Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about "Lappet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

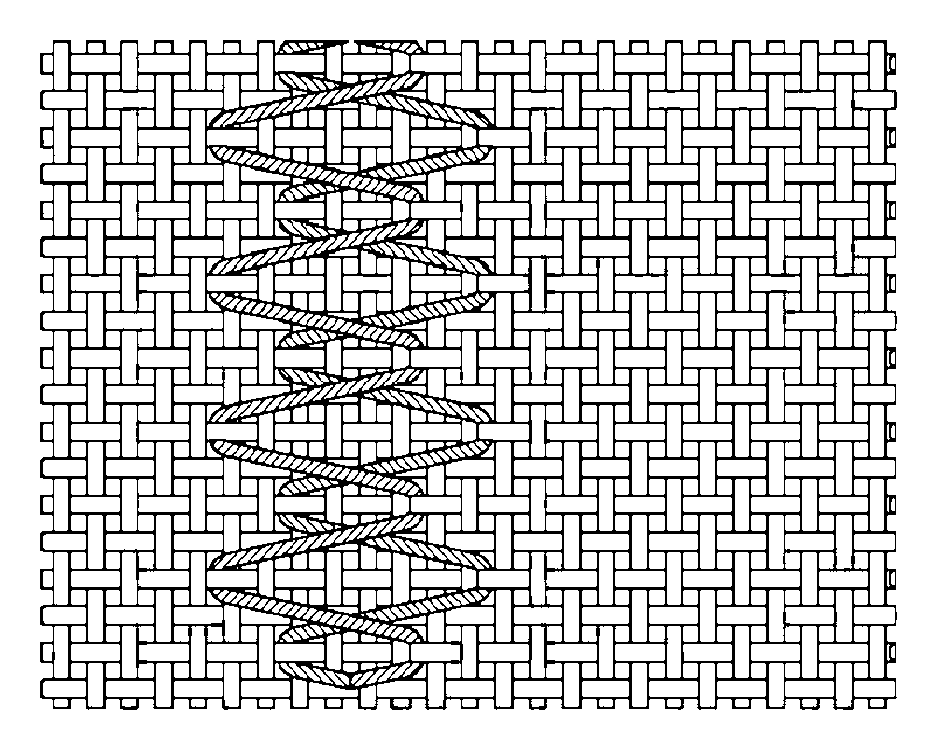

Silk spinning machine for weaving brocade and weave method thereof

InactiveCN1560343ASolve the problem of multiple inter-filament pointsNot easy to damageLappetEngineering

The invention discloses a silk weaving machine for weaving brocade patterns and its weaving method, and there is a press-obstructing mechanism in the brocade wooden machine arranged in the jacquard orifice part of ordinary silk weaving machine, the two ends of the top frame of an obstructor in the mechanism are hung on a fixed spring, and a conveyer belt connected with the two ends of the bottom frame of the obstructor is connected with vertical hooks in the heald lifting mechanism through supporting and turning wheels. It adopts a double-section single-harness mounting technique and a press-obstructing technique in the silk weaving machine to make gained plate, installs the warps, passing through ocular shield, hooks, connects, installs the press-obstructing mechanism, threads the warps, installs shutters, and starts the machine to weave. It adopts the press-obstructing technique and presses down one of the fours warps in the part with patterns, which are flat and beautiful and the pattern silks are uneasy to break, thus implementing the weaving of brocaded products in ordinary silk weaving machine.

Owner:NANJING YUNJIN RES INST

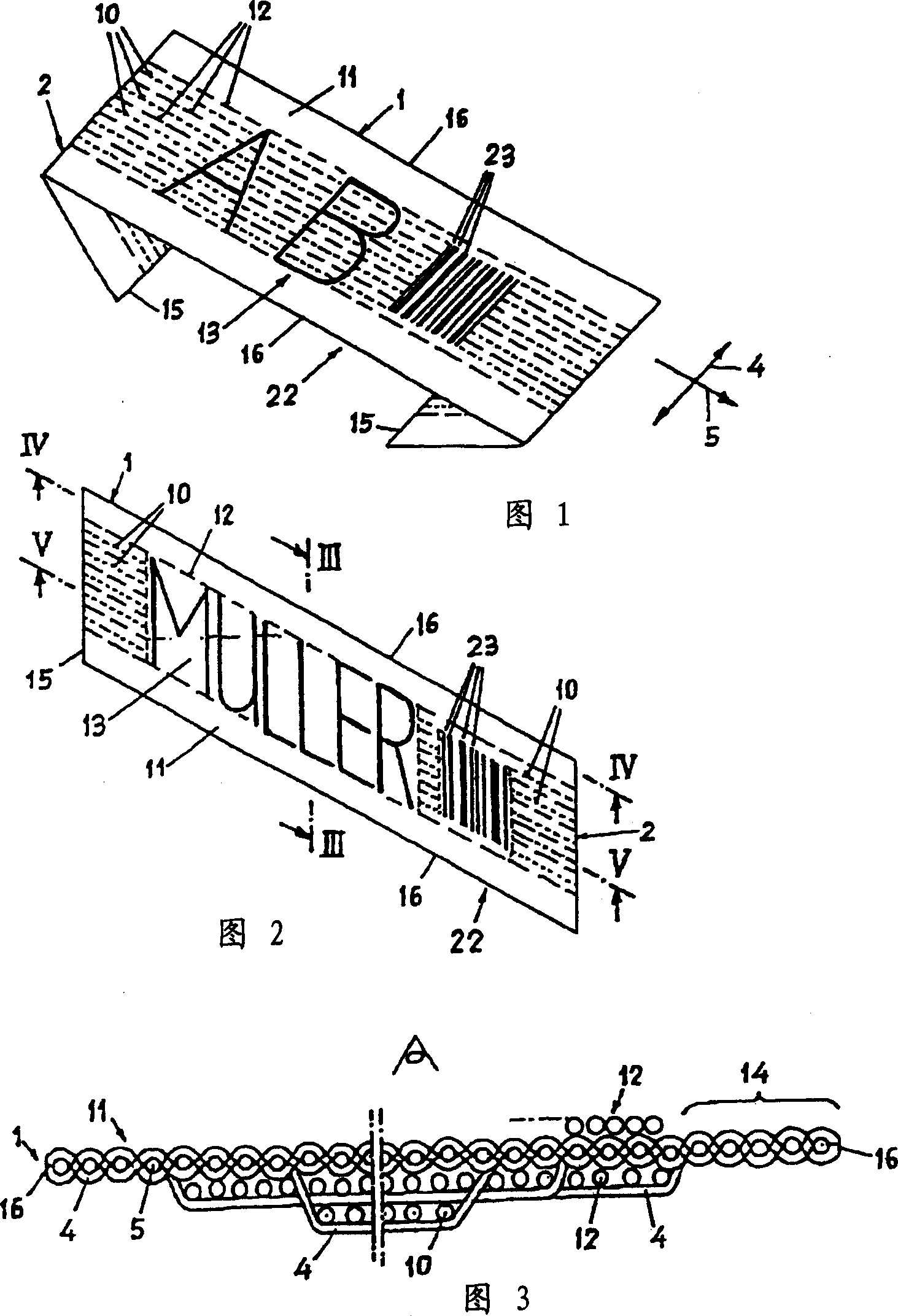

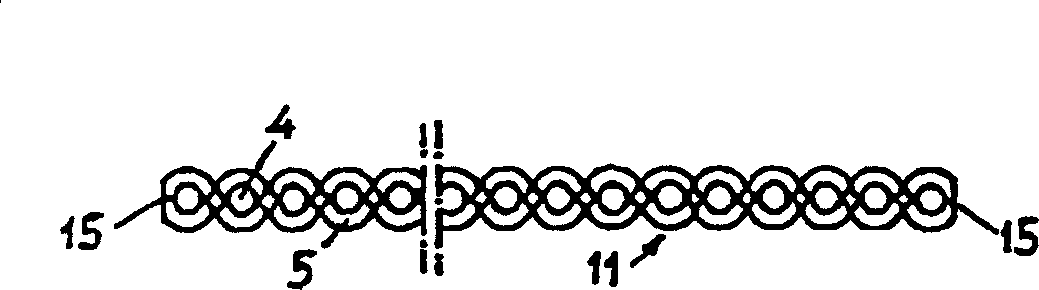

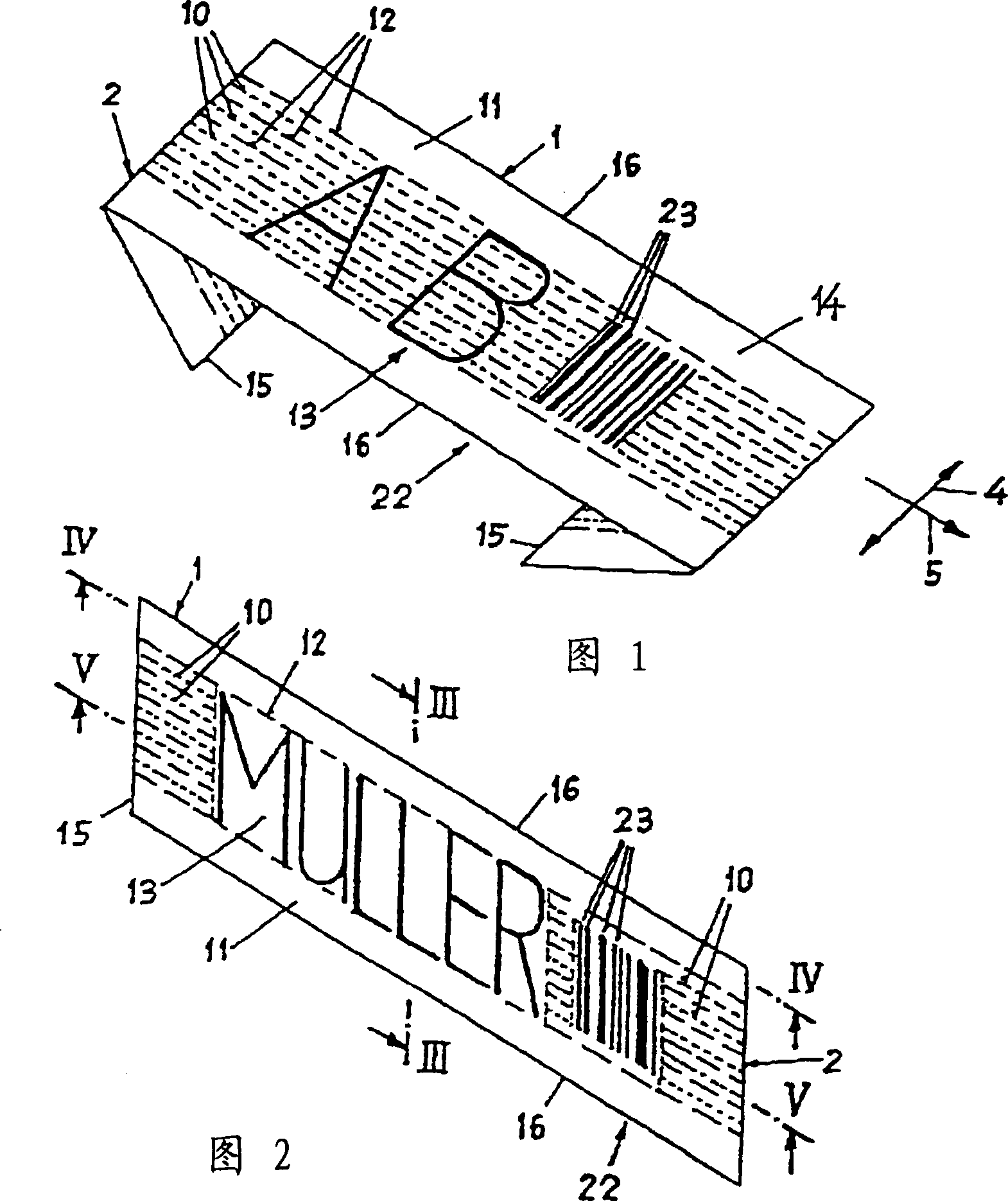

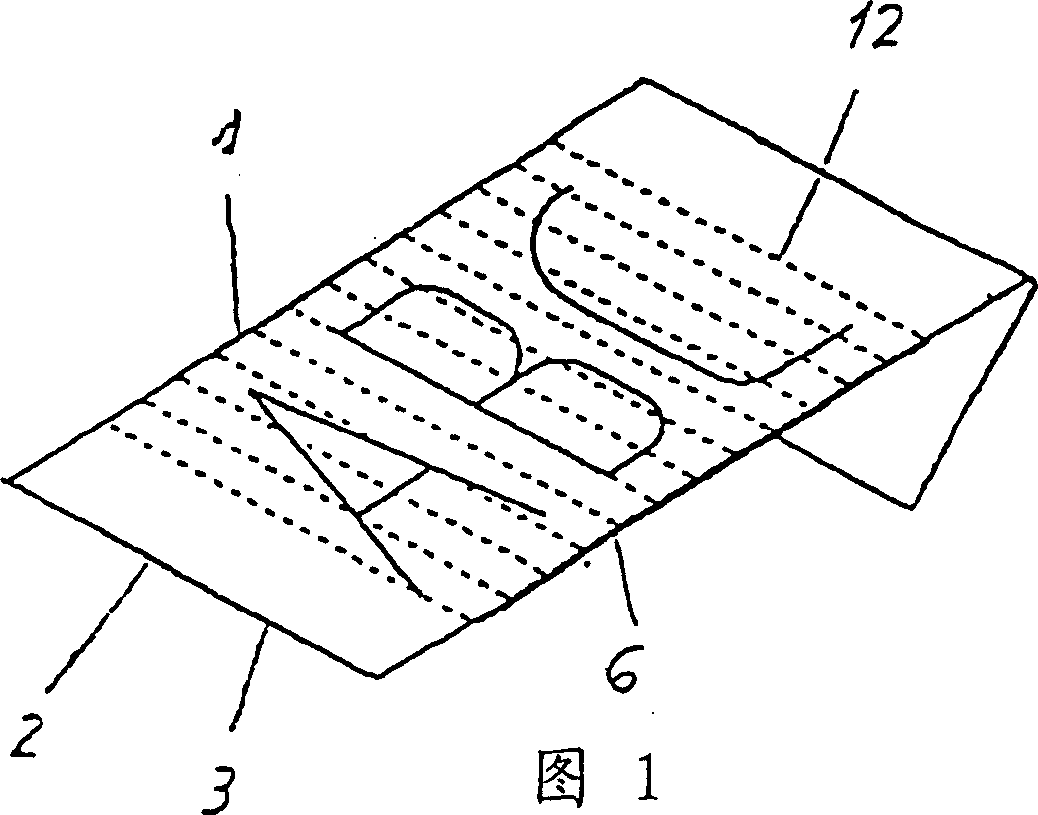

Method for producing in visible barcode and barcode thus produced

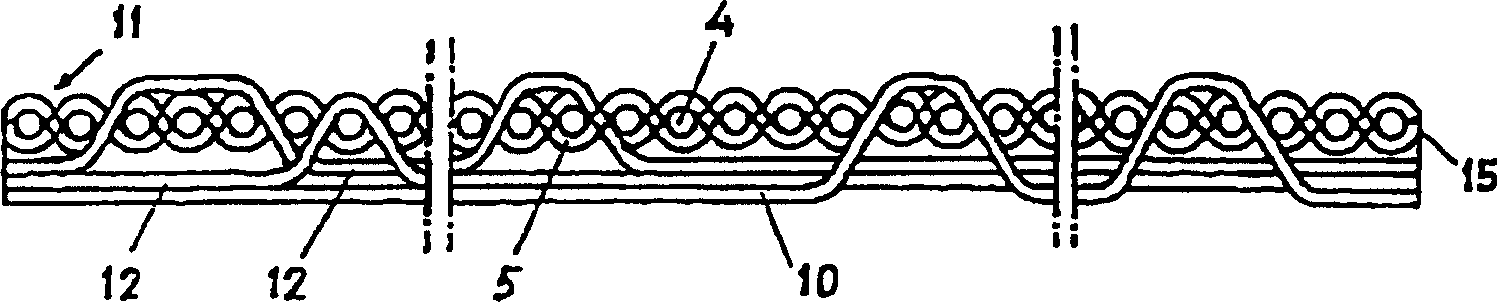

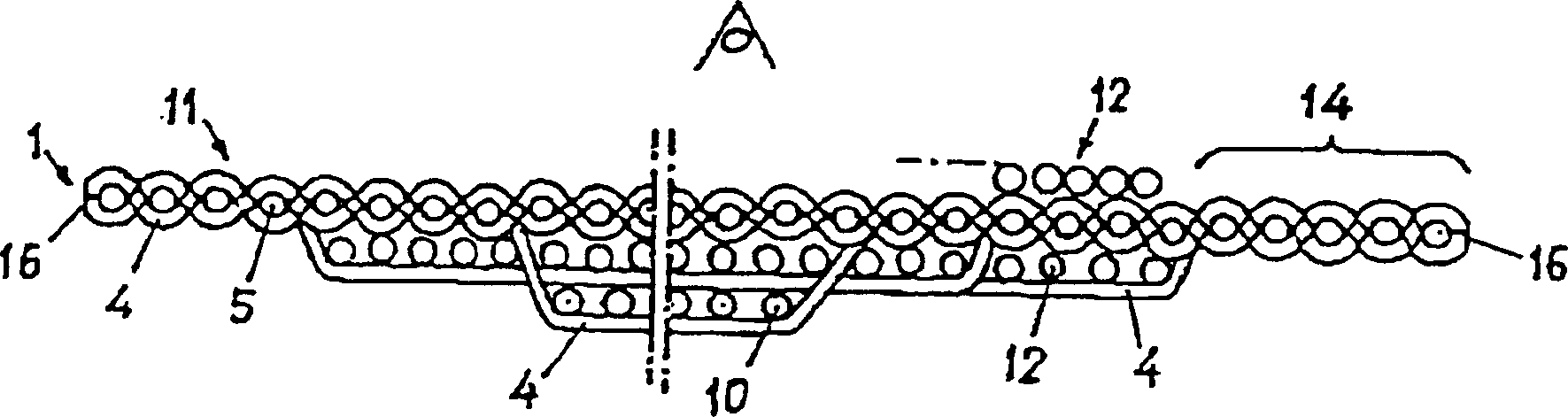

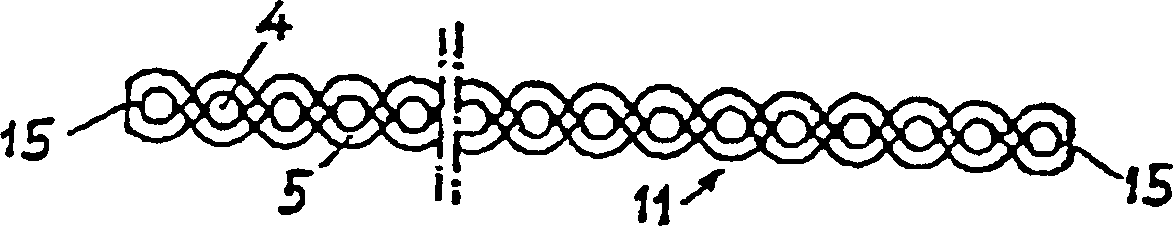

The label has two non-folded longitudinal sides (1) and two foldable narrow sides (2) and consists of a backing fabric (11) with warp threads (4) and basic picks (5), in addition to embroidery picks (12) made of a fusible thread material forming the pattern. The embroidery picks (12) forming the pattern extend parallel and at a distance to the unfolded longitudinal sides (1) of the backing fabric (11). The non-folded longitudinal side (1) is an edge of a cut formed in the backing fabric outside the area (13) of the pattern. The label has the advantage that the edges of the cuts on the longitudinal sides are soft and skin friendly thereby substantially improving wearing comfort. Due to the fact that the edge of the cuts produced by the basic picks have practically no brows and the picks extend parallel in relation to the longitudinal side of the labels, and even appearance is achieved on the entire length of the label since the picks cover evenly the back part.

Owner:TEXTILMA AG

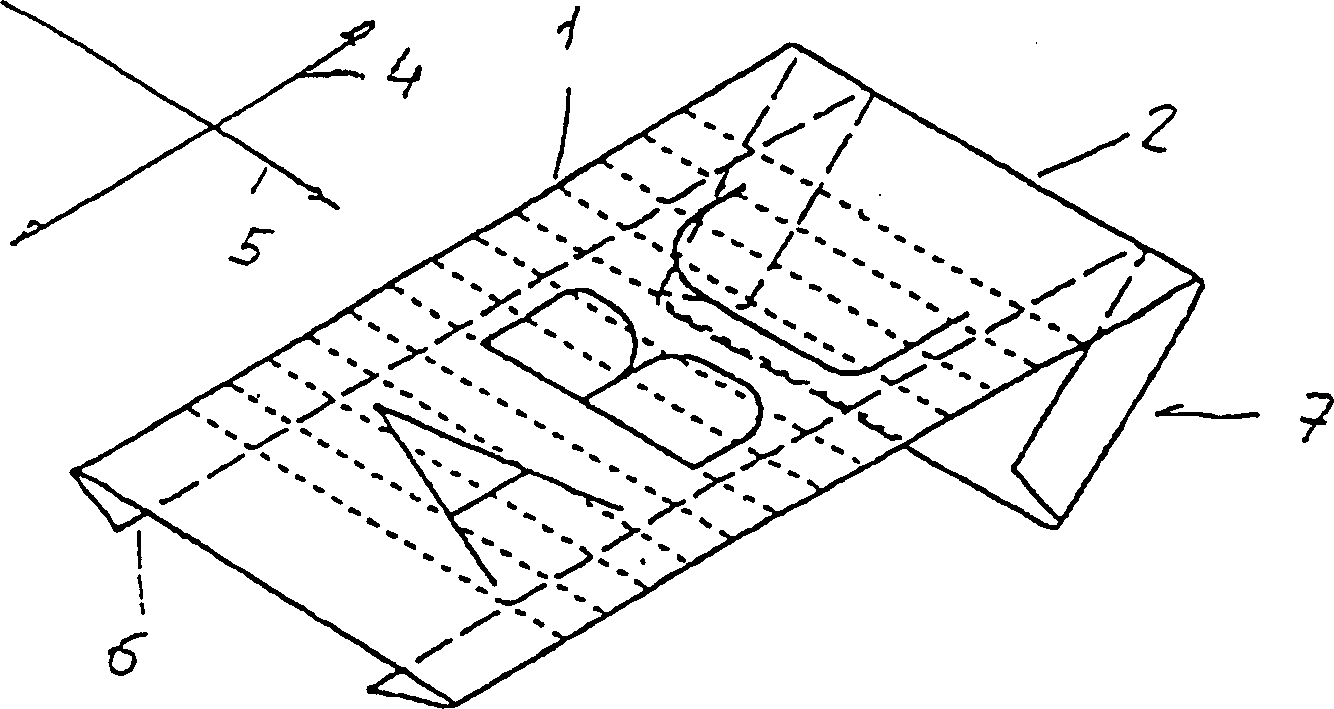

Ribbon Needle Loom for Manufacturing a Strip, in Particular a Label Strip, Having a Woven-In Conductive Thread, in Particular Antenna Thread

