Metal air bag door system

An airbag door and metal technology, which is applied in the field of metal airbag door structure and system, can solve the problems of glass breakage, large turning radius, occupant injury, etc., and achieve the effect of reducing the turning speed, reducing the turning radius and alleviating the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention is further described, so that it can better understand the function and characteristics of this patent.

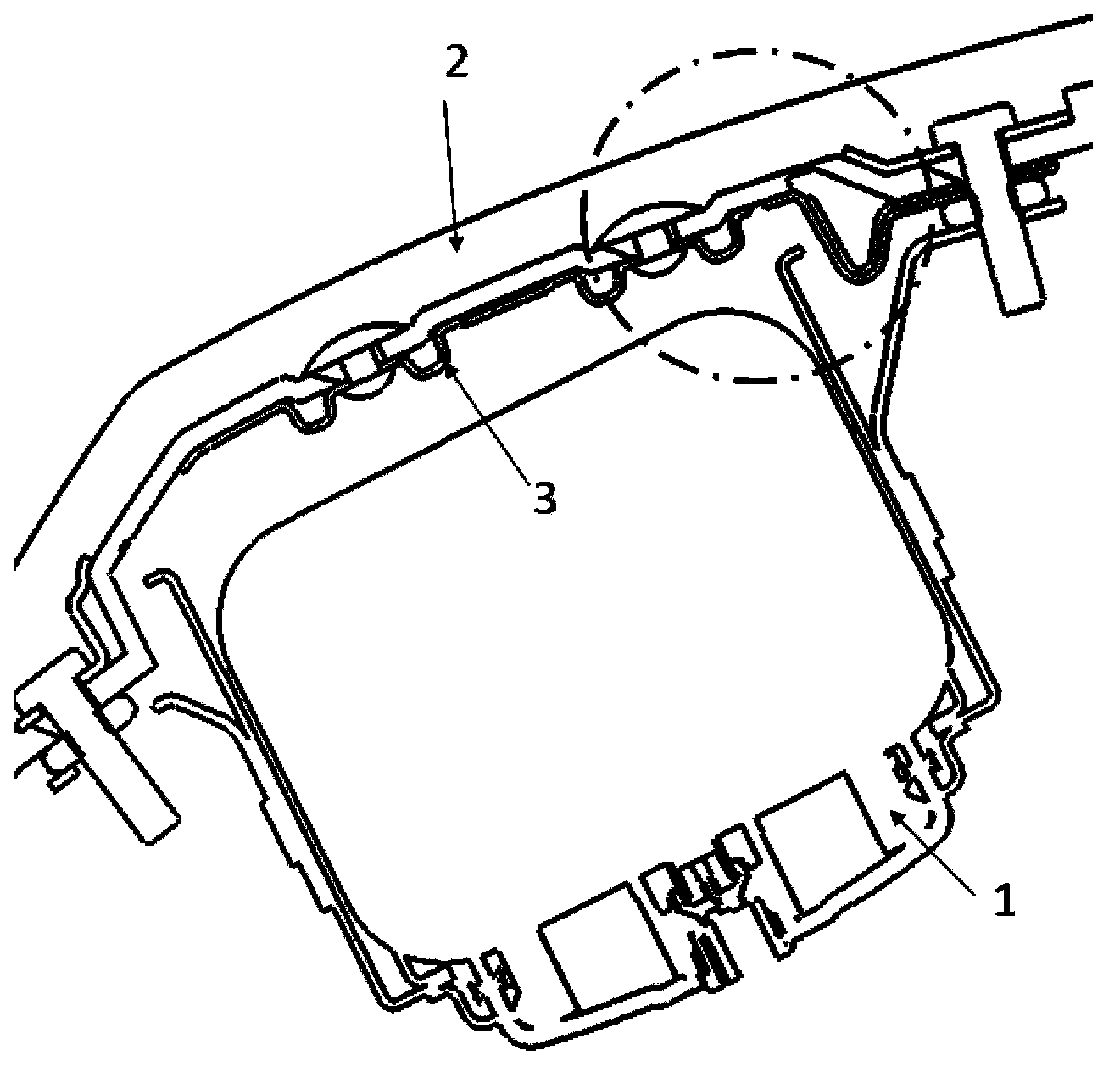

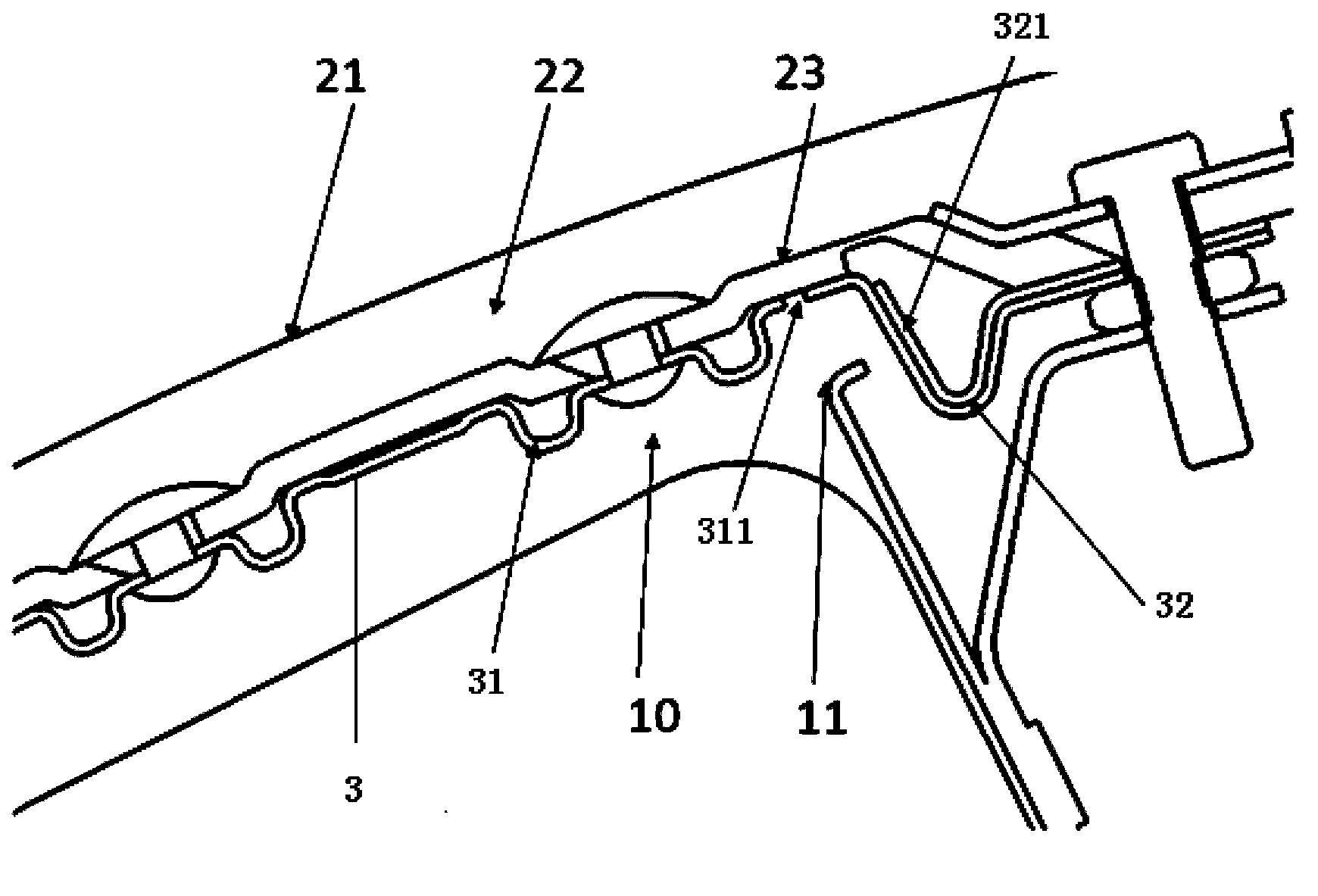

[0029] see Figures 1 to 3 , the metal airbag door system of this embodiment covers the airbag opening 10 of the airbag module 1 on the passenger side of the instrument panel, and includes the instrument panel cover 2 and the metal airbag door structure 3 .

