Horizontal steel tube bending machine

A bending machine and steel pipe technology, applied in metal processing equipment, stripping devices, manufacturing tools, etc., can solve the problems of low pipe bending efficiency, inability to automatically feed and discharge materials, etc., to achieve high pipe bending efficiency and fully automatic The effect of pipe bending operation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

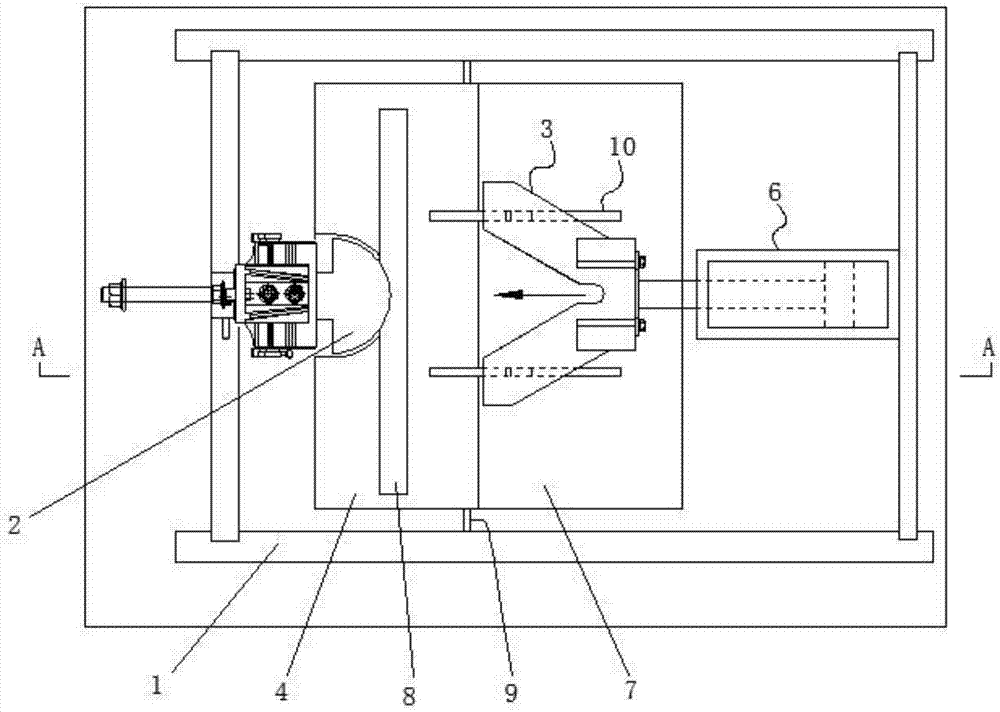

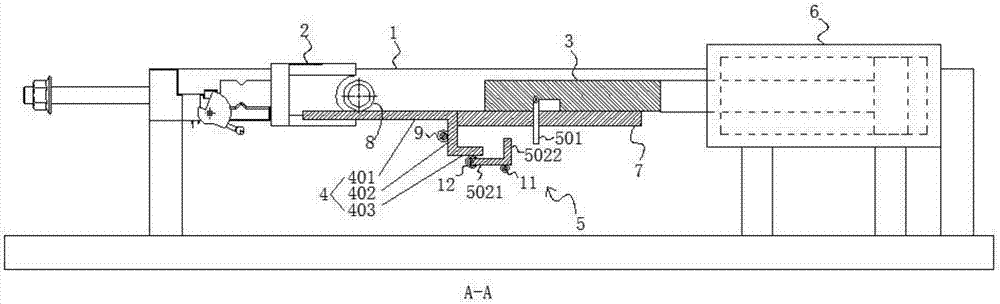

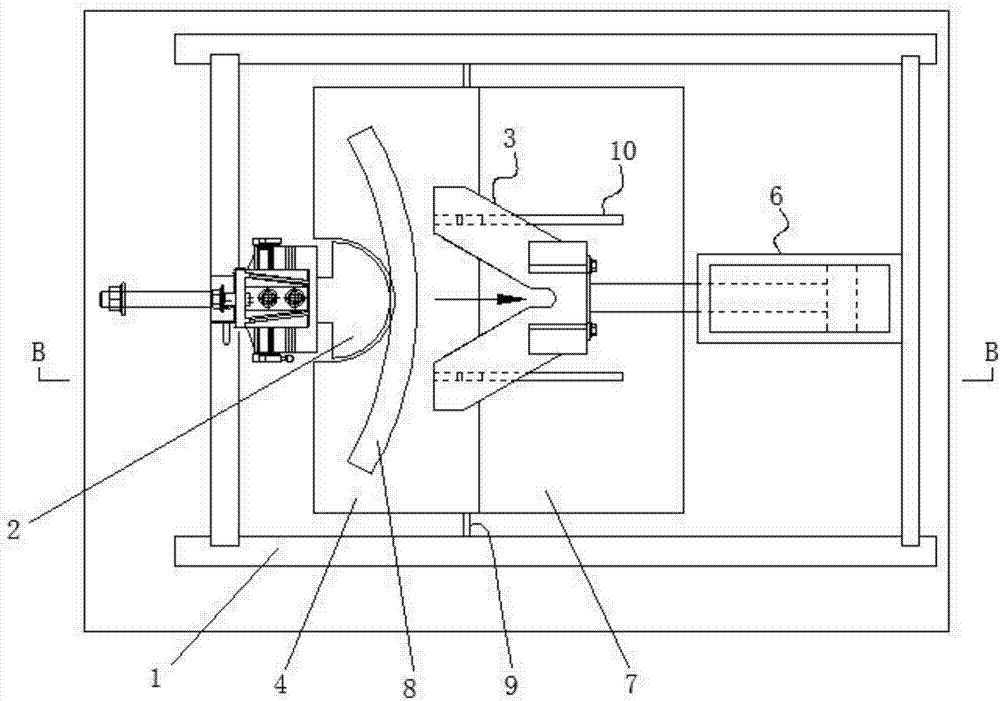

[0016] like Figure 1 to Figure 4 As shown, the horizontal steel pipe bending machine of this embodiment includes a frame 1 , a mold 2 , a punch 3 , a movable plate 4 , a rotating plate mechanism 5 , a hydraulic cylinder 6 and a bearing plate 7 .

[0017] The mold 2 is a semicircular part with grooves on the sides. The mold 2 is mainly used to help bend the steel pipe 8. The specific shape of the mold 2 is freely determined according to the size of the steel pipe 8 to be processed. Both the die 2 and the hydraulic cylinder 6 are installed on the frame 1 and are at the same level; the punch 3 is V-shaped, the punch 3 is installed on the piston rod of the hydraulic cylinder 6, and the hydraulic cylinder 6 drives the punch 3 relative to the die 2 reciprocating motion.

[0018] like figure 2 As shown, the cross section of the movable plate 4 is Z-shaped, the upper plate 401 of the movable plate 4 is horizontal and loads the steel pipe 8, the middle plate 402 of the movable plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com