Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Improve pipe bending efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

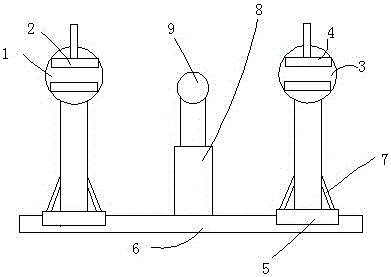

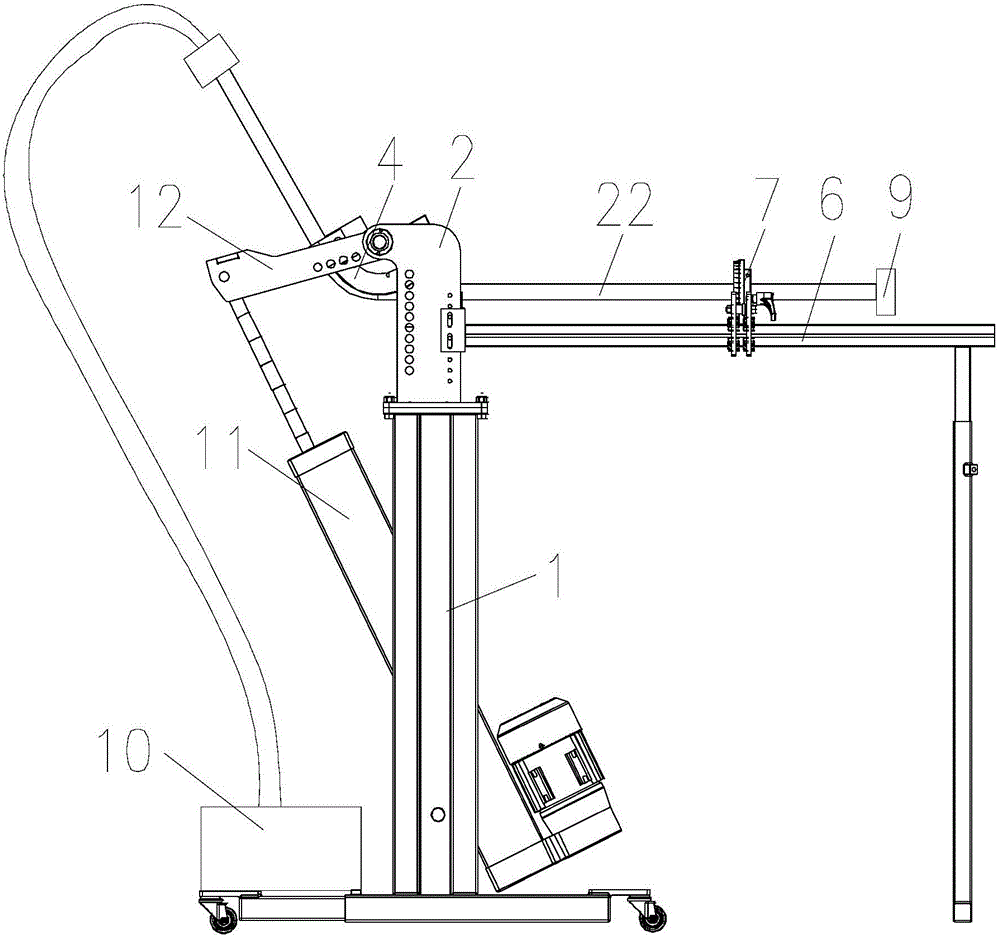

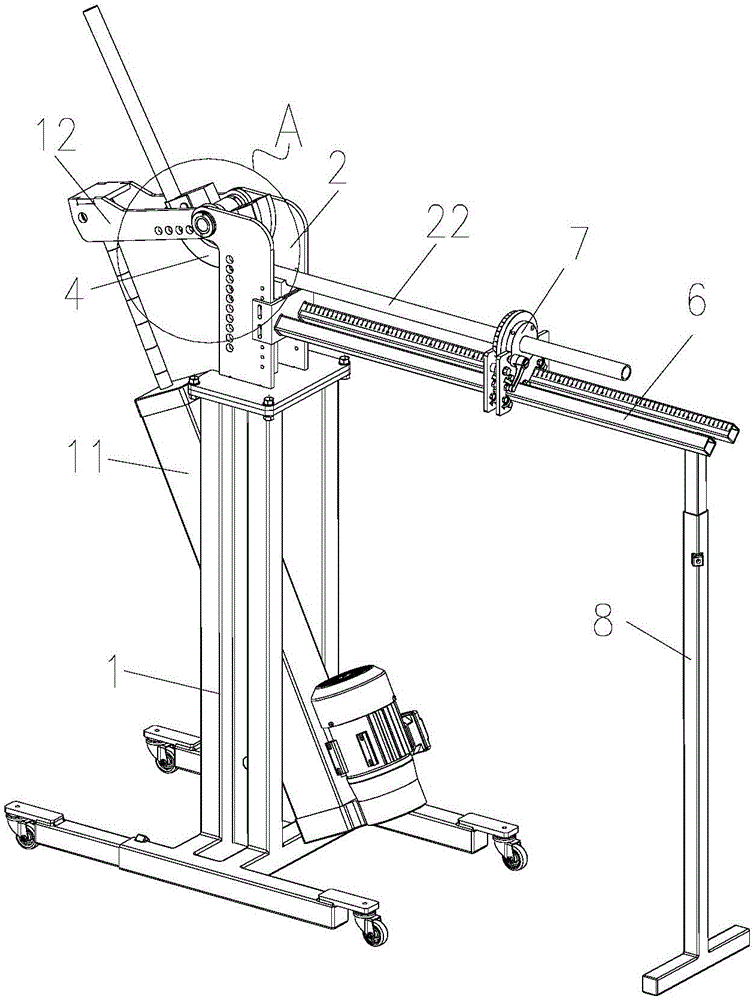

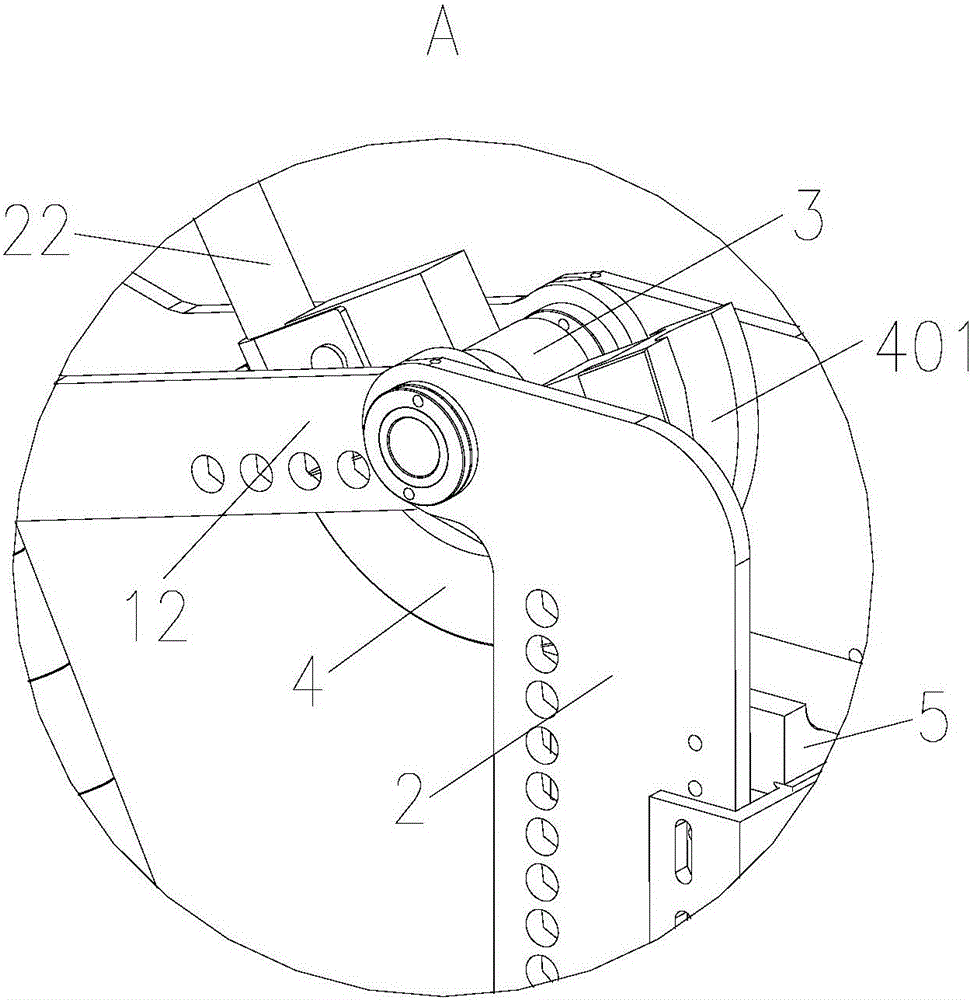

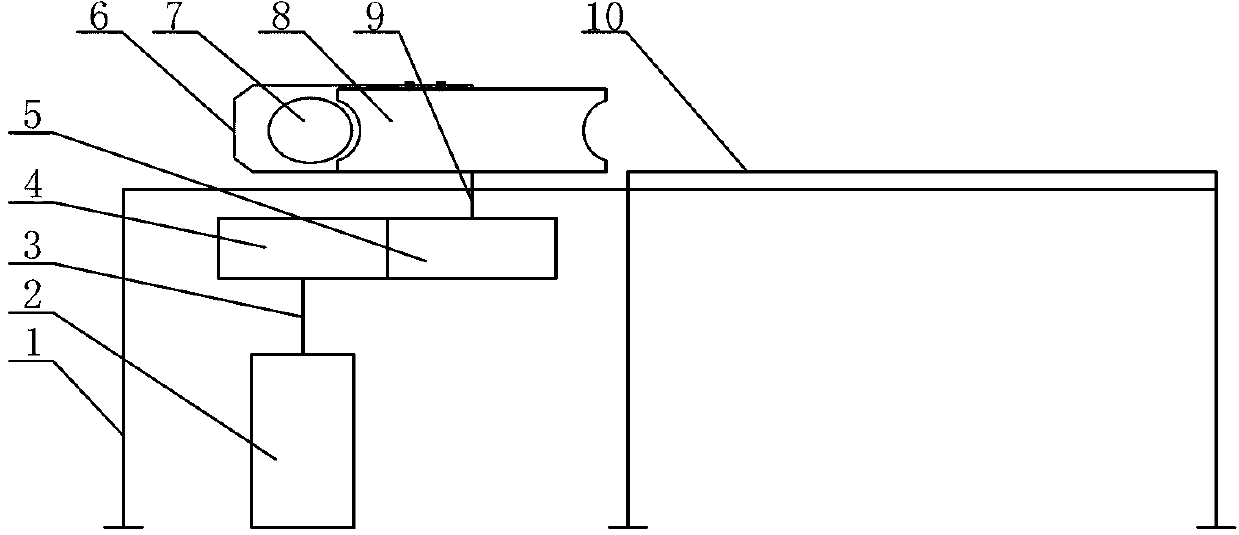

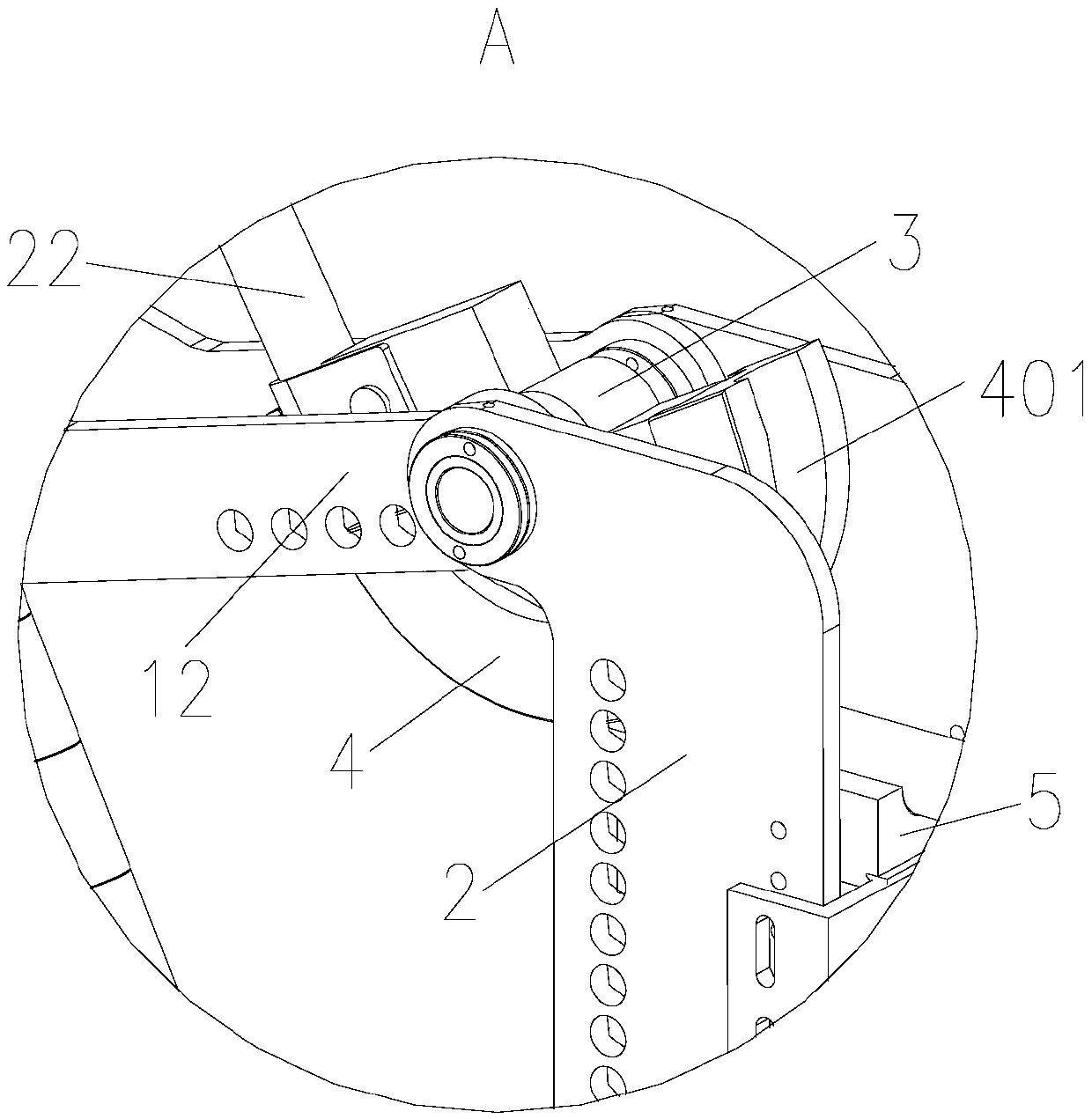

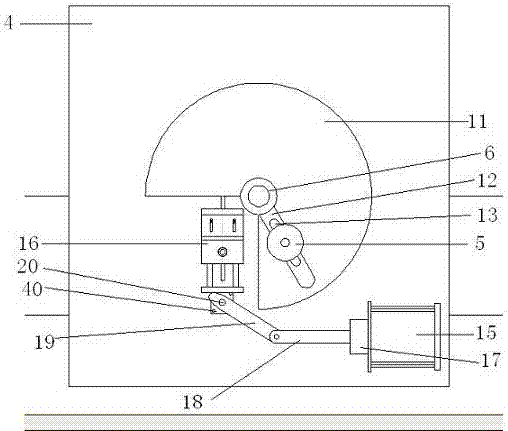

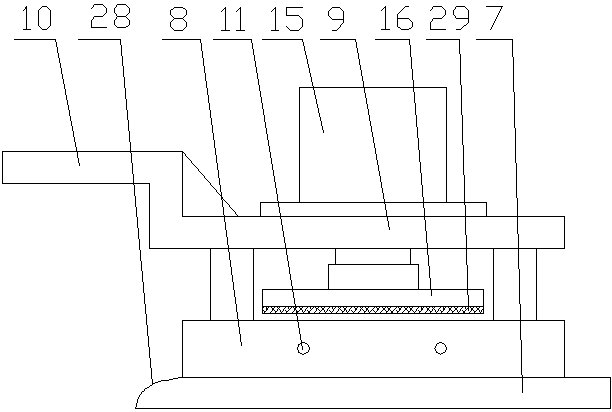

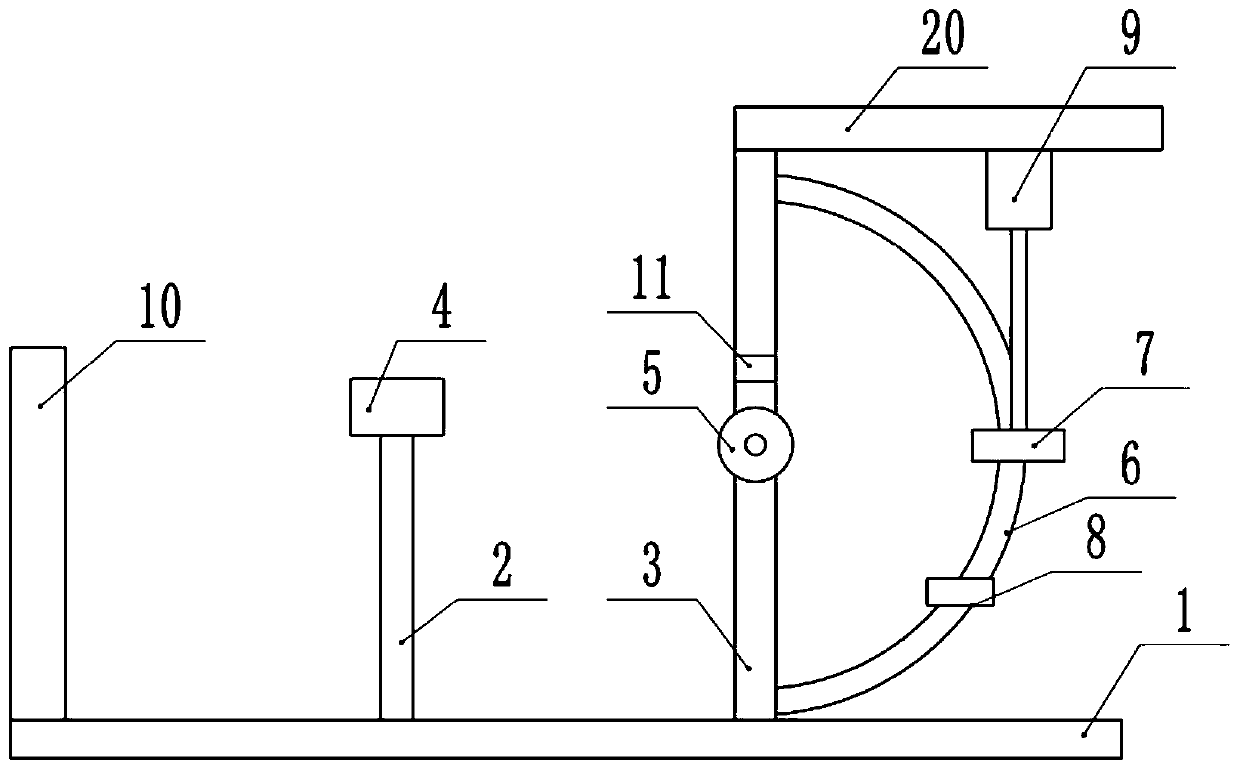

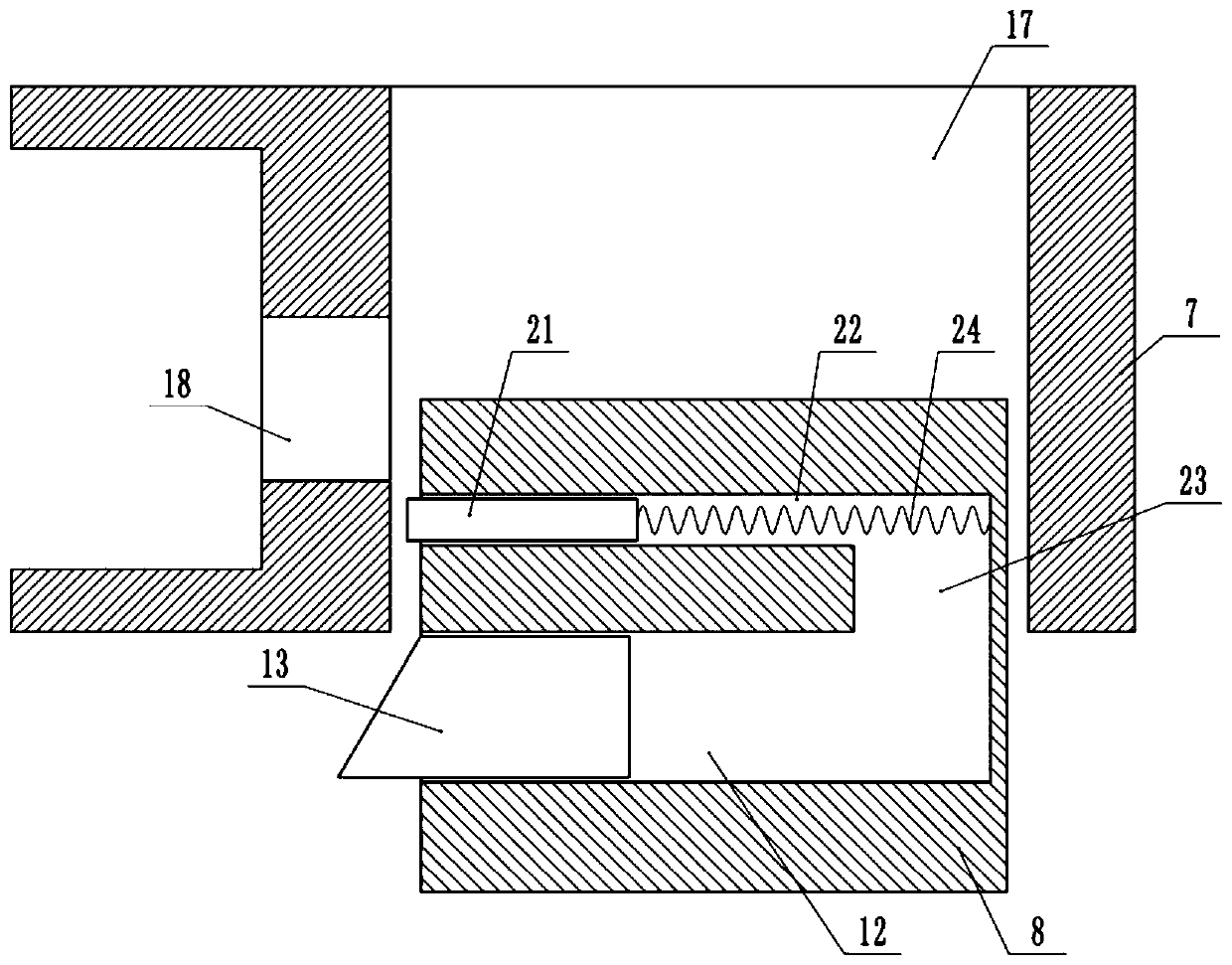

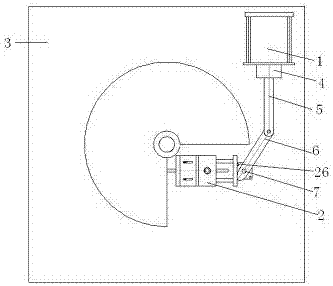

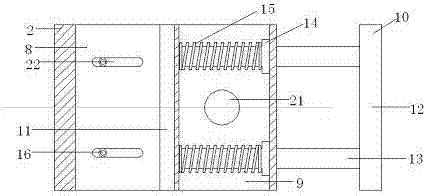

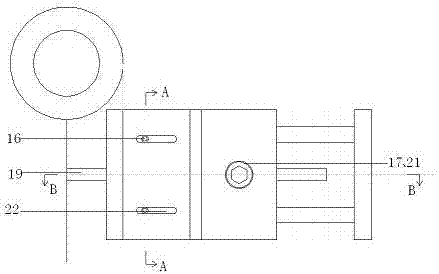

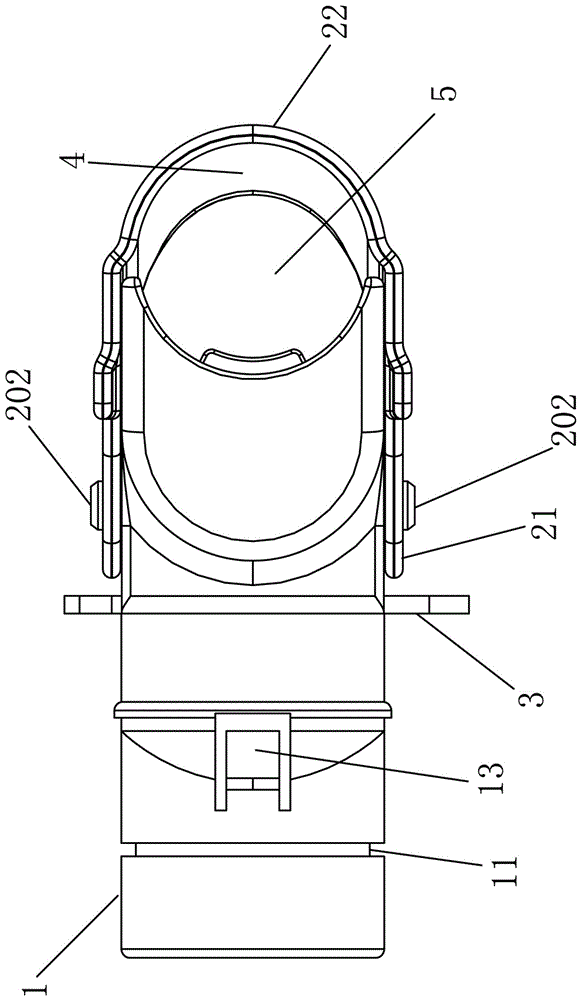

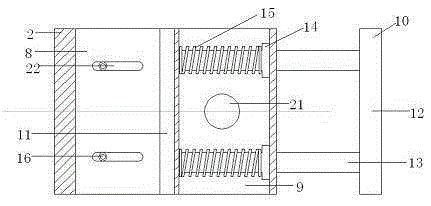

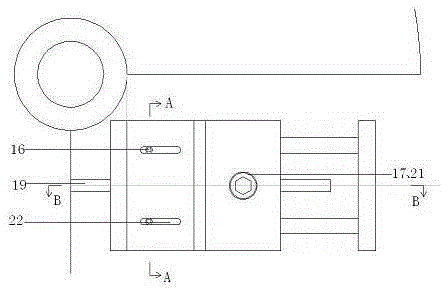

Pipe bending machine with sliding chuck

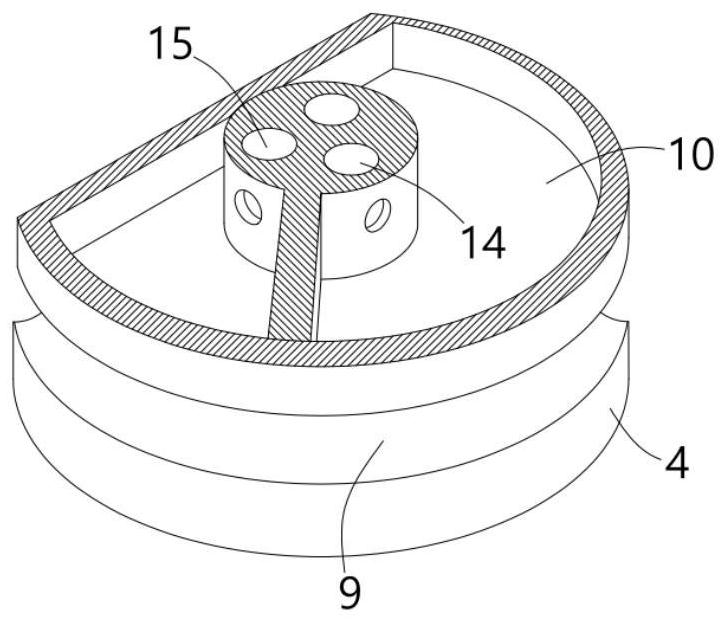

InactiveCN107433295ASimple organizationEasy to manufacture and installMetal-working feeding devicesPositioning devicesEngineeringRotating disc

The invention discloses a pipe bending machine with a sliding chuck. The pipe bending machine comprises a first fixing portion, a second fixing portion and a middle bending portion, the first fixing portion comprises a first rotating disc and a first clamping jaw fixed on the first rotating disc, the second fixing portion comprises a second rotating disc and a second clamping jaw fixed on the second rotating disc, the middle bending portion is arranged between the first fixing portion and the second fixing portion, the first rotating disc and the second rotating disc are arranged vertically, the rear portion of each disc body is movably connected with the upper end of a supporting rod, a fixing seat is arranged on the lower portion of the supporting rod, and a bottom sliding rail capable of sliding freely on the fixing seat is arranged on the lower portion of the fixing seat. The pipe bending machine is simple in integral structure and convenient to mount, manufacture and operate, pipe bending quality and pipe bending efficiency of the pipe bending machine can be improved effectively, and the pipe bending machine is high in practicability.

