Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about "Polyazo dyes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dye type polarizing plate

InactiveUS20050003109A1Improve heat resistanceImprove polarization performanceLiquid crystal compositionsMonoazo dyesPolyvinyl alcoholPolarizer

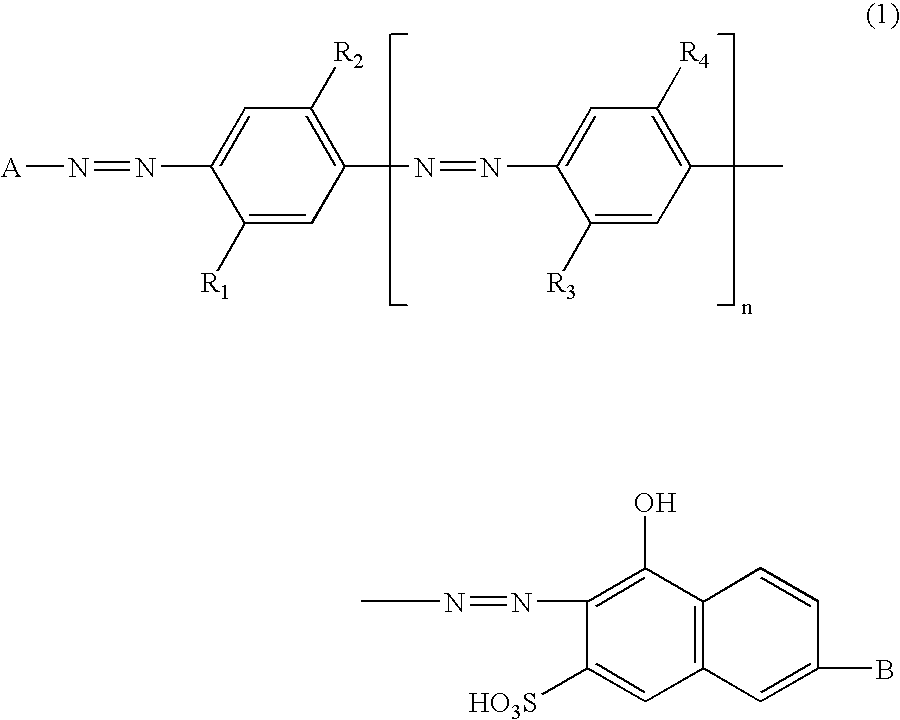

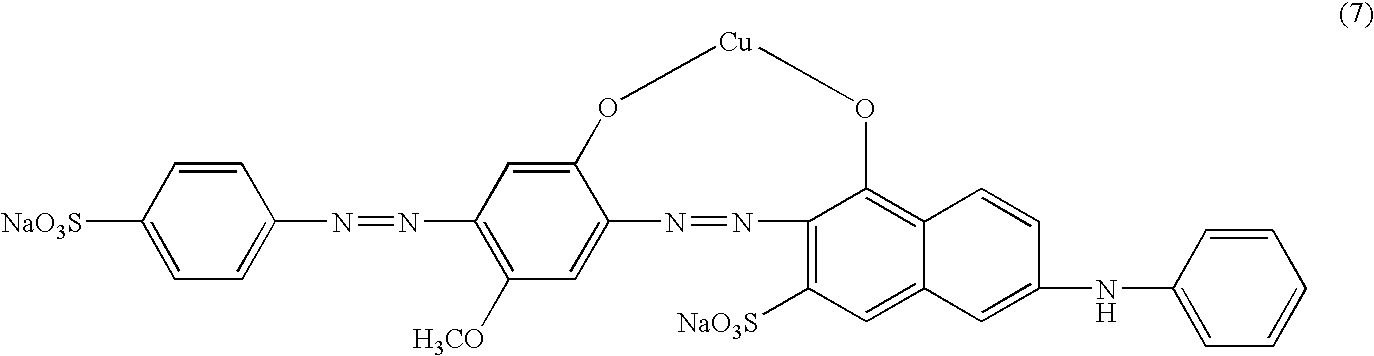

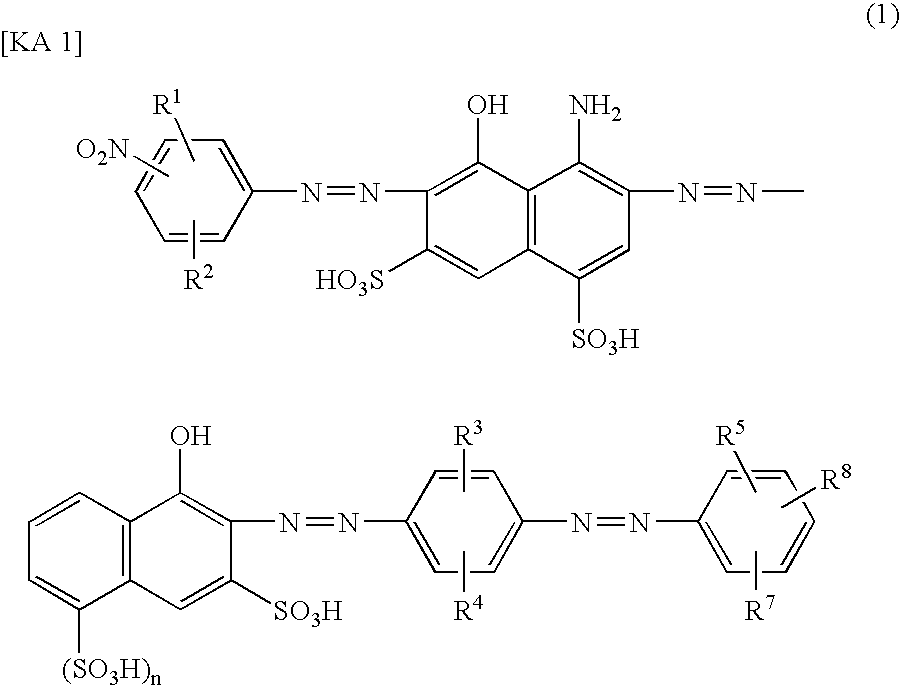

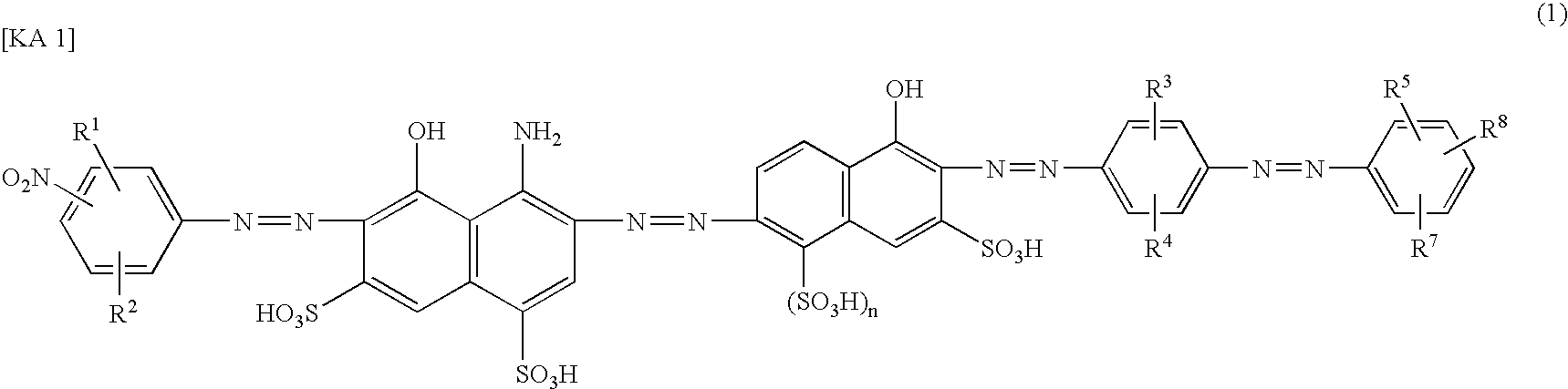

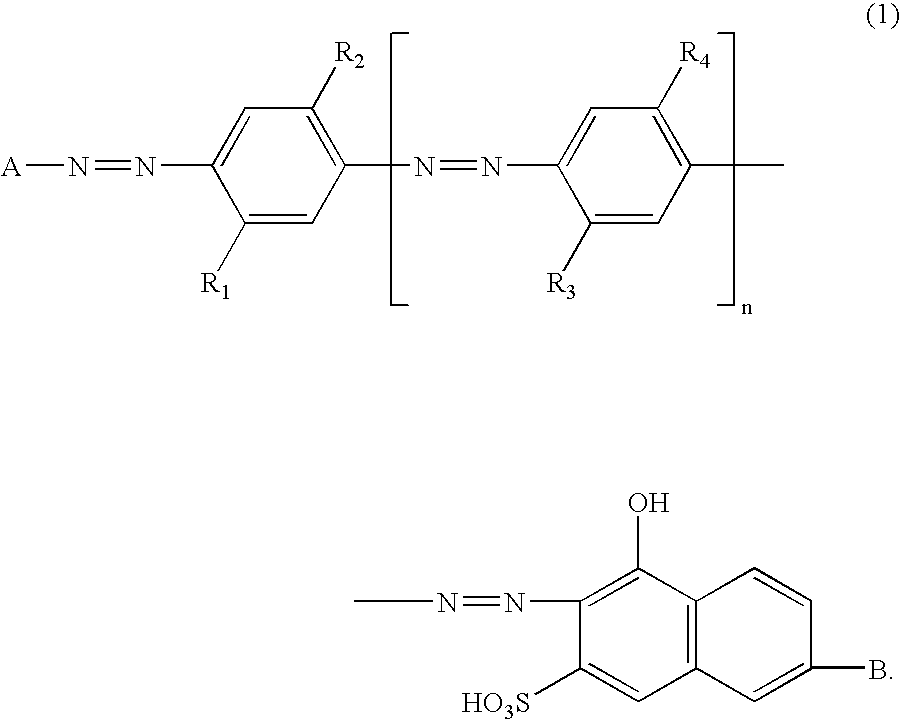

This invention relates to a polyvinyl alcohol type polarizing film or plate which comprises a water-soluble dye having the formula (1) in a free acid form or a copper complex salt thereof. The said polarizing plate has excellent polarizing performance capability and durability, and is suitably used for the green channel of a liquid crystal projector when B in formula (1) is a benzoylamino group and the water-soluble dye has a wave length for maximum absorption (λmax) of 520 nm or more and less than 580 nm.

Owner:NIPPON KAYAKU CO LTD

Dyes for anisotropic dye films, dye compositions for anisotropic dye films, anisotropic dye films and polarizing elements

