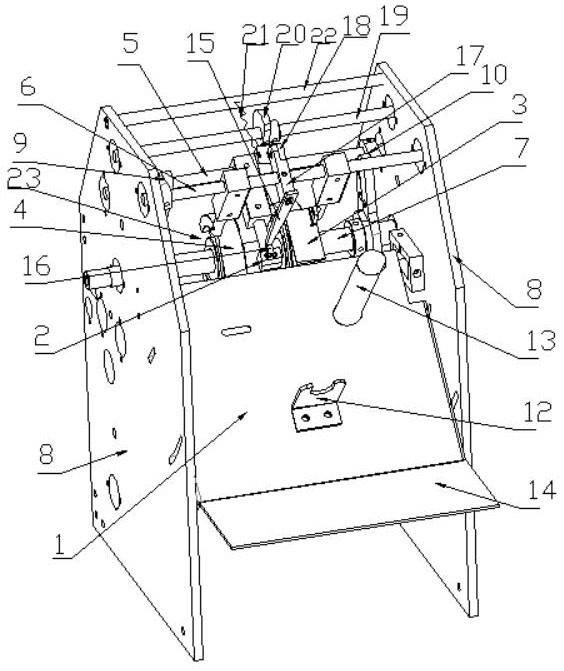

Method and device for making box of corrugated cardboard sheet

ActiveCN101873926ASmall spanEasy to handleBoxes/cartons making machineryPaper-makingCountermeasureCardboard box

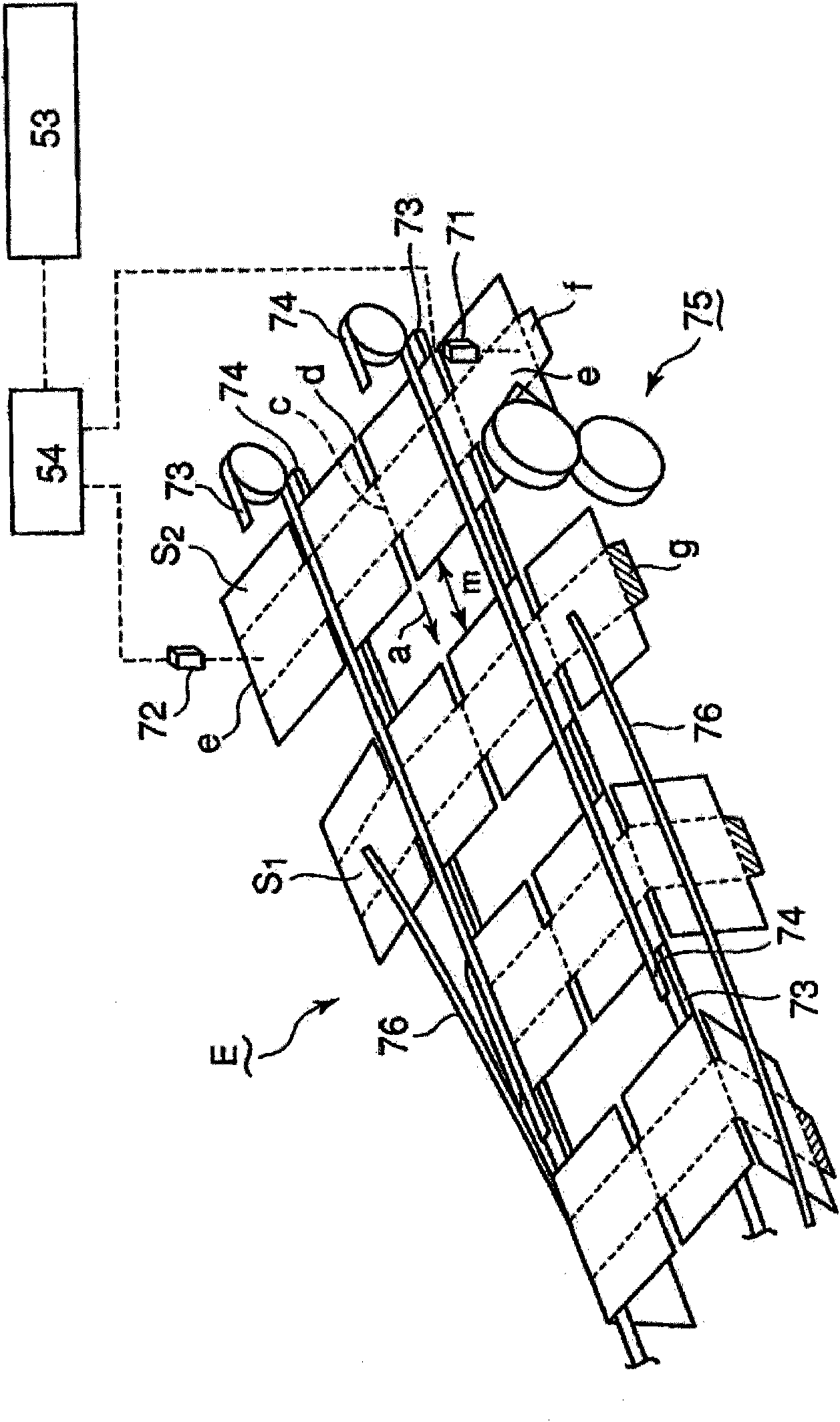

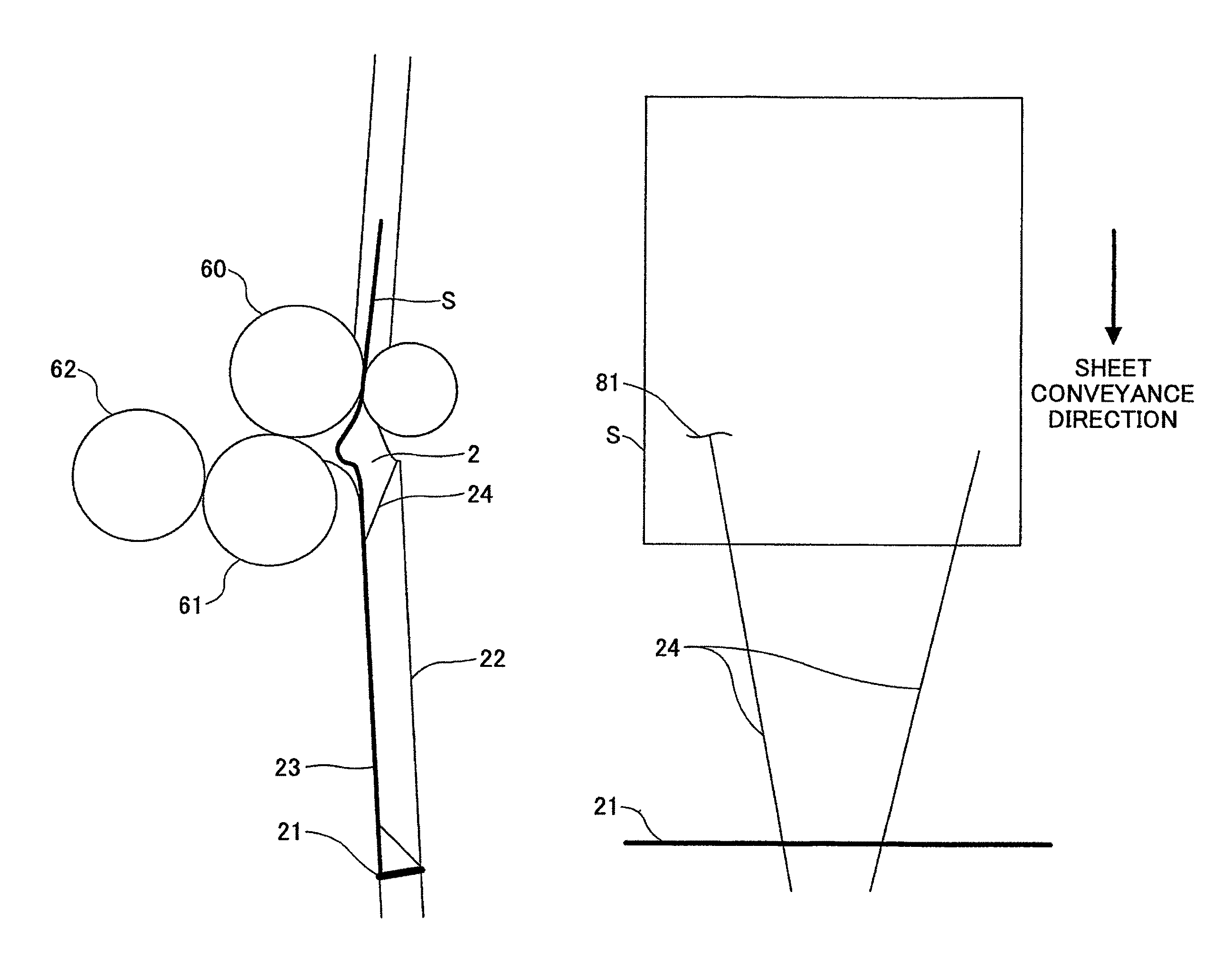

Disclosed is a method for producing a cardboard box by performing a box-making process of a corrugated cardboard sheet which is formed to have dimensions of a plurality of cardboard boxes wherein the yield of the cardboard sheet and the production efficiency are enhanced and a countermeasure can be taken against paper powder. A method for making a box of a corrugated cardboard sheet by performinga box-making process of a cardboard sheet (S) which is formed to have dimensions of a plurality of cardboard boxes and then cutting the cardboard sheet (S) into dimensions of one cardboard box comprises a step (I) for cutting the cardboard sheet (S) into dimensions of one cardboard box by a cut line (k) in the direction intersecting the conveyance direction (a) along a box making line (PL) after a ruling and grooving step (C) and before a pasting and folding step (E), and a speed increase step (J) for spacing the cardboard sheets (S1) and (S2) thus cut by a set dimension following to the cutting step (I) by increasing the speed of the cardboard sheets (S1) and (S2) while conveying toward a subsequent step.

Owner:MITSUBISHI HEAVY IND MACHINERY SYST LTD

Flexible OLED (Organic Light Emitting Diode) display panel and display device

ActiveCN106711183ARealize repeated bendingAccurate control of bending radiusSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

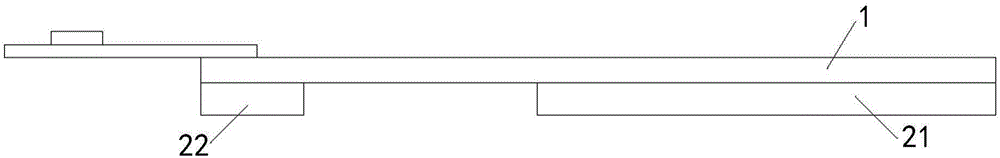

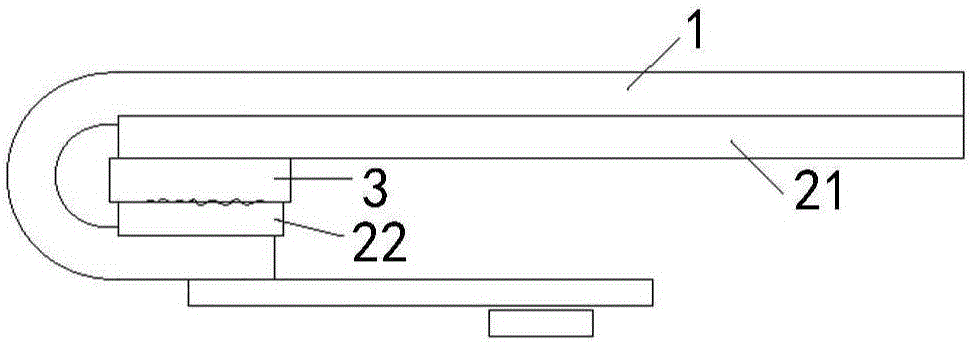

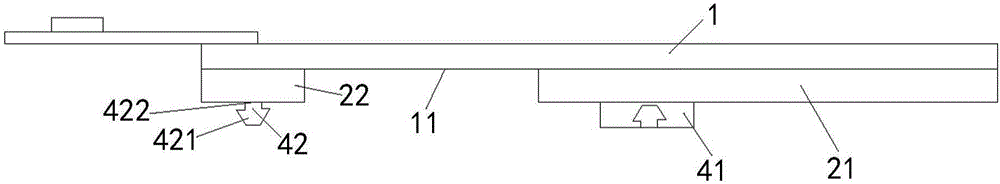

The invention discloses a flexible OLED (Organic Light Emitting Diode) display panel and a display device. The flexible OLED display panel comprises a flexible substrate, a supporting layer and a connecting structure, wherein the flexible substrate is provided with a first surface; the supporting layer is fixedly arranged on the first surface of the flexible substrate; the connecting structure comprises a first connector and a second connector, and is arranged on the first surface; the first connector and the second connector are connected detachably and are in a connected state, and the flexible substrate between the first connector and the second connector forms a bent area. Repeated bending of the bent area can be realized by connection and separation of the first connector and the second connector to adjust the bending radius. On the other hand, the bending radius of the bent area can be accurately controlled by cooperation of the first connector and the second connector, so that the folding precision is improved.

Owner:BOE TECH GRP CO LTD

Method and device for determining the accuracy of a fold position

InactiveUS20020113977A1Quick analysisReduce riskMechanical working/deformationFunction indicatorsBiomedical engineering

Owner:HEIDELBERGER DRUCKMASCHINEN AG

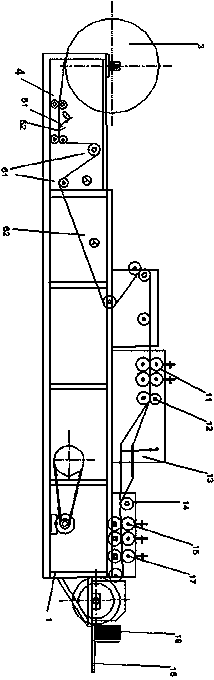

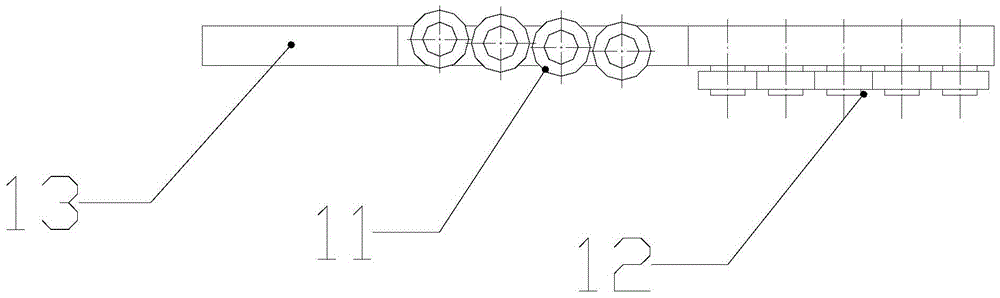

Technique for folding and producing adsorption type napkin paper and device thereof

InactiveCN101474891ARealize in-line printingRealize the collectionPaper/cardboard articlesHigh ratePulp and paper industry

The invention relates to a high-speed adsorption napkin paper folding and manufacturing process and device needing wire printing and folding. The prior adopted mechanical linkage vertical folding structure has the defects of complex structure, low folding accuracy, more fault points, low rate of finished products, low production efficiency, and the like. Therefore, the invention designs the adsorption napkin paper folding and manufacturing process and device. The process comprises that: the napkin paper is pulled by a traction mechanism, aligned and longitudinally folded by a longitudinal folding mechanism, smoothed by a compression roller and then aligned by an aligning mechanism, fed into an adsorption transversely folding mechanism through the traction mechanism and then aligned and transversely folded; and then the longitudinally folded paper is cut by a cutting knife roll, and manufactured into finished products by an adsorption counting mechanism and a collecting and packaging mechanism. The process and the device achieve wire printing and folding of the napkin paper conveniently and reliably, have the advantages of high folding accuracy, few fault points, high rate of finished products, high production efficiency, stable quality of the products and low production cost, and are suitable for large-scale industrialized production.

Owner:李玉龙

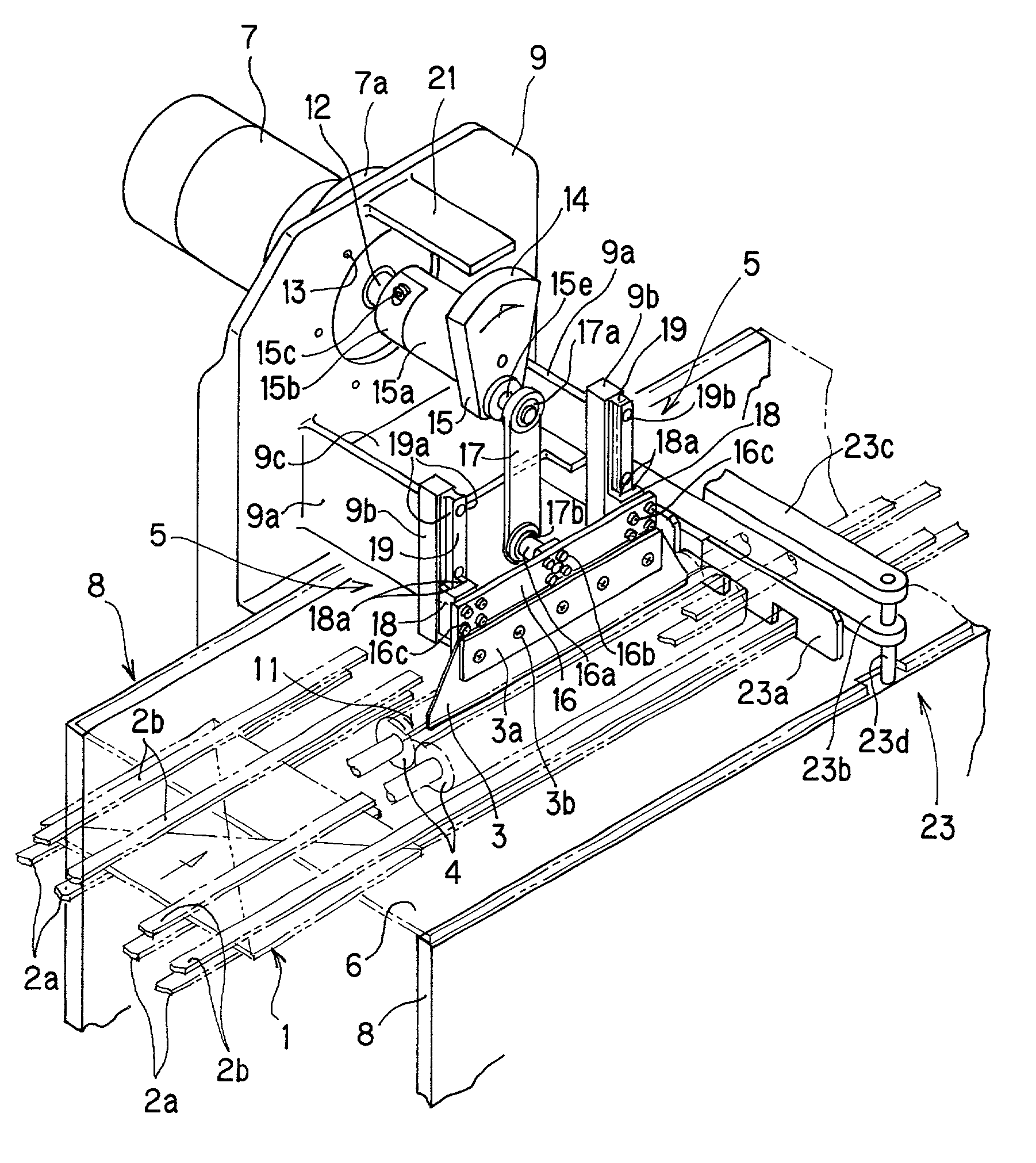

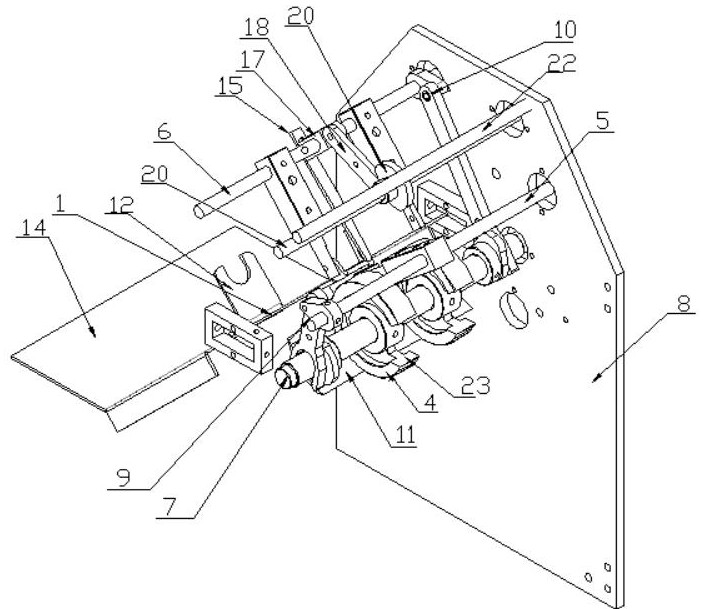

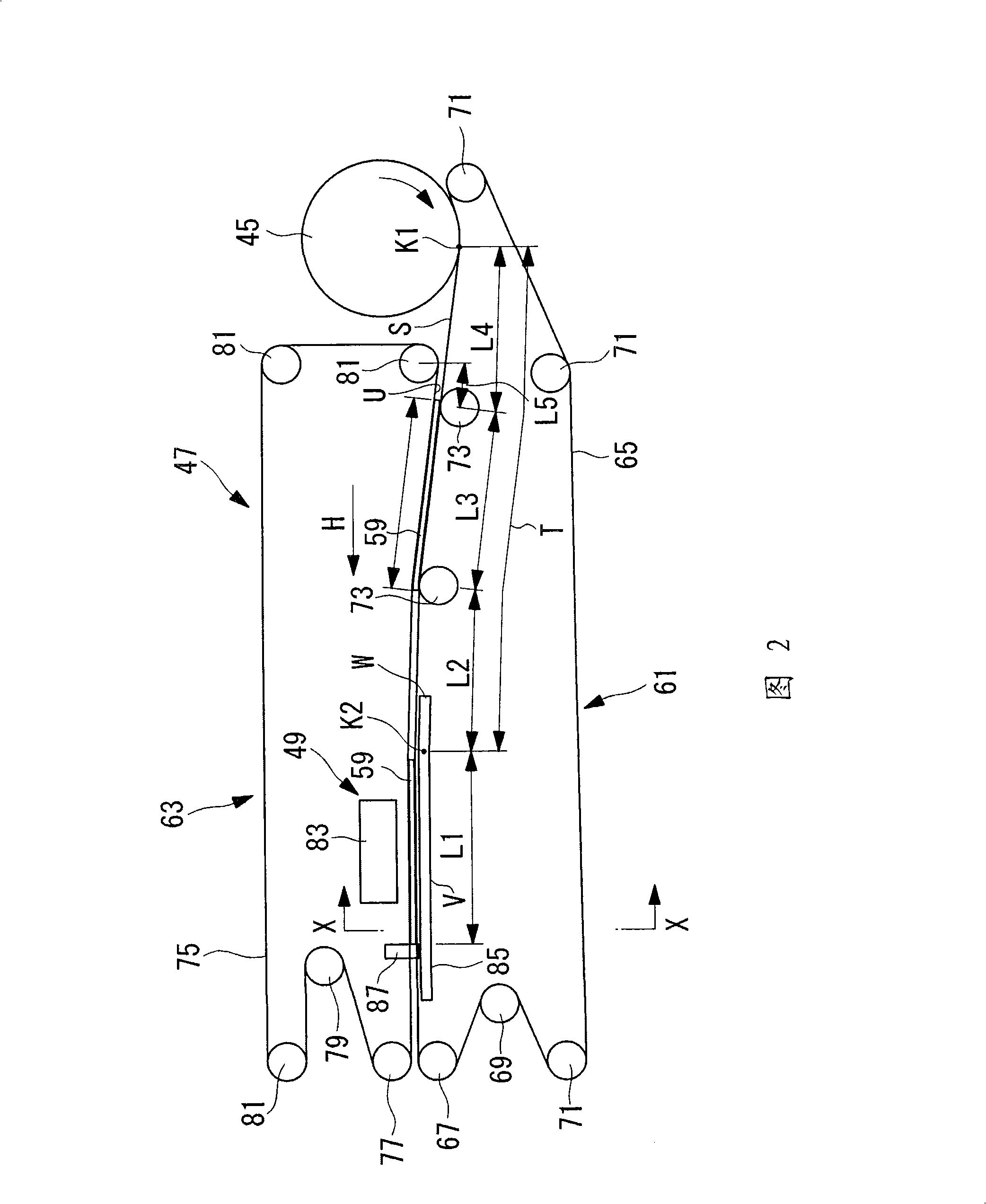

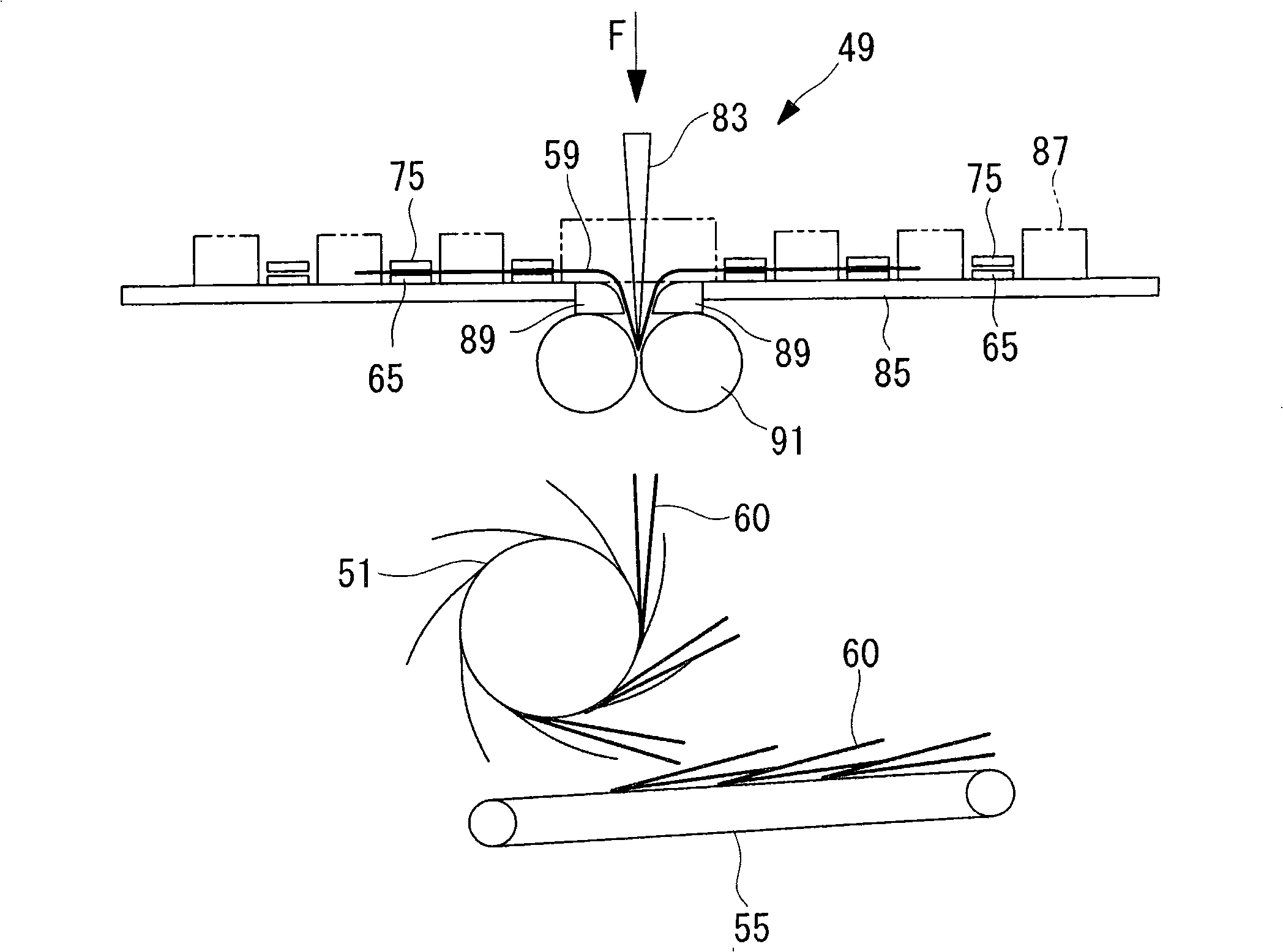

Chopper folder for rotary press

InactiveUS7022059B2Reduce necessityRun at high speedMechanical working/deformationFolding thin materialsReciprocating motionKnife blades

A chopper folder for a rotary press folds signatures which are periodically conveyed, one signature at a time, from a folding machine. The chopper folder includes a pair of folding rollers for folding a signature parallel to the conveyance direction, a prime mover, a crank arm fixed to an output shaft of the prime mover to be rotated together with the output shaft, a blade holder connected to the crank arm via a link, a chopper blade held in the blade holder and adapted to push the signature from an upper surface thereof in order to insert the signature into a space between the pair of folding rollers, and guide units for restricting motion of the blade holder such that the blade holder reciprocates only in a direction perpendicular to a conveyance plane along which the signature is conveyed.

