Thread rolling method and thread rolling machine

A technology of thread rolling machine and thread rolling board, which is applied in the direction of mechanical equipment, threaded products, and other household appliances, etc., which can solve the problems of low thread rolling efficiency, high manufacturing cost, and increased processing cost of large-diameter bolts, etc., to achieve shrinkage Overall structure, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment is a method of thread rolling, which is as follows: using the principle of leverage to increase the running distance of the linear reciprocating power movement, and driving the thread rolling plate to reciprocate the thread rolling movement.

[0024] The basic idea of this embodiment is: the shorter moving distance of the linear power source is amplified to a longer moving distance through the lever, that is, the length of the resistance arm of the lever is greater than the length of the power arm of the lever.

[0025] The effect of this embodiment is: the slow linear power source, such as: after the movement of the hydraulic cylinder is amplified by the lever, it can form a thread rolling action with a long movement distance and fast movement. This form of thread rolling motion is very useful for thread rolling of large bolts.

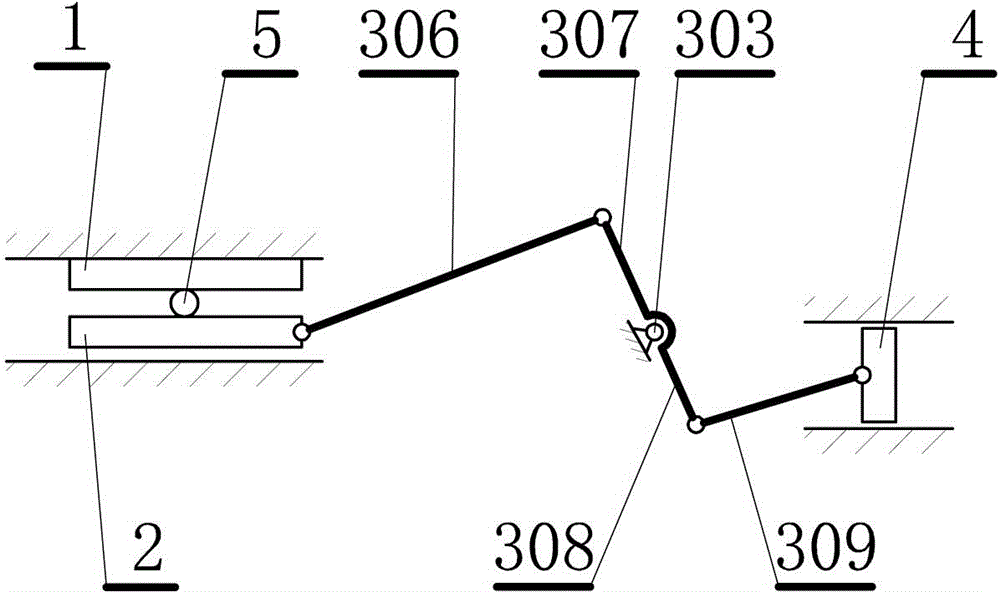

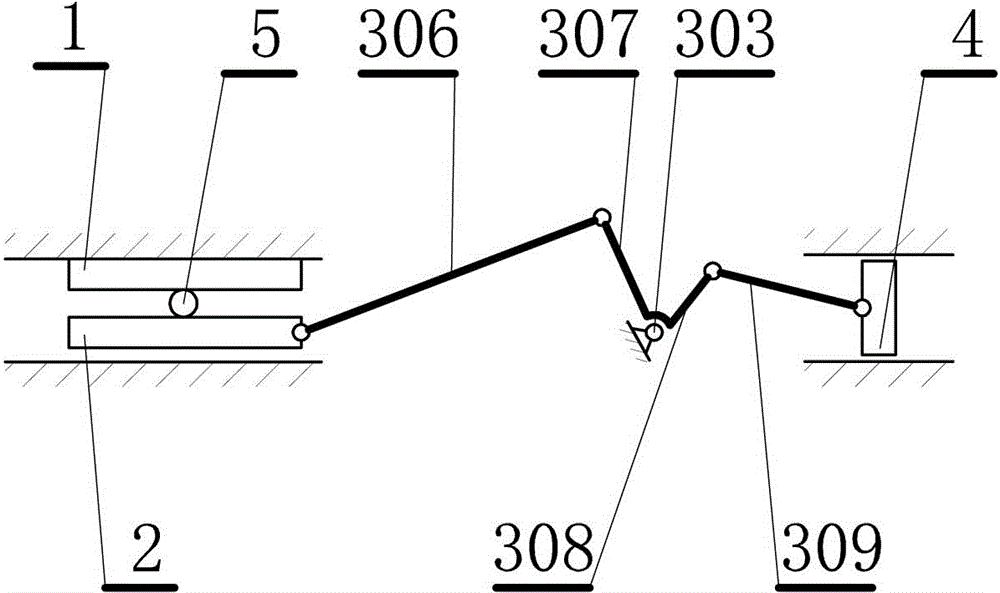

[0026] The lever scaling mechanism may be a crank rocker mechanism, or a scaling mechanism formed by meshing large and smal...

Embodiment 2