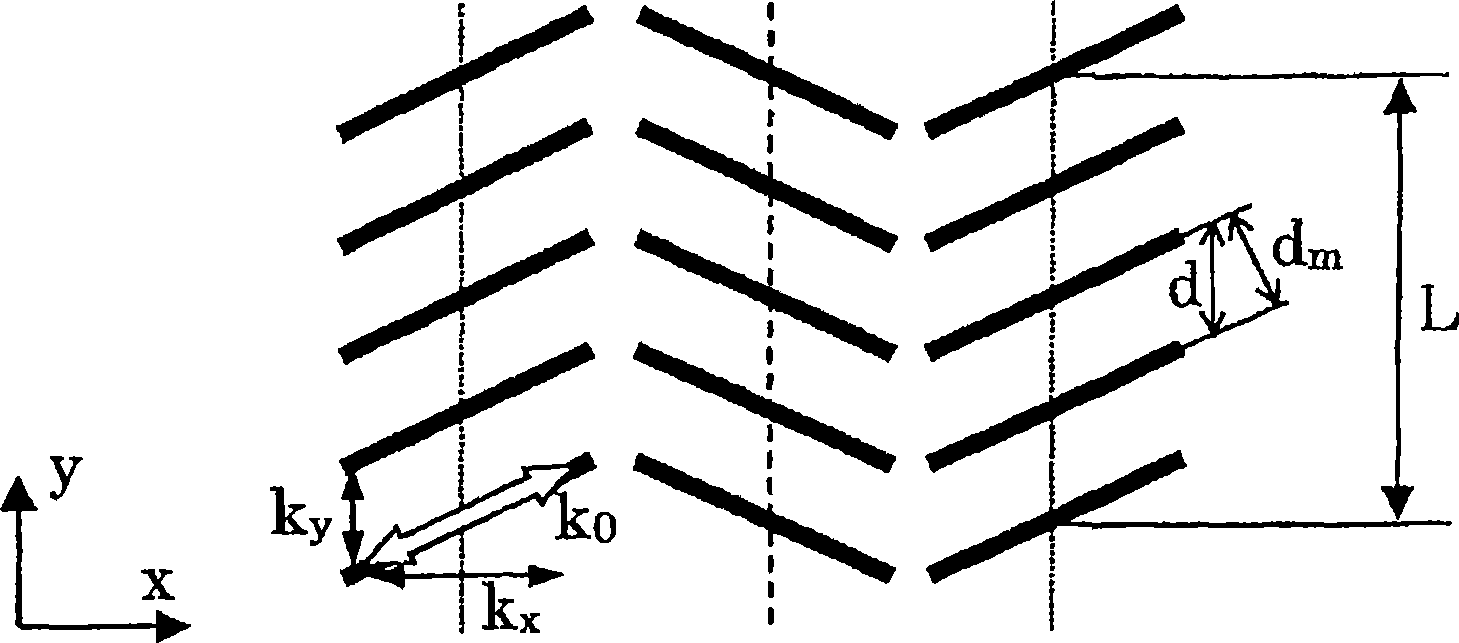

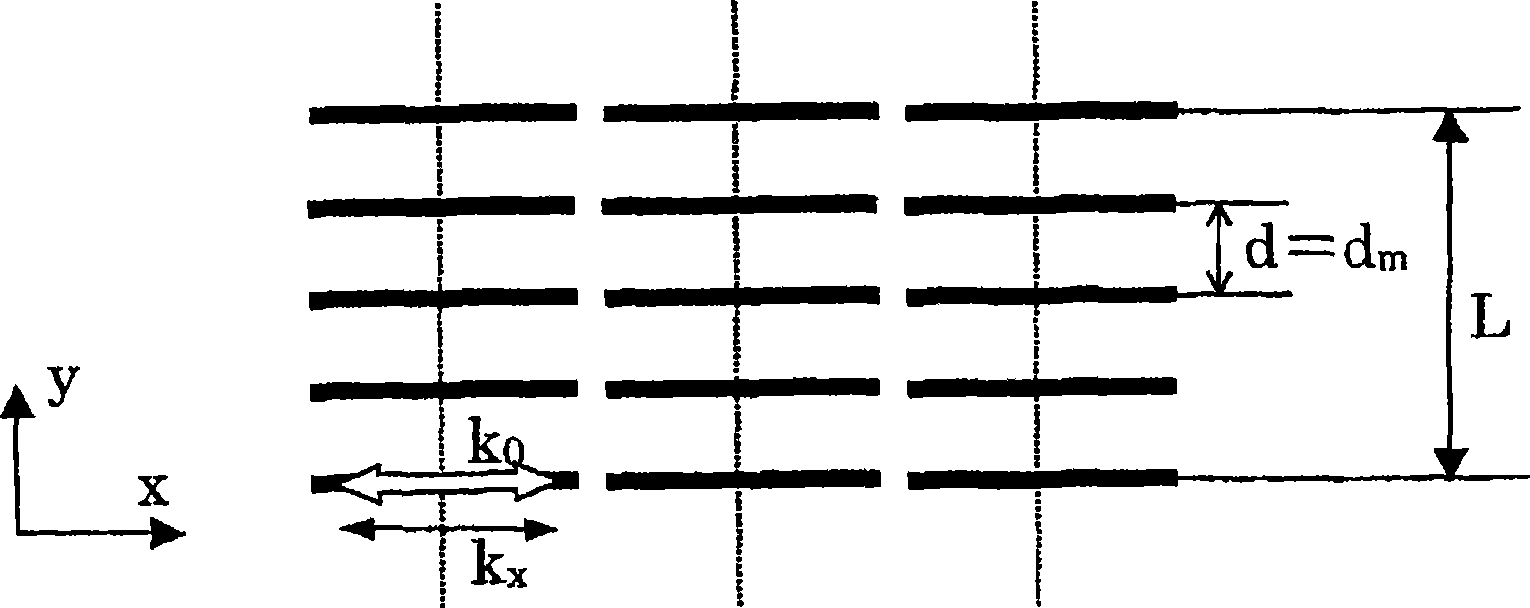

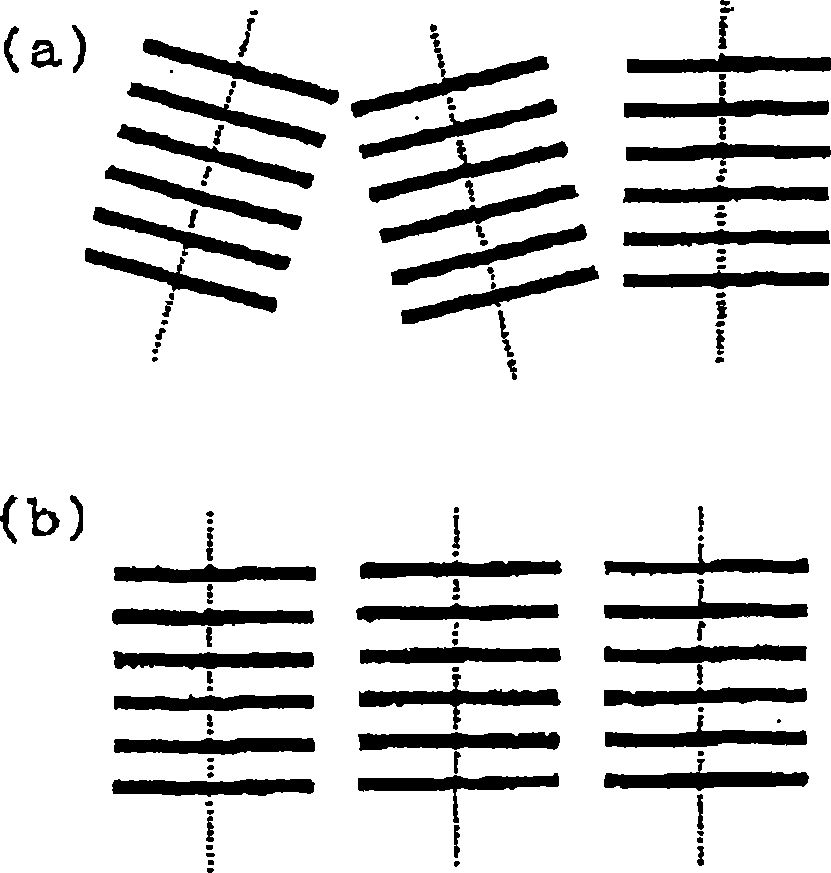

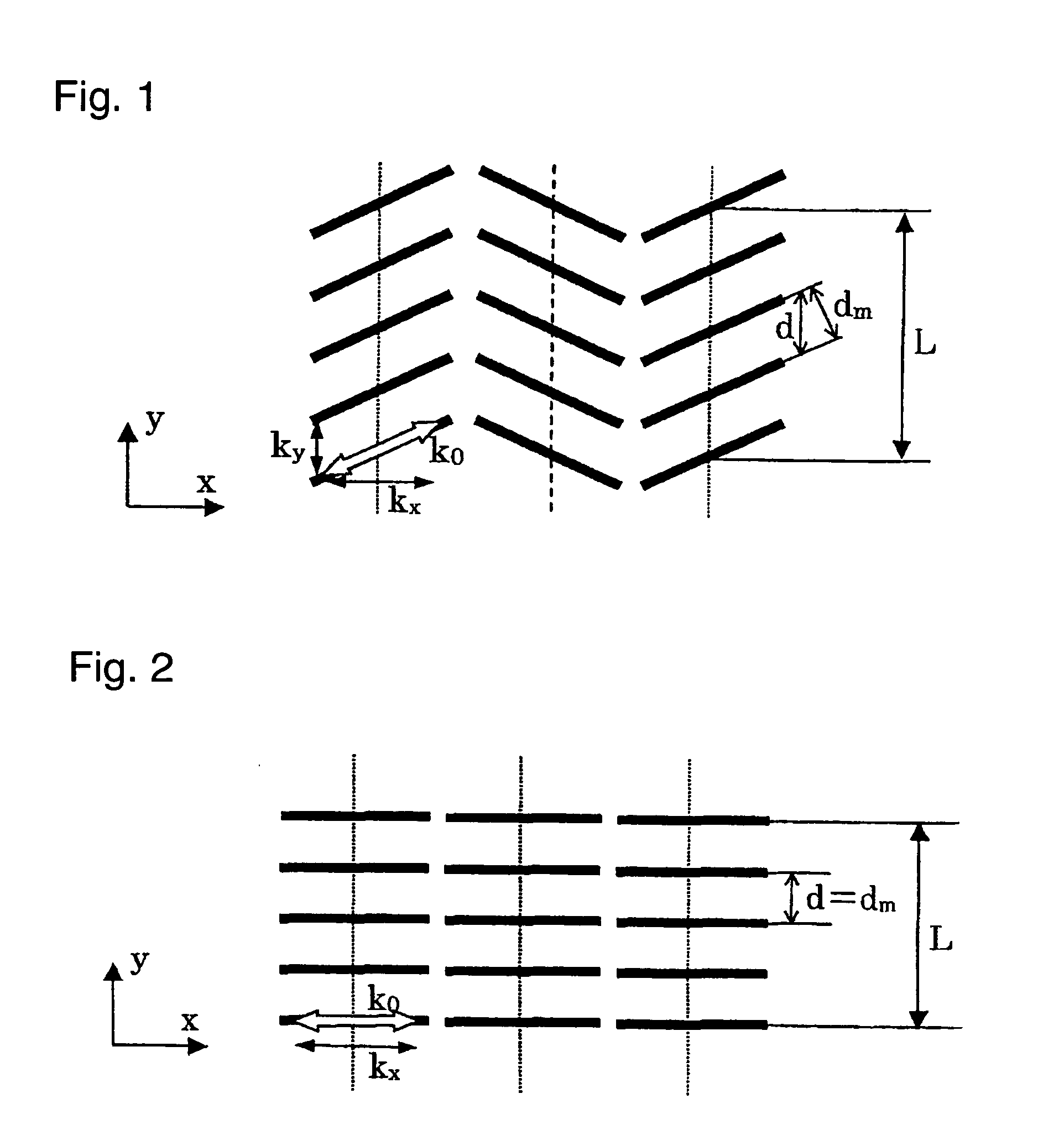

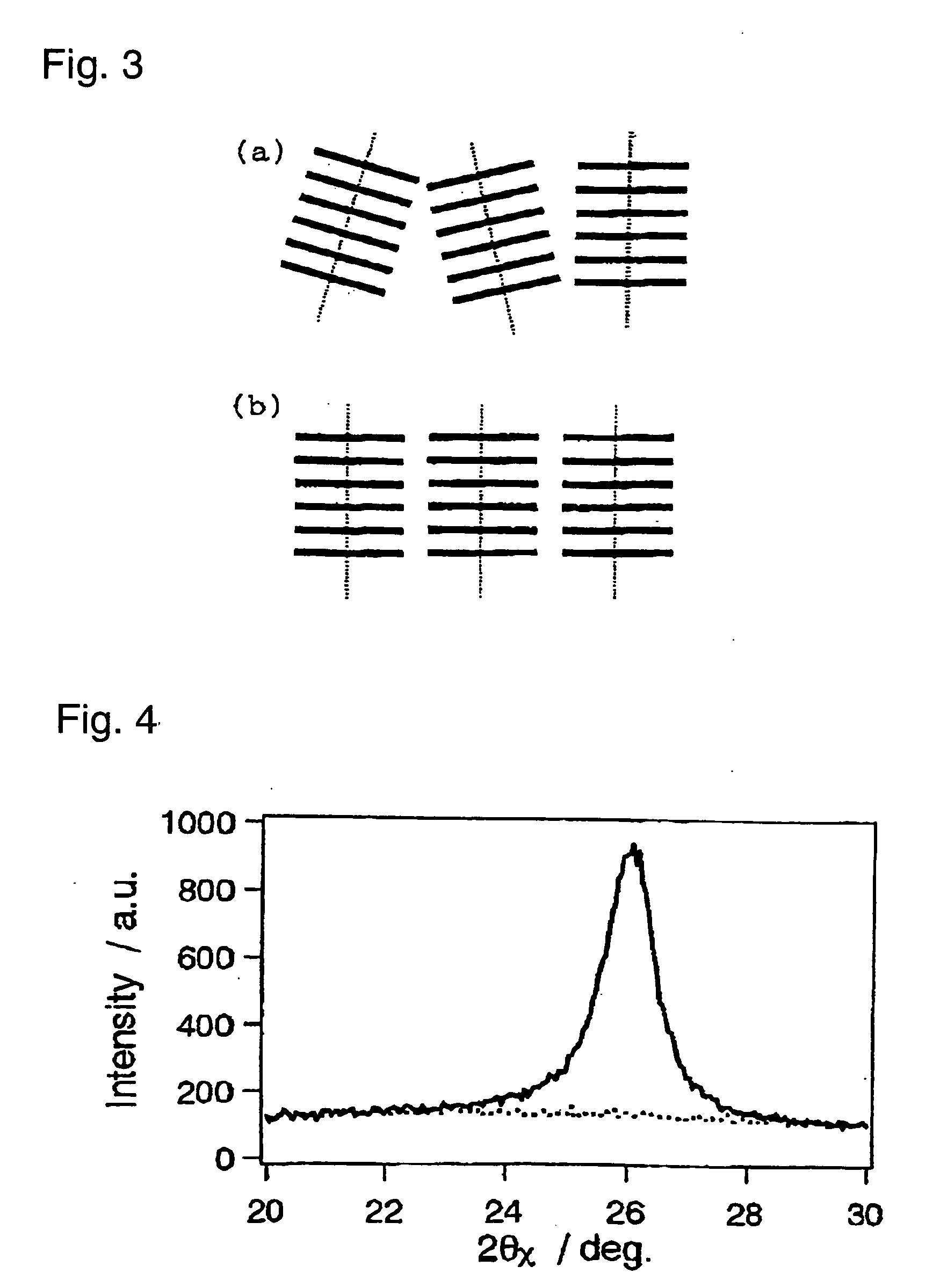

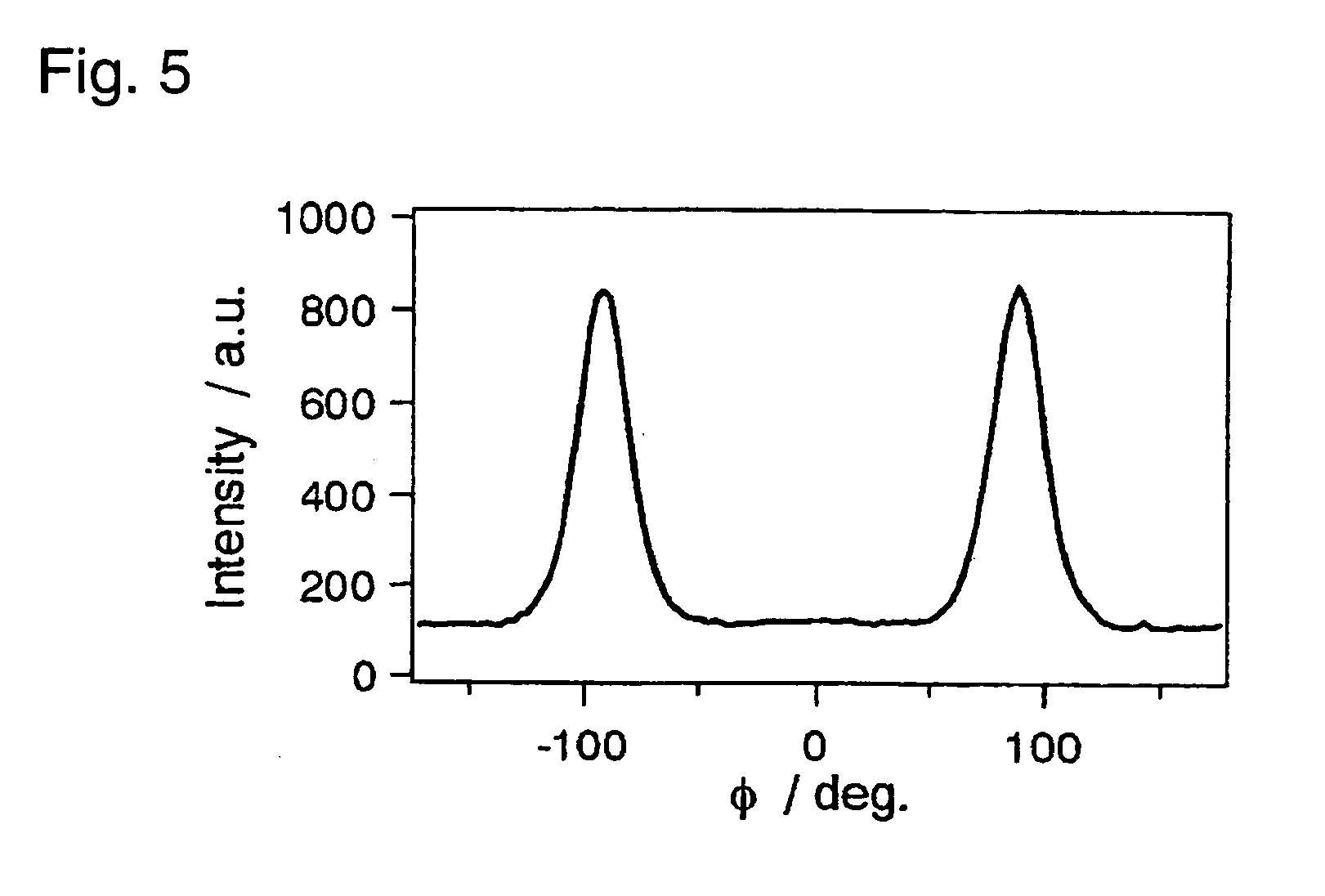

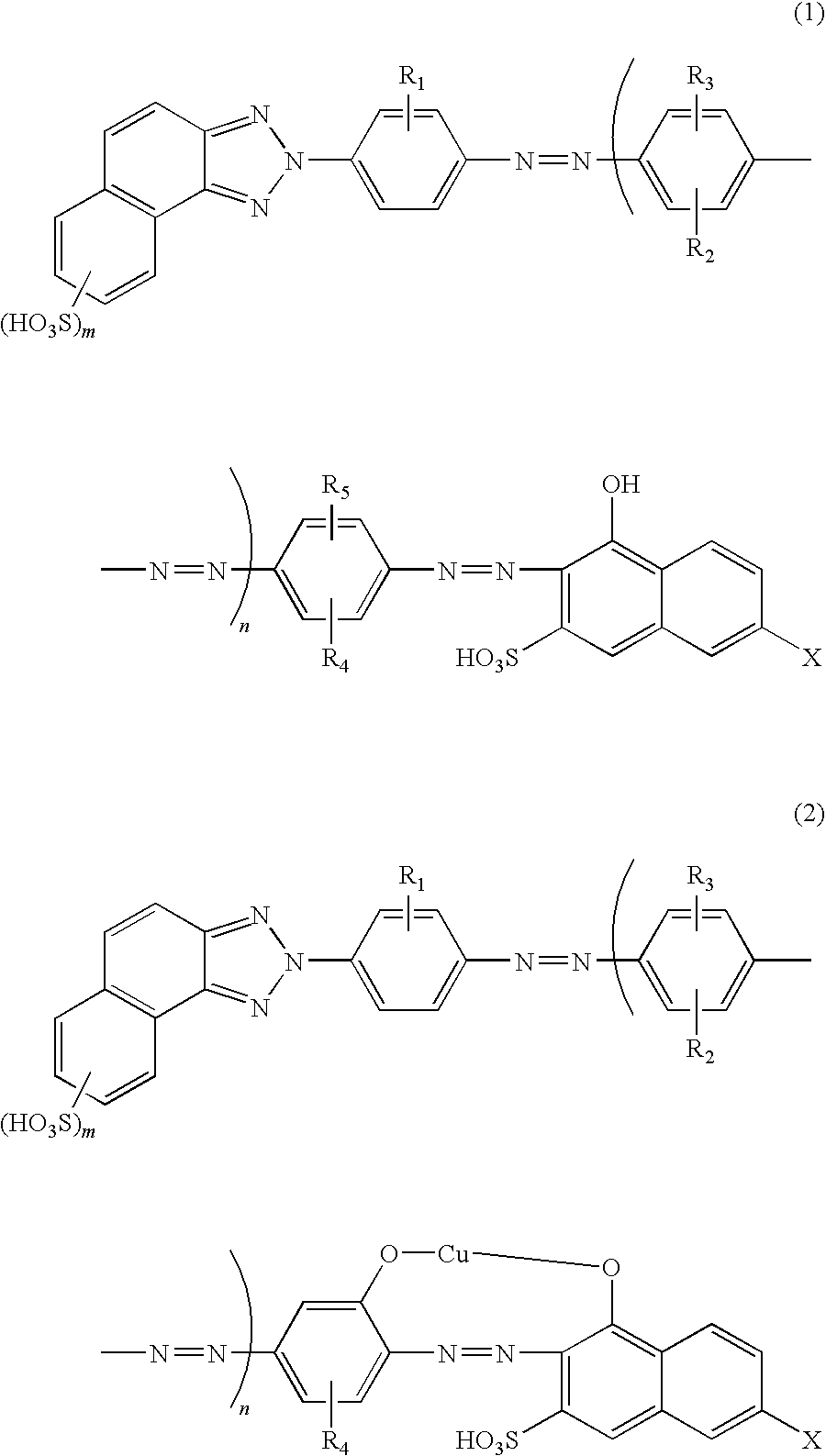

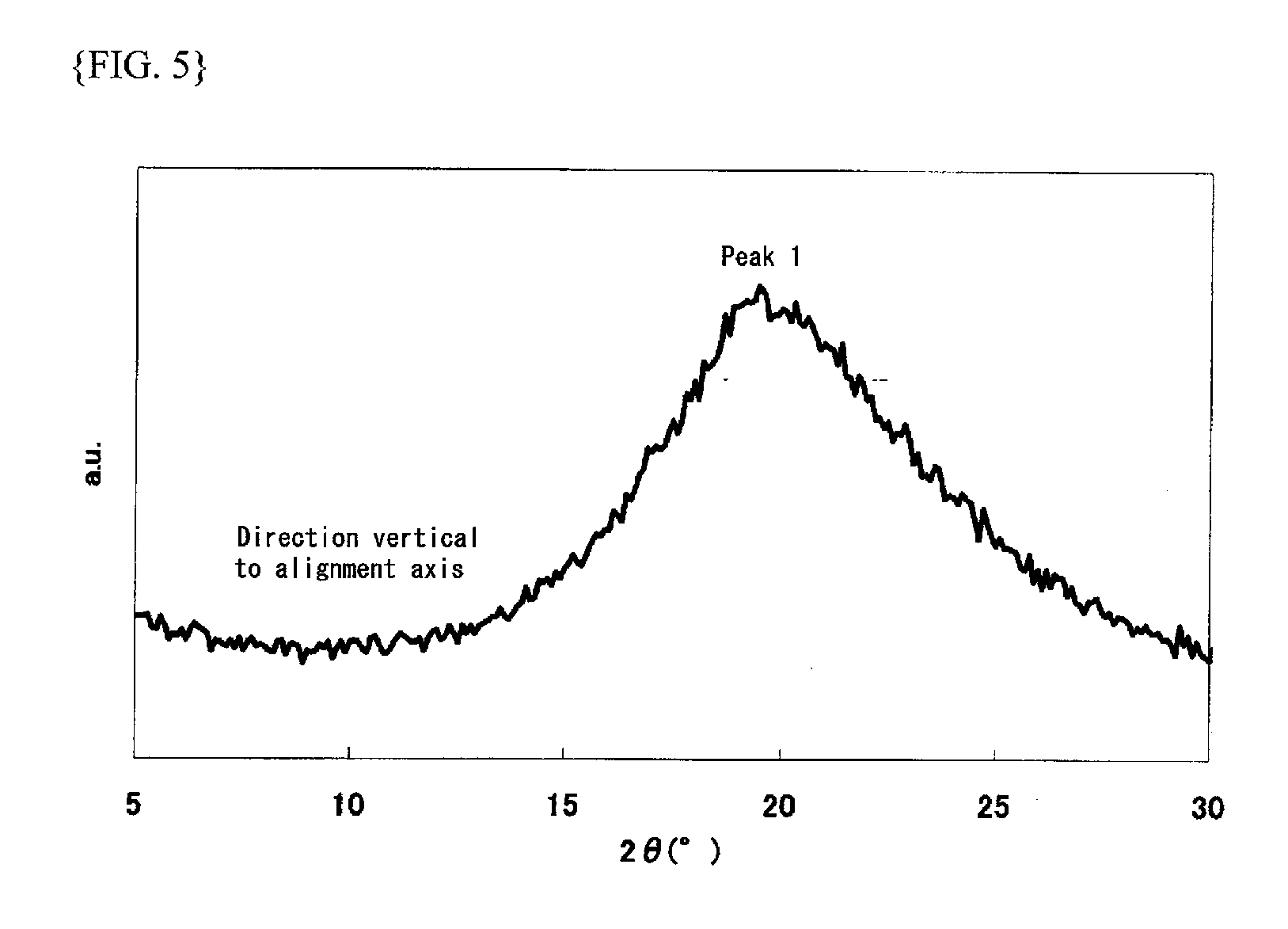

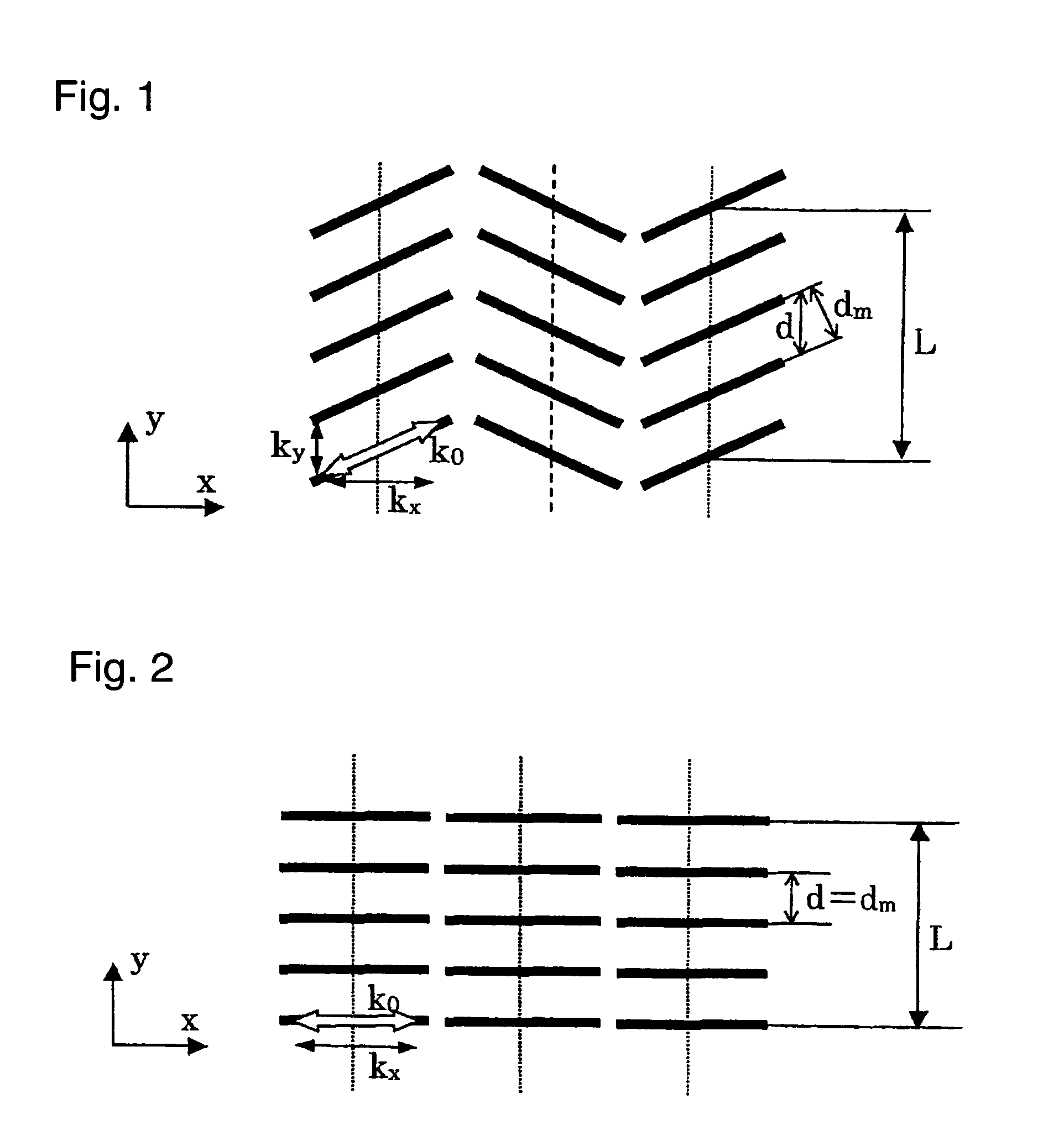

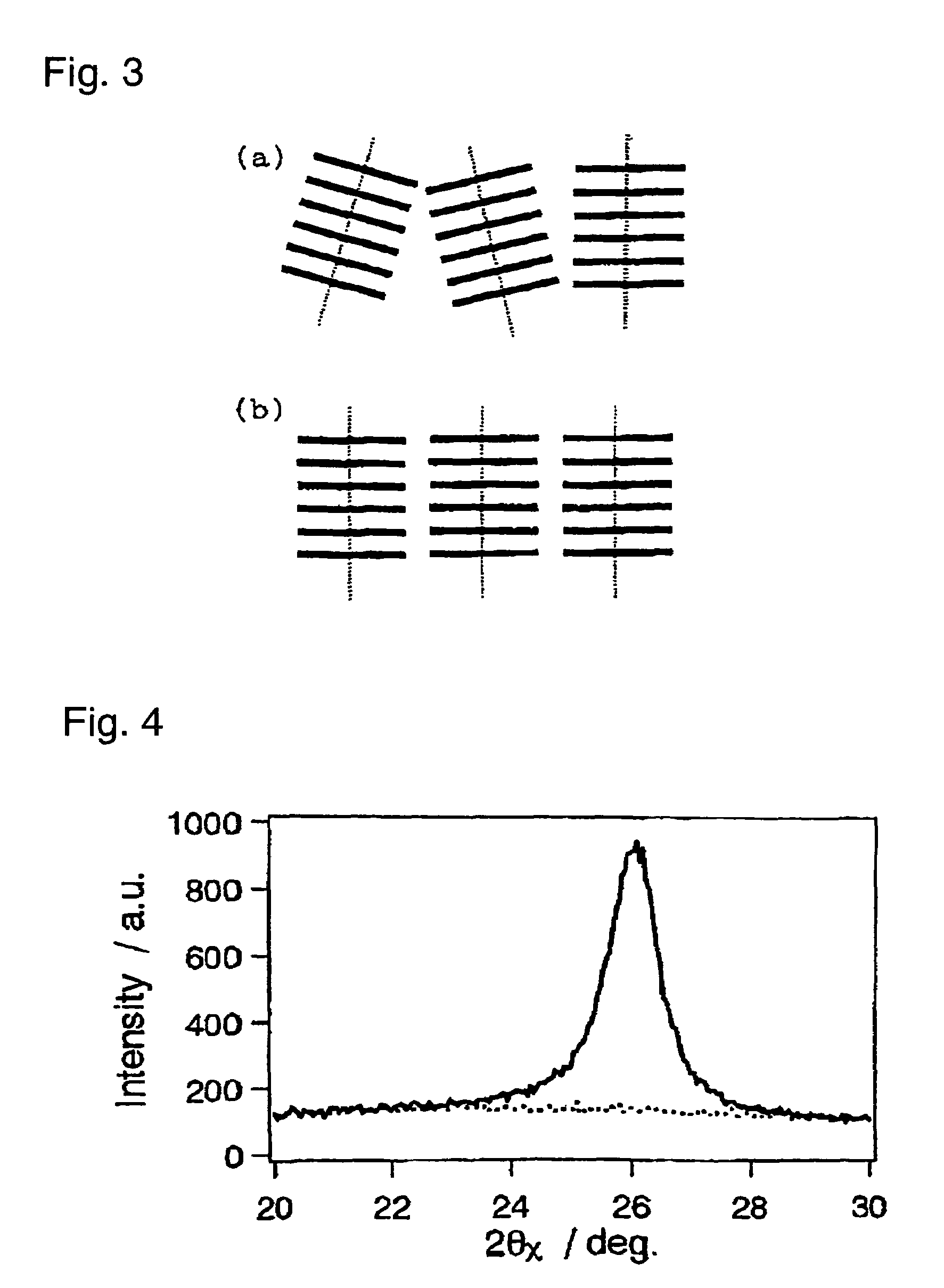

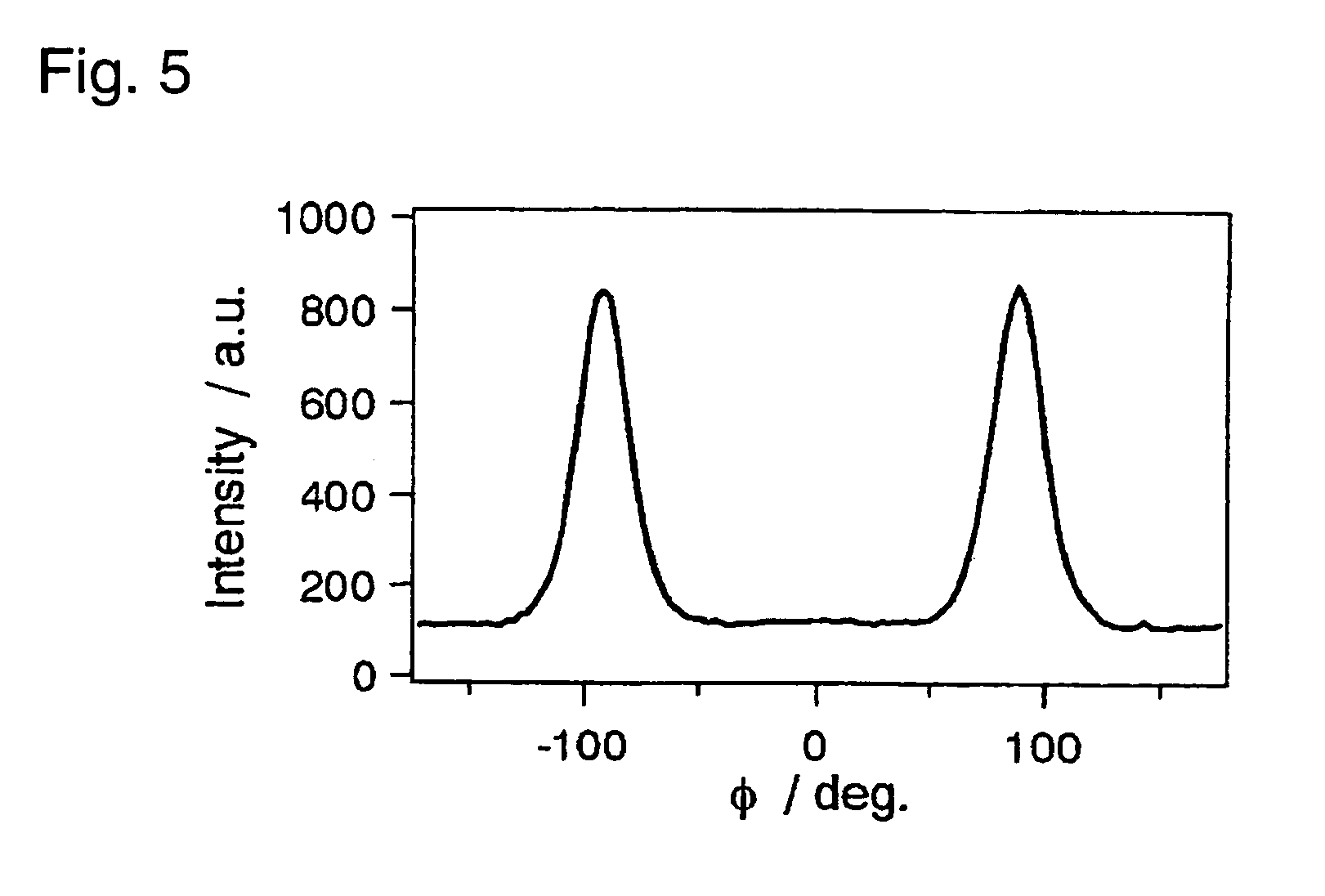

An anisotropic dye film having high dichromatic properties is provided. An anisotropic dye film wherein the period d attributable to molecular stacking is at most 3.445 AA, and the column length L thereof is at least 105 AA. The anisotropic dye film preferably has a degree of orientation of the molecular stacking axes of at least 85% and a film thickness of at most 30 m, and is formed by a wet film-forming method. Since it has a molecular alignment suitable to develop a dichroic ratio, it provides high dichromatic properties. A polarizing element having this anisotropic dye film is excellent in heat resistance, light fastness and polarizing performance.