Owner:TOKYO KIKAI SEISAKUCHI LTD

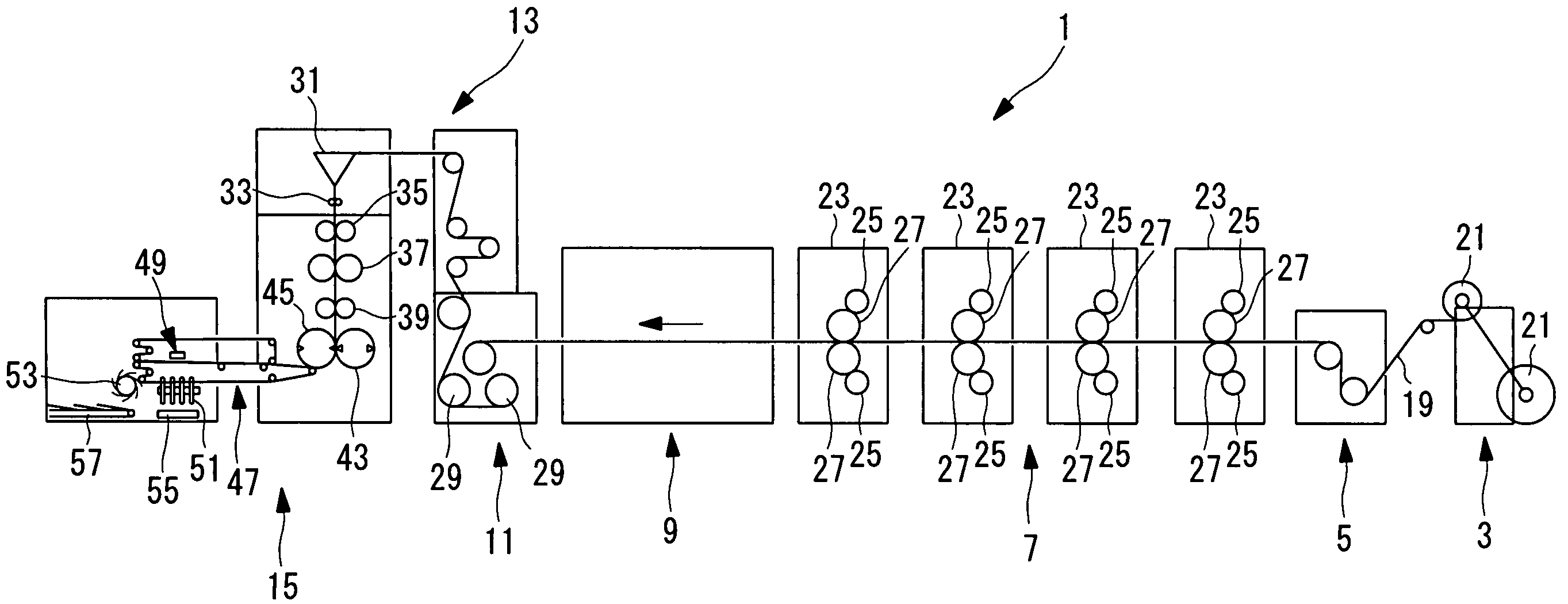

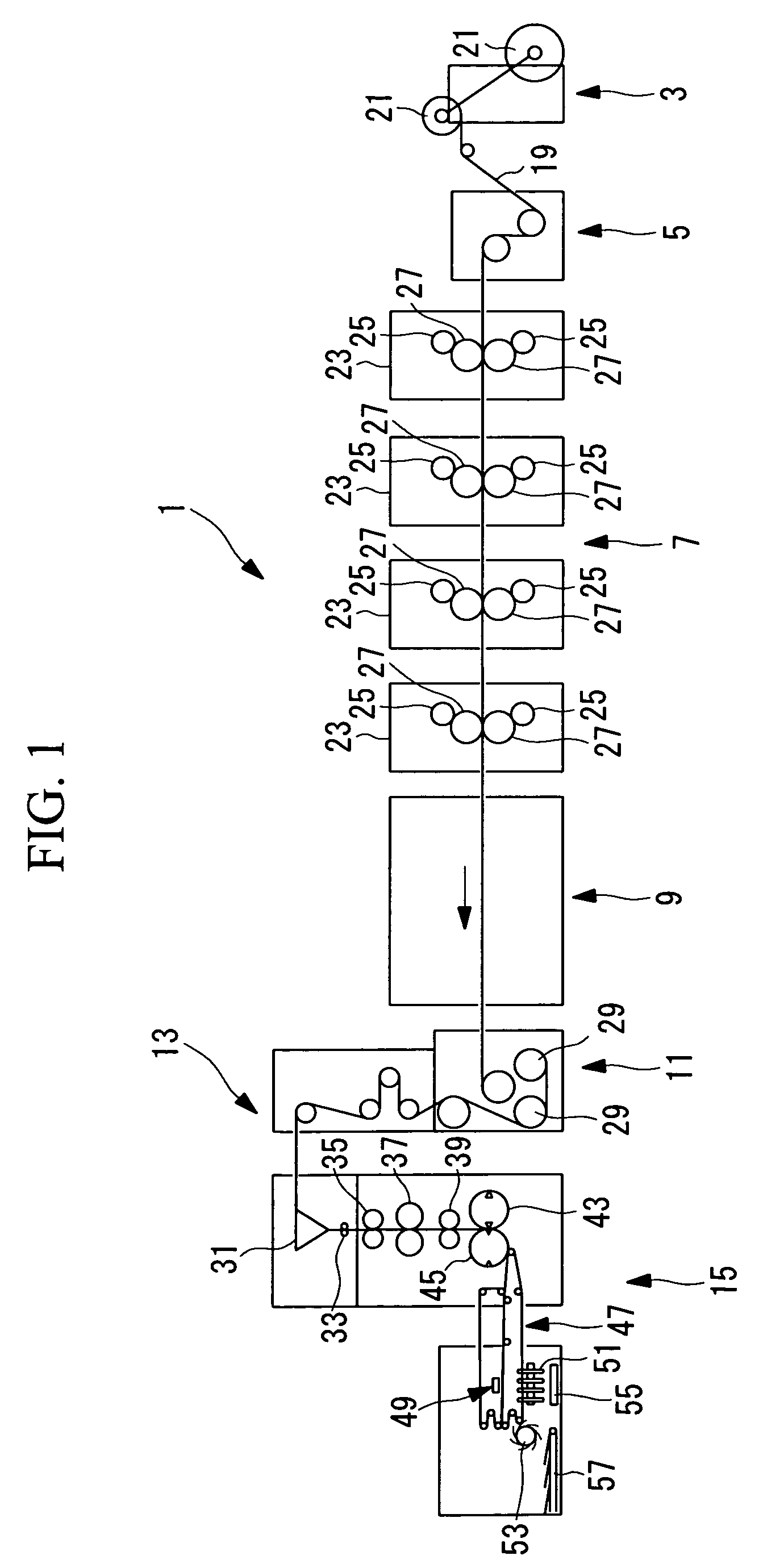

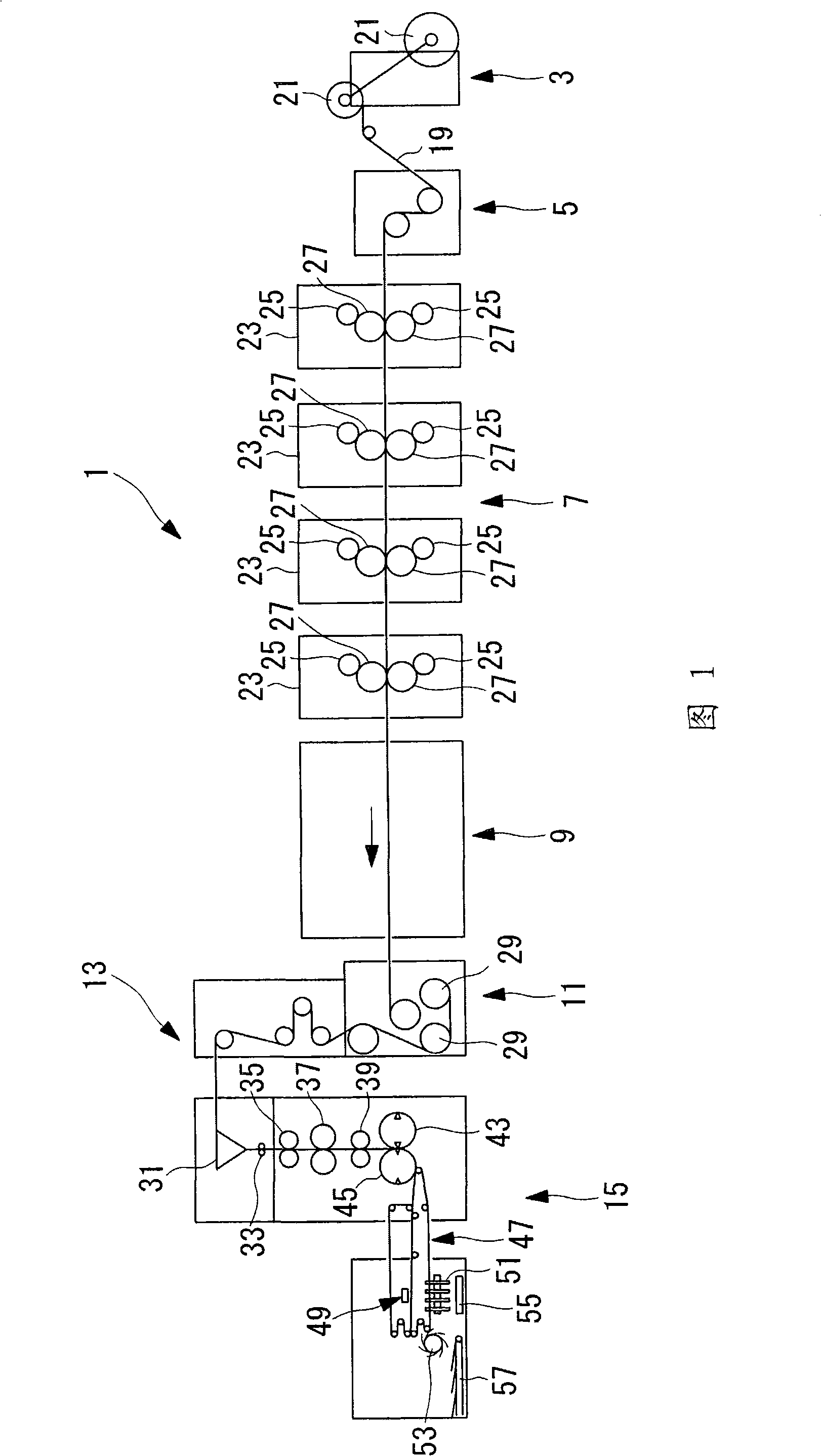

Folding machine and printing machine using same

InactiveUS20080277858A1Improve the accuracy of foldingSimple structureFolding thin materialsRotary pressesStatic friction coefficientStatic friction

A folding machine includes a lower conveyance belt that forms a lower conveyance path section for guiding and conveying a signature by a lower conveyance surface, an upper conveyance belt that forms an upper conveyance path section for guiding and conveying the signature by an upper conveyance surface, a chopper table for guiding the lower conveyance belt, a stopper for aligning a downstream end position of the signature, and a chopper blade for forming a chopper signature. A coefficient of static friction of the lower conveyance surface and the upper conveyance surface to an iron surface is 0.2 or more and less than 0.3, and a nip roller for increasing holding force to the signature between the lower conveyance surface and the upper conveyance surface is provided at a part more upstream side than the stopper by at least a length of the signature.

Owner:MITSUBISHI HEAVY IND PRINTING & PACKAGING MACHINERY

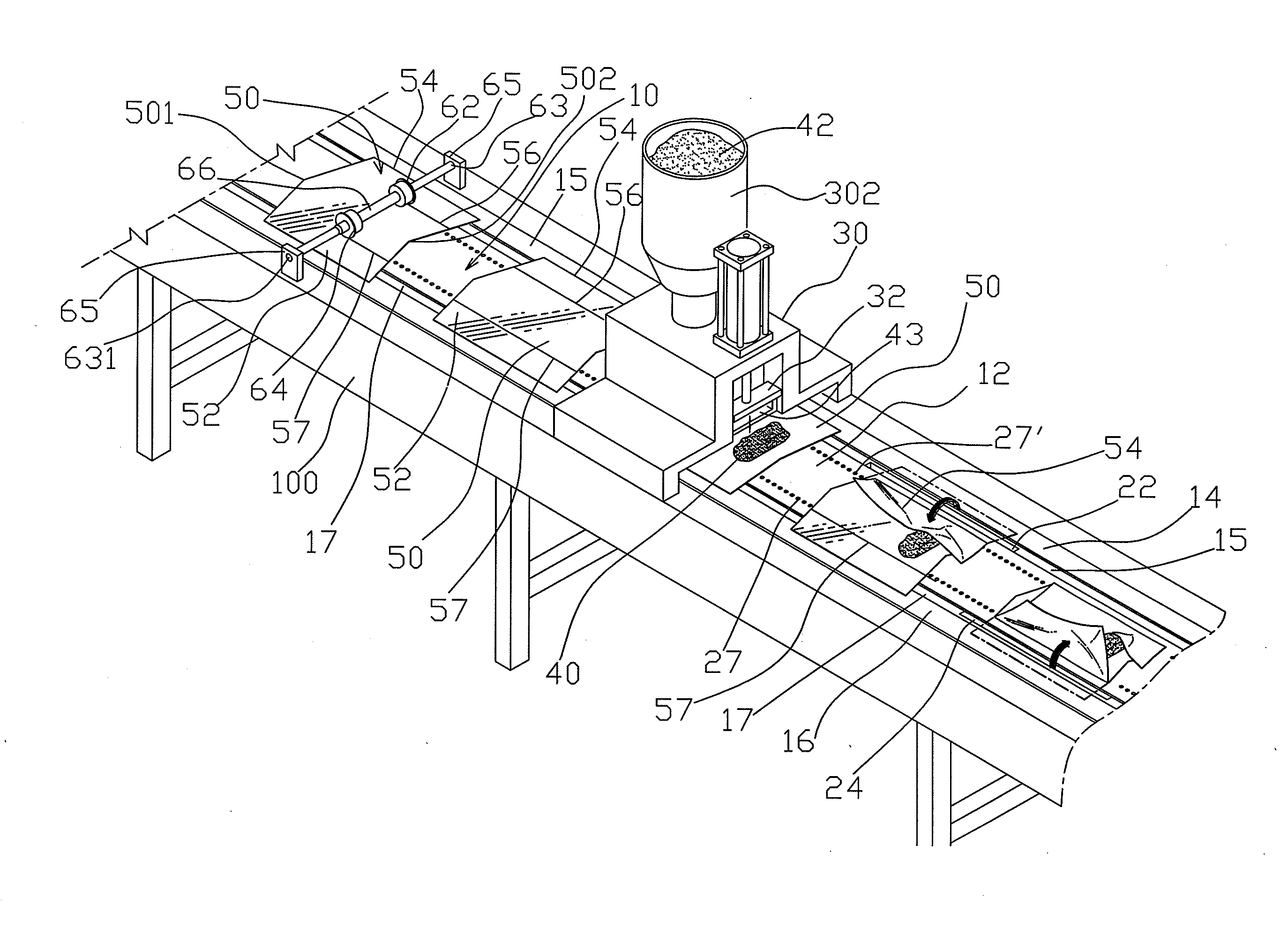

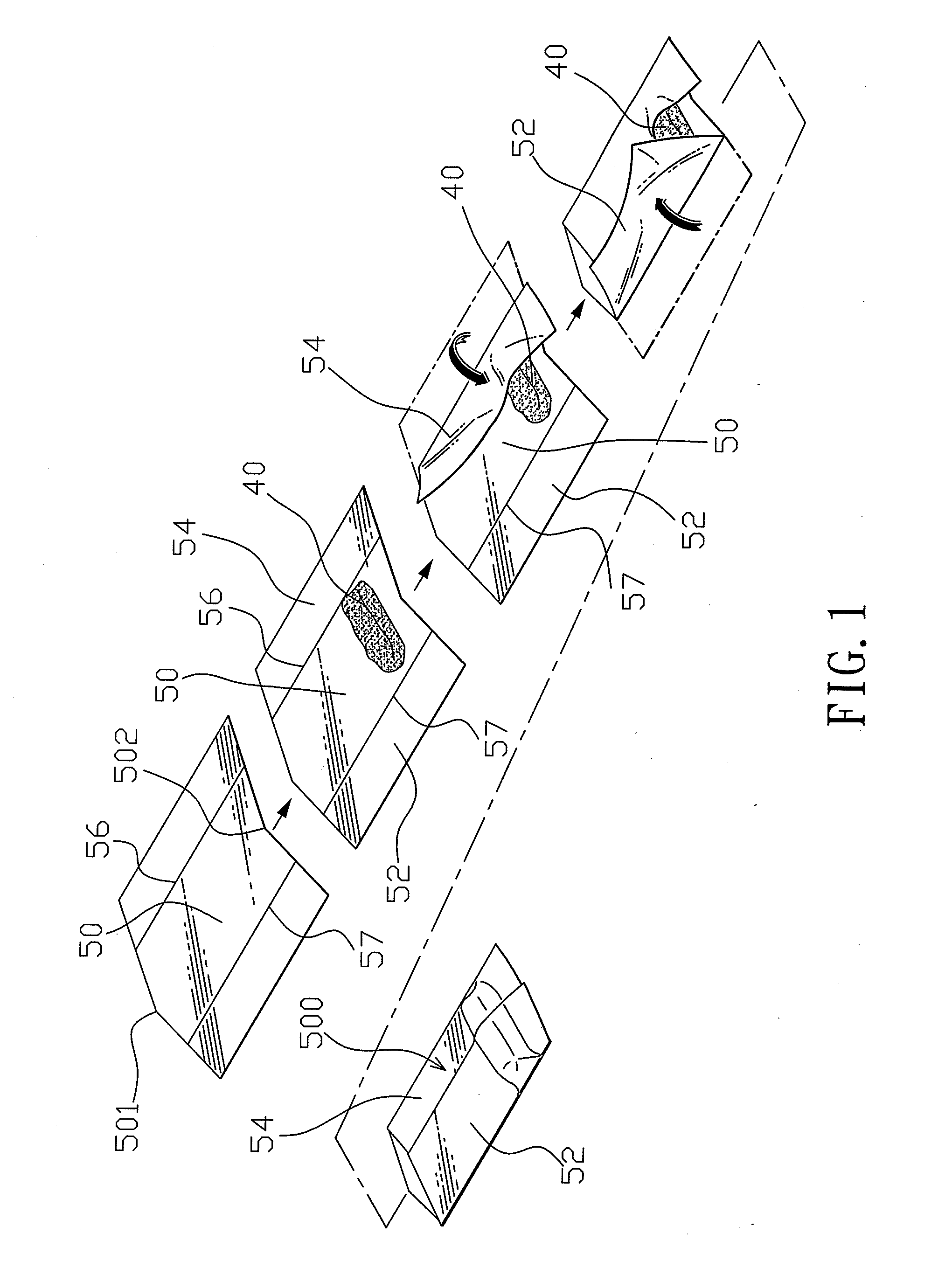

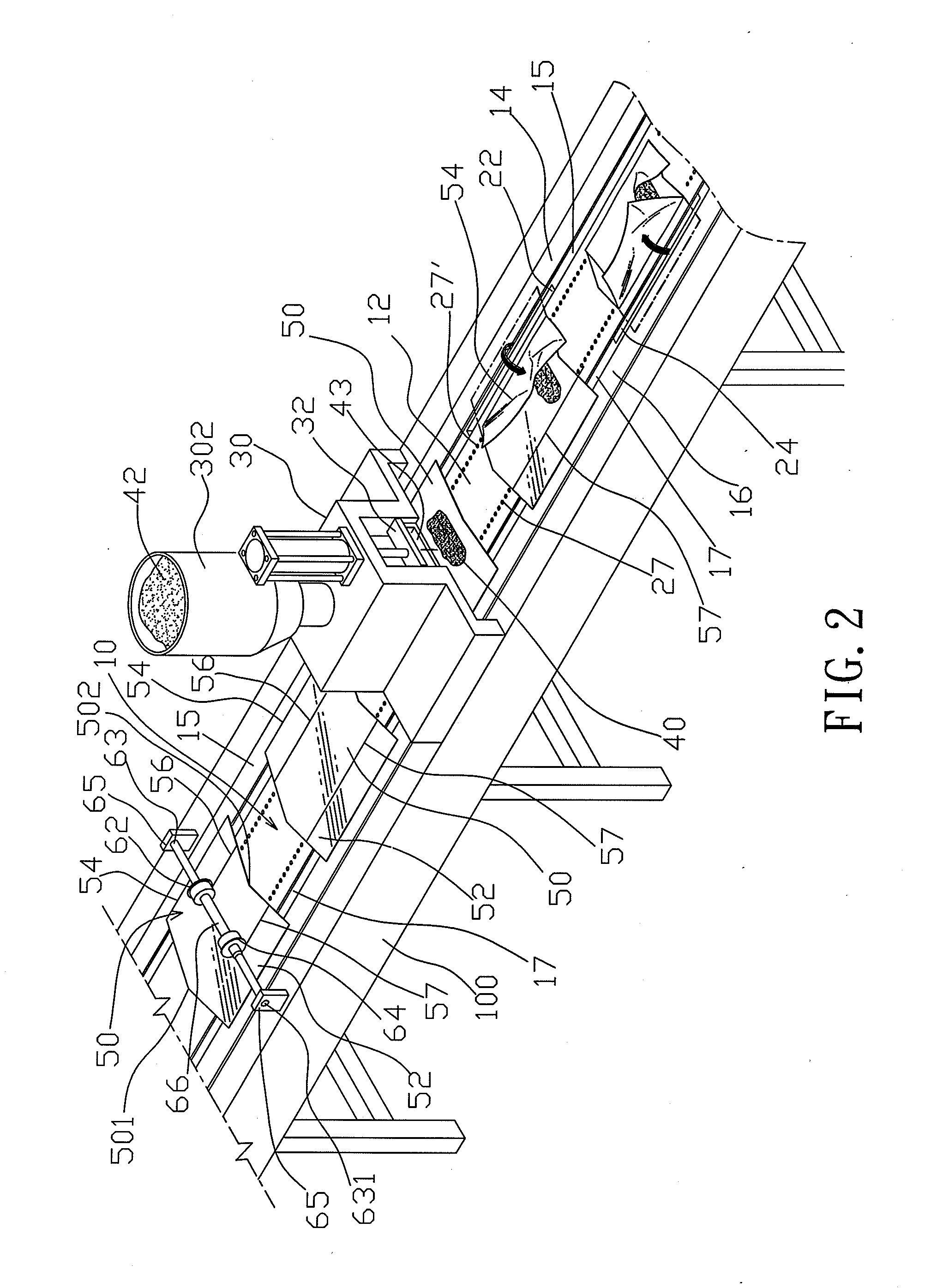

Folding control apparatus for left and right lateral pieces of slice food

InactiveUS20080135458A1Constant shapeImprove the accuracy of foldingFood shapingSortingLow noiseHigh pressure

A folding control apparatus for left and right lateral pieces of slice food is provided, such that when the slice food is moving forward on a transfer belt surface, the slice food is attached and positioned on the transfer belt surface; and a left and right lateral pieces of the slice food are blown by high-pressure air at a different time sequence to be folded and overlapped with respect to each other, so as to cover a stuffing strip on a surface of the slice food for forming a food enclosing material, thereby further simplifying a structure for folding the slice food to reduce a manufacturing cost and lower noise.

