Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about "Levers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

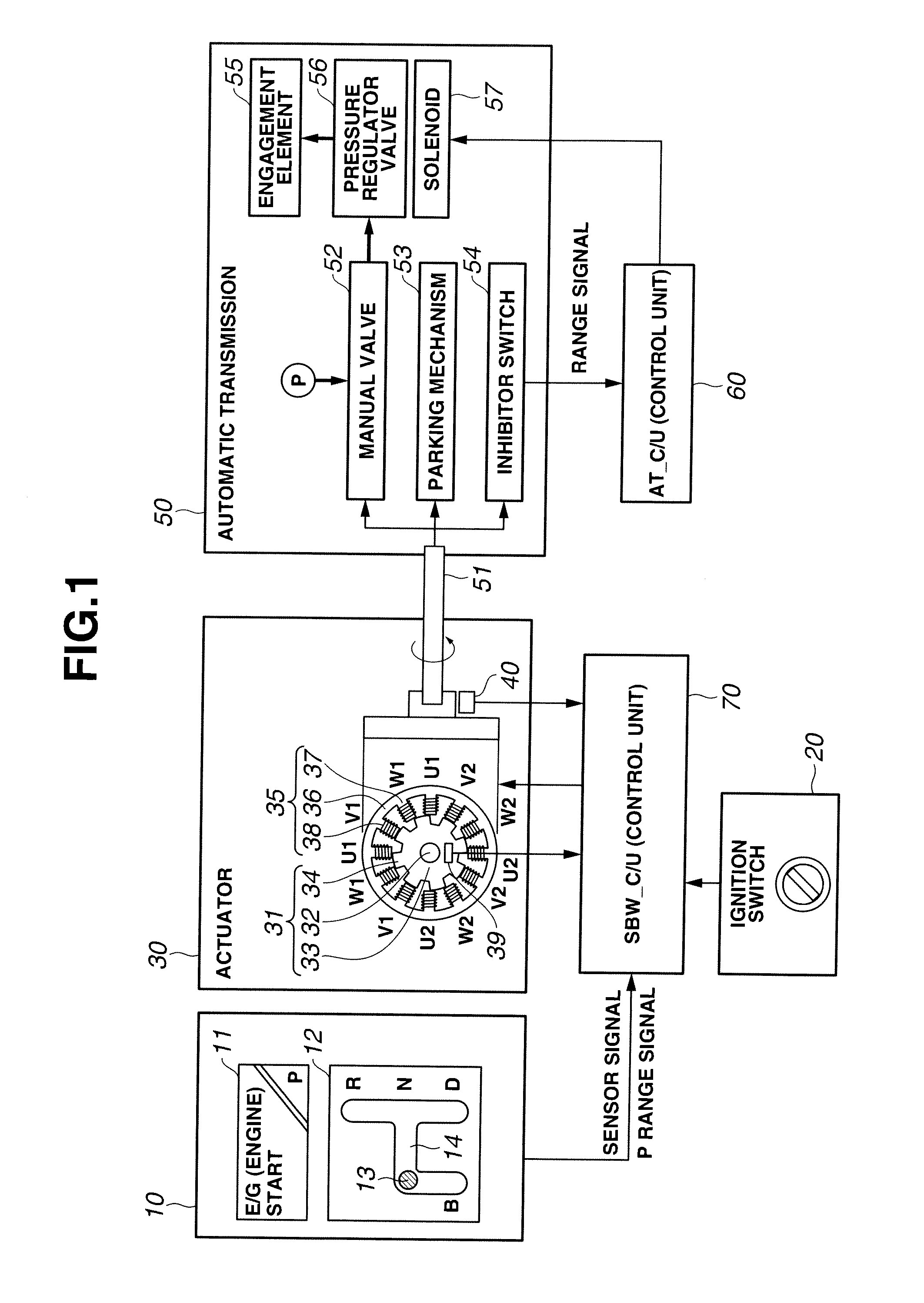

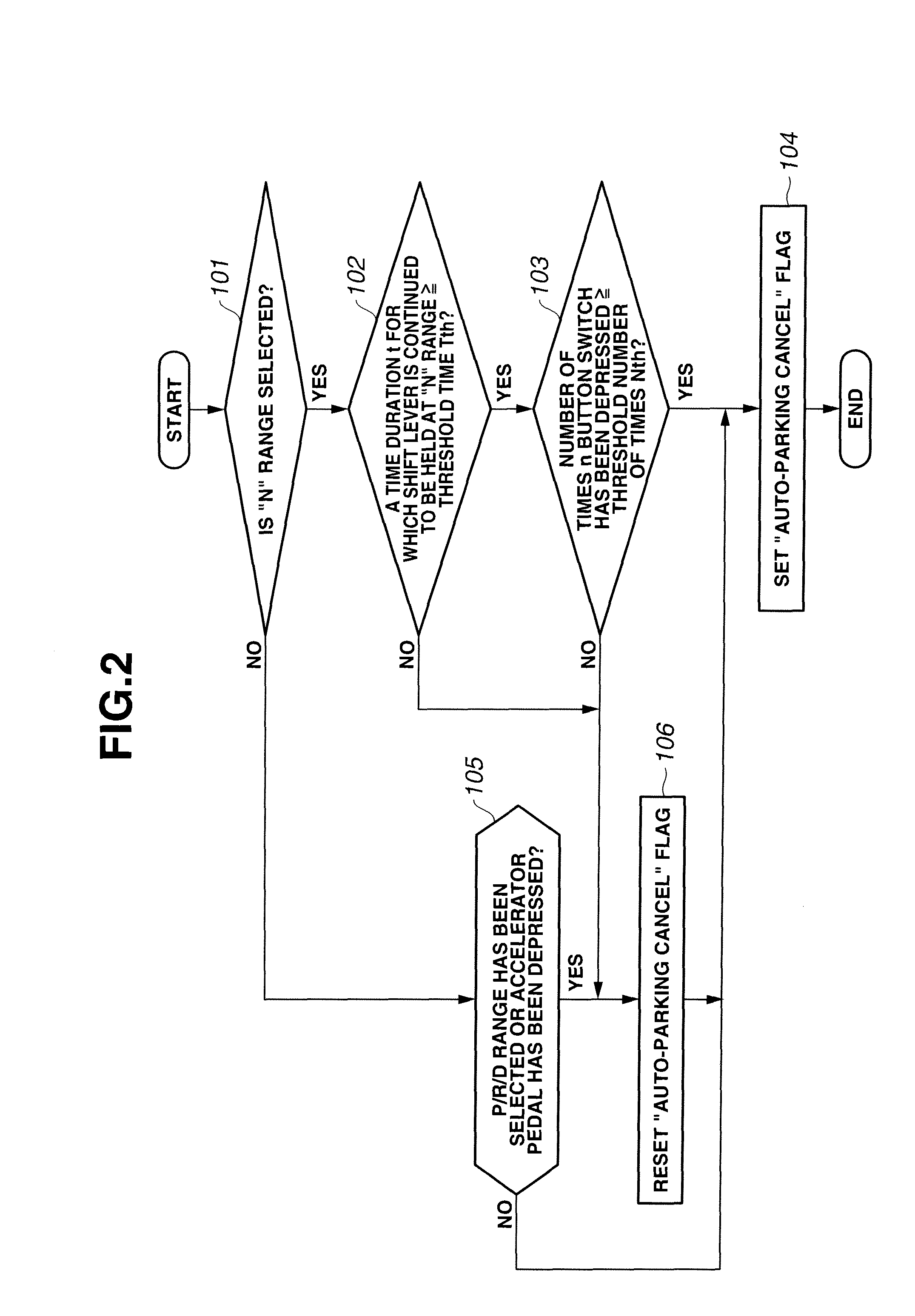

Vehicular control apparatus and method for shift-by-wire device

ActiveUS20100206118A1Possible releaseInhibition releaseManual control with multiple controlled membersDigital data processing detailsParking spaceOperation mode

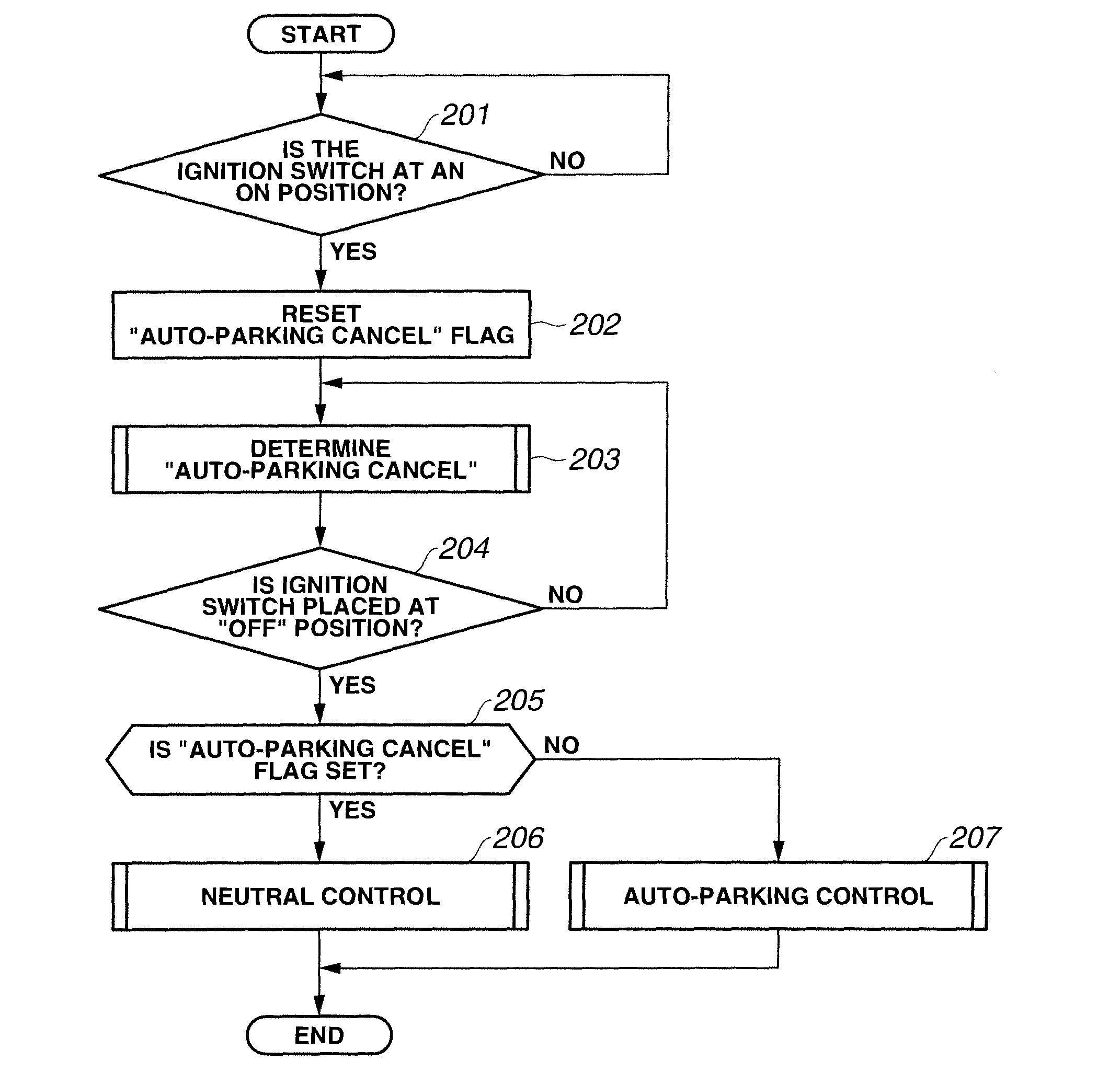

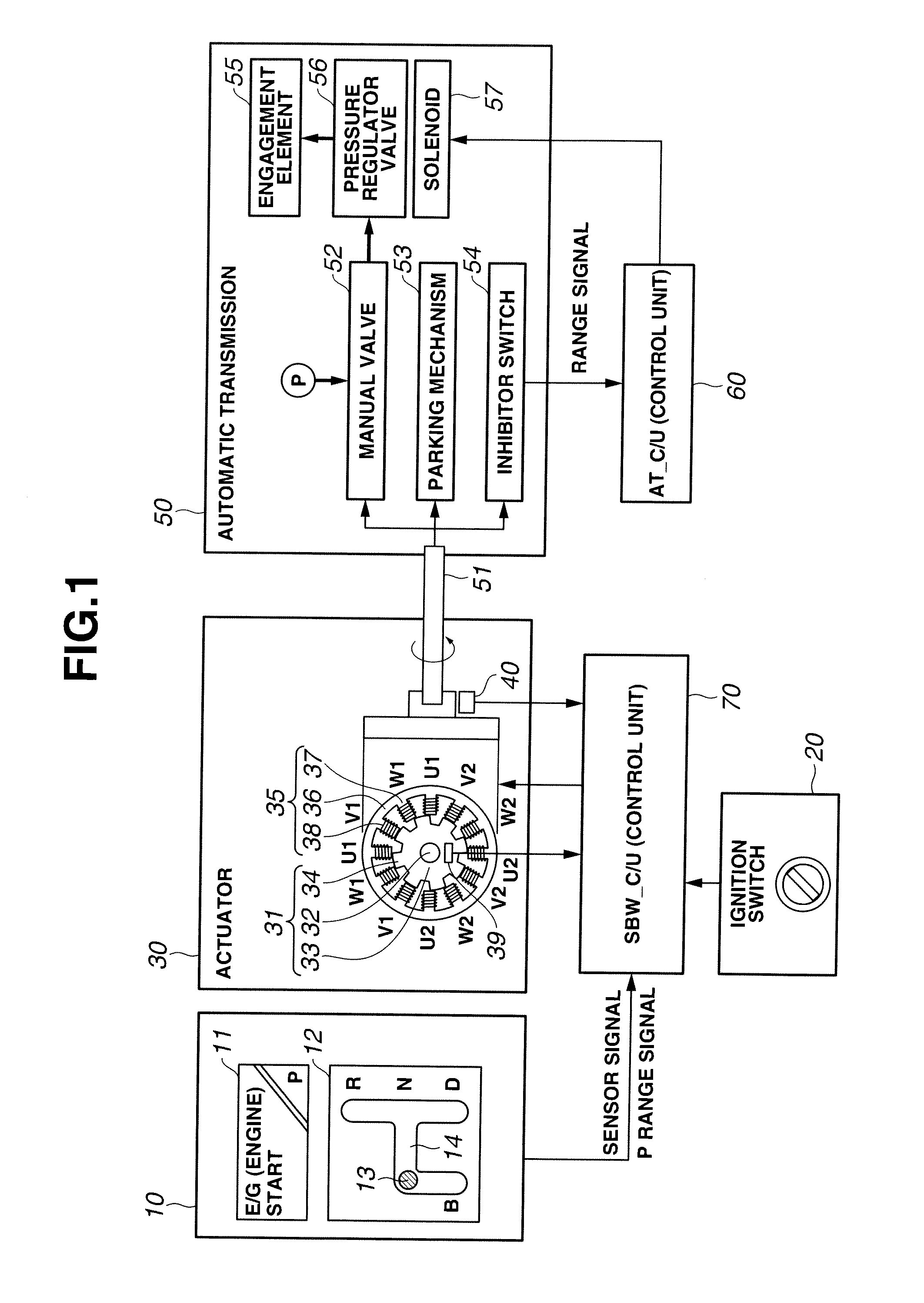

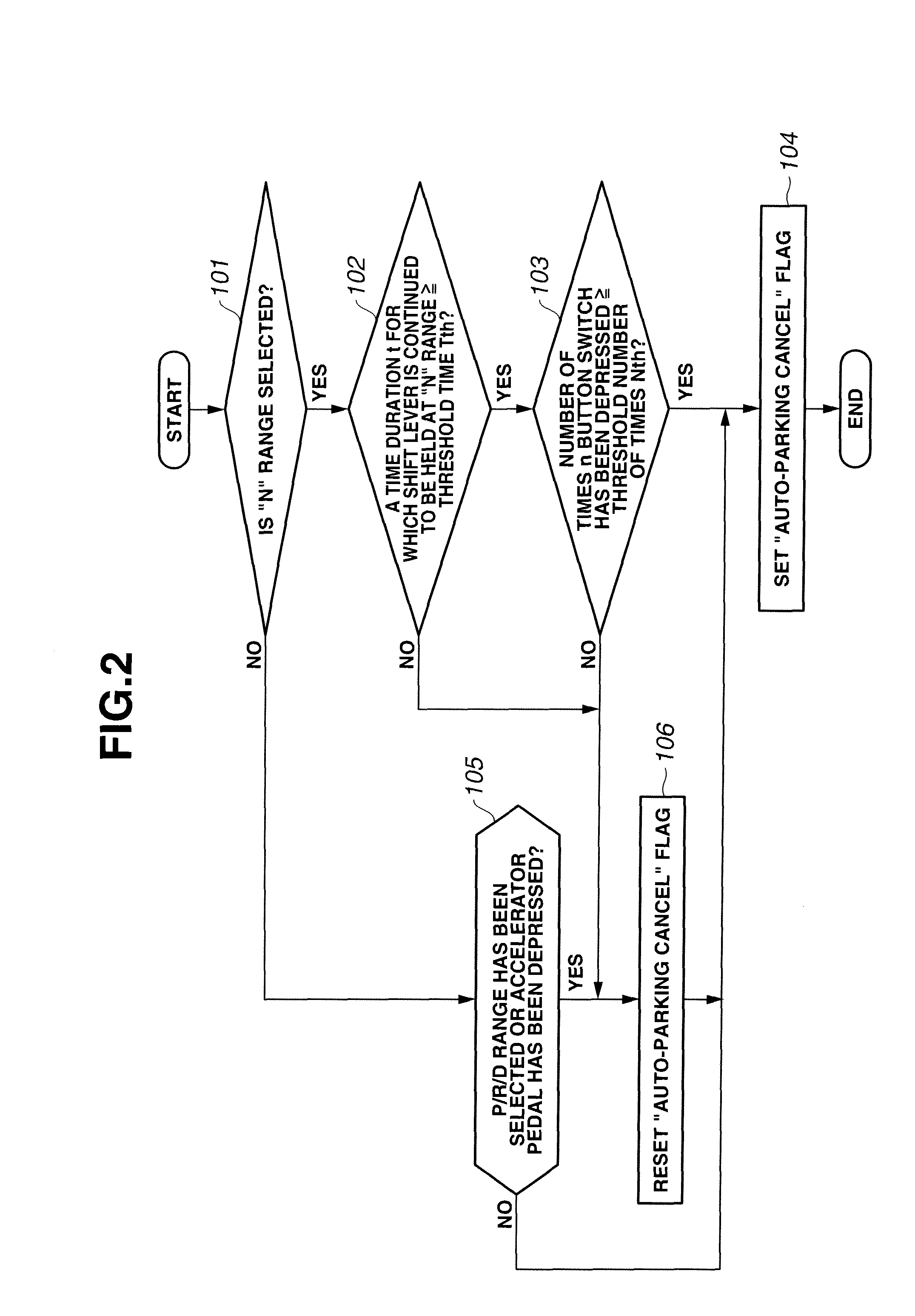

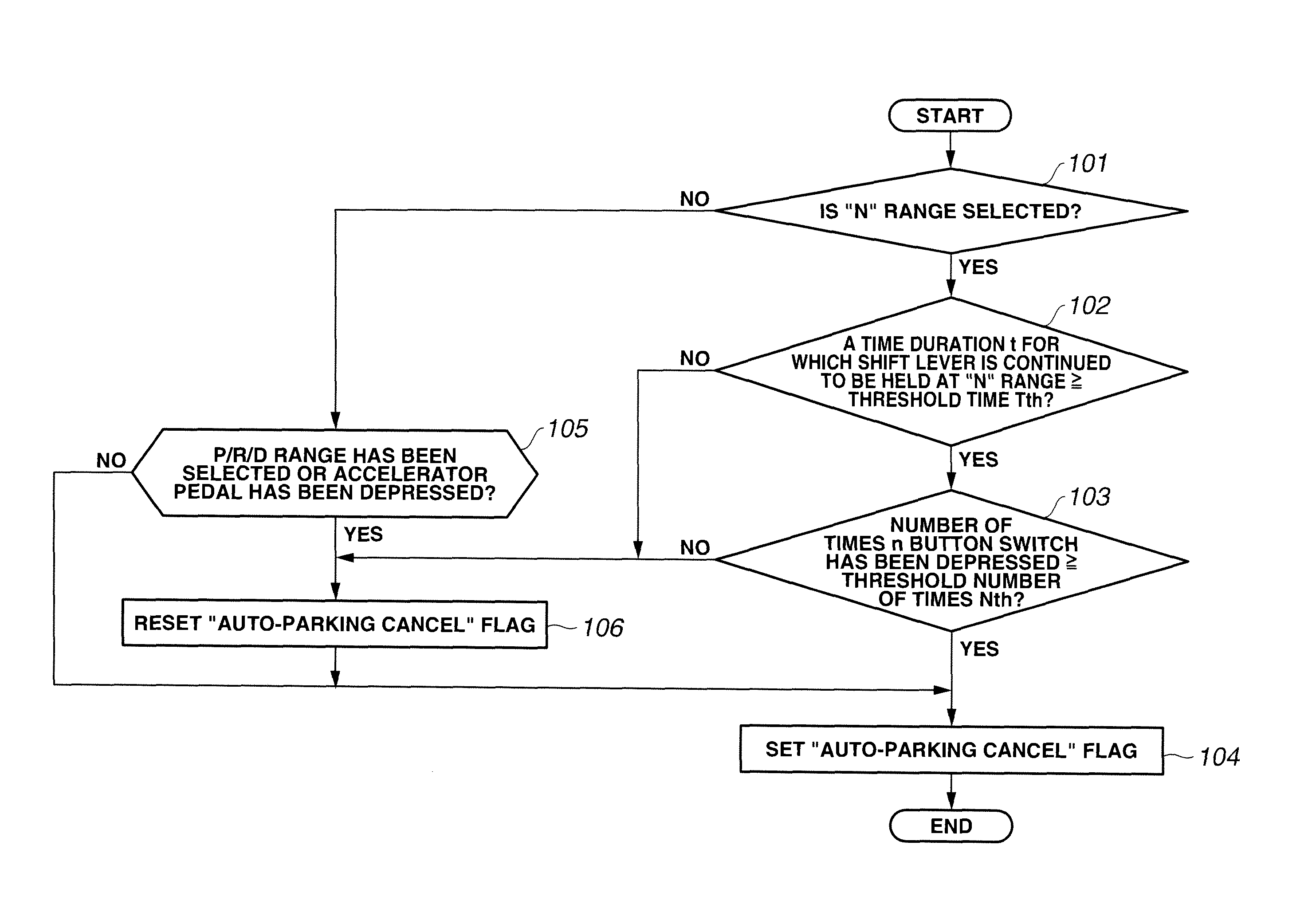

In vehicular control method and apparatus for a shift-by-wire device, a selected shift position is modified to at least one of a vehicular parking position, a neutral position, and a traveling position, the selected shift position is modified to the vehicular parking position when a power switch is switched to an OFF position, and the modification of the shift position to the vehicular parking position is inhibited when an operation pattern of an operation input section while the power switch is in the ON position is made coincident with the operation pattern prescribed as a cipher code which inhibits the shift position modification to the vehicular parking position, the operation patterns being constituted by a combination of operation patterns which would not be carried out in the operation section during an ordinary traveling.

Owner:JATCO LTD

Vehicular control apparatus and method for shift-by-wire device

ActiveUS8301348B2Inhibition releasePossible releaseManual control with multiple controlled membersLeversParking spaceOperation mode