Owner:MITSUBISHI RAYON CO LTD

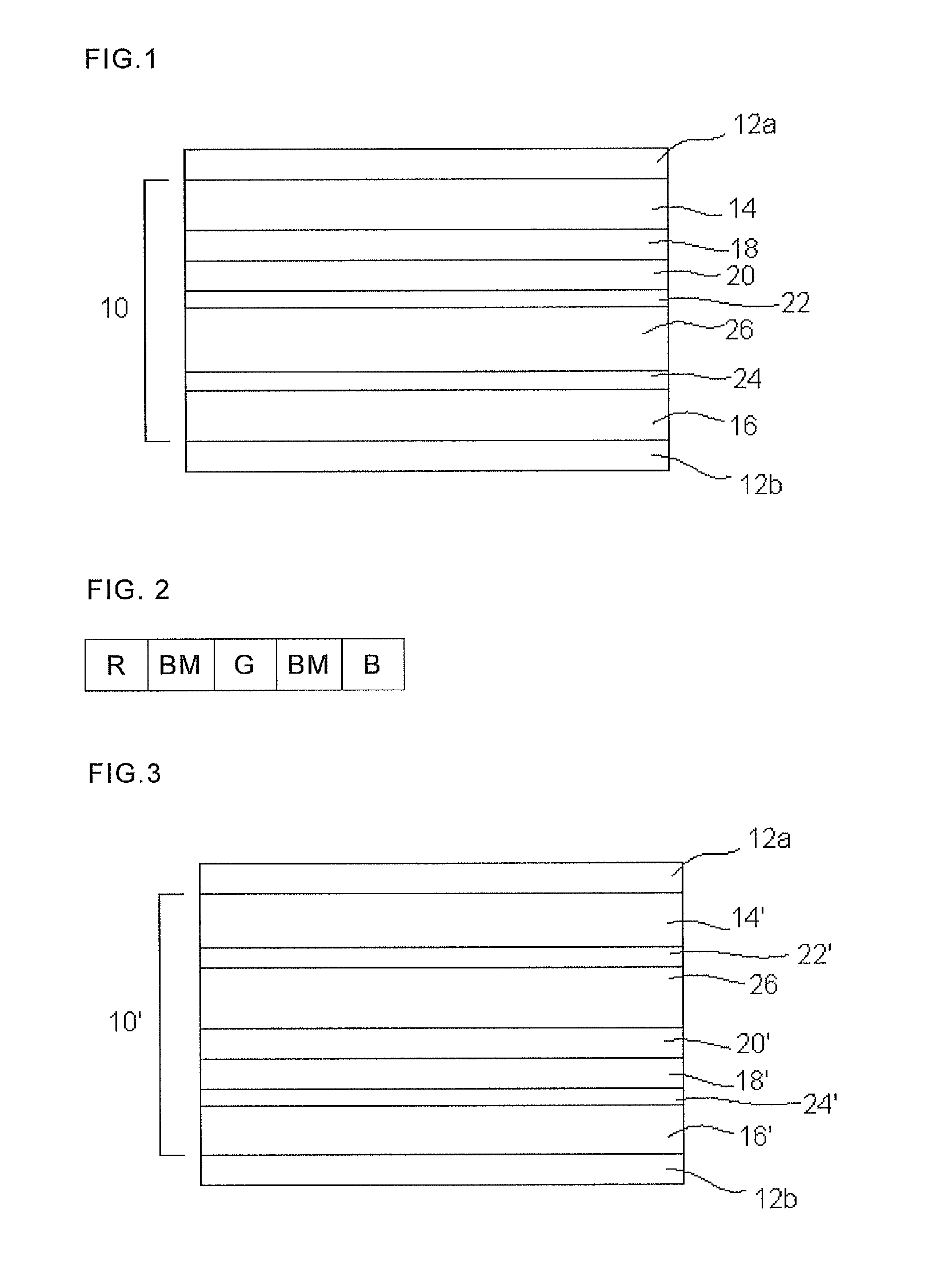

Polarizing film, laminate, and liquid crystal display device

InactiveUS20110051052A1Enhance depolarizationIncrease volumeStyryl-azo dyesTrisazo dyesLiquid-crystal displayPolarizer

A polarizing film, satisfying DI′ / P′≦4.3×10−4 which expresses relation between degree of polarization P′, and depolarization index DI′ calculated by the equation below is disclosed. X represents a value calculated by the equation below, provided that a polarizing plate having degree of polarization of P, the polarizing film, and a polarizing plate having degree of polarization P, having azimuths of transmission axes of a°, b° and c°, respectively, are stacked in this order as viewed from a light source, to give brightness written as [a / b / c].DI′=1+2PP′+P2+X(P2-1)P2(1+X)X=[0 / 0 / 0][0 / 90 / 90]

Owner:FUJIFILM CORP

Water-base black ink composition and colored material

The present invention relates to a water-based black ink composition comprising a water-soluble black dye (A) exhibiting ozone fastness and a condensate compound (B) of 4,4′-dinitrostilbene-2,2′-disulfonic acid and aminobenzenes or a reduction product (C) thereof. Said ink composition is suitable for use in ink-jet recording, and realizes neutral hue and black color of high printing density. Further, a printed matter obtained is excellent in ozone gas fastness, light fastness, moisture fastness and color rendering properties. Still further, storage stability as a recording liquid is excellent.

Owner:NIPPON KAYAKU CO LTD

Dyes for anisotropic dye films, dye compositions for anisotropic dye films, anisotropic dye films and polarizing elements

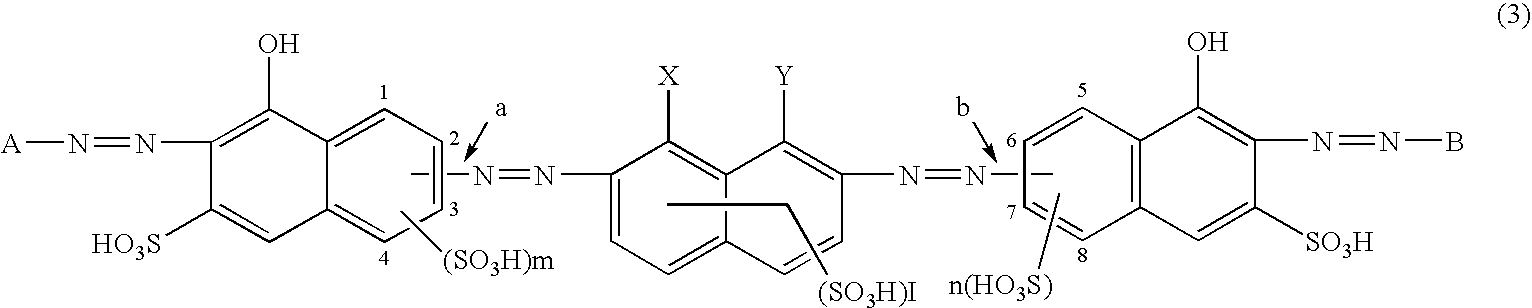

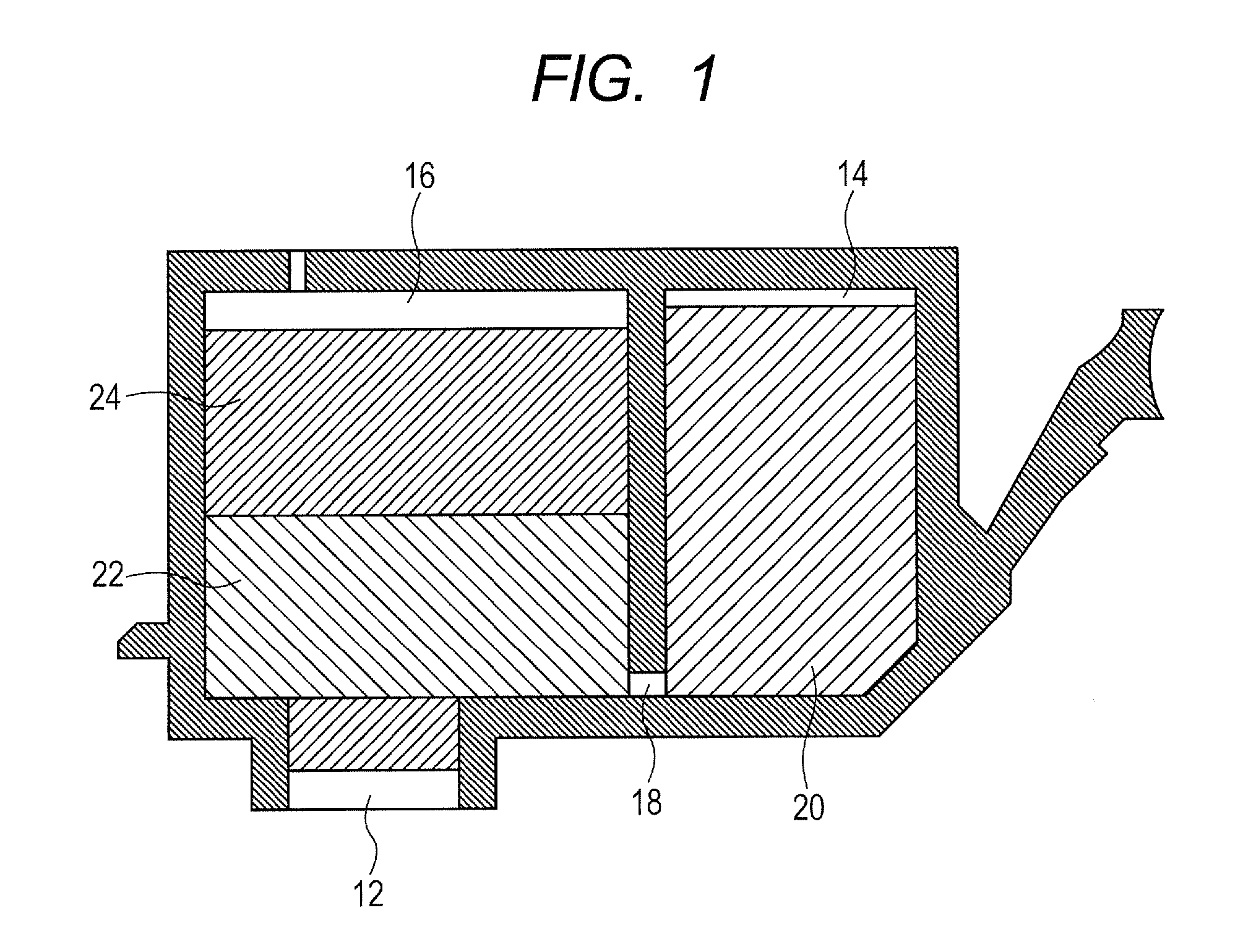

InactiveUS20060182902A1High dichromatic propertyImprove heat resistanceLiquid crystal compositionsSynthetic resin layered productsHeat resistancePhotochemistry

An anisotropic dye film having high dichromatic properties is provided. An anisotropic dye film wherein the period d attributable to molecular stacking is at most 3.445 Å, and the column length L thereof is at least 105 Å. The anisotropic dye film preferably has a degree of orientation of the molecular stacking axes of at least 85% and a film thickness of at most 30 μm, and is formed by a wet film-forming method. Since it has a molecular alignment suitable to develop a dichroic ratio, it provides high dichromatic properties. A polarizing element having this anisotropic dye film is excellent in heat resistance, light fastness and polarizing performance.

