Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Change the placement angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

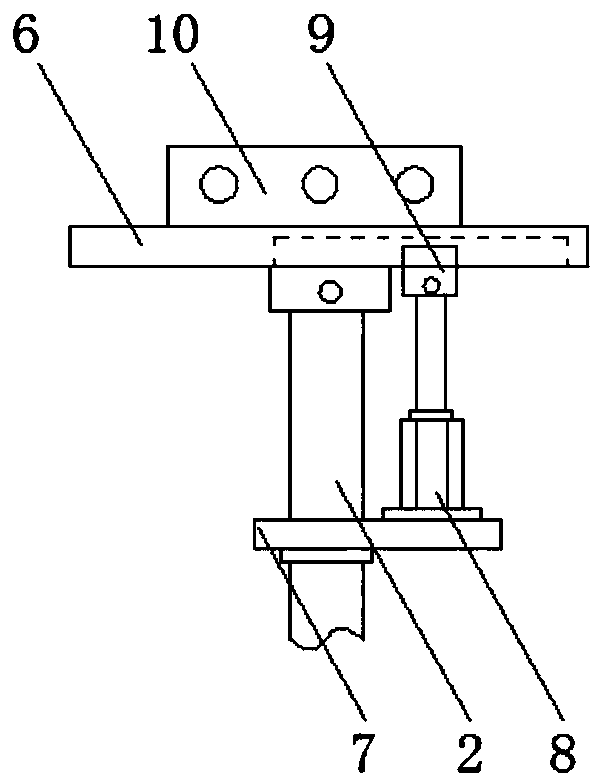

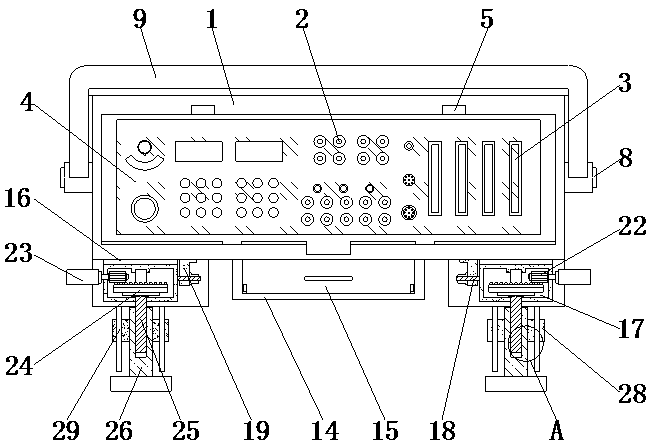

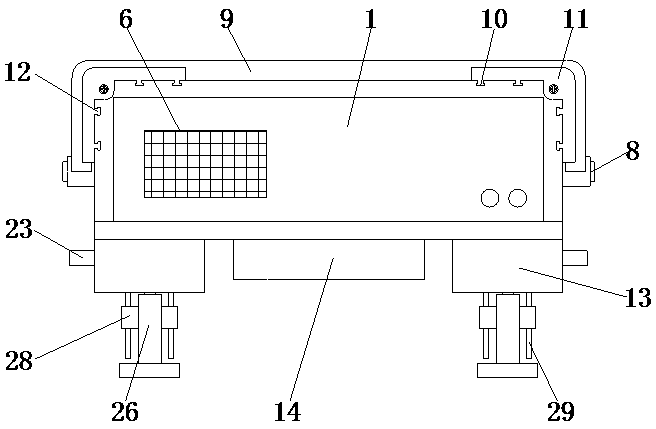

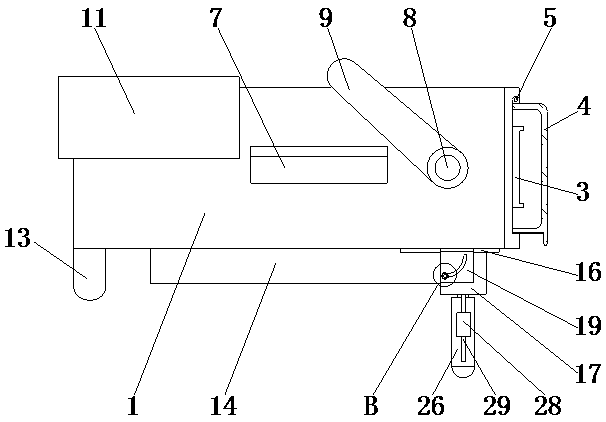

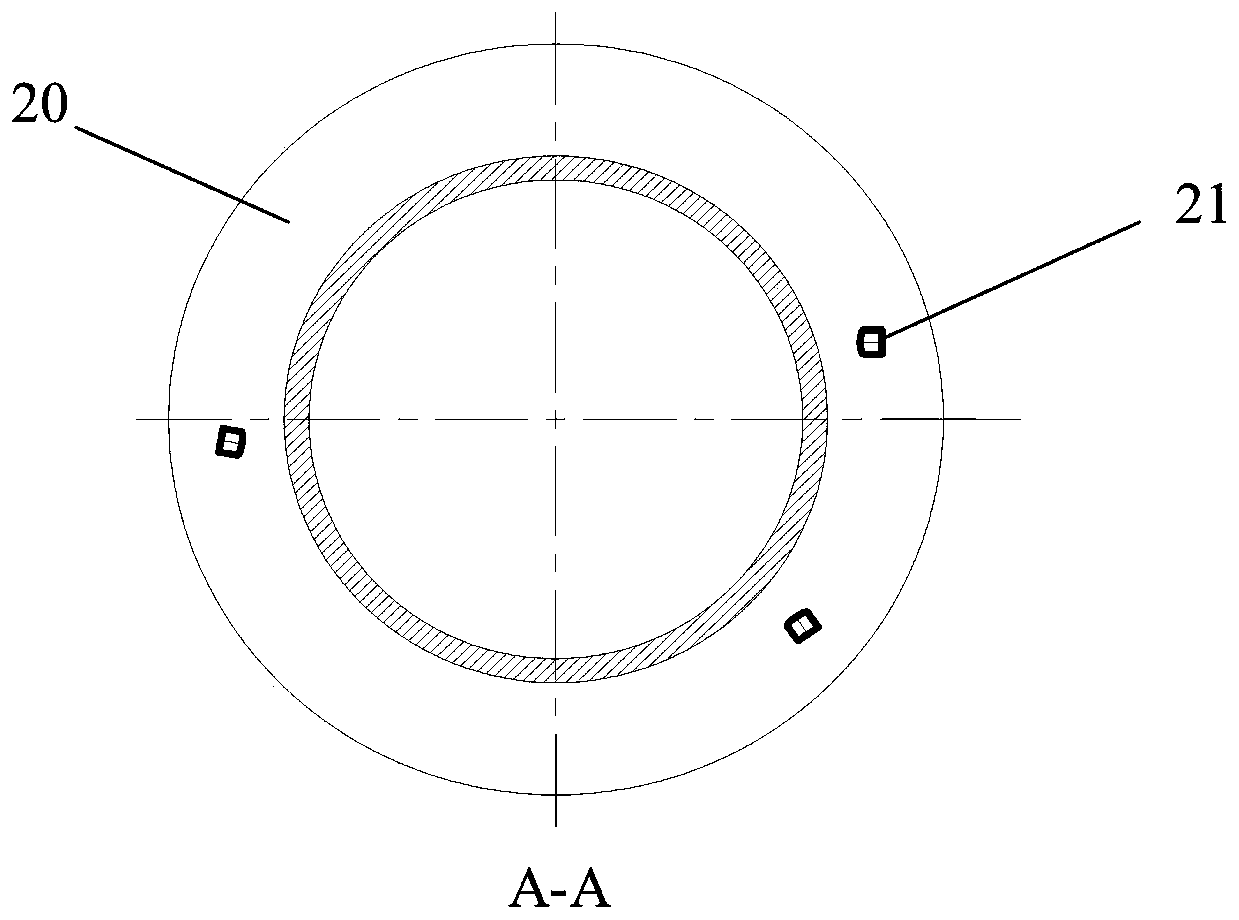

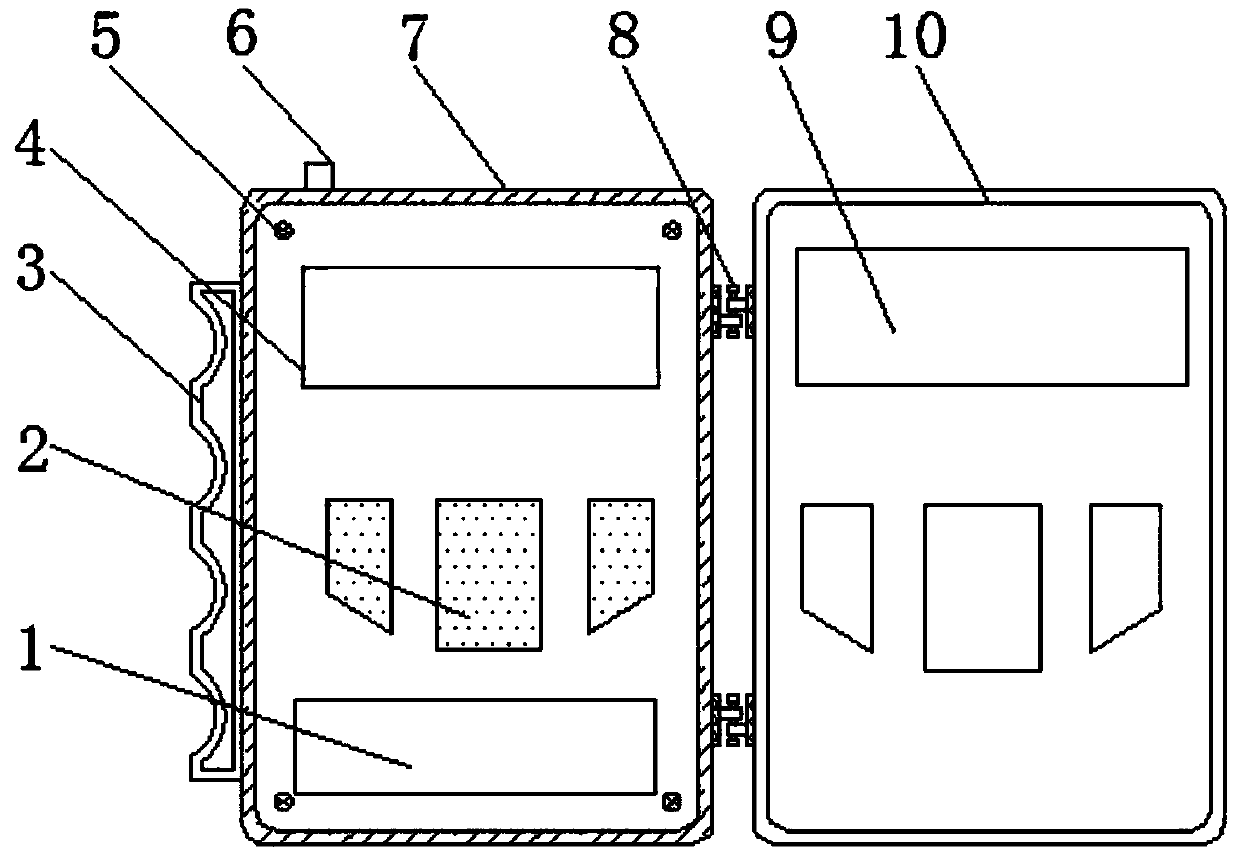

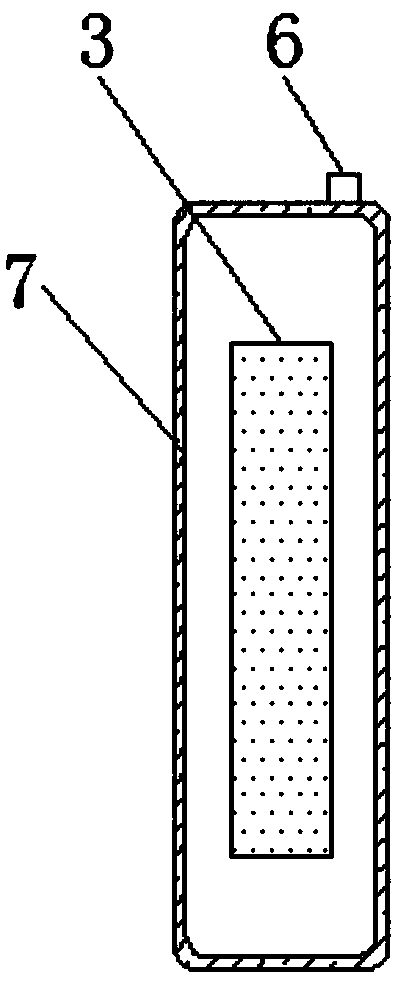

Fabric light transmission detection system and detection method thereof

ActiveCN110095439AChange angleDetect light transmittanceTransmissivity measurementsVertical planeEngineering