Owner:OU-YOUNG ROBERT

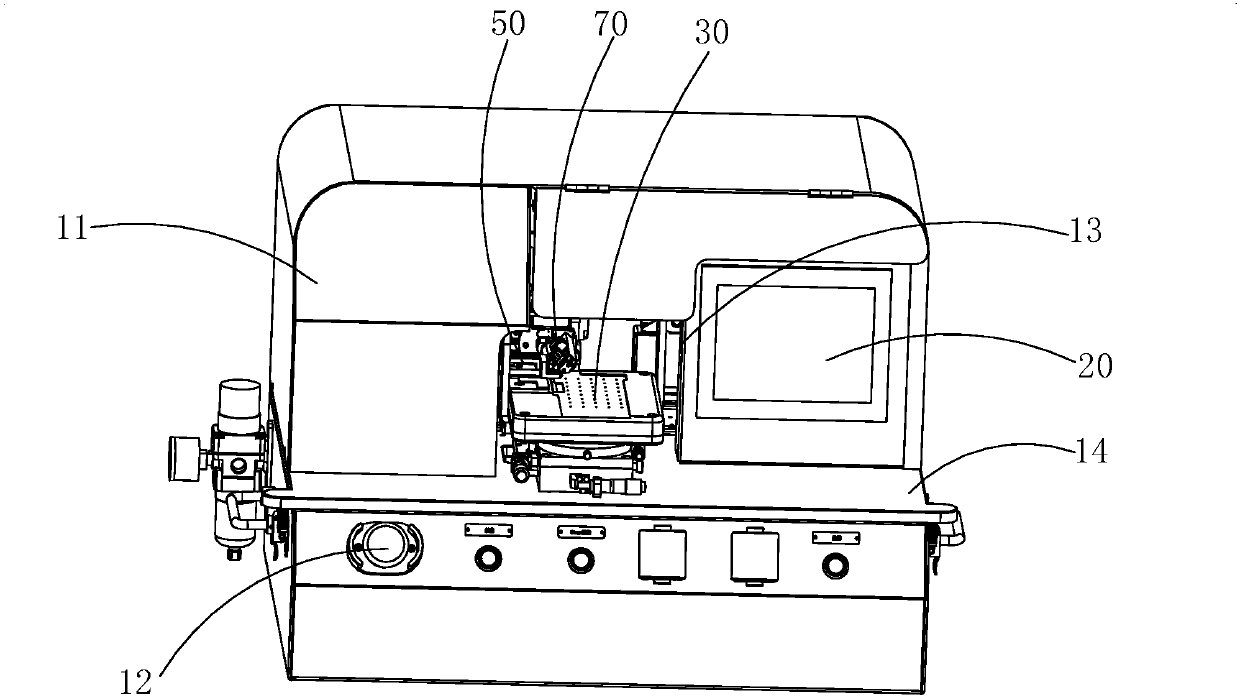

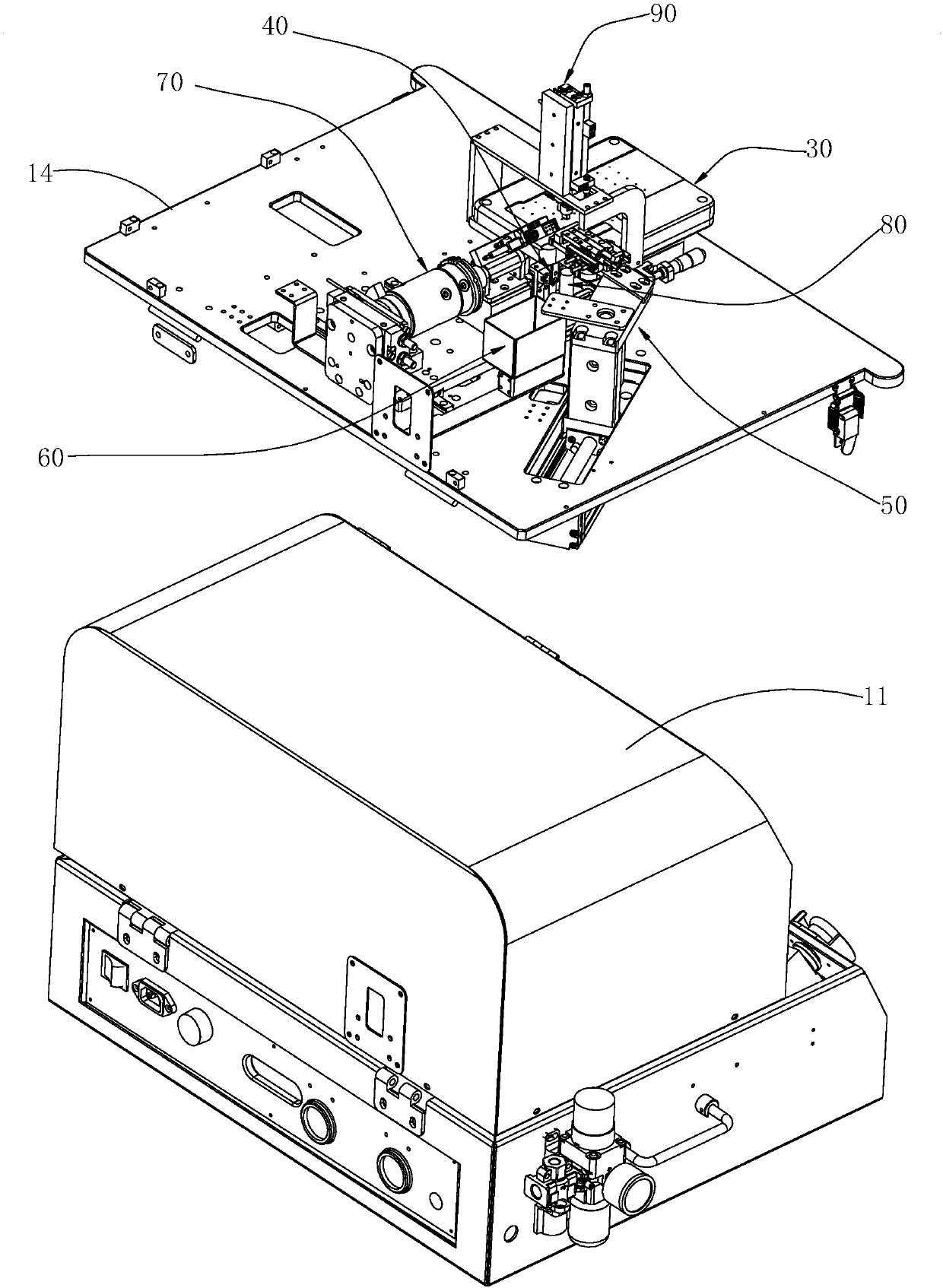

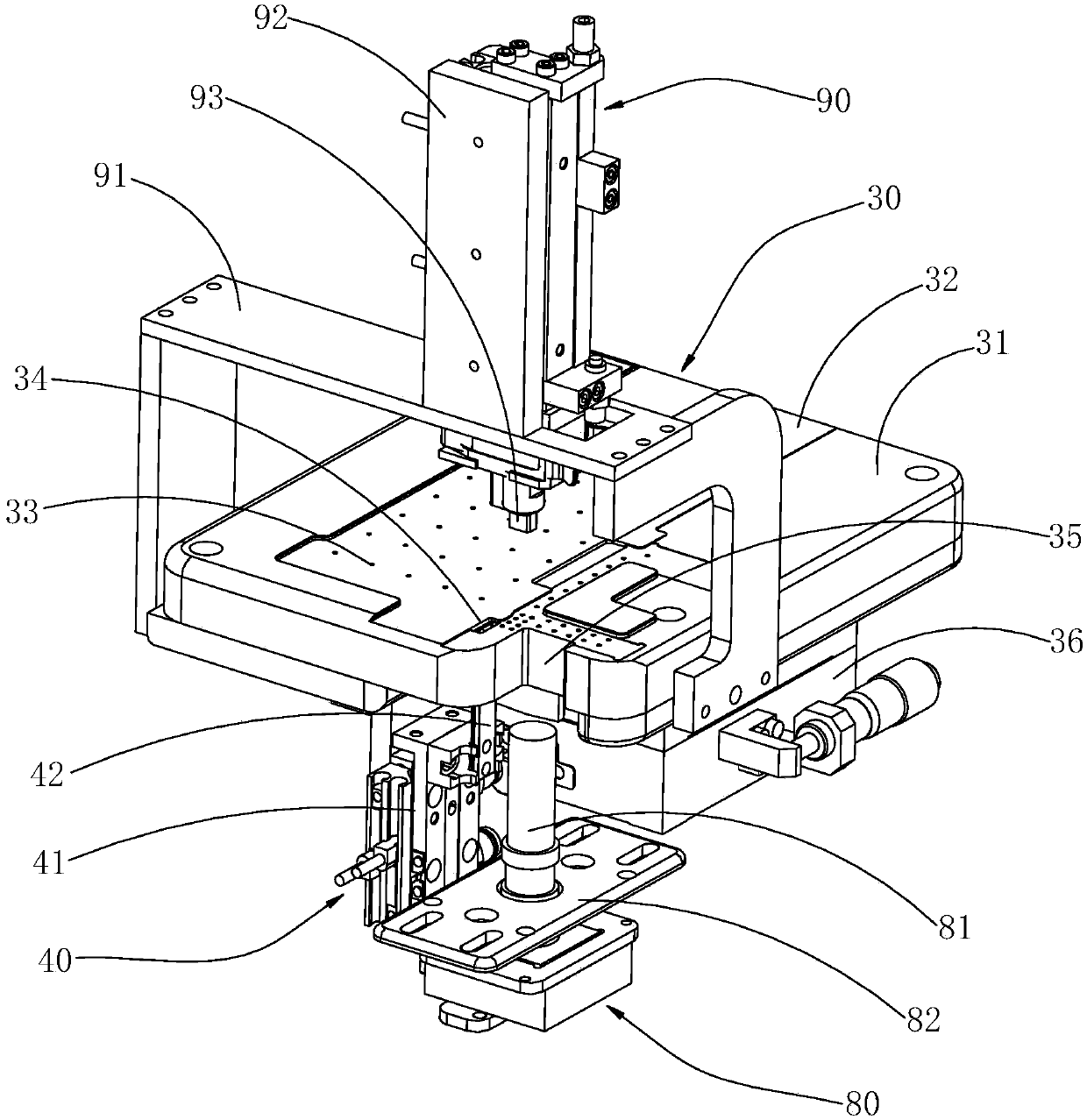

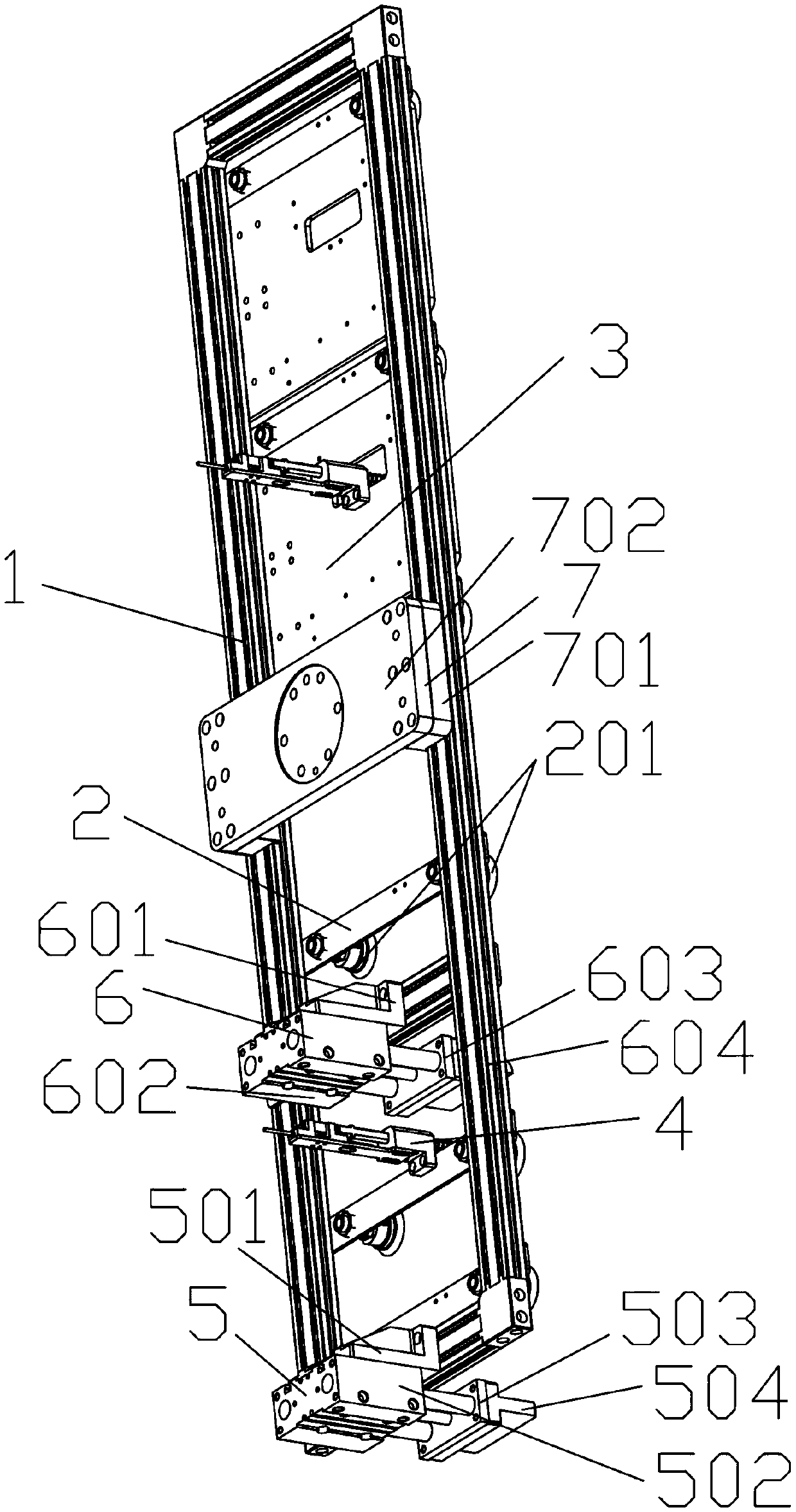

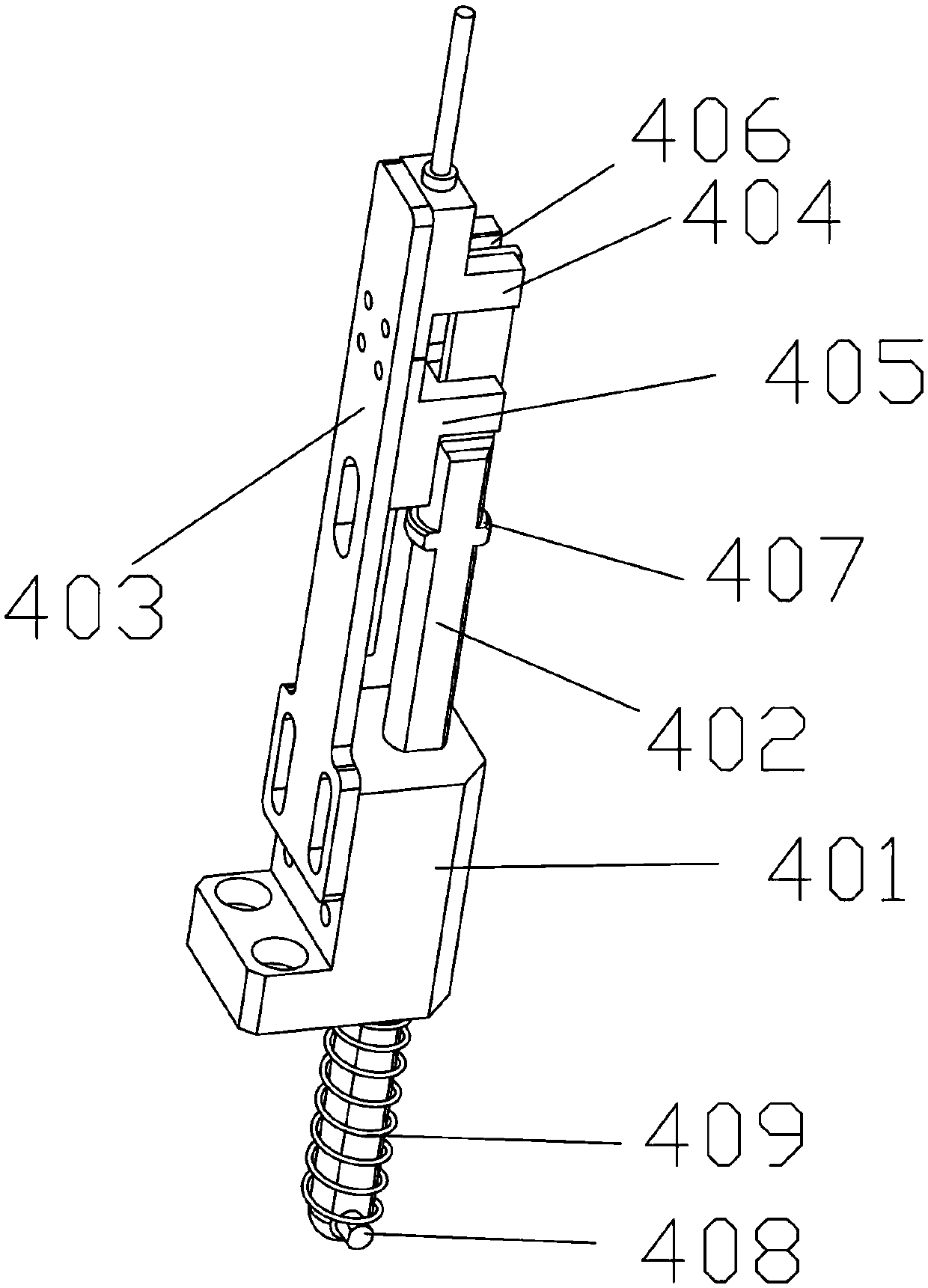

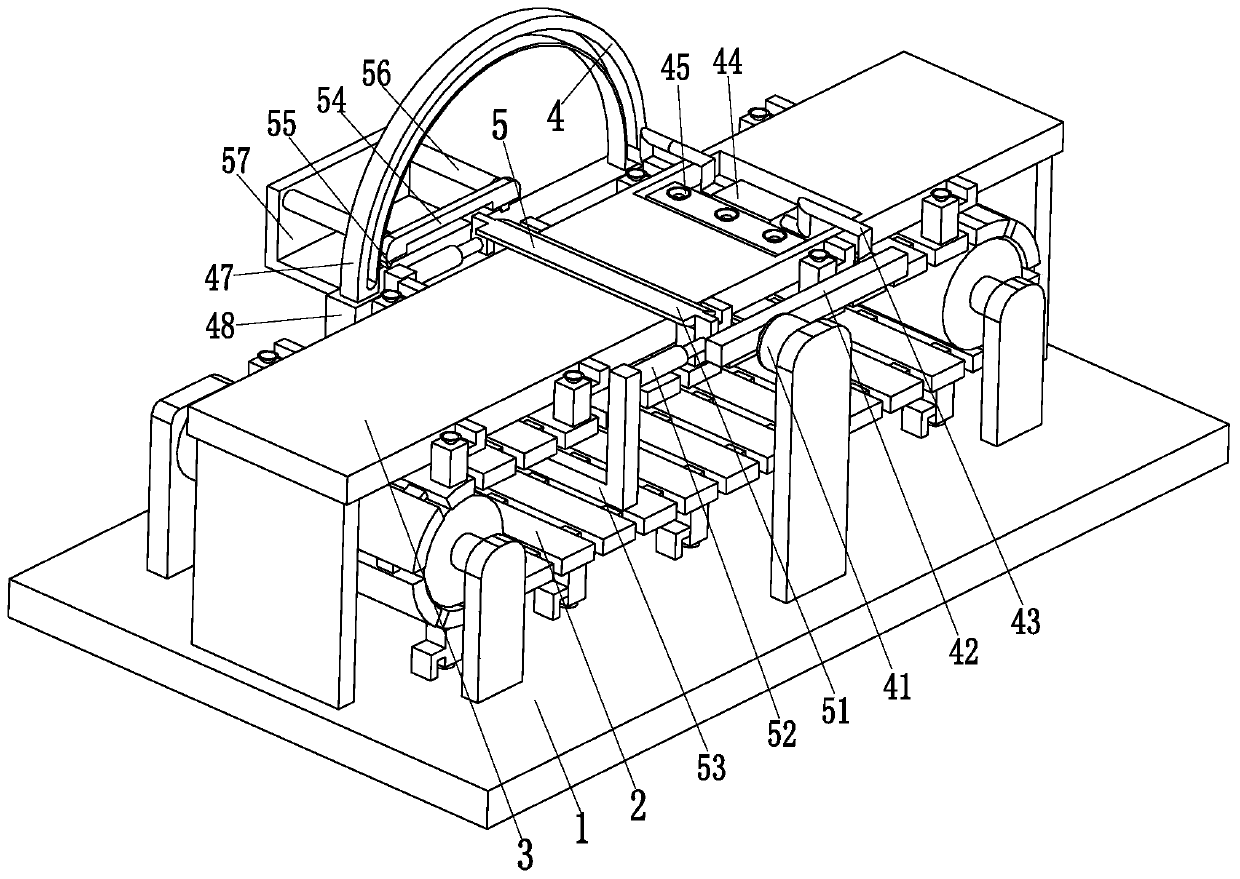

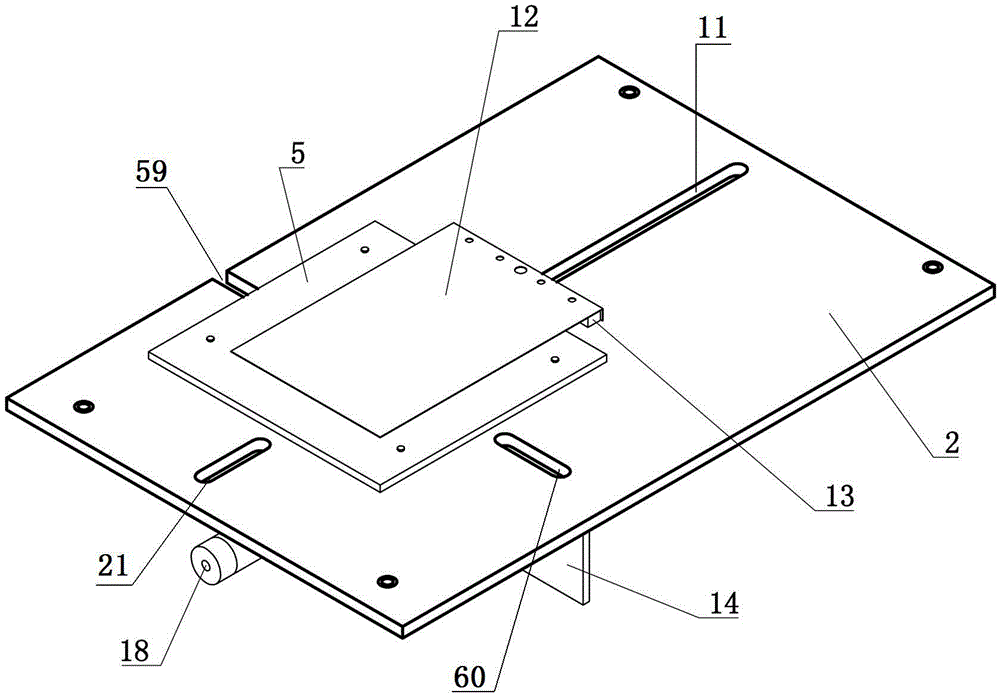

FPC (flexible printed circuit) turnover machine

ActiveCN108112163AAutomatic separationGood adhesionPrinted circuit detailsPrinted circuit aspectsEngineeringMechanical engineering

The invention discloses an FPC (flexible printed circuit) turnover machine, which comprises a test table, a jig, a circuit board pushing and ejecting device, a film tearing device, a turnover device and a laminating device. The jig is fixed on the test table and is located on one side of the test table. The circuit board pushing and ejecting device, the film tearing device, the turnover device andthe laminating device are arranged corresponding to the jig respectively. The jig comprises a jig plate. A product placement area is arranged on one side, away from the test table, of the jig plate.A product fixing structure is arranged on the product placement area. The circuit board pushing and ejecting device is located on one side, close to the test table, of the jig plate. A through hole used for allowing the circuit board pushing and ejecting device to penetrate through is formed in the jig plate. According to the invention, the automatic turnover and forming of an FPC is realized without the manual operation. Therefore, the manual cost is reduced, and the turnover precision is further improved.