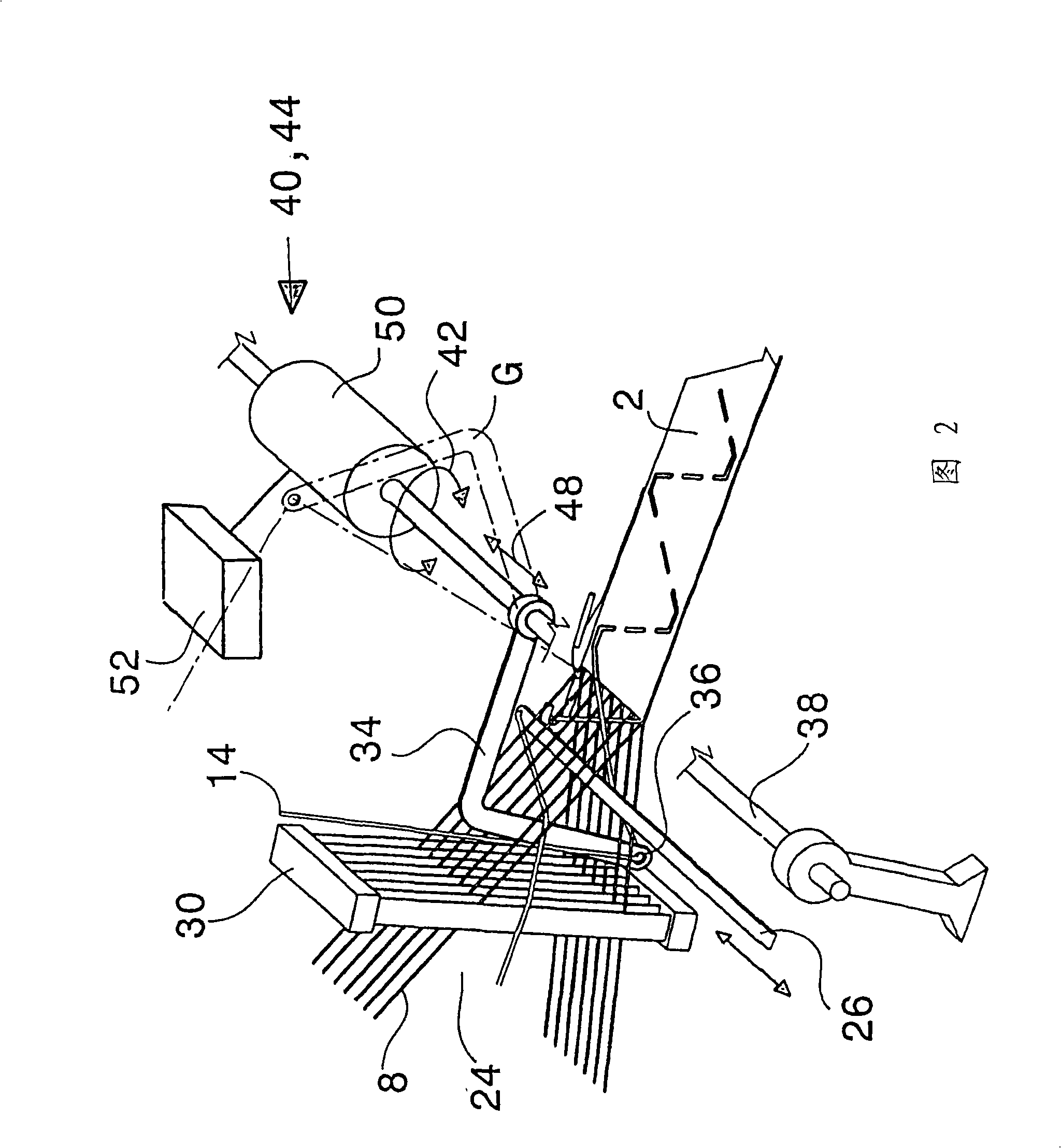

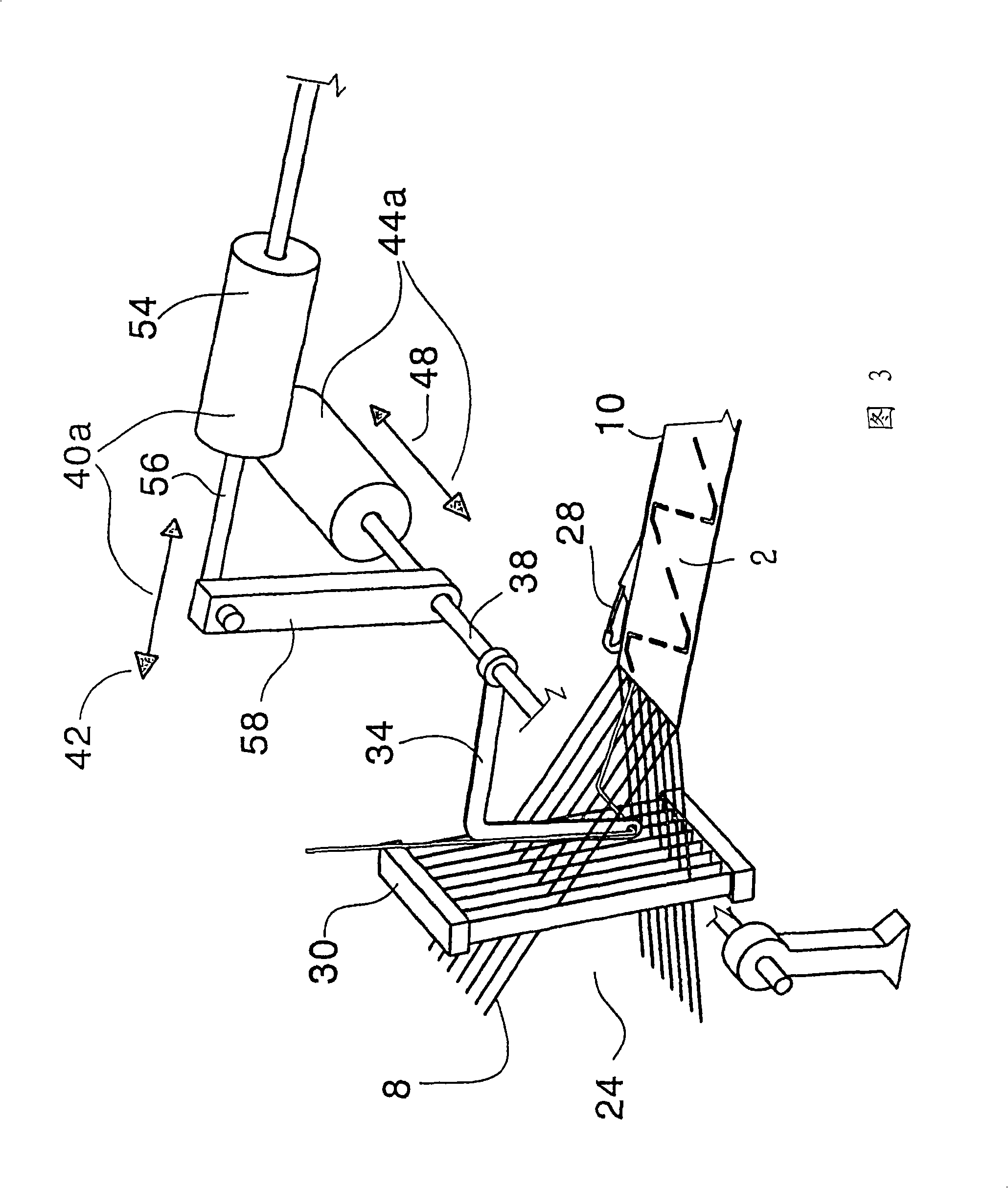

In order to make it possible to weave in a conductive thread, in particular an antenna thread, in a very wide variety of ways in a ribbon needle loom for manufacturing a strip, in particular a label strip, having a shedding apparatus for forming a shed (24) from warp threads (8), a weft insertion needle (26) for inserting weft thread loops, a reed (30) and having a feed apparatus (34) for a thread which has a blade (34) which dips into the shed (24) between warp threads (8) as far as under the insertion path of the weft insertion needle (26), it is proposed that the blade is arranged on a shaft (38) which is oriented transversely with respect to the warp direction. The shaft is connected to a first drive apparatus (40a) for performing a pivoting movement of the shaft. As a result of the pivoting, the blade (34) dips into and out of the shed (24). Furthermore, the shaft is connected to a second drive apparatus (44a) for movement in the axial direction. As a result, the blade (34) can be moved over the width of the strip (2).

Owner:TEXTILMA AG

Weft insertion belt knitting machine used for producing belt, especially label belt knitted with conductive fine yarn specifically antenna fine yarn

Owner:TEXTILMA AG

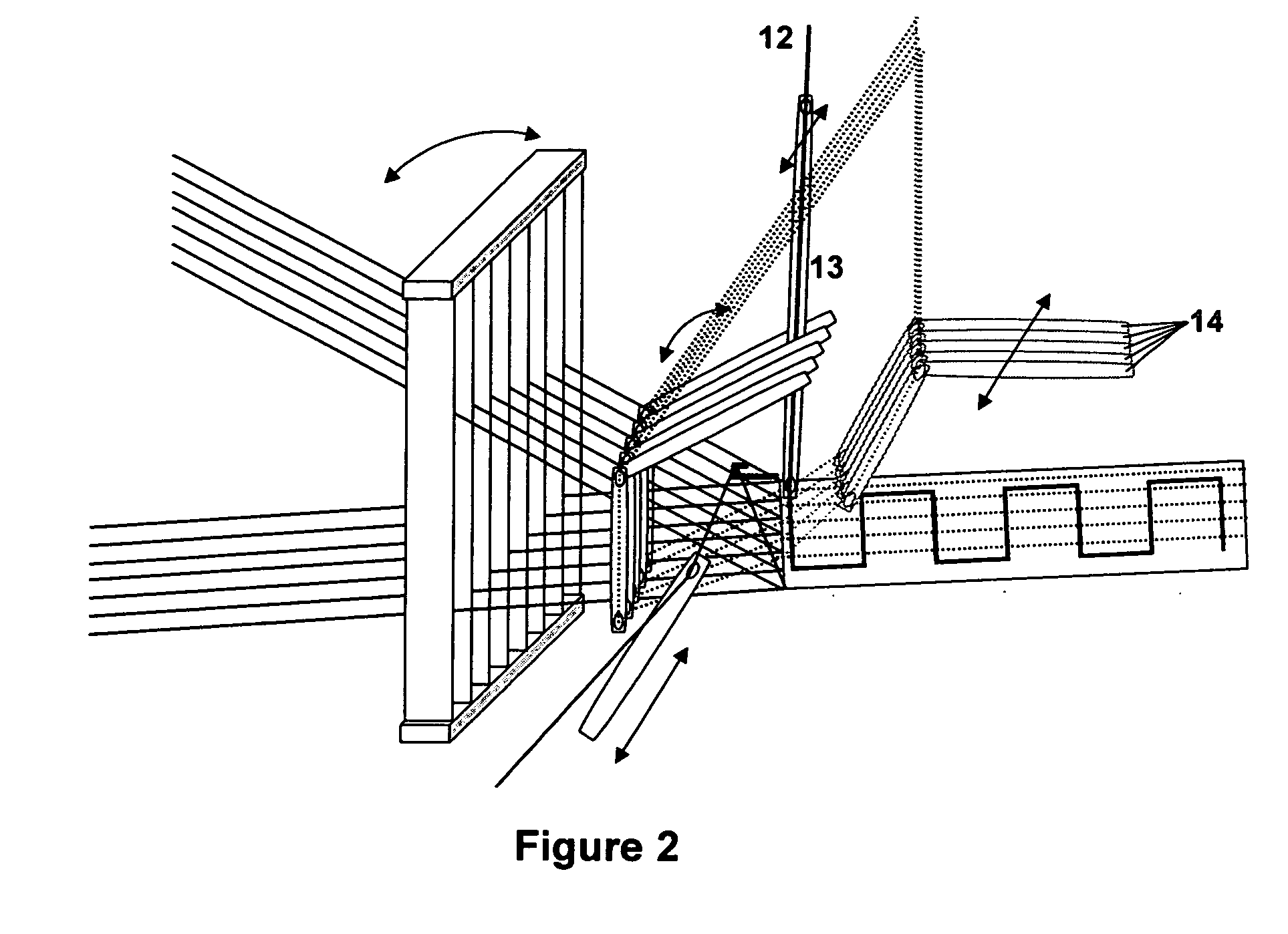

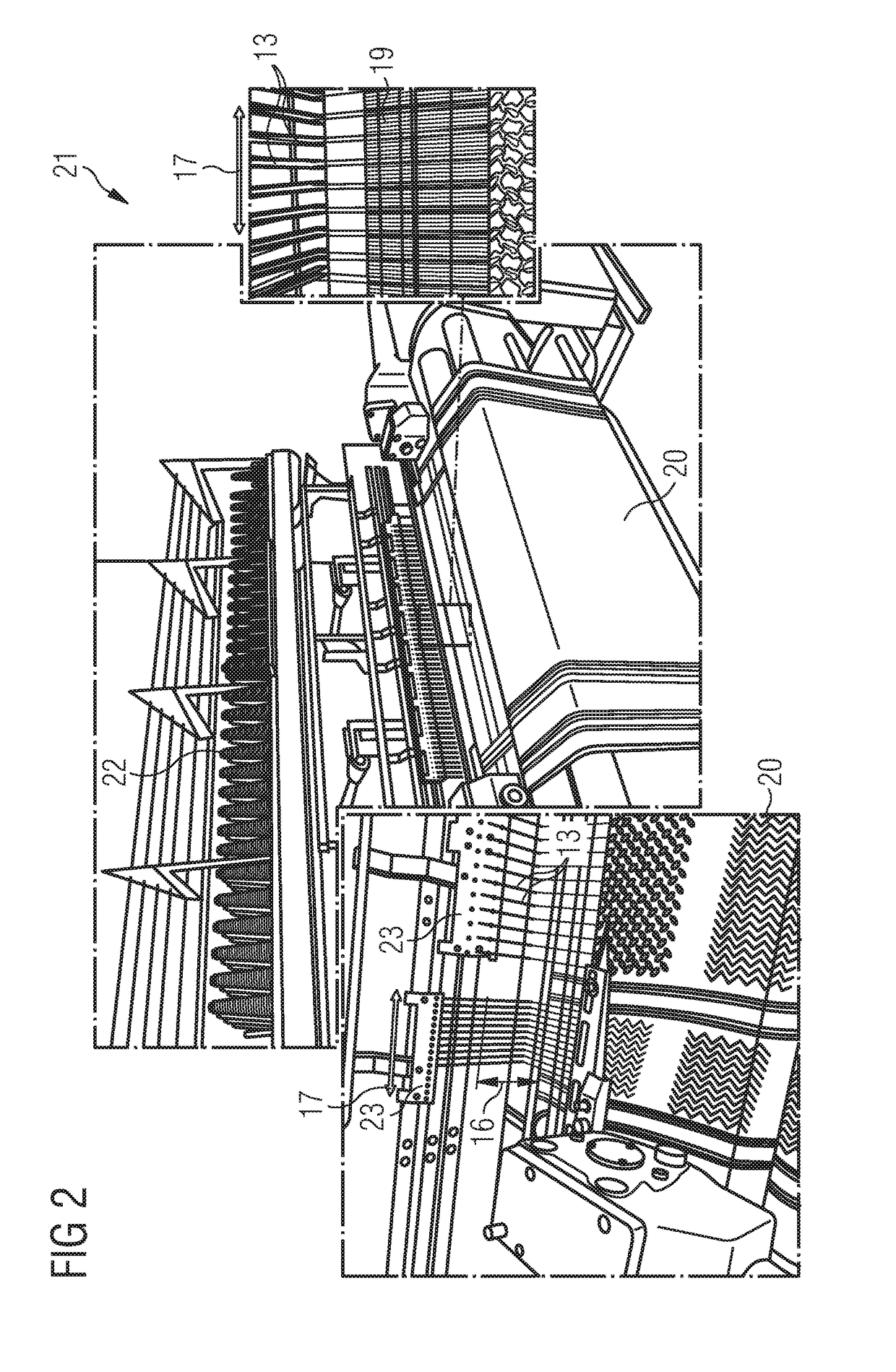

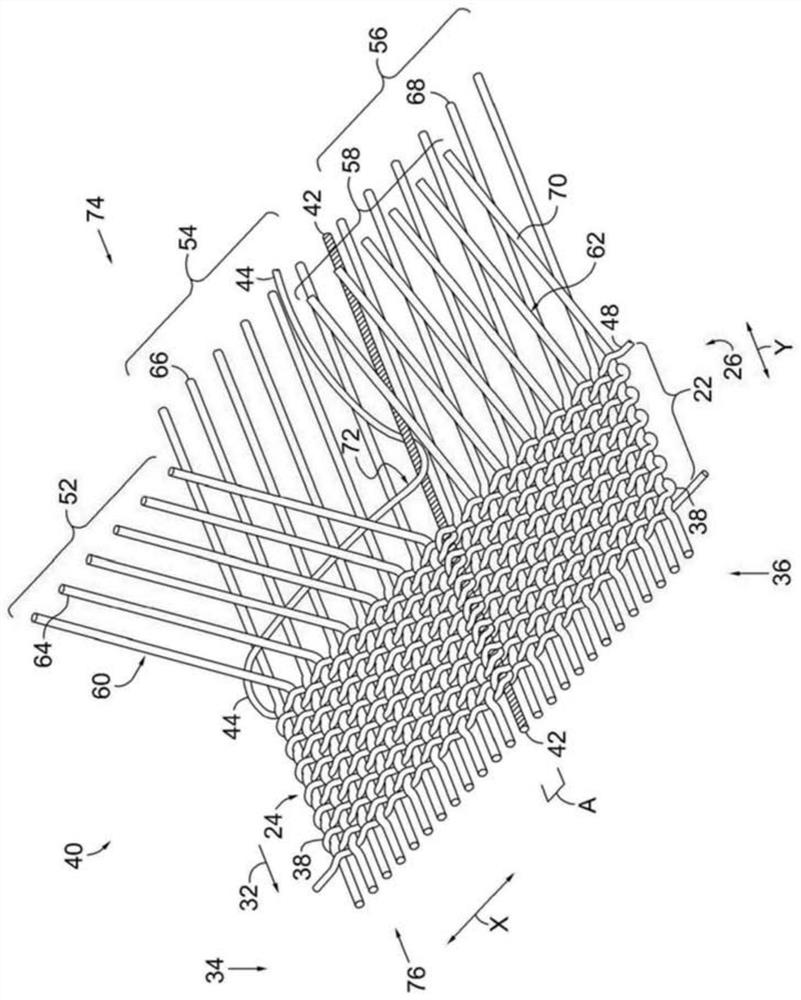

Loom for producing woven goods or material with an incorporated cover thread

InactiveCN103097597ADefects that change the structureChange defectsSmallware loomsLappetYarnInsertion device

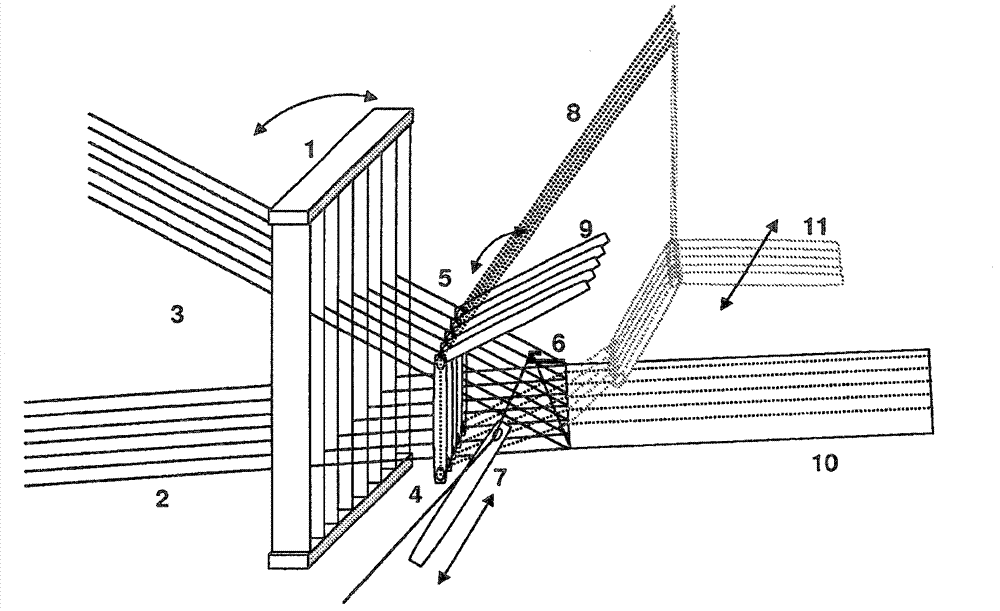

In order to improve a loom for producing woven goods or material (10) with an incorporated cover thread (12), it is proposed to provide a laying device at least one cover thread (12) and also a warp-laying device (9) with warp-laying elements (14) for laying further warp threads (8). The warp- laying device (9) is designed such that it can make the further warp threads (8) penetrate from a starting position through the upper shed (5) to the lower shed (4), or through the lower shed to the upper shed, and therefore the weft-insertion device (7) crosses the further warp threads (8). The laying device has at least one cover-thread guide (13) which, in the starting position of the warp-laying device (9), can be displaced transversely to the warp threads (2) by way of a transverse-movement means.

