Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Eliminate light leaks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

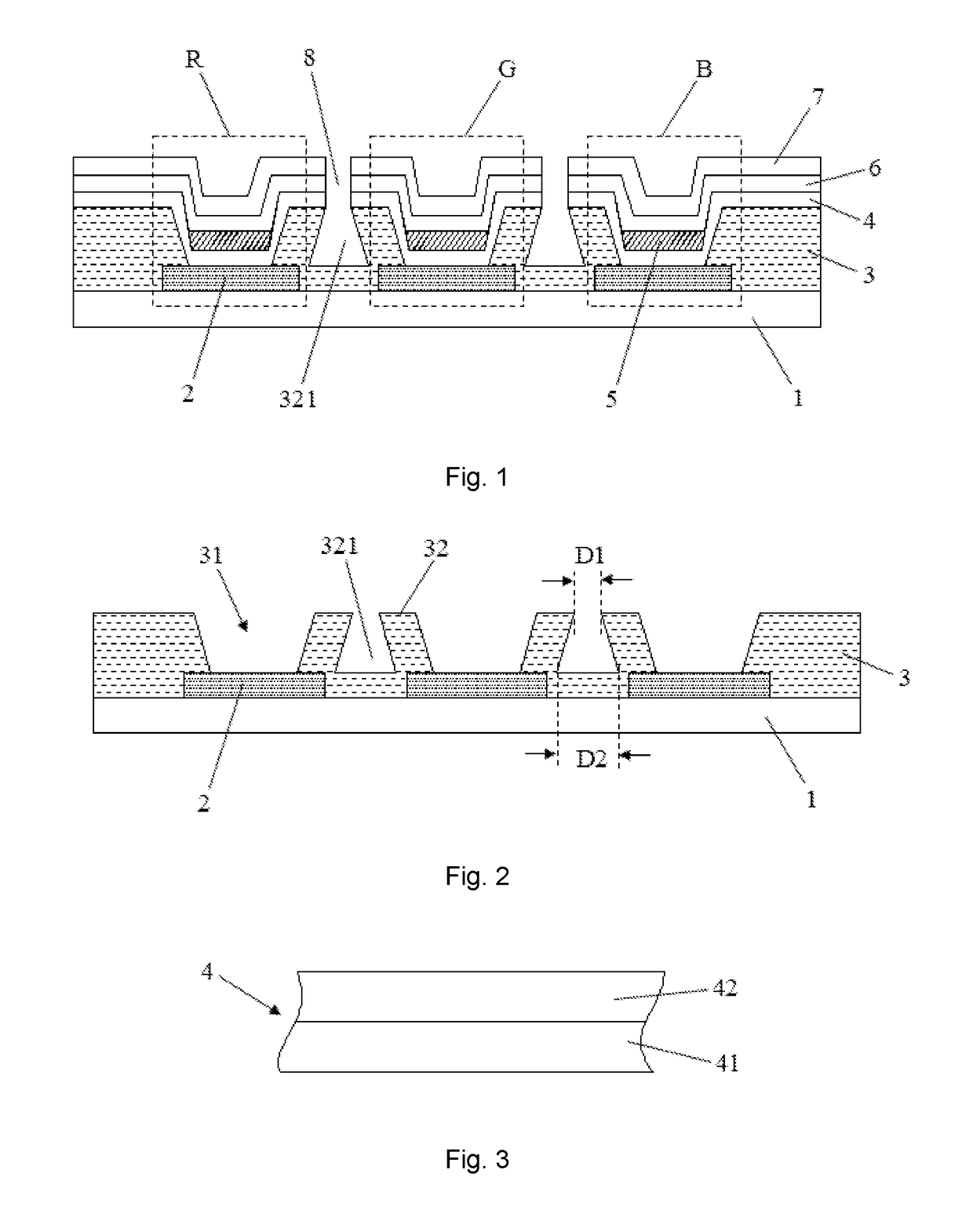

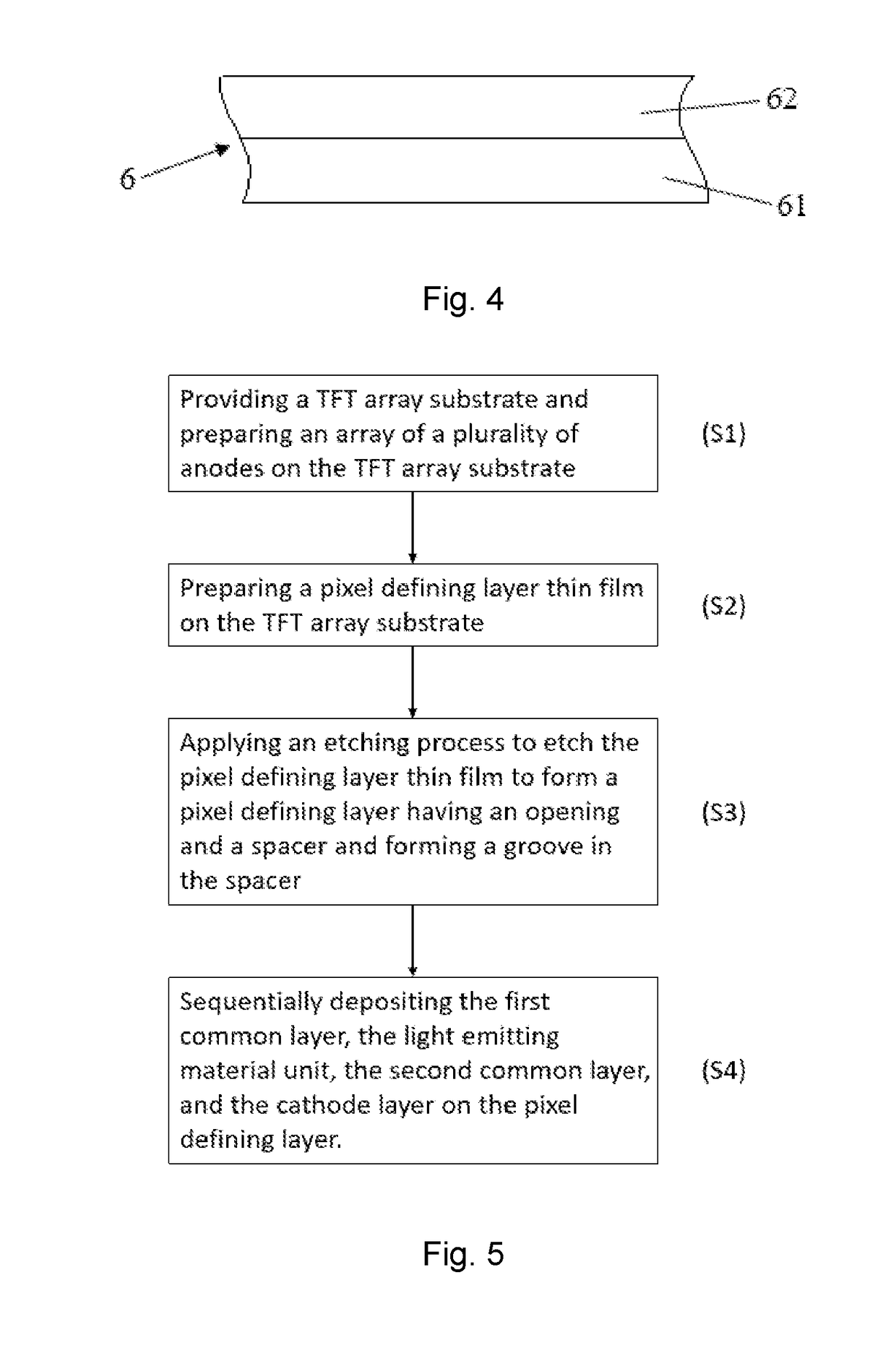

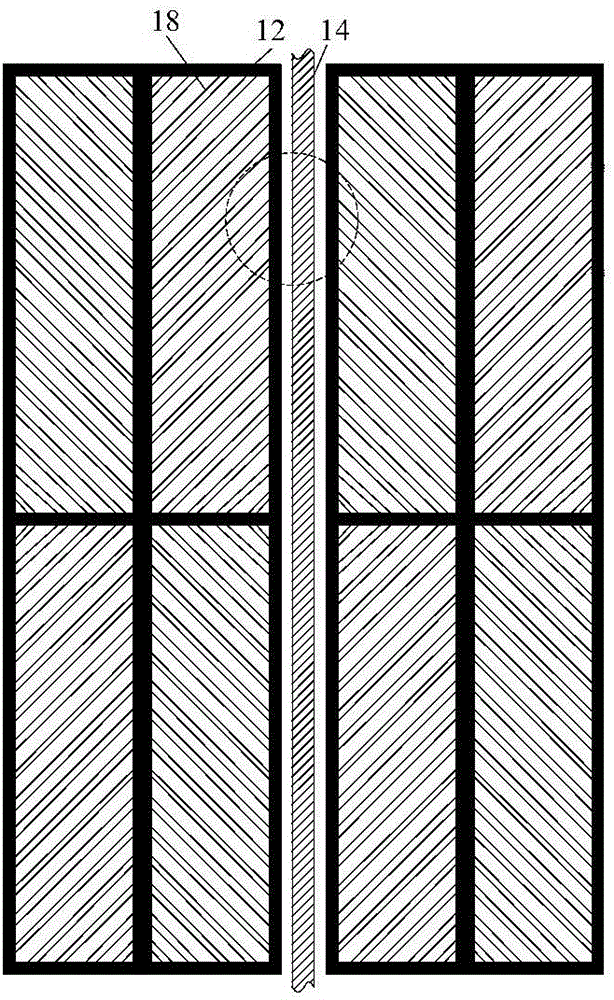

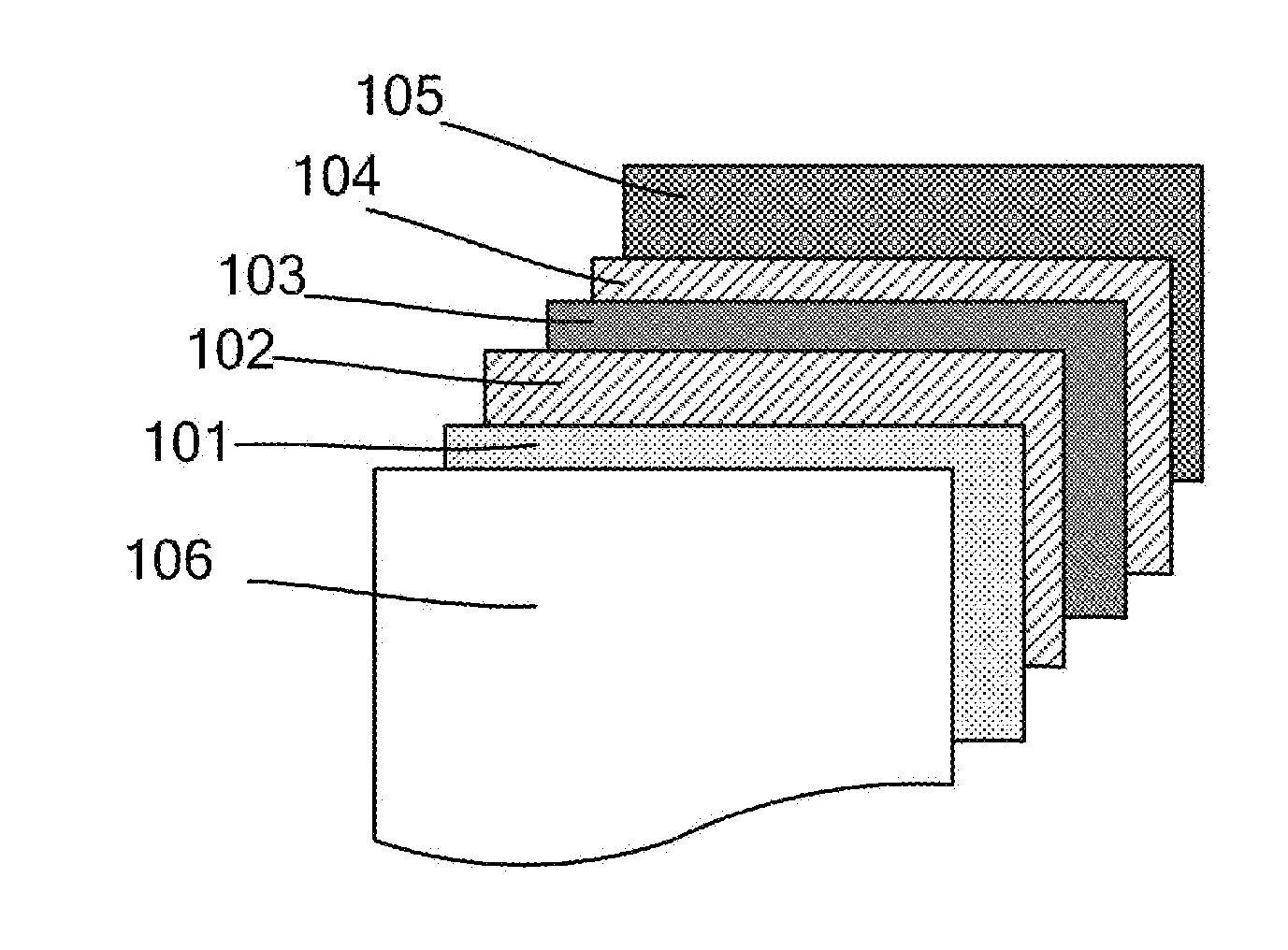

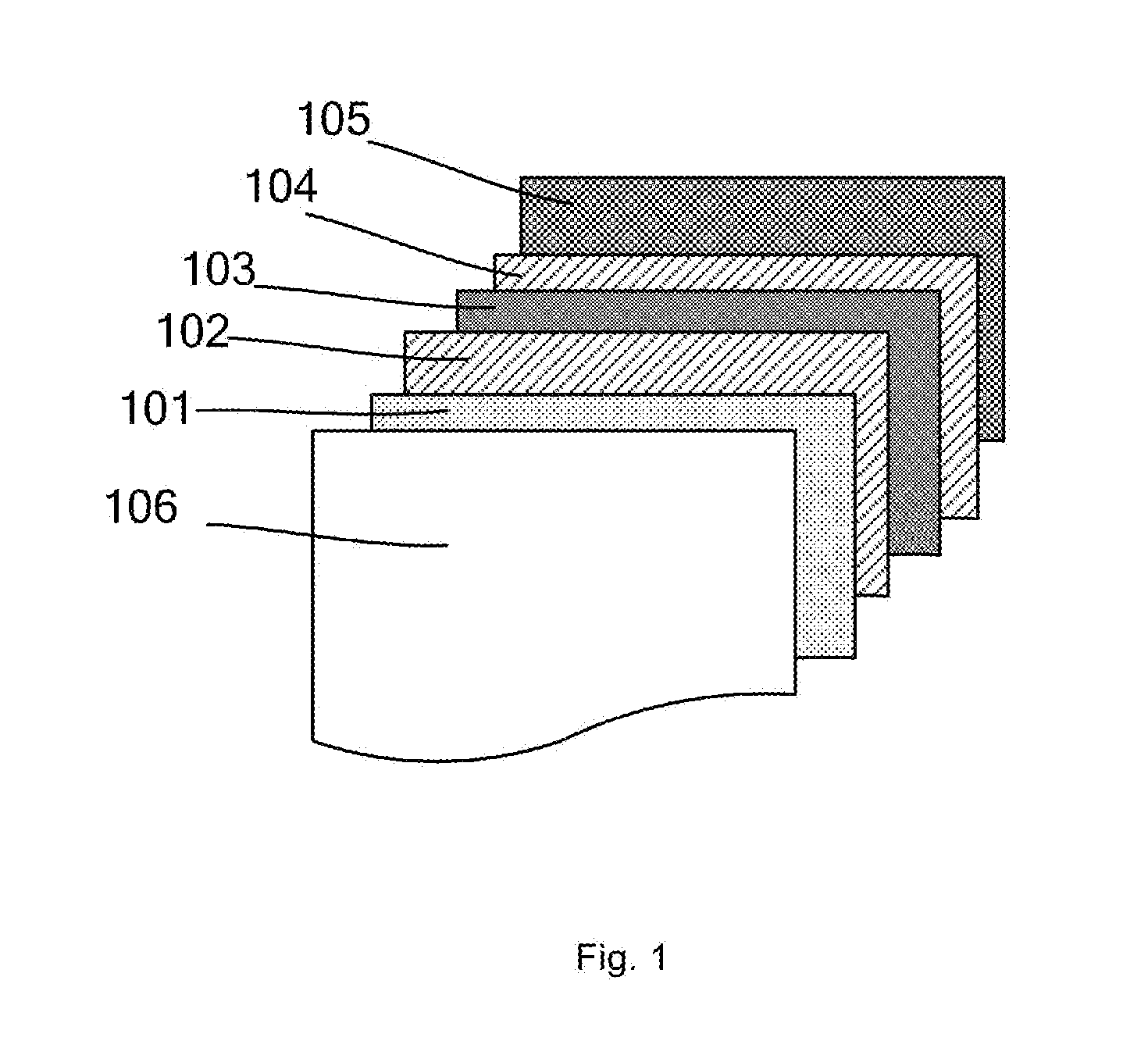

OLED (Organic Light Emitting Diode) display panel, preparation method of display panel, and display device

ActiveCN106876331AImprove display qualityEliminate light leaksSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

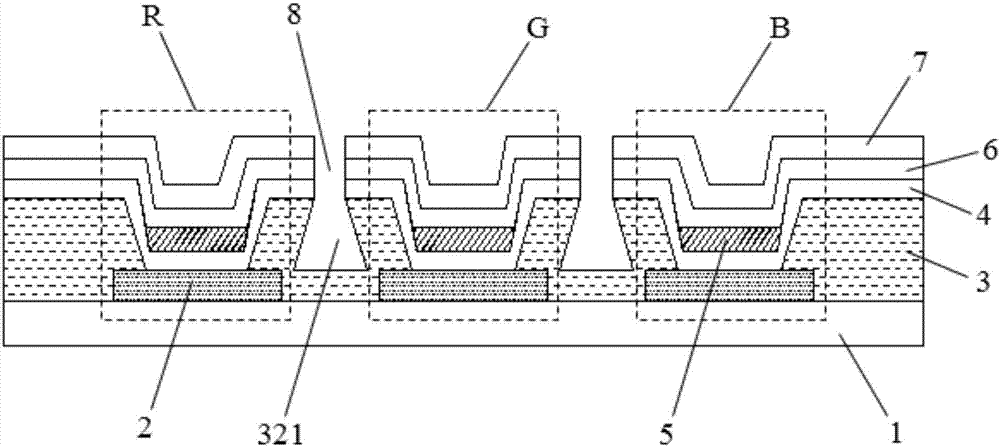

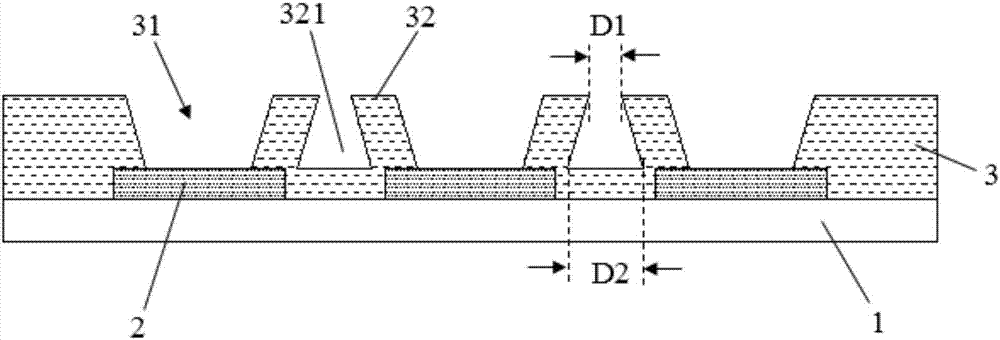

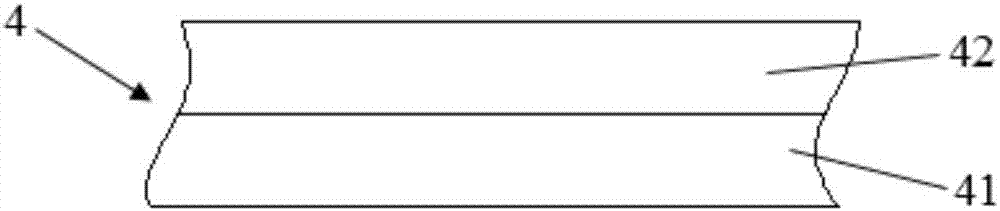

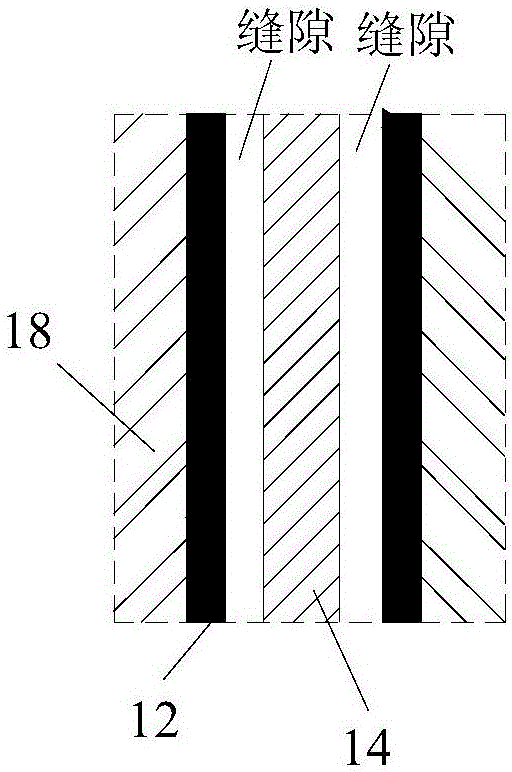

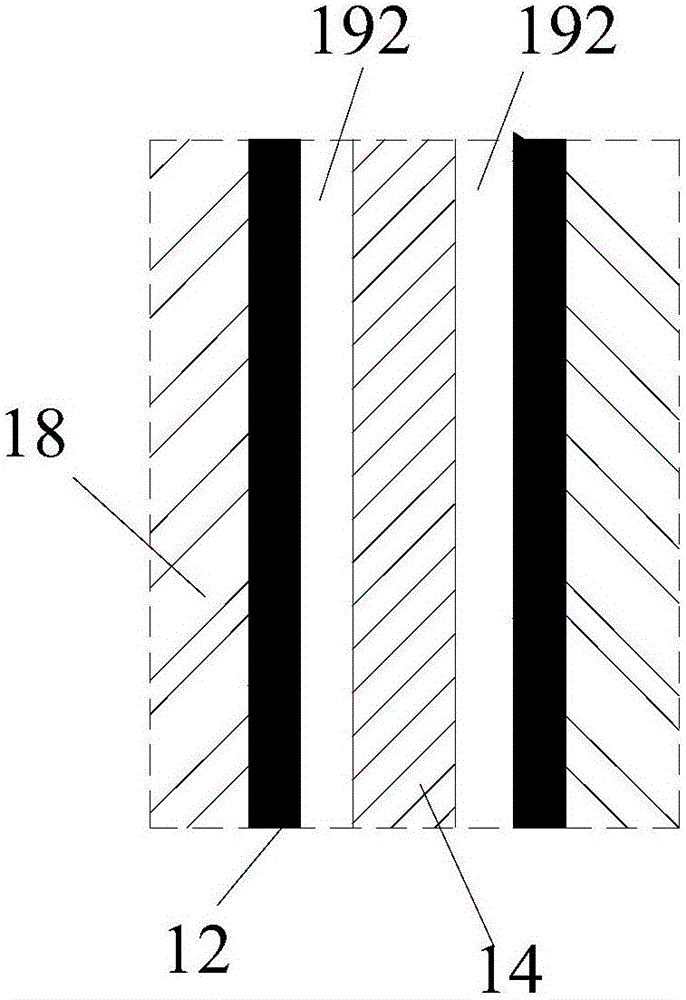

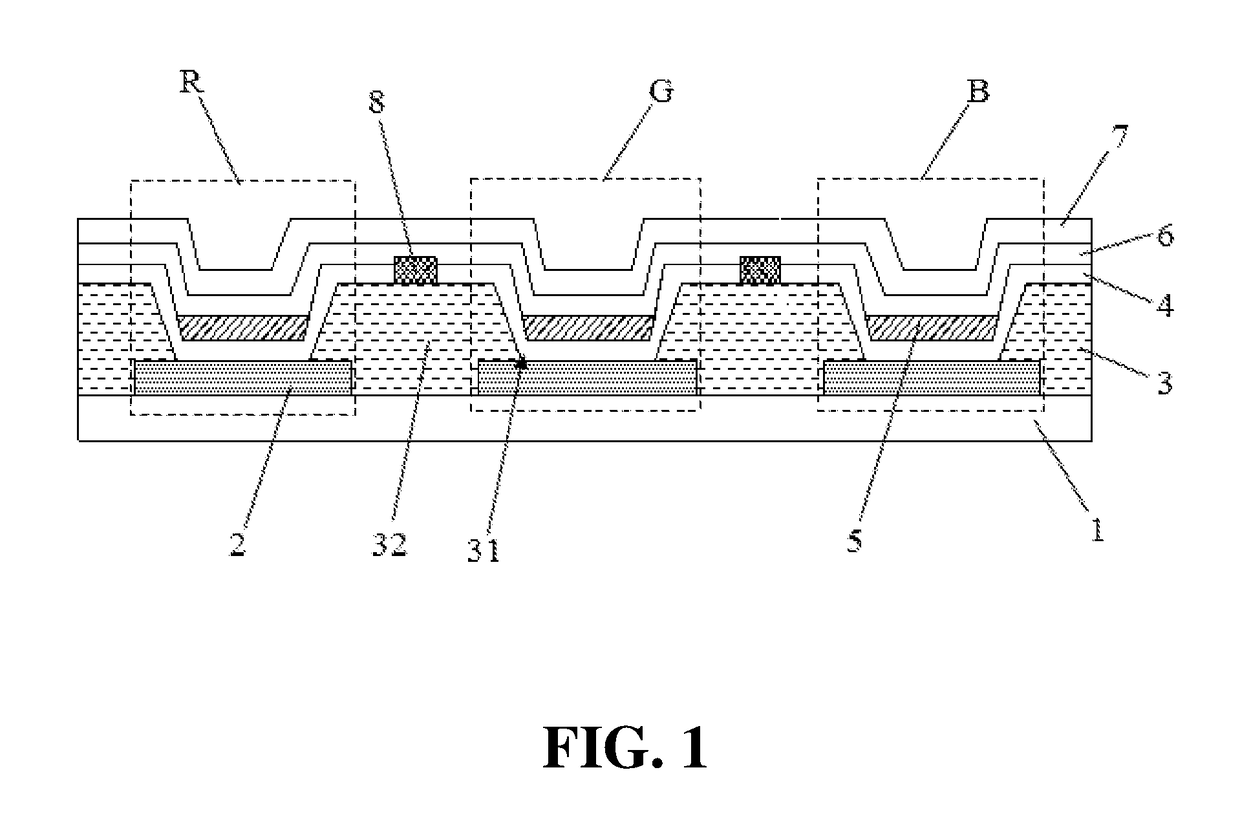

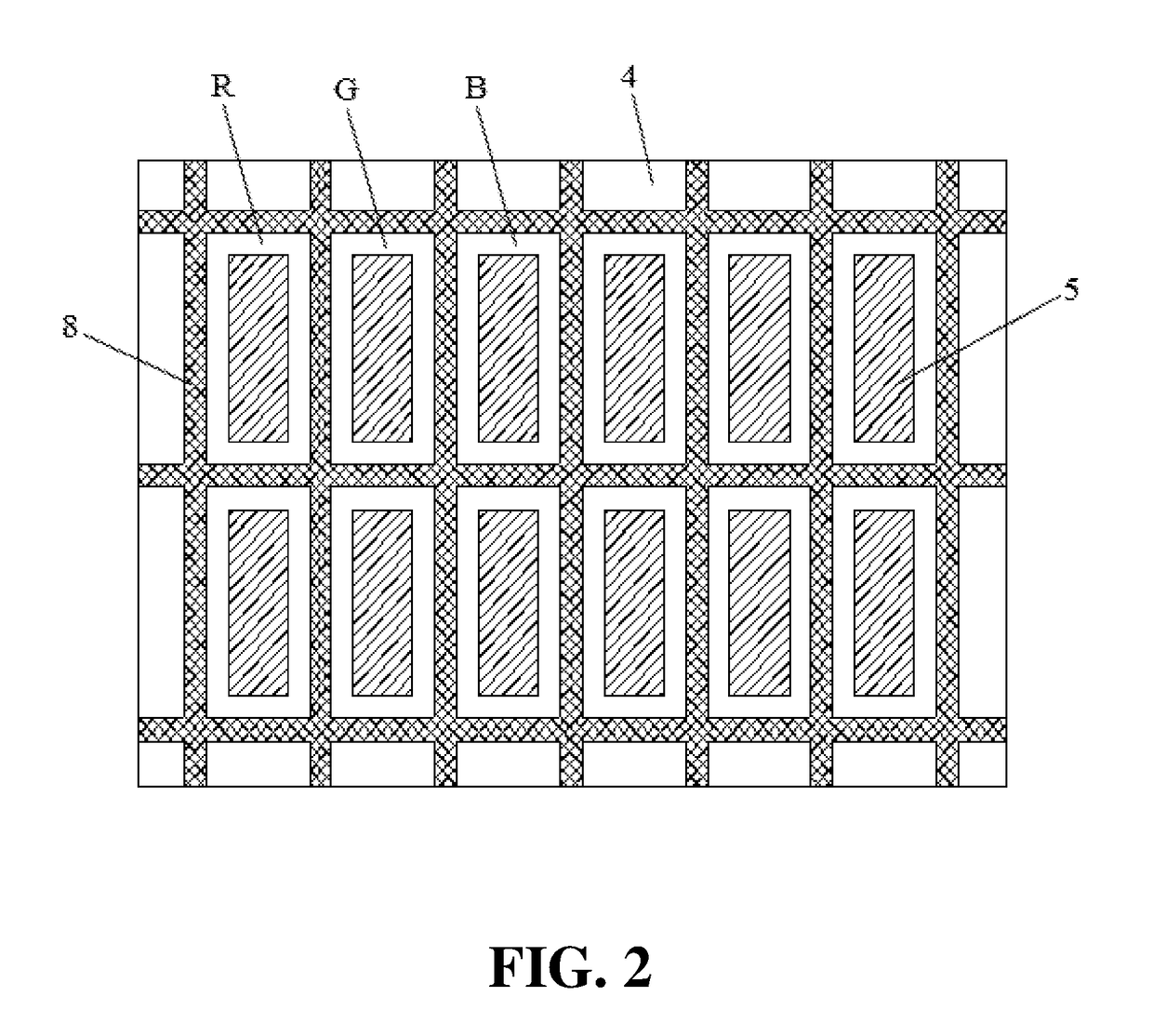

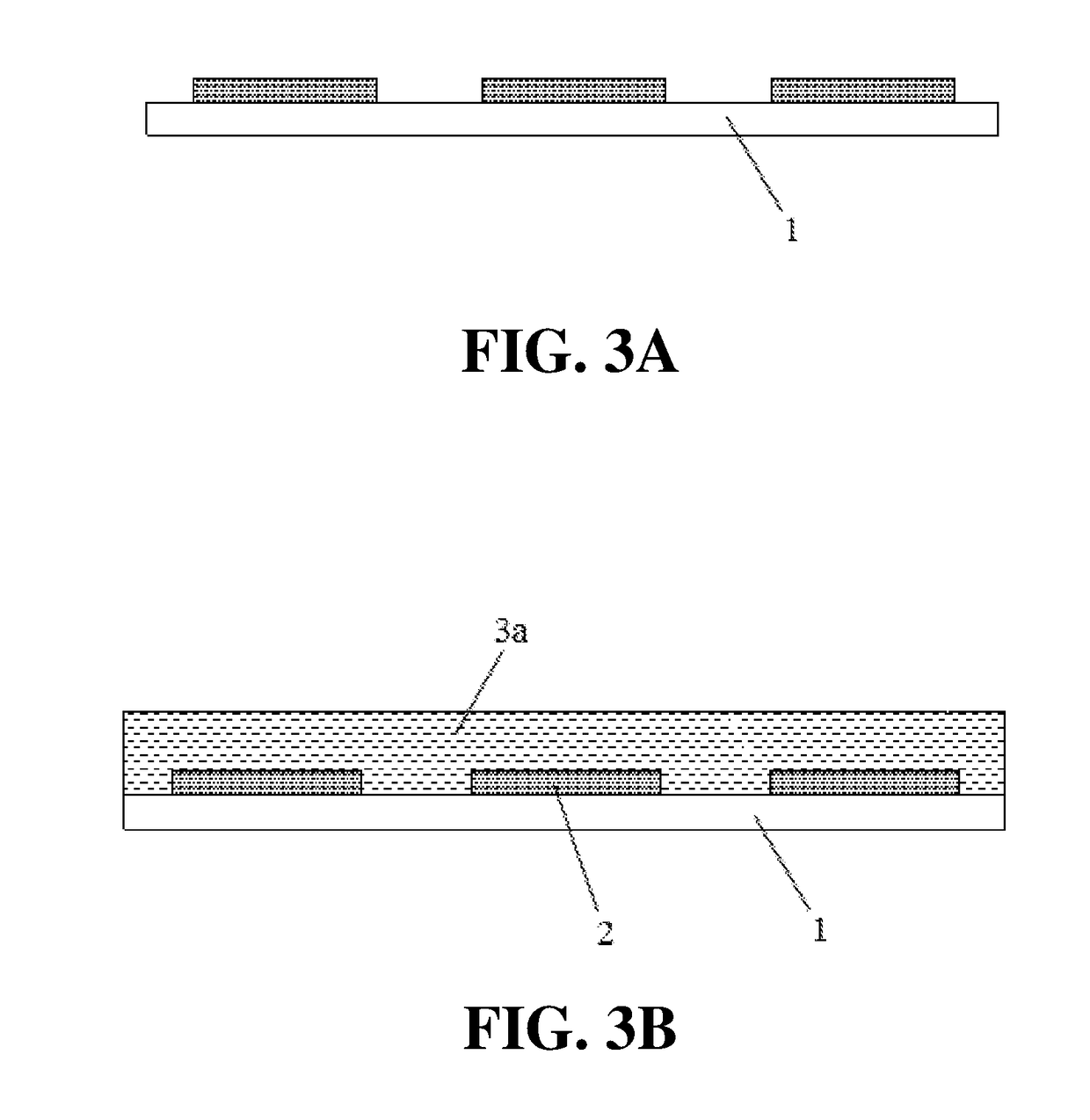

The invention discloses an OLED (Organic Light Emitting Diode) display panel which comprises a TFT (Thin Film Transistor) array substrate and a plurality of anodes arranged on the TFT array substrate in an array manner, wherein a pixel definition layer is arranged on the TFT array substrate in a coating manner, and comprises opening parts exposed out of the anodes and spacing parts used for spacing every two adjacent anodes; grooves are formed in the spacing parts; openings are formed at the upper parts of the grooves; each opening part corresponds to a sub-pixel region; a first common layer, a second common layer and a cathode layer are sequentially arranged on the pixel definition layer; an emissive unit is arranged corresponding to each sub-pixel region between the first common layer and the second common layer; and the first common layer, the second common layer and the cathode layer are provided with gaps corresponding to the grooves. The invention further discloses a preparation method of the OLED display panel and a display device comprising the OLED display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