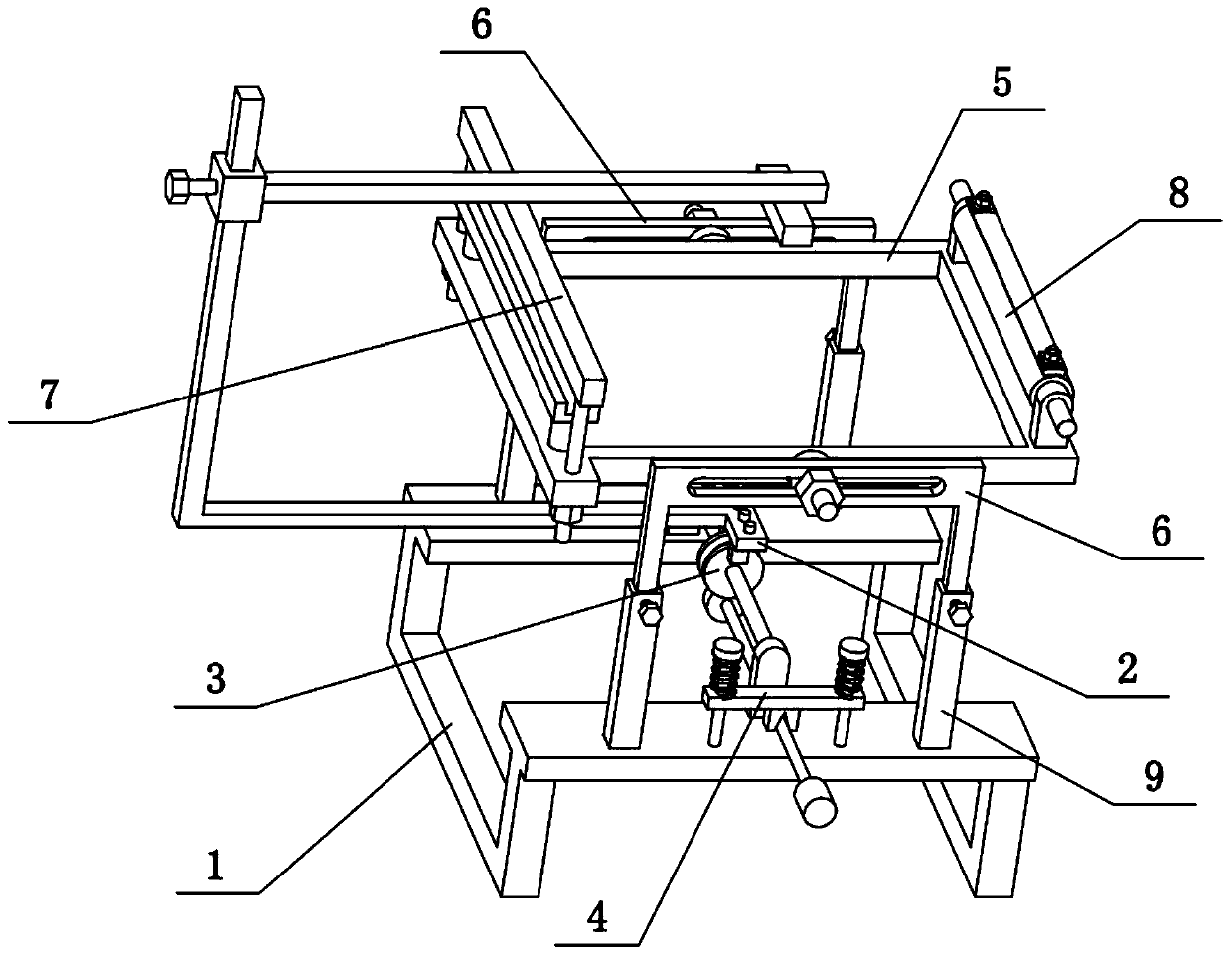

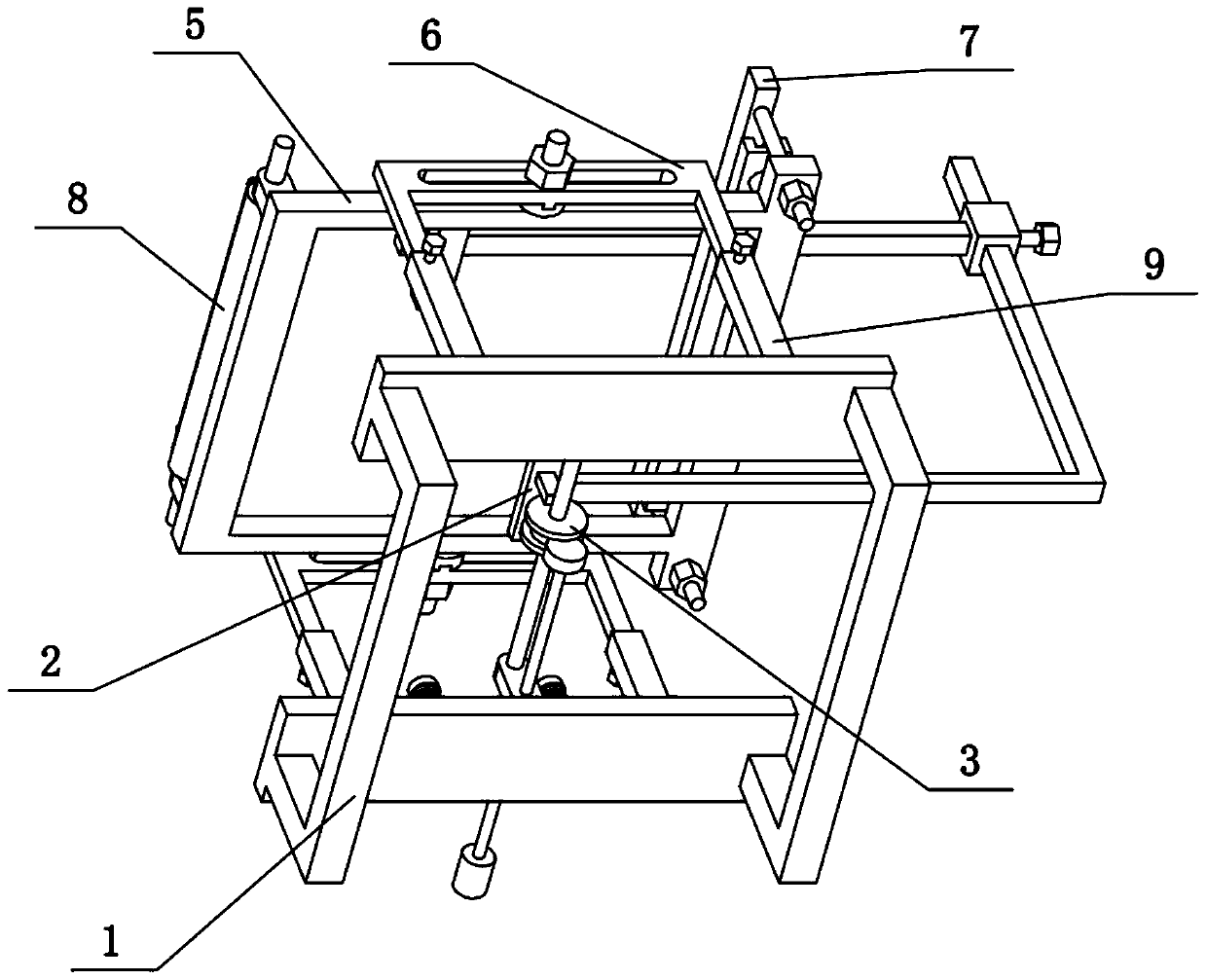

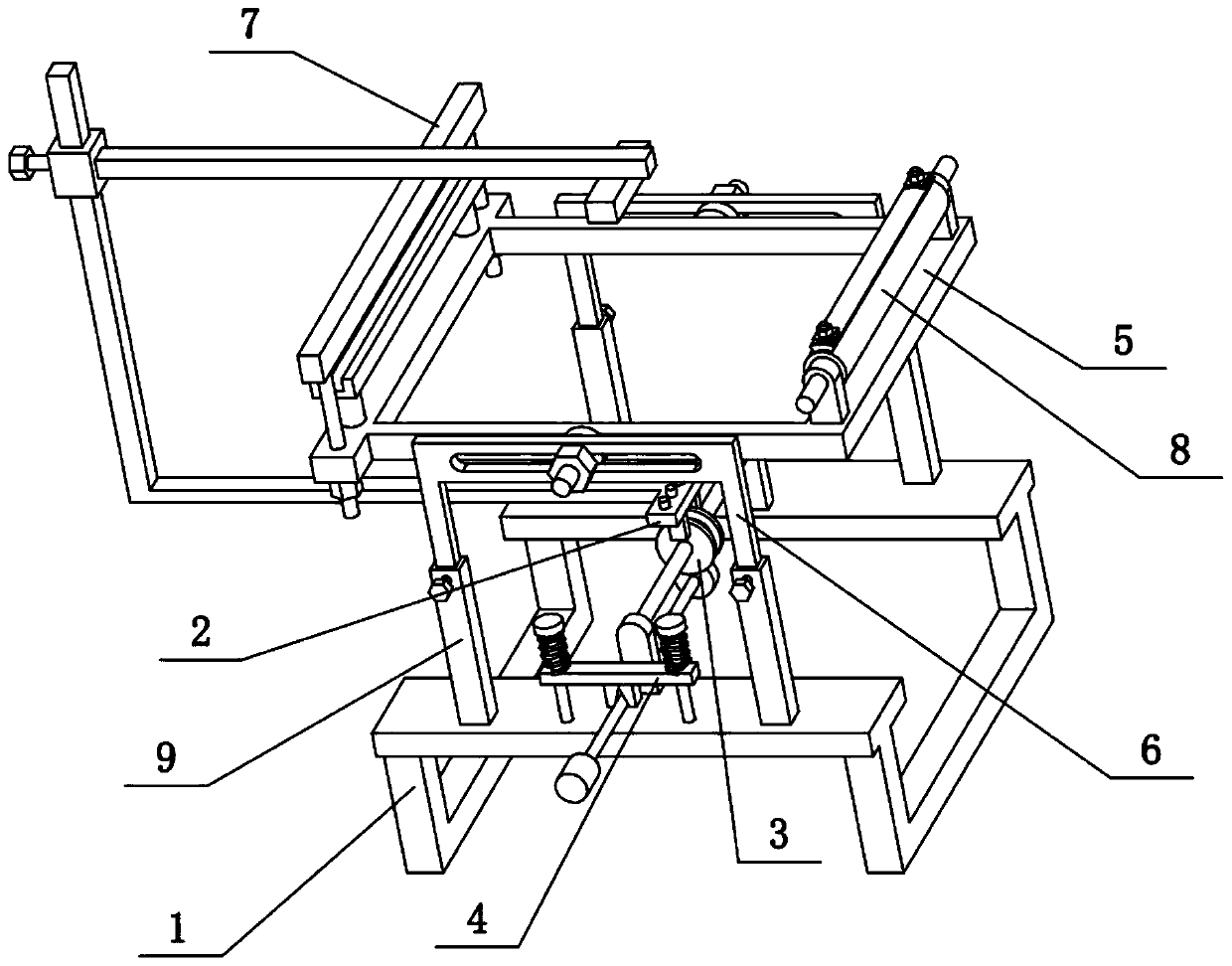

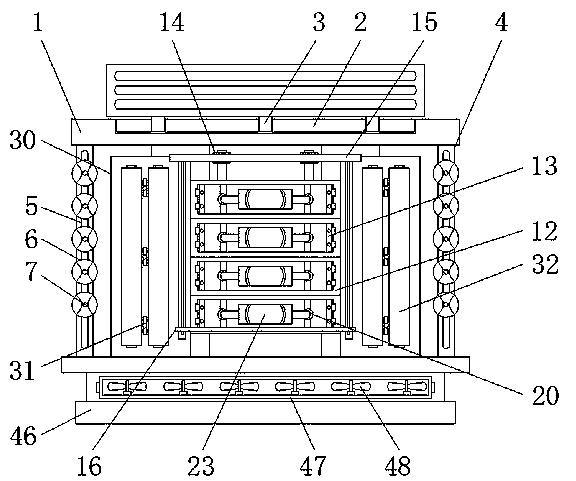

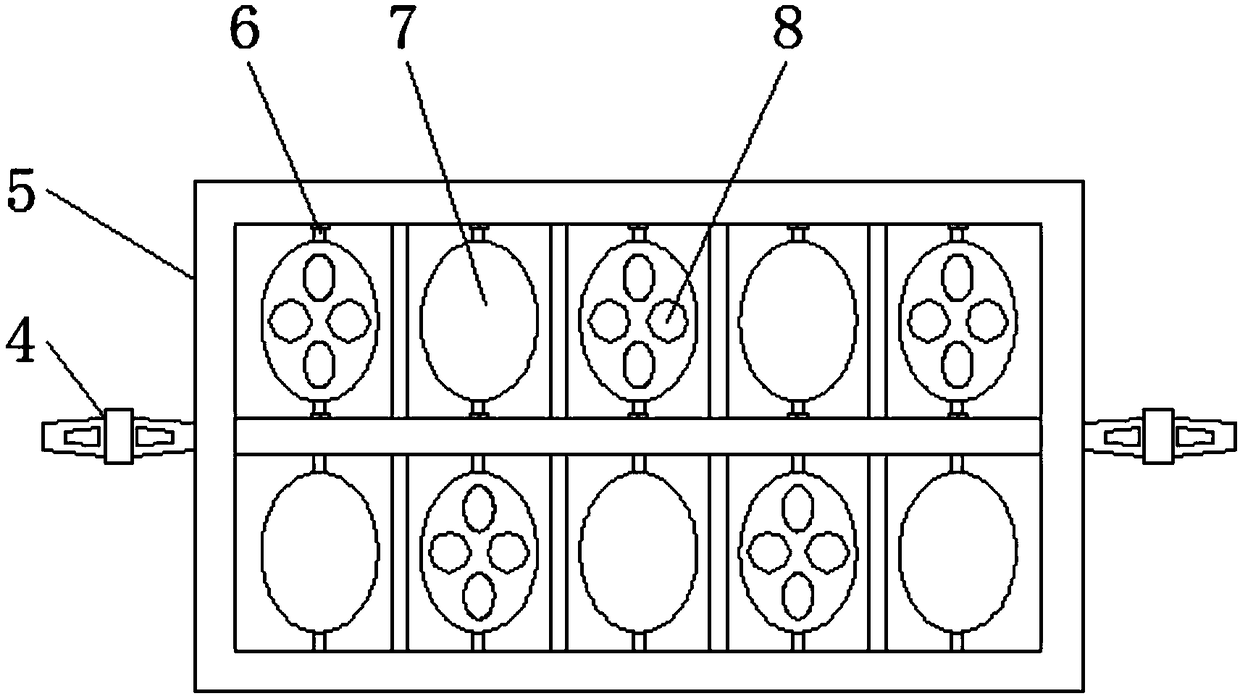

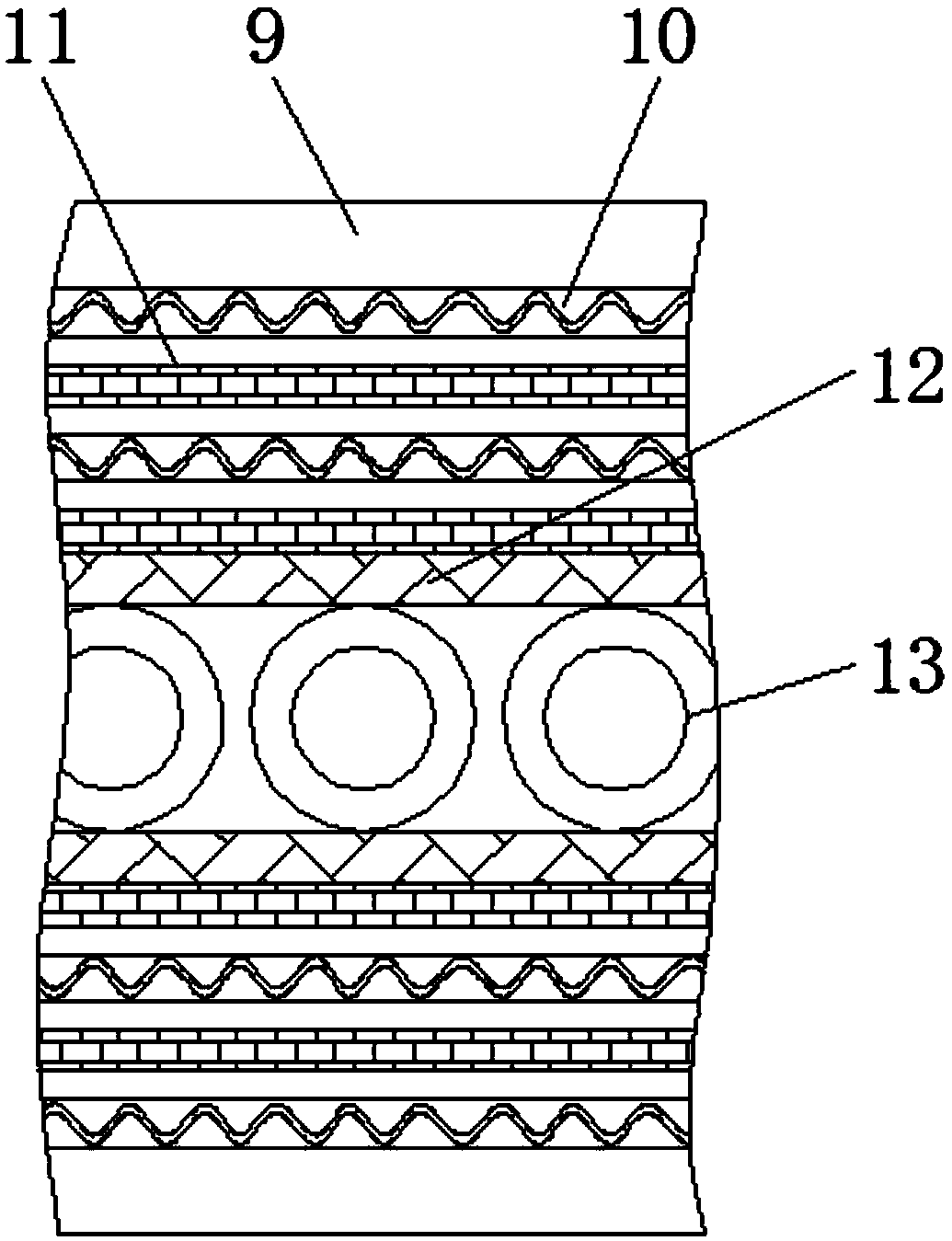

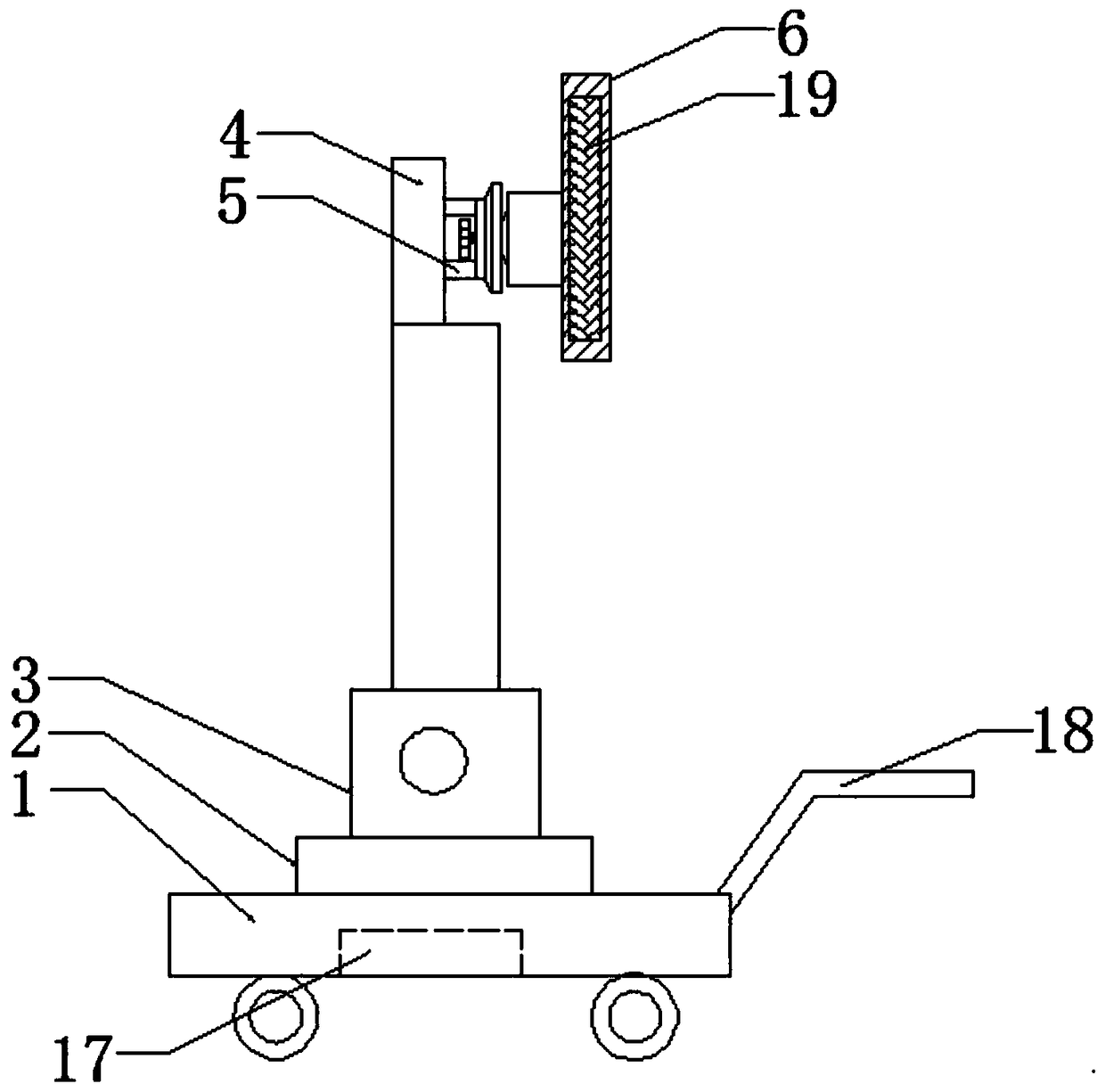

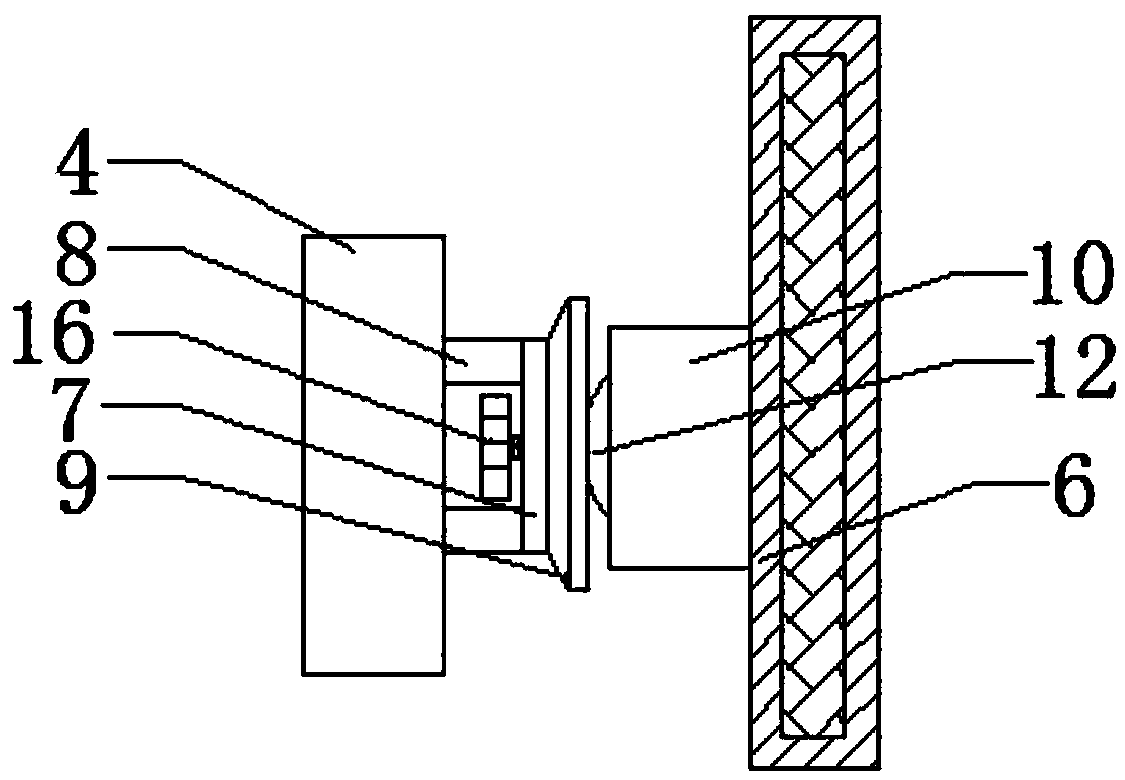

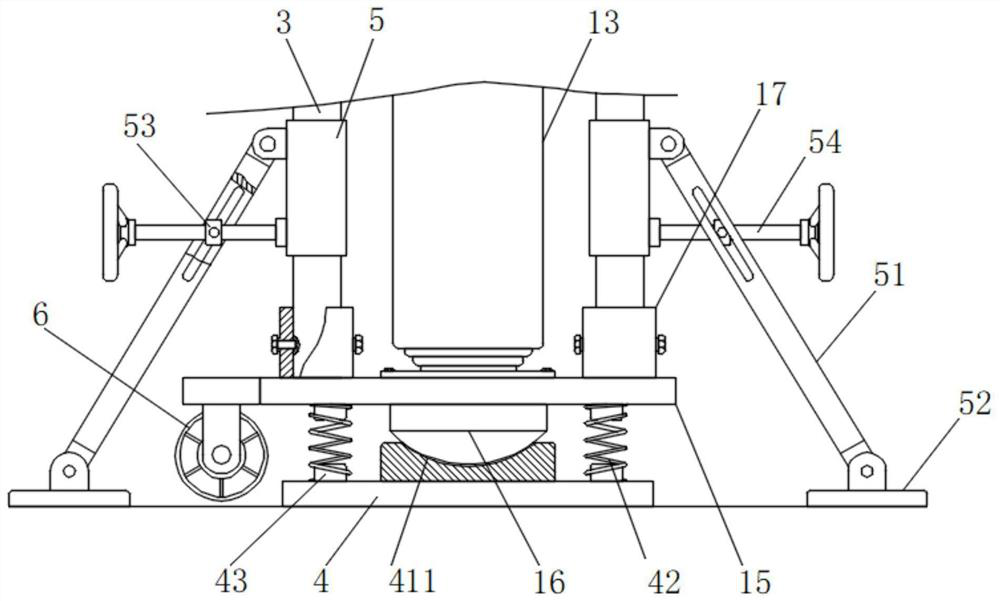

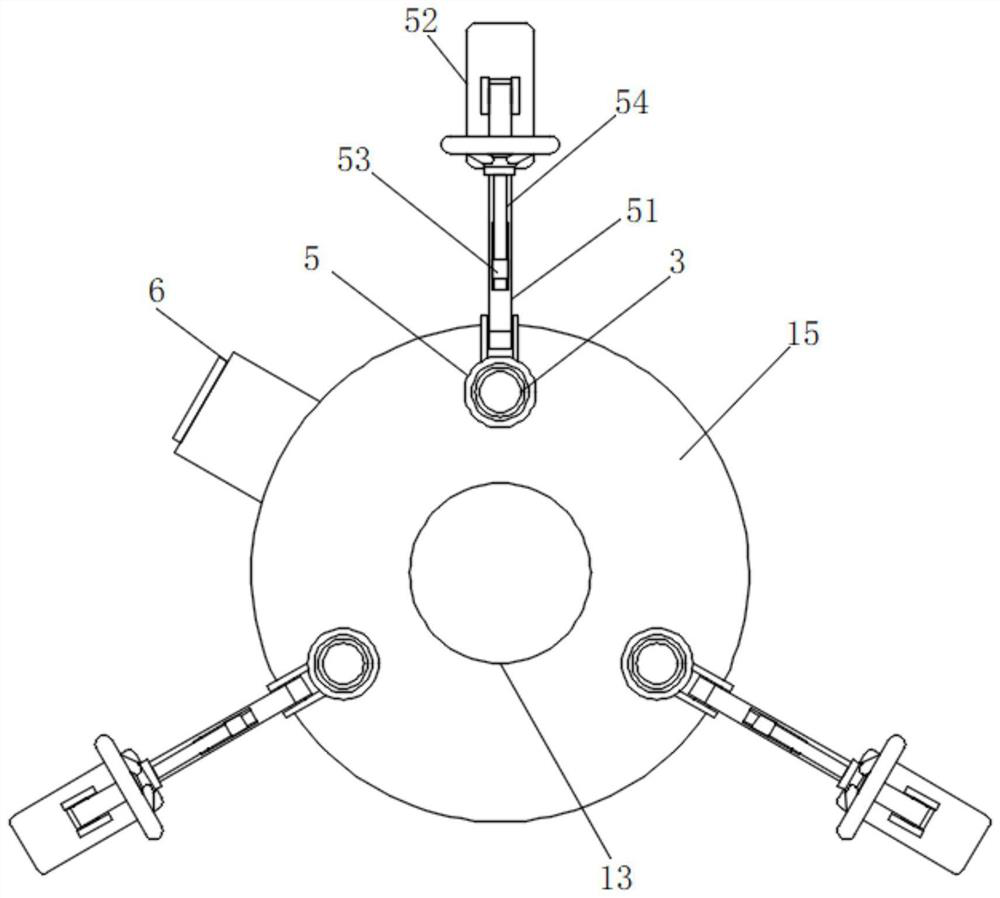

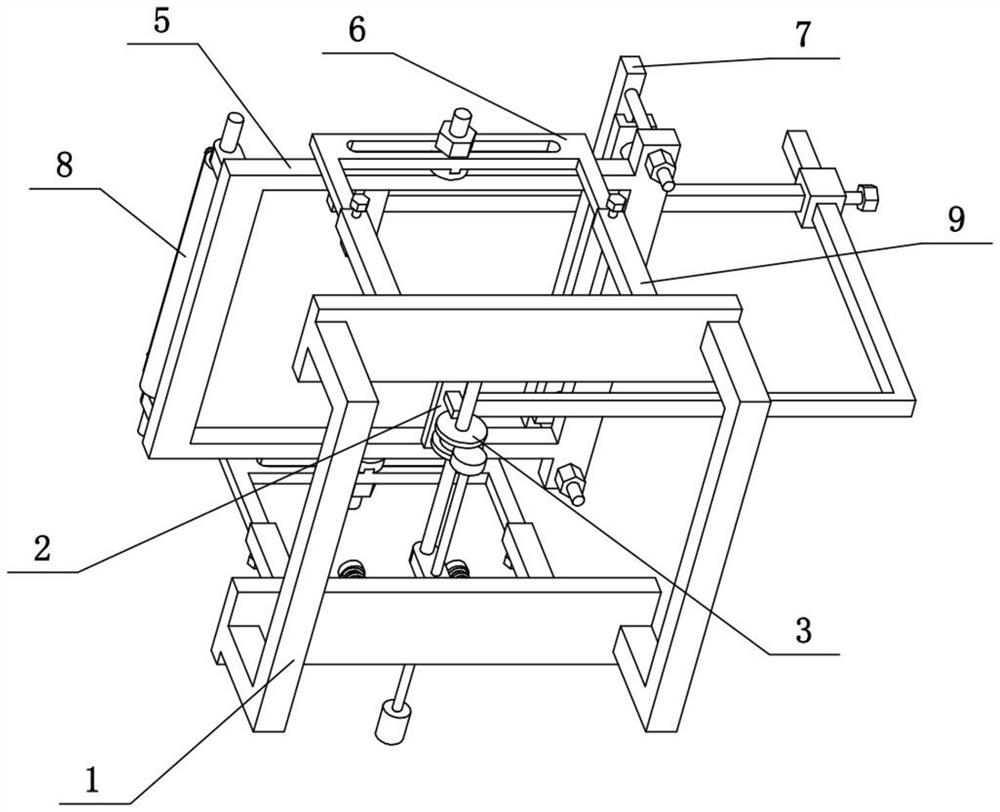

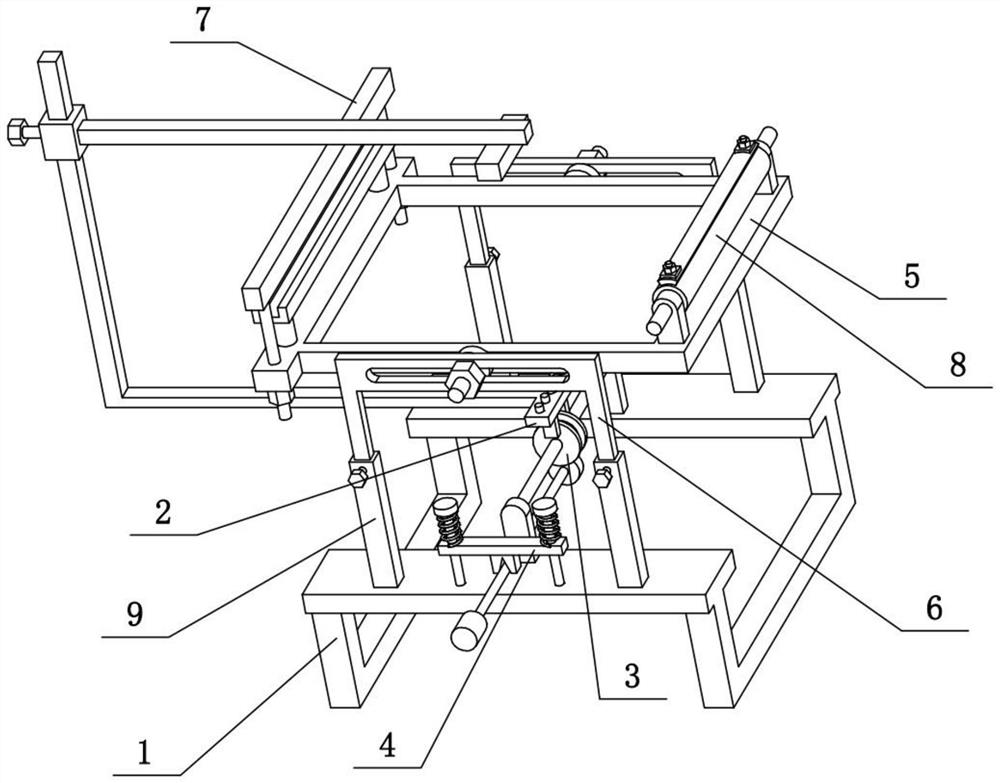

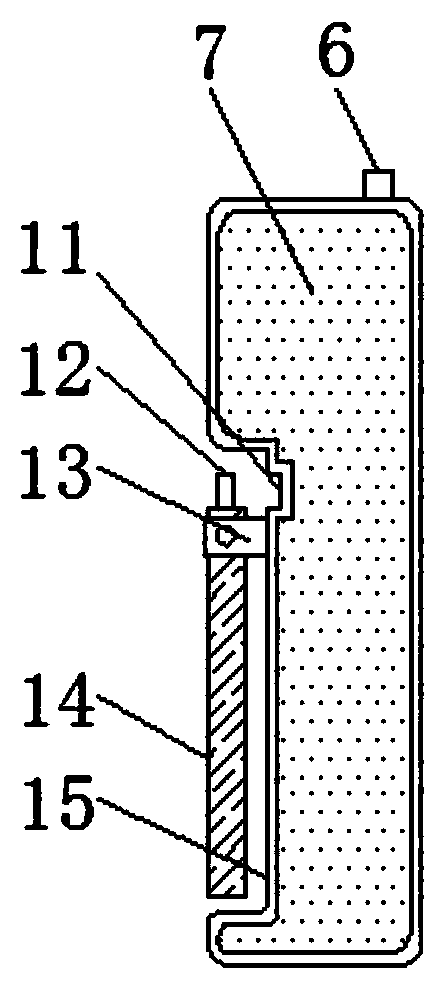

The invention relates to the field of fabric light transmission detection, more particularly to a fabric light transmission detection system and a detection method thereof. The detection system comprises a base, a light emitter, a light receiver, a regulator, a fixed frame and fixed frame brackets. The detection system is capable of carrying out light transmission detection on the fabric under various conditions. The light emitter disposed above the base can move back and forth and can rotate on a vertical plane, wherein the position of the light emitter is adjusted by the regulator. The lightreceiver corresponds to the light emitter; and the light receiver is always disposed in the direction of the light emitted by the light emitter. The frontend and the rear end of the base are fixedlyconnected with the fixed frame brackets; and the fabric fixed frame is arranged between the two fixed frame brackets. The light receiver and the light emitter are respectively arranged at the upper side and the lower side of the fabric fixed frame.

Owner:东莞市听雨轩服装有限公司

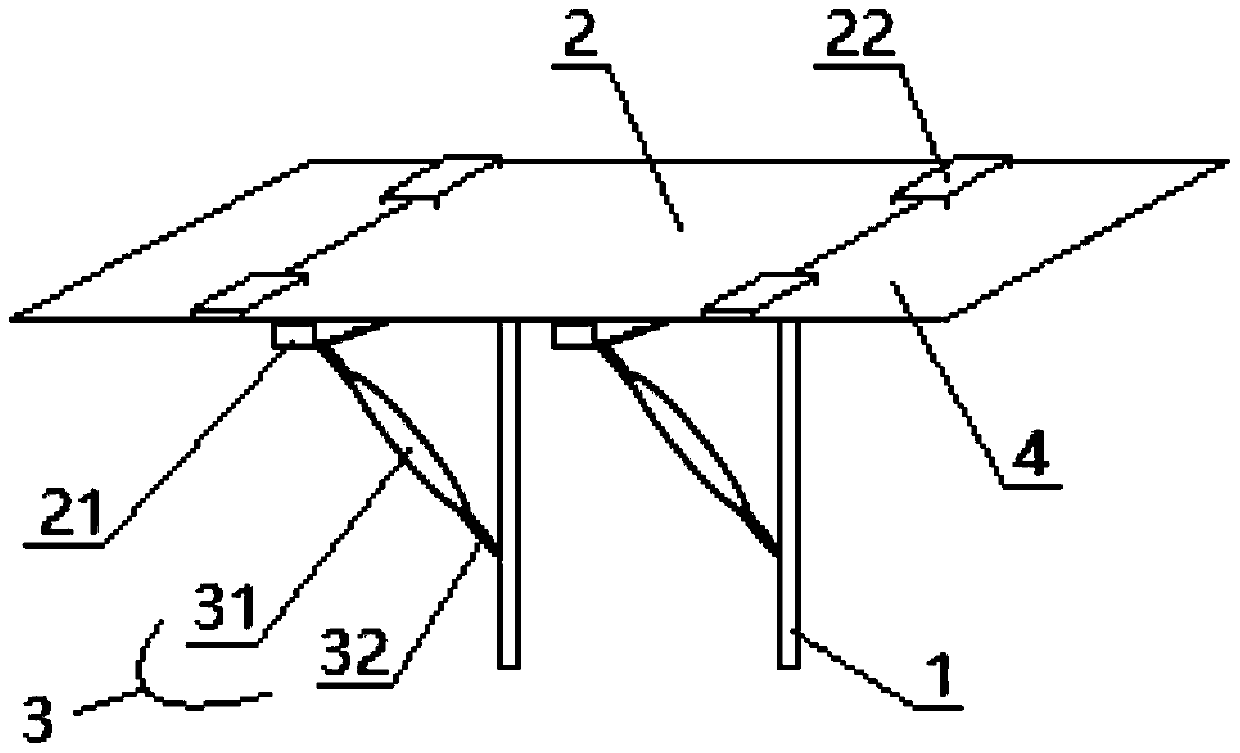

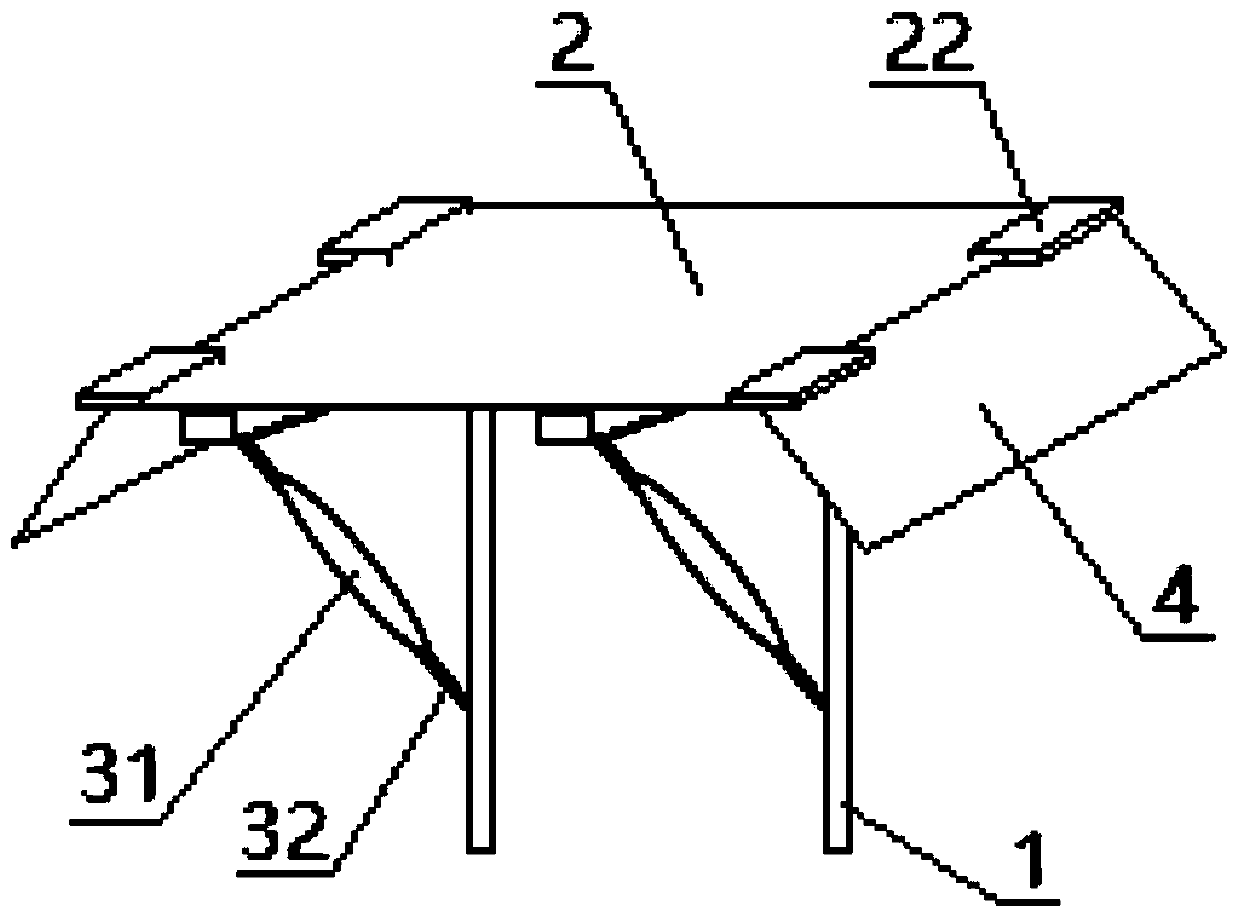

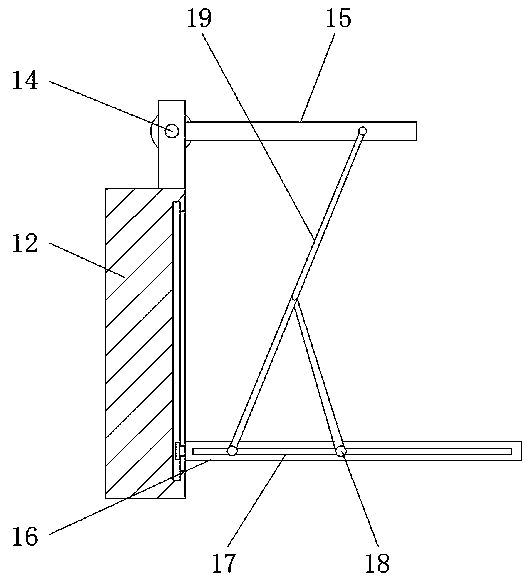

Solar canopy with adjustable angles

InactiveCN110685410AChange the placement angleFunction maximizationPhotovoltaic supportsRoof covering using slabs/sheetsEngineeringAtmospheric sciences

The invention discloses a solar canopy with adjustable angles. The solar canopy comprises supports, wherein canopy plates are arranged on the supports, and the canopy plates are hinged to the supports; telescopic rods are connected to the canopy plates, and the telescopic rods are used for adjusting the placement angles of the canopy plates; and the upper surfaces of the canopy plates are coveredwith solar panels. The canopy plates are hinged to the supports so that the canopy plates can freely rotate on the supports, and the placement angles of the canopy plates are determined by the telescopic rods; and the lengths of the telescopic rods can be changed so that the placement angles of the canopy plates can be driven to be changed according to the shine and rain conditions of the weather,and the canopy can maximize the function of the canopy under different uses.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