Owner:TEXTILMA AG

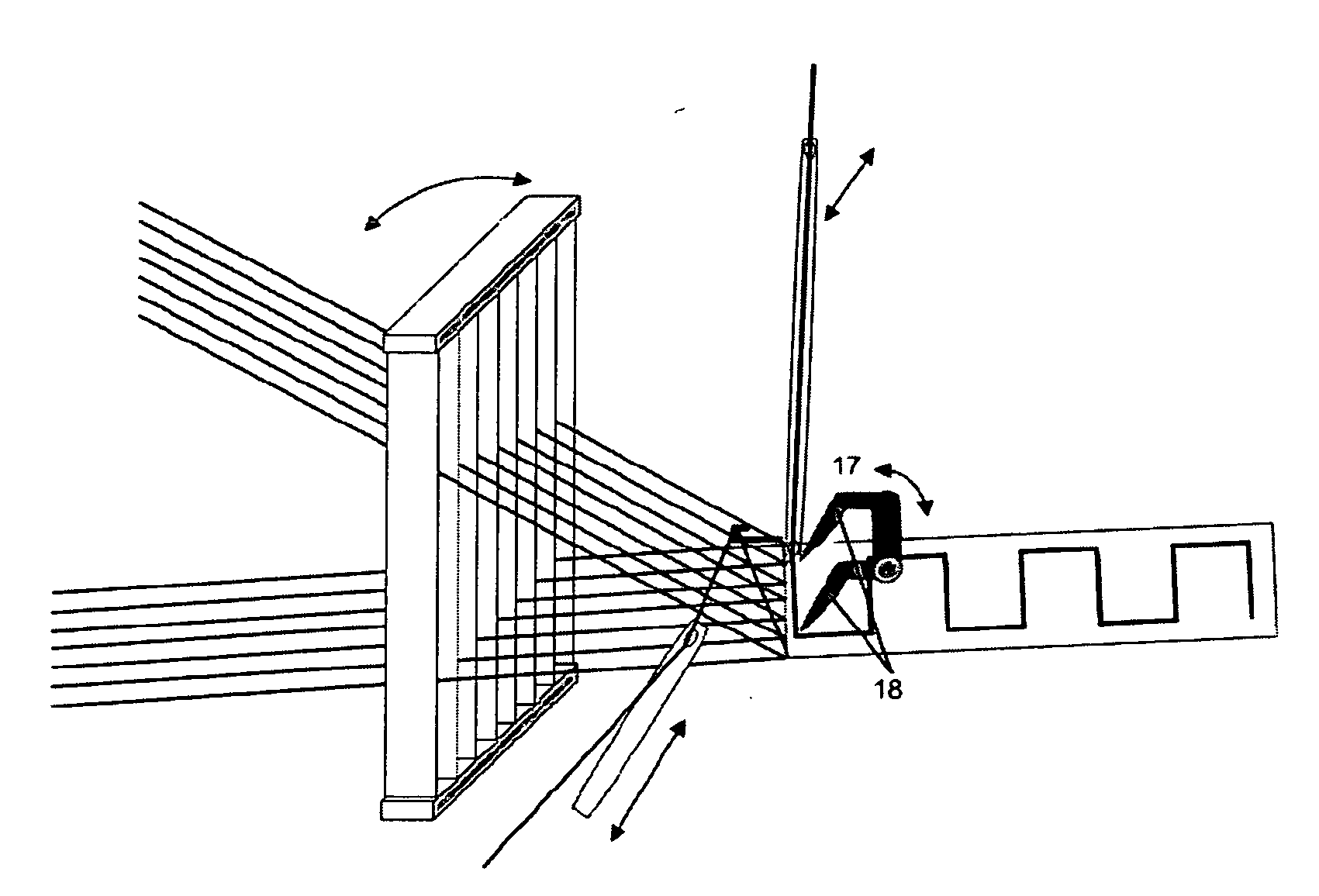

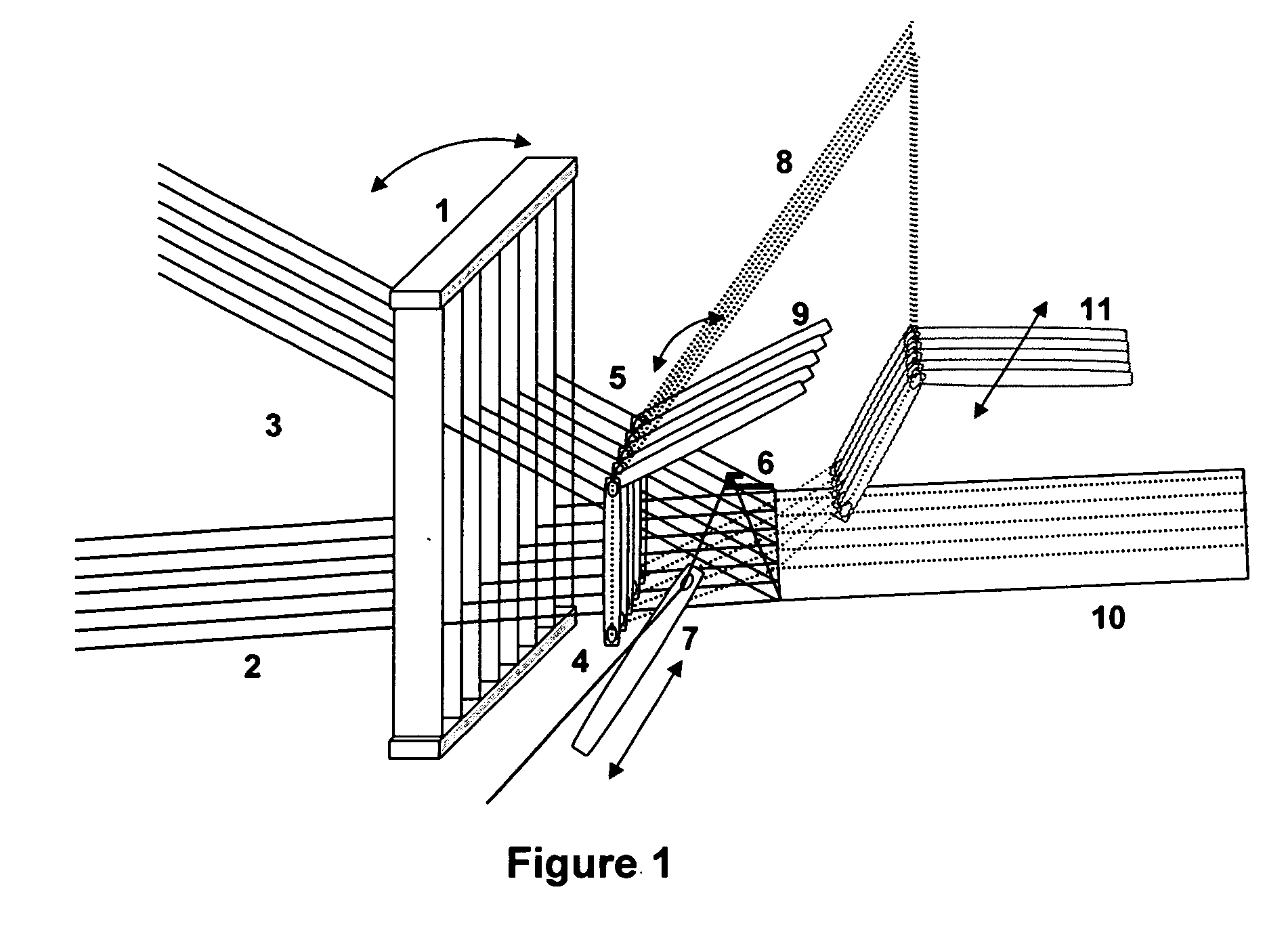

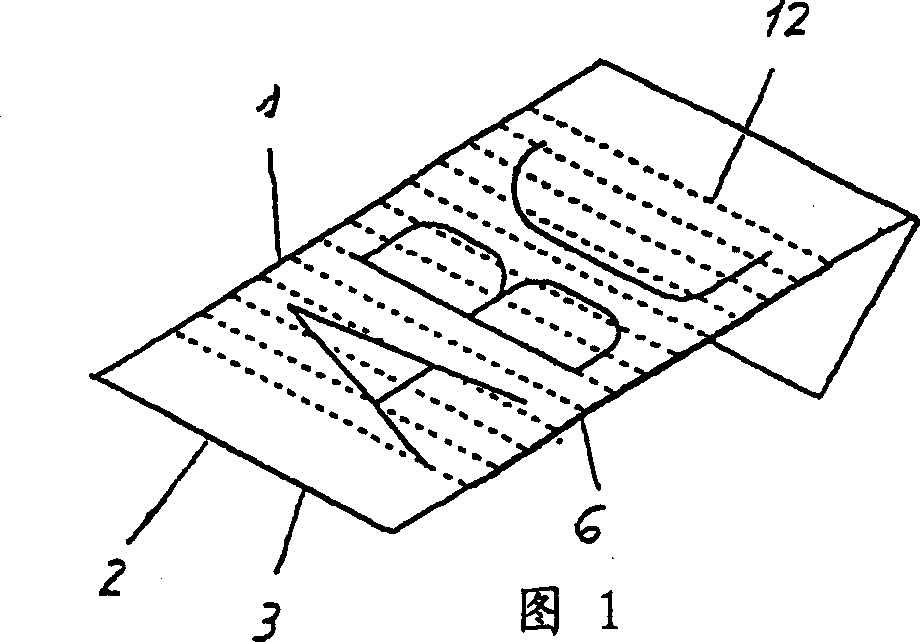

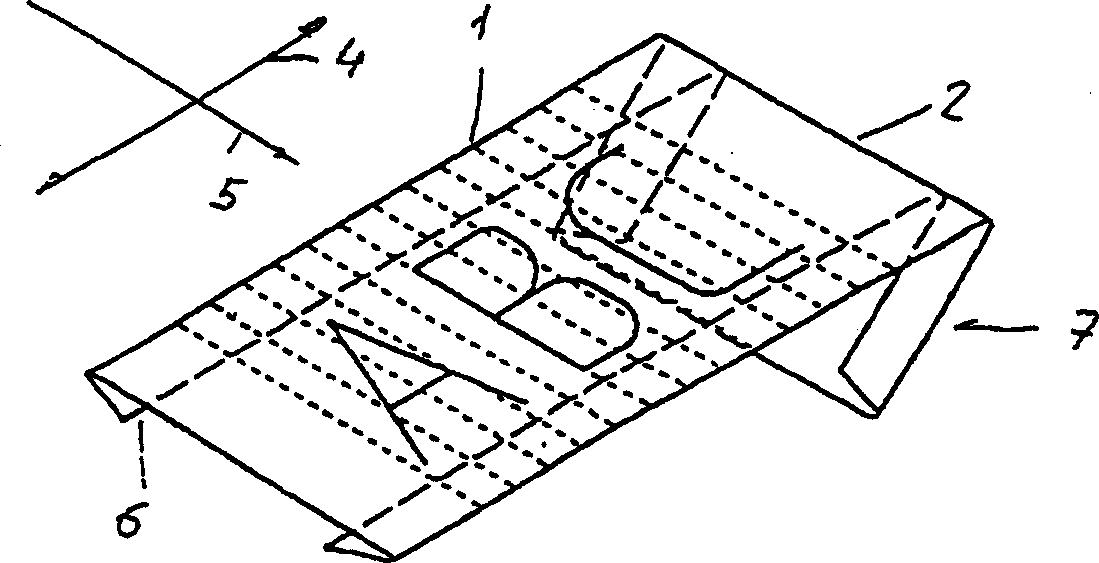

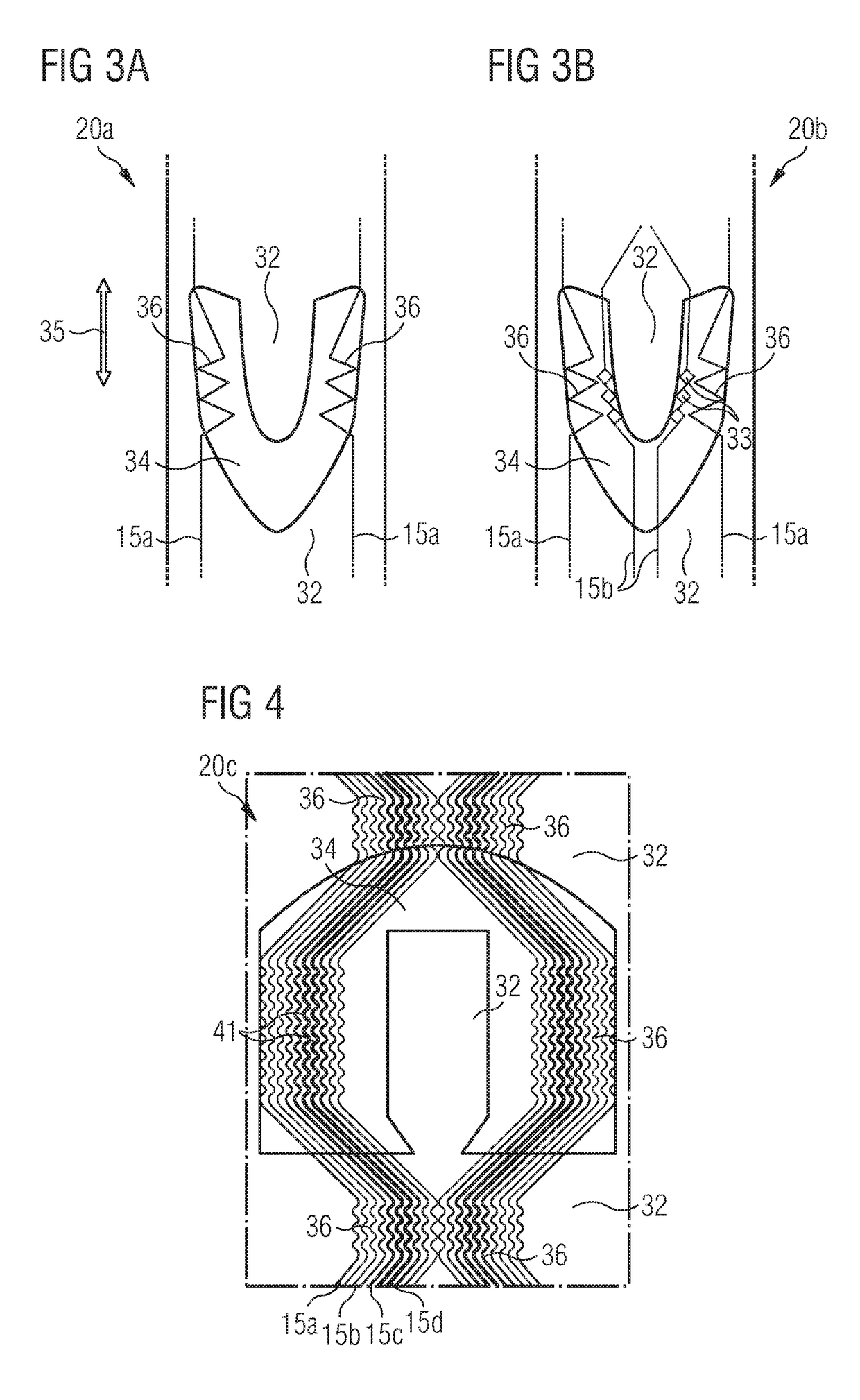

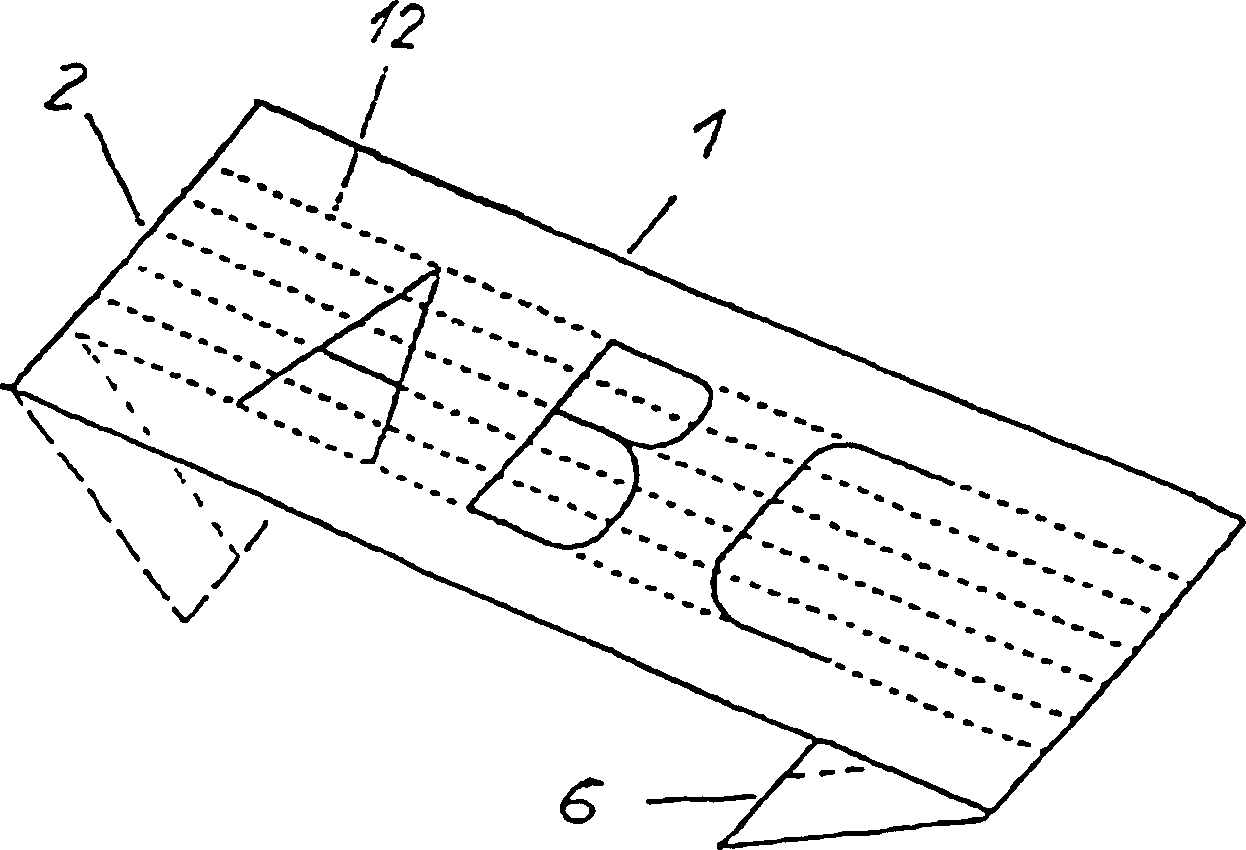

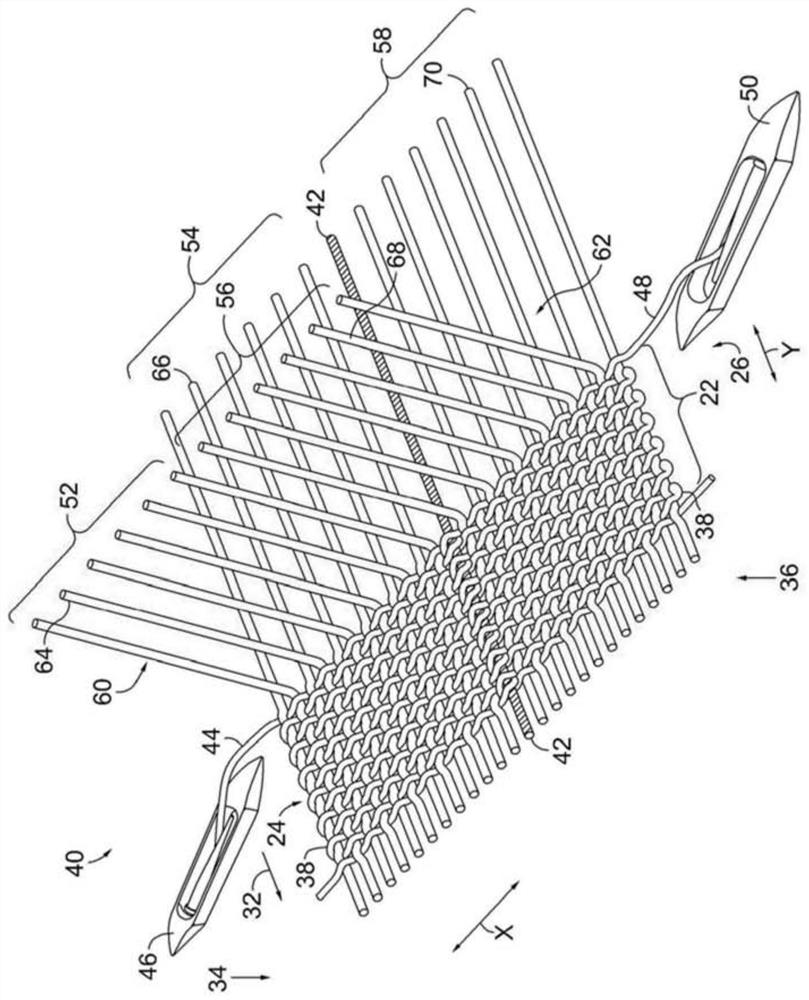

Method and loom for producing woven fabrics having added weft effects

InactiveCN102844482AAvoid crossingImprove weaving efficiencyLappetLeno shedding mechanismMechanical engineeringNeedle Shape

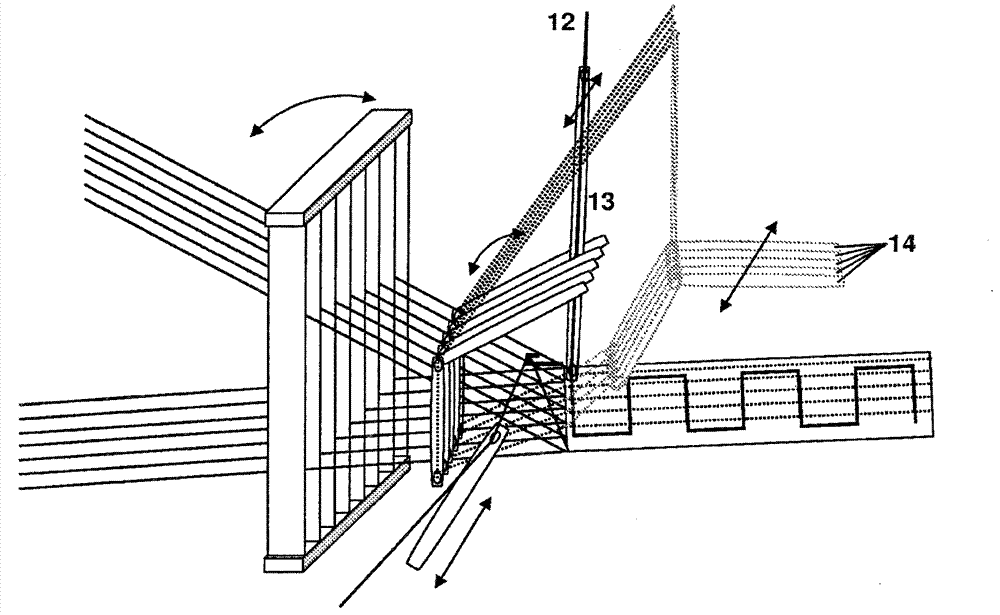

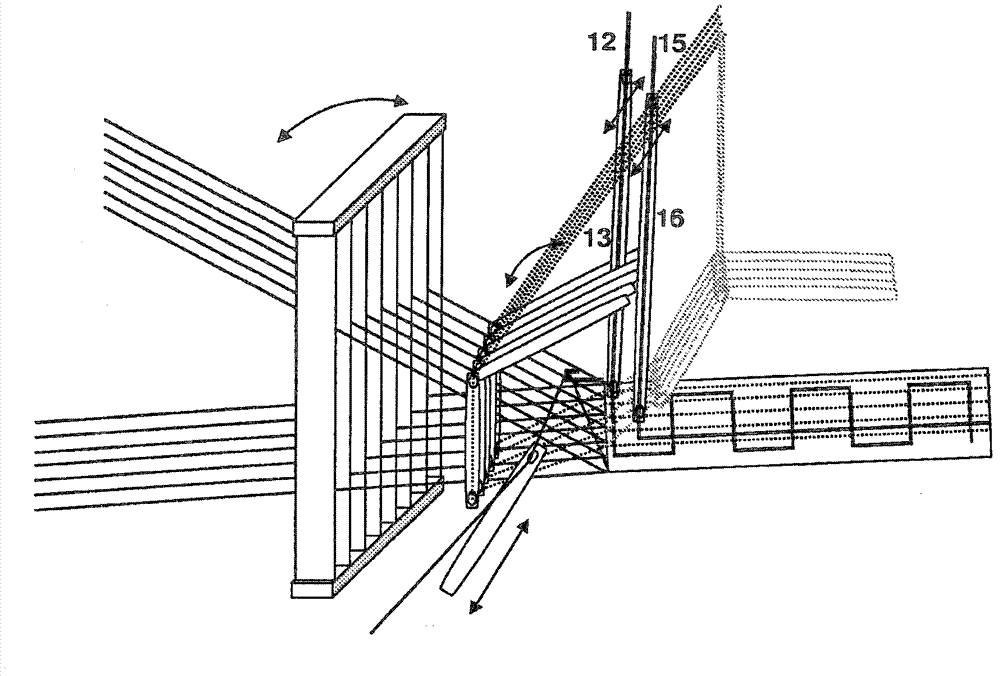

In a loom for producing woven fabrics (0) having added weft effects, an effect thread (2) fed in the warp direction above a weft thread (3) to be inserted is displaced in the weft direction (12) over a freely programmable displacement path (A) by means of a plurality of adjacent warp threads (1) drawn into different reed gaps (14). In order to interlace the effect thread (2) with the weft thread (3), the effect thread (2) is positioned beneath the weft thread (3) to be inserted and at the same time enters the open reed gaps (14) of a weaving reed device (10, 7, 7.1) that are upwardly open on one side. At the same time, a needle-shaped guide means (11) for the effect thread (2) is moved vertically and in the weft direction (12) in a plane that is located between the shedding elements (4) and the position of the weaving reed device (10, 7, 7.1) during weft insertion. The guide means (11) is displaced by an electromotive displacement drive (6) with respect to a shedding element (4), said drive driving the guide means (11) vertically.