Owner:张家港博洋机械制造有限公司

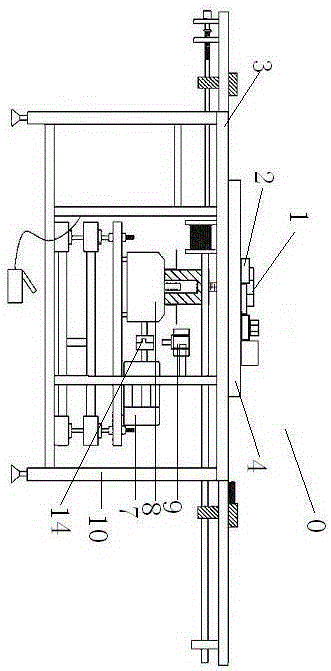

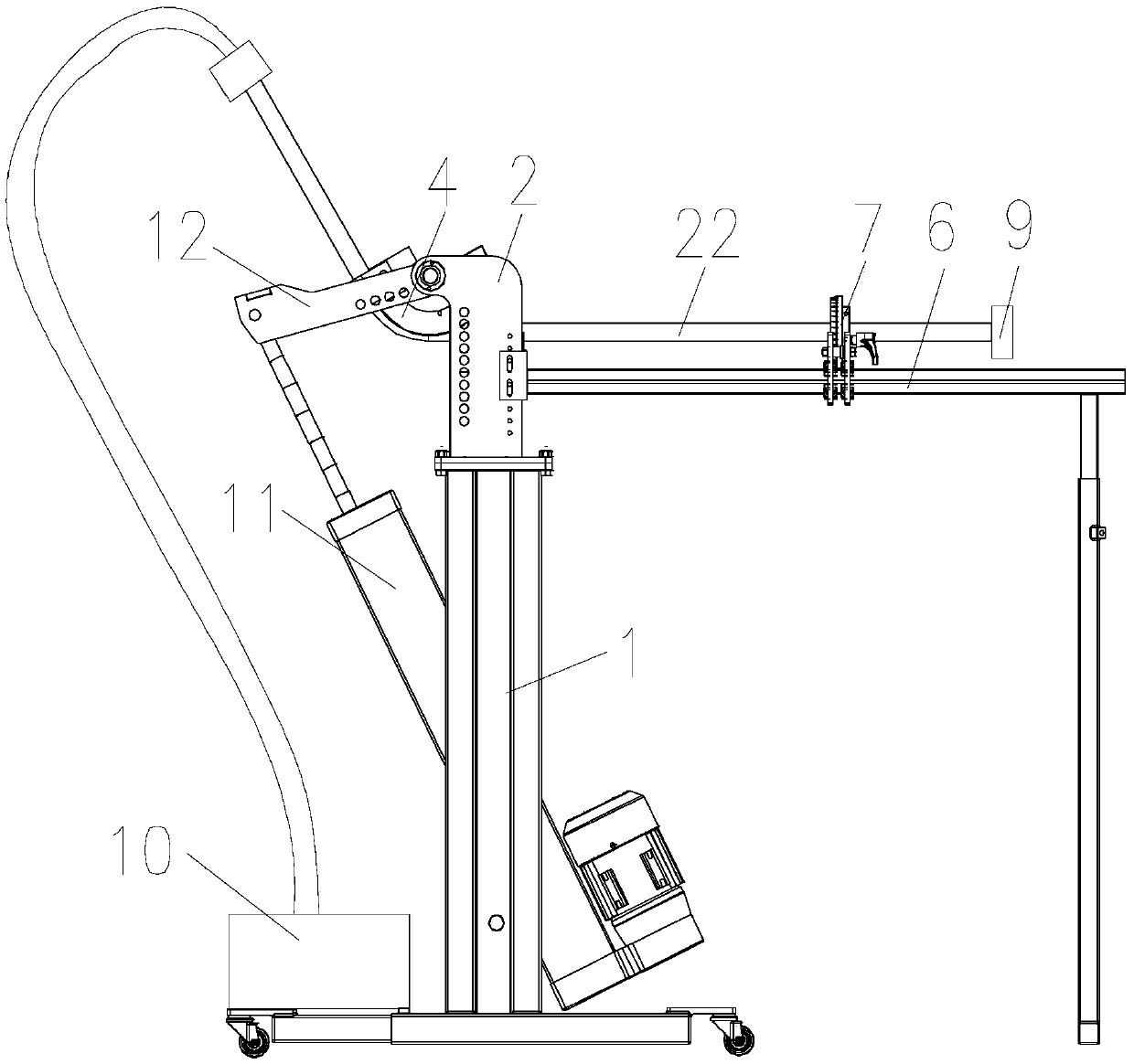

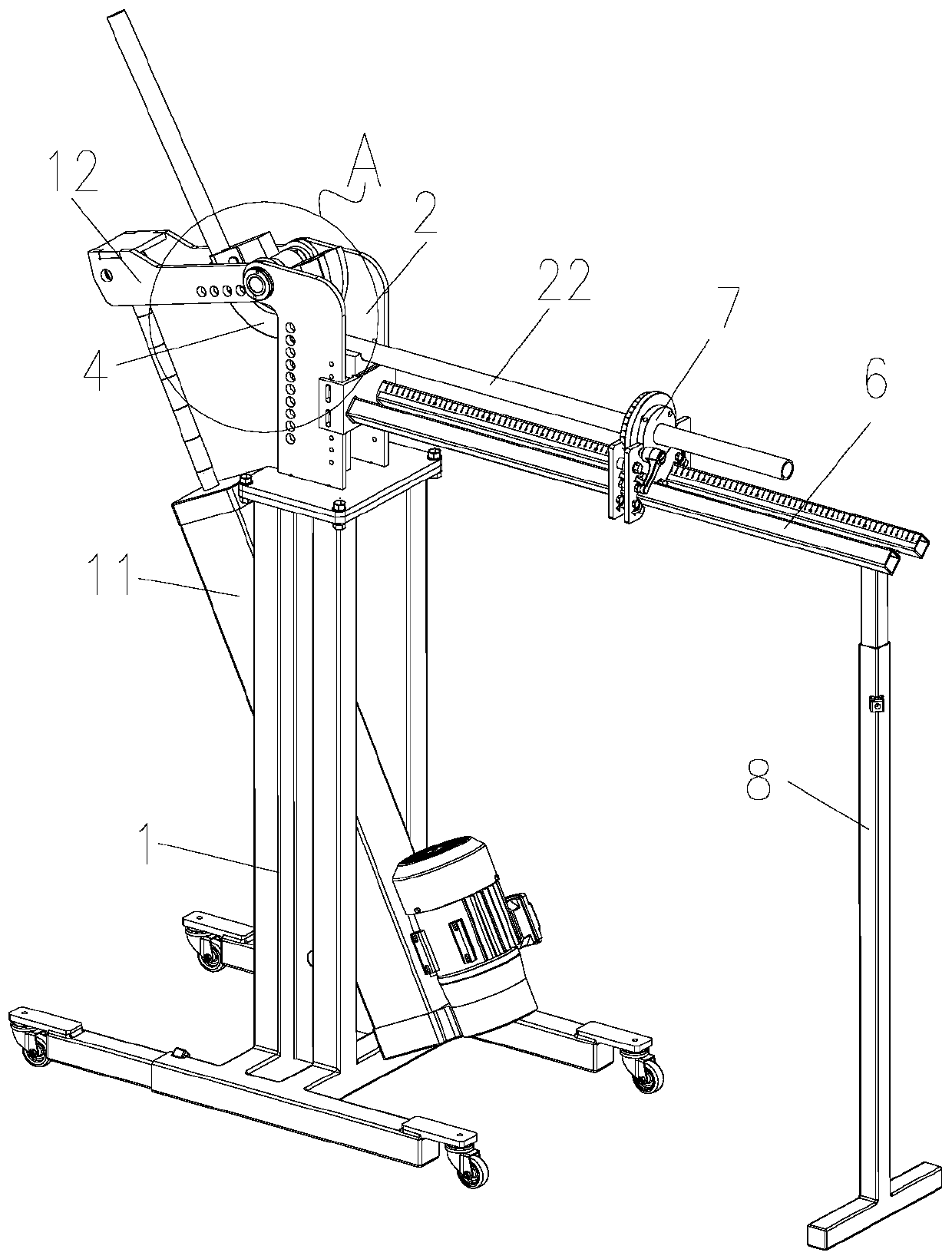

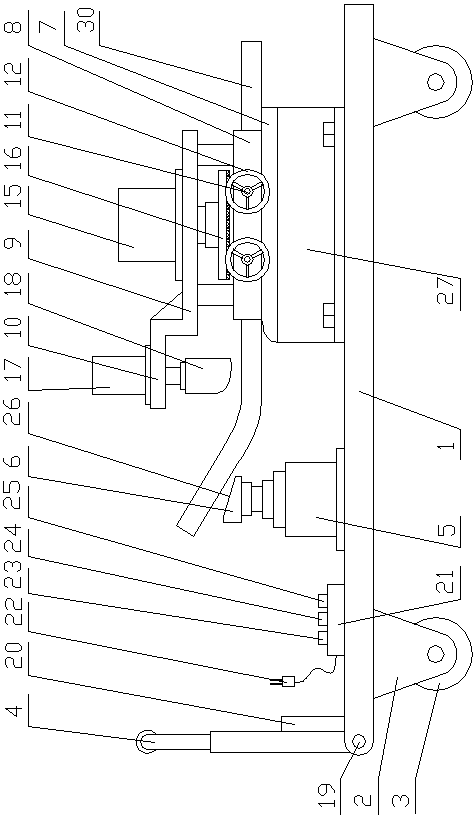

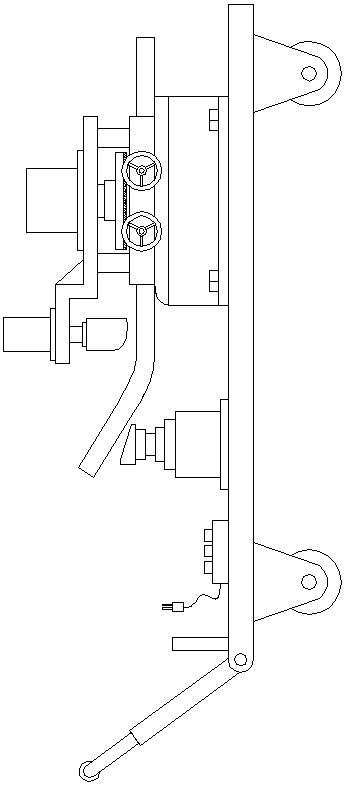

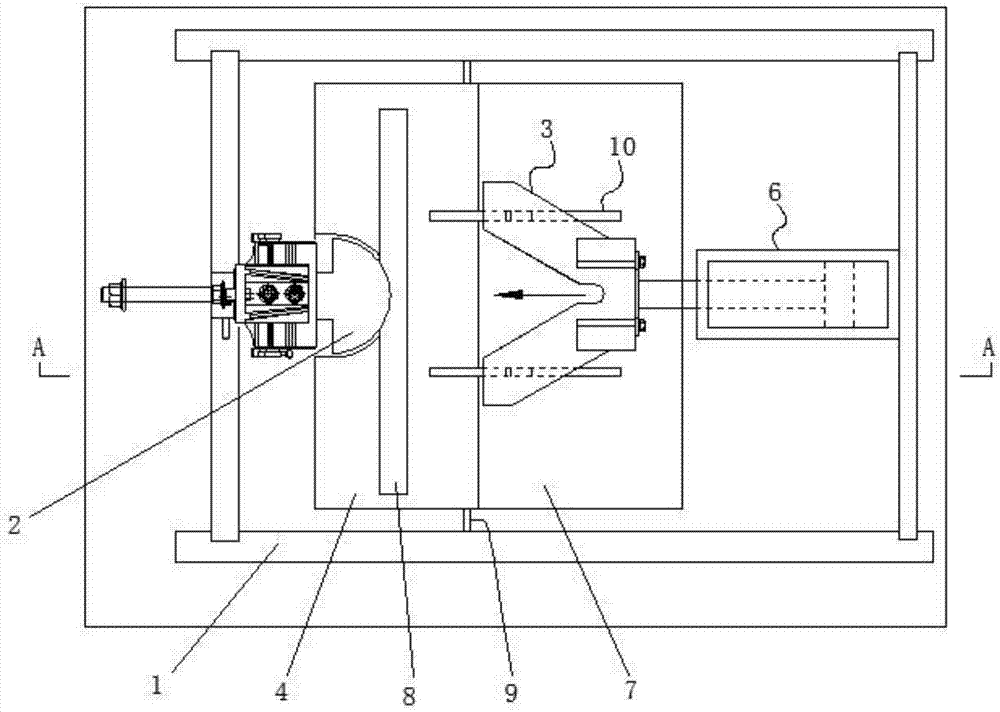

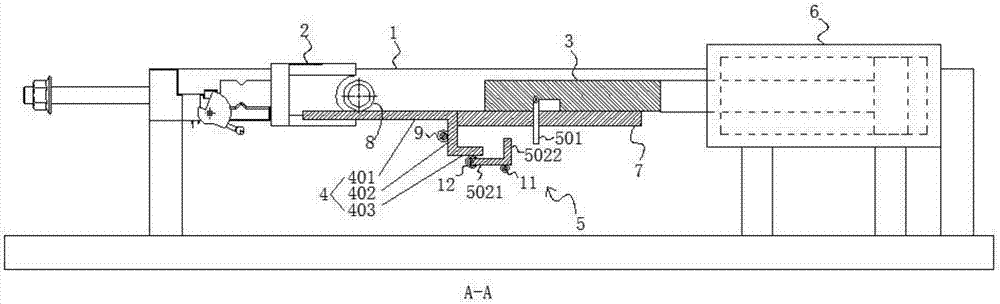

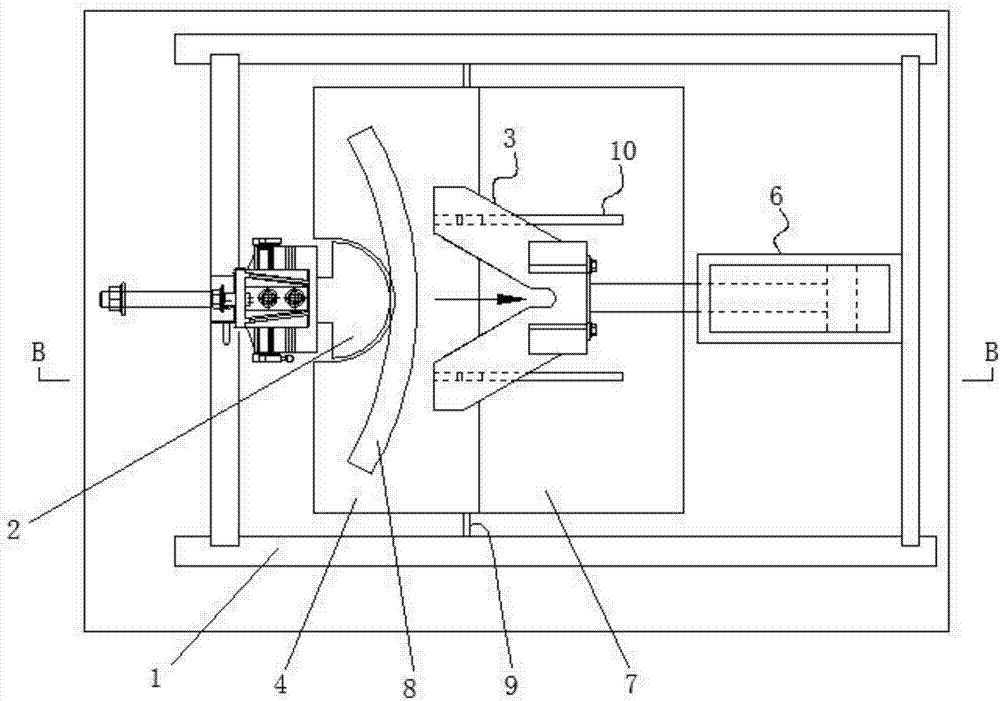

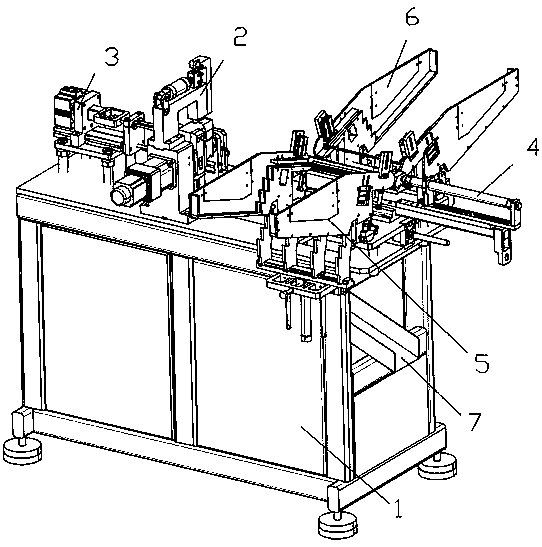

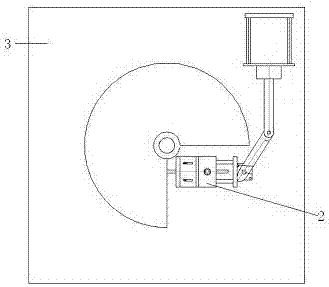

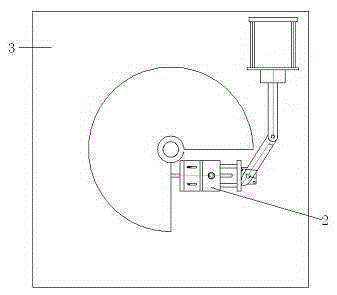

Full-automatic pipe bending machine

InactiveCN105215111ASimple structureReasonable designMetal-working feeding devicesPositioning devicesOptical axisEngineering

The invention discloses a full-automatic pipe bending machine. The full-automatic pipe bending machine is characterized by comprising a pipe bending device, a clamping device and an automatic aligning device, wherein a telescopic cylinder pushes a connecting rod and drives a regulating rod, so that the tip end of the regulating rod is resisted against a pressure plate of a clamping part, and therefore, a clamping plate of the clamping part clamps a workpiece, the operation is simple and quick, the labor force is small, the labor cost is reduced, and the pipe bending efficiency is also improved; during aligning, an aligning air cylinder drives an optical axis at one side to move; a gear is matched with a rack, so that an optical axis at the other side synchronously and oppositely moves, and then left and right slide paths on side plates at the two sides of the full-automatic pipe bending machine are synchronously aligned, and therefore, the aligning position is accurate, the aligning efficiency is high and manual aligning is completely replaced, the aligning is time-saving and labor-saving, working efficiency of pipe bending is greatly improved, and pipe bending process is optimized; and meanwhile, the full-automatic pipe bending machine is low in manufacturing cost, and production cost is reduced.