Owner:JATCO LTD

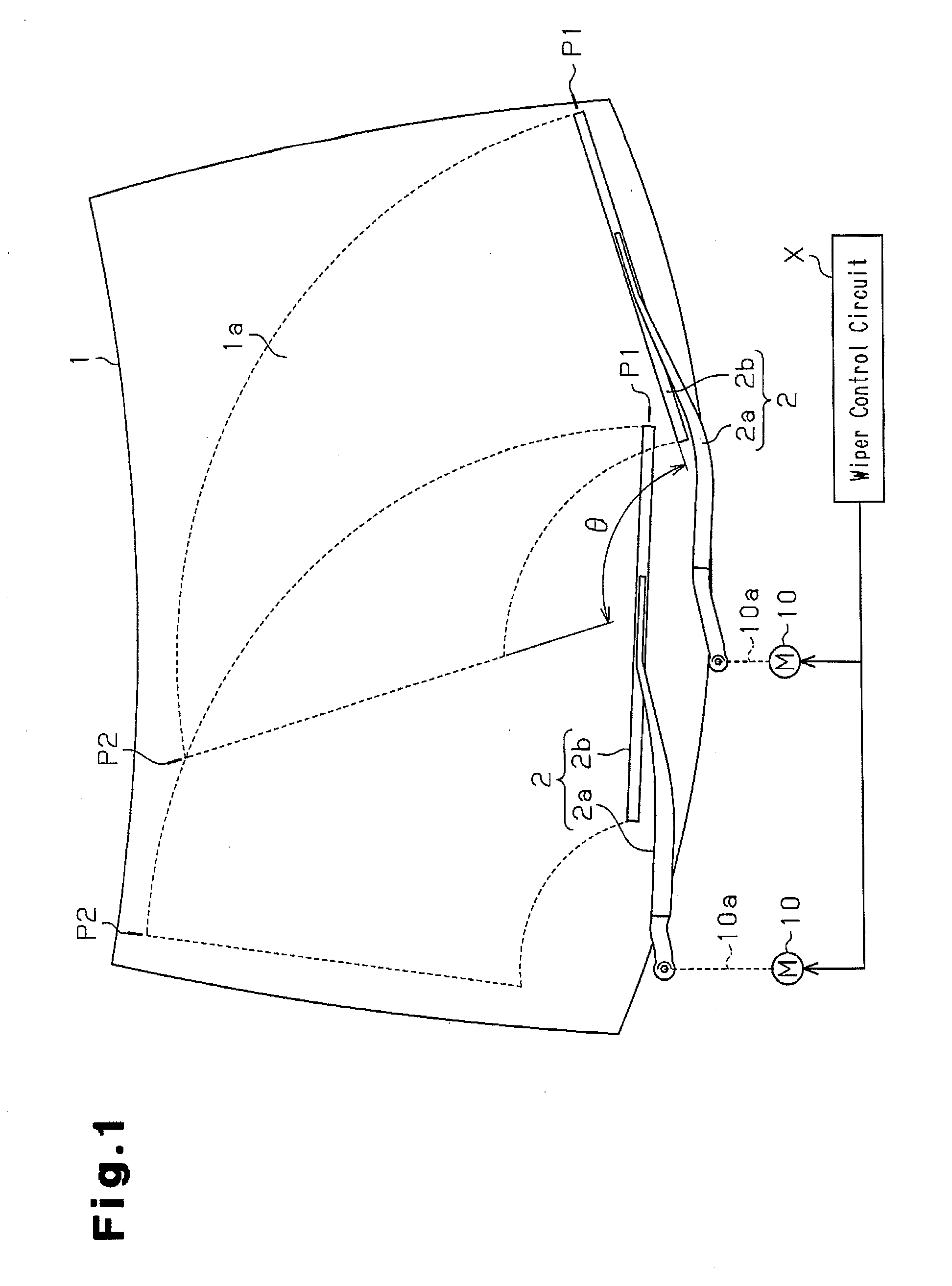

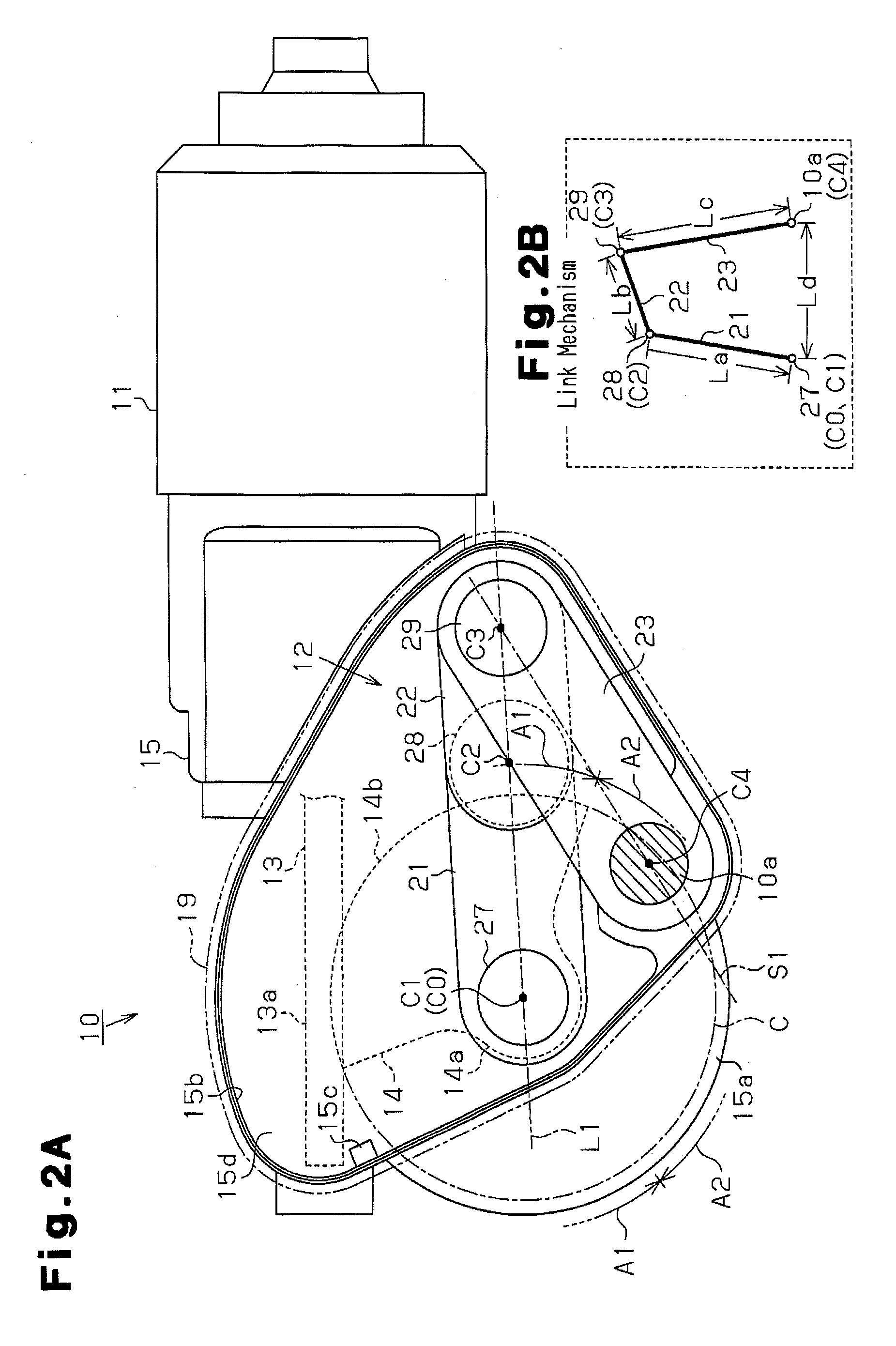

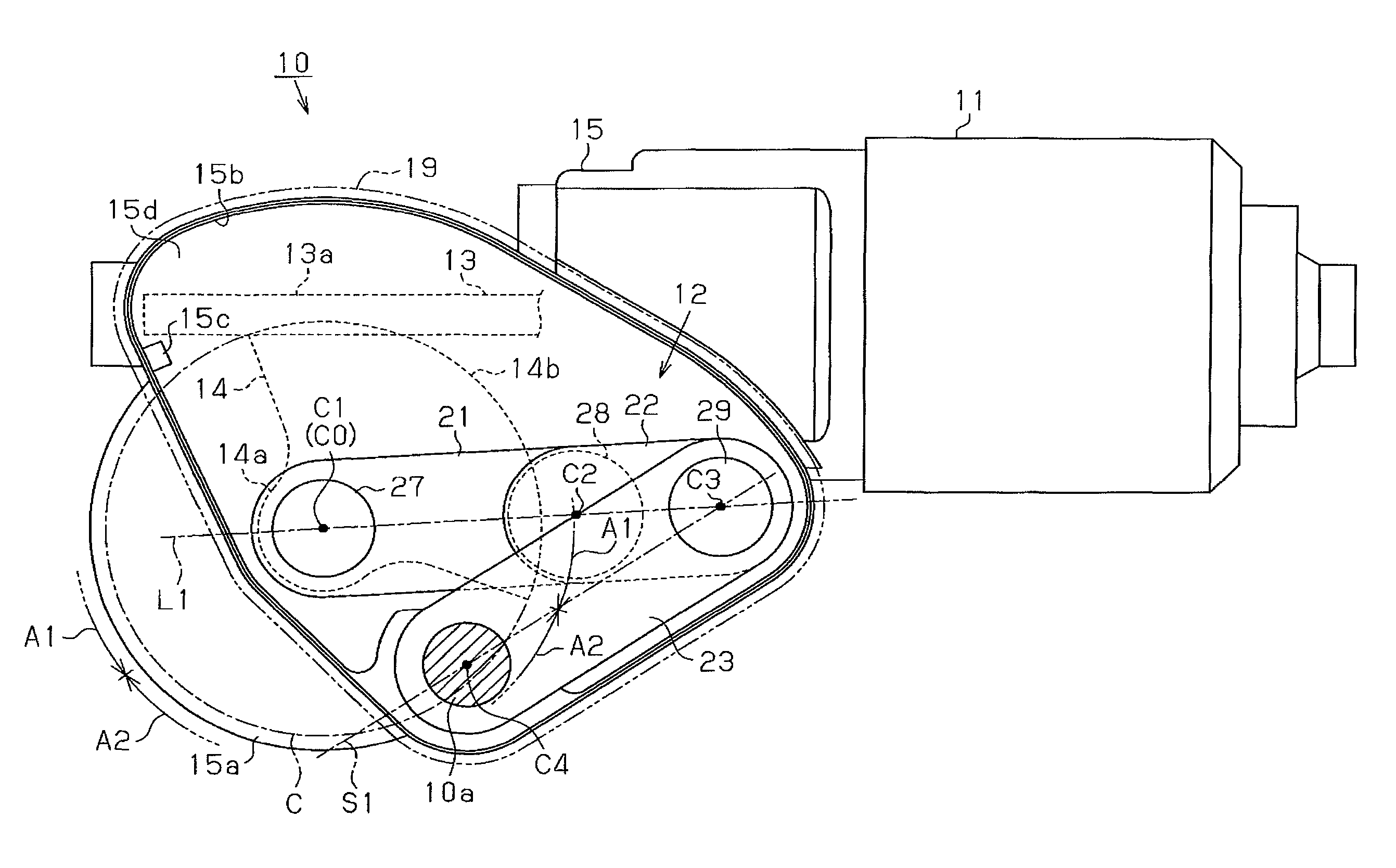

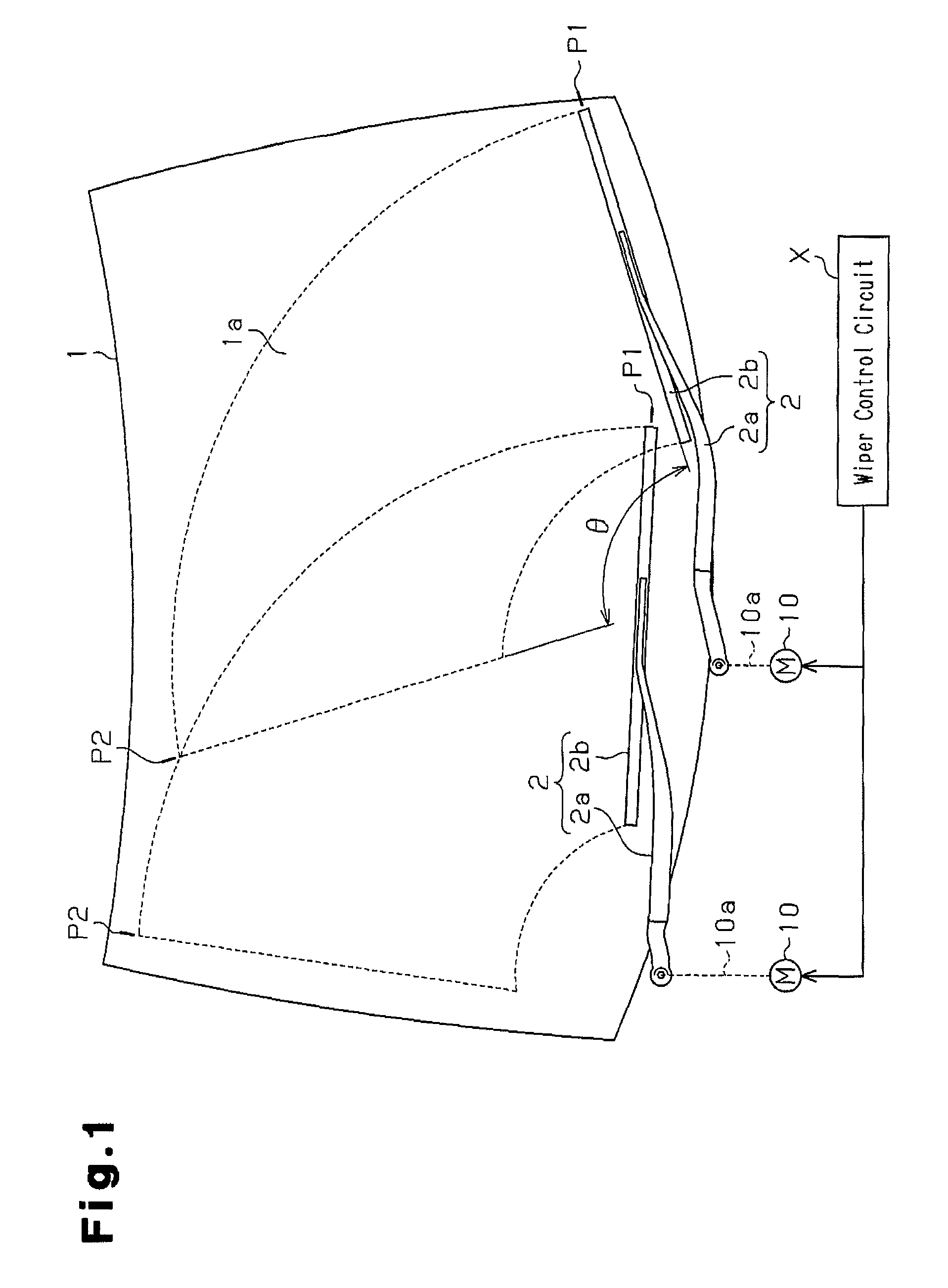

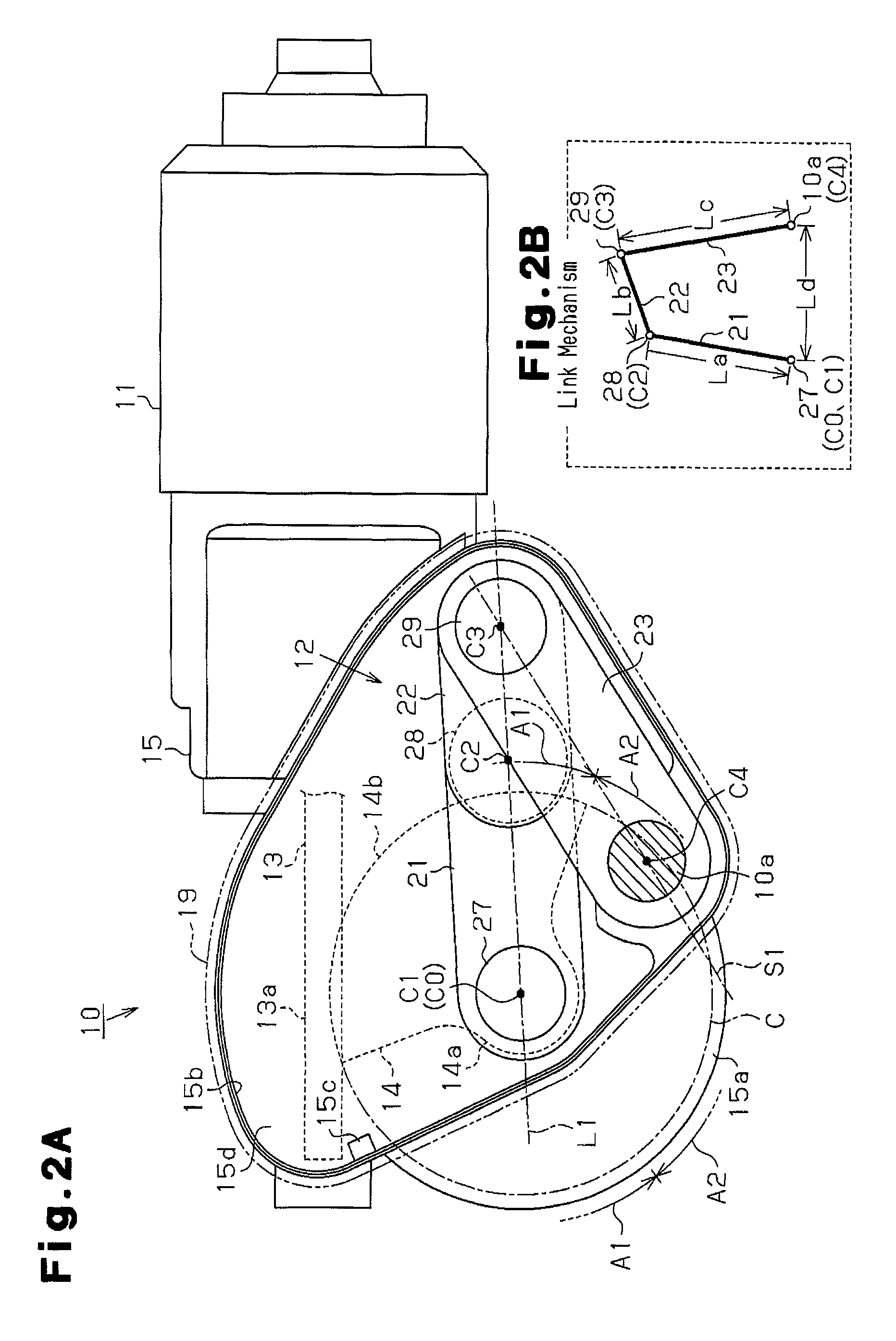

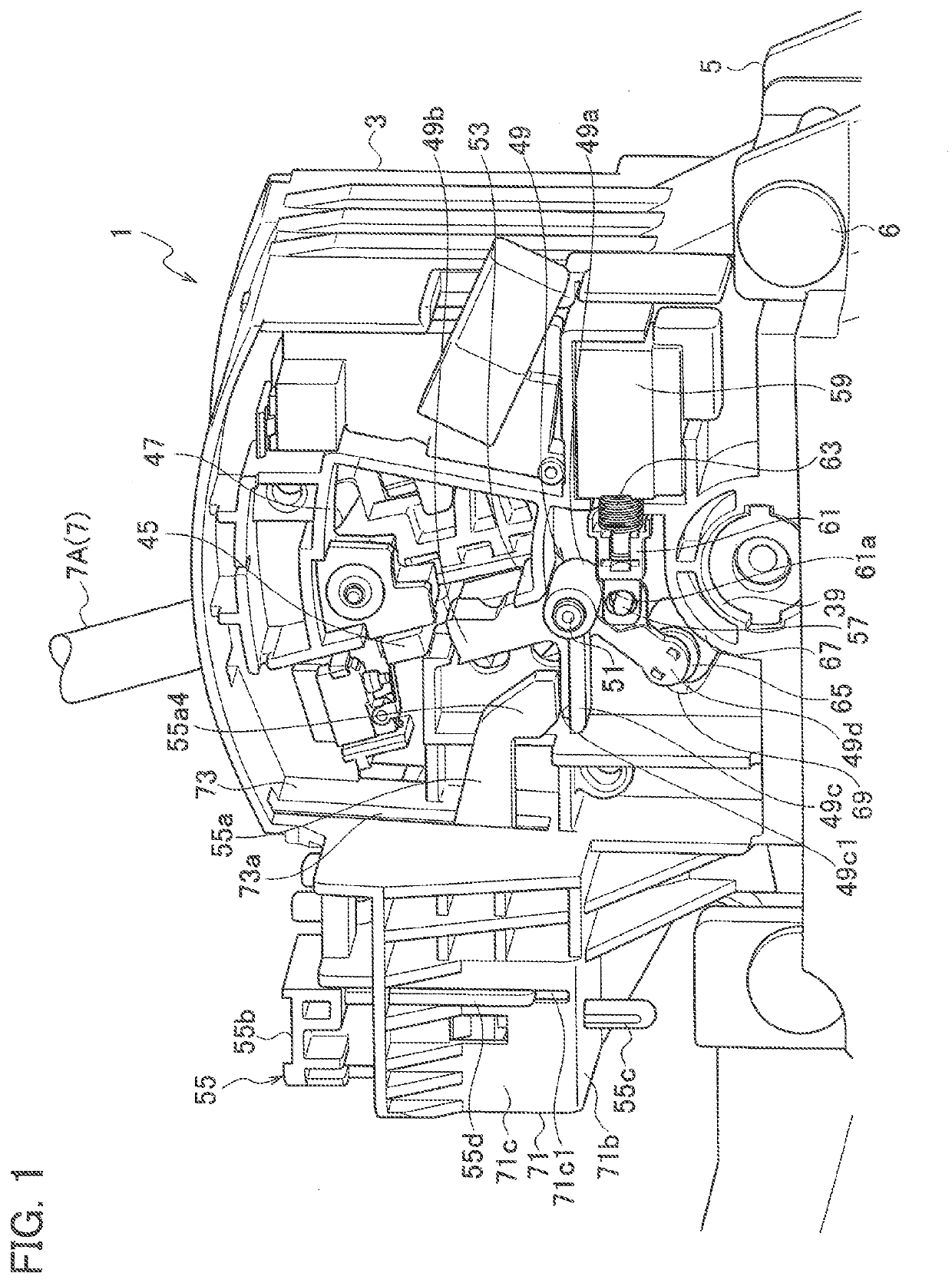

Motor device and wiper apparatus

Owner:ASMO CO LTD

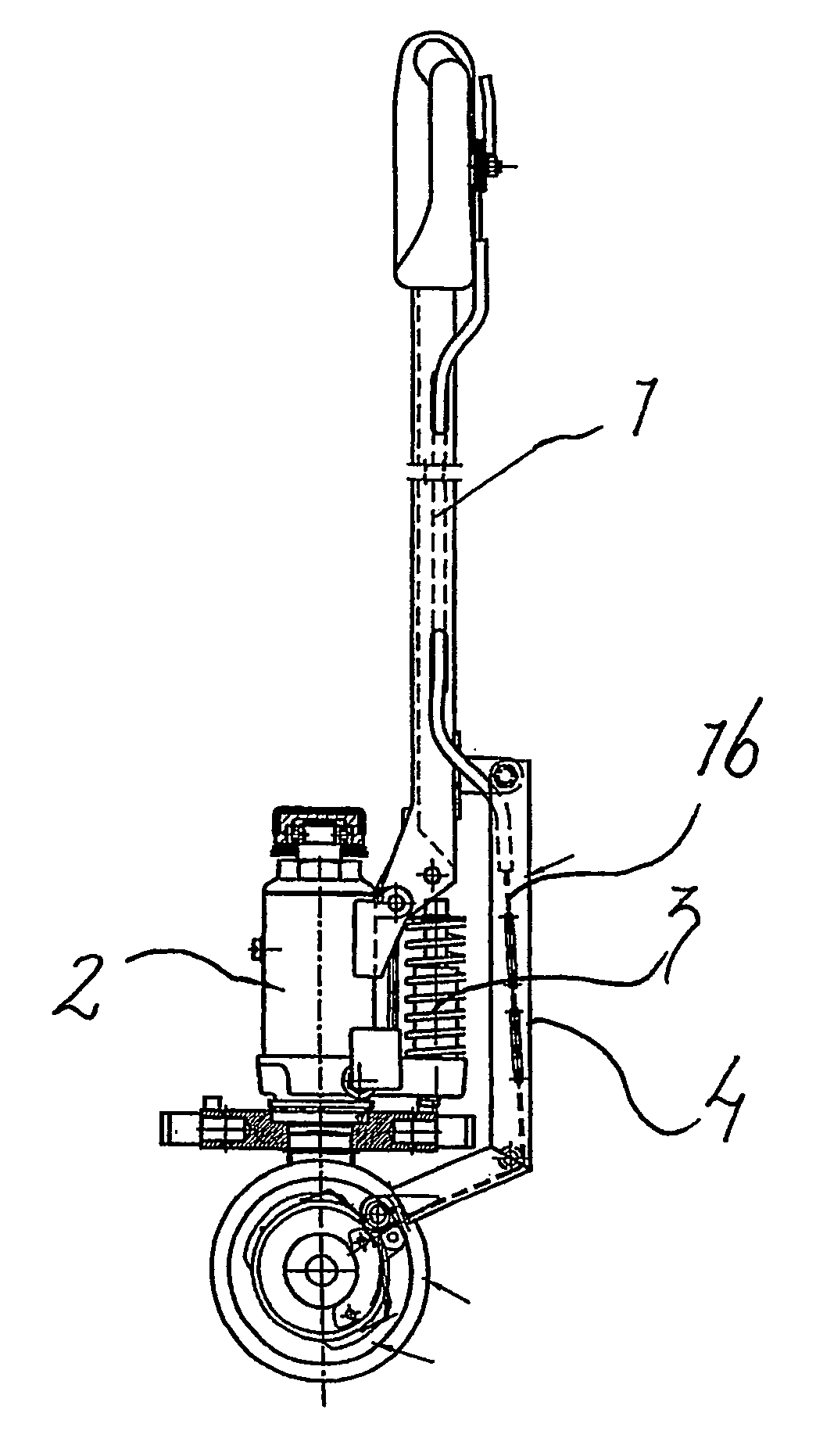

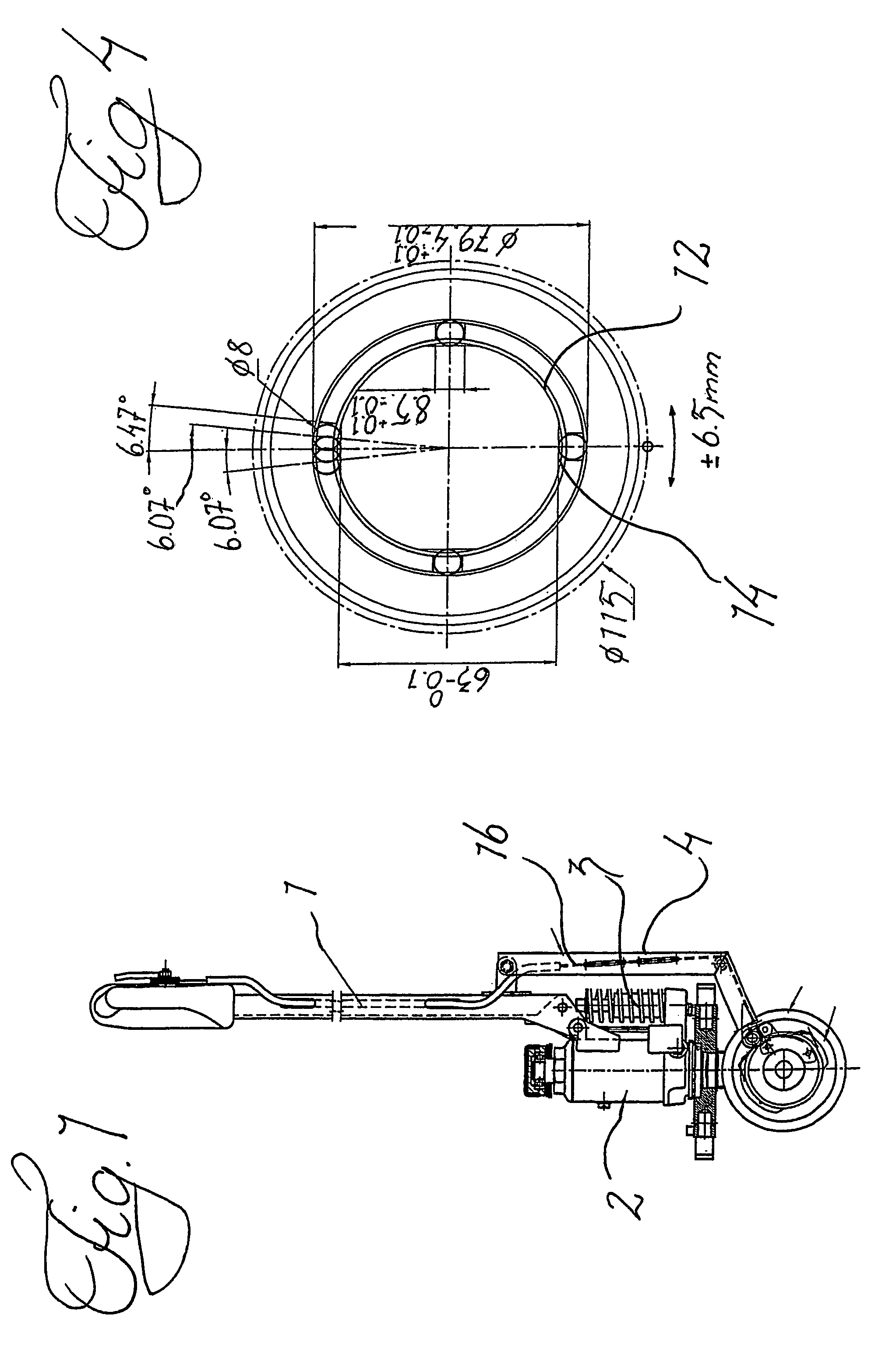

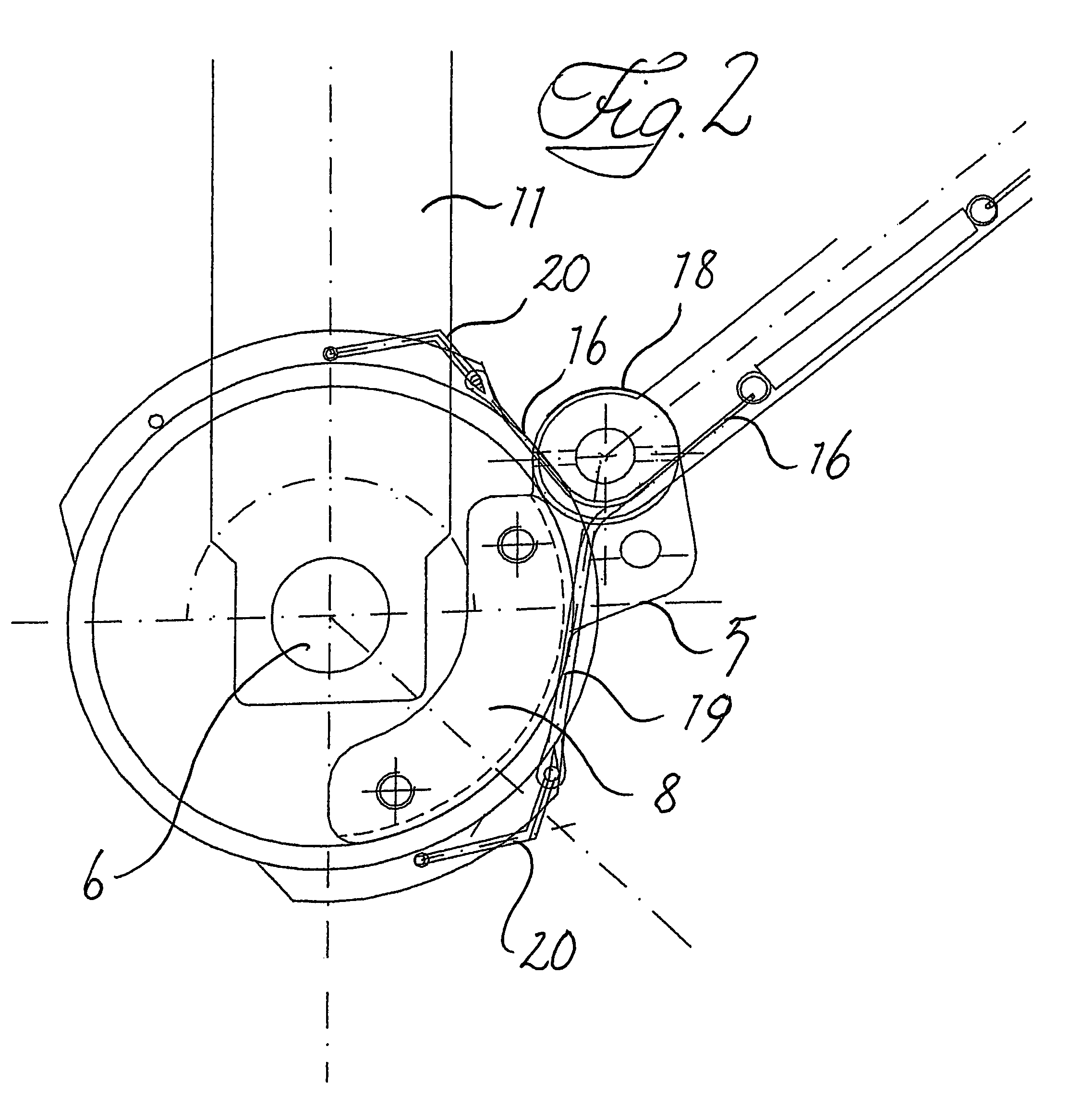

Device at handtruck

Tiller truck provided with force transmitter in order to transmit a pumping movement with the tiller to the wheels via a coupling in order to facilitate the movement of the truck. The coupling is arranged so that it can be set for force transfer forward or rearward or in an entirely free position. A control for the control of the coupling is arranged in the tiller handle.

Owner:BT INDS

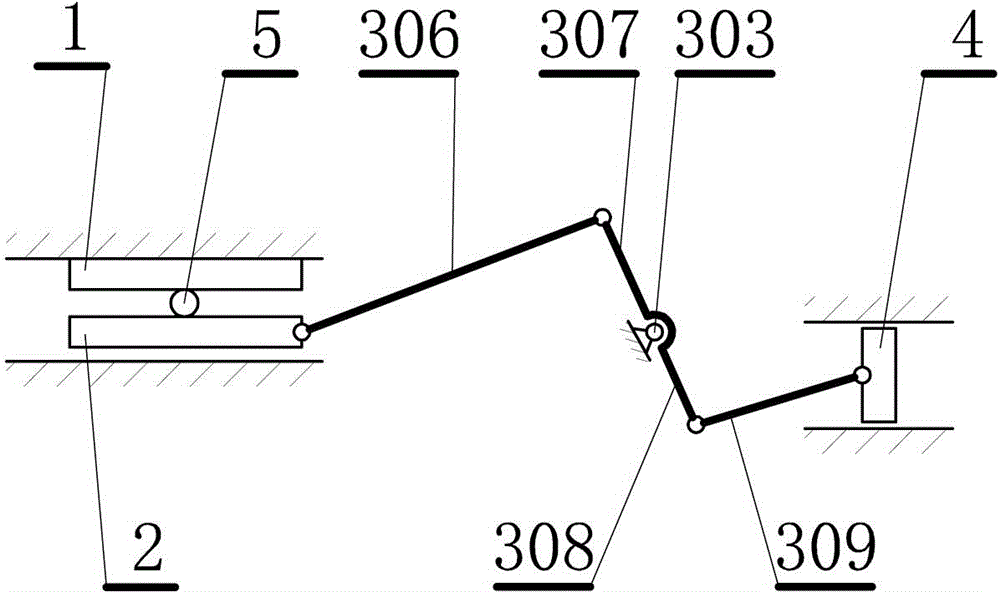

Thread rolling method and thread rolling machine

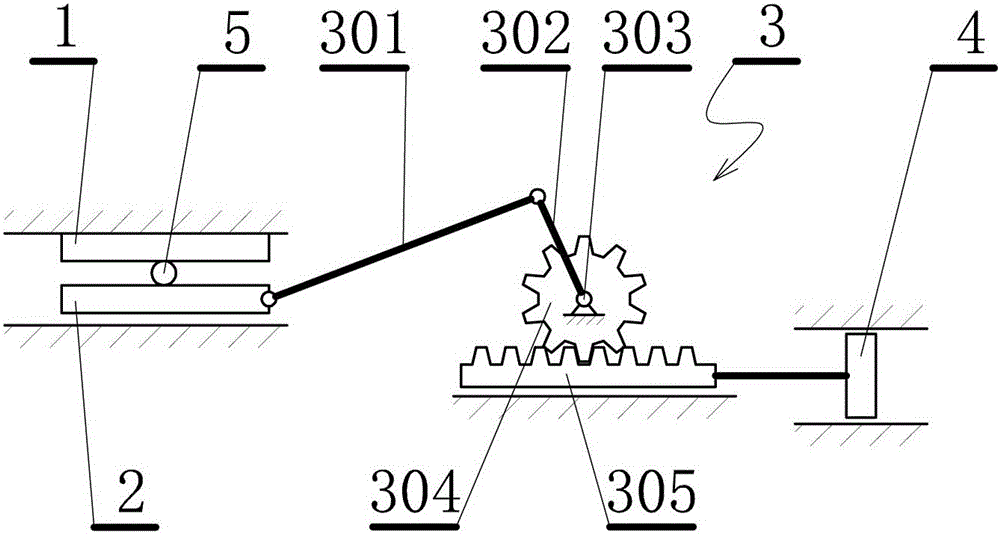

The invention relates to a thread rolling method and a thread rolling machine. The thread rolling machine comprises a fixed thread rolling plate and a gliding thread rolling plate mounted on a bed body; the gliding thread rolling plate is connected with a movement zooming mechanism, and the movement zooming mechanism is connected with a liner reciprocating power mechanism. By lever principle, the zooming of a movement distance is formed; meanwhile, zooming of movement speed is generated, slow action of hydraulic movement is changed so as to adapt to the rapid movement of thread rolling. The method can be well applied to the thread rolling of a large bolt, thereby changing the situation of applying a very big crank rocker mechanism to the thread rolling of a big bolt, shortening an overall structure of the thread rolling machine, and reducing the cost.

Owner:WHENZHOU ZHONGTE STANDARD PARTS CO LTD

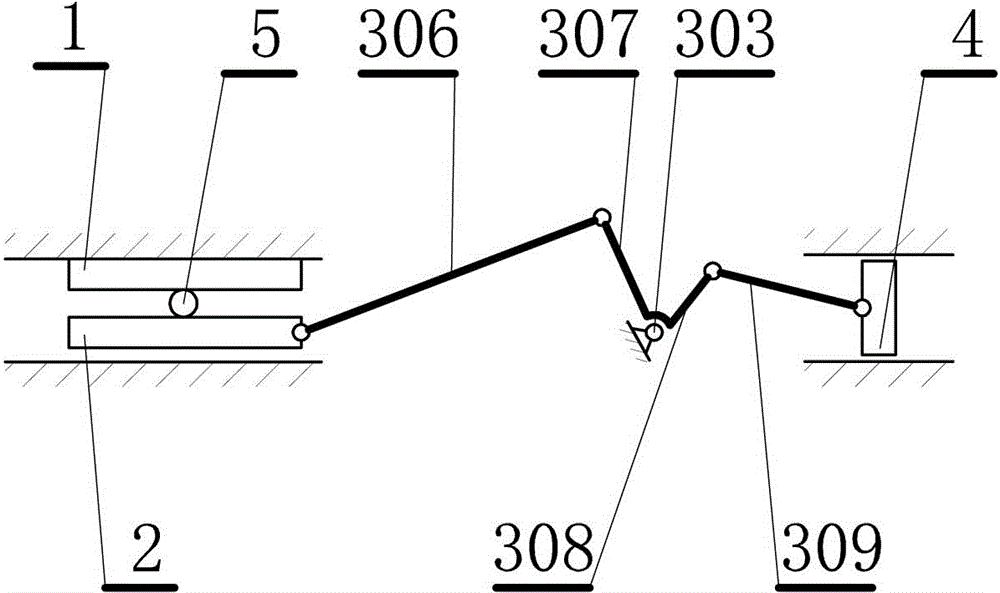

Electric Servo Dump Gate System On A Crop Duster

ActiveUS20210107630A1Reduce power densityAvoid excessive changesControlling membersConjoint controlsControl engineeringLocation data

The present invention is an Electric servo system which controls and automates gate openings based on GPS speed and position data that results in precise and reliable modern variable and constant rate application. The Electric servo system also allows for Mechanical gate linkages to remain intact, resulting in few changes to the aircraft and redundancy of emergency components. A Mechanical input connect / disconnect is used to effortlessly transfer between the automated Electric servo system and the Mechanical gate system.

Owner:REABE TROY

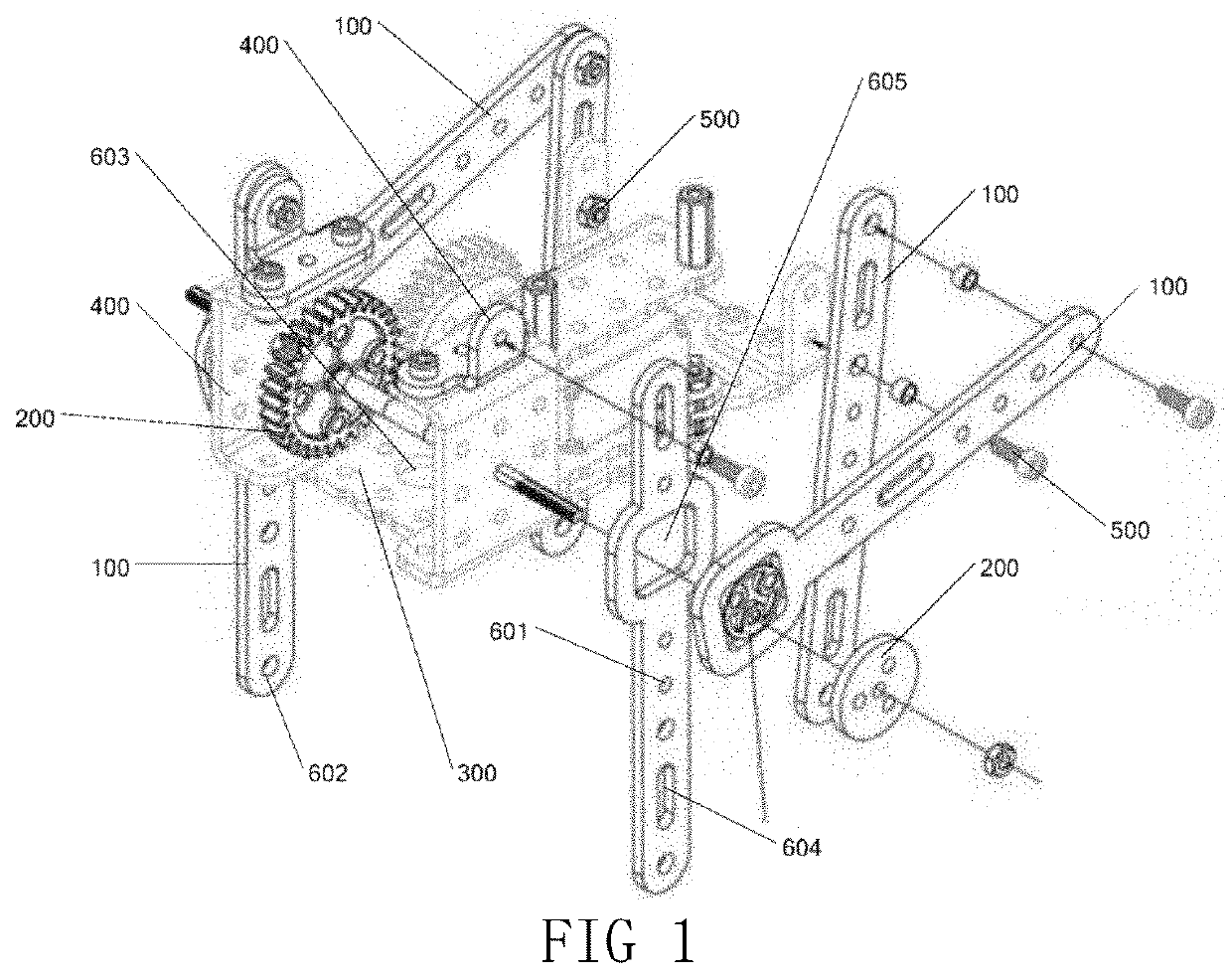

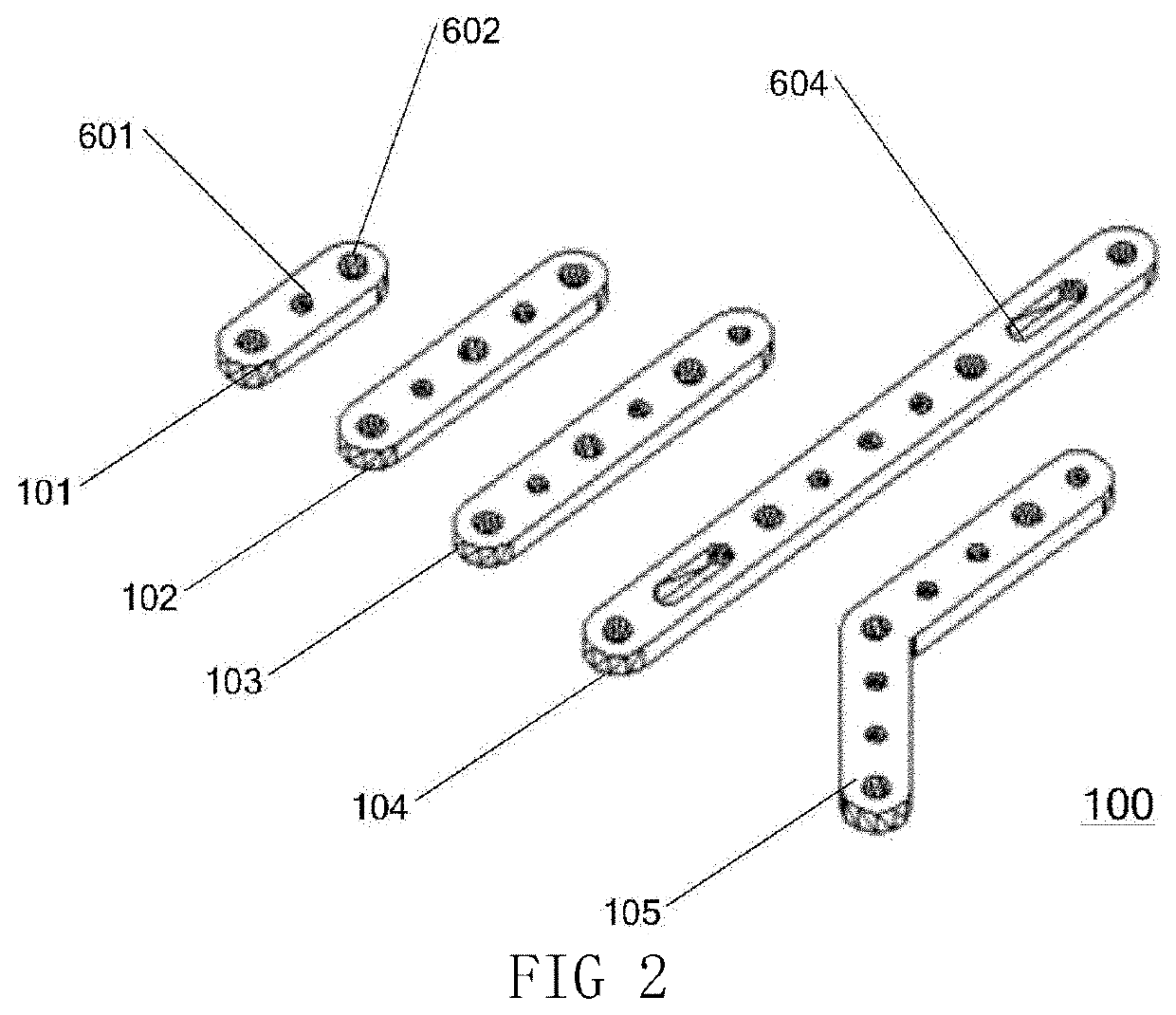

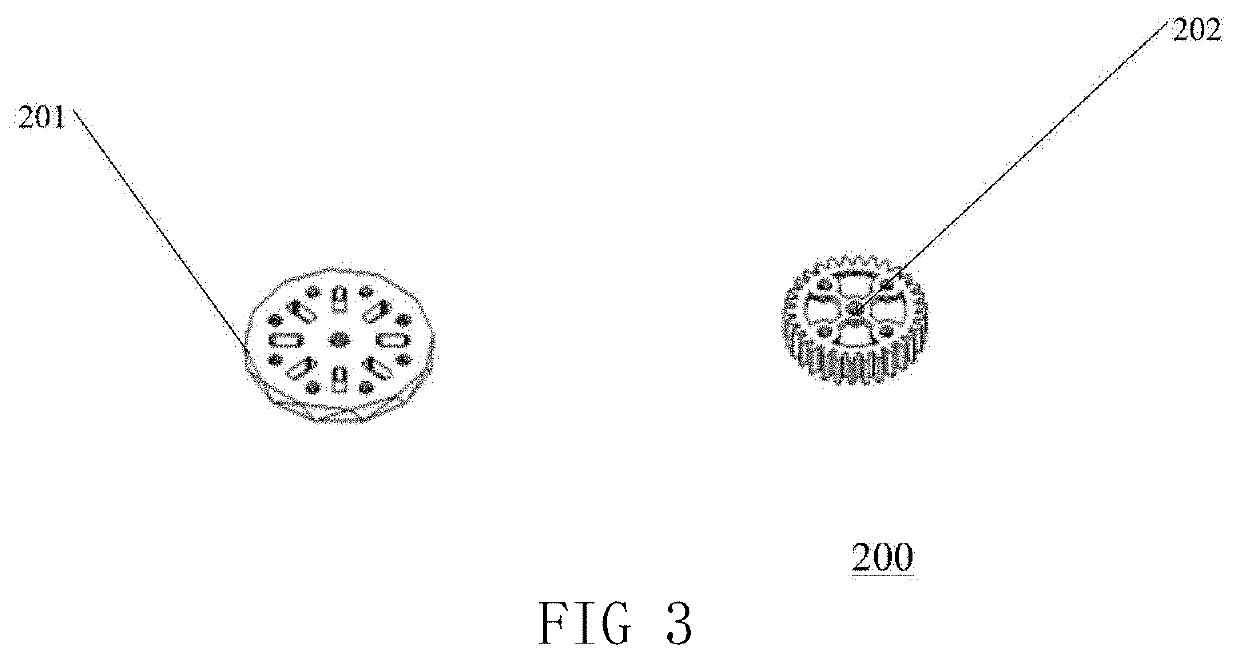

Bar member, assembled component and robot

ActiveUS10598264B2Variety of movement functionsIncrease diversityProgramme-controlled manipulatorControlling membersStructural engineeringMechanical engineering

Robot includes an assembled component having a fixed member and a moving member. The moving member includes a multi-hole bar member and a multi-hole circular plate. The multi-hole bar member has a width four times longer than its thickness. The multi-hole bar member includes a set of connecting holes running through the multi-hole bar member along a thickness direction of the multi-hole bar member. The multi-hole circular plate has a central hole and fixed holes distributed around the central hole and arranged circumferentially. The fixed member includes a multi-hole plate and a multi-hole bent plate. The thickness of the multi-hole plate is the same as the thickness of the multi-hole bar member. A bent portion is formed by bending at least one end of the multi-hole bent plate. The fixed holes are arranged in a matrix on the multi-hole plate and distributed on the multi-hole bent plate in a matrix.