Owner:LINDAUER DORNIER GMBH

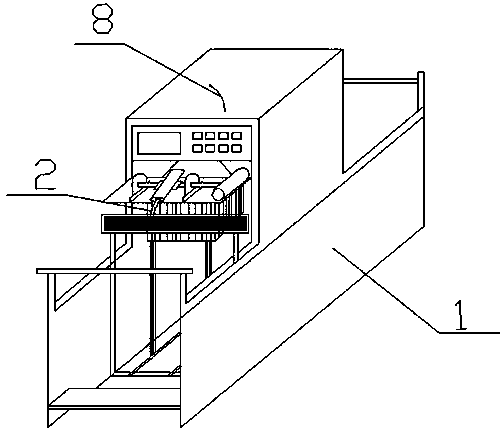

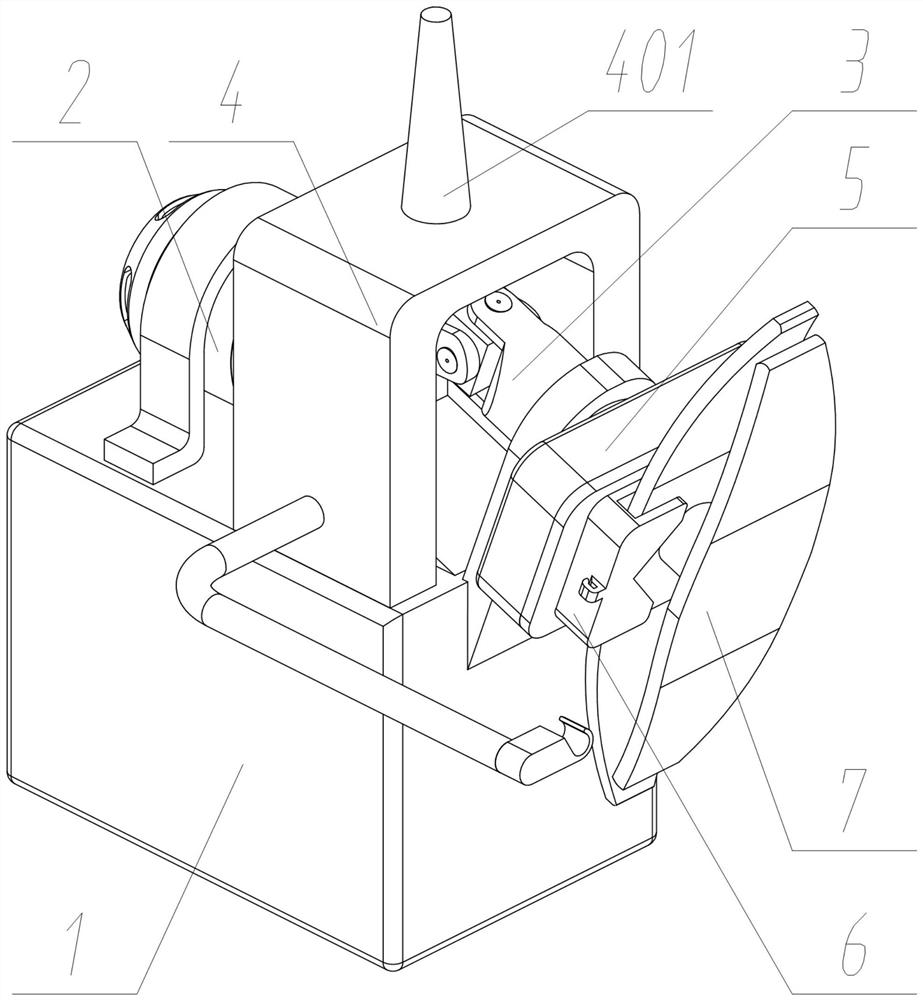

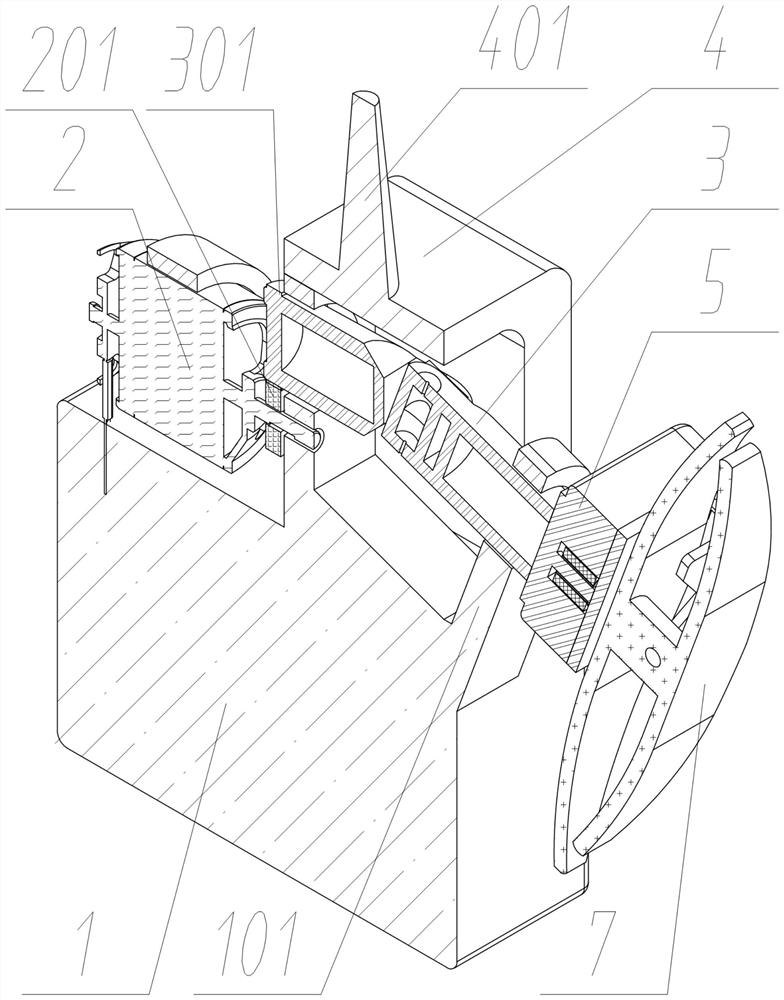

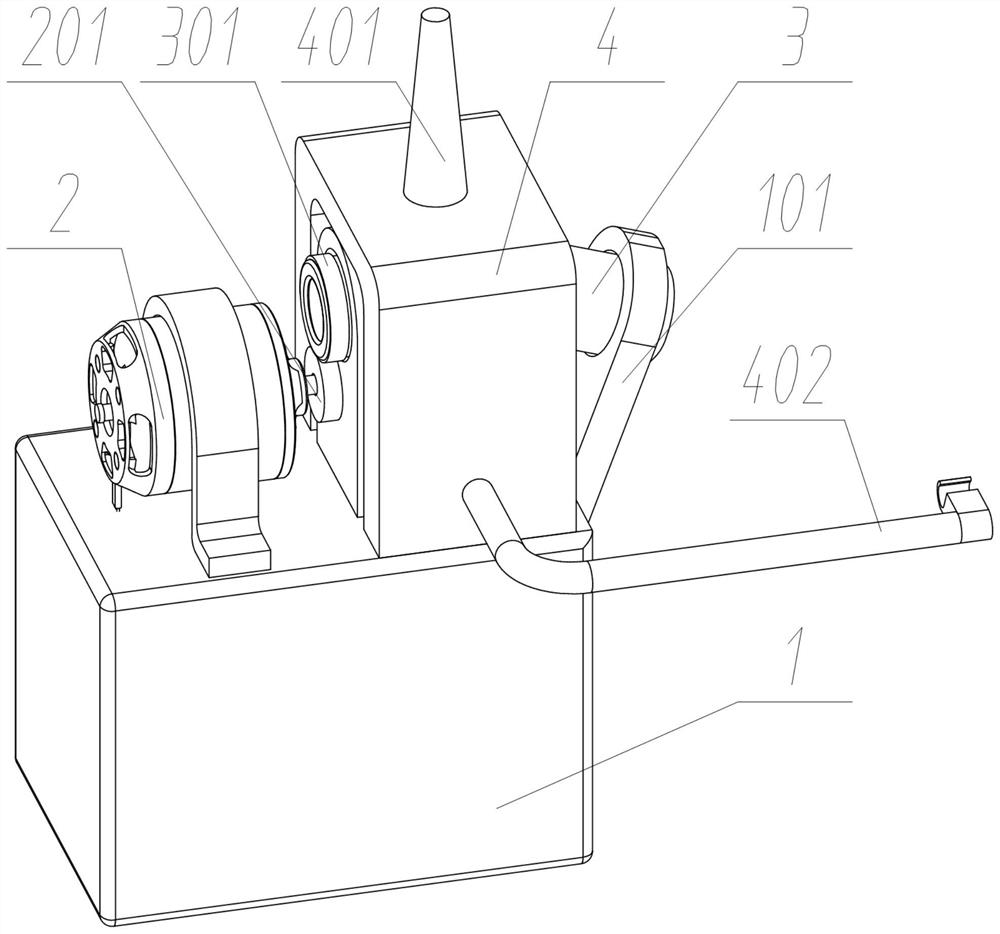

Portable semi-automatic Kesi-weaving machine device

The invention discloses a portable semi-automatic Kesi-weaving machine device. The portable semi-automatic Kesi-weaving machine device comprises a frame, a warp-conveying device, a wefting device and a coiling device. A motor opening device is arranged between the warp-conveying device and the coiling device. A pattern-reflecting plate is further installed between the motor opening device and the coiling device. The position, where the right side of the pattern-reflecting plate protrudes out of the frame, is provided with a pattern-reflecting plate hand wheel. A weft-beating device is arranged between the wefting device and the coiling device. The portable semi-automatic Kesi-weaving machine device has following advantages: the portable semi-automatic Kesi-weaving machine device is conveniently carried and favorably used for modern teaching; transfer from factorization to small-sized home-based design is achieved; a conventional mode of drawing on warp yarns is discarded so that a weaving mode is further realized; by adoption of the method of the pattern-reflecting plate, the effect of not deforming a finished product is achieved; and the opening device is flat during opening operation so that bright light rays are realized for facilitating selecting wefts.

Owner:IANGSU COLLEGE OF ENG & TECH

Loom for producing woven goods or material with an incorporated cover thread

In order to improve a loom for producing woven material (10) with an incorporated cover thread (12), it is proposed to provide a laying device for at least one cover thread (12) and also a warp-laying device (9) with warp-laying elements (14) for laying further warp threads (8). The warp-laying device (9) is designed such that it can make the further warp threads (8) penetrate from a starting position through the upper shed (5) to the lower shed (4), or through the lower shed to the upper shed, and therefore the weft-insertion device (7) crosses the further warp threads (8). The laying device has at least one cover-thread guide (13) which, in the starting position of the warp-laying device (9), can be displaced transversely to the warp threads (2) by way of a transverse-movement means.

Owner:TEXTILMA AG

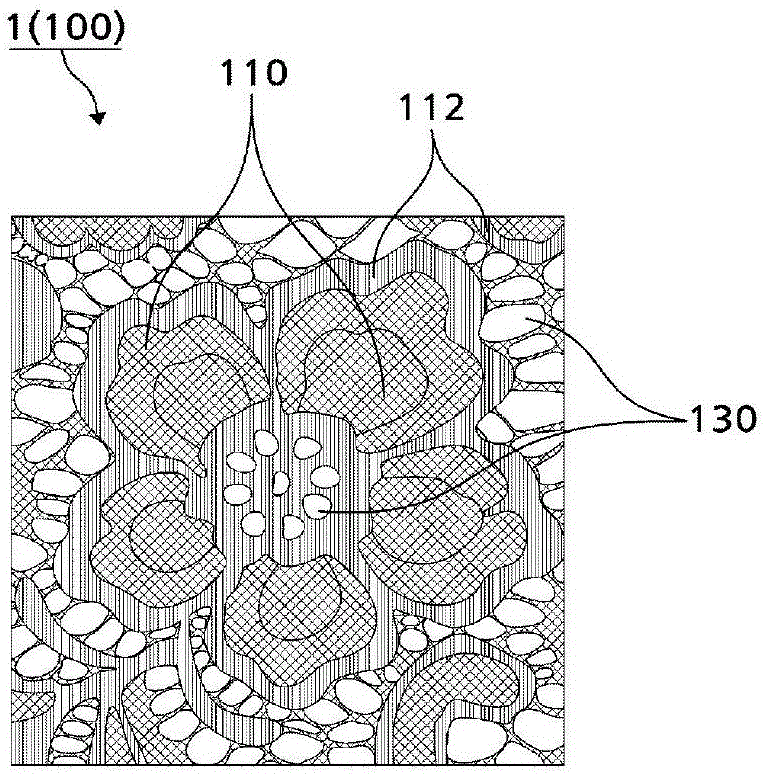

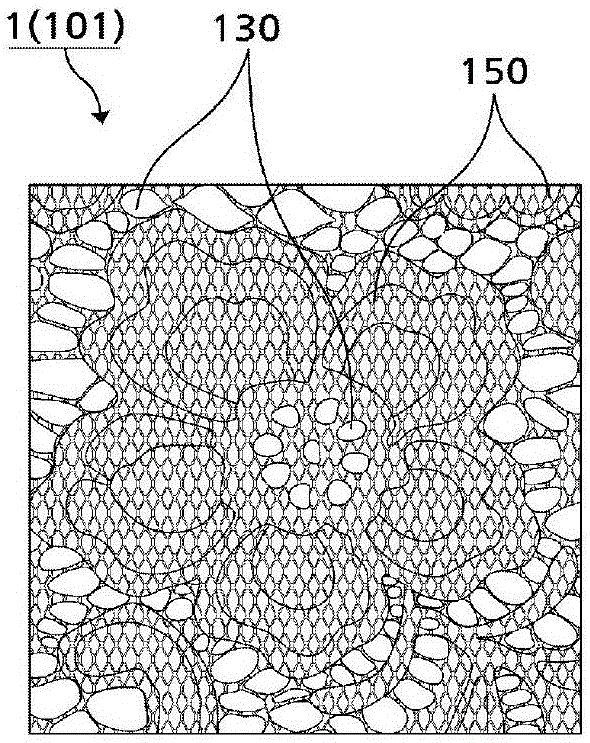

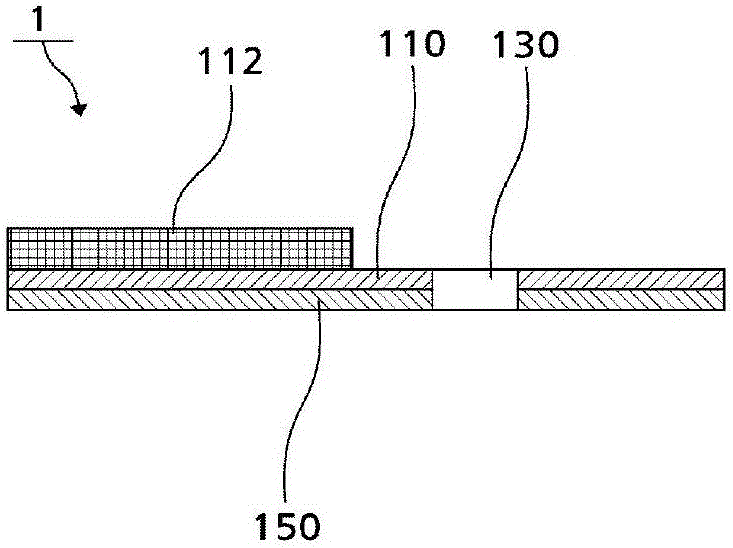

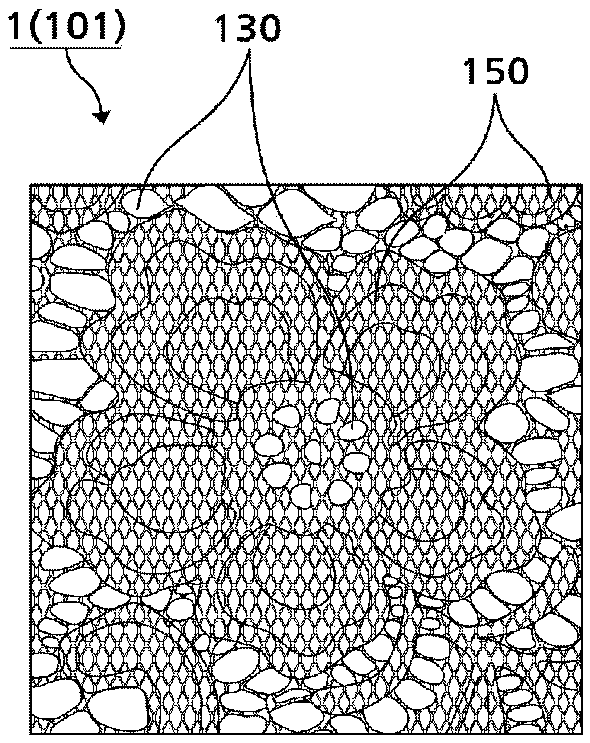

Lace fabric having hot-melt function

The present invention relates to a novel lace fabric. The lace fabric (1) of the present invention is a lace fabric which is woven with two different types of threads, wherein a through-hole area and a cover factor area are formed by weaving a bottom yarn; the lace fabric is formed by weaving a motive thread on a surface of a bottom yarn layer being a cover factor area; and a wick surface of the bottom yarn is hot-melt coated, while the motive thread is not hot-melt coated.

Owner:赵景惠

Weaving process for Zhuanghua woolen product and weaving equipment thereof

The invention relates to a weaving process for a Zhuanghua woolen product and weaving equipment thereof. A method for weaving the Zhuanghua woolen product by a Dahualou jacquard loom comprises the following steps of picking up stripe pick patterns according to pattern sample information with an anti-weaving method; lifting and dragging a bundle heald; weaving a ground pick when a model frame is opened; when the bundle heald and an obstacle frame are subjected to hybrid opening, weaving a stripe pick; when only the bundle heald is opened, weaving a steel wire; forming a Zhuanghua woolen semi-finished product by the processes of battening, coiling and warp pacing; after the Zhuanghua woolen semi-finished product is taken out of the machine, pile warps coated on the steel wire are cut off to form the Zhuanghua woolen finished product. According to the weaving equipment disclosed by the invention, the pile warp pacing part of a common Dahualou loom is provided with a constant force independent warp pacing device; pile warps in the device are respectively coiled on a tension heavy punch and a pipe on which velvet lines are coiled; a friction heavy punch is hung on the fixed pipe on which velvet lines are coiled. According to the invention, the Zhuanghua woolen variety with the highest technical content in brushed fabric can be weaved, and meanwhile, the Zhuanghua woolen weaving technology and equipment failing to be handed down from past generations for more than a centenary can be copied.

Owner:南京锦绣盛世云锦织造有限公司

Reed and weaving machine for weaving pattern formation in woven fabrics with additional pattern effects

InactiveUS8770235B2Easy to manufactureGuaranteed functionLappetLeno shedding mechanismEngineeringMechanical engineering

For producing woven fabrics with additional pattern effects, one or more effect threads are supplied substantially in the warp direction and are moved over neighboring warp threads in the weft direction, above a weft thread that is to be inserted, in various motion cycles of a weaving machine. Subsequently the effect threads are positioned below a subsequent weft thread, by submerging the effect threads into upwardly open reed gaps of a reed. To facilitate this, the reed includes first reed blades which, at their upper end, each include a sloping thread guide element projecting in the longitudinal direction of the reed, so as to at least partially extend over the upwardly facing opening of a neighboring reed gap. The reed further includes second reed blades having no such sloping thread guide elements. The guide elements guide the effect threads down into the proper reed gaps.