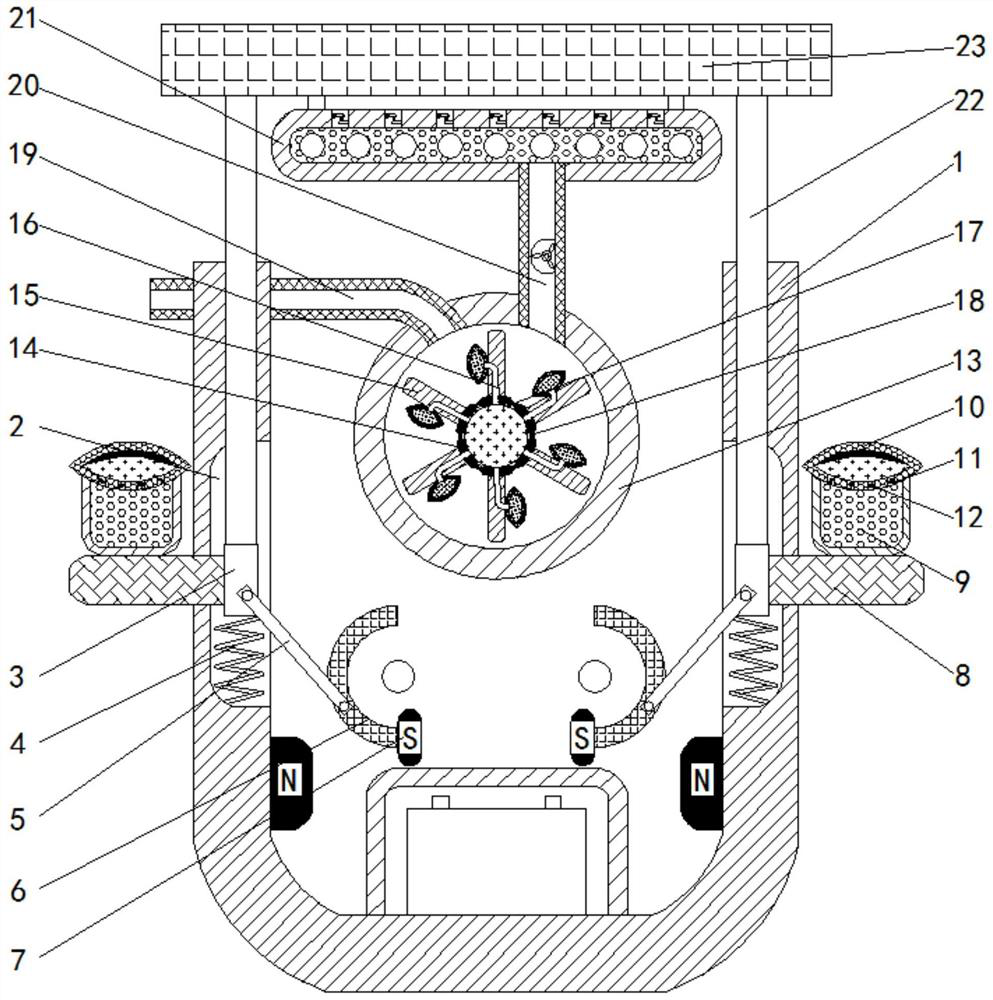

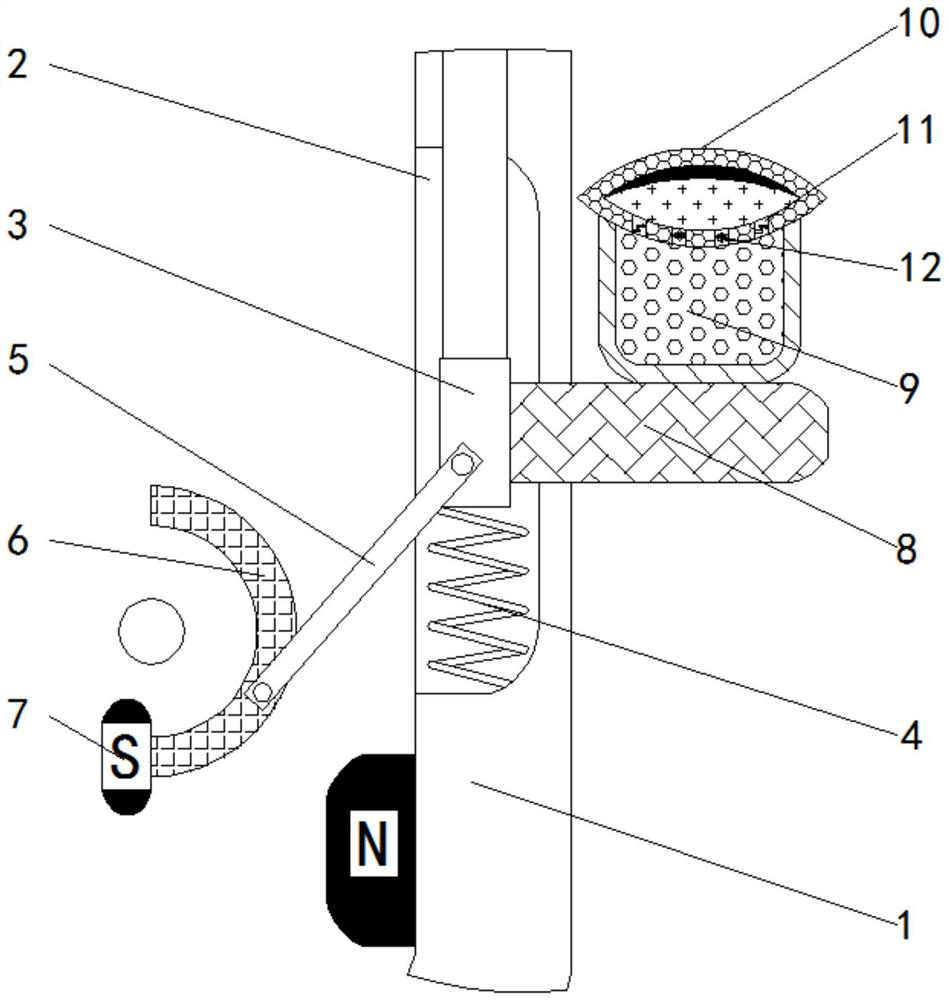

Device capable of changing placement angle of solar cell panel andperforming cleaning and cooling

InactiveCN112217451AChange the placement angleChange anglePhotovoltaic supportsSolar heating energySolar batteryMechanical engineering

The invention relates to the technical field of photovoltaic power generation, and discloses a device capable of changing the placement angle of a solar cell panel and performing cleaning and cooling.The device comprises a cooling and cleaning device main body, a sliding groove is formed in the inner wall of the cooling and cleaning device main body, a sliding block is slidably connected to the interior of the sliding groove, and a spring is fixedly mounted at the bottom of the sliding groove. And a movable rod is movably connected to the right side of the sliding block, a rotating wheel is movably installed at the bottom of the movable rod, and a monopole magnet is fixedly installed on the right side of the rotating wheel. A solution in the reservoir is evaporated through irradiation oflight and enters the air bag, the weight of the reservoir is reduced, the rotating force of the rotating wheel is limited to be reduced, the single-pole magnet on the rotating wheel can be attracted by the other single-pole magnet, the rotating wheel rotates to jack up the sliding block, and the solar cell panel ascends. And when the light intensity of the left side is strong, the rising height ofthe left side is increased, and the effect of changing the angle of the solar cell panel according to different illumination intensities is achieved.

Owner:ZHEJIANG OYA OPTOELECTRONICS TECH

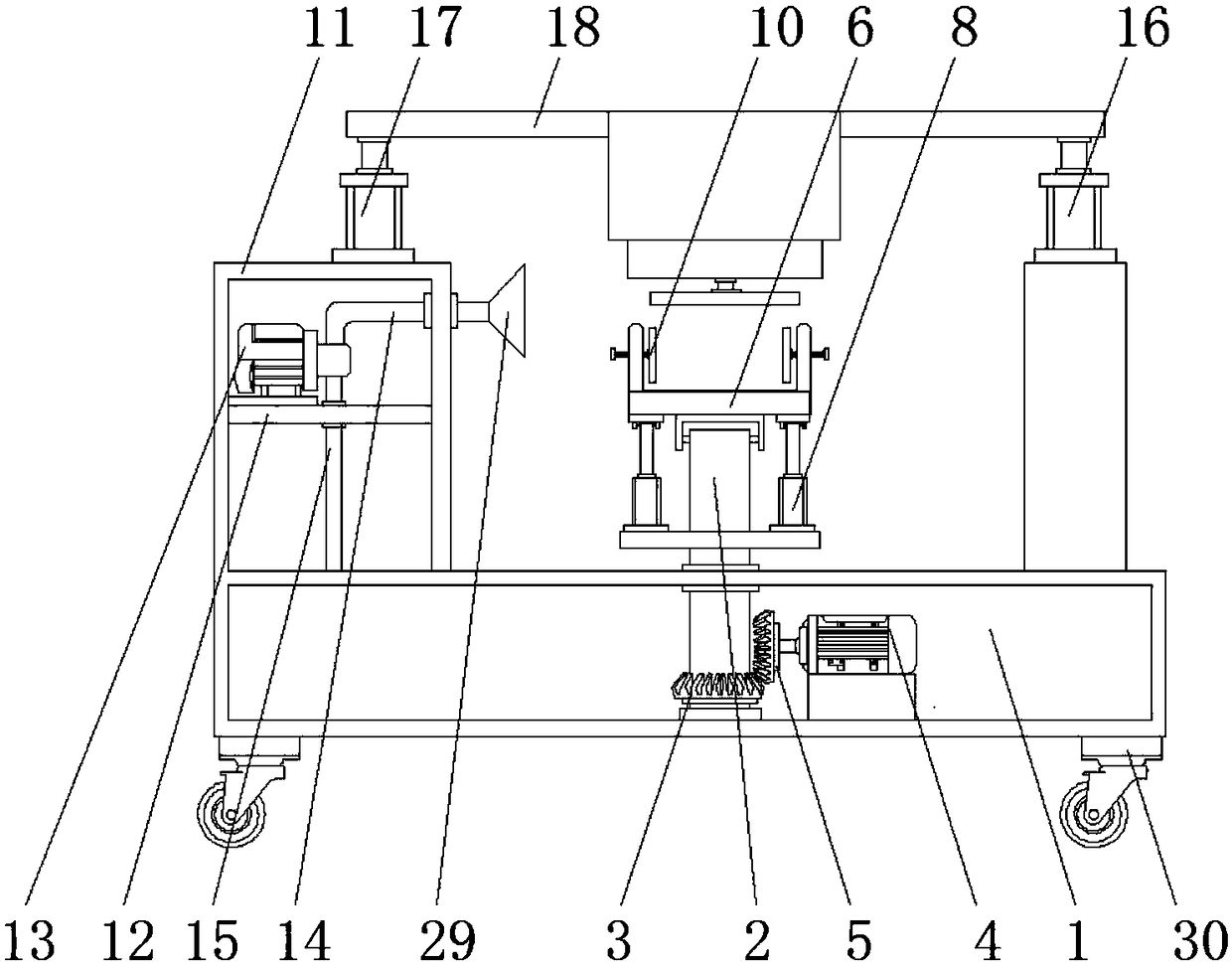

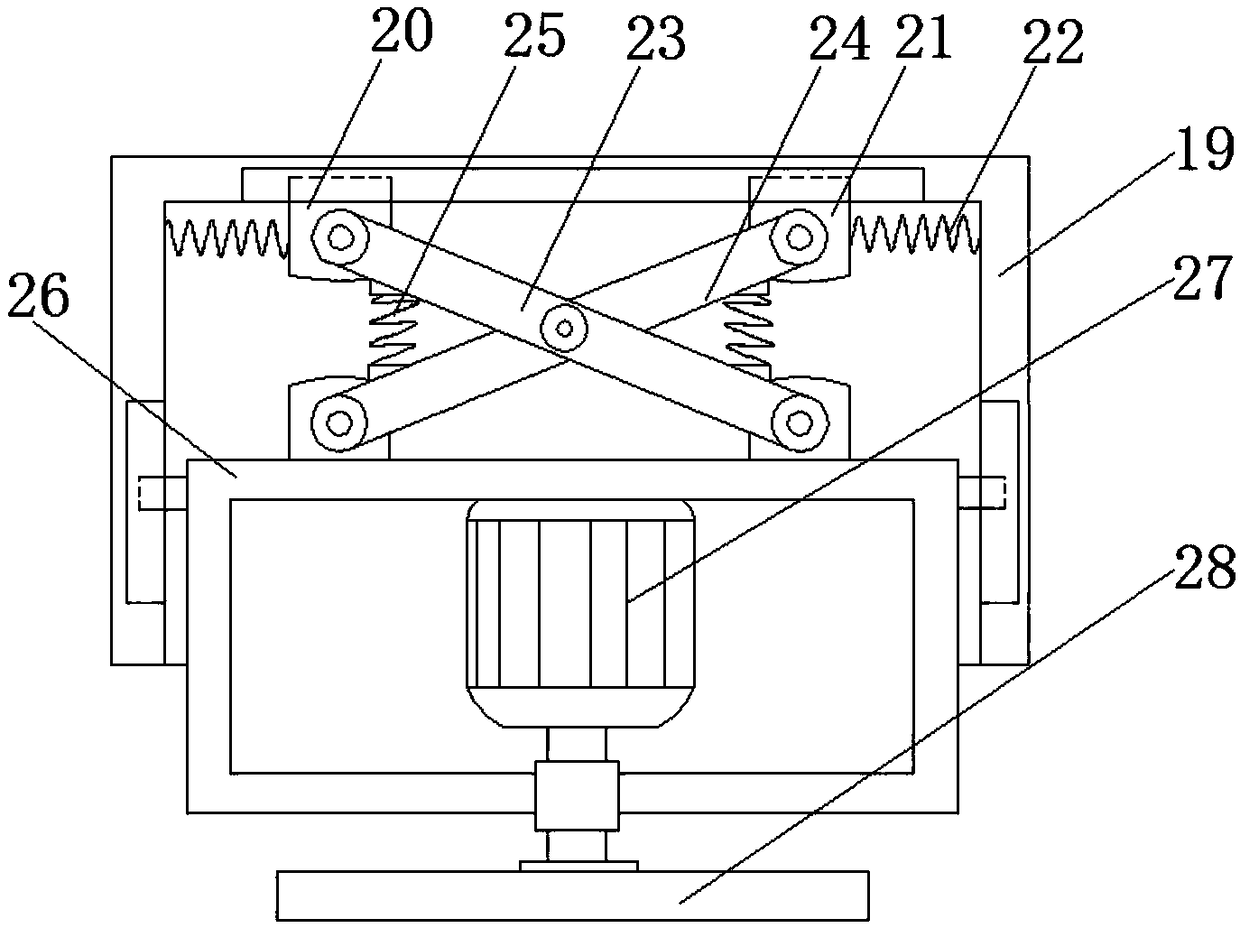

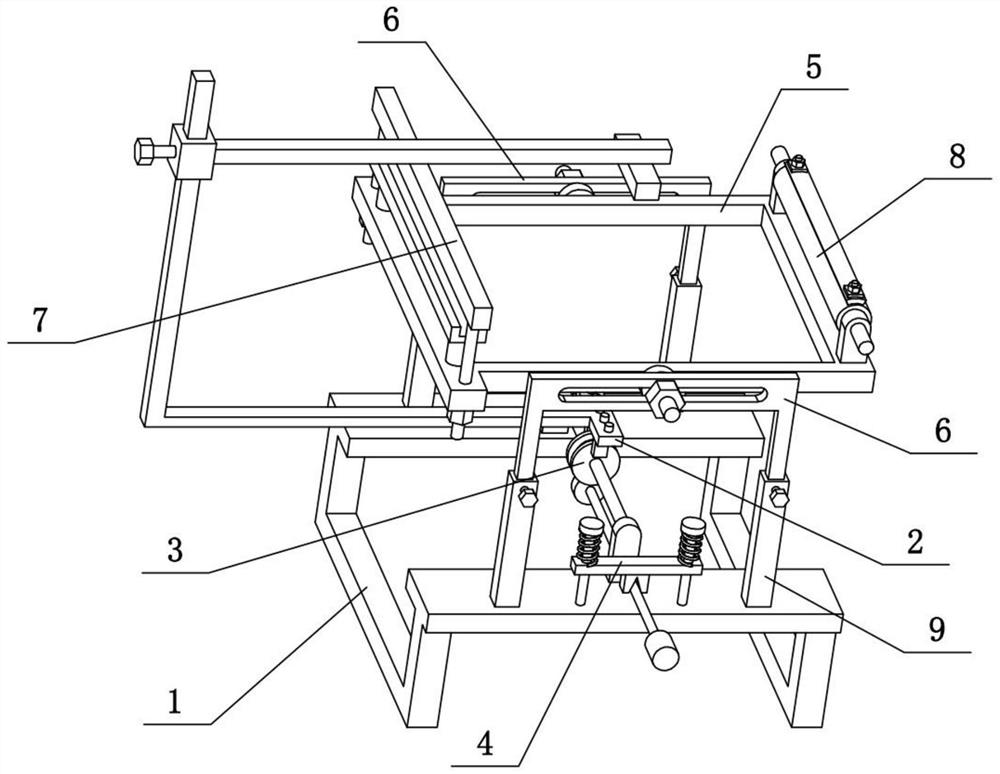

Hardware part grinding device

InactiveCN108214203AChange the placement angleEasy to polishGrinding drivesGrinding machinesHydraulic cylinderEngineering

The invention discloses a hardware part grinding device, and relates to the technical field of hardware machining. The hardware part grinding device comprises a bottom box, and the bottom of an innercavity of the bottom box is rotationally connected with a rotary shaft. The top end of the rotary shaft penetrates a top plate of the bottom box and extends to the upper portion of the bottom box. A first bevel gear is fixedly mounted on the portion, located in the bottom box, of the rotary shaft, and a first rotary motor is fixedly mounted at the bottom of the inner cavity of the bottom box. A second bevel gear is fixedly mounted at an output shaft of the first rotary motor, and the second bevel gear and the first bevel gear are engaged. The end, extending to the upper portion of the bottom box, of the rotary shaft is rotationally connected with a supporting plate, and a baffle is fixedly mounted at the position, located below the supporting plate, of the surface of the rotary shaft. According to the hardware part grinding device, the rotary shaft and the supporting plate are driven to rotate through the first bevel gear and the second bevel gear, and a first hydraulic cylinder is started to drive the supporting plate to rotate; and by means of the design, the placing angle of a material can be changed in an omnibearing manner, grinding is convenient, and the grinding quality is improved.

Owner:浙江固柏电力科技有限公司

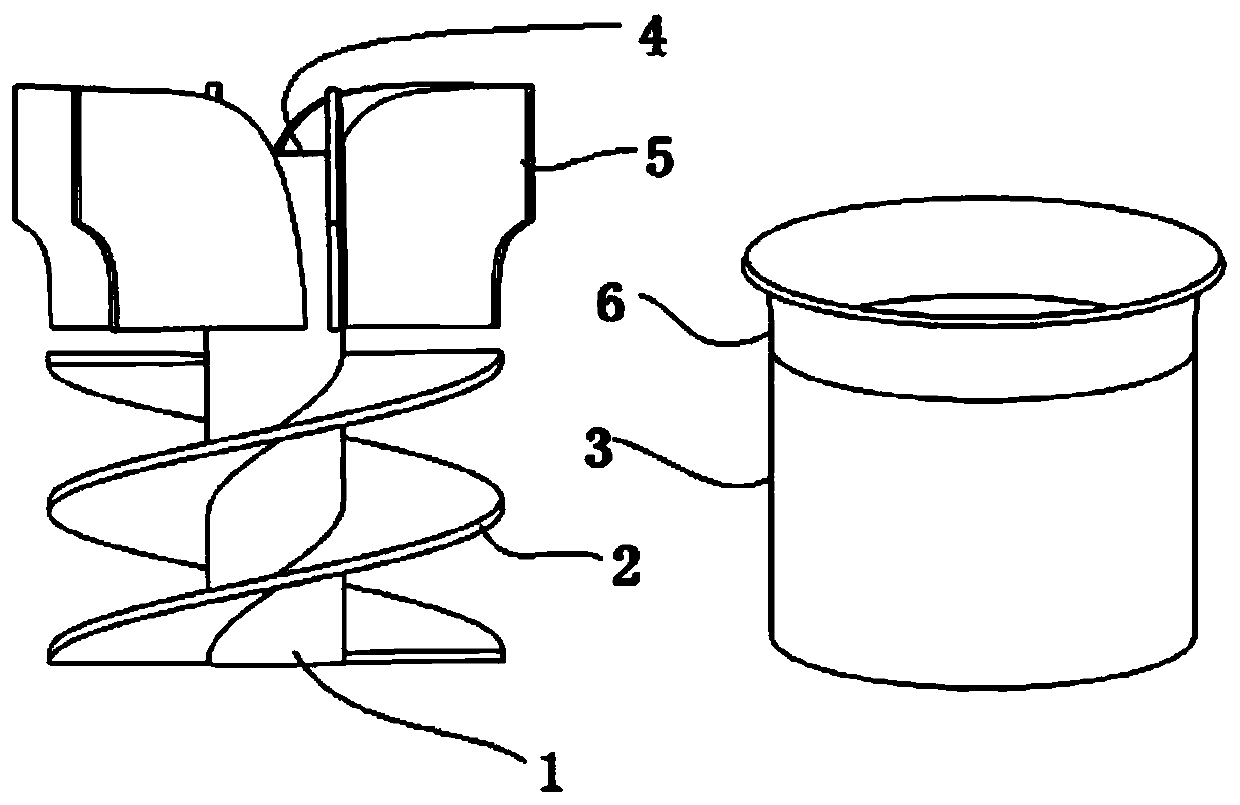

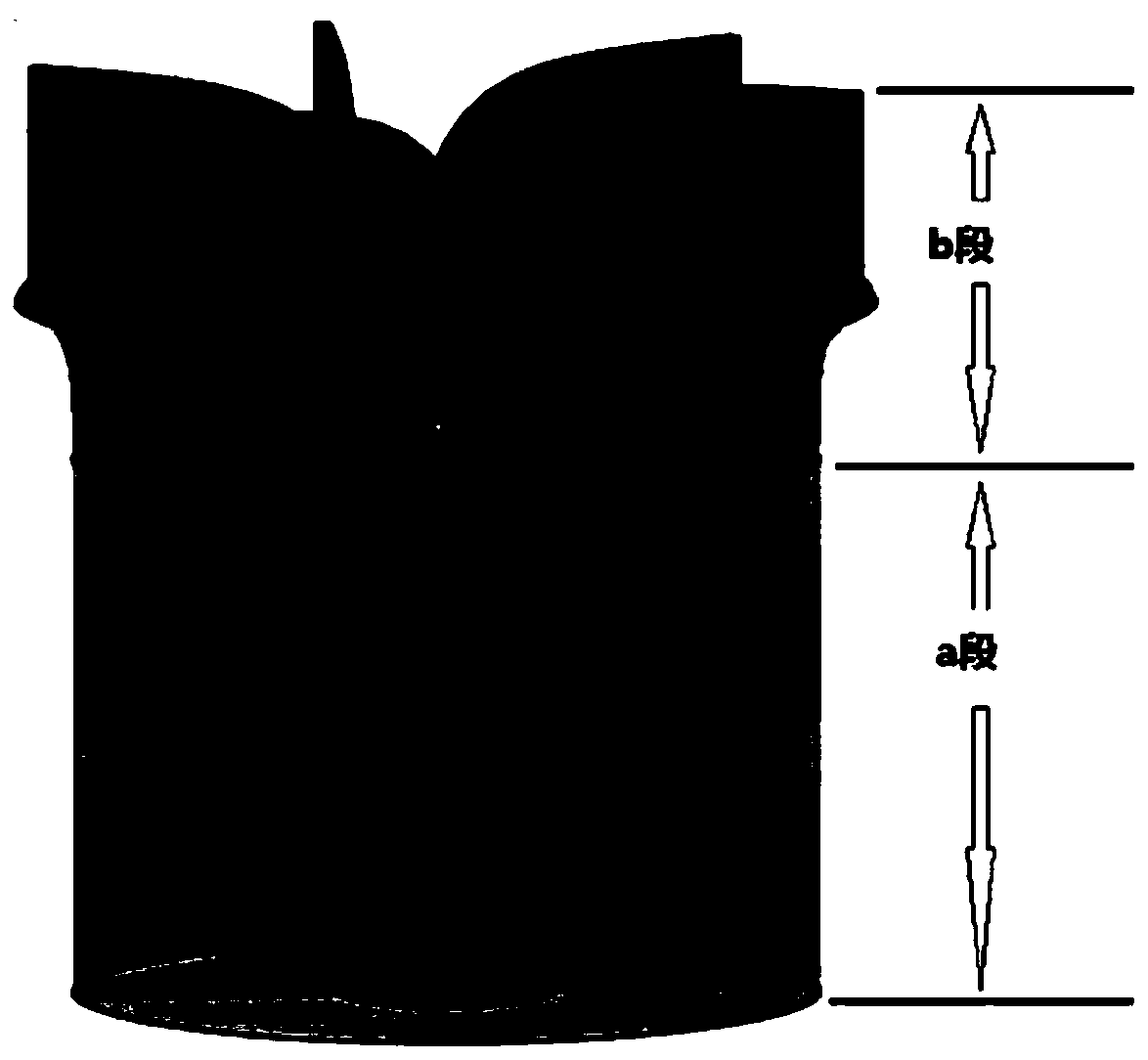

Water pump impeller for dish washing machine

The invention relates to a water pump impeller for a dish washing machine. The water pump impeller comprises an impeller core and an outer cover barrel. The outer cover barrel is a pure barrel or is an equivalent barrel formed by other close articles around blades. The equivalent barrel and the impeller core form an actual water flow runner. The impeller core is formed by a center shaft and the blades of multiple sets of water flow conveying units evenly distributed on the circumferential face of the outer side of the center shaft. The impeller core is divided into an impeller core upper segment and an impeller core lower segment, and centrifugal wheels are arranged on the impeller core upper segment. The water pump impeller is characterized in that the impeller core lower segment is formed by one stage or two stages or above of water flow conveying units; blade bodies of the centrifugal wheels on the impeller core upper segment are distributed non-radially on the circumferential faceof the outer side of the center shaft; and the impeller core and the outer cover barrel are integrated or split. The spiral runner is applied, water flow can be easily lifted, the impeller can work stably in different rotating speed zones of the motor, efficiency is high, flow is large, and propelling of water flow is stronger.