Owner:JIANGSU XINSIWEI PHOTOELECTRIC CO LTD

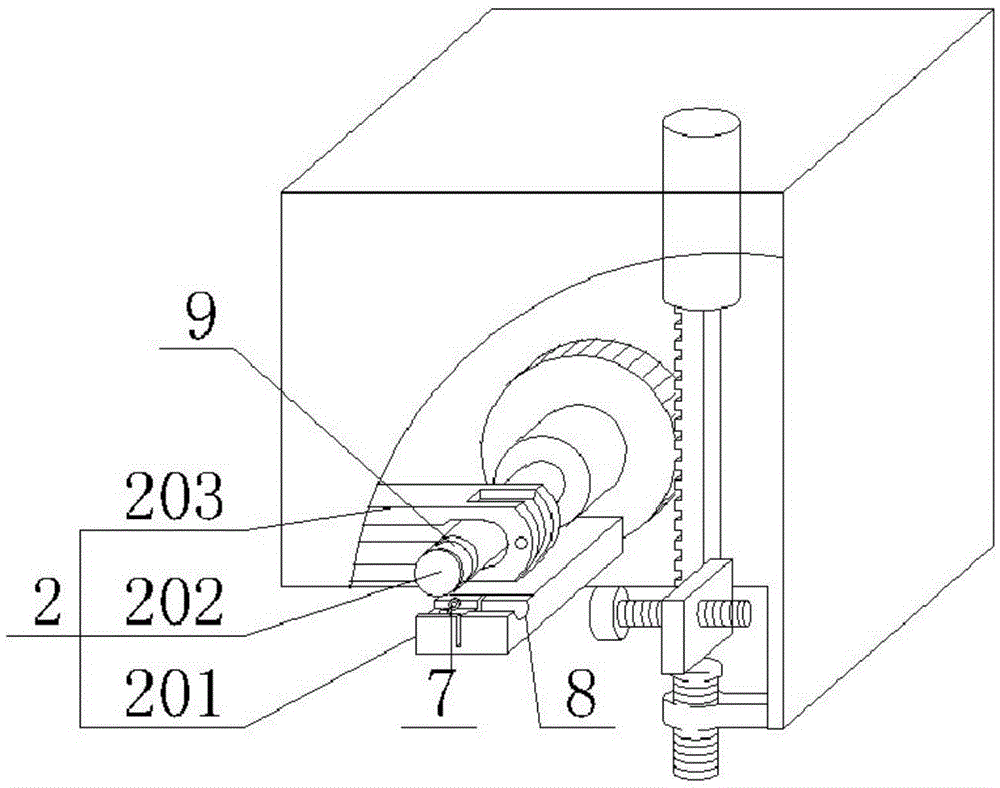

Seamless steel pipe bending machine

The invention relates to the technical field of tube bending machines, in particular to a seamless steel tube bending machine. The seamless steel tube bending machine comprises a rack and two side wings arranged on the rack. A rotating block is rotationally connected between the side wings and detachably connected with a semicircular tube bending die. A tube bending groove matched with a seamless steel tube is formed in the circumferential face of the tube bending die. A drive mechanism is arranged on the rack. A supporting plate is arranged below the rotating block and provided with a supporting groove matched with the seamless steel tube. A clamping mechanism for clamping the seamless steel tube to the tube bending die is arranged on the rotating block. A sliding frame is arranged at the side of the side wings and is in sliding connection with a sliding block. A plug is arranged at one end of the seamless steel tube, and the other end of the seamless steel tube is communicated with a high-pressure air source. The seamless steel tube bending machine is simple in structure and convenient to use, the tube bending die is conveniently replaced, and the tube bending efficiency is high; and high-pressure air is introduced into the seamless steel tube, and therefore some steel tubes with the small wall thickness can be prevented from collapsing or wrinkling inside during tube bending, and the tube bending precision is high.

Owner:JIANGSU WUJIN STAINLESS STEEL PIPE GRP

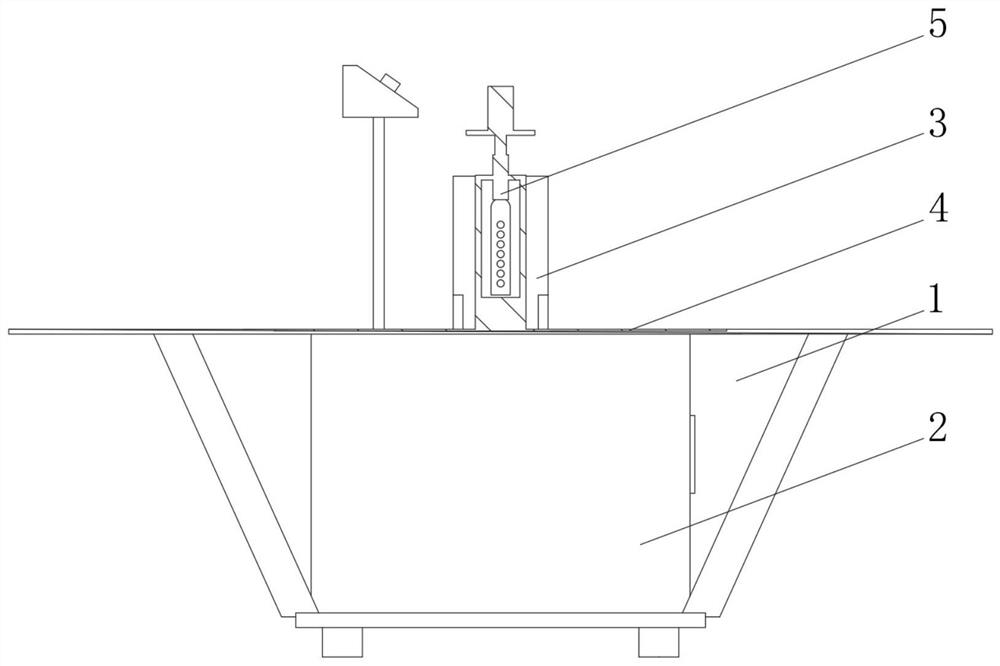

PE pipe pressing tooling

The invention discloses a PE pipe pressing tooling and relates to the technical field of PE pipe machining. The PE pipe pressing tooling comprises a working table, a hydraulic cylinder, an upper pressing die and a lower pressing die. Guide supports are disposed on the two sides of the working table vertically and upwards; a fixing rack is disposed at the upper ends of the guide supports; the hydraulic cylinder is mounted on the fixing rack; the upper pressing die comprises a movable rod; the movable rod is connected with a piston rod of the hydraulic cylinder; the two ends of the movable rod are in sliding joint with the guide supports; a plurality of connecting rods are disposed at the lower end of the movable rod; the heights of the connecting rods are increased gradually from the connecting rods in the middle to the connecting rods on the two sides; rolling wheels are disposed at the lower ends of all the connecting rods; the lower pressing die comprises a fixing plate and a plurality of support frames arranged on the fixing plate; the heights of the support frames are reduced gradually from the support frames in the middle to the support frames on the two sides; the fixing plate is disposed on the working table; and PE pipes are mounted on the support frames. By means of the design, the structure is simple and reasonable, abrasion and scratches to the surfaces of the PE pipes are not prone to occur, the pipe bending efficiency is improved, and the quality of the PE pipes is guaranteed.

Owner:WUHU NEW UNIVERSAL ENVIRONMENTAL SCI TECH

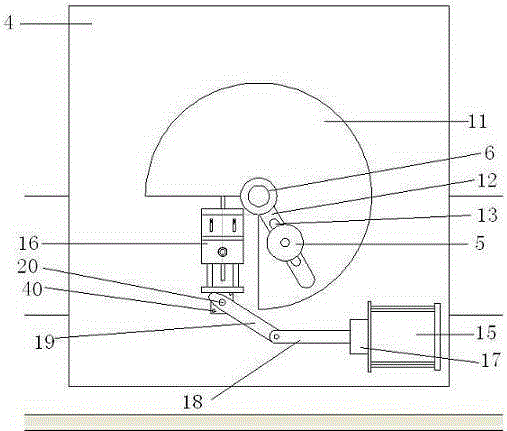

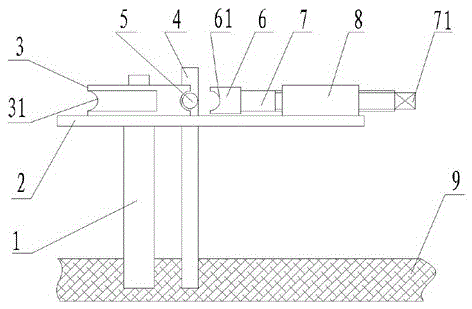

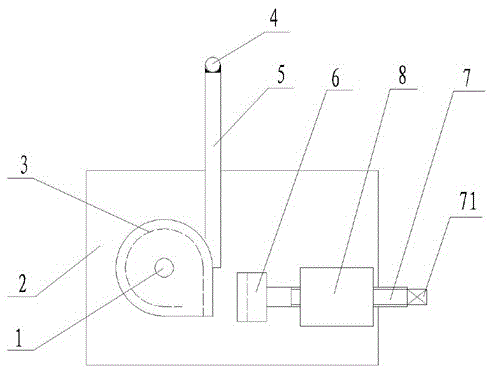

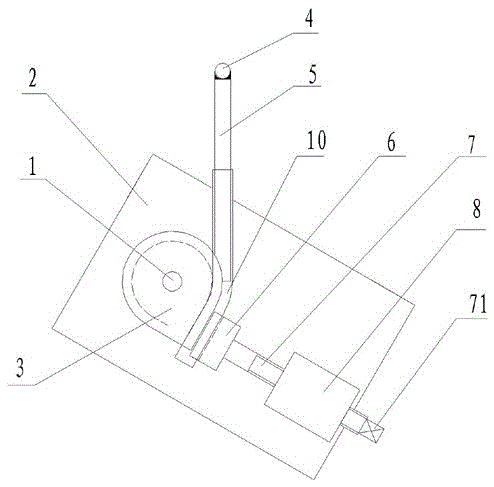

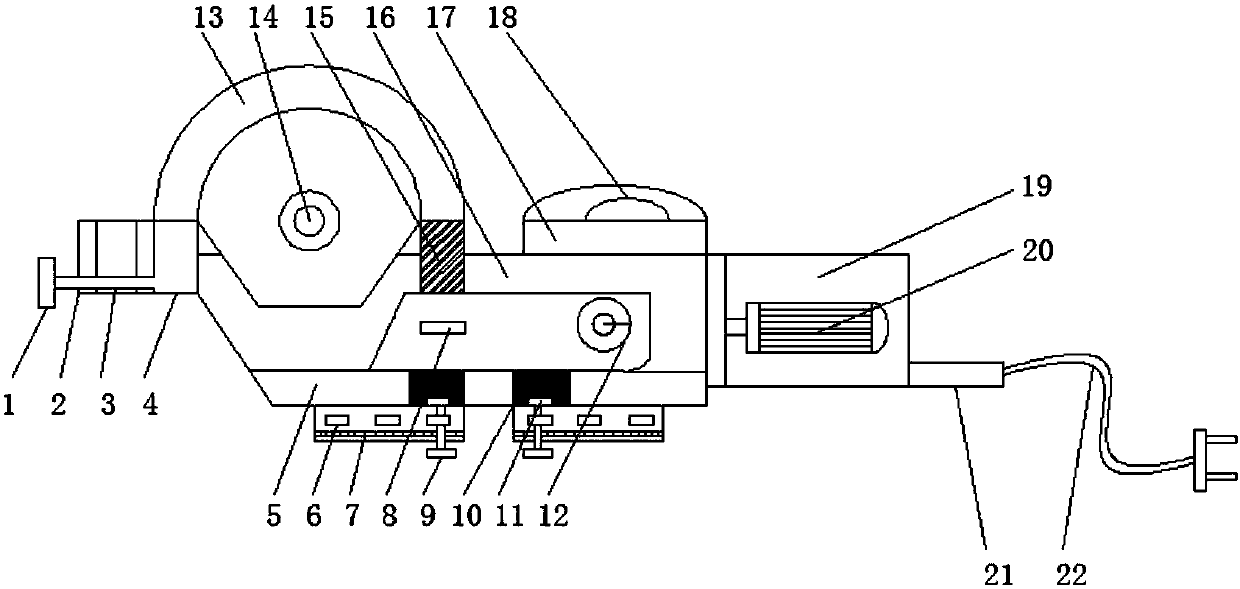

Sacrificial anode steel pipe iron core pipe bender

InactiveCN103100586ASimple and efficient operationImprove pipe bending efficiencySteel tubeMotor drive

The invention belongs to the field of bend equipment and particularly relates to a sacrificial anode steel pipe iron core pipe bender. The sacrificial anode steel pipe iron core pipe bender is characterized by comprising a machine frame, a bend disc, a motor and a transmission mechanism. The motor drives the bend disc through the transmission mechanism, a guide plate is arranged on the bend disc, and an iron core hole is formed in the guide plate. The sacrificial anode steel pipe iron core pipe bender is convenient to operate, enables the bent steel pipe iron core to penetrate through the iron core installation hole when used, starts the motor to drive the steel pipe iron core to rotate around the bend disc, achieves bending of the pipe, is high in pipe blending efficiency, is simple and reasonable in structure, low in cost, easy and convenient to repair and maintain in daily life, wide in application range and capable of manufacturing bends with various arcs and changes sizes of the bend discs according to the final different bend arcs.

Owner:SHANDONG DERUI ANTI-CORROSION MATERIAL CO LTD

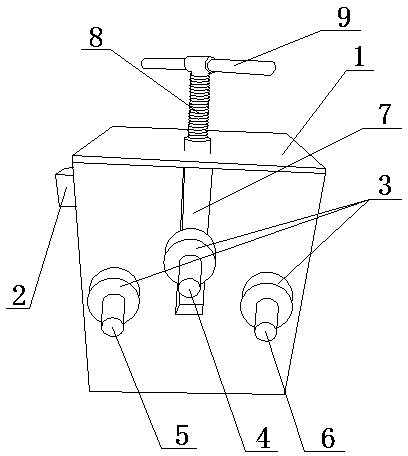

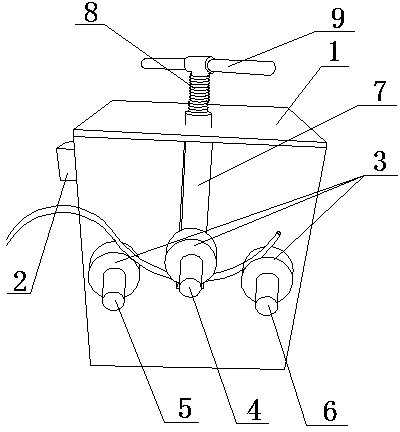

Pipe bending machine

The invention relates to a pipe bending machine and belongs to the technical field of pipe bending device design. The pipe bending machine comprises a casing, a power switch, a motor, rotary shafts and grinding tools. The motor is arranged in the casing and connected with the rotary shafts through a transmission belt. Slots are formed in the casing, the rotary shafts stretch out of the casing through the slots, and the grinding tools are sleeved on portions of the rotary shafts, which stretch out of the casing. The pipe bending machine is characterized in that the rotary shaft comprises an upper rotary shaft, a lower left rotary shaft and a lower right rotary shaft; the grinding tools are arranged on the upper rotary shaft, the lower left rotary shaft and the lower right rotary shaft; a shifting groove is formed in the casing, the upper rotary shaft stretches out of the casing through the shifting groove, and the lower left rotary shaft and the lower right rotary shaft stretch out of the casing through the slots; a threaded press bar, a threaded hole and an effort-saving transmission apparatus are arranged at the top of the casing, the threaded press bar penetrates the threaded hole and presses on the upper rotary shaft through the effort-saving transmission apparatus, and a rotation handle is arranged on the threaded press bar. The pipe bending machine is reasonable and simple in structure, easy to manufacture and capable of reducing cost and improving production efficiency.