[0029] This embodiment is an improvement of the first embodiment, and is a refinement of the first embodiment regarding linear reciprocating power motion. The linear reciprocating power movement described in this embodiment is one of hydraulic, pneumatic or electric linear drive.

[0030] Linear reciprocating power motion can have many forms, the key is to provide power. In practice, there are not many ways to provide linear power, such as electricity, gas and hydraulic. These three linear reciprocating motions with power have their own characteristics. Generally speaking, hydraulic pressure is more suitable for the power of thread rolling.

Embodiment 3

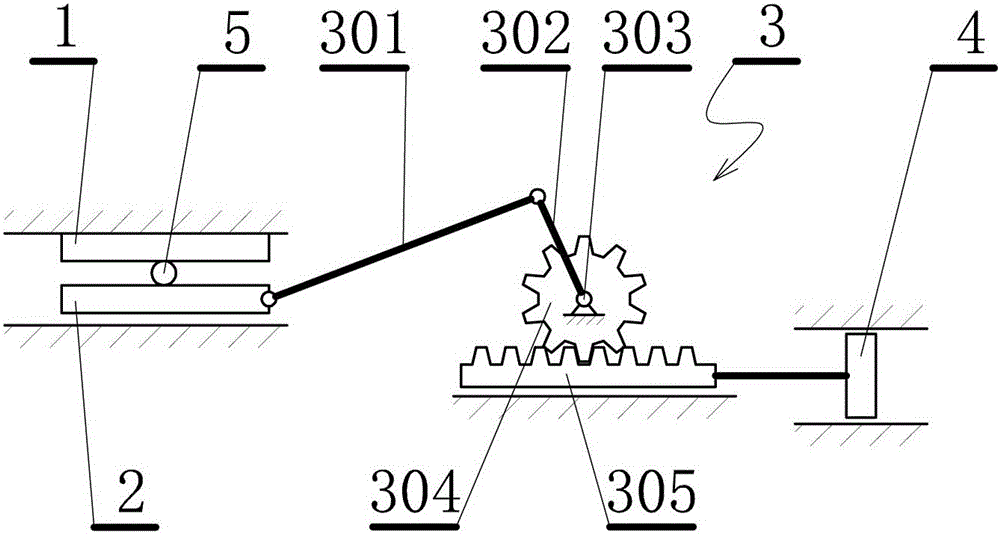

[0032] This embodiment is a thread rolling machine, comprising: a fixed thread rolling board 1 and a sliding thread rolling board 2 installed on the bed, the sliding thread rolling board is connected with a motion zoom mechanism 3, and the motion zoom mechanism is connected with Linear reciprocating power mechanism 4 connections, such as figure 1 shown.

[0033] The fixed thread rubbing board and the sliding thread rubbing board that clamp the workpiece 5 and perform rubbing processing need to have linear motions parallel to each other to realize rubbing processing. In this embodiment, the linear driving force of the linear reciprocating power mechanism is amplified by a lever mechanism to produce a thread-rolling motion with fast movement and a relatively large movement distance.

[0034] The effect of using the motion scaling mechanism is to amplify the short-distance motion of the linear reciprocating power mechanism into a longer-distance motion while increasing the motio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com