Owner:殷章标

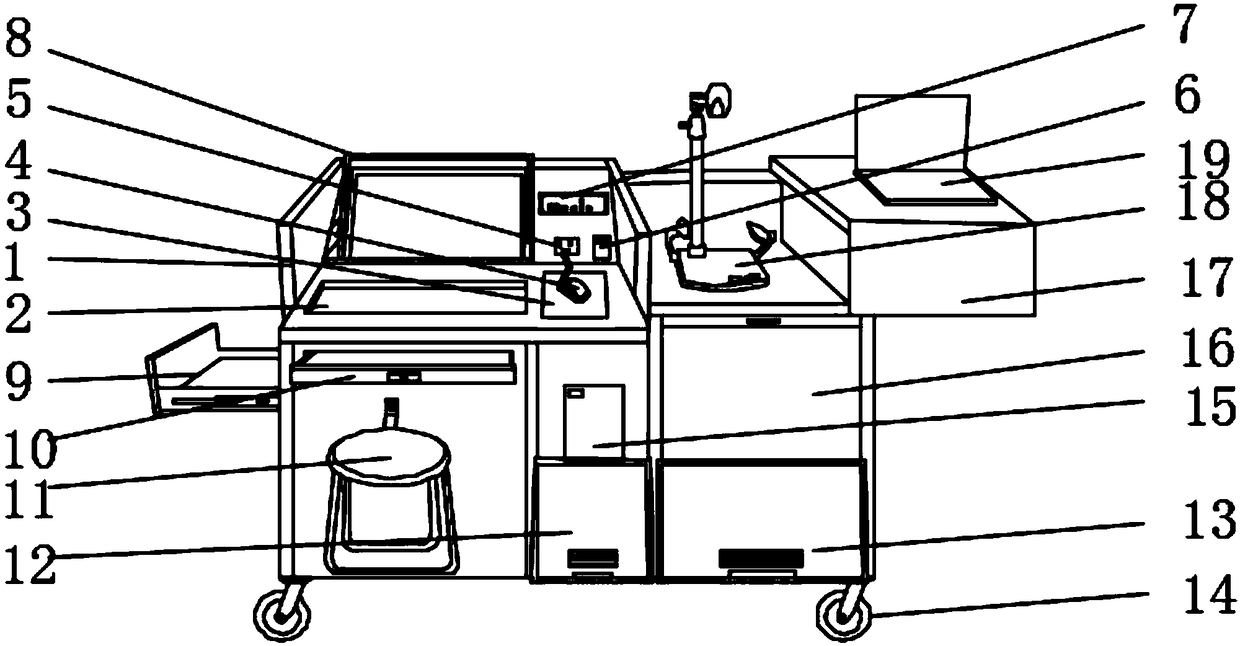

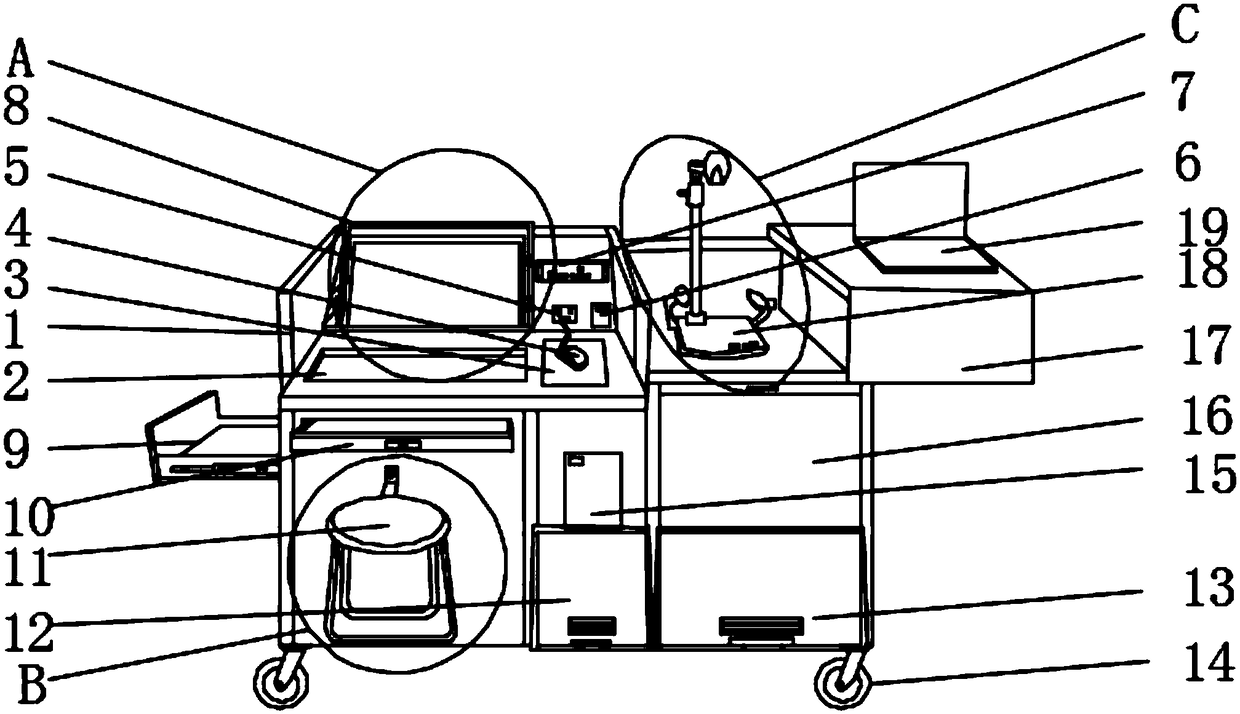

Multifunctional platform for educational science and technology

InactiveCN109077450AHeight adjustableImprove teaching efficiencyPulpitsLecternsLiquid-crystal displayManagement science

The invention relates to the technical field of multifunctional platforms, and discloses a multifunctional platform for educational science and technology. The multifunctional platform comprises a main multifunctional platform body, a keyboard placement frame is fixedly mounted at the upper end of the main multifunctional platform body, the side, away from the keyboard placement frame, of the outer surface of the upper end of the main multifunctional platform body is provided with a mouse pad, and the upper end of the mouse pad is provided with a mouse; the upper end of the keyboard placementframe is provided with an overturning table top, a liquid crystal display screen is fixedly mounted on the outer surface of the front end of the overturning table top, a hidden computer connection line is fixedly mounted at one side of the overturning table top, and a power supply plug and a wiring hole are fixedly mounted in the lower end of the hidden computer connection line. According to the multifunctional platform for educational science and technology, the liquid crystal display screen can be protected from external force through the arrangement of the overturning table top, the angle can be freely adjusted, a user can conveniently take a rest through the additional arrangement of a round stool, the height of a microphone can be adjusted, and different demands are met.

Owner:GUANGDONG HAIXIANG EDUCATION TECH CO LTD

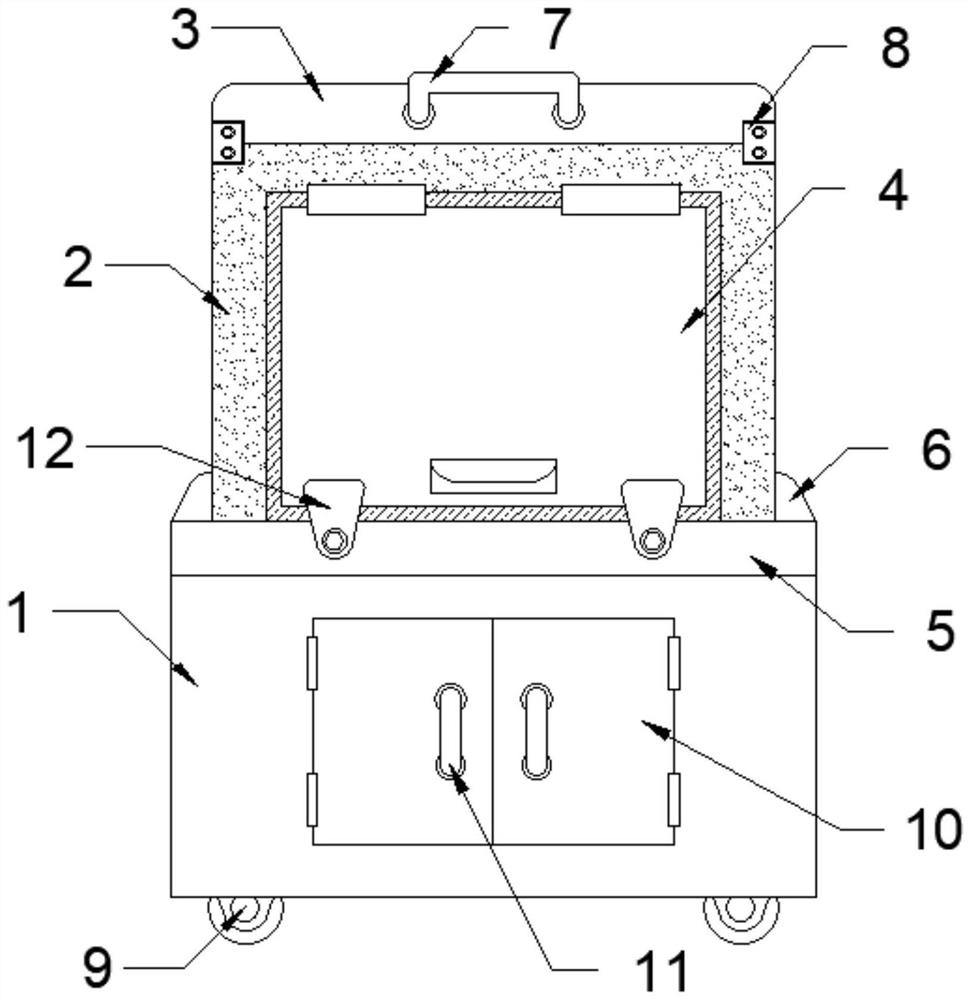

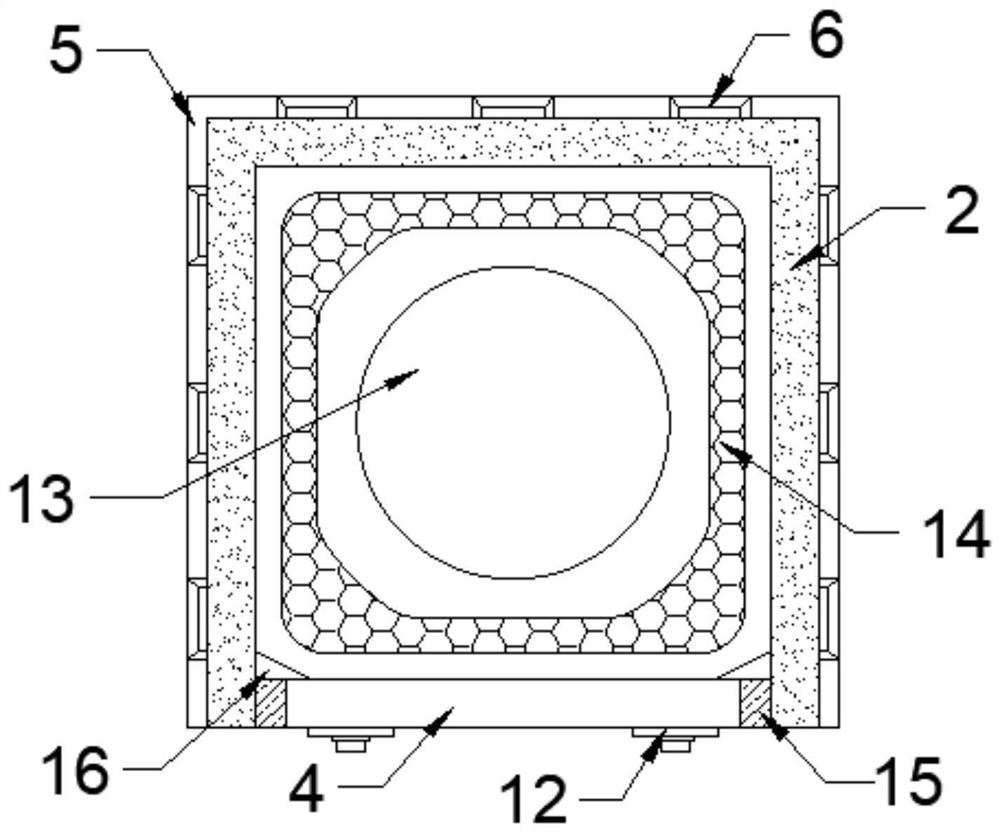

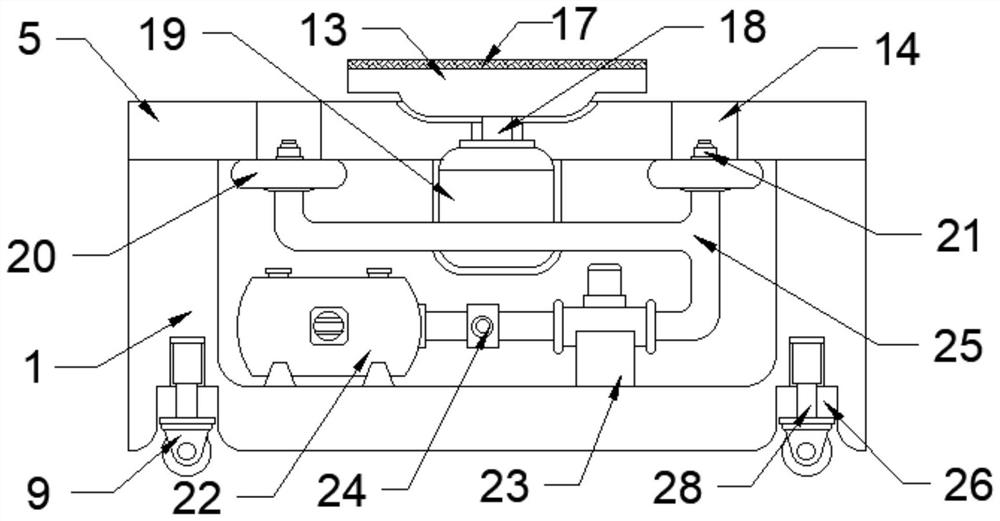

Cultural relic display cabinet with nitrogen constant-humidity function and using method thereof

PendingCN112167894ASolve the problem of having nitrogen constant humidity functionAchieve constant humidity environmentShow cabinetsShow shelvesEngineeringNitrogen gas

The invention discloses a cultural relic display cabinet with a nitrogen constant-humidity function and a using method thereof, relates to the technical field of cultural relic display cabinets, and aims to solve the problem that moisture entering the display cabinet is not easy to release again, so that the moisture content in the display cabinet is gradually increased, and as the moisture content in the display cabinet is too high, internal cultural relics can be damaged, and storage of the cultural relics is not facilitated. A display table is arranged above the cabinet body, a glass frameis arranged above the display table, a cover plate is arranged above the glass frame, a moisture sensor is arranged in the center of the lower portion of the cover plate, a nitrogen outlet annular groove is formed in the display table, and a gas disc is arranged below the nitrogen outlet annular groove. A nitrogen tank is arranged in the cabinet body, a vacuum pump is arranged on one side of the nitrogen tank, gas guide pipes are arranged on the two sides of the vacuum pump, and electromagnetic valves are arranged outside the gas guide pipes.

Owner:郑州凌智陈列设备制造有限公司

A charging fixing device for charger

InactiveCN108988441APosition and height can be adjusted flexiblyEasy winding installationBatteries circuit arrangementsModifications for power electronicsBobbinEngineering

A charging fixing device for a charger comprises a lifting plate and a holding box, wherein a connecting shaft is installed in the middle of the lifting plate, a panel is arranged above the connectingshaft, support rods are fixed on the left and right sides under the lifting plate, a sliding groove is arranged on the surface of the support rods, a sealing plate is installed on the inner side of the holding box, and the holding box is located in the middle of the lower side of the lifting plate. The charging fixing device for the charger is provided with a panel, Lamp fittings can be installed, the panel can be rotated with the connecting shaft so as to be used, By using the support rods and the sliding groove arranged on the support rods, a support for a sliding structure of that spool can be provided, In the bobbin, the charging wire is wound and collected by a crimping plate, and the charging wire is provided with an anti-skid cushion protection by a cushion plate and a cushion block. The crimping plate can be freely lifted and lowered on the vertical pole under the action of a force by utilizing the size cooperation between the crimping plate and the spiral groove, and the height of the crimping plate on the vertical pole can be flexibly adjusted.

Owner:DONGGUAN UNIV OF TECH

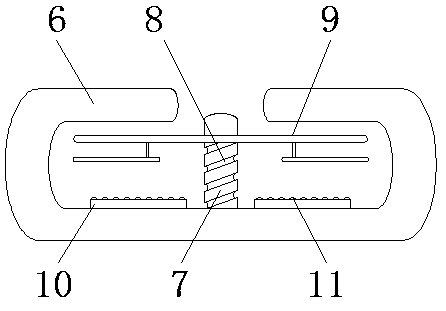

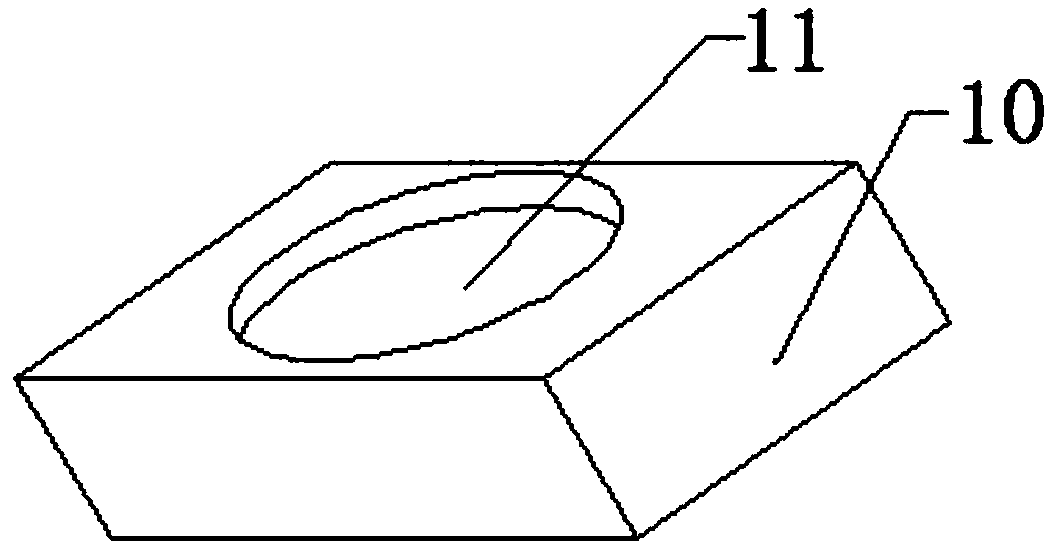

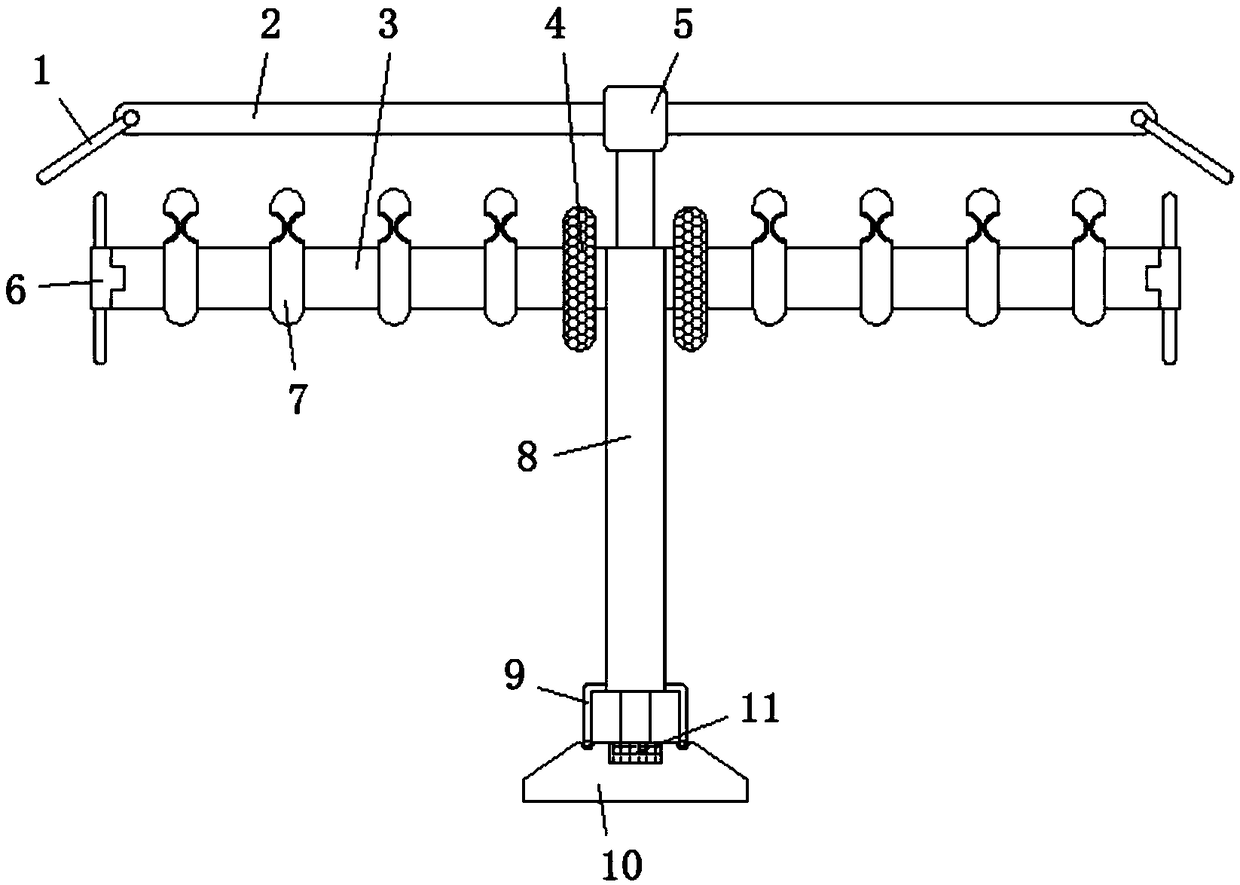

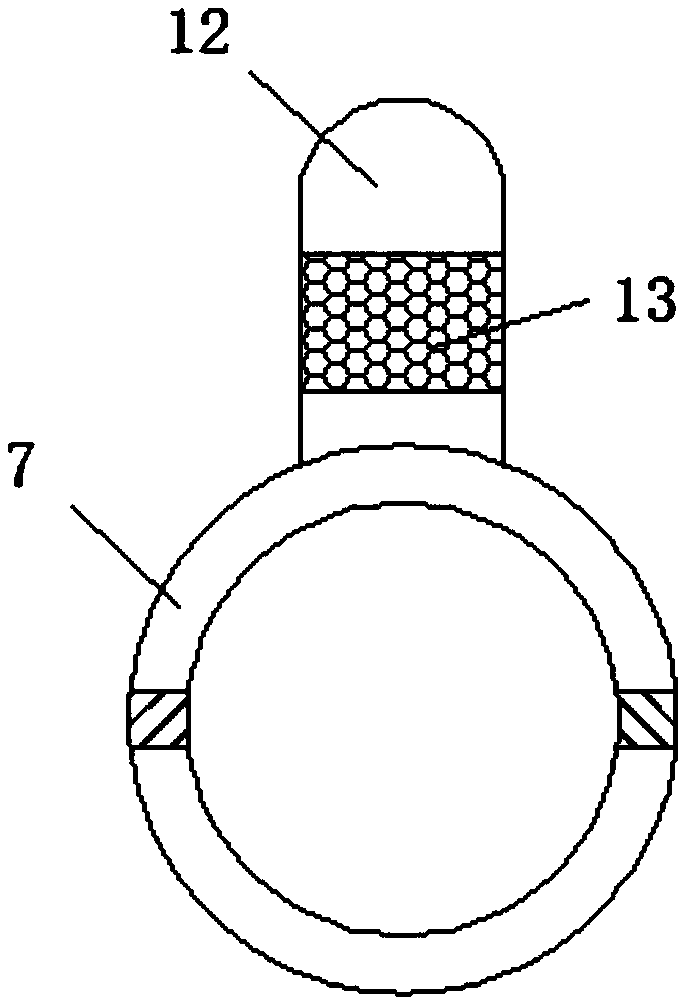

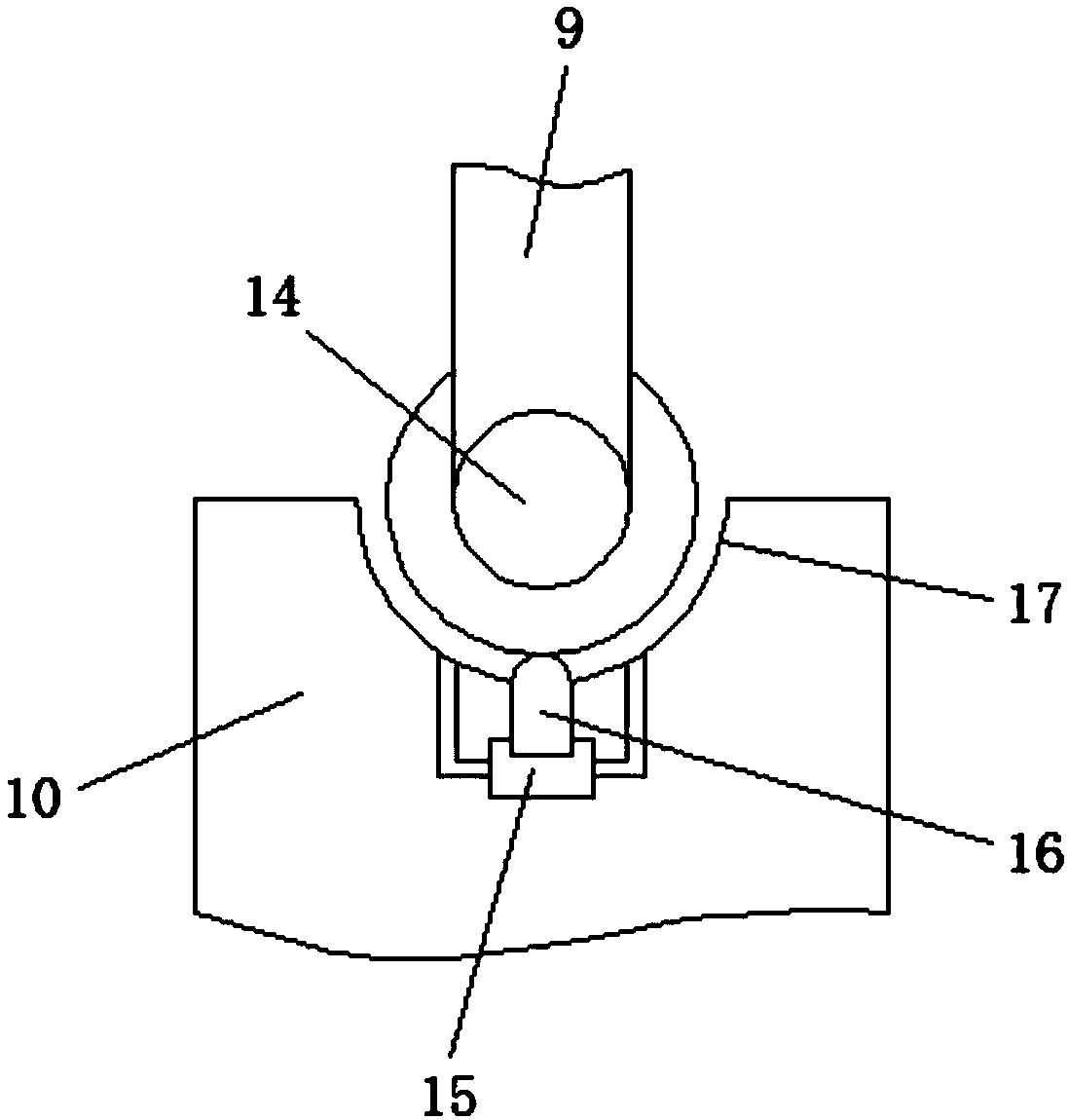

Fastening device for optical cable and electric cable

InactiveCN108879502AProtection from wear and tearChange the angle at willSuspension arrangements for electric cablesOptical fibre/cable installationEngineeringElectric cables

The invention discloses a fastening device for the optical cable and the electric cable. The fastening device comprises a bottom plate, a second clamping block, a pressing bolt and a stop bolt; a mounting groove is arranged on the middle position inside the bottom plate, and a bearing is fixedly connected to the inside of the mounting groove; a rotating shaft is rotationally connected with the bearing, and a base is rotationally and fixedly connected with the top end of the rotating shaft; a pressing plate is arranged on one end of the base, and the second clamping block is arranged below thepressing plate; the second clamping block and the pressing plate are fixedly connected via a second spring, and a first clamping block is arranged below the second clamping block; the first clamping block is fixedly connected with the base via a first spring. According to the fastening device for the optical cable and the electric cable, a plurality of cables can be secured at the same time; in addition, a protection pad is arranged on the inner wall of the clamping port so that the cable skin is effectively protected from being worn; the two clamping block pairs are provided so that the cables of different wire diameters can be clamped and the cable connection angle can be freely changed thereby improving the practicability of the whole device.

