Method and device for making box of corrugated cardboard sheet

A corrugated board and corrugated technology, applied in the field of boxes and devices used to produce corrugated boards, can solve the problems of polluting the surrounding environment and reducing the quality of corrugated board boxes, and achieve double production efficiency, improved cutting accuracy, and improved folding accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

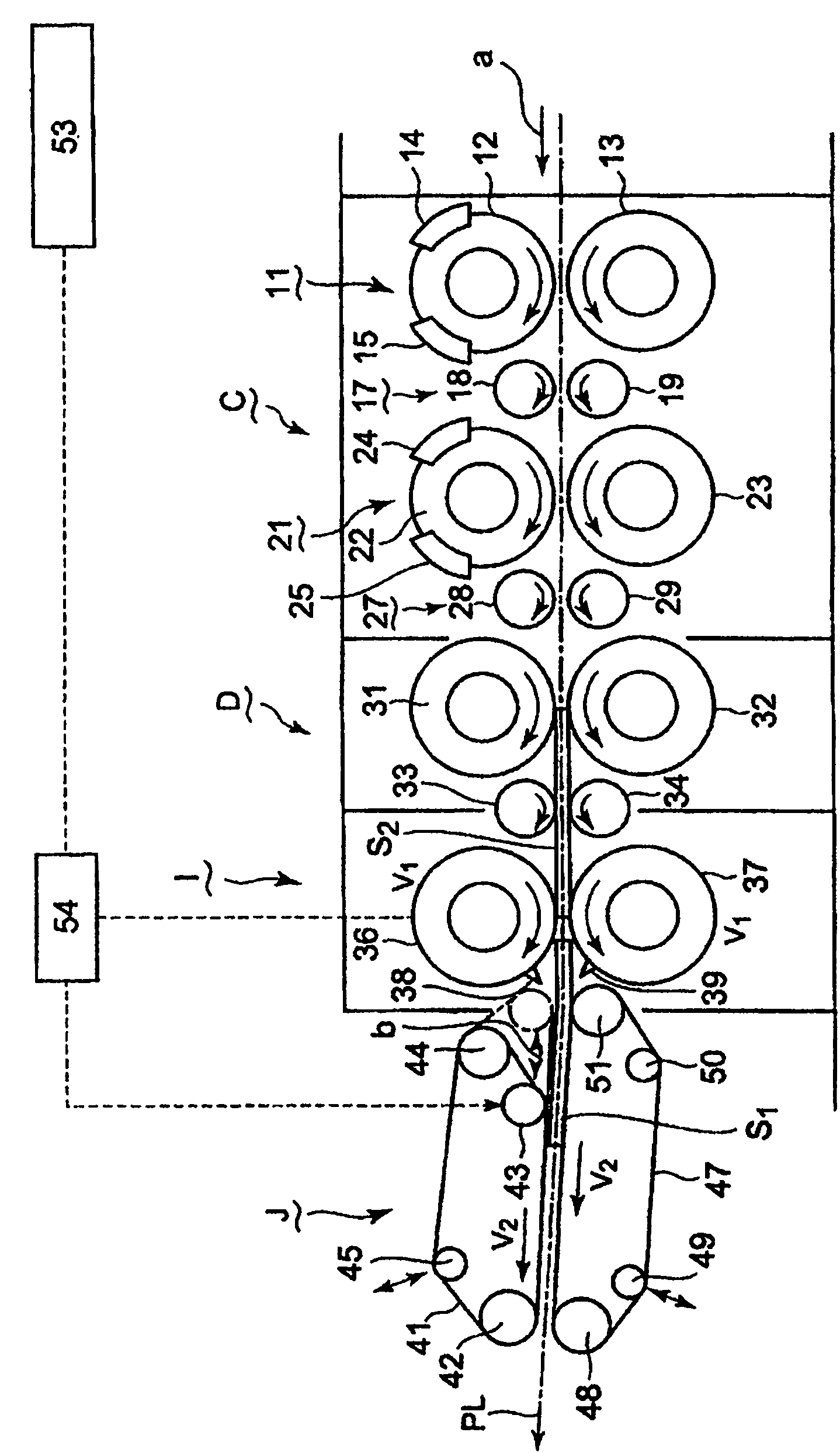

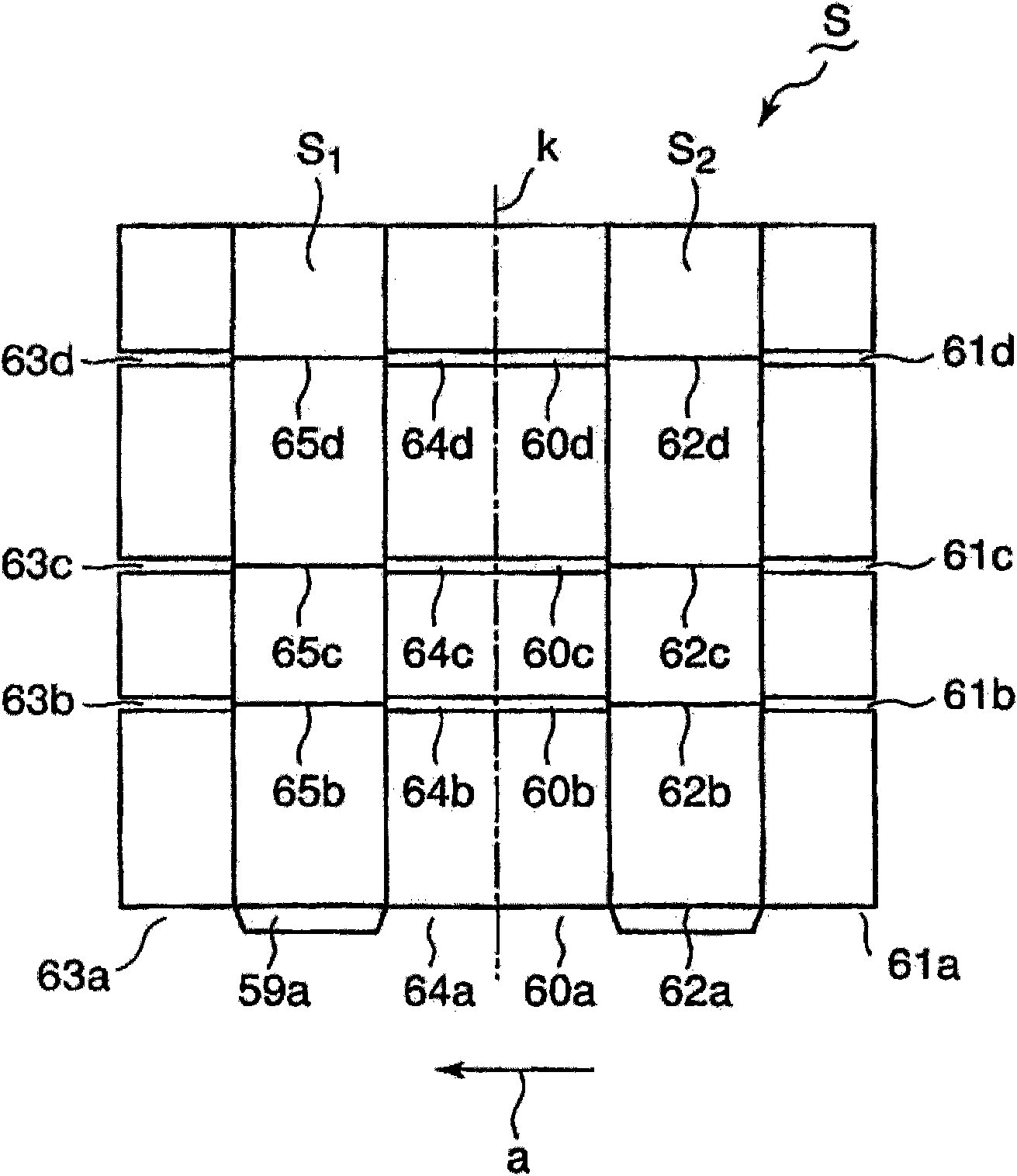

[0049] refer to figure 1 and figure 2 The first embodiment of the present invention is explained. figure 1 A part of the box production line of this embodiment is shown. figure 2 A two-box joining panel S (after the creasing and slitting steps) is shown, having the dimensions of two corrugated board boxes, to be produced in a box production line. exist figure 1 In , the corrugated board sheet S that has been printed by a flexographic printing machine not shown in the figure is transferred to the groover·crisler unit C. The slotting machine creasing machine unit C has a first slotting machine unit, a first creasing machine unit 17, a second slotting machine unit 21, and a second crimping machine unit arranged from upstream to downstream along the traveling direction of the corrugated sheet. Folding unit 27. The first notcher unit 11 comprises an upper notcher 12 and a lower notcher 13 arranged to be inserted into the conveyor line PL of the corrugated sheet. The uppe...