Owner:INTERFACE TECH CHENGDU CO LTD +2

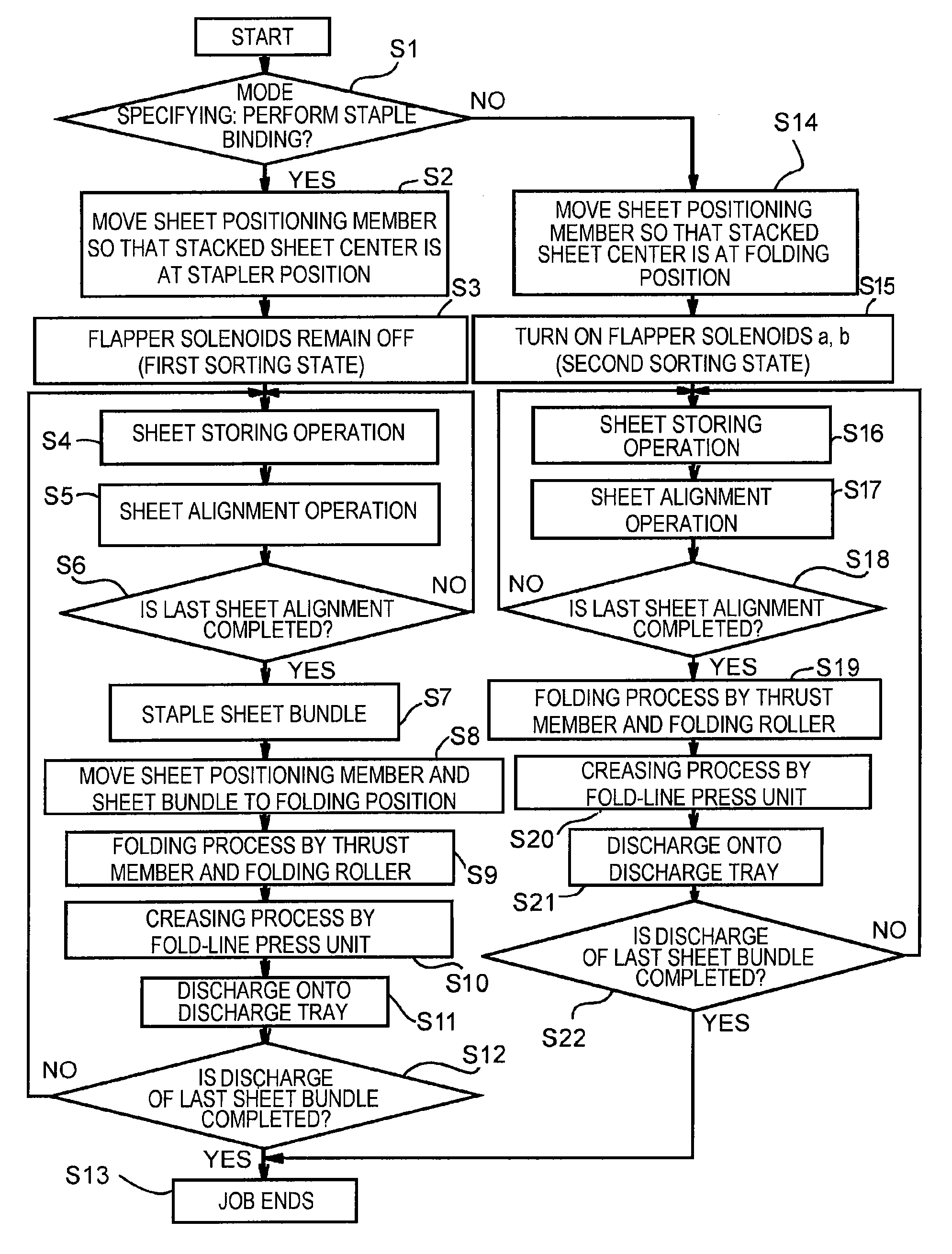

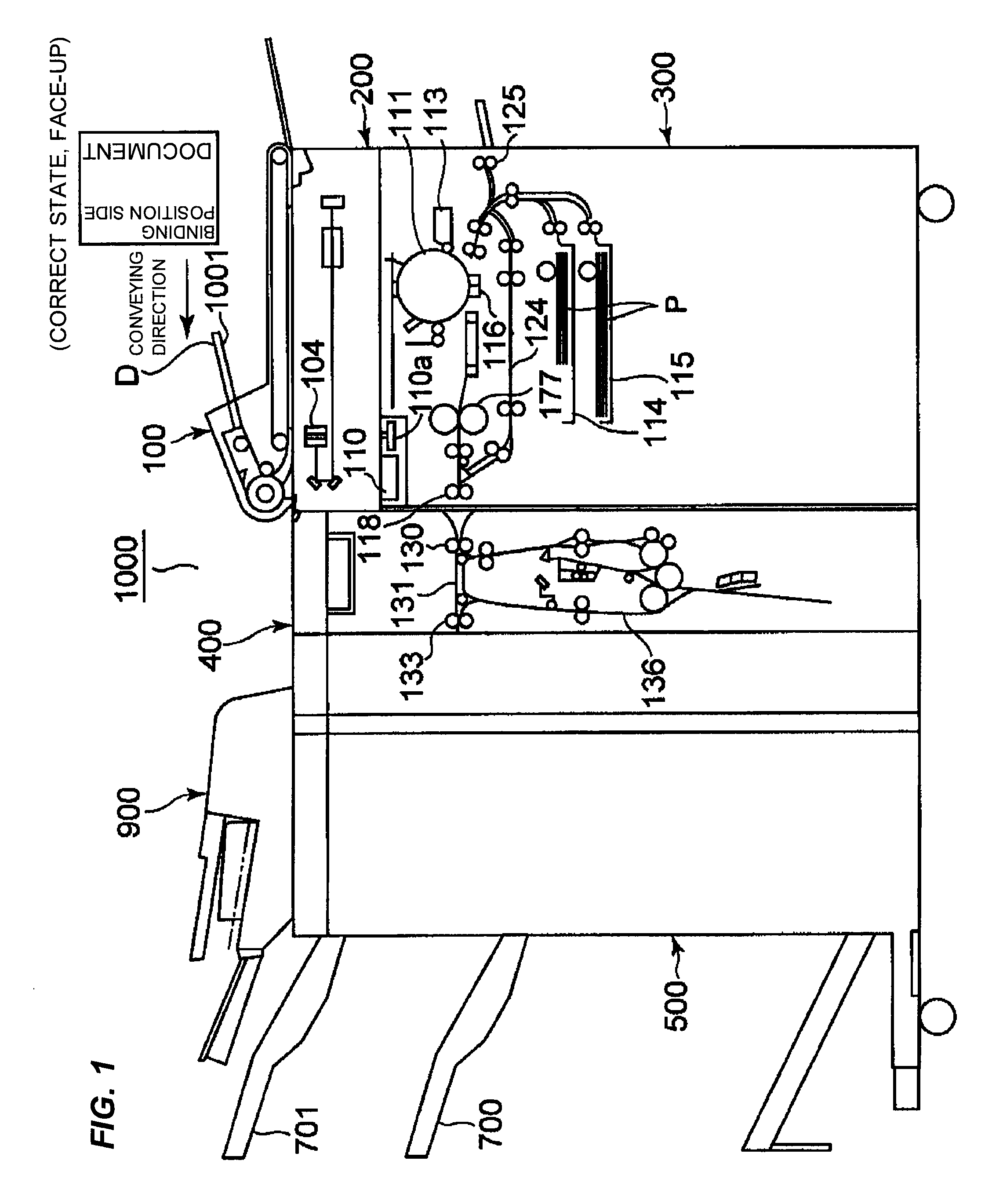

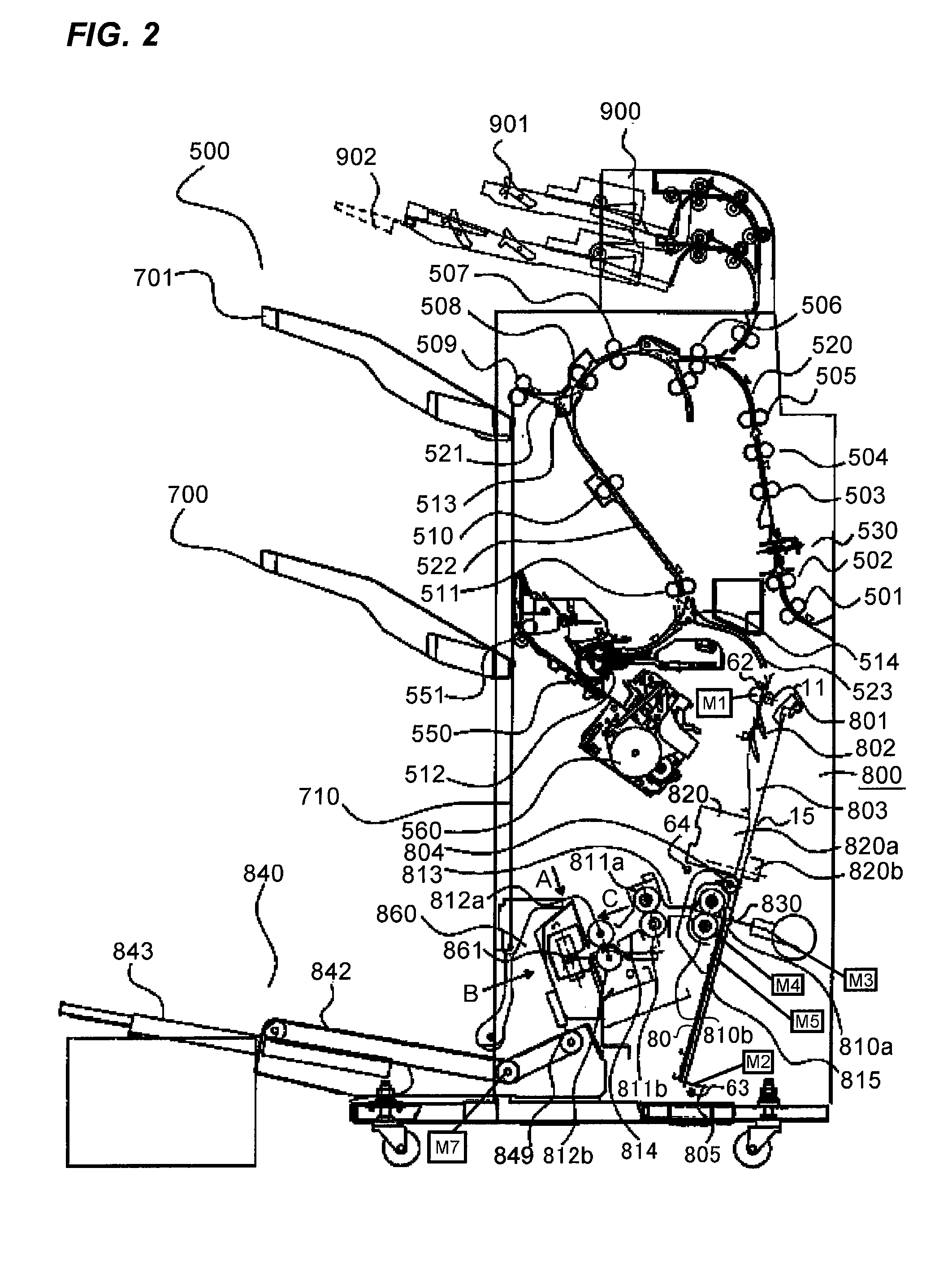

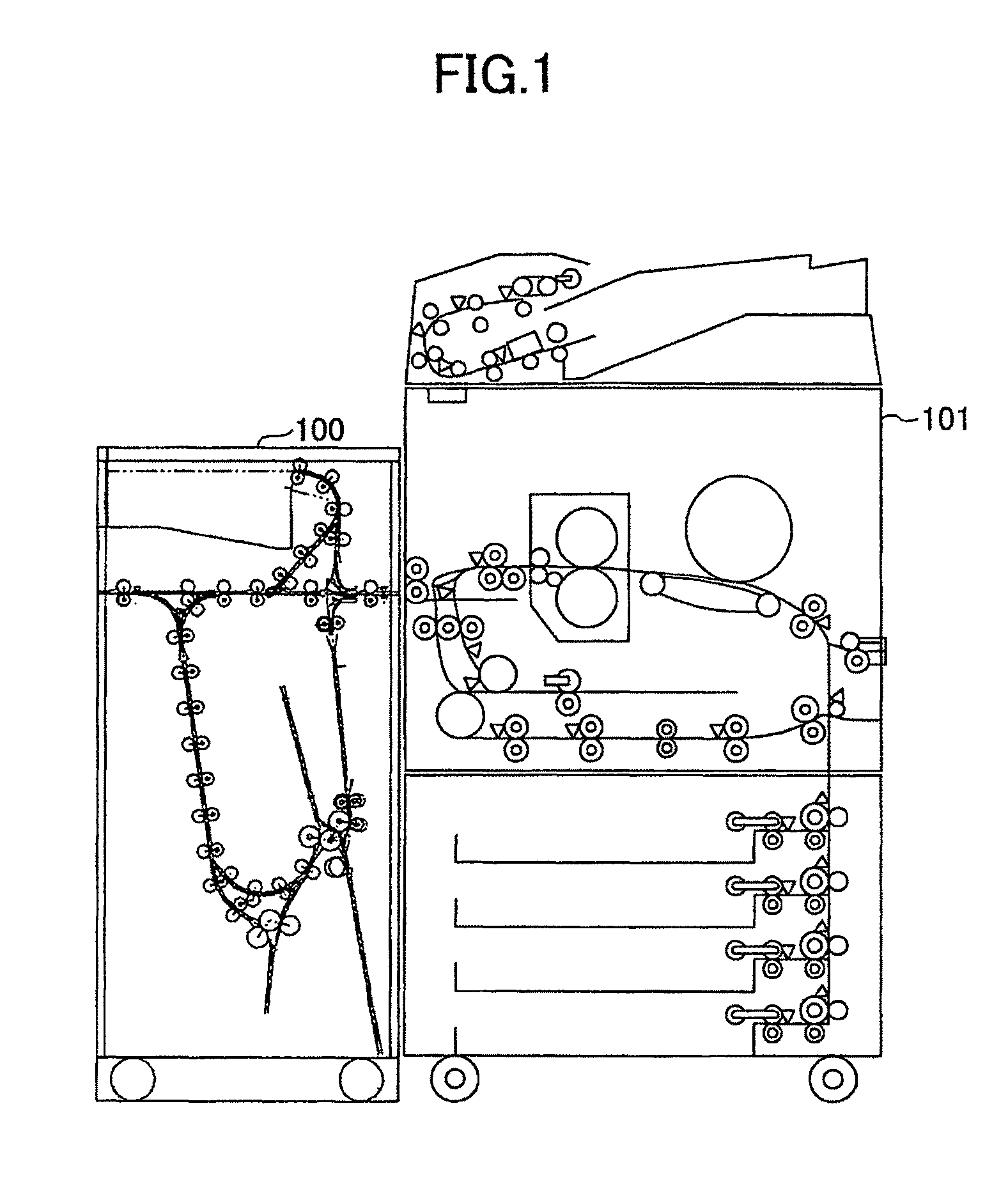

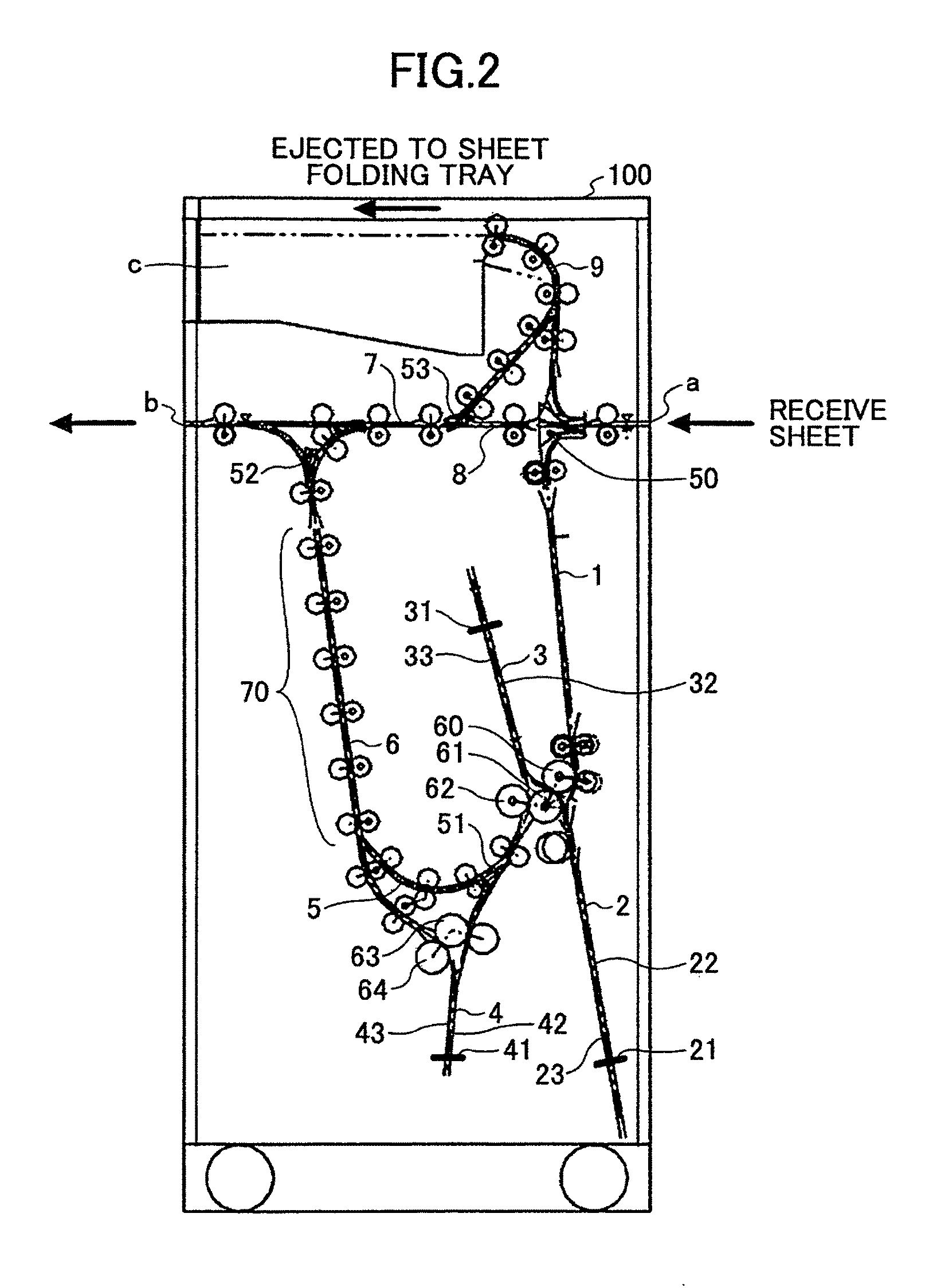

Sheet processing apparatus and image forming apparatus

ActiveUS20100007072A1Improve the accuracy of foldingIncrease productivityFunction indicatorsFolding thin materialsEngineeringTreatment unit

The present invention provides a sheet processing apparatus including: a conveying portion which conveys a sheet; a stacking portion which stacks the sheet conveyed by the conveying portion; a first processing unit which performs a process to the sheet at a first process position on the stacking portion; a second processing unit which performs a process to the sheet at a second process position on the stacking portion, the second process position being at the downstream side in the conveying direction of the first process position; and a controlling portion which performs positioning of the sheet at the first process position when the first processing unit performs the process to the sheet and positioning of the sheet at the second process position when the second processing unit performs the process to the sheet which is passed through the first process position without being positioned.