Owner:MITSUBISHI CHEM CORP

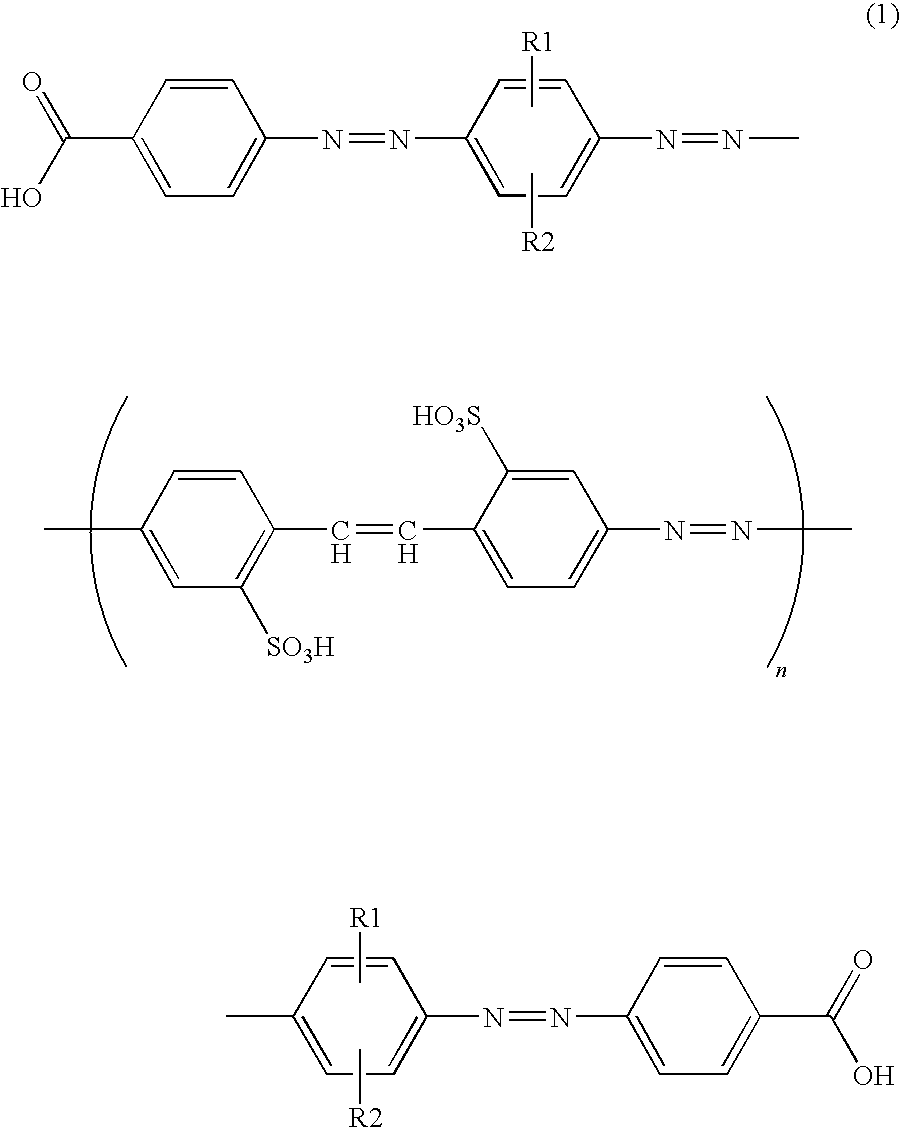

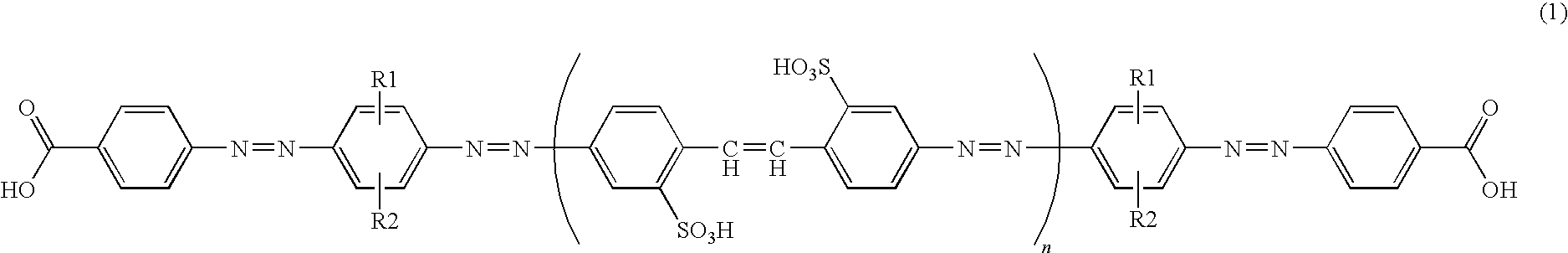

Azo Compound, And Dye-Containing Polarizing Film Comprising The Same

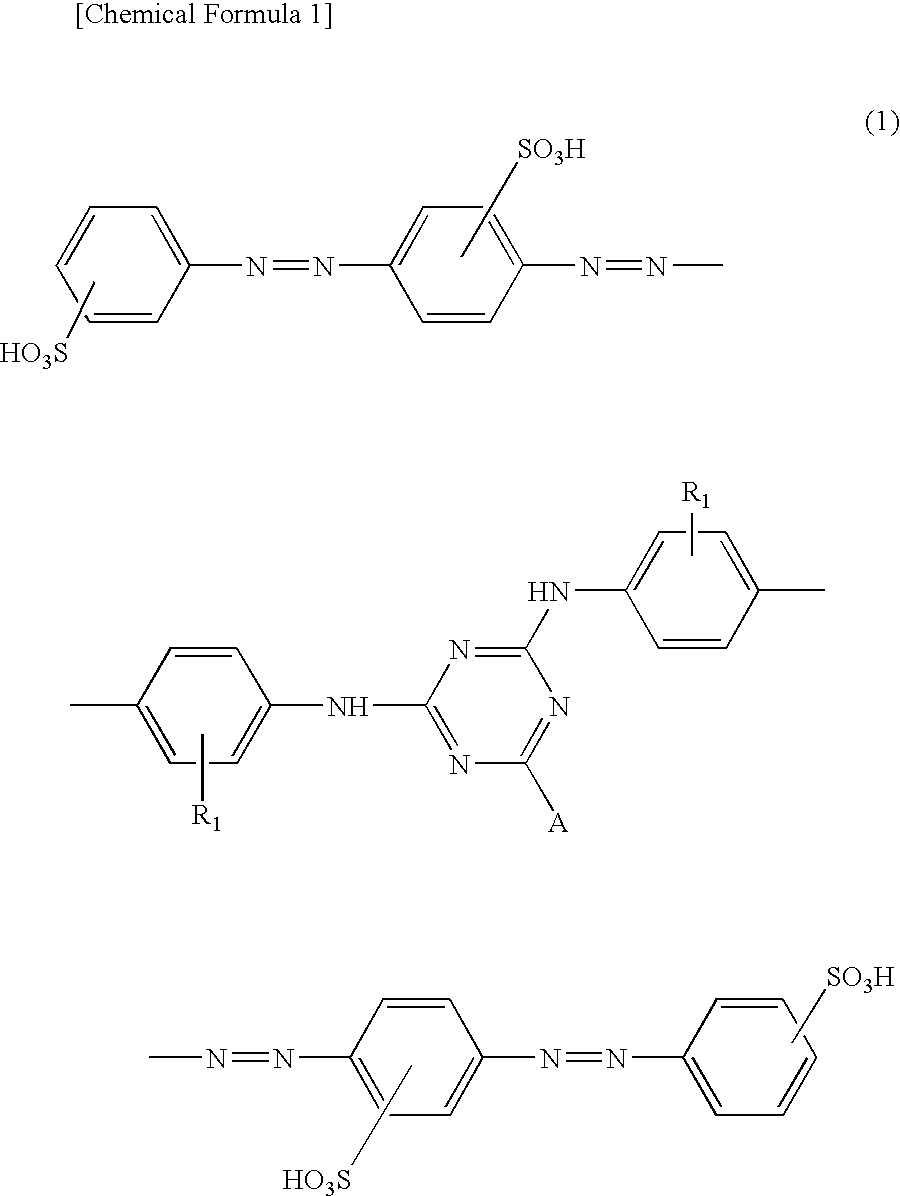

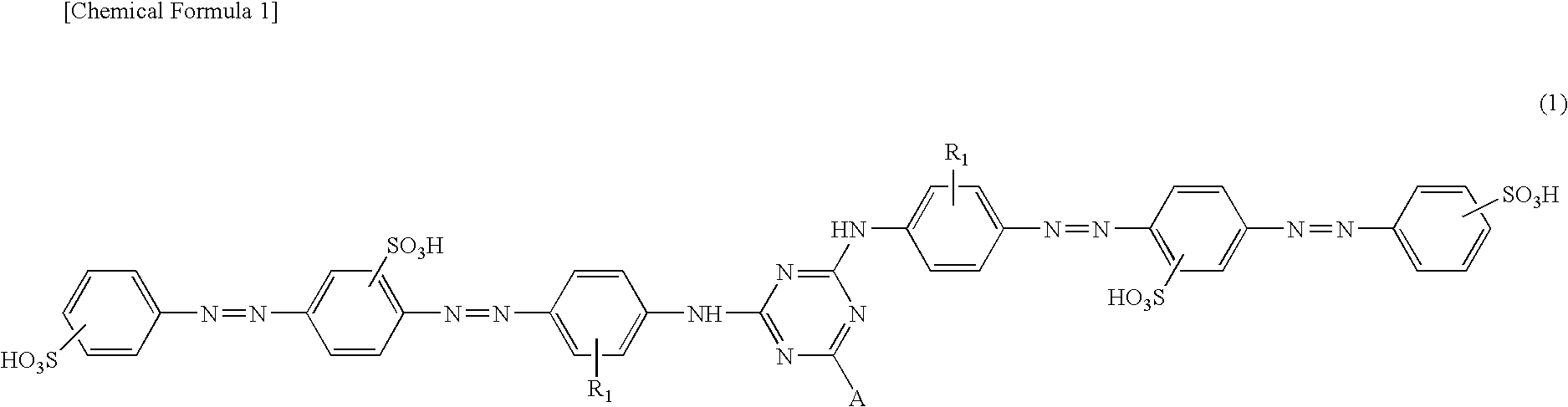

InactiveUS20100226008A1Improve performanceImprove the heating effectDisazo dyesOrganic chemistryLCD projectorPhenyl group