Owner:LINDAUER DORNIER GMBH

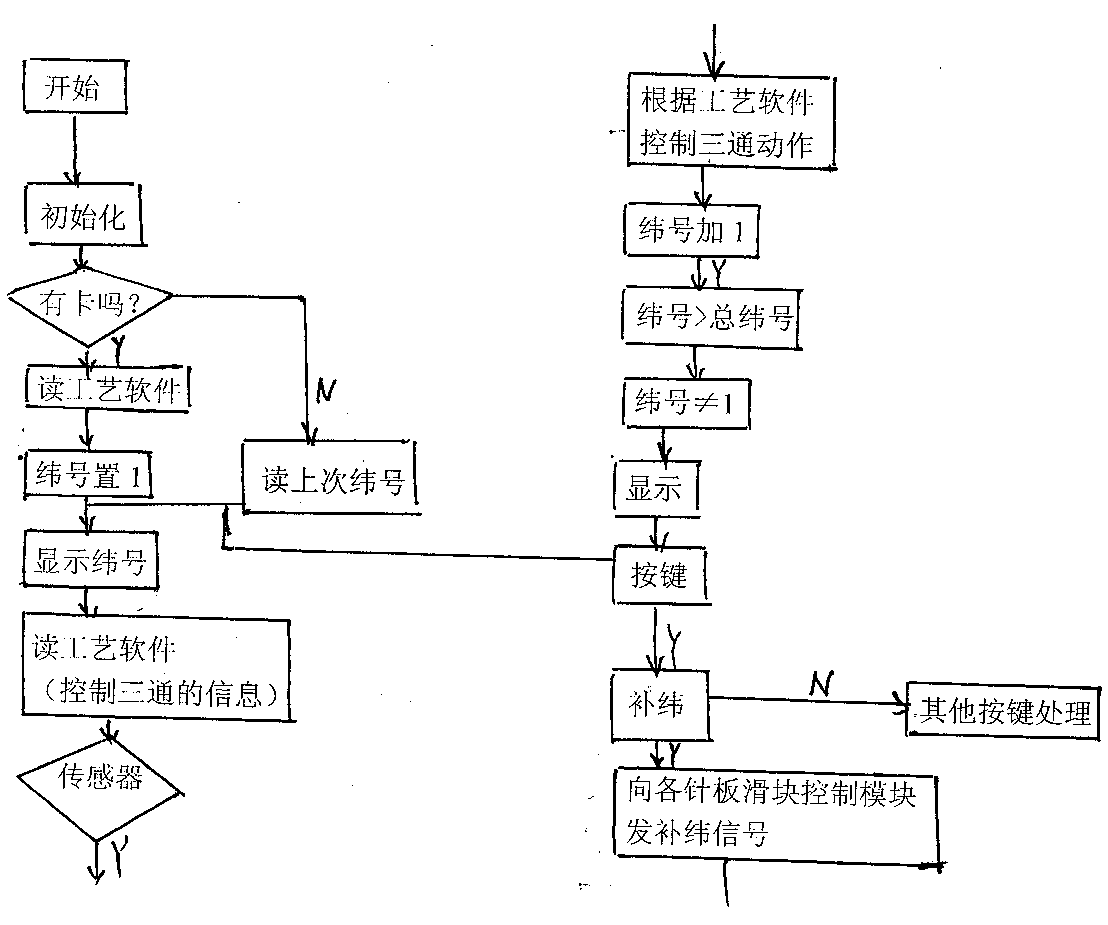

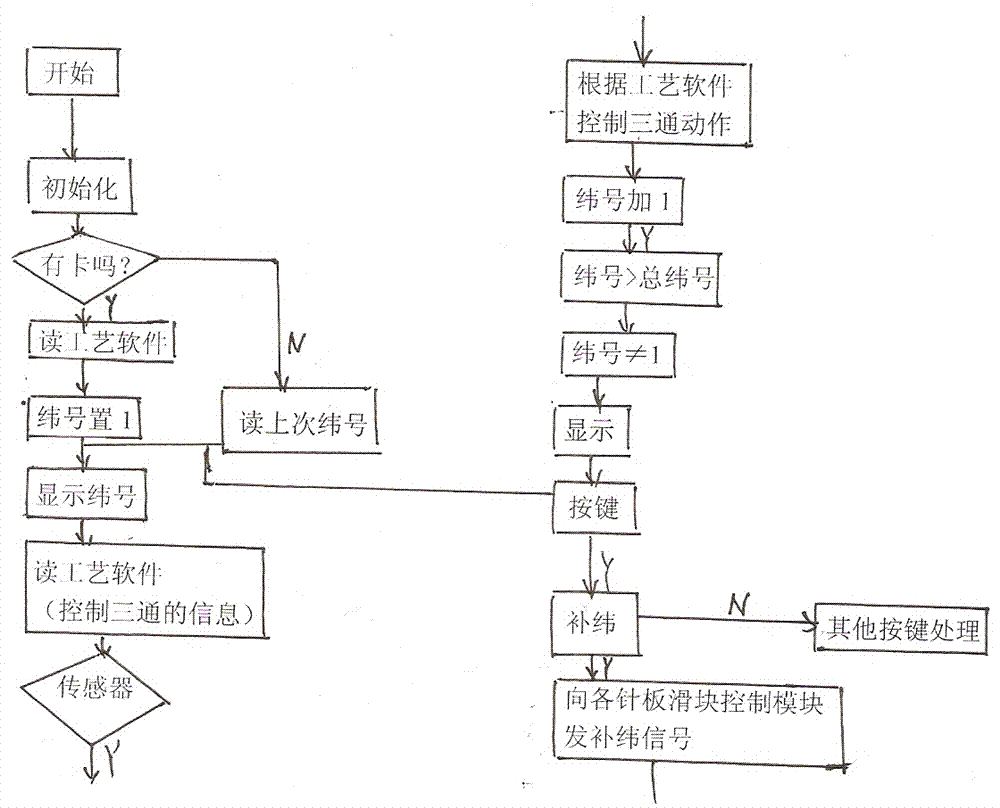

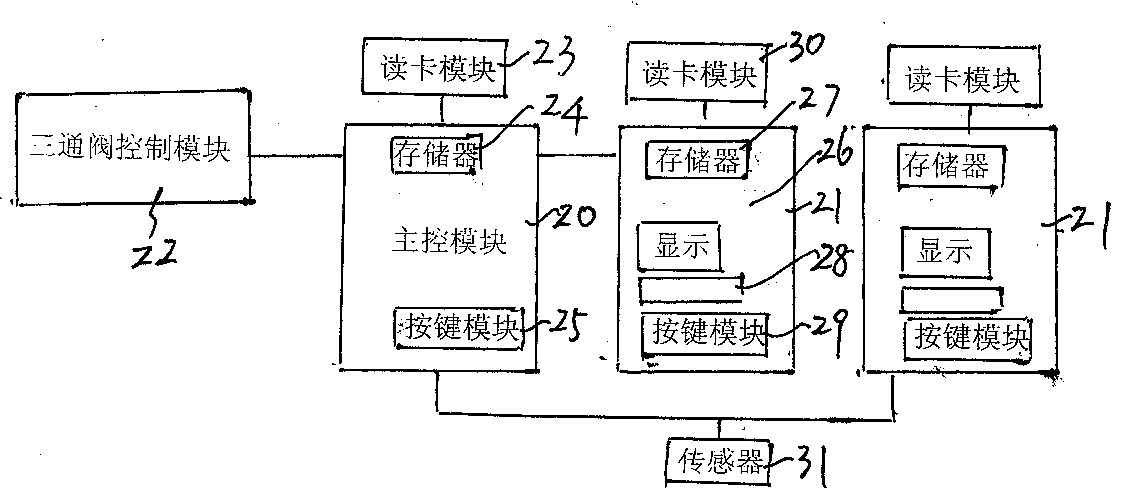

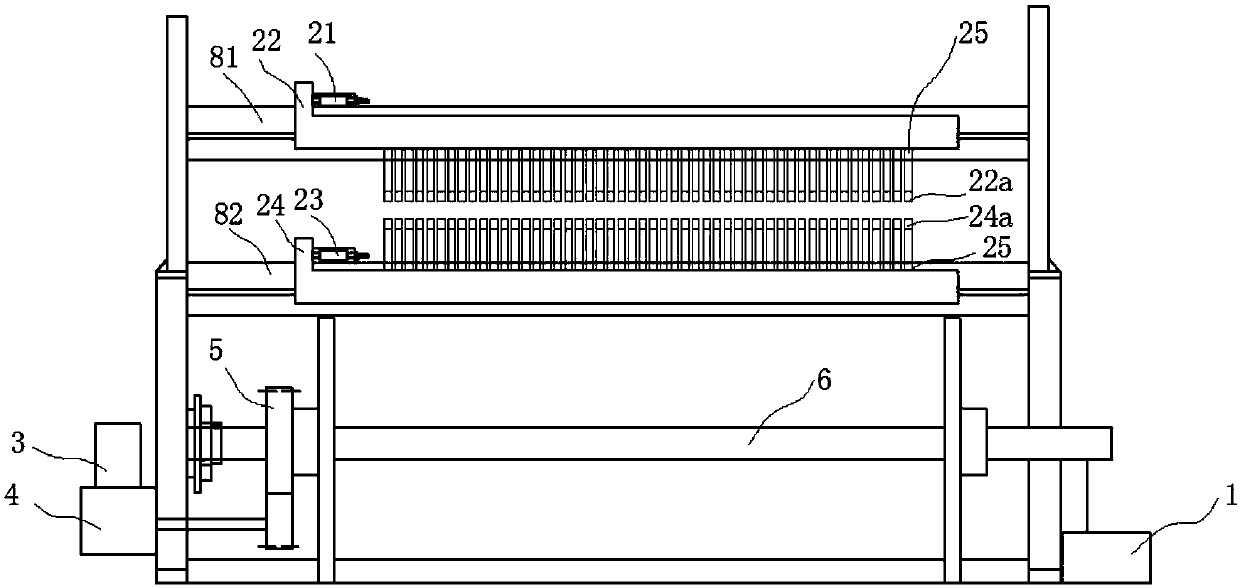

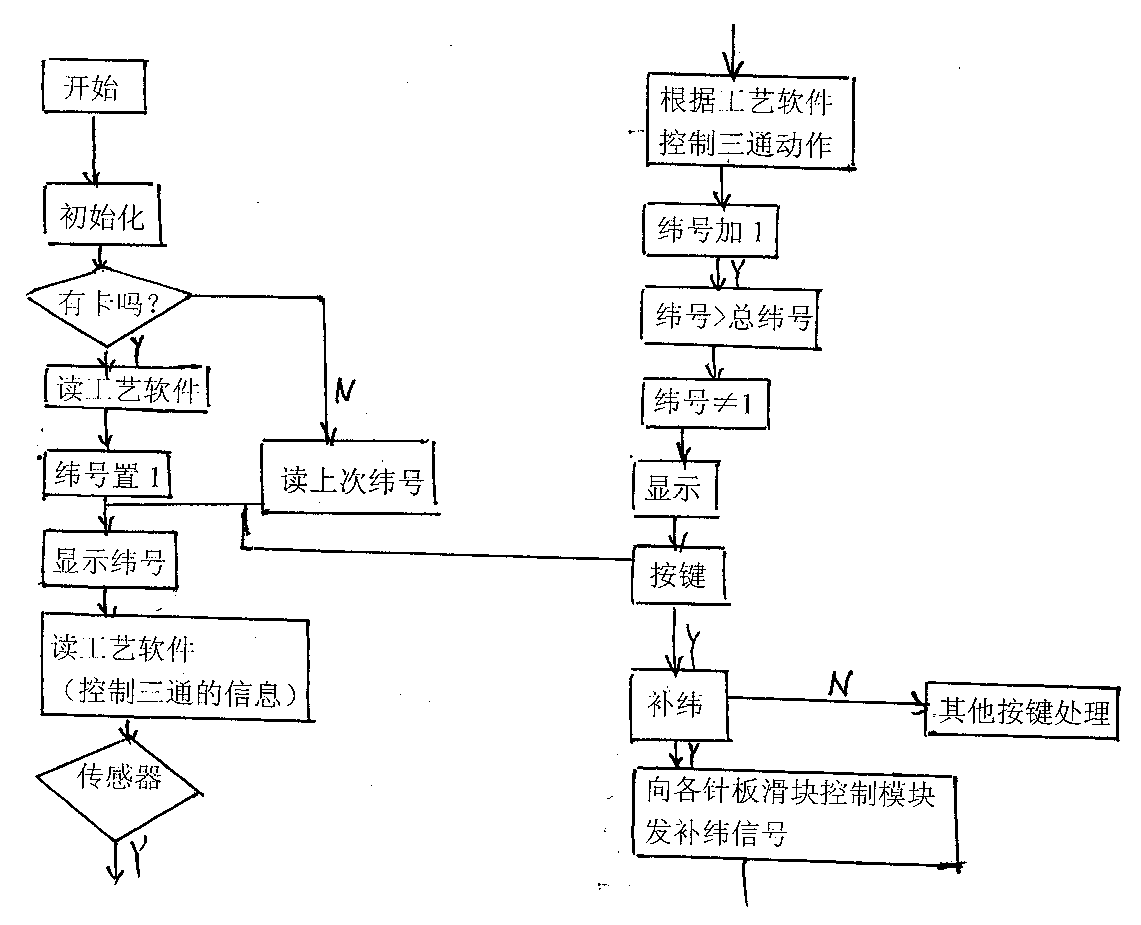

High-precision control method for float weaving

InactiveCN103806200ARealize automatic controlSimple design and operationLappetAutomatic controlControl system

The invention discloses a high-precision control method for float weaving. According to the method, an intelligent float weaving control system is adopted for control. The system comprises a mechanical device and a control device, wherein the mechanical device comprises a faller base connected with a faller lifting rod, a rotor in contact with a cam on a main shaft of a loom is mounted at the lower end of the faller lifting rod, and the upper portion of the faller base is connected with a spring resetting mechanism enabling the faller base to be reset; a left cylinder piston rod and a right cylinder piston rod moving vertically in a left cylinder and a right cylinder respectively are fixedly mounted below the left end of the faller base and the right end of the faller base respectively, the left cylinder and the right cylinder are connected with an air compressor through a three-way valve, and the control device controls the three-way valve and a stepping motor to work. According to the method, the structure is reasonable, automatic control of float weaving is achieved, design and color variety setting can be achieved easily and visually, weaving control precision is high, varieties can be changed fast, and improvement cost is saved.

Owner:NANTONG VOCATIONAL COLLEGE

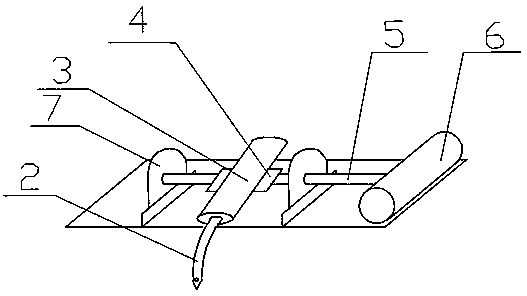

Textile sample weaving machine with seam quilting function

InactiveCN103469449AThe fabric is beautiful and smoothImprove the decorative effectLappetMultiple loomsYarnEngineering

The invention discloses a textile sample weaving machine with a seam quilting function. The textile sample weaving machine comprises a textile proofing machine, and is characterized by also comprising a yarn picking needle, wherein the yarn picking needle is fixedly arranged on an air cylinder for realizing vertical movement, a spiral rod is driven through an electric motor, the air cylinder is fixedly arranged on a screw seat for realizing the horizontal movement, and finally, the vertical and horizontal movement of textile proofing machine is set to be synchronous with the vertical and horizontal movement of the yarn picking needle. Through the design, when the textile proofing machine carries out proofing weaving, yarns with different colors are woven through the yarn picking needle, pattern varieties similar to pattern varieties embroidered by a seam quilting machine are directly formed, the woven cloth samples are attractive, flat and smooth, and the decoration performance is high.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

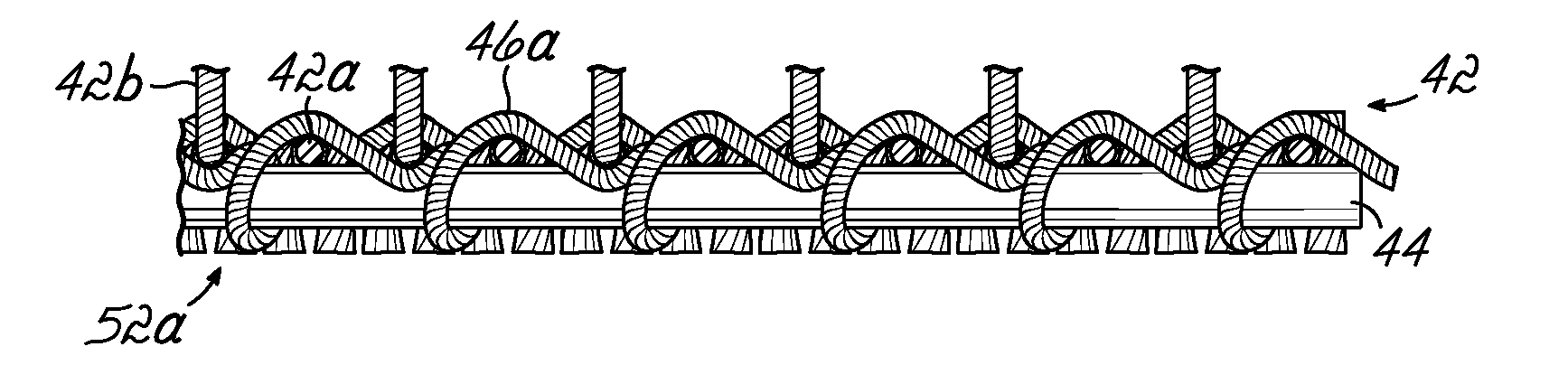

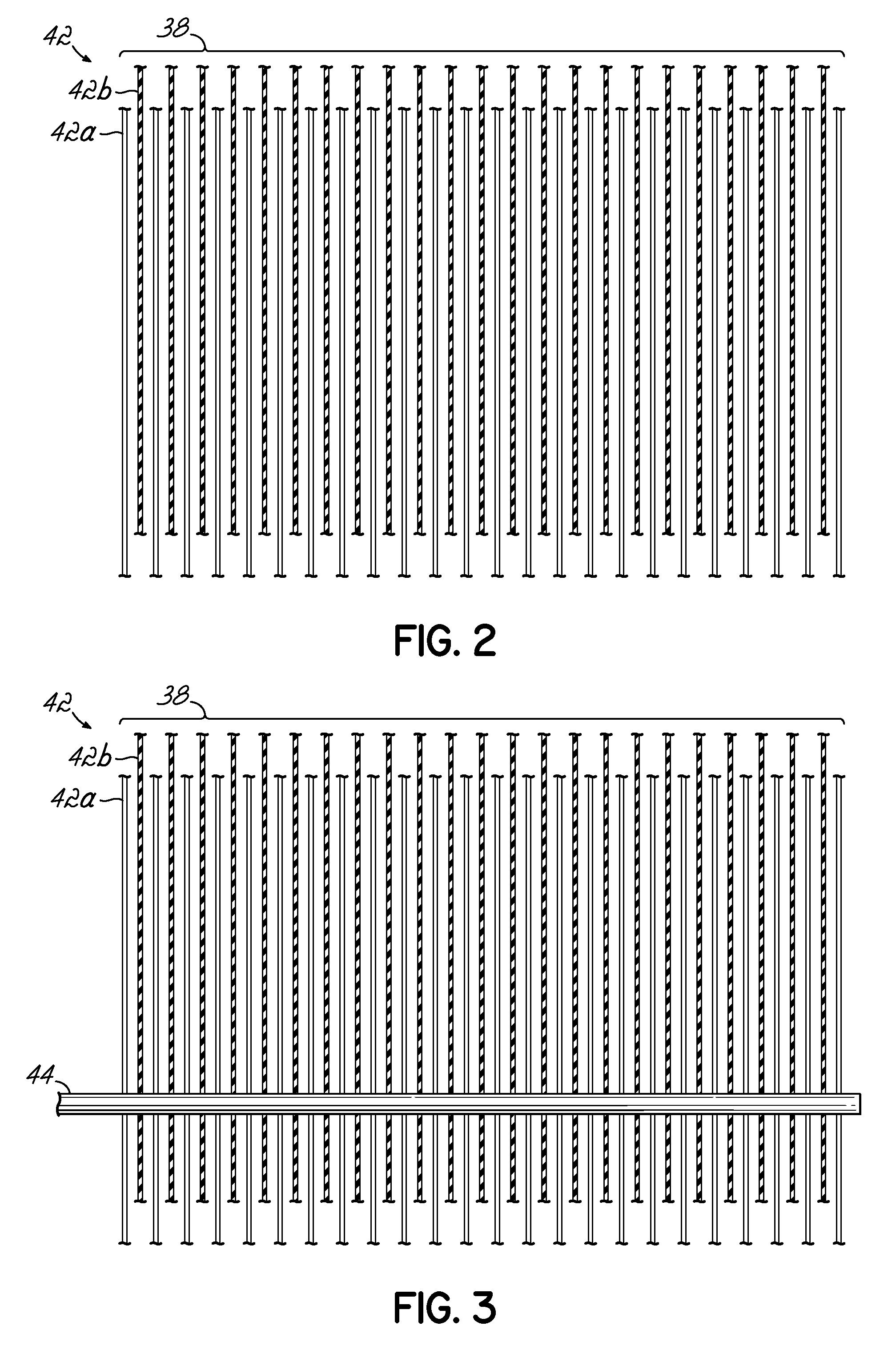

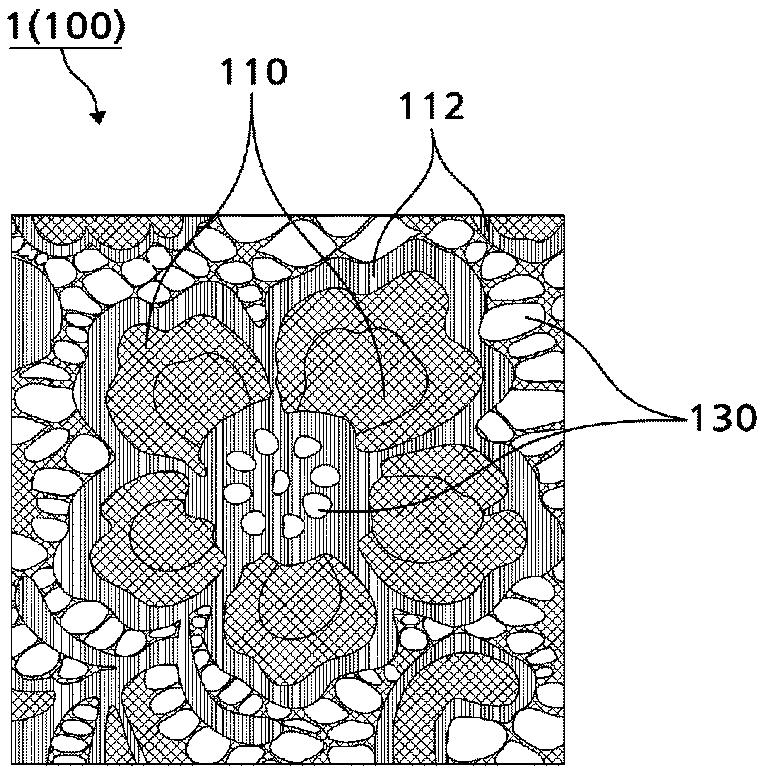

Method and system for producing simulated hand-woven rugs

A rug, a loom for making a rug and a method of making a rug are various aspects of this invention. The loom for weaving a rug includes a frame defining a workspace for weaving the rug in which the frame includes a first, a second and a third frame member with a number of warp yarns extending across the workspace. Each of the warp yarns is coupled to the third frame member and a first set of the warp yarns is coupled to the first frame member and a second set of the warp yarns is coupled to the second frame member. The loom also includes at least one rod adapted to extend within the workspace to receive a first yarn pile thread looped thereon and about the first set of warp yarns to form a first yarn pile. The rod also receives a second yarn pile thread looped thereon and about the second set of warp yarns to form a second yarn pile. A method of making a rug as well as a rug itself is a further aspect of this invention.

Owner:PRESNELL III SAMUEL C

Woven Barcode made of smeltable yarn material

The label has two non-folded longitudinal sides (1) and two foldable narrow sides (2) and consists of a backing fabric (11) with warp threads (4) and basic picks (5), in addition to embroidery picks (12) made of a fusible thread material forming the pattern. The embroidery picks (12) forming the pattern extend parallel and at a distance to the unfolded longitudinal sides (1) of the backing fabric (11). The non-folded longitudinal side (1) is an edge of a cut formed in the backing fabric outside the area (13) of the pattern. The label has the advantage that the edges of the cuts on the longitudinal sides are soft and skin friendly thereby substantially improving wearing comfort. Due to the fact that the edge of the cuts produced by the basic picks have practically no brows and the picks extend parallel in relation to the longitudinal side of the labels, and even appearance is achieved on the entire length of the label since the picks cover evenly the back part.

Owner:TEXTILMA AG

Label and method for produicng labels and device for implementing said method

The label has two non-folded longitudinal sides (1) and two foldable narrow sides (2) and consists of a backing fabric (11) with warp threads (4) and basic picks (5), in addition to embroidery picks (12) made of a fusible thread material forming the pattern. The embroidery picks (12) forming the pattern extend parallel and at a distance to the unfolded longitudinal sides (1) of the backing fabric (11). The non-folded longitudinal side (1) is an edge of a cut formed in the backing fabric outside the area (13) of the pattern. The label has the advantage that the edges of the cuts on the longitudinal sides are soft and skin friendly thereby substantially improving wearing comfort. Due to the fact that the edge of the cuts produced by the basic picks have practically no brows and the picks extend parallel in relation to the longitudinal side of the labels, and even appearance is achieved on the entire length of the label since the picks cover evenly the back part.

Owner:TEXTILMA AG

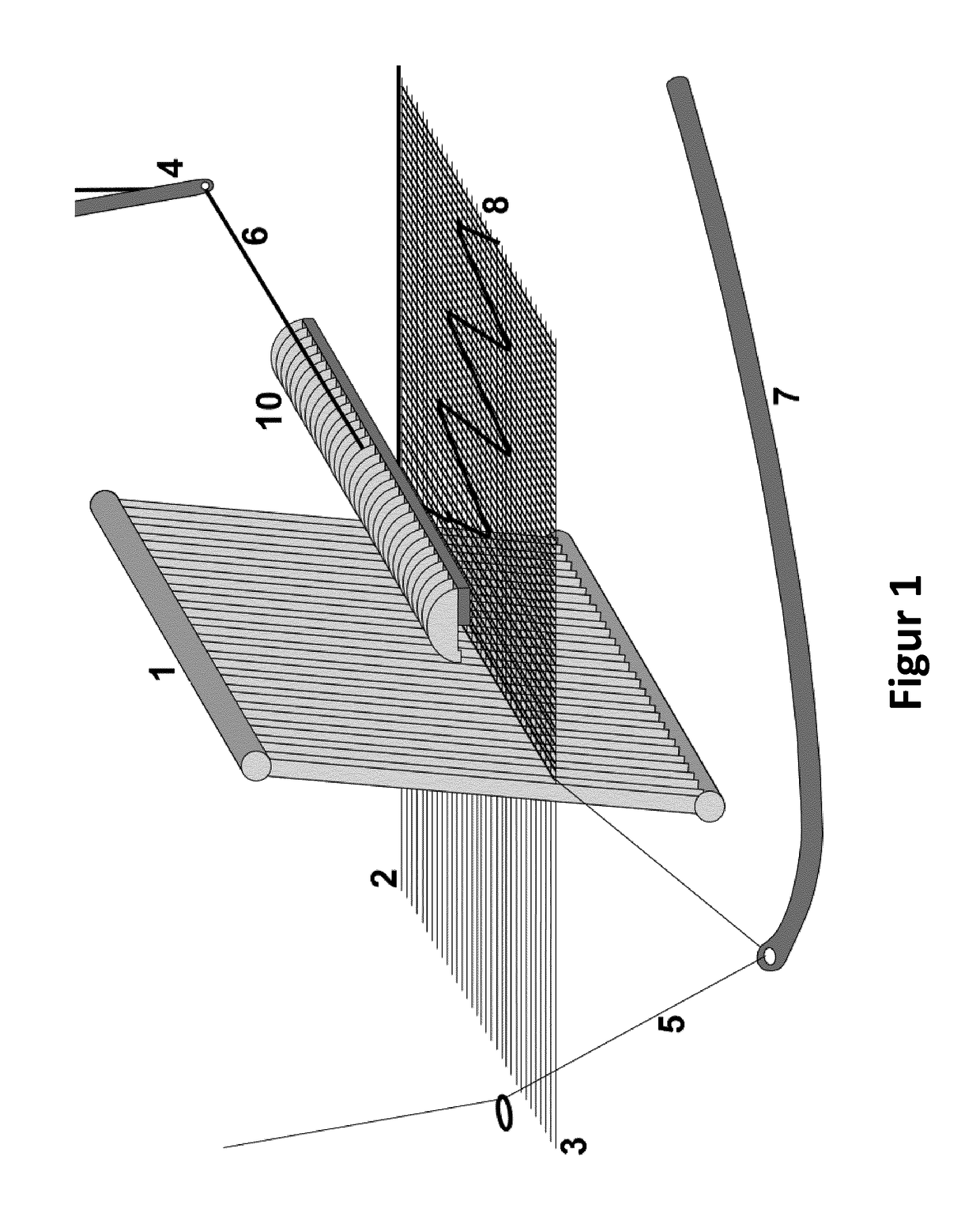

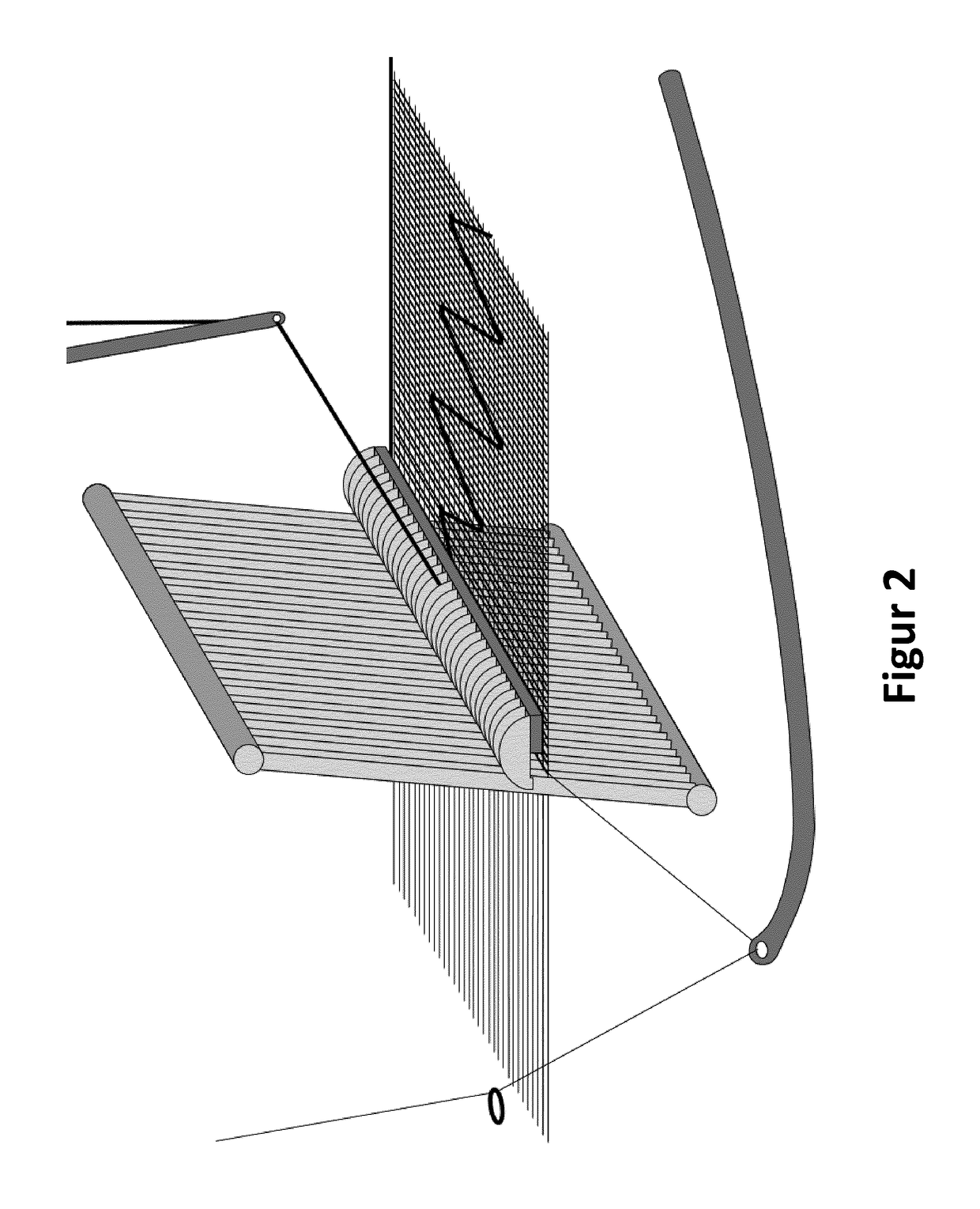

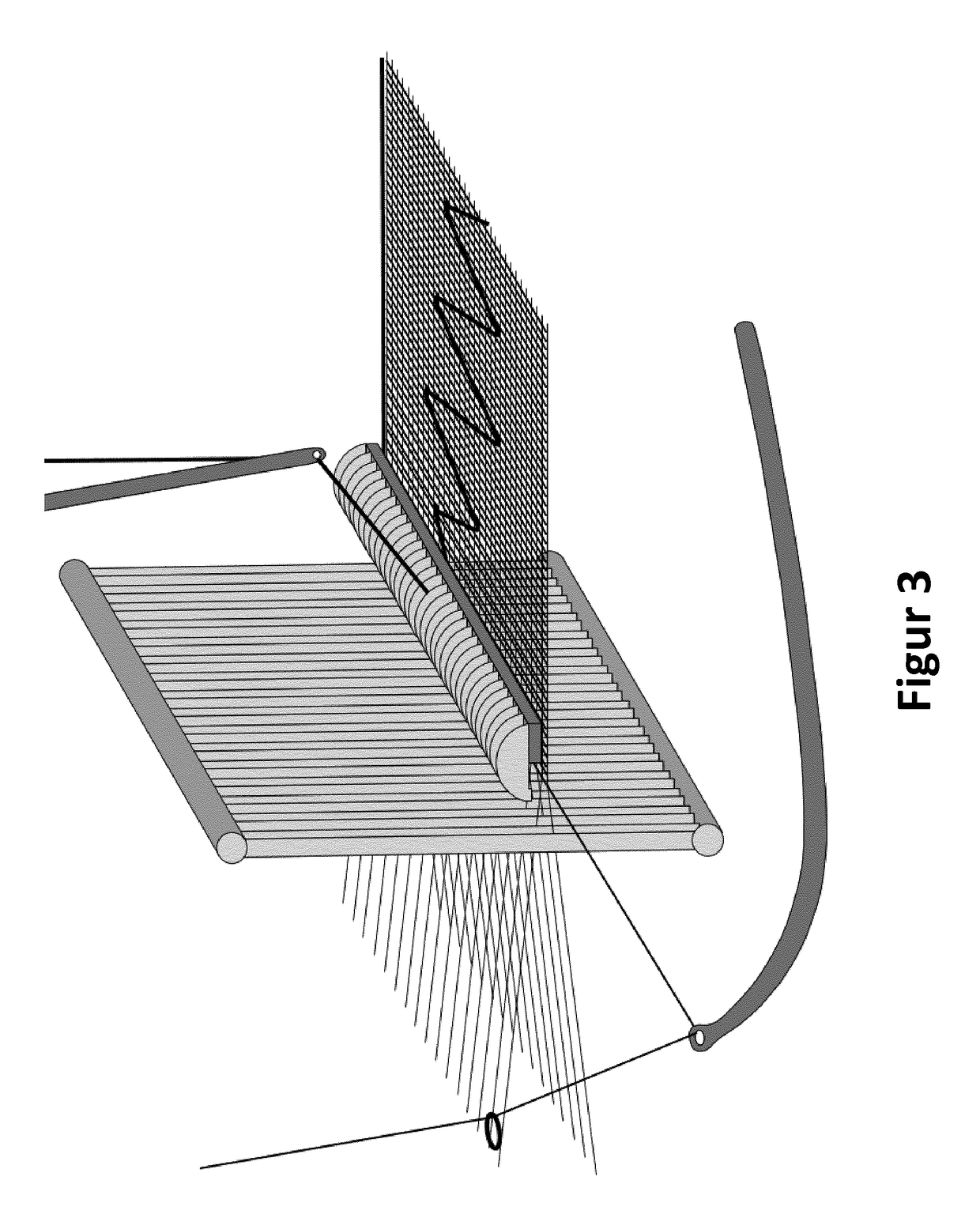

Loom for Producing Woven Material, Having Incorporated Knitting Threads or Cover Threads