Owner:CANON KK

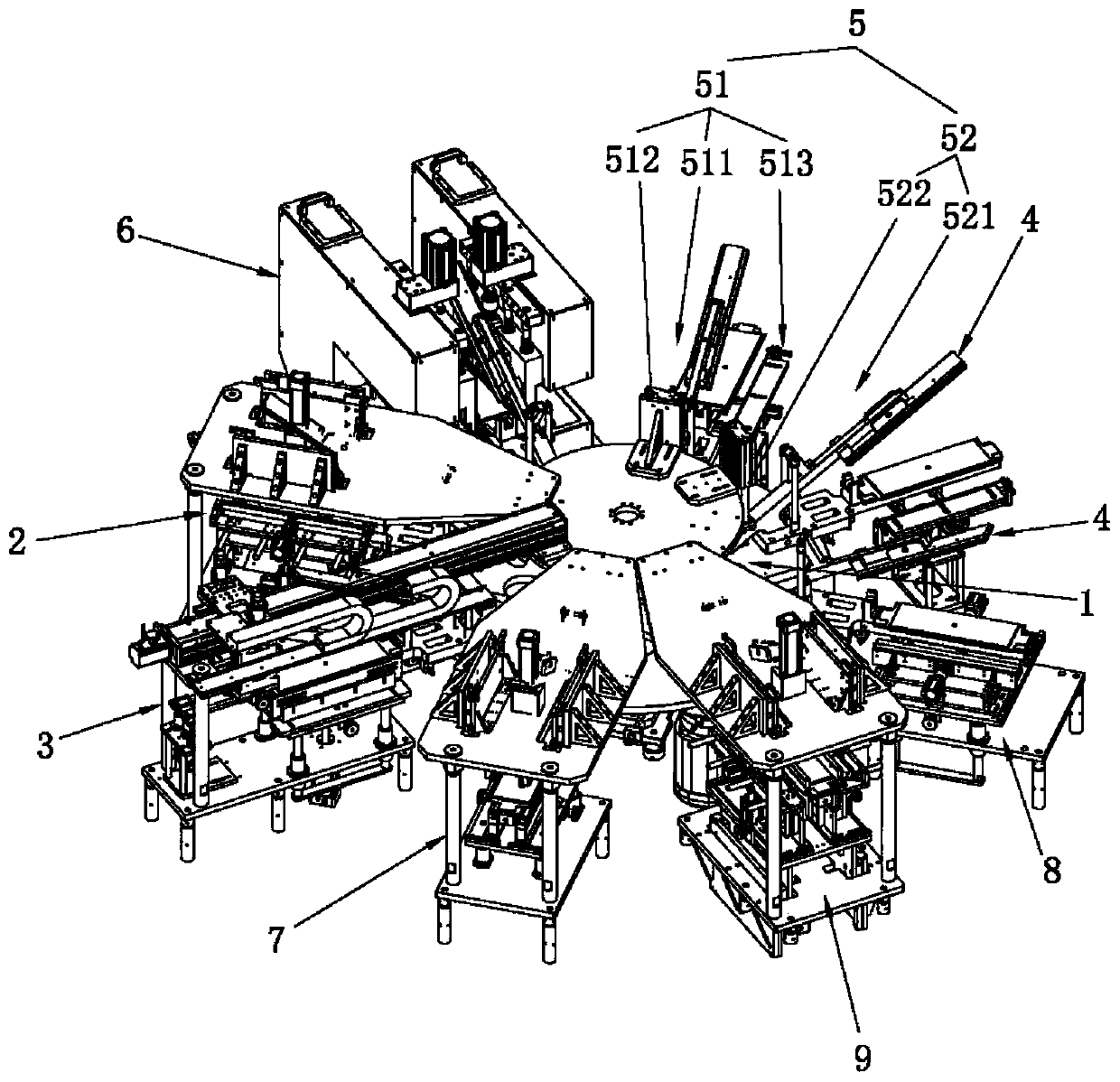

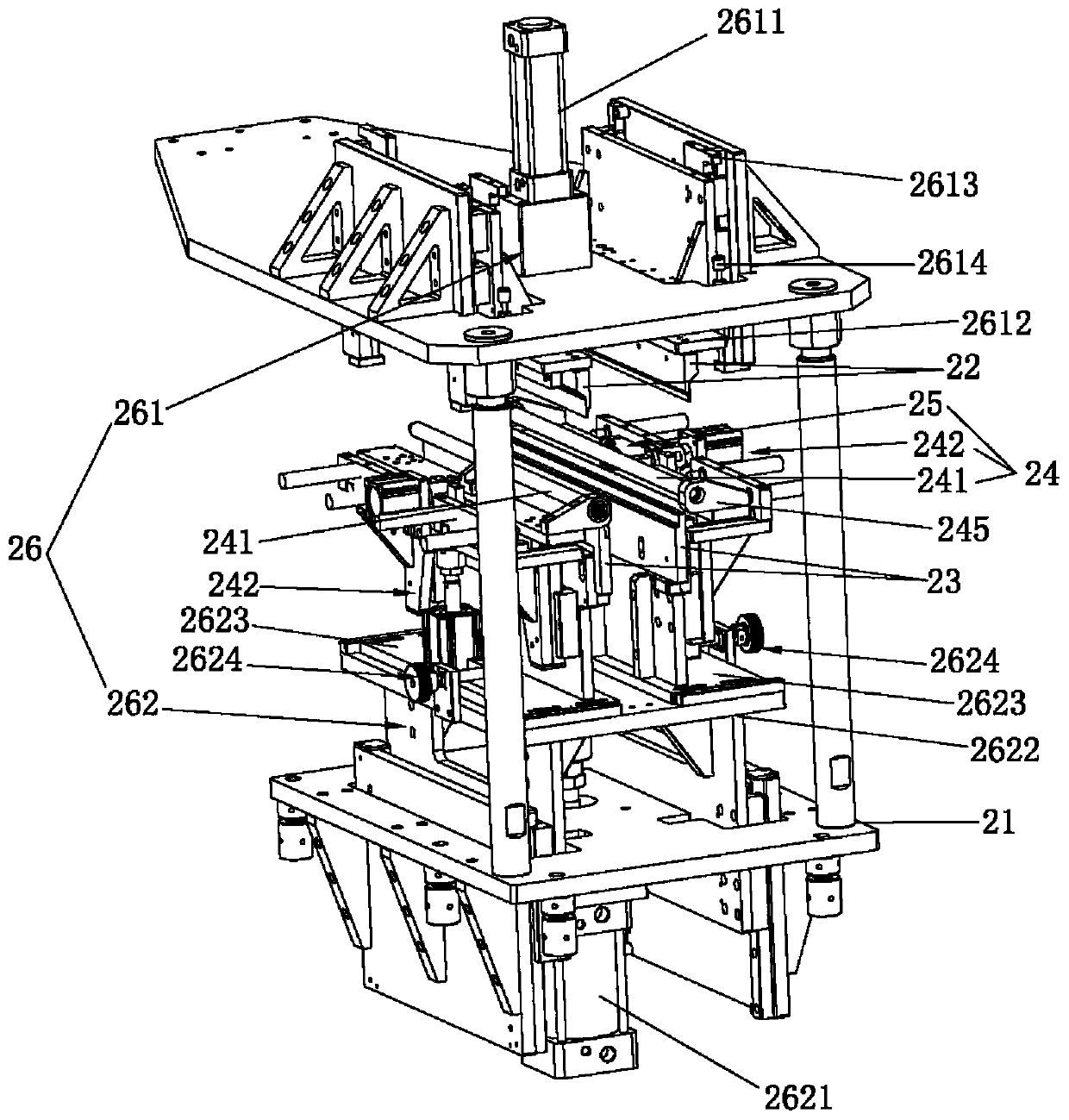

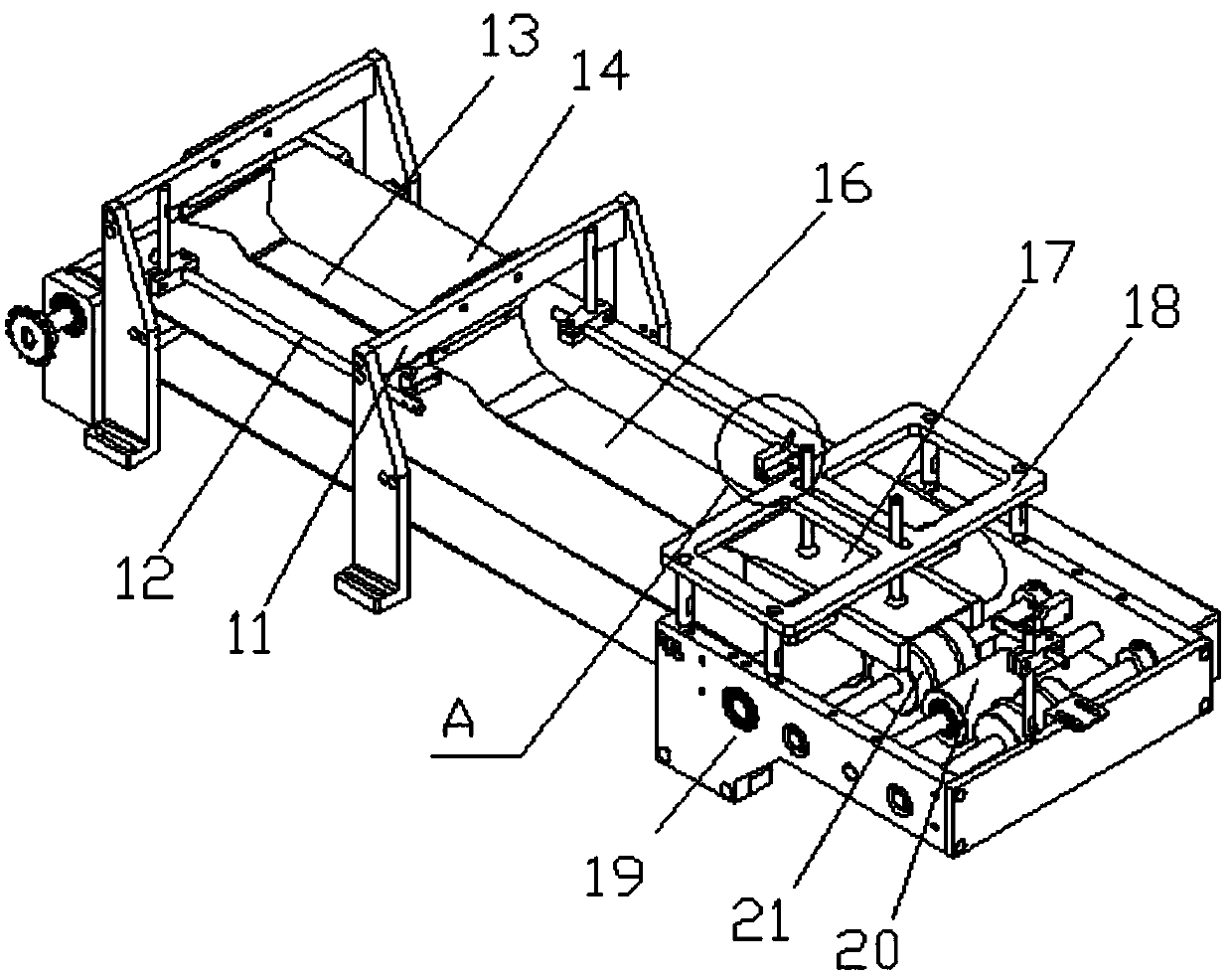

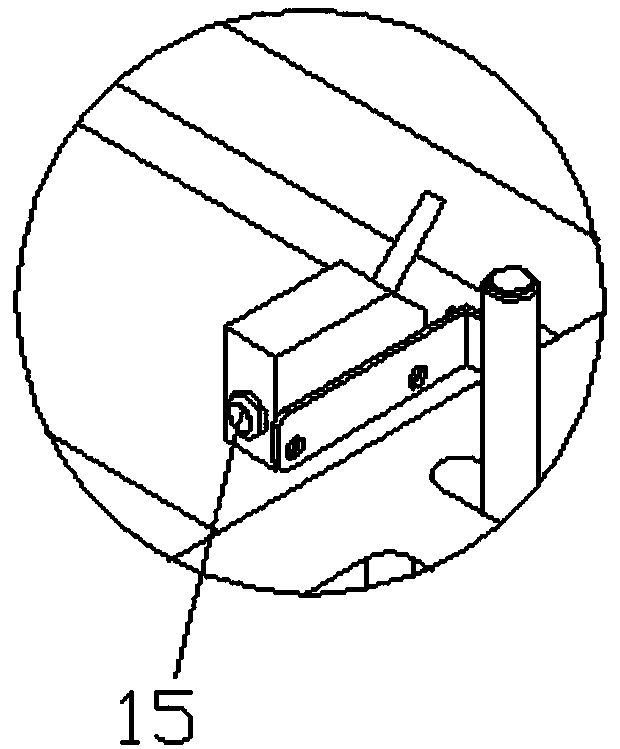

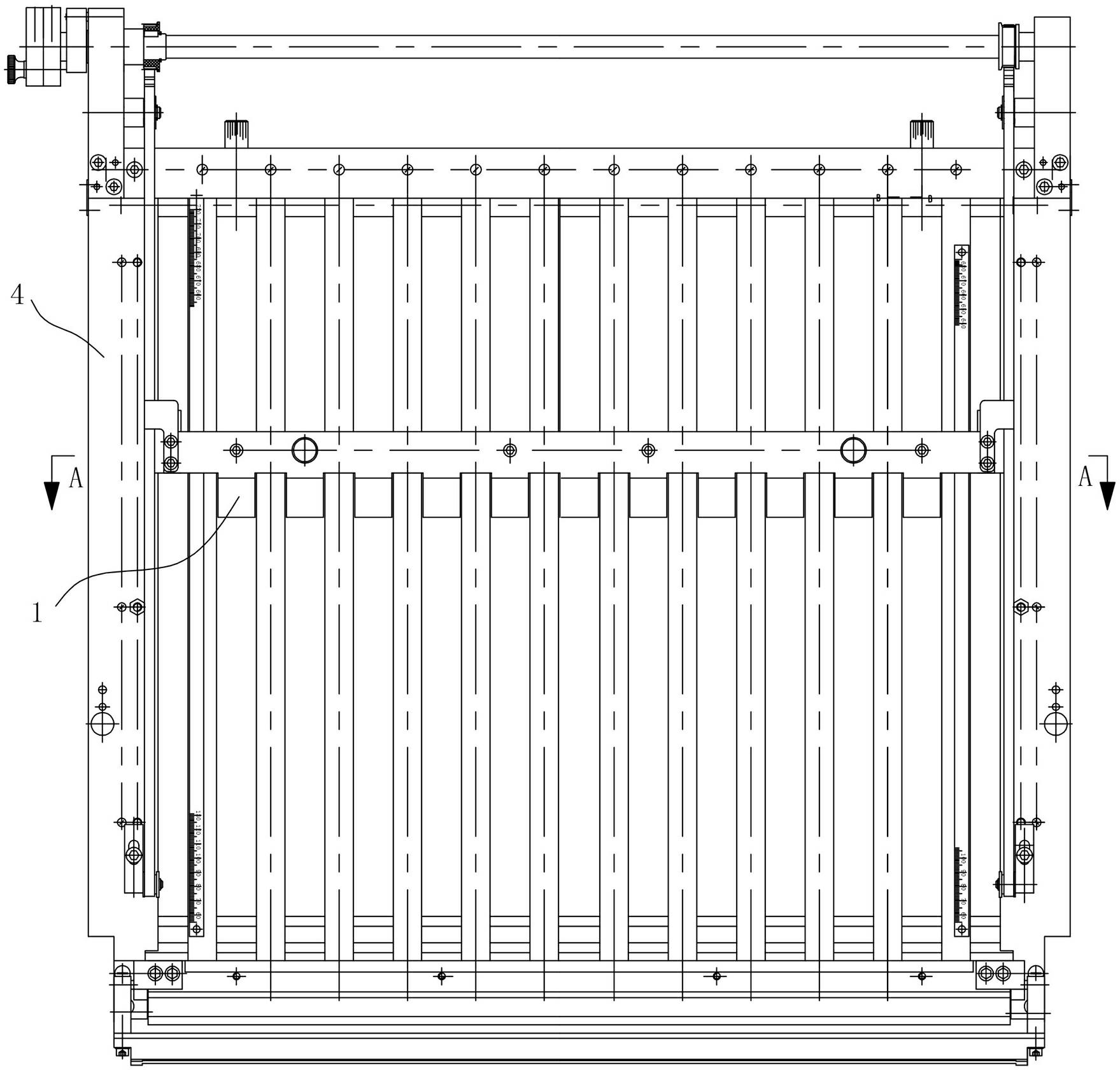

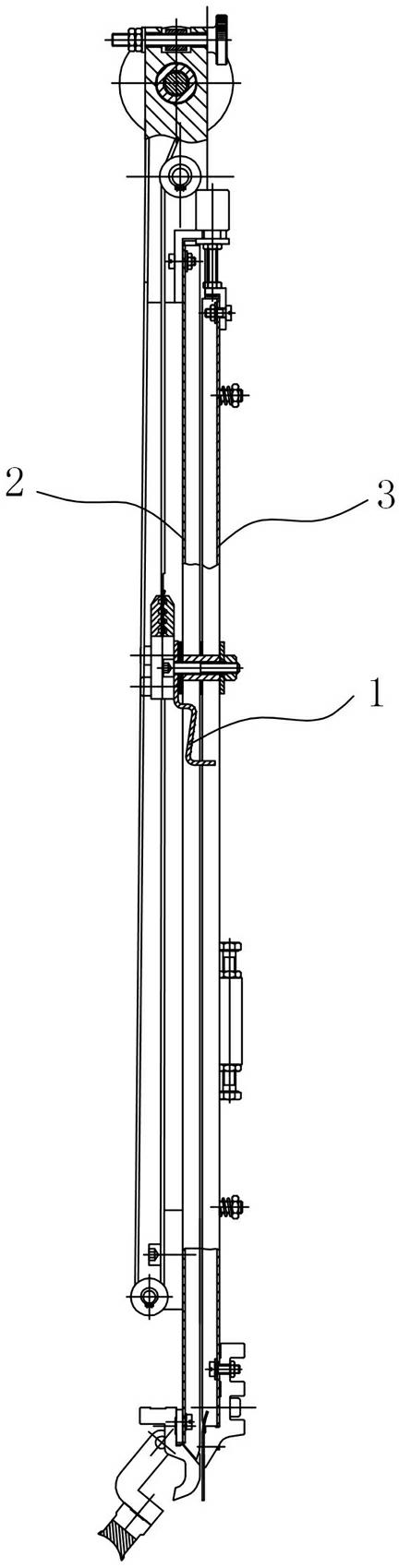

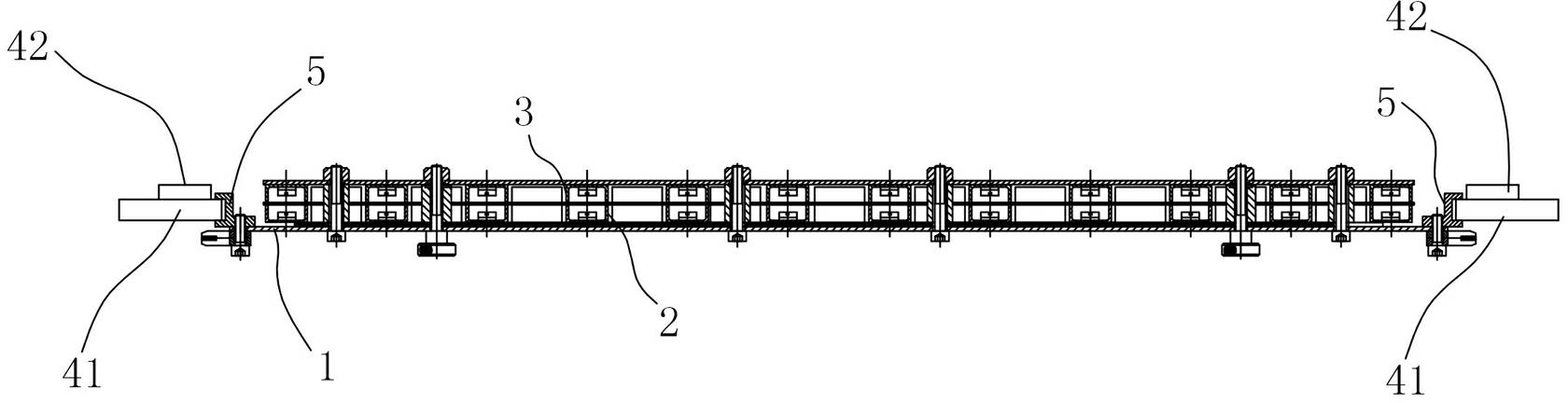

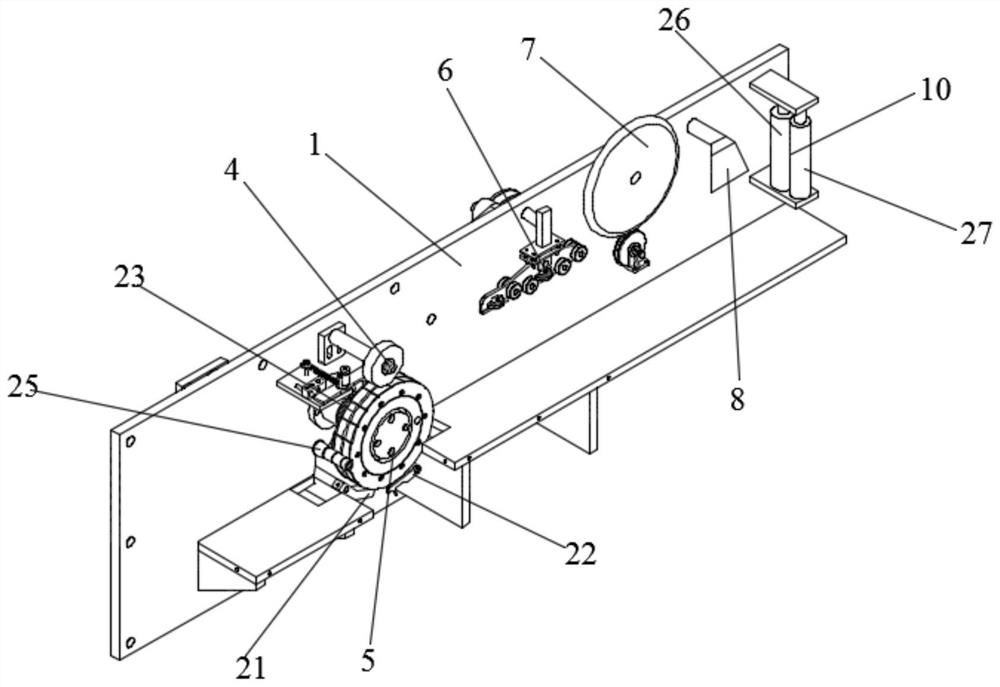

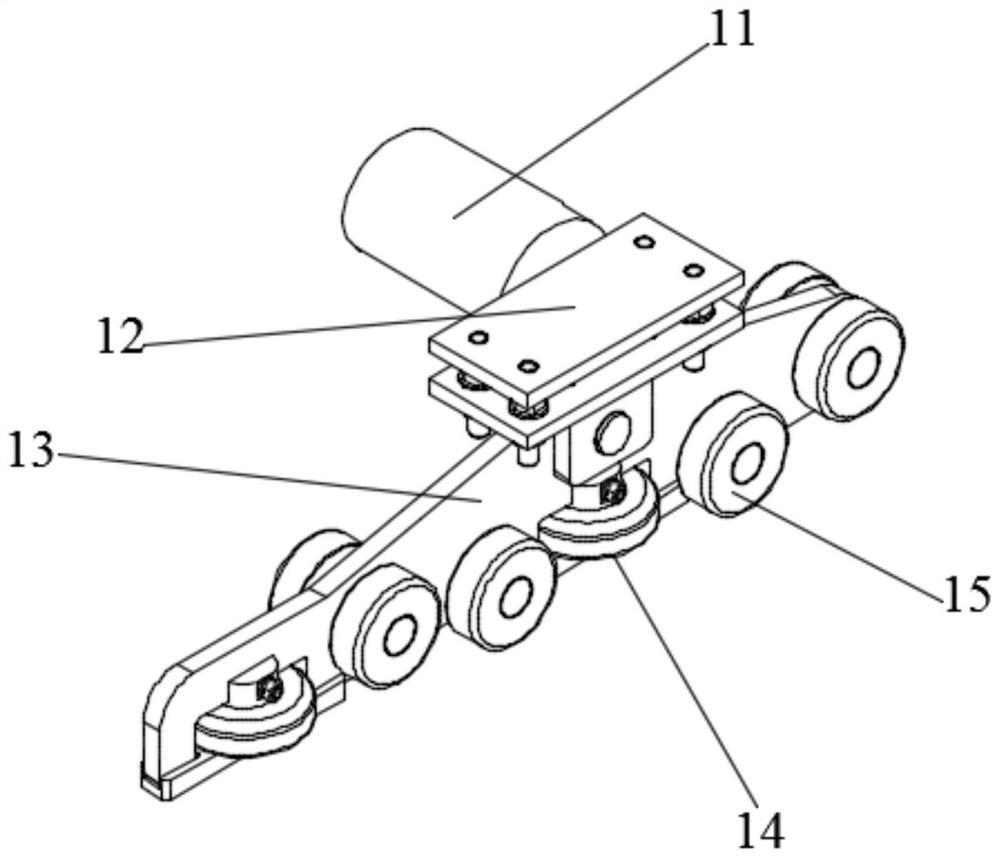

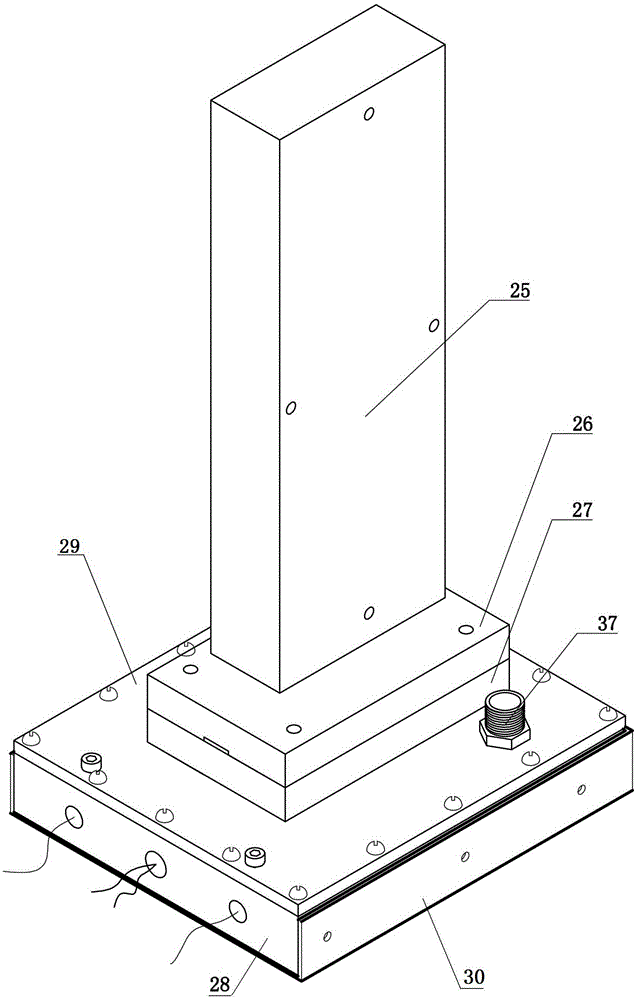

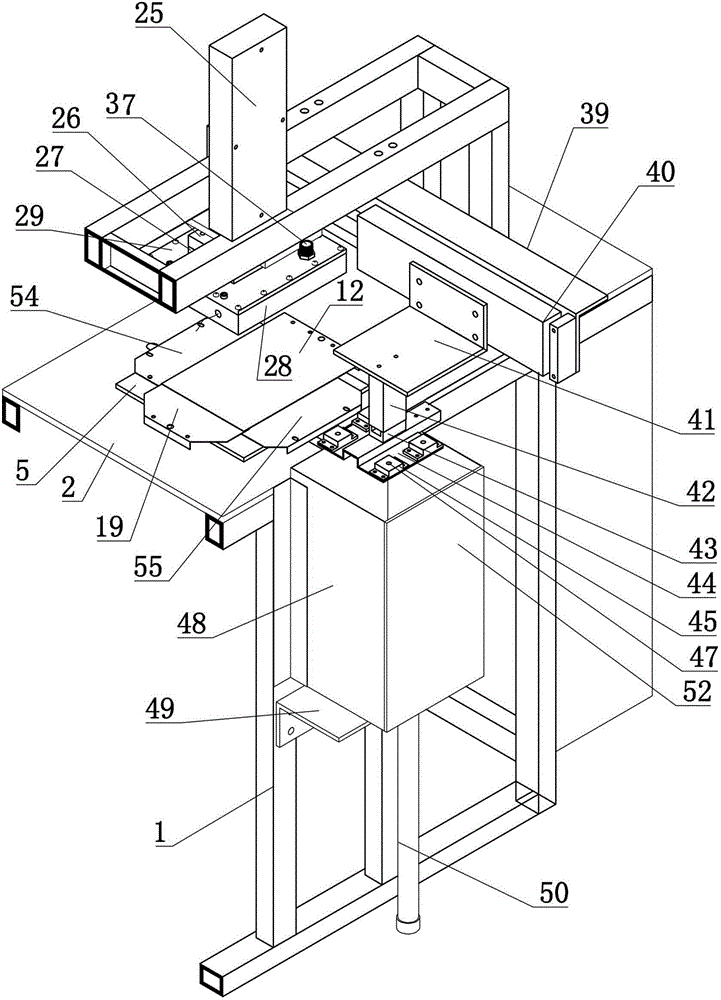

Edge folding equipment and edge folding method thereof

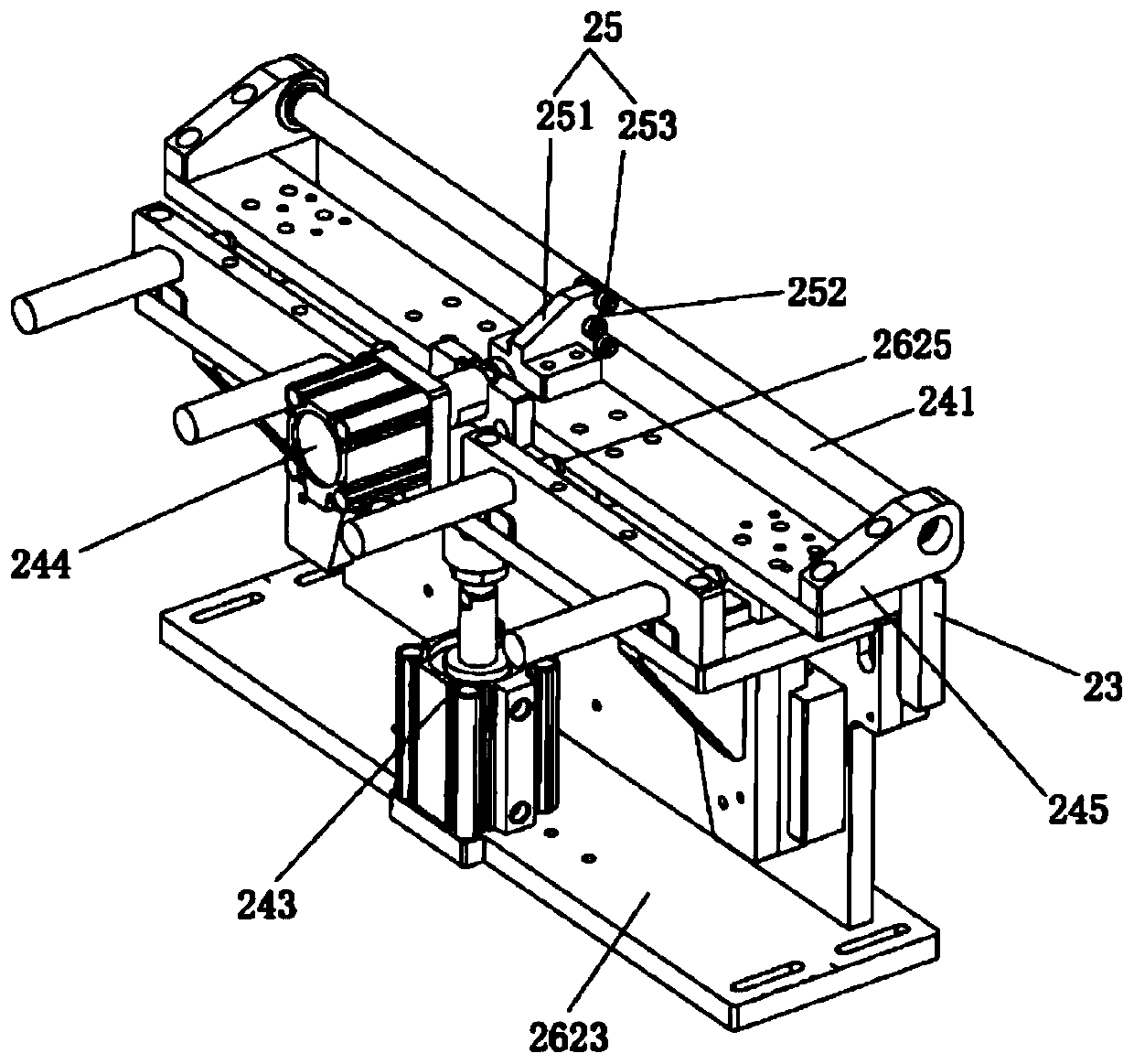

PendingCN111509289AGuaranteed positioning accuracyGuaranteed positional stabilityFinal product manufactureElectrolyte accumulators manufactureMechanical engineeringBattery cell

The invention relates to the technical field of battery production, in particular to edge flanging equipment and an edge flanging method thereof. The edge flanging equipment comprises a circulating conveying device, a plurality of clamping devices and a feeding and discharging device, an edge cutting device, a first edge folding device, a second edge folding device, a hot pressing device, a thirdedge folding device and a shaping device which are sequentially arranged on the periphery of the circulating conveying device. The circulating conveying device is used for conveying the multiple clamping devices to sequentially move to the feeding and discharging device, the edge shearing device, the first edge folding device, the second edge folding device, the hot pressing device, the third edgefolding device and the shaping device. According to the invention, feeding, edge cutting, 90-degree edge folding, 180-degree edge folding, hot-pressing shaping, 270-degree edge folding, shaping and discharging of the battery are automatically realized; the battery edge folding device is high in automation degree and edge folding efficiency, labor intensity and labor cost are reduced, a battery isclamped on the clamping device all the time in the whole edge folding process, the position precision and stability of the battery are guaranteed, the edge folding precision is high, the edge foldingquality is good, and the quality of the battery after edge folding is guaranteed.

Owner:DONGGUAN CHAOYE PRECISION EQUIPMENT CO LTD

Sheet processing apparatus and image forming apparatus

InactiveUS8534660B2Improve the accuracy of foldingMechanical working/deformationFolding thin materialsImage formationEngineering

Disclosed is a sheet processing apparatus that forms folding lines at a predetermined position of a sheet after image formation and outputs the sheet. The apparatus includes a contact unit with which a tip end or a rear end of the conveyed sheet comes into contact and by which a deflection is formed at a middle part of the sheet; folding units that form the folding lines by conveying the middle part of the sheet, at which the deflection is formed by the contact unit, between the folding units; and a deflection controlling unit that controls the deflection at the middle part of the sheet formed by the contact unit.

Owner:RICOH KK

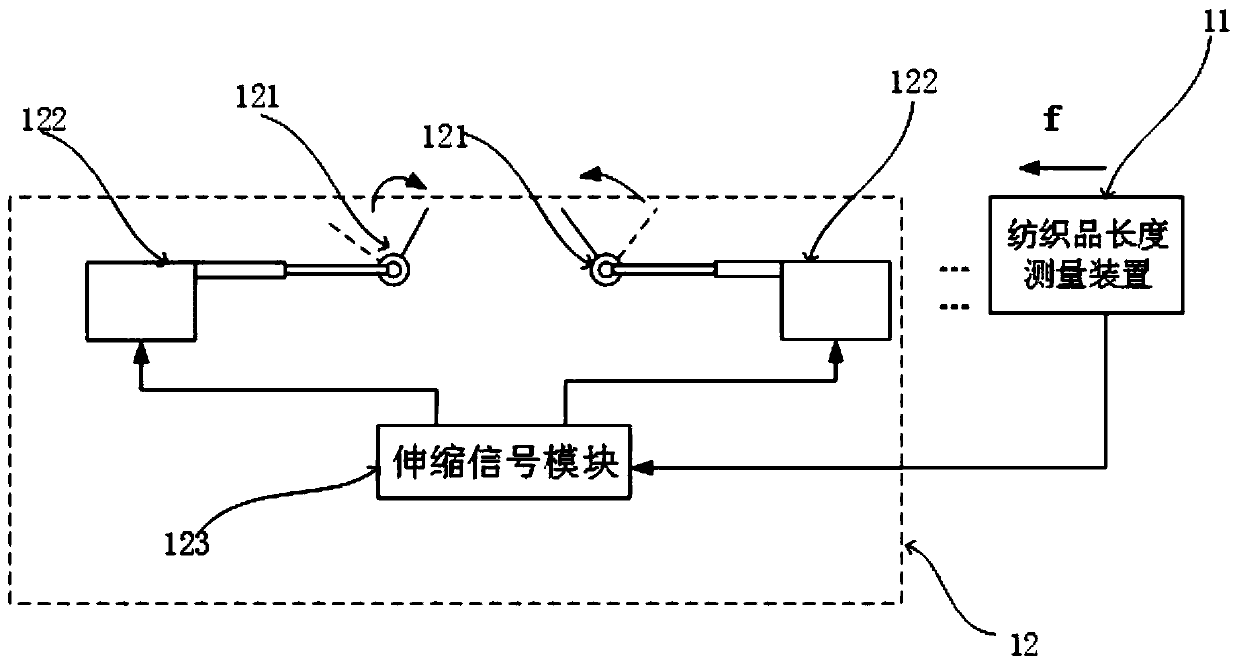

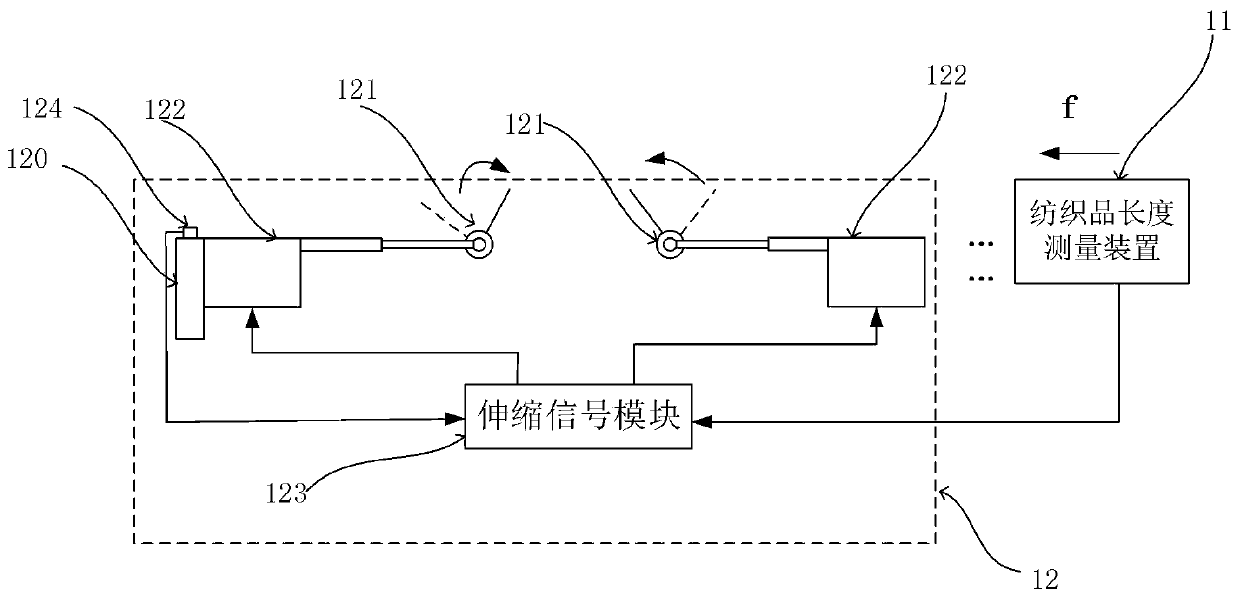

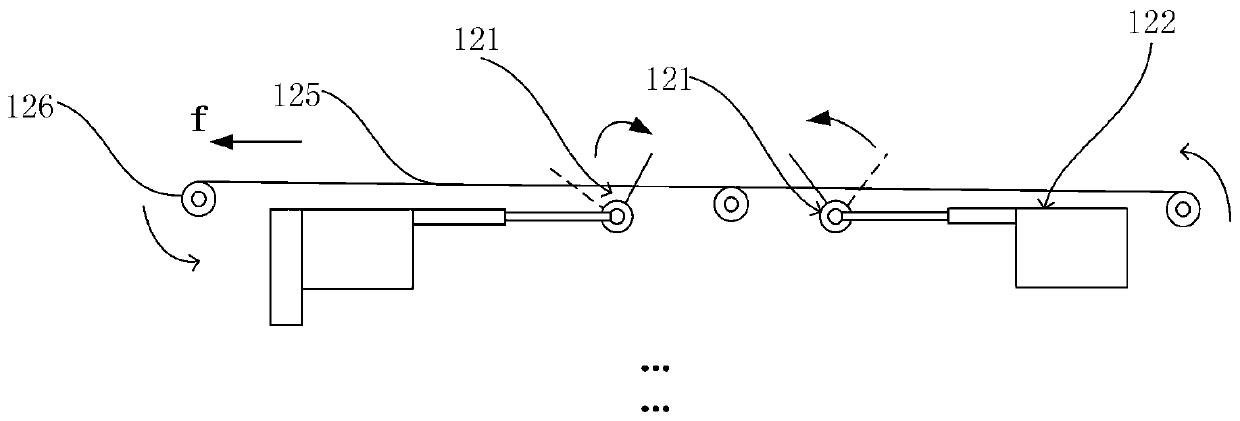

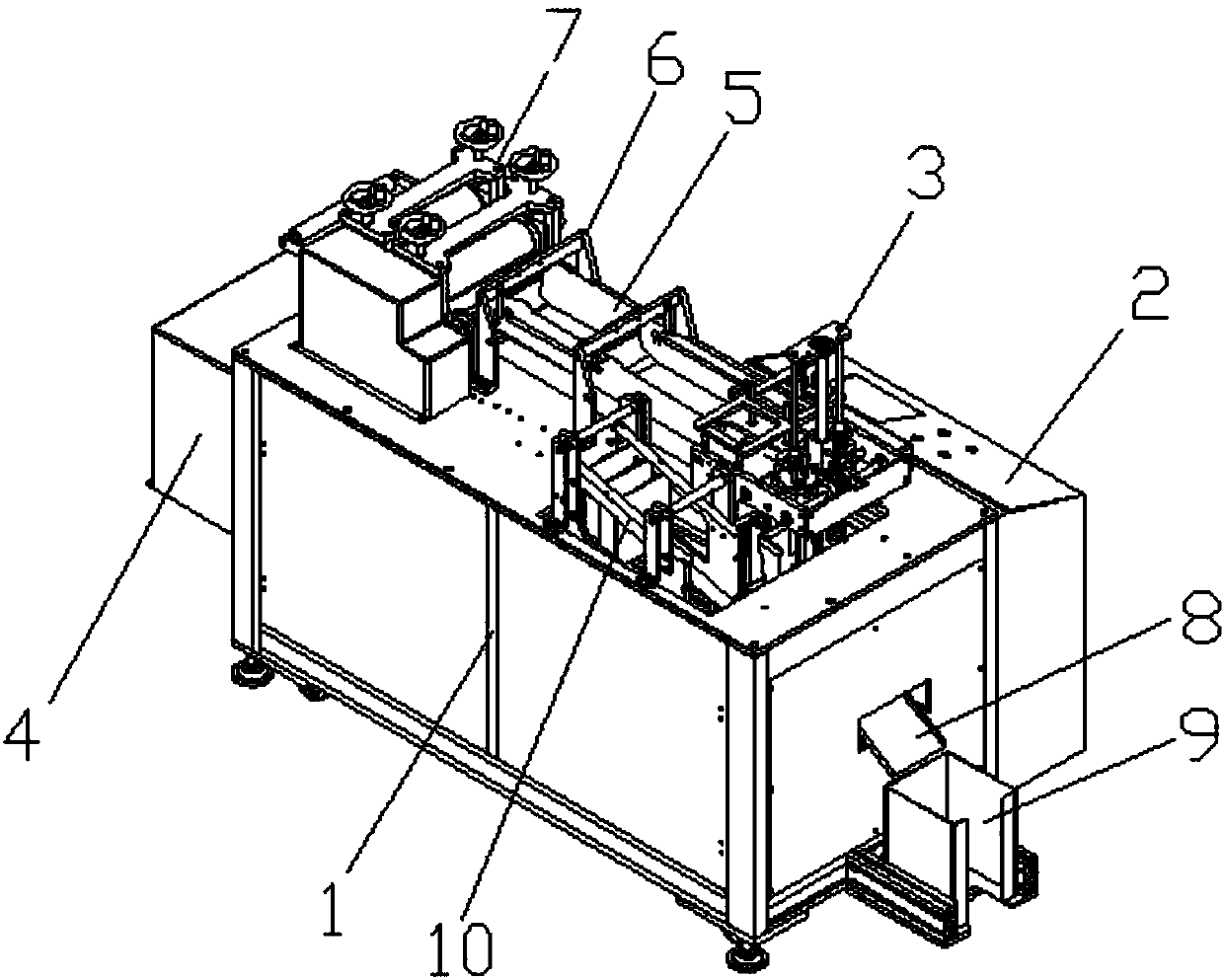

Automatic textile folding machine

InactiveCN110329836AEasy alignmentImprove the accuracy of foldingFolding thin materialsAgricultural engineeringLinkage concept

The invention discloses an automatic textile folding machine, a textile length measuring device and a longitudinal folding device, wherein the textile length measuring device is located on the feedingside of the longitudinal folding device; the longitudinal folding device comprises a longitudinal folding body, two or more folding mechanisms, telescopic linkages and telescopic signal modules; eachfolding mechanism is connected with the longitudinal folding body through the telescopic linkages; the textile length measuring device and the telescopic linkages are both electrically connected withthe telescopic signal module; and the telescopic signal module adjusts distances between two or more folding mechanisms. Through measuring textile length and adjusting the distances between the folding mechanisms, folded turf can be aligned well; and folding precision is high.

