Paper folding machine and press using the same

A technology for folding machines and conveyor belts, which is applied to printing machines, rotary printing machines, printing, etc., can solve problems such as difficulties, inability to fully alleviate the impact of collision paper stoppers, complex structure of guillotine folding devices, etc., and achieve good transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

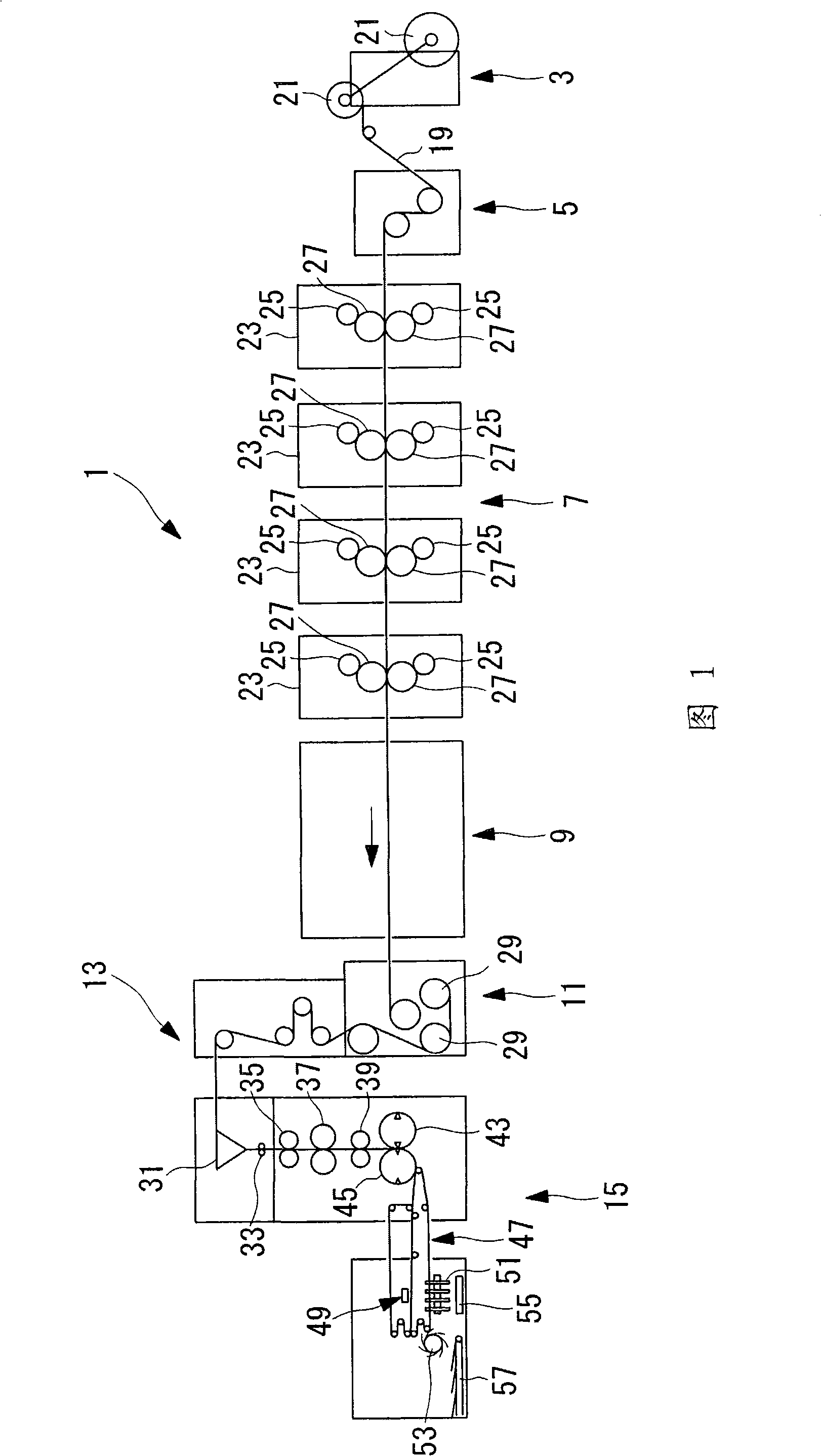

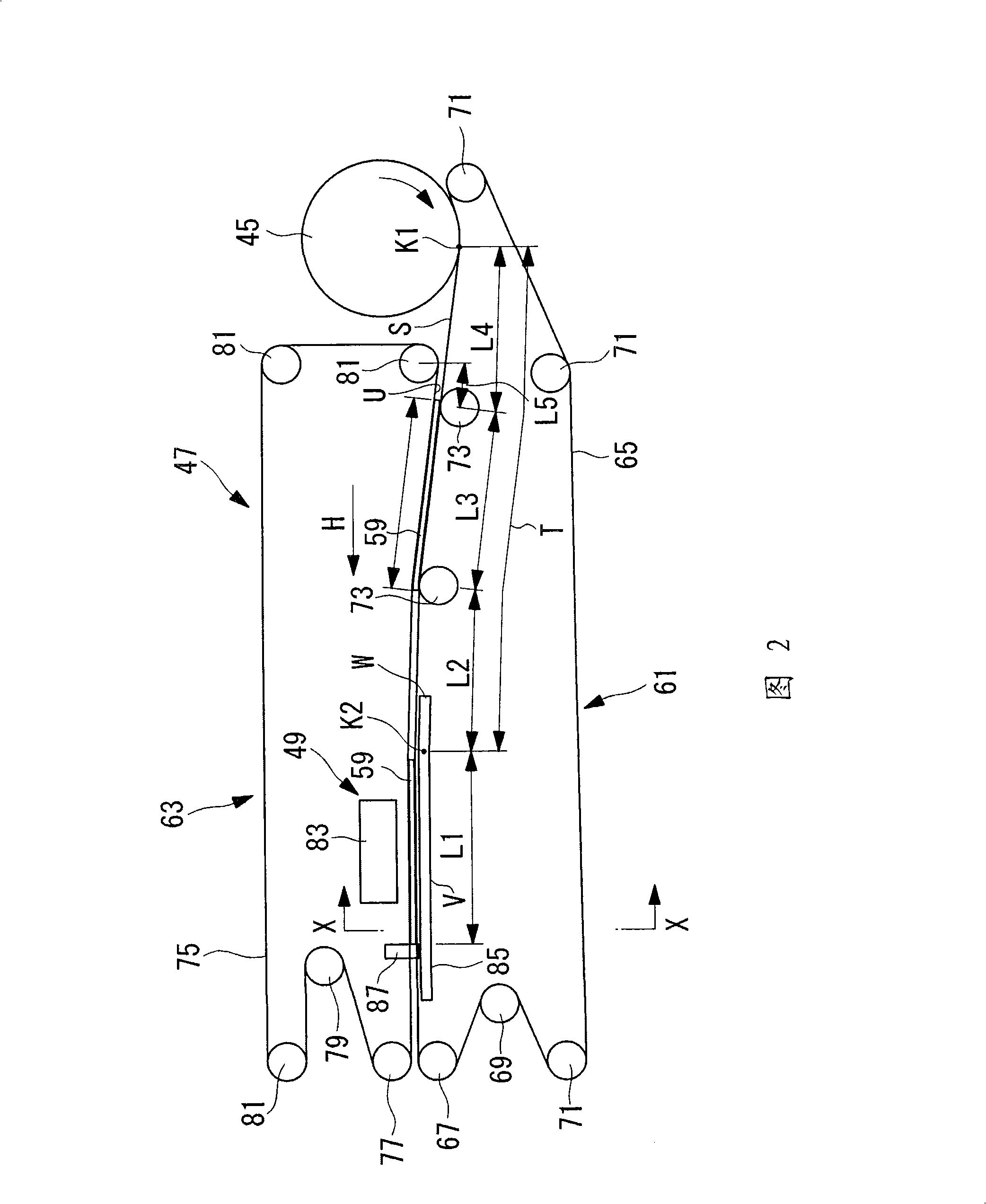

[0061] Below, refer to Figure 1- Figure 6 The first embodiment of the present invention will be described.

[0062] This embodiment is a proposal in which the present invention is applied to a rotary offset-cylinder type rotary printing machine that performs multi-color printing on both sides of a web (web).

[0063] FIG. 1 is a front view showing an overall schematic configuration of a rotary printing machine (printing machine) 1 .

[0064] The rotary printing machine 1 has along the conveying direction of the web 19: a paper feeding device 3, a paper feeding device (inflight device) 5, a printing part 7, a drying device 9, a cooling device 11, a paper path part (ウエブブパス part). ) 13 and folding machine 15.

[0065] The paper feeding device 3 is a device for feeding the rolled paper 19 and is configured to hold two paper rolls 21 on which the rolled paper 19 is wound in a roll shape.

[0066] While paper is being fed from one paper roll 21, the other paper roll 21 is instal...