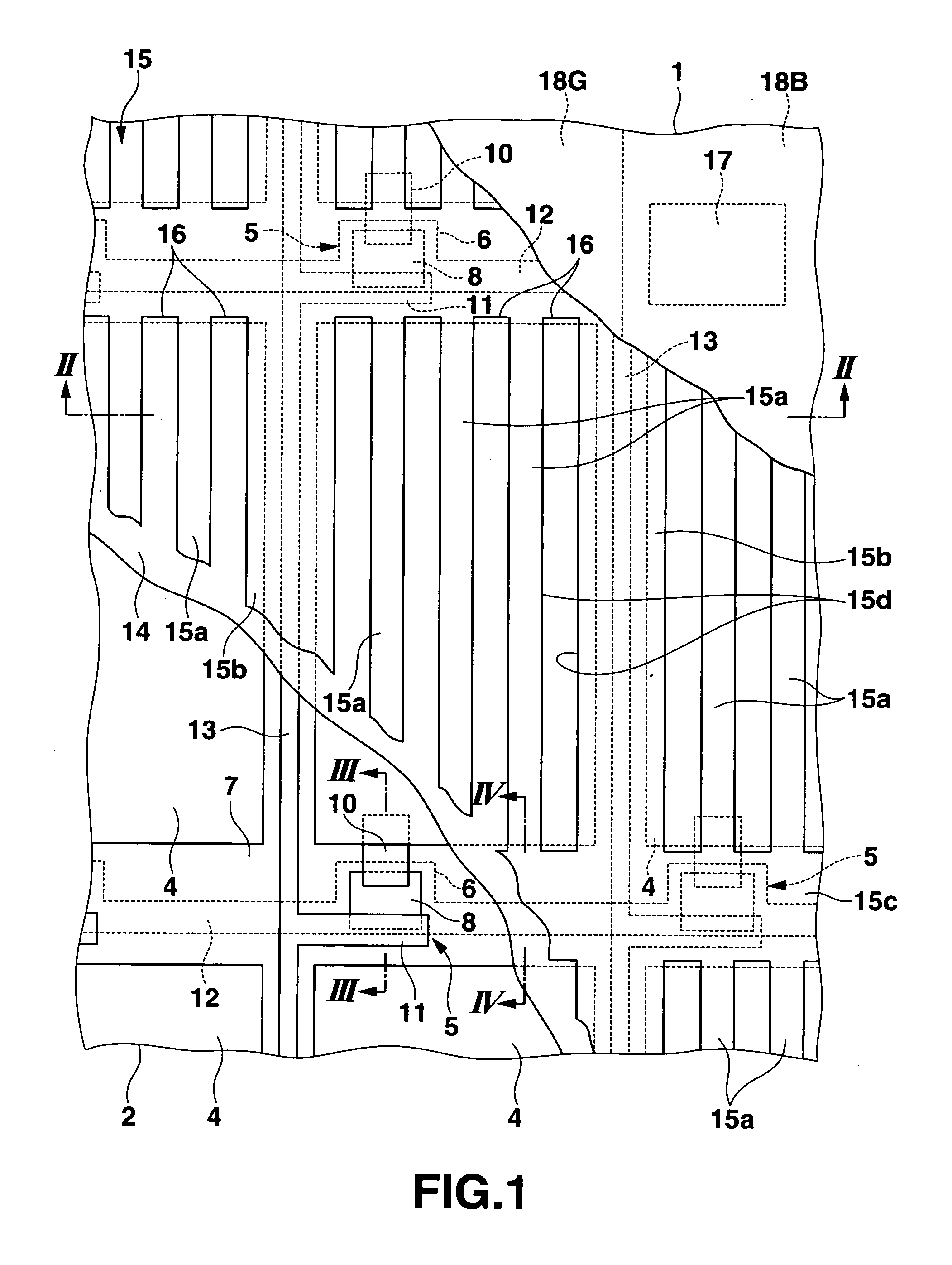

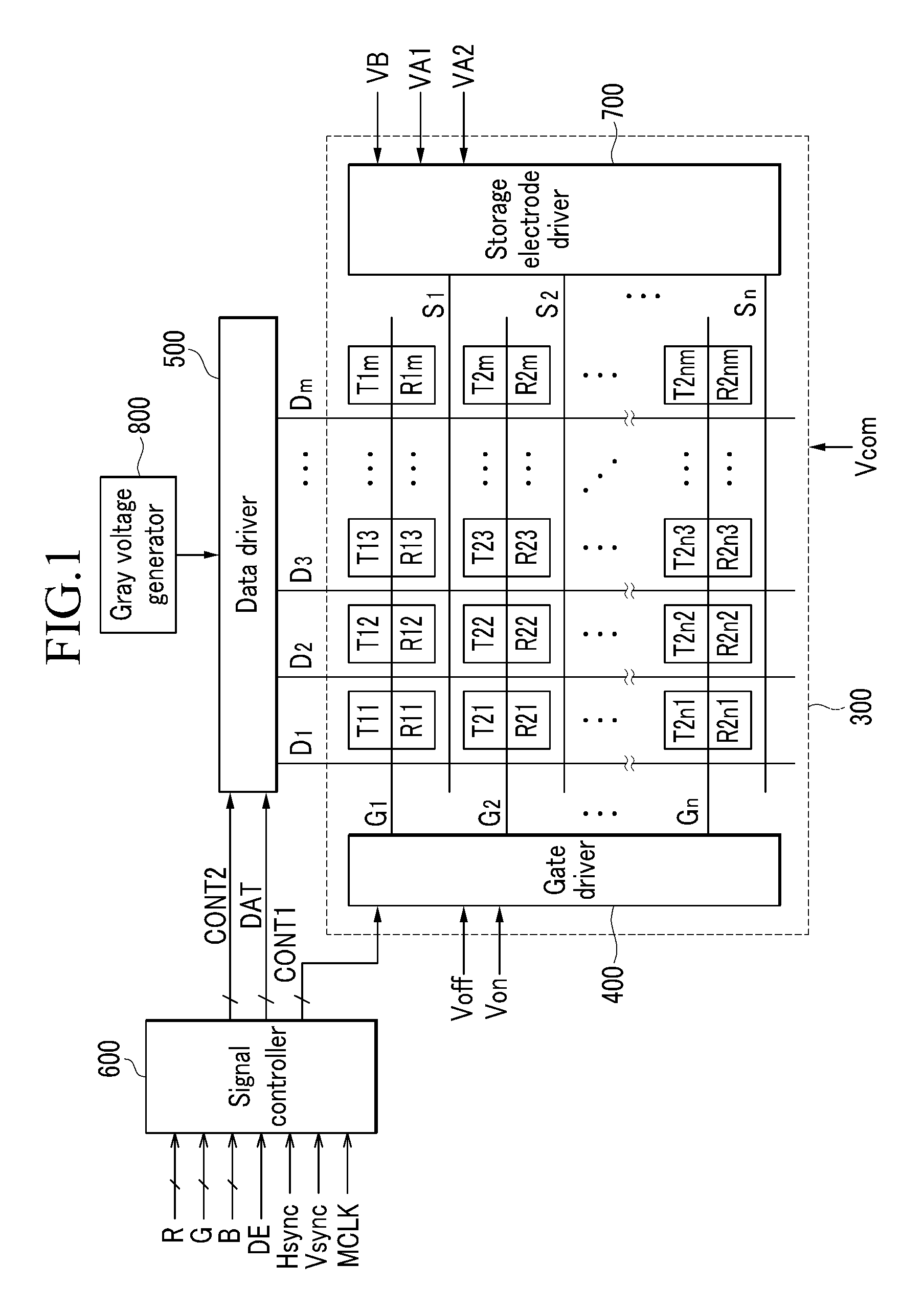

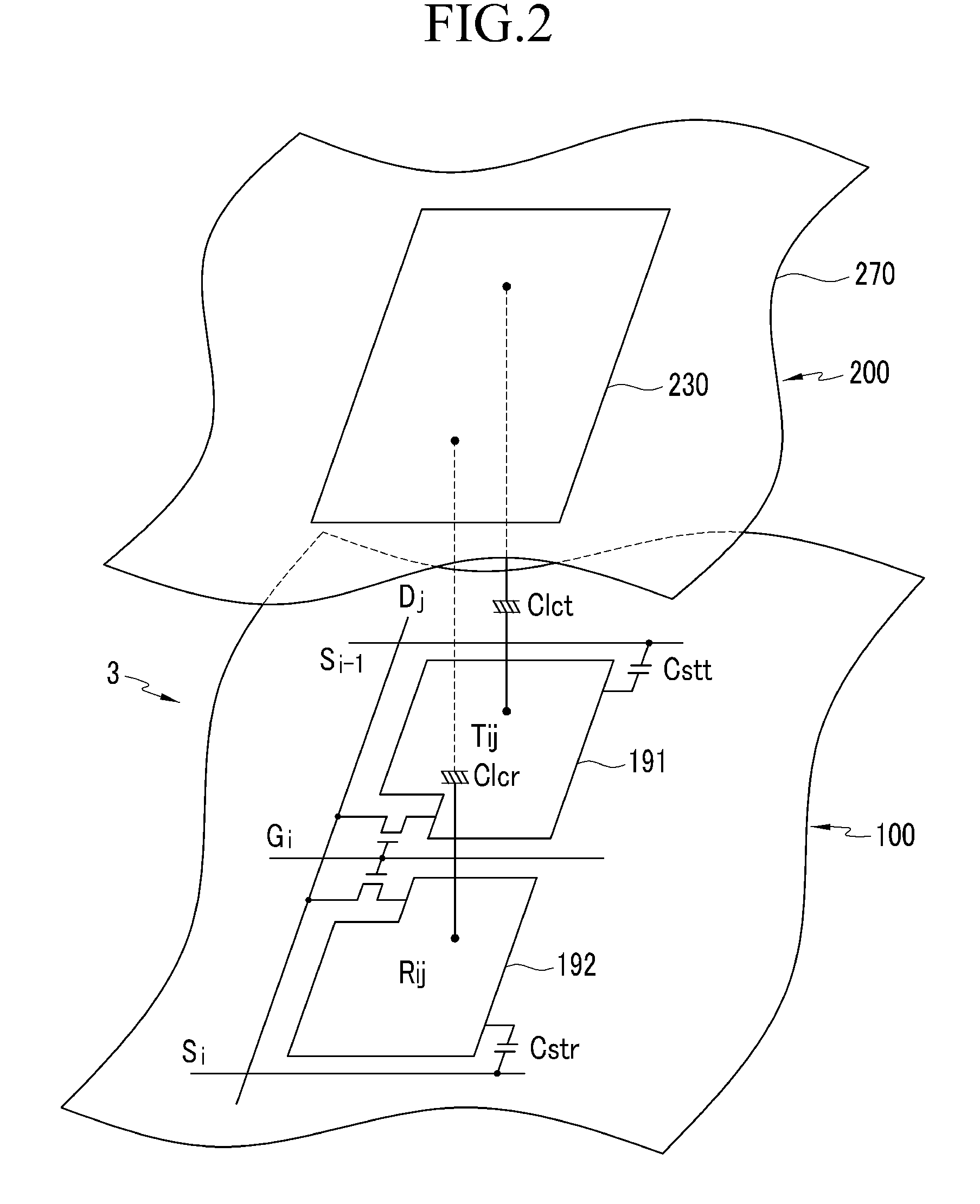

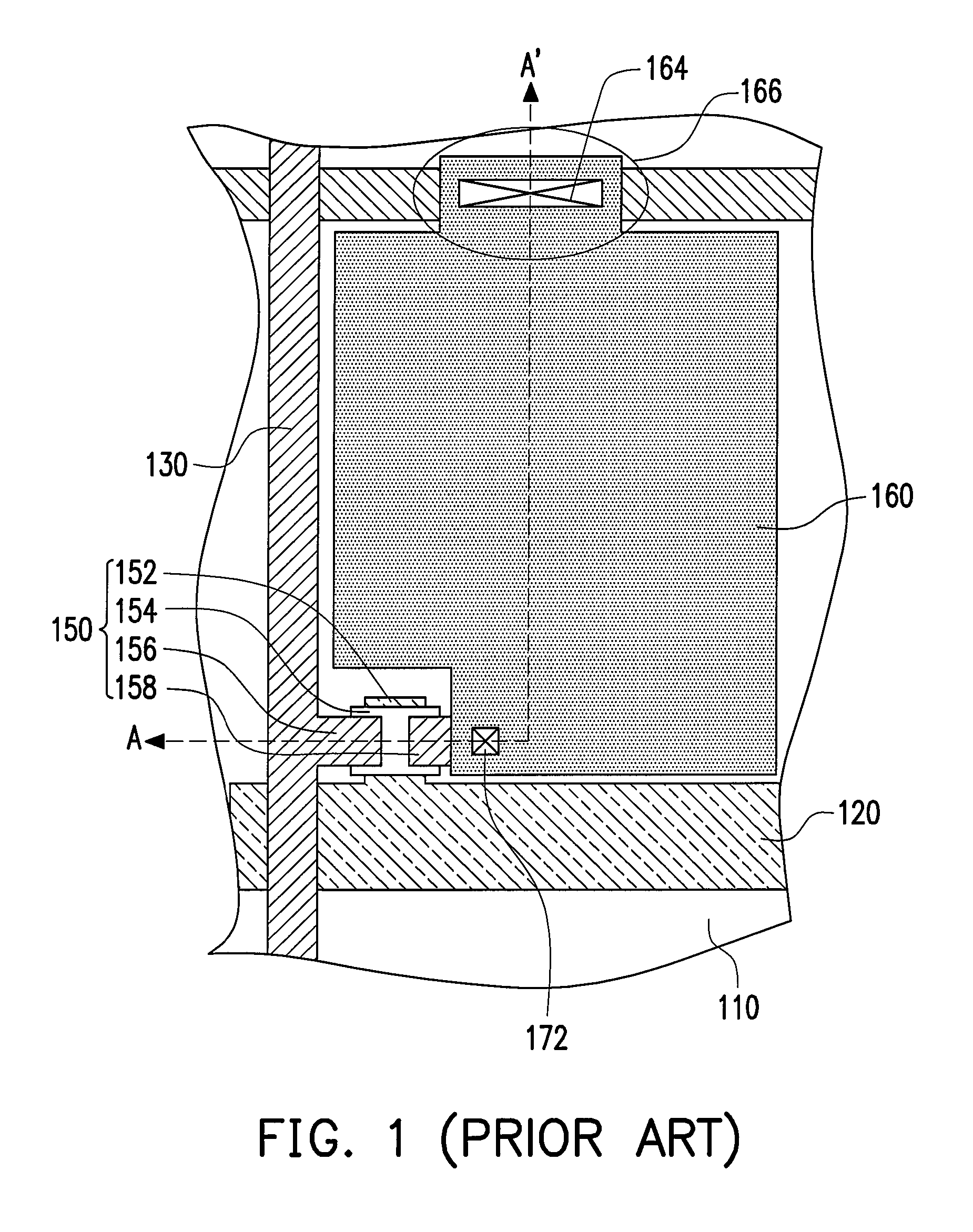

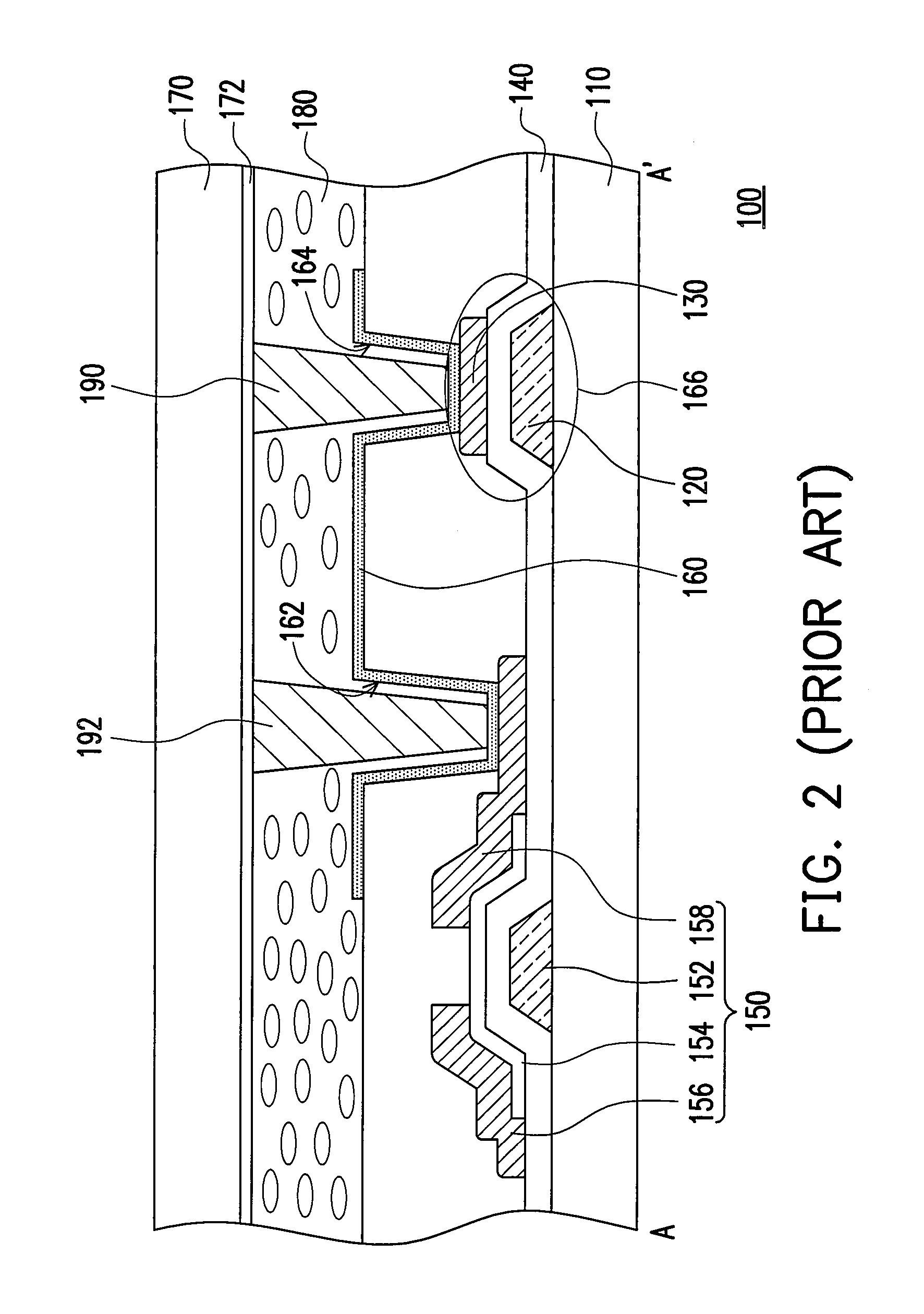

Liquid crystal display apparatus which performs display by using electric field in direction substantially parallel with substrate surfaces to control alignment direction of liquid crystal molecules

ActiveUS20070177090A1Increase the aperture ratioImprove contrast ratioNon-linear opticsSubstrate surfaceElectric field

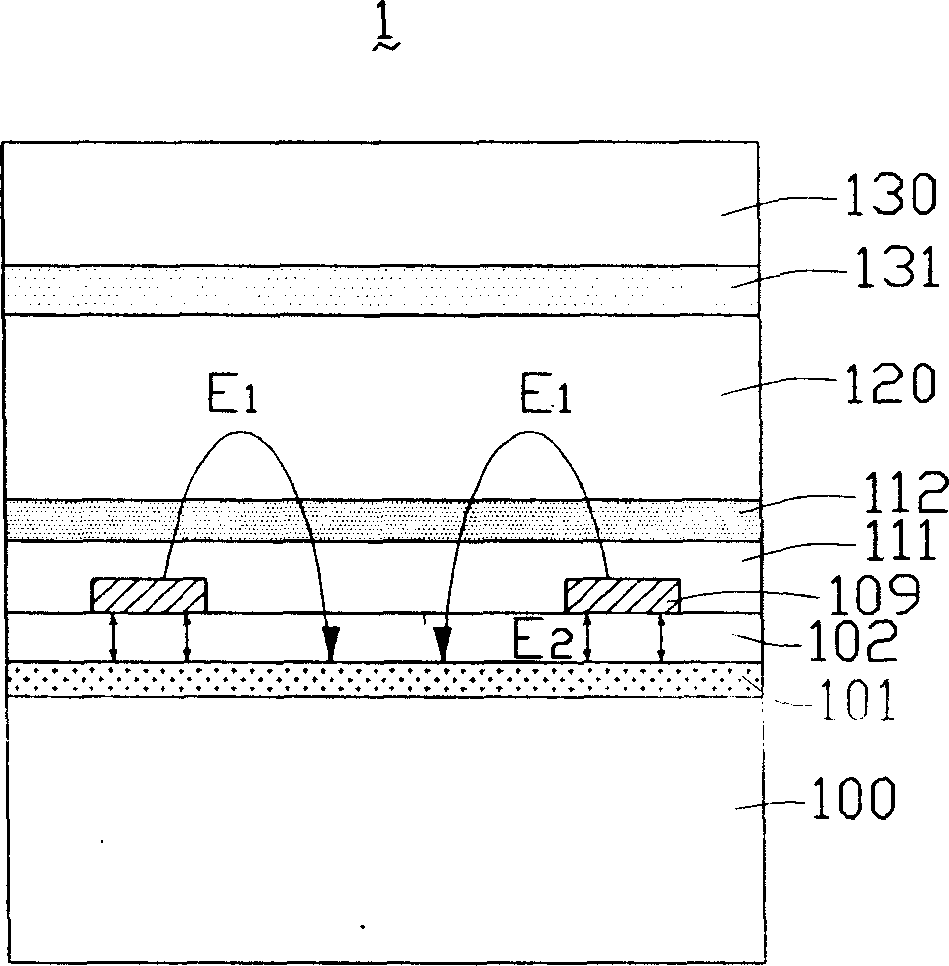

A liquid crystal display apparatus includes a liquid crystal layer which is disposed in a gap between first and second substrates with long axes of liquid crystal molecules being aligned in one direction, in substantially parallel to substrate surfaces. A plurality of thin film transistors are arranged in row and column directions on an upper side of the first substrate. Pixel electrodes are provided on the upper side of the first substrate to be electrically connected with the thin film transistors. A common electrode is formed on the upper side of the first substrate between the substrate and the liquid crystal layer to correspond to the pixel electrode through an insulating film, and generates an electric filed which controls an alignment direction of the liquid crystal molecules in a plane substantially parallel with the substrate surfaces between itself and the pixel electrode.

Owner:UNIFIED INNOVATIVE TECH

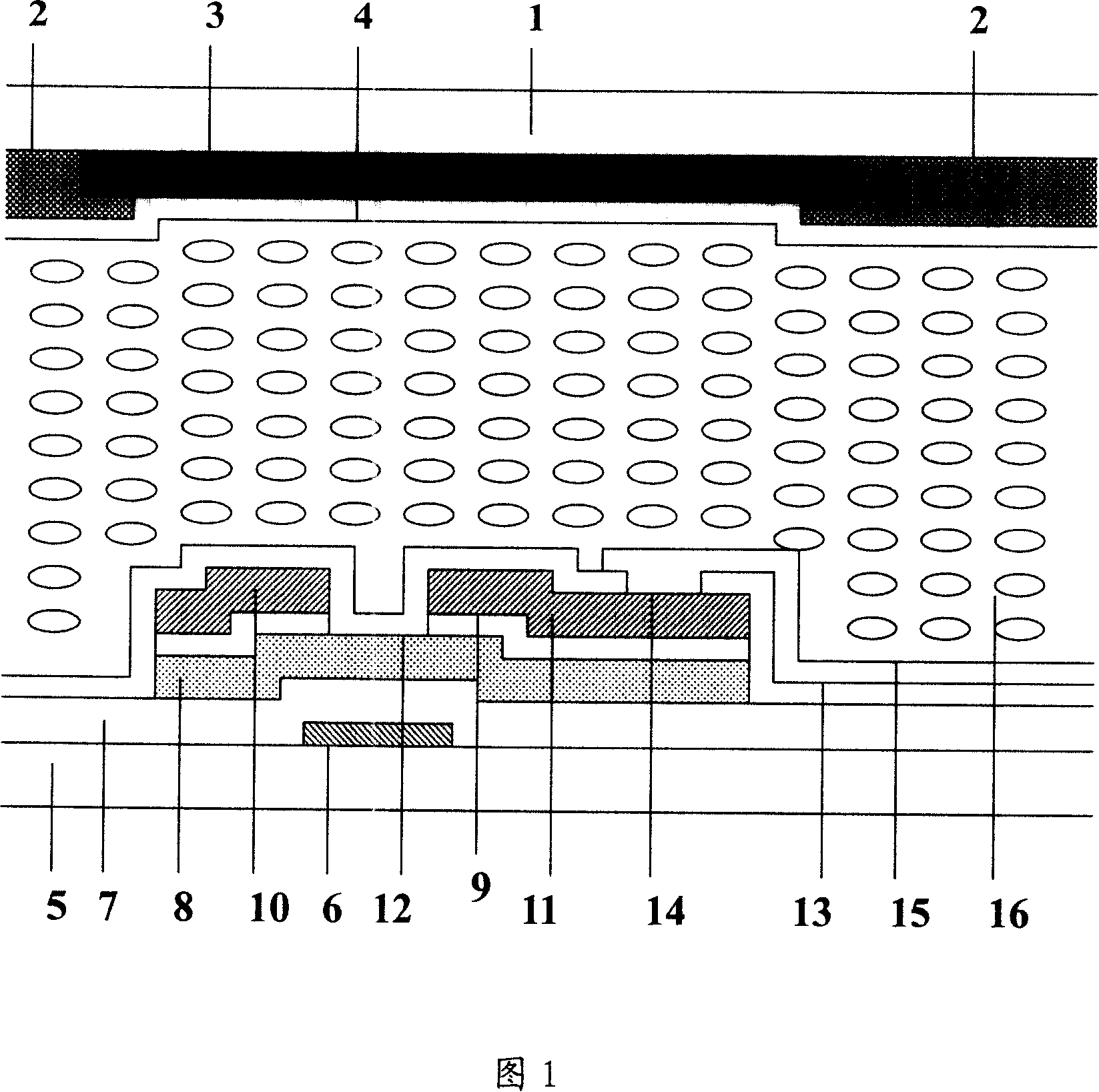

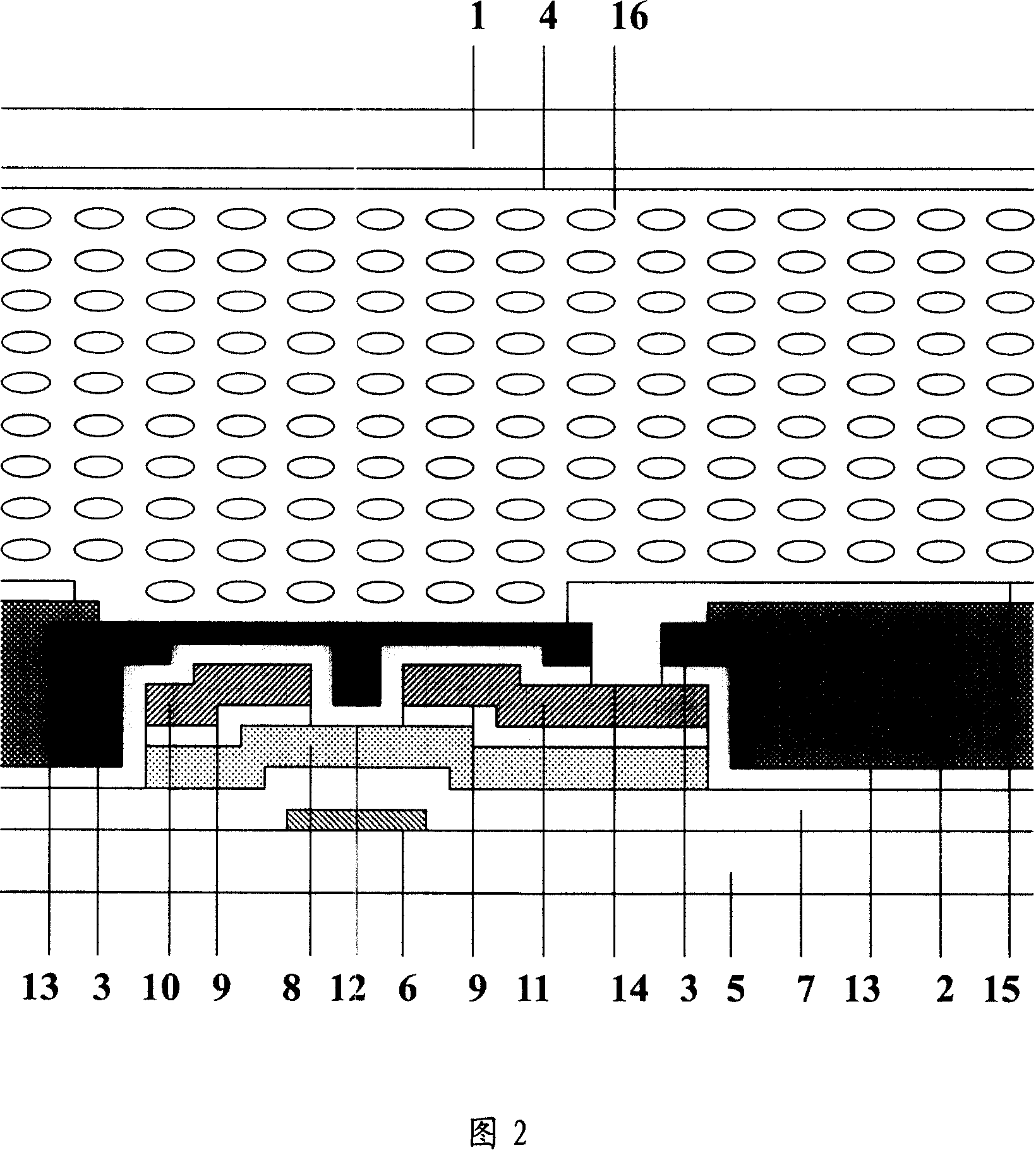

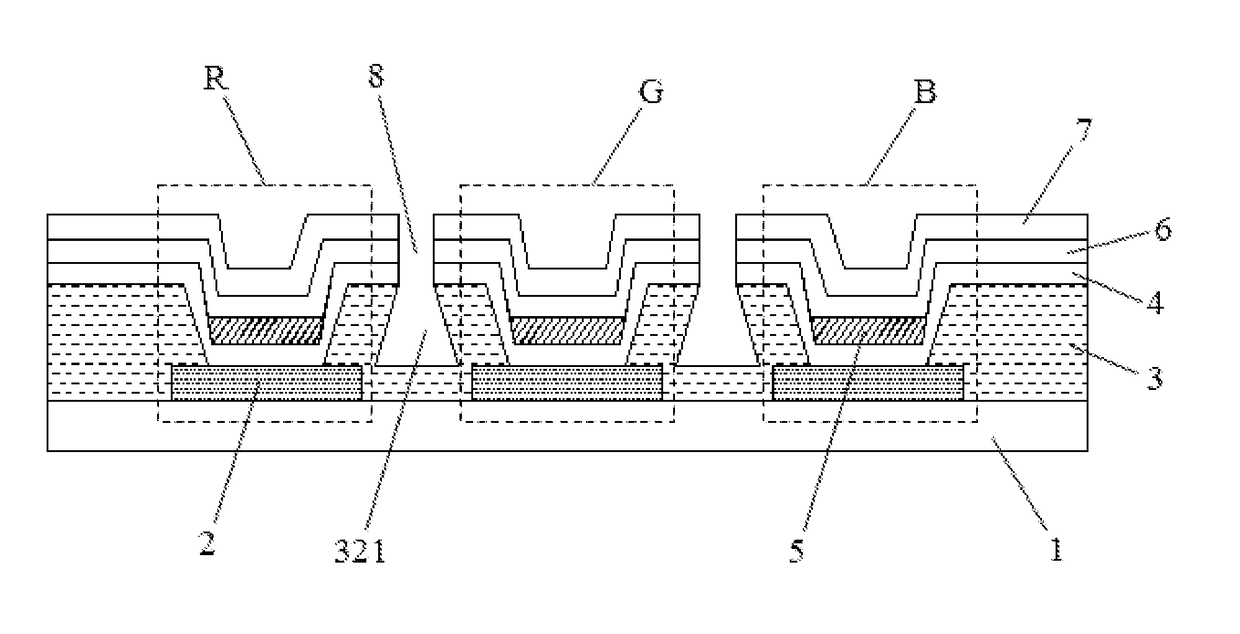

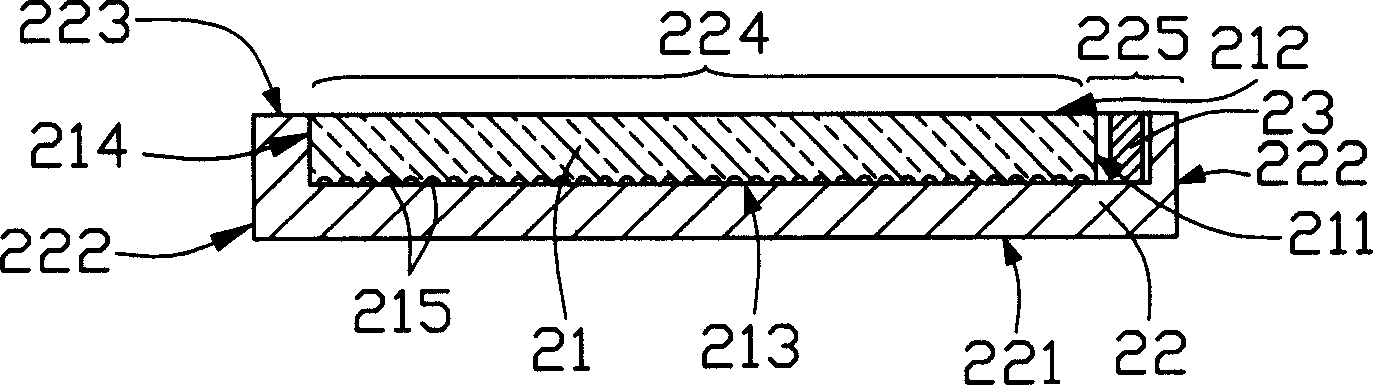

Liquid crystal display device with color film on thin-film transistor and its manufacture method