Owner:CHANGGUANG COMM SCI & TECH JIANGSU CO LTD

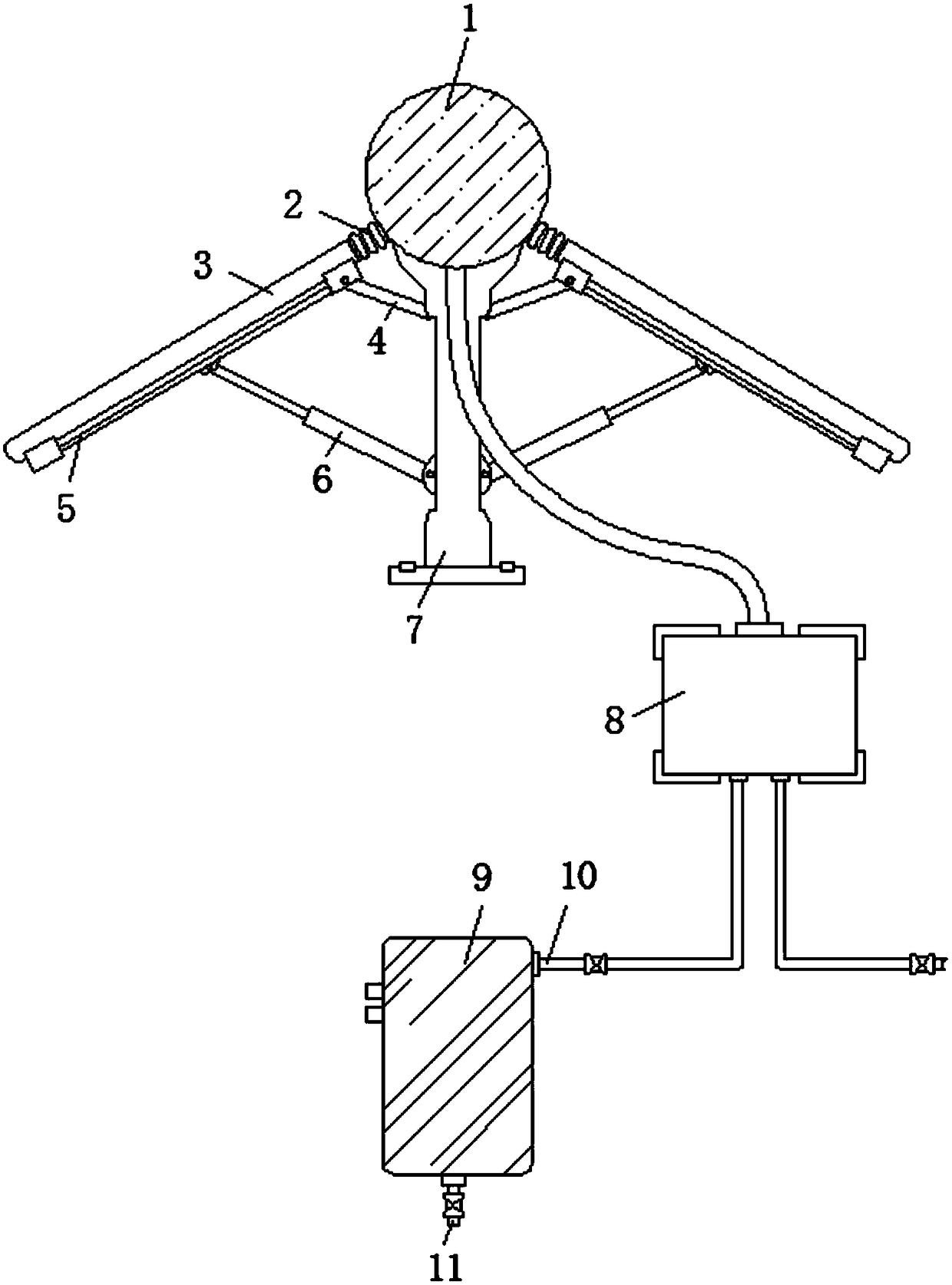

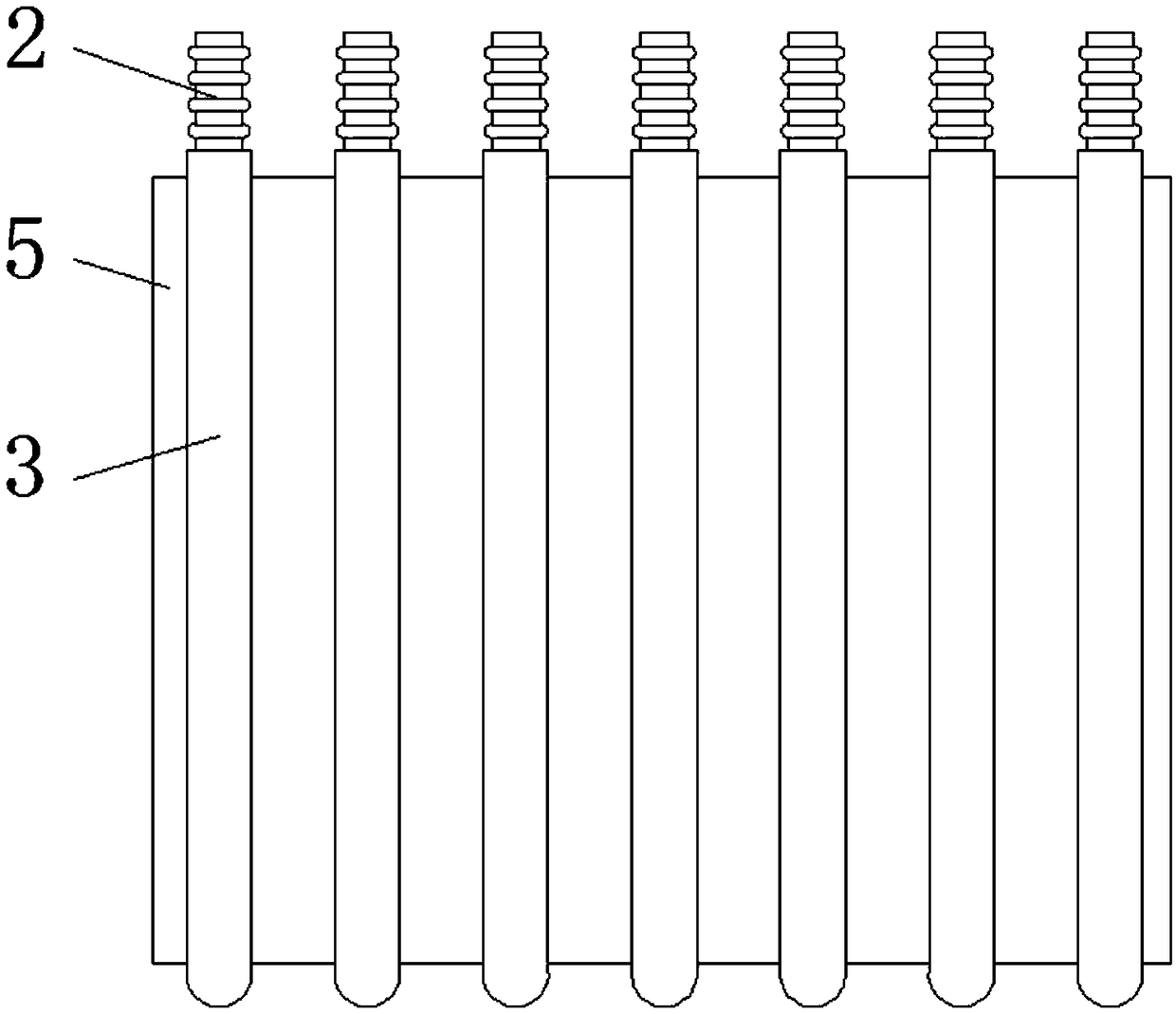

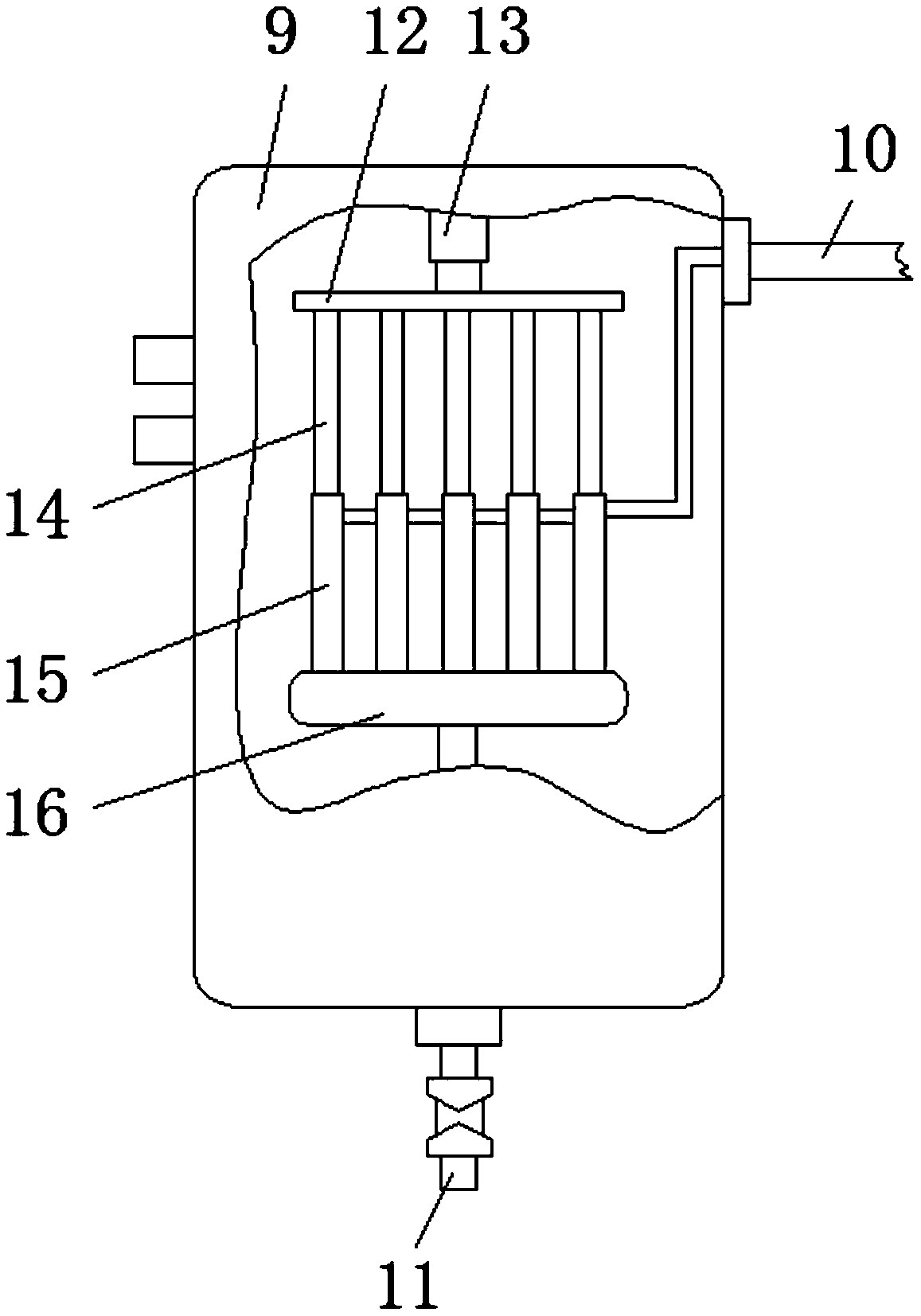

Energy-saving environment-friendly solar gas boiler

InactiveCN108981198AChange the placement angleChange angle positionSolar heating energyFluid circuit connectionsWater storage tankEngineering

The invention discloses an energy-saving environment-friendly solar gas boiler, comprising a water storage tank, a plurality of heat collector tubes and a gas boiler, and characterized in that the water storage tank is fixedly connected to the top of a support; oblique bars are symmetrically welded to the tops of the two sides of the support; a fixing plate is movably connected to the ends of theoblique bars; the heat collector tubes are fixedly connected to the fixing plate at equal intervals; the bottom center of the fixing plate is movably connected with one side of the support through a first XTL100 electric telescopic bar. The energy-saving environment-friendly solar gas boiler has the advantages that the first XTL100 electric telescopic bar can telescope to change the holding angleof the fixing plate so as to change the angular positions of the heat collector tubes, and therefore, the heat collector tubes can gain contact with direct sunlight constantly, and solar utilization efficiency is improved; the heat collector tubes and their angle changing structures are of two symmetric groups, so that solar utilization efficiency is further improved.

Owner:张凯帆

Heating apparatus with wind and light integration power generation function and heat energy storage function

InactiveCN108518723AImprove utilization efficiencyGood angular mobilityPhotovoltaic supportsSolar heating energyEngineeringHeating energy

The invention discloses a heating apparatus with the wind and light integration power generation function and the heat energy storage function. The heating apparatus comprises a tower and warm plates.Battery boxes are installed on the lower part of the tower. A support is fixed to the middle of the tower. Wavy heating plates are installed inside each warm plate. The warm plates are located on theleft side and the right side of the lower part of the tower respectively. According to the heating apparatus with the wind and light integration power generation function and the heat energy storagefunction, because light supplementation plates are arranged, the solar energy utilization efficiency of the apparatus is improved, the light supplementation plates have the good capability of moving for a certain angle relative to the support under the connection action of pin rods; because of the action of connecting rods, rotation structure foundations can be provided for lenses and reflectors respectively, and the placement angles of the lenses and the reflectors on the light supplementation plates are changed, wherein the lenses are used for light ray projection, so that light rays deflectfor a certain angle, the reflectors are used for reflecting light rays to change the transmission path of the light rays, and then, the light rays can make good contact with all solar photovoltaic panels.

Owner:江苏兆平能源科技有限公司

City billboard

Owner:SHENZHEN ZHIHUI QIANXIAN TECH CO LTD

Medical elastic transformable multipurpose rehabilitation support

InactiveCN108553208AChange tilt angleAct as a bufferRoller massageNon-surgical orthopedic devicesEngineeringMedical treatment

The invention discloses a medical elastic transformable multipurpose rehabilitation support. The medical elastic transformable multipurpose rehabilitation support comprises a base, a first roller anda rehabilitation rack and is characterized in that a base plate is mounted above the base, drawable plates are arranged on the left side and the right side of the middle of the base plate, a supportrod is fixed at the top of the base plate, a second roller is arranged on the right of the first roller, the first roller is located on the left top of a corresponding support, support rods are mounted on the left side and the right side of the rehabilitation rack, and the rehabilitation rack is located above a support plate. The medical elastic transformable multipurpose rehabilitation support has the advantages that by a drawable structure formed between the drawable plate and the base plate, the drawable plates can move on the base plate so as to change the positions of footboards, the footboards are connected to rotary plates through bearing springs, the rotary plates are connected with the drawable plates in an assembled manner, the angles of the rotary plates can be adjusted by the connection relation between the rotary plates and the drawable plates so as to change the inclination angles of the footboards, and folded plates are used for lifting the soles of feet so as to allow people who have difficulty in walking to rest or maintain self-balance.

Owner:LIXIN COUNTY FENGYASONG ELECTROMECHANICAL TECH CO LTD

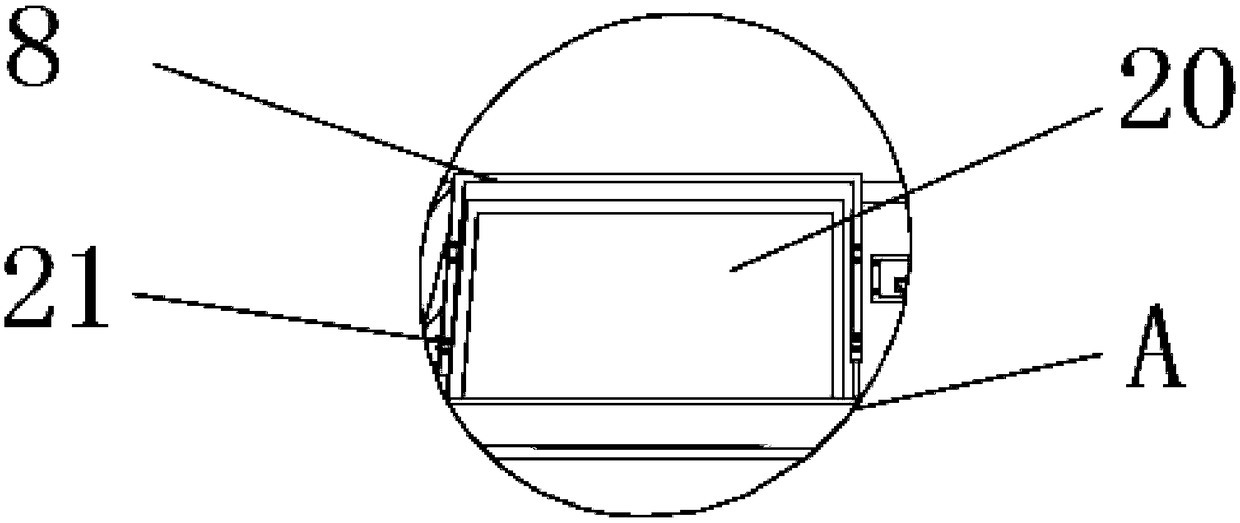

Integrated circuit test instrument with anti-blocking function

ActiveCN111308313AWith anti-clogging functionAvoid cloggingElectronic circuit testingMeasurement instrument housingGear wheelIntegrated circuit

The invention discloses an integrated circuit test instrument with an anti-blocking function. The instrument comprises a shell, protection pads and rotating rods; a lead interface is formed in the surface of one side of the shell; the adjacent side of the lead interface is provided with a test port. The outer side of the lead interface and the outer side of the test port are provided with dustproof covers. Clamping grooves are formed in the adjacent positions, away from protruding columns, of connecting grooves and one side of the top of the shell. The protection pads are connected into the clamping grooves through clamping strips. The rotating rods are connected into disc teeth in a penetrating mode, and the ends, extending out of a gear box, of the rotating rods are connected into threaded holes in a support. According to the integrated circuit test instrument with the anti-blocking function, the dustproof covers are arranged; by rotating the dustproof covers on one side of the shell, the dustproof covers rotates through rotating shafts; and when the dustproof covers shield the positions of the lead interface and the test port on one side of the shell, the dustproof covers eliminate impurities such as external dust, thereby preventing the interface position from being blocked.

Owner:深圳市瀚翔工业设计有限公司

Spine shell resetter

The invention discloses a spine shell resetter which comprises a bottom plate. A first supporting rod is arranged on the top of the bottom plate. A lifting rod is arranged on one side of a first connecting rod. A first connecting bearing is arranged at the top end of the first supporting rod. A second connecting rod is arranged on the top of the first connecting bearing. A reset plate is arrangedat the top end of the second connecting rod. A reset groove is formed in the top of the reset plate. A rotating shaft is arranged on the inner wall of the reset groove. The outer wall of the rotatingshaft is sleeved with a reset roller. A heating pipe is arranged at the bottom of the reset groove. A second connecting bearing is arranged on the reset groove. A fixed rod is pulled out of a limitingplate, the position of a limiting rod in a limiting groove is moved according to the use requirements of a patient, and therefore the placement angle of an adjusting rod and a bolster is changed, thespine part of the neck of the patient can be well protected, the use comfort level is improved, rehabilitation time is reduced, and the relapse probability is reduced.

Owner:孙元亮

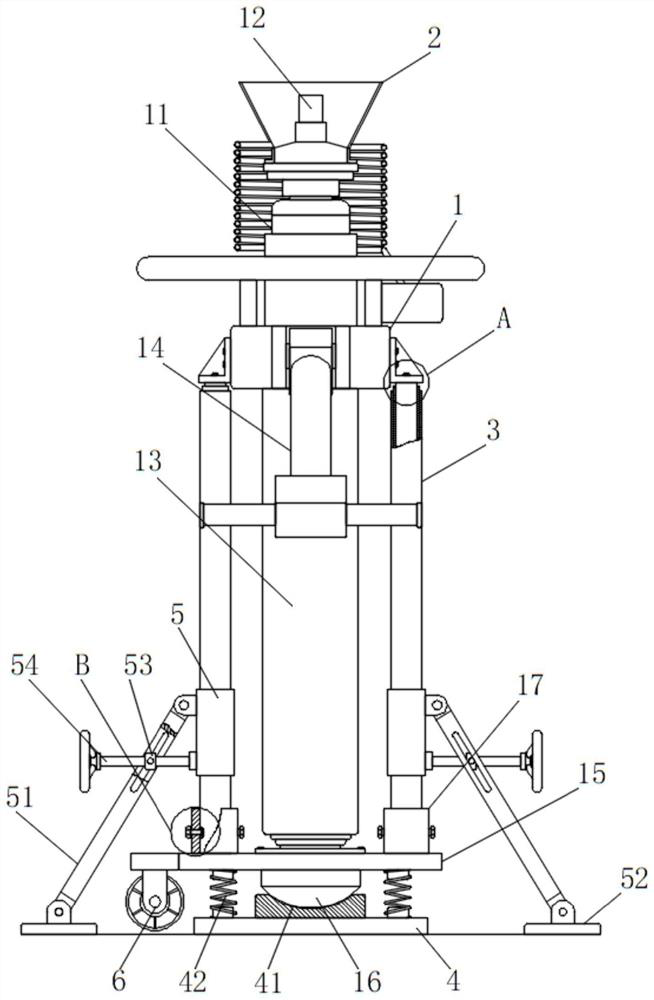

Anchor rod drilling machine with geological recognition function

ActiveCN112482991AWork up and down smoothlyGuaranteed stabilitySurveyConstructionsRock boltDrilling machines

The invention discloses an anchor rod drilling machine with a geological recognition function. The anchor rod drilling machine comprises a pneumatic anchor rod drilling machine body, wherein the pneumatic anchor rod drilling machine body comprises a driving assembly; a drill rod connector is in transmission connection with the top of the driving assembly; a rock mass collecting and observing device is arranged at the top of the driving assembly; supporting legs are arranged at the bottom of the driving assembly; an operating arm assembly is rotationally installed on one side of the driving assembly; a bottom connecting plate is fixedly connected to the bottoms of the supporting legs through bolt assemblies; and a supporting base is arranged at the bottom of the bottom connecting plate. According to the anchor rod drilling machine, through sliding fit of a sliding rod, a lining rod and an outer sleeve rod, lifting of the driving assembly is guided and supported, so that the equipment ismore stable during working and lifting; and a ground grabbing plate at the bottoms of three inclined supporting rods is in contact with the ground for supporting, so that the stability of overall placement of the equipment is guaranteed, then the convenience and practicability of the equipment are greatly improved, and the safety of the equipment is guaranteed.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

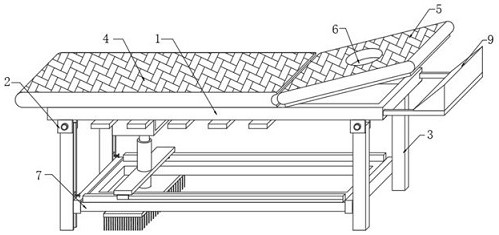

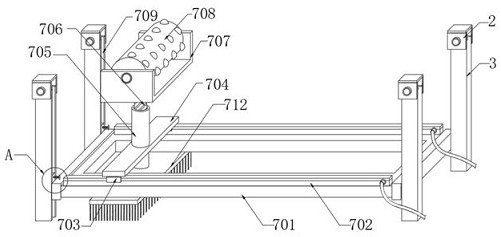

Folding massage bed with automatic bed bottom cleaning function

InactiveCN113616454AImprove stabilityImprove massage comfortCarpet cleanersOperating tablesMassageStructural engineering

The invention discloses a folding massage bed with an automatic bed bottom cleaning function. The folding massage bed comprises a bed frame, folding rotating pieces fixed on the periphery of the lower end of the bed frame, a mattres placed on one side of the upper end face of the bed frame, a cleaning assembly arranged at the lower end of the bed frame and a point pressing assembly arranged in an inner cavity of the bed frame, and supporting columns are fixed at the rotating ends of the folding rotating pieces; and a headrest is placed on the other side of the upper end face of the bed frame, and a ventilation through opening is formed in the headrest. According to the folding massage bed with the automatic bed bottom cleaning function, under the action of the cleaning assembly, sliding grooves formed in the surfaces of the supporting columns can sleeve the supporting frame through sliding blocks, so that the stability of the folding bed is improved; and meanwhile, when an electric sliding sleeve reciprocates on the surface of an electric control guide rail, a cleaning brush and a roller can be driven to reciprocate, the cleaning brush can sweep the bottom of the bed, the traditional manual cleaning mode is changed, the cleaning operation is easier, the returning roller can extrude the point pressing assembly to perform the point pressing operation, and the massage comfort is improved.