Owner:四川德才汇实业有限公司

Full-automatic mask folding packer

InactiveCN107826299AEasy to operateIncrease productivityPaper article packagingEngineeringHigh productivity

The invention relates to a fully automatic facial mask folding packaging machine, which includes a frame and a control box. A conveying mechanism is arranged on the frame. The conveying mechanism includes a conveyor belt arranged on the frame. Mechanism, half-folding bag mechanism, the feeding mechanism is set on the upper left of the conveyor belt, the half-folding bag mechanism is set on the upper right of the conveyor belt, and the front side of the half-folding bag mechanism is provided on the frame to cooperate with the half-folding bag mechanism The packaging bag material guide mechanism, conveying mechanism, feeding mechanism, folding mechanism, half-folding bag-in mechanism, and packaging bag material guiding mechanism are all connected to the control box; the product is folded in half by starting the folding mechanism, and the product is folded twice before entering From the fold-in-bag mechanism, the mask product is automatically loaded into the packaging bag after the third fold is completed, realizing a fully automatic mask folding packaging machine that is easy to operate, stable and reliable, and has high production efficiency.

Owner:DONGGUAN UNIV OF TECH

Box-opening clamping jaw

Owner:BOZHON PRECISION IND TECH CO LTD

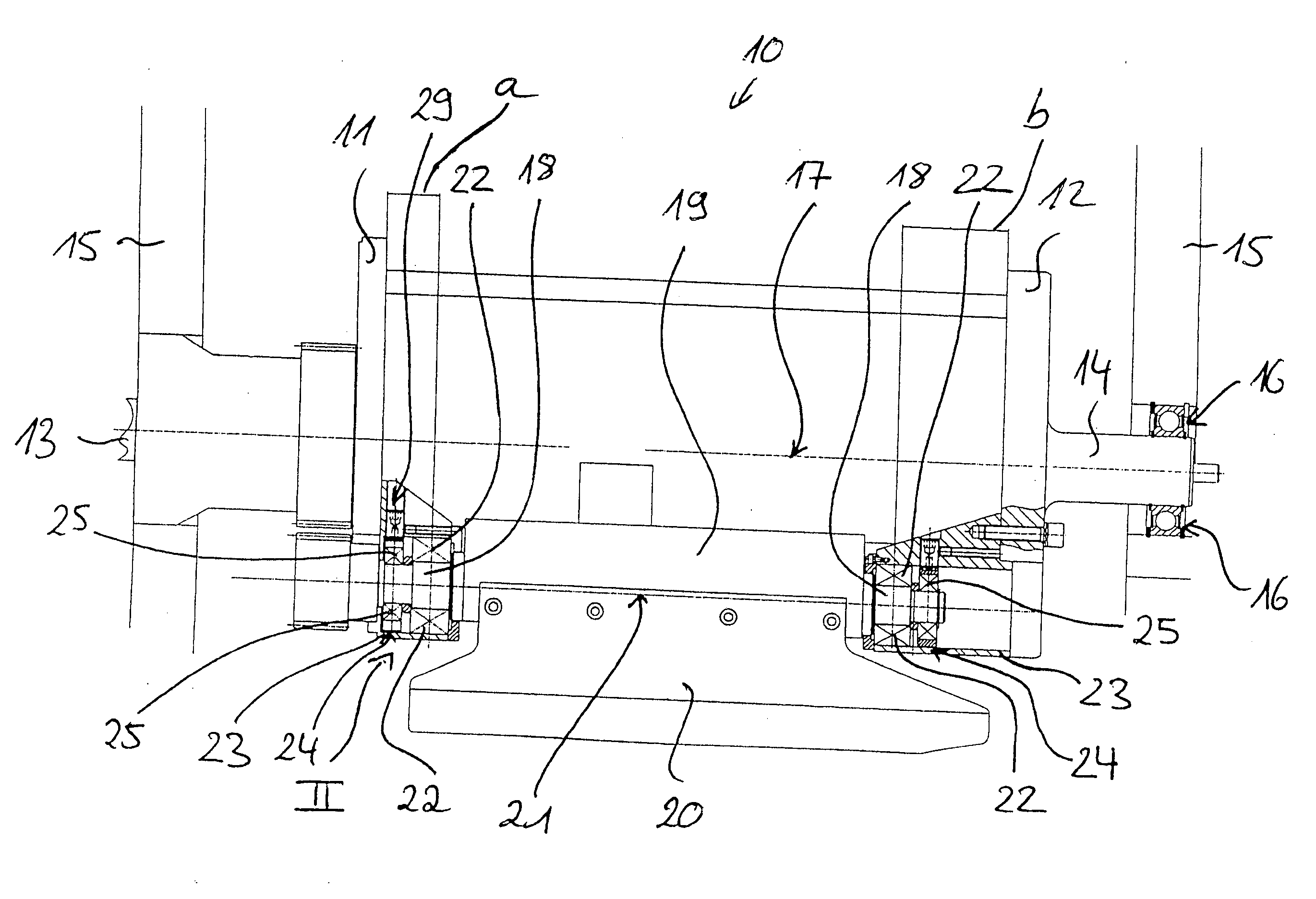

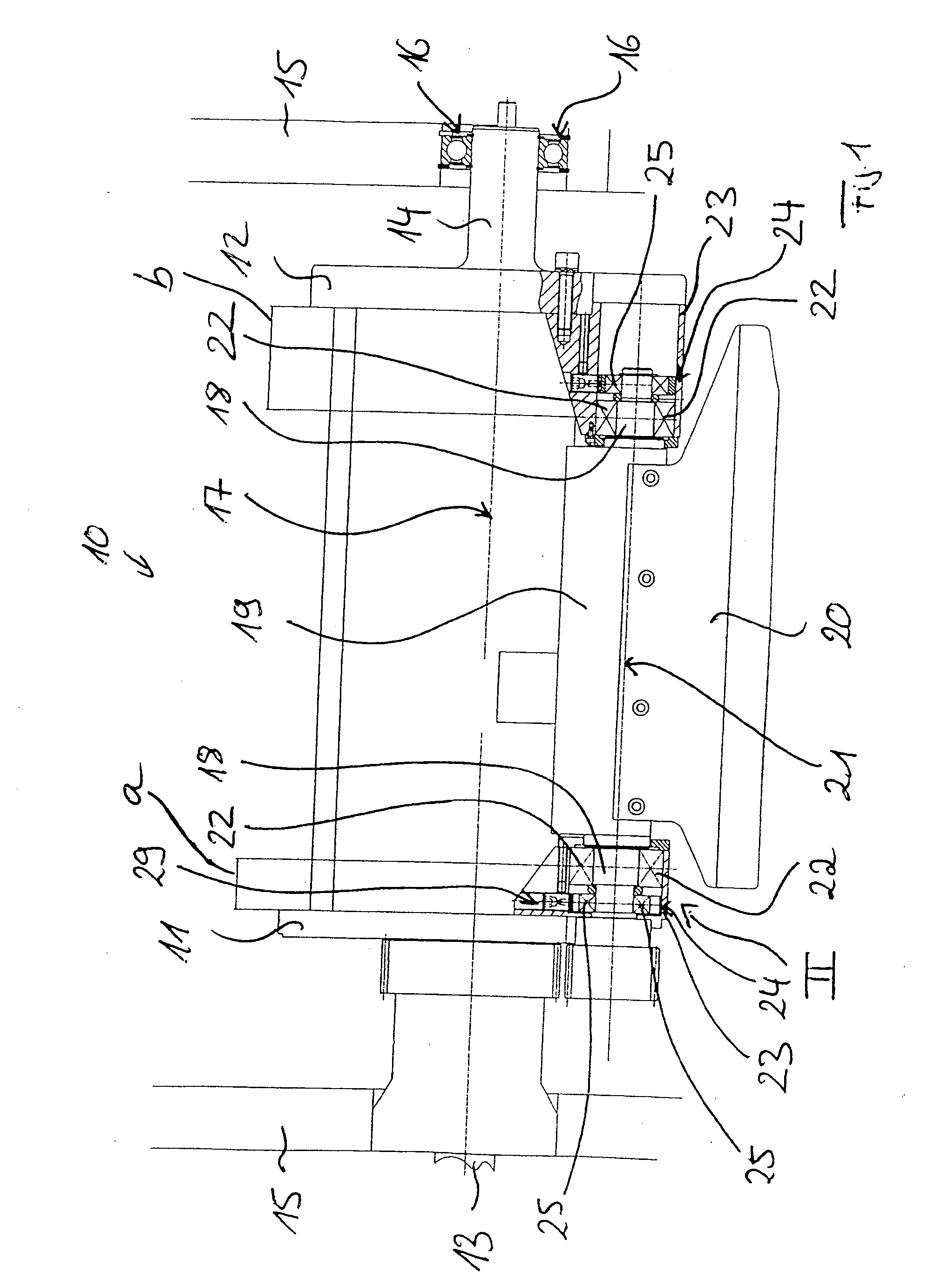

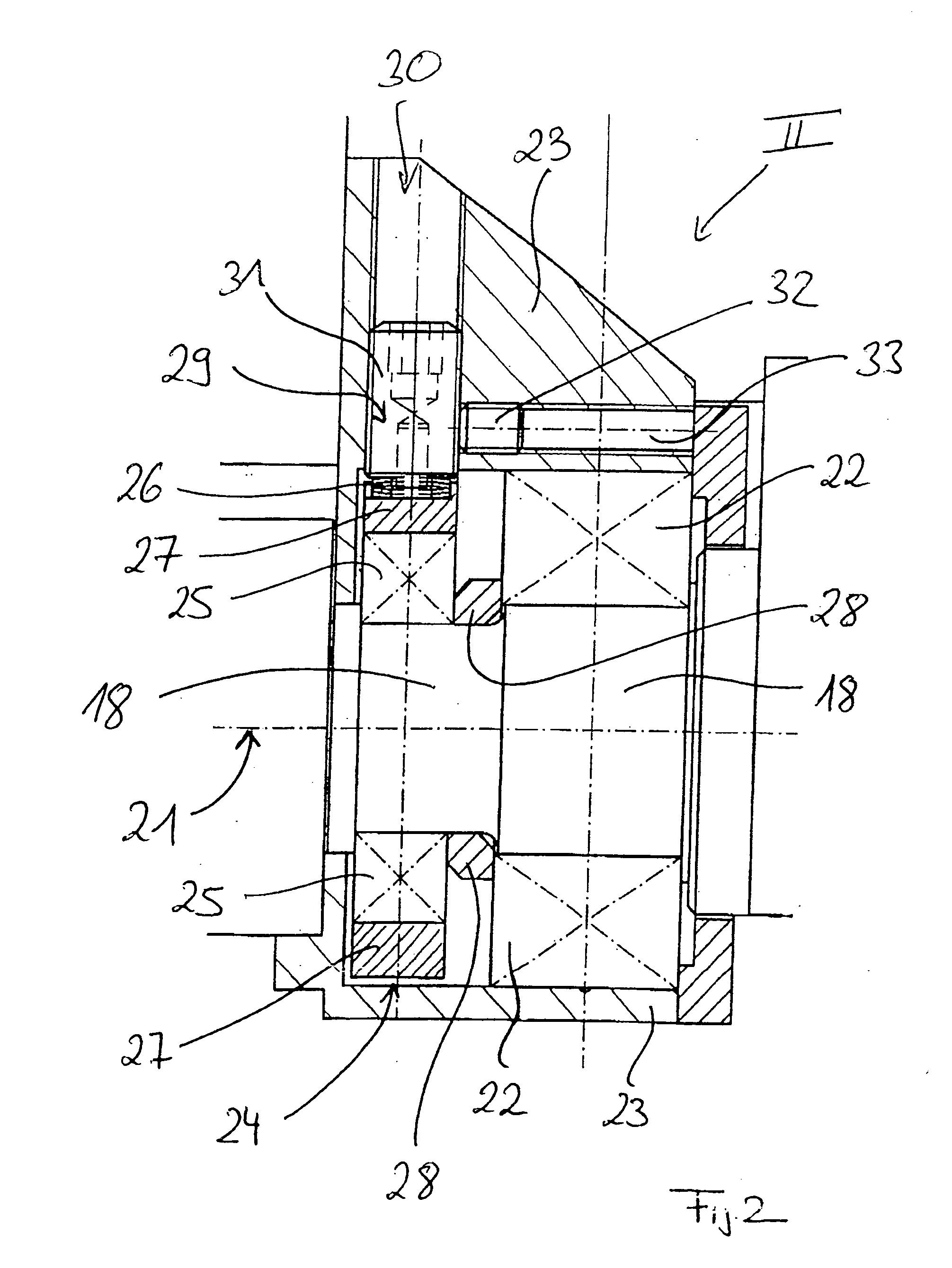

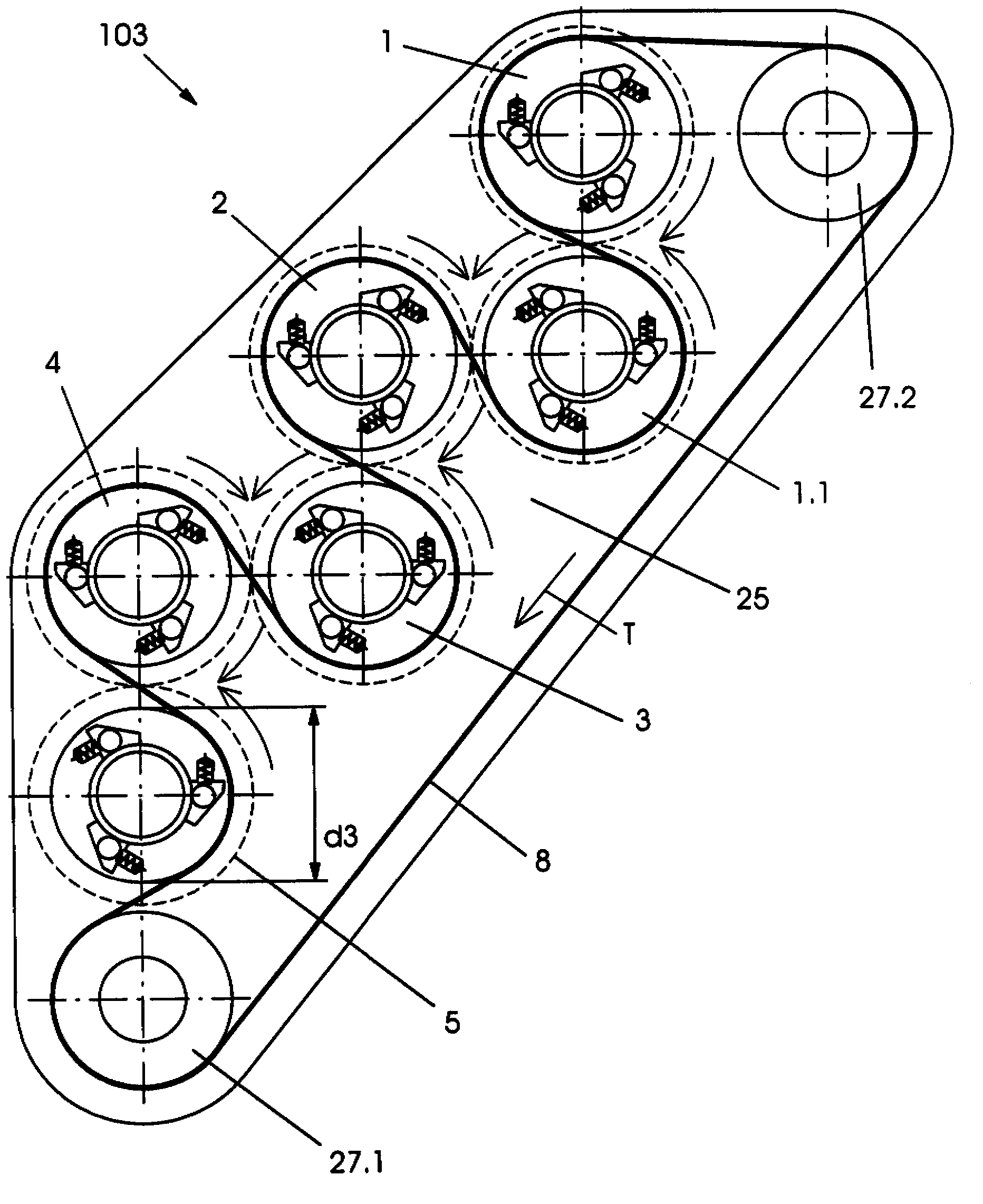

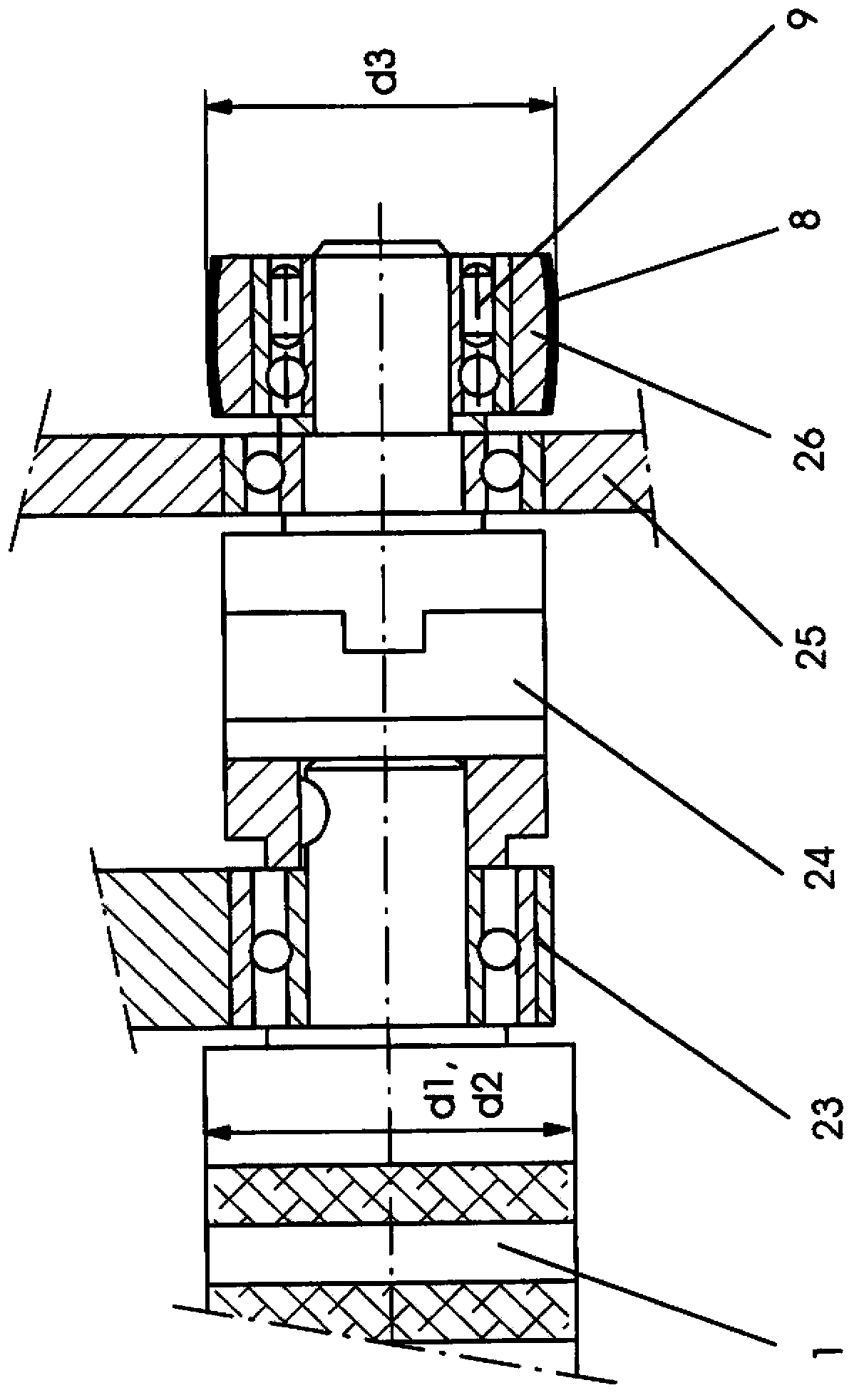

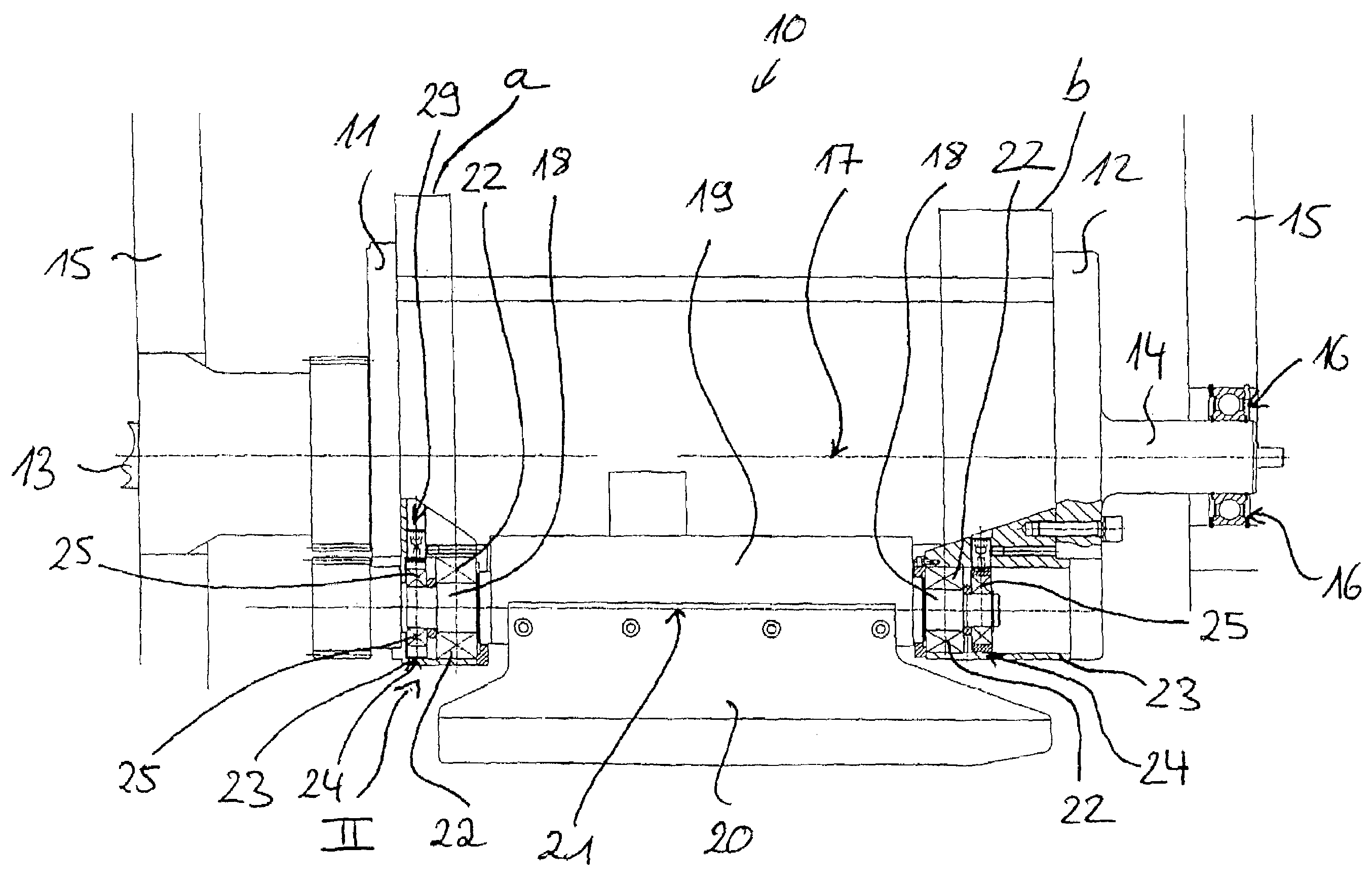

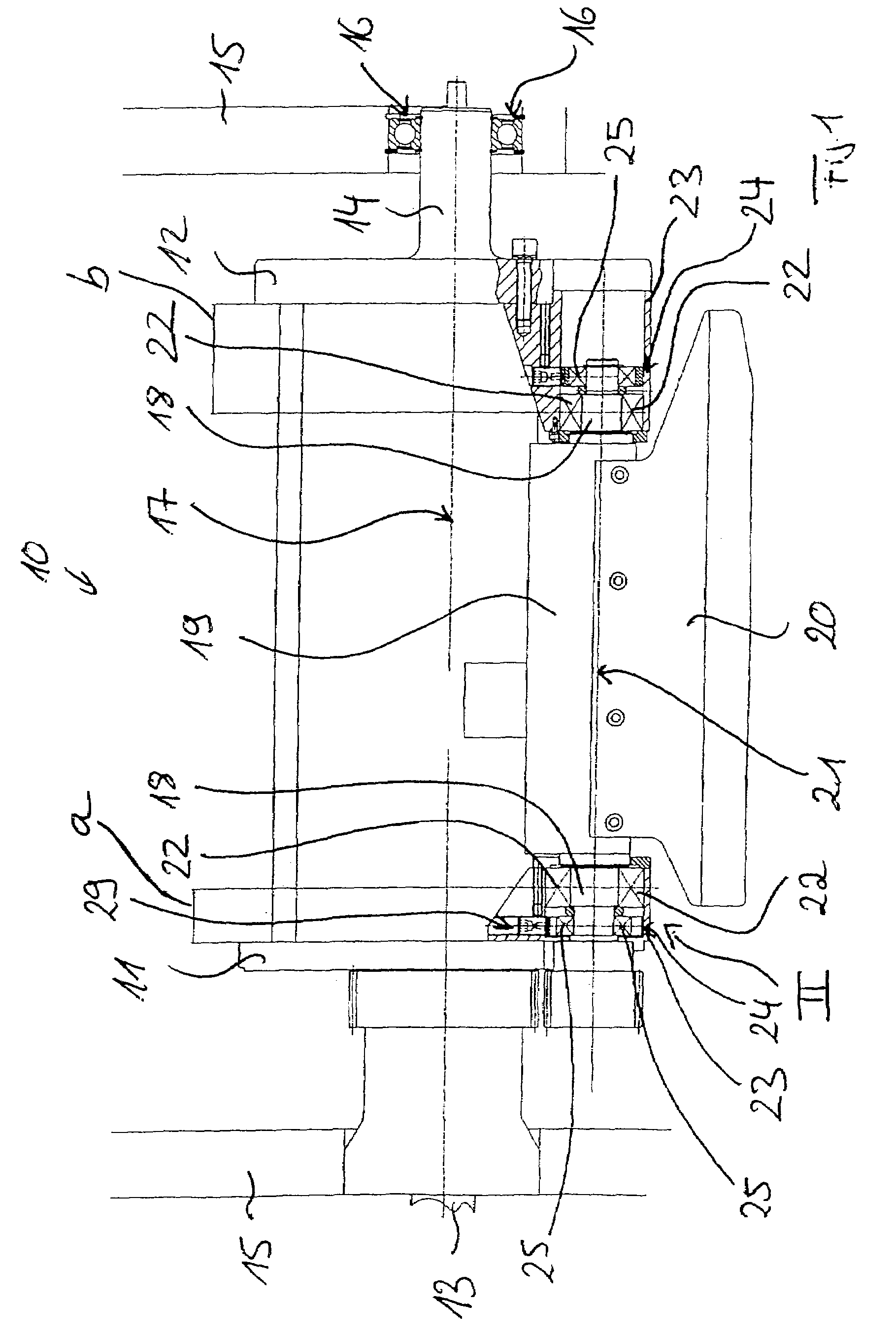

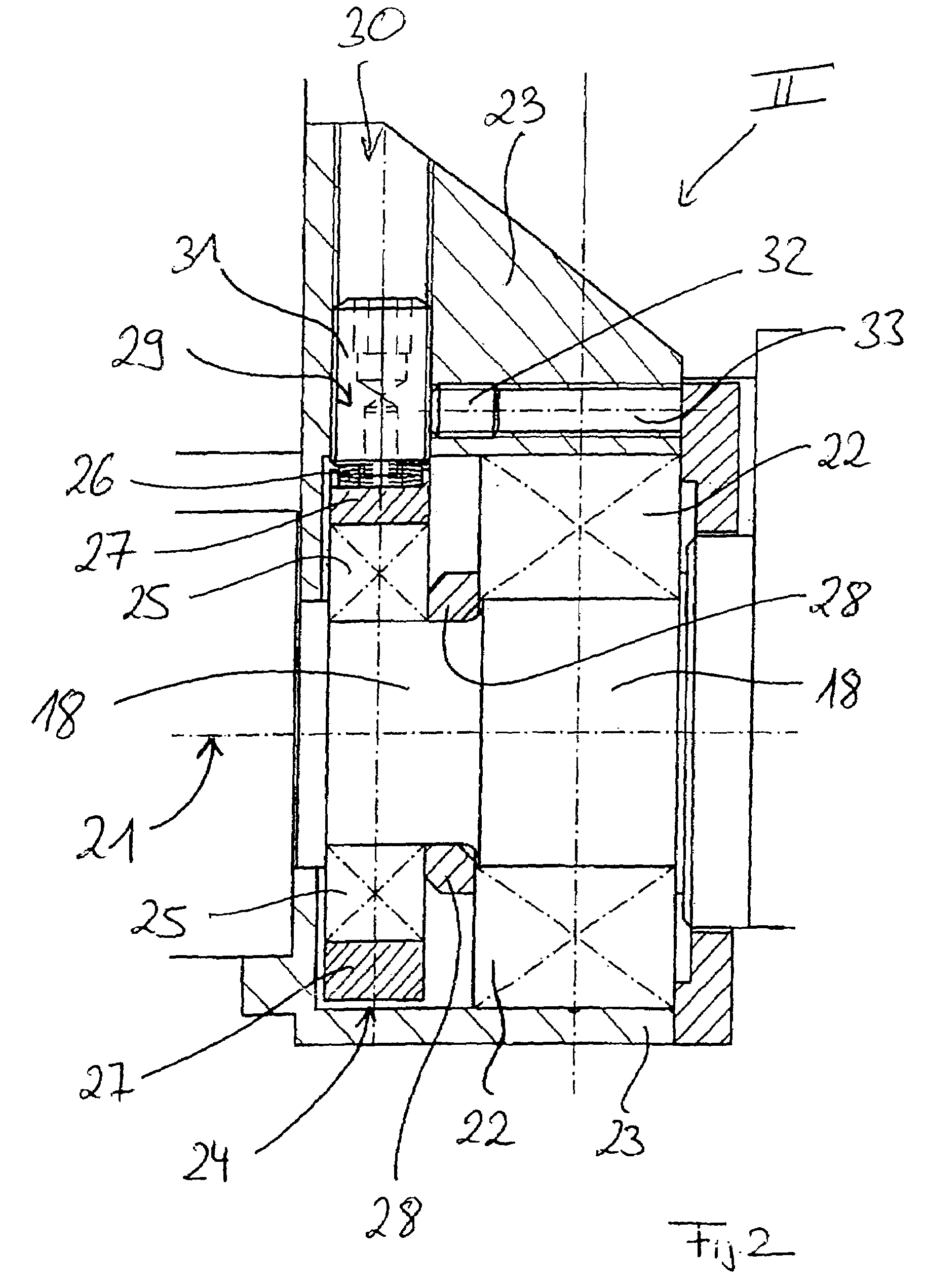

Folding drum of a folder of a printing press

InactiveUS20070037683A1Reduce wearReduce MechanismsMechanical working/deformationFolding thin materialsEngineeringPrinting press

A folding drum includes folding-drum side walls lying opposite one another, journals lying opposite one another and acting on the folding-drum side walls, a frame on which the folding drum is mounted rotatably via the folding-drum side walls and the journals, a folding-blade spindle arranged between the folding-drum side walls, at least one folding blade arranged on the folding-blade spindle, roller bearings for rotatably mounting the folding-blade spindle, and at least one device positioned laterally next to the roller bearings and serving to mount the folding-blade spindle in order to introduce a radial force into the folding-blade spindle and therefore to prestress the respective roller bearing in a radial direction.

Owner:MANROLANAD AG

Shoe-shaped gold ingot machine and paper folding process

ActiveCN112141769ASolve the disadvantages of folding one side moreReduce R&D investment costsRegistering devicesFolding thin materialsPaper sheetManufacturing engineering

The invention provides a shoe-shaped gold ingot machine and a paper folding process. The shoe-shaped gold ingot machine comprises a supply system, a before-folding conveying system, a folding system and a stacking system; the supply system comprises a bin; the bin comprises a bottom plate with the bottom obliquely arranged; a feed assembly is provided at the top of the bin; and the feed assembly comprises a swingable negative-pressure suction nozzle, and a clamping jaw capable of being inserted between the last piece of shoe-shaped gold ingot paper and dozens of shoe-shaped gold ingot paper. The paper folding process for the shoe-shaped gold ingot machine is a sheet-shaped gold ingot paper folding process, and comprises a sheet-shaped gold ingot paper feeding step, a folding and edge opening step and a large and small angle folding step. The paper folding machine utilizes a negative-pressure adsorption mode to implement single-piece feeding of shoe-shaped gold ingot paper to achieve good feeding stability, and performs edge opening treatment at a paper outlet of the folding machine to provide necessary conditions for subsequent small-angle folding so as to effectively prevent paperstacking in the subsequent step due to error accumulation of position precision. The process solves the problem that the existing shoe-shaped gold ingot machine cannot use dozens of sheet-shaped goldingot paper, and is ingenious in design, high in stability and good in use effect.

Owner:潍坊合一机械有限公司

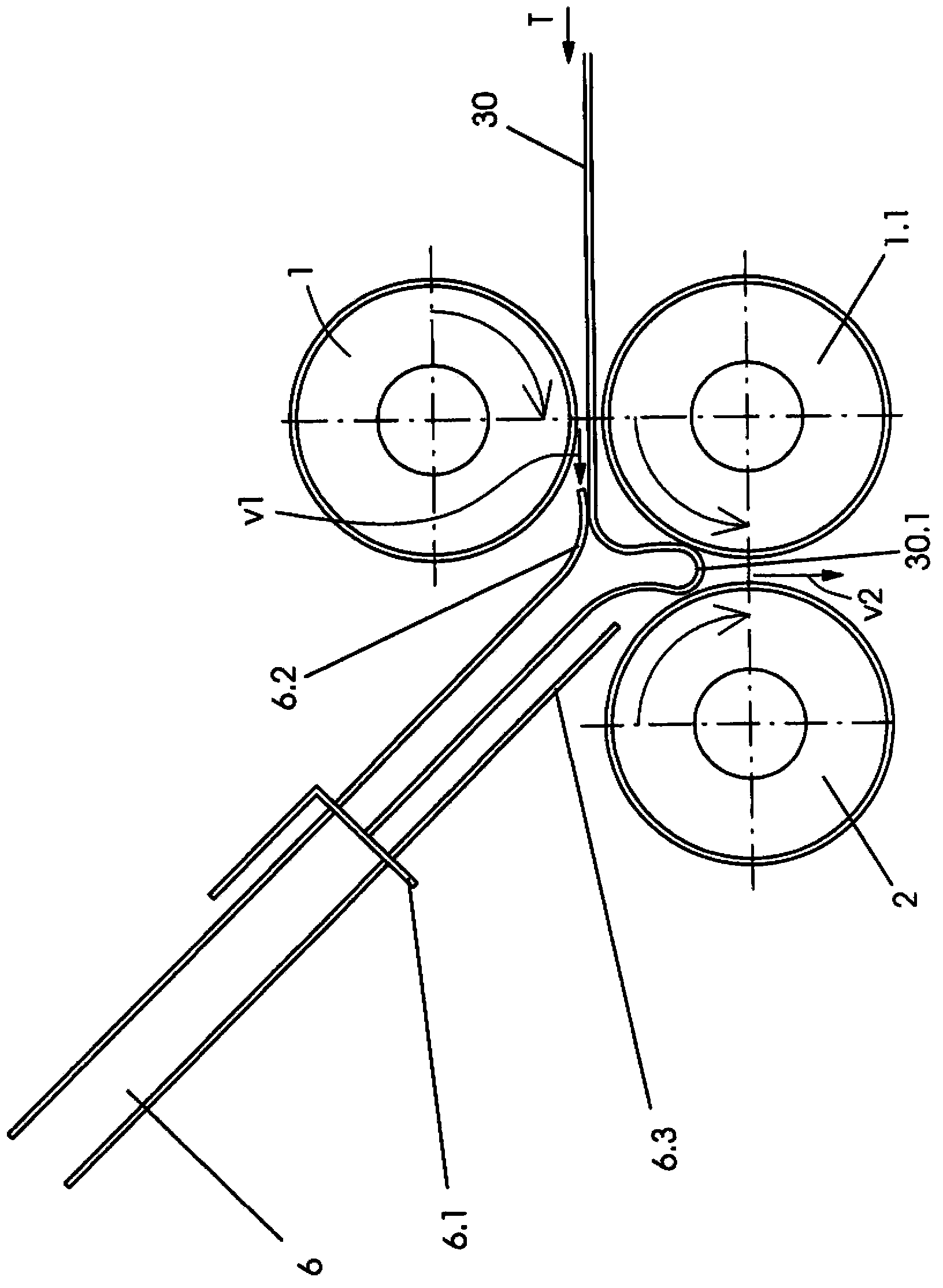

Method for folding and buckle plate folding machine

The invention relates to a method for folding applied for a buckle plate folding machine. The buckle plate folding machine has at least one first roller pair, a first later folding buckle plate at the paper running direction and a later folding roller pair at the paper running direction, wherein the the peripheral speed of one roller in the folding roller pair is always higher than the peripheral speed of of the other folding roller. A paper is drawn to pass through a folding station in a tension state through the speed difference. The invention also relates to the folding machine employing the method, wherein the application schemes of a standard rolling unit and a special rolling unit are set. According to the invention, the drive line or the folding roller diameter of the folding machine is adjusted.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

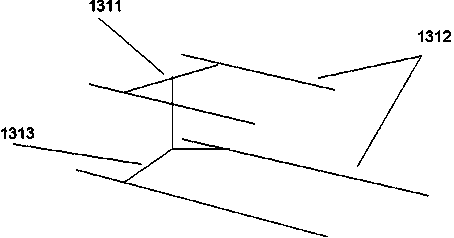

Triangular paper folding device and method for paper jams and automatic regulating mechanism

ActiveCN105540324AExtend your lifeGood folding effectFolding thin materialsPulp and paper industryIn degree