ActiveCN101149541AEliminate light leaksReduce process stepsSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusGratingBaseboard

This invention discloses a sort of liquid crystal display that the chromatic film is above the thin film transistor, and it consists of the nether baseboard, the grating line, the grating pole, the thin film transistor is formed above the grating pole, the data wire, the power pole which connects with the data wire and the corresponding leakage pole are formed above the thin film transistor, the deactivation protective foil is formed above the channel of the thin film transistor, and it has the bore in the part which is corresponds to the leakage pole, the black matrix is formed above the deactivation protective foil, and it has the bore in that bore position, the hatch of the black matrix corresponds to the picture element area, the chromatic filter layer is formed in the hatch of the black matrix, a picture element pole is formed above the chromatic filter layer, and it connects with the leakage pole by the bore, the upper baseboard, the common pole which is formed above the nether baseboard, a liquid molecule layer is formed between the upper baseboard and the nether baseboard. This invention discloses the manufacturing method of this crystal display at the same time. This invention advances the penetrant rate and the hatch rate of the liquid crystal display, and it predigests the technique.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

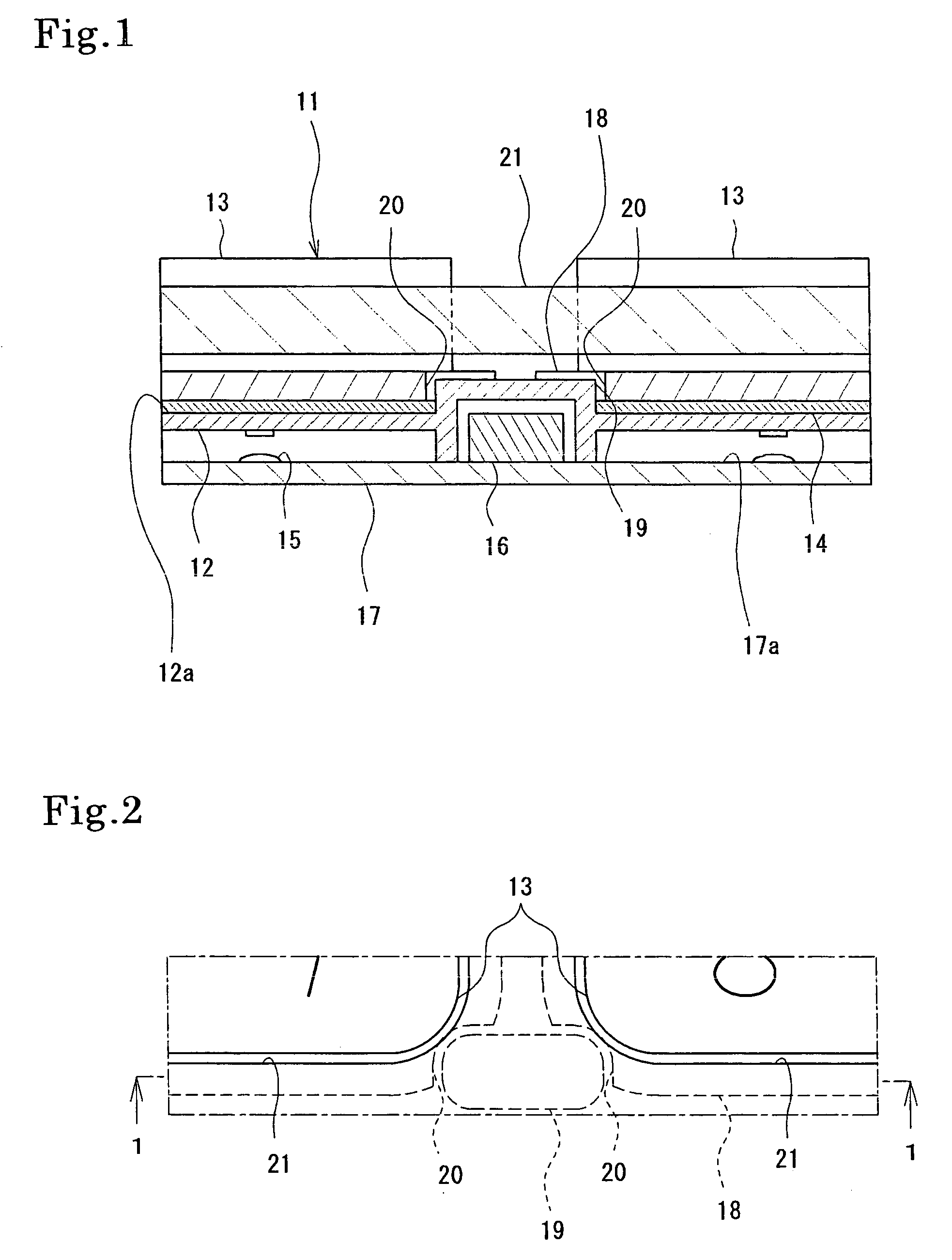

Key pad, resin key top injection mold, and resin key top manufacturing method

InactiveUS7014377B2Small sizeReduce thicknessMeasurement apparatus componentsLegendsEngineeringMechanical engineering

Owner:POLYMATECH CO LTD

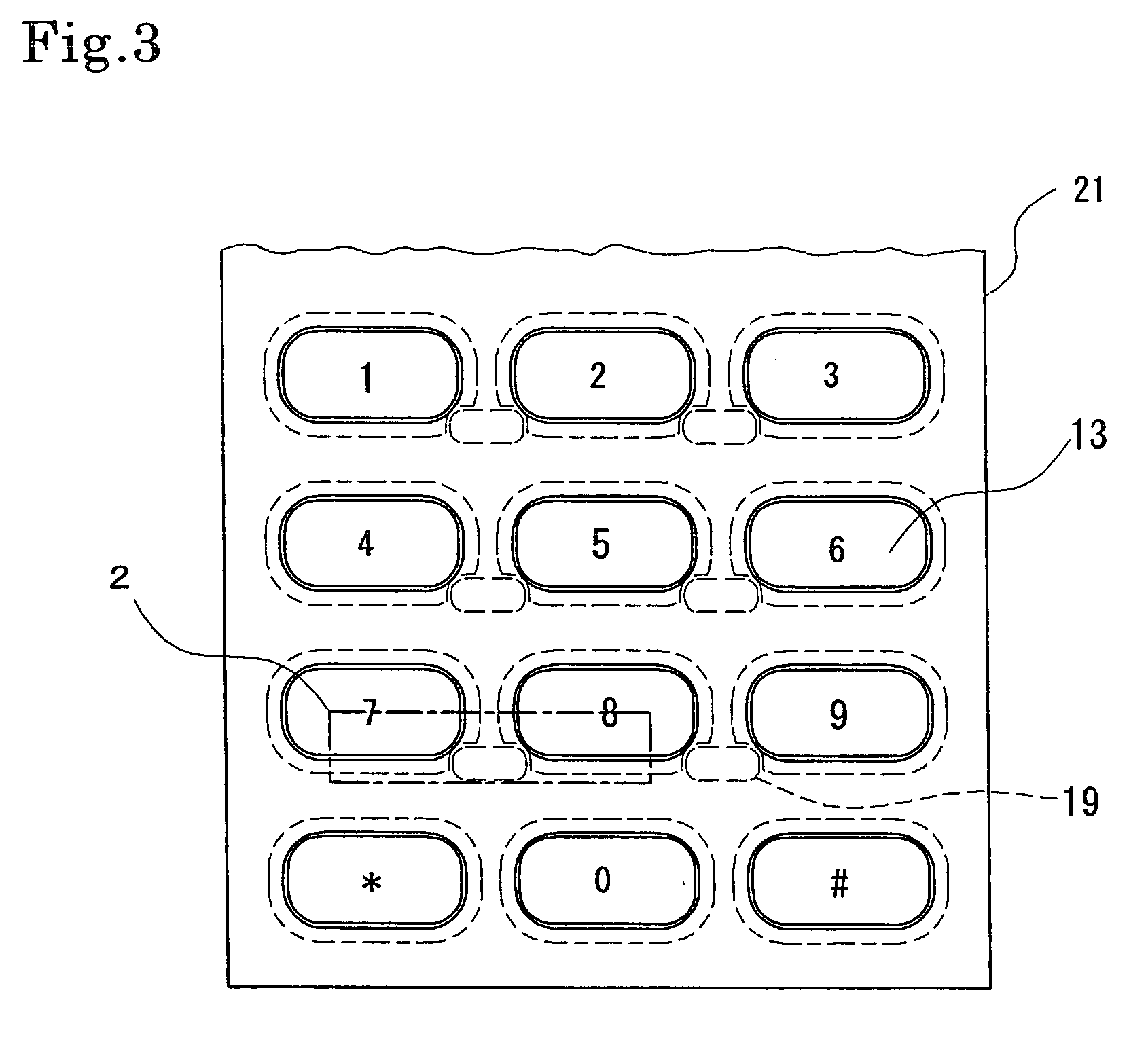

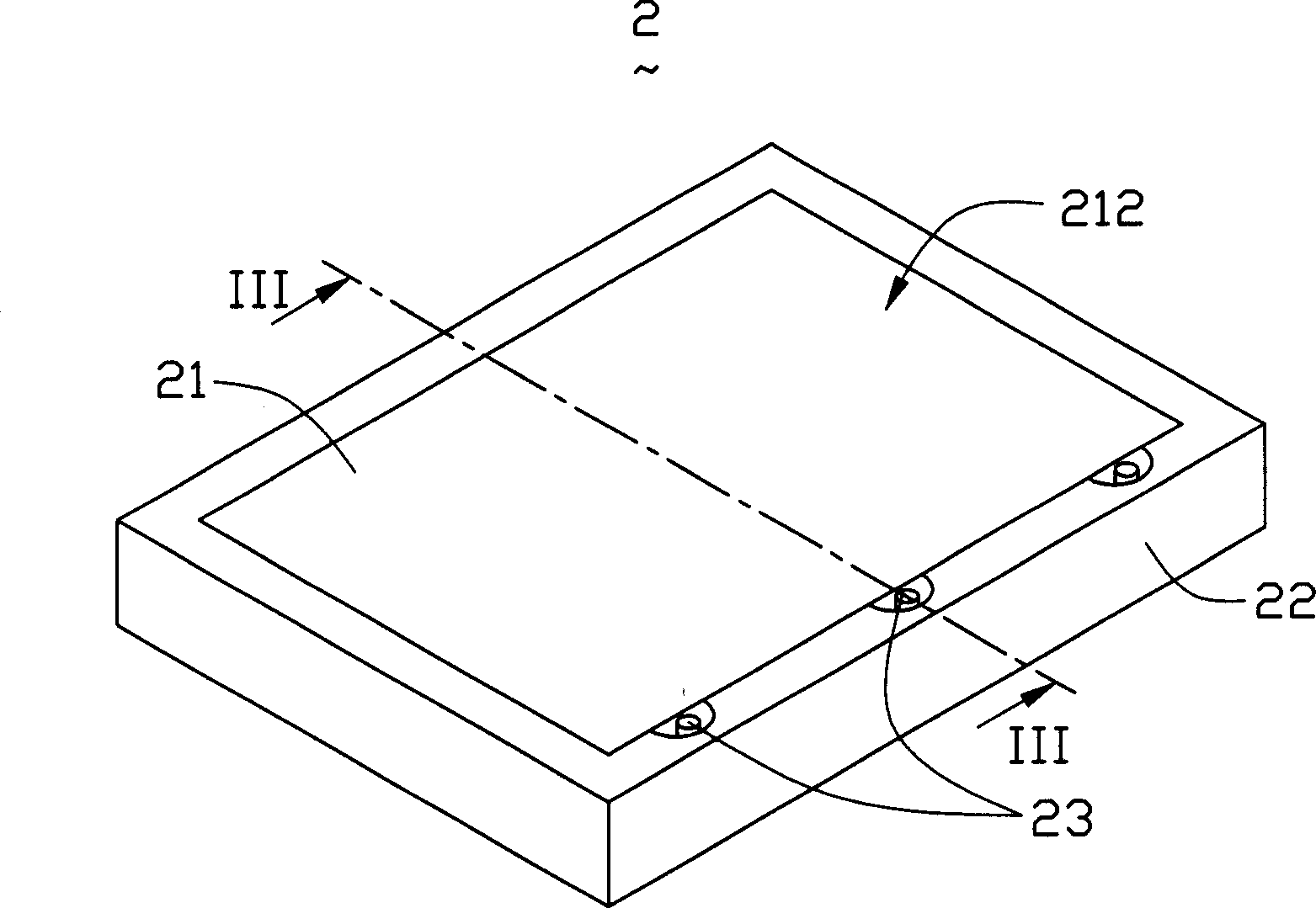

Illuminating device, display device, and method of manufacturing light modulation element

InactiveCN101713503AOptically anisotropicSmall difference in refractive indexMechanical apparatusElectric lightingLight equipmentLight guide

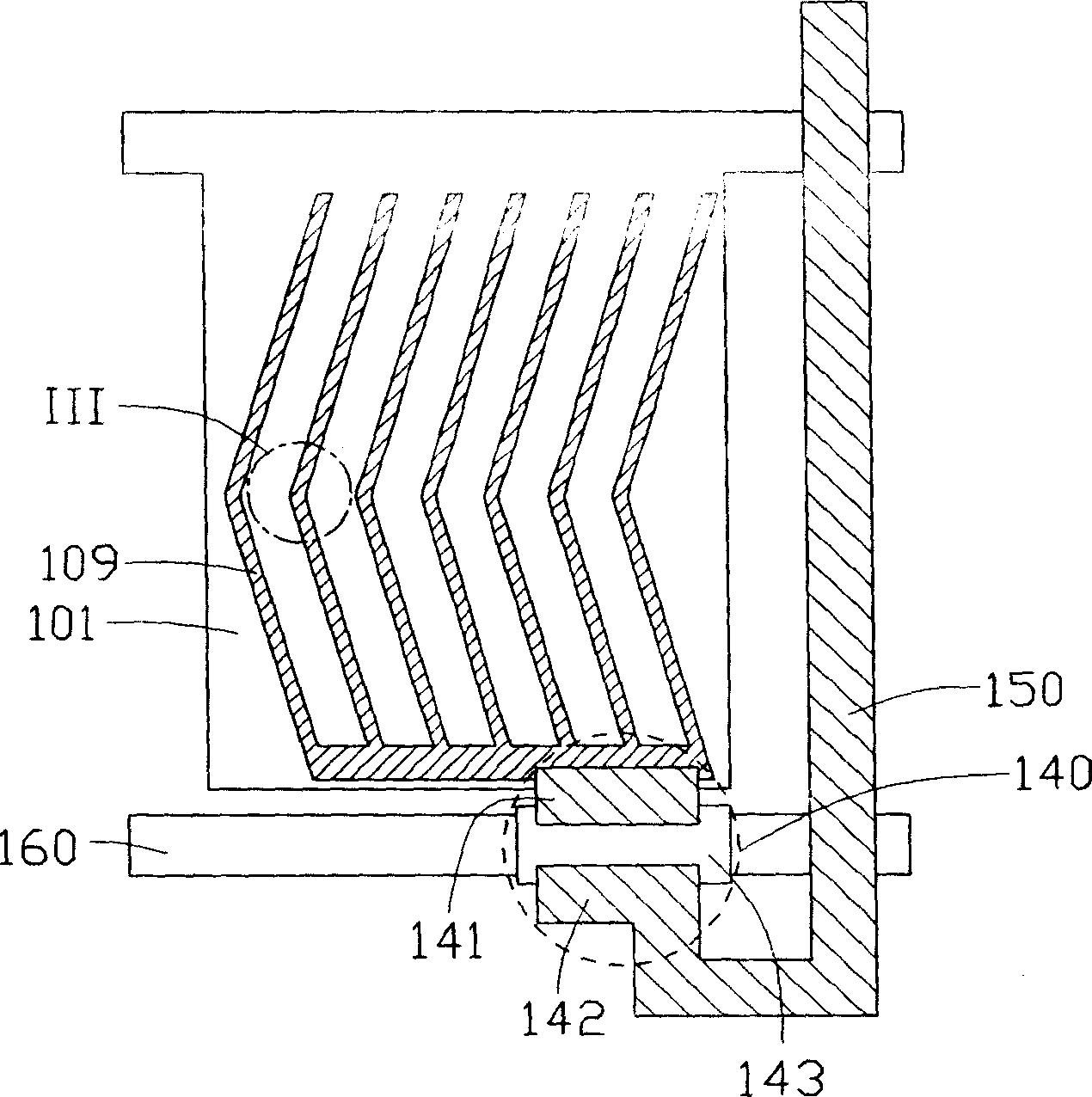

The invention provides an illuminating device, display device, and method of manufacturing light modulation element. The illuminating device includes a light guide plate, a light source disposed on a side face of the light guide plate, and a light modulation element disposed on a surface or on inside of the light guide plate and joined to the light guide plate. The light modulation element has a pair of transparent substrates disposed apart from each other and opposed to each other, a pair of electrodes provided on surfaces of the pair of transparent substrates, and a light modulation layer provided in a gap between the pair of transparent substrates. The light modulation layer includes a first region and a second region both having optical anisotropy and having response speeds to an electric field different from each other.