Owner:广东立曜工业有限公司

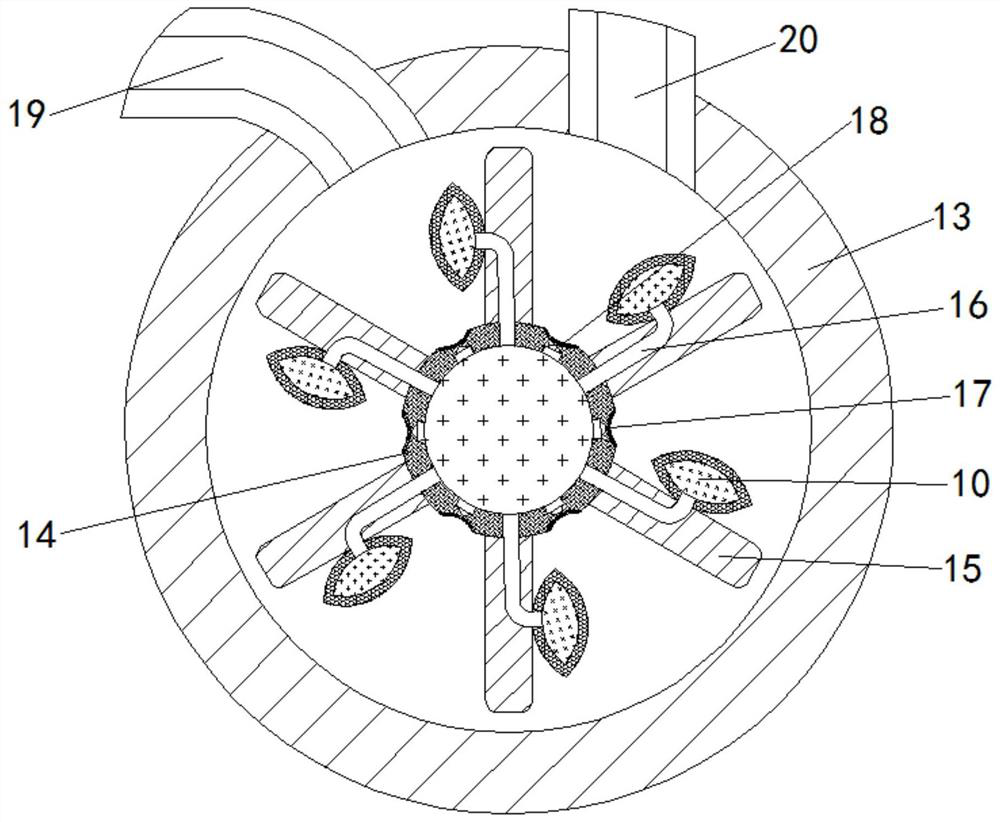

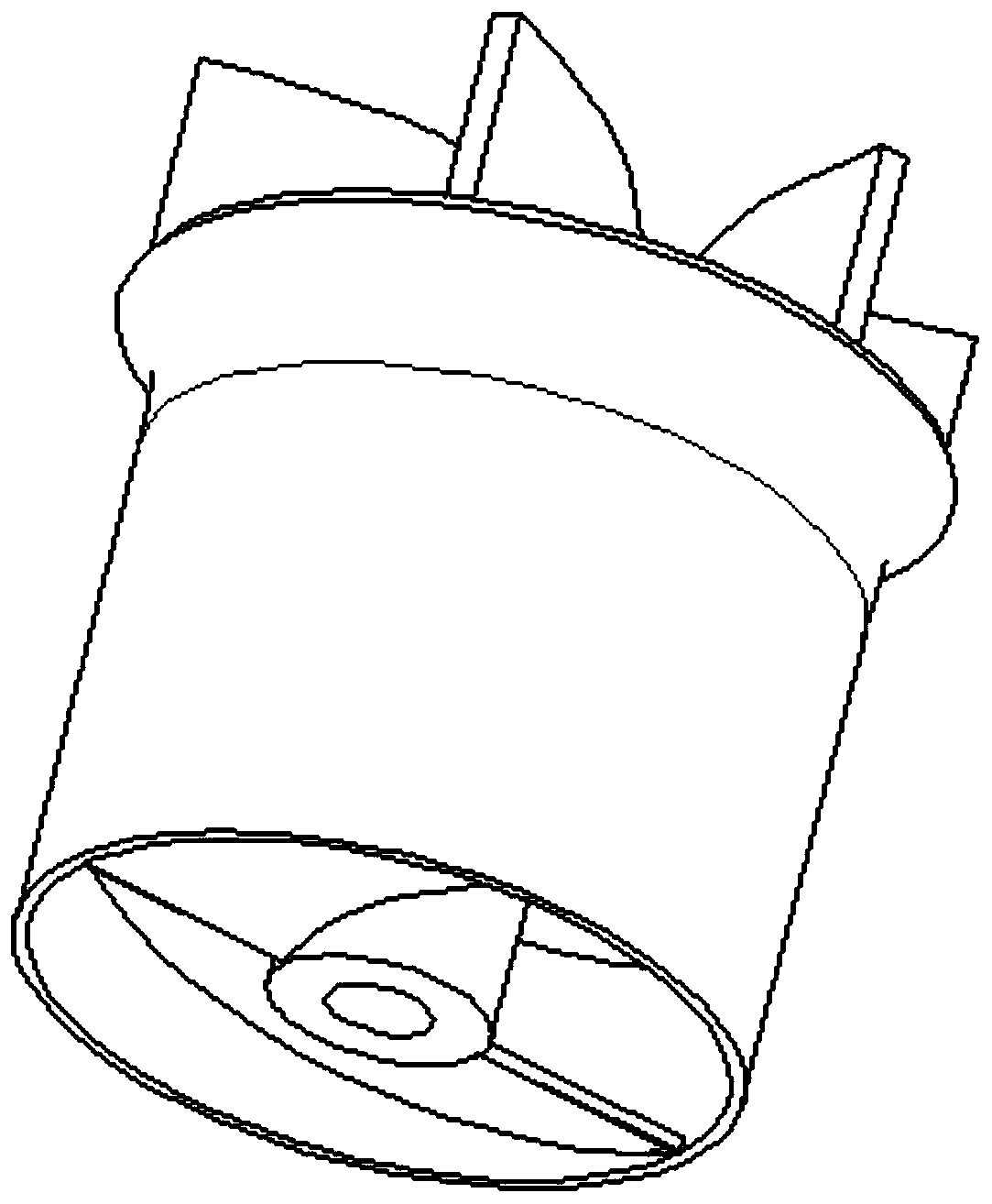

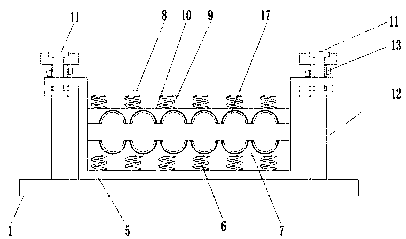

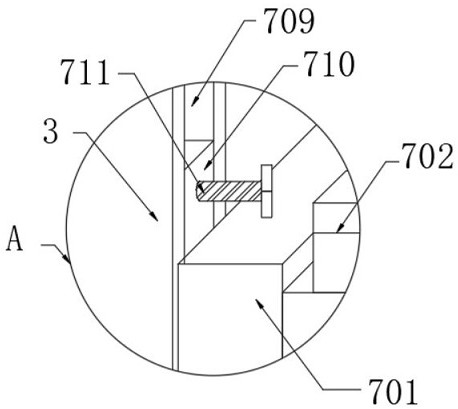

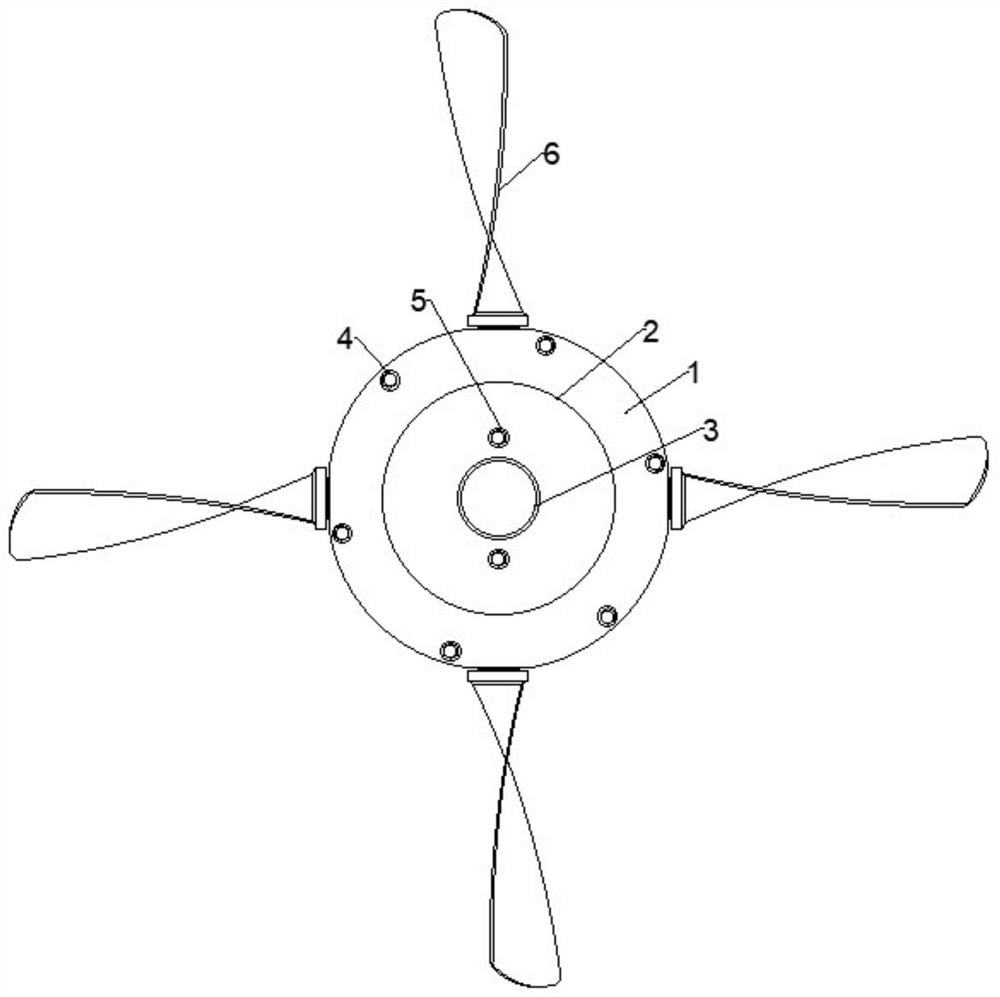

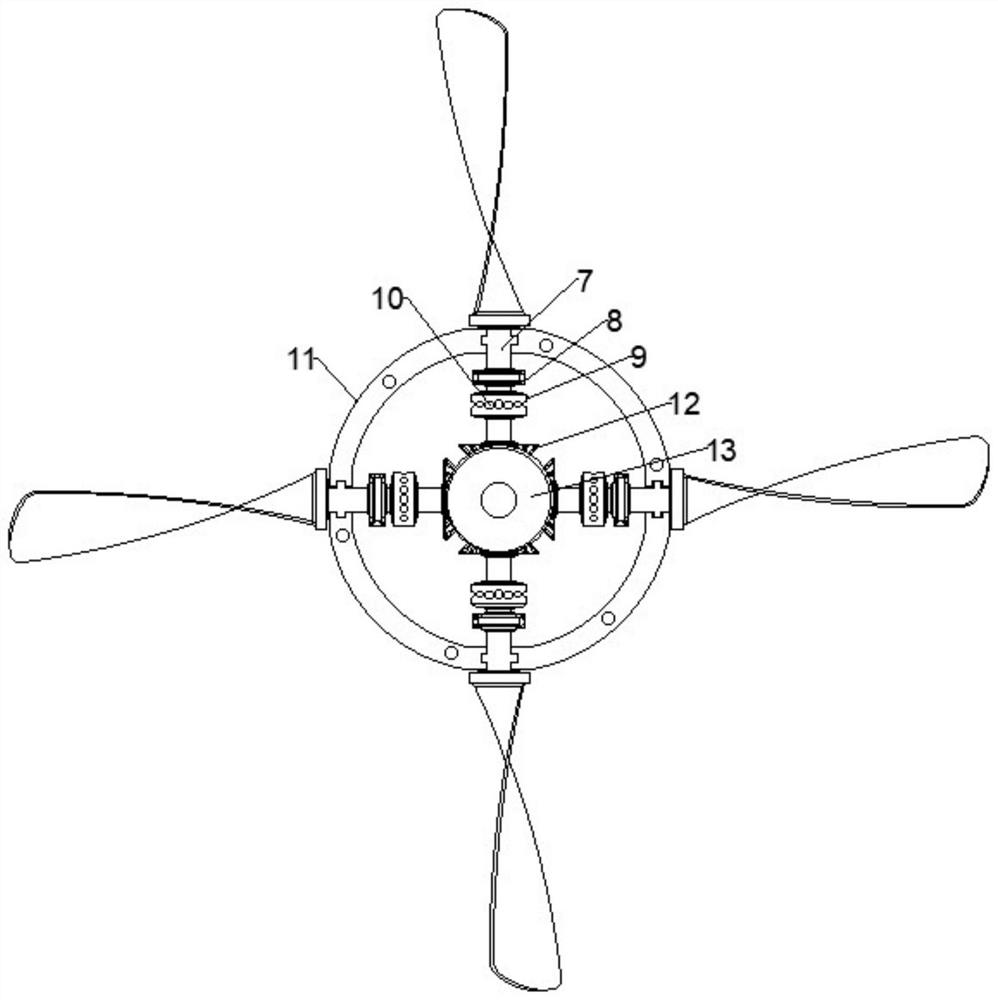

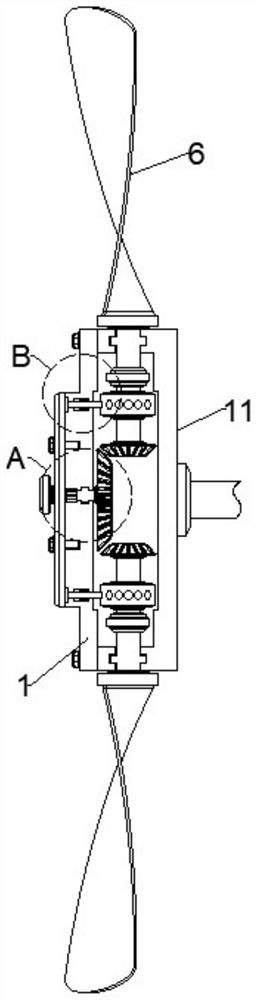

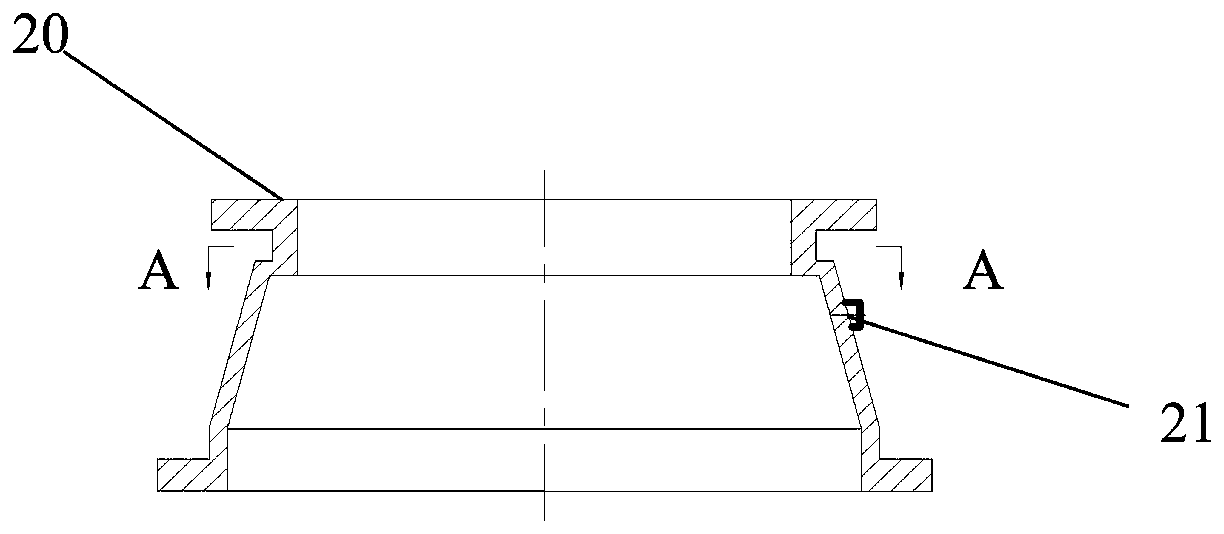

Adjustable impeller structure and hydroelectric equipment

ActiveCN112128038AChange the placement angleInnovative designHydro energy generationReaction enginesImpellerClassical mechanics

The invention discloses an adjustable impeller structure and hydroelectric equipment. The adjustable impeller structure comprises a shell and a rear cover detachably connected with the shell, and further comprises a plurality of blades, a rotating shaft penetrating through the side wall of the shell is fixed to the side, facing the shell, of each blade, a first bevel gear is fixed to the end, awayfrom the corresponding blade, of each rotating shaft, the first bevel gears are engaged with a second bevel gear rotationally mounted on the rear cover, and the second bevel gear is connected with anadjusting mechanism arranged on the outer side of the shell. A limiting disc is further installed on each rotating shaft, a plurality of limiting holes are formed in each limiting disc, and the limiting holes are matched with a clamping pin assembly arranged on the rear cover. The adjusting mechanism is separated from the rear cover, the clamping pin assembly is automatically separated from the limiting holes at the moment, the arranged adjusting mechanism drives the second bevel gear to rotate, and when the second bevel gear rotates, the rotating shafts and the blades connected with the rotating shafts are driven to rotate through rotation of the first bevel gears engaged with the second bevel gear, so that the placement angles of the blades are changed.

Owner:湖南新邵筱溪水电开发有限责任公司

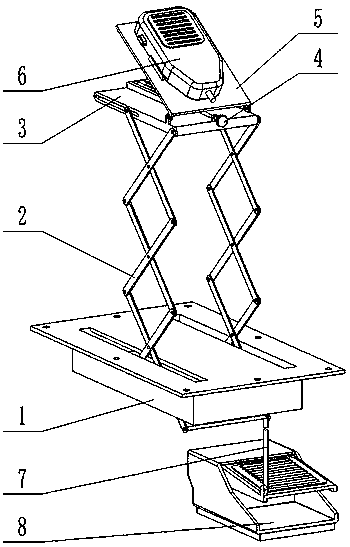

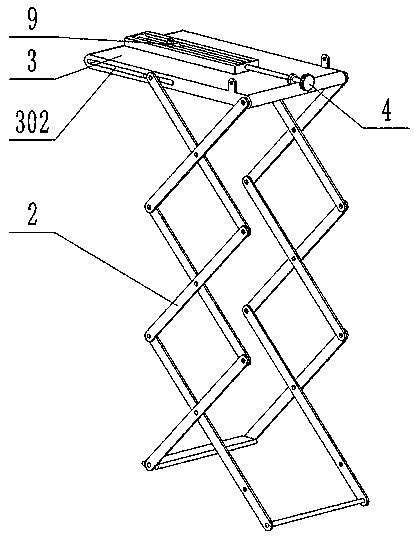

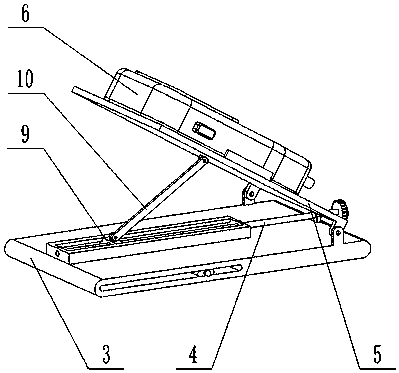

Lifting and pressing type megaphone used in imaging department

InactiveCN110505560AChange the placement angleReduce occupancyPublic address systemsEngineeringFoot operations

Owner:胡丹萍

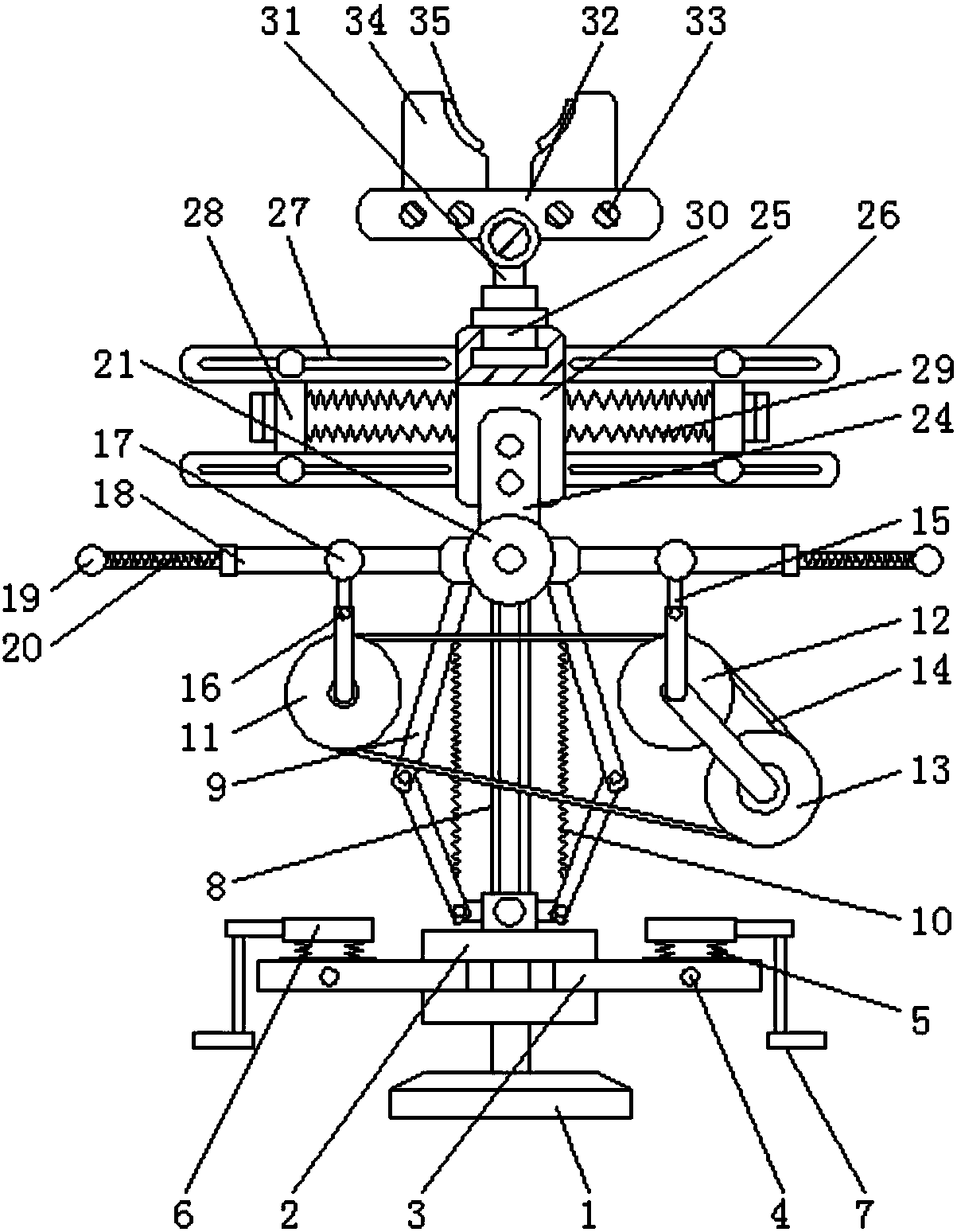

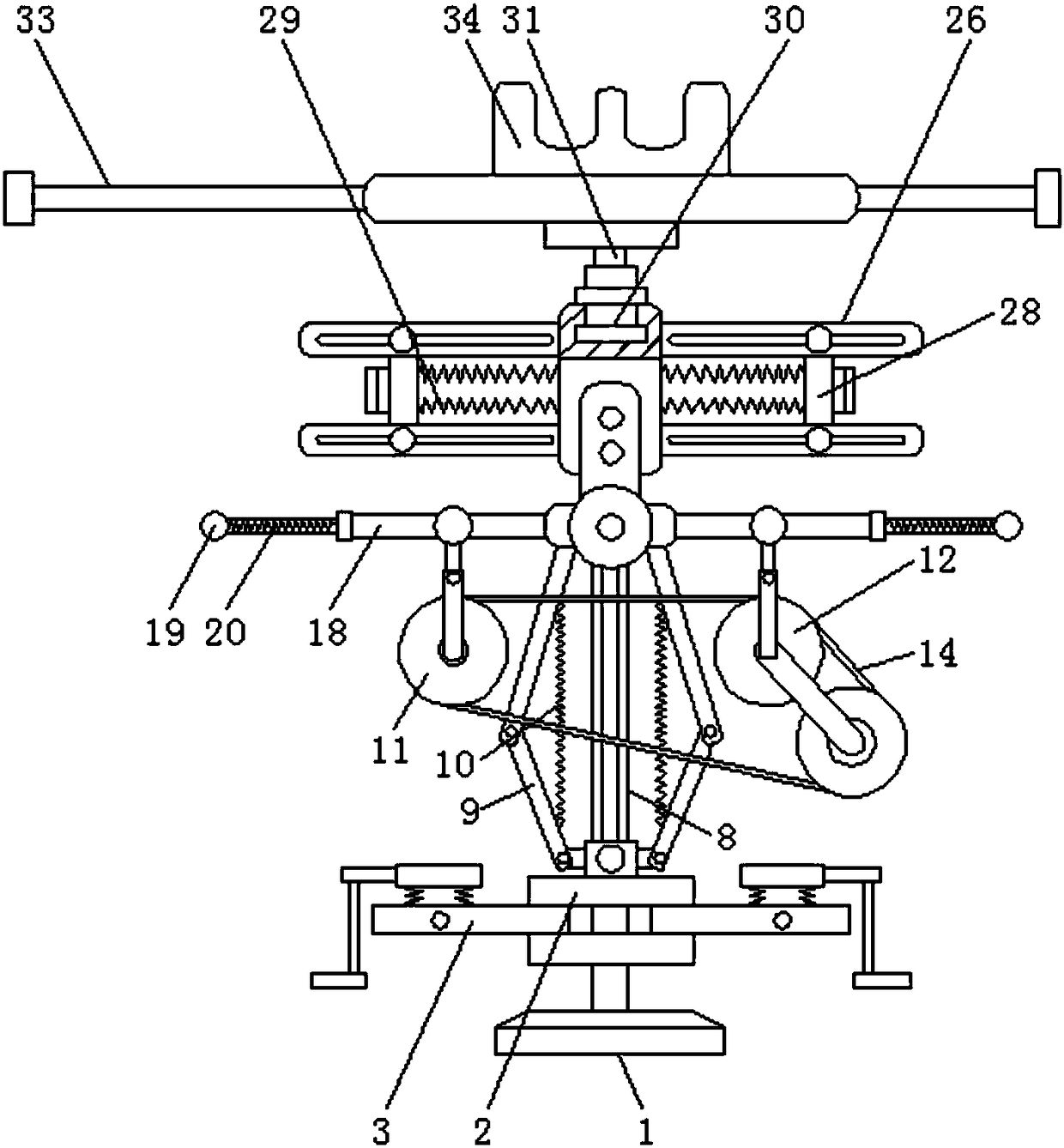

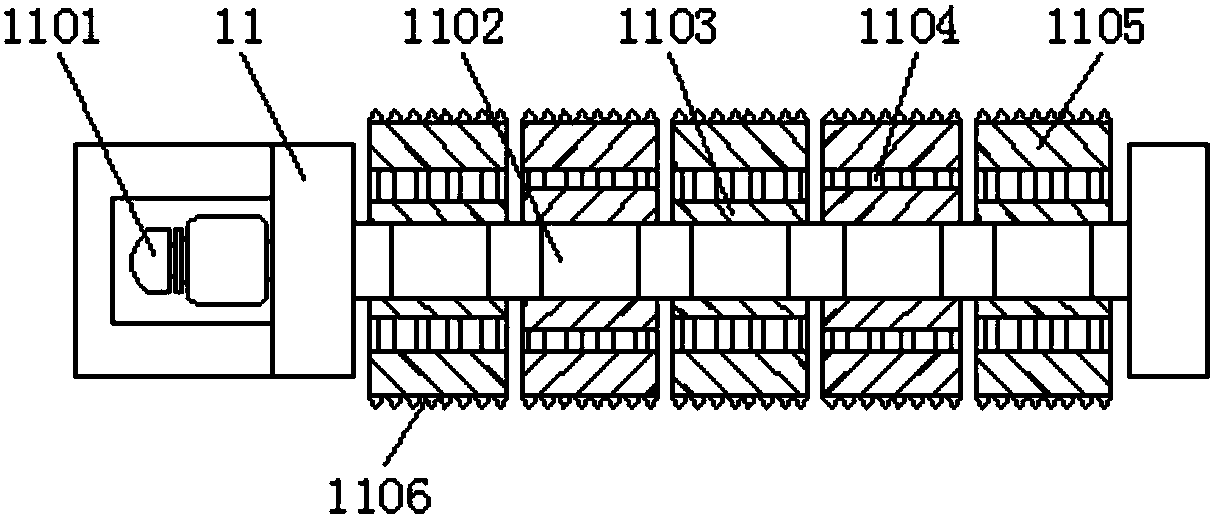

A kind of fabric light transmission detection system and detection method

ActiveCN110095439BChange angleDetect light transmittanceTransmissivity measurementsVertical planeFixed frame

The present invention relates to the field of fabric light transmission detection, more specifically a fabric light transmission detection system and detection method, including a base, a light emitter, a light receiver, an adjuster, a fixed frame and a fixed frame bracket, which are the components of the present invention The advanced detection system can perform light transmission detection on fabrics in various situations. The light emitter is arranged above the base, the light emitter can move back and forth, and the light emitter can rotate on the vertical plane, the position of the light emitter is adjusted by the regulator, the light receiver corresponds to the light emitter, The light receiver is always set in the direction of the light emitted by the light emitter. The front and rear ends of the base are fixedly connected with fixed frame supports. The fabric fixed frame is arranged between the two fixed frame supports. The light receiver and light emitter are respectively located on The fabric fixes the upper and lower sides of the frame.

Owner:东莞市听雨轩服装有限公司

Placing frame for storing molybdenum rod electric heating element

PendingCN108609287ASimple structural designImprove the stability of useExternal framesDrive shaftEngineering

The invention discloses a placing frame for storing a molybdenum rod electric heating element. The frame comprises a supporting column, a sleeve pipe sleeves the top of the supporting column, and a top plate is welded to the outer surface wall of the sleeve pipe; hanging frames are welded to the outer surface wall of the supporting column in an equal-angle mode, one end, close to the supporting column, of the surface of the hanging frames is sleeved with an inner ring limiting ring, and the bottom of the supporting column is rotationally connected with a base through a transmission shaft; andauxiliary supporting rods are symmetrically welded at the bottom ends of the outer surfaces of the two sides of the supporting column, moreover, the bottom end of auxiliary supporting rods are connected with a groove in the upper surface of the base through limiting sliding wheels in a sliding mode, an oil storage bin is arranged inside the base and located below the groove, and a pressing block is arranged above the oil storage bin. According to the frame, the supporting column is simple and reasonable in overall structural design, the supporting column can be horizontally operated in a rotation mode through a bearing, so that the placing angles of the hanging frames can be changed, so that people can be prevented from placing the molybdenum rod heating element by walking, and the workload of workers is further reduced.