Owner:ROBOT TIME BEIJING TECH CO LTD

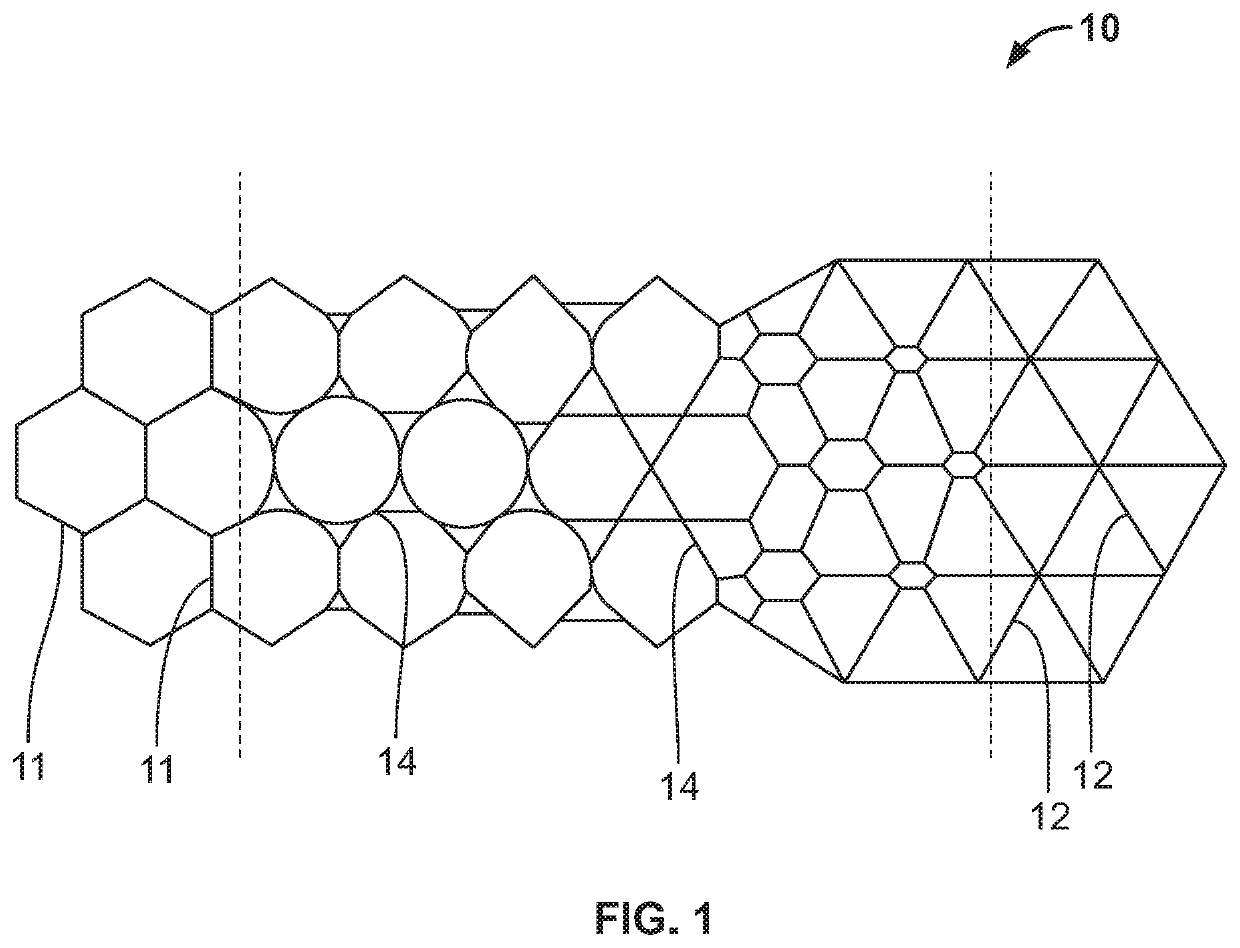

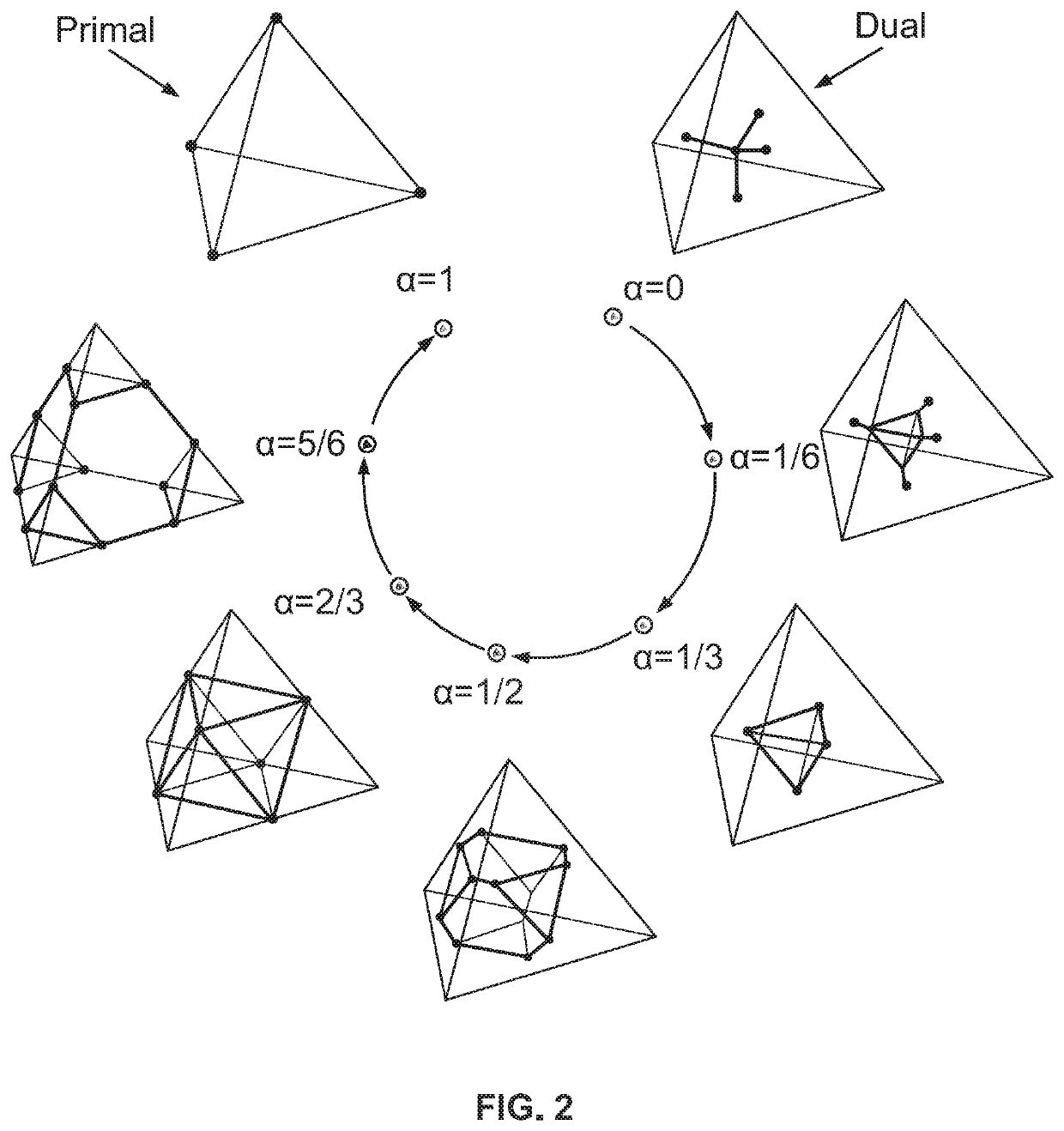

Lattice transitioning structures in additively manufactured products

PendingUS20210246959A1Additive manufacturing apparatusSpringsMechanical engineeringAdditive layer manufacturing

An additively manufactured lattice structure includes (a) a first three-dimensional lattice including a repeating interconnected array of a first lattice unit cell, (b) a second three-dimensional lattice including a repeating interconnected array of a second lattice unit cell, wherein said second lattice unit cell is different from said first lattice unit cell, and (c) a first transition segment interconnecting said first three-dimensional lattice and said second three-dimensional lattice. The first transition segment includes (i) a first three-dimensional transitional lattice including a repeating array of said first lattice unit cell and (ii) interleaved with and interconnected to said first three-dimensional transitional lattice, a second three-dimensional transitional lattice including a repeating array of said second lattice unit cell.

Owner:CARBON INC

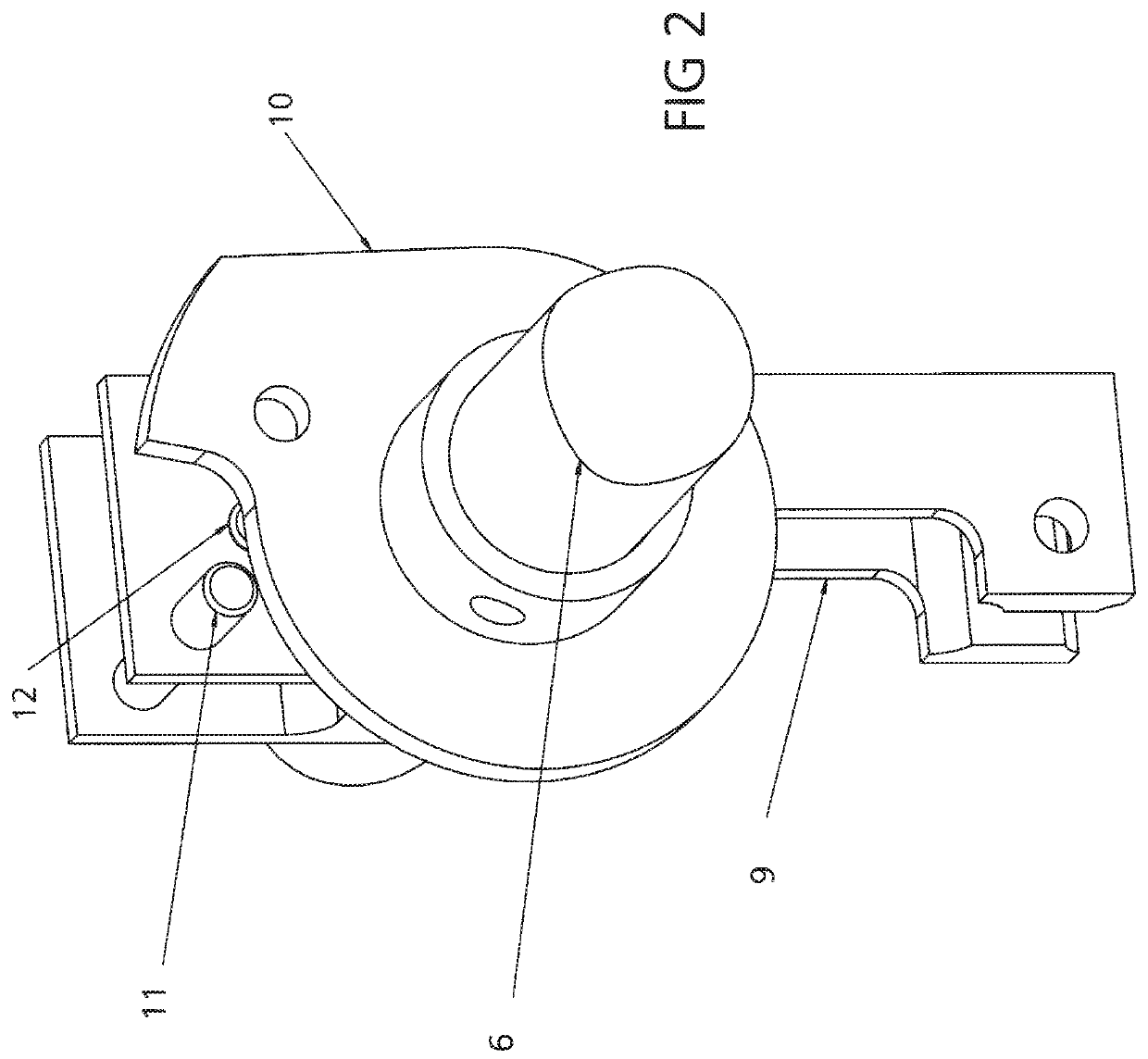

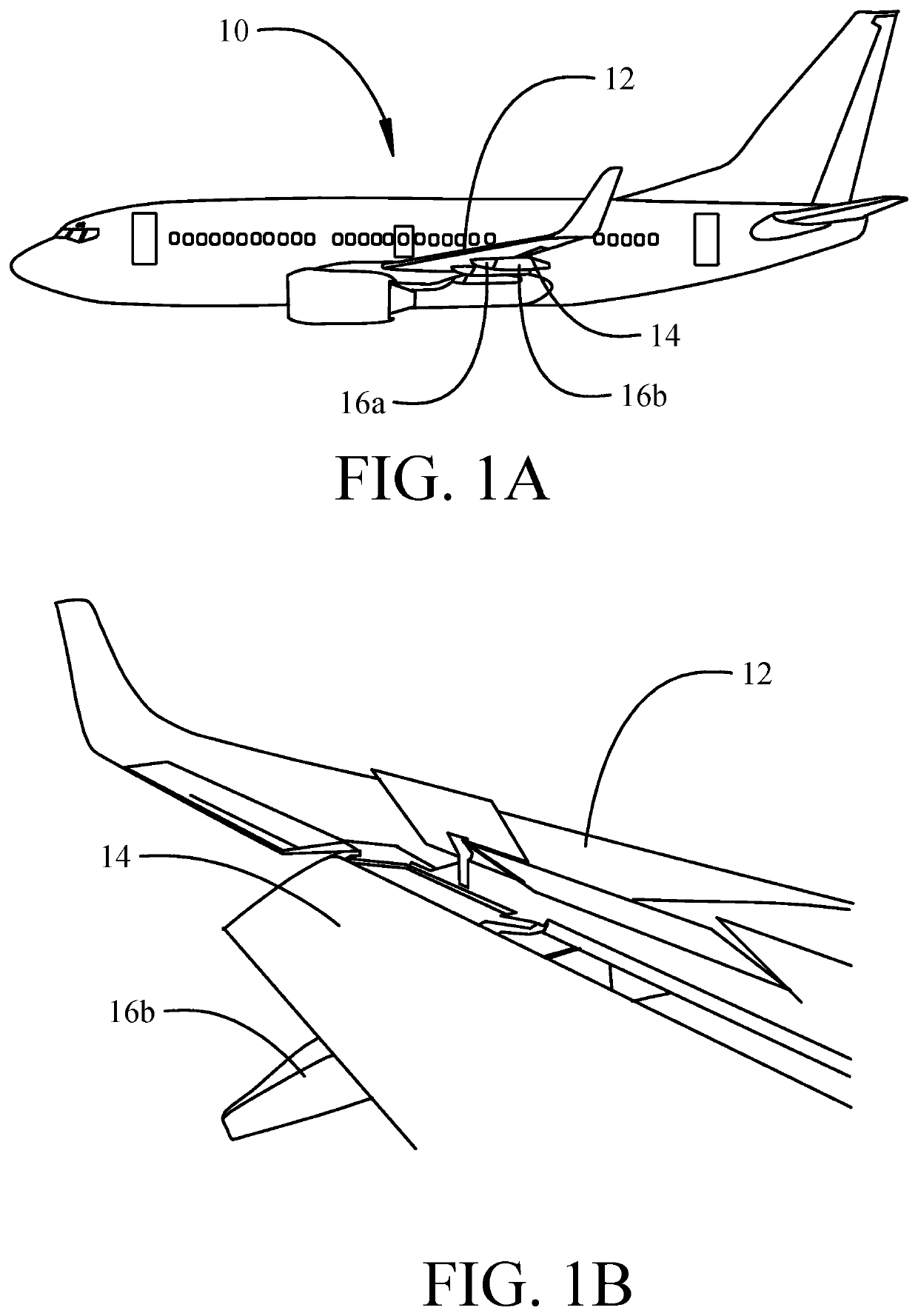

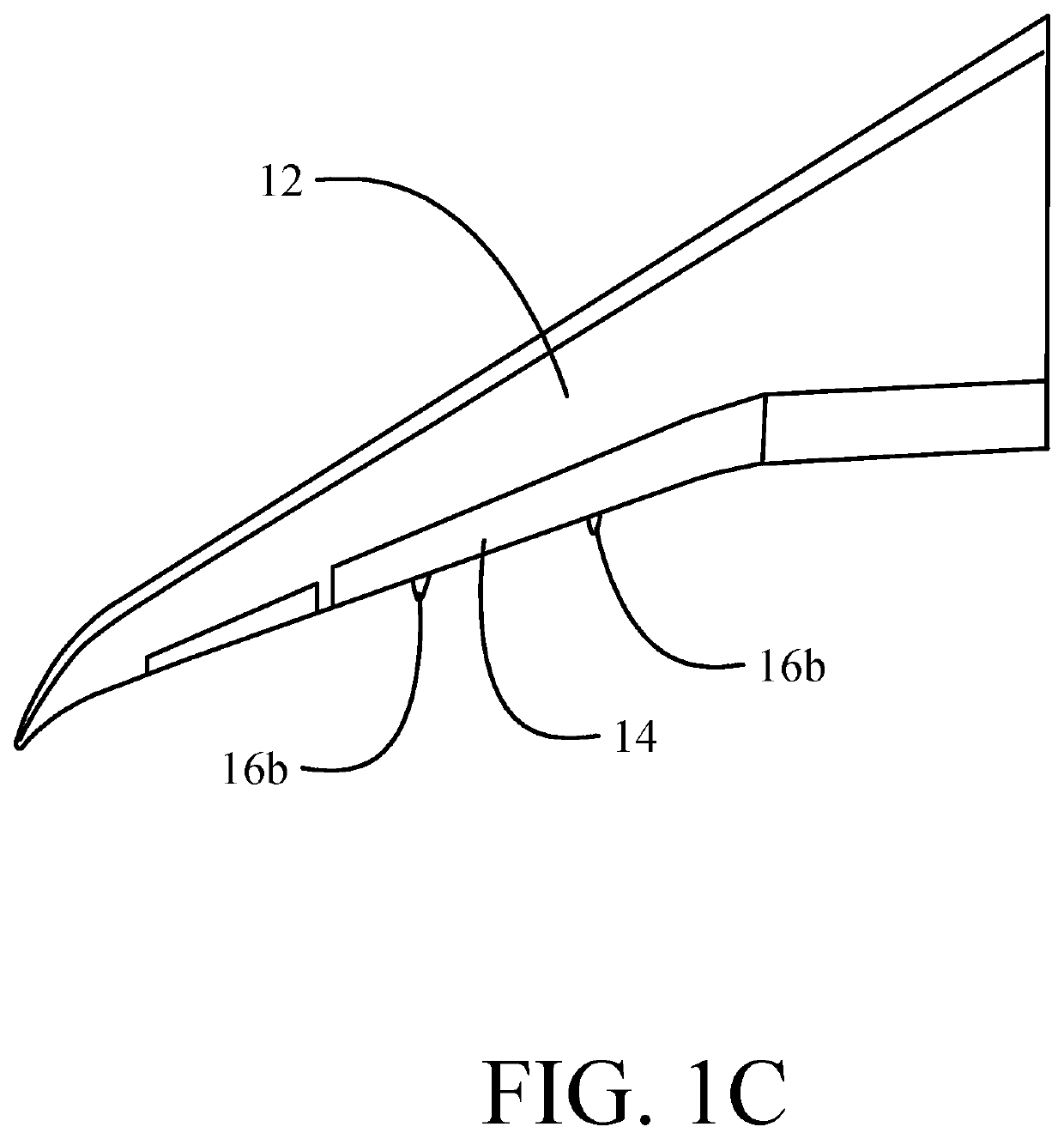

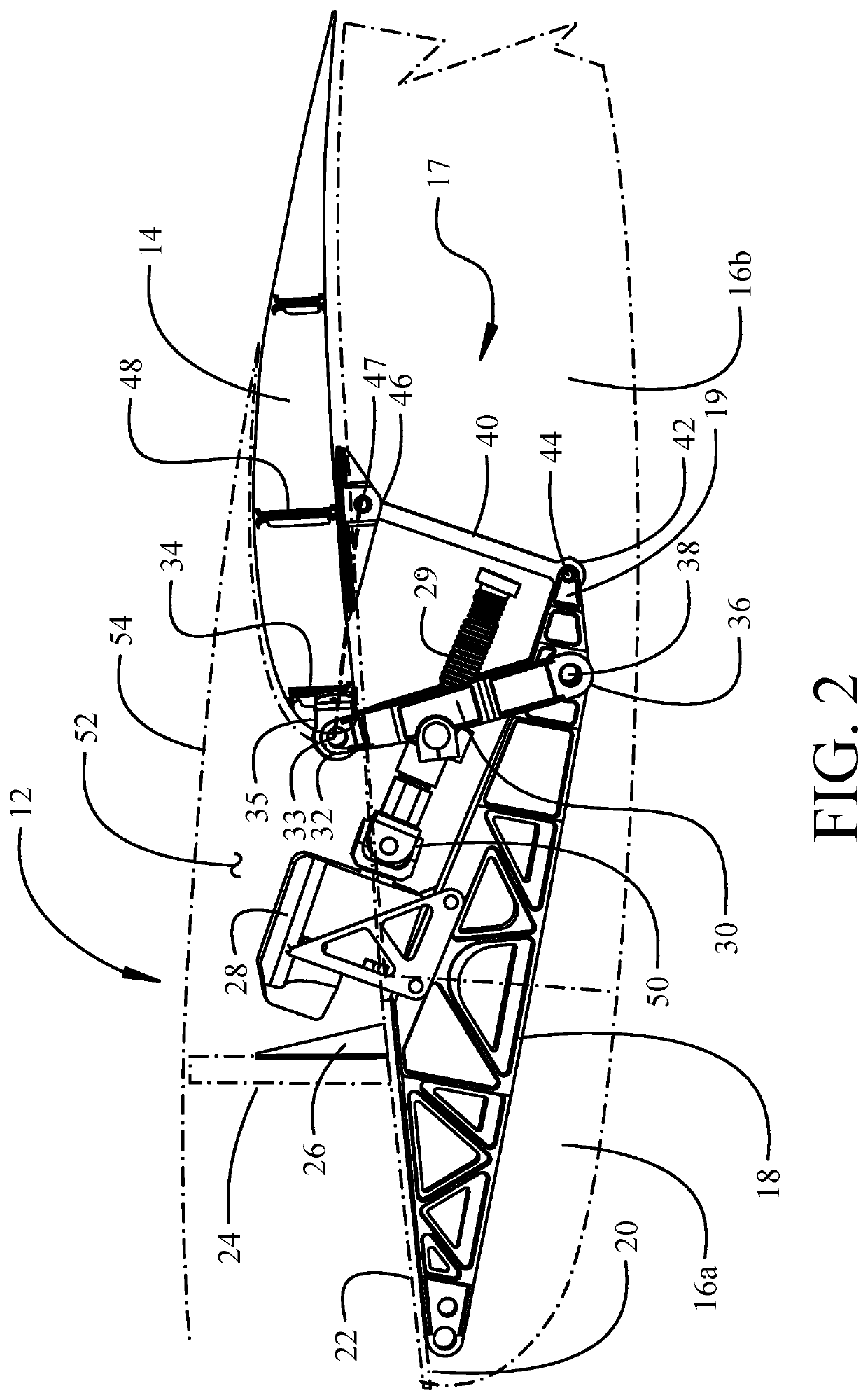

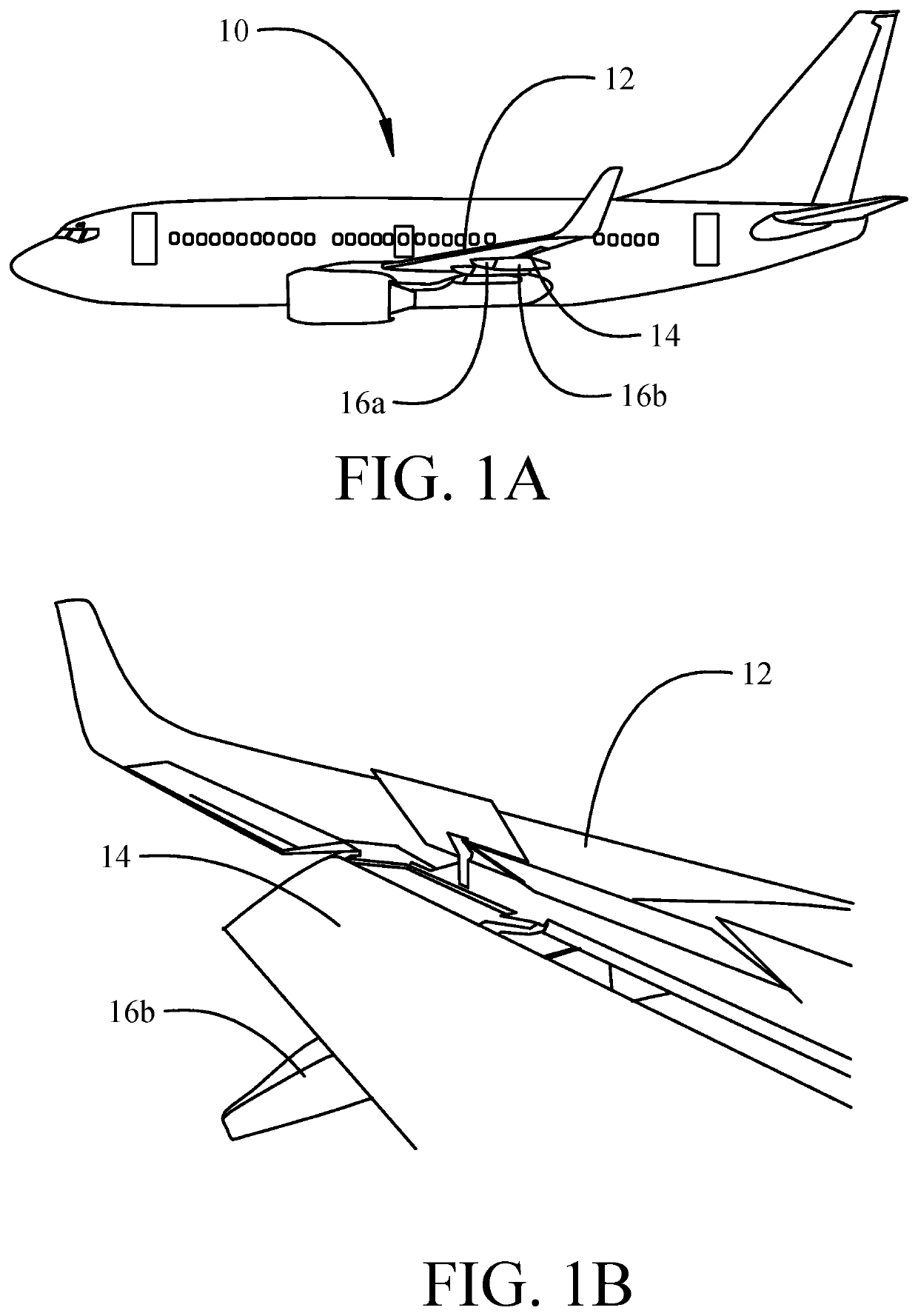

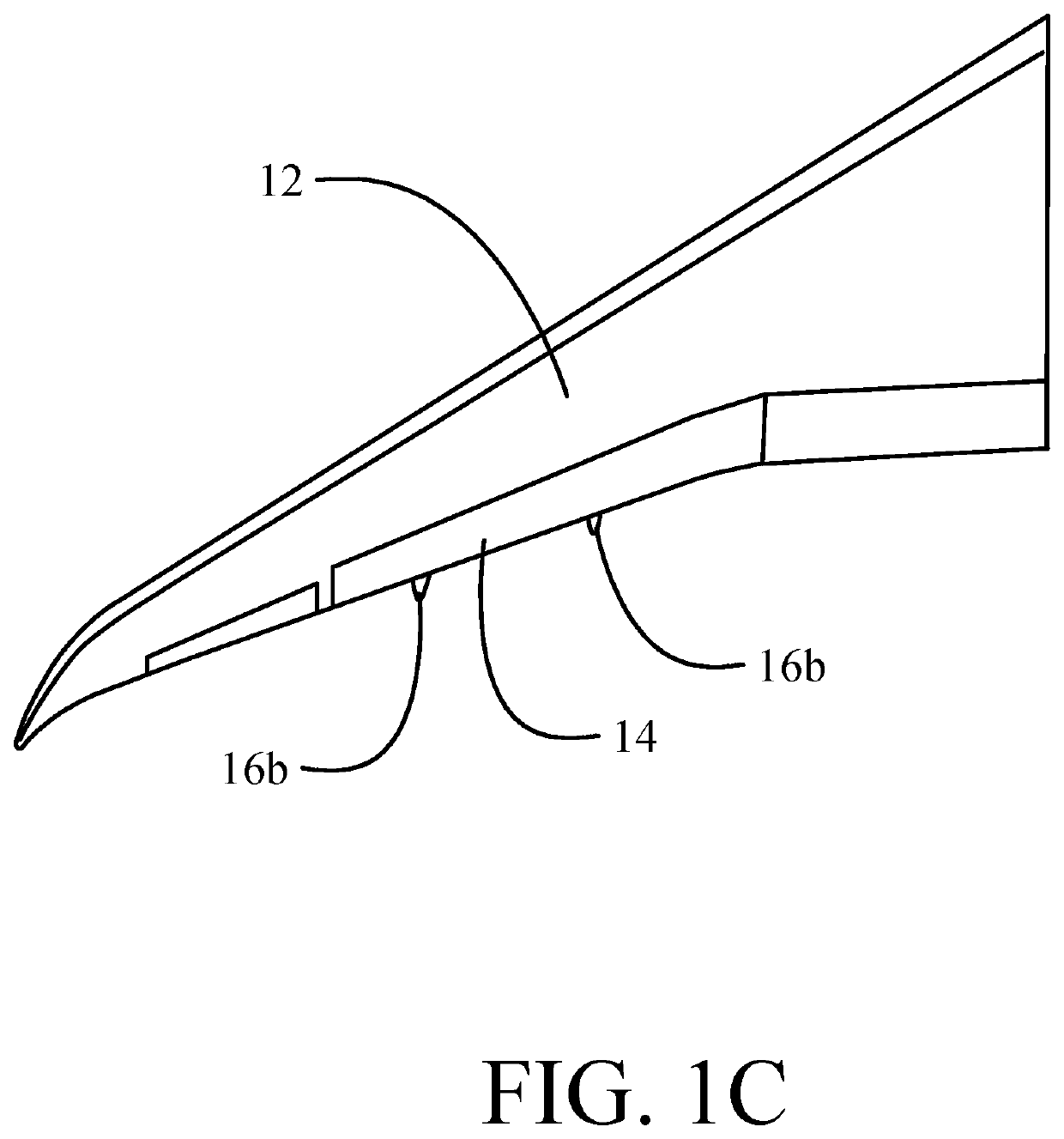

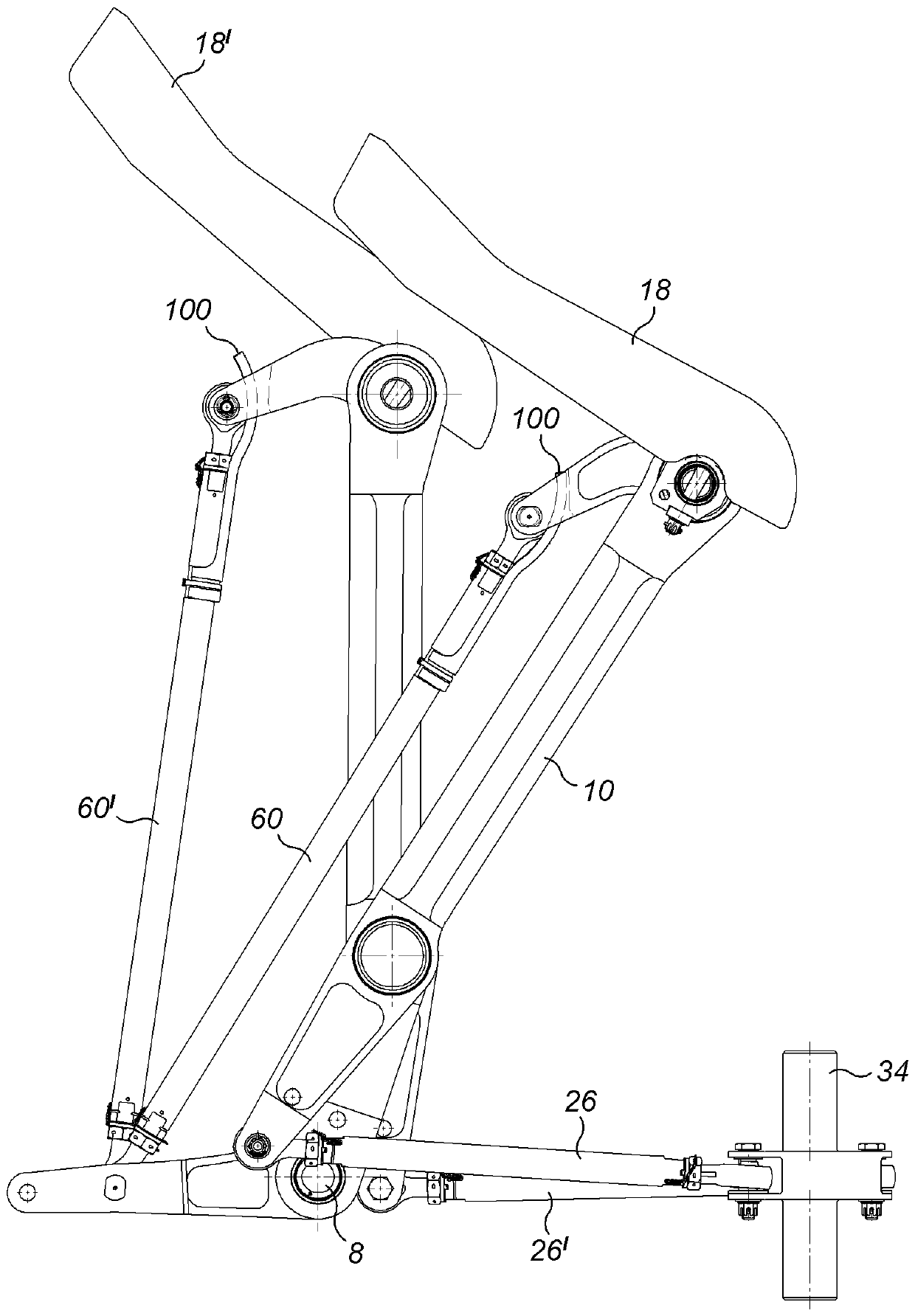

Flap support mechanism - c bar

ActiveUS20200130809A1Narrow downEnhanced increasing camberAircraft stabilisationLeversBall screw driveUniversal joint

A trailing edge flap actuation mechanism has a flap drive link with a first end pivotally coupled to a fore flap structure of a flap and a second end pivotally coupled to an underwing support structure. An aft tension link has a leading end pivotally coupled proximate an aft end of the underwing support structure and a trailing end coupled to a mid-section structure of the flap. An actuator, when actuated, rotates the flap drive link about a first pivot axle to move the flap between a retracted position and a deployed lowered position. The actuator, including a ball-screw drive shaft having a universal joint, is positioned in a cove above the underwing support structure whereby the extent that the underwing support structure protrudes below the wing is reduced.