Owner:SONY CORP

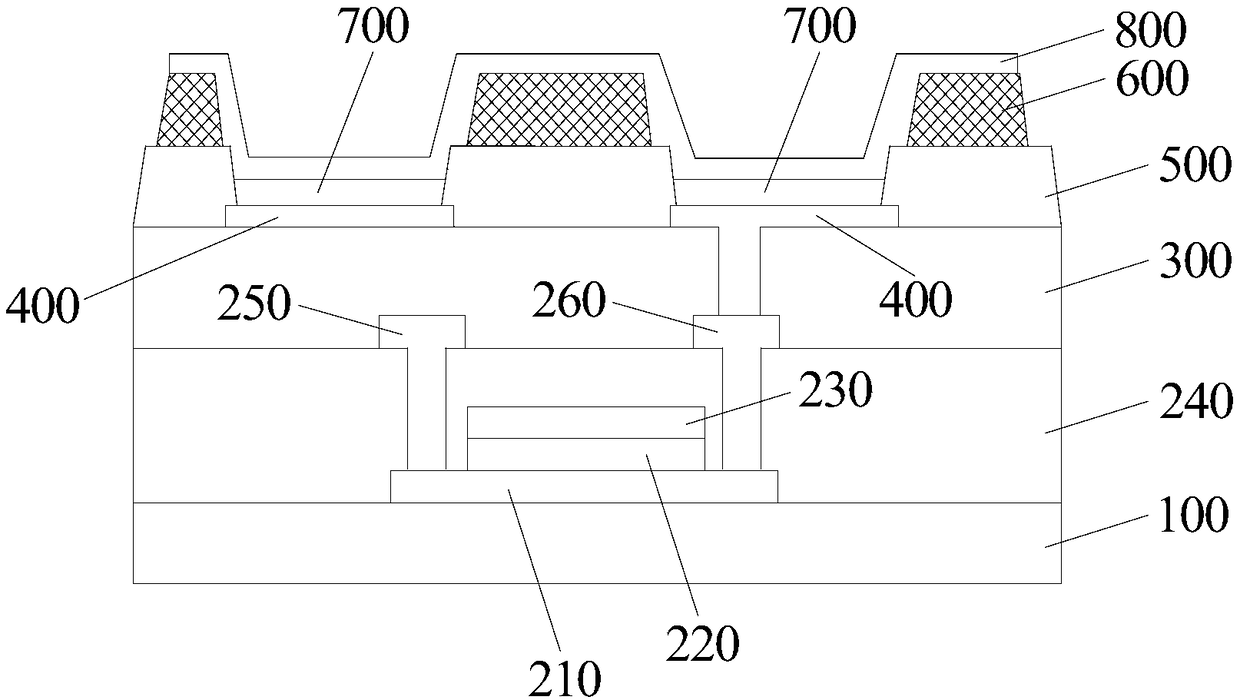

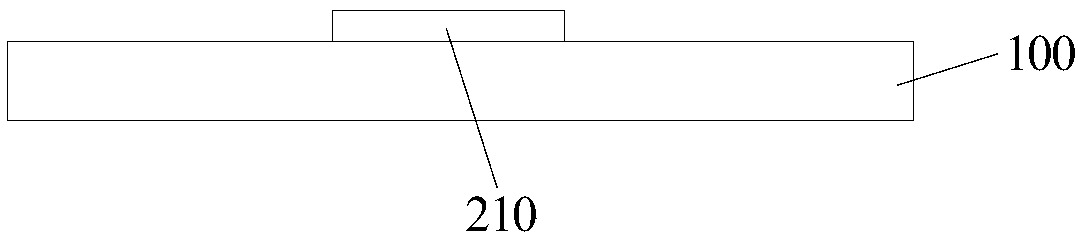

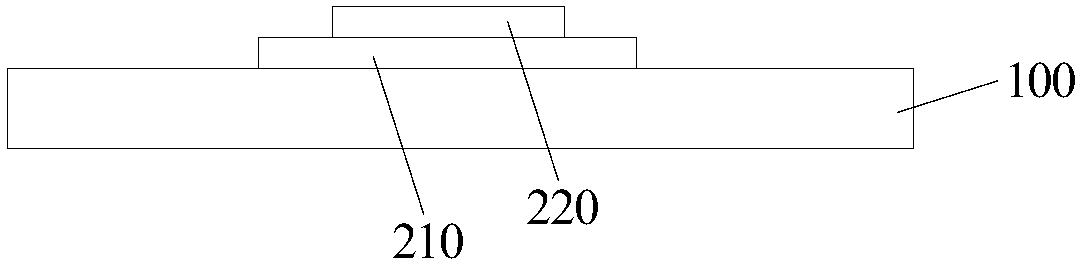

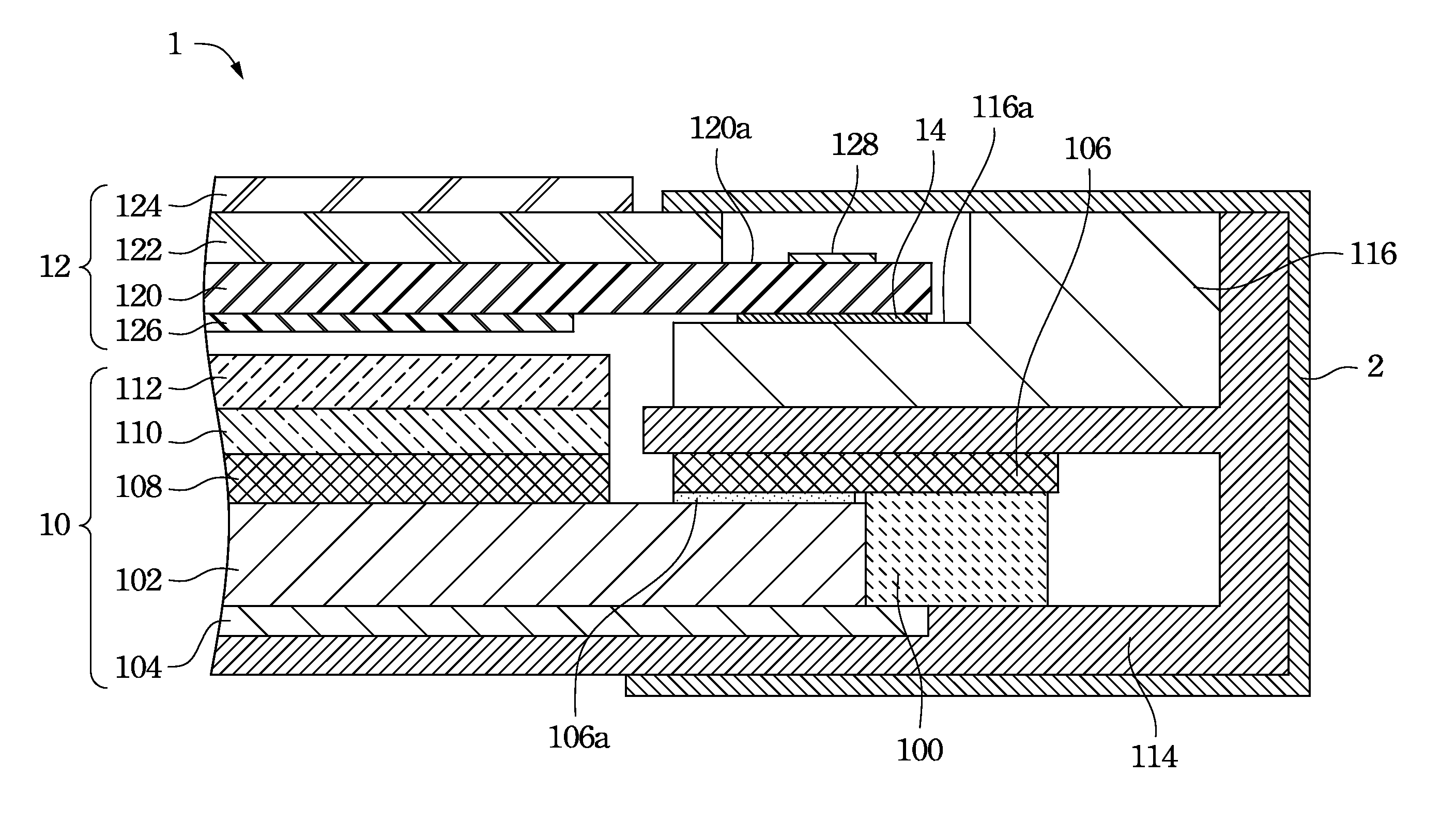

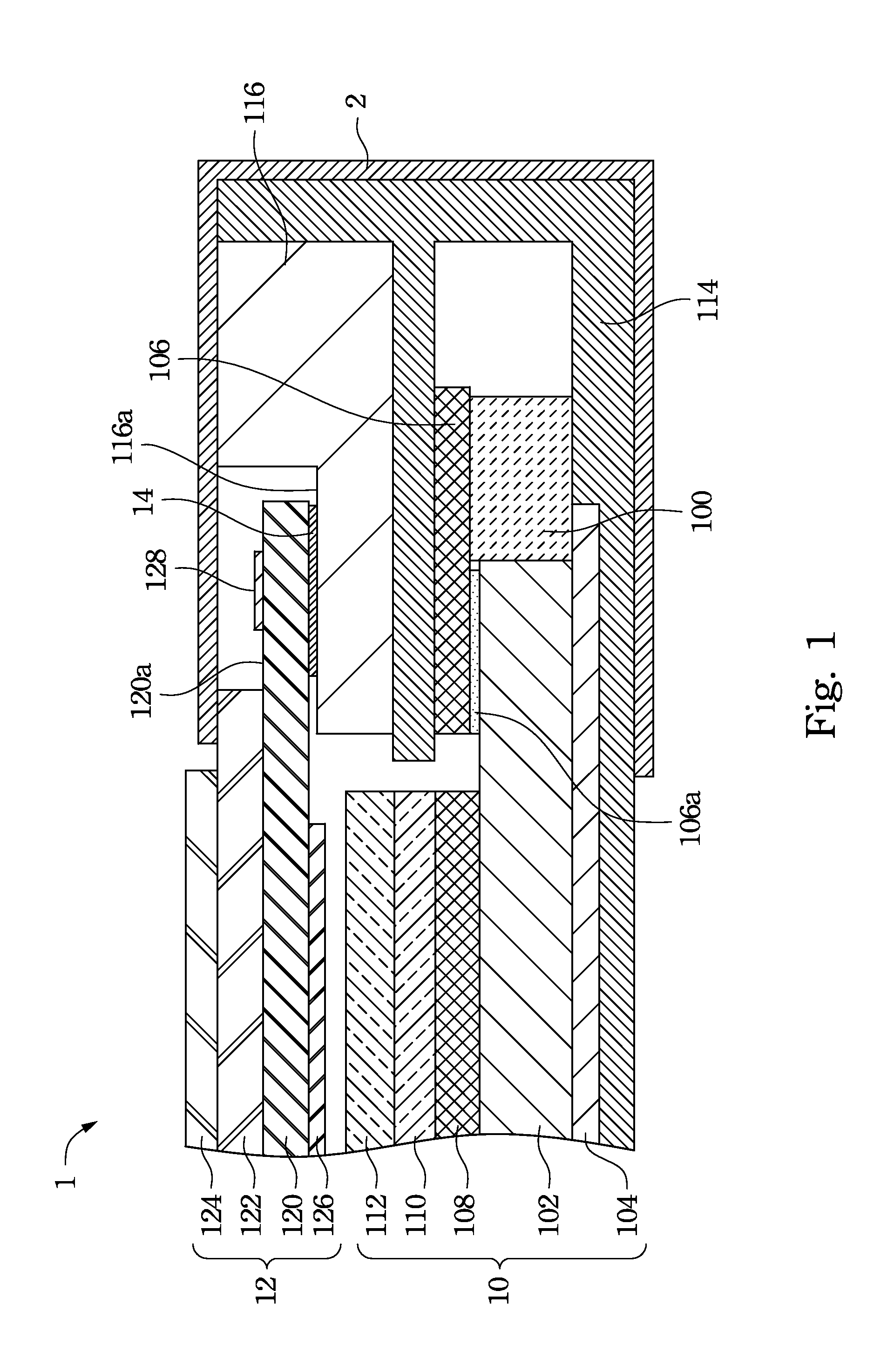

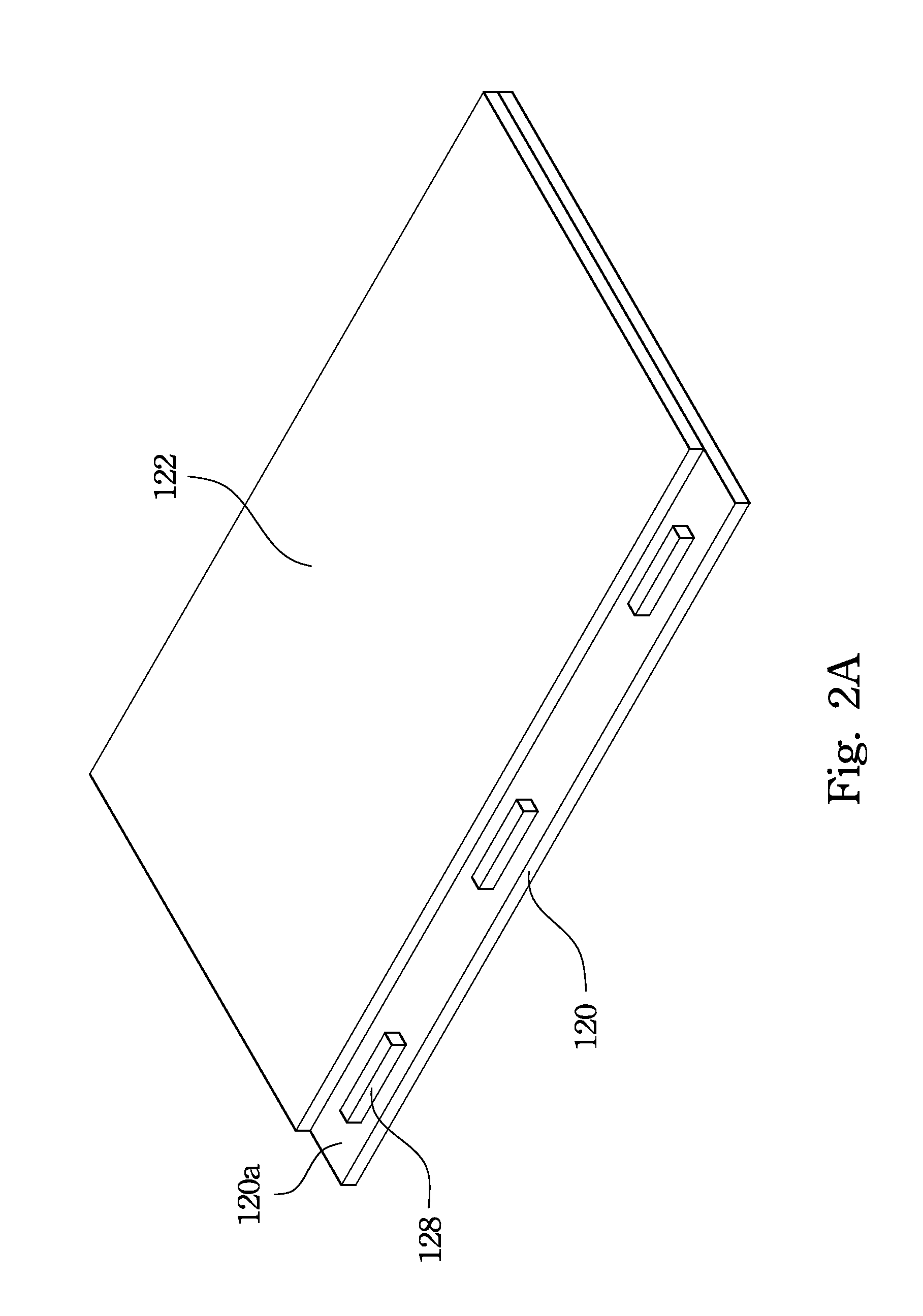

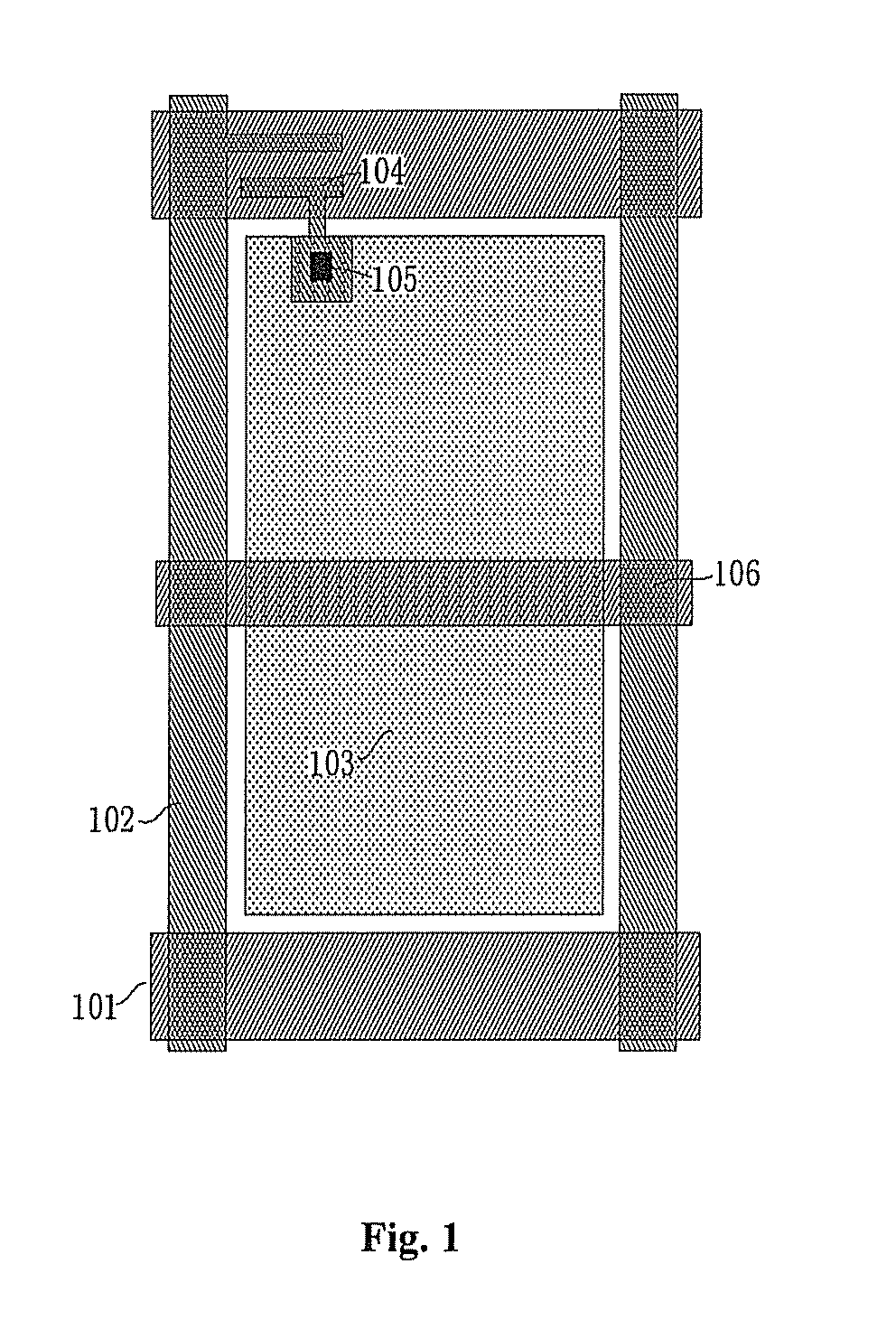

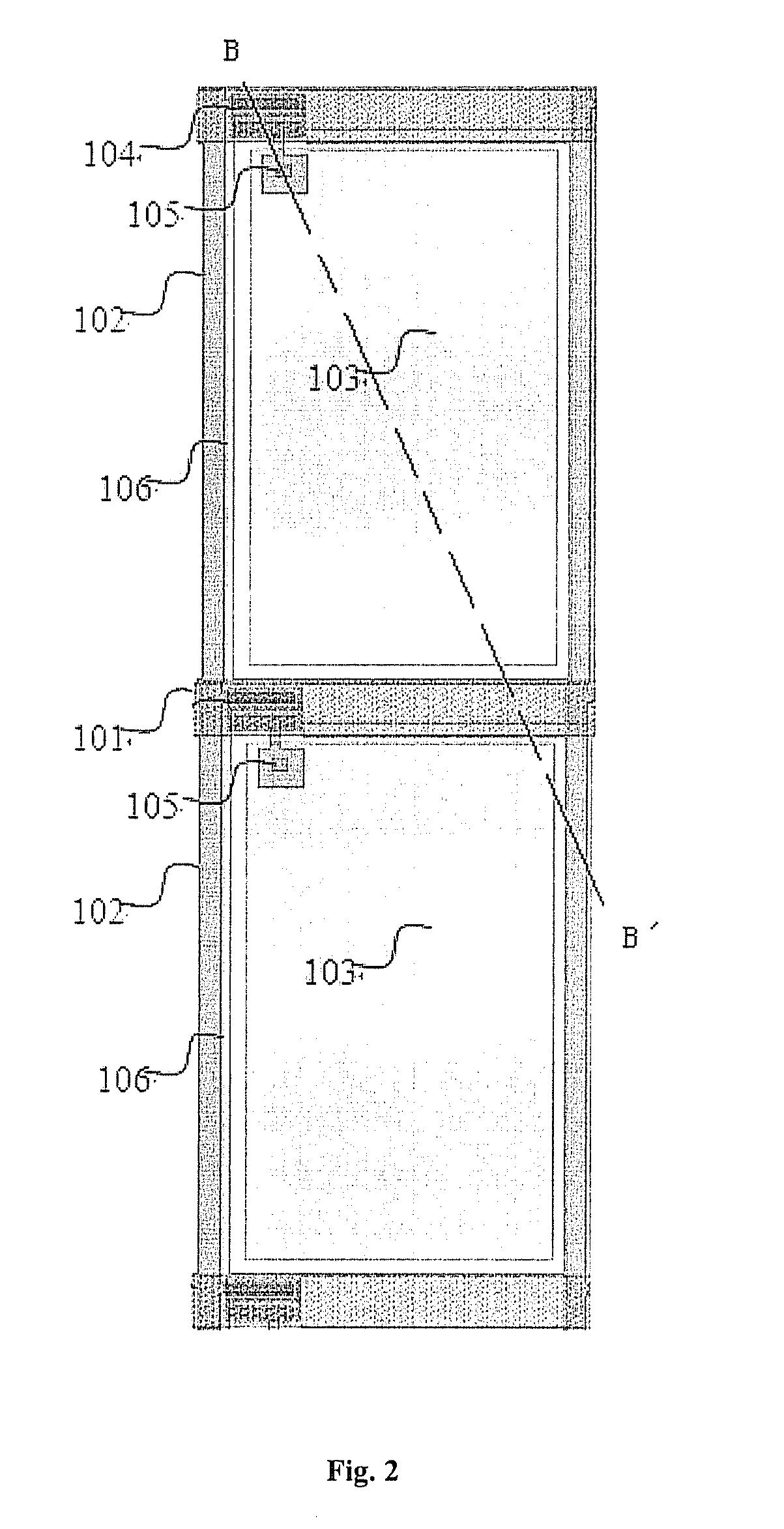

Display panel and manufacturing method thereof

InactiveCN108231840AEliminate light leaksImprove the display effectSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeTransistor

The invention provides a display panel which comprises a substrate, a flat body, an anode, a pixel defining layer, a shading layer, an OLED (Organic Light Emitting Diode) functional layer and a cathode, wherein a thin film transistor is arranged on the substrate; the flat layer is arranged on the thin film transistor; the anode is arranged on the flat layer and penetrates through the flat layer tobe connected with the thin film transistor; the pixel defining layer is arranged on the flat layer; the shading layer is arranged on the pixel defining layer; pixel defining holes for exposing the anode are formed in the shading layer and the pixel defining layer; the OLED functional layer is arranged on the exposed anode; and the cathode is arranged on the shading layer and the OLED functional layer. The invention further provides a manufacturing method of the display panel. The shading layer is formed on the pixel defining layer, so that light leaking from the side of the OLED functional layer in the pixel defining hole can be shaded; and therefore, the pixel light leakage problem in the prior art can be eliminated, and the display effect of the display panel is further improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

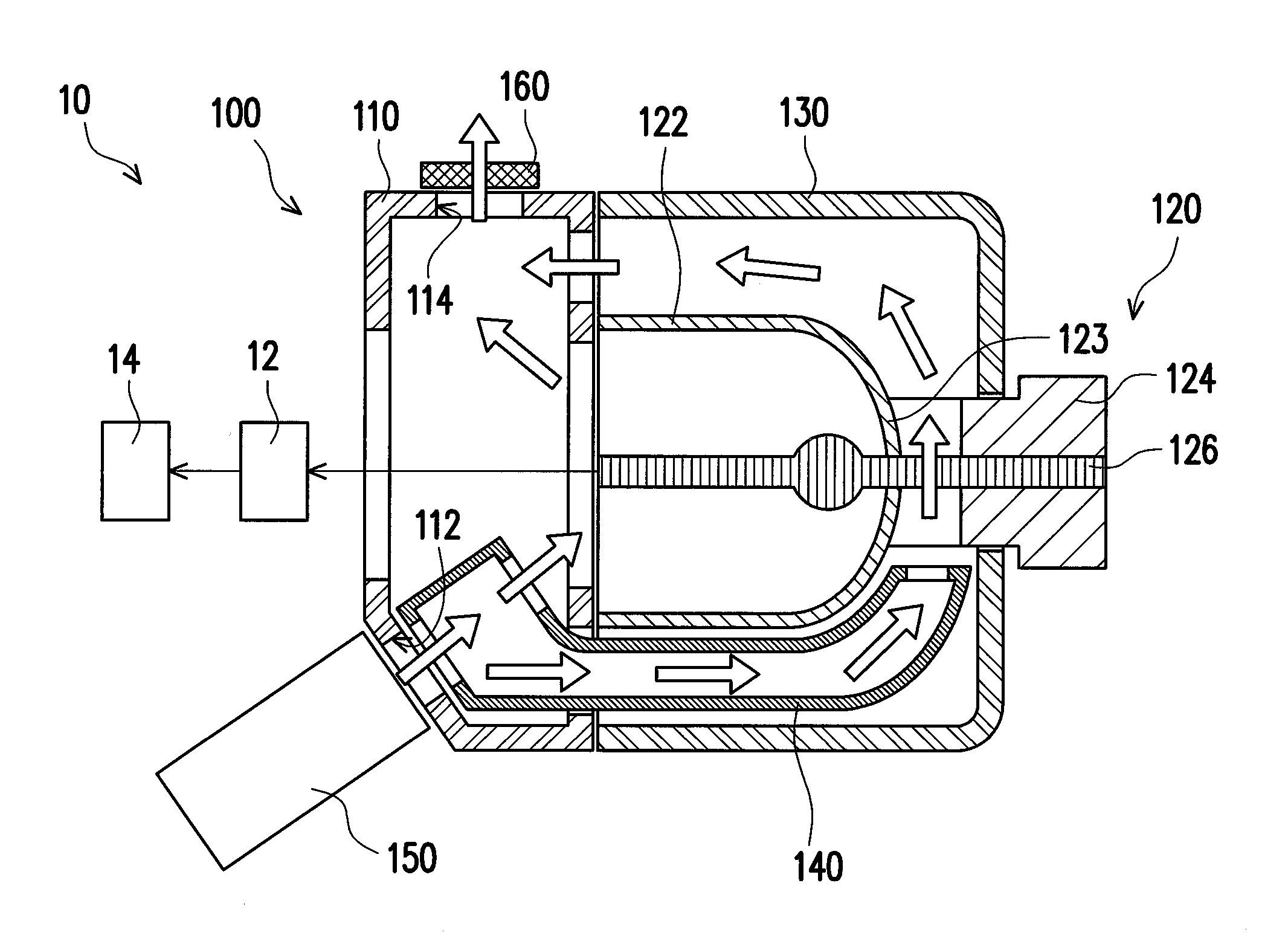

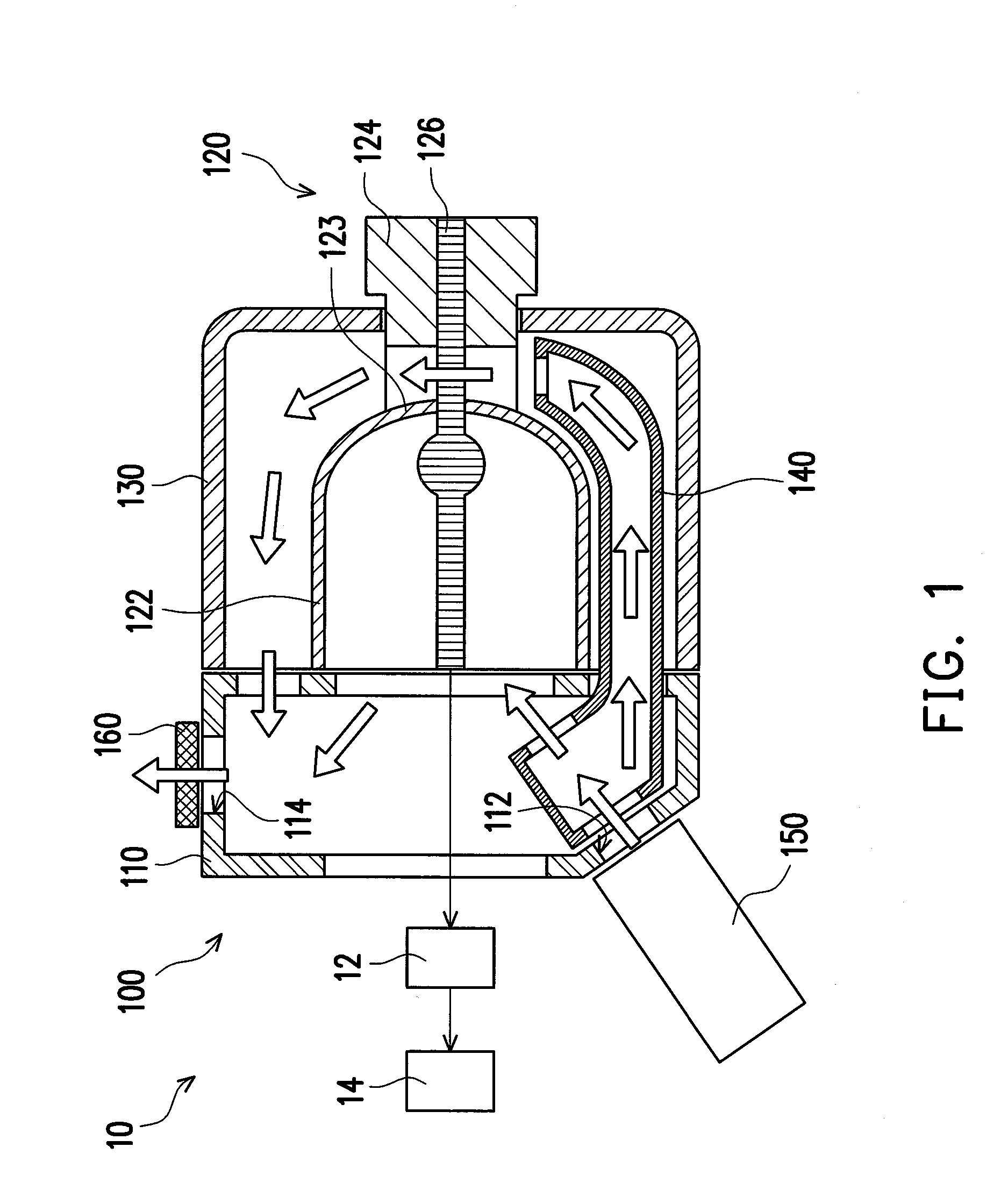

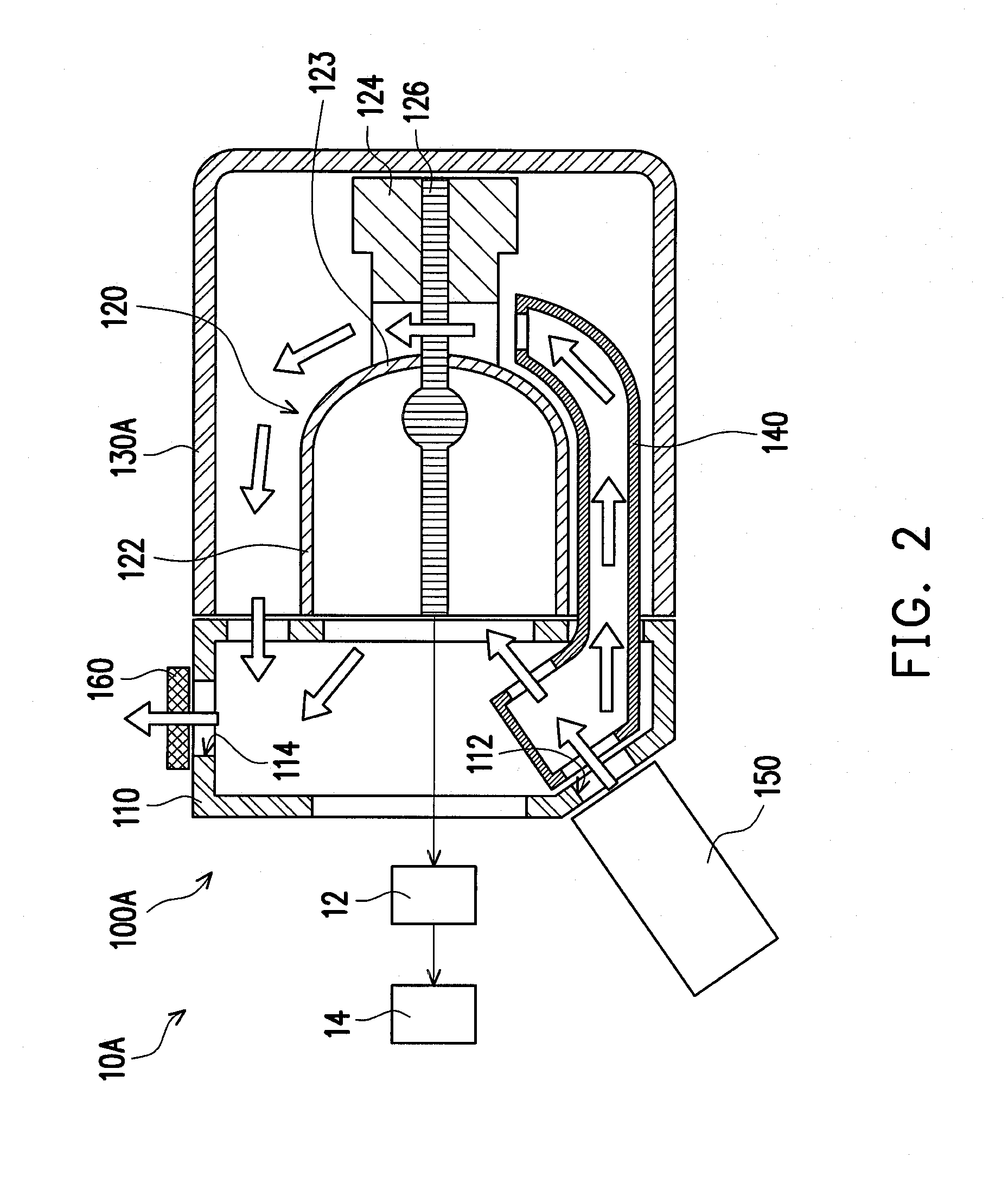

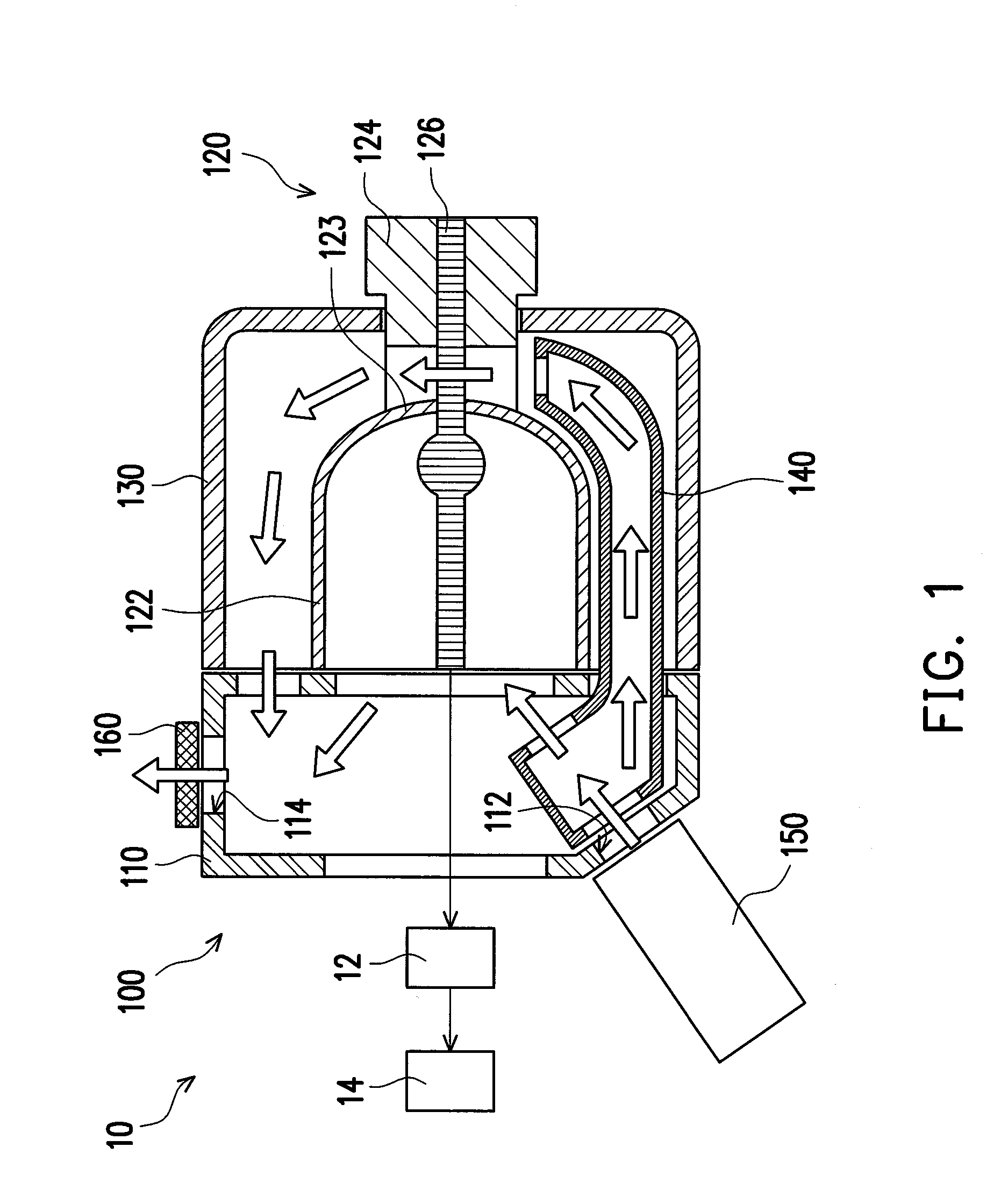

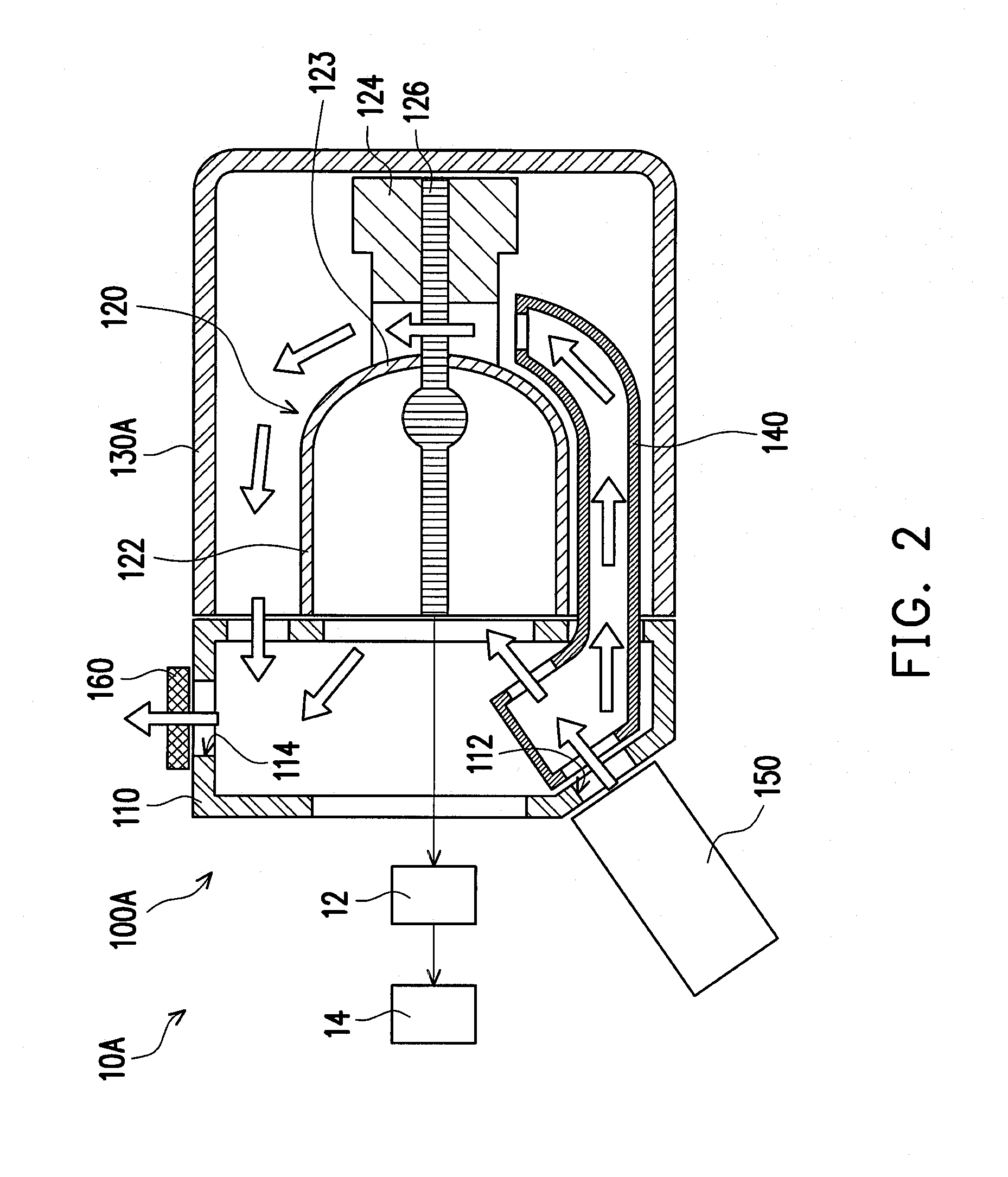

Lamp source module and projection system

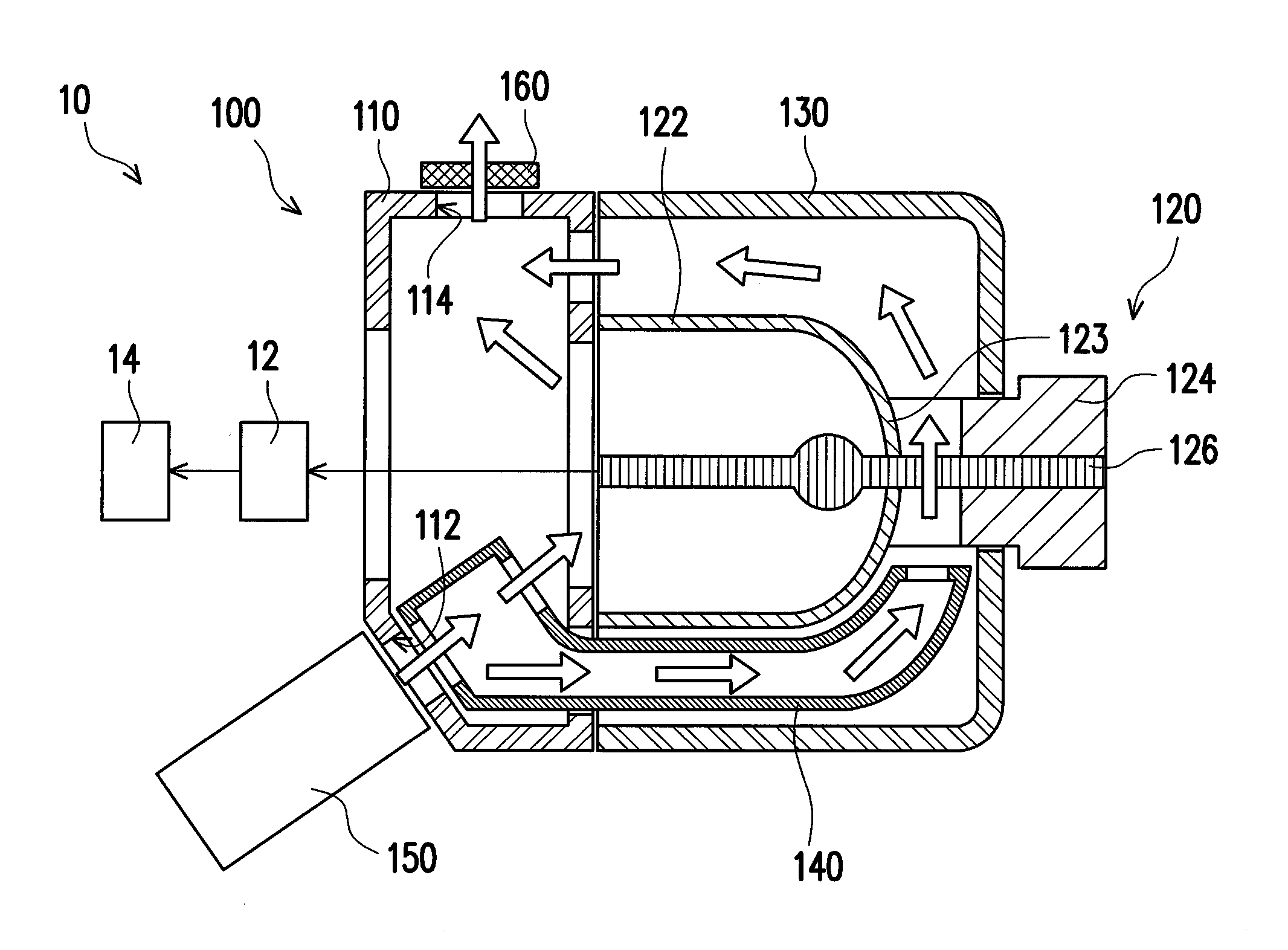

ActiveUS20110032491A1Improve shadingGood explosion preventionLighting heating/cooling arrangementsProjectorsGas-discharge lampCombustor

A lamp source module includes a holder having an air inlet and an air outlet, a gas discharge lamp having a lamp reflector assembled onto the holder and a burner disposed in the lamp reflector, a light cover assembled on the holder and surrounding the lamp reflector, a blower duct communicating with the air inlet and extending along the exterior of the lamp reflector to the bottom of the lamp reflector, and an airflow generator communicating with the blower duct and capable of providing a cooling airflow. The air inlet is capable of causing the cooling airflow to enter the blower duct. The blower duct is capable of directing the cooling airflow to the bottom of the lamp reflector to make the cooling airflow pass through a sandwiched space surrounded by the lamp reflector and the light cover and then discharge from the air outlet.