Owner:JIANGSU BAOLE IND

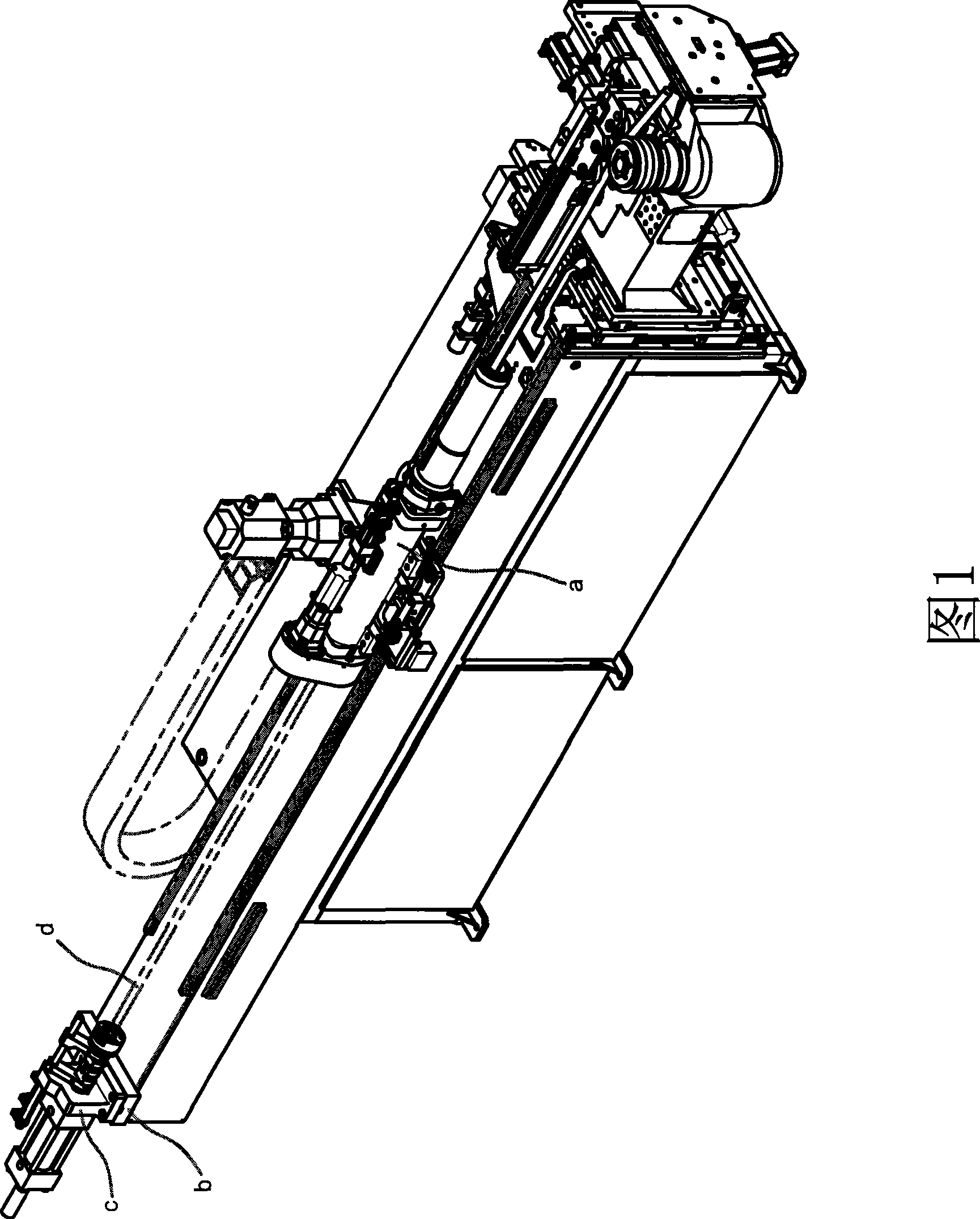

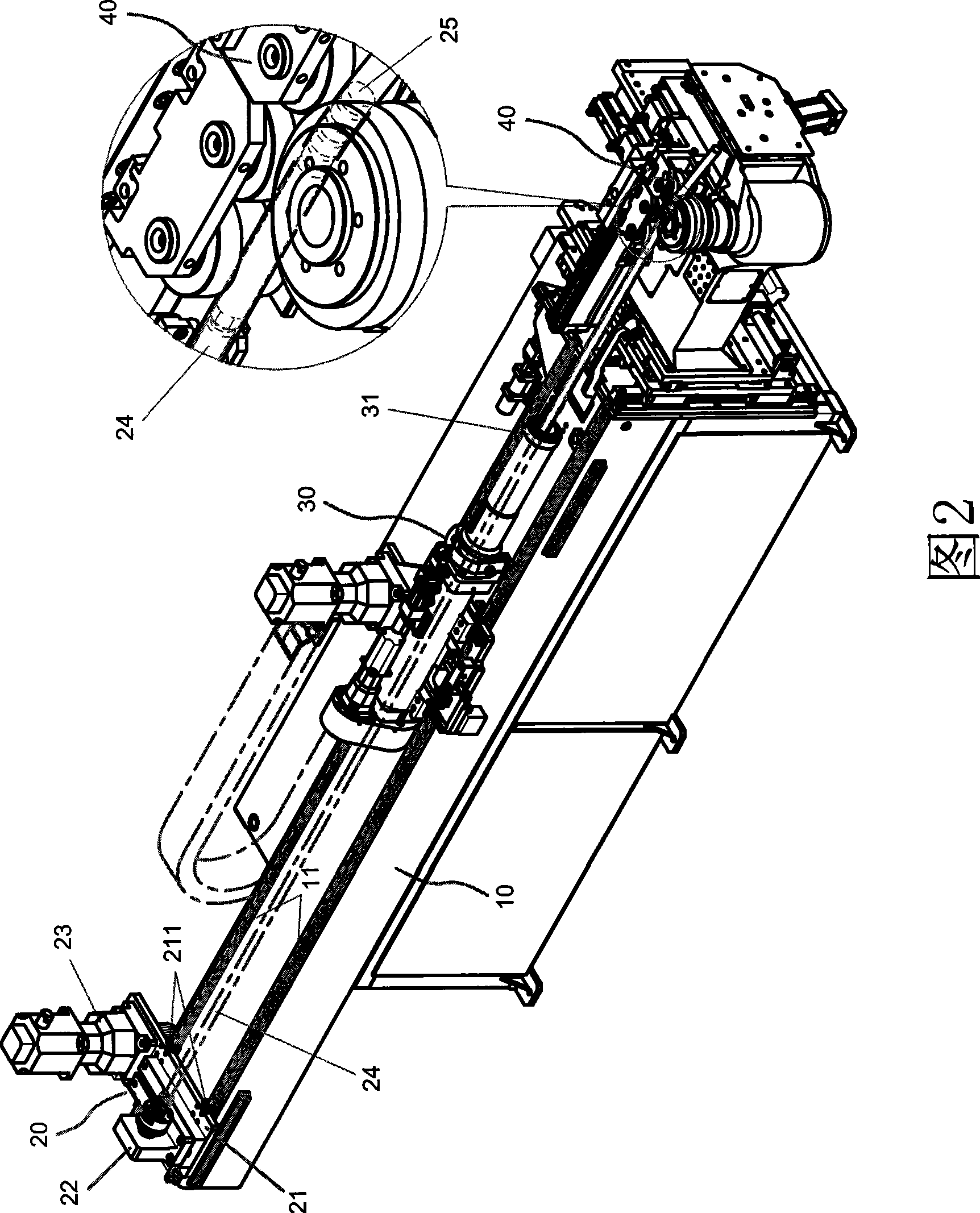

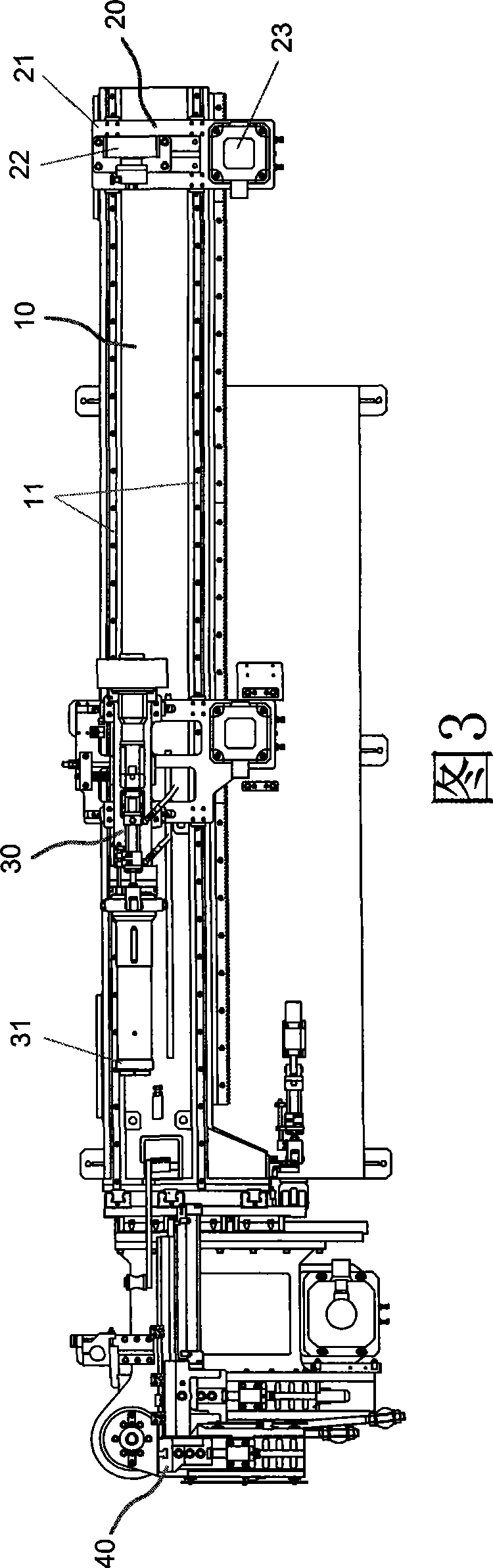

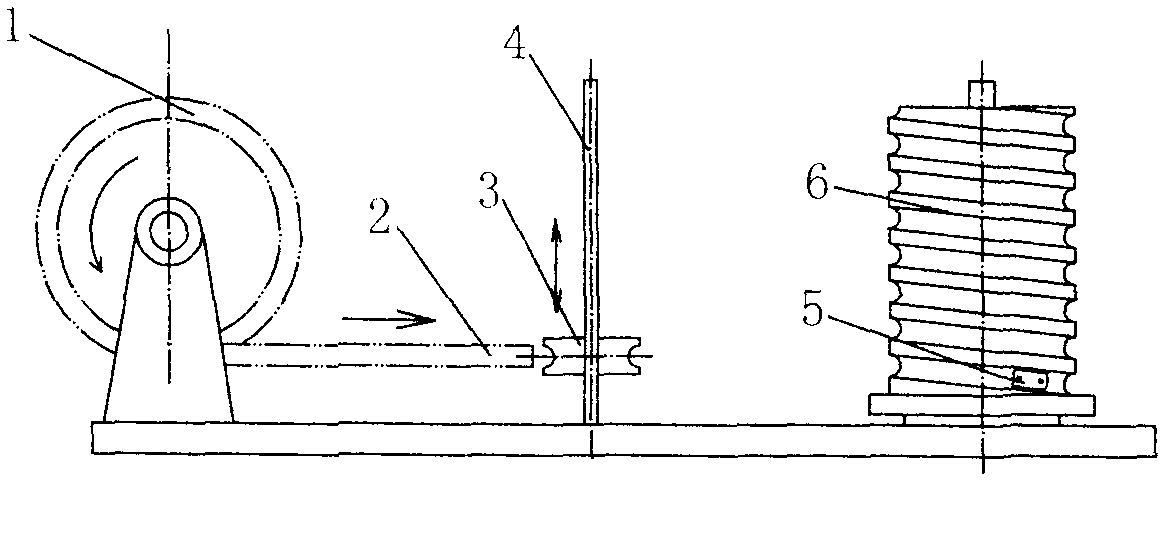

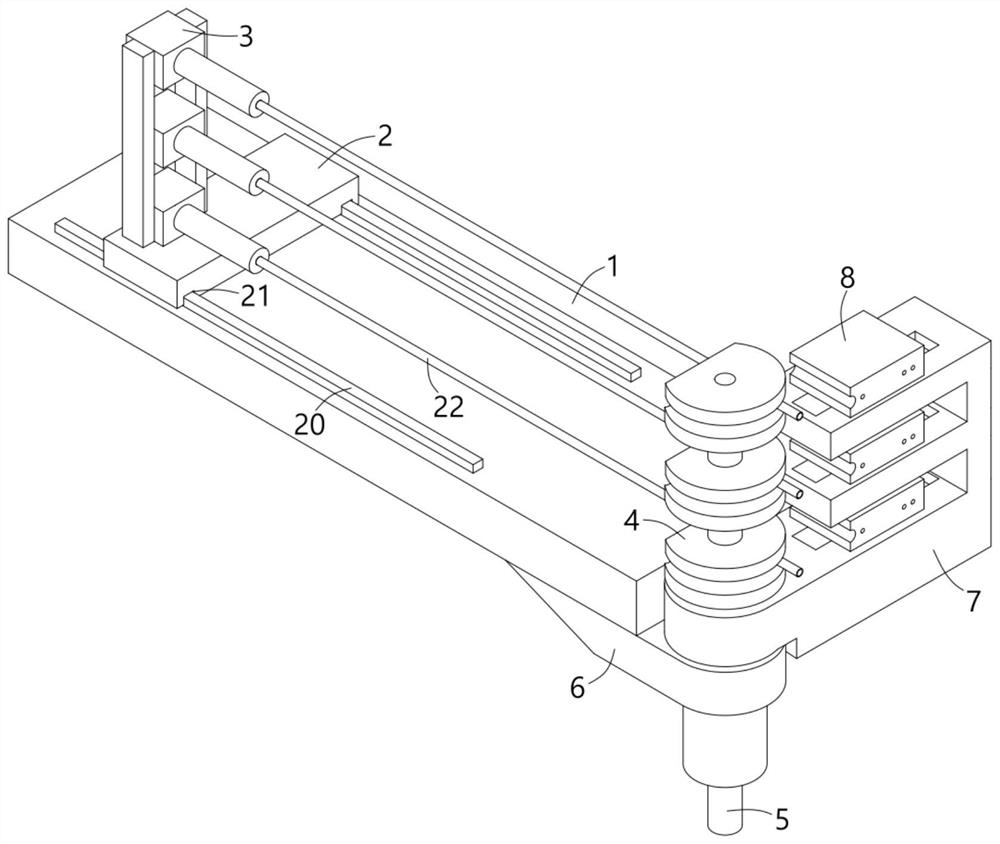

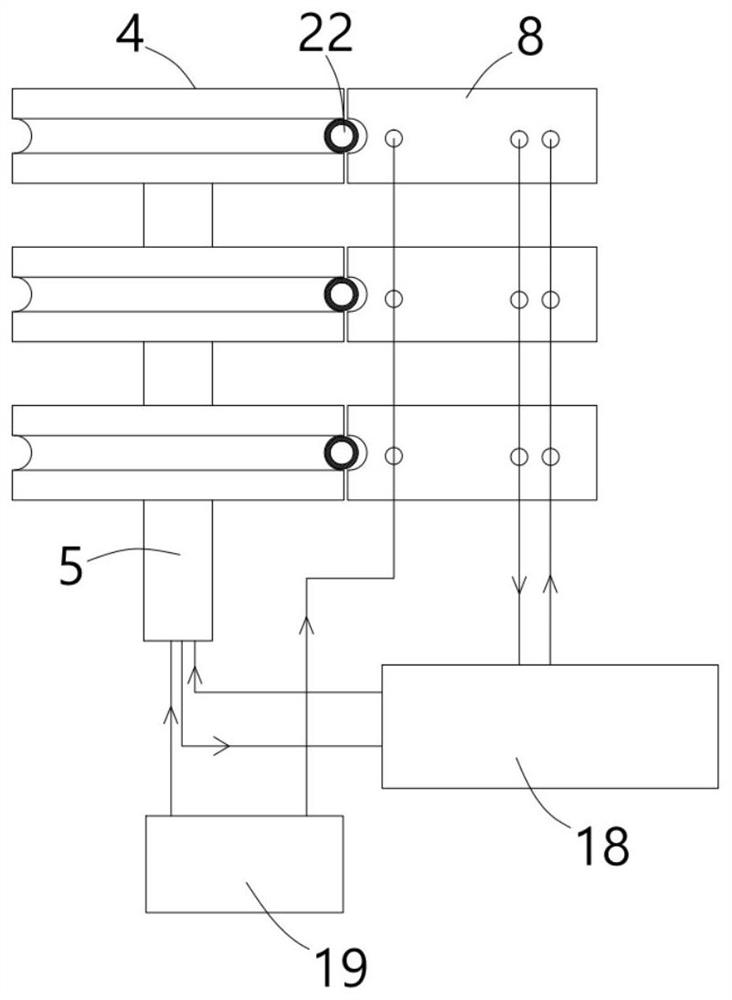

Pipe bender with mandrel driving mechanism

The invention discloses a tube bending machine provided with a concentric actuating mechanism, which comprises a machine table provided with a track, the concentric actuating mechanism, a tube pushing and delivering device and a tube bending device, wherein the concentric actuating mechanism is arranged upon the machine table and is provided with a base which is provided with a power source so as to drive the concentric actuating mechanism to move on the track of the machine table, the base is provided with a permanent seat for assisting a tube; the tube pushing and delivering device is arranged upon the machine table and assists the tube to pass through and is matched with the progress of bending the tube to be processed so as to drive the tube to be processed to move to the tube bending device; and the tube bending device can bend tubes. The concentric actuating mechanism can be used to match the function of freely adjusting the length of the tube to be processed on the machine table so as to shorten the length of the assisting tube and guarantee the quality of bending tubes to be processed.

Owner:YING LIN MACHINE INDAL

Seamless steel tube bending machine

The invention relates to the technical field of tube bending machines, in particular to a seamless steel tube bending machine. The seamless steel tube bending machine comprises a rack and two side wings arranged on the rack. A rotating block is rotationally connected between the side wings and detachably connected with a semicircular tube bending die. A tube bending groove matched with a seamless steel tube is formed in the circumferential face of the tube bending die. A drive mechanism is arranged on the rack. A supporting plate is arranged below the rotating block and provided with a supporting groove matched with the seamless steel tube. A clamping mechanism for clamping the seamless steel tube to the tube bending die is arranged on the rotating block. A sliding frame is arranged at the side of the side wings and is in sliding connection with a sliding block. A plug is arranged at one end of the seamless steel tube, and the other end of the seamless steel tube is communicated with a high-pressure air source. The seamless steel tube bending machine is simple in structure and convenient to use, the tube bending die is conveniently replaced, and the tube bending efficiency is high; and high-pressure air is introduced into the seamless steel tube, and therefore some steel tubes with the small wall thickness can be prevented from collapsing or wrinkling inside during tube bending, and the tube bending precision is high.

Owner:JIANGSU WUJIN STAINLESS STEEL PIPE GRP

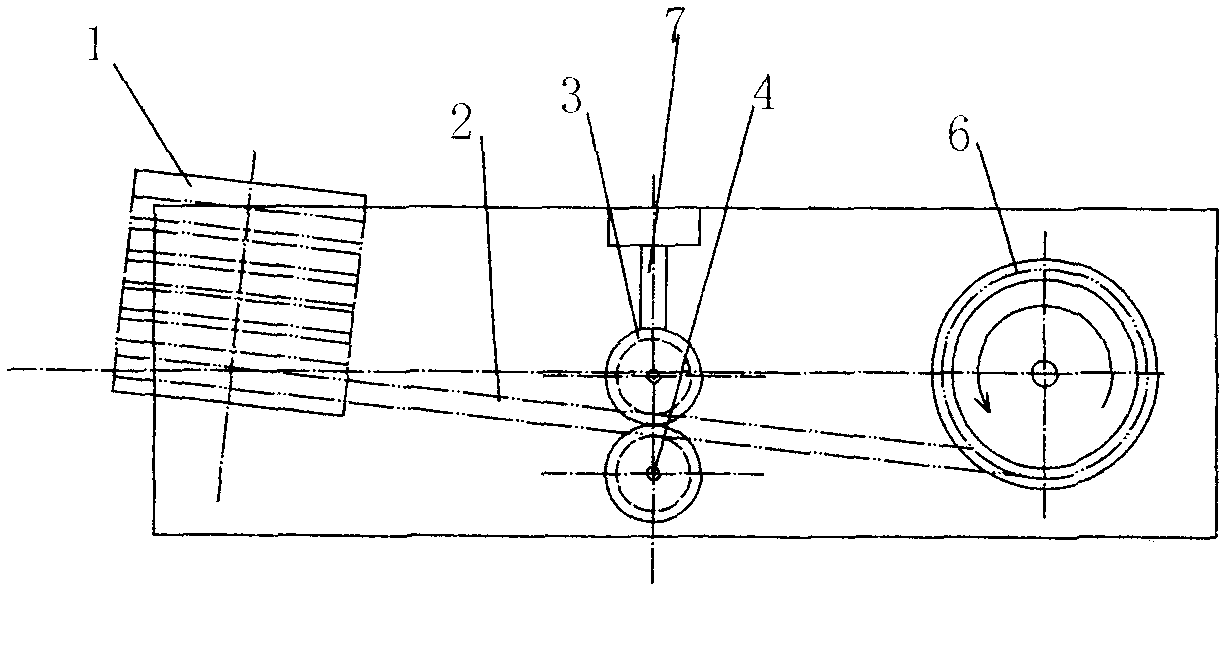

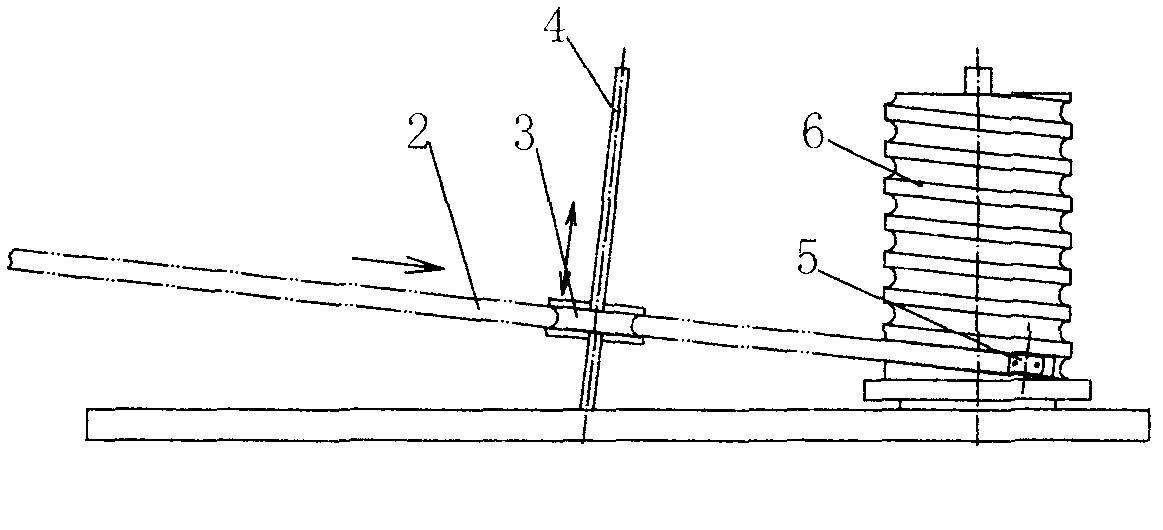

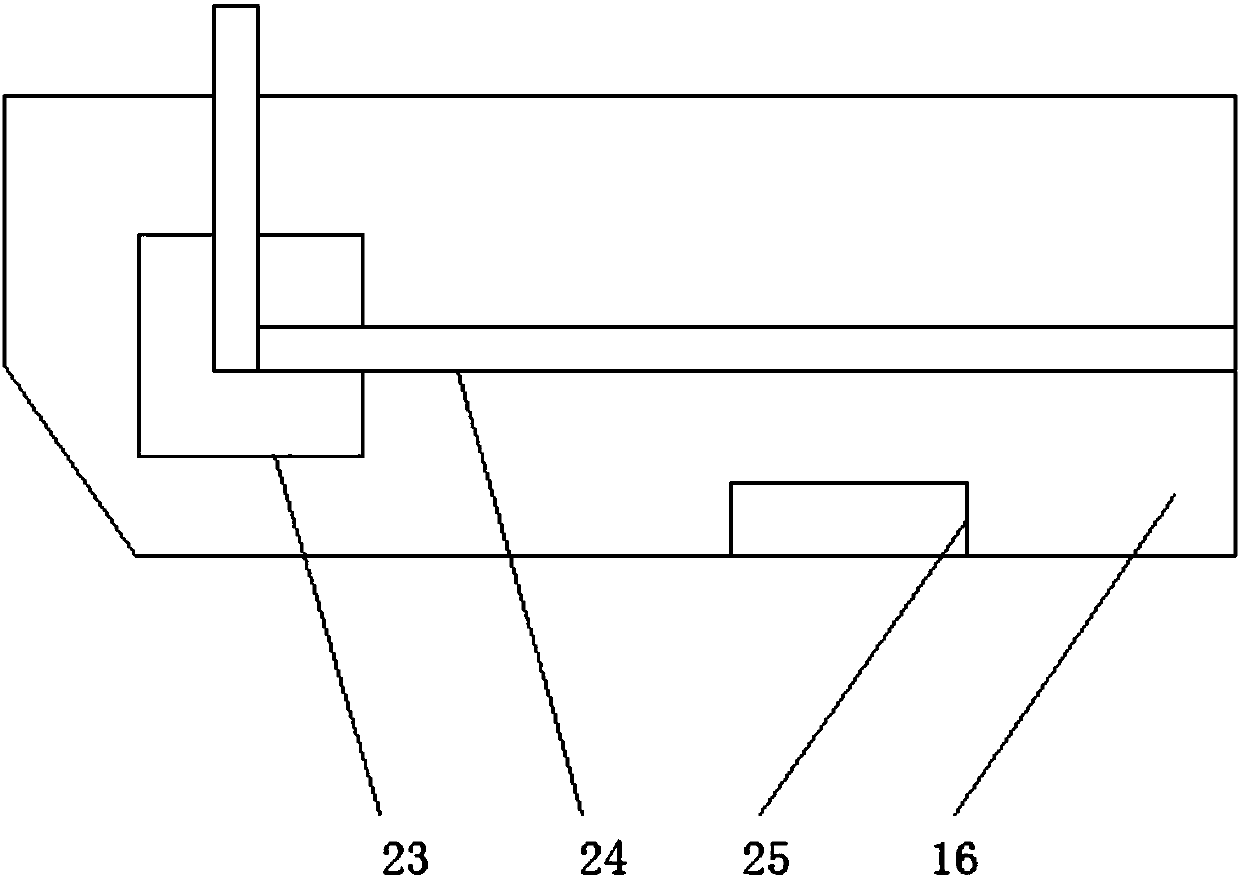

Tube discharging mechanism of tube bender

InactiveCN103286175AImprove pipe bending efficiencyMeet the needs of mass productionEngineeringTube bending

The invention relates to a tube discharging mechanism of a tube bender. The tube discharging mechanism comprises a shaft, wherein the shaft is sleeved with roller wheels which can move along the shaft vertically, and annular concaved surfaces matched with a tube blank are formed in the roller wheels. The tube discharging mechanism can continuously feed the tube blank, the moving speeds of the roller wheels on the tube discharging mechanism can be adjusted according to actual conditions, the tube discharging mechanism is matched with a follow-up tube bending mechanism for bending tubes, so that the tube bending efficiency is high, and large-scale production requirements can be met.