ActiveUS20180363170A1Avoid disadvantagesGood flexibilitySmallware loomsLappetEngineeringInsertion device

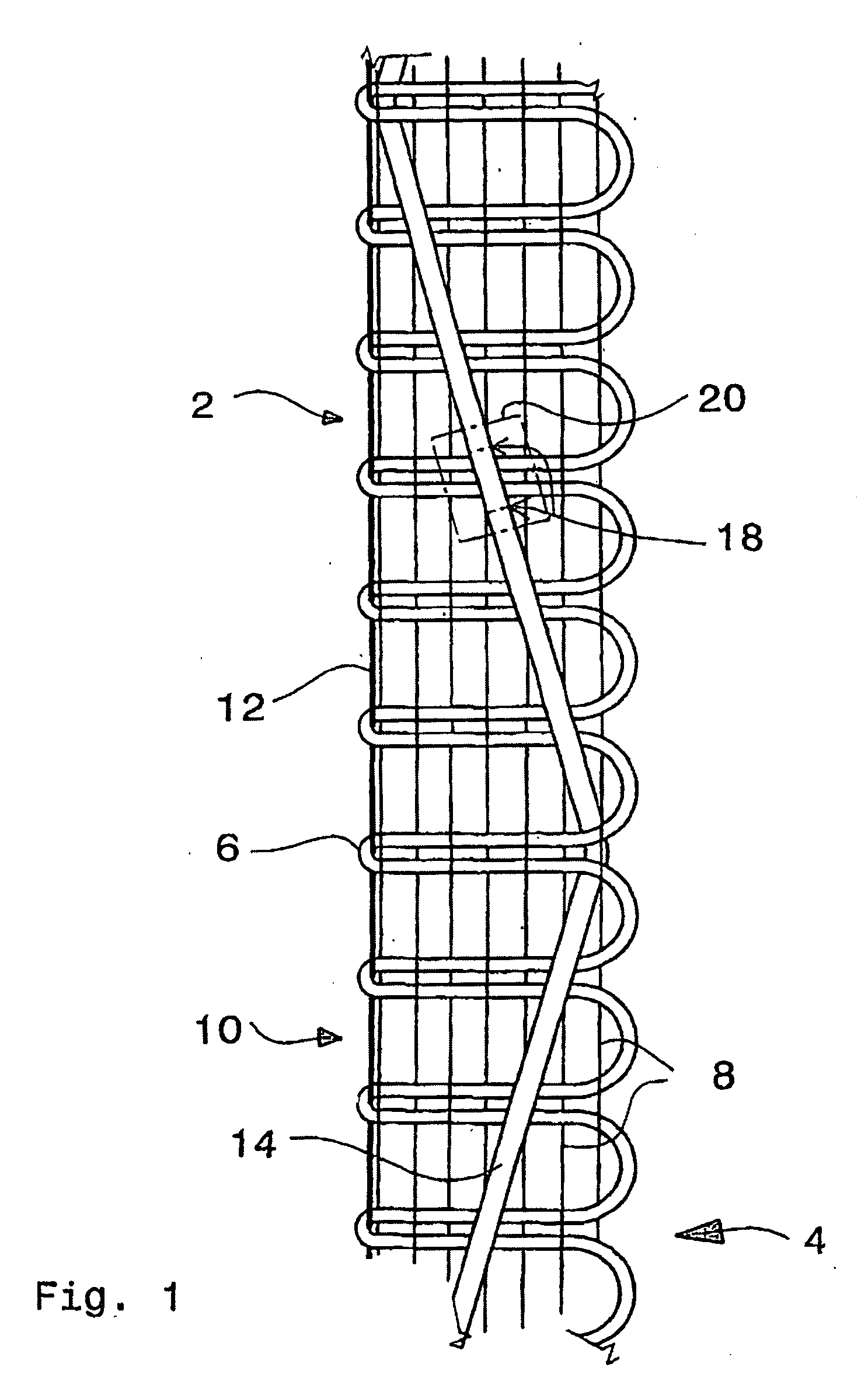

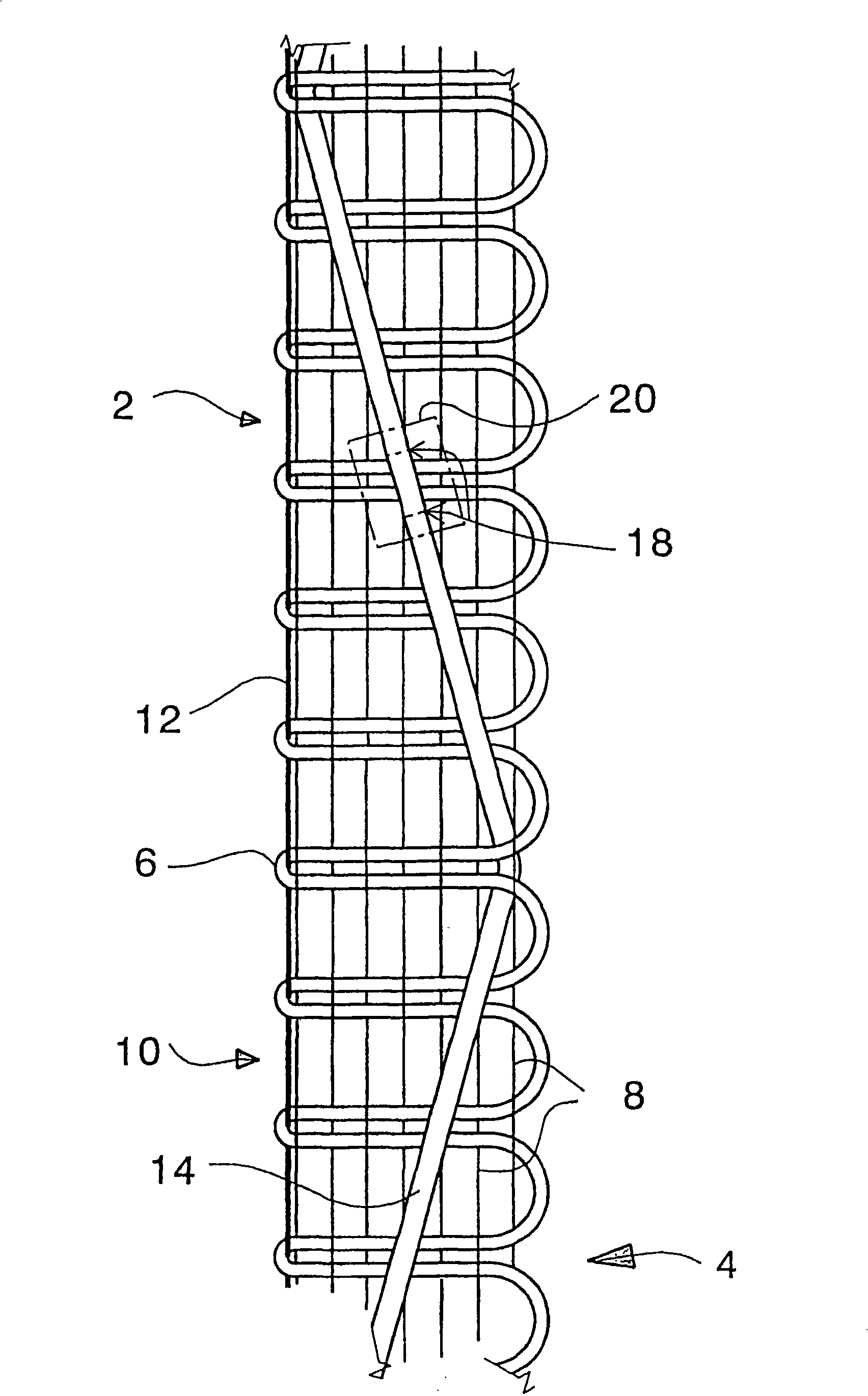

In order to provide a weaving loom having incorporated knitting threads, it is provided that the corresponding device for incorporating knitting threads comprises a feeding device for each knitting thread and, also for each knitting thread, a dipping guide needle (4) which comprises a thread guiding eye and which can be dipped between warp threads (2, 3) into the shed all the way below the insertion path of the weft-insertion device (7). Each one of the dipping guide needles (4) is slidingly arranged transversely to the warp direction, thus being able to move across the width of the woven material. Furthermore, there is provided a combing shaft (10) that comprises a plurality of teeth with intermediate spaces arranged therebetween for guiding the knitting threads. The combing shaft (10) that is slidable transversely to the direction of the warp thread and is rotatable around an axis in the direction of the rail is arranged transversely to the direction of the warp thread behind the stop position of the reed. The teeth of the combing shaft comprise protrusions which are designed in such manner that the teeth can retain the knitting threads in at least one rotational position of the combing shaft.

Owner:TEXTILMA AG

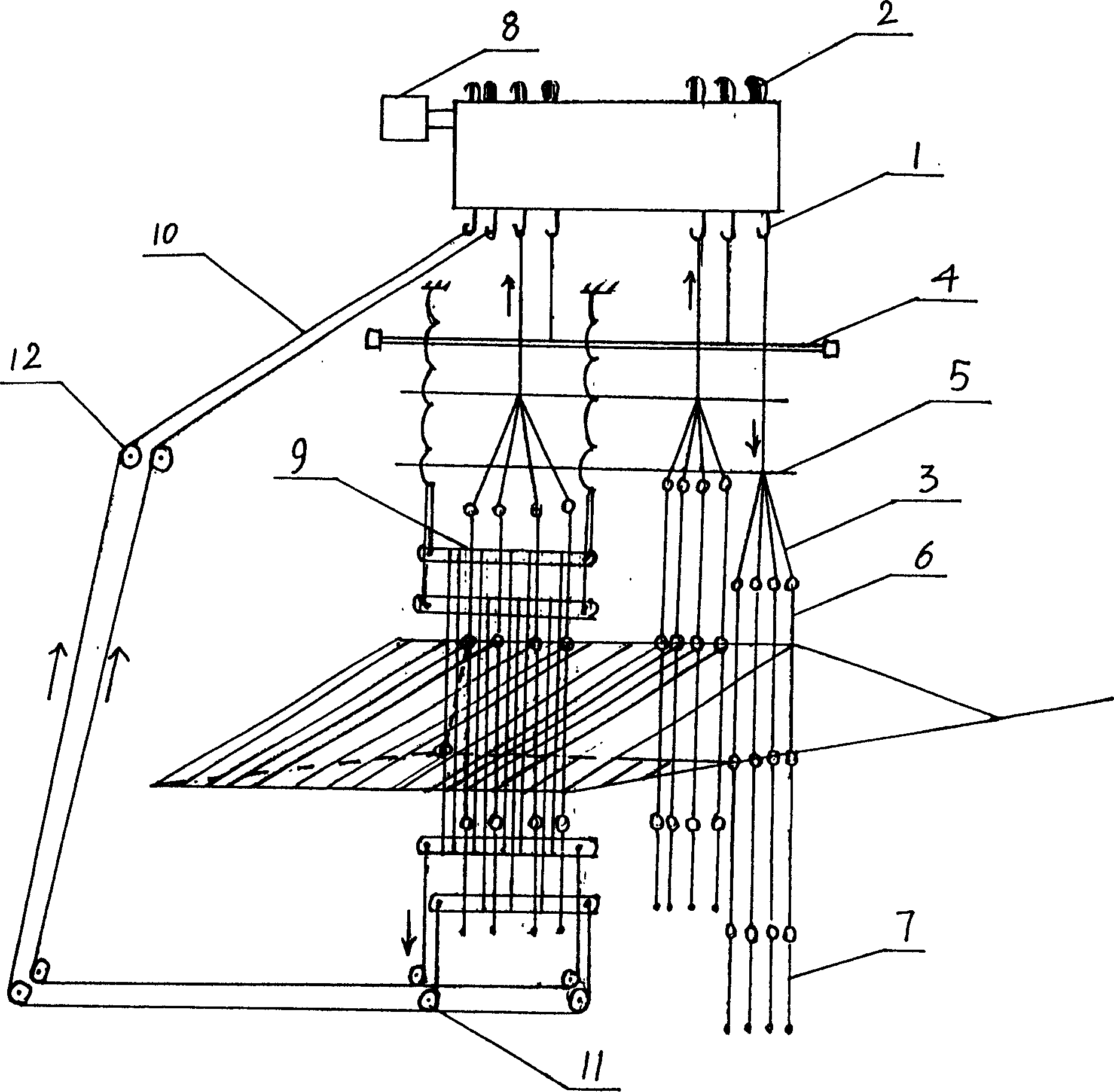

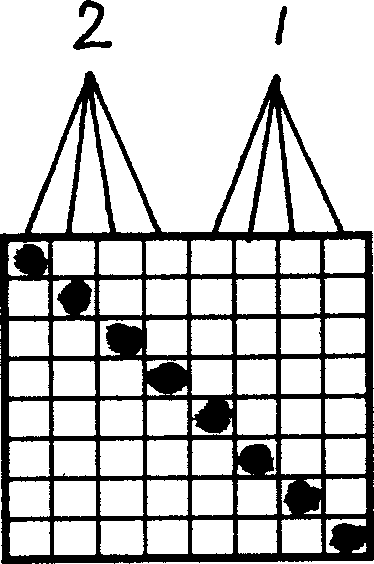

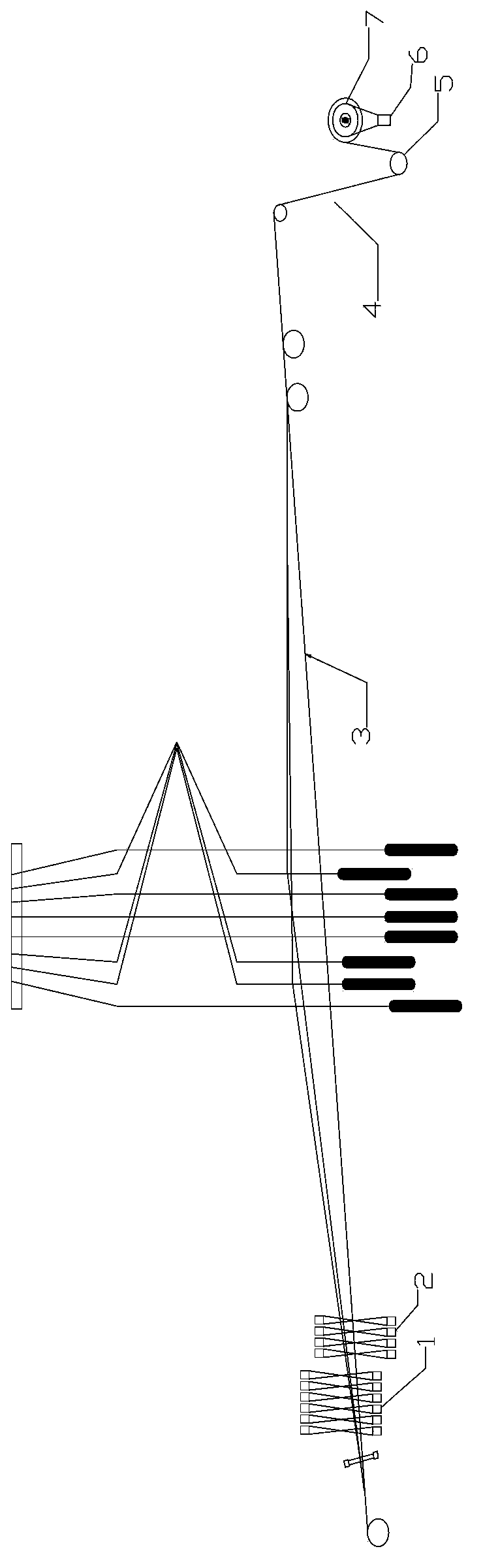

Uninterrupted staple yarn knitting machine

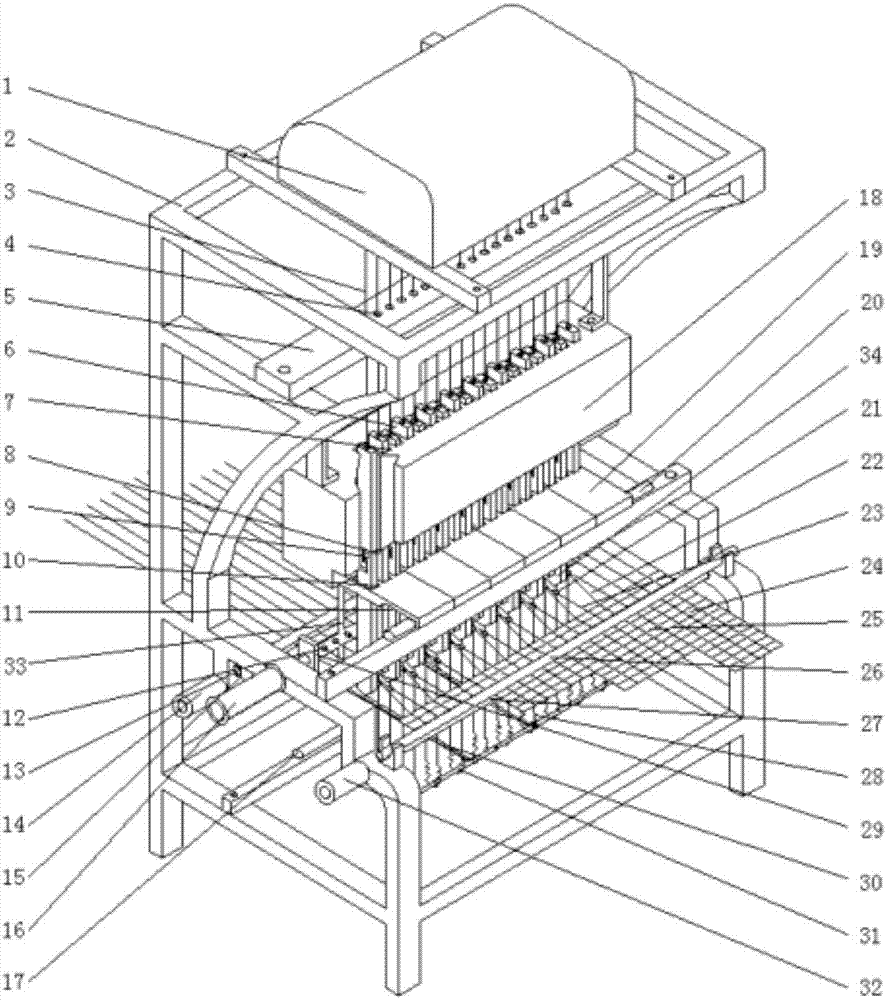

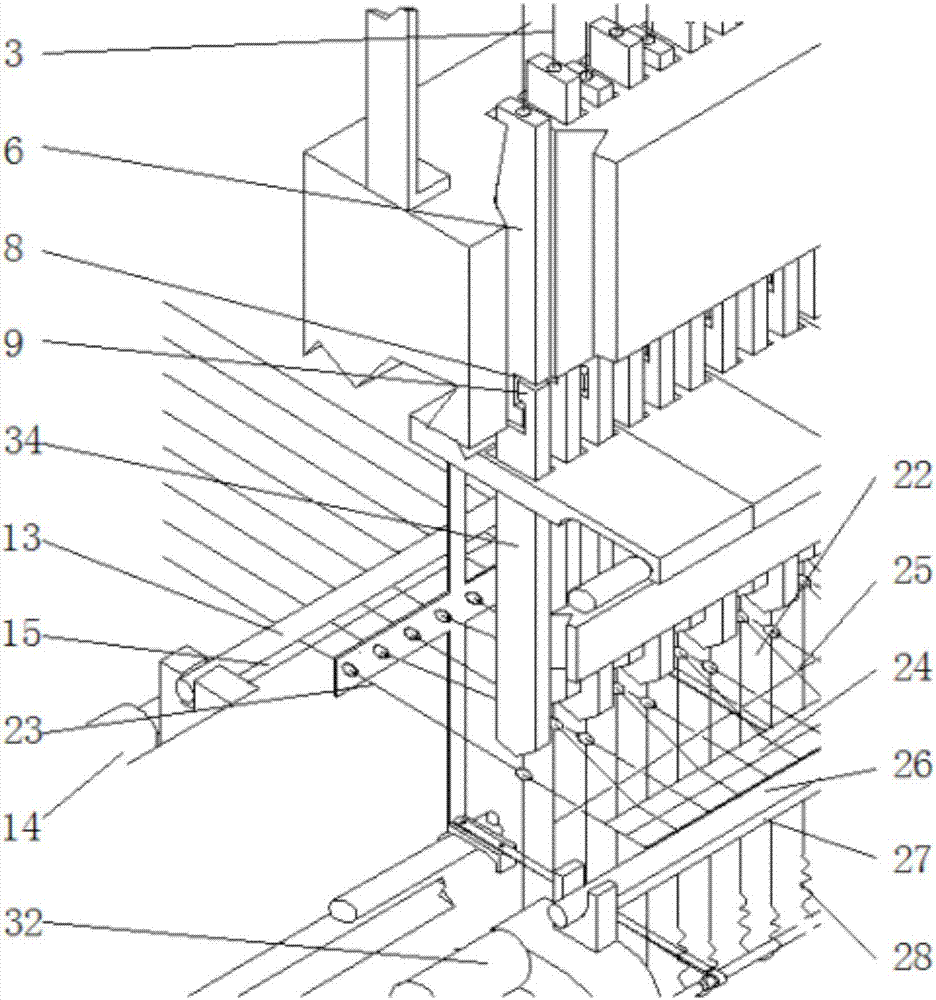

The invention discloses an interrupted short yarn knitting machine. A jacquard machine is mounted above a rectangular rack; a comber board is located below the jacquard machine and fixedly mounted on the rack; a main control board is located below the comber board; a sliding rod I and a sliding rod II are arranged on the rack and support the main control board; a moving mechanism and a moving-out and addition mechanism are located right in front of a warp yarn controller; a reeling mechanism and a let-off mechanism are horizontally mounted in front of and at back of the warp yarn controller respectively and controlled through a motor A and a motor B, and the warp yarn controller is located below the main control board. Warp yarn which is all knitted into a fabric is moved out through constant circulation, a certain amount of warp yarn is added correspondingly for continuous knitting, shorter warp yarn can be continuously knitted without connection, and the purposes of controlling the interweaving rule of warp and weft yarn through the computer jacquard machine and realizing jacquard weaving and mechanical weaving are achieved.