Owner:THE BOEING CO

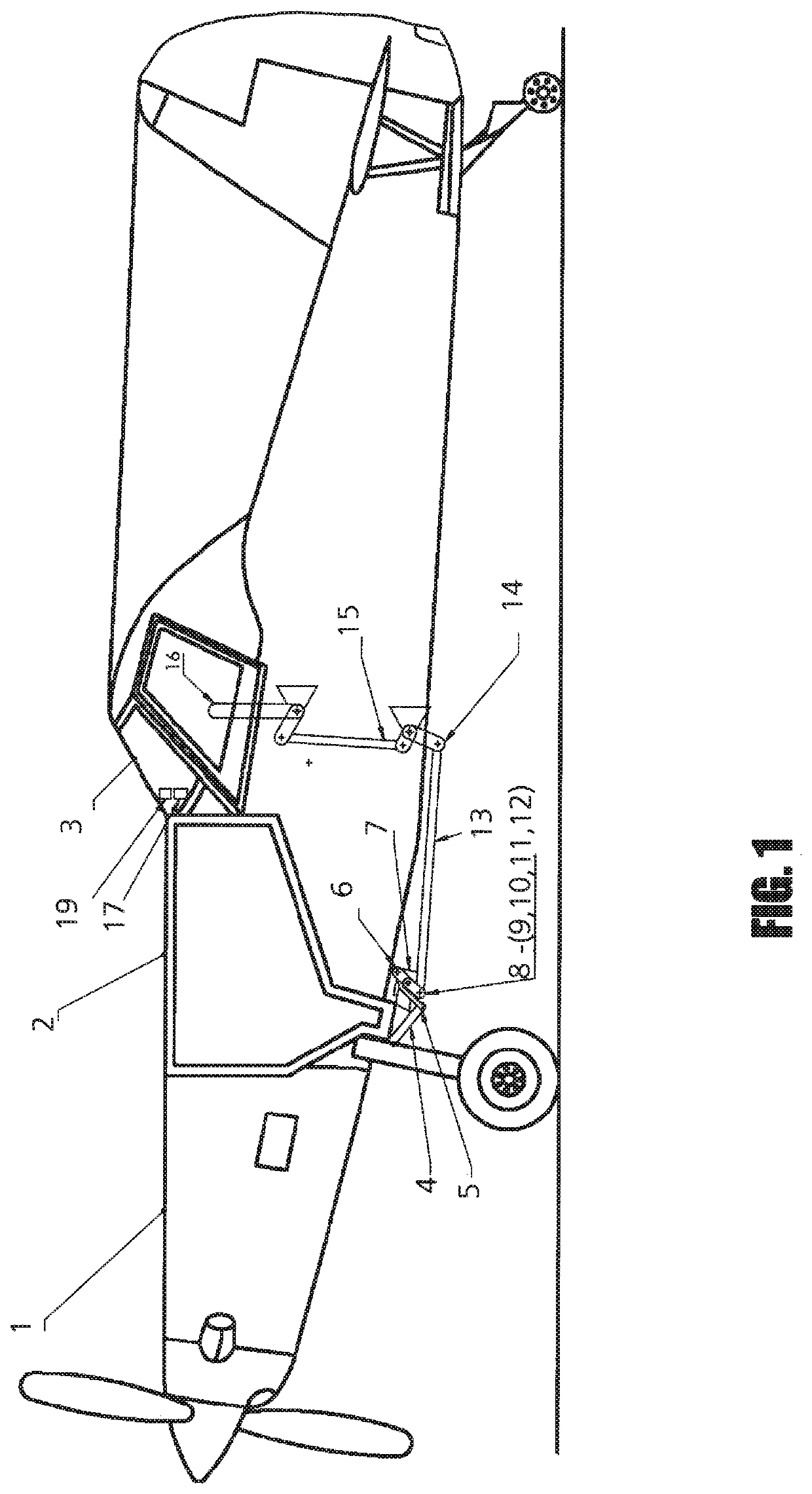

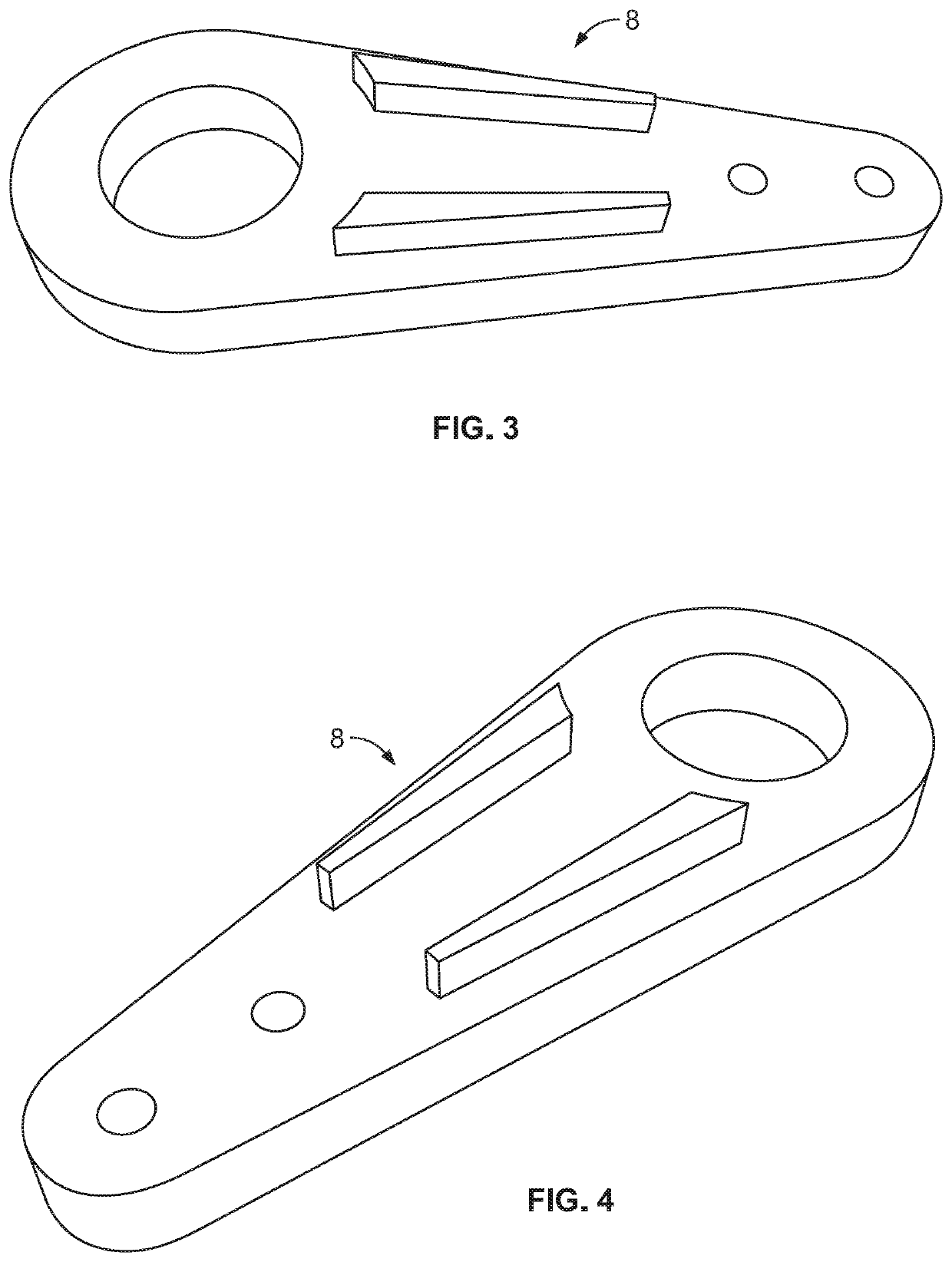

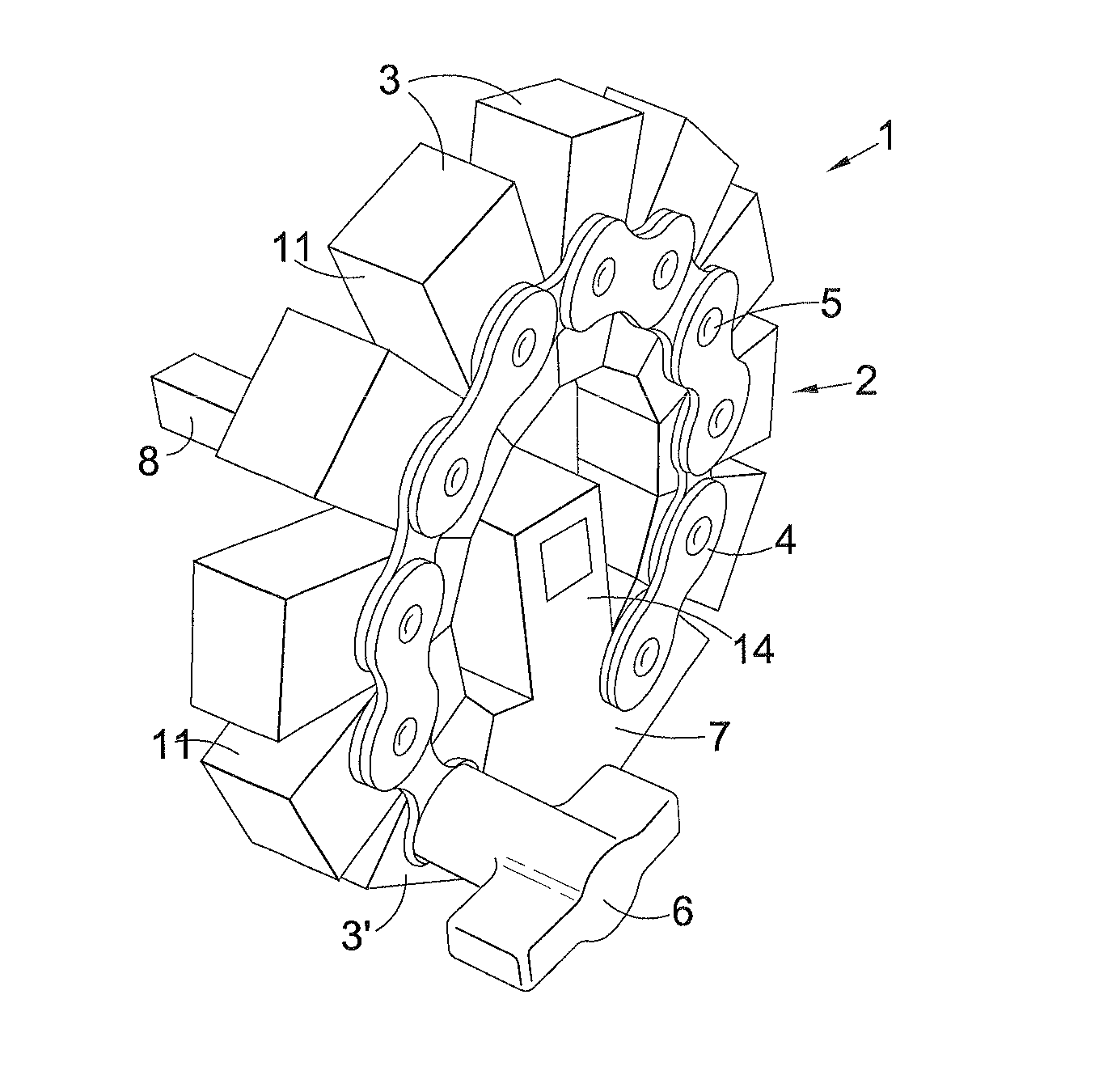

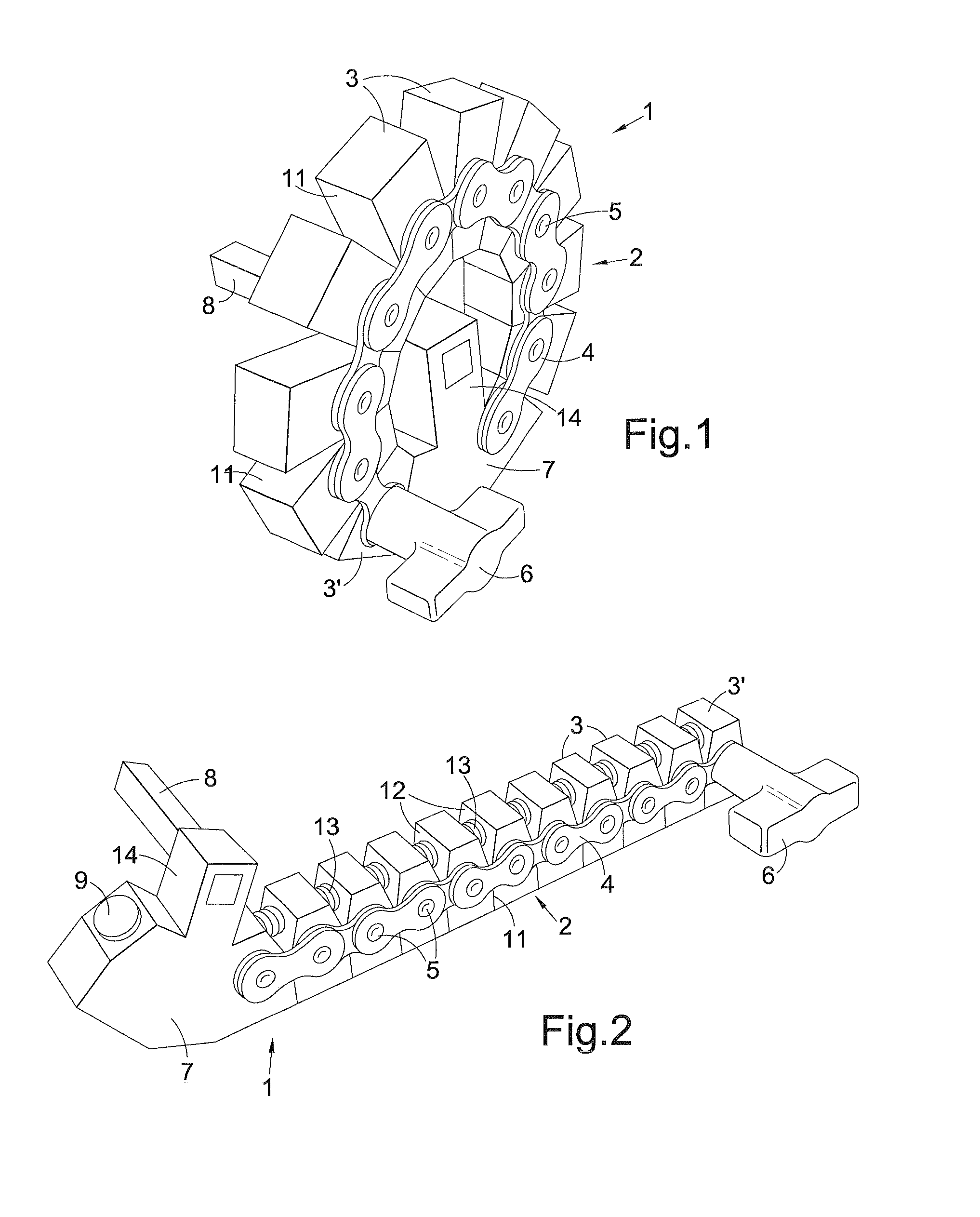

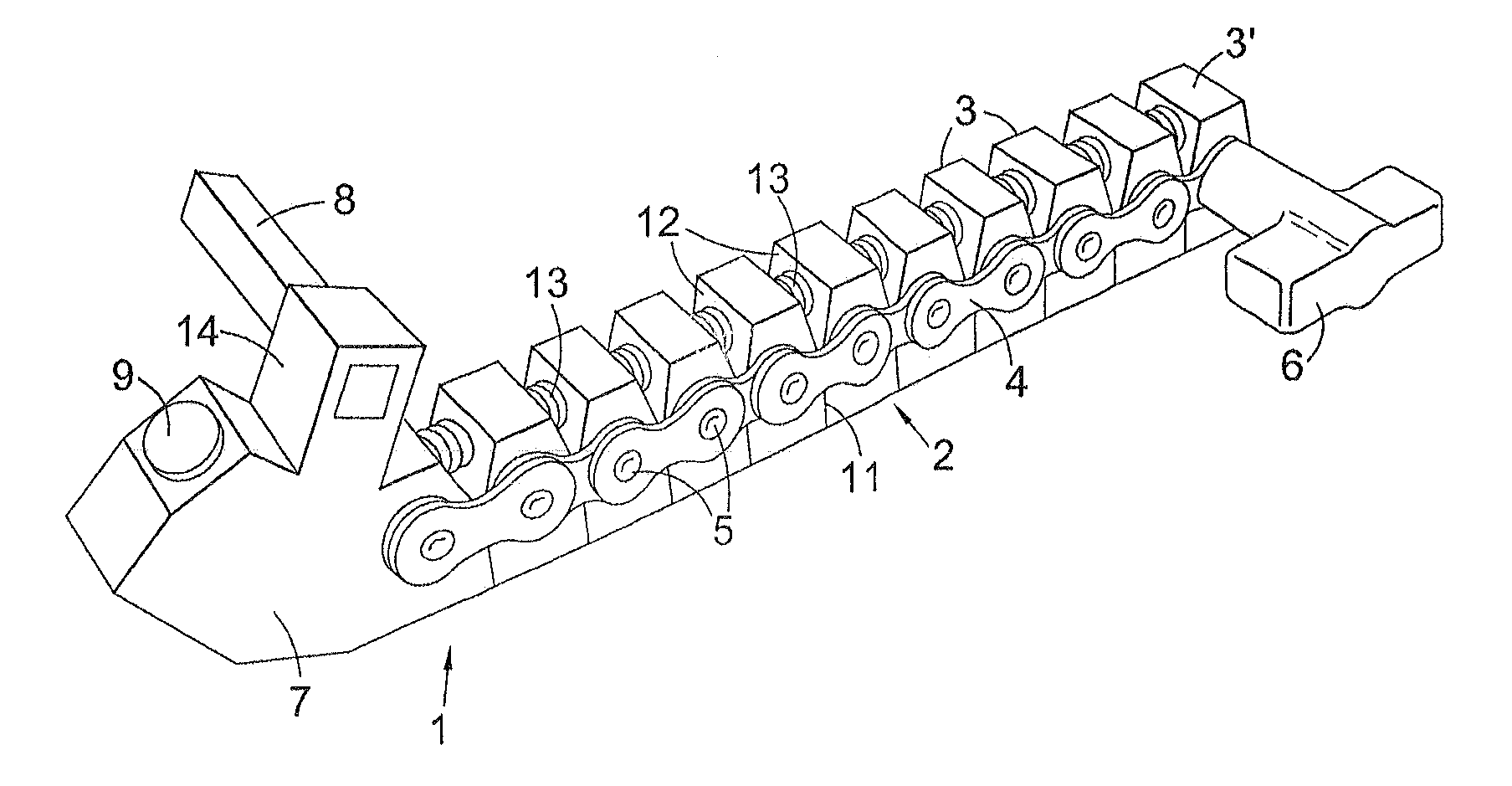

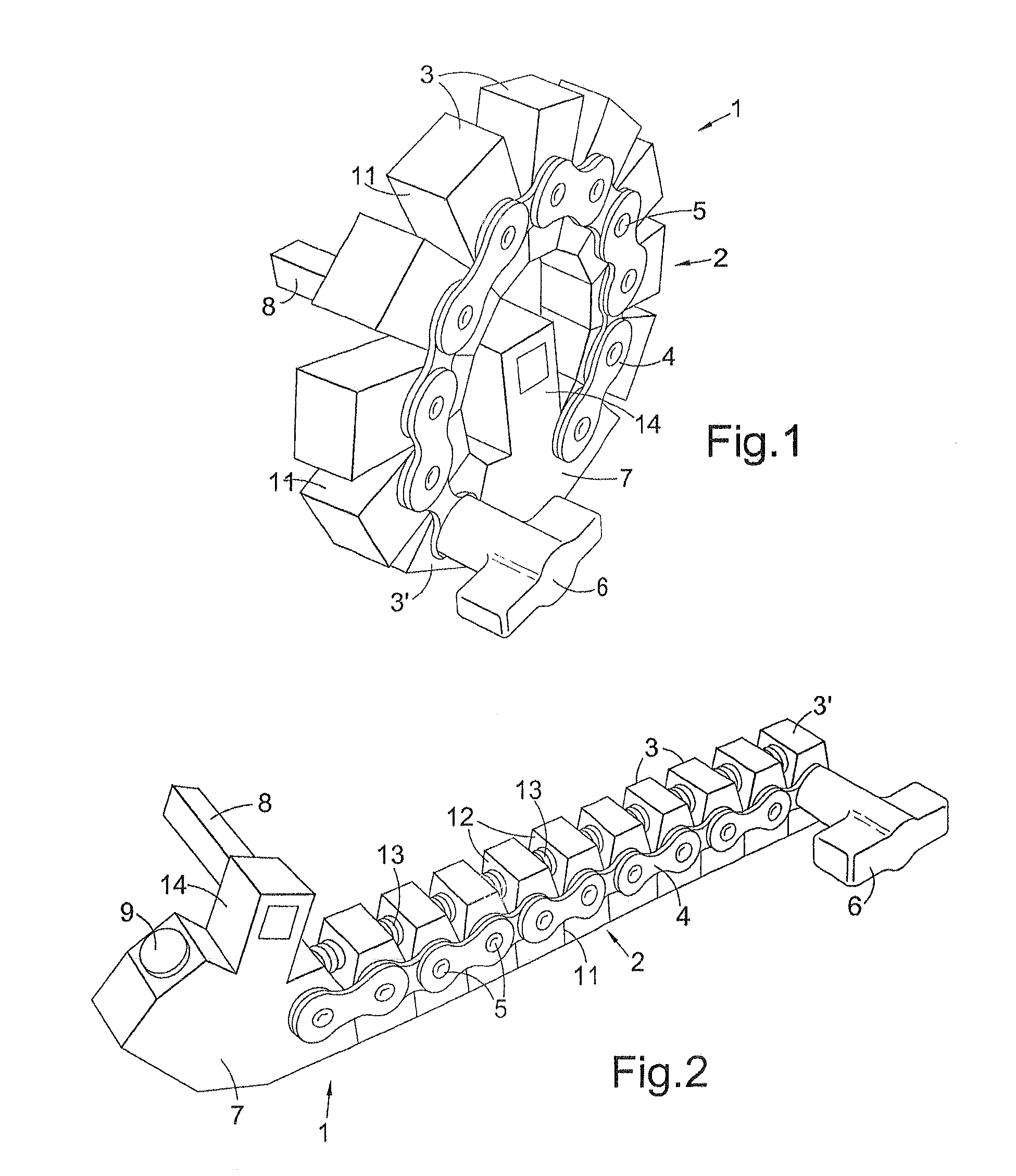

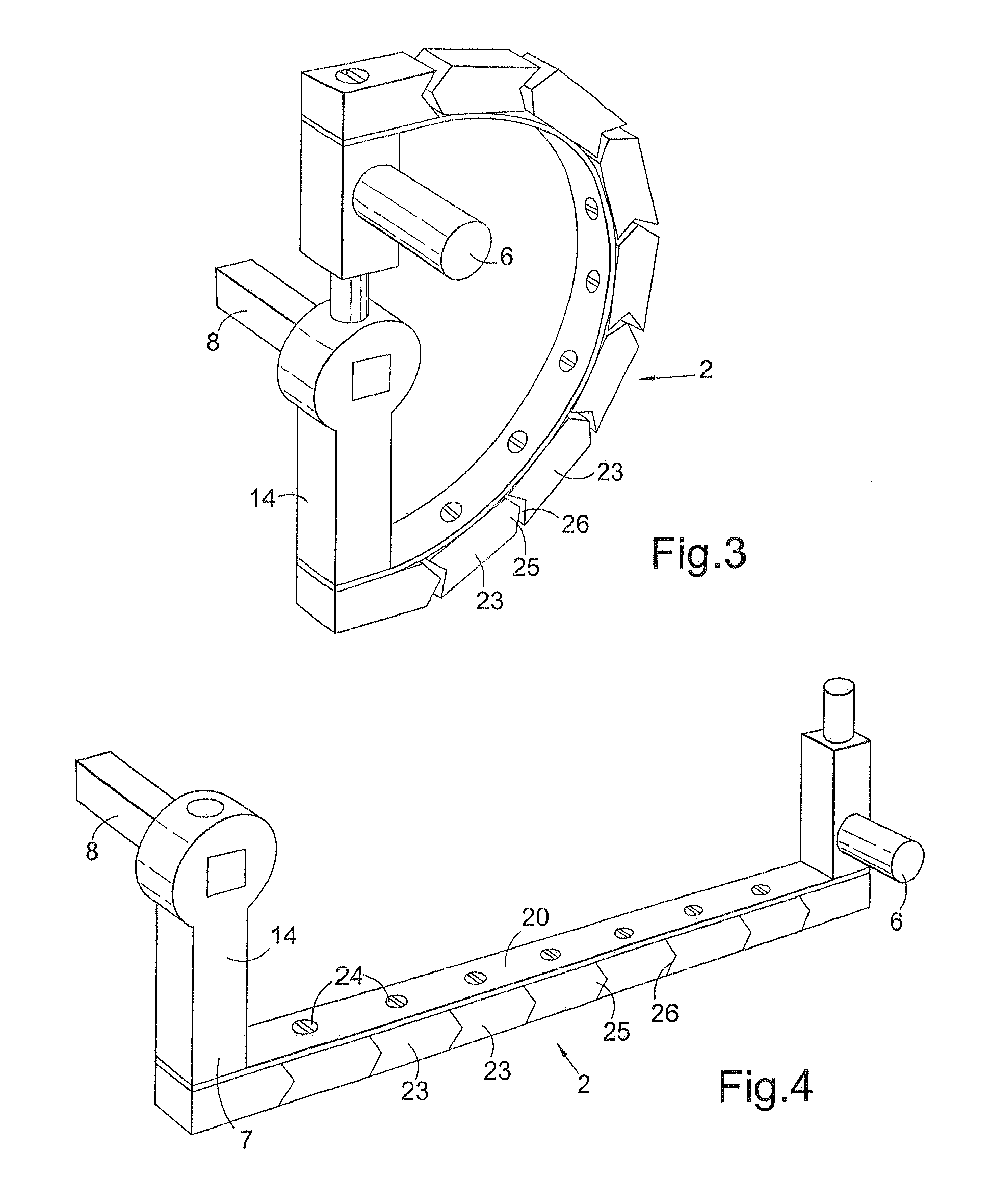

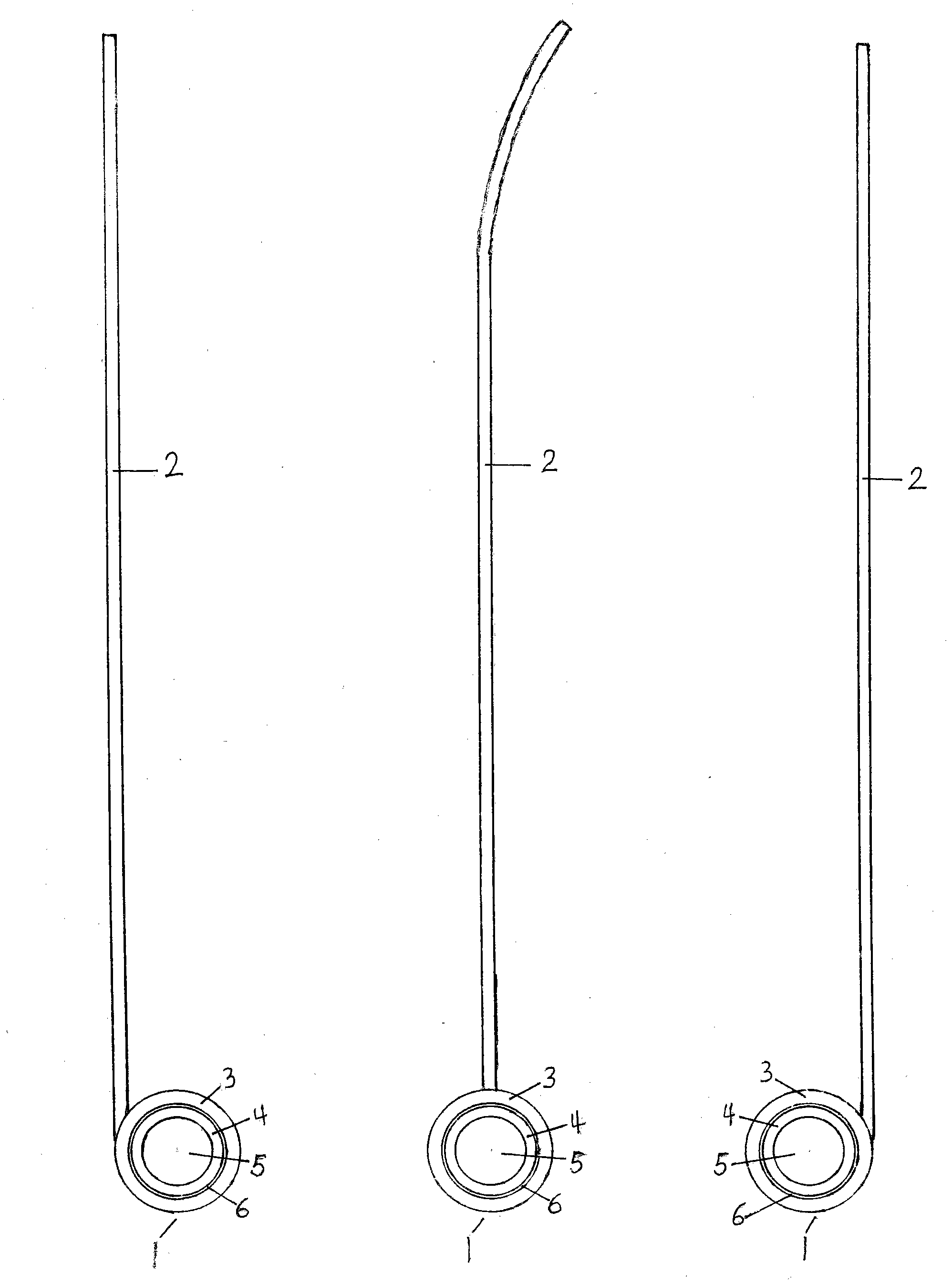

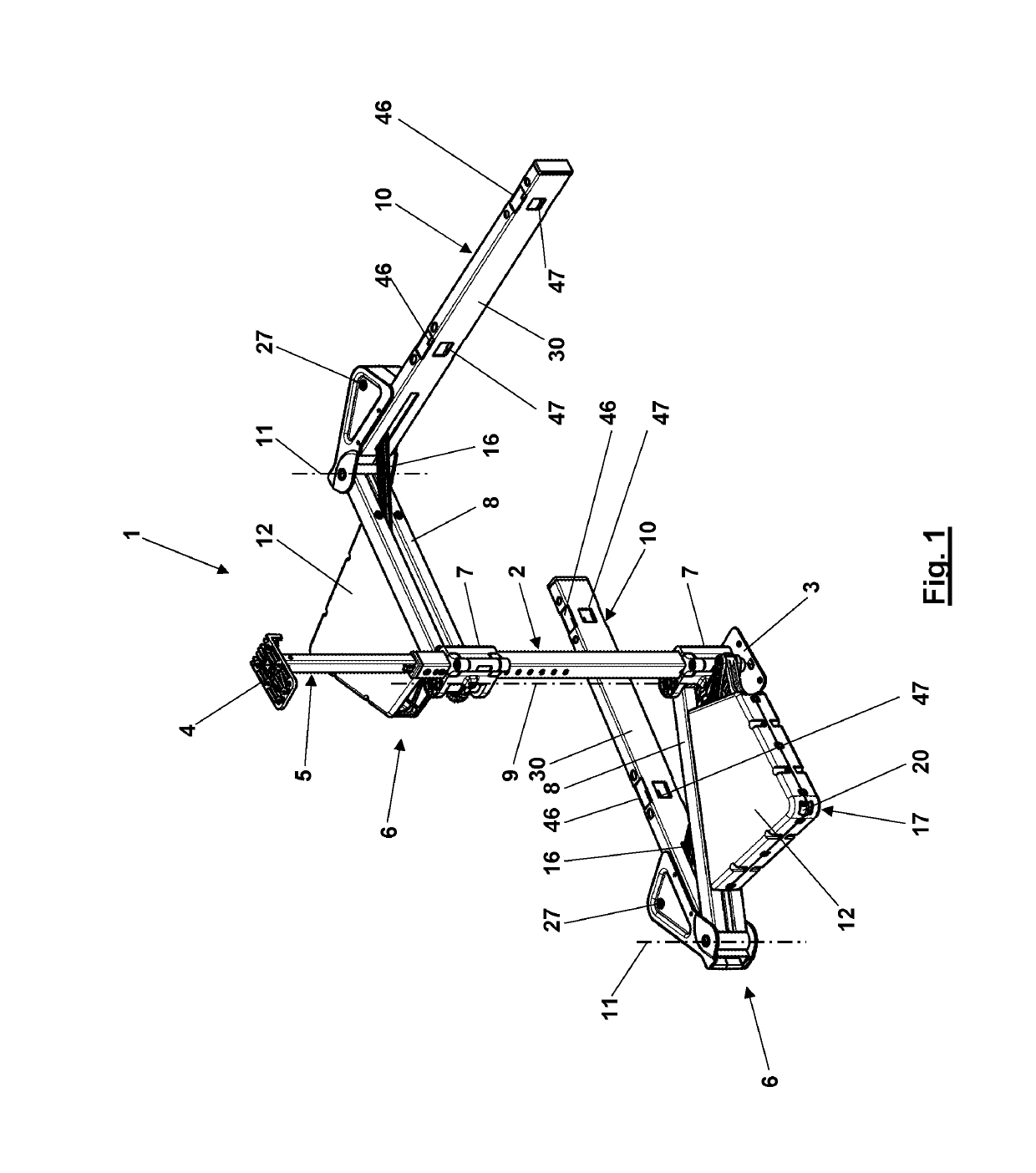

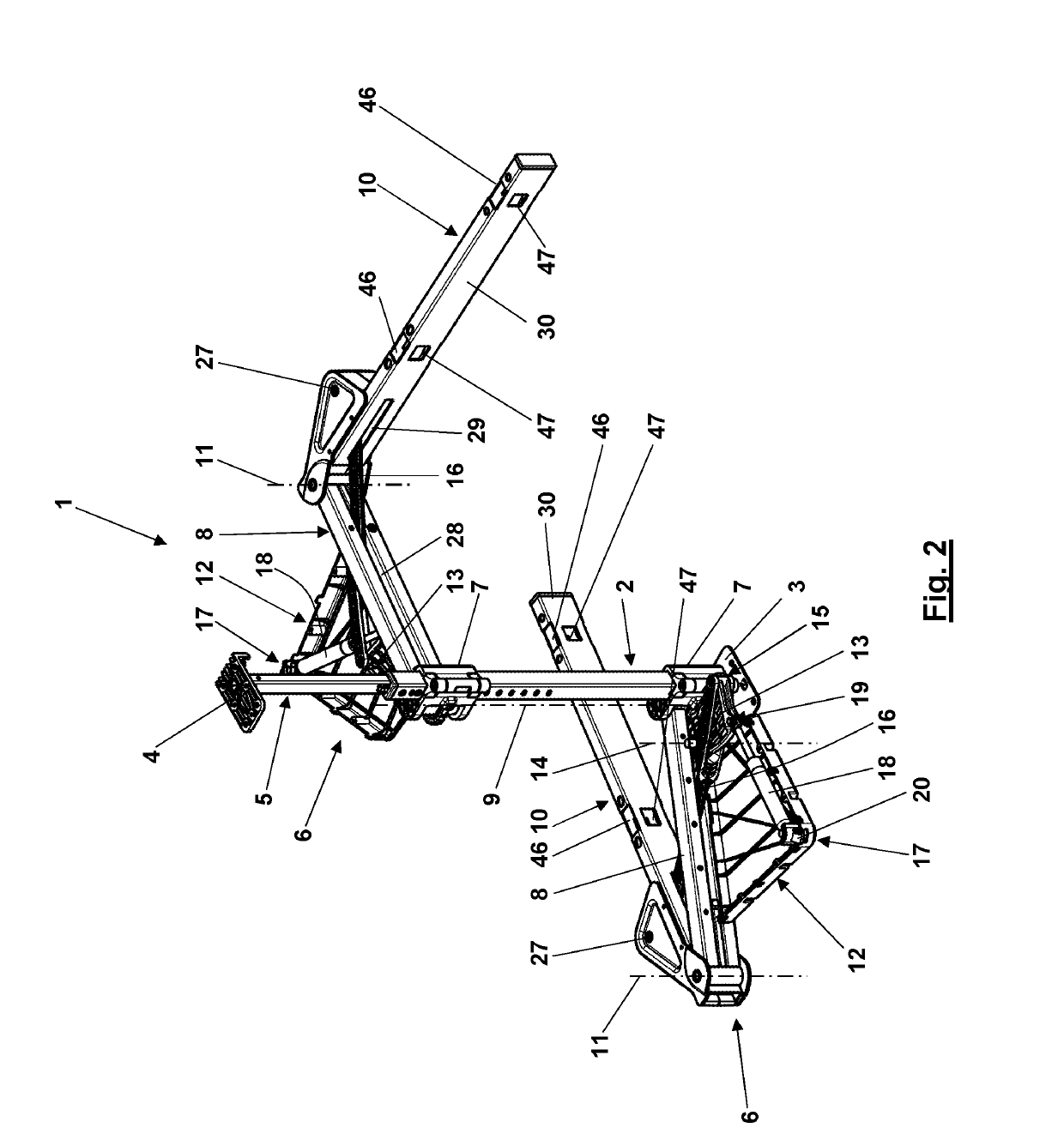

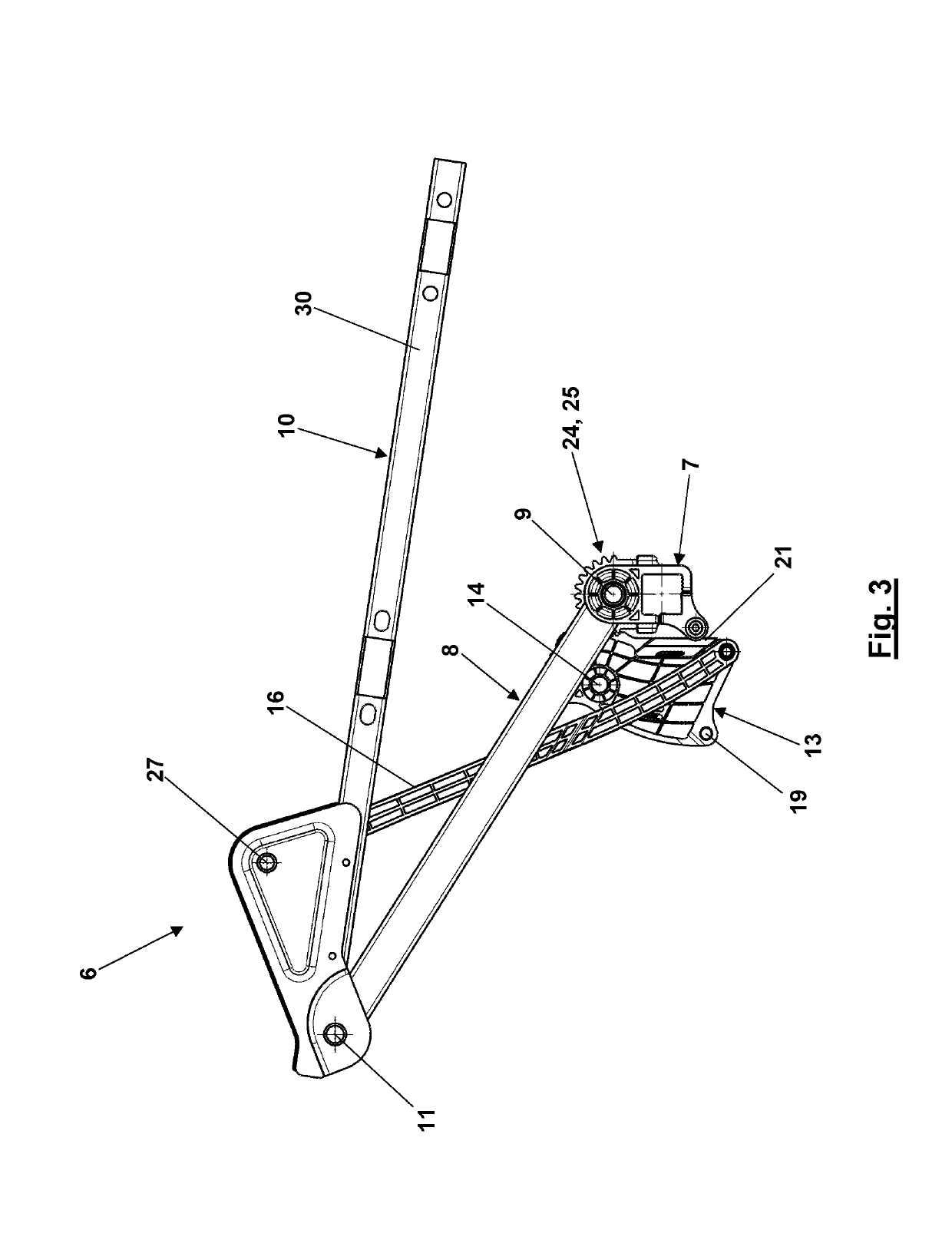

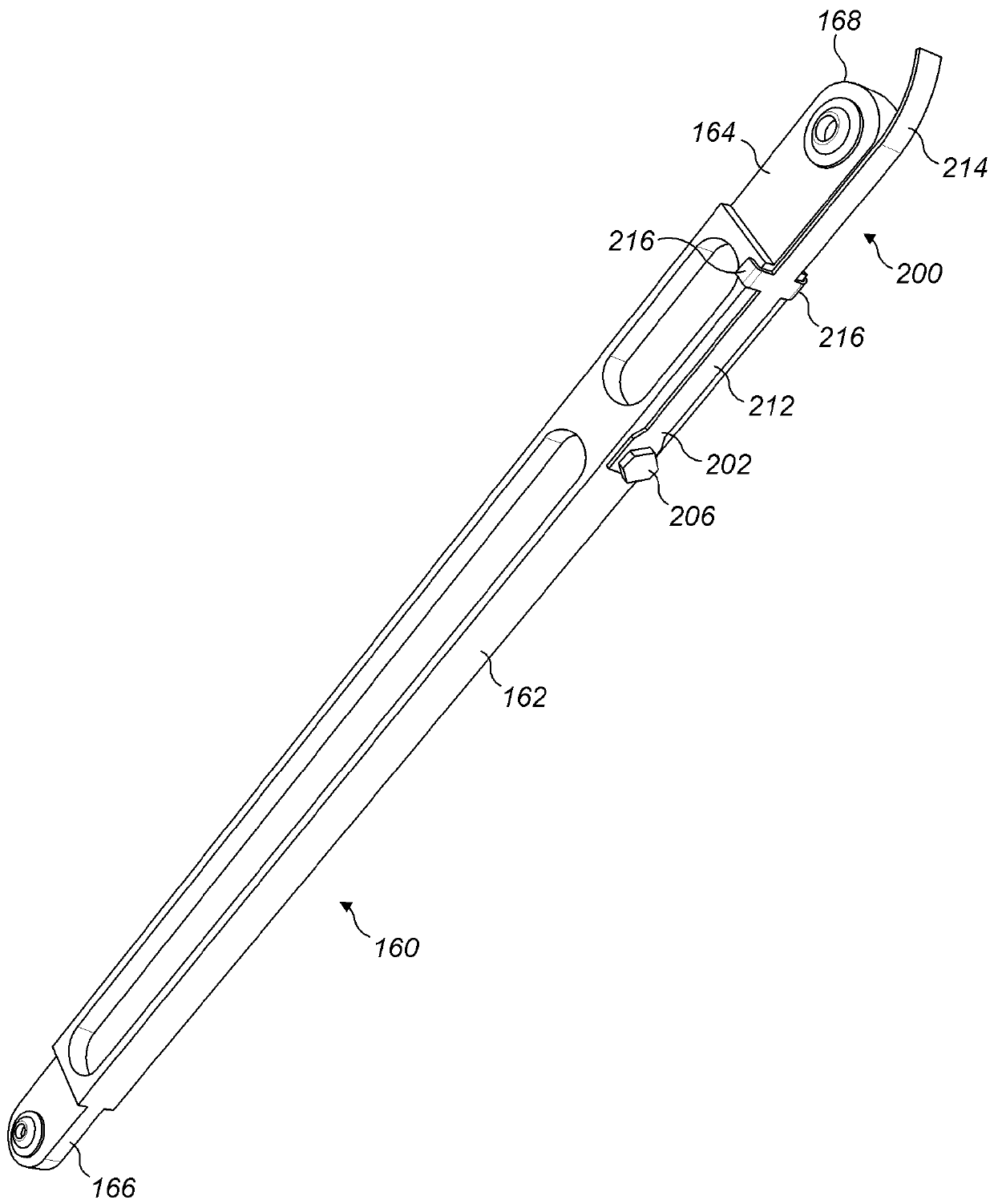

Variable radius lever arm assembly

InactiveUS20140216199A1Increase static frictionPrevent discoveryControlling membersLeversJackscrewEffective length

A curled variable radius lever comprises a lever arm of variable effective length that curls and uncurls about a drive axis. In a preferred arrangement the lever assembly has a plurality of rigid blocks linked together by a chain or spring steel strip. Each block has a pair of walls 11 that face and abut each other in an uncurled, straightened state of the lever arm. The abutment of the walls of the lever arm rigidifies the arm and prevents the arm from bending further in the direction of uncurling when a driving force is applied by users to a handle. The lever may be used with socket sets, yacht winch, fishing rod reel, a bicycle crank or a jack assembly.