Owner:JIANGSU YONGLONG ELECTRIC

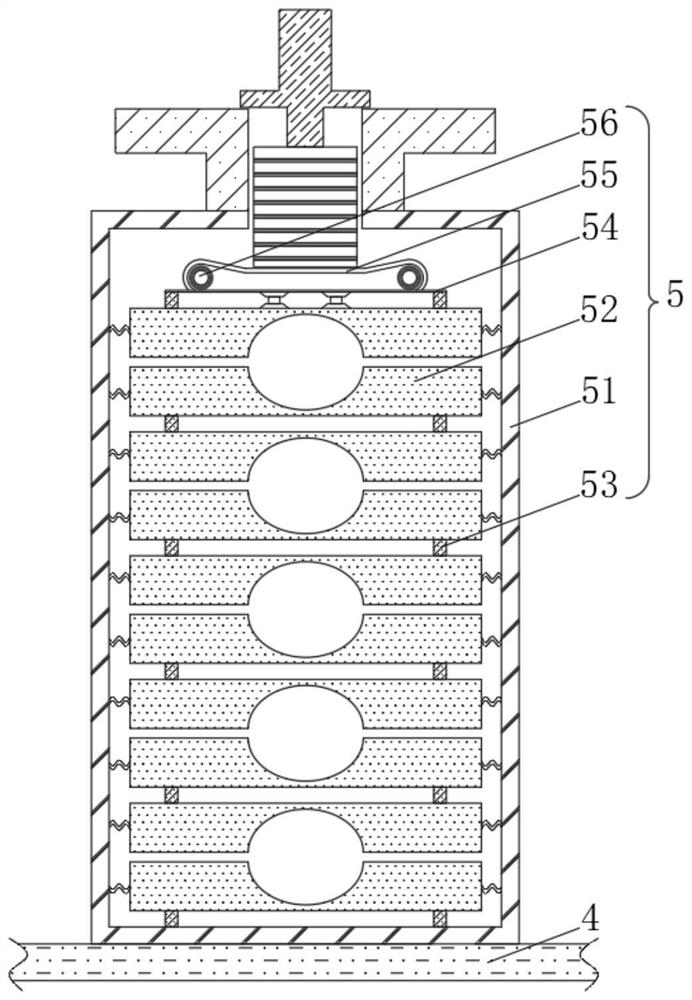

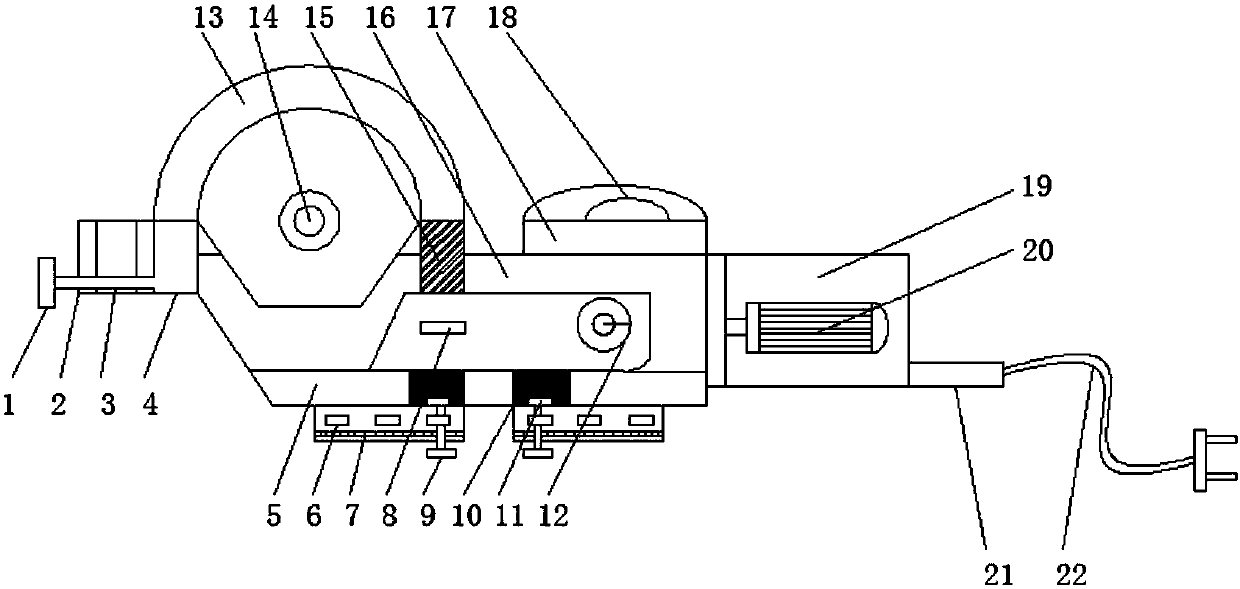

Titanium pipe bending machine

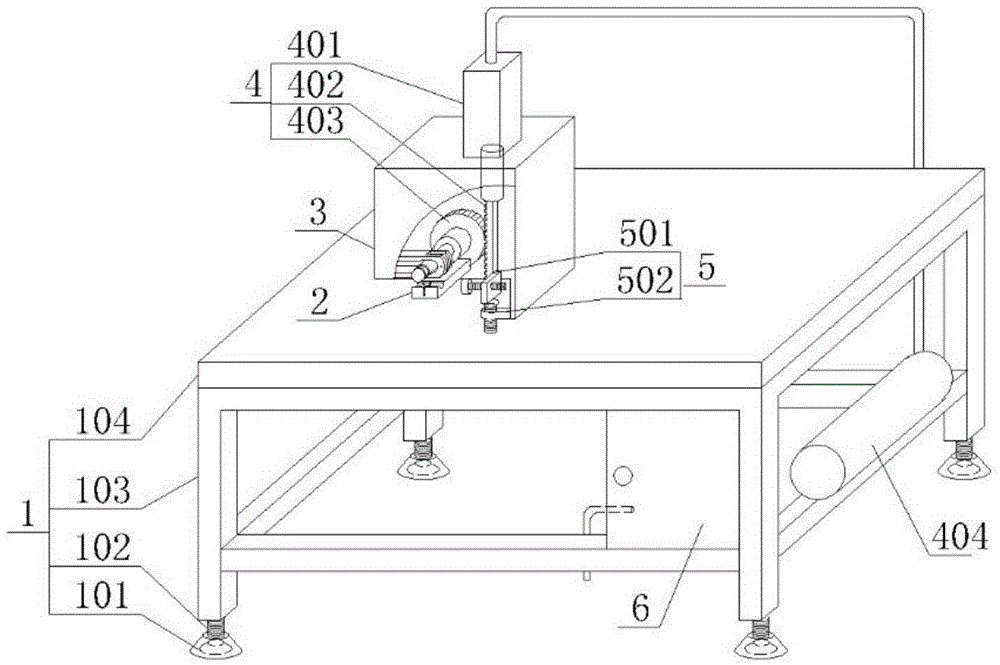

PendingCN110918709AImprove pipe bending efficiencySolve the problem that the efficiency of pipe bending cannot be improvedMetal-working feeding devicesPositioning devicesDrive wheelElectric machinery

The invention discloses a titanium pipe bending machine, which structurally comprises a workbench, a control box, a first motor, a pulley, a supporting frame, a supporting plate, a storage plate, an electric push rod, a fixed clamping block, a rotating wheel, a bin door and a conveying device, wherein the control box is arranged on the left side of the front end of the workbench and connected withthe workbench through bolts; and the first motor is arranged in the middle of the front end of the workbench. According to the titanium pipe bending machine disclosed in the invention, as a conveyingdevice is arranged, a titanium pipe enters a conveying belt through a pipe inlet, five titanium pipes can be inserted through fixing clamping grooves at the same time, the control box controls and starts a second motor to drive a driving wheel to rotate, the driving wheel drives a driven wheel to move circularly through the conveying belt to drive the titanium pipes to be conveyed, the titanium pipes are discharged through the pipe outlet, the control box controls the electric push rod to press downwards to bend the five titanium pipes, and the problems that in the prior art, the pipe bendingefficiency cannot be improved, and much inconvenience is caused are solved.

Owner:江苏华致智能装备有限公司

A fully automatic pipe bending machine

InactiveCN105215111BSimple structureReasonable designMetal-working feeding devicesPositioning devicesOptical axisMechanical engineering

A fully automatic pipe bending machine, characterized in that the fully automatic pipe bending machine includes a pipe bending device, a clamping device and an automatic centering device, and the telescopic cylinder pushes the connecting rod and drives the adjusting rod so that the tip of the adjusting rod Press the clamping plate of the clamping part to force the clamping plate of the clamping part to clamp the workpiece. The operation is simple, fast, and the labor force is small, which reduces the labor cost and improves the bending efficiency. When centering, the centering cylinder drives a The optical axis on one side moves, and through the cooperation of the gear and the rack, the optical axis on the other side moves synchronously with it, and then drives the left and right slides on the side plates on both sides to be centered synchronously, and the centering position is accurate , High efficiency, completely replaces manual centering, saves time and effort, greatly improves the work efficiency of the pipe bending, and saves the pipe bending process. At the same time, the device is low in cost and saves production costs.