Owner:SICHUAN S Y MOLY TECH CO LTD

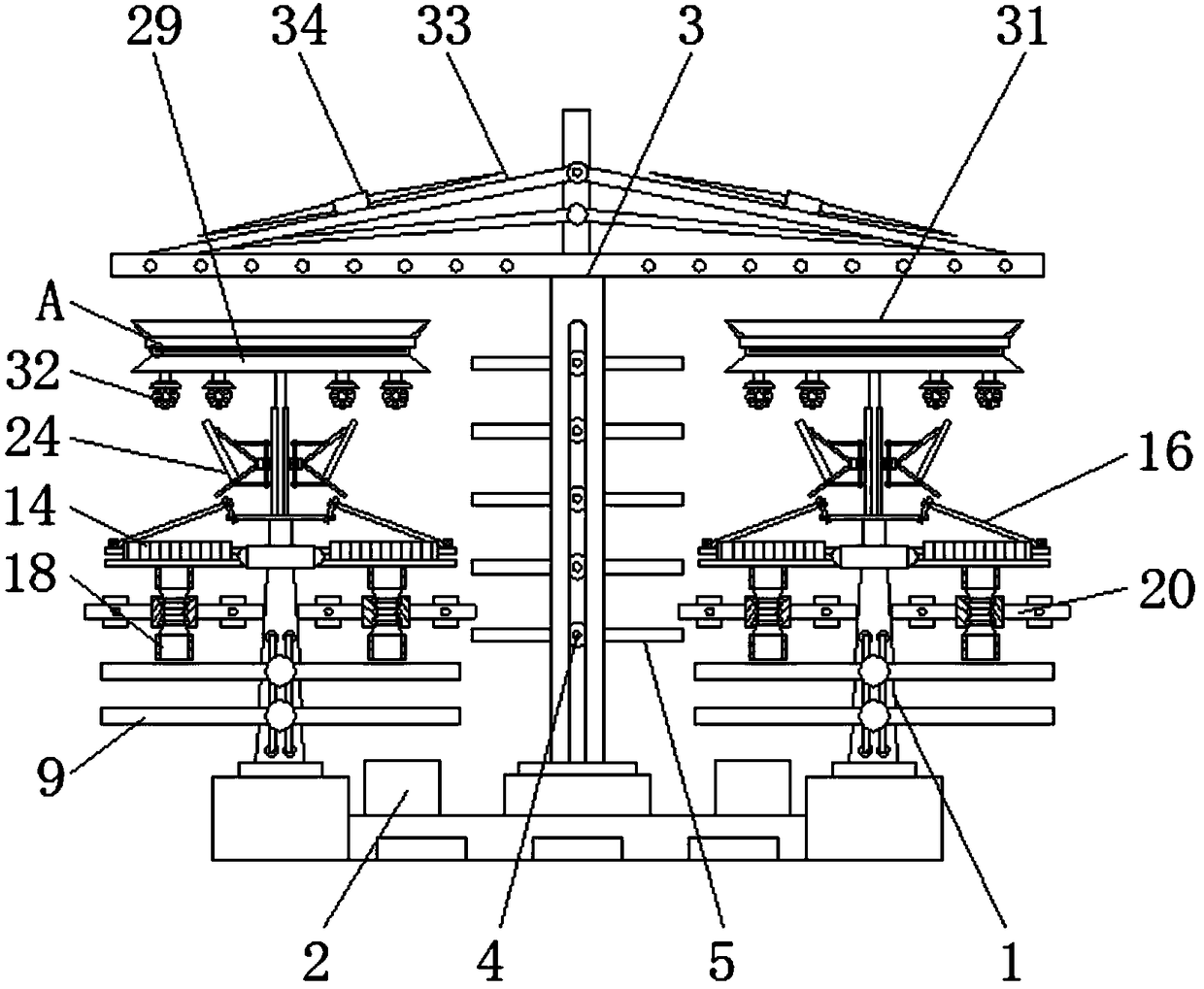

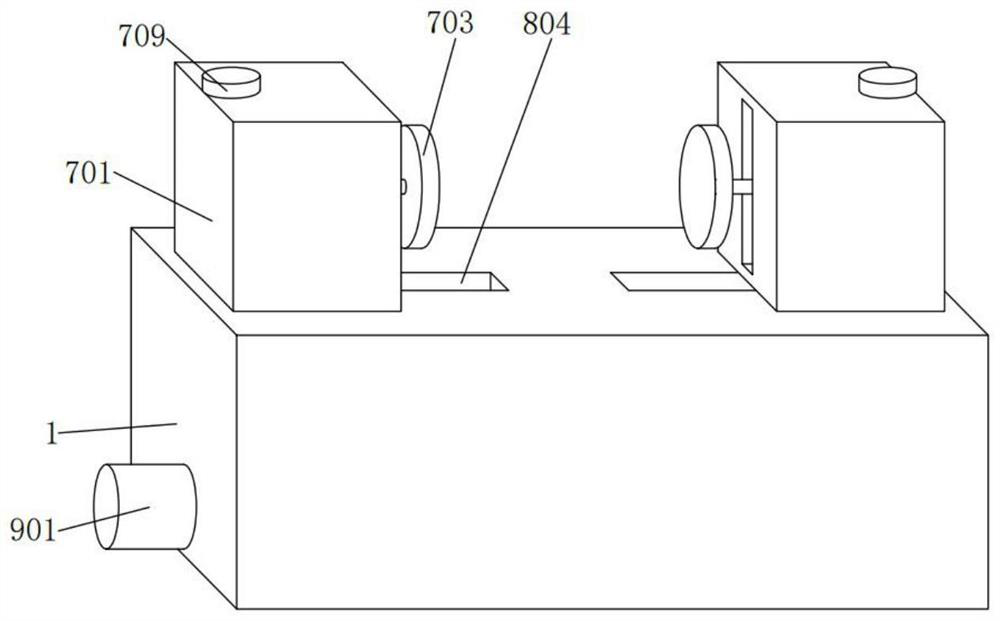

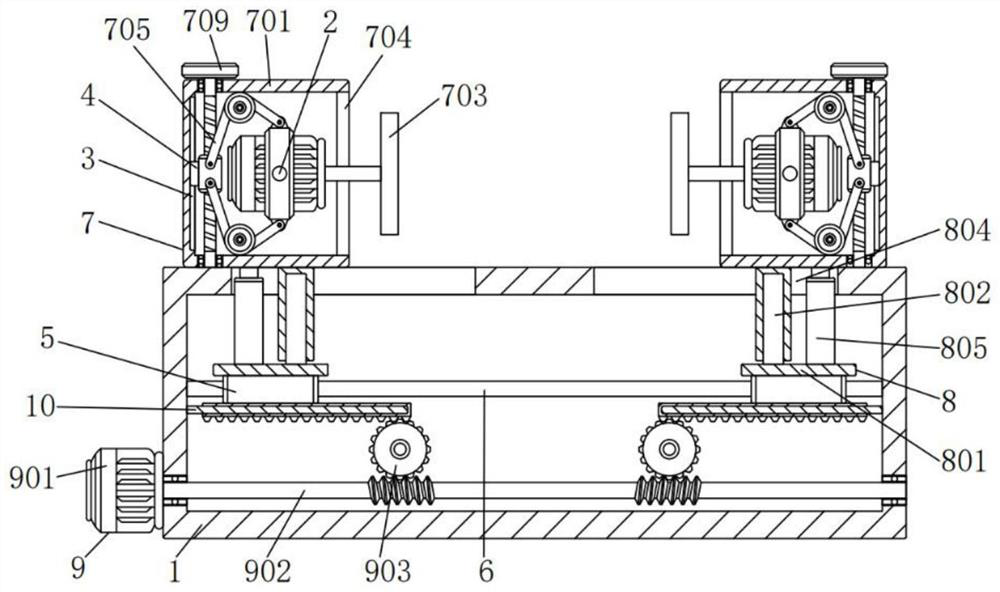

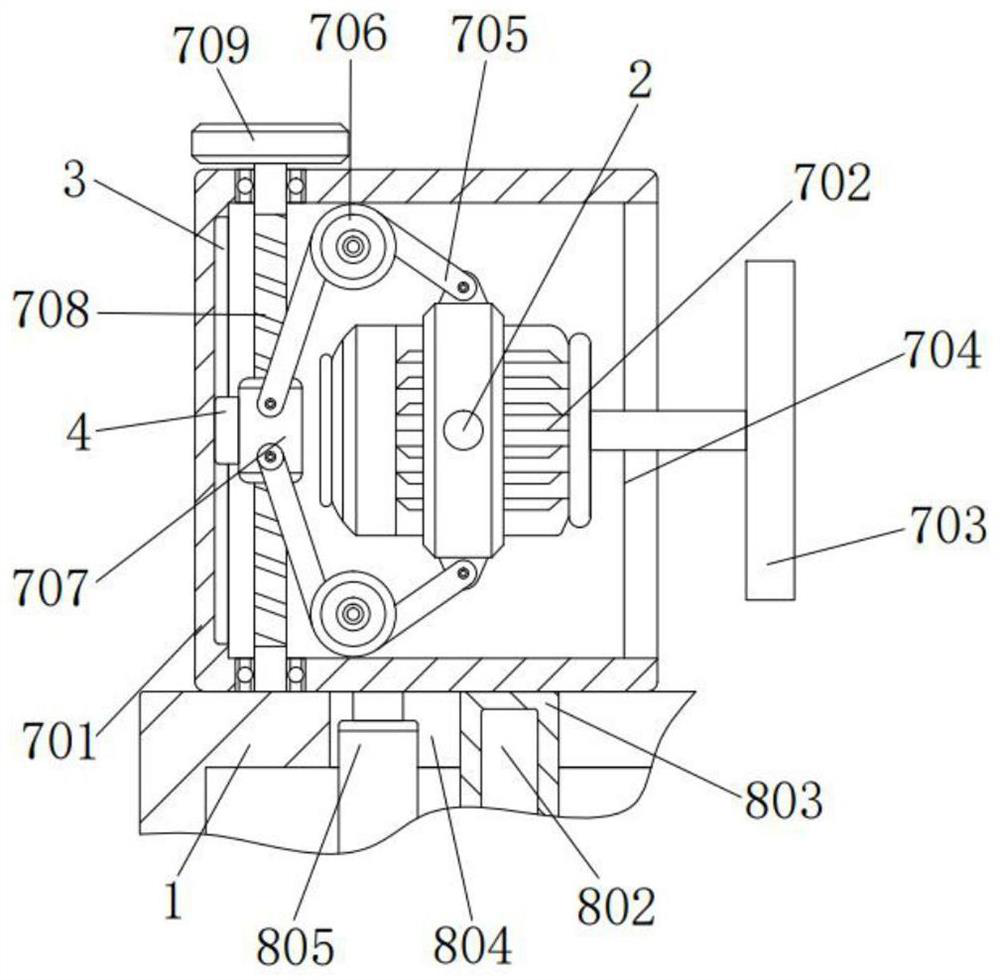

High-precision double-sided numerical control grinding machine tool

PendingCN114178960AImprove stabilityChange the placement angleGrinding drivesGrinding machinesPhysicsElectric machinery

The high-precision double-face numerical control grinding machine tool comprises a box body, grinding mechanisms are arranged at the two ends of the top of the box body, each grinding mechanism comprises a shell, a first motor, a grinding knife, a first through groove, a rope body, a grooved wheel, a threaded sleeve, a threaded rod and a handle, and the two shells are attached to the two ends of the top of the box body correspondingly. According to the high-precision double-sided numerical control grinding machine tool, a handle in the grinding mechanism rotates and drives a screw rod to rotate, when the screw rod rotates, a sliding block and a sliding groove are connected in a sliding mode, the sliding block can conduct lifting guide on a threaded sleeve and drive the threaded sleeve to conduct lifting motion, and when the threaded sleeve conducts lifting motion, two rope bodies can be driven to conduct lifting motion; through traction of the rope body, the first motor is driven to conduct upward or downward angle adjustment with the round rod as the circle center, then the placement angle of the grinding cutter is changed according to the actual machining requirement, and then grinding machining of different angles can be conducted on a workpiece.

Owner:南京创维镜成科技有限公司

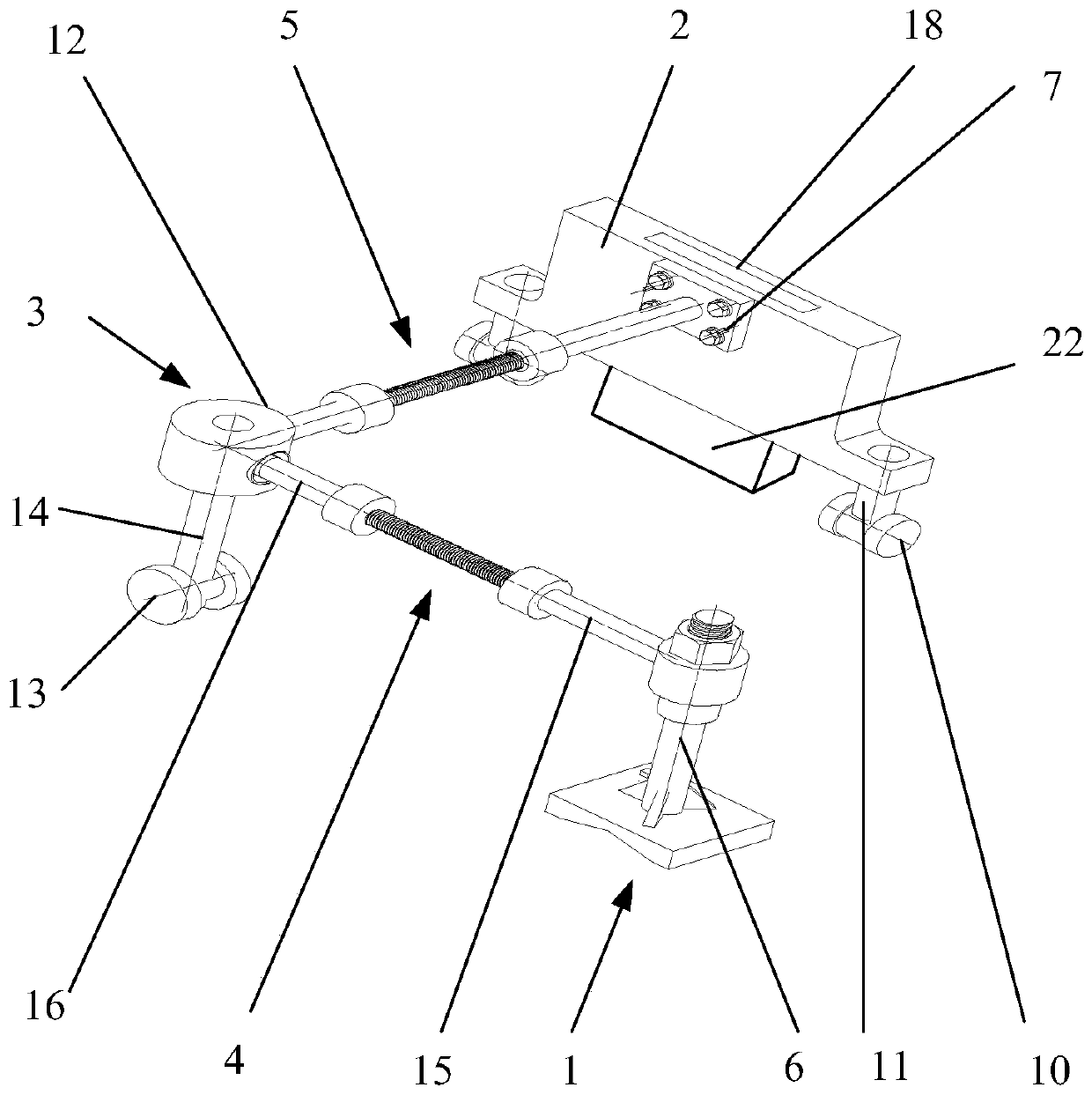

Positioning tool for eccentric boss of gas turbine case

ActiveCN110125700BChange the placement angleReduce processing difficultyLarge fixed membersPositioning apparatusMachine buildingStructural engineering

The invention discloses a positioning tool for an eccentric boss of a gas turbine casing, and belongs to the technical field of gas turbine product mechanical manufacture. The positioning tool comprises a base, a positioning plate, a connection assembly, a first telescopic rod and a second telescopic rod. The base comprises a centering rod. One end of the first telescopic rod is hinged to the centering rod. The first telescopic rod is perpendicular to the centering rod. The other end of the first telescopic rod is connected with the connection assembly. One end of the second telescopic rod isconnected with the connection assembly, and the other end of the second telescopic rod is perpendicularly connected with the positioning plate. The second telescopic rod is perpendicular to the firsttelescopic rod and the centering rod. The surface, connected with the second telescopic rod, of the positioning plate comprises a positioning line. The positioning line is parallel to the axis of thecentering rod. According to the positioning tool, positioning of the eccentric boss can be completed in the manner of regulating the length of the telescopic rods and rotating the positioning tool, and the machining difficulty is lowered.

Owner:WUHAN MARINE MACHINERY PLANT

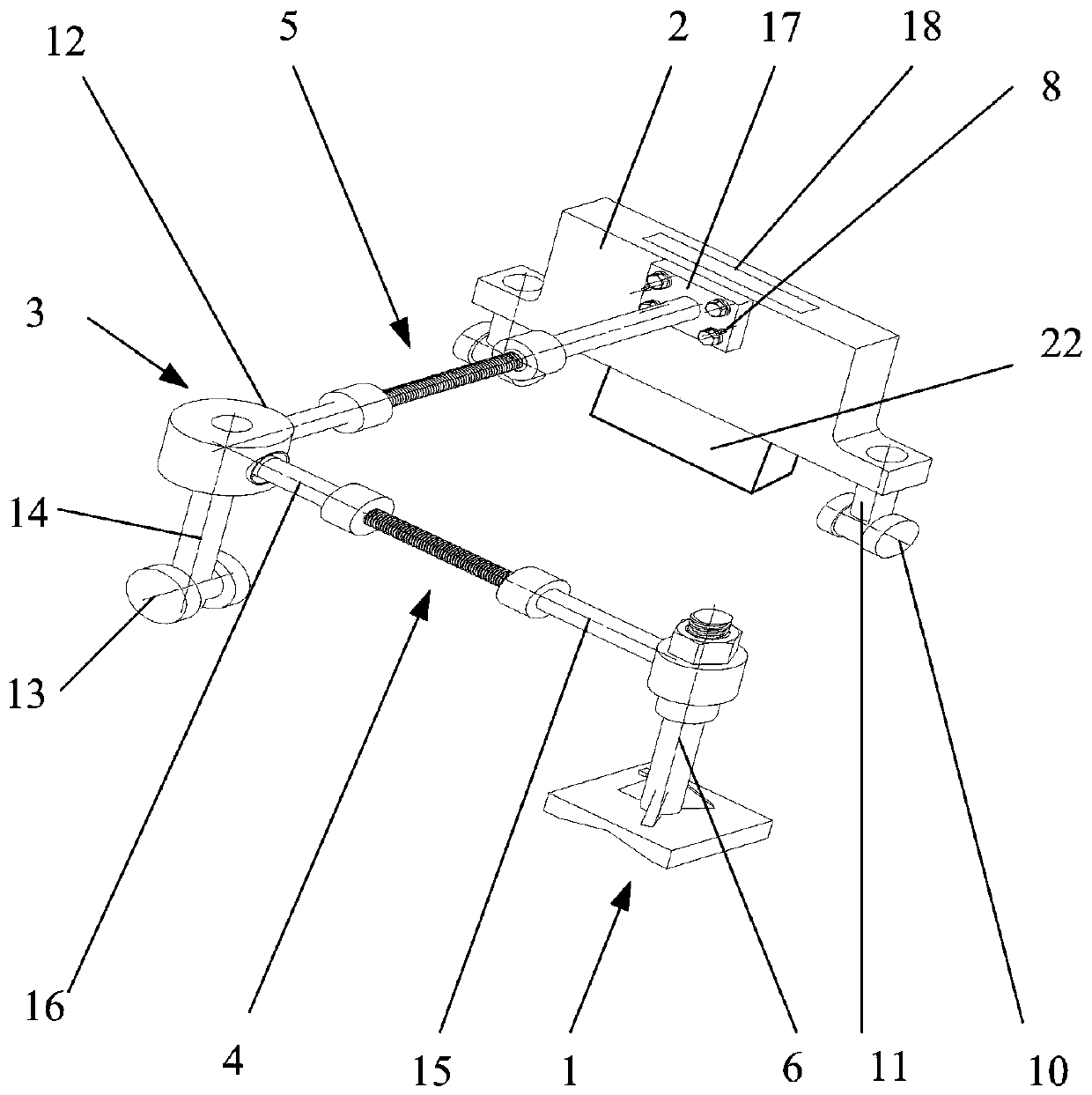

Novel computer keyboard

InactiveCN105117027AEasy to useDoes not require external power consumptionInput/output for user-computer interactionAudio power amplifierComputer science

The invention relates to a novel computer keyboard, which comprises a keyboard frame and keys, wherein the keys are embedded in the keyboard frame; a sensor, a ray amplifier and a ray collector, which are successively connected, are laid on the surface of the keyboard frame in which the keys are embedded; a photoelectric converter is arranged in the keyboard frame and is connected with the ray collector; each key comprises a key column and a key shell, wherein the key shell is sheathed on the key column, a symbol is marked on the key column, and the key shell is made of transparent materials; and a illuminant is arranged between each key column and each key shell and is connected with the photoelectric converter. The novel computer keyboard converts ray emitted from a computer screen into electric energy, the illuminant is installed in each key, the illuminants illuminate the keyboard by the converted electric energy so as to cause the novel keyboard to be normally used in dark places without consuming external electric energy, and therefore, the novel computer keyboard has the advantages of energy saving and environment protection.

Owner:陈丹

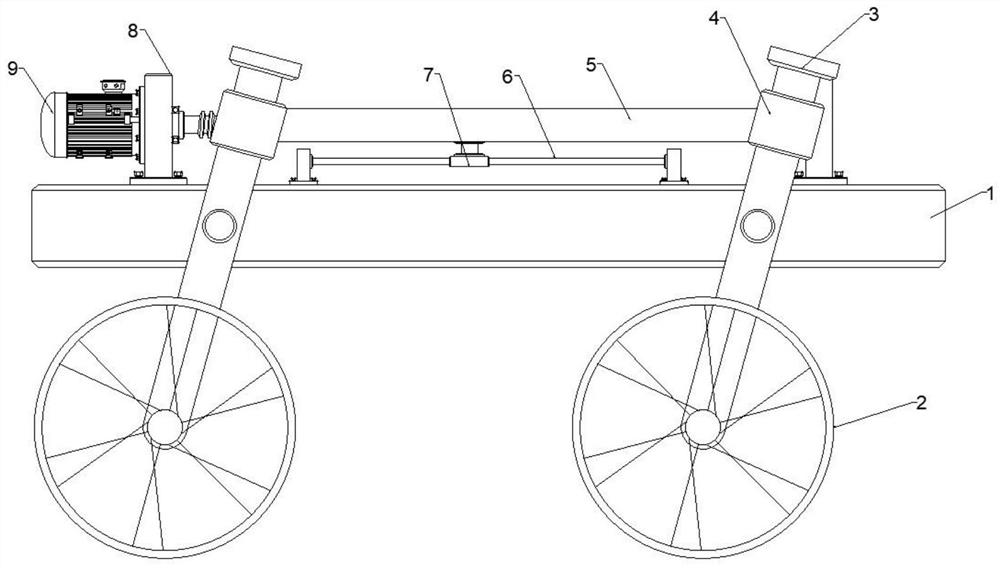

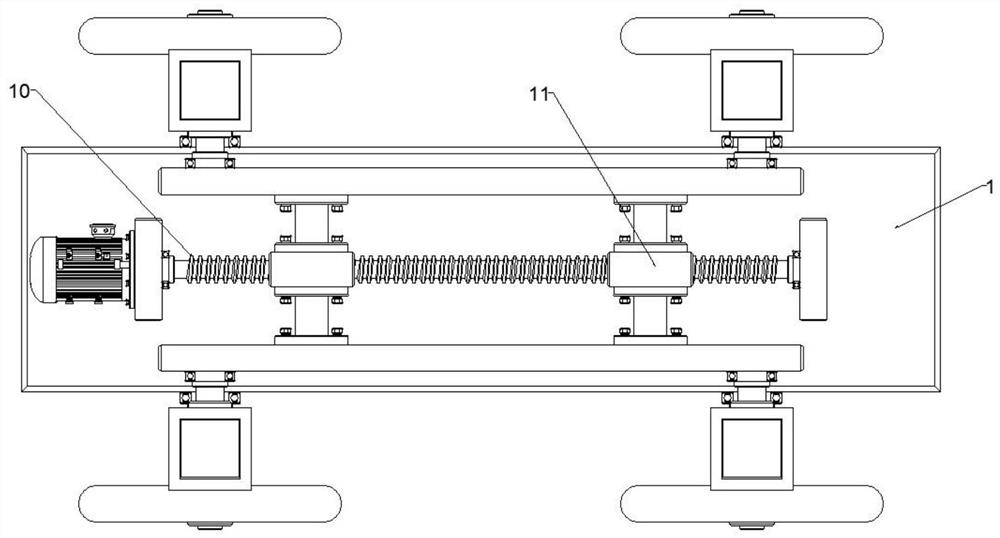

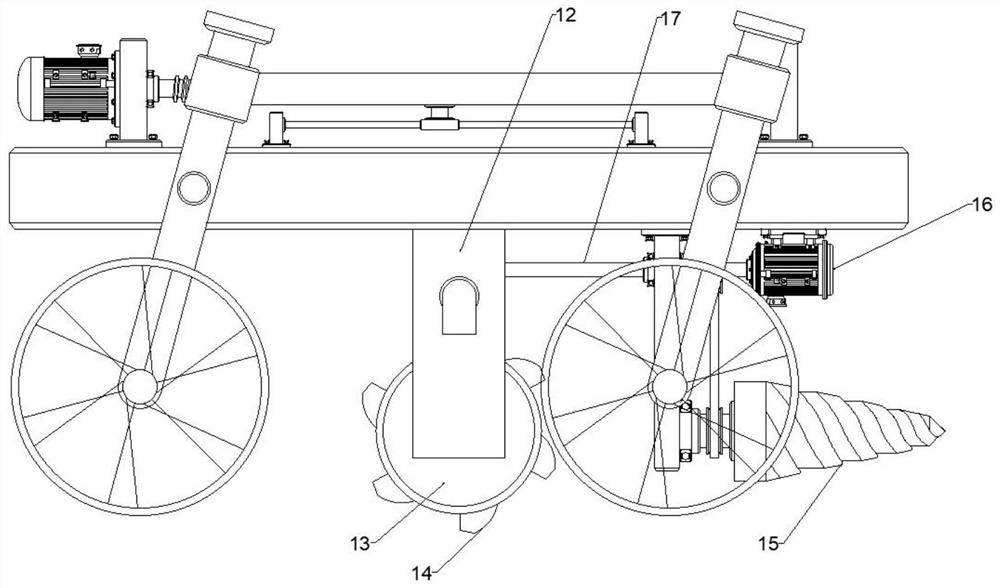

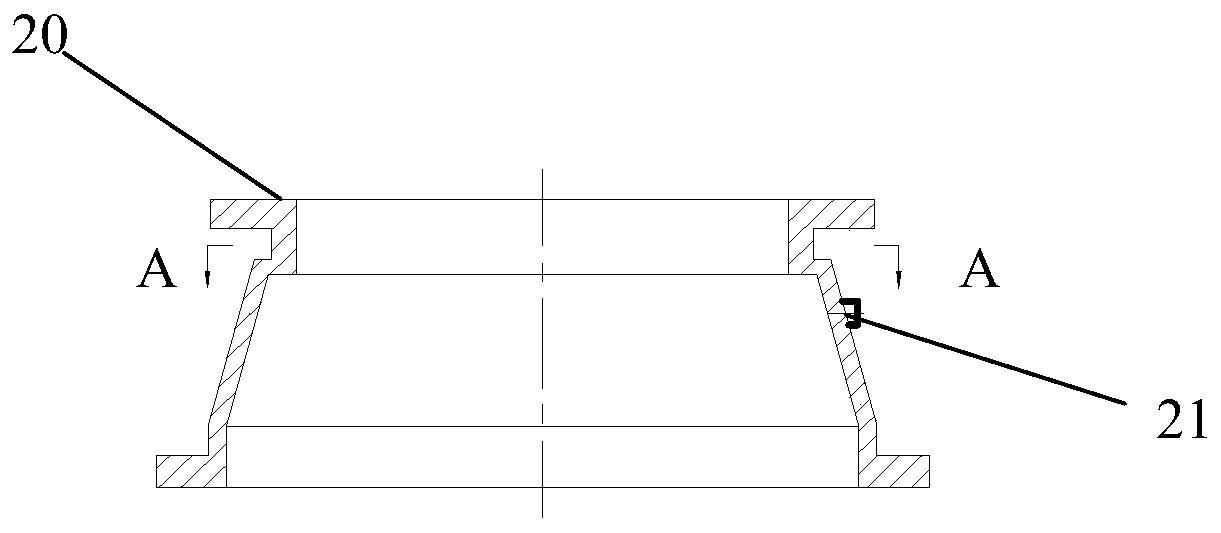

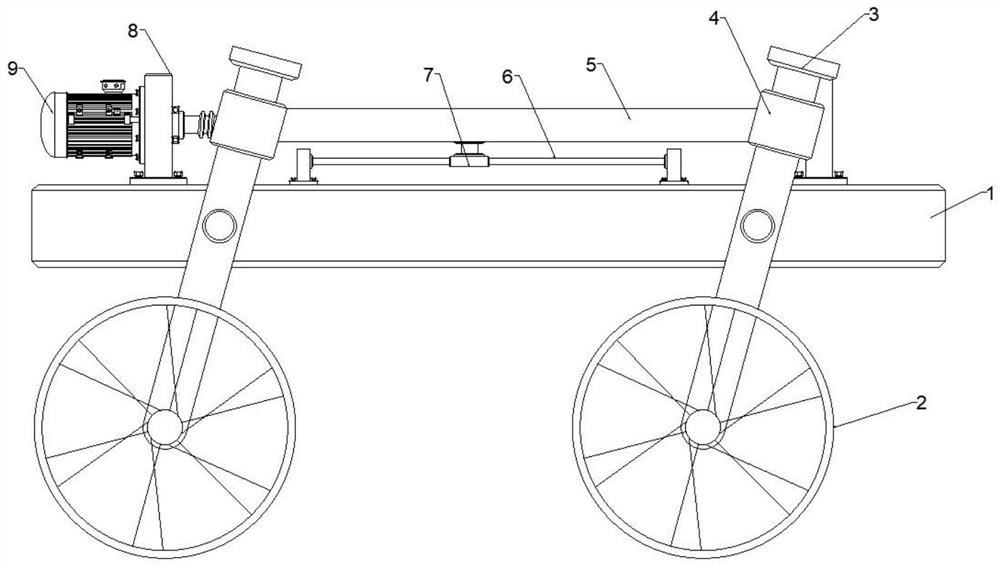

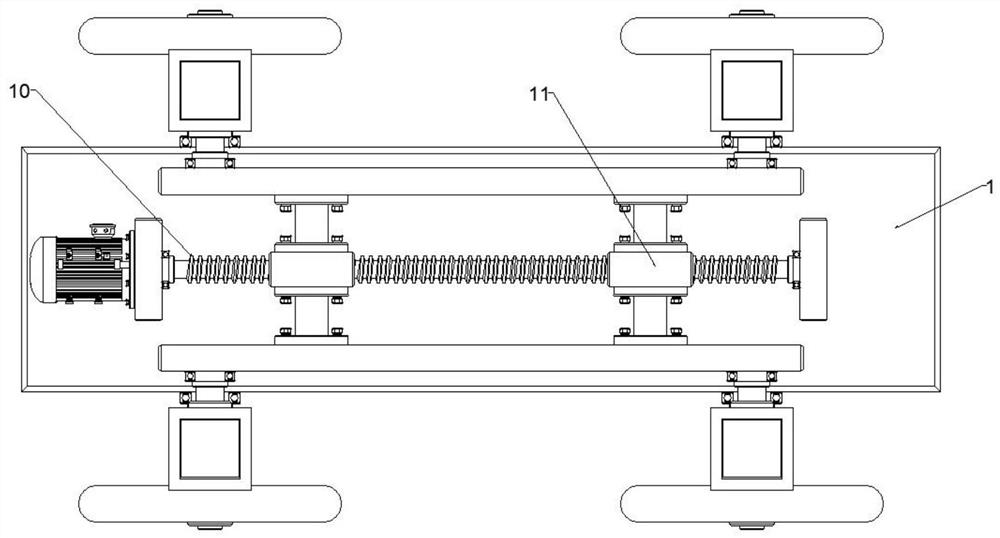

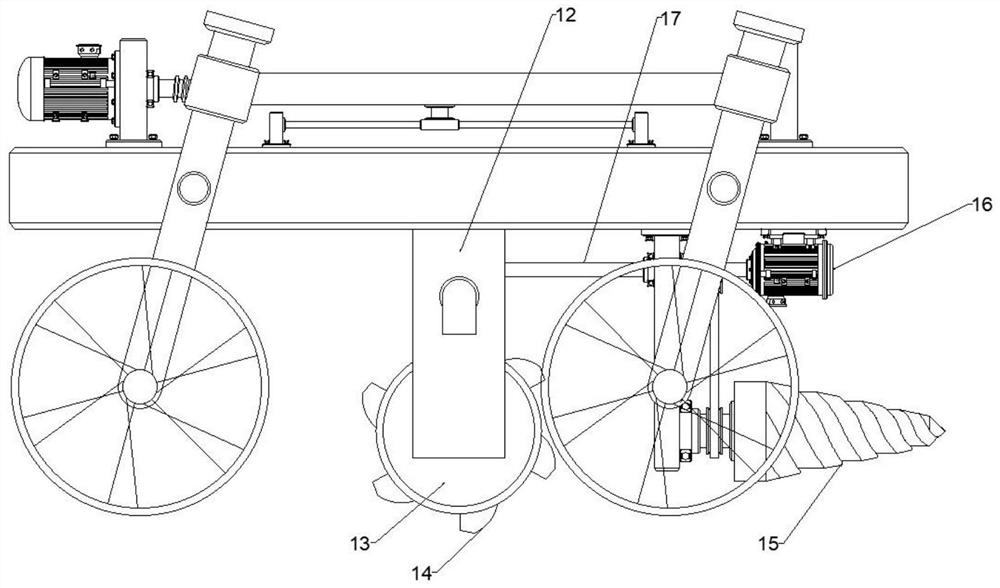

A height-adjustable mechanical arm and a farmland ditch-drilling robot

ActiveCN112627263BChange the placement angleGuaranteed stabilityMechanical machines/dredgersVehicle frameControl theory

The invention relates to a height-adjustable mechanical arm and a robot for farmland ditching. The height-adjustable mechanical arm includes a vehicle frame and two sets of roller assemblies installed on both sides of the vehicle frame. The roller assemblies are included in Rotate the support frame mounted on the vehicle frame and the wheel mounted on the support frame. The support frame is covered with a movable sleeve that slides with it. The two supports on the same side of the vehicle frame The movable sleeve on the frame is rotatably connected with the driving rod movably installed on the vehicle frame, and the driving rod is slidably connected with the vehicle frame through a guide assembly, and is connected with a mobile driving mechanism arranged on the vehicle frame. Drive the driving rod to move horizontally through the moving drive mechanism, so as to cooperate with the action of the movable sleeve to drive the support frame to rotate to change the placement angle of the support frame. When connecting the ditch roller, the depth of the ditch can be adjusted without facing the ditch roller. The frame is adjusted to ensure the stability of the ditch roller during work.