[0030] The instrument panel cover 2 includes a skin 21 , a foam layer 22 and a skeleton 23 which are sequentially connected from top to bottom, and the instrument panel cover 2 is provided with a metal airbag door weakening line.

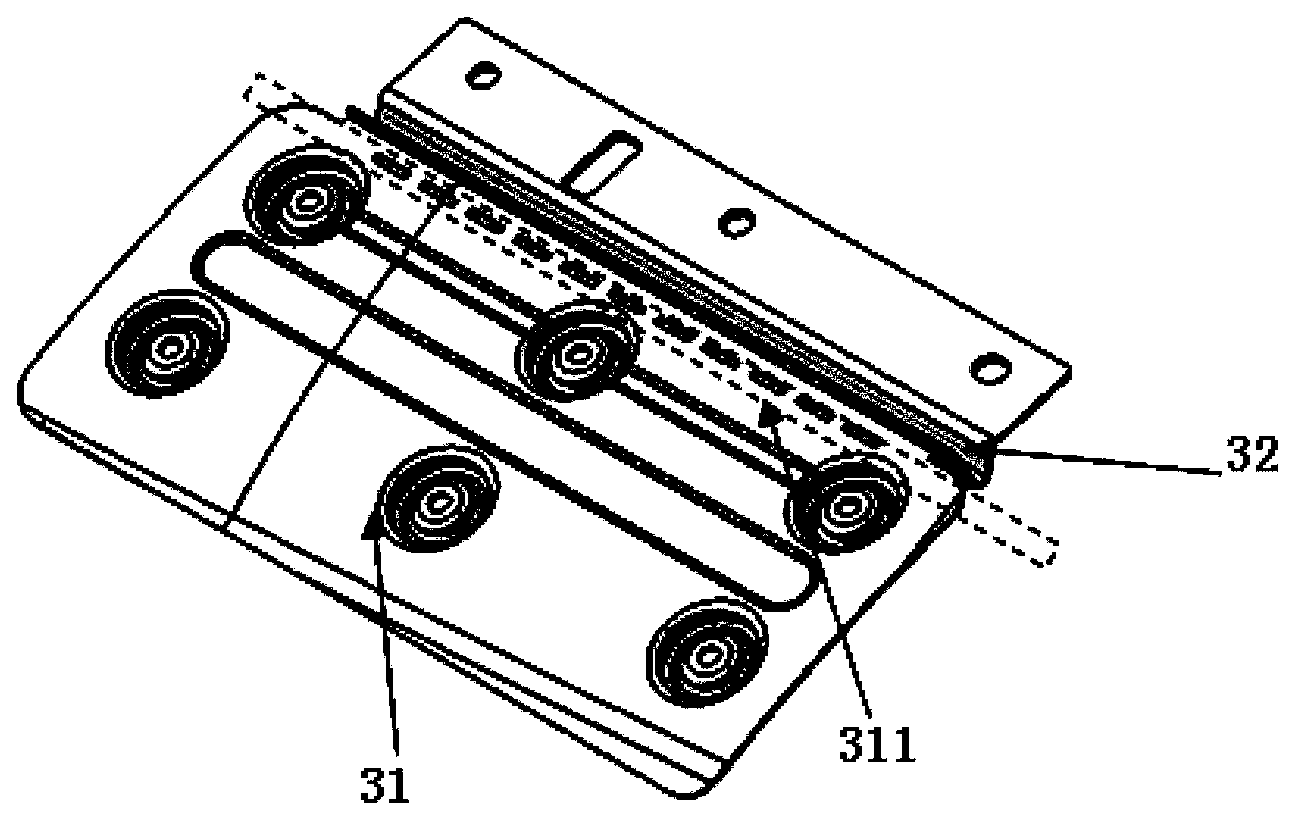

[0031] The metal airbag door structure 3 is used to turn over the metal airbag door structure 3 , and includes an airbag door body 31 and a hinge portion 32 connected to one side of the airbag door body 31 . Wherein, the airbag door body 31 is fixedly connected to the bottom surface of the frame 23 , and the hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com