Owner:JIANGSU XINSIWEI PHOTOELECTRIC CO LTD

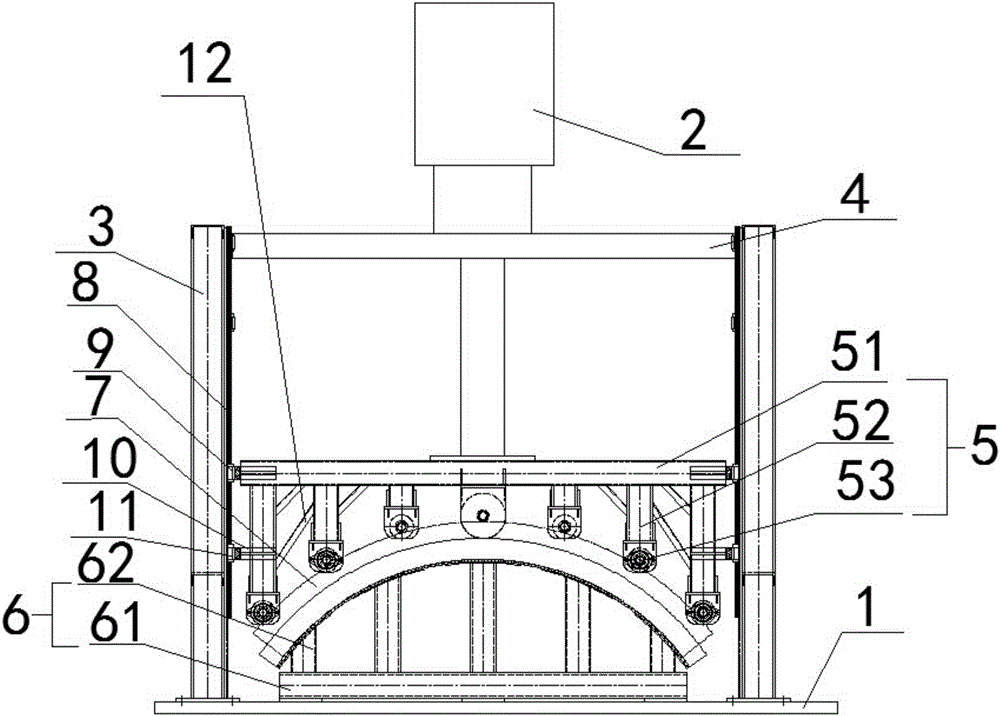

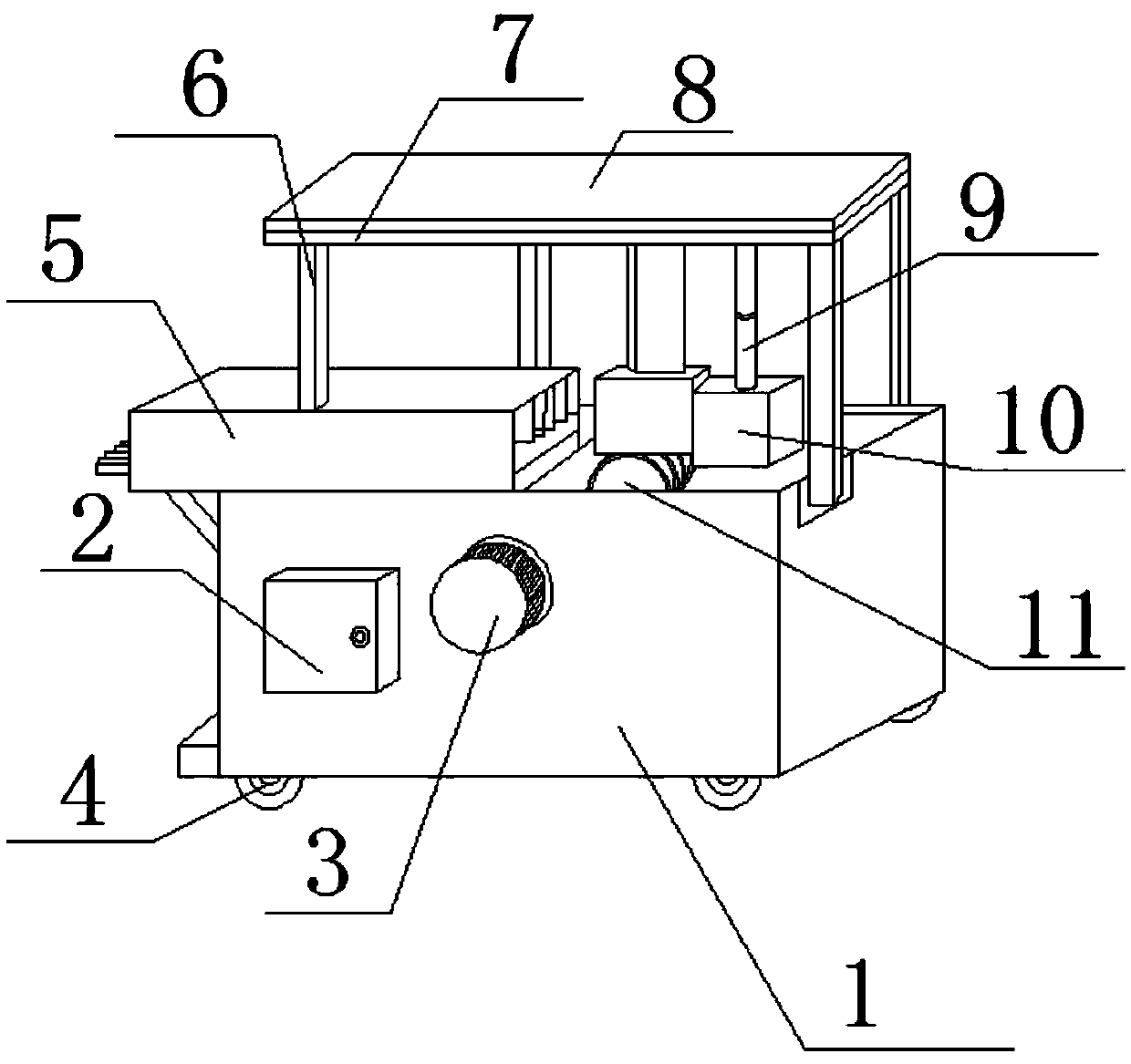

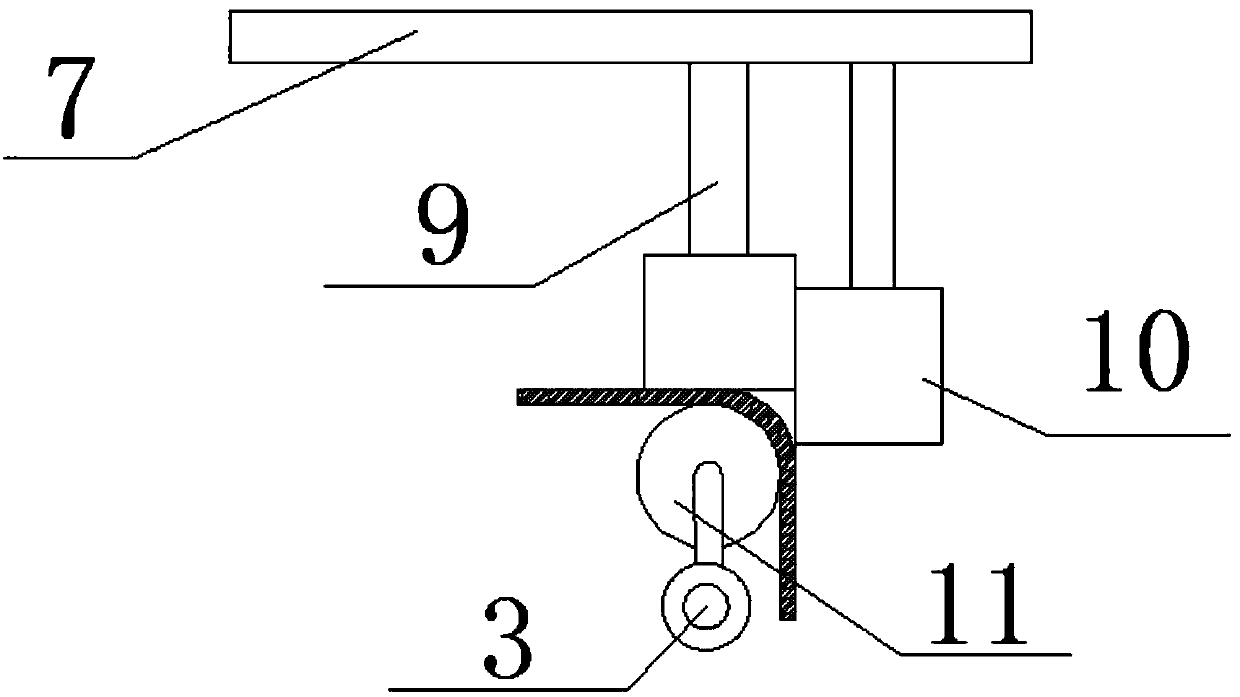

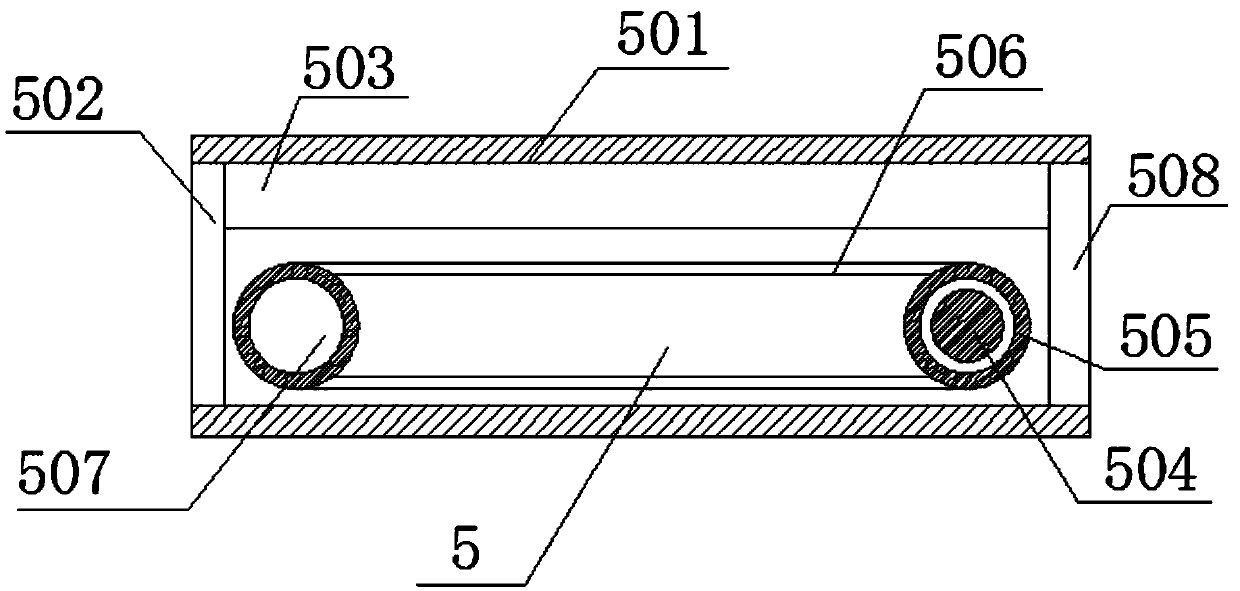

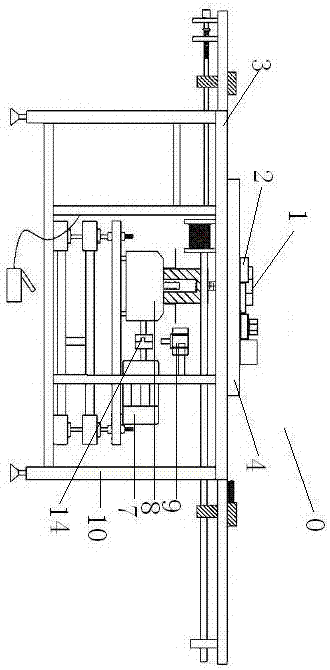

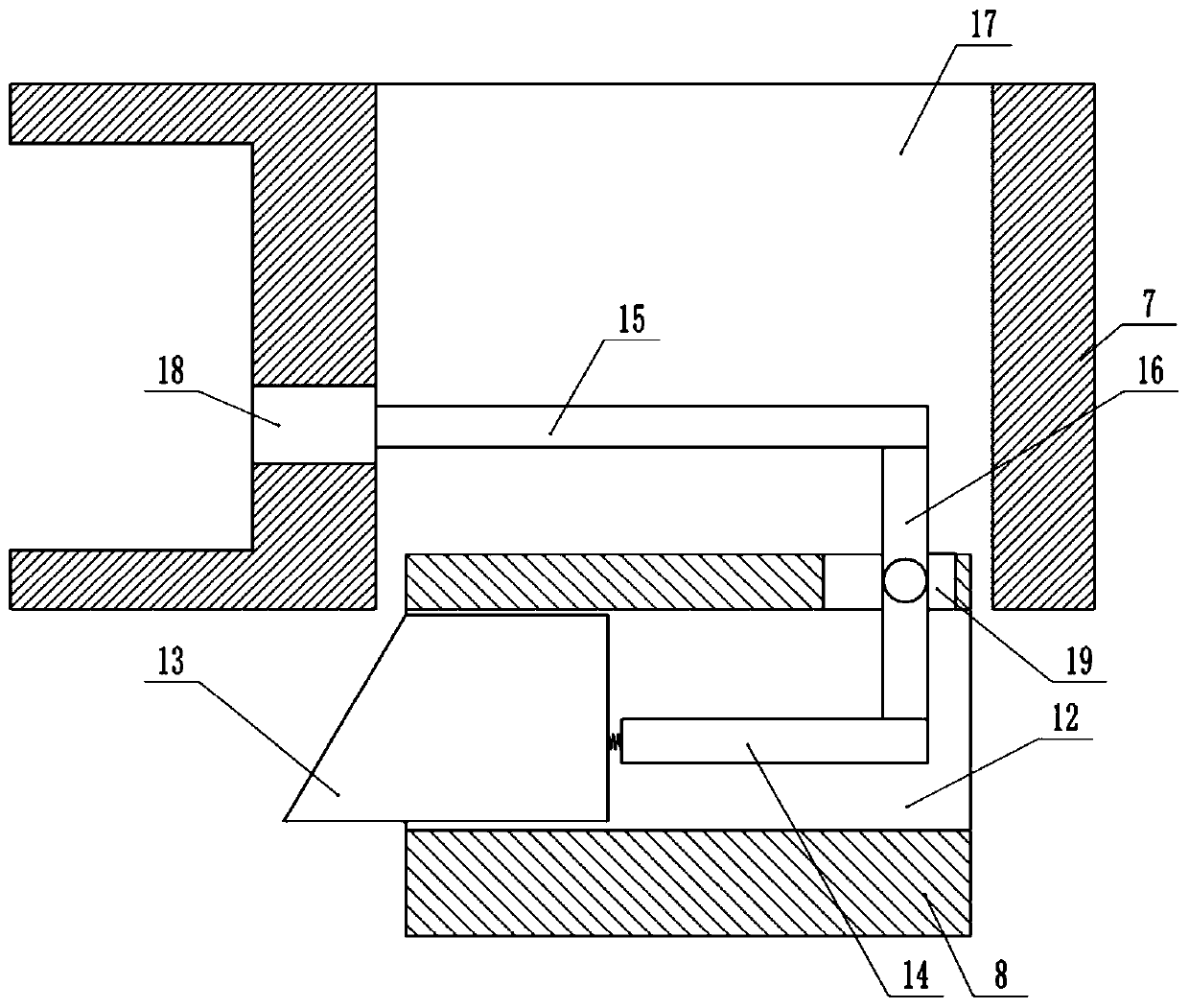

Mechanical device for group bending of pipes

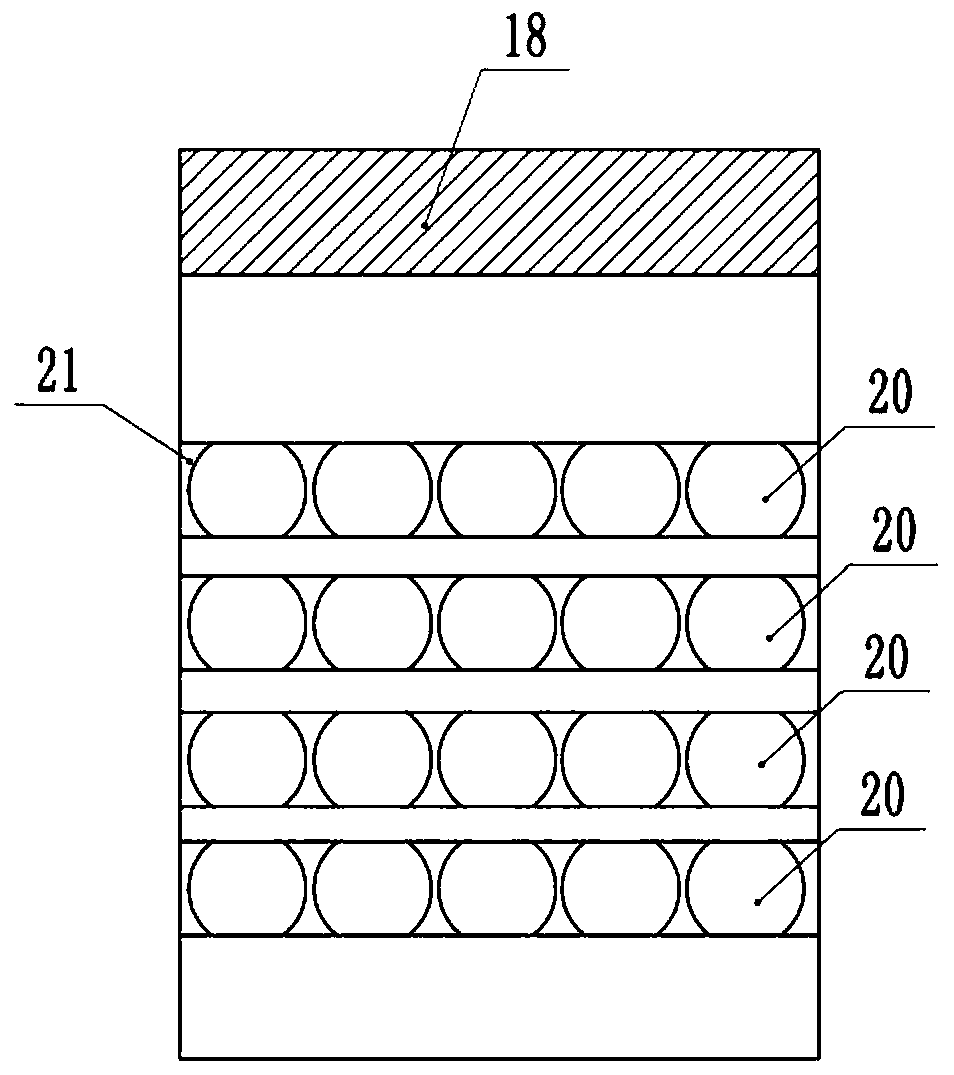

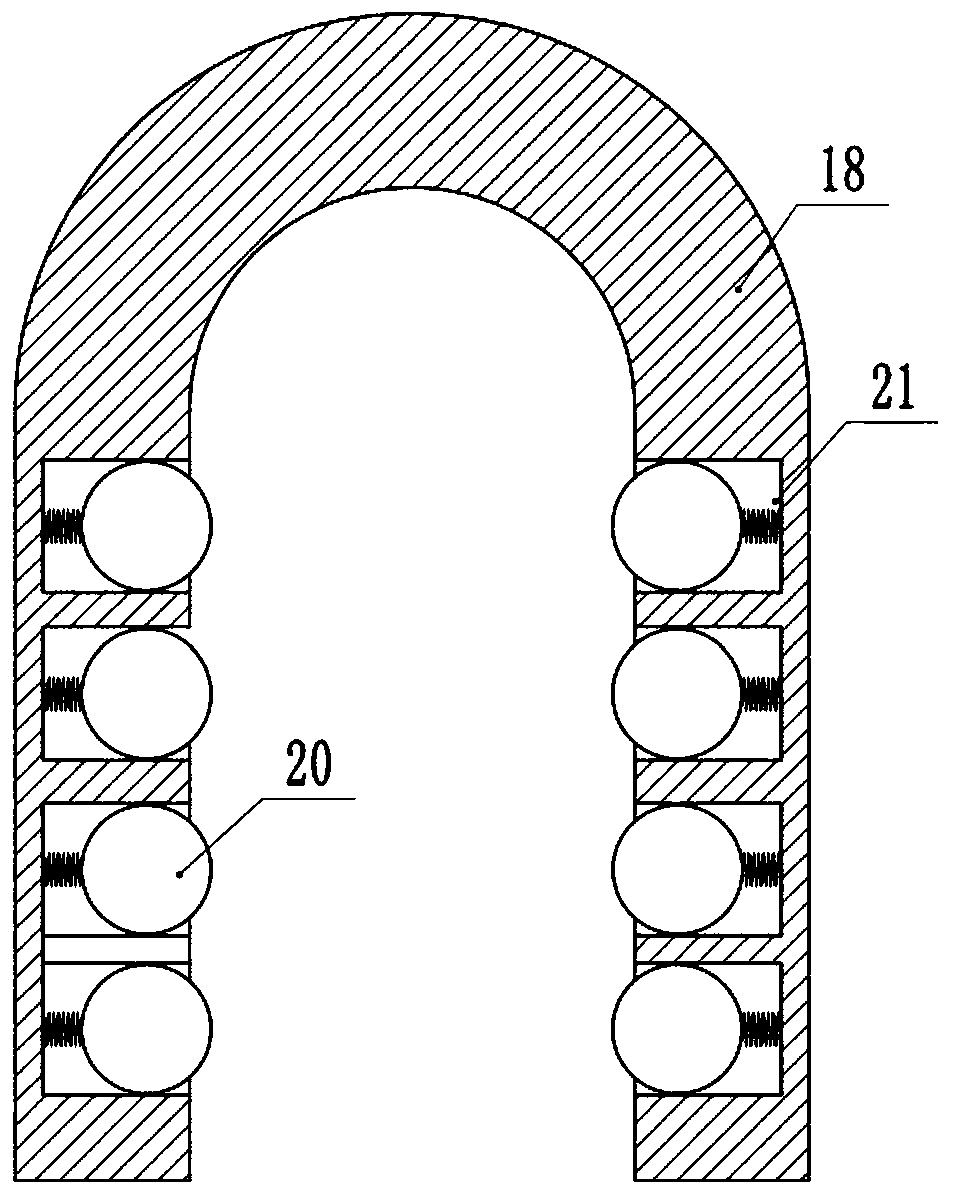

InactiveCN108057741APrevent crushingAvoid breakingMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

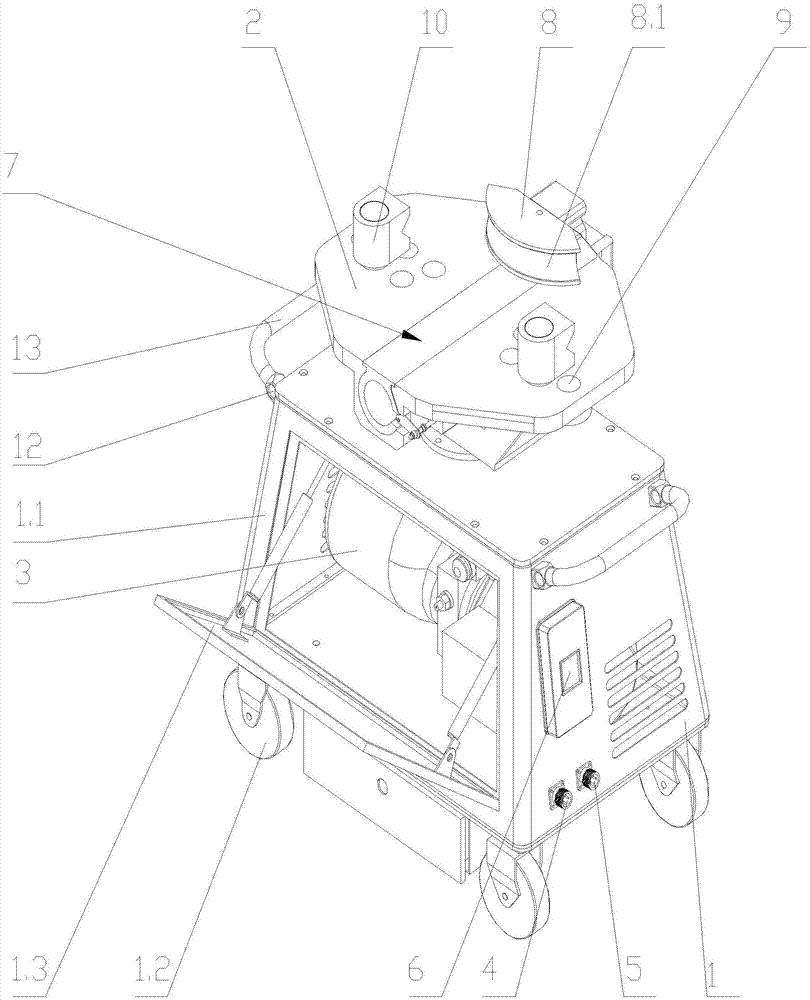

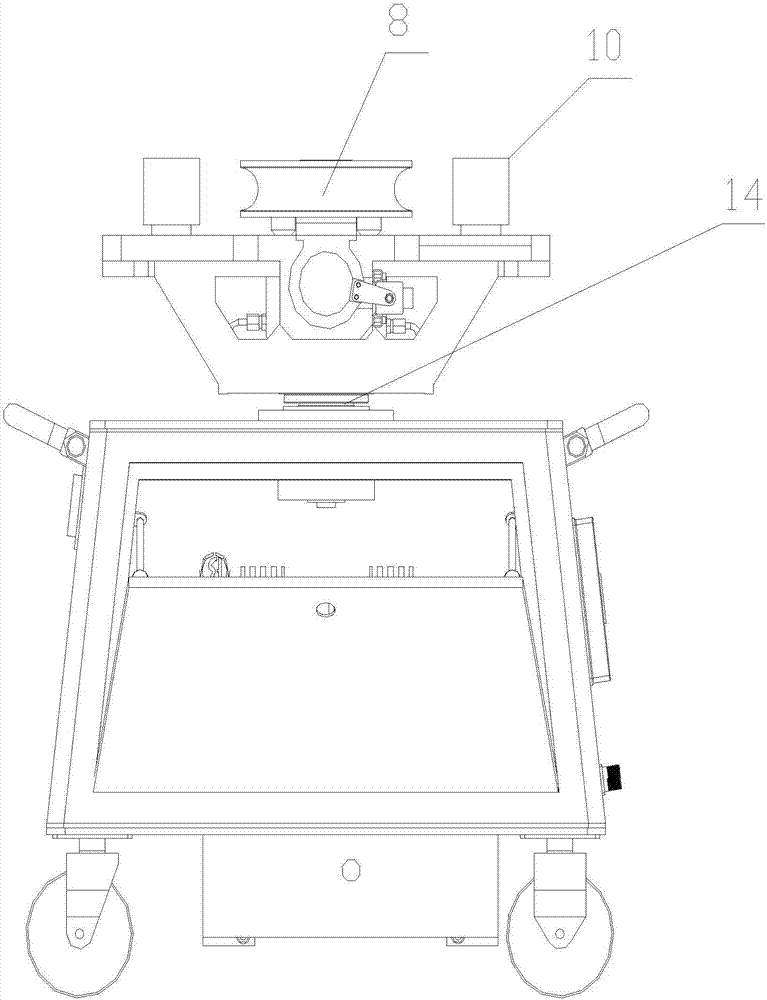

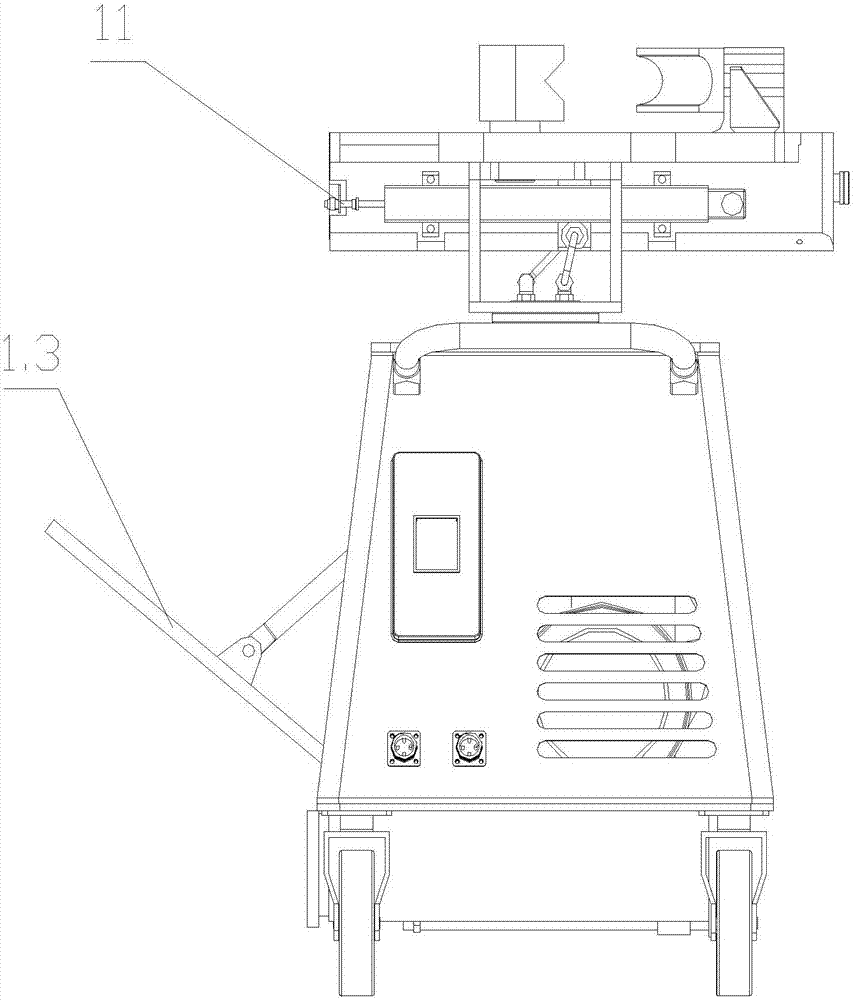

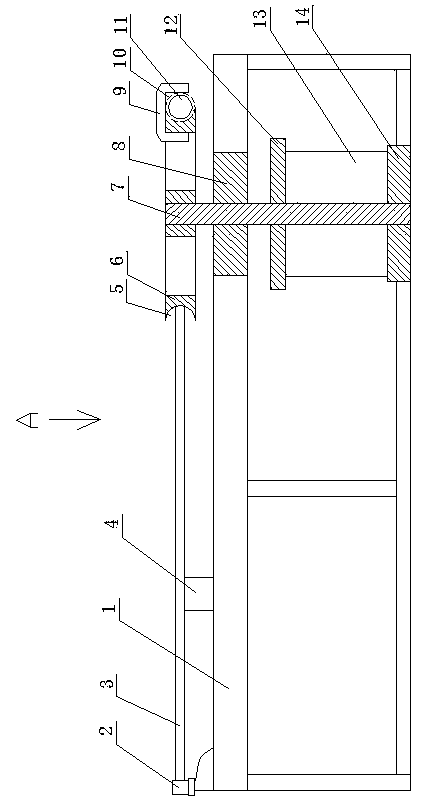

The invention discloses a mechanical device for group bending of pipes. The mechanical device for group bending of the pipes comprises a vehicle plate frame; a jacking cylinder is arranged in the middle of the vehicle plate frame and matched with a jacking head; the other end of the vehicle plate frame is detachably connected with a bottom plate frame; side plate frames are welded to the two sidesof the upper portion of the bottom plate frame; the tops of the side plate frames are connected with a top plate frame; an end plate frame is welded to one end of the top plate frame; a set of adjusting screw rods are connected to the side plate frames in a screwed mode; one end of each adjusting screw rod is in key connection with a hand wheel; the other ends of the adjusting screw rods are in rotating fit with an adjusting head through a bearing; the top plate frame is provided with a fixing cylinder matched with a fixing pressure head; and the end plate frame is provided with a downward pressing cylinder matched with a downward pressing head. The mechanical device for group bending of the pipes is convenient to move and is operated after being energized, simple and labor-saving operation is achieved, labor of workers is saved, the pipe bending efficiency is high, and the pipes can be bent in groups by the same angle.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

A pipe bending device

The invention relates to a steel pipe bending device, which comprises a working platform rotationally supported on a platform upright post. The steel pipe bending device is characterized in that the platform upright post is sleeved with a pipe bending wheel of which the circumferential surface is provided with a groove; the pipe bending wheel is fixedly connected with the working platform; one side of the pipe bending wheel is provided with a clamping die holder with a clamping groove; the clamping die holder is driven to clamp a workpiece in cooperation with the pipe bending wheel through a lead screw; the lead screw is in threaded fit with a nut fixed on the working platform; a guide rod is arranged in the groove close to the pipe bending wheel; the guide rod is fixedly connected with a guide rod upright post; the guide rod upright post and the platform upright post are fixed in parallel on an anchoring part. The steel pipe bending device has the advantages of simple structure, low manufacturing cost, effective prevention of harmful deformation of steel pipes, high efficiency and easiness in controlling the molding angle.

Owner:WEIHAI SHIDAO HEAVY IND

Horizontal steel tube bending machine

ActiveCN107952842ASimple and efficient operationImprove pipe bending efficiencyStripping-off devicesSteel tubeTorsion spring

The invention discloses a horizontal steel tube bending machine. The horizontal steel tube bending machine comprises a frame, a die, a punch, a movable plate and a linear driver, wherein the die and the linear driver are installed on the frame and are located at the same horizontal height, the punch is installed on the linear driver, and the linear driver drives the punch to do reciprocating motion relative to the die; the movable plate is arranged on the frame through a first rotating shaft, a first torsion spring is arranged on the first rotating shaft, the first torsion spring is used for maintaining the horizontal position of the movable plate, and the movable plate in the horizontal state is located between the die and the linear driver; the surface of the movable plate is used for containing a steel tube; and a rotating plate mechanism is arranged on the punch, when the linear driver drives the punch to return, the movable plate rotates through shifting of the rotating plate mechanism, and the steel tube on the movable plate slides along the inclined movable plate, so that the automatic discharging function is realized. According to the horizontal steel tube bending machine,operation workers only need to add the steel tube to the movable plate at a certain frequency when the steel tube bending machine is used, so that the operation is simpler and more convenient, and tube bending efficiency is higher.