Owner:湖南鸿云杭萧绿建科技有限公司

Positioning tool for eccentric boss of gas turbine casing

ActiveCN110125700AChange the placement angleReduce processing difficultyLarge fixed membersPositioning apparatusGas turbinesEngineering

The invention discloses a positioning tool for an eccentric boss of a gas turbine casing, and belongs to the technical field of gas turbine product mechanical manufacture. The positioning tool comprises a base, a positioning plate, a connection assembly, a first telescopic rod and a second telescopic rod. The base comprises a centering rod. One end of the first telescopic rod is hinged to the centering rod. The first telescopic rod is perpendicular to the centering rod. The other end of the first telescopic rod is connected with the connection assembly. One end of the second telescopic rod isconnected with the connection assembly, and the other end of the second telescopic rod is perpendicularly connected with the positioning plate. The second telescopic rod is perpendicular to the firsttelescopic rod and the centering rod. The surface, connected with the second telescopic rod, of the positioning plate comprises a positioning line. The positioning line is parallel to the axis of thecentering rod. According to the positioning tool, positioning of the eccentric boss can be completed in the manner of regulating the length of the telescopic rods and rotating the positioning tool, and the machining difficulty is lowered.

Owner:WUHAN MARINE MACHINERY PLANT

Handheld terminal public opinion equipment

InactiveCN109839989AEasy to fixImprove protectionDigital data processing detailsIndustrial engineering

Owner:袁辉

Photographing equipment for criminal investigation

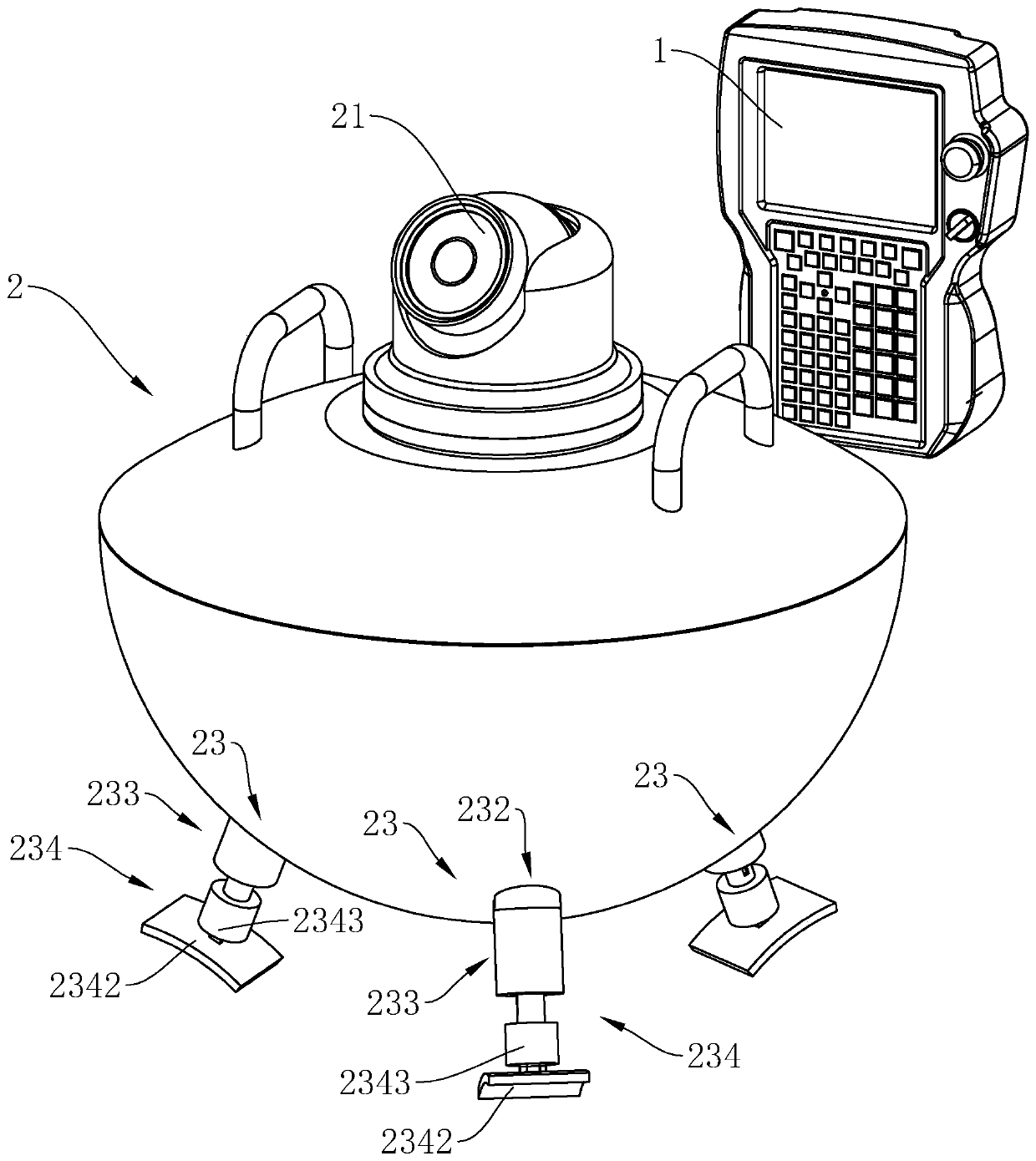

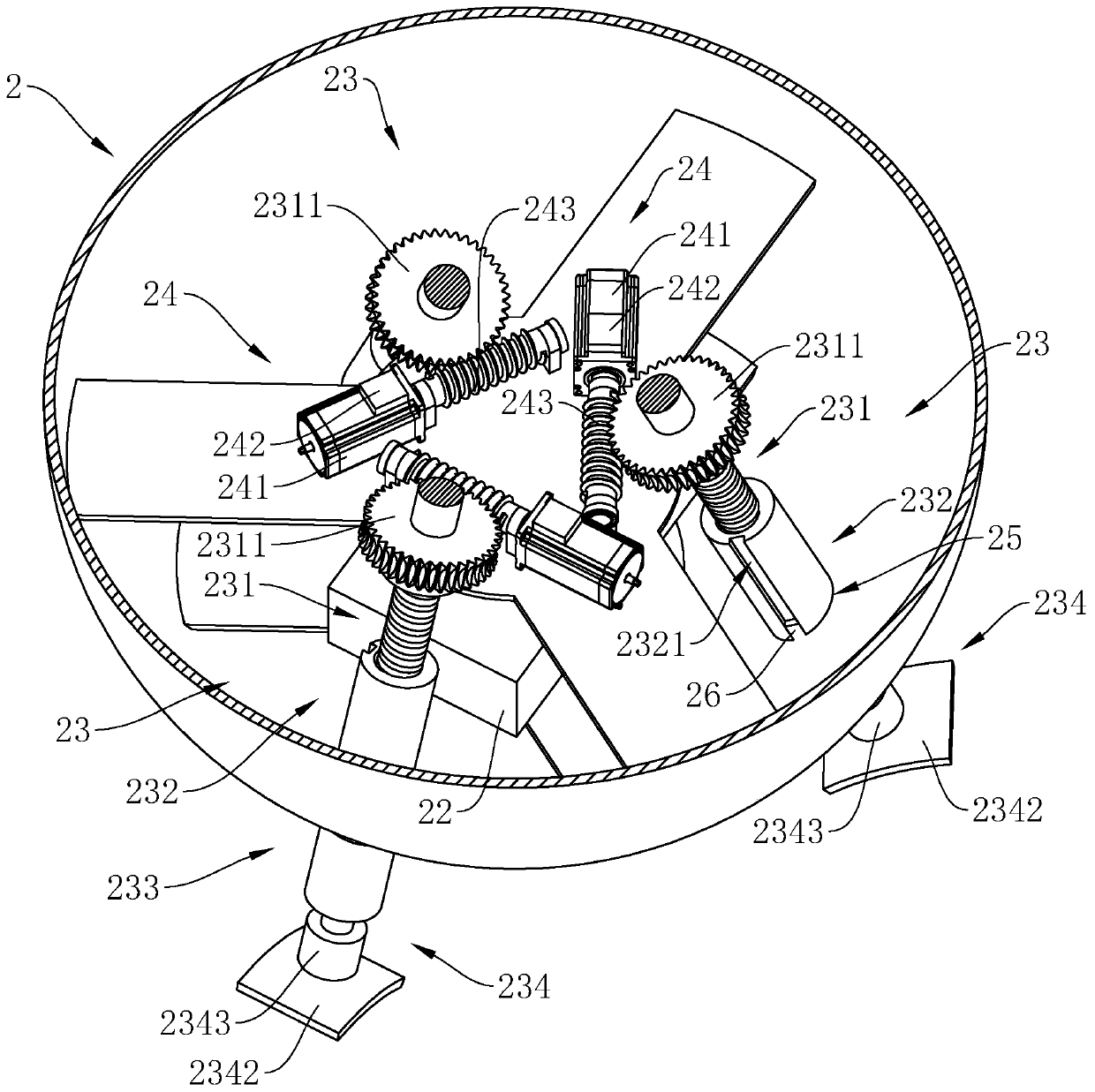

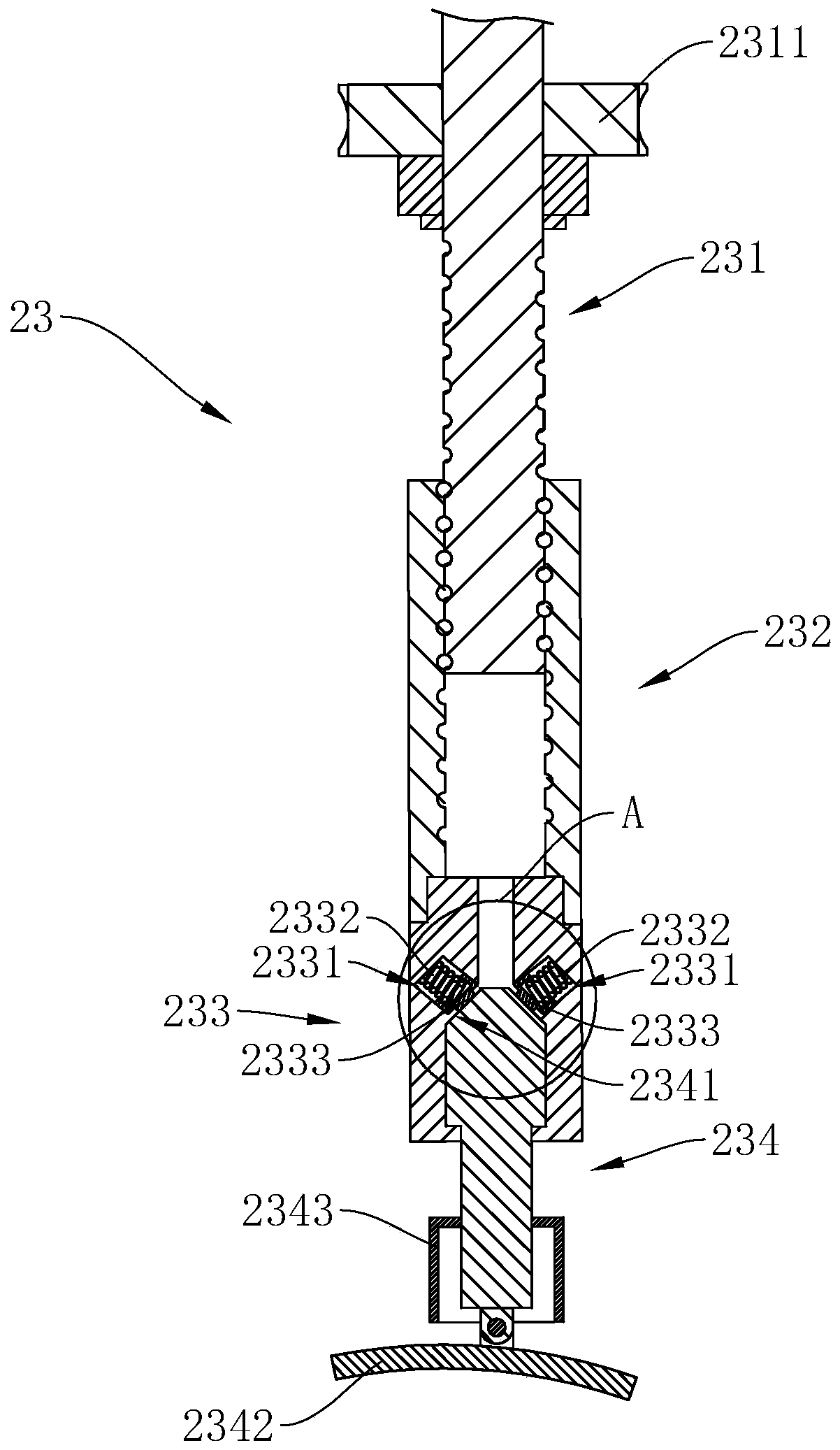

ActiveCN110336936AChange the placement angleAdjust the placement angleTelevision system detailsColor television detailsEngineering

The invention relates to photographic equipment for criminal investigation. The photographic equipment comprises a remote controller, a shell and a panoramic camera mounted at the top of the shell; astorage battery, three adjusting assemblies and three driving assemblies are installed in the shell. Each adjusting assembly is connected to the corresponding driving assembly; the driving assembly and the panoramic camera are electrically connected to the storage battery and are wirelessly connected to the remote controller; each adjusting assembly comprises a lead screw rotationally supported inthe shell. The three screw rods are obliquely arranged and form a triangular pyramid shape; the outer sides of the screw rods are in threaded connection with adjusting sleeves; three extending holesare formed in the positions, corresponding to the three adjusting sleeves, of the bottom of the shell, the adjusting sleeves extend out of the shell through the corresponding extending holes, blockinggrooves are formed in the side walls of the adjusting sleeves, a blocking block is fixed to the position, corresponding to each blocking groove, in the shell, and the blocking blocks are matched withthe blocking grooves. The panoramic equipment has the effect that the shell can be adjusted so as to change the placement angle of the panoramic camera.

Owner:小雨信通(北京)科技有限公司

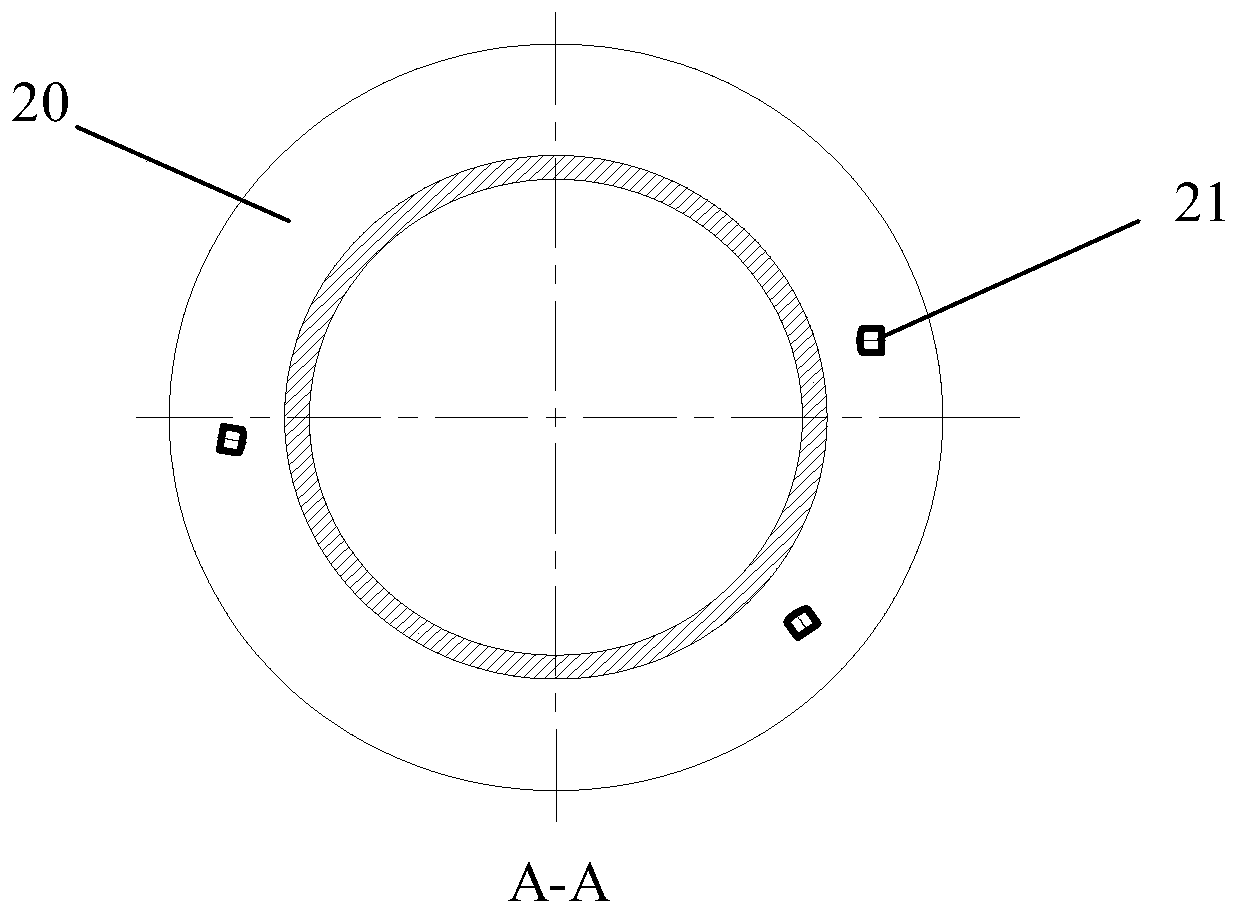

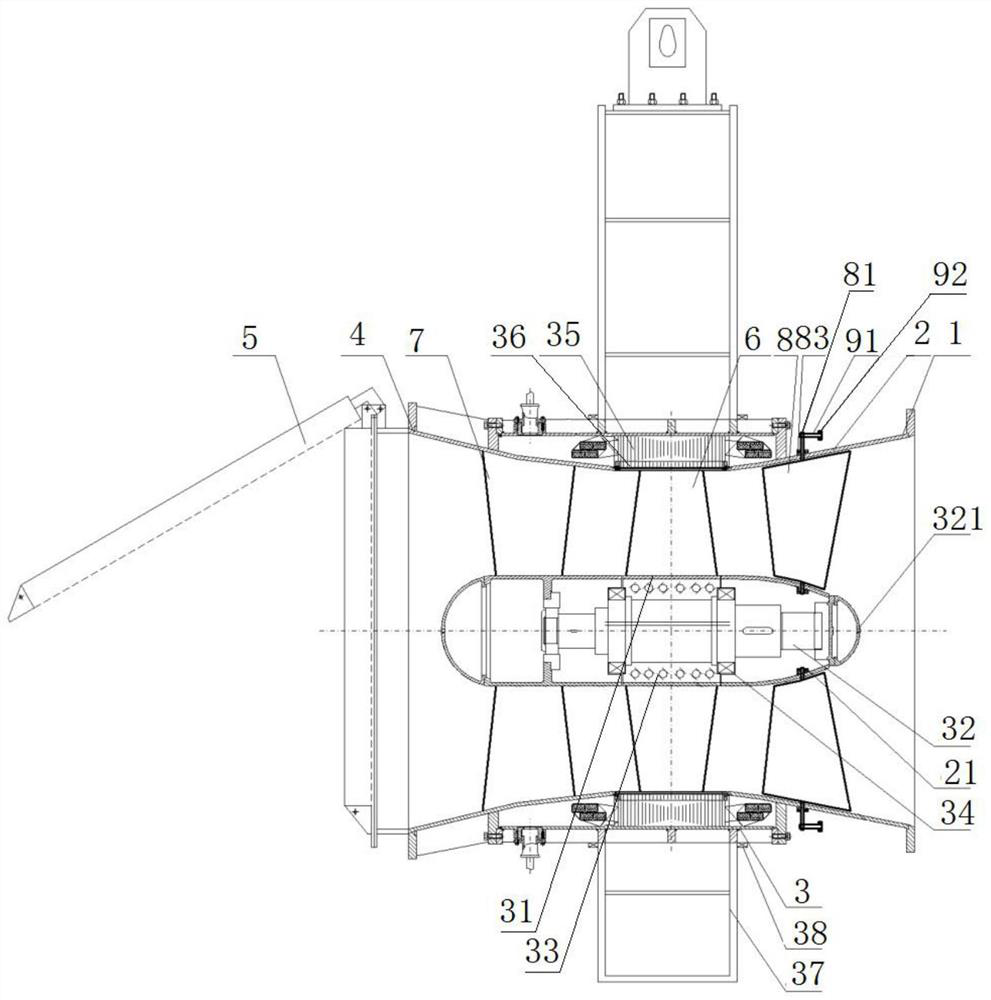

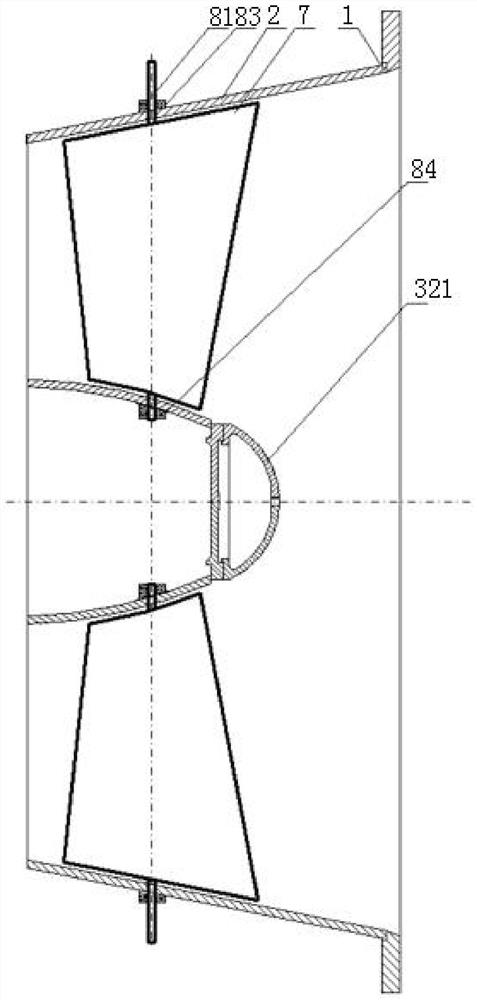

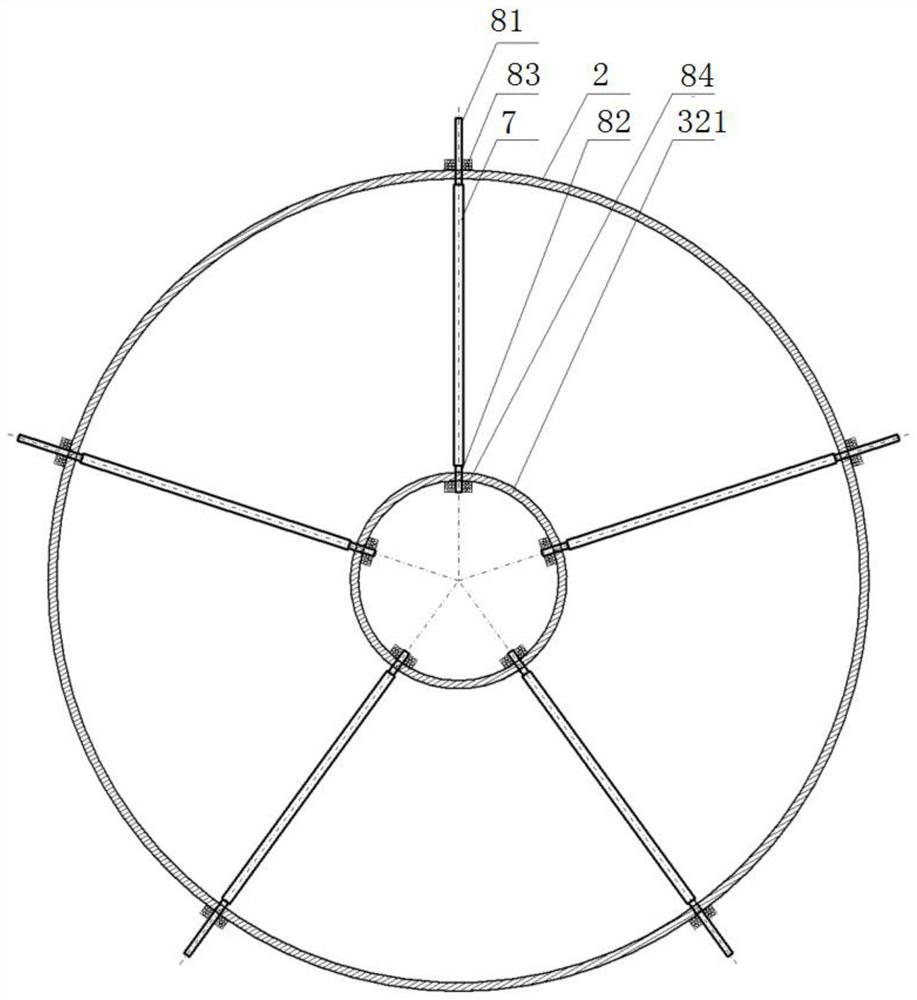

Submersible full-through-flow gate pump with front guiding vane with adjustable placing angle

PendingCN113464492AImplement dynamic configurationAchieve maximum utilizationPump componentsCircumferential flow pumpsImpellerWater flow

The invention discloses a submersible full-through-flow gate pump with a front guiding vane with an adjustable placing angle, and relates to the field of water conservancy and water affairs and fluid machinery optimization design. The submersible full-through-flow gate pump with the front guiding vane with the adjustable placing angle sequentially comprises a water inlet horn mouth, a front guiding vane body, a pump shell, a rear guiding vane body and a flap valve from a water flow inlet to a water flow outlet, wherein impeller hubs are arranged in the front guiding vane body, the pump shell and the rear guiding vane body; stators are arranged in the pump shell, and rotors are arranged in the stators; one ends of impellers are welded with inner cavities of the rotors, and the other ends are connected with the impeller hubs; pump shafts are arranged in the impeller hubs, and the inner parts of the impeller hubs are connected with the pump shafts through pump shaft bearings; one end of a rear guiding vane is welded with an inner cavity of the rear guiding vane body, and the other end is connected with the impeller hubs. According to the submersible full-through-flow gate pump with the front guiding vane with the adjustable placing angle, by adjusting the placing angle of the front guiding vane, accurate and intelligent adjustment of the water supply flow of a main canal can be achieved, and then the traditional working mode that the overflowing flow is adjusted by changing the lifting amplitude of a gate along a line is replaced.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Elevation-adjustable mechanical arm and robot for farmland channeling

ActiveCN112627263AChange the placement angleGuaranteed stabilityMechanical machines/dredgersVehicle frameControl theory

The invention relates to an elevation-adjustable mechanical arm and a robot for farmland channeling. The elevation-adjustable mechanical arm comprises a frame and two groups of roller components arranged at two sides of the frame, wherein each roller component comprises a support frame rotationally arranged on the frame and a wheel rotationally arranged on the support frame; movable sleeves matched with the support frames in a sliding mode are arranged on the support frames in a sleeved mode; the movable sleeves on the two support frames located at the same side of the frame are rotationally connected to a drive rod movably arranged on the frame; and the drive rod is connected to the frame in a sliding mode through a guide component and connected to a moving driving mechanism arranged on the frame. The moving driving mechanism drives the drive rod to move horizontally, so that the support frames are driven to rotate under the action of the movable sleeves, the placement angles of the support frames are changed, when a channeling roller is connected, the channeling depth can be adjusted, the channeling roller does not need to be adjusted relative to the frame, and the stability of the channeling roller in the working process is guaranteed.

Owner:湖南鸿云杭萧绿建科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com