Owner:YOUNG GREEN ENERGY

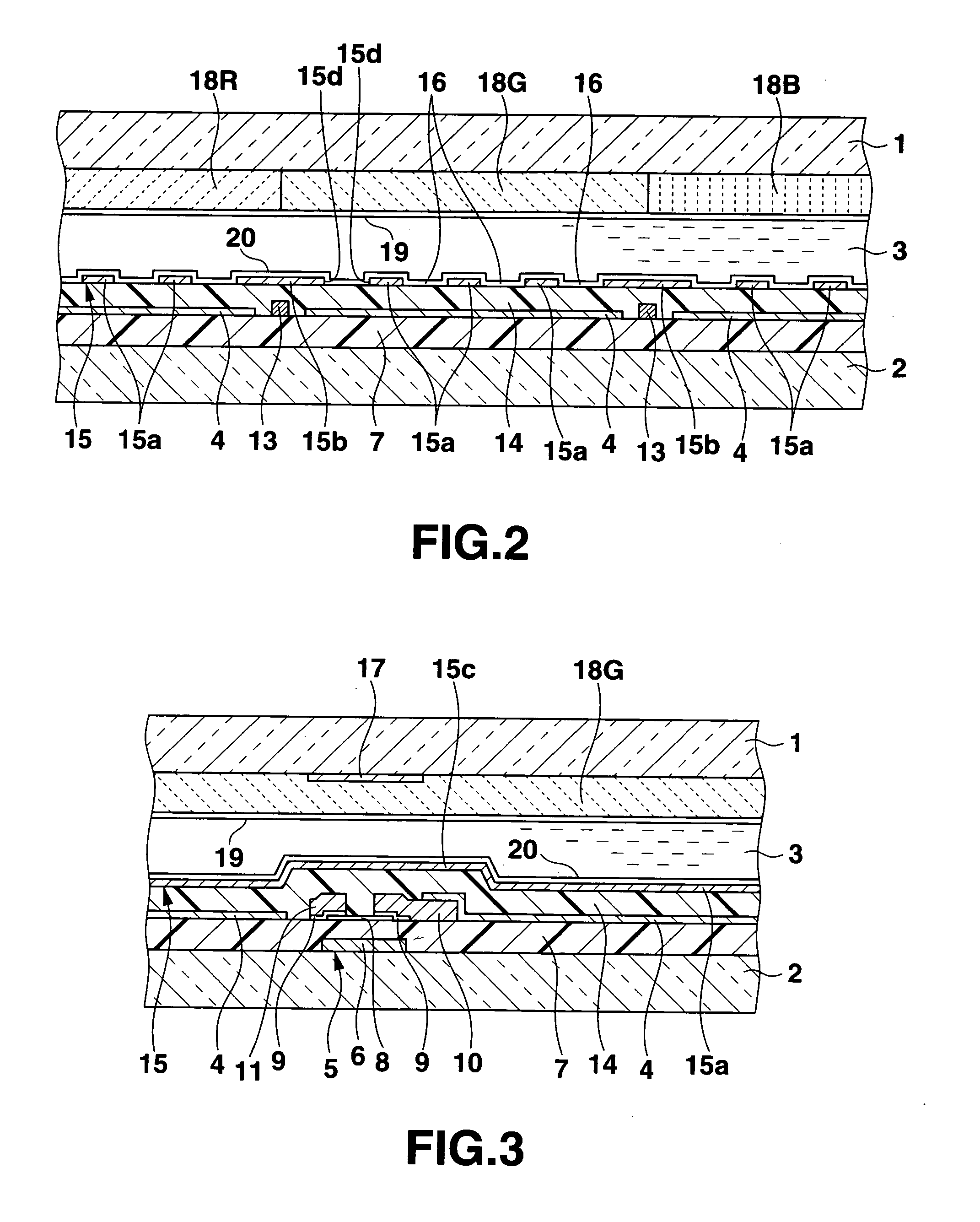

OLED display panel and manufacturing method and display device thereof

ActiveUS20180301521A1Reduce leakageEliminate effectiveSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The present disclosure provides an OLED display panel including a TFT array substrate and a plurality of anodes array arranged on the TFT array substrate, a pixel defining layer is covered on the TFT array substrate, the pixel defining layer includes an opening for exposing the anode and a spacer for spacing two adjacent ones of the anodes, a groove having an upper opening is arranged in the spacer, each of the openings corresponds to a sub-pixel area; wherein, a first common layer, a second common layer and a cathode layer are sequentially arranged on the pixel defining layer, the first common layer, the second common layer and the cathode layer are arranged with a light emitting material unit corresponding to each sub-pixel area. The present disclosure also discloses a method of manufacturing an OLED display panel as described above and a display device including the OLED display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

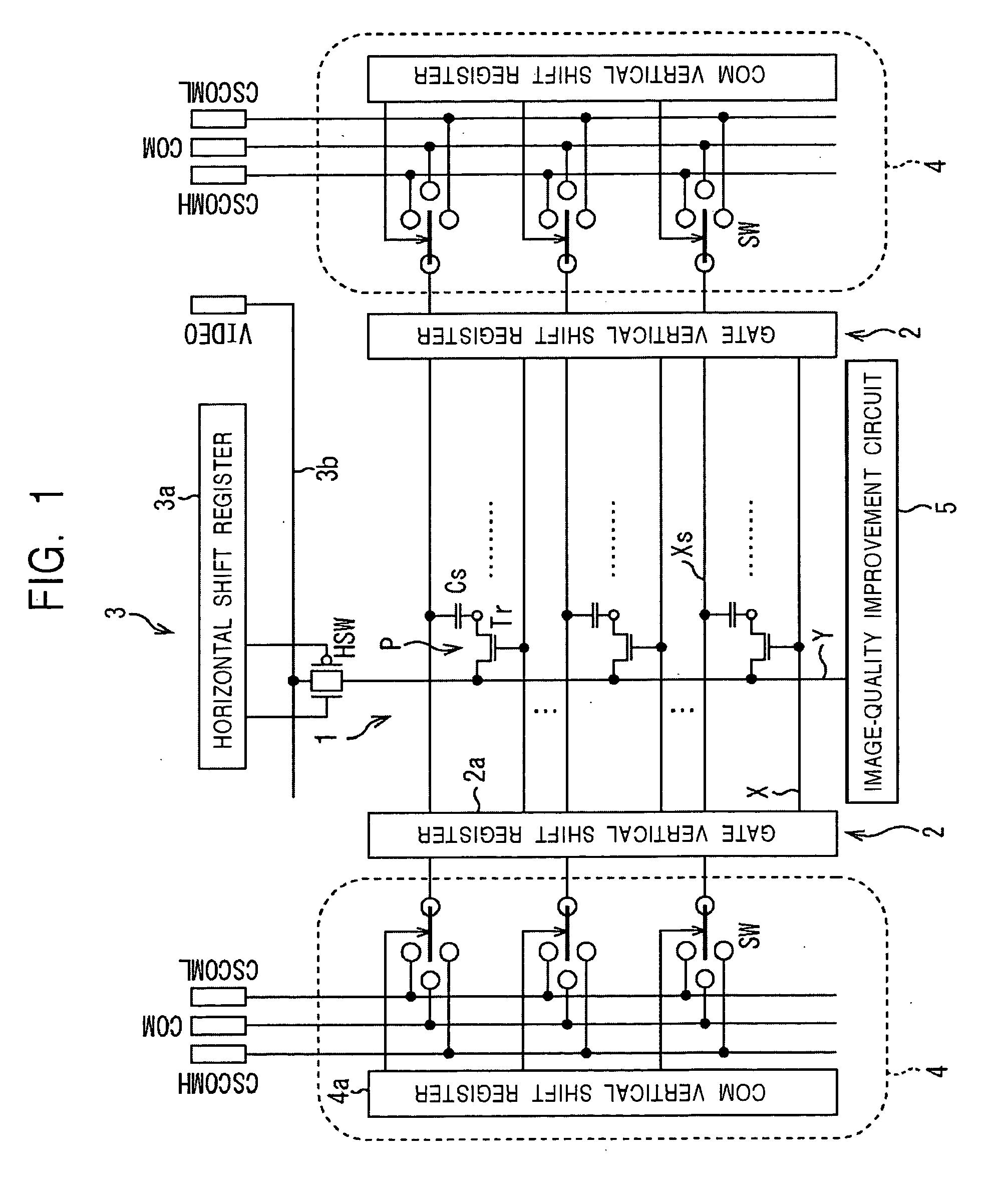

Display and method for driving the same

InactiveUS20050035938A1Supply amount is increasedReduce the amplitudeStatic indicating devicesNon-linear opticsCapacitanceScan line

A display includes a pixel array, a vertical scan circuit, a horizontal drive circuit, and an auxiliary scan circuit. The pixel array includes scan lines, signal lines, pixels, and auxiliary scan lines. Each pixel includes a transistor, a pixel electrode, and an auxiliary capacitor. The auxiliary scan circuit sequentially applies auxiliary pulses, of which potential is reversed between a high level and a low level relative to a predetermined reference potential, to the auxiliary scan lines synchronously with selection pulses to control such that a potential of one electrode of each auxiliary capacitor in a selected pixel row is opposite in polarity to that of a signal written in the corresponding pixel electrode in the selected row, and further control such that the potential of the electrode of each auxiliary capacitor is returned to the reference potential when the selected row is released.

Owner:SONY CORP

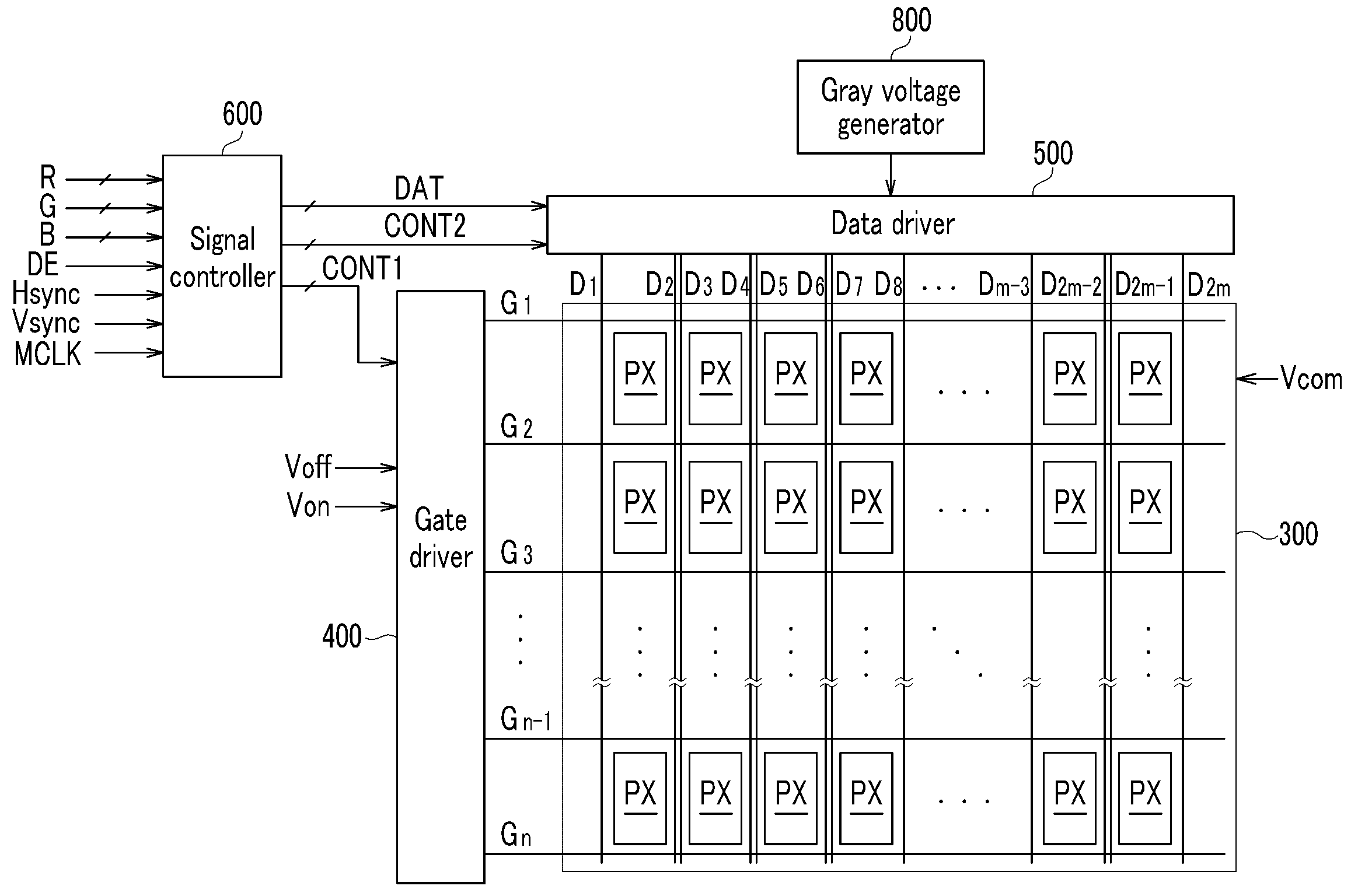

Display device

InactiveUS20100118220A1Reduce and substantially eliminate side light leakageReduce manufacturing costStatic indicating devicesNon-linear opticsLiquid-crystal displayDisplay device

A display device, including a lower substrate; an upper substrate disposed opposite to the lower substrate; a liquid crystal layer interposed between the lower substrate and the upper substrate; and a plurality of pixels, each of the pixels including at least one reflective electrode and at least one transparent electrode; the reflective electrodes and the transparent electrodes disposed on the lower substrate and electrically insulated from each other, wherein a reflective region corresponds to a region of the reflective electrodes and a transmissive region corresponds to a region of the transparent electrodes, and when a display luminance in the reflective region and the transmissive region is increased, a first voltage applied to the liquid crystal layer in one of the reflective region and the transmissive region is increased and a second voltage applied to the liquid crystal layer in the other of the reflective region and the transmissive region is decreased.

Owner:SAMSUNG DISPLAY CO LTD

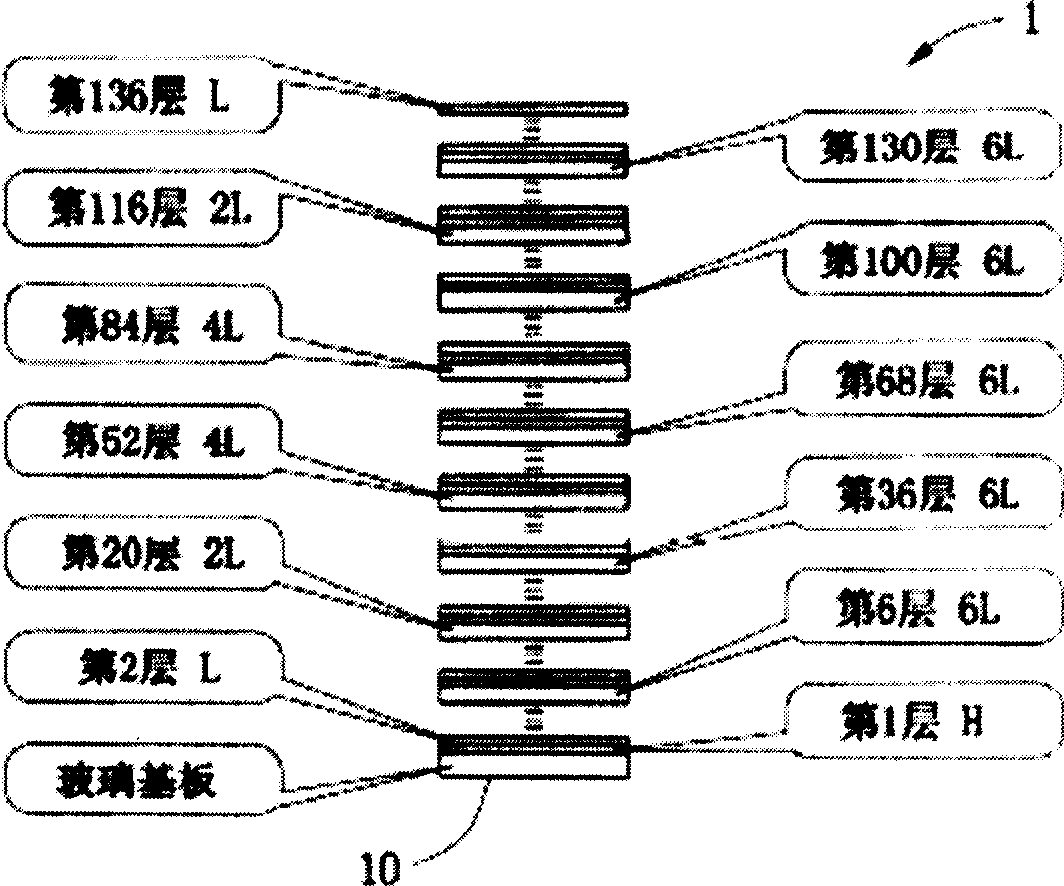

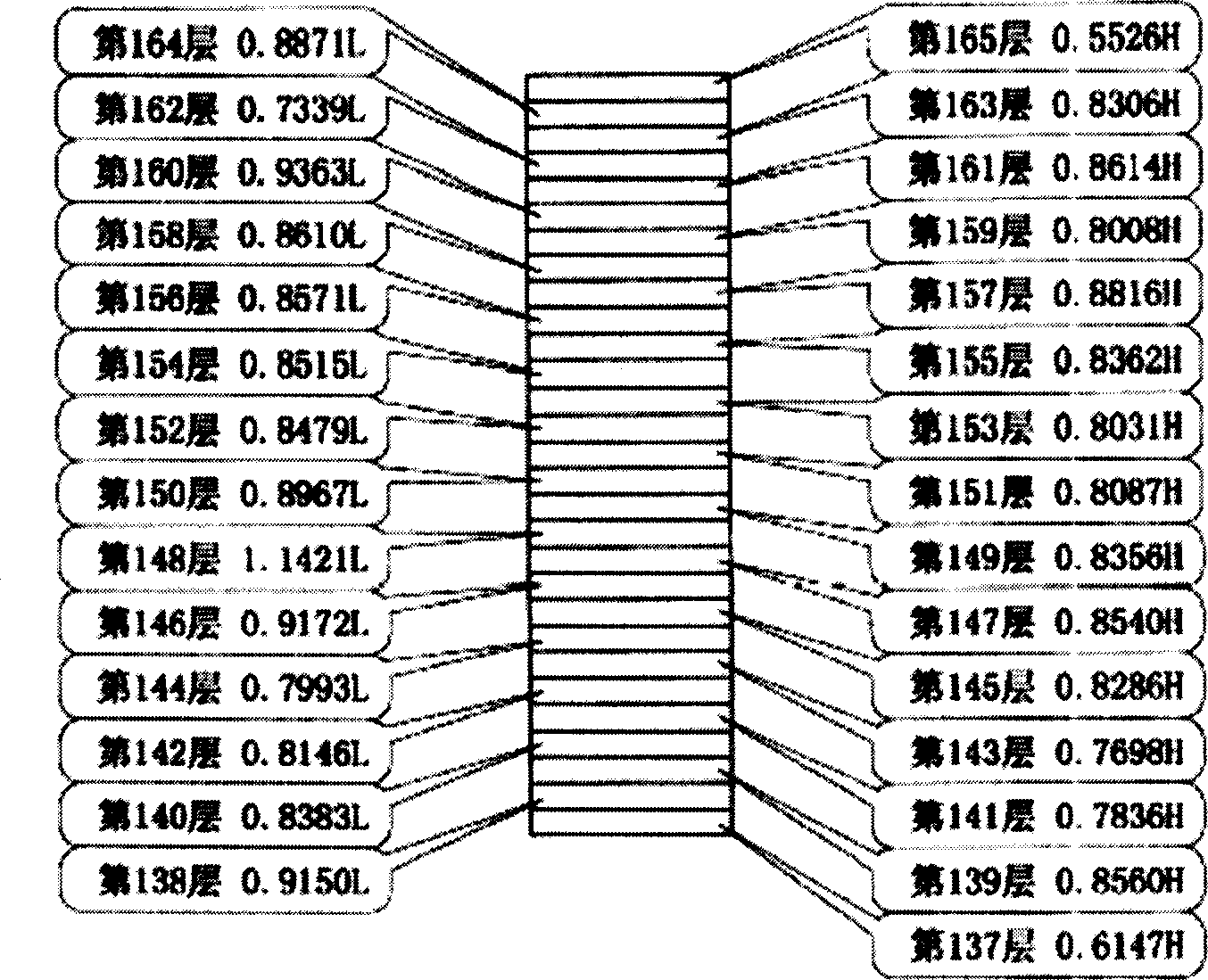

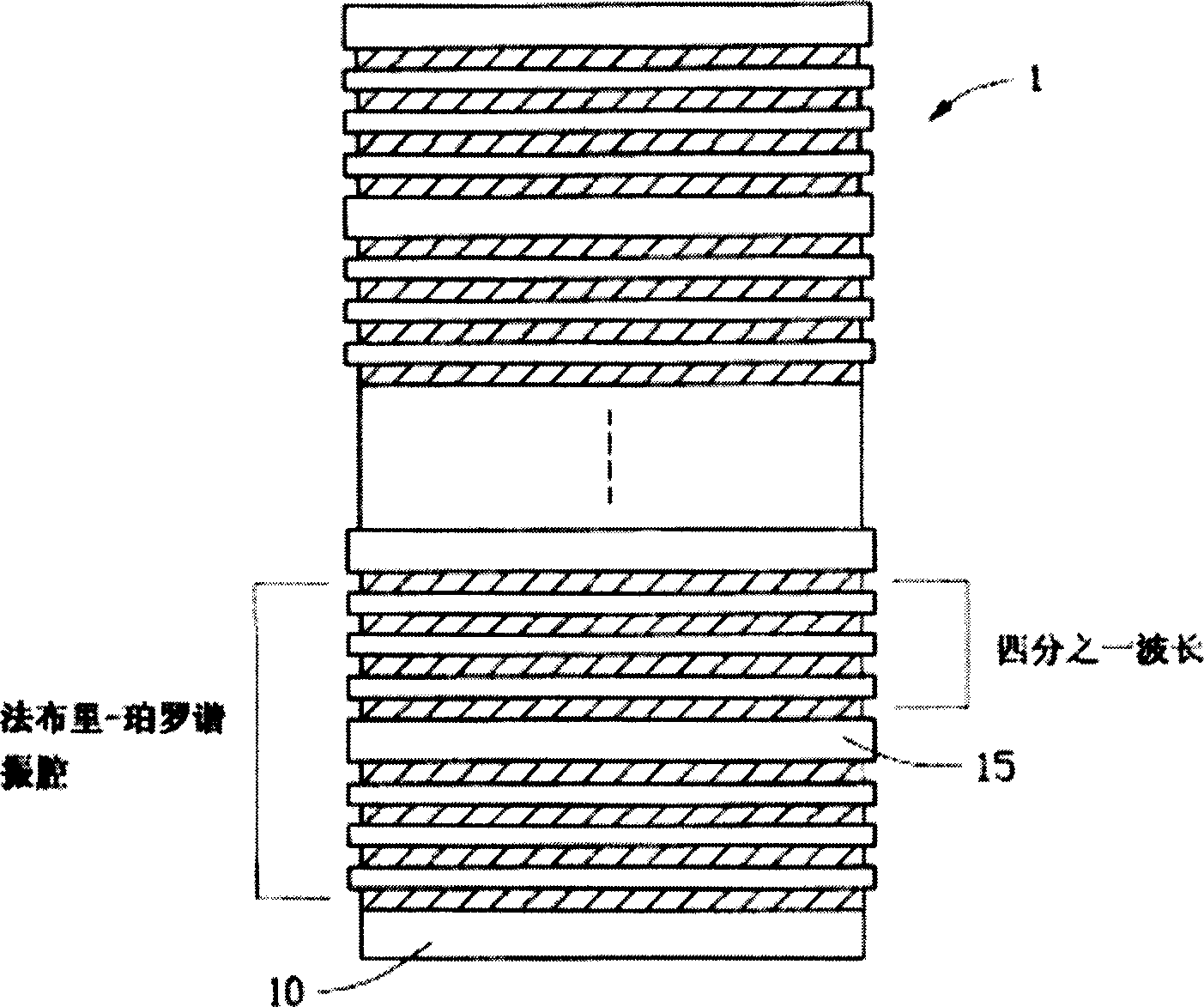

CWDM light filter

InactiveCN1721887AEliminate light leaksCancel noiseOptical filtersOptical multiplexRefractive indexLength wave

The invention relates to a CWDM filter glass which comprises first part and second part, wherein first part comprises at least two Fabry-Perot cavity resonator structures; second part comprises foil structure which is formed by coupled high, low refractivity foil layer non-quarter ware of first part. The at least two Fabry-Perot cavity resonator structures of first part is a generally adopted structure. The foil thickness of non-quarter ware is casual generated by computer with the center ware at 1470 nm according to the given ware range.