Owner:江苏博创升降机械有限公司

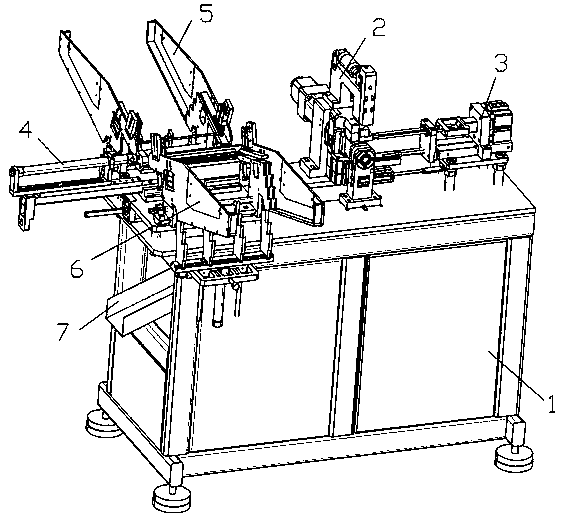

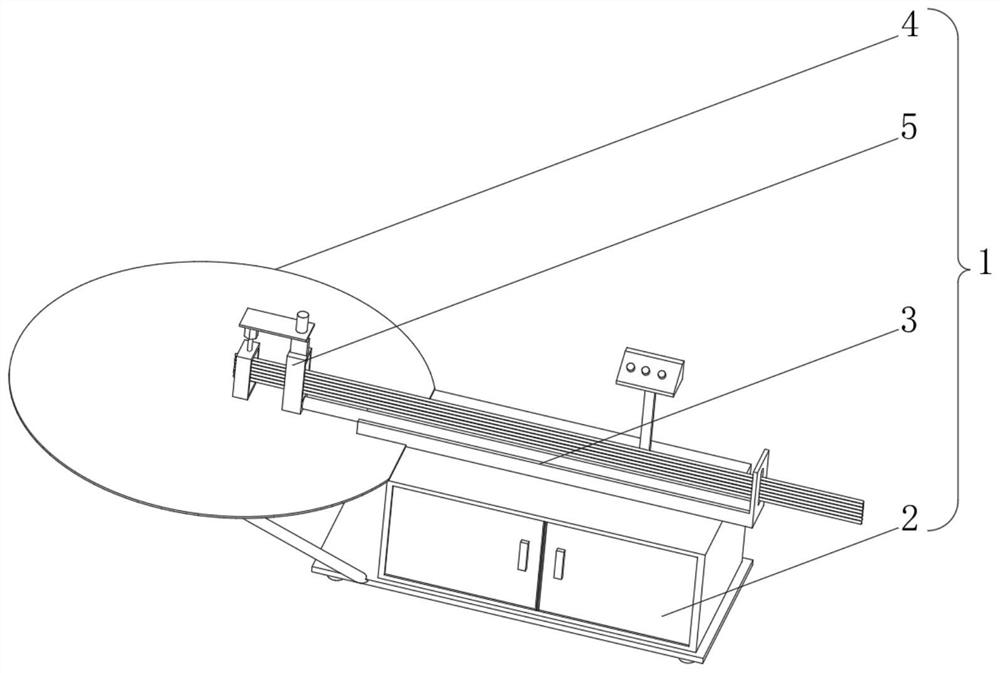

Double-station automatic short pipe bending equipment

ActiveCN111014374ARealize automatic feeding processRealize double-pipe deliveryMetal-working feeding devicesPositioning devicesStructural engineeringWorkbench

The invention relates to double-station automatic short pipe bending equipment. The pipe bending equipment comprises a workbench, a short pipe bending mechanism is arranged in the middle of the uppersurface of the workbench, an anti-stretching device for assisting short pipe bending is arranged on the left side of the short pipe bending mechanism, a square through hole is formed in the position,corresponding to the working end of the short pipe bending mechanism, of the upper surface of the workbench, a discharging sliding groove is formed below the square through hole, the upper end of thedischarging sliding groove is fixedly connected with the lower surface of the table top of the workbench, a short pipe feeding device is arranged on the right side of the short pipe bending mechanism,a first short pipe feeding device and a second short pipe feeding device are arranged on the front side and the rear side of the short pipe feeding device correspondingly, the first short pipe feeding device and the second short pipe feeding device are oppositely arranged, and discharging openings of the first short pipe feeding device and the second short pipe feeding device are connected with the working end of the short pipe feeding device. The pipe bending equipment is high in automation degree, the labor cost is saved, the pipe bending efficiency and quality are improved, and the good market application value is achieved.

Owner:新乡创想自动化科技有限公司

Water pan special-shaped connecting pipe forming device

The invention provides a water pan special-shaped connecting pipe forming device. The water pan special-shaped connecting pipe forming device comprises a pipe bending machine table; a translation seat is arranged on one side of the pipe bending machine table; a plurality of pipe feeding mechanisms are evenly installed in the vertical direction of the translation seat at intervals; a plurality of special-shaped pipe bending rollers are movably arranged on one side of the pipe bending machine table; a pipe bending seat is further movably installed on a supporting seat; a through hole allowing a rotating shaft to be inserted is formed in the pipe bending seat in a penetrating mode; the oil supply channels communicate with a plurality of oil supply holes formed in a pipe bending groove of the special-shaped pipe bending roller in an annular array mode; and the oil supply channels communicate with oil supply ways formed in the rotating shaft. According to the invention, the pipe bending efficiency is greatly improved without increasing the floor area, and lubricating oil can be added into a pipe bending sliding block, the pipe bending roller and the pipe bending groove in the pipe bending process; and a circulating cooling device is used for cooling the pipe bending sliding block and the pipe bending roller, so that heat generated in the pipe bending process is discharged in time, and the service life of equipment is prolonged.

Owner:合肥美菱有色金属制品有限公司

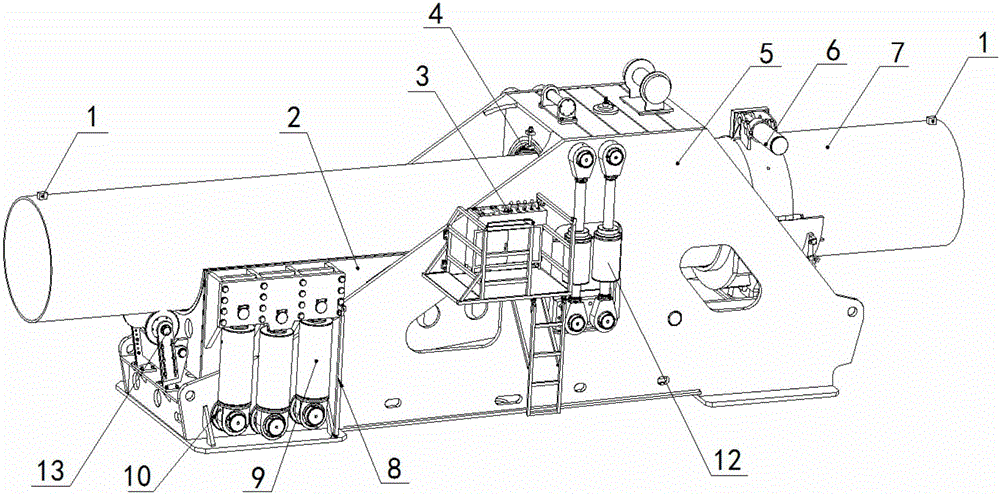

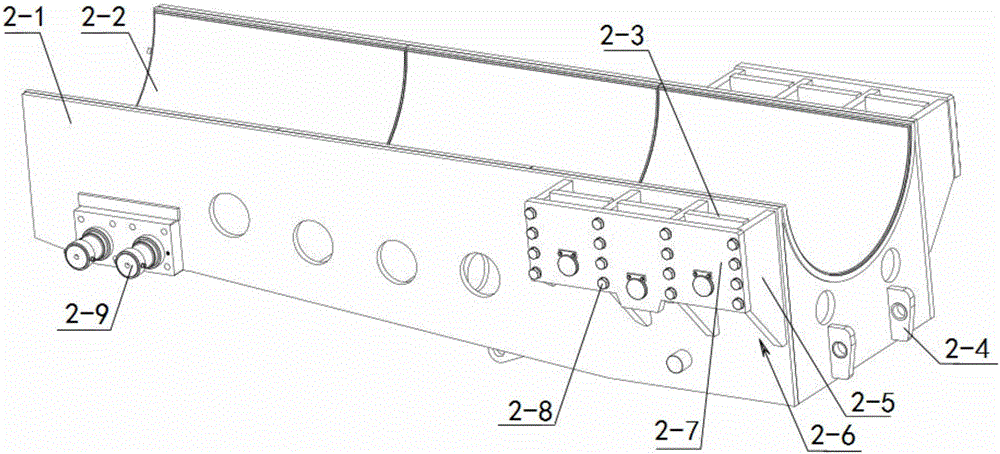

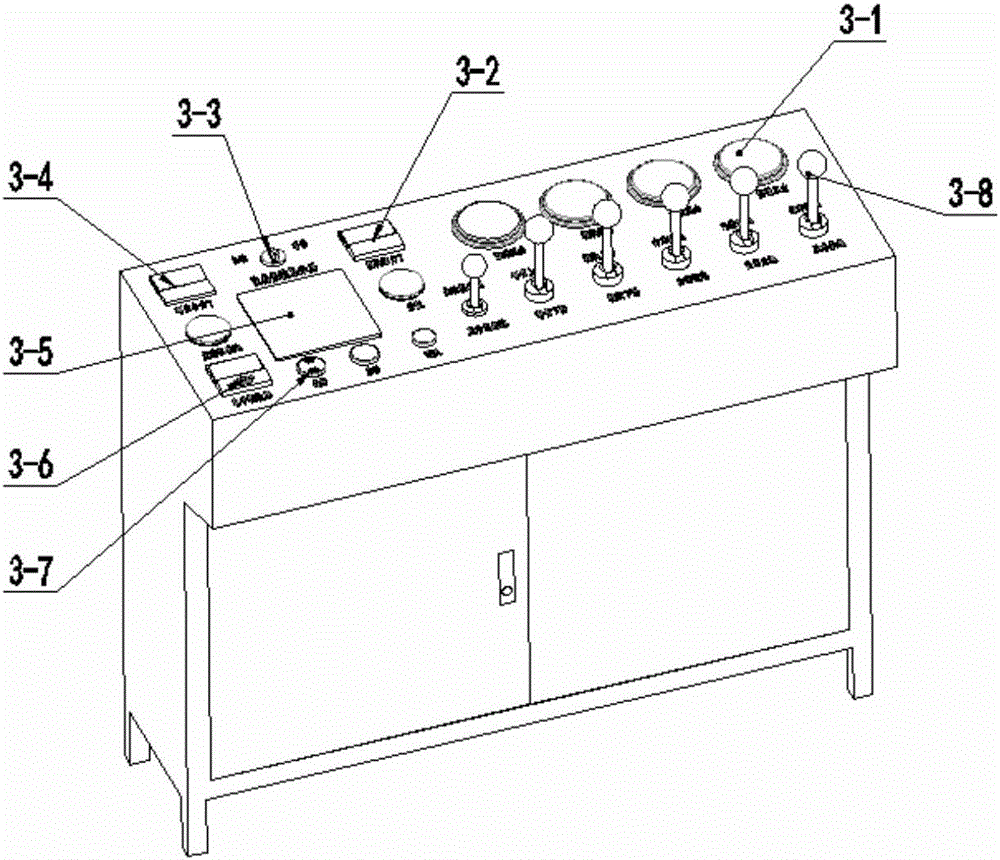

Super-large intelligent vertical hydraulic cold pipe bender

ActiveCN106180320AQuality assuranceReduce laborMetal-working feeding devicesMetal working apparatusDouble curveProcessing cost

The invention provides a super-large intelligent vertical hydraulic cold pipe bender comprising a bender body main frame as well as an upper mould, a lower mould, a clamping mould and a driving mechanism which are arranged on the bender body main frame. The super-large intelligent vertical hydraulic cold pipe bender is technically characterized in that the clamping mould, the upper mould and the lower mould are sequentially arranged along the length direction of a steel pipe, and a wedge block cylinder mechanism is arranged under a base of the clamping mould; the side wall of the outer side of the bender body main frame is provided with an intelligent console on which a liquid crystal touch display screen, an alarm, pressure gauges, a bending resultant force display instrument, a wedge block supporting force display instrument, an electronic receiver and a control mode switch are arranged; and each of two ends of the steel pipe is provided with an electronic emitter provided with a magnetic base, and inlets of bending cylinders are provided with pressure sensors. The super-large intelligent vertical hydraulic cold pipe bender is simple in processing technology and low in processing cost; and the difficulty of processing double curved surfaces on the upper mould is solved, and meanwhile, all steps for bending the pipe by using the pipe bender are finished once, so that the pipe bending process is programmed and intelligentized, the labor amount of a worker is reduced, and the pipe bending efficiency is increased.

Owner:SHENYANG FEIYAN AVIATION EQUIP

Numerical control hydraulic push-bending pipe bending machine and rebound compensation method thereof

ActiveCN107442619ASimple structureReduce frictionComplex mathematical operationsNumerical controlControl engineering

The invention discloses a numerical control hydraulic push-bending pipe bending machine, and relates to the structure of a pipe bending machine. The pipe bending machine comprises a bending mold and a bending mold driving mechanism; the bending mold driving mechanism comprises a guide groove and a cylinder body; the bending mold is connected to the end part of one end of the cylinder body; a piston cavity is formed in the side, close to the bending mold, of the cylinder body; a piston rod is arranged in the piston cavity; a check block which is fixedly connected to the end part of the free end of the piston rod and plugs a cavity opening of the piston cavity is arranged at the cavity opening of the piston cavity; two oil ducts which are arranged at intervals and penetrate through the check block are arranged in the piston rod; a sealing block is arranged on the piston rod in a sleeving mode; a sealing gasket is arranged between the sealing block and the piston cavity; a sensor placement groove is formed in the side, away from the bending mold, of the cylinder body; a displacement sensor is arranged in the sensor placement groove; and the check block and an operation panel are of an integrated structure. According to the pipe bending machine, the working efficiency can be improved, and the occupied area can be decreased. The invention further relates to a rebound compensation method of the numerical control hydraulic push-bending pipe bending machine.

Owner:WUHAN HUAYE AUTOMATION MACHINERY

Pipe bending machine

The invention provides a pipe bending machine and relates to a metal pipe bending device. The pipe bending machine comprises a machine frame, an anti-shriveling plug and a clamp, wherein a lower supporting seat is arranged under the machine frame, an upper supporting seat is arranged above the lower supporting seat, a pipe bending wheel is arranged above one side of the machine frame, an arc-shaped groove is formed in the periphery of the pipe bending wheel, the pipe bending wheel is connected with a spindle, and the spindle is supported in the upper supporting seat and the lower supporting seat. The spindle is connected with a speed reducing device, and the speed reducing device is connected with a power device. A vertically-arranged rotating shaft is connected above the other side of the machine frame, a connecting rod is connected onto the rotating shaft, the other end of the connecting rod faces the pipe bending wheel, and a cushion block is arranged between the connecting rod and the machine frame. During pipe bending, a straight pipe firstly sleeves the end of the connecting rod, then the anti-shriveling plug is arranged in the straight pipe, then the straight pipe is put in the groove of the pipe bending wheel and fixed with the pipe bending wheel through the clamp, the power device is started to drive the spindle to rotate, and the pipe bending wheel is driven to rotate to bend the straight pipe to be semi-circular. The pipe bending machine is high in pipe bending efficiency and reduces the labor intensity of workers, and the pipe does not deform after being bent.

Owner:扬州安顺电气有限公司

Novel continuous bending equipment

InactiveCN105522027ASolve wear and tearSolve the deformationHeat exchange apparatusSheet steelGear wheel

The invention discloses novel continuous bending equipment. The novel continuous bending equipment is characterized by comprising a support table, a pipe bending mold, a limiting mechanism, a power mechanism, a machine body protecting shell and an electric control box; the support table consists of a stand and a support plate; adjustable support legs are arranged at the bottom of the stand; the pipe bending mold includes a pipe bending lower mold, a pipe bending mold head and a U-shaped limiting block; the limiting mechanism consists of a pipe limiting mechanism and a travel limiting mechanism; the power mechanism includes a power cylinder, an air pressure tank, a rack and a rotating shaft with a gear; the machine body protecting shell is produced by a steel plate with a thickness of not smaller than 5 mm; a fan-shaped window is formed in the frontal surface of the machine body protecting shell; the electric control box is mounted on the stand; and a grounding protection device is arranged in the electric control box. The novel continuous bending equipment is excellent in whole stability, high in safety, convenient for use, simple in operation and suitable for continuous bending of metal pipes.

Owner:HEFEI GREAT WALL REFRIGERATION TECH

Intelligent tube bending equipment

PendingCN113118264AGuaranteed stabilityHas a buffering effectMetal-working feeding devicesShaping safety devicesPipe fittingEngineering

The invention discloses intelligent tube bending equipment. The intelligent tube bending equipment comprises an intelligent tube bending equipment body consisting of an electric control mechanism, a feeding mechanism, a tube bending mechanism and a clamping mechanism, wherein the electric control mechanism is electrically connected to the feeding mechanism; the feeding mechanism is in sliding connection to the tube bending mechanism through a pipeline part; the tube bending mechanism is fixedly connected with the clamping mechanism; the clamping mechanism comprises a clamping frame; and the inner wall of the clamping frame is in sliding connection to a clamp; the top of the clamp is in sliding connection to a bearing block. The invention relates to the technical field of intelligent manufacturing equipment. The intelligent tube bending equipment solves problems that indentations are provided on the surface of the pipeline part as a tube bender directly clamps the pipeline part through a clamp in a pipeline processing process, pipe fitting scrap is caused by sliding during local tube bending if diameters of pipeline parts have difference, and generate noises are generated, the surrounding environment is severely affected and the service life of the clamp is reduced as mutual friction between the clamp and the pipeline part exists when the pipeline fitting feeds back and forth.

Owner:王学峰

Intermediate frequency hot bending method for steel pipe

ActiveCN102133588BRealize on-site simmeringReduce purchasing costsBridge engineeringIntermediate frequency

The invention belongs to the field of water conservancy and hydropower engineering, and provides an intermediate frequency hot bending method for a steel pipe. A special bending jig frame is adopted in the method, fulcrums at two ends support the steel pipe, the steel pipe is symmetrically heated by adopting two pieces of intermediate frequency induction heating system equipment, pressure is applied to the steel pipe in the middle by using a hydraulic jack mechanism, the inner arc of the steel pipe is heated and pressed, the steel of the pipe wall is shrunk and deformed, and a catenary arch axis of design requirement is formed by technical means. The method makes the field hot bending of the ultra-long big-diameter high-strength steel pipe possible, fills the international and national blank, and brings huge economic benefit; intermediate frequency pipe bending machine purchasing and reforming costs can be saved, a large amount of big member transport cost can be saved, the pipe bending efficiency can be improved, and the processing cost is reduced; and the adopted intermediate frequency heating reduces the performance influence on the parent metal of the steel pipe, and simultaneously solves the catenary hot bending problem that X70 pipeline steel is applied to a bridge engineering arch rib.

Owner:SINOHYDRO ENG BUREAU 15

A pipe bending device

Owner:巨野宏源金属制品有限公司

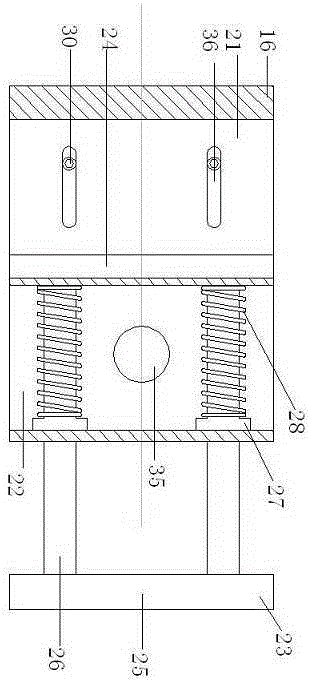

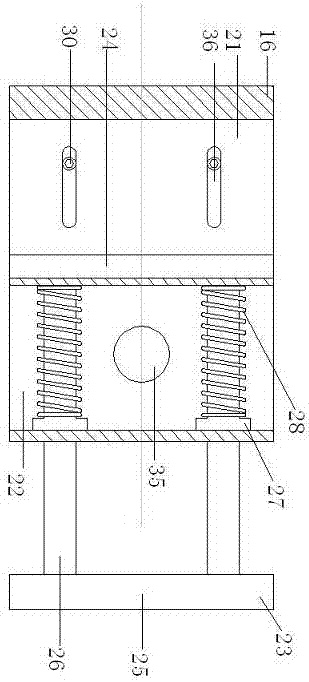

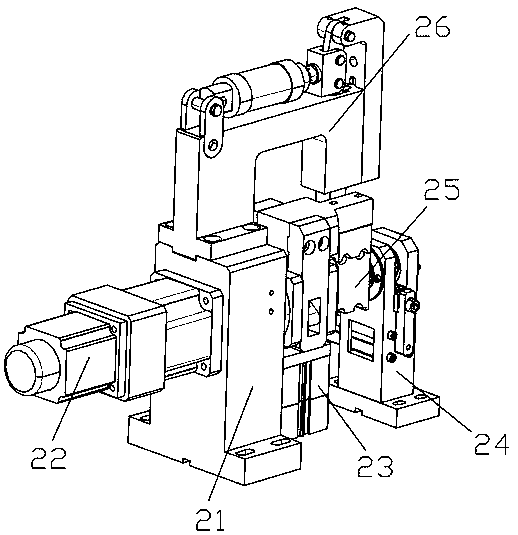

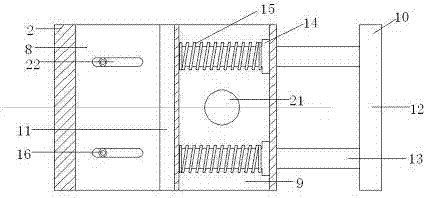

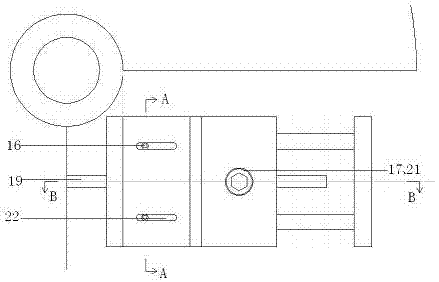

Clamping part for automatic pipe bending machine

The invention relates to a clamping part for a fully automatic pipe bending machine. The clamping part includes a clamping part, a spring part and an expansion plate. Through three-point positioning, the accuracy of the installation position of the clamping part is ensured. The waist-shaped hole and the strip-shaped positioning groove are used together, and the gap between the guide strip and the guide strip groove can be adjusted flexibly on the strip-shaped direction of the positioning groove. The installation process of the clamping piece is very simple. , extremely convenient, in summary, the present invention has the characteristics of simple installation, simple structure, flexible adjustment, high installation precision, simple and fast operation, small labor force, low labor cost and high pipe bending efficiency.

Owner:山东欧盛建材有限公司

A clamping device for a fully automatic pipe bending machine

InactiveCN105234225BSimple structureReasonable designMetal-working feeding devicesPositioning devicesEngineeringFully automatic

A clamping device for a fully automatic pipe bender, which is characterized in that it includes a telescopic cylinder and a clamping part, and the clamping part is detachably connected to the panel of the pipe bender through a fixed structure. The structure of the invention is simple , the design is reasonable, the connecting rod is pushed by the telescopic cylinder, and the adjusting rod is driven, so that the tip of the adjusting rod is pressed against the pressure plate of the clamping part, forcing the splint of the clamping part to clamp the workpiece, the operation is simple and fast, the labor force is small and the reduction It reduces the labor cost and improves the bending efficiency. At the same time, through three-point positioning, the accuracy of the installation position of the clamping parts is guaranteed. The waist-shaped hole of the fixing hole and the strip-shaped positioning groove are used together. The clearance fit of the strip groove can make the clamping part flexibly adjust in the strip direction of the positioning groove, and the installation process of the clamping device is very simple and convenient.