no. 2 example

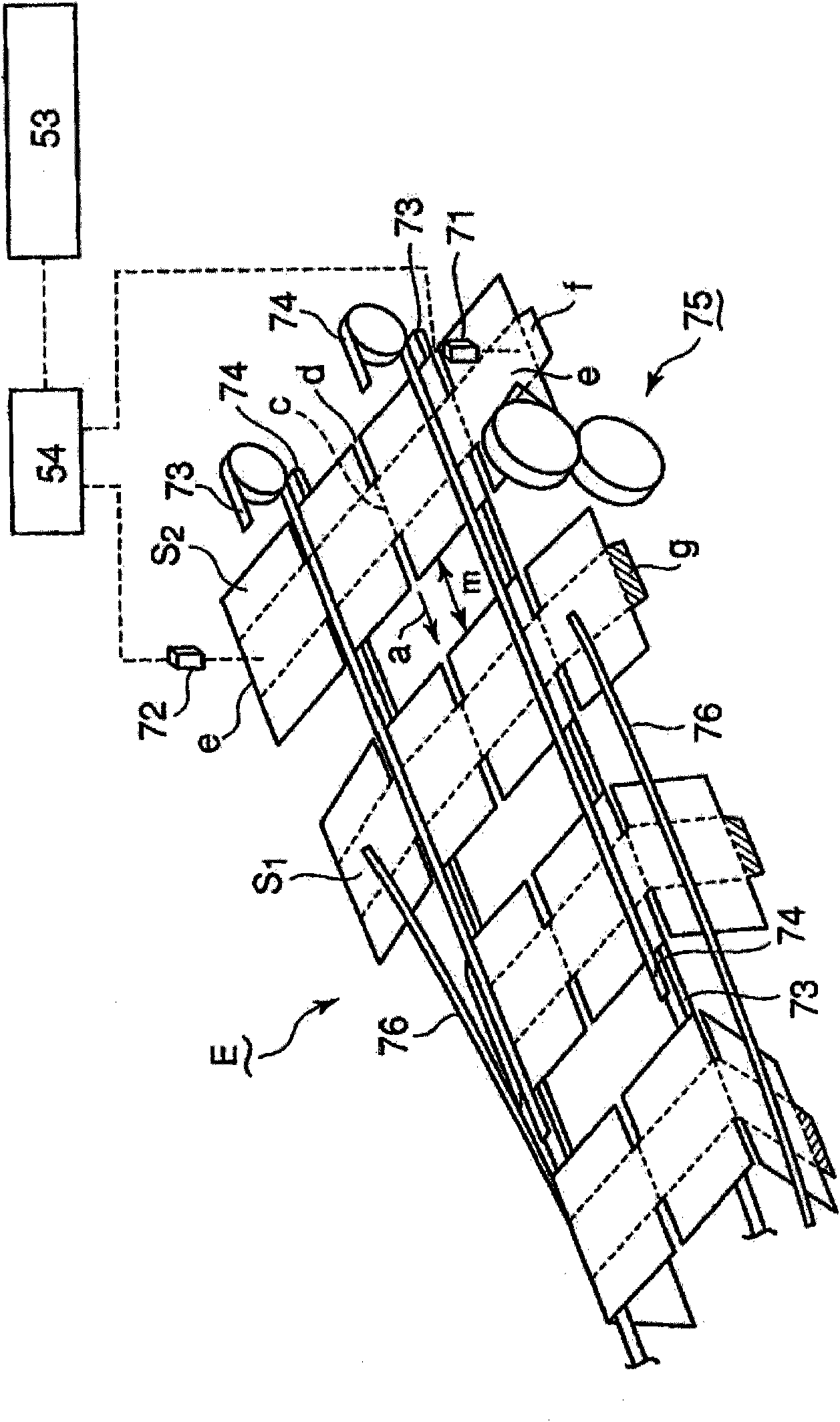

[0074] Next, refer to image 3 A second embodiment of the present invention is explained. image 3 is a perspective view of the folding unit E installed continuously on the downstream side of the speed increasing unit J of the second embodiment. In this embodiment, the structure of the box production line on the upstream side of the speed increasing unit J is the same as that of the first embodiment. as in image 3 As shown in the small corrugated sheet S 1 and S 2 In the state of being placed between the left and right paired guide rails 73, 73 and the left and right paired transfer belts 74, 74, the cut portion I is symmetrically cut and is transferred in the folding unit E along the direction shown with the arrow a The small corrugated plates S separated by the speed increasing unit J 1 and S 2 .

[0075] While being transferred, the gluing unit 75 applies glue g to the gluing edge f and the folding bars 76 arranged on the left and right sides of the transfer directi...

no. 3 example

[0079] Below, refer to Figure 4 A third embodiment of the present invention is explained. Figure 4 shown corresponding to figure 1 , the box manufacturing line of the present embodiment. exist Figure 4 Among them, a pair of transfer rollers 81a and 81b are arranged to be inserted into the conveying line PL of the corrugated board sheet on the immediately downstream side of the upper and lower cutting rollers and transfer the cut small corrugated board along the transfer direction a of the corrugated board sheet Slices 1 and S 2. The transfer roller 81a is connected to the output shaft of the servo motor 82 and is rotated by the servo motor. The transfer roller 81b is a driven roller and guides the small corrugated sheet S passing the transfer rollers 81a and 81b in the transfer direction a 1 and S 2 .

[0080] A detector 83 such as a rotary encoder is connected to the rotation shaft of the upper cutting roller 36, and detects the cutting timing at which the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com