Clamping part for automatic pipe bending machine

A technology of clamping parts and pipe bending machines, which is applied in the field of clamping parts for automatic pipe bending machines, can solve problems affecting product qualification rate, high labor cost, lack of flexibility, etc., and achieve simple structure, low labor cost, Simple and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

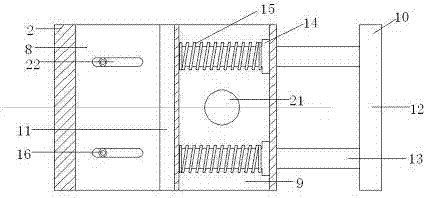

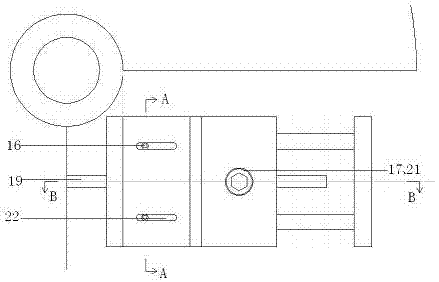

[0019] A clamping part for a fully automatic pipe bender, characterized in that the clamping part 2 includes a clamping part 8, a spring part 9 and a telescopic plate 10, and the telescopic plate 10 includes a splint 11 located at the clamping part, The pressing plate 12 and the spring telescopic rod 13 that are positioned at one side of the spring part 9, the number of the spring telescopic 13 rods are 2, the two ends of which are respectively connected to the splint 11 and the pressing plate 12, and the middle of the spring telescopic rod 13 is provided with a bump 14, the said The bump 14 is located in the spring part 9, and the spring part 9 is provided with a spring 15. The number of the springs 15 is 2, which are respectively fitted on the 2 spring telescopic rods 13, and one end of the spring 15 is pressed against the bump 14, the other end is pressed against the inner wall of the spring part 9;

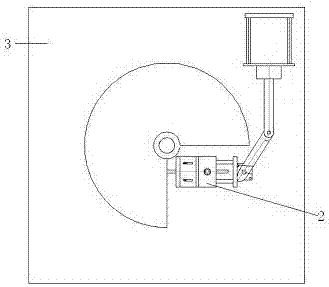

[0020] The clamping member 2 is detachably connected to the panel 3 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com