Buffer breakage-proof flat bottom silo

A flat-bottomed, anti-shattering technology, applied in loading/unloading, container, packaging, etc., can solve the problems of difficult maintenance, complex structure, etc., to achieve the effect of low operating costs, high crushing rate, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

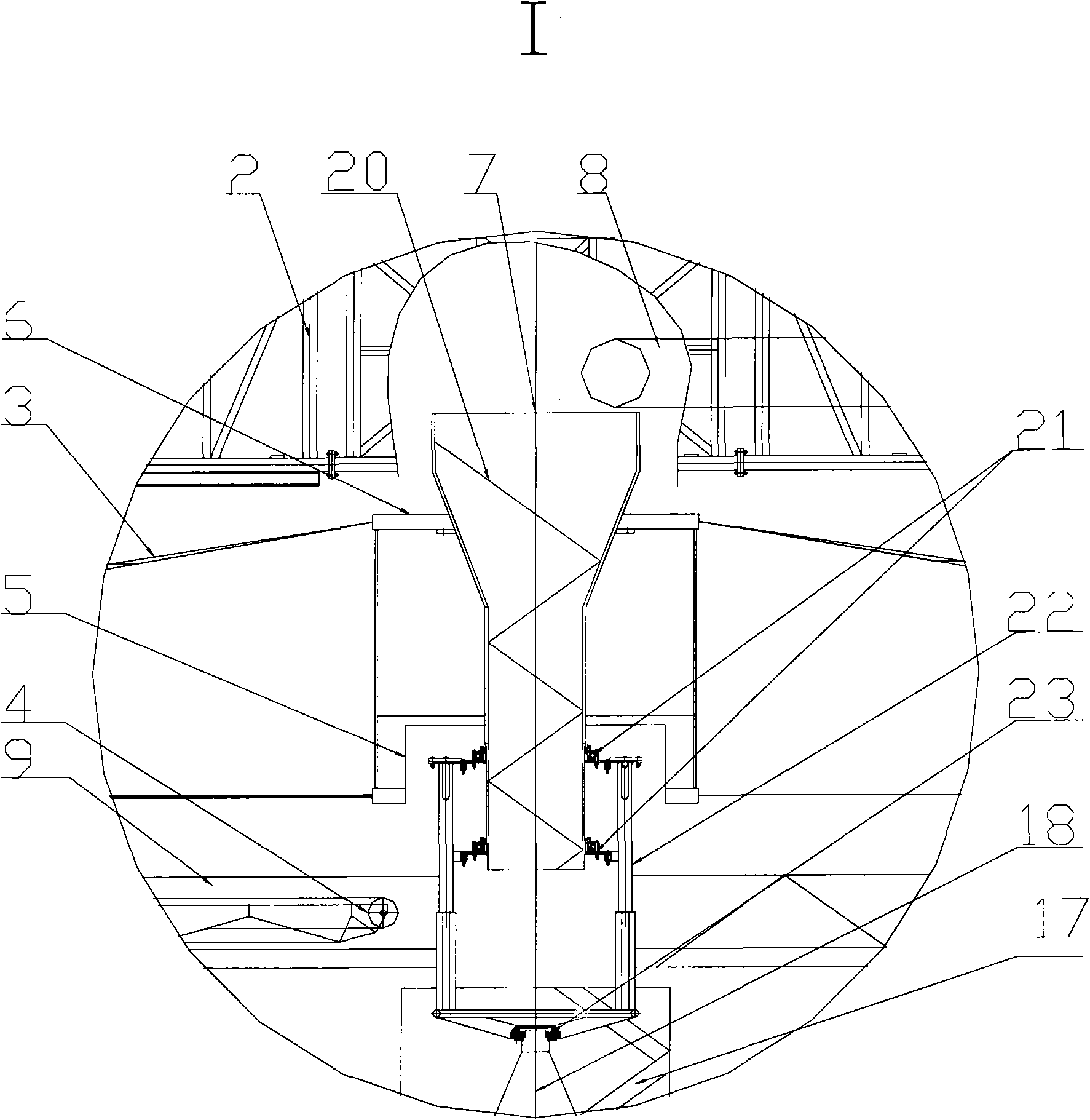

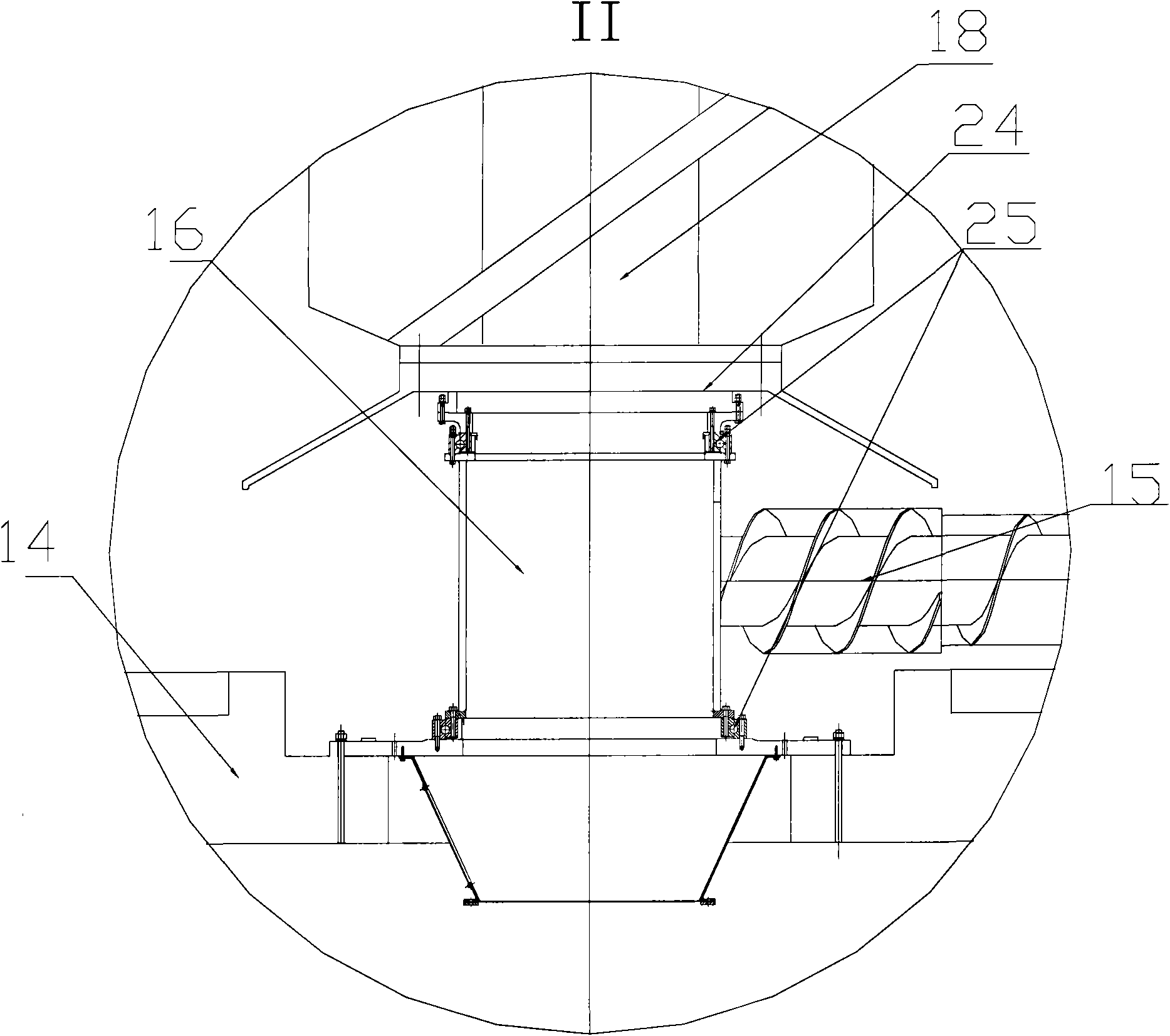

[0024] The structure of the feeding buffer and anti-shattering device of the flat-bottomed silo is as follows: figure 1 As shown, it includes girder 2, center blanking barrel 7, feed port 8, rotary distribution bridge 9, lower rotary center blanking barrel 16, center column outer spiral chute 17, center column 18, rigid mechanism 19, center blanking barrel Inner spiral chute 20.

[0025] Such as figure 2 As shown, the central blanking cylinder 7 with the inner spiral chute 20 is connected with the silo ceiling 3 and the silo wall 12 through the top flange 6; The central reinforcing ring 5 in 1 is connected as a whole. The center blanking cylinder 7 is fixed in the center of the silo.

[0026] The rigid mechanism 19 is made up of a plurality of connecting rods 22 . The upper part is connected with the central blanking cylinder 7 through double slewing bearings 21, and the lower part is connected with the central column 18 through self-aligning bearings 23.

[0027] The ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com