Owner:四川天艺家科技有限公司 +1

Woven Shoe Upper

PendingUS20190075888A1Increased average area weightImprove performanceSolesLappetEngineeringWeft yarn

The present invention concerns a shoe upper comprising a woven portion, wherein the woven portion comprises a plurality of warp yarns; a plurality of weft yarns; at least one stitching yarn, wherein the stitching yarn is integrally woven into the fabric during the weaving process by laterally displacing the stitching yarn substantially along the weft direction and moving the stitching yarn in and out of at least one open reed gap in a reed.

Owner:ADIDAS

A alternating rear beam and its assembly and usage how to use

The invention discloses an alternate flipping rear beam and an assembly method and a use method thereof. The invention provides a 90 DEG dislocation mounting warp bracket and a reversible special rearbeam. The mechanical transmission of the weaving motion alternately flips the rear beam, so that the warp yarns of the adjacent supported sections alternately have large tension differences, and theeffect of the fancy seersucker with concave and convex in the alternating areas of the cloth surface is formed. The above-mentioned device and its assembly and use method have the unique effect of theseersucker fabric and the wide adaptability to the fiber material, and are particularly suitable for the development of the synthetic yarn material and the single material of the seersucker fabric.

Owner:WUJIANG FUHUA WEAVING +1

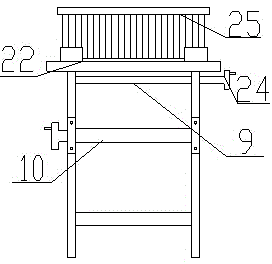

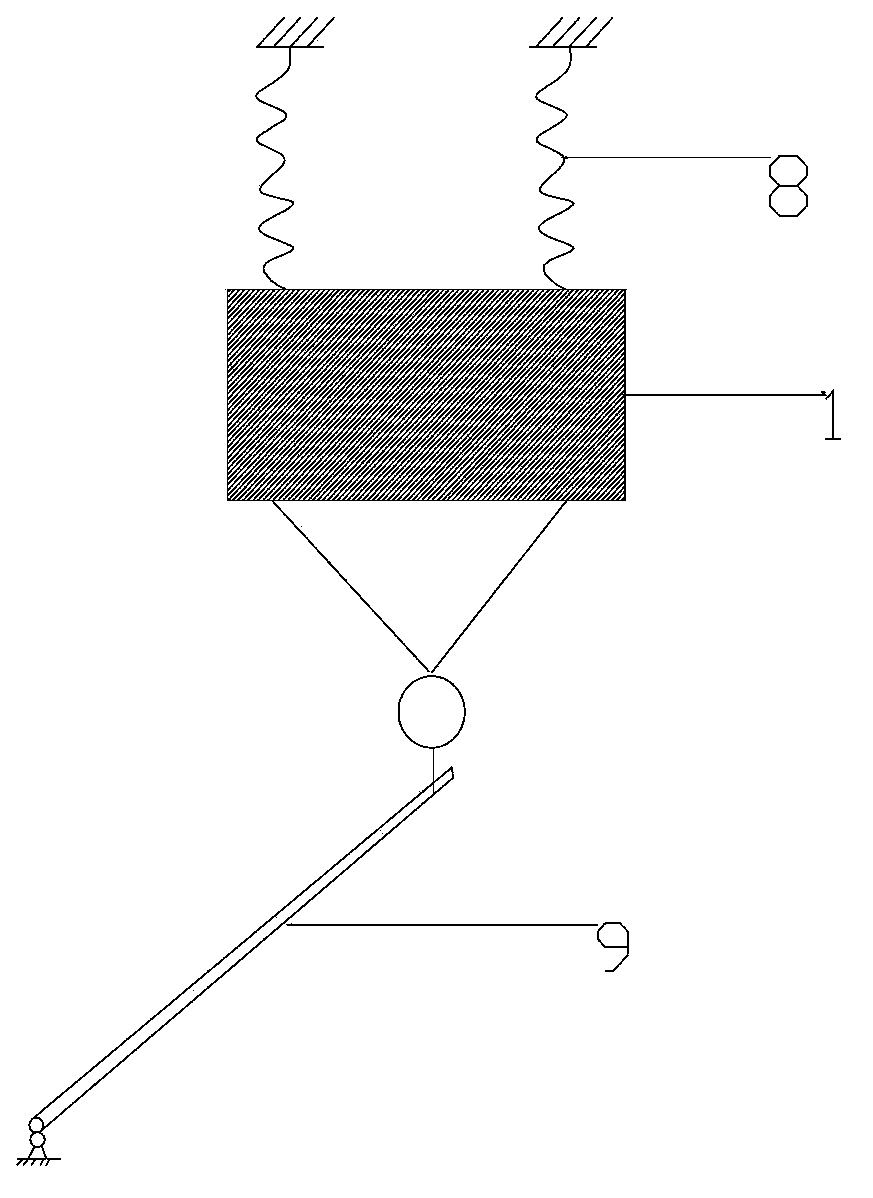

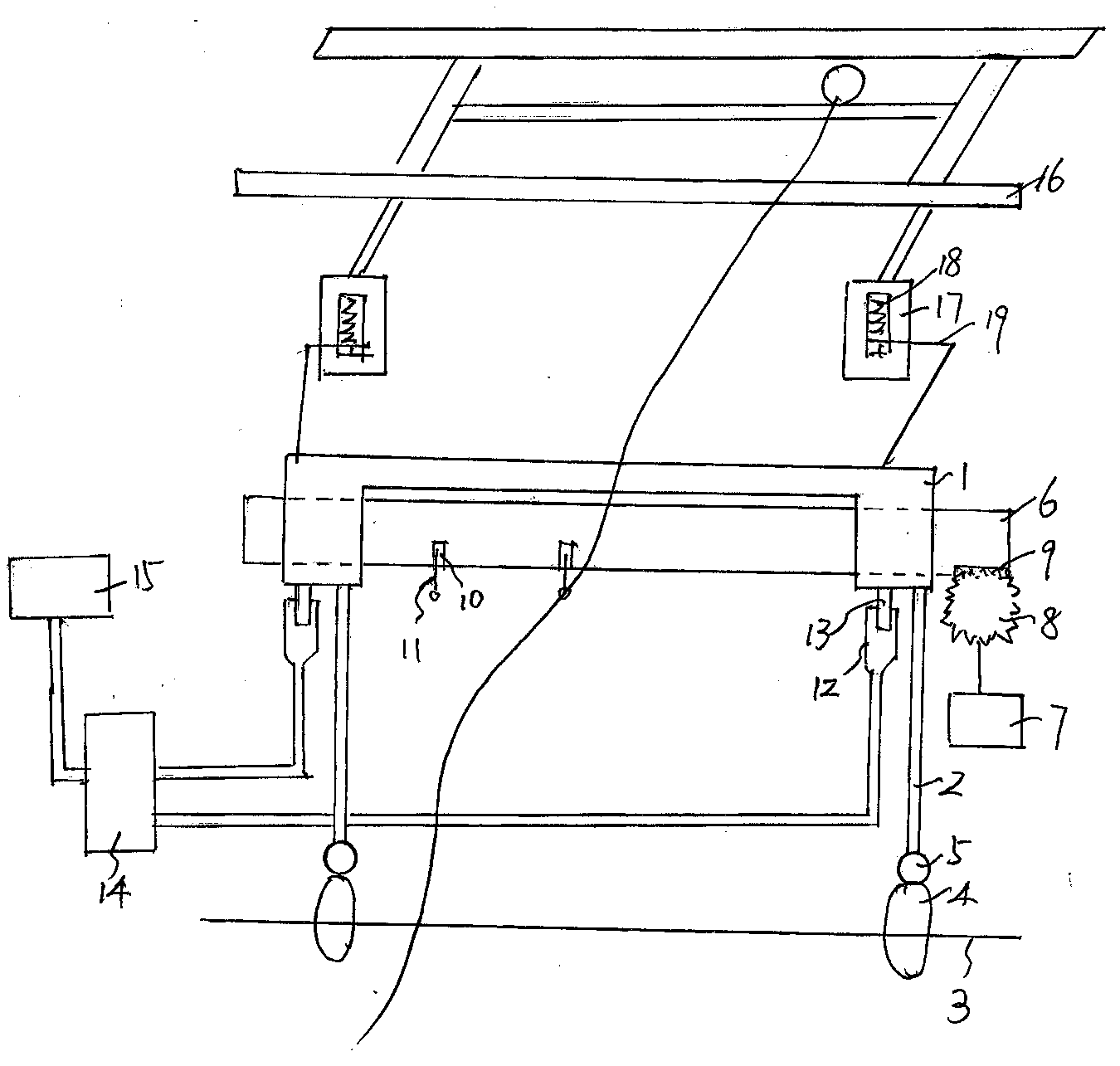

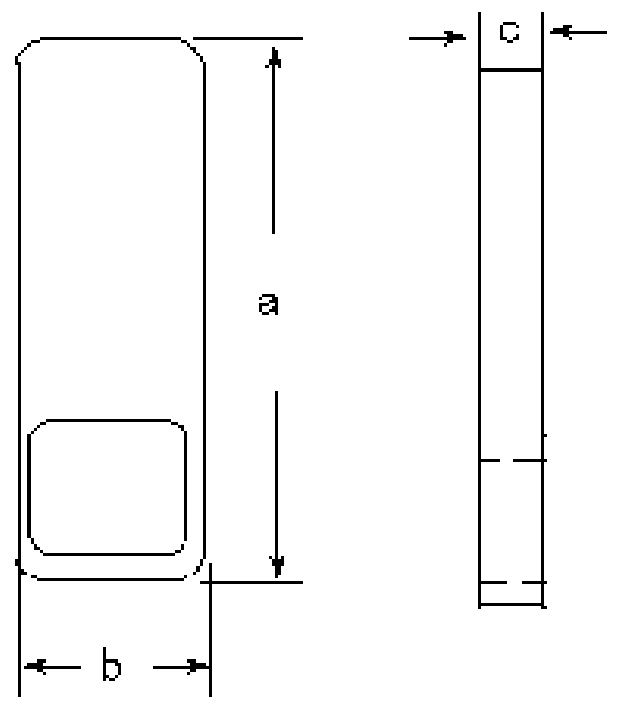

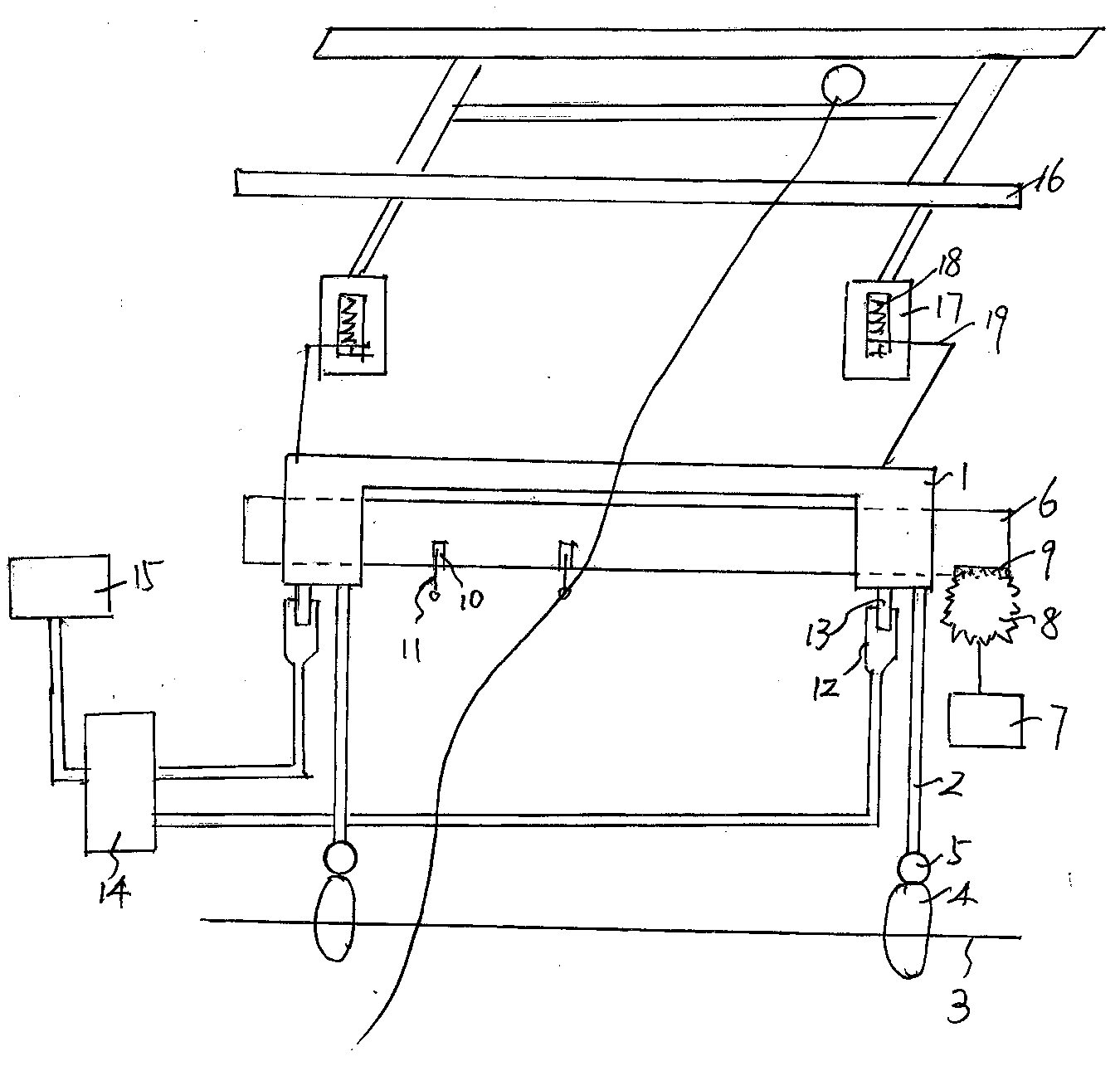

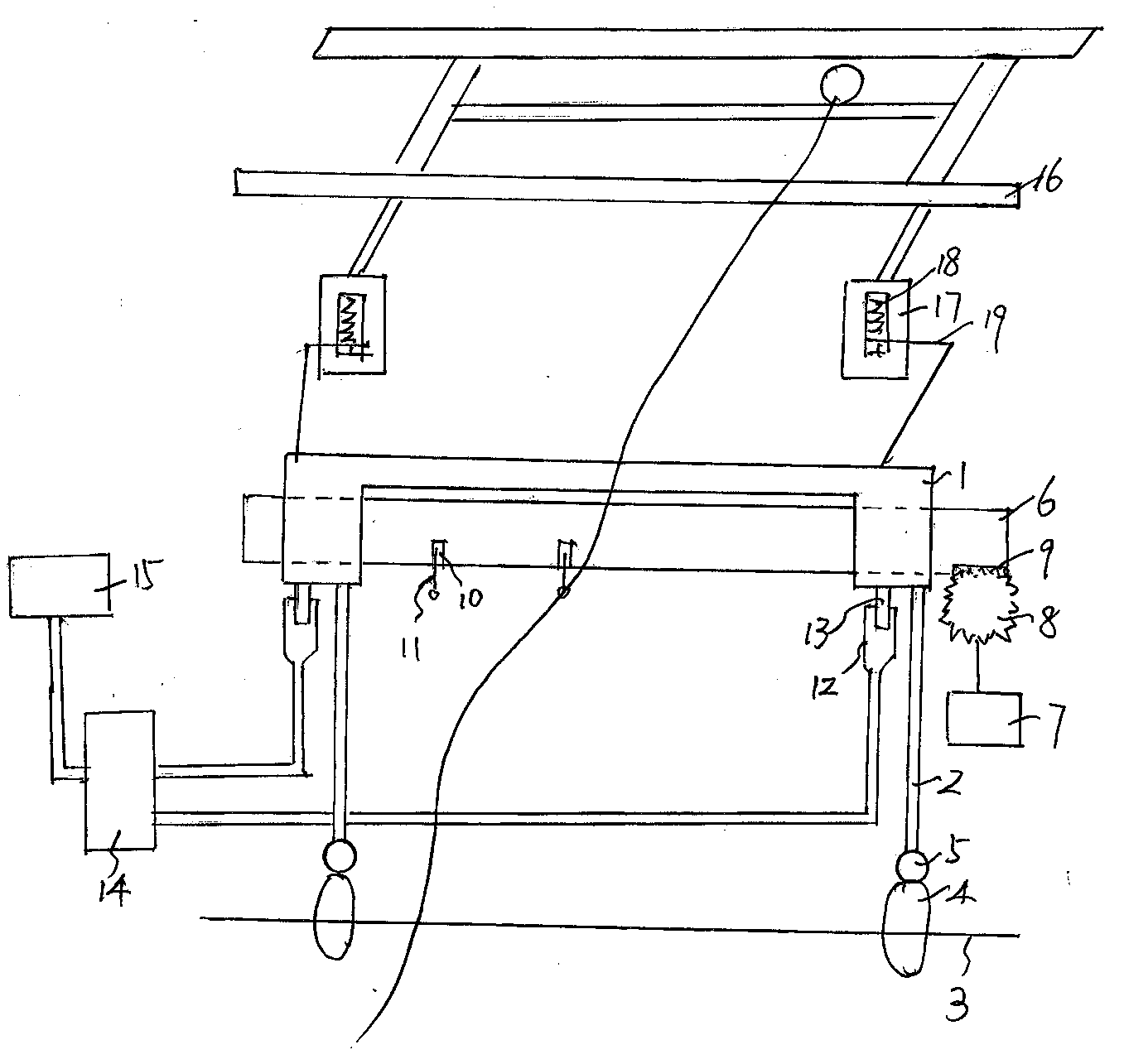

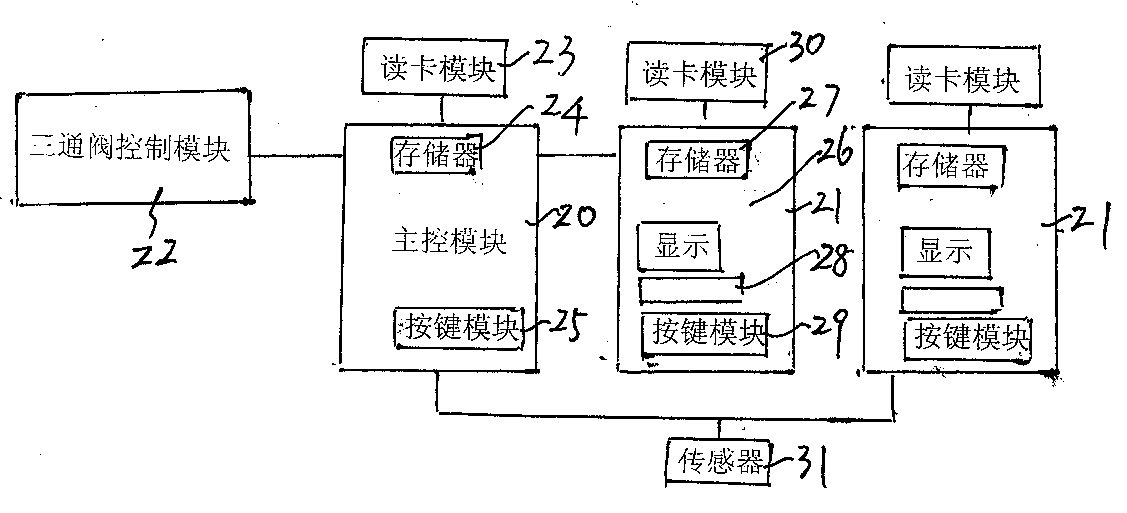

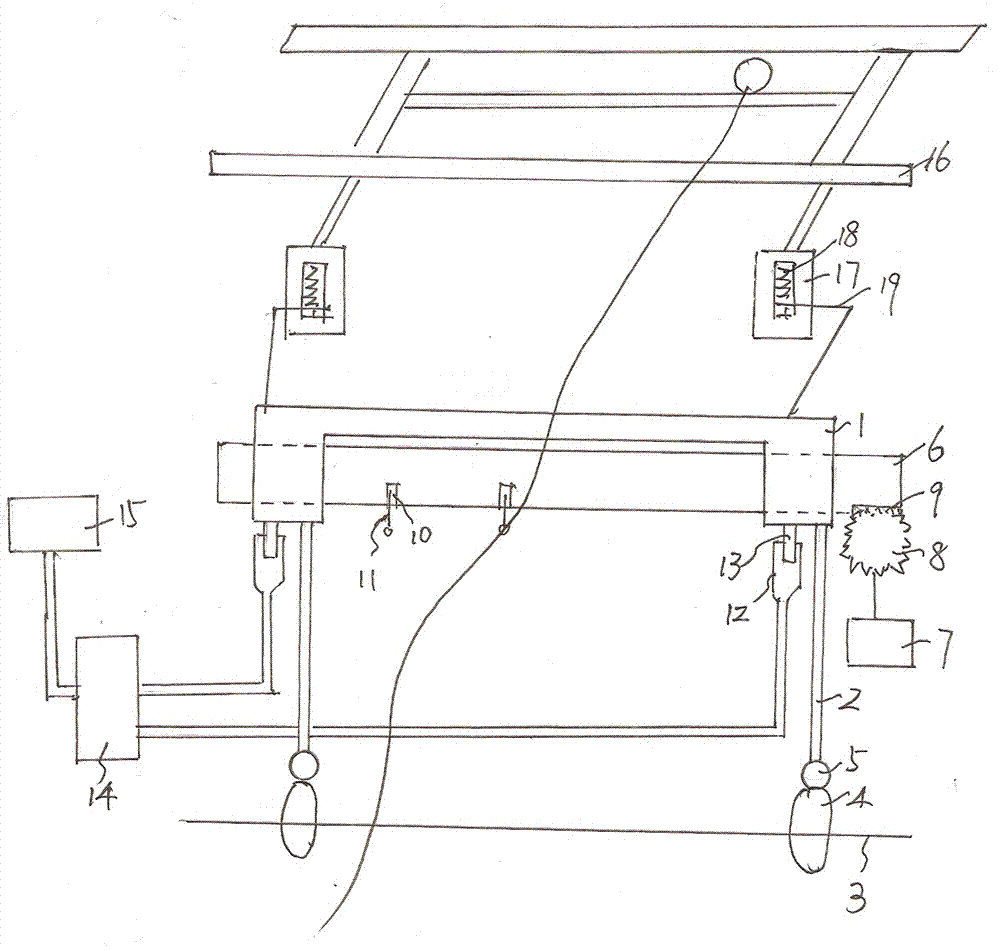

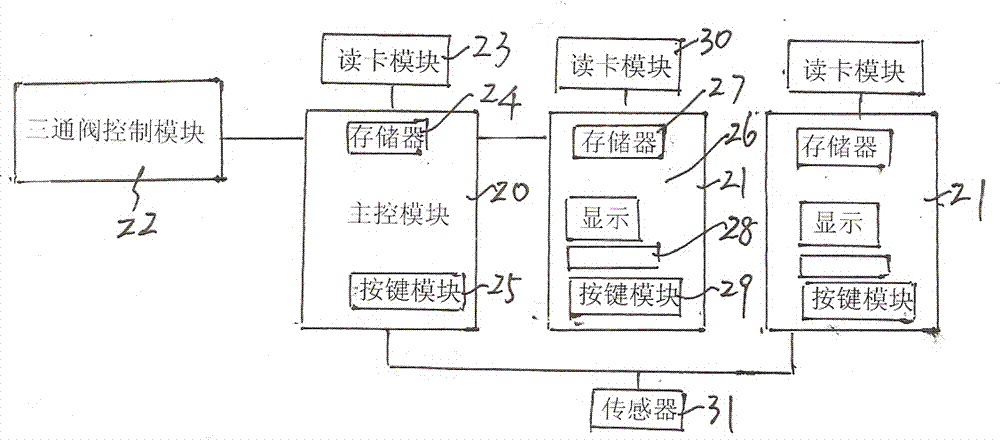

High-precision weaving control system with float design varieties easy to change

InactiveCN103806199BRealize automatic controlSimple design and operationLappetAutomatic controlControl system

The invention discloses a high-precision weaving control system with float design varieties easy to change. The system comprises a mechanical device and a control device, wherein the mechanical device comprises a faller base connected with a faller lifting rod, a rotor in contact with a cam on a main shaft of a loom is mounted at the lower end of the faller lifting rod, and the upper portion of the faller base is connected with a spring resetting mechanism enabling the faller base to be reset; the spring resetting mechanism comprises a fixed part fixed to a beam of the loom, a hole is formed in the fixed part, a reset spring is arranged in the hole, and the lower end of the reset spring is pressed on a floating connecting rod connected with the faller base; a left cylinder piston rod and a right cylinder piston rod moving vertically in a left cylinder and a right cylinder respectively are fixedly mounted below the left end of the faller base and the right end of the faller base respectively, the left cylinder and the right cylinder are connected with an air compressor through a three-way valve, and the control device controls the three-way valve and a stepping motor to work. The system is reasonable in structure, automatic control of float weaving is achieved, design and color variety setting can be achieved easily and visually, weaving control precision is high, varieties can be changed fast, and improvement cost is saved.