Owner:MALTBY MALORY

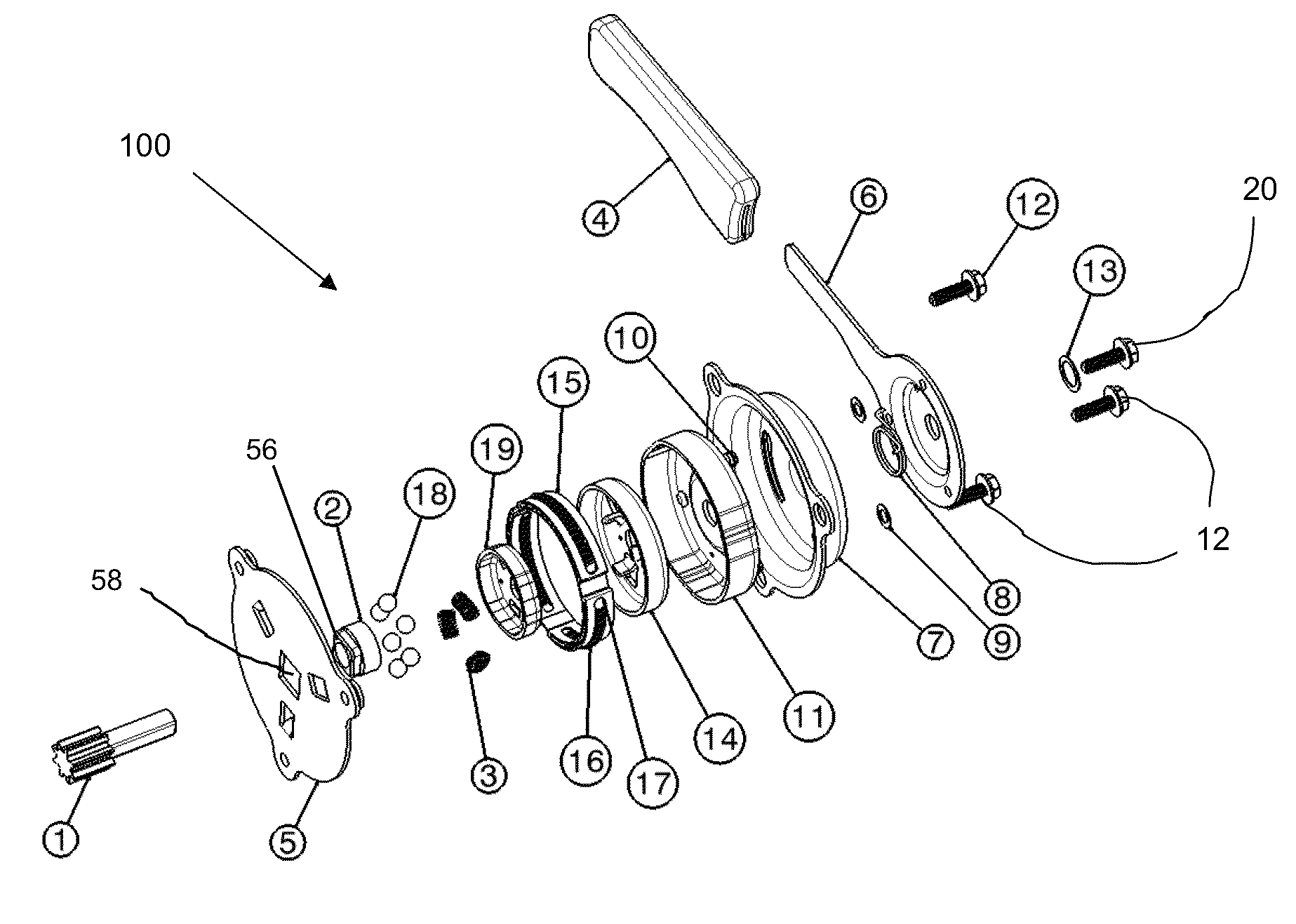

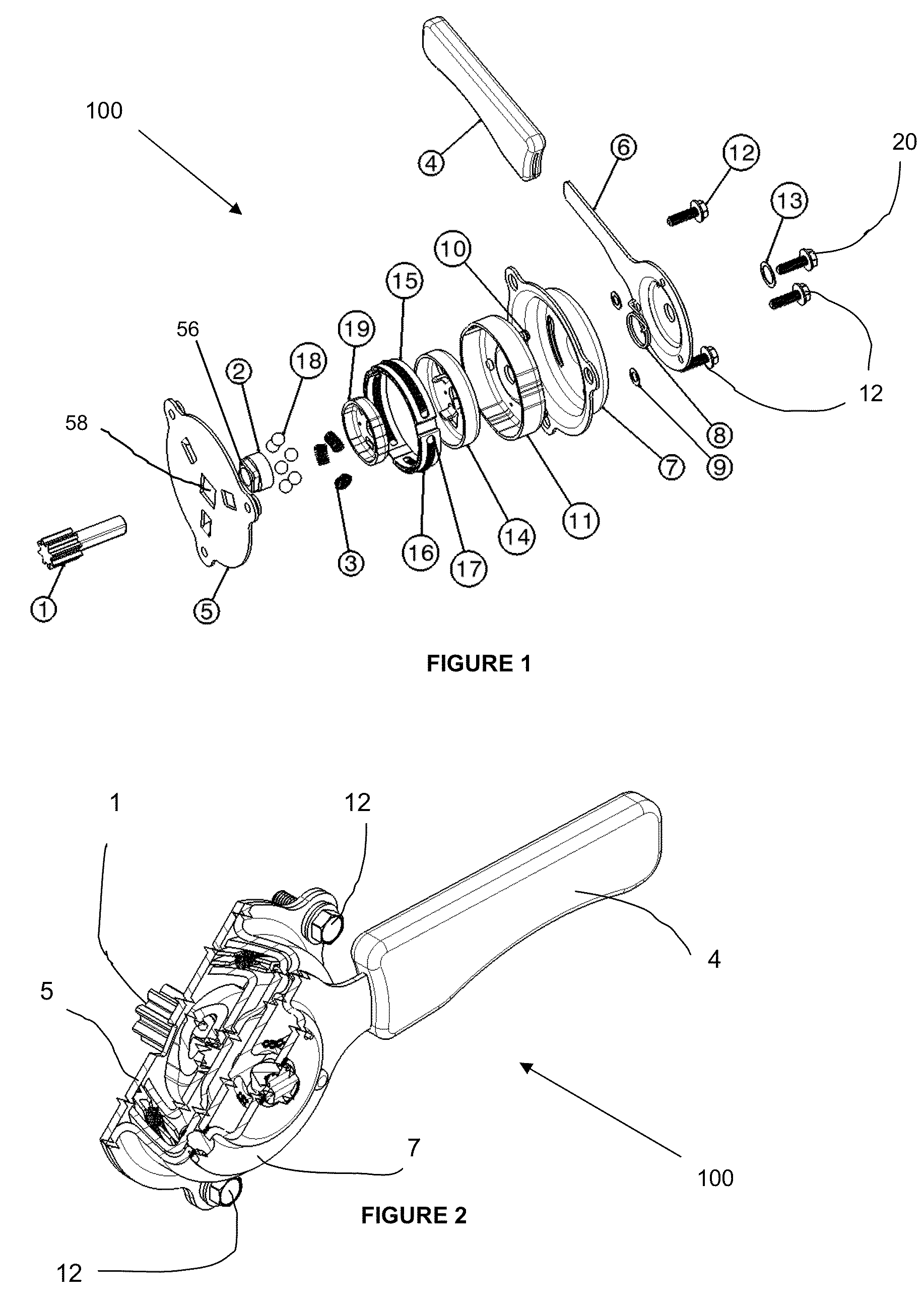

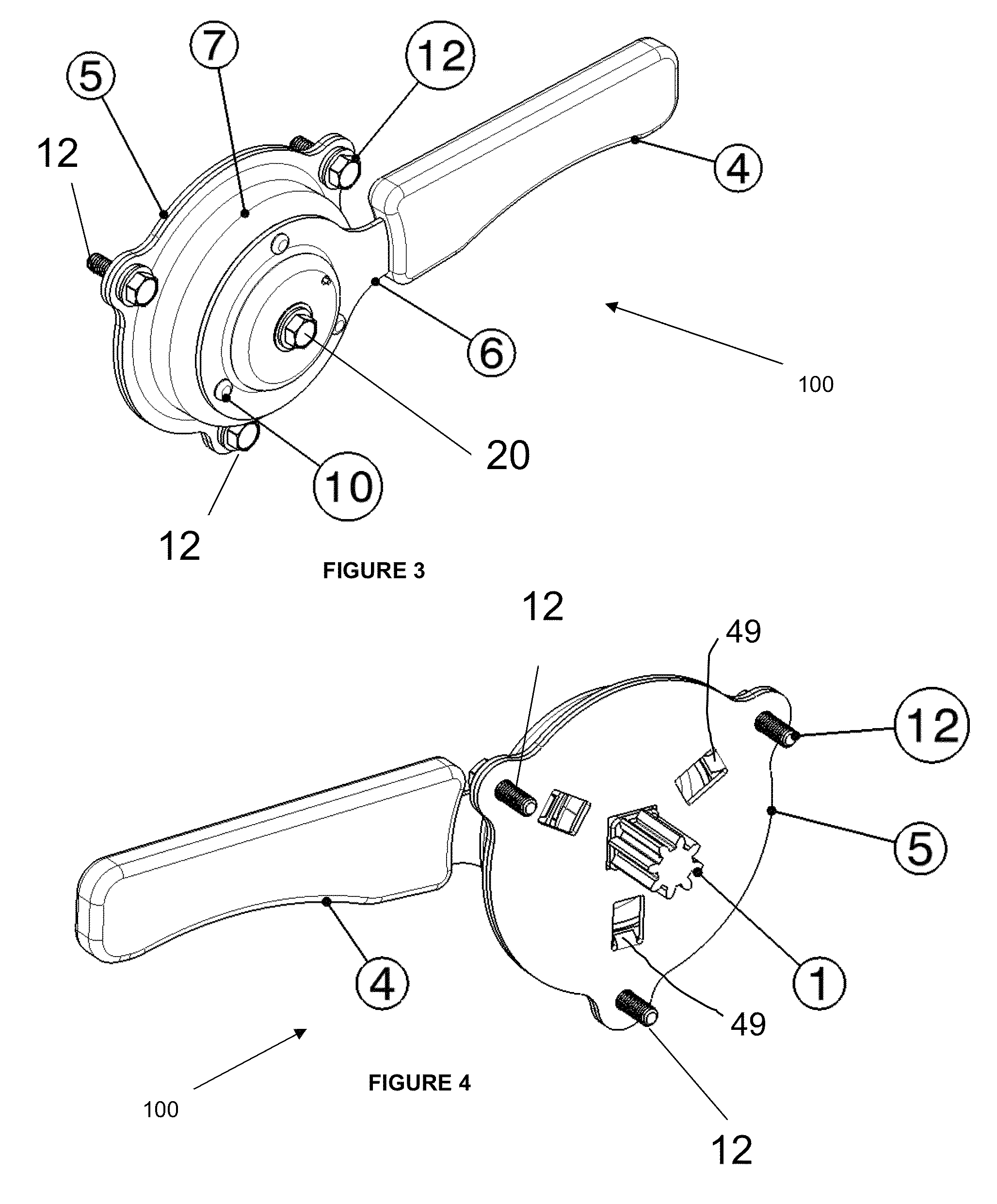

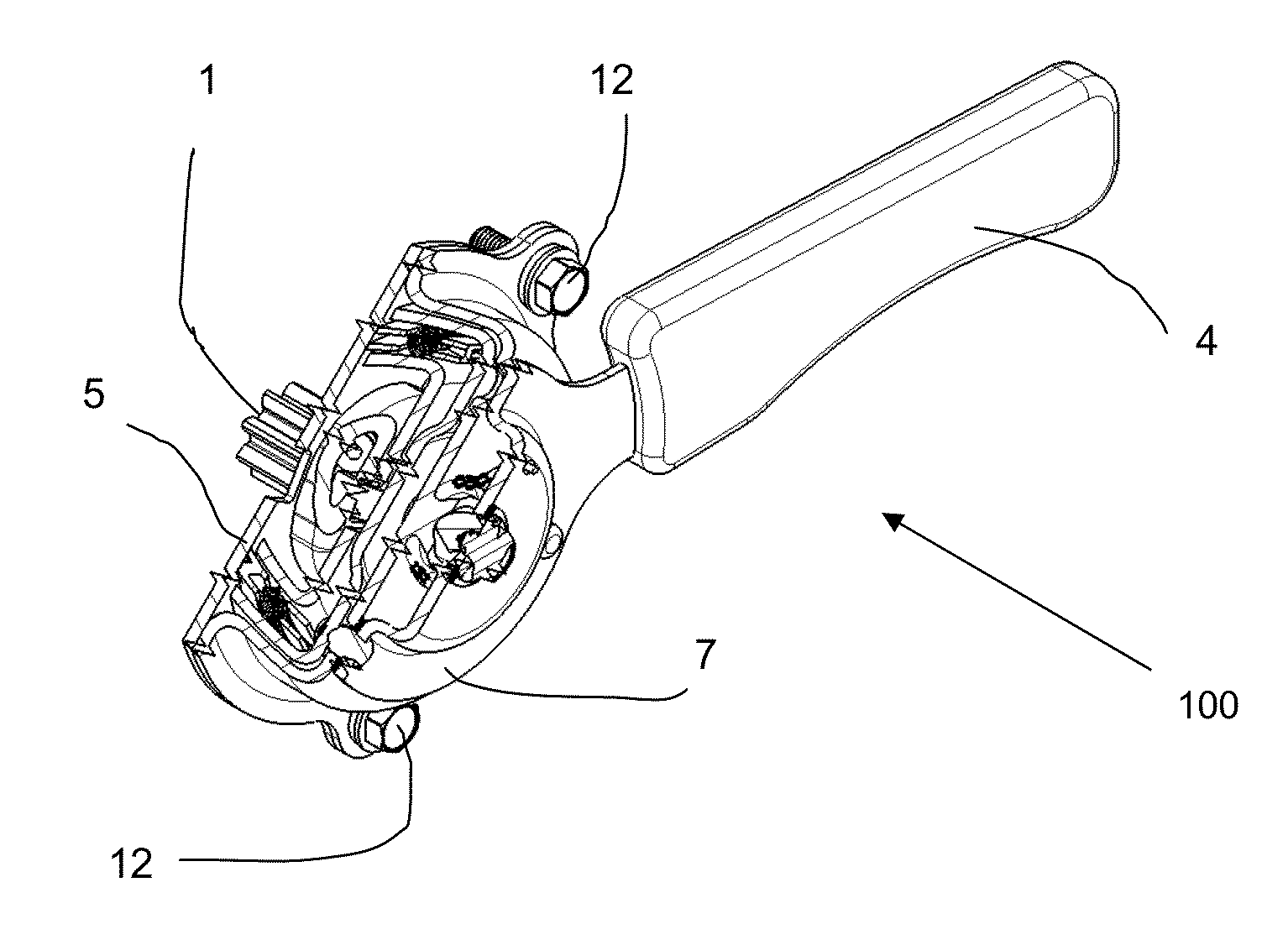

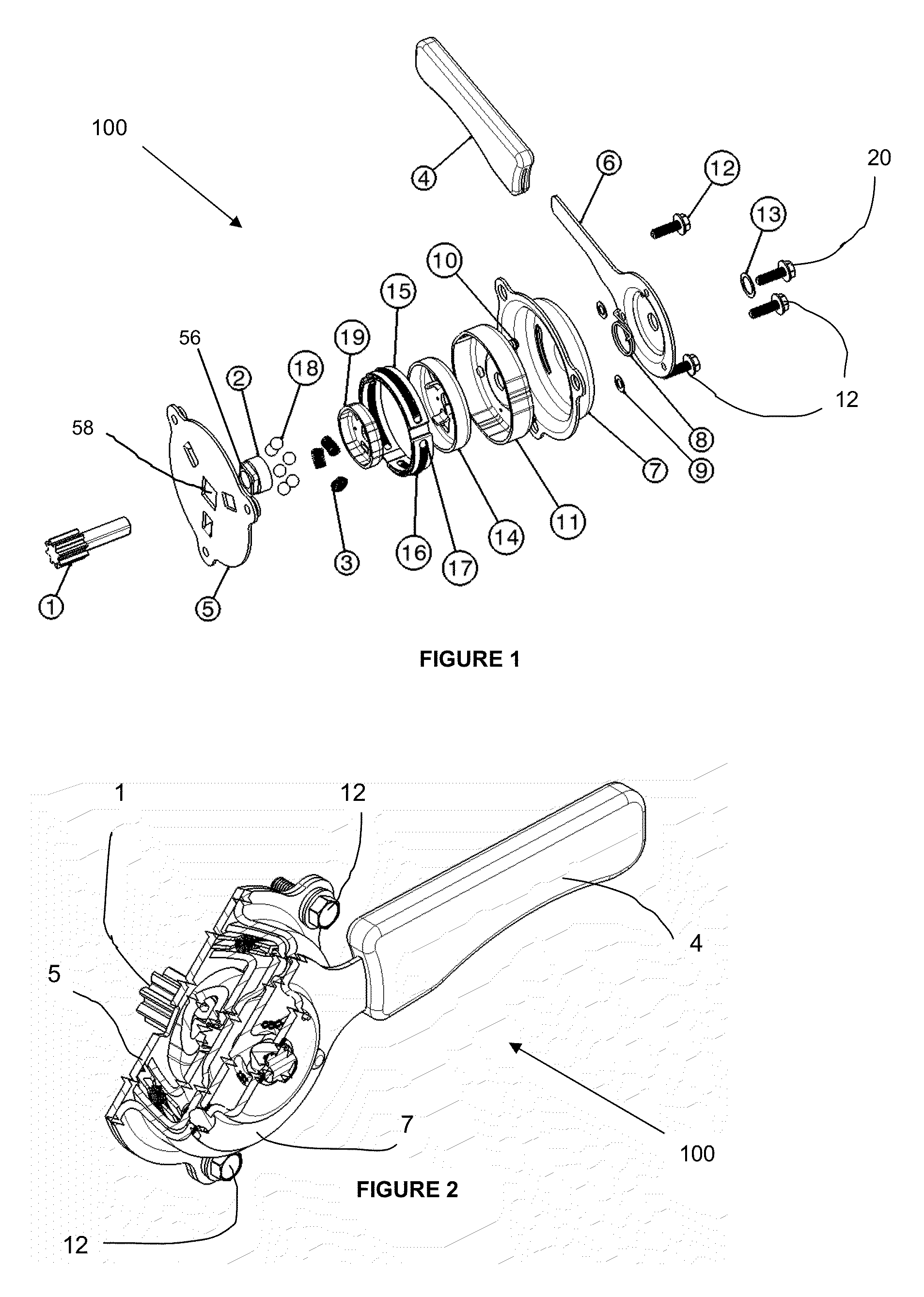

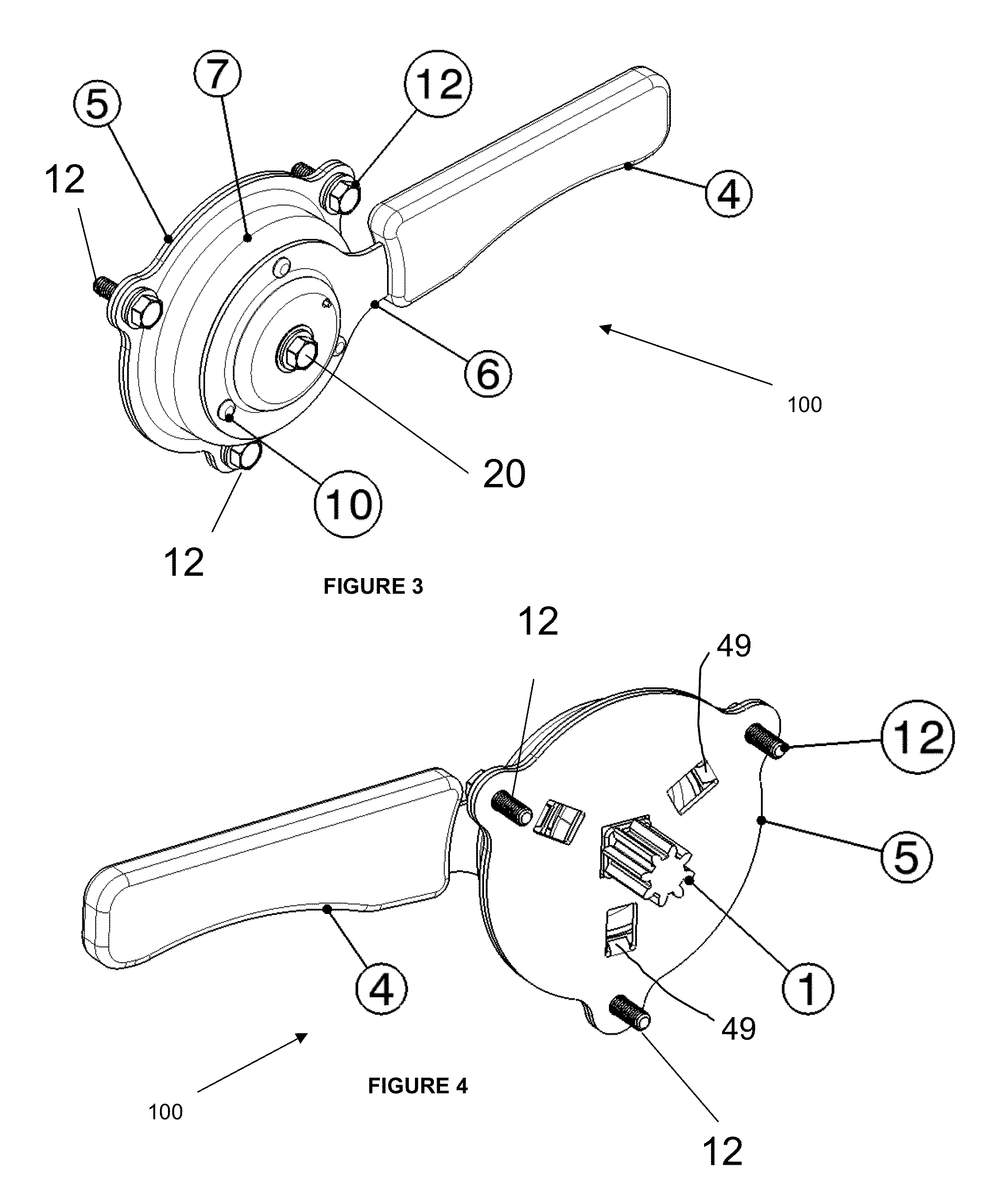

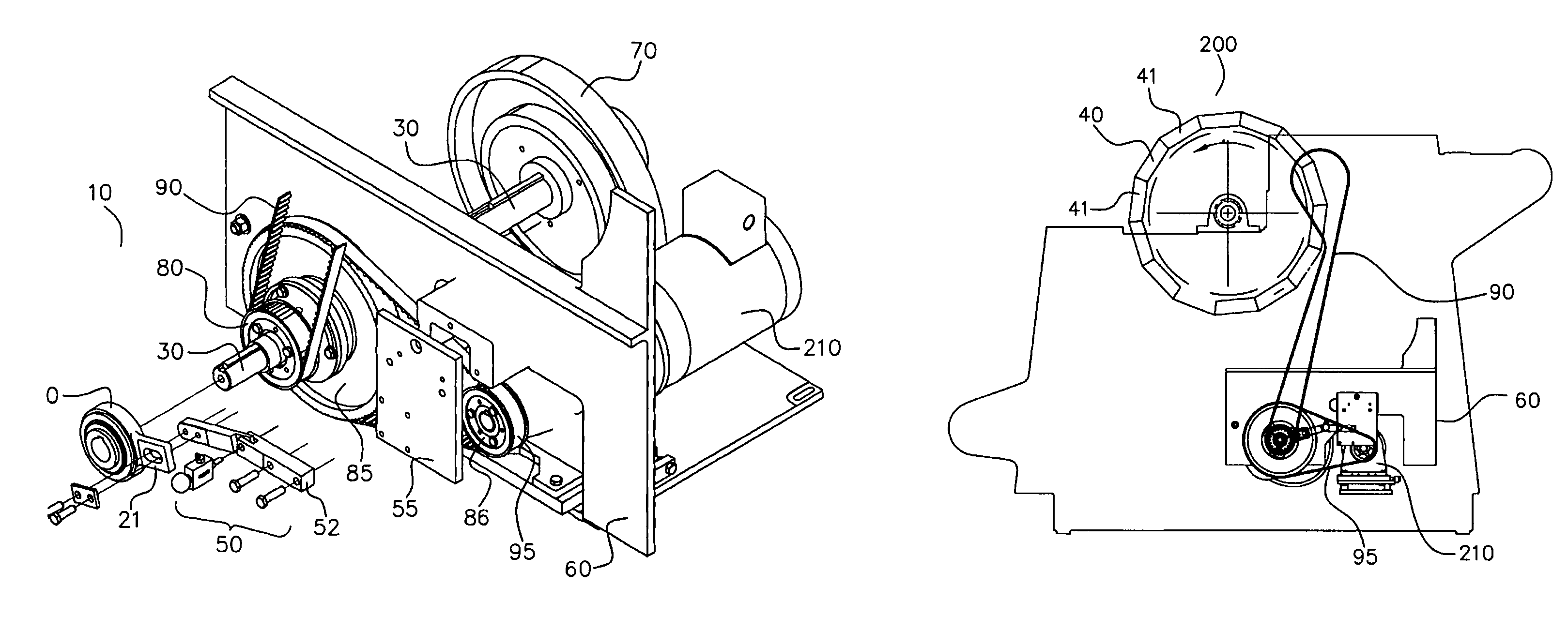

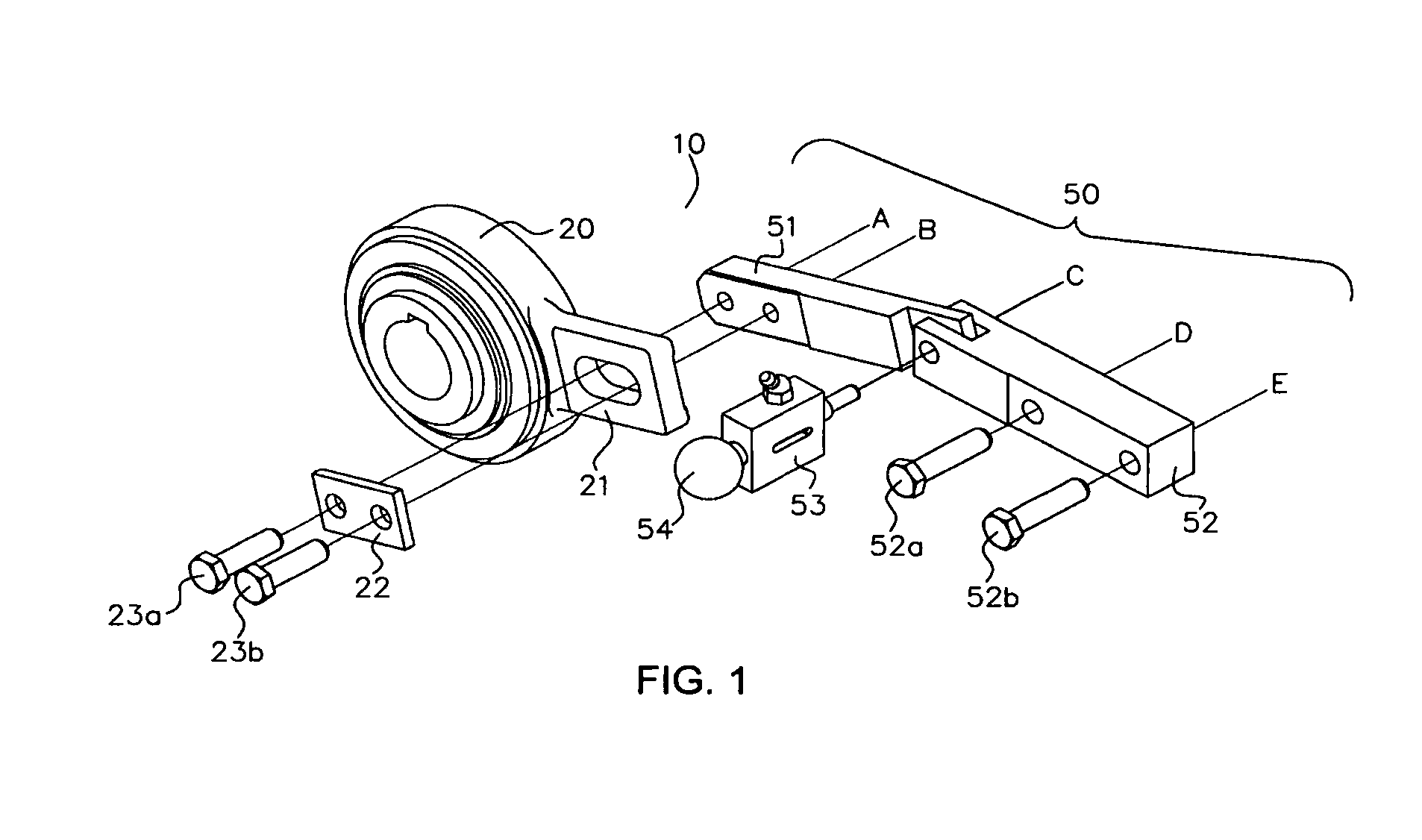

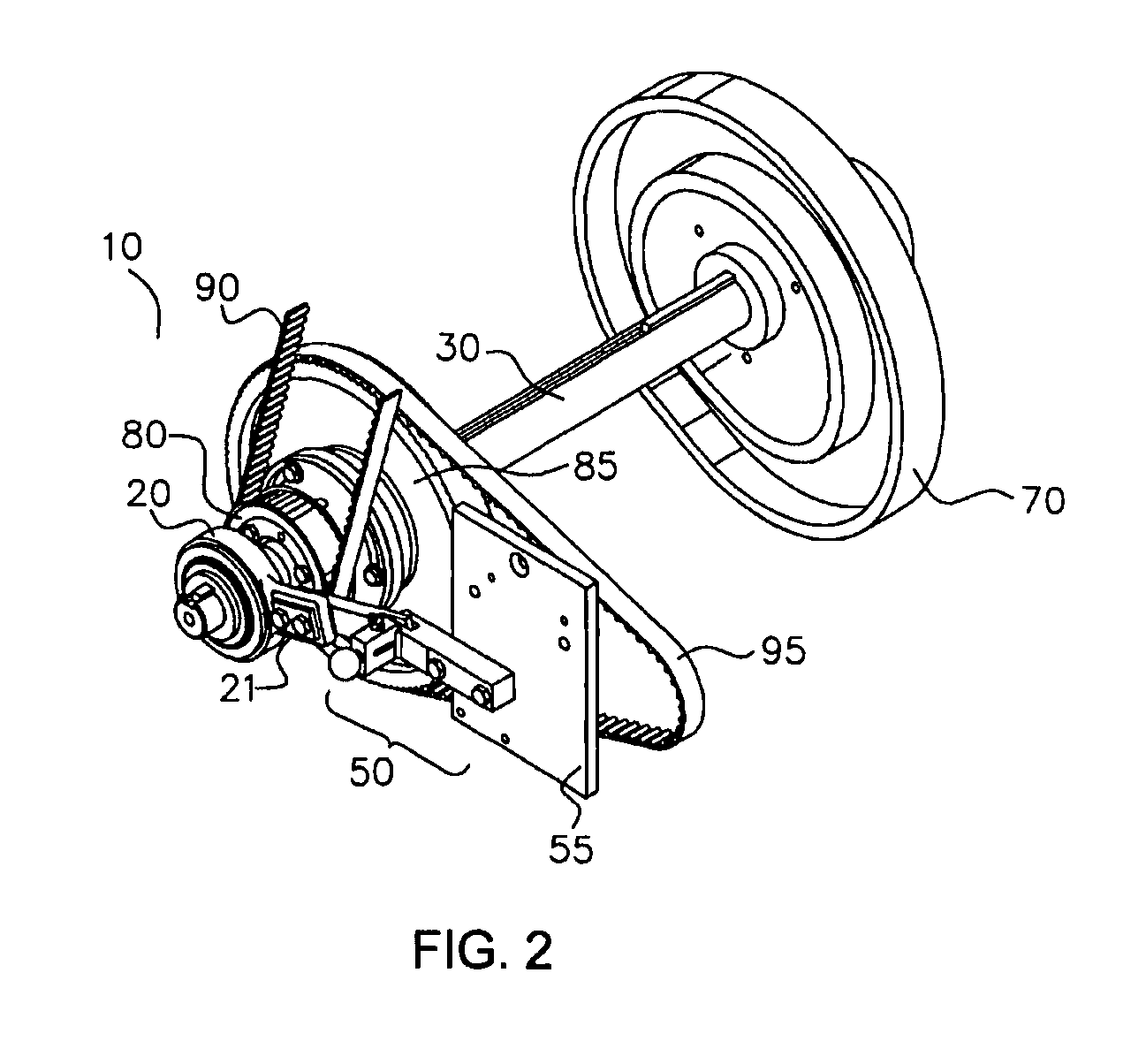

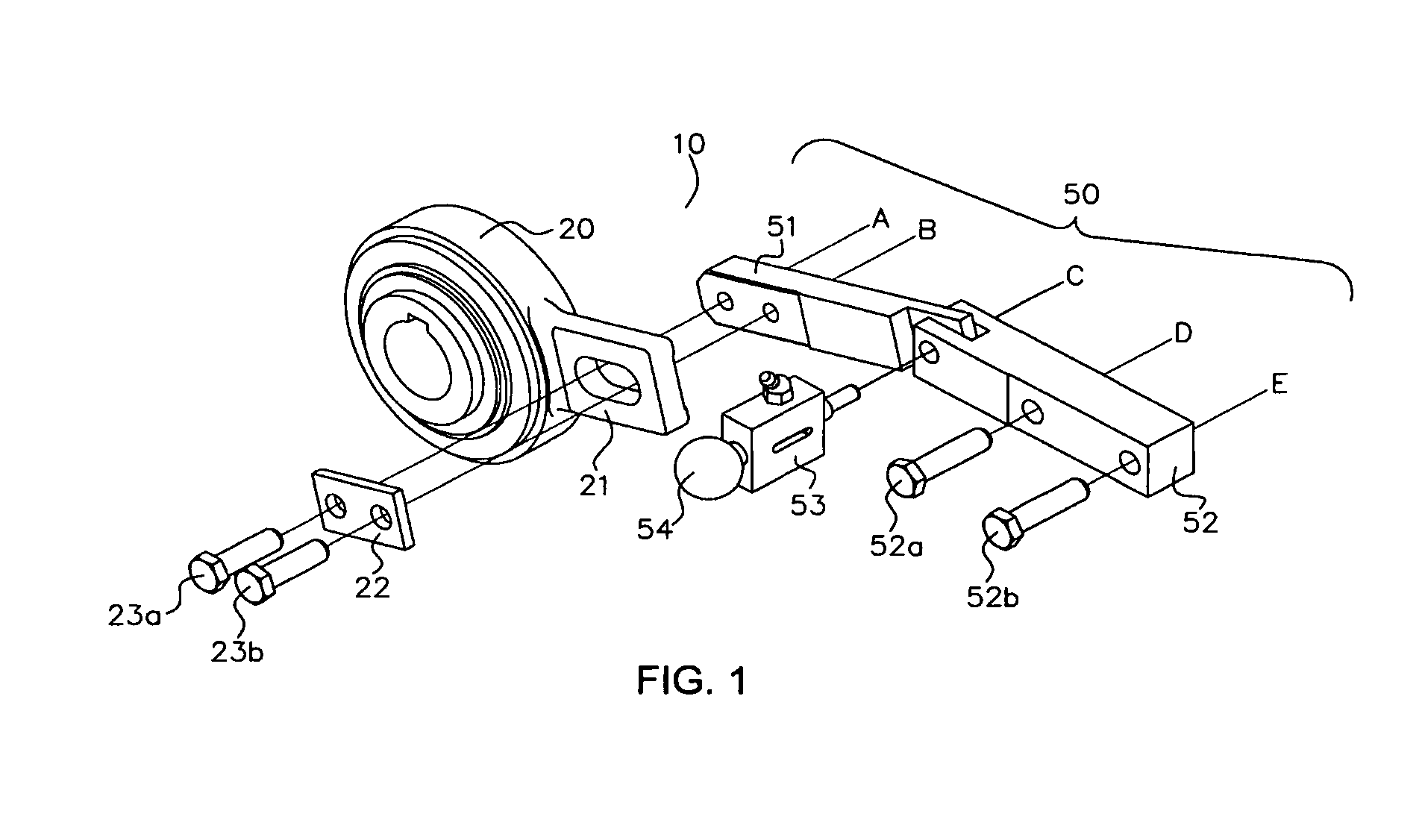

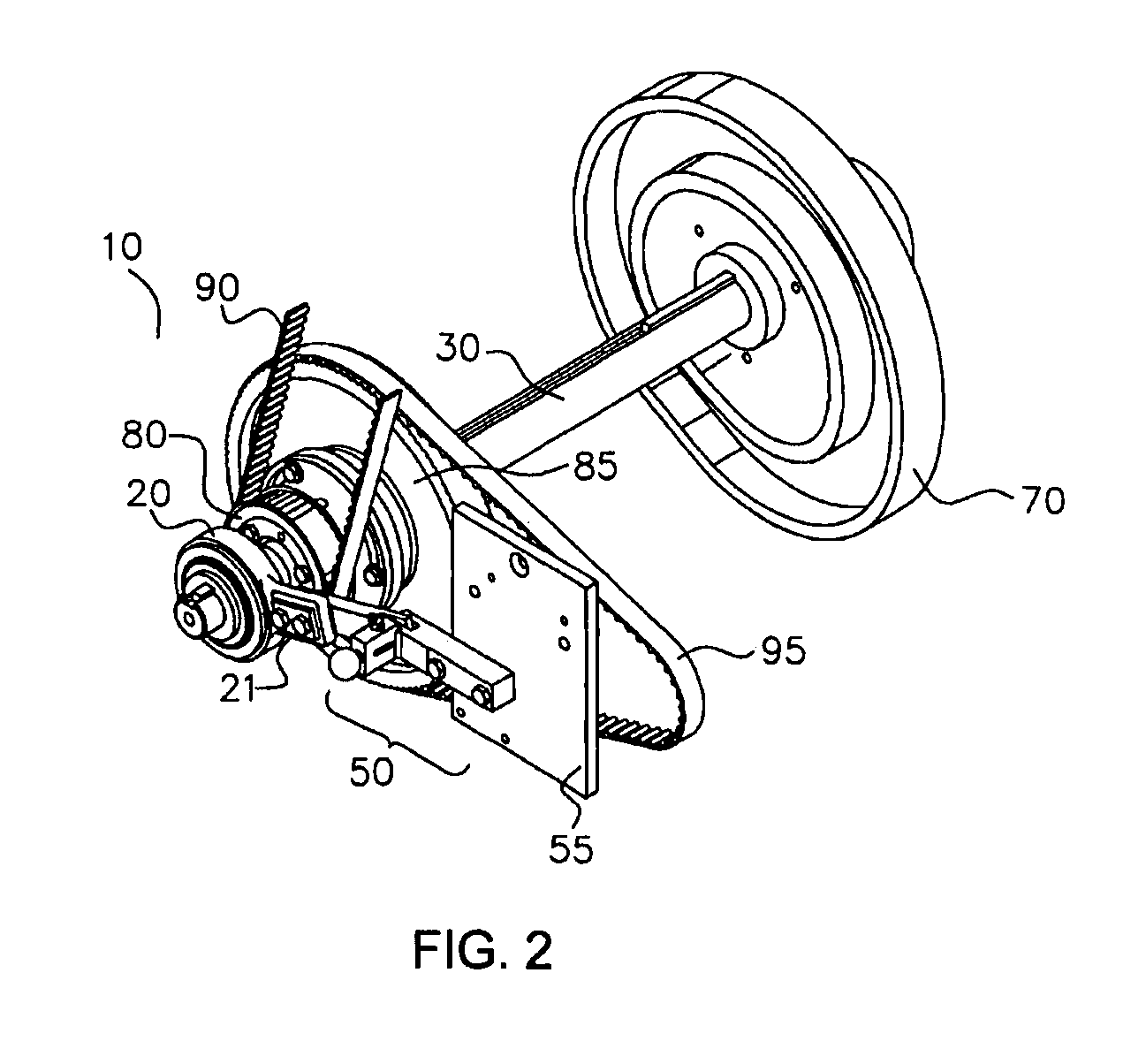

Seat height adjustment actuating device

An actuating device comprises a handle, a housing, and a driven member connected to the handle, the driven member being rotatable about a longitudinal axis thereof, the housing containing: a brake mechanism, for restricting rotation of the driven member when the brake mechanism is engaged; a means for disengaging the brake mechanism; a means for rotating the driven member in either the clockwise or counter-clockwise direction; and, a clutch mechanism for restricting reverse rotation of the driven member when driven in the clockwise or counter-clockwise direction. The actuating device of the invention is particularly suited for actuating a seat height adjustment mechanism of a vehicle.

Owner:SLIFE HLDG INC

Seat Height Adjustment Actuating Device

An actuating device comprises a handle, a housing, and a driven member connected to the handle, the driven member being rotatable about a longitudinal axis thereof, the housing containing: a brake mechanism, for restricting rotation of the driven member when the brake mechanism is engaged; a means for disengaging the brake mechanism; a means for rotating the driven member in either the clockwise or counter-clockwise direction; and, a clutch mechanism for restricting reverse rotation of the driven member when driven in the clockwise or counter-clockwise direction. The actuating device of the invention is particularly suited for actuating a seat height adjustment mechanism of a vehicle.