The invention discloses a triangular paper folding device and method for paper jams and an automatic regulating mechanism. The automatic regulating mechanism comprises a conveyor belt, the triangular paper folding device, a mounting plate, a transmission component, a first drive device and a second drive device, wherein one end of the mounting plate is connected with the triangular paper folding device, and the other end of the mounting plate is connected with the transmission component; the transmission component is connected with the first drive device and the second drive device. The triangular paper folding device comprises a triangular paper folding block, a horizontal paper folding assembly and an oblique paper folding assembly, wherein the surface, needing to be turned over, of paper is turned over by 90 degrees through the triangular paper folding block, the paper continues to be turned over by 90 degrees by the horizontal paper folding assembly and the oblique paper folding assembly, and then paper folding is completed. The first drive device is used for regulating the horizontal position of the triangular paper folding device, and the second drive device is used for regulating the vertical position of the triangular paper folding device. The triangular paper folding device is simple in structure, low in cost, convenient and reliable to regulate and high in degree of automation, and improves the paper folding precision.

Owner:广州高印力信息技术有限公司

Folding drum of a folder of a printing press

InactiveUS7416522B2Reduce wearReduce MechanismsMechanical working/deformationFolding thin materialsEngineeringPrinting press

A folding drum includes folding-drum side walls lying opposite one another, journals lying opposite one another and acting on the folding-drum side walls, a frame on which the folding drum is mounted rotatably via the folding-drum side walls and the journals, a folding-blade spindle arranged between the folding-drum side walls, at least one folding blade arranged on the folding-blade spindle, roller bearings for rotatably mounting the folding-blade spindle, and at least one device positioned laterally next to the roller bearings and serving to mount the folding-blade spindle in order to introduce a radial force into the folding-blade spindle and therefore to prestress the respective roller bearing in a radial direction.

Owner:MANROLANAD AG

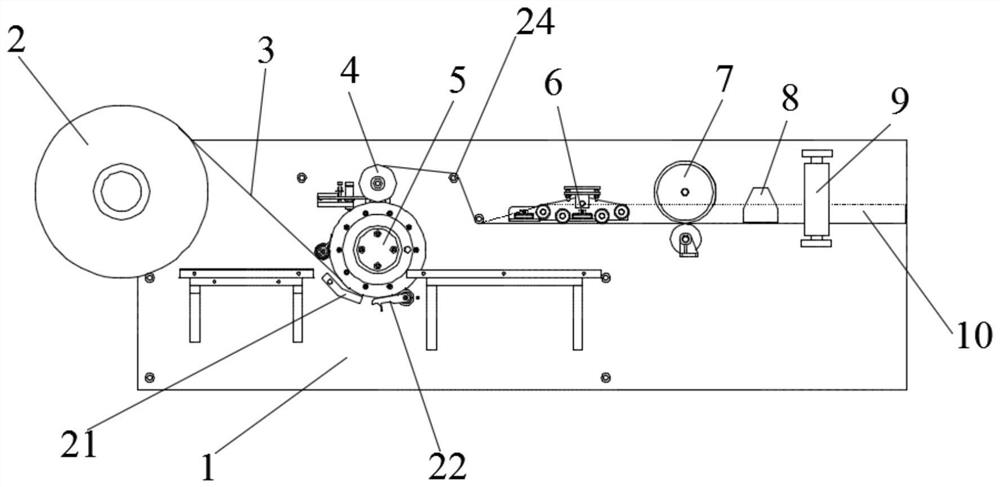

Three-dimensional paper bag making machine capable of achieving heat sealing

PendingCN110815944ARealize automatic controlImprove folding accuracyBag making operationsPaper-makingPaper sheetParafilm

The invention discloses a three-dimensional paper bag making machine capable of achieving heat sealing. The three-dimensional paper bag making machine comprises a rack, wherein an outer paper roll isarranged at one end of the rack; outer-layer paper on the outer paper roll is conveyed to a film applying mechanism under the guidance of a plurality of guide rollers; the film applying mechanism is provided with a heat sealing film for sealing at a sealing position of each paper bag; a cutting roller is arranged at a lower station of the film applying mechanism; the cutting roller is used for cutting a smooth opening for a fruit stem to pass through on the paper; an upper rubber roller is arranged at a lower station of the cutting roller; a three-dimensional forming mechanism for extruding the paper into a three-dimensional cavity is arranged at a lower station of the upper rubber roller; the paper passes through the three-dimensional forming mechanism, and then the paper bag is pressed to be superposed from top to bottom by a pressing roller; and a bag cutting roller for cutting the continuous paper bag into single paper bags is arranged at a lower station of the pressing roller. Thethree-dimensional paper bag making machine disclosed by the invention is capable of producing single-layer or double-layer paper bags capable of achieving heat sealing, and high in folding precision;and the produced paper bags are suitable for being used on an automatic bagging machine, and have a relatively good market popularization prospect.

Owner:谢晓兵

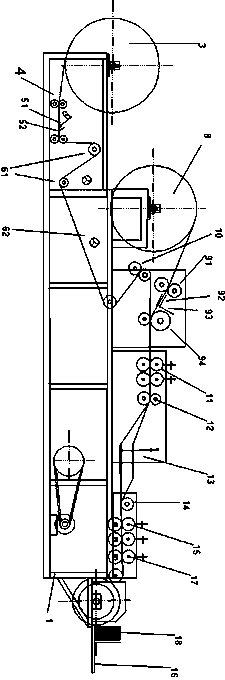

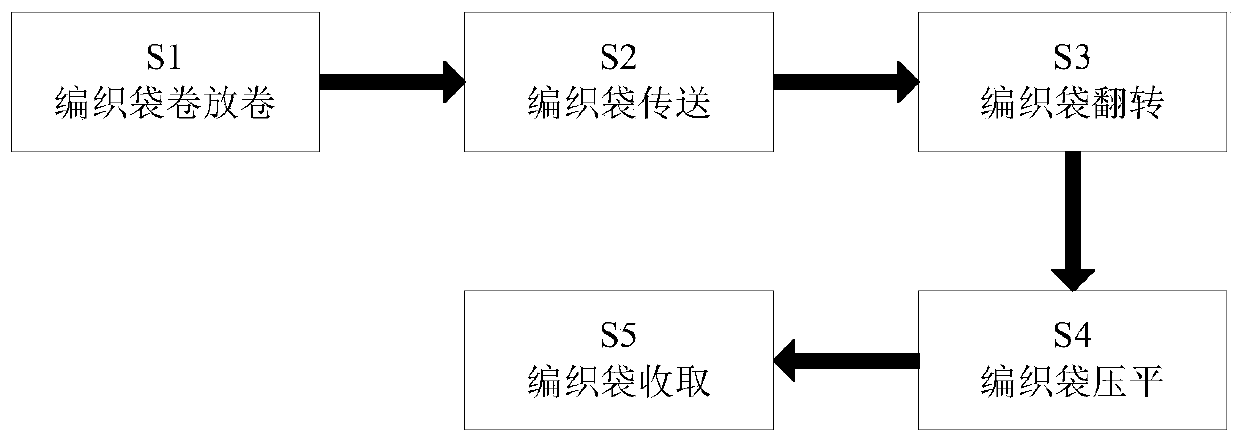

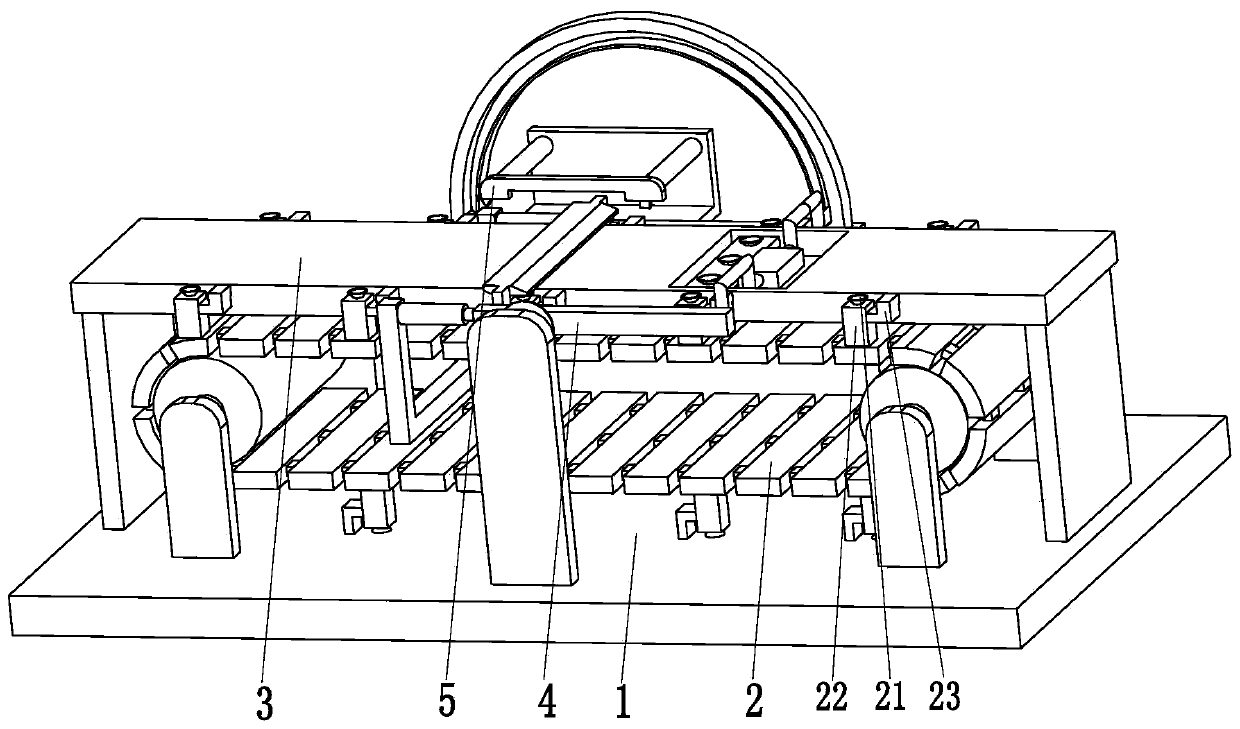

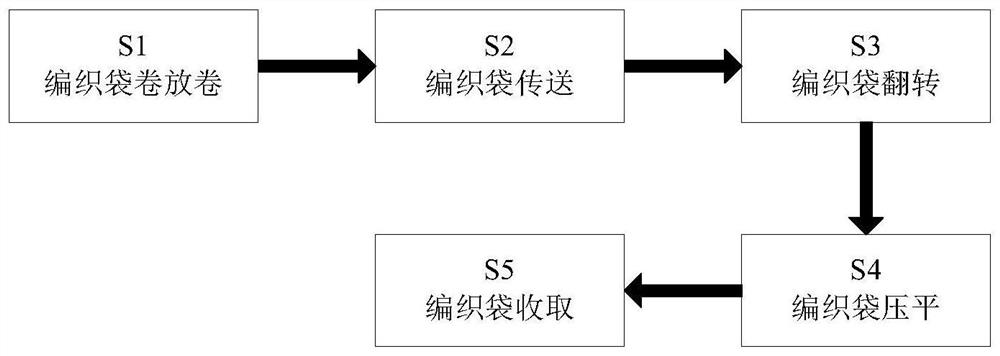

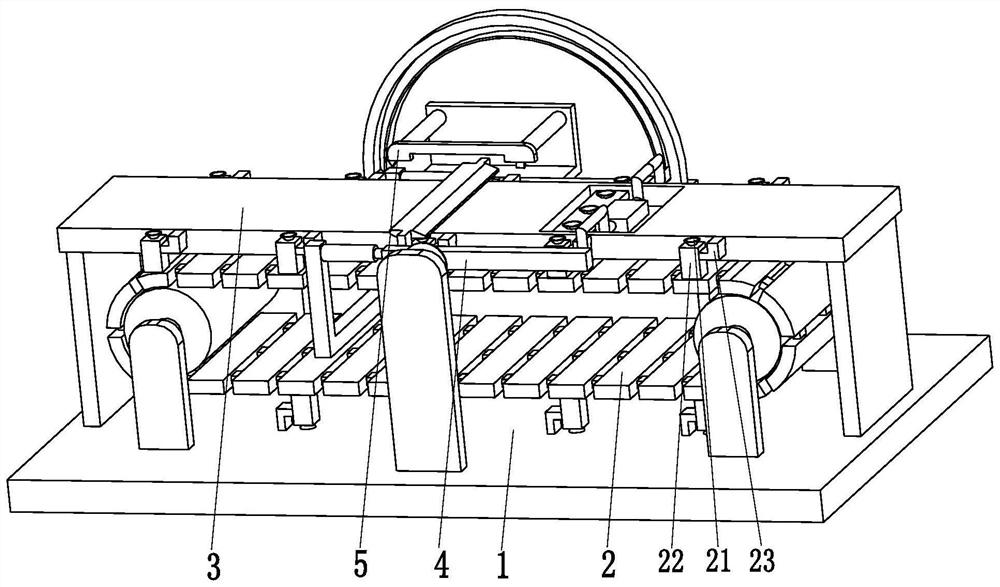

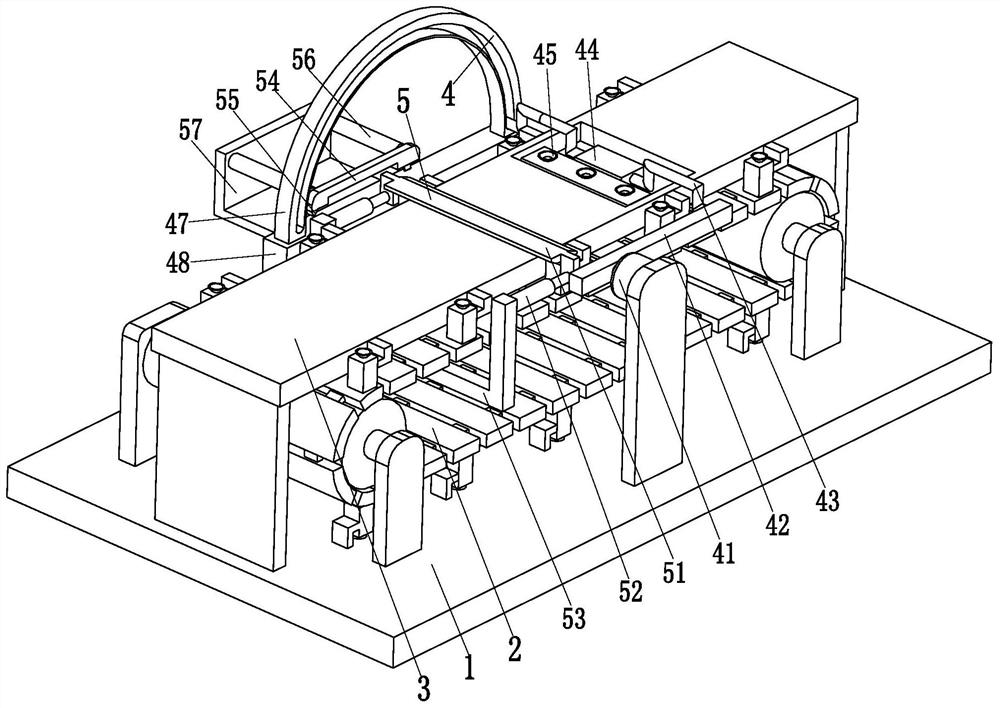

Manufacturing method of composite plastic woven bag

ActiveCN110893701AImprove the accuracy of foldingNo creasesBag making operationsPaper-makingRotational axisAir pump

The invention relates to a manufacturing method of a composite plastic woven bag. A composite plastic woven bag manufacturing device adopted in the method comprises a bottom plate, a conveying chain plate, a bearing table, a rotating mechanism and a leveling mechanism; the rotating mechanism comprises a rotating motor, a rotating connecting rod, a rotating shaft, a rotating turning plate, a fixedsucker, an air pump, a supporting ring and a supporting plate. The manufacturing method comprises the following steps: S1, unwinding a woven bag roll; S2, conveying the woven bag; S3, overturning thewoven bag; S4, pressing the woven bag; and S5, collecting the woven bag. The problems that in the prior art, size offset is likely to occur when the woven bag is manually folded, the woven bag is folded in half in a staggered mode, and the folded woven bag is prone to wrinkling when the woven bag is folded can be solved.

