Numerical control hydraulic push-bending pipe bending machine and rebound compensation method thereof

A bending and hydraulic technology, applied in complex mathematical operations and other directions, can solve the problems of pipe stumbling, reduced bending force, small bending force, etc., and achieve reduced guide length, increased bending strength, and bending efficiency. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

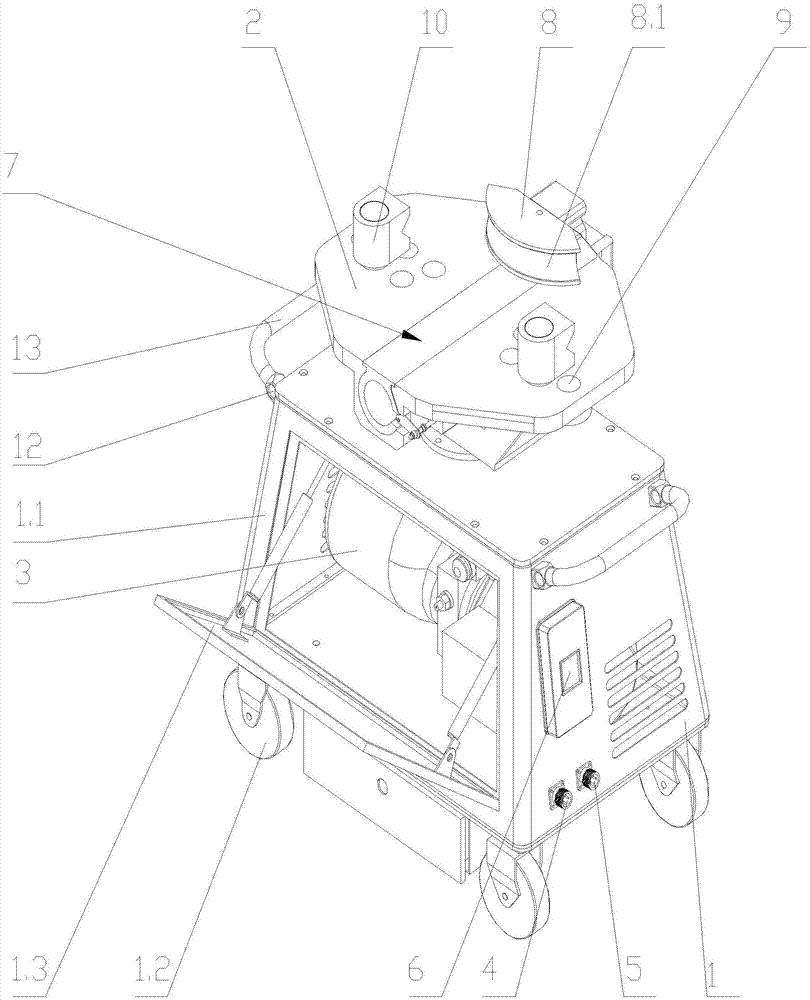

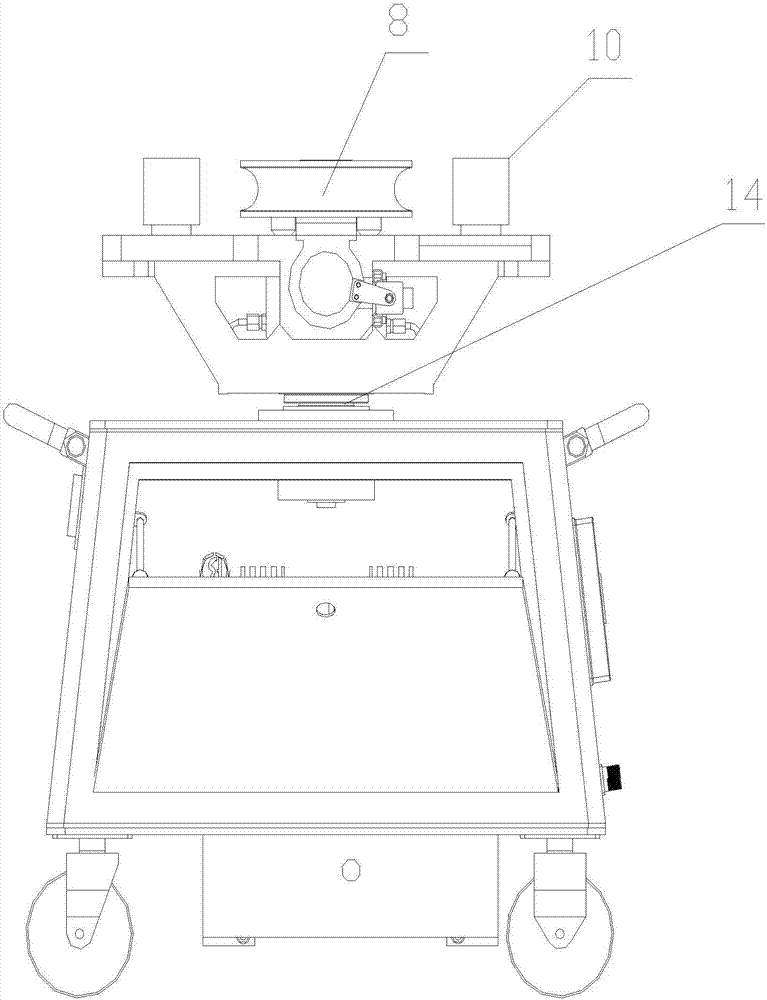

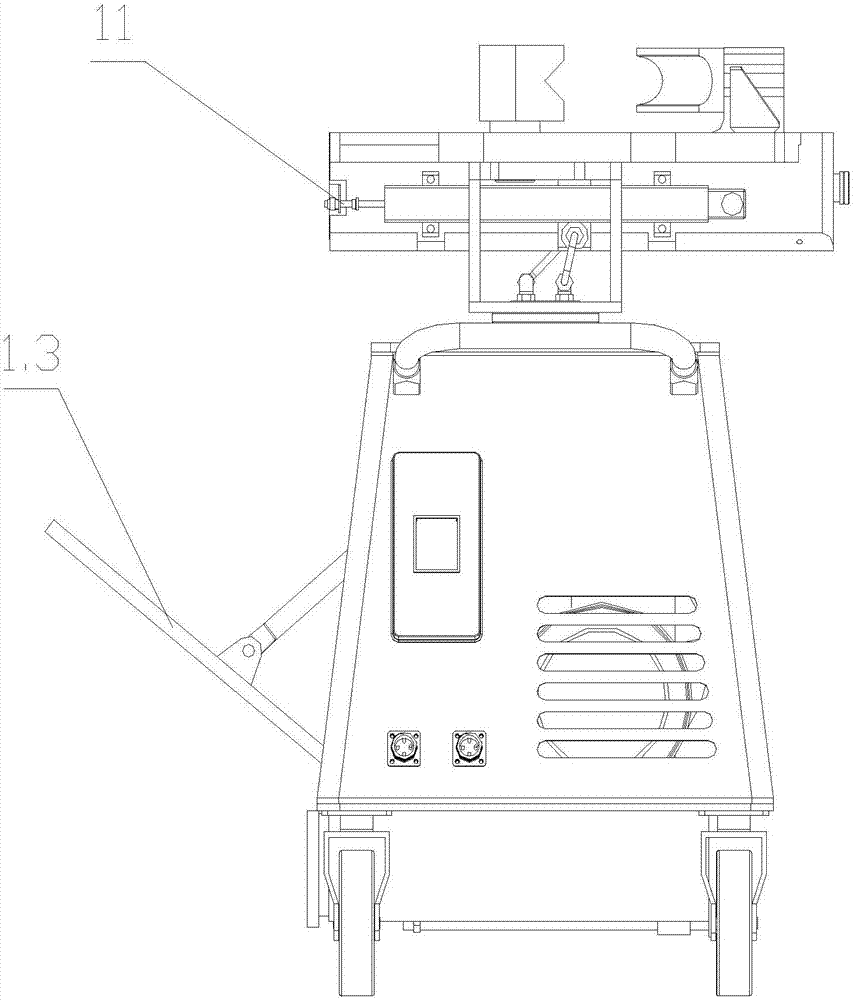

[0044] Referring to the accompanying drawings, it can be seen that a numerically controlled hydraulic top bending pipe bender includes a bending die 8 installed above the operation panel 2, and a bending die installed in the middle of the operation panel 2 that can drive the bending die 8 to move back and forth on the operation panel 2 The driving mechanism 7 is characterized in that: the bending die driving mechanism 7 includes a guide groove 21 located in the middle of the operation panel 2, and a cylinder 22 located inside the guide groove 21 and capable of sliding in the guide groove 21, the bending die 8 It is connected with one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com