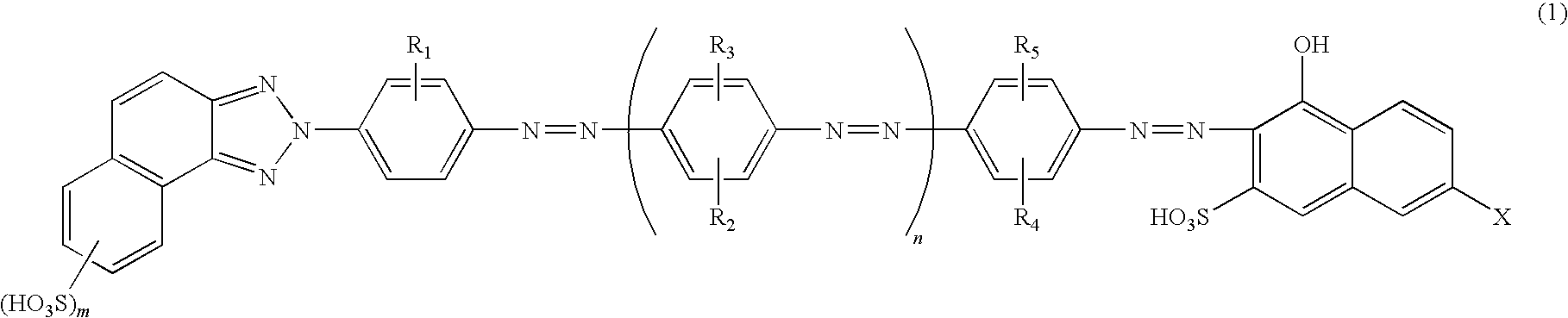

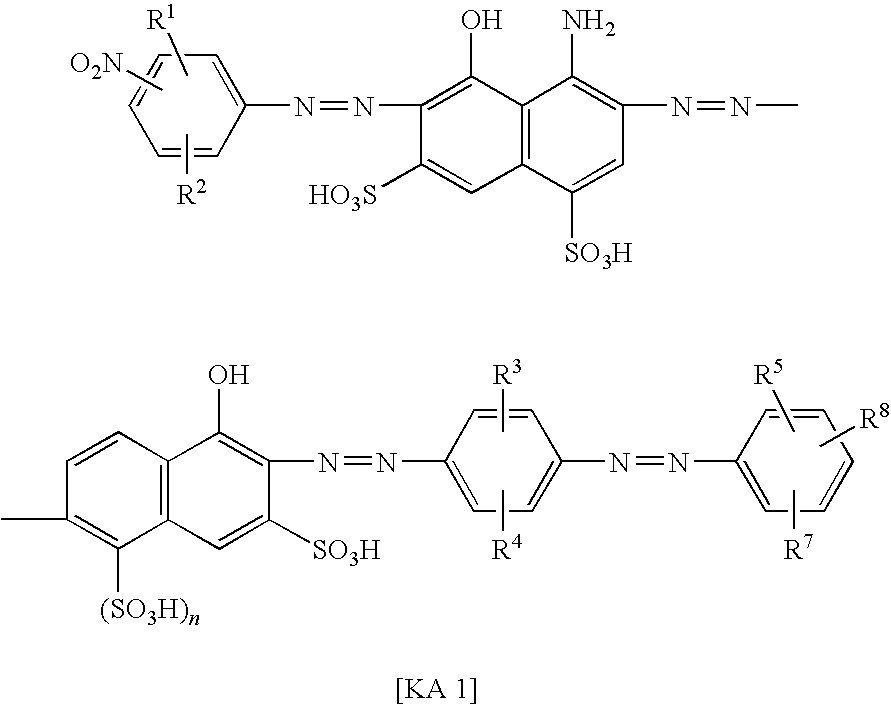

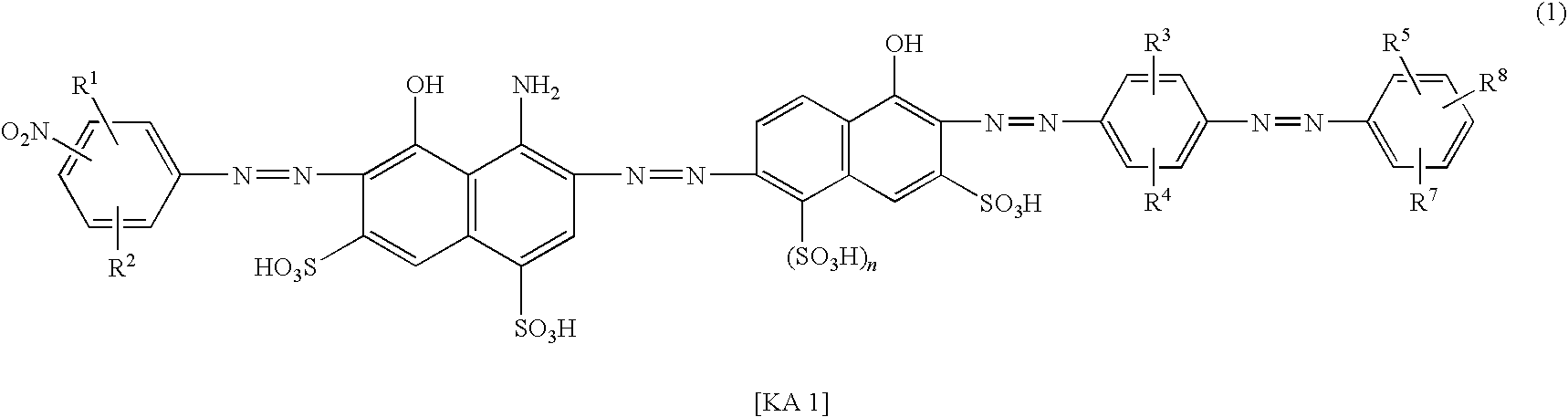

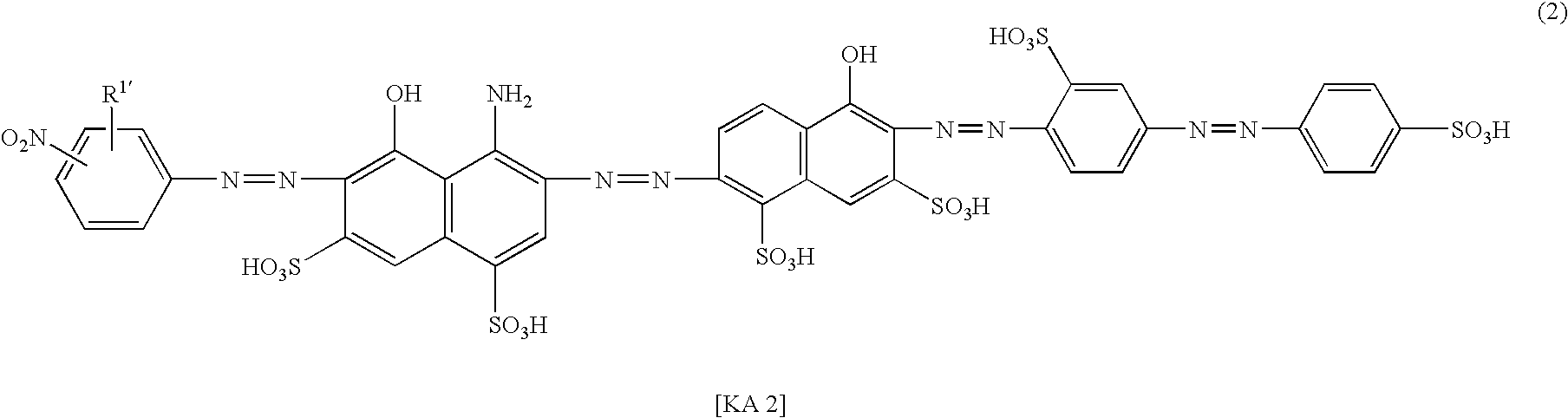

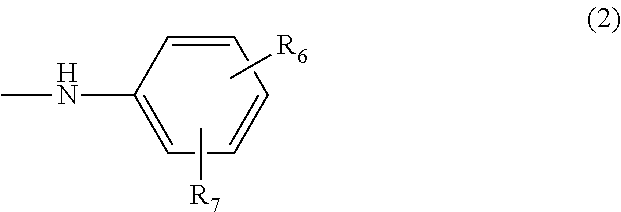

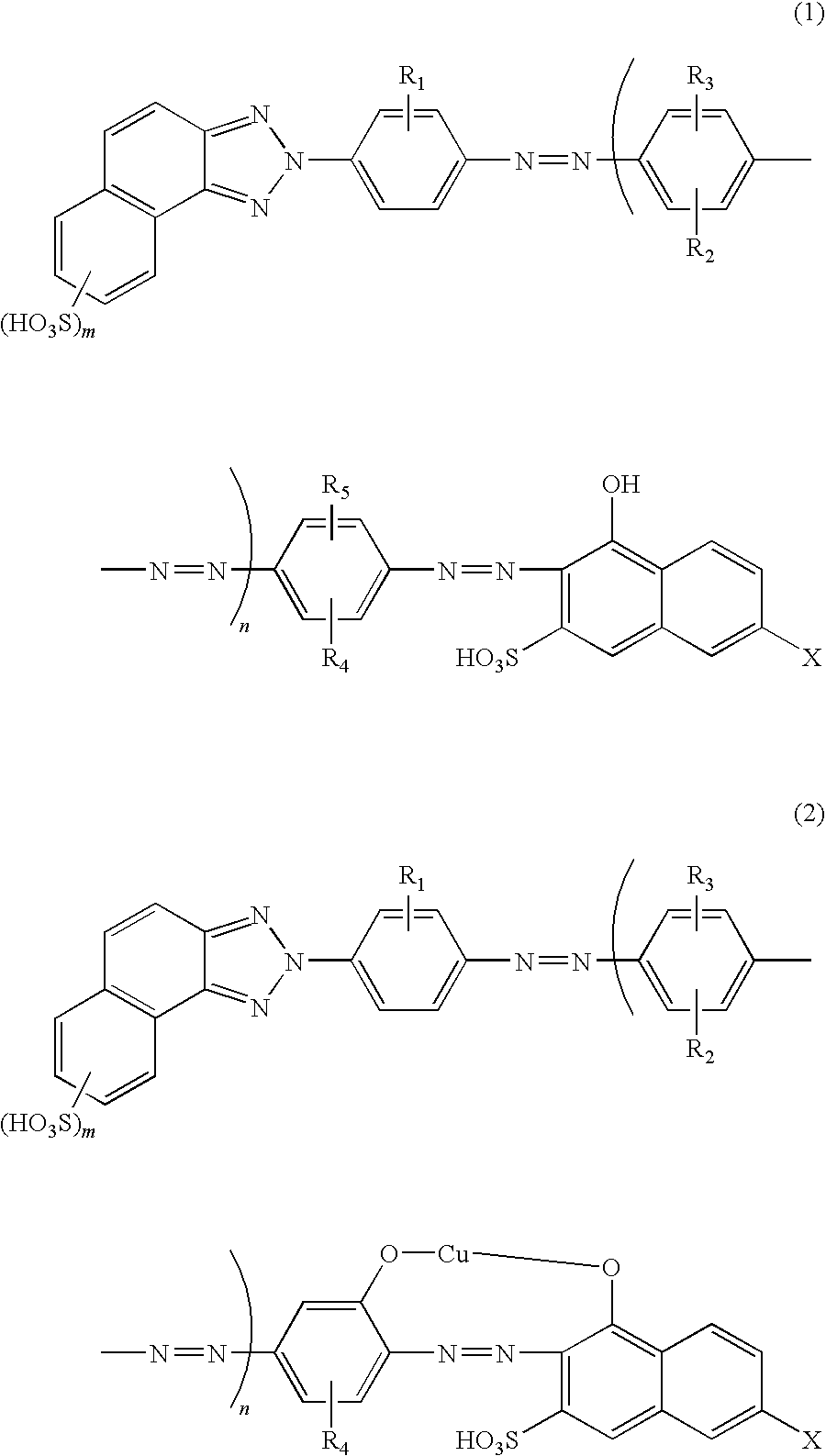

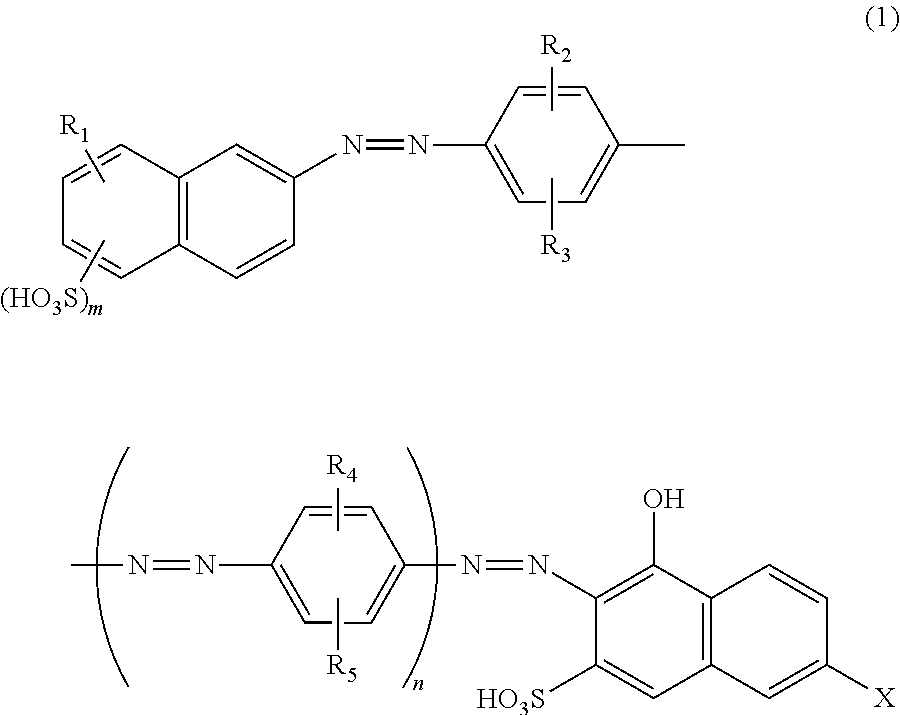

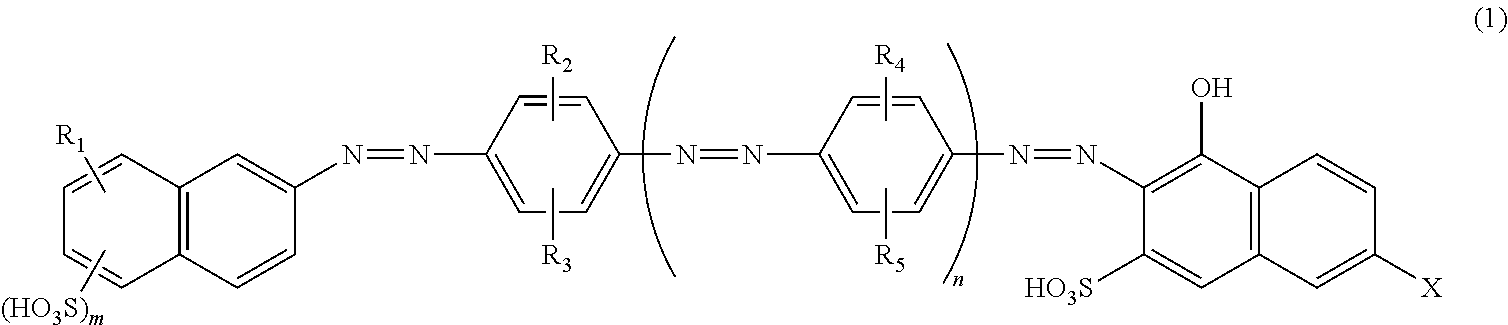

Disclosed is an azo compound represented by the formula (1) or (2) or a salt thereof. The azo compound or the salt thereof has an excellent light-polarizing property, and is extremely useful as a dichroic dye for use in a polarizing plate that shows less color leakage in a visible light range or a polarizing plate for a liquid crystal projector comprising the aforementioned polarizing plate. (1) (2) wherein R1 represents a hydrogen atom, a lower alkyl group, a lower alkoxy group, a hydroxyl group, a sulfonate group or a carboxyl group; R2 to R5 independently represent a hydrogen atom, a lower alkyl group, a lower alkoxy group or an acetylamino group; X represents a benzoylamino group which may have a substituent, a phenylamino group which may have a substituent, a phenylazo group which may have a substituent, or a naphthotriazole group which may have a substituent; m represents a numeral number of 1 or 2; and n represents a numeral number of 0 or 1.

Owner:NIPPON KAYAKU CO LTD +1

Dichroic dye composition, light absorption anisotropic film, and polarizing element

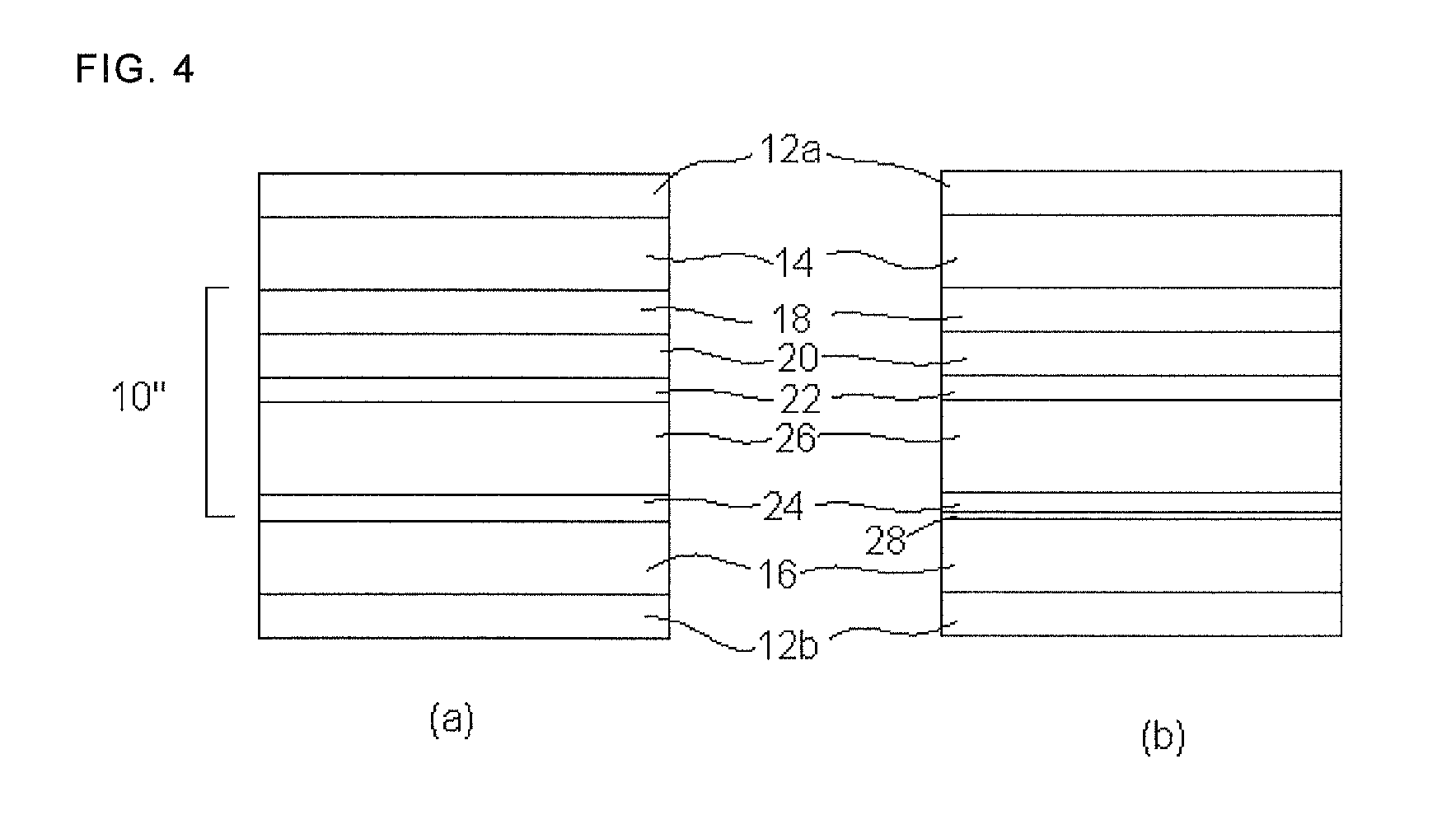

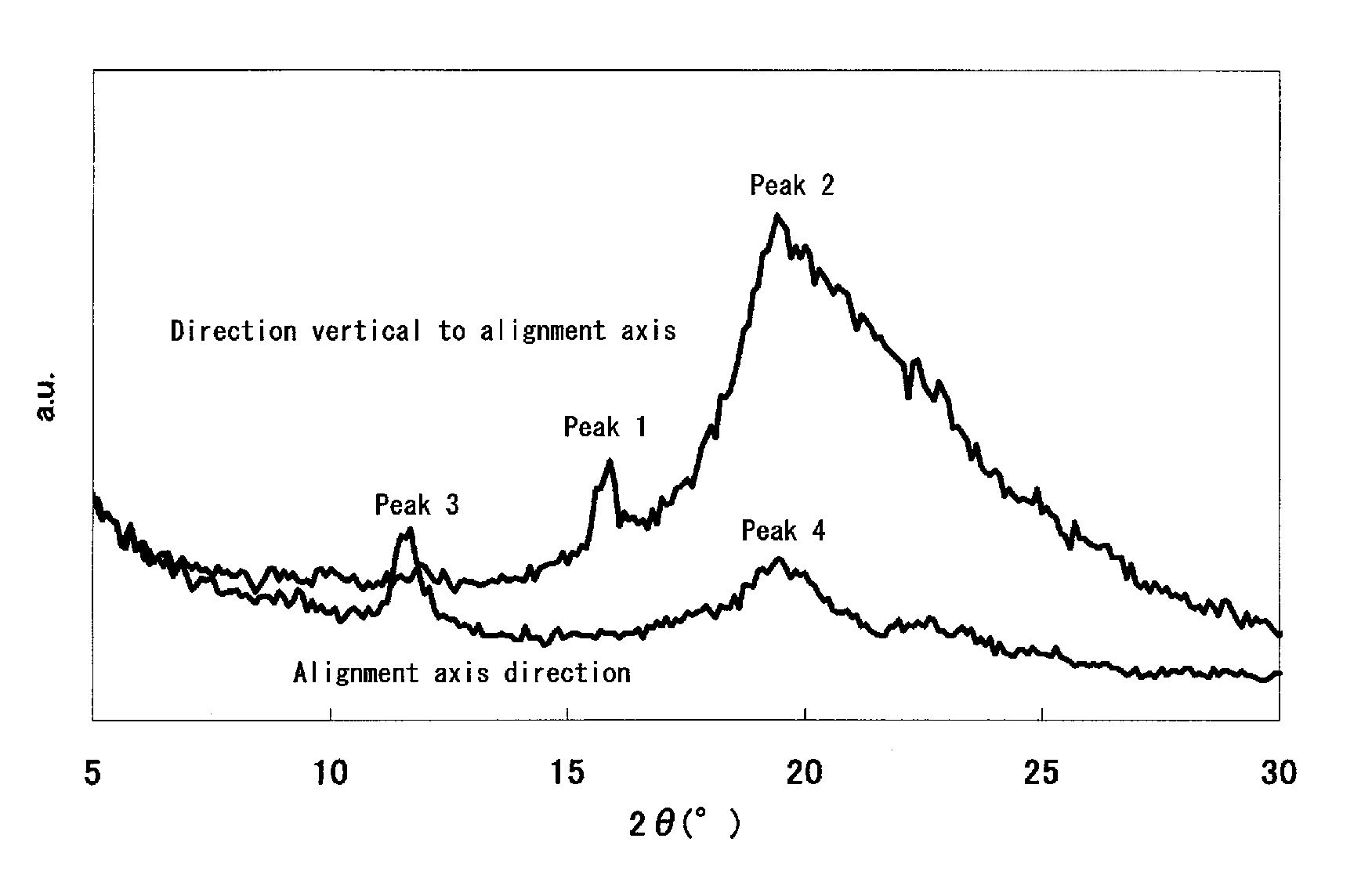

ActiveUS20110177315A1Improve heat resistanceGood light fastnessMonoazo dyesOrganic chemistrySoft x rayX-ray

A light absorption anisotropic film, having at least one dichroic dye, in which the light absorption anisotropic film shows a diffraction peak derived from a periodic structure in a direction in a plane of the light absorption anisotropic film in X-ray diffraction measurement and the diffraction peak has a half width of 1.0 Å or less.

