Tube bender

A technology of pipe bending device and splint, which is used in feeding device, positioning device, stripping device, etc., can solve the problems of poor steel pipe clamping and easy movement of steel pipe, so as to avoid inaccurate bending size, less power mechanism, etc. Low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

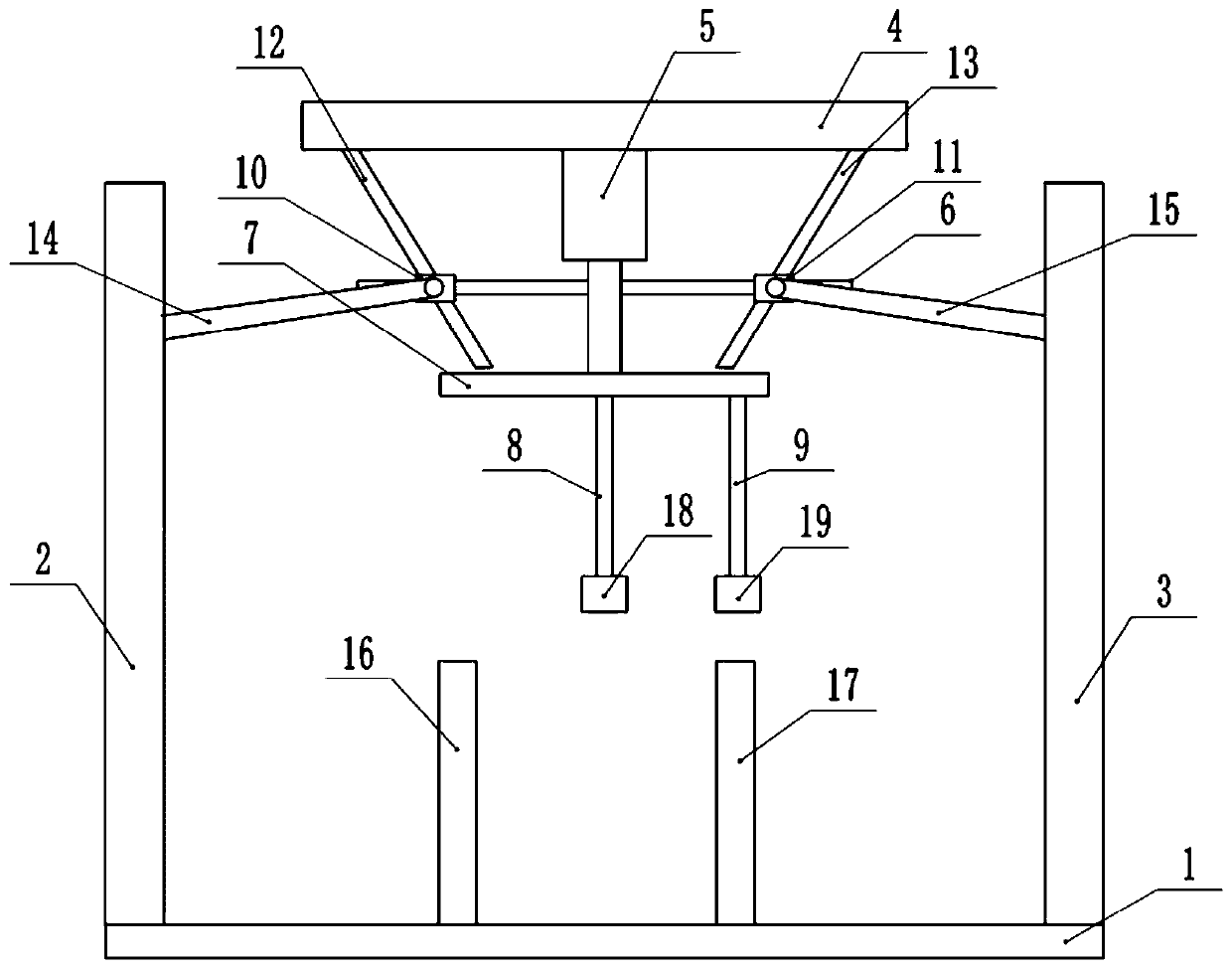

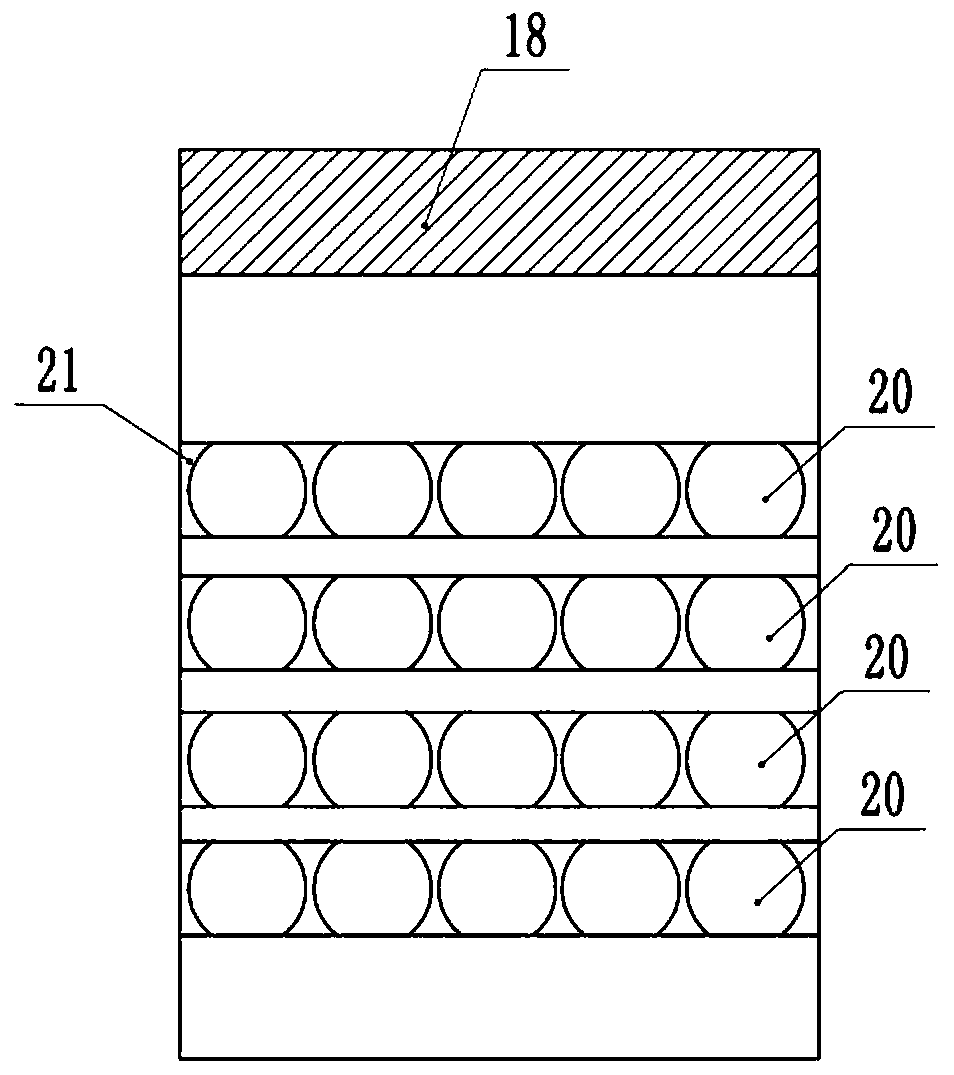

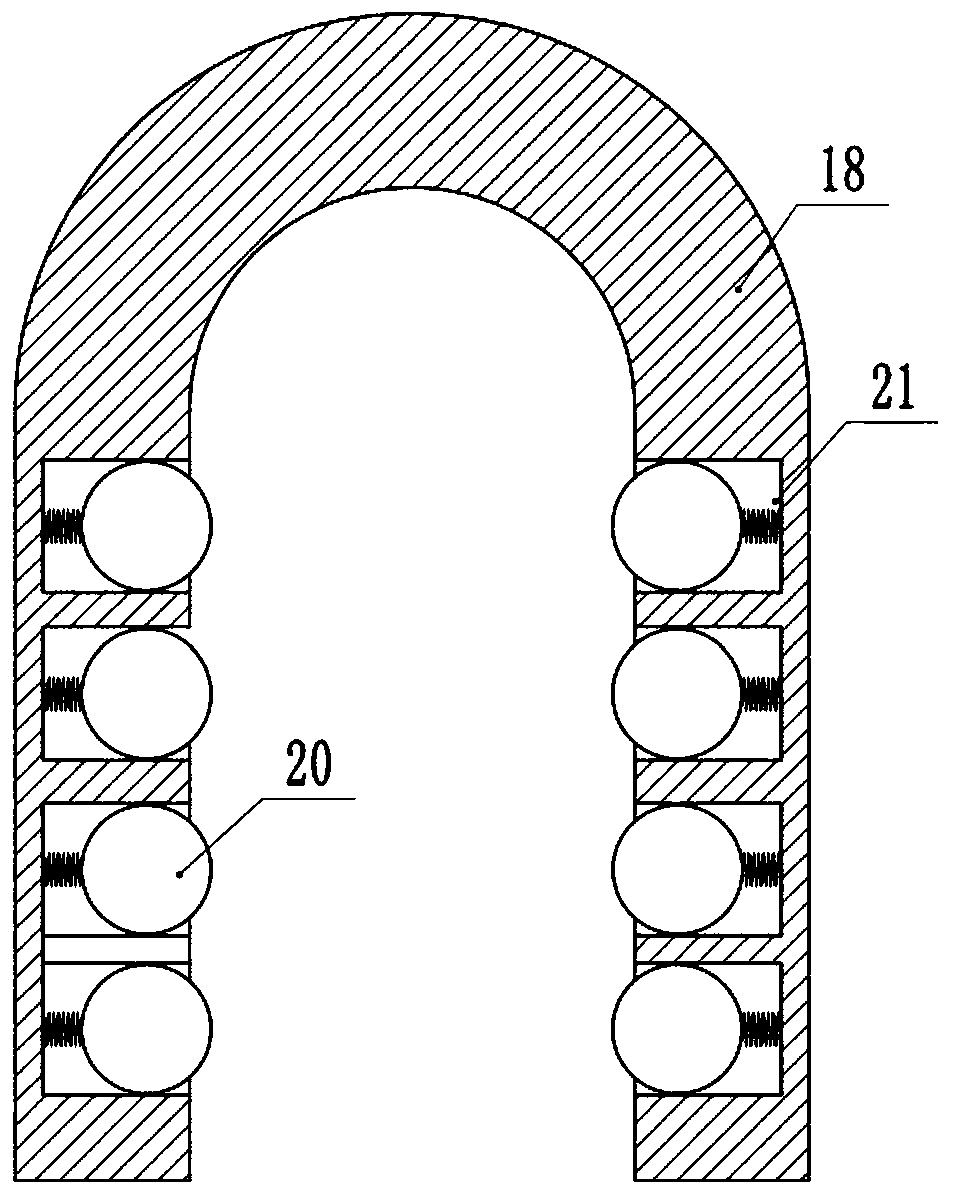

[0022] The reference signs in the drawings of the description include: base 1, first splint 2, second splint 3, crossbeam 4, cylinder 5, crossbar 6, crossplate 7, first compression rod 8, second compression rod 9, first compression rod One slide block 10, the second slide block 11, the first oblique bar 12, the second oblique bar 13, the first connecting rod 14, the second connecting rod 15, the first support rod 16, the second support rod 17, the first buckle Groove 18, second buckle groove 19, ball 20, through groove 21.

[0023] Such as figure 1 As shown, the pipe bending device includes a base 1, a first splint 2, a second splint 3 and a column, a slide rail is installed on the base 1, rollers are installed on the lower ends of the first splint 2 and the second splint 3, the first splint 2 and The second clamping plate 3 is installed in the slide rail by rollers; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com