Owner:江苏凯普特动力机械股份有限公司

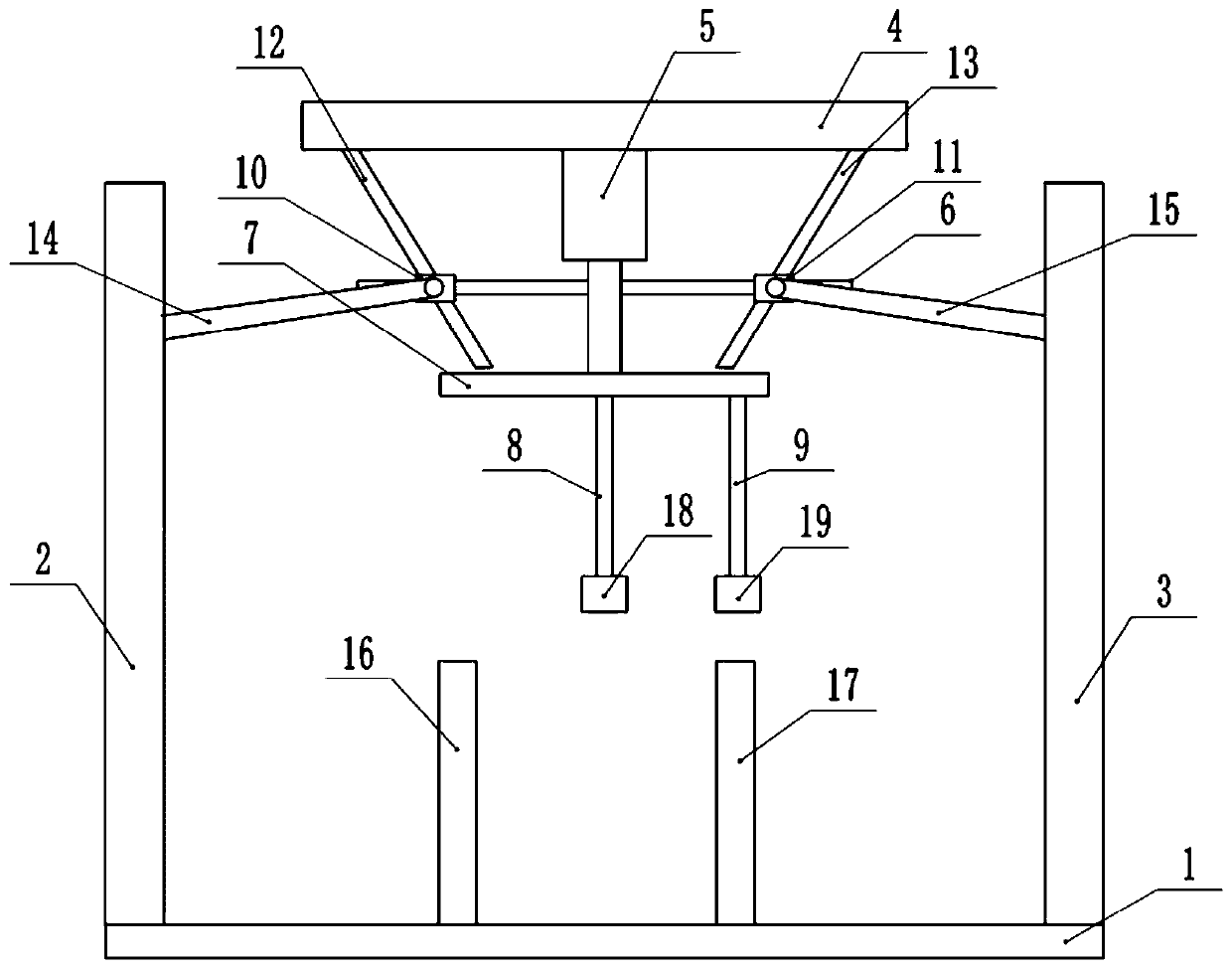

Tube bender

ActiveCN108296329BRealize automatic clampingHigh speedMetal-working feeding devicesStripping-off devicesPiston rodIndustrial engineering

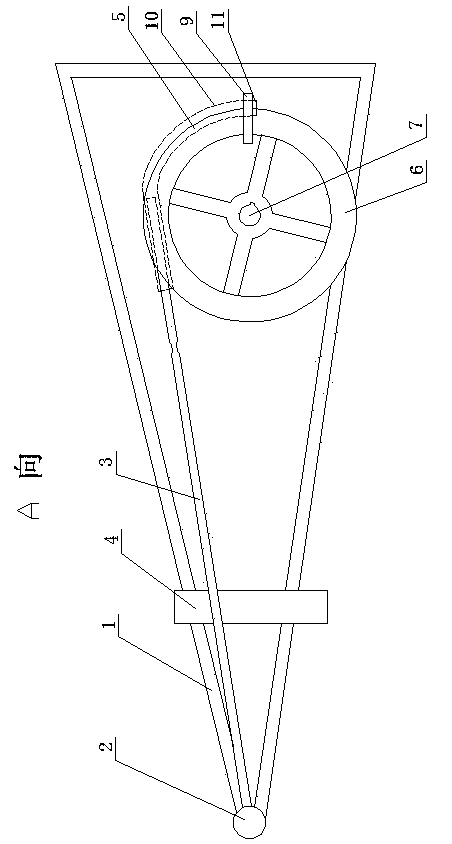

The invention belongs to the technical field of pipe bending equipment, and particularly discloses a pipe bending device. The pipe bending device comprises a base, a first clamping plate, a second clamping plate, a stand column, a first supporting rod and a second supporting rod are arranged on the base, a transverse beam is arranged on the stand column and is provided with an air cylinder, a first inclined rod and a second inclined rod, a transverse plate and a transverse rod are arranged on a piston rod, a first pressing rod is arranged on the transverse plate, the two ends of the transverserod are provided with a first sliding block and a second sliding block which are in sliding connection with the transverse rod, and the first sliding block and the second sliding block are in slidingconnection with the first inclined rod and the second inclined rod correspondingly; and a first connecting rod and a second connecting rod are hinged to the first sliding block and the second slidingblock correspondingly, the end, far away from the first sliding block, of the first connecting rod is hinged to the first clamping plate, and the end, far away from the second sliding block, of the second connecting rod is hinged to the second clamping plate. The pipe bending device is mainly used for bending a steel pipe, and the problem that pipe clamping is not good in the pipe bending processis solved.

Owner:CHONGQING JIANAN IND & TRADE

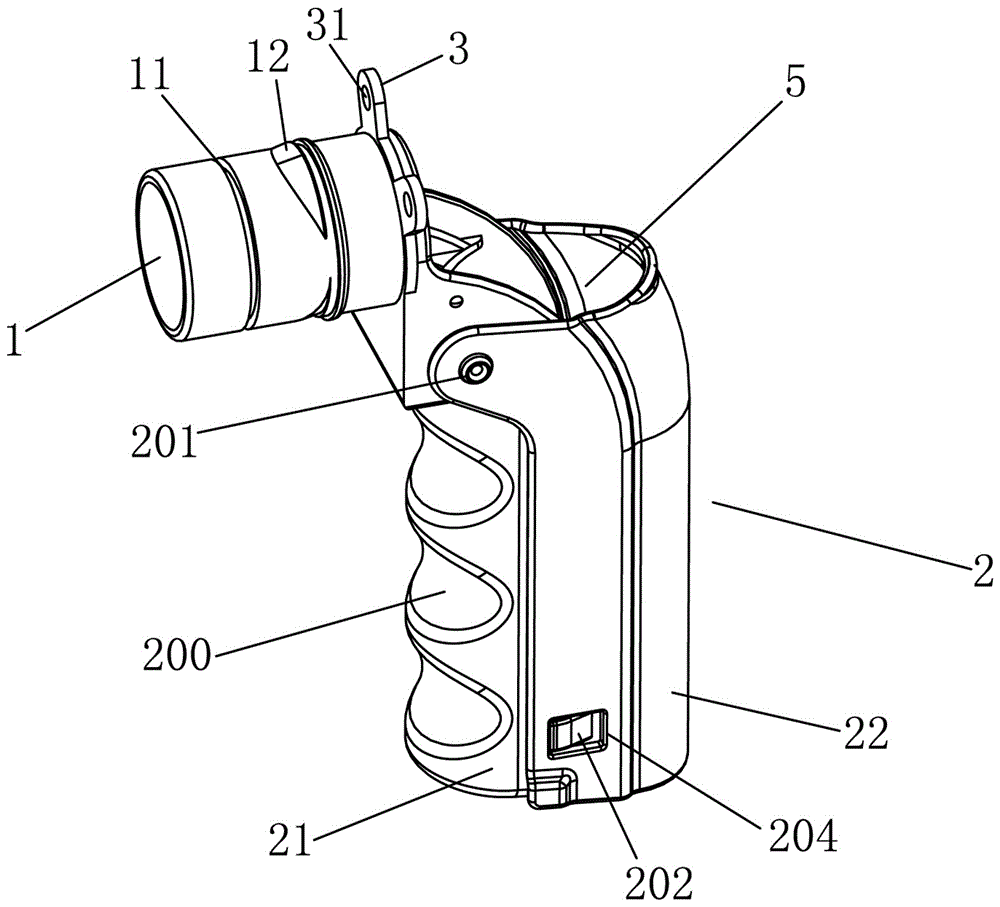

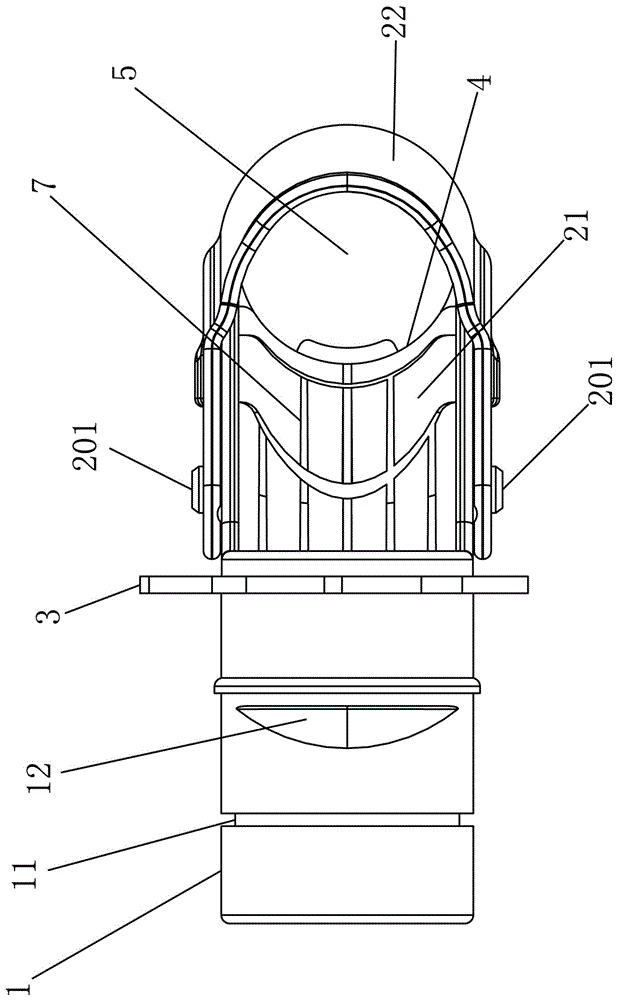

Soft pipeline installing device

ActiveCN105822833AAvoid deformationEasy to operatePipe supportsFlexible pipesEngineeringStructural engineering

The invention relates to a soft pipeline installing device. The soft pipeline installing device comprises a handle and a gun pipe; the handle further comprises a holding part and a pressure applying part; an included angle is formed between the holding part and the gun pipe; the holding part and the gun pipe are connected through an arc-shaped rotating corner; the upper end of the pressure applying part is connected to the holding part in a pivoted manner; and the lower end of the pressure applying part rotates within the range of the axis of the gun pipe and the axis of the holding part. When the lower end of the pressure applying part rotates to the axis of the gun pipe, a soft pipeline stretches into the gun pipe along the lower end of the pressure applying part; when the lower end of the pressure applying part moves to the axis of the holding part, the soft pipeline is bent by the pressure applying part; and when the lower end of the pressure applying part is buckled with the holding part, the soft pipeline is clamped in a channel formed by the pressure applying part and the holding part. According to the soft pipeline installing device, by rotating the pressure applying part, pipe bending operation of the soft pipeline can be easily performed, the pipe bending difficulty is greatly reduced, the bent soft pipeline can be hidden in the channel formed by the holding part and the pressure applying part, deformation of the soft pipeline is avoided, and the pipe bending effect is improved.

Owner:FOSHAN BUILDING INTEGRATED HOUSING TECH CO LTD

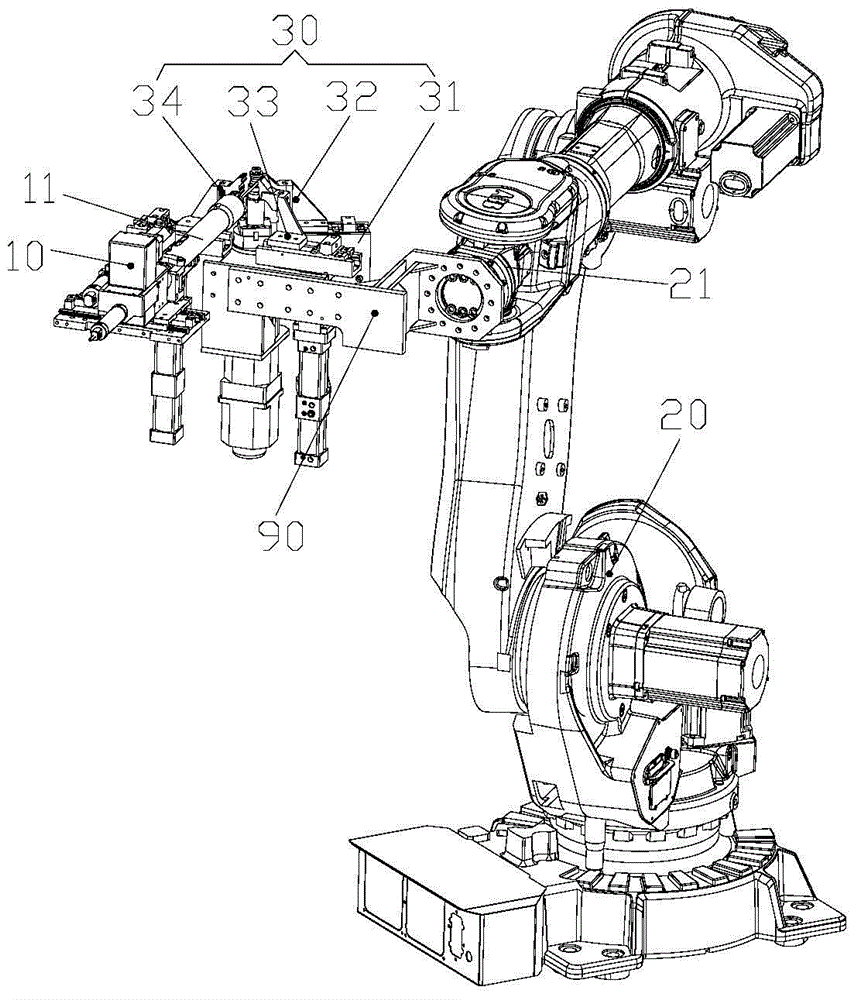

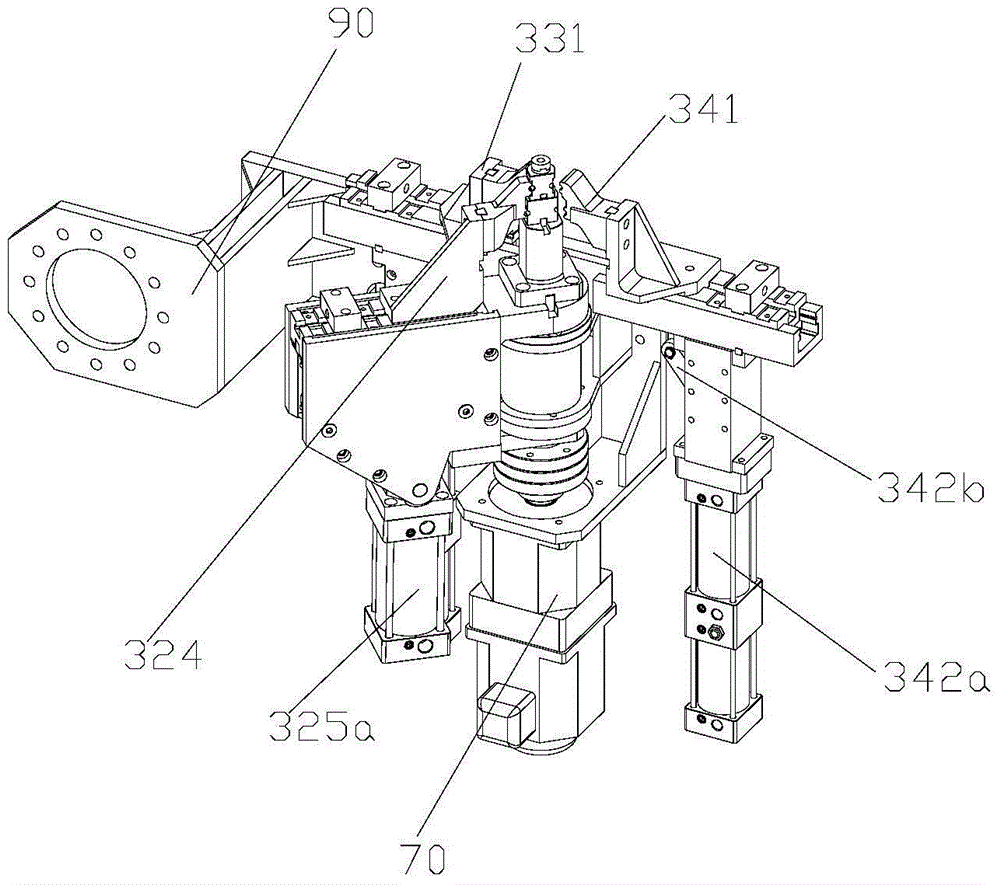

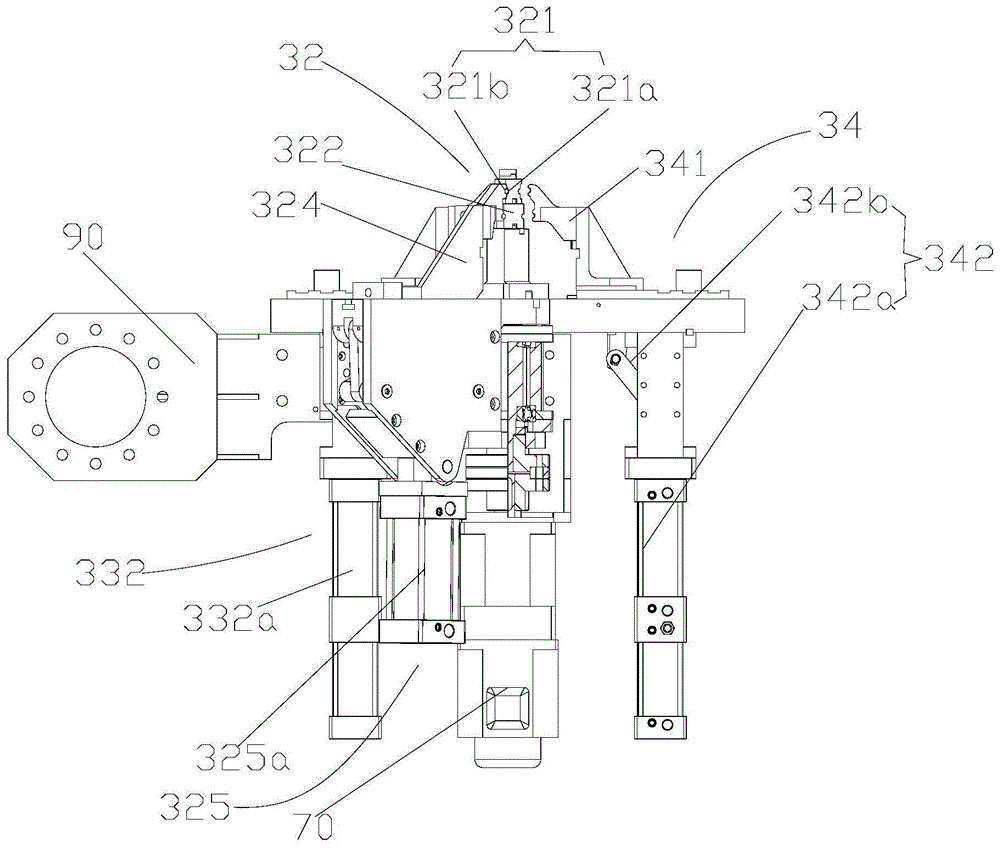

Pipe bender and its control method

ActiveCN104690116BRealize right-curved operationLow costMetal-working feeding devicesMetal working apparatusEngineeringMechanical engineering

Owner:GREE ELECTRIC APPLIANCES INC

Clamping piece for full-automatic pipe bending machine

The invention relates to a clamping piece for a full-automatic pipe bending machine. The clamping piece for the full-automatic pipe bending machine comprises a clamping part, a spring part and a telescopic plate. The precision of the installation position of the clamping piece is ensured through three-point positioning. A kidney-shaped hole shown by a fixing hole and a bar-shaped positioning groove are used in a matched manner. A guiding bar and a guiding bar groove are in clearance fit. The clamping piece can be flexibly adjusted in the bar-shaped direction shown by the positioning groove. The installation process of the clamping piece is very simple and extremely convenient. In conclusion, the clamping piece has the characteristics that installation is easy, the structure is simple, adjustment is flexible, installation precision is high, operation is easy and fast, labor force is small, labor cost is low, and the pipe bending efficiency is high.

Owner:山东欧盛建材有限公司

Curved passage transportation equipment with stable function

InactiveCN109877196AEasy to bendImprove pipe bending efficiencyMetal working apparatusKey pressingComputer module

The invention discloses curved passage transportation equipment with a stable function. The equipment comprises a ring locker, a fine and smooth object, a constructed model, a meter-like member and amain control circuit module, a button is installed on the front surface of the meter-like member, a reset button is installed on the right side of the button, a scale is installed below the fine and smooth object, pair holes are formed in the part below the scale, the main control circuit module is installed on the right side of the meter-like member, a motor is installed in the main control circuit module, the main control circuit module is connected with a power line through a performance protector, a connecting device is installed in the meter-like member, a computing device is installed onthe left side of the meter-like member, the constructed model is installed in the front surface of the meter-like member, a rolling cylinder is installed on the surface of the constructed model, thering locker is installed on the left side of the rolling cylinder, the ring locker is connected with an adjusting shaft through a screw rod, and an inserting hole is formed in the left side of the ring locker. The equipment has the advantages that the bending of a pipeline is achieved through rapid temperature increasing to allow the pipeline to be softened, a curved surface pipeline with stable functions is formed after cooling, and the equipment is extremely convenient.

Owner:吴雨桐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com