Owner:SLIFE HLDG INC

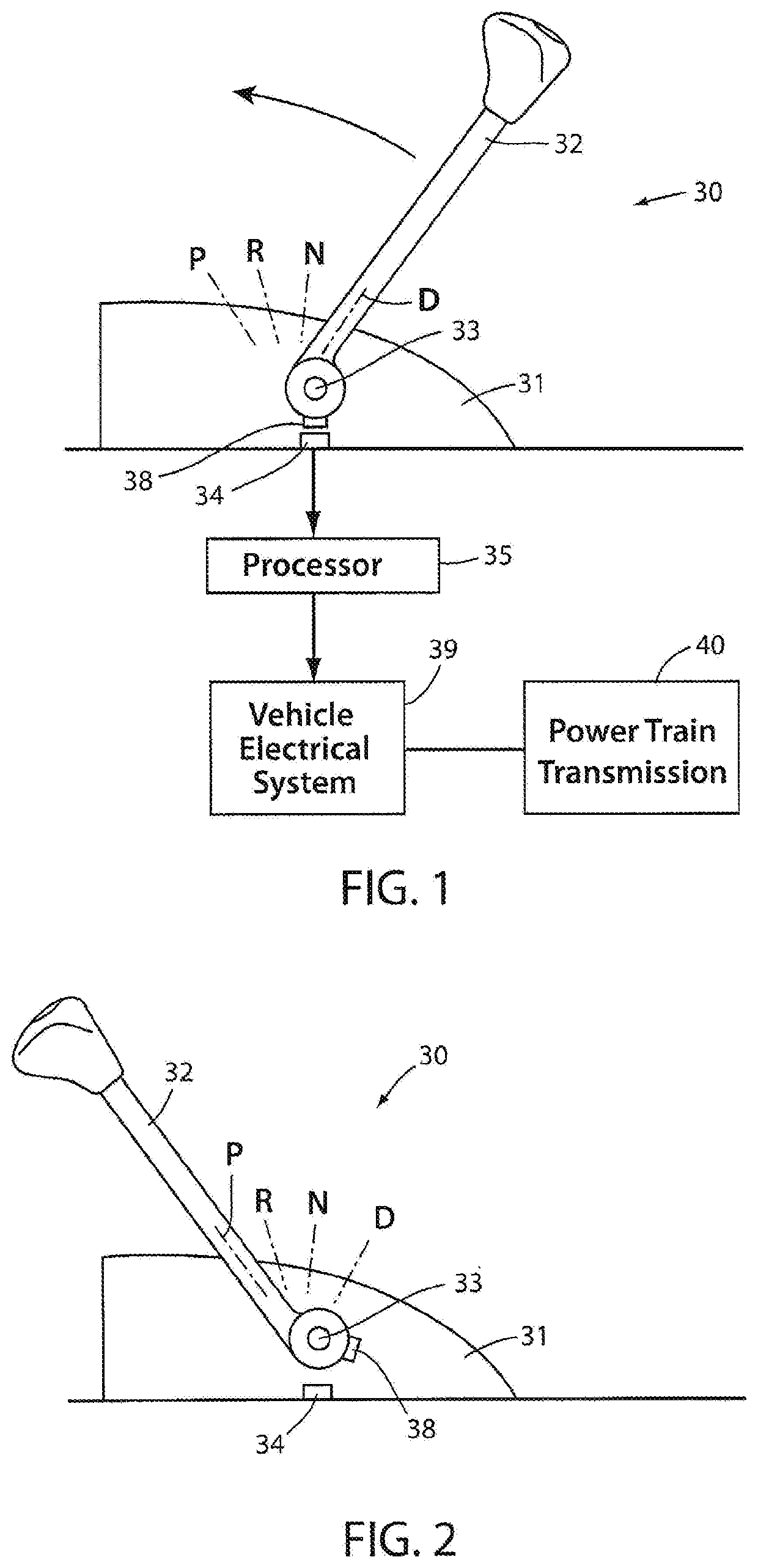

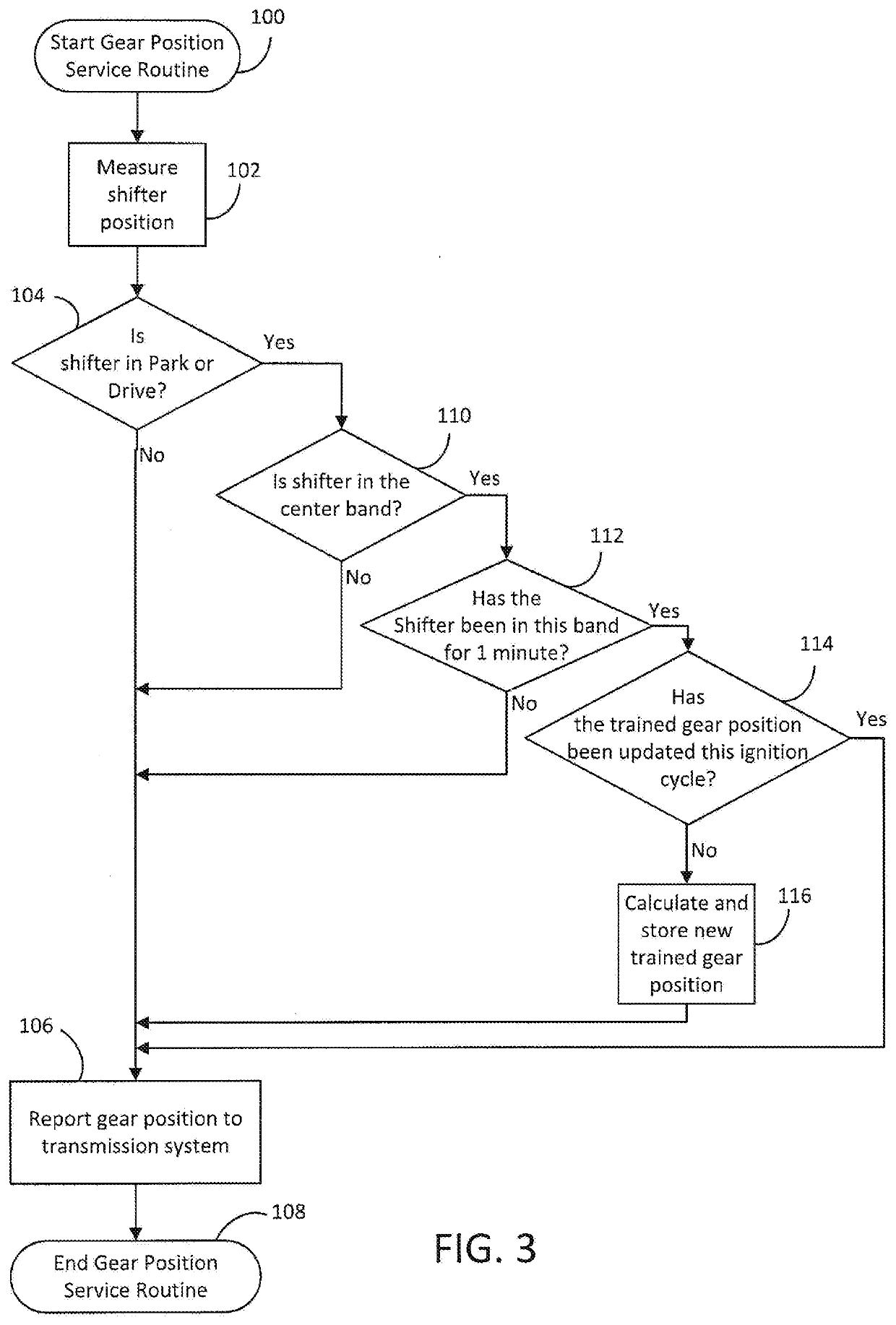

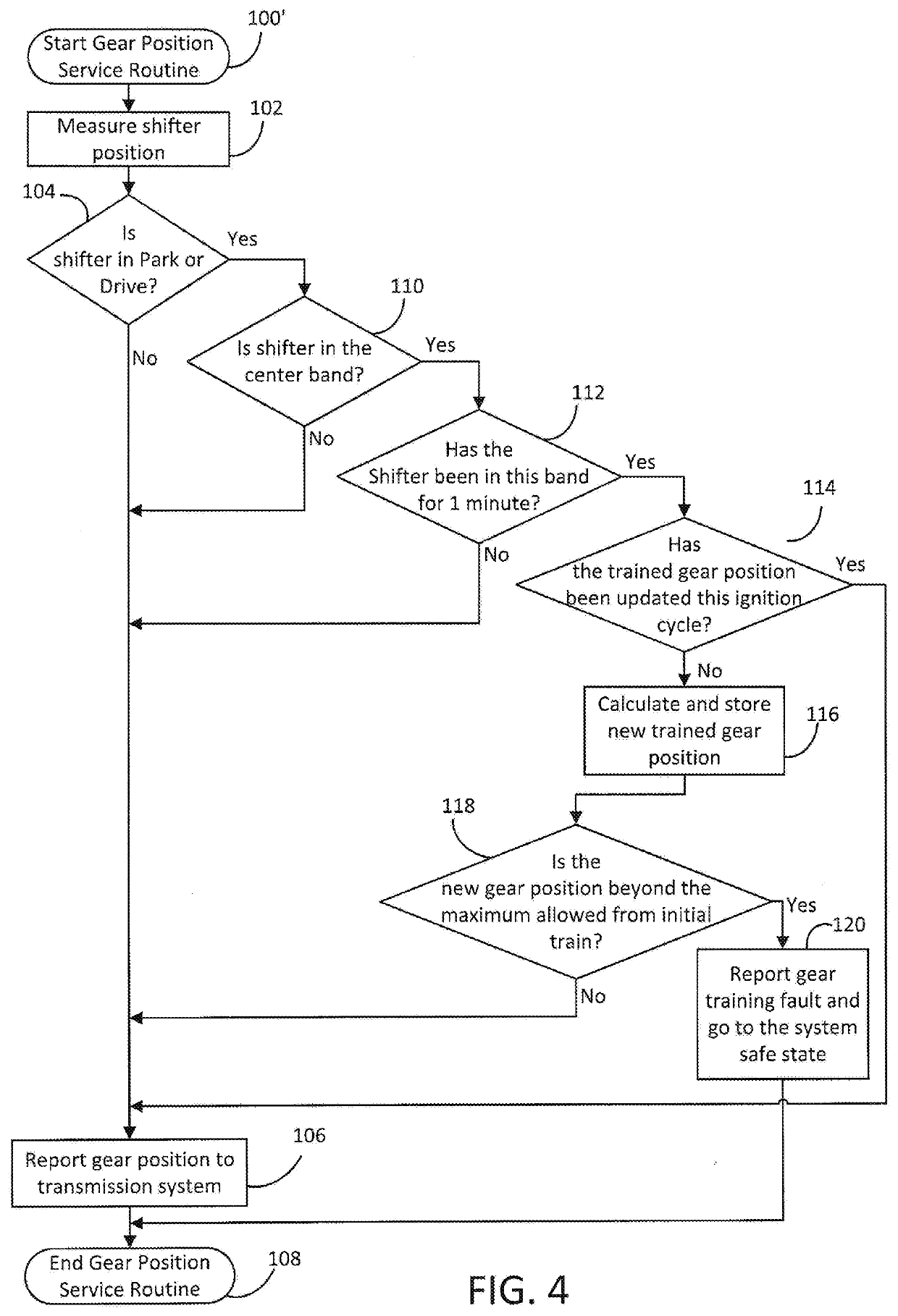

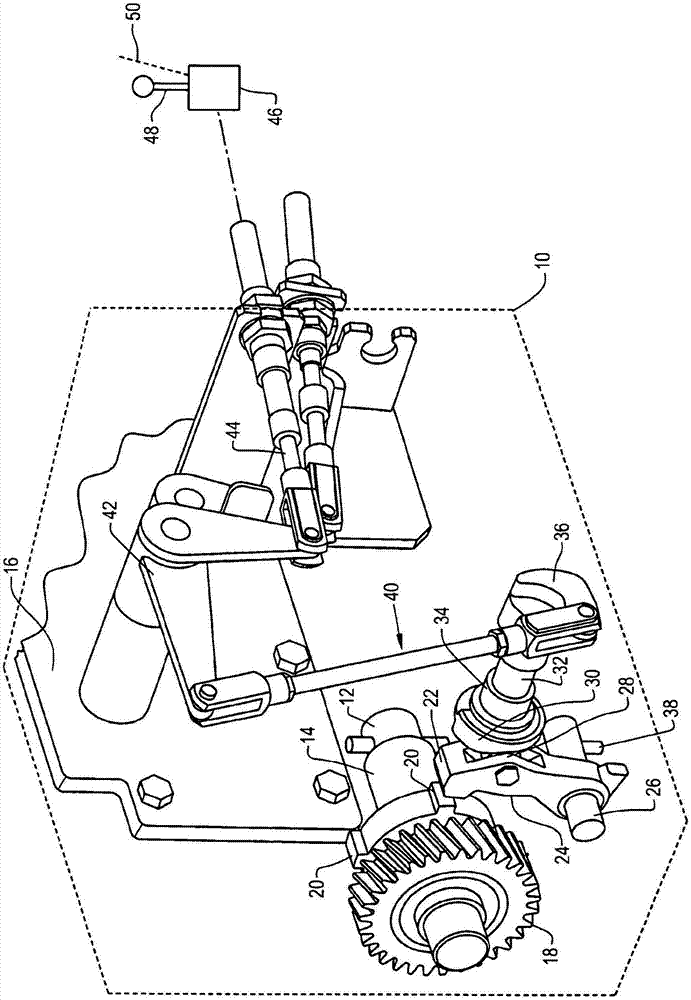

Transmission shifter with trained gear position set points

An apparatus and method of transmission control includes a shift lever supported between gear positions P, R, N, D, and a sensor operably connected to a vehicle electrical system for generating a variable signal corresponding to the P, R, N, D gear positions. The electrical system is initially set to control shifting a transmission between P, R, N, and D gear positions based on initial P and D position-indicating signals and interpolated / proportional R and N position-indicated signals. The apparatus and method further include adjusting shifting control for improved shift location accuracy after worn shifter components have mechanically worn or electrically drifted, by determining “new” P and D gear positions when the shift lever is in component-worn P and D gear positions, respectively, and then calculating new R and N position-indicating signals.

Owner:GHSP

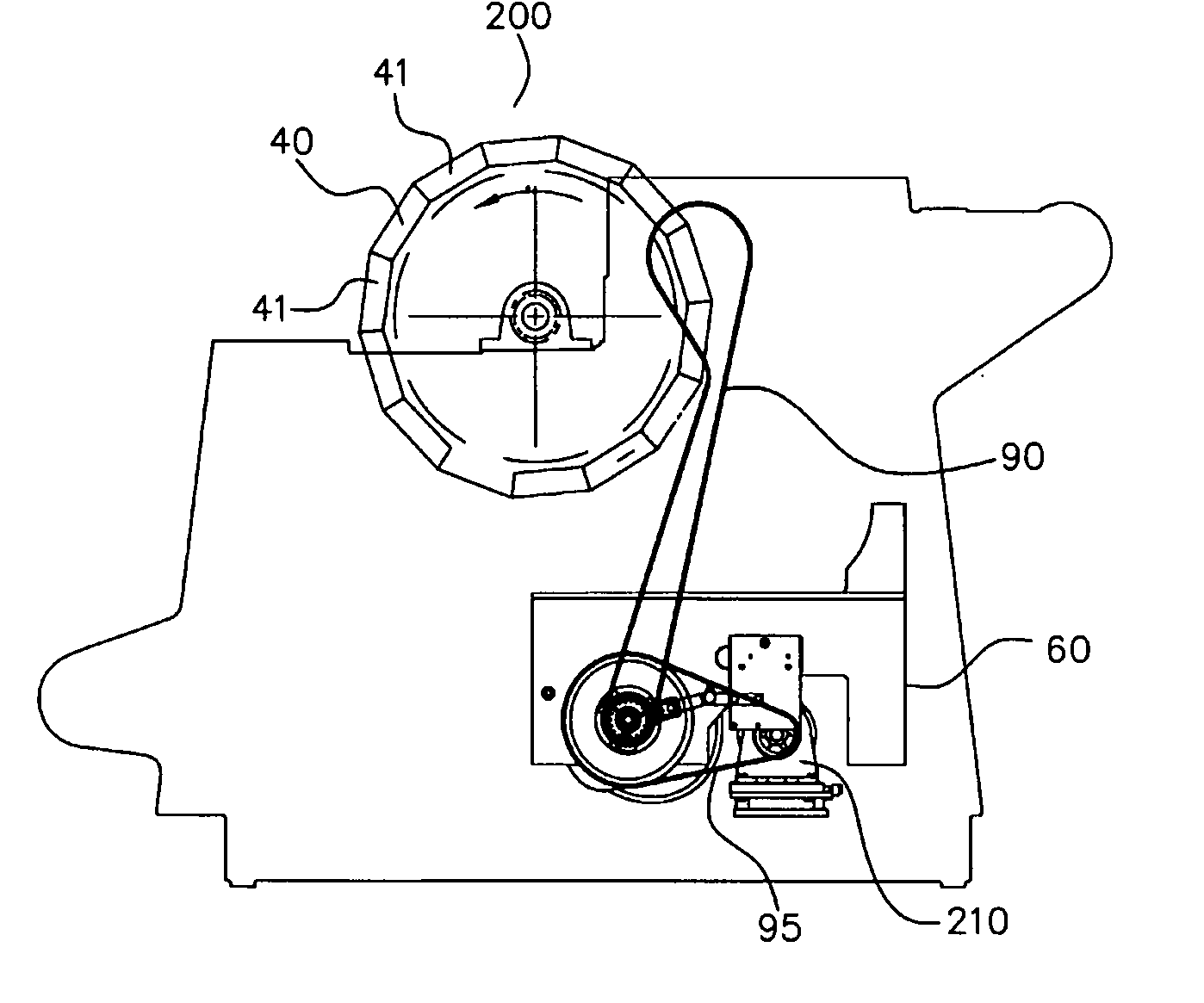

Rotational control assembly in packaging machines

The present invention provides an assembly for controlling the rotational movement of a die wheel in packaging machinery and includes a first component operationally interconnected to both the die wheel and camshaft, and a second component physically connected to both the first component and the framework of the packaging machine wherein the second component is detachably mounted to the framework.

Owner:BEMIS COMPANY INC

Motor device and wiper apparatus

Owner:ASMO CO LTD

Rotational control assembly in packaging machines

The present invention provides an assembly for controlling the rotational movement of a die wheel in packaging machinery and includes a first component operationally interconnected to both the die wheel and camshaft, and a second component physically connected to both the first component and the framework of the packaging machine wherein the second component is detachably mounted to the framework.

Owner:BEMIS COMPANY INC

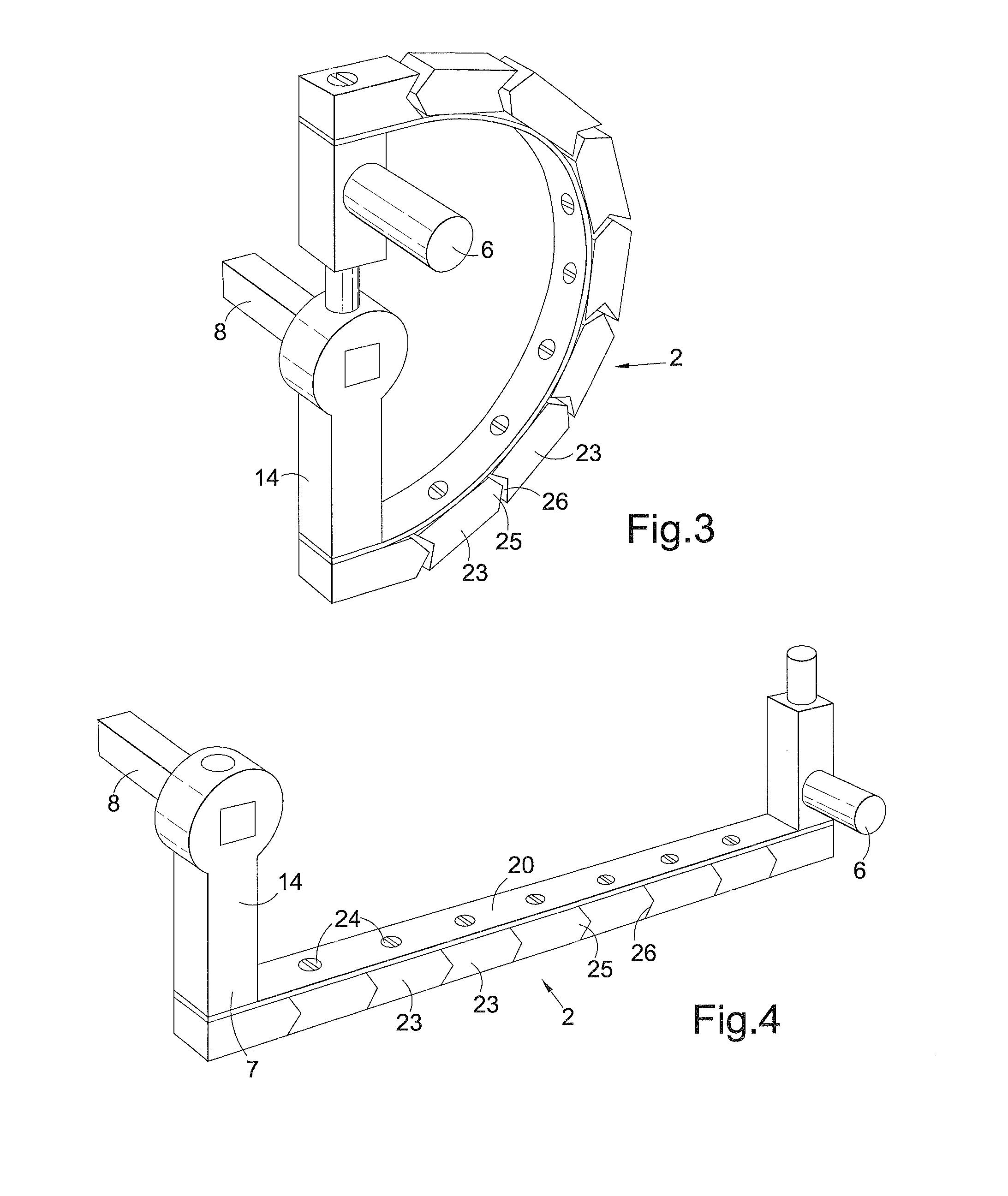

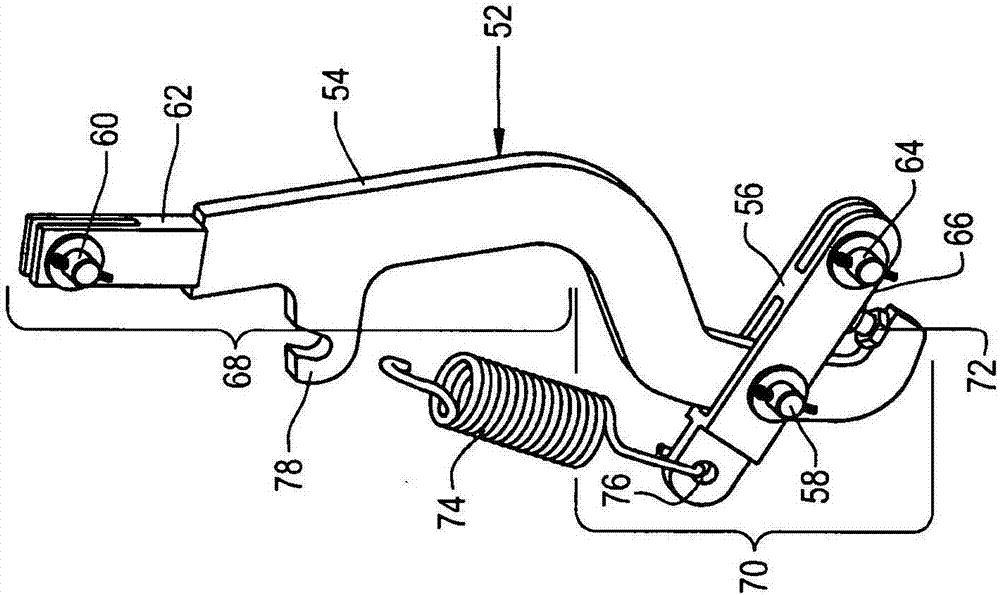

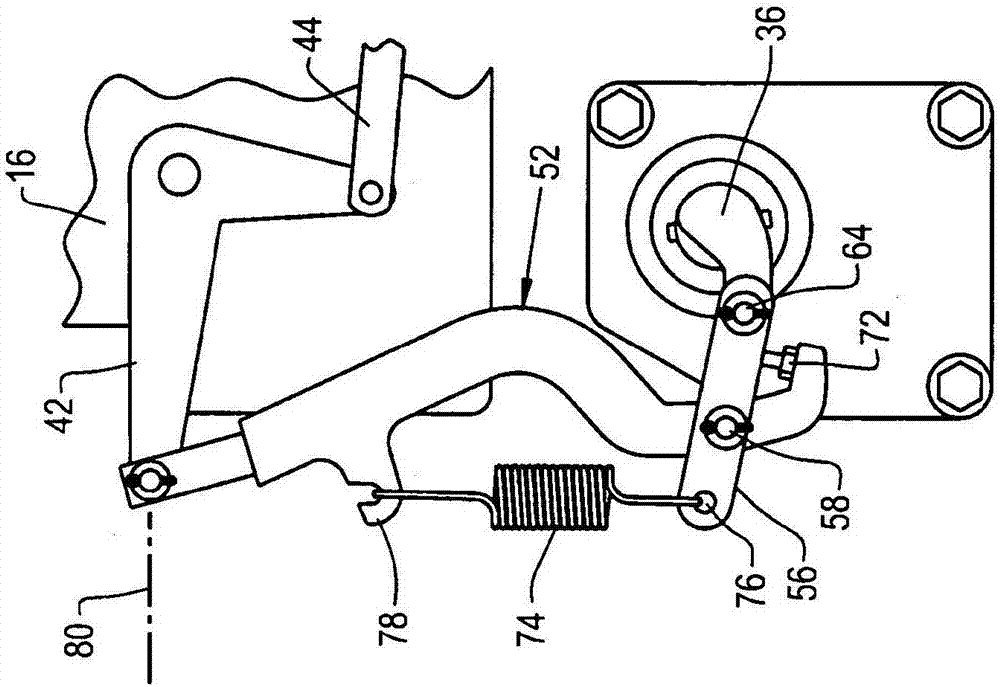

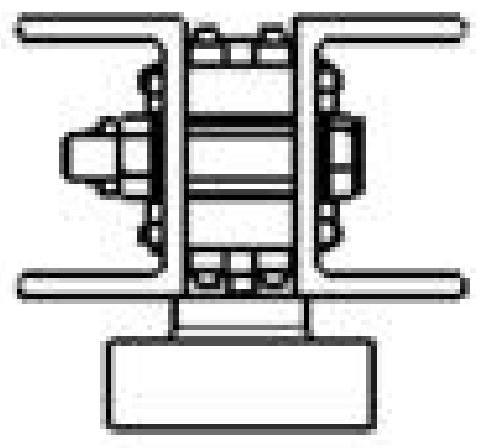

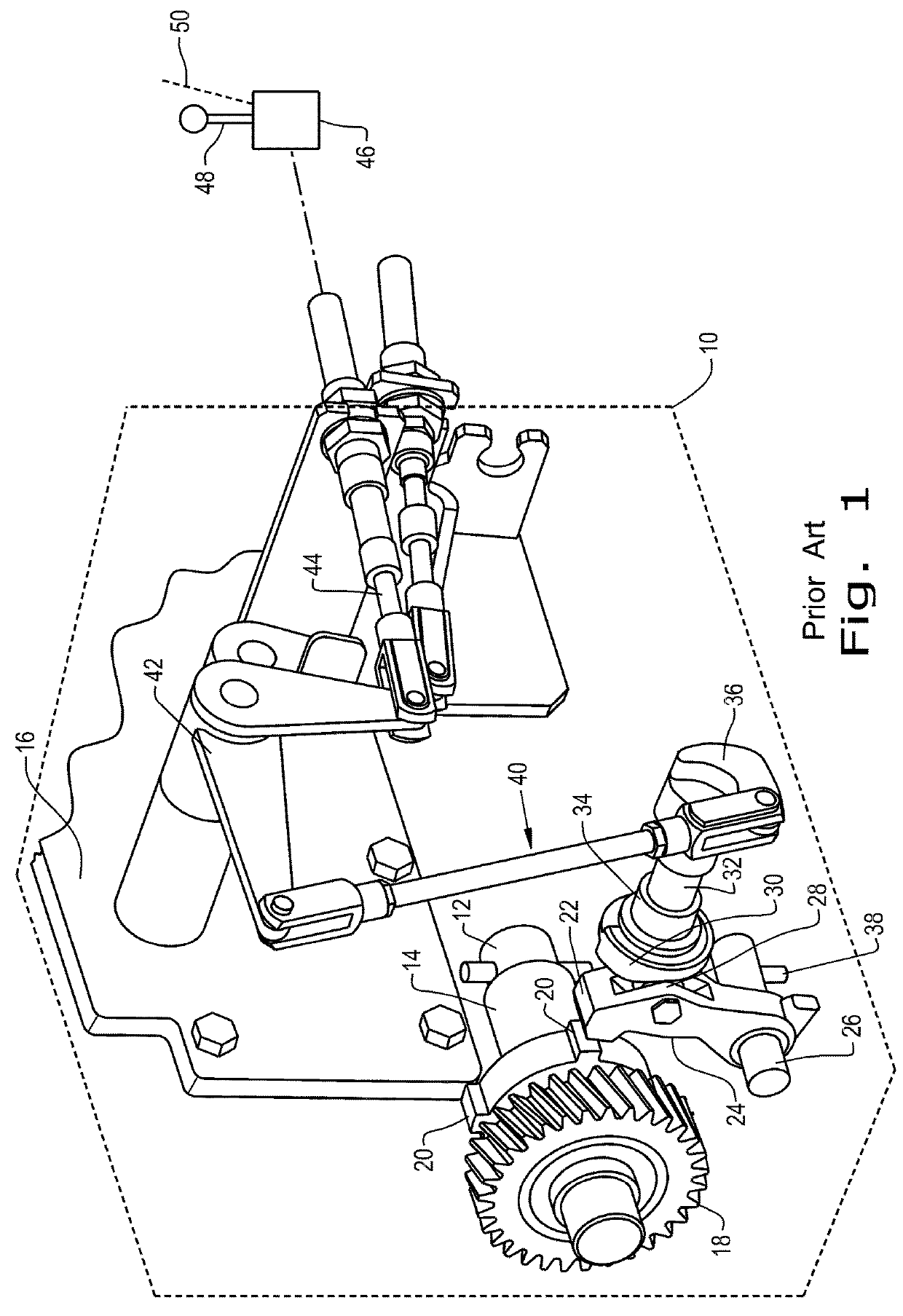

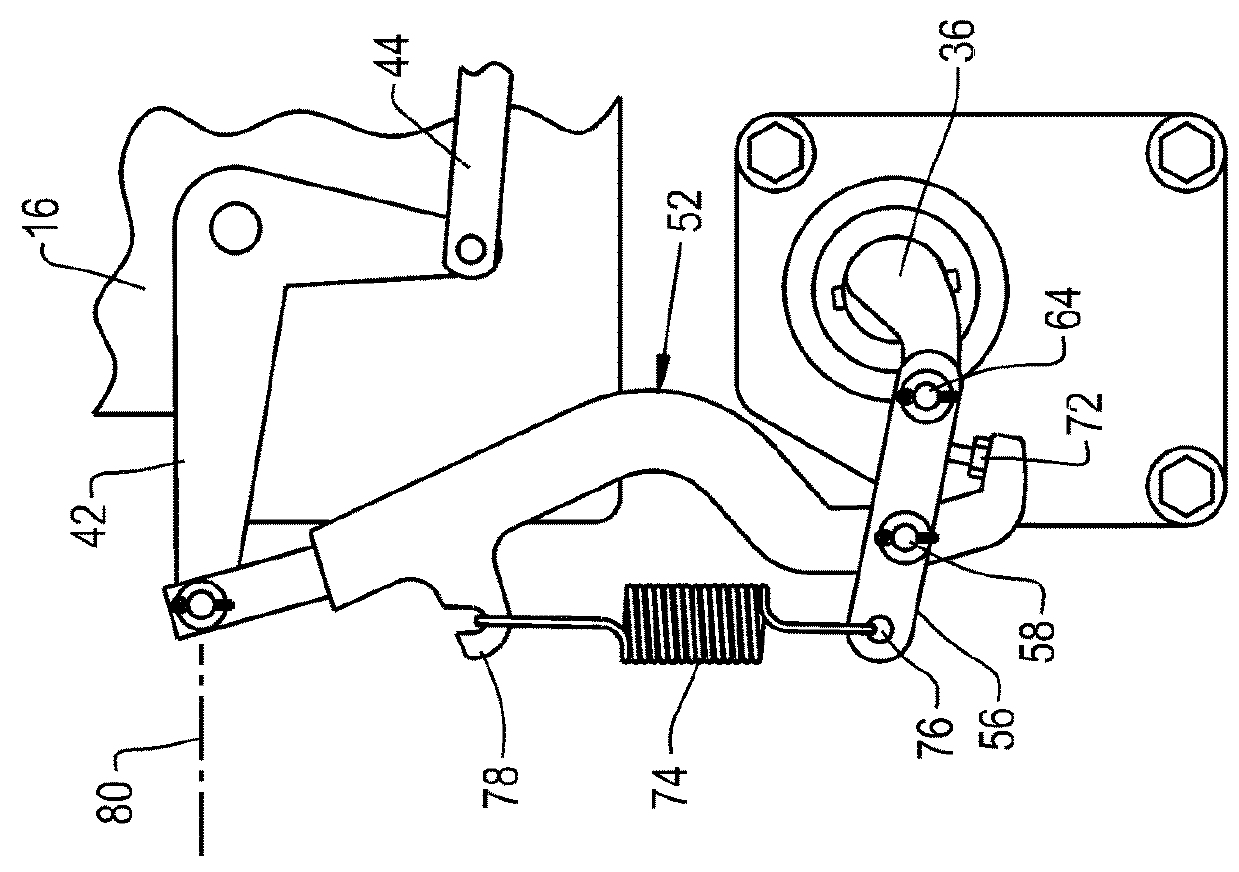

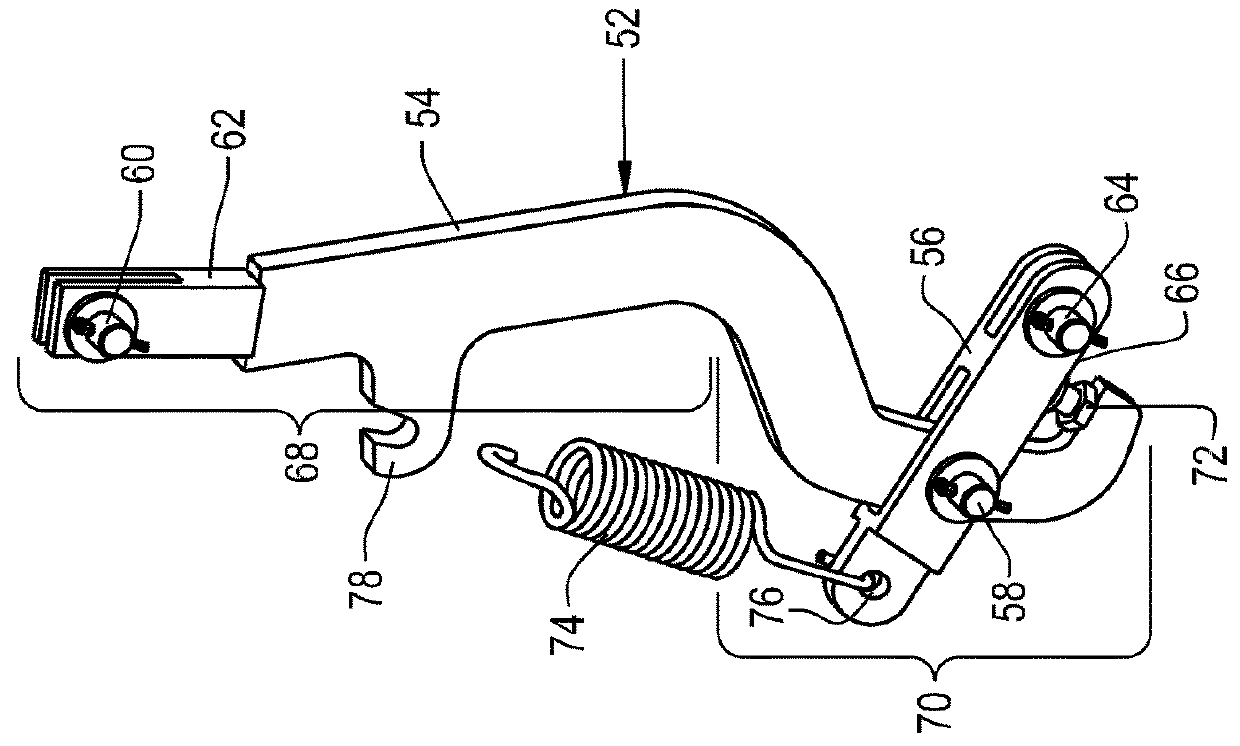

Parking lock pre-selection system

ActiveCN107107881ASimple structureNot easy to influenceBraking element arrangementsLeversMechanical engineeringPre selection

A parking lock pre-selection mechanism for a work machine (10) in which a pawl (22) is engageable with teeth (20) on a power train output shaft (12) to lock it in place. An operator lever (48) is used to preselect the parking lock position (50). The mechanism includes first and second pivotally interconnected links (54, 56), urged by a spring (74) to a maximum length set by a stop (72). The spring (74) causes the pawl (22) to be urged into place when the teeth (20) and pawl (22) are in proper alignment.

Owner:CNH IND MASCH (HARBIN) CO LTD

Variable radius lever arm assembly

A curled variable radius lever comprises a lever arm 2 of variable effective length that curls and uncurls about a drive axis. In a preferred arrangement the lever assembly has a plurality of rigid blocks 3 articulated together by a chain 4 with link pivots 5 which are affixed to respective blocks 3. Each block 3 has a pair of facing walls 11 and a pair of facing mutually inclined sloping walls 12 which abut when the lever arm 2 is in a curled condition. The lever arm 2 is pulled into the curled condition by a coiled tension spring 13 and restrained in this position by a magnet 9. When it is uncurled the walls 11 abut. The chain 4 then prevents the arm 2 from bending further when a driving force is applied by users to a handle 6. The lever may be used with socket sets, yacht winch, fishing rod reel, a bicycle crank or a jack assembly.

