OLED display device and manufacturing method thereof

A manufacturing method and display technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as light leakage and affecting display effects, and achieve the effects of eliminating light leakage, improving display effects, and improving display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

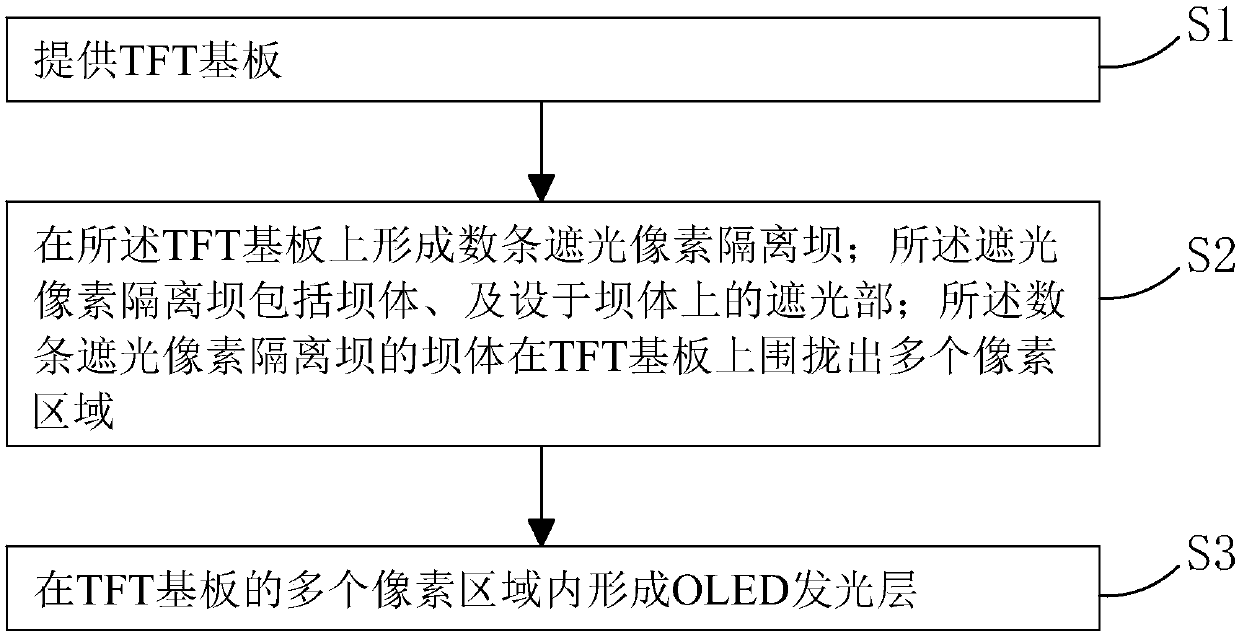

[0037] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

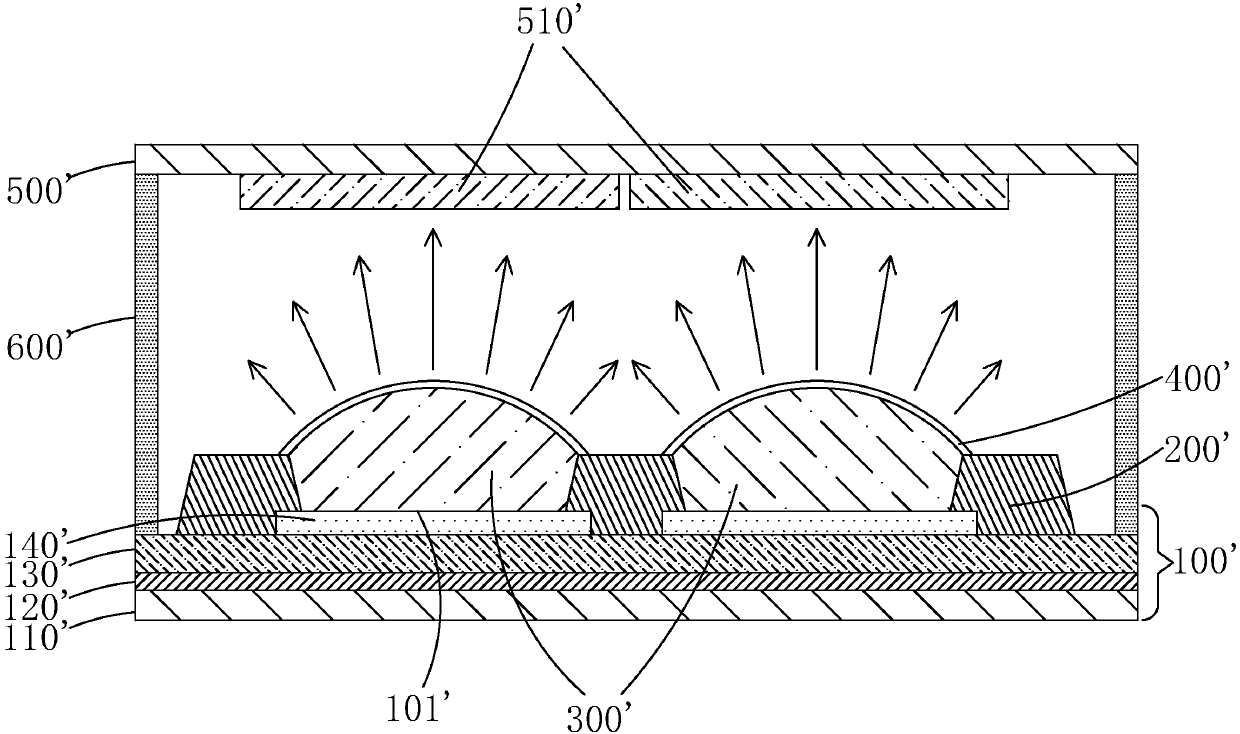

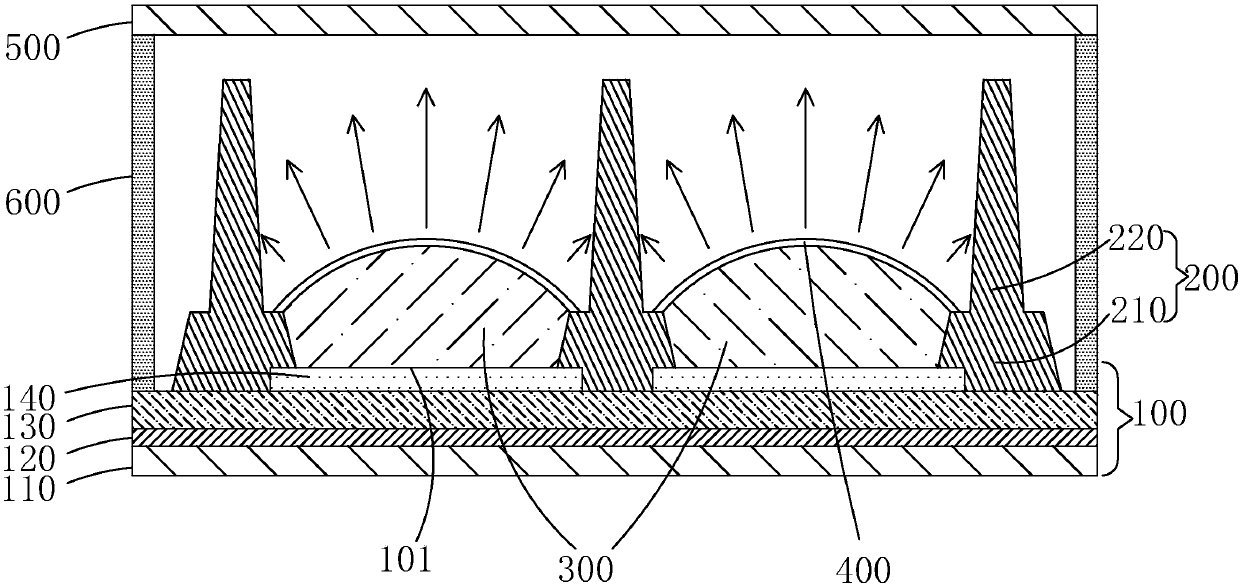

[0038] see figure 2 , the present invention provides an OLED display, comprising: a TFT substrate 100, several light-shielding pixel isolation dams 200 arranged on the TFT substrate 100, a plurality of OLED light-emitting layers 300 arranged on the TFT substrate 100, respectively arranged on multiple A plurality of cathodes 400 on each OLED light-emitting layer 300, an encapsulation cover 500 located above the light-shielding pixel isolation dam 200 and the cathode 400, and an encapsulation cover 500 and the TFT substrate 100 between the encapsulation cover 500 and the TFT substrate 100 Connected frame glue 600;

[0039] It should be noted that the light-shielding pixel isolation dam 200 includes a dam body 210 and a light-shielding portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com