Owner:NANTONG VOCATIONAL COLLEGE

Shuttle for winding and cross-stitch in manual spinning

The invention discloses a shuttle for winding and cross-stitch in manual spinning, relates to the technical field of winding shuttles, and solves the problems that the existing shuttle for winding and cross-stitch needs manual winding, two hands of an operator need to be matched, time is wasted, and the winding efficiency is low. The shuttle comprises a supporting base, wherein the rear end of the top of the supporting base is fixedly connected with a set of driving motors; the top of the supporting base is fixedly connected with a set of auxiliary supporting frames; the front side of the top of the supporting base is rotationally connected with a set of universal transmission shafts; the front parts of the universal transmission shafts are fixedly connected with a group of shuttle bases; two groups of shuttle clamping blocks are connected in the shuttle bases in a sliding manner; and a group of cross-stitch shuttles are fixedly connected between the two groups of shuttle clamping blocks. The two groups of shuttle clamping blocks clamp the cross-stitch shuttles through the elasticity of springs, so that the operation is more convenient; a cotton thread is fixed on a thread locking groove, so that manual knotting by operators is not needed, and the operation is simpler; and the shuttle bases are driven by the driving motors to achieve automatic thread winding of the cross-stitch shuttles, and the operation amount of operators is reduced.

Owner:江西博用环保材料有限公司

High-precision weaving control system with float design varieties easy to change

InactiveCN103806199ARealize automatic controlSimple design and operationLappetAutomatic controlControl system

The invention discloses a high-precision weaving control system with float design varieties easy to change. The system comprises a mechanical device and a control device, wherein the mechanical device comprises a faller base connected with a faller lifting rod, a rotor in contact with a cam on a main shaft of a loom is mounted at the lower end of the faller lifting rod, and the upper portion of the faller base is connected with a spring resetting mechanism enabling the faller base to be reset; the spring resetting mechanism comprises a fixed part fixed to a beam of the loom, a hole is formed in the fixed part, a reset spring is arranged in the hole, and the lower end of the reset spring is pressed on a floating connecting rod connected with the faller base; a left cylinder piston rod and a right cylinder piston rod moving vertically in a left cylinder and a right cylinder respectively are fixedly mounted below the left end of the faller base and the right end of the faller base respectively, the left cylinder and the right cylinder are connected with an air compressor through a three-way valve, and the control device controls the three-way valve and a stepping motor to work. The system is reasonable in structure, automatic control of float weaving is achieved, design and color variety setting can be achieved easily and visually, weaving control precision is high, varieties can be changed fast, and improvement cost is saved.

Owner:NANTONG VOCATIONAL COLLEGE

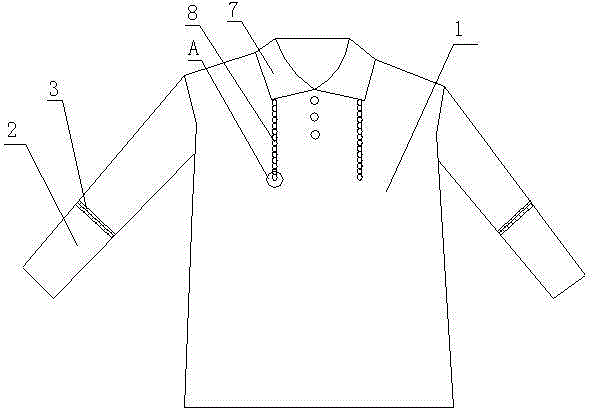

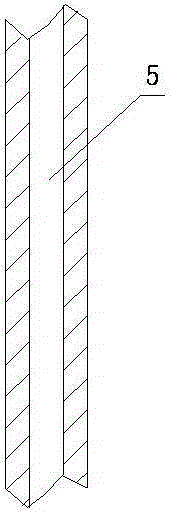

Traveling clothing for old people

The invention relates to traveling clothing for old people. The traveling clothing is characterized by comprising a clothing main body (1), wherein two sleeves (2) are arranged on the clothing main body (1); the two sleeves (2) are connected to the clothing main body (1) by virtue of zippers (3); on the outer sides of arms at front ends, the sleeves (2) are perforated and are provided with transparent plastic (4); an interlayer (5) is arranged below the transparent plastic (4); a clock (6) is arranged inside the interlayer (5); a collar (7) is arranged on the upper part of the clothing main body (1); a hanging chain (8) is additionally arranged on the clothing main body (1); and the hanging chain (8) has two sections one end of each of which is fixed with the collar (7) and the other end is provided with a chain buckle (9). The traveling clothing for old people enables the old people to master time accurately, and the traveling clothing for old people is provided with a pair of presbyopic glasses.

Owner:JIANGYIN SHANGFENG TEXTILE

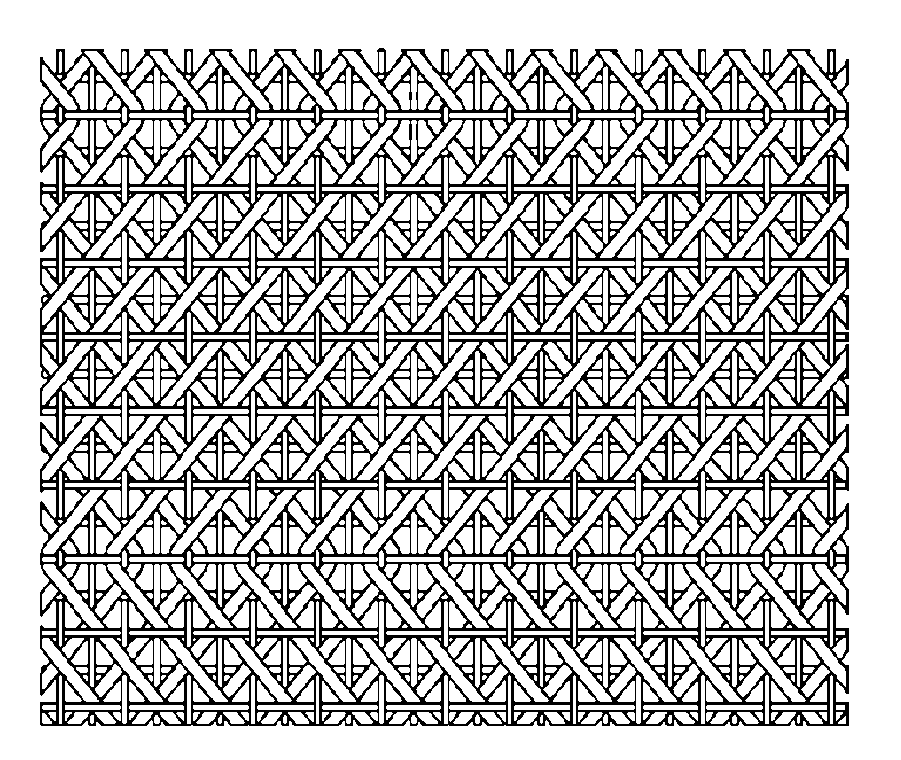

Gap pattern weaving device for leather shuttle loom

The invention relates to a gap pattern weaving device for a leather shuttle loom. The gap pattern weaving device comprises a gap induction mechanism and a leather warp yarn dislocation mechanism, thegap induction mechanism includes a worm, a worm gear, a transmission shaft, an induction wheel, an induction plate and a sensor, the leather warp yarn dislocation mechanism comprises an upper air cylinder, an upper heald frame, a lower air cylinder and a lower heald frame, the upper heald frame is provided with a plurality of upper leather warp yarn ports for leather warp yarn at the upper layer to go through, the lower heald frame is provided with a plurality of lower leather warp yarn ports for leather warp yarn at the lower layer to go through, and the width of each upper leather warp yarnport is equal to that of each lower leather warp yarn port; the gap pattern weaving device is additionally installed on the existing shuttle loom, the gap induction mechanism and the leather warp yarndislocation mechanism work in a cooperative mode, the leather warp yarn at the upper layer and the leather warp yarn at the lower layer are interwoven and staggered to be woven into an X-shaped pattern, and the pattern is very beautiful, elegant and attractive to consumers, the current machines are fully utilized, the equipment utilization rate is increased, and the actual production needs are met.

Owner:饶学政

Label and method for producing the same

The label has two non-folded longitudinal sides (1) and two foldable narrow sides (2) and consists of a backing fabric (11) with warp threads (4) and basic picks (5), in addition to embroidery picks (12) made of a fusible thread material forming the pattern. The embroidery picks (12) forming the pattern extend parallel and at a distance to the unfolded longitudinal sides (1) of the backing fabric (11). The non-folded longitudinal side (1) is an edge of a cut formed in the backing fabric outside the area (13) of the pattern. The label has the advantage that the edges of the cuts on the longitudinal sides are soft and skin friendly thereby substantially improving wearing comfort. Due to the fact that the edge of the cuts produced by the basic picks have practically no brows and the picks extend parallel in relation to the longitudinal side of the labels, and even appearance is achieved on the entire length of the label since the picks cover evenly the back part.

Owner:TEXTILMA AG

Lace fabric and method of attaching lace fabric to an adherend

The invention relates to a lace fabric and a method for attaching the lace fabric to an adherend. The lace fabric (1) of the present invention is a lace fabric woven from two different types of threads, wherein the through-hole area and the cover factor area are formed by weaving the bottom yarn; The surface of the bottom yarn layer is formed by weaving pattern threads; and the surface of the core of the bottom yarn is hot-melt coated, while the pattern thread is not hot-melt coated. Since no adhesive film is used at all, not only is manufacturing easy to accomplish, but it is also extremely easy to use. Attachment of the lace fabric is easily achieved by merely placing the lace fabric on the adherend followed by ironing.

Owner:赵景惠

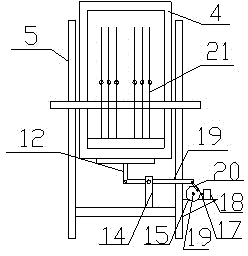

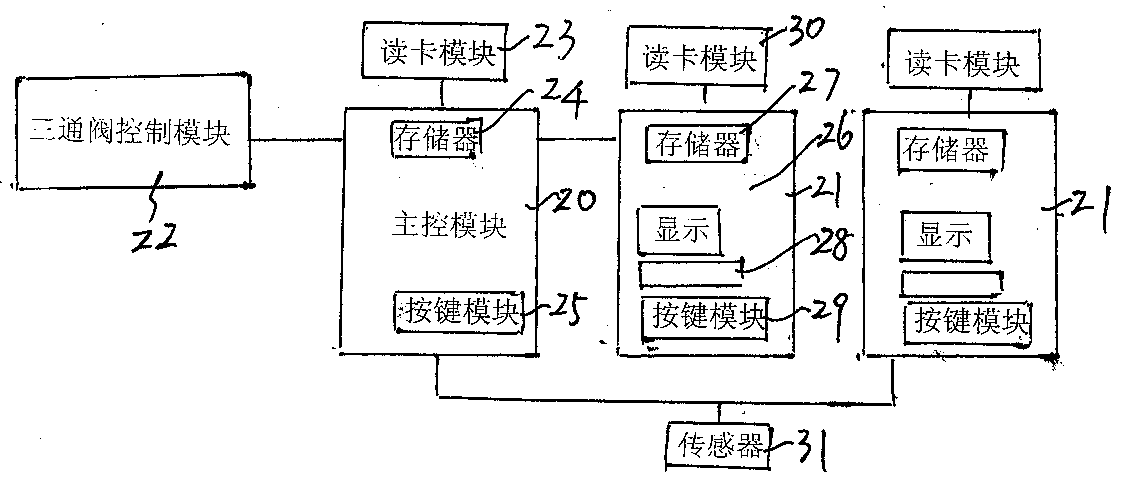

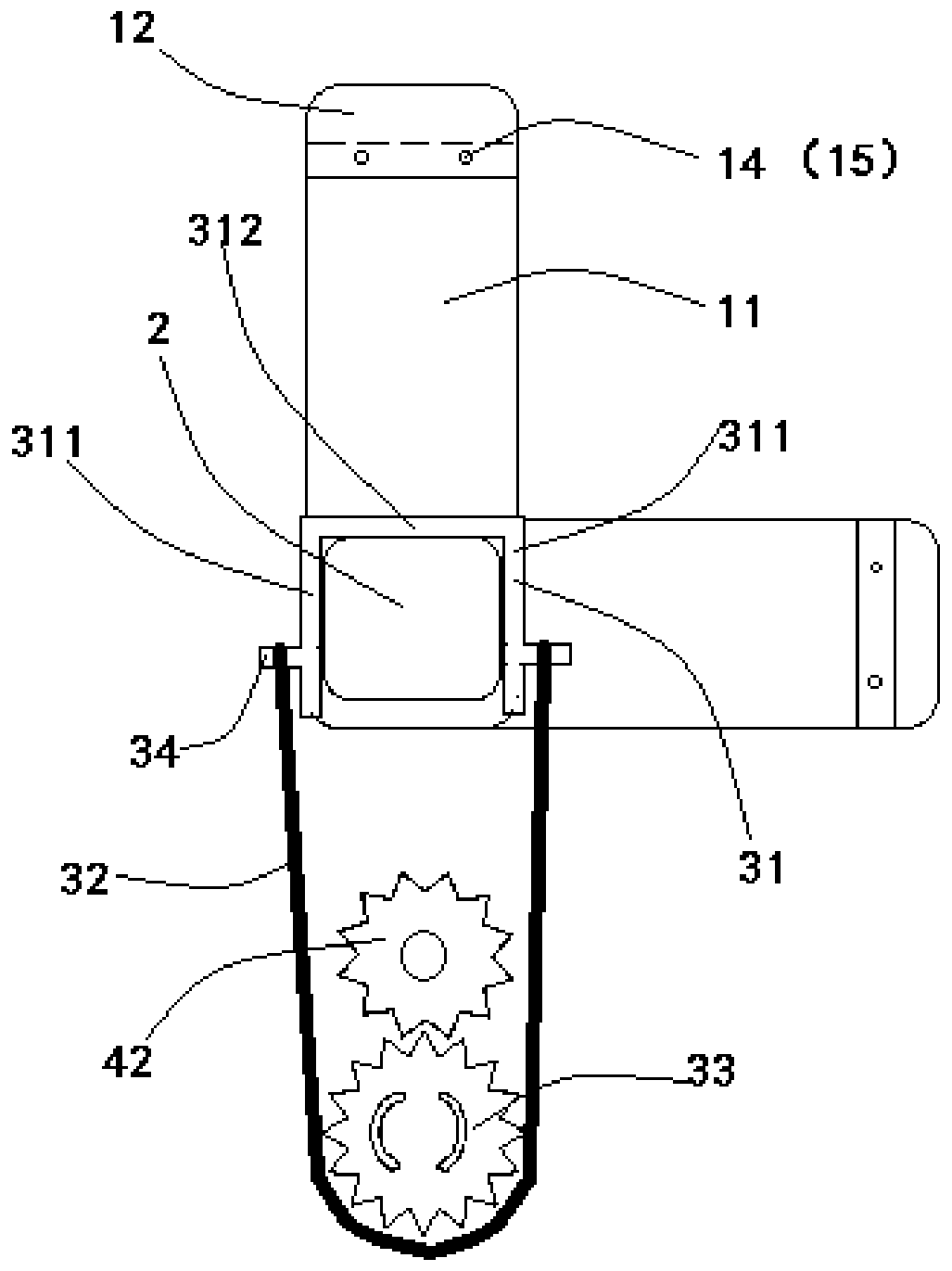

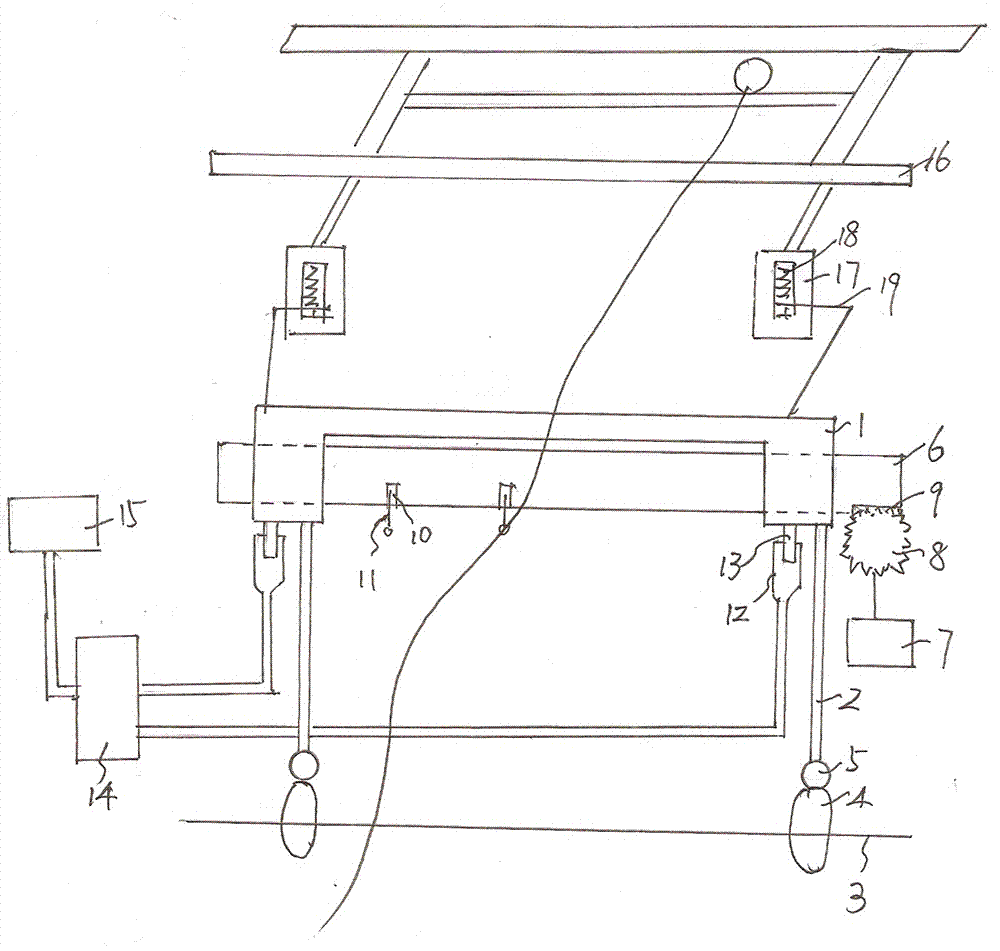

Intelligent float weaving control system

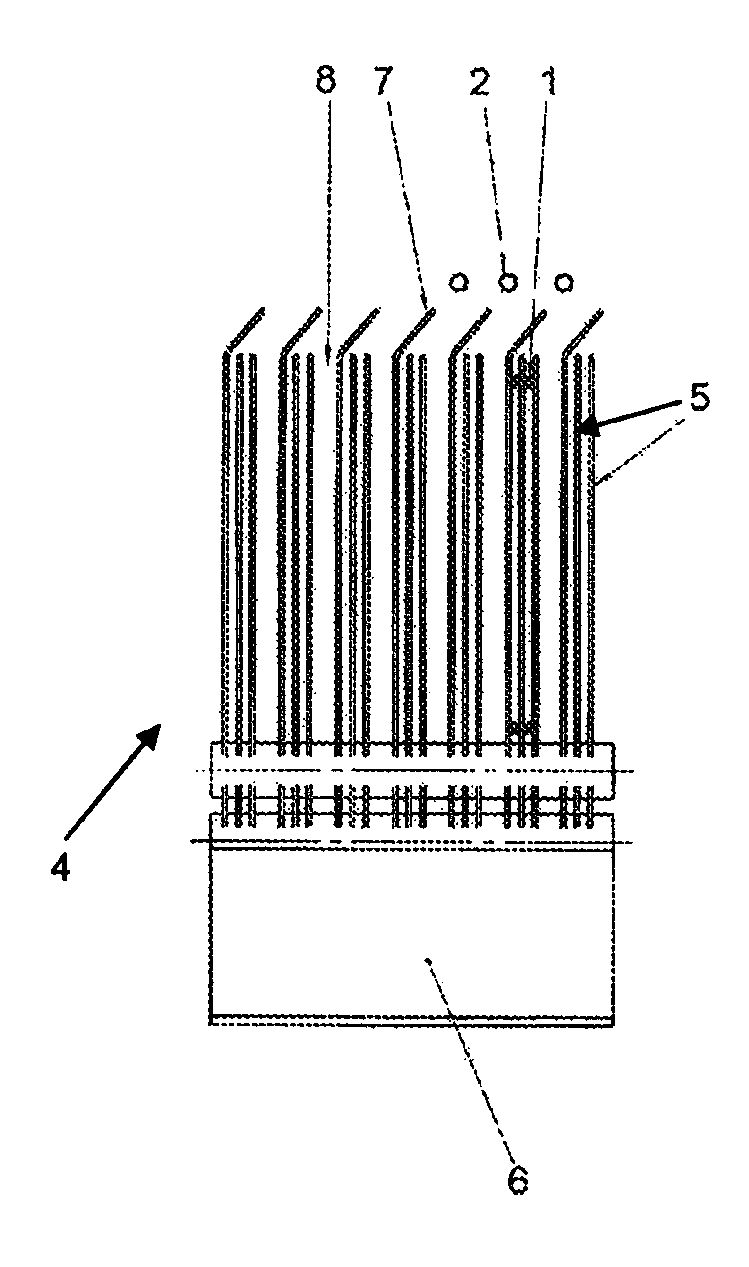

InactiveCN103061006BRealize automatic controlSimple design and operationLappetAutomatic controlGear drive

The invention discloses an intelligent float weaving control system which comprises a mechanical device and a control device. The mechanical device comprises a needle plate seat connected with needle plate lifting rods, a rotor contacting with a cam on a weaving machine spindle is mounted at the lower end of each needle plate lifting rod, and the upper portion of the needle plate seat is connected with a spring reset mechanism enabling the needle plate seat to reset. Needle plate sliders sliding bilaterally are mounted inside the needle plate seat, a rack which is meshed with a gear driven by a stepping motor is mounted on each sliding plate slider, needle mounting holes are arranged at the lower ends of the needle plate sliders, and a needle for float weaving is mounted in each needle mounting hole. A left cylinder piston rod and a right cylinder piston rod which vertically move in a left cylinder and a right cylinder are fixedly mounted on the lower portions of the left end and the right end of the needle plate seat respectively, the left cylinder and the right cylinder are connected with an air compressor through a three-way valve, and the control device controls working of the three-way valve and the stepping motor. The intelligent float weaving control system has the advantages of reasonable structure, automatic control of float weaving, simplicity and visuality in operation of color and variety design, high weaving control precision, fast variety change, improvement cost saving and the like.

Owner:NANTONG VOCATIONAL COLLEGE

Multi-shuttle divisional knitting device, method and material

Provided are a multi-shuttle zoned knitting system and a method of manufacturing a zoned knitting material. The multi-shuttle system includes a first weft yarn, a second weft yarn, and one or more intermediate warp yarns for covering by the first weft yarn and the second weft yarn. A zoned weaving method includes receiving a first weft yarn from a first origin via a first shed, wrapping it around one or more zoned warp yarns, and returning it to the first weft yarn origin after exchanging the first shed upper and lower yarns . In other aspects, the second weft yarn is received from the second weft yarn origin via the second shed, wrapped around the same intermediate zone warp yarn, and returned to the second weft yarn origin after exchanging the second shed yarn. In one aspect, the first weft yarn and the second weft yarn are interlocked during the covering of the common warp yarn.

Owner:NIKE INNOVATE CV

High-precision control method for float weaving

InactiveCN103806200BRealize automatic controlSimple design and operationLappetAutomatic controlControl system

The invention discloses a high-precision control method for float weaving. According to the method, an intelligent float weaving control system is adopted for control. The system comprises a mechanical device and a control device, wherein the mechanical device comprises a faller base connected with a faller lifting rod, a rotor in contact with a cam on a main shaft of a loom is mounted at the lower end of the faller lifting rod, and the upper portion of the faller base is connected with a spring resetting mechanism enabling the faller base to be reset; a left cylinder piston rod and a right cylinder piston rod moving vertically in a left cylinder and a right cylinder respectively are fixedly mounted below the left end of the faller base and the right end of the faller base respectively, the left cylinder and the right cylinder are connected with an air compressor through a three-way valve, and the control device controls the three-way valve and a stepping motor to work. According to the method, the structure is reasonable, automatic control of float weaving is achieved, design and color variety setting can be achieved easily and visually, weaving control precision is high, varieties can be changed fast, and improvement cost is saved.

Owner:NANTONG VOCATIONAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com