Owner:MALTBY MALORY

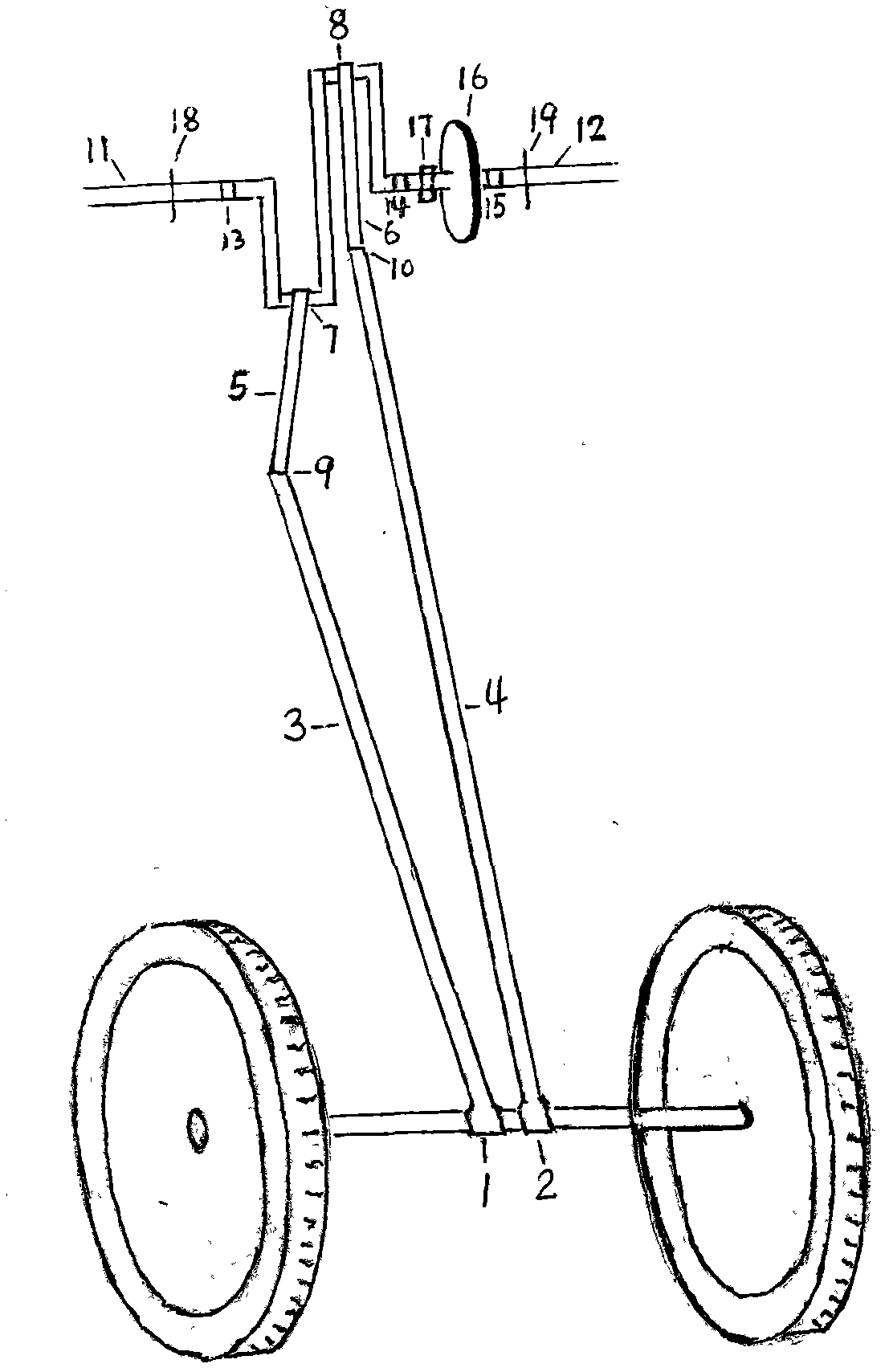

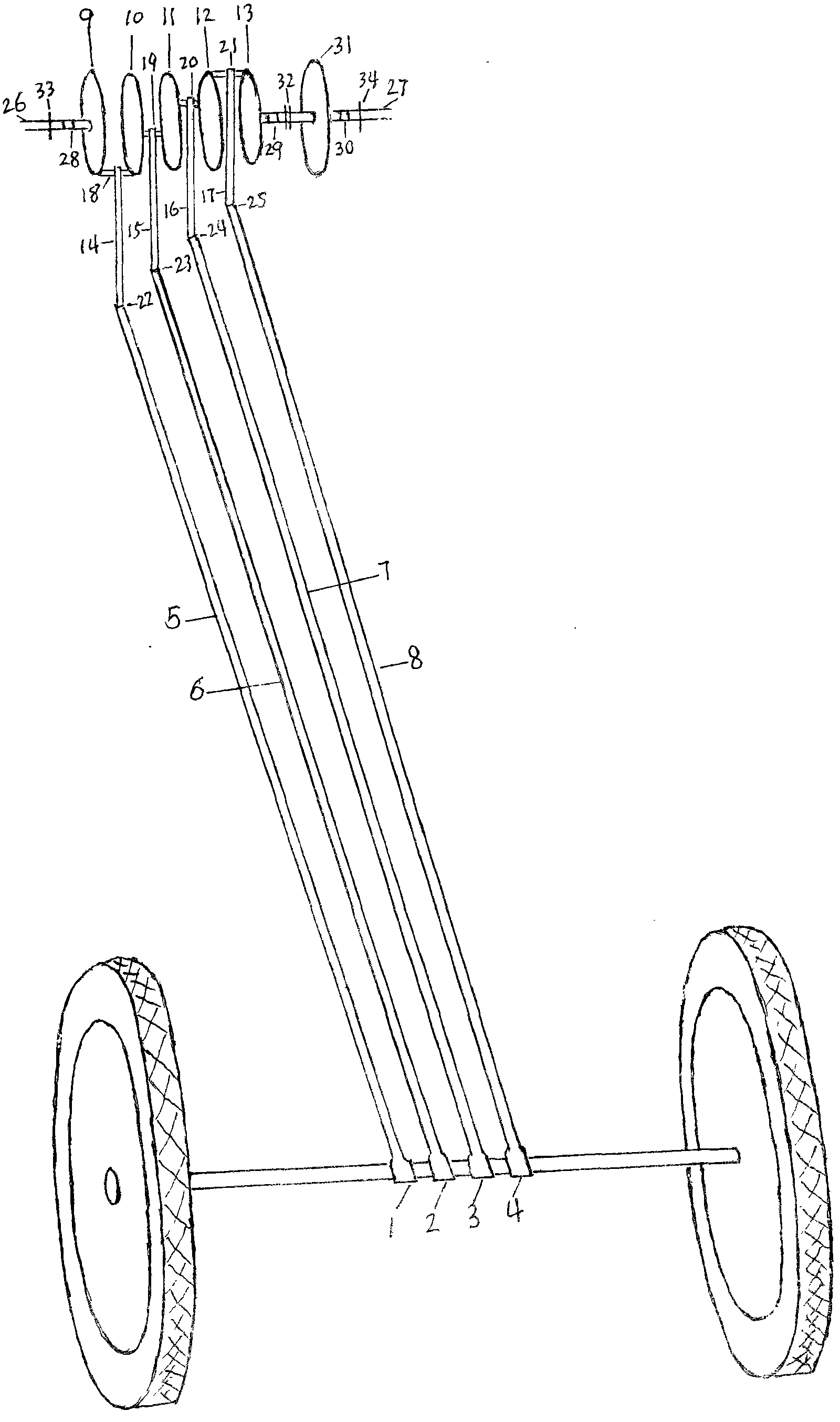

Energy-saving prying driving method for vehicle

The invention discloses prying bar driving wheels for driving a vehicle, two vehicle driving devices matched with the prying bar driving wheels and a driving method. Two to a plurality of prying bar driving wheels are arranged in the middle of a rear transverse shaft of the vehicle and are used for prying the rear transverse shaft of the vehicle and enabling rear wheels to rotate forwards. The vehicle driving devices matched with the prying bar driving wheels are generally arranged at the rear of a vehicle head or at the front, in the middle or on the lower part of a vehicle body, two to a plurality of connecting rods are movably connected to the vehicle driving devices, the other end of each connecting rod is movably connected with a prying bar head of the corresponding prying bar driving wheel, and when the vehicle driving devices are driven electrically or driven by a fuel machine, the connecting rods are pulled to vertically move and then pull prying bars of the prying bar driving wheels to perform sequential relay-type prying. Continuous high-frequency alternative prying of the prying bars drives the vehicle to run forwards. The prying bars of the prying bar driving wheels are long or ultra-long, and therefore, the prying bars and the matched vehicle driving devices can drive the vehicle in a labor-saving manner. A vehicle comprising the prying bar driving wheels and the matched vehicle driving devices is energy-saving and environment-friendly.

Owner:陈翮

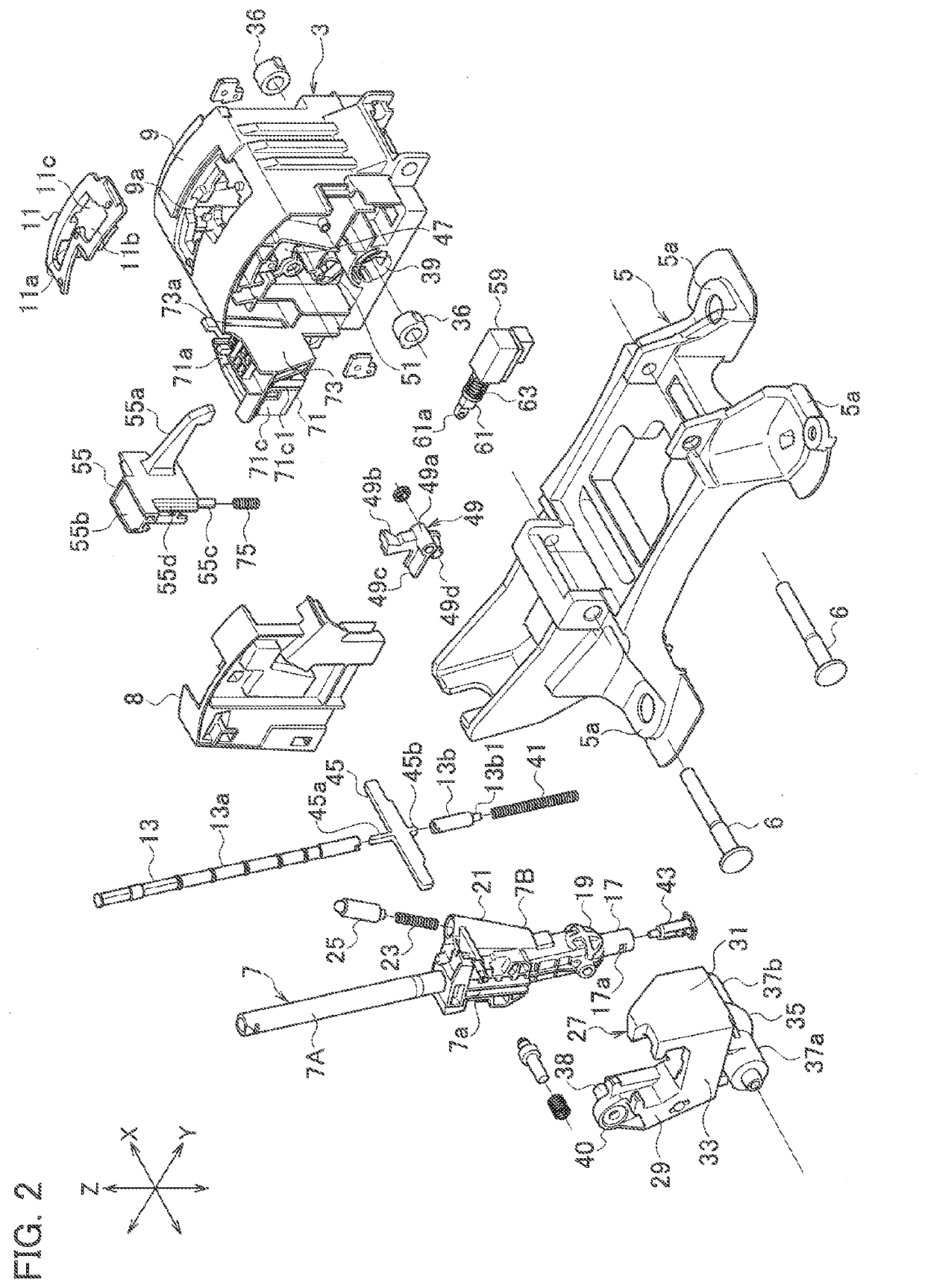

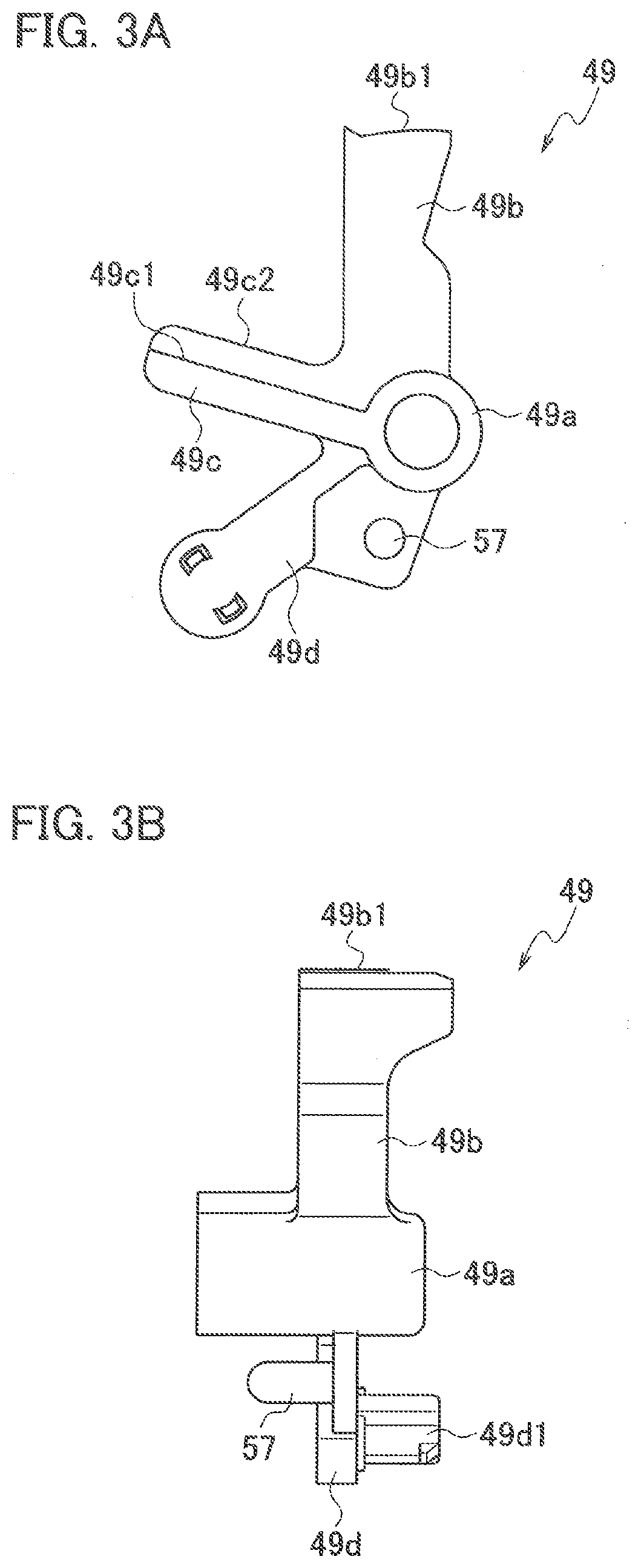

Gearshift lever device

InactiveUS20200072346A1LeversGearing controlMechanical engineeringElectrical and Electronics engineering

Owner:FUJI KIKO CO LTD

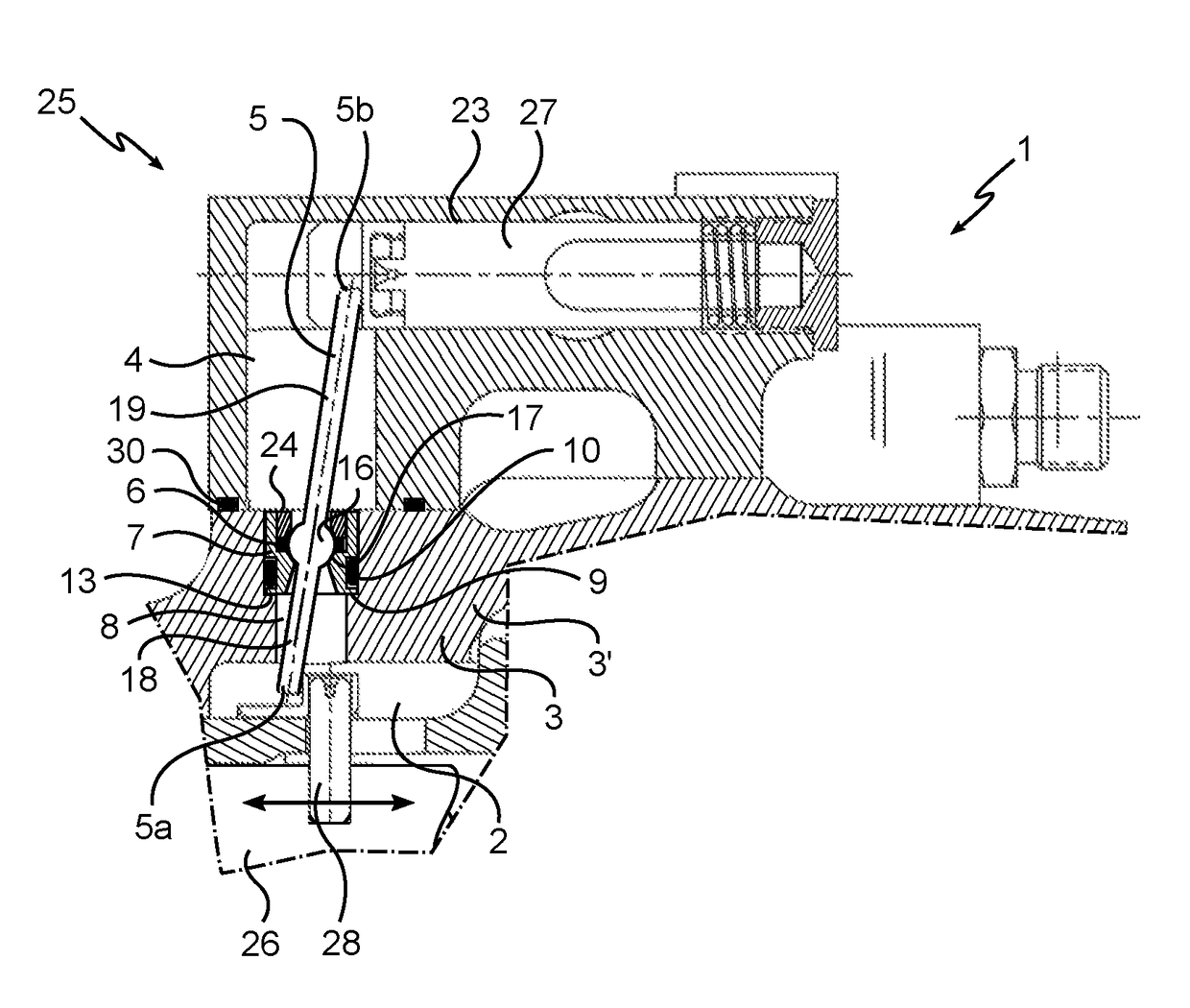

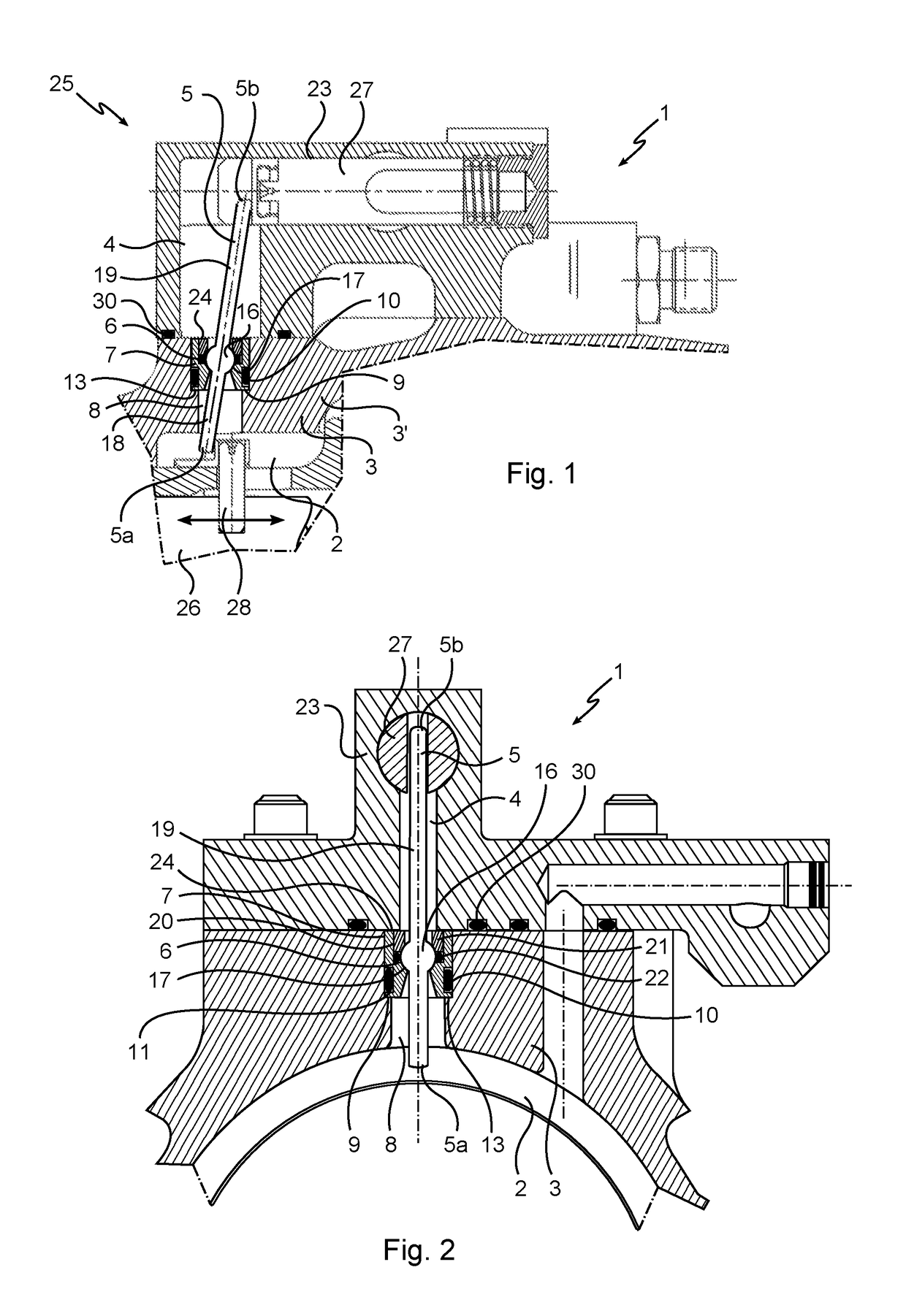

Control system comprising a control rod

Control system (1) comprising a control rod (5) extending between a first zone (2) situated in a hydraulic chamber delimited by a chamber wall (3) and a second zone (4) situated outside the hydraulic chamber. The control system (1) further comprising a seal (6) arranged around and against this control rod (5) to oppose the passage of fluid between the first and second zones (2, 4). The system further comprises a guide piece (7) assembled removably with respect to the chamber wall (3), the seal (6) is assembled inside the guide piece (7) so as to allow relative movement of the rod (5) with respect to the guide piece (7) while at the same time achieving sealing between the first and second zones (2, 4).

Owner:SAFRAN LANDING SYSTEMS

Lid controlling apparatus and rod driving device thereof

Owner:QUISDA CORP

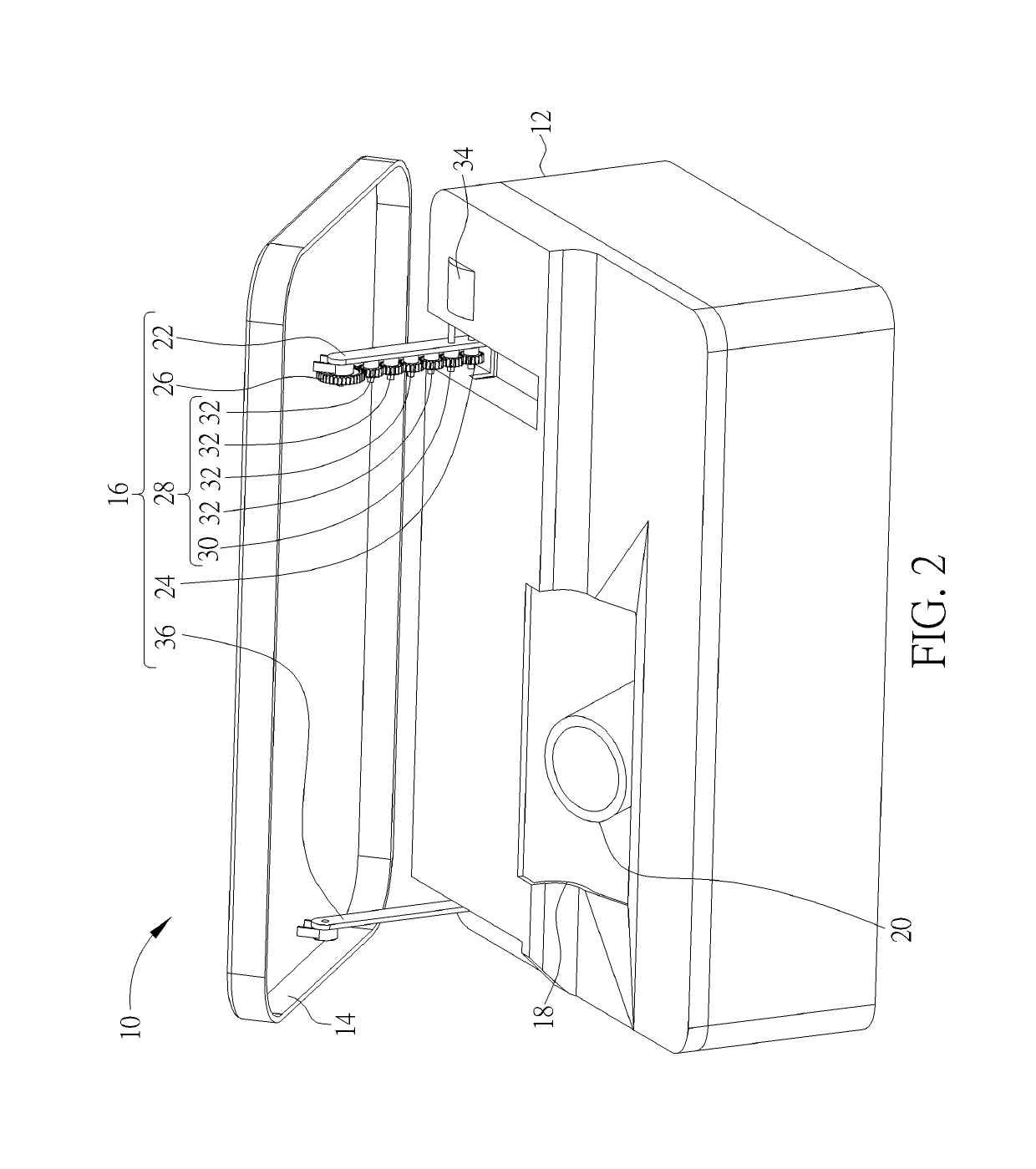

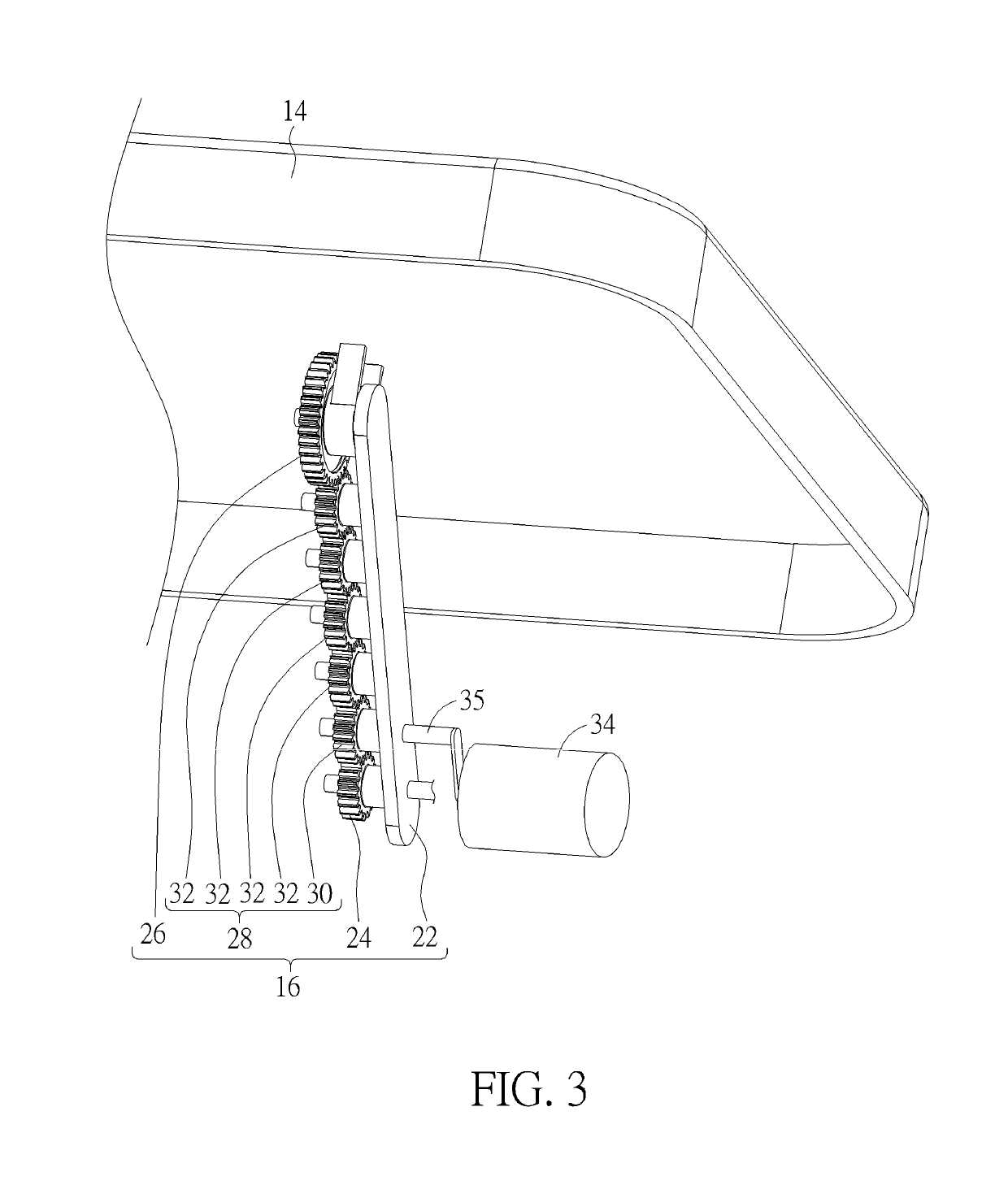

Corner cabinet fitting for the gearwheel-controlled movable mounting of a shelf in a corner cabinet

A corner cabinet fitting (1) for movably mounting of a shelf (34) in a corner cabinet (37) has a bearing pedestal (7), a supporting arm (8) which is mounted on the bearing pedestal (7) so as to be pivotable in a first pivoting movement about a first vertical pivot axis (9), a shelf carrier (10) which is mounted on the supporting arm (8) so as to be pivotable in a second pivoting movement about a second vertical pivot axis (11), and a coupling mechanism which couples the second pivoting movement to the first pivoting movement. The coupling mechanism comprises a first rolling element (24) and a second rolling elements (22), which roll on one another directly or via a belt or a chain, the first rolling element (24) being coupled to the bearing pedestal (7) and the second rolling element (22) being coupled to the shelf carrier.