Owner:东莞信泰光学有限公司

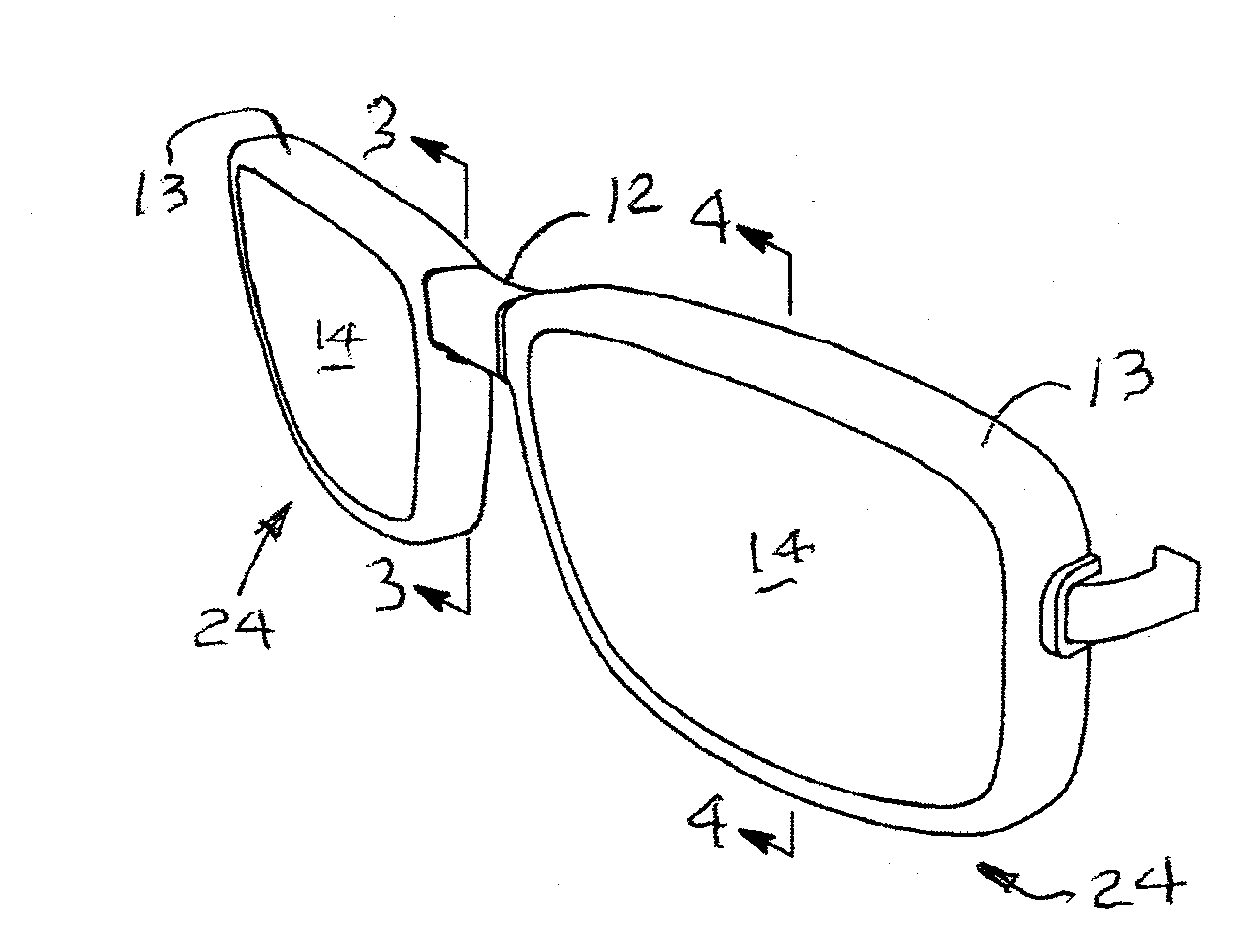

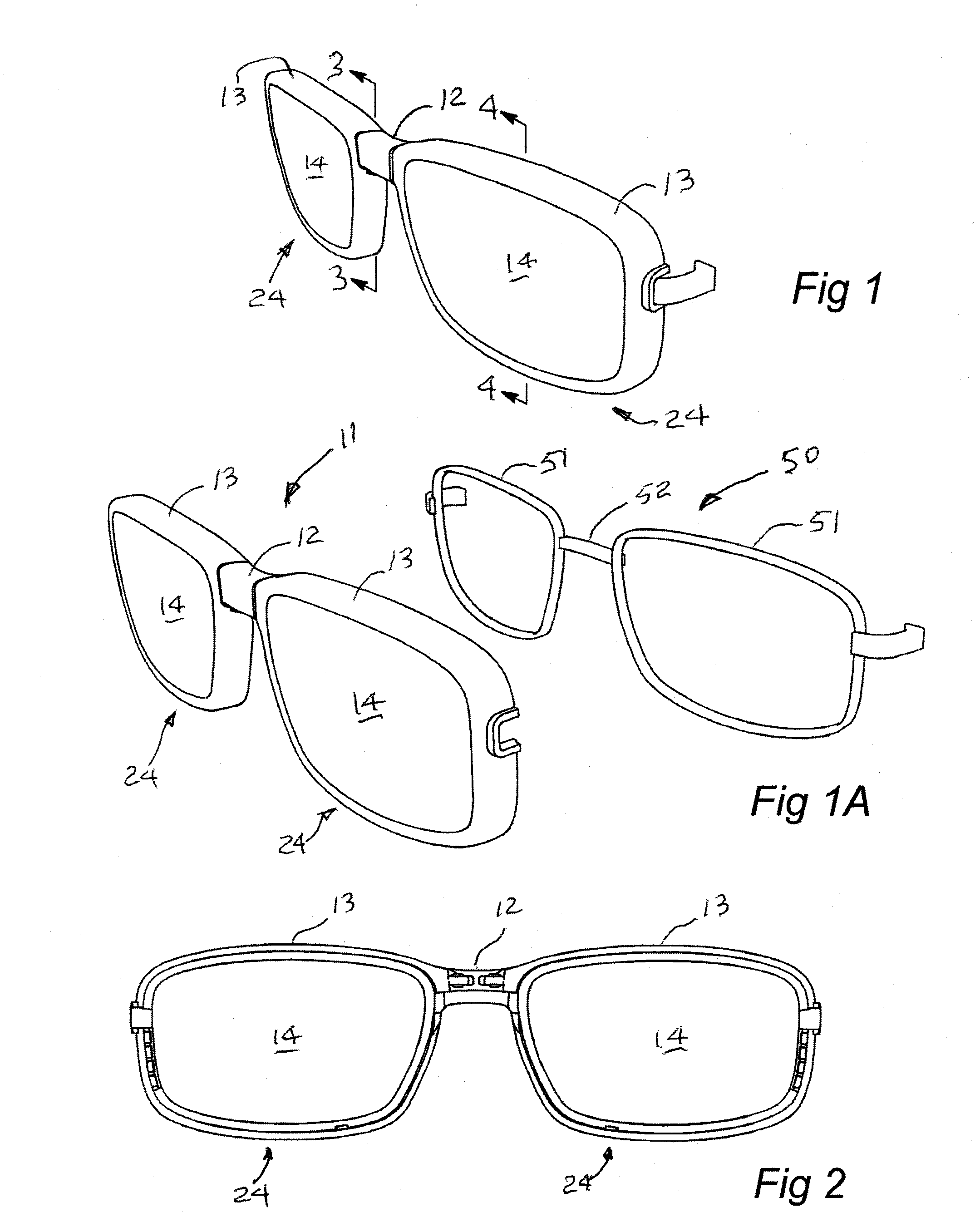

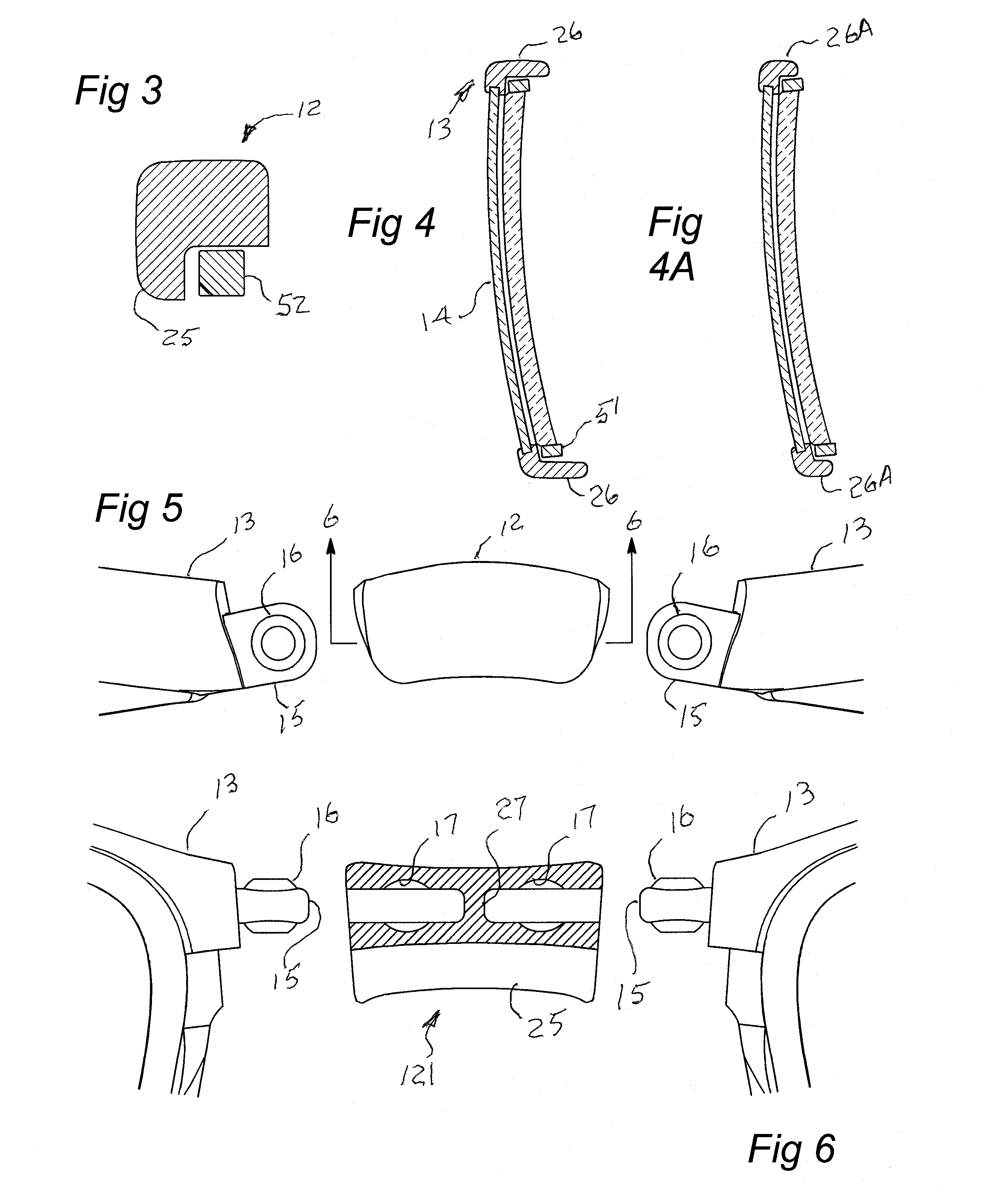

Attachable Front for Eyeglasses

ActiveUS20160223840A1Eliminate light leaksEliminate gapsSpectales/gogglesAuxillary optical partsEngineeringBall joint

Owner:SUNBIRD

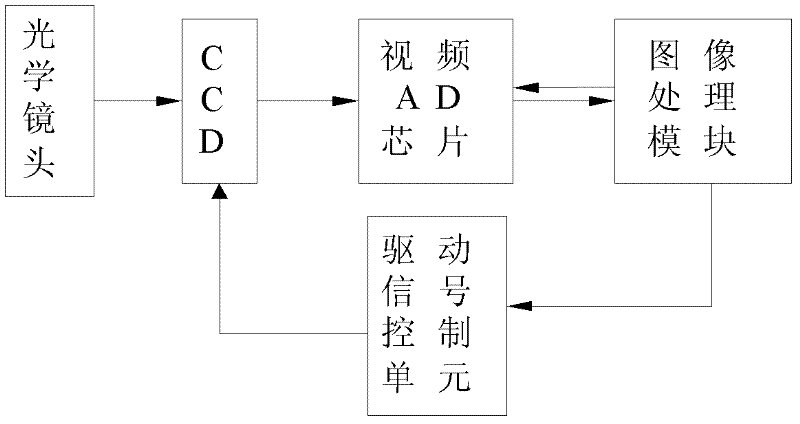

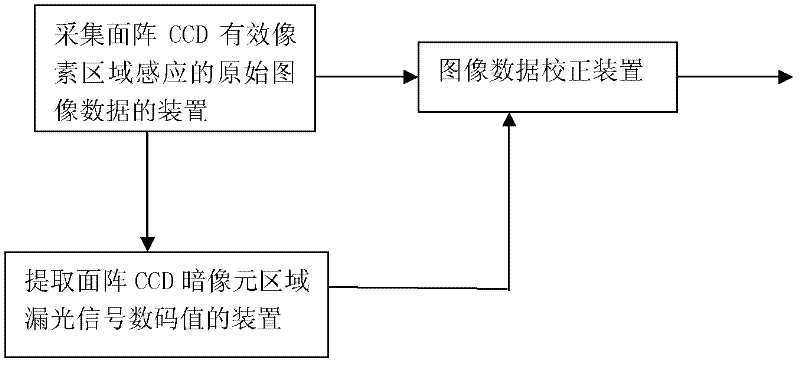

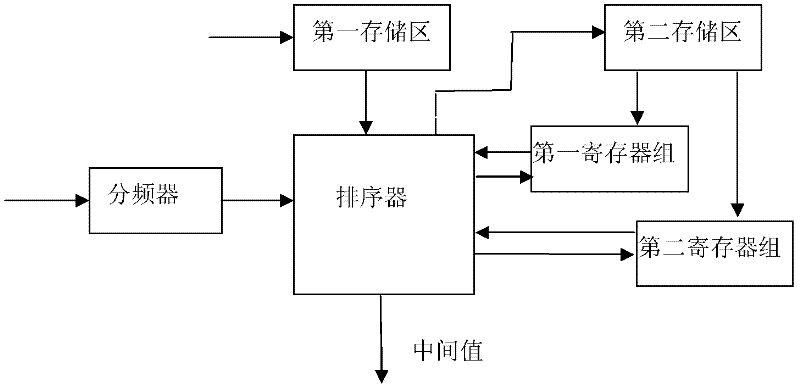

Real-time light leak phenomenon removing device for space and line space transfer CCD (charge coupled device) camera

InactiveCN102316283ARestore accuratelyEliminate light leaksTelevision system detailsColor television detailsCcd cameraComputer science

The invention relates to a real-time light leak phenomenon removing device for a space and line space transfer CCD (charge coupled device) camera, which comprises a device for collecting original image data sensed in effective pixel area of the CCD, a device for extracting the light leak signal numeral code in a dark pixel area of the CCD, and an image data correcting device, wherein the image data correcting device is used for correcting corresponding column data of the original image by utilizing the light leak signal numeral code extracted from the dark pixel area of the CCD, and the imagedata of which the light leak signal is removed can be obtained. According to the invention, the column data of the original image is corrected by utilizing the light leak signal numeral code extracted from the dark pixel area of the CCD, the calculated amount is small, the real time is good, and since the light leak signal can accurately stand for light leak charge of a high light area, the lightleak phenomenon is better removed without changing the CCD working conditions.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

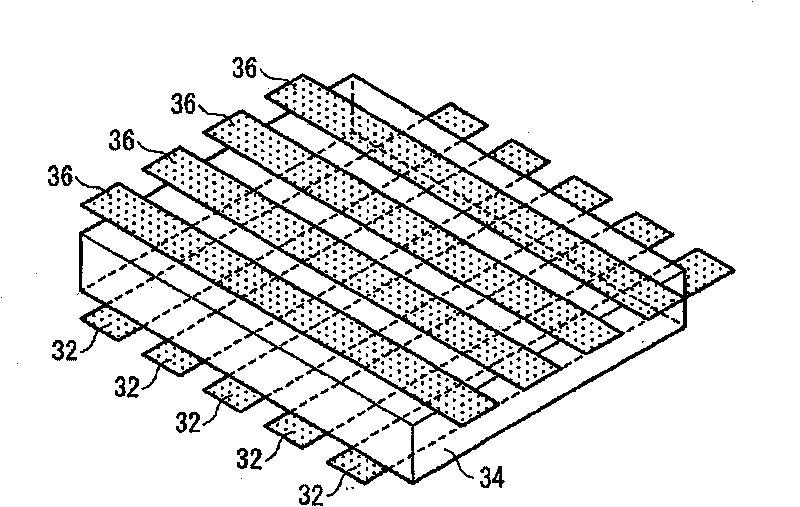

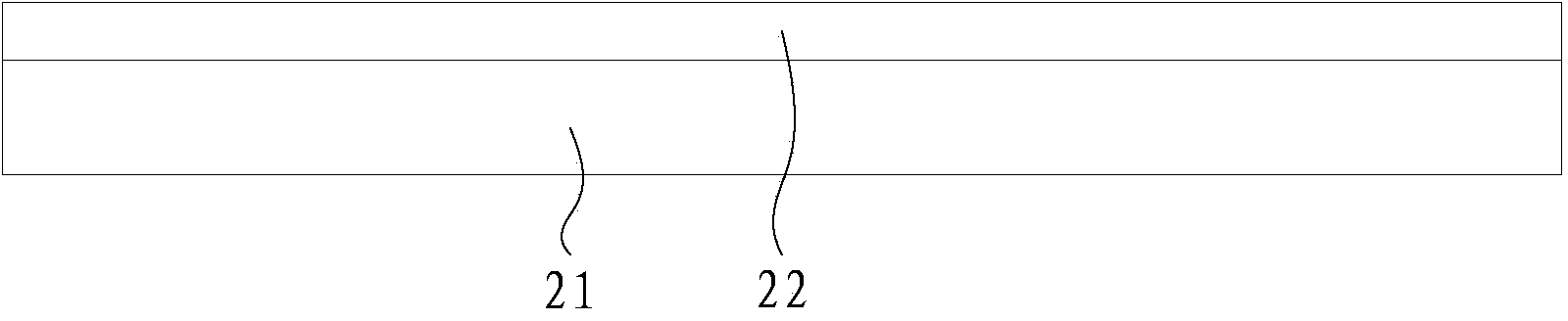

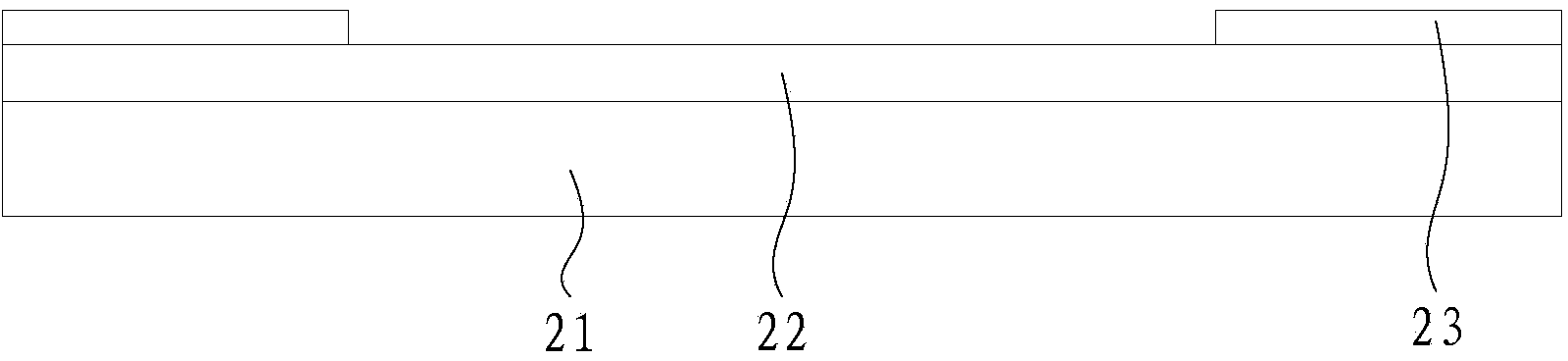

Array substrate, manufacturing method thereof and curved surface liquid crystal display panel

InactiveCN106773392AEliminate light leaksIncrease opening ratioNon-linear opticsLiquid-crystal displayEngineering

The invention provides an array substrate, a manufacturing method thereof and a curved surface liquid crystal display panel. The array substrate comprises: a substrate, a metal shielding layer arranged on the substrate and comprising a plurality of metal shielding lines, an insulating layer arranged on the metal shielding layer and the exposed substrate, a data line arranged on the insulating layer, a first passivation layer arranged on the data line and the exposed substrate, a color barrier layer arranged on the first passivation layer, a second passivation layer arranged on the color barrier layer, and an ITO layer arranged on the second passivation layer and used for forming a pixel electrode, wherein the metal shielding line close to the data line directly extends to the bottom of the data line to be overlapped with the data line. The array substrate provided by the invention can eliminate light leakage gaps on both sides of the data line, and can also omit a black matrix on the direction of the data line.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid crystal display equipment

InactiveCN1700077AImprove viewing angle characteristicsEliminate chromatic aberrationTransistorNon-linear opticsLiquid-crystal displayElectrode

The invention discloses a LCD which comprises upper placode, lower placode, pixel electrode, common electrode, insulating inlay and at least one arranged inlay, wherein upper placode is arranged relatively with lower placode; the pixel electrode and common electrode are posited on the same placode; the common placode is planar plate-like; the insulating inlay is between pixel electrode and common electrode; the arranged inlay is on upper placode or lower placode and has first arranged direction and second arranged direction.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

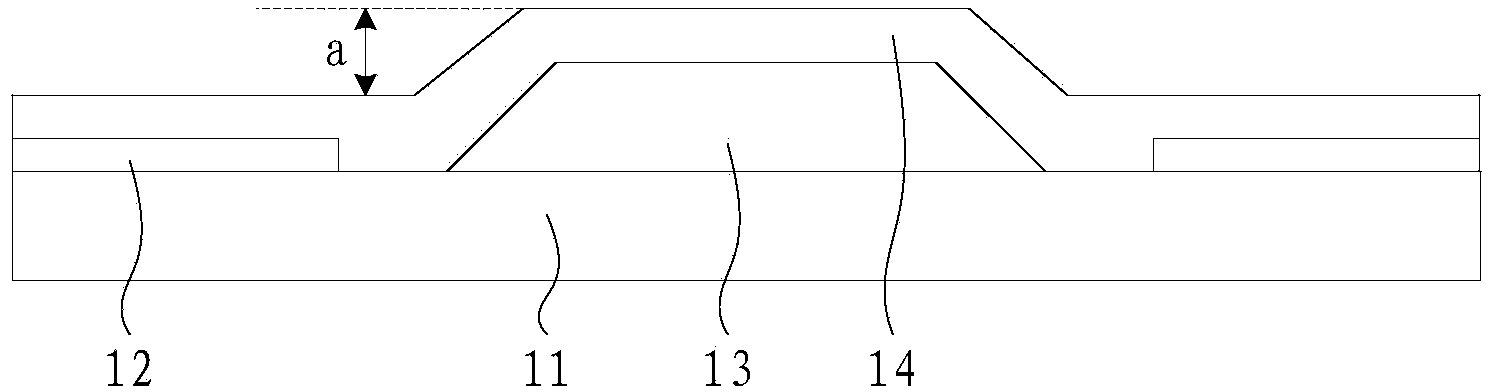

TFT (Thin Film Transistor) array substrate, manufacturing method thereof, and display device

InactiveCN104392920AReduce the differenceEliminate light leaksSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides a TFT (Thin Film Transistor) array substrate, a manufacturing method thereof, and a display device. the manufacturing method comprises steps: Passivation layers are formed on a substrate provided with a data line, wherein the passivation layers comprise a first passivation layer covering the data line and a second passivation layer covering other regions expect the data line; and the first passivation layer with a first preset thickness is removed to enable the thickness of the first passivation layer to be smaller than the thickness of the second passivation layer. in the above manufacturing method, through removing a passivation layer with a certain thickness covering the data line after the passivation layers are formed so as to enable the thickness of the passivation layer covering the data line to be smaller than the thickness of the passivation layer covering other regions expect the data line, segment difference caused as the thickness of the data line is thick can be effectively reduced problems of light leak, reduced contrast ratio and the like can be eliminated, and the display quality is improved.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

Light guide plate and backlight module

InactiveUS20100097823A1Increase the itineraryEasy to adjustPlanar/plate-like light guidesNon-linear opticsLight guideEngineering

A light guide plate includes a plate-shaped transparent body and a plurality of stripe-shaped planar structures. The plate-shaped transparent body is bent to form a top portion, a bottom portion, and a curved portion connected between the top portion and the bottom portion, and the top portion and the bottom portion are substantially parallel to each other and define a gap therebetween. The stripe-shaped planar structures are connected with each other on an outer surface of the curved portion.

Owner:CORETRONIC

Backlight source luminance control method and device used under wide-screen film display mode

ActiveCN104240650AIncrease contrastEliminate light leaksStatic indicating devicesCine Display ModeComputer science

Owner:HISENSE VISUAL TECH CO LTD

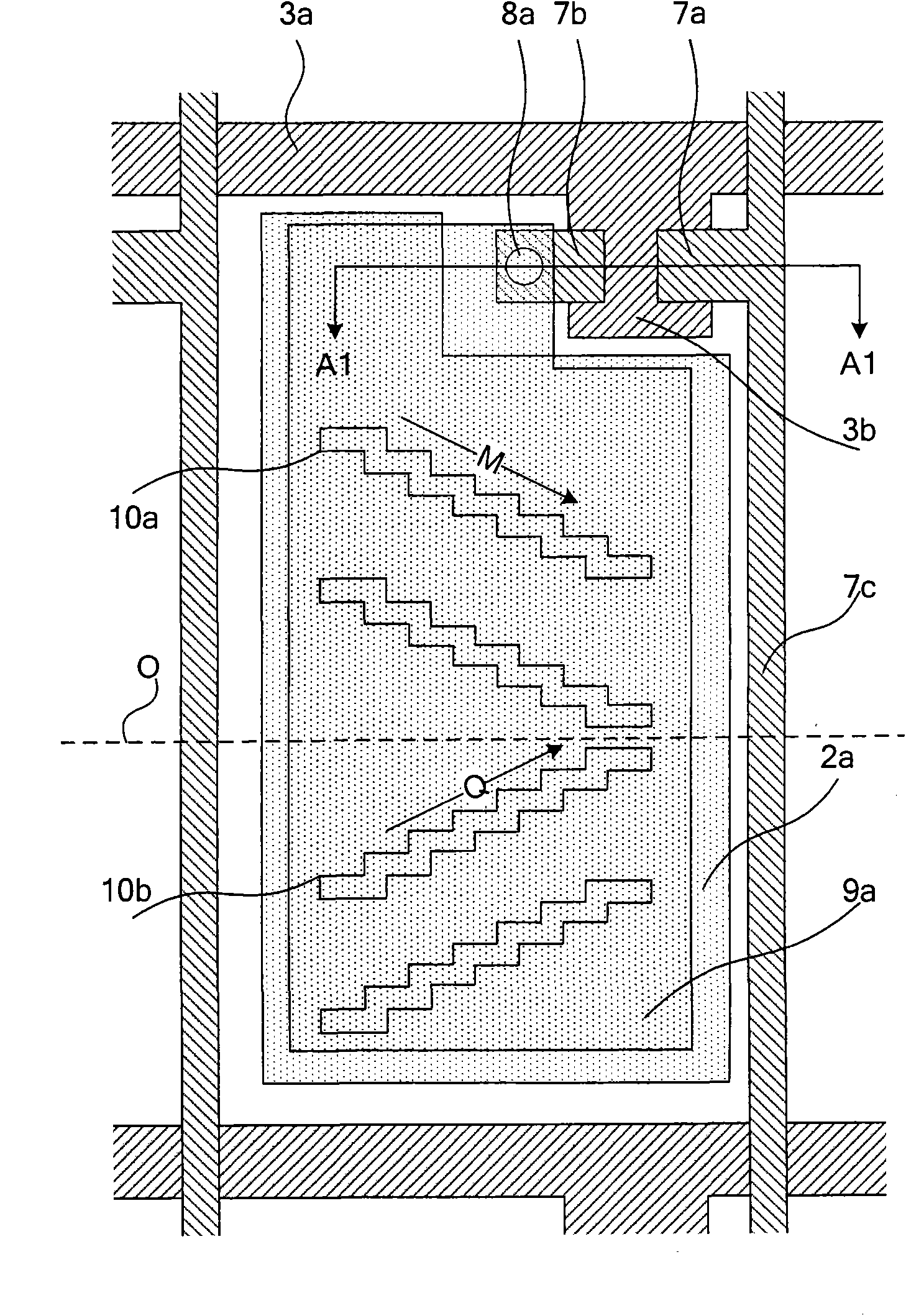

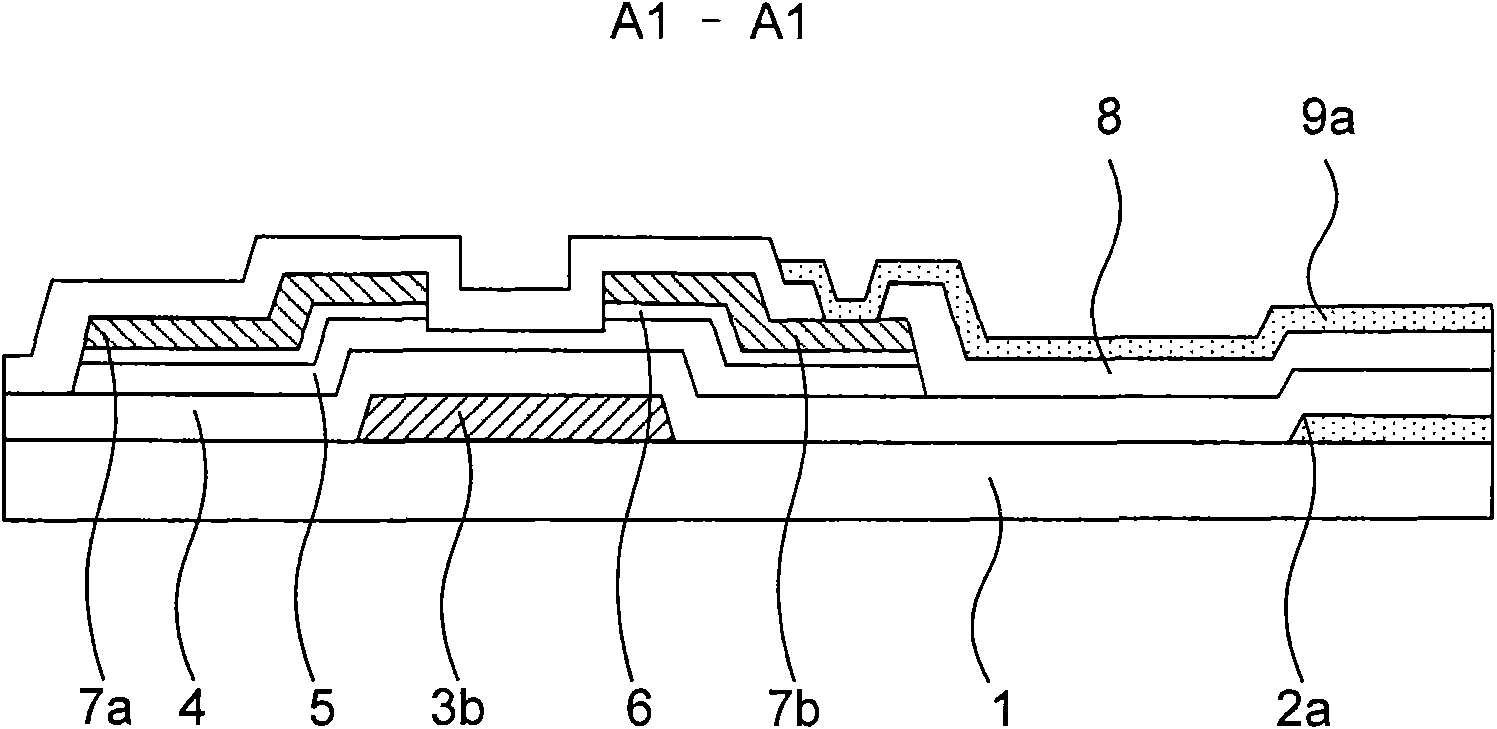

FFS (Fringe Field Switching) type TFT-LCD (Thin Film Transistor-Liquid Crystal Display) array substrate and manufacturing method thereof

InactiveCN101846857AWiden perspectiveEliminate color shiftSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

The invention discloses an FFS (Fringe Field Switching) type TFT-LCD (Thin Film Transistor-Liquid Crystal Display) array substrate and a manufacturing method thereof, comprising a grid line and a data line. A pixel electrode, a common electrode and a thin film transistor are formed in a pixel area limited by the grid line and the data line, wherein the pixel electrode and / or the common electrode are / is provided with a plurality of ladder-shaped strip-shaped grooves which enable a plurality of horizontal electric field in multiple directions to be formed between the pixel electrode and the common electrode, and each strip-shaped groove at least comprises two zigzag structures. In the FFS type TFT-LCD array substrate and the manufacturing method thereof, by setting the pixel electrode into figures comprising a plurality of ladder-shaped broken lines, a polydomain liquid crystal working mode can be provided, the visual angle is enlarged, and the color drifting can be eliminated.