Owner:FUJIFILM CORP

Azo compound, ink composition and colored article

ActiveUS7503967B2Good water solubilityHigh print densityMonoazo dyesOrganic chemistryHydrogen atomAlkoxy group

An azo compound represented by the following Formula (1) or a salt thereof, and an ink composition comprising the same(wherein, each of R1, R2, R5, R6 and R7 independently represents a hydrogen atom, a carboxyl group, a sulfo group and the like, each of R3 and R4 independently represents a hydrogen atom, a sulfo group, a nitro group, a (C1 to C4) alkyl group (which may be substituted by a hydroxyl group or a (C1 to C4) alkoxy group), a (C1 to C4) alkoxy group (which may be substituted by a hydroxyl group, a (C1 to C4) alkoxy group, a sulfo group or a carboxyl group) and the like, and n represents 0 or 1, respectively).

Owner:NIPPON KAYAKU CO LTD

Ink set, inkjet recording method and recorded material

An ink set including at least a yellow ink composition, a magenta ink composition and a cyan ink composition, wherein the yellow ink composition contains, as the yellow colorant, at least one member selected from the group consisting of a compound represented by a specific structure and a salt thereof, each of the yellow colorant, the magenta colorant and the cyan colorant contained in the yellow ink composition, the magenta ink composition and the cyan ink composition, respectively, has at least one ionic hydrophilic group, the counter ion of the ionic hydrophilic group contains a lithium ion, and the lithium ion concentration is 70 mol % or more based on all cations in each ink composition.

Owner:FUJIFILM CORP

Azo Compound And Salts Thereof, As Well As Dye-Based Polarization Films And Polarizing Plates Comprising The Same

InactiveUS20110164208A1Increased durabilityImprove polarization performanceLiquid crystal compositionsMonoazo dyesHydrogen atomPhenyl group

Azo compounds represented by formula (1) (In the formula, R1 represents a lower alkoxy group with a sulfone group. R2-R5 each independently represents a hydrogen atom, lower alkyl group or lower alkoxy group. X is an optionally substituted amino group, optionally substituted benzoylamino group, optionally substituted phenylamino group, optionally substituted phenyl azo group or optionally substituted naphthotriazole group. m represents 1 or 2 and n represents 0 or 1.) and salts thereof.

Owner:NIPPON KAYAKU CO LTD +1

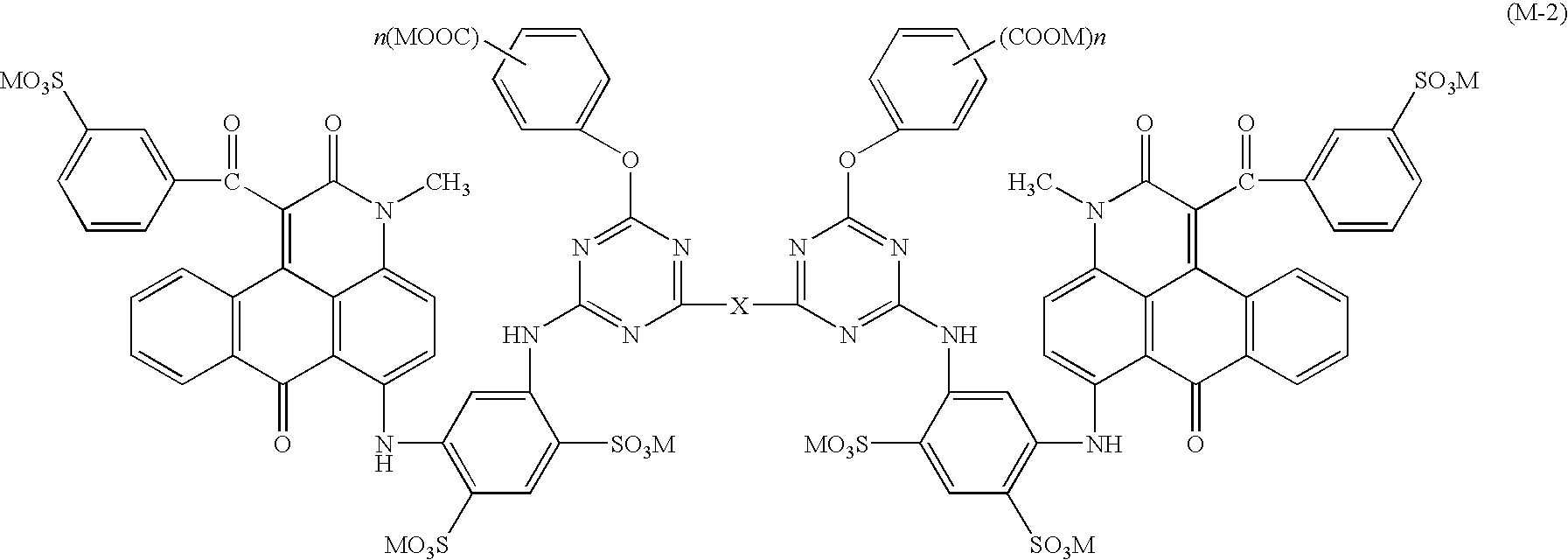

Ink set, ink cartridge, inkjet recording method, and recorded matter

An ink set containing at least a yellow ink composition, a magenta ink composition, and a cyan ink composition:said magenta ink composition containing as a colorant at least one type of compound expressed by the formula M-1 in claim 1, and at least one type of compound expressed by the following formula M-2 in claim 1, the yellow ink composition containing as a colorant at least one type of compound expressed by the formula Y-1 in claim 1; andthe cyan ink composition containing as a colorant at least one type of compound selected from the group consisting of compounds or salts thereof expressed by the Formula C-1 in claim 1.

Owner:SEIKO EPSON CORP

Azo Compound, Ink Composition and Colored Article

ActiveUS20080193660A1Good water solubilityHigh print densityMonoazo dyesOrganic chemistrySolubilityHydrogen atom

[Problems] A compound of a black ink which has such excellent fastnesses of a recorded article as light fastness, ozone gas fastness and moisture fastness, excellent solubility, and storage stability as a recording liquid, when used for inkjet recording and writing tools, and an ink composition comprising the same are provided.[Method for solving the problems] An azo compound represented by the following Formula (1) or a salt thereof, and an ink composition comprising the same(wherein, each of R1, R2, R5, R6 and R7 independently represents a hydrogen atom, a carboxyl group, a sulfo group and the like, each of R3 and R4 independently represents a hydrogen atom, a sulfo group, a nitro group, a (C1 to C4) alkyl group (which may be substituted by a hydroxyl group or a (C1 to C4) alkoxy group), a (C1 to C4) alkoxy group (which may be substituted by a hydroxyl group, a (C1 to C4) alkoxy group, a sulfo group or a carboxyl group) and the like, and n represents 0 or 1, respectively).

Owner:NIPPON KAYAKU CO LTD

Azo compound, and dye-containing polarizing film comprising the same

InactiveUS8232375B2Improve performanceImprove the heating effectDisazo dyesOrganic chemistryLCD projectorDichroic dye

Disclosed is an azo compound represented by the formula (1) or (2) or a salt thereof. The azo compound or the salt thereof has an excellent light-polarizing property, and is extremely useful as a dichroic dye for use in a polarizing plate that shows less color leakage in a visible light range or a polarizing plate for a liquid crystal projector comprising the aforementioned polarizing plate. (1) (2) wherein R1 represents a hydrogen atom, a lower alkyl group, a lower alkoxy group, a hydroxyl group, a sulfonate group or a carboxyl group; R2 to R5 independently represent a hydrogen atom, a lower alkyl group, a lower alkoxy group or an acetylamino group; X represents a benzoylamino group which may have a substituent, a phenylamino group which may have a substituent, a phenylazo group which may have a substituent, or a naphthotriazole group which may have a substituent; m represents a numeral number of 1 or 2; and n represents a numeral number of 0 or 1.

Owner:NIPPON KAYAKU CO LTD +1

Polarizing film, laminate, and liquid crystal display device

InactiveCN102004278AMitigate depolarizationSuppress light leakageStyryl-azo dyesSynthetic resin layered productsLiquid-crystal displayDegree of polarization

The invention discloses a polarizing film, a laminate, and a liquid crystal display device. The polarizing film, satisfying Dl' / P'<=4.3X10-4 which expresses relation between degree of polarization P', and depolarization index Dl' calculated by the equation below is disclosed. X represents a value calculated by the equation below, provided that a polarizing plate having degree of polarization of P, the polarizing film, and a polarizing plate having degree of polarization P, having azimuths of transmission axes of a DEG, b DEG and c DEG, respectively, are stacked in this order as viewed from a flight source, to give brightness written as [a / b / c].

Owner:FUJIFILM CORP

Azo Compound And Salt Thereof, And Dye-Containing Polarizing Film Comprising The Compound Or Salt

InactiveUS20110060134A1Improve performanceIncrease resistanceOrganic chemistryProjectorsHydrogen atomAlkoxy group

Disclosed is an azo compound represented by the general formula (1) or a salt thereof:wherein R1 and R2 independently represent a hydrogen atom, a lower alkyl group or a lower alkoxy group; and n represents 1 or 2. Also disclosed are a dye-containing polarizing film and a dye-containing polarizing plate, each of which comprises a polarizing film base material and the azo compound contained in the base material.

Owner:NIPPON KAYAKU CO LTD +1

Azo Compound And Salt Thereof, And Dye-Based Polarizing Film And Polarizing Plate Containing The Same

ActiveUS20130314786A1Good water solubilityIncreased durabilityOrganic chemistryLayered productsHydrogen atomLCD projector

The present invention relates to an azo compound represented by the following formula (1) [wherein, A represents a naphthyl group having a substituent, R1 to R6 each independently represent a hydrogen atom, an alkyl group having a carbon atom number of 1 to 5, an alkoxy group having a carbon atom number of 1 to 5, a sulfo group, or an alkoxy group having a sulfo group and a carbon atom number of 1 to 5, and X represents a benzoylamino group having a substituent, a phenylamine group having a substituent, a phenylazo group having a substituent, or a naphthotriazole group having a substituent] and a salt thereof. By using the azo compound or a salt thereof of the present invention, a neutral color polarizing plate and a color polarizing plate for a liquid crystal projector being excellent in polarization performance and durability and having less color leakage in a visible light region can be provided.

Owner:NIPPON KAYAKU CO LTD +1

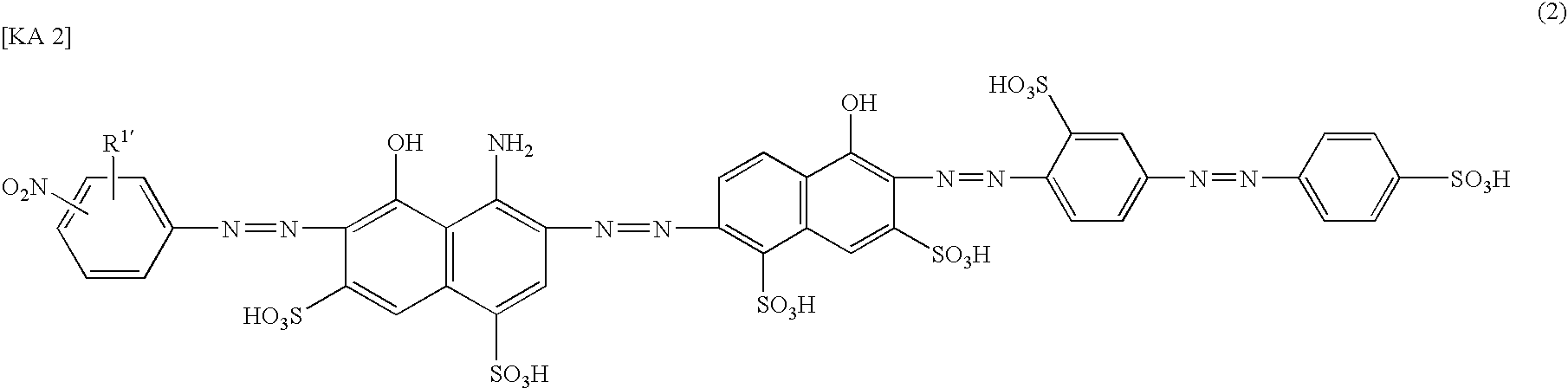

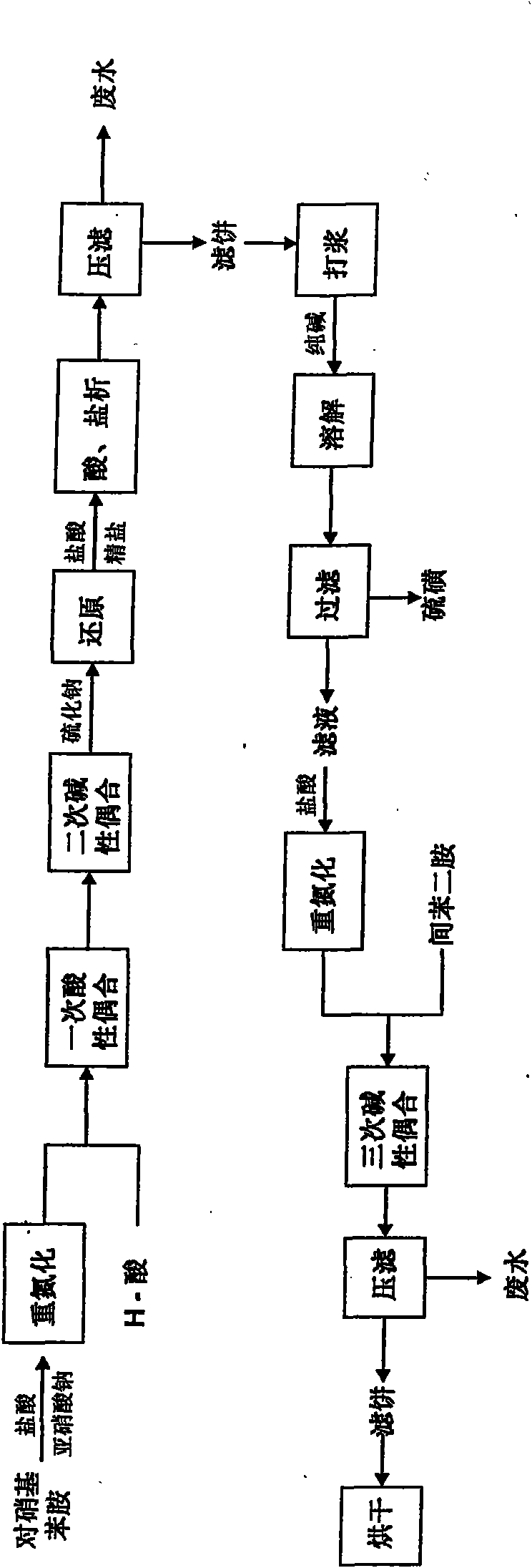

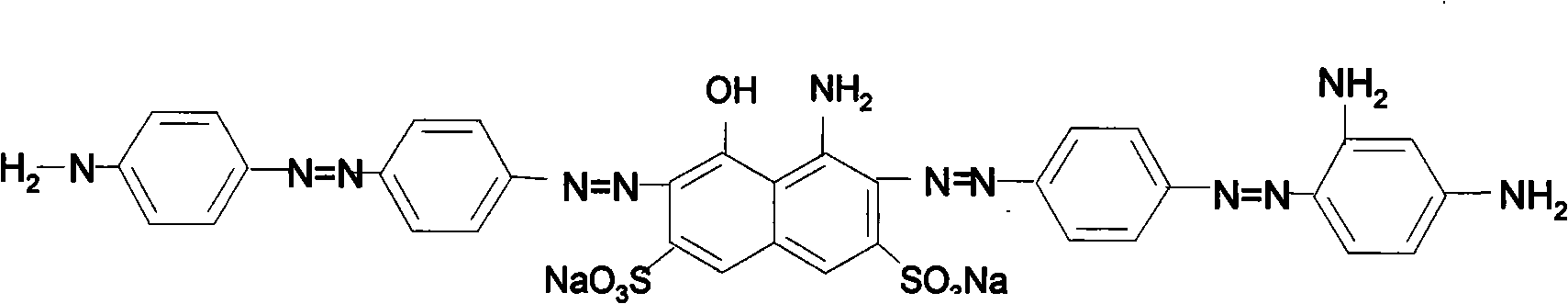

Pollution-free production technology of direct fast black G

The invention relates to a pollution-free production technology of direct fast black G, comprising the following implementation steps: firstly, primary acid coupling is carried out on nitroaniline after diazotization and H-acid; after the full reaction of the H-acid is detected, sodium carbonate is added and pH is adjusted to 8 to 8.2 to carry out secondary basic coupling; the coupling product is added into a sodium sulfide solution for reduction, and the temperature gradually raises to t of 38 DEG C to 40 DEG C in the reaction process; after the sodium carbonate is added into the reduction product after acidification to adjust the pH of a medium to 7.5 to 8, the mixture is adsorbed by activated carbon and filtered, and ternary coupling is carried out on the obtained filter liquor after diazotization and lentine; and after the reaction is detected to be end point, the materials are directly delivered to a drying tower for spray drying. In the invention, the reduced reaction solution does not need the processes of salting out, acidification and filtration, activated carbon adsorption is adopted instead. In the process, no waste liquor is generated, and environment pollution caused in the production process of dye is greatly reduced. Simultaneously, wastewater processing is not needed, and the cost is saved. The optimized technology directly transfers the reaction solution after ternary coupling into the drying tower for spray drying; and the yield and the coloring intensity of the dye are effectively increased, energy is saved, the consumption is reduced, and the effect is obvious.