Owner:VAUTH SAGEL HLDG

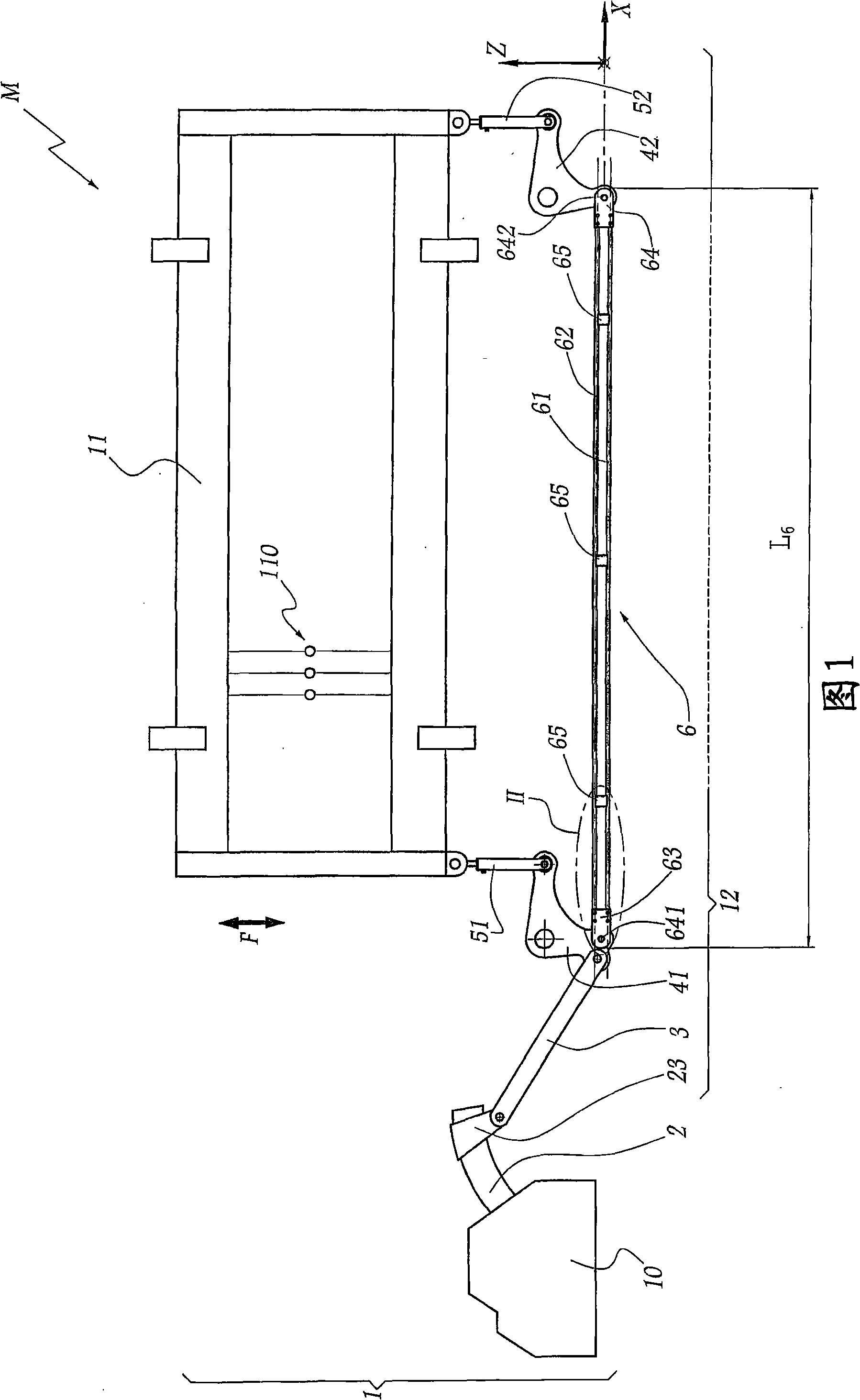

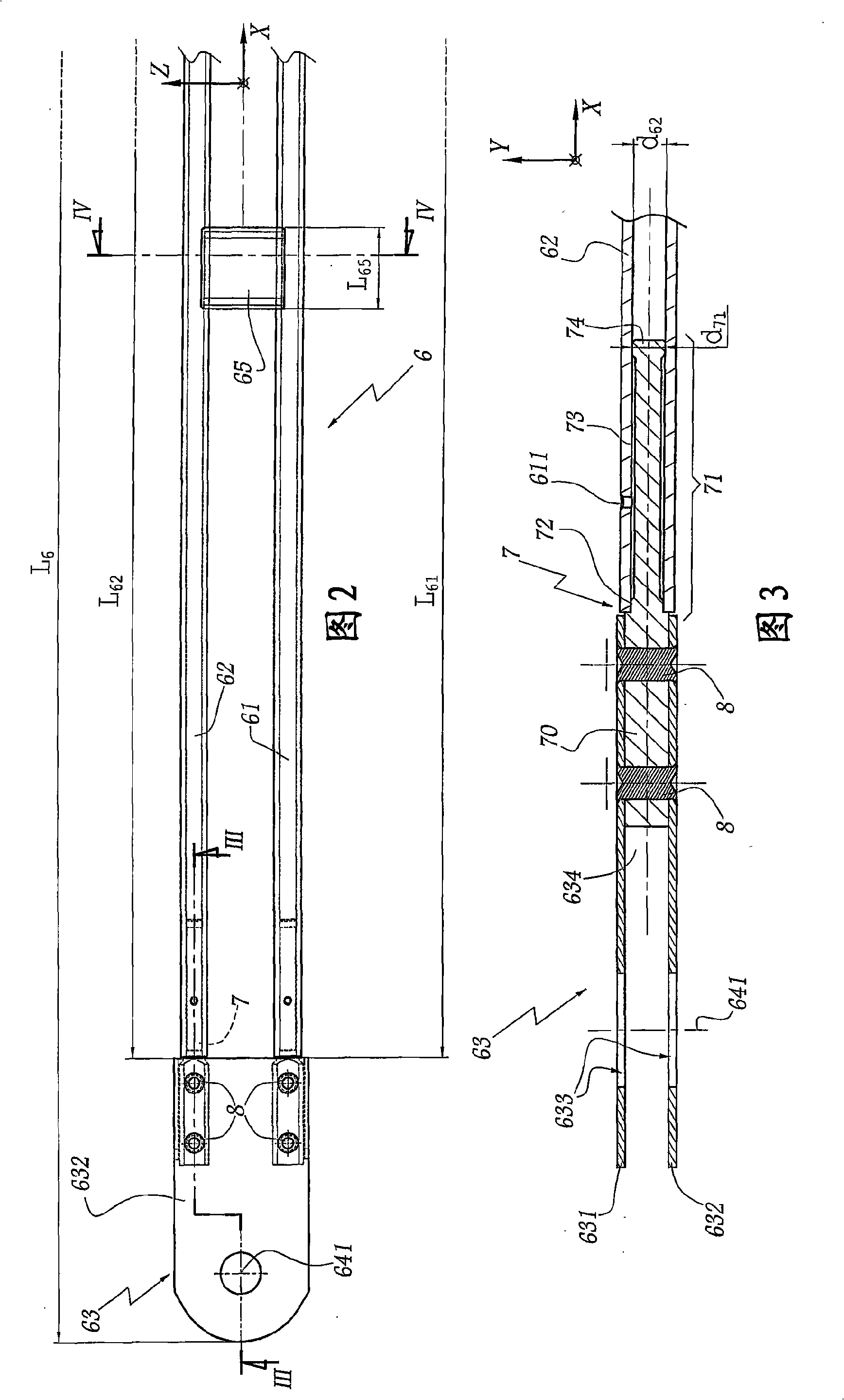

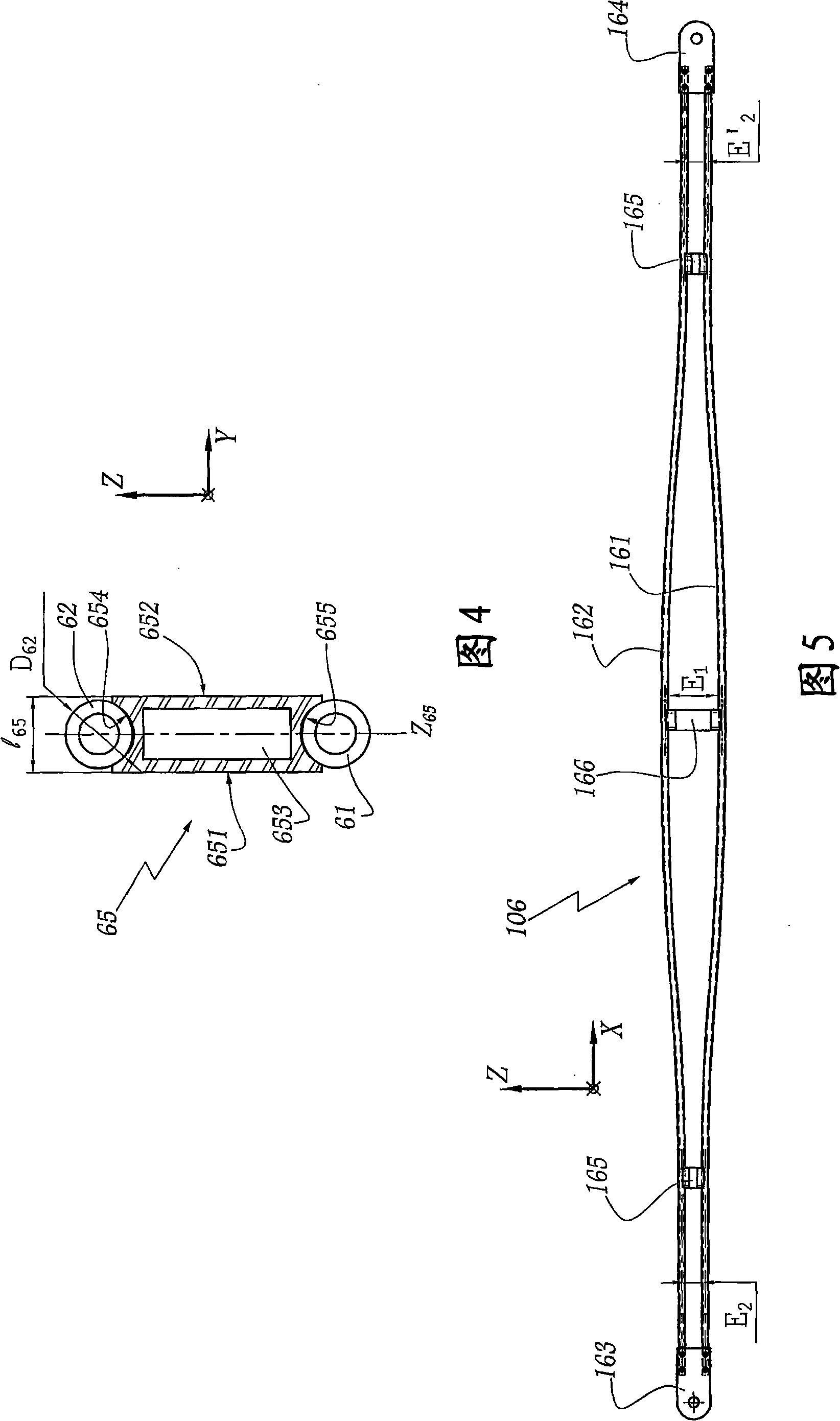

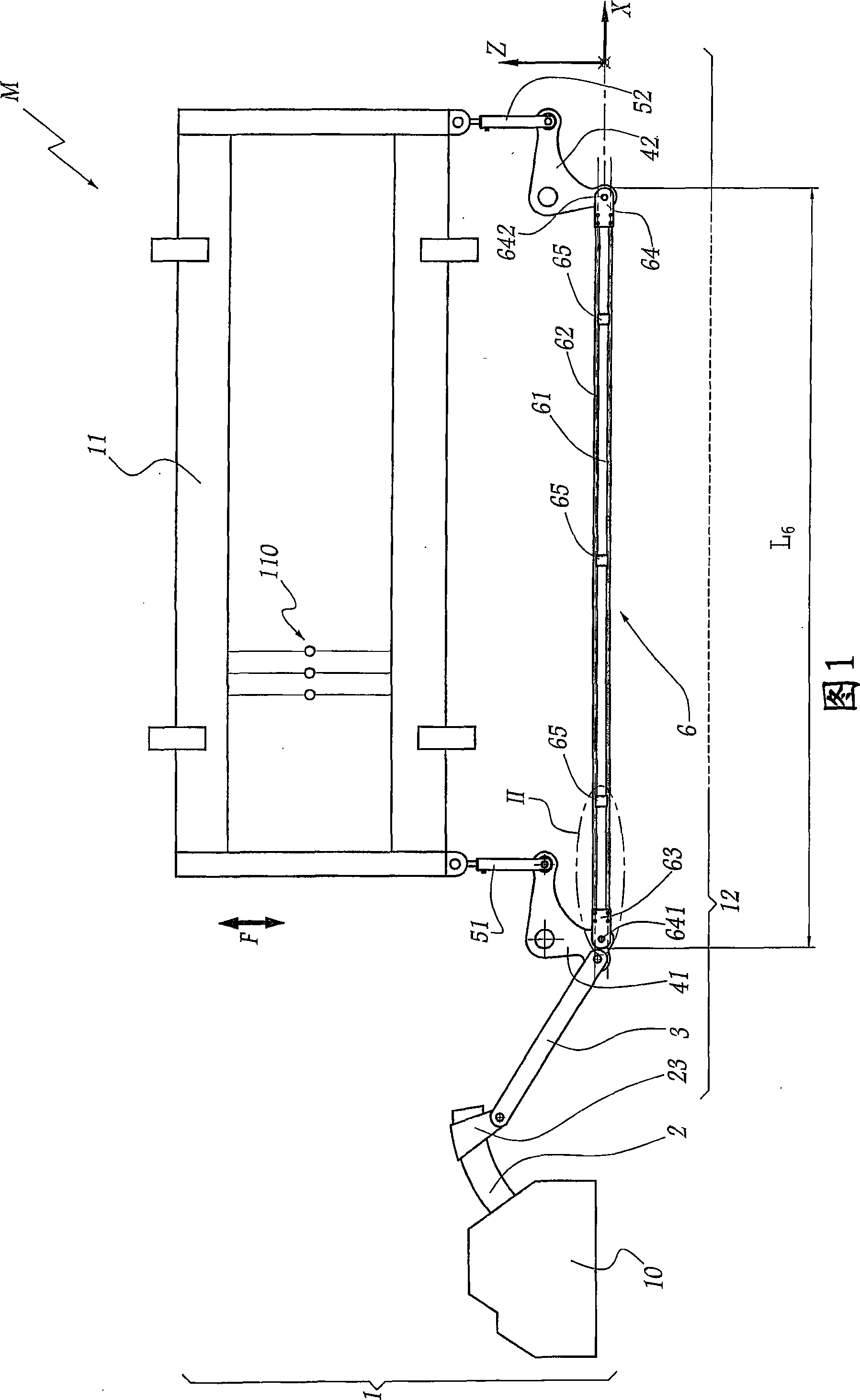

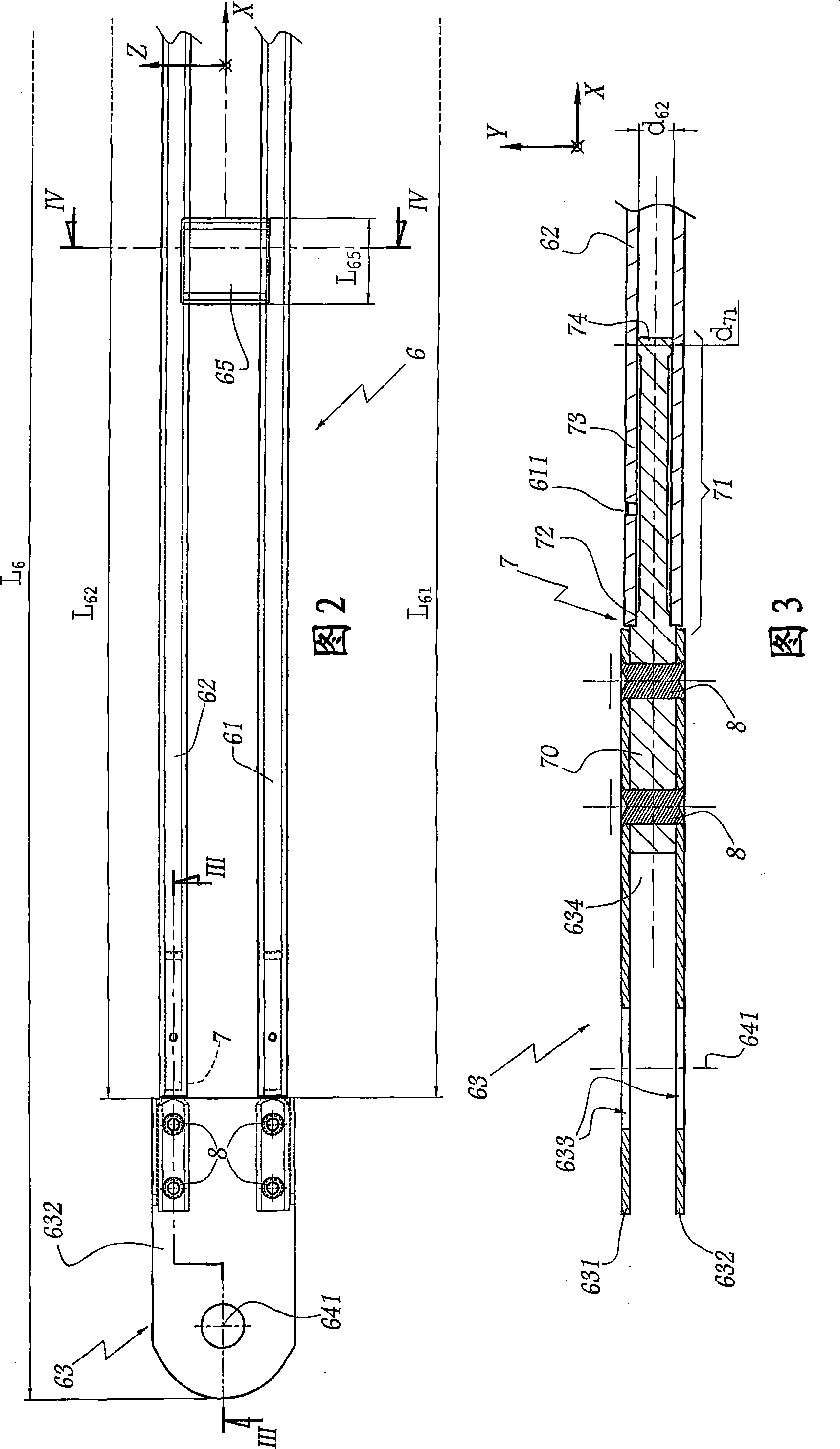

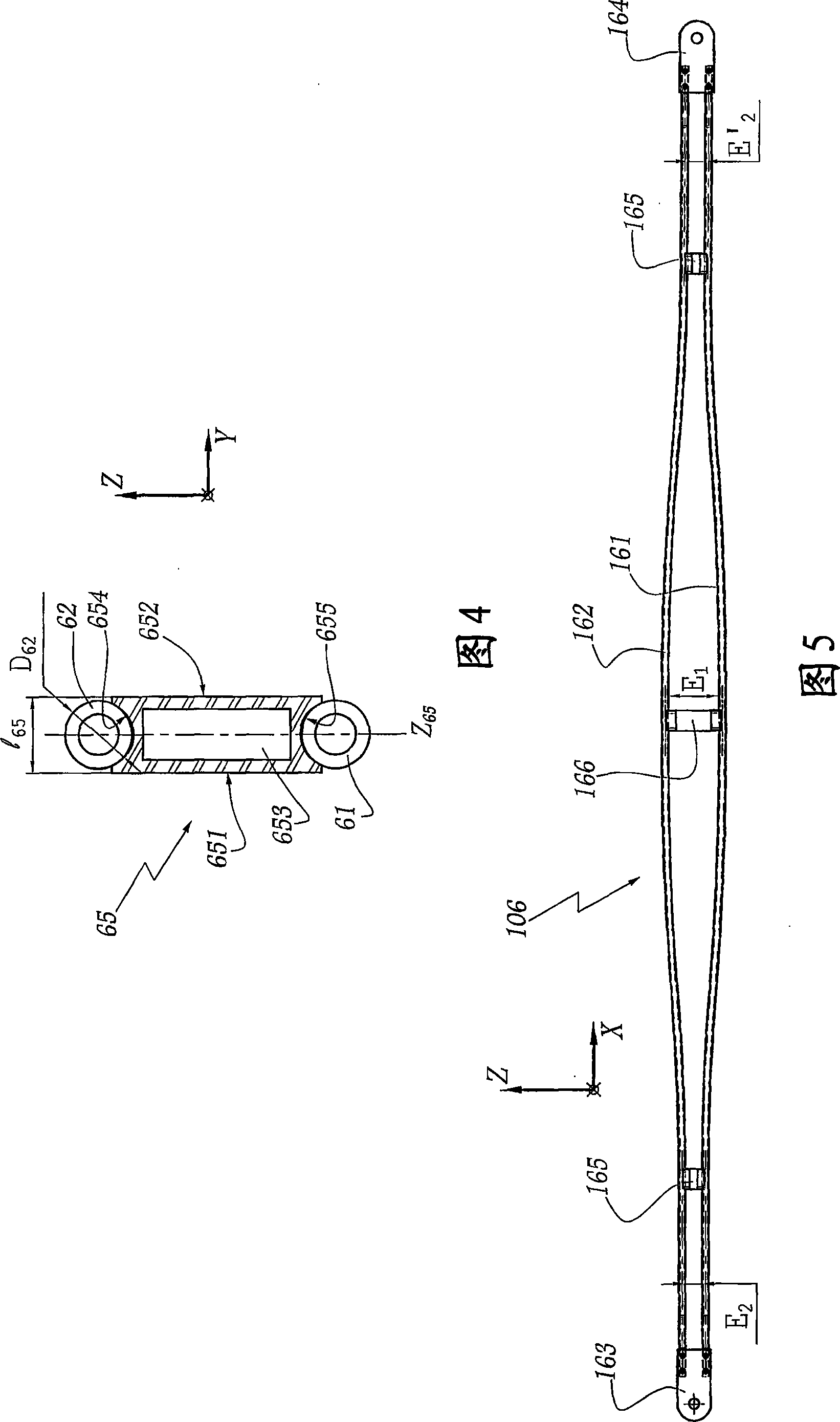

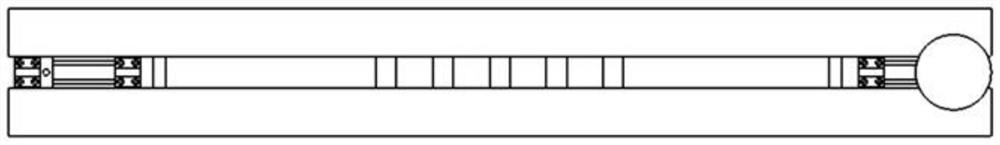

Connecting rod for drawing system and loom comprising such a connecting rod

A connecting rod (6) used in a drawing system (12) of a loom extends along a longitudinal direction (X), which comprises at least two overlapped main rods (61, 62), extending approximately along the longitudinal direction (X), and at least a spacer arranged between the main rods (61, 62), wherein the spacer or each spacer (65) is away from each end part of the connecting rod.

Owner:STAUBLI FAVERGES SA

Connecting rod for drawing system and loom comprising such a connecting rod

A connecting rod (6) used in a drawing system (12) of a loom extends along a longitudinal direction (X), which comprises at least two overlapped main rods (61, 62), extending approximately along the longitudinal direction (X), and at least a spacer arranged between the main rods (61, 62), wherein the spacer or each spacer (65) is away from each end part of the connecting rod.

Owner:STAUBLI FAVERGES SA

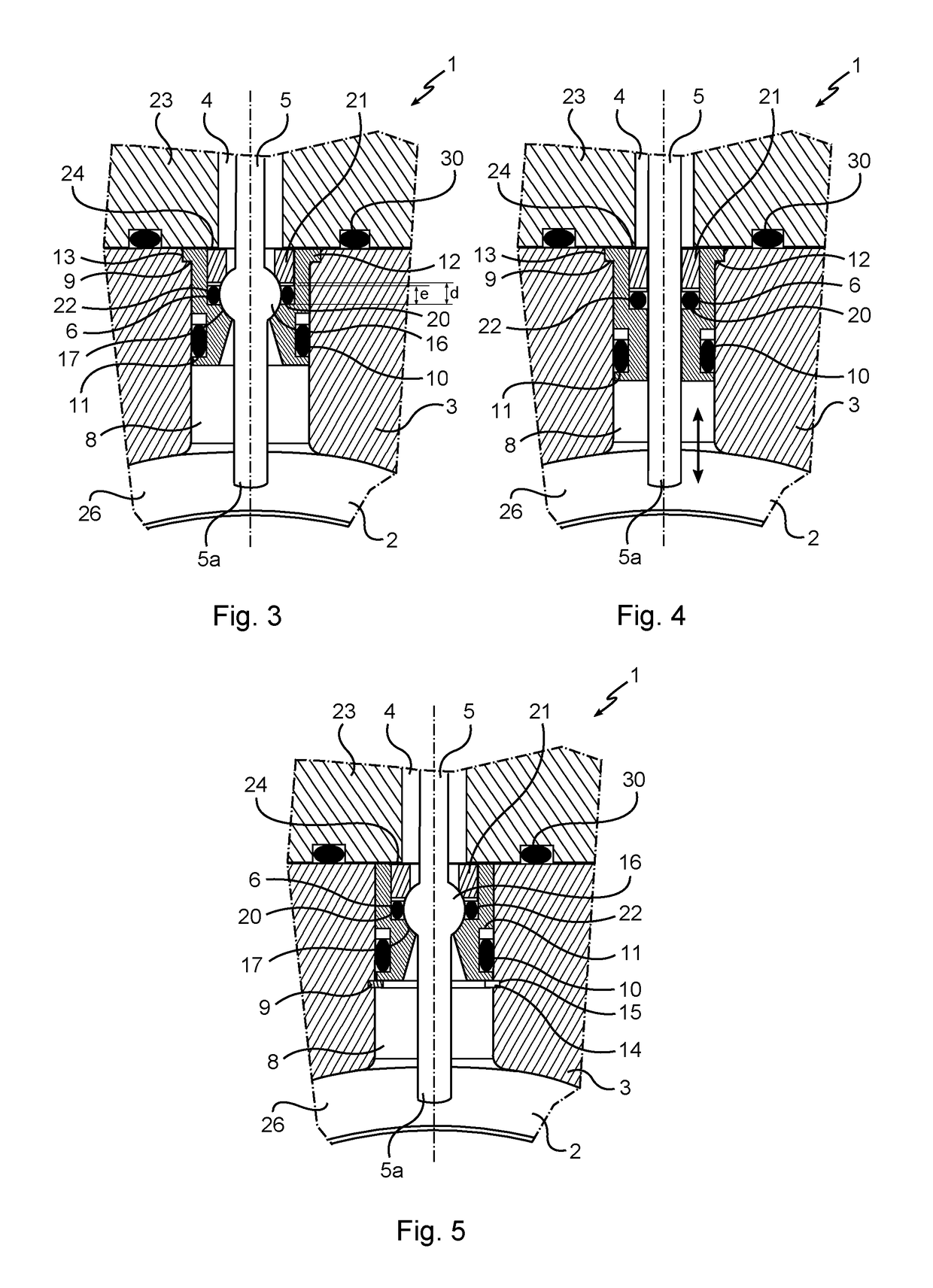

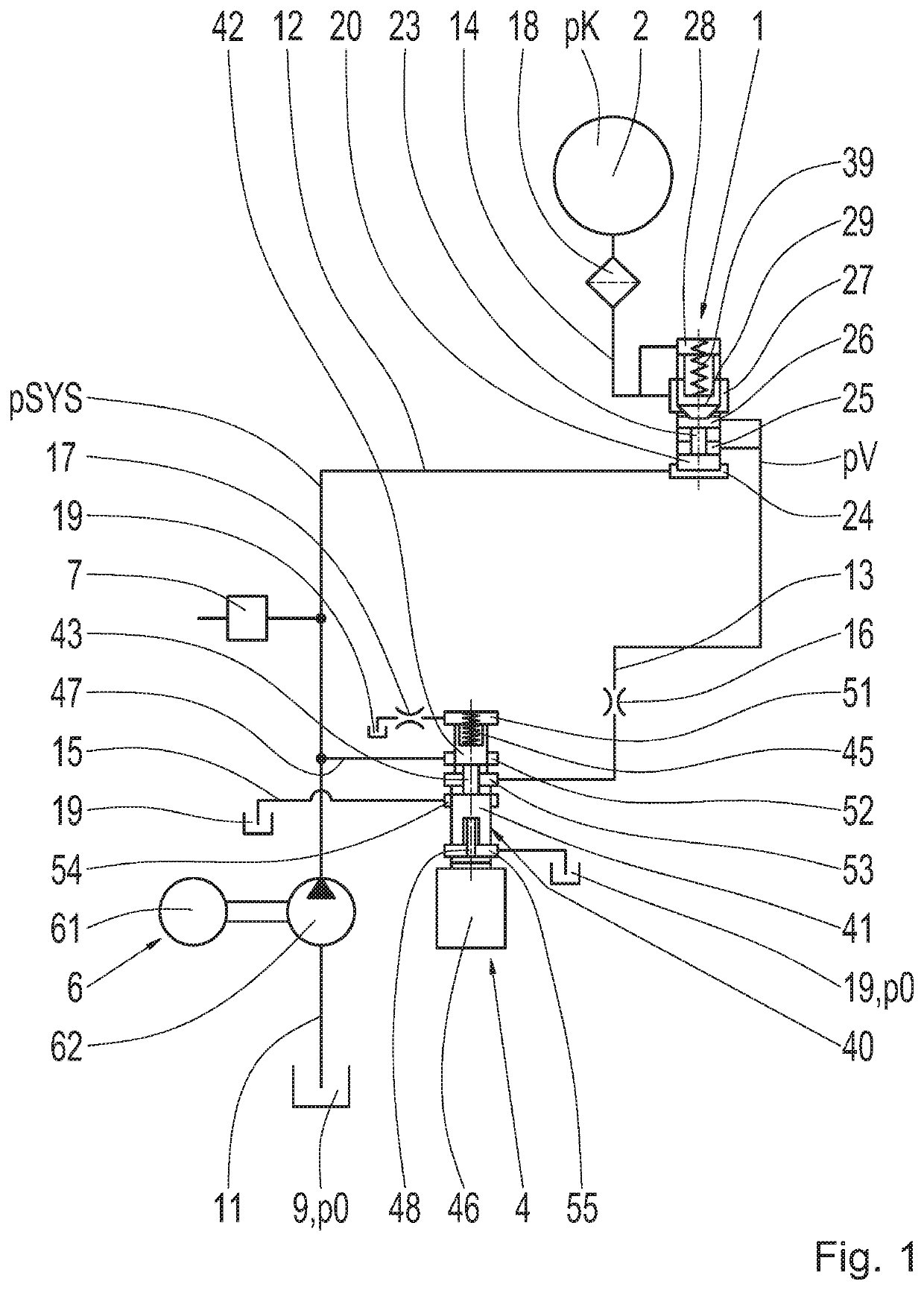

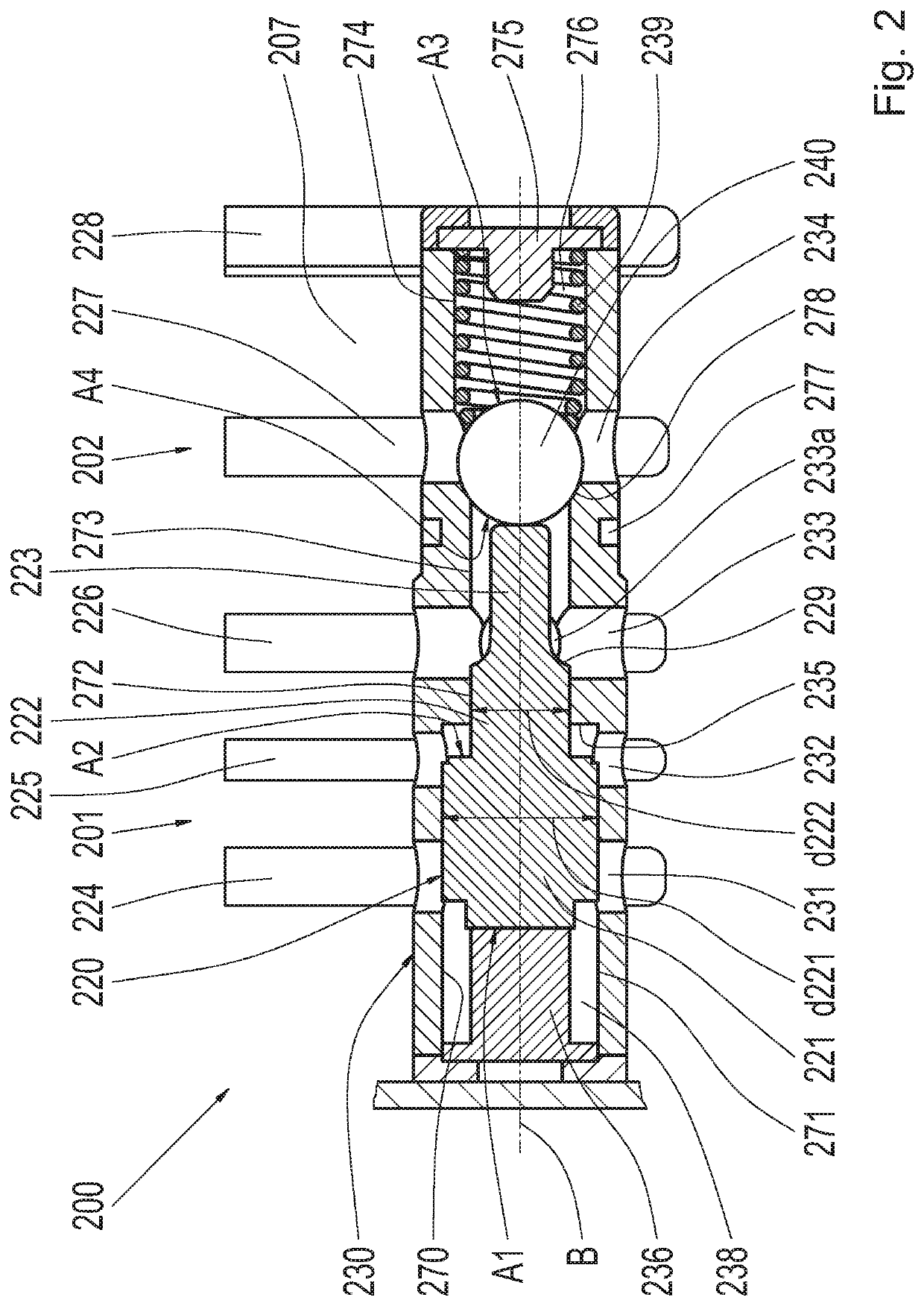

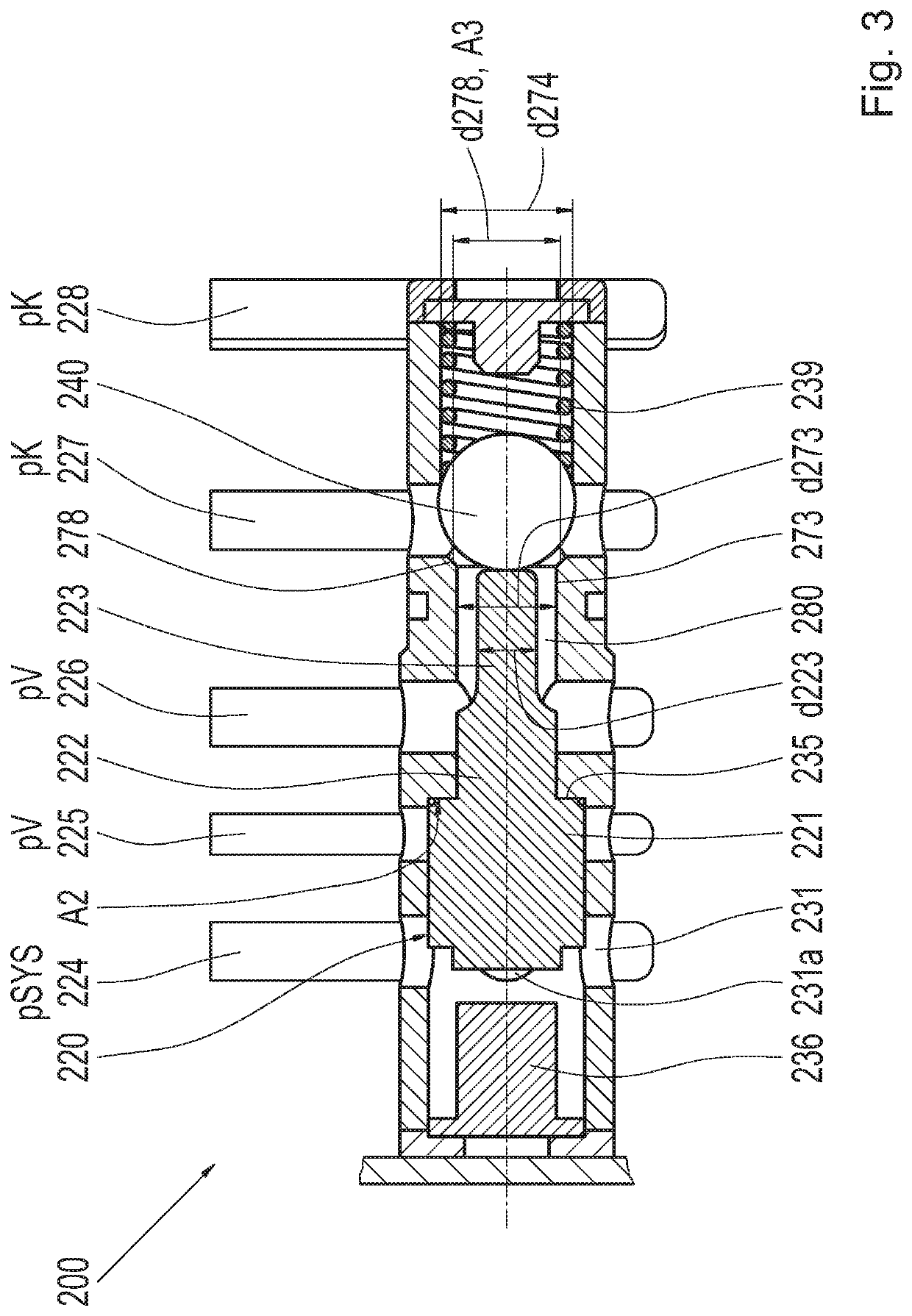

Pressure back-up valve

ActiveUS11105416B2Improve efficiencyPower loss ariseServomotor componentsLeversEngineeringMechanical engineering

A pressure back-up valve (300) includes a release piston (320) movable between first and second stop positions and a closing body (340) movable to a closing position in which this separates first and second connection pressure chambers (327, 326) when the release piston (320) is in a first stop position. The release piston (320) moves the closing body (340), in the second stop position, into an opening position. The release piston (320) is pressurizable on a first pressure surface (A1) from a first side via a third connection pressure chamber (324) and on a second pressure surface (A2) from a second side via a second connection pressure chamber (326). The closing body (340) is pressurized, in the closing position, from a first side via the second connection pressure chamber (326) on a first pressure surface (A4) and from a second side via the first connection pressure chamber (327) on a second pressure surface (A3) of the closing body (34).

Owner:ZF FRIEDRICHSHAFEN AG

Flap support mechanism—C bar

ActiveUS11034432B2Enhanced increasing camberAircraft stabilisationLeversBall screw driveUniversal joint

A trailing edge flap actuation mechanism has a flap drive link with a first end pivotally coupled to a fore flap structure of a flap and a second end pivotally coupled to an underwing support structure. An aft tension link has a leading end pivotally coupled proximate an aft end of the underwing support structure and a trailing end coupled to a mid-section structure of the flap. An actuator, when actuated, rotates the flap drive link about a first pivot axle to move the flap between a retracted position and a deployed lowered position. The actuator, including a ball-screw drive shaft having a universal joint, is positioned in a cove above the underwing support structure whereby the extent that the underwing support structure protrudes below the wing is reduced.

Owner:THE BOEING CO

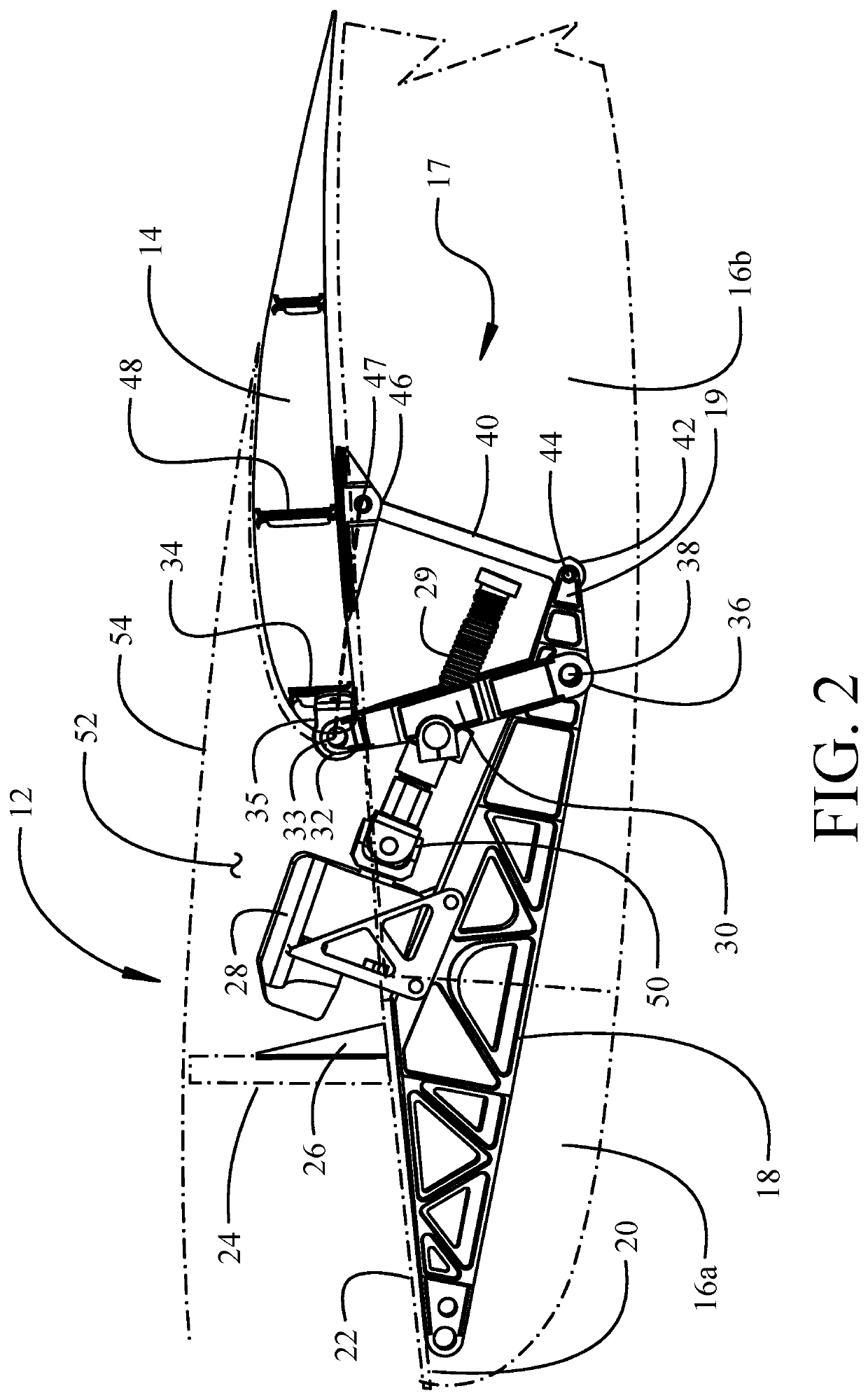

General lever system with adjustable gravity center

PendingCN114838106AReasonable structural designReduce manufacturing costLeversEngineeringGravity center

The general lever system with the adjustable gravity center comprises a lever, the center of the lever in the axial length direction is provided with a resultant force loading area, and the lever is sequentially provided with a component force loading area and a gravity center adjusting area from the center to the two sides in the axial length direction; the resultant force loading area comprises a plurality of resultant force bolt groups which are distributed at intervals along the axial length direction of the lever; the component force loading area comprises a component force bolt group which is adjustably arranged along the axial length of the lever; the gravity center adjusting area comprises at least two gravity center adjusting assemblies which are arranged along the axial length of the lever in an adjustable mode. The lever ratio can be adjusted, and when the resultant force acting point of the lever is located in the middle bolt hole, balance weight and gravity center adjustment do not need to be considered; when the resultant force acting point of the lever is not in the center, the gravity center can be adjusted to the force center through the counterweight system; the gravity center adjusting device can be matched with different balancing weights according to different positions, and meanwhile the gravity center can be adjusted more accurately by adjusting the positions of the balancing weights.

Owner:江苏集萃碳纤维及复合材料应用技术研究院有限公司

Parking lock pre-selection system

ActiveUS20180273002A1Easy constructionLess sensitivityBraking element arrangementsLeversEngineeringMechanical engineering

A parking lock pre-selection mechanism for a work machine is disclosed in which a pawl is engageable with teeth on a power train output shaft to lock it in place. An operator lever is used to preselect the parking lock position. The mechanism includes first and second pivotally interconnected links, urged by a spring to a maximum length set by a stop. The spring causes the pawl to be urged into place when the teeth and pawl are in proper alignment.

Owner:BLUE LEAF I P INC

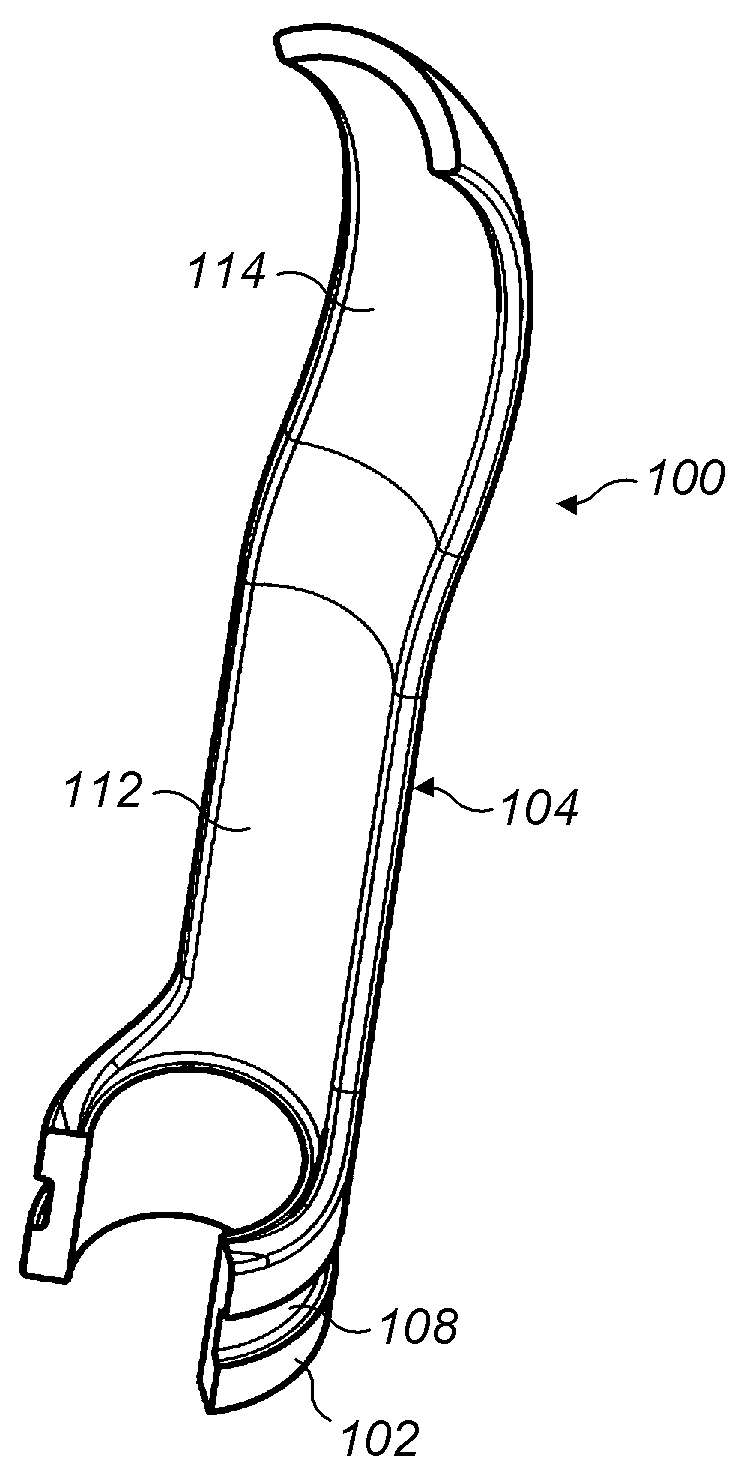

Brake rod

A brake rod (60) for a steering / braking mechanism (2) comprises a rod body (62) having a longitudinal axis (A), a rod end (64) at a first end of the rod body (62), the rod end (64) having a bore (68)therethrough having a bore axis (B) arranged generally perpendicular to the rod longitudinal axis (A), and a rod end shield (100) mounted to the rod (60) and extending in a longitudinal direction axially beyond the rod end (64).

Owner:拉季埃-菲雅克有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com