Owner:BOE TECH GRP CO LTD +1

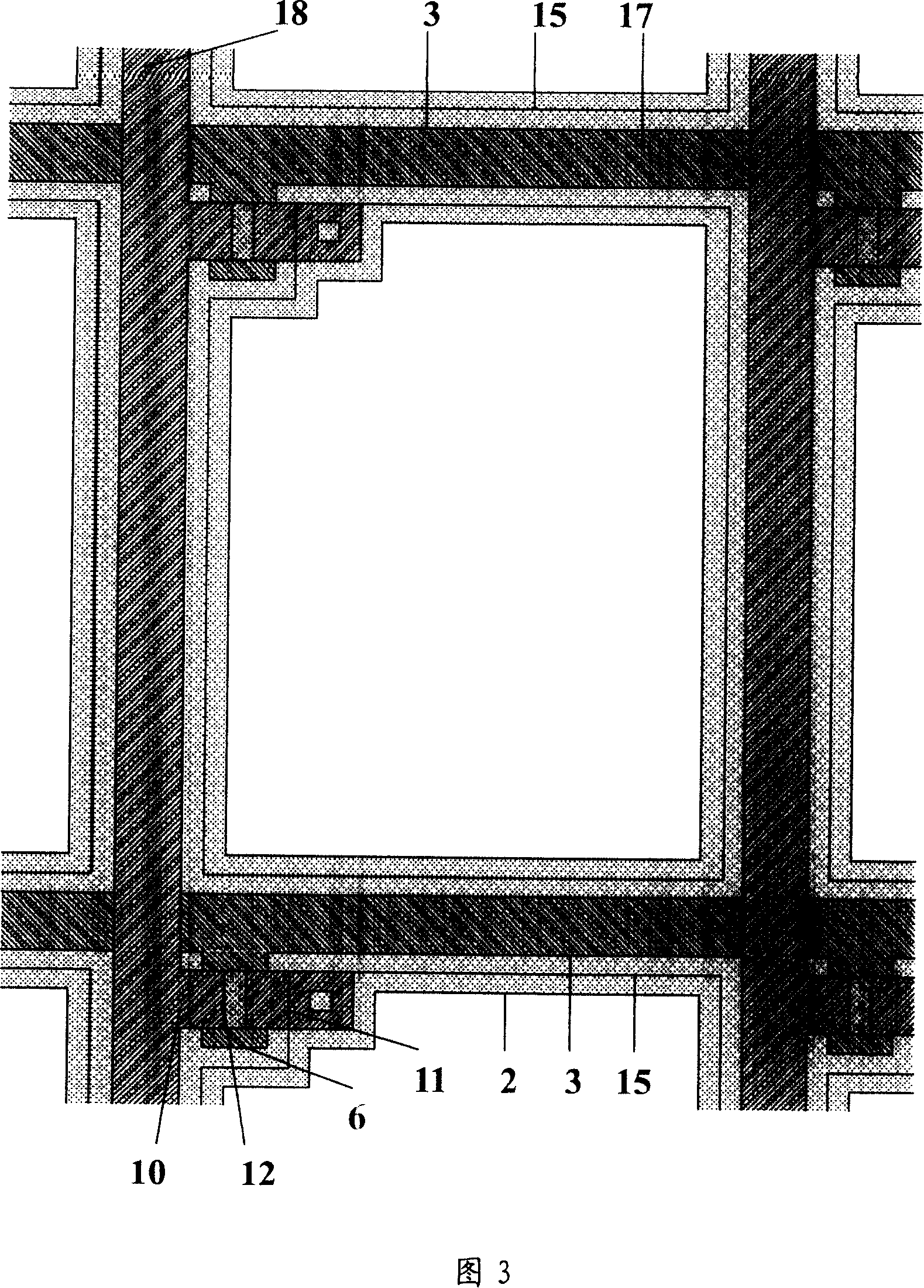

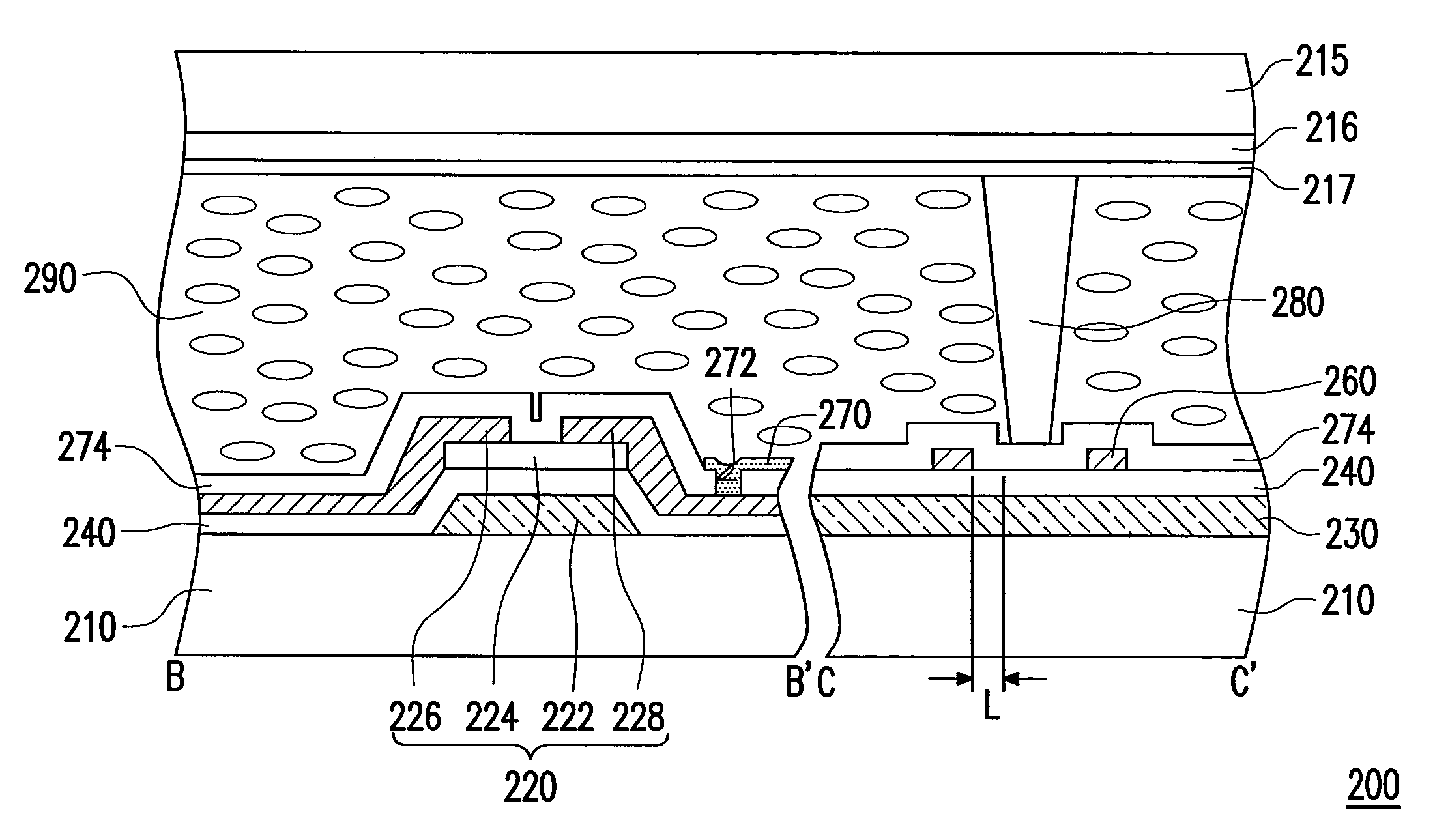

OLED display panel and method for manufacturing the same, and display device

ActiveUS20180375052A1Improve display qualityEliminate light leaksSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The present disclosure discloses an OLED display panel, including a TFT array substrate and a plurality of anodes disposed in an array on the TFT array substrate, the TFT array substrate has a pixel defining layer disposed thereon, the pixel defining layer includes opening portions and spacing portions, and each opening portion corresponds to one sub-pixel area; wherein, the pixel defining layer has a first common layer, a second common layer and a cathode layer sequentially disposed thereon, and a light emitting material is disposed between the first common layer and the second common layer corresponding to each sub-pixel area; wherein, a hole blocking portion is further disposed above the spacing portion, and the hole blocking portion spaces the first common layer between two adjacent sub-pixel areas. The present disclosure further discloses a method for manufacturing the OLED display panel as mentioned above.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

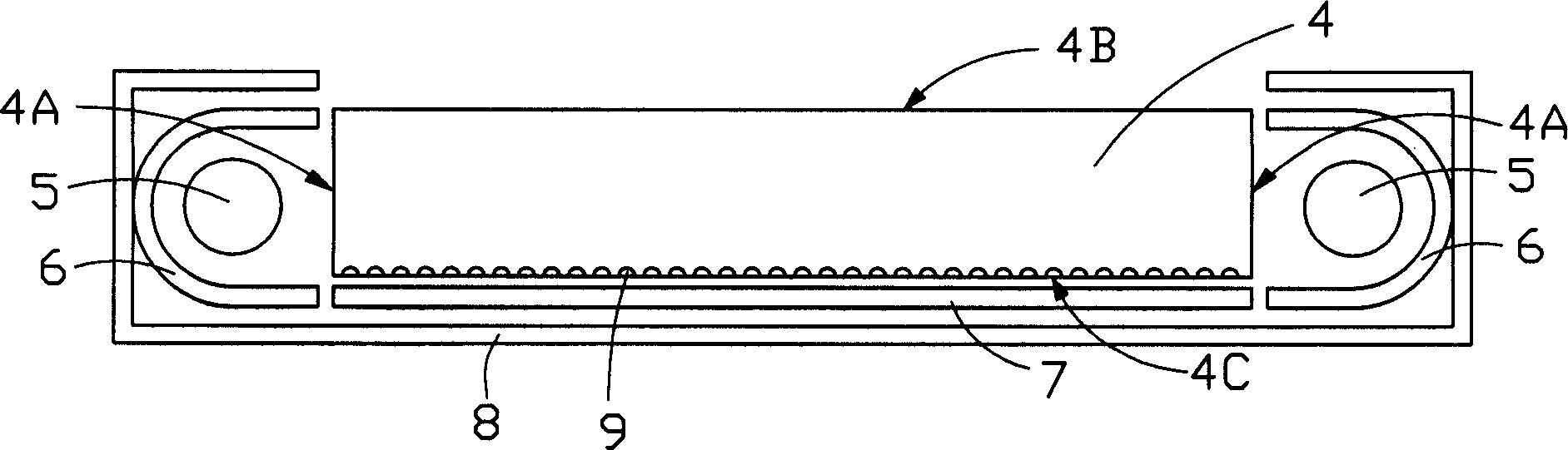

Lamp source module and projection system

ActiveUS8322861B2Good shading and explosion prevention and cooling effectEliminate light leaksLighting heating/cooling arrangementsProjectorsGas-discharge lampCombustor

A lamp source module includes a holder having an air inlet and an air outlet, a gas discharge lamp having a lamp reflector assembled onto the holder and a burner disposed in the lamp reflector, a light cover assembled on the holder and surrounding the lamp reflector, a blower duct communicating with the air inlet and extending along the exterior of the lamp reflector to the bottom of the lamp reflector, and an airflow generator communicating with the blower duct and capable of providing a cooling airflow. The air inlet is capable of causing the cooling airflow to enter the blower duct. The blower duct is capable of directing the cooling airflow to the bottom of the lamp reflector to make the cooling airflow pass through a sandwiched space surrounded by the lamp reflector and the light cover and then discharge from the air outlet.

Owner:YOUNG GREEN ENERGY

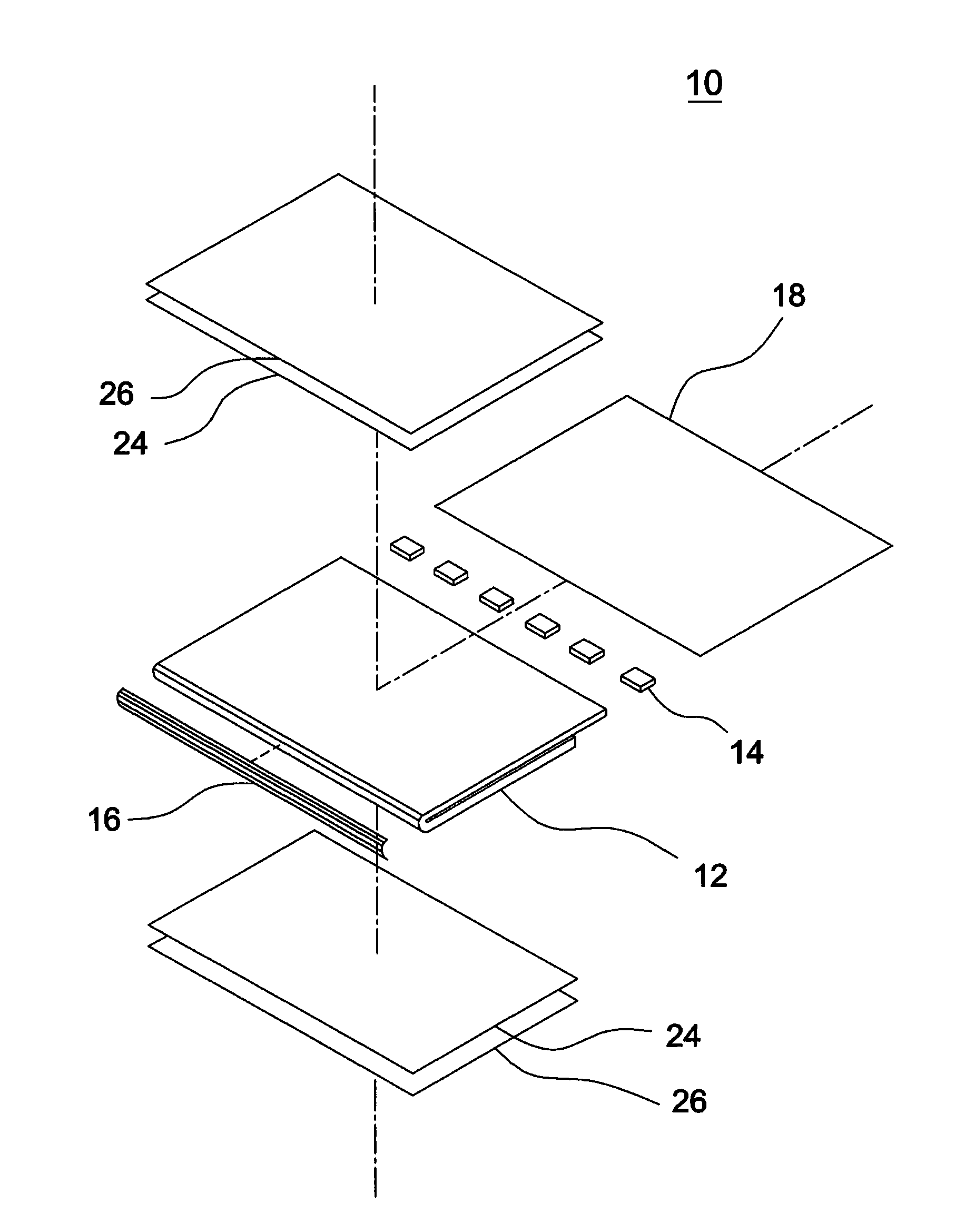

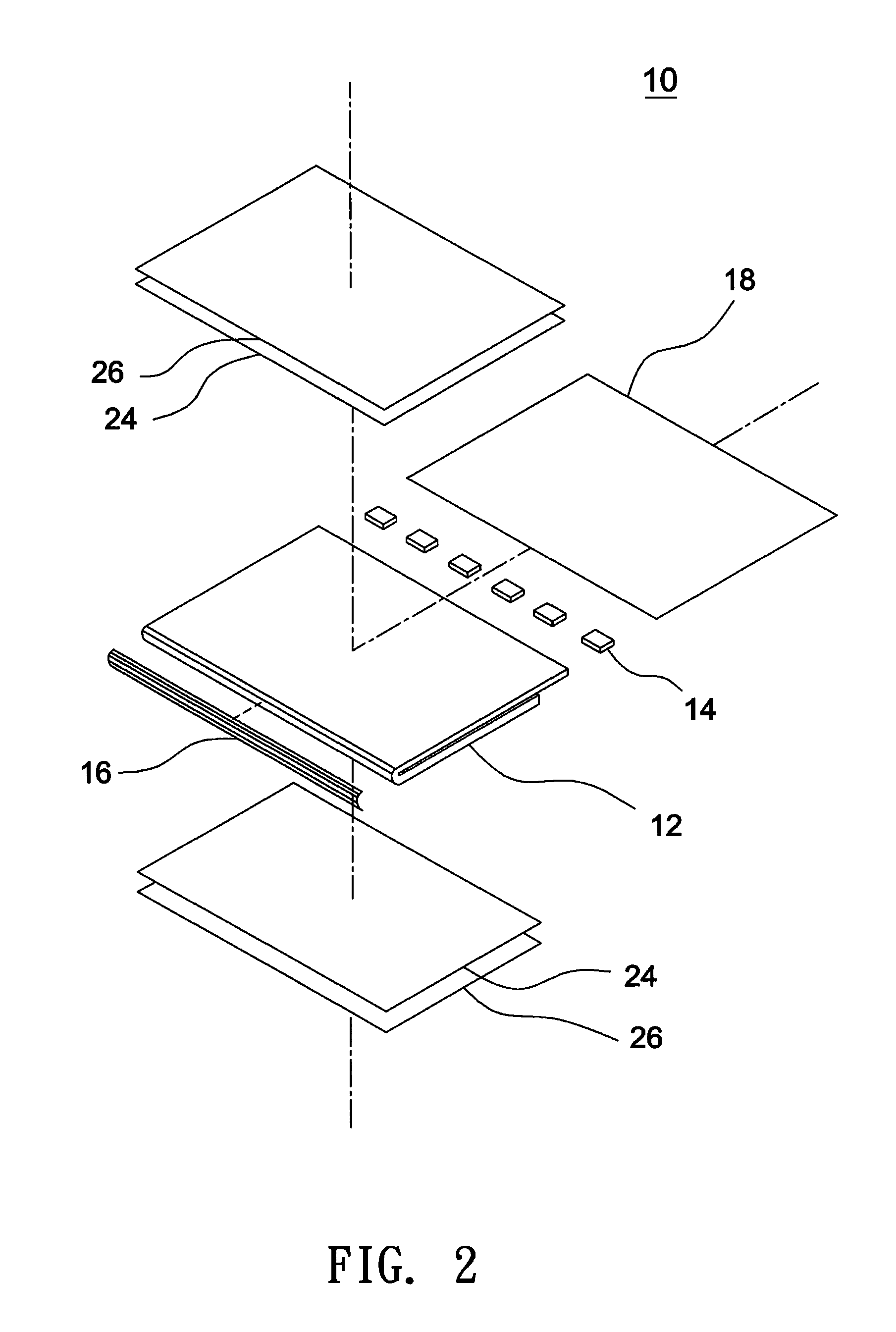

Polarizing Sheet, Substrate Structure And Display Panel

InactiveUS20150309215A1Simple processRealize processingPolarising elementsTelescopesTectorial membranePolarizer

The invention provides a polarizing sheet, a substrate structure and a display panel. The polarizing sheet comprises an adhesive film, a first protection film, a polarization film, a second protection film and a surface protection film, wherein the adhesive film is a conductive adhesive film for exporting the static electricity generated by a corresponding substrate. In addition to a polarization function, the polarizing sheet or the substrate structure according to the invention also has a conduction function because it comprises a conductive adhesive film. Moreover, the polarizing sheet or the substrate structure according to the invention may simplify the realization process of electro-static discharge protection, the problem of poor fixing may be eliminated, and the problem of light leakage due to the fixing of a conductive gasket may be eliminated.

Owner:BOE TECH GRP CO LTD +1

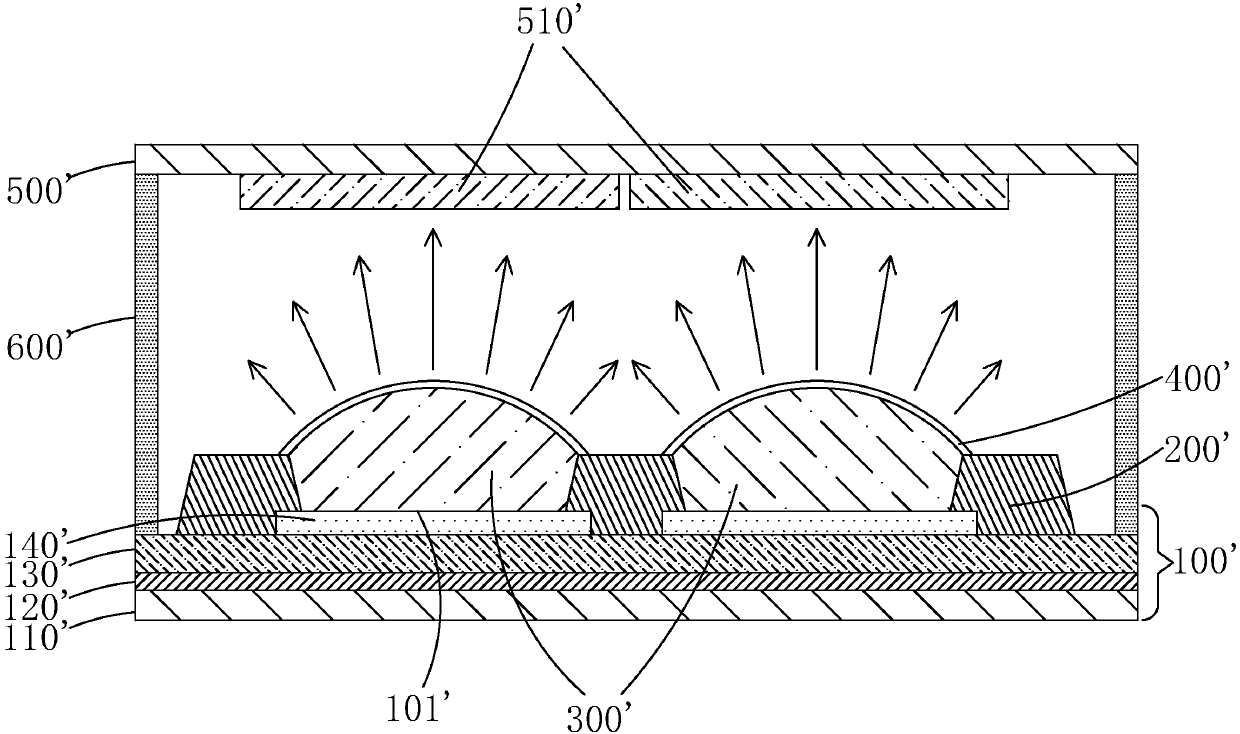

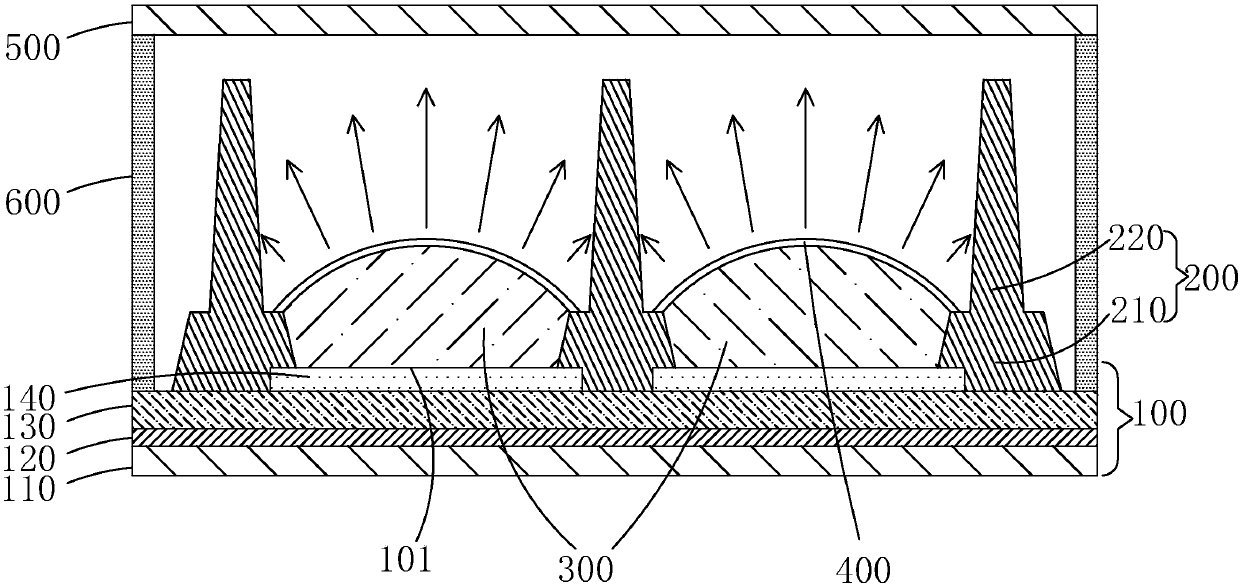

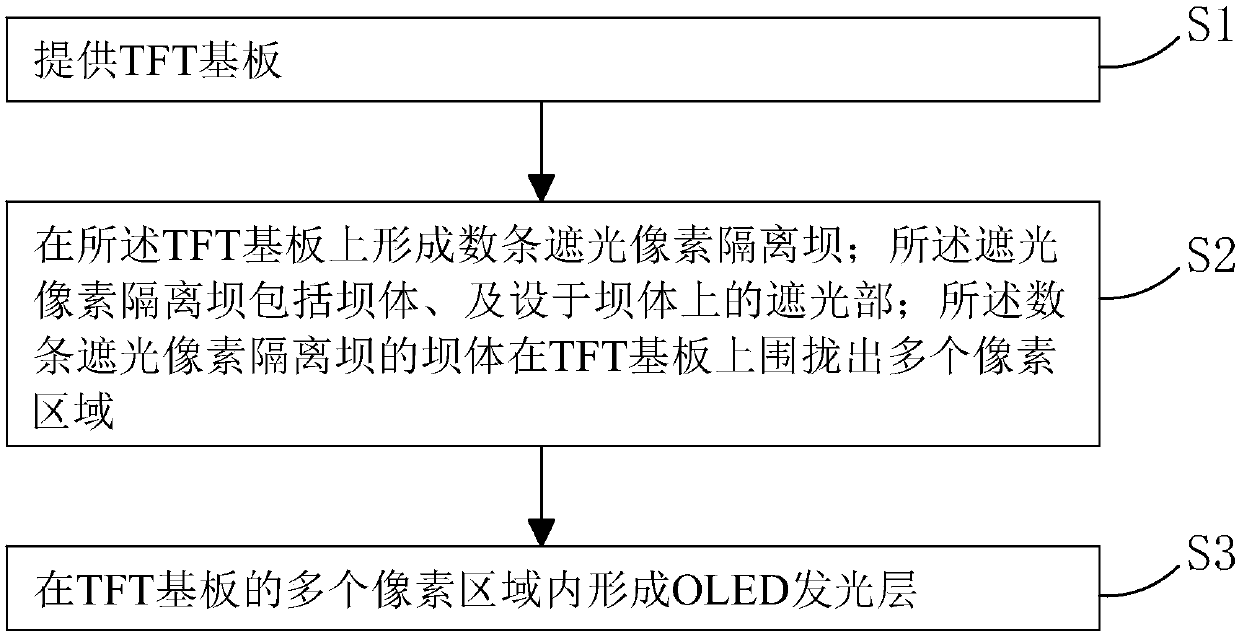

OLED display device and manufacturing method thereof

InactiveCN107919379AImprove the display effectImprove display qualitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides an OLED display device and a manufacturing method thereof. According to the OLED display device, a plurality of shading pixel isolation dams are arranged on a TFT substrate. Theshading pixel isolation dams include dam bodies and shading parts arranged on the dam bodies; a plurality of pixel regions are encircled by the dam bodies of the plurality of shading pixel isolationdams on the TFF substrate; and a plurality of OLED layers are arranged in the plurality of pixel regions. With the shading pixel isolation dams having shading parts, a problem of light leakage causedby inclined incidence of light in adjacent pixel regions during light emitting of the OLED layers is solved, so that the display effect of the OLED device is improved effectively.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Display apparatus

ActiveUS20130256671A1Eliminate light leaksSolid-state devicesPlanar/plate-like light guidesEngineeringSupport surface

A display apparatus includes a backlight module, a panel module, and a plurality of double-sided adhesive tapes. The backlight module includes a bezel. The frame has a supporting surface. The panel module includes a glass substrate and a plurality of chips. The glass substrate is disposed on the supporting surface. An edge of the glass substrate has a bonding region. The chips are disposed at the bonding region. The chips and the supporting surface are respectively located at two opposite sides of the glass substrate. The double-sided adhesive tapes are disposed between the supporting surface and the bonding region. Each of the double-sided adhesive tapes is aligned with a gap between two adjacent chips.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

Back light system and its manufacturing method

InactiveCN1612019AEliminate light leaksImprove light brightnessDiffusing elementsNon-linear opticsPhysicsLighting system

The invention is a backlight system, comprising a frame body, a light guide plate and at least a light source, where the frame body has a concave region with a mouth upward and at least a cavity connected with the concave region, the light source is arranged in the cavity, and the light guide plate is arranged in the concave region b the buried-in ejection forming technique, thus forming an integrated structure together with the frame body.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

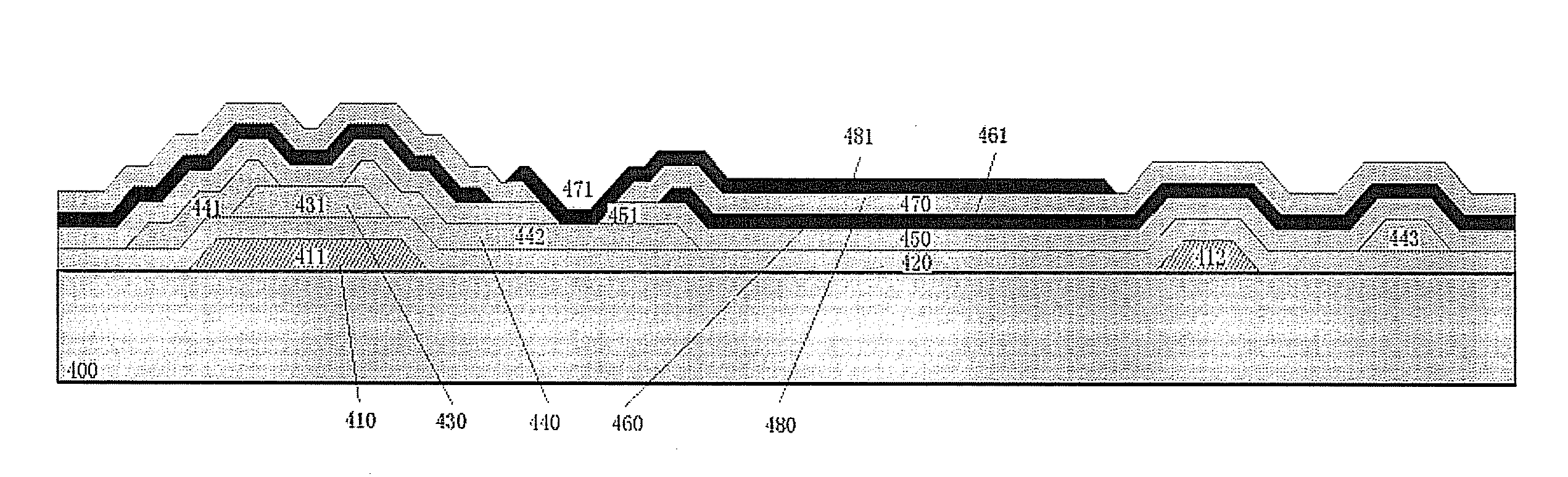

Liquid crystal display panel

InactiveUS20150192832A1Uniform sizeIncrease the aperture ratioNon-linear opticsElectricityLiquid-crystal display

The present disclosure relates to a liquid crystal display panel including an array substrate, the array substrate comprising: a substrate; a plurality of common electrode lines arranged on the substrate; a plurality of scan lines and data lines arranged on the substrate in a staggered manner to form a plurality of pixel areas; and a plurality of pixel units, each of which is arranged in a pixel area and includes a pixel electrode and a switching element, wherein the switching element is electrically connected to the scan line, the data line and the pixel electrode and is turned on under the action of a voltage signal of the scan line to transmit a voltage signal on the data line to the pixel electrode, so that the pixel electrode has a corresponding potential; and wherein in each pixel area, a shielding electrode electrically connected to the pixel electrode or the common electrode line covers the above of the scan line and the data line. The liquid crystal display panel of the present invention can reduce a phenomenon of light leakage and further have an improved aperture ratio of the pixel units.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