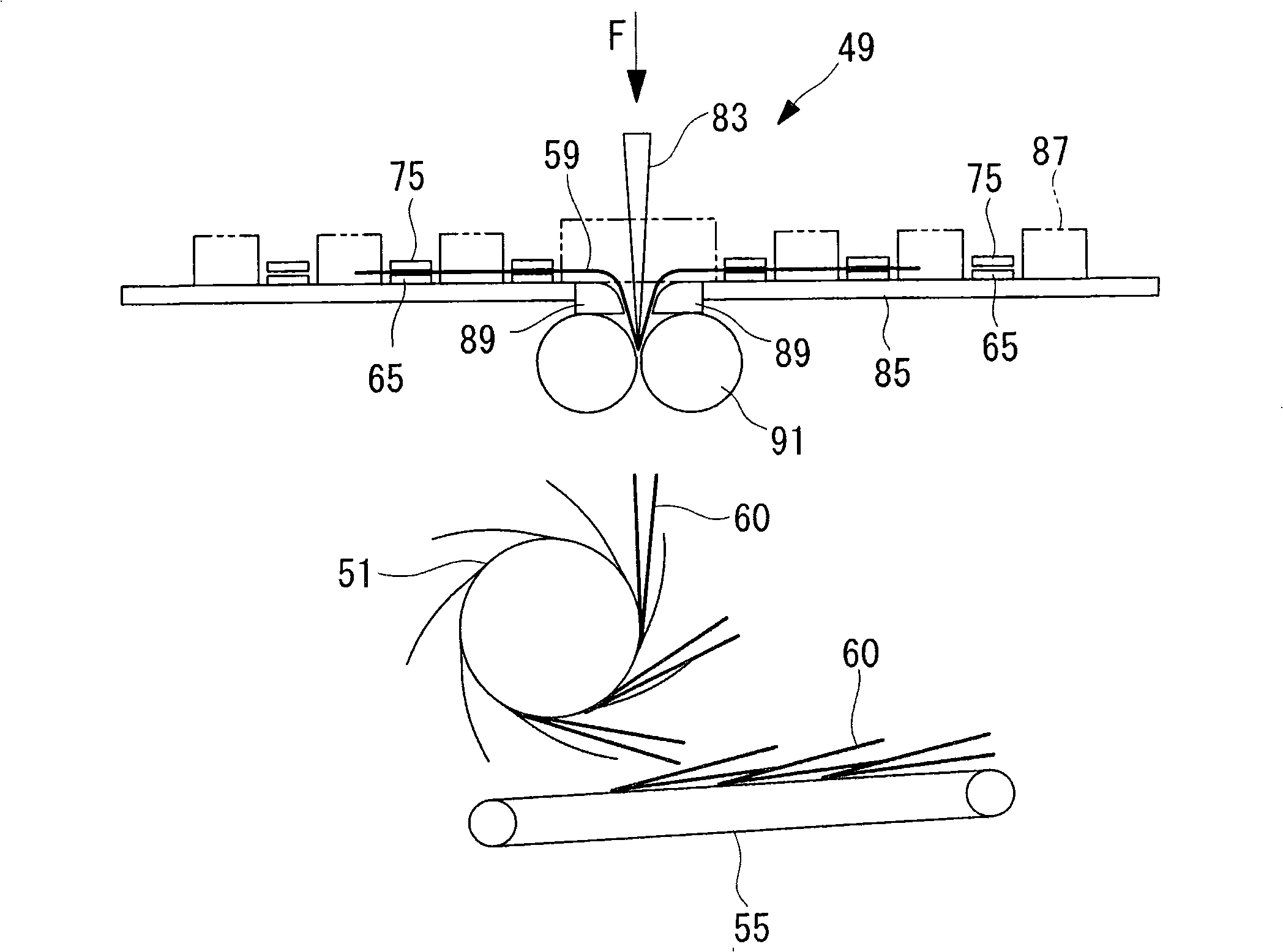

Embodiment

[0169] As the lower conveyor belt 65 and the upper conveyor belt 75 of the printing machine LITHOPIA MAX AY1-700 of Mitsubishi Heavy Industries, Ltd., the Figure 4 Polybelt (registered trademark) KCS-350 (width: 15 mm, thickness: 1.1 mm) manufactured by nitta Co., Ltd. with the structure shown in the figure was printed and operated to obtain 16-page guillotine signatures 60 of A4 size.

[0170] In addition, the static friction coefficient of the lower conveying surface 103 and the upper conveying surface 105 against the surface formed of the iron-based material is 0.2 or more and less than 0.3.

[0171] At this time, as the roll paper 19, the grammage is 49g / m 2 、73g / m 2 Two types of coated paper, the printing speed, that is, the rotation speed of the printing plate cylinder 25 changes to 600, 650, 700, 750, 800rpm, and it is measured whether the signature 59 that contacts the paper stopper 87 occurs at each rotation speed Destruction (collision destruction).

no. 2 approach

[0190] Next, a rotary printing press 1 according to a second embodiment of the present invention will be described with reference to FIG. 8 .

[0191] Since the basic structure of this embodiment is compared with that of the first embodiment, only the structure of the clamping force increasing part is different, so here the description will be mainly focused on the different parts, and the parts that are the same as those of the aforementioned first embodiment will be omitted. Repeat instructions.

[0192] In addition, the same code|symbol is attached|subjected to the same component as 1st Embodiment.

[0193]In the present embodiment, the upstream curved portion (plate member) of the knife table 85 extends upstream, for example, to the vicinity of the upper paper guide roller 81 on the upstream side.

[0194] The curved portion W may have a certain degree of curvature, or may sequentially change the degree of curvature.

[0195] Unlike the first embodiment, the pinch roller...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com