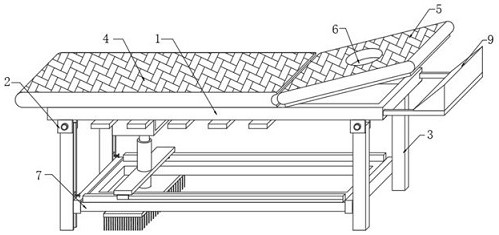

Folding massage bed with automatic bed bottom cleaning function

An automatic cleaning and folding technology, applied in vibration massage, carpet cleaning, floor cleaning, etc., can solve the problems of heavy workload of medical staff, poor experience of the people to be massaged, and large dust accumulation at the bottom of the bed, so as to improve the comfort of massage. , The effect of easy cleaning and comfortable neck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

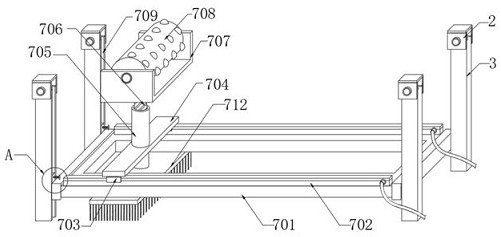

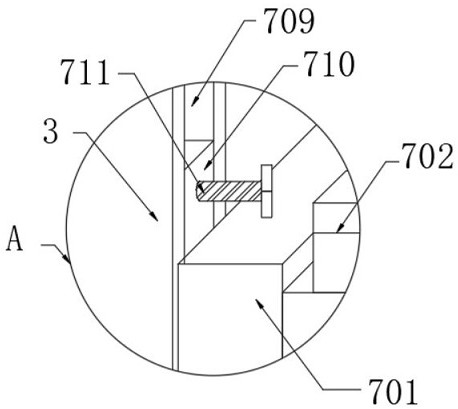

[0031] See 2- image 3 , in the embodiment of the present invention, the cleaning assembly 7 includes: a support frame 701 arranged under the bed frame 1, two electric control guide rails 702 are fixed on the upper end of the support frame 701, and electric sliding sleeves 703 are slidingly sleeved on the surface of the electric control guide rails 702; The connecting plate 704 at the upper end of the two electric sliding sleeves 703 is fixed with a sleeve 705 inside the connecting plate 704, and a cleaning brush 712 is fixed on the lower surface of the sleeve 705; The upper end surface is fixed with a C-shaped plate 707, and the inner cavity of the C-shaped plate 707 is horizontally rotated by a bearing to have a roller 708; 701 is fixedly connected to the slider 710, the internal thread of the slider 710 is engaged with a fastening bolt 711, and the fastening bolt 711 is connected with the inner cavity of the chute 709, and is used to fix the installation height of the slide...

Embodiment 2

[0033] see Figure 4-Figure 5The difference from Embodiment 1 is that the click assembly 8 includes: several support plates 801 fixed to the inner cavity of the bed frame 1 at equal distances in the horizontal direction, and several push rods 802 are inserted through the interior of the several support plates 801 , and several push rods 802 The upper end of the push rod 802 is fixed with a little press head 805; and the top plate 803 fixed on the lower end of several push rods 802, the first spring 804 is fixed between the top plate 803 and the lower end surface of the bed frame 1, and the top plate 803 is set opposite to the roller 708 for Squeeze the click head 805 to move upwards, the roller 708 rotates and squeezes several top plates 803, several top plates 803 can drive the click head 805 to move upward, and the click head 805 can squeeze the mattress 4, making the mattress 4 It can be squeezed to form a bulge, thereby being able to squeeze the acupoints of the person to ...

Embodiment 3

[0035] see Figure 6 The difference from Embodiment 1 is that the headrest assembly 9 includes: two inner rods 901 socketed on one side of the bed frame 1, and a cushion box 902 is fixed on the upper end surface of the inner rods 901; A vibrating plate 903, a vibrating motor 904 is fixed on the lower end of the vibrating plate 903; The inner tube 907 socketed in the inner cavity of 905, the inner tube 907 is fixedly installed with the lower end of the vibrating plate 903, the vibrating plate 903 is arranged opposite to the head pad 5, and is used to make the head pad 5 vibrate, and the end of the bed frame 1 close to the inner rod 901 is equipped with a spring latch , The surface of the inner rod 901 is provided with a plurality of aligning grooves, when the spring pin snaps into the aligning grooves, the inner rod 901 can be fixed.

[0036] The working principle of the present invention is: first place the massage bed at a designated position, and by manually rotating the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com