Owner:INNER MONGOLIA XINYA CHEM

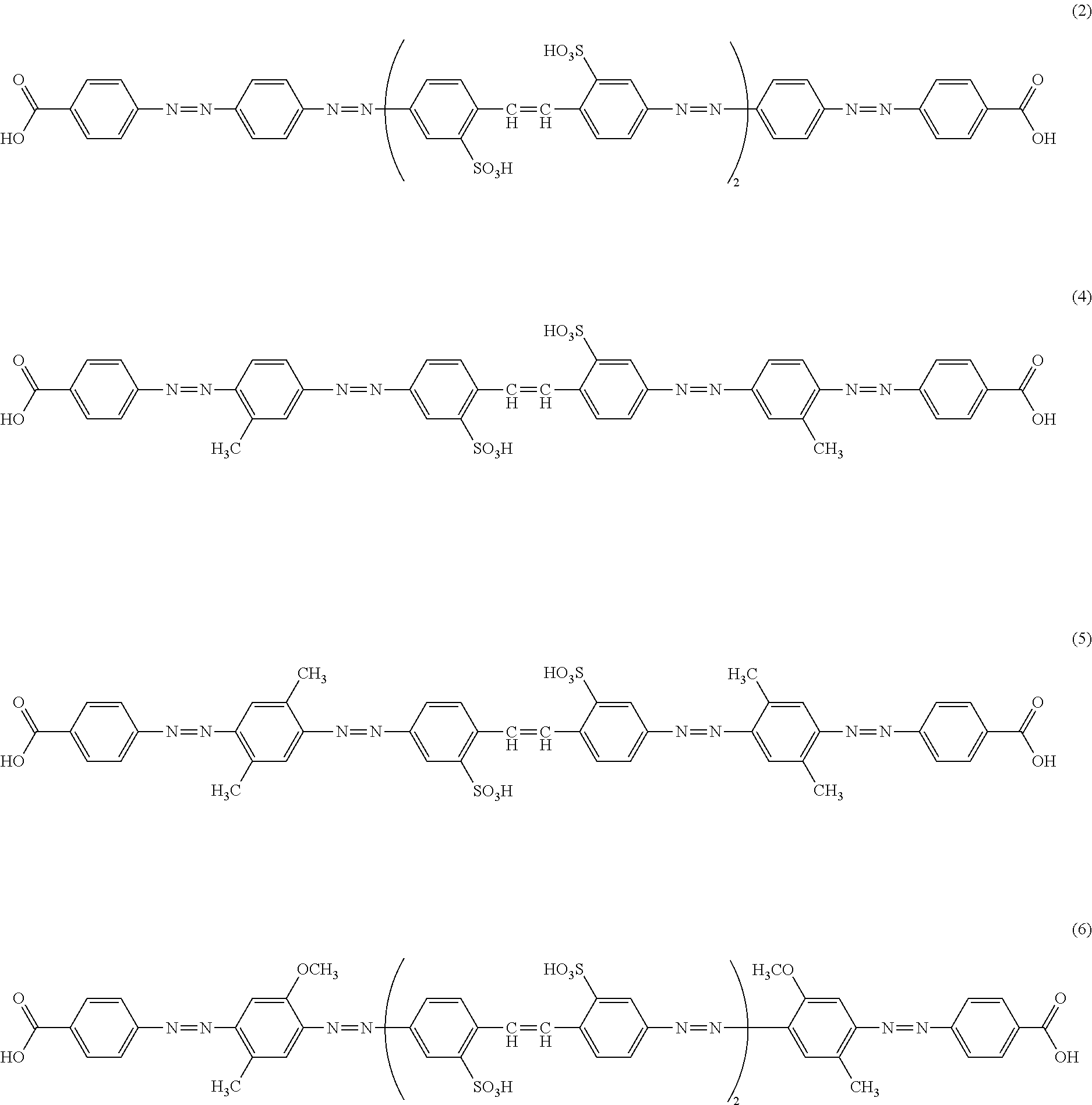

Water-base black ink composition and colored product

The present invention relates to a water-based black ink composition comprising a water-soluble black dye (A) exhibiting ozone fastness and a condensate compound (B) of 4,4′-dinitrostilbene-2,2′-disulfonic acid and aminobenzenes or a reduction product (C) thereof. Said ink composition is suitable for use in ink-jet recording, and realizes neutral hue and black color of high printing density. Further, a printed matter obtained is excellent in ozone gas fastness, light fastness, moisture fastness and color rendering properties. Still further, storage stability as a recording liquid is excellent.

Owner:NIPPON KAYAKU CO LTD

Dyes for anisotropic dye films, dye compositions for anisotropic dye films, anisotropic dye films and polarizing elements

InactiveUS7527862B2High dichromatic propertyHigh fastnessLiquid crystal compositionsSynthetic resin layered productsHeat resistancePhotochemistry

Owner:MITSUBISHI CHEM CORP

Azo Compound, Dye-Based Polarizing Film And Polarizing Plate

ActiveUS20130302538A1Good water solubilityGood optical performanceLiquid crystal compositionsOrganic chemistryHydrogen atomLCD projector

The present invention relates to an azo compound represented by the following formula (1), [wherein, A represents a phenyl group which may have a substituent, R1 to R6 each independently represent a hydrogen atom, an alkyl group having a carbon atom number of 1 to 5, an alkoxy group having a carbon atom number of 1 to 5, a sulfo group, or an alkoxy group having a sulfo group and a carbon atom number of 1 to 5, and X represents an amino group which may have a substituent, a benzoylamino group which may have a substituent, a phenylamino group which may have a substituent, a phenylazo group which may have a substituent, or a naphthotriazole group which may have a substituent] or / and a salt thereof and to a polarizing film and a polarizing plate which contain it. The polarizing plate of the present invention using the above-described azo compound has a high polarization ratio and a high contrast, causes less color-leakage in a visible light region, is excellent in optical performance and durability, and can be widely used in liquid crystal displays such as liquid crystal projectors, and the likeThe formula (1)

Owner:NIPPON KAYAKU CO LTD +1

Dye type polarizing plate

InactiveUS7108897B2Excellent polarizing performance and moisture proofnessLess color leakageLiquid crystal compositionsMonoazo dyesPolyvinyl alcoholLCD projector

Owner:NIPPON KAYAKU CO LTD

Azo compound, ink composition, and colored object

ActiveUS7427319B2Improve solubilityGood storage stabilityMonoazo dyesOrganic chemistryHydrogen atomAlkoxy group

The present invention relates to an azo compound represented by the following formula (1):(wherein, in the formula (1), R1 represents a hydrogen atom; a hydroxyl group; a carboxyl group; a (C1-C4)alkyl group which may be substituted by a hydroxyl group or a (C1-C4)alkoxy group; or the like, and A represents an aliphatic amine residue having a carboxyl group or a sulfo group, respectively;) or a salt thereof; an ink composition containing the same; and an inkjet recording method and a colored object using the same. Said azo compound has a high color value and has a hue between yellow and red or a brown hue. The ink containing said azo compound has satisfactory storage stability, and exhibits, when printed therewith, a stable ejection property even on a thermal type inkjet printer, and gives a print of high quality (superior in light fastness, ozone gas fastness and moisture fastness).

Owner:NIPPON KAYAKU CO LTD

Azo compound and salts thereof, as well as dye-based polarization films and polarizing plates comprising the same

InactiveUS8477268B2Good light fastnessIncreased durabilityLiquid crystal compositionsMonoazo dyesHydrogen atomAlkoxy group

Azo compounds represented by formula (1) (In the formula, R1 represents a lower alkoxy group with a sulfone group. R2-R5 each independently represents a hydrogen atom, lower alkyl group or lower alkoxy group. X is an optionally substituted amino group, optionally substituted benzoylamino group, optionally substituted phenylamino group, optionally substituted phenyl azo group or optionally substituted naphthotriazole group. m represents 1 or 2 and n represents 0 or 1.) and salts thereof.

Owner:NIPPON KAYAKU CO LTD +1

Ink composition and ink jet recording method using the same

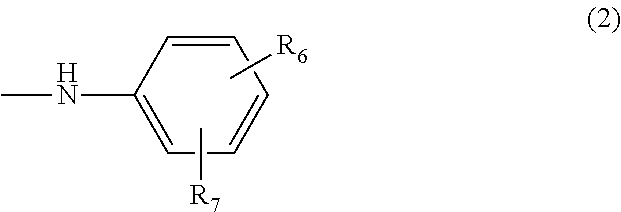

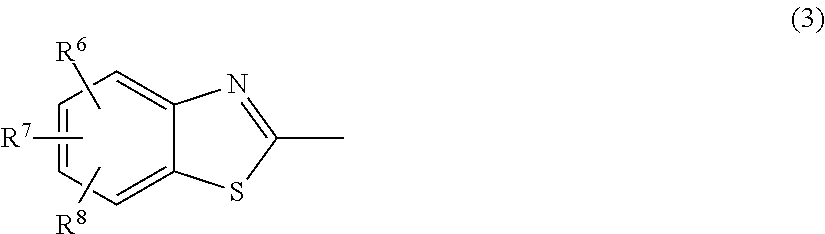

ActiveUS8496746B2Improve balanceExcellent gas resistanceDuplicating/marking methodsInksThermodynamicsChemical compound

An ink composition includes: water, a compound represented by the following general formula (1) or a salt thereof, and a compound represented by the following general formula (21) or a salt thereof.(in the formula (1), n represents 0 or 1,each of R1, R2, R3, and R4 represents a substituent,Group A represents a substituted heterocyclic group represented by the following general formula (2) or (3):in the formula (2), R5 represents a substituent.in the formula (3), each of R6, R7, and R8 represents a substituent, and Group B has a substituted phenyl group or naphthyl group).(in the formula (21), each of R21, R22, R23, R24, R25, R26, R27, and R28 represents a substituent, and X represents a divalent crosslinking group).

Owner:SEIKO EPSON CORP

Ink, ink cartridge and ink jet recording method

ActiveUS8814341B2Improve moisture resistanceNot easy to changeMeasurement apparatus componentsInksLithiumHigh humidity

Provided is an ink capable of recording an image that is excellent in ozone resistance, hardly causes blurring or color change even in a high-humidity environment, and is excellent in humidity resistance. The ink includes a coloring material and a lithium ion. The coloring material includes a compound represented by the following general formula (I) and a content of the lithium ion in the ink is 3.5 times or more in terms of molar ratio with respect to a content of the compound represented by the general formula (I).

Owner:CANON KK

Azo Compound, Ink Composition, and Colored Object

ActiveUS20070257975A1Improve solubilityStable ejection propertyMonoazo dyesOrganic chemistryHydrogen atomAlkoxy group

The present invention relates to an azo compound represented by the following formula (1): (wherein, in the formula (1), R1 represents a hydrogen atom; a hydroxyl group; a carboxyl group; a (C1-C4)alkyl group which may be substituted by a hydroxyl group or a (C1-C4)alkoxy group; or the like, and A represents an aliphatic amine residue having a carboxyl group or a sulfo group, respectively;) or a salt thereof; an ink composition containing the same; and an inkjet recording method and a colored object using the same. Said azo compound has a high color value and has a hue between yellow and red or a brown hue. The ink containing said azo compound has satisfactory storage stability, and exhibits, when printed therewith, a stable ejection property even on a thermal type inkjet printer, and gives a print of high quality (superior in light fastness, ozone gas fastness and moisture fastness).

Owner:NIPPON KAYAKU CO LTD

Dichroic dye composition, light absorption anisotropic film, and polarizing element

ActiveUS8927070B2Convenient lightingIncrease resistanceLiquid crystal compositionsStyryl dyesX-rayDichroic dye

A light absorption anisotropic film, having at least one dichroic dye, in which the light absorption anisotropic film shows a diffraction peak derived from a periodic structure in a direction in a plane of the light absorption anisotropic film in X-ray diffraction measurement and the diffraction peak has a half width of 1.0 Å or less.

Owner:FUJIFILM CORP

Ink composition, inkjet recording method and colored body

ActiveUS20130257974A1Satisfactory storage stabilityHigh print densityOther printing matterInksColor saturationImage density

An aqueous black ink composition that produces a black recorded image that is stable even when stored for a long time period, exhibits a neutral black to gray color with low color saturation and no tinge, has a high printed image density and exhibits excellent fastness properties of the recorded image, particularly ozone-gas resistance. The ink composition contain at least one kind of coloring matter (I), which a coloring matter represented by formula (1) below, a tautomer thereof, or a salt of the coloring matter or the tautomer; at least one kind of coloring matter (II), which is a coloring matter represented by formula (2) below or a salt thereof; and coloring matter (III), which is a coloring matter having an azo group other than coloring matters (I) and (II), or a salt thereof.

Owner:NIPPON KAYAKU CO LTD

Azo compound and salt thereof, and dye-containing polarizing film comprising the compound or salt

InactiveUS20090126127A1Improve performanceIncrease resistanceMonoazo dyesDisazo dyesHydrogen atomAlkoxy group

Disclosed is an azo compound represented by the general formula (1) or a salt thereof:wherein R1 and R2 independently represent a hydrogen atom, a lower alkyl group or a lower alkoxy group; and n represents 1 or 2. Also disclosed are a dye-containing polarizing film and a dye-containing polarizing plate, each of which comprises a polarizing film base material and the azo compound contained in the base material.

Owner:NIPPON KAYAKU CO LTD +1

Azo compound, ink composition, recording method and colored material

ActiveUS20130321523A1Good storage stabilityLow color-rendering propertyMonoazo dyesOrganic chemistryHueCOLORED MATERIAL

A coloring matter which exhibits excellent (ozone) gas resistance, high print density, low color rendering properties, low color saturation, and high-quality black hue when is recorded on a paper only for inkjet exclusive use, i.e., an azo compound represented by formula (1), a tautomer of the azo compound, or a salt of the azo compound or the tautomer; and an ink composition containing the coloring matter, particularly a black ink composition for inkjet recording applications.

Owner:NIPPON KAYAKU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com