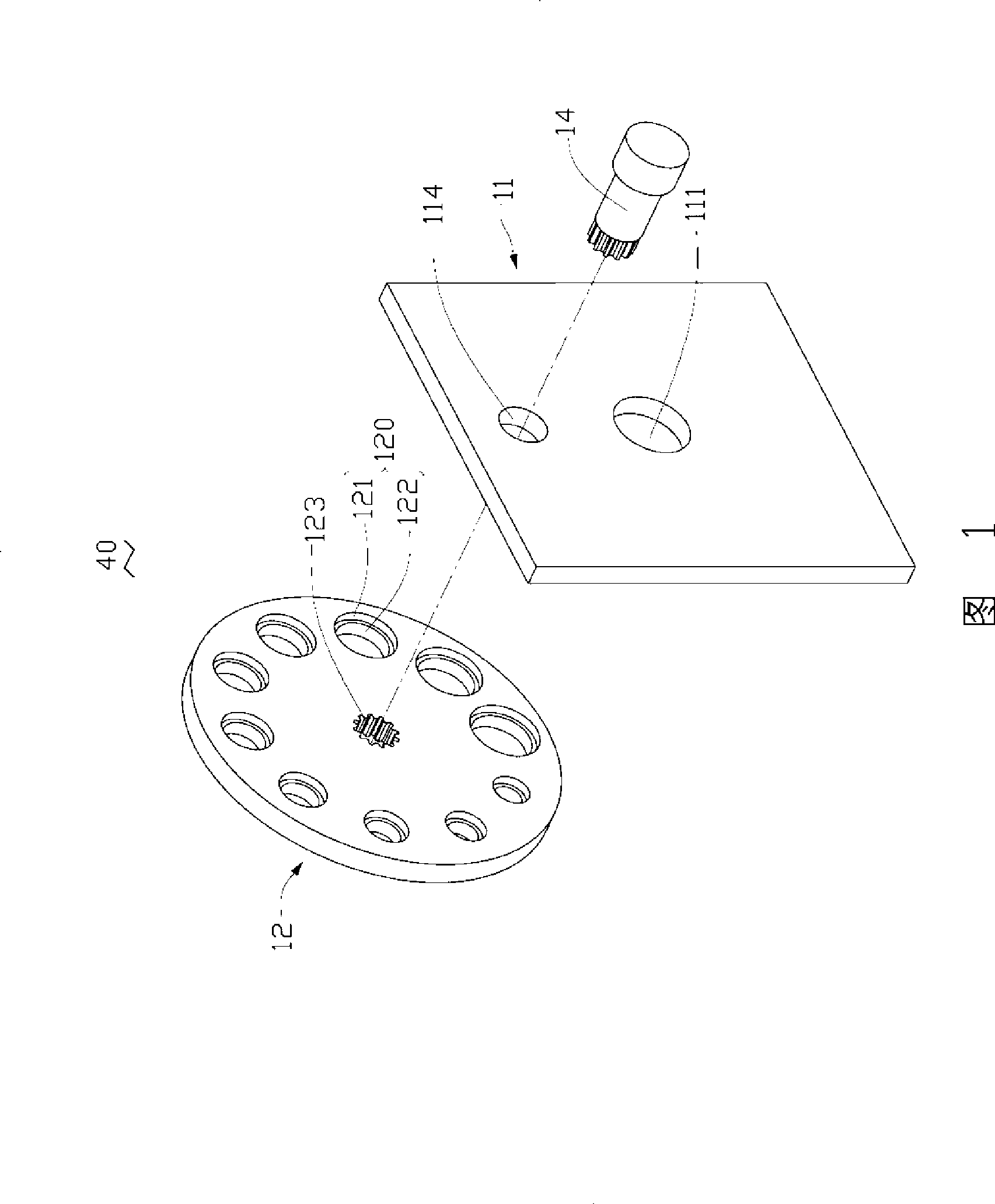

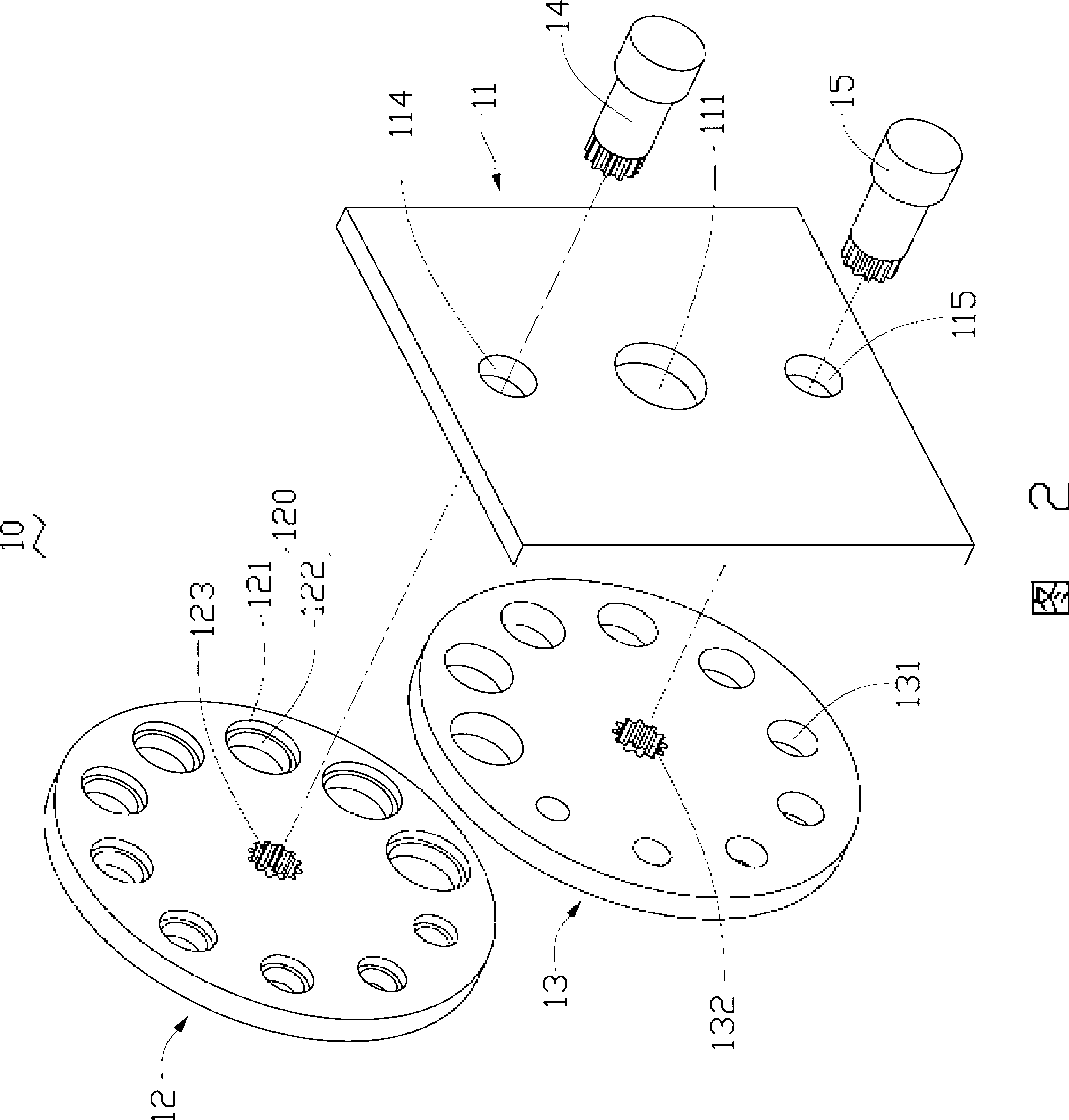

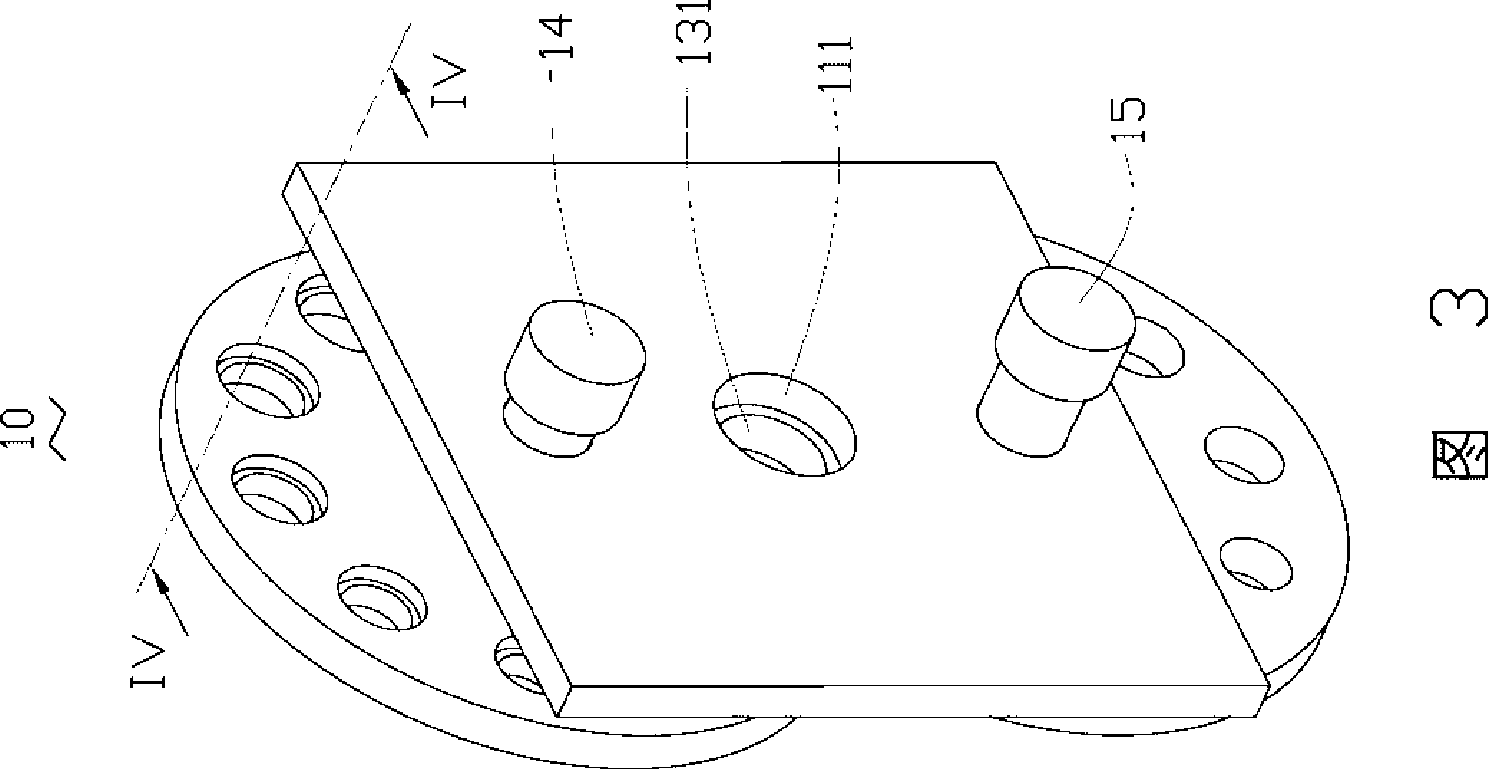

Spectrum measuring fixture

InactiveCN101387572AImprove accuracyImprove measurement accuracySpectrum investigationTesting optical propertiesEngineeringLuminous flux

The invention relates to a spectrum measuring device, comprising a fixing board of which the center is provided with a circular first loophole; an arrangement board provided with a plurality of circular containing holes of different sizes while each containing hole is provided with a containing part and a second loophole at the bottom center of the containing hole and the aperture of the second loophole is little smaller than the diameter of the containing part; and a luminous flux screen provided with a plurality of third circular loopholes of same number of the containing holes while the third loopholes are corresponding to the containing holes one-to-one and the aperture of each third loophole is little smaller than the diameter of the containing part. The fixing board is respectively connected with the arrangement board and the luminous flux screen. The arrangement board and the luminous flux screen can be rotated to align the centers of the first loopholes, the third loopholes and the third loopholes corresponding to the second loopholes.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Liquid crystal display panel and fabricating method thereof

InactiveUS20080055532A1Maintain contrastMaintain contrast and brilliance uniformityNon-linear opticsLiquid-crystal displayLiquid crystal

A liquid crystal display panel includes a first substrate; a plurality of scan lines and a plurality of data lines disposed on the first substrate; an insulation layer disposed between the scan line and the data line; a plurality of thin film transistors (TFT), each TFT including a gate, a channel layer, a source, and a drain; a plurality of pixel electrodes; a plurality of retaining wall patterns disposed on the insulation layer and the material thereof is selected from at least one of the source / drain and channel layer; a second substrate disposed opposite to the first substrate; a liquid crystal layer between the first and second substrate; and a plurality of pillar spacers between the first and second substrate, wherein one end of the pillar spacer is disposed inside the retaining wall pattern.

Owner:CHUNGHWA PICTURE TUBES LTD

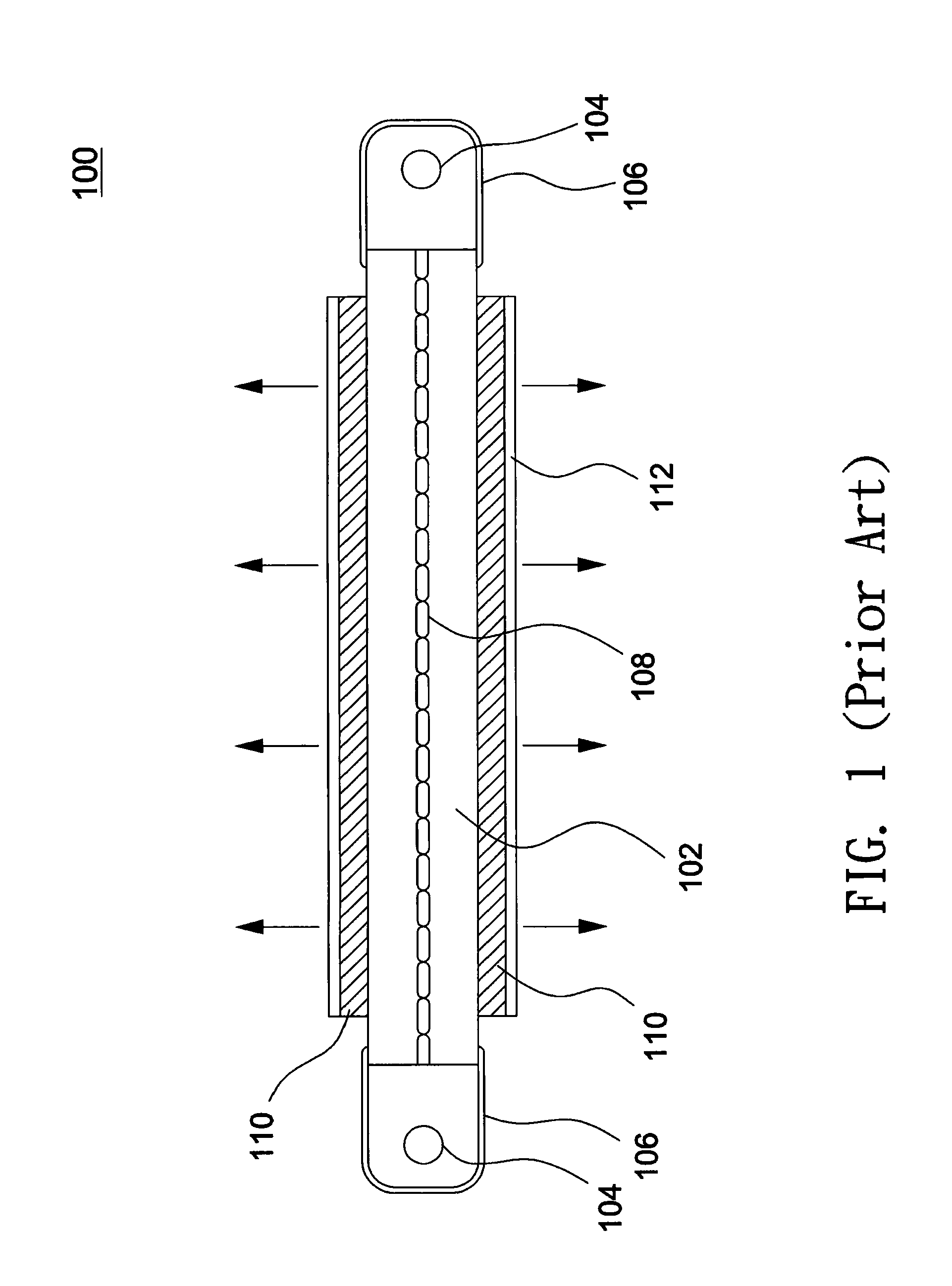

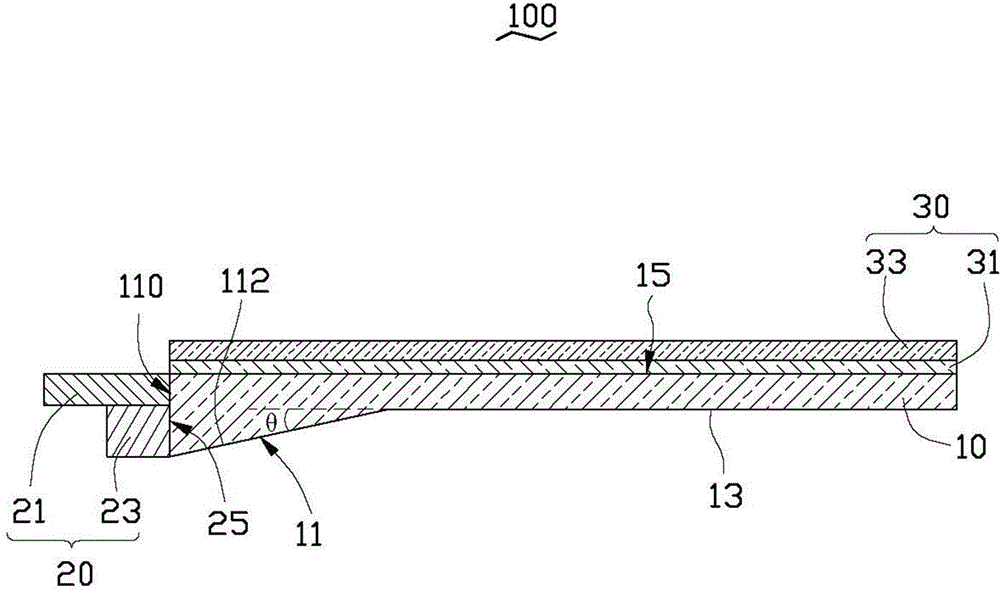

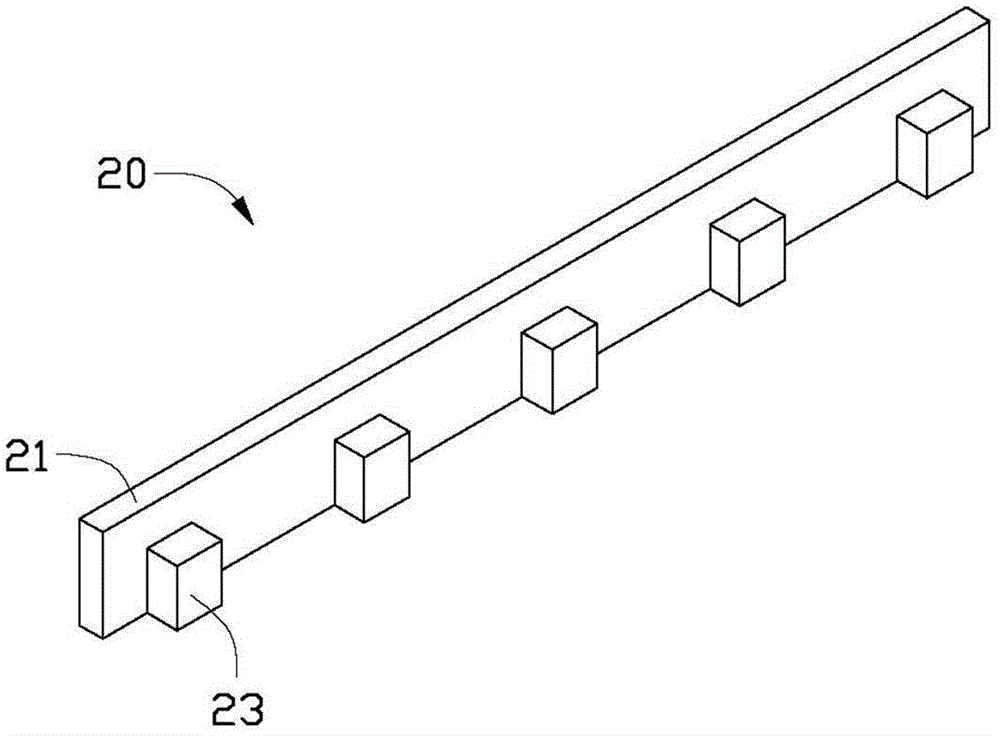

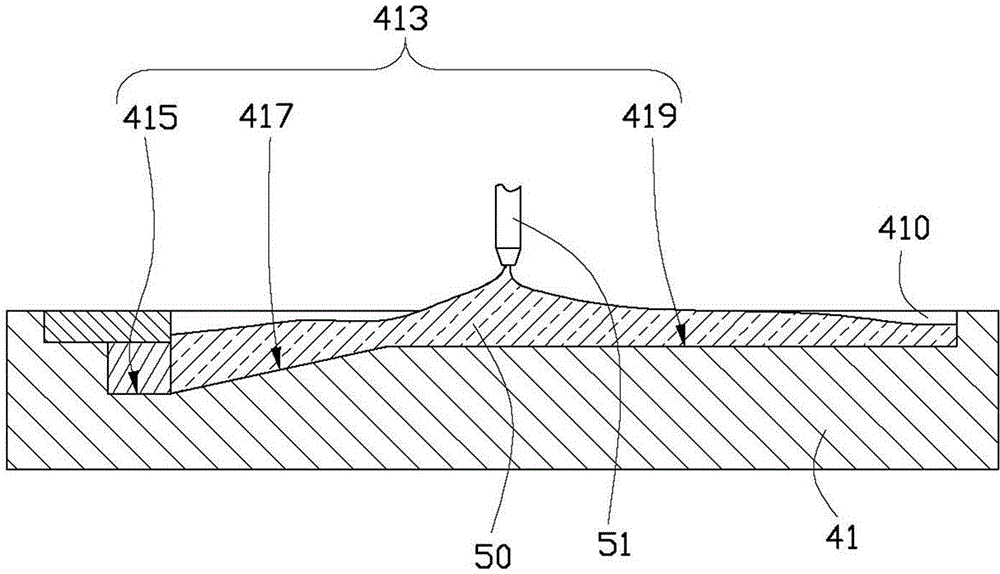

Backlight module and manufacturing method for same

InactiveCN104061489AEliminate light leaksIncrease brightnessMechanical apparatusPoint-like light sourceOptoelectronicsLight guide

The invention discloses a backlight module, which comprises a light guide film and a light bar, wherein the light guide film comprises a wedged part and a flat plate part adjacent to the wedged part; the wedged part and the flat plate part have a common plane; the wedged part is provided with a light incident surface which is perpendicular to the plane; the thickness of the wedged part is gradually decreased to that of the flat plate part from the light incident surface to the interior of the light guide film; the light bar comprises a light emergent surface which is closely attached to the light incident surface. The invention also relates to a manufacturing method for the backlight module.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

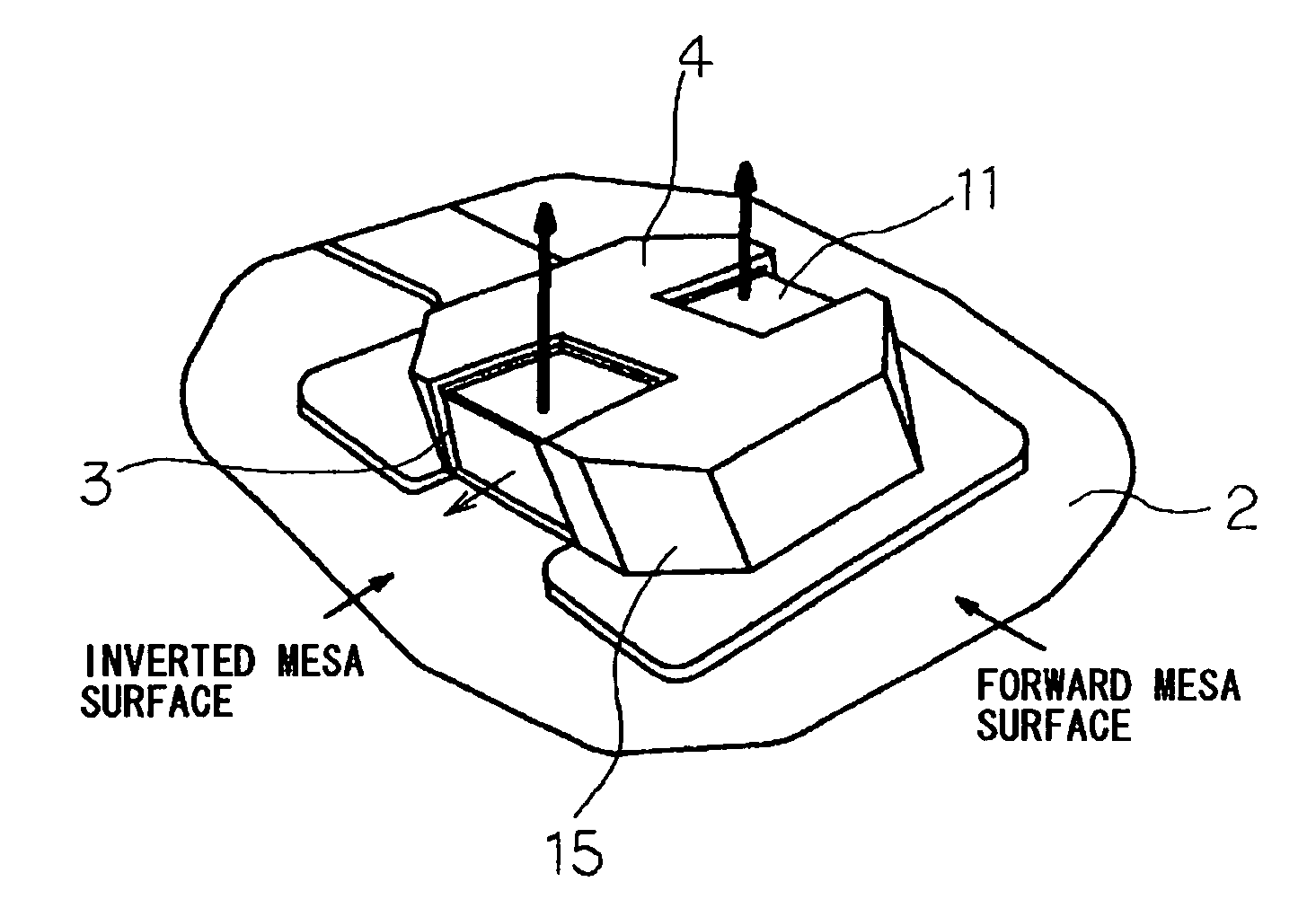

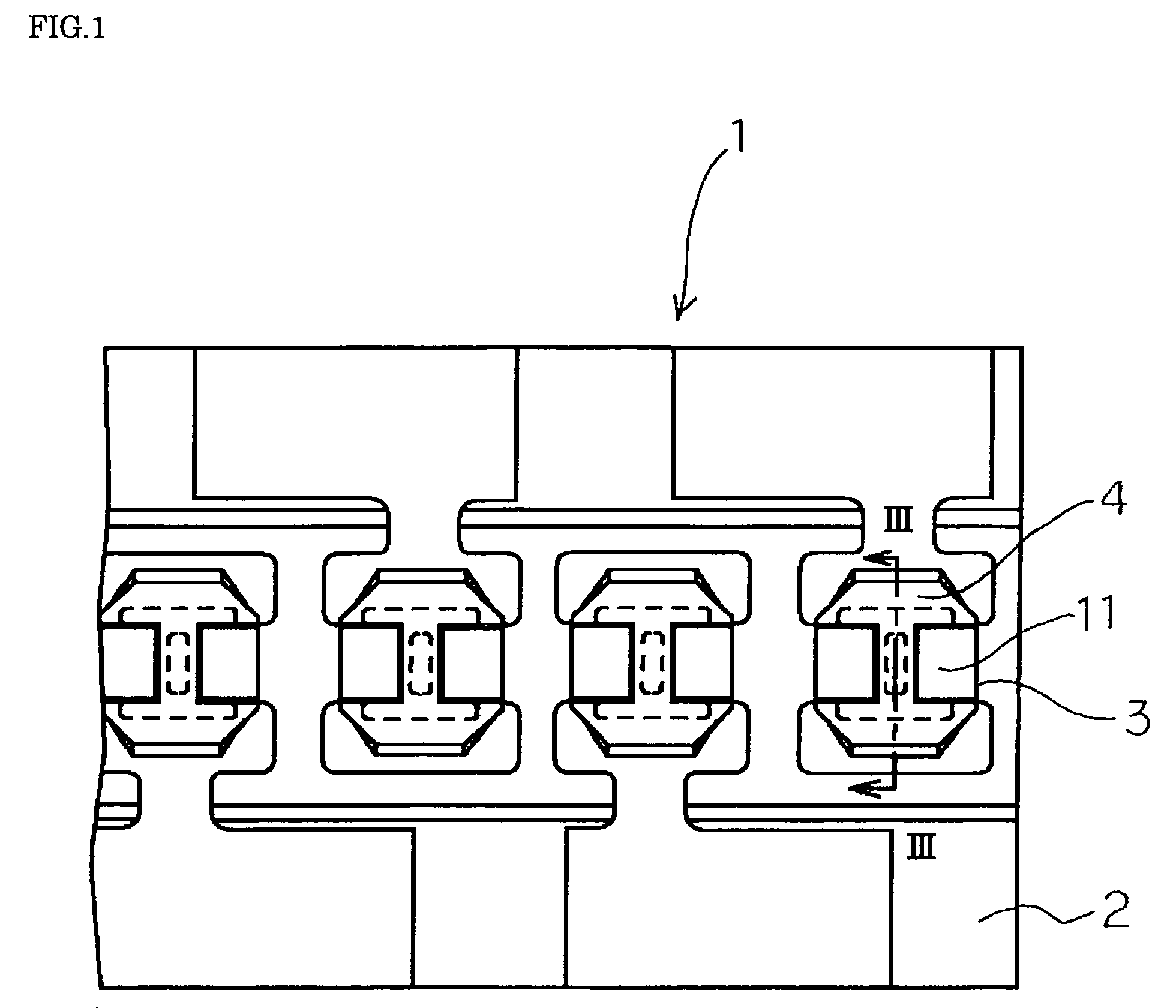

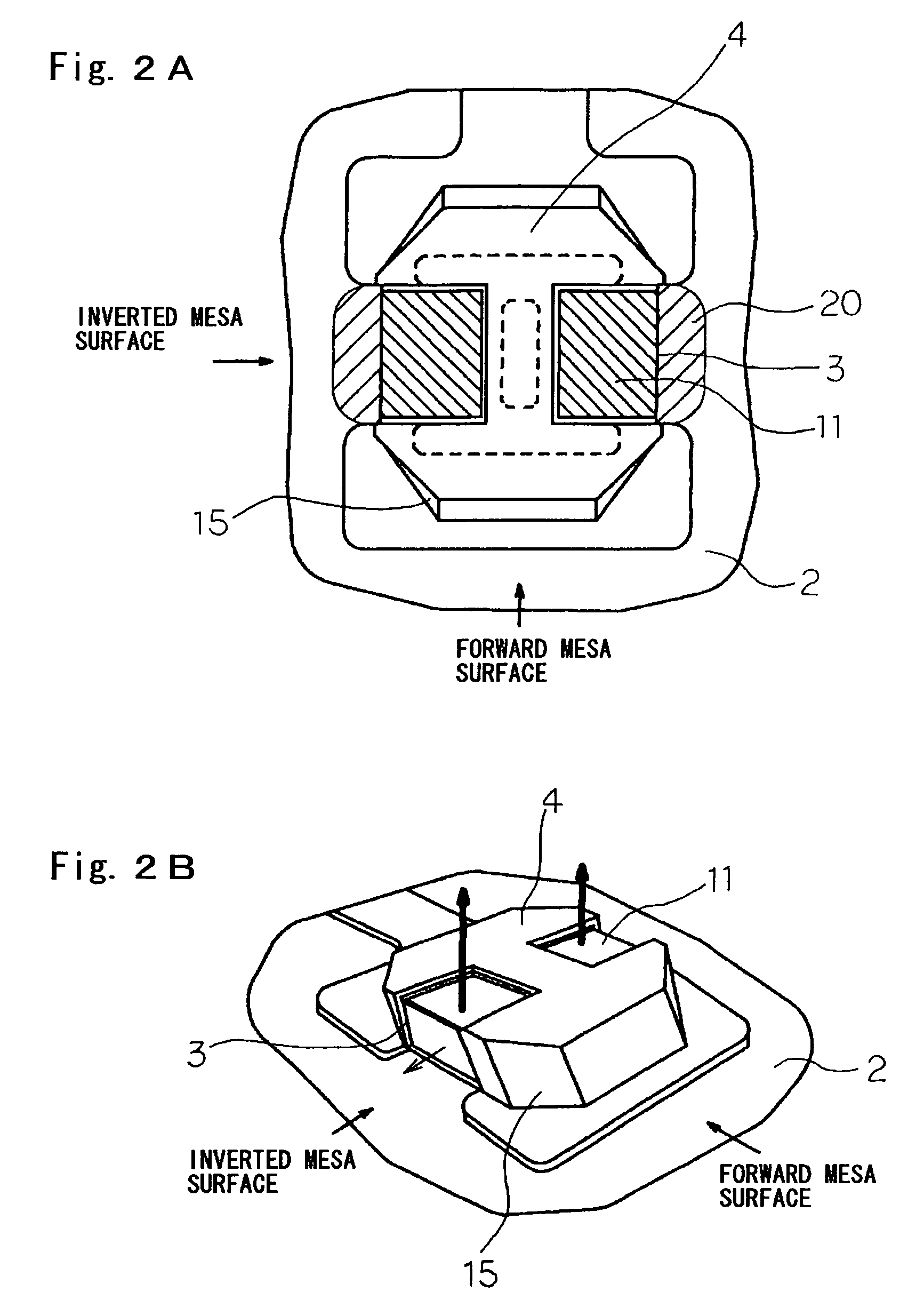

Light-emitting diode array, light-emitting diode, and printer head

InactiveUS7915623B2Eliminate light leaksPrevent leakageSolid-state devicesPrintingEngineeringLight-emitting diode

A light emitting diode array in which, when viewed from the above, the shape of an almost square light emitting diode is square-chamfered or round-chamfered at the corners thereof in order to minimize light leakage at a reverse mesa surface to allow an electrode layer to surround the three directions of a light emitting unit, and part in the vicinity of the corner of the reverse mesa surface is extended up to a substrate unit to cover it. Accordingly, the light emitting diode array minimized in light leakage at the reverse mesa surface can be provided.

Owner:SANYO ELECTRIC CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com