Owner:浙江嘉智控股有限公司

Paper folding machine and press using the same

InactiveCN101301807AShock mitigationInhibition of ruptureFolding thin materialsRotary pressesStatic friction coefficientStatic friction

A folding machine includes a lower conveyance belt that forms a lower conveyance path section for guiding and conveying a signature by a lower conveyance surface, an upper conveyance belt that forms an upper conveyance path section for guiding and conveying the signature by an upper conveyance surface, a chopper table for guiding the lower conveyance belt, a stopper for aligning a downstream end position of the signature, and a chopper blade for forming a chopper signature. A coefficient of static friction of the lower conveyance surface and the upper conveyance surface to an iron surface is 0.2 or more and less than 0.3, and a nip roller for increasing holding force to the signature between the lower conveyance surface and the upper conveyance surface is provided at a part more upstream side than the stopper by at least a length of the signature.

Owner:MITSUBISHI HEAVY IND PRINTING & PACKAGING MACHINERY

Folding machine fence board with front gauge guiding device

ActiveCN102616605AImprove the accuracy of foldingAvoid jammingFolding thin materialsArticle deliveryBlock matchMechanical engineering

The invention discloses a folding machine fence board with a front gauge guiding device. The folding machine fence board comprises a front gauge assembly, a plurality of paper pressing rods, a plurality of paper supporting rods and a pair of support plate assemblies arranged in parallel, wherein the paper pressing rods and the paper supporting rods are arranged in a paired way to form a plurality of rod groups; the plurality of rod groups are arranged between the pair of support plate assemblies in parallel; the front gauge assembly is hollowly sleeved on the plurality of rod groups; and a guiding block matched with the support plate assembly is mounted at least one end of the front gauge assembly. The folding machine fence board with the front gauge guiding device has the advantages that the front gauge is guided stably and reliably and is flexible and accurate in movement and the folding precision of the folding machine can be improved.

Owner:长沙奥托机械股份有限公司

Automatic folding device for packaging bag film

InactiveCN114536870AEasy to foldImprove folding accuracyBag making operationsPaper-makingThin membraneMechanical engineering

Owner:HUBEI UNIV OF EDUCATION

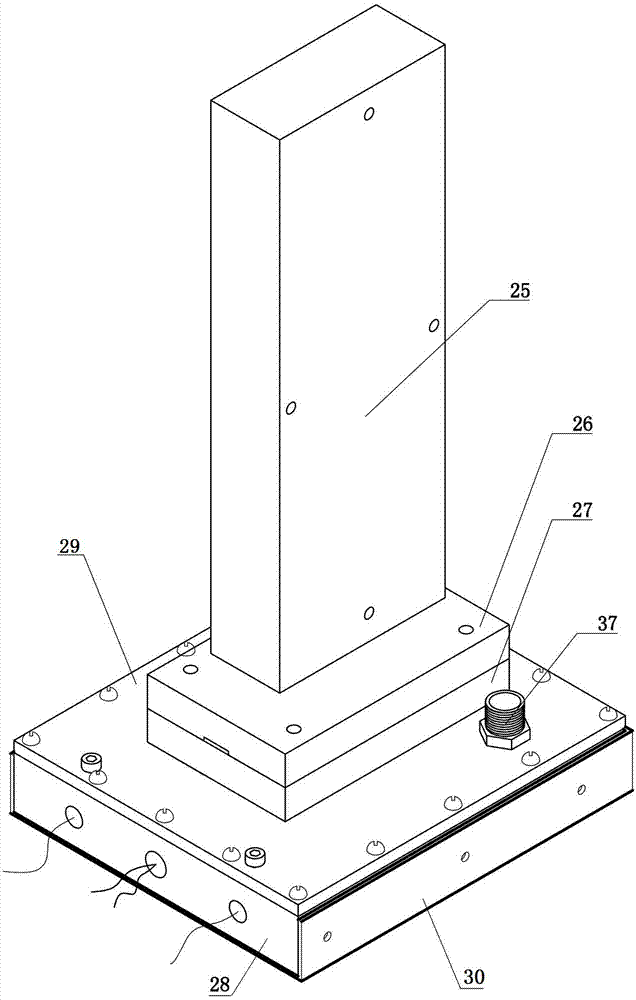

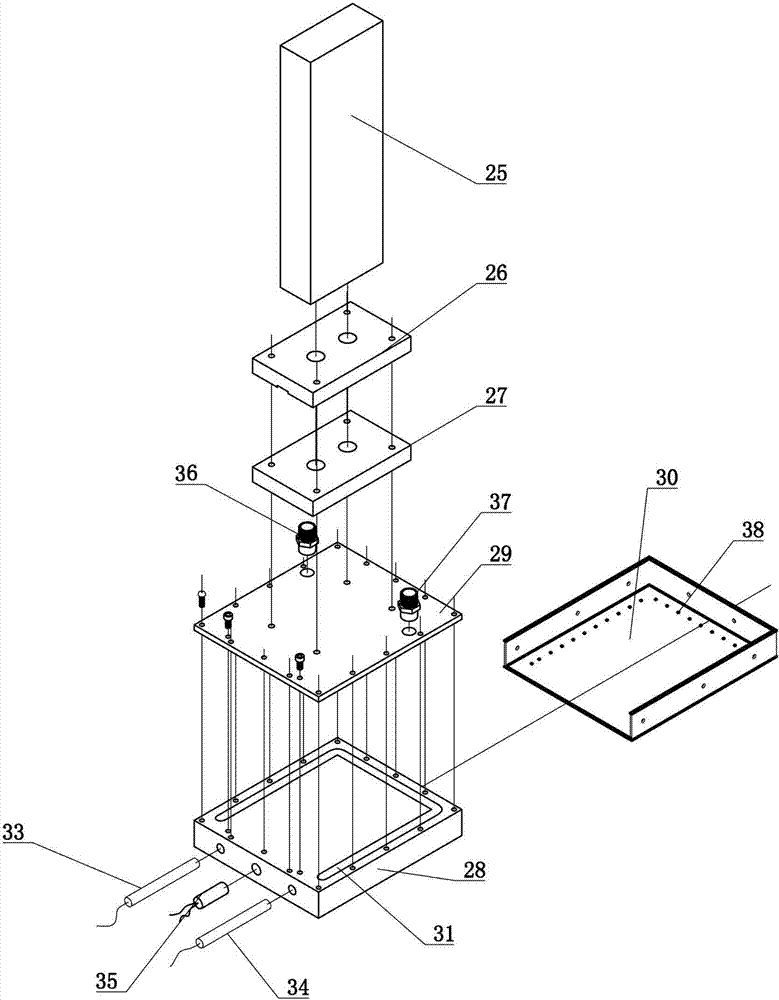

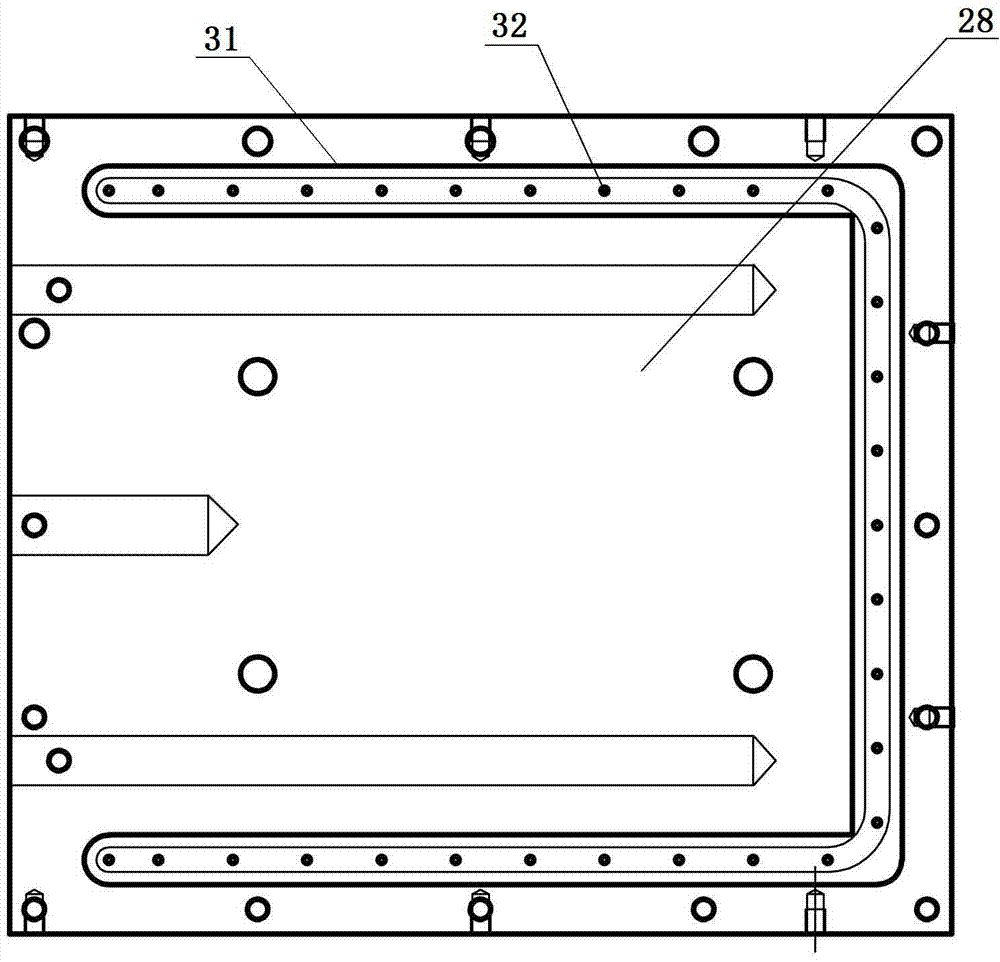

Hot-pressing machine of pocket cloth edgefolds of uniform clothes

ActiveCN103027416BImprove the accuracy of foldingEasy to operateIroning apparatusPile receiversEngineeringLarge size

The invention relates to a hot-pressing machine of pocket cloth edgefolds of uniform clothes. The pocket cloth edgefolds hot-pressing machine comprises a stander, a working platform fixedly arranged at the middle part of the stander, a folding and ironing device arranged at the middle part of the working platform, edge folding devices arranged above, below and at one side of the folding and ironing device, a hot-pressing device which is arranged at the upper part of the stander and corresponds to the folding and ironing device, and a finished product taking and stacking-up device arranged at one side of the hot-pressing device. The hot-pressing machine is used for carrying out edge folding and hot pressing on pocket cloth of the uniform clothes by using mechanical devices and has the advantages of improving the edge folding precision of the pocket cloth, enabling the edgefolds to be flatly, straightly and smoothly hot-pressed, saving the time and labor, greatly improving the production efficiency and ensuring the product quality. The hot-pressing machine disclosed by the invention is simple and convenient to operate and suitable for large-scale popularization and application of large-size clothing enterprises.

Owner:JIHUA 3502 PROFESSIONAL GARMENT

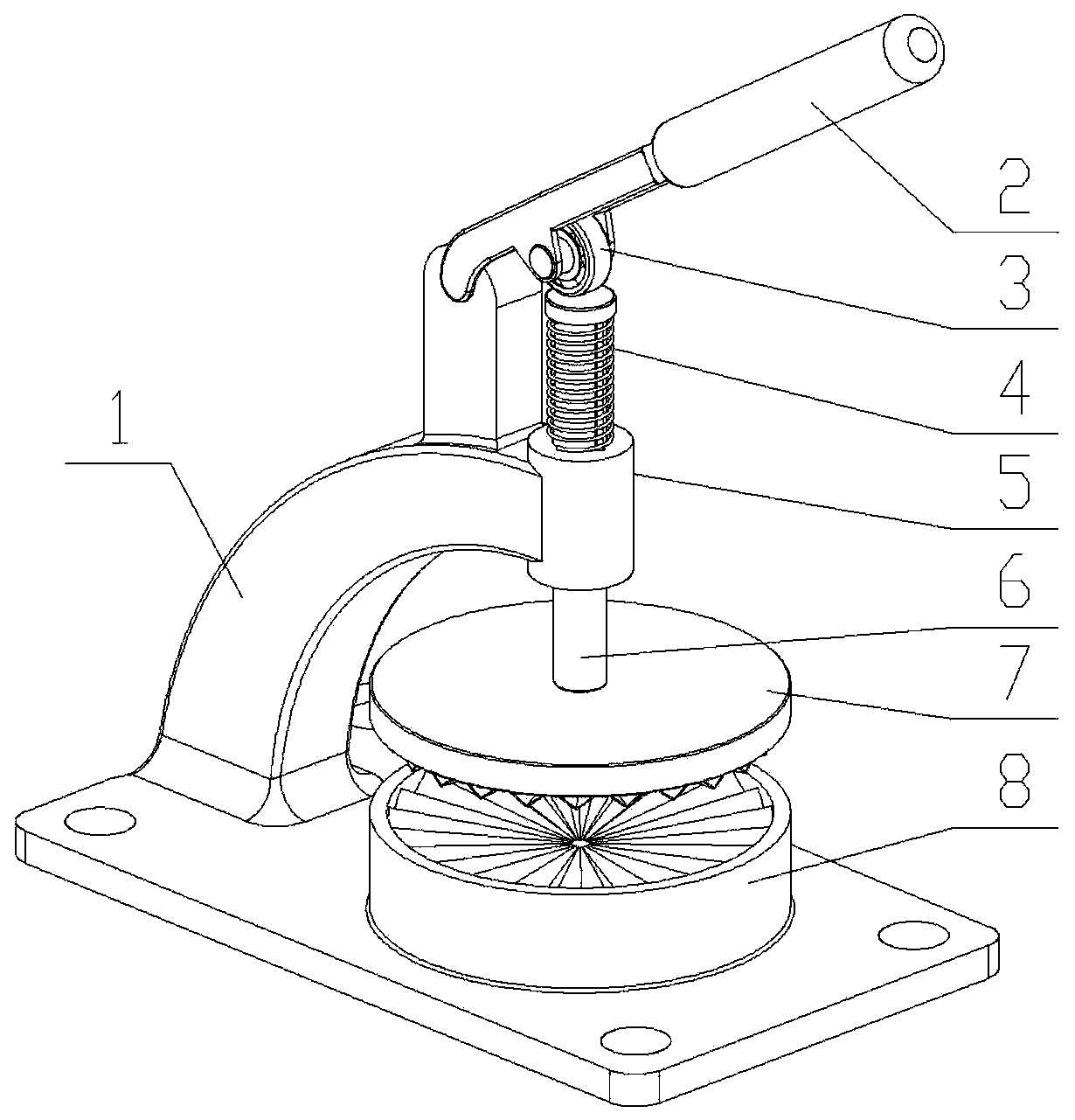

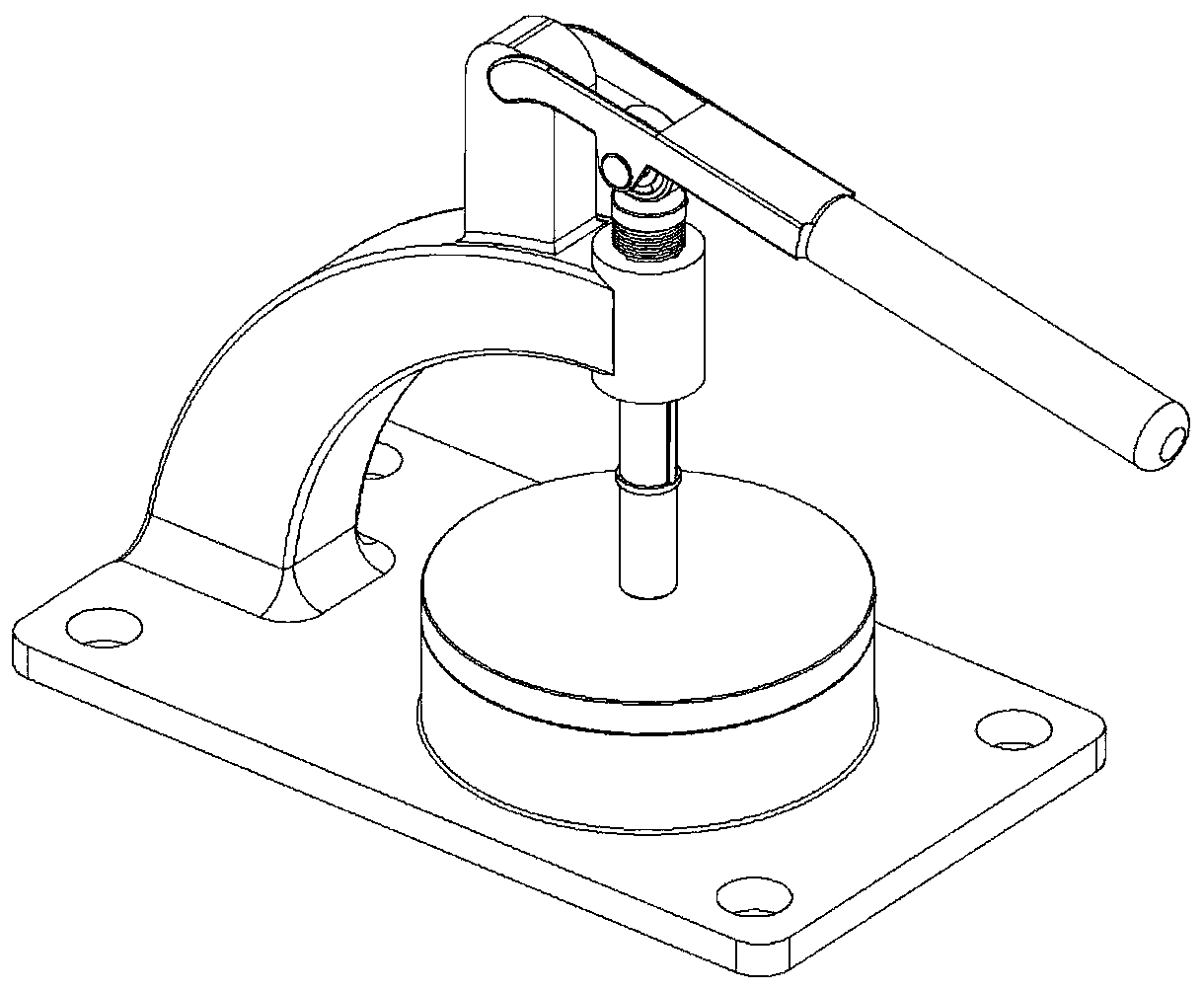

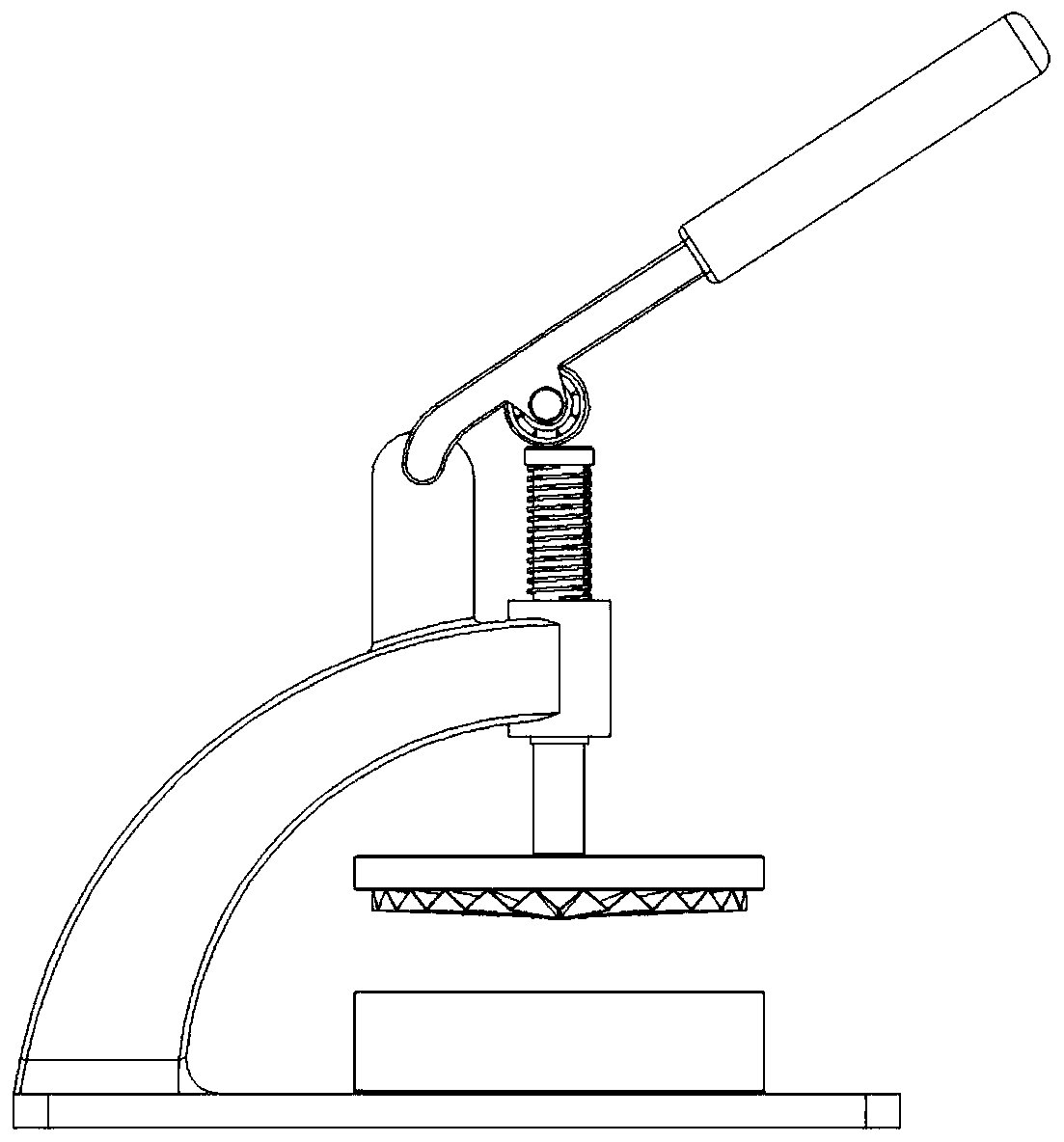

Device and method capable of rapidly folding filter paper

PendingCN110182645AQuality improvementSave human effortFolding thin materialsPulp and paper industryFilter paper

The invention relates to a device capable of rapidly folding filter paper. The device capable of rapidly folding the filter paper comprises a base bracket which is provided with a downwards pressing transmission structure, a concave paper folding mould, a convex paper folding mould and a reset spring; a downwards pressing handle is arranged on the base bracket; a downwards pressing rolling bearingis fixedly mounted on the downwards pressing handle; the inner ring of the downwards pressing rolling bearing is fixedly connected with the downwards pressing handle through a cylindrical pin; a downwards pressing guide rod capable of moving perpendicularly is arranged on the base bracket along a guide channel; the reset spring is mounted on the downwards pressing guide rod through the guide channel and downwards pressing guide rod limitation; and limiting devices are arranged at the parts, located at the lower end of the guide channel and at the upper end of the reset spring, of the downwards pressing guide rod. Through the professionally designed filter paper folding moulds, the finished filter paper is produced rapidly in bulk, the finished filter paper is high in quality, standardizedand normalized, the manpower and the time are saved, and the device capable of rapidly folding the filter paper has important significance in aspects of improving the detection efficiency, improvingthe detection accuracy, and the like.

Owner:HUNAN SOIL & FERTILIZER INST +1

Triangular folding device, automatic adjustment mechanism and folding method for cardboard folding

The invention discloses a triangular paper folding device and method for paper jams and an automatic regulating mechanism. The automatic regulating mechanism comprises a conveyor belt, the triangular paper folding device, a mounting plate, a transmission component, a first drive device and a second drive device, wherein one end of the mounting plate is connected with the triangular paper folding device, and the other end of the mounting plate is connected with the transmission component; the transmission component is connected with the first drive device and the second drive device. The triangular paper folding device comprises a triangular paper folding block, a horizontal paper folding assembly and an oblique paper folding assembly, wherein the surface, needing to be turned over, of paper is turned over by 90 degrees through the triangular paper folding block, the paper continues to be turned over by 90 degrees by the horizontal paper folding assembly and the oblique paper folding assembly, and then paper folding is completed. The first drive device is used for regulating the horizontal position of the triangular paper folding device, and the second drive device is used for regulating the vertical position of the triangular paper folding device. The triangular paper folding device is simple in structure, low in cost, convenient and reliable to regulate and high in degree of automation, and improves the paper folding precision.

Owner:广州高印力信息技术有限公司

A pressing device of a standard garment pocket cloth folding and pressing machine

ActiveCN103005762BImprove the accuracy of foldingIncrease productivityIroning apparatusPile receiversEngineeringMechanical engineering

The invention relates to a hot-pressing device for a uniform pocket cloth folding hot-pressing machine. The hot-pressing device comprises an iron lifting cylinder fixedly arranged on the top of a hot-pressing machine frame, an iron connecting plate fixedly arranged at the lower end of a piston rod of the iron lifting cylinder, a non-metallic thermal baffle fixedly arranged at the lower end of the iron connecting plate, and an iron device fixedly arranged at the lower end of the non-metallic thermal baffle. According to the invention, a mechanical device is used for hot-pressing uniform pocket cloth, the folding accuracy of the pocket cloth is improved, folded edges are smoothly and straightly pressed, time and labor are saved, the production efficiency is greatly improved and the product quality is guaranteed. The hot-pressing device is easy and convenient to operate, and is suitable for large-scale promotion and application in large clothing enterprises.

Owner:JIHUA 3502 PROFESSIONAL GARMENT

A kind of composite plastic woven bag manufacturing method

ActiveCN110893701BImprove the accuracy of foldingNo creasesBag making operationsPaper-makingRotational axisComposite material

The invention relates to a manufacturing method of a composite plastic woven bag. The composite plastic woven bag manufacturing method adopts the following composite plastic woven bag manufacturing device. The composite plastic woven bag manufacturing device includes a bottom plate, a transmission chain plate, a supporting platform, a rotating mechanism, a leveling Mechanism; the rotating mechanism includes a rotating motor, a rotating connecting rod, a rotating shaft, a rotating flap, a fixed suction cup, an air pump, a support ring and a supporting plate; the above-mentioned composite plastic woven bag manufacturing device is used for the production method of the composite plastic woven bag, It includes the following steps: S1, unwinding of the woven bag roll; S2, transmission of the woven bag; S3, turning over of the woven bag; S4, pressing of the woven bag; S5, collection of the woven bag. The present invention can solve the problems existing in the conventional folding of the woven bag: when the woven bag is manually folded, the size deviation is likely to occur, resulting in the phenomenon that the woven bag is half-folded and dislocated, and the folded woven bag is prone to wrinkles and the like.

Owner